High-temperature-resistant flexible adhesive cured at normal temperature and preparation method thereof

A high-temperature flexible, room-temperature curing technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of decreased adhesive strength, increased viscosity, high price, etc., to increase the flexible structure, increase High temperature resistance and toughness, the effect of deepening the degree of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

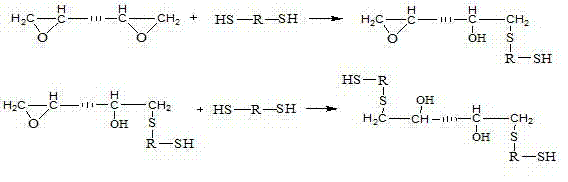

Method used

Image

Examples

Embodiment 1

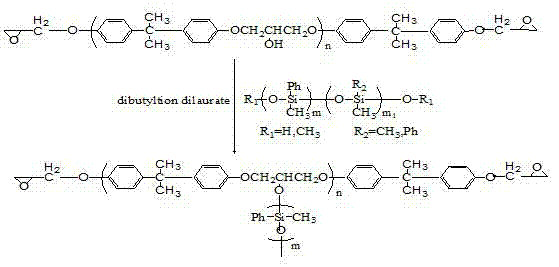

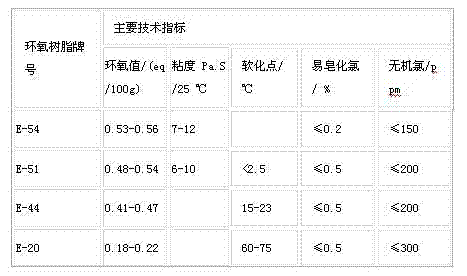

[0034] Component A: bisphenol A epoxy resin E51 100Kg, E20 15Kg, silicone resin 15Kg, liquid polysulfide rubber 30Kg, dibutyltin dilaurate 0.2Kg, dibutyl phthalate 5Kg and KH-560 1Kg.

[0035] Component B: polyamide 650 60Kg, m-phenylenediamine 15Kg, dicyandiamide 5Kg, DMP-30 2Kg, KH-560 1Kg.

[0036] Component C: basic magnesium carbonate 10Kg, mica powder 40Kg.

[0037]The preparation method of component A is to put E51, E20 epoxy resin, organotin, dibutyl phthalate, KH-560, and silicone resin into the reaction kettle, stir and react at 150°C for 2 hours, and cool to Add polysulfide rubber at room temperature, then heat to 100°C, and react for 1 hour to obtain the adhesive component; the preparation method of component B is to put each component Kg into a mixture equipped with an electromagnetic stirrer, a heating jacket, a condenser and a thermometer. In the reaction kettle, start stirring, heat to 100°C, and keep for 5 minutes; add component C to the prepared component B,...

Embodiment 2

[0039] Component A: bisphenol A epoxy resin E54 100Kg, E12 20Kg, silicone resin 10Kg, liquid polysulfide rubber 40Kg, stannous octoate 0.5Kg, dibutyl phthalate 3Kg and KH-560 1Kg.

[0040] Component B: polyamide 650 60Kg, m-phenylenediamine 5Kg, succinic acid hydrazide 5Kg, DMP-30 3Kg, KH-560 1Kg.

[0041] Component C: basic magnesium carbonate 10Kg, mica powder 20Kg, asbestos powder 15Kg.

[0042] The preparation method of component A and curing component is the same as that in Example 1. The ratio of component A and curing component is 1:0.5 for mixing and preparation to obtain a room-temperature-curable high-temperature-resistant flexible adhesive. At room temperature, its shear strength is 20.56 Mpa, and its elongation at break is 20.31%. After placing it at 160°C for 1 hour, and maintaining it at 160°C, its shear strength is 1.96 Mpa.

Embodiment 3

[0044] Component A: Bisphenol A epoxy resin E44 100Kg, E12 8Kg, silicone resin 15Kg, liquid polysulfide rubber 20Kg, dibutyltin di(dodecylsulfide) 0.5Kg, dibutyl phthalate 10Kg and KH -560 1Kg.

[0045] Component B: polyamide 650 40Kg, m-phenylenediamine 7Kg, dicyandiamide 5Kg, DMP-30 5Kg, KH-560 1Kg.

[0046] C component: asbestos powder 20Kg, silicon dioxide 20Kg.

[0047] The preparation method of component A and curing component is the same as that in Example 1. The ratio of component A and curing component is 1:0.8 for mixing and preparation to obtain a room temperature curing high temperature resistant flexible adhesive. At room temperature, its shear strength is 19.78 Mpa, and its elongation at break is 19.26 %; when placed at 160°C for 1 h, and maintained at 160°C, its shear strength is 2.04 Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com