Patents

Literature

210results about "Alkali metal hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

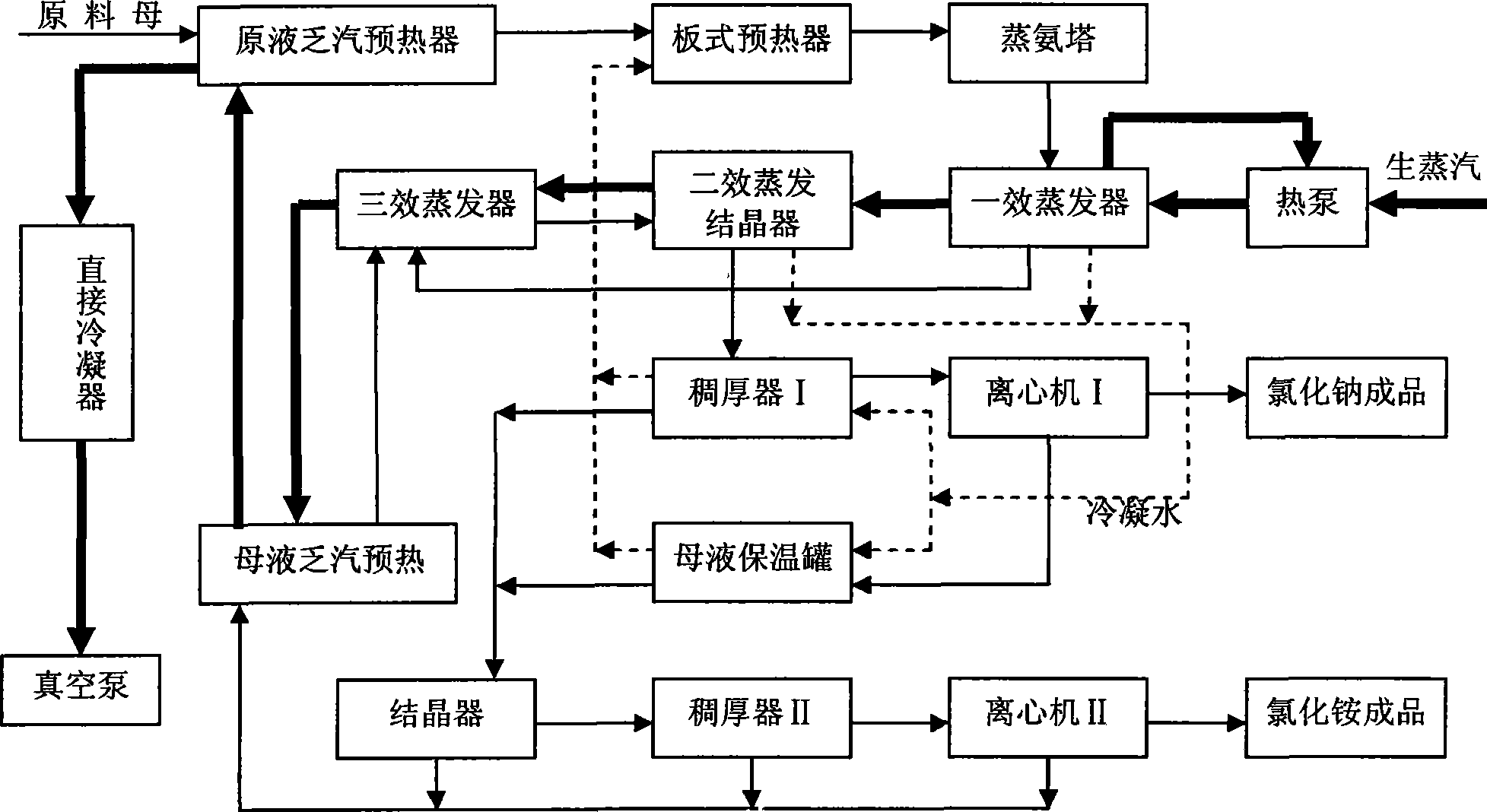

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

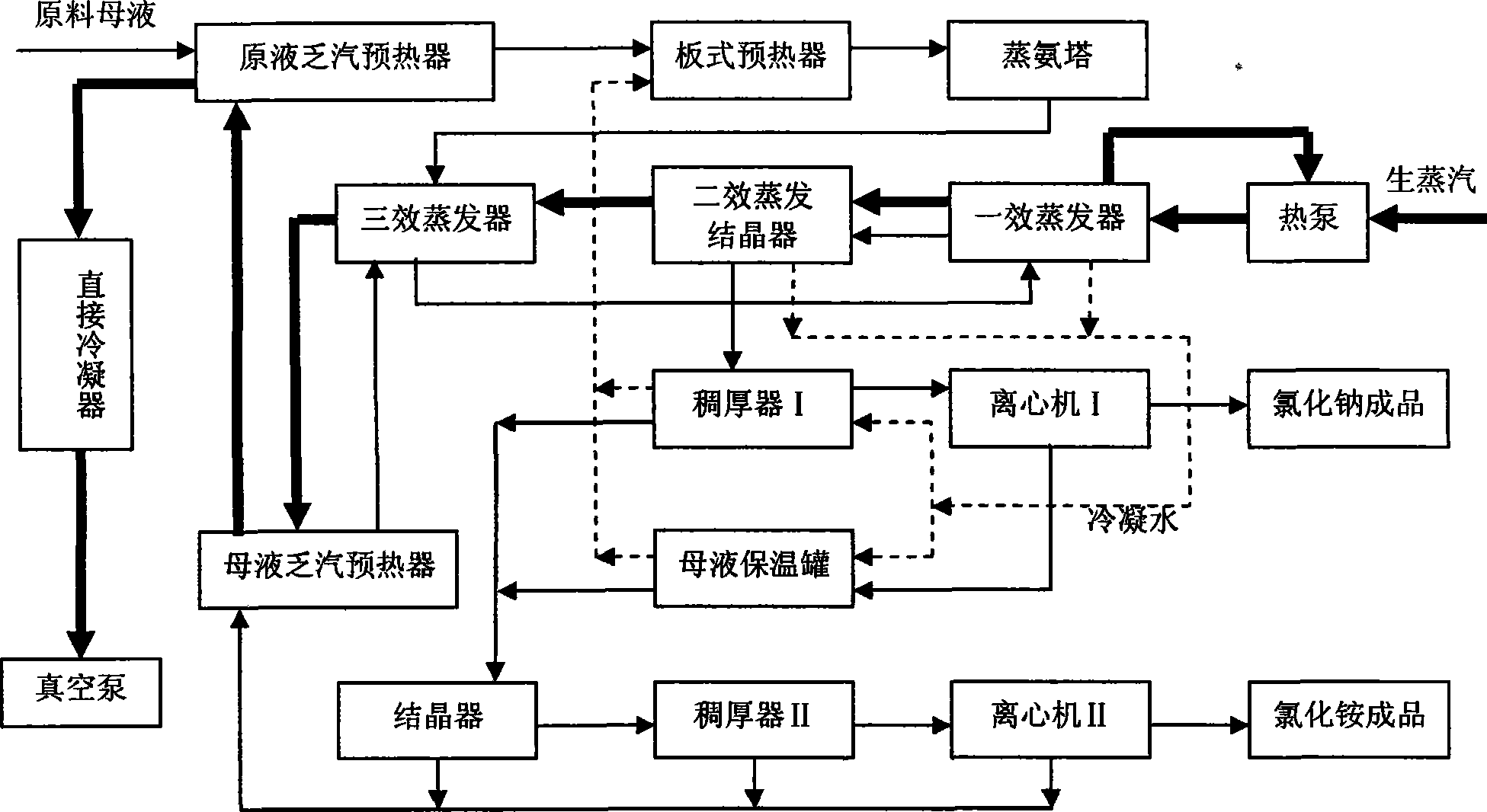

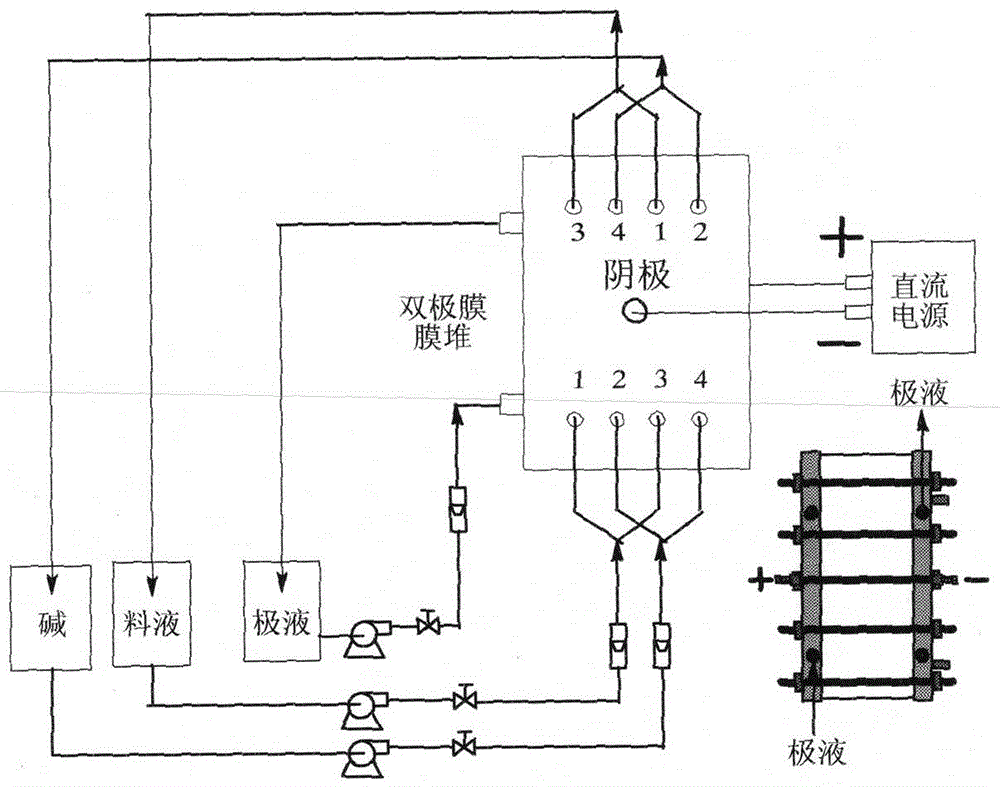

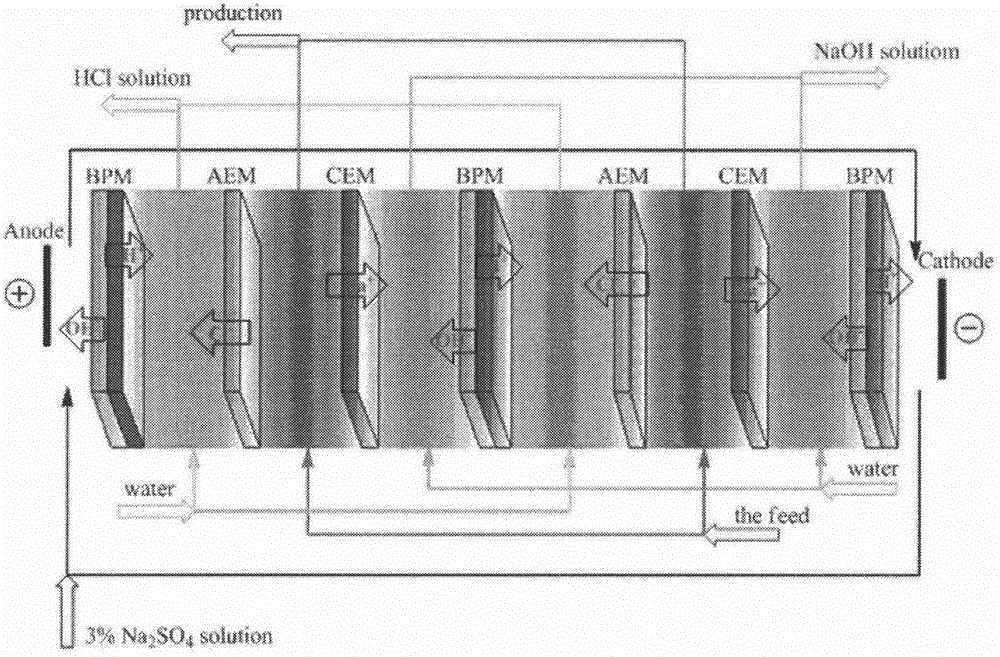

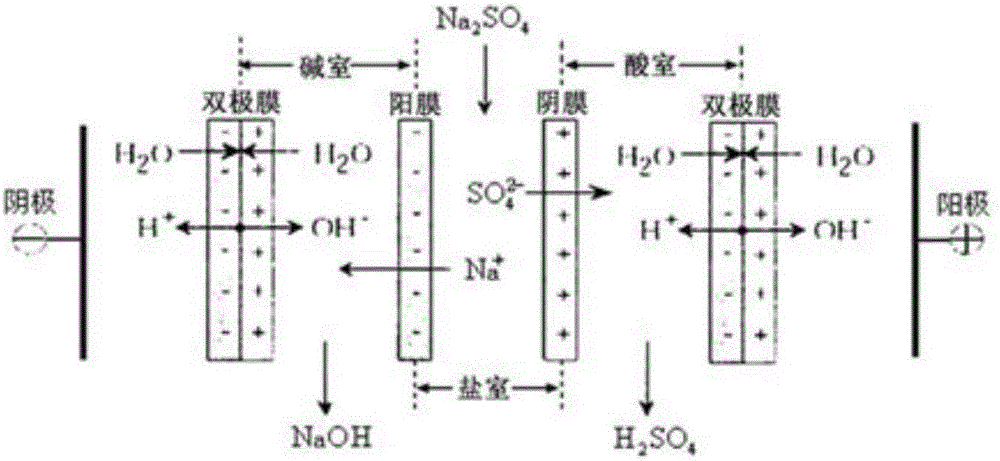

Method for producing sulfuric acid and sodium hydroxide by using bipolar membrane electroosmosis device

The invention relates to a method for producing sulfuric acid and sodium hydroxide by using a bipolar membrane electroosmosis device. The method comprises the following steps of: injecting sodium sulfate solution into a compartment formed by an anion selection membrane and a cation selection membrane; injecting water into compartments formed by a bipolar membrane, the anion selection membrane, and the cation selection membrane; and under the action of direct current electric field force, obtaining sodium hydroxide in the compartment formed by the cation selection membrane and an anion selection surface of the bipolar membrane which faces an anode, and / or a compartment formed by the cation selection membrane and a cathode; and obtaining sulfuric acid in the compartment formed by the anion selection membrane and a cation selection surface of the bipolar membrane which faces the cathode, and / or a compartment formed by the anion selection membrane and the cation. By the method, sodium sulfate waste liquid can be utilized again, the sulfuric acid and the sodium hydroxide which can be reutilized can be produced, waste materials are changed into things of value, and the method has obvious economic benefit and environmental benefit.

