Patents

Literature

265results about How to "Influence intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

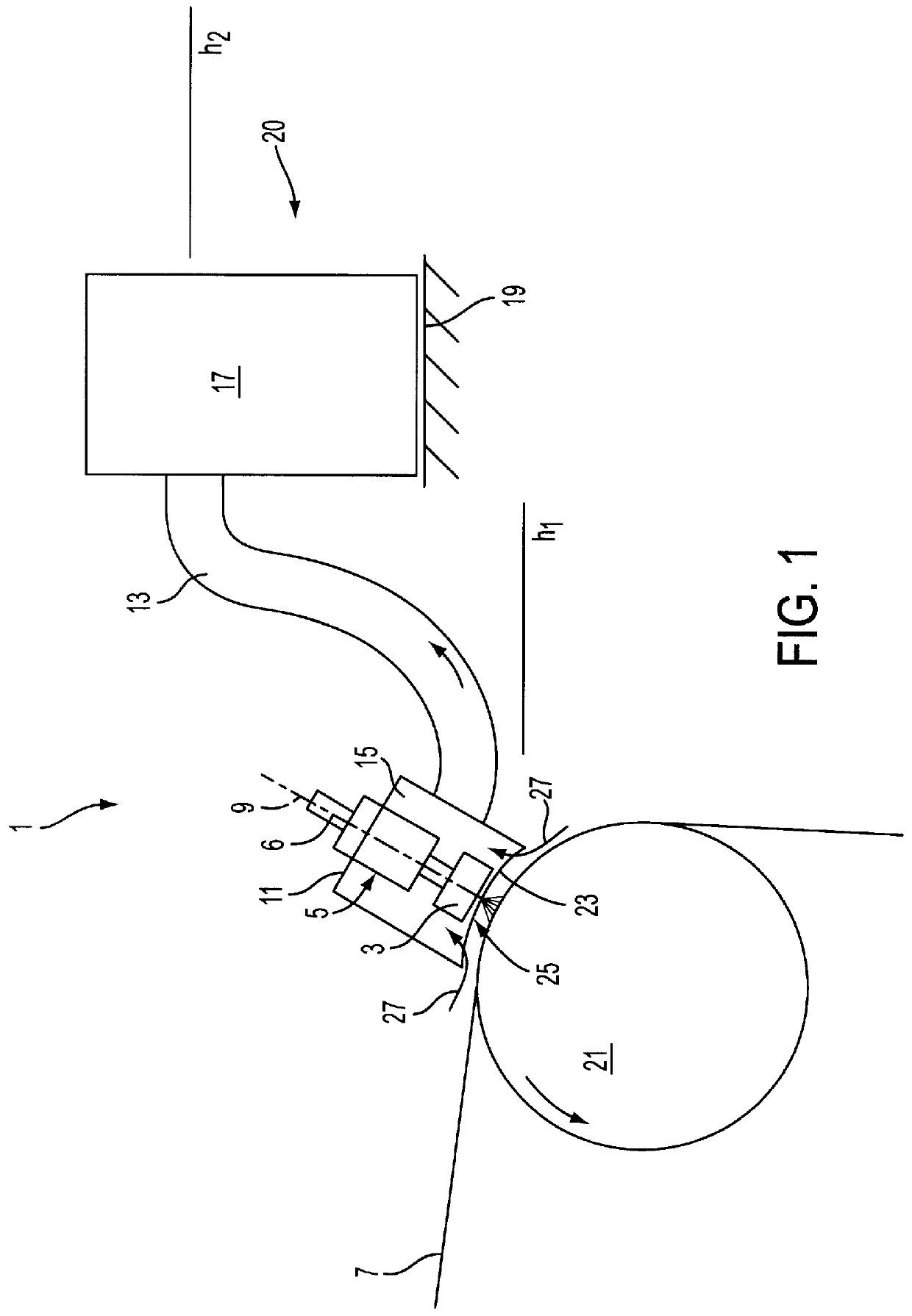

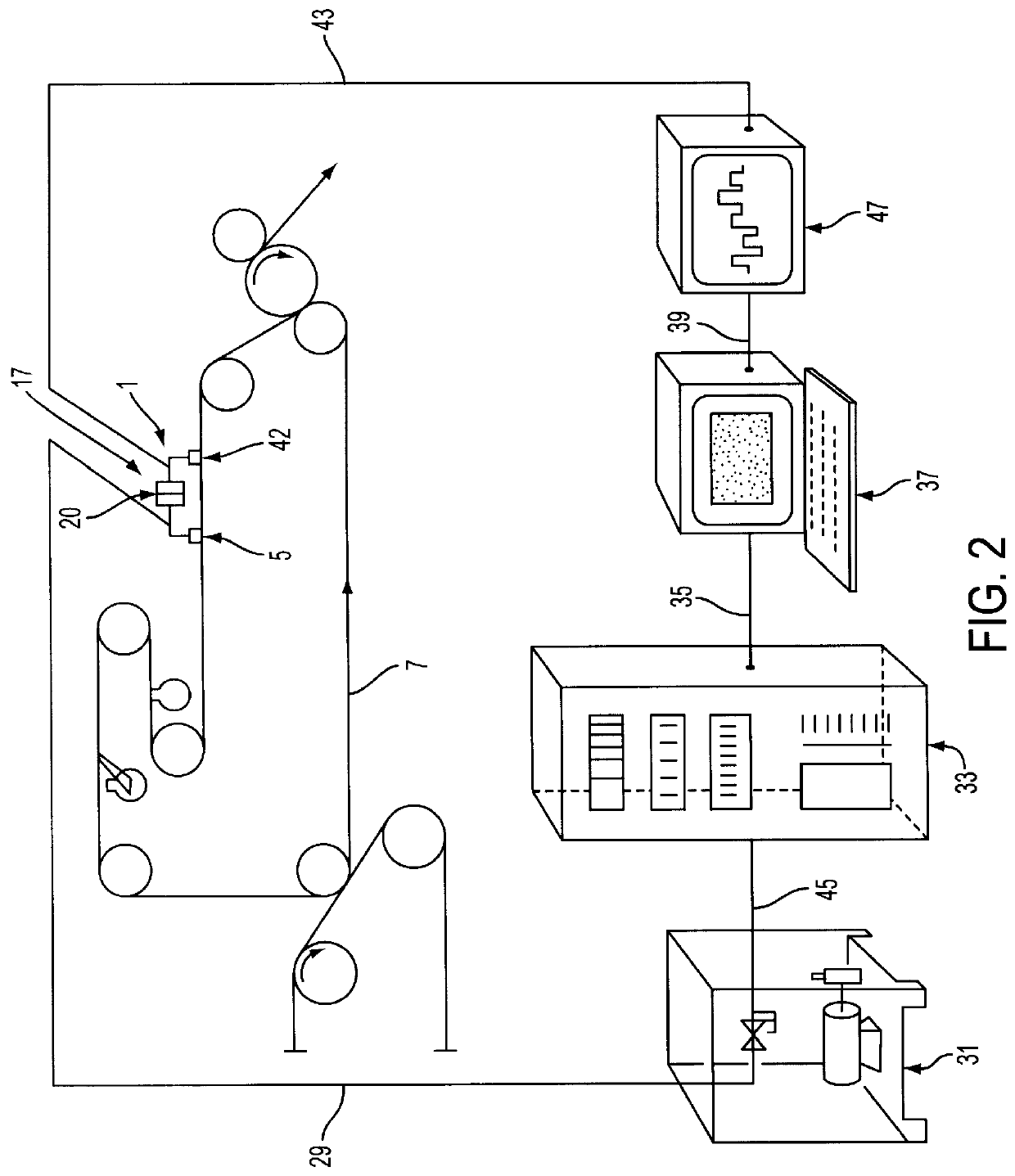

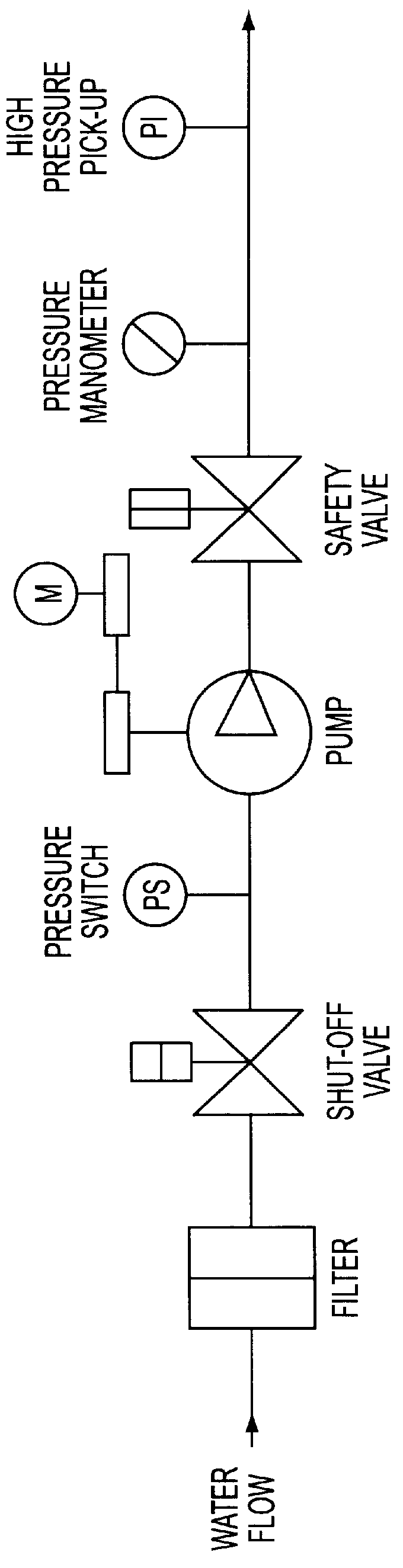

Process for cleaning a transport belt

InactiveUS6143092AEasy to cleanConsumption of cleaningElectrostatic cleaningMachine wet endEngineeringMechanical engineering

Process for cleaning a transport belt of a machine for manufacturing and / or processing a material web with at least one cleaning device. The process includes detecting the contamination of the transport belt with at least one sensor, generating a state matrix which contains the location coordinates of the detected contamination, and one of controlling and regulating the at least one cleaning device for cleaning over at least a width of the transport belt with a varying desired intensity of cleaning in accordance with the generated state matrix.

