Method for comprehensive treatment of wastewater and sludge gas utilization of cane sugar factory

A comprehensive treatment, cane sugar technology, applied in food industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as mixed discharge, increase calorific value, reduce production costs, Eliminates polluting and corrosive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

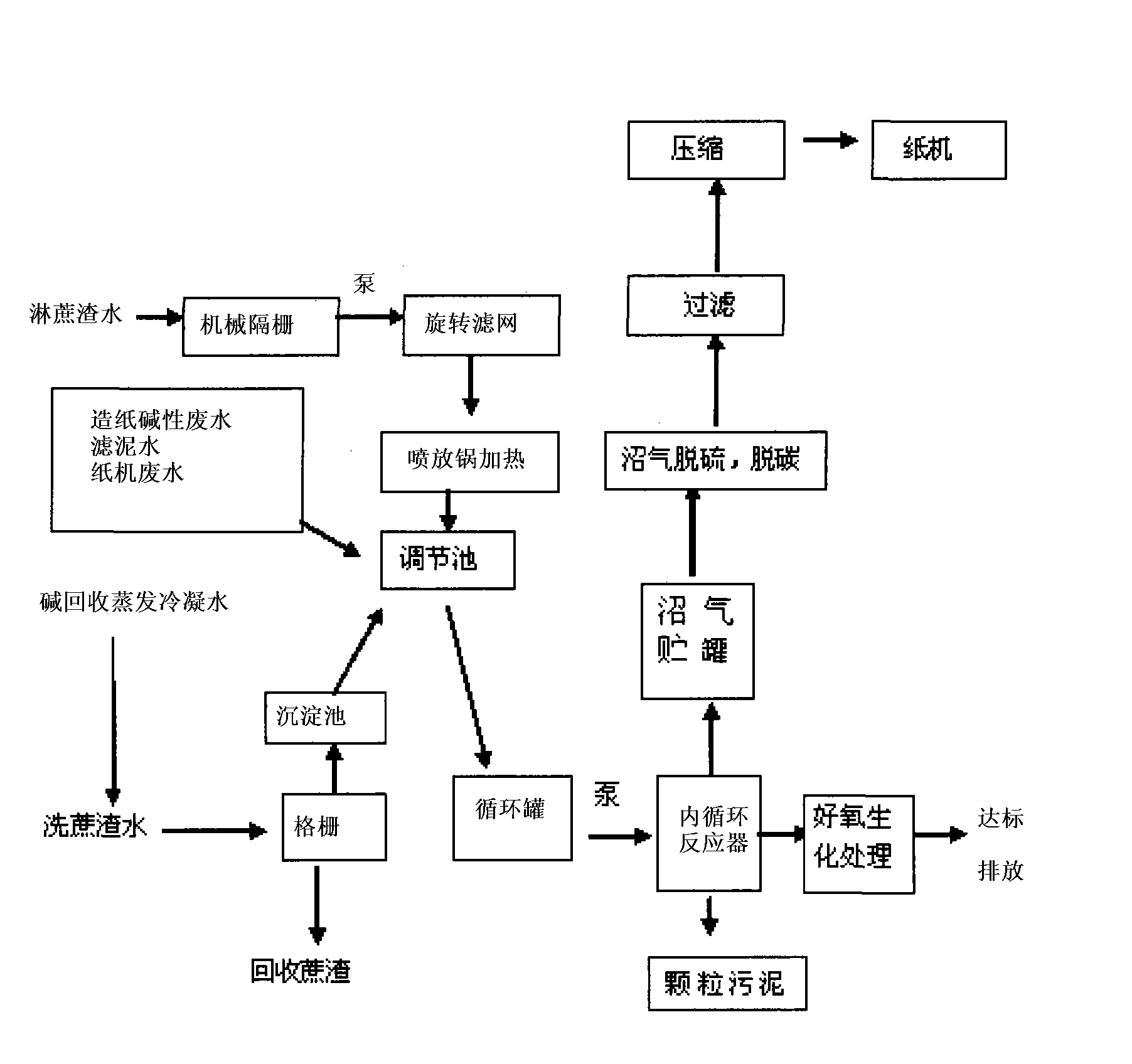

[0030] Embodiment of the present invention is illustrated below in conjunction with accompanying drawing: Implementation process of the present invention is as follows: figure 1 As shown, the bagasse spray water is separated from the bagasse with a mechanical screen and then filtered with a rotary filter, and then the steam in the papermaking spray pot is heated to 30-45°C and the spray water is placed in the adjustment tank; the bagasse water will be Alkali recovery evaporative condensed water washes the pressed bagasse, and filters it with a grid. The bagasse is recycled for papermaking. After sedimentation, the waste water is put into the adjustment tank and combined with the bagasse spray water: papermaking alkaline waste water, mud filter water and paper machine After the waste water is combined, it is put into the adjustment tank and combined with bagasse spray water and bagasse washing water. The mixture is sent to the internal circulation anaerobic reactor through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com