Nanoscale high-purity aluminum oxide preparation method

A high-purity alumina, nano-scale technology, applied in the direction of alumina/aluminum hydroxide, nanotechnology, etc., can solve the problems of troublesome roasting process, alumina can not reach the nano-scale, long roasting time, etc., to achieve fine grain size , less agglomeration and better grain development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 306g of aluminum isopropoxide and 282.6g of isopropanol into a 1000ml three-neck flask equipped with an electric stirring device and a reflux condenser, heat to 70°C, and stir evenly. Then add 81g of deionized water, 6.3g of nitric acid with a weight concentration of 68% and 235.5g of isopropanol, stir and reflux for 3h, and then spin dry the sol at a temperature of 60°C and a gauge pressure of -64kPa for 1.7h , to recover the solvent. The obtained hydrated alumina powder is heated from room temperature to 900°C at a constant rate of 2.9°C / min, and the holding time is 3h, and then cooled to room temperature with the furnace to obtain the nano-alumina product of the present invention.

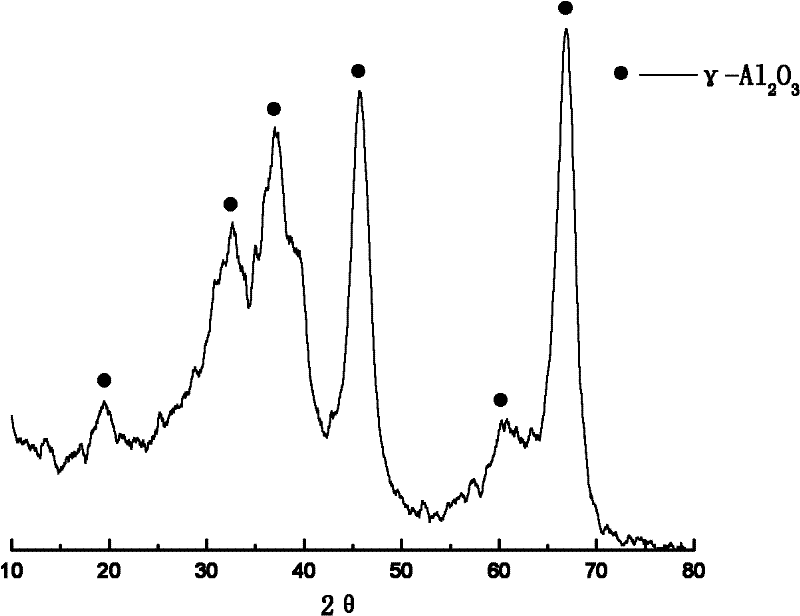

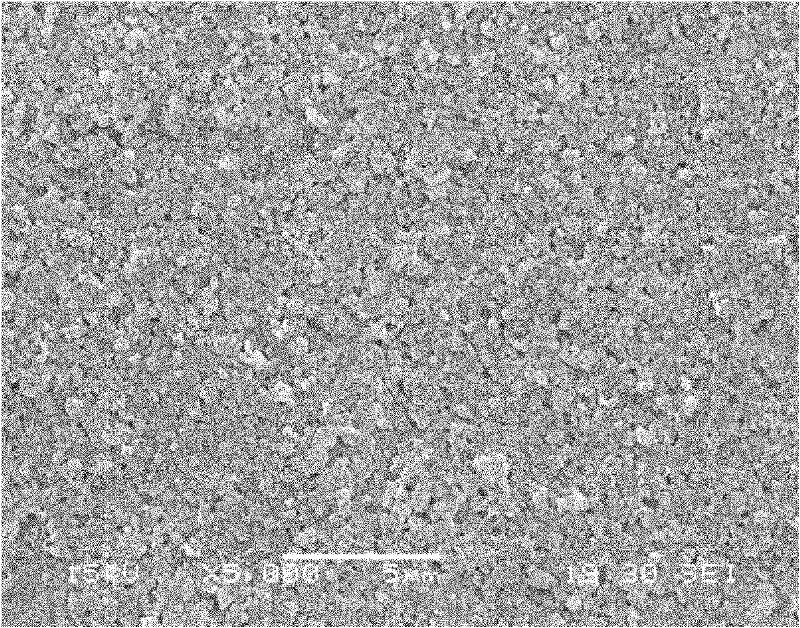

[0033] The resulting product is shown in the X-diffraction pattern figure 1 , for γ-Al 2 o 3 , the grains are well developed; the TEM photos are shown in figure 2 , its primary particle size is 10-35nm, its shape is spherical, no large hard agglomerated particles are seen; its sp...

Embodiment 2

[0036] Add 306g of aluminum isopropoxide and 212g of isopropanol into a 1000ml three-necked flask equipped with an electric stirring device and a reflux condenser, heat to 50°C, and stir evenly. Then add 54g of deionized water, 6.3g of nitric acid with a weight concentration of 68% and 117.75g of isopropanol, stir and reflux for 4h, then spin dry the sol at a temperature of 70°C and a gauge pressure of -42kPa for 2.4h , Recovery of solvent. The obtained hydrated alumina powder is heated from room temperature to 750°C at a constant speed of 2.5°C / min, the holding time is 2h, and then cooled to room temperature with the furnace to obtain the nano-alumina product of the present invention.

[0037] The obtained product was analyzed as γ-Al by X-ray diffraction 2 o 3 ; The primary particle size is 6-22nm according to the transmission electron microscope photo, the shape is spherical, and no large hard agglomerated particles are seen; the specific surface area is 258m 2 / g; purit...

Embodiment 3

[0040] Add 306g of aluminum isopropoxide and 212g of isopropanol into a 1000ml three-necked flask equipped with an electric stirring device and a reflux condenser, heat to 80°C, and stir evenly. Then add 81g of deionized water, 6.3g of nitric acid and 157g of isopropanol with a weight concentration of 68% to it, stir and reflux for 2h, and then the sol is rotated and dried at a temperature of 50°C and a gauge pressure of -80kPa for 2h, and recovered solvent. The obtained hydrated alumina powder was heated from room temperature to 850 °C at a constant rate of 2.7 °C / min, the holding time was 0.5 h, and then cooled to room temperature with the furnace to obtain the product of the present invention.

[0041] The obtained product was analyzed as γ-Al by X-ray diffraction 2 o 3 ; According to the analysis of transmission electron microscope photos, the primary particle size is 7-25nm, the shape is spherical, and no large hard agglomerated particles are seen; the specific surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com