Owner:福建海能新材料有限公司

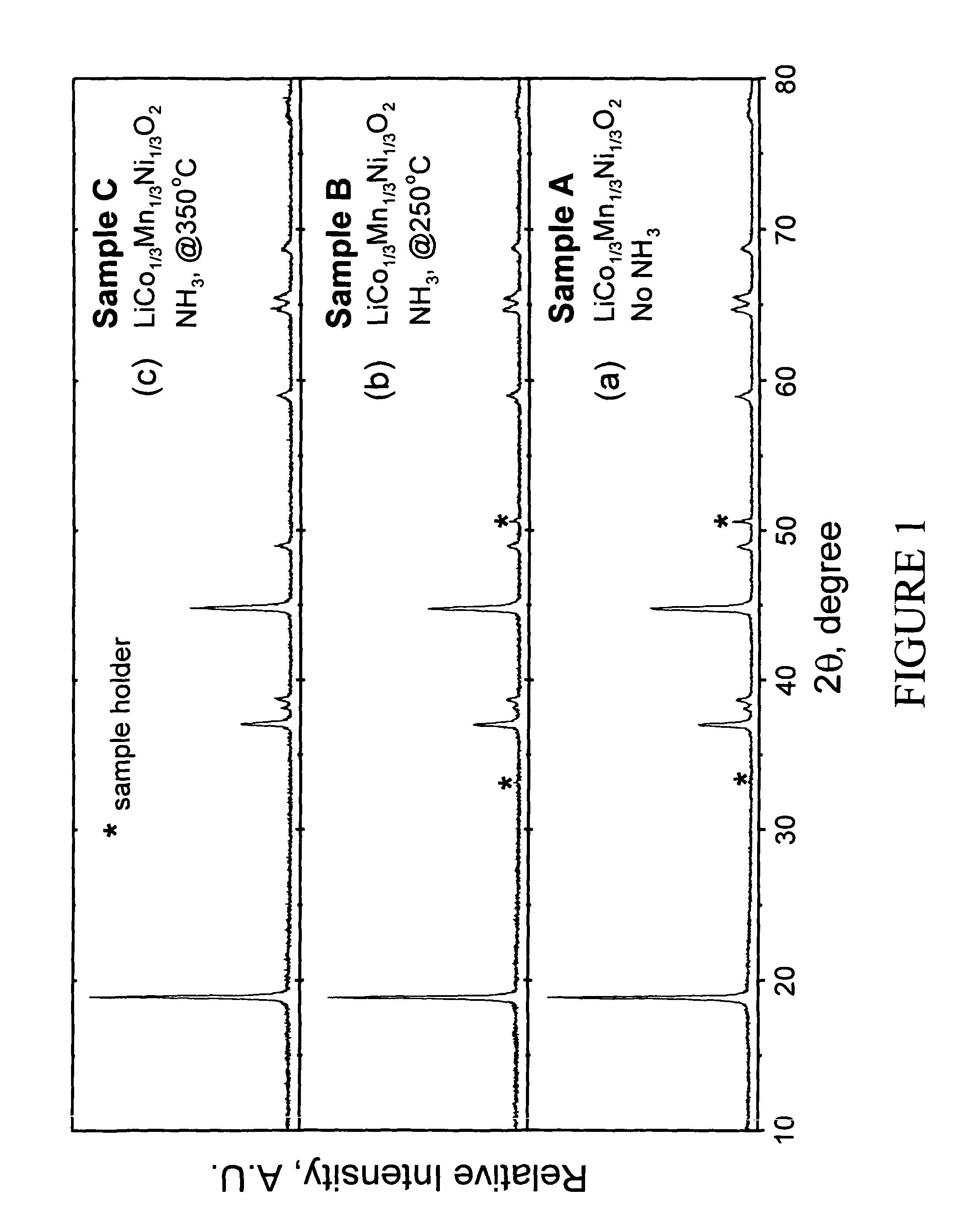

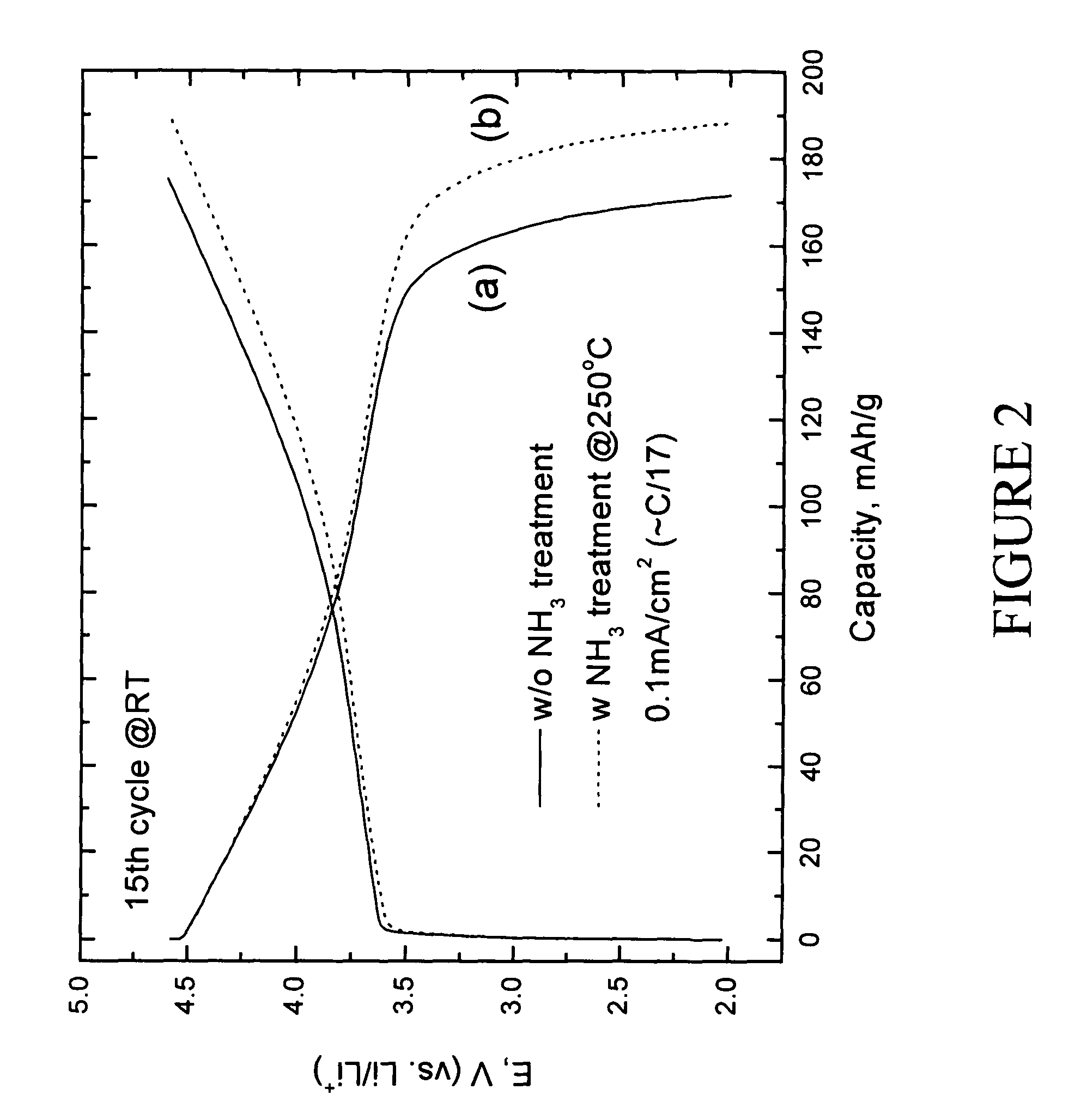

Lithium metal oxide electrodes for lithium batteries

Owner:UCHICAGO ARGONNE LLC +1

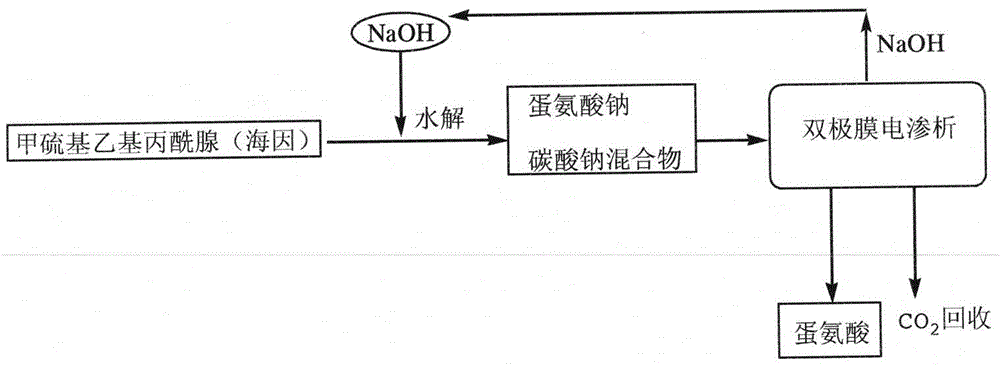

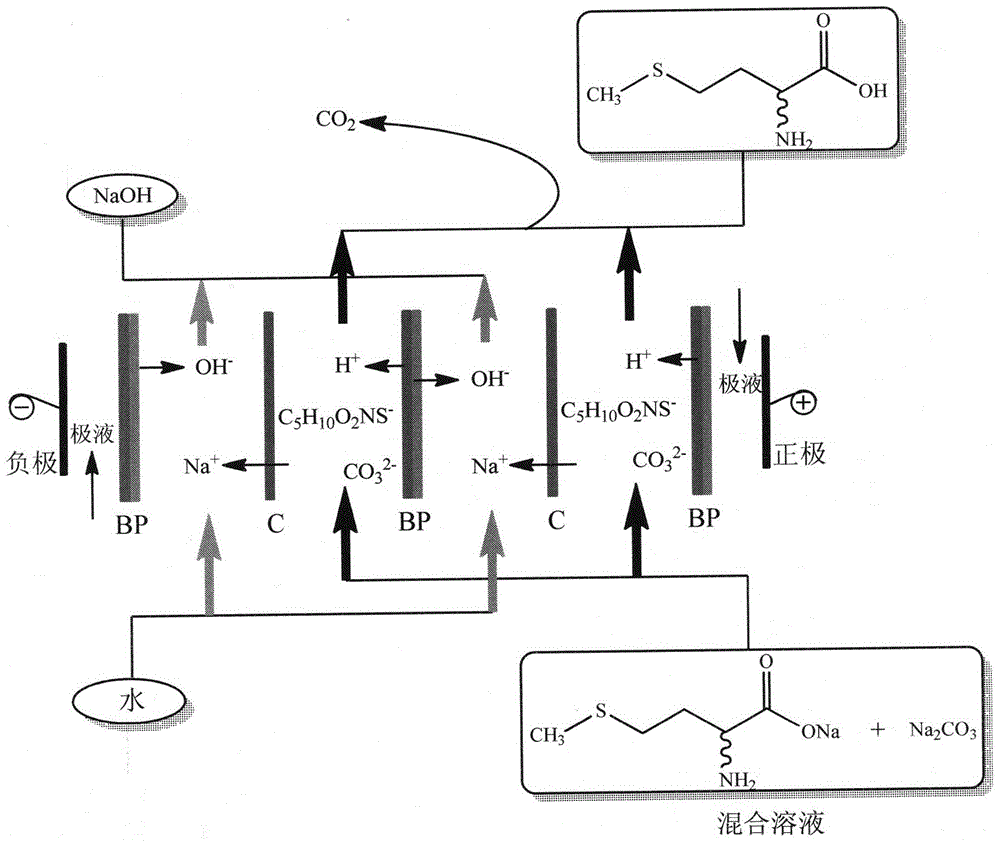

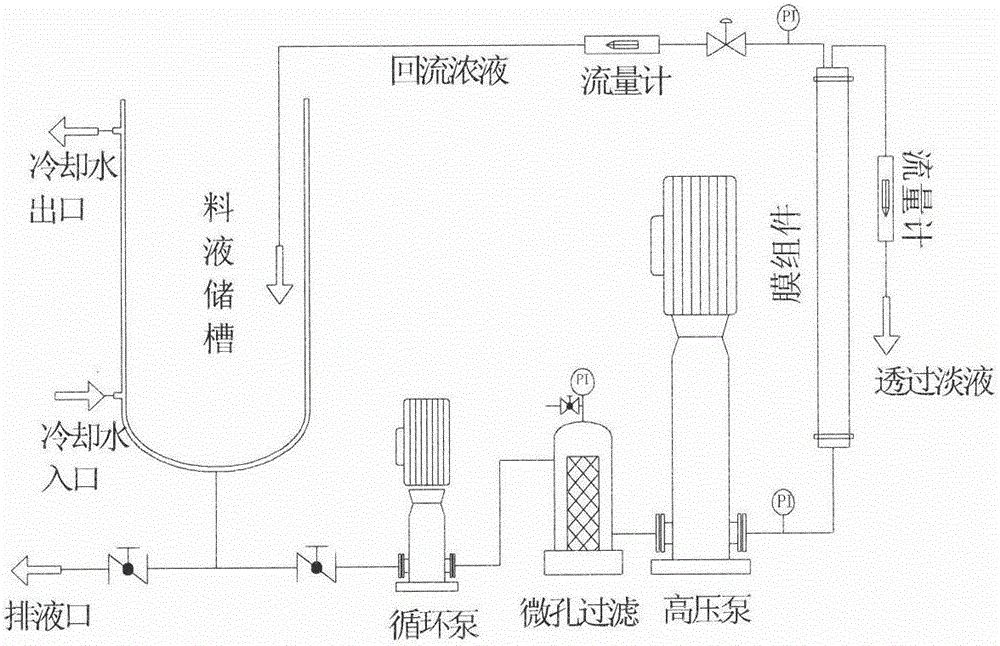

Method for preparing methionine and sodium hydroxide through bipolar membrane electrodialysis

InactiveCN103933861ARealize cleaner productionSignificant industrial application valueOrganic compound preparationAlkali metal hydroxidesMethionine recyclingHydrolysate

The invention discloses a method for preparing methionine and sodium hydroxide through applying a bipolar membrane electrodialysis technology. The method comprises the specific process: diluting a methylthioethyl hydantoin (hydantoin) hydrolysate to one-third to one-fifth of the original concentration, and filtering with a microporous filter; then pumping the hydrolysate into one of a salt chamber or a salt / acid chamber of a bipolar membrane electrodialysis device, and injecting a certain concentration of an electrolyte solution into other compartments; connecting a cathode and an anode of the bipolar membrane electrodialysis device respectively with a negative electrode and a positive electrode of a direct-current power source, starting the bipolar membrane electrodialysis device, controlling the current density of a direct-current electric field to be 50-150 mA / cm<2> and the temperature at 20-40 DEG C, and thus obtaining methionine with higher purity in an acid chamber, wherein the methionine recycling rate reaches more than 95% and the current efficiency reaches about 70%; and at the same time, collecting obtained carbon dioxide, and thus obtaining sodium hydroxide with the concentration of 4-6% in an alkali chamber. The method has the advantages of high yield, no pollution, less use of raw materials, and good application prospects.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

