Patents

Literature

722results about "Alkali metal carbonates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting and sequestering carbon dioxide

InactiveUS6890497B2Reduce CO burdenWithout significant expenditureCalcium/strontium/barium carbonatesCombination devicesDicarbonateAlkaline earth metal

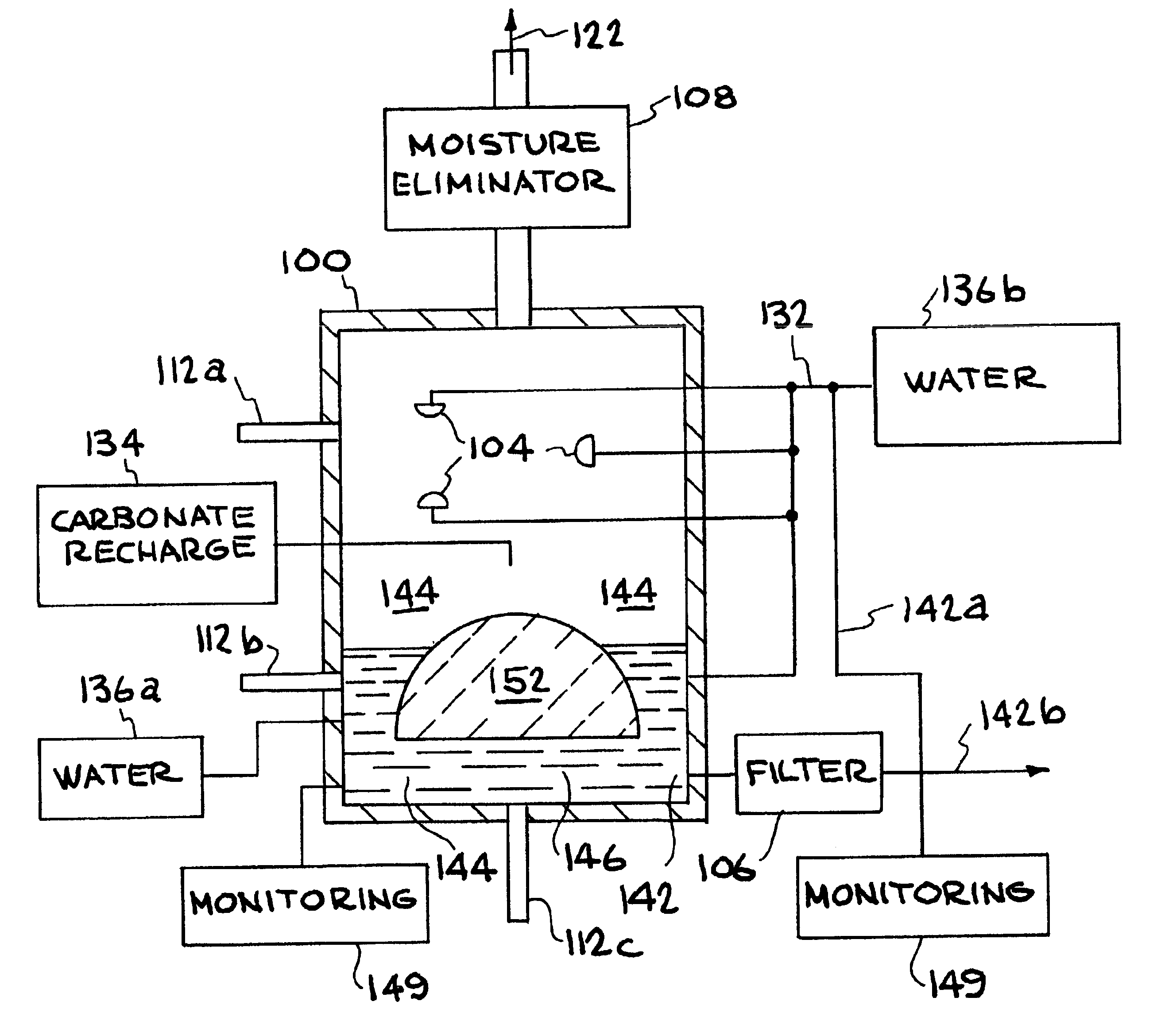

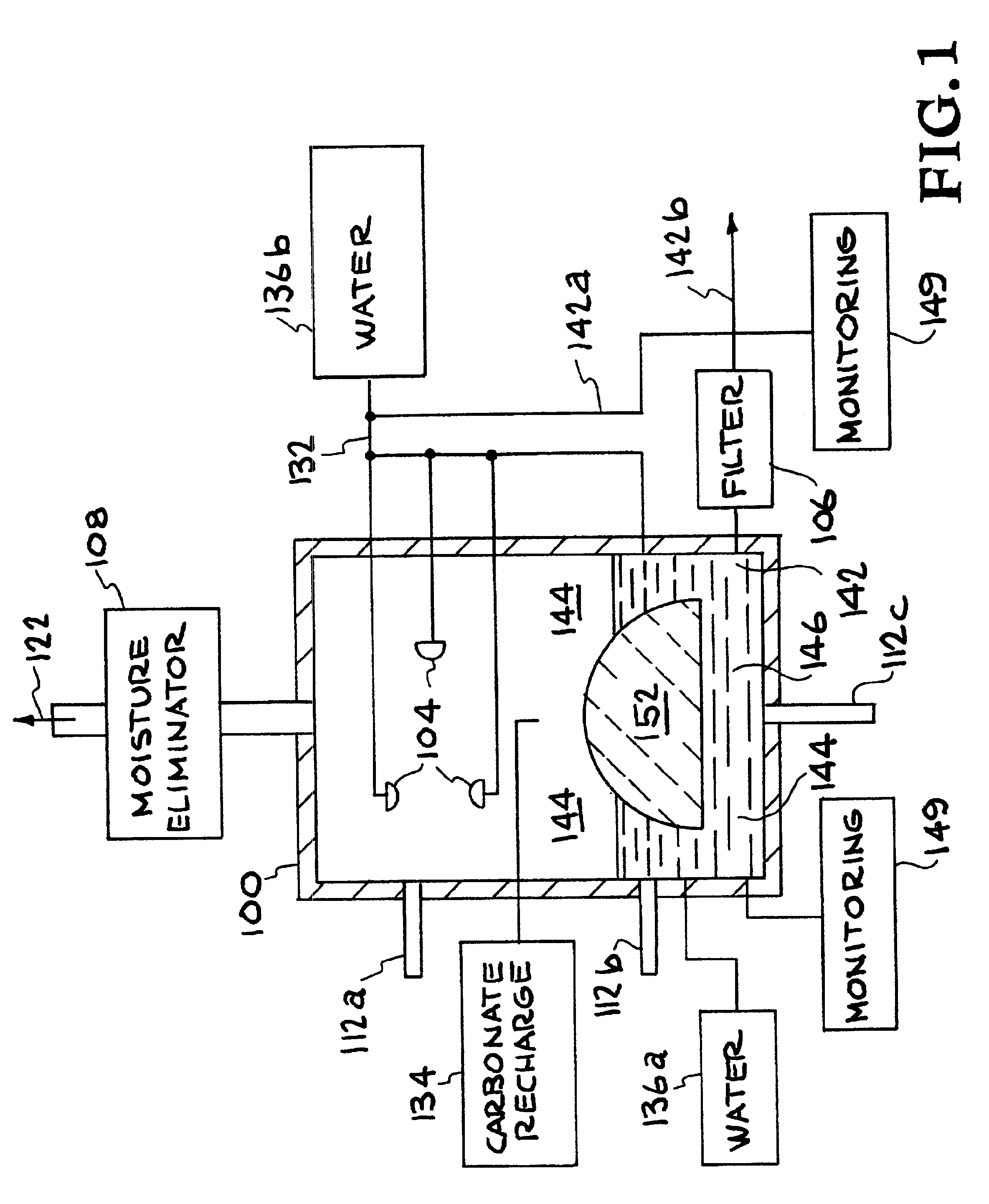

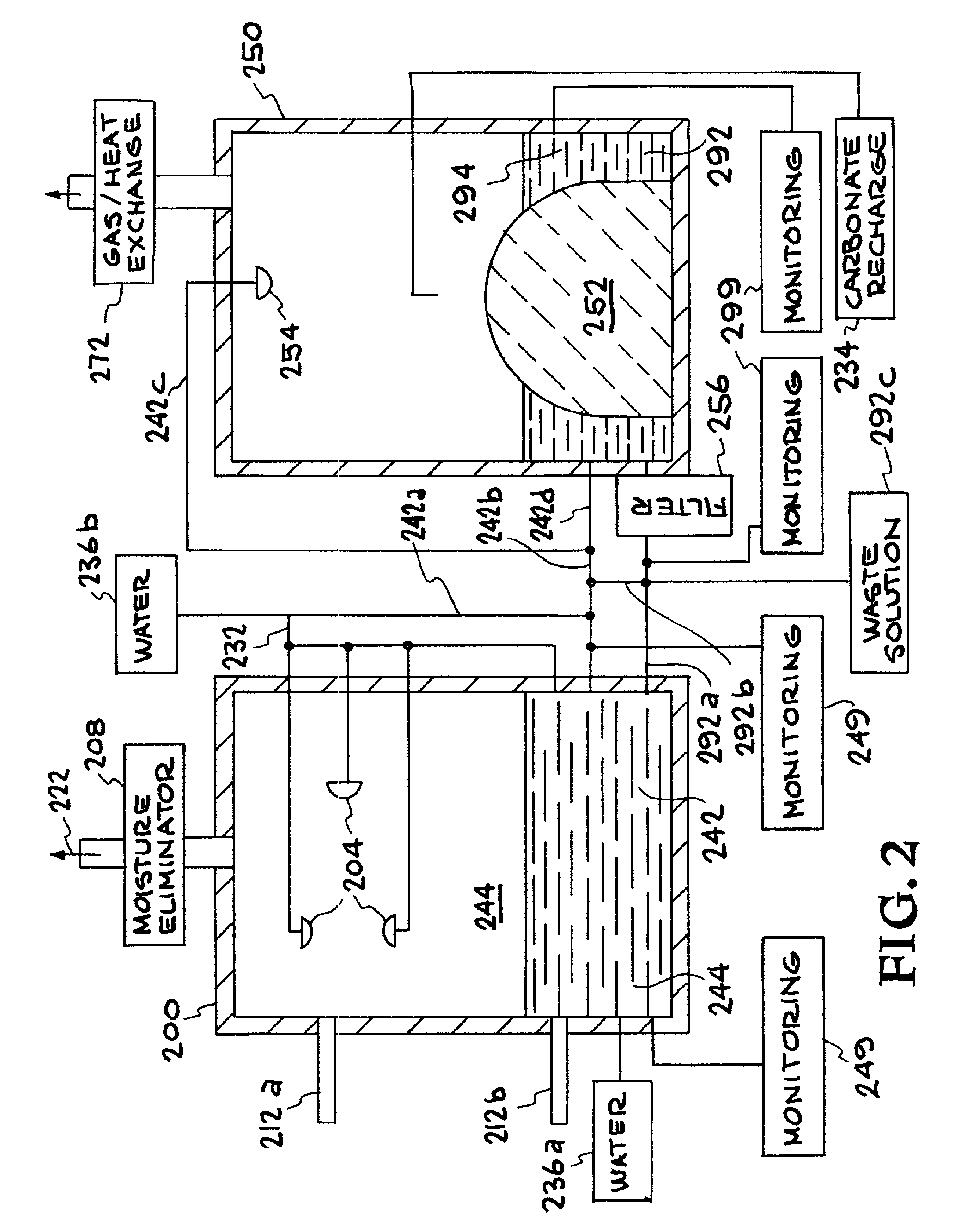

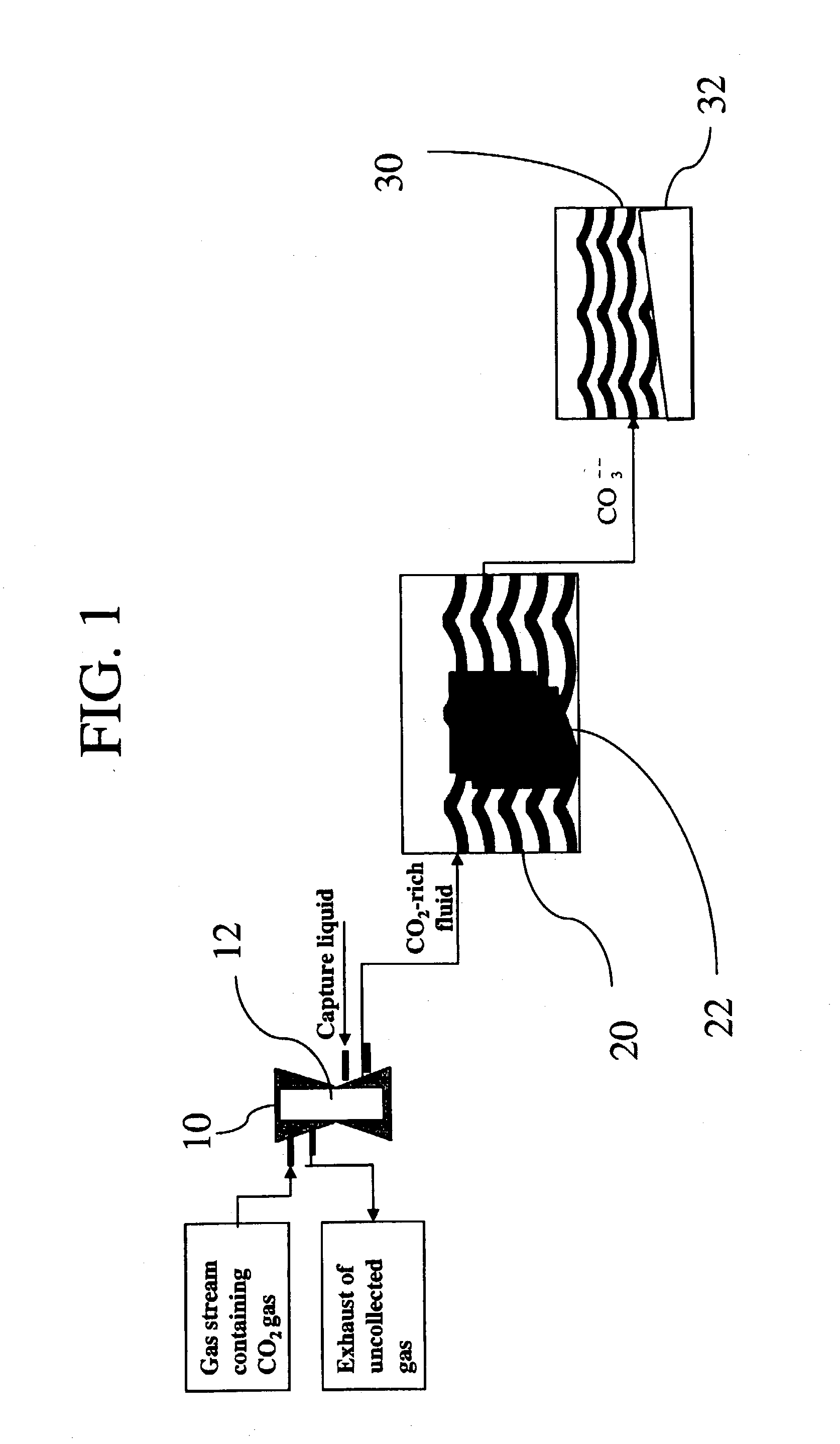

A method and apparatus to extract and sequester carbon dioxide (CO2) from a stream or volume of gas wherein said method and apparatus hydrates CO2, and reacts the resulting carbonic acid with carbonate. Suitable carbonates include, but are not limited to, carbonates of alkali metals and alkaline earth metals, preferably carbonates of calcium and magnesium. Waste products are metal cations and bicarbonate in solution or dehydrated metal salts, which when disposed of in a large body of water provide an effective way of sequestering CO2 from a gaseous environment.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Sequestration of carbon dioxide

ActiveUS7132090B2Safe storageLarge specific surface areaCalcium/strontium/barium carbonatesProductsProduct gasMineral ions

