Patents

Literature

213 results about "REL" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The proto-oncogene c-Rel is a protein that in humans is encoded by the REL gene. The c-Rel protein is a member of the NF-κB family of transcription factors and contains a Rel homology domain (RHD) at its N-terminus and two C-terminal transactivation domains. c-Rel has an important role in B-cell survival and proliferation. The REL gene is amplified or mutated in several human B-cell lymphomas, including diffuse large B-cell lymphoma and Hodgkin's lymphoma.

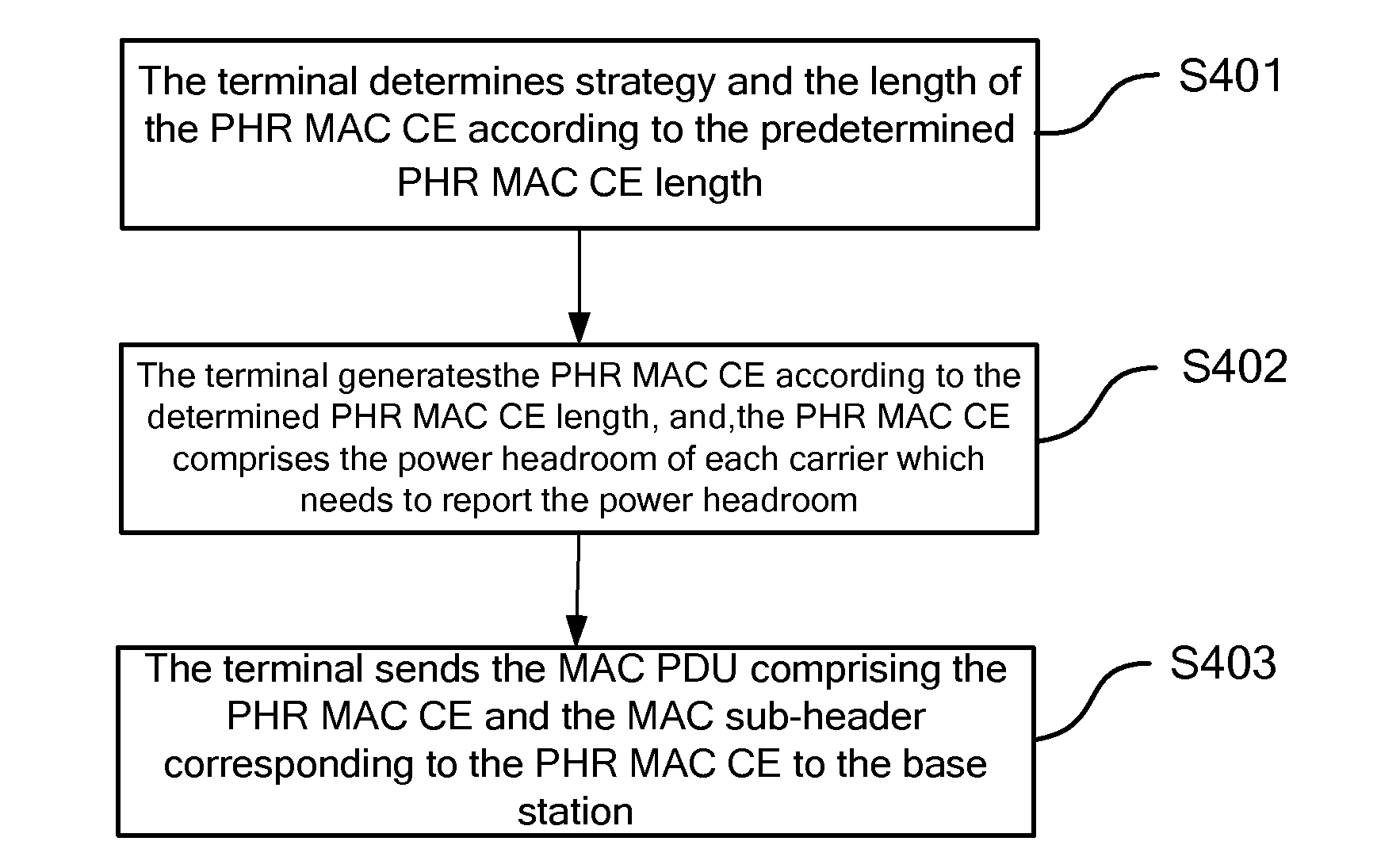

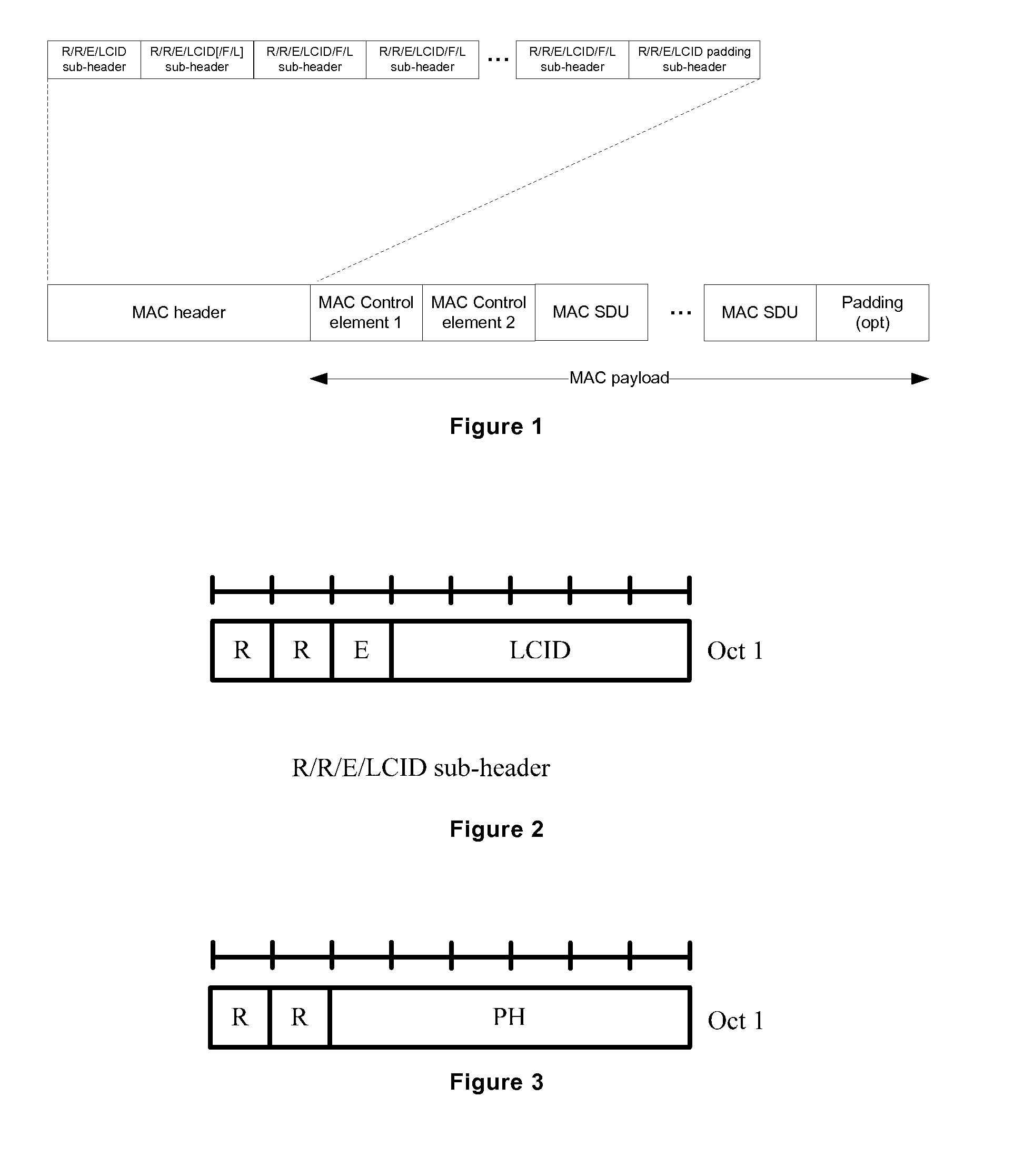

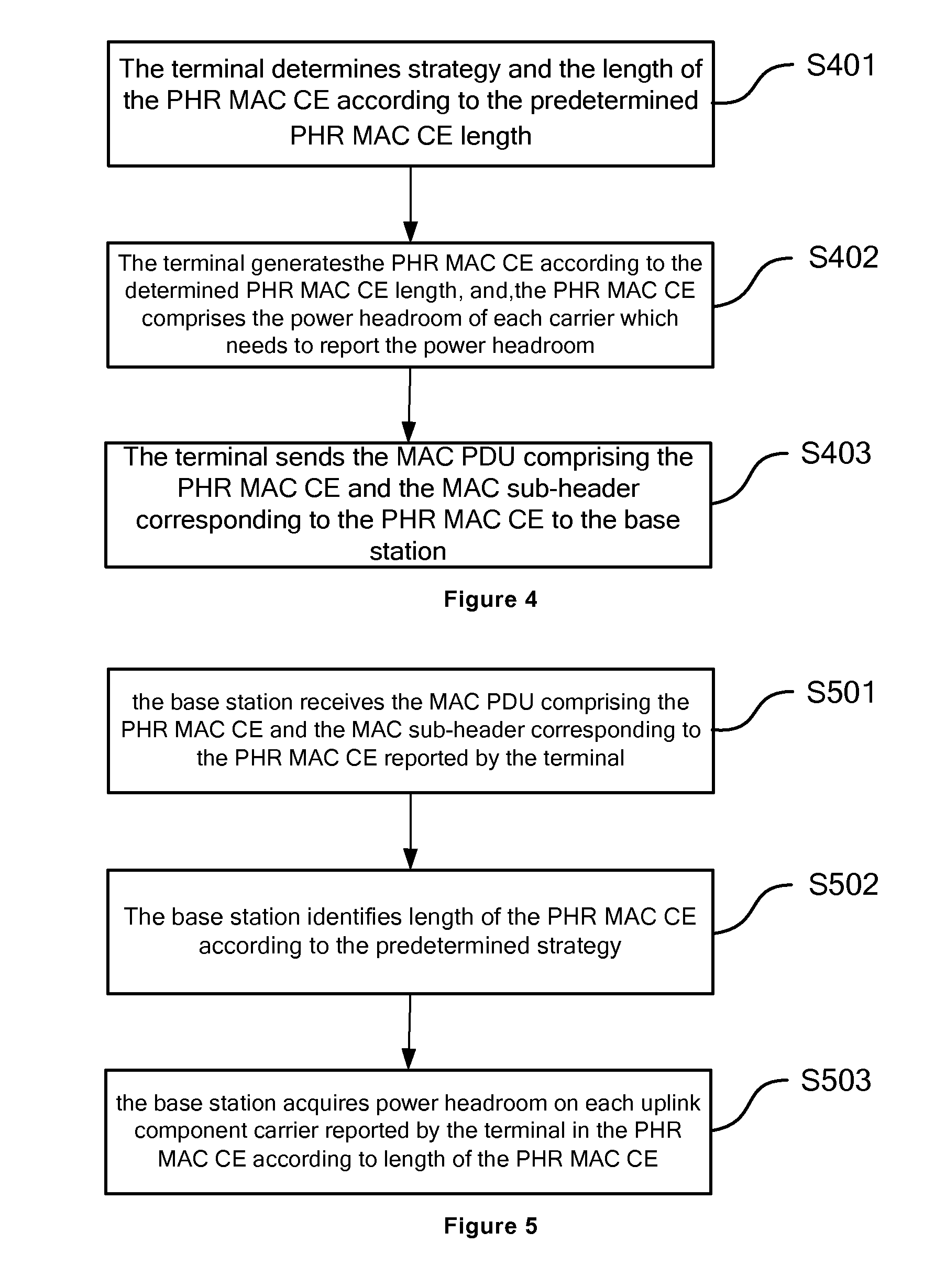

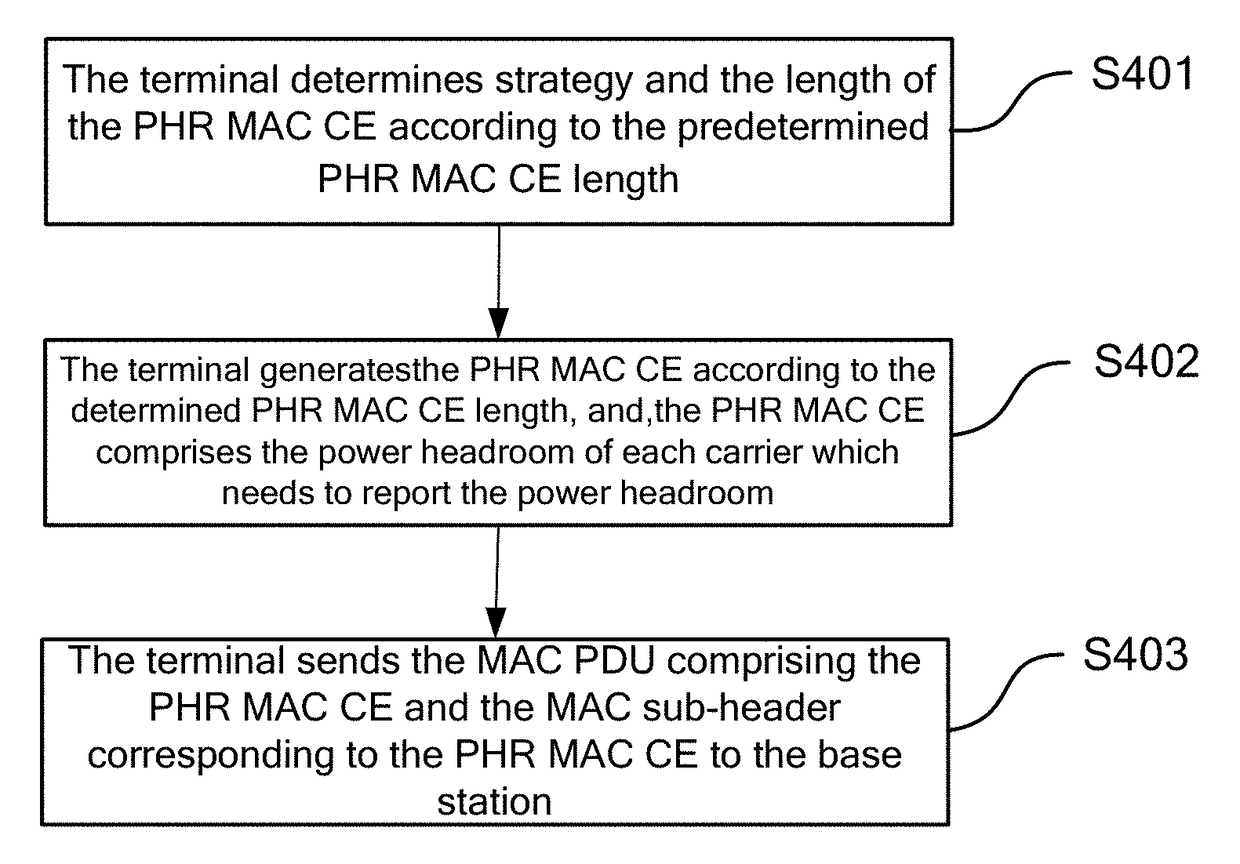

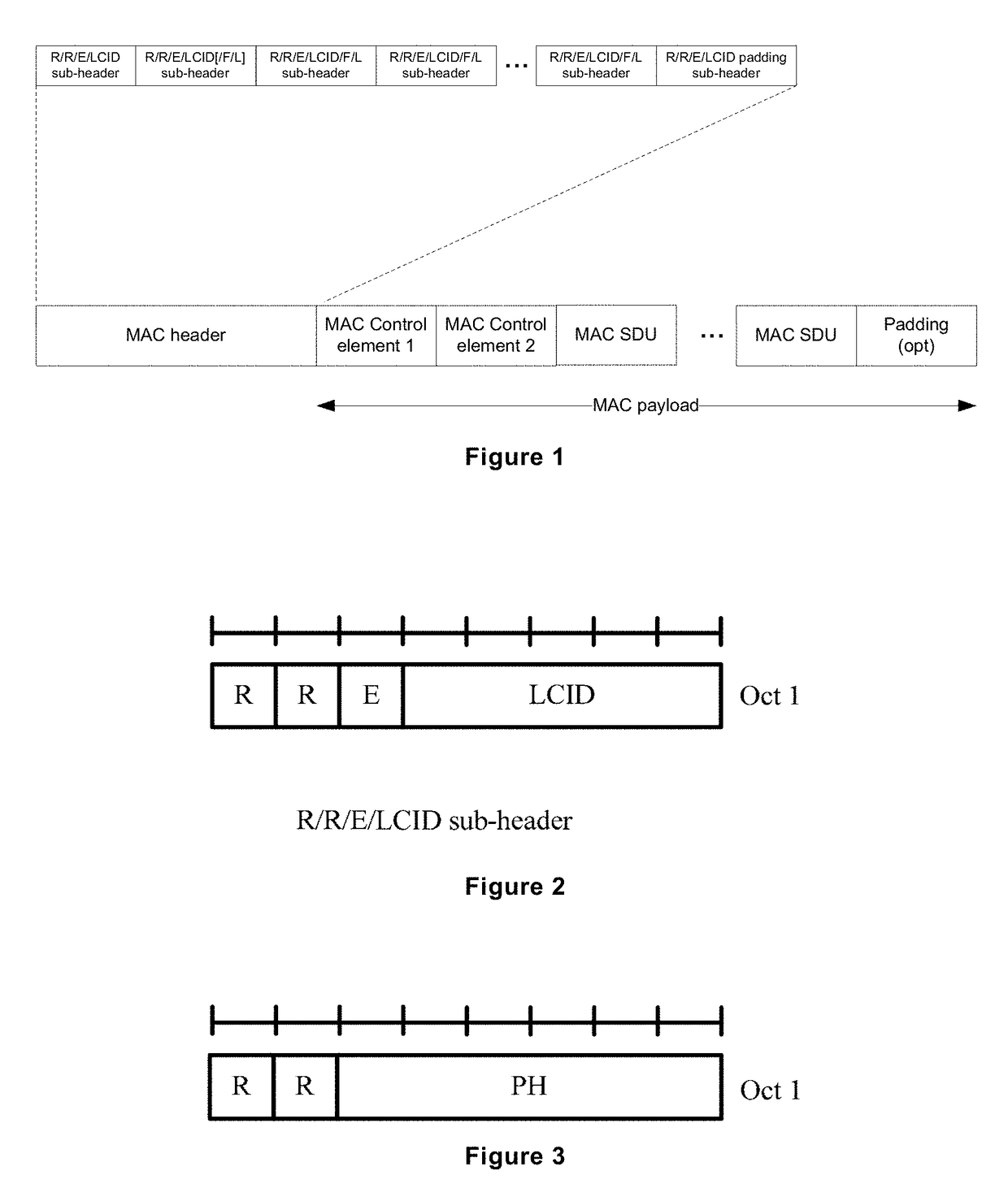

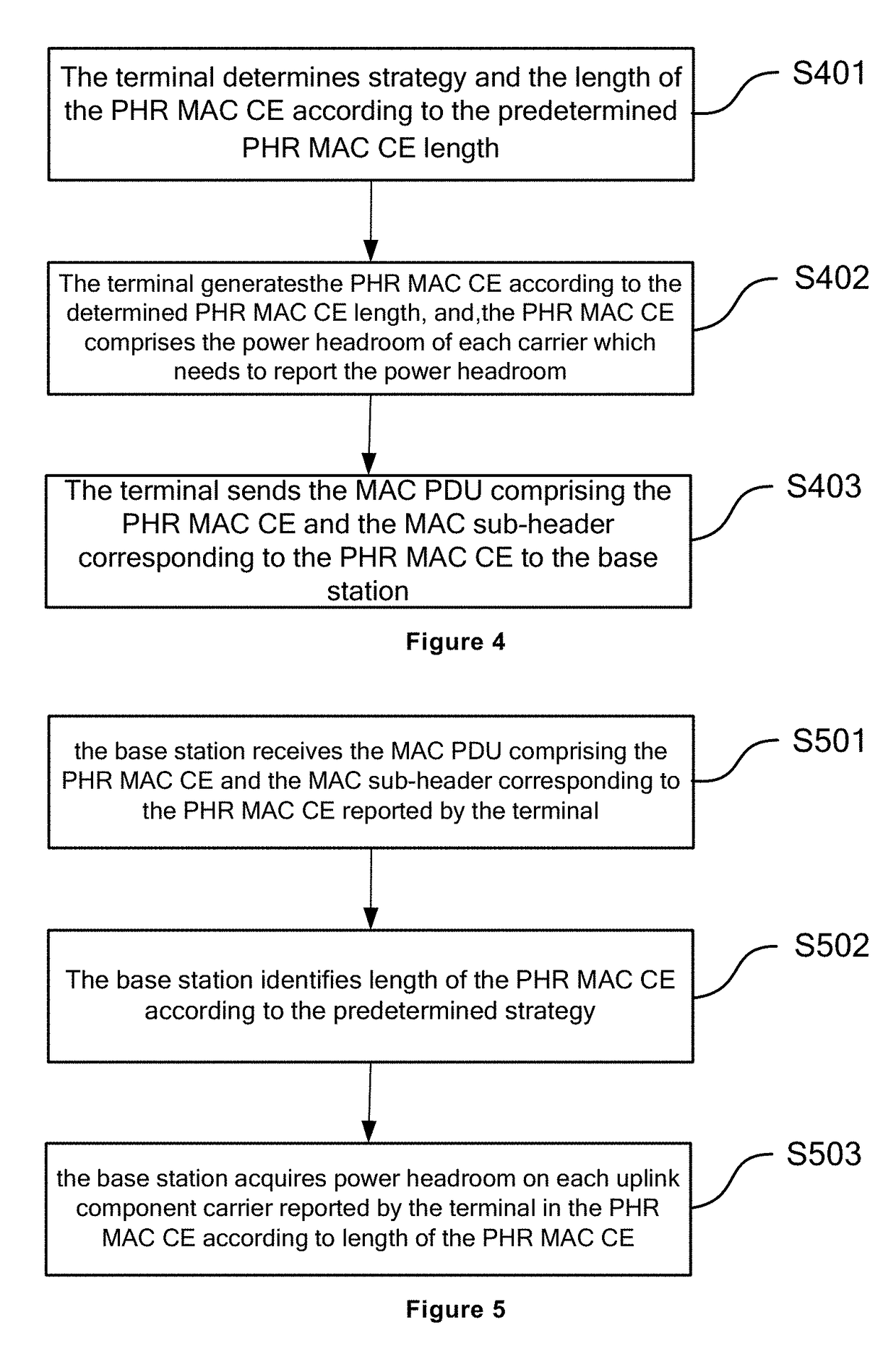

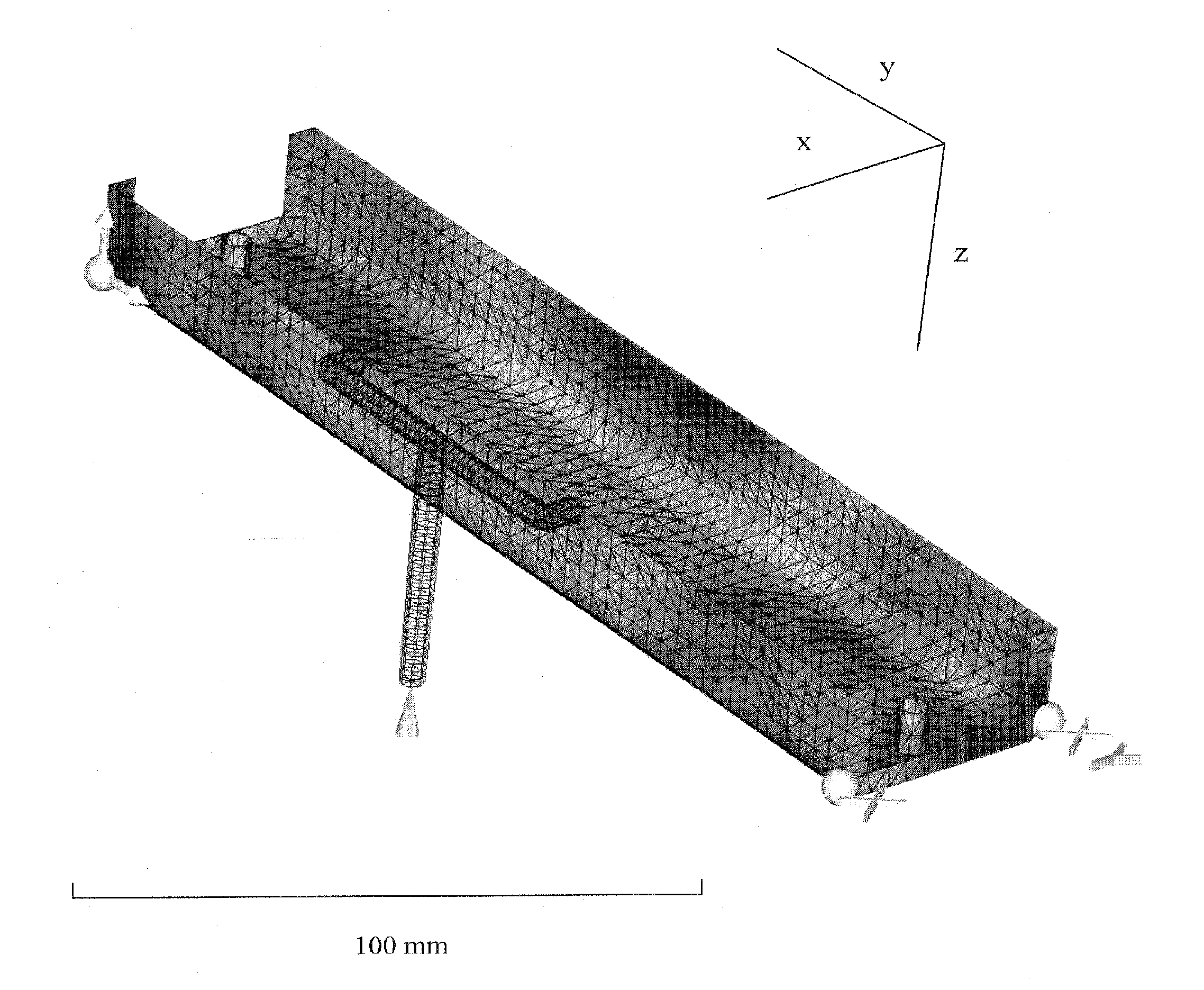

Method and apparatus for reporting power headroom in carrier aggregation scenario

ActiveUS20130188570A1Accurate powerPower managementTransmission path divisionCarrier signalVirtual power

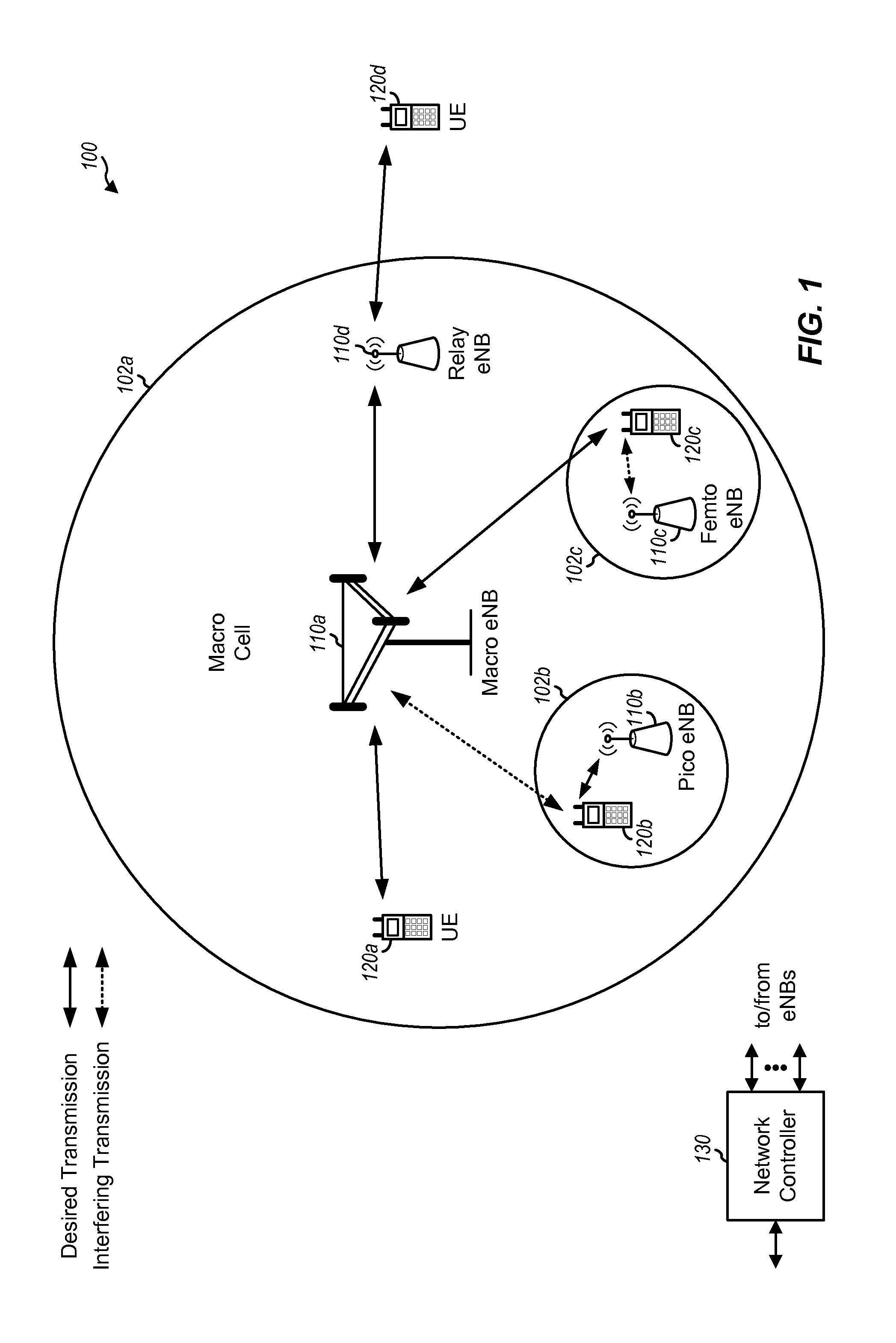

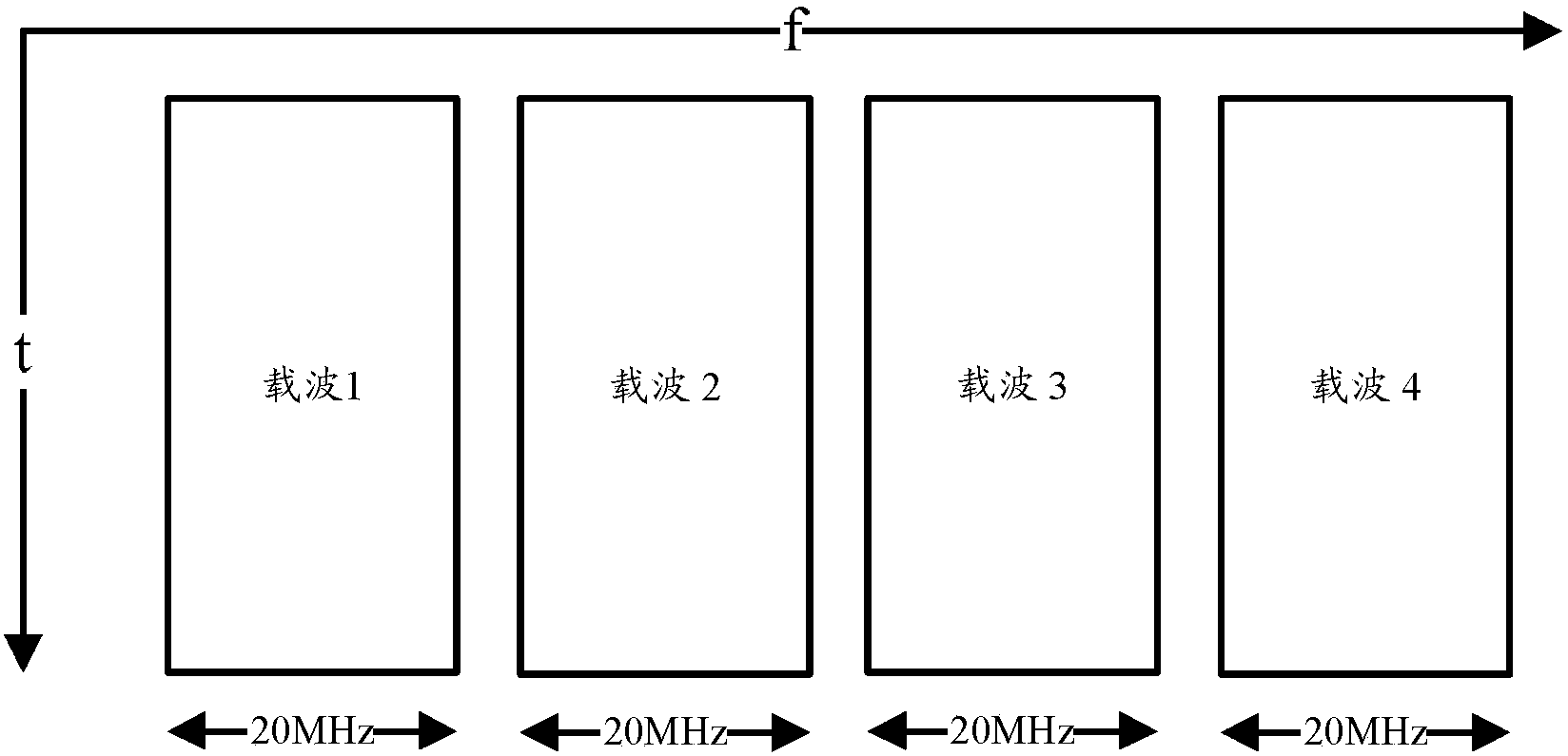

Disclosed are a method and an apparatus for reporting power headroom in a carrier aggregation context. By applying the technical solutions of the embodiments of the present invention, PHR MAC CE and a corresponding MAC sub-header are determined according to the number of uplink component carriers needing to report power headroom and a type of the power headroom to be reported, and indication information such as length information of the PHR MAC CE, type information of the power headroom, and information about whether the power headroom is virtual power headroom is carried therein, so that a base station can precisely obtain the power headroom of each uplink component carrier. In this way, the problem that the PHR MAC CE format in the current LTE Rel-8 / 9 is not applicable to an LTE-A system is solved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

