Patents

Literature

58 results about "Al2o3 nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of Al2O3 nanoparticle reinforced aluminum-based composite material

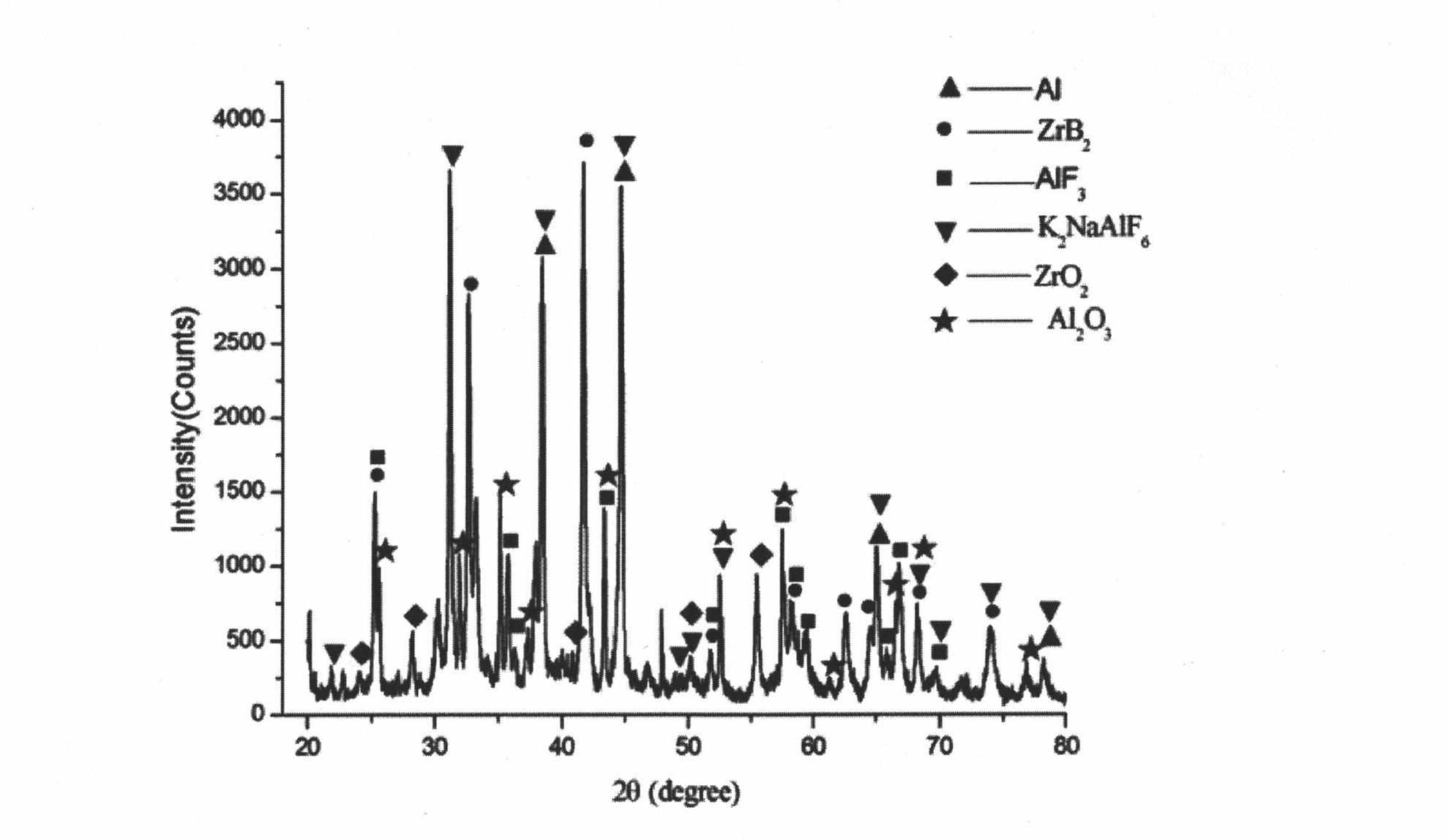

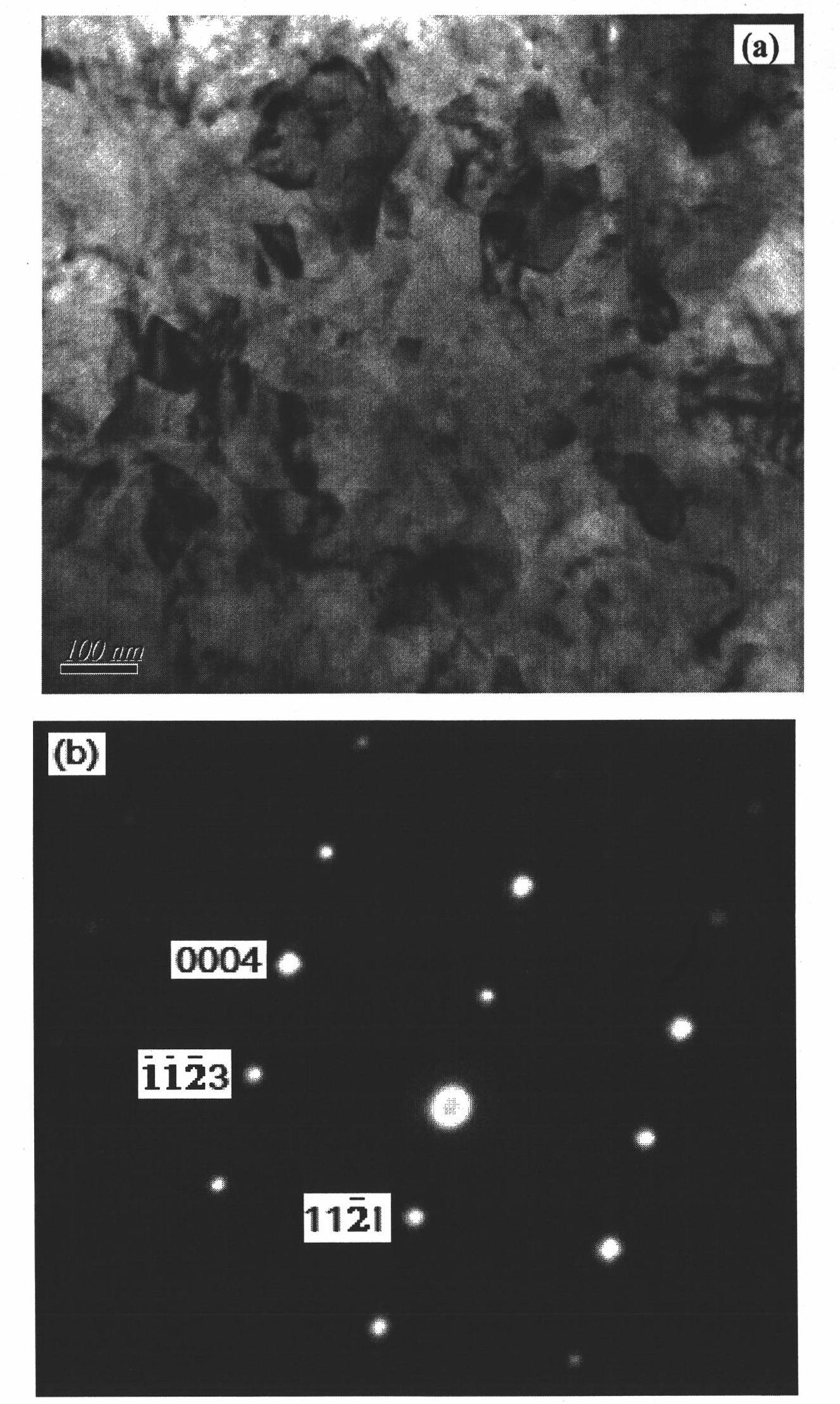

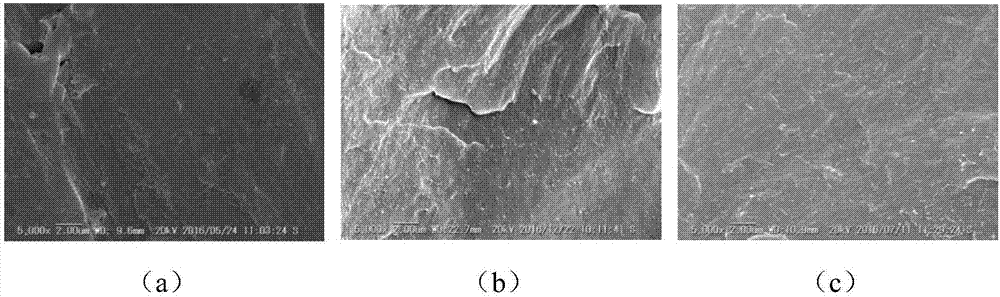

The invention provides a preparation method of a Al2O3 nanoparticle reinforced aluminum-based composite material, belonging to the technical field of the aluminum-based composite material. The method uses sodium borate (Na2B4O7.10H2O) type boride and K2ZrF6 type fluoride powder as the reaction mixed salt and adopts the direct reaction of molten metal to directly synthetize the nano-Al2O3 particlereinforced aluminum-based composite material in molten aluminum. The invention mainly has the following advantages: the reaction system can effectively control the growth of Al2O3 particles and ensure that the size of the reinforcement phase is controlled to the nanoscale; and the synthesis temperature of the reaction system is 800-850 DEG C, and the defects of the traditional method which uses oxide to prepare the Al2O3 particle reinforced aluminum-based composite material can be overcome, wherein the defects are that the particles are easy to grow, the size can not be controlled and the reaction temperature is high. In addition, with the increase of the addition amount of the reaction mixed salt in the reaction system, the reinforcing particles have smaller size and more uniform distribution; the interface binding of the particles and the substrate is good, no pollution is caused; and the preparation method is an effective method which is suitable for preparing the high-performance nanoparticle reinforced composite material at a low temperature.

Owner:JIANGSU UNIV

A cross-scale in-situ particle reinforced aluminum matrix composite material and its preparation method

ActiveCN102296196AStrong designabilityAchieving Cross-Scale Composite StrengtheningNanoparticleMicroparticle

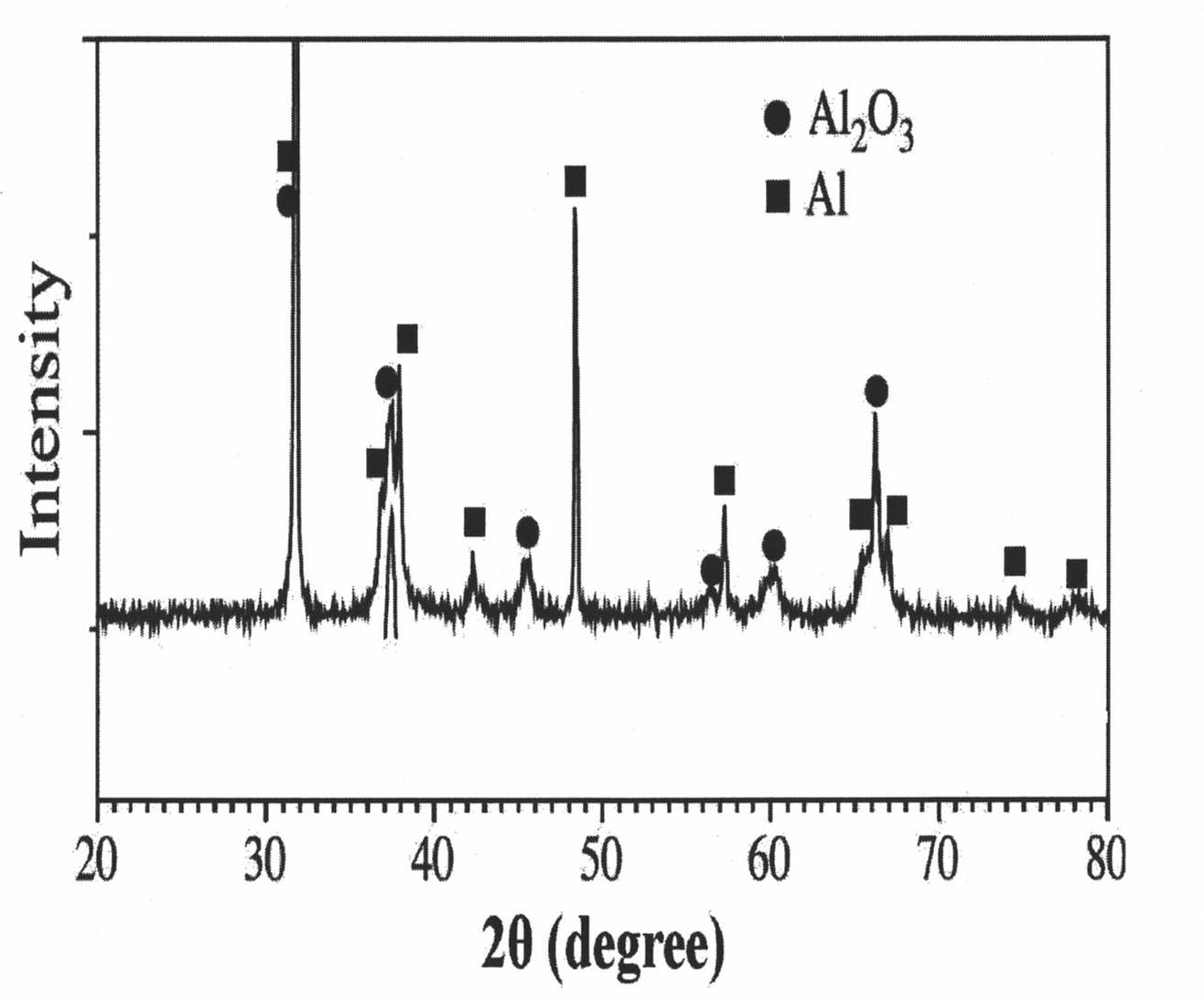

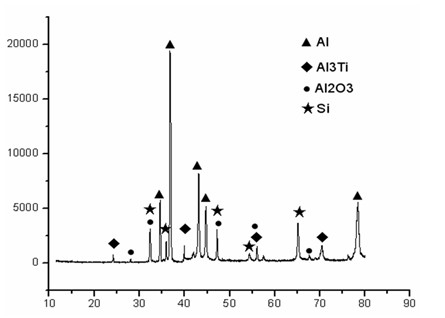

The invention relates to an in-situ particle reinforced aluminum matrix composite material, in particular to a cross-scale in-situ particle reinforced aluminum matrix composite material and a preparation method thereof. The method comprises the following steps of: melting Al-Si alloy; adding 10-25 percent by weight of SiO2 for melting according to proportioning requirement of volume fraction of reinforcing particles of different scales in the composite material; heating to 800-850 DEG C, preserving the heat for 5-10 minutes and then refining; subsequently performing ultrasonic treatment; adding 1-2 percent by weight of titanium powder and 0.3-0.5 percent by weight of rare earth during ultrasonic treatment; standing for 5-10 minutes; slagging off; adjusting temperature for pouring; and finally forming (Si+Al3Ti) microparticle and Al2O3 nanoparticle reinforced aluminum matrix composite material. The method has the advantages of simple preparation process, low cost, low overall reaction temperature and less aluminum burnt loss.