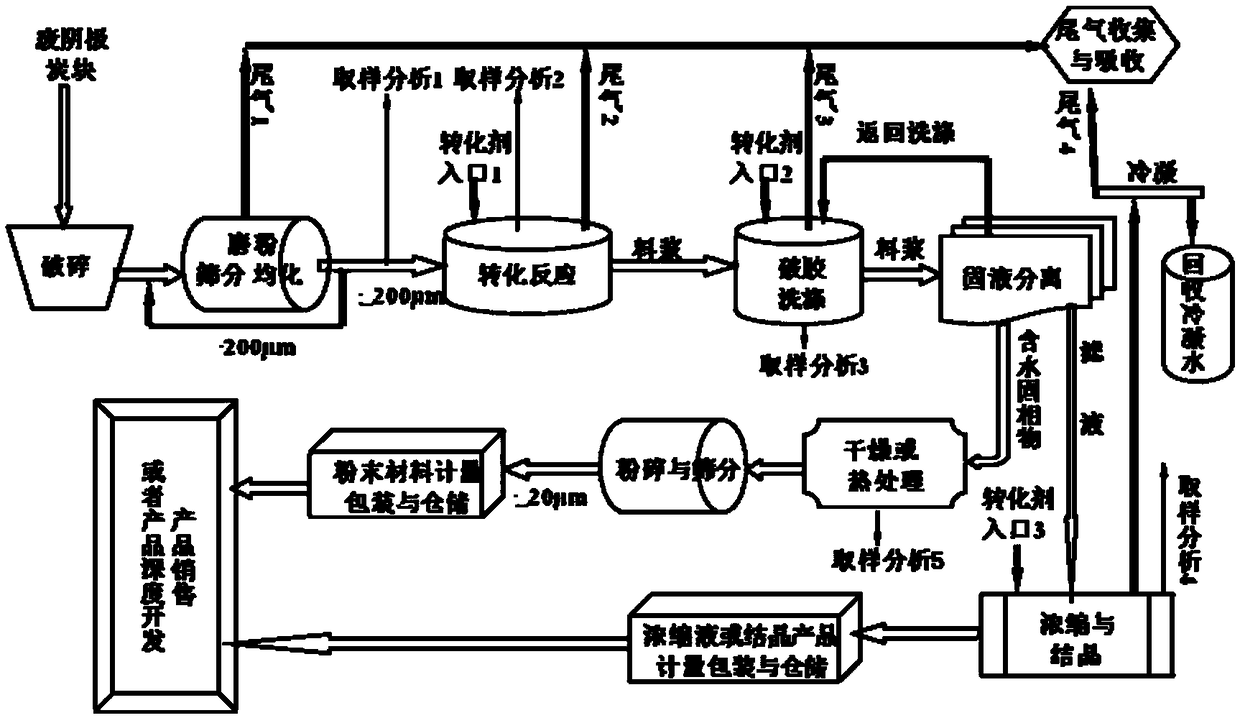

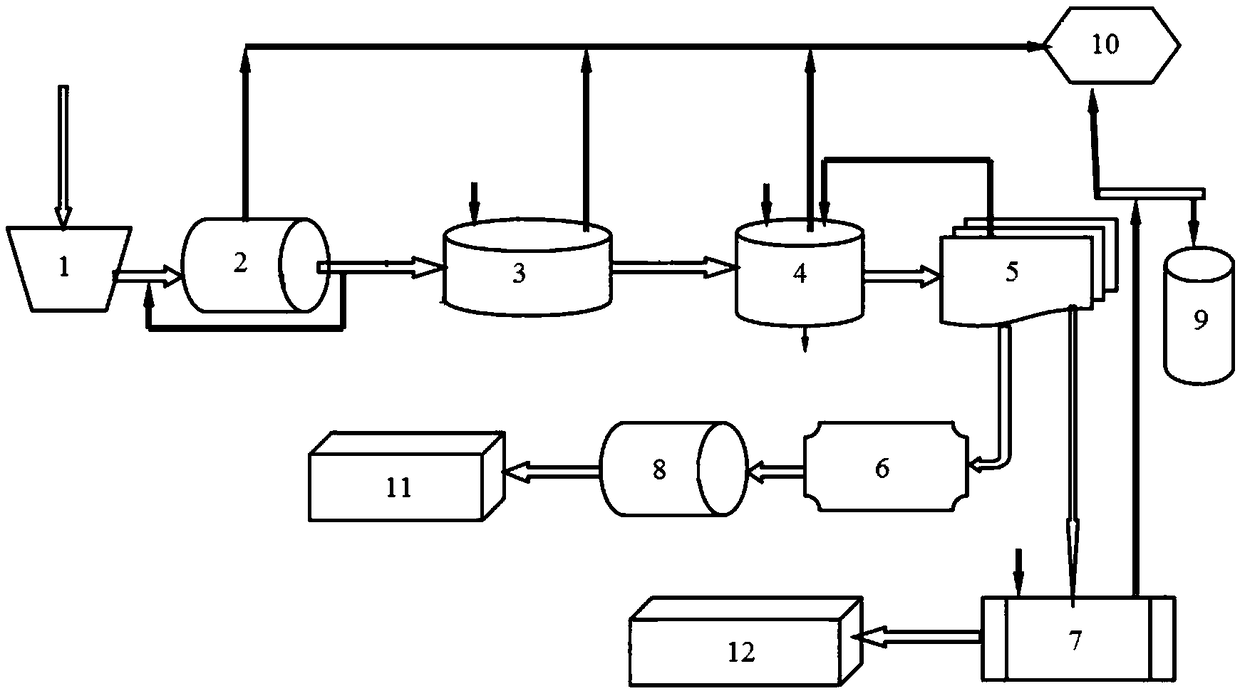

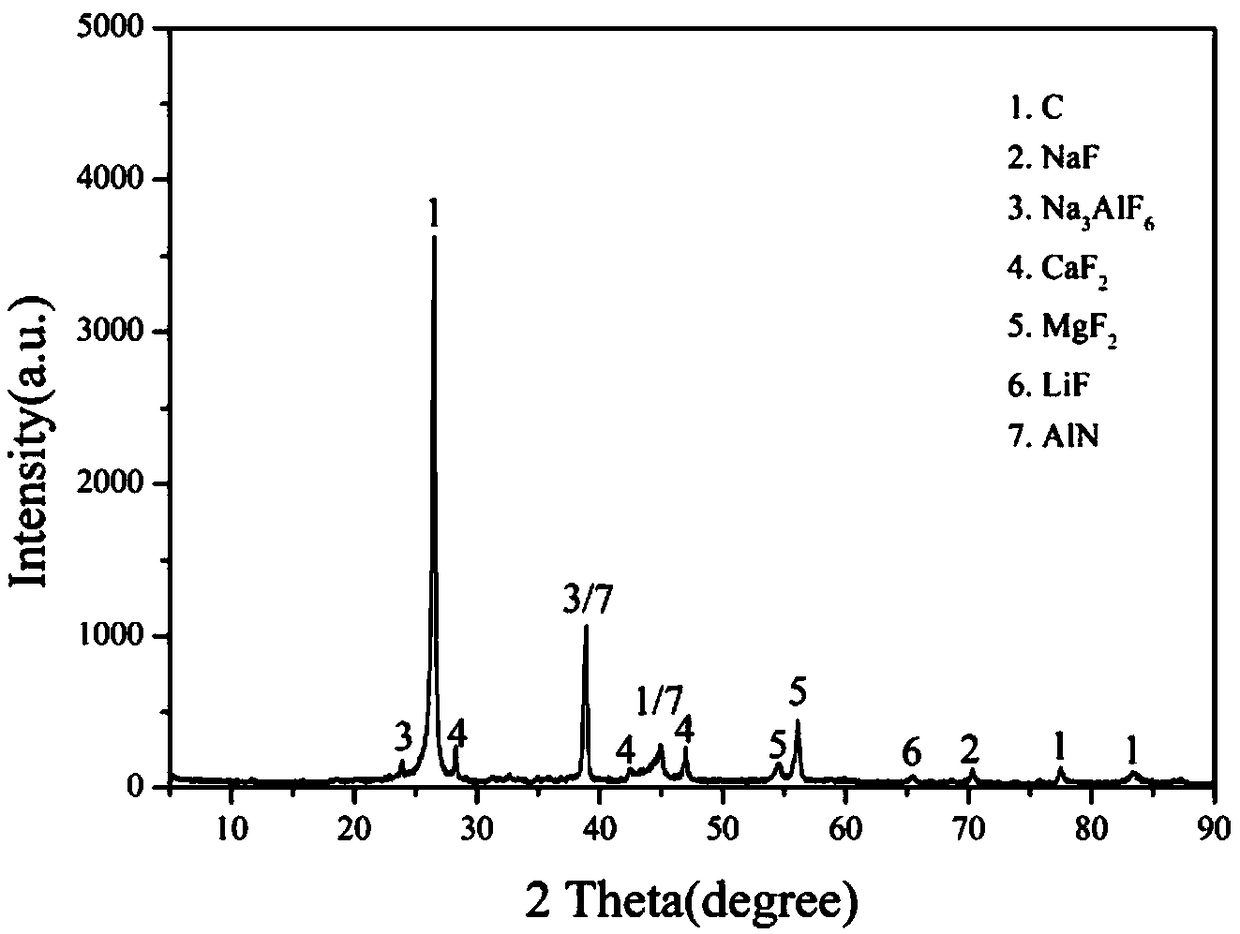

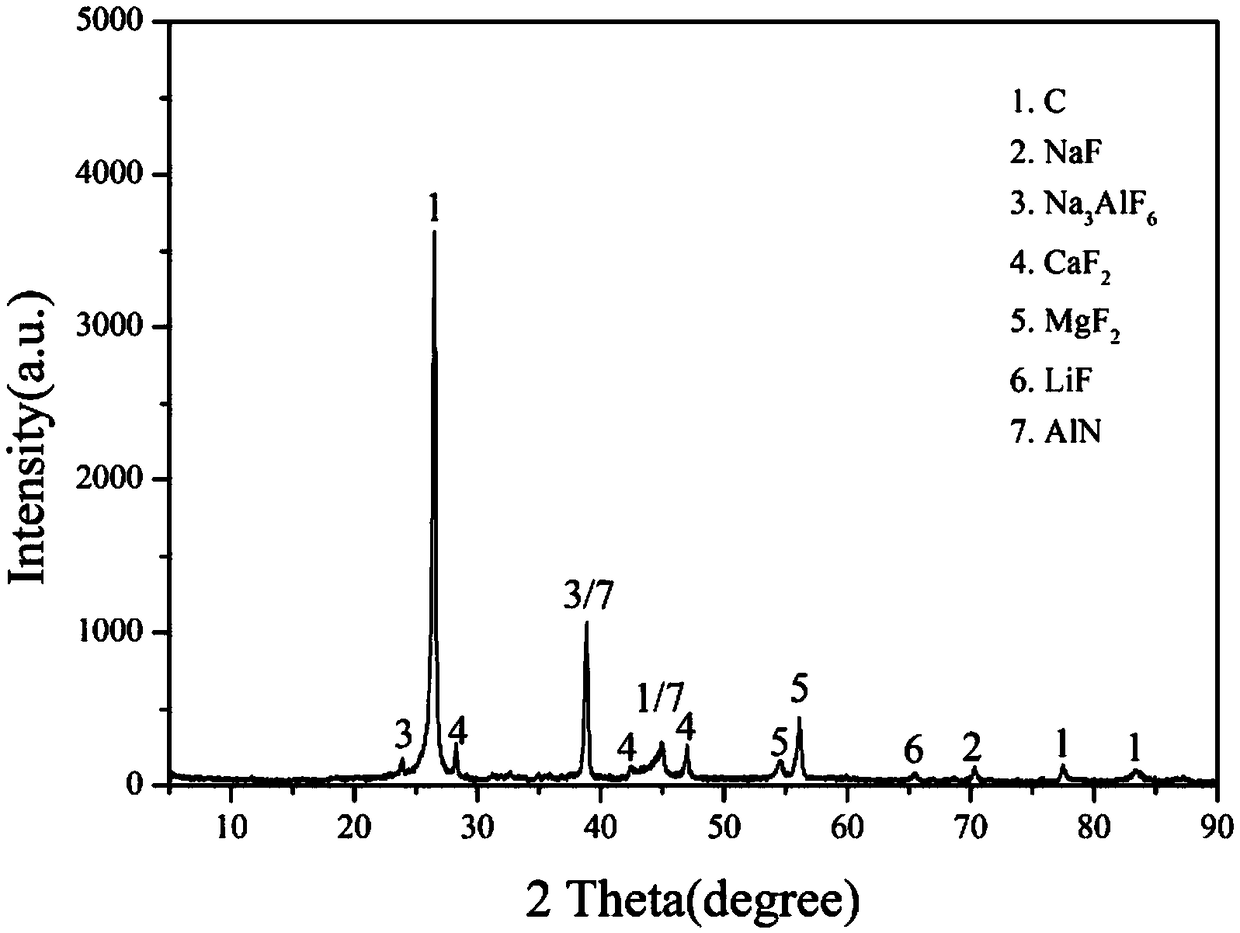

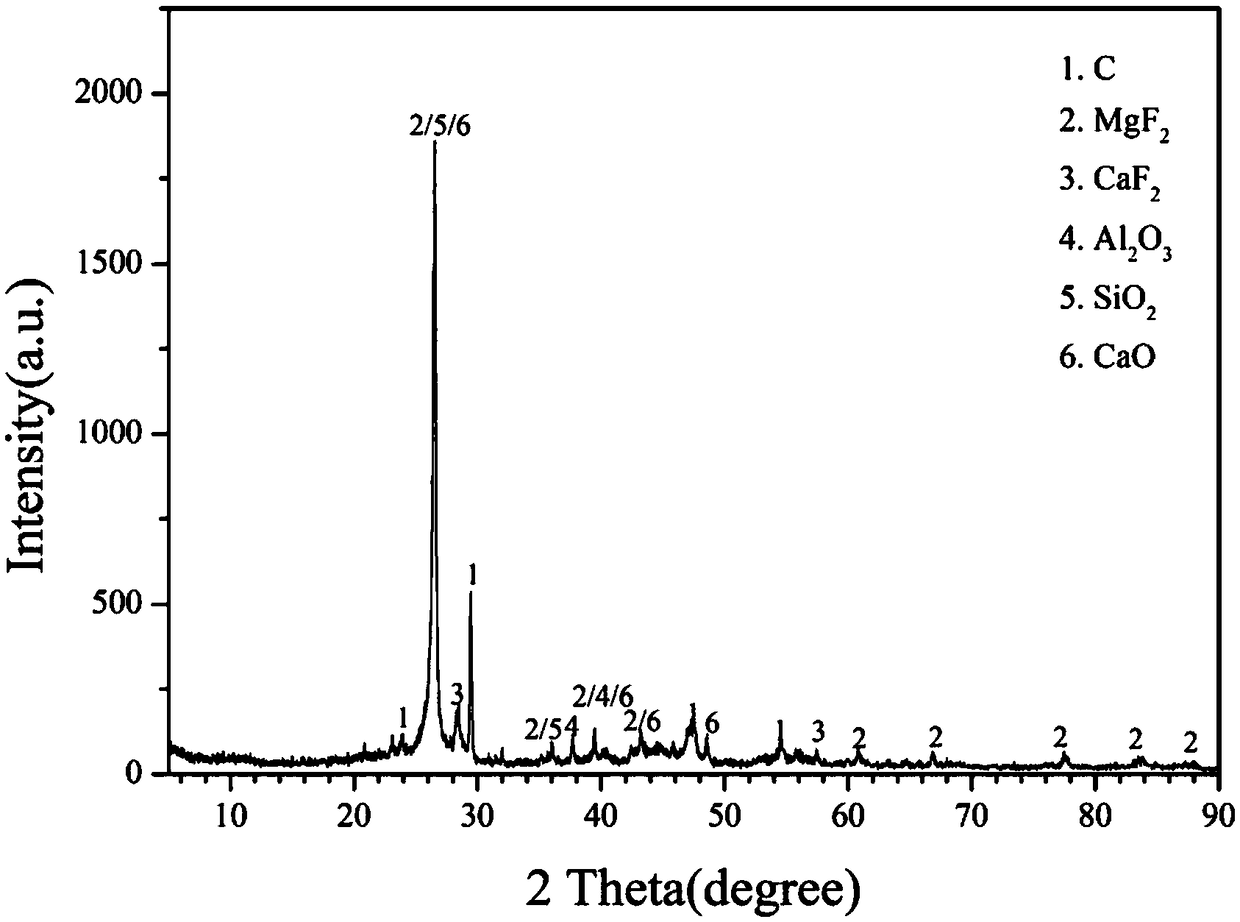

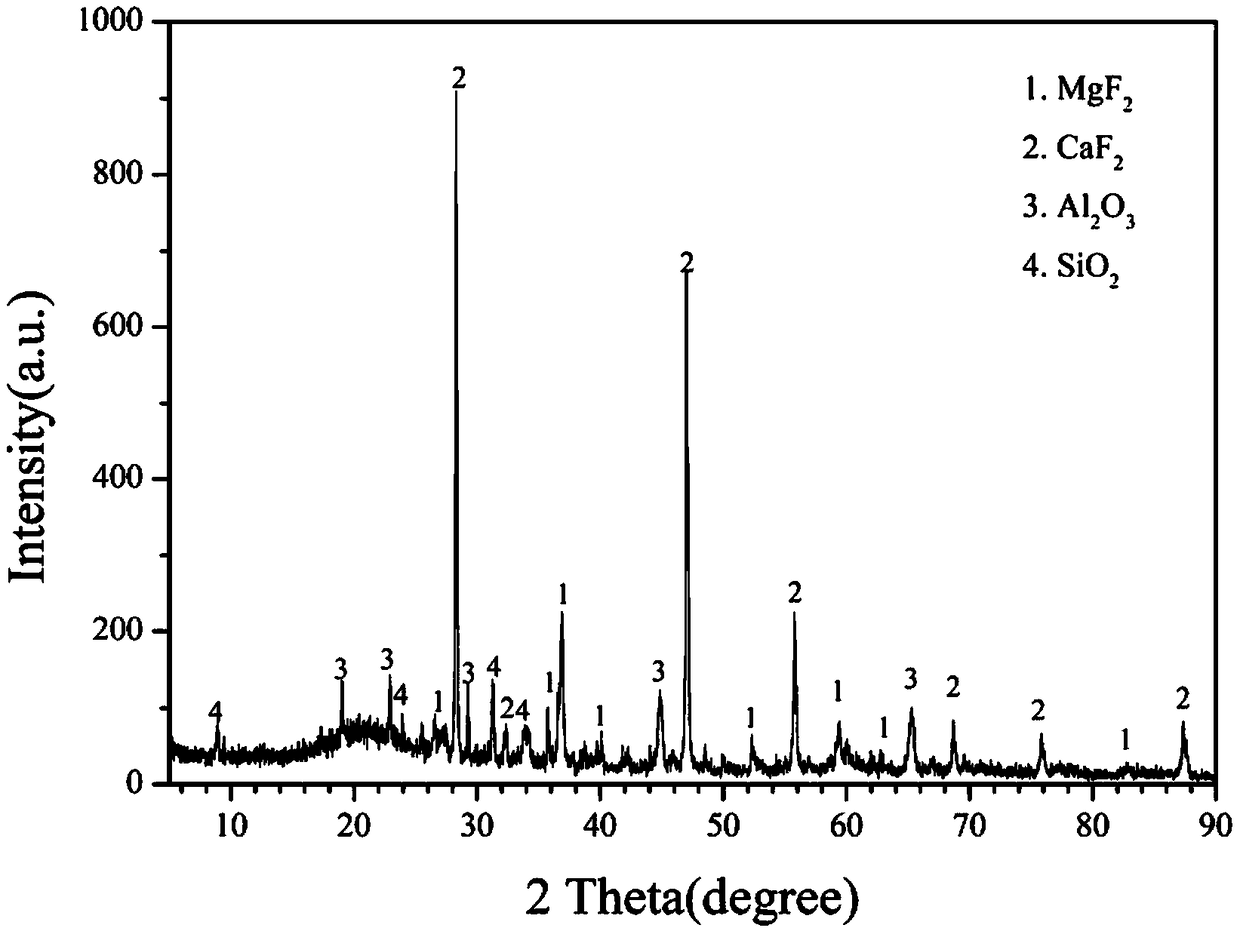

Method and system for converting sodium-containing and fluorine-containing compounds in waste cathode carbon block of aluminum electrolytic cell

ActiveCN109047285AEasy to controlEasy to industrializeMagnesium fluoridesTransportation and packagingPollutionHeat treated

The invention relates to a method and system for converting sodium-containing and fluorine-containing compounds in a waste cathode carbon block of an aluminum electrolytic cell. The conversion methodcomprises the step that a conversion agent is used for converting the sodium-containing compound in the waste cathode carbon block of the aluminum electrolytic cell into a fluorine-free soluble sodiumcompound, converting the fluorine-containing compound into an insoluble and harmless mineral fluorine compound and converting a cyanide-containing compound into harmless N2 or NH3 and CO2 in an oxidized manner through a mechanochemical conversion reaction in a conversion mill, and therefore the hazards of fluoride and cyanide in the waste cathode carbon block of the aluminum electrolytic cell arecompletely eliminated. The conversion system comprises a waste cathode carbon block crushing device, a milling device, the conversion mill, a stirred reactor and a solid-liquid separation device which are sequentially connected in series, and the solid-liquid separation device is then directly connected with a concentration or crystallization device and a drying or heat treatment device, and thedrying or heat treatment device is connected to the crushing device. By means of the method and system, the process is simple, mass production is easy, the production cost is low, pollution of three wastes is avoided, and the method and system are environmentally friendly.

Owner:XIANGTAN UNIV

High value-added greening comprehensive utilization method for medium and low-grade zinc oxide ores

The invention discloses a high value-added greening comprehensive utilization method for medium and low-grade zinc oxide ores (mainly comprising willemite, hemimorphite and calamine). The method comprises the following steps: (1) crushing and grinding the zinc oxide ores, then mixing the ground zinc oxide ores and ammonium sulfate solution, and drying, dehydrating and roasting the mixture (the calamine needs to be calcined before mixing); (2) dissolving the roasted product in water, filtering the solution, and then removing impurities by an ammoniojarosite method to obtain zinc sulfate refining solution; (3) electrodepositing the zinc sulfate refining solution to prepare zinc, and introducing ammonia into the electrodepositing waste solution to prepare ammonium sulfate for reclaiming; and (4) treating the filter residue (mainly containing oxides of silicon and iron) by alkali to prepare a silicon oxide product, and using the residue as an iron-making raw material or deeply processing the residue into a high value-added product. The method is suitable for treating various medium and low-grade zinc oxide ores, has simple process flow and simple and convenient equipment, has no waste emission of solid, liquid and gas so as not to cause secondary pollution, and realize high value-added greening comprehensive utilization of the medium and low-grade zinc oxide ore resources with lower cost.

Owner:NORTHEASTERN UNIV

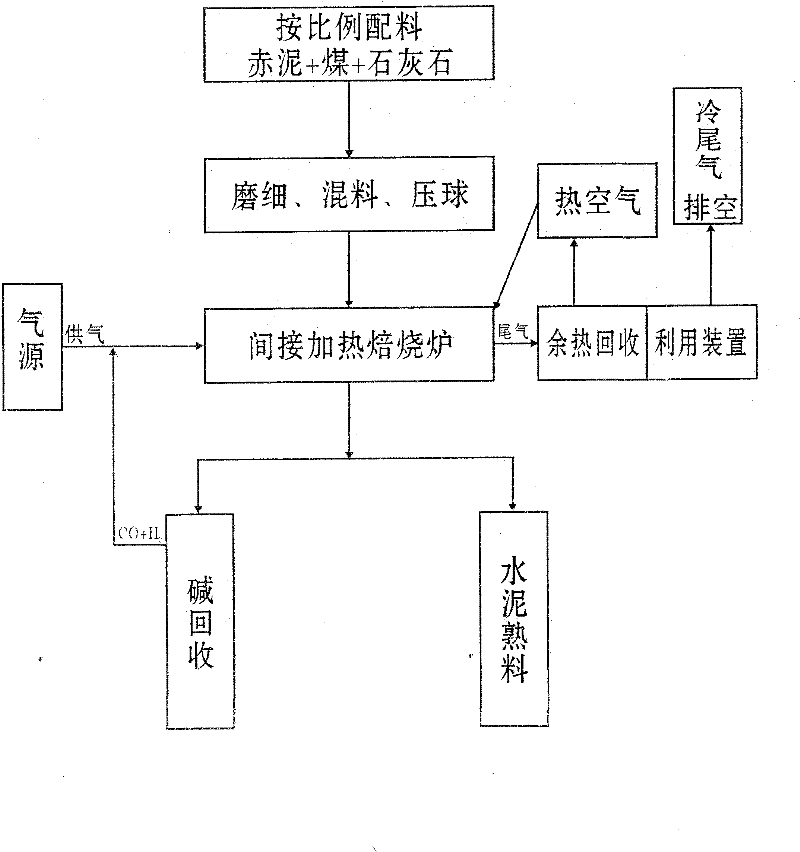

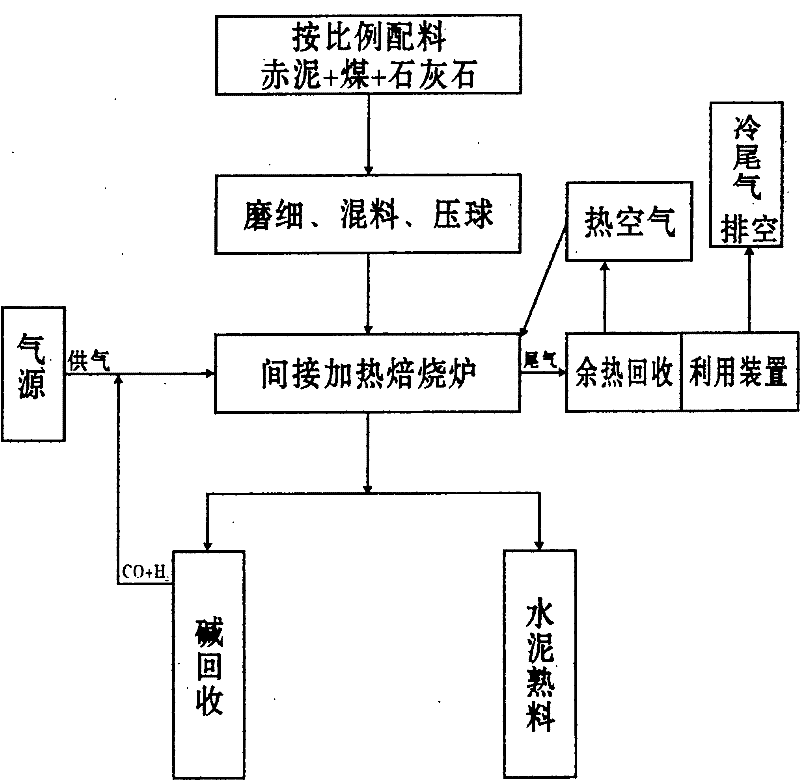

Process for recycling alkali and synchronously producing cement by roasting red mud

InactiveCN102234171ASludge treatment by thermal conditioningCement productionEcological environmentRed mud

The invention discloses a process for recycling alkali and synchronously producing cement by roasting red mud, belonging to the field of aluminum industry production. 1.2-2.1 tons of red mud as a byproduct is produced while 1 ton of aluminum oxide is produced, wherein the red mud contains 5-7% of alkali which is large in amount and harmful to the environment; and the alkali is a significant environmental pollution source for restraining the development of the aluminum industry and the comprehensive utilization of the red mud and damaging the ecological environment. At present, removing and recycling of the alkali in the red mud is still a difficult problem in the world. The invention solves the problem on removing and recycling the alkali in the red mud, and realizes that the cement is synchronously produced while the alkali is removed and recycled; therefore, the zero emission of solid waste residuals is realized for aluminum oxide production enterprises. The process is crucially characterized in that a condition of oxygen-free strong reduction is created for separating the alkali in the red mud, thereby a reducing / decomposing reaction of Na2O(solid)+C(solid)=2Na(gas)+CO(gas) can be performed successfully. According to the process provided by the invention, the red mud is indirectly heated and is decomposed under an air-insulated and oxygen-free strong reduction condition to generate Na metal atoms; and the Na metal atoms are led to the outside of the furnace together with a byproduct CO, and enter a recycling tower to synthesize alkali (NaOH) with water. After the alkali is separated and recycled, the residues are synchronously sintered into cement.

