Epoxy anticorrosive paint for underwater steel

An epoxy anti-corrosion coating, steel technology, applied in epoxy coatings, anti-fouling/underwater coatings, coatings, etc., can solve the problems of poor environmental protection, low volume shrinkage of cured products, unfavorable construction, etc., to achieve anti-corrosion The effect of strong performance, excellent adhesion and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

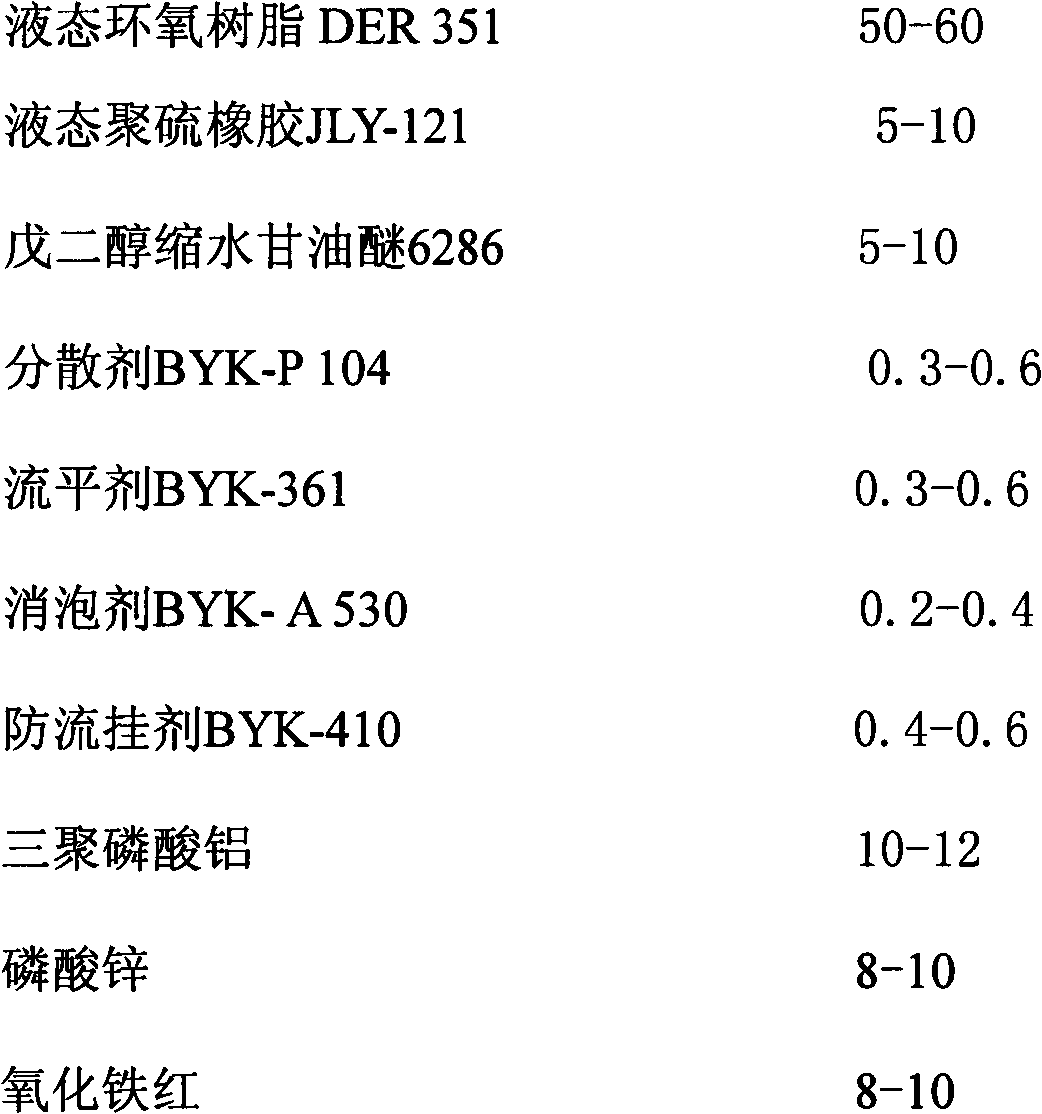

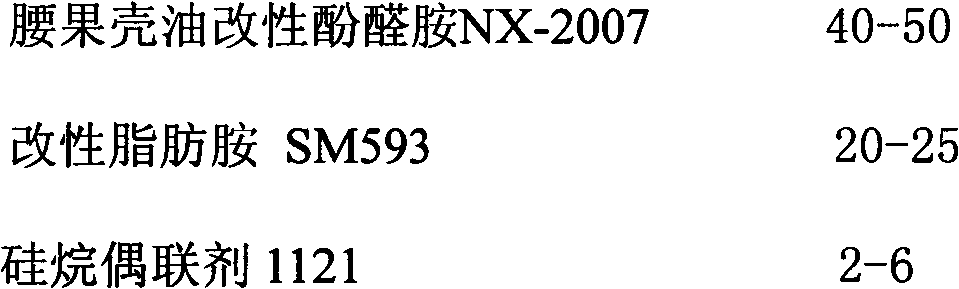

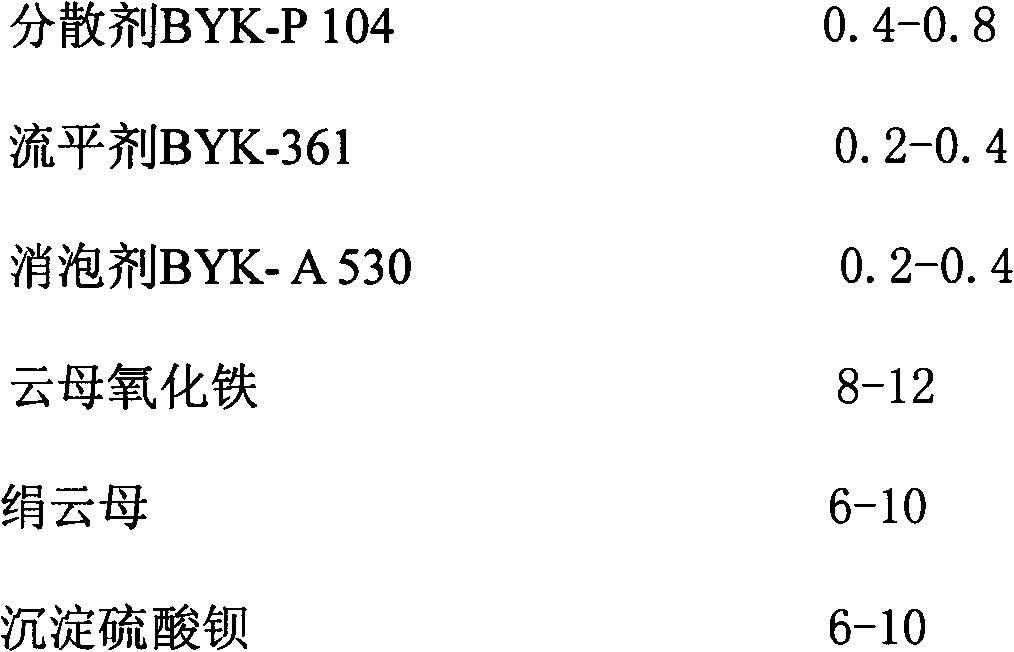

[0028] The present invention is described in further detail below in conjunction with specific examples: a kind of epoxy anticorrosion coating for steel under water, take liquid epoxy resin DER 351 as base material, take liquid polysulfide rubber JLY-121 as toughening agent, use pentylene glycol Glycidyl ether 6286 is used as diluent, aluminum tripolyphosphate, zinc phosphate, and iron oxide red are used as active antirust pigments, mica iron oxide, sericite, and precipitated barium sulfate are used as fillers, cashew nut shell oil is used to modify phenalkamine and Modified aliphatic amine is used as curing agent, silane coupling agent 1121 is used as adhesion promoter, and a solvent-free, two-component epoxy anticorrosion coating for underwater steel is prepared through a conventional preparation process with the cooperation of functional additives; in the coating The ingredients are as follows:

[0029] A component:

[0030]

[0031] The measurement units of the above c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com