Owner:JIANGSU UNIV

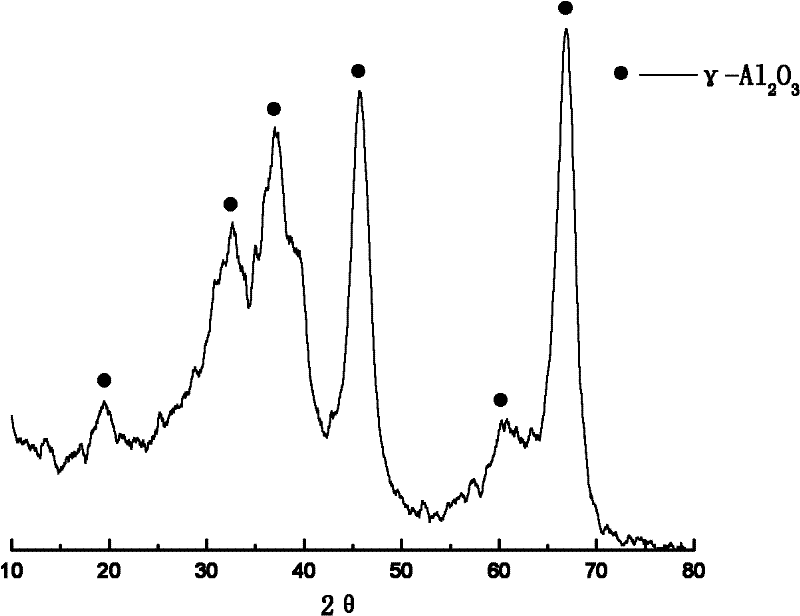

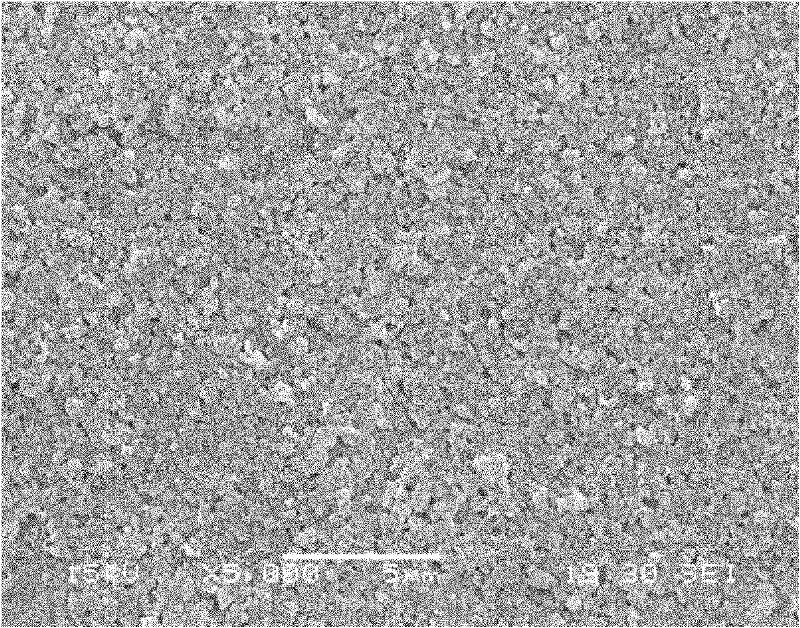

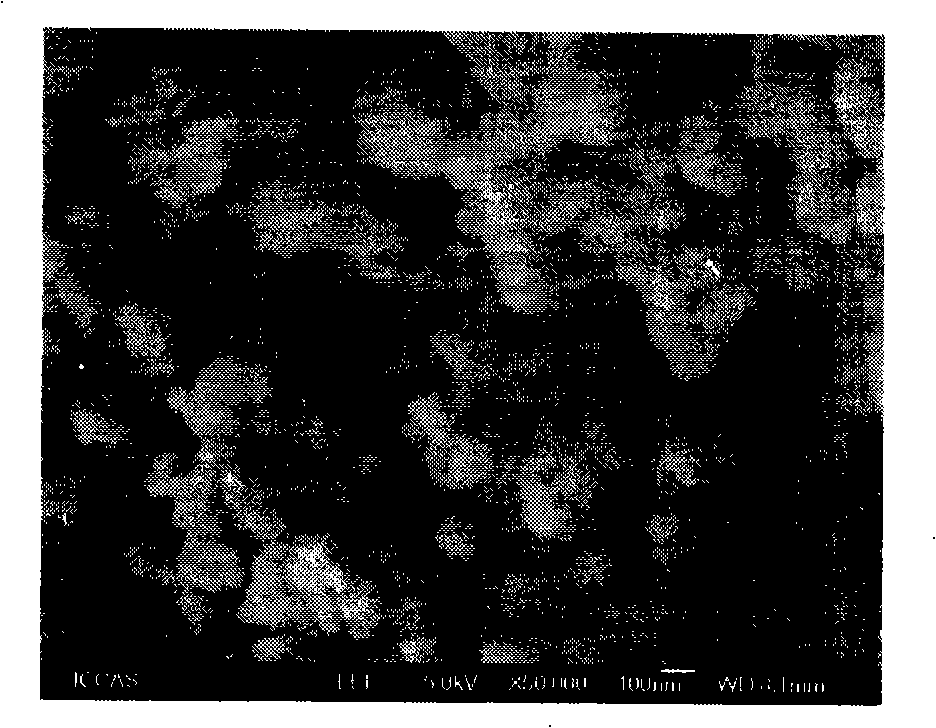

Nanoscale high-purity aluminum oxide preparation method

ActiveCN102531009AAvoid replacementReduce reunionNanotechnologyAluminium oxides/hydroxidesCooking & bakingDispersity

The invention provides a nanoscale high-purity aluminum oxide preparation method. The method comprises the steps of (1) dissolving organic aluminum alkoxide in an ethanol solvent to obtain a aluminum alkoxide phase A; (2) adding a catalyst, water and the ethanol solvent to the aluminum alkoxide phase A, and refluxing at 50 to 85 DEG C for 2 to 5h for hydrolysis to obtain a sol; and (3) drying to obtain hydrated aluminum oxide powder, uniformly rising temperature at a speed of 2.4 to 2.9 DEG C / min to a phase inversion temperature, keeping the temperature for 0.5 to 4h, and cooling the product to room temperature to obtain nanoscale high-purity aluminum oxide, wherein the phase inversion temperature is 700 to 920 DEG C. The method provided by the invention has simple process and easy operation, can improve the property of gamma-Al2O3 by controlling the baking conditions, and can be industrialized easily. The gamma-Al2O3 nanoparticles prepared by the method have the advantages of fine primary grain, good grain development condition, less agglomeration and good dispersity.

Owner:SHANGHAI HUAMING HI TECH GRP

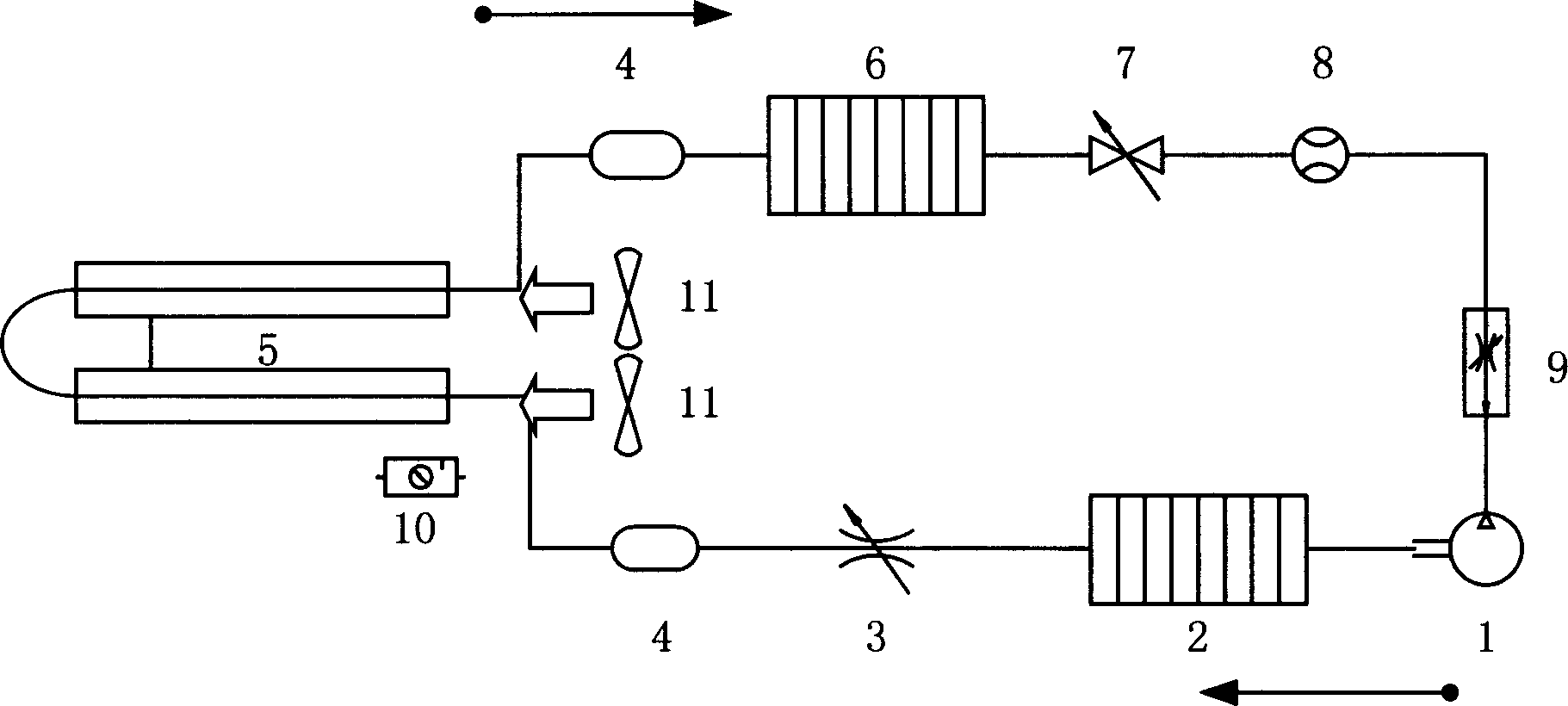

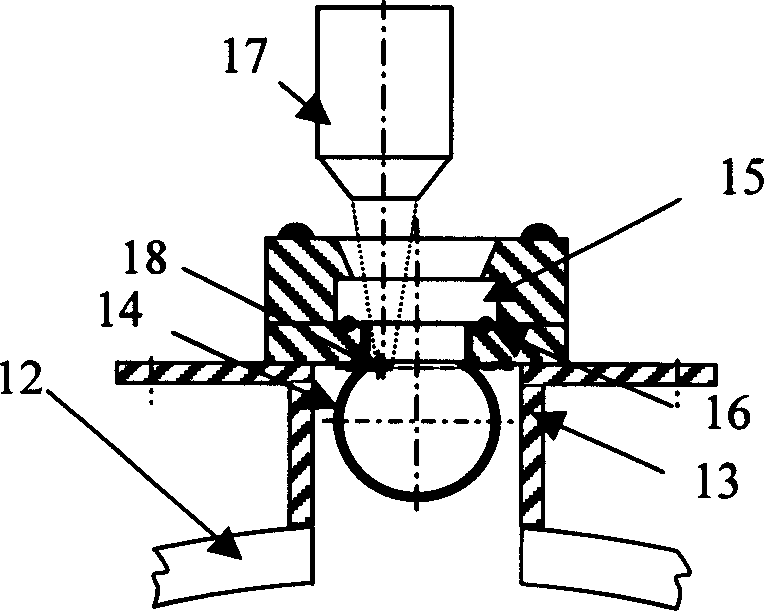

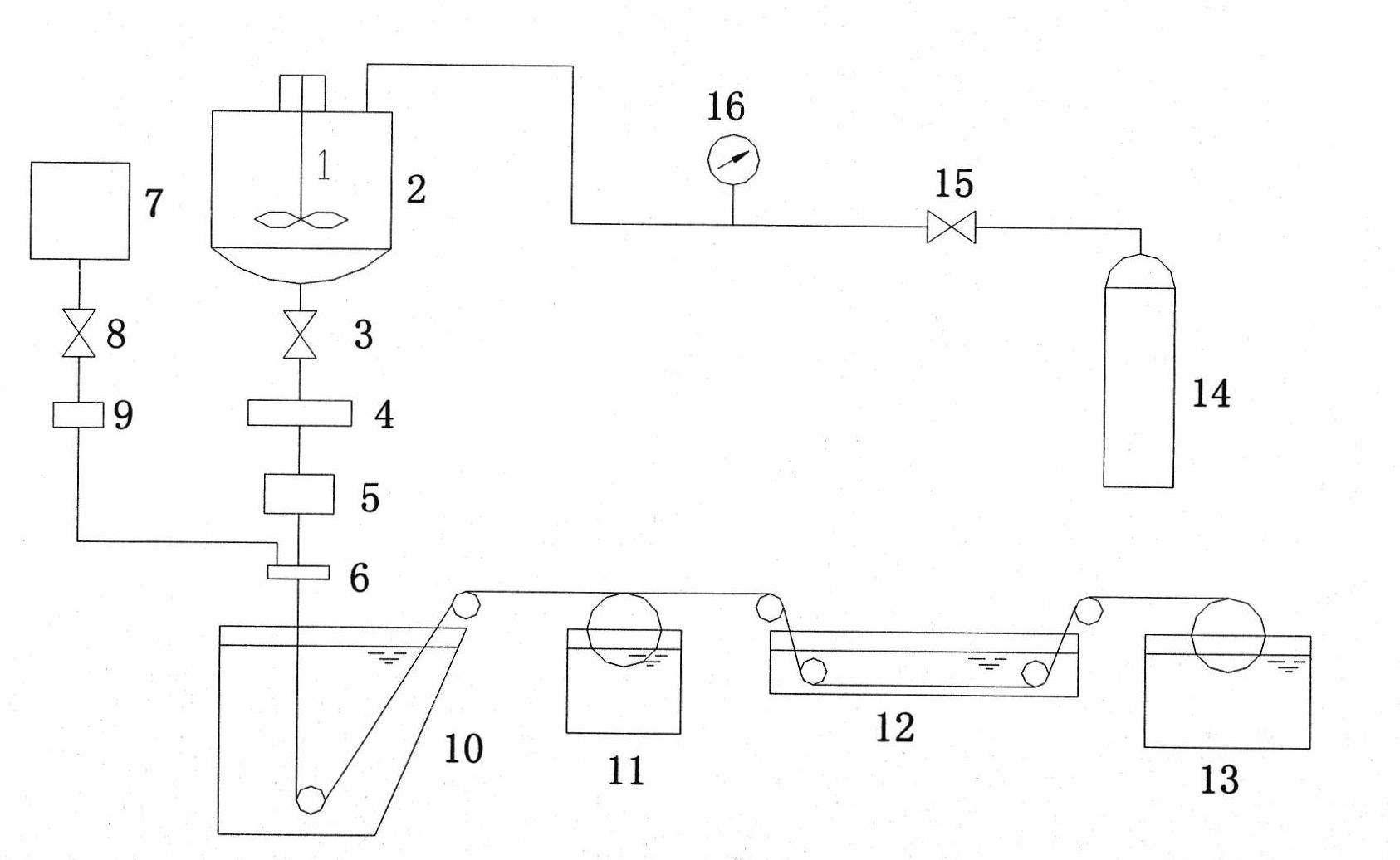

Nano refrigerant, and experimental apparatus for capability of heat transferring pressure drop of gas-liquid two phases

InactiveCN1696238AIncrease typeRaise the ratioEnergy efficient heating/coolingStructural/machines measurementAl2o3 nanoparticlesRefrigerant

A nano-refrigerant is prepared from the granular refrigerant composed of Cu, Ni or Al2O3 nanoparticles whose diameter is less than 100 nm. Its expriment equipment for the gas-liquid heat-transfer pressure drop performance is composed of compressor, condenser, electromagnetic expansion valve, mixers, experiment segment, evaporator, valves, flowmeter, liquid accumulator, and high-speed camera.