Owner:骆群

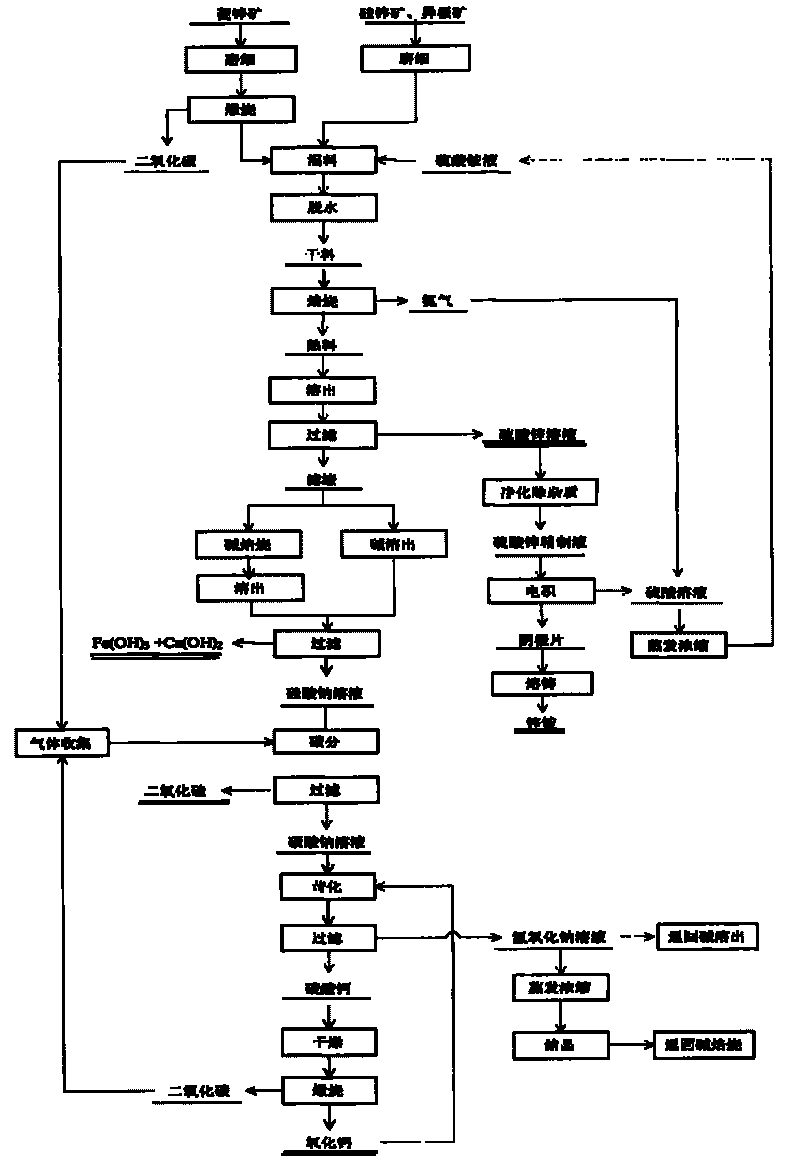

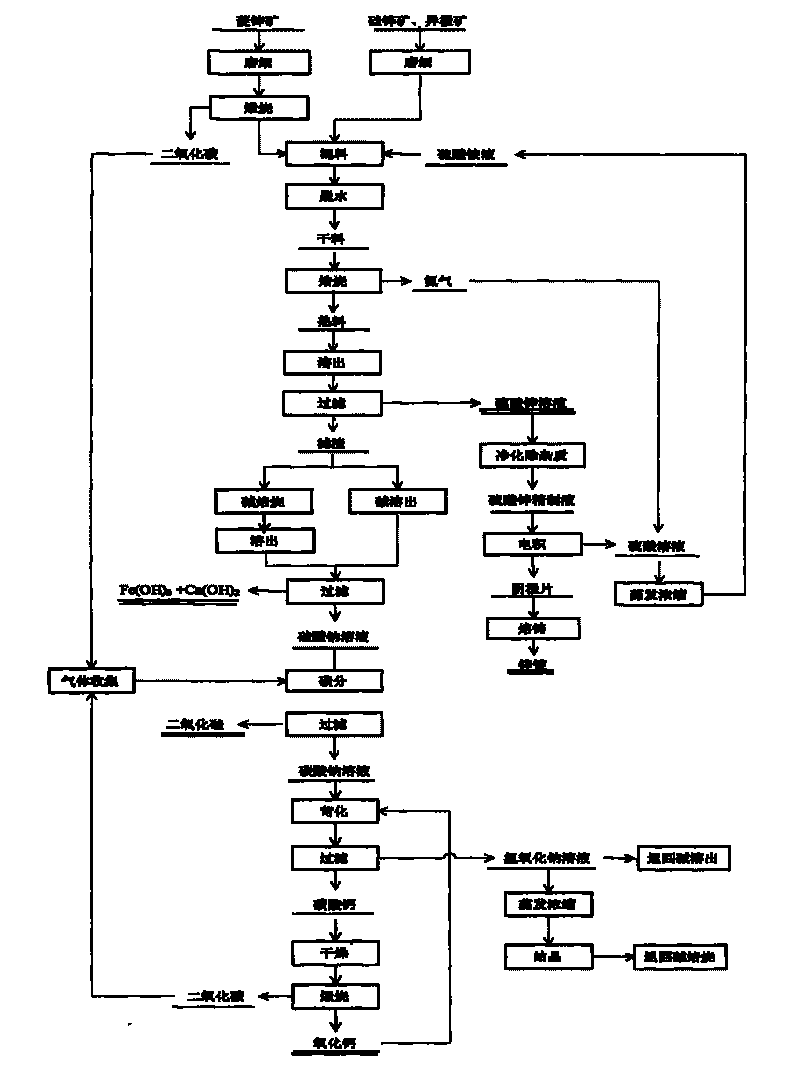

Method for recycling alkali and aluminum in process of treating bayer red mud by calcification-carbonization method

ActiveCN103934258APromote incomeReduce energy consumptionSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

The invention relates to the field of environment protection, and in particular relates to a method for recycling alkali and aluminum in a process of treating bayer red mud by a calcification-carbonization method. The method comprises the steps of mixing the bayer red mud with calcium aluminate or lime and the calcium aluminate to obtain a mixture, performing calcification dealkalization transformation on the mixture in high-concentration alkali liquid with the caustic alkali concentration being 100-300g / L, totally converting silicon-containing phases in the red mud into calcified slag generated in a dealkalization process in the form of hydrate garnet, carbonizing the calcified slag to obtain carbonized slag, then o carrying out low-temperature aluminum smelting and aluminum precipitation to obtain a calcium aluminate product, and recycling the calcium aluminate product in the red mud calcification dealkalization transformation process. Part of alkali and aluminum-containing liquid phases subjected to calcification dealkalization transformation can be reused as supplement alkali in a bayer production process. The method disclosed by the invention can realize recycling of alkali and aluminum in the red mud and harmless treatment of the bayer red mud, and is an energy-saving and environment-friendly red mud utilization method.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

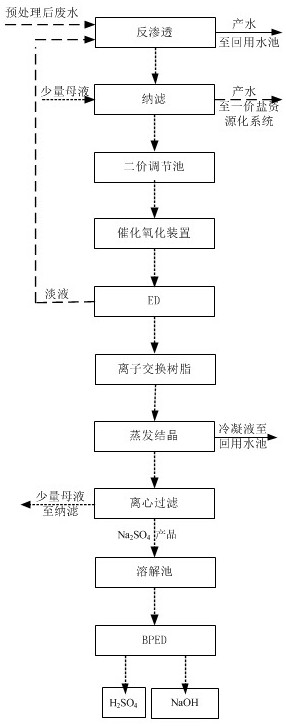

Method for recovering acid and alkali from viscose sodium sulfate waste liquor through bipolar membrane electrodialysis way

ActiveCN103342433AExtended service lifeHigh yieldSulfur compoundsMultistage water/sewage treatmentLiquid wasteFiltration

The invention discloses a method for recovering acid and alkali from viscose sodium sulfate waste liquor through a bipolar membrane electrodialysis way. The method is characterized by sequentially comprising the following steps of: crystallizing; adjusting pH (Potential of Hydrogen); initially filtering at the first time; oxidizing reducing substances through O3; initially filtering at the second time; removing organic substances through activated carbon; removing zinc ions through ion exchange resin; filtering and performing refined filtration through pp micropores; preparing acid and alkali; and concentrating. By adopting the method, the regenerative recovery rate of the acid and alkali in the viscose sodium sulfate waste liquor is increased, and the damage of impurities in the waste liquor to a bipolar membrane is reduced, so that the service life of the bipolar membrane is prolonged, and the bipolar membrane electrodialysis and subsequent processes can be able to be carried out smoothly; in addition, sodium hydroxide crystals of which the alkali concentration is controlled to 96%, 98% and 99% can be obtained, which can be directly marketed, thus the benefit is brought.

Owner:宜宾海翔化工有限责任公司 +2

Method for recovering aluminum hydroxide and sodium hydroxide from liquid waste of aluminum industry alkali waste

InactiveCN108069449AAvoid manual cleaning difficultiesRestore production capacityAlkali metal hydroxidesAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationLiquid wasteAluminum Ion

Disclosed is a method for recovering aluminum hydroxide and sodium hydroxide from liquid waste of aluminum industry alkali waste. The method comprises the following steps of (1) obtaining liquid wastecontaining free alkali and aluminum ions at a ratio of 3.0-3.5; (2) adding seed crystal inside the liquid waste; (3) precipitating aluminum hydroxide; (4) performing solid-liquid separation on the liquid waste to recovering the aluminum hydroxide as well as alkali liquor containing sodium hydroxide. The method for recovering the aluminum hydroxide and the sodium hydroxide from the liquid waste ofthe aluminum industry alkali waste can effectively recover the aluminum hydroxide meeting national standard to achieve high-value resource reutilization of waste aluminum, to reduce the scaling riskof recovery equipment and to greatly prolong the maintenance period, and meanwhile, can on line recycle the alkali liquor containing the sodium hydroxide to reduce the production cost of mold boilingand further to achieve zero emission of liquid waste and waste residue of a mold boiling workshop.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

Mechano-chemical conversion and recovery method for sodium-containing compound and fluorine-containing compound in aluminum electrolysis cell waste cathode carbon blocks

ActiveCN108941167AEasy to controlEasy to industrializeMagnesium fluoridesSolid waste disposalRecovery methodElectrolysis

The invention relates to a mechano-chemical conversion and recovery method for a sodium-containing compound and a fluorine-containing compound in aluminum electrolysis cell waste cathode carbon blocks. The method comprises the steps that the aluminum electrolysis cell waste cathode carbon blocks are crushed, ground and homogenized at first, so that waste cathode carbon powder with particles beingsmaller than or equal to 200 [mu]m is obtained; the waste cathode carbon powder, a sodium compound and fluorine compound conversion agent, a cyanide conversion agent, a grinding aid and water are added into a conversion mill; and under synchronous action of high-energy mechanical force, the sodium-containing compound in the waste cathode carbon powder is converted into a fluorine-free soluble sodium compound, the fluorine-containing compound is converted into an insoluble and harmless mineral substance fluorine compound, a cyanogen-containing compound is oxidized and converted into harmless N2or NH3 and CO2, and therefore harm of fluoride and cyanide in the aluminum electrolysis waste cathode carbon blocks are removed thoroughly, and harmless resource recycling of the aluminum electrolysis waste cathode carbon blocks is achieved. The mechano-chemical conversion and recovery method is simple in process, low in production cost, free of three-waste pollution and environmentally friendly,and large-scale production is easy to implement.

Owner:XIANGTAN UNIV

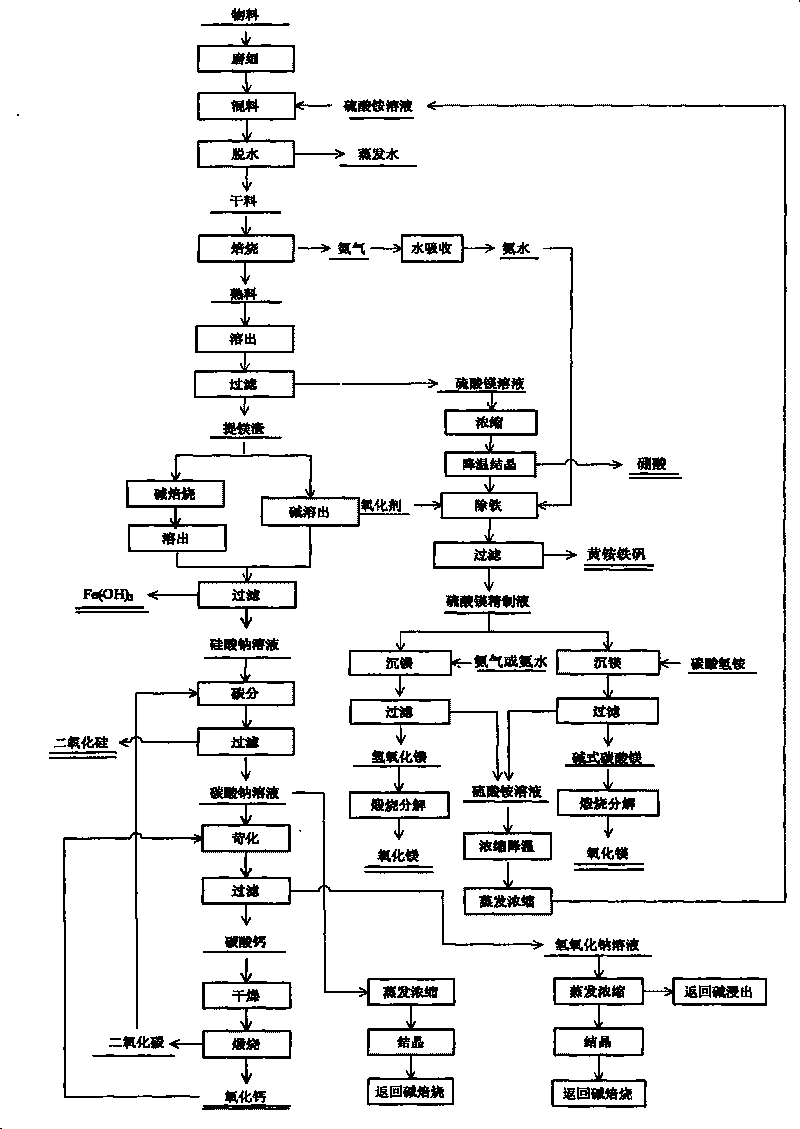

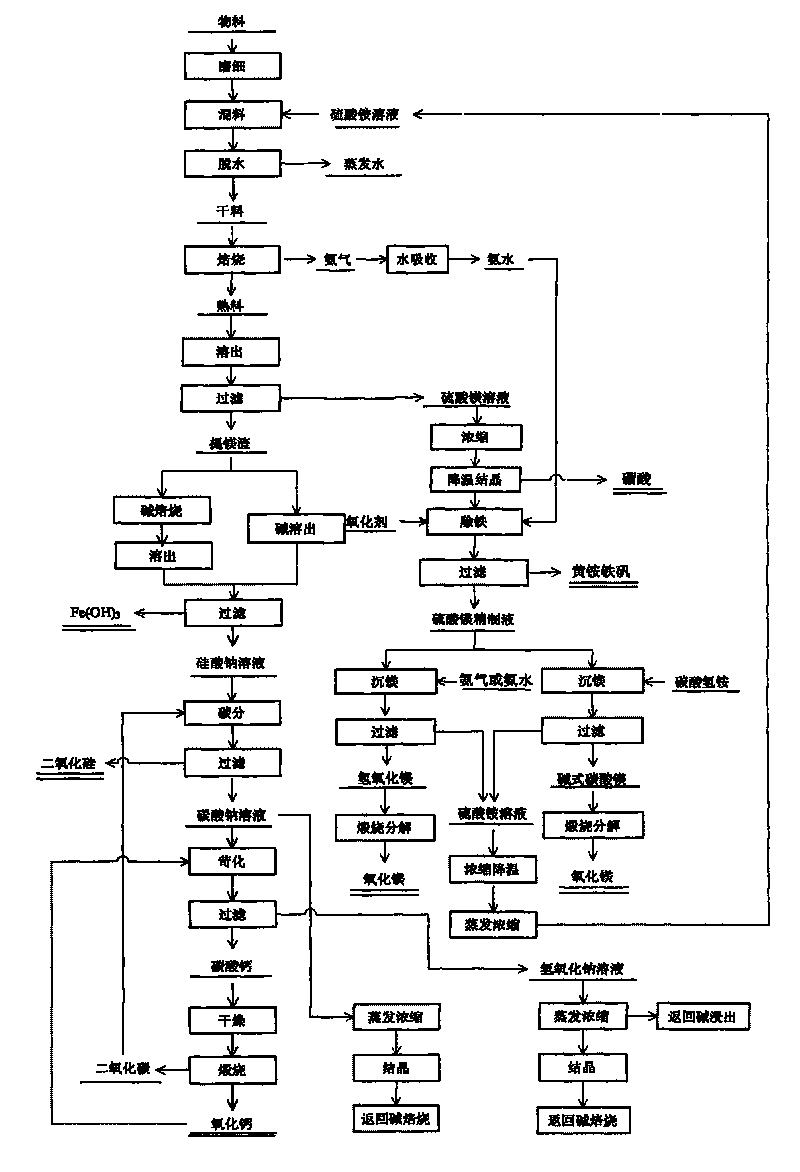

High value-added greening comprehensive utilization method of boron concentrate, boron-containing iron concentrate and ludwigite

A high value-added greening comprehensive utilization method of boron concentrate, boron-containing iron concentrate and ludwigite comprises the following steps: (1) crushing and grinding the boron concentrate, the boron-containing iron concentrate and the ludwigite and then mixing with ammonium sulfate for roasting; (2) dissolving a roasted product with water to obtain magnesium sulfate solution (wherein also containing a small amount of ferric sulfate, ferrous sulfate and boric acid) and extracting magnesium slag (mainly containing silica and iron oxide); (3) reducing the temperature of the magnesium sulfate solution to precipitate boric acid crystal, then removing iron to obtain magnesium sulfate refined liquid, and then using ammonia water or ammonia gas for adjusting pH value to produce magnesium hydroxide precipitate or adding ammonium bicarbonate to produce basic magnesium carbonate precipitate; and (4) extracting the magnesium slag which can be directly used as ironmaking material according to the iron content, or treating with alkali to extract the silica which is used as the ironmaking material. The high value-added greening comprehensive utilization method is suitable for treating the boron concentrate, the boron-containing iron concentrate and the ludwigite, has simple process, and simple and convenient equipment, and realizes the high value-added greening comprehensive utilization of the boron concentrate, the boron-containing iron concentrate and the ludwigite with lower cost.