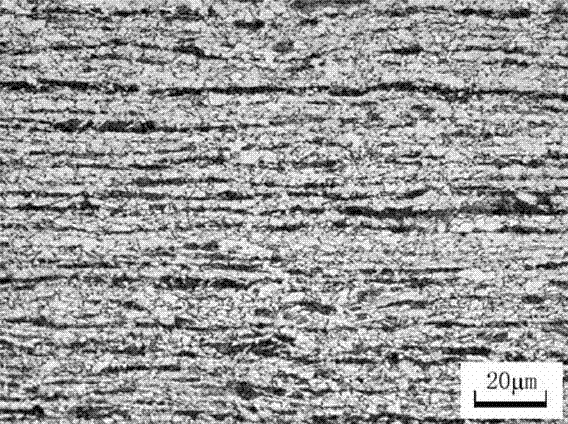

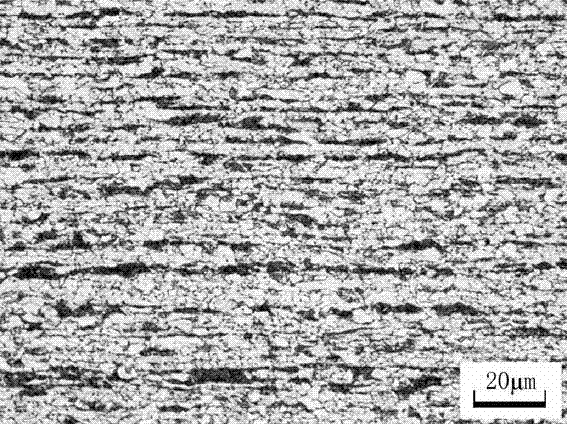

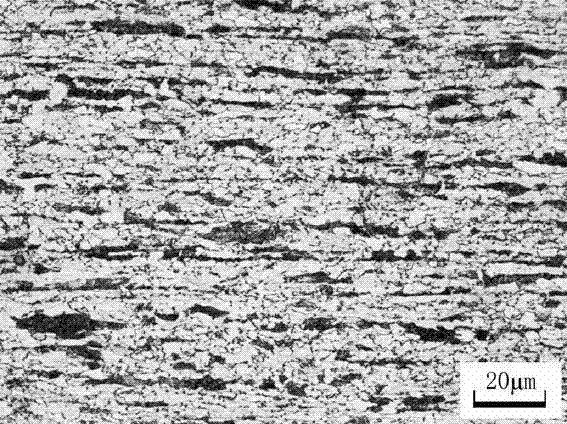

Large scale process for polymerization of dapbi-containing polyaramid

A method for obtaining an aromatic polyamide crumb from an aromatic diamine and an aromatic diacid chloride, which aromatic polyamide comprises 5(6)-amino-2-(p-aminophenyl)benzimidazole terephthalamide units and has a relative viscosity ηrel of at least 3, by: (1) adding at least monomers (i)-(iii) in N-methyl pyrrolidone as solvent wherein (i) is 0-30 mole % para-phenylenediamine (PPD), (ii) is 20-50 mole % 5(6)-amino-2-(p-aminophenyl)benzimidazole (DABPI), (iii) is 49.05-50.05 mole % terephthaloyl dichloride (TDC), and optionally calcium chloride to obtain a CaCl2 / aromatic diamine molar ratio less than 0.5, and an aromatic diamine / aromatic diacid chloride ratio between 0.99 and 1.01; (2) mixing the monomers and the optional calcium chloride to a homogenous mixture having a monomer concentration of 5 to 12 wt %; followed by (3) adding calcium chloride to the homogeneous mixture to obtain a CaCl2 / aromatic diamine molar ratio 0.6-1.0; and (4) polymerizing the mixture.

Owner:TEIJIN ARAMID BV

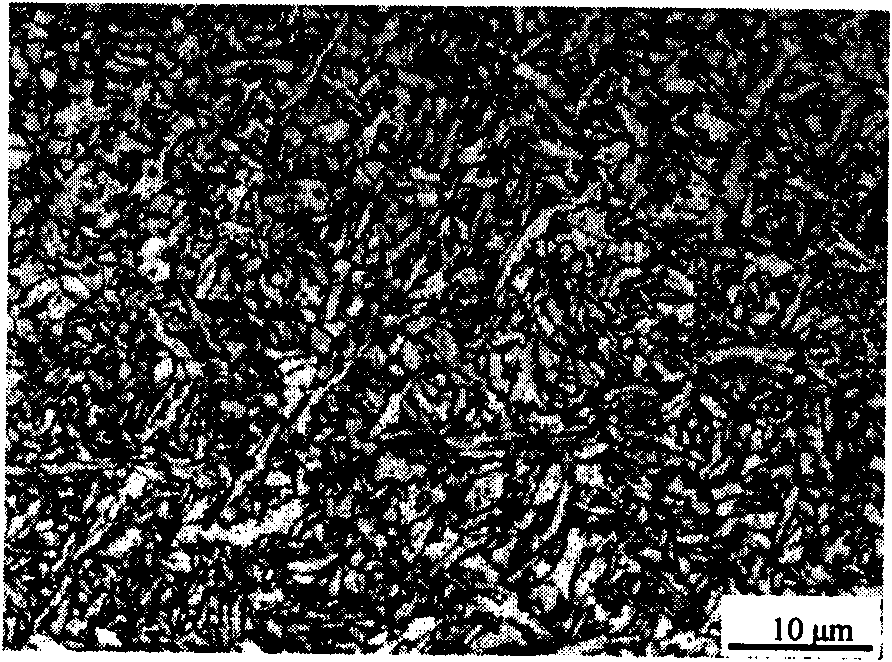

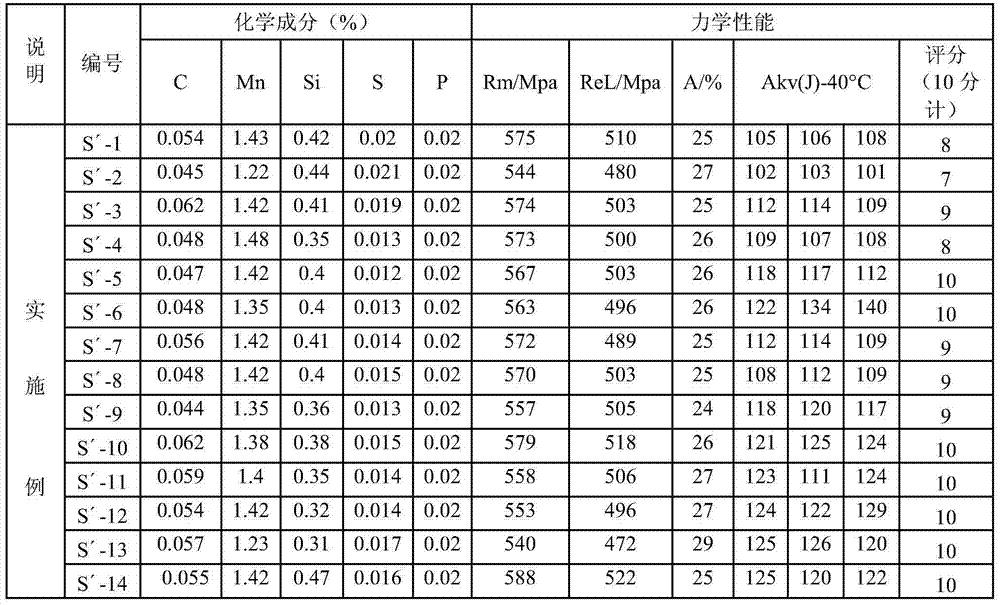

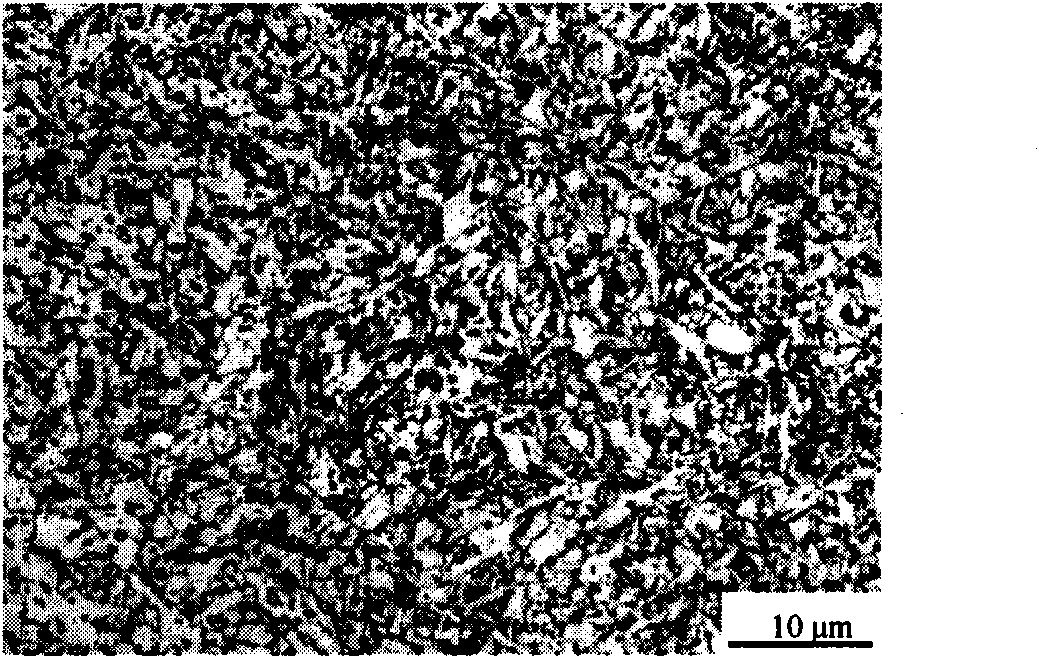

High-strength high ductility gas protecting welding stick

InactiveCN101234457ASimple welding processStable welding wire qualityWelding/cutting media/materialsSoldering mediaChemical compositionUltra fine

