Nano transparent abrasion resistant composite paint

A composite coating and transparent technology, applied in the direction of polyester coating, epoxy resin coating, coating, etc., can solve the problem of limited wear resistance, and achieve the effect of thin coating and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

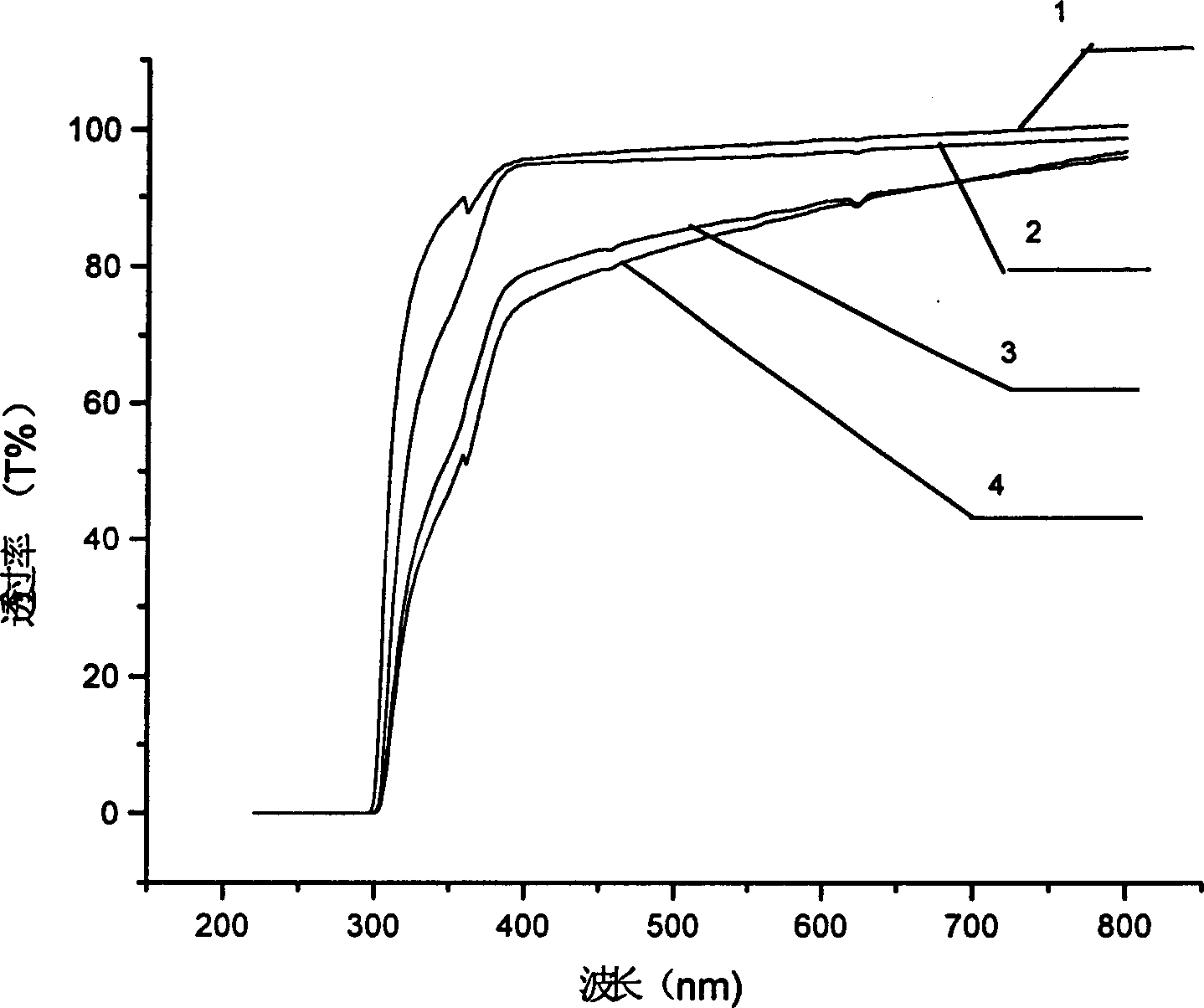

Image

Examples

example 2

[0031] Weight ratio Example 1 Example 2 Example 3 Example 4

[0032] ingredients

[0033] Component A:

[0034] Hydroxy acrylic resin (FX3060) 50

[0035] Saturated hydroxylated polyester tree (PE8043) 45

[0036] Epoxy resin (E-44) 40

[0037] Alkyd resin (3880) 45

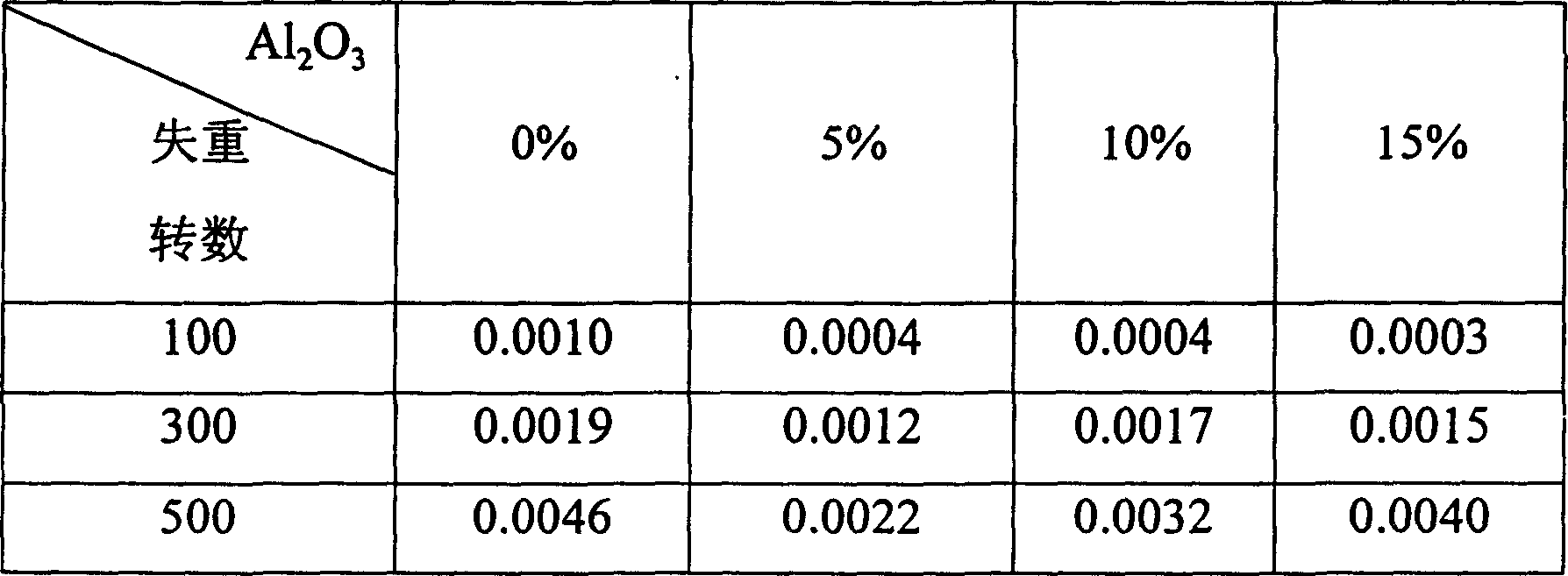

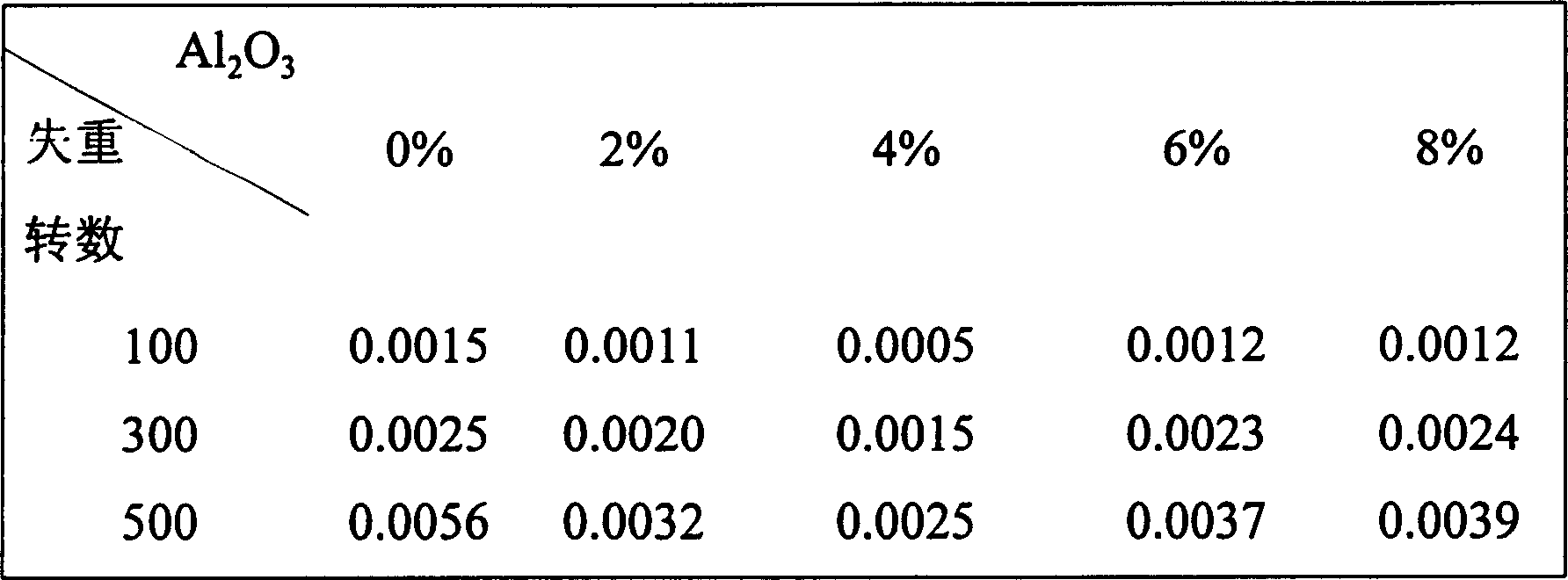

[0038] Aluminum oxide (Oxide C) 10 8.5 9.5 9.5

[0039] Wetting and dispersing additive (902) 1 2 1 2

[0040] Leveling agent (810) 2.7 0.2 0.2 0.2

[0041] Defoamer (5300) 0.3 0.3 0.3 0.3

[0042] Xylene 6 8 8 8

[0043] Butyl acetate 4 6 5 5

[0044] Component B:

[0045] Curing agent 190 (solid content 90%) 13

[0046] Curing agent 740 (solid content 40%) 18

[0047] Polyamide 65 25

[0048]PU curing agent 775 25

[0049] Butyl acetate 13 12 11 5

[0050] The present invention provides four embodiments of the composition of one-component composite paint, as shown in table 2:

[0051] Table 2

[0052] Ingredient Weight Ratio Example 1 Example 2 Example 3 Example 4

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com