Owner:NORTHEASTERN UNIV

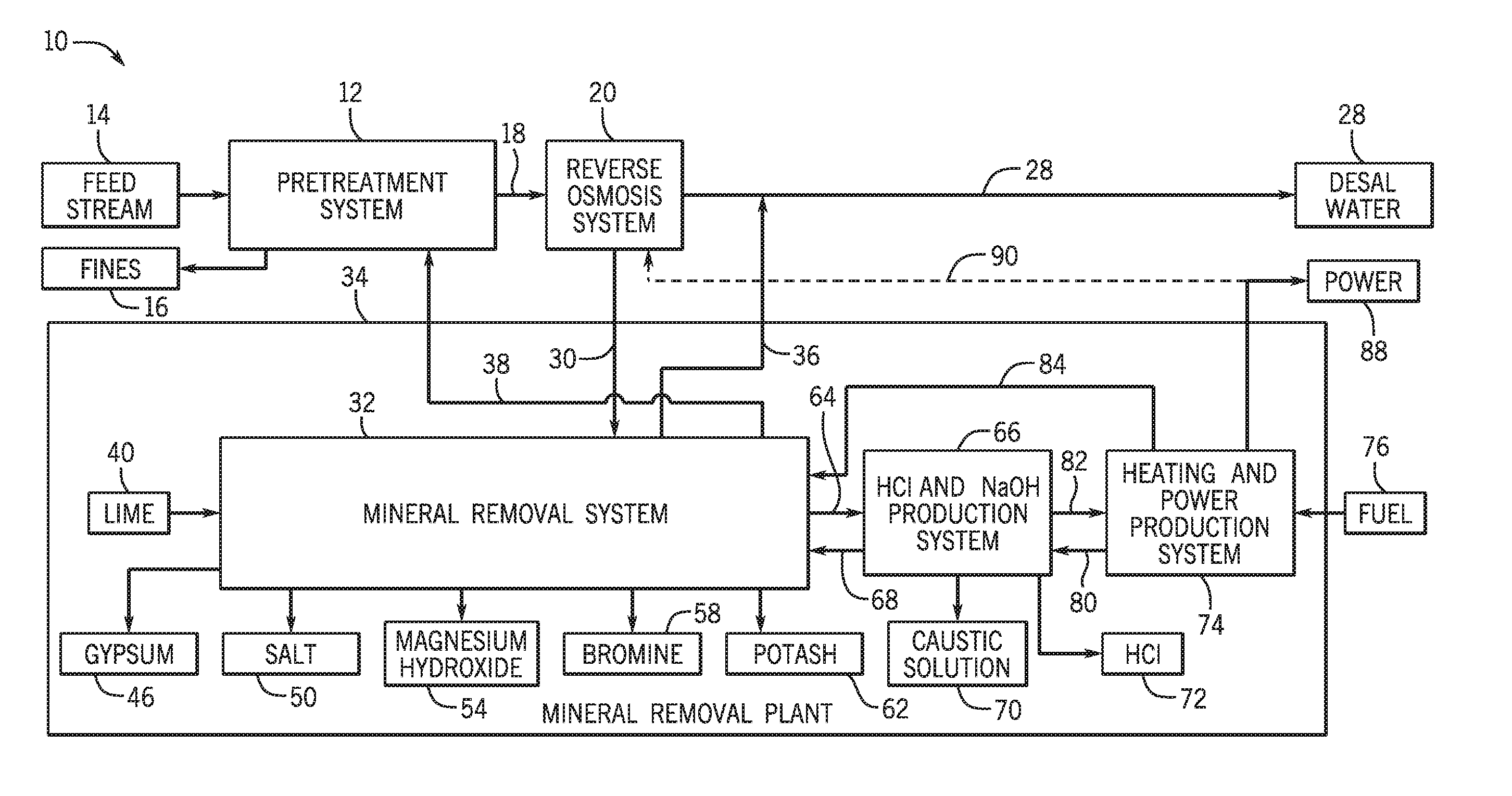

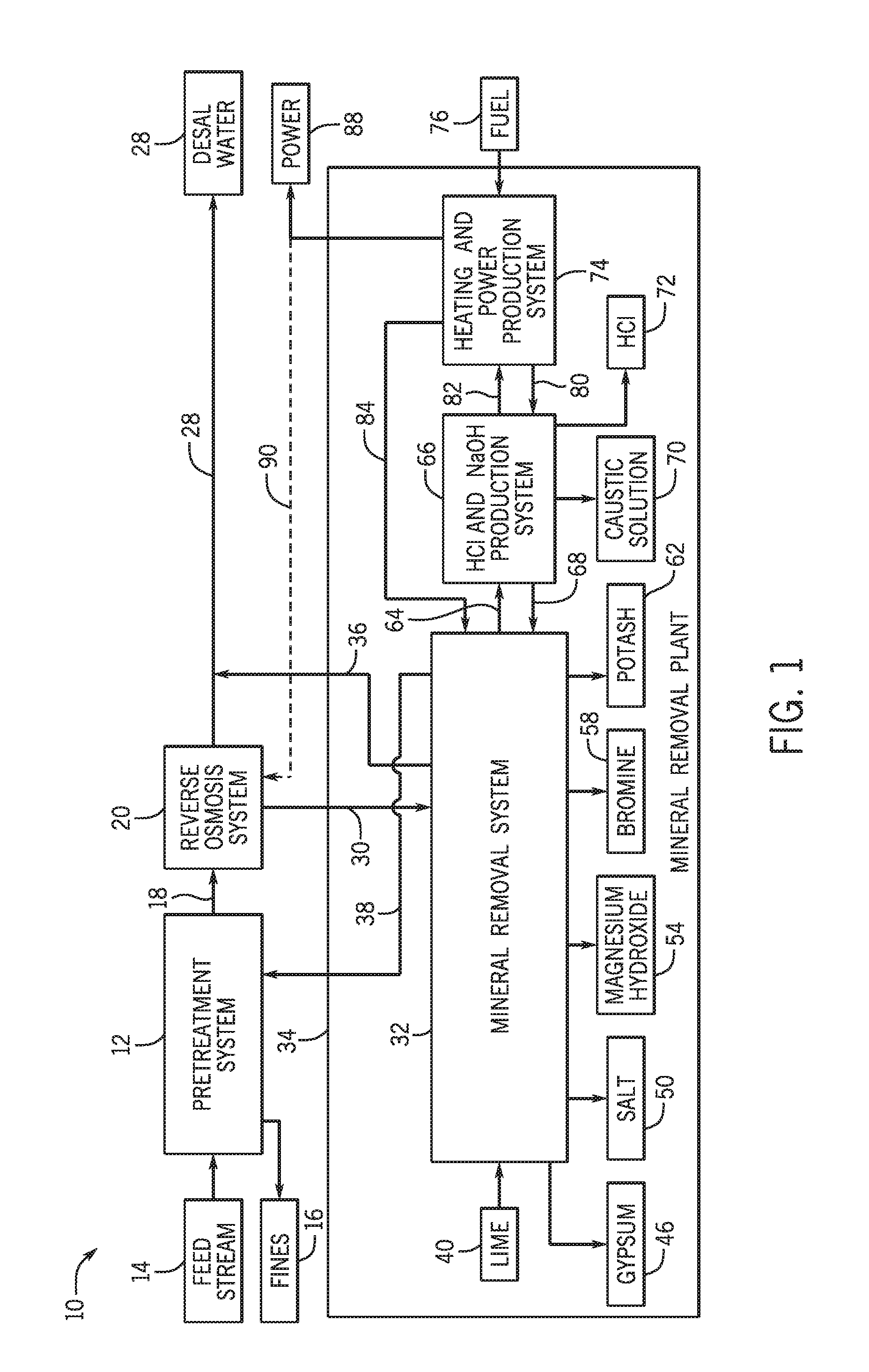

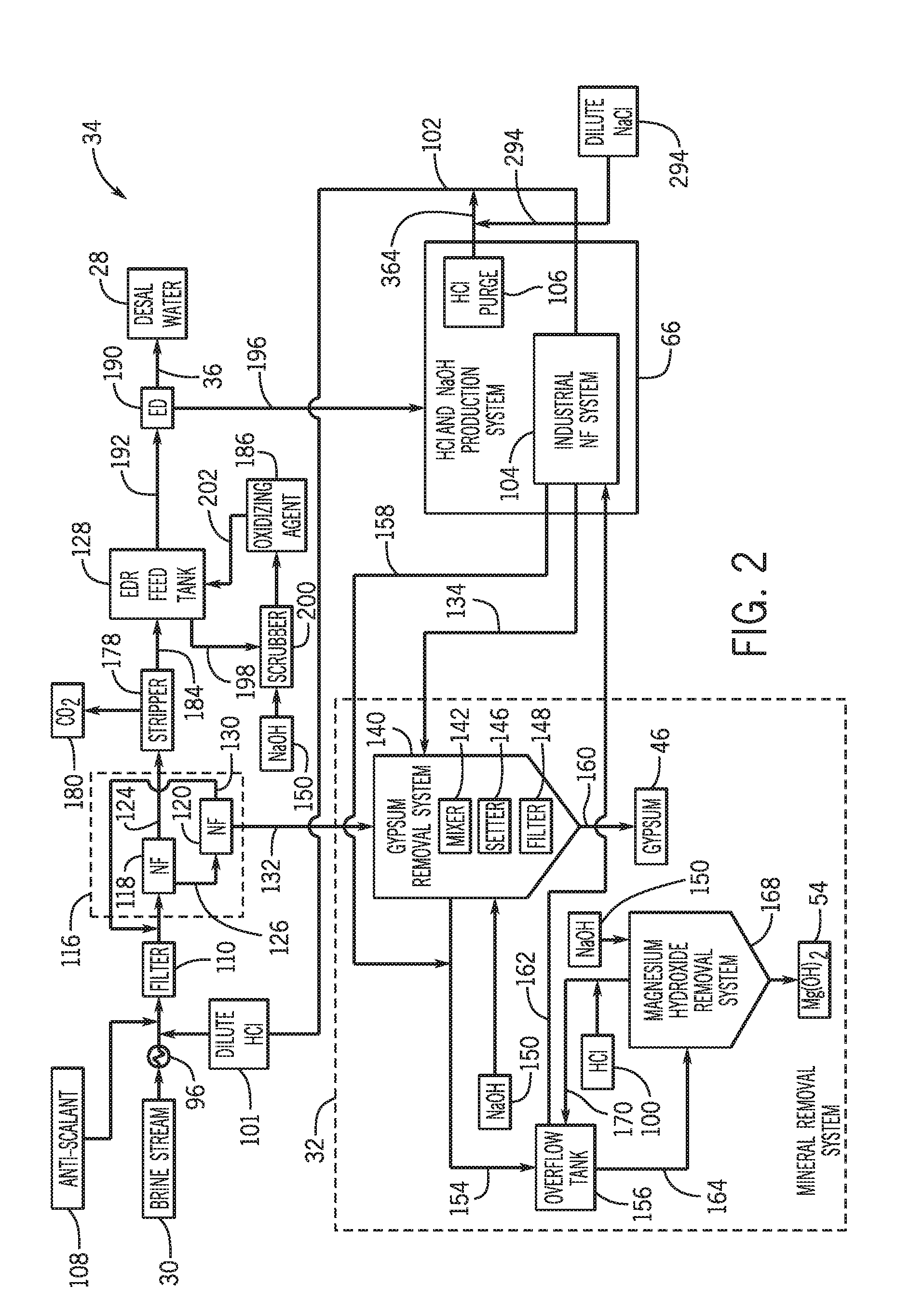

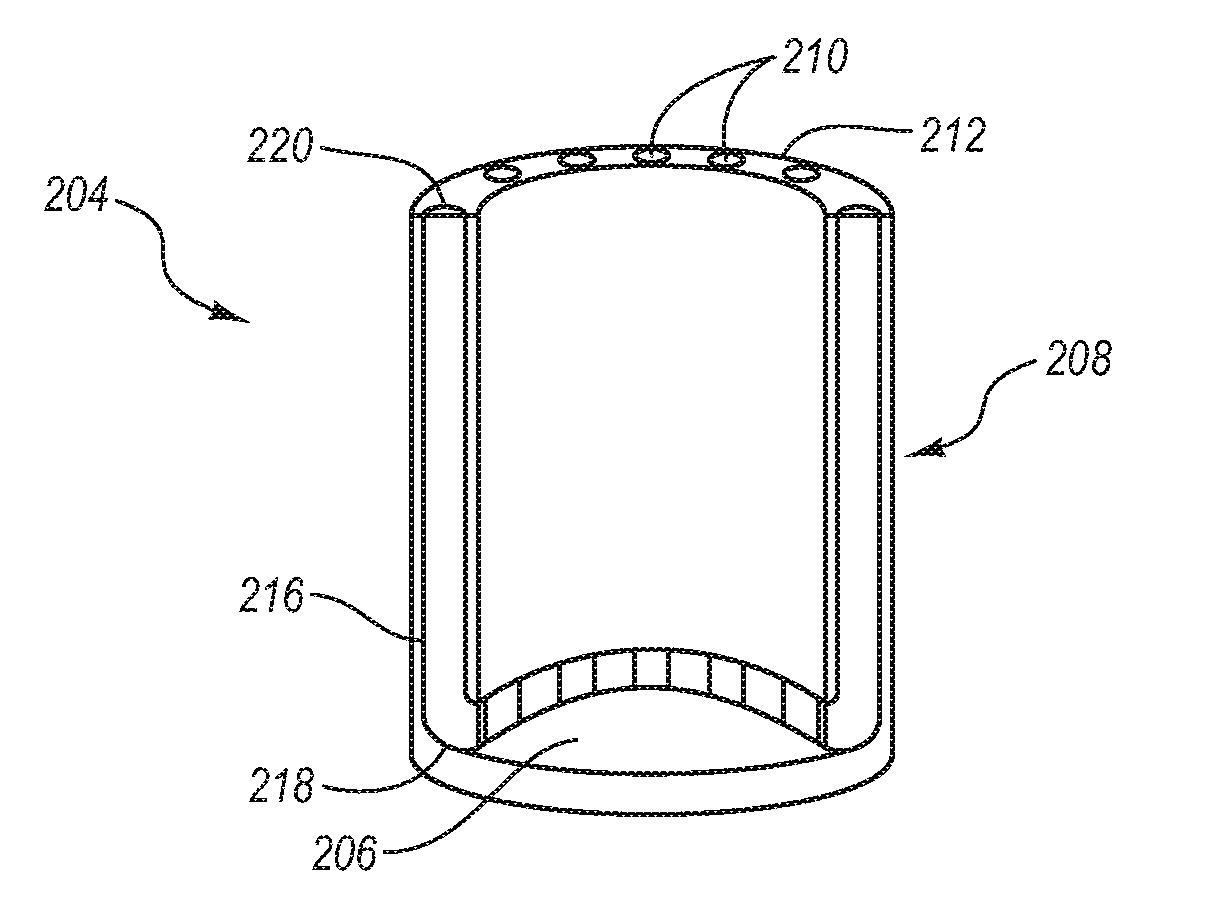

System and methods for removing minerals from a brine using electrodialysis

ActiveUS20160289099A1Chlorine/hydrogen-chloride purificationCalcium/strontium/barium chloridesSaline waterNanofiltration

A method includes treating a first brine stream including a plurality of minerals with an anti-scalant to produce a treated brine. The first brine stream is provided by a wastewater treatment system. The method also includes directing the treated brine to a first nanofiltration (NF) system disposed downstream from and fluidly coupled to the wastewater treatment system, generating a first NF permeate stream and a first NF non-permeate stream from the treated brine in the first NF system, directing the first NF non-permeate stream to a mineral removal system disposed downstream from and fluidly coupled to the first NF system, and removing the plurality of minerals from the first NF non-permeate stream to generate a first overflow stream in the mineral removal system. The first overflow stream comprises at least a portion of the plurality of minerals. The method also includes routing a first portion of the first overflow stream to a hydrochloric acid (HCl) and sodium hydroxide (NaOH) production system disposed downstream from and fluidly coupled to the mineral removal system. The HCl and NaOH production system includes a second NF system that may receive the first portion of the first overflow stream and may generate a second brine stream from the first portion of the first overflow stream. The method further includes directing the second brine stream to a first electrodialysis (ED) system disposed within the HCl and NaOH production system and fluidly coupled to the second NF system. The first ED system may generate HCl and NaOH from the second brine stream.

Owner:ENVIRO WATER MINERALS COMPANY

A method for recovering alkali and aluminum in course of treatment of bayer red mud by using calcification-carbonation method

ActiveUS20170036920A1Comprehensive utilization of valuable elementLow costSolid waste disposalContaminated soil reclamationHigh concentrationRecovery method

A method for recovering alkali and aluminum during treatment of Bayer red mud using a calcification-carbonation method, including steps of mixing the Bayer red mud with calcium aluminate or with calcium aluminate and lime, performing calcification dealkalization conversion in a high-concentration alkaline liquor, and carbonizing the calcified residues produced during dealkalization to obtain carbonized residues; and then performing low-temperature aluminum dissolution, aluminum precipitation and the like to obtain calcium aluminate products, which is returned to the calcification dealkalization conversion of the red mud for recycling. Part of an alkali-containing and aluminum-containing liquid phase after calcification dealkalization conversion can be used as supplementary alkali in the Bayer production course for recycling. The method is energy-saving and environmentally-friendly, and allows recovering alkali and aluminum from the red mud and harmless treatment of the Bayer red mud.

Owner:NORTHEASTERN UNIV

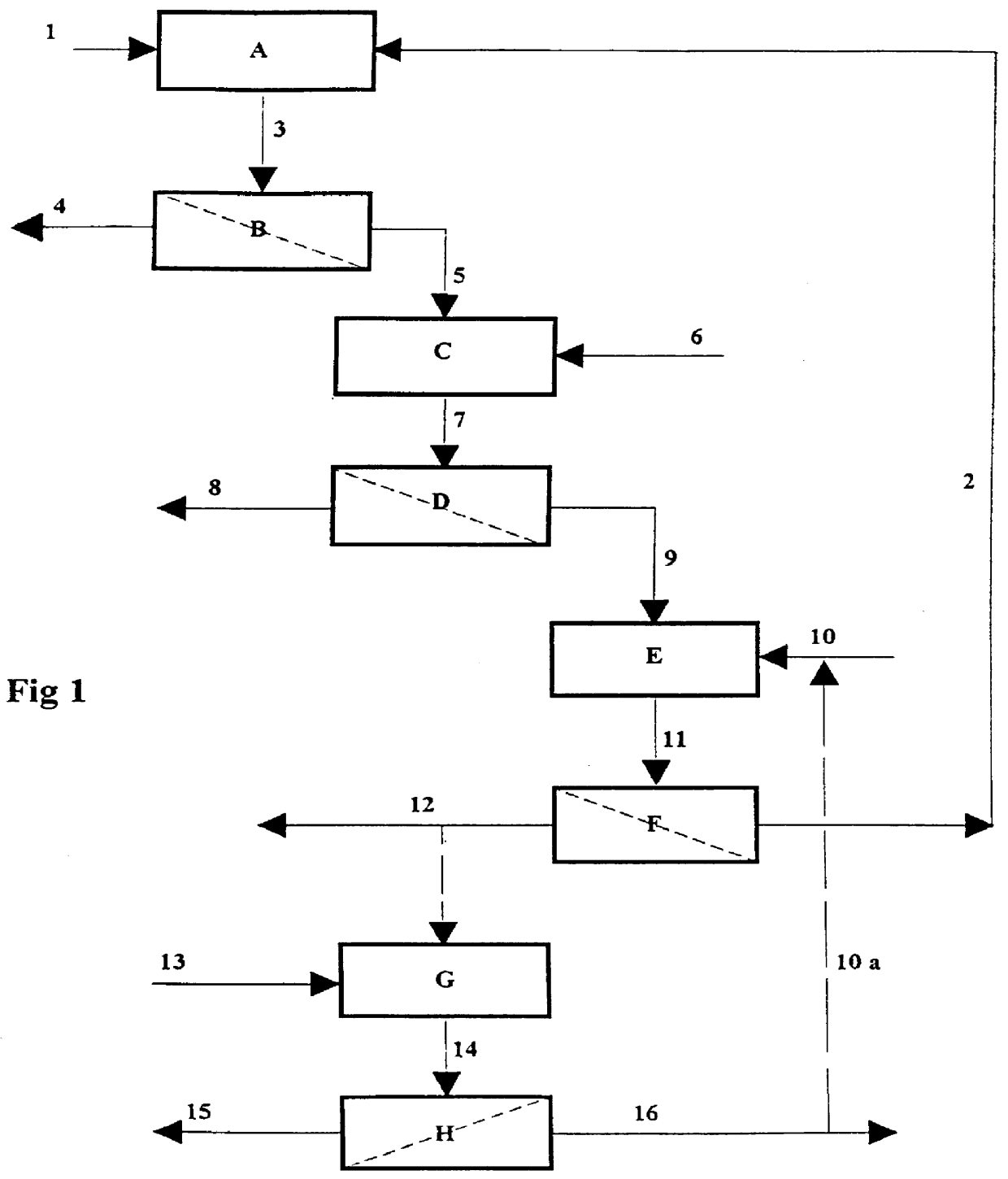

Process for recovering the sodium contained in industrial alkaline waste

InactiveUS6110377AEasy to eliminateLow costSolvent extractionIon-exchanger regenerationRed mudElution

The invention concerns a process that uses an ion exchanger resin to recover the sodium contained in industrial alkaline waste and, in particular, in the "red mud" and sodium effluents coming from the manufacture of aluminum hydrate according to the Bayer process. It includes putting the alkaline resins (1), usually "red mud" in the form of an aqueous suspension in contact with an RH+ type cationic resin, preferably, a carboxylic resin to attach the sodium selectively and quantitatively to the resin (5) and then to extract it quantitatively in the form of NaOH (8) by displacement using a lime suspension (6), preferably, lime milk. The resin (9), after attaching the calcium, is then regenerated for reuse at the beginning of the process (2) by elution of the calcium as CaCl2 (12) with a diluted hydrochloric acid solution (10).