Owner:VOITH SULZER PAPIERMASCHEN GMBH

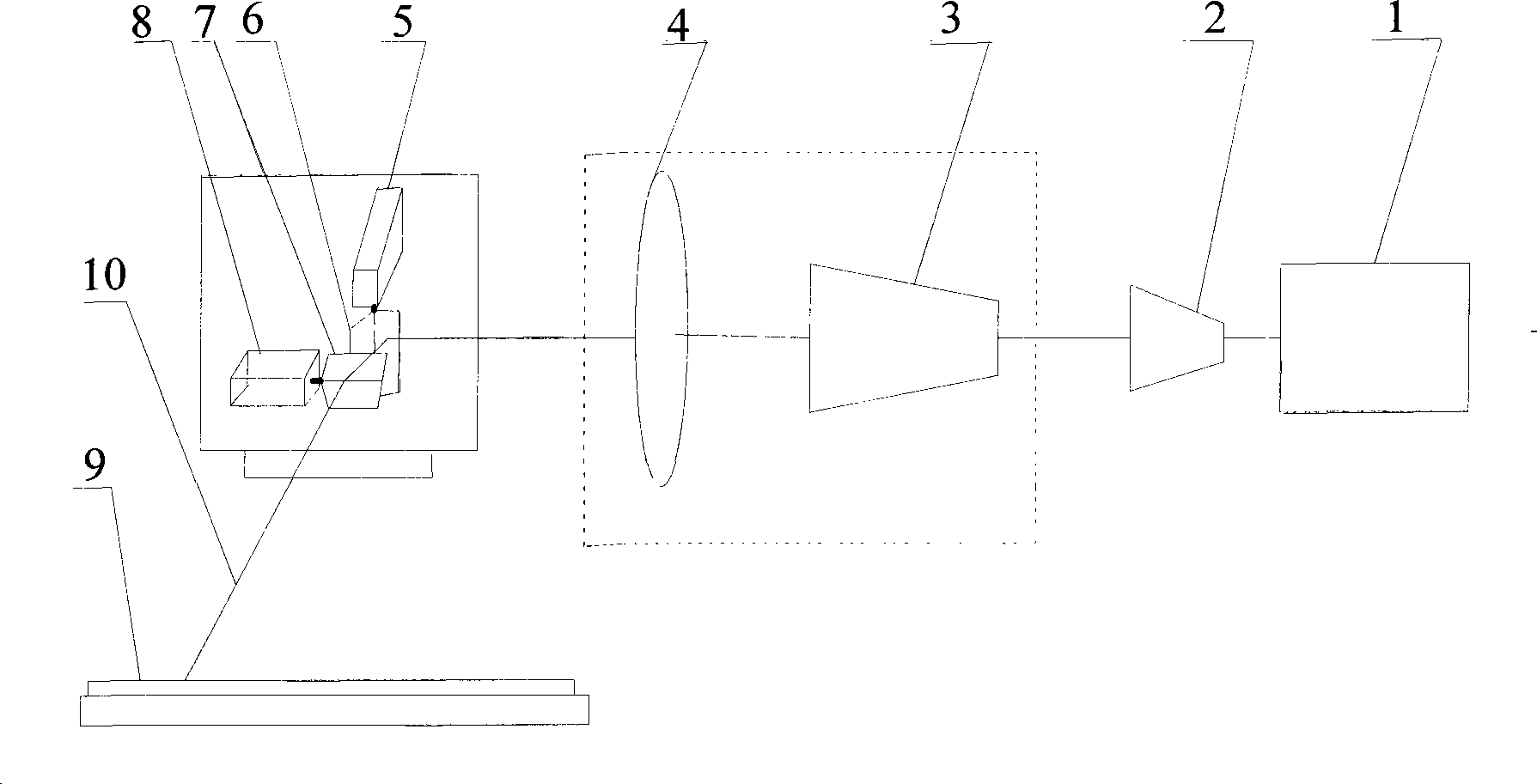

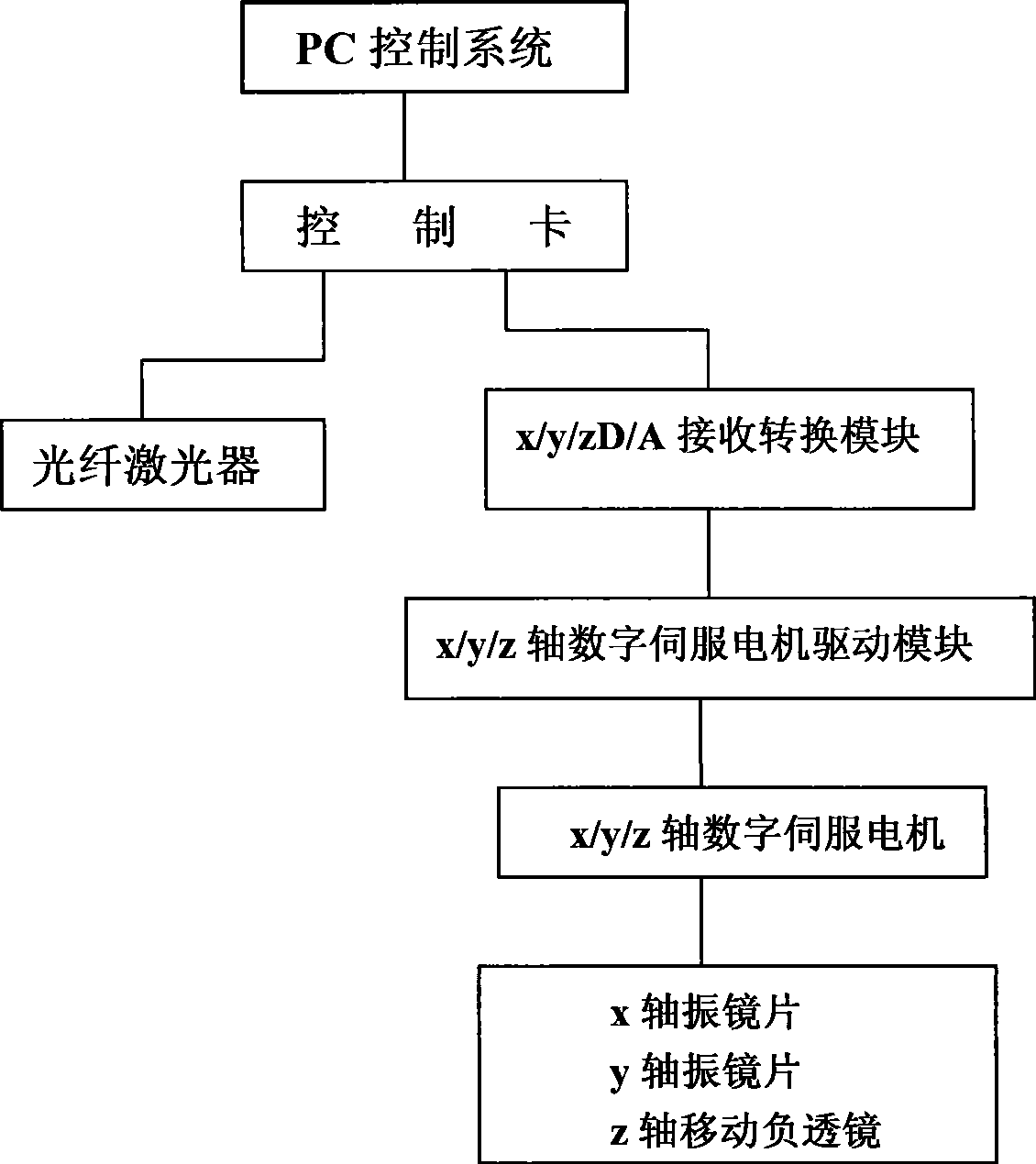

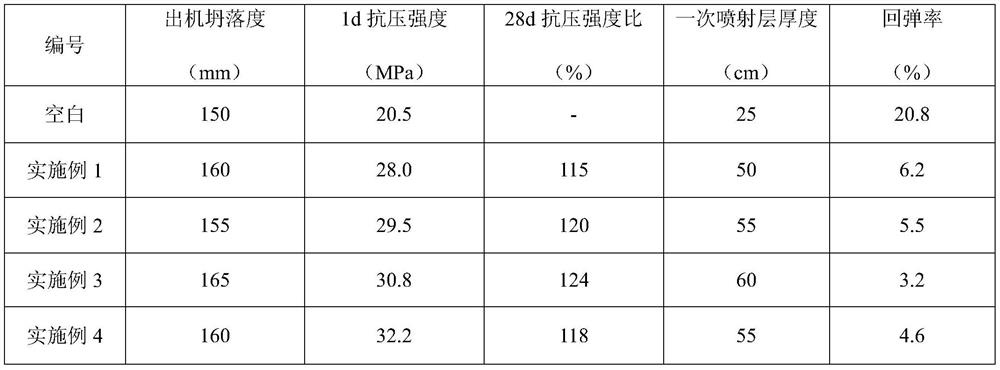

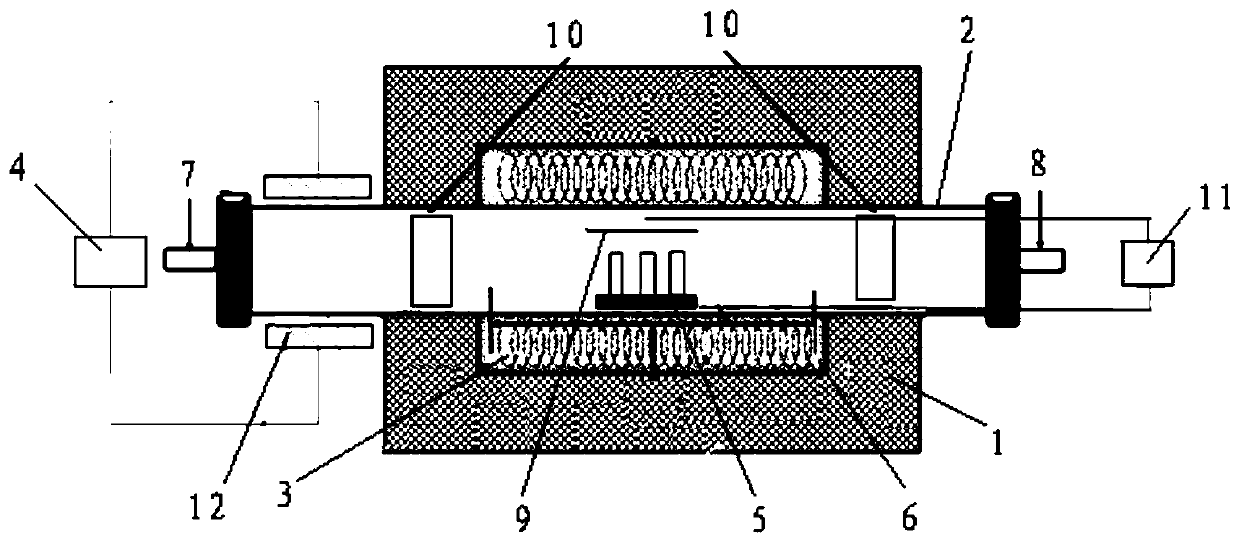

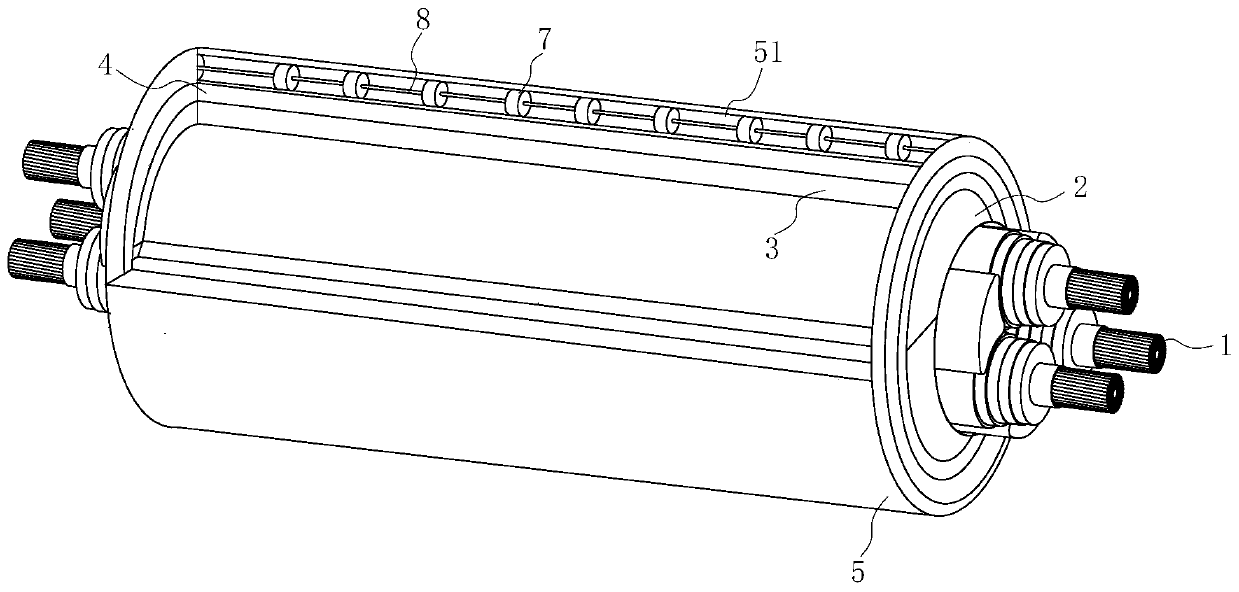

Optical fiber laser dynamic focusing vibration mirror scanning type spot welding system and welding method thereof

InactiveCN101439441AFast welding speedInfluence intensityLaser beam welding apparatusOptical elementsControl systemLight beam

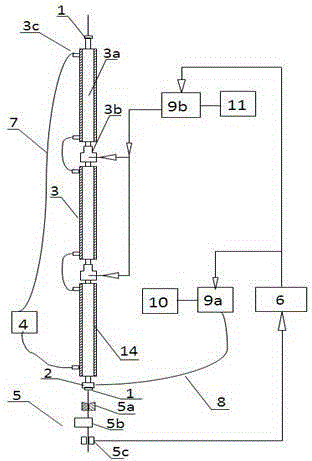

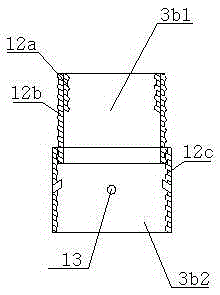

The invention discloses an oscillating-mirror scanning spot welding system which focuses optical-fibre laser dynamically. The system comprises a PC control system and a fibre laser, a beam expanding lens, a dynamic focusing unit, an X-axis vibration lens and a Y-axis vibration lens which are connected in sequence along a light path. The X-axis vibration lens is arranged on a rotating shaft of an X-axis servo motor; the Y-axis vibration lens is arranged on a rotating shaft of a Y-axis servo motor; the dynamic focusing unit consists of a moving negative lens and a focusing lens; the moving negative lens is arranged on a rotating shaft of a Z-axis servo motor; and a stepping motor is controlled by a PC or hand control, so as to realize long-distance travel of the moving negative lens and the Z-axis servo motor along the transferring direction of the light beam, thereby obtaining different working distances (focuses); therefore, the corresponding scanning range changes between 200 millimetres and 1450 millimetres and the spot diameter is between 30 microns and 200 microns.

Owner:广州瑞通千里激光设备有限公司

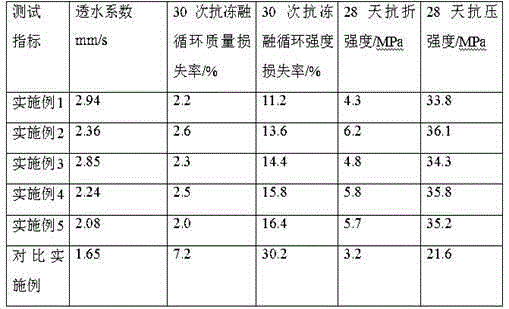

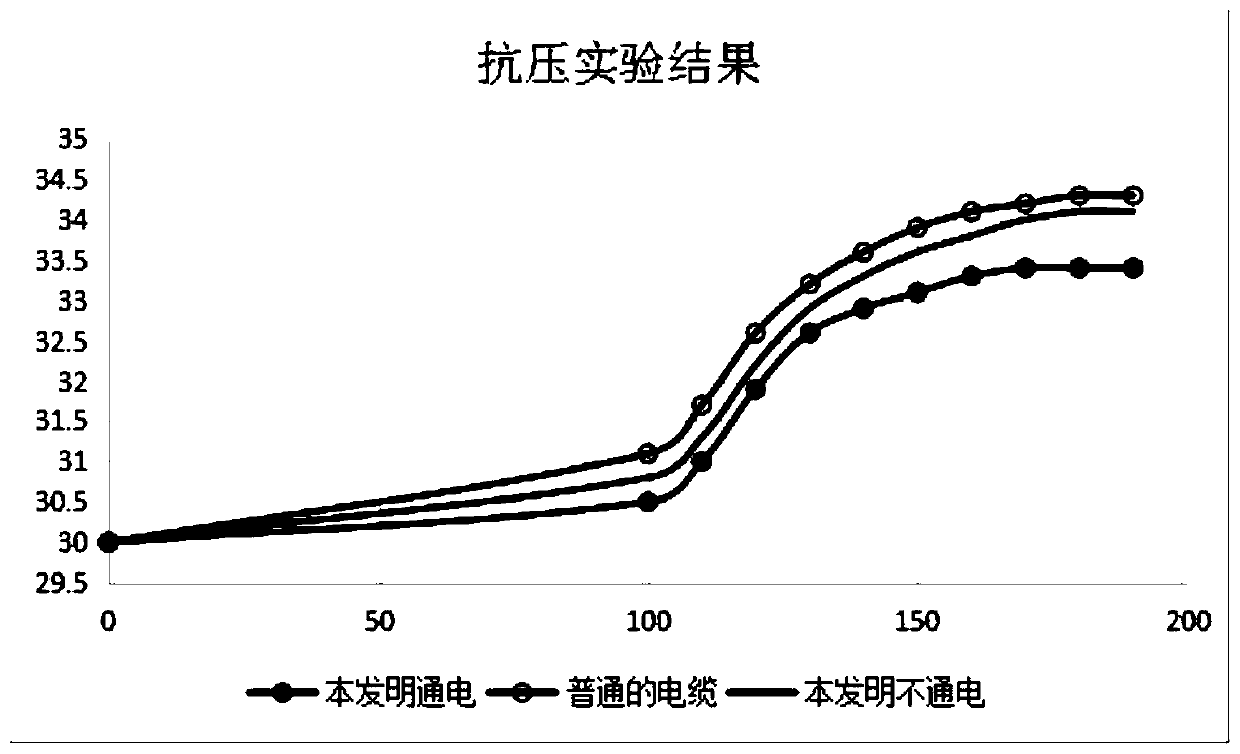

Pervious concrete and construction method

The invention provides pervious concrete with the characteristics of high strength, long service life and durability. According to the technical scheme adopted in the invention, the pervious concrete comprises components of raw materials in parts by weight as follows: 400-500 parts of cement, 1600-1650 parts of broken stone, 10-20 parts of a reinforcing agent, 0-10 parts of a water reducing agent and 100-130 parts of water. The cement is an ordinary portland cement with the strength grade being not lower than 42.5 grade, and the reinforcing agent adopts a silicone acrylic emulsion.

Owner:SHANDONG QUANJIAN ENG TESTING CO LTD

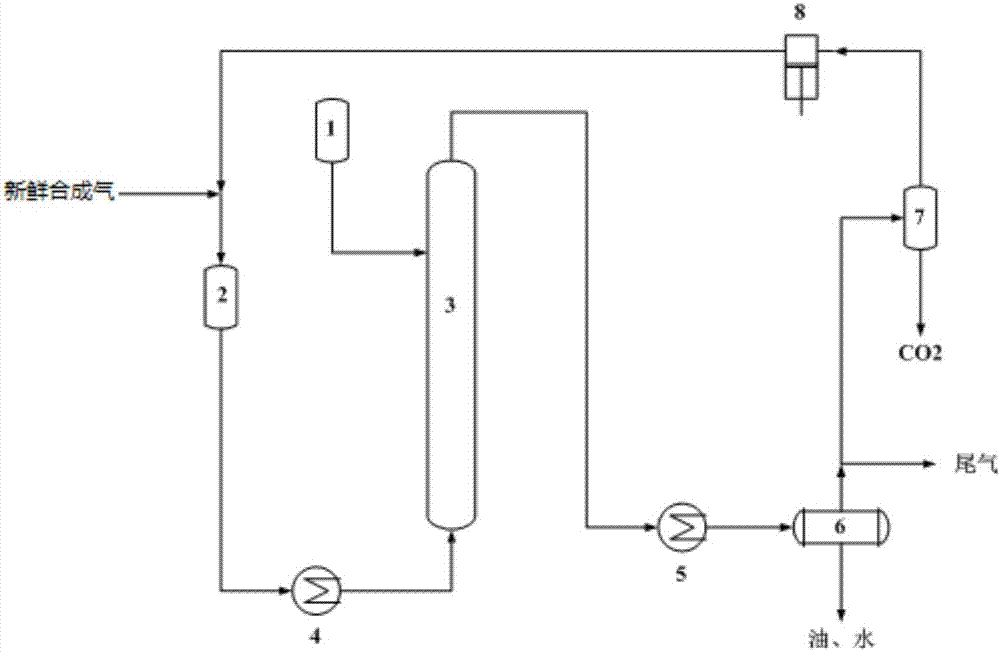

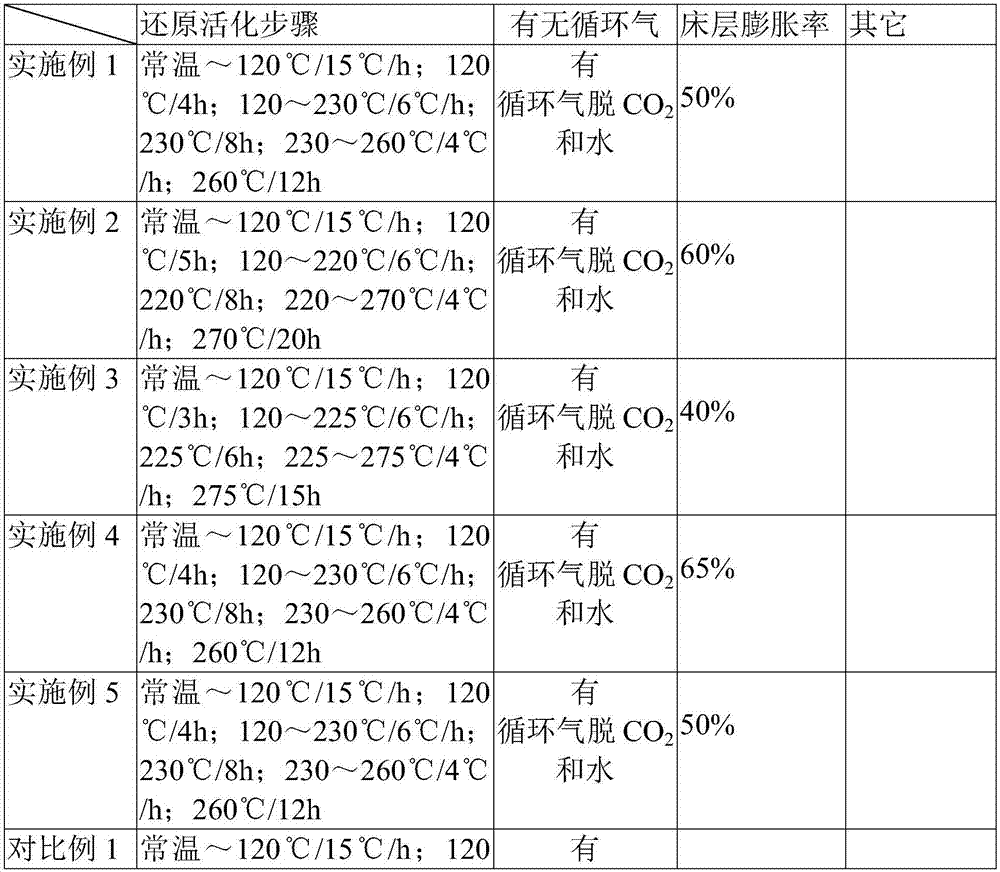

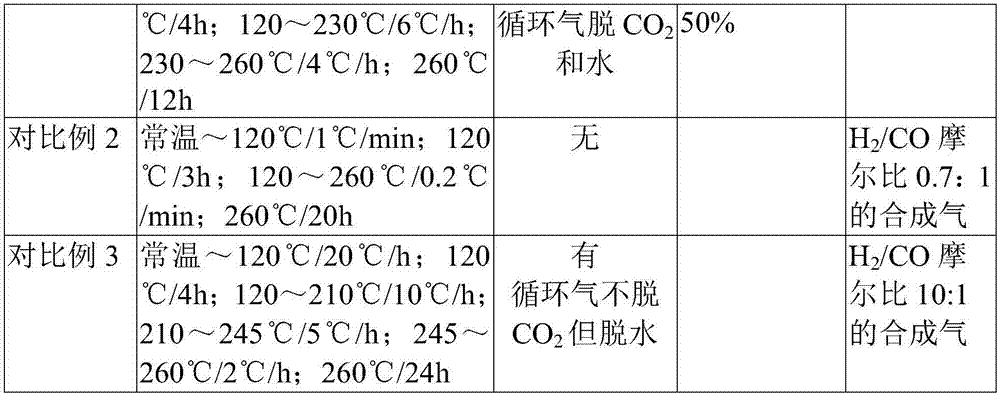

Reduction method for a Fischer-Tropsch synthesis iron-based catalyst

ActiveCN107149948AHigh activityLow selectivityCatalyst activation/preparationLiquid hydrocarbon mixture productionFluidized bedRoom temperature

The present invention relates to the field of Fischer-Tropsch synthesis iron-based catalyst reduction, and discloses a reduction method for a Fischer-Tropsch synthesis iron-based catalyst. The reduction method comprises: in the presence of a reducing gas, carrying out programmed heating reduction on Fischer-Tropsch synthesis iron-based catalyst particles in a fixed fluidized bed reactor, wherein the programmed heating reduction comprises that the heating rate is 10-20 DEG C / h and constant temperature treatment is performed for 2-8 h at a temperature of 120 DEG C when the temperature is from room temperature to 120 DEG C, the heating rate is 5-10 DEG C / h and constant temperature treatment is performed for 3-10 h at a temperature of 220-230 DEG C when the temperature is from 120 DEG C to (220-230) DEG C, and the heating rate is 3-5 DEG C / h and constant temperature treatment is performed for 10-30 h at a temperature of 260-280 DEG C when the temperature is from (220-230) DEG C to (260-280) DEG C. With the reduction method of the present invention, the Fischer-Tropsch synthesis iron-based catalyst can be smoothly subjected to the reduction reaction so as to reduce the influence on the water and the catalyst strength, and with the application of the reduced catalyst in the Fischer-Tropsch synthesis, the advantages of no breaking, high catalyst activity, low CO2 selectivity and low low-carbon hydrocarbon selectivity can be provided.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

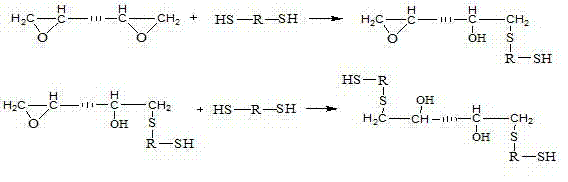

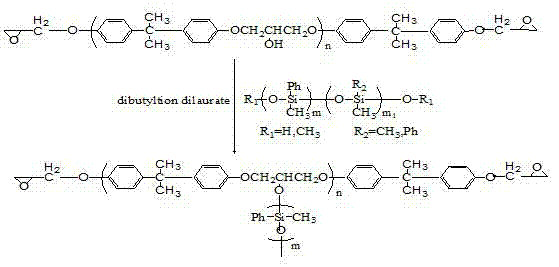

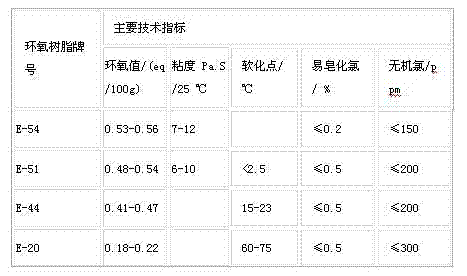

High-temperature-resistant flexible adhesive cured at normal temperature and preparation method thereof

InactiveCN102732209AImprove high temperature resistanceImprove toughnessNon-macromolecular adhesive additivesPolymer sciencePolysulfide rubber

The invention discloses a high-temperature-resistant flexible adhesive cured at normal temperature and a preparation method thereof. The high-temperature-resistant flexible adhesive is prepared by adopting bisphenol-A epoxy resin, high-polymerization-degree epoxy resin, polysulfide rubber and organic silicon resin as bonding components, adopting polyamide as a main curing component, and adding inorganic auxiliary materials with different proportions. The high-temperature-resistant flexible adhesive disclosed by the invention has the advantages that a Si-O chain section in organic silicon and a flexible chained structure in the polysulfide rubber are formed by changing grafting positions of the organic silicon and the epoxy resin, so that not only are the high-temperature resistance and the toughness of a cured product improved, but also the consumption of epoxy groups in a process of modification is reduced. The epoxy resin adhesive prepared by the method solves the problems that the cost is high, the purchasing of raw materials is difficult and the modification of the bonding components consumes a great quantity of epoxy groups to cause insufficient curing reaction and further cause reduction of the strength of the adhesive in the epoxy resin adhesive in the prior art. The high-temperature-resistant flexible adhesive has the characteristics that the operation can be carried out under the room-temperature condition, and simultaneously the high temperature can be resisted.