Owner:SHANGHAI JIAO TONG UNIV

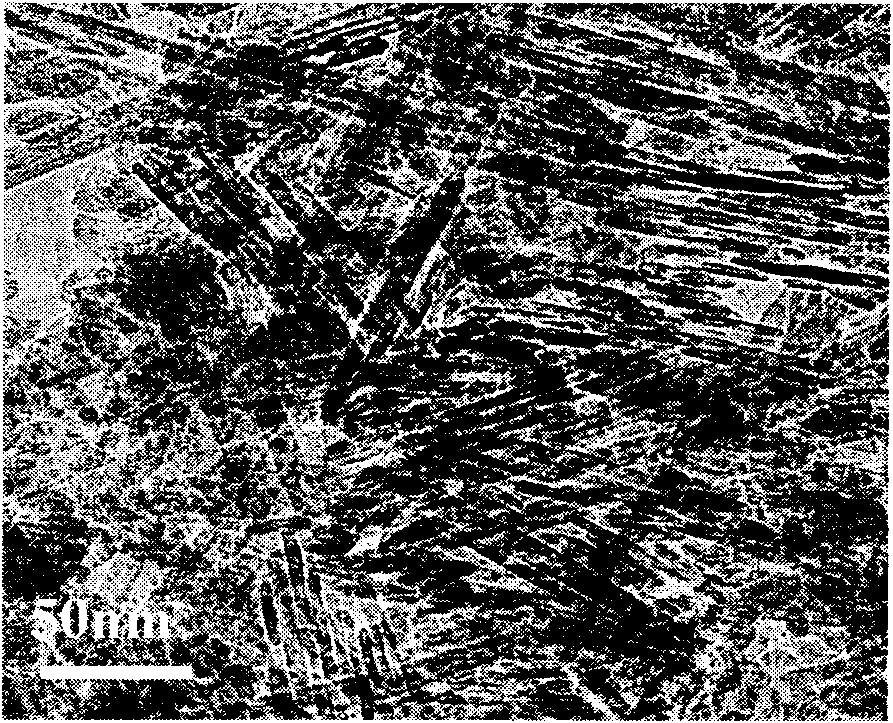

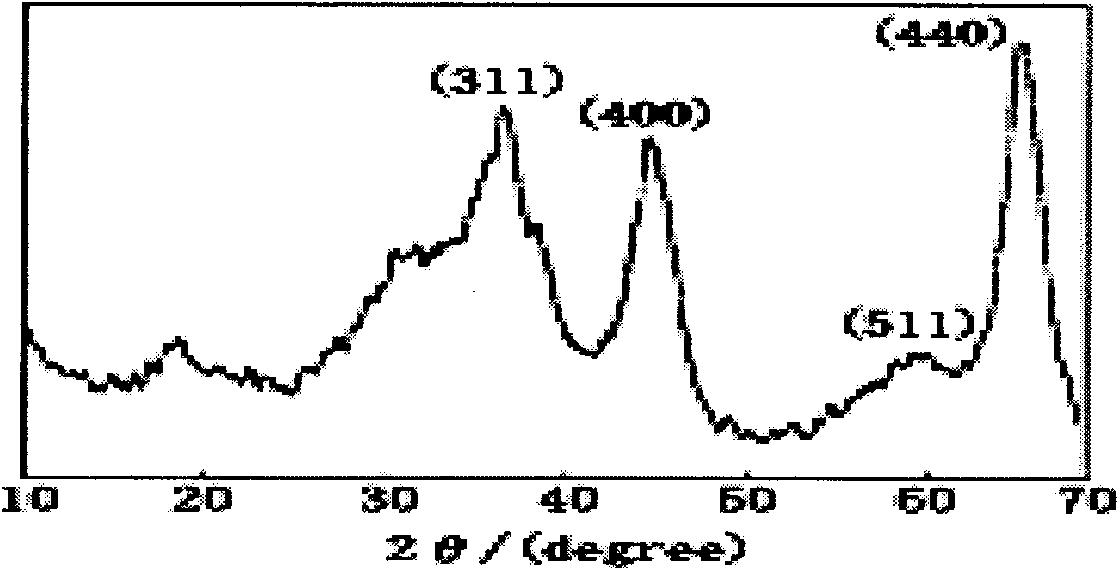

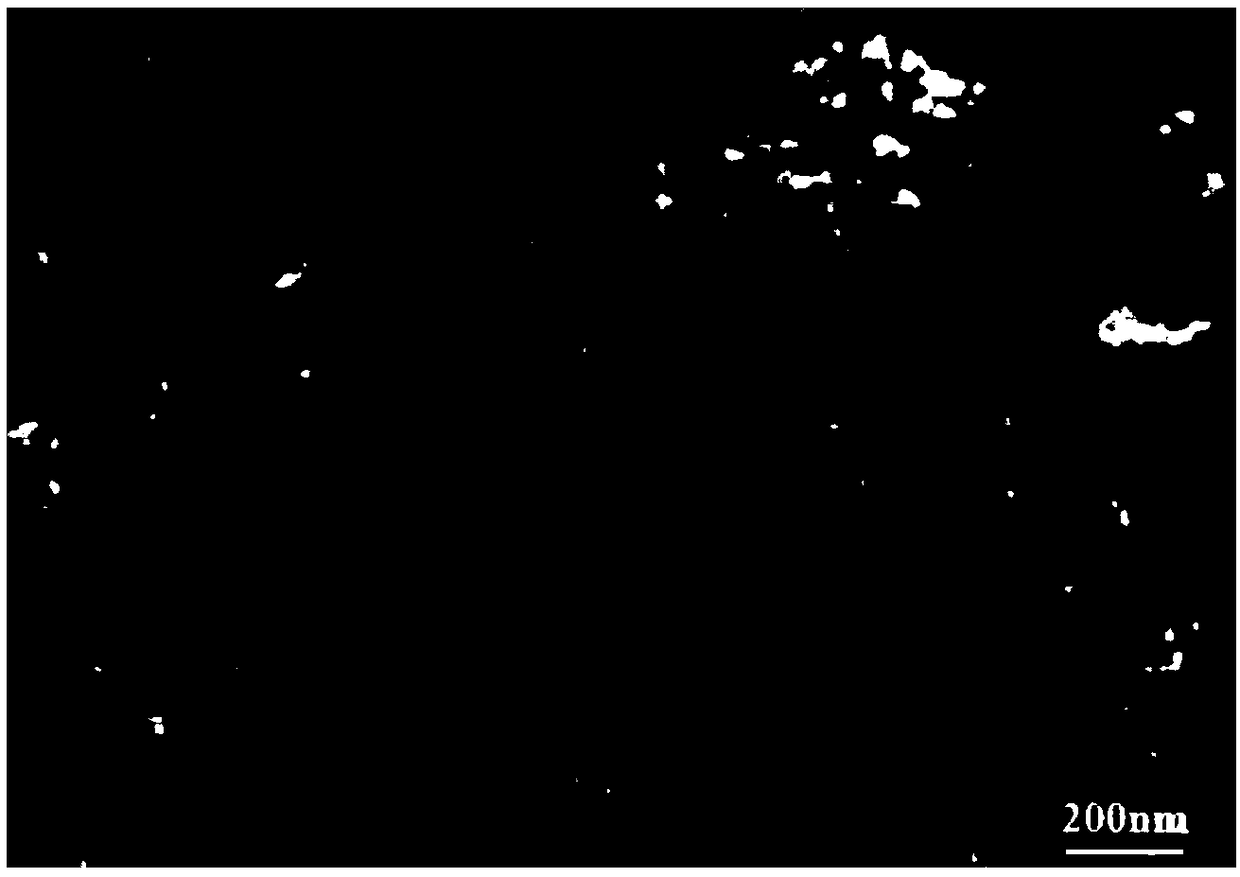

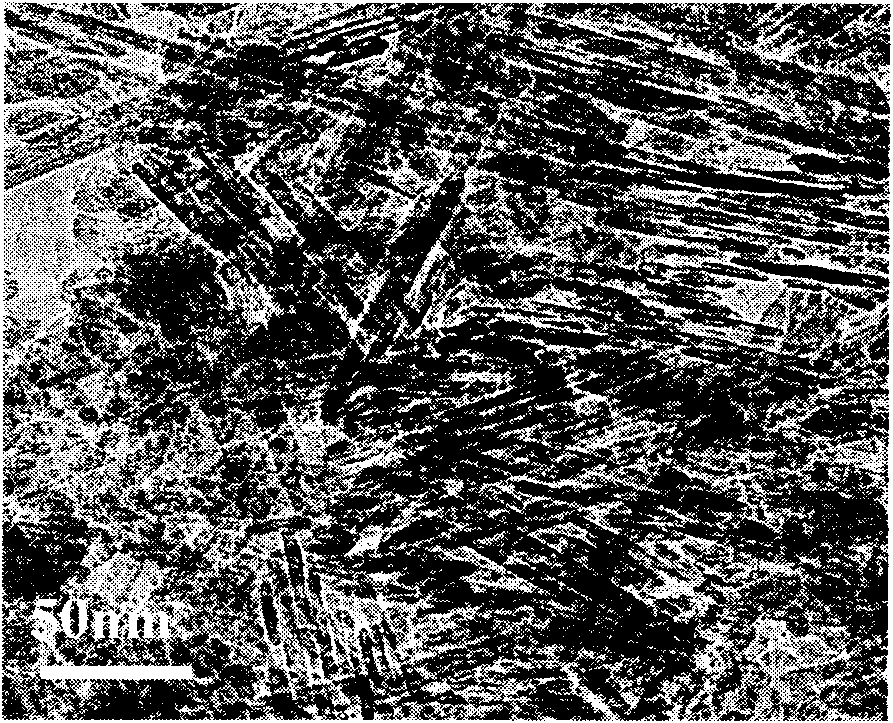

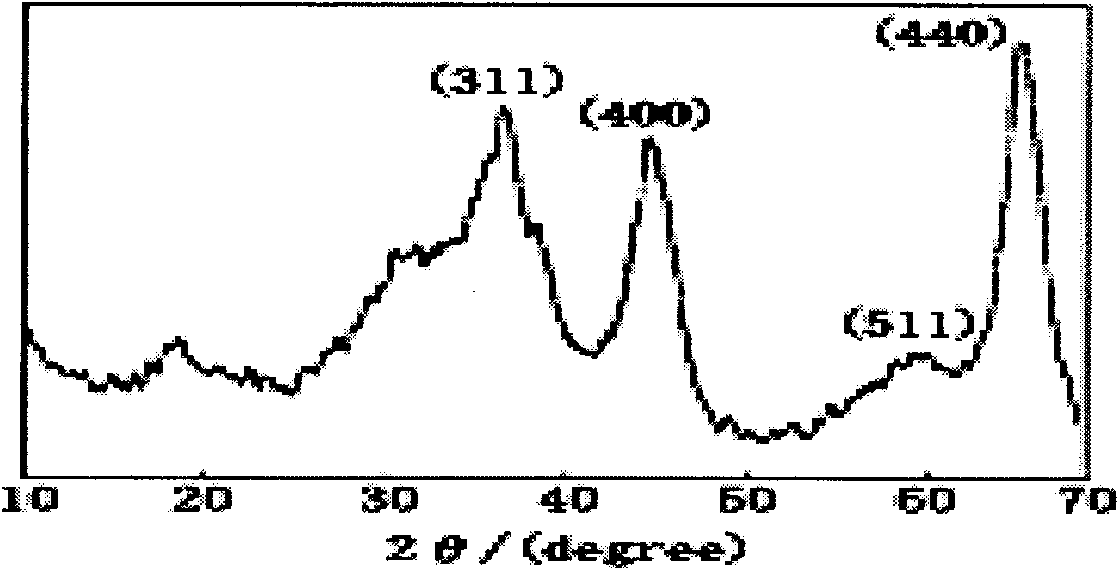

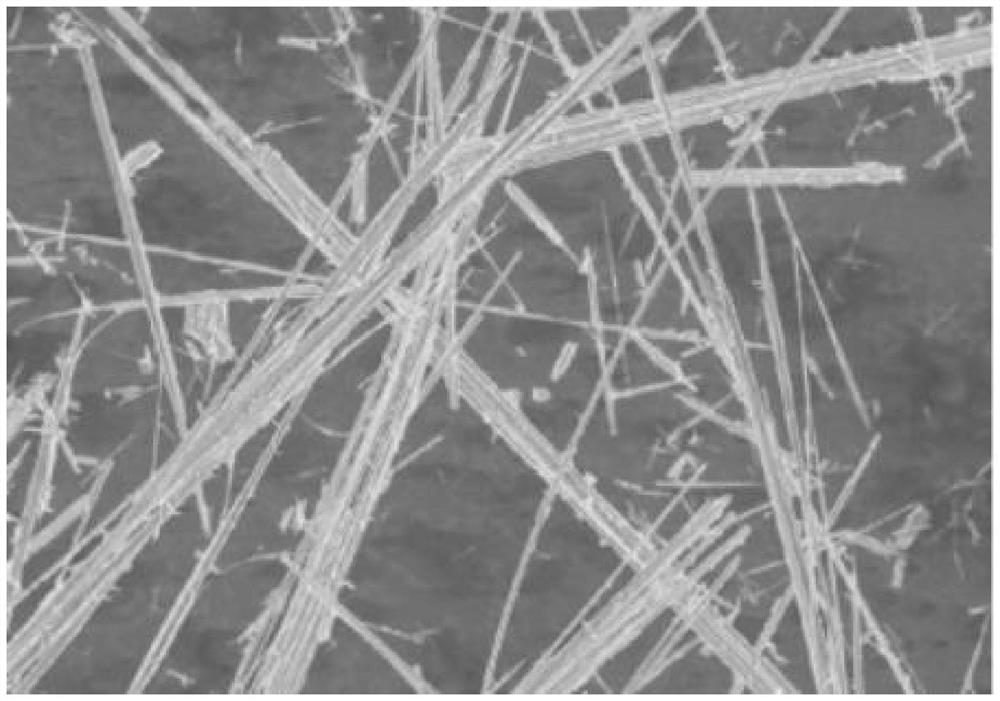

Rod-like one-dimensional polycrystalline gamma-Al2O3 nanocrystal grains and preparation method thereof

The invention discloses rod-like one-dimensional polycrystalline gamma-Al2O3 nanocrystal grains and a preparation method thereof. The preparation method comprises the following steps of: emulsifying a compound surfactant, water and solvent oil into stable emulsion; simultaneously adding an aluminum source solution and an alkali source solution into the emulsion; and after the emulsion is demixed and stable, transferring the uppermost organic phase into an autoclave, sealing for reaction, and washing, separating, drying and roasting a reaction product to obtain the gamma-Al2O3 nanocrystal grains, wherein the gamma-Al2O3 nanocrystal grains have the diameter of 10 to 25nm and the length of 80 to 500nm and are regular-shaped rod-like one-dimensional polycrystalline gamma-Al2O3 nanocrystal grains, and have high specific surface area. The gamma-Al2O3 nanocrystal grains can be applied to the fields of catalysts, adsorbents, selective separation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for fabricating ceramics of silicon carbide toughened by Nano bars of alumina

This invention provides a method for producing SiC ceramic tougnened with Al2O3 nanorods. The SiC ceramic utilizes Al2O3 nanorods with a low aspect ratio instead of whiskers or fibers with a high aspect ratio as the toughening component. The rod-like Al2O3 nanoparticles can be uniformly mixed with other raw materials, which can realize uniform toughening. Besides, the rod-like Al2O3 nanoparticles have a low cost, which can reduce the cost of the tougnened SiC ceramic. This invention also considers such advantageous toughening effects as microcrack, crack deflection, crack bridging, pullout and grain refinement.

Owner:NINGBO UNIV

Method for mfg. nano alumina

InactiveCN1401575ASmall particle sizeSmall sizeColloidal chemistry detailsAluminium oxides/hydroxidesAl2o3 nanoparticlesMaterials science

A gamma-Al2O3 nanoparticle (less than 20 nm) is prepared through reverse sol-gel method, supercritical fluid drying method, and calcining at 900 deg.C for 2 hr. Its specific surface area is 140 sq.m / g.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation process for nanoparticle reinforced die steel

The invention discloses a preparation process for nanoparticle reinforced die steel. The process comprises the following steps of: performing pre-dispersion mixing on in-situ synthesized TiNC / Si3N4 nano mixed powder and pre-dispersion iron powder, preparing a dispersed precast block, adding the precast block into a steel ladle, synthesizing the precast block into TiNC / Si3N4 / Al2O3 mixed nanoparticles in molten steel in situ by using the high-temperature molten steel, uniformly dispersing the TiNC / Si3N4 / Al2O3 nanoparticle mixed powder in a die steel matrix by using an electromagnetic agitator and forming the die steel by adopting a casting method. By the preparation process, the in-situ synthesized nanoparticles are adopted, so the wettability of the nanoparticles and the matrix is improved; and the die steel with uniformly distributed nanoparticles is obtained by secondary dispersion and electromagnetic agitating processes, so the die steel is modified and reinforced. The volume fraction of the nanoparticles is regulated by regulating the addition of the nanoparticles, so the requirements of different working conditions can be met. The nano modified die steel with high abrasive resistance has high mechanical properties, and is simple in preparation and low in preparation cost.

