Patents

Literature

47results about How to "Diameter stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

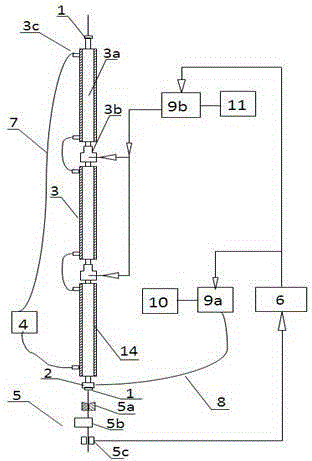

Micro air bubble generation device and method, water treatment device using the same

InactiveCN1899978AGenerate efficientlyDiameter stableWater/sewage treatment by oxidationMicrobubblesProduct gas

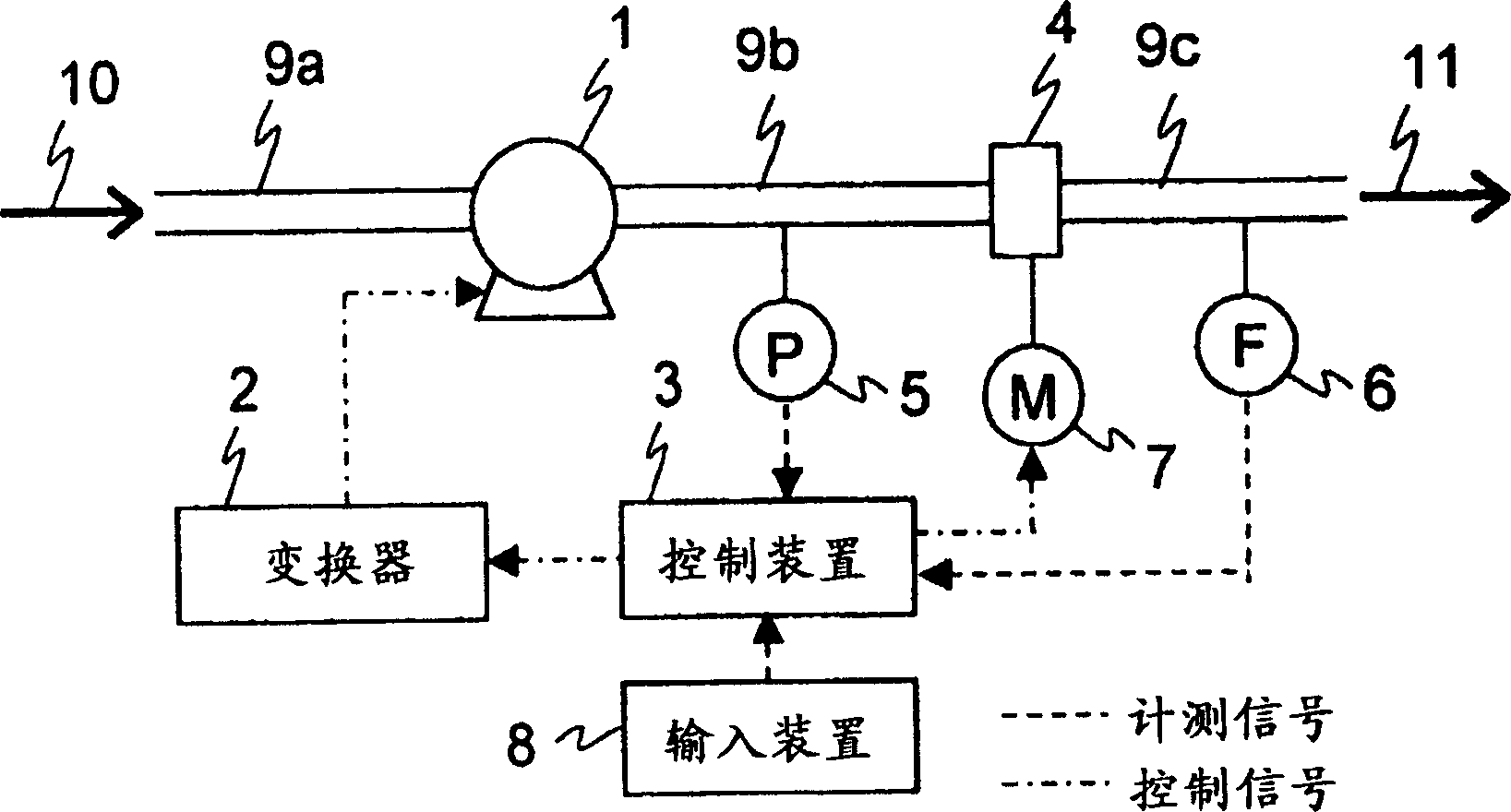

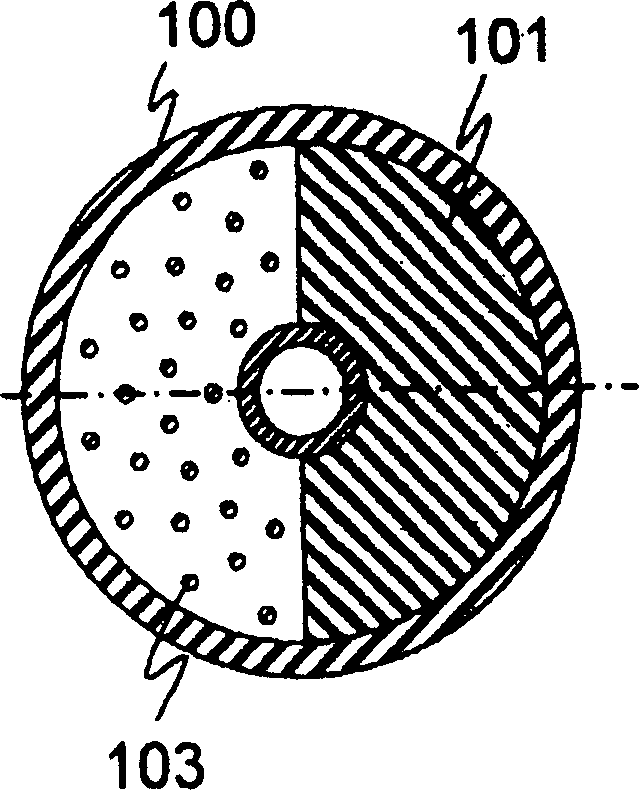

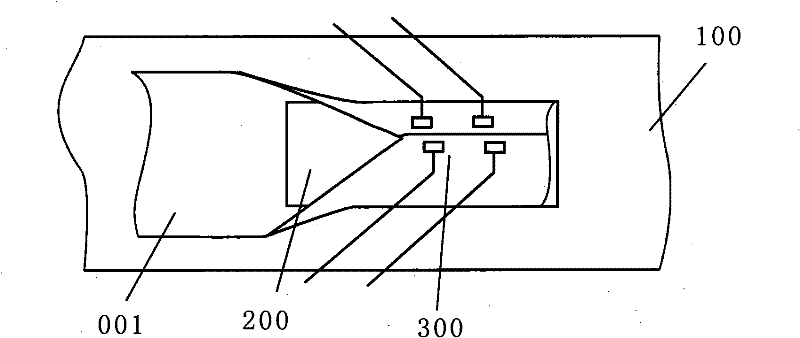

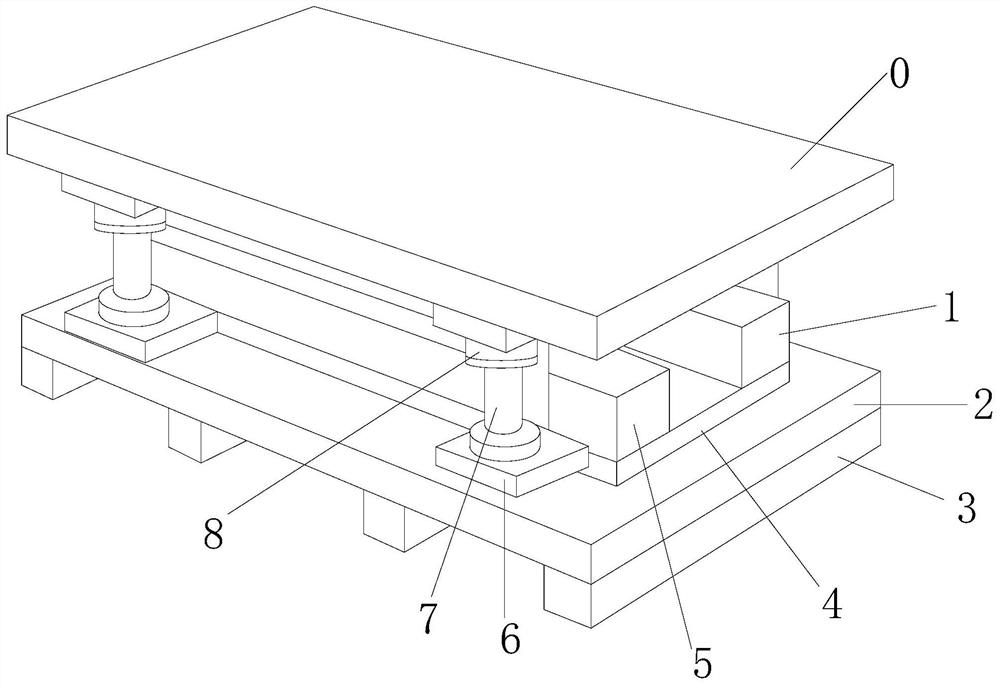

The invention provides an apparatus and a method for producing microbubbles. Fluid in which gas is dissolved under pressure with a pump 1 flows into a porous plate unit 4 and when passing through the porous plate, the fluid is decompressed and dissolved gas is deposited to form microbubbles. A controller 3 changes rotational frequency of the pump 1 via an inverter 2 to control an ejection flow rate of microbubble-containing water 11. At the same time, the controller 3 changes the number of pores in a narrow flow passage via a driving gear 7 to keep pressurizing pressure above a minimum value of pressure required for producing microbubbles and below a predetermined maximum value.

