Method and system for converting sodium-containing and fluorine-containing compounds in waste cathode carbon block of aluminum electrolytic cell

A technology for waste cathode carbon blocks and aluminum electrolytic cells, which is applied in the fields of alkali metal compounds, chemical instruments and methods, and solid waste removal, and can solve the problems of high energy consumption, high impurity content in electrolytes and carbon materials, and process parameter control Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

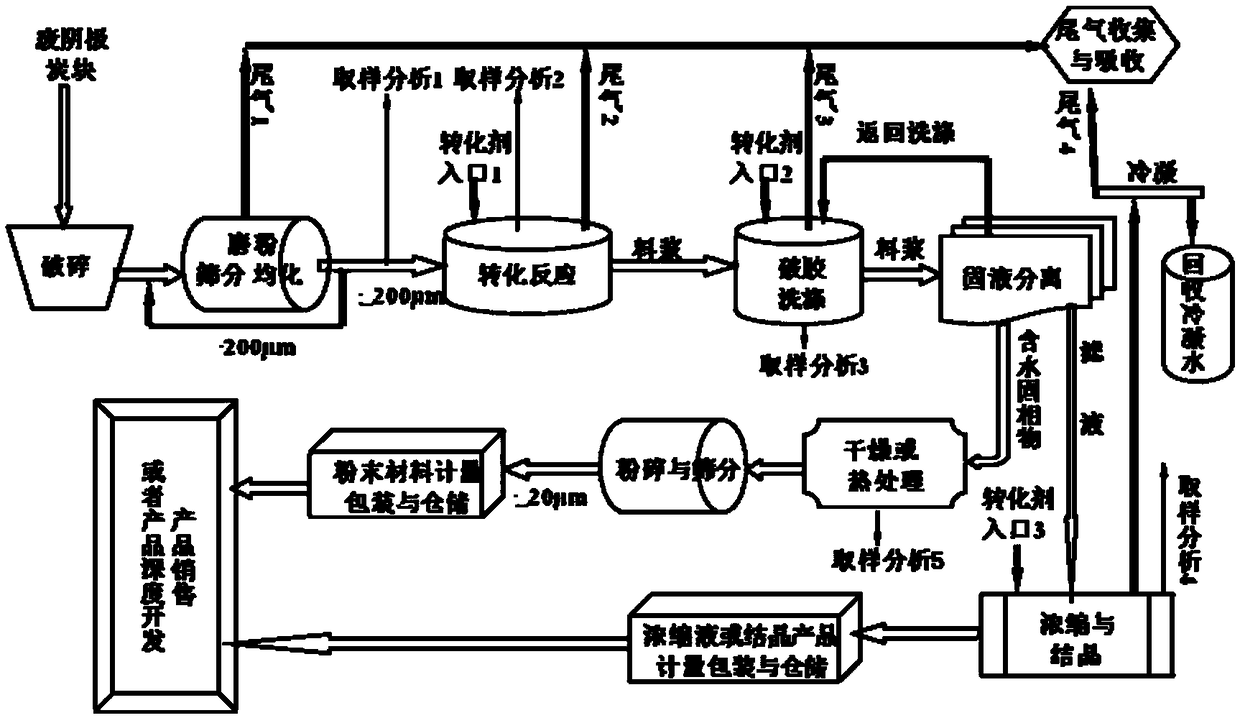

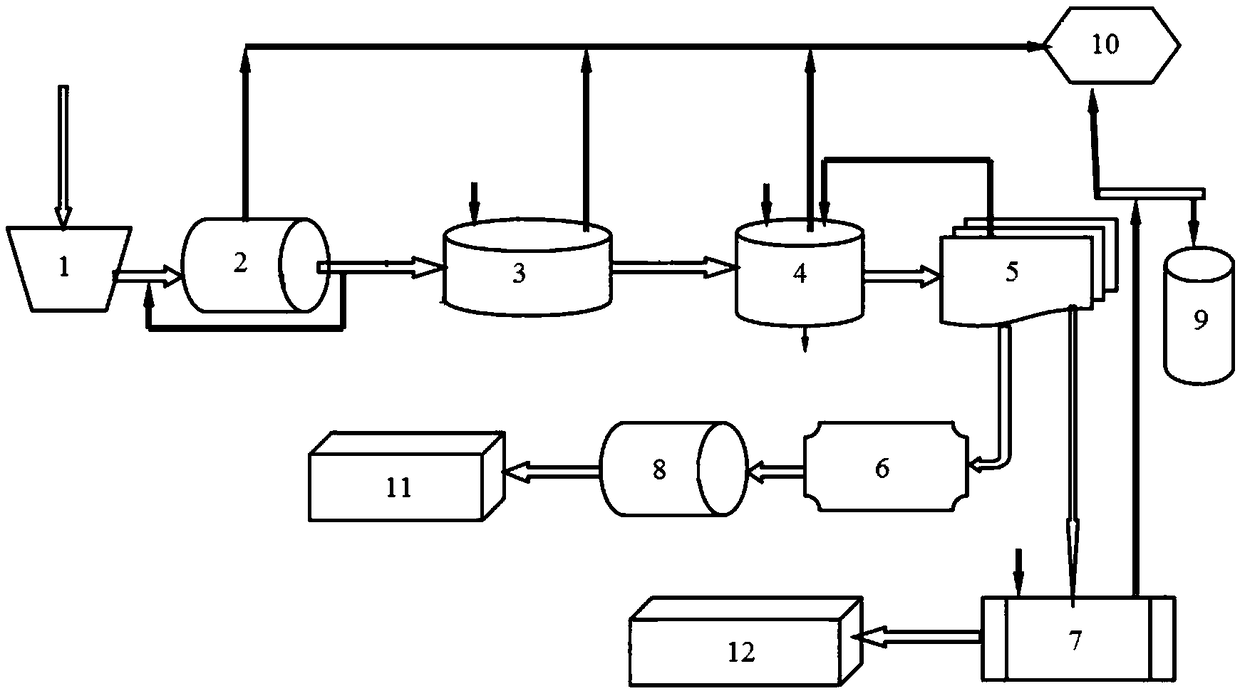

Method used

Image

Examples

Embodiment 1

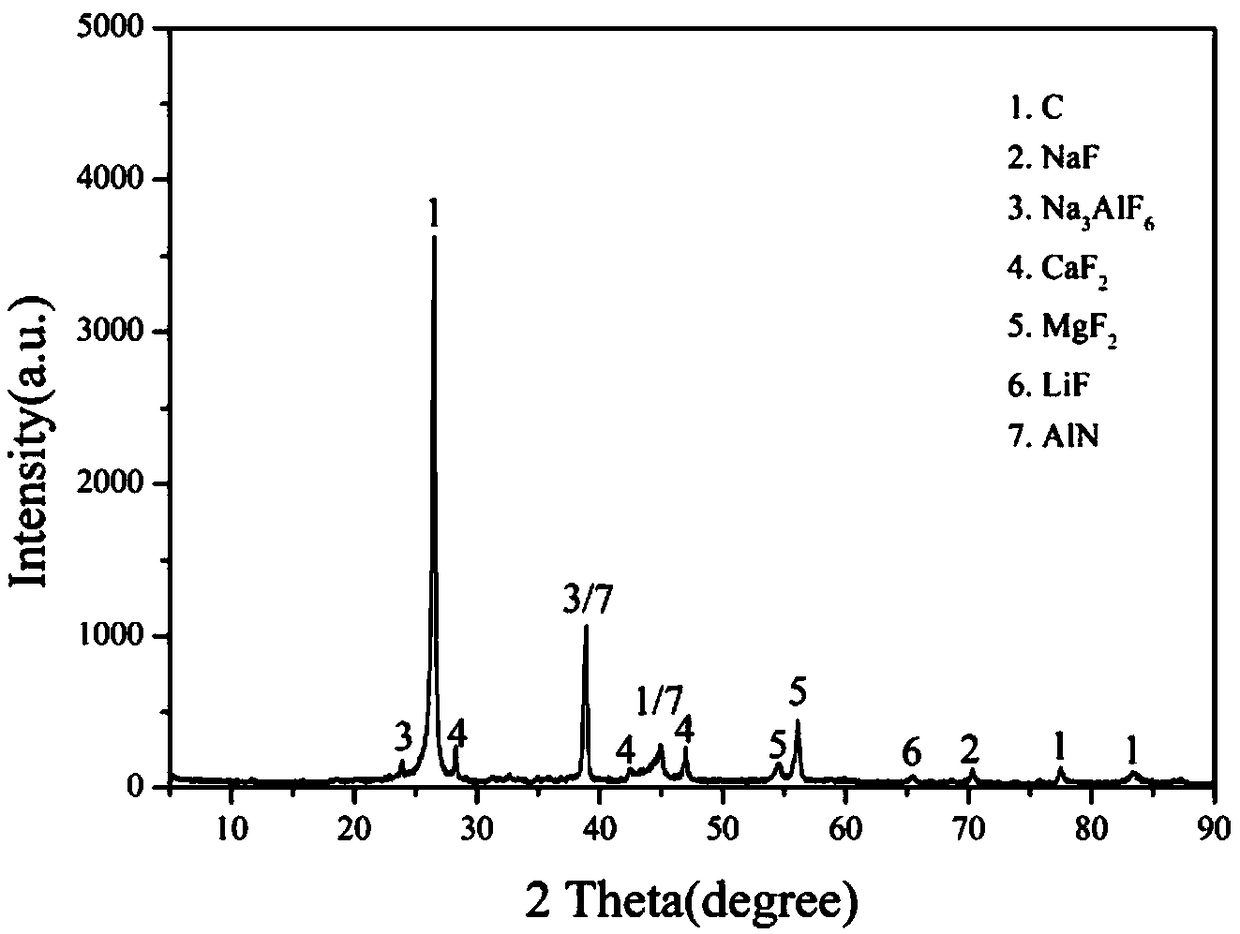

[0081] (1) Pulverize the spent cathode carbon block of the aluminum electrolytic cell in a high-speed pulverizer, sieve it with a 200-mesh sieve, and use the spent cathode carbon powder of the undersieve to carry out mechanochemical conversion of sodium-containing and fluorine-containing compounds. Determine the mass content of sodium and fluorine elements in the waste cathode carbon powder of the unit mass aluminum electrolytic cell by chemical analysis method, and determine the CN in the waste cathode carbon powder of the unit mass aluminum electrolytic cell by chemical analysis method - The mass content of ions.

