Patents

Literature

593 results about "Polysulfide rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

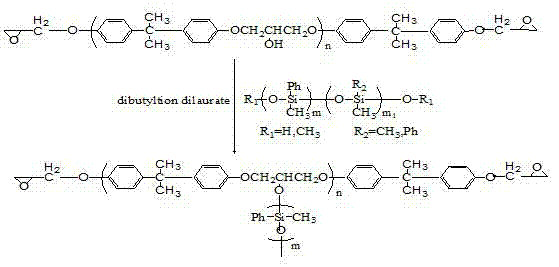

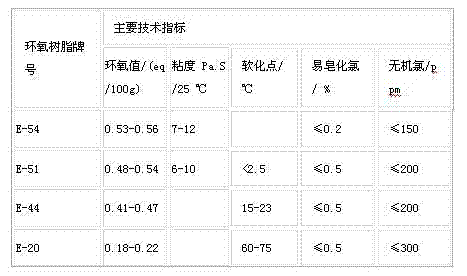

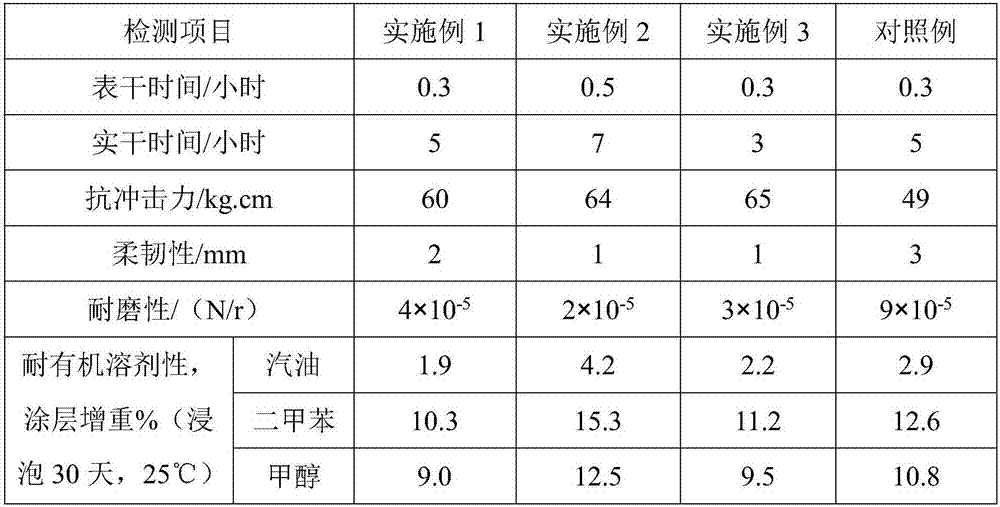

Preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material

InactiveCN101445583ASolve the problem of poor flexibilityHigh bonding strengthPolyurea/polyurethane coatingsDiphenylmethaneWear resistant

The invention discloses a preparing technology of polyurethane modified ethoxyline resin adapted for composite wear-resistant coating material. Polyether dihydroxy alcohol having a degree of functionality of 2 and an average relative molecular weight of 1200 to 2200 is reacted with toluene di-isocyanate or diphenylmethane-4,4'-diisocyanate prepared for preheating to synthetize polyether dihydroxy alcohol polyurethane performed polymer for reservation; one of bisphenol A E-44 and E-51 after pre-dehydration is selected for reservation; polyurethane modified epoxy is formed through polyaddition reaction in which a mass ratio of polyether dihydroxy alcohol polyurethane performed polymer to epoxide resin is 15 to 70: 100. The polyurethane modified epoxy obtained by the technology has high bonding strength, good flexibility and shock resistance with basal bodies of spare parts, totally without using plasticizers, such as dibutyl phthalate, dioctylphthalate, etc., without using or using less plasticizers, such as polysulfide rubber, liquid acrylonitrile butadiene rubber, etc., thereby not only solving the problem that general epoxide resin has bad flexibility but also saving the production cost.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Solid buoyancy material prepared through chemical blowing process

InactiveCN1563134AMeet the requirements of strength-density ratioImprove the modulus of compressionUnderwater equipmentPolysulfide rubberCompressive strength

A solid floatage material is copmosed of core material and surface material of which the core material is made of hard foamed plastic of polyurethane-epoxy and the surface material is water-resisting layer made of epoxy, polysulfide rubber, flaky packing, light packing, coupling agent and curing agent.

Owner:MARINE CHEM RES INST

High-weather-fastness polysulfide sealant

ActiveCN102838964AGood weather resistanceGood mechanical propertiesNon-macromolecular adhesive additivesOther chemical processesVulcanizationBase cream

