Method for recycling alumina and sodium oxide from bayer process red mud

A Bayer red mud and alumina technology, applied in the direction of alumina/aluminum hydroxide, alkali metal oxides, etc., can solve the high temperature and high pressure in the dissolution process, it is difficult to achieve economical, efficient recovery, and high hardness of sodium oxide in red mud And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

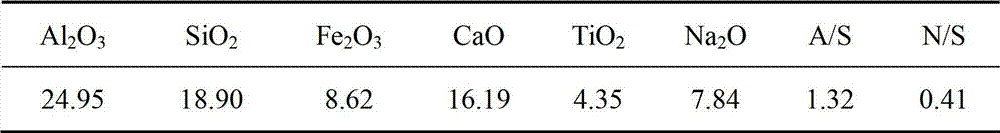

[0066] With the method for recovering alumina and sodium oxide from Bayer process red mud of the present invention, the red mud of a certain Bayer process alumina plant in Henan is used as raw material to recover alumina and sodium oxide. The red mud composition of the alumina plant (mass percentage, wt%, the same below) as described in Table 1:

[0067] Table 1

[0068]

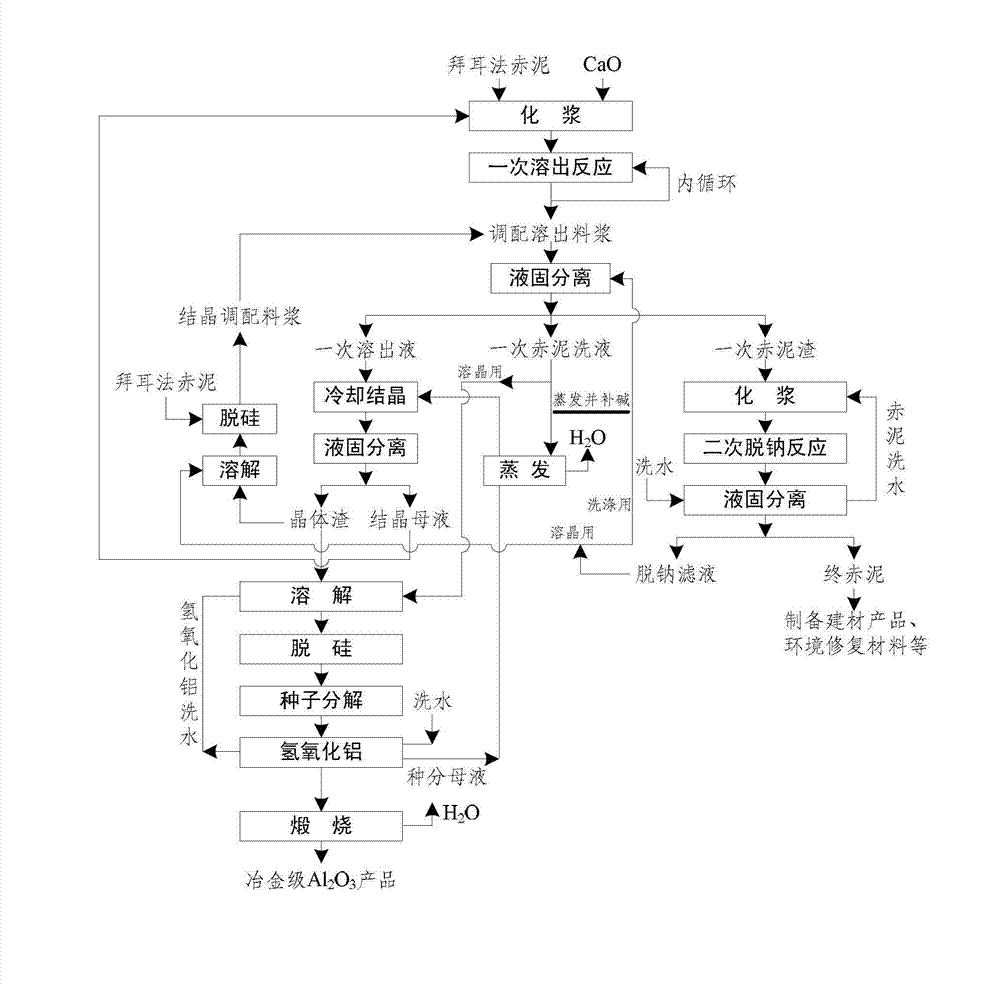

[0069] Its production process is as figure 1 The methods shown include:

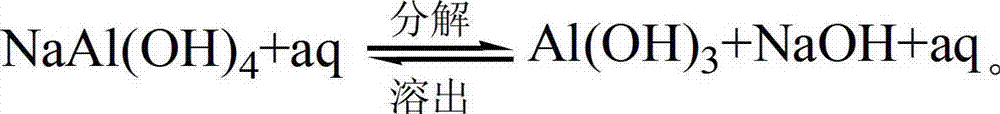

[0070] (1) Mix red mud and concentrated sodium hydroxide solution from an alumina plant in Henan to prepare a slurry with a liquid NaOH mass fraction of 40% and a ratio of liquid NaOH mass to dry red mud mass of 2.5:1. And add lime to make CaO and SiO in the solid phase 2 The ratio of the amount of the substance is 1.4:1, and then the slurry is placed in a high-pressure reactor for a stripping reaction. The stripping reaction temperature is 210 ° C, and the stripping time is 0.3 hours, and the stripping solution containing sodium...

Embodiment 2

[0076] With the method for reclaiming alumina and sodium oxide from Bayer process red mud of the present invention, the red mud of a certain Bayer process alumina plant in Henan as described in Table 1 is still used as raw material to reclaim alumina and sodium oxide, and the production process is as follows Said:

[0077] (1) Mix the crystallization mother liquor of Example 1 with the prepared concentrated NaOH solution and the Bayer process red mud evenly, and adjust the liquid phase NaOH mass fraction to 50%, and the ratio of the liquid phase NaOH mass to the dry basis red mud mass is 3:1 slurry, and add lime to make CaO and SiO in the solid phase 2 The ratio of the amount of the substance is 1.6:1, and then the slurry is placed in a high-pressure reactor for a stripping reaction. The stripping reaction temperature is 240 ° C, and the stripping time is 0.2 hours, and the stripping solution containing sodium aluminate and slag are obtained. The solid-liquid mixture, the rel...

Embodiment 3

[0083] With the method for reclaiming alumina and sodium oxide from Bayer process red mud of the present invention, the red mud of a certain Bayer process alumina plant in Henan as described in Table 1 is still used as raw material to reclaim alumina and sodium oxide, and the production process is as follows Said:

[0084] (1) Mix the red mud of an alumina plant in Henan with concentrated sodium hydroxide solution to prepare a slurry with a liquid NaOH mass fraction of 55% and a ratio of liquid NaOH mass to dry red mud mass of 4:1. And add lime to make CaO and SiO in the solid phase 2 The ratio of the amount of the substance is 1.3:1, and then the slurry is placed in a high-pressure reactor for a stripping reaction. The stripping reaction temperature is 270 ° C, and the stripping time is 0.5 hours, and the stripping solution containing sodium aluminate and slag are obtained. The solid-liquid mixture, the relative dissolution rate of alumina entering the solution is 88.4%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com