Owner:ZHENGZHOU UNIV

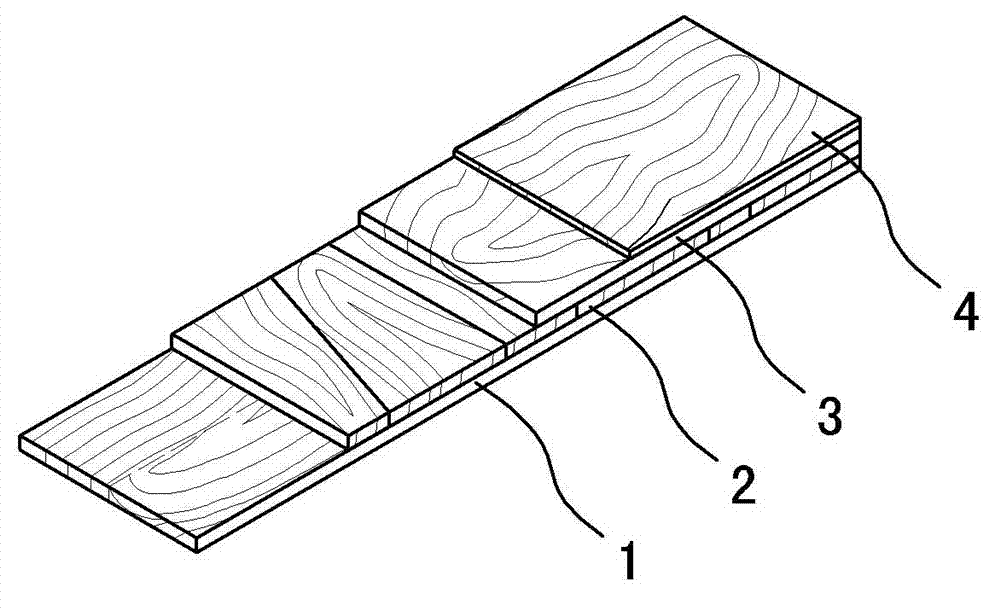

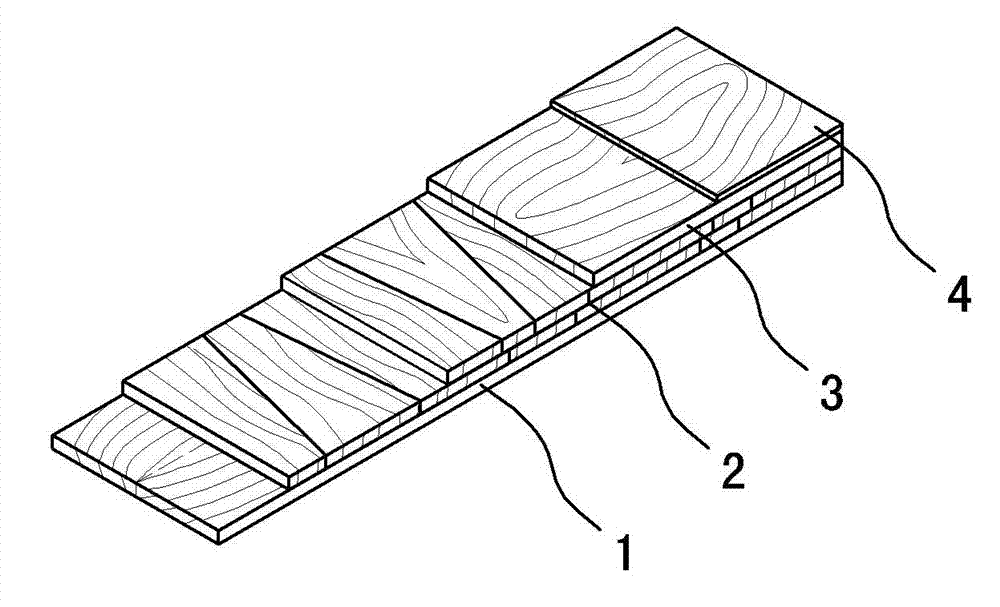

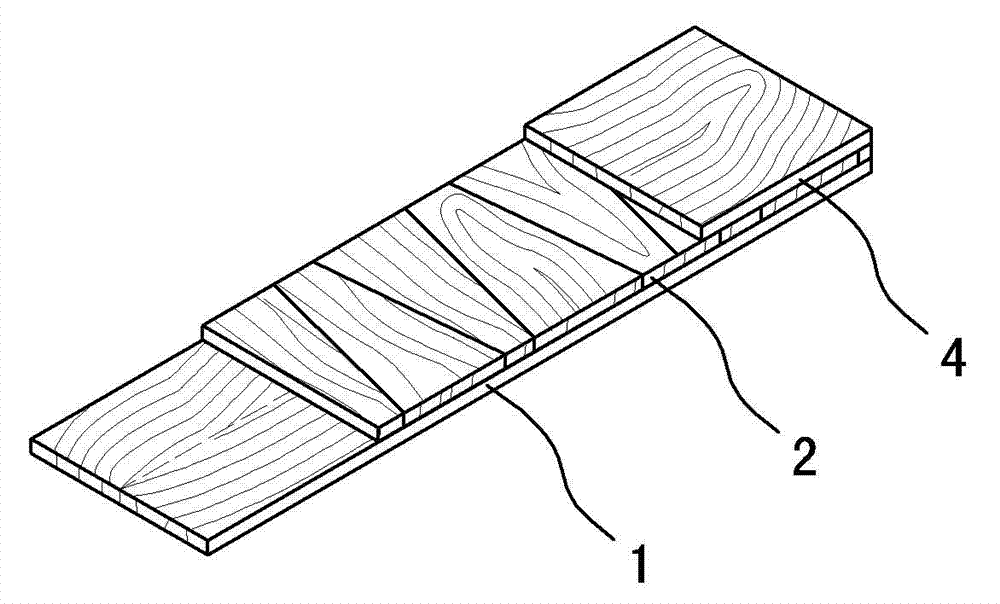

Composite carbon-based floor and production method thereof

InactiveCN102733579AStrong weather resistanceStrong dimensional stabilityLaminationWood working apparatusAdhesive cementCold area

The invention relates to a composite carbon-based floor and a production method of the floor; a raw wood is sliced by a vertical veneer slicer into a veneer for manufacturing a base plate, a core plate and a secondary surface veneer of a substrate and a veneer for manufacturing a surface veneer; the base plate, the core plate, the secondary surface veneer and the veneer to be carbonized are subjected to high temperature carbonization treatment, the carbonized base plate, veneer and secondary surface veneer are bonded with a surface wooden veneer or a surface carbonized veneer by glue, or the carbonized base plate, the carbonized core plate veneer and the surface carbonized veneer or the surface wooden veneer are bonded by glue, so as to obtain the floor. The composite carbon-based floor has very high weather resistance and size stability, is green, nontoxic, insect-resistant and anticorrosive, long in service life, and free from limit of amplitude width. The floor is suitable for terrestrial heat condition of cold areas and does not deform and crack. The composite carbon-based floor production method has the advantages of low material consumption, low energy consumption, low cost, and small pollution.

Owner:薜继武

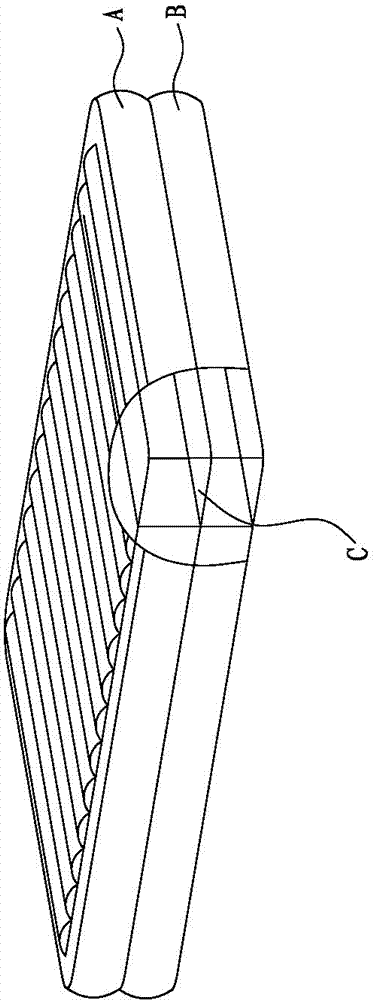

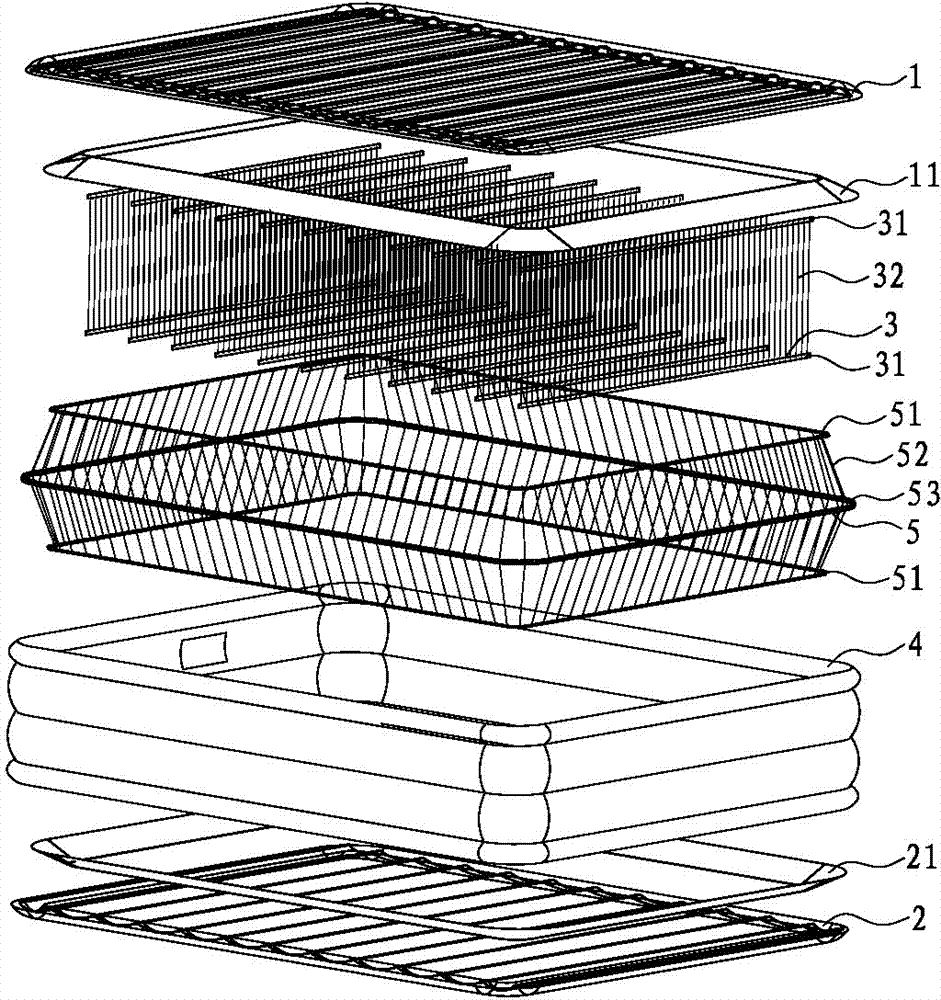

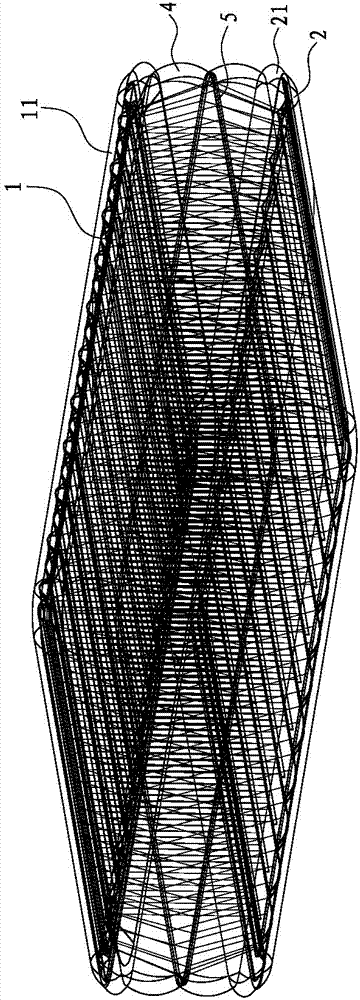

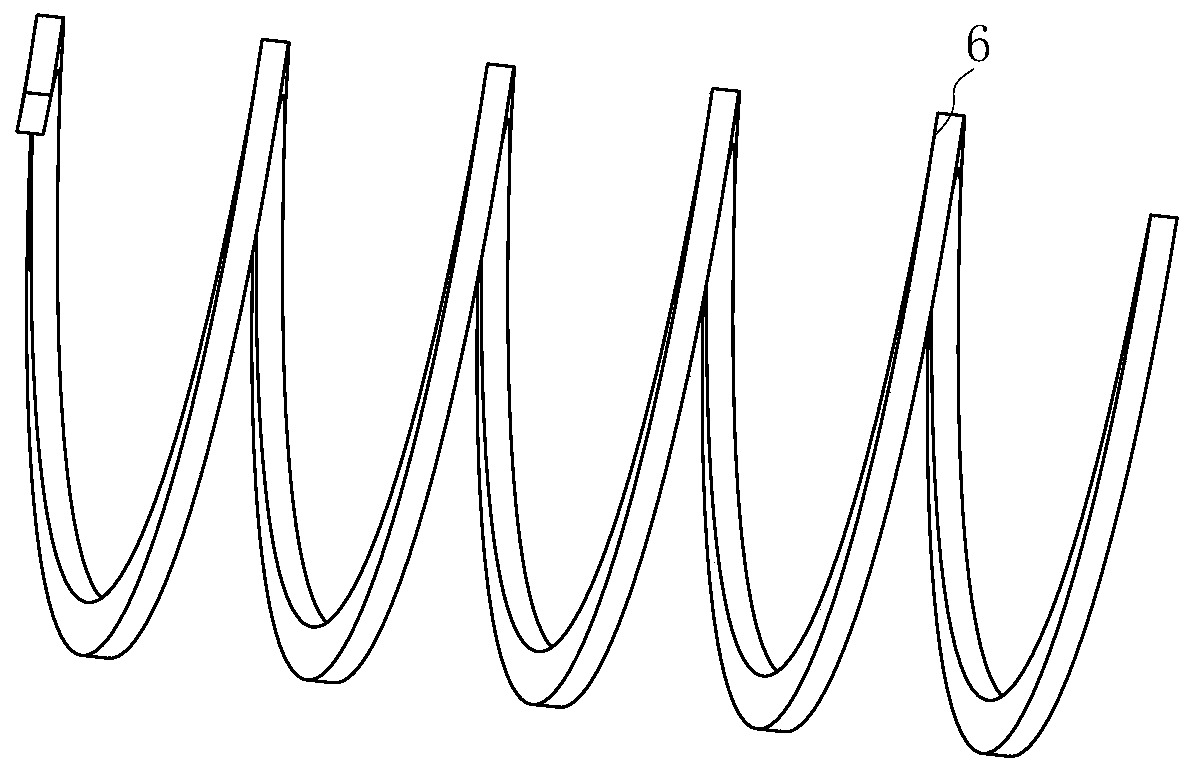

Reinforcing structure of inflatable product

InactiveCN103110297AInfluence intensityAffect aestheticsFluid mattressesEngineeringUltimate tensile strength

The invention discloses a reinforcing structure of an inflatable product. The reinforcing structure comprises an upper sheet, a lower sheet, a plurality of drawstrings and an enclosing sheet, wherein two ends of each drawstring are respectively connected to the lower surface of the upper sheet and the upper surface of the lower sheet, and meanwhile, the upper edge and the lower edge of the enclosing sheet are respectively connected with the circumferential edge of the upper sheet and the circumferential edge of the lower sheet to form an inflatable product with an inflatable space; and the reinforcing structure further comprises a side enclosing drawstring, wherein one end of the side enclosing drawstring is connected to the middle part of the inner surface of the enclosing sheet, the other end of the side enclosing drawstring is connected to the lower surface, close to the circumferential edge, of the upper sheet and the upper surface, close to the circumferential edge, of the lower sheet, or the other end of the side enclosing drawstring is connected to the opposite surface of the enclosing edge connected with the one end of the side enclosing drawstring. According to the reinforcing structure, the side enclosing drawstring can have a certain traction limiting effect on the middle part of the enclosing sheet of the inflatable product with high height so as to prevent the inflatable product from protruding outwards too much to influence the strength and attractive appearance of the inflatable product, therefore not only is the material cost of the inflatable product effectively reduced, but also the manufacturing cost of the inflatable product can be effectively reduced.

Owner:INTEX IND (XIAMEN) CO LTD

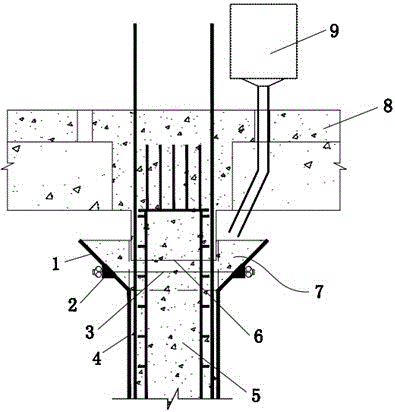

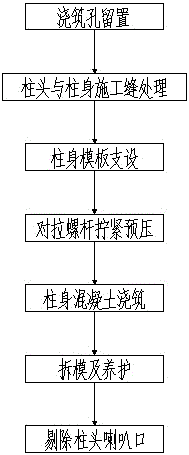

Basement reverse-construction scape post-casting pre-stressed construction method

ActiveCN105839850AInfluence intensityExtend the vibration time per pointArtificial islandsStrutsBasementPre stress

A basement reverse-construction scape post-casting pre-stressed construction method belongs to the technical field of building engineering. In the method, construction of a beam plate of the ground floor is completed at first, and then construction of a beam plate in the first underground layer of the basement is carried out, and finally construction of first underground layer scapes which connect the beam plates in the ground floor and the first underground layer is carried out. The construction method includes the steps of: retaining pouring holes, performing construction seam treatment of chapiters and scapes, establishing scape templates, tightening and pre-stressing opposite-pull screw rods, performing scape concrete pouring, detaching the templates and maintaining the scapes, and removing hornlike mouth of the chapiters. The construction method greatly simplifies pouring and tamping construction and the concrete can be delivered from the top board of the ground floor to the pillars in the first underground layer of the basement directly, wherein the pouring and tamping construction starts during transportation, so that the method saves time and labor, and solves a problem that the concrete needs to lift up to the beam plate on the first underground layer with a tower crane. The method greatly increases pouring and tamping construction speed of the scape, reduces construction time, has excellent promoting effect, and is suitable for engineering of secondary pouring and tamping the scapes in a basement through the reverse construction.

