High-welding-speed sintered flux for submerged-arc welding of X100 pipeline steel and preparation method thereof

A technology of sintering flux and submerged arc welding, which is applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problem of no flux materials for submerged arc welding, and achieve the effect of improving low temperature impact toughness and welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention also provides the preparation method of above-mentioned flux, implement according to the following steps:

[0018] 1) Weigh the following mineral powders: fluorite, fused magnesia, wollastonite, bauxite, manganese ore, SiFe and light rare earth oxides;

[0019] 2) Put the weighed substances in the same container and mix them so that the content of each substance according to the mass percentage is: 19%~25% CaF 2 , 25%~29% MgO, 5%~8% CaO, 21%~25% Al 2 o 3 , 4%~8% MnO, 1%~2.5%, 0.8%~1.2% Re, the balance is SiO 2 , the sum of the mass percentages of the above components is 100%;

[0020] Of which SiO 2 It is added through mineral powder, and SiO in the finished flux 2 The content should not exceed 20%.

[0021] 3) After mixing evenly, add binder according to 22%~25% of the mass of all components, carry out wet mixing evenly to make it semi-solid, then rub back and forth in the container basin to form granules, and pass through an 8-mesh sieve, ...

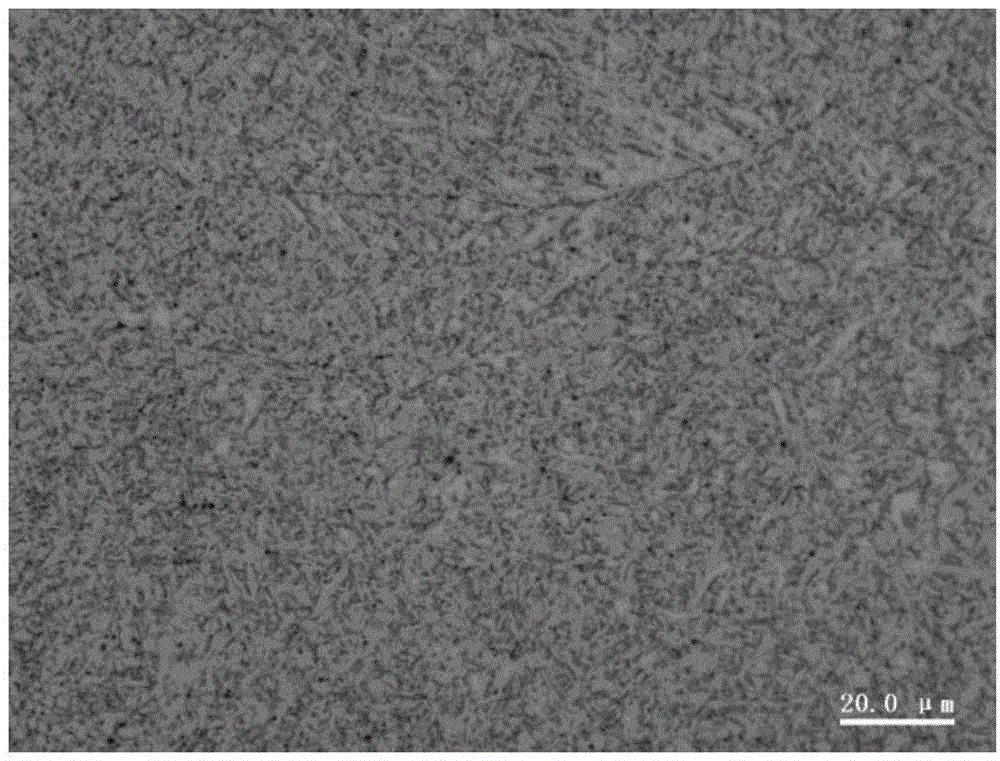

Embodiment 1

[0039] Weigh 25% CaF with a balance according to the mass percentage 2 , 29% MgO, 5% CaO, 25% Al 2 o 3 , 8% MnO, 2.5% SiFe, 0.8% Re, and the balance is SiO 2 , the sum of the mass percentages of the above components is 100%.

