Patents

Literature

2083 results about "Submerged arc welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Submerged arc welding (SAW) is a common arc welding process. The first patent on the submerged-arc welding (SAW) process was taken out in 1935 and covered an electric arc beneath a bed of granulated flux. Originally developed and patented by Jones, Kennedy and Rothermund, the process requires a continuously fed consumable solid or tubular (metal cored) electrode. The molten weld and the arc zone are protected from atmospheric contamination by being "submerged" under a blanket of granular fusible flux consisting of lime, silica, manganese oxide, calcium fluoride, and other compounds. When molten, the flux becomes conductive, and provides a current path between the electrode and the work. This thick layer of flux completely covers the molten metal thus preventing spatter and sparks as well as suppressing the intense ultraviolet radiation and fumes that are a part of the shielded metal arc welding (SMAW) process.

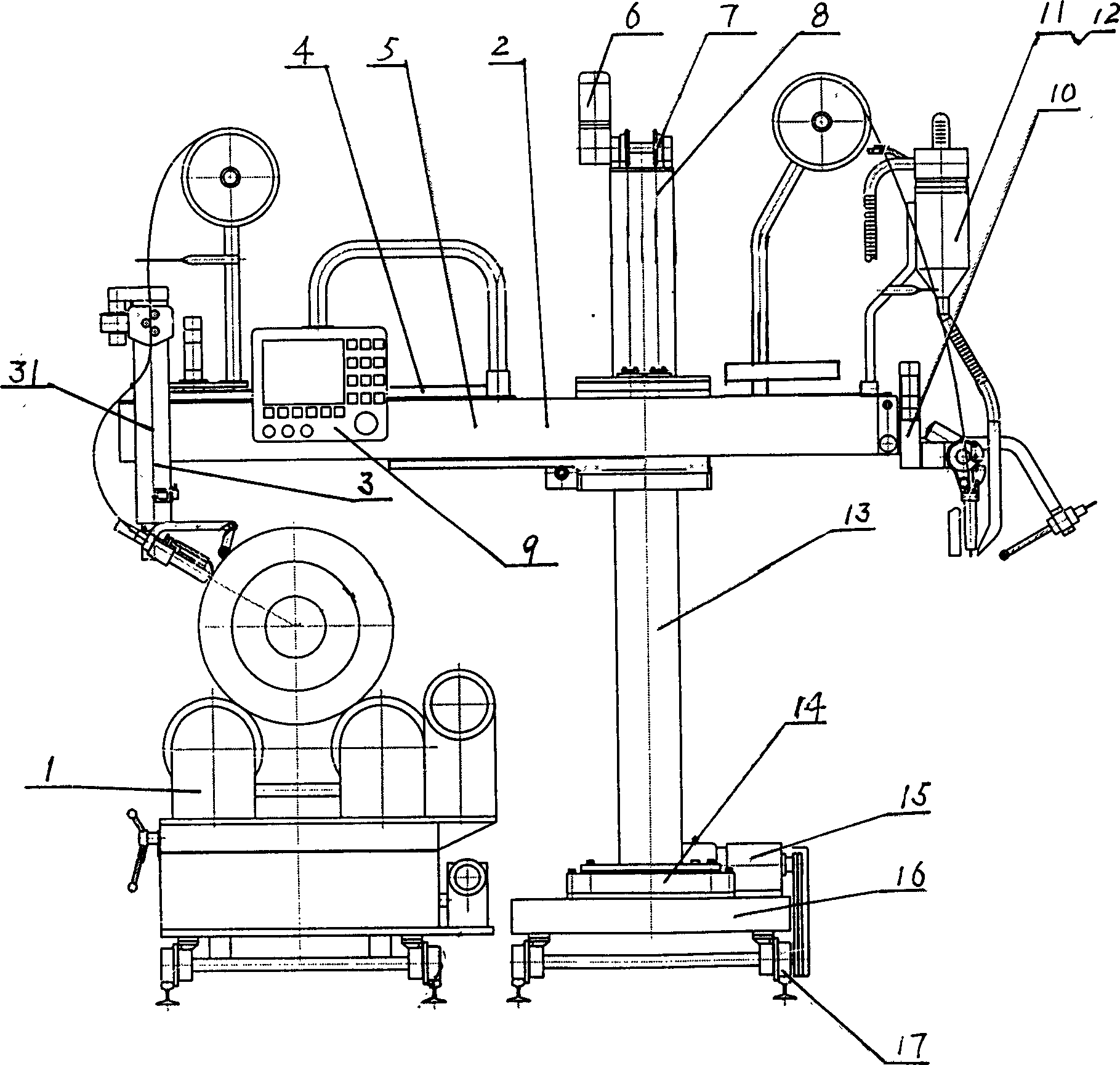

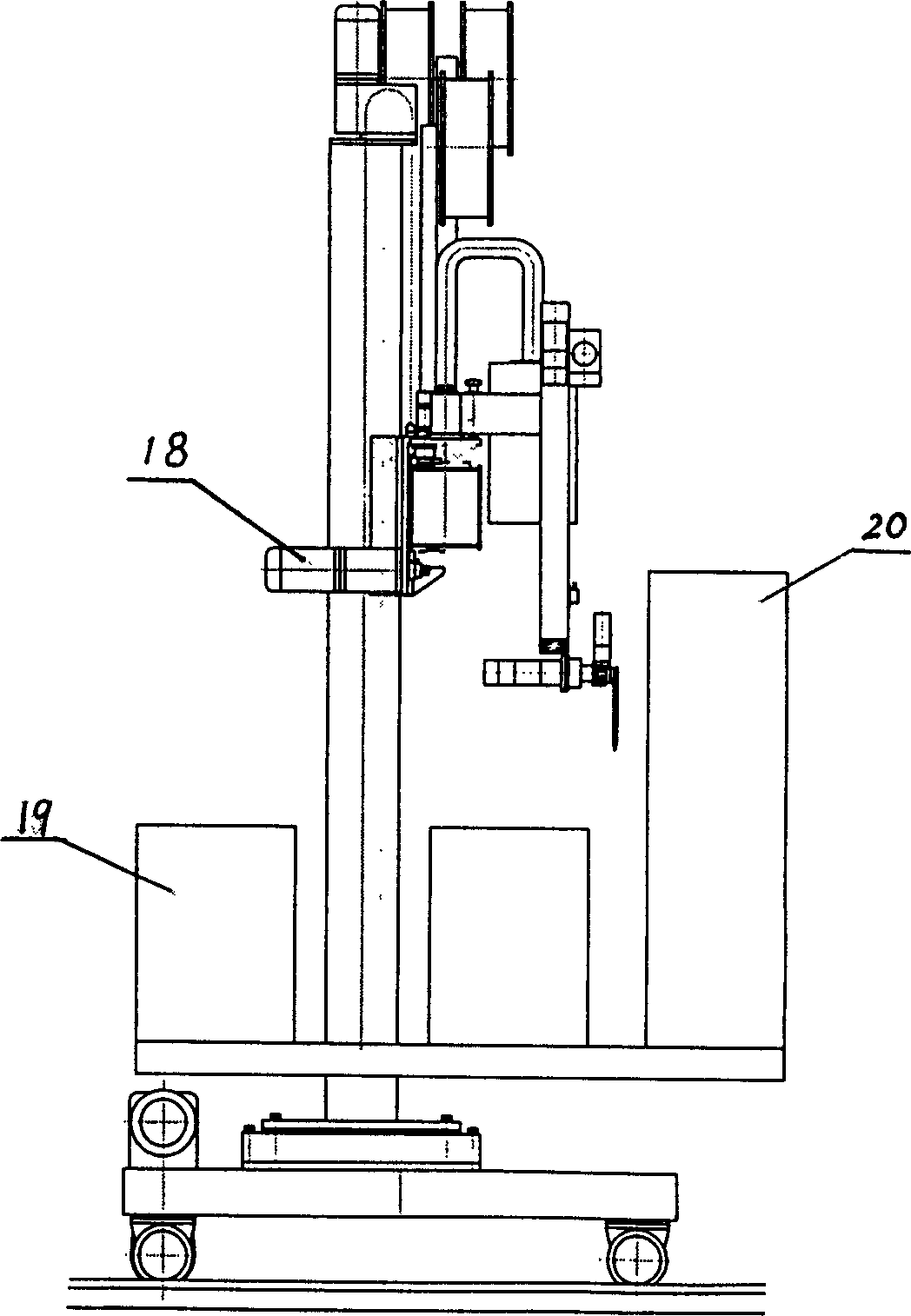

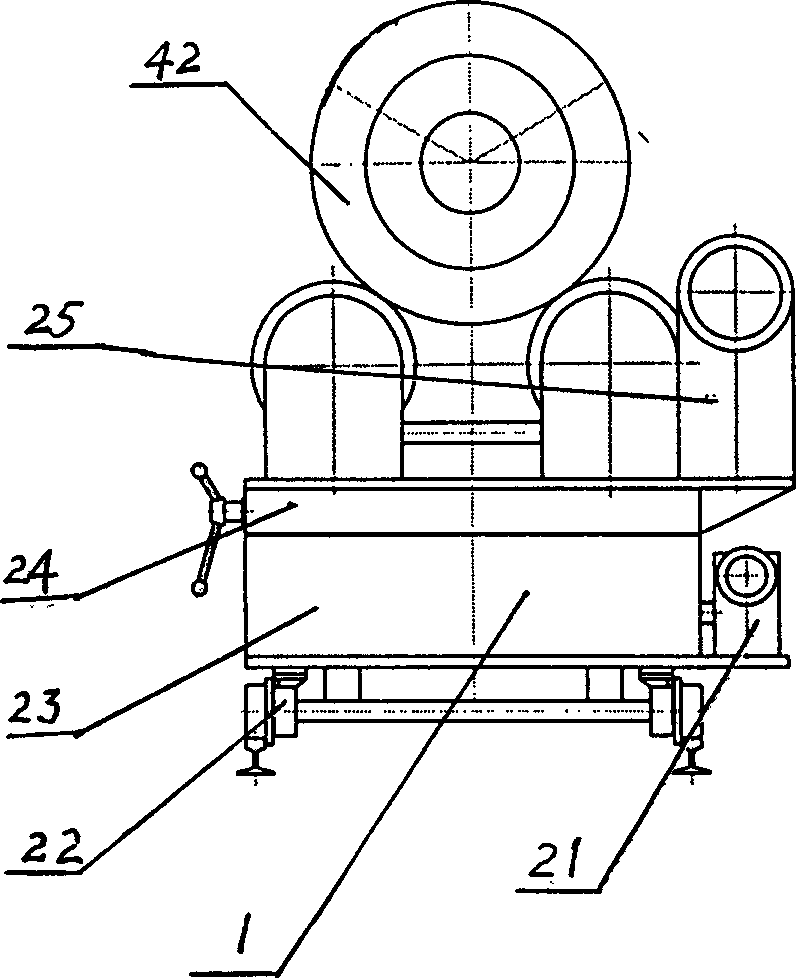

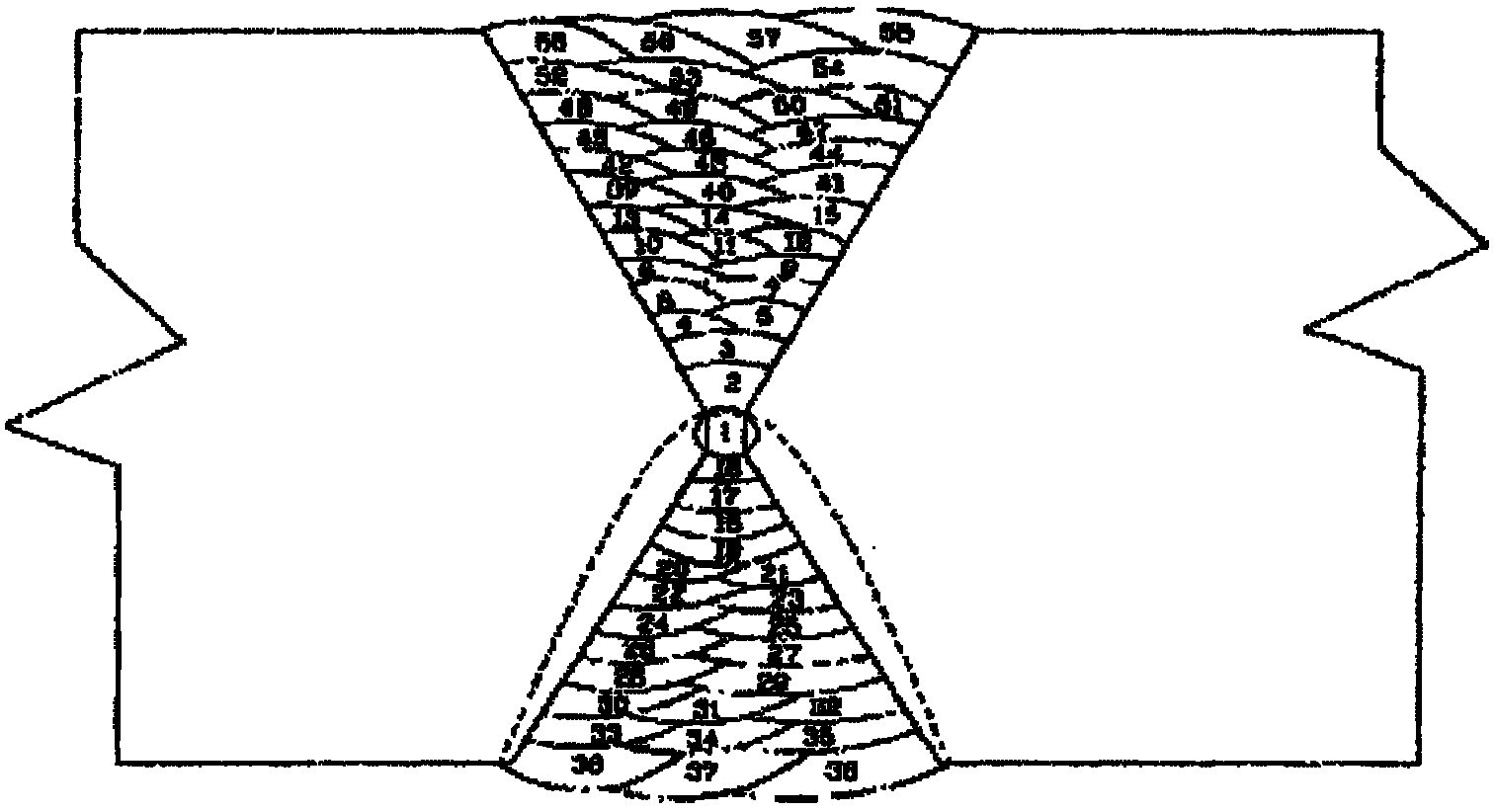

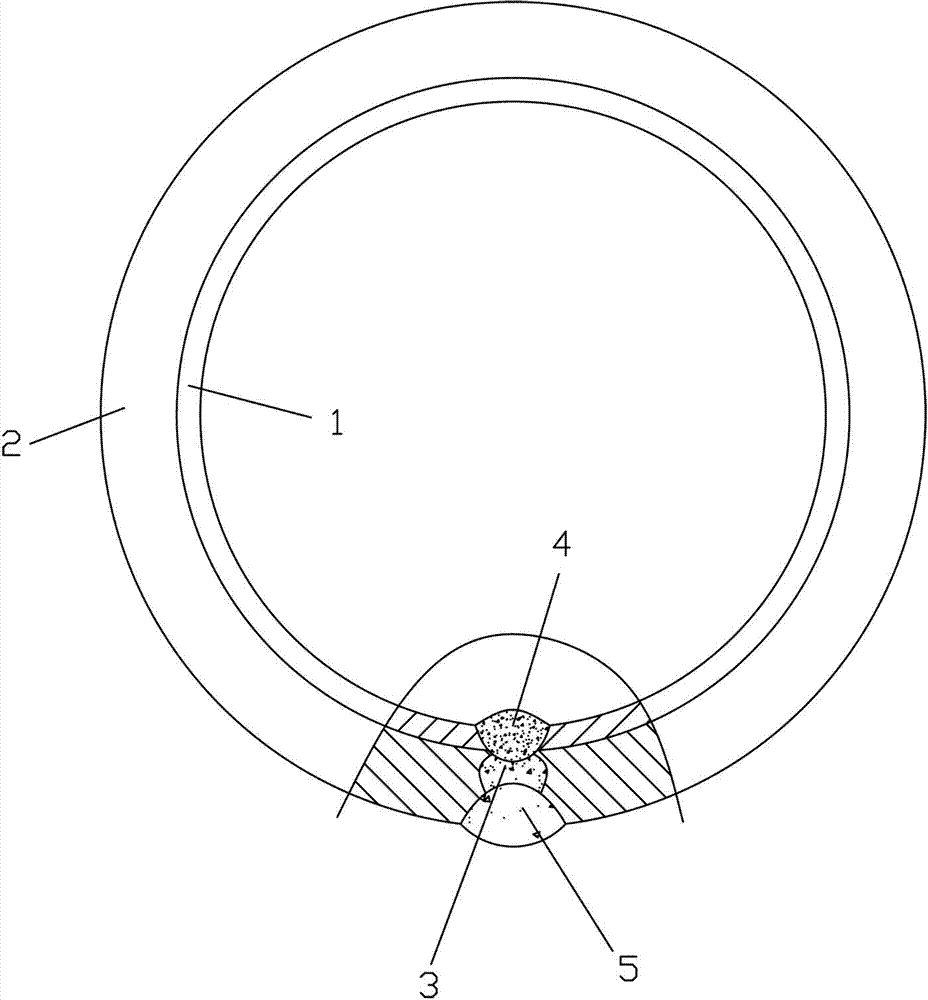

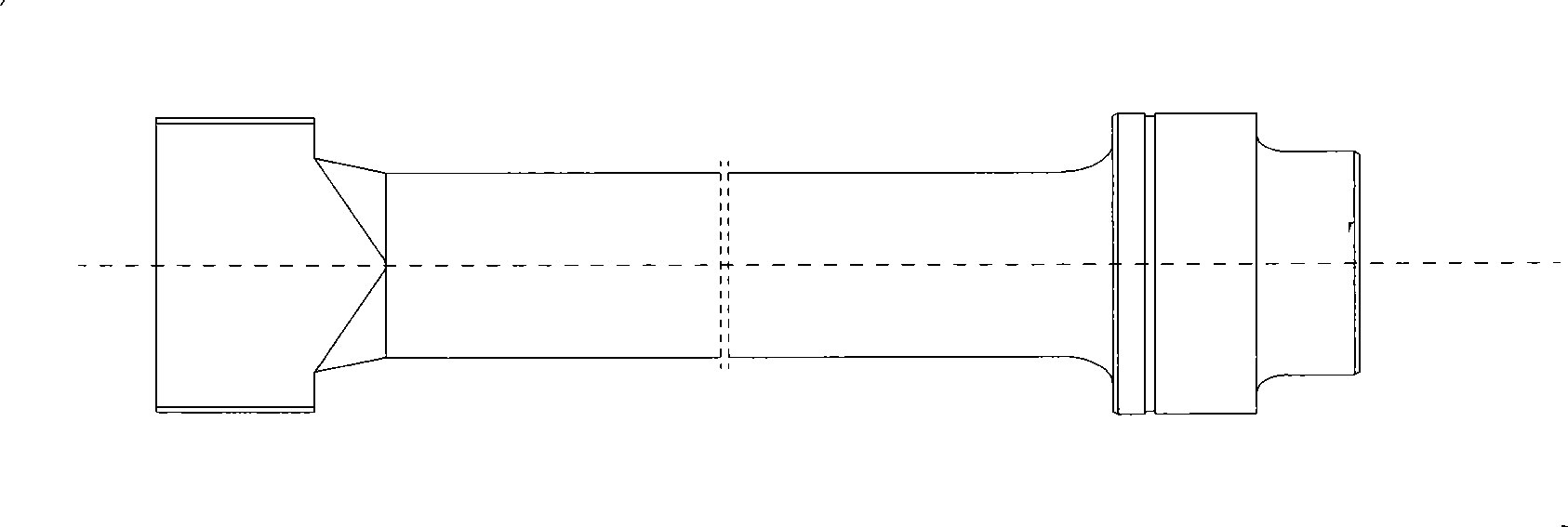

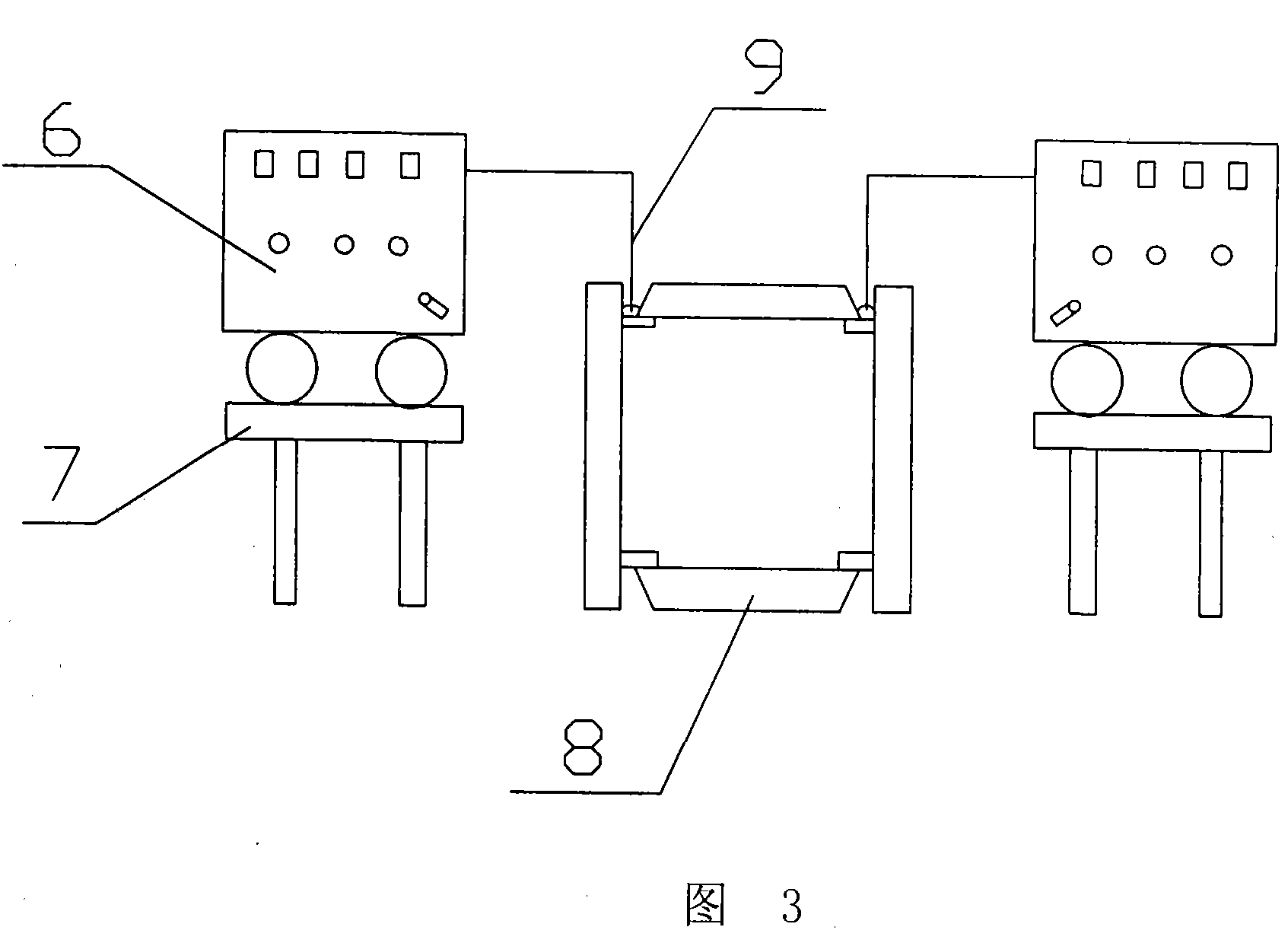

Process and device for automatic argon arc welding and narrow gap burial arc welding for circular pipe header seam

ActiveCN1714978AAutomatically calculate relative coordinate origin positionEnsure shapeArc welding apparatusBogieEngineering

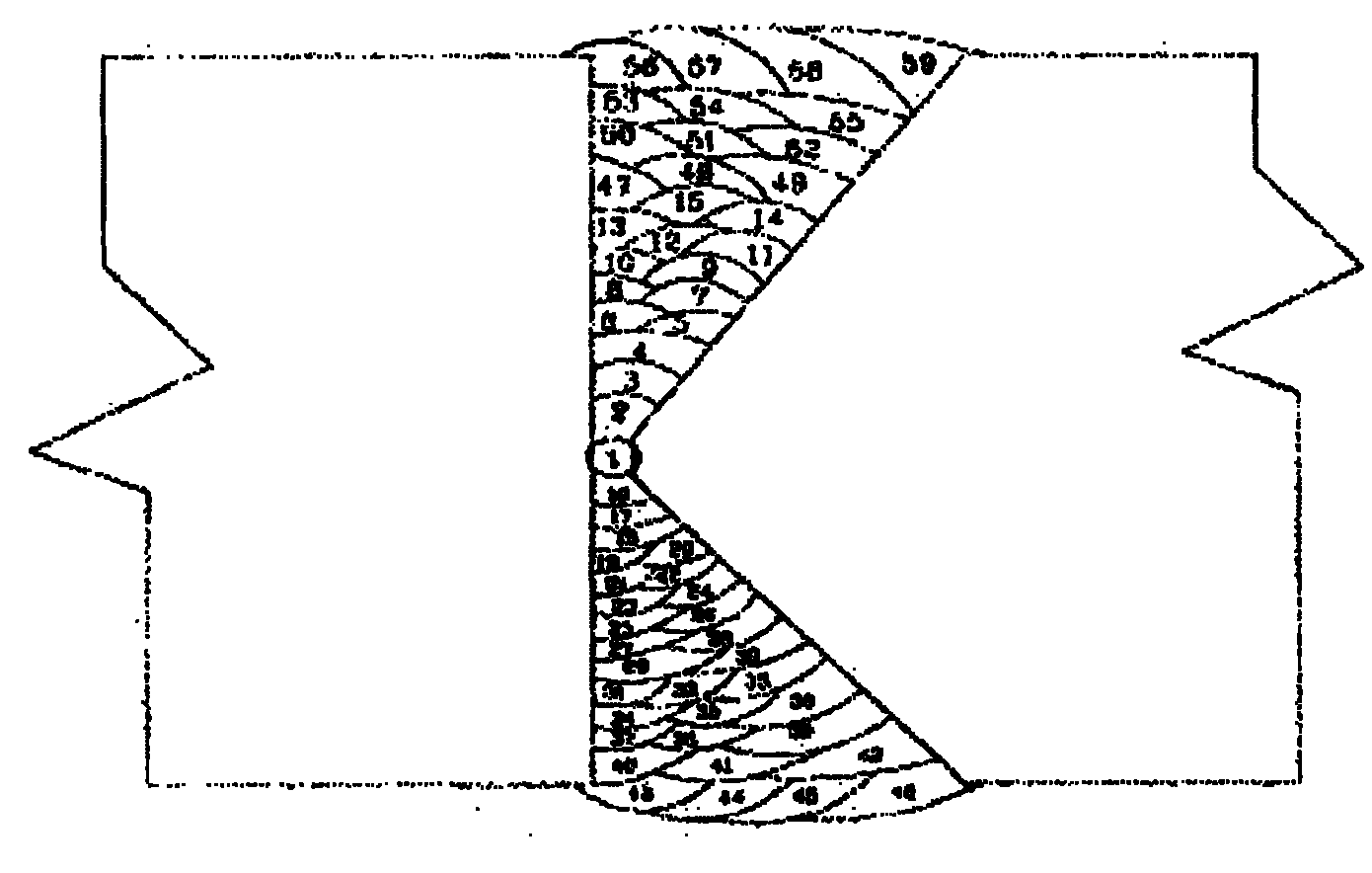

The automatic argon arc welding and narrow gas submerged arc welding process for circular pipe header seam features the first horizontal and vertical welding with immobile workpiece and using automatic cold welding TIG wire until completing over one third of circle; the subsequent welding in the other two thirds of circle with automatically rotating welding roller frame; and the performing in the identical site of the annular seam assembling and the welding. The welding apparatus for the said technological process consists of roller device and welding frame bogie, and the welding frame bogie on some tracks parallel to roller frame tracks is movable. The present invention has the advantages of automatic operation, raised welding quality, etc.

Owner:SHANGHAI BOILER WORKS

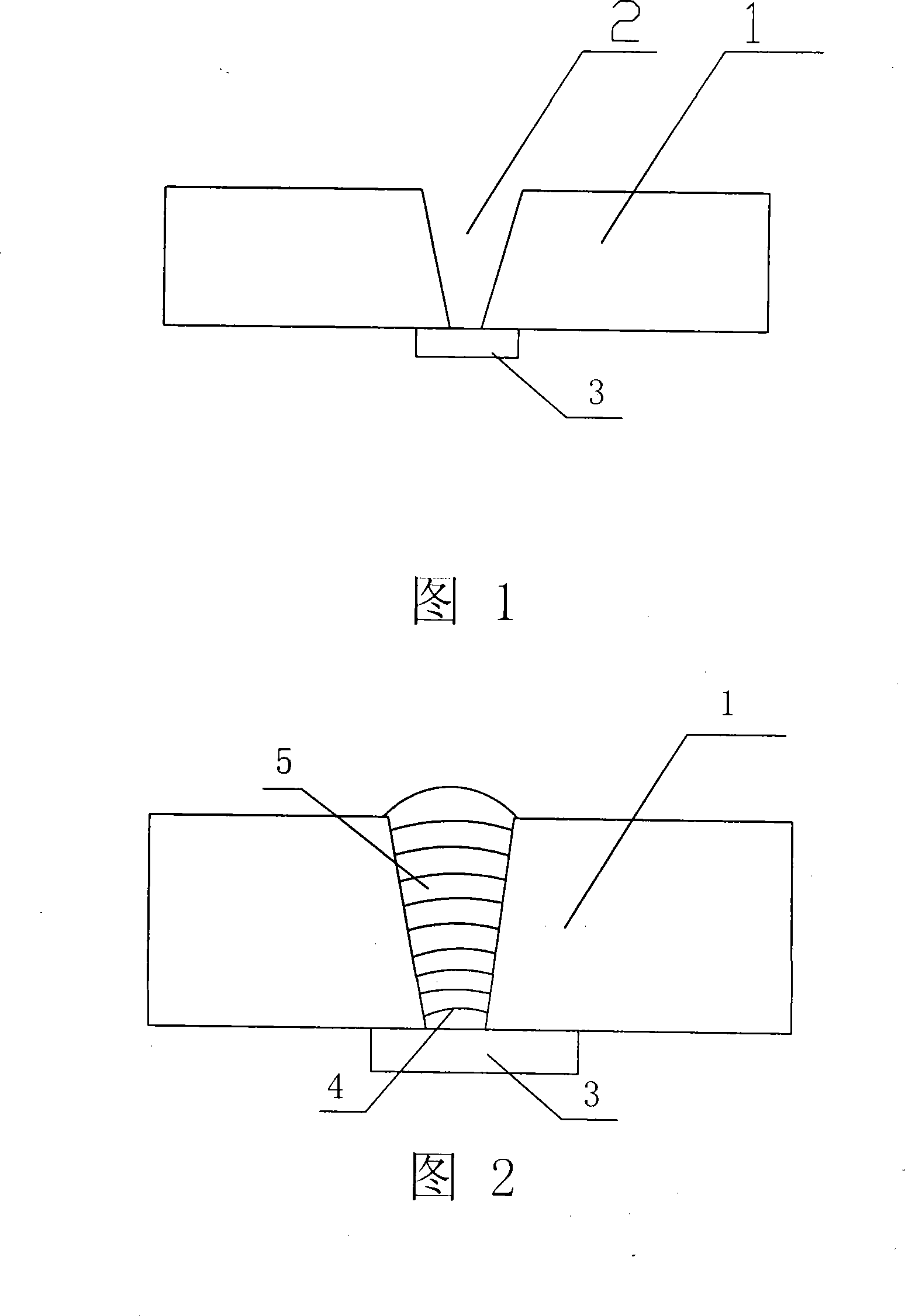

Marine engineering large thick steel plate submerged arc welding process method in low-temperature environment

InactiveCN101879645AIncrease productivityReduce labor intensityArc welding apparatusWelding/cutting media/materialsEngineeringWeld seam