Owner:JIANGSU YINYU MOLD MATERIAL

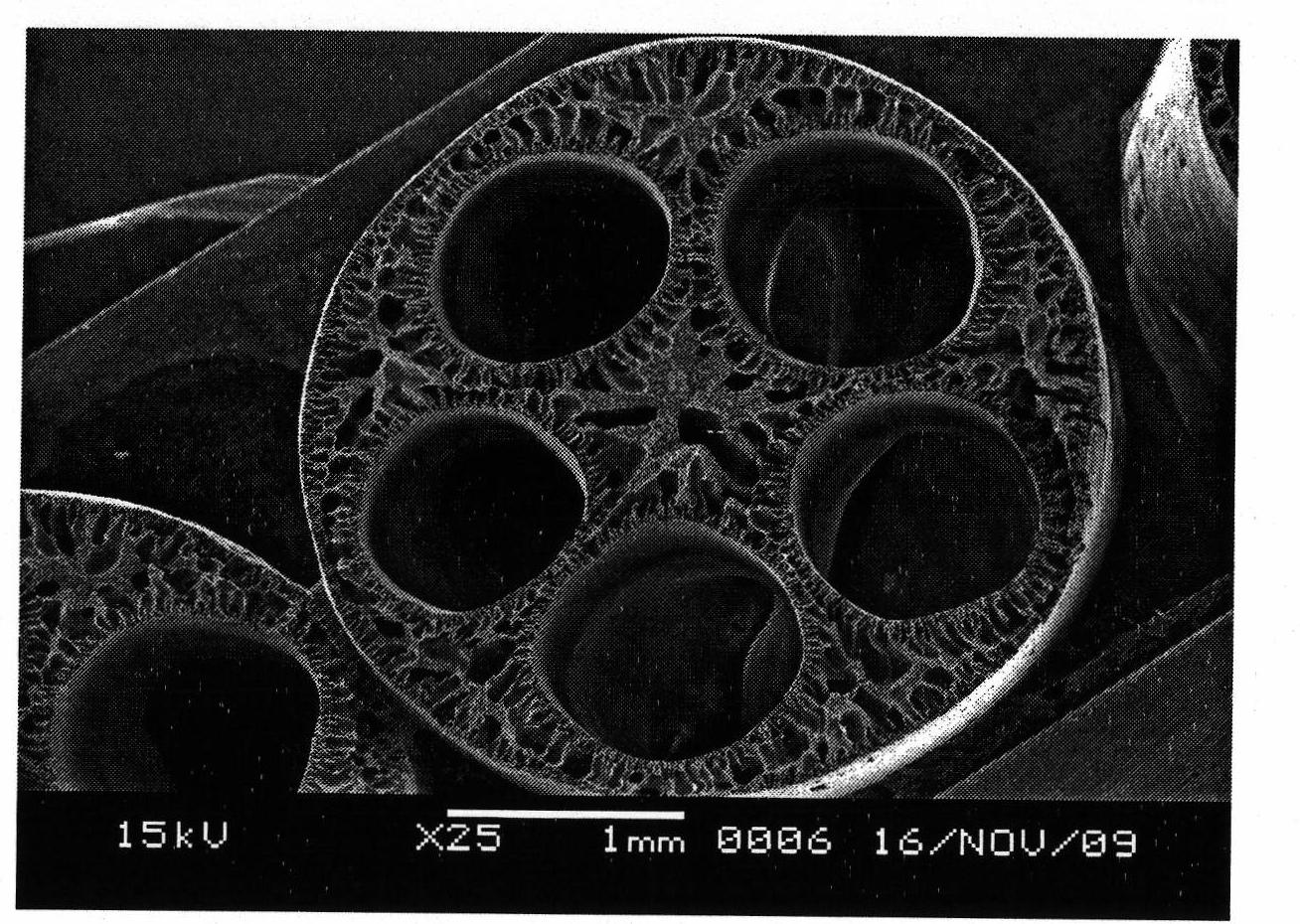

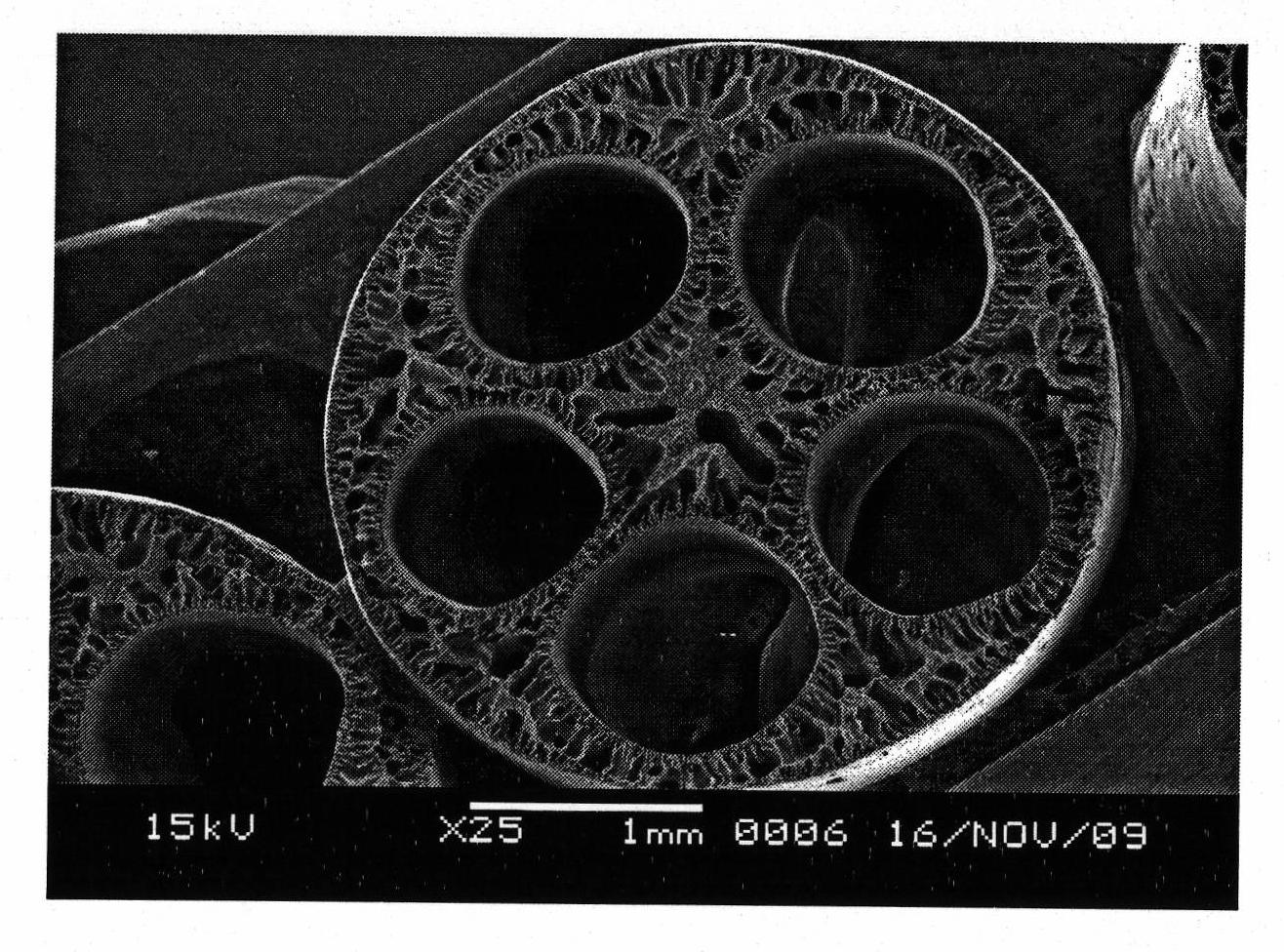

Three-component five-hole hollow fibrous membrane and preparation method thereof

InactiveCN101773794AImprove mechanical propertiesLarge water fluxSemi-permeable membranesFiberPolyvinyl chloride

The invention relates to a three-component five-hole hollow fibrous membrane, which comprises the following components: 60-80wt% of polyvinylidene fluoride, 10-30wt% of polymethylmethacrylate and 10-30wt% of polrvinyl chloride; and the section of the membrane is provided with five holes. The membrane is divided into five layers from the outside to the inside, which are sequentially a cortical layer, a sub finger-shaped hole supporting layer, a thumb-shaped hole supporting layer, a sub finger-shaped hole supporting layer and an endodermis layer and is in a bidirectional asymmetrical structure. The preparation method comprises the steps of adding solvent and PVP for dissolution after mixing the materials in a certain proportion, oscillating Al2O3 nanoparticles and the solvent via ultrasound for 2 hours, evenly stirring the solution, standing still for 24h for deaeration, and then making the membrane through spinning with a dry-wet spinning process. The five-hole membrane has the advantages of large water flux, high rejection rate, excellent mechanical properties and the like, the preparation process is simple, the energy consumption and the operation cost are low, raw materials are obtained conveniently and are environmentally friendly, and the method is suitable for industrial production.

Owner:DONGHUA UNIV

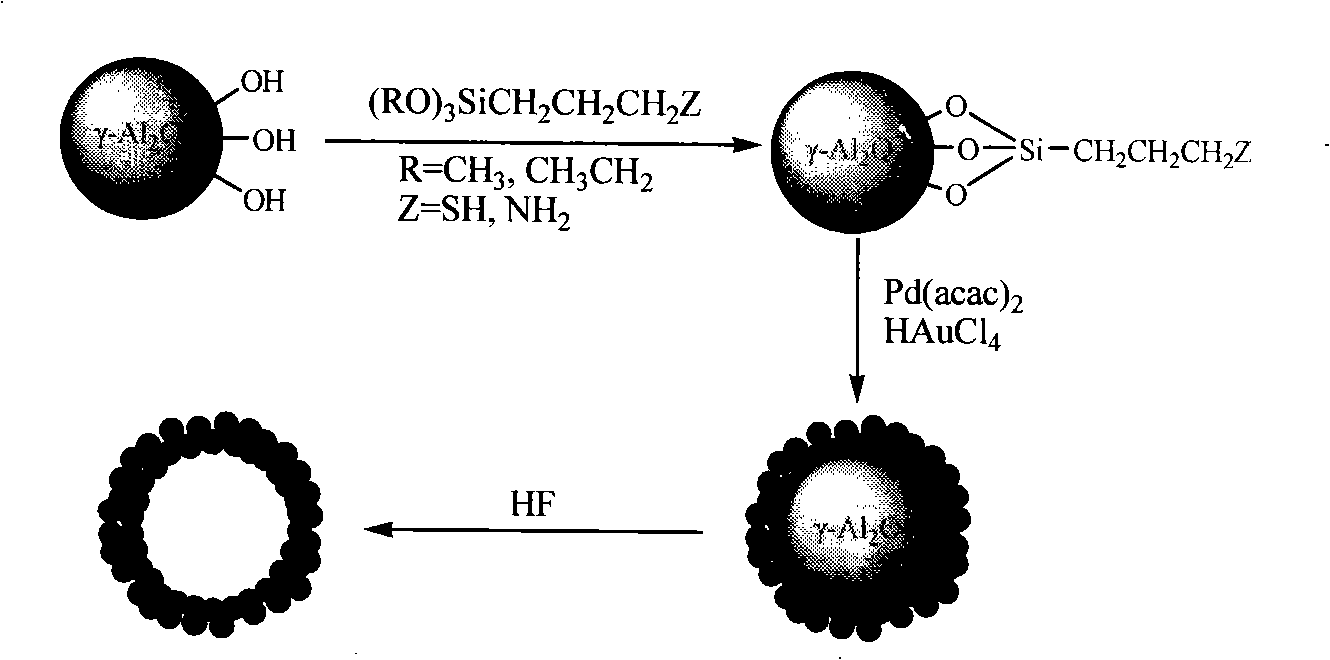

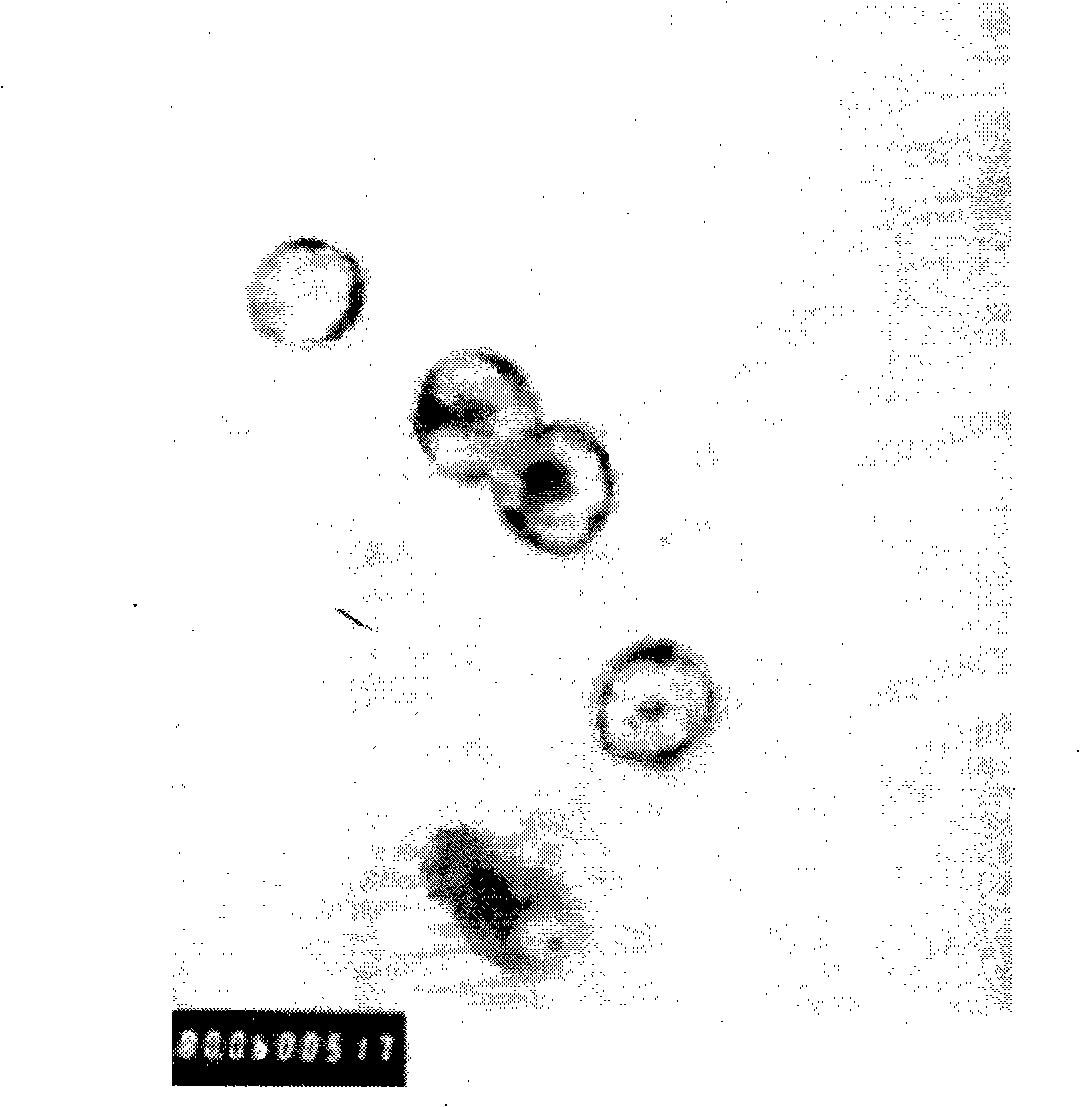

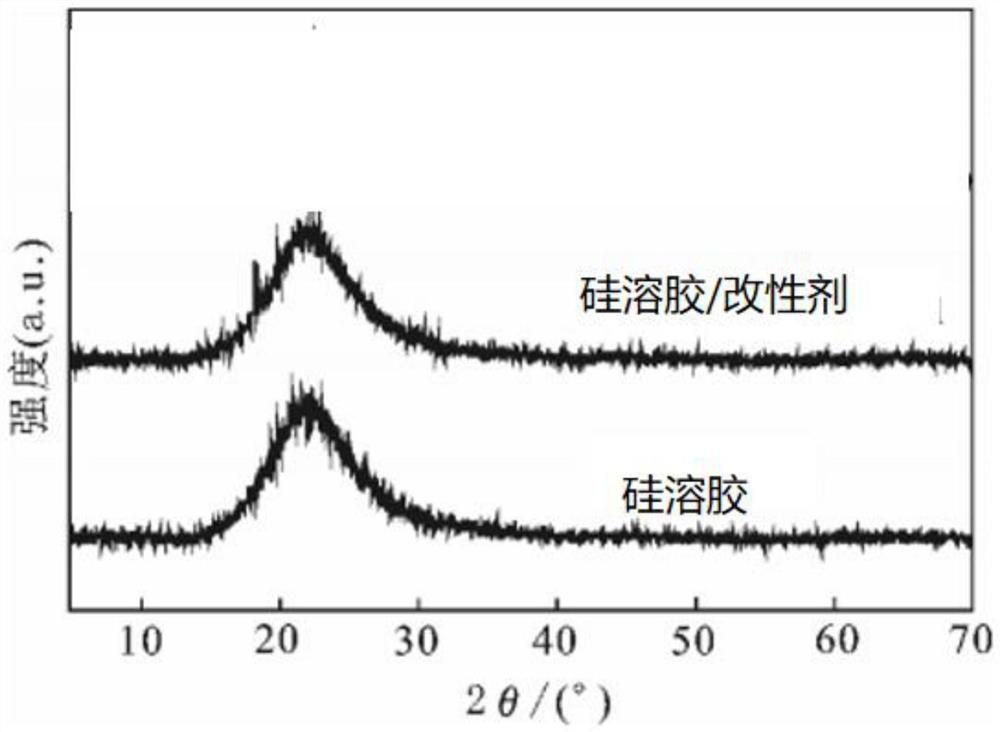

Method for preparing hollow metal nano-particle with gamma-aluminum oxide nano-particle as mould plate

InactiveCN101314182AAvoid destructionSimple preparation processPigment treatment with organosilicon compoundsChemical treatmentAl2o3 nanoparticles

The invention discloses a method for preparing hollow metal nanometer particles by using gamma-Al2O3 nanometer particles as templates. The method comprises the following steps that: firstly, a silane coupling agent is used to perform surface modification to the gamma-Al2O3 nanometer particles, then the gamma-Al2O3 nanometer particles are added into a palladium acetylacetonate solution or a chlorogold acid solution, and finally hollow palladium or gold nanometer particles are produced by using 40wt percent HF solution to remove the gamma-Al2O3 nanometer particle templates. The method has the advantages that: the method takes the commercial gamma-Al2O3 nanometer particles as the templates; the surfaces of the gamma-Al2O3 nanometer particles are easy to modify with functional groups such as sulfhydryl groups or amidocyanogen and so on, by the silane coupling agent; the method is easy to promote to the preparation of hollow nanometer materials of other materials; and the method does not need high temperature or rigorous chemical treatment during the removal of the templates, and has simple preparation process and easy operation.

