Patents

Literature

63results about How to "Reduce drive power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

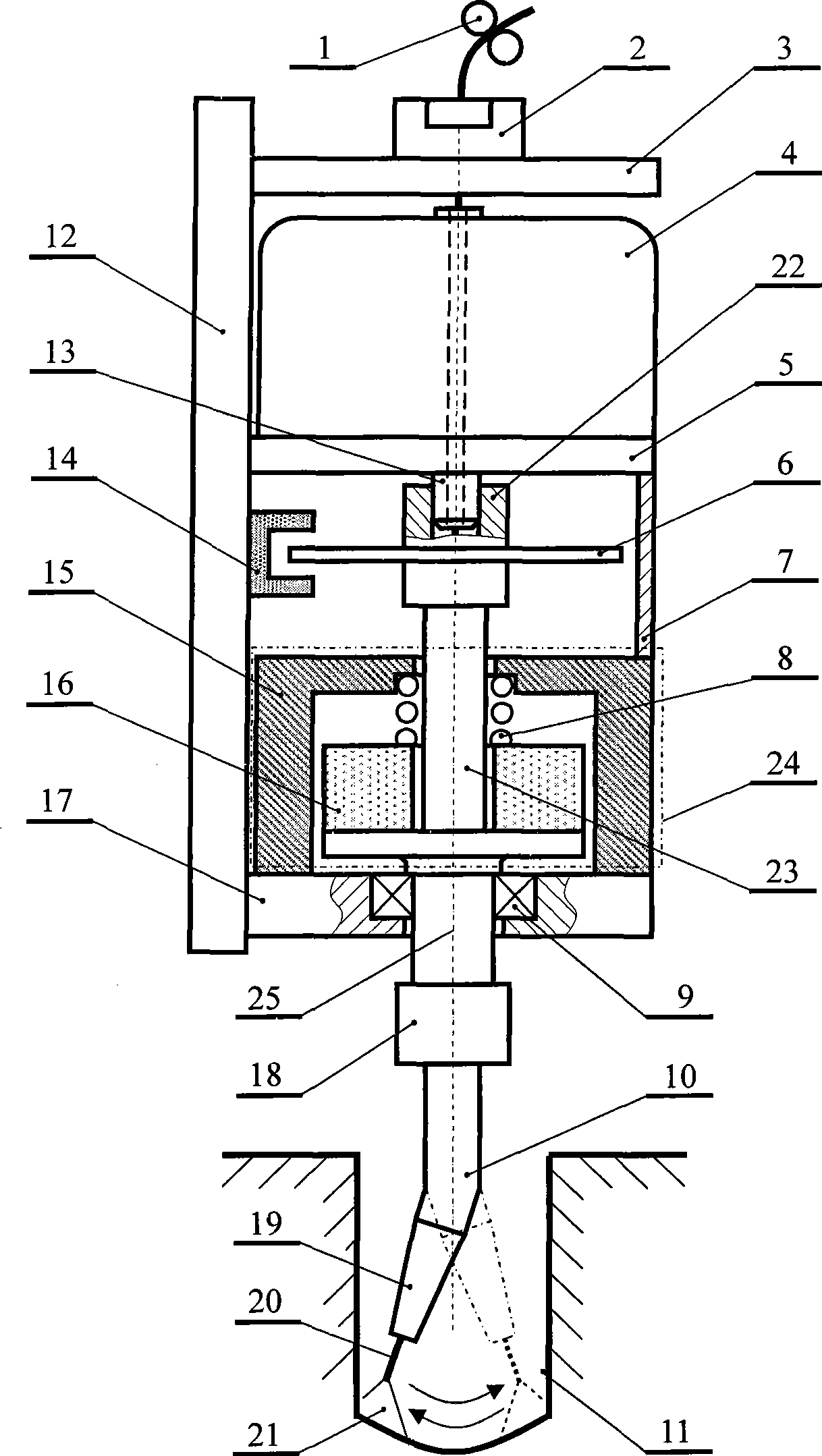

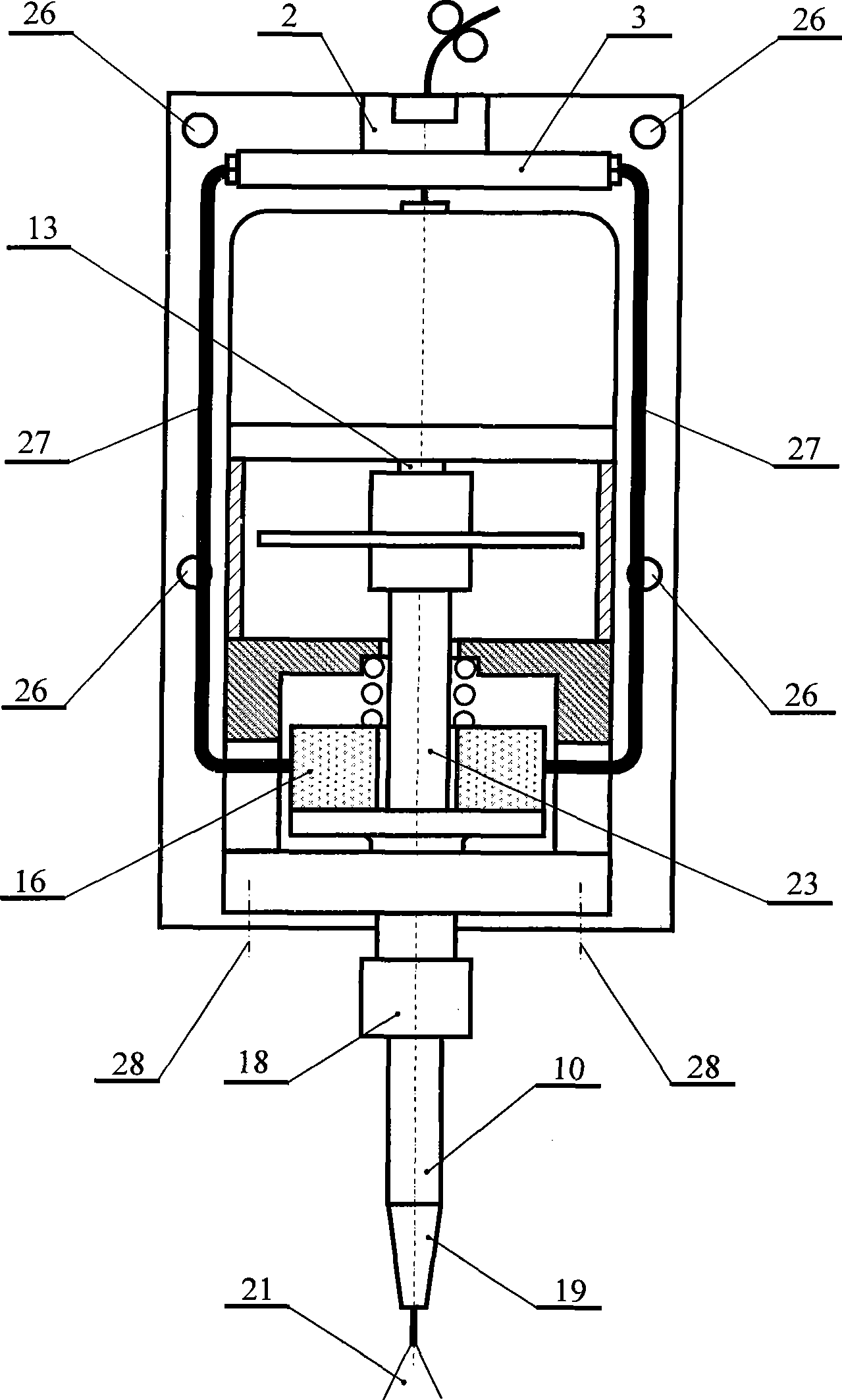

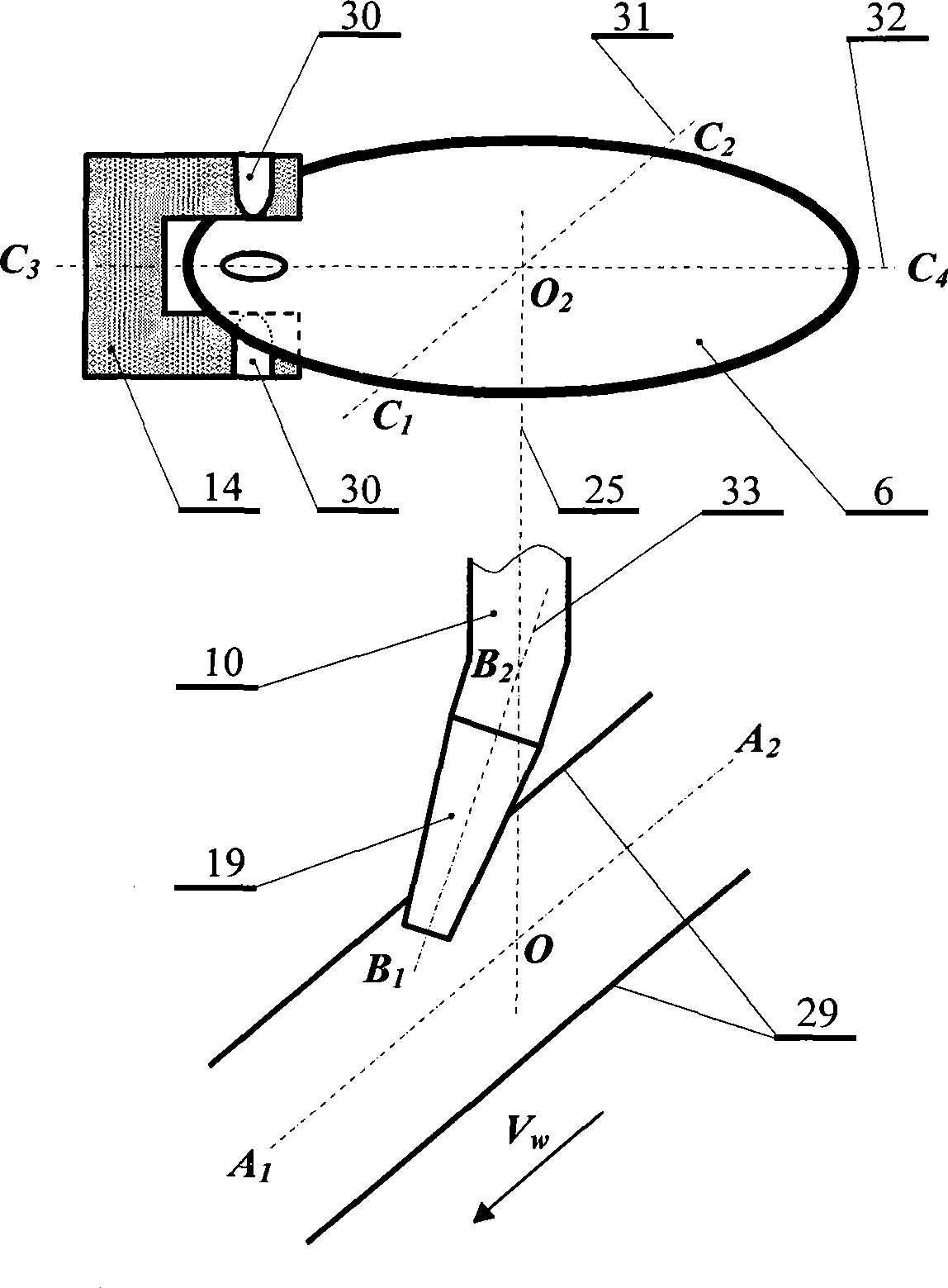

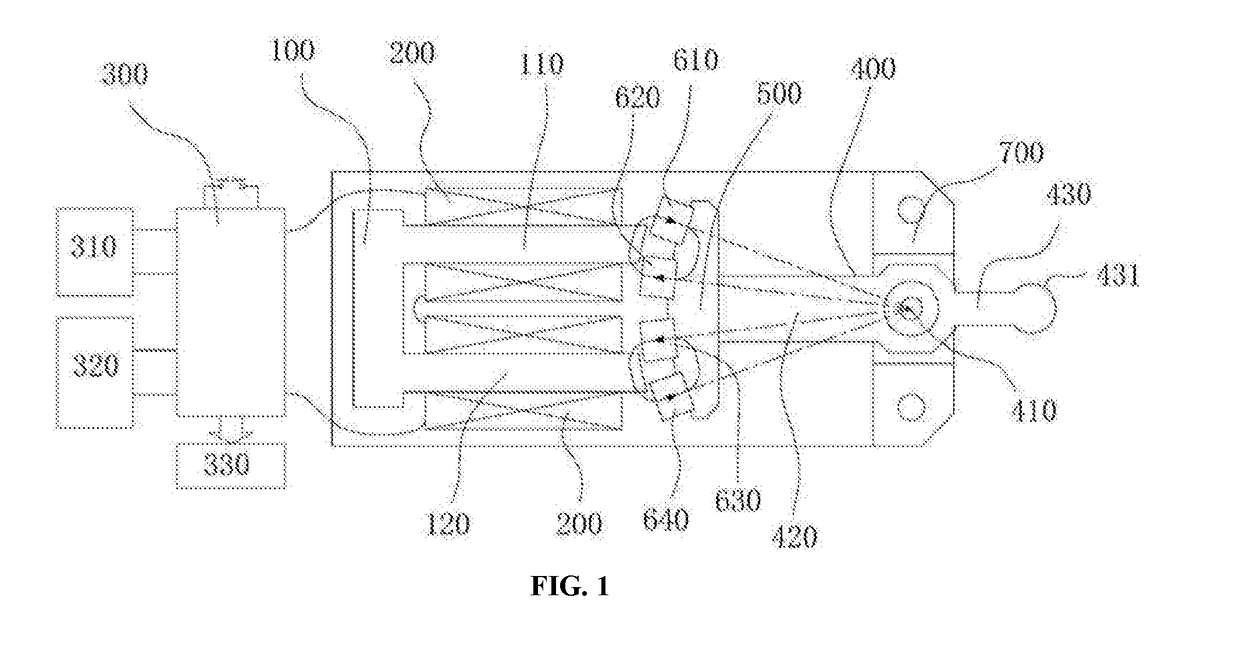

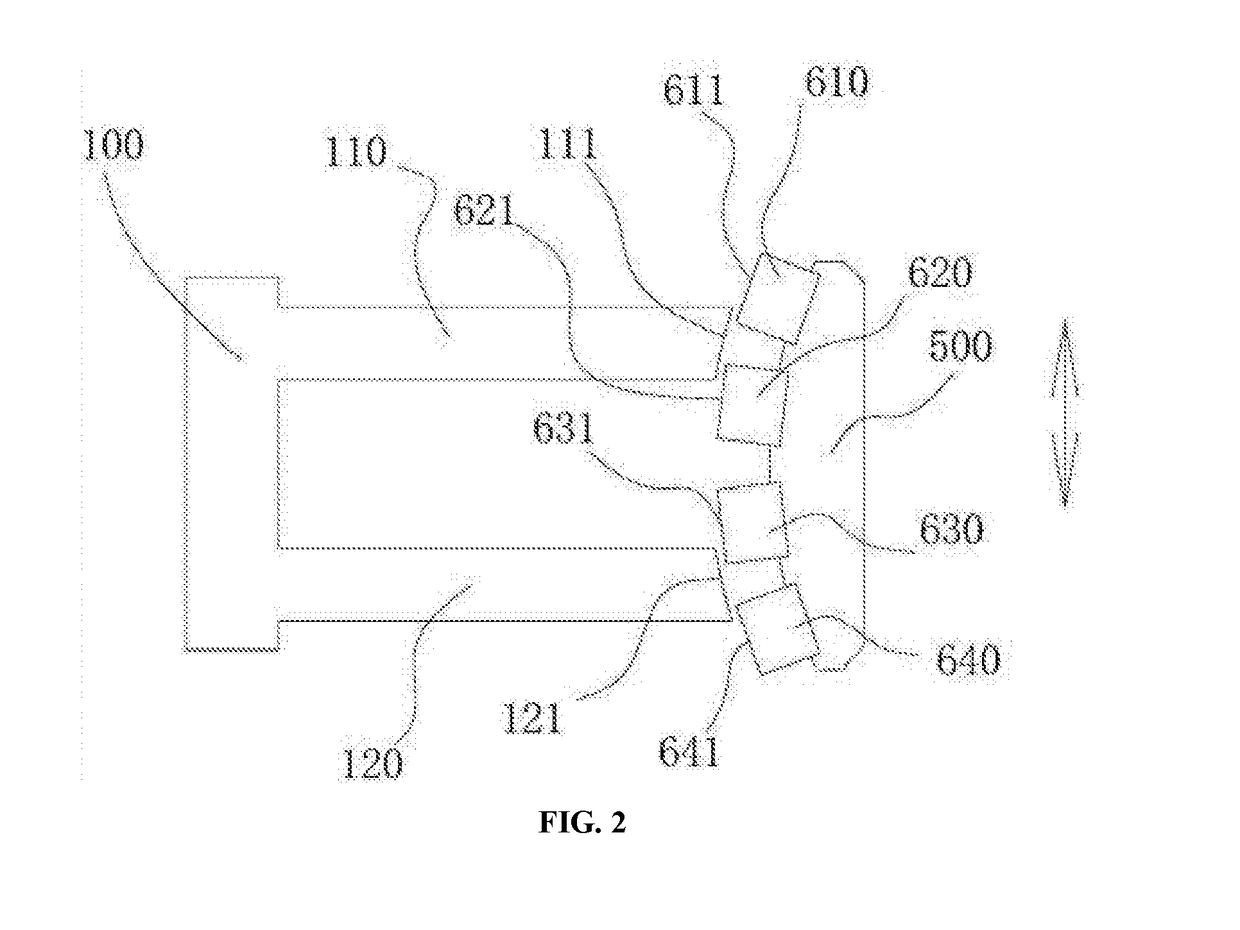

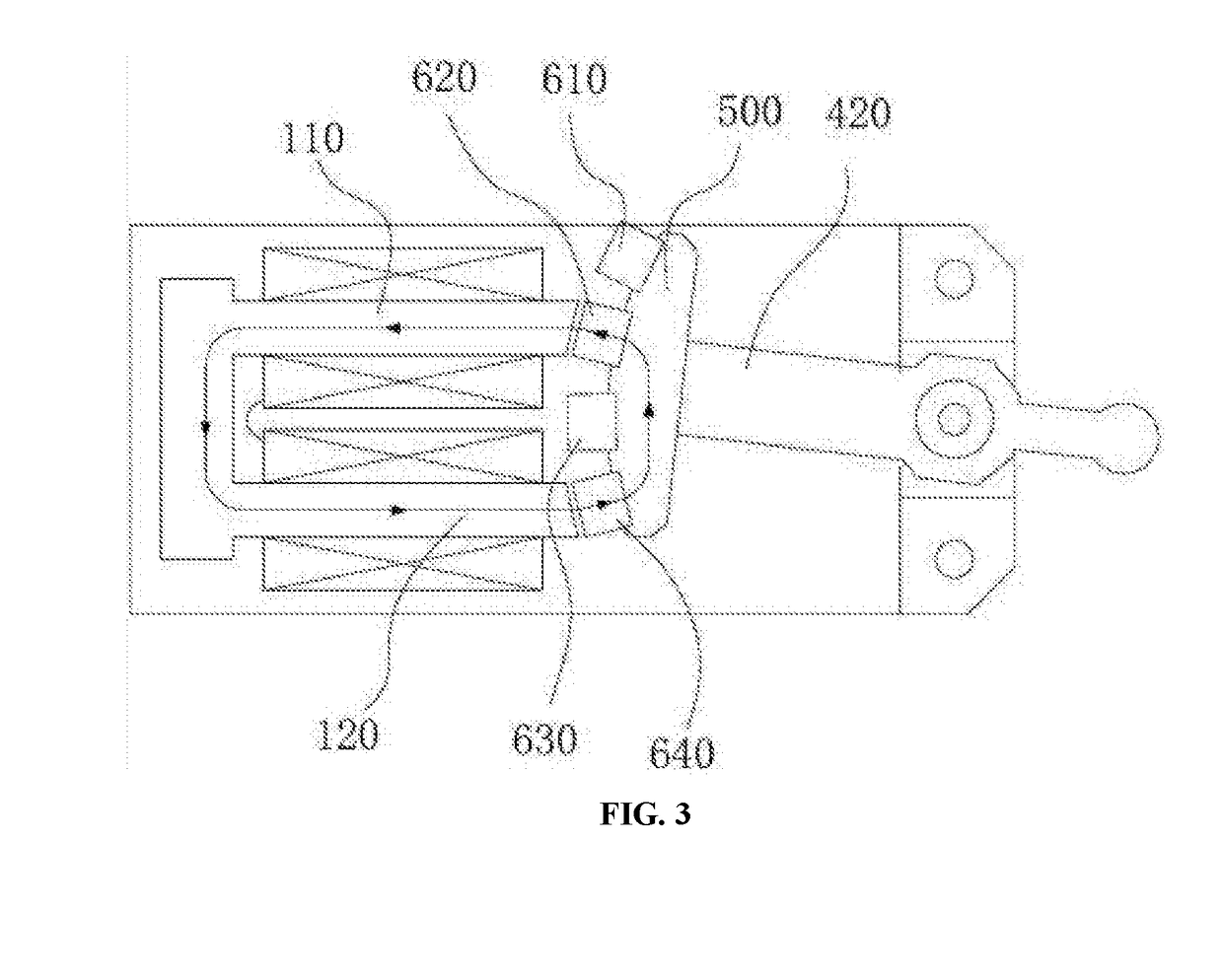

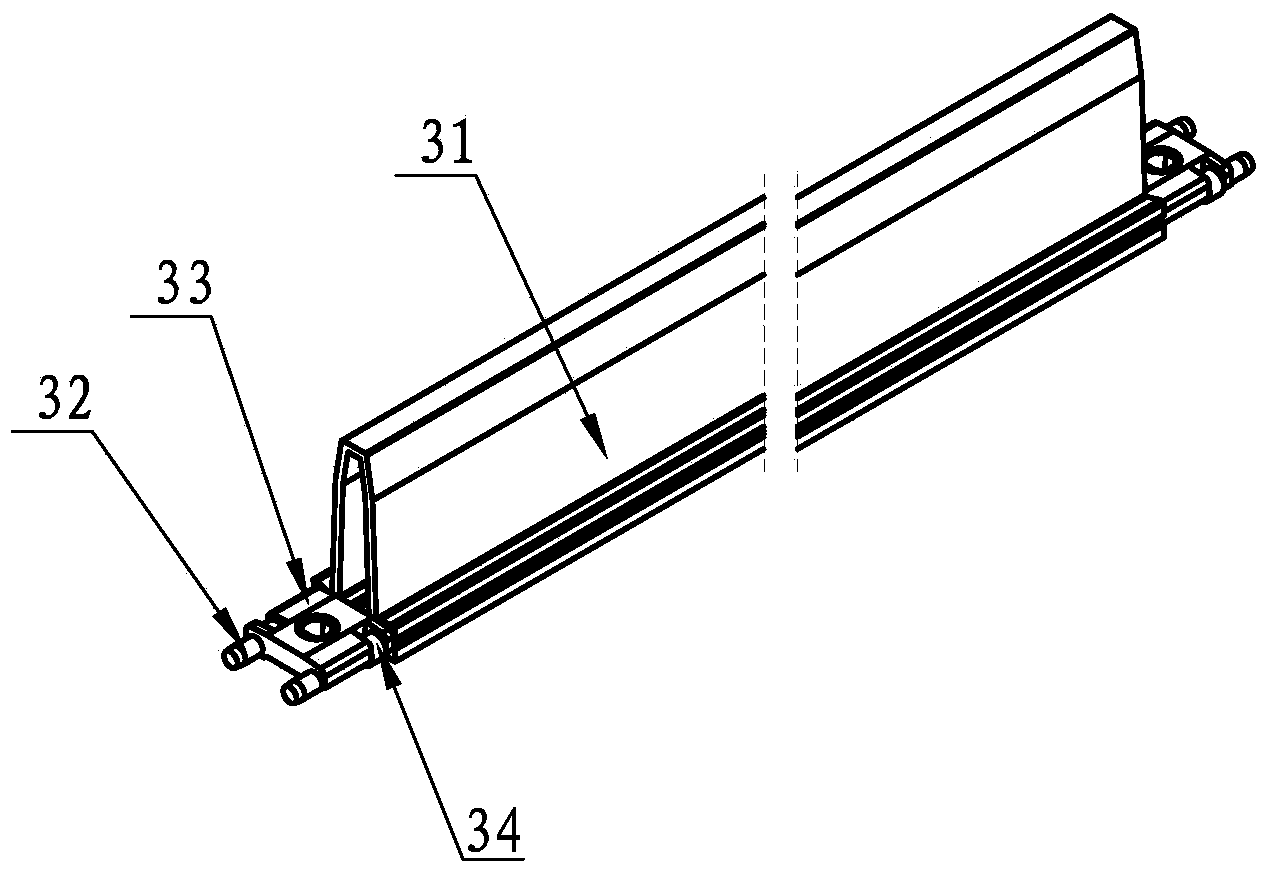

Method for welding rocking arc narrow clearance melting electrode with gas protection and welding torch

InactiveCN101412143AMeet the needs of different welding processes for weldsReduce drive powerElectrode supporting devicesCouplingEngineering

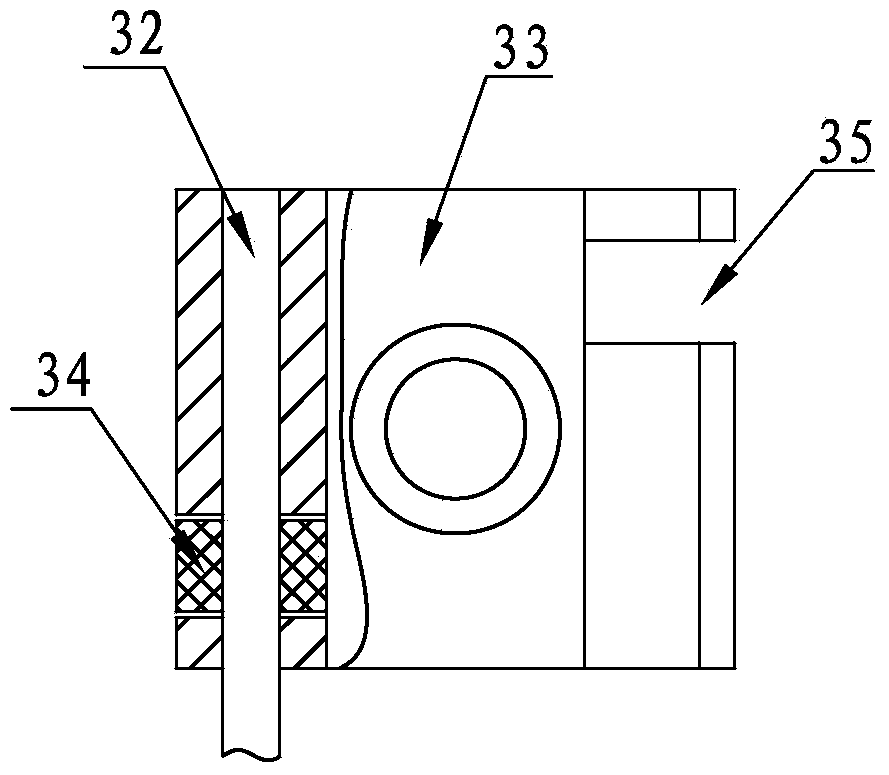

The invention discloses a rocking arc narrow gap consumable electrode gas shielded welding method and a welding torch. The method comprises the following steps: a connecting cable is fixed on an electric brush mechanism and a coupling head; a hollow shaft motor is connected with a straight conducting rod through a shaft joint; a welding wire passes through a center hole of a cable coupling head, and penetrates out a center hole of a current contact nozzle; the lower end of the straight conducting rod is fixed with a connecting piece; and one end of a minor bend conducting rod is connected with the straight conducting rod through the connecting piece, while the other end of the minor bend conducting rod is connected with the current contact nozzle. The hollow shaft motor directly drives the straight conducting rod and the minor bend conducting rod capable of extending into a divided edge of a workpiece to make reciprocating rotation around the central axial line of the welding torch, thereby driving electric arc of the end of the welding wire send from the center hole of the current contact nozzle to make arc rocking in the divided edge of the workpiece so as to realize rocking arc narrow gap welding. The welding torch has the advantages of simple and compact structure, low implementation cost, high reliability of operation, strong practicality, and can adapt requirement of welding process for mean position and spatial position with different welding seams. The welding wire has strong rocking regulation, good directivity of the electric arc, and high welding quality.

Owner:JIANGSU UNIV OF SCI & TECH

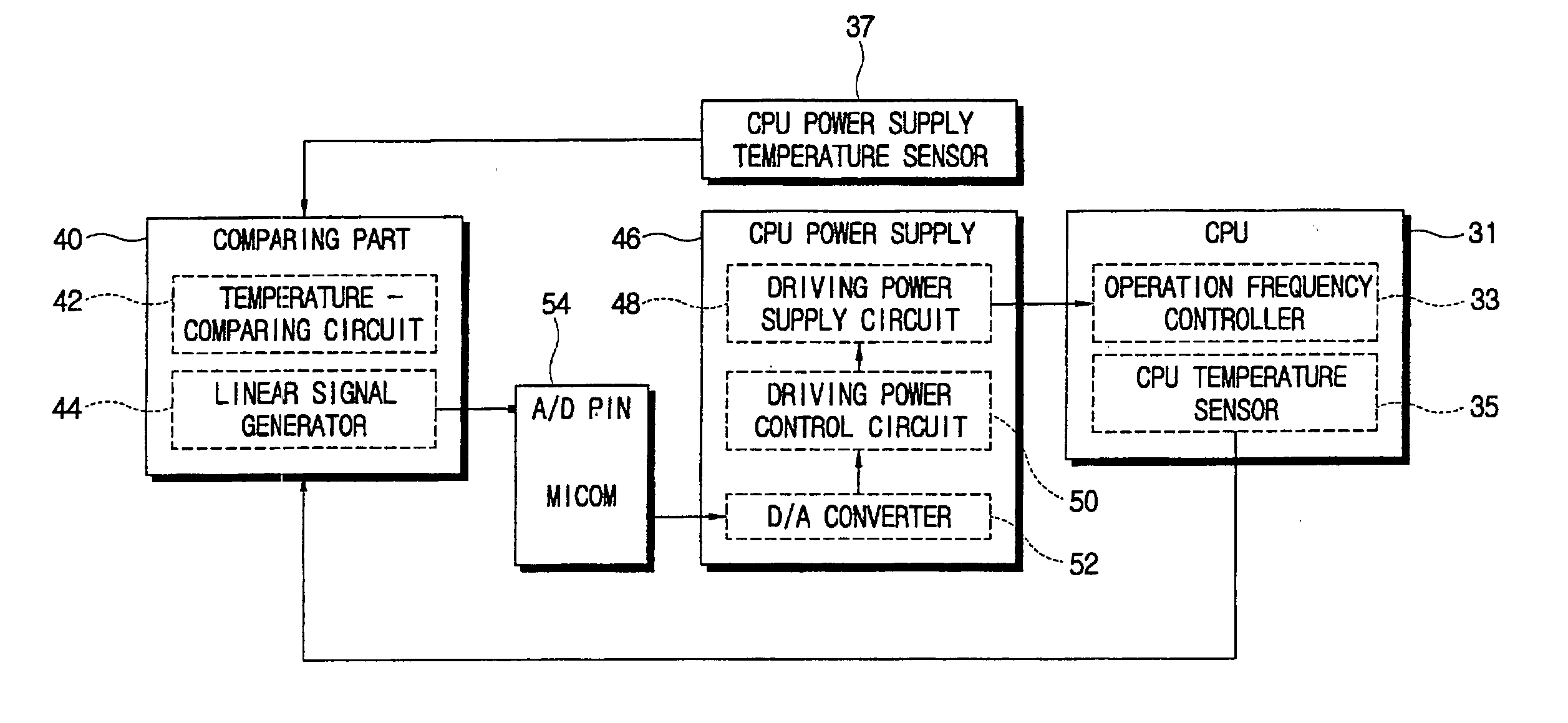

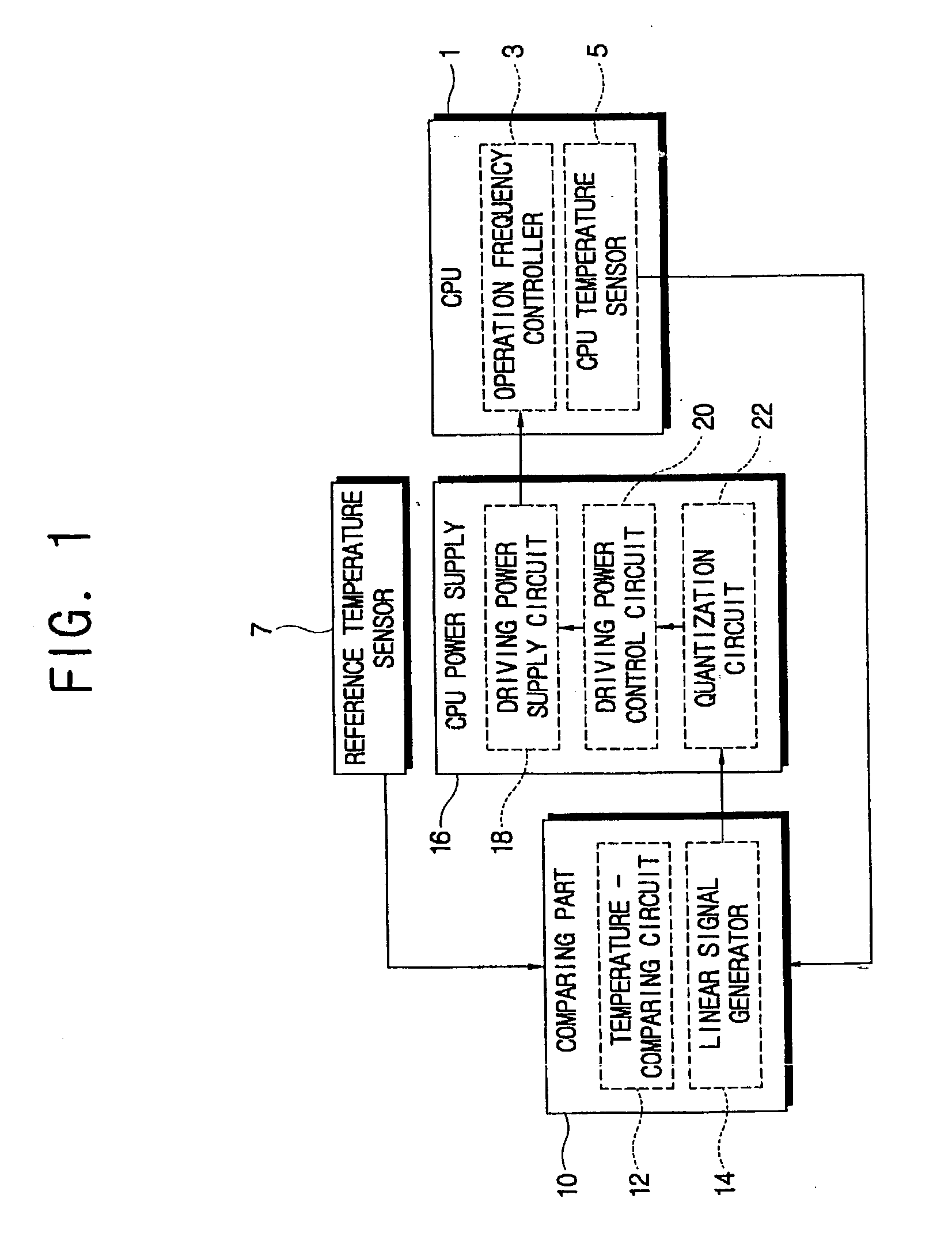

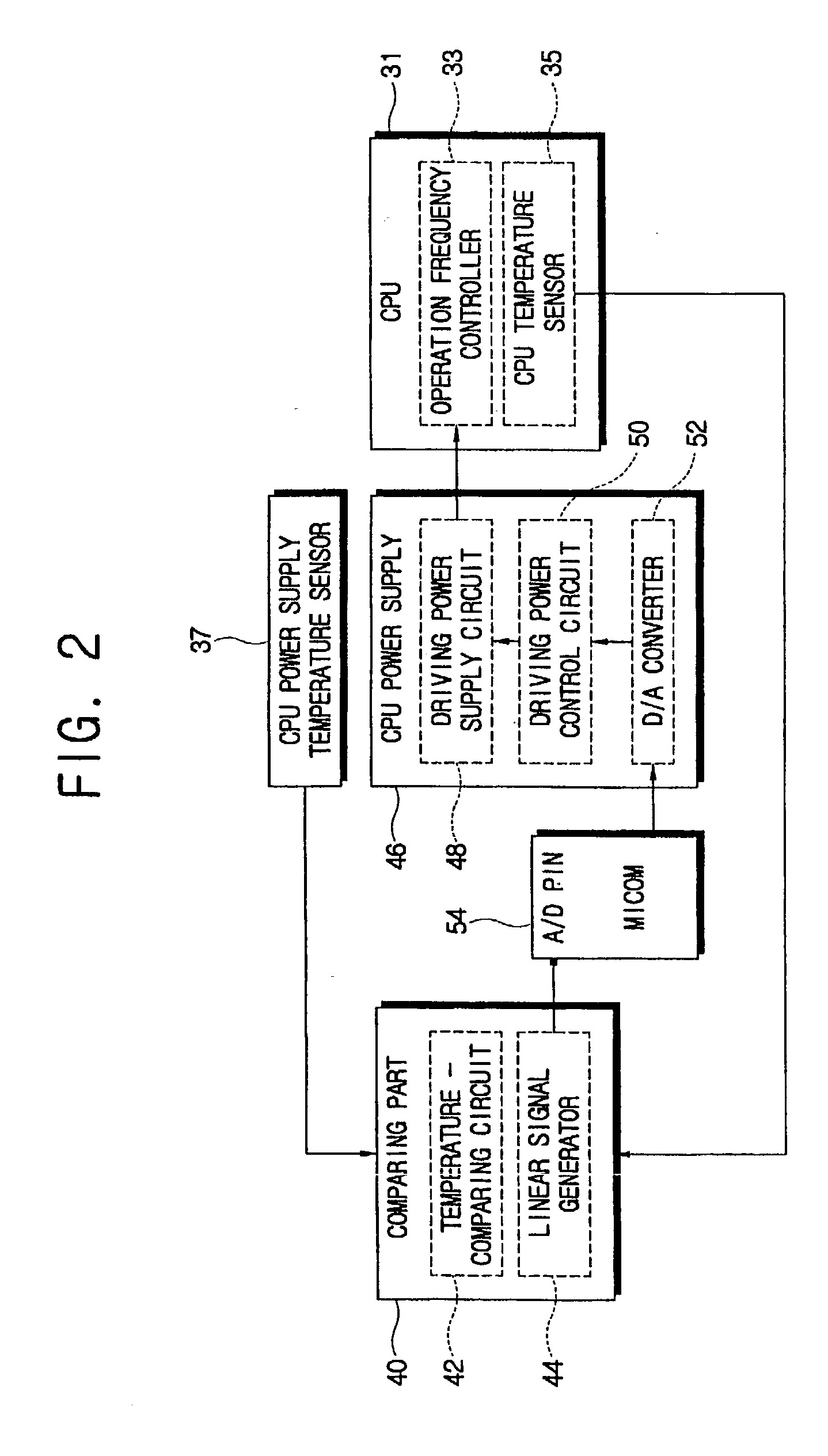

System, controller, software and method for protecting against overheating of a CPU

InactiveUS20040088593A1Decreases driving signalReduce drive powerThermometer detailsEnergy efficient ICTVoltage variationSystem controller

A system for protecting against overheating of a CPU whose operation frequency is changed due to voltage variation of a driving power, includes a CPU temperature sensor to detect the temperature of the CPU, a reference temperature sensor to detect the temperature of a circuit block or multiple circuits heated due to the operation frequency of the CPU, a comparing part to output a signal indicating a higher temperature of the temperature of the CPU and the temperature of the circuit block or multiple circuits by comparing temperature values detected by the respective CPU and reference temperature sensors, and a CPU power supply to supply a stepwise decreasing driving power to decrease the operation frequency of the CPU in a stepwise fashion when the temperature value increases based on the signal indicating the higher temperature indicated by the comparing part. Thus, a system for protecting against overheating of a CPU enables only one overheating-protection circuit to solve the problem of overheating of multiple circuits that are easily heated due to the frequency of operation of the CPU, thus maximizing the operation efficiency of the CPU and also efficiently protecting the CPU from damage.