The invention belongs to the field of welding, in particular to a process method applicable to marine engineering large thick steel plate submerged arc welding in low-temperature environment, which comprises a welding method, welding material selection, a welding order, a welding process and the selection and control of various welding process parameters. The method renders with carbon dioxide gas protection welding, and fills and faces through an automatic submerged arc welding; stops welding when the welding reaches more than two thirds of the thickness of a large groove during the welding process, clears chips on the back side and completes the welding of the other side; finally completes the welding of the first side; strictly controls all relevant process parameters of the welding during the welding process, and solves the problems of poorer anti-crack toughness of welding seams and heat affected zones caused by too high cooling speed of the welding seams and too high temperature; can ensure good anti-crack toughness of a welding seam connector without heat treatment after welding; and can meet the requirements of welding of an E36 plate with the thickness of 35 to 77mm under the working environment at the temperature of above -30DEG C, simplifies the production process, shortens the production cycle and reduces the cost.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

Manufacturing method for box type pillar beam

ActiveCN102896472AAdvanced preparation technologyReasonable preparation processArc welding apparatusNumerical controlSlag (welding)

The invention relates to a manufacturing method for a pillar beam for the building field and especially relates to the manufacturing method for a box type pillar beam. The manufacturing method comprises the processes of steel check, line marking, cutting, material receiving, assembling, welding, finishing, coating, and marking. The manufacturing method comprises the following steps: splicing big plates and cutting the box type pillar beam under numerical control; adding lining strips and leaving gaps during the grouping process of four main welding seams of the box type pillar beam; welding the four main welding seams by adopting an automatic submerged arc welding method; welding box type separating plates by adopting non-melting nozzle electro-slag welding; keeping the welding seams of the non-melting nozzle electro-slag welding under an abreast state; machining after grouping the separating plates of the box type pillar beam; and end-milling the two ends of the box type pillar beam. According to the manufacturing method, during a manufacturing process of the box type pillar beam, an advanced box type separating plate non-melting nozzle electro-slag welding technology is adopted; the welding and the assembling are alternately performed; the welding sequence is scientific and reasonable; multiple measures are simultaneously taken for preventing welding deformation; the precise equipment is adopted for processing the end part, so that the manufacturing technology for the box type pillar beam is more advanced and reasonable; and the manufacturing method is suitable for the box type pillar beams in various cross section sizes and plate thicknesses.