Owner:NANCHANG UNIV

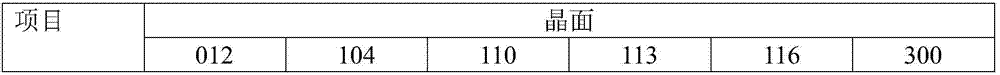

Casting technique of casting roll surface nano modification

The invention discloses a surface nano-modification process of a cast roller, which comprises the steps of mixing Al2O3 nanoparticles and refractory aggregate by a ratio of (1 to 12): 10; grinding by a rolling mill for casting for 10 to 15 min to obtain coating nanopowder for casting; adding industrial alcohol or water to prepare casting coating 0.08 to 0.1 Kg / L; spraying or applying the coating on the cast mold surface; and filling the cast mold with molten metal to obtain the cast roller. The surface nano-modification process has the advantages that the cast roller manufactured by the process has fine surface grain structure, improved hardness (improved by 30%), reduced size of inter-crystal inclusion (reduced by one order of magnitude), and significantly improved strength, rigidity and thermal fatigue strength in comparison with a conventional process product due to the enrichment of a nano-level high-hard phase particle layer on the surface layer. The service life of the roller is improved by 60% average. Since the surface high-hard phase particles are formed before curing the roller, the surface quenching process is simpler and controllable, the subsequent thermal treatment process is simplified, and the energy consumption is lowered. Due to the high purity of nanoparticles, the secondary contamination problem of molten steel caused by alloy can be solved.

Owner:MCC XIANGTAN HEAVY IND EQUIP

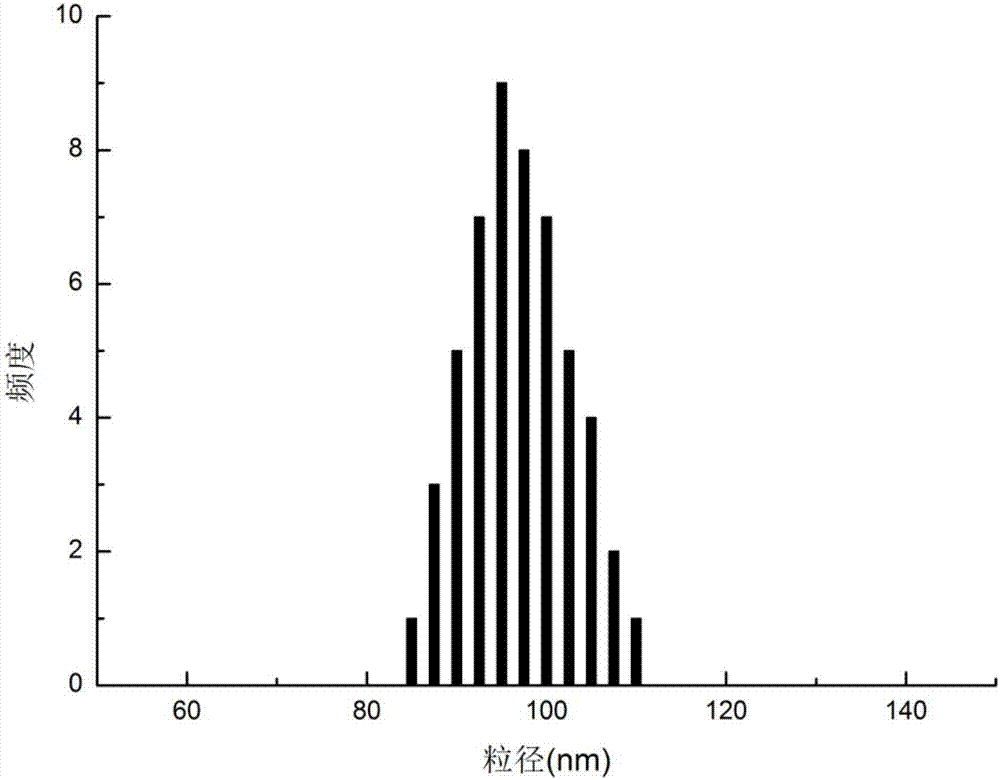

Molybdenum alloy doped with aluminum oxide and preparation method thereof as well as molybdenum alloy wire

The invention relates to a molybdenum alloy doped with aluminum oxide and a preparation method thereof as well as a molybdenum alloy wire, and belongs to the technical field of high-temperature refractory materials. The molybdenum alloy doped with the aluminum oxide is prepared from alpha-Al2O3 nanoparticles with the mass percent of 0.1 percent to 0.5 percent and the balance of molybdenum and unavoidable impurities. The preparation method of the molybdenum alloy doped with the aluminum oxide, provided by the invention, comprises the following steps: preparing AlOOH nanoparticle suspension liquid by a hydrothermal method; preparing ammonium molybdate and AlOOH nanoparticle composite powder by adopting a spray drying process; carrying out calcination, hydrogen gas reduction, pressing and sintering on the composite powder to prepare the molybdenum alloy. The molybdenum alloy wire provided by the invention is a molybdenum alloy wire with the diameter of 0.18mm to 0.60mm, which is prepared from the molybdenum alloy through rolling and wiredrawing processes. The alpha-Al2O3 nanoparticles have the characteristics of high rigidity, high wear resistance, good chemical and thermal stability and the like, so that the molybdenum alloy wire provided by the invention has good wear-resisting property and electric-arc ablation resisting property.

Owner:HENAN UNIV OF SCI & TECH

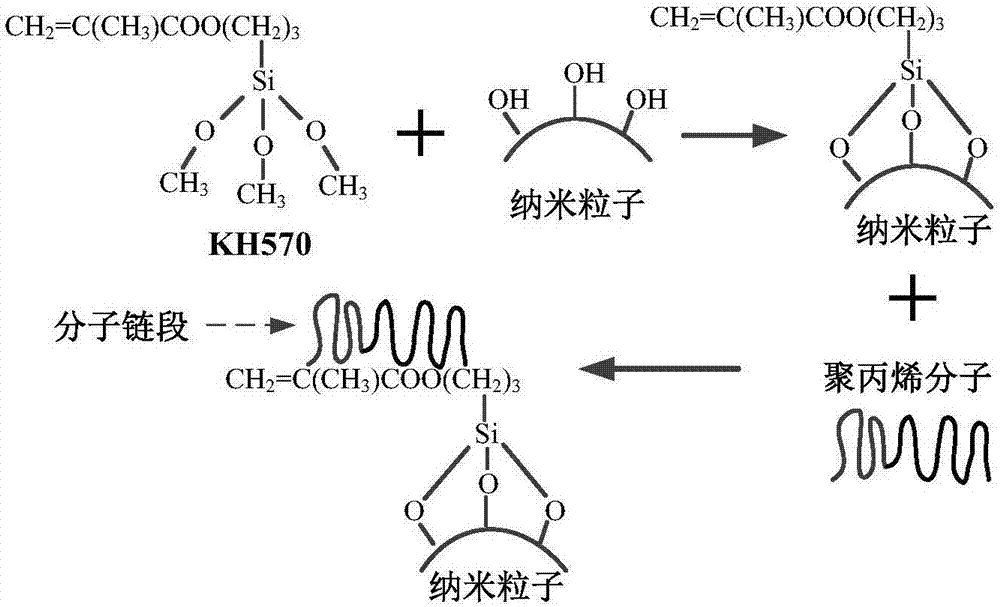

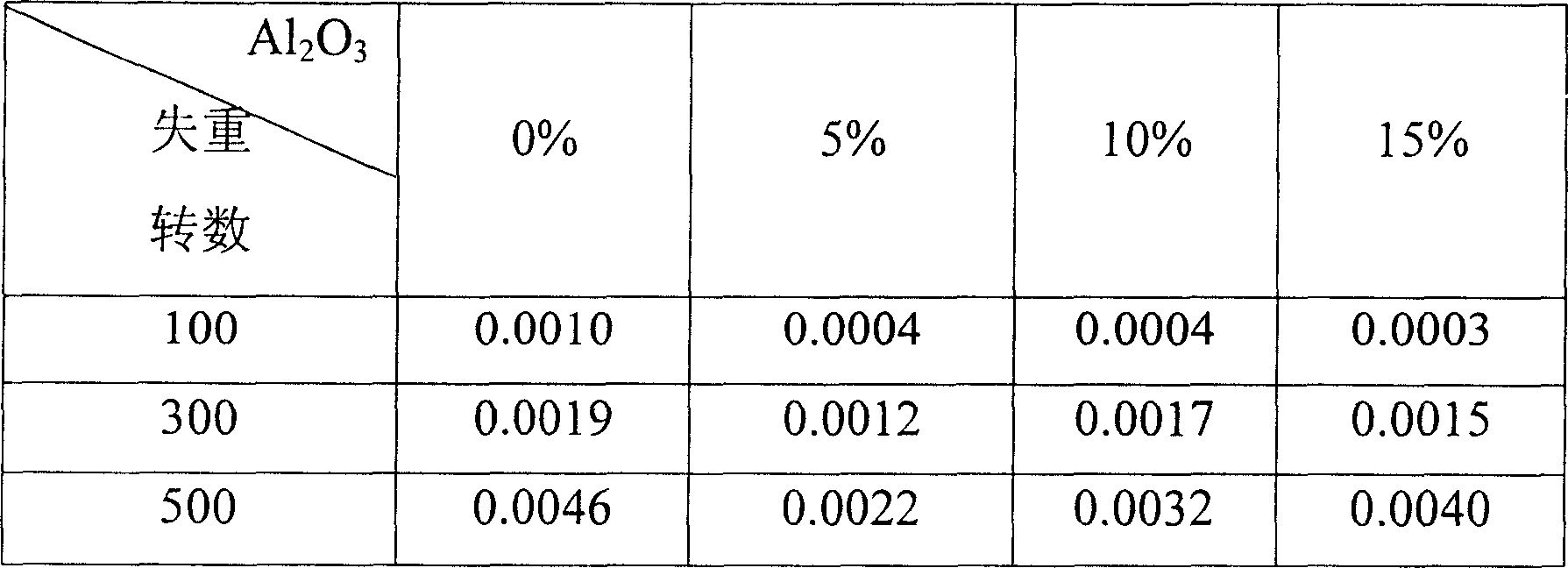

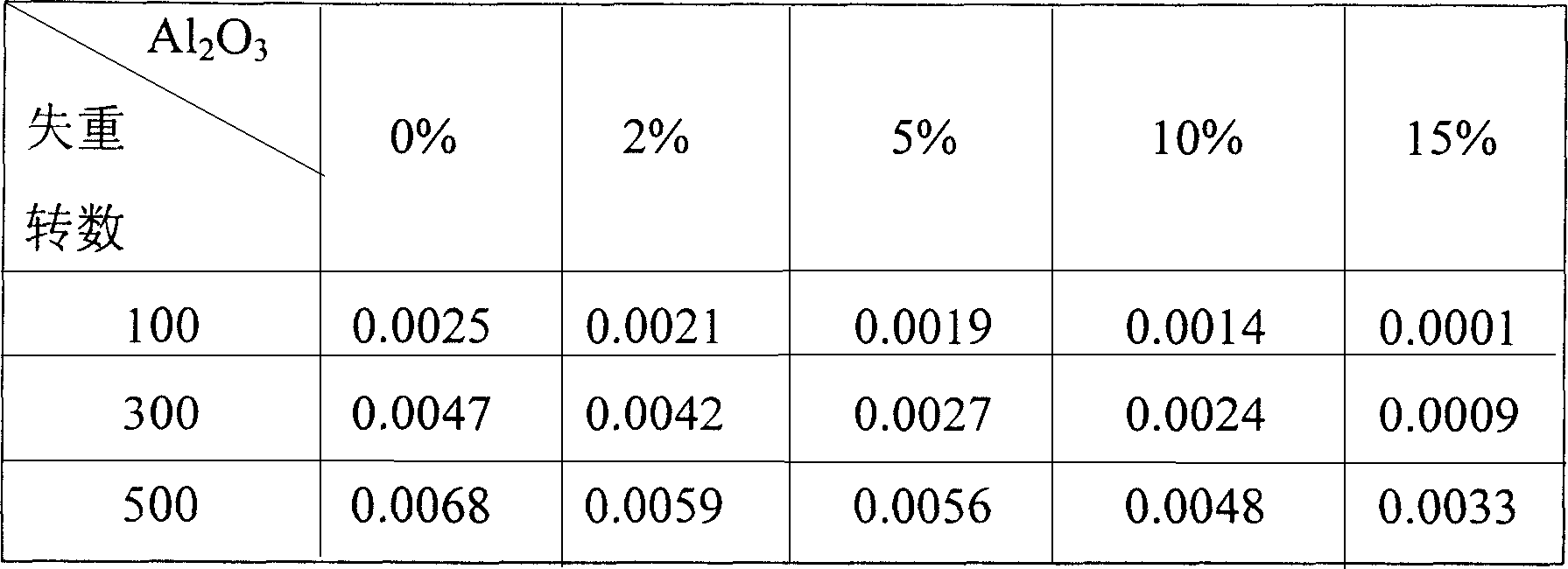

Method for preparing polypropylene / nano composite dielectric with high direct current breakdown field strength

ActiveCN107163401AEvenly dispersedImprove bridgingFixed capacitor dielectricFlat articlesDielectricNanoparticles dispersion

The invention discloses a method for preparing a polypropylene / nano composite dielectric with high direct current breakdown field strength, and the method is as follows: (1) silane coupling agent KH570 is selected for surface modification of AlN nanoparticles and alpha-phase Al2O3 nanoparticles to enhance the bridging effect of inorganic nanoparticles and a polymer matrix; (2) a polypropylene base material is added in a high temperature torque rheometer cavity, when the particles are melted, silane coupling agent modified AlN and Al2O3 nanoparticles are respectively added, and after high-speed stirring for a certain time at high temperature, the nano composite dielectric with uniformly dispersed nanoparticles can be prepared; and (3) polypropylene / AlN and polypropylene / Al2O3 thin film samples with the thickness of 150 mu m can be prepared by use of a press vulcanizer by hot pressing by a sandwich structure. The direct current breakdown field strength can be tested by a continuous voltage increasing mode, and test results show that: the direct current breakdown field strength of the polypropylene / AlN nano composite dielectric and the direct current breakdown field strength of the polypropylene / Al2O3 nano composite dielectric are respectively increased by 13% and 35% compared with that of a pure polypropylene medium.

Owner:XI AN JIAOTONG UNIV +1

Far-infrared antibacterial polyester fiber

InactiveCN108977925AImprove antibacterial propertiesPlay an antibacterial effectMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The application relates to a far-infrared antibacterial polyester fiber. The polyester fiber is prepared with polyester as substrate and composite filler A and composite filler B as additives by meltblending. The composite filler A consists of Al-Mg-CuO composite particles and porous ZnFe<2>O<4> nanospheres; and the composite filler B consists of MgO nanoparticles, Al<2>O<3> nanoparticles, TiO<2>nanoparticles, ZnO nanoparticles and porous ZnFe<2>O<4> nanospheres.