Owner:SAMSUNG ELECTRONICS CO LTD

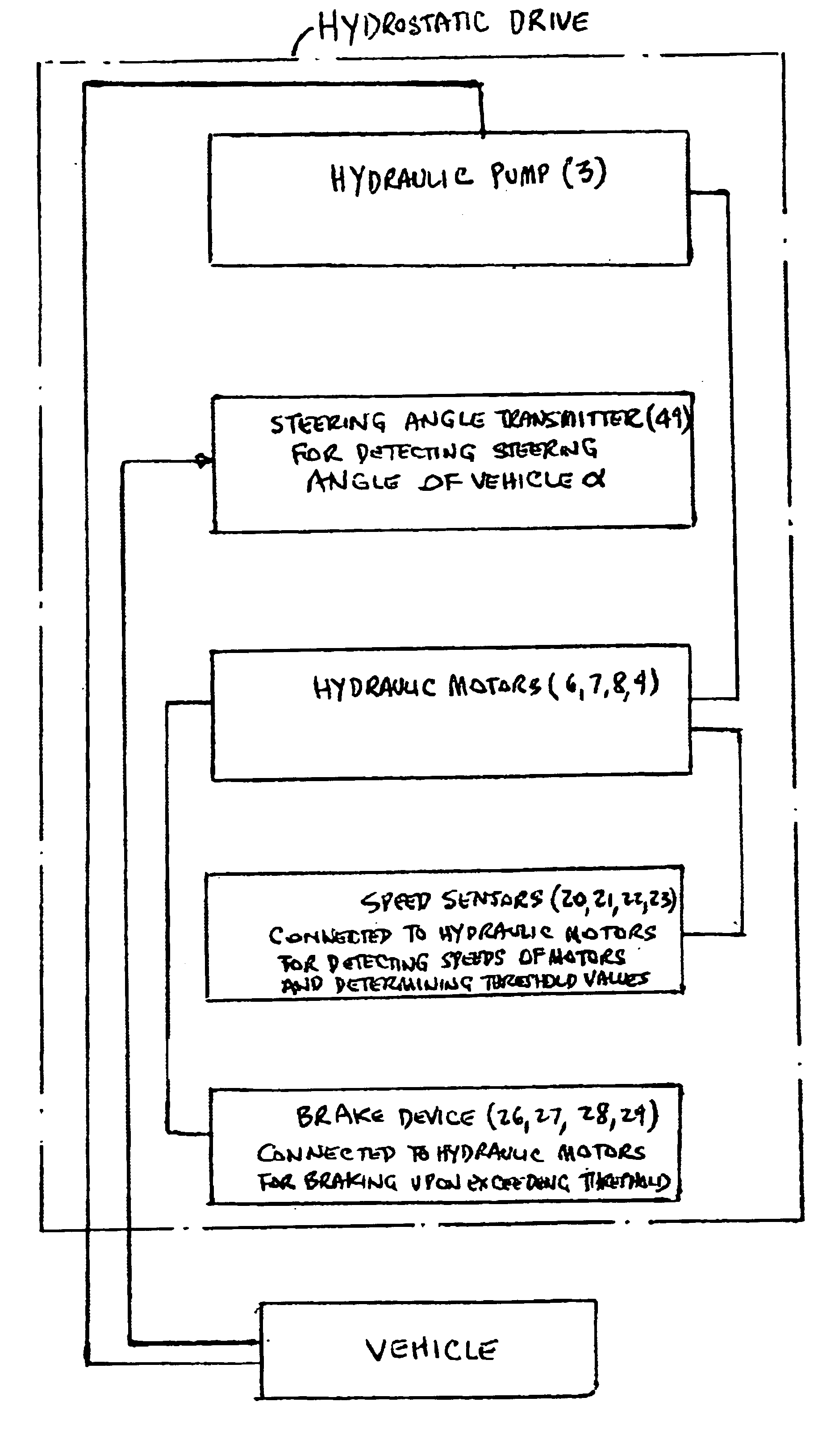

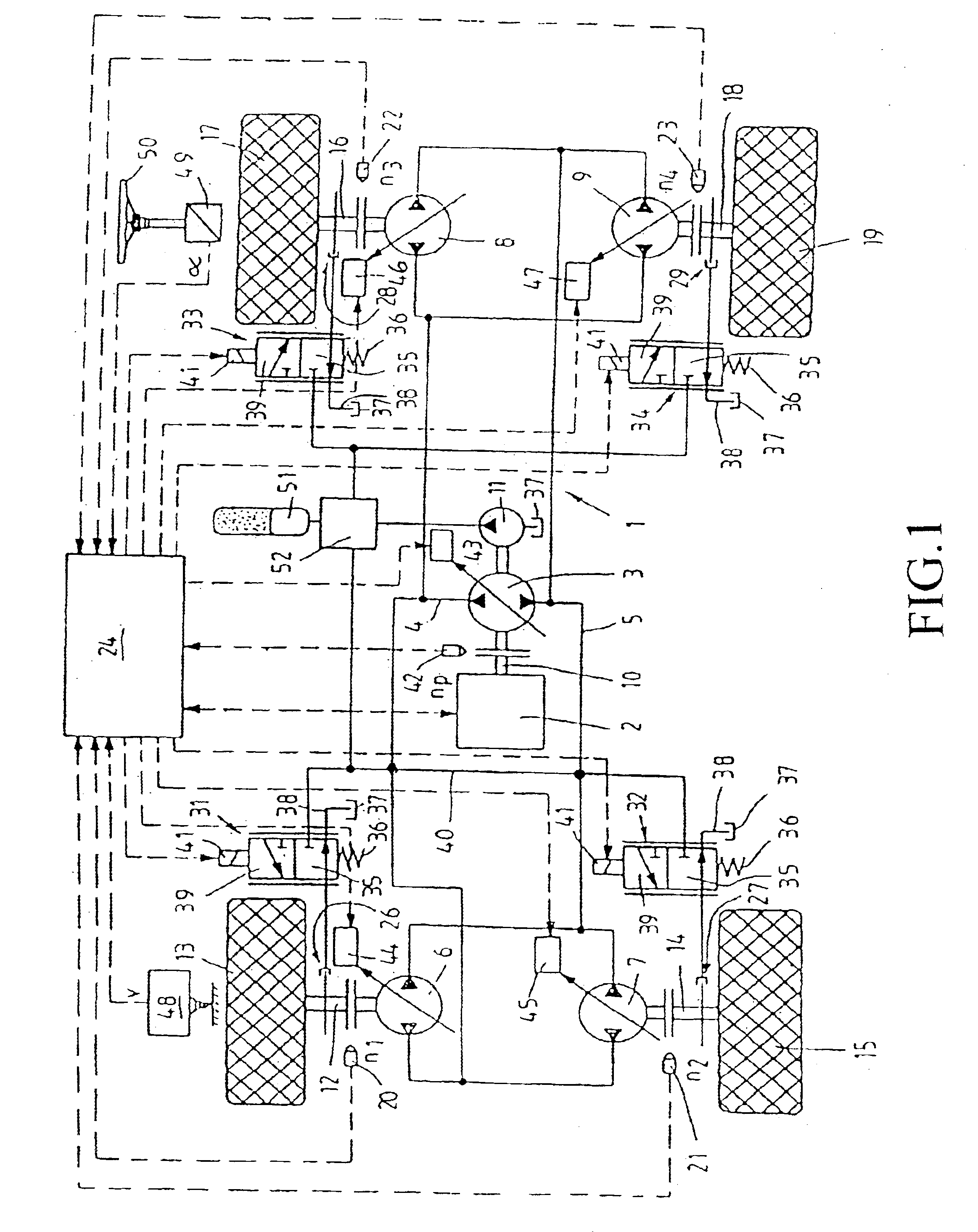

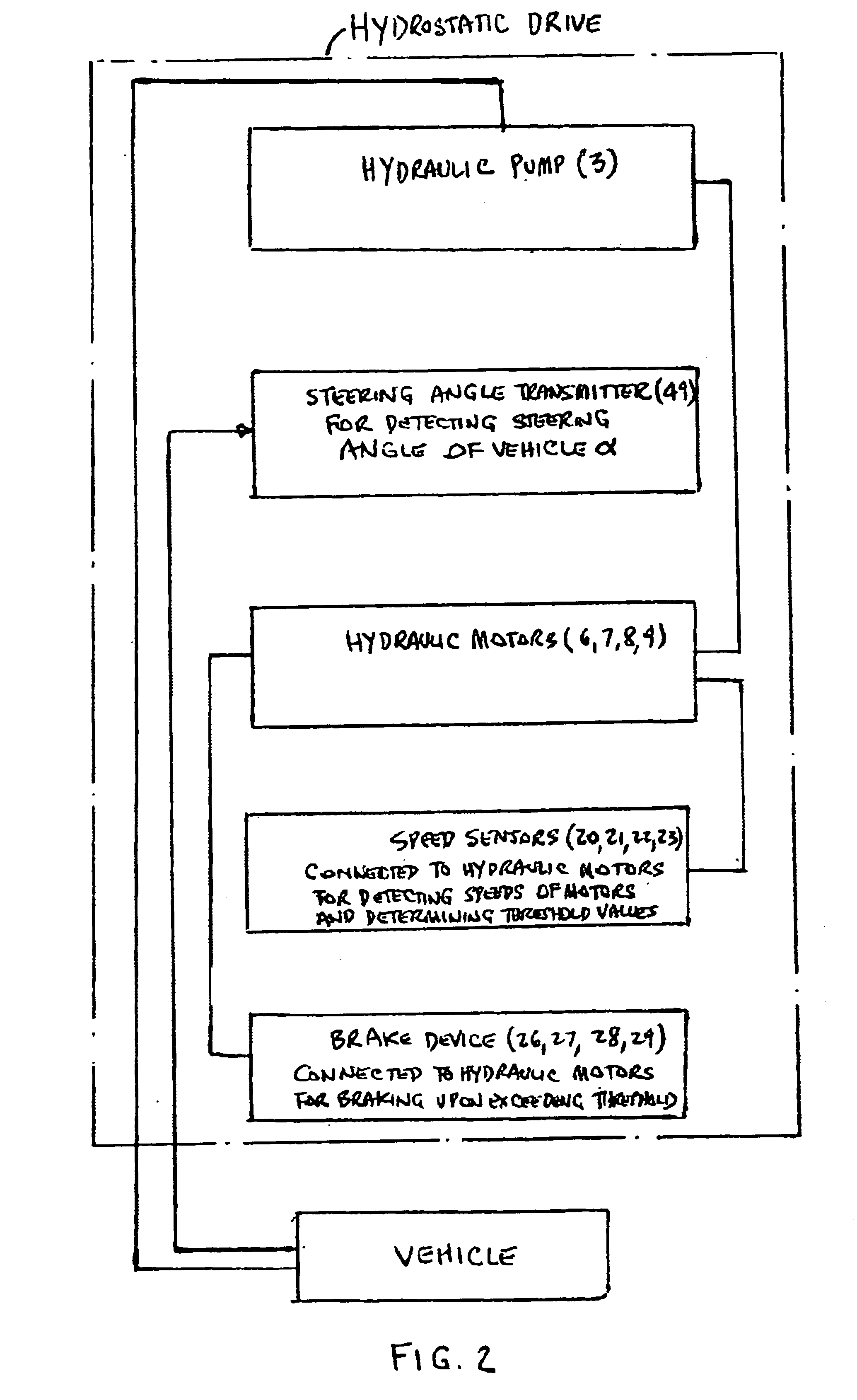

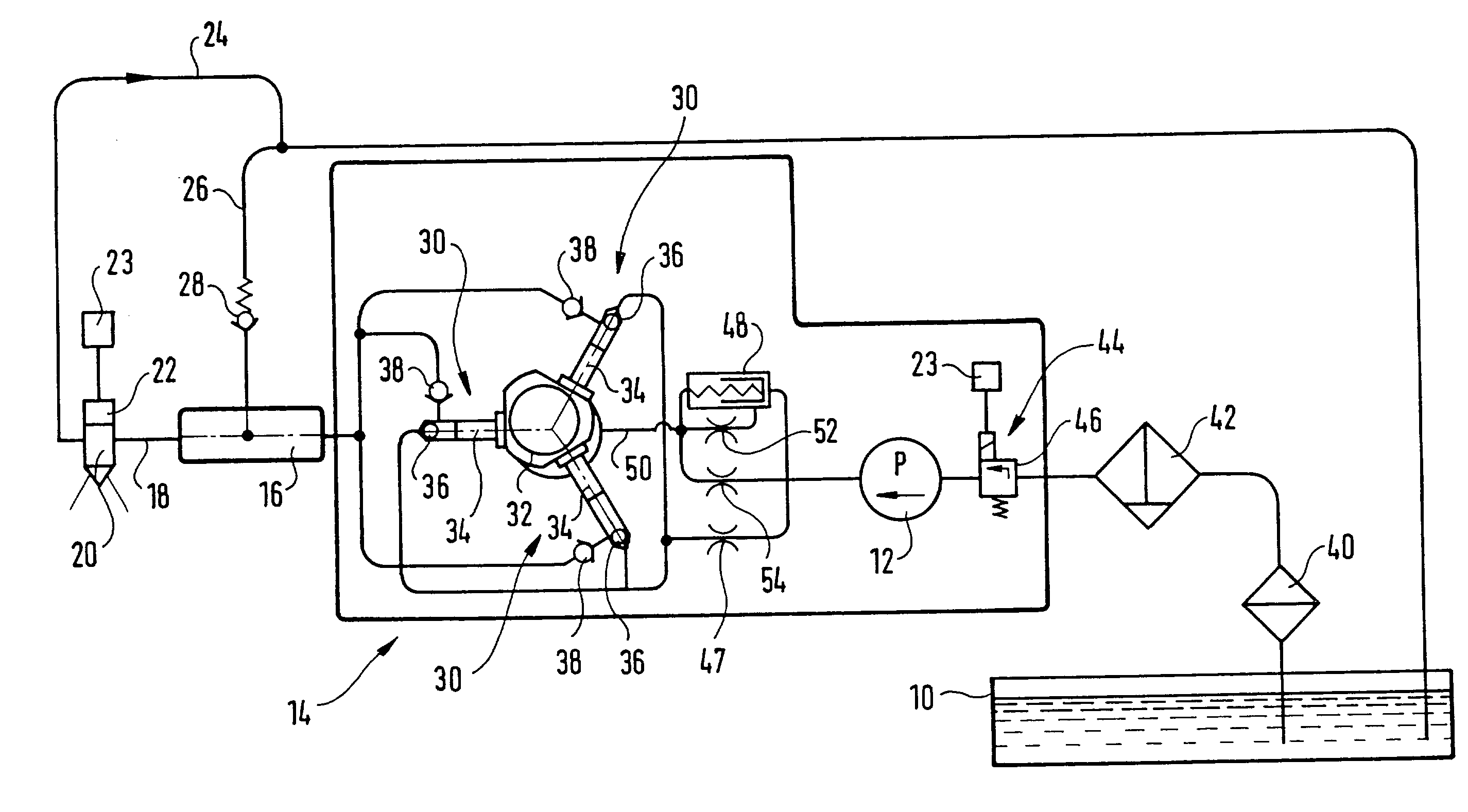

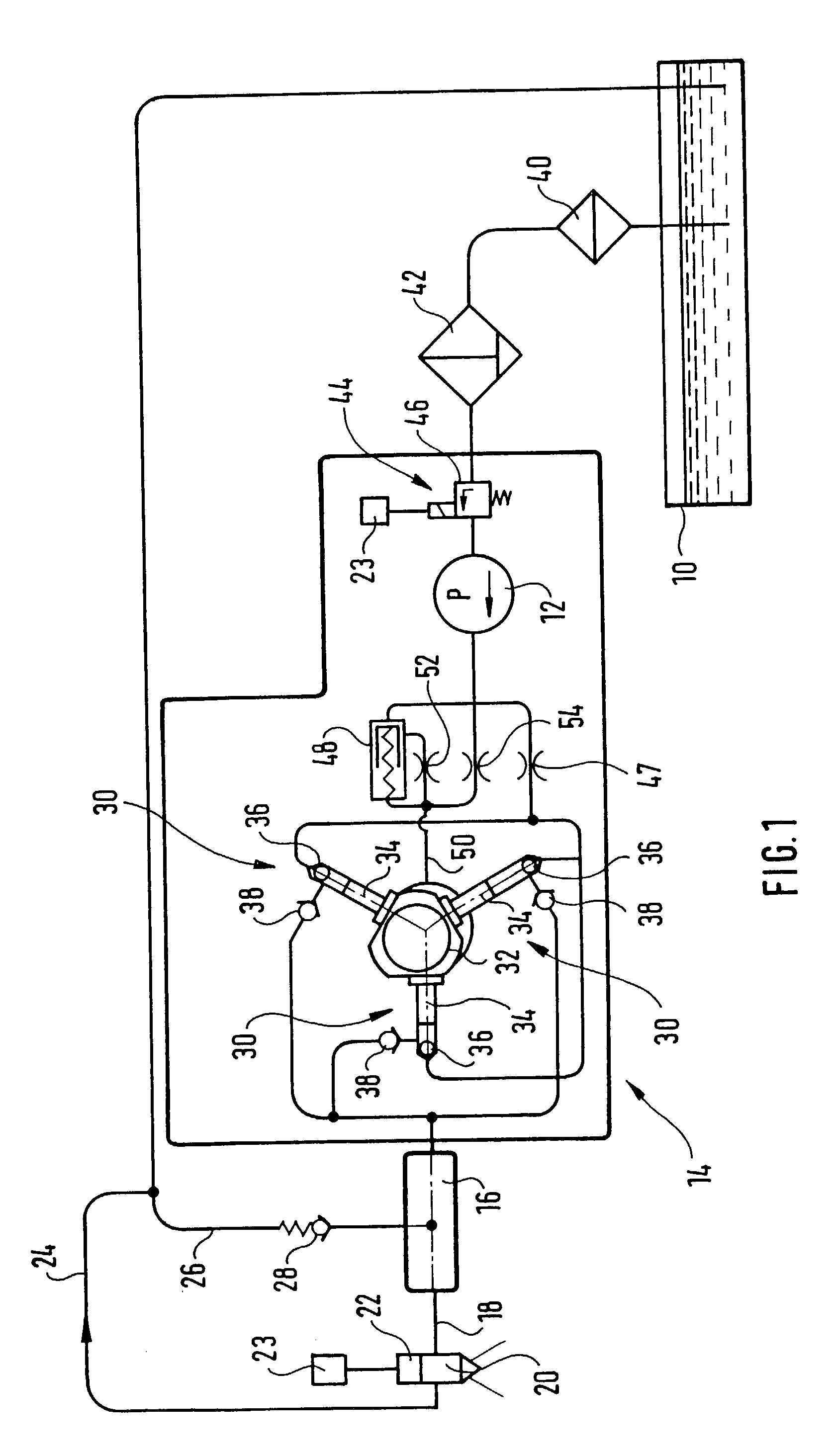

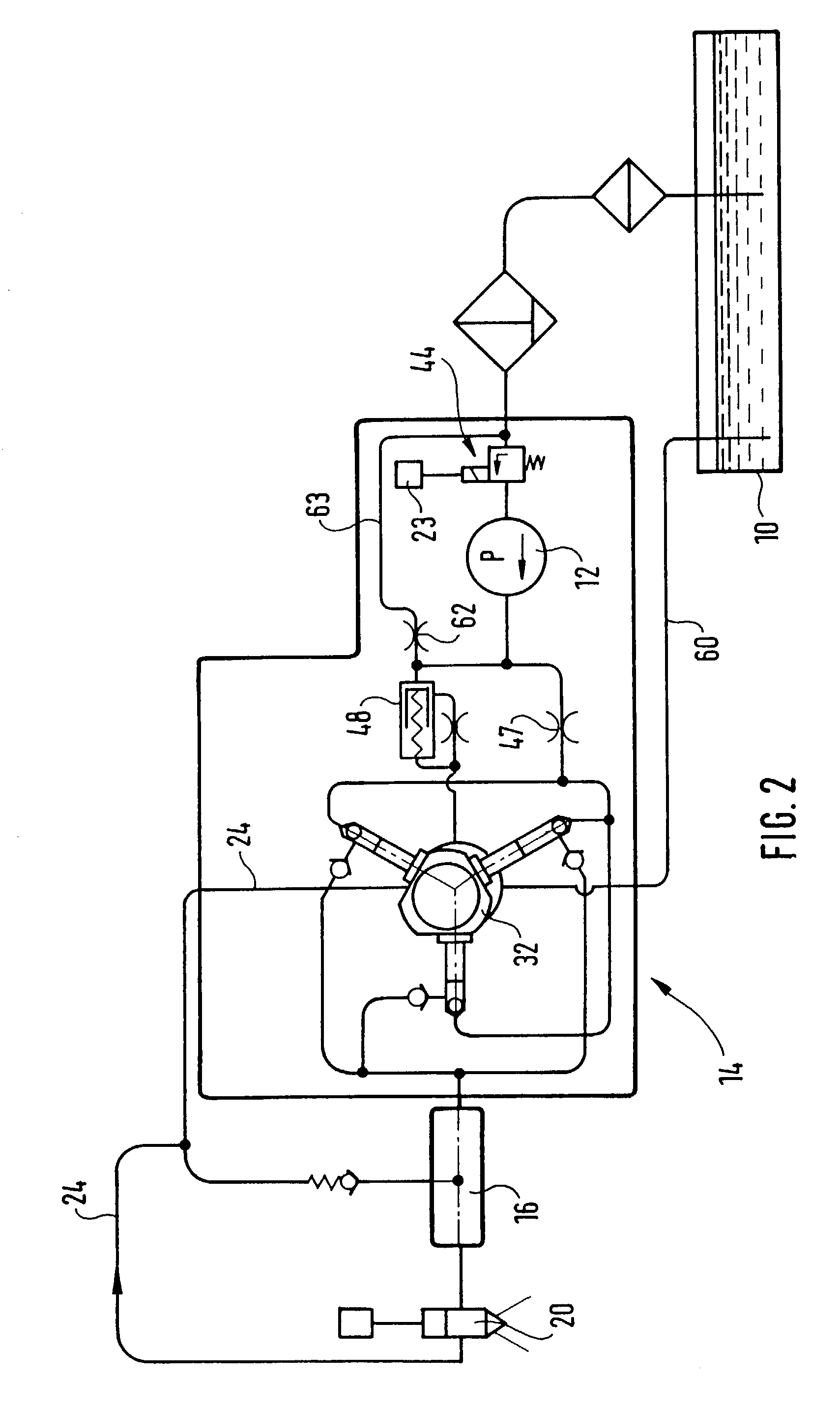

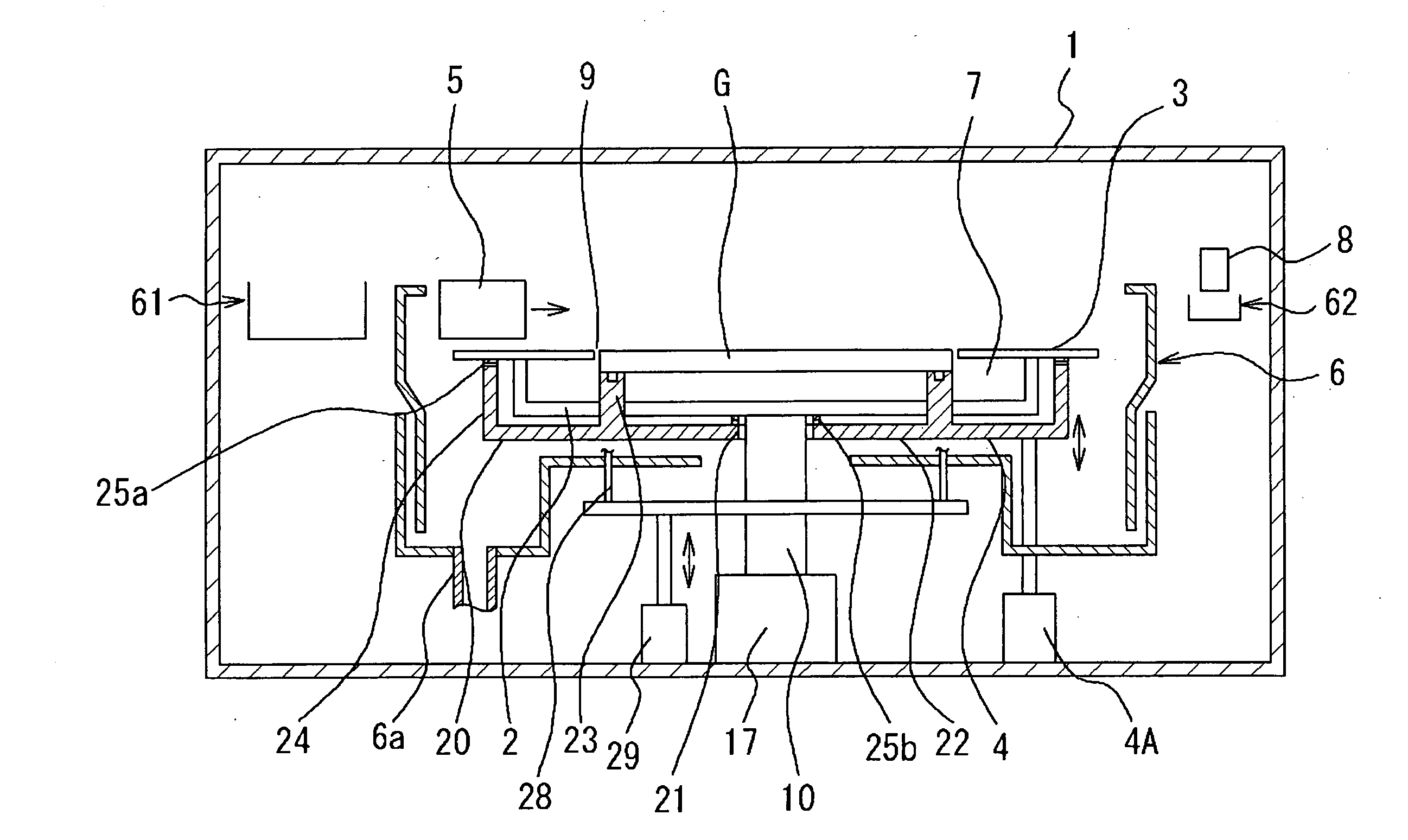

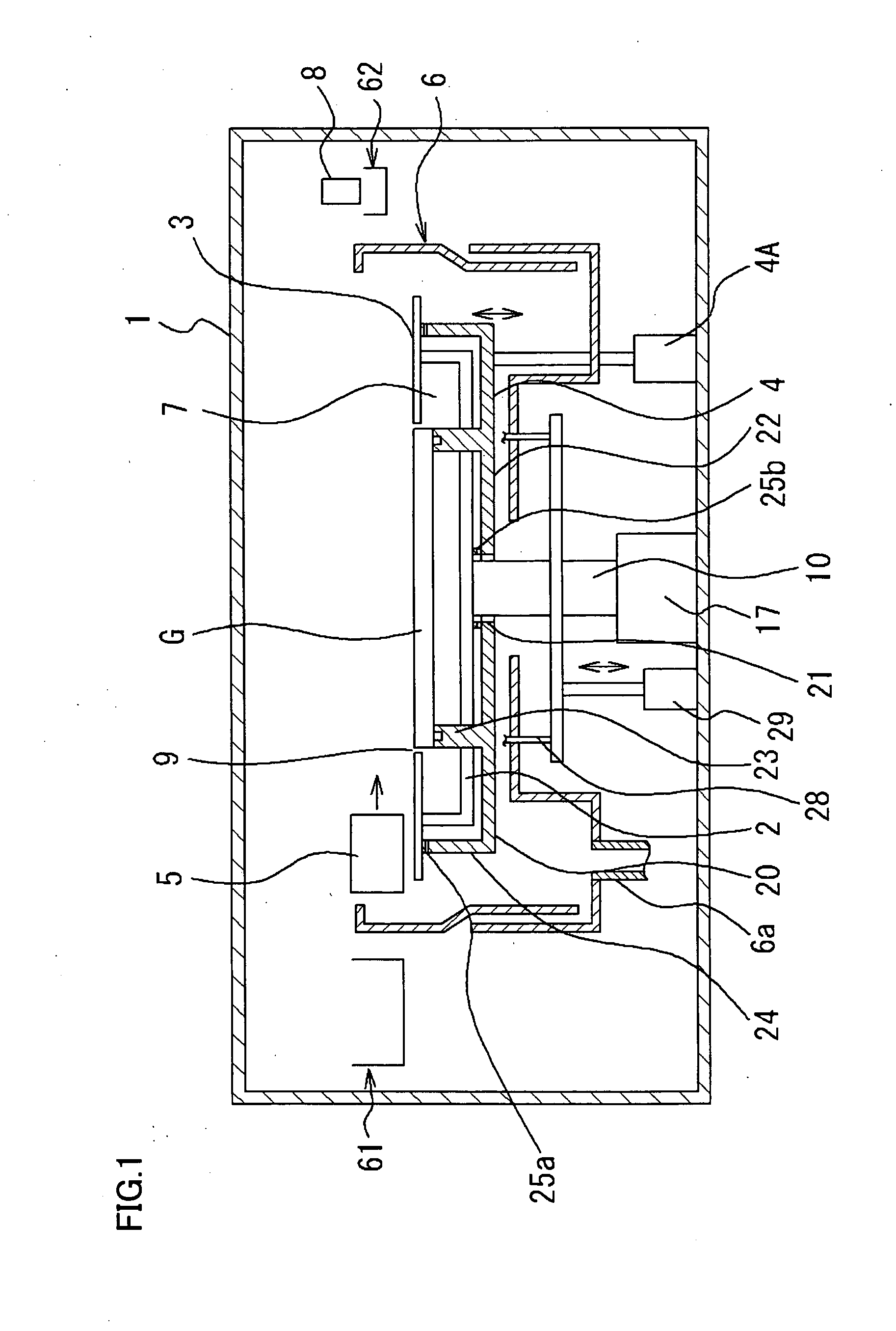

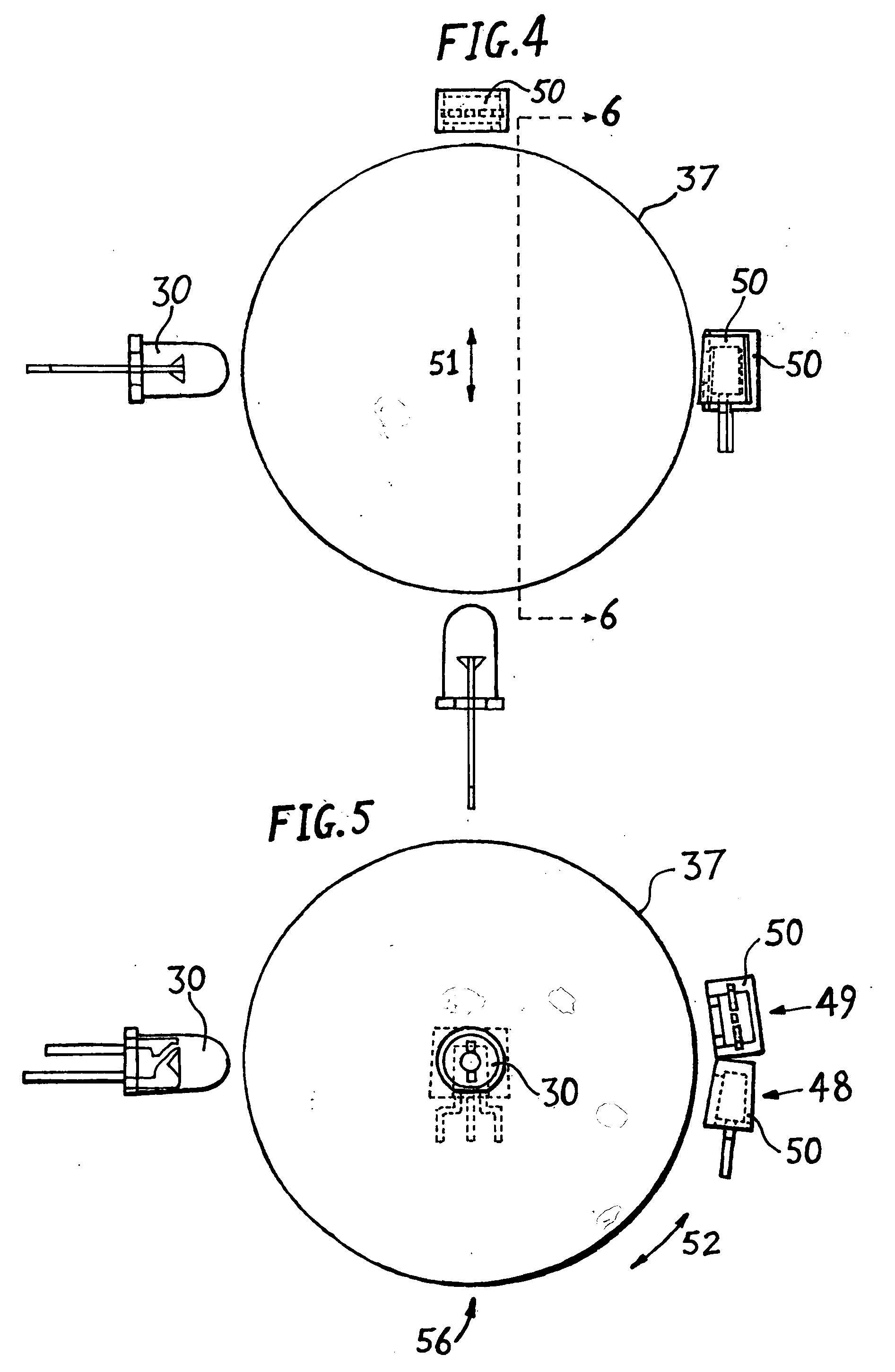

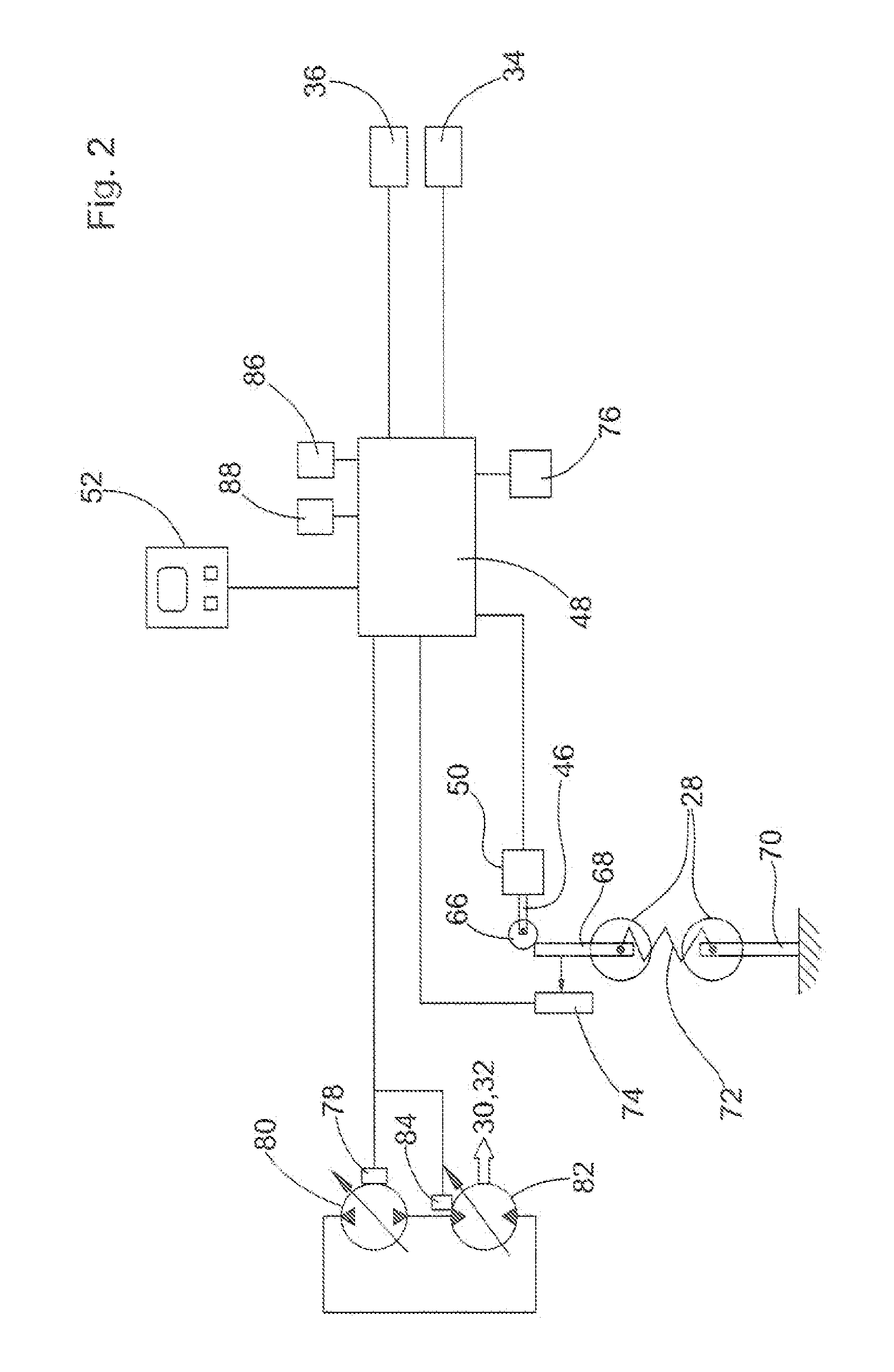

Hydrostatic drive and method for operating such a hydrostatic drive

InactiveUS6904993B1Reduce drive powerAvoid excessive wearBraking action transmissionGearing controlHydraulic motorHydraulic pump

A hydrostatic drive (1) with a hydraulic pump (3) and a plurality of hydraulic motors (6-9) that are hydraulically linked with the hydraulic pump (3). One speed sensor (20; 21; 22; 23) each allocated to a respective hydraulic motor (6; 7; 8; 9) and is linked with a control device (24) and detects the speed (n1; n2; n3; n4) of the allocated hydraulic motor (6; 7; 8; 9). Every hydraulic motor (6; 7; 8; 9) is functionally linked with a brake device (26; 27; 28; 29) that in turn is linked with the control device (24). When the speed (n1; n2; n3; n4) of one of the hydraulic motors (6; 7; 8; 9) exceeds a predetermined threshold value (ng), the control device (24) triggers the brake device (26; 27; 28; 29) allocated to the associated hydraulic motor (6; 7; 8; 9).