Owner:ALUMINUM PECHINEY

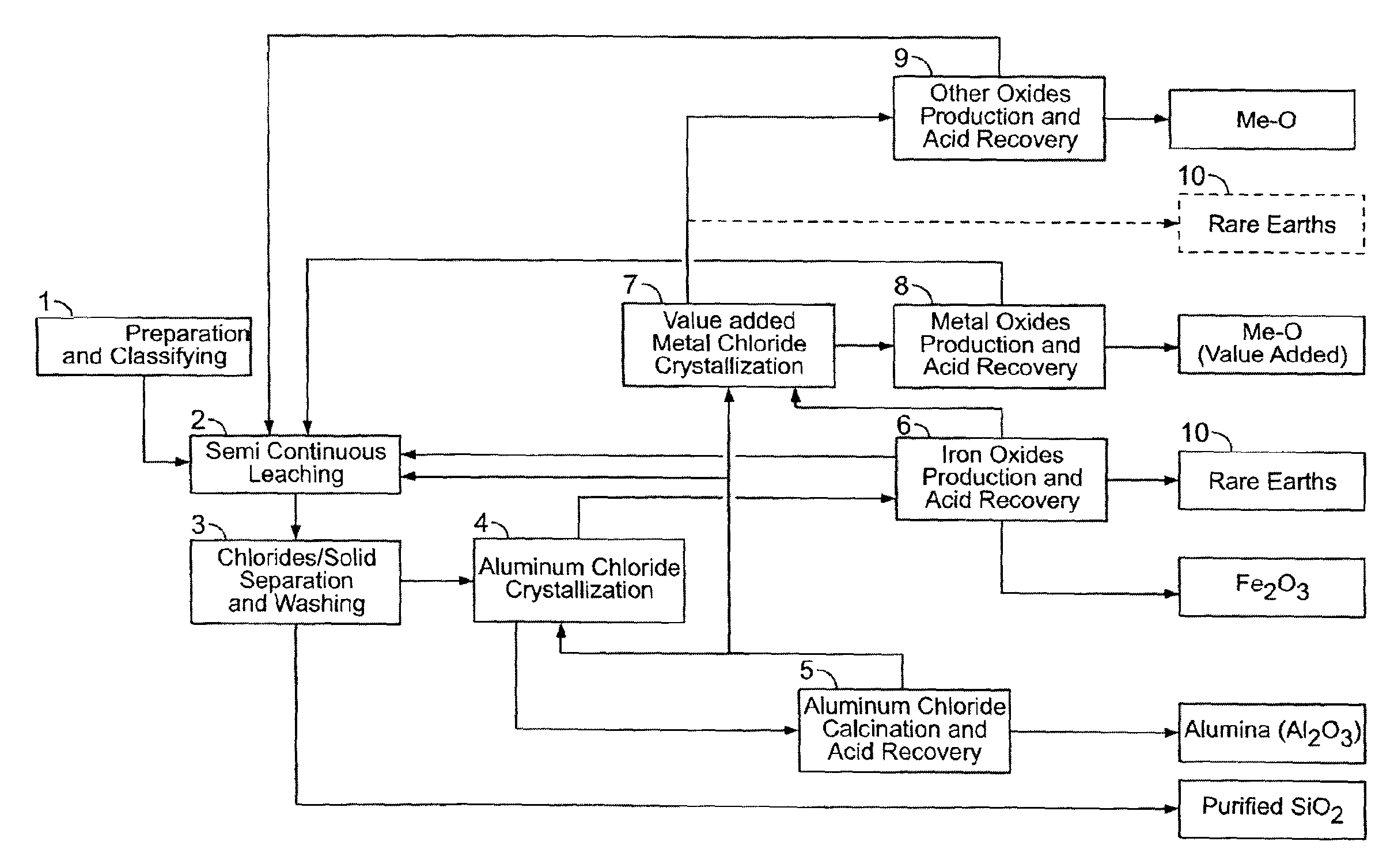

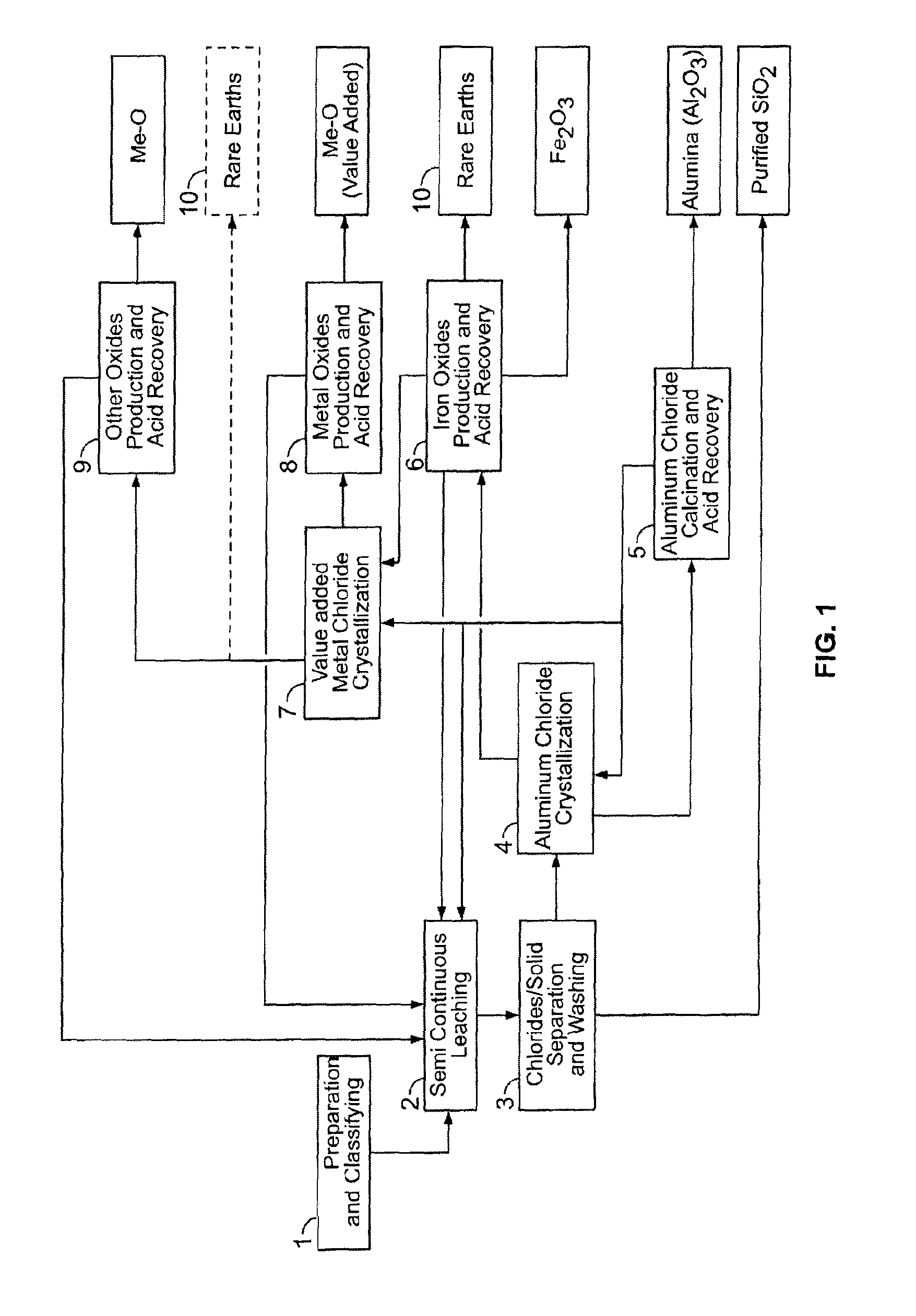

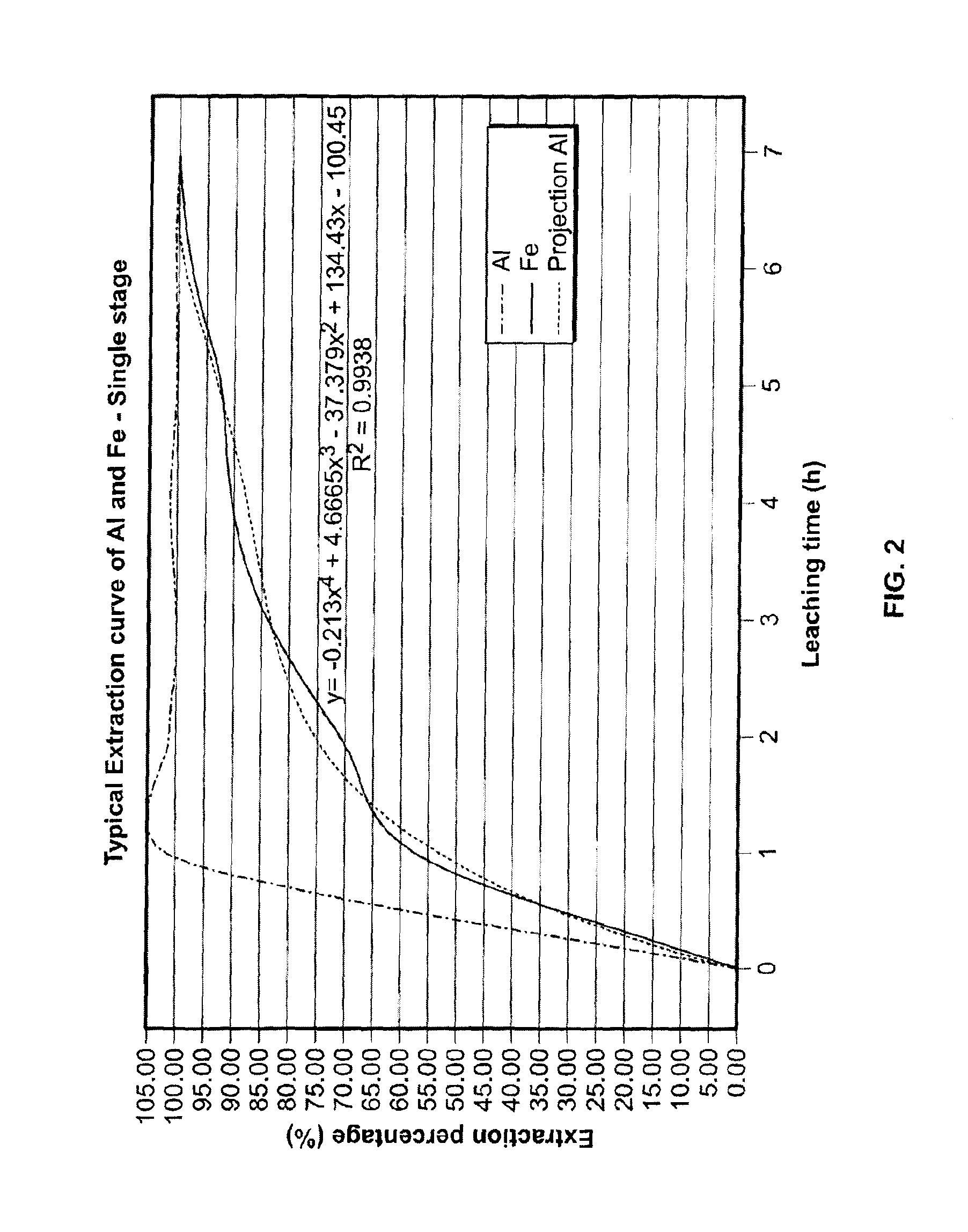

Processes for treating fly ashes

There are provided processes for treating fly ash. For example, the processes can comprise leaching fly ash with HCl so as to obtain a leachate comprising aluminum ions and a solid, and separating the solid from the leachate; reacting the leachate with HCl so as to obtain a liquid and a precipitate comprising the aluminum ions in the form of AlCl3, and separating the precipitate from the liquid; and heating the precipitate under conditions effective for converting AlCl3 into Al2O3 and optionally recovering gaseous HCl so-produced.

Owner:ORBITE ALUMINAE INC

New technique for preparing sodium hydroxide

InactiveCN101092240AQuality improvementImprove qualityCalcium/strontium/barium carbonatesAlkali metal hydroxidesSodium bicarbonateSlag

This invention discloses a method for preparing caustic soda and light calcium carbonate with wide industrial applications by reacting carbide slag as a substitute for slaked lime with sodium carbonate or sodium bicarbonate. The method can well address the problems of utilizing causticization method and treating carbide slag. The method is environmentally friendly, and has good social and economic benefits.

Owner:北京清华紫光英力化工技术有限责任公司

Resource recycling method of glyphosate mother liquor

InactiveCN101792216AImprove economyEasy to handleBiocideGroup 5/15 element organic compoundsPhosphorous acidSeparation technology

The invention particularly relates to a resource recycling method of glyphosate mother liquor, which separates each component of mother liquor generated from producing glyphosate by a phosphorous acid dimethyl ester method by a multistage membrane separation technology, sufficiently recycles each useful component, reduces wastewater treatment capacity and realizes resource recycling. The method comprises the following steps: preparing the glyphosate mother liquor in glyphosate production by the phosphorous acid dimethyl ester method; removing solid impurities and viscous components by microfiltration, ultrafiltration and the like, and then continuously entering all stages of membrane separation devices for separating and concentrating; each stage of membrane separation device has different functions, wherein the first-stage membrane separation device separates and concentrates for obtaining a solution A being rich in mineral salt of sodium chloride or ammonia chloride and the like; the second-stage membrane separation device separates and concentrates for obtaining a solution B being rich in sodium hydroxide; the third-stage membrane separation device separates and concentrates for obtaining a solution C being rich in phosphorous acid; and the forth-stage membrane separation device separates and concentrates for obtaining a solution D being rich in glyphosate, and the rest is a solution E being rich in other impurities and byproducts.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

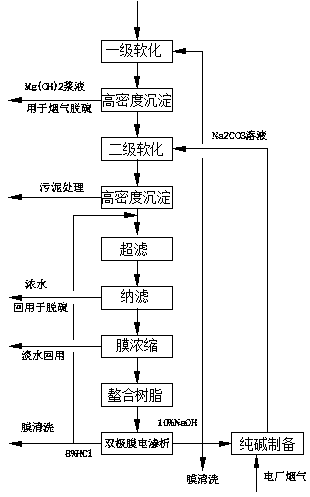

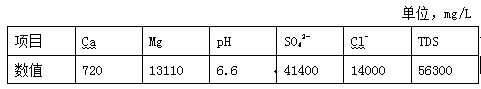

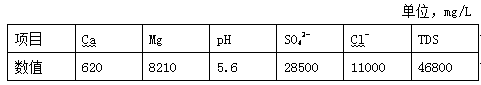

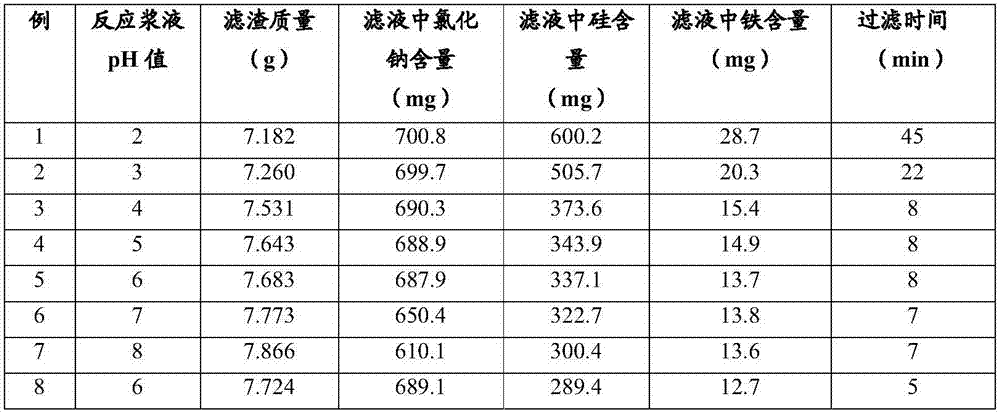

Method for magnesium oxide method power plant desulfurization wastewater zero discharging treatment

PendingCN110104851AReduce usageReduce processing costsChlorine/hydrogen-chlorideDispersed particle separationSlurryChelation

The invention discloses a method for magnesium oxide method power plant desulfurization wastewater zero discharging treatment. The method comprises the steps that wastewater is subjected to primary softening to remove Mg2+ and heavy metal ions, a primarily softened mud and water mixture enters a first high density precipitation unit, an obtained supernate enters a secondary softening unit to remove Ca2+, a secondarily softened mud and water mixture enters a second high density precipitation unit for precipitation, a supernate is treated through a film system, obtained fresh water is recycled,produced concentrated water enters a chelation resin unit, calcium, magnesium and heavy metal ions are removed deep, outflow water enters a bi-polar membrane electrodialysis unit, and a sodium hydroxide solution with the concentration being 10% and a hydrochloric acid with the concentration being 8% are obtained through treatment; the method achieves recycling of magnesium hydroxide slurry, the consumption of flue gas desulfurization magnesium oxide is greatly lowered, the bi-polar membrane electrodialysis acid-alkali producing technology is adopted, meanwhile, carbon dioxide in flue gas of apower plant is used for preparing sodium carbonate, recycling of salt in wastewater is achieved, and no softening medicament needs to be purchased additionally.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

Red mud comprehensive utilization treatment method

InactiveCN107879367ALow equipment requirementsLower requirementAluminium hydroxide preparationAlkali metal hydroxidesRed mudSlurry

The invention belongs to the technical field of aluminum industry waste residue treatment, and specifically discloses a comprehensive utilization treatment method of red mud produced in production ofalumina. According to the red mud comprehensive utilization treatment method, red mud acidification treatment is performed, specifically, a hydrochloric acid solution is employed, appropriate pH value, temperature and reaction time are specifically controlled, the pH value is controlled to be 4 to 7, a reaction is carried out at 0 to 100 DEG C for 0.5 to 50 hours; after the reaction, solid-liquidseparation is easily performed on the slurry, the separated solid phase is a weak acidic alkali-removed red mud residue, and the obtained liquid phase can be used as a mother liquor for preparing caustic alkali; and the weak acidic alkali-removed red mud residue is classified to obtain a fine-grained product and a coarse-grained product, wherein fine-grained product is used as a filler, and the coarse-grained product is used as a building material or an iron-selecting material. The red mud comprehensive utilization treatment method provided by the invention effectively solves the problems of land occupation and pollution of ground surfaces and groundwater caused by red mud accumulation.