Owner:WENZHOU CONSTR GROUP

Method for reinforcing concrete structure

The invention provides a concrete structure reinforcement method, comprising the steps of: grinding the concrete base surface; grinding the exposed steel bars, and brushing the rust inhibitor on the surface of the steel bars; removing the loose part of the base surface, and brushing the bottom layer interface on the base surface Treatment agent; when the interface treatment agent is not dry, apply the top facade repair mortar on the damaged part until the original concrete base contour is restored; when the top facade repair mortar is not dry, paint the concrete protective paint on the entire base surface. The concrete structure reinforcement method provided by the present invention can completely isolate the exposed steel bars from moisture and air by applying a rust inhibitor, preventing oxidation and corrosion again and affecting the strength of the steel bars; by applying an interface treatment agent, the repair mortar can be strengthened At the same time, it can prevent the corrosion of the steel bar and the base surface; by applying the concrete protective coating, the strength of the repaired base surface can be effectively improved, and the combination with the repair mortar can effectively improve the strength of the repaired part.

Owner:STATE GRID CORP OF CHINA +1

Ultrahigh strength steel wire dip-coated with Zn-Al-Mg-Si alloy coating, preparation method thereof and application thereof

InactiveCN105331918AHigh strengthImprove toughnessHot-dipping/immersion processesHigh intensityAlloy coating

The invention relates to an ultrahigh strength coating steel wire dip-coated with a Zn-Al-Mg-Si alloy coating, a preparation method thereof and an application thereof. The alloy coating consists of the following components in percentage by mass: 30-97% of Zn, 5-80% of Al, 0.02-11% of Mg, and 0.05-5.0% of Si, based on 100% in total. The preparation method comprises the following steps: inspecting performances of an original coil rod; carrying out surface treatment; carrying out wire drawing; preparing a hot dipping Zn-Al-Mg-Si alloy coating; and carrying out stabilization treatment. The ultrahigh strength coating steel wire with the Zn-Al-Mg-Si alloy coating provided by the invention has corrosion resistance and mechanical performance superior to those of a current high-strength zinc-coated steel wire; the preparation method is easy to implement, meets needs of special environments such as a marine corrosion environment and the like on a bridge steel wire, and has a wide market prospect.

Owner:BAOSTEEL GRP NANTONG WIRE PROD

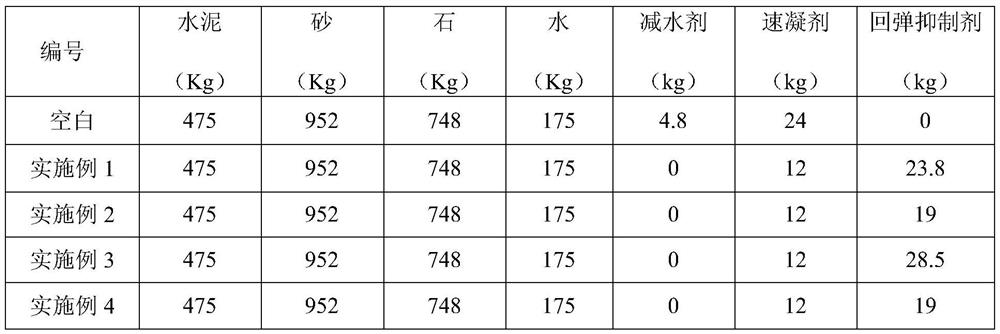

Shotcrete springback inhibitor and using method thereof

The invention discloses a shotcrete springback inhibitor and a using method thereof. The springback inhibitor is prepared by mixing the following raw materials: 50%-60% of a composite admixture, 15%-30% of nano calcium silicate, 15%-25% of an efficient water reducing agent, 1%-5% of redispersible latex powder, 1%-5% of a water retaining agent, 1%-5% of a thickening agent and 0.5%-1.0% of an exciting agent. When shotcrete is prepared, cement, sand, stone and the springback inhibitor are added into a stirrer together to be stirred; the mixing amount of the springback inhibitor is 3-8% of the total consumption of the cementing material. According to the shotcrete springback inhibitor and the using method thereof of the invention, under the condition that a water reducing agent is not added and the mixing amount of an accelerator is reduced, the springback rate of the shotcrete is greatly reduced, the working performance of the shotcrete is improved, meanwhile, the mechanical property andthe durability are improved. The method is particularly suitable for preparing the high-performance shotcrete. The one-time spraying thickness of the shotcrete can reach 50 cm or above, the early strength of the shotcrete is remarkably improved, the adverse effects of the accelerator on the strength, durability and the like of the shotcrete are avoided, the construction efficiency is improved, andthe engineering cost is saved.

Owner:刘翠芬

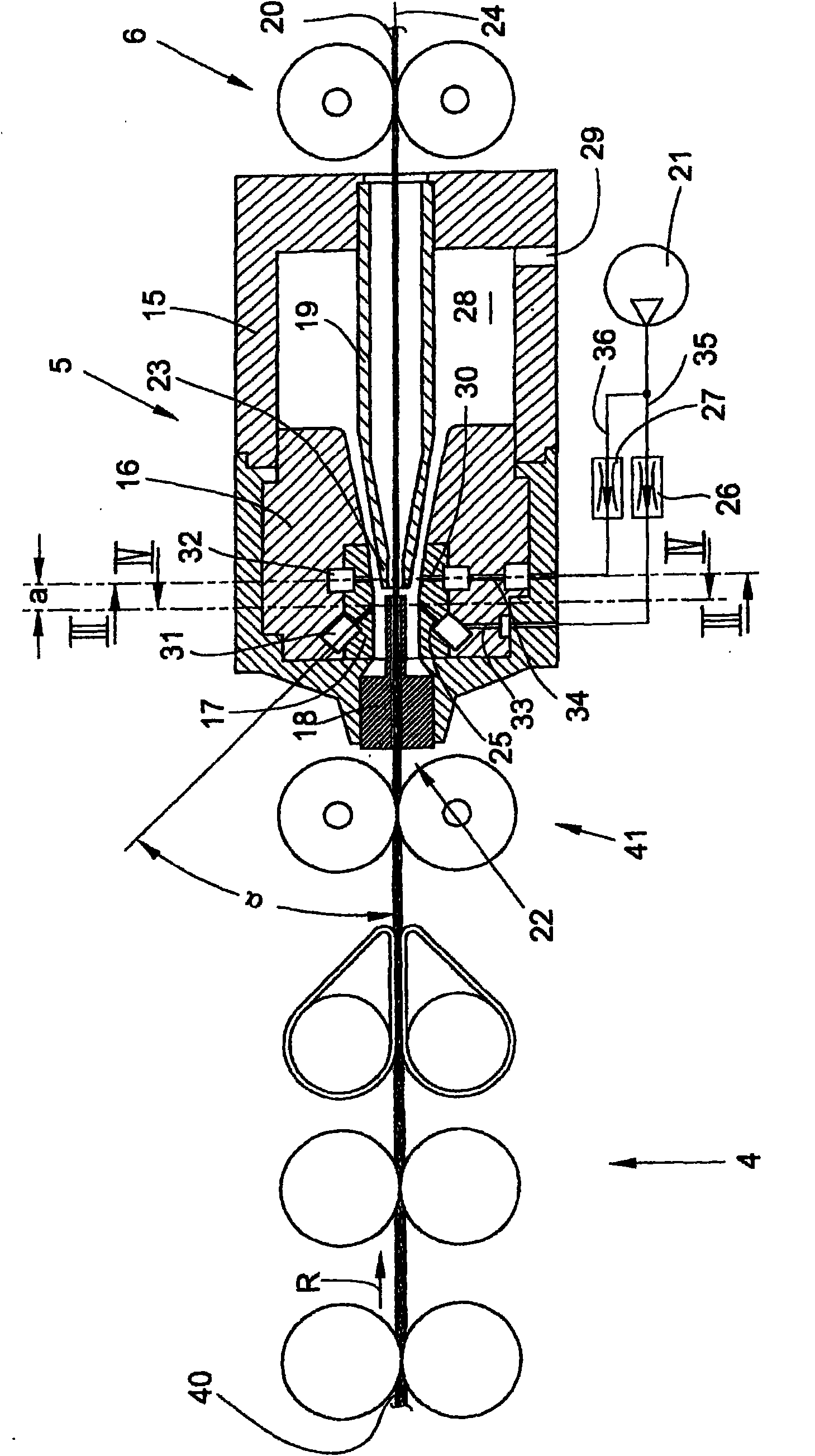

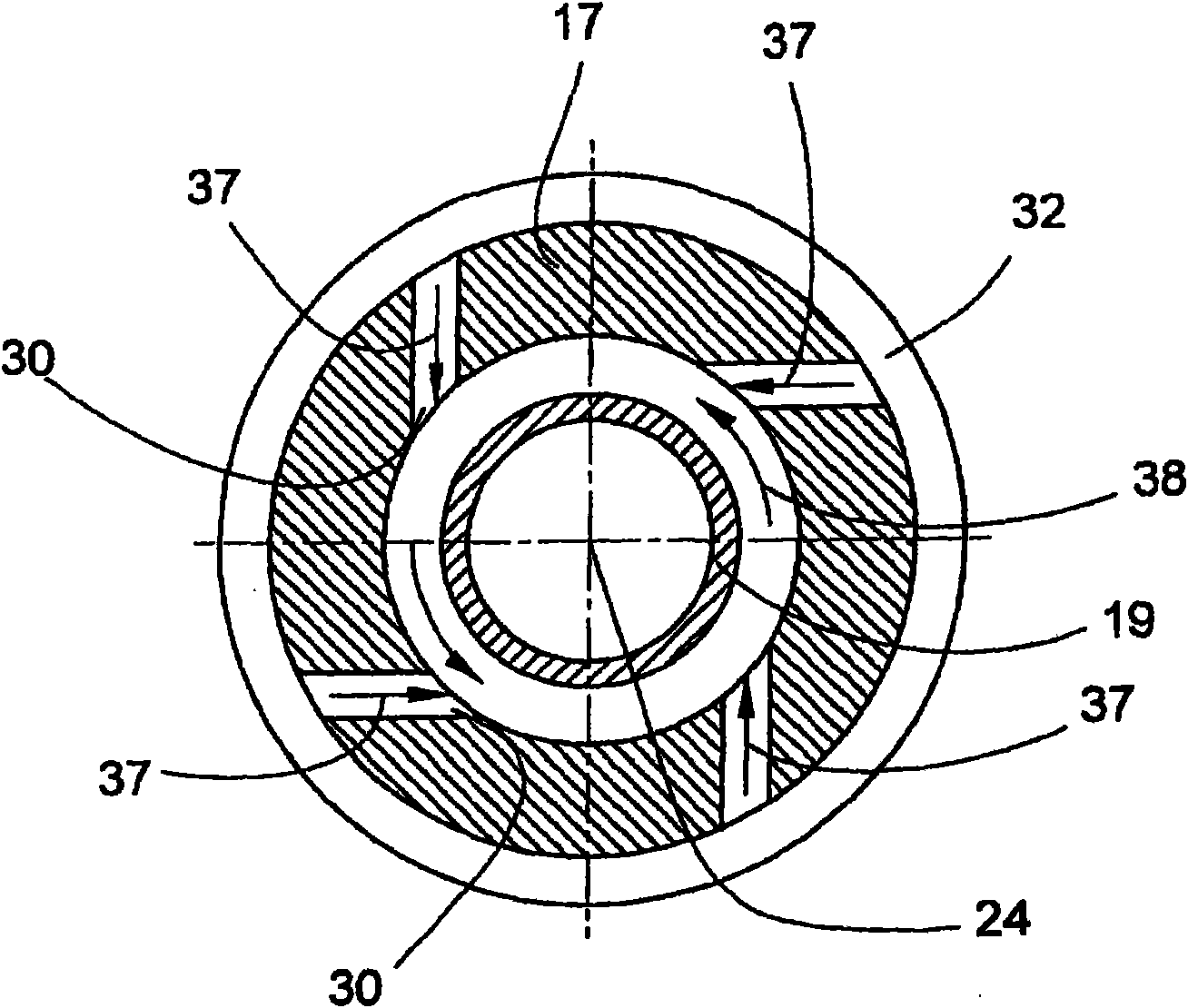

Jet spinning apparatus

ActiveCN101600826AEffective assistanceSoft treatmentContinuous wound-up machinesOpen-end spinning machinesYarnUltimate tensile strength

The invention relates to a jet spinning apparatus (5) for producing a thread (20) by means of a circulating airflow, having a hollow spinning cone (19) which is arranged in a spinning housing (15), and having two separate groups of blown air nozzles (25, 30) which can be loaded with compressed air independently of one another, wherein the strength of a vacuum flow which acts on a sliver inlet opening (22) during the spinning process can be set via the arrangement of a first group of blown air nozzles (25) and the strength of an airflow which circulates in the region of the spinning cone (19) can be predefined via the arrangement of a second group of blown air nozzles (30). There is provision according to the invention for the blown air nozzles (25) of the first group to be arranged offset at a spacing (b) with regard to the longitudinal centre axis (24) of the jet spinning apparatus (5), with the result that an airflow can be introduced into the jet spinning apparatus (5) via the blown air nozzles (25) during the spinning process, which airflow has a tangential blown air component in order to assist the airflow which circulates in the region of the spinning cone (19).

Owner:SAURER GERMANY GMBH & CO KG

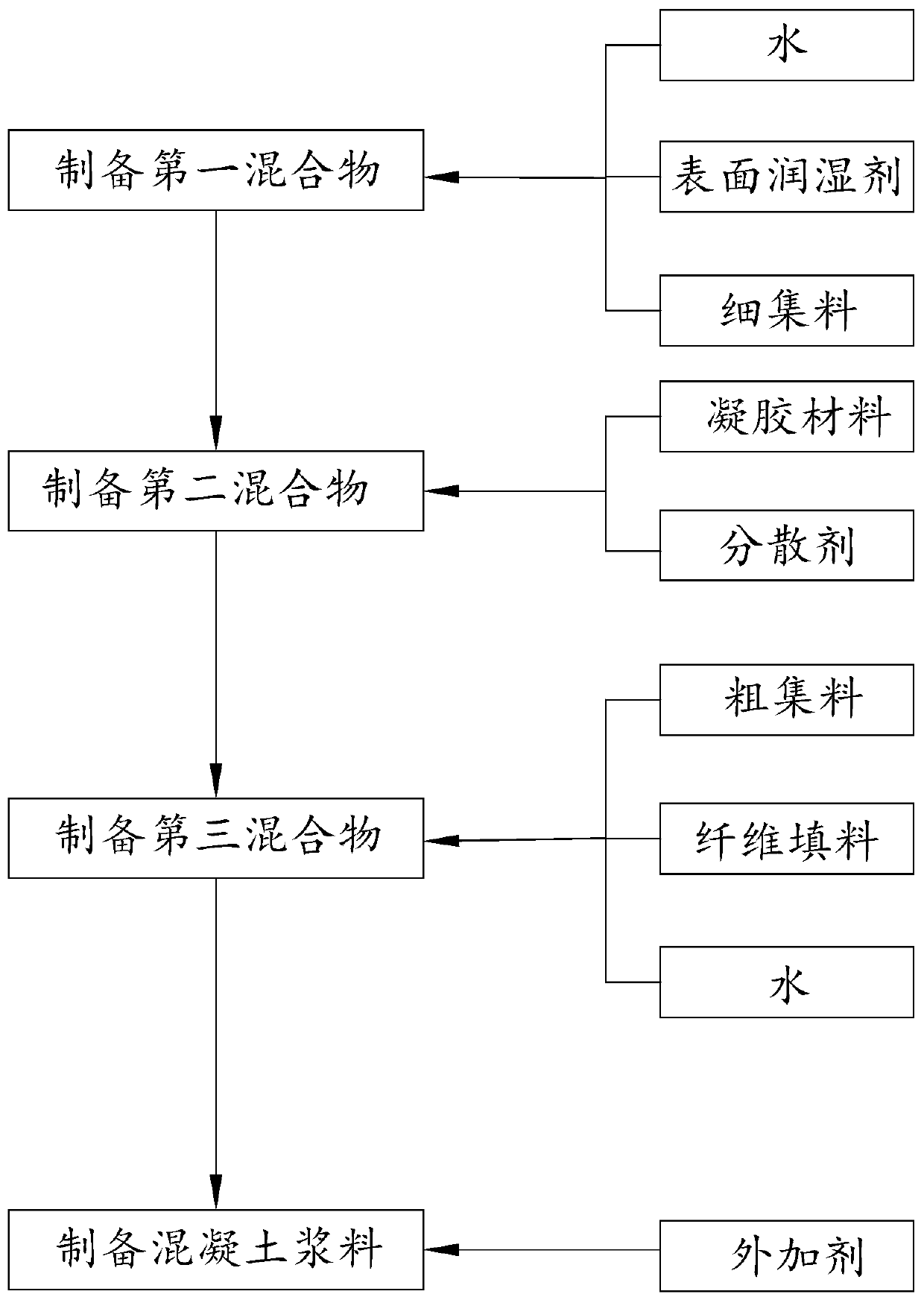

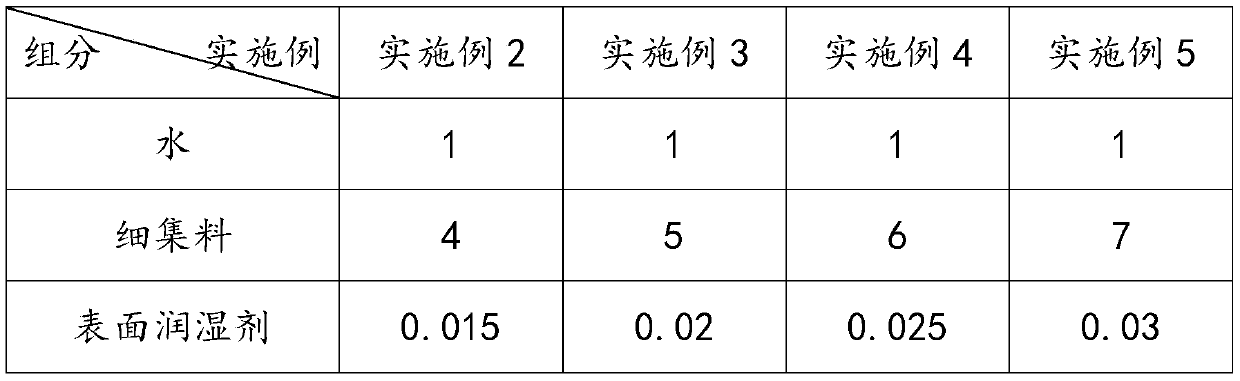

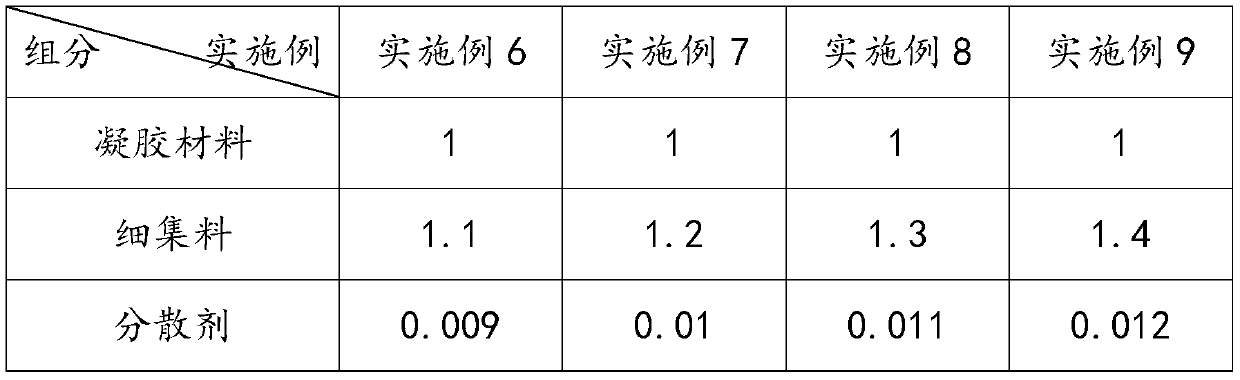

Concrete preparation process

The invention relates to a concrete preparation process, which comprises the following process steps: s1, uniformly stirring water and a surface wetting agent, adding a fine aggregate, and uniformly stirring to obtain a first mixture; wherein the weight ratio of water, fine aggregate and surface wetting agent is 1: (3-7): (0.01-0.03); s2, adding a gel material and a dispersant into the first mixture, and uniformly stirring to obtain a second mixture; wherein the weight ratio of gel material, fine aggregate and dispersant is 1: (1-1.4): (0.008-0.012); s3, adding a coarse aggregate, a fiber filler and water into the second mixture, and uniformly stirring to obtain a third mixture; wherein the weight ratio of fine aggregate, coarse aggregate, fiber filler and water is 1: (2-2.4): (0.06-0.1):(0.08-0.12); and s4, adding an additive into the third mixture and uniformly stirring to prepare concrete slurry; wherein the weight ratio of additive to fine aggregate is (0.02-0.03): 1. The workability and working performance of the mixed soil are improved by reasonably setting the feeding sequence of concrete raw materials.