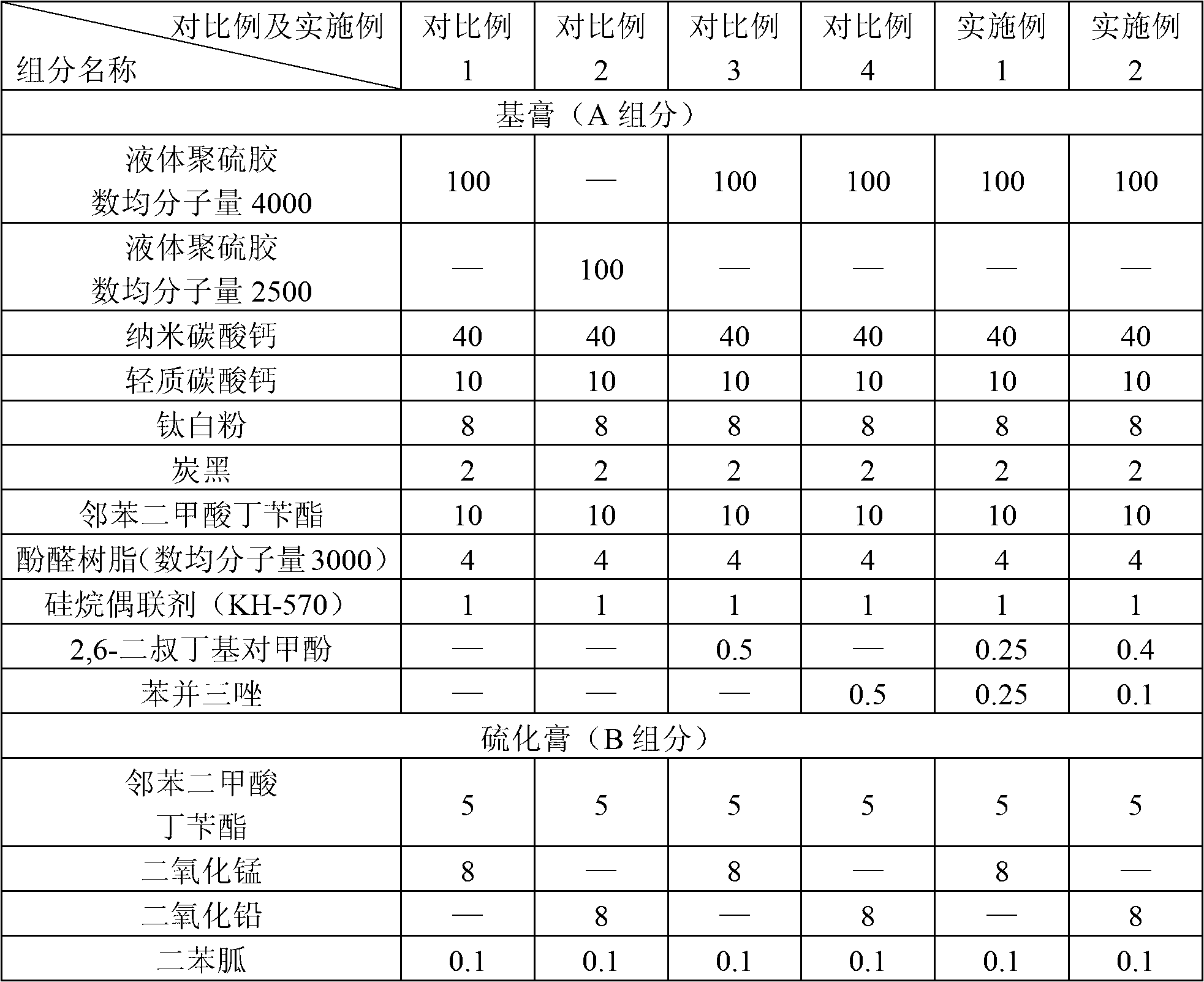

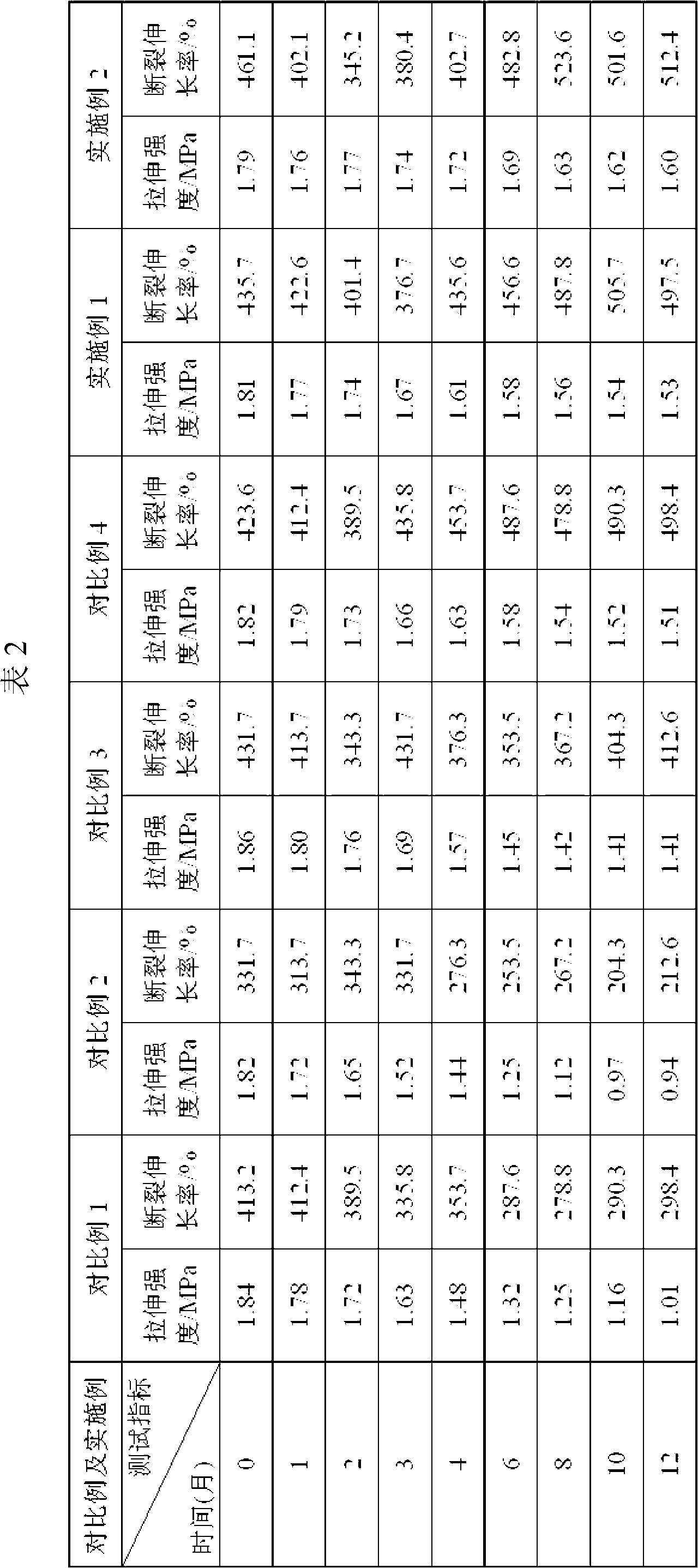

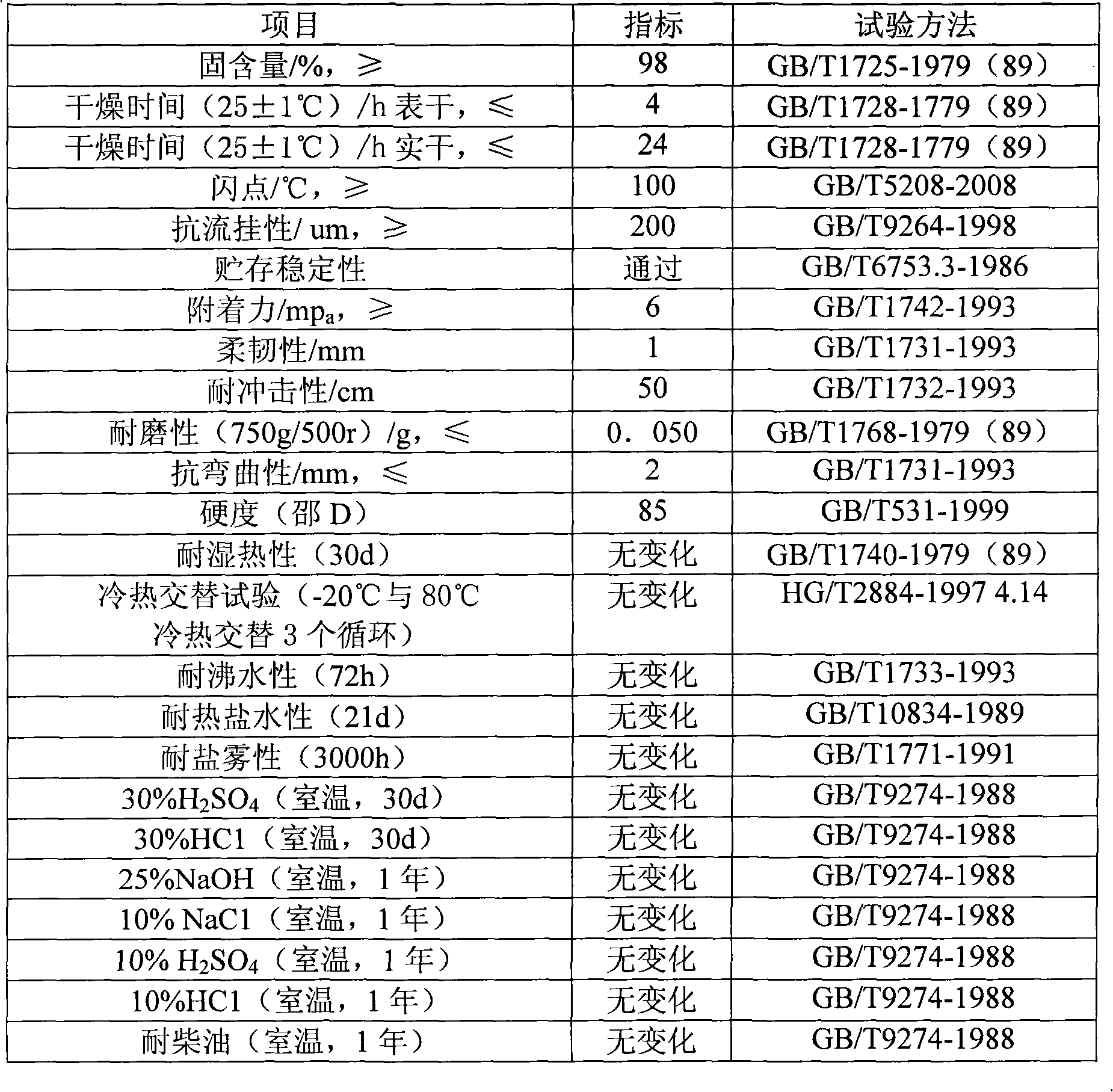

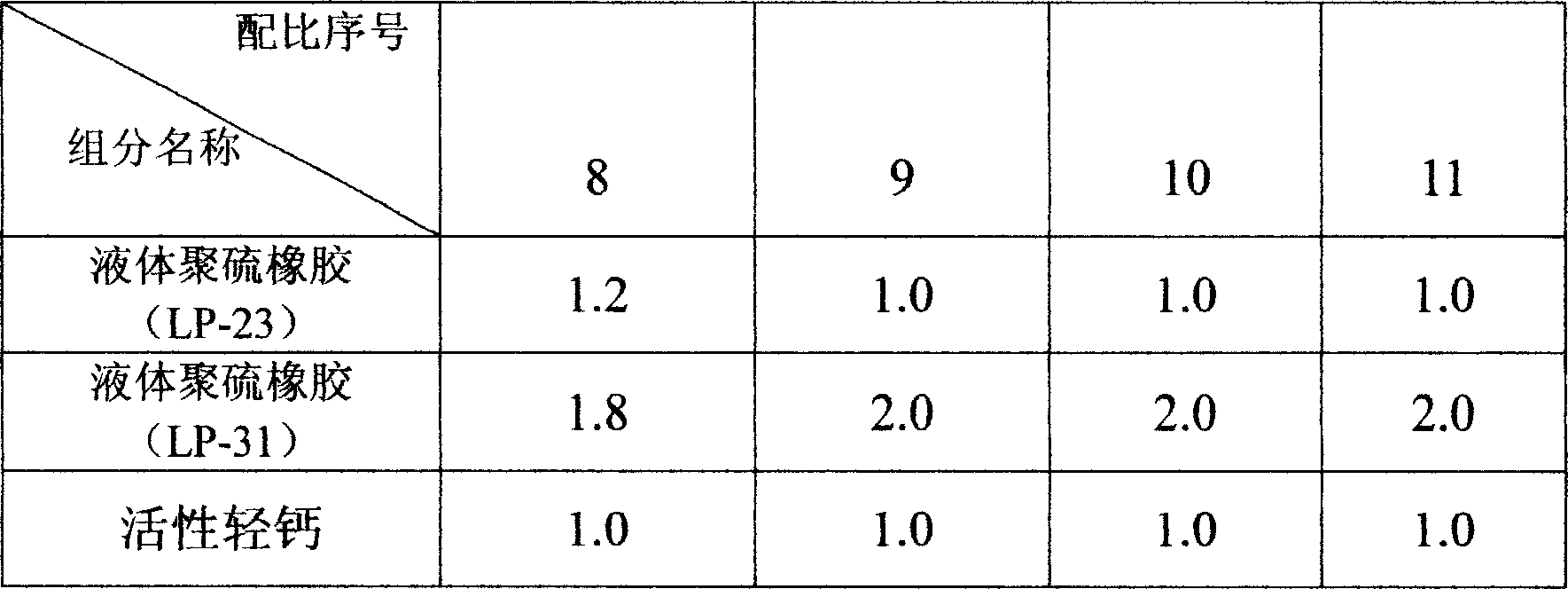

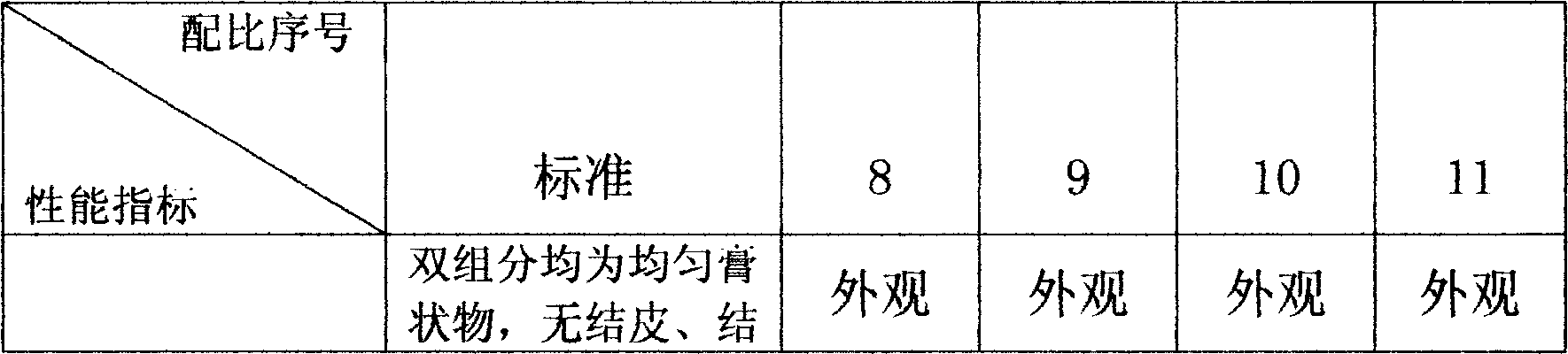

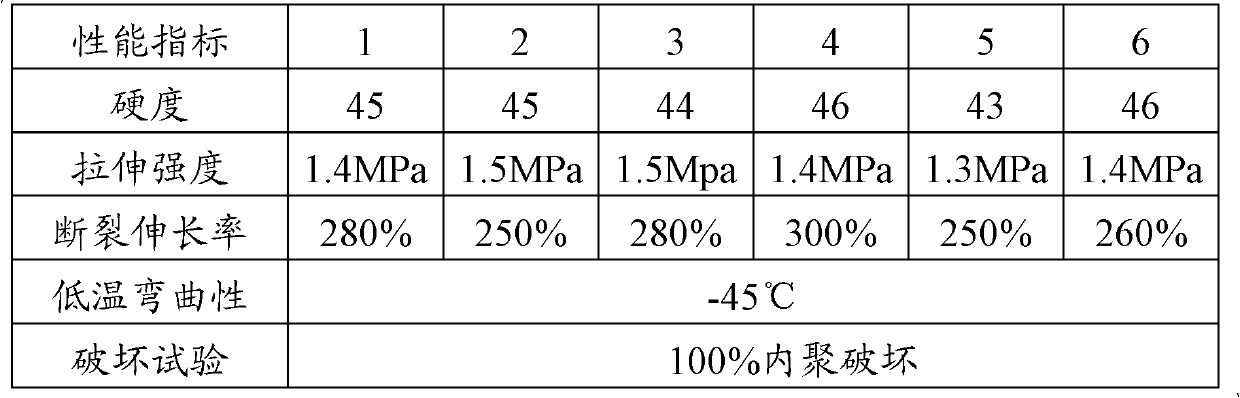

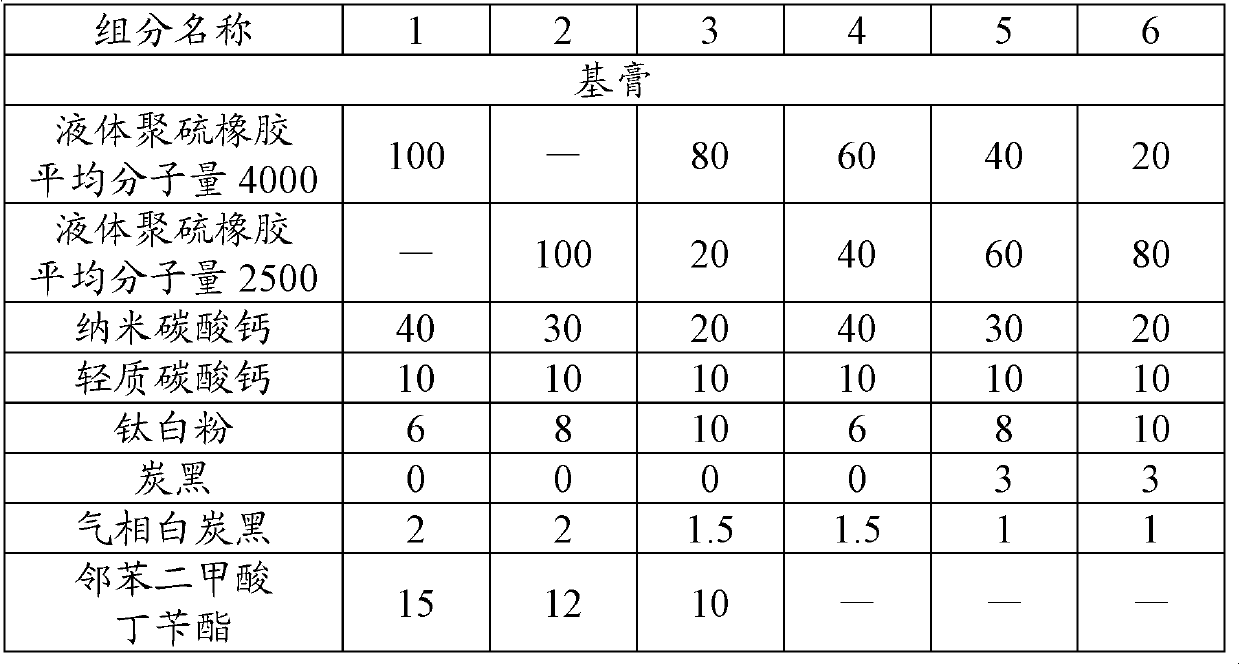

The invention discloses high-weather-fastness polysulfide sealant, which comprises base cream and vulcanizing cream, wherein the base cream comprises the components by weight: 30-70% of liquid polysulfide rubber, 20-60% of padding, 1-10% of tackifier, 3-20% of plasticizer, 0.3-5% of coupling agent, 0.1-2% of antioxidant and 0.05-1% of anti-ultraviolet agent; the vulcanizing cream comprises the components by weight: 25-70% of vulcanizing agent, 25-70% of plasticizer and 0.5-5% of vulcanization accelerator; and the mixed weight ratio of the base cream to the vulcanizing cream is 100 to (6-14). The invention also discloses a preparation method of the polysulfide sealant. The invention also discloses a preparation of the high-weather-fastness polysulfide sealant. The polysulfide sealant is characterized in that the weather fastness of the sealant is improved by the antioxidant and the anti-ultraviolet agent; the material cost is low, the process is stable, and the reproducibility is good. The high-weather-fastness polysulfide sealant disclosed by the invention can be used for bonding sealing elements of buildings, ships, high-speed trains, automobiles and the like, therefore, the high-weather fastness polysulfide sealant has a great application value in industry.

Owner:ZHEJIANG UNIV

Heavy corrosion resistant, heat insulating and static conductive coating

InactiveCN101899257AStrong adhesionGood static conductivityAnti-corrosive paintsEpoxy resin coatingsNon toxicityPetrochemical

The invention discloses a heavy corrosion resistant, heat insulating and static conductive coating, which is prepared by the following steps of: dissolving acrylic acid modified epoxy resin which is taken as a substrate into active and inactive diluents in a way of taking liquid polysulfide rubber as a toughening agent in the presence of a functional pigment and an aid to prepare a first component; preparing a second component in a way of taking cashew nut shell liquid-synthesized modified amine as a curing agent under the cooperation of an accelerator and a hydrophilic agent; and mixing the first and second components in the weight ratio of 2:1. The heavy corrosion resistant, heat insulating and static conductive coating has the characteristics of no solvent, high adhesive power, high static conductivity, heavy corrosion resistance, high heat-insulating property, environmental friendliness, non-toxicity, wet rusty thick coating capability, great coating cost reduction, and applicability to the corrosion-resistant coating of inner and outer walls of large oil tanks, ballast tanks of ships, offshore drilling platforms, bridges, open petrochemical equipment, ships, high-speed trains and the like.

Owner:北京虹霞正升装饰装修工程有限责任公司

Epoxy anti-corrosive paint used for underwater concrete

InactiveCN102719173AStrong adhesionExcellent abrasion resistanceAnti-corrosive paintsEpoxy resin coatingsMicrosphereSolvent free