Owner:CHINA 22MCC GROUP CORP

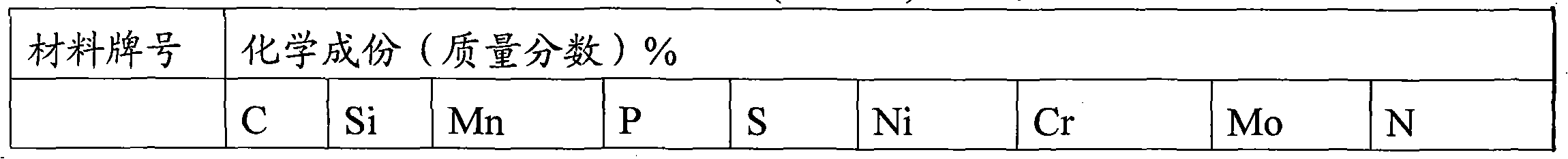

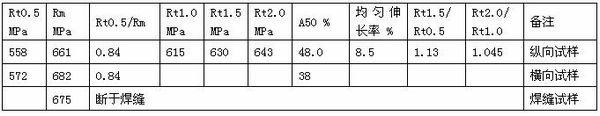

Manufacture method of X80 pipeline JCOE direct sew submerged arc welding tube

The invention discloses a method for producing a JCOE longitudinal submerged arc welded pipe of an X80 pipeline steel. The invention is used for producing an oil and gas conveying tube with high intensity and high tenacity. The method includes using an HTP X80 controlled rolling steel pipe with a chemical composition of 0.03 to 0.05 percent of C, 0.20 to 0.30 percent of Si, 1.65 to 1.75 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.15 percent of Nb plus Ti and 0.5 to 0.7 percent of Ni plus Cr plus Cu. A steel plate is made into the oil and gas conveying tube with high intensity and high tenacity through the working procedures like edge milling, edge bending, a 'JCO' forming technique under multi-pass pressing, gas protection prewelding, inside welding, outside welding, diameter enlarging, ultrasonic checking, x-ray checking, hydraulic pressure testing, tube end to arris, ultrasonic checking and X-ray checking, etc. The inside welding and the outside welding of a steel tube adopt four-wire serial union melt welding and control the technical parameters of welding through selecting a suitable welding wire and a welding fluid; thereby controlling the components and organizations of a weld joint to lead the performance of the weld joint to reach the performance requirements of X80.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

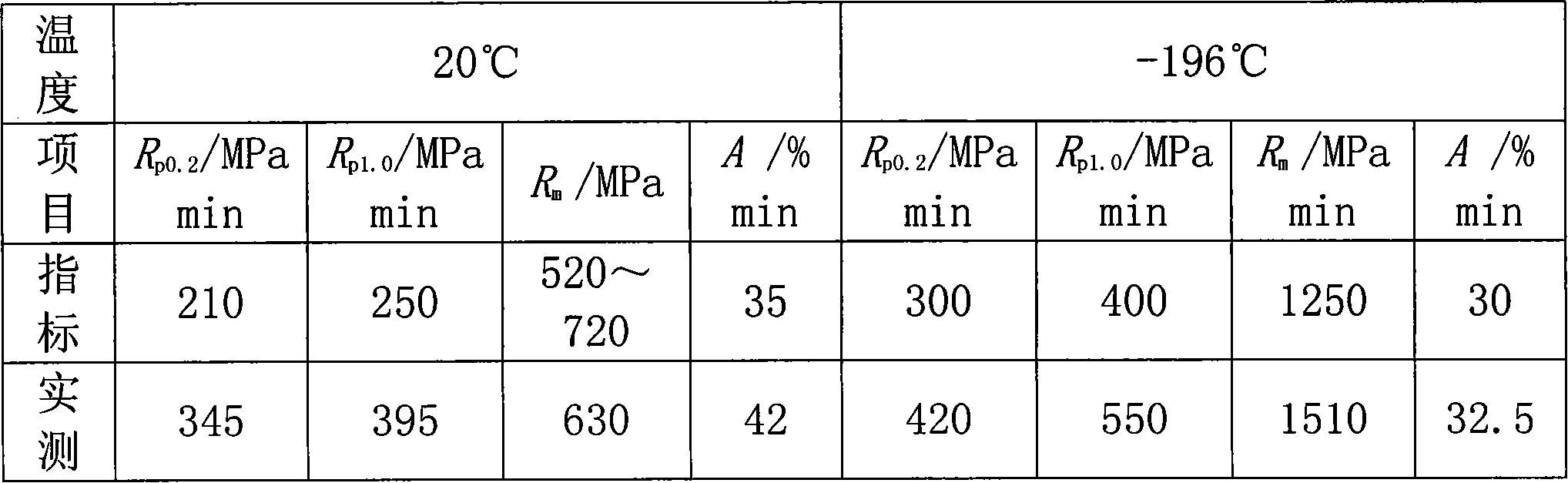

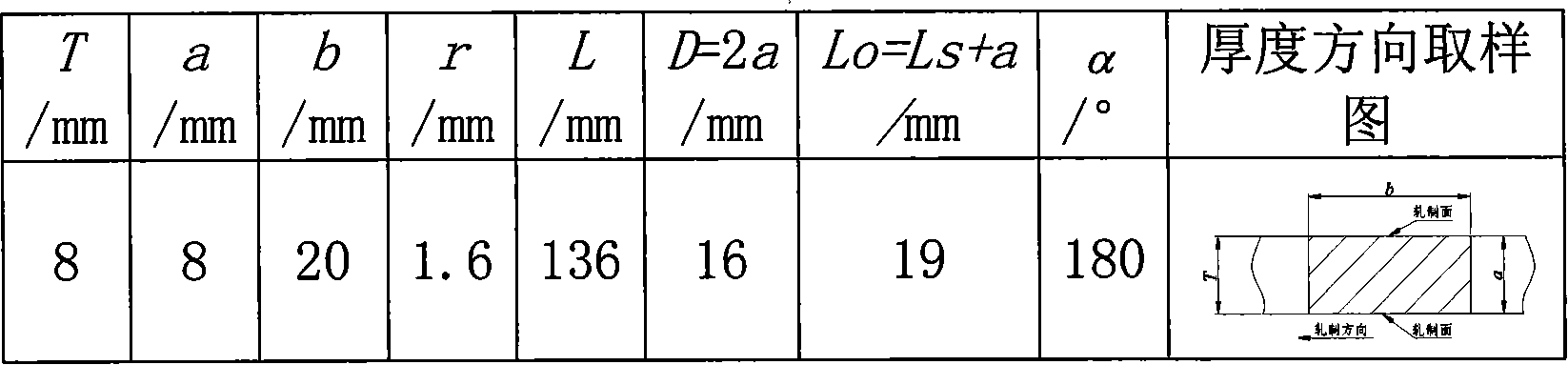

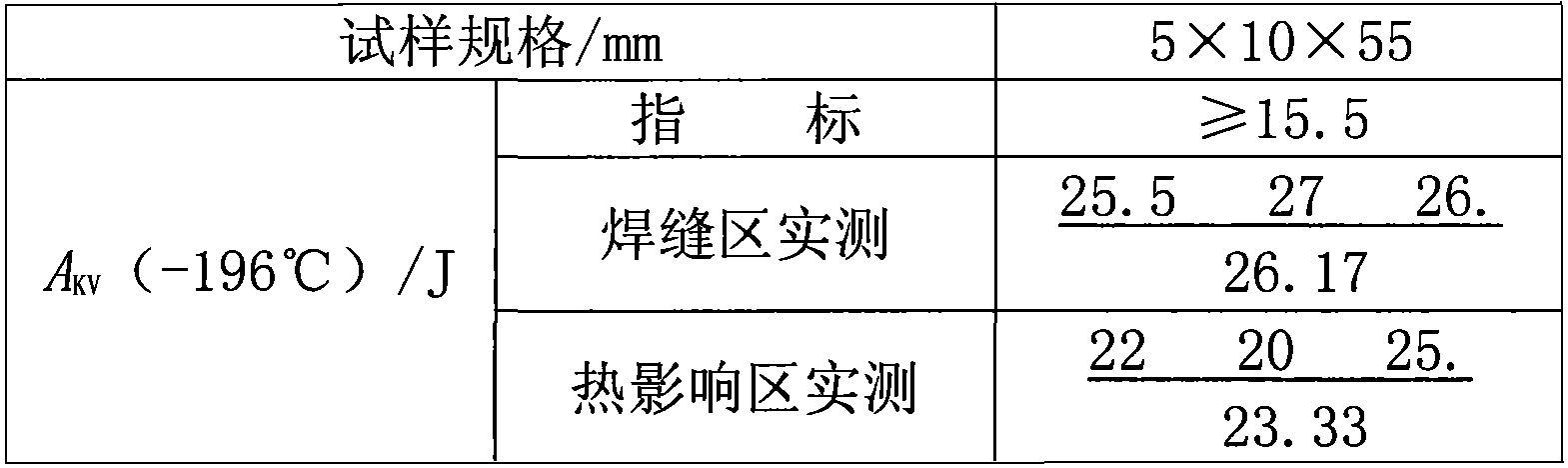

Austenitic stainless steel buried arc welding wire for low-temperature equipment

ActiveCN101244494AEasy to rollImprove low temperature resistanceWelding/cutting media/materialsSoldering mediaSteelmakingChemical composition

The invention relates to a welding wire, in particular to a welding wire applying to austenitic submerged arc welding for low-temperature equipments, in terms of chemical composition and weight percent, comprising Cr: 19.0 to 23.0%, Ni: 9.0 to 12.0%, C: <=0.03%, Mn: 1.60 to 2.50%, Si: 0.30 to 0.60%, Mo: <=0.30%, Cu: <=0.30%, Co: <=0.20%, Ti: <=0.015%, Nb: <=0.05%, V: <=0.10%, B: <=0.005% and Fe as allowance. The welding wire has the advantages that: the welding wire steelmaking craft is stable; the drawing performance is good; the invention meets the welding technical requirements of the high-intensity, high-toughness and anti-corrosion steel with low temperature and low temperature equipments; the invention can apply to the steel of 500 to 750MPa strength level; the invention is suitable for large range of welding current and no blowhole; the moulding is beautiful; the weld joint can be well matched with the base material.

Owner:哈焊所华通(常州)焊业股份有限公司

Submerged arc welding flux material used for high grade pipe line steel

InactiveCN100999043AHigh strengthGood stress corrosionArc welding apparatusWelding/cutting media/materialsChemical compositionMetallurgy

The present invention provides a welding flux material for submerged arc welding for welding high-grade line pipe steel and other structure steel. Its chemical composition includes (by wt%) 15%-25% of CaF2, 15%-25% of MgO, 15%-20% of Al2O3, 5%-10% of MnO, 5%-10% of TiO2, 10%-15% of SiO2, 5%-10% of CaO, 1.0%-2.5% of Na2O, 1.5%-3.0% of B2O3, 0.2%-0.4% of Re(Mg) and 3%-5% of ZrO2. Said welding flux material can be prepared by adopting sintering process. Besides, said invention also provides its application method.

Owner:XIAN UNIV OF TECH

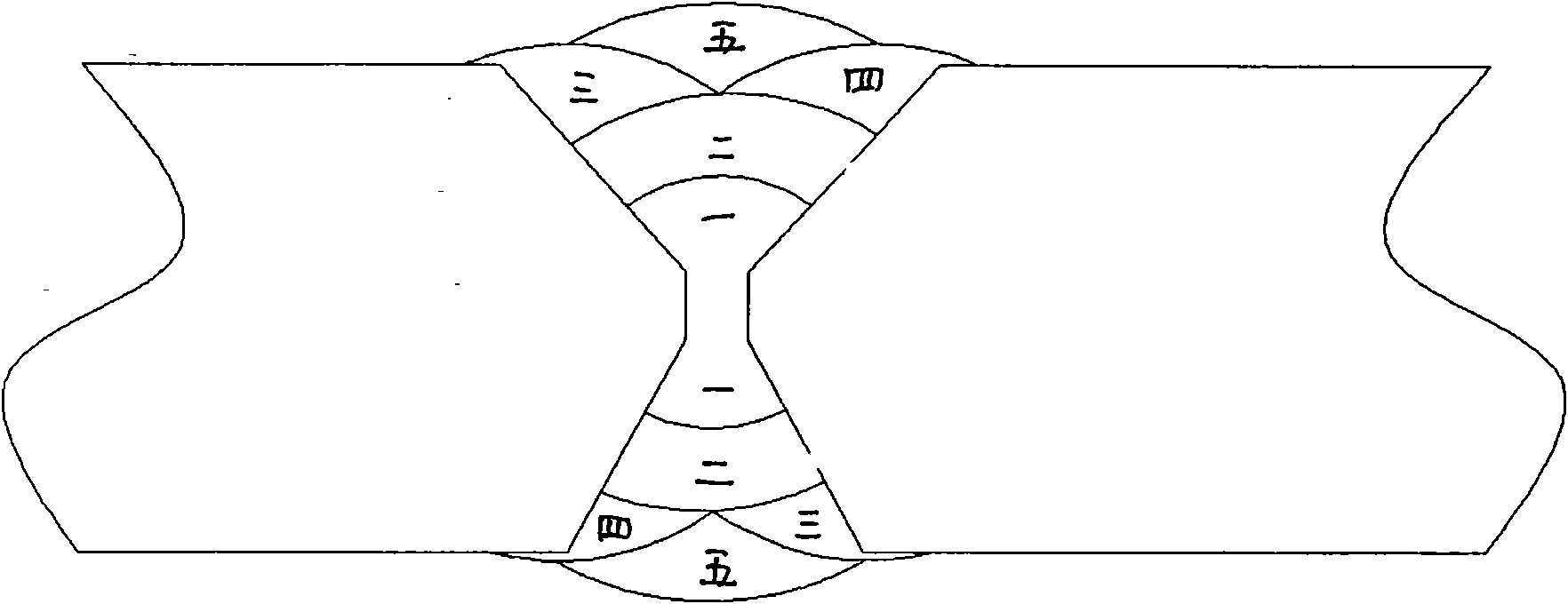

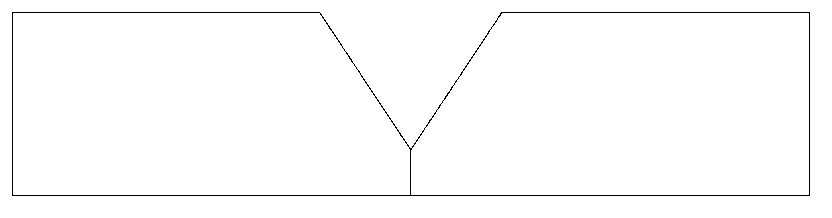

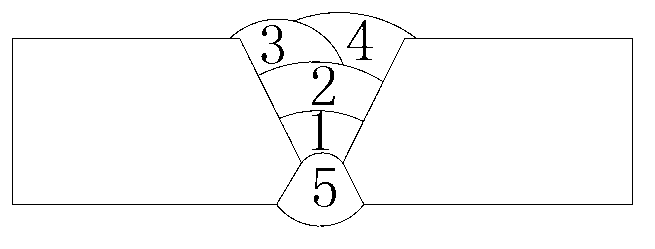

Girth welding technology for vacuum container

ActiveCN102357741AGuaranteed absolute penetrationAvoid the phenomenon of localized high temperatureArc welding apparatusWorkpiece edge portionsShielded metal arc weldingButt welding

The invention discloses a girth welding technology for a vacuum container, which comprises the following steps: processing beveled edges, assembling and welding. In the step of processing the beveled edges, a 14mm thick 0Cr18Ni9 austenitic stainless steel material is selected as a cylinder base material, X-shaped beveled edges are adopted, an inside beveled edge is processed for 10mm with a single-side angle of 32.5 degrees, an outside beveled edge is processed for 4mm with a single-side angle of 35 degrees, and no truncated edge is left. In the step of assembling, reserved clearances of 2.0-2.5mm are assembled, argon tungsten-arc welding is adopted to position, a positioning welding length is 10-15mm, an interval is 200mm, and then a 'strut having a shape of Chinese character 'mi' which is used for adjusting the roundness of a cylinder is welded in the cylinder. In the step of welding, an argon arc welding double-gun butt-welding method is used for bottoming the interior of the cylinder, two layers are filled in an inner welding bead of the cylinder in the manner of manual arc welding, an external welding bead is covered in the manner of submerged-arc welding, and finally, the inner welding bead is covered in the manner of manual arc welding. The girth welding technology can be used for controlling the welding deformation and has the advantages that the method is simple and is easy to realize.

Owner:无锡市创新低温环模设备科技有限公司

High chromium cast iron self protective build-up welding cored welding wire and its usage

InactiveCN1714986ARealize direct surfacingOverlay welding wear-resistant and corrosion-resistantArc welding apparatusWelding/cutting media/materialsHigh carbonManganese

The self-protective high chromium cast iron cored build-up welding wire has metal powder core comprising nickel powder 6-8 wt%, middle carbon manganese iron 8-10 wt%, No. 45 ferrosilicon 9-12 wt%, high carbon ferrochromium 65-75 wt%, metal Cr powder 18-21 wt%, ferromolybdenum 5-7 wt% and Al-Mg powder 1.5-2.5 wt%, and with one welding wire filling amount of 0.49-0.53. The present invention makes it possible to use the welding wire in submerged arc welding without needing added flux and protecting gas, results in raised comprehensive welding performance and raised welding quality, and may be applied widely in build-up welding field requiring high antiwear, anticorrosive and anticracking performance.

Owner:XIANGTAN UNIV

Submerged-arc welding wire for high-strength pipeline steel

InactiveCN1709634AImprove toughnessExcellent strong corrosionWelding/cutting media/materialsSoldering mediaResistSubmerged arc welding

The present invention relates to the high intensity pipeline steel burying arc solder. It solutes the question that because of the Cu's deposition, it leads to separate out Cu easily and ossify the steel in the smelting and the disposal of the heat and contains too many microelements so that it has disbennifits to the smelting technical control. The technical steps are that the weight percent of the chymic component is C 0.04~0.12,Si 0.005~0.10,Mn 1.20~2.00,Ni 0.10~0.60,Cr 0.10~0.60,Mo 0.10~0.50,Ti 0.04~0.15,B 0.002~0.012,P<=0.015,S<=0.01, and the allowance is Fe. The invention solders matchingly with the alkalescence sinter flux. The resist drawing intensity of the welding line is higher than 650MPa.The intensity of the welding line of the jointing X80 pipe line steel reaches 740MPa, and the -20 Deg. C concussion power is higher than 120J.Then the content of the welding line S and P is low and the degree of purity is high. It applies to the burying arc jointing of the X80 high intensity pipeline steel and the other corresponding intensity low levels' alloy which resisted drawing intensity is between 620 and 740MPa.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Submerged arc welding wire for steel pipeline

ActiveCN101104229AEasy to implementLow costArc welding apparatusWelding/cutting media/materialsSheet steelWeld seam

The invention relates to a submerged arc welding wire used on a pipeline steel, which is applied in the submerged arc welding of an X80 high steel grade pipeline steel plate used on high-pressure oil and high-pressure gas conveying pipelines. The chemical components comprise (according to weight percent): C 0.02-0.07; Si 0.10-0.30; Mn 1.80-2.50; P is less than 0.010; S is less than 0.010; Cr 0.10- 0.50; Ti 0.05-0.08; Mo 0.20-0.50; B 0.003-0.004; and the rest is Fe. The welding wire is matched with BGSJ101-G flux and other special flux for pipeline steel welding , and then the best strength and toughness of welding seam can be obtained; the tensile strength ob of welded seam metal is more than or equal to 700MPa. Impact energy AkV of the welded seam metal in the minus 20 DEG C is more than or equal to 150J. And thus, the invention is suitable for the submerged arc welding of the X80 high steel grade pipeline steel plate.