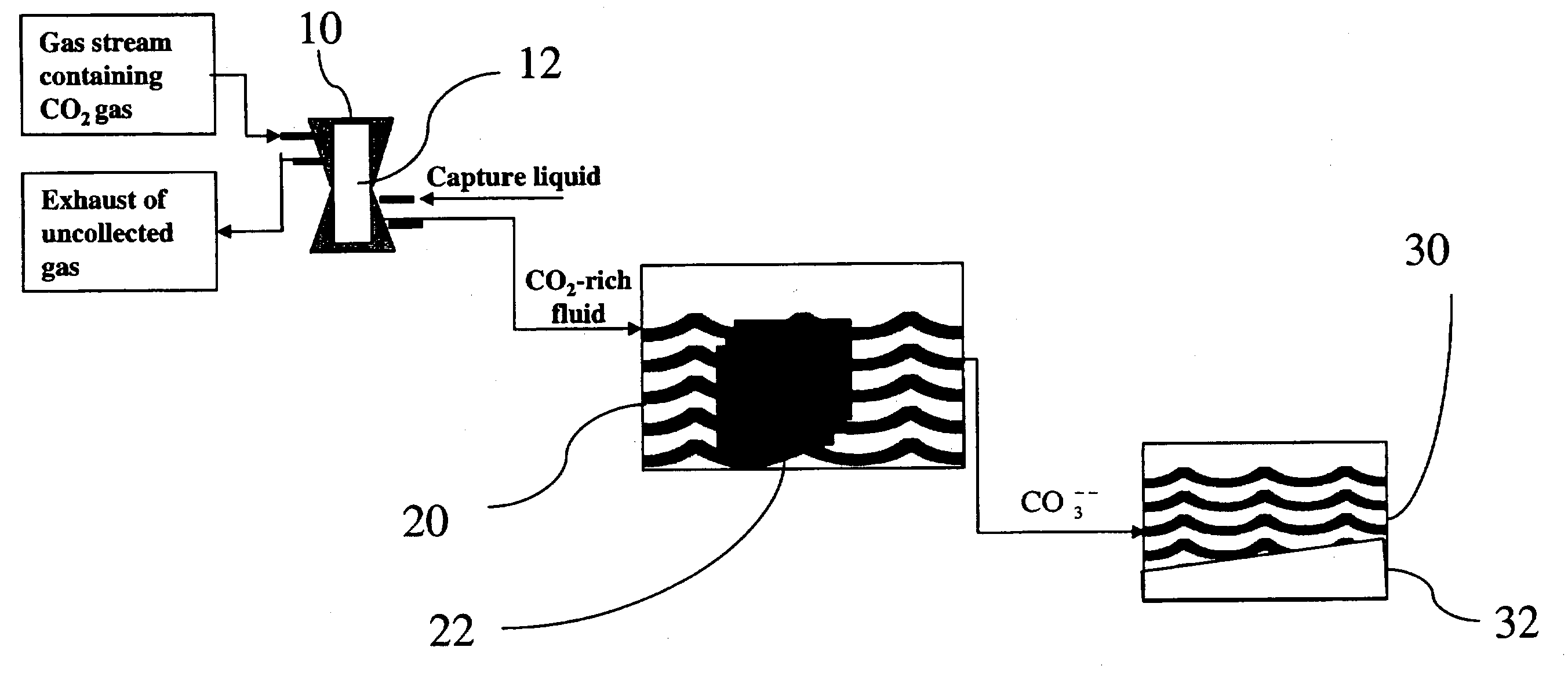

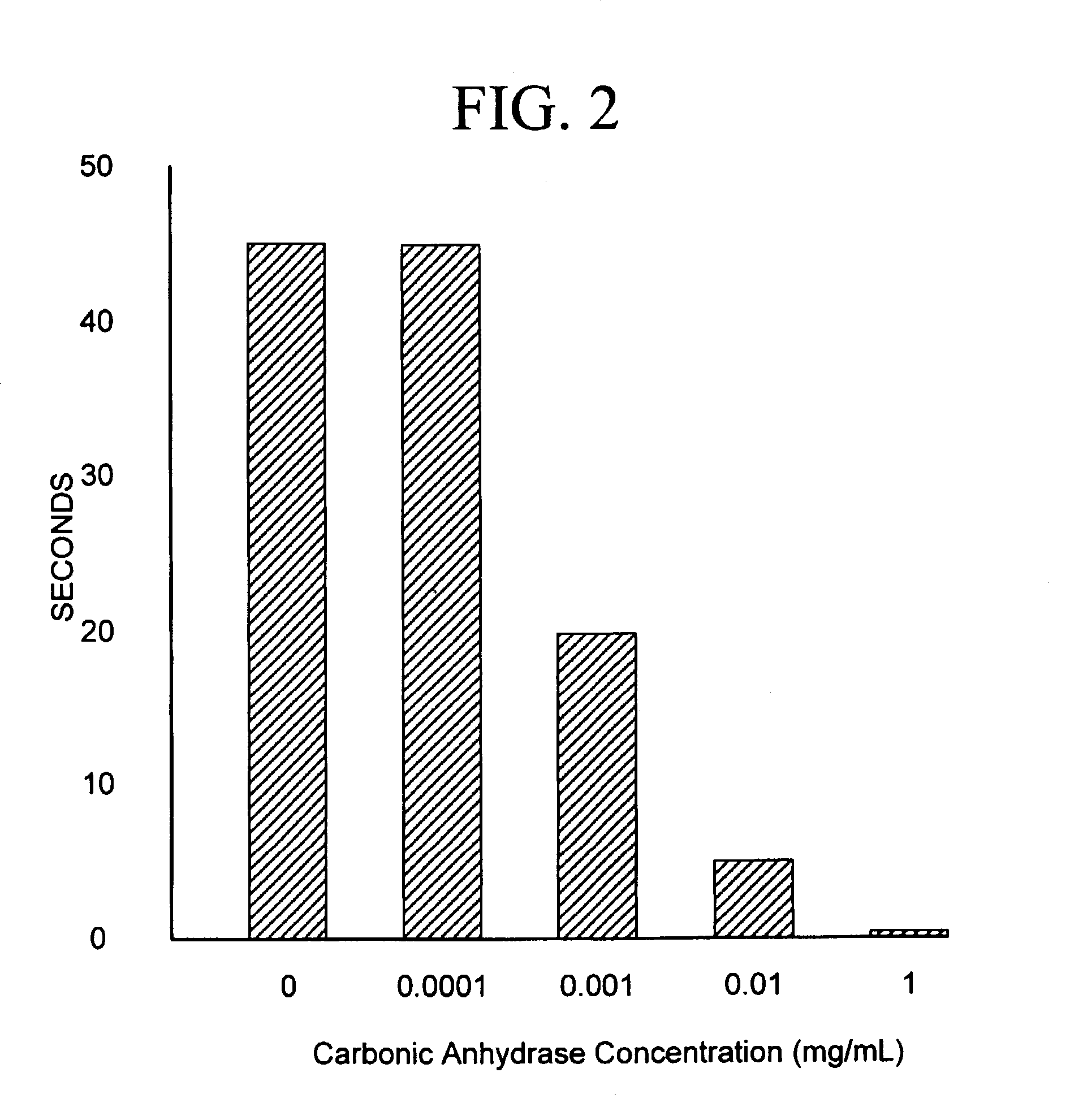

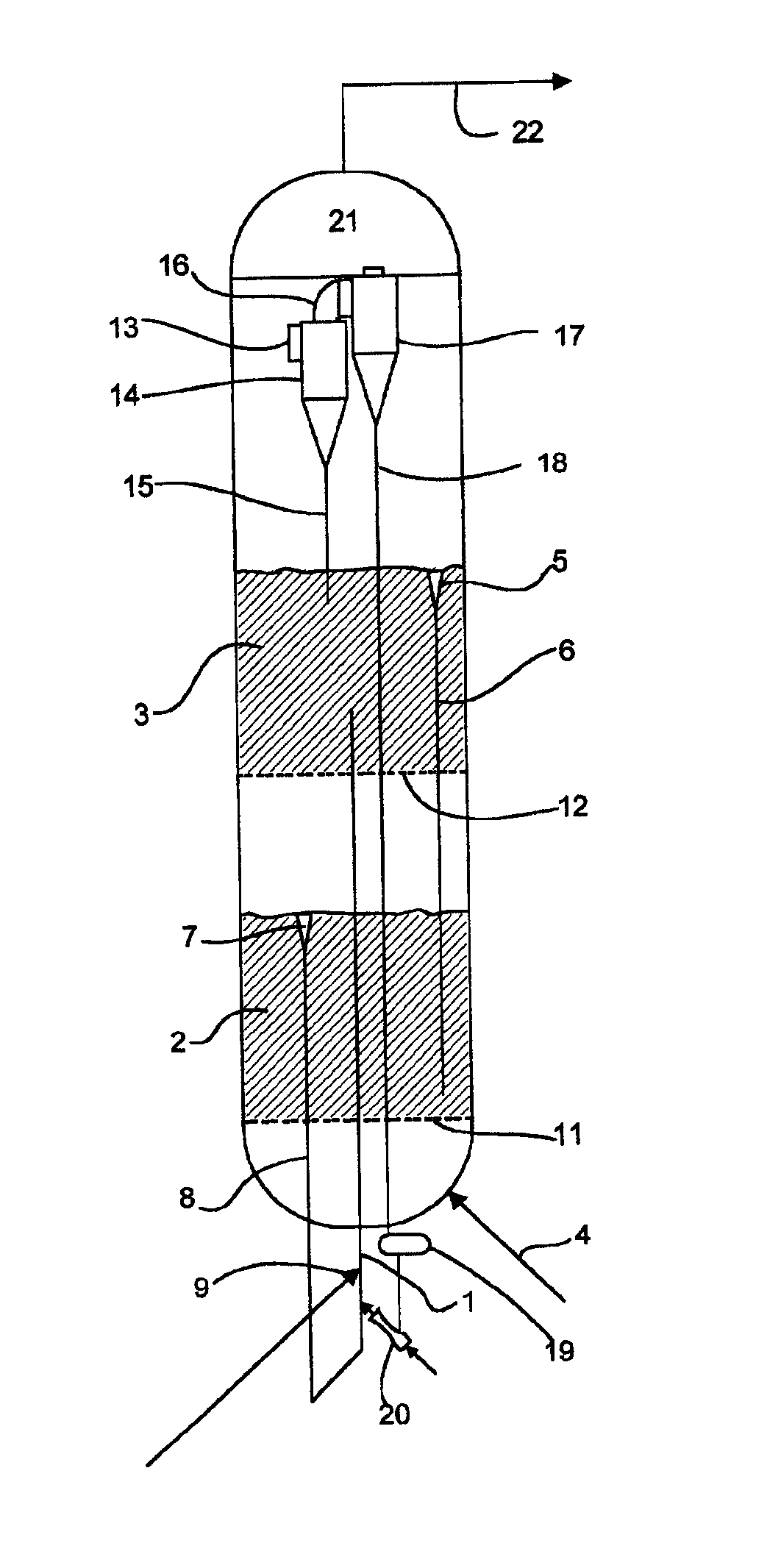

A process for selectively removing carbon dioxide from a gaseous stream by converting the carbon dioxide to a solid, stable form is provided. In a sequestration process, carbon dioxide enriched air is passed through a gas diffusion membrane to transfer the carbon dioxide to a fluid medium. The carbon dioxide rich fluid is then passed through a matrix containing a catalyst specific for carbon dioxide, which accelerates the conversion of the carbon dioxide to carbonic acid. In the final step, a mineral ion is added to the reaction so that a precipitate of carbonate salt is formed. This solid mineral precipitate can be safely stored for extended periods of time, such as by burying the precipitate in the ground or depositing the precipitate into storage sites either on land or into a body of water. An apparatus for removing carbon dioxide from a gaseous stream is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Conversion of petroleum residua to methane

InactiveUS6955695B2Eliminate needReduce usageThermal non-catalytic crackingElectrolysis componentsParticulatesGas phase

This invention discloses improvements on previous inventions for catalytic conversion of coal and steam to methane. The disclosed improvements permit conversion of petroleum residua or heavy crude petroleum to methane and carbon dioxide such that nearly all of the heating value of the converted hydrocarbons is recovered as heating value of the product methane. The liquid feed is distributed over a fluidized solid particulate catalyst containing alkali metal and carbon as petroleum coke at elevated temperature and pressure from the lower stage and transported to the upper stage of a two-stage reactor. Particulate solids containing carbon and alkali metal are circulated between the two stages. Superheated steam and recycled hydrogen and carbon monoxide are fed to the lower stage, fluidizing the particulate solids and gasifying some of the carbon. The gas phase from the lower stage passes through the upper stage, completing the reaction of the gas phase.

Owner:PETRO2020

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169448A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesPhysical chemistryAlkali metal

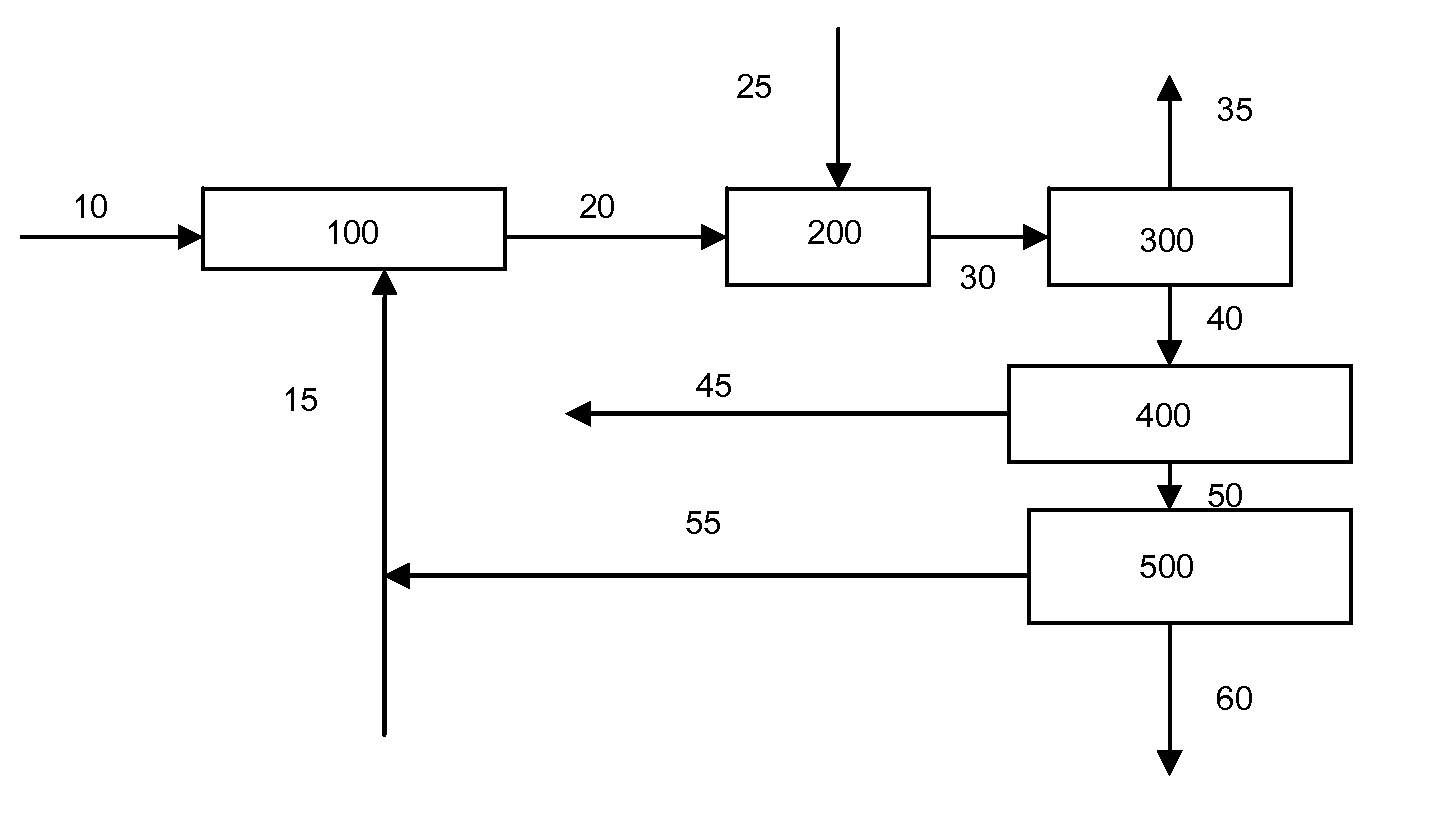

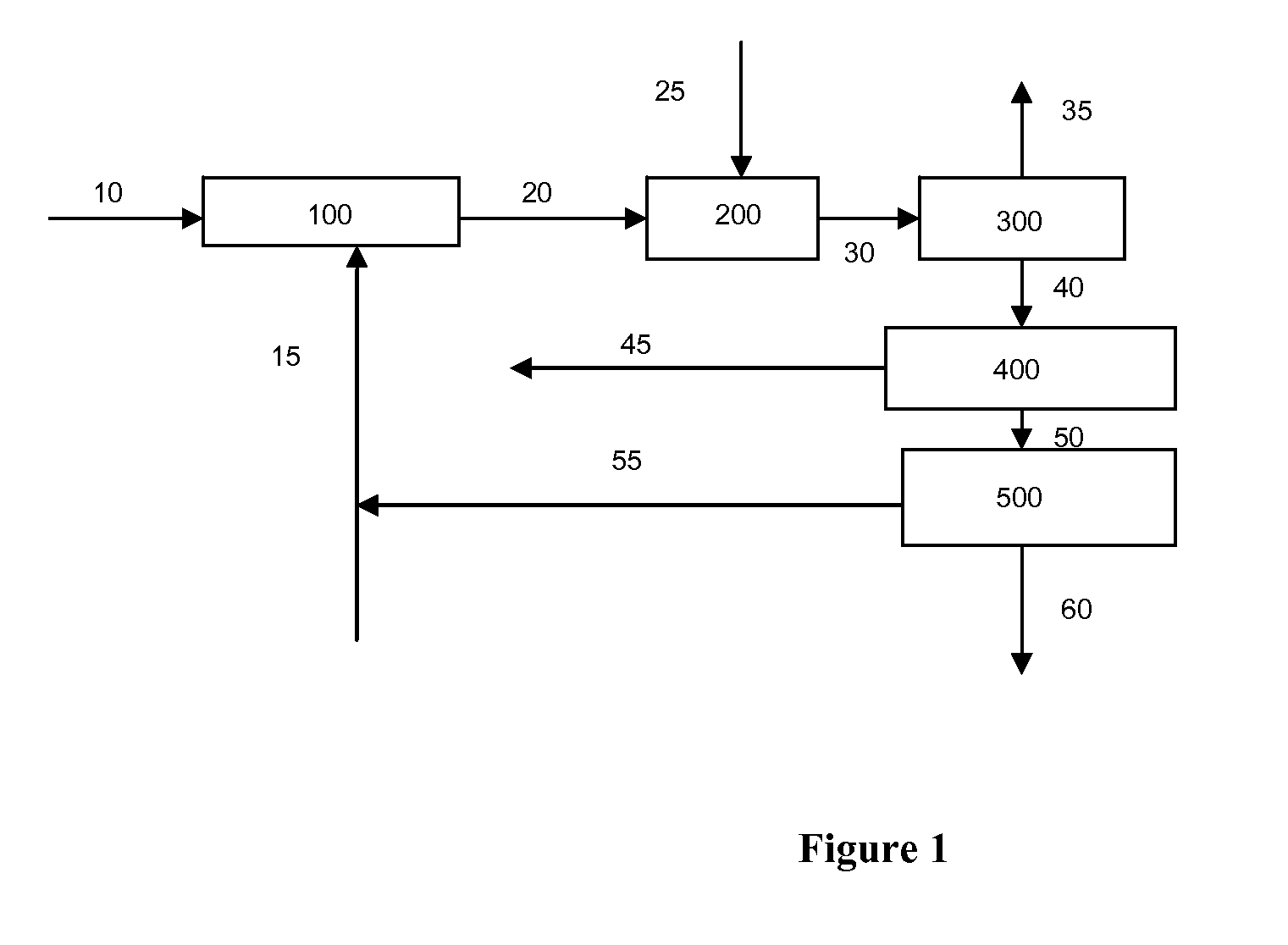

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169449A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

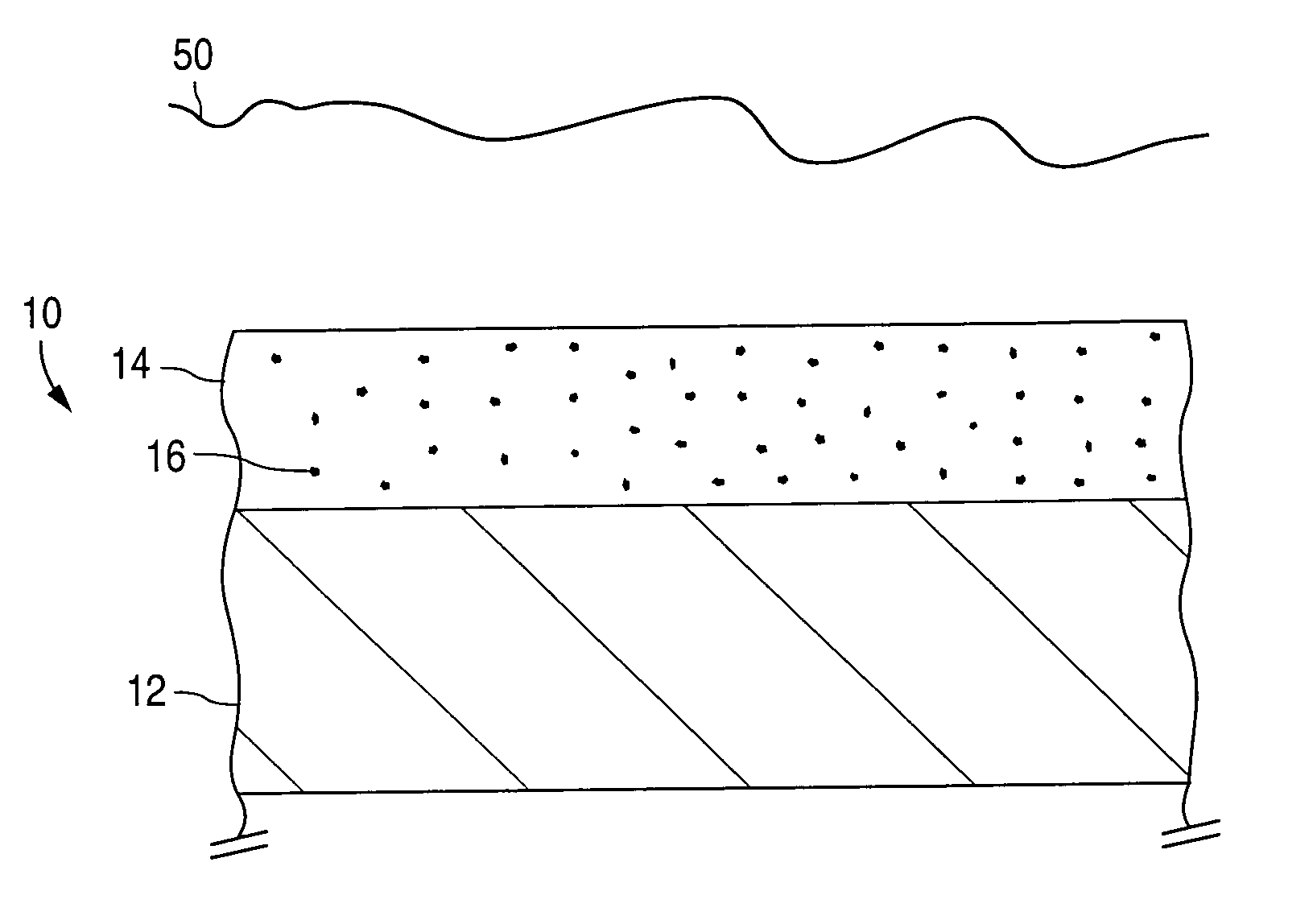

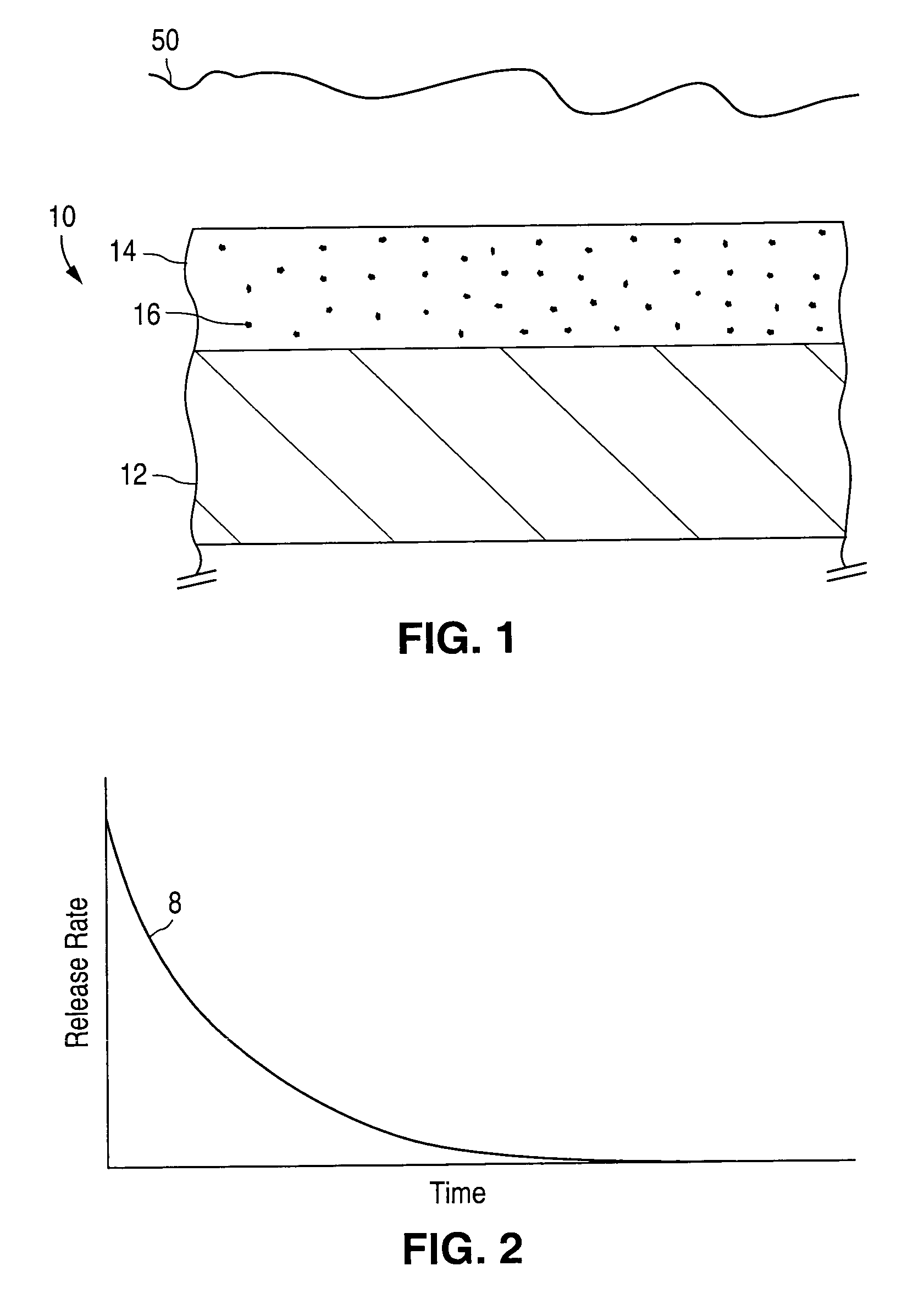

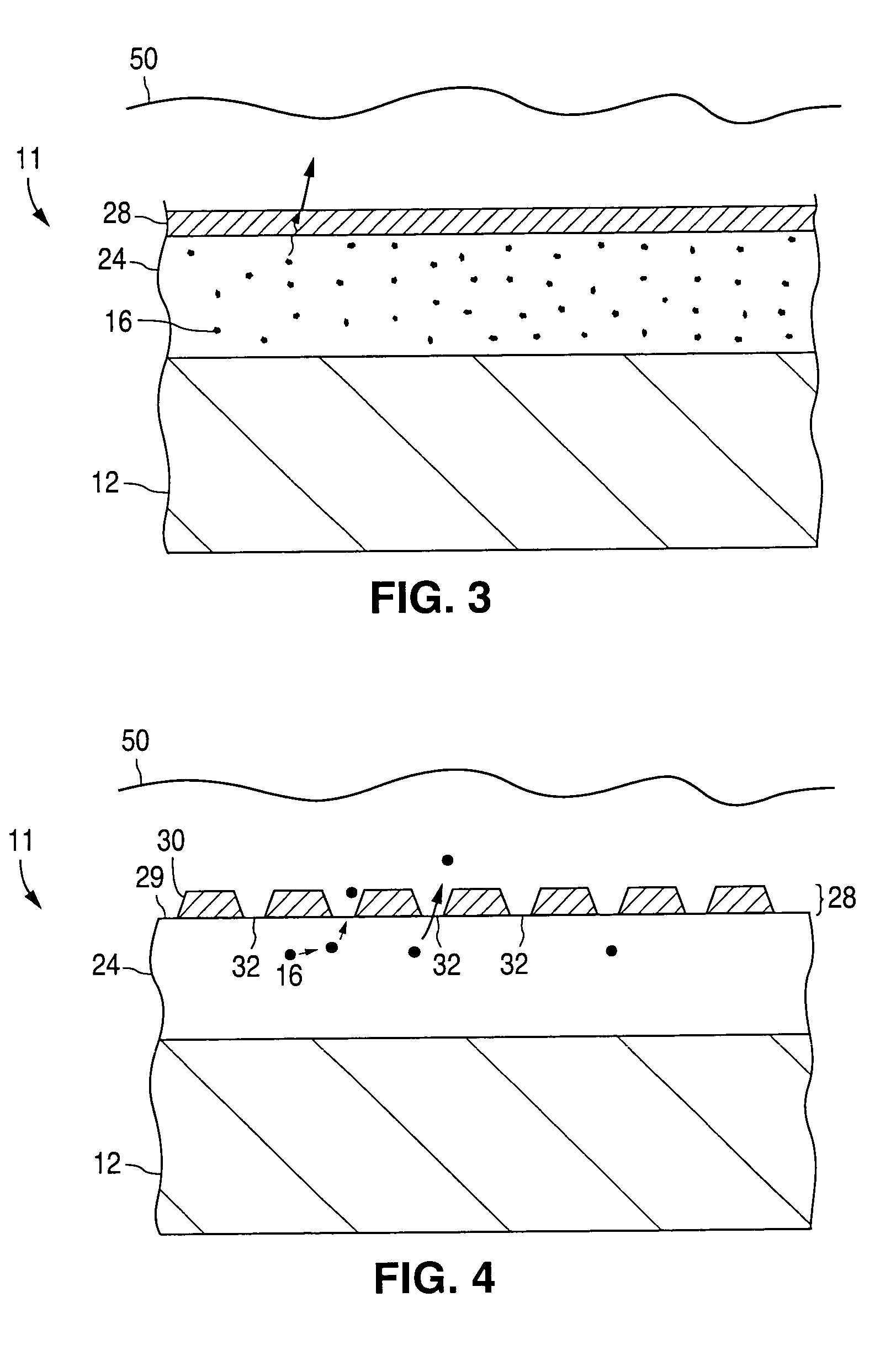

Barriers for polymer-coated implantable medical devices and methods for making the same

InactiveUS6953560B1Reduce and prevent and inflammationReduce and prevent proliferationStentsSurgeryHafniumPt element

An implantable medical device and methods for making the implantable medical device are disclosed. The implantable medical device includes a substrate. At least a portion of the substrate is coated with a first layer including a polymer containing a drug. A barrier overlies the first layer. The barrier significantly reduces the rate of release of the drug from the polymer, thereby sustaining release of the drug from the medical device for a longer time.The barrier may be a homogeneous layer overlying the first layer, or a number of discrete deposits over the first layer. Alternatively, the barrier may be intermixed with an outer portion of the first layer. The barrier material is biocompatible, and typically has a thickness ranging from about 50 angstroms to about 20,000 microns. Suitable materials for the barrier include, but are not limited to, inorganic compounds, such as inorganic silicides, oxides, nitrides, carbides, as well as pure metals such as aluminum, chromium, gold, hafnium, iridium, niobium, palladium, platinum, tantalum, titanium, tungsten, zirconium, and alloys of these metals. The barriers disclosed may be applied to the first layer by several techniques, depending on the material being applied. Exemplary deposition techniques include physical vapor deposition, alkoxide hydrolysis, and electroless plating.The implantable device may be a stent or a graft, among other possibilities.