Owner:FOSHAN NANHAI DISTRICT JIAYAN UNDERWEAR CO LTD

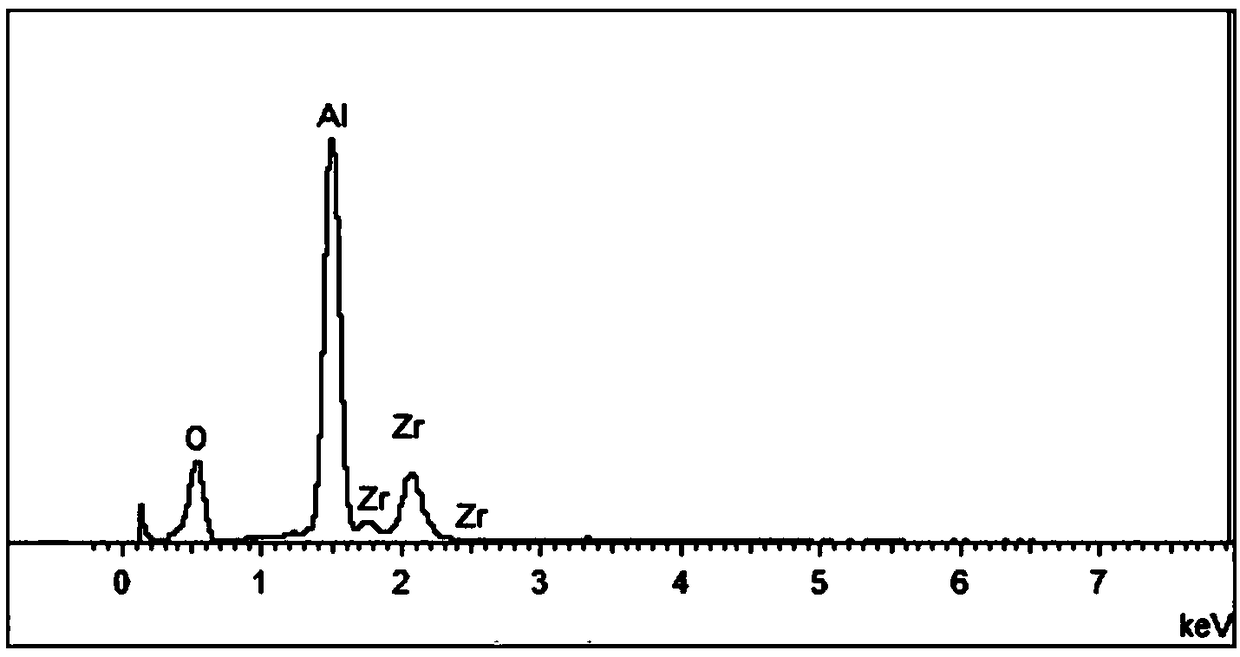

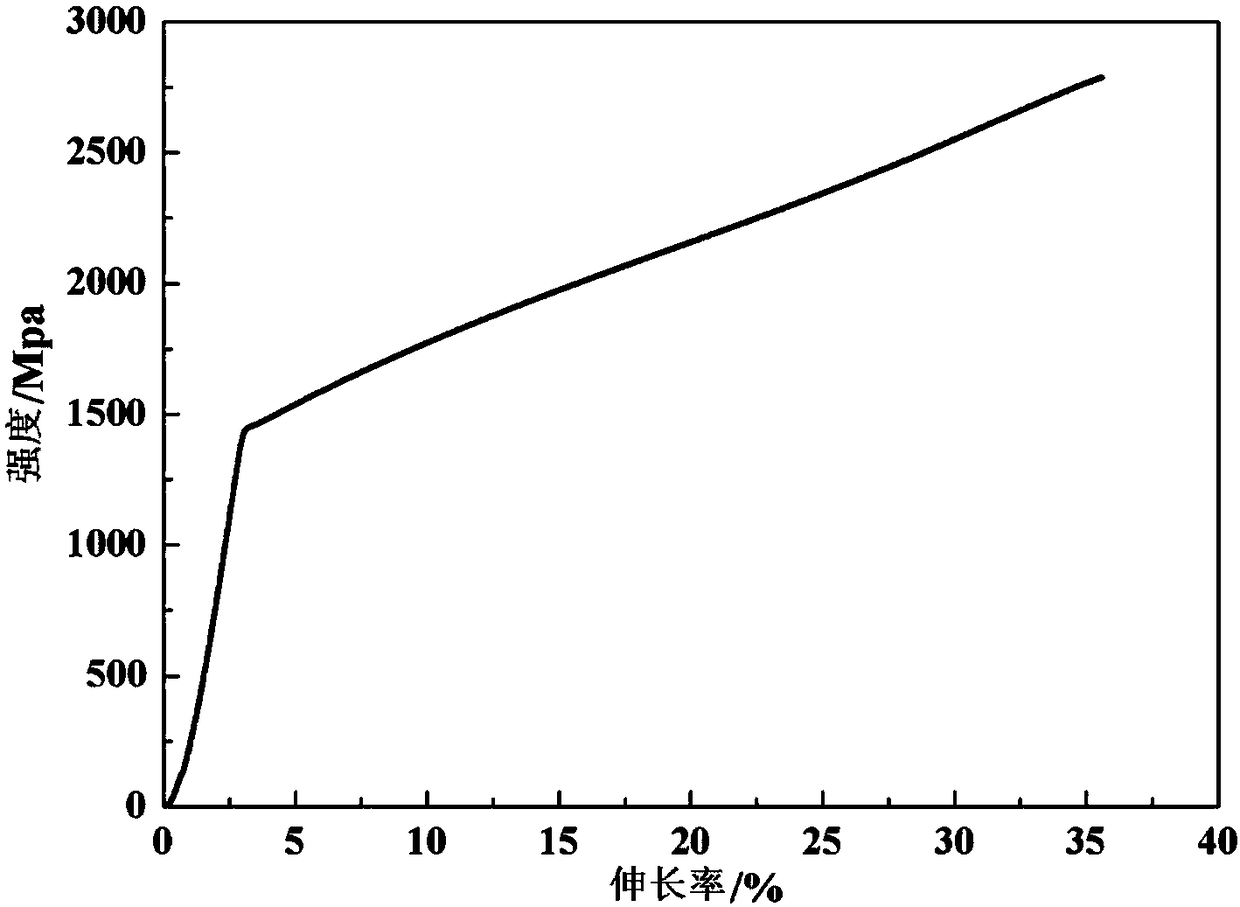

High-wearing-resistance tungsten alloy powder metallurgy material for precise instrument and preparation method of high-wearing-resistance tungsten alloy powder metallurgy material

The invention belongs to the field of tungsten alloy materials and discloses a high-wearing-resistance tungsten alloy powder metallurgy material for precise instruments and a preparation method of thehigh-wearing-resistance tungsten alloy powder metallurgy material. A tungsten alloy comprises the following components in percentage by mass: 88.3-93.0% of tungsten, 6.0-7.0% of adhesive-phase nickeland iron, 0.1-0.3% of aluminum oxide, 0.08-2.1% of zirconium oxide and inevitable trace impurities. The preparation method comprises the following steps: uniformly mixing the components, performing low-energy ball milling, and performing isostatic cool pressing molding, sintering and quenching treatment, thereby obtaining a high-wearing-resistance tungsten alloy. The hardness of the tungsten alloy is greater than 430HV, and the yield strength of the tungsten alloy is greater than 1400MPa. Due to addition of a proper amount of 3mol.% Y2O3 and a part of stable ZrO2 and alpha-Al2O3 nanoparticles, tungsten crystal granules can be refined, the hardness and the wearing resistance of the tungsten alloy can be improved, and meanwhile due to ZrO2 phase-change toughening mechanisms, the toughness of the tungsten alloy can be improved, and the tungsten alloy is applicable to the field of precise instruments.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for graphene oxide doped reinforced ODS copper

The invention provides a preparation method for graphene oxide doped reinforced ODS copper, and belongs to the technical field of preparation of copper-based composite materials. Atomized Cu-Al alloypowder serves as raw materials, graphene oxide is doped, oxygen is introduced, and diffusion bonding with Al in a substrate occurs to form Al2O3 nanometer particles which are uniformly dispersed in the substrate. Meanwhile, graphene losing oxygen-containing functional groups serves as a second reinforced phase to be dispersed in the substrate, a powder metallurgy technology and later plastic processing are combined to obtain compact graphene doped reinforced ODS copper composite materials with high strength and good processing performance. The strength of the Cu-based composite materials is improved, and the conduction performance of the Cu-based composite materials is guaranteed. By adding the graphene, the problem that traditional ODS copper is difficult to process is solved, and the preparation method is suitable for large-scale industrial production.

Owner:阿尔泰新材料(香河)有限公司

Functionalized nanoparticles

The present invention discloses functionalized nanoparticles comprising on the surface a covalently bound radical of formula (1), wherein the nanoparticles are SiO2, Al2O3 or mixed SiO2 and Al2O3 nanoparticles, R1 and R2 are independently of each other hydrogen, nanoparticle surface-O-, or a substituent, n is 1, 2, 3, 4, 5, 6, 7 or 8, and Y is a radical of formula -B1-D1 (2a), wherein B1 is the direct bond or a bridge member, and D1 is a radical of a cationic dye, a radical of a phthalocyanine dye which carries no water-solubilizing group, or a radical selected from a fluorescent dye, or Y is a radical of formula -B2 D2 (2b), wherein B2 is an organic radical comprising at least one group having a negative charge, and D2 is a cationic dye selected from the group consisting of monoazo, disazo, polyazo, methine, azamethine, diphenylmethane, triphenylmethane, triaminotriaryl methane, azine, oxazine, cyanine and anthraquinone dyes.

Owner:CIBA SPECIALTY CHEM HLDG INC

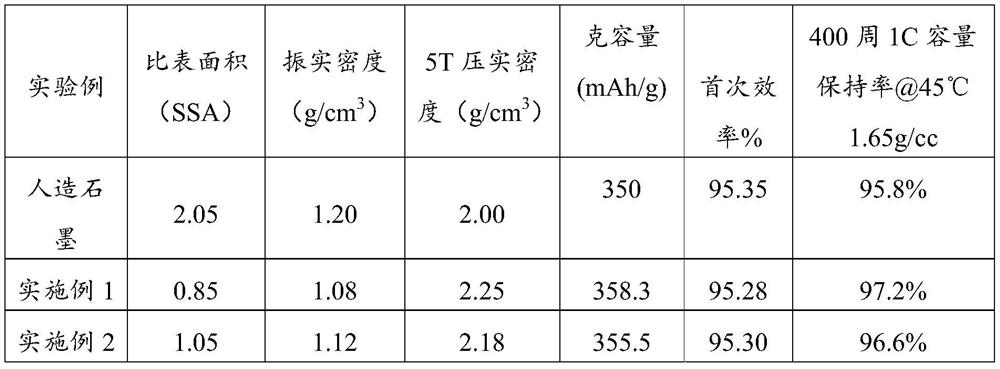

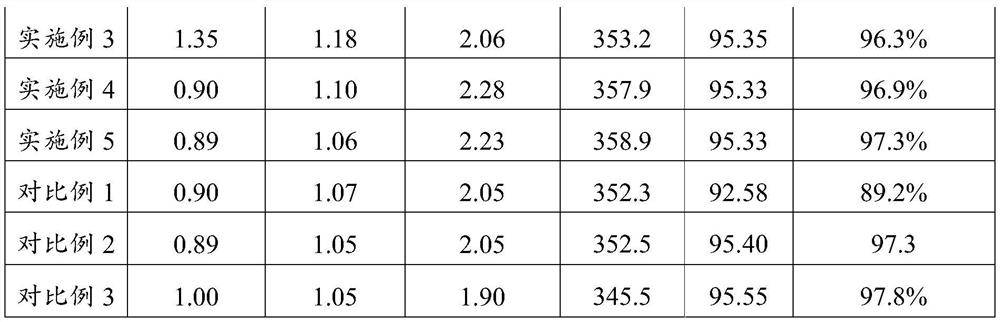

Low-crystallization-degree coating material and preparation method thereof, anode material and lithium battery anode

ActiveCN111785915AIncrease energy densityMaterial nanotechnologyElectrode thermal treatmentPhysical chemistryGraphite

The invention relates to the field of materials, in particular to a low-crystallization-degree coating material and a preparation method thereof, an anode material and a lithium battery anode. The preparation method of the low-crystallization-degree coating material mainly comprises the following steps: mixing Al2O3 nanoparticles and asphalt, and carrying out heat treatment to carbonize the asphalt. Al2O3 nano particles are mixed with asphalt, carbonizing the asphalt to form a microcrystalline structure through heat treatment, so that the Al2O3 nano particles can prevent the microcrystalline structure from being further fused and expanded to obtain a coating material with a low crystallization degree, and the crystallization degree of the coating material is lower than that of conventionalsoft carbon. More lithium intercalation sites can be obtained by coating graphite with the coating material, and the energy density of the material can be improved.

Owner:HUNAN SHINZOOM TECH

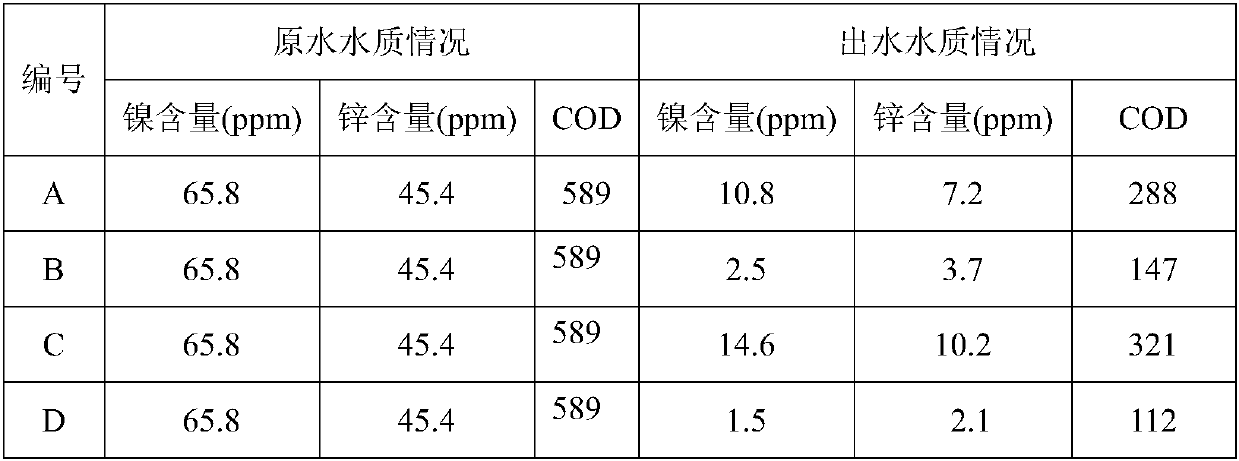

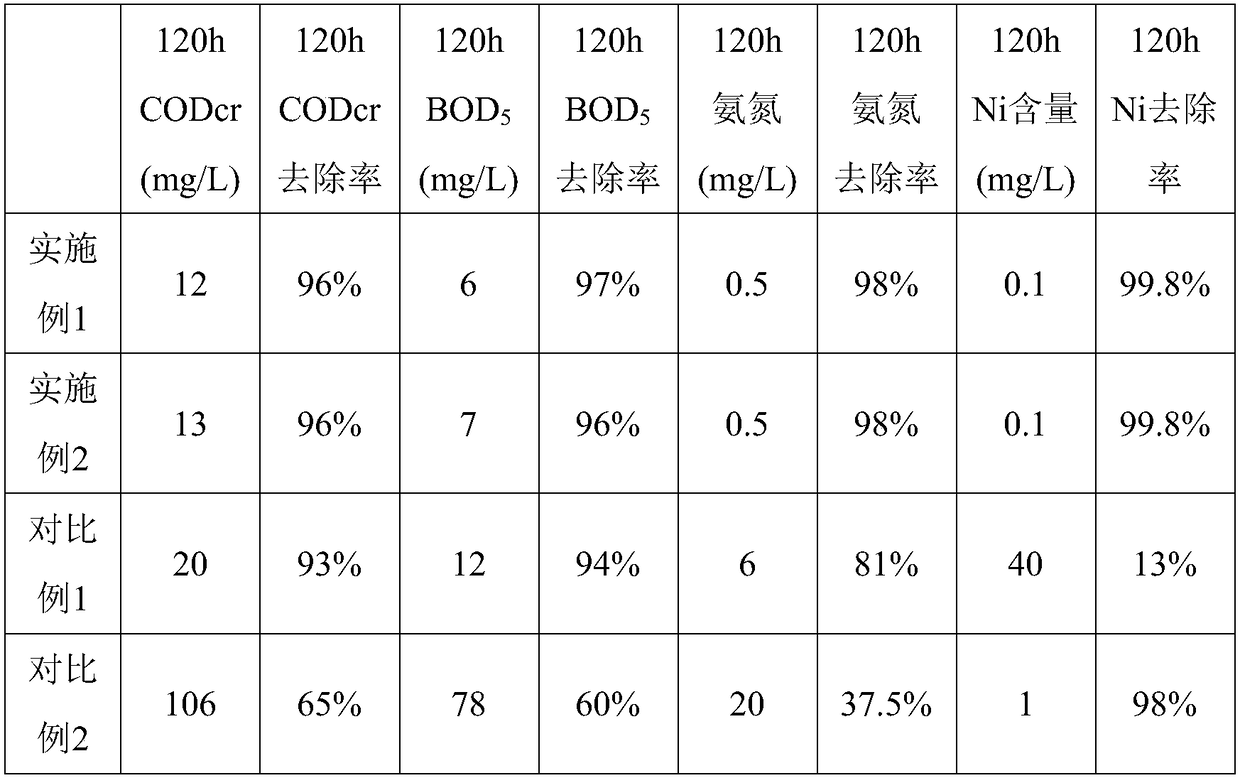

Preparation and application of activated (Cu-Fe-Ce)/Al2O3 nanoparticle electrode

ActiveCN110002546ASpeed up the transfer processEasy to captureWaste water treatment from metallurgical processWater/sewage treatment apparatusCatalytic oxidationElectron transfer

The invention discloses an activated (Cu-Fe-Ce) / Al2O3 nanoparticle electrode. The activated (Cu-Fe-Ce) / Al2O3 nanoparticle electrode is prepared with an impregnation method, then reduced with 10% sodium borohydride, so that a primary battery like structure is formed on the surface of an activated Al2O3 carrier, electron transfer and capture are accelerated under the action of an external electric field, so that a catalytic oxidation reaction of organic pollutants on the surface of the nanoparticle electrode is enhanced. The nanoparticle electrode utilizes the high specific surface area (280-360m<2> / g) of activated Al2O3, the capacity of active components in the nanoparticle electrode is increased, and the catalytic oxidation activity of the nanoparticle electrode is improved. The inventionalso discloses a preparation method of the nanoparticle electrode.