Owner:BOSCH REXROTH AG

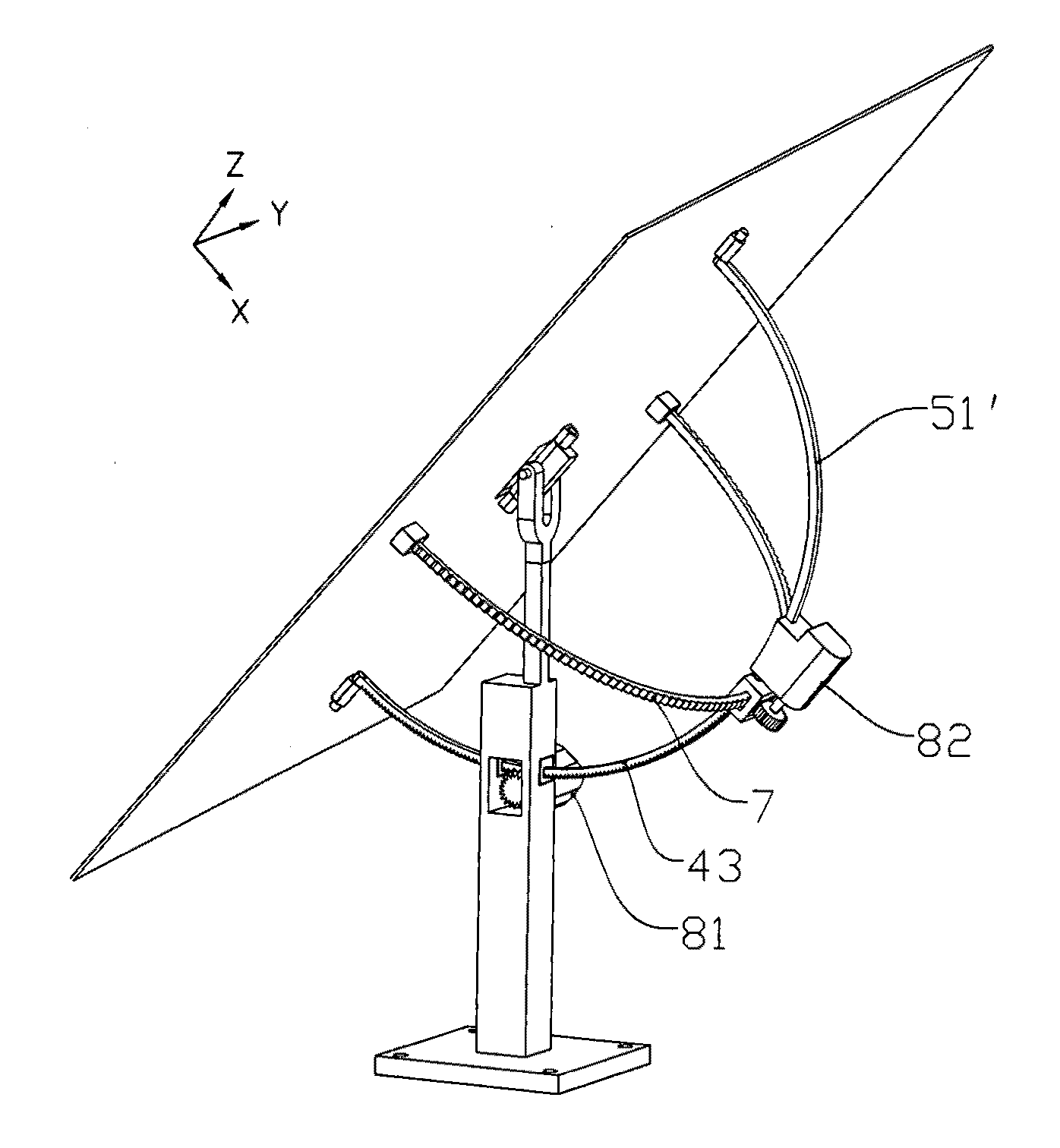

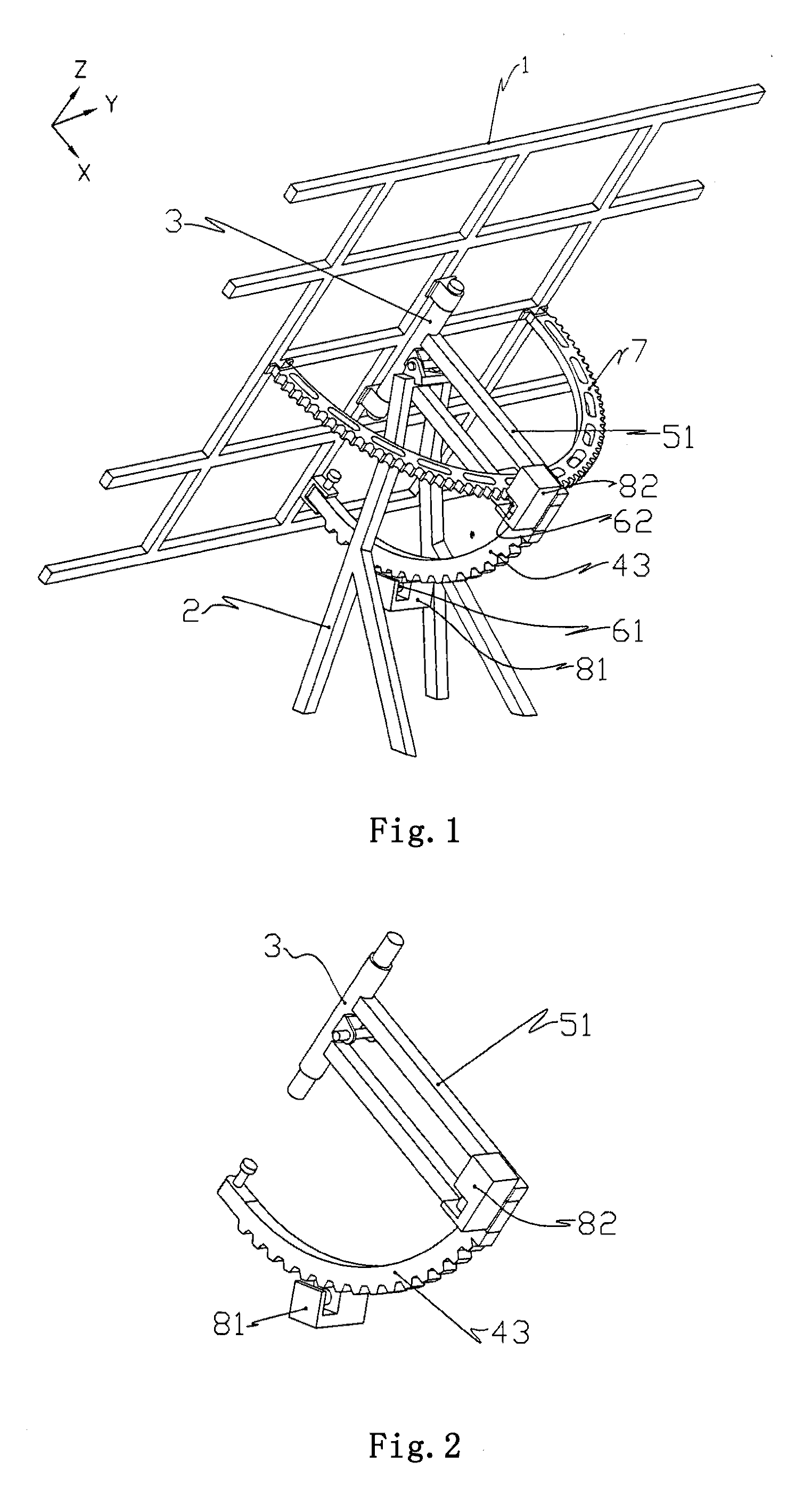

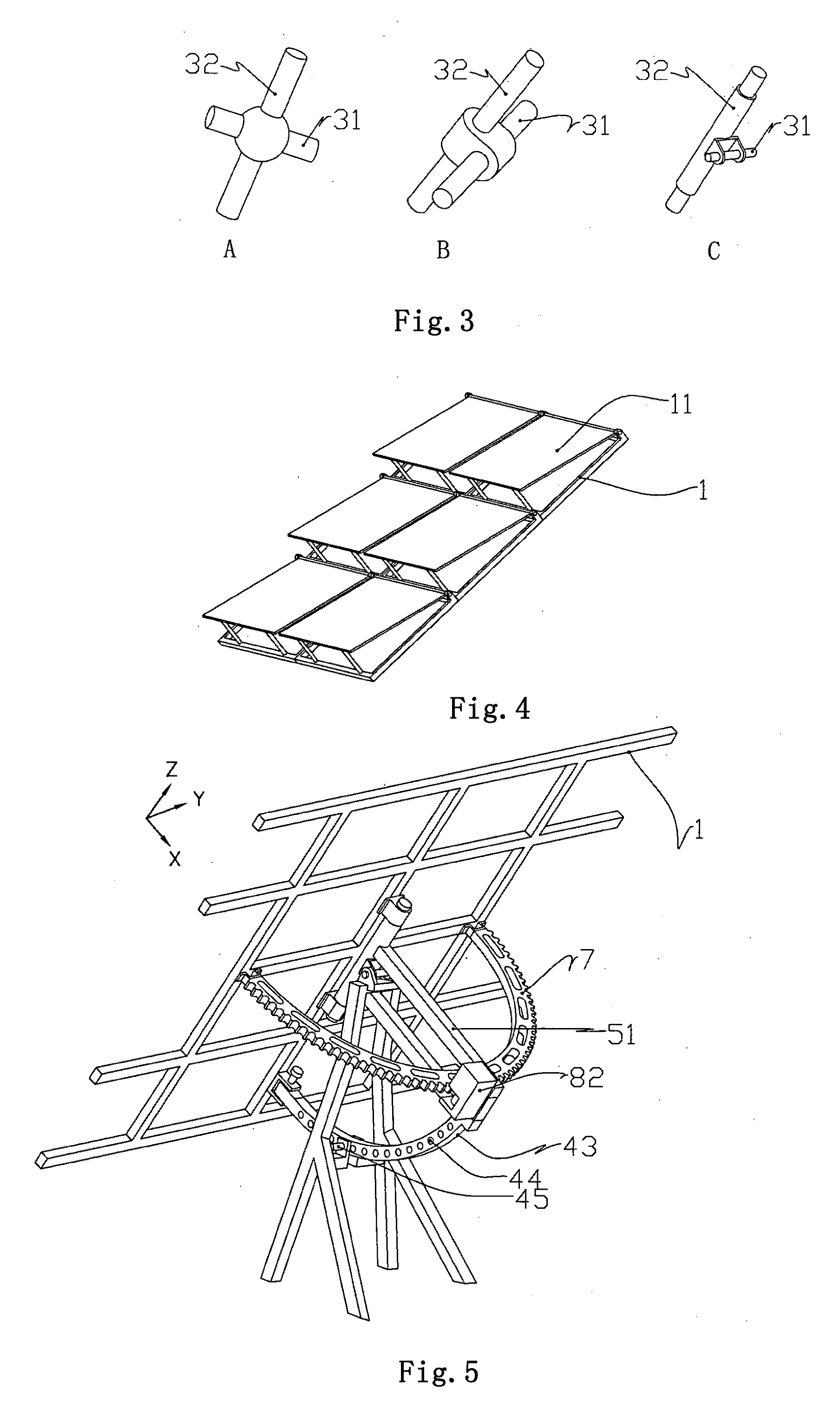

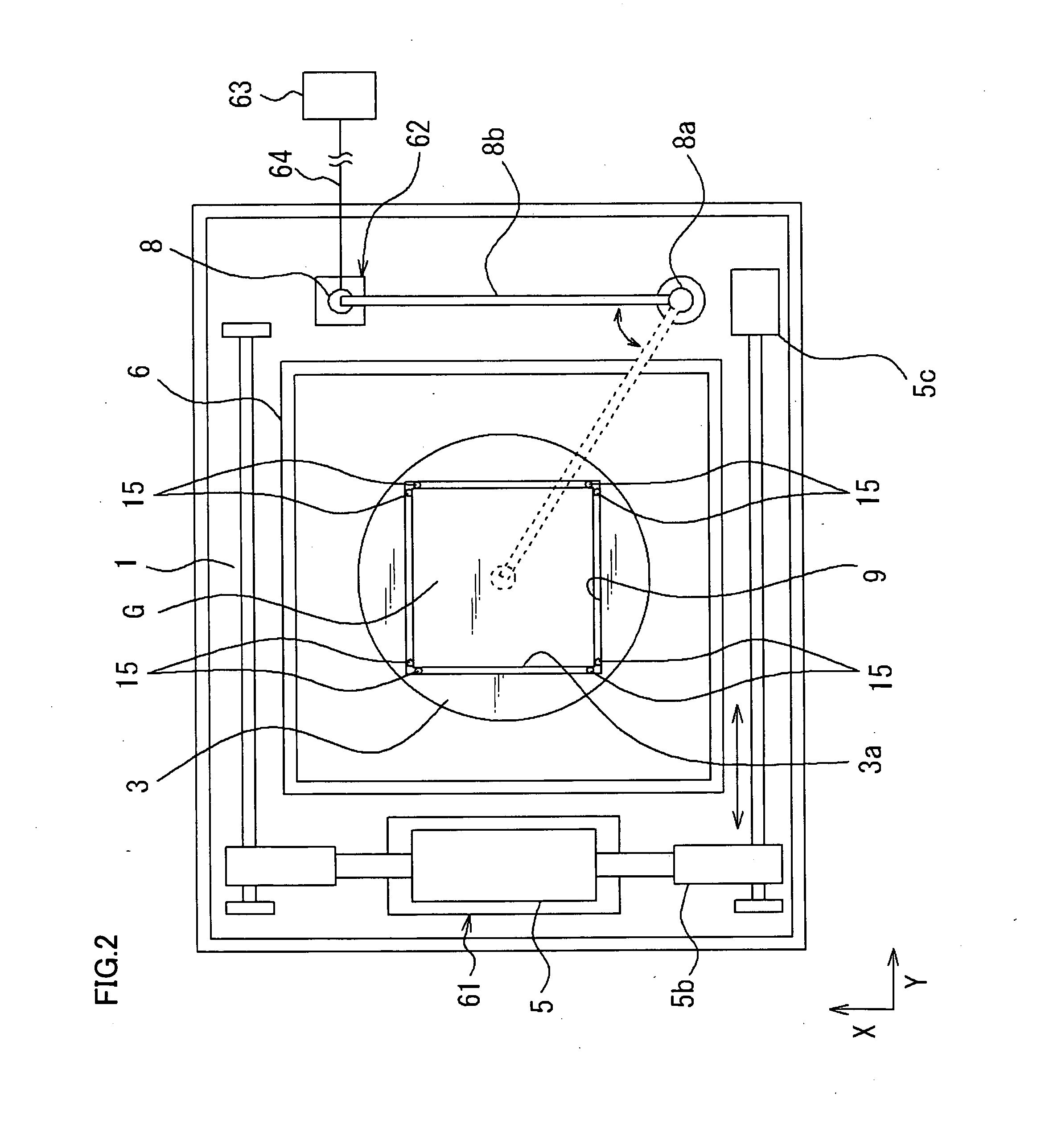

Automatic sunlight tracking device

InactiveUS20120318325A1Simplified and reasonable and firm structureImprove mechanical propertiesPhotovoltaic supportsSolar heating energyEngineeringDaylight

Disclosed is an automatic sunlight tracking device comprising a solar panel holder (1), a mounting (2), a pitching angle tracking member, and a swing angle tracking member. The solar panel holder (1) is coupled with the mounting (2) through a three-dimensional assembly (3), and the pitching tracking member comprises a first transmission part and a first drive device (81) cooperating with the first transmission part. The swing tracking member comprises a second transmission part and a second drive device (82) cooperating with the second transmission part. The three-dimensional assembly (3) includes two rotation supporting shafts arranged in a cross shape. The automatic sunlight tracking device has a high operation accuracy, a reasonable structure, low operation energy consumption. It is easy to be controlled, and installation and maintenance is facilitated.

Owner:LIU JIANZHONG

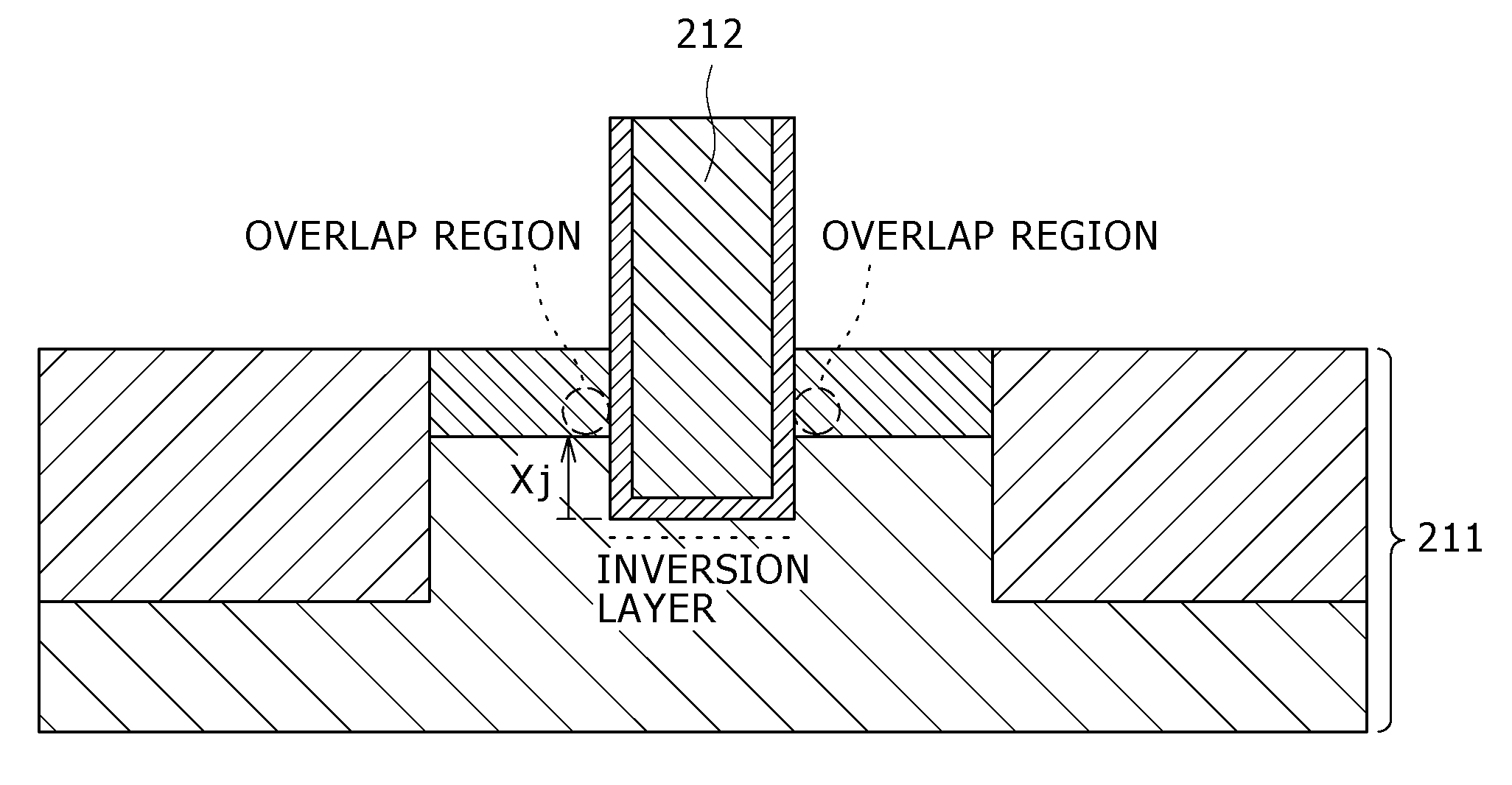

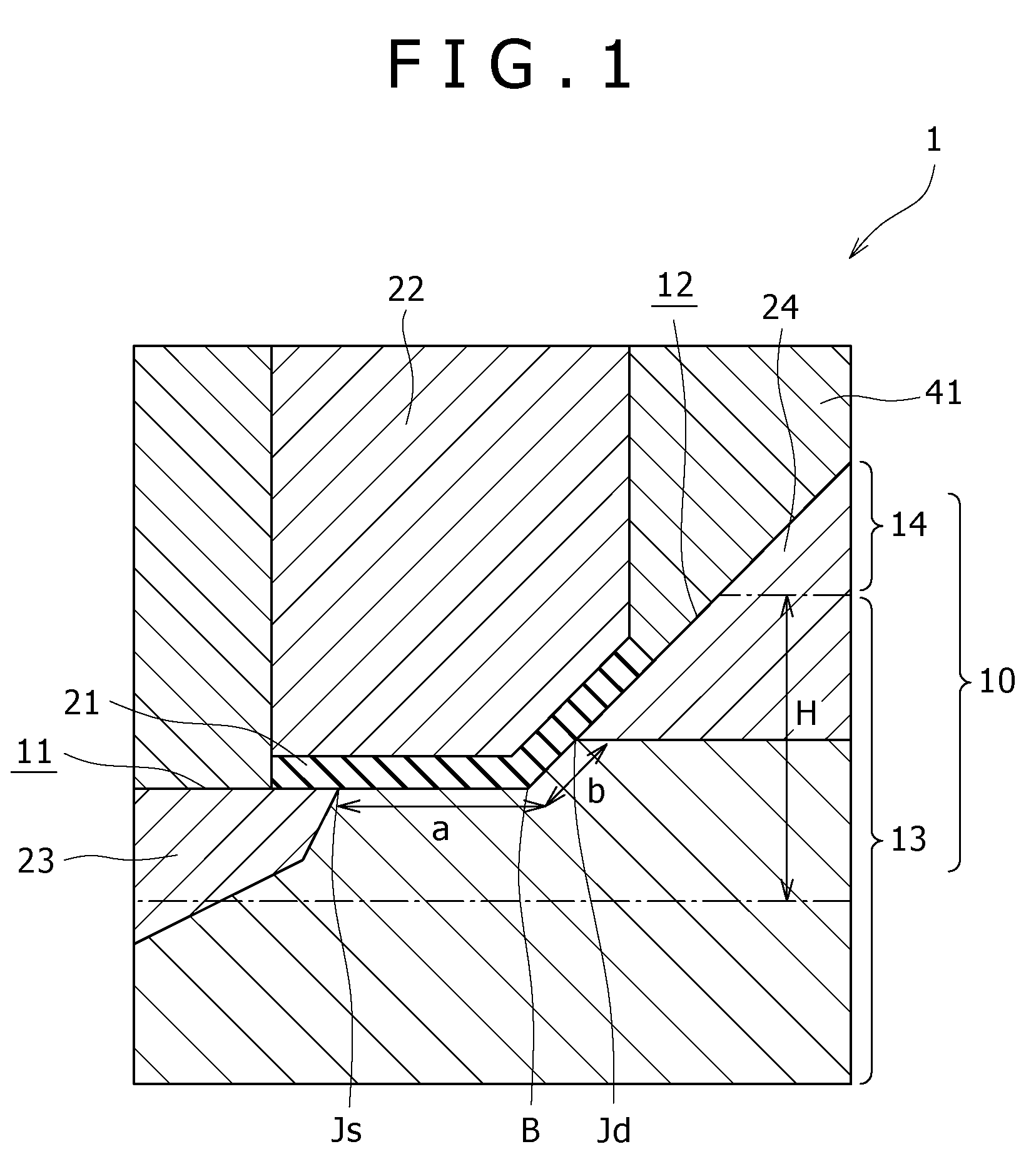

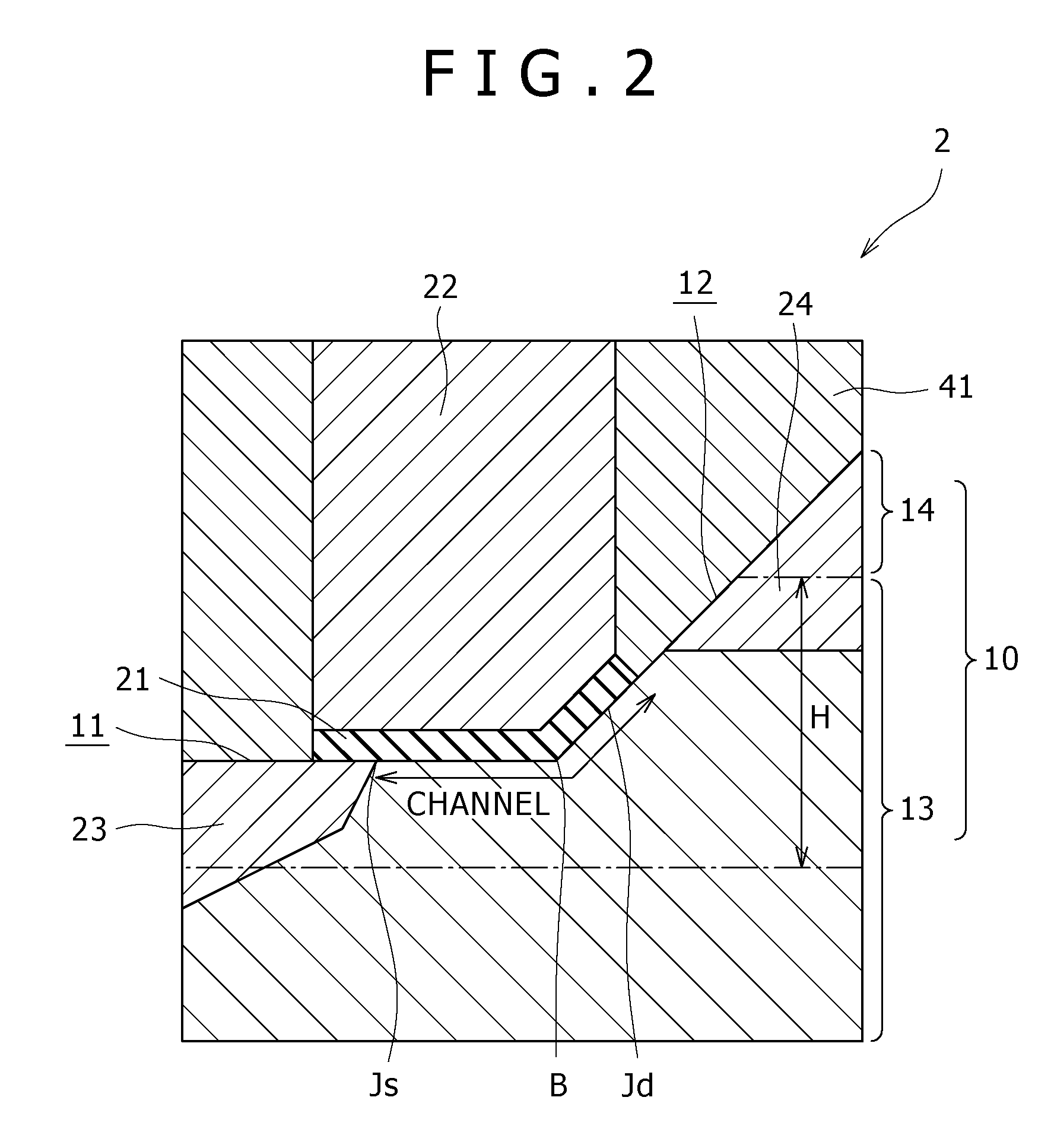

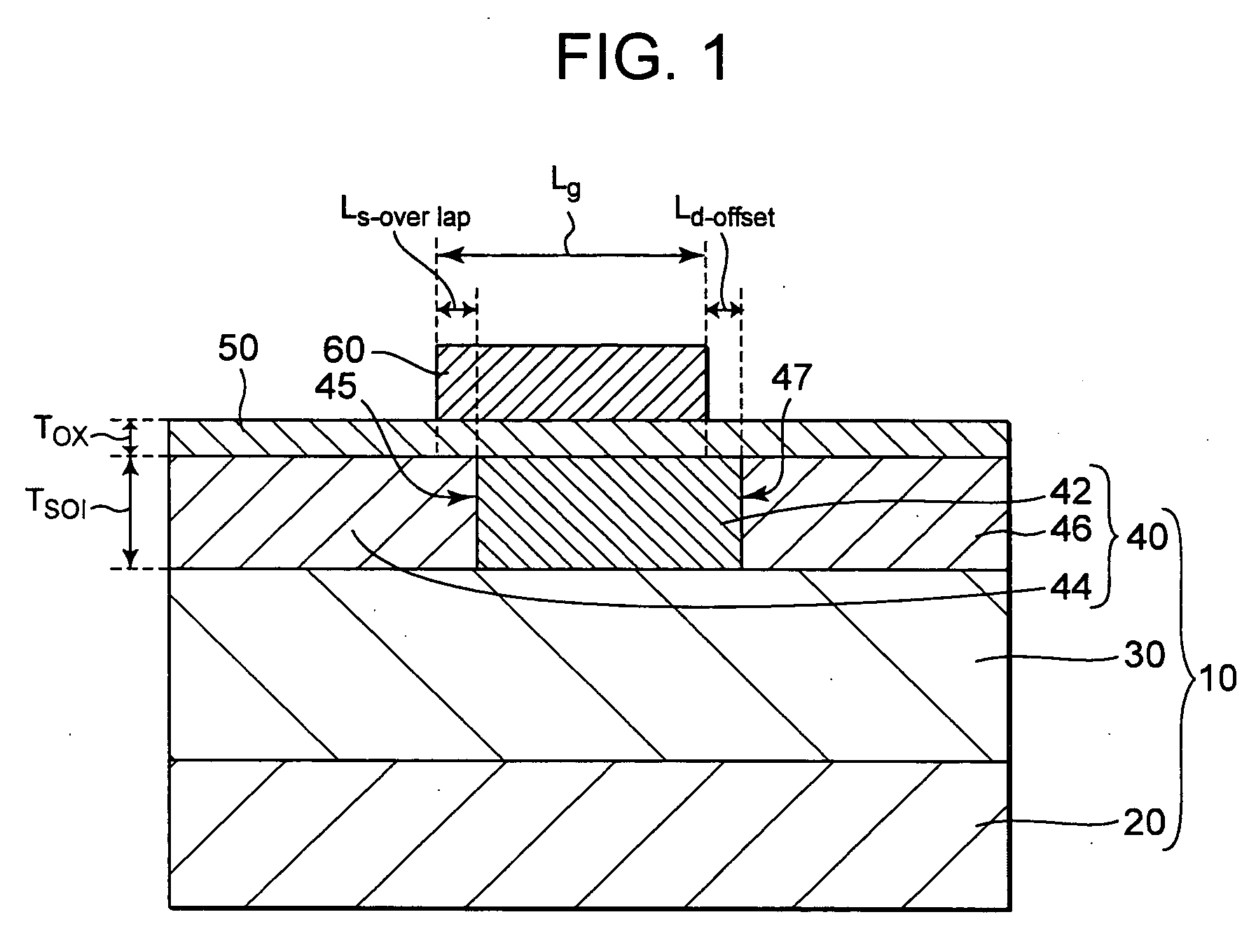

Semiconductor device and method of manufacturing semiconductor device

ActiveUS20080054352A1Decrease in sheet carrier densityLower threshold voltageTransistorSemiconductor/solid-state device manufacturingElectrical conductorDevice material

A semiconductor device including: a semiconductor region having a first semiconductor face and a second semiconductor face connected to the first semiconductor face and having an inclination with respect to the first semiconductor face; a gate insulating film formed on the first and on the second semiconductor faces; a gate electrode formed on the gate insulating film including a part on a boundary between the first semiconductor face and the second semiconductor face; a source impurity region formed in the semiconductor region so as to overlap the gate electrode within the first semiconductor face with the gate insulating film interposed between the source impurity region and the gate electrode; and a drain impurity region formed in the semiconductor region directly under the second semiconductor face at least.

Owner:SONY CORP

Fuel injection system for an internal combustion engine

InactiveUS20040007214A1Severe heatingReduce drive powerElectrical controlLow pressure fuel injectionFuel tankEngineering

A fuel injection system having a fuel reservoir, a high-pressure fuel pump by which fuel is pumped into the fuel reservoir as a function of engine operating parameters, a prefeed pump by which fuel is pumped from a fuel tank to the intake side of the high-pressure fuel pump, a fuel metering device for adjusting the fuel quantity pumped into the fuel reservoir by the high-pressure fuel pump, and at least one injector, communicating with the fuel reservoir, for fuel injection to the engine. The metering device is disposed between the fuel tank and the intake side of the prefeed pump. The high-pressure fuel pump has a drive region, which for the sake of its lubrication can be made to communicate with the outlet of the prefeed pump, via a pressure valve that opens towards the drive region.

Owner:ROBERT BOSCH GMBH

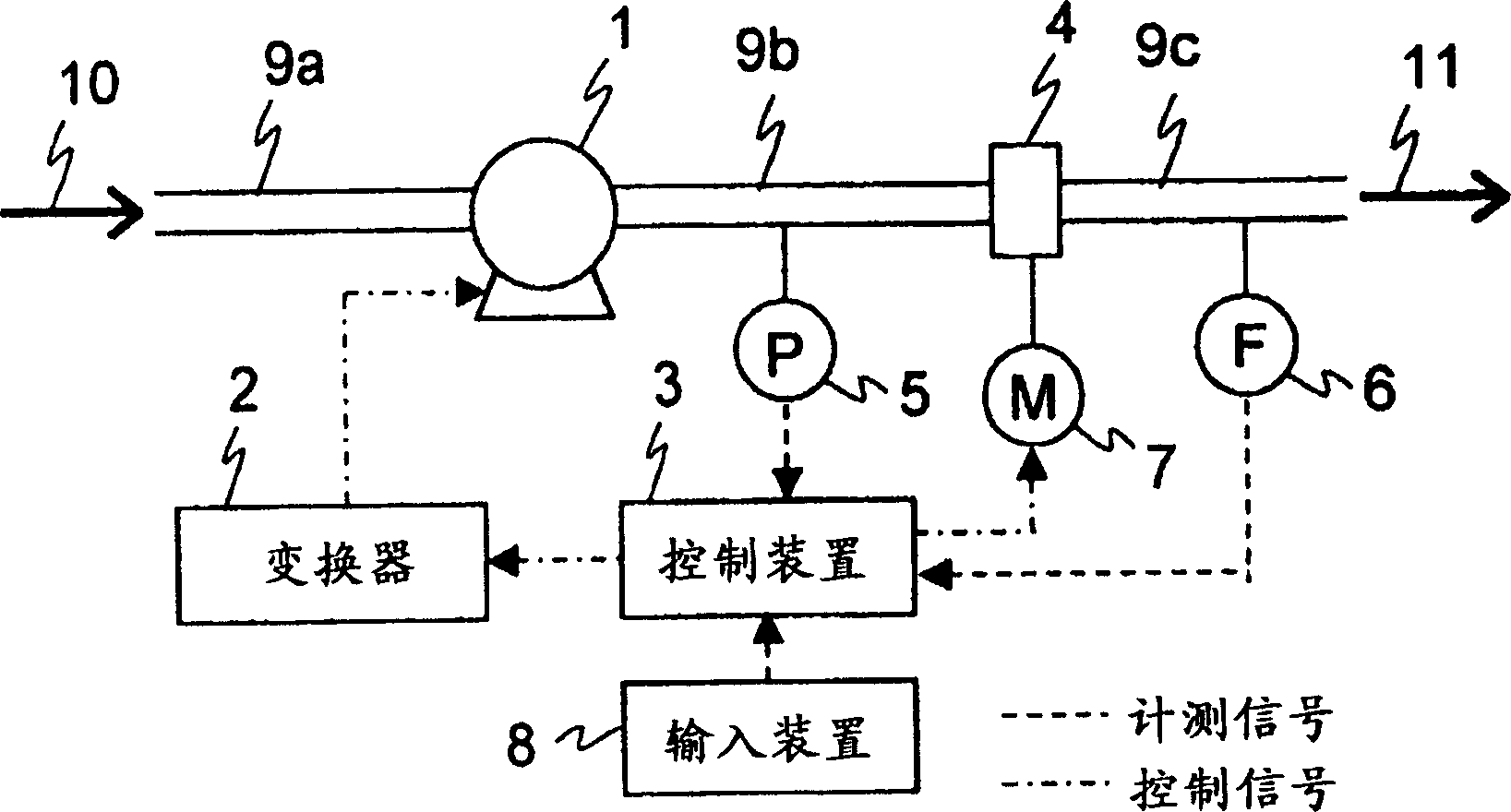

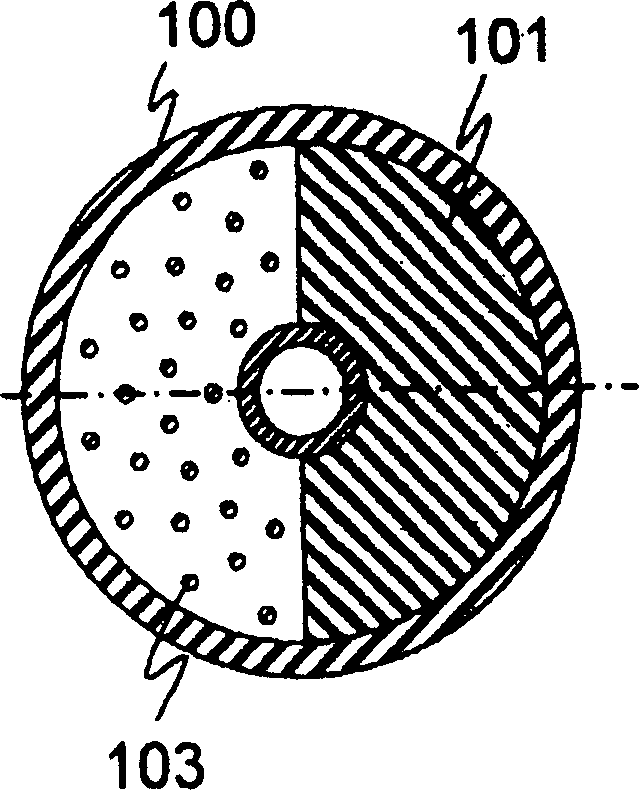

Micro air bubble generation device and method, water treatment device using the same

InactiveCN1899978AGenerate efficientlyDiameter stableWater/sewage treatment by oxidationMicrobubblesProduct gas

The invention provides an apparatus and a method for producing microbubbles. Fluid in which gas is dissolved under pressure with a pump 1 flows into a porous plate unit 4 and when passing through the porous plate, the fluid is decompressed and dissolved gas is deposited to form microbubbles. A controller 3 changes rotational frequency of the pump 1 via an inverter 2 to control an ejection flow rate of microbubble-containing water 11. At the same time, the controller 3 changes the number of pores in a narrow flow passage via a driving gear 7 to keep pressurizing pressure above a minimum value of pressure required for producing microbubbles and below a predetermined maximum value.