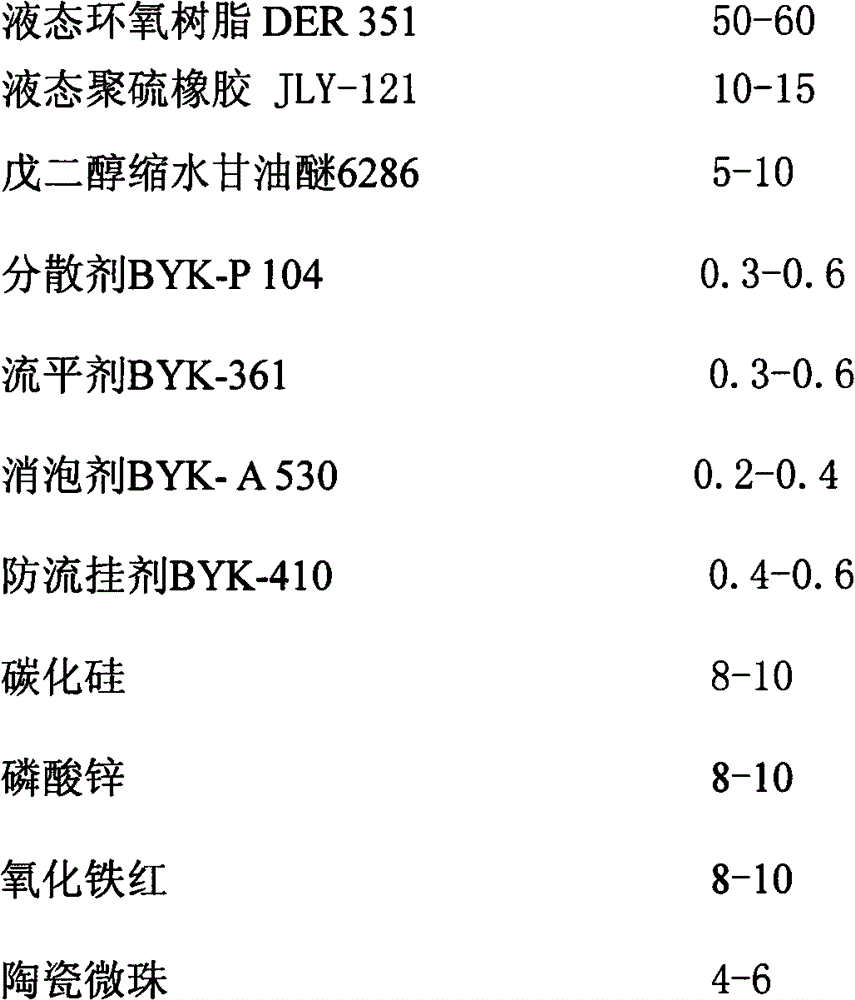

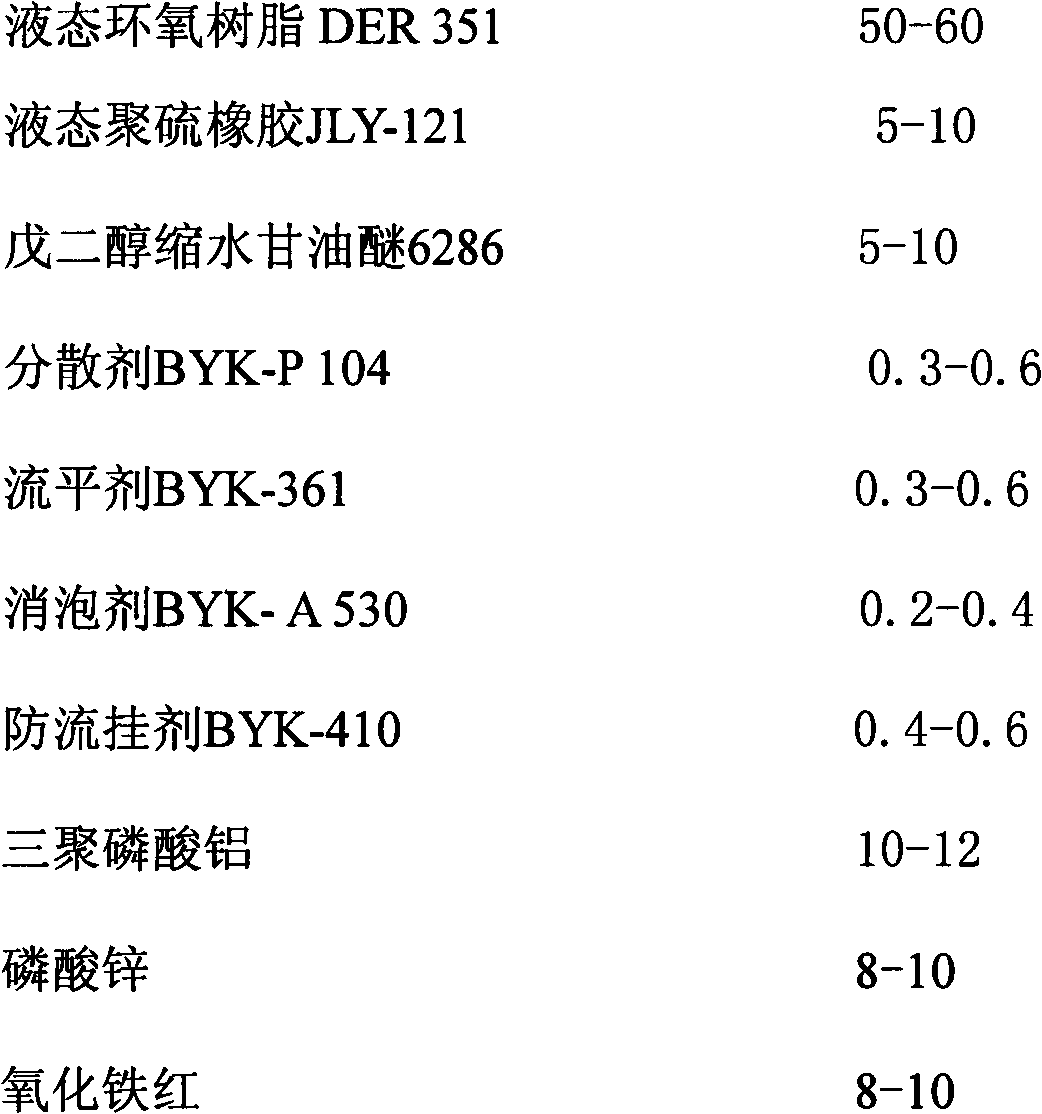

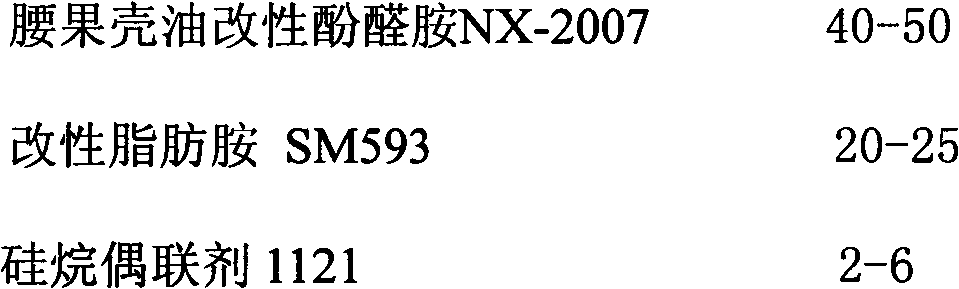

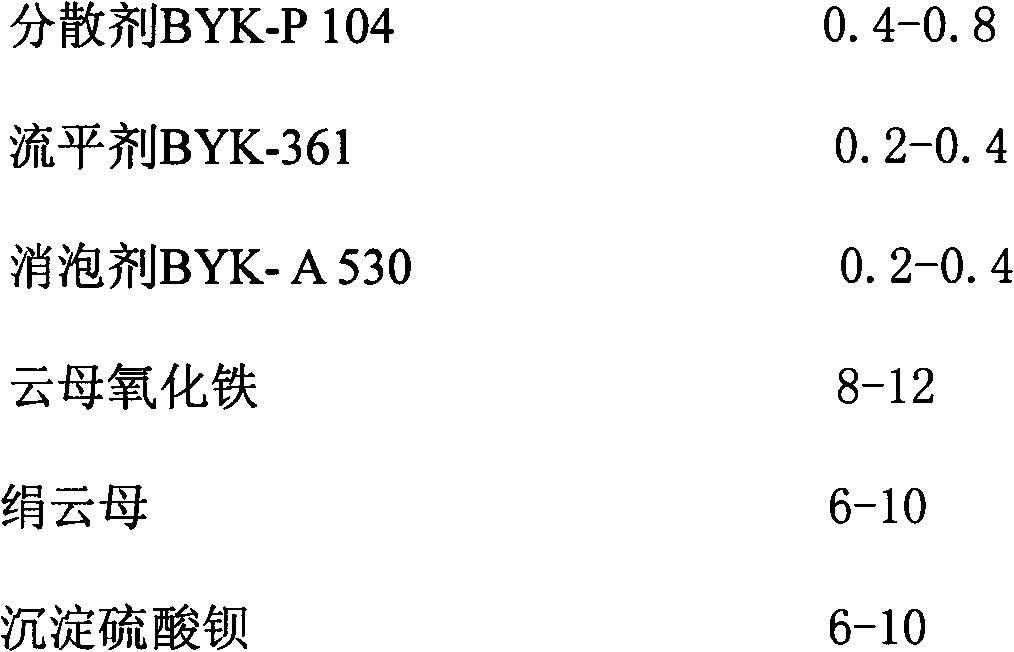

The invention discloses epoxy anti-corrosive paint used for underwater concrete. Liquid epoxy resin DER351 is used as a base material; polysulfide rubber is used as a flexibilizer; pentanediol diglycidyl ether 6286 is used as a diluent; zinc phosphate and iron oxide red are used as active anti-corrosive pigment; spherical silicon carbide, ceramic microspheres, mica iron oxide, sericite and precipitate vitriolic barium are used as fillings; cashew shell oil, modified phenolic aldehyde amine and modified aliphatic amine are used as curing agents; and a silane coupling agent 1121 is used as an adhesion promoter. With the cooperation of functional promoters, the raw materials are made into solvent-free double-component epoxy anti-corrosive paint used for underwater concrete through conventional preparation technique equipment. The epoxy anti-corrosive paint used for underwater concrete is highly environmental-friendly and can be directly painted or smeared on damp interfaces of underwater concrete and rapidly solidified into films; the coating has great adhesion and strong abrasion resistance and corrosion prevention. The epoxy anti-corrosive paint used for underwater concrete is widely applied to the corrosion prevention of various underwater concrete facilities.

Owner:北京国泰瑞华精藻硅特种材料有限公司

Epoxy anticorrosive paint for underwater steel

InactiveCN102719174AStrong adhesionPromote environmental protectionAntifouling/underwater paintsPaints with biocidesSolvent freeSolvent

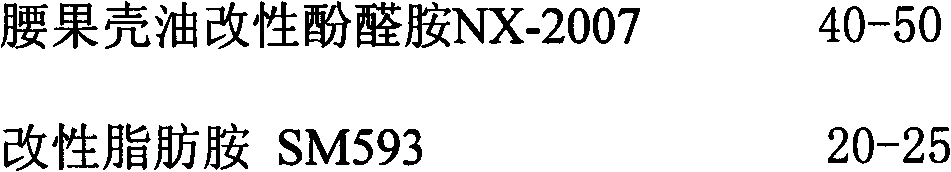

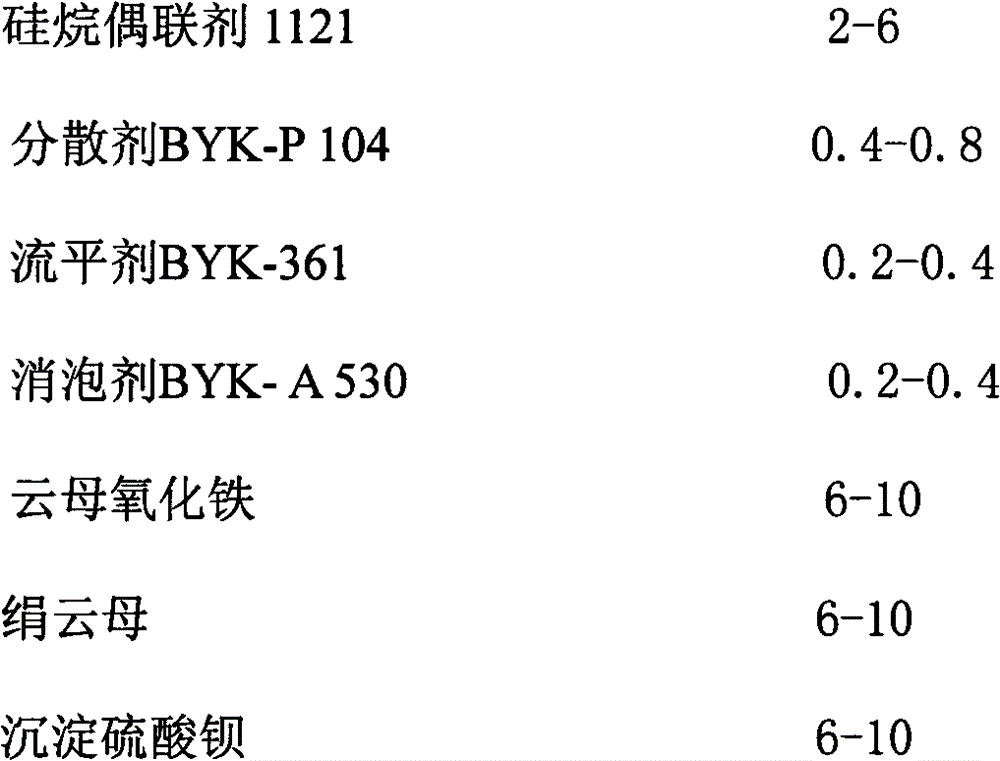

The invention discloses epoxy anticorrosive paint for underwater steel. Liquid epoxy resin DER351 is used as base materials, liquid polysulfide rubber JLY-121 is used as toughening agent, pentanediol glycidyl ether 6286 is used as diluents, aluminum tripolyphosphate, zinc phosphate and iron oxide red are used as active rustproofing pigment, micaceous iron oxide, sericite and precipitated barium sulphate are used as filler, cashew shell oil modified phenolic aldehyde and modified fatty amine are used as curing agents, silane coupling agent 1121 is used as adhesion promoter, and solvent-free bicomponent epoxy anticorrosive paint for underwater steel is prepared by the normal preparation process under the cooperation of functional auxiliaries. The epoxy anticorrosive paint for underwater steel has fine environment friendliness, can be brushed or scraped at rusted damp interfaces of underwater steel, can be quickly cured to form films, excellent in coating adhesive power, capable of removing, converting and stabilizing rusts, high in resistance to impact, abrasion and corrosion and widely applicable to corrosion resistance of various underwater steel facilities.