Owner:HITACHI LTD

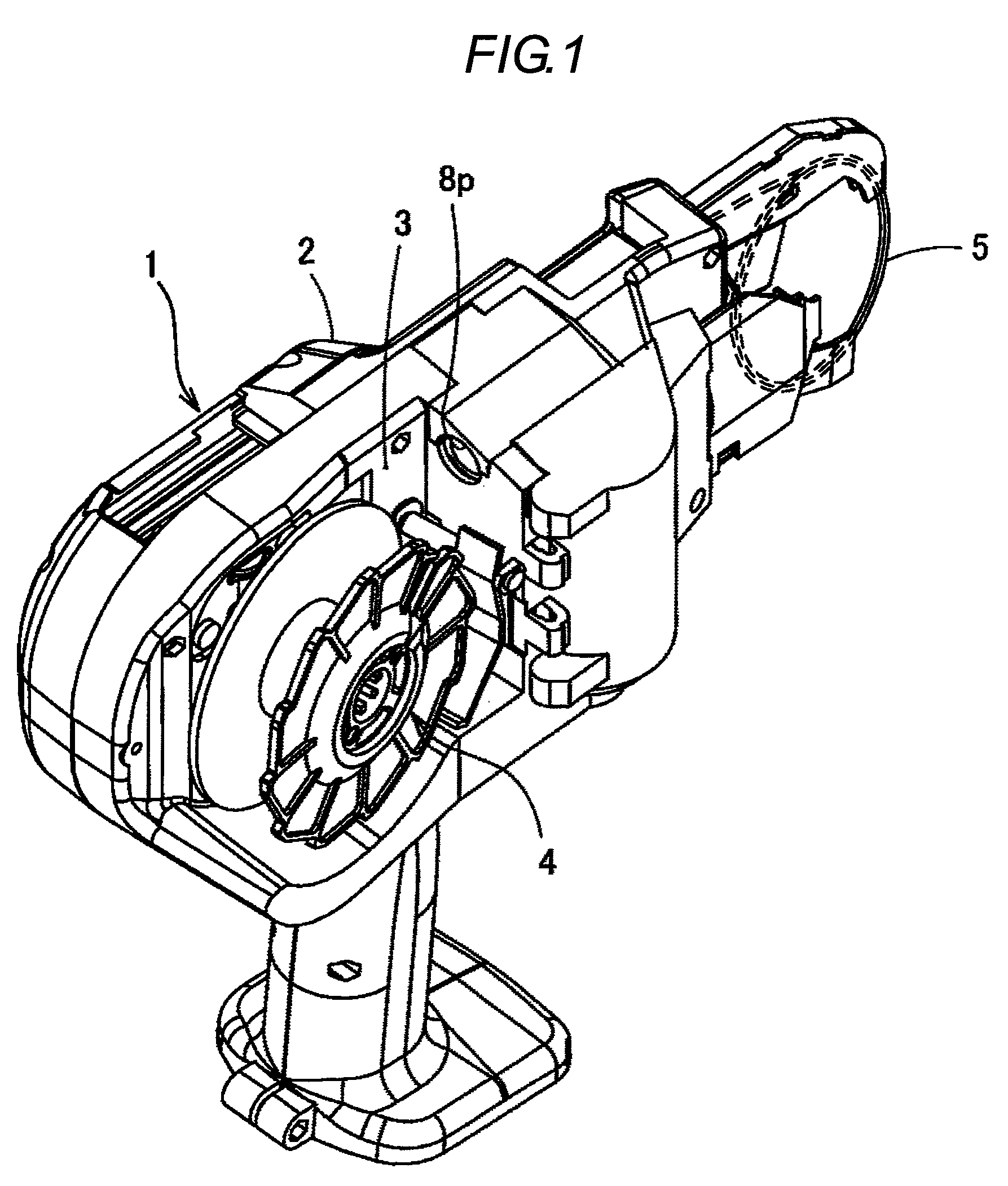

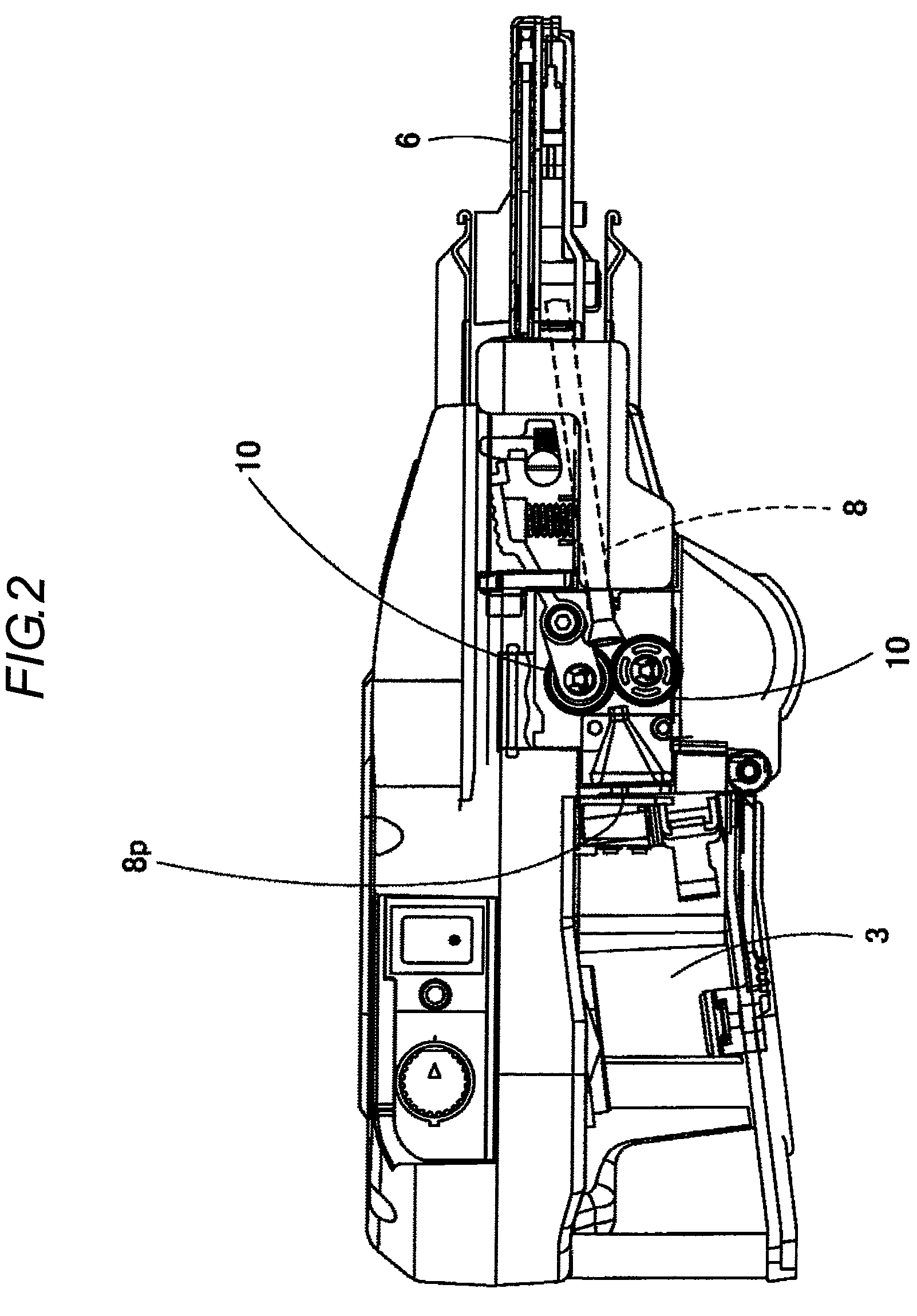

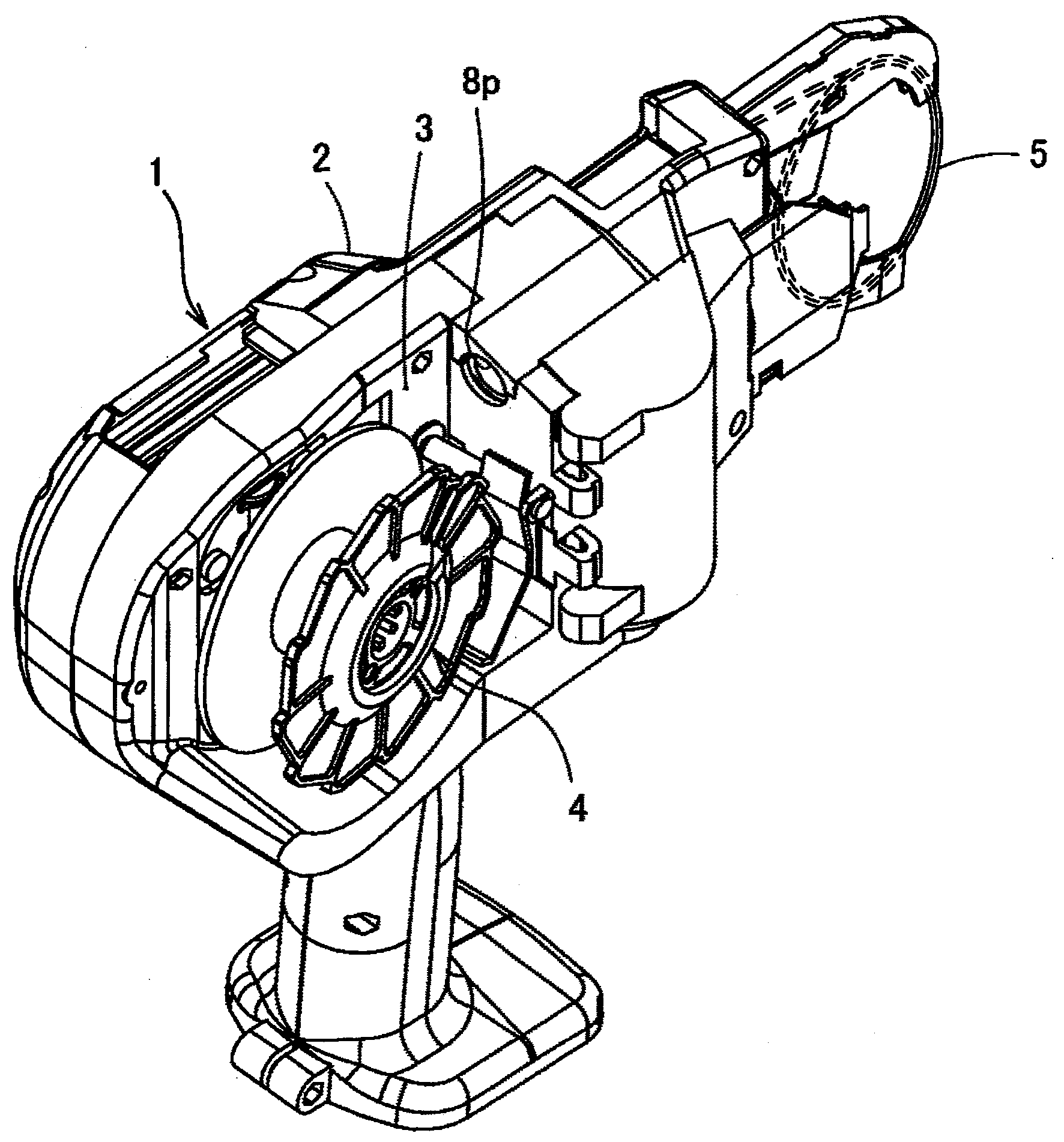

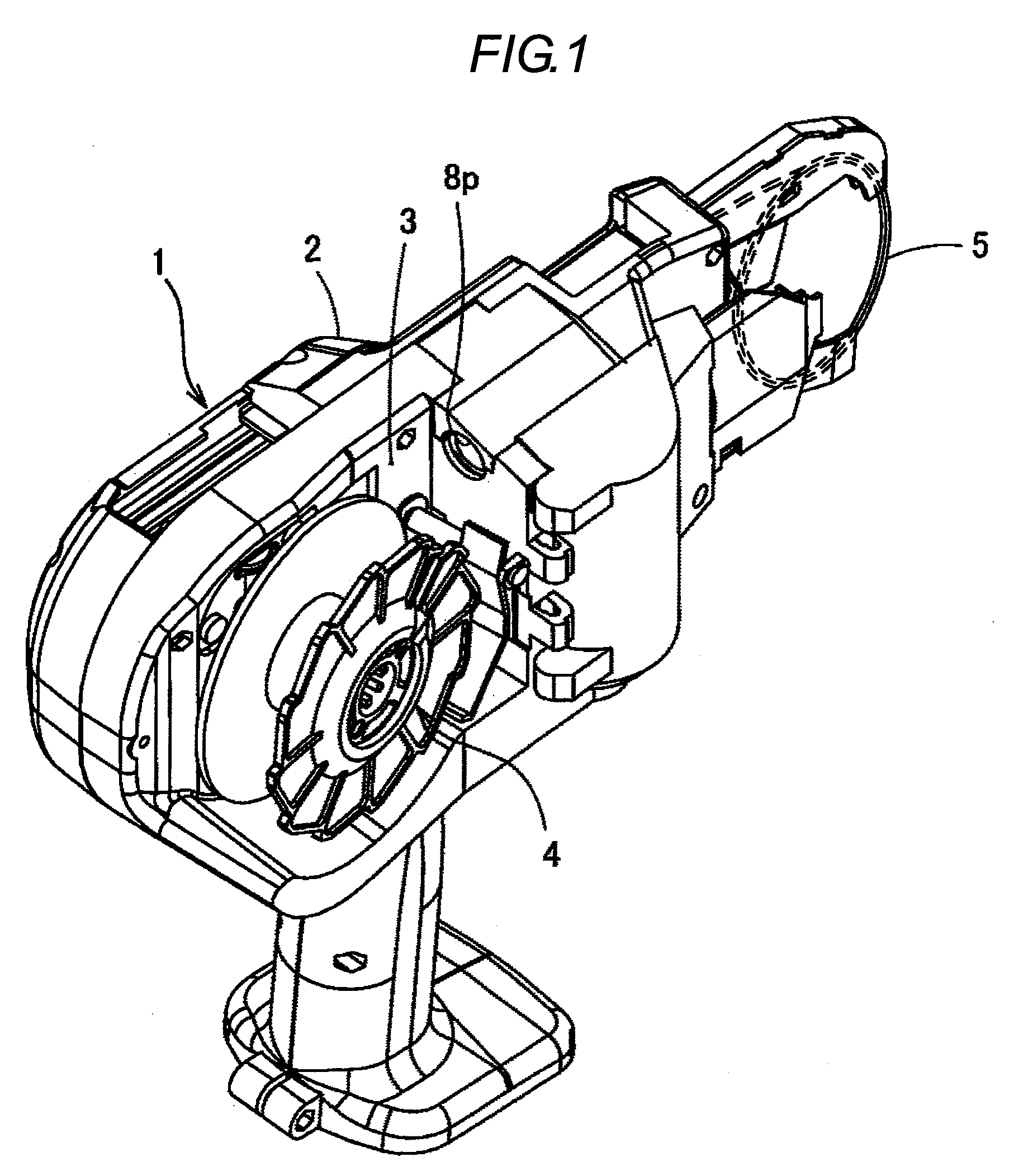

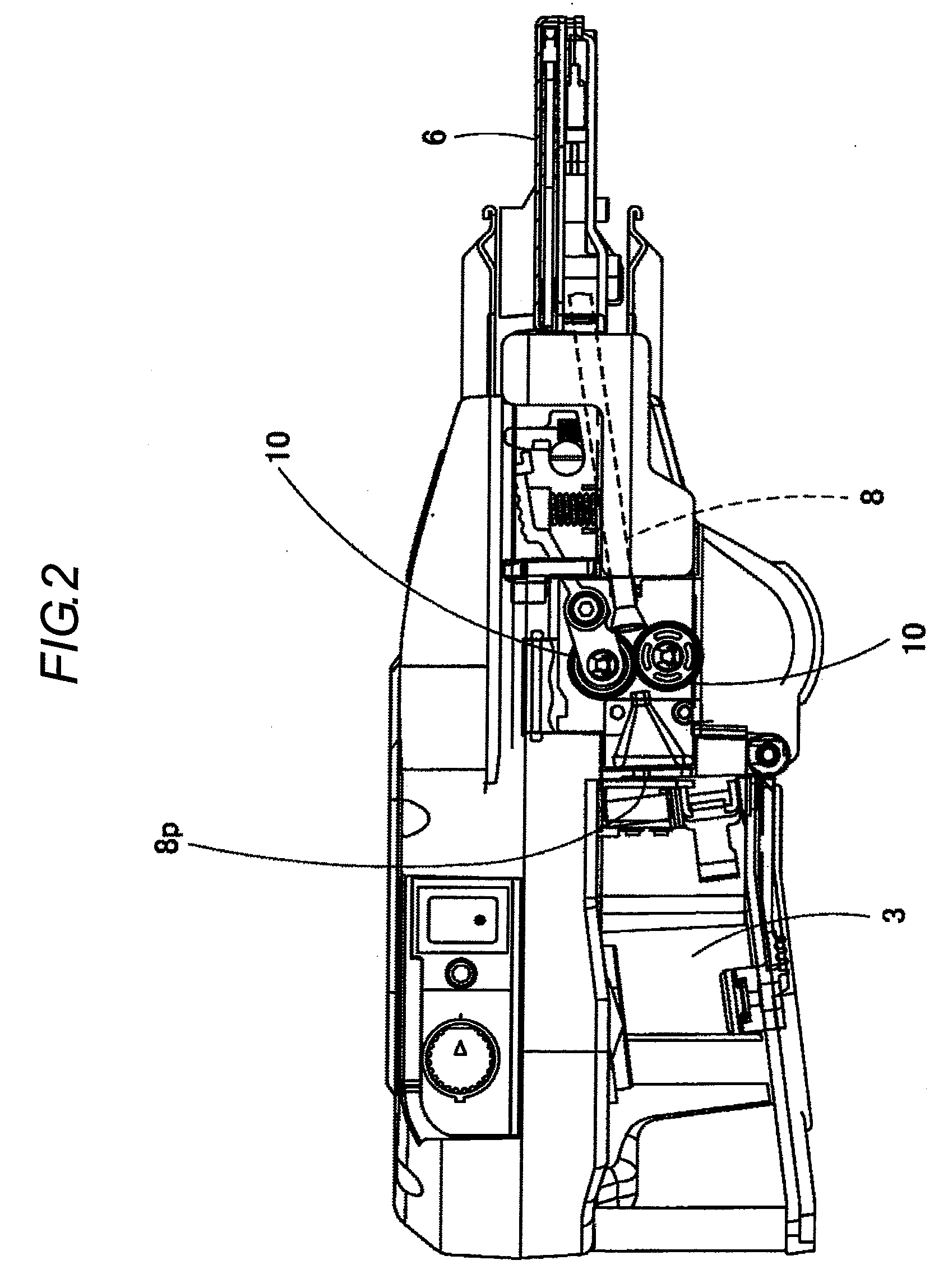

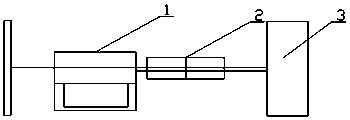

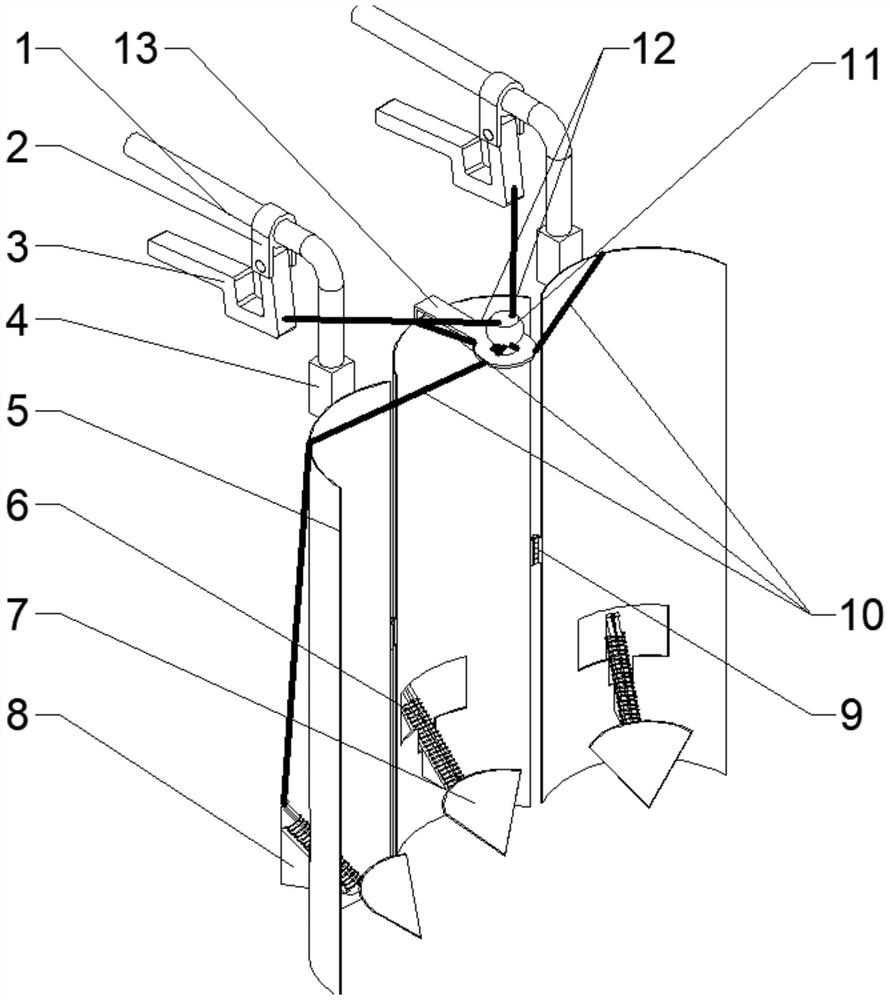

Reinforcing bar binding machine

ActiveUS8127803B2Improve accuracyEasy to shapeWire articlesOther manufacturing equipments/toolsWire rodWire cutting

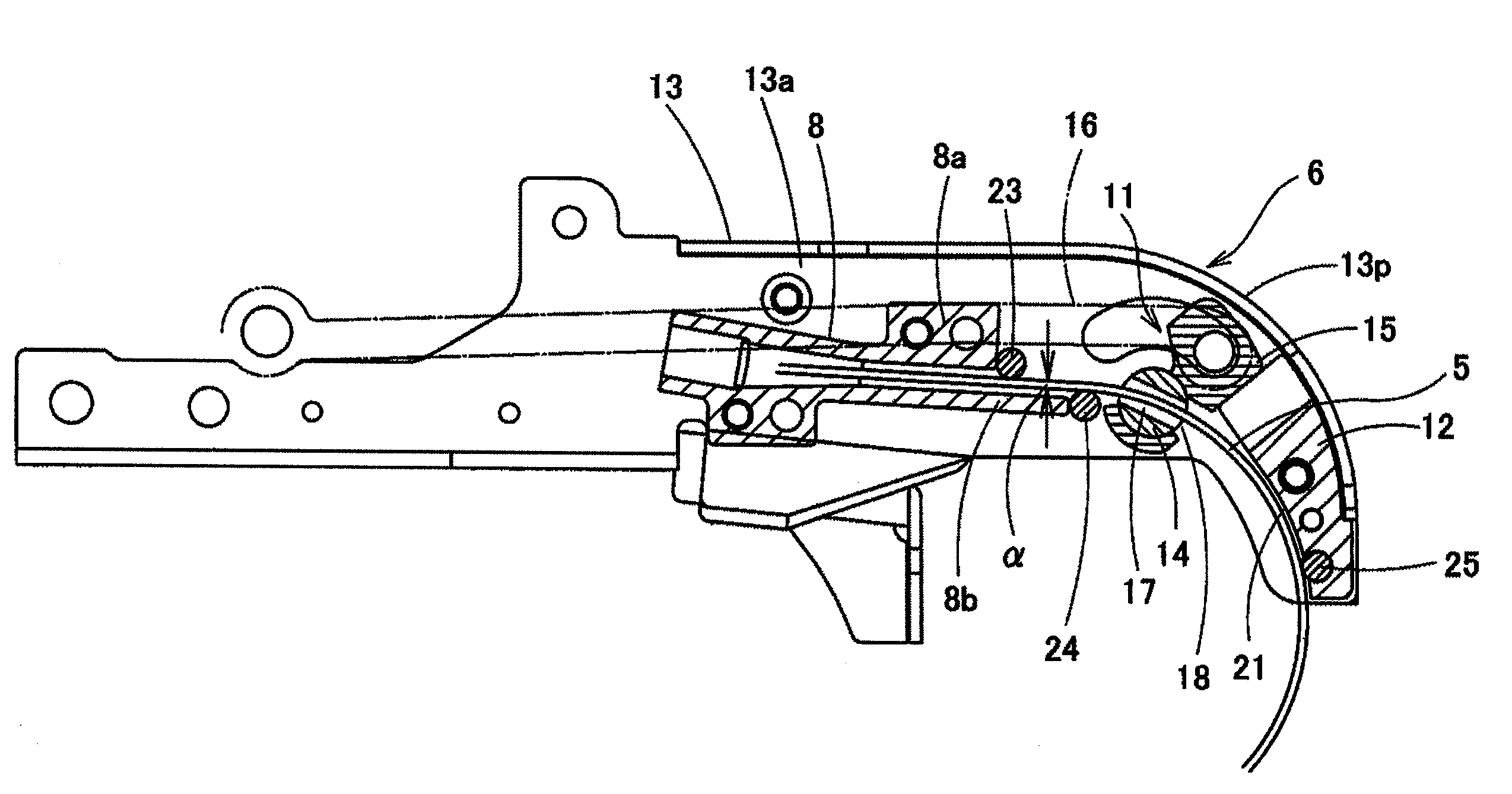

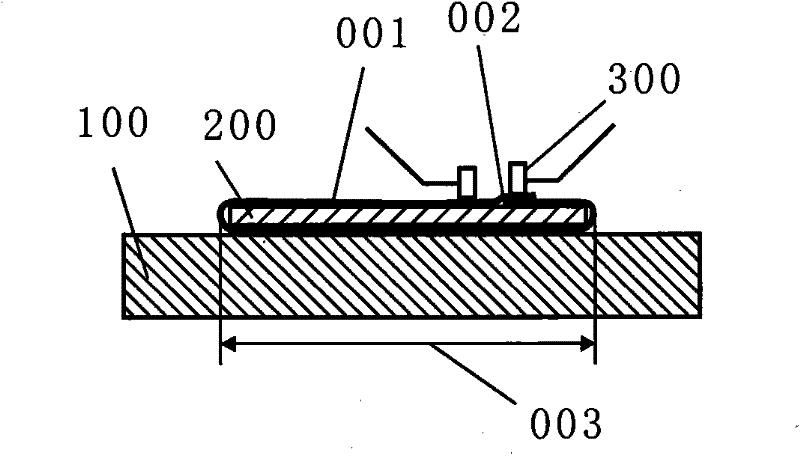

A reinforcing bar binding machine is provided with: a guide tube for guiding a wire from a wire reel mounted on a binding machine body; a curl guide; a wire cutting mechanism disposed between the guide tube and the curl guide; a first guide pin that is disposed at an end portion of the guide tube or in a vicinity of the end portion of the guide tube, and guides an outer side surface which is an outer side of a wire curve; a second guide pin that is disposed at the end portion of the guide tube or in a vicinity of the end portion of the guide tube, and guides an inner side surface which is an inner side of the wire curve; and a third guide pin that is disposed inside of the curl guide and guides the outer side surface. The wire is brought into contact with the first guide pin, the second guide pin, and the third guide pin, when the wire is fed around a reinforcing bar.

Owner:MAX CO LTD

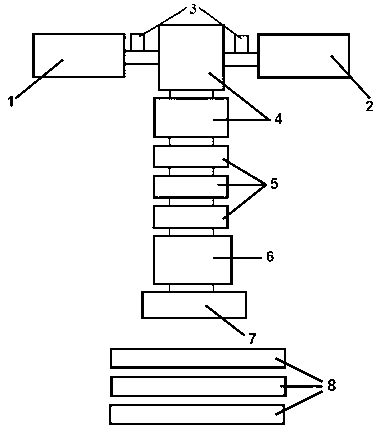

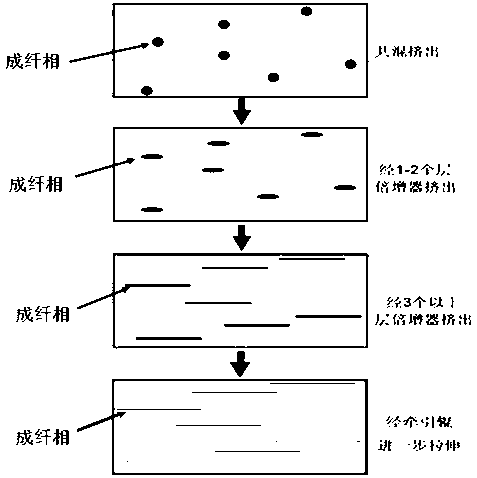

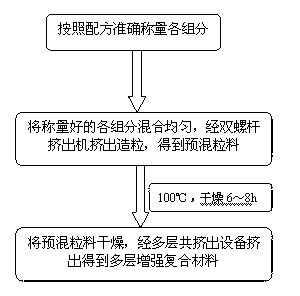

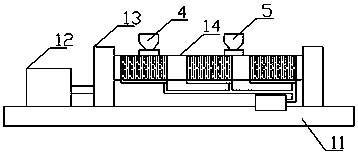

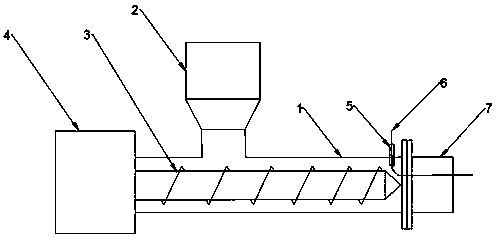

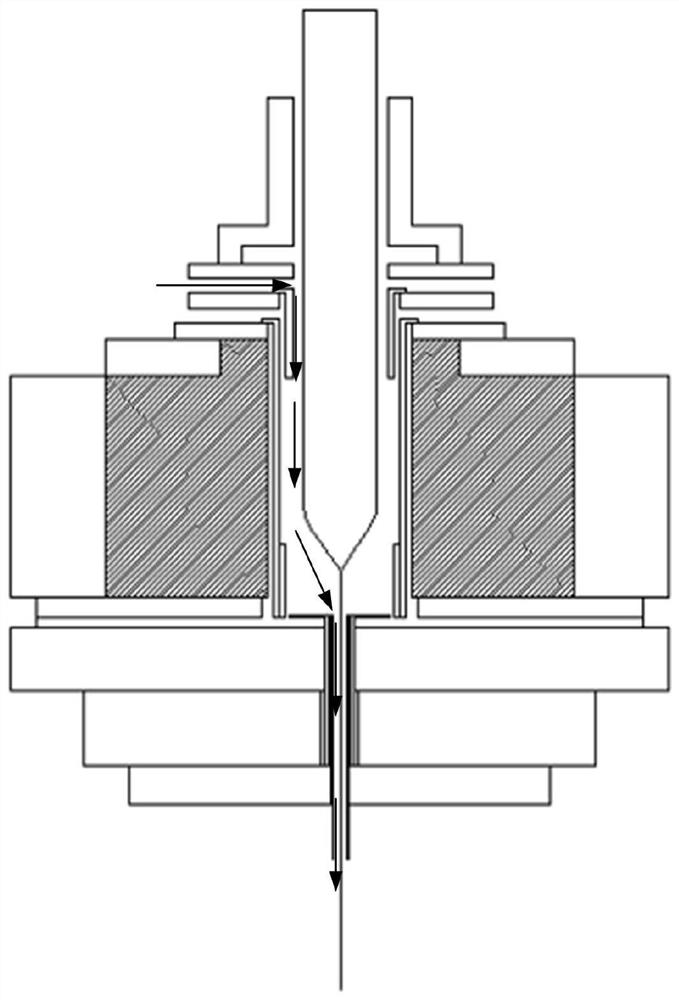

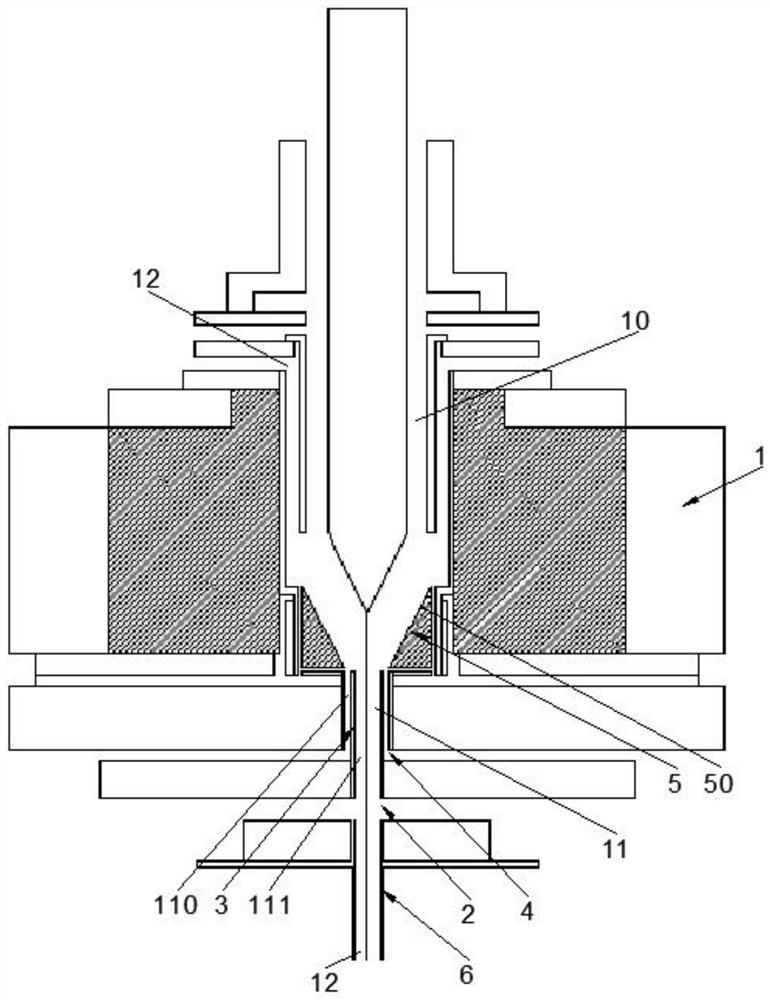

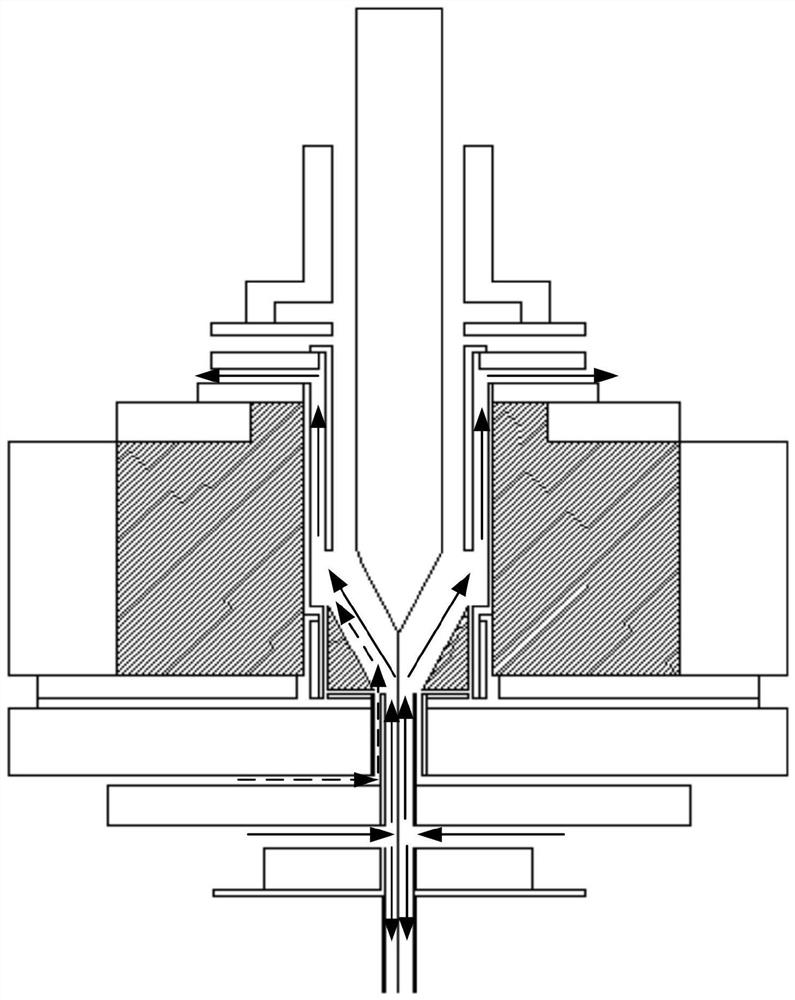

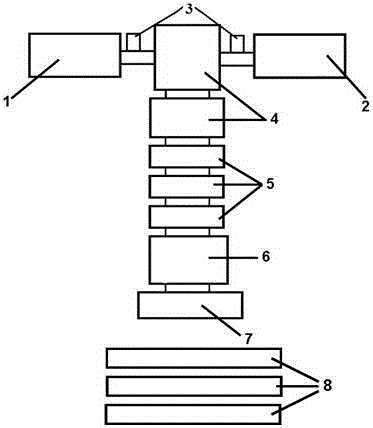

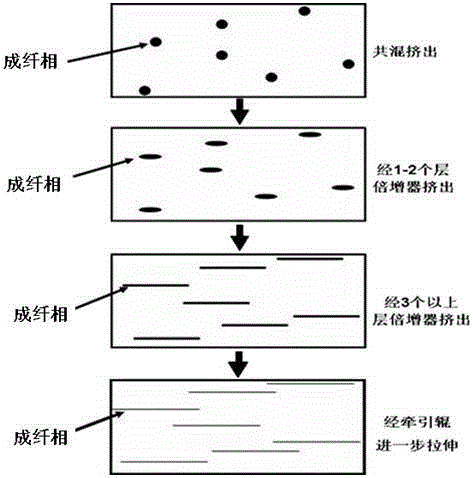

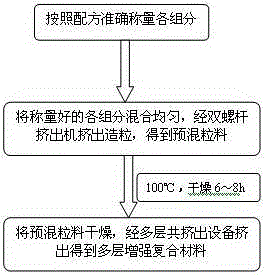

In-situ composite fiber forming reinforced polymer material as well as preparation method and device thereof

InactiveCN103059387AAvoid degradationGood compatibilitySynthetic resin layered productsFiberPolymer science

The invention discloses an in-situ composite fiber forming polymer material. The in-situ composite fiber forming polymer material comprises the following components in parts by weight: 70-90 parts of matrix, 5-25 parts of fiber forming phase, 1-9 parts of compatilizer and 0.1-0.5 part of accessory ingredient. According to the in-situ composite fiber forming polymer material disclosed by the invention, the compatibility of the fiber forming phase and the matrix phase is well improved; the interface tension between the two phase interfaces is reduced; the fiber forming phase is dispersed in the matrix more uniformly under the high-speed shearing action of the extrusion process, so that that the fiber dimension of the fiber forming phase fibers is more uniform, the fiber distribution is more uniform, the matrix material is reinforced better; and the in-situ composite fiber forming polymer material has better tensile property and mechanical property.