Owner:ABBOTT CARDIOVASCULAR

Processes for preparing highly pure lithium carbonate and other highly pure lithium containing compounds

ActiveUS20110200508A1Electrolysis componentsLithium organic compoundsLithium carbonateLithium hydroxide

Owner:TERRALITHIUM LLC

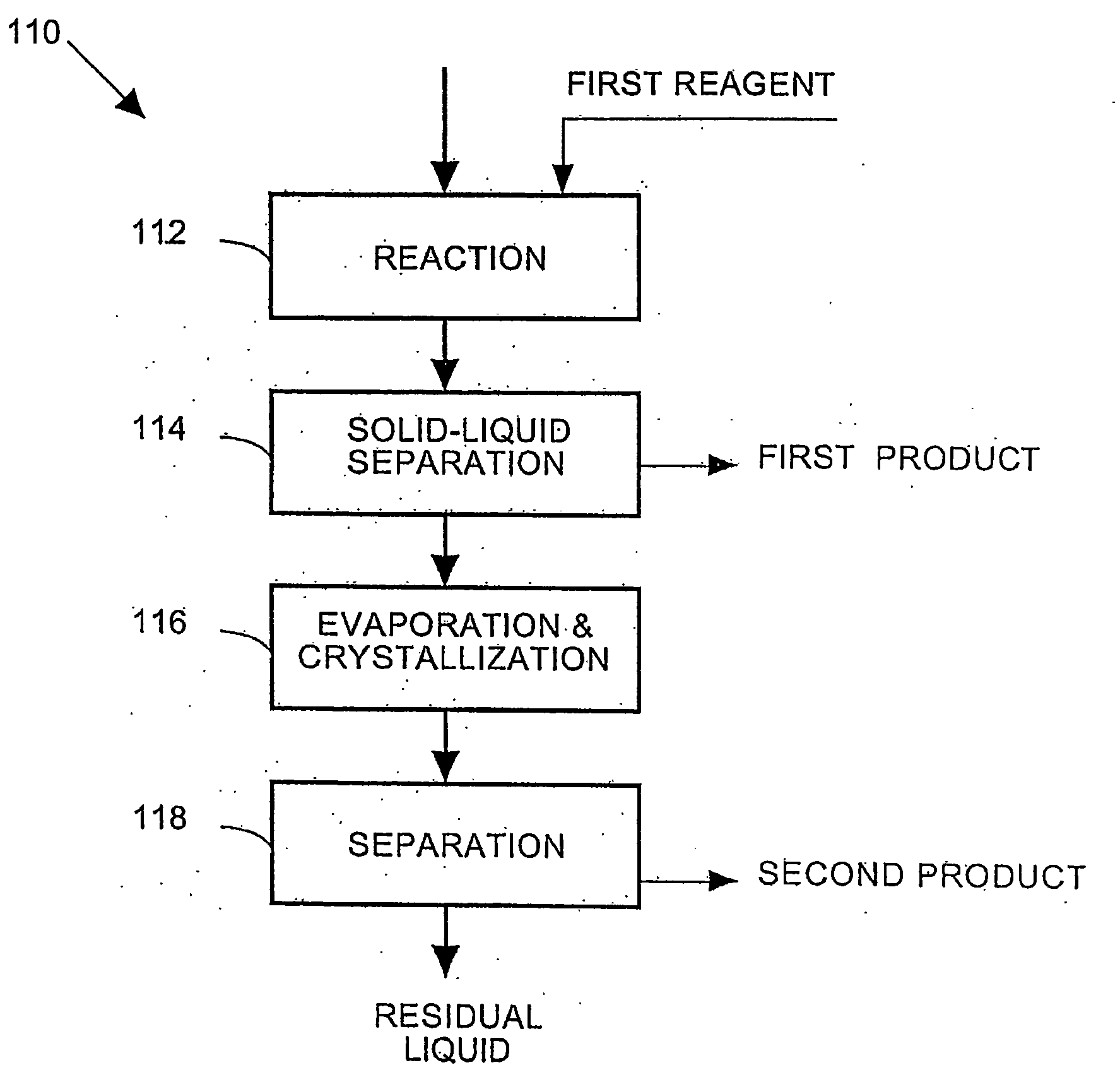

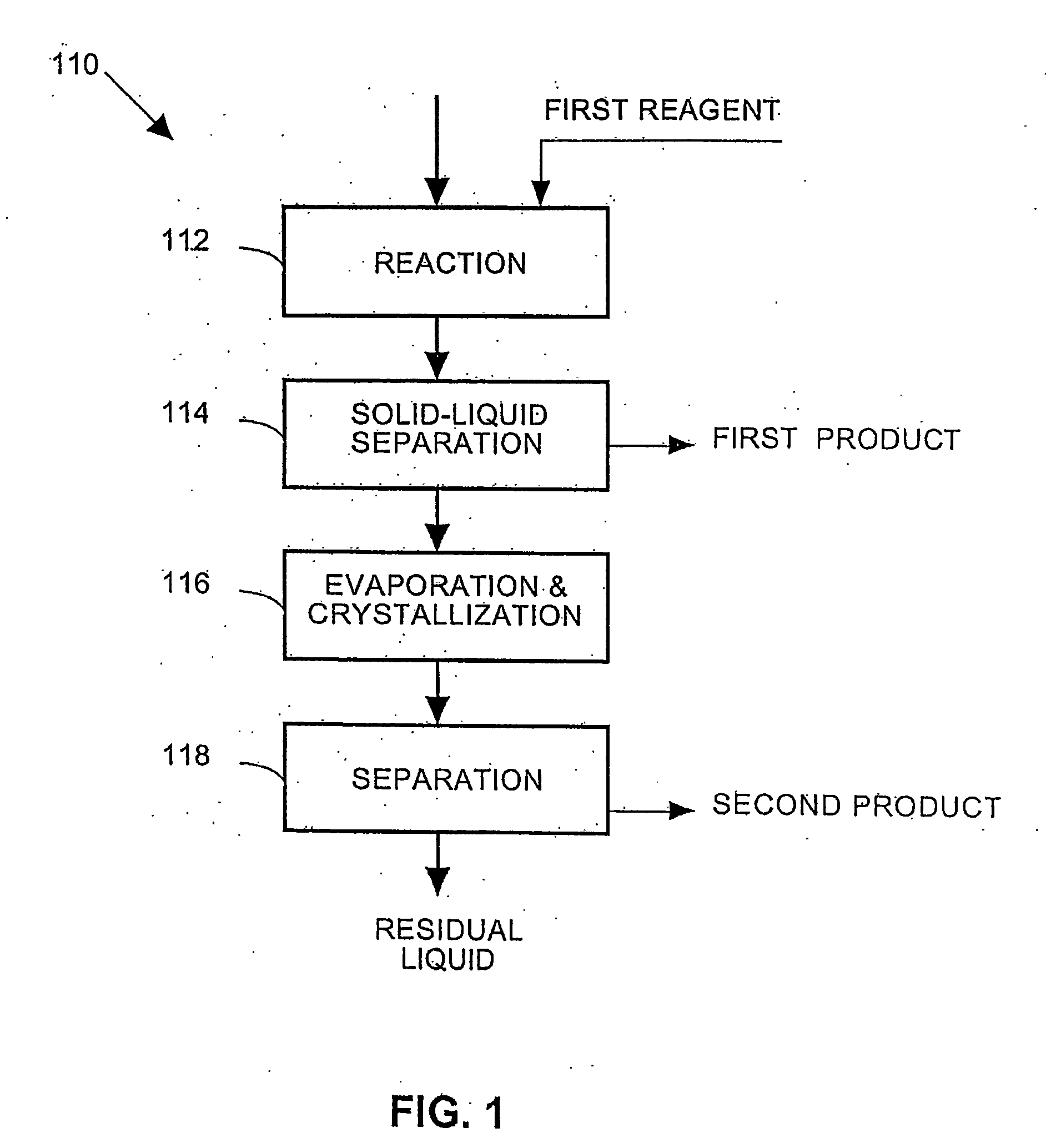

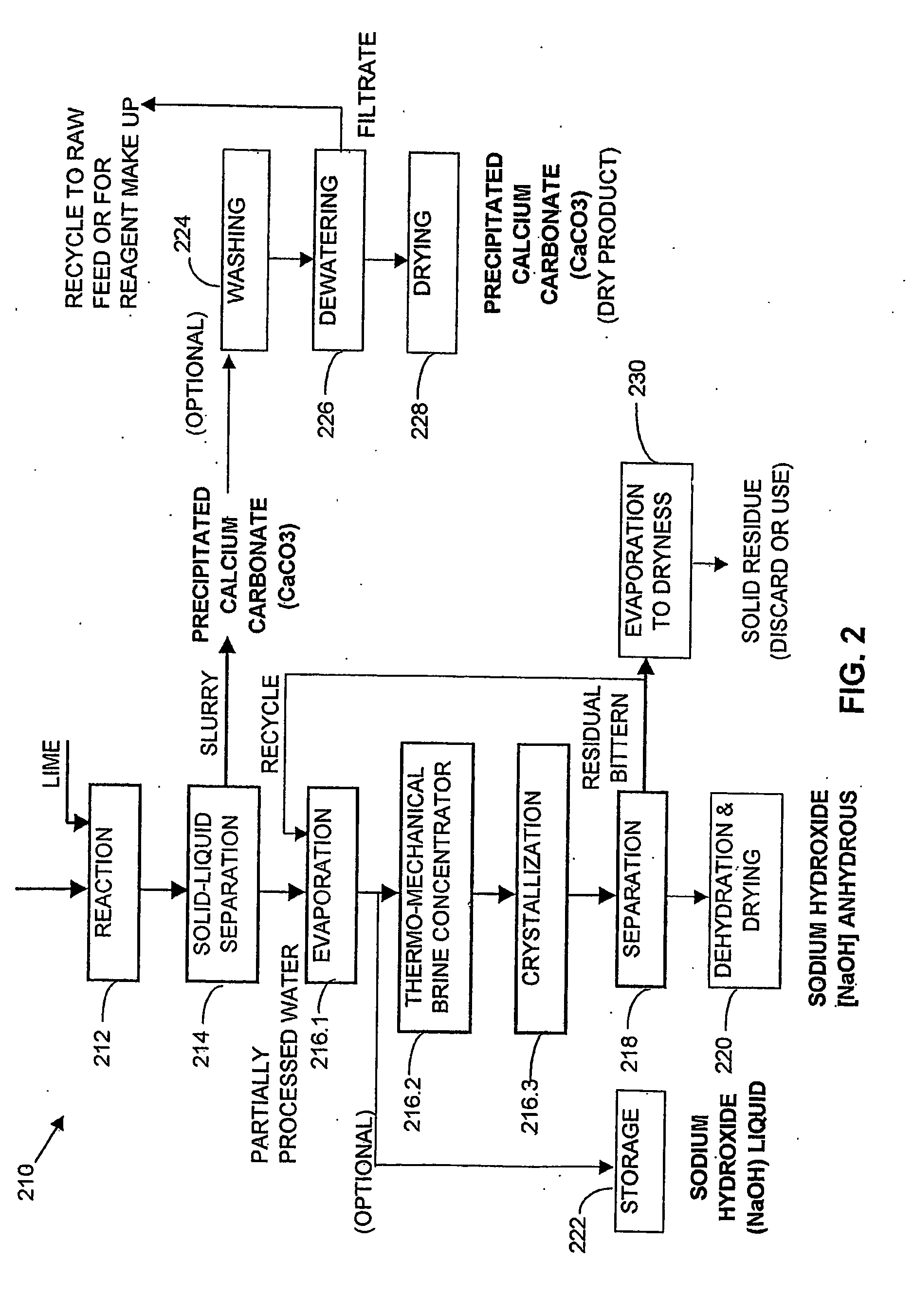

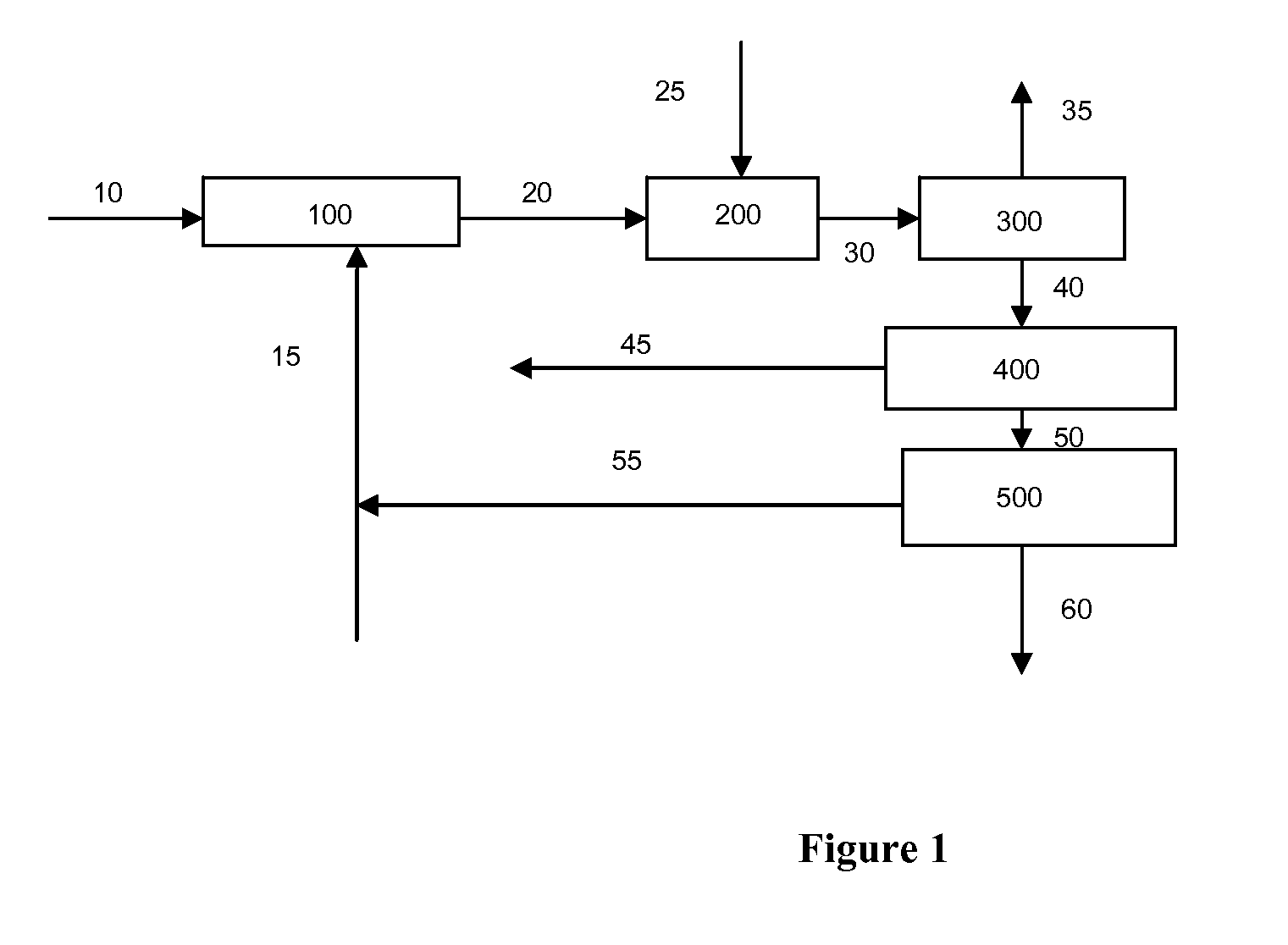

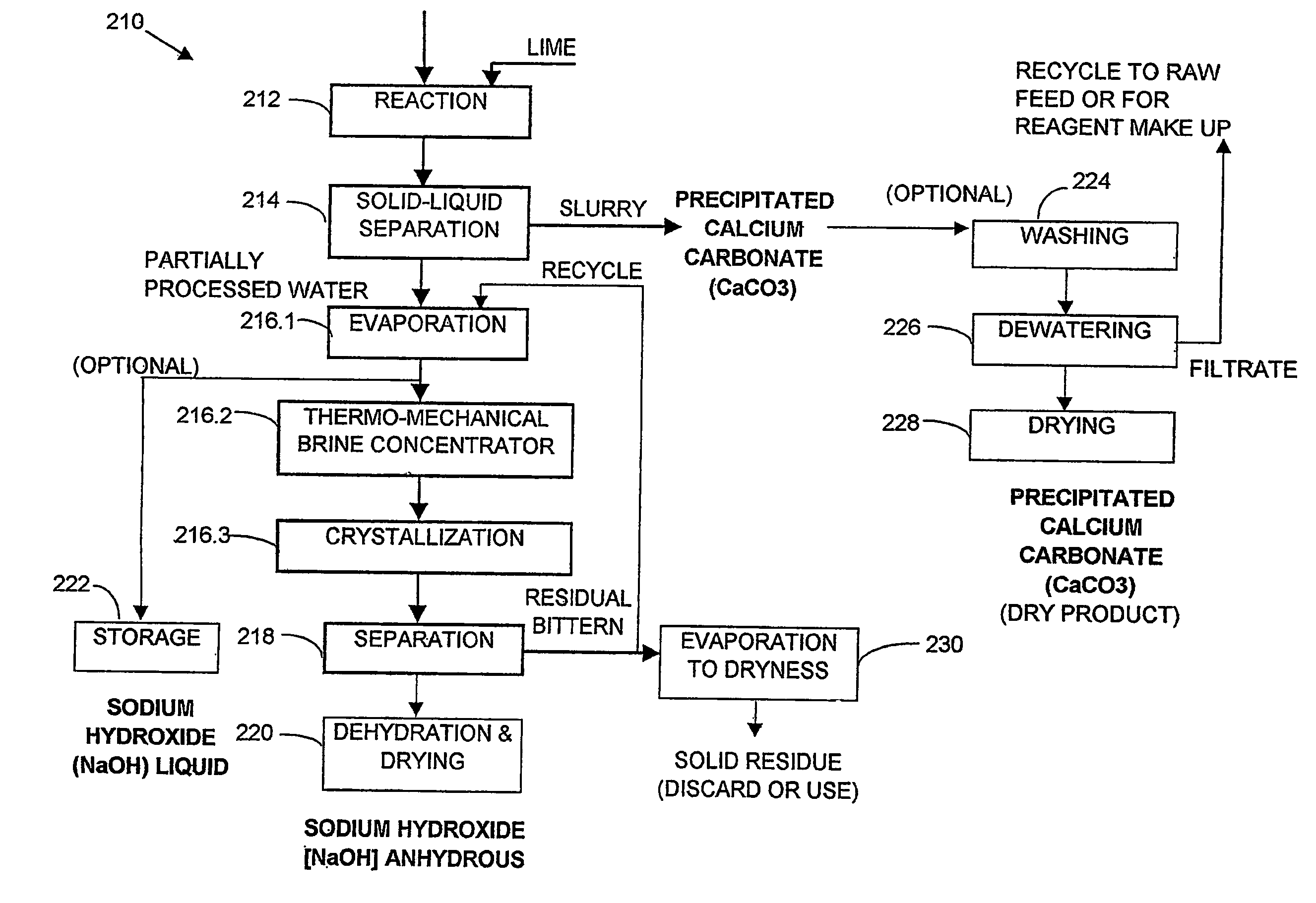

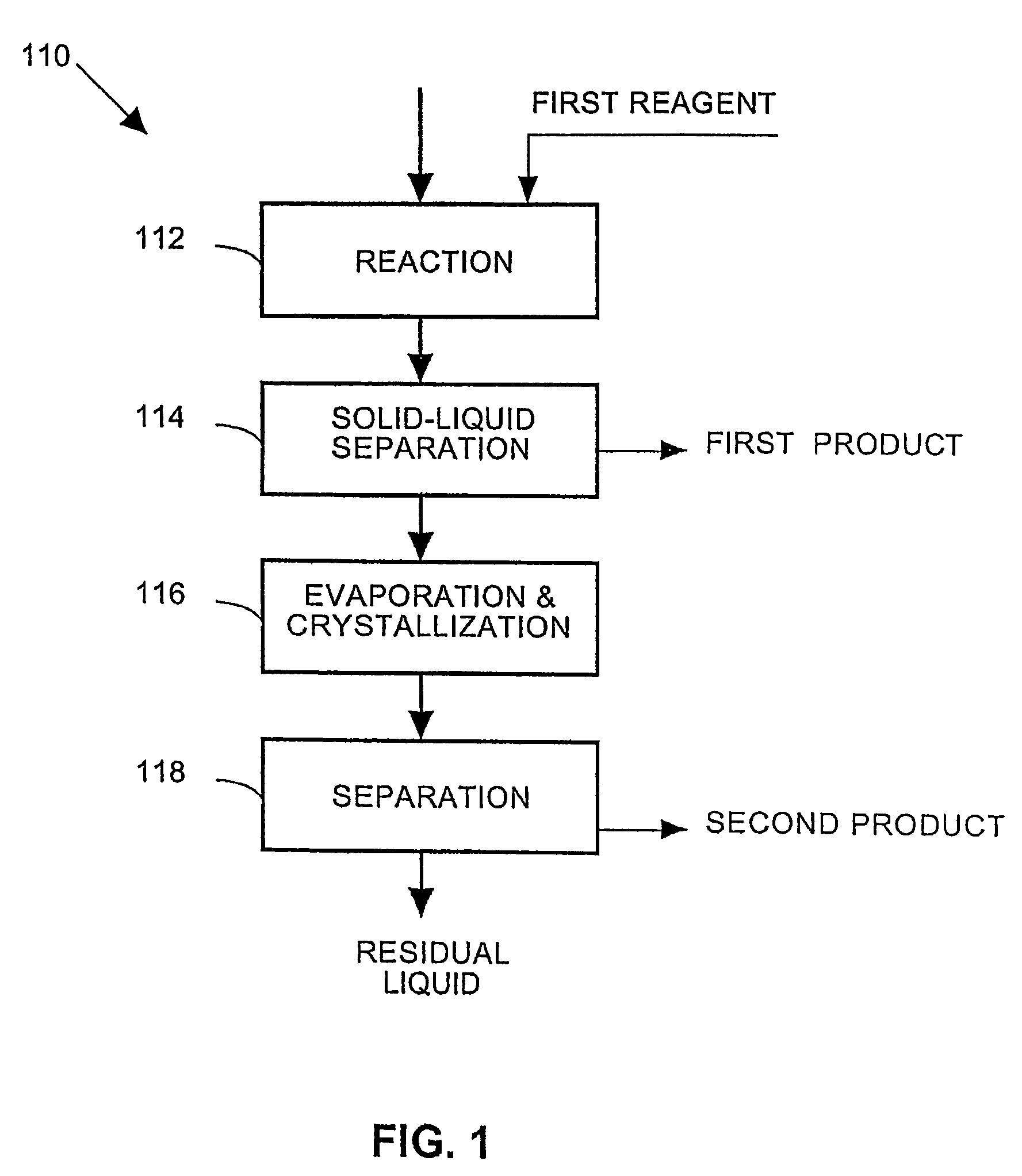

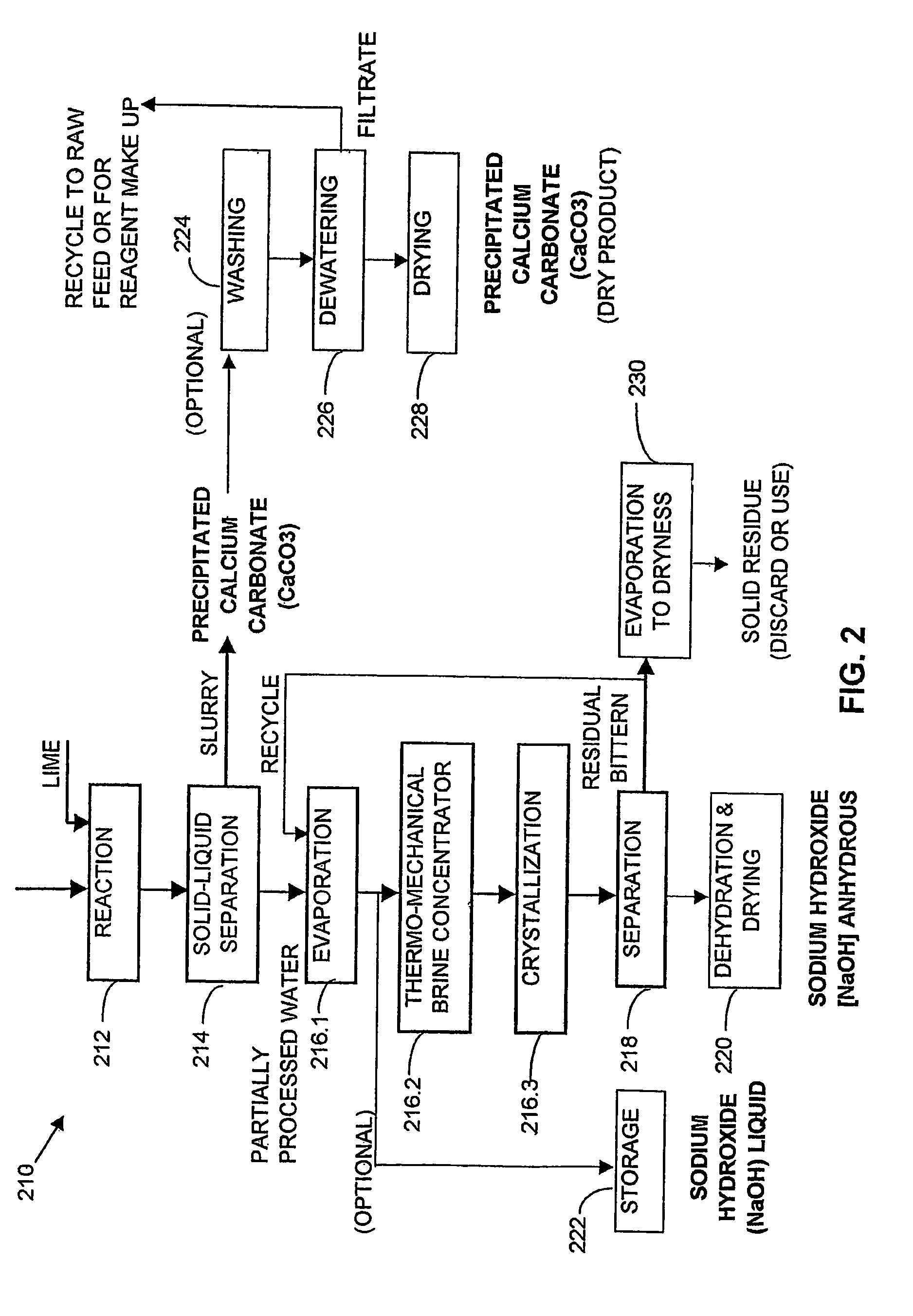

Process and apparatus for the treatment of saline water

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

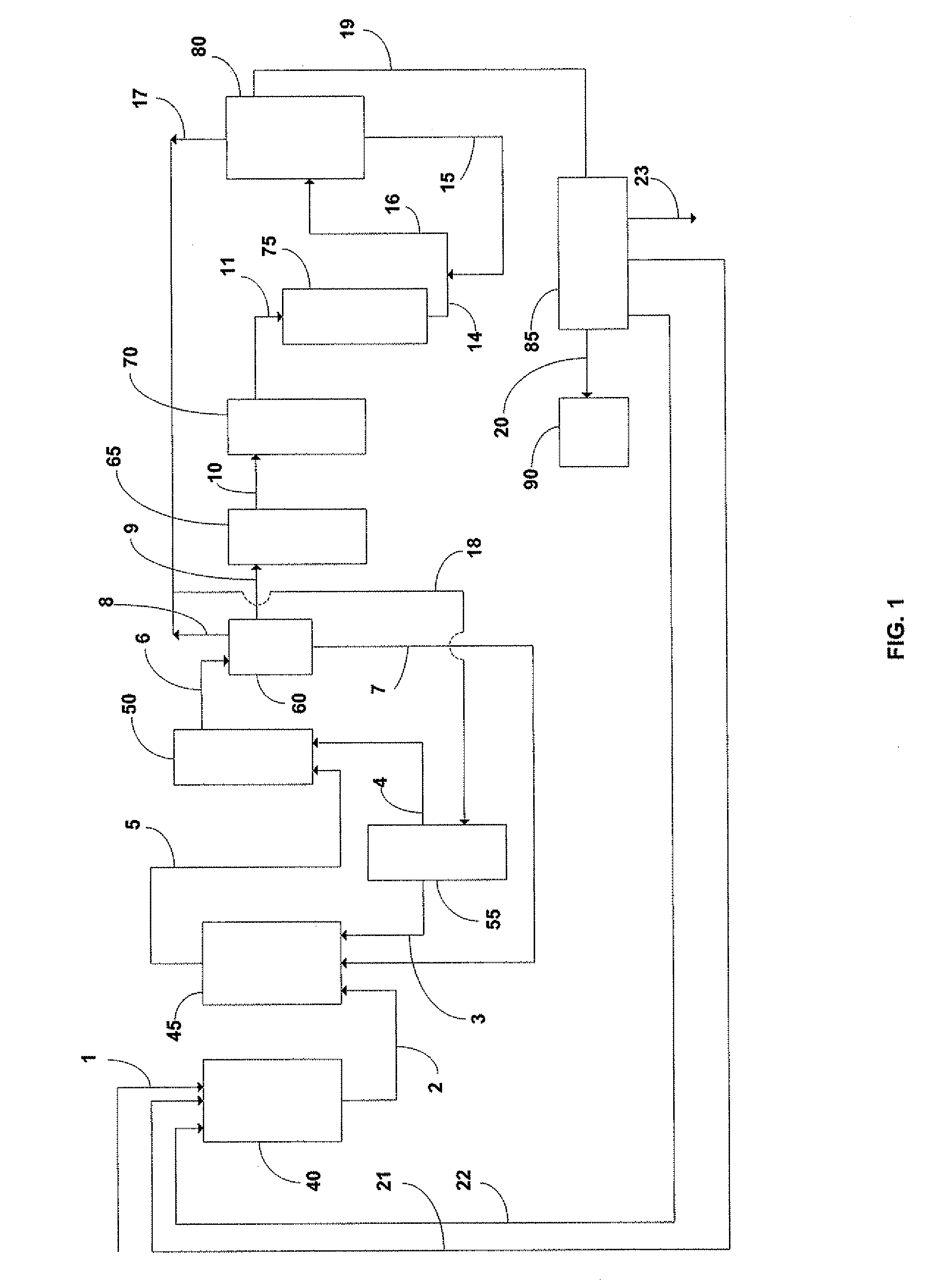

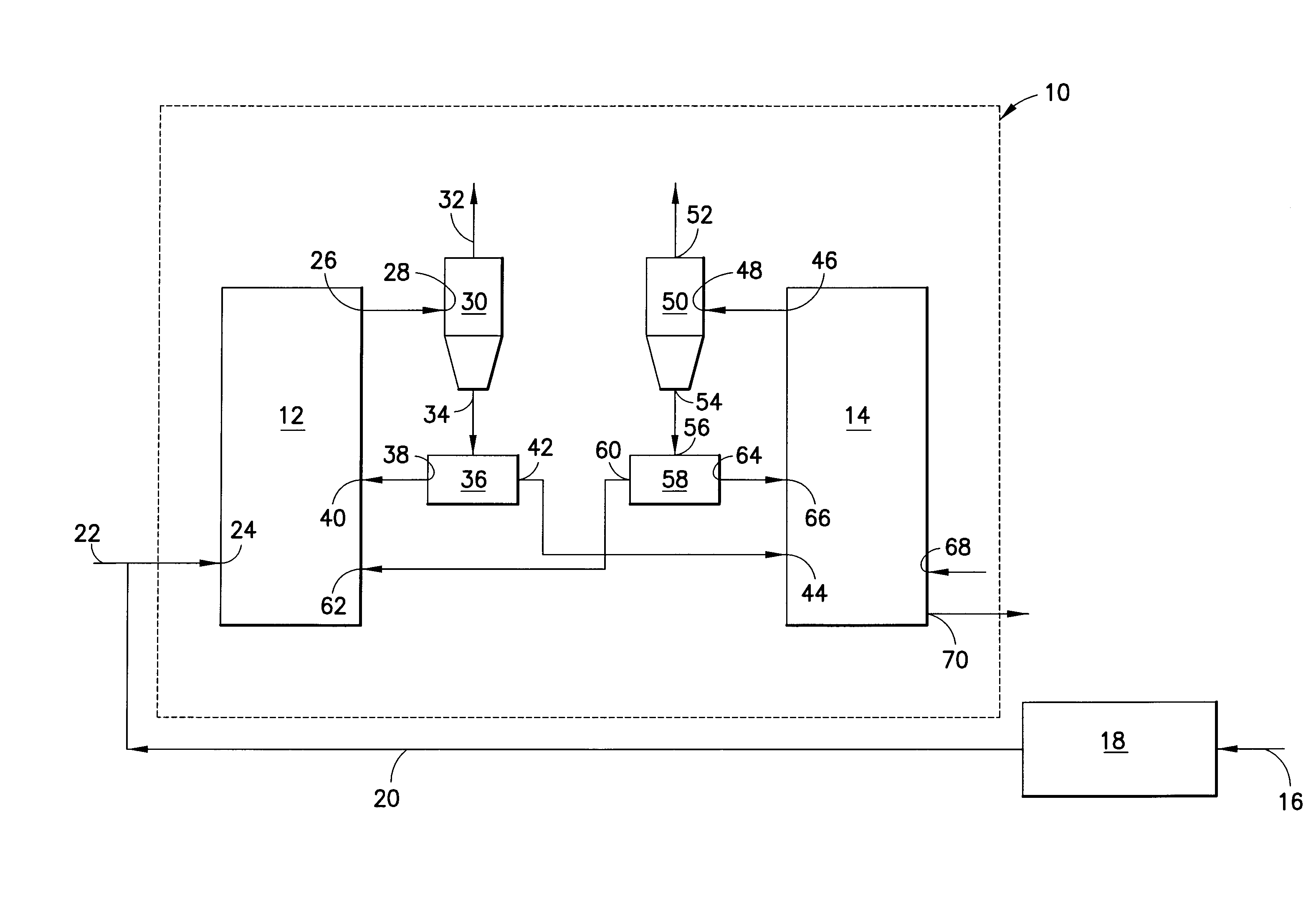

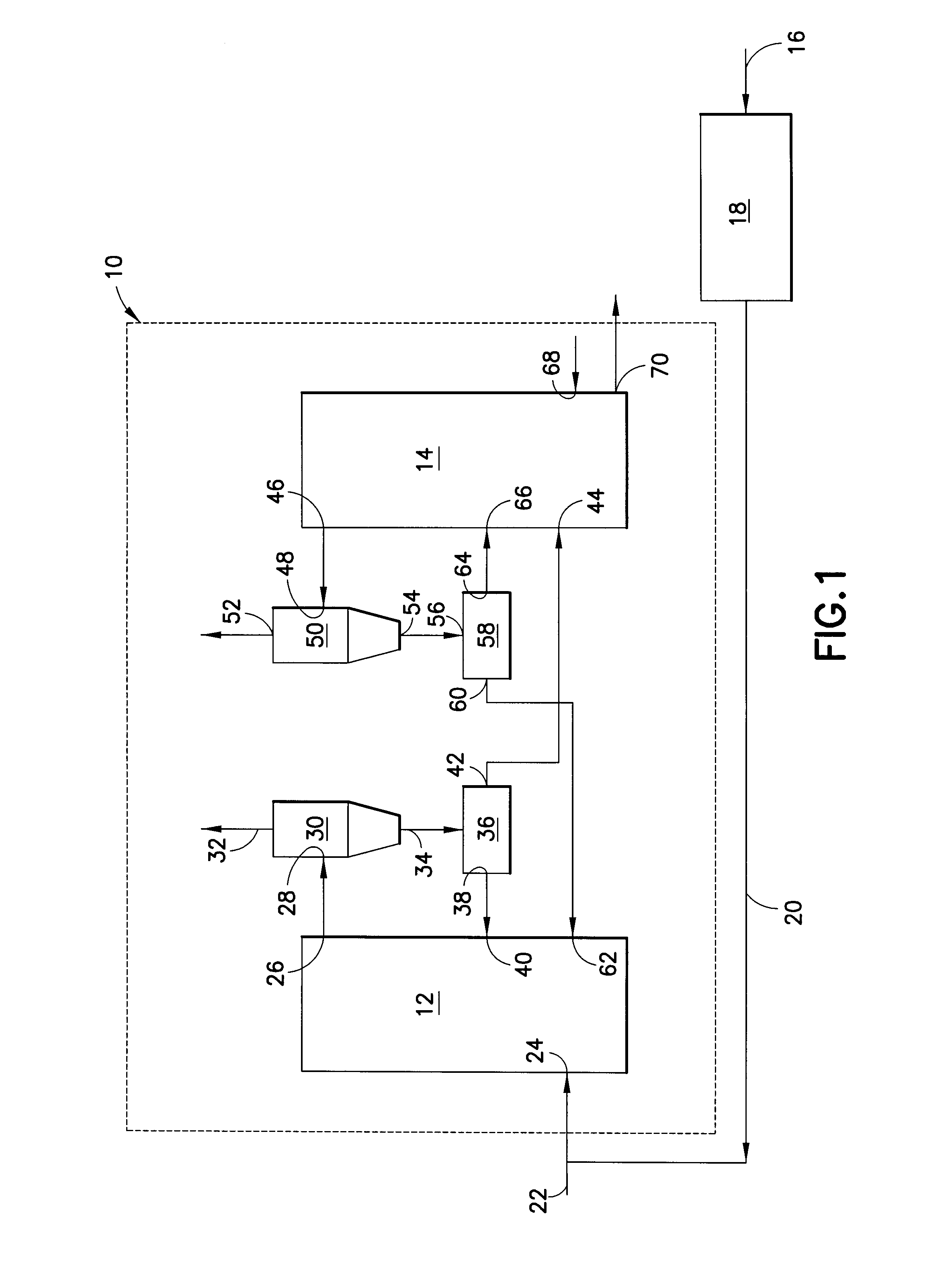

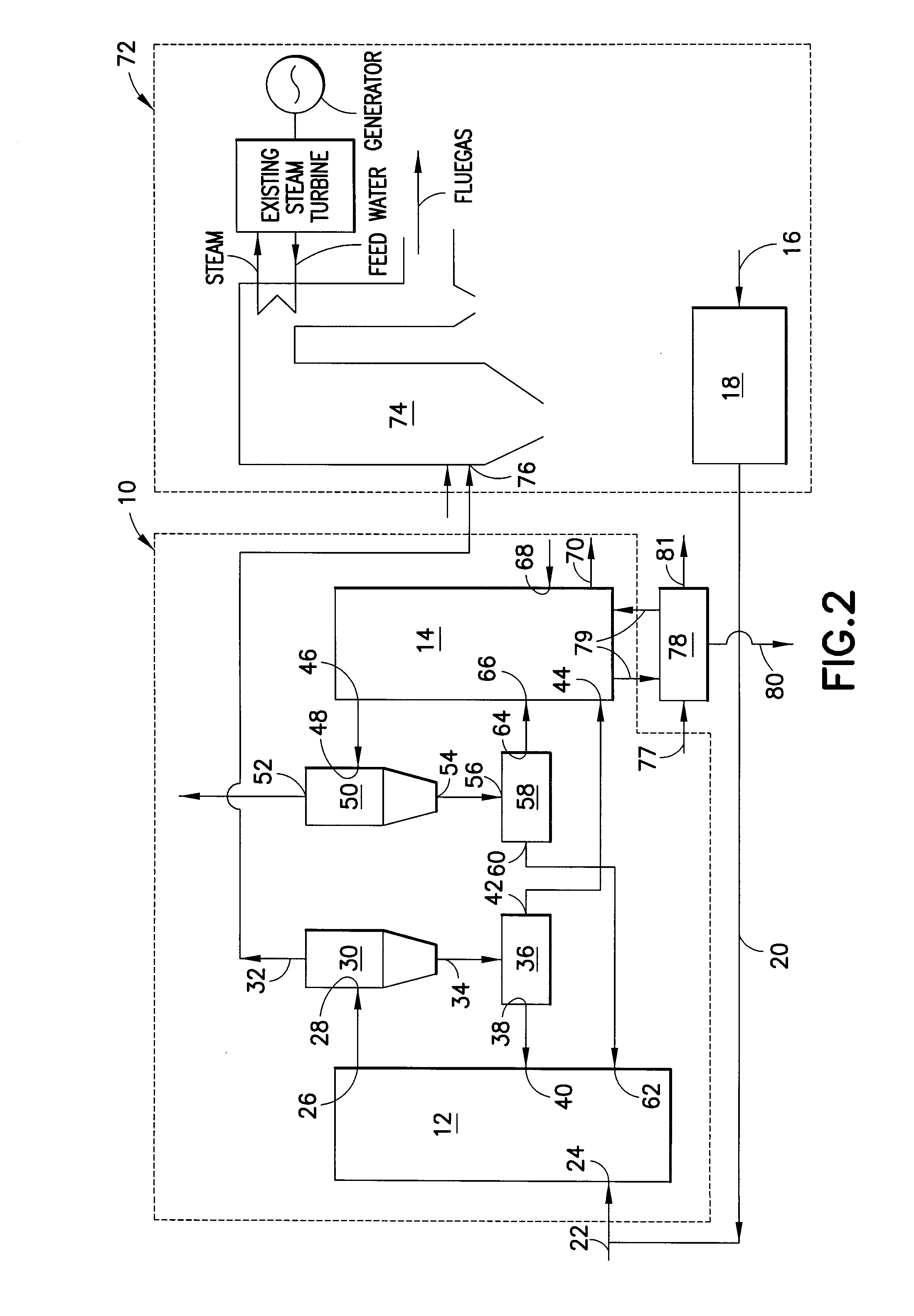

System for hot solids combustion and gasification

ActiveUS8110012B2Enhanced overall recoveryEliminate needGas modification by gas mixingCombustion enginesCombustionReducer

Owner:AIR PROD & CHEM INC +1

Recovery of common salt and marine chemicals from brine

InactiveUS6776972B2High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

Catalyst for fluidized catalytic cracking of heavy hydrocarbon oil and method of fluidized catalytic cracking