The invention relates to a gas shielded welding wire with high strength and high toughness, which solves the defects that the existing strength grade in the technical field is unsuitable for market demand and is of high cost. The technical scheme of the invention is that the components of the welding wire (according to the weight percentage) are as follows: 0.04 to 0.10 of C, 0.30 to 0.80 of Si, 1.30 to 2.0 of Mn, 0.40 to 0.89 of Ni, 0.20 to 0.50 of Cr, 0.20 to 0.60 of Mo, 0.56 to 0.80 of Cu, 0.05 to 0.20 of Ti, 0.002 to 0.010 of B, less than 0.020 of P, less than 0.015 of S, less than 0.03 of Als and the rest of Fe and inevitable impurities. The welding wire of the invention has stable quality. The mechanical property of a deposited metal is that Rel is equal to 810MPa; Rm is equal to 840MPa; A is equal to 16 percent and Z is equal to 66 percent. The average impact power AKV in minus 20 DEG C is 141J; and the average impact power AKV in minus 40 DEG C is 128J; and the average impact power AKV in minus 60 DEG C is 70J. The welding wire is suitable for gas shielded welding of 800MPa grade of ultra-fine steel; as the content of Ni is reduced, the cost of the welding wire is reduced dramatically and the implementation is easy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

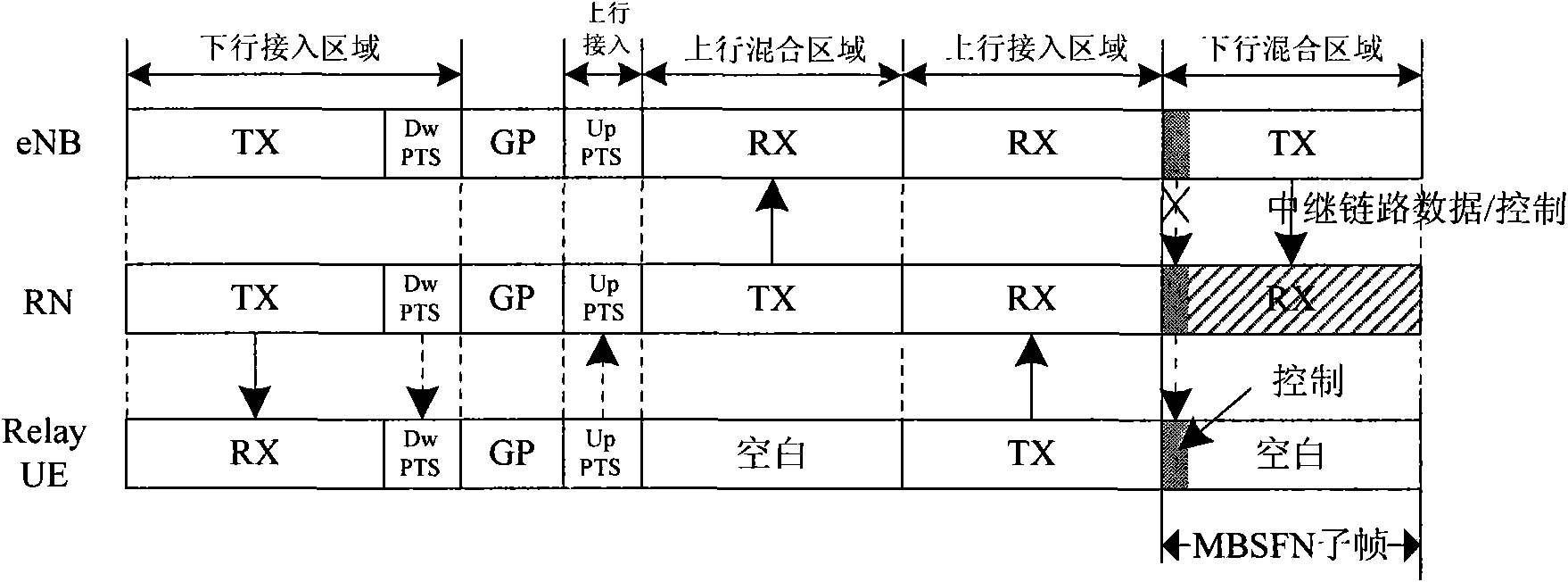

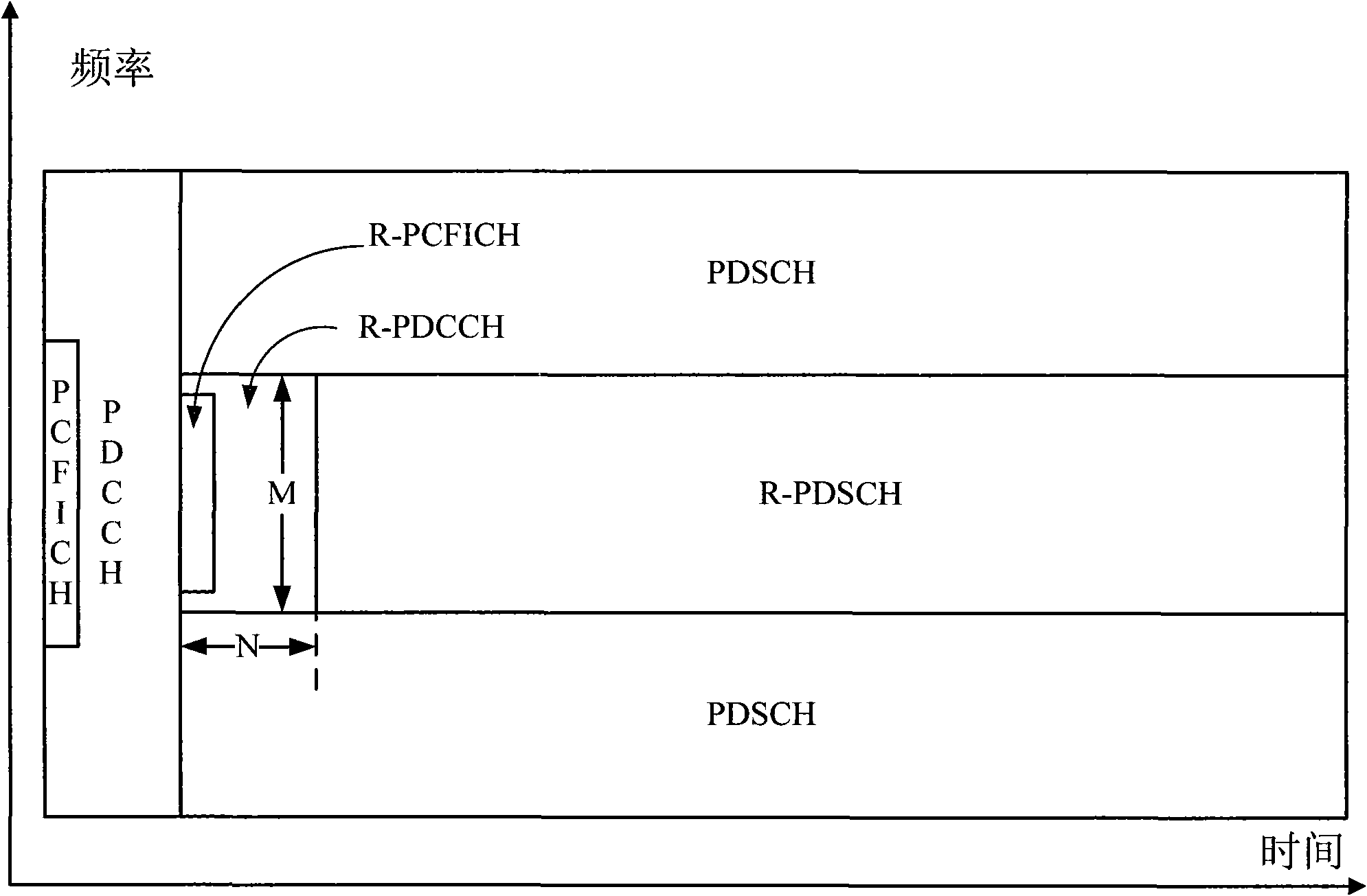

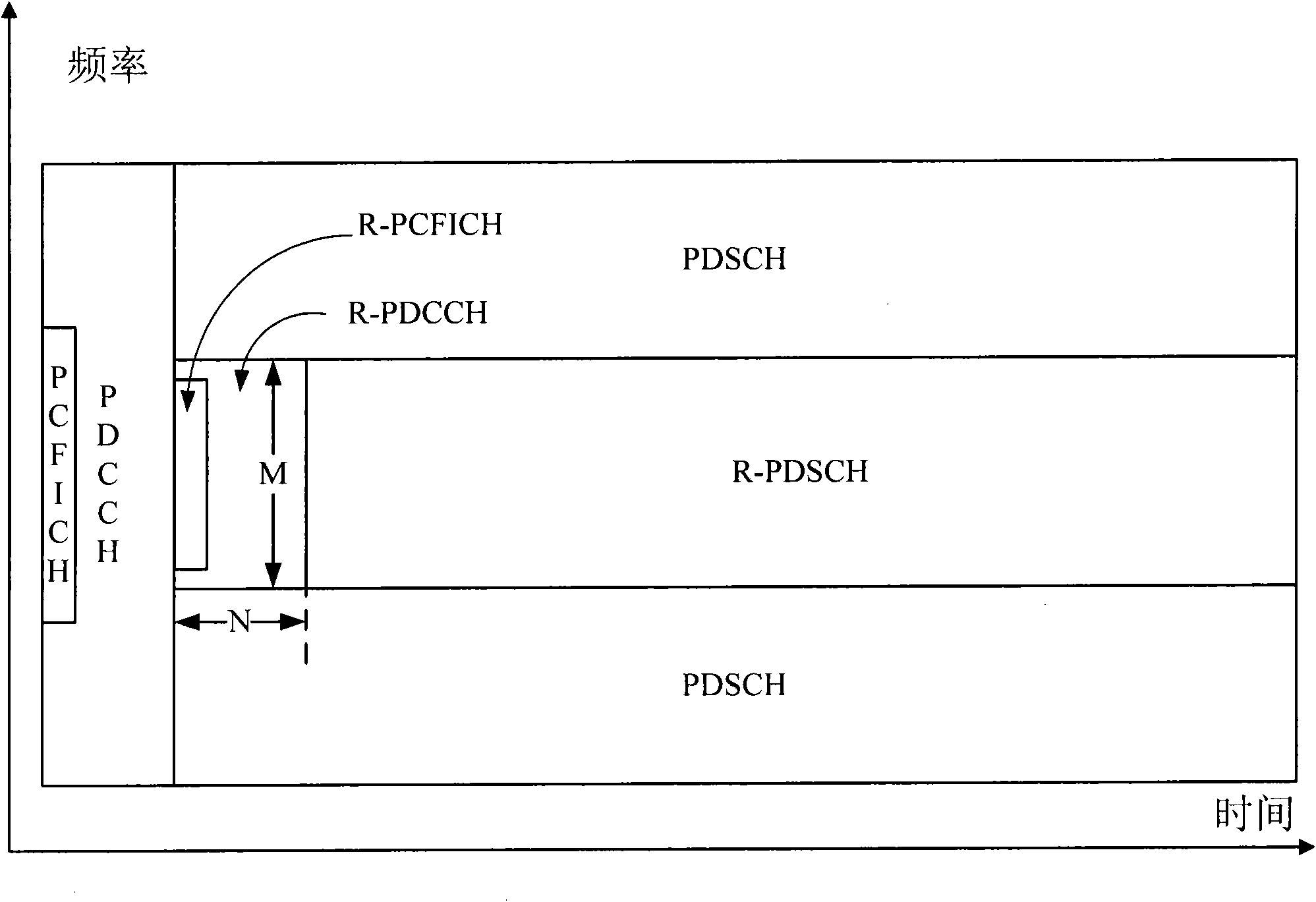

Method and device for controlling downlink subframe and transmitting data of trunk link

ActiveCN101868033AMeet the design requirementsMulti-frequency code systemsWireless communicationResource blockControl channel

Owner:DATANG MOBILE COMM EQUIP CO LTD

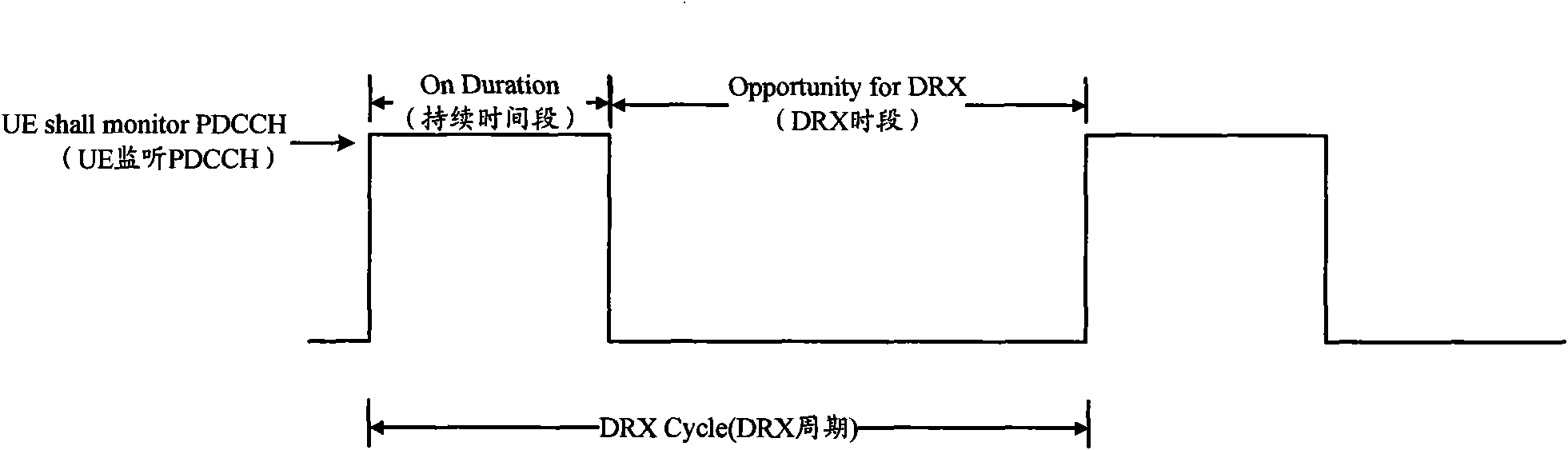

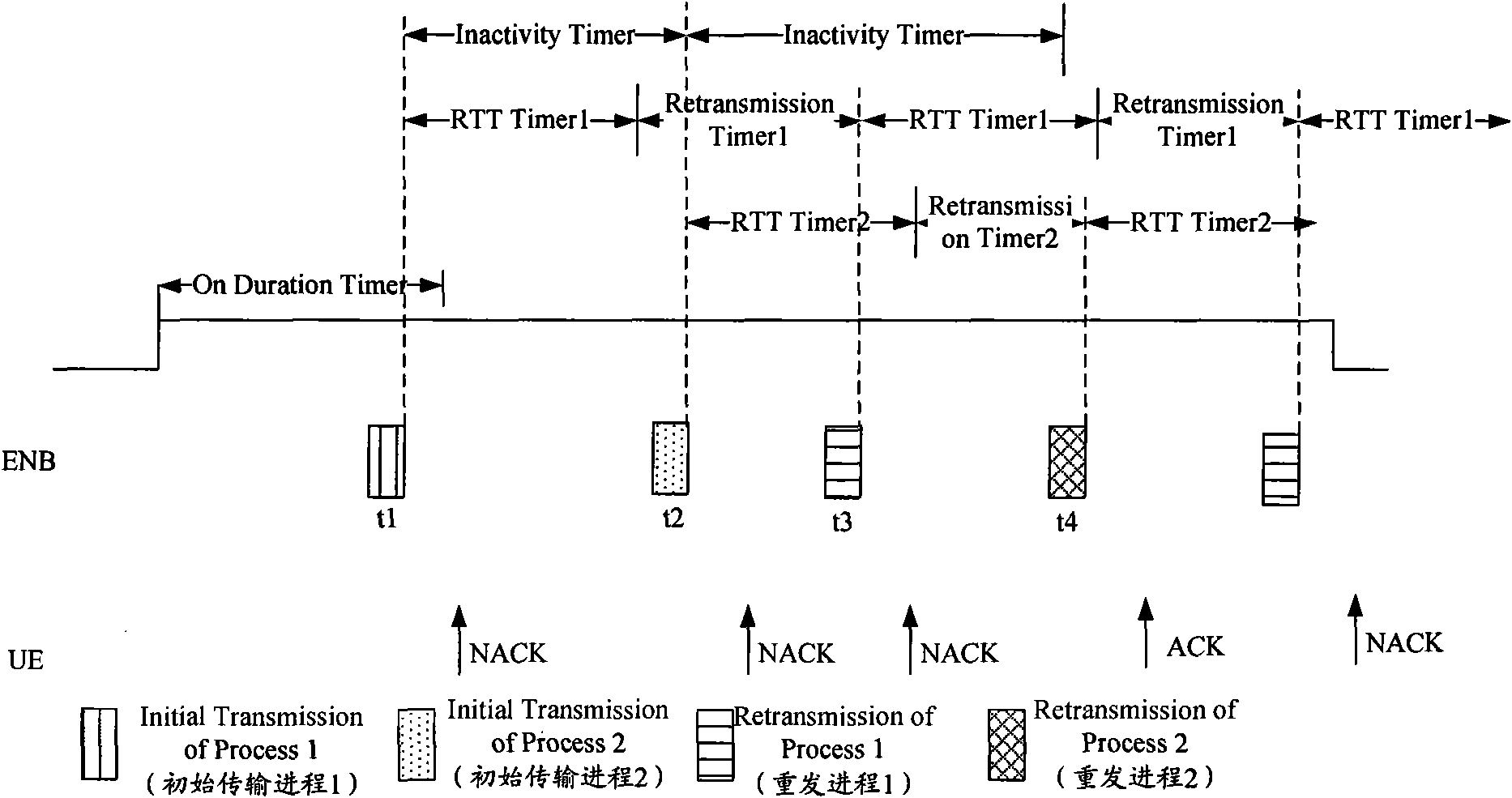

Discontinuous reception processing method and equipment

ActiveCN101965037AFlexible schedulingEffective power savingPower managementCurrent supply arrangementsTelecommunicationsFlexible scheduling

The invention discloses a discontinuous reception processing method and discontinuous reception processing equipment. The discontinuous reception processing method comprises that: in a multicarrier aggregation system, an evolved NodeB (eNB) determines to send a Physical Downlink Control Channel (PDCCH) CC set used aiming at a scheduling signaling of certain User Equipment (UE) and determines a Physical Downlink Shared Channel (PDSCH) CC set required for use and the number of PDSCH CC activated in the PDSCH CC at any time according to a data rate required by the UE; the eNB sends the scheduling signaling to the UE according to a Discontinuous Reception (DRX) parameter through the PDCCH CC set, wherein the scheduling signaling indicates at which time-frequency resources of the PDSCH CC set the UE receives data; and the UE periodically monitors the PDCCH CC set according to the DRX parameter, and receives the data on the PDSCH CC set according to the scheduling signaling acquired by the monitoring. Through the mode, the scheme provided by the method provides a discontinuous reception mechanism under a multicarrier aiming at Rel-10UE, and the mechanism is suitable for PDCCH 1a and PDCCH 1b, and can ensure flexible scheduling and effectively save the power at the same time.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Acknowledgment transmissions under cross-subframe resource allocation in lte-a