Owner:贵州省复合改性聚合物材料工程技术研究中心

Reinforcing bar binding machine

ActiveUS20090283168A1Improve accuracyEasy to shapeWire articlesOther manufacturing equipments/toolsWire rodWire cutting

A reinforcing bar binding machine is provided with: a guide tube for guiding a wire from a wire reel mounted on a binding machine body; a curl guide; a wire cutting mechanism disposed between the guide tube and the curl guide; a first guide pin that is disposed at an end portion of the guide tube or in a vicinity of the end portion of the guide tube, and guides an outer side surface which is an outer side of a wire curve; a second guide pin that is disposed at the end portion of the guide tube or in a vicinity of the end portion of the guide tube, and guides an inner side surface which is an inner side of the wire curve; and a third guide pin that is disposed inside of the curl guide and guides the outer side surface. The wire is brought into contact with the first guide pin, the second guide pin, and the third guide pin, when the wire is fed around a reinforcing bar.

Owner:MAX CO LTD

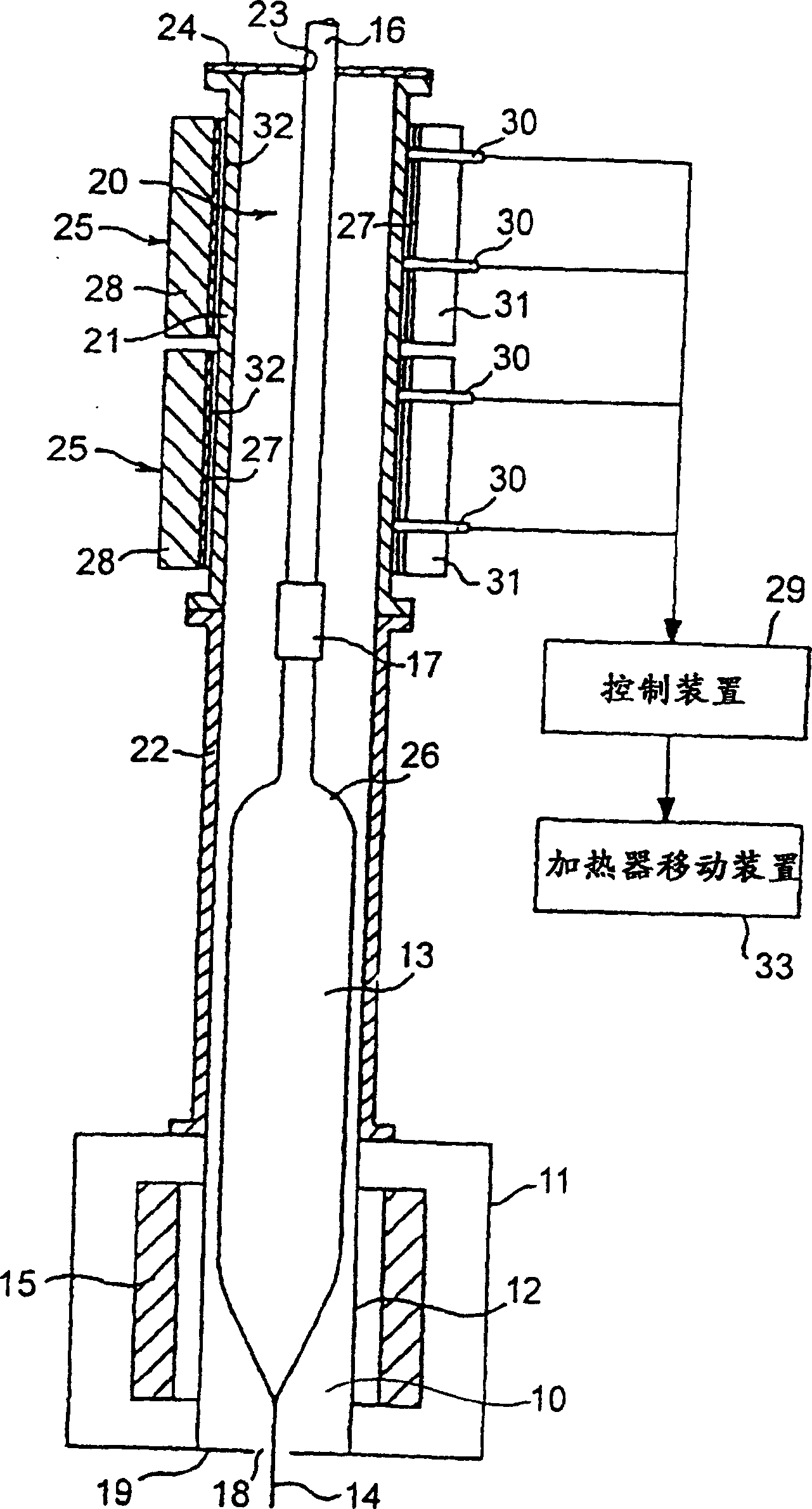

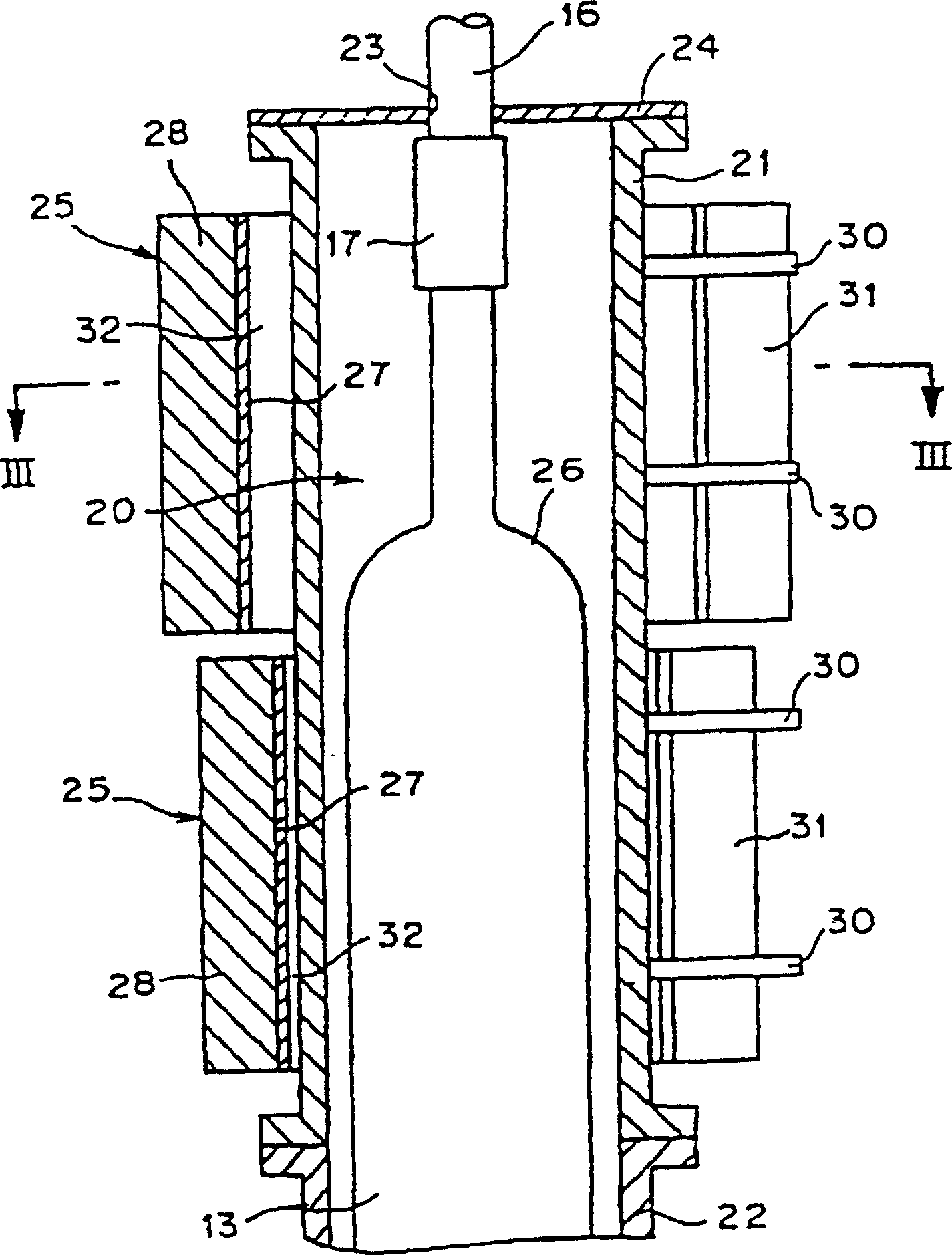

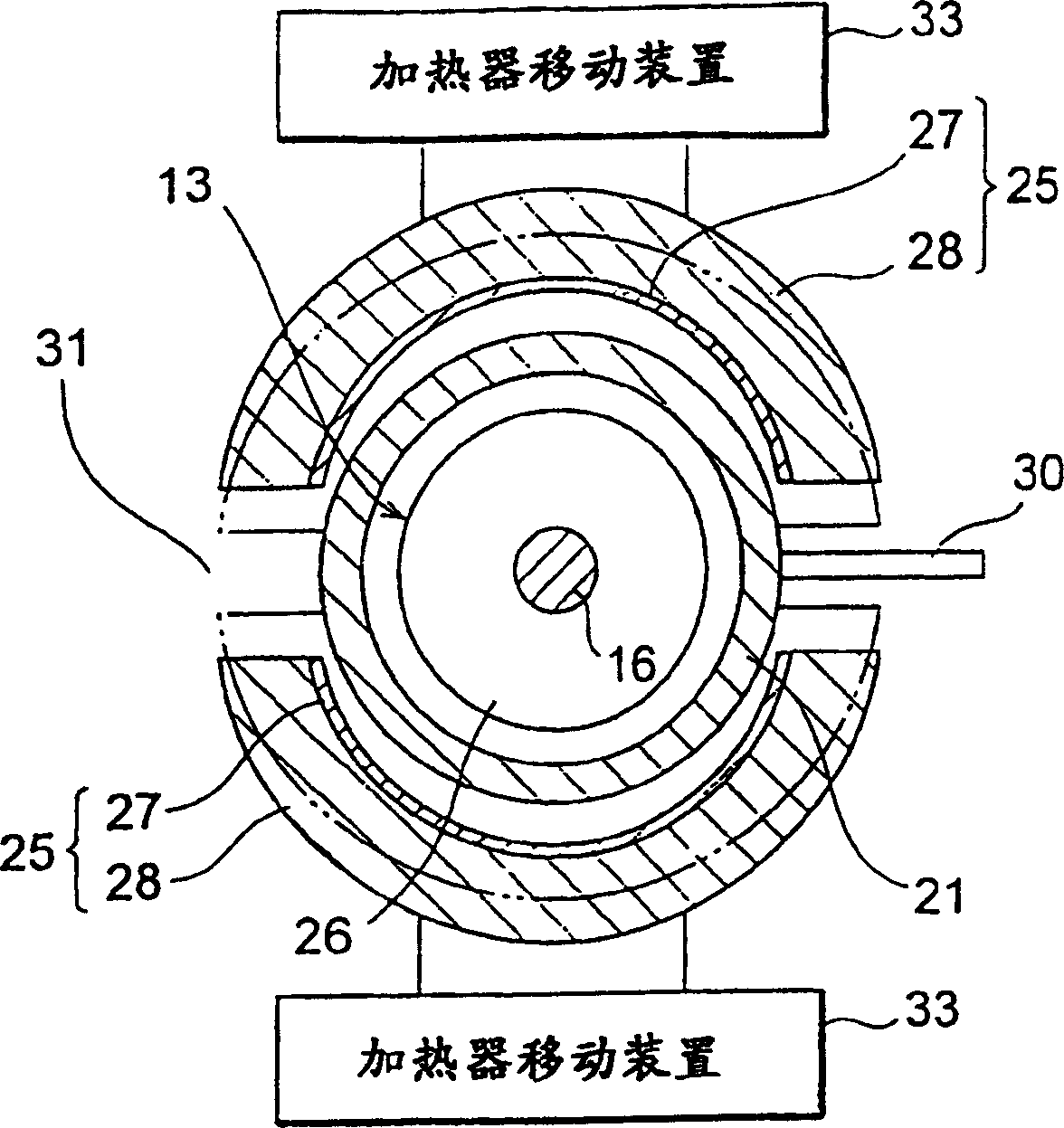

Optical fiber drawing method and drawing furnace

InactiveCN1557755AReliable diameterDiameter stableGlass fibre drawing apparatusOptical light guidesFiber drawingOptical fiber cable

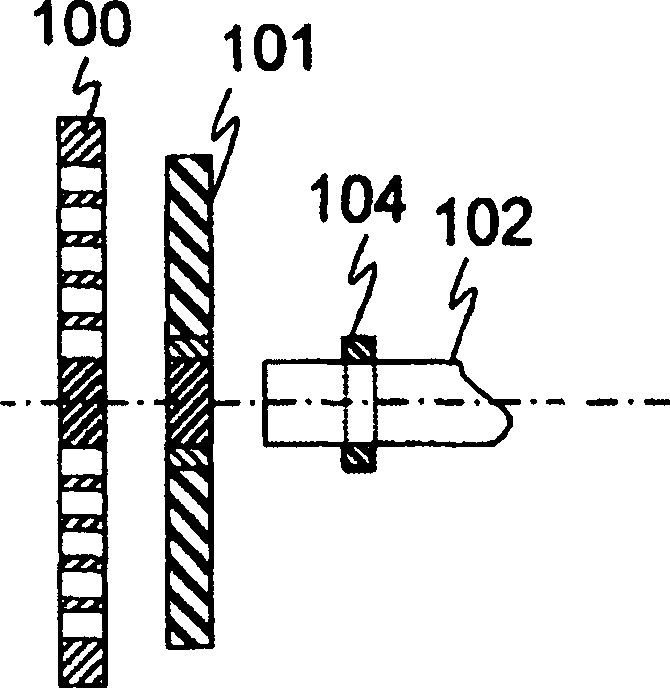

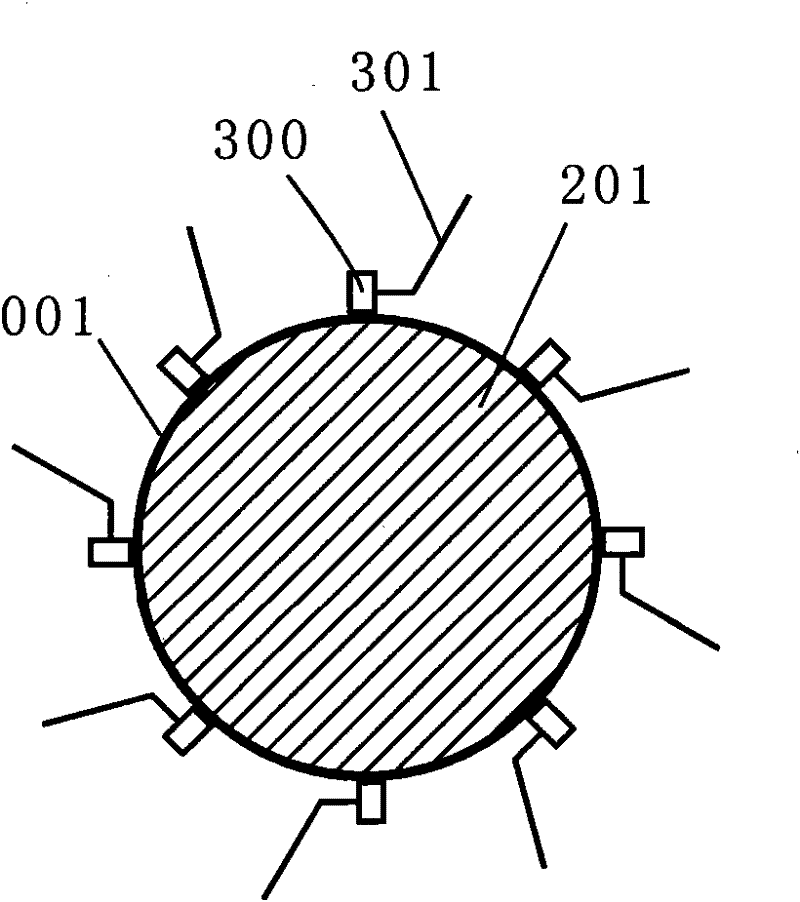

A fiber drawing method according to the present invention is a drawing method of optical fiber for drawing an optical fiber 14 from one end of a fiber preform 13 by softening with heat, wherein the fiber preform 13 is set in a semi-closed space 10, 20 opening in part at a lower end in a fiber drawing furnace, the fiber preform 13 is heated by a heater 15 disposed on the lower end side of this semi-closed space 10, 20, and fiber drawing is carried out with adjusting a quantity of heat dissipation from the upper portion 20 of this semi-closed space.

Owner:SUMITOMO ELECTRIC IND LTD

Novel optical fiber wiredrawing cooling system

ActiveCN105236732AImprove coating qualityDiameter stableGlass fibre drawing apparatusInsulation layerCooling effect

Owner:ZHONGTIAN TECH FIBER OPTICS +1

Preparation method of polylactic acid transparent straw

InactiveCN108976731AImprove extrusion stabilityDiameter stableTubular articlesStraight tubeDiameter ratio

The invention discloses a preparation method of a polylactic acid transparent straw. According to the preparation method, 94-96% of PLA, 2-3% of PEO, 1-2% of ParaloidKM-355P, 0.4-0.8% of VINNEX*2525 and 0.1-0.2% of EBS. The preparation method comprises the following steps of: adding the PLA into a double-screw extruder, adding the PEO, the ParaloidKM-355P, the VINNEX*2525 and the EBS into the double-screw extruder from a side feeding port, and carrying out extrusion, bracing, cooling, drying and slicing to obtain a modified resin for PLA straws, wherein a barrel temperature is 160 DEG C, a diehead temperature is 165 DEG C and a screw length-diameter ratio of the extruder is 52: 1; adding the obtained modified resin for PLA straws into a beverage straw manufacturing machine to carry out extrusion, traction, cooling and trimming so as to obtain a transparent a polylactic acid straight tube, wherein the barrel temperature is 160 DEG C, the die head is additionally provided with a melt pump, the die head temperature is 165 DEG C, and a cooling water temperature is 40-50 DEG C; and putting the transparent a polylactic acid straight tube into a full-automatic bendable straw forming machine to obtain a PLA high-transparency straw. According to the preparation method, the PLA application field is extended, traditional PP straws can be replaced so that the white pollution can be decreased, and the PLA is a natural bacteriostasis material and is beneficial for human health.

Owner:ANHUI JUMEI BIOLOGICAL TECH

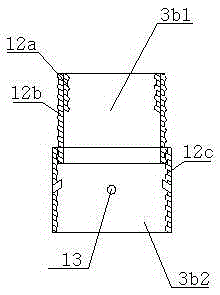

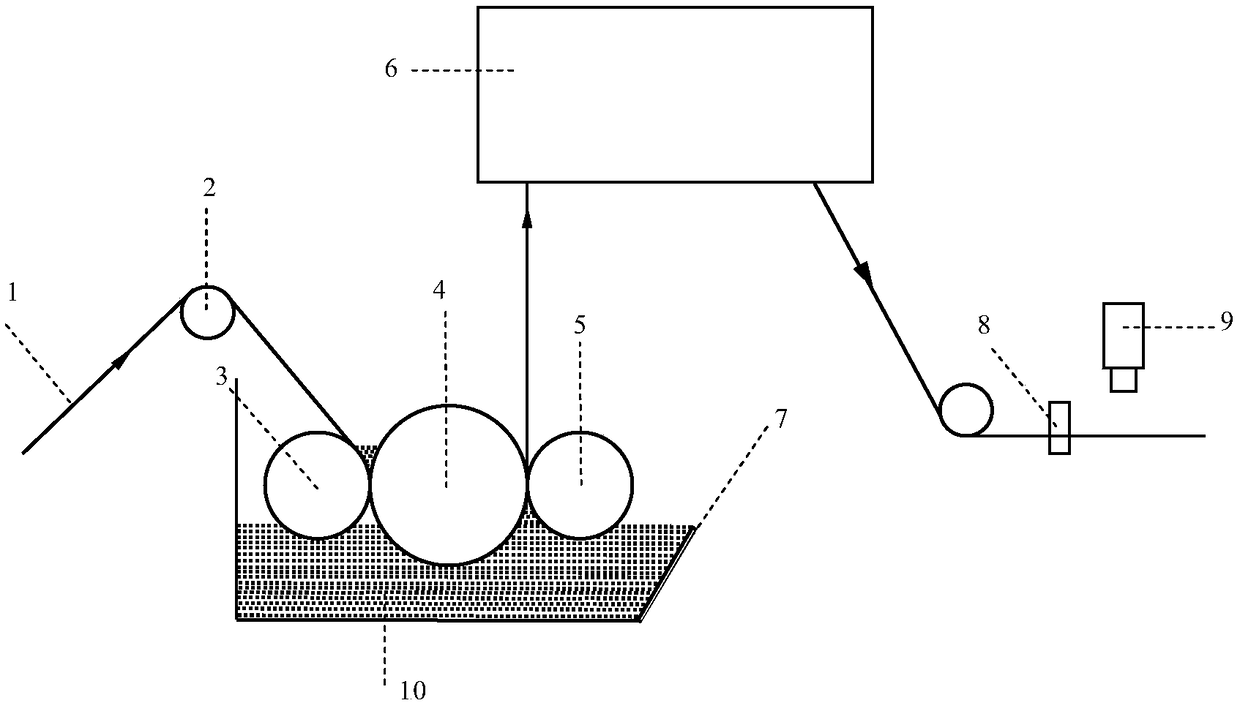

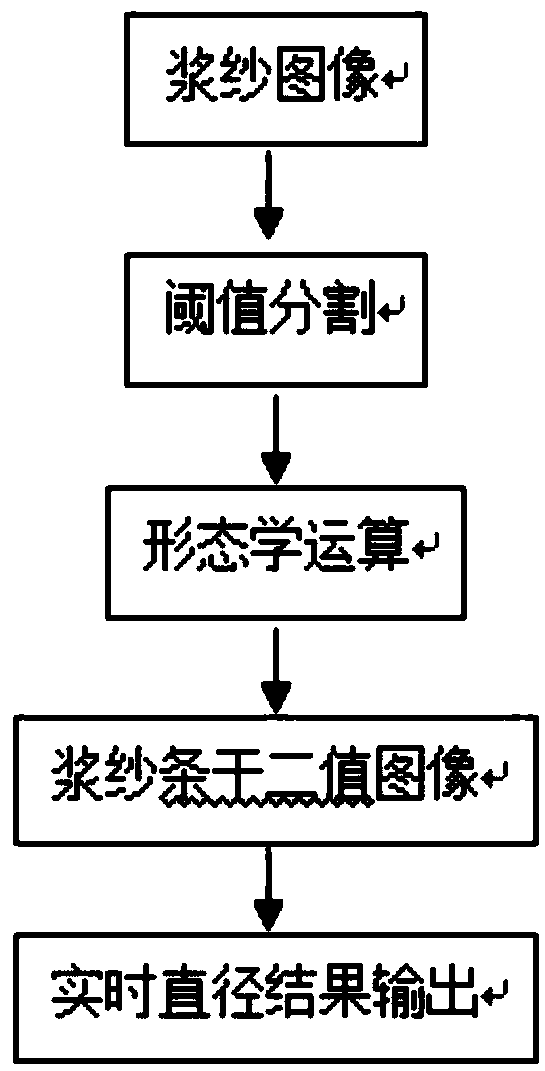

Sizing percentage online regulation and control method based on yarn form change

ActiveCN109493327ADiameter stableGuaranteed stabilityImage enhancementImage analysisFeature vectorYarn

The invention relates to a sizing percentage online regulation and control method based on yarn form change. The sizing percentage online regulation and control method comprises the following specificsteps: 1) acquiring a dried sheet yarn video image; 2) measuring the diameter of each yarn in each frame of video image, and calculating a mean value d; 3), taking the average diameter of the yarn within 10-15 minutes after driving as the standard diameter D of the batch of yarn; 4) calculating the difference value Delta d between the current yarn diameter mean value d and the standard diameter D, Delta d = d-D; 5) taking Delta d as one of the input layer feature vectors, and calculating the size of a grouting force change value Delta F by adopting a deep learning neural network; and 6) adjusting the grouting force in real time according to the grout force change value Delta F obtained in the step 5). The diameter variation Delta d is obtained by measuring the instant diameter d of the dried yarn and comparing the instant diameter d with the standard diameter D, and the squeezing force is further adjusted on line according to the size of the Delta d, so that the diameter of the driedyarn tends to be stable, and the stability of the sizing quality in the sizing production process is guaranteed.