Owner:BEIJING GUOTAI RUIHUA DIATOMS APPL TECH

High-strength polysulfide sealant

ActiveCN102329595ANon-macromolecular adhesive additivesOther chemical processesVulcanizationPolysulfide rubber

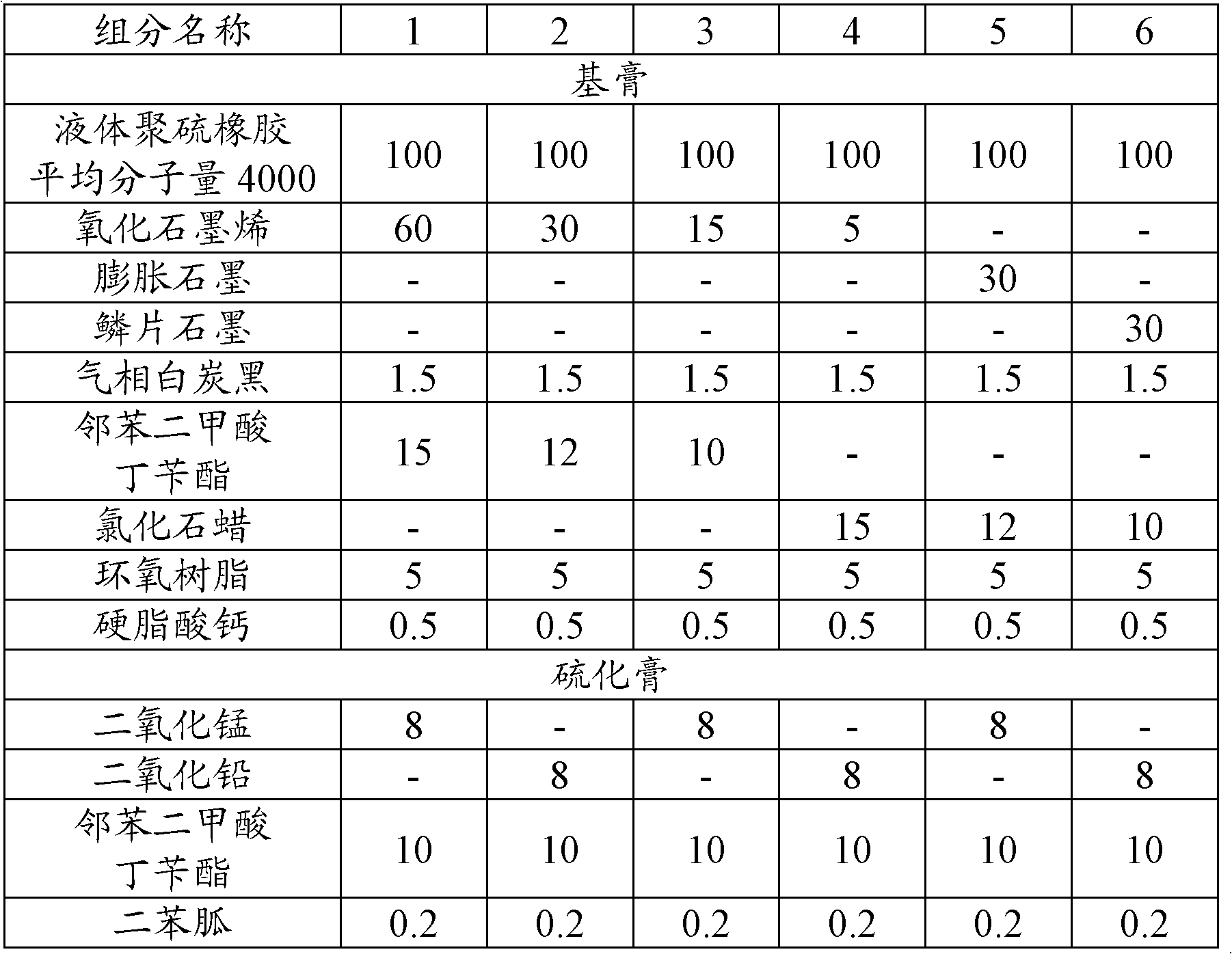

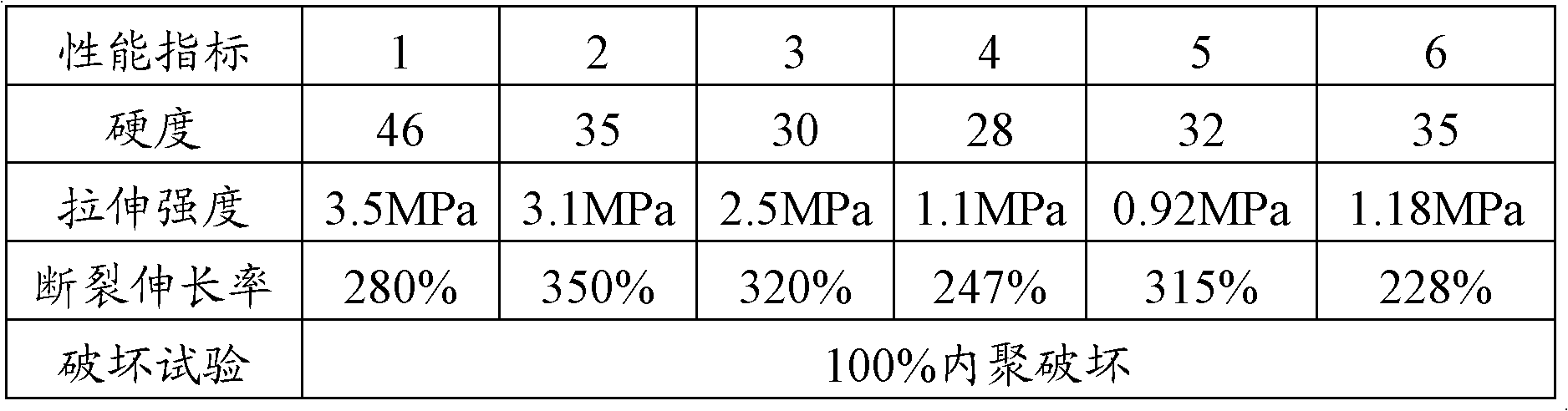

The invention discloses a high-strength polysulfide sealant which comprises a base paste and a vulcanized paste, wherein the base paste comprises 30-80% of liquid polysulfide rubber, 5-60% of graphene oxide, 0.5-10% of tackifier, 5-20% of plasticizer and 0-5% of addition agent; the vulcanized paste comprises 25-70% of vulcanizing agent, 25-70% of plasticizer and 0.5-5% of vulcanization accelerator; and the weight ratio of the base paste to the vulcanized paste is (100: 6)-(100: 15). The high-strength polysulfide sealant disclosed by the invention has the characteristics that because of adopting the graphene oxide as a reinforcing agent, the tensile strength of the polysulfide sealant is increased; and the material is stable in process and good in repeatability. The material disclosed by the invention can be applied to the bonding of sealing parts such as airplanes, high-speed trains and vehicles and the like, therefore, the polysulfide sealant disclosed by the invention has great application value in industry.

Owner:ZHEJIANG UNIV

Cementation type polysulfide sealant

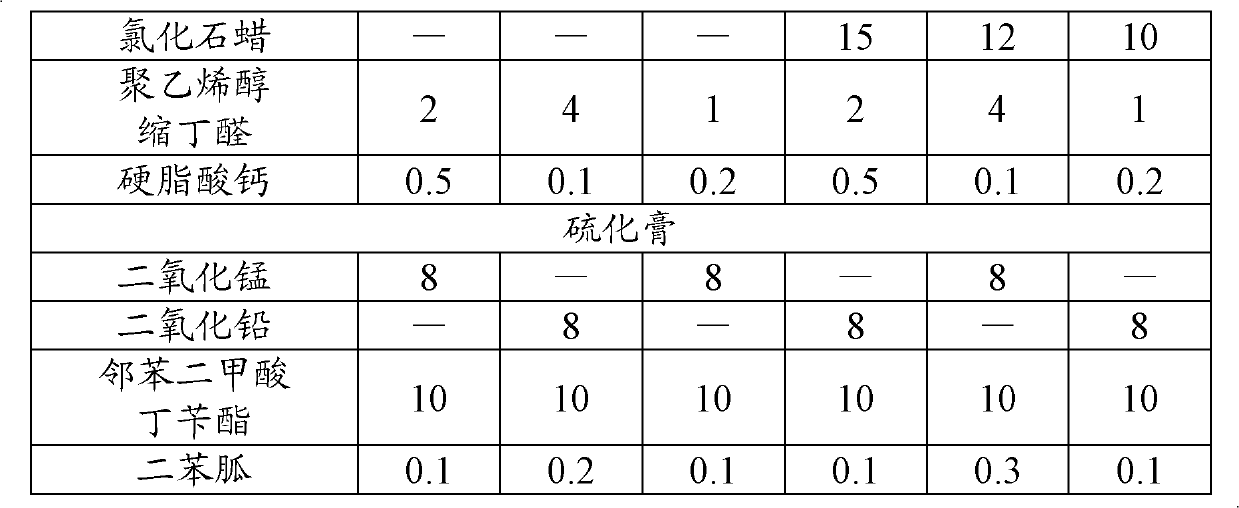

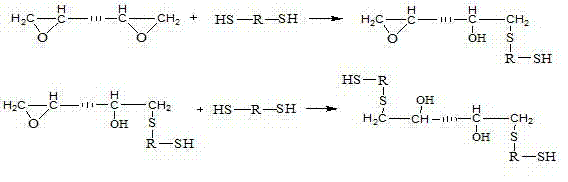

ActiveCN1958709AFlame retardantThe deployment process is simpleOther chemical processesPolysulfide rubberPolymer science

This invention discloses a bi-component polysulfide rubber sealant with MnO2 as the curing agent. The polysulfide rubber sealant has binding, sealing and flame-retarding functions. This invention utilizes epoxy resin to modified liquid polysulfide rubber, thus increasing the binding strength, breaking elongation rate and peel strength of the polysulfide rubber sealant. Besides, the polysulfide rubber sealant has flame-retarding effect due to the addition of flame retardant. The polysulfide rubber sealant can satisfy the binding and sealing requirements of magnetic suspending trains and automobiles.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

High-adhesion polysulfide sealant

InactiveCN101906285AOther chemical processesMacromolecular adhesive additivesPolyvinyl butyralPolysulfide rubber

The invention discloses a high-adhesion polysulfide sealant, which comprises base paste and vulcanizing paste. The base paste comprises 30 to 70 percent of liquid polysulfide rubber, 20 to 60 percent of filler, 0.5 to 10 percent of thickener, 5 to 20 percent of plasticizer and 0 to 5 percent of assistant, wherein the thickener polyvinyl butyral and adjusting the adhesive property of the sealant. The vulcanizing paste comprises 25 to 70 percent of vulcanizing agent, 25 to 70 percent of plasticizer and 0.5 to 5 percent of vulcanization accelerator. The mixing weight ratio of the base paste to the vulcanizing paste is 100:6-14. The invention also discloses a method for preparing the polysulfide sealant. The sealant and the method are characterized in that: the polyvinyl butyral is used as the thickener; the adhesive strength of the polysulfide sealant is improved; the use cost of the materials is low; the process is stable; and the repeatability is high. The material of the invention can be used for adhering sealing parts of airplanes, rapid trains, automobiles and the like. Therefore, the sealant has a high industrial application value.

Owner:ZHEJIANG UNIV

Bi-component polysulfide fireproofing flame retardant sealant and preparation method thereof

ActiveCN101575493AImprove fire performanceNot corrosiveNon-macromolecular adhesive additivesOther chemical processesPolysulfide rubberPlasticizer

The invention relates to a bi-component polysulfide fireproofing flame retardant sealant and a preparation method thereof, wherein the bi-component polysulfide fireproofing flame retardant sealant is prepared from the following components according to parts by weight: component A: 50-100 parts of liquid polysulfide rubber, 30-70 parts of flame retardant plasticizer, 50-150 parts of flame retardant filler, 60-200 parts of calcium carbonate, 0.3-1.2 parts of main agent micro-molecular finishing agent and 0.5-1.5 parts of silane coupling agent; component B: 10-30 parts of manganese dioxide, 20-60 parts of plasticizer, 1-3 parts of semi-strengthening agent carbon black and 0.4-1.5 parts of accelerant. The preparation method comprises the following steps of: mixing, stirring, vacuumizing, inspecting and packaging all the ingredients of component A; and mixing, stirring, vacuumizing, grinding, inspecting and packaging all the ingredients of component B. The sealant can be used by uniformly mixing A and B according to the mass rate of A: B being equal to 100:6-100:12. the sealant has good flame retardant property that is tested to be FV-0 level according to GB / T 2408-1996, and the oxygen index is tested to be 36.6 percent according to GB / T 2406-1993, and the both levels reach or exceed state-specified standards,.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

Water-borne epoxy resin paint and preparation method thereof

ActiveCN103087611AImprove mechanical propertiesEasy to prepareAnti-corrosive paintsEpoxy resin coatingsEnvironmental resistancePolysulfide rubber

The invention discloses a water-borne epoxy resin paint and a preparation method thereof. The water-borne epoxy resin paint mainly comprises the following components in parts by weight: 100 parts of epoxy resin emulsion, 10-50 parts of water-borne curing agent and 5-40 parts of polysulfide rubber emulsion. The epoxy resin emulsion and the polysulfide rubber emulsion in amounts of the formula are placed in a dispersion machine, dispersion is carried out at the temperature of 10-30 DEG C, the water-borne curing agent in the amount of the formula is added after the emulsions are fully dispersed, and then the dispersion is carried out again, so that the water-borne epoxy resin paint is obtained after full dispersion is completed. The paint provided by the invention has good room temperature storage stability, excellent mechanical property and strong anti-corrosion property and can be applied to the fields such as environmental protection, ships and automobiles; and the preparation method provided by the invention is simple in process and environment-friendly, and quality of a produced film is high, so that the paint provided by the invention has a broad application prospect.

Owner:南雄市毅豪化工有限公司

Low-melt-viscosity thermoplastic polyurethane hot melt adhesive and preparation method thereof

ActiveCN105199652AMeet the needs of conventional bonding pottingPolyureas/polyurethane adhesivesPolyesterShear strength

The invention discloses a low-melt-viscosity thermoplastic polyurethane hot melt adhesive and a preparation method thereof; the low-melt-viscosity thermoplastic polyurethane hot melt adhesive is prepared from raw materials of polyester polyol, polyether glycol, polysulfide rubber, diisocyanate, a catalyst and a chain extender in proportion, and the concrete method comprises the steps: carrying out high temperature dehydration on polyester polyol, polyether glycol and polysulfide rubber, then carrying out a reaction with diisocyanate at the temperature of 60+ / -5 DEG C for 1-2 h, next carrying out a reaction at the temperature of 80+ / -5 DEG C until the viscosity is increased, then adding a catalyst, continuing to carry out a reaction for 2-3 h, adding the chain extender, stopping heating when the reactant is thickened, becomes shiny and can be wire-drawn, and thus obtaining the product. The prepared low-melt-viscosity thermoplastic polyurethane hot melt adhesive has the melt viscosity of lower than 5 Pa*S / 180 DEG C, has the bonding shear strength on aluminum Ly-12 of more than 4 MPa, can be used for large-area bonding and encapsulation, can meet the demand of conventional bonding and encapsulation, and expands an application scope of the polyurethane hot melt adhesive.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Special structure film for mirror seat of rear-view mirror in automobile and preparation method thereof

ActiveCN102516894AGood film formingSave materialNon-macromolecular adhesive additivesFilm/foil adhesivesPolysulfide rubberAdhesive

The invention relates to a special structure film for a mirror seat of a rear-view mirror in an automobile. The structure film is prepared from the following raw materials in parts by weight: 20-100 parts of acrylonitrile-butadiene rubber, 0-70 parts of polysulfide rubber which is not cured fully, 5-40 parts of bisphenol A type epoxy resin, 10-60 parts of modified epoxy resin, 0.1-2.5 parts of cross-linking agent, 0.2-2.5 parts of softening agent, 3-20 parts of curing agent, 1-10 parts of accelerant, 20-100 parts of inorganic filler and 0.1-3.0 parts of silane coupling agent. The structure film disclosed by the invention has the advantages of good film-forming performance, good aging resistance, simple curing process, high strength of structural adhesive after curing, good toughness, excellent heat resistance and cold resistance and the like.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

