Submerged-arc welding process for T-type joint for extra thick steel plate

A technology of super-thick steel plate and submerged arc welding, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of easy occurrence of thermal cracks, high labor intensity, undercutting, etc., and reduce the deterioration of mechanical properties and reduce the Labor intensity, the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

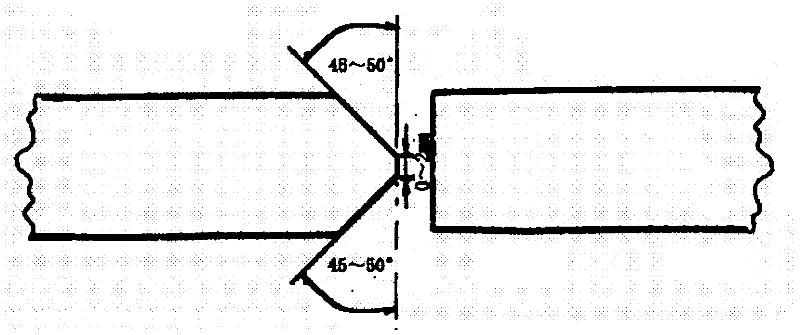

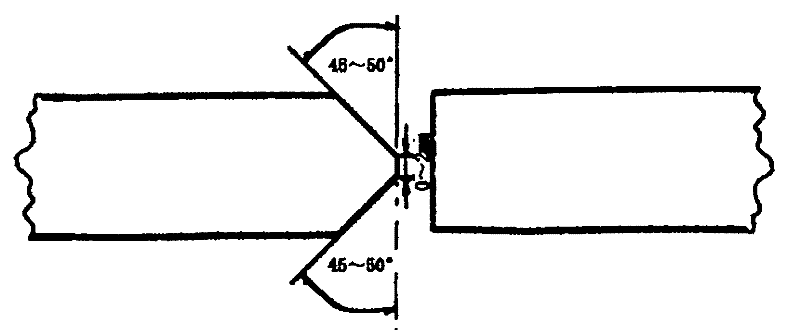

[0018] Base material: 80mm thick E550 steel plate produced by quenching and tempering process, the mechanical properties are: yield strength 710MPa, tensile strength 730MPa, elongation 20.0%, impact energy at -40°C 197J. The test plate has a symmetrical K-shaped groove, the groove angle is 45°, the steel plate size is 1200mm×200mm×80mm, no blunt edge is left, and there is no gap between the two plates.

[0019] Welding material matching: use OK Autrod 13.40 submerged arc welding wire with OK Flux 10.62 flux produced by Sweden ESAB company with a diameter of 4mm.

[0020] The 80mm+80mm thick E550 steel plate is preheated to 120°C with a flame before welding, the interlayer temperature is controlled at 120-150°C, the groove is polished with a grinder before welding, and the submerged arc welding is used for bottoming , filling, covering.

[0021] The welding current of the bottom pass is controlled at 450-500A, the welding voltage is controlled at 24-27V, and the welding speed ...

Embodiment 2

[0025] Base material: 50mm thick E500 steel plate produced by TMCP + tempering process, the mechanical properties are: yield strength 560MPa, tensile strength 675MPa, elongation 23.5%, impact energy at -40°C 268J. The test plate has a symmetrical K-shaped groove, the groove angle is 50°, the steel plate size is 1200mm×200mm×80mm, no blunt edge is left, and a gap of 1mm is left between the two plates.

[0026] Welding material matching: use OK Autrod 12.34 submerged arc welding wire and OK Flux 10.62 flux produced by Sweden ESAB company with a diameter of 4mm for welding.

[0027] Preheat the 50mm+50mm thick E550 steel plate to 100°C with a flame before welding, control the interlayer temperature at 100-150°C, grind the groove with a grinder to see the light before welding, and use submerged arc welding to make the bottom , filling, covering.

[0028] The welding current of the bottom pass is controlled at 450-500A, the welding voltage is controlled at 24-26V, and the welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com