ActiveUS20110286406A1Error prevention/detection by using return channelSignal allocationControl channelData transmission

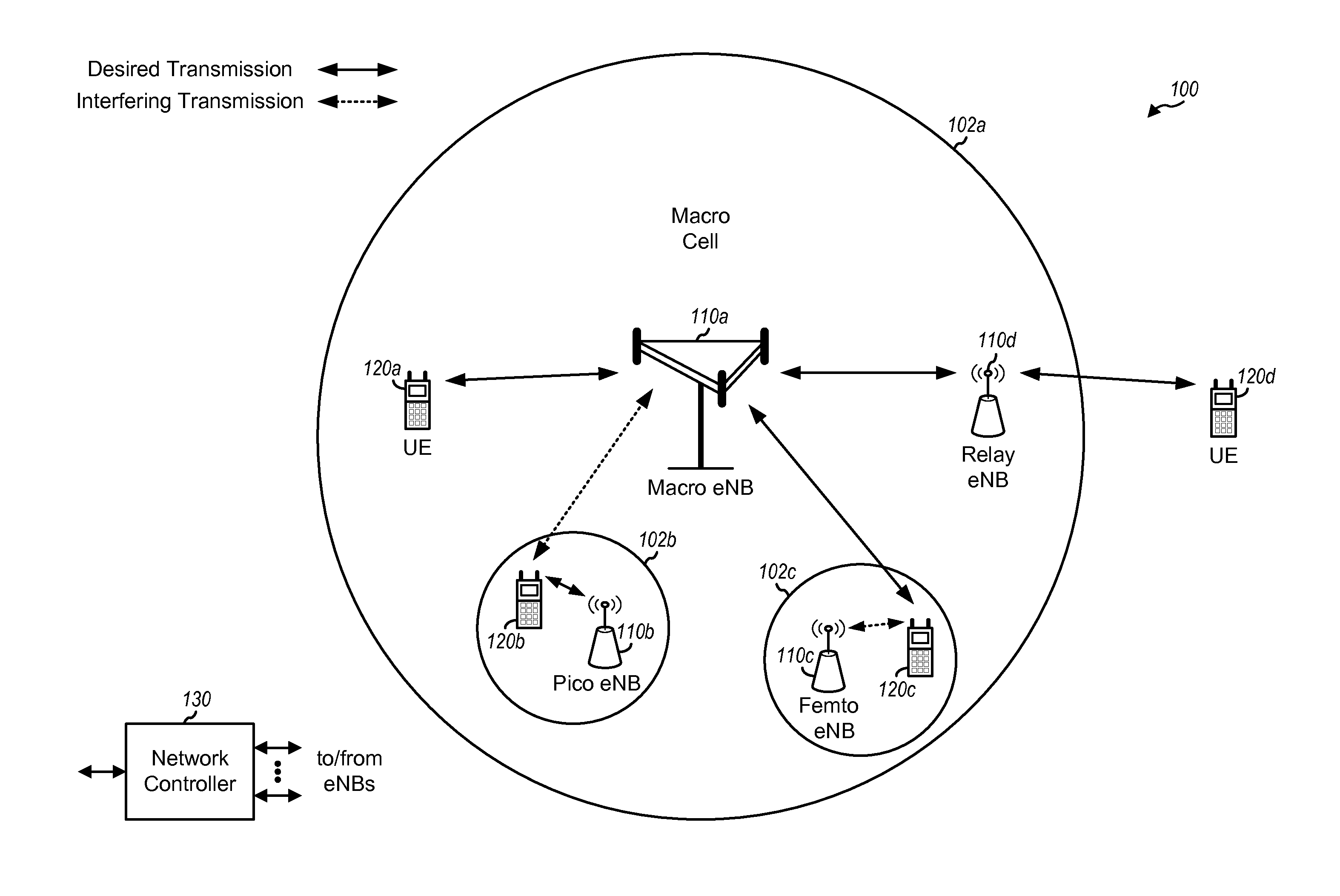

In release 8 of the LTE standard (“Rel-8”), downlink data transmissions of one or more user equipments (UEs) in one subframe may be scheduled by control channels of different subframes. The resources for use in acknowledging whether or not a downlink data transmission was successfully received by a UE may be based on a starting control channel element (CCE) of a corresponding control channel. Two or more control channels of different subframes may have the same starting CCE, which may lead to acknowledgment resource collisions between the one or more UEs. Therefore, certain aspects of the present disclosure provide techniques to avoid acknowledgment resource collisions between the one or more UEs.

Owner:QUALCOMM INC

Flame-retartant coating

The invention relates to a flame-retardant coating which forms an insulating layer and is based on substances which carbonize and form a foam layer in the event of a fire, on film-forming binders, on blowing agents and on customary auxiliaries and additives, wherein the blowing agent present comprises melamine polyphosphate. The novel flame-retardant coating which forms an insulating layer is particularly stable under tropical conditions (up to 100% rel. humidity, about 75° C.), i.e. it releases only an extremely small amount of NH3.

Owner:CLARIANT PROD DEUT GMBH

Vehicle forward collision warning method based on vehicle networking technology

ActiveCN103350670AAccurately obtain real-time locationAccurately get the environmentElectric/fluid circuitRear-end collisionReal-time data

The invention discloses a vehicle forward collision warning method based on a vehicle networking technology. The method includes the following steps: (1) collecting real-time data through a vehicle-mounted terminal device; (2) adjusting a dynamic threshold value: adjusting the value of a dynamic regulation factor of vehicles according to vehicle disposition information, driver information, sensor information, real-time positions of the vehicles and road types; (3) calculating the theoretical safe distance S(safe) between two vehicles, wherein V(sv) is a vehicle speed acquired through a CAN bus, T(r) is the dynamic regulation factor, V(rel) is the absolute value of the relative speed of the two vehicles, TTC is a time from the current time to a collision time, and the time can be configured through the vehicle-mounted terminal device so as to reflect the warning sensitivity level of the system; (4) carrying out judgment and warning: comparing the theoretical safe distance with a real vehicle distance acquired by a distance measuring sensor, and sending out warning information if the real vehicle distance is smaller than the theoretical safe distance. The method guarantees objectivity and accuracy of a calculation model to the maximum and avoids rear-end collisions most accurately.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

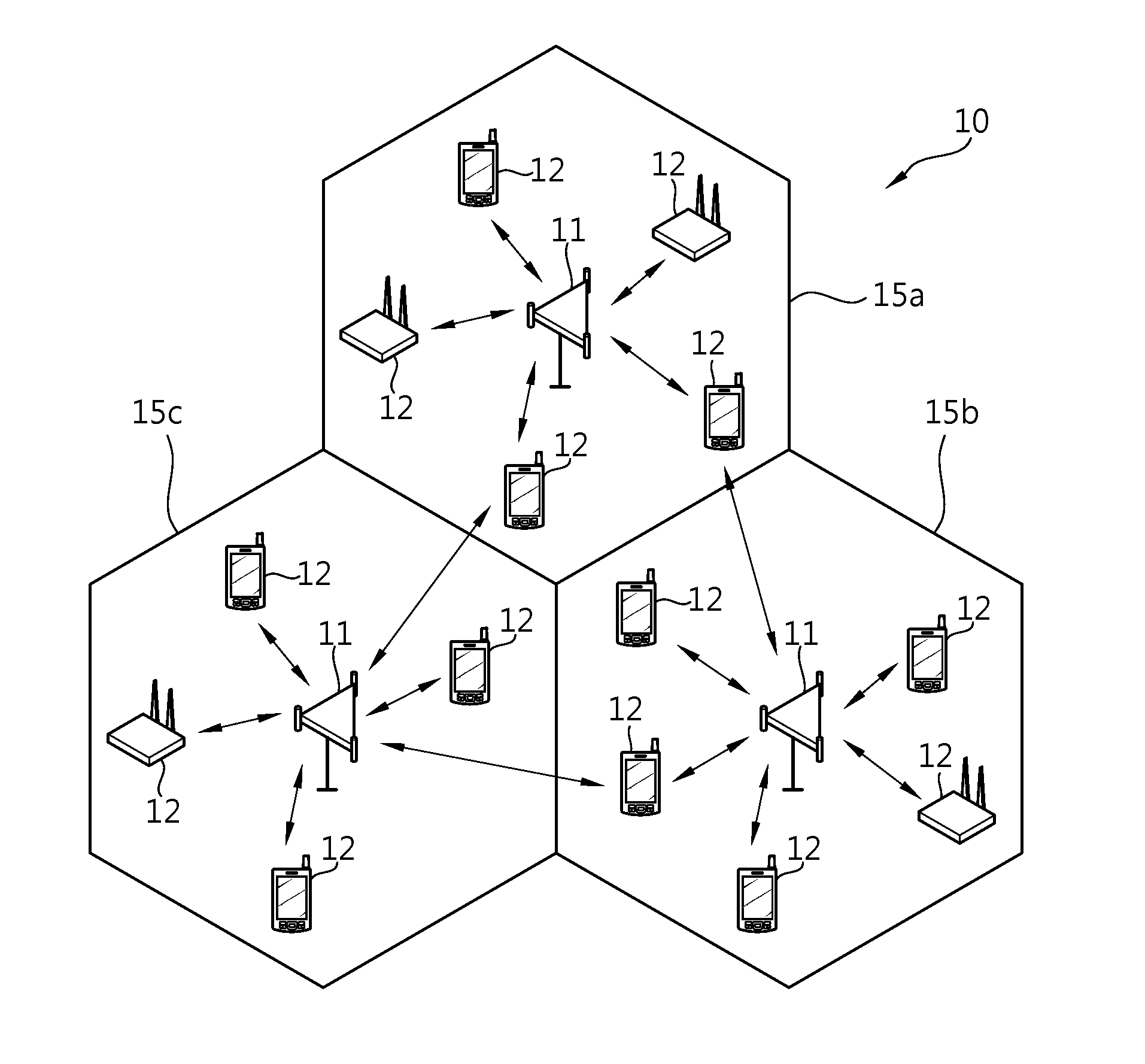

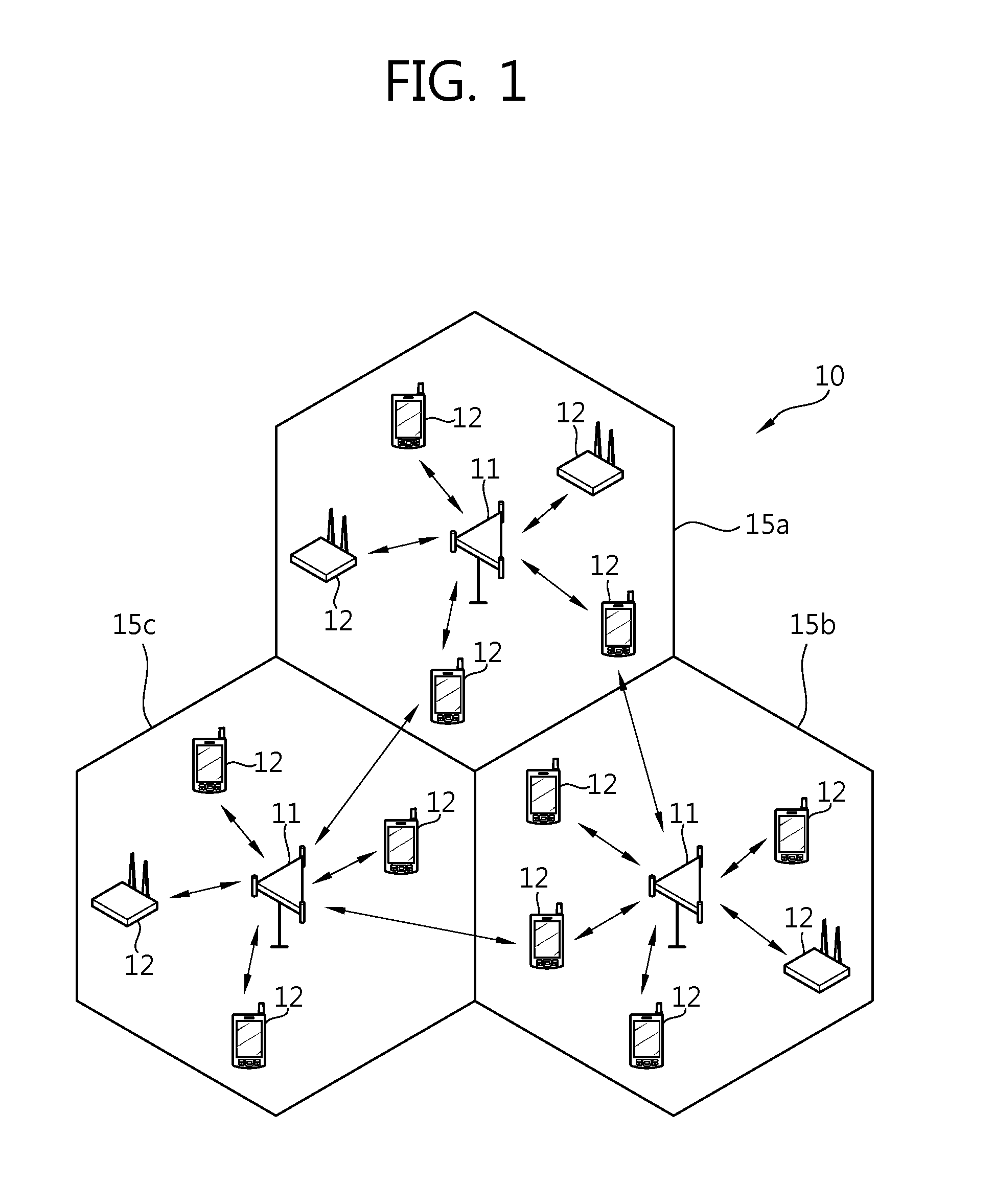

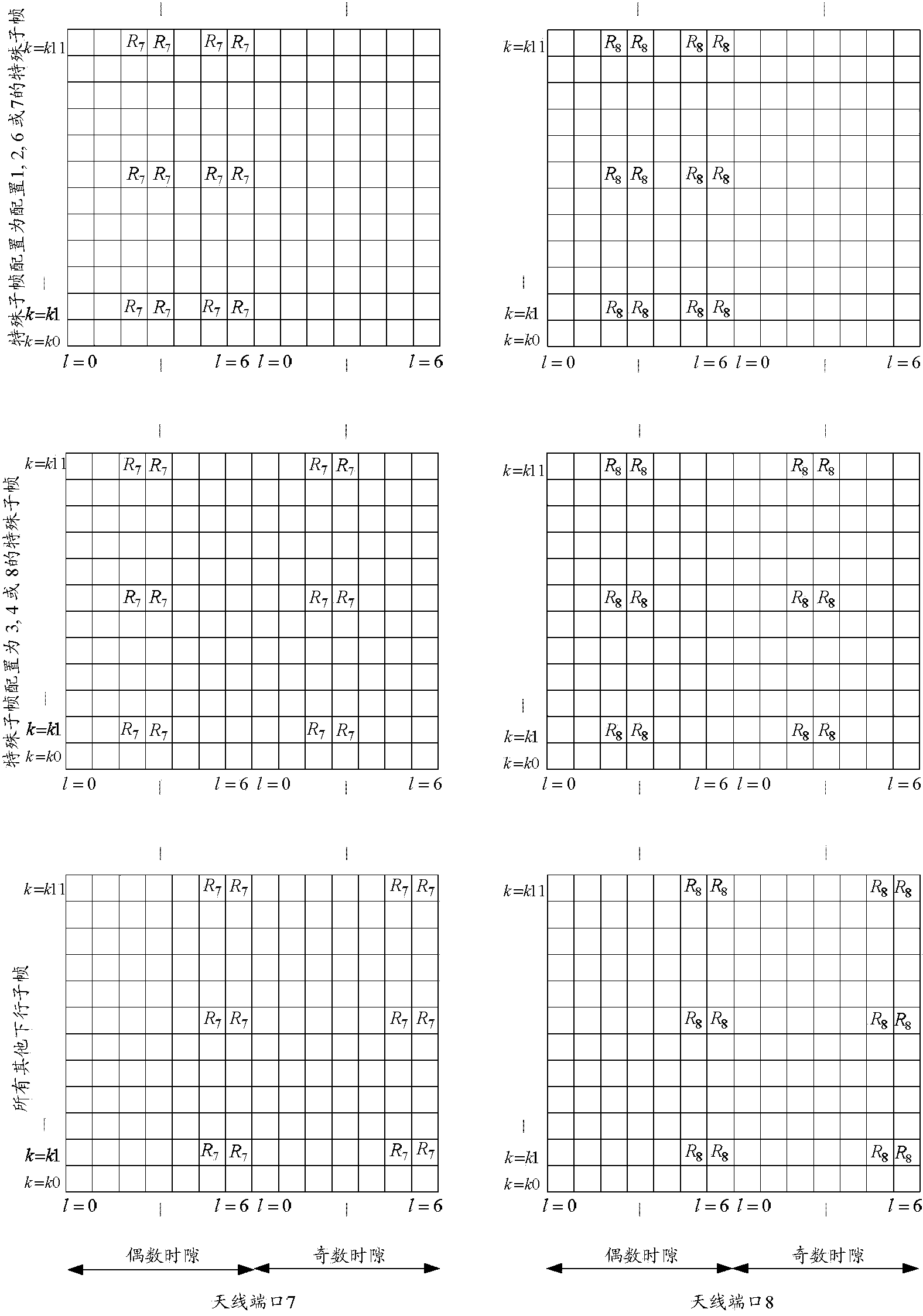

Method and apparatus for transmitting reference signal in wireless communication system including relay station

ActiveUS20120113889A1Reduce signaling overheadFrequency-division multiplex detailsTransmission path divisionVIT signalsREL

Provided are a method and an apparatus for transmitting reference signals in a wireless communication system including a relay station. A base station respectively generates a plurality of reference signals for a plurality of antenna ports, maps the plurality of reference signals into relay zones within at least one resource block according to predetermined reference signal patterns, and transmits the at least one resource block through the plurality of antenna ports. At this point, the plurality of reference signals includes at least one cell-specific reference signal (CRS) of a 3rd generation partnership project (3GPP) long-term evolution (LTE) Rel-8 system.

Owner:LG ELECTRONICS INC

Microalloy HRB500E steel bar containing chrome and nitrogen and production method thereof

The invention discloses a microalloy HRB500E steel bar containing chrome and nitrogen and a production method thereof. By fully utilizing the strengthening effect and the corrosion-proof effect of chrome on the steel bar, solid solution strengthening elements, namely manganese and silicon, are partially substituted, and a microalloy element, namely vanadium or columbium is partially or fully substituted; a cheap nitrogen element is used for performing microalloy treatment on the steel bar, so that the micro nitrogen separating strengthening effect is achieved; by the production method, the HRB500E steel bar can be produced; Rel of the steel bar is 520 to 580MPa, Rm of the steel bar is 640 to 730 MPa, A is 22 to 32 percent, Rm / Rel is 1.30 to 1.40, the cold bending qualified rate is 100 percent, the welding carbon equivalent weight is less than or equal to 0.50, and the comprehensive cost of one ton of steel bar is 40-100 yuan lower than that of one ton of the steel bar produced by the conventional method; during aging of three months, the fluctuation values of the Rm value and the Rel value are less than 10MPa; and the steel bar has excellent welding performance and good corrosion-proof property.