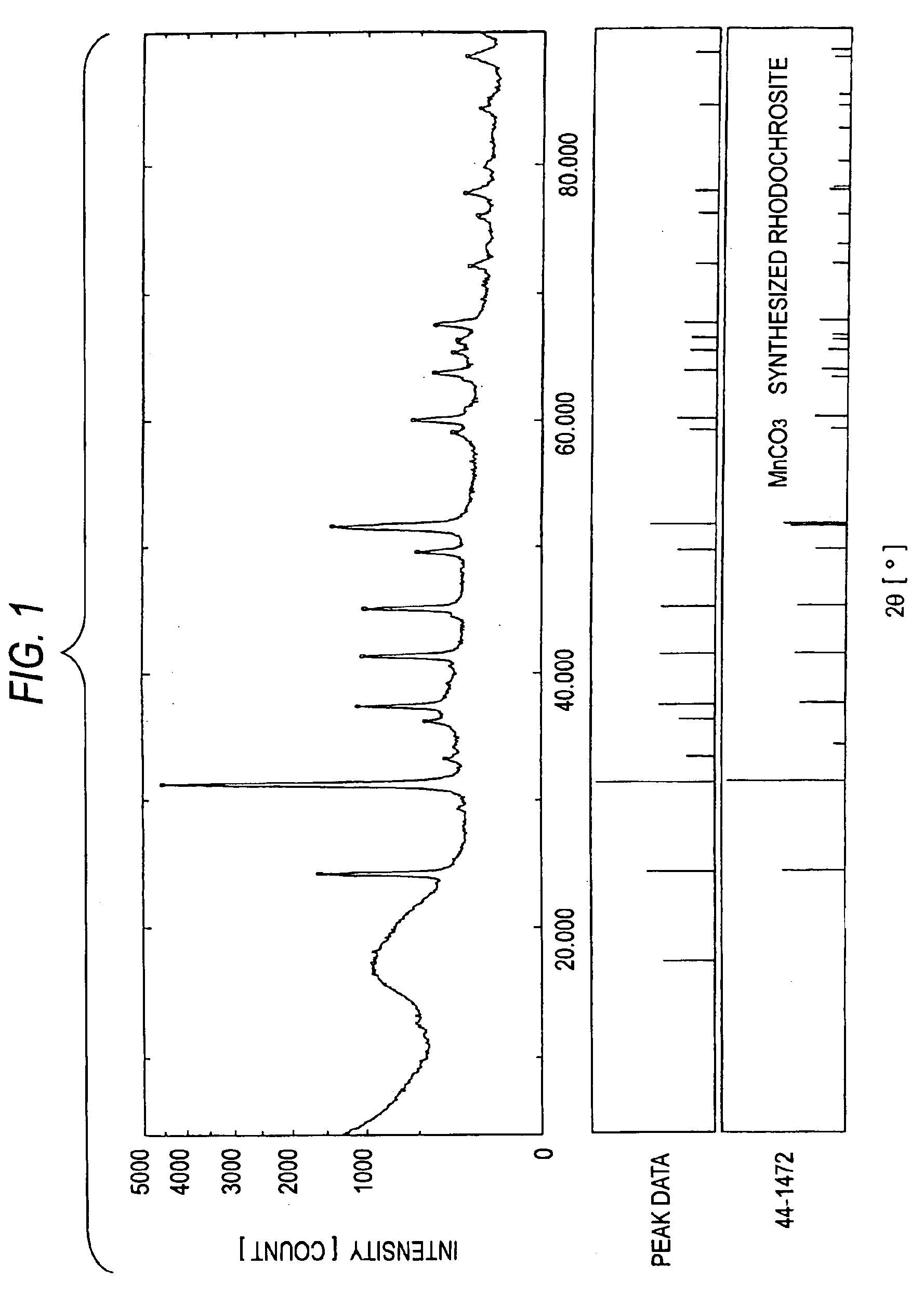

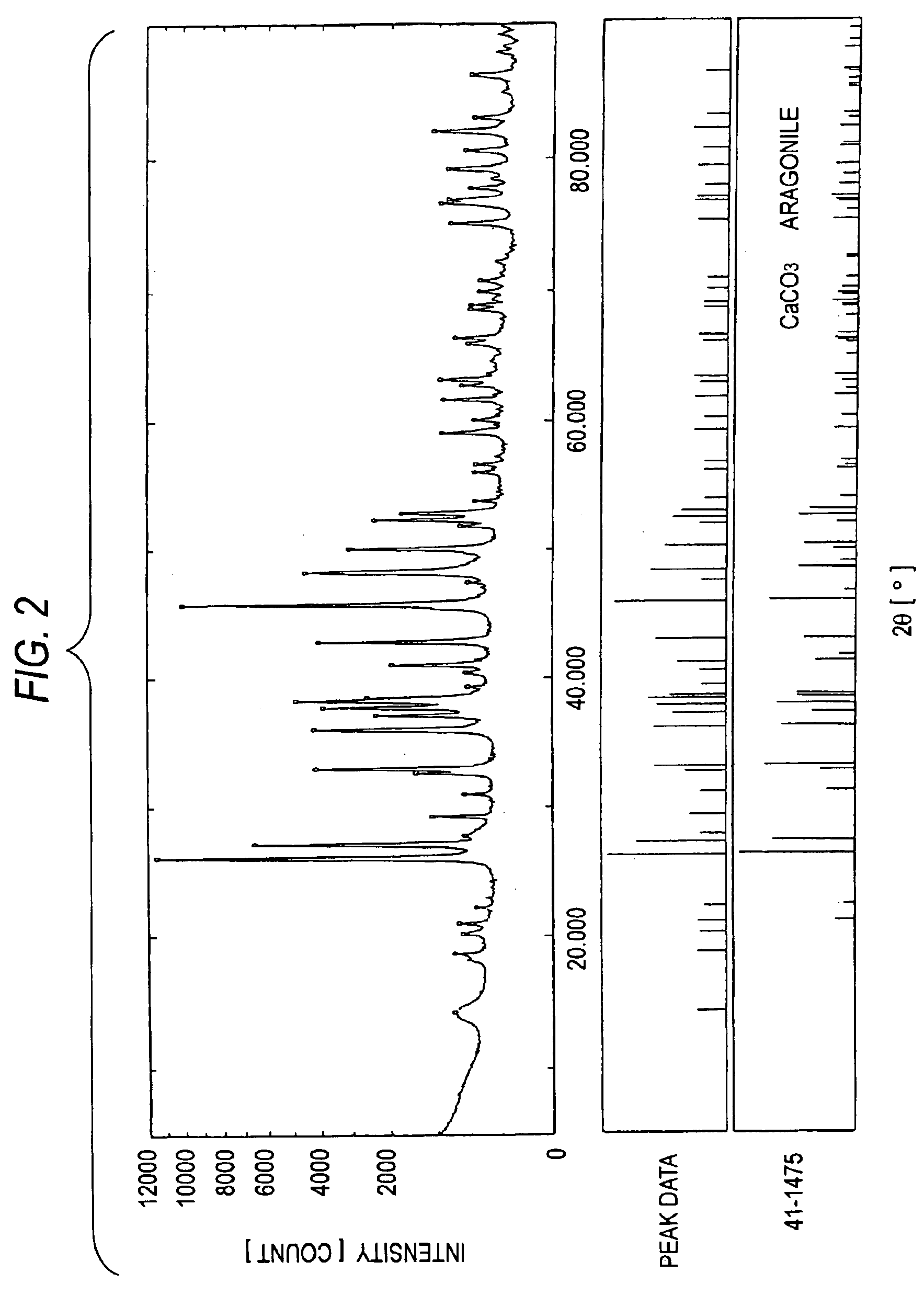

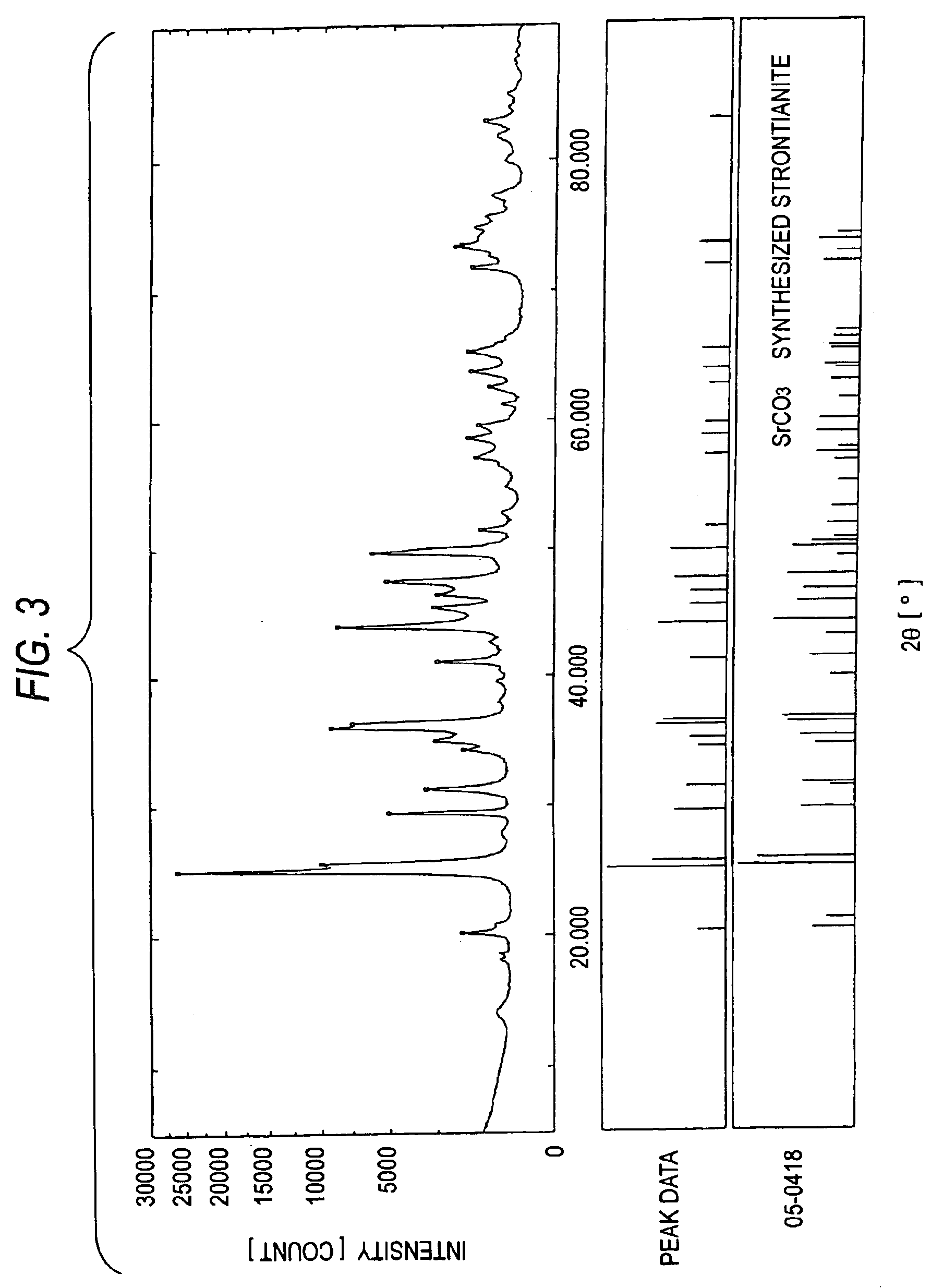

InactiveUS6916762B2Efficient inactivationReduce the amount requiredCalcium/strontium/barium carbonatesAluminium compoundsHydrogenOxide matrix

An FCC catalyst which not only deactivates catalyst poison metals, such as nickel, vanadium and the like, in feedstock oils, inhibits the generation of hydrogen or coke, has excellent cracking activity and bottom oil-treating ability, and can yield a gasoline and LCO fraction in high yields, but also retains the performances on a high level over long and has an improved catalyst life; and an FCC method using the catalyst. The FCC catalyst has a compound of a bivalent metal or of bivalent and trivalent metals showing an XRD pattern of a carbonate of the bivalent metal; an inorganic oxide matrix and the compound dispersed therein; or an inorganic oxide matrix and the compound dispersed therein together with a crystalline aluminosilicate zeolite, and relates to an FCC method in which at least one of the catalysts are used in combination with an FCC catalyst obtained by evenly dispersing a crystalline aluminosilicate zeolite in an inorganic oxide matrix.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