[0040] According to the formula, use a balance to weigh the required raw materials and place them in the same container. After mixing the powders evenly, add 25% of the binder (K-Na mixed water glass), carry out wet stirring to become semi-solid, and stir evenly. The wet material was rubbed back and forth in the container basin to form granules, and passed through an 8-mesh sieve, and the granulated flux was placed at room temperature and ventilated for 5 hours to dry. Then put it into a drying furnace for drying, the temperature is controlled at 250°C, after drying, put the flux into the sintering furnace and heat it to 900°C, the sintering time is not less than 2 hours, and the sintered flux is sieved through a 30-mesh sieve The finished flux is ob...

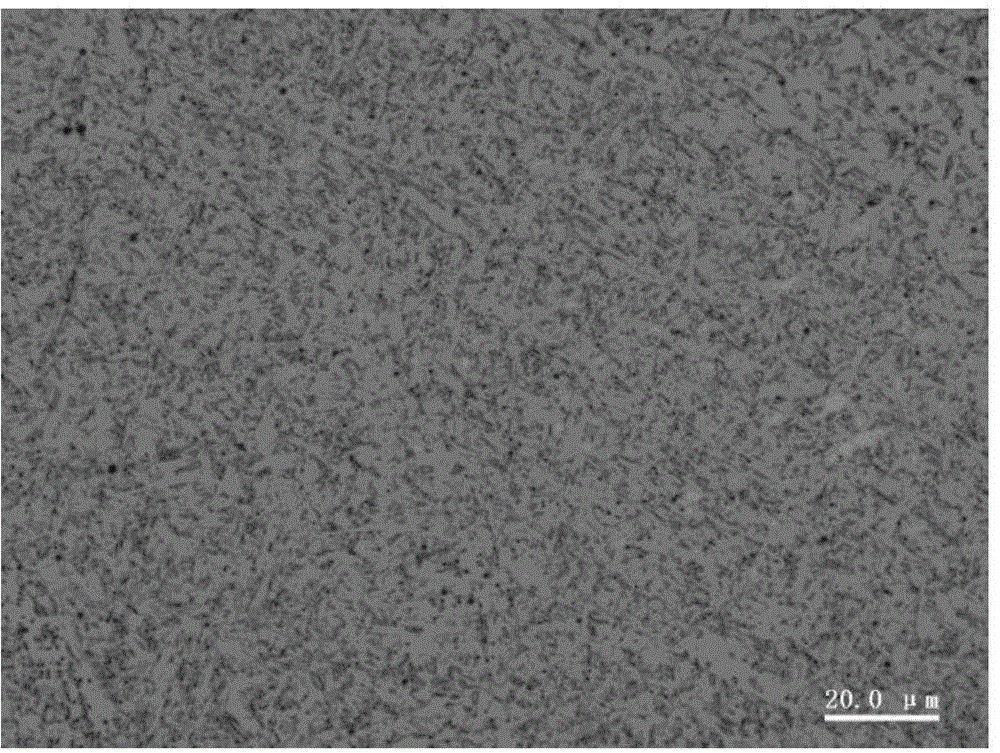

Embodiment 2

[0049] Weigh 23% CaF with a balance according to the mass percentage 2 , 26% MgO, 6% CaO, 23% Al 2 o 3 , 6% MnO, 2% SiFe, 1% Re, and the balance is SiO 2 , the sum of the mass percentages of the above components is 100%.

[0050] According to the formula, use a balance to weigh the required raw materials and put them in the same container. After mixing the powders evenly, add 23% binder (K-Na mixed water glass), carry out wet stirring to become semi-solid, and stir evenly The wet material was rubbed back and forth in the container basin to form granules, and passed through an 8-mesh sieve, and the granulated flux was placed at room temperature and ventilated for 4 hours to dry. Then put it into a drying furnace for drying, the temperature is controlled at about 250°C, after drying, put the flux into the sintering furnace and heat it to 750°C, the sintering time is not less than 2 hours, and the sintered flux is passed through a 40-mesh sieve Sieve to get the finished flux....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com