Owner:HITACHI LTD

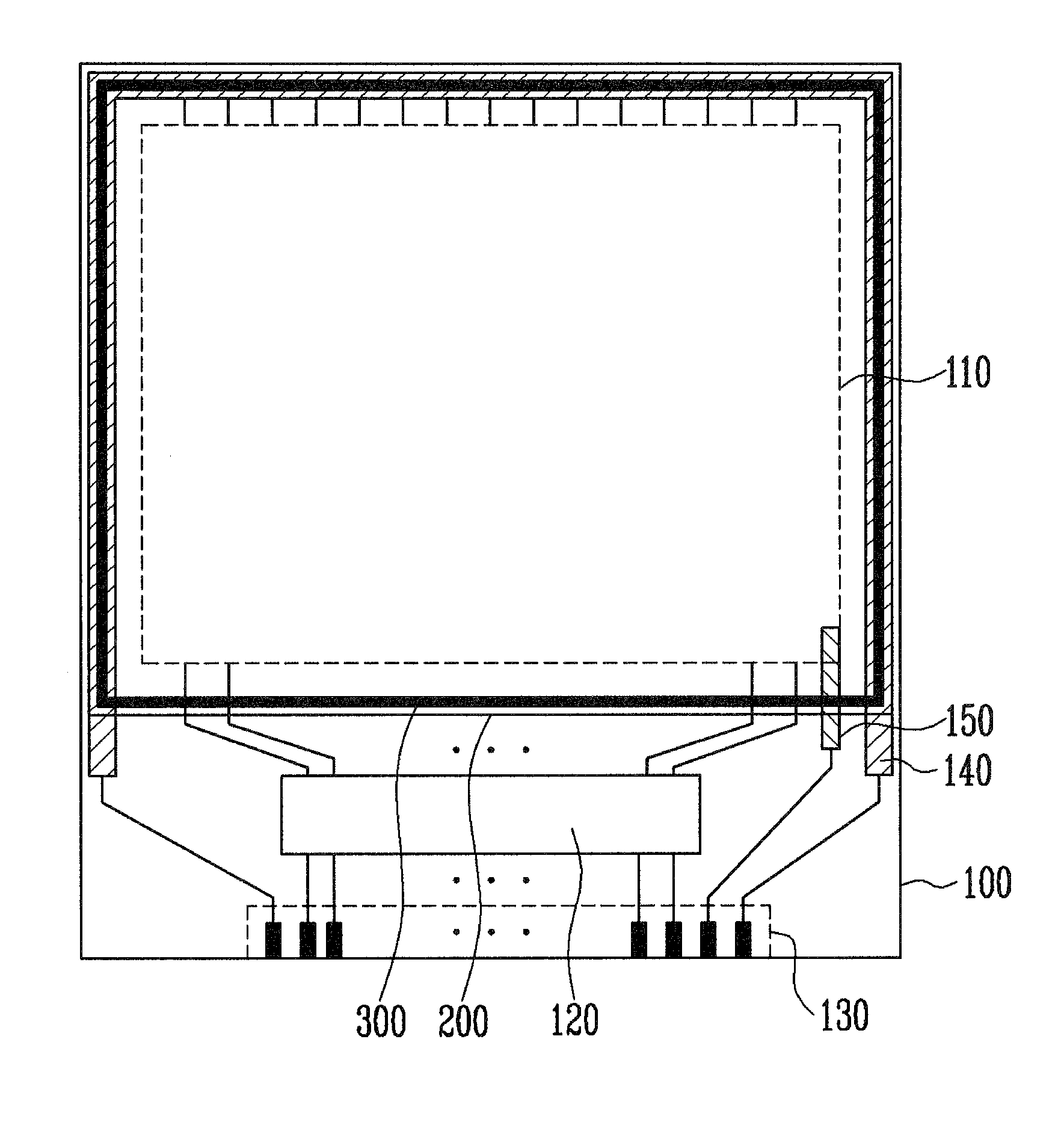

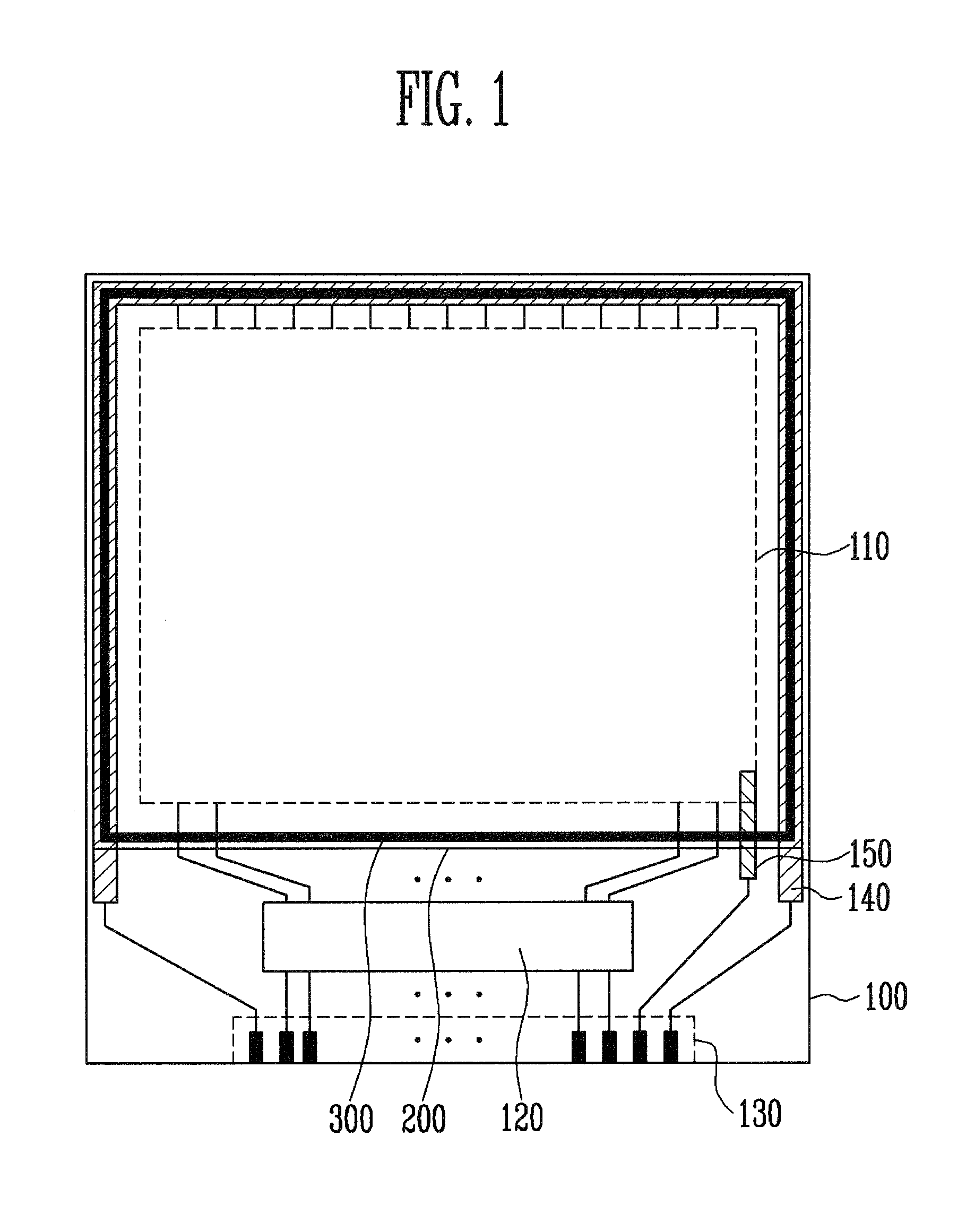

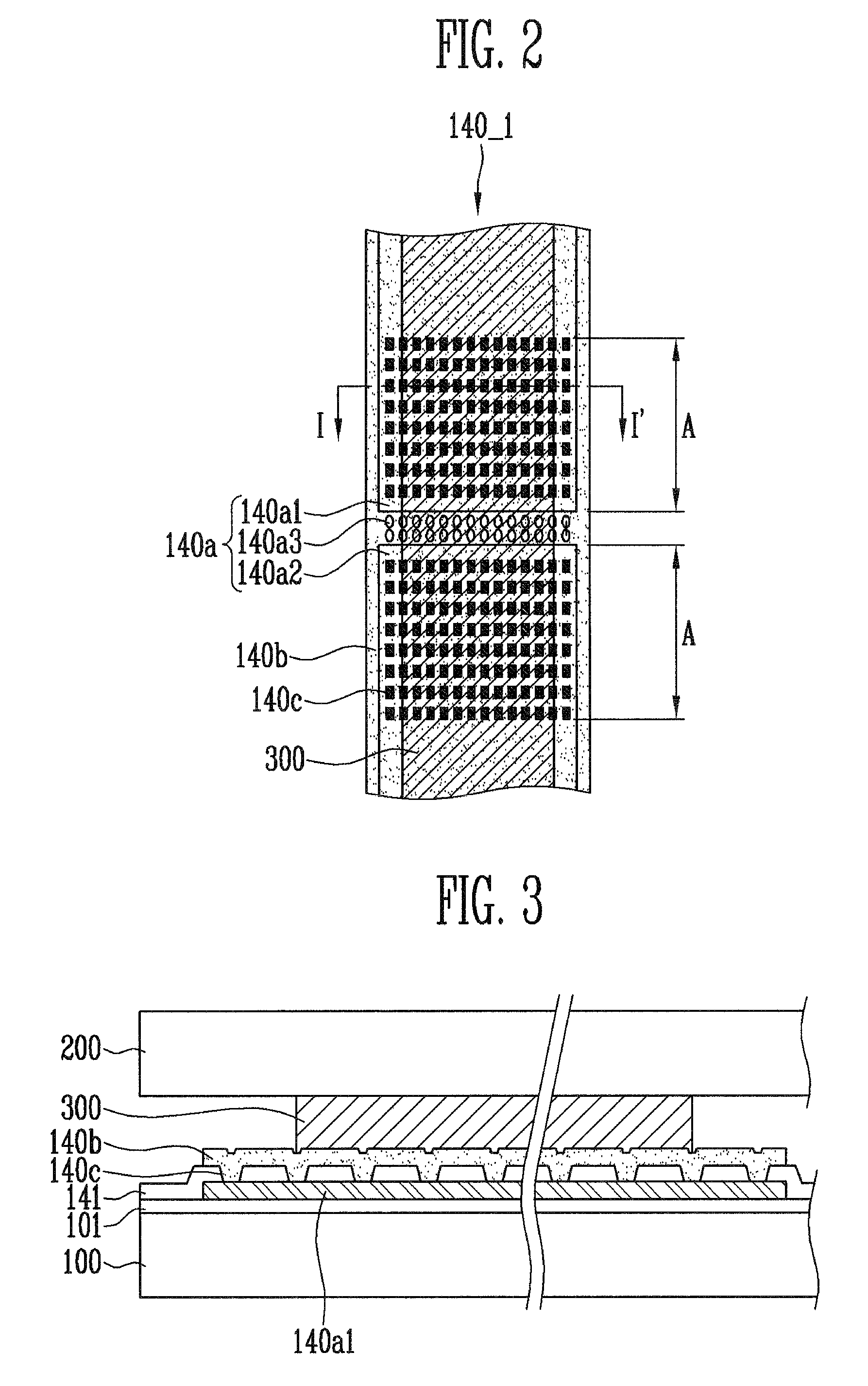

Organic light emitting display device

ActiveUS20090218925A1Reduce drive powerImprove uniform image qualityElectrode assembly support/mounting/spacing/insulationDischarge tube luminescnet screensPhysicsOptoelectronics

An organic light emitting display device. The organic light emitting display device includes a first substrate, a second substrate overlapping with at least one region of the first substrate and a sealing agent attached between the first substrate and the second substrate to seal a display unit therebetween. A conductive wire on the first substrate overlapping with at least a portion of the sealing agent includes a first conductive layer and a second conductive layer having at least one region formed at different levels to be electrically coupled to each other through contact holes. The first conductive layer and the second conductive layer are configured to reduce a resistance of the conductive wire and improve an adhesive force of the sealing agent.

Owner:SAMSUNG DISPLAY CO LTD

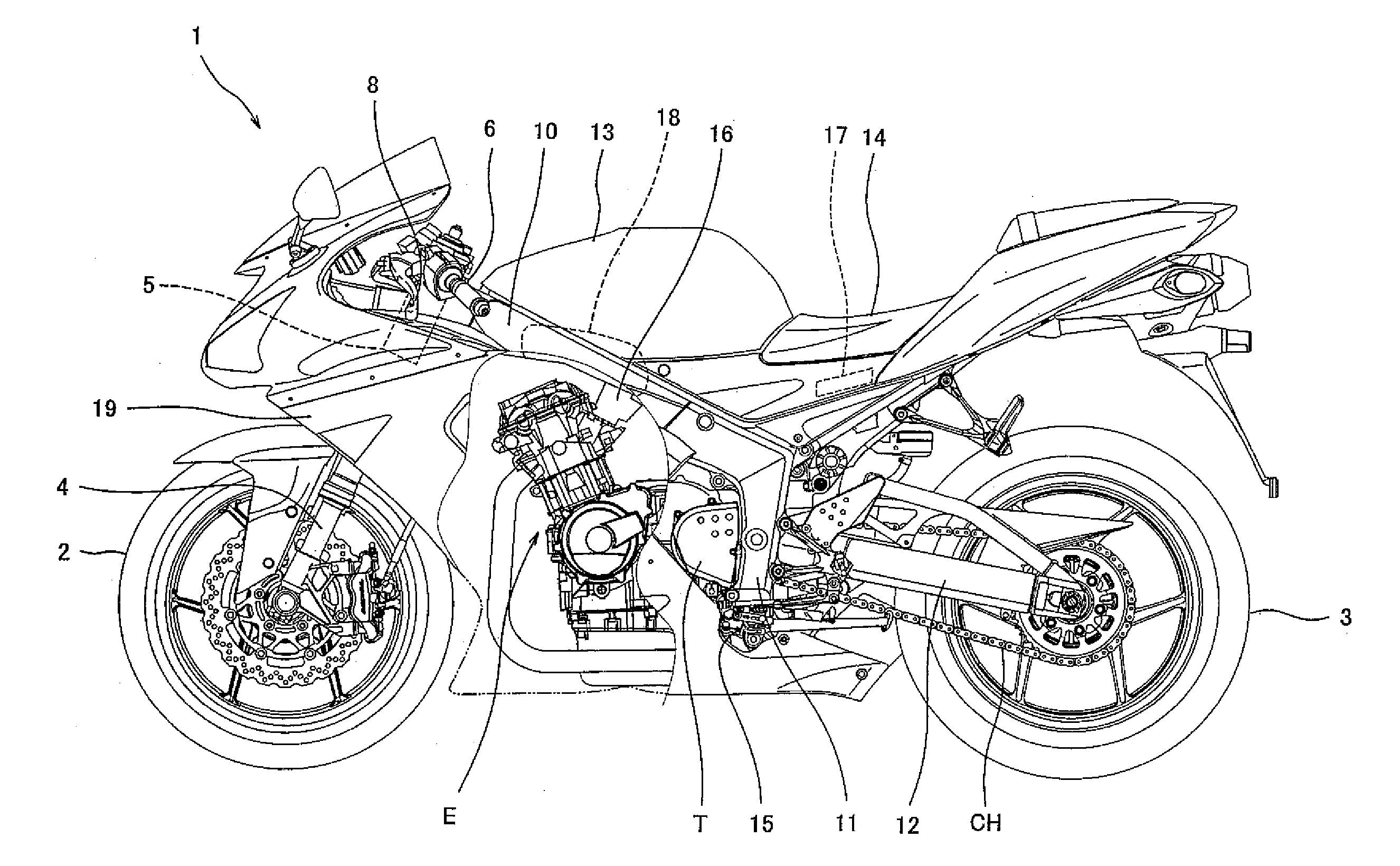

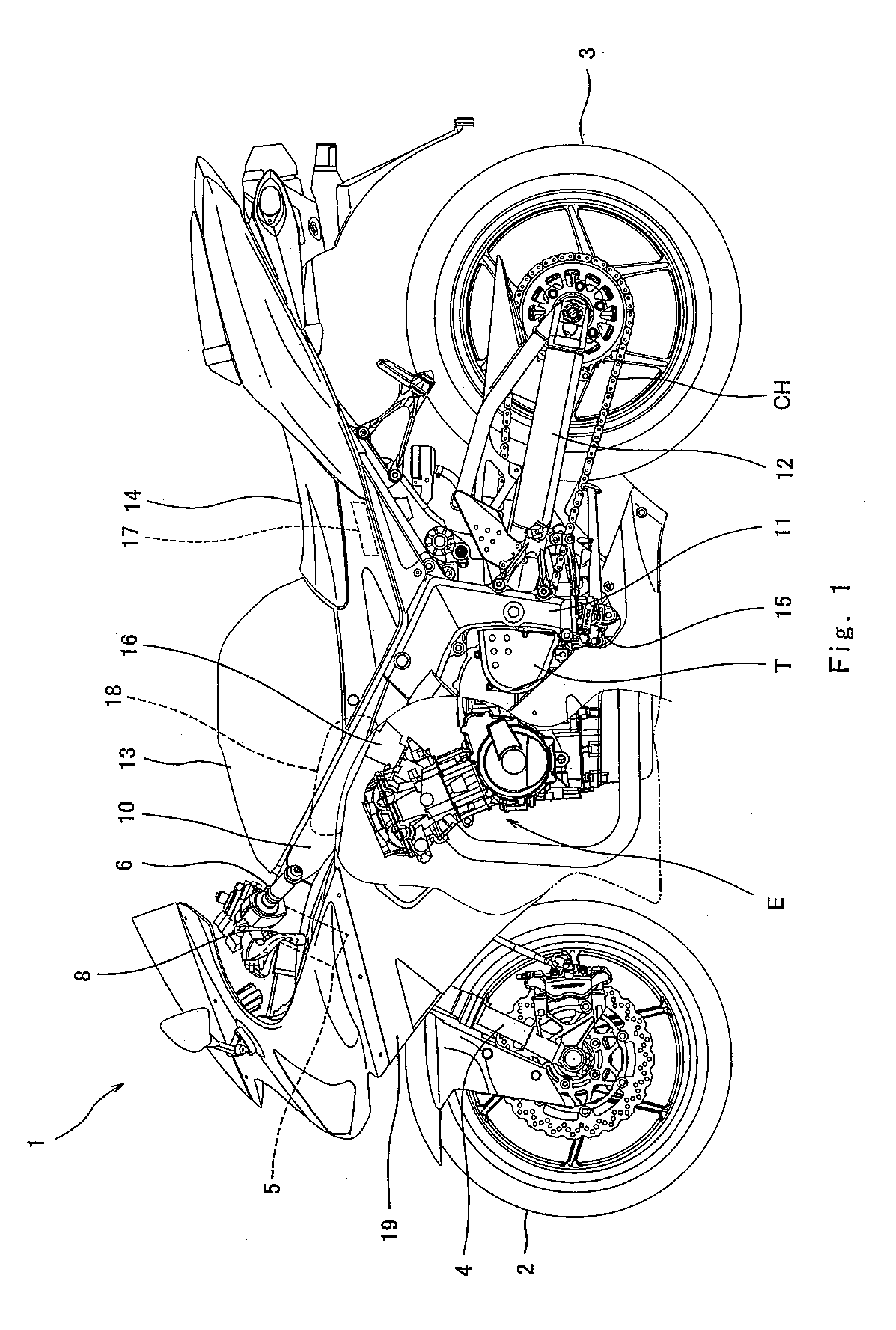

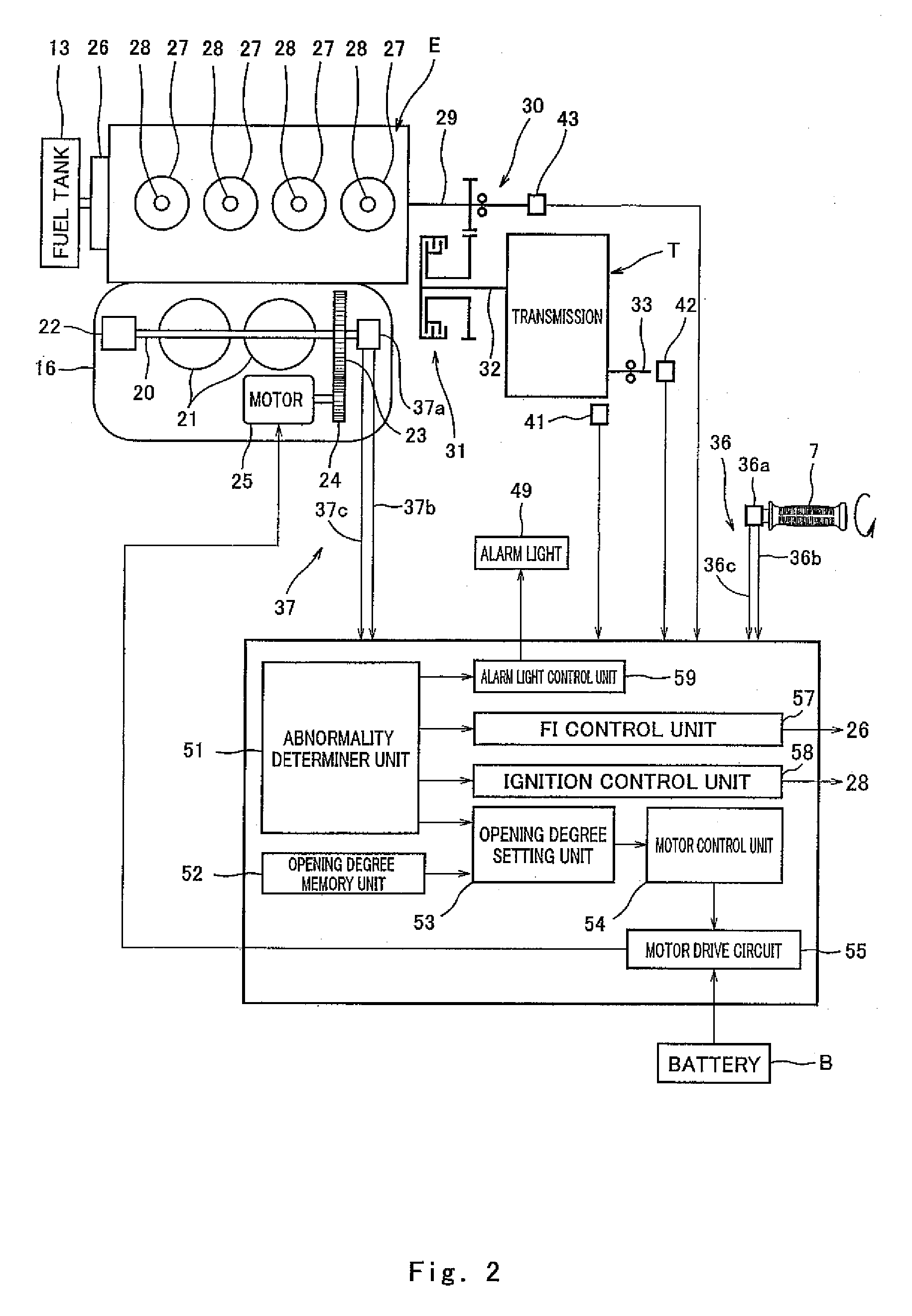

Vehicle and Controller Thereof

InactiveUS20090312147A1Suppress increaseReduce drive powerElectrical controlMachines/enginesOutput deviceControl theory

A vehicle comprises a driving state detecting device configured to detect a driving state, a command signal output device configured to output a detected command signal indicating an engine driving power change command, an opening degree signal output device configured to output a detected opening degree signal, a valve drive device configured to drive a throttle valve; and a controller which is configured to set a target opening degree of the throttle valve based on the detected command signal and to control the valve drive device to cause an opening degree to match the target opening degree. The controller is configured to set, according to the driving state, the target opening degree to a smaller value than when the command signal and the opening degree signal are normal, when at least one of the command signal and the opening degree signal is abnormal.

Owner:KAWASAKI HEAVY IND LTD

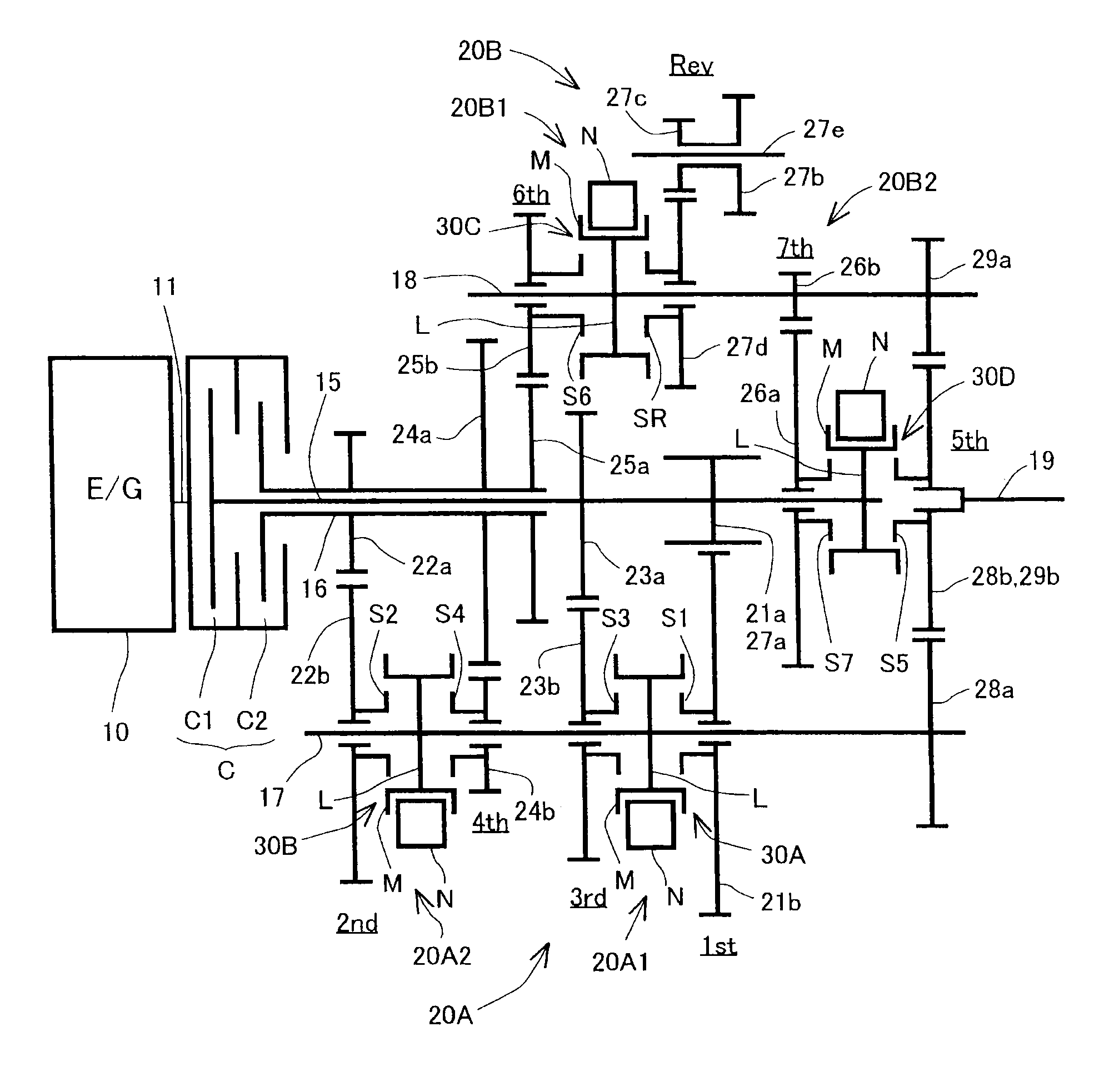

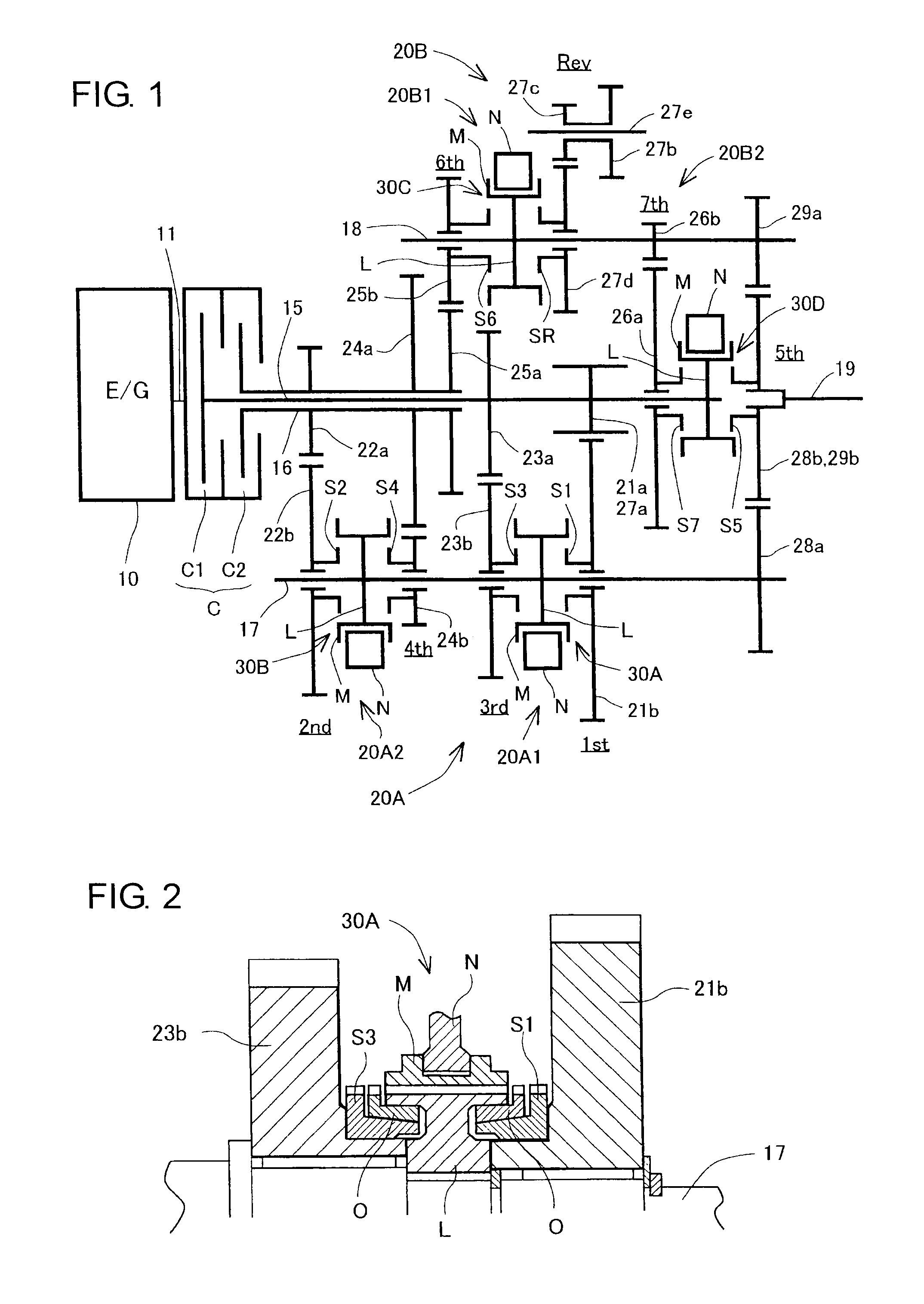

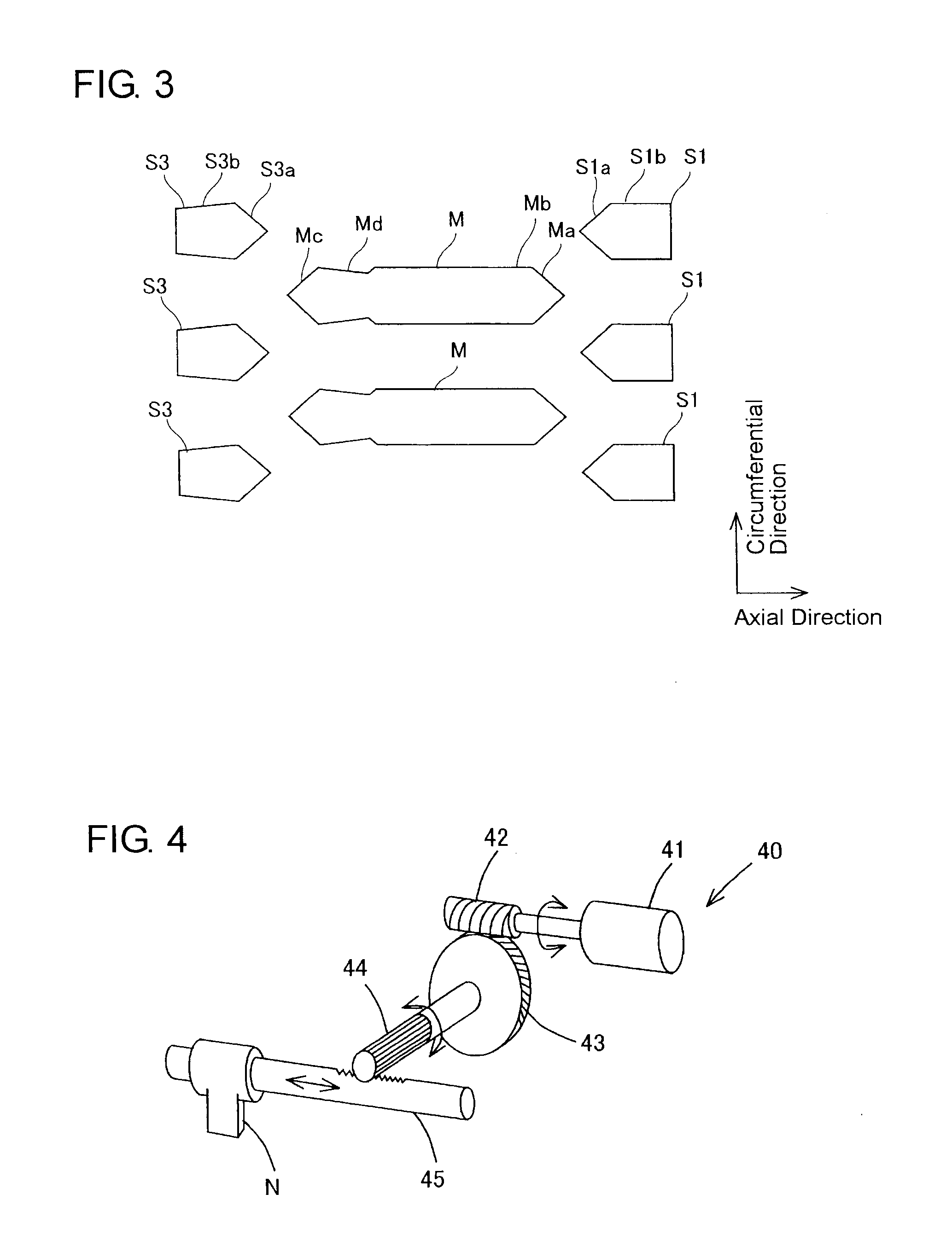

Automatic dual-clutch transmission

InactiveUS20110167957A1Reduce drive powerLarge contact loadMechanical actuated clutchesToothed gearingsLow speedGear wheel

An automatic dual-clutch transmission is able to establish a parking lock by bringing one of a first input shaft and a second input shaft into engagements with a low speed stage gear train as well as with a reverse stage gear train in performing a parking. Gears of an engaging member and a mating sleeve in at least one of a low speed stage shift clutch and a reverse stage shift clutch which are simultaneously brought into engagements to establish the parking lock are able to mesh with each other at axially extending side surfaces thereof which are formed to extend linearly in parallel to an axial direction thereof.

Owner:AISIN AI CO LTD

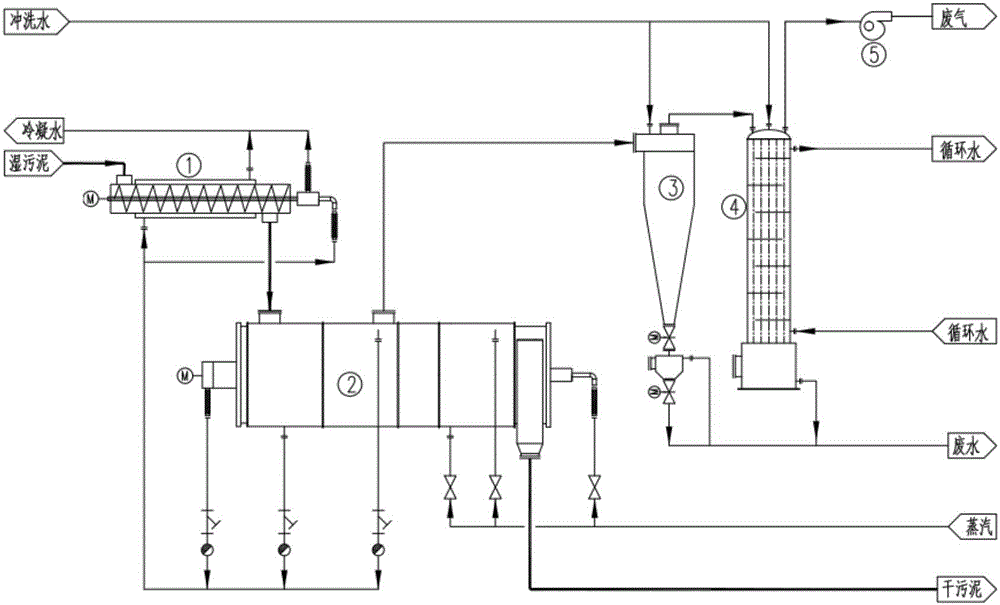

Energy-saving sludge drying process and device

InactiveCN106145605AReduce air volumeReduce drive powerSludge treatment by de-watering/drying/thickeningIsolation valveLiquid state

Provided is an energy-saving sludge drying method. A sludge preheater, an indirect heating sludge dryer, a cyclone dust collector, a waste gas condenser and a waste gas draught fan are adopted. Steam is conveyed into the indirect heating sludge dryer (2) through a pipeline, steam condensate generated after the steam releases heat in the indirect heating sludge dryer contains excess heat, the steam condensate is conveyed into the sludge preheater (1) through a pipeline, the excess heat is released again, and sludge to be dried is preheated with the excess heat. The wet sludge is conveyed into the sludge preheater (1) through a pipeline and preheated through the sludge preheater, and the temperature of the sludge rises to 50 DEG C or above; the sludge is heated in the indirect heating sludge dryer (2), and moisture and other volatilizable components in the sludge are heated and generate gas. A material accumulation hopper is arranged below the cyclone dust collector, the hopper and a dust collector body are provided with normally open isolation valves, an outlet in the lower portion is provided with a normally closed sewage discharge isolation valve, the volume of the waste gas is reduced after the waste gas is changed into a liquid state from a gaseous state, and then the waste gas is discharged through the waste gas draught fan.