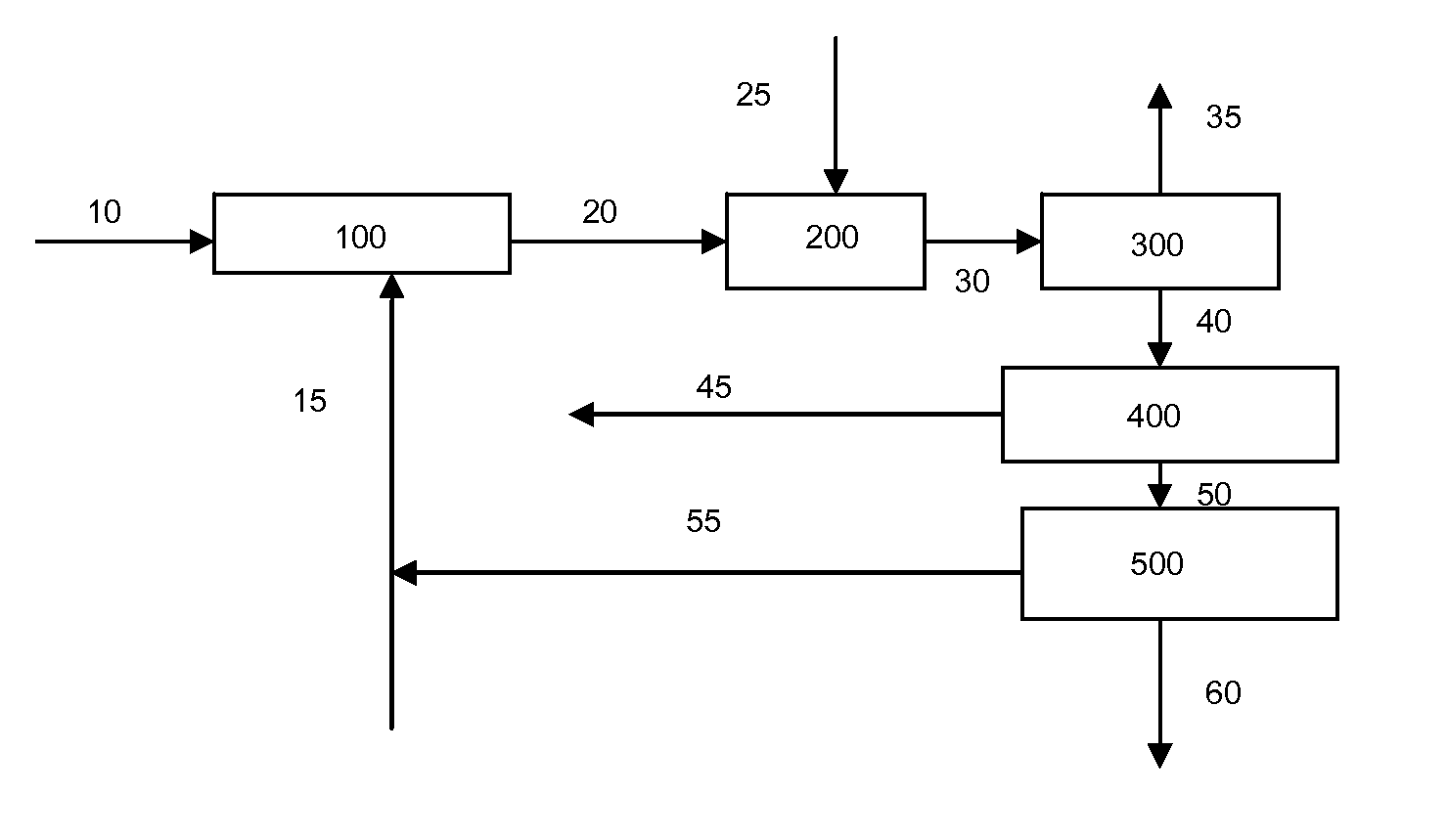

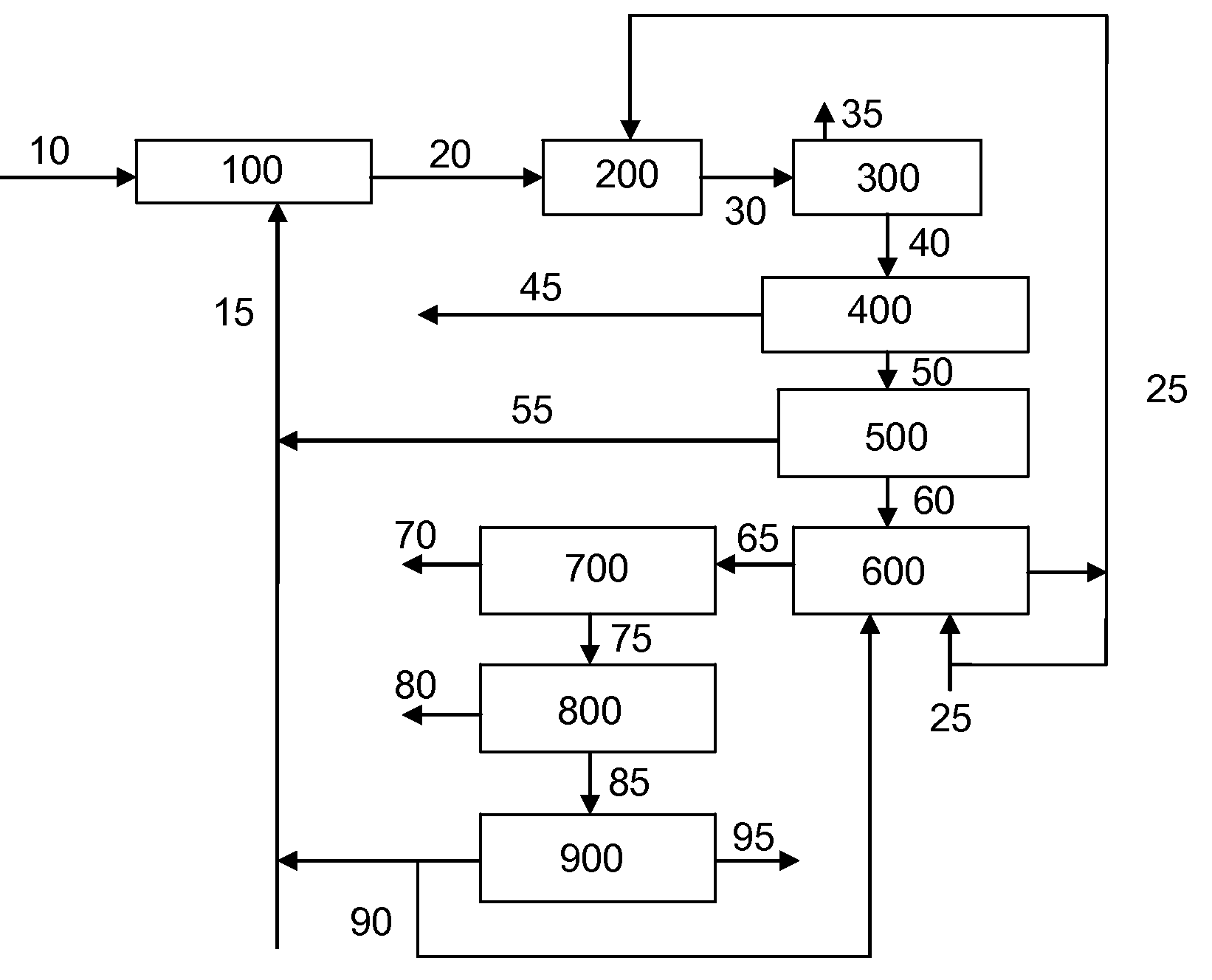

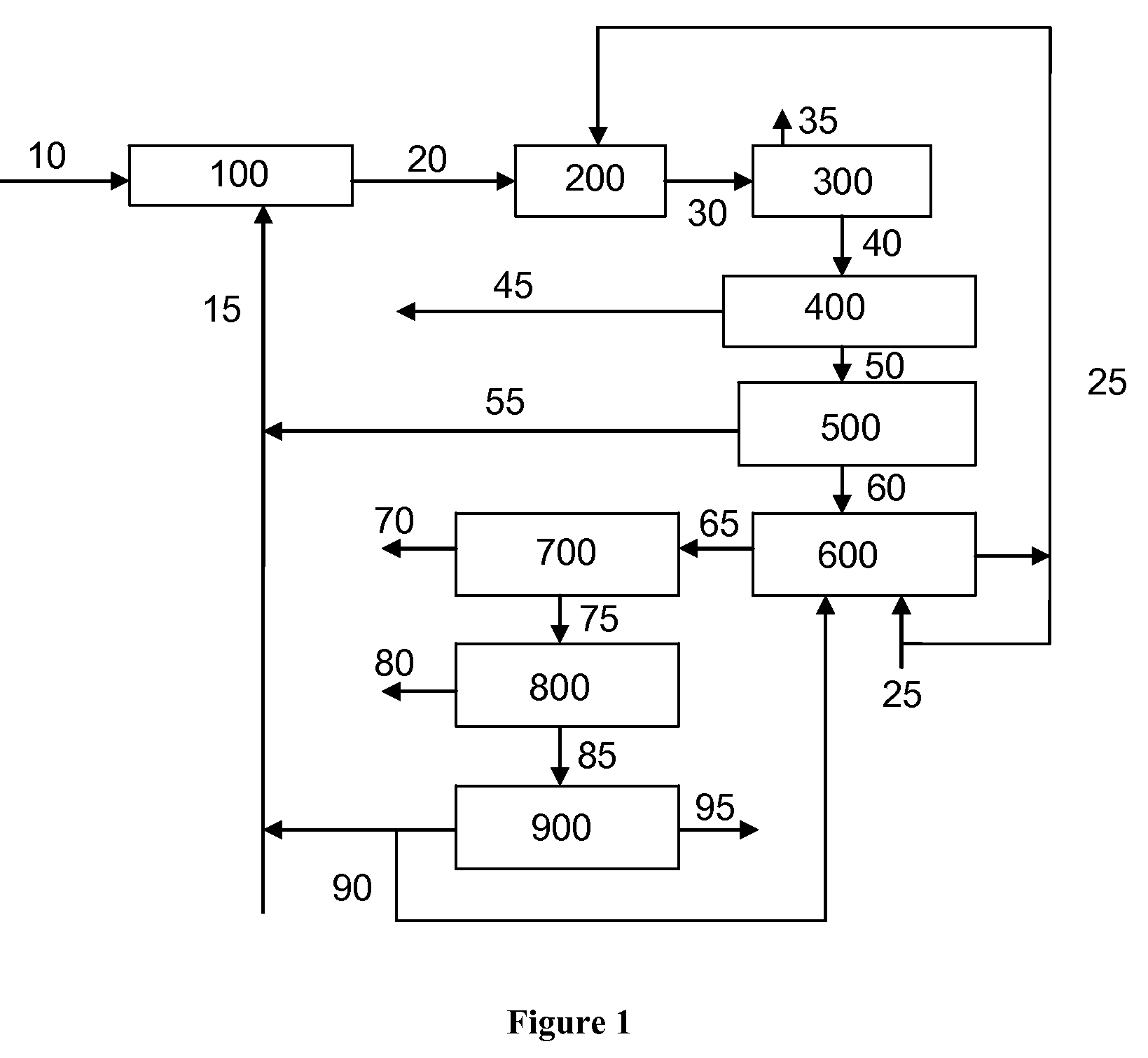

Catalytic gasification process with recovery of alkali metal from char

ActiveUS7897126B2Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

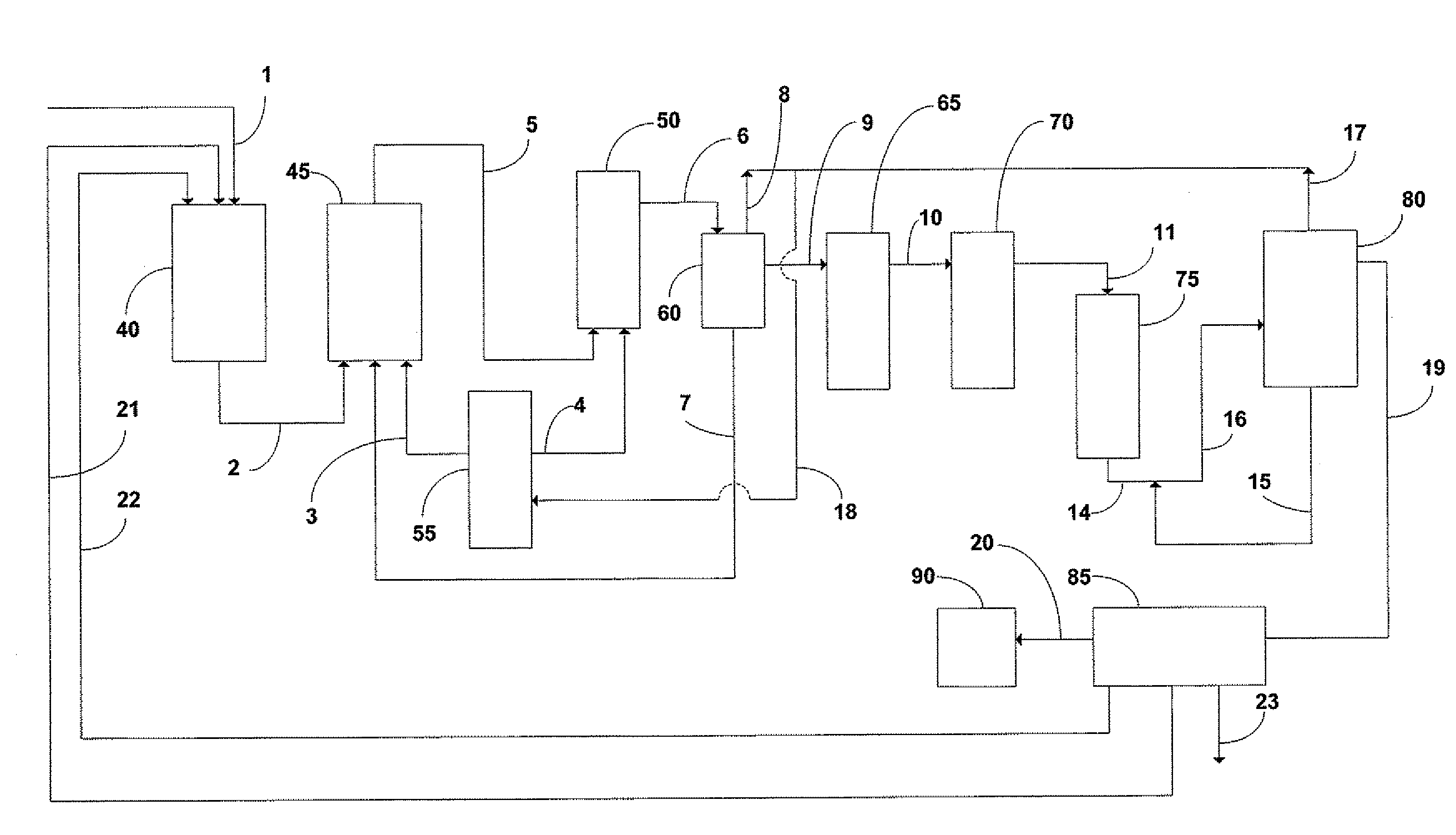

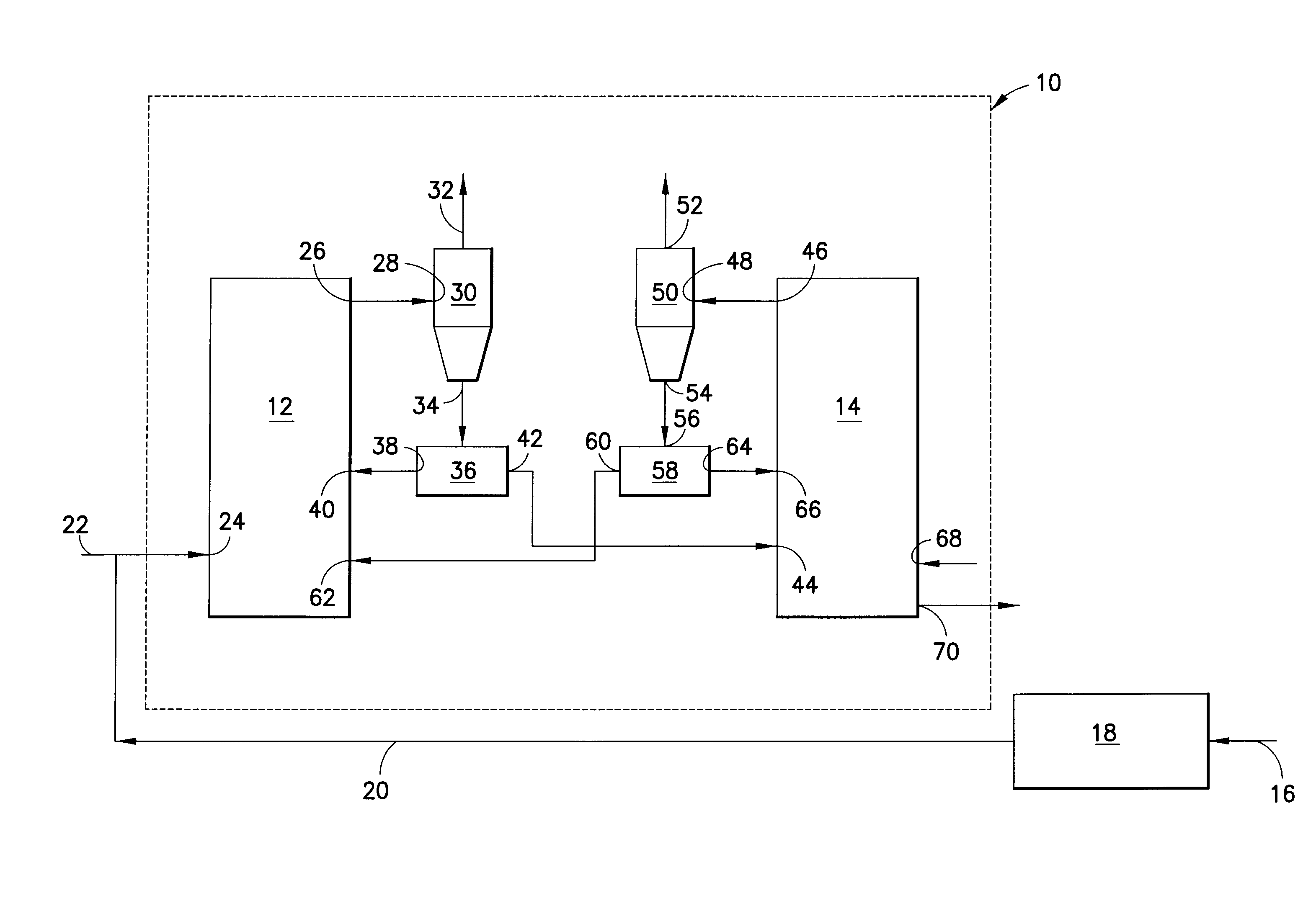

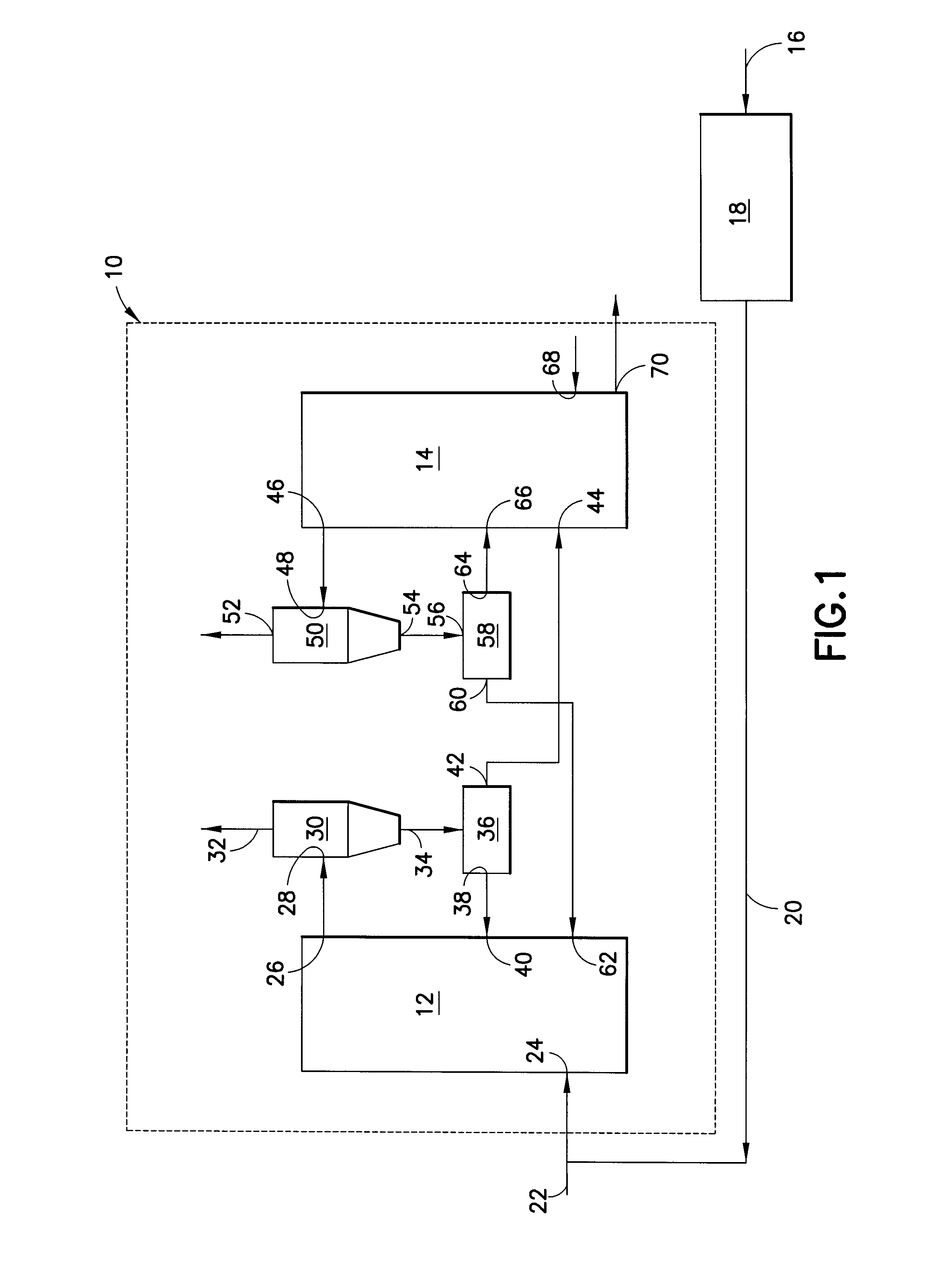

System for hot solids combustion and gasification

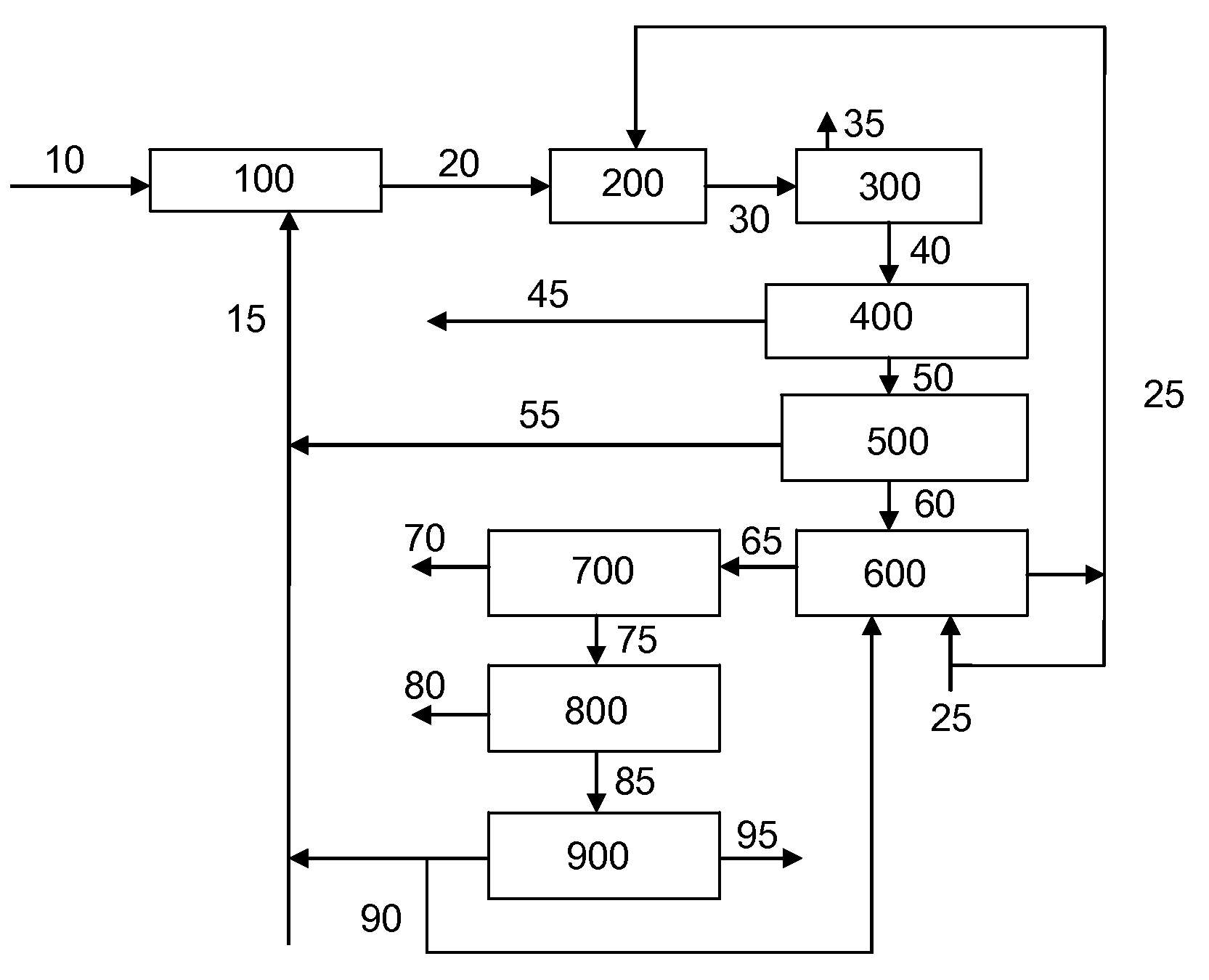

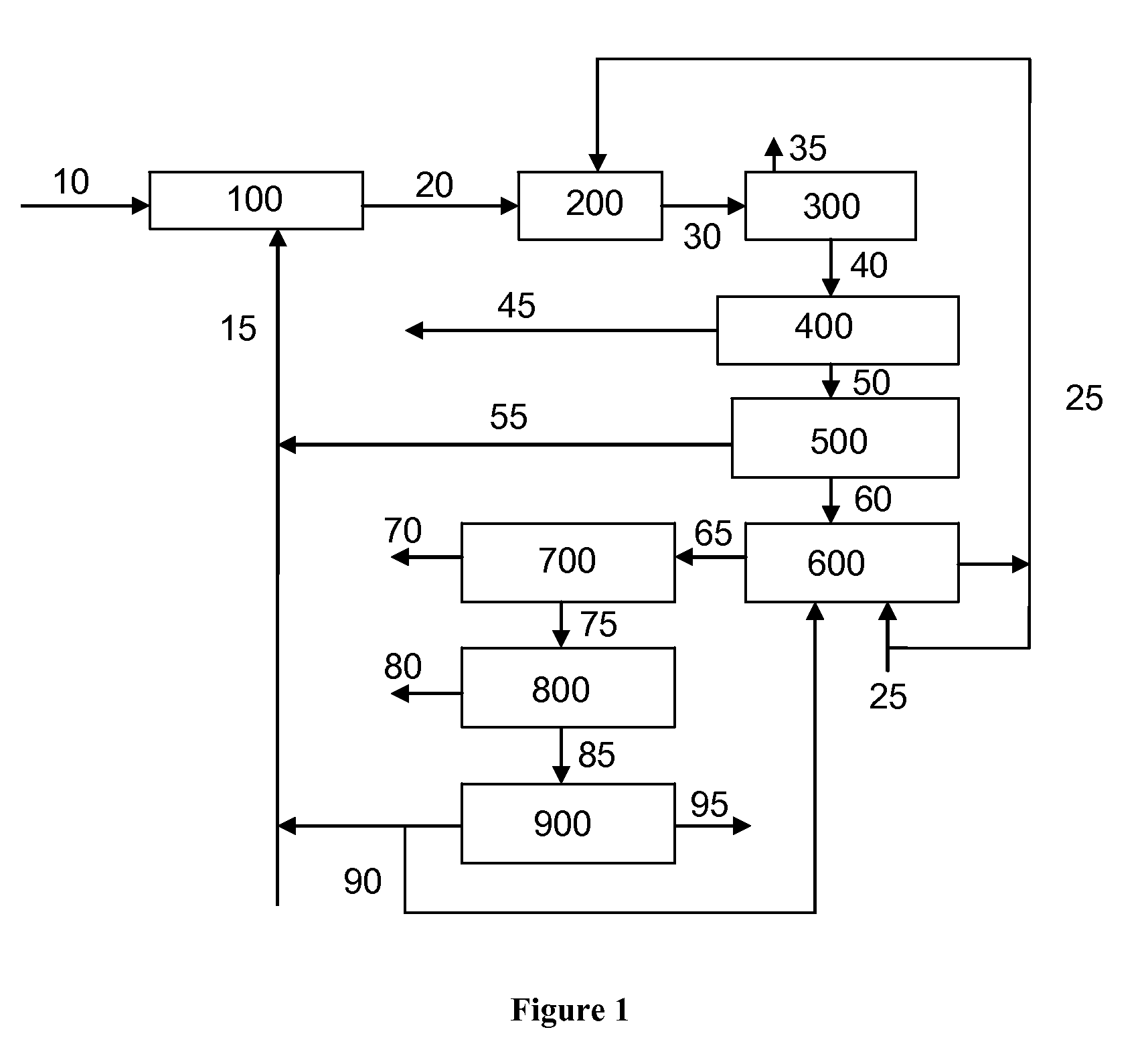

ActiveUS20100050654A1Small modificationEnhanced overall recoveryGas modification by gas mixingCombustion enginesCombustionEngineering

In a retrofit system for hot solids combustion and gasification, a chemical looping system includes an endothermic reducer reactor 12 having at least one materials inlet 22 for introducing carbonaceous fuel and CaCO3 therein and a CaS / gas outlet 26. A first CaS inlet 40 and a first CaSO4 inlet 64 are also defined by the reducer reactor 12. An oxidizer reactor 14 is provided and includes an air inlet 68, a CaSO4 / gas outlet 46, a second CaS inlet 44, and a second CaSO4 inlet 66. A first separator 30 is in fluid communication with the CaS / gas outlet 26 and includes a product gas and