[0082] (2) Add 200g of corundum balls to the conversion mill, weigh 100g of spent cathode carbon powder, 44g of CaSO 4 2H 2 O, 3g Ca(OH) 2 Add to the transformation mill and mix well, use N 2 Replace the air in the conversion mill, then add 300g H 2 O. The conversion mill was turned on, the rotation speed was 500 rpm, the temperature was 30° C., and the conve...

Embodiment 2

[0093] (1) Pulverize the spent cathode carbon block of the aluminum electrolytic cell in a high-speed pulverizer, sieve with a 200-mesh sieve, and carry out mechanochemical conversion of sodium-containing and fluorine-containing compounds by using the undersieve. Determine the mass content of sodium and fluorine elements in the waste cathode carbon powder of the unit mass aluminum electrolytic cell by chemical analysis method, and determine the CN in the waste cathode carbon powder of the unit mass aluminum electrolytic cell by chemical analysis method - The mass content of ions.

[0094] (2) Add 300g of corundum balls to the transformation mill, weigh 100g of spent cathode carbon powder, 35g of CaO, and 1g of polyvinyl alcohol and add them to the transformation mill and mix evenly. 2 Replace the air in the conversion mill, then add 400g H 2 O. The conversion mill was turned on, the rotation speed was 800 rpm, the temperature was 40° C., and the conversion reaction time was ...

Embodiment 3

[0102] (1) Pulverize the spent cathode carbon block of the aluminum electrolytic cell in a high-speed pulverizer, sieve with a 200-mesh sieve, and carry out mechanochemical conversion of sodium-containing and fluorine-containing compounds by using the undersieve. Determine the mass content of sodium and fluorine elements in the waste cathode carbon powder of the unit mass aluminum electrolytic cell by chemical analysis method, and determine the CN in the waste cathode carbon powder of the unit mass aluminum electrolytic cell by chemical analysis method - The mass content of ions.

[0103] (2) Add 200g of corundum balls to the conversion mill, weigh 100g of spent cathode carbon powder, 50g of MgSO 4 Add to the transformation mill and mix well, use N 2 Replace the air in the conversion mill, then add 350g H 2 O. The conversion mill was turned on, the rotation speed was 900 rpm, the temperature was 50° C., and the conversion reaction time was 4 h.

[0104] After the conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com