Owner:JIANGSU HELPER FUNCTIONAL MATERIALS

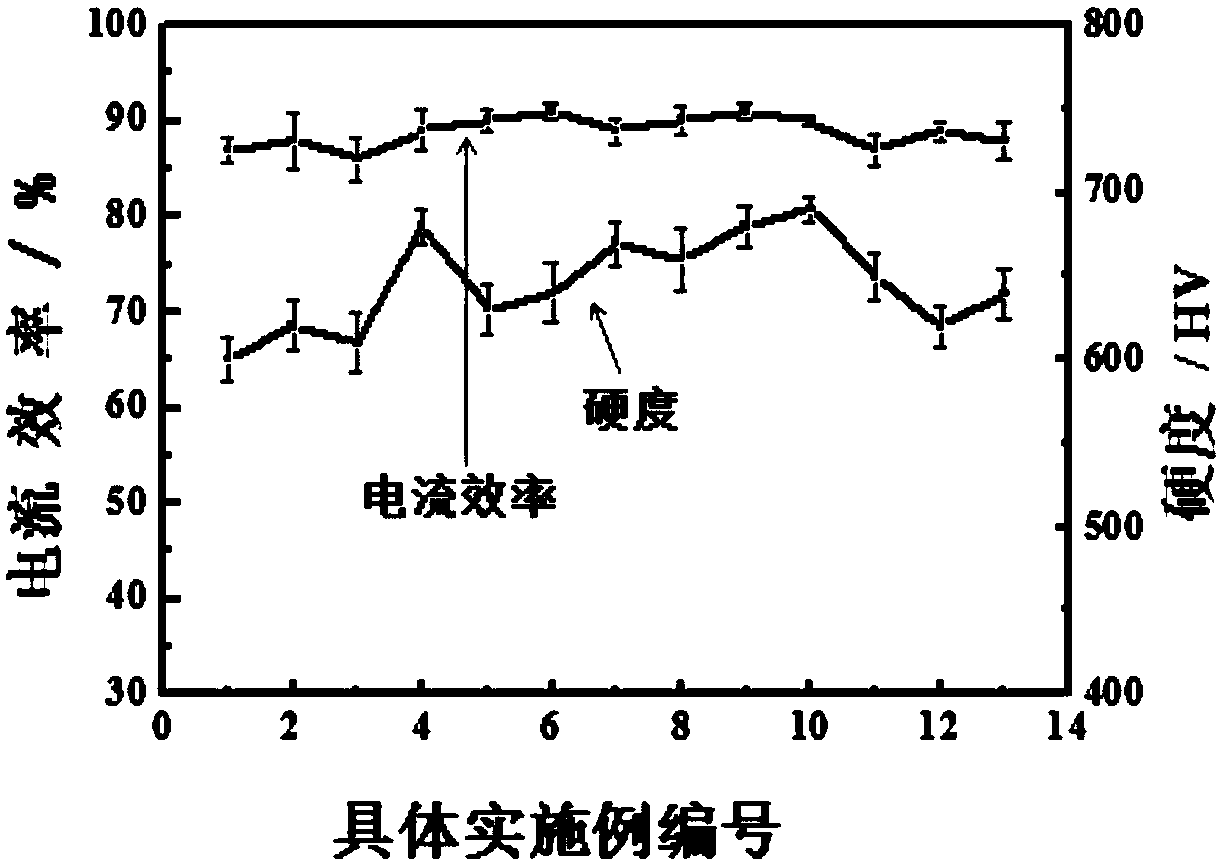

Alkaline cyanide-free Zn-Ni-Al2O3 electroplating solution, and preparation method and application thereof

InactiveCN108866606AHigh hardnessIncrease current densityElectrolytic coatingsHigh current densityEthylenediamine

The invention belongs to the technical field of electroplating of Zn-Ni-Al2O3 composite coatings, and relates to an alkaline cyanide-free Zn-Ni-Al2O3 electroplating solution, and a preparation methodand application thereof. The plating solution is prepared from a primary coordinating agent, an auxiliary coordinating agent, zinc sulfate, nickel sulfate, potassium carbonate, an Al2O3 nanoparticle suspension and ultrapure water, wherein the main coordinating agent is hydantoin and derivatives thereof, and the auxiliary coordinating agent is amine organic matter such as ethylenediamine; the composite coatings are prepared according to an electrodeposition method. The alkaline cyanide-free Zn-Ni-Al2O3 electroplating solution, and the preparation method and the application thereof have the advantages that the electroplating process is optimized by screening and applying the coordinating agents, and the obtained coatings have high corrosion resistance and high hardness; the electroplating solution has high stability and high current density (higher than 85%), and its overall performance is improved remarkably as compared with that of a single coordinating agent.

Owner:NORTHEASTERN UNIV

Preparation method of heavy metal adsorbent alpha-Al2O3 nanoparticles

The invention relates to a preparation method of heavy metal adsorbent alpha-Al2O3 nanoparticles and belongs to the technical field of preparation of a nanometer sewage treating agent. A glycol aluminum precursor is prepared by an alcohol aluminum hydrolysis method and high-temperature calcination is conducted to obtain the alpha-Al2O3 nanoparticles. The preparation method comprises the followingsteps: A, dissolving aluminum powder into anhydrous glycol, controlling the molar ratio of the aluminum powder to the anhydrous glycol to be 1:(25-30), stirring, adding PEG6000, adding AlCl3, performing catalytic reaction, and stirring for 5 to 8 hours by controlling the temperature to be 50 to 70 DEG C to obtain glycol aluminum white precipitate; B, adding deionized water into the glycol aluminumwhite precipitate obtained in the step A, stirring by controlling the temperature and performing hydrolysis at 60 to 70 DEG C for 2 to 5 hours to obtain hydrated alumina gel; C, drying the hydrated alumina gel at 60 to 80 DEG C for 24 to 48 hours to obtain dry gel; and D, heating to 1100 to 1200 DEG C at the heating speed of 5 to 10 DEG C / min and calcining the dry gel for 2 to 3 hours to preparethe alpha-Al2O3 nanoparticles. The method is mild and stable in preparation process; and the prepared nanometer aluminum oxide has high purity and has high adsorptive property on various heavy metal ions.

Owner:HEBEI MILSON TITANIUM DIOXIDE

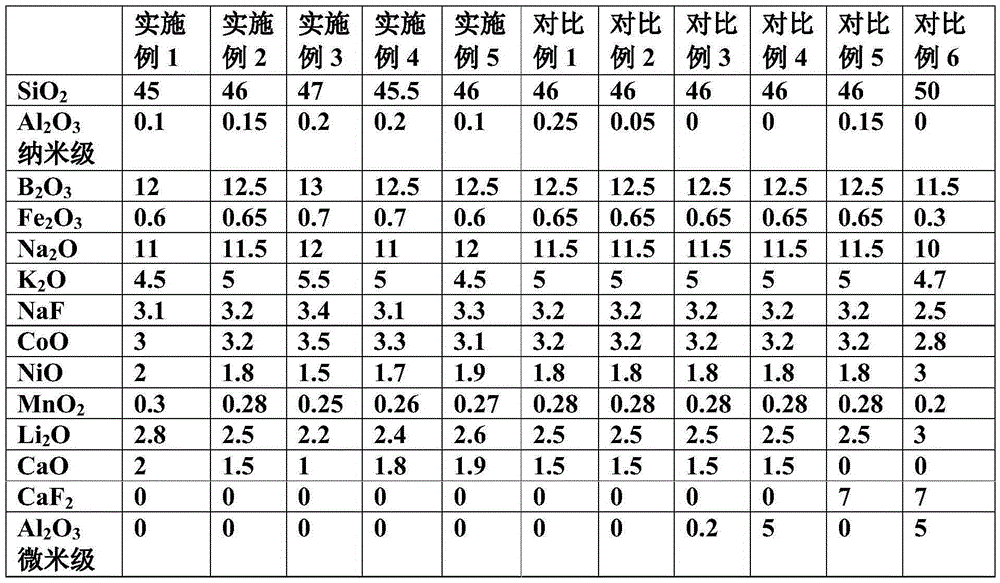

Enamel glaze powder and enamel liner of water heater

ActiveCN106810073AGood for high temperature fusionImprove acid resistanceFluid heatersAl2o3 nanoparticlesMaterials science

The invention provides enamel glaze powder and an enamel liner of a water heater. The enamel glaze powder is used for the enamel liner of the water heater and is prepared from the following raw materials in parts by weight: 45 to 47 parts of SiO2, 0.1 to 0.2 part of Al2O3 nanoparticle, 12 to 13 parts of B2O3, 0.6 to 0.7 part of Fe2O3, 11 to 12 parts of Na2O, 4.5 to 5.5 parts of K2O, 3.1 to 3.4 parts of NaF, 3 to 3.5 parts of CoO, 1.5 to 2 parts of NiO, 0.25 to 0.3 part of MnO2, 2.2 to 2.8 parts of Li2O and 1 to 2 parts of CaO. The enamel liner of the water heater, which is prepared from the enamel glaze powder, can be subjected to 1 million times of pulse impacting tests (with rated pressure of 0.85MPa), and the utilization requirements of commercial-grade water heater products are met.

Owner:QINGDAO HAIER NEW ENERGY ELECTRIC APPLIANCE

Preparation method of fiber reinforced composite

InactiveCN111363989AImprove mechanical propertiesImprove stabilityFiber-reinforced compositeAl2o3 nanoparticles

The invention discloses a preparation method of a fiber reinforced composite, and belongs to the technical field of composites. The method solves the technical problem that fiber reinforced compositesmade of basalt fiber are low in adhesion and tensile resistance. According to the preparation method of the fiber reinforced composite, basalt fiber is subjected to acetic acid pretreatment and jointmodification treatment by a titanate coupling agent and by Al2O3 nanoparticles and a titanate coupling agent. Cut samples of the fiber reinforced composite obtained finally are in a scale of 300.0mm*300.0mm. Under detection by the prior art, the tensile strength of the fiber reinforced composite is over 3500 Mpa which is 7-9 times that of steel, the tensile elastic modulus of the fiber reinforcedcomposite is 23000-43000 Mpa which is higher than that of steel, and the specific strength, i.e. the ratio of strength to density of the material can reach 2000 Mpa / (g / cm3) or above.

Owner:CHANGCHUN A&Z SCI CO LTD

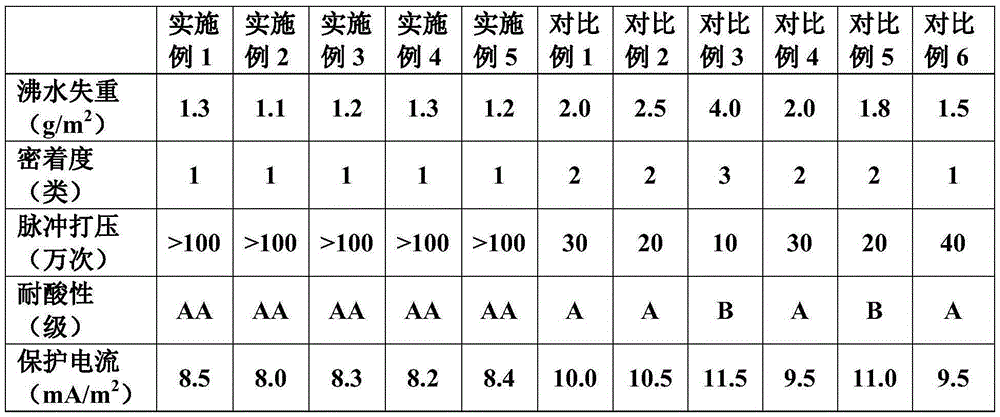

Improved sewage treatment PVDF thin film

InactiveCN104759209AImprove anti-pollution performanceImprove connectivitySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisNanoparticleAl2o3 nanoparticles

The invention relates to the technical field of thin films and in particular relates to an improved sewage treatment PVDF thin film. The improved sewage treatment PVDF thin film comprises five layers, namely an upper PVDF thin film layer, an Al2O3 nanoparticle layer, a middle layer, a TiO2 nanoparticle layer and a lower PVDF thin film layer from top to bottom; the middle layer is of a cellular structure. The surfaces of the Al2O3 and TiO2 nanoparticle layers of the thin film contain rich hydroxyls, so that the connectivity of film pores can be enhanced for hydrophilic curing to a certain extent; as a result, the pollution resistance of the film can be enhanced; due to the adopted cellular paper structure, the material can be saved and the thermal insulating effect can be achieved.