a CaS / gas outlet 32 and 34 from which CaS is introduced into said first and second CaS inlets. A second separator 50 is in fluid communication with the CaSO4 / gas outlet 46 and has an outlet 52 for discharging gas therefrom, and a CaSO4 outlet from which CaSO4 is introduced into the first and second CaSO4 inlets 62, 66. The chemical looping system is in fluid communication with at least a portion of an existing power generation system.

Owner:AIR PROD & CHEM INC +1

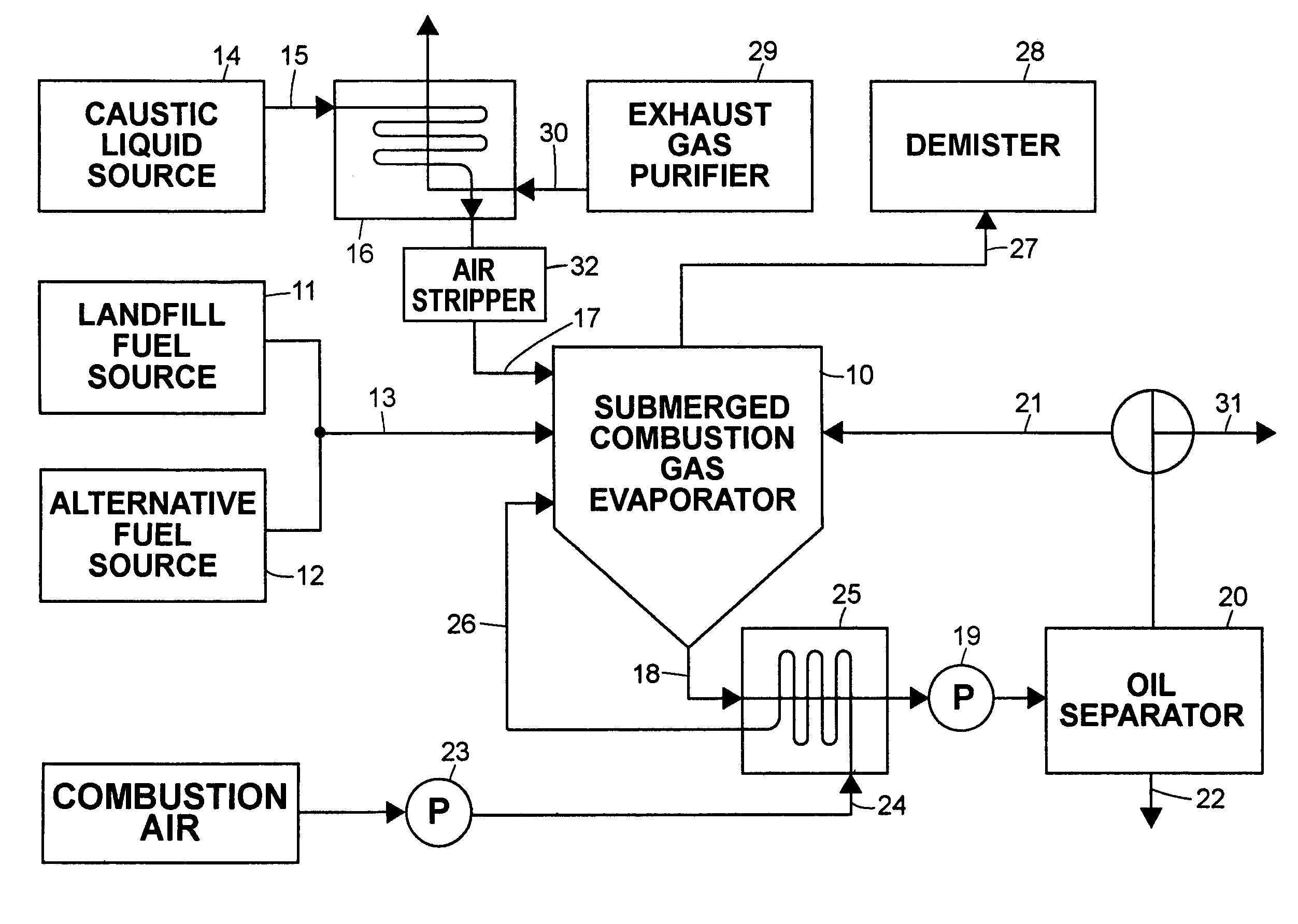

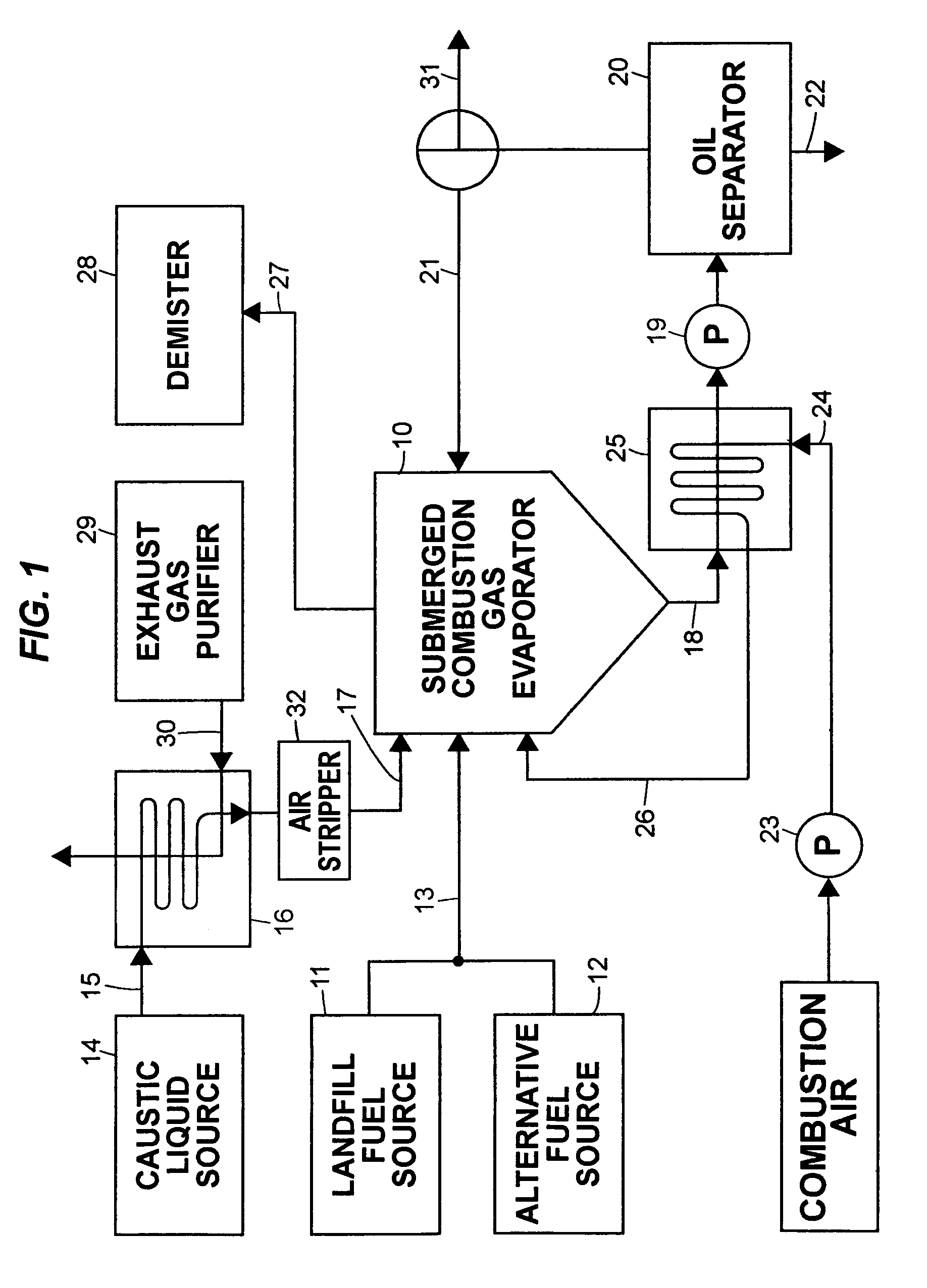

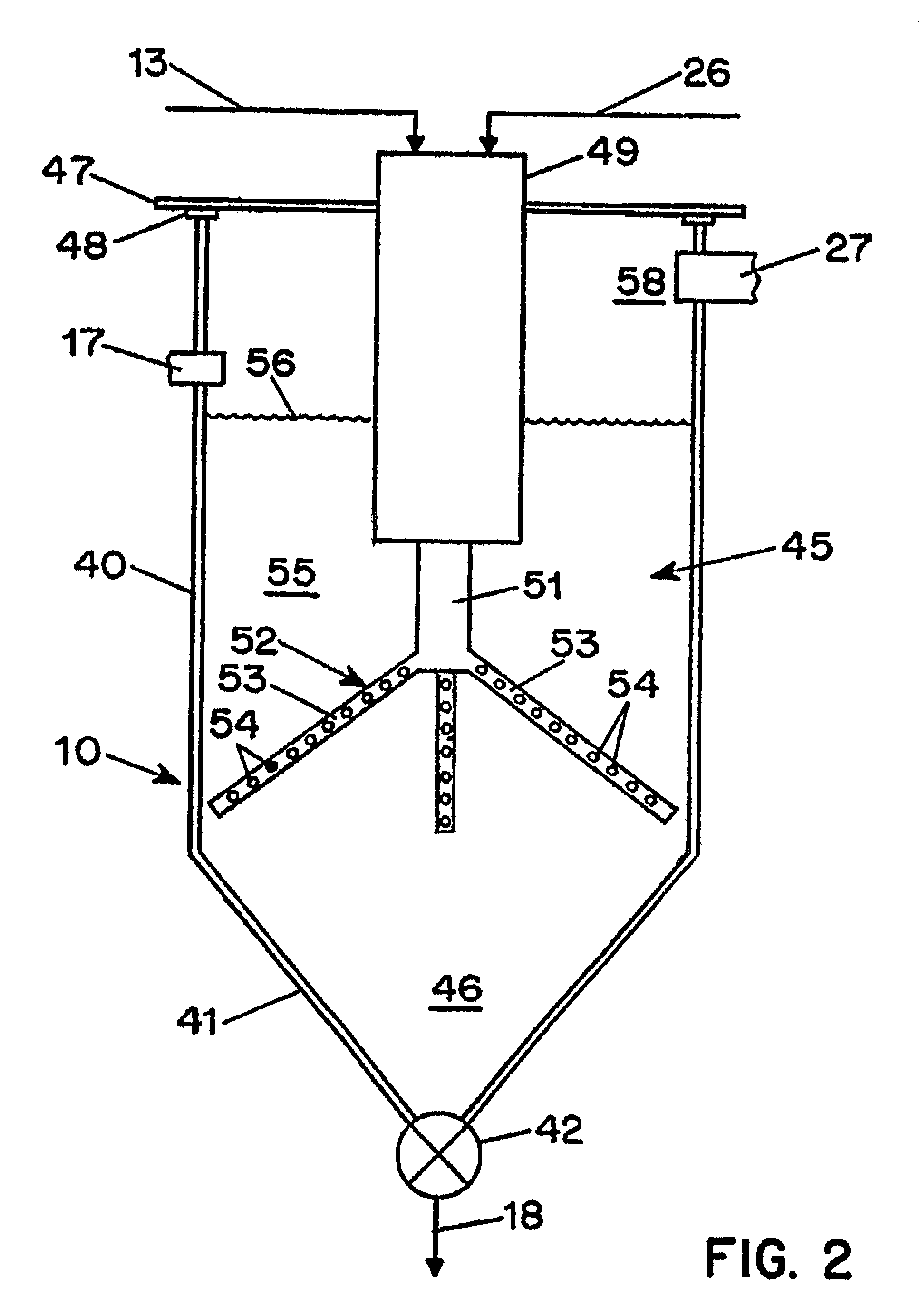

Treatment of spent caustic refinery effluents

InactiveUS7214290B2Avoid spreadingDrying using combination processesLiquid degasificationLiquid wasteCombustion

In the methods for treatment of caustic effluents described in the specification, a spent caustic refinery effluent is supplied to a submerged combustion gas evaporator in which hot combustion gas containing carbon dioxide is injected into the caustic liquid to concentrate the liquid and convert a hydroxide constituent to a carbonate. Where the caustic effluent is from a petroleum refinery, oil in the waste liquid is separated from the aqueous constituent before, during or after concentration.