Owner:长沙东鑫环保材料有限责任公司

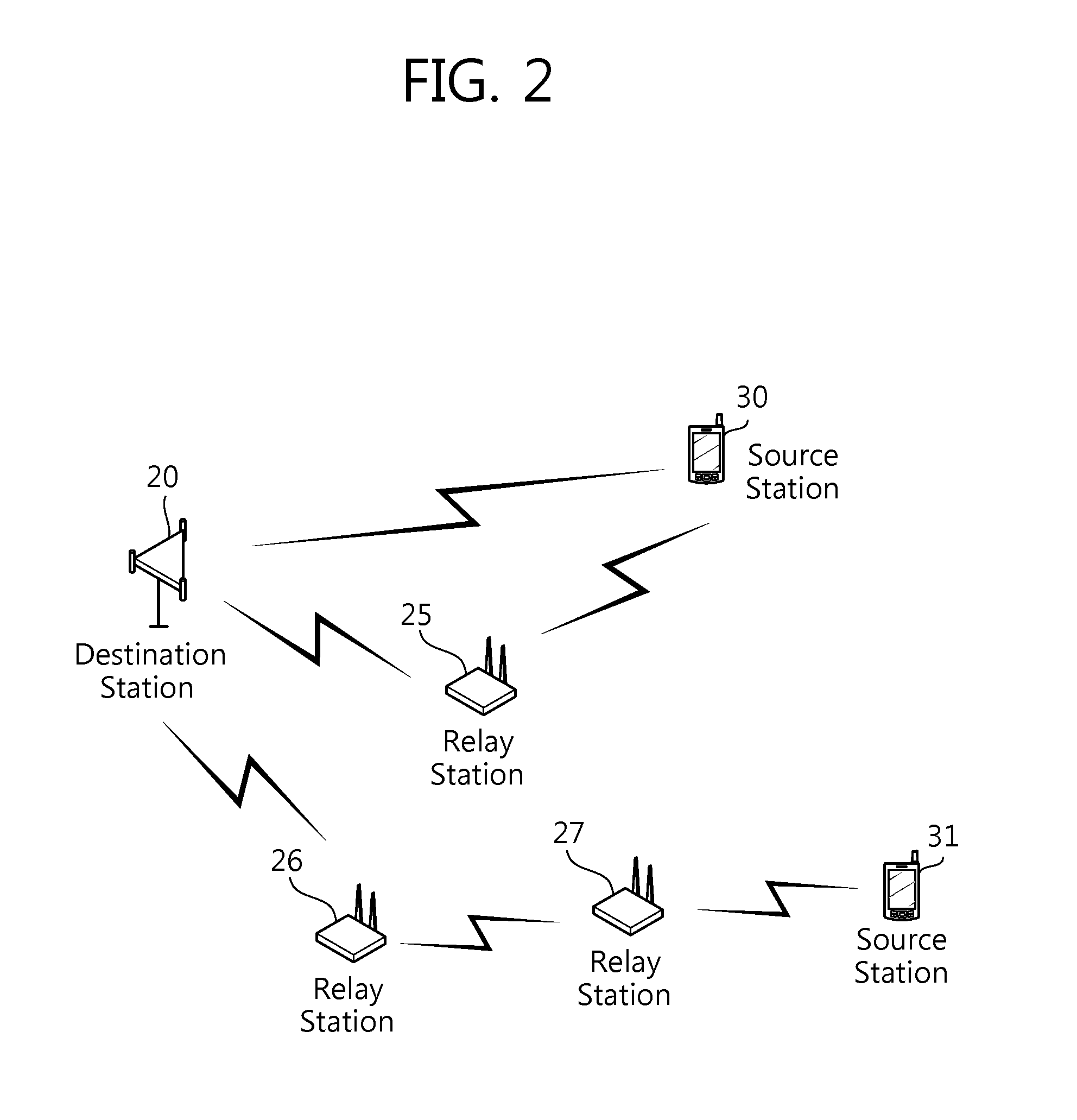

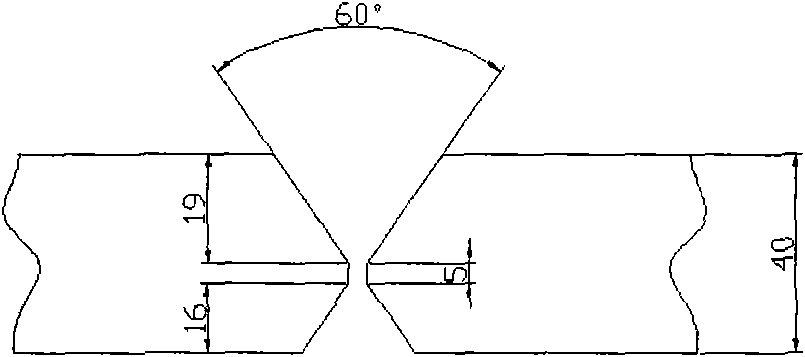

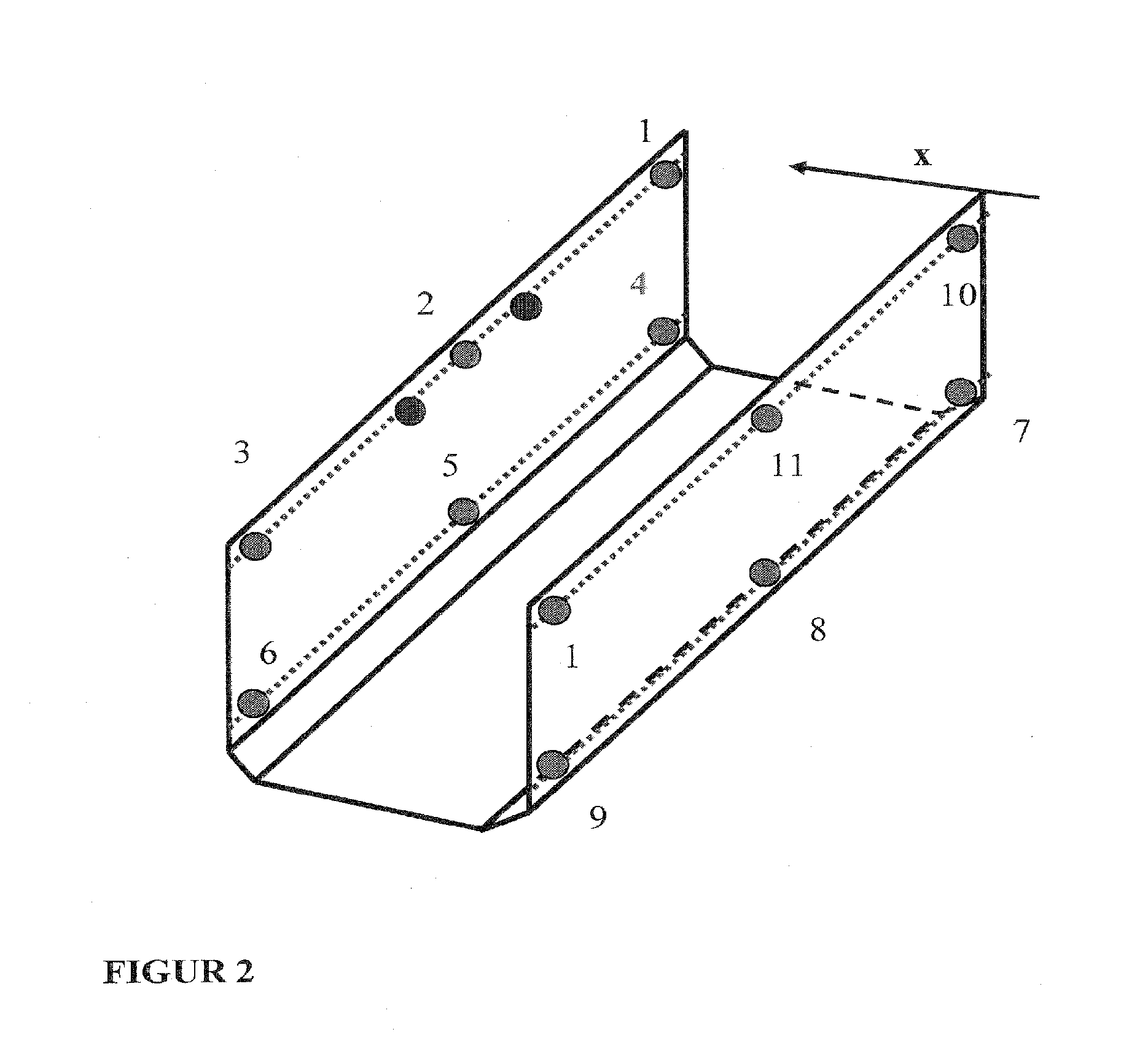

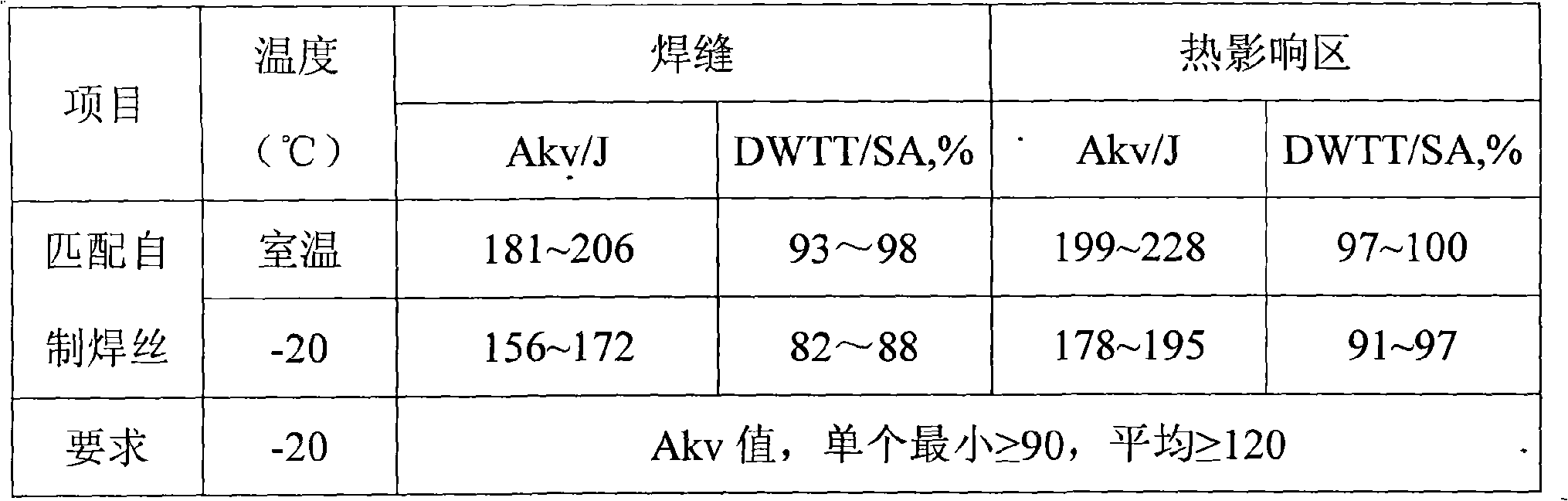

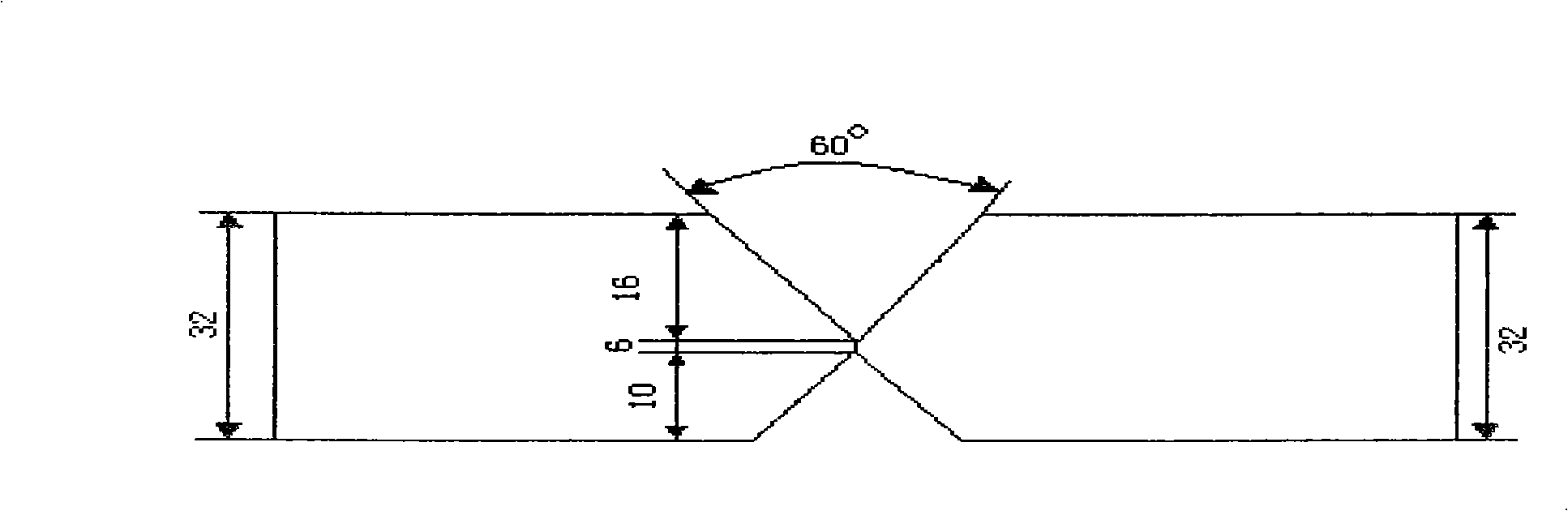

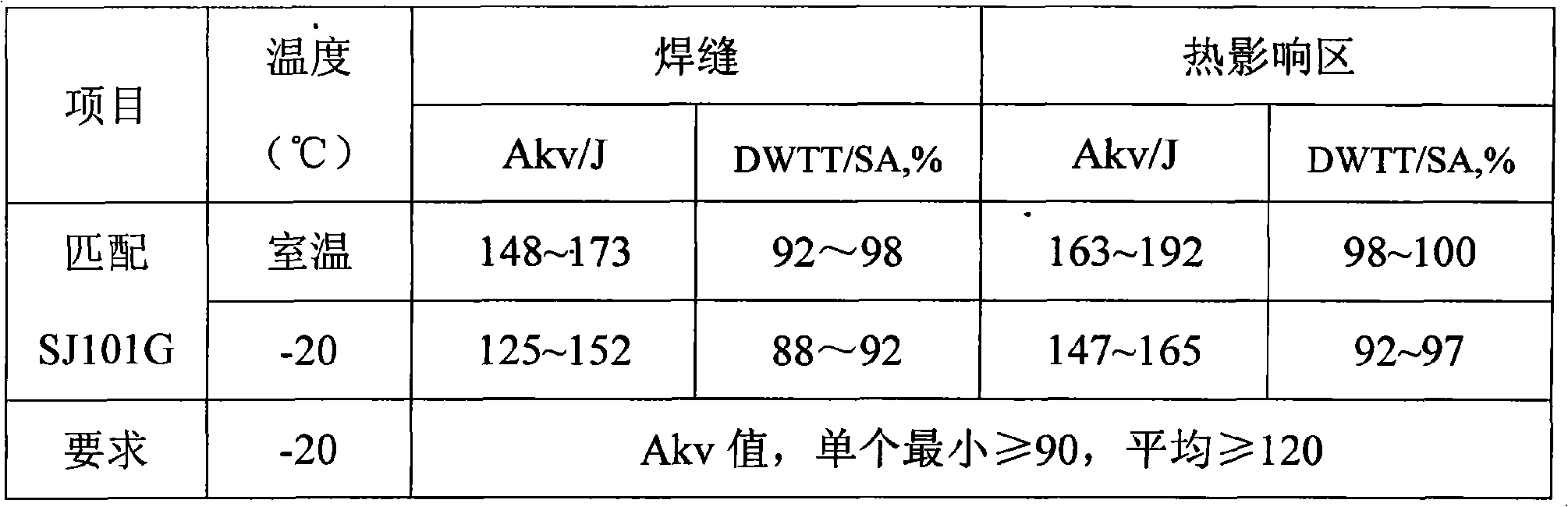

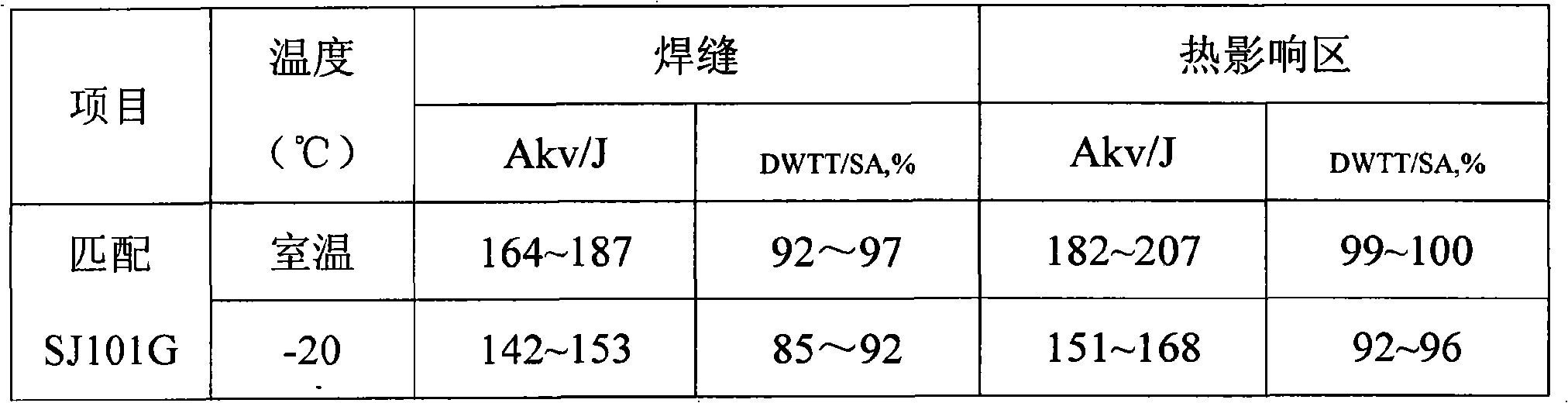

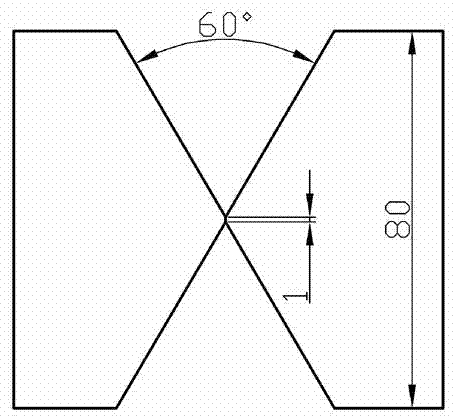

Butt joint submerged-arc welding method of bridge steel with tensile strength more than 690Mpa grade

InactiveCN101658970AHigh tensile strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsButt jointWeld seam

The invention relates to a butt joint submerged-arc welding method of bridge steel with tensile strength more than 690Mpa grade, overcoming the defects that at the present, bridge steel and other engineering structural steel which are in 690Mpa strength grade needs preheating before welding and heat treatment after welding and has severe welding environment and the like during manual and gas protective welding. The butt joint submerged-arc welding method comprises the following steps: adopting steel with tensile strength Rm of between 690Mpa and 745Mpa, the yield strength ReL of between 550 and 690Mpa, the extension rate A of between 19 percent and 21 percent, KV2 ballistic work of between 165J and 180J at 40 DEG C below zero and the thickness of 40mmm, and adopting same-thickness butting;adopting matched welding wires with the tensile strength more than 690Mpa and diameter phi of 4.0mm, and using CHF105 as a welding flux; adopting a double-sided X-type asymmetrical submerged-arc welding groove with the angle of 60 degrees and the truncated edge of 5mm; continuously welding until welding seams are full, and under the conditions that the welding current is 570A, the voltage is 31V,the speed is 35cm / min and the linear energy is 30kj / cm; baking the welding flux for 1 hour at 350DEG C and keeping the temperature of welding layers between 100 DEG C and 150DEG C.

Owner:武钢集团有限公司

High-strength thin steel plate produced by CSP (cast steel plate) process and preparation method of plate

ActiveCN102965573AImprove wear resistanceMeeting the demands of high-strength steelSheet steelLaminar cooling

The invention discloses a high-strength thin steel plate produced by a CSP (cast steel plate) process and a preparation method of the plate. The high-strength thin steel plate comprises the following components by percent: 0.15-0.25 of C, not larger than 0.10 of Si, 1.00-1.80 of Mn, not larger than 0.020 of P, not larger than 0.010 of S, 0.09-0.20 of Ti, 0.02-0.08 of Als, and not larger than 0.008 of N; and the metallographic structure is a mixture of 20-35% of perlite, 55-75% ferrite and a little of bainite. The preparation method of the high-strength thin steel plate comprises the following steps of smelting and carrying out continuous cast to form blanks; uniformly heating; rolling; carrying out laminar cooling; and reeling. According to the thin steel plate with a hot-rolled structure, disclosed by the invention, the yield strength (ReL) is not less than 700 MPa, the tensile strength (Rm) is not less than 750 MPa, and the wear resistance is good; and according to the preparation method disclosed by the invention, a hot rolling process can replace a cold rolling process, a thin steel plate can replace a thick steel plate, and the prepared high-strength thin steel plate can totally meet requirements of high-strength steel for an engineering structure.