Owner:CHANGZHOU HUITIAN NEW MATERIALS

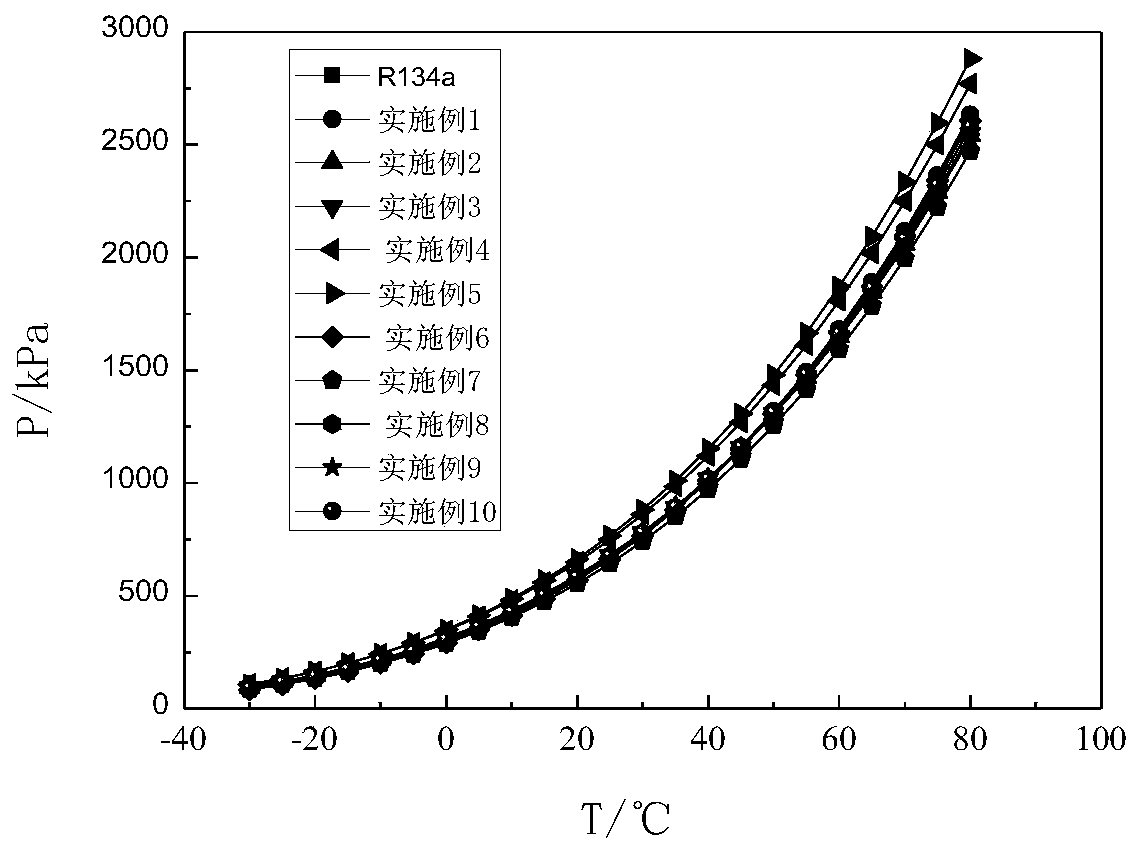

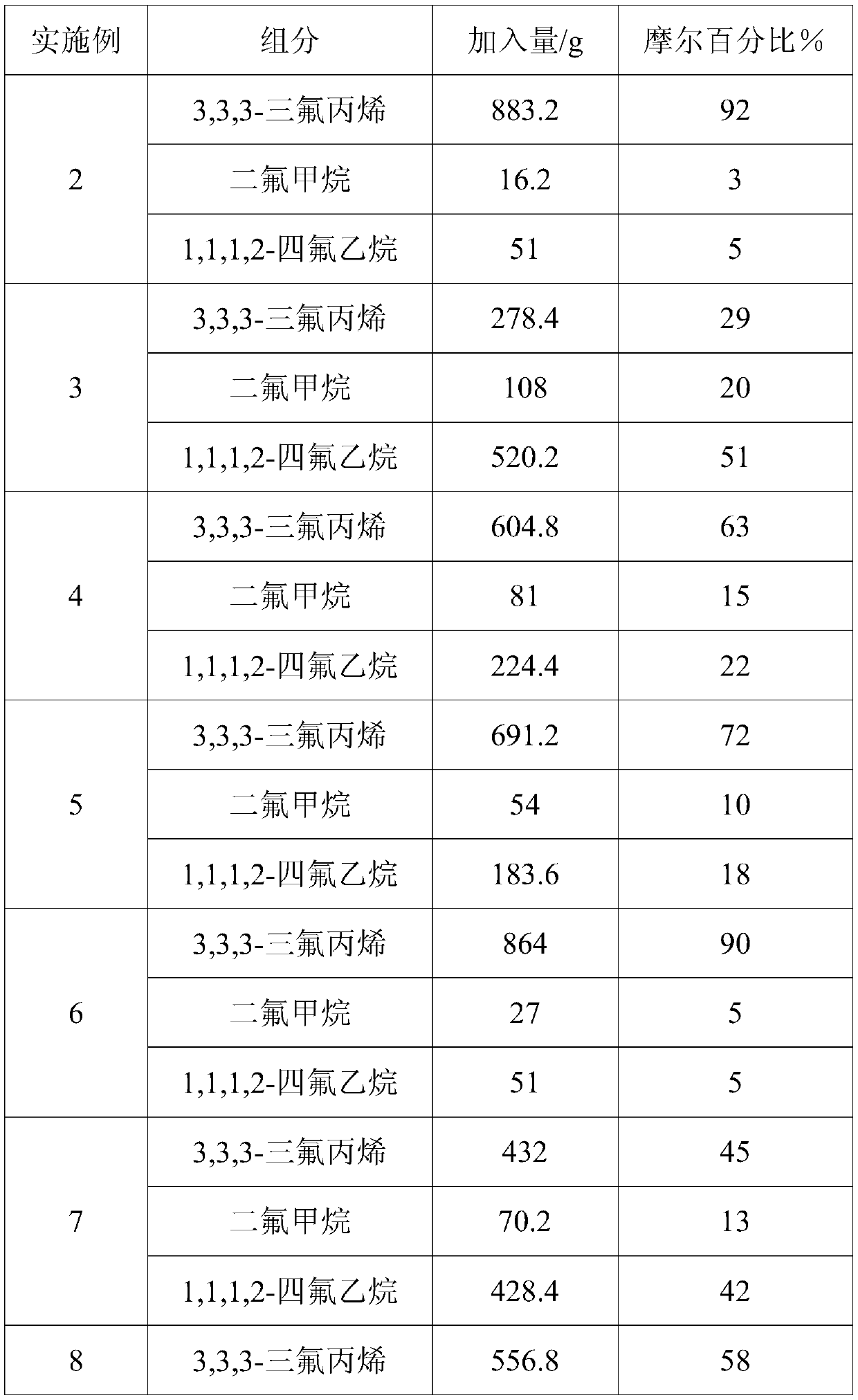

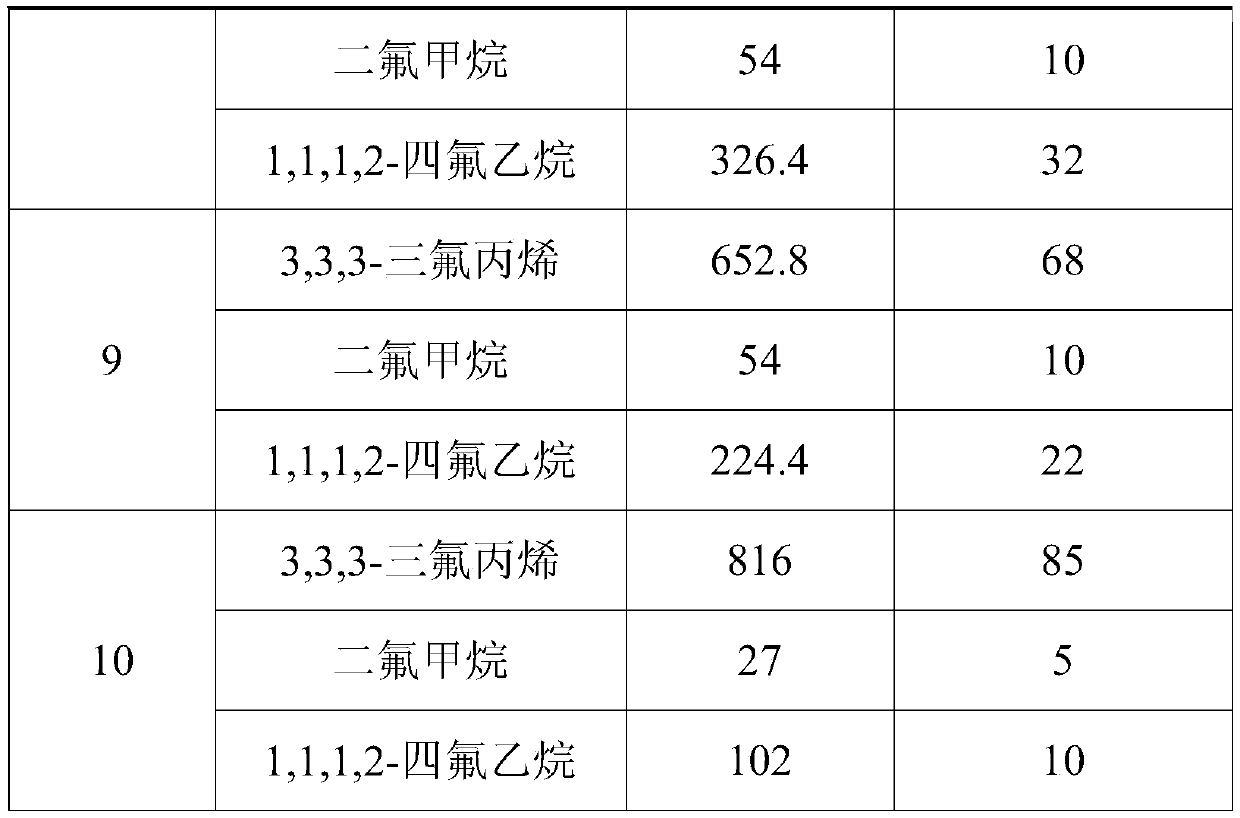

Environmentally-friendly mixed refrigerant used for replacing R134a and preparation method of refrigerant

ActiveCN109722226AEnvironmental protection is goodODP value decreasedHeat-exchange elementsEngineeringAl2o3 nanoparticles

The invention discloses an environmentally-friendly mixed refrigerant used for replacing R134a and a preparation method of the refrigerant. The environmentally-friendly mixed refrigerant used for replacing the R134a is composed of the following components, in percentages by molar: 29-92% of 3,3,3-trifluoropropene, 3-20% of difluoromethane and 5-61% of 1,1,1,2-tetrafluoroethane. According to the refrigerant and preparation method provided by the invention, the 3,3,3-trifluoropropene and the 1,1,2,2-tetrafluoroethane are added into the 1,1,1,2-tetrafluoroethane, so that the environmentally-friendly properties of the mixed refrigerant are improved, and the GWP value is significantly reduced compared with that of the R134a; in addition, the environmentally-friendly mixed refrigerant prepared by the method has excellent thermal parameters and thermal performance, the circulation efficiency, the refrigeration coefficient and the unit volume refrigeration capacity in the refrigeration systemare superior or equivalent to those of the R134a, the saturated vapor pressure is similar to that of the R134a, and the refrigerant can directly replace the R134a. The invention also discloses the environmentally-friendly mixed refrigerant. Fe2O3, MnO2, ZnO or Al2O3 nanoparticles are added into the above mixture, so that compatibility between the refrigerant and mineral-type refrigerating machineoil is improved.

Owner:XIAN MODERN CHEM RES INST

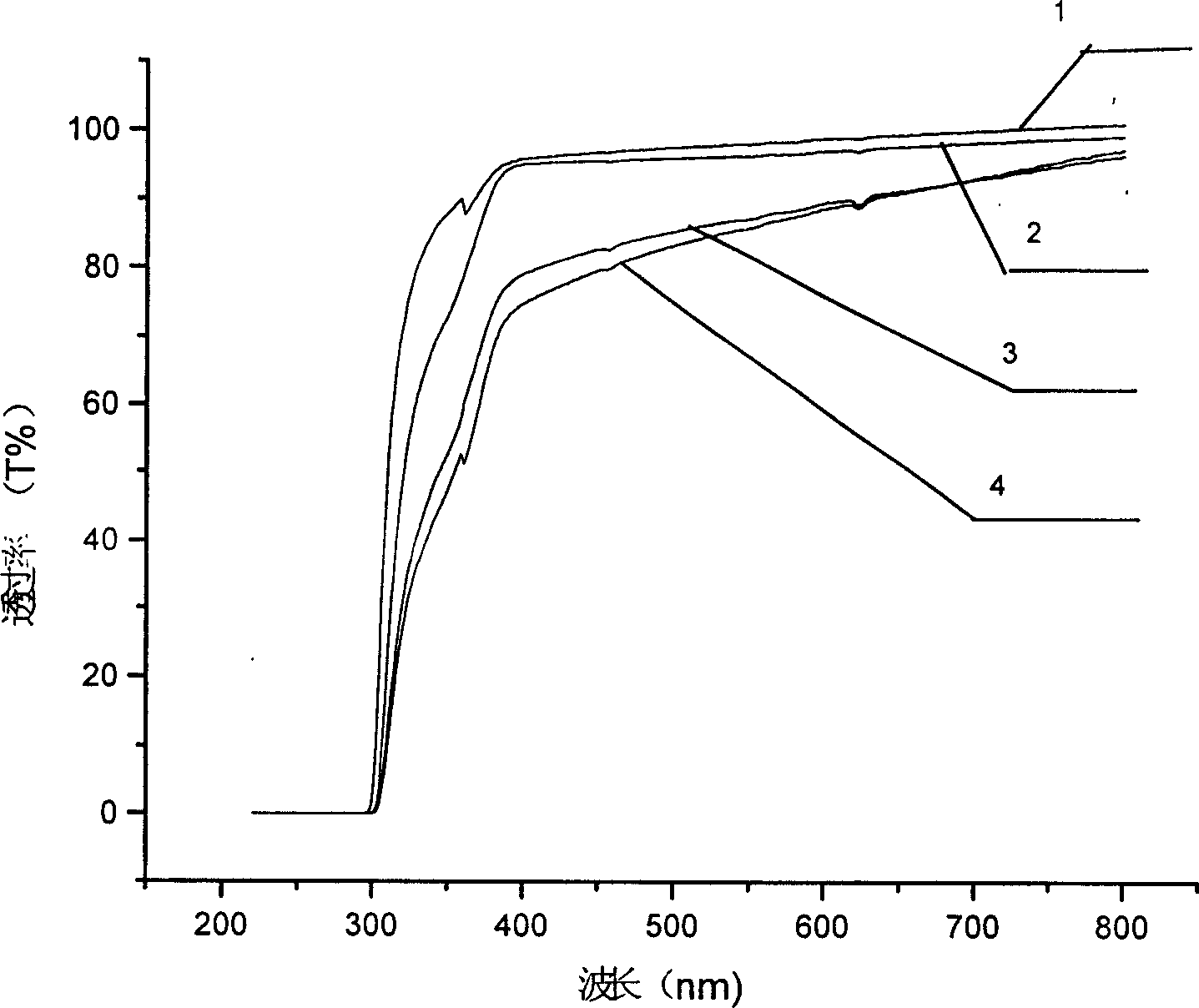

Nano transparent abrasion resistant composite paint

InactiveCN1227309CImprove wear resistanceStrong adhesionEpoxy resin coatingsPolyester coatingsDiluentUltraviolet

An antiwear transparent nano-class composite paint includes the dual-component composite paint consisting of high-molecular resin as filming material, Al2O3 nanoparticles, assistant, solvent, diluent and solidifying agent and the single-component composite paint consisting of high-molecular water resin, Al2O3 nanoparticles, assistant, and water. Its advantages are high adhesion and high ultraviolet shielding power.

Owner:NANJING TECH UNIV

Rod-like one-dimensional polycrystalline gamma-Al2O3 nanocrystal grains and preparation method thereof

The invention discloses rod-like one-dimensional polycrystalline gamma-Al2O3 nanocrystal grains and a preparation method thereof. The preparation method comprises the following steps of: emulsifying a compound surfactant, water and solvent oil into stable emulsion; simultaneously adding an aluminum source solution and an alkali source solution into the emulsion; and after the emulsion is demixed and stable, transferring the uppermost organic phase into an autoclave, sealing for reaction, and washing, separating, drying and roasting a reaction product to obtain the gamma-Al2O3 nanocrystal grains, wherein the gamma-Al2O3 nanocrystal grains have the diameter of 10 to 25nm and the length of 80 to 500nm and are regular-shaped rod-like one-dimensional polycrystalline gamma-Al2O3 nanocrystal grains, and have high specific surface area. The gamma-Al2O3 nanocrystal grains can be applied to the fields of catalysts, adsorbents, selective separation and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microbial preparation for treatment of industrial sewage, preparation method and application thereof

InactiveCN108163994AEfficient degradationEliminate ChromaSpecific water treatment objectivesBiological water/sewage treatmentAmino functionalizedImmobilized lipase

The invention discloses a microbial preparation for treatment of industrial sewage. The microbial preparation is composed of core-shell structure particles, which consist of a compound preparation, anintermediate shell layer, and an outer shell layer that are arranged from the inside out in order. The compound preparation includes the marine Bacillus amyloliquefaciens BMF01 fermentation broth andimmobilized lipase, and the immobilized lipase is obtained by immobilization of lipase on the surfaces of amino functionalized Al2O3 nanoparticles. The intermediate shell layer is a shell composed ofa plant glue. The outer shell layer is composed of inorganic gel, calcium chloride and calcium acetate. The invention also discloses a preparation method and application of the microbial preparation.The microbial preparation provided by the invention can achieve efficient treatment of industrial wastewater to substantially remove organic matters, ammonia nitrogen and heavy metals from industrialwastewater.

Owner:江苏世邦生物工程科技有限公司

NaOH-Al2O3/GO catalyst and anisole catalytic synthesis thereof

ActiveCN110787786AAvoid reunionReduce forceChemical recyclingMetal/metal-oxides/metal-hydroxide catalystsPtru catalystEngineering

The invention discloses a NaOH-Al2O3 / GO catalyst and anisole catalytic synthesis thereof. Graphene oxide (GO) prepared by a modified Hummrs method serves as a carrier, hydrothermal method is used forloading Al2O3 nanoparticles, and then NaOH is loaded at a high temperature to prepare the NaOH-Al2O3 / GO catalyst. The GO in the catalyst can effectively prevent the agglomeration of the Al2O3 nanoparticles, the nanoparticles can in turn reduce the interlayer force of the GO, the GO has a large specific surface area, so that the loaded catalytic active components are greatly increased, and catalytic activity is further improved; and meanwhile the NaOH loaded in the catalyst provides alkalinity for the catalyst (dimethyl carbonate accelerates the reaction with phenol under alkaline conditions).Therefore, the catalyst is used for catalyzing the reaction between the dimethyl carbonate and the phenol, the yield of the anisole is greatly increased, the environmental protection pressure is reduced, the cost of raw materials can also be lowered, and the environmental protection and economic requirements of industrial anisole production are met.

Owner:YULIN UNIV +1

Water-based inorganic coating and preparation method thereof

InactiveCN114085557AHigh temperature resistanceEasy to picklingFireproof paintsPhysical chemistryPhotopigment

The invention discloses a water-based inorganic coating and a preparation method thereof. The water-based inorganic coating comprises the following components in parts by weight: 20-50 parts of a film forming matter, 10-35 parts of high-temperature-resistant inorganic pigment filler, 0.5-3 parts of an auxiliary agent and 15-50 parts of deionized water. Modification treatment is performed on the basis of Al2O3 nanoparticles to obtain a film forming matter. The sum of the components in the water-based inorganic coating is 100. The particle size of the high-temperature-resistant inorganic pigment filler is 400-800 meshes, and the high-temperature-resistant inorganic pigment filler comprises an inorganic pigment and an inorganic filler. The inorganic filler is obtained based on sintering treatment. The water-based inorganic coating disclosed by the invention is excellent in low-temperature film-forming property, has the characteristics of high temperature resistance and easiness in acid pickling, is suitable for tracking and marking of a high-temperature object, has the waterproof characteristic and can be cleaned by acid pickling within a short time. According to the preparation method, the water-based inorganic coating with high-temperature resistance as high as 1000 DEG C can be prepared, so that the water-based inorganic coating is suitable for tracking and marking high-temperature objects, and the technical problem that the high-temperature objects are difficult to track and mark is solved.

Owner:河北欧禹科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com