Owner:SHOUGANG CORPORATION +1

Welding flux for X100 pipe line steel submerged arc-welding and preparation method thereof

ActiveCN102218623AImprove matchHigh strengthArc welding apparatusWelding/cutting media/materialsLine tubingSlag

The invention discloses a welding flux for X100 pipe line steel submerged arc-welding and a preparation method thereof. The welding flux comprises, in percentage by weight, main components including 5-13% of SiO2, 26-40% of MgO, 15-24% of Al2O3, 18-25% of CaF2, 1-4% of CaO, 4-8% of MnO, 1-2% of Na2O, 1-2% of K2O and 1.0-6.0% of TiO2, and a bonder accounting for 15-20wt% of the total weight. The preparation method comprises the steps of: uniformly mixing the main components according to proportions; then adding the bonder for pelleting; and baking at low temperature, sintering at high temperature and sifting. When the welding flux is matched with a special welding wire CHW-SG10, a soldered seam has excellent performances, such as high strength, high toughness, better corrosion resistance, lower rigidity and the like approaching to those of an X100-level steel pipe body, and the welding flux can be used for carrying out single or multiple-wire welding and internal and external high-speed welding; and a multiple-wire large-line energy welding speed can reach 120 m / h, and the soldered seam performance and air holes, slag inclusions, cracks, appearance edge, undercut and the like of the soldered seam all meet the requirements of the technical standard of the X100 pipe line steel submerged arc-welding.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

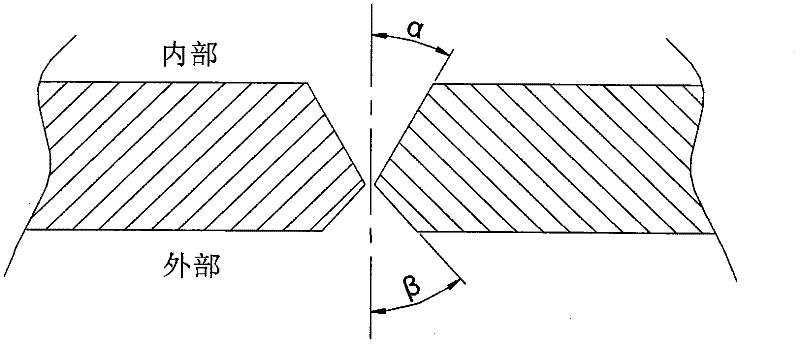

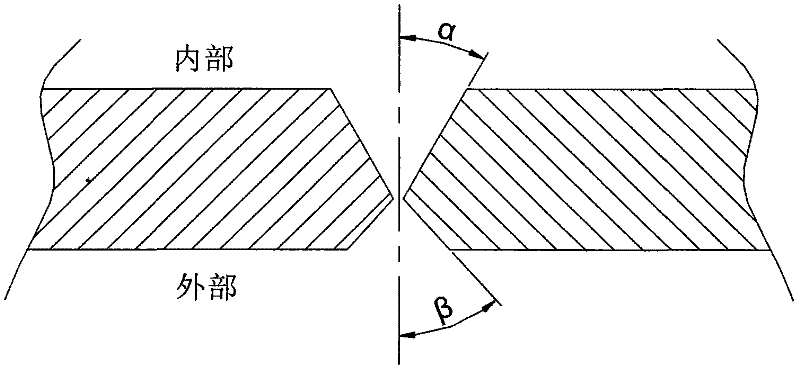

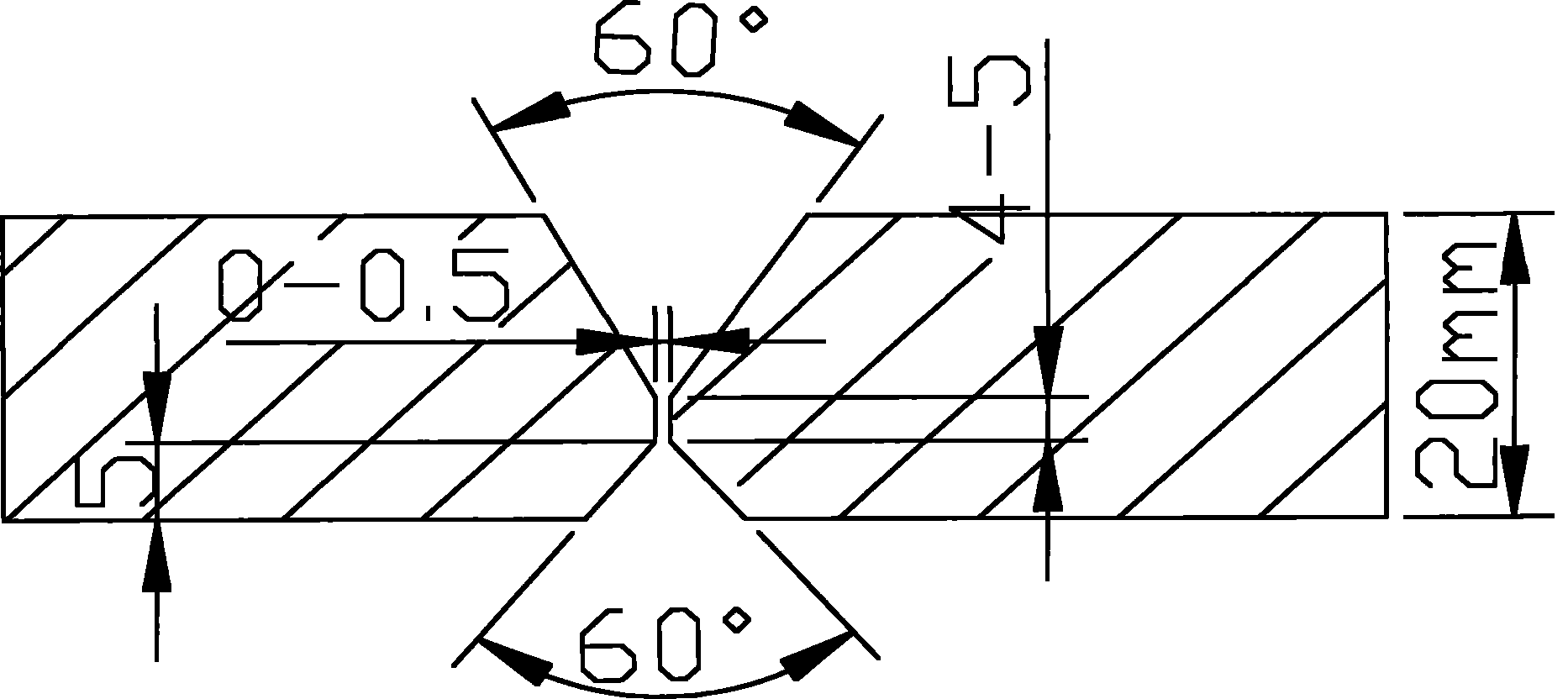

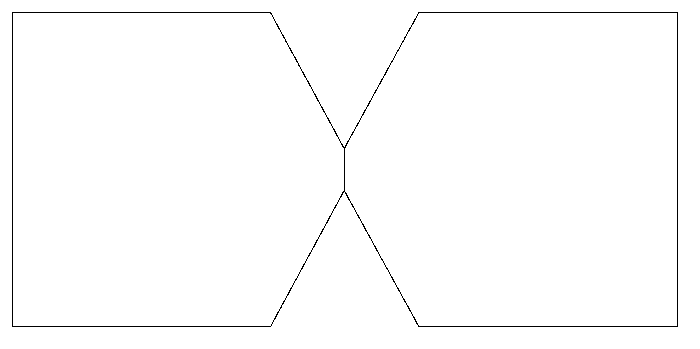

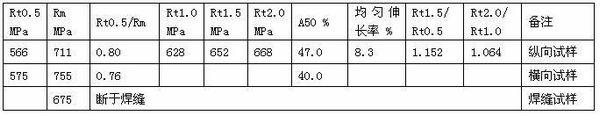

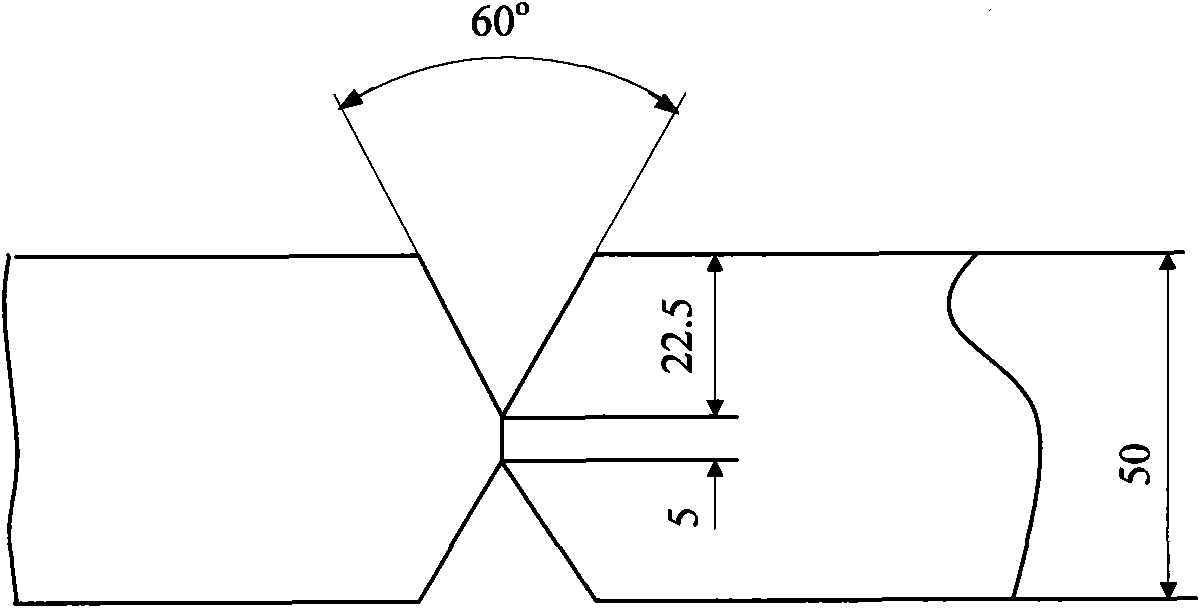

Butt joint submerged-arc welding method of bridge steel with tensile strength more than 690Mpa grade

InactiveCN101658970AHigh tensile strengthImprove toughnessArc welding apparatusWelding/cutting media/materialsButt jointWeld seam

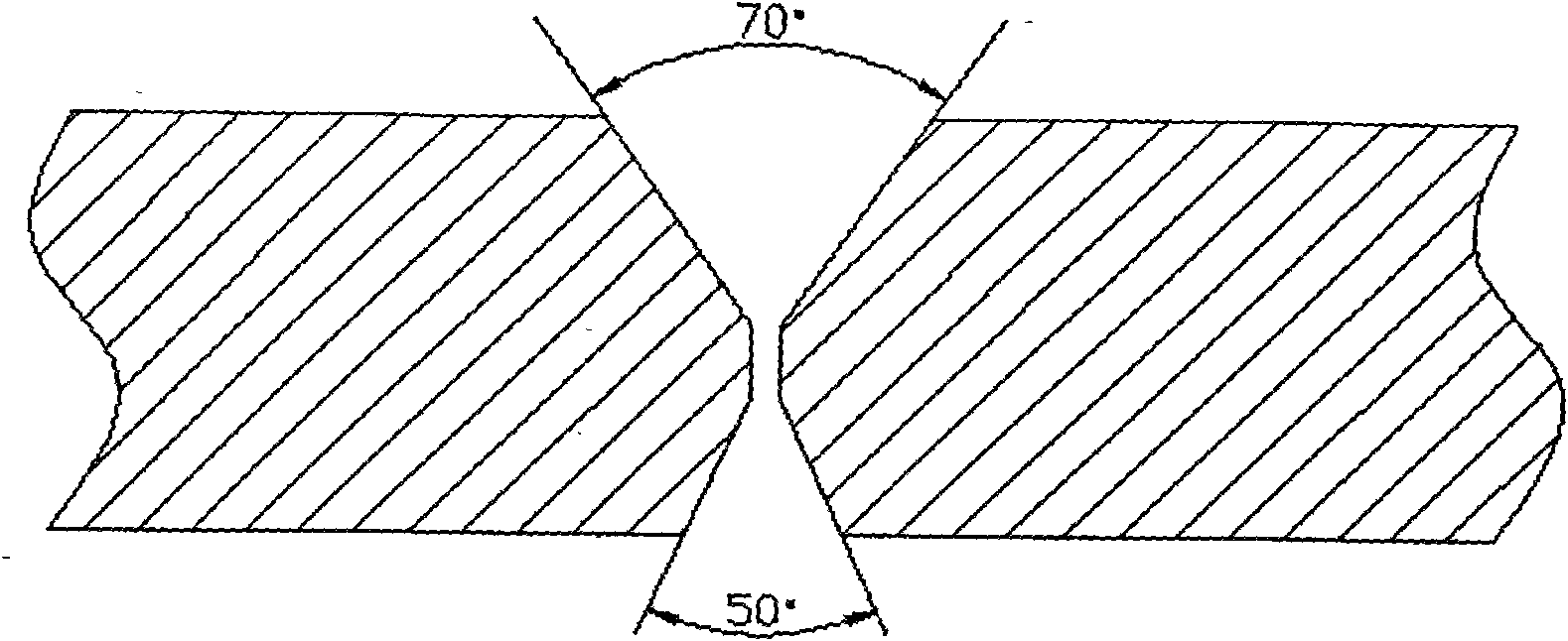

The invention relates to a butt joint submerged-arc welding method of bridge steel with tensile strength more than 690Mpa grade, overcoming the defects that at the present, bridge steel and other engineering structural steel which are in 690Mpa strength grade needs preheating before welding and heat treatment after welding and has severe welding environment and the like during manual and gas protective welding. The butt joint submerged-arc welding method comprises the following steps: adopting steel with tensile strength Rm of between 690Mpa and 745Mpa, the yield strength ReL of between 550 and 690Mpa, the extension rate A of between 19 percent and 21 percent, KV2 ballistic work of between 165J and 180J at 40 DEG C below zero and the thickness of 40mmm, and adopting same-thickness butting;adopting matched welding wires with the tensile strength more than 690Mpa and diameter phi of 4.0mm, and using CHF105 as a welding flux; adopting a double-sided X-type asymmetrical submerged-arc welding groove with the angle of 60 degrees and the truncated edge of 5mm; continuously welding until welding seams are full, and under the conditions that the welding current is 570A, the voltage is 31V,the speed is 35cm / min and the linear energy is 30kj / cm; baking the welding flux for 1 hour at 350DEG C and keeping the temperature of welding layers between 100 DEG C and 150DEG C.

Owner:武钢集团有限公司

Welding method for Q345qDNH weather-resisting steel for bridge

ActiveCN102837105AGood mechanical propertiesEasy to upgradeArc welding apparatusWelding/soldering/cutting articlesShielded metal arc weldingButt joint

The invention discloses a welding method for Q345qDNH weather-resisting steel for a bridge. According to the welding method provided by the invention, specific to the special chemical components, suitable technical conditions and different slab thickness of the Q345qDNH weather-resisting steel for the bridge, a welded joint is jointed in a butt-jointed or T-shaped corner jointed form. According to the welding method, submerged-arc welding, drug core CO2 gas shielding semi-automatic welding or shielded metal arc welding is adopted and the weld preheating temperature is confirmed according to the different slab thickness. According to the welding method provided by the invention, the joint form and the thickness size of a bridge structure are completely covered; the technical scheme is simple and the applicability is strong; the implementing effect meets the technical demands of the present related standard for the construction of the bridge steel and the bridge structure; and the welding method can be practically applied to the welding of the Q345qDNH weather-resisting steel bridge structure.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

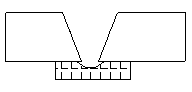

Submerged-arc welding process for T-type joint for extra thick steel plate

ActiveCN102240841AImprove welding qualityReduce the deterioration of mechanical propertiesArc welding apparatusCrazingThick plate

The invention discloses a submerged-arc welding process for a T-type joint for an extra thick steel plate and belongs to the technical field of welding of extra thick plates. The process comprises the following steps of: before welding, pre-heating the extra thick steel plate to 100 to 150 DEG C; removing pollutants of oxides, greasy dirt and the like on the surface of the groove of the extra thick steel plate; bottoming the extra thick steel plate by submerged-arc welding; forming systematical grooves and after the front face of the extra thick steel plate is bottomed, welding and filling; performing back gouging on the reverse side of the extra thick steel plate and welding and filling the reverse side; and filling welding wires on the front side of the extra thick steel plate and covering the side. The problems that manual bottoming efficiency is low, labor intensity is high, and heat cracking, undercutting, mechanical slag inclusion, large working amount of back gouging of the reverse side and the like are easily caused by submerged-arc welding bottoming when the T-type joint of the extra thick plate of which the thickness is 50 to 150mm is welded are solved; by the selection of an appropriate groove form, the welding sequence, and welding process parameters, and slow cooling measures, slag is easy to clean in a filling weld pass, the working amount of back gouging is reduced, the welding deformation is reduced, the welding residual stress is reduced and the quality of a weld joint is guaranteed; and the submerged-arc welding process is easy to operate and implement, and is convenient to popularize.