Owner:四川信敏绿色新建筑材料科技有限公司

Grouting material for expressway bridge bearings and preparation method thereof

The invention discloses a grouting material for expressway bridge bearings, which comprises the following components in parts by weight: 400-500 parts of cement, 300-450 parts of quartz sand, 10-20 parts of fly ash, 2-4 parts of a water reducing agent, 1-1.5 parts of a coagulation accelerator, 1-4 parts of an expander, 1-3 parts of a retarder, 2-3 parts of a defoamer, 2-5 parts of a thickener, and1-1.5 parts of polypropylene reticular fibers. The invention further discloses a preparation method of the grouting material for expressway bridge bearings. The cement uses in the grouting material adopts sulphoaluminate cement and ordinary portland cement, which not only realizes the characteristics of early strength, but also avoids the problem of strength substantial decline caused by the useof the ordinary portland cement alone. The raw materials of the grouting material have a wide range of sources and low price. The preparation method is simple, and suitable for large-scale promotion,and the grouting material has good construction performance, can realize self-flow leveling, has long operation time, and has a smooth surface after being poured, and the shortcomings of traditional mortar such as irregularity, easy cracking, easy stripping and easy dusting can be overcome.

Owner:石家庄国辰知识产权服务有限公司

Powdery metallurgical finished product process

InactiveCN102672180AHigh glossQuality improvementFurnace typesHeat treatment furnacesMetallurgyLubricant

The invention discloses a powdery metallurgical finished product process. The powdery metallurgical finished product process comprises the following steps: adding components of a lubricant and an MCF-078 in a basic raw material low-alloy steel powder JDYTAB, wherein counted by to the mass of the basic raw material low-alloy steel powder JDYTAB, the adding amount of the lubricant is 0.7% and the adding amount of the MCF-078 is 0.3%; and stirring, forming, sintering, turning, performing thermal processing, performing vibration grinding, performing oil immersion and packaging metallurgical powder into a finished product. Compared with the prior art, the powdery metallurgical finished product process has the advantages of stable production process, high reliability; and a produced powdery metallurgical product is good in gloss, excellent in quality, high in performance and wide in application and can be applied to production of a gear, internal and external rotors, an output shaft and the like.

Owner:TAICANG JINLIDE POWDER METALLURGY

Pretreatment method and device for hard alloy cutter before diamond coating deposition

ActiveCN109811298AIncrease gas energyHigh activitySolid state diffusion coatingPlasma activationCemented carbide

The invention relates to a pretreatment method and a device for a hard alloy cutter before diamond coating deposition. The device comprises a furnace body, a hearth, an electric heater, plasma generating power supply and a sample table. The pretreatment method comprises the steps of chemical micro-etching, plasma activation, plasma enhanced gaseous boronizing and plasma cleaning on the surface ofthe hard alloy cutter. According to the invention, plasma equipment is clamped on a constant temperature tube furnace, equipment obtained by reforming a bias device is added, and a set of appropriateprocesses are added to solve the problems in the prior art. The equipment provided by the invention has a simple structure and convenient operation, realizes plasma activation, plasma enhanced gaseousboronizing and plasma cleaning of workpieces, optimizes the existing microwave plasma gaseous boronizing process, greatly reduces the process cost, has good boronizing effect, and is suitable for large-scale industrial production.

Owner:HU-NAN NEW FRONTIER SCI & TECH LTD

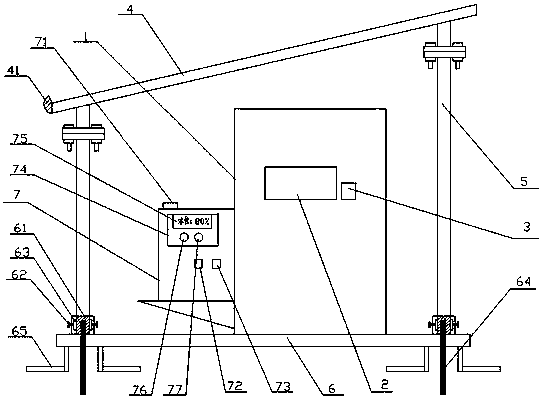

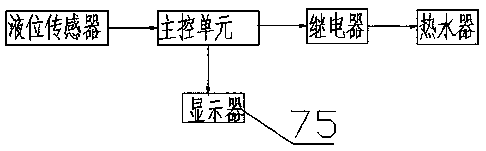

Charging pile

InactiveCN108656996ASolve the service lifeEasy to viewCharging stationsElectric vehicle charging technologyEnvironment effectEngineering

The invention discloses a charging pile. The charging pile comprises a charging pile body; a display control screen is arranged in the middle of the charging pile body, a main control unit is arrangedon the rear side of the display control screen, a wireless connection module is arranged on the right side of the main control unit, and a card swiping sensing area is arranged on the right side of the display control screen; the charging pile further comprises a shielding plate on the upper portion of the charging pile body, supporting rods used for supporting the shielding plate, and a chargingpile base at the bottom of the charging pile body; the bottoms of the supporting rods are connected with the charging pile base, and the tops of the supporting rods are connected with the shielding plate; a drinking water cabinet is arranged on the left side of the charging pile body and internally provided with a water heater and a water tank; and the drinking water cabinet is provided with a water injecting opening, a hot water outlet and a cold water outlet; a sealing cap is arranged on the water injecting opening, the water injecting opening communicates with a water inlet in the water tank through a water pipe, the drinking water cabinet is provided with an observation window, and the output end of the main control unit is connected with a relay used for controlling the water heaterto work. The charging pile is simple in structure and is not affected by rainwater and the severe environment, and the design of the drinking water cabinet is reasonable and humanized.

Owner:河南水天环境工程有限公司

Novel optical fiber wiredrawing cooling system

ActiveCN105236732AImprove coating qualityDiameter stableGlass fibre drawing apparatusInsulation layerCooling effect

Owner:ZHONGTIAN TECH FIBER OPTICS +1

Method for machining involute gear

InactiveCN1660534AInfluence intensityGuaranteed transmission accuracyGear teethGear wheelInvolute gear

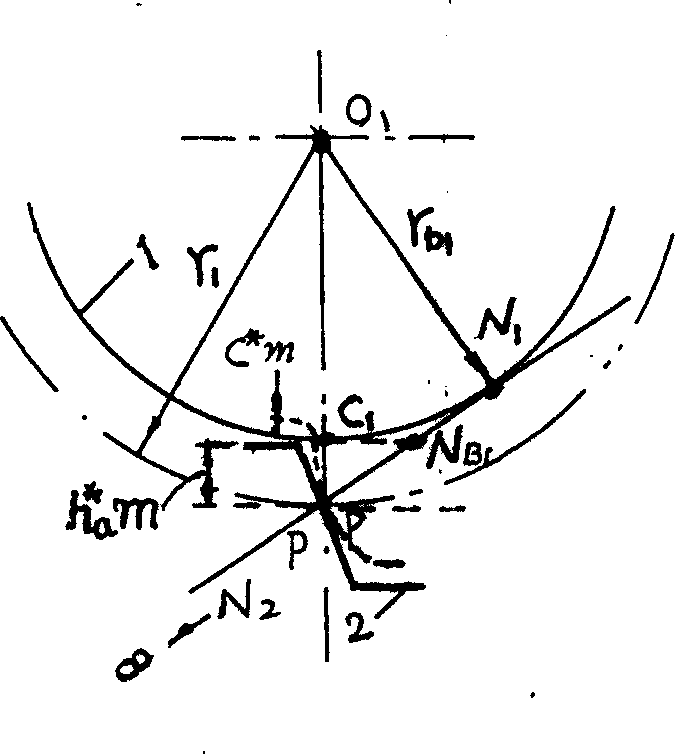

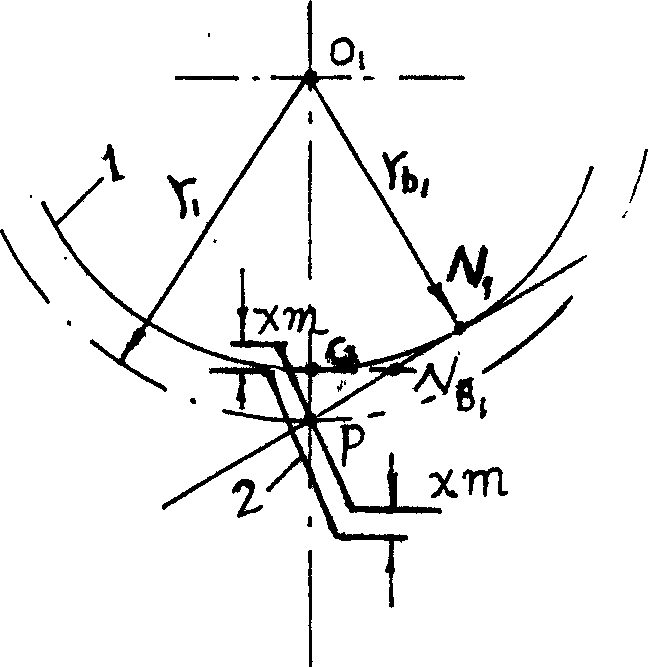

A technology for machining the involute gear is disclosed. When the tooth top line of standard rack bar tool is tangent with the base circle of gear to be machined, it is an extreme position of advancing tool. When it is said extreme position, the crossing point between said tooth top line and the engaging line is the extreme engaging point. When said tooth top line is advanced to the extreme engaging point, the minimal number of the teeth on the gear is 33.16. When the number of the teeth on the gear is less than 33.16, the rack bar tool moves is the base circle of the gear of machine the involute gear.

Owner:喻胜

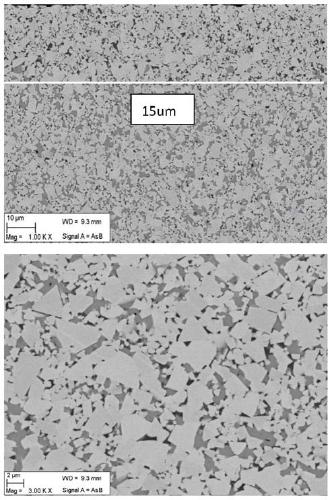

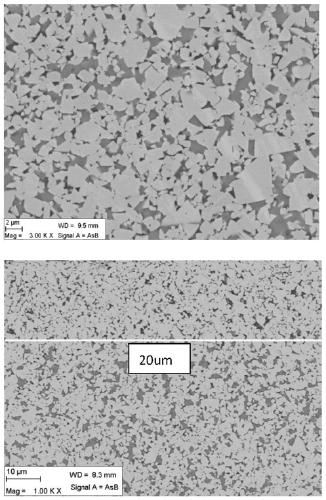

Carbide blade and preparation method thereof

The invention provides a carbide blade and a preparation method thereof, and belongs to the field of mechanical technology. The carbide blade solves the problem that existing cutting blades are not high in universality and have certain limitations. The carbide blade uses Co as a bonding phase, and tungsten carbide and titanium-containing cubic phase compound as hard phases; mass fraction of the bonding phase is 4.5-9.5 wt.%, and mass fraction of the hard phases is 90.5-95.5 wt.%; mass fraction of the titanium-containing cubic phase compound in the carbide blade ranges from 2 wt.% to 8 wt.%; grain distribution of the tungsten carbide is of a double-peak structure; the tungsten carbide comprises coarse grain tungsten carbide and fine grain tungsten carbide; the average grain size of the coarse grain tungsten carbide is 1.5-3.0 microns; and the average grain size of the fine grain tungsten carbide ranges from 0.4 micron to 1.0 micron. The carbide blade is high in hardness, toughness and strength, and is excellent and stable in cutting performance.

Owner:台州市锐安硬质合金工具有限公司

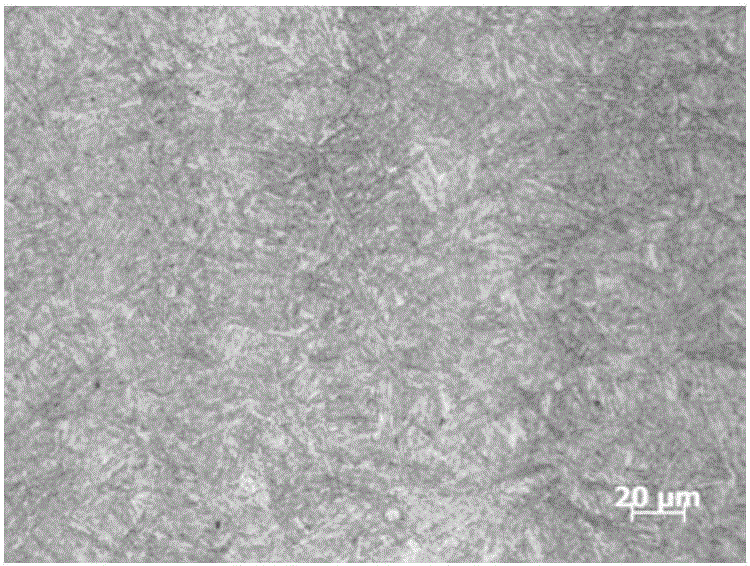

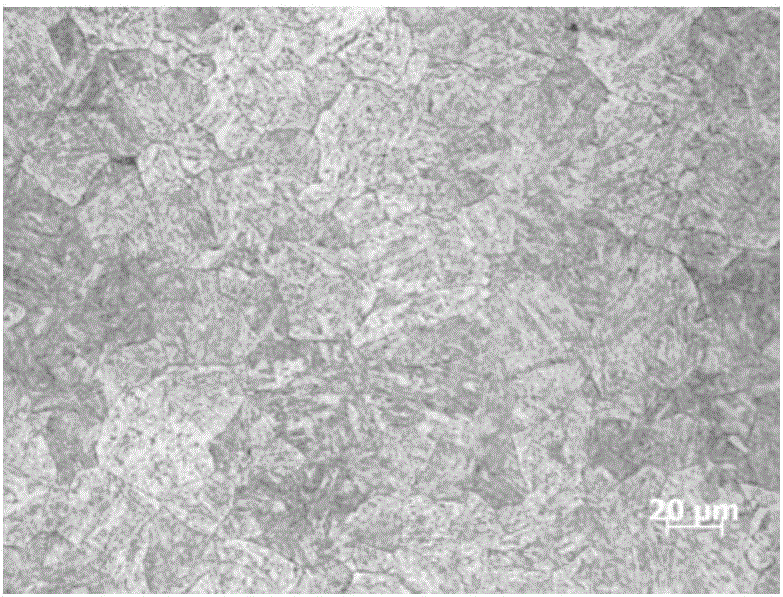

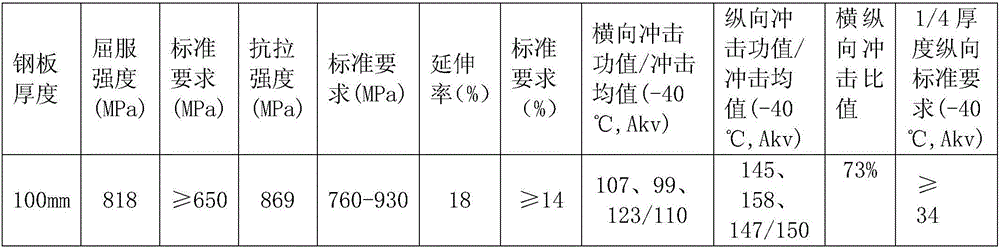

Production method of high-transverse/longitudinal-impact-ratio high-thickness Q690E high-strength steel

The invention discloses a production method of high-transverse / longitudinal-impact-ratio high-thickness Q690E high-strength steel. The production method comprises the following procedures: molten iron desulfurization pretreatment; converter smelting; LF and RH refining; continuous casting; casting blank piling and slow cooling; casting blank inspection; casting blank judgment; casting blank acceptance check; casting blank heating; descaling; rolling; air cooling; flaw detection; shot blasting; quenching; tempering; straightening; cutting and sampling; identifier spray printing; inspection; and warehousing. According to the invention, the production method has short production work procedures and low cost; and the produced steel is favorable in mechanical property, high in strength, high in toughness, high in plasticity, high in transverse / longitudinal impact work value and stable in weldability.

Owner:NANJING IRON & STEEL CO LTD

High-strength impact-resistant flame-retardant insulation cable

ActiveCN110246615AHigh strengthImprove impact resistanceInsulated cablesFire rescueGlass fiberThermal deformation

The invention belongs to the technical field of a cable and particularly relates to a high-strength impact-resistant flame-retardant insulation cable. The high-strength impact-resistant flame-retardant insulation cable includes a cable core and a cable base, wherein the cable core is externally wrapped in the cable base, an outer surface of the cable base is sleeved with a shape memory alloy layer, a surface of the shape memory alloy layer is sleeved with a glass fiber layer, an outer surface of the glass fiber layer is sleeved with an elastic base, the elastic base is internally provided with a chamber, the chamber is internally disposed with extinguishing chemical, and the fire extinguishing flame retardation effect is achieved for a fire through the extinguishing chemical in the chamber. After the shape memory alloy layer on the outer surface of the cable base expands, deformation wrapping for the cable base is generated, so strength and anti-impact performance of the cable base are improved, when internal thermal deformation of the cable base is prevented, softening of the cable base is generated, so strength and stiffness of the cable base are influenced, the glass fiber layer not only has the fire retardant effect, but also has the insulation effect.