Owner:GEI LIQUID SOLUTIONS +1

Catalytic gasification process with recovery of alkali metal from char

ActiveUS7901644B2Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

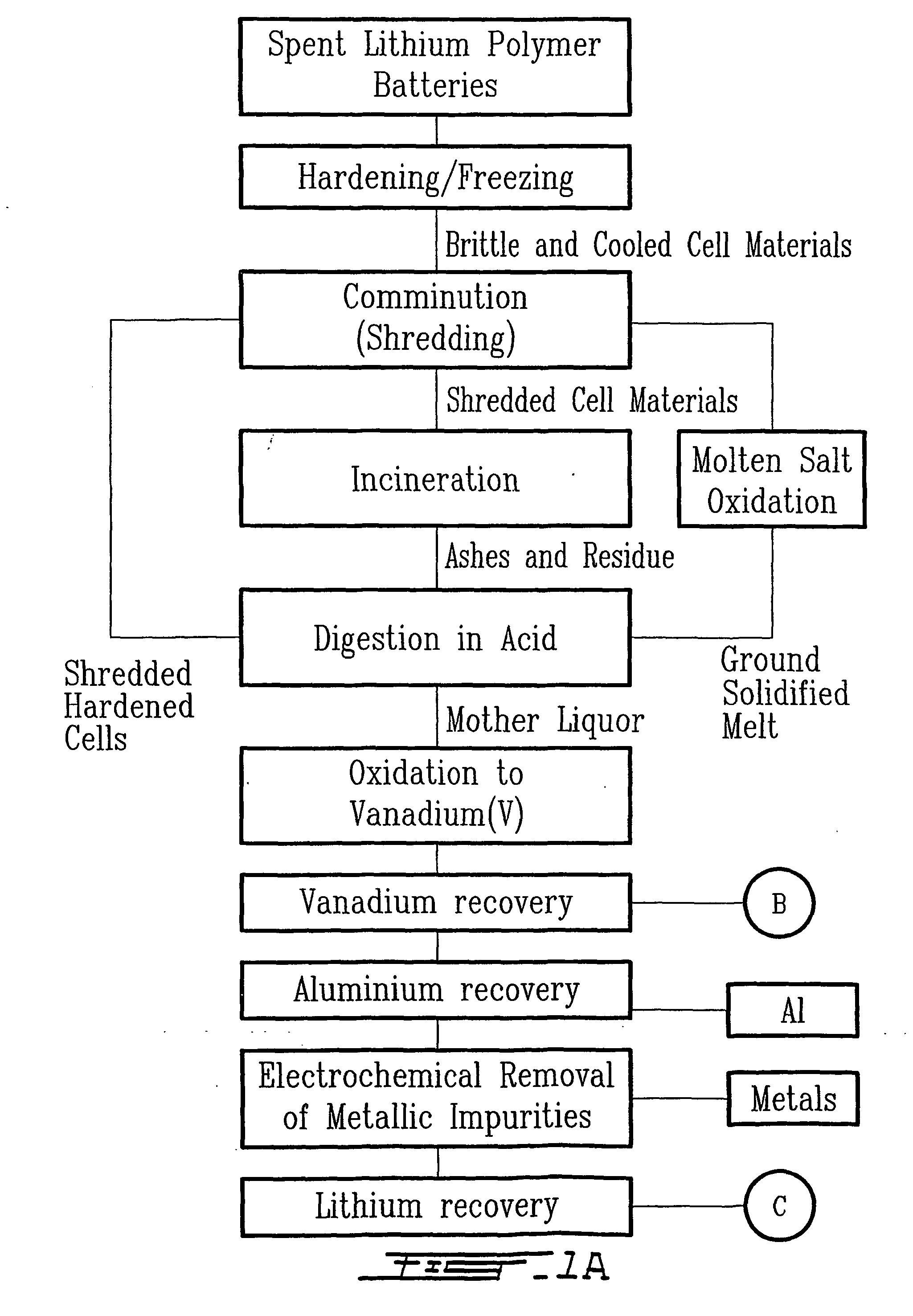

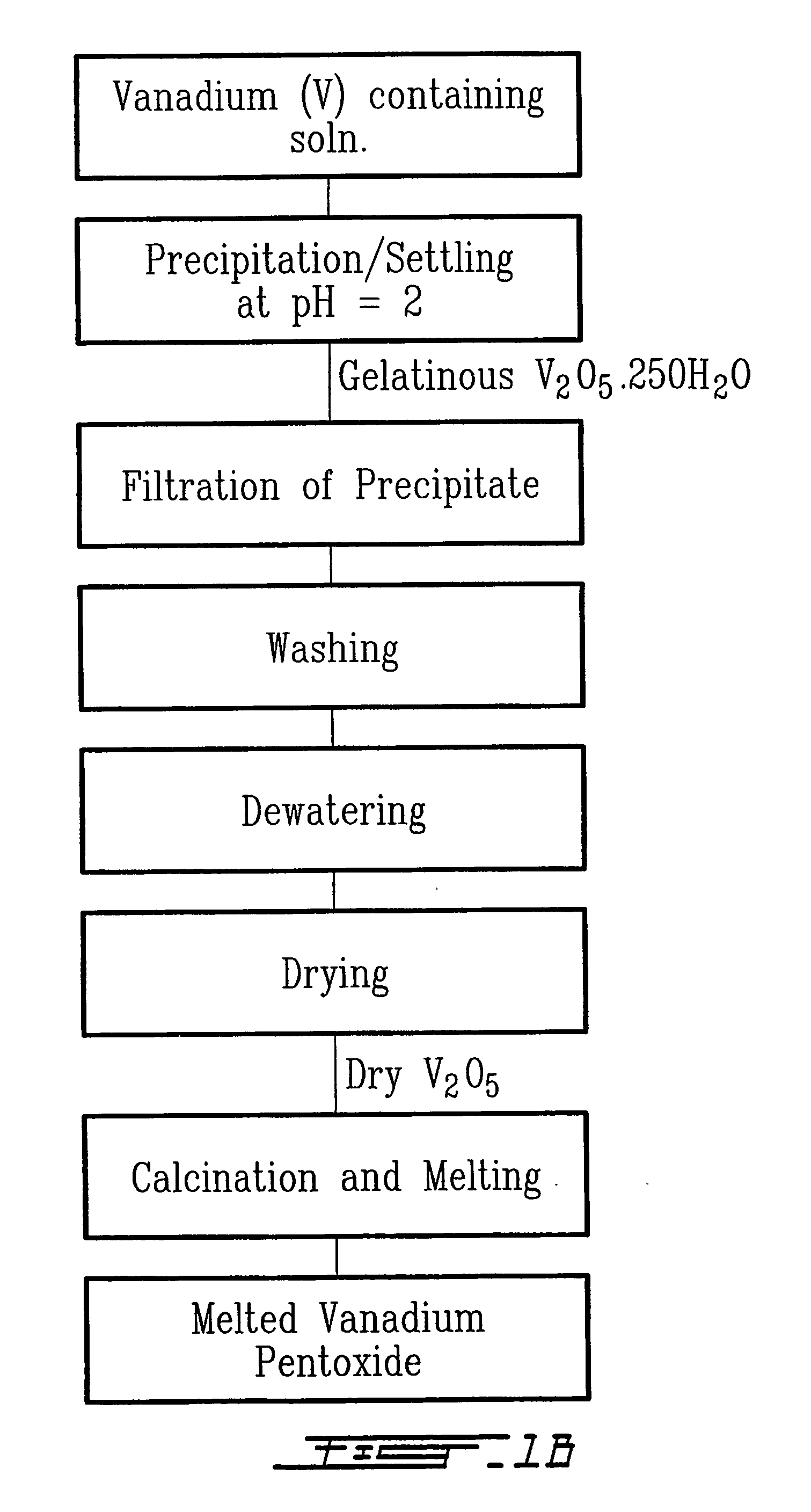

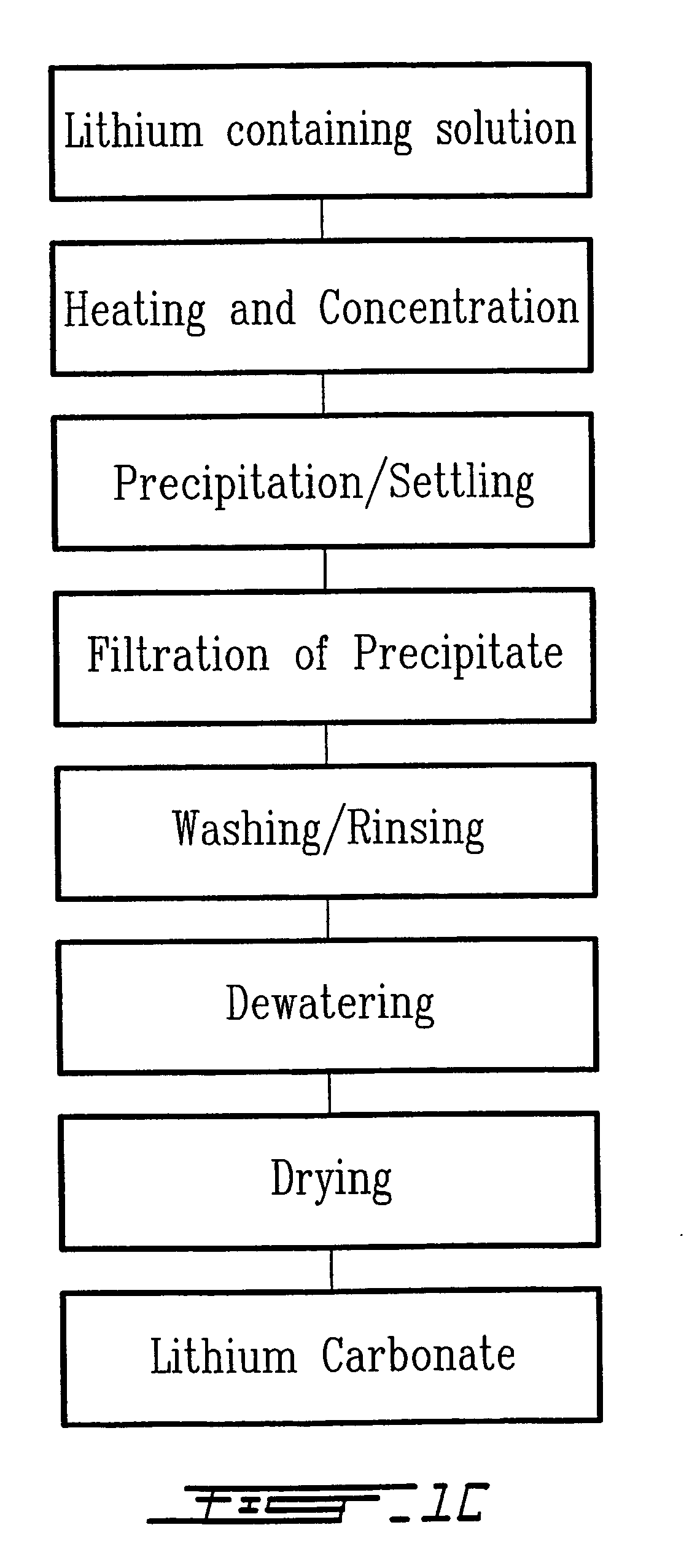

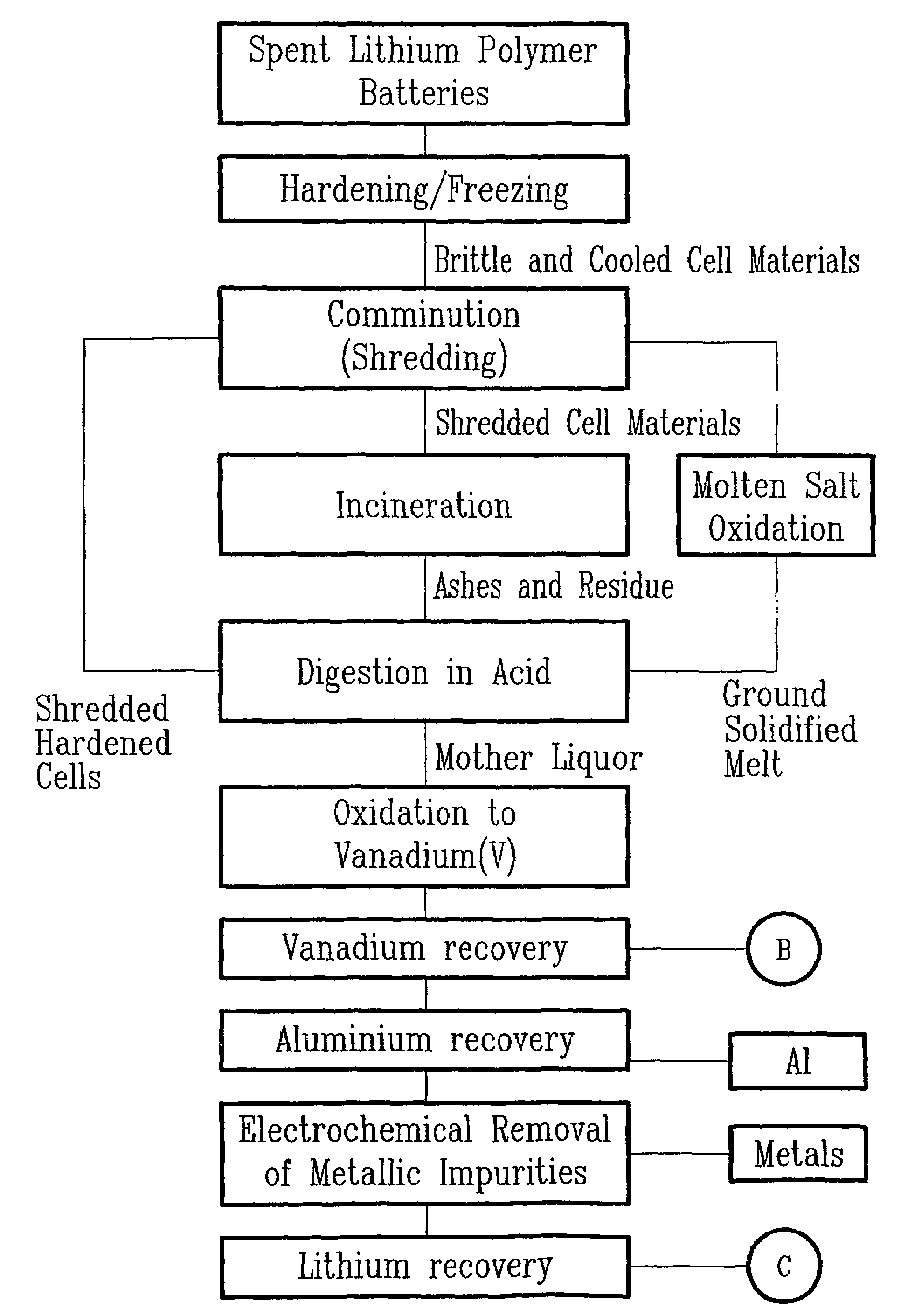

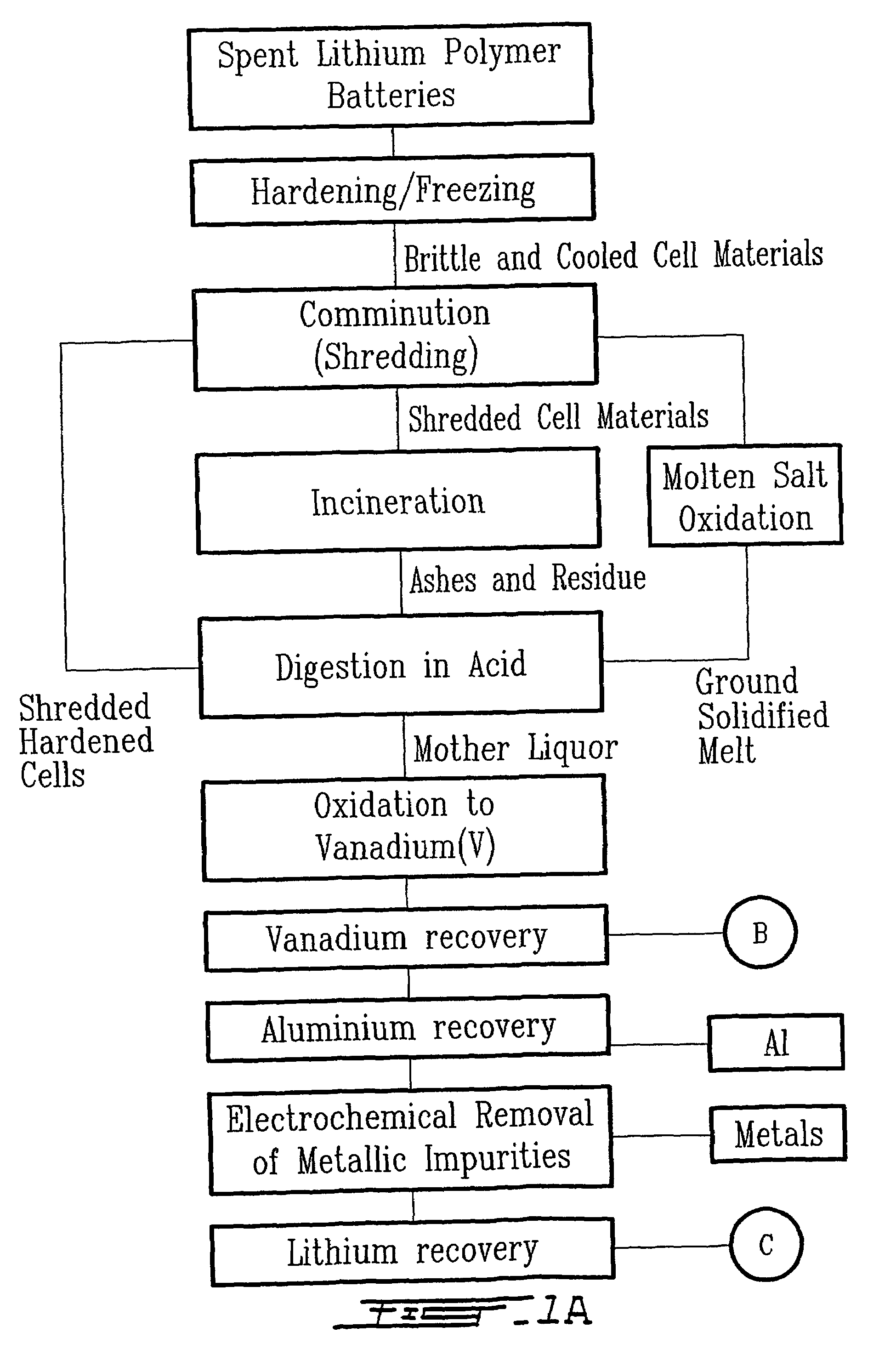

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

Recovery of common salt and marine chemicals from brine

InactiveUS20030080066A1High purityLow costGeneral water supply conservationSeawater treatmentSaline waterEvaporation

A new process for recovery of common salt, potassium chloride, concentrated magnesium chloride with enriched bromide, and high purity magnesia from brine in an integrated manner, said process comprises preparation of calcium chloride by reaction of hydrochloric acid generated in the process with limestone, desulfatation of brine with calcium chloride, production of sodium chloride of superior quality in solar pans, solar evaporation of bittern thereby producing carnallite and end bittern, processing carnallite through established processes to produce potassium chloride, recovering end bittern containing highly concentrated magnesium chloride and enriched bromide and calcination of a part of the end bittern after solidification to produce high purity magnesia and hydrochloric acid utilizable in the process.

