Life-cycle water-free cooling solution

A water-cooled, full-life technology, applied in the field of engine coolant, can solve problems such as scaling, and achieve the effects of eliminating corrosion, saving fuel, and quickly dissipating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

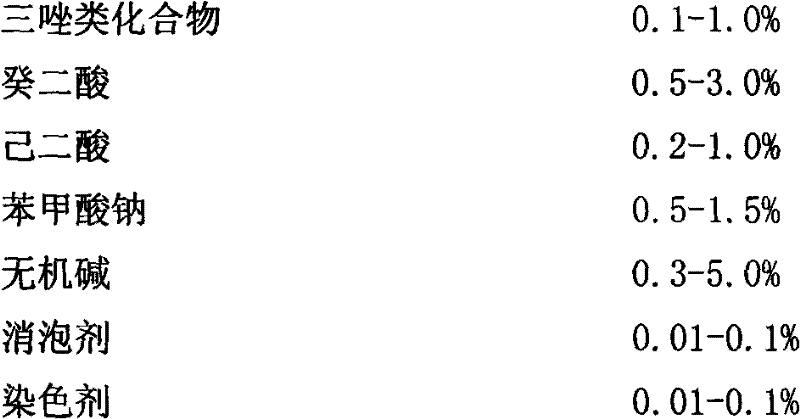

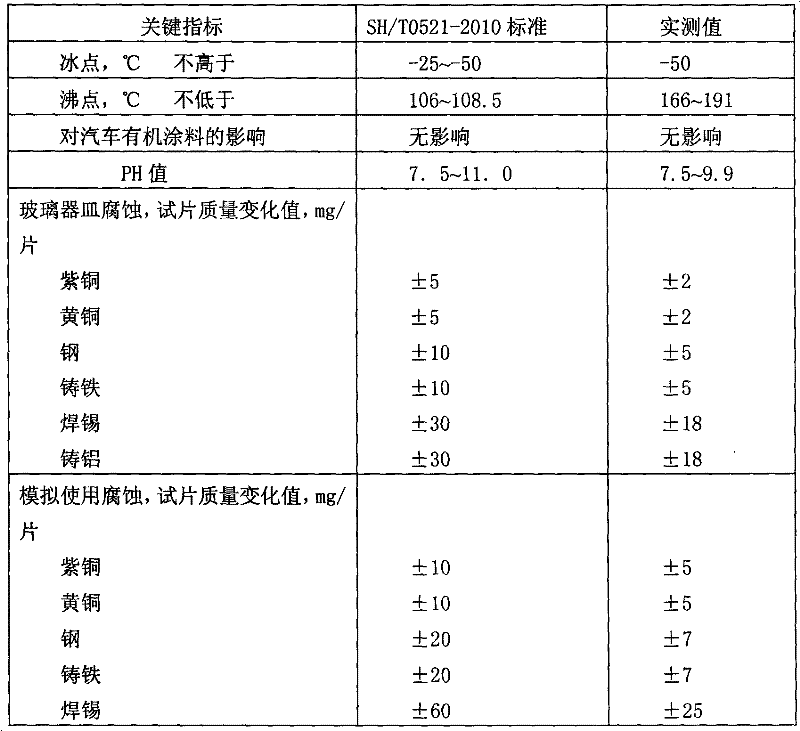

[0031] A full-life coolant, components and weight percentages:

[0032]

[0033] Preparation process: Mix the components and stir evenly to obtain the cooling liquid of the present invention, with a freezing point below -50°C, a boiling point of 166°C, and a pH of 8.21.

Embodiment 2

[0035] A kind of engine coolant without water, each component and weight percent (%):

[0036]

[0037] Preparation process: Mix the components and stir evenly to obtain the cooling liquid of the present invention, with a freezing point below -50°C, a boiling point above 182°C, and a pH value of 8.08.

Embodiment 3

[0039] A kind of engine coolant without water, each component and weight percent (%):

[0040]

[0041] Preparation process: Mix all components and stir evenly to obtain the cooling liquid of the present invention, which has a freezing point below -50°C, a boiling point of 191°C, and a pH value of 8.13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com