Owner:宁波卡倍亿新材料科技有限公司

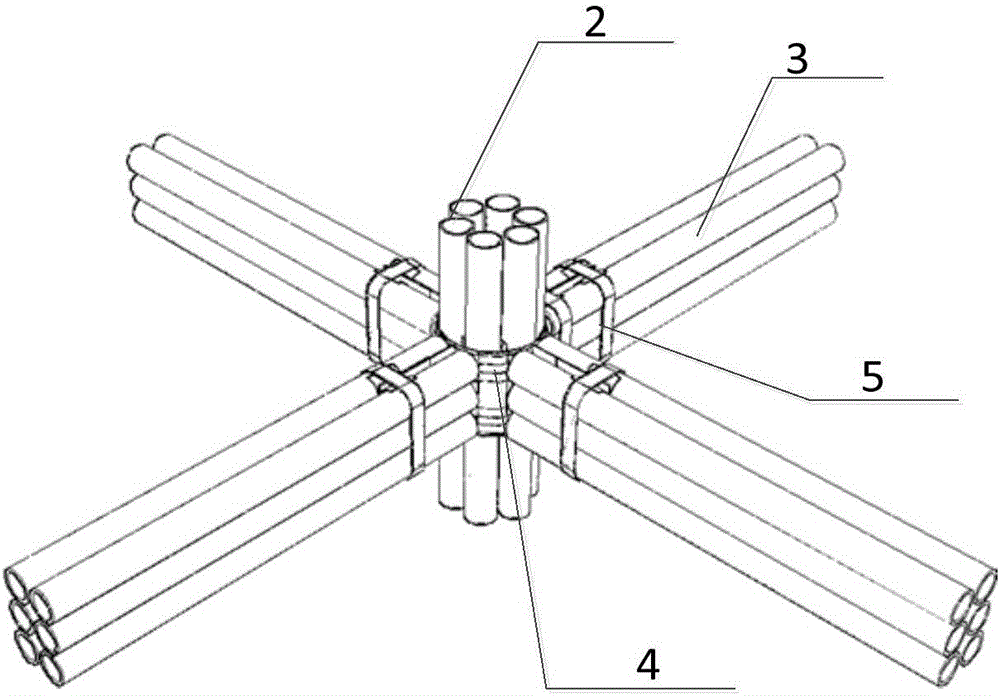

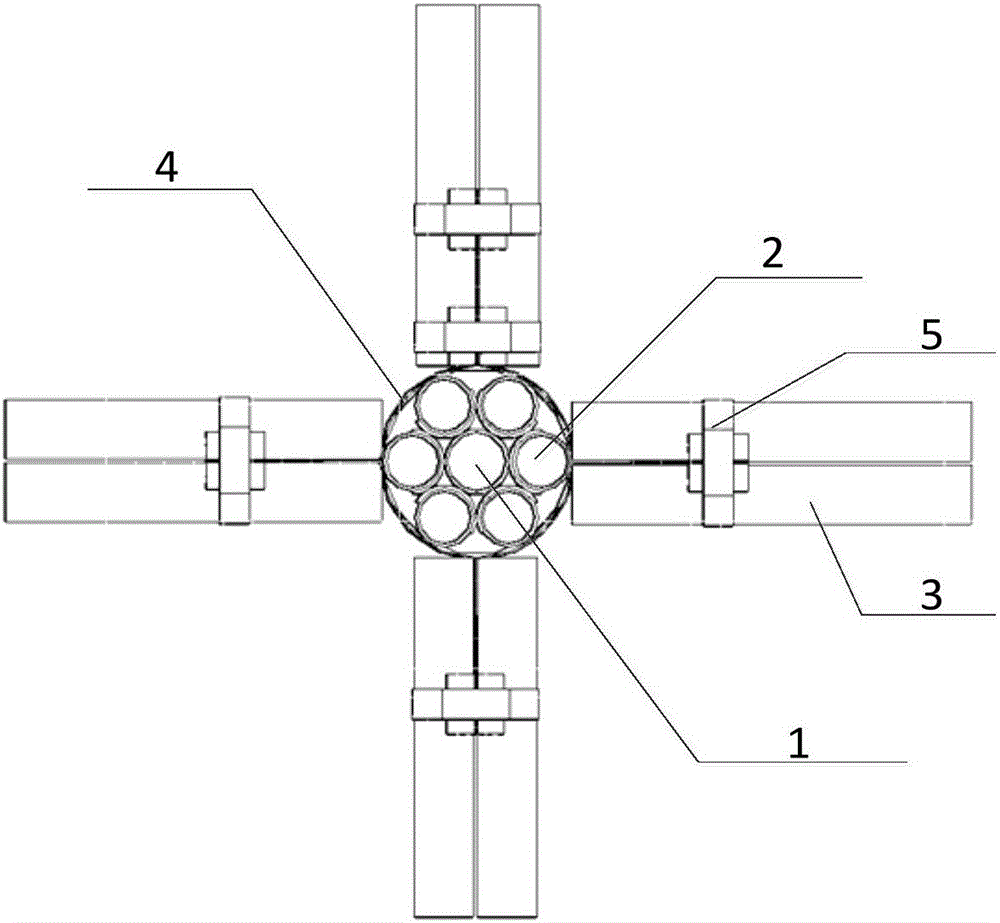

Beam-column semi-rigid connection structure based on bamboo frame

InactiveCN106703194AIncrease the bearing areaImprove bearing capacityBuilding constructionsEngineeringStructure based

The invention discloses a beam-column semi-rigid connection structure based on a bamboo frame; the beam-column semi-rigid connection structure comprises a column and beams; the column includes a center connector, a first connection plate, a second connection plate, a plurality of first bamboo pieces and a plurality of first rings, wherein the center connector comprises a center steel pipe and a plurality of first fixing plates, and wherein one first fixing plate corresponds to one first bamboo piece, the back of the first fixing plate is fixed to the side of the center steel pipe, and the front of the first fixing plate is provided with an arc face mating with the side of the corresponding the first bamboo piece; the first bamboo pieces are embedded in the fronts of the front fixing plates, both the center connector and the first bamboo pieces are nested in the first rings, the first connection plate is arranged between the first rings and the first bamboo pieces, the end of the second connection plate is connected to the lateral side of the first connection plate, the first rings are passed through the lateral side of the second connection plate; a joint of the structure herein is friendly to raw bamboo, and the structure is long in service life and high in bearing capacity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

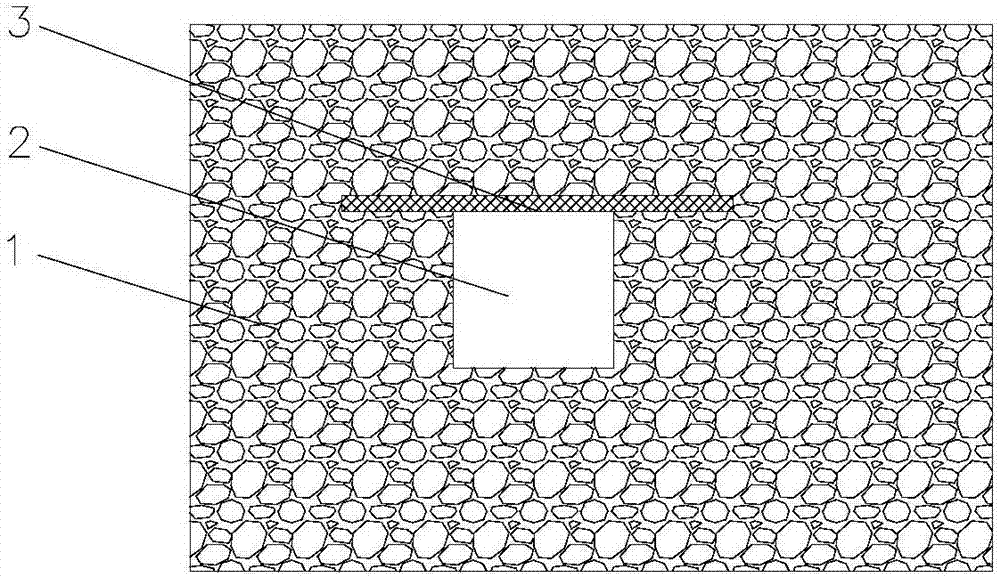

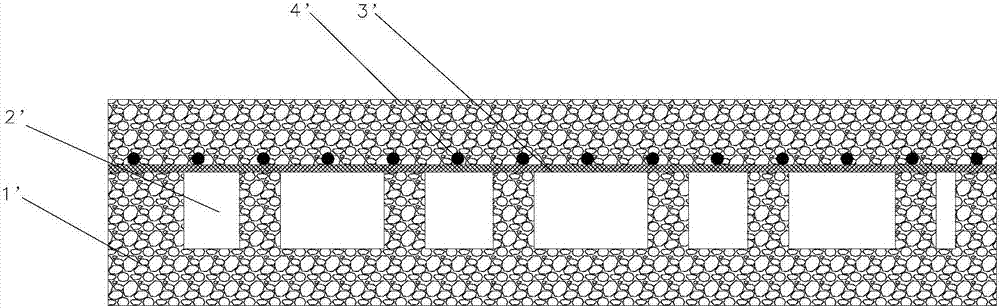

3D printed wall body with hollow or spanning structure and machining method for 3D printed wall body

InactiveCN107366381AInfluence intensityTaking into account the firmnessAdditive manufacturing apparatusConstruction materialCement mortarMachining

The invention discloses a 3D printed wall body with a hollow or a spanning structure. A cavity is reserved in a wall body in the printing process of the wall body by utilizing a 3D printing device, a spanning screen board is laid on the reserved cavity, the two ends of the spanning screen board are in an overlapping joint with cement mortars of the reserved cavity, and the overlapping length is not less than one-fourth of the width of a spanning groove, and the cement mortars are printed on the spanning screen board layer by layer. According to the 3D printed wall body with the hollow or the spanning structure, various required holes can be directly reserved on the 3D printed wall body during fabricating of the wall body by adding the spanning screen board, the facts that materials are wasted caused by supporting by using formworks, and operation of the 3D printing device are not convenient are avoided, meanwhile, the screen board can be firmly combined with the wall body due to the fact that screen holes are formed in the spanning screen board, and the condition that the overall strength of the wall body is affected due to the fact that contact parts between a traditional transverse beam and the wall body is not firm enough is avoided.

Owner:NANJING JIAYING PRECISION MACHINERY MFGCO

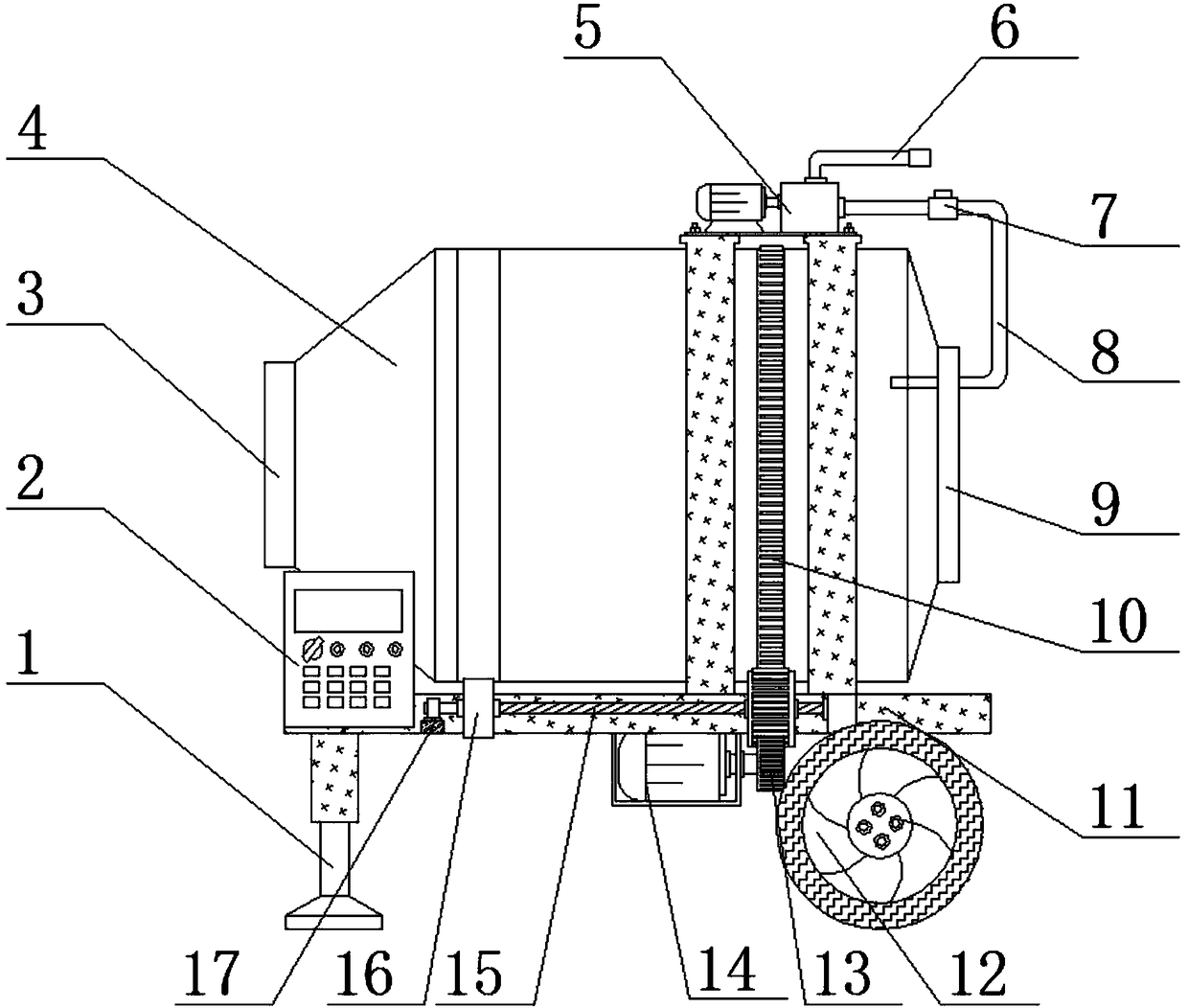

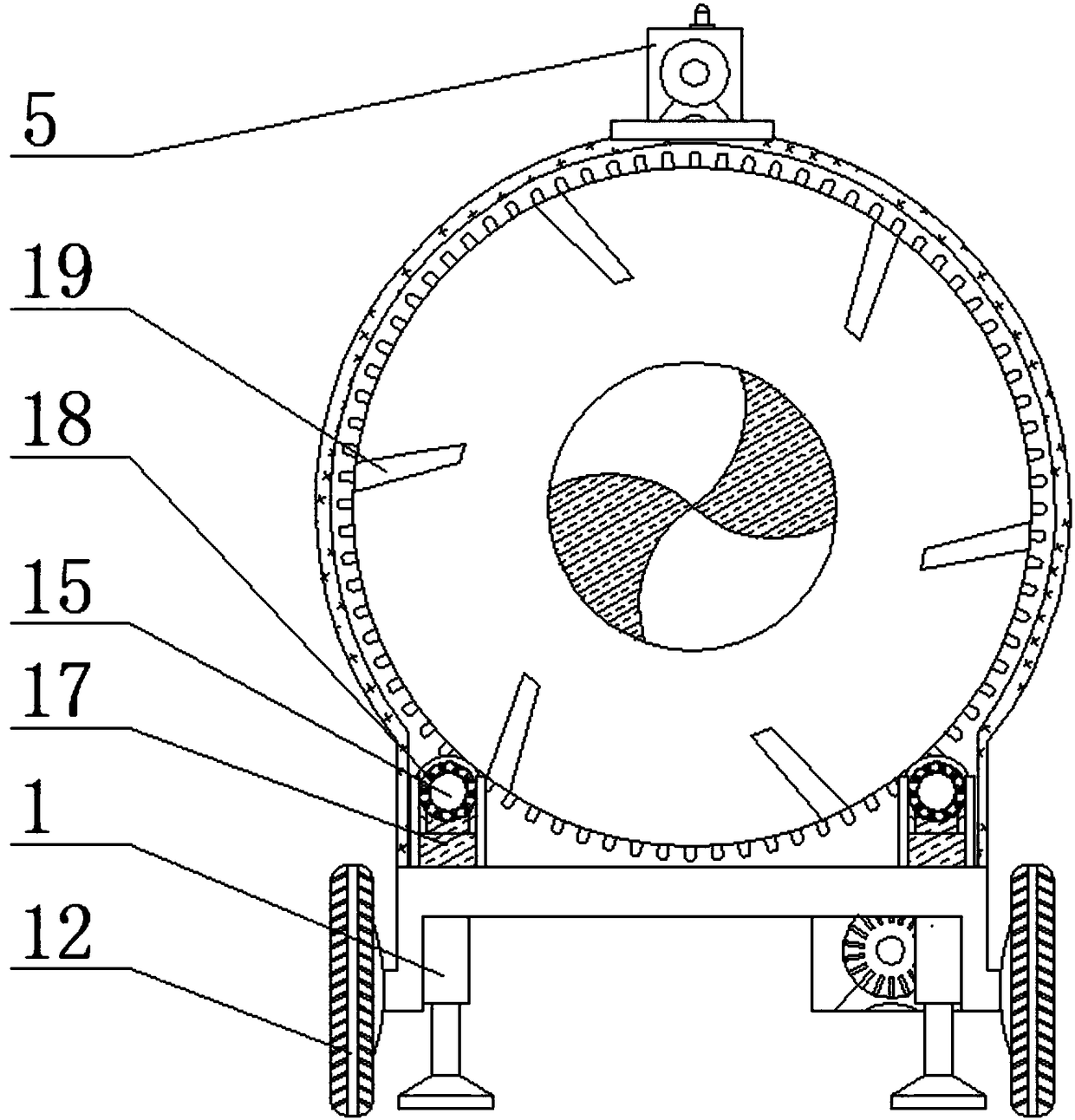

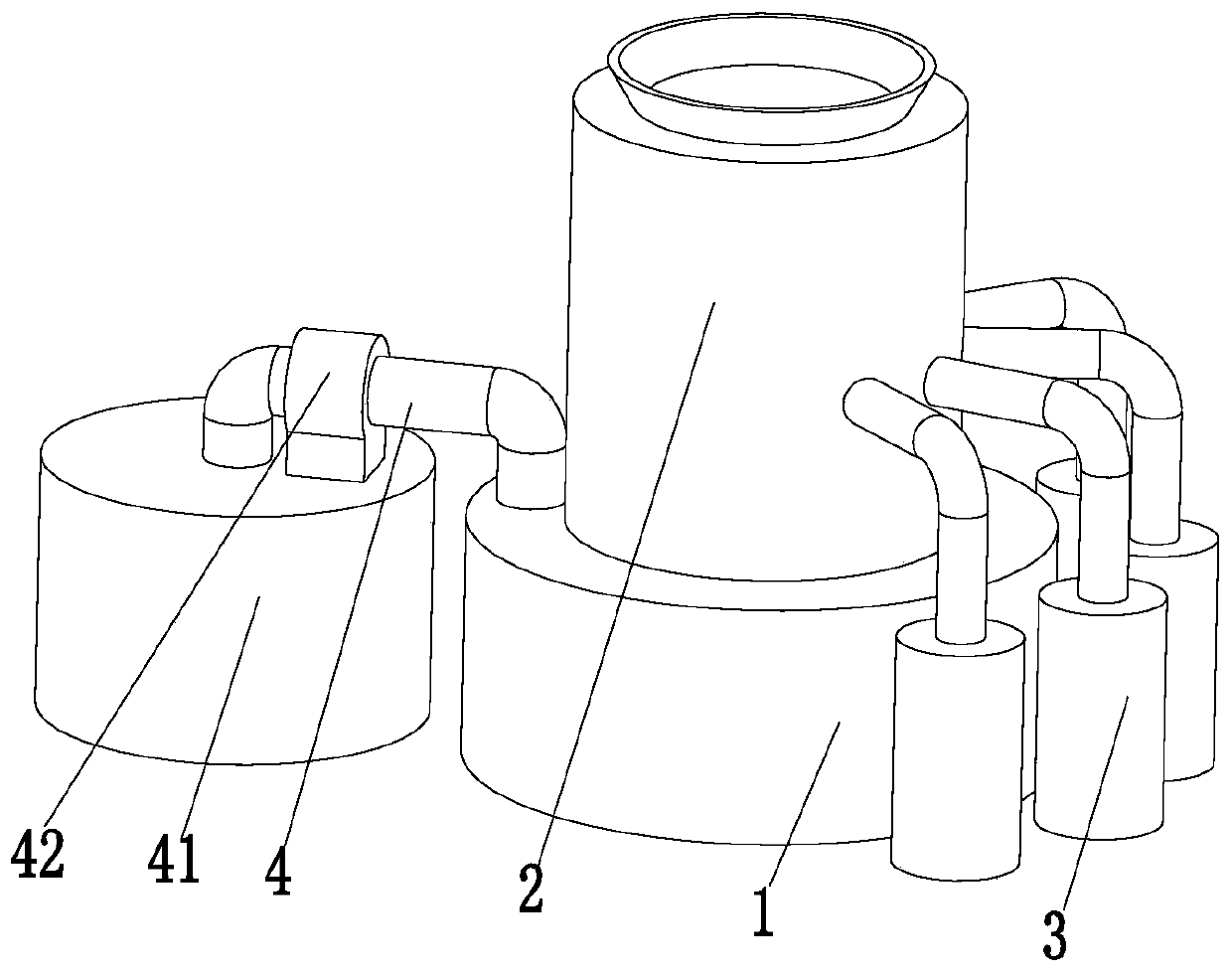

Automatic matching and water adding concrete stirring machine special for civil engineering

InactiveCN108858790AInfluence intensityQuality improvementCement mixing apparatusLiquid ingredients supply apparatusUltimate tensile strengthStreamflow

The invention discloses an automatic matching and water adding concrete stirring machine special for civil engineering. The machine comprises a water conveying pump, a stirring machine supporting frame and a servo motor; a supporting foot frame is arranged below the left of the stirring machine supporting frame, a control panel is arranged at the position, close to the upper portion of the supporting foot frame, of the left side of the stirring machine supporting frame, the water conveying pump is arranged at the position, close to the upper portion of the right of a stirring roller, above thestirring machine supporting frame, and the water conveying pump, a flow sensor, the servo motor and a pressure sensor are electrically connected with the control panel. The machine is scientific andreasonable in structure and safe and convenient to use, the pressure sensor can detect the weight of cement gravel added into the stirring roller, the flow sensor can meter the added water amount, water adding according to the proportion is facilitated, the phenomenon that due to too much or little water adding, the concrete strength is affected is avoided, the quality of produced concrete is improved, the construction quality is improved, and the hidden danger of the engineering quality is avoided.

