Method for preparing dispersible insoluble sulfur with high polymer material coating

A high-molecular material and high-dispersion technology, which is applied in the treatment of dyed high-molecular organic compounds, dyed low-molecular organic compounds, and fibrous fillers. Performance and other issues, to achieve the effect of facilitating rubber processing, improving dispersion, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

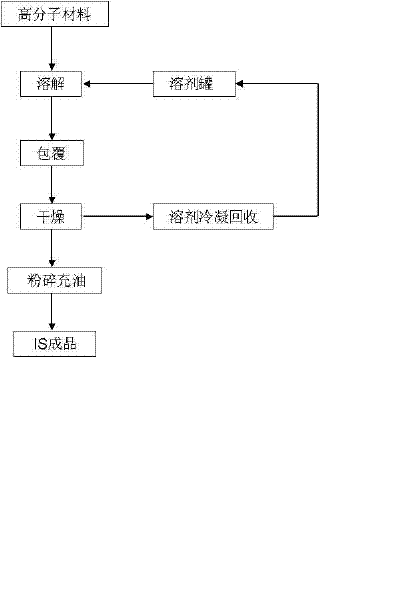

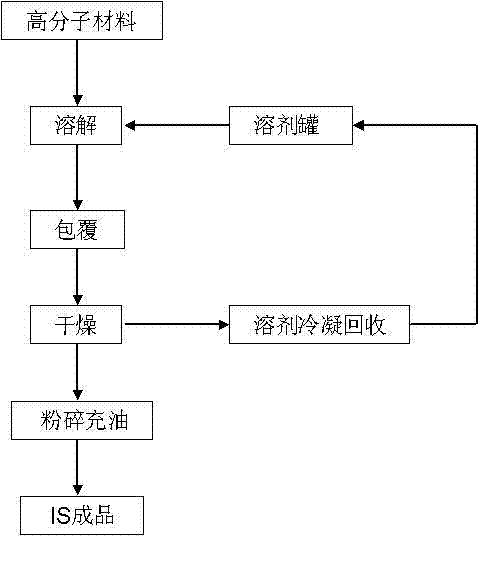

Image

Examples

Embodiment 1

[0015] Embodiment 1. After dissolving 0.1% (relative to the mass of sulfur) stearic acid with carbon disulfide, it is added to the drying tank of insoluble sulfur, and the carbon disulfide is condensed by a drying condenser for repeated use. The semi-finished product after drying and crushing is filled with 20% (relative to the total mass) of naphthenic oil to obtain the finished product of insoluble sulfur.

Embodiment 2

[0016] Example 2. After dissolving 0.3% (relative to the mass of sulfur) paraffin in chloroform, it was added to a drying tank for insoluble sulfur, and the chloroform was condensed by a drying condenser and reused. The semi-finished product after drying and pulverization is filled with 20% (relative to the total mass) oil to obtain the finished product of insoluble sulfur.

Embodiment 3

[0017] Example 3, after dissolving 0.5% (relative to the mass of sulfur) EVA resin in chloroform, it was added to the drying tank of insoluble sulfur, and the chloroform was condensed by a drying condenser and reused. The semi-finished product after drying and pulverization is filled with 20% (relative to the total mass) oil to obtain the finished product of insoluble sulfur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com