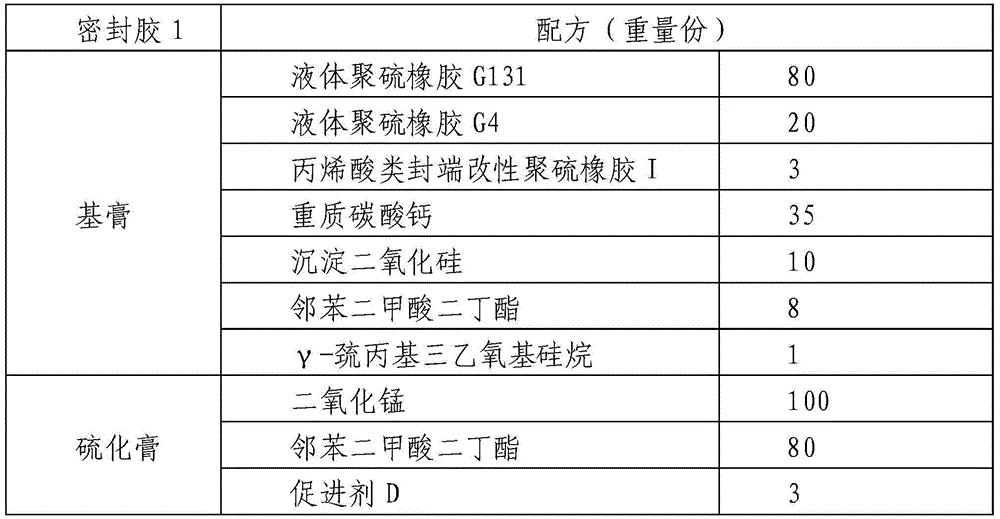

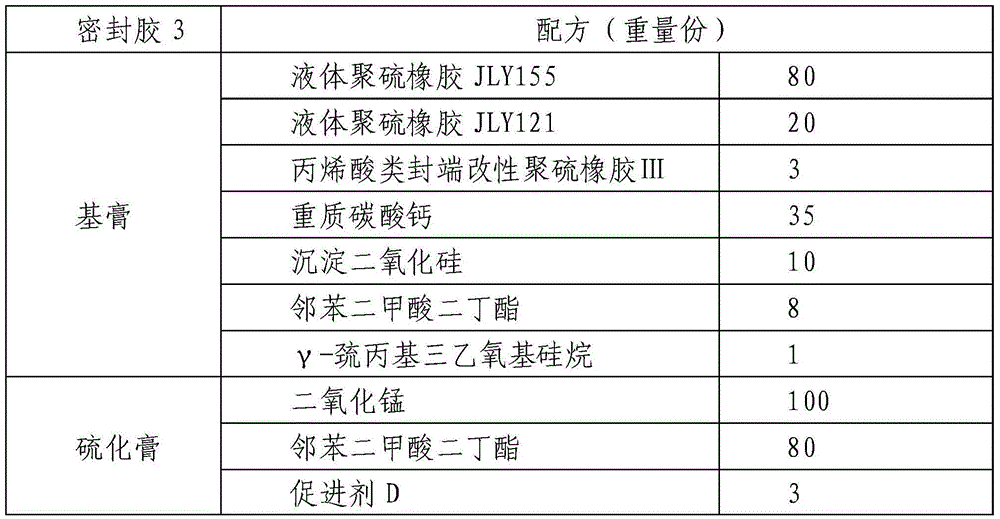

High peeling strength polysulfide sealant and sealing method

ActiveCN103555264AGood adhesionAdhesion does not increaseNon-macromolecular adhesive additivesOther chemical processesPolysulfide rubberPolymer science

The invention belongs to the technical field of polymer sealants, and relates to a high peeling strength polysulfide sealant and a method for sealing by using the sealant. The sealant is composed of a component A-based paste and a component B sulfur paste, wherein the component A is composed of a filler, a plasticizer, a crylic acid-terminated modified polysulfide rubber, a coupling agent and a liquid polysulfide rubber; and the component B is composed of manganese dioxide, dibutyl phthalate and an accelerator D. The invention provides the high peeling strength polysulfide sealant and a sealing method thereof. The adhesive property of the sealant is increased without increasing the viscosity of the sealant.

Owner:BAIMTEC MATERIAL CO LTD

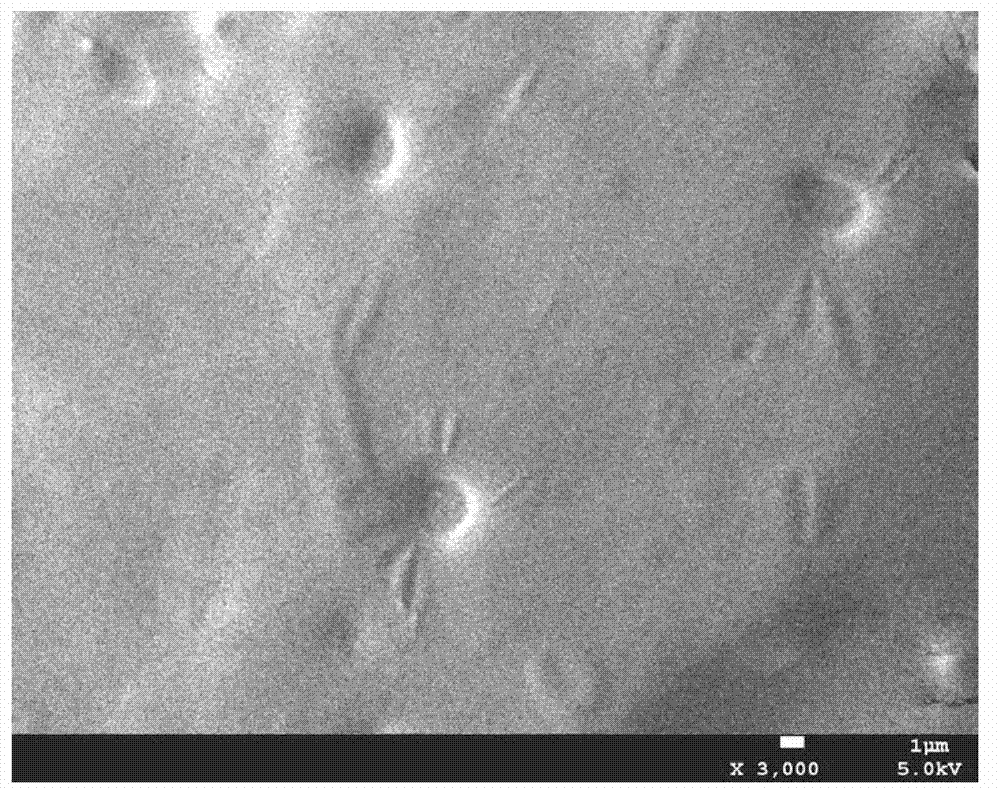

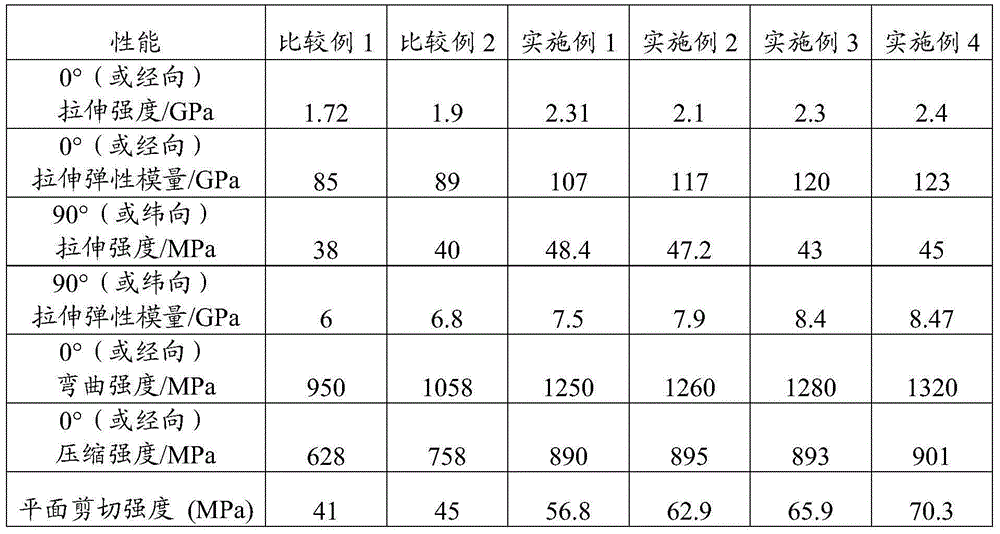

Epoxy resin composition for prepreg, carbon fiber prepreg and carbon fiber compound material

The invention provides an epoxy resin composition for prepreg. The epoxy resin composition comprises epoxy resins, modified epoxy resins and a curing agent; liquid rubber comprises one kind or several kinds of carboxyl nitrile liquid rubber, hydroxy-terminated copolybutadiene butyronitrile liquid rubber, hydroxy-terminated copolybutadiene polybutadiene liquid rubber, carboxyl terminated polybutadieneliquid rubber, hydroxyterminated copolybutadiene polyisoprene liquid rubber, carboxyl terminated polyisoprene liquid rubber, polyurethane modified liquid rubber, liquid silicon rubber and liquid polysulfide rubber. The liquid rubber is used for modifying an epoxy resin basal body, so that the binding force between a system for using epoxy resins as basal bodies, and a carbon fiber material interface is improved, and the mechanical property of the fibers is further improved. The invention further provides carbon fiber prepreg and a carbon fiber compound material. The stretching strength of the carbon fiber compound material provided by the invention at 0 degree (or in the radial direction) is 2.4GPa, the bending strength is 1320MPa, and the plane cutting strength is 70.3MPa.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

High-temperature-resistant sealant

InactiveCN104046307AImprove water resistanceImprove high temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesGas phaseAluminium hydroxide

A disclosed high-temperature-resistant sealant is prepared from the following raw materials in parts by weight: 6-10 parts of bamboo charcoal fiber, 4-8 parts of hollow bead, 8-14 parts of nitrile butadiene rubber, 10-20 parts of EVA thermoplastic elastomer, 6-12 parts of paraffin oil, 3-8 parts of graphene, 4-9 parts of isocyanate, 5-8 parts of aluminium hydroxide, 2-6 parts of terpene resin, 4-8 parts of gas-phase white carbon black, 7-11 parts of diaryl secondary amine, 7-14 parts of polysulfide rubber, 5-10 parts of zinc oxide, 10-20 parts of epoxy resin, 20-30 parts of acrylate emulsion, 8-16 parts of chitin, 7-9 parts of ethanol, 5-11 parts of kerosene, 5-8 parts of illite powder and 4-8 parts of attapulgite. The provided high-temperature-resistant sealant is excellent in waterproof performance and good in high-temperature resistance and flame resistance.

Owner:QINGDAO CHENQING INFORMATION TECH

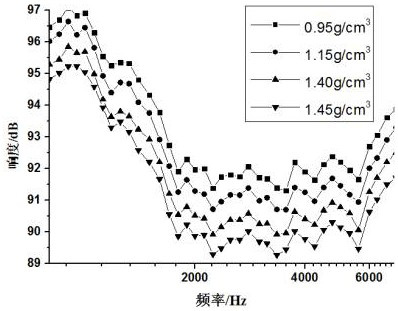

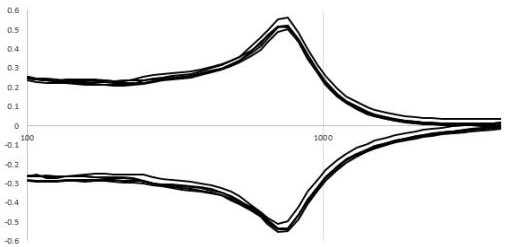

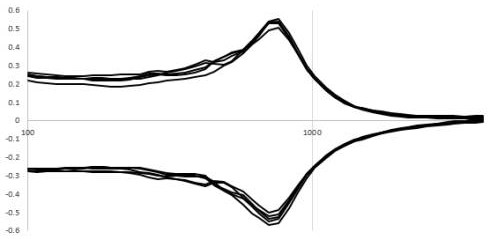

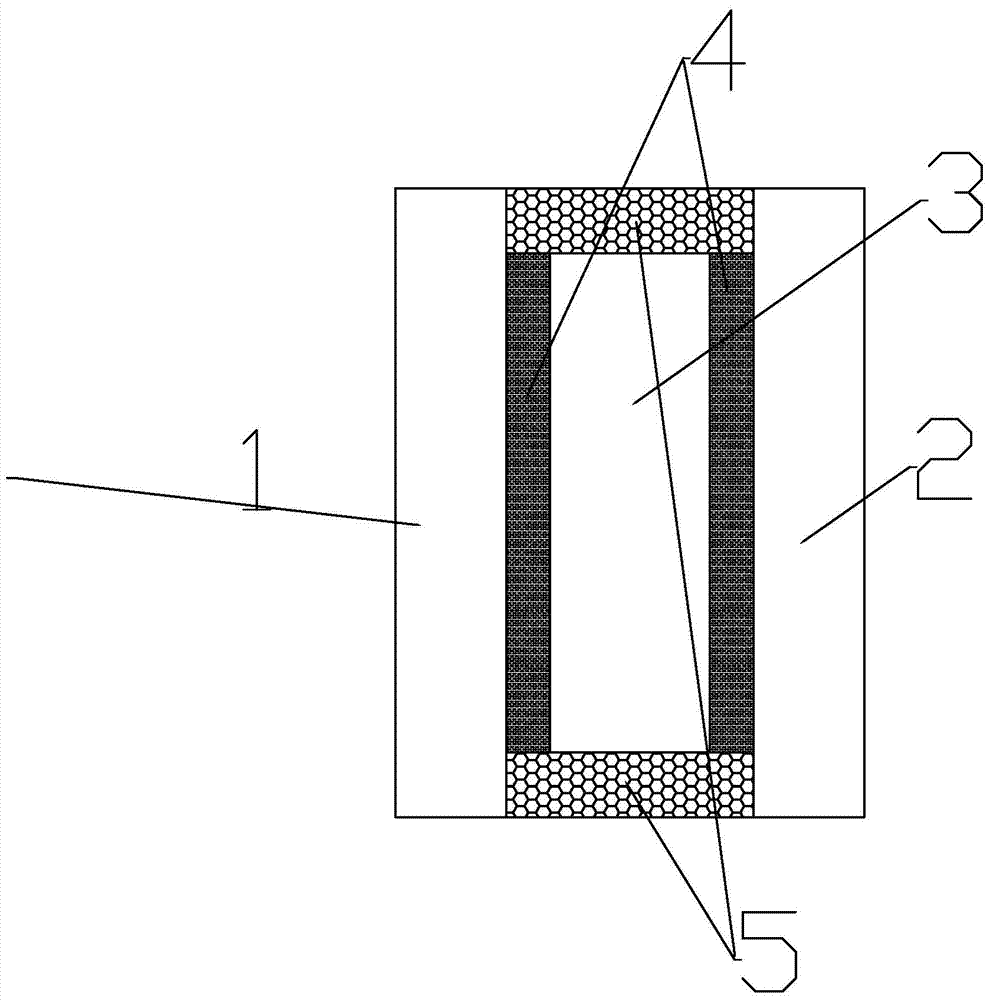

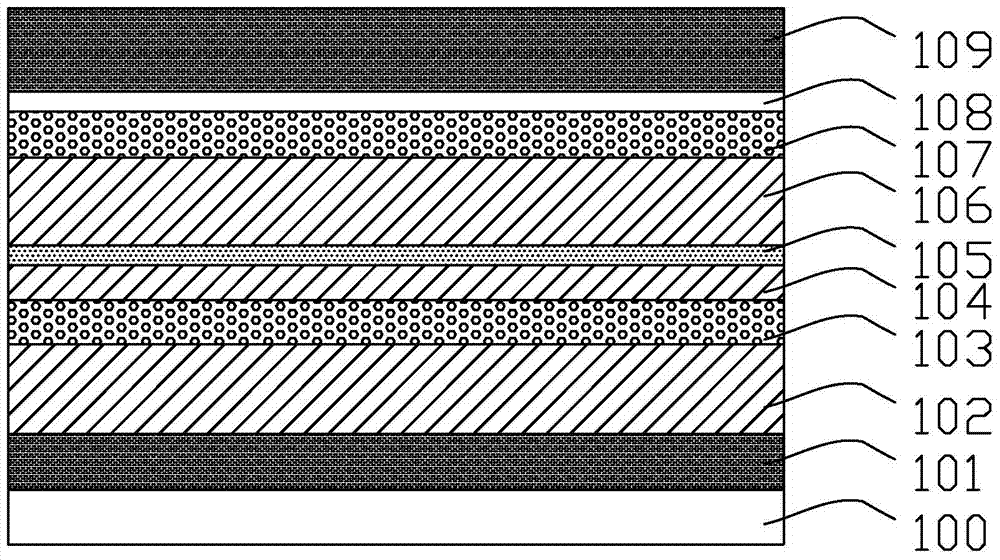

Vibrating diaphragm of sound production device and preparation method thereof and sound production device