Owner:JIANGNAN UNIV

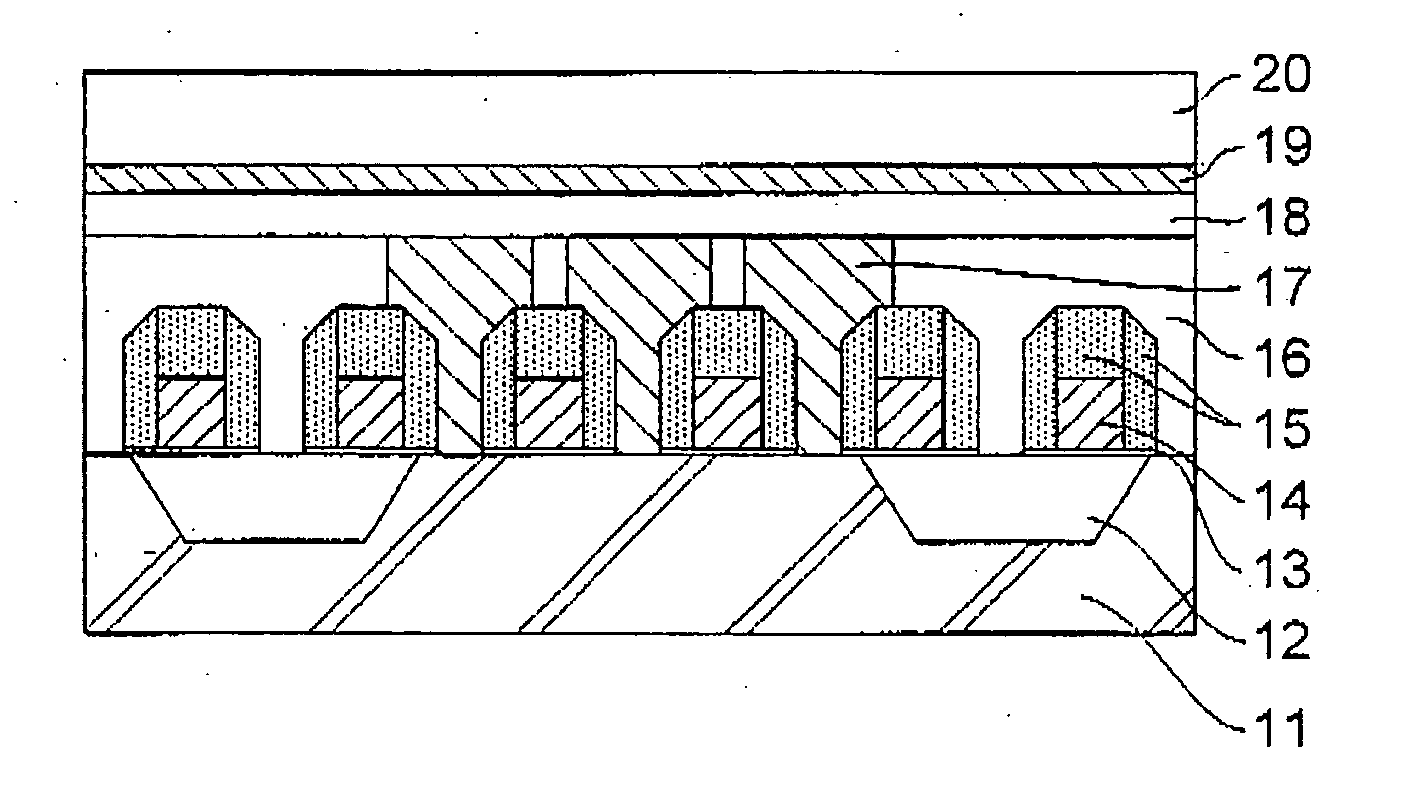

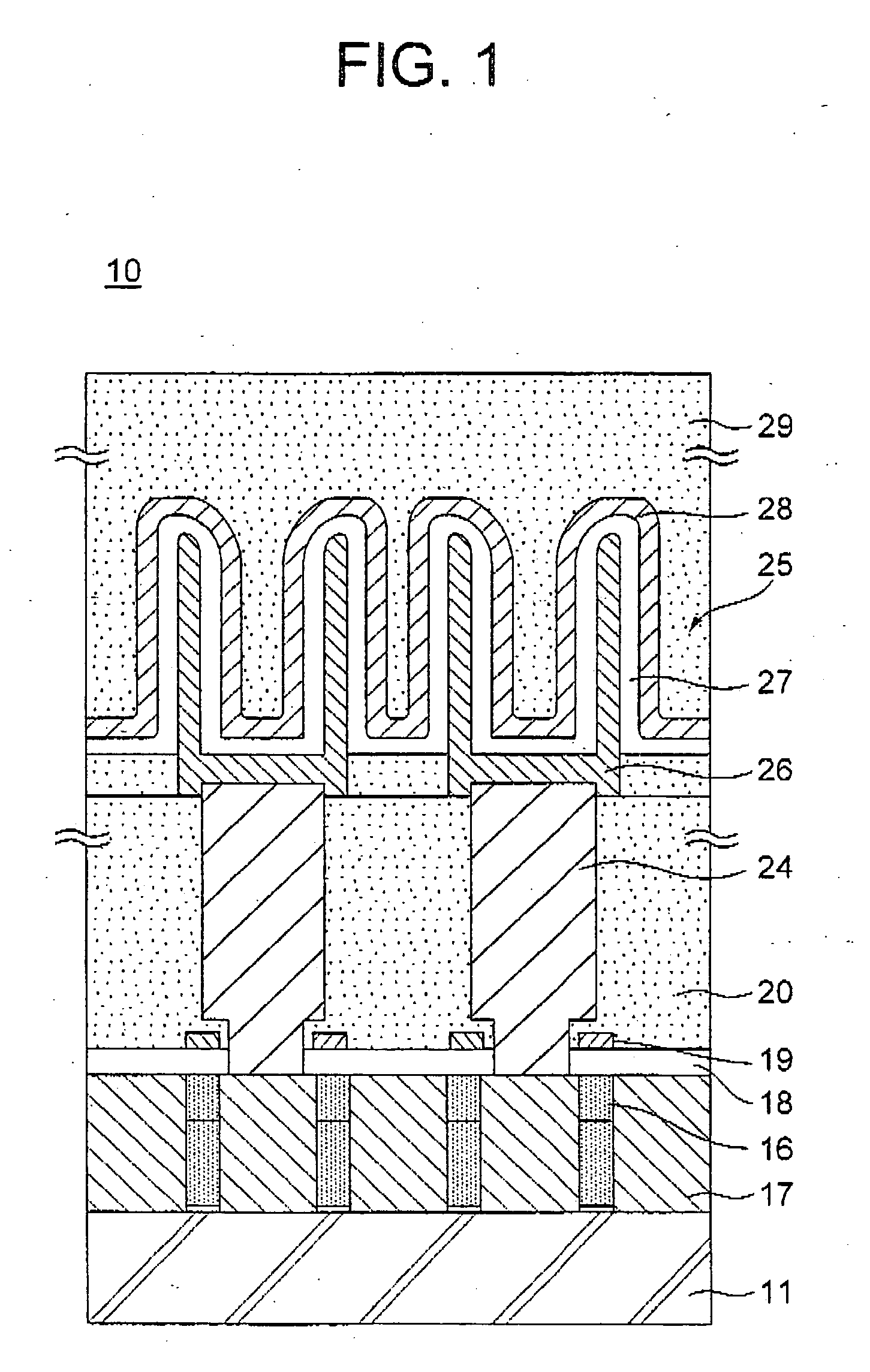

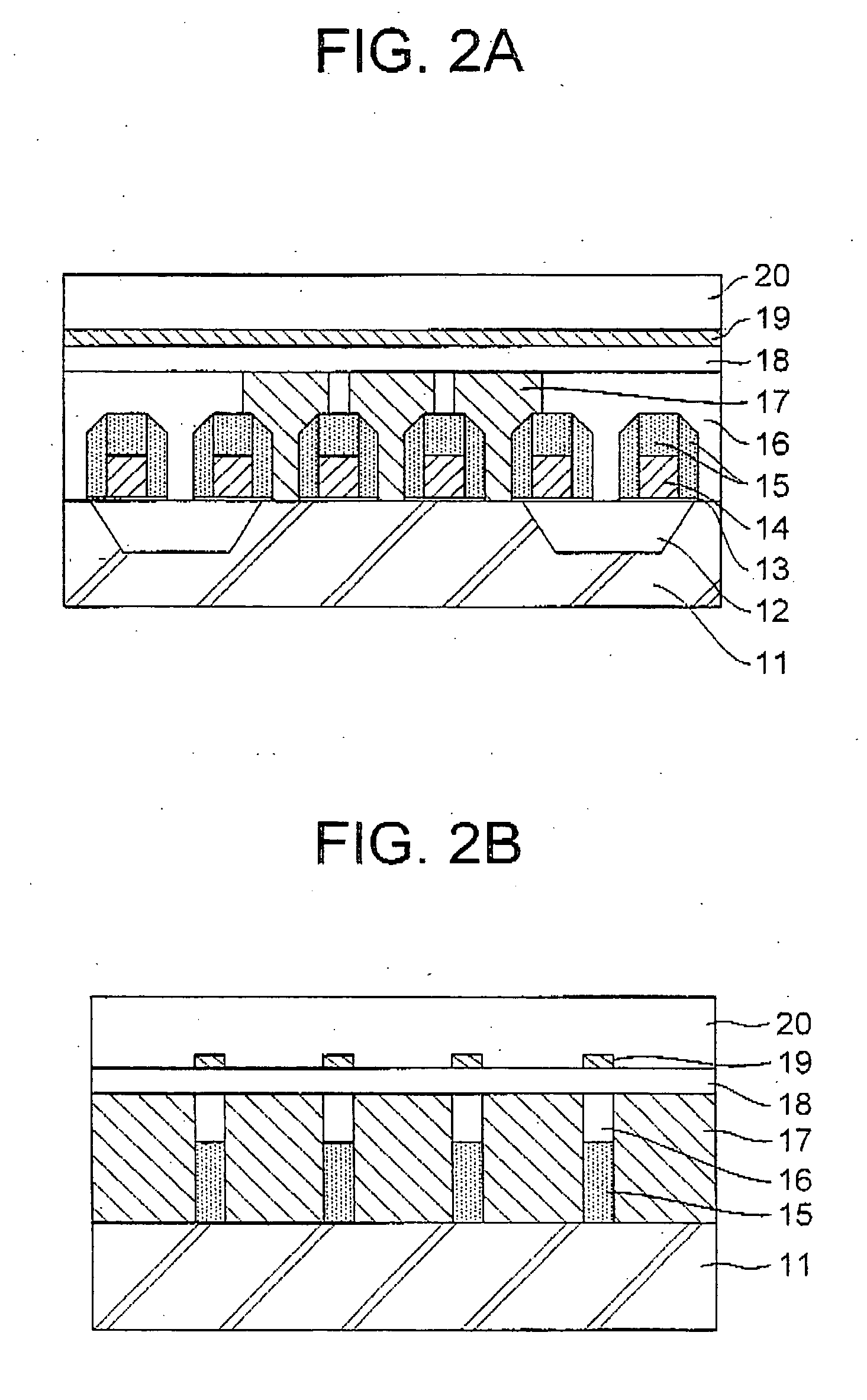

Method for manufacturing a semiconductor device having a stepped contact hole

InactiveUS20070077774A1Improve etch selectivityDiameter stableSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

A process for forming a stepped contact hole includes: dry-etching a portion of a silicon oxide film using a mixed gas including carbon-rich fluorocarbon gas to form a first contact hole, forming a specific film on the sidewall of the first contact hole; dry-etching the remaining portion of the silicon oxide film at the bottom of the first contact hole by using the specific film as a mask to form a second contact hole extending from the first contact hole; and removing the specific film.

Owner:ELPIDA MEMORY INC

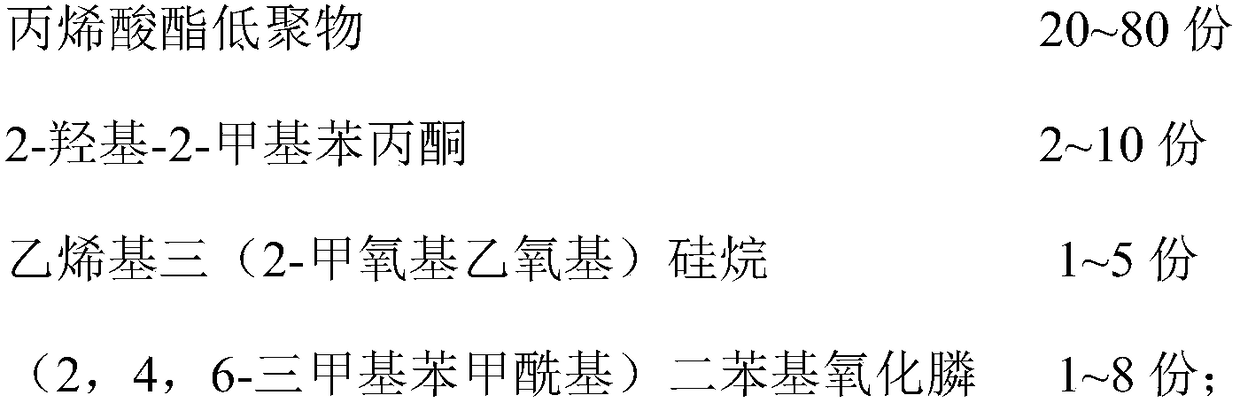

High temperature resistant optical fiber and preparation method thereof

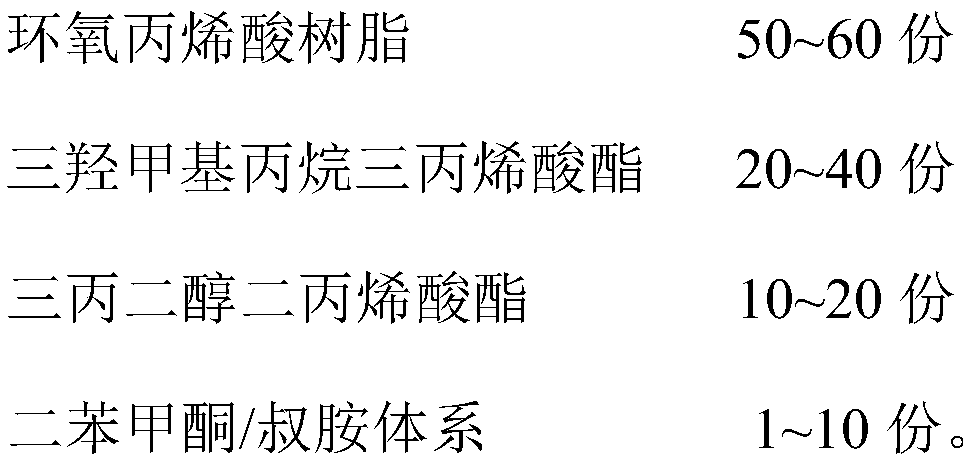

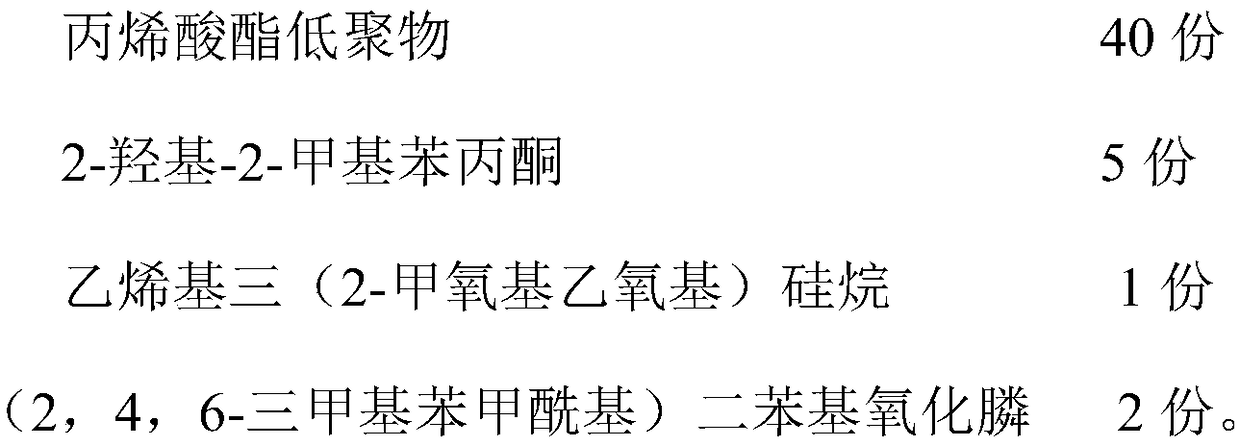

ActiveCN109180023AImprove toughnessHigh strengthGlass optical fibreOptical waveguide light guideUltrasound attenuationOligomer

The invention provides a high temperature resistant optical fiber and a preparation method thereof. The high temperature resistant optical fiber comprises an optical fiber core layer, a cladding layerand a double-layer coating, wherein, the coating material of an inner coating is composed of an acrylate oligomer, 2-hydroxyl-2-methyl propiophenone, vinyl tri(2-methoxy ethoxyl) silane and (2,4,6-trimethyl benzoyl)diphenyl phosphine xide; an outer coating is a high temperature resistant acrylic resin outer coating. The high temperature resistant optical fiber still maintains the reliability of optical transmission at a high temperature environment of 150DEG C for a long time, optical fiber coating has no aging phenomena of yellowing and blackening. The method is simple. The optical fiber transmission loss of the high temperature resistant optical fiber prepared at the wiredrawing speed of 2000-2200m / min, the attenuation value of the optical fiber at 1550nm is not more than 0.25dB / km, theadditional attenuation value of the optical fiber at environment of 150DEG C for a long time is not more than 0.05dB / km.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

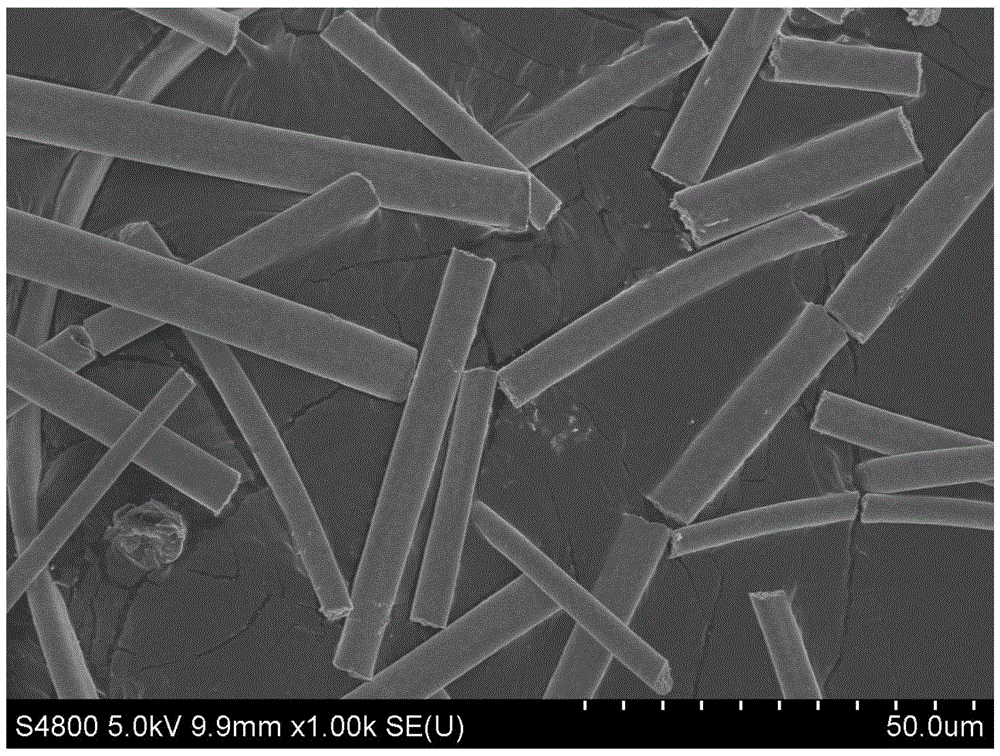

Barium zirconate fiber and method for preparing same

ActiveCN105624834AGood crystallization performanceUniform diameterInorganic material artificial filamentsSolventChemistry

The invention relates to a barium zirconate fiber and a method for preparing the same. The diameter of the barium zirconate fiber is 1-20 micrometers, and crystalline phases of the barium zirconate fiber are cubic phases and can keep stable under the condition of high temperatures of 1500 DEG C. The method includes proportionally sufficiently stirring basic zirconium carbonate, barium sources, acid sources and solvents under the condition of temperatures of 10-90 DEG C until solution is clear and transparent, and concentrating the solution under vacuum conditions to obtain barium zirconate precursor spinning solution; carrying out high-speed centrifugal thread throwing on the precursor spinning solution to obtain a diameter precursor fiber and carrying out high-temperature heat treatment on the diameter precursor fiber to obtain the barium zirconate fiber. The barium zirconate fiber and the method have the advantages of simple processes, low cost, high yield, environmental friendliness and the like. Besides, the barium zirconate fiber is reliable in quality, has the uniform diameter and has a broad application prospect in the field of high-temperature heat-insulation materials, high-temperature proton conductors, fuel batteries and the like.