Owner:SHOUGANG CORPORATION

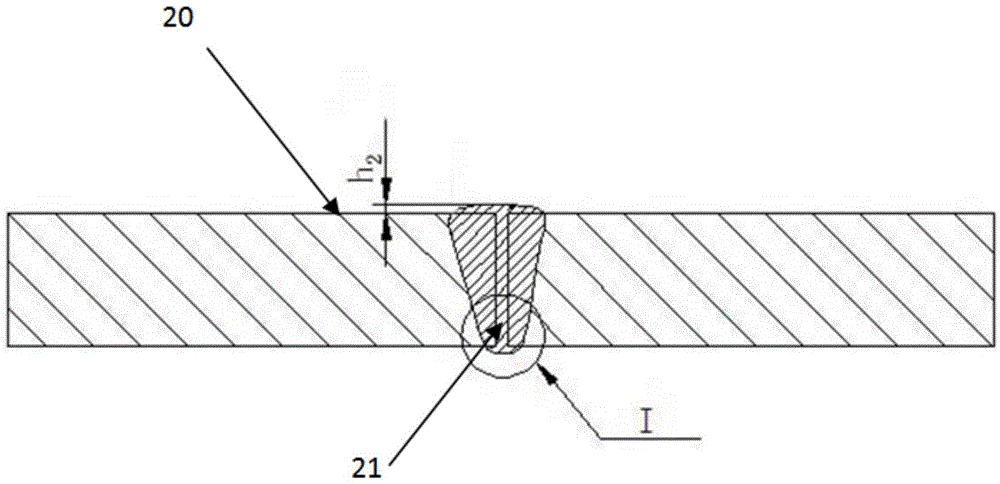

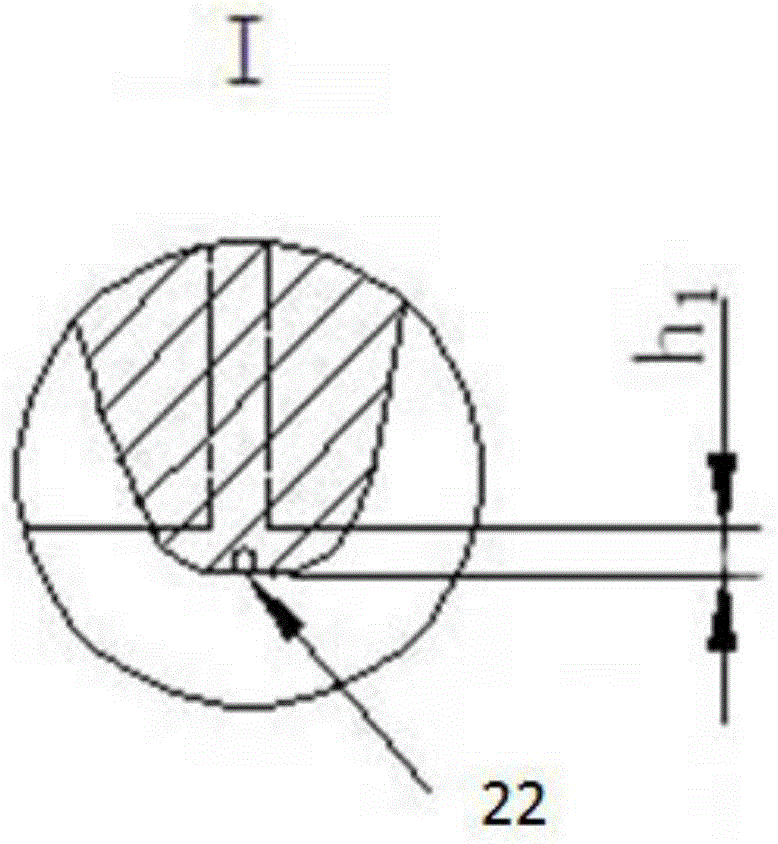

Vacuum milling method for metal compound plate

The invention provides a vacuum milling method for a metal compound plate, which relates to a compound plate production method and comprises the following steps that: 1, circumference lead angle beveled edges are processed on the circumference of the single side of a base plate, and the circumference dimension of a stainless steel plate is smaller than the dimension of the circumference lead angle beveled edges; 2, a right-angle hole is drilled between the lead angle beveled edges; 3, the stainless steel plate is flatly paved on the lead angle beveled edges side of the base plate, in addition, a soldering flux layer is flatly paved between the stainless steel plate and the base plate, and the circumference sealing welding is carried out on a pressure platform; 4, the vacuum pumping is carried out through the right-angle hole of the base plate, and the sealing and plugging is carried out after the vacuum pumping; 5, the two prepositive blank stainless steel surfaces are combined, in addition, a high-temperature adhesion-prevention agent layer is flatly paved between the two prepositive blank stainless steel surfaces, then, separation plates with the same circumference lengths are in dot welding on the circumference, and next, submerged arc welding sealing welding is carried out between the two lead angle beveled edges and the separation plates; 6, a plurality of vent holes are drilled on a sealing and welding ring frame and the separation plates, 7, the hot milling is carried out; and 8, the edge milling separation is carried out. The vacuum milling method has the advantages that the prepositive blank processing and the vacuum pumping are firstly carried out, then, air holes are drilled, excessive air can be exhausted during the milling, and the plate material quality is ensured.

Owner:SANMING TIANZUN STAINLESS STEEL CLADDING TECH

Method for manufacturing double metal composite wear-resistant metallurgical rollers

ActiveCN103009015AIncrease the amount of steelAvoid Roll Breaking AccidentsArc welding apparatusWear resistantHardness

A method for manufacturing double metal composite wear-resistant metallurgical rollers includes steps of roller core processing, preheating, surfacing of a composite layer, finish machining and thermal treatment. The roller core processing step includes subjecting steel good in tensile strength, yield strength and impact resistance to forging, pressing and tempering, manufacturing roller core blanks, subjecting the roller core blanks to rough machining to reserve size for a surfaced composite layer. The preheating step includes preheating the roller cores to the optimum surfacing temperature of 380 DEG C + / - 5 DEG C. The surfacing step of the composite layer includes surfacing and filling the reserved surfaced composite layer by flux-cored wires on the surface of the preheated roller cores by means of submerged-arc welding process. The finish machining step includes processing the surfaced double metal composite wear-resistant metallurgical roller blanks into design size. The thermal treatment step includes quenching and tempering the double metal composite wear-resistant metallurgical rollers subjected to finish machining, so that the surfaces of the double metal composite wear-resistant metallurgical rollers can meet the requirements for good anti-sticking abrasion, grain abrading resistance, red hardness, resistance to cold and hot fatigue, and peeling resistance.

Owner:邯郸市永固冶金备件有限公司

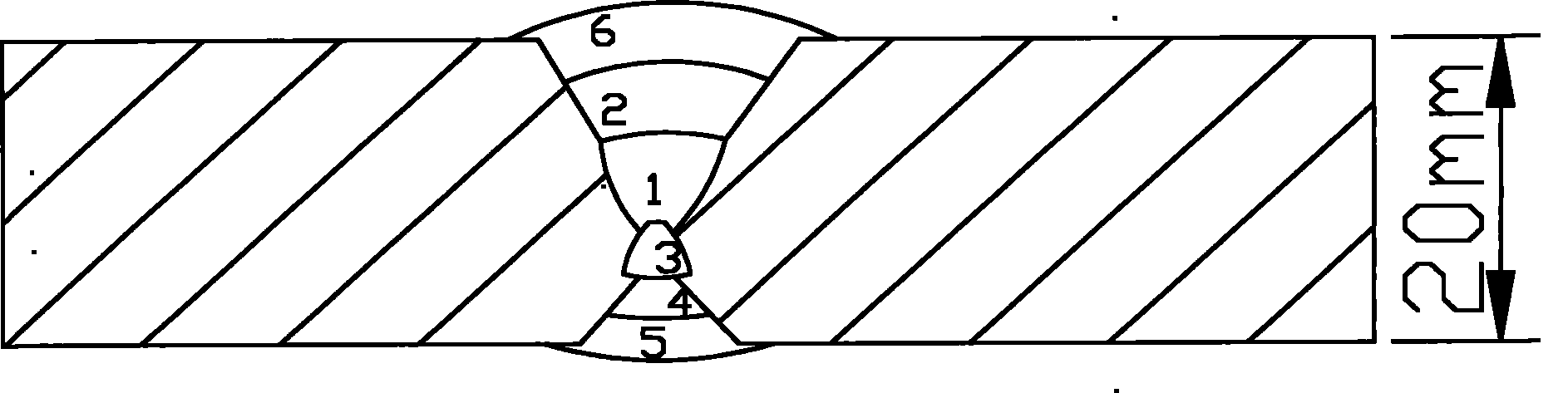

Two phase stainless steel submerged-arc welding SAW welding procedure

ActiveCN101913012AGood academic performanceImprove corrosion resistanceArc welding apparatusMechanical propertyWeld line

The invention relates to an economic and practical submerged arc welding procedure applicable to welding of common two phase stainless steel 022CrNi5Mo3(S31803 and S2205). The invention is characterized in that the procedure includes the following steps: 1) the performance characteristics of two phase stainless steel are researched; 2) welding material is selected and welding procedure is determined; 3) welding edge preparation is carried out; 4) clean-up and final inspection are carried out on the surface of work piece to be welded; 5) submerged arc welding is carried out on the common two phase stainless steel. The invention is based on research of chemical constituents and performance characteristics of common two phase stainless steel, economic and practical domestic submerged arc welding material combination applicable to common two phase stainless steel and reasonable submerged arc welding procedure are selected, and the invention has the advantage that efficient welding of two phase stainless steel is realized by adopting high line energy submerged arc welding. Welding of common two phase stainless steel is carried out by adopting the invention, the chemical constituents of welding line can be ensured to meet standard requirement, ferrite content of welding joint (including welding line and heat affected zone) is controlled to be 30-65%, and the welding joint has good mechanical properties and pitting corrosion resistance.

Owner:NANJING BAOSE

Submerged arc welding method of plank boards and jointing boards

InactiveCN101607342AMeet the standard requirementsQuality assuranceArc welding apparatusWorkpiece edge portionsPass rateEngineering

The invention discloses a submerged arc welding method of plank boards and jointing boards, which is characterized in that through steps of reasonable welding material selection, strict pre-welding preparation, scientific pre-welding preheating, welding process and welding technology, the welding quality of submerged arc automatic welding of plank boards with the thickness of 25mm to 45mm is controlled. The pass rate of welding seams by shooting once reaches 100 percent, and welding distortion is controlled ideally. The mechanical property of a welding joint meets standard requirements, and ensures the quality of products.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