ActiveCN111935602AIncrease dampingIncrease intermolecular forcesPolymeric diaphragmsSynthetic resin layered productsPolymer sciencePolysulfide rubber

The invention discloses a vibrating diaphragm of a sound production device and a preparation method thereof and the sound production device. The vibrating diaphragm comprises at least one modified diaphragm layer, the modified diaphragm layer is made of a blend polymer formed by blending and modifying silicone rubber and a modifier, and the modifier is at least one of a butadiene-acrylonitrile copolymer, a butadiene-styrene copolymer, polysulfide rubber, polyurethane rubber and polybutadiene. The vibrating diaphragm provided by the invention is made of a blend polymer formed by blending and modifying silicon rubber and a modifier; the modifier is at least one of a butadiene-acrylonitrile copolymer, a butadiene-styrene copolymer, polysulfide rubber, polyurethane rubber and polybutadiene; the intermolecular force and / or steric hindrance of the silicone rubber can be increased, so that the vibrating diaphragm has excellent damping performance, and the sound production device has excellentconsistency, excellent anti-polarization capability, reduced distortion performance and higher tone quality in the vibration process.

Owner:GOERTEK INC

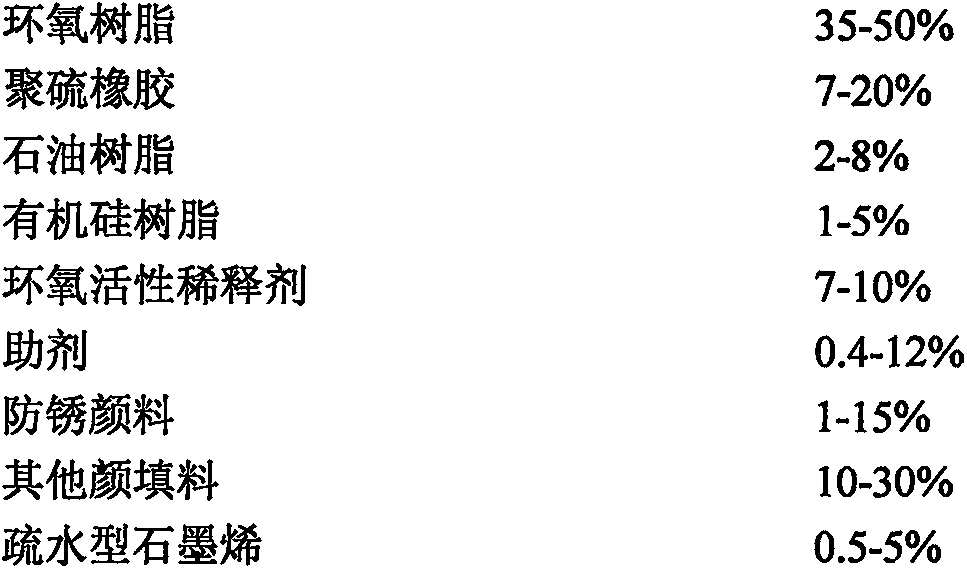

Hydrophobic graphene solvent-free epoxy underwater curing coating and preparation method thereof

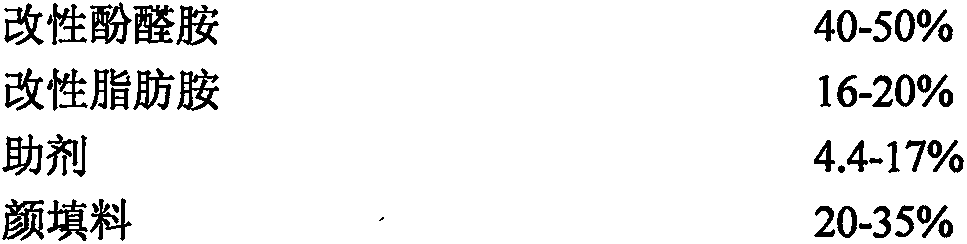

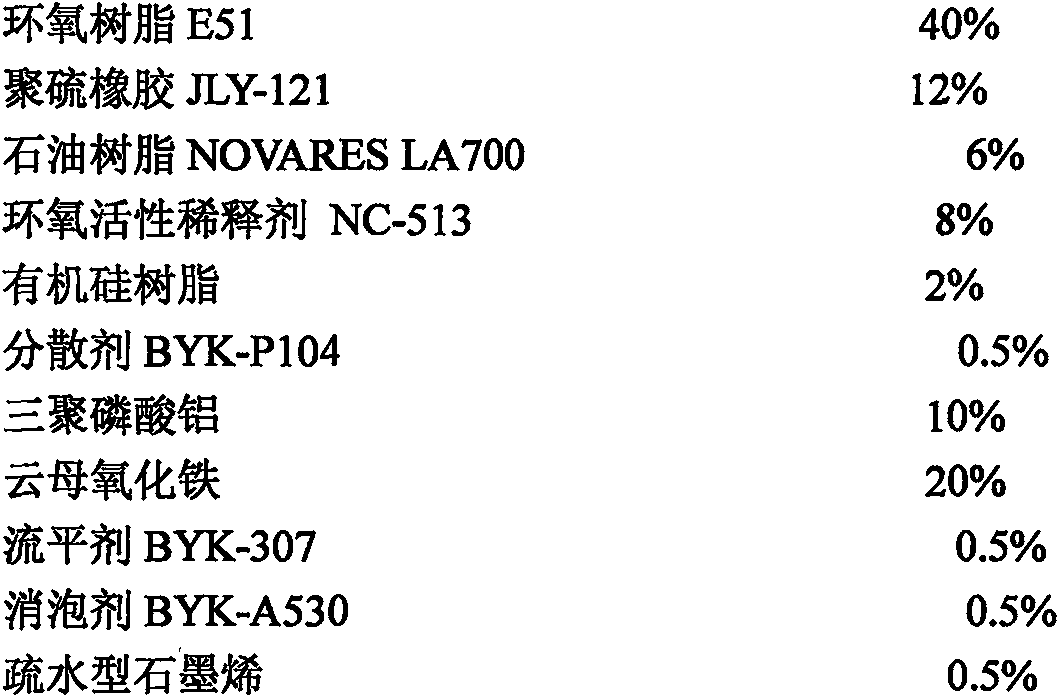

The invention provides a hydrophobic graphene solvent-free epoxy underwater curing coating and a preparation method thereof. The hydrophobic graphene solvent-free epoxy underwater curing coating is prepared from a component A and a component B in the weight ratio being 100:(30-55), wherein the component A comprises raw materials as follows: 35%-50% of epoxy resin, 6%-10% of polysulfide rubber, 2%-8% of petroleum resin, 7%-10% of a reactive diluent, 1%-5% of organic silicon resin, 20%-40% of antirust pigments, 0.2%-6% of an aid and 0.5%-5% of hydrophobic graphene; the component B comprises rawmaterials as follows: 40%-50% of modified phenolic amine, 15%-20% of modified aliphatic amine, 0.5%-15% of an aid and 18%-30% of pigment and filler. The invention provides the hydrophobic graphene solvent-free epoxy underwater curing coating and the preparation method thereof, and the hydrophobic graphene solvent-free epoxy underwater curing coating can be constructed on surfaces of underwater substrates, can be cured quickly and has excellent adhesive force and corrosion resistance.

Owner:燕园众欣纳米科技(北京)有限公司

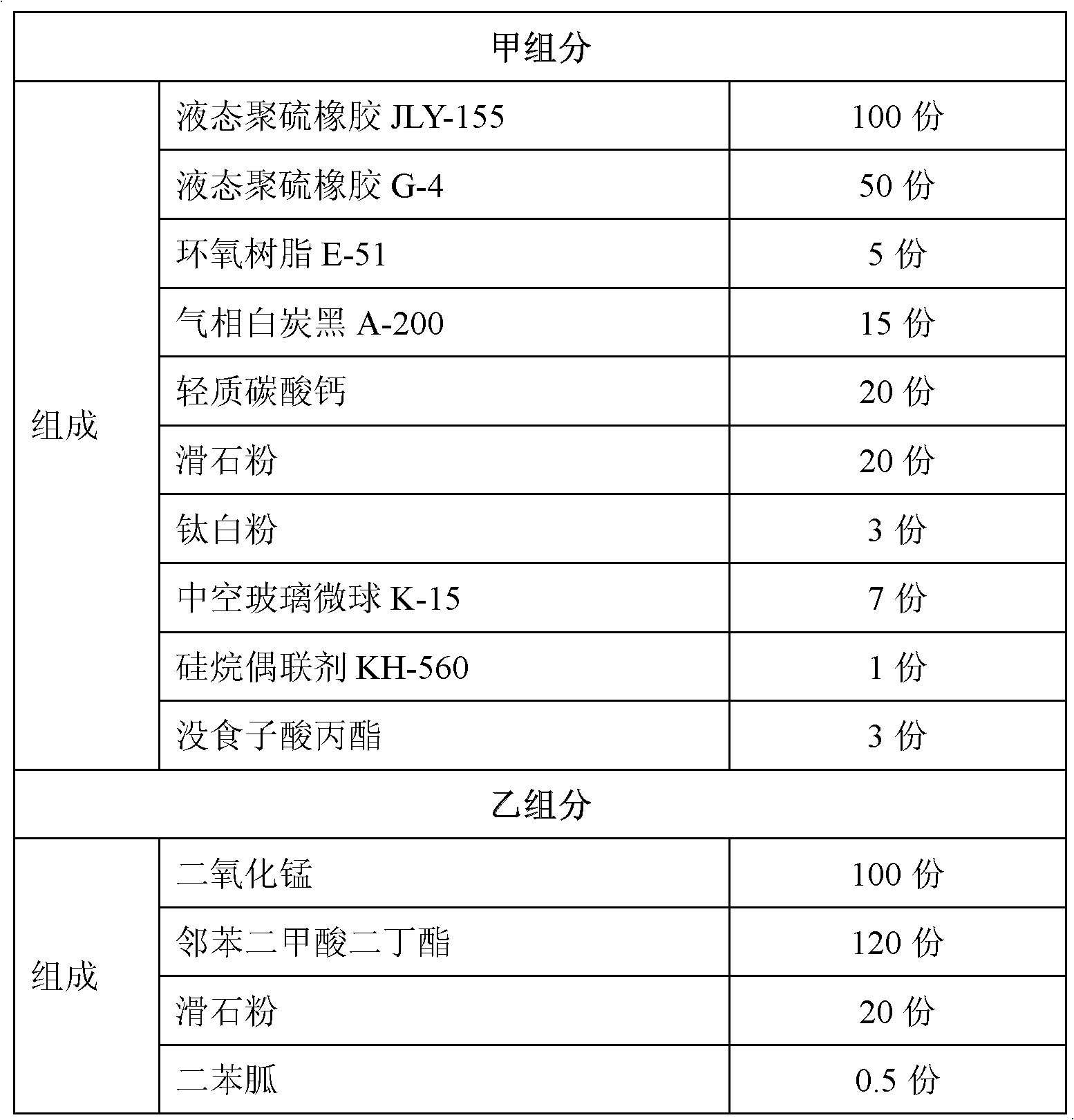

Bi-component polysulfide sealant and preparation method thereof

InactiveCN102618207AExcellent thermal degradation resistanceGood strength retentionNon-macromolecular adhesive additivesOther chemical processesThermal ageingPolymer science