Owner:SHANDONG UNIV

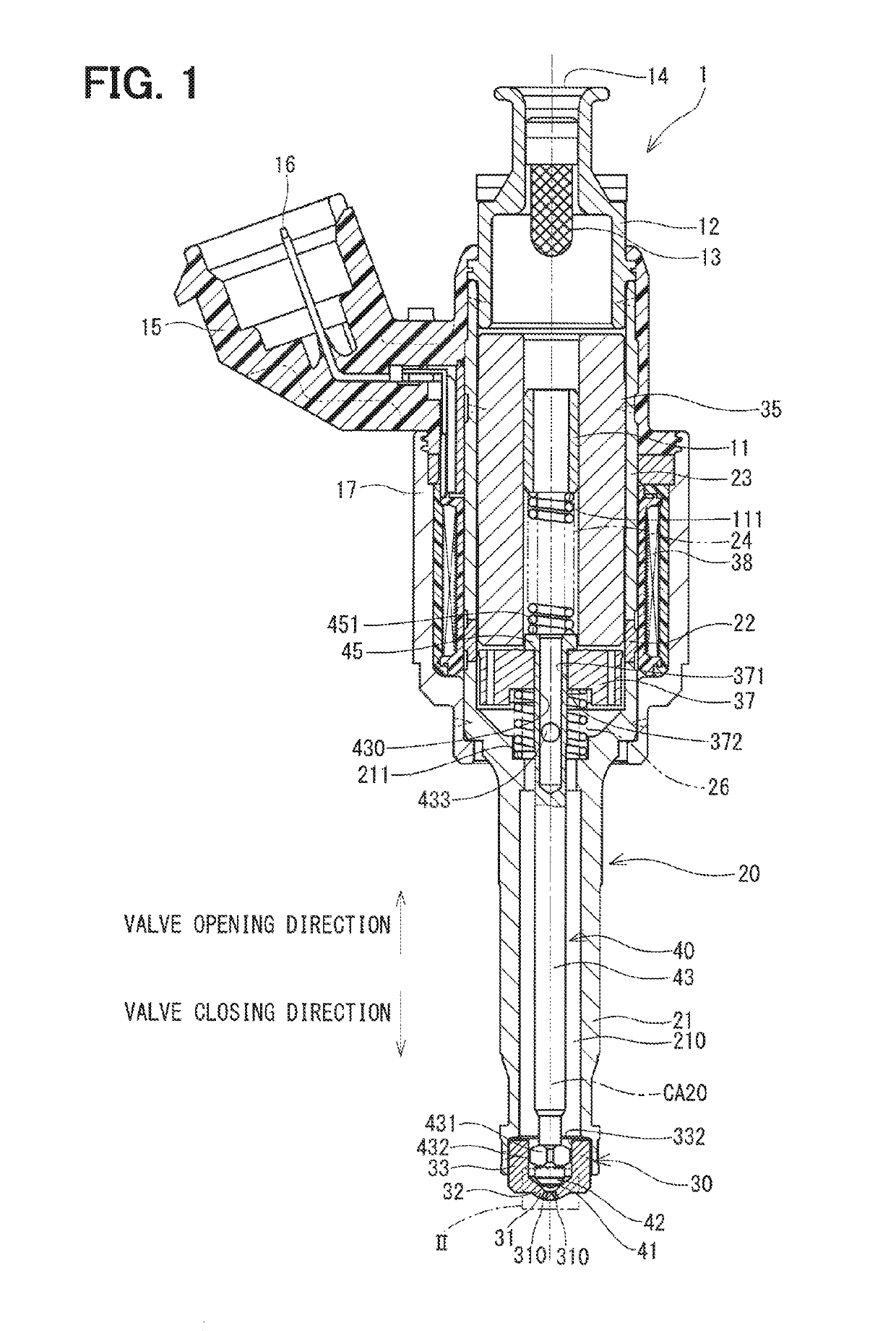

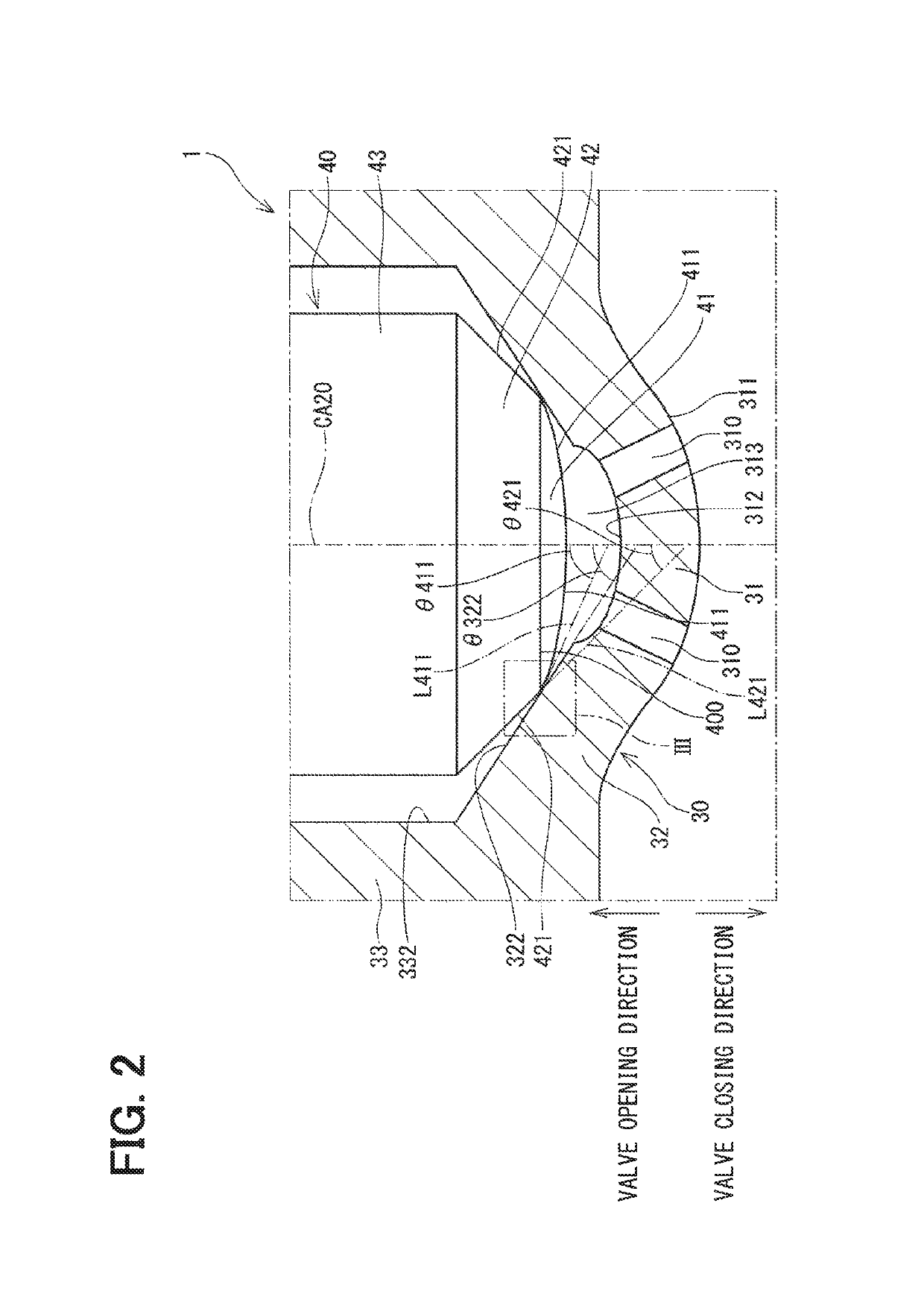

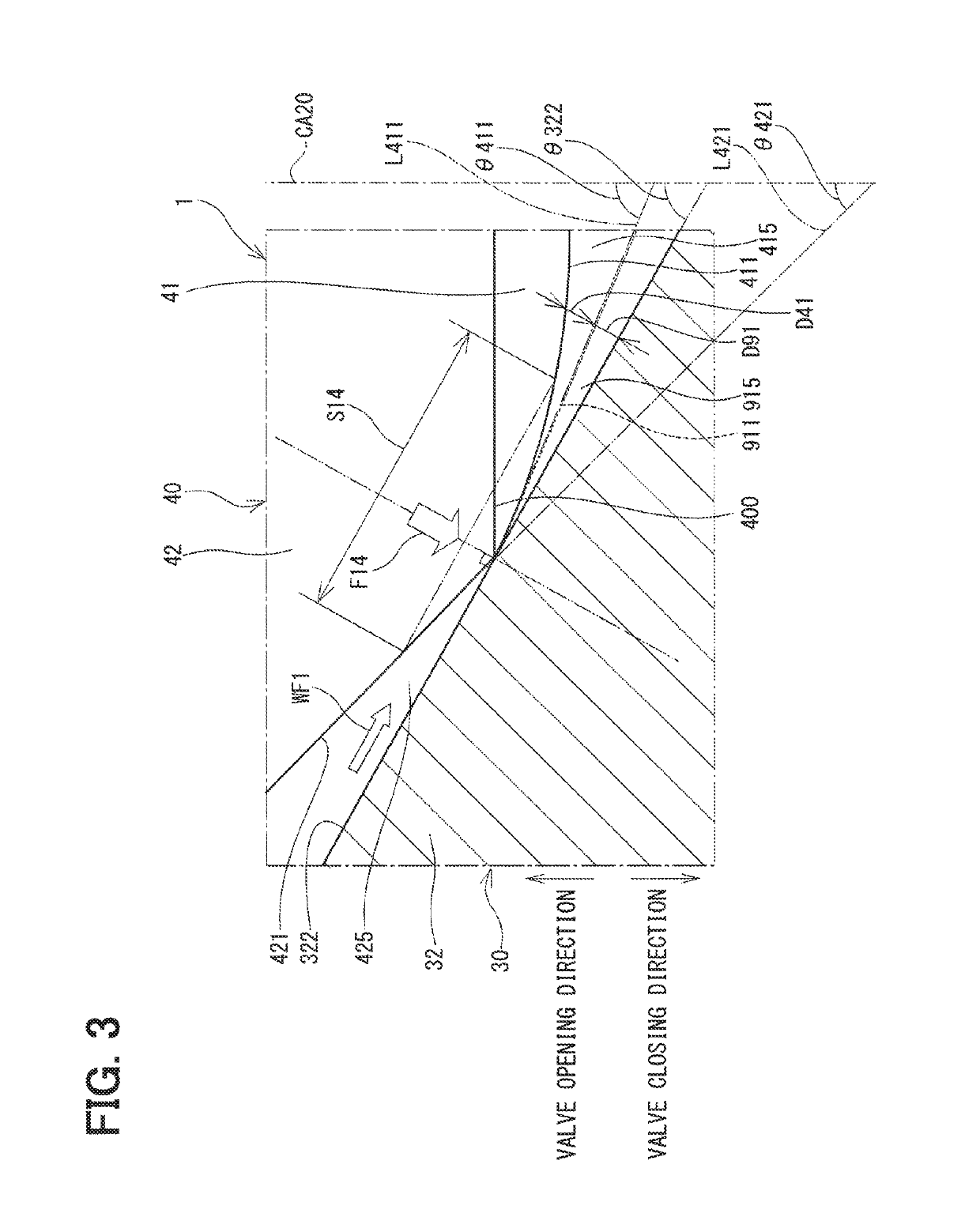

Fuel injection valve

ActiveUS10302054B2Slow changeReliable supplyOperating means/releasing devices for valvesWear reducing fuel injectionEngineeringSpherical form

A needle includes a first seal portion, which is formed at an end portion of the needle located on a side where an injection hole is placed, and a second seal portion, which is formed on a side of the first seal portion where a stationary core is placed. When a boundary between a first outer wall of the first seal portion and a second outer wall of the second seal portion is lifted away from or is seated against an inner wall, the injection hole is opened or closed. Thereby, a seat diameter of the boundary and the inner wall is stabilized, and a change in a fuel injection quantity caused by aging can be reduced. Furthermore, the first outer wall of the first seal portion is shaped into a form of a spherical surface.

Owner:DENSO CORP

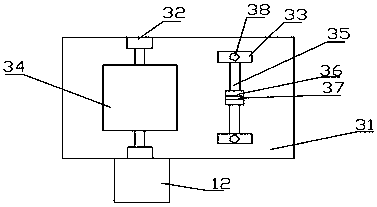

Automatic wire diameter control device of cable extruder

PendingCN109192404AGood heat shrinkabilityDiameter stableInsulating conductors/cablesMotor driveAutomatic control

FIELD OF THE INVENTION that present invention relate to the field of cable extrusion device control, in particular to a wire diameter automatic control device of a cable extruder, including extruders,cooling device, Coil-wire mechanism and control device, the extruder includes a base, A motor, a gear device and a barrel, wherein a screw is arranged in the barrel, the motor drives the screw to rotate through the gear device, an electromagnetic heating device is arranged on the barrel, the electromagnetic heating device is connected with a control device, the electromagnetic heating device is used for heating the barrel, and a first feeding mechanism, a second feeding mechanism and the like are respectively arranged on the barrel along the axial direction. The invention has simple structure, stabilizes cable diameter, ensures product quality, reduces waste of materials, reduces production cost of cable manufacturing industry, has perfect production assurance and fault handling capacity,realizes remote on-line monitoring of production process data, and improves automation degree of production equipment. The invention is simple in structure, has stable cable diameter, ensures productquality, reduces waste of materials, reduces production cost of cable manufacturing industry, and has perfect production assurance and fault handling ability.

Owner:湖州新得意特种电磁线有限公司

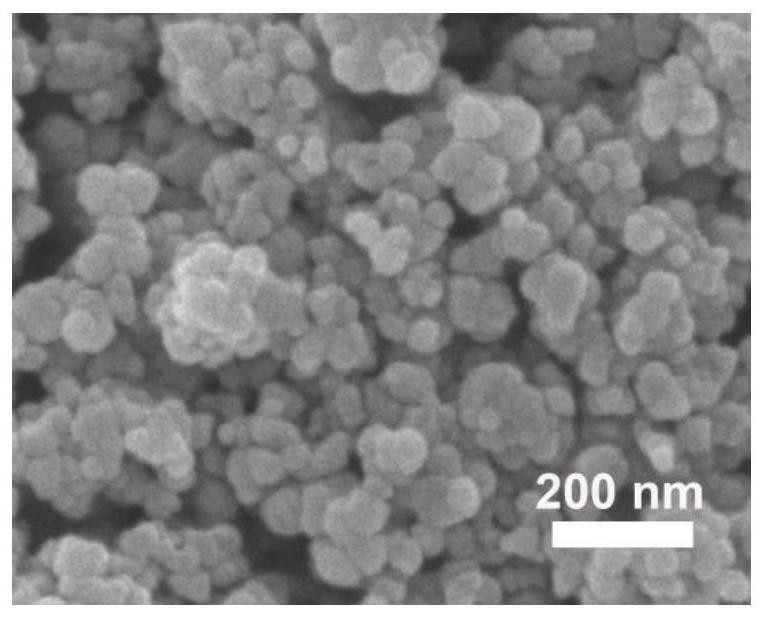

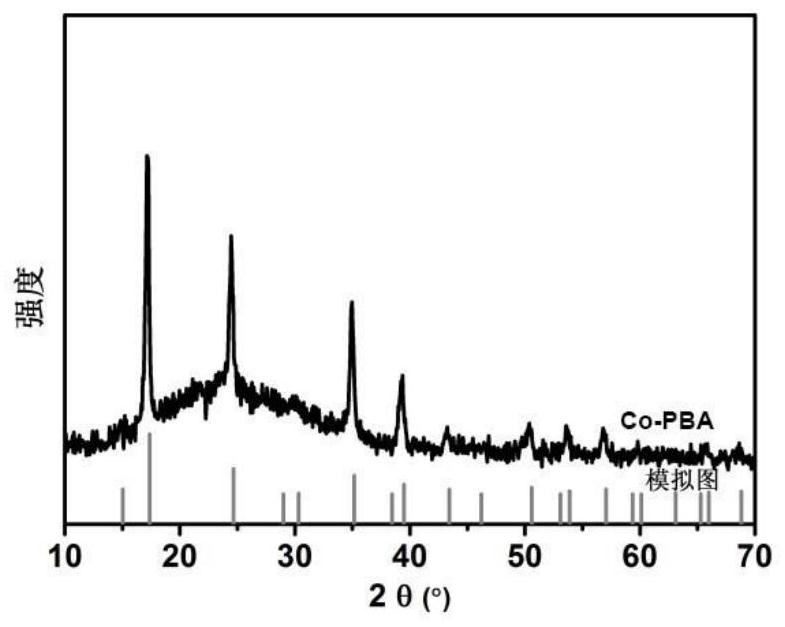

Thermal or solvent dual-stimulus color-changing response nanofiber membrane and preparation method and application thereof

ActiveCN112430898AEvenly distributedSpeed up the application processMonocomponent synthetic polymer artificial filamentNon-woven fabricsSpinningComposite nanofibers

The invention provides a thermal or solvent dual-stimulus color-changing response nanofiber membrane and a preparation method and application thereof. The preparation method comprises the following steps that a Prussian blue analogue is prepared firstly, and then electrostatic spinning is carried out on the Prussian blue analogue and a high-molecular compound polyacrylonitrile to obtain the nanofiber membrane. The inorganic stimuli-responsive color-changing material has the advantages of being easy to synthesize, low in toxicity and high in stability. Effective combination of the color-changing material and electrostatic spinning is achieved, the composite nanofiber membrane with good self-supporting performance and flexibility can be directly prepared, and subsequent application of the composite nanofiber membrane is facilitated. The obtained fiber membrane has the advantages of rapid color response to thermal and solvent dual stimulation, good reusability and the like, and can be used in the fields of anti-counterfeiting, secret communication and the like.

Owner:SHANDONG UNIV

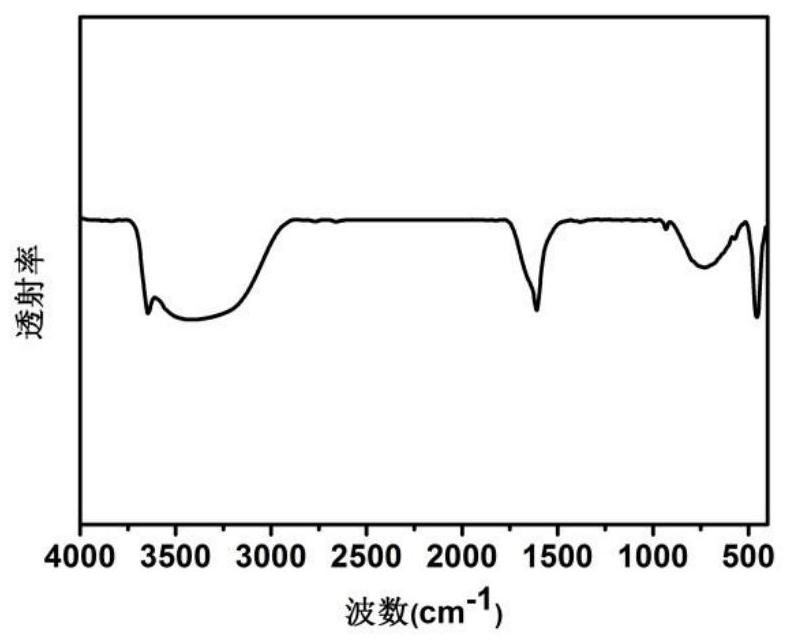

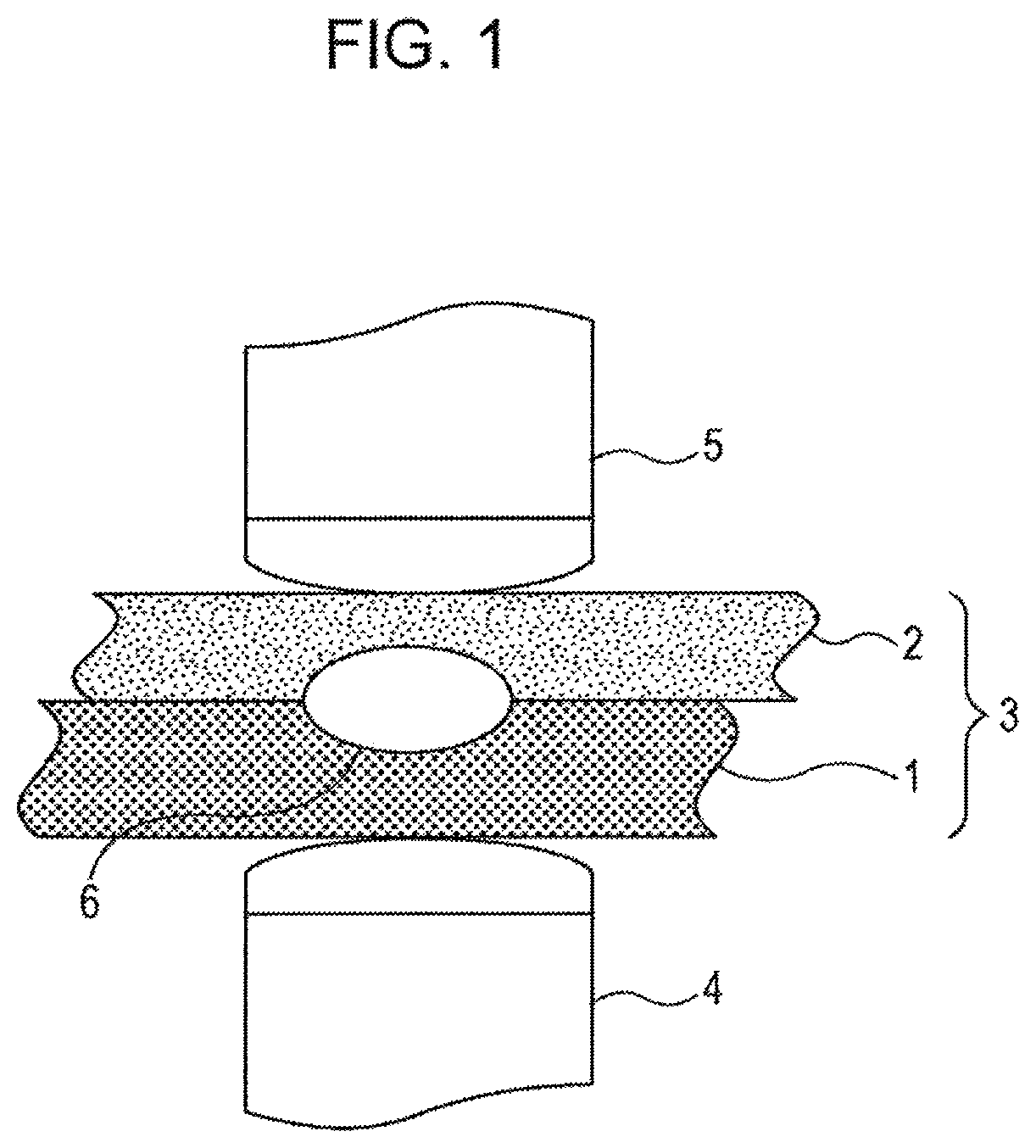

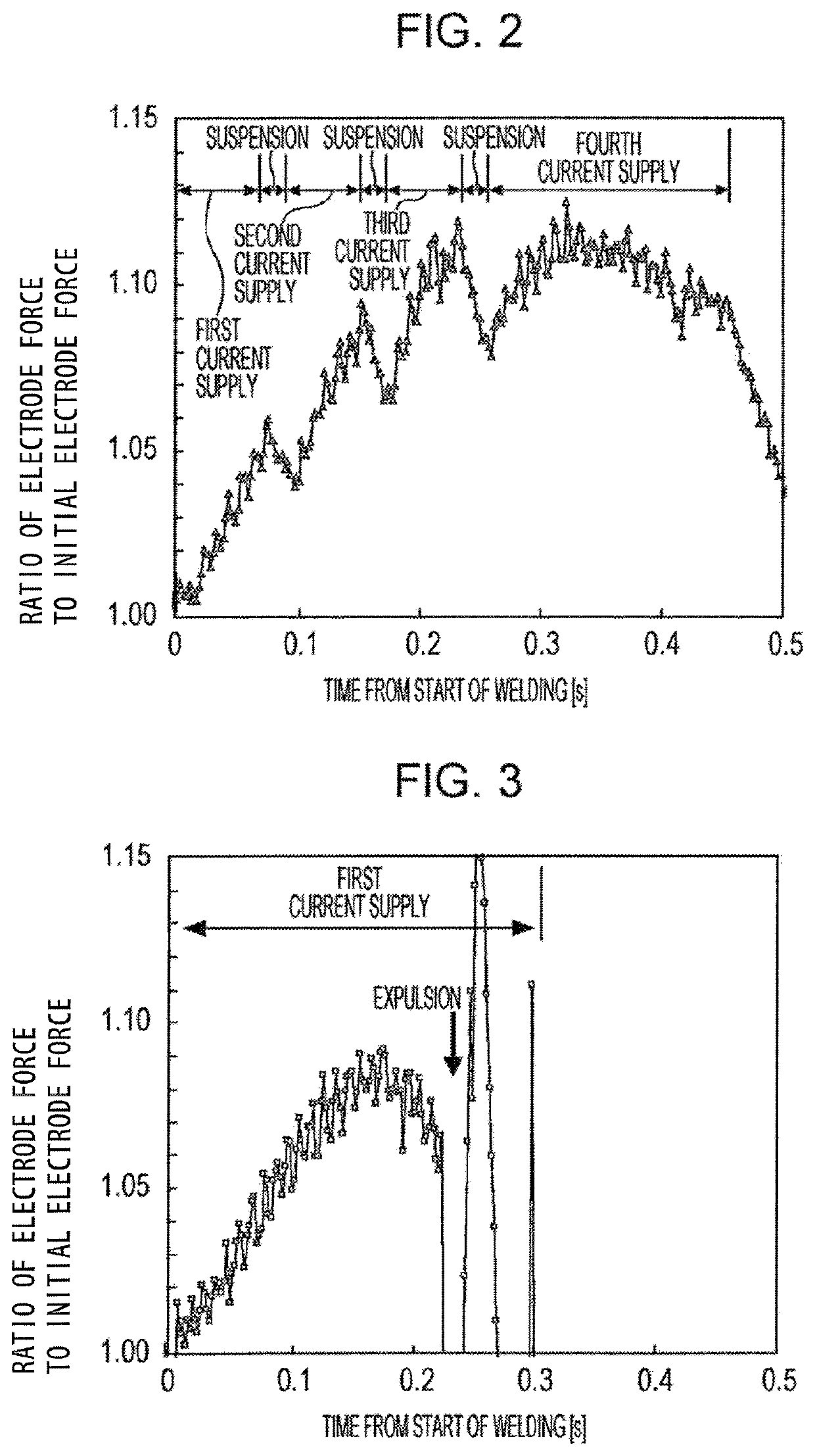

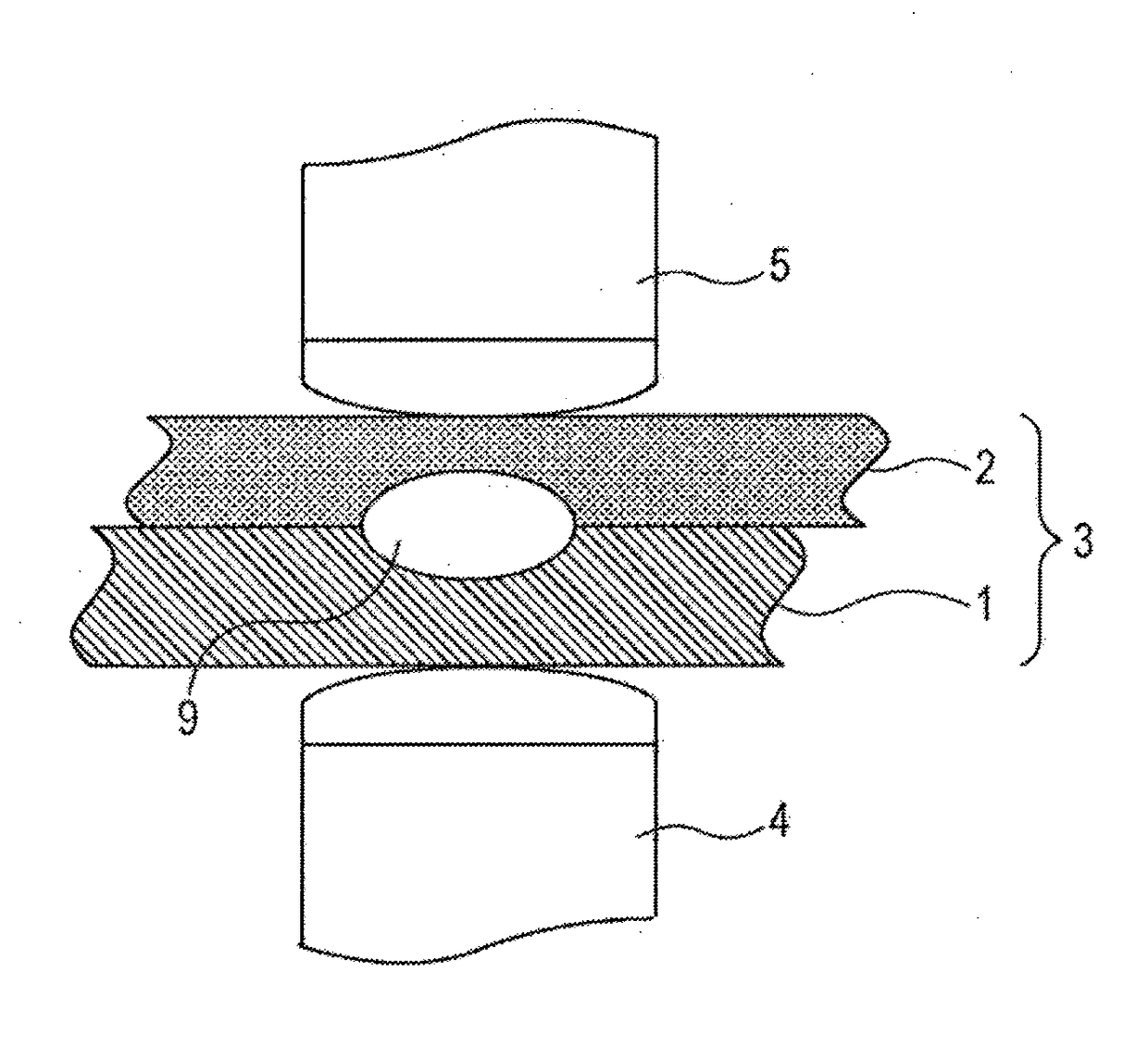

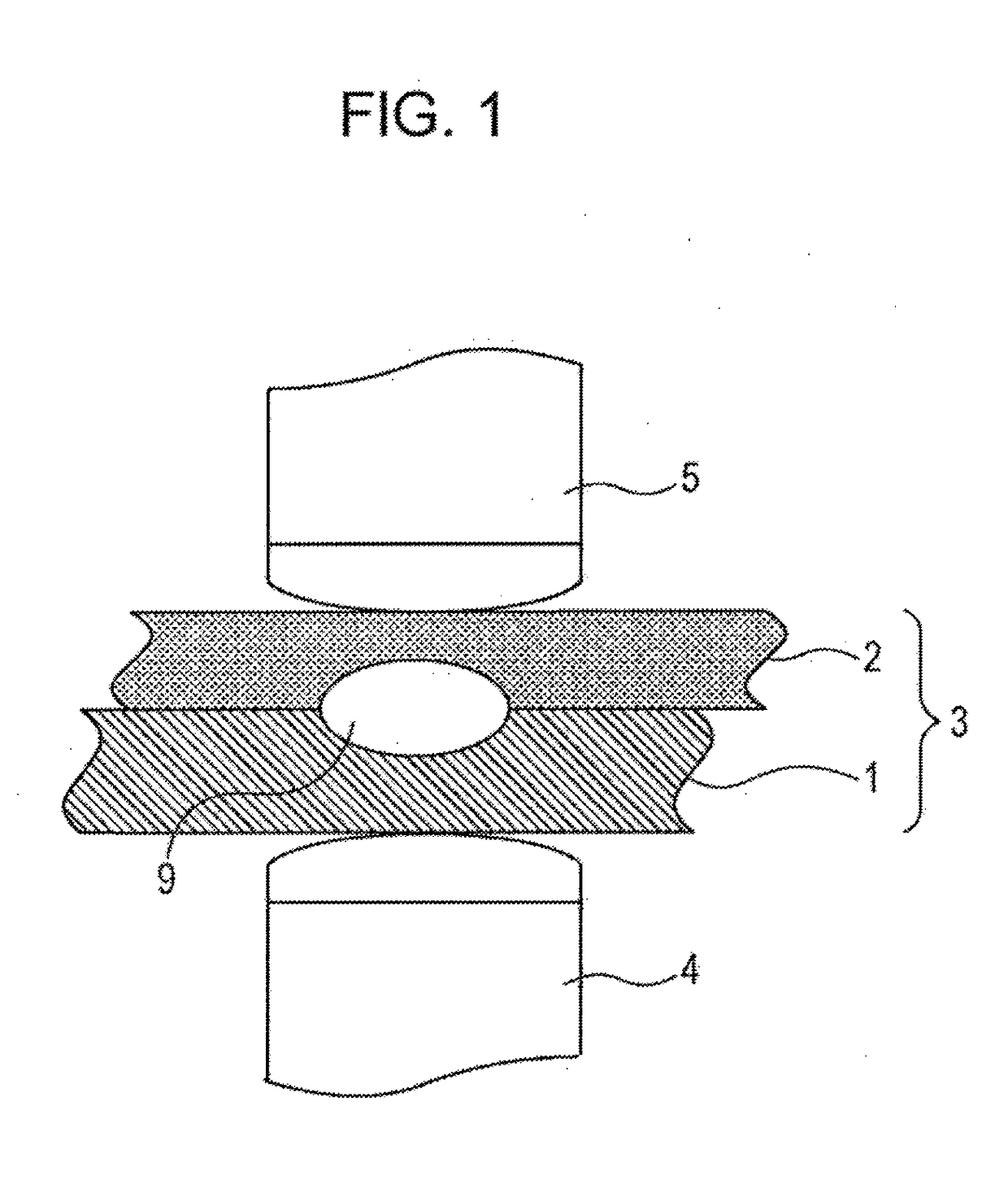

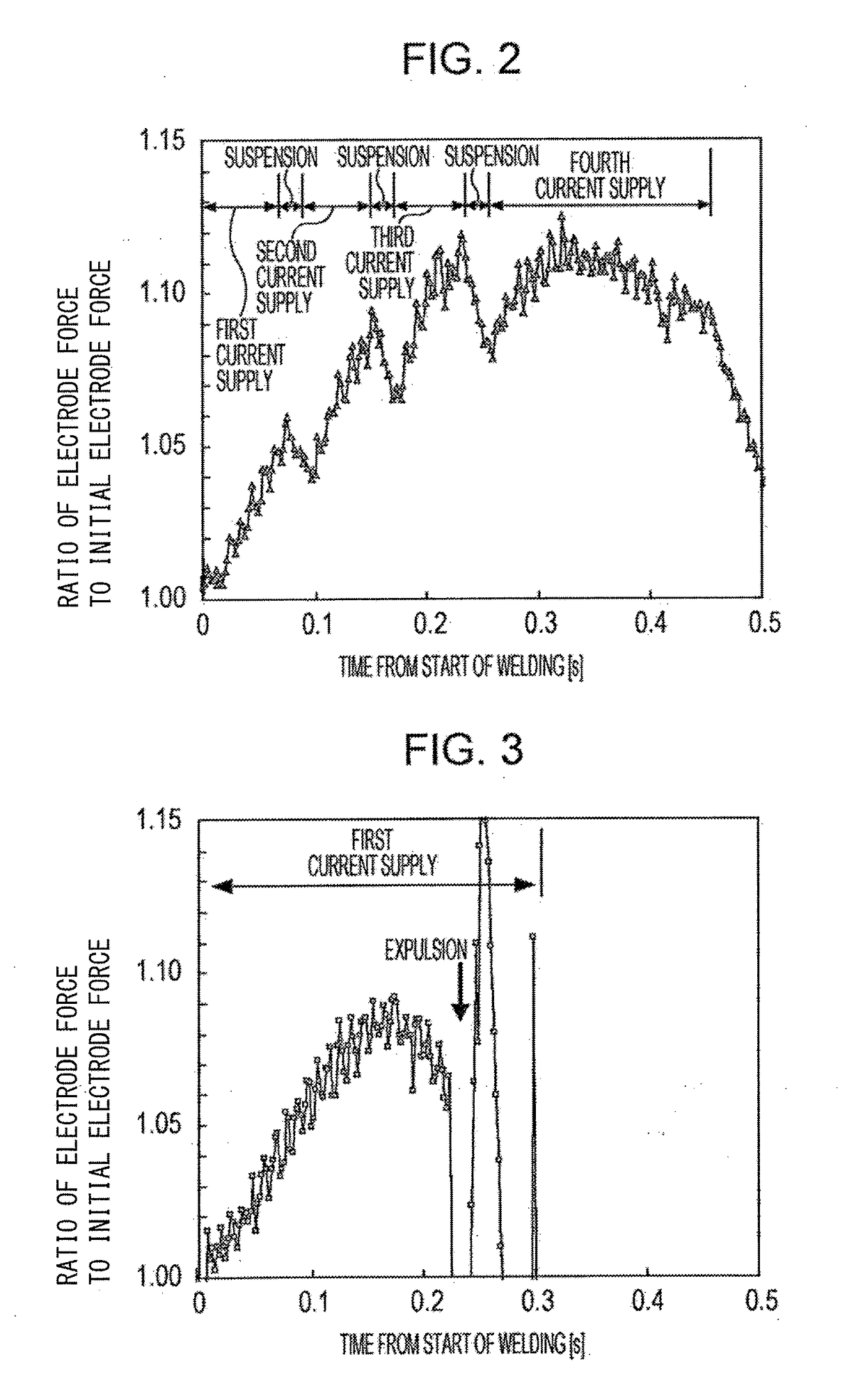

Resistance spot welding method and weld joint

ActiveUS10641304B2Avoid it happening againDiameter stableElectrode supporting devicesWelding electric suppliesElectrical resistance and conductanceSpot welding

Owner:JFE STEEL CORP

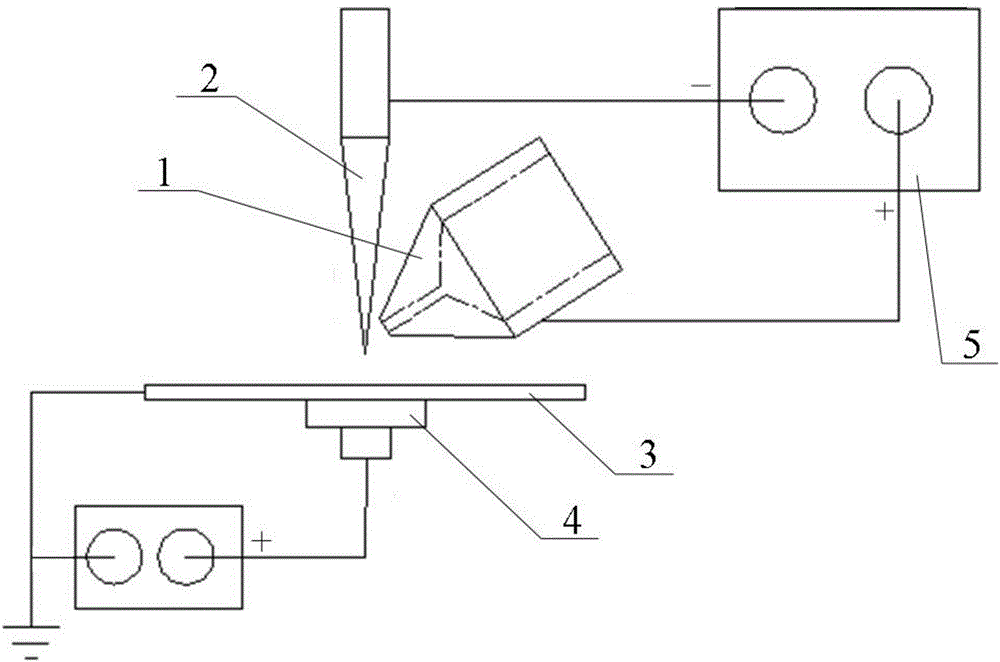

Fusion electro-spinning jet flow excitation stability improving device

InactiveCN106515009AImproved jet excitation stabilityEliminate disturbanceAdditive manufacturing apparatusManufacturing material handlingJet flowElectrical polarity

The invention discloses a fusion electro-spinning jet flow excitation stability improving device. The improving device comprises a feeding needle cylinder for discharging fusion materials according to the preset feed amount, a jet flow needle head which is used for attracting the fusion materials discharged by the jet flow needle head and enabling the fusion materials to be condensed into a Taylor cone, and a printing plate which is arranged below the jet flow needle head and moves in a horizontal plane according to a preset path; the bottom of the printing plate is provided with a polar plate; the jet flow needle head has polarity, and the polarity of the polar plate is opposite to that of the jet flow needle head; and the printing plate is connected with the ground. In this way, as the fusion materials are fused in the feeding needle cylinder and discharged at first and then are attracted and condensed through the jet flow needle head, finally polarity is given to the fusion materials, and directional jet is conducted; thus, the process that the fusion materials are heated inside the jet flow needle heat in an electric heating mode is omitted, electric charge disturbance of the fusion materials at the tail end of the jet flow needle head is eliminated, and the diameter tends to be stable after jet flow is excited; and accordingly, the whipping phenomenon in the jet flow excitation process is weakened, and the accuracy degree of a jet flow drop point and the printing precision of a biological scaffold are improved.

Owner:GUANGDONG UNIV OF TECH

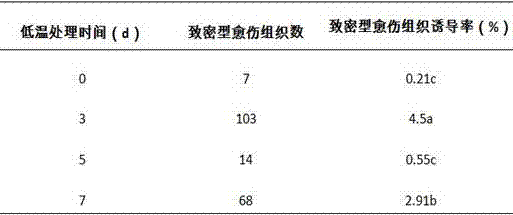

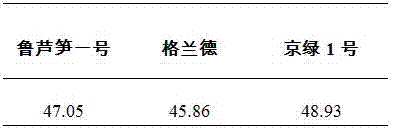

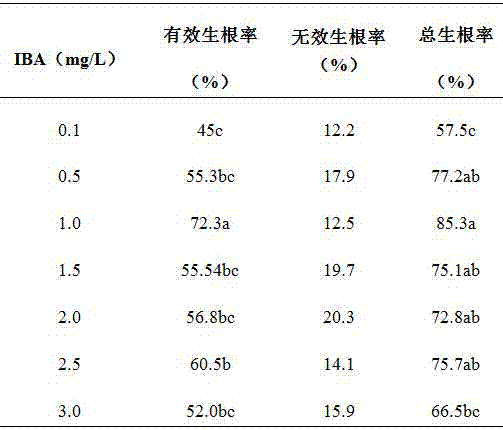

Method for acquiring asparagus homozygous diploid by culturing anther

InactiveCN107873519ADiameter stableUniform diameterHorticulture methodsPlant tissue cultureAsparagalesBiology

The invention provides a method for acquiring asparagus homozygous diploid by culturing anther. The method comprises the following steps: acquiring asparagus anther, pre-treating the asparagus anther,performing callus induction for the asparagus anther, performing sub-generation differentiation for the asparagus anther, rooting a test-tube seedling, and multiplying haploid chromosome. By adoptingthe method for acquiring the asparagus homozygous diploid by culturing anther, the induction rate of callus with hard and compact texture of the asparagus anther is 7.2 to 17 percent; and the callusinduction rate of the variety ''champion'' with hard and compact texture is 15.8 to 17 percent or higher. According to the method for acquiring asparagus homozygous diploid by culturing anther, the haploid differentiation rate is 2.2 to 7.2 percent, the success rate for obtaining the homozygous diploid and multiploid by inducing the haploid is 45.86 to 49.73 percent, and the ratio of the homozygous diploid is 1.6 to 2.9 percent.

Owner:SHANDONG WEIFANG ACADEMY OF AGRICULTURAL SCIENCES

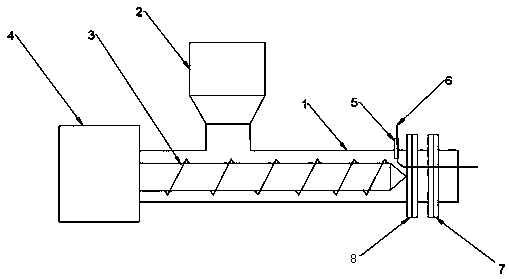

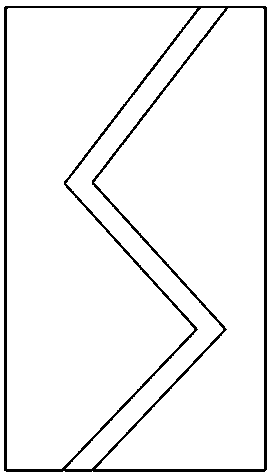

Forming method of hard alloy bar with spiral hole

The invention discloses a forming method of a hard alloy bar with a spiral hole. According to the forming method, hard alloy powders and a polymer wire are used as raw materials, a hard alloy blank with the polymer wire is formed after the raw materials are extruded and molded through a screw, and the hard alloy bar with the spiral hole is obtained after the hard alloy blank is sintered. Accordingto the forming method, through cooperation of a screw extruder and a rotary die head, stable and continuous production of the hard alloy bars is achieved, and the diameter and number of the spiral holes on the hard alloy bar can be controlled through adjusting the diameter and the number of thread lines, so that it is ensured that the diameter and the spiral lifting angle of the spiral hole are stable.

Owner:HUNAN UNIV OF TECH

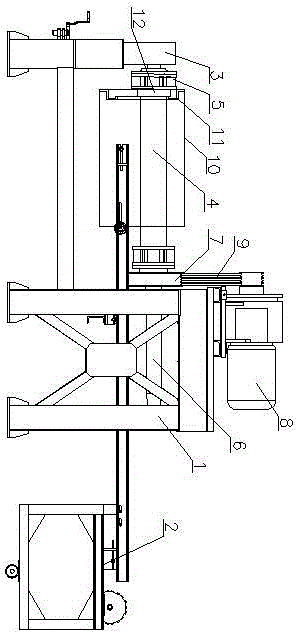

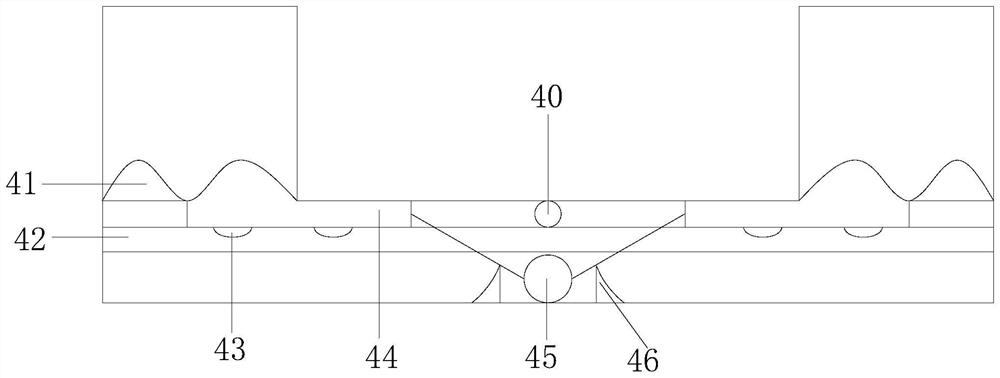

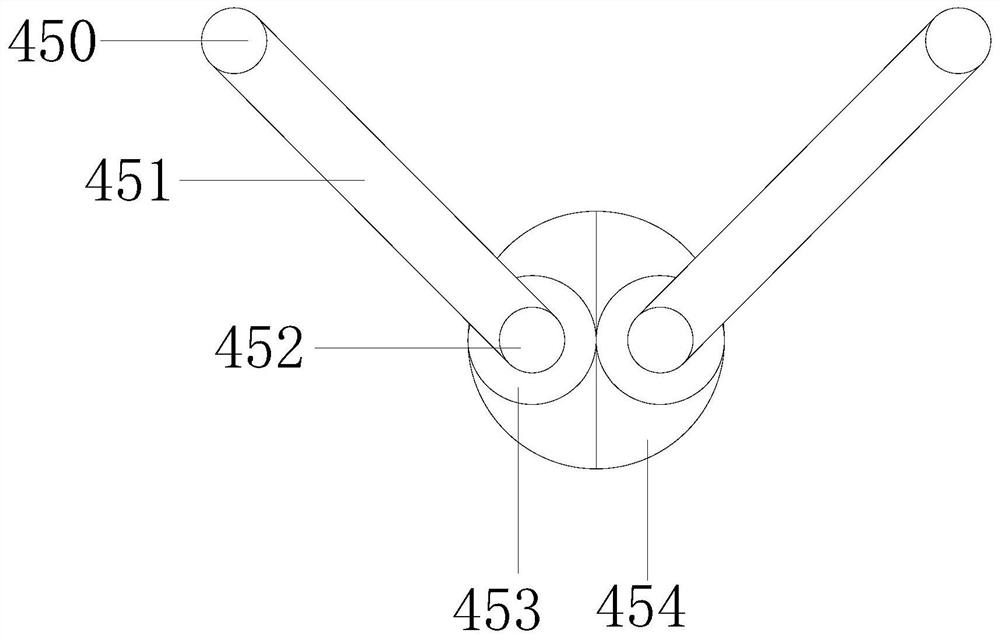

Anti-climbing hanging roller machine

The invention relates to an anti-climbing hanging roller machine. The machine comprises a main frame; a feeder is arranged at the front end of the main frame; a door frame is arranged at the back end of the main frame; a hanging roller shaft is arranged between the door frame and the main frame; the back end of the hanging roller shaft is connected with a rotating shaft on the door frame through a flange; a main shaft is arranged in the main frame; a belt wheel is mounted at the back end of the main shaft; the front end of the hanging roller shaft is connected with the belt wheel through a flange; a motor is arranged on the main frame; an output end of the motor is connected with the belt wheel through a belt; the hanging roller shaft is coated with a hanging roller mold; and an anti-climbing stop sleeve is arranged between a bearing port body of the hanging roller mold and the flange at the back end of the hanging roller shaft. The machine is simple in structure and convenient to manufacture, is additionally provided with the anti-climbing stop sleeve between the bearing port body and the flange for effectively preventing a step in the bearing port body from climbing onto the flange, guarantees stable operation of the mold, is high in safety, and guarantees stable diameter of a cement pipe.