Owner:COUNCIL OF SCI & IND RES

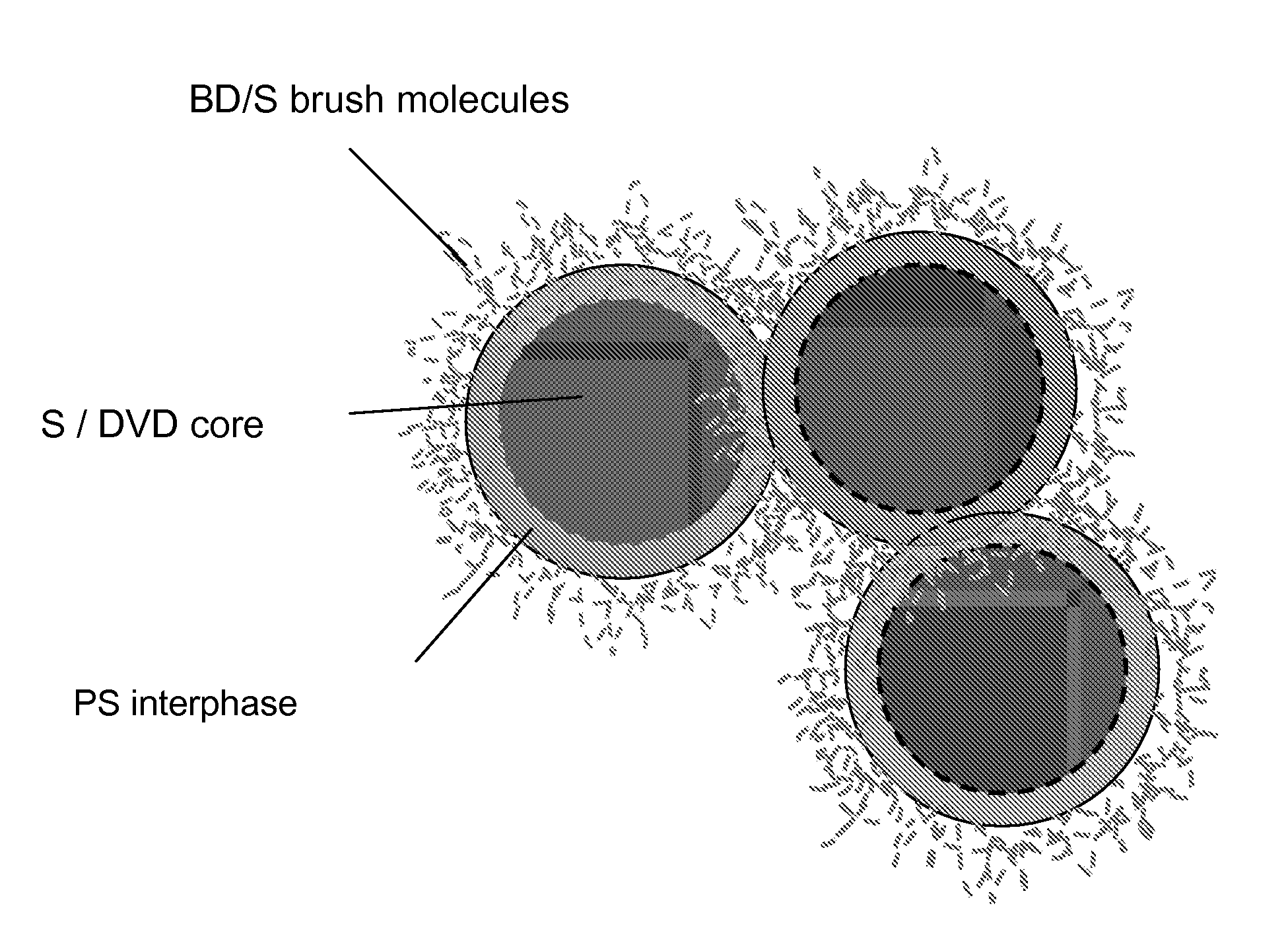

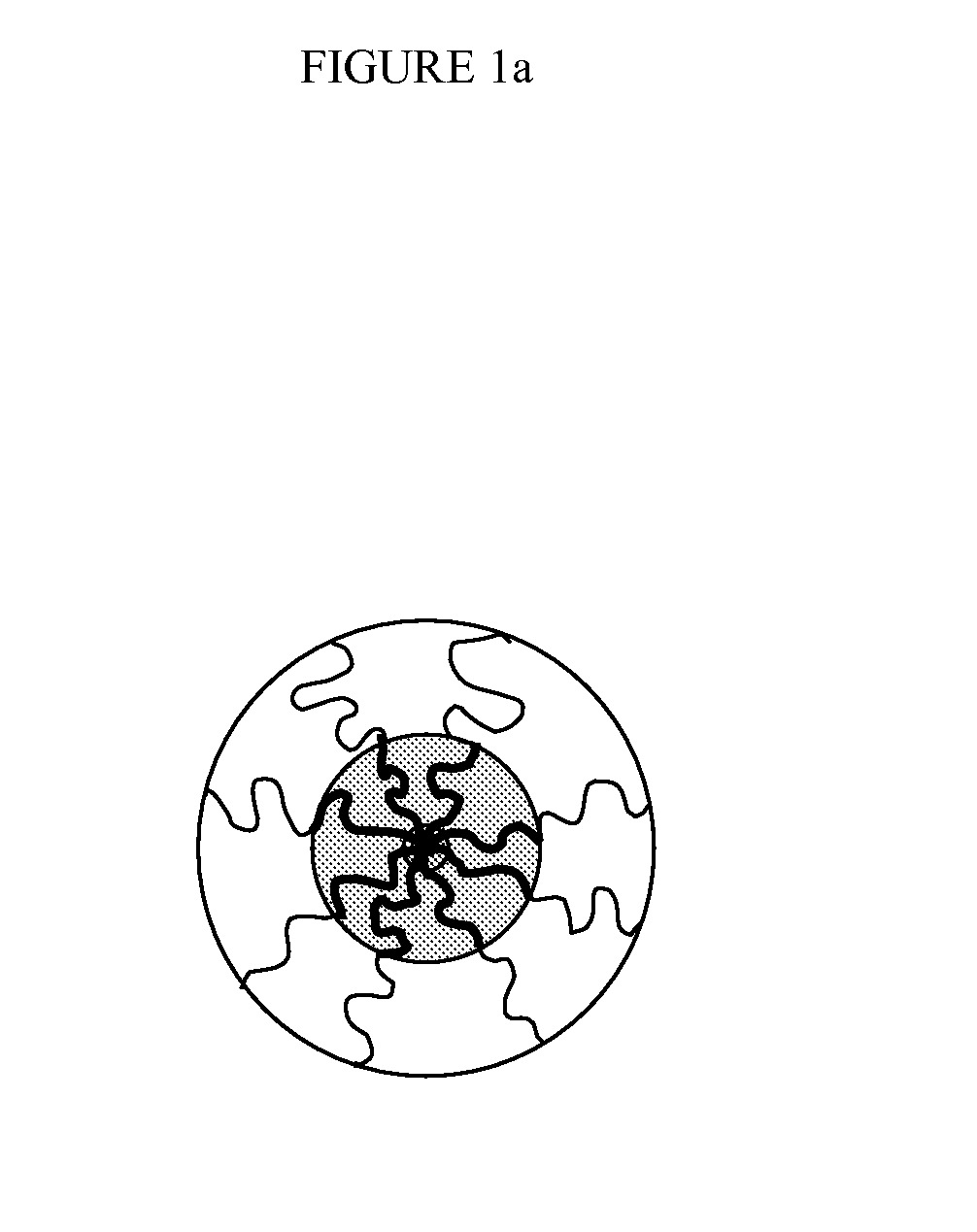

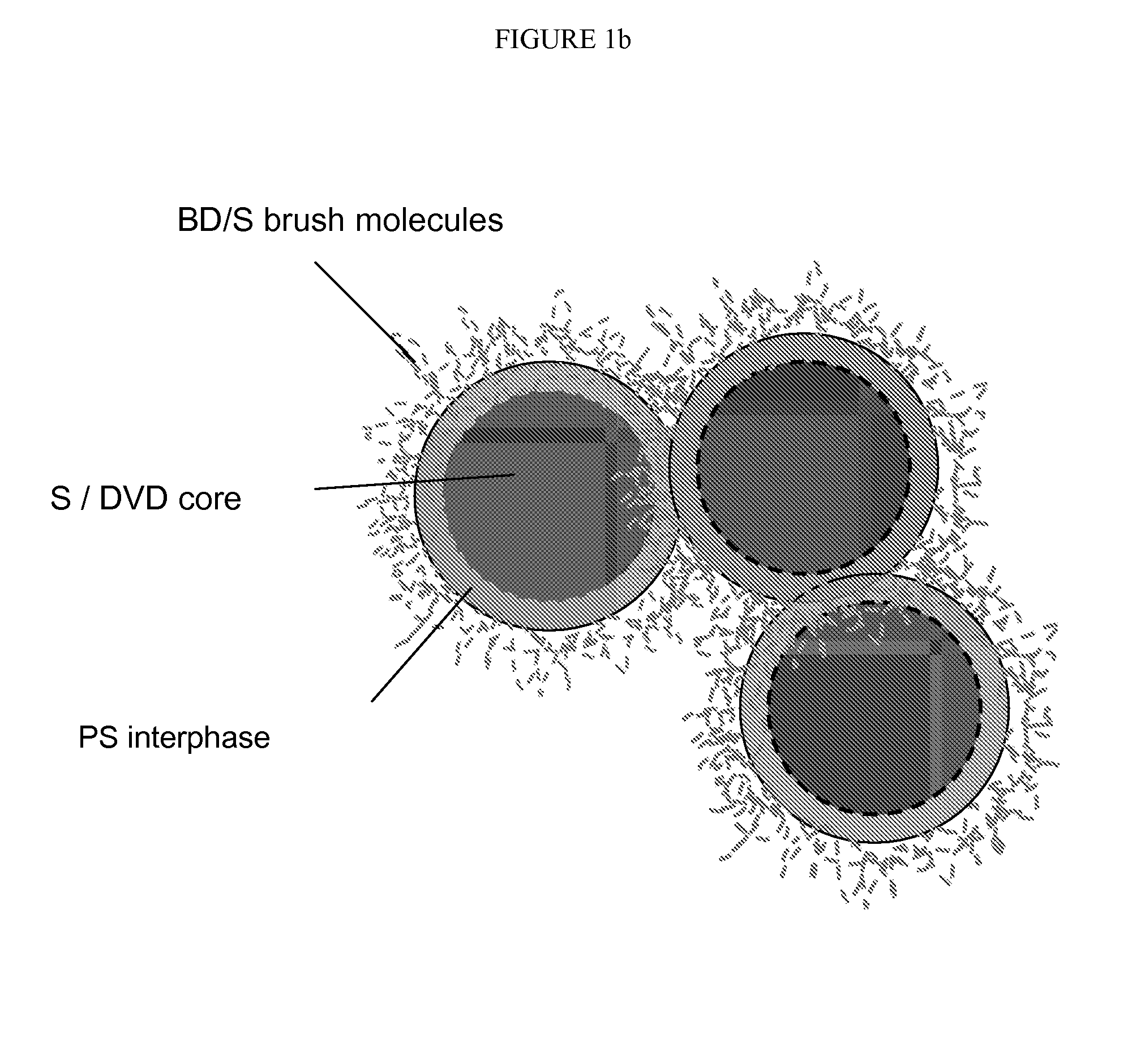

Polymeric core-shell nanoparticles with interphase region

ActiveUS20100004398A1High strengthMaterial nanotechnologyIndividual molecule manipulationCore shell nanoparticlesParticle composition

A polymeric nanoparticle composition is provided. The nanoparticle may be of a core / shell configuration with an interphase region connecting the core and the shell. The mean average diameter of the polymer nanoparticles may be less than about 250 nm. The size, composition, and / or configuration of the interphase region may be varied to achieve desired physical and / or chemical properties of the resulting polymeric nanoparticles, and of the compositions into which the nanoparticles are compounded.

Owner:BRIDGESTONE CORP

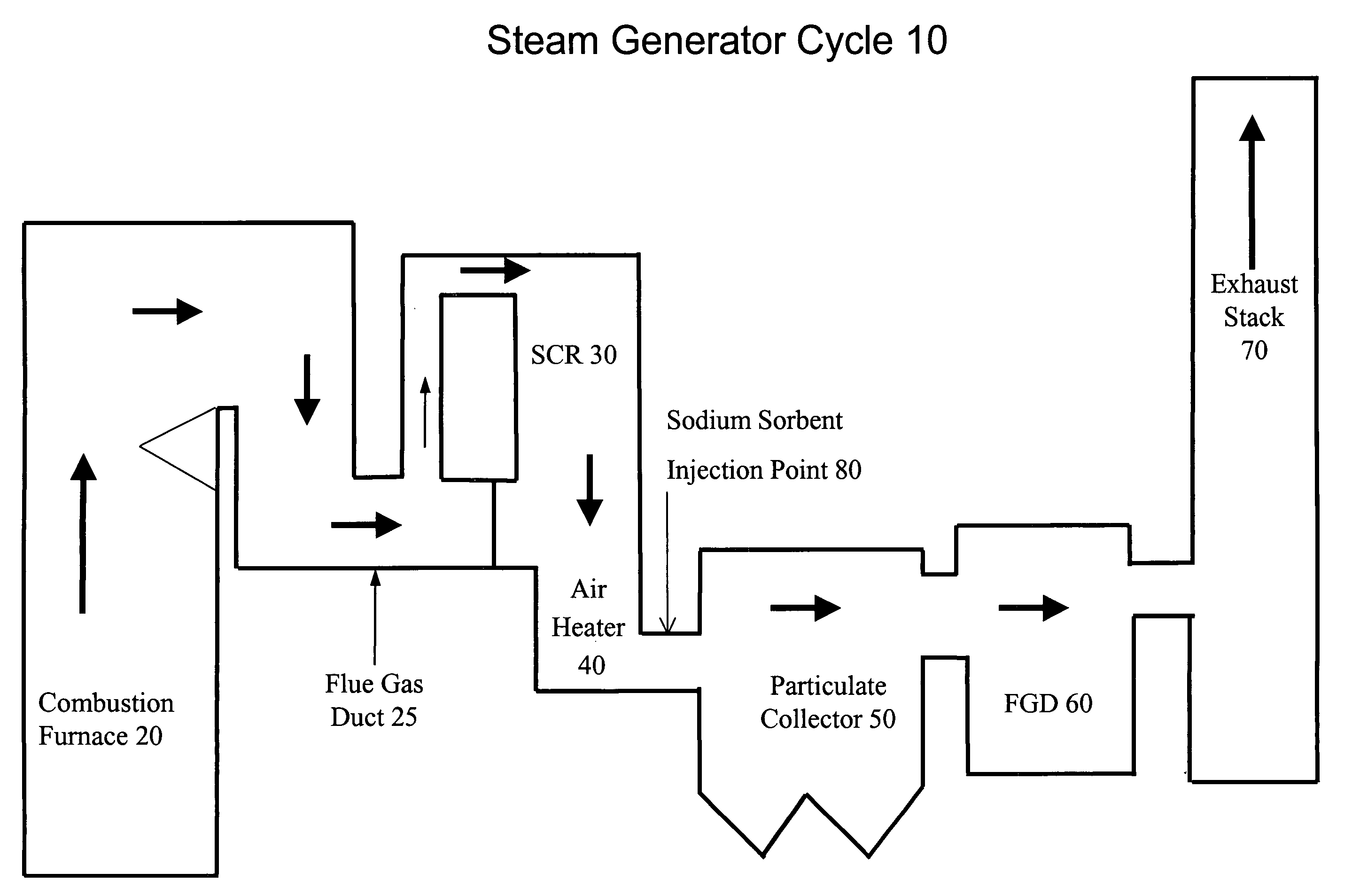

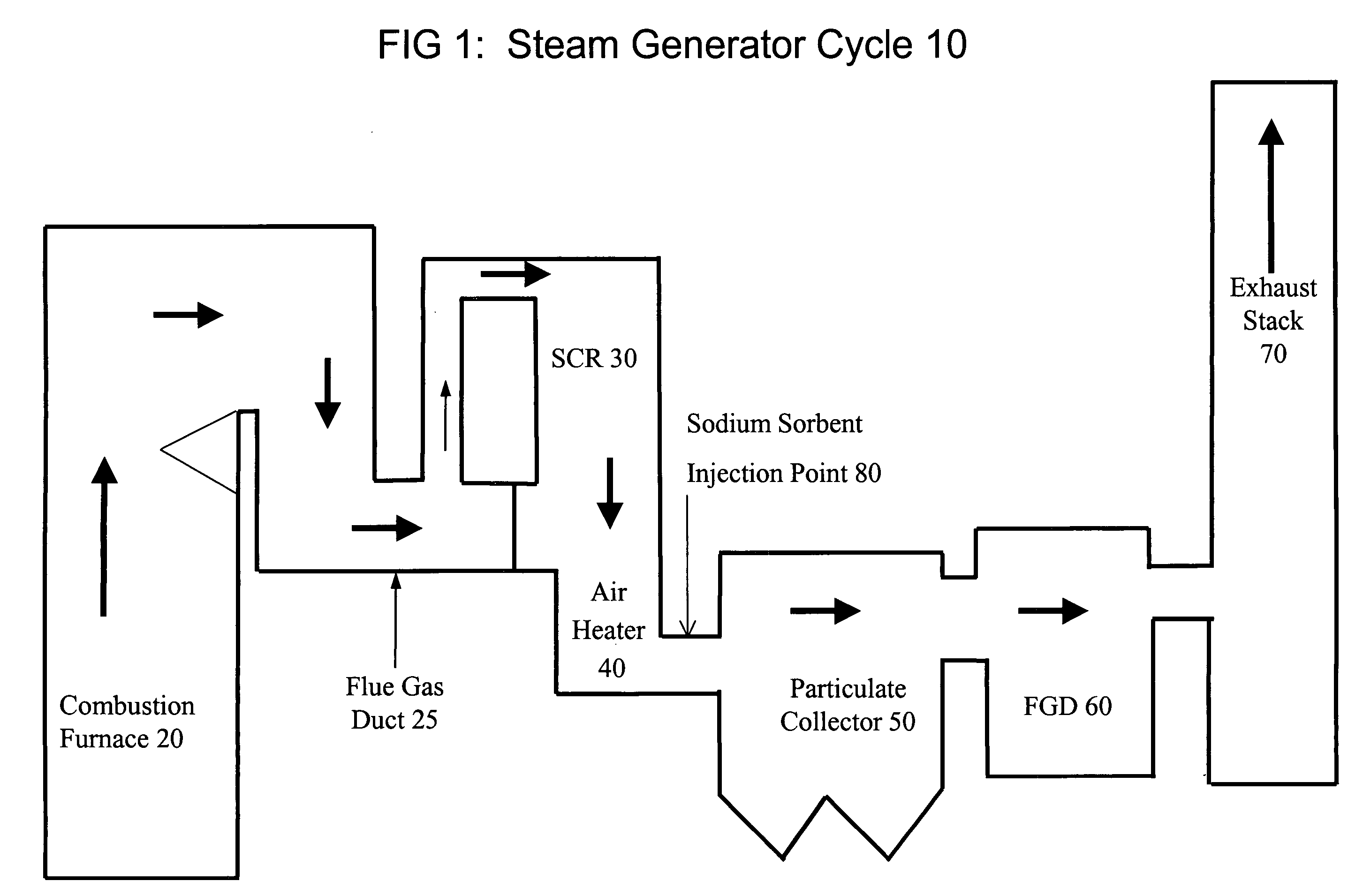

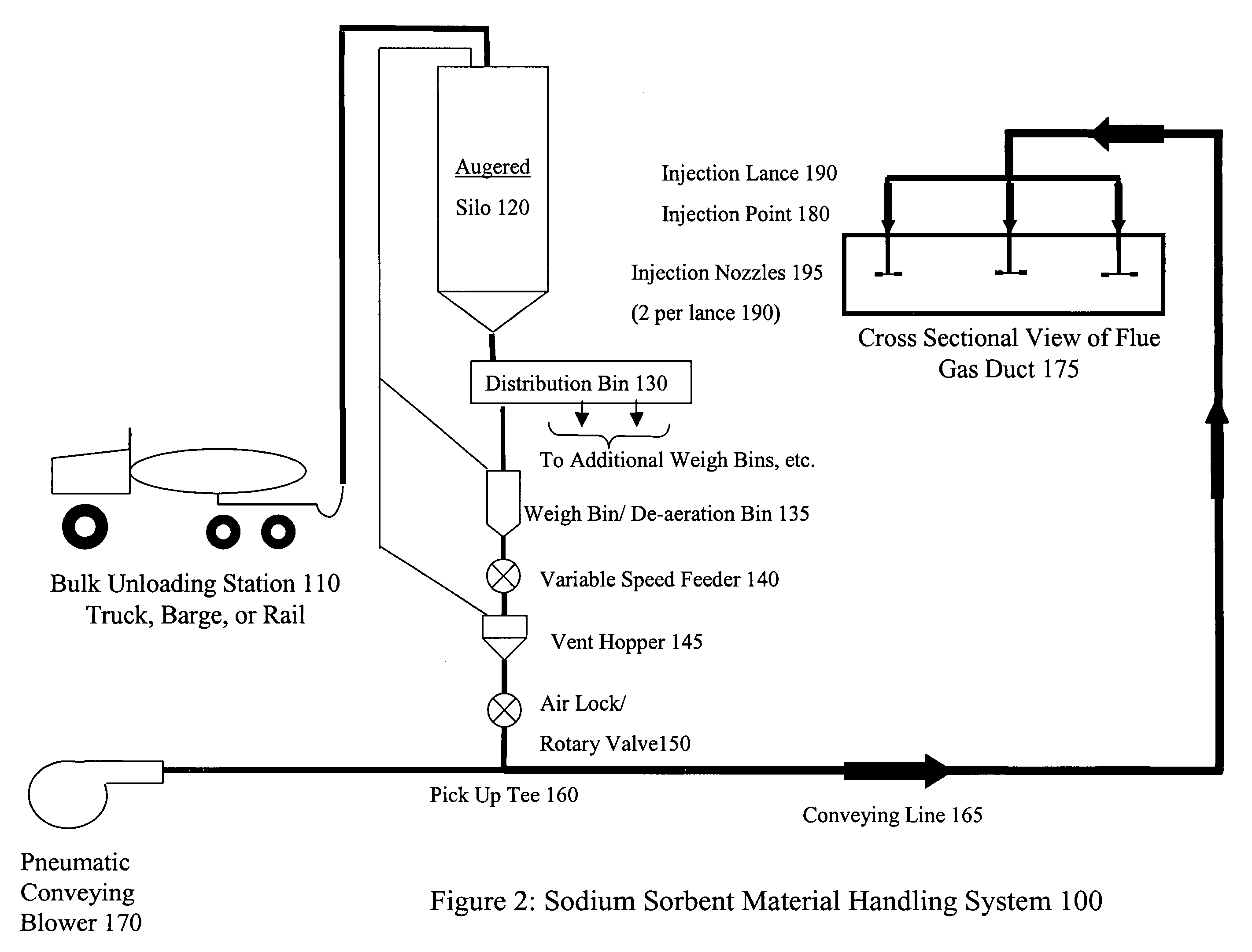

System and method for treating a flue gas stream

PendingUS20050201914A1Lower volume resistivityEfficient removalCombination devicesGas treatmentParticulatesDicarbonate

The present invention is a system and method for treating a flue gas stream to remove strong acid compounds selected from the group consisting of hydrofluoric acid (HF), hydrochloric acid (HCl), sulfuric acid (H2SO4), and sulfur trioxide (SO3) by injecting a sodium sorbent selected from the group consisting of sodium sesquicarbonate, sodium carbonate-bicarbonate, trona ore, mechanically refined trona ore, and trona into the flue gas stream, calcining substantially all of the sodium sorbent in the presence of the flue gas stream to form a soda ash, reducing the concentration of the at least one strong acid compound in the flue gas stream by reacting the at least one strong acid compound with the soda ash to form a sodium based by-product; and changing the chemistry of the flue gas stream to reduce the overall average resistivity of the particulate matter.

Owner:AMERICAN ELECTRIC POWER CO INC

Process for the treatment of waste streams

The present invention is directed to a process for treating, reducing, and / or stabilizing various wastes or flue gases. In one embodiment, the process is directed to treatment of alkali bearing wastes that include nitrate and / or nitrite-rich wastes. Optionally, the disclosed method can be utilized for treatment of hazardous wastes, including radioactive hazardous waste compounds. In general, the present invention includes processing a waste or gaseous stream with the addition of suitable carbon-containing additives to treat and reduce nitrogen-containing compounds in the waste. Additives may be gaseous, liquid or solid reduction-promoting agents, catalysts, and the like. The reaction products obtained from the process of the invention include mainly alkali carbonate, nitrogen, hydrogen, carbon monoxide and carbon dioxide.

Owner:MFG & TECH CONVERSION INT

Method for recycling spent lithium metal polymer rechargeable batteries and related materials

The method relates to a pyrometallurgical and hydrometallurgical process for the recovery and recycling of lithium and vanadium compounds from a material comprising spent rechargeable lithium batteries, particularly lithium metal gel and solid polymer electrolyte rechargeable batteries. The method involves providing a mass of the material, hardening it by cooling at a temperature below room temperature, comminuting the mass of cooled and hardened material, digesting with an acid its ashes obtained by incineration, or its solidified salts obtained by molten salt oxidation, or the comminuted mass itself, to give a mother liquor, extracting vanadium compounds from the mother liquor, separating heavy metals and aluminium therefrom, and precipitating lithium carbonate from the remaining solution.

Owner:AVESTOR