Owner:CEEP CO LTD

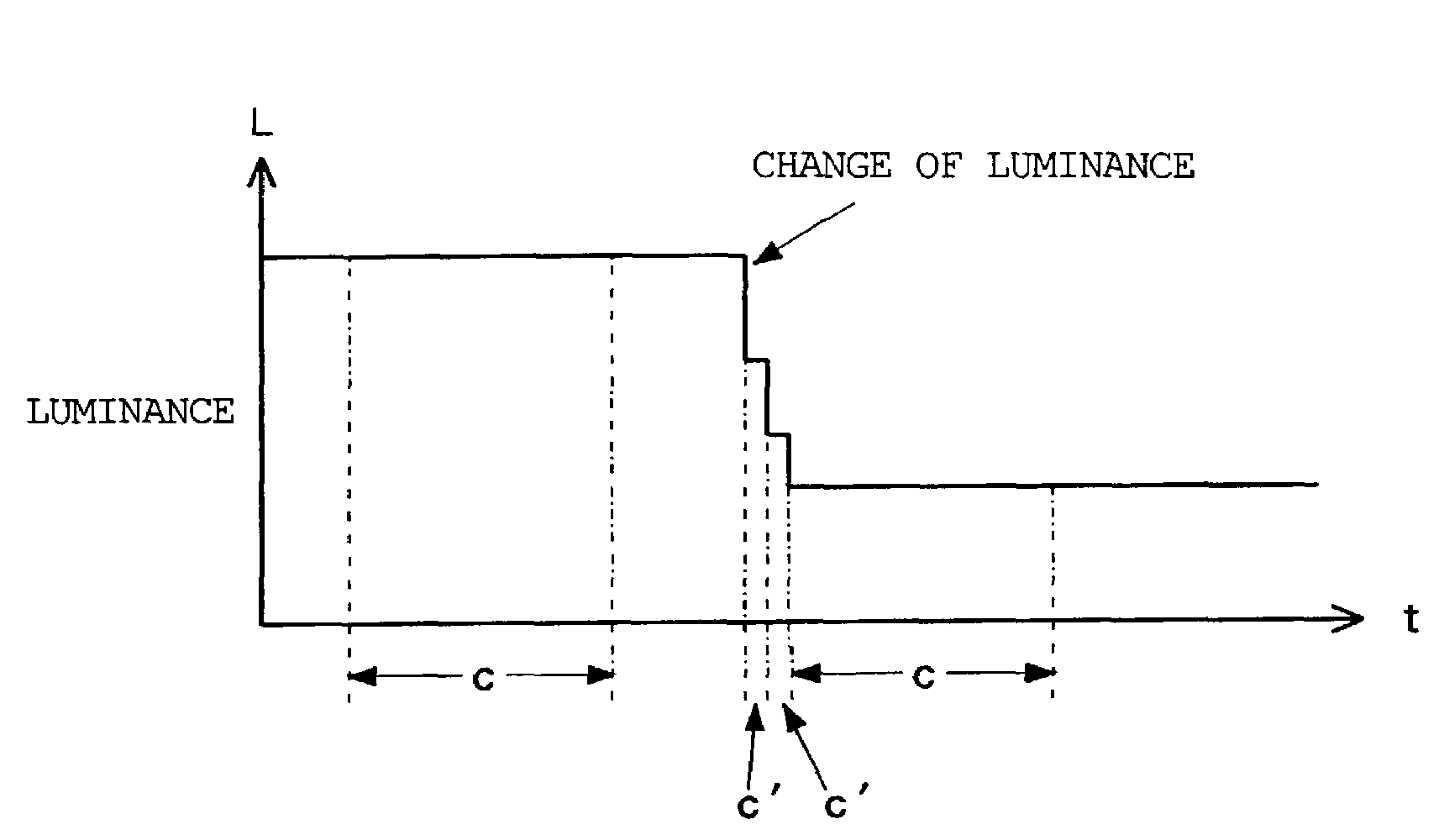

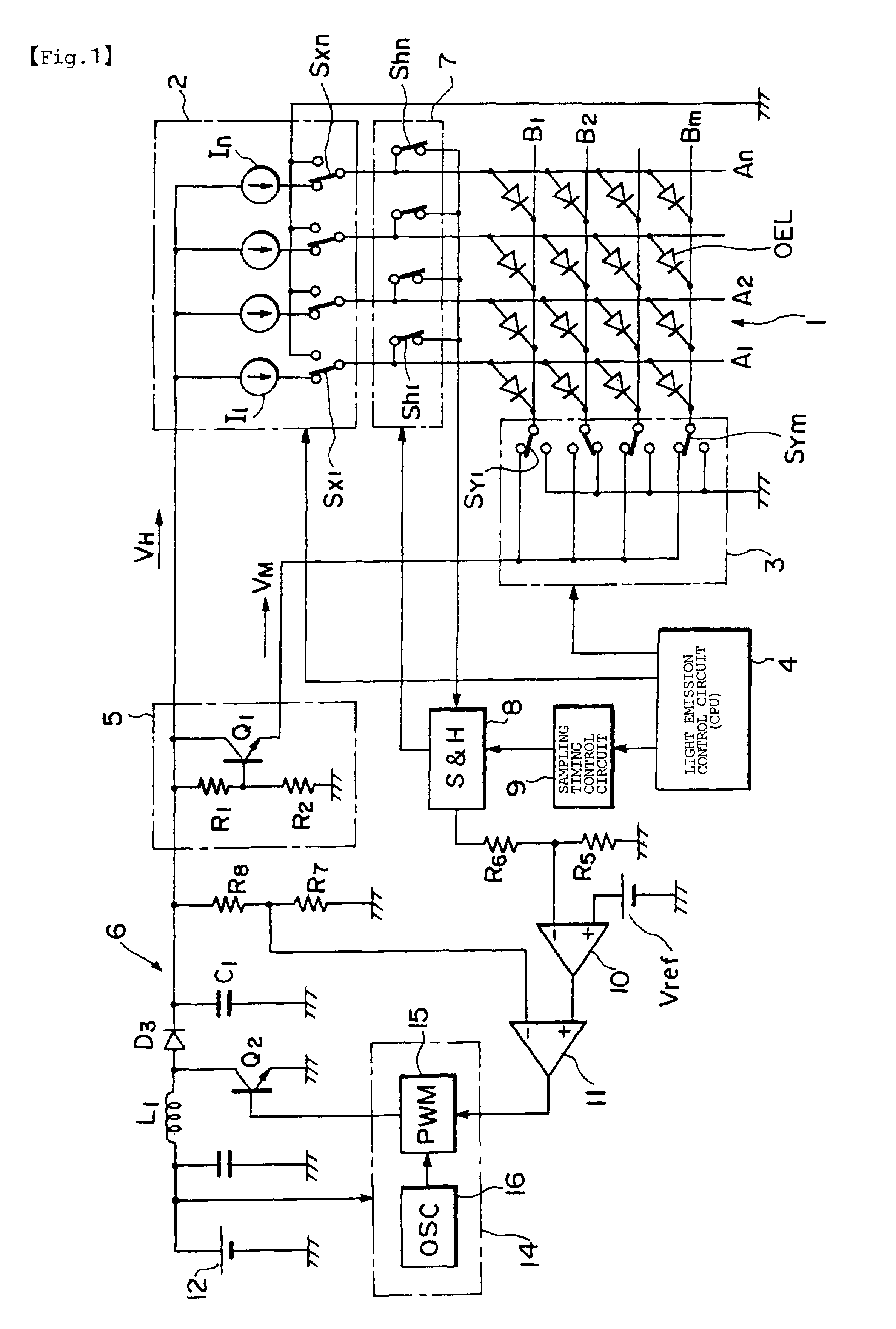

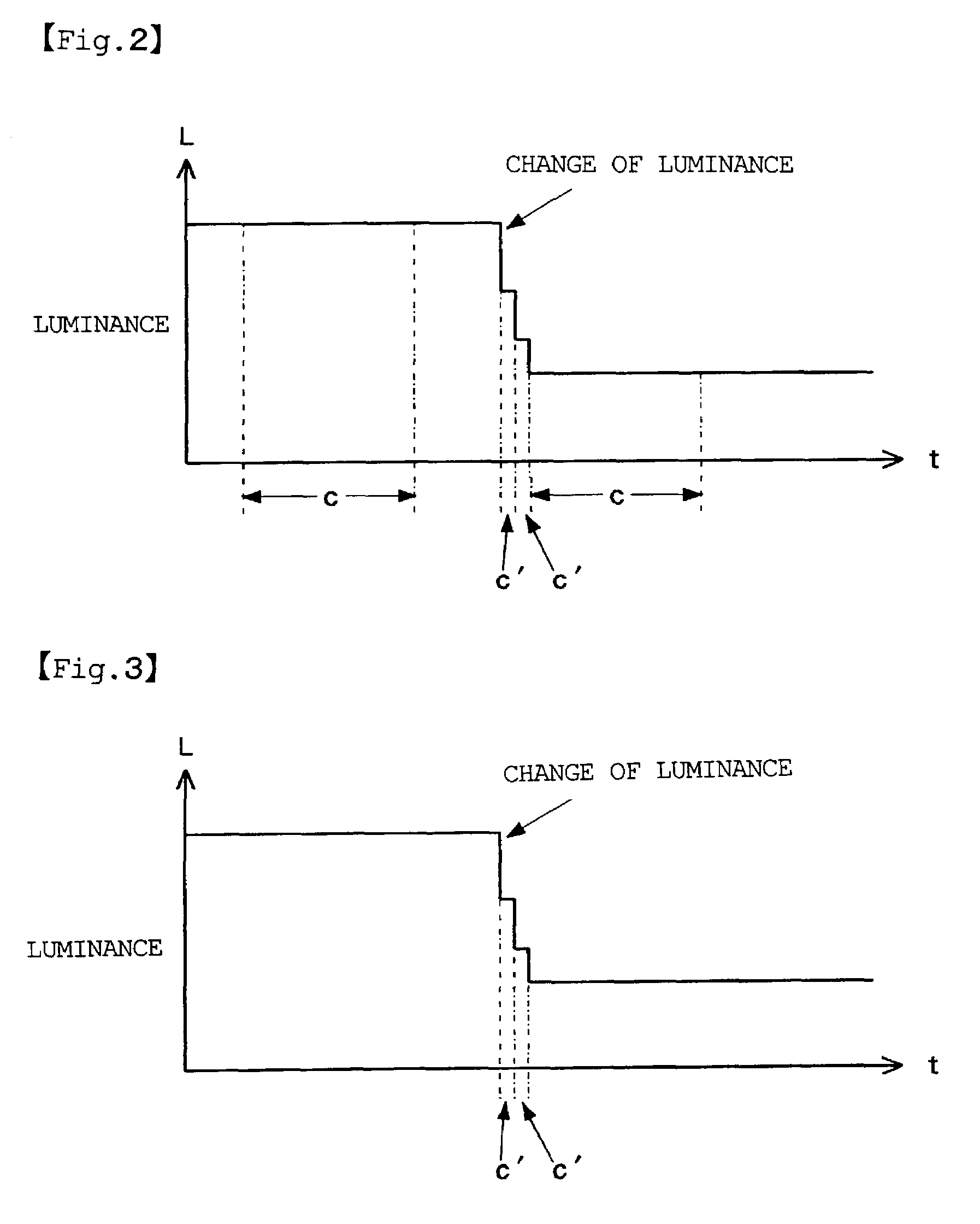

Drive method of light-emitting display panel and organic EL display device

InactiveUS7236148B2Improving gentle operation characteristicReduce drive powerElectroluminescent light sourcesSolid-state devicesDc dc converterControl signal

Light-emitting elements disposed on a light-emitting display panel are driven by constant currents, and the forward direction voltages of the light-emitting elements are obtained by a sampling / holding circuit. Then, the voltage output from a drive voltage source composed of a DC-DC converter is controlled by the forward direction voltages obtained by the sampling / holding circuit. For example, in a case in which the light emission luminance of the light-emitting display panel is changed or in other case, a sampling and holding operation is executed by the sampling / holding circuit in response to a control signal from a sampling timing control circuit at intervals shorter than ordinary intervals. With this arrangement, when light emission luminance of a light-emitting display panel is changed, the gentle changing characteristics of the light emission luminance thereof can be improved.

Owner:TOHOKU PIONEER CORP

Development processing device

InactiveUS20080176172A1Reduce drive powerSimple structureLiquid surface applicatorsLiquid processingEngineeringNozzle

A device includes a rotary base; an approach stage; a substrate holding table and a nozzle head. The substrate holding table holds the work by suction, and comes into intimate contact with the approach stage and the rotary base through first and second annular seal members to form a liquid storage space, respectively. When the suction holding and the intimate contact are released, the substrate becomes rotatable together with the rotary base and the approach stage.

Owner:TOKYO ELECTRON LTD

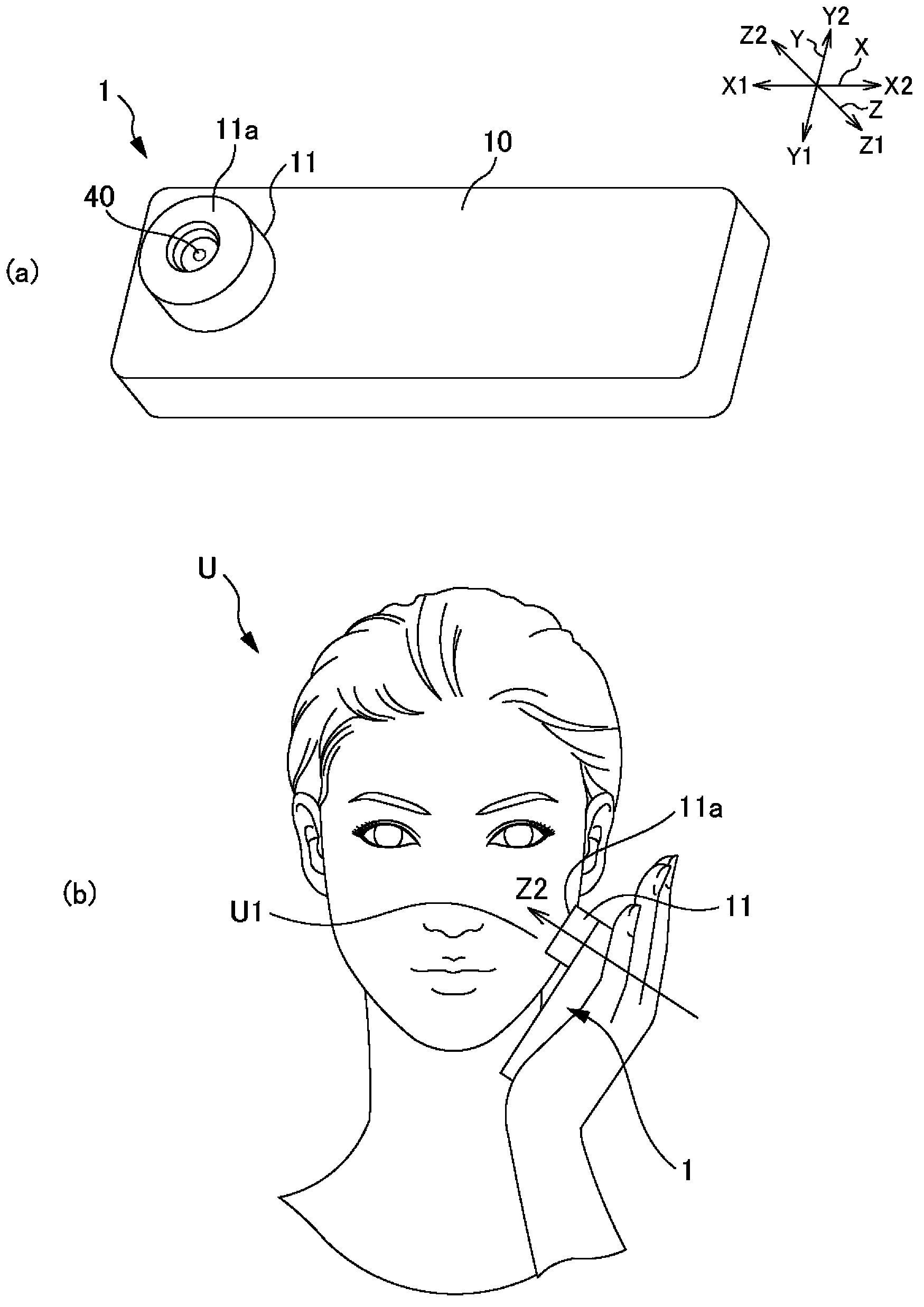

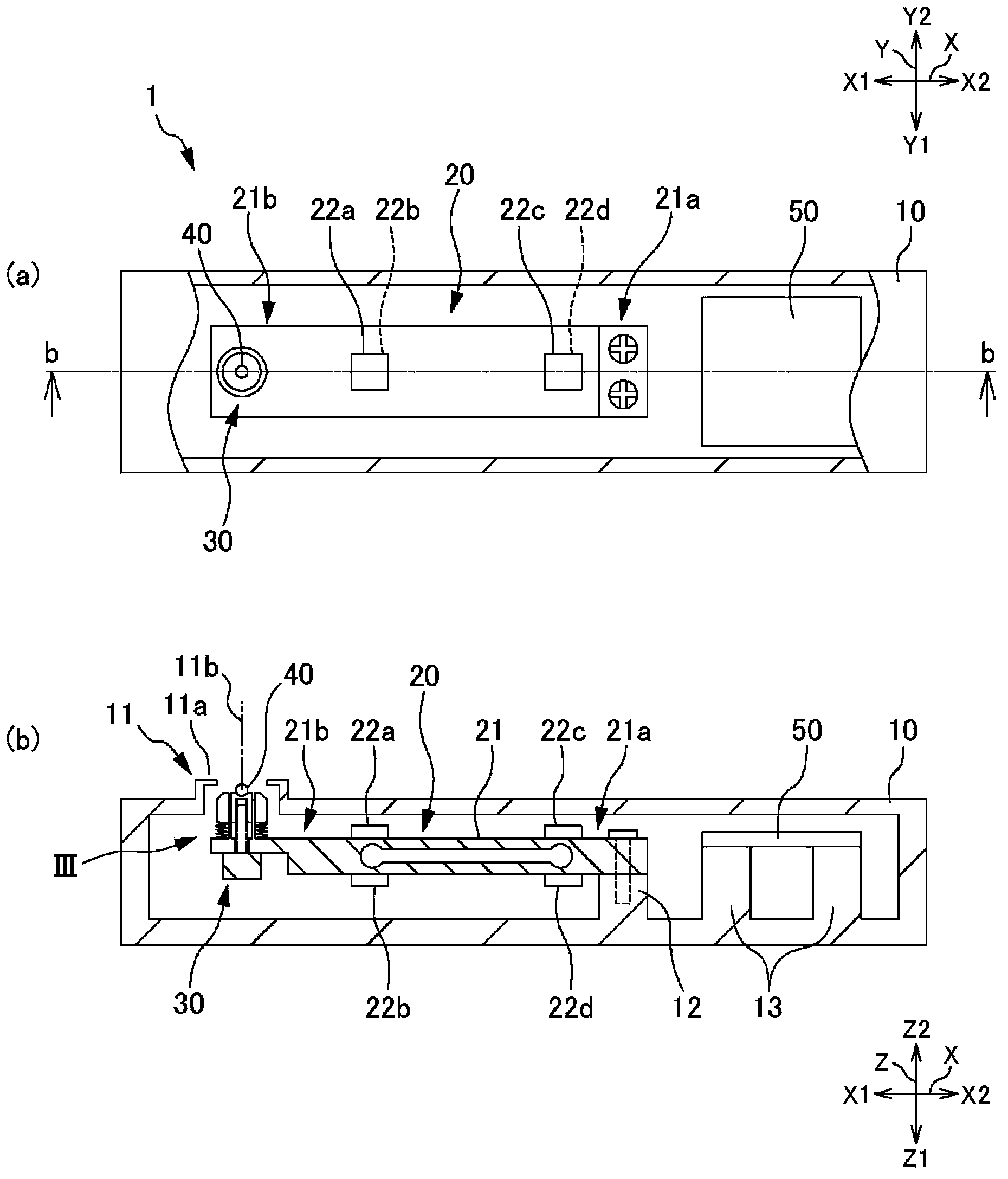

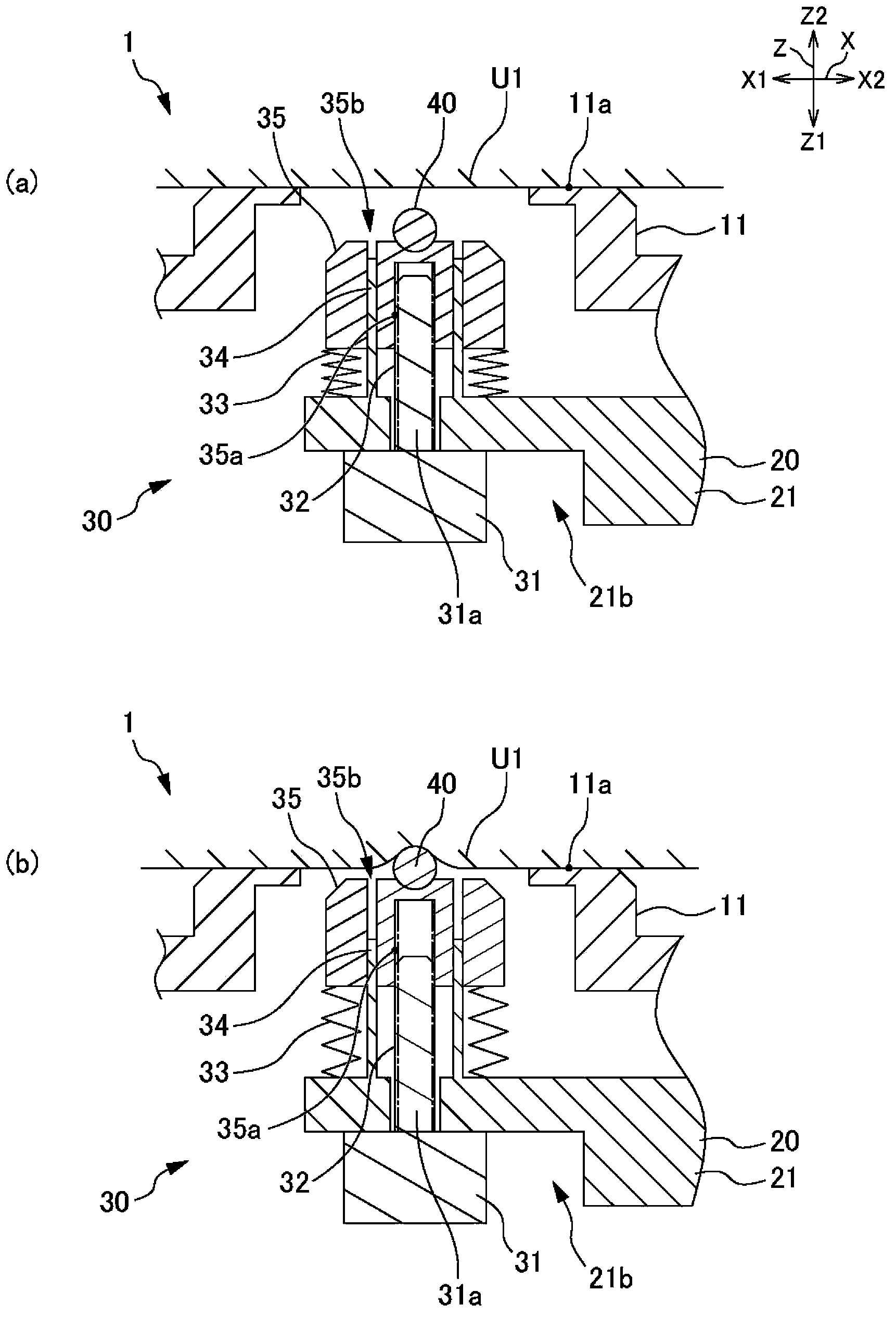

Viscoelasticity measuring apparatus

InactiveCN103565414ASmall driving forceReduce the effect of jitterDiagnostics using pressureForce measurementMeasurement deviceEngineering

A viscoelasticity measuring apparatus that measures viscoelasticity of a measurement target with high precision is provided. The measuring apparatus includes: a casing; a surface contact part provided in the casing and brought into surface contact with skin; a ball indenter that moves toward the skin more than the surface contact part and is pushed into the skin; a driving unit that supports the ball indenter and moves the ball indenter toward the skin; a load cell whose right end side is fixed to the casing and left end side supports the driving unit, the load cell detecting a pushing load that pushes the ball indenter into the skin; and a control unit that obtains displacement of the ball indenter.

Owner:TANITA CORP +1

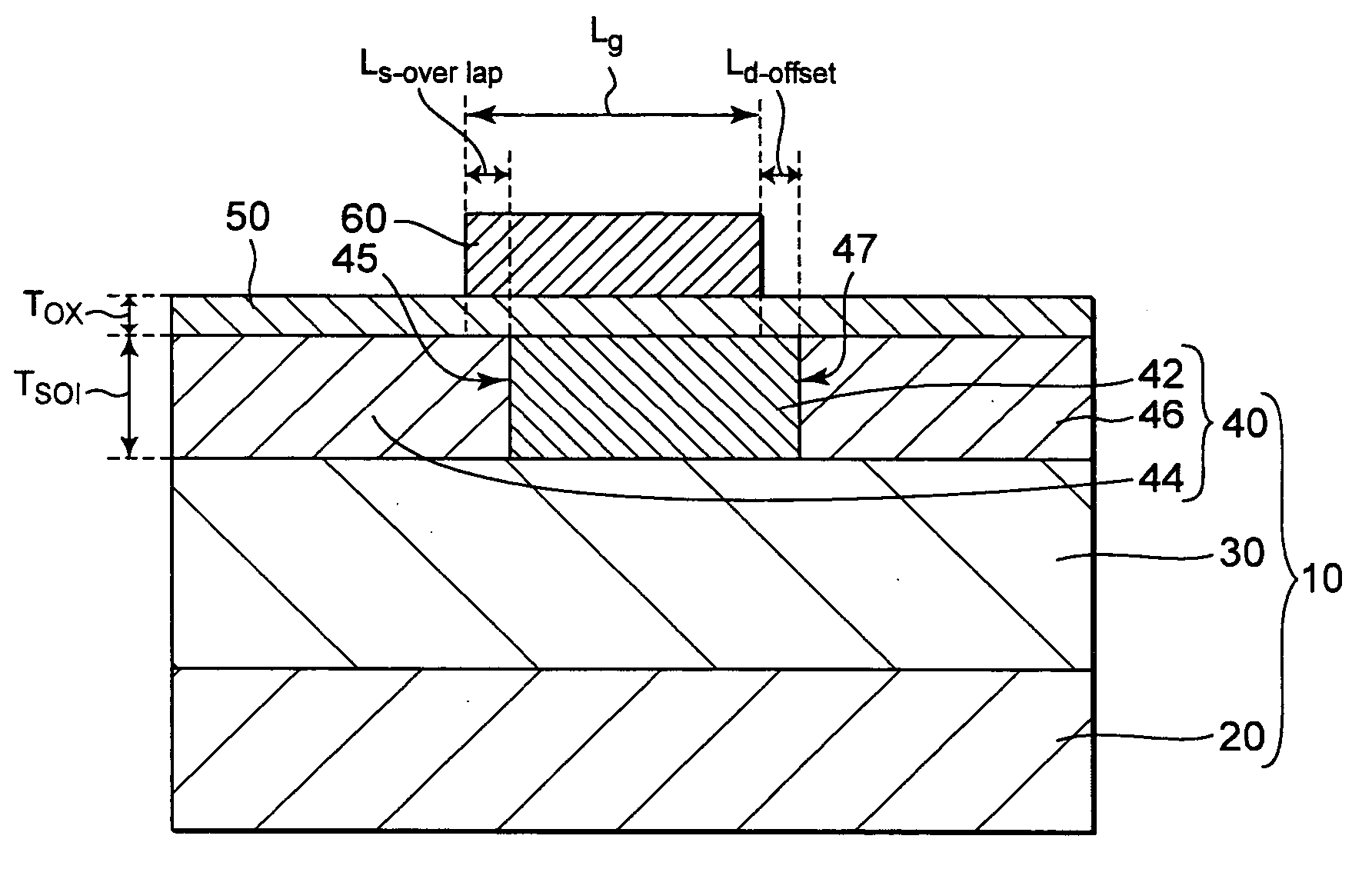

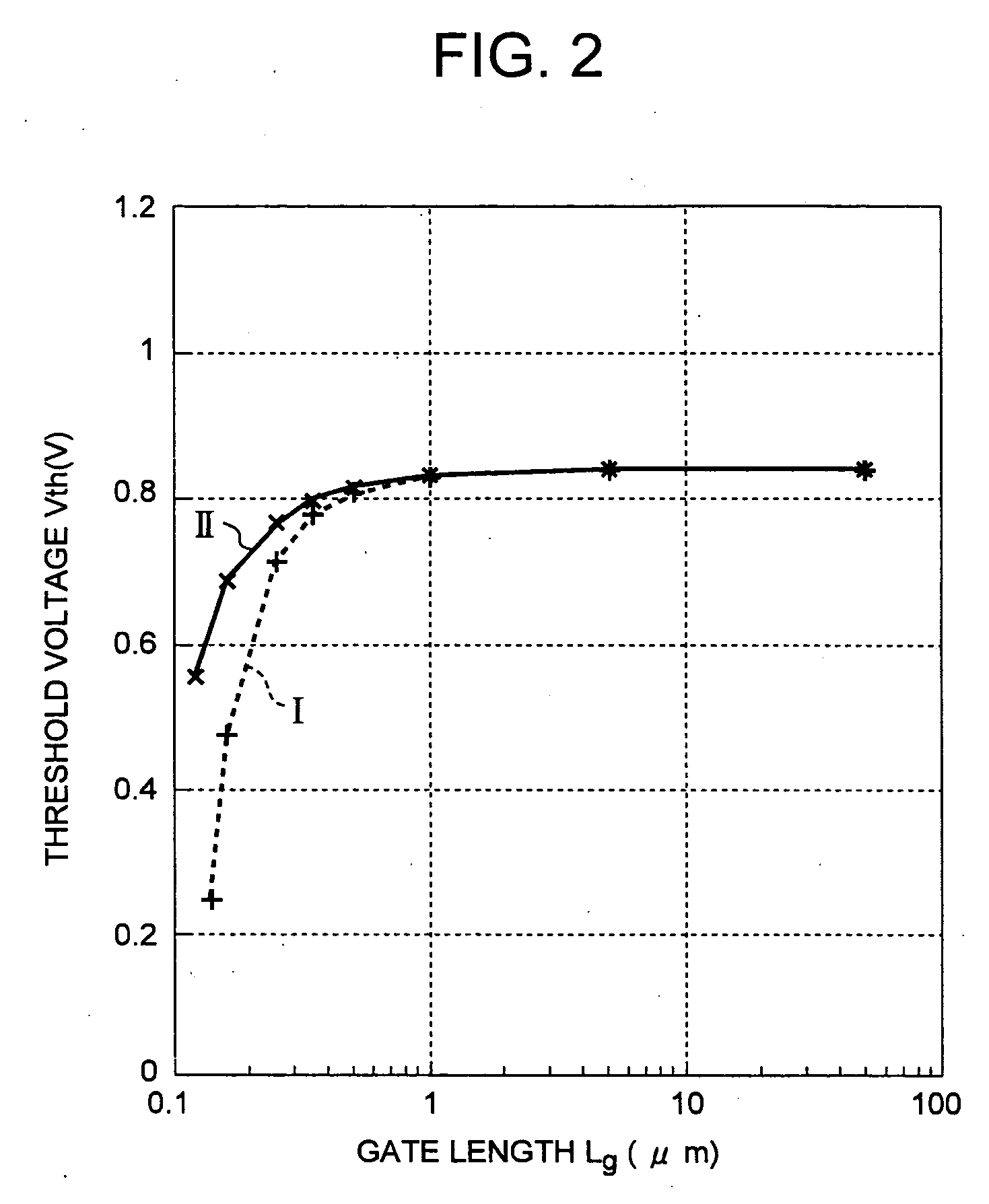

Semiconductor device

InactiveUS20070023836A1Reduce drive powerShort effectSolid-state devicesSemiconductor devicesMOSFETSemiconductor

The present invention provides an MOSFET having a semiconductor substrate, an insulating layer provided on the semiconductor substrate, and an SOI layer provided on the insulating layer. A source region and a drain region are provided in the SOI layer. A non-doped region is provided at a position interposed between the source region and the drain region in the SOI layer. A gate electrode is provided over the SOI layer through a gate insulating film interposed therebetween. The drain region is provided at a position offset from the gate electrode, the source region is provided at a position where it overlaps with the gate electrode, and the offset length of drain region ranges from over 10 nm to under 75 nm.

Owner:LAPIS SEMICON CO LTD

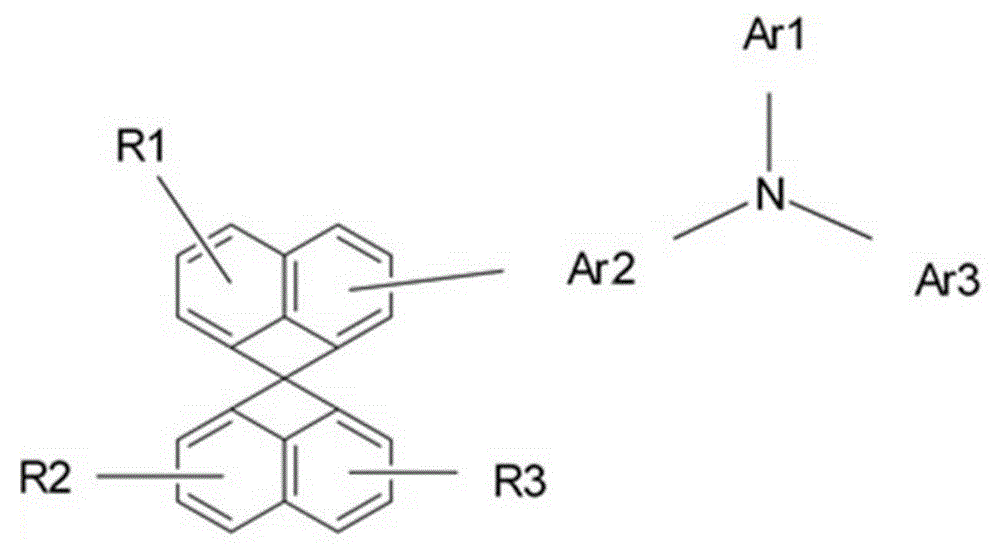

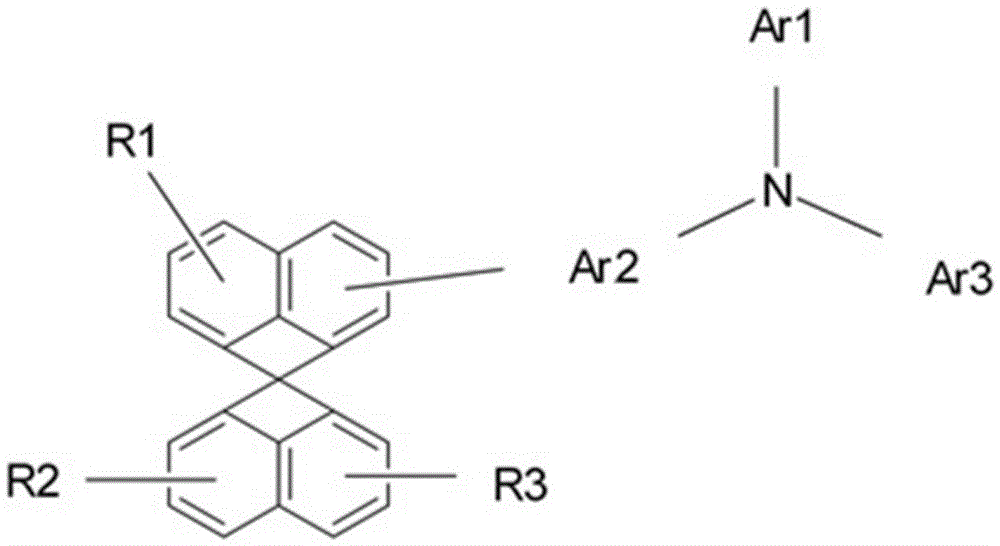

Novel organic compound and materials for organic electroluminescent devices comprising the same and organic electroluminescent devices comprising the same

ActiveCN106397301AExtend your lifeReduce the driving voltageOrganic chemistrySolid-state devicesSimple Organic CompoundsHole injection layer

The invention provides a novel organic compound and materials for organic electroluminescent devices comprising the same and organic electroluminescent devices comprising the same. The organic compound used for luminescent layer materials such as a hole injection layer material, a hole transport layer material, an electronic blocked layer material, a green phosphorescent or red main material and the like can be used for organic electroluminescent devices, thereby reducing the driving voltage, improving the luminous efficiency, the brightness, the thermostability, the colour purity, and prolonging the service life of the device.