Owner:湖南绿脉环保科技股份有限公司

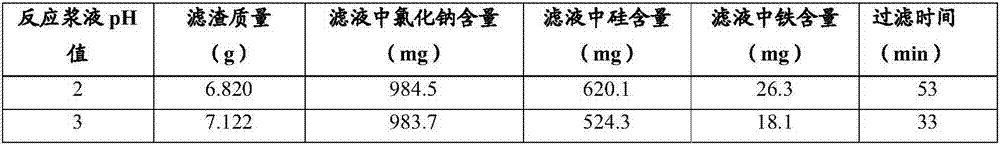

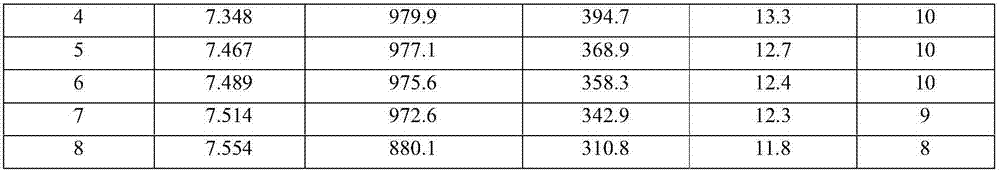

Process for treating chemical fiber cotton pulp black liquor

ActiveCN101585617AReduce pollutionReduce manufacturing costMultistage water/sewage treatmentWater/sewage treatment by heatingFiberChemical reaction

The invention discloses a process for treating chemical fiber cotton pulp black liquor, which comprises the following steps: filtering the chemical fiber cotton pulp black liquor and wood pulp black liquor by a black liquor filter, mixing the two black liquors according to a proportion, then evaporating the mixture through a two-stage evaporator, spraying the thick black liquor after evaporating into an alkali reclaiming furnace, drying the thick black liquor sprayed into the furnace by using heat in the furnace, drying, fully burning and oxidizing the thick black liquor during falling, and introducing the burned molten substances into a dissolving tank to form green liquor; and conveying the green liquor in the dissolving tank to a slaking slag extractor, simultaneously adding enough amount of calcium oxide into the slaking slag extractor so as to carry out chemical reaction on the that the green liquor and the calcium oxide, and conveying emulsion generated in the reaction to a causticizer to generate NaOH. The process overcomes the defects of low combustion value and high treatment cost existing in the process of treating the chemical fiber cotton pulp black liquor only by using an alkali reclaiming system, lowers the production cost and reduces environment pollution; and the obtained alkali liquor can be recycled.

Owner:山东光华纸业集团有限公司

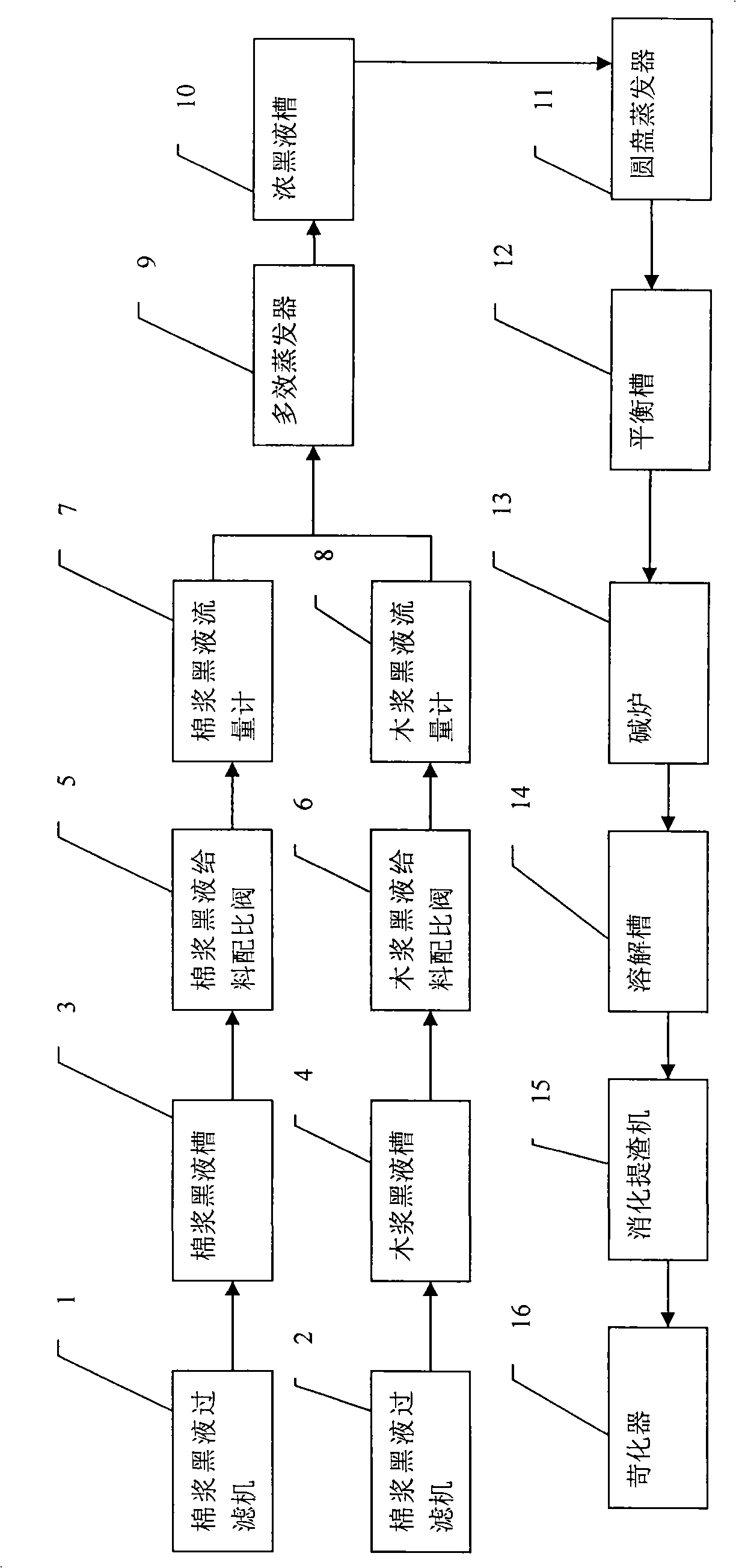

Regeneration method for sulphureous alkali residues

ActiveCN103769407AFull recoveryCausticizing regeneration is easySolid waste disposalSulfur preparation/purificationHigh concentrationCalcium sulfite

The invention relates to a regeneration method for sulphureous alkali residues comprises three parts, namely, SO2 acidification of the alkali residues, extraction and recycling of petroleum acid, and causticization and regeneration, wherein SO2 used in the step of SO2 acidification is SO2-containing gas from a Klaus sulfur production device, meanwhile tail gas of the Klaus sulfur production device is introduced as carrier gas, and acidification is stopped when the pH of acidulous water generated by acidification reaches 2-4. Three phases, including gas, oil and water, are generated in the acidification process, wherein the gas enters the Klaus sulfur production device so as to separate and recycle acid oil, and the water phase is subjected to solvent extraction so as to recycle petroleum acid, and then is causticized with Ca(OH)2 and precipitated to separate calcium sulfite to generate a sodium hydroxide solution which is recycled as alkali liquor for alkali washing of oil. The method provided by the invention has the advantages that the investment is low, the operation condition is mild, sulfide, petroleum acid and sodium ions can be recycled, no odorous gas is discharged, no high-concentration or high-salinity waste liquor flows into a sewage disposal station, and certain economic benefits are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process method for converting high-salinity wastewater into NaOH solution

PendingCN111592148ASimple methodLess investmentSludge treatmentWater contaminantsSulfate radicalsFiltration

The invention relates to a process method for converting high-salinity wastewater into a NaOH solution, which comprises the following steps: step 1, introducing the high-salinity wastewater into a reaction tank, adding calcium-aluminum composite salt into the reaction tank, controlling the pH value at 11-12, stirring and reacting for 2-6 hours, and removing sulfate ions and chloride ions to form amixed solution; 2, feeding the mixed solution into a sedimentation tank from the bottom, adding a flocculating agent, adding a heavy metal removing agent for removal if the mixed solution contains complex copper, and subjecting the mixed solution to sedimentation in the sedimentation tank for 1-2 hours to form a supernatant in the upper portion of the sedimentation tank; and step 3, overflowing the supernatant to a multi-medium filter tank for filtration, adding sodium carbonate into the multi-medium filter tank for precipitation if the calcium hardness is high during overflowing, and formingclear liquid containing a small amount of sodium chloride or sodium sulfate from the solution filtered by the multi-medium filter. The process method for converting the high-salinity wastewater intothe NaOH solution, provided by the invention, is simple, low in investment and low in operation difficulty.

Owner:导洁(北京)环境科技有限公司

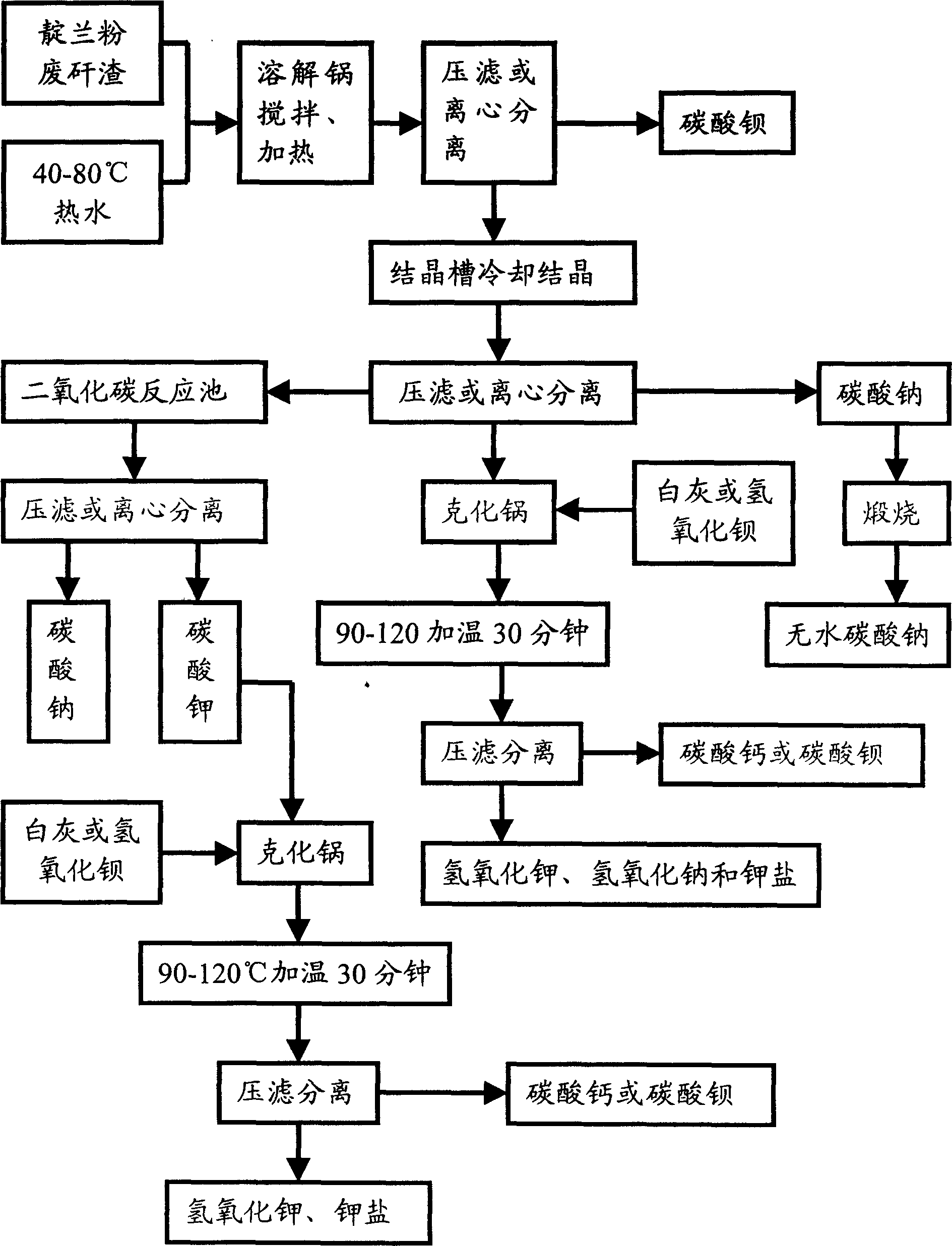

Comprehensive process for recovering and treating indigo blue powder waste slag

InactiveCN1557708AReasonable process designThe preparation method is simple and feasibleSolid waste disposalAlkali metal hydroxidesSlagPotassium hydroxide

The comprehensive indigo powder waste gangue slag recovering treatment process includes heating the mixture of waste gangue slag and water in a reactor to 4-80 deg.c for the waste gangue slag to dissolve fully; centrifugally separating to eliminate dreg and create mother liquid A; cooling mother liquid an in a crystallizing tank for 12-30 hr; press filtering or centrifuging to separate crystal as mixture of crystal carbonate and natron from crystallized liquid A; and calcining the crystal mixture to obtain anhydrous sodium carbonate. The said process can recover sodium hydroxide, potassium hydroxide, potassium carbonate, potassium salt and sodium carbonate in low cost and high yield.

Owner:贾升

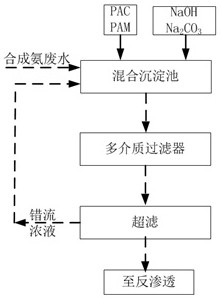

Synthetic ammonia organic wastewater divalent salt recycling and zero discharge process

PendingCN113716772AComponent cleanup and purificationRemove completelyGeneral water supply conservationWater contaminantsCatalytic oxidationReverse osmosis

The invention discloses a synthetic ammonia organic wastewater divalent salt recycling and zero discharge process which comprises the following steps: lifting pretreated effluent by a pump to enter reverse osmosis, conveying produced desalted water to a reuse water tank, conveying reverse osmosis concentrated water to a nanofiltration system, conveying nanofiltration produced water to a monovalent salt recycling system, conveying nanofiltration concentrated water to a divalent adjusting tank, enabling the nanofiltration concentrated water to enters a catalytic oxidation reaction device to be subjected to oxygenolysis after adjustment; carrying out electrodialysis for concentration, removing foreign ions by resin adsorption, and entering an evaporative crystallization device; preparing and obtaining a sodium sulfate product with the purity above 99%, centrifugally separating mother liquor to flow back to a nanofiltration system, conveying evaporation condensate to a recycling water tank, dissolving the sodium sulfate product to prepare a solution with a certain concentration to enter a bipolar membrane electrodialysis device so as to prepare an acid-base product. Through the combined process of pretreatment, reverse osmosis, nanofiltration, catalytic oxidation, electrodialysis and evaporative crystallization, and the reverse osmosis concentrated water of the wastewater, zero emission of the wastewater is realized in a real sense.

Owner:清创人和生态工程技术有限公司

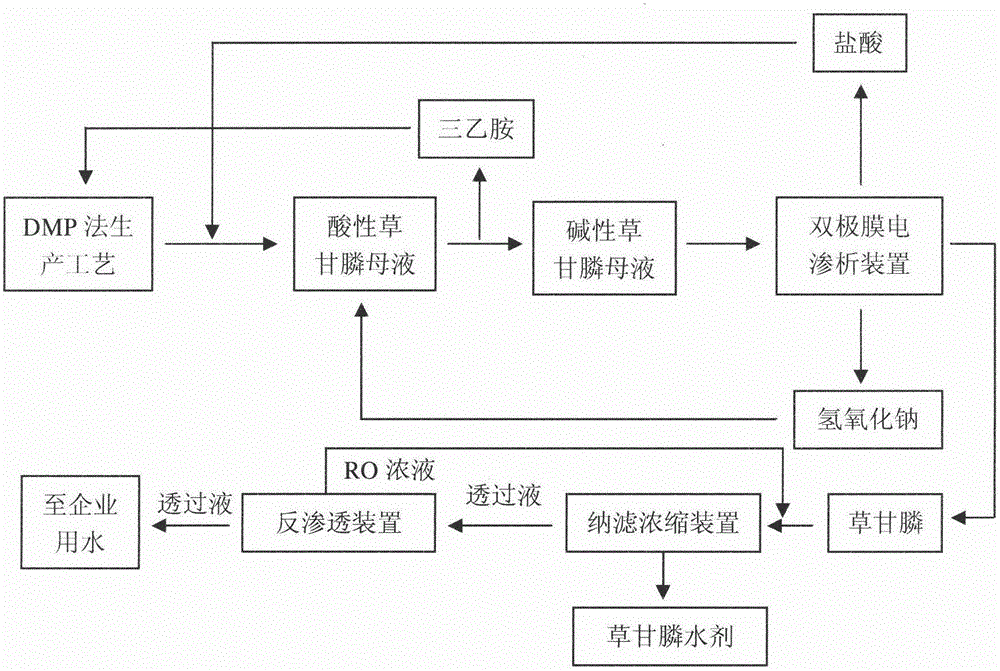

Method and apparatus for resourceful treatment of glyphosate mother liquor by bipolar membrane electrodialysis integrated nanofiltration and reverse osmosis technology

InactiveCN103949160AImprove pollutionAchieve resource recyclingChlorine/hydrogen-chlorideBiocideReverse osmosisHydrolysis

The invention discloses a method and apparatus for resourceful treatment of glyphosate and neutralization of mother liquor by integrated membrane electrodialysis integrated nanofiltration and reverse osmosis technology. The bipolar membrane electrodialysis technology is used for treating glyphosate and neutralizing mother liquor; sodium ions in the mother liquor enter into an alkali chamber through a cation exchange membrane, and combine with hydroxyl ions produce by the bipolar membrane to produce sodium hydroxide; and chloride ions enter into an acid chamber through an anion exchange membrane, and combine with the hydrogen ions generated by the bipolar membrane to form hydrochloric acid. When the conductance in the mother liquor is less than 10000, the desalinated mother liquor is subjected to desalination concentration and reverse osmosis concentration by the nanofiltration membrane, so as to recover glyphosate. The concentration of acid and alkali obtained by the invention is above 2 mol / L, the obtained hydrochloric acid can be used for hydrolysis of esterification reaction in a production process, sodium hydroxide can be used for recycling tri ethylamine, and the concentrated glyphosate has concentration more than 10%. The invention achieves glyphosate mother liquor cleaning technology with zero discharge and can be widely applied to treatment of the glyphosate mother liquor with high salt content.