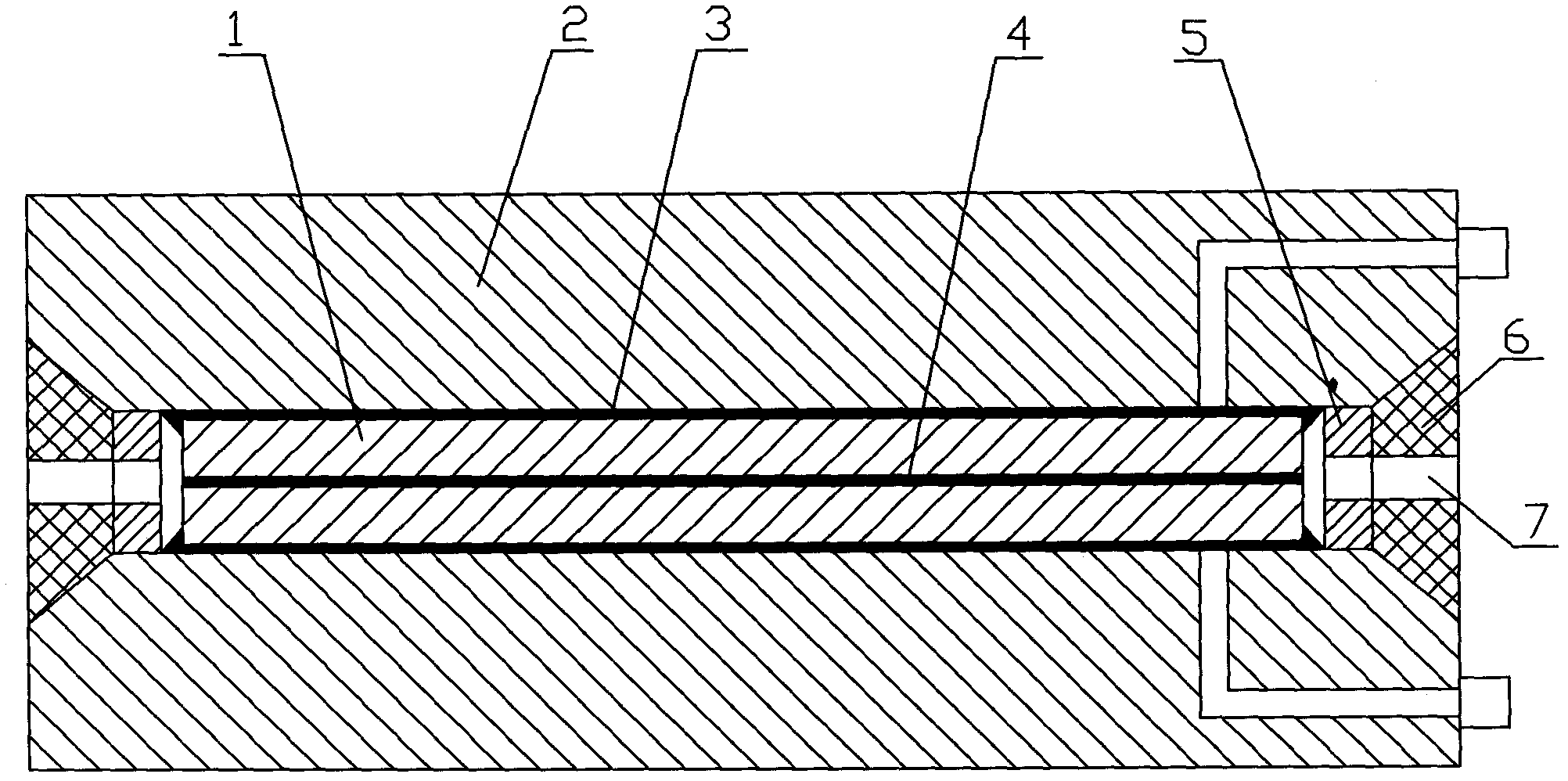

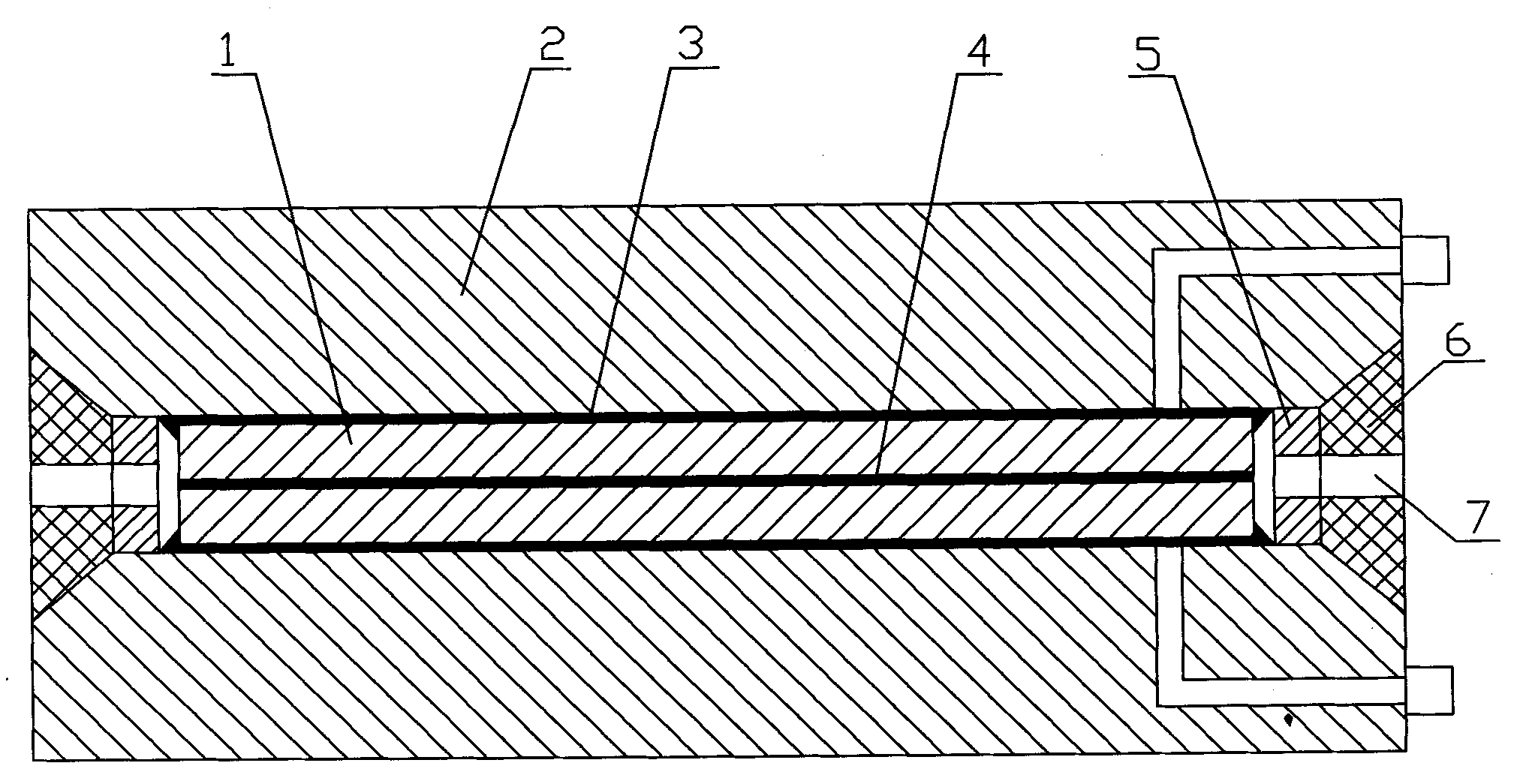

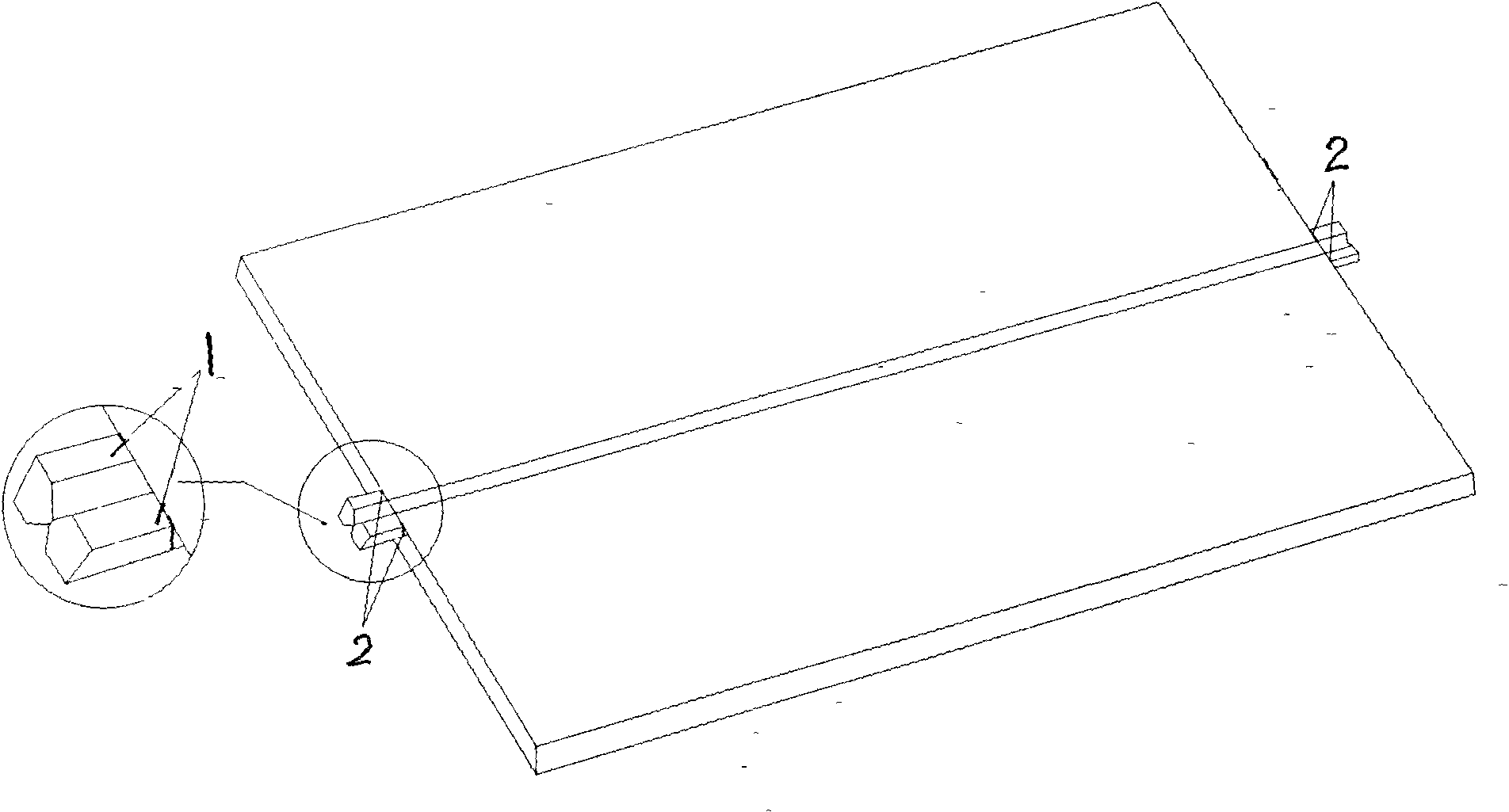

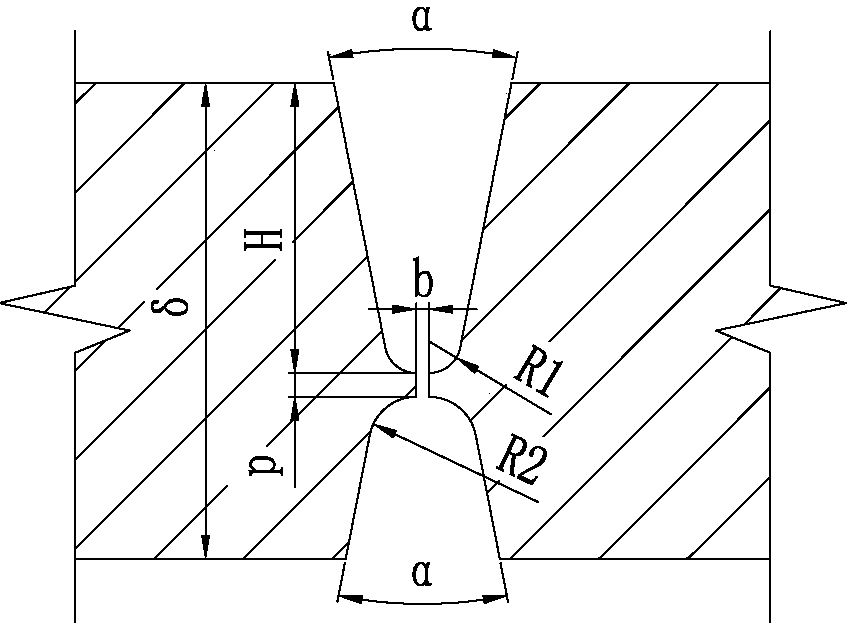

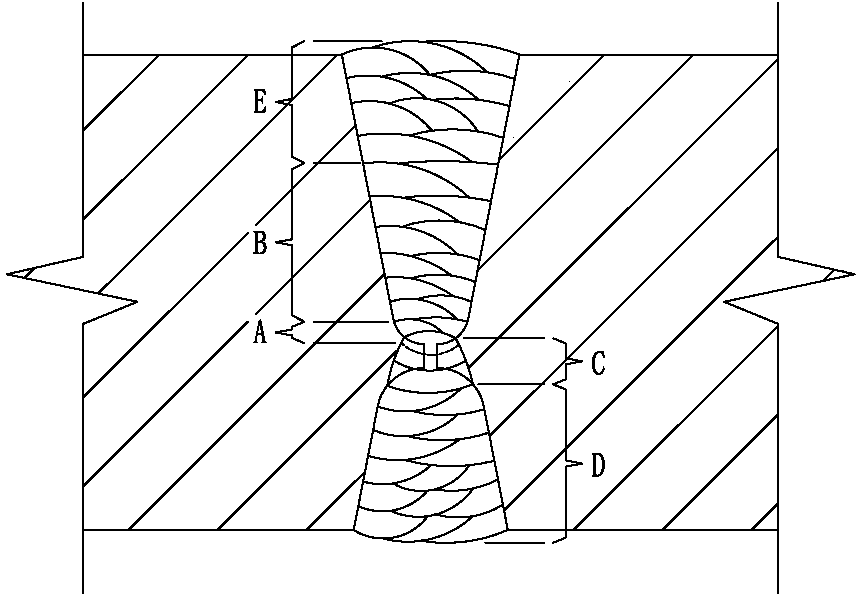

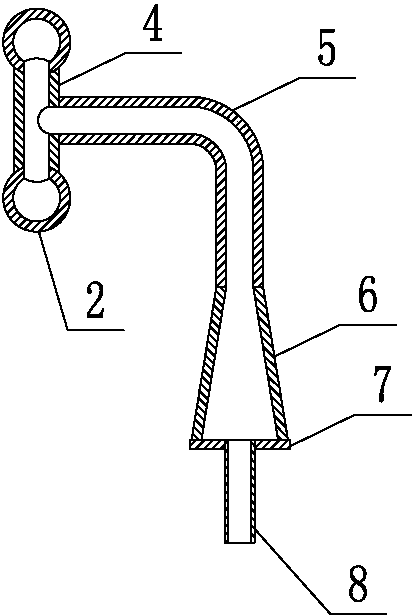

Longitudinal seam red copper liner welding process of steel sheet pressure vessel and red copper liner used by same

InactiveCN104128694AAvoid melting intoImprove product qualityWelding/cutting auxillary devicesPipeline systemsCopperWater pipe

The invention discloses a longitudinal seam red copper liner welding process of a steel sheet pressure vessel. The longitudinal seam red copper liner welding process sequentially comprises the steps of (a), aligning and splicing a longitudinal seam of a machined cylinder and carrying out point welding fixation; (b), placing the inner longitudinal seam of the machined cylinder on a red copper liner; (c), aligning the longitudinal seam of the machined cylinder to the center line of a welding groove of the red copper liner, fixing the machined cylinder and the red copper liner through an air cylinder, and guiding water into a cooling water pipe of the red copper liner; (d), carrying out welding; (e), disassembling the machined cylinder after the longitudinal seam of the machined cylinder is welded. The welding process has the advantages that automatic submerged arc welding of one-side welding and two-side forming is achieved, the RT flaw detection qualification rate is high, welding flux is saved, the manufacturing quality of the steel sheet pressure vessel is improved, and the production cost is lowered.

Owner:江门市新会区同达化工机械制造有限公司

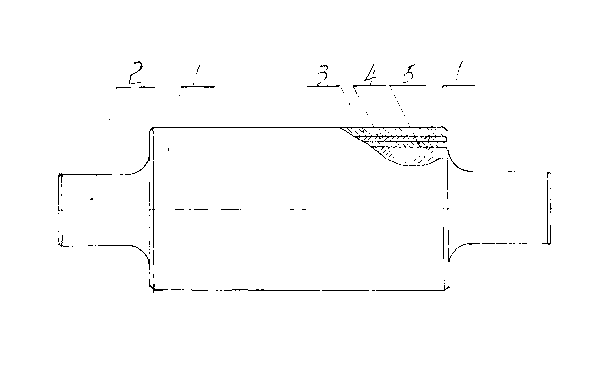

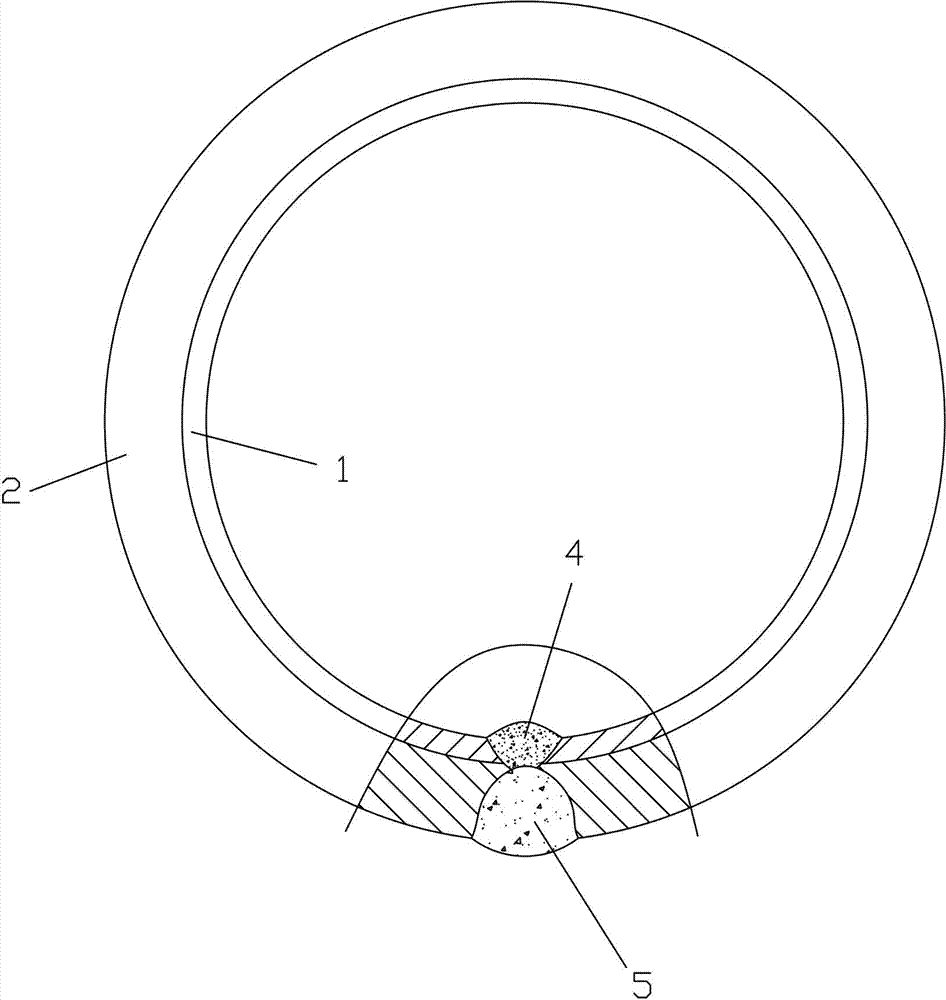

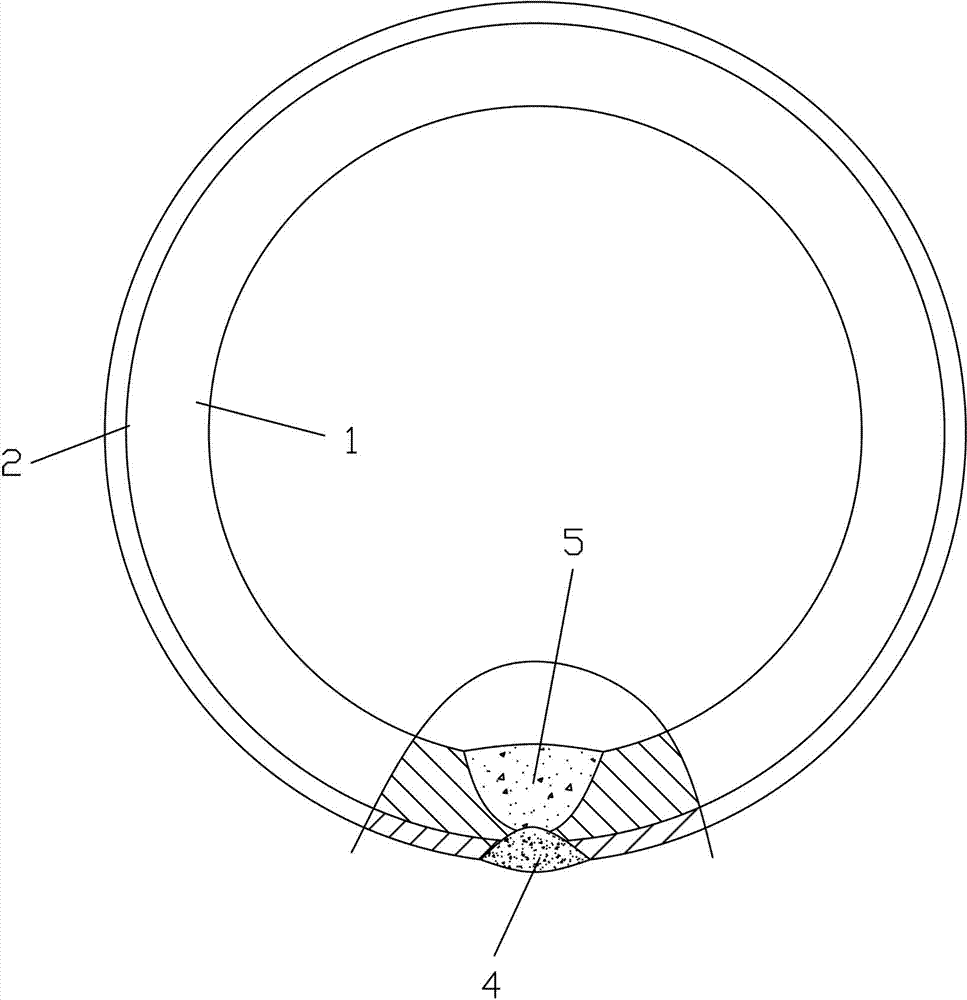

Stainless steel compound welding steel pipe and manufacturing method thereof

ActiveCN102889434AImprove corrosion resistanceImprove structural strengthRigid pipesStainless steel electrodeUltimate tensile strength

The invention discloses a stainless steel compound welding steel pipe and a manufacturing method thereof. The stainless steel compound welding steel pipe is formed by welding stainless steel compound hotly-rolled rolling plates through a welding line, wherein the welding line is formed by a stainless steel compound welding line and a carbon steel welding line. The manufacturing method comprises the following steps of: milling an edge and arranging a groove; when putting a stainless steel compound layer on the inner layer, firstly utilizing gas shield welding to weld a middle layer; then, utilizing a stainless steel welding strip to weld a stainless steel compound layer welding line in an argon arc welding manner; then, utilizing a carbon steel welding strip to weld the carbon steel welding line by a submerged-arc welding manner; when the stainless steel layer is less than 0.9 mm, directly welding a stainless steel welding line by submerged-arc welding; and when the stainless steel compound layer is located at the outer layer, firstly welding the carbon steel welding line by adopting the carbon steel welding strip and the submerged-arc welding, and adopting the stainless steel welding strip and the argon arc welding manner to weld the stainless steel compound layer welding line. According to the stainless steel compound welding steel pipe and the manufacturing method thereof, the manufactured stainless steel compound welding steel pipe has high structural strength and strong corrosion resistance; and the bonding strength of an inner pipe and an outer pipe is not less than 200 MPa.

Owner:ZHEJIANG KINGLAND & PIPELINE TECH

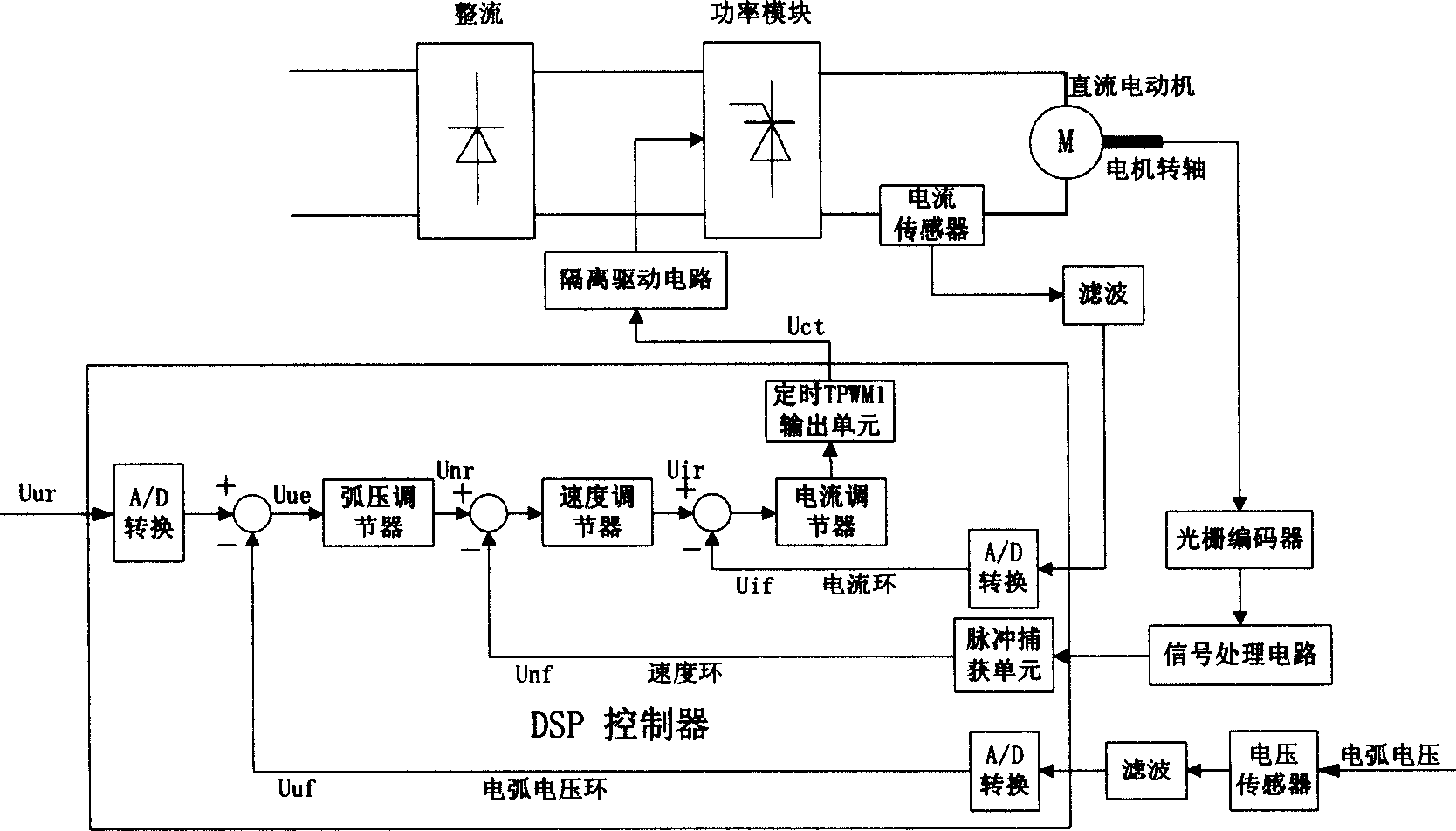

Full-digital speed change control method for wire feeding for submerged arc welding

InactiveCN1634676ARealize full digital controlFlexible adjustmentArc welding apparatusLoop controlControl signal

This invention relates to whole digital buried arc welding varying wire feed control method, which adopts series three-loop control structure with inner one as current ring, second ring as rotary speed ring and outer ring as arc voltage ring with one adjustor in each ring for arc voltage, rotation speed and current. It adopts high speed digit signals processor as central control part to form whole digital DC servo motor control system whose all control strategies area realized by software and the hardware completes digital trigger function and signal process function.