Owner:武汉钢铁有限公司

Method and apparatus for reporting power headroom in carrier aggregation scenario

Disclosed are a method and an apparatus for reporting power headroom in a carrier aggregation context. By applying the technical solutions of the embodiments of the present invention, PHR MAC CE and a corresponding MAC sub-header are determined according to the number of uplink component carriers needing to report power headroom and a type of the power headroom to be reported, and indication information such as length information of the PHR MAC CE, type information of the power headroom, and information about whether the power headroom is virtual power headroom is carried therein, so that a base station can precisely obtain the power headroom of each uplink component carrier. In this way, the problem that the PHR MAC CE format in the current LTE Rel-8 / 9 is not applicable to an LTE-A system is solved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Polyamide molding materials reinforced with glass fibers and injection molded parts thereof

ActiveUS20110240930A1High transversal rigidityLow viscosityMaterial nanotechnologyConductive materialFiberCarbon fibers

The present invention relates to reinforced polyamide molding materials with high notch impact strengths, comprising low viscous polyamides and flat glass fibers as a reinforcing medium, characterized in a polyamide matrix, comprising the following components: (A) 0 to 60 wt.-% of at least one aliphatic, partly crystalline polyamide with a solution viscosity, measured in m-cresol (0.5 wt-%), of ηrel less than 1.9, (B) 0 to 60 wt.-% of at least one amorphous or microcrystalline polyamide based on aliphatic, cycloaliphatic or aromatic diamines, dicarboxylic acids, lactams and / or aminocarboxylic acids, preferably with 6 to 36 carbon atoms, or a mixture of such homopolyamides and / or copolyamides, wherein the components (A) and (B) fulfill the condition: (A)+(B)=20 to 60 wt.-% and that, in the case of a mixture of components (A) and (B), at least 50 weight parts aliphatic blocks (A) are present in the mixture, and a filler component, comprising: (C) 40 to 80 wt.-% flat glass fibers with elongated shape, and the glass fibers have a non-circular cross-sectional area and a size ratio of the main cross-sectional axis to the secondary cross-sectional axis of between 2 to 5, particularly between 3 and 4, and (D) 0 to 40 wt.-% particle like or layer like fillers, with the prerequisite that carbon fibers are excluded, wherein the polyamide molding materials optionally comprise up to 5 wt.-% of further usual additives and auxiliary agents (E), and wherein the weight of the components (A) to (E) sums up to 100%.

Owner:EMS CHEM AG

Low-cost and high-strength steel for automobile crossbeam and manufacturing method thereof

ActiveCN101805873AFully solid solutionLow costTemperature control deviceManufacturing convertersRELImpact toughness

The invention relates to a low-cost and high-strength steel for automobile crossbeam and a manufacturing method thereof. The automobile crossbeam comprises the following components by weight percent: C: 0.04-0.10%; Si: 0.2%-0.5%; Mn: 1.4-2.0%; P: less than 0.015%; S: less than 0.01%; Ti: 0.08-0.15%; Nb: 0.04-0.07%; N: less than 0.005%; O: less than 0.002% and the balance of Fe. The components for producing the automobile crossbeam are rolled by controlled rolling and cooling technology and can achieve the following comprehensive properties: ReL: 700-800MPa, delta >=18%.In addition, the components feature in excellent cold-bending and welding property, can meet manufacturing requirements of steel for the automobile crossbeam and enjoy excellent impact toughness.

Owner:SHANDONG IRON & STEEL CO LTD

Submerged arc welding flux material for X80 pipeline steel and preparing method thereof

InactiveCN101549445AEasy to getVarious sourcesArc welding apparatusWelding/cutting media/materialsWeld seamUltimate tensile strength

A submerged arc welding flux material for X80 pipeline steel comprises the following components according to weight percentage: 15 percent to 25 percent of CaF2, 15 percent to 30 percent of MgO, 10 percent to 14 percent of Al2O3, 5 percent to 10 percent of CaSiO3, 5 percent to 9 percent of SiO2, 5 percent to 10 percent of MnO, 5 percent to 10 percent of TiO2, 1.0 percent to 2.5 percent of Na2O, 1.5 percent to 3.0 percent of B2O3, 0.2 percent to 0.4 percent of Re(Mg) and 6 percent to 10 percent of ZrO2, wherein the weight percentage of CaSiO3 plus SiO2 is less than or equal to 15 percent of the total weight of all the components, and the residual is mineral powder impurity. When being matched with alkali sintered flux for use, the welding flux material that is obtained by adopting a sintering method has the properties of strong weld seam strength, better H2S stress corrosion resistance and better low-temperature flexibility, the weld seam strength and the flexibility can be matched with substrate of high-grade pipeline steel, and the material is suitable for welding pipeline steel with the strength level ReL of more than or equal to 555 MPa and above and other structural steel.

Owner:XIAN UNIV OF TECH

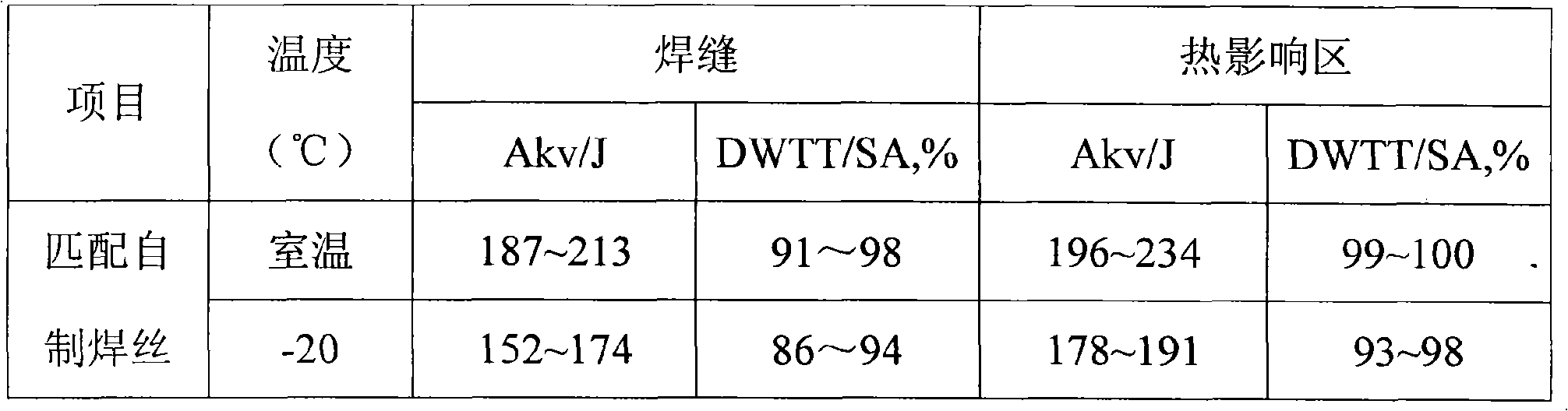

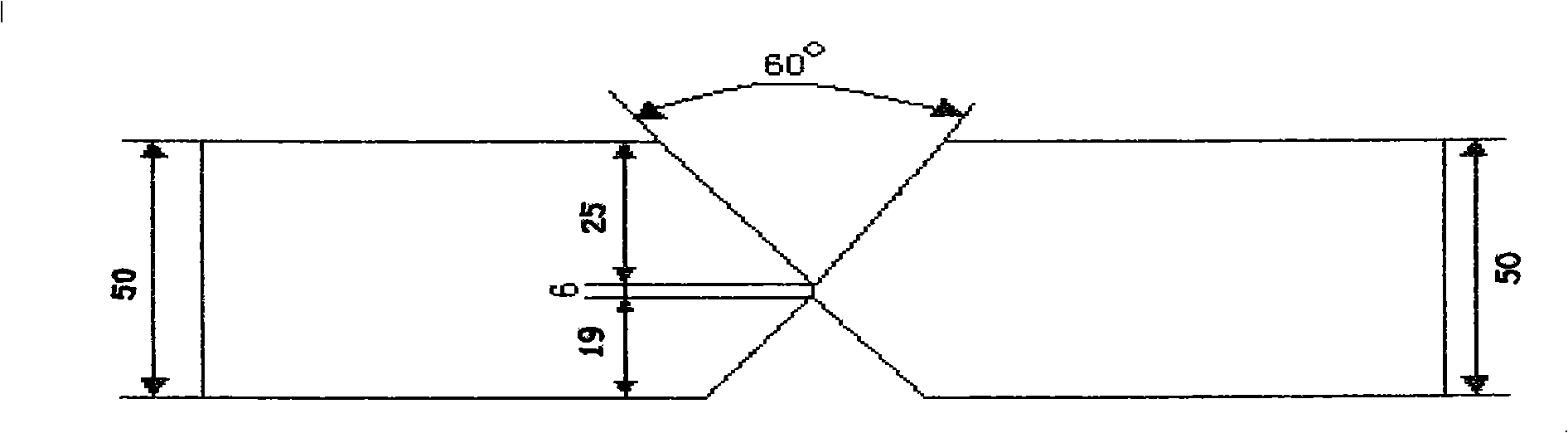

Submerged arc welding method of bridge steel of different intensity scale

InactiveCN101337301AImprove toughnessImprove securityArc welding apparatusWelding/cutting media/materialsSheet steelIntensity scaling

The invention discloses a hidden arc welding method for bridge steel at different levels of strength, which adopts two steel types with different tensile strengths, namely 510-550MPa and 570-650MPa as the subject of hidden arc welding; an X-type asymmetric divided edge is adopted as the divided edge of hidden arc welding; the adopted steel types are 14MnNbq steel and WNQ5709 steel; the yield strength ReL of the 14MnNb steel is 370-415MPa, the tensile strength Rm thereof is 510-550MPa, the unit extension A thereof is 20-35%, and the -40 DEG C AKV impact energy thereof is 120-290J; the yield strength Rel of the WNQ570 steel is 420-560MPa, the tensile strength Rm thereof is 570-650MPa, the unit extension A thereof is 18-27%, and the -40 DEG C AKV impact energy thereof is 120-270J; the thickness of steel plates is 32-60mm; the angle of the divided edge is 60 DEG; and the length of the truncated edge is 6mm. The hidden arc welding method meet the requirements for using the key hidden arc welding technique to manufacture dissimilar steel joints with a novel bridge structure of large-span, heavy-duty, high-speed, high-strength and high-tenacity. The joints made through hidden arc welding have good tensile strength and cold-bending performance; the impact energy of the three areas of the joint reaches a high level; and the joints have relatively high impact tenacity reserve and safety margin.

Owner:武钢集团有限公司

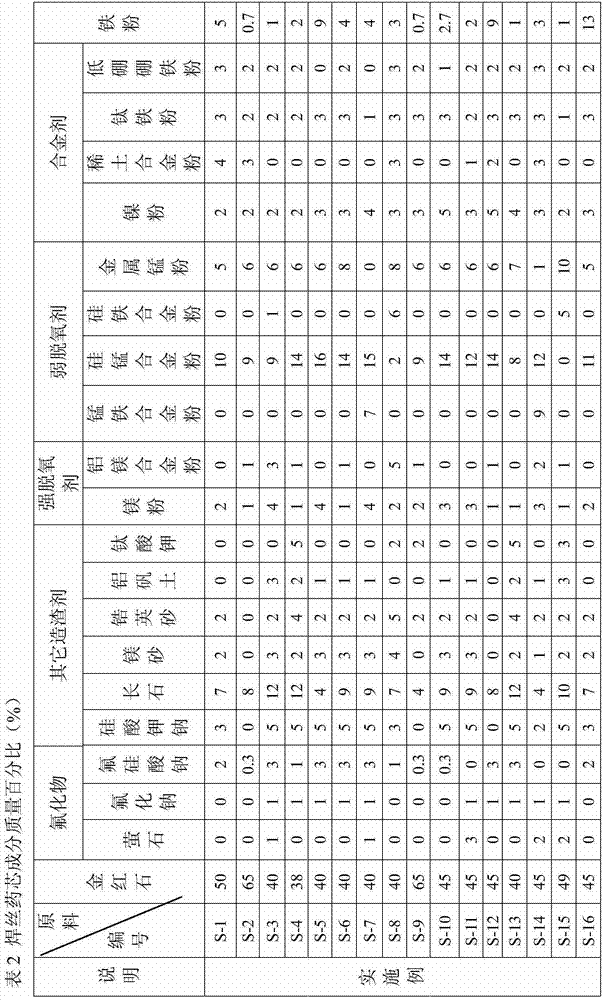

Gas-shielded flux-cored wire for maritime engineering

The invention discloses a gas-shielded flux-cored wire for maritime engineering. The flux-cored wire consists of a low-carbon steel outer skin and a flux core, wherein the flux core comprises the following components in percentage by mass: 40 to 65 percent of rutile, 0.3 to 5 percent of fluoride, 8 to 30 percent of other slag forming constituent, 2 to 7 percent of strong deoxidizer, 15 to 22 percent of weak deoxidizer, 3 to 12 percent of alloying agent and the balance of iron powder, and the alloying agent at least contains nickel powder which accounts for 2 to 5 percent of the total mass of the flux core. The flux-cored wire disclosed by the invention is good in manufacturability and mechanical property which reach the standard level of the titanium type flux-cored wire of which the main flux powder raw material is rutile, the yield strength Rel is greater than or equal to 375Mpa, the tensile strength Rm is 495 to 660Mpa, the elongation percentage A is greater than or equal to 22 percent, and the impact absorbing energy Akv(20 DEG C below zero) under the condition of 20 DEG C below zero is greater than or equal to 100J.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

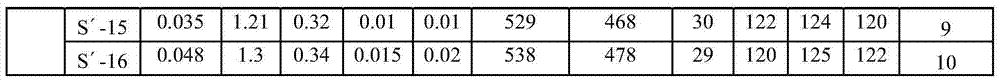

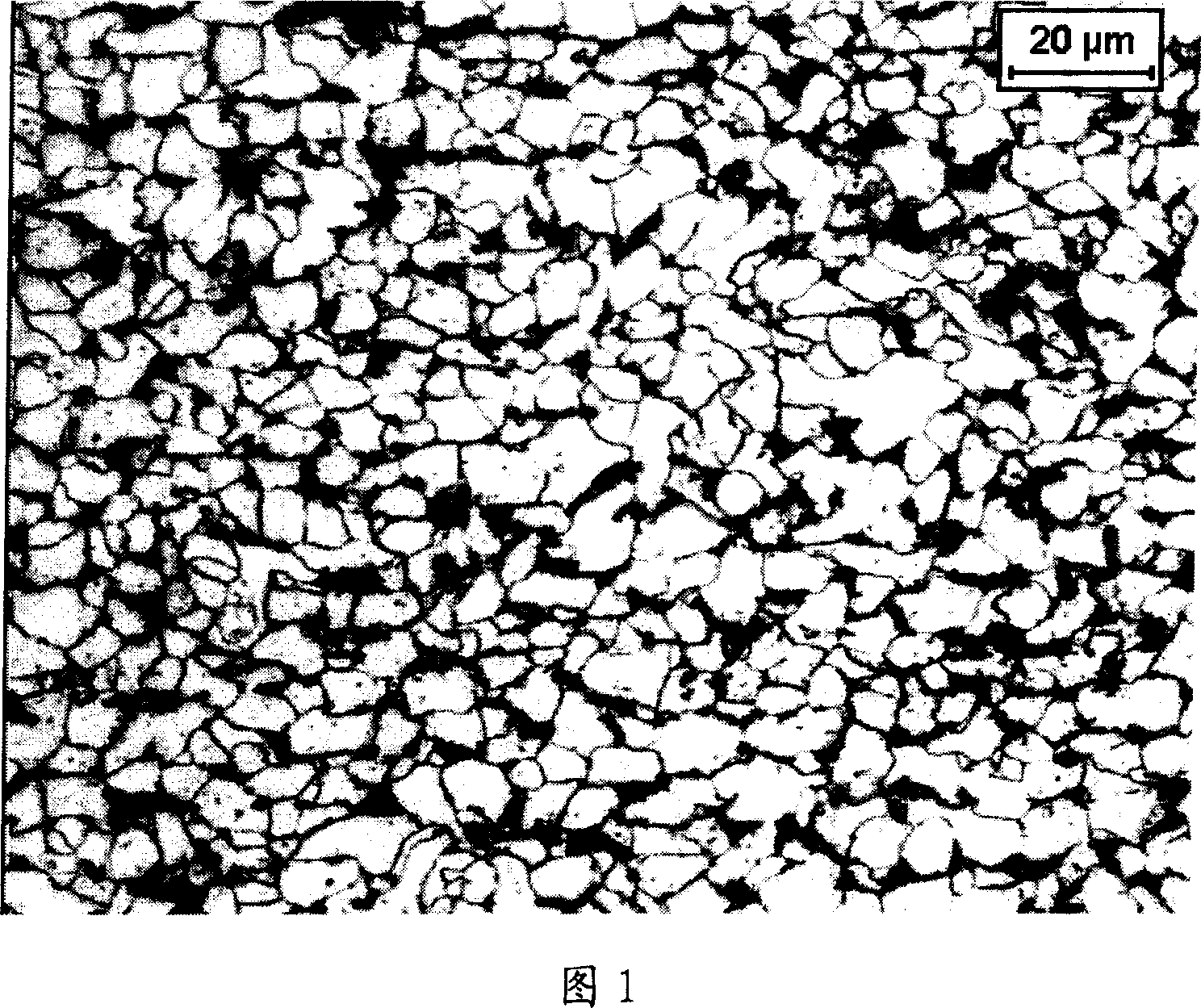

Process for manufacturing low yield strength ultrafine grain belt steel

InactiveCN1928130ASolve technical problemsTemperature control deviceHeat treatment process controlStrip steelConductor Coil

The present invention discloses making process of low yield / tensile ratio superfine grain band steel, and the making process can lower the yield / tensile ratio of the band steel effectively while ensuring fined grain. The making process includes the following steps: heating the carbon manganese steel billet to 1150-1200 deg.c; rolling in the initial rough rolling temperature of 1050-1150 deg.c, final rough rolling temperature of 1000-1050 deg.c, initial precision rolling temperature of 950-1000 deg.c, and final precision rolling temperature of 830-870 deg.c; fast cooling the rolled band steel to 710-735 deg.c at the cooling speed of 20-40 deg.c / s, slowly cooling for 3-5 sec, and fast cooling to 650-670 deg.c; and winding. The low yield / tensile ratio superfine grain band steel has yield strength of 295-415 Mpa, tensile strength of 460-510 Mpa, elongation of 26-40 wt%, yield / tensile ratio Rel / Rm not greater than 0.80.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Microalloy HRB400E steel bar containing chrome and nitrogen and production method thereof

The invention discloses a microalloy HRB400E steel bar containing chrome and nitrogen and a production method thereof. By fully utilizing the strengthening effect and the corrosion-proof effect of chrome on the steel bar, solid solution strengthening elements, namely manganese and silicon, are partially substituted, and a microalloy element, namely vanadium or columbium is partially or fully substituted; a cheap nitrogen element is used for performing microalloy treatment on the steel bar, so that the micro nitrogen separating strengthening effect is achieved; by the production method, the HRB400E steel bar can be produced; Rel of the steel bar is 430 to 490MPa, Rm of the steel bar is 570 to 650 MPa, A is 24 to 35 percent, Rm / Rel is 1.30 to 1.40, the cold bending qualified rate is 100 percent, the welding carbon equivalent weight is less than or equal to 0.45, and the comprehensive cost of one ton of the steel bar is 20 to 80 yuan lower than that of one ton the steel bar produced by the conventional method; during aging of three months, the fluctuations of the Rm value and the Rel value are less than 10MPa; the welding performance is excellent; and the steel bar has good corrosion-proof property.

Owner:长沙东鑫环保材料有限责任公司

Submerged arc welding wire material for X80 pipeline steel and preparing method thereof

InactiveCN101549443AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaWeld seamUltimate tensile strength

A submerged arc welding wire material for X80 pipeline steel comprises the following components according to weight percentage: 0.040 percent to 0.060 percent of C, 0.010 percent to 0.200 percent of Si, 1.700 percent to 2.000 percent of Mn, 0.500 percent to 1.000 percent of Ni, 0.200 percent to 0.700 percent of Mo, 0.200 percent to 0.600 percent of Cr, 0.005 percent to 0.040 percent of Ti, 0.100 percent to 0.250 percent of Ce, 0.200 percent to 0.300 percent of Cu and the residual percentage of Fe, and the weight sum of the components is 1.00 percent. When being matched with alkali sintered flux for use, the welding wire material that is obtained by adopting an electric furnace smelting method has the properties of strong weld seam strength, better H2S stress corrosion resistance and better low-temperature flexibility, the weld seam strength and the flexibility can be matched with substrate of high-grade pipeline steel, and the material is suitable for welding pipeline steel with the strength level ReL of more than 555 MPa and above and other structural steel.