Owner:周洁

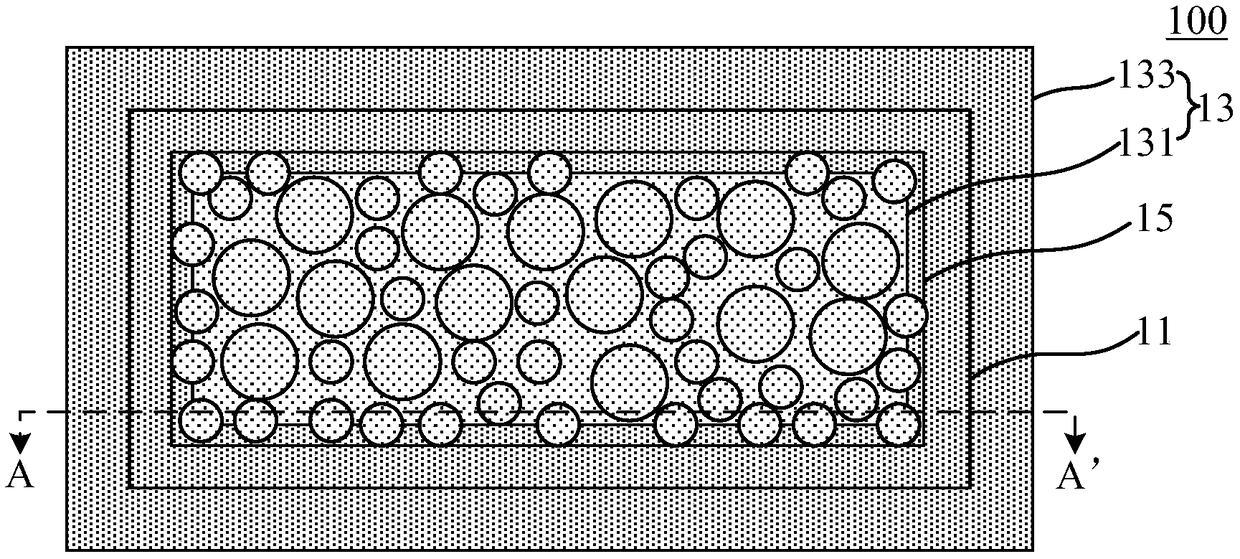

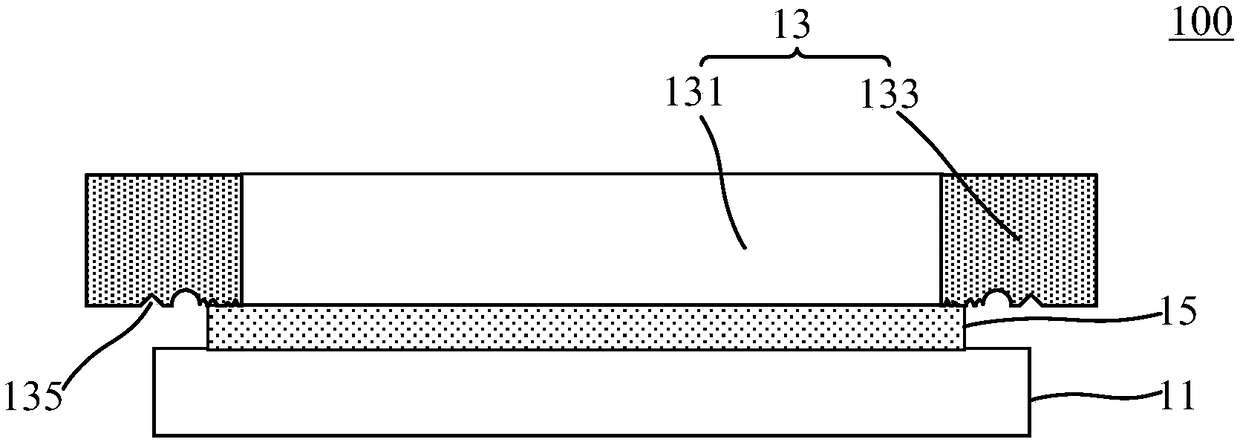

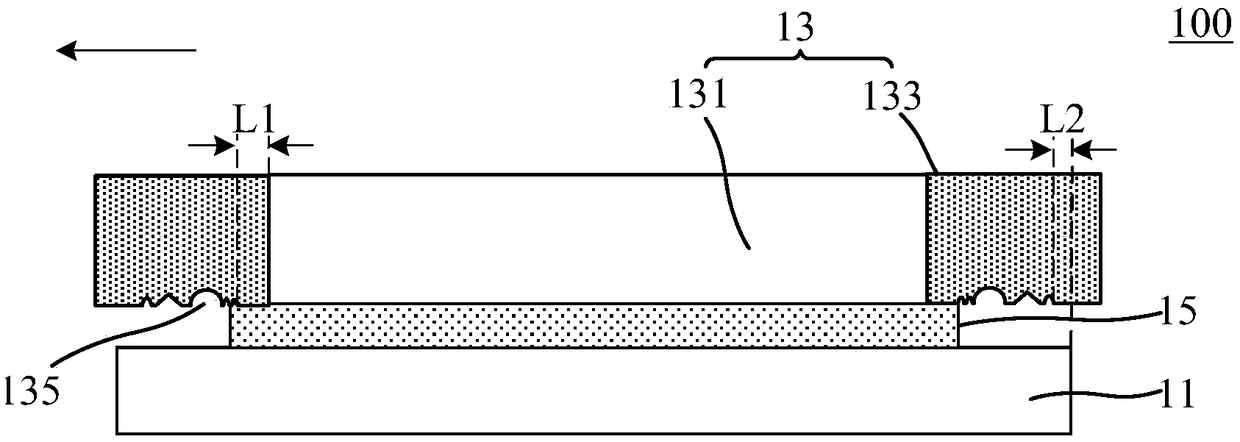

Display device and preparation method thereof

ActiveCN108877500AInfluence intensityGuaranteed firmnessLiquid surface applicatorsCoatingsDisplay deviceEngineering

The embodiment of the invention provides a display device and a preparation method thereof, and relates to the technical field of display. The amount of optical cement is controlled to avoid infirm attachment and cement overflow. The display device comprises a display module, a to-be-attached part stacked on the light emitting side of the display module, and the optical cement, wherein the to-be-attached part comprises a visible area and a frame area surrounding the visual area, and the optical cement is arranged between the display module and the to-be-attached part; the optical cement is used for making the display module attached to the to-be-attached part, and the orthographic projection, on the plane where the to-be-attached part is located, of the optical cement covers the visible area; a first cement collecting groove area is formed in the frame area; the surface of the side, close to the optical cement, of the first cement collecting groove area is provided with a first cementcollecting groove; the orthographic projection, on the plane where the first cement collecting groove area is located, of the edge of the optical cement is located in the first cement collecting groove area. The display device is used for display.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

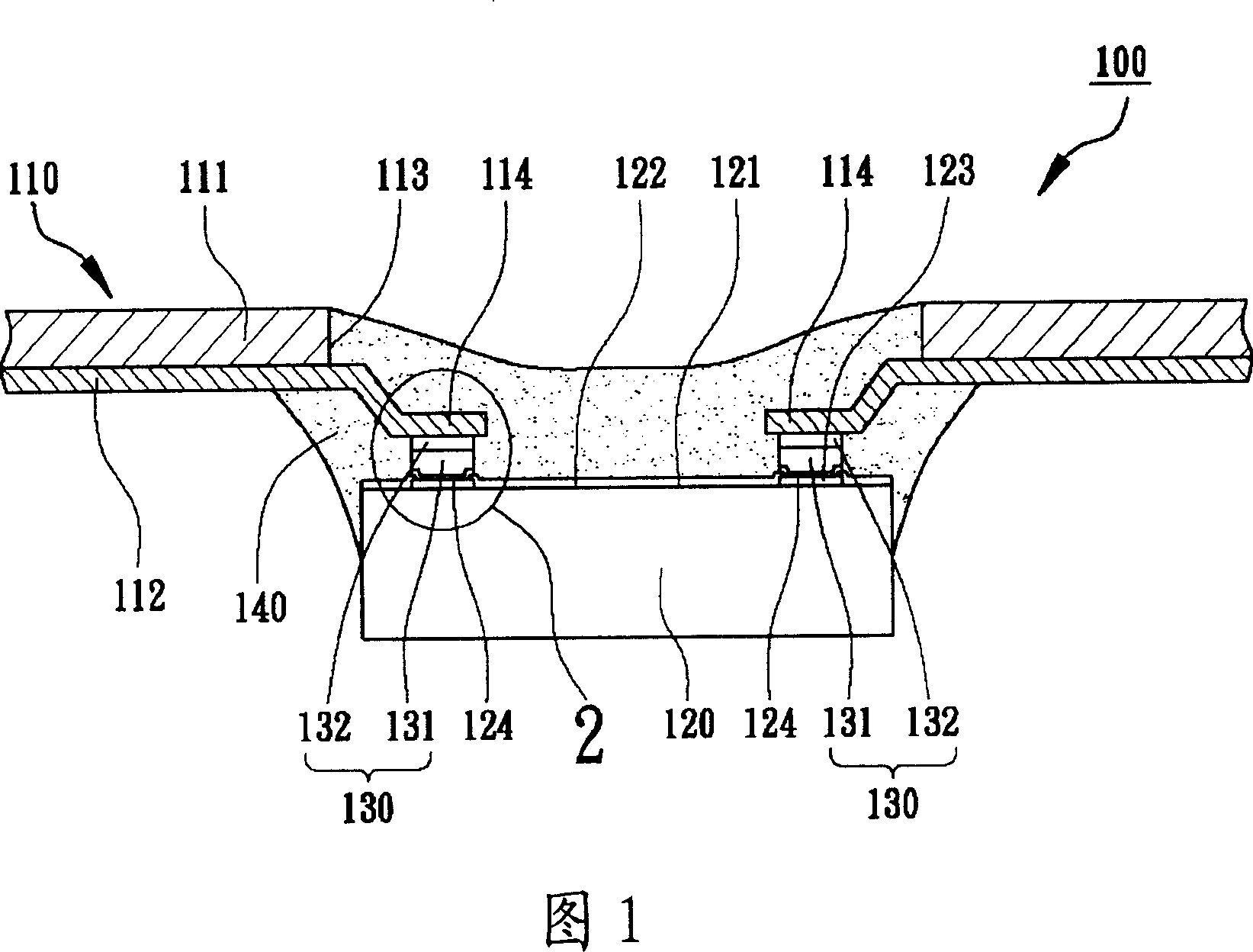

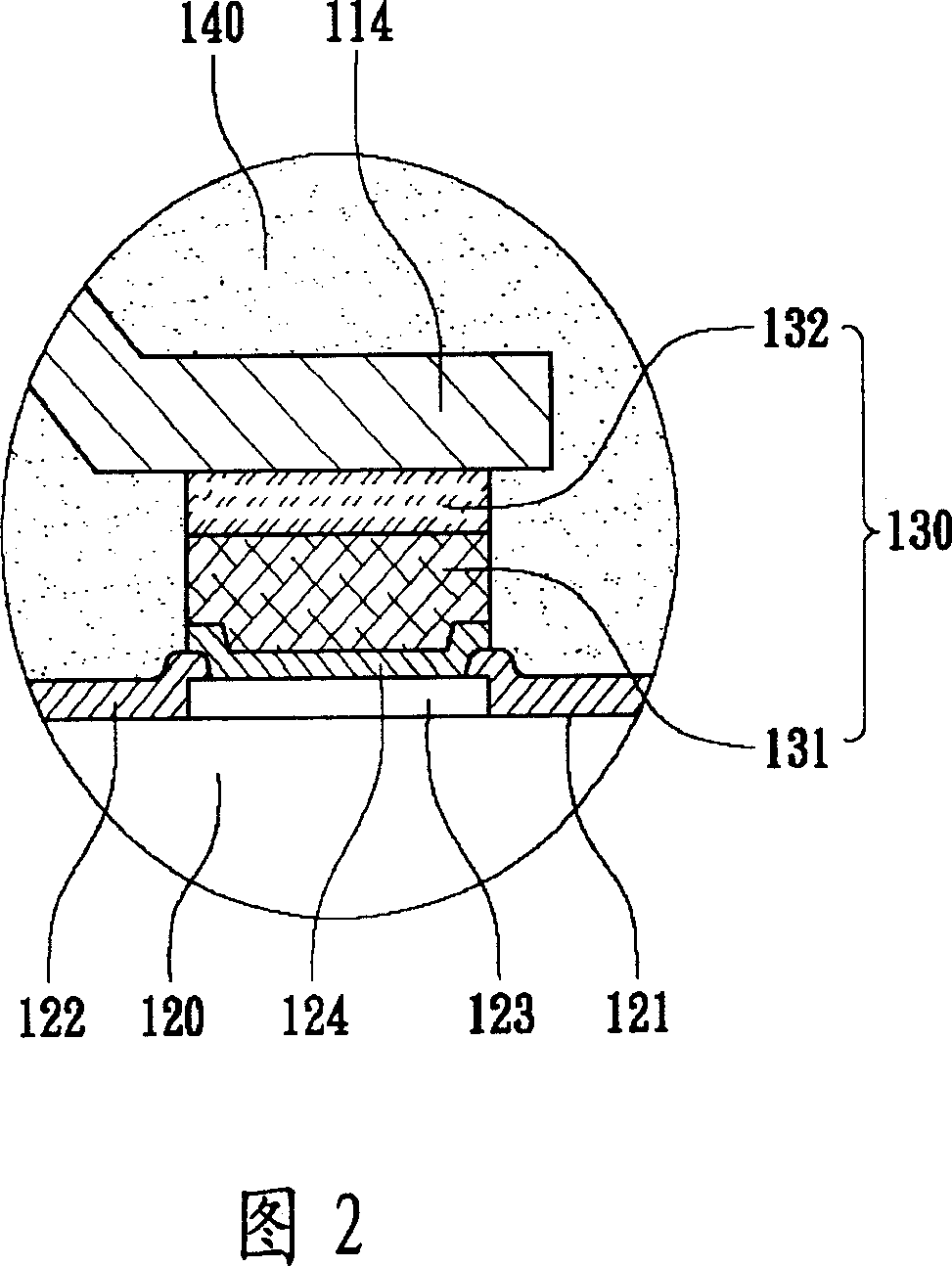

Driving chip packaging structure engaged by multilayer lug and driving chip

InactiveCN1925146APrevent collapseInfluence intensitySemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

This invention relates to drive chip seal structure and drive chip by use of multiple layer of protruding block, which comprises one circuit film and one drive chip, wherein, the film conductor circuit layer has multiple connection terminal; the drive chip has one active surface to form multiple weld pads and protruding blocks set on the main surface of chip to supply thermal binding bench connection terminals; each multiple protruding blocks comprise one basic metal layer and one binding metal layer.

Owner:CHIPMOS TECH INC

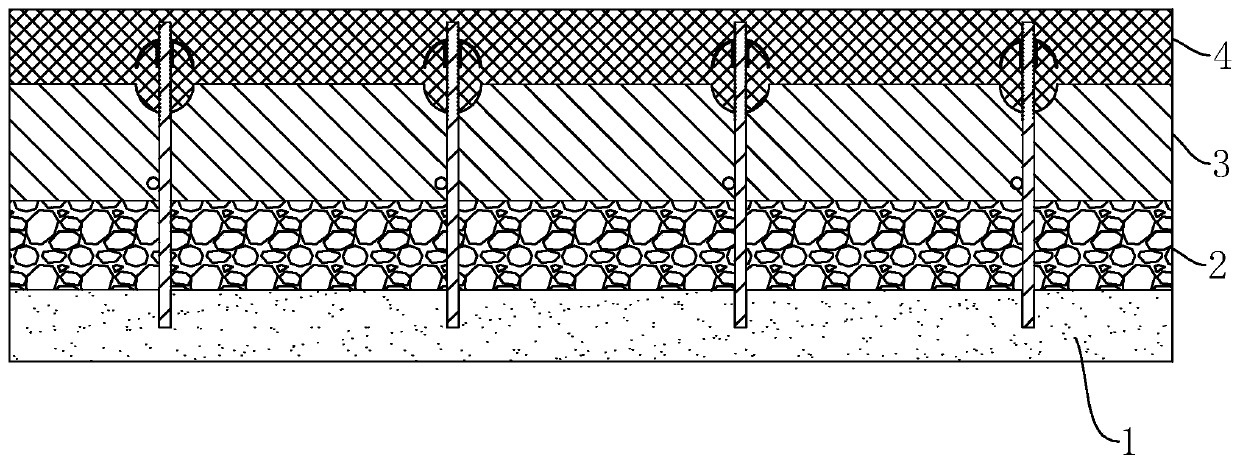

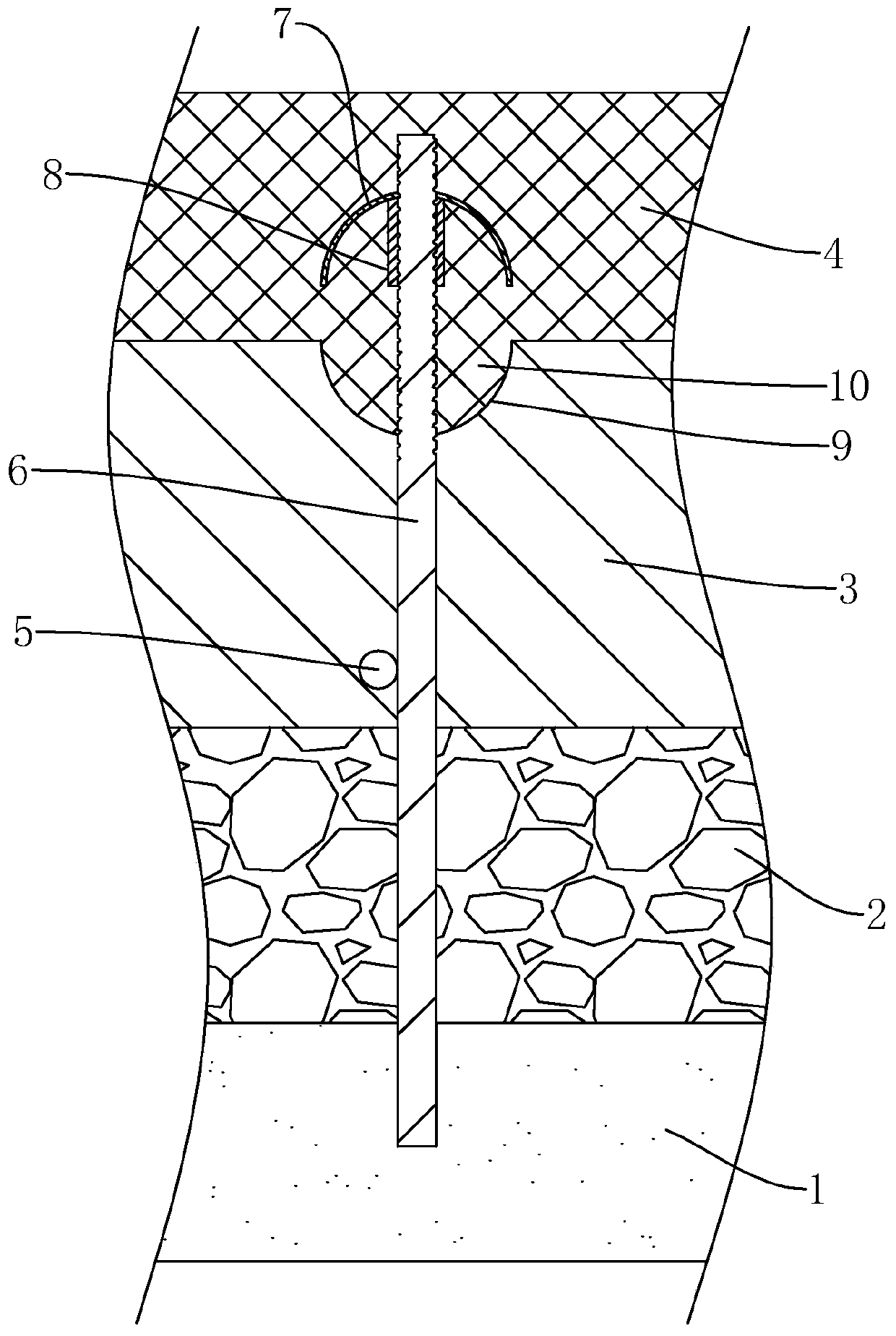

Asphalt pavement and construction method thereof

ActiveCN110284389ATightly boundAvoid misalignmentPaving reinforcementsIn situ pavingsEngineeringRoad surface