Owner:SHANGHAI JIAO TONG UNIV

Method for welding Q500qE ultralow-carbon bainite steel for bridge

ActiveCN103286427ASolve welding process problemsAvoid cold cracksArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention provides a method for welding Q500qE ultralow-carbon bainite steel for a bridge. The method is excellent in joint mechanical performance and high in welding efficiency and specifically includes that aiming at specific chemical components, applicable technical conditions and different plate thicknesses of the Q500qE ultralow-carbon bainite steel for the bridge, preheating temperature before welding, groove types and welding process parameters are determined; a welding joint type adopts butt joint, penetration angle joint or ship position T-shaped angle joint; a welding method adopts submerged arc welding, CO2 gas shielded semiautomatic welding or shielded metal arc welding. By the welding method, the joint type and thickness specifications of a bridge structure are comprehensively covered, the technical scheme is simple, convenient and high in adaptivity, all implementing effects meet technical requirements of standards related to building of bridge steel and the bridge structure, and the method is of great significance in promoting upgrading of the bridge steel and development of large-span steel bridge building technology. The method can be applied to building of the bridge structure, can also be applied to welding of other ultrathin-carbon bainite steel and is high in adaptivity.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

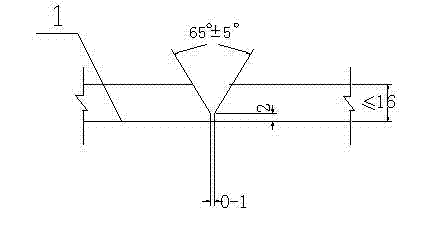

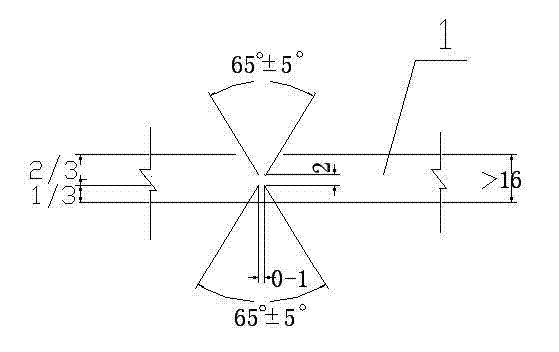

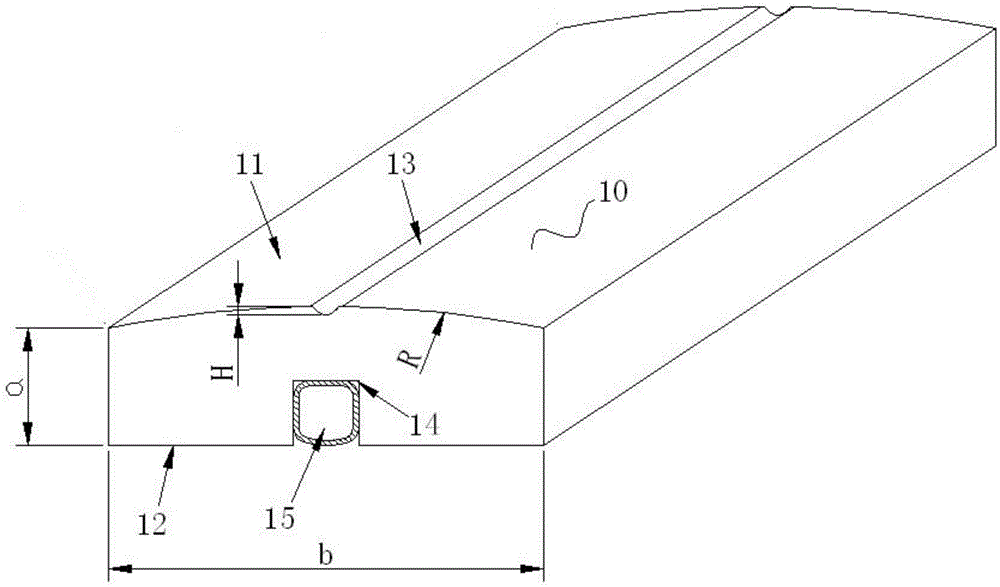

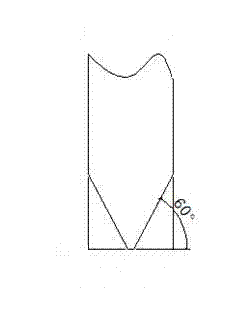

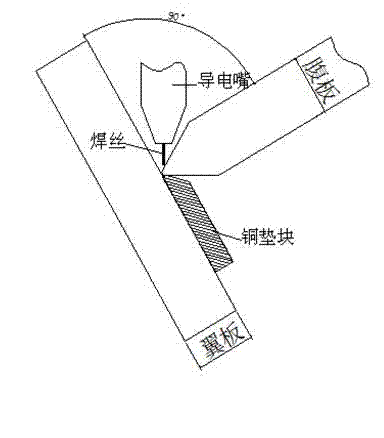

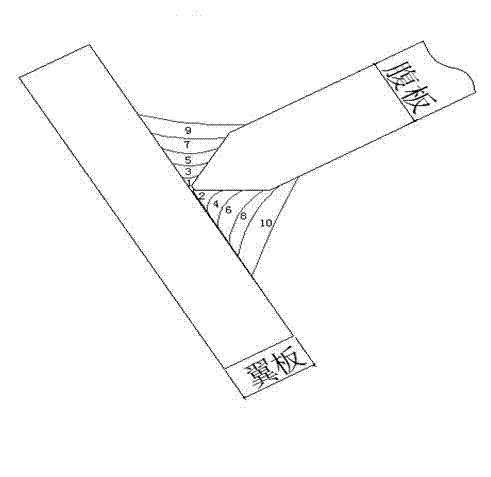

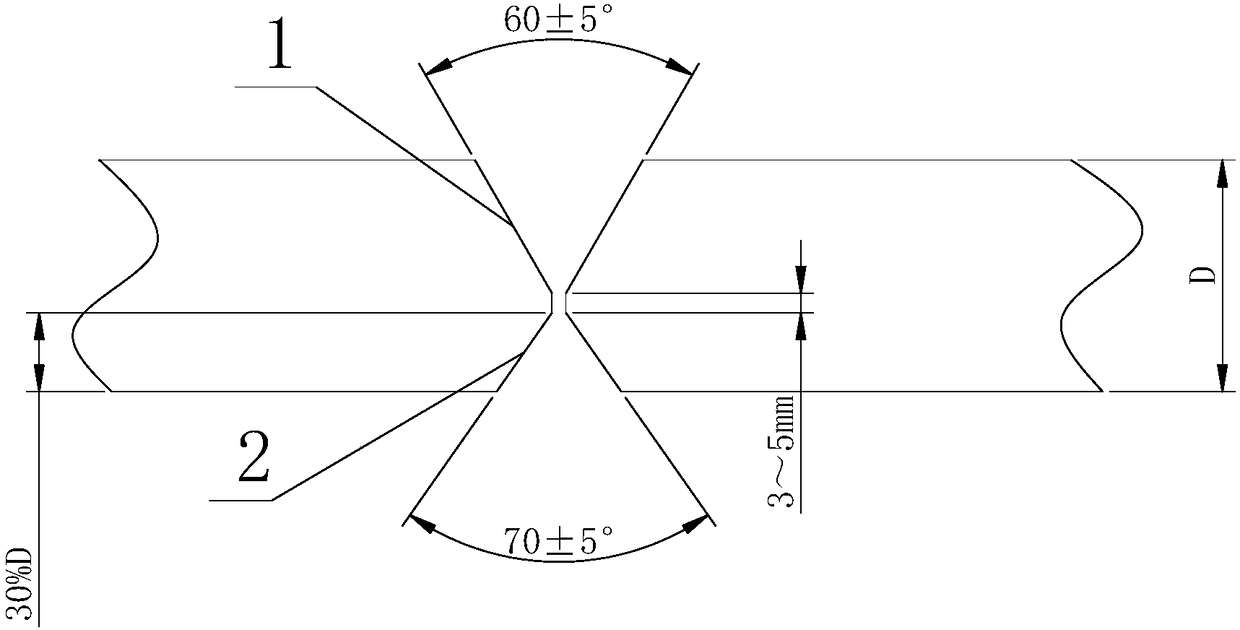

Submerged-arc welding process method for welding H-shaped steel with web plate more than 16mm thick

ActiveCN102950370AReduce contact areaReduce pollutionArc welding apparatusWorkpiece edge portionsEngineeringCopper

The invention relates to the technical field of welding of H-shaped steel and particularly relates to a back-chipping-free full-penetration submerged-arc welding process method for welding H-shaped steel with a web plate more than 16mm thick. The process method comprises the steps of material selection, edge preparation, assemblage of the H-shaped steel, positioned welding, preparation before welding, welding and the like, wherein the assemblage is required to be zero assembling, and an assembling interval is less than or equal to 0.5mm; the angles of K-shaped symmetrical beveled edges are designed to be at 60+ / -2 degrees, and the truncated edges of the beveled edges range from 1mm to 2mm; and the standard lengths of copper cushion blocks are designed to be 530mm and 130mm. The submerged-arc welding process method has the advantages of low cost, high efficiency, labor saving, reduction in environmental pollution and the like; and according to primary measurement and calculation, the welding process method can reduce the cost for welding the H-shaped steel with the web plate more than 16mm thick by 25%.

Owner:SHANDONG ZHONGTONG STEEL STRUCTURE ENG

Technology for repairing surfacing of piston rod of super large marine diesel engine

InactiveCN101444881ALow roughness requirementsLow cleanliness requirementsArc welding apparatusRoom temperatureEngineering

The invention discloses a technology for repairing surfacing of a piston rod of a super large marine diesel engine, and the technology can carry out the deep repair of the surface of the piston rod. The adopted surfacing process is as follows: flaw detection and straightening are carried out on the piston rod, turning machining is carried out on the surface of the piston rod to remove a defect layer, and individual deeper cracks are manually removed by grinding; fire whirl is used for heating the piston rod twice, the first heating is carried out till 200 DEG C-250 DEG C, the heating is stopped, the race rotation is carried out for 30 minutes, the second heating is further carried out after the temperature difference between the interior and the exterior is reduced, and a surfacing machine tool is rotated after reaching 250 DEG C-300 DEG C; submerged arc welding is used for rotating dual heads of the surfacing machine tool and a 2Cr13 flux-cored welding wire for carrying out the simultaneous surfacing, and asbestos cloth is used for wrapping and keeping the temperature during the welding process; the piston rod wrapped by the asbestos cloth for slow cooling after the surfacing achieves the size requirement, when the temperature is decreased to be lower than 100 DEG C, the piston rod wrapped by the asbestos cloth is vertically placed till the temperature is decreased to the room temperature, and then the temperature-keeping cloth is removed. The surface of the piston rod after the repair by employing the method has no weld defects, the piston rod fully meets the performance requirements, and the cost is only about one fifth of the cost for fabricating a new piston rod.

Owner:DALIAN XINZHONG GRP +1

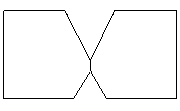

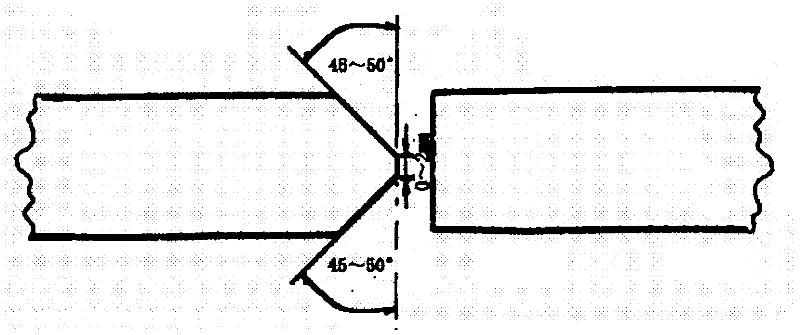

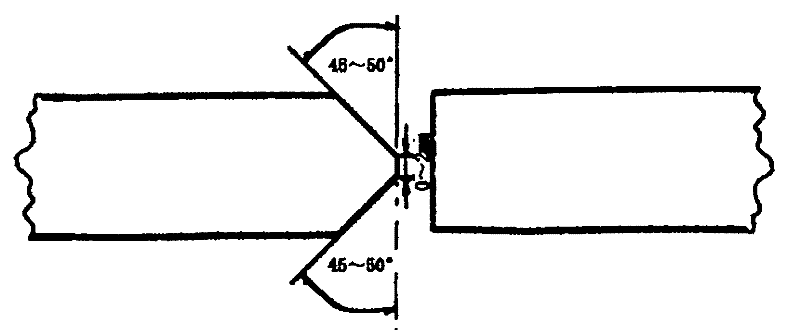

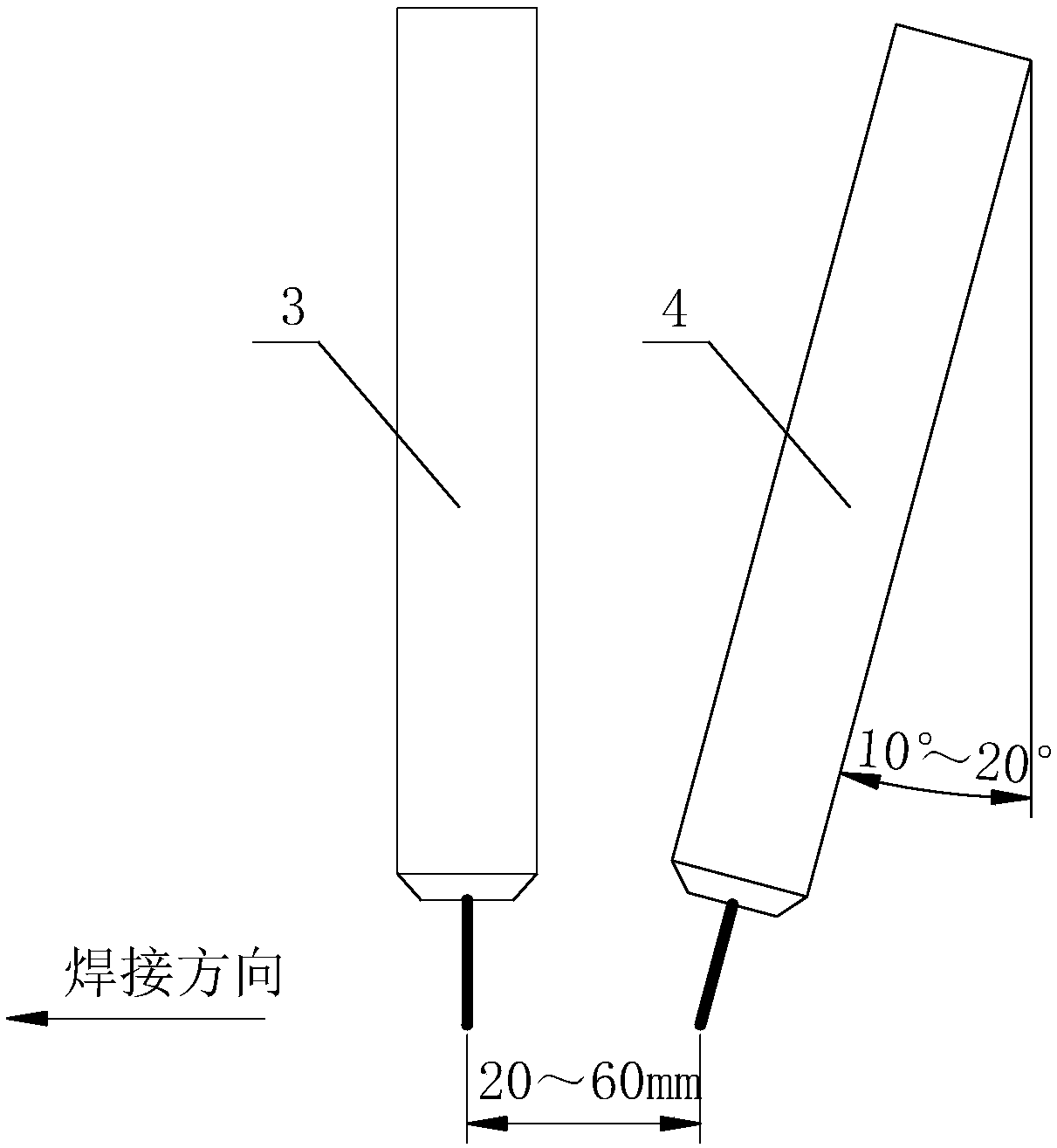

Small bevel angle full-automatic CO2 gas shielded welding and automatic submerged arc welding combined welding technique

The invention relates to a welding technique, especially a combined welding process combining small bevel angle full-automatic CO2 gas shielded protection welding with unionmelt welding, comprising following steps: (1) opening a corresponding small angle bevel on the weldment with a bevel angle of 25+50DEG; (2) paring, ensuring welding space of 8+20mm; (3) grounding welding by using full-automatic CO2 gas shielded protection welding; (4) performing filling in and capping welding by using unionmelt welding. The advantages of the invention are: (1) small bevel angle welding, saving material and improving productivity; (2) grounding welding by using unionmelt welding, the electrical arc heat quantity is centralized, the heated area is small, the welding speed is quick, head affection range is contracted, and welding deformation is small; (3) crackle generation tendency is decreased; (4) bottom slag cleaning is avoided to prepare for narrow gap welding and welding efficiency is increased; (5) filling in and capping are performed by using unionmelt welding, so that welding speed and external appearance forming quality are assured.