Owner:XIAN UNIV OF TECH

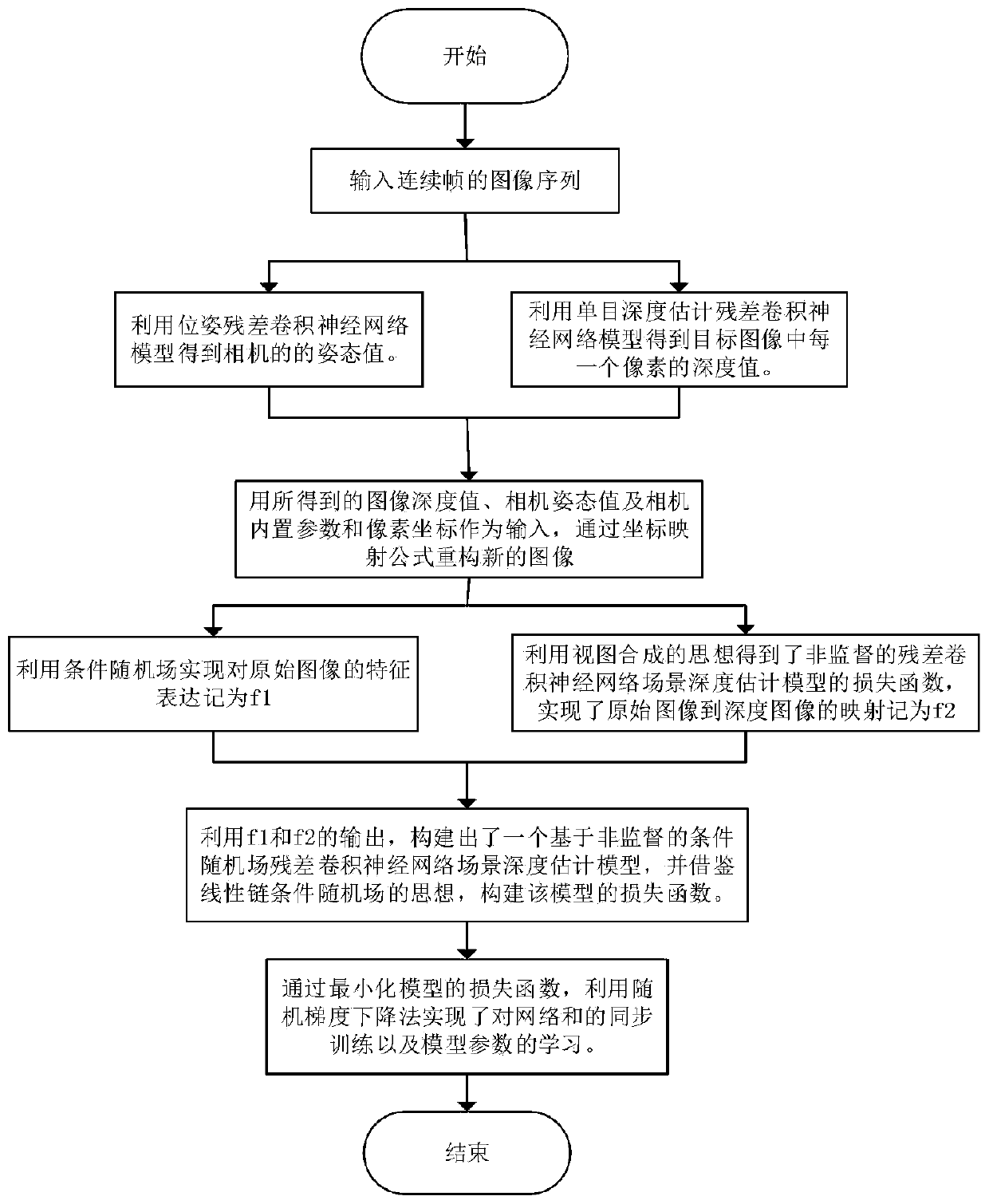

Unsupervised convolutional neural network-based monocular scene depth estimation method

ActiveCN110503680ASolve the problem of manual data labelingSave human effortImage analysisInternal combustion piston enginesConditional random fieldEstimation methods

The invention discloses an unsupervised convolutional neural network-based monocular scene depth estimation method. The method comprises the following steps of obtaining a depth value of each pixel point of a target image; obtaining a camera pose value when the pixel coordinates on the target image are transferred to the next frame of image; constructing a loss function; and performing depth estimation based on an unsupervised conditional random field residual convolutional neural network scene. The problem that manual data labeling is difficult is well solved through an unsupervised method, manpower is saved, and economic benefits are improved. According to the invention, a linear chain conditional random field thought is adopted to realize feature expression of an original image. An unsupervised conditional random field residual convolutional neural network scene depth estimation model is formed by combining an unsupervised residual convolutional neural network scene depth estimationmodel. The model provided by the invention is superior to other three models in average relative error (rel) and accuracy (acc).

Owner:DALIAN MARITIME UNIVERSITY

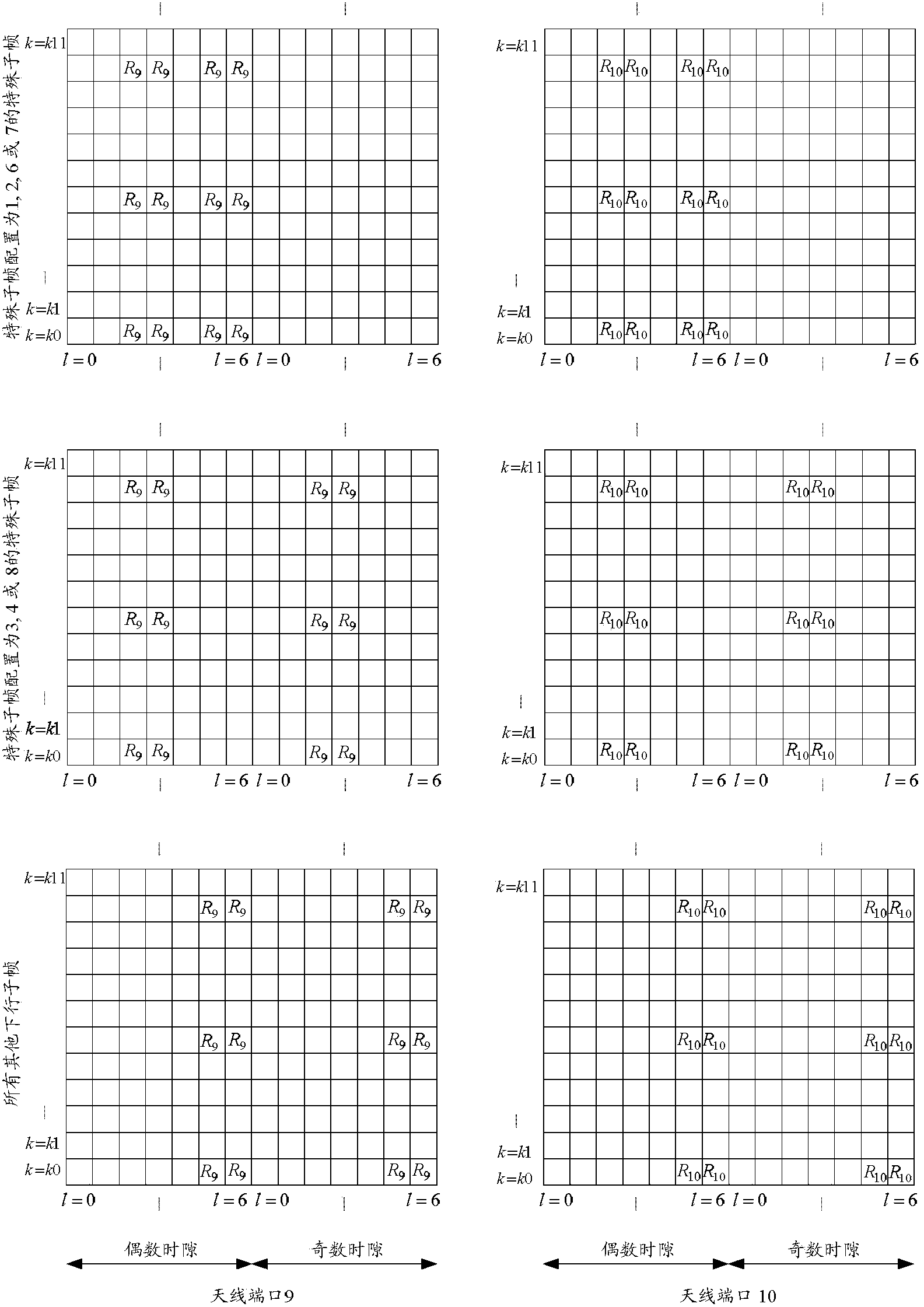

Downlink UE-specific DM-RS transmission method, UE and network-side device

ActiveCN103517345AReduce transmission overheadImprove throughputNetwork traffic/resource managementTransmission path divisionComputer scienceREL

The invention discloses a downlink UE-specific DM-RS transmission method, UE and a network-side device. The method comprises: according to a pre-appointment of the UE and a network side, or according to configuration information sent by the network side, determining a DM-RS resource mapping manner used by a downlink channel, the DM-RS resource mapping manner comprising a first class DM-RS resource mapping manner and a second class DM-RS resource mapping manner, the first class DM-RS resource mapping manner being a DM-RS resource mapping manner defined in a long term evolution-advanced (LTE-A) Rel-10 system, and the second class DM-RS resource mapping manner being a mapping manner having reduced DM-RS occupied resources relative to the first class DM-RS resource mapping manner; and in a transmission resource of the downlink channel, acquiring DM-RS information according to the determined DM-RS resource mapping manner. According to the present invention, the DM-RS transmission overheads can be reduced, and the throughput can be improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

High-welding-speed sintered flux for submerged-arc welding of X100 pipeline steel and preparation method thereof

InactiveCN102909492AMeet the use requirementsImprove impact toughnessWelding/cutting media/materialsSoldering mediaWeld seamAlloy

The invention discloses a high-welding-speed sintered flux for submerged-arc welding of X100 pipeline steel. The high-welding-speed sintered flux comprises the following components in percent by mass: 19 to 25 percent of CaF2, 25 to 29 percent of MgO, 5 to 8 percent of CaO, 21 to 25 percent of Al2O3, 4 to 8 percent of MnO, 1 to 2.5 percent of SiFe, 1.5 to 3 percent of ZrO2, and the balance of SiO2, wherein the sum of the mass percents of the components is 100 percent. When the SiO2 which is carried by mineral powder, a flux material prepared by adoption of a sintering method and a matched soldering wire are used under high input energy at a high welding speed (1.8m / min), the welding manufacturability is excellent, a soldered joint has the properties of high low-temperature impact ductility, high welding seam strength, better capacity of removing S and P, a function of transiting alloys and the like, and the welding seam strength and the tenacity can be completely matched with a base material of high-grade pipeline steel, so that the high-welding-speed sintered flux is suitable for welding pipeline steel of which the ReL is more than or equal to 610MPa.

Owner:XIAN UNIV OF TECH

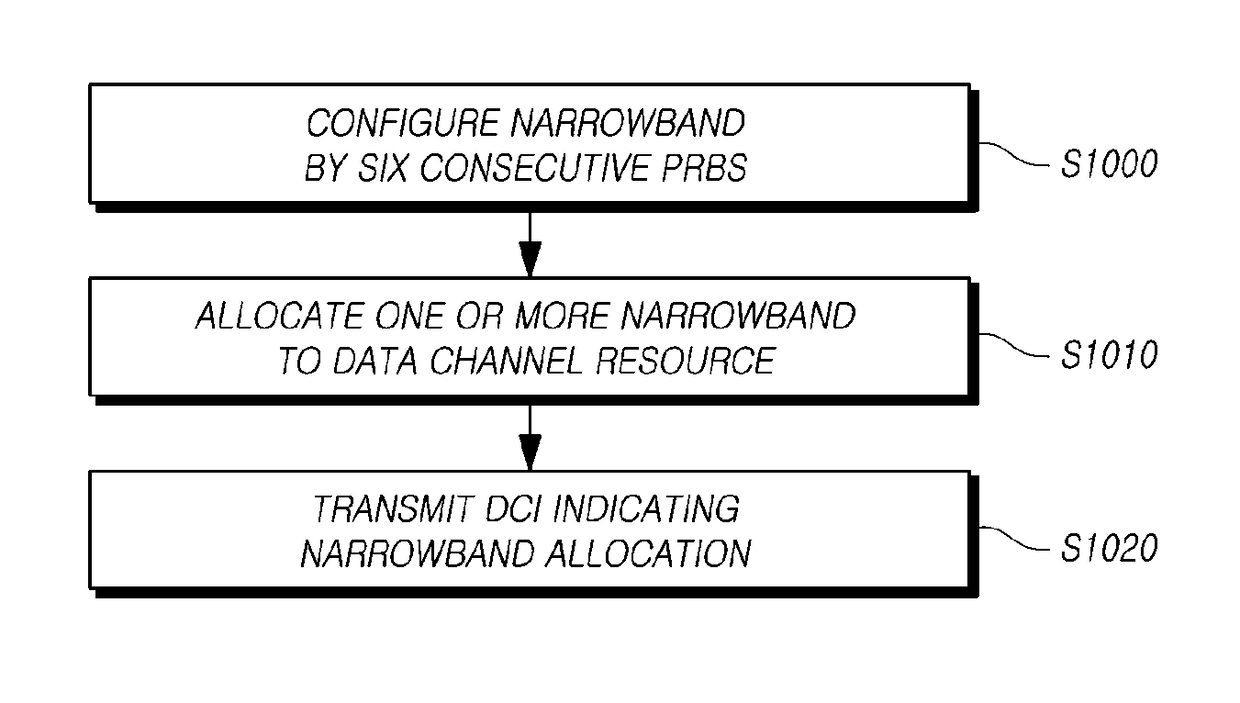

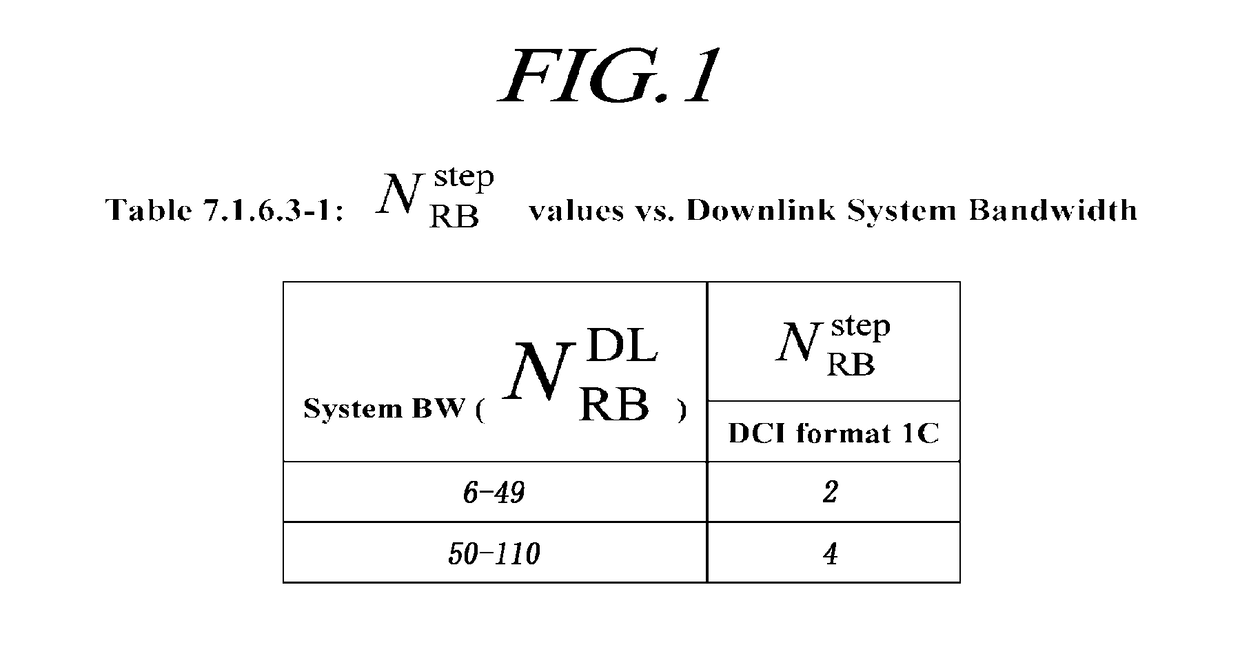

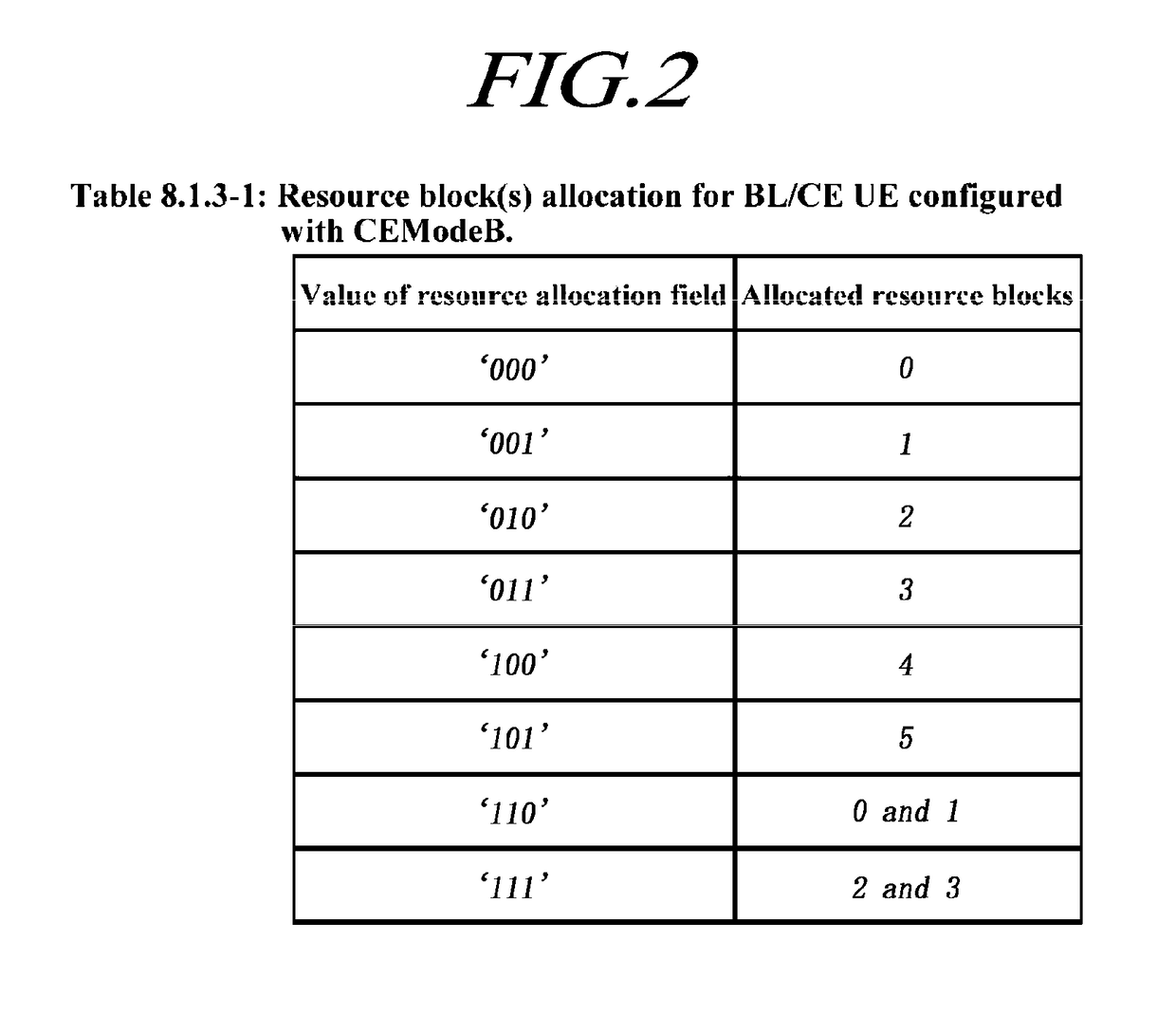

Methods for allocating data channel resources in a wireless communication system and apparatuses

Methods may be provided for allocating up / downlink data channel (that is, PDSCH and PUSCH) resource for a machine type communication (MTC) terminal in 3GPP LTE / LTE advanced system and for configuring a Downlink Control Information (DCI) for it. Further, a method may be provided for allocating up / downlink data channel resource for further enhanced MTC terminal which supports a up / downlink data channel (that is, PDSCH and PUSCH) bandwidth enhanced as compared with the MTC terminal (BL / CE UE) defined in LTE rel-13.