Owner:NANJING TOPTO MATERIALS CO LTD

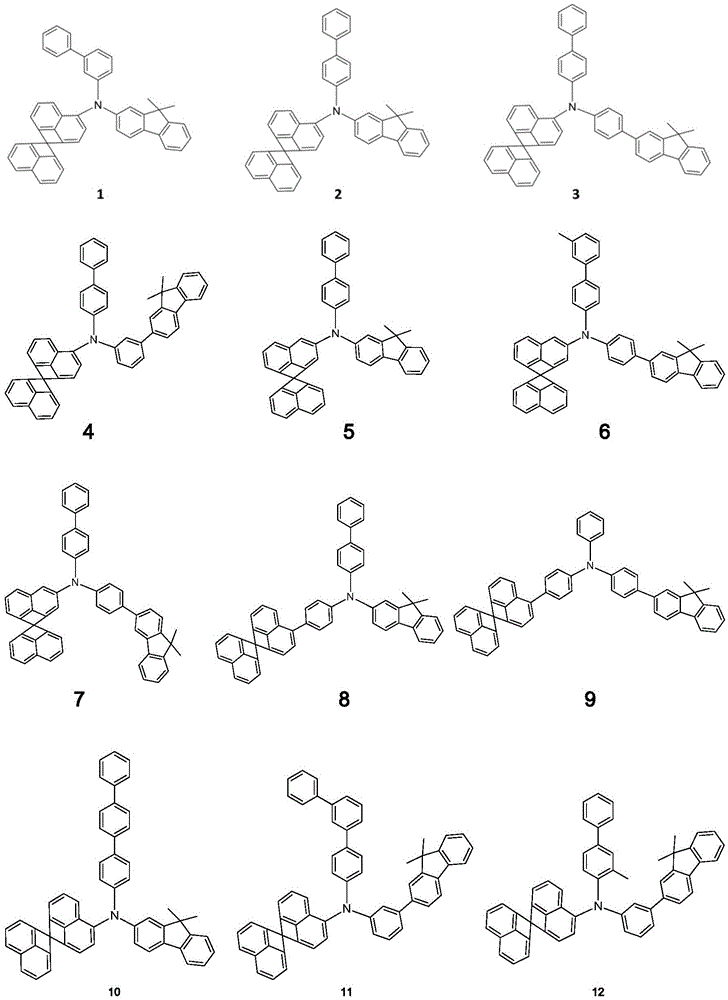

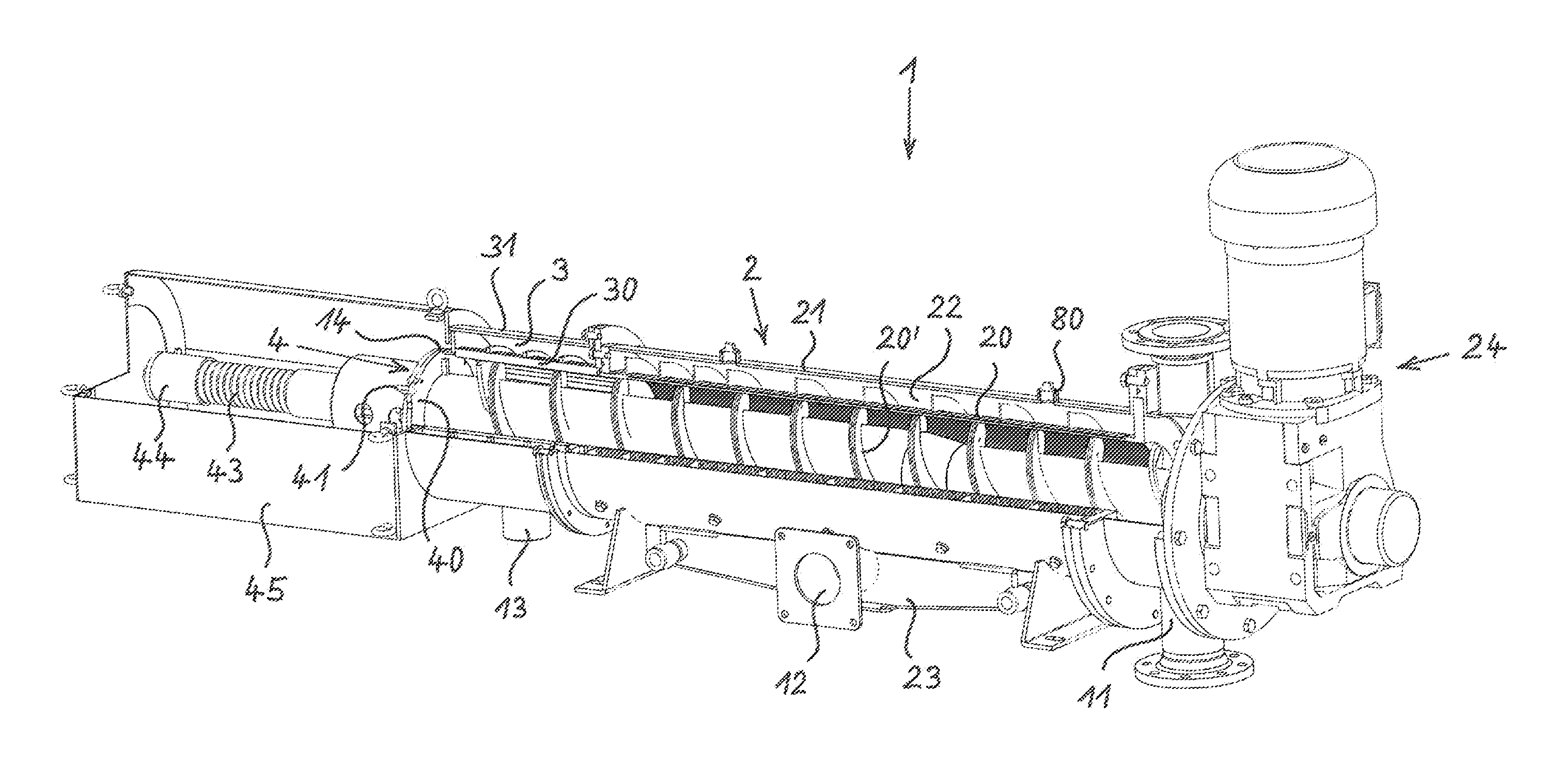

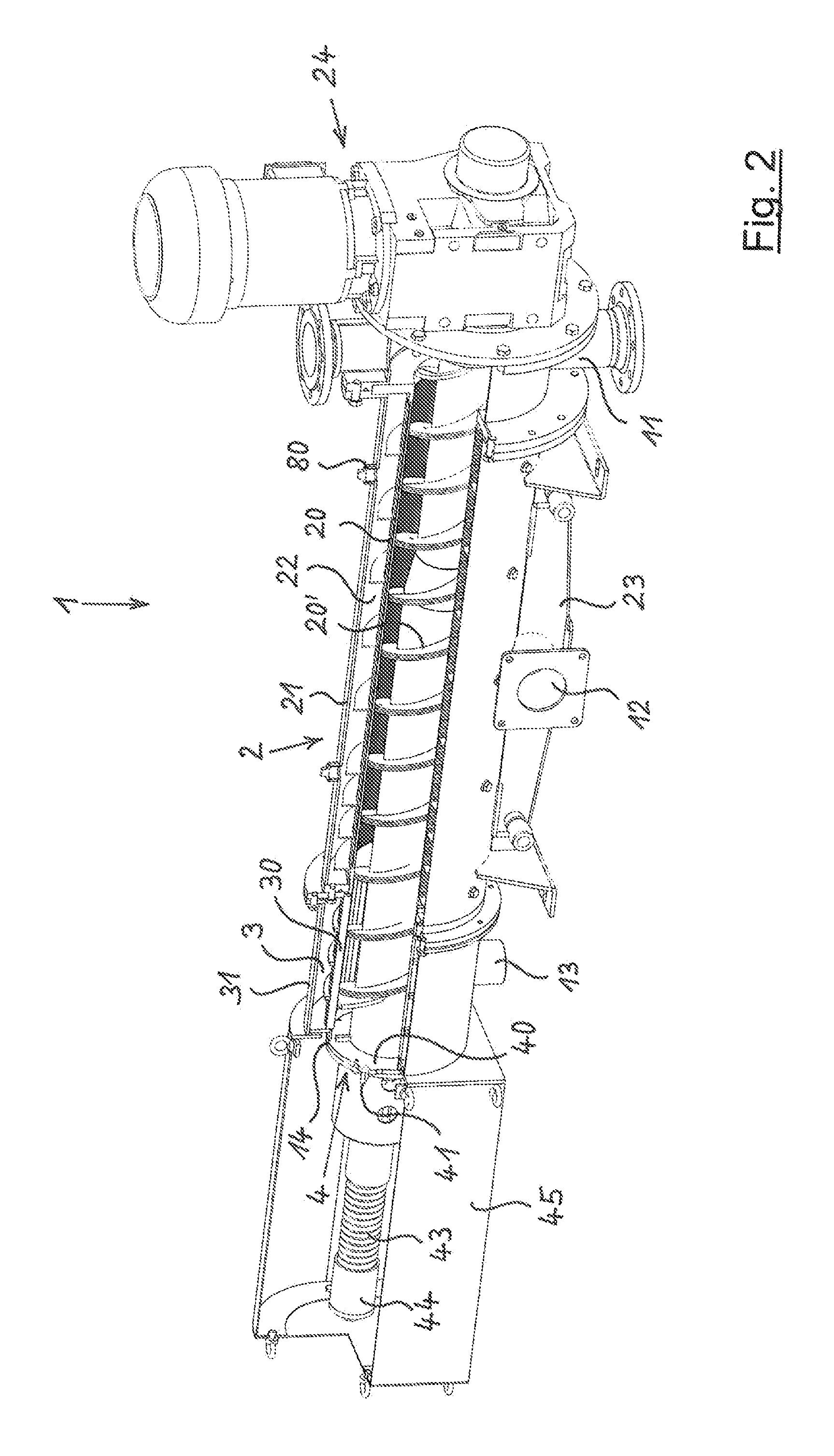

Device and method for thickening liquid substrate containing solid material

InactiveUS20150182879A1Reduce drive powerSimple designSludge treatmentLiquid suspension thickening by filtrationEngineeringScrew conveyor

A device for thickening liquid substrate containing solid material, having a liquid permeable filter pipe that retains solid material, and a rotatable screw conveyor in the filter pipe. A substrate inlet leads into and a liquid outlet and a solid material outlet go out from the filter pipe. Solid material from the introduced substrate is deposited on an inner surface of the filter pipe, and, using the screw conveyor, solid material for the forming a solid material plug is pressed into a pressure duct situated between the filter pipe and the solid material outlet, and is discharged from the pressure duct through the solid material outlet. The screw conveyor has an outer diameter that is smaller than the inner diameter of the filter pipe by an amount that permits the formation of a carpet-type solid material coating, forming a fine filter, on the inner circumference of the filter pipe.

Owner:BOERGER

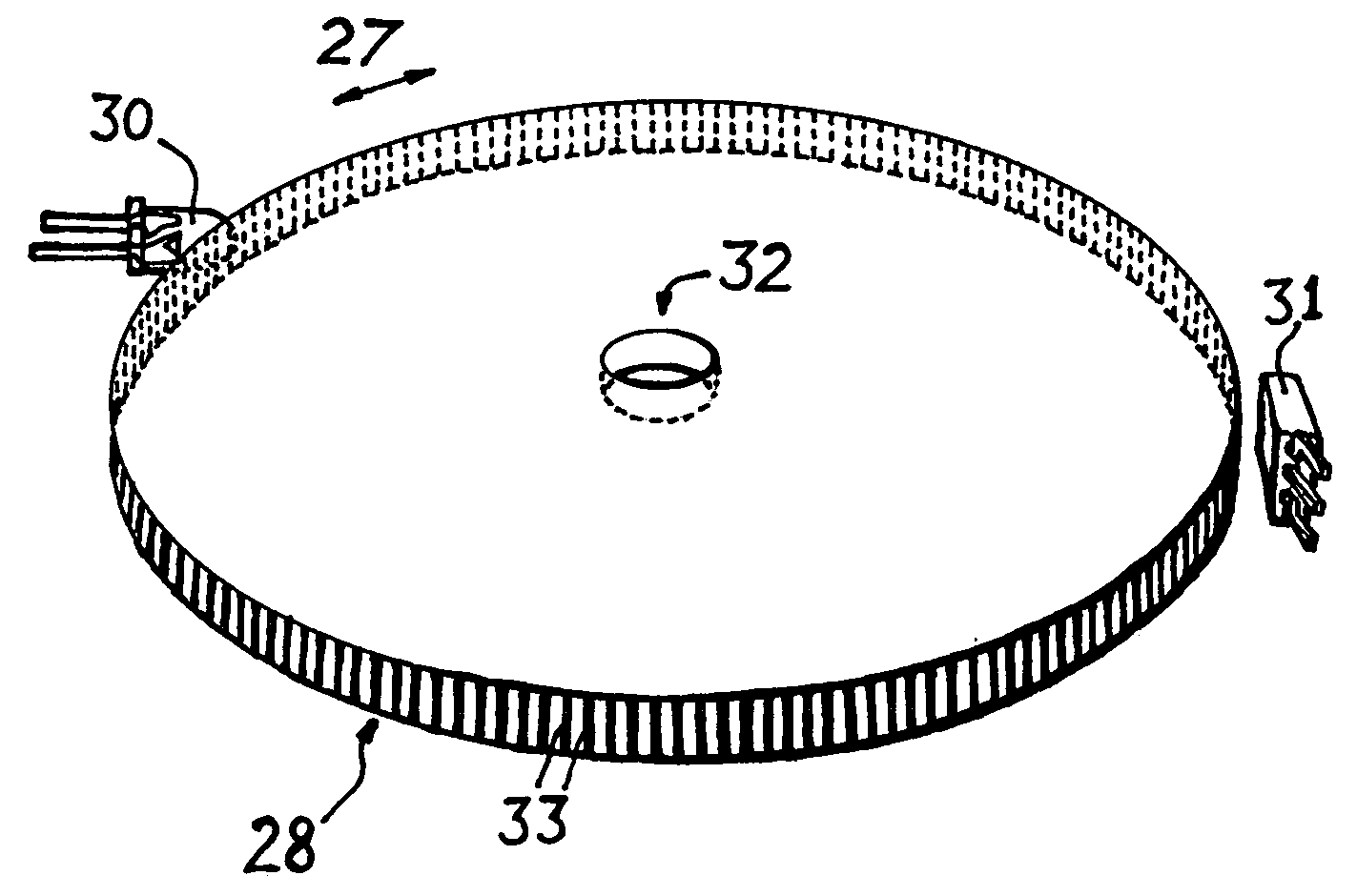

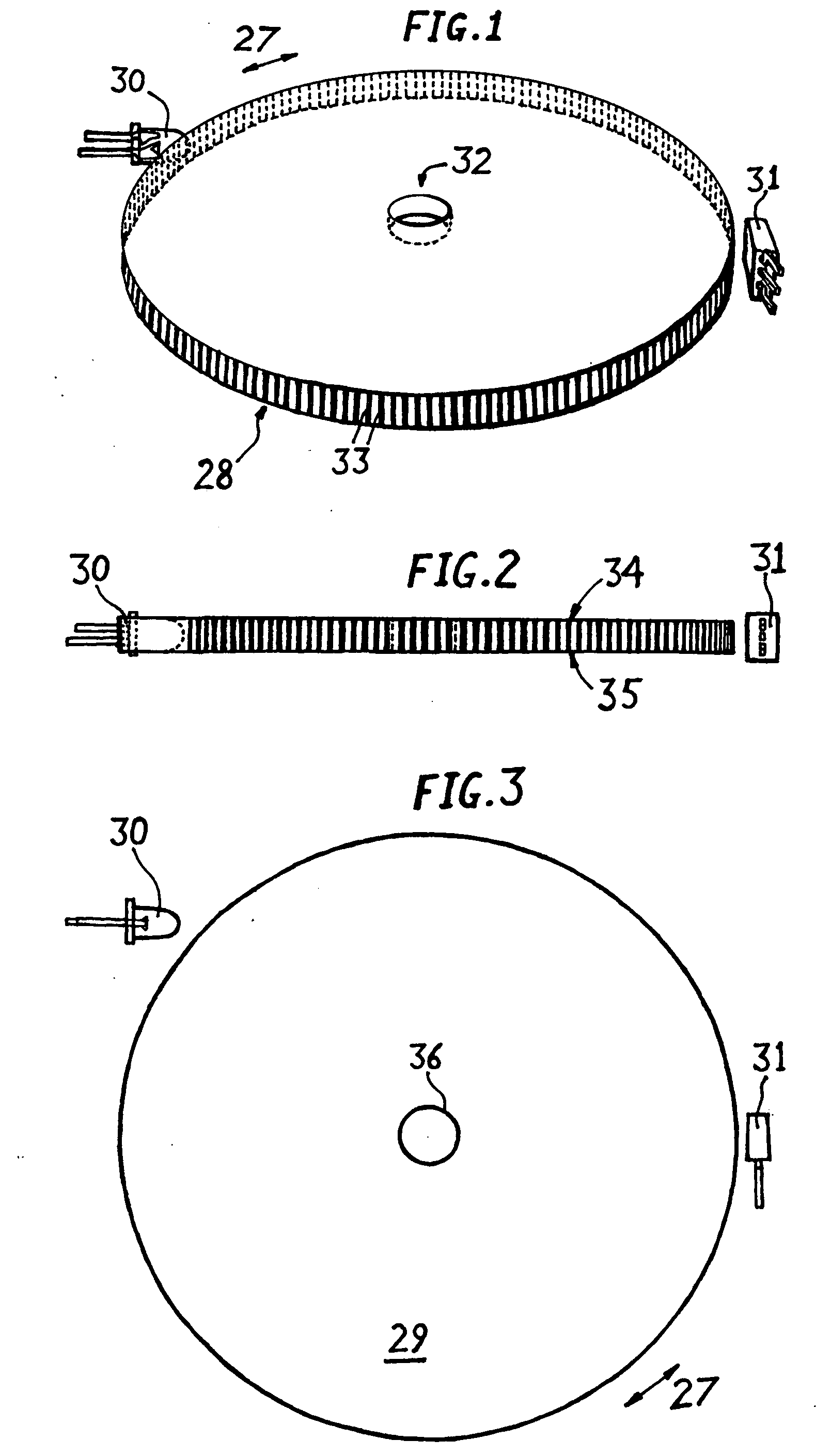

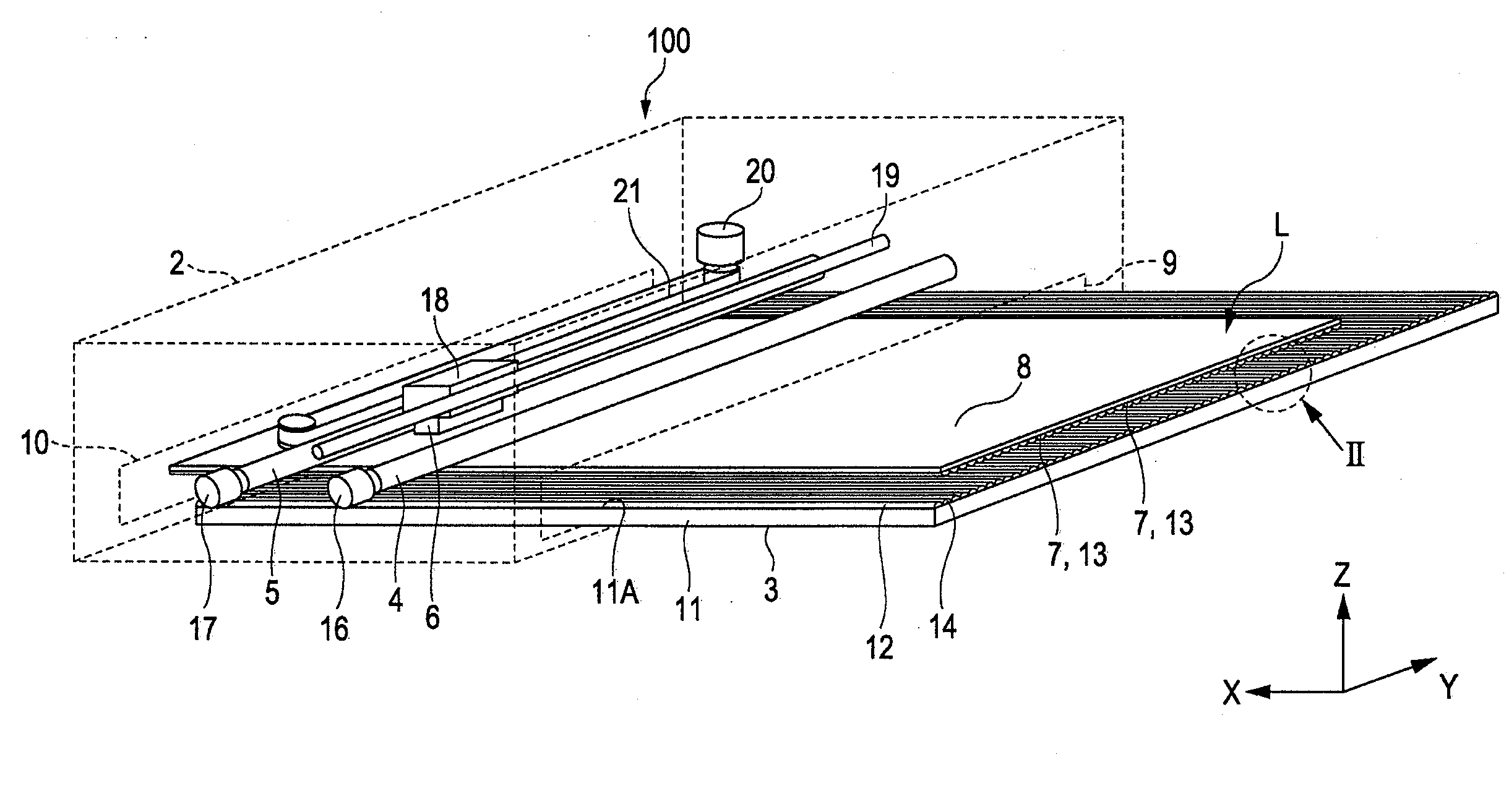

Opto-electronic encoder with three-dimensional scales

InactiveUS20060011821A1Easy to disassembleIncreasing of complexityMaterial analysis by optical meansCathode-ray tube indicatorsCombined useOpto electronic

A single-, two- or three-axis opto-electronic encoder, or error-inputting device, with an optical scale which is overall cylindrical, spherical or volumetric, as opposed to extant planar, circular optical scales; mostly parallel rays of light enter from the cylindrical or spherical surface of the scale, travel, with or without being modulated in intensity due to rotation / rotations of, or distortion / distortions in, the scale, along elliptical and / or circular sectional planes of the scale and exit to fall upon an obstructing opto-electronic sensor or a plurality of such sensors. A photo-transmissive spherical float on a photo-opaque liquid sealed inside a spherical optical scale, moving vertically under the influence of an external force, upwardly displacing the photo-opaque liquid to block the light that enters the spherical optical scale from reaching any of the opto-electronic sensors, produces a distinct electronic condition for auxiliary use in addition to or conjunction with encoder or error-inputting device output or outputs.

Owner:PAL ANADISH KUMAR

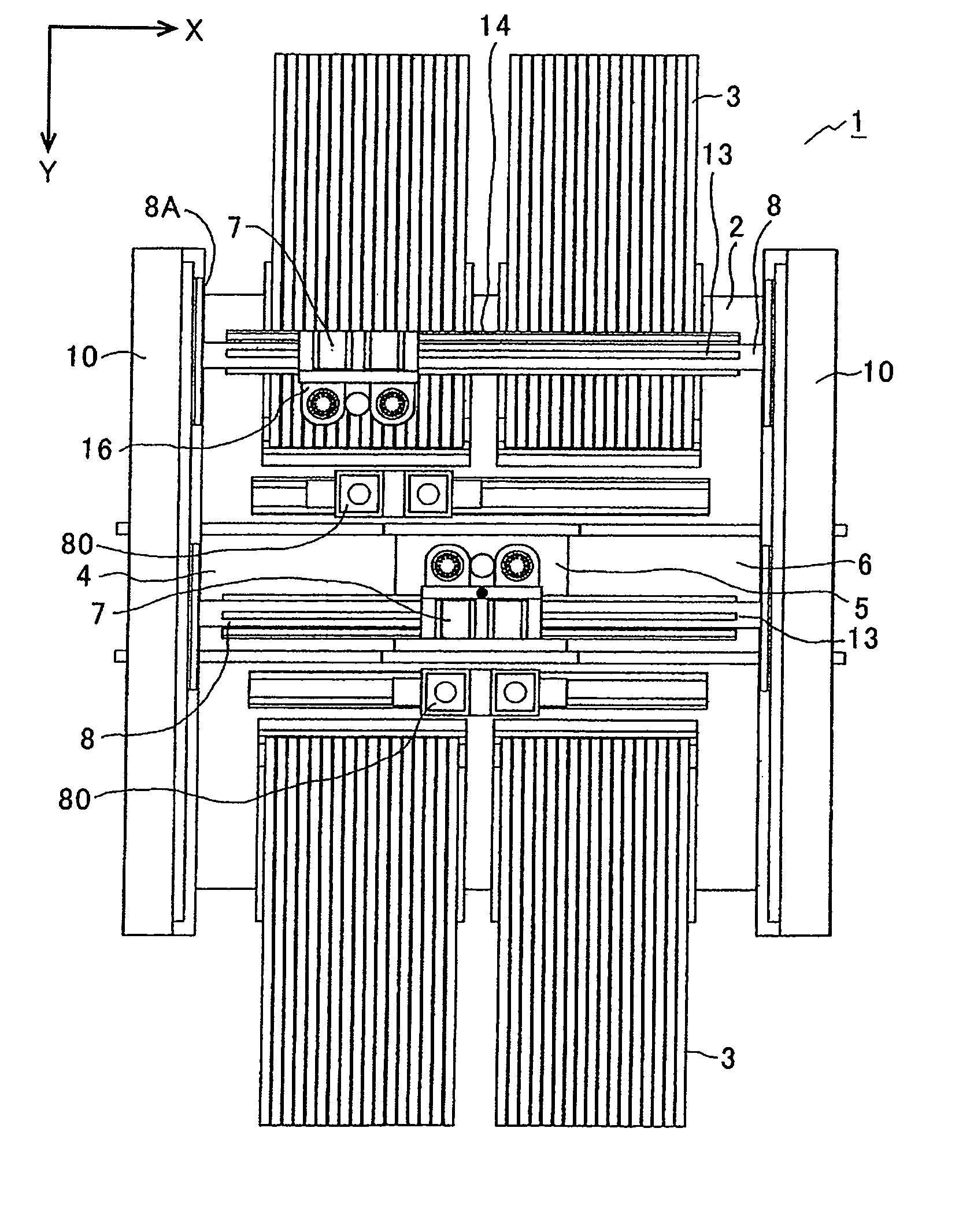

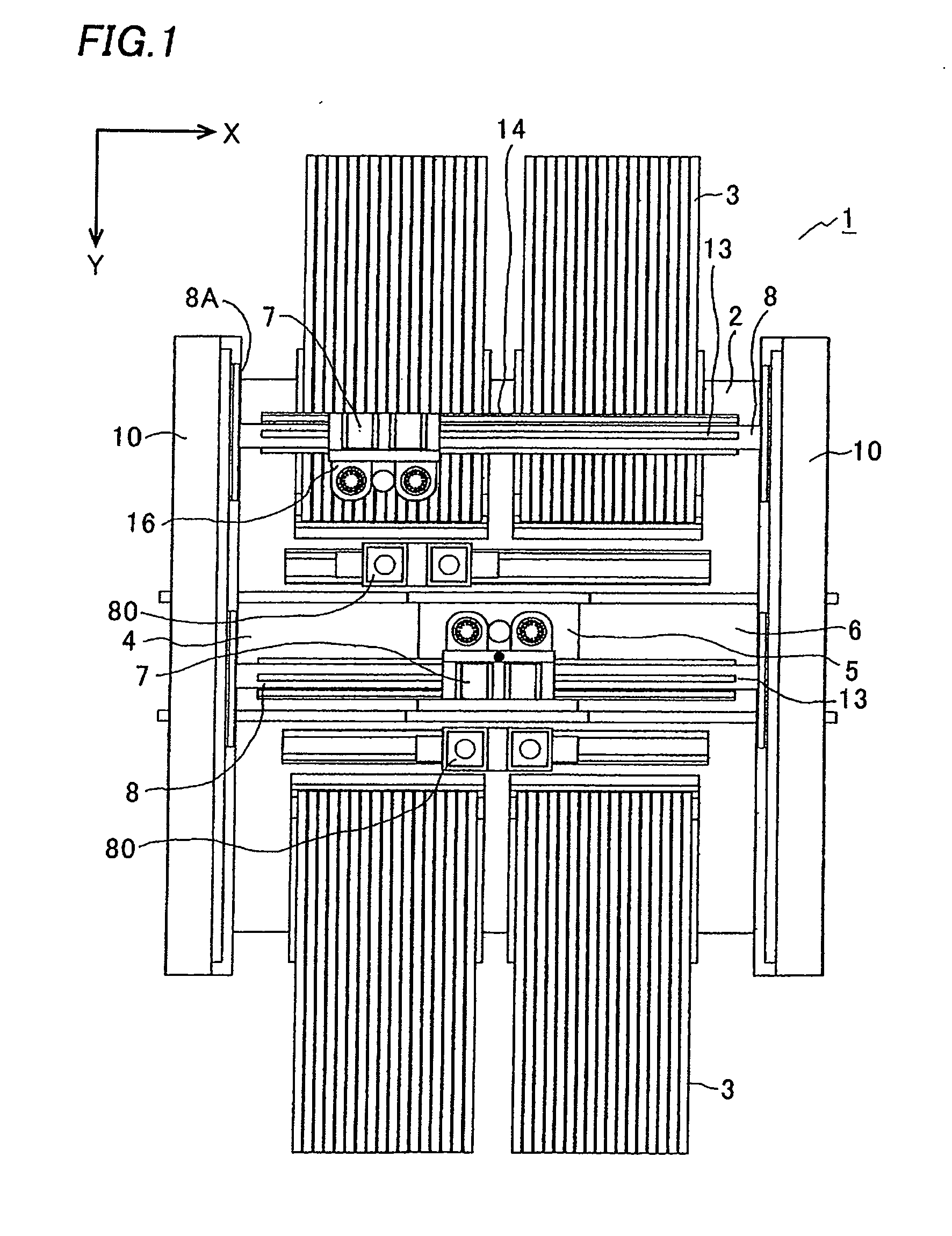

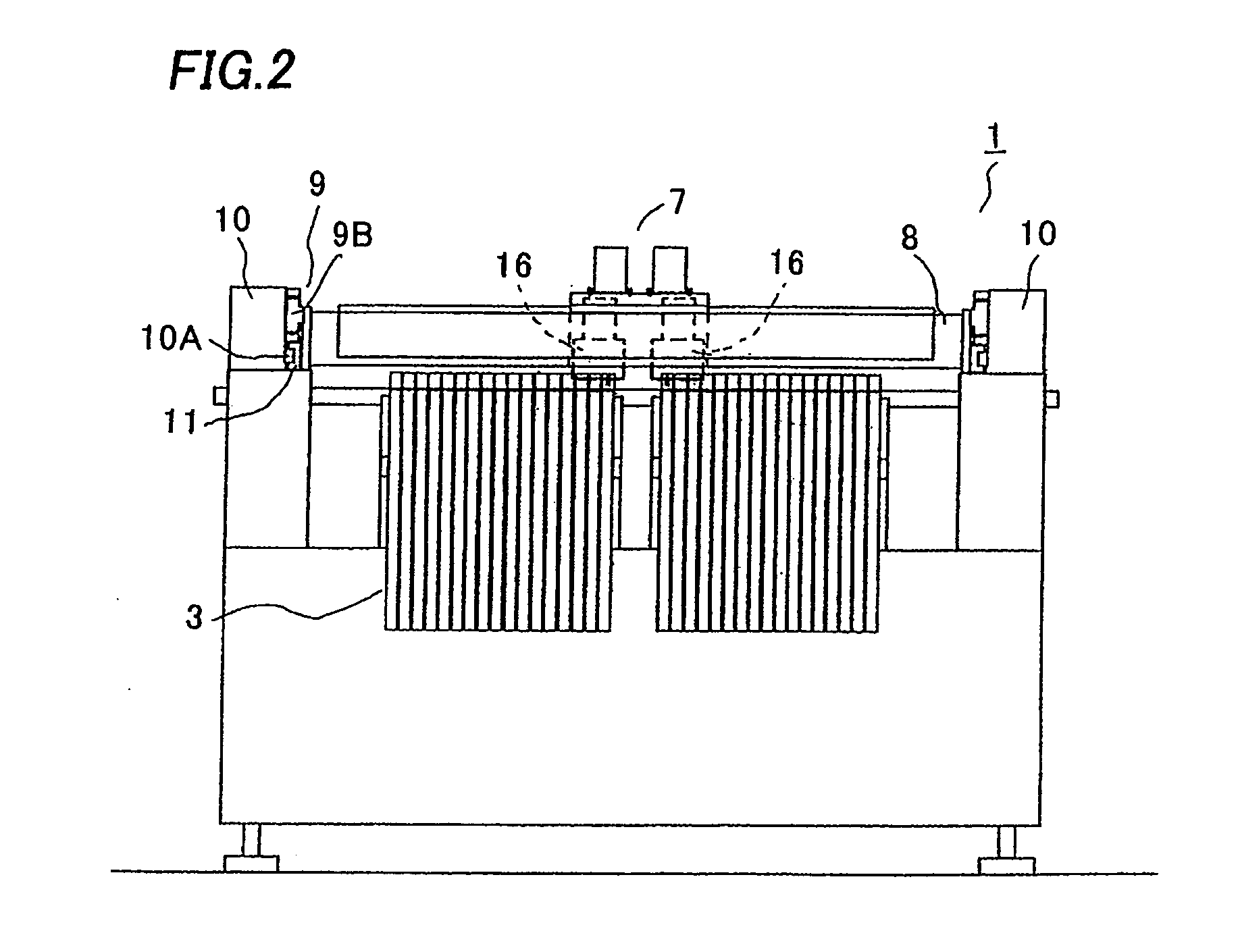

Electronic component mounting apparatus

ActiveUS20050132565A1Easy to driveReduce drive powerAutomatic control devicesAssembly machinesDriver/operatorElectronic component

The invention is directed to quick adjustment of a positional relationship between two axes when an error occurs in the positional relationship between the axes when a beam is moved by two drive sources. According to movement of the beam for component picking and mounting operations, linear scale signals (outputs relating to positions of one drive axis and another drive axes) from linear scale reading heads are inputted to a Y2 driver and a Y1 driver respectively. Since each of the Y2 driver and the Y1 driver has a calculation means and a control means, when inputted with both the linear scale signals, each of the Y2 driver and the Y1 driver calculates a difference between positions of the drive axes of the beam by the calculation means, and controls a moving member of a linear motor by the control means based on the difference so as to increase thrust of one drive axis in a case where the one drive axis is in a more backward position than another drive axis and reduces the thrust of one drive axis in a case where the one drive axis in a more forward position than another drive axis.

Owner:YAMAHA MOTOR CO LTD

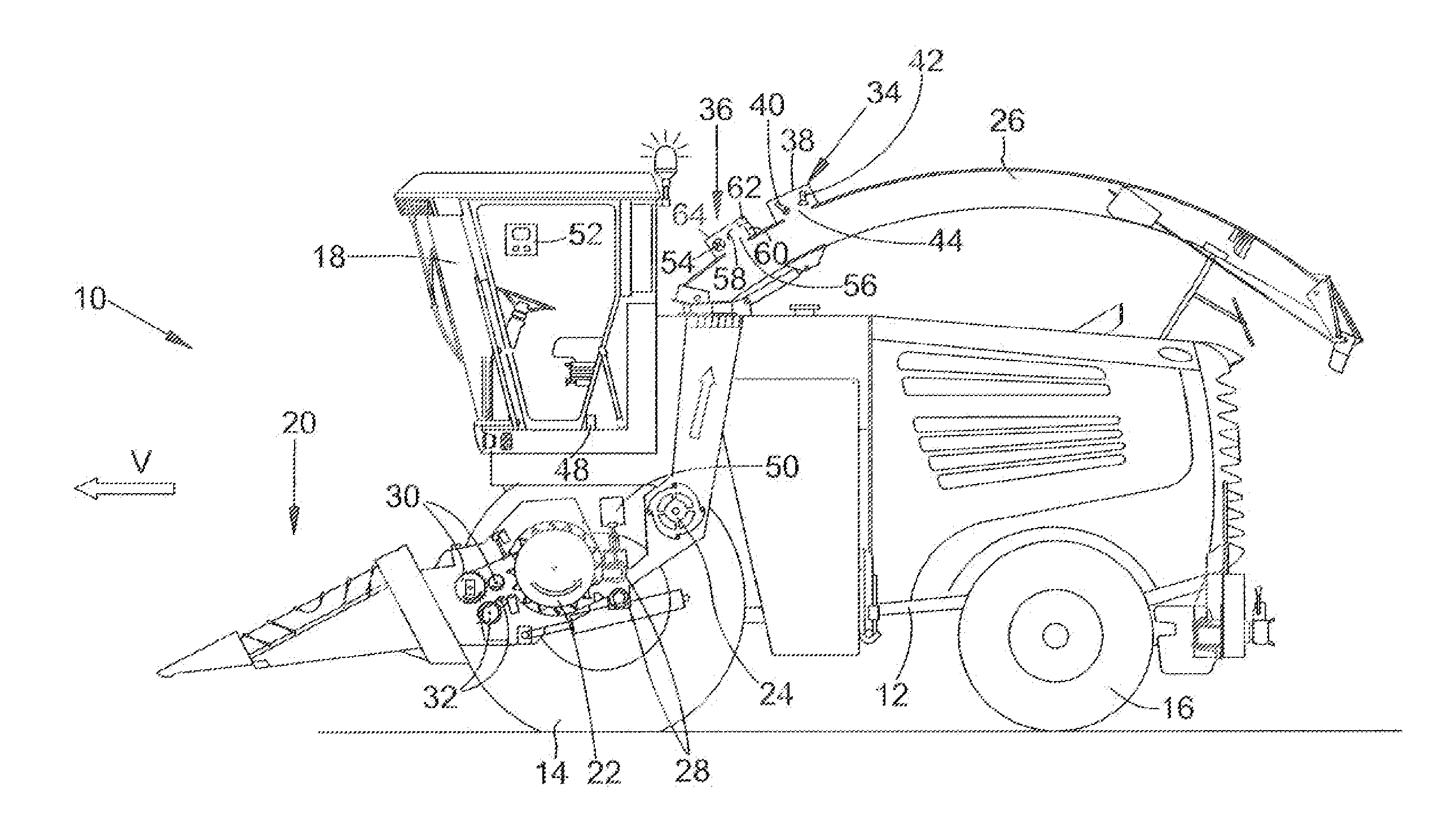

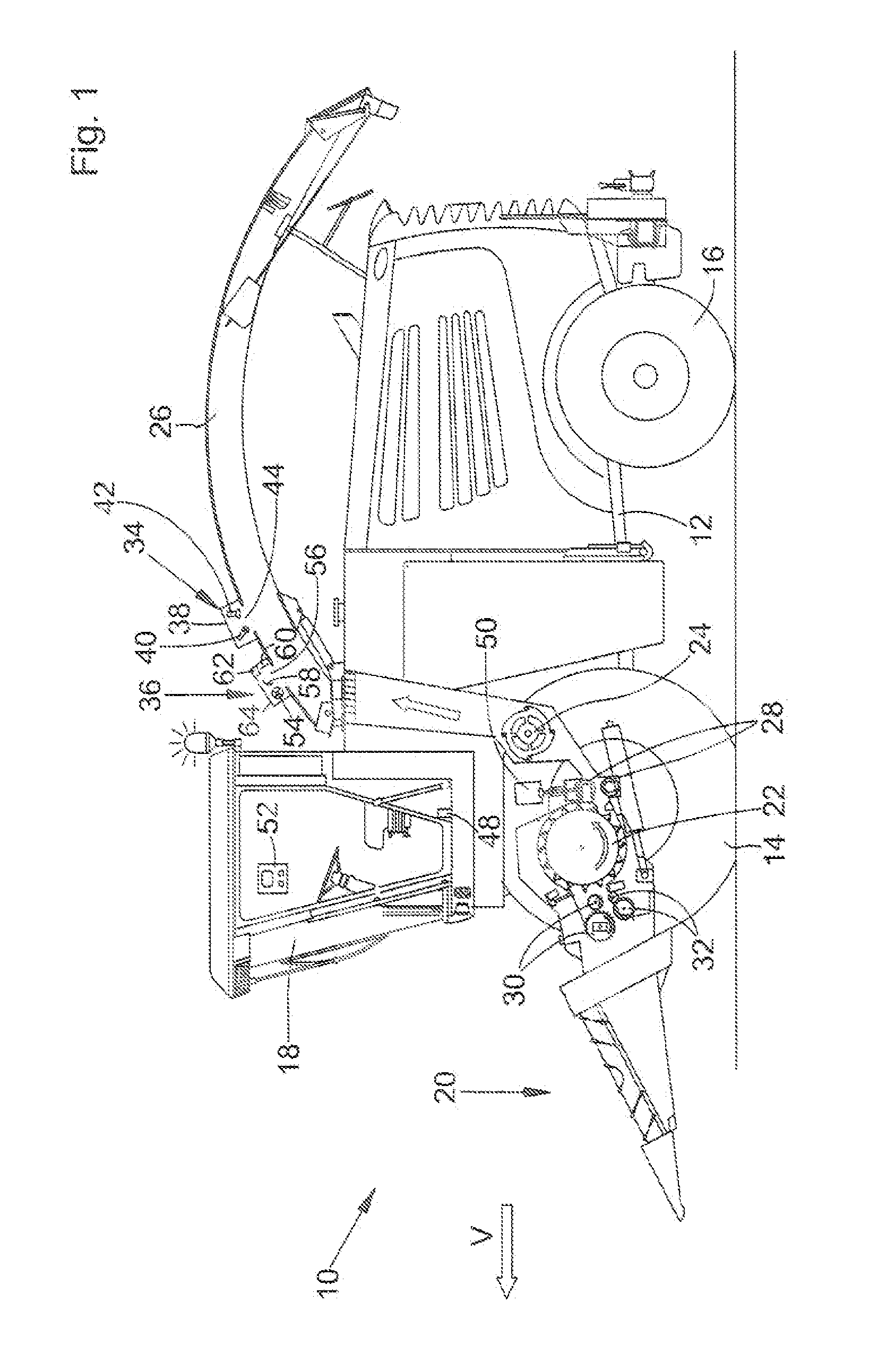

Forage Harvester With A Chopping Mechanism And A Reworking Device Located Downstream From The Chopping Mechanism

InactiveUS20120185140A1Reliable strikingIncrease the lengthAnalogue computers for trafficMowersEngineeringForage harvester

A forage harvester is provided with a chopping arrangement and a reworking device downstream from the chopping arrangement. The reworking device having two rolls between which the harvested crop chopped by the chopping mechanism can be passed through and whose spacing and / or compressive force is adjustable by a unit that is actuated by an external force and is connected with a control device. The control device is acted upon by information with regard to the cut length of the chopping arrangement and directs the unit as a function of the cut length.