Owner:MCC JINGTANG CONSTR

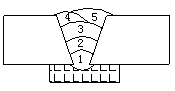

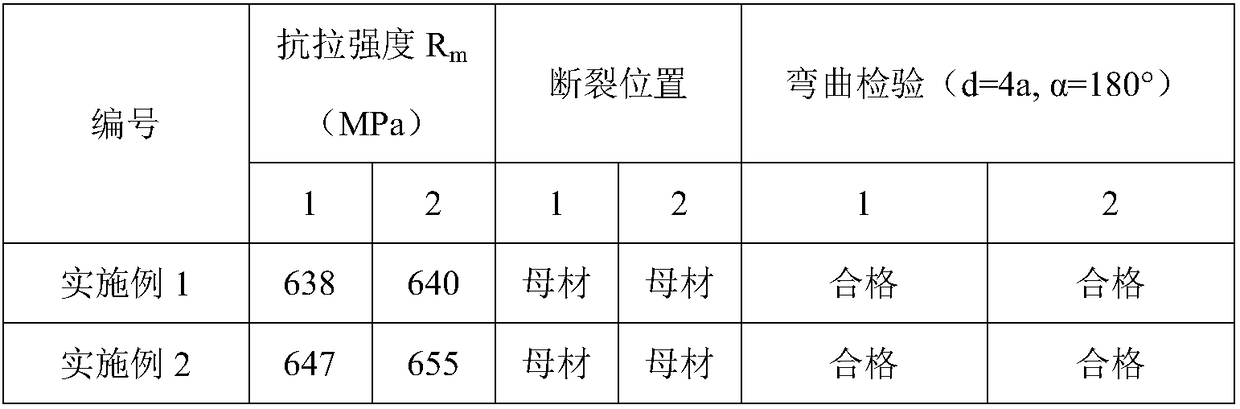

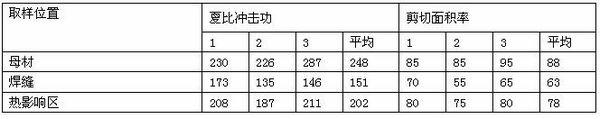

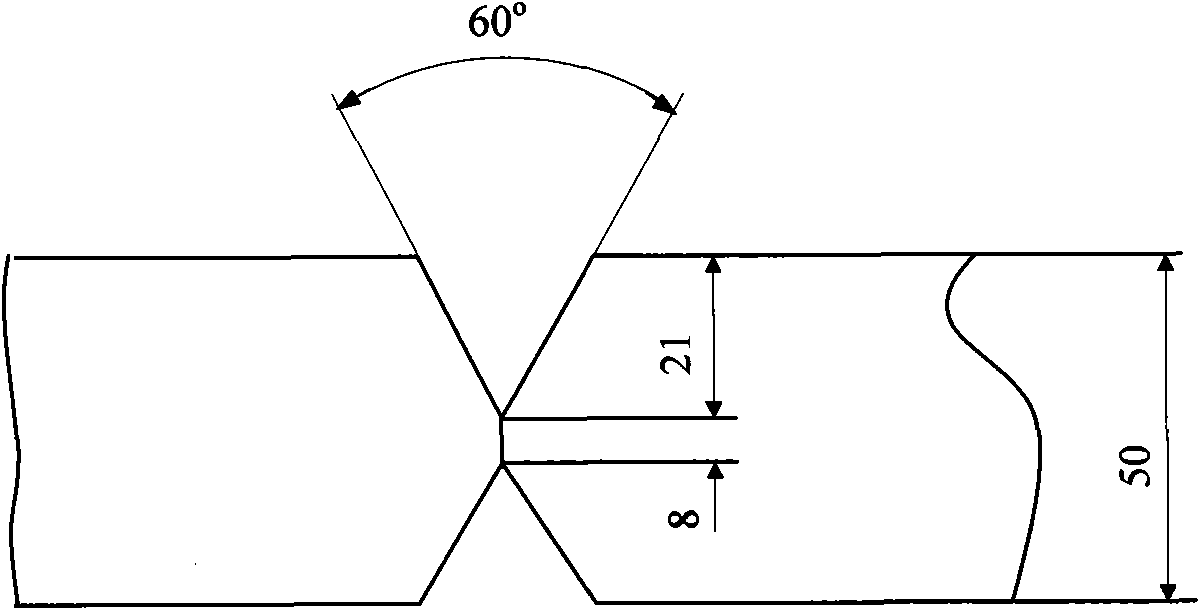

Double-wire submerged arc welding method for high heat input energy welding of high-strength super-thick steel plates

InactiveCN109014513AImprove performanceSimple methodArc welding apparatusWelding/cutting media/materialsSheet steelEngineering

The invention relates to a double-wire submerged arc welding method for the high heat input energy welding of high-strength super-thick steel plates. Double-wire submerged arc welding is carried out on the steel plates of which the thickness is larger than 50mm without carrying out preheating before welding or carrying out heat treatment after welding. The total welding heat input energy of double-wire submerged arc welding is controlled at 100+ / -5kJ / cm, interlayer temperature is controlled between 100DEG C and 150DEG C, and the welding groove type belongs to a non-symmetrical X type. The double-wire submerged arc welding method has the advantages that the method is simple, easy to operate and efficient, saves energy and is particularly suitable for guiding the building construction of a large steel structure; and the quality of welding joints is excellent, the deformation degree of the welded plates is very small, welding defects are effectively avoided, welding deformation is controlled, the welding efficiency is increased, and the welding operation intensity is reduced.

Owner:ANGANG STEEL CO LTD

Method for manufacturing X70 steel-level large deformation-resistant longitudinally submerged arc welding pipe

The invention discloses a method for manufacturing X70 steel-level large deformation-resistant longitudinally submerged arc welding pipes, which is applied to the manufacture of special welding pipes for oil and gas transmission. In the method, a controllable rolled steel plate is used, wherein the controllable rolled steel plate has a ferrite-bainite double-phase metallurgical microstructure and contains the following chemical components: 0.04 to 0.07 percent of C, 1.60 to 1.85 percent of Mn, 0.15 to 0.30 percent of Si, not more than 0.003 percent of S, not more than 0.010 percent of P, 0.15 to 0.30 percent of Ni, not more than 0.020 percent of Ti, 0.015 to 0.040 percent of Al, 0.010 to 0.065 percent of Nb, not more than 0.006 percent of N, not more than 0.30 percent of Cu, 0.10 to 0.25 percent of Cr, and not more than 0.0005 percent of B. The method comprises the following steps: (1) milling edges of the steel plate; (2) pre-bending bended edges; (3) performing JCO forming; (4) pre-welding joint seams; and (5) performing finish-welding on the inner and the outer sides of the joint seams. The method is applied to the manufacture of large-deformation-resistant welding pipes which are used in seismic belts, frozen soil areas, landslide area and other areas with high risk of deformation. The method has the advantages as follows: in the JCO forming process, the local deformation amounts and straight edge sizes of the steel plate in different rolling passes are analytically acquired according to the width, thickness and strength of the steel plate and the size of a die so as to determine the rolling passes and ensure uniform deformation at all parts of the steel plate after forming; and in the diameter expansion process, the minimum diameter expansion amount is determined according to the size and shape of the formed steel pipe, so as to ensure the size, shape and physiochemical properties of the steel pipe after diameter expansion.

Owner:CNPC BOHAI EQUIP MFG +2

Super-thick steel plate welding method

ActiveCN104384677AImprovement design is reasonableImproved Design ReliabilityWelding/soldering/cutting articlesMetal working apparatusSocial benefitsHydrogen

The invention relates to a super-thick steel plate welding method. According to the method, the fabrication weldability of super-thick steel can be effectively improved, and the construction efficiency and the weld inspection first-pass yield can be improved. The method comprises the following steps of 1, processing a welding groove; 2, preparing before welding; 3, preheating before welding; 4, welding. The method is simple; the improved design of the welding groove is reasonable and reliable, and the method is suitable for common domestic single wire submerged arc welding machines and is high in practicability; a combined welding process of taking super low hydrogen electrode arc welding as backing weld and adopting submerged arc welding for filling and cosmetic welding is adopted, and the welding advantages of the two processes are integrated; the fabrication weldability of the super-thick steel plate is greatly improved, the welding quality of the super-thick steel plate is controlled, the first-pass yield of super-thick steel plate butt weld inspection is improved, and the method can be widely applied to welding construction of low-alloy high-strength structural steel super-thick steel plates which are 60-300mm in thickness and has good technical, economic and social benefits.

Owner:NO 9 METALLURGICAL CONSTR

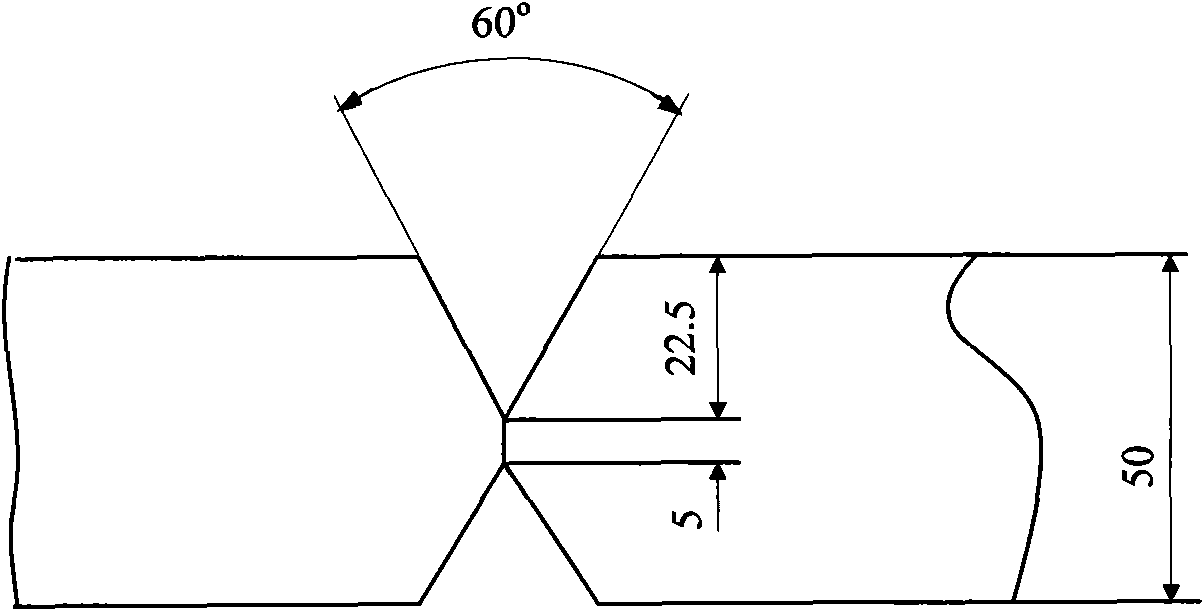

Method of submerged-arc welding of thick sheet S355NL for low-temperature wind tower

InactiveCN101862887AImprove low temperature impact toughnessImprove securityArc welding apparatusWelding/cutting media/materialsMechanical propertyHeat treated

The invention discloses a method of submerged-arc welding of a thick sheet S355NL for a low-temperature wind tower, which comprises the following steps: adopting an S355NL thick sheet satisfying requirements for chemical composition, weight percentage and technical conditions, wherein the carbon equivalent Ceq of steel is less than or equal to 0.42 percent; using welding wires satisfying requirements for chemical composition and weight percentage; adopting symmetric double-sided X type grooves as submerged-arc welding groove, wherein the groove angle is 60 degrees, the groove gap is 0.5mm, and when the thickness of the sheet is less than or equal to 50mm and the ambient temperature is no lower than 10 DEG C, no preheating is needed for welding; and selecting welding parameters, wherein the welding heat input is less than or equal to 50kJ / cm. The invention realizes the welding process that no preheating is needed prior to welding and no heat treatment is needed after welding during manufacture of the thick sheet structure of the butt joint of the steel plate S355NL for the low-temperature wind tower in marine and cold regions. Due to the multi-layer multi-channel continuous welding, the welded joint has excellent comprehensive mechanical properties, and weld joints and weld heat-affected zones has large impact toughness reserves and safety margins. Therefore, the invention is suitable for promotion and application in the manufacture of the low-temperature wind tower in the factory.

Owner:NANJING IRON & STEEL CO LTD

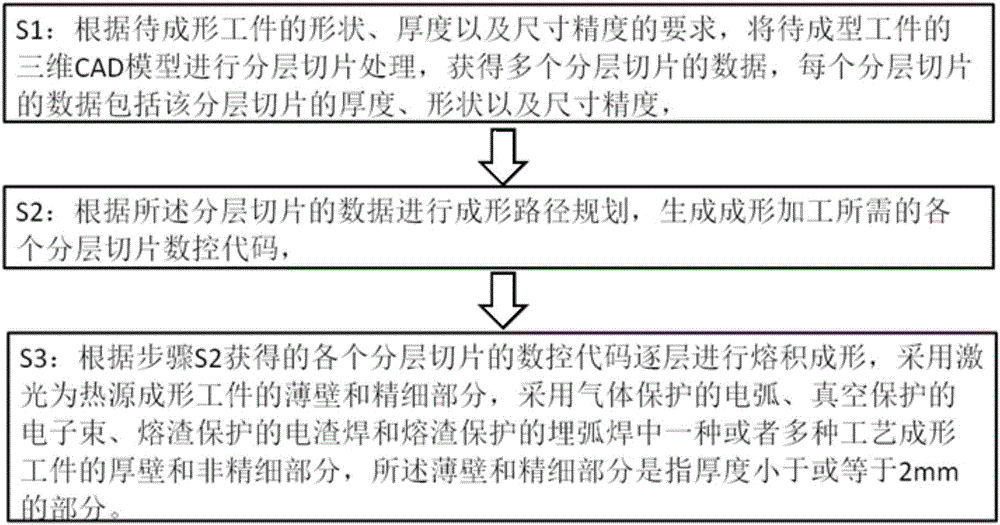

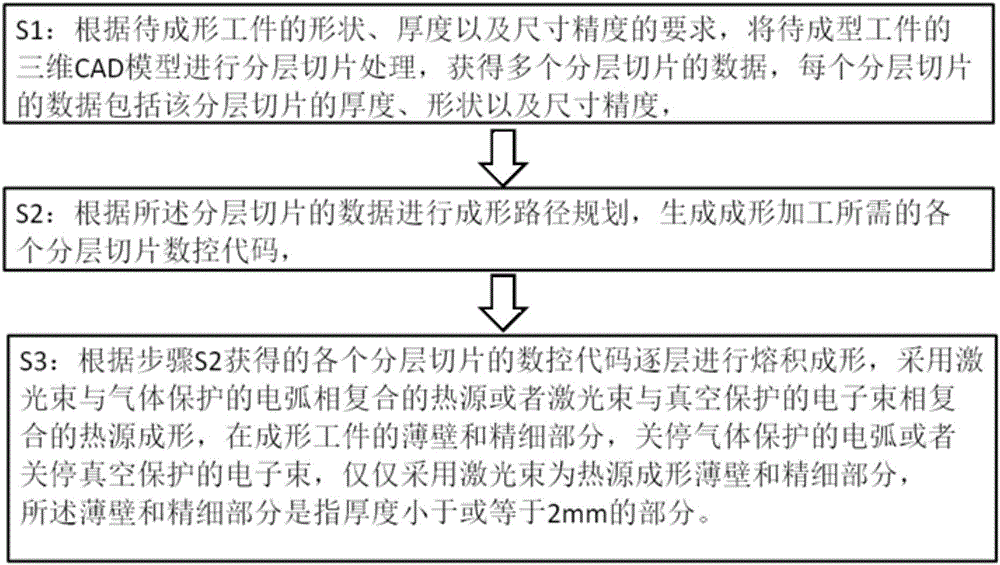

Deposition forming manufacturing method of parts and molds

ActiveCN105945281AImprove mechanical propertiesImprove metallurgical qualityAdditive manufacturing apparatusIncreasing energy efficiencyElectricityStructure property

The invention discloses a deposition forming manufacturing method of parts and molds, and belongs to the field of non-mold growing manufacturing and remanufacturing. The method comprises the following steps that S1, the three-dimensional CAD model of a workpiece to be formed is subjected to hierarchical slicing; S2, the CNC codes of all hierarchical slices are acquired; S3, deposition forming is conducted layer by layer according to the CNC codes of all the hierarchical slices, the fine portions of the workpiece are formed by laser, and one or more technologies in electric arc welding, electron beam welding, electroslag welding and submerged-arc welding is or are adopted to form the thick wall and the non-fine portions of the workpiece; or in the S3, a heat source which is compounded by laser beams and gas protection electric arcs or a heat source which is compounded by the laser beams and vacuum protection electronic beams is adopted for forming the thin wall and the fine portions of the workpiece, and the gas protection electric arcs or the vacuum protection electron beams are shut down. According to the deposition forming manufacturing method, direct deposition forming can be achieved to obtain parts and molds which are stable in structure property and high in manufacturing precision and are provided with thin walls or fine portions.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com