Owner:ZHEJIANG CIRCLE TECH MEMBRANE TECH +1

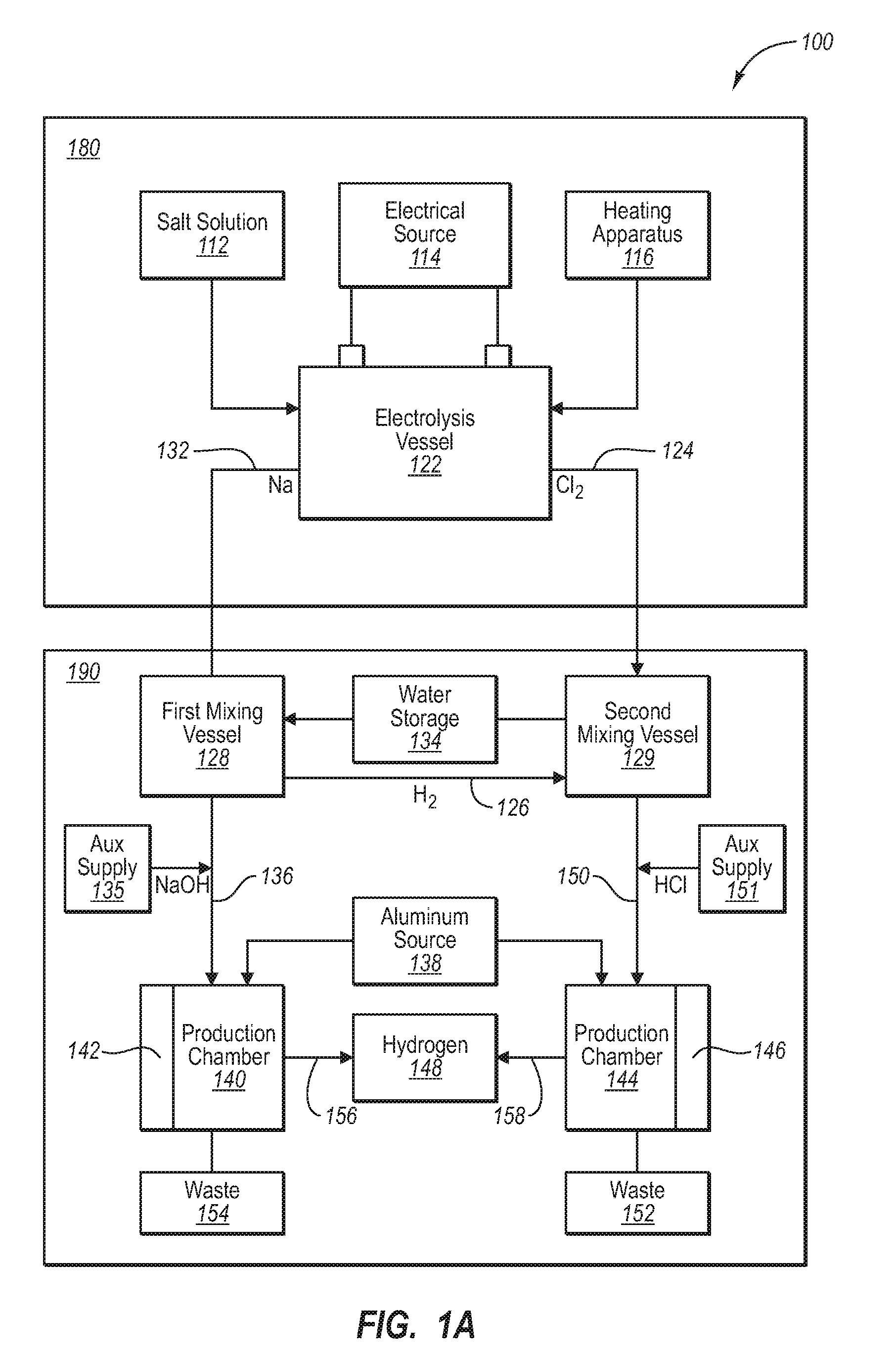

Generation of hydrogen on demand

InactiveUS20110094894A1Smoothes variabilitySimple and safe processSamplingRegenerative fuel cellsElectrolysisSolar power

The methods and systems for producing hydrogen on demand use aluminum, a heat source and an electrical source, such as, but not limited to, solar power. The heat source and electrical source is used to produce chemical intermediates from sodium chloride via electrolysis. The chemical intermediates from the sodium chloride may be reacted with aluminum to produce hydrogen. The on-demand hydrogen systems can generate a continuous stream of hydrogen that can power a home or business. Alternatively, or in addition, the on-demand hydrogen system can be incorporated into a vehicle to power the vehicle.

Owner:MASON DENNIS B

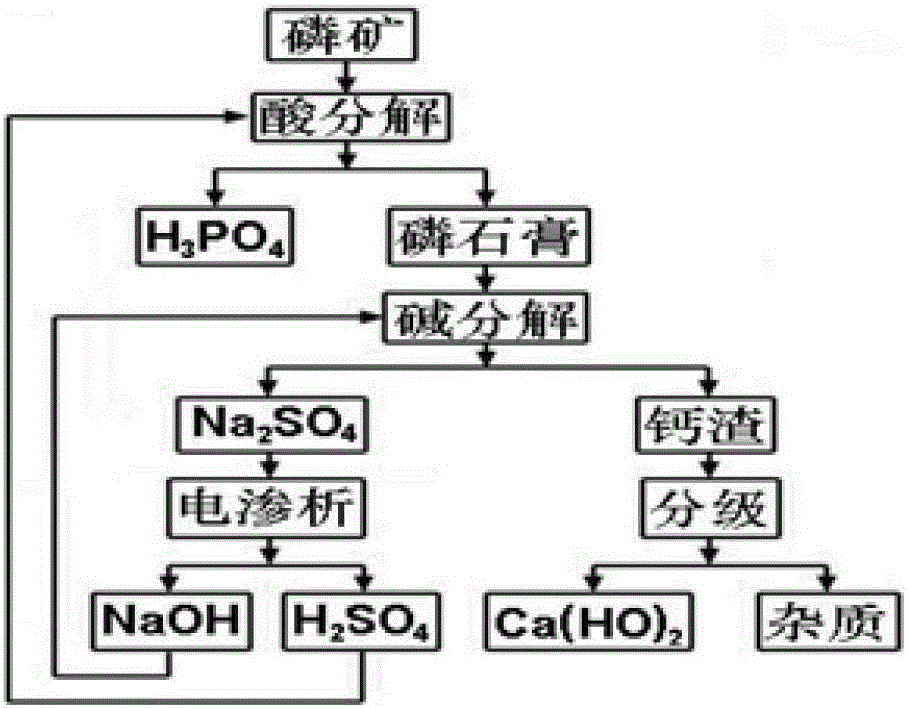

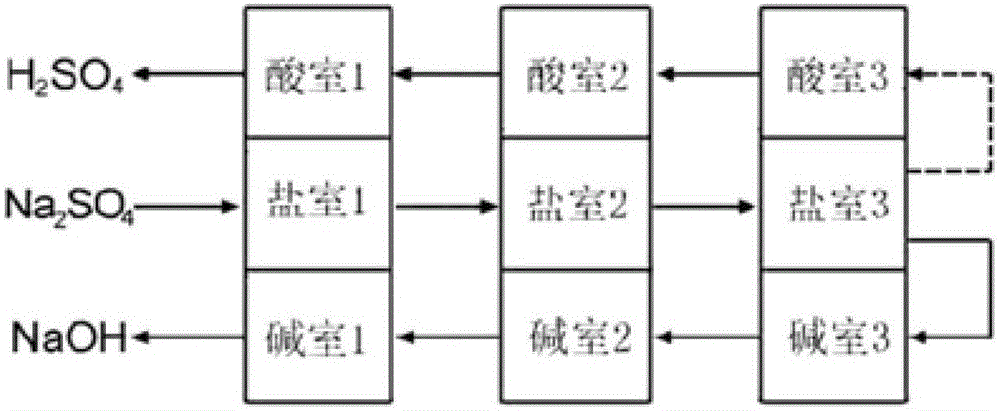

Technology for cyclic decomposing, transforming and using ardealite with two-step method

InactiveCN106115742AAtom economyLow costSulfur compoundsSulfate/bisulfate preparationPhosphateSodium sulfate

The invention belongs to the technical field of ardealite comprehensive utilization and particularly relates to a technology for cyclic decomposing, transforming and using of ardealite with a two-step method. The technology comprises the steps that firstly, ardealite is decomposed and transformed into sodium sulfate and calcium hydroxide, in other words, a sodium hydroxide solution and ethyl alcohol are added into the ardealite raw material, a reaction is carried out under the room-temperature stirring condition, solid and liquid are separated through settling and filtering after the reaction is finished, a sodium sulfate solution and calcium residues are obtained, calcium hydroxide in the calcium residues is separated from other impurity ingredients with a grading method, a calcium hydroxide product with the content of Ca(OH)2 higher than or equal to 90% is obtained, and the remaining impurities can serve as accessories for preparing cement or serve as building raw materials; secondly, a three-grade adverse current bipolar membrane electrodialysis system is used for transforming the sodium sulfate solution into sulfuric acid and a sodium hydroxide solution, wherein the sodium hydroxide solution can be circularly used for decomposing and transforming ardealite, and sulfuric acid can be circularly used for decomposing phpsphorite for preparing phosphate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

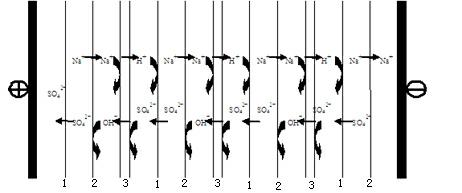

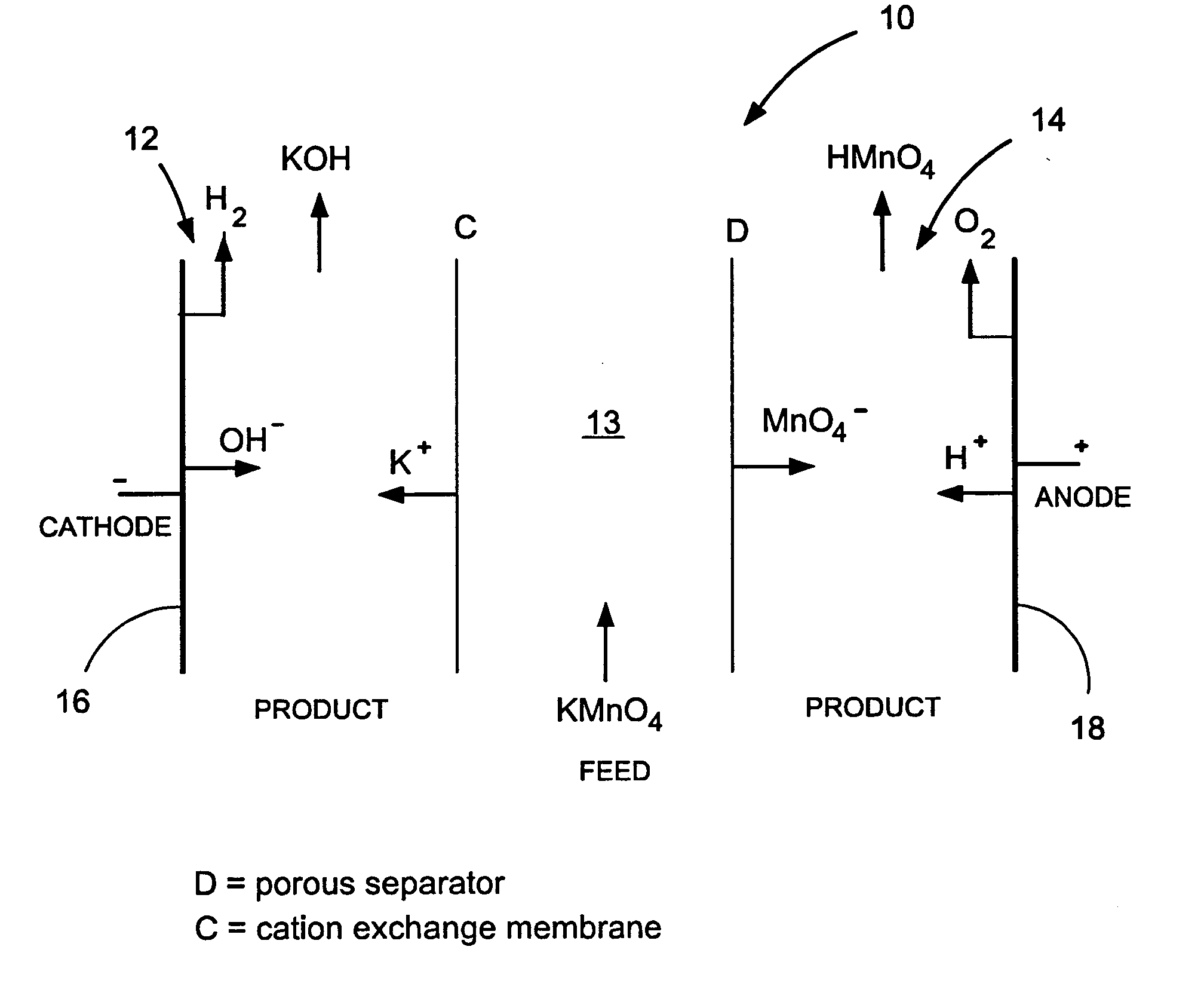

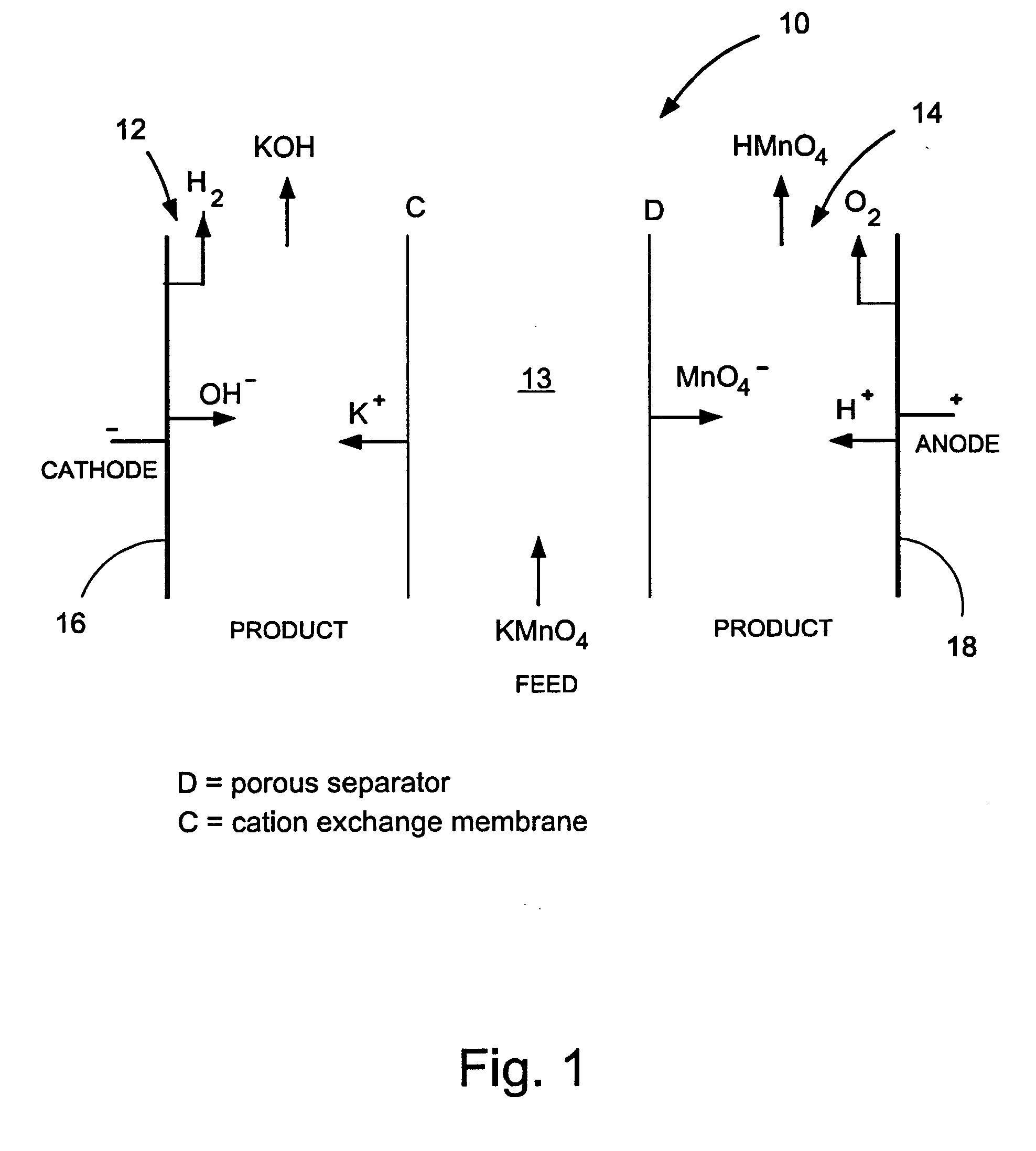

Methods and apparatus for electrodialysis salt splitting

InactiveUS20060000713A1Affect performanceSludge treatmentVolume/mass flow measurementIon-exchange membranesElectrochemical cell

Novel electrochemical cell configurations comprise ion-exchange membranes in combination with at least one porous separator for use in salt splitting methods, including metathesis electrodialysis salt splitting. Methods include production of chemically different oxidizing agents from a first oxidizing agent feed, along with value added salt by-products without adversely affecting permselectivity of the ion-exchange membranes of the cell.

Owner:CARUS CORP

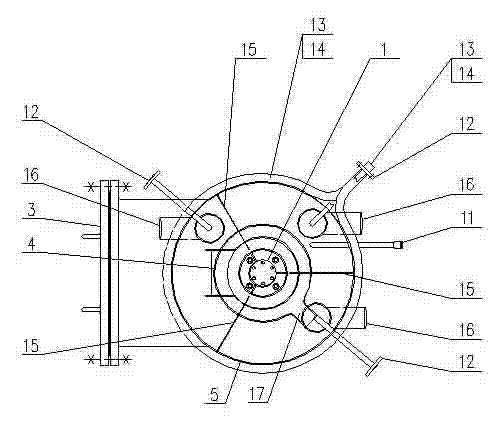

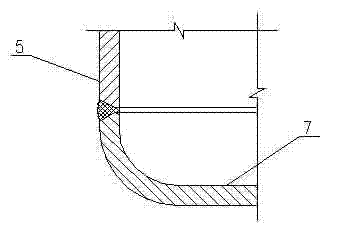

Three-channel alkali liquor distributor

ActiveCN102180432AIncrease productivityAvoid lossLiquid flow controllersAlkali metal hydroxidesMolten saltNitrogen

The invention relates to a three-channel alkali liquor distributor. The three-channel alkali liquor distributor adopts a technical scheme that: a cylinder body, a top plate and a bottom plate are welded together to form a closed tank; the top plate is provided with an alkali liquor inlet pipe, and the bottom plate is provided with three alkali liquor outlet pipes; a molten salt pipe coil and a steam pipe coil are arranged outside the tank, and the steam pipe coil is clung to the molten salt pipe coil; the wall of the tank is provided with a manhole, a thermometer interface, a nitrogen inlet and three steam sweeping pipes; the lower part of the tank is divided into three cavities by using a division plate, each cavity corresponds to one alkali liquor outlet pipe, the three steam sweeping pipes correspond to the three alkali liquor outlet pipes respectively, and each steam sweeping pipe is concentric with the corresponding alkali liquor outlet pipe; and an alkali liquor overflow cylinder is arranged in the tank, the lower end of the alkali liquor inlet pipe extends into the alkali liquor overflow cylinder, the alkali liquor overflow cylinder is provided with an outlet, and a rotating device passes through the bottom plate and is connected with the alkali liquor overflow cylinder. The three-channel alkali liquor distributor is easy to maintain, is safe and stable to operate, and has a long service life, and the molten alkali liquor can be switched at any time according to production requirements.

Owner:沈阳东方钛业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com