Owner:DEERE & CO

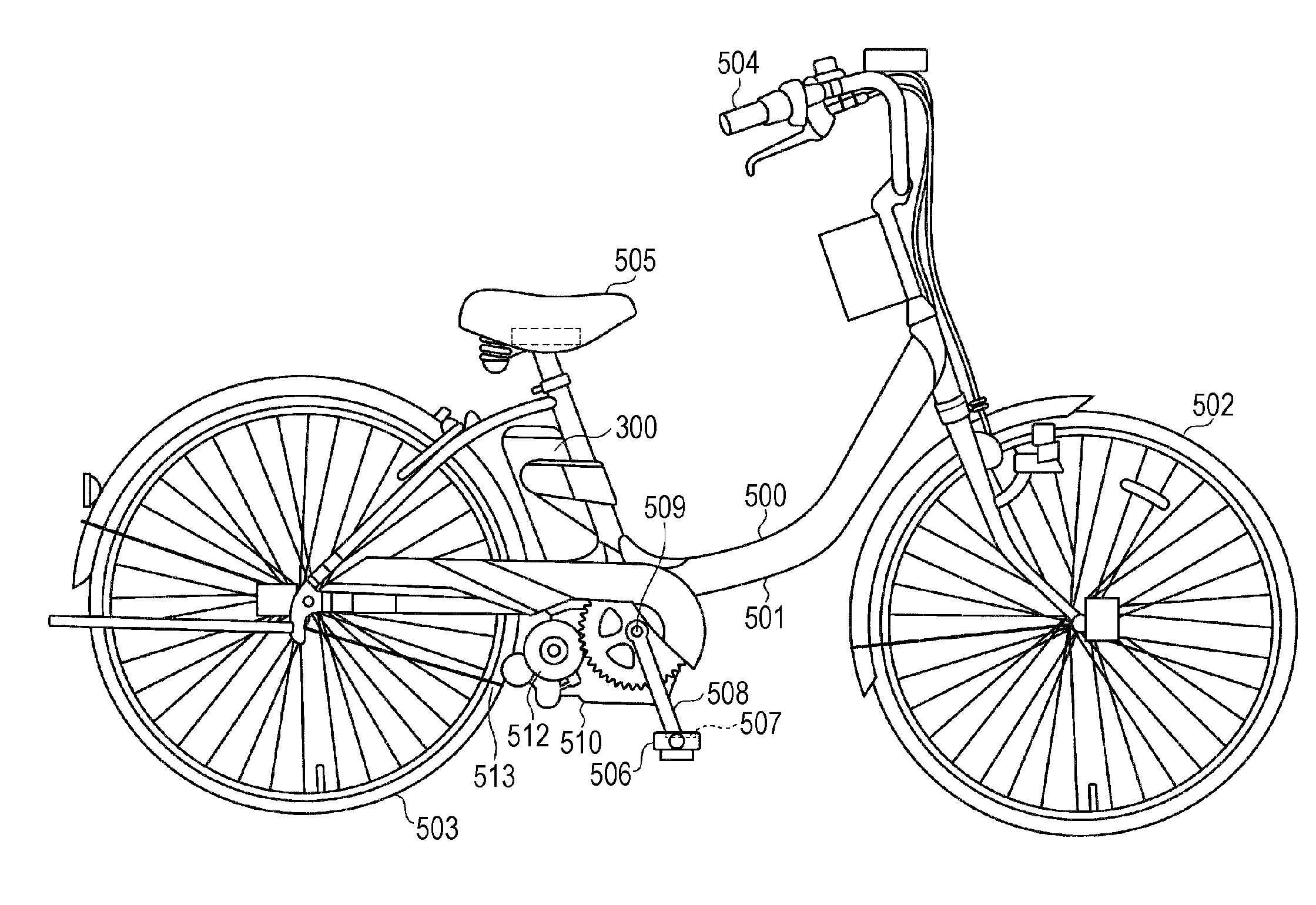

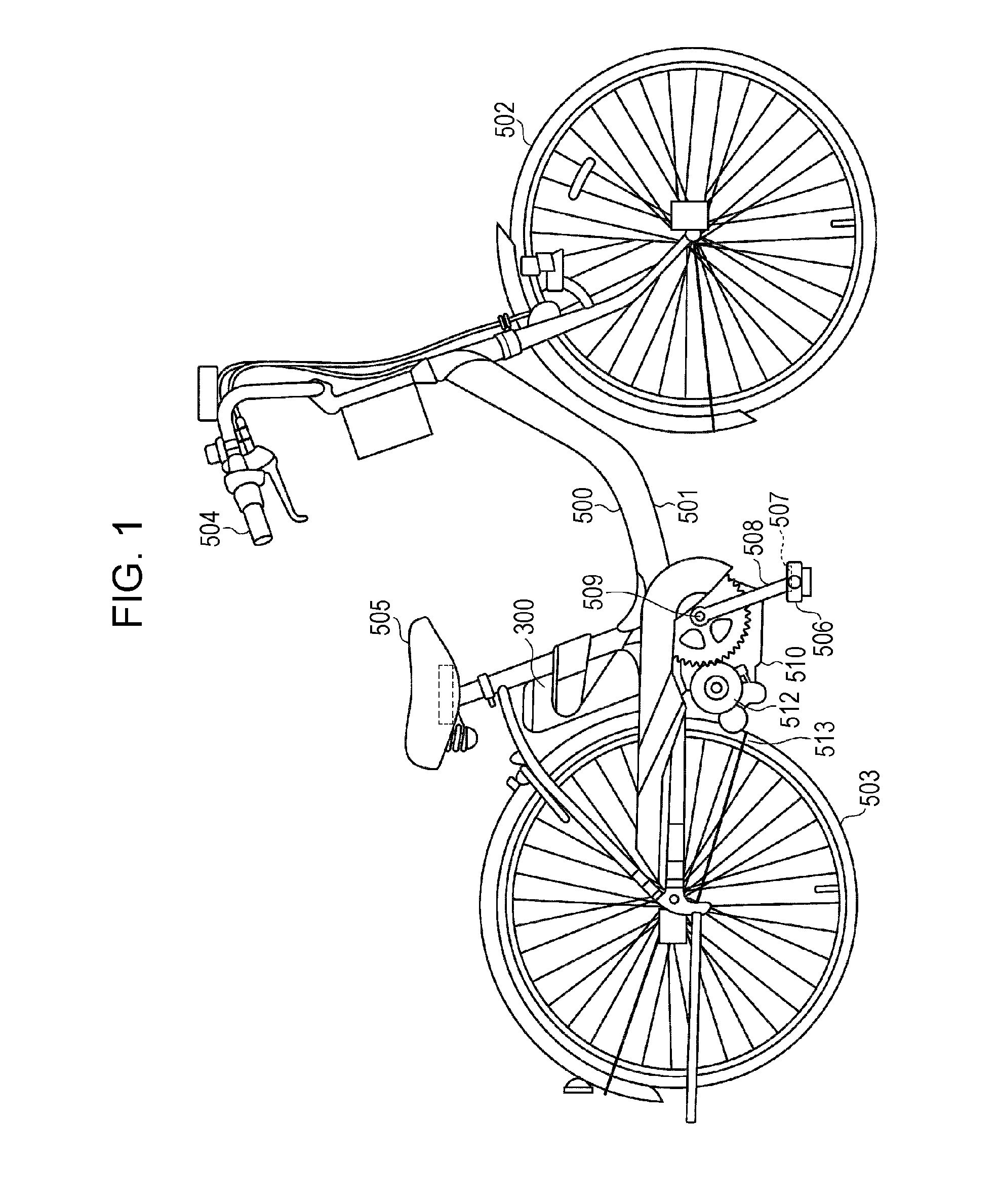

Power storage device and control method thereof

ActiveUS20160200394A1Reduce drive powerReduce total powerBatteries circuit arrangementsVehicular energy storageMotor driveElectric power

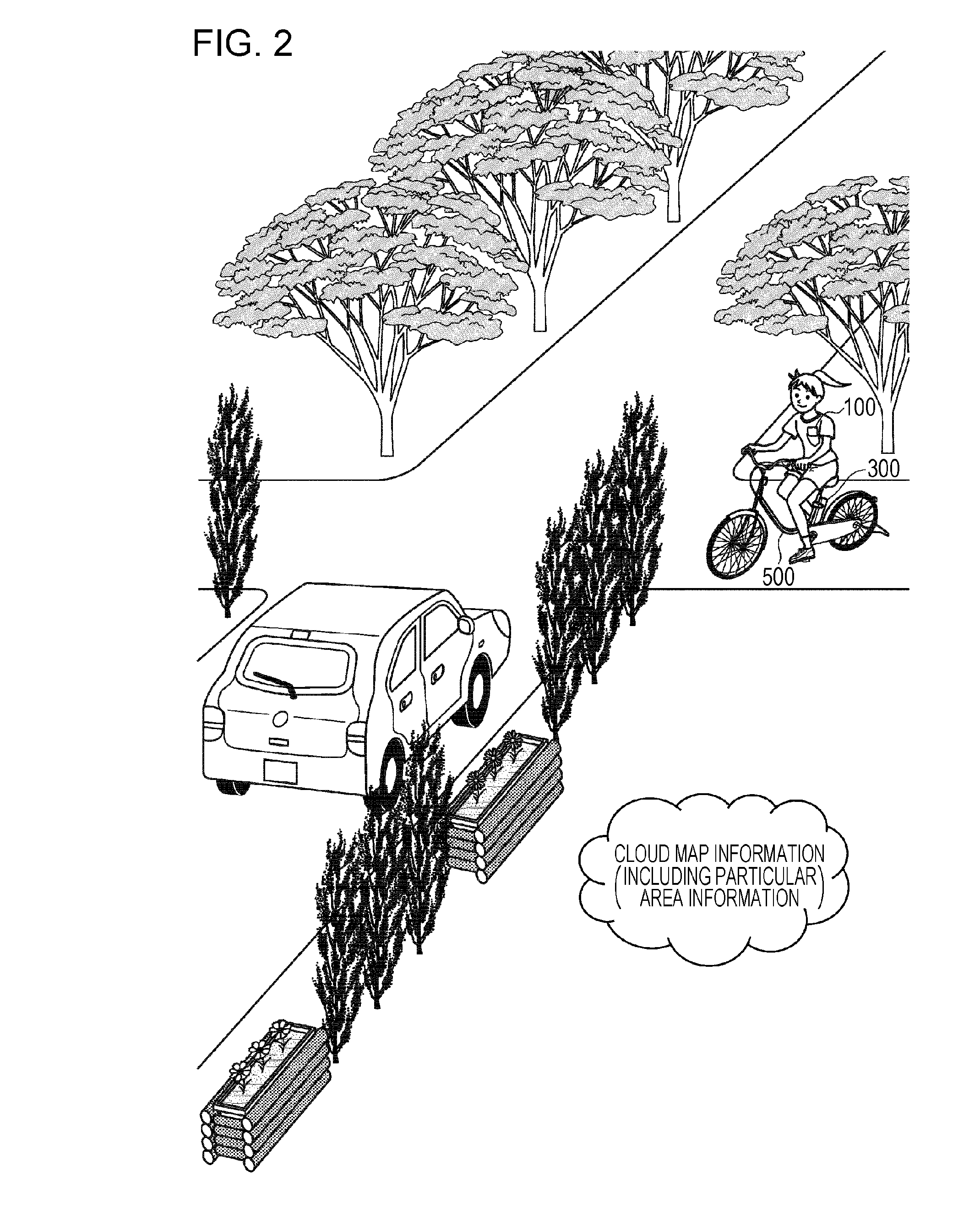

A power storage device includes a storage battery, a mounting unit that detachably mounts the power storage device on a motor-driven moving object, an output controller that controls output of driving power from the storage battery to the motor-driven moving object, and a controller that, when the motor-driven moving object is within a particular area, causes the output controller to reduce the driving power supplied from the power storage device to the motor-driven moving object compared to the driving power when the motor-driven moving object is outside the particular area.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

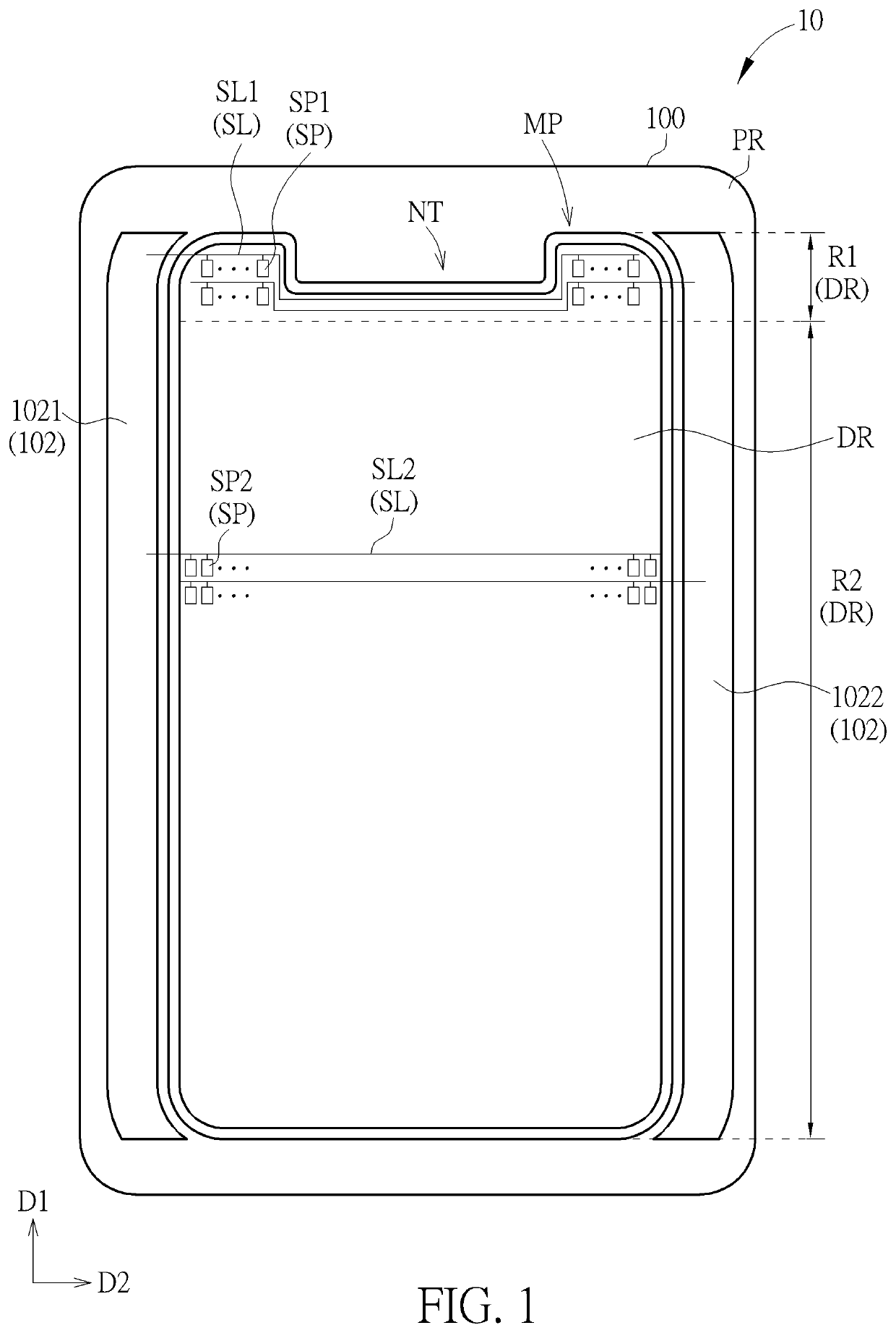

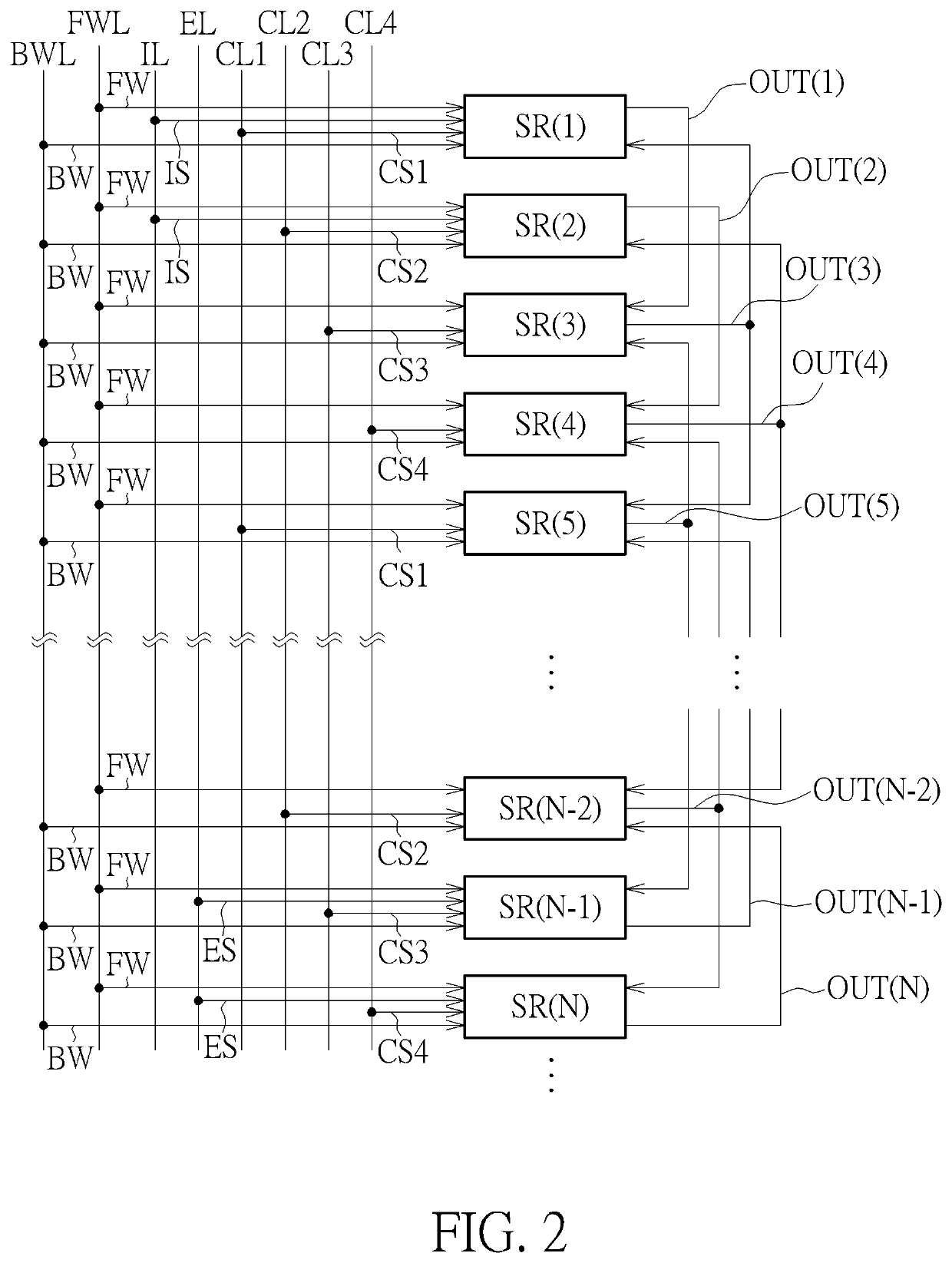

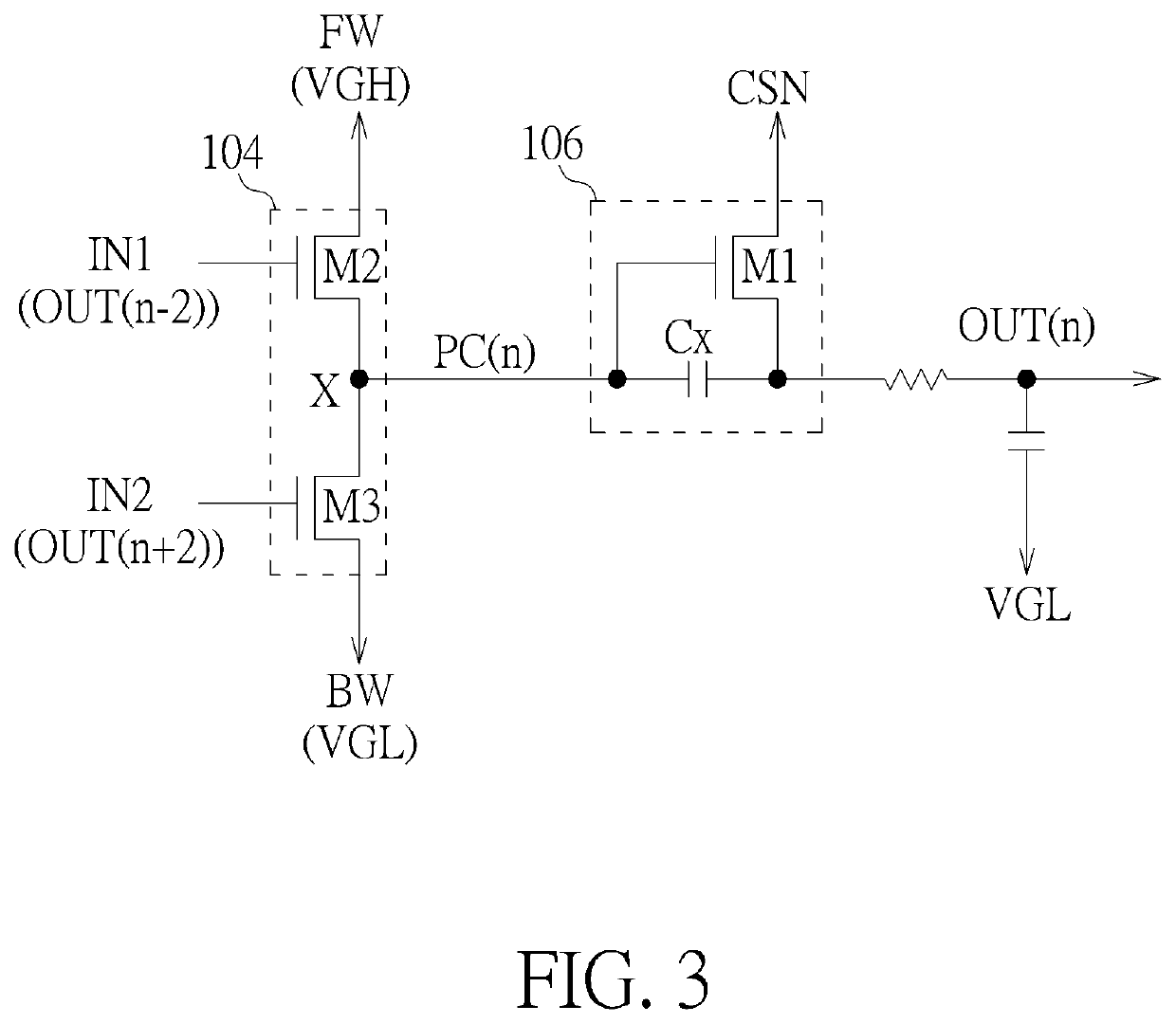

Display panel and method of improving display quality thereof

ActiveUS20200058242A1Improve display qualityDecreased first widthStatic indicating devicesSolid-state devicesComputer hardwareScan line

A display panel includes a substrate having a display region and a peripheral region, first and second sub pixels, first and second gate driving units. The display region includes a first area having first scan lines and first sub pixels and a second area having second scan lines and second sub pixels. A portion of the first sub pixels and a portion of the second sub pixels are respectively electrically connected to the first and second scan line. The first gate driving unit includes a first driving transistor. The second gate driving unit includes a second driving transistor. The number of the first sub pixels driven by the first gate driving unit is less than the number of the second sub pixels driven by the second gate driving unit. The channel width of the first driving transistor is less than the channel width of the second driving transistor.

Owner:HANNSTAR DISPLAY CORPORATION

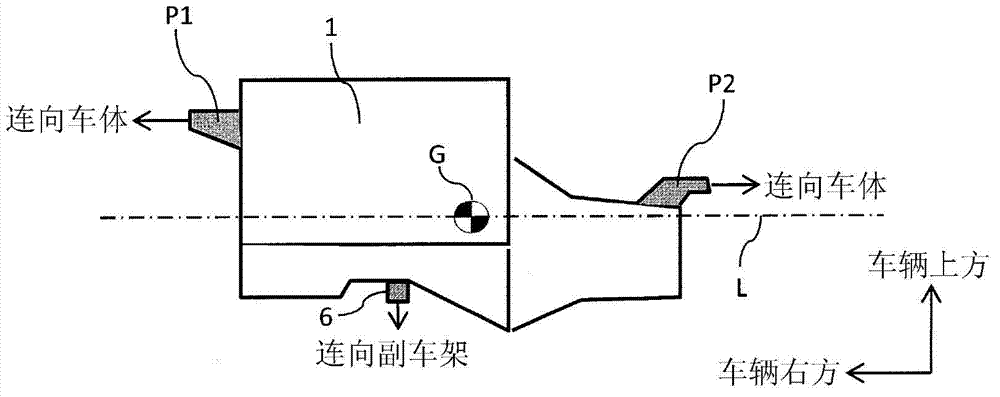

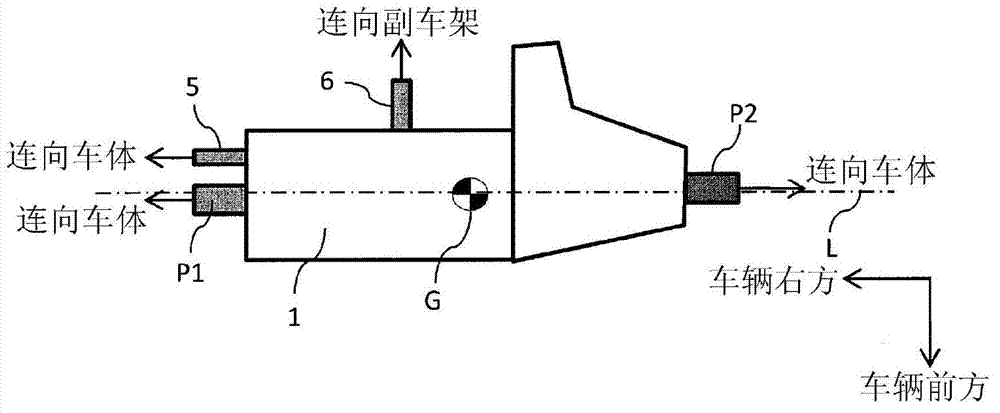

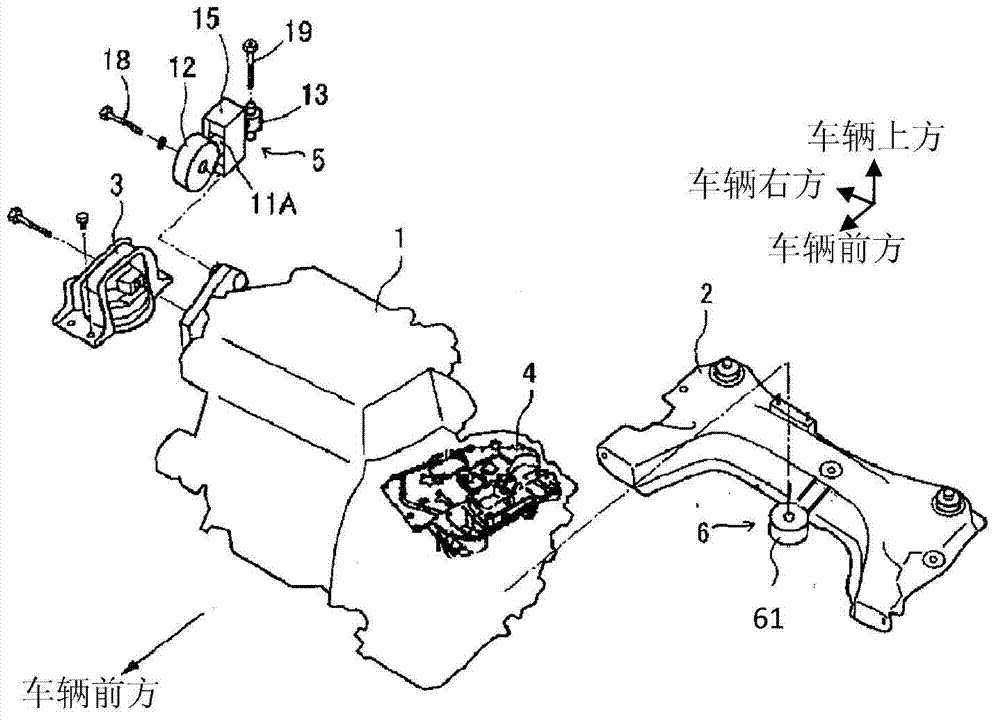

Vibration isolating unit for vehicle

InactiveCN102900804AReduce drive powerNon-rotating vibration suppressionMachines/enginesElectric controlActuator

The invention provides a vibration isolating unit for vehicles. Driving power of an actuator can be reduced by the device. The vibration isolating unit for vehicles comprise a rod (11) with one end (12) thereof fixed on an engine (1) and the other end (13) fixed on the vehicle body; an inertia block (15) supported on the rod (11); an actuator (17) for driving the inertia block to move backward and forward in an axis direction of the rod; an electric control component (26) for driving the actuator; and an electric power storage component (26) for supplying electric power to the electric control component; wherein the actuator does not drive, the electric control component converts vibration of the inertia block into electric power and charge the electric power into the electric power storage component.

Owner:NISSAN MOTOR CO LTD

Method for reducing a driving power of a vehicle drive

InactiveUS20110295451A1Reduce drive powerReduce total powerHybrid vehiclesAnalogue computers for vehiclesAutomotive engineeringTemperature difference

A method for reducing a driving power of a vehicle drive includes detecting a temperature difference between a temperature of at least one component of the vehicle drive and a temperature threshold value, detecting an instantaneous driving state of the vehicle drive, establishing whether or not the instantaneous driving state allows for a reduction in the driving power of the vehicle drive, and reducing the driving power of the vehicle drive for lowering the temperature of the at least one component in order to increase the temperature difference if the instantaneous driving state allows for the reduced driving power.

Owner:ROBERT BOSCH GMBH

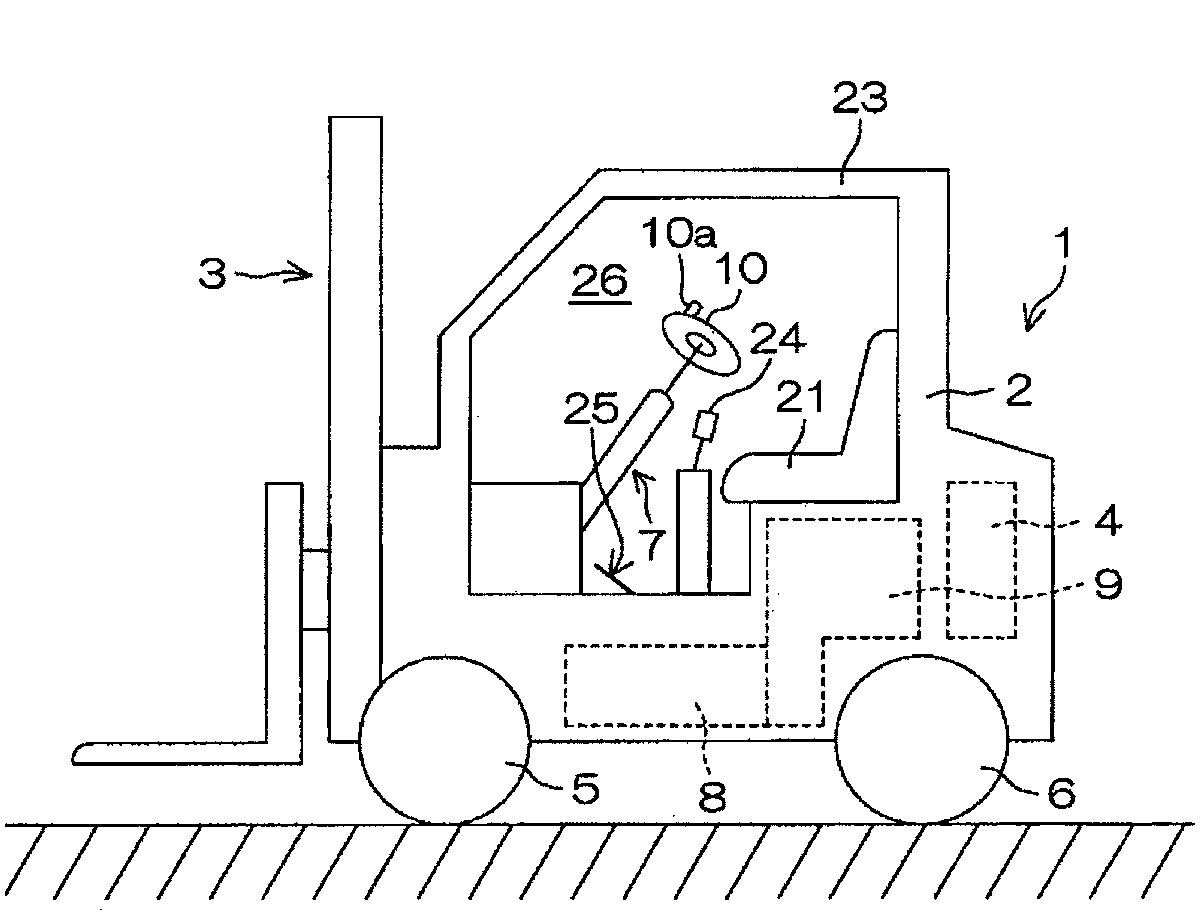

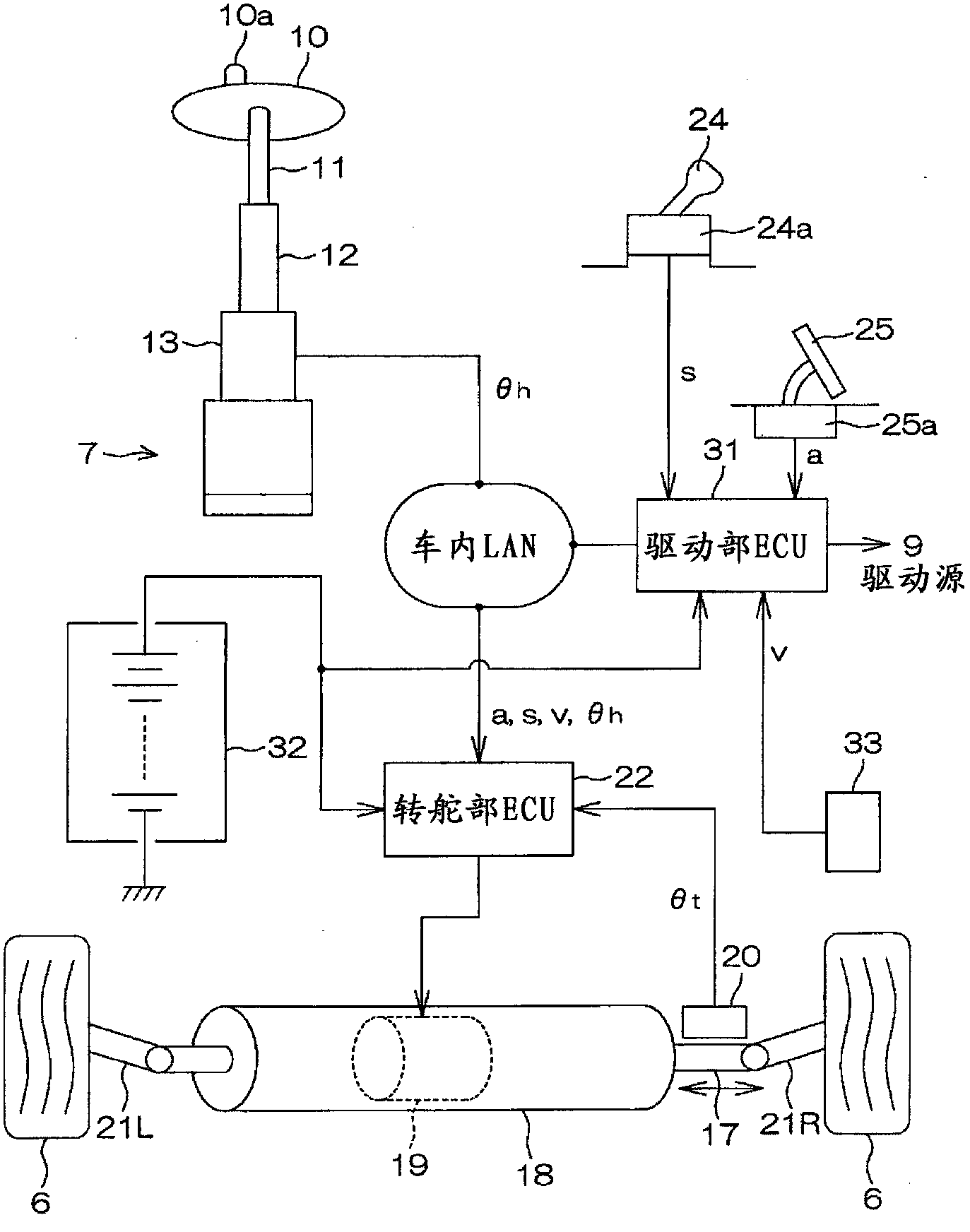

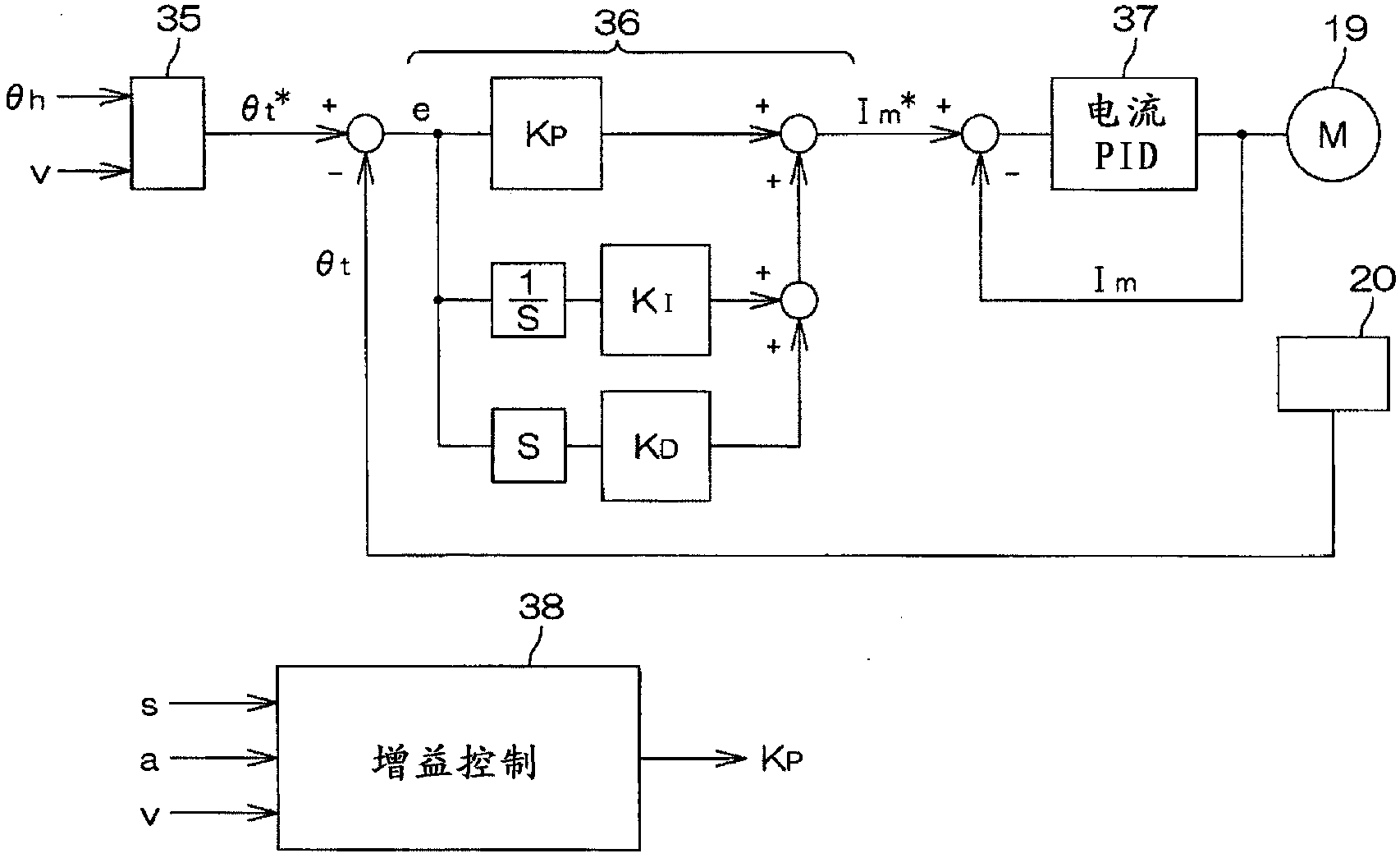

Control apparatus for steering mechanism

InactiveCN103085860AShorten speedReduce drive powerSteering linkagesLifting devicesDriving currentDrive wheel

The invention provides a control apparatus for steering mechanism. In a material handling vehicle such as an electric forklift, a depression amount of an accelerator pedal (26) that provides an instruction on a control amount of a drive motor (9) for driving a drive wheel (5) is detected. When the depression amount of the accelerator pedal (25) is equal to or larger than a predetermined value and a forward-backward switching signal that indicates that a shift lever (24) is operated is received, a drive current for a steered system motor (19) is set to a value smaller than a normal drive current within a predetermined time period (T) that starts upon reception of the forward-backward switching signal.