The invention relates to the technical field of road construction, in particular to an asphalt pavement and a construction method thereof. The asphalt pavement has the advantages that the road is not easy to damage. The asphalt pavement sequentially comprises a soil layer, a graded gravel layer, a concrete layer and an asphalt layer from bottom to top, a concave hemispherical groove is formed in the upper surface of the concrete layer, and a hemispherical bulge corresponding to the hemispherical groove is formed in a position, corresponding to the hemispherical groove, of the asphalt layer. The hemispherical groove is formed in the concrete layer to cooperate with the hemispherical bulge of the asphalt layer, so as to achieve the effect of tightly combining the concrete layer and the asphalt layer. Meanwhile, the mutually cooperatively inserted structure of the concrete layer and the asphalt layer can also play a role in preventing dislocation between the concrete layer and the asphalt layer.

Owner:安徽兴罗建设集团有限公司

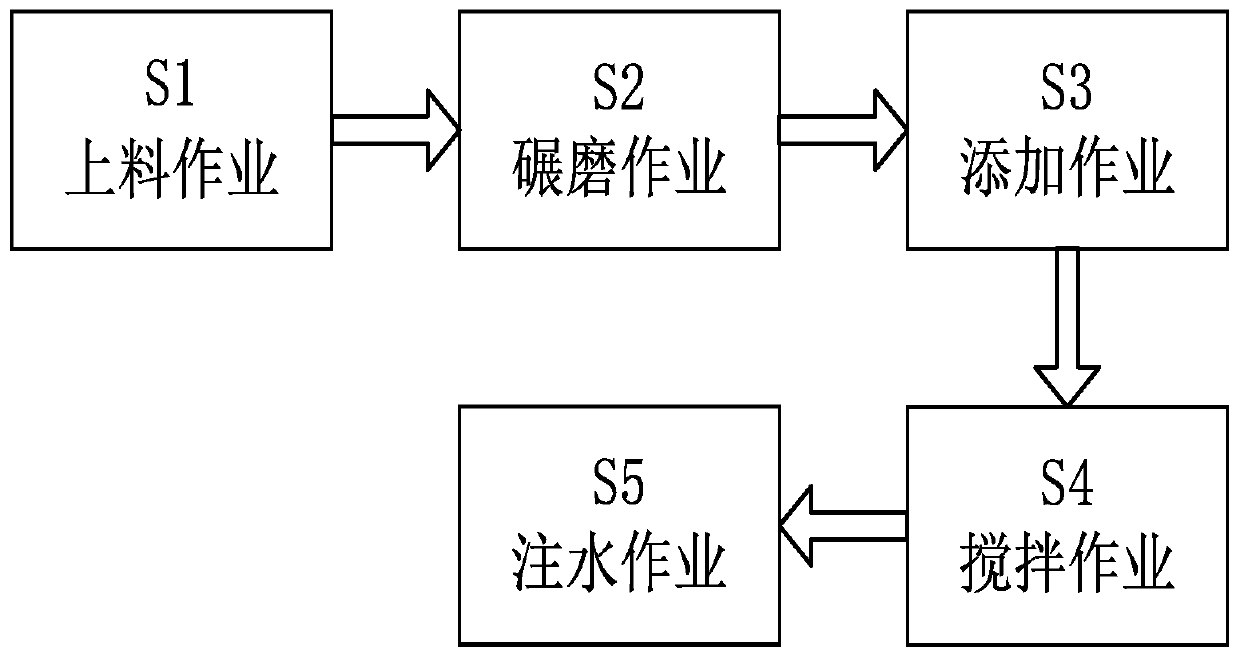

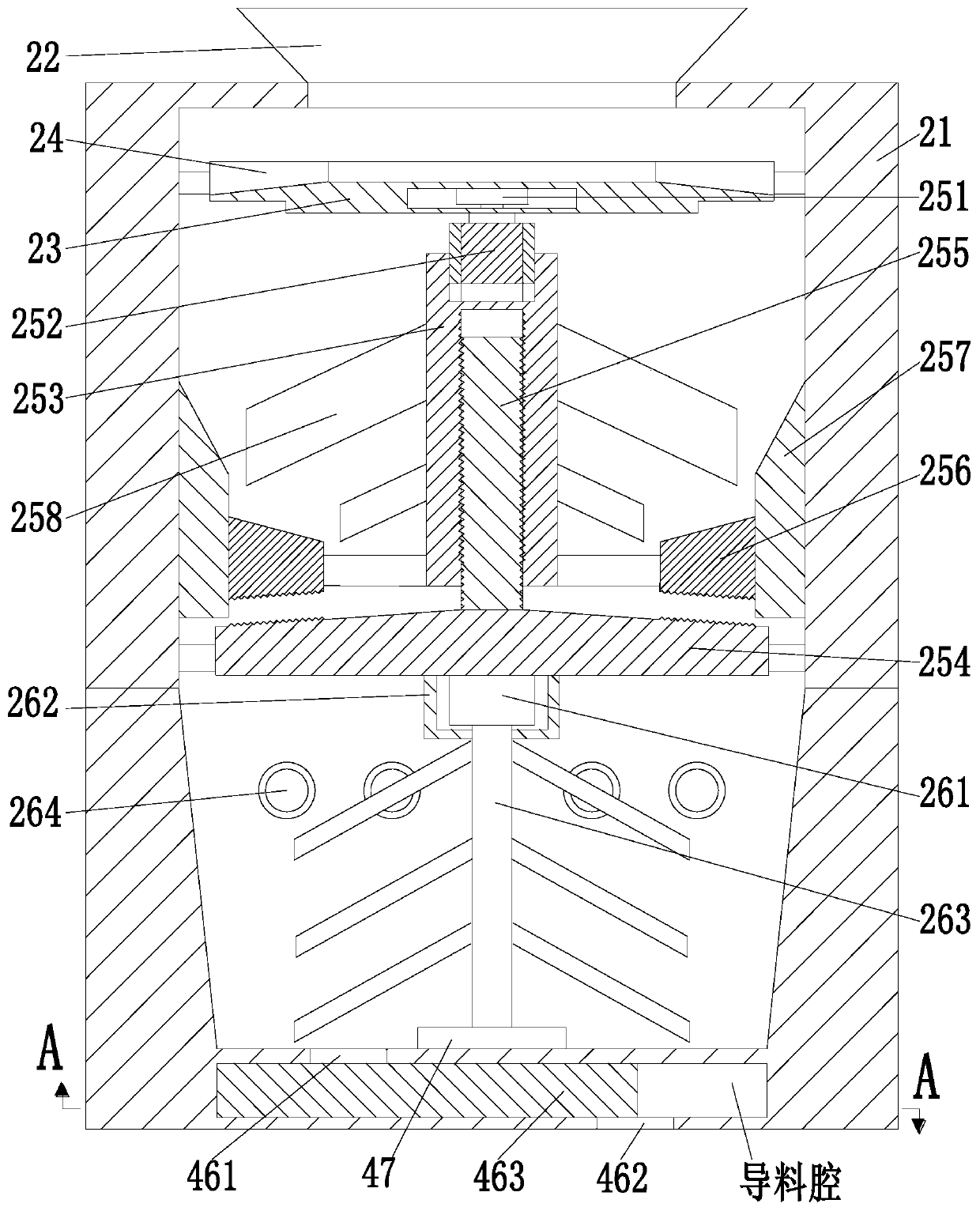

Hierarchical multi-grade type concrete mortar preparation material mixing treatment technology

ActiveCN111300643ASolve the strength problemSolve viscosityMixing operation control apparatusPretreatment controlMaterials scienceTreatment unit

The invention relates to a hierarchical multi-grade type concrete mortar preparation material mixing treatment technology adopting a concrete mortar preparing device. The concrete mortar preparing device comprises a mixing cylinder, a treatment unit, an additive cylinder and a water feeding unit. The treatment unit is arranged at the upper end of the mixing cylinder. The left end of the mixing cylinder is connected with the water feeding unit through a pipeline. The right end of the treatment unit is connected with the additive cylinder through a pipeline. By designing the pagoda type multi-grade structure of the material mixing device, the manner of feeding sand, stone and cement at the first grade, feeding various additives at the second grade, feeding water at the third grade is adopted, each step of the technology is treated in a separated manner, and then the problem that since residual additives and moisture can conduct a reaction with the sand, stone and cement earlier, the strength of the concrete is lowered is solved. According to the hierarchical multi-grade type concrete mortar preparation material mixing treatment technology, by feeding the mortar at a fixed quantity and then feeding water at a fixed volume, the problem that due to excessively fed water, the strength and viscosity of the concrete are influenced is solved.

Owner:江西萍乡南方建材有限公司

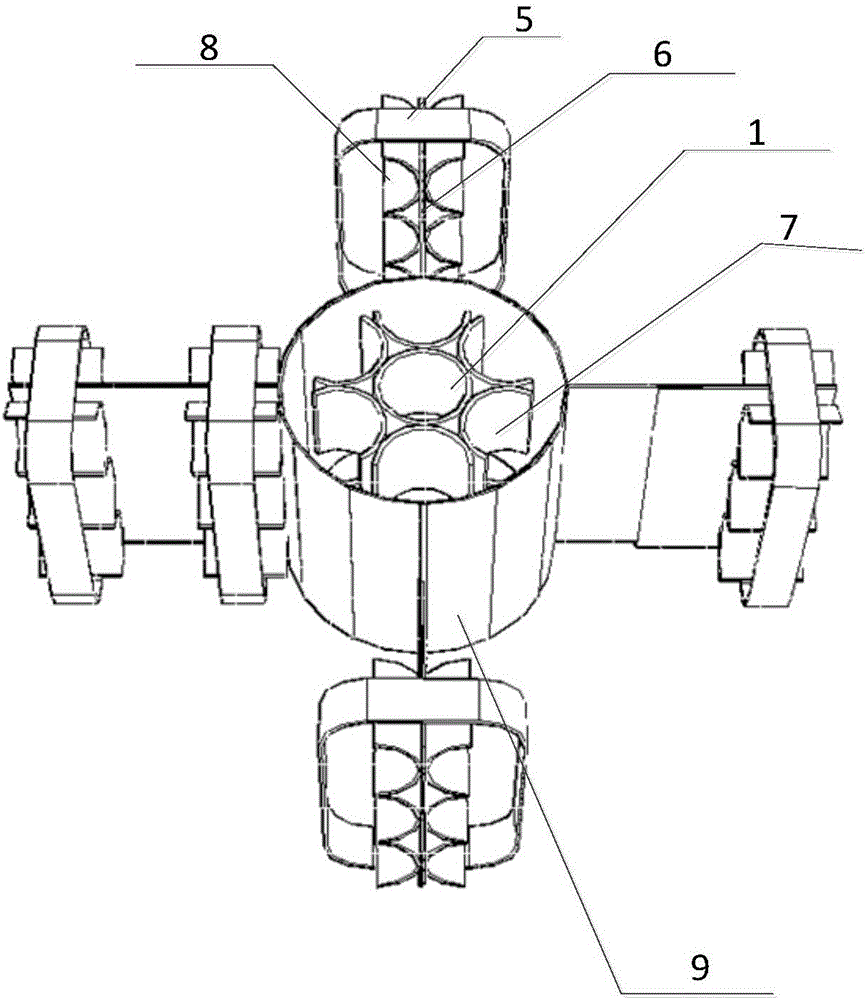

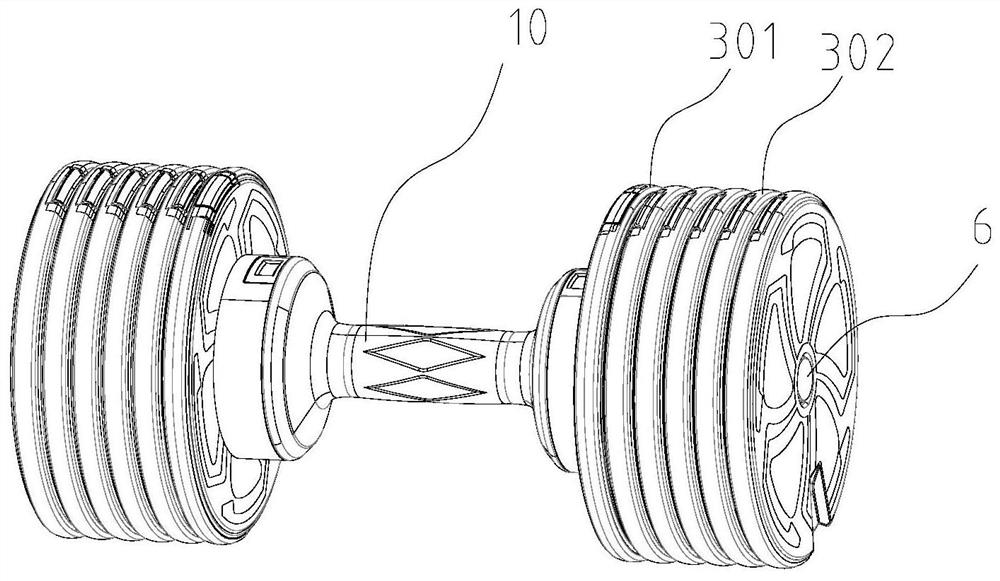

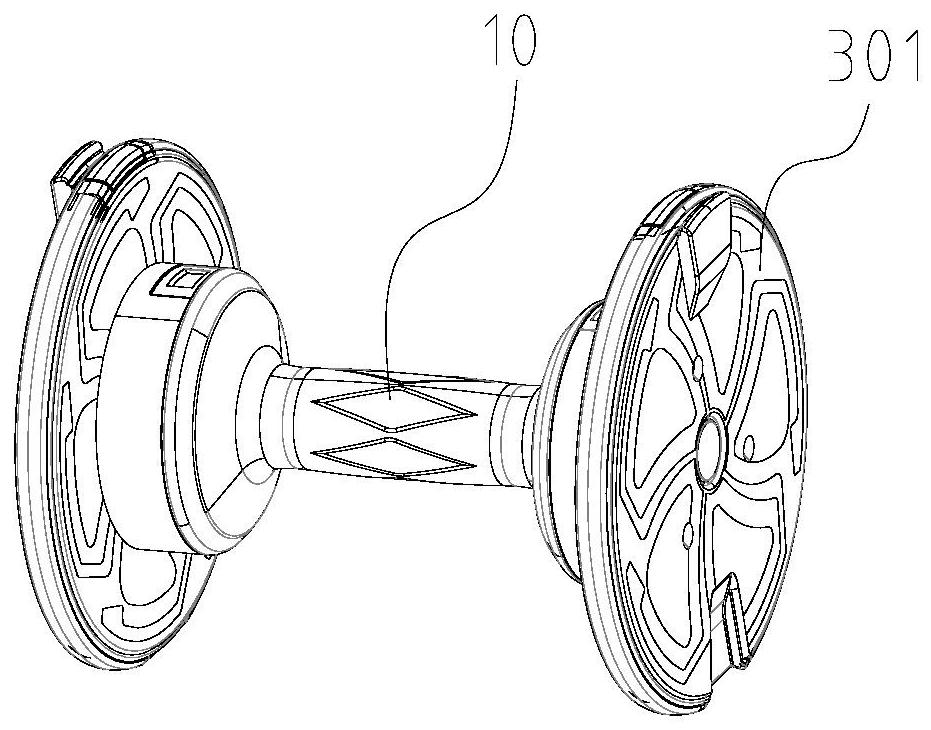

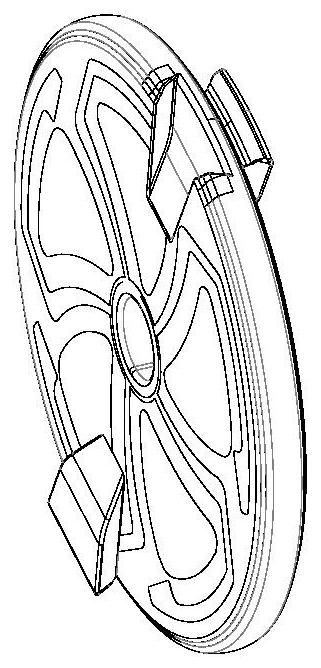

Quick adjusting dumbbell and dumbbell suite

PendingCN113144514AInfluence intensitySolve static maintenanceDumb-bellsToothed gearingsDumbbellGear wheel

The invention relates to a fast adjusting dumbbell. The fast adjusting dumbbell comprises a dumbbell body and dumbbell pieces attached to two ends of the dumbbell body in an accumulative mode, wherein the dumbbell body comprises a holding rod, a planetary gear system and a telescopic rod, the telescopic rod stretches out and draws back through rotation of the holding rod and transmission of the planetary gear system, then the number of the dumbbell pieces is adjusted, operation is convenient, and implementation is easy; flange transmission parts are fixedly assembled at the two ends of the holding rod, the planetary gear system comprises an outer shell, a planetary gear mechanism is arranged in a closed mode through the installation mode that the flange transmission parts are connected with the outer shell, and the situation that work of the planetary gear mechanism is affected by dust accumulation is prevented; by setting a load-bearing iron ring in the planetary gear system, the effects of bearing and limiting the planet carrier are achieved, and the heavy dumbbell pieces are prevented from influencing the structural strength of the planetary gear system.

Owner:黄京爱

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com