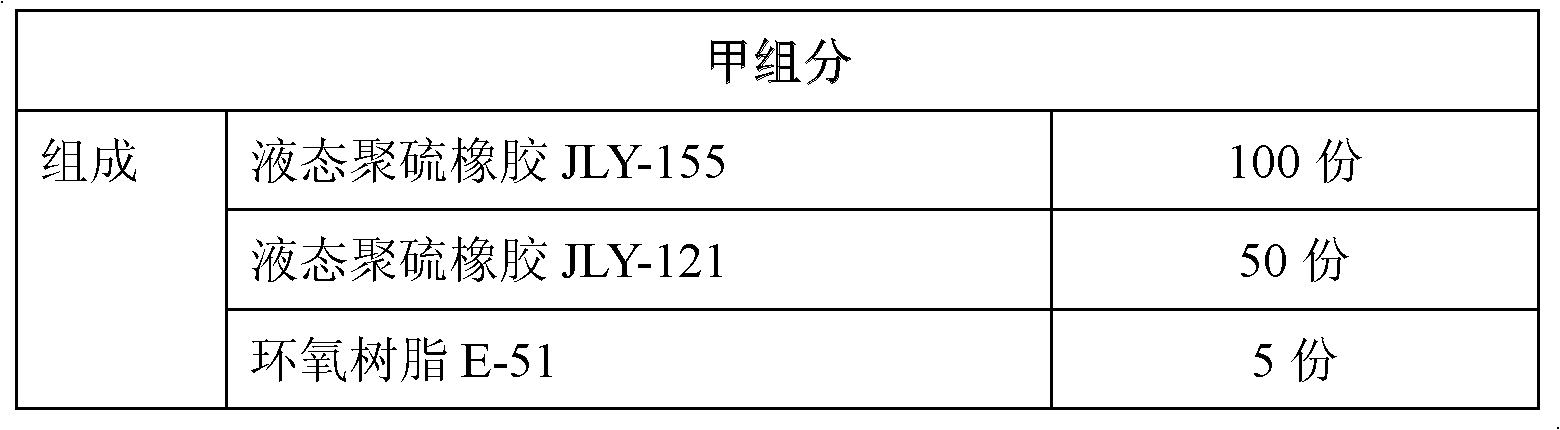

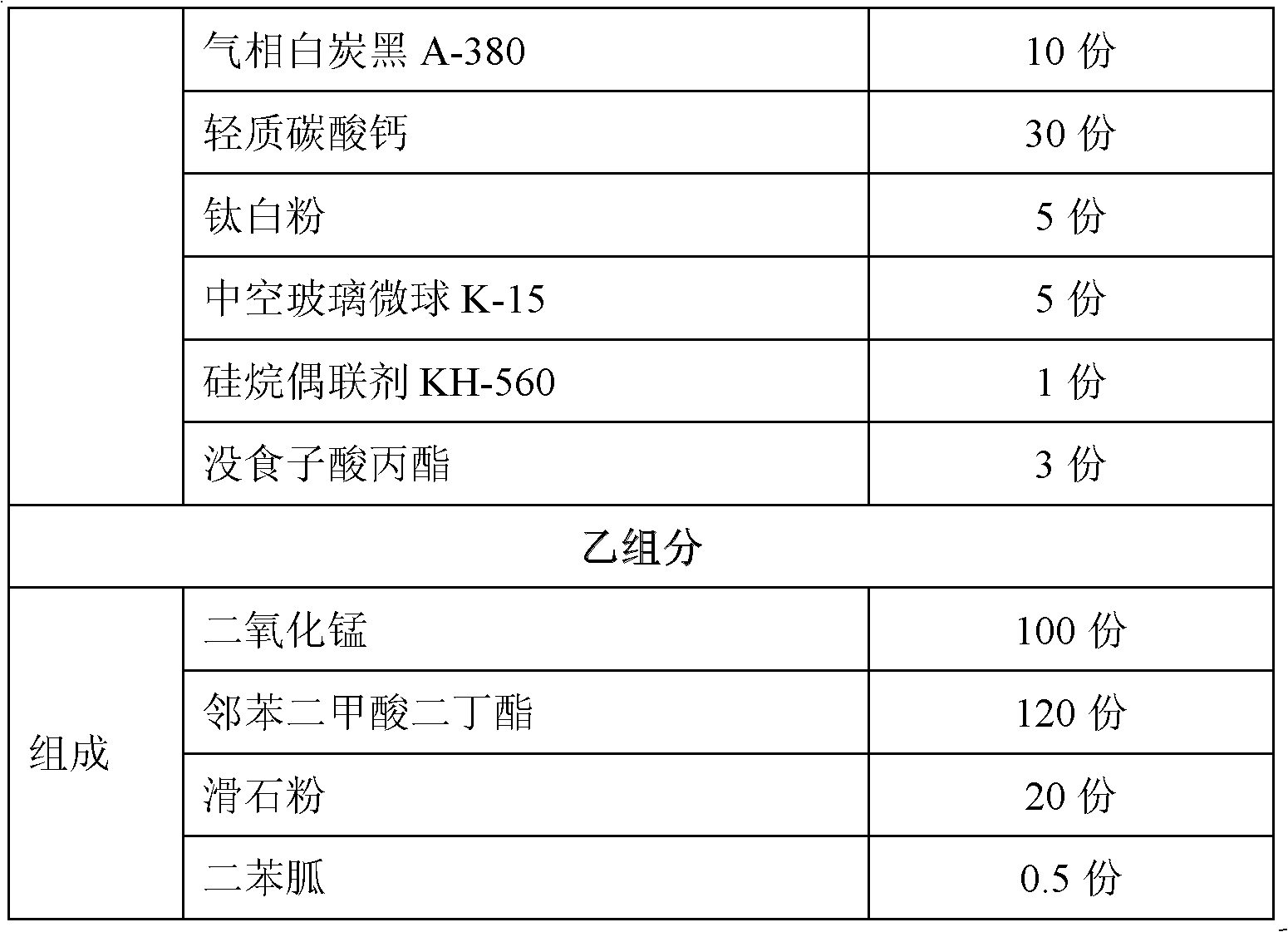

Bi-component polysulfide sealant and a preparation method thereof relate to a high-polymer sealing material and a preparation method thereof and aim to solve the problems of high density and poor heatproof degradation performance of existing sealant after being sulfurized. A component includes liquid polysulfide rubber, epoxy resin, thixotropic agent, reinforcing filler, hollow glass microballs, titanium dioxide, silane coupler and antiager, B component includes manganese dioxide, plasticizer, talcum powder and melaniline. The preparation method includes: the A component is prepared by addingthe thixotropic agent, the titanium dioxide, the reinforcing filler and the antiager to grind after the liquid polysulfide rubber and the epoxy resin are pre-polymerized and then adding treated hollow glass microballs to grind; the B component is prepared by mixing and grinding the manganese dioxide, the plasticizer and the talcum powder and then adding the melaniline to grind. The bi-component polysulfide sealant with the density smaller than or equal to 1.3g / cm3 is not crispy and not viscous in flowing after thermal ageing at the temperature of 180 DEG C for 10 hours. The preparation methodis applicable to preparation of polysulfide sealant.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

High-temperature-resistant flexible adhesive cured at normal temperature and preparation method thereof

InactiveCN102732209AImprove high temperature resistanceImprove toughnessNon-macromolecular adhesive additivesPolymer sciencePolysulfide rubber

The invention discloses a high-temperature-resistant flexible adhesive cured at normal temperature and a preparation method thereof. The high-temperature-resistant flexible adhesive is prepared by adopting bisphenol-A epoxy resin, high-polymerization-degree epoxy resin, polysulfide rubber and organic silicon resin as bonding components, adopting polyamide as a main curing component, and adding inorganic auxiliary materials with different proportions. The high-temperature-resistant flexible adhesive disclosed by the invention has the advantages that a Si-O chain section in organic silicon and a flexible chained structure in the polysulfide rubber are formed by changing grafting positions of the organic silicon and the epoxy resin, so that not only are the high-temperature resistance and the toughness of a cured product improved, but also the consumption of epoxy groups in a process of modification is reduced. The epoxy resin adhesive prepared by the method solves the problems that the cost is high, the purchasing of raw materials is difficult and the modification of the bonding components consumes a great quantity of epoxy groups to cause insufficient curing reaction and further cause reduction of the strength of the adhesive in the epoxy resin adhesive in the prior art. The high-temperature-resistant flexible adhesive has the characteristics that the operation can be carried out under the room-temperature condition, and simultaneously the high temperature can be resisted.

Owner:ZHENGZHOU UNIV

Heavy-duty corrosion-resistant spraying polyurea coating and preparation method thereof

InactiveCN103820013AGood resistance to organic solvent corrosionExtended service lifeAnti-corrosive paintsPolyurea/polyurethane coatingsHeavy dutyPetroleum

The invention discloses heavy-duty corrosion-resistant spraying polyurea coating and a preparation method thereof. The coating comprises an A component and a B component, wherein the A component comprises 60-80 parts by weight of isocyanate and 20-40 parts by weight of polyol, and the B component comprises 40-70 parts by weight of liquid-state polysulfide rubber, 20-50 parts by weight of a liquid-state amine chain extender, 0-10 parts by weight of pigment and filling materials, and 0-10 parts by weight of an auxiliary agent. The coating has excellent coating corrosion resistance, and particularly has excellent resistance to organic solvent corrosion. The coating is particularly suitable as anti-corrosion protection materials for petroleum pipelines, chemical engineering storage tanks, and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Processing technique for bent aluminum strip double-silver LOW-E hollow glass

InactiveCN104291691ALow water vapor transmission rateAvoid it happening againGlass/slag layered productsMetal layered productsPolysulfide rubberMoisture permeability

Belonging to the technical field of building materials, the invention relates to a processing technique for a bent aluminum strip double-silver LOW-E hollow glass. The process includes the steps of: cleaning and drying double-silver LOW-E glass and tempered glass respectively; calculating the aluminum strip length according to the glass size and glue depth, bending the aluminum strip and conducting filling with a drying agent, welding the joint to obtain an aluminum frame; coating both sides of the aluminum frame strip with butyl rubber evenly; putting the double-silver LOW-E glass on one side of the aluminum frame strip coated with butyl rubber, putting the dried tempered glass to the other side of the aluminum frame strip, laminating the two glass sheets into a hollow glass primary product; conducting secondary sealing on the hollow glass primary product with polysulfide rubber or structural silicone rubber, and finally carrying out curing to obtain the bent aluminum strip double-silver LOW-E hollow glass. Being simple and practicable, the processing technique provided by the invention reduces the moisture permeability of hollow glass joints, endows the prepared glass with high bending strength and impact strength, and further prolongs the service life.

Owner:NINGBO HEXIN GLASS TECH

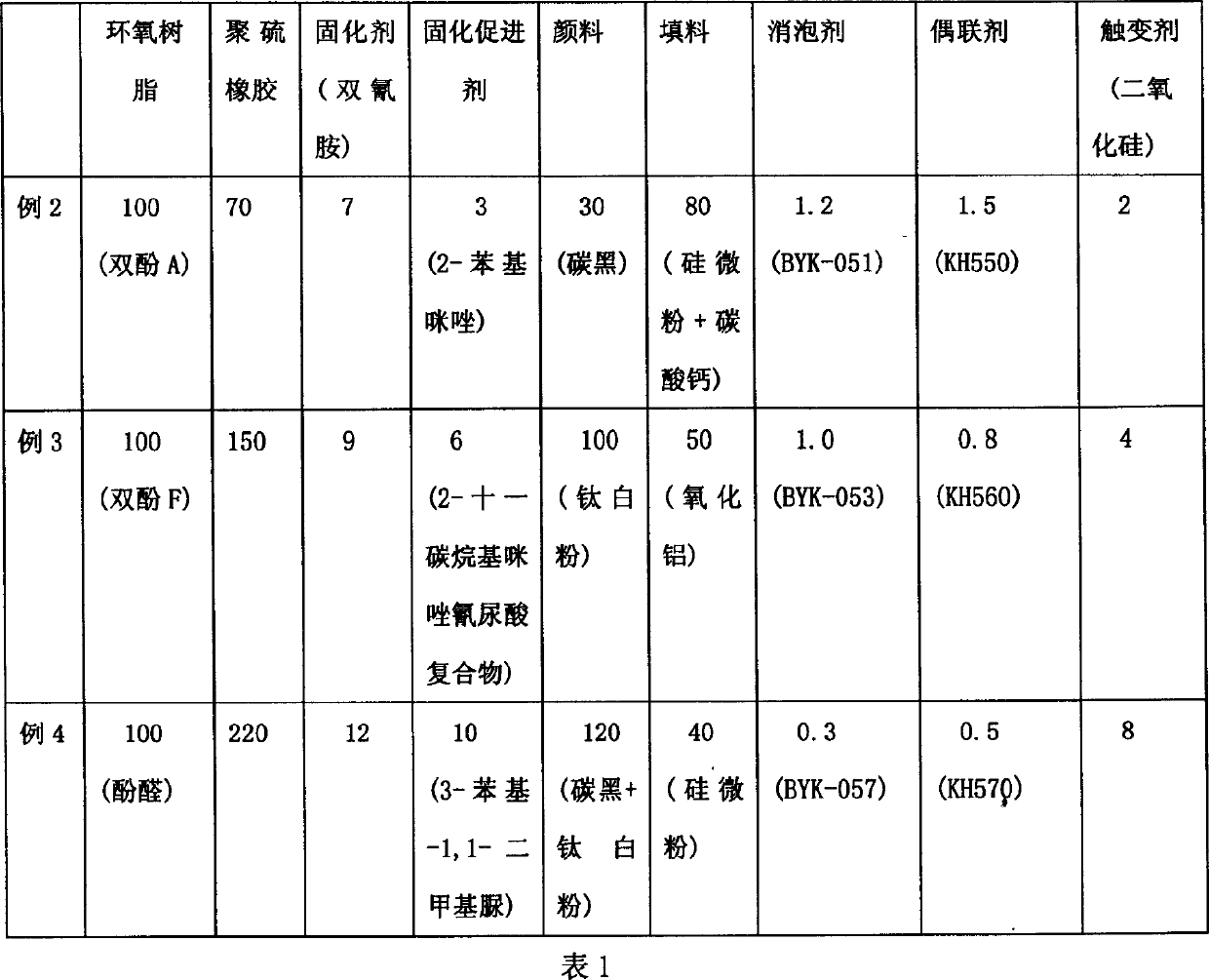

Single-component high-elasticity epoxy adhesive

InactiveCN1454956AIncrease elasticityImprove thixotropyEpoxy resin adhesivesPolysulfide rubberDefoaming Agents

The present invention relates to a single-component high-elasticity epoxy adhesive. Said adhesive system is formed from epoxy resin whose molecule contains more than two epoxy groups, polysulfide rubber, solidifying agent, solidification promotor, defoaming agent, silicone coupling agent, pigment filling material and thixotropic agent. The epoxy adhesive prepared by said compsition has high elasticity, good cohesive property and good thixotropy, and has the transmission viscosity which can be used by mechanical group, so that it is a good engineering adhesive.

Owner:HASCO VISION TECHNOLOGY CO LTD +1

Two-component toughened anti-shock epoxy structural adhesive and preparation method thereof

InactiveCN104497941AAdjustable flexibilityMaintain propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolysulfide rubberWorking life

The invention provides a two-component toughened anti-shock epoxy structural adhesive and a preparation method thereof. The two-component toughened anti-shock epoxy structural adhesive comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 10-30 parts of epoxy resin, 10-50 parts of modified polysulfide rubber and 0-30 parts of a reactive diluent; the component Bcomprises the following raw materials in parts by weight: 20-50 parts of a curing agent and 1-3 parts of an accelerant; and the component A and the component B are mixed at the weight ratio of 100 to (20-80), so as to prepare the two-component toughened anti-shock epoxy structural adhesive. The method has the advantages that the two-component toughened anti-shock epoxy structural adhesive is small in smell, convenient to construct, long in working life, slow in heat release; the prepared epoxy material is good in flexibility, high in bonding strength and good in damping property, and can be widely applied to the fields such as electronics, machinery, ships, automobiles and buildings.