Owner:JTEKT CORP

Oscillating motor and electric clippers

ActiveUS20180361601A1High torqueReduce drive powerDynamo-electric machinesMetal working apparatusElectric clipperElectrical polarity

Provided is an oscillating motor and electric clippers. The oscillating motor includes a U-shaped magnetic yoke, four permanent magnets and a swing arm. The U-shaped magnetic yoke causes end faces of two support legs to produce alternating magnetic poles with the control circuit. The four permanent magnets are fixedly mounted to an inner arm via a second magnetic yoke. The four permanent magnets are sequentially distributed on a same circumferential surface having a fulcrum being a circle centre. The polarities of radial end faces of the first permanent magnet and the fourth permanent magnet are the same. The polarities of radial end faces of the second permanent magnet and the third permanent magnet are the same, and the opposite of the polarity of the radial end face of the first permanent magnet. When a coil is electrified, the four permanent magnets produce torque having the same direction of rotation.

Owner:HU JIANKUN

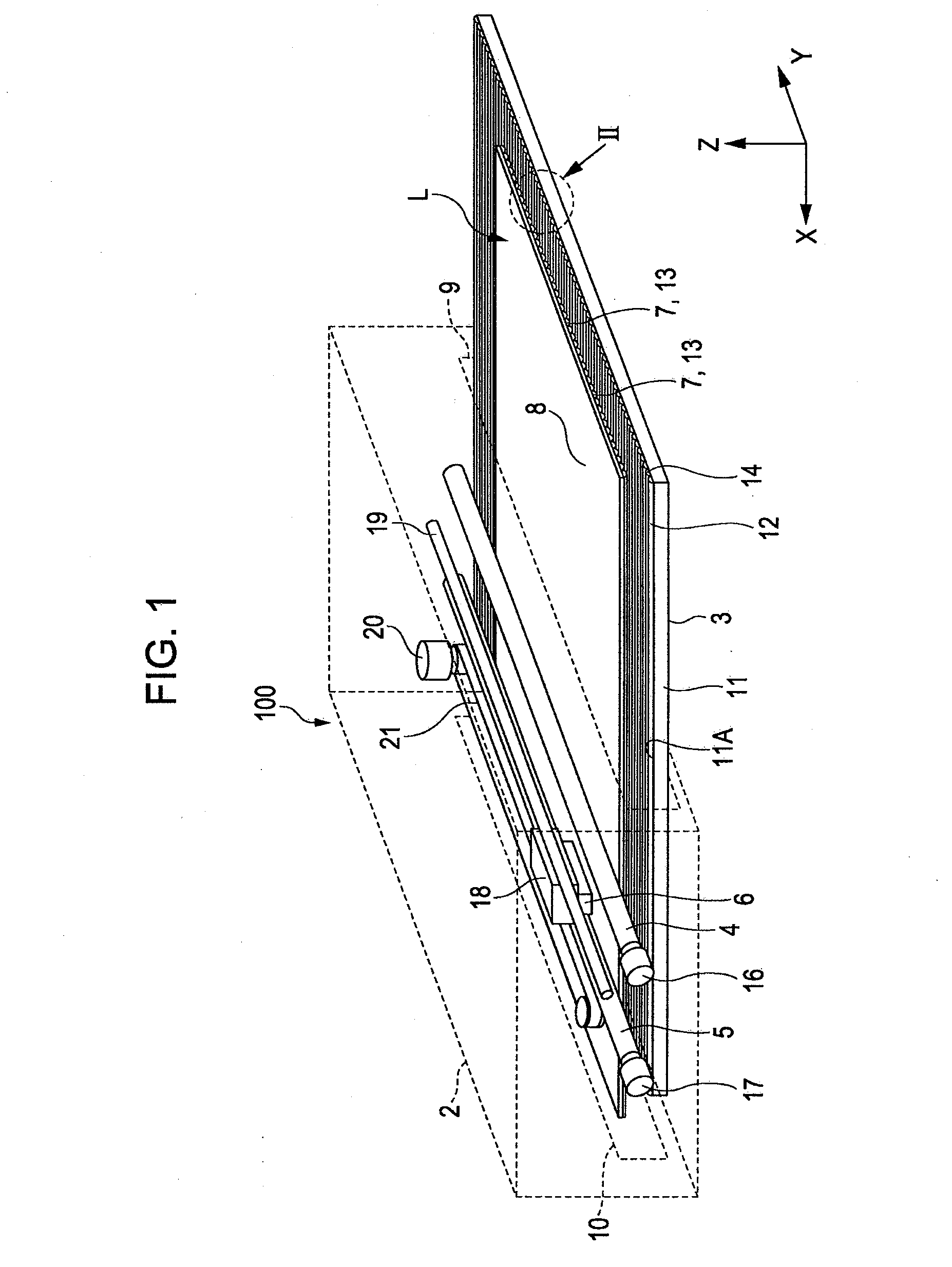

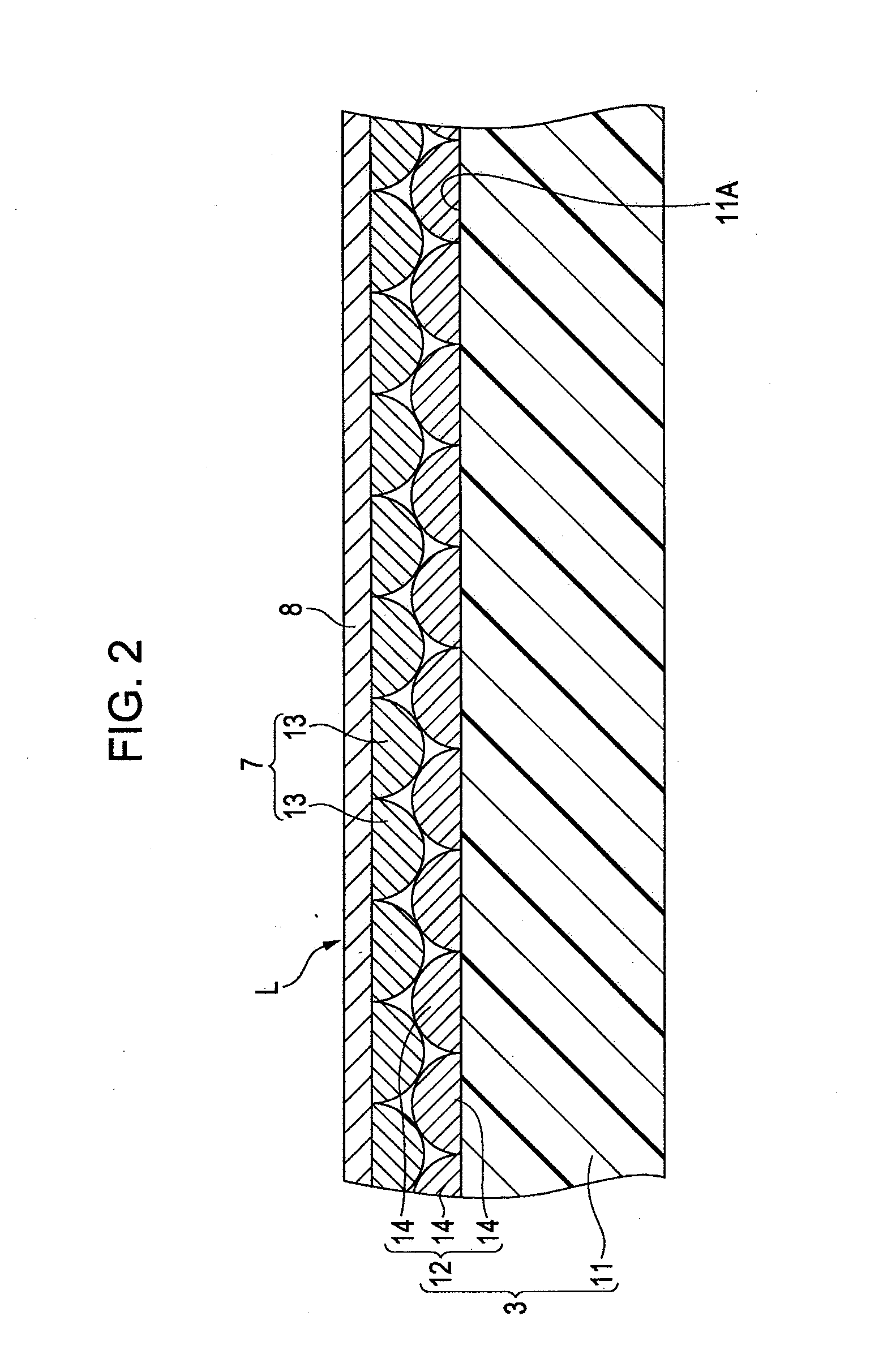

Recording target medium and recording apparatus

ActiveUS20100165036A1High precisionEasy to controlDuplicating/marking methodsTypewritersComputer scienceMechanical engineering

Owner:SEIKO EPSON CORP

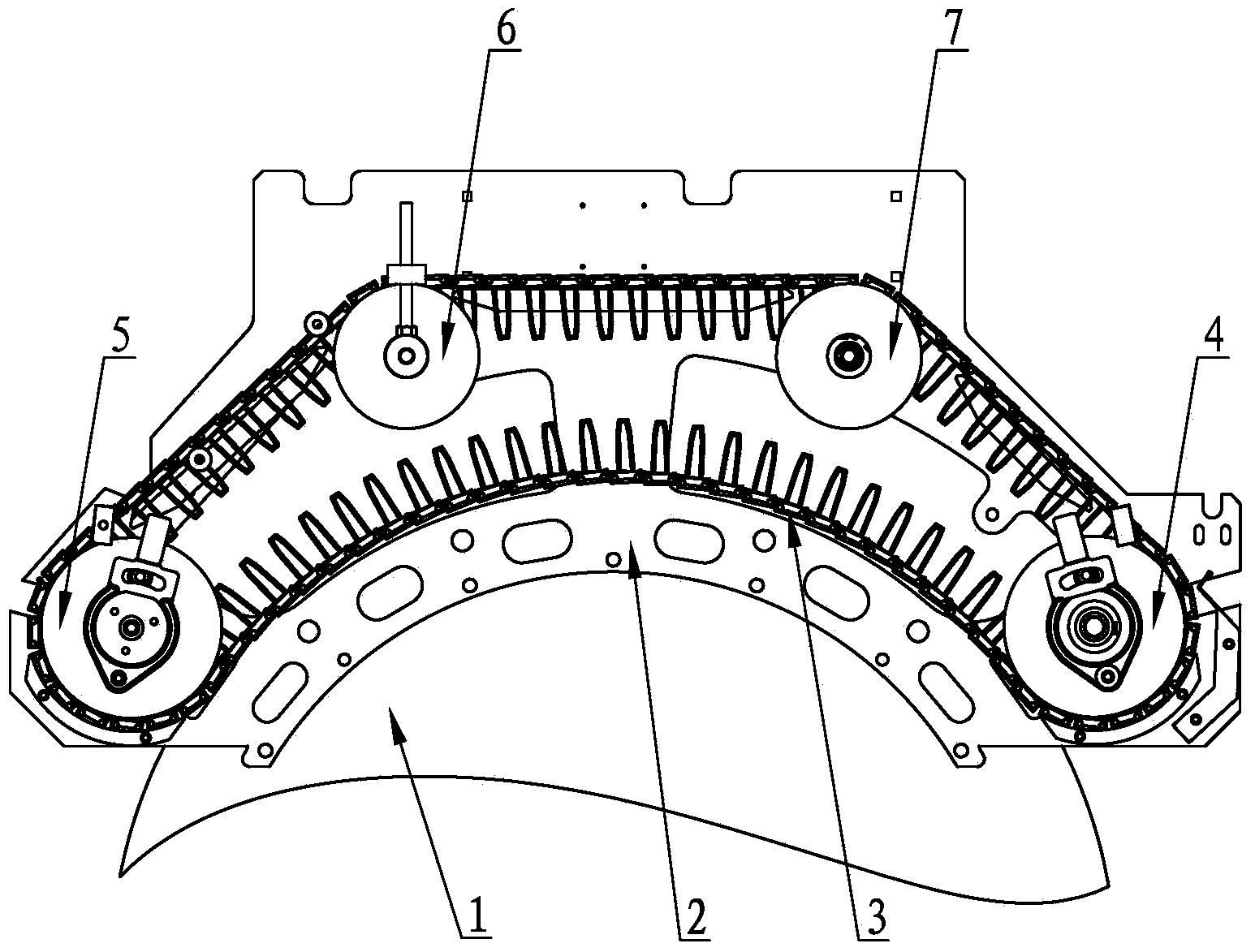

Movable cover board carding device for cotton carding machine

The invention relates to a movable cover board carding device for a cotton carding machine, which comprises a cylinder, a guide rail, a movable cover board, a driving wheel, a driven wheel, a tensioner and a transition wheel. The guide rail is fixedly arranged on a surface plate of the cylinder; the movable cover board comprises a cover board skeleton, cover board hinge pins, fixing blocks and bearing rolling sleeves; the cover board hinge pins are fixedly connected to both ends of the bottom of the cover board skeleton; the cover board hinge pins are sleeved with the fixing blocks; hinge pin holes on the fixing blocks are provided with limiting grooves; the positions of the two limiting grooves are staggered along the axial directions of the hinge pins; the cover board hinge pins in the limiting grooves are sleeved with the bearing rolling sleeves; the bearing rolling sleeves are in rolling contact with the guide rail; the driving wheel and the driven wheel are arranged in round backs at both ends of the movable cover board; and the tensioner and the transition wheel are arranged at the horizontal end of the movable cover board. Due to adoption of the structure, the distance between the movable cover board and the cylinder is stable; the movable cover board carding device is reliable to operate; maintenance cost is reduced; labor intensity is reduced; the device has superior stability in the actual operating process; a small number of neps and cotton impurities in generated cotton slivers are generated; and the cotton slivers have high fiber quality.

Owner:常州金阳纺织机械有限公司

High intensity vibration testing using an empirically modified reference specification and method thereof

ActiveUS20200232874A1Less risk of damageImprove fluencyVibration testingControl systemControl engineering

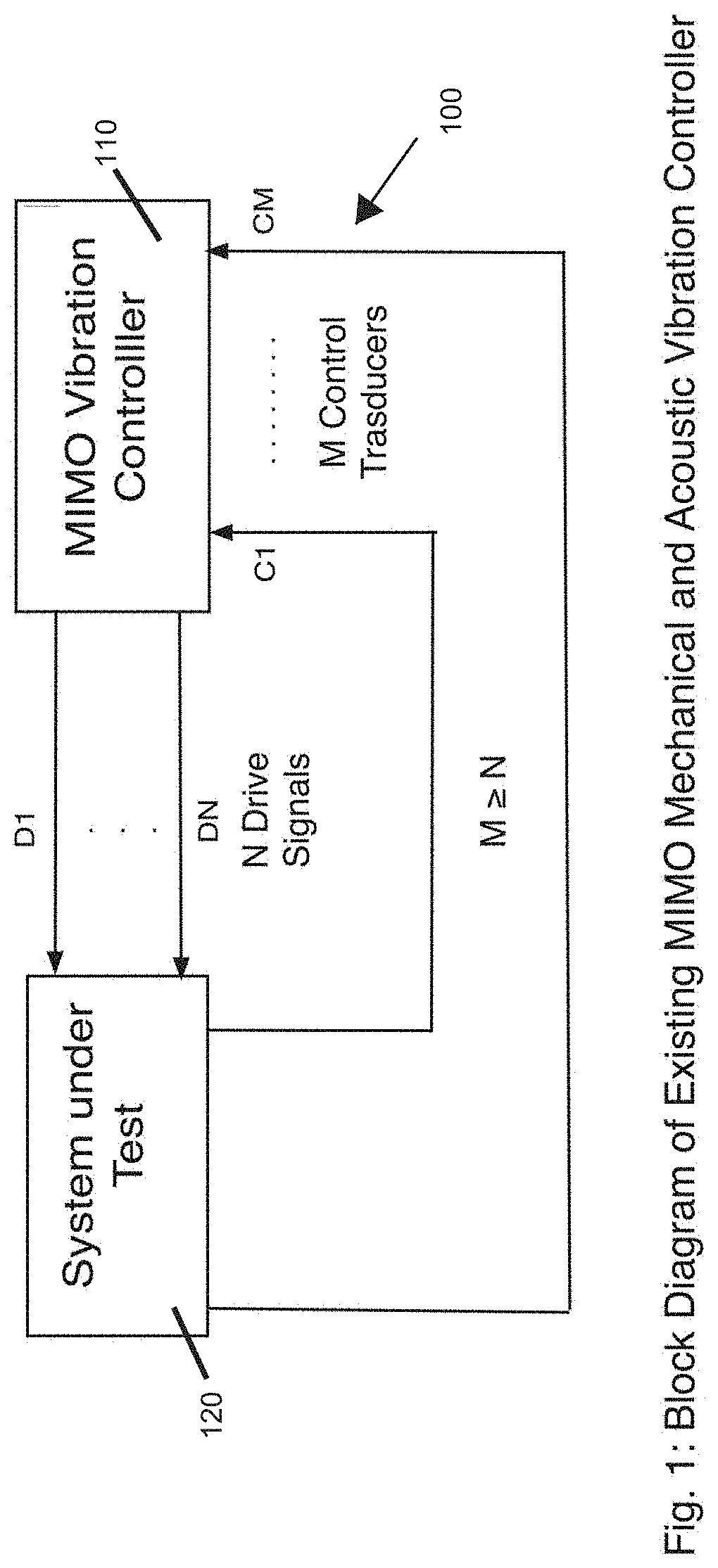

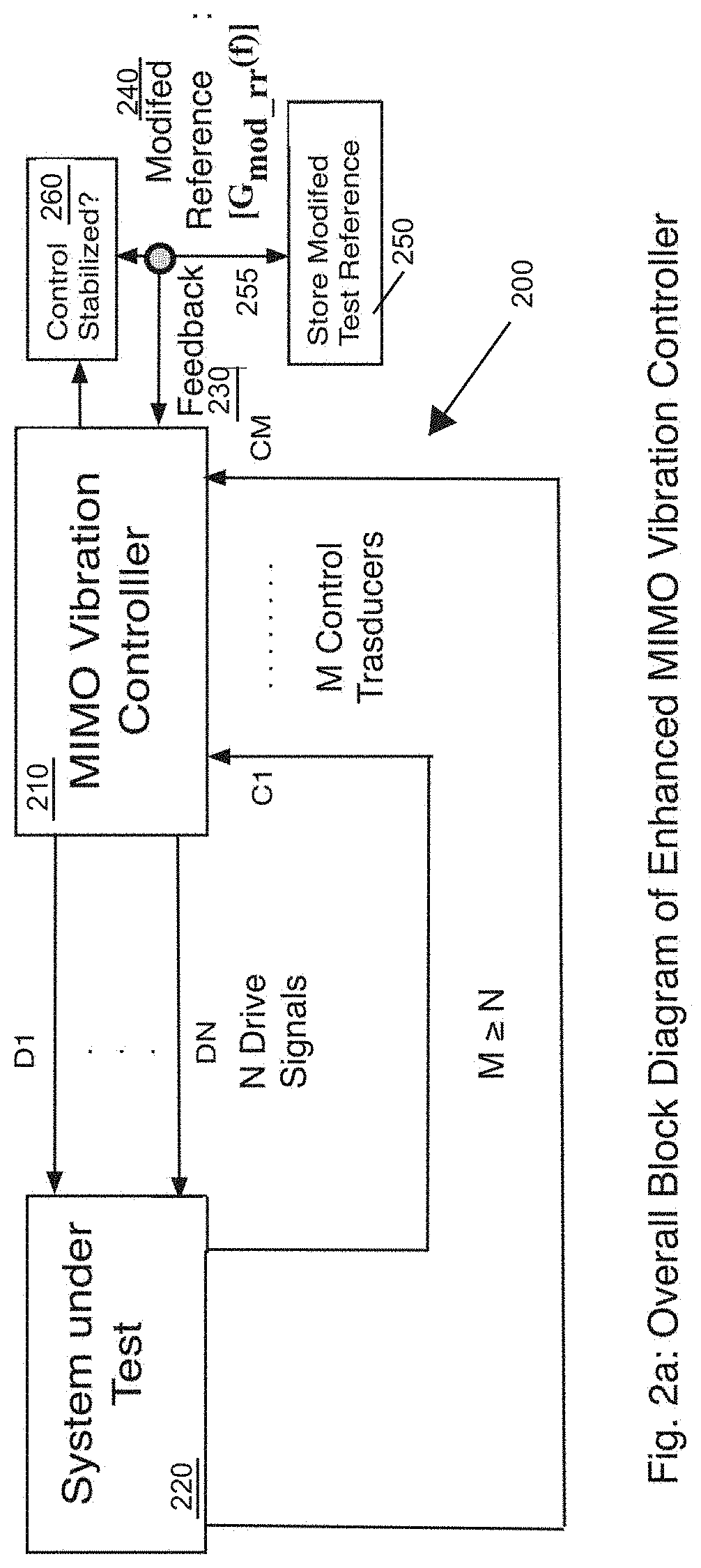

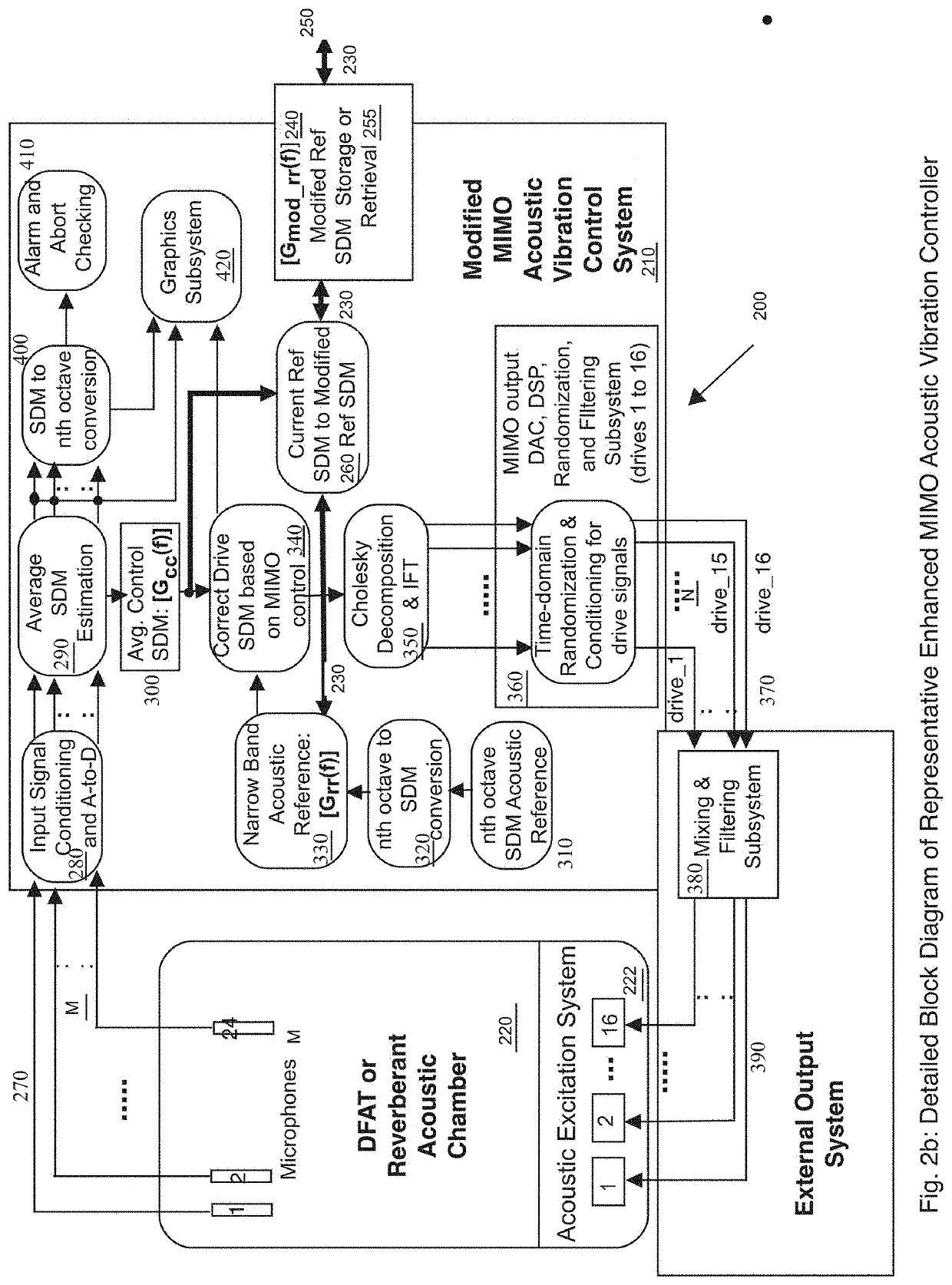

An acoustic or mechanical vibration testing system includes a MIMO control system coupled to at least two separately controllable groups of vibration transducers and at least two control sensor transducers wherein the number of control sensor transducers need not be equal to the number of controller output drives or number of separately controllable groups of vibration transducers. The MIMO control system utilizes both a predetermined initial reference specification and a modified reference specification, wherein data acquired during system operation under conventional MIMO control is used to create the modified reference specification based on actual system performance and limitations thereof so as to maintain closer correspondence to the predetermined initial reference specification with less required system drive power, as a function of the predetermined initial reference, and less risk of damage to the test system and the test article during the performance of a test.

Owner:UNDERWOOD MARCOS

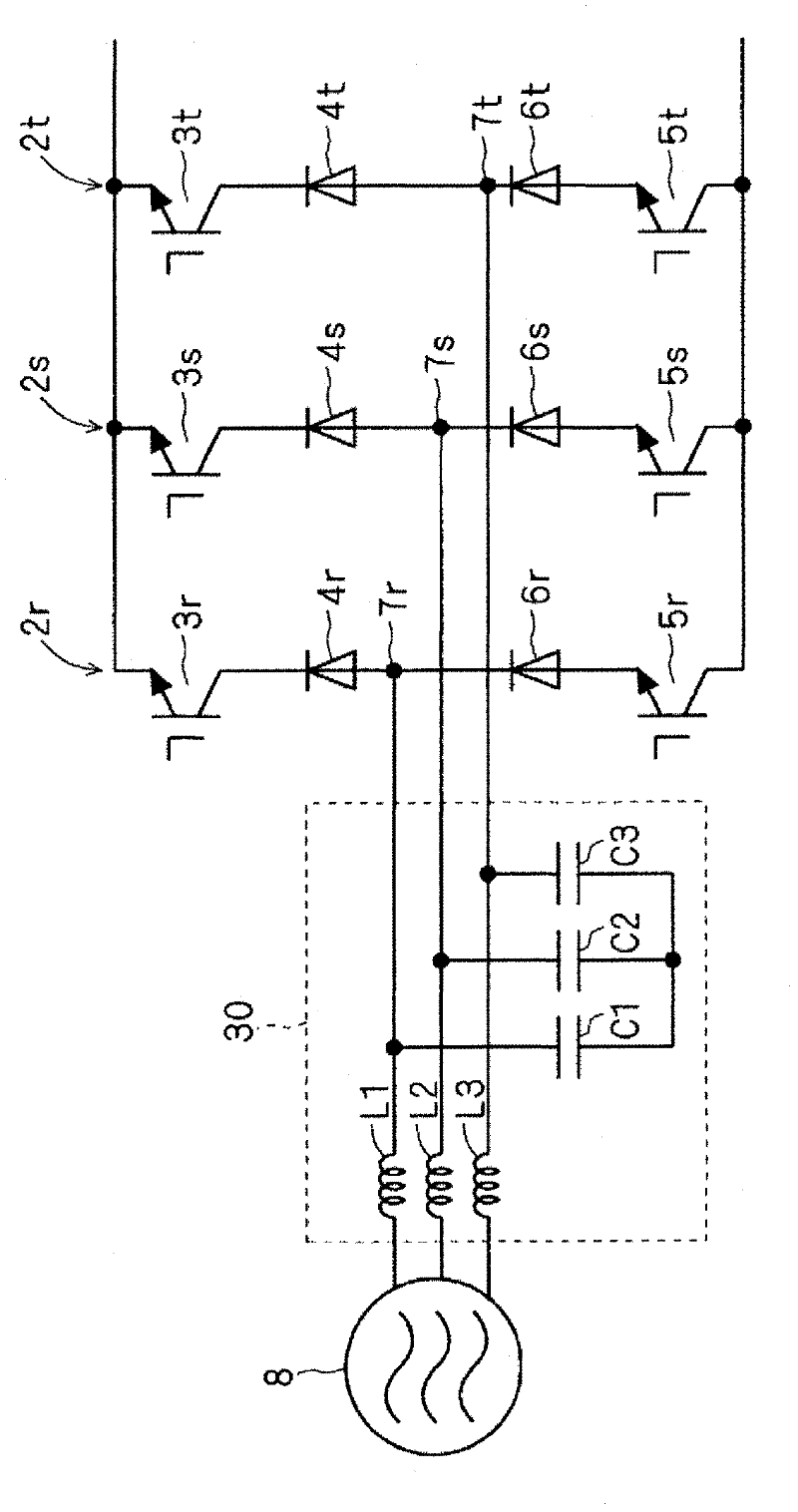

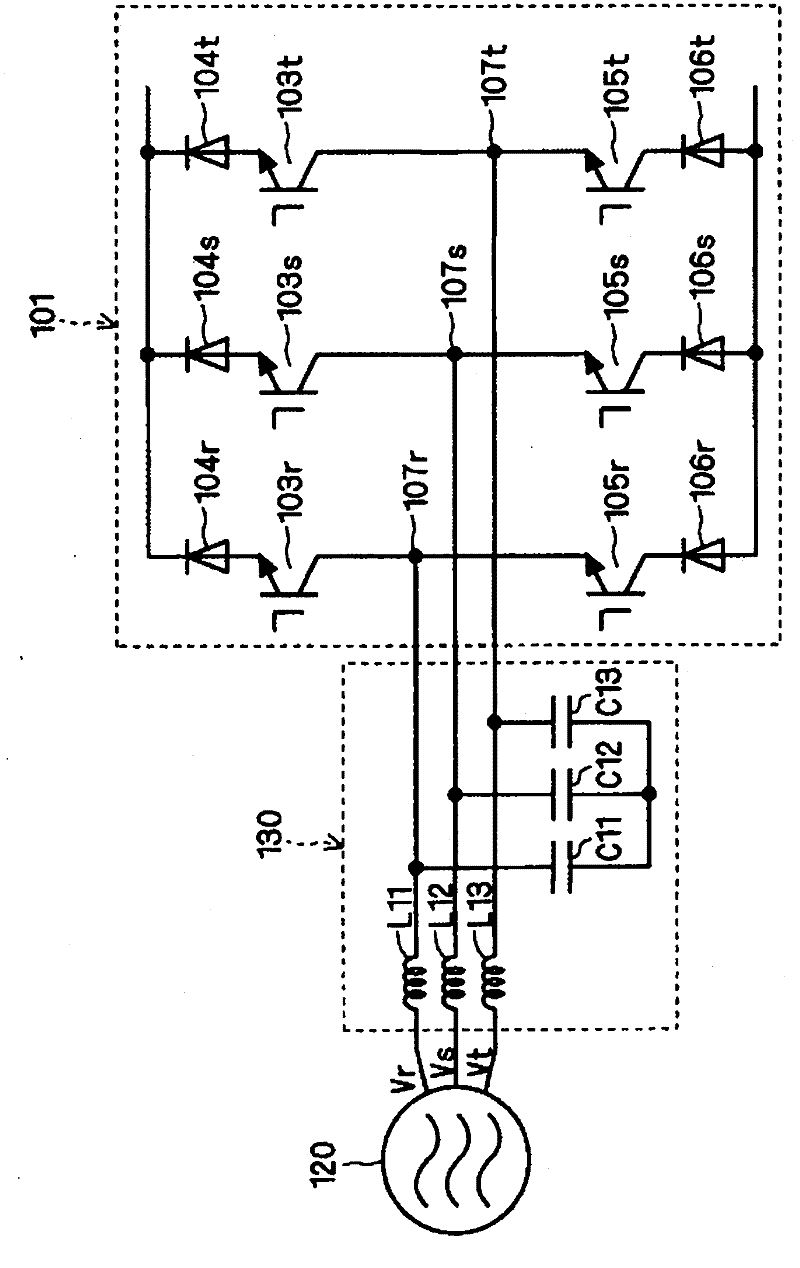

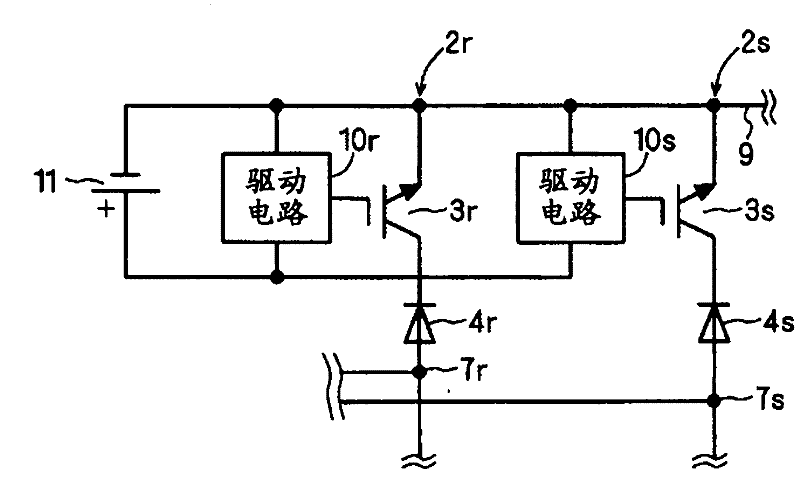

Current source power conversion circuit

InactiveCN102246406AReduce drive powerCheap and simple structureAc-dc conversionPower flowElectric power

A current source power conversion circuit uses a reduced number of driving power supplies and has an inexpensive and simple configuration. The current source power conversion circuit is provided with a plurality of half-bridge rectifier circuits (2r, 2s, 2t) which are connected in parallel, each comprising a first switch circuit comprising a first self-arc-extinguishing element (3r, 3s, 3t) and a first diode (4r, 4s, 4t) which are connected in series with each other, and a second switch circuit comprising a second self-arc-extinguishing element (5r, 5s, 5t) and a second diode (6r, 6s, 6t) which are connected in series with each other, the first switch circuit and the second switch circuit being connected in series. A first current electrode of the first self-arc-extinguishing element (3r, 3s, 3t) of one half-bridge rectifier circuit (2r, 2s, 2t) and a first current electrode of the first self-arc-extinguishing element (3r, 3s, 3t) of the other half-bridge rectifier circuit (2r, 2s, 2t) are short-circuited and connected.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com