Owner:KT CORP

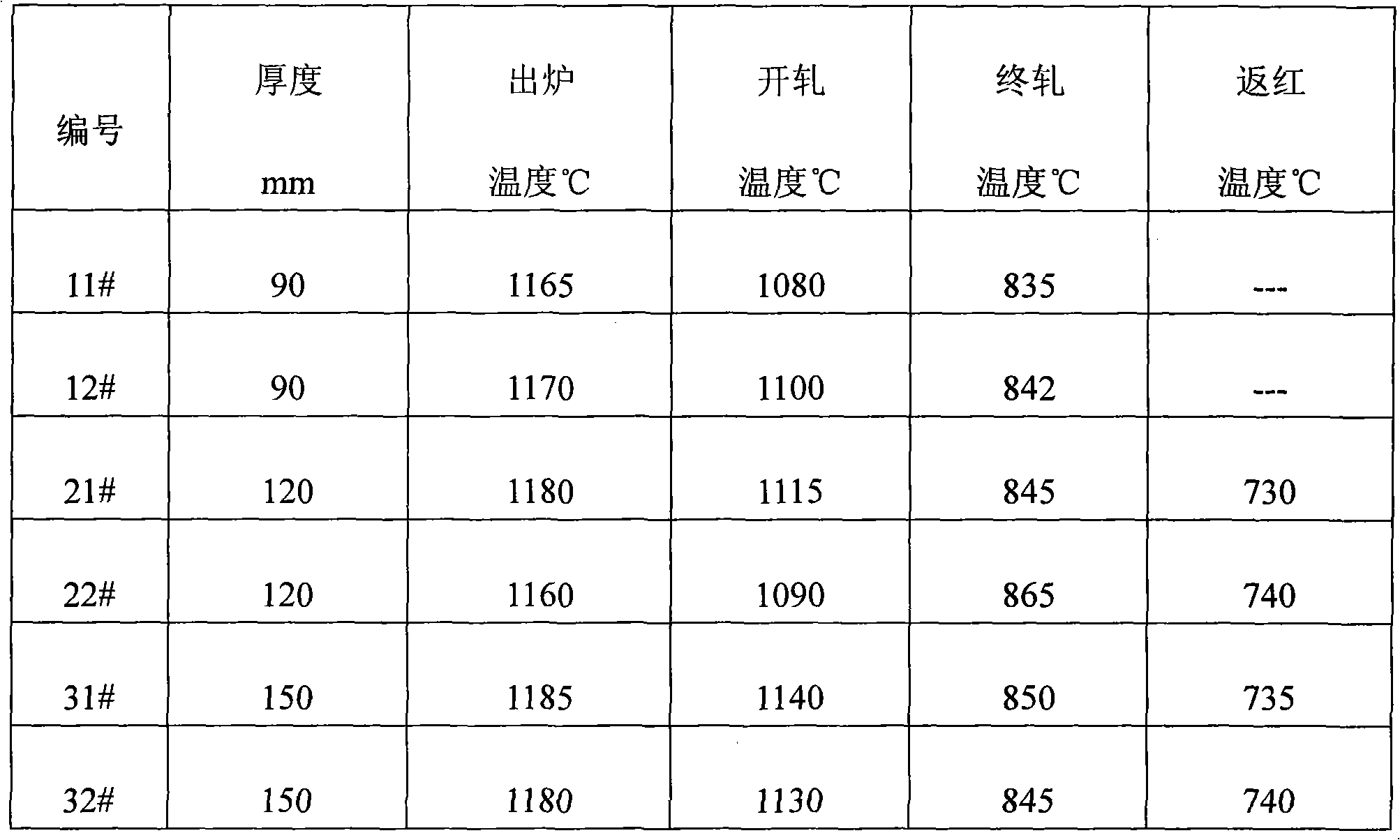

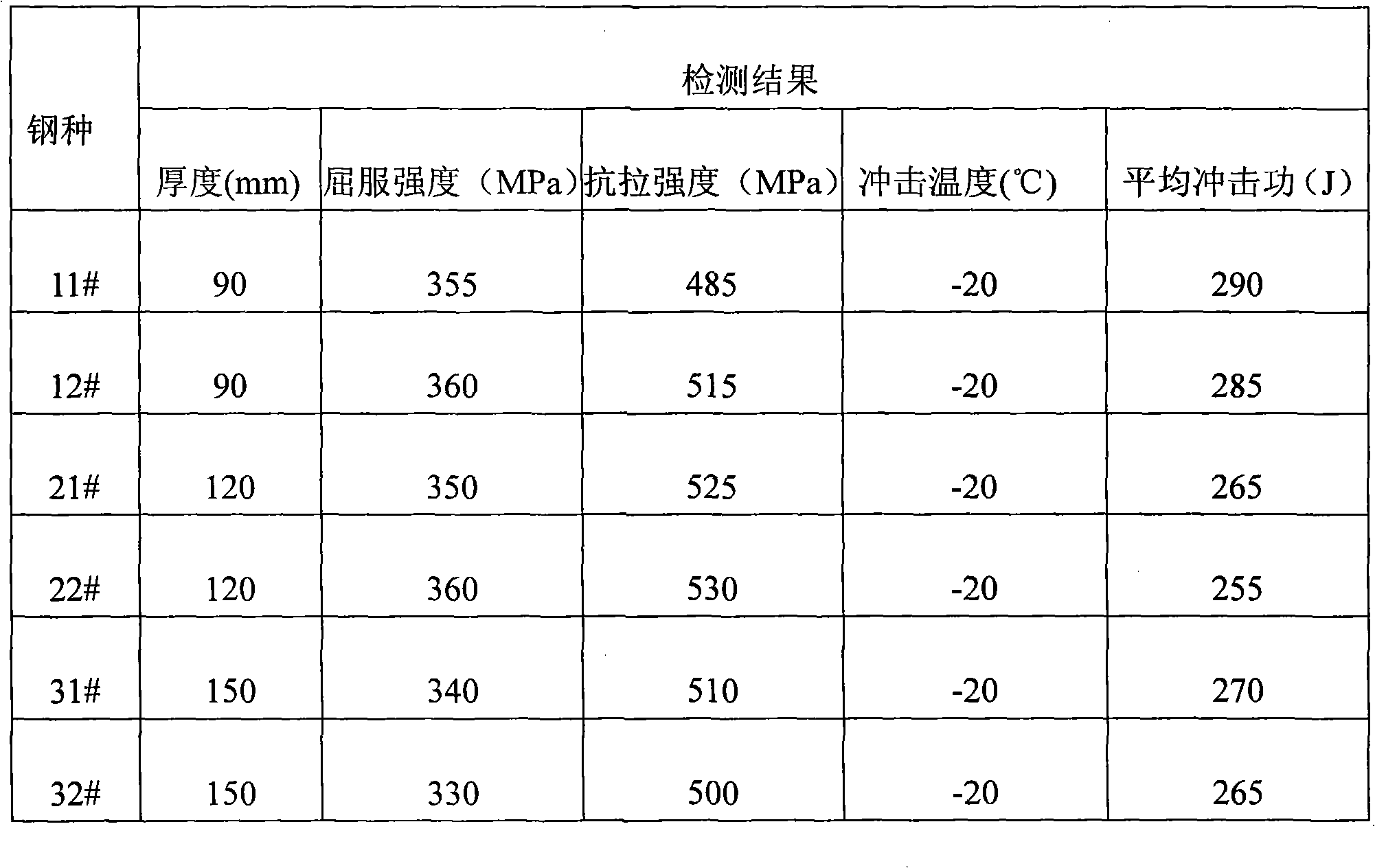

Production method of ultra-thick steel plate

ActiveCN102029305AIncrease productivityEase of mass productionTemperature control deviceManufacturing convertersHigh pressure waterHigh pressure

The invention discloses a production method of an ultra-thick steel plate, mainly comprising pretreatment of molten iron, smelting in a converter, external refining, and continuous casting, rolling and cooling of a slab. The production method is characterized in that LF (ladle furnace) refining treatment and VD (vacuum degassing) are adopted; ferrovanadium is added before tapping, the added amount is 1-1.5kg / t steel, an electromagnetic stirring technology is applied in the continuous casting process, the heating temperature of the slab before rolling is controlled to be 1150-1220 DEG C so as to guarantee fine austenitic grain, high-pressure water is used for removing phosphorus fully before rolling and in the rolling process, the starting rolling temperature of a steel billet is controlled to be 1100 plus or minus 50 DEG C, and the thickness of a middle billet is controlled to be 1.2-1.49 times that of a finished product; the final rolling temperature is 830 plus or minus 20 DEG C when the thickness is 71-100mm, then air cooling is carried out till room temperature; and the final rolling temperature is 860 plus or minus 20 DEG C when the thickness is 101-150mm, the steel plate enters laminar flow for cooling, and the red-returning temperature is 720 plus or minus 20 DEG C after cooling. The production method has the advantages that the production efficiency is high, large-batch production is favored, the mechanical properties are good and the like; and the yield strength Rel is larger than or equal to 330MPa, the impact power AKv at the temperature of -20 DEG C is larger than or equal to 150J, and the production method is applicable to most of mechanical members and use temperature.

Owner:ANGANG STEEL CO LTD

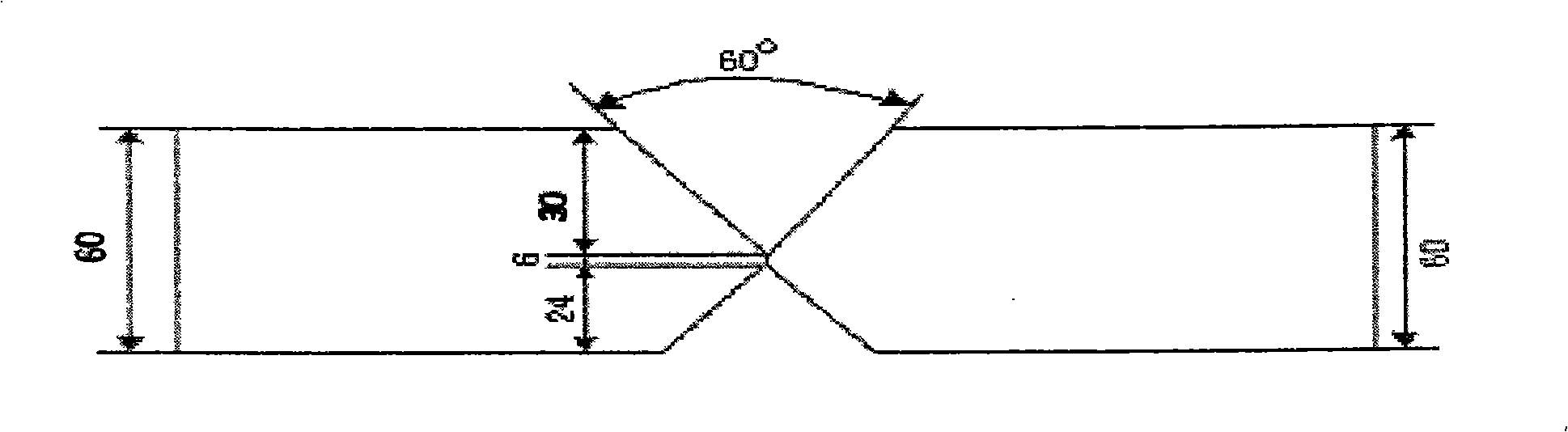

Butt-joint manual welding method for high-strength bridge steel with thickness of 80 mm

InactiveCN102784998AHigh tensile strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsTO-18Sheet steel

The invention provides a butt-joint manual welding method for high-strength bridge steel with a thickness of 80 mm. The butt-joint manual welding method comprises the following steps of: using an equal-thickness bridge steel to carry out butt joint, wherein the equal-thickness bridge steel has Rm which is more than or equal to 570 MPa, ReL which is more than or equal to 420 MPa, an extension rate A which is more than or equal to 18%, KV2 at minus 40 DEG C which is more than or equal to 120J and the thickness of 80 mm; and the anti-tension strength of a matched welding wire is more than or equal to 600 MPa, and a diameter phi of a welding bar is 4.0 mm; a welding groove is an X type symmetrical groove, a groove angle is 60 degrees; and continuously welding in conditions of current of 165-170 A, voltage of 24-25V, a speed of 14-15 cm / min and linear energy of 16-17 kJ / cm, and controlling an interlayer temperature within a range of 135-145 DEG C. According to the butt-joint manual welding method provided by the invention, although the thickness of the bridge steel is up to 80 mm, no crack is generated through crack detection after a butt-joint connector is subjected to treatment without pre-heating before welding and without heating after welding. Furthermore, the impact power of KV2 of three areas of the connector at minus 40 DEG C reaches to 155-243 J, so that the technical requirements of manufacturing a large-span bridge structure can be entirely met.

Owner:武钢集团有限公司

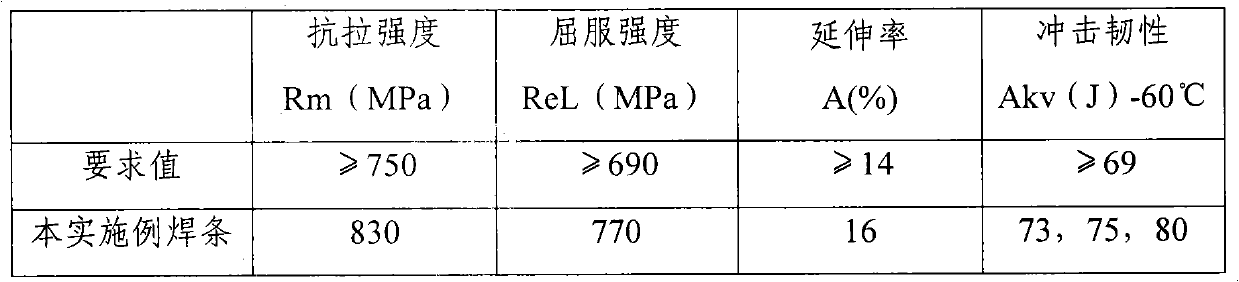

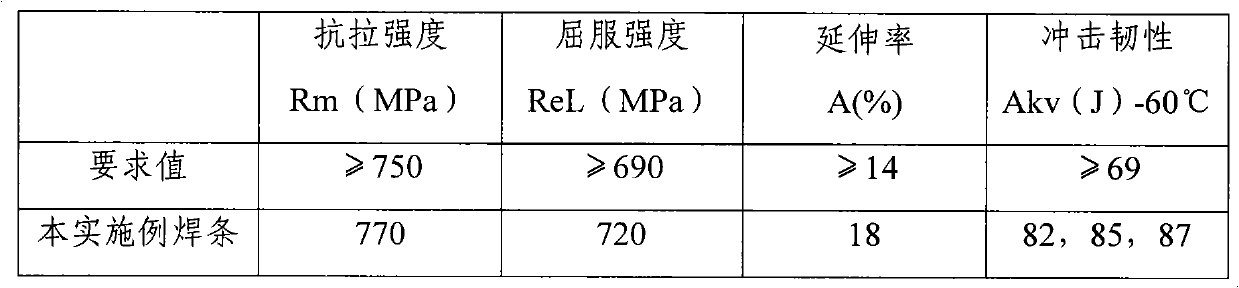

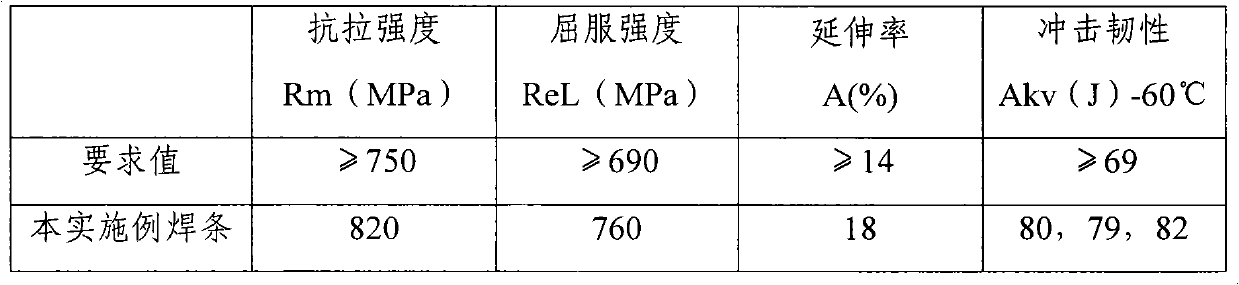

Electrode for welding high-strength and high-toughness steel and preparation and application thereof

InactiveCN101905389AHigh strengthHigh tensile strengthArc welding apparatusWelding/cutting media/materialsRare-earth elementHydrogen

The invention discloses an electrode for welding high-strength and high-toughness steel. A deposited metal of the electrode comprises the following chemical components in percentage by weight: 0.04 to 0.08 percent of C, 0.30 to 0.50 percent of Si, 1.0 to 1.7 percent of Mn, 3.0 to 3.5 percent of Ni, less than or equal to 0.010 percent of S, less than or equal to 0.015 percent of P, 0.003 to 0.006 percent of Zr, 0.02 to 0.04 percent of Ti, 0.4 to 0.8 percent of Mo, 0.005 to 0.010 percent of rare earth element, and the balance of Fe, wherein the weight ratio of C to Zr is 8-24:1. The deposited metal of the electrode has high strength ReL of more than or equal to 690MPa and high toughness Akv (-60 DEG C) of more than or equal to 69 J, and the electrode is a super-low hydrogen electrode, and the measured diffusible hydrogen [H] of the deposited metal is 1.8 to 2.2 milliliters per 100 grams by a mercury method.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Method for preventing and/or treating insulin resistance

Described is the use of Eubacterium hallii et rel. and / or Alcaligenes faecalis et rel., as well as pharmaceutical, food, or feed compositions comprising these bacteria as a medicament, in particular, for preventing and / or treating insulin resistance and / or insulin resistance-related complications such as metabolic syndrome, dyslipidemia and type 2 diabetes mellitus, as well as insulin resistance in endocrine diseases (e.g., obese subjects with type 1 diabetes mellitus, Cushing's disease and lipodystrophy syndromes. Also described is a method for preventing and / or treating insulin resistance and / or insulin resistance-related complications such as dyslipidemia and type 2 diabetes mellitus as well as insulin resistance in endocrine diseases (e.g., obese subjects with type 1 diabetes mellitus, Cushing's disease and lipodystrophy syndromes) in a subject in need thereof, the method comprising the step of increasing the level of Eubacterium hallii et rel. and / or Alcaligenes faecalis et rel. in the small intestine.

Owner:ACADEMISCH MEDISCH CENT BIJ DE UNIV VAN

Mobile station

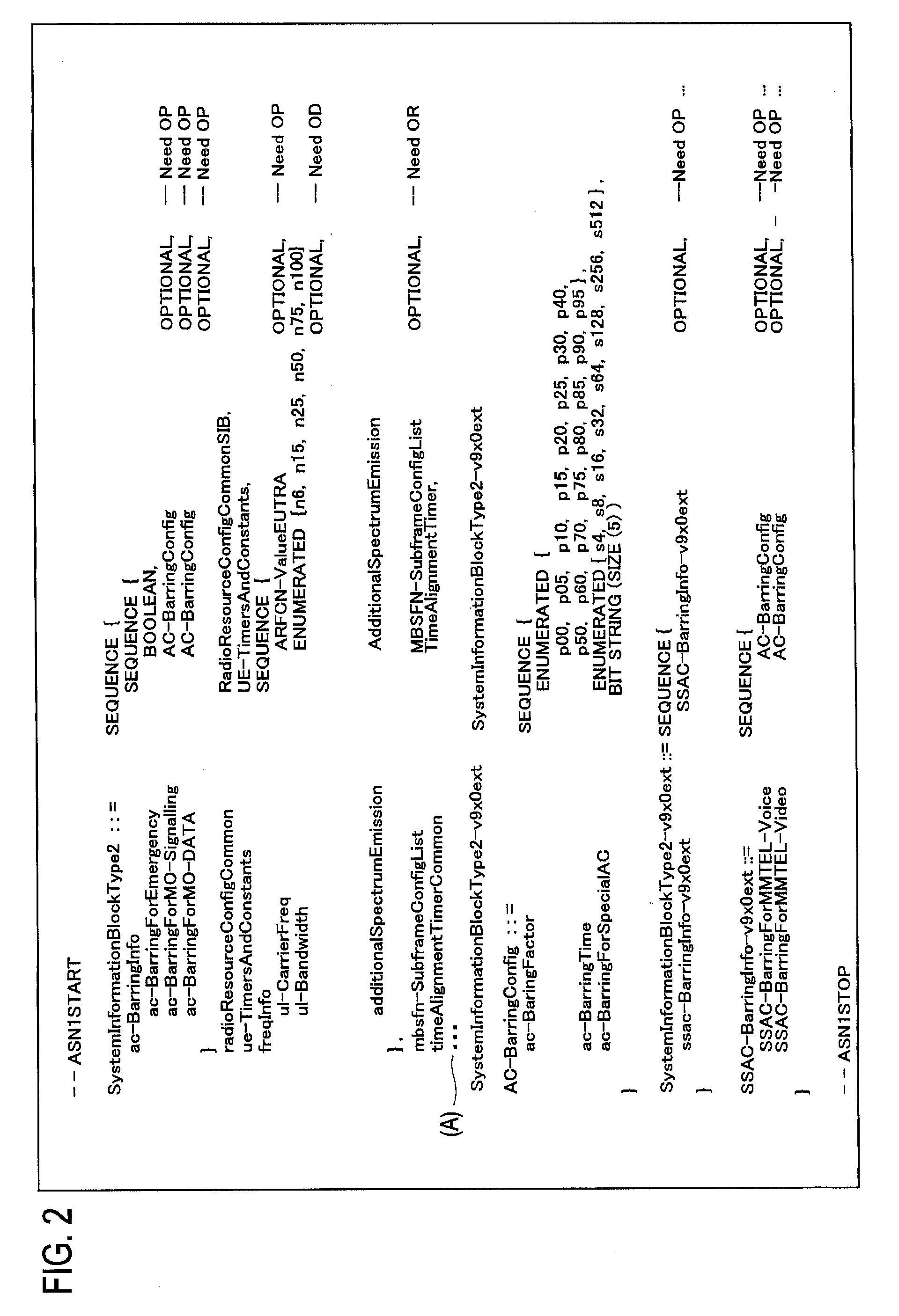

InactiveUS20120250626A1Assess restrictionConnection managementMobile stationMobile communication systems

Even when it is not possible for a radio base station eNB to transmit SSAC barring information in an LTE Rel. 9 scheme, access barring control is performed for “MMTEL mobile originating call”. In a mobile station UE according to the present invention, an AS layer function 10 includes a broadcast information reception unit 11 configured to receive broadcast information including first barring information used in a mobile communication system in an LTE Rel. 8 scheme from a radio base station eNB, an adjustment unit 13 configured to generate second barring information used in a mobile communication system in an LTE Rel. 9 scheme, based on AC of the mobile station UE and the first barring information, and a notification unit 14 configured to notify an MMTEL / IMS layer function 30 of the second barring information, wherein the MMTEL / IMS layer function 30 includes a determination unit 24 configured to determine whether it is possible to perform a call request process, based on the second barring information.

Owner:NTT DOCOMO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com