Owner:SHANGHAI UNIV

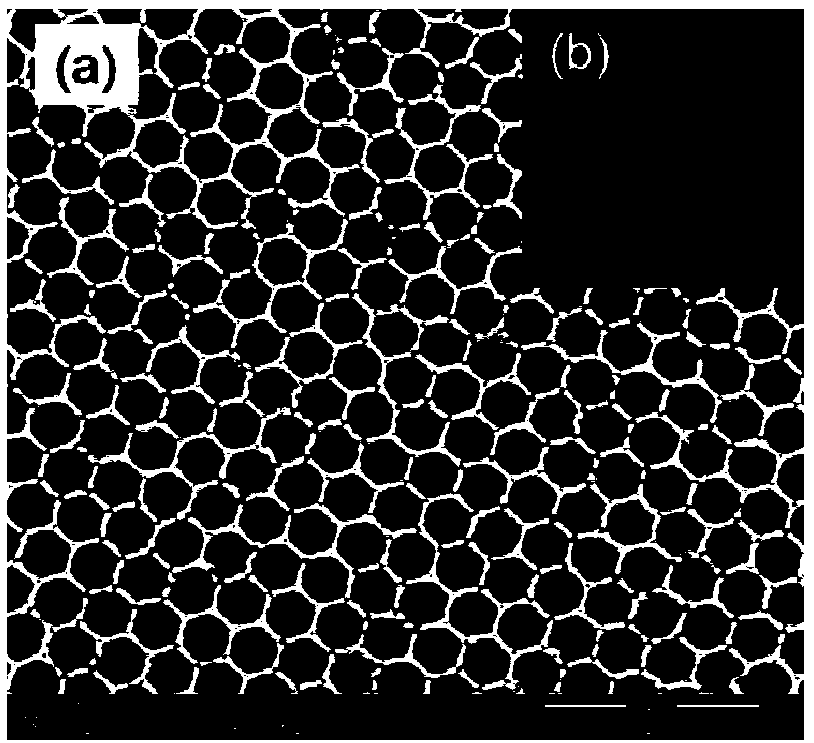

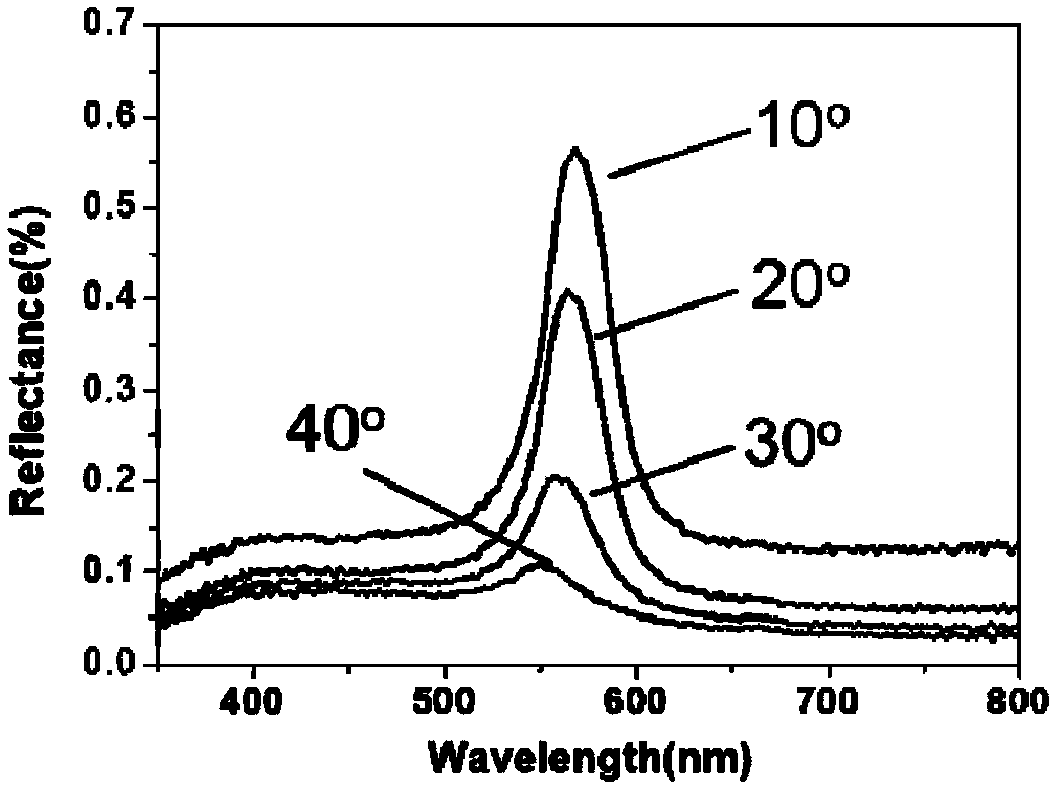

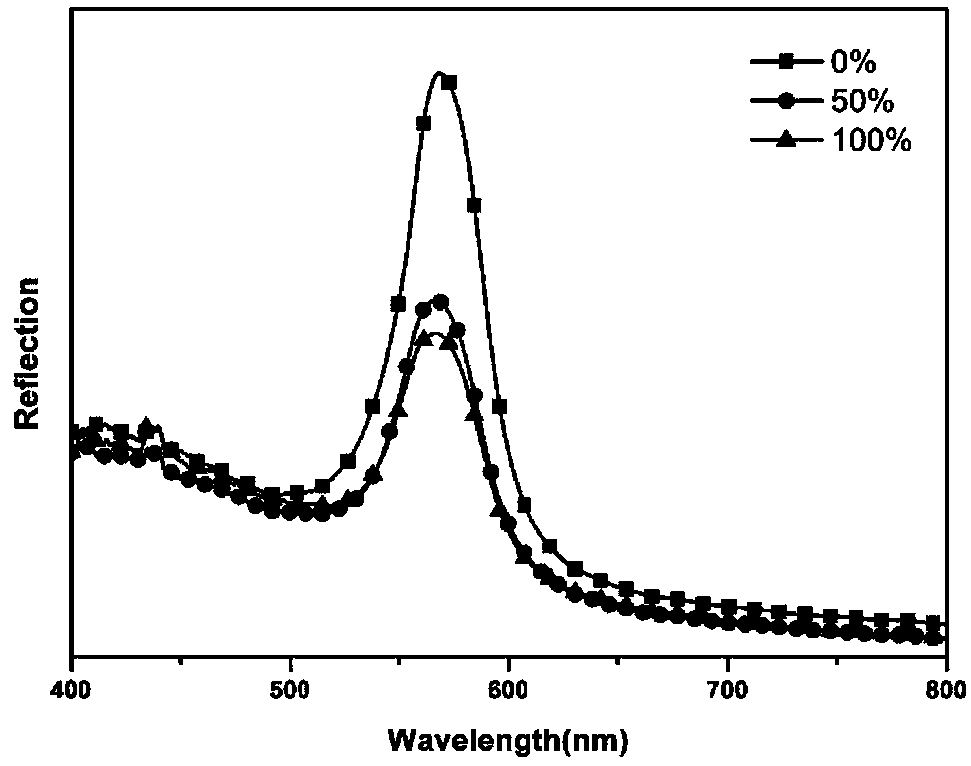

Strength enhanced type low angle dependency structure color material and preparation method thereof

The invention relates to a strength enhanced type low angle dependency structure color material and a preparation method thereof, in particular to a preparation method of the strength enhanced type low angle dependency structure color material, and belongs to the preparation field of color generation materials. The strength enhanced type low angle dependency structure color material consists of aninverse opal photonic crystal and an elastomer filled in protein structure gaps of the inverse opal photonic crystal, wherein the elastomer comprises polydimethylsiloxane, polyurethane, polysulfide rubber and polybutadiene rubber. The method is low in cost, simple and practicable, provides more possibilities for structure color materials in actual application, and especially has wide applicationprospects in the coloring field of building and packaging materials.

Owner:DALIAN UNIV OF TECH

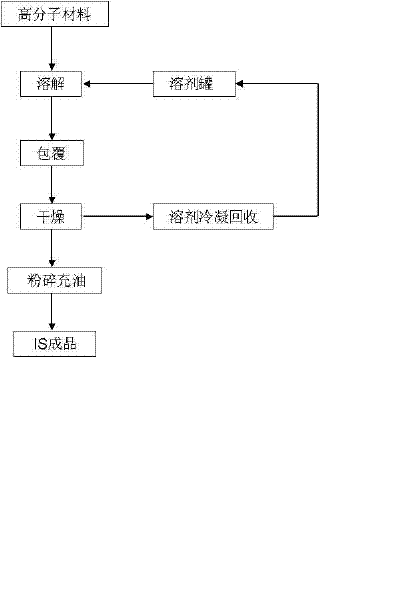

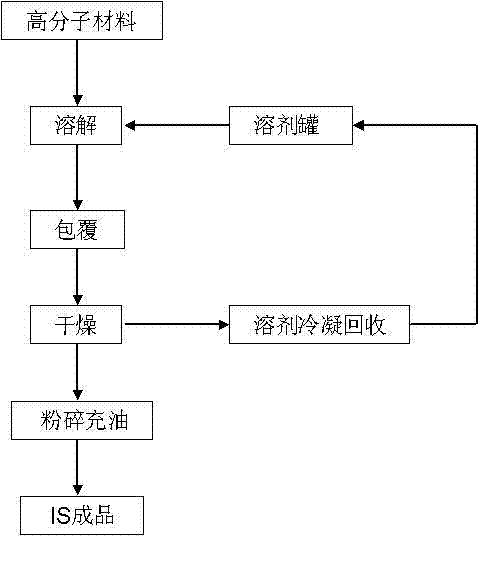

Method for preparing dispersible insoluble sulfur with high polymer material coating

ActiveCN102352129AGood dispersionEasy to processPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolymer sciencePolyethylene glycol

The invention provides a method for improving the dispersibility of insoluble sulfur, characterized by adding a high polymer material coating agent in the drying process of preparation of the insoluble sulfur to carry out coating on IS powder, wherein, the high polymer material is added in the IS powder through dissolving with a solvent, and the addition of the high polymer material coating agent is 0.1-5 %. The high polymer material coating agent comprises stearic acid, paraffin, EVA resin, hydroxypropyl ethyl cellulose, polyethylene glycol, polyvinyl acetal resin, polyvinyl resin, natural rubber, polysulfide rubber, chloroprene rubber, butadiene-acrylonitrile rubber, styrene butadiene rubber and other high polymer substances. The solvent can be recycled after drying and condensation. The method has the advantages of simple operation and high efficiency, and is suitable for industrial production.

Owner:SHANDONG SUNSINE CHEM

Preparation method for polysulfide polyurethane (urea) with self-repairing function

The invention discloses a preparation method for polysulfide polyurethane (urea) with a self-repairing function. The preparation method comprises the steps that prepolymer synthesis is carried out, specifically, mercapta-terminated liquid polysulfide rubber and 2,2'-aminophenyl disulfide are mixed and are heated for reaction under an alkaline condition so as to obtain anilino-modified liquid polysulfide; and curing is carried out, specifically, curing reaction is carried out on the anilino-modified liquid polysulfide and isocyanate so as to prepare polysulfide polyurethane (urea) with the self-repairing function. The preparation method has the advantages that the reaction activity of the liquid polysulfide rubber and isocyanate is effectively improved, and water vapor interference in the preparation process is reduced; 2,2'-aminophenyl disulfide contains benzene rings, and the hard segment and the mechanical strength of a material of polyurethane (urea) are effectively regulated and controlled by adding different amounts; and the tensile strength of the prepared polysulfide polyurethane (urea) is greater than or equal to 8 MPa, the elongation at break is 300-500%, cut samples makecontact with each other for 4-8 hours at 100-130 DEG C, and the repair rate is 55-90%.

Owner:NANJING UNIV

Polysulfide sealant and preparation method thereof

InactiveCN104531037ANon-macromolecular adhesive additivesOther chemical processesPolymer scienceTriol

The invention discloses a polysulfide sealant and a preparation method thereof. The polysulfide sealant comprises polyether triol, thio alcohol, isocyanate, liquid polysulfide rubber, graphene oxide, epoxypropane butyl ether, acrylate emulsion, phenolic resin, dibutyl ester, filling materials, a tackifier, and a plasticizer. The preparation method comprises the following steps: performing coarse mixing of polyether triol, thio alcohol, isocyanate, liquid polysulfide rubber, graphene oxide, epoxypropane butyl ether, acrylate emulsion, phenolic resin, and dibutyl ester in a kneader, transferring the mixture into a reaction device, stirring at 30-50 DEG C, then adding the filling materials, the tackifier, and the plasticizer, performing vacuum-pumping, heating to 50-60 DEG C, keeping vacuum, performing heat preservation and stirring for 1-2 hours, cooling with a cooling device, filtering by a filter device, filling with an automatic filling device, and storing the product. The purpose of the invention is to provide the polysulfide sealant with reasonable components and ratios, and good adhesive property, and the preparation method.

Owner:GUANGDONG XINZHAN NEW CHEM MATERIAL

Solvent-free anticorrosive coating based on polyurea elastomer and preparation method of solvent-free anticorrosive coating

InactiveCN106928426AGood resistance to organic solvent corrosionIncrease elasticityAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerSolvent free

The invention discloses a solvent-free anticorrosive coating based on a polyurea elastomer. The coating contains a component A and a component B, wherein the component A contains the following substances in parts by weight: 70-100 parts of aromatic diisocyanate and 5-20 parts of a viscosity reducer; and the component B contains the following components in parts by weight: 50-70 parts of halogenated amino-terminated resin, 20-30 parts of an amino-terminated chain extender, 15-30 parts of liquid-state polysulfide rubber, 20-40 parts of pigments, 0.5-5 parts of a coupling agent and 0.5-10 parts of a hydroxyl ultraviolet absorber. By utilizing the halogenated amino-terminated resin and a small amount of liquid-state polysulfide rubber, the solvent-free anticorrosive coating disclosed by the invention has both good corrosion resistance and relatively good elasticity and wear resistance.

Owner:GUANGDONG ZHONGXING TECH

Skin damage repair method for aluminum alloy skin foam sandwich part

InactiveCN105750815AGuaranteed normal flightEasy to operateAircraft componentsNon-macromolecular adhesive additivesPolysulfide rubberAdhesive

The invention belongs to the technical field of aerial foam sandwich part manufacturing and relates to a skin damage off-site repair method for an aluminum alloy skin foam sandwich part.The method is mainly used for maintaining skin damage faults of the aluminum alloy skin foam sandwich part.According to a prepared curing adhesive, the weight ratio of E-51 epoxy resin, quartz powder, m-xylylenediamine and 201 polysulfide rubber in the curing adhesive is 100:20:22:50.Besides, according to the shape of a damage range, a set of high-strength glass cloth patches identical in shape and different in size are cut, and the edge distance of the patches adjacent in size in each set is 25 mm.The patches are laid sequentially in the damaged position from small to large, the curing adhesive is evenly coated between the patches, the number of the patches is determined by the thickness of aluminum alloy skin, and it is guaranteed that a repaired damage area is flush with surrounding skin.

Owner:SHAANXI AIRCRAFT CORPORATION

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com