Owner:江苏江桥机械制造有限公司

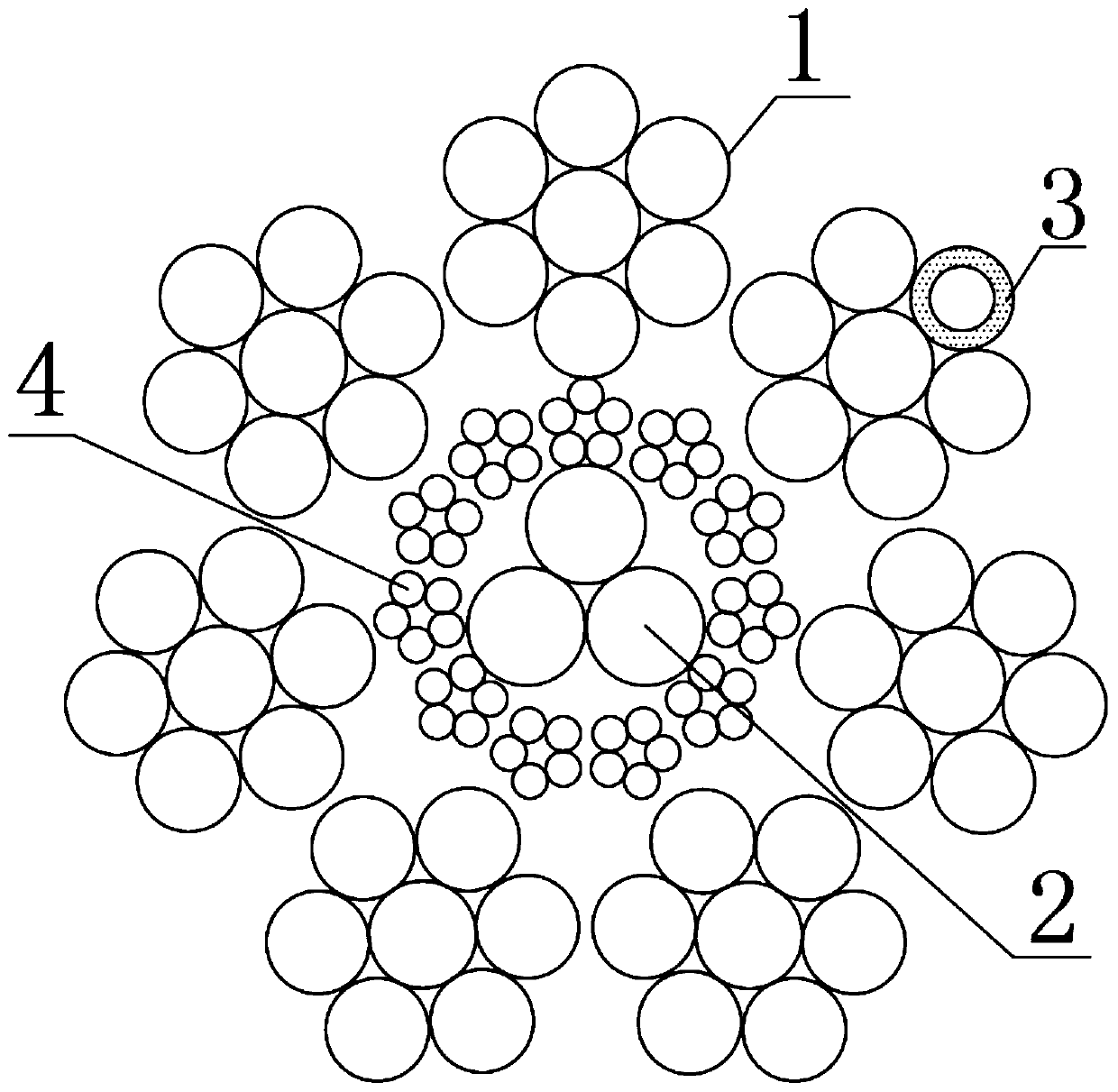

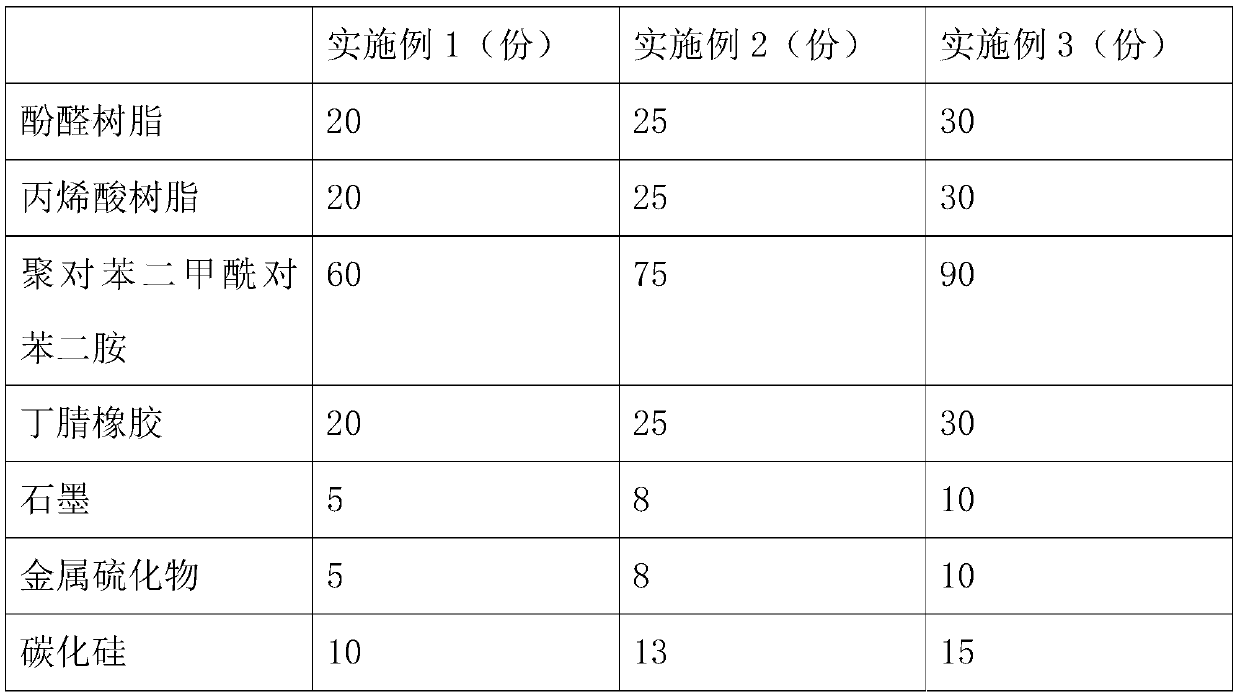

High-performance steel wire rope with sisal hemp core

InactiveCN110846915AAvoid deformationImprove toughnessConjugated synthetic polymer artificial filamentsCoatingsCarbide siliconNitrile rubber

The invention discloses a high-performance steel wire rope with a sisal hemp core. The high-performance steel wire rope with the sisal hemp core comprises a steel wire layer and the sisal hemp core,wherein a zinc layer is arranged on the outer wall of the steel wire layer; a composite layer is arranged on the side wall of the sisal hemp core in a twisting manner; the steel wire layer is arrangedon the outer wall of the composite layer in a twisting manner; and the sisal hemp core is formed by stranding three sisal hemp ropes. The formula of the composite layer comprises the following components by mass: 20-30 parts of phenolic resin, 20-30 parts of acrylic resin, 60-90 parts of poly (p-phenylene terephthalamide), 5-10 parts of graphite, 20-30 parts of nitrile rubber, 5-10 parts of metalsulfide and 10-15 parts of silicon carbide. The service life of the steel wire rope and the service life of the sisal hemp core can be prolonged, the sisal hemp core is protected, the corrosion resistance of the sisal hemp core is improved, and the strength of the steel wire rope is improved.

Owner:JIANGSU SAFETY STEEL WIRE ROPE

Optical fiber drawing furnace with low helium consumption

ActiveCN112811809AReduce dosageDiameter stableGlass making apparatusGlass productionEngineeringFiber drawing

The invention relates to an optical fiber drawing furnace with low helium consumption, and relates to the technical field of optical fiber manufacturing, the optical fiber drawing furnace comprises a drawing furnace body and a first gas inlet, and an optical fiber preform rod heating area and an optical fiber forming area which are communicated with each other are arranged in the drawing furnace body in the length direction; two exhaust ports are respectively formed in two ends of the fiber drawing furnace body, and are respectively communicated with the optical fiber preform rod heating area and the optical fiber forming area; the first gas inlet is located between the two gas outlets and is communicated with the optical fiber forming area, so that first gas is introduced into the optical fiber forming area and is discharged from the two gas outlets. According to the invention, by adopting a mode of introducing gas from the first gas inlet and exhausting the gas up and down respectively, the speed of discharging the first gas out of the furnace body is greatly reduced, the retention time of the first gas in the furnace body is prolonged, and the use amount of helium in the first gas is greatly reduced while a protection effect is achieved in the optical fiber forming process.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

Composite in-situ fiber-forming reinforced polymer material and its preparation method and device

InactiveCN103059387BAvoid degradationGood compatibilitySynthetic resin layered productsFiberPolymer science

Owner:贵州省复合改性聚合物材料工程技术研究中心

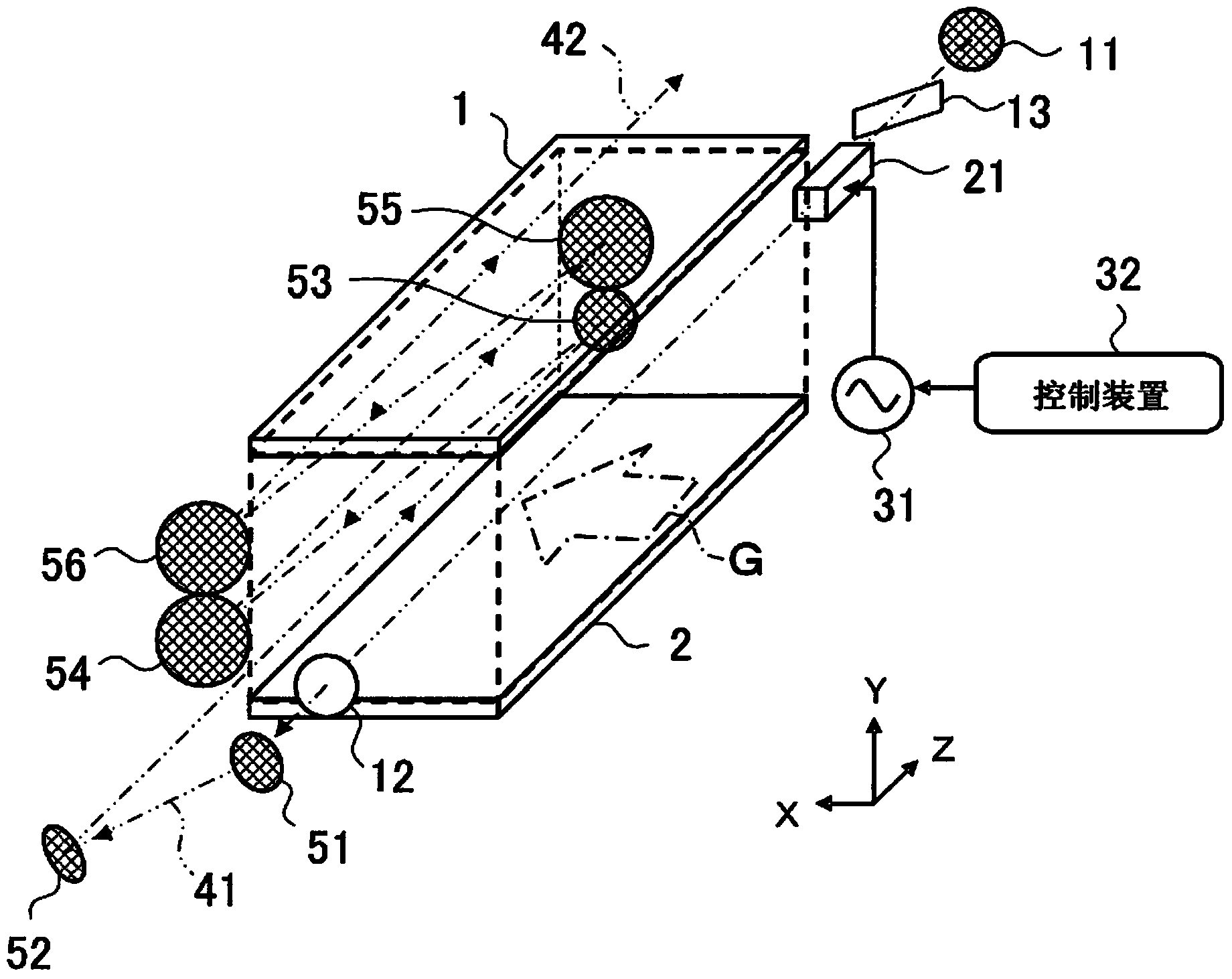

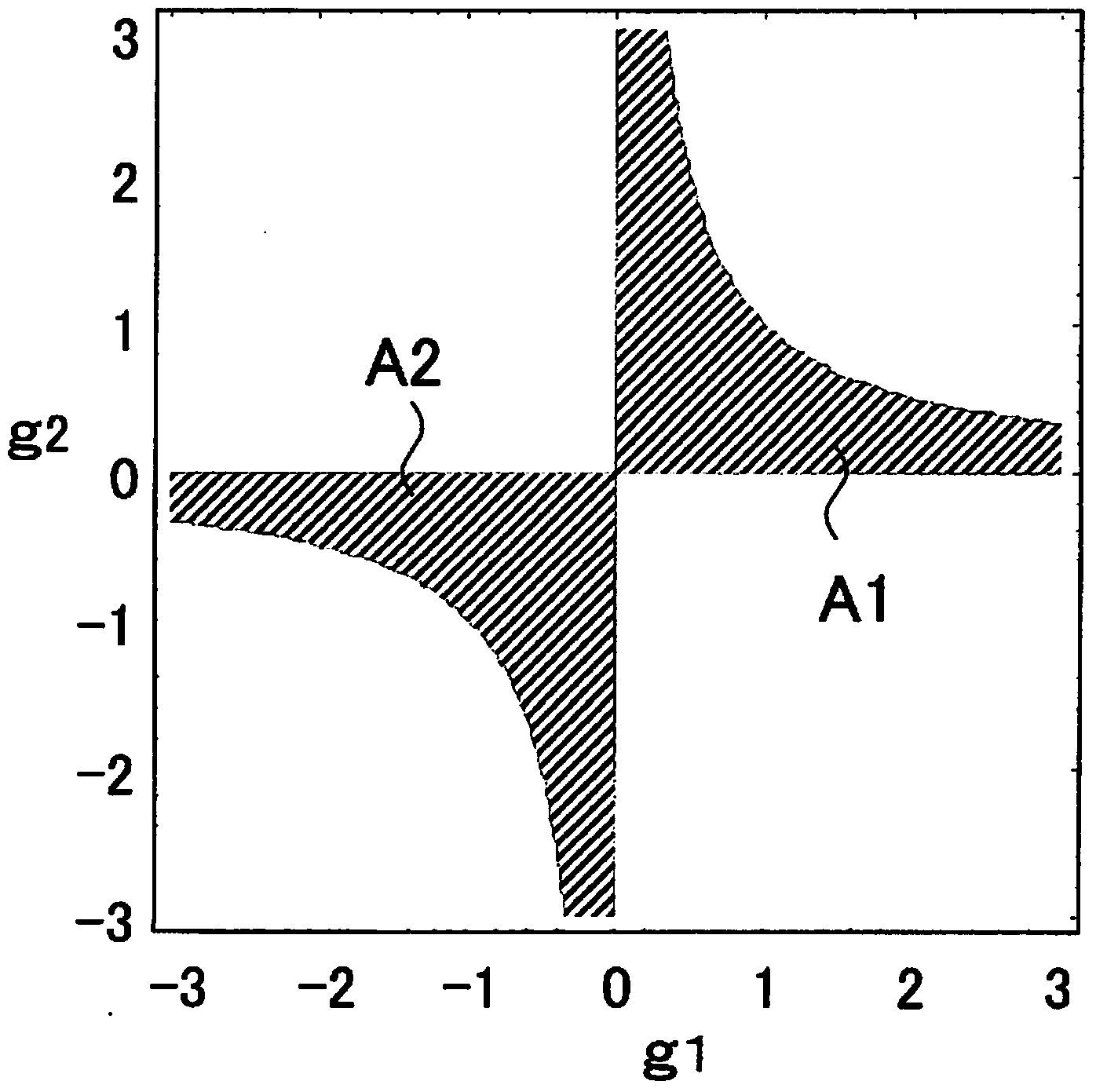

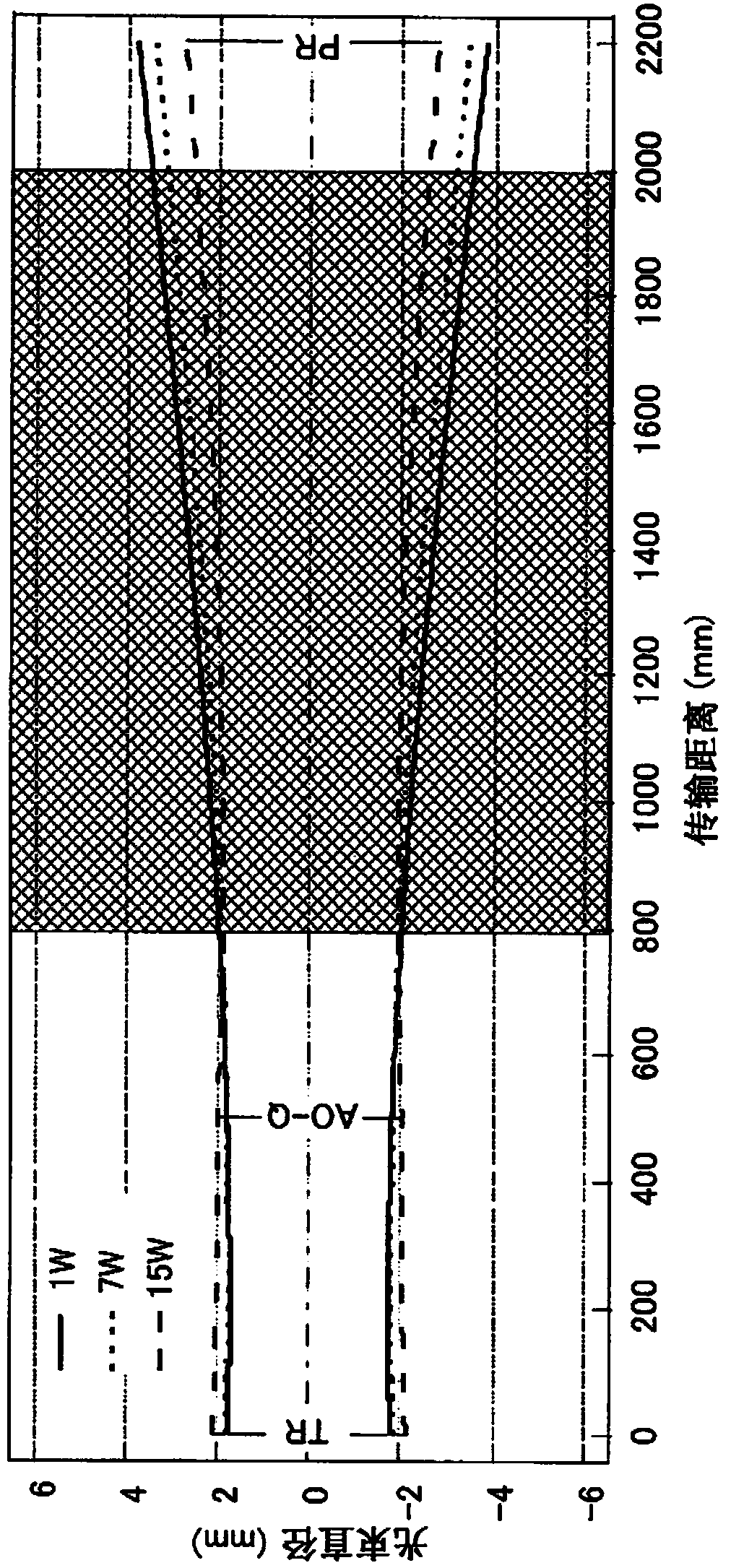

CO2 laser device and CO2 laser processing device

ActiveCN103999301ADiameter stableHigh outputOptical resonator shape and constructionNon-linear opticsBeam diameterLight beam

The purpose of the present invention is to obtain a CO2 laser device and CO2 laser processing device for beaming at high output a pulse laser having a stable beam diameter that is not dependent on the repeat frequency. The present invention is provided with: laser gas (G), which acts as a CO2 laser medium; a nearly concentric stable optical resonator installed so that the curvature radius of at least one resonator mirror is equal to the distance between the optical switch and the resonator mirror; an optical switch provided within the stable optical resonator; and transmission mirrors (51-56) provided so that the laser light (41) generated from the stable optical resonator passes through the CO2 laser medium again.

Owner:MITSUBISHI ELECTRIC CORP

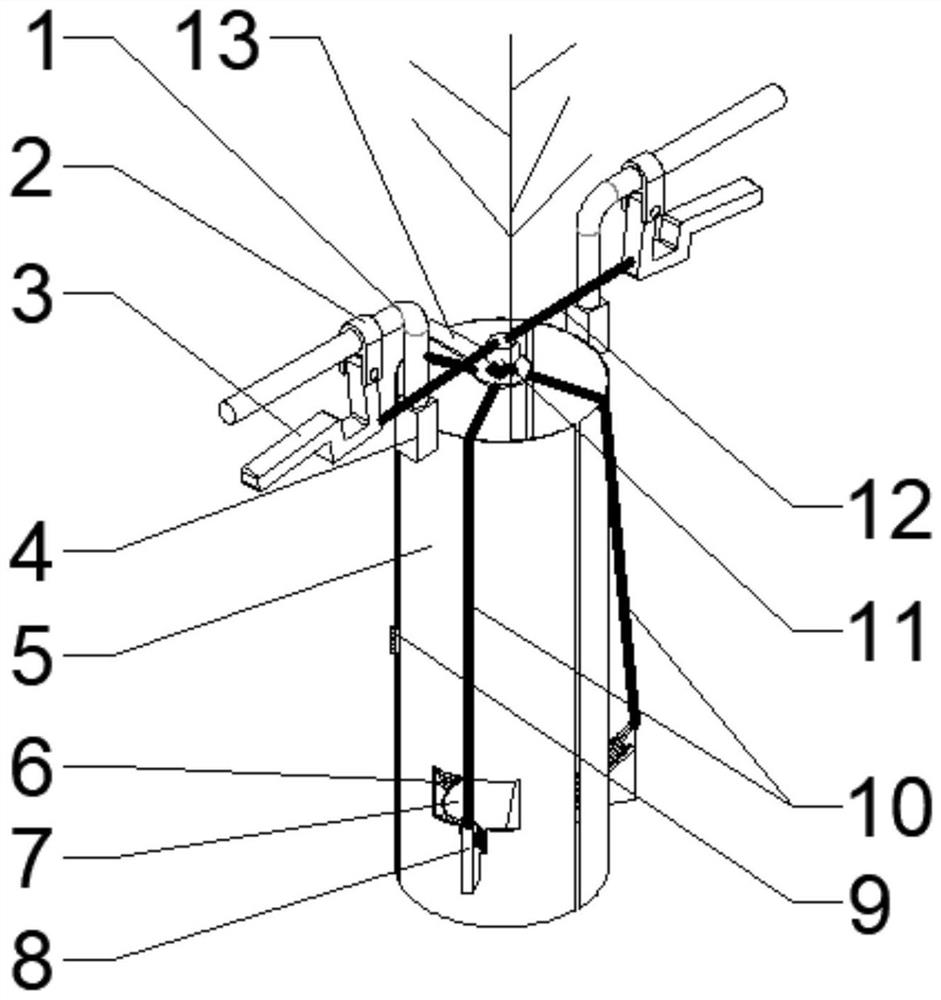

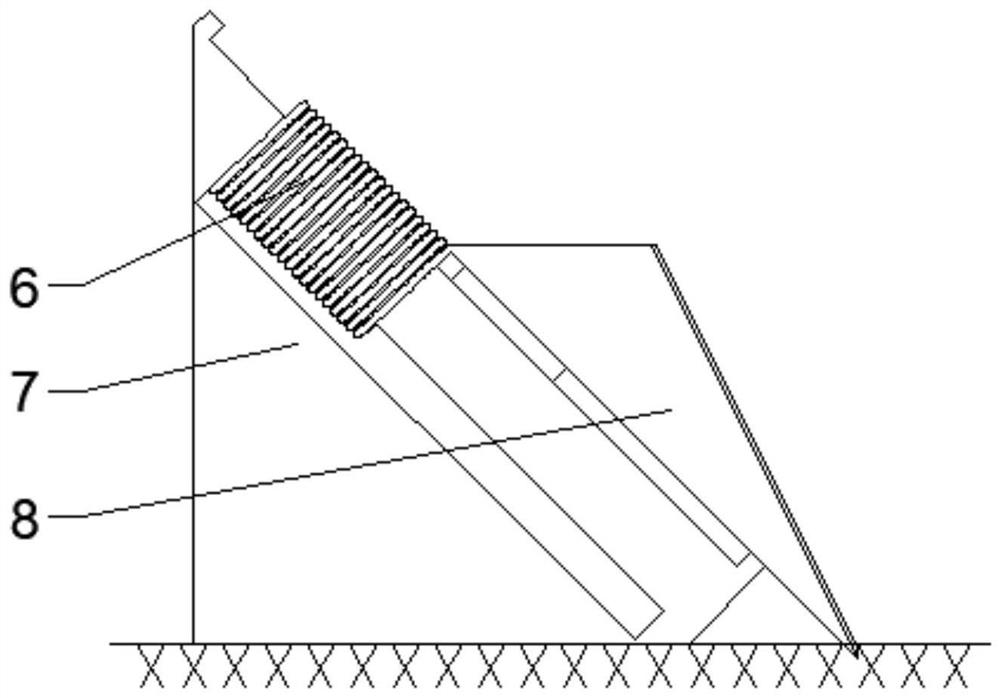

Sapling transplanting device

PendingCN113812326AThe diameter of the stabilizing bagStable depthForestryBrakeAgricultural engineering

The invention discloses a sapling transplanting device. The sapling transplanting device comprises a handle, hand brake fixing blocks, hand brakes, a handle mounting block, a shell, a spring, a conical shovel, a guide plate, a hinge, traction ropes, a connecting ball, contraction ropes, a rope gathering plate, a shovel surface, a baffle, a T-shaped guide rail, a spring guide rail, a limiting plate and a T-shaped guide groove. The guide plate is welded to the shell, the conical shovel is assembled on the guide plate, one ends of the three traction ropes are connected with the conical shovel, and the other ends of the three traction ropes are connected with one end of the connecting ball through holes of the rope gathering plate; and the other end of the connecting ball is connected with the two contraction ropes, the other ends of the two contraction ropes are correspondingly connected with the two hand brakes, the hand brakes are rotationally connected with one ends of the hand brake fixing blocks, the other ends of the hand brake fixing blocks are coaxially connected with the handle in a fastening mode, the handle is fixed to the handle mounting block, and the handle mounting block is fixed to the shell. The sapling transplanting device has the advantages of being easy to operate, high in efficiency, low in cost, stable in diameter and depth of seedling root soil bags and suitable for saplings of different crown types.

