Novel optical fiber wiredrawing cooling system

A cooling system and optical fiber technology, applied in glass fiber drawing devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems affecting the cooling effect and optical fiber strength, large fluctuations in coating diameter, large amount of helium gas, etc., to improve thermal efficiency Effect of exchange effect, less helium consumption, stable coating diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

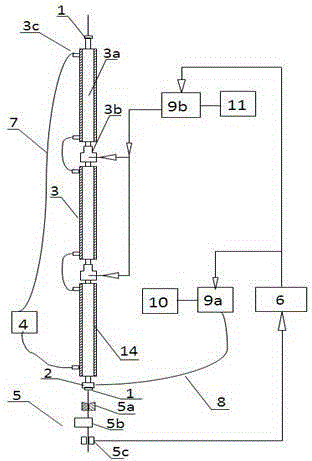

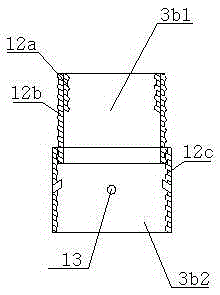

[0021] Such as figure 1 A novel optical fiber drawing cooling system is shown. The novel optical fiber drawing cooling system includes cooling pipe upper and lower shutters 1, drainage plug 2, cooling pipe body 3, cooling water circulation cooling device 4, coating curing device 5, coating Wire diameter control system 6, water pipe 7 and air pipe 8 are composed; the upper end of the shutter 1 under the cooling pipe is installed with a helium drainage plug 2, and the upper end of the helium drainage plug 2 is connected to the cooling pipe body 3, and the lower part of the cooling pipe is a coating Overlay the curing device 5, and the helium drainage plug 2 is connected to the first mass flow meter 9a and the drainage pump 10 in turn through the air pipe 8; the cooling pipe body 3 includes a single cooling pipe 3a and a helium gas inlet device 3b. The cooling pipe body 3 is composed of the single-section cooling pipe 3a described in Sections 3-6. The single-section cooling pipes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com