Owner:NORTHWEST A & F UNIV

Resistance spot welding device

ActiveUS20180043461A1Avoid expulsionDiameter stableWelding electric suppliesWelding monitoring devicesEngineeringPower flow

A resistance spot welding device for welding at least two overlapping steel sheets held between a pair of welding electrodes is provided. The resistance spot welding device includes the pair of electrodes, an electrode force gauge that measures an electrode force, and a controller that controls an electric current supply to the electrodes according to the electrode force measured by the electrode force gauge. The controller controls the electric current such that the electrode force F measured by the electrode force gauge after the start of the electric current supply is adjusted to a prescribed value.

Owner:JFE STEEL CORP

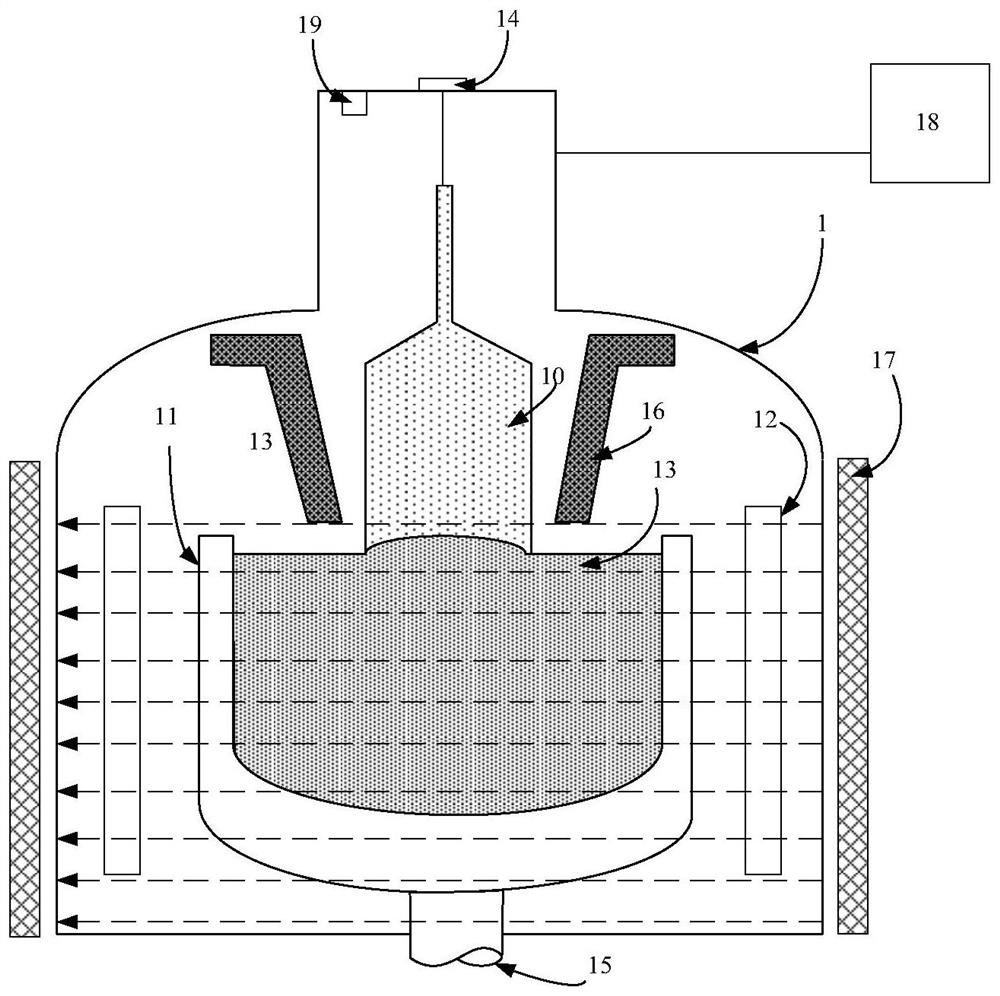

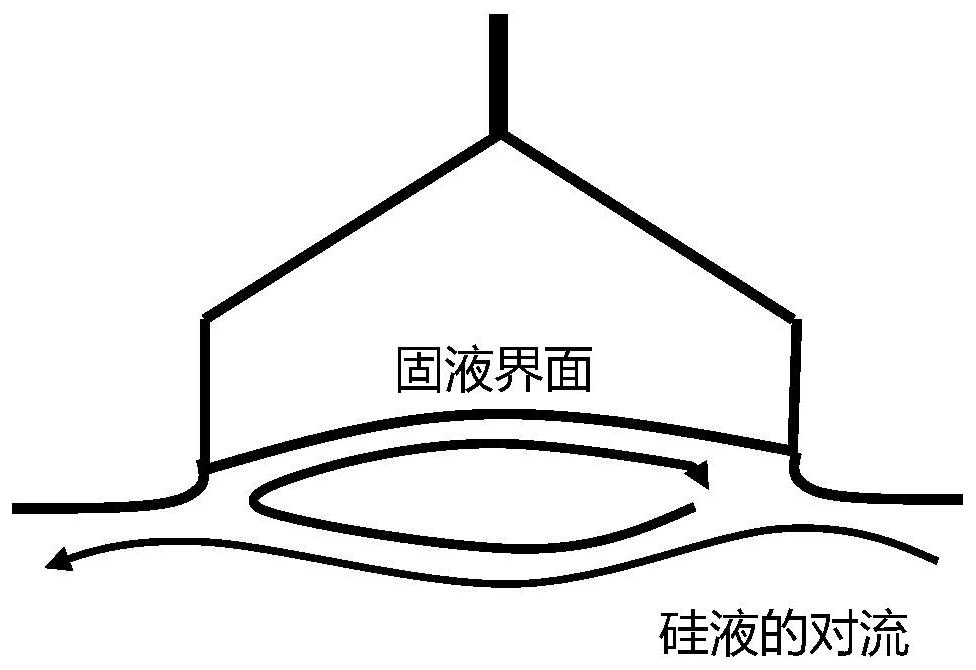

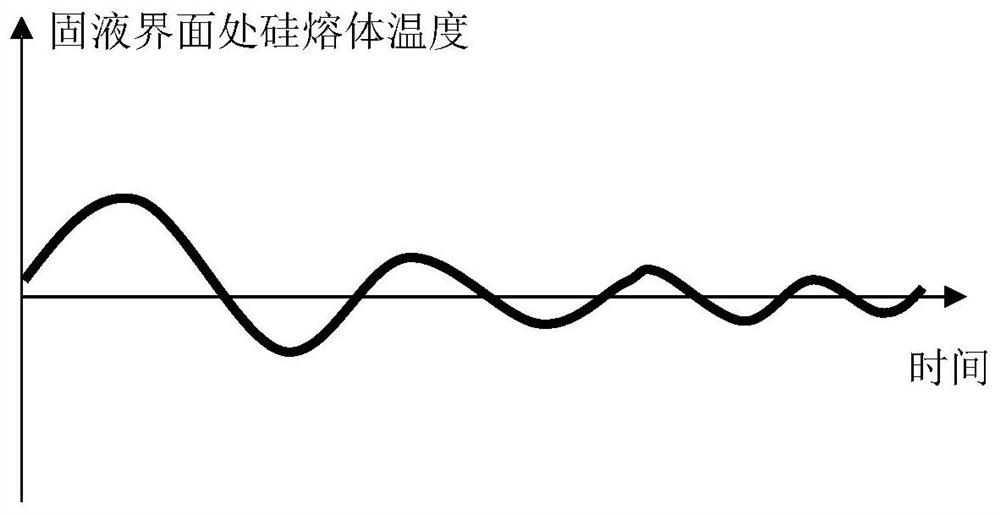

Crystal pulling method and crystal pulling device

InactiveCN112831836ADiameter stableSmall fluctuationPolycrystalline material growthBy pulling from meltCrucibleCondensed matter physics

The invention discloses a crystal pulling method and a crystal pulling device. The method comprises the steps that in the crystal pulling process, a crucible used for containing a silicon melt is kept rotating, meanwhile, a magnetic field in the horizontal direction is applied to the silicon melt in the crucible, wherein when the magnetic field intensity of the magnetic field is changed and / or after the magnetic field intensity of the magnetic field is changed, fluctuation of the solid-liquid interface temperature of a silicon crystal bar and the melt is likely to be caused; the forced convection of the silicon melt in the crucible is changed by changing the rotating speed of the crucible, so that the temperature fluctuation of a solid-liquid interface caused by the change of the magnetic field intensity is quickly reduced, and the diameter of a crystal bar obtained in the crystal pulling process tends to be stable.

Owner:ZING SEMICON CORP

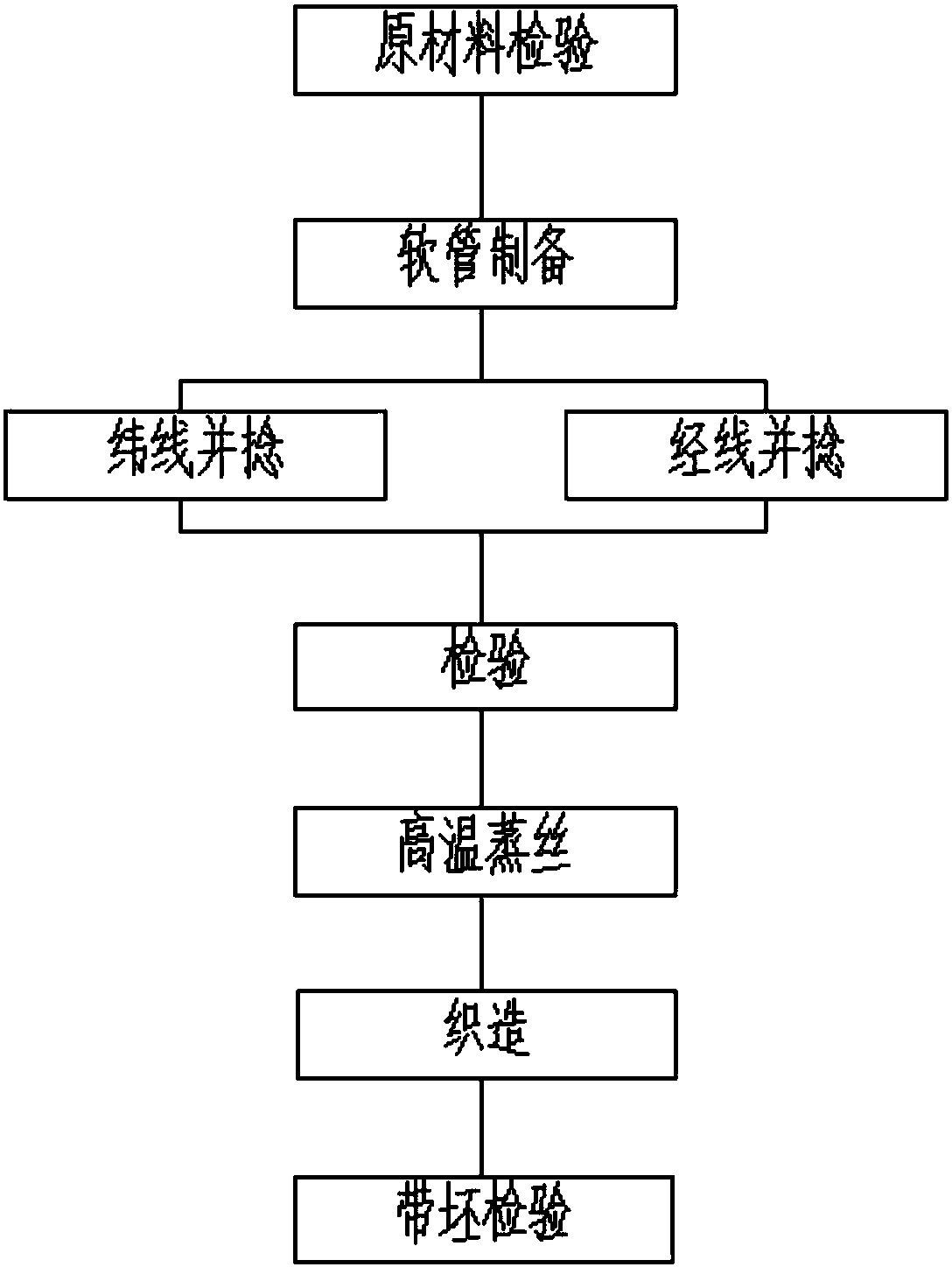

Novel water hose production method

InactiveCN108443601AExtended service lifeUniform extrusion thicknessFlexible pipesWoven fabricsPolyesterYarn

The invention discloses a novel water hose production method. The preparation method specifically comprises the following steps that 1, raw materials of a lining water hose body of the water hose andbraided fabric raw materials on the outer surface of the water hose are tested through equipment; 2, a hose is directly extruded by adopting a cold feed extruder by utilizing the raw materials of thelining water hose body; 3, the warp and weft preparation process of single yarn winding, splicing, twisting and fiber manufacturing are carried out, a worker makes polyester yarns into polyester silkthrough a twisting frame in the twisting process, and warp and weft are woven according to different materials to serve as the raw materials; step 4, the appearance and the pulling elongation of the hose extruded by the cold feed extruder are tested, the appearance and the physical tensile strength of the warp and weft are tested, the thickness of the extruded hose is uniform, the diameter is stable, the extrusion flow rate of an adhesive is stable, and adhesion can be avoided after the adhesive is cooled. The novel water hose production method has very high practicability, the application prospect of an overall device is wide, and the method is suitable for wide popularization.

Owner:泰州市神龙消防科技有限公司

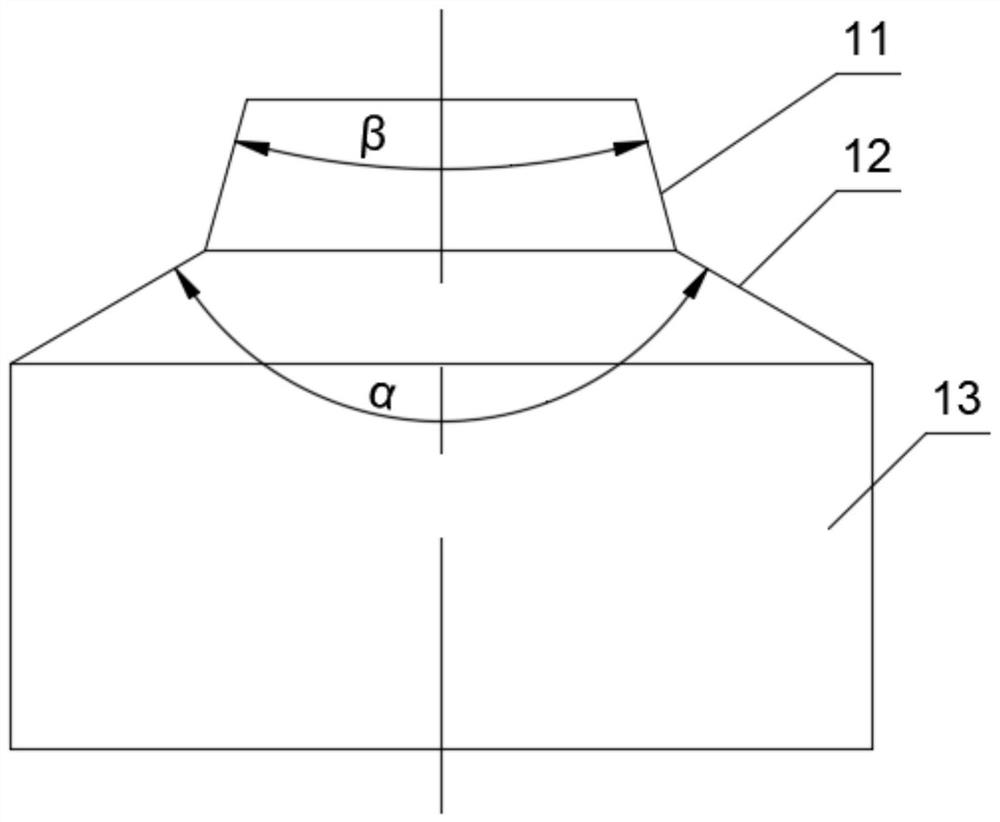

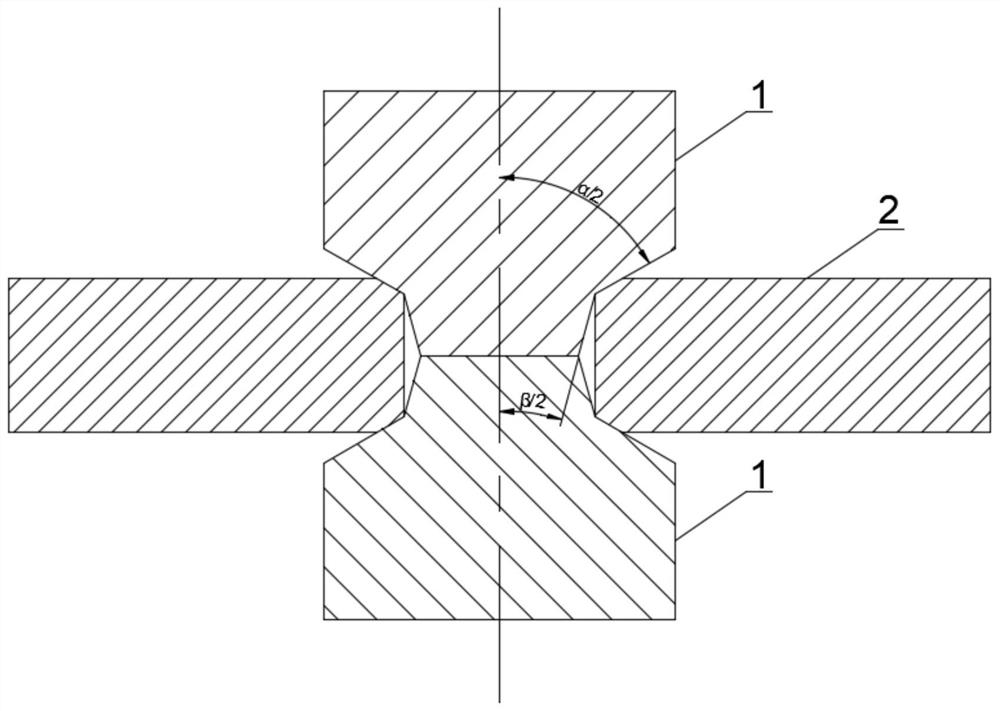

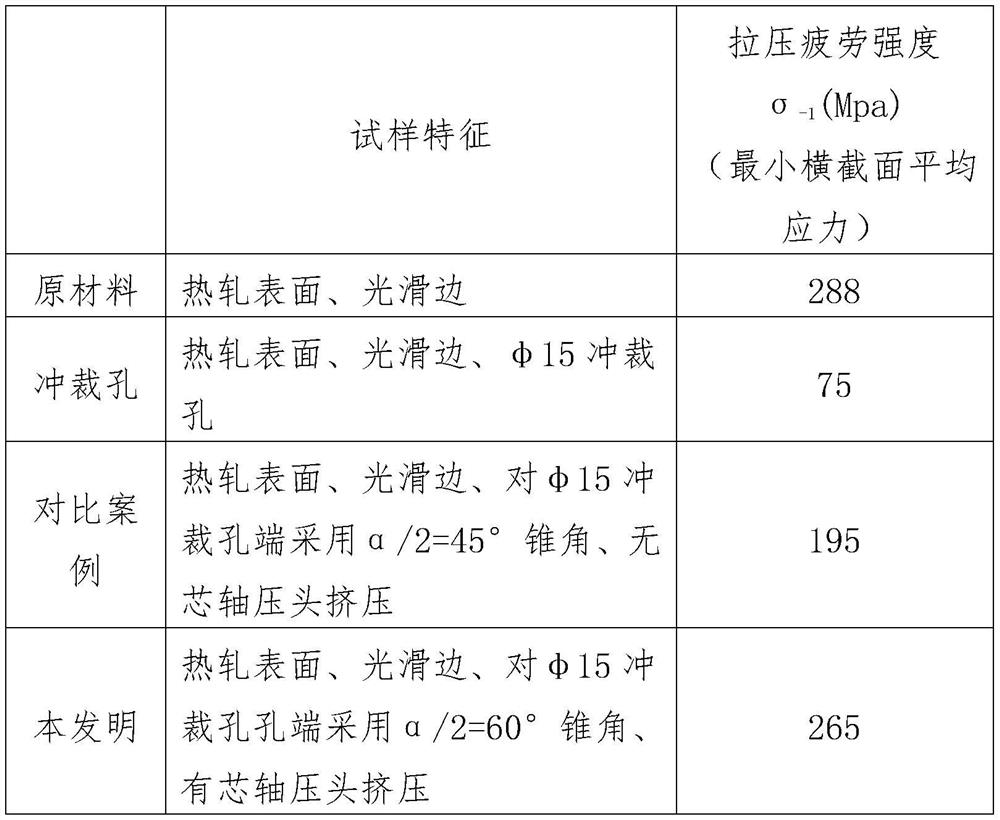

Extrusion mould used for improving fatigue strength at hole end of metal plate and method

The invention relates to an extrusion mould used for improving fatigue strength at a hole end of a metal plate and a method, and belongs to the technical field of machining. The extrusion mould head comprises a pressure head and a mandrel, wherein the pressure head is of a circular table shaped structure, and is positioned in a hole mouth of a through hole for extruding the through hole, so that achamfer is formed at the hole mouth of the through hole; the mandrel is of a tapered or circular table shaped structure and is positioned in the through hole for supporting the through hole, so thatthe through hole defines a set shape and a set diameter; and the upper bottom surface of the pressure head is connected to the lower bottom surface of the mandrel, and the axis of the mandrel is superposed with that of the pressure head. The pressure head can control materials to flow towards the through hole during plastic deformation chamfering, limits the hole end plane from bulging, is beneficial for forming stable residual pressure stress in the through hole, and ensures that a ring-shaped bulge is not formed on the surface of the hole end. The mandrel can avoid naturally forming a ring-shaped bulge or sink in the through hole during plastic deformation chamfering, forms stable pressure stress on the surface of the through hole, and guarantees improvement range of the fatigue strength.

Owner:DONGFENG COMML VEHICLE CO LTD

Center-seal & gusset mechanism of center-seal & gusset machine of film label

ActiveCN101691075BWon't scratchThere will be no problem of large diameter deviationMechanical working/deformationEngineeringElectrical and Electronics engineering

The invention discloses a center-seal & gusset mechanism of a center-seal & gusset machine of a film label. The center-seal & gusset mechanism comprises a cylinder-shaped mould and a pressing part arranged around the mould. The center-seal & gusset mechanism has the advantages of no damage to the film label and stable folding diameter of the film label, thus improving the quality of the film label.

Owner:SHANGHAI ZIQUAN LABEL CO LTD

Width-changeable steel bar stamping die

The invention discloses a width-changeable steel bar stamping die which structurally comprises an upper stamping plate, a first limiting steel block, a lower stamping plate, a supporting transverse column, a steel diameter adjusting plate, a second limiting steel block, a lower abutting plate, telescopic columns and upper abutting rings. The four abutting rings are connected to four corners belowthe stamping plate through nails. The four telescopic columns are arranged and slidably connected to the lower portions of the upper abutting rings. A swing device is arranged on the structure, an upper hinge wheel at the top of the swing device can pull diameter adjusting frames at the two ends to move towards the middle, the ruler distance between the first limiting steel block and the second limiting steel block is decreased, then the diameter of a formed steel bar is controlled, and multiple functions are achieved by one machine. An anti-moving frame is arranged on the structure, after thedistance is adjusted by an adjusting arm, the adjusting arm can be supported and fixed through ejection pieces at the two ends, the phenomenon that a diameter adjusting frame slides away due to impact force in the punching process is avoided, and the diameter of the steel bar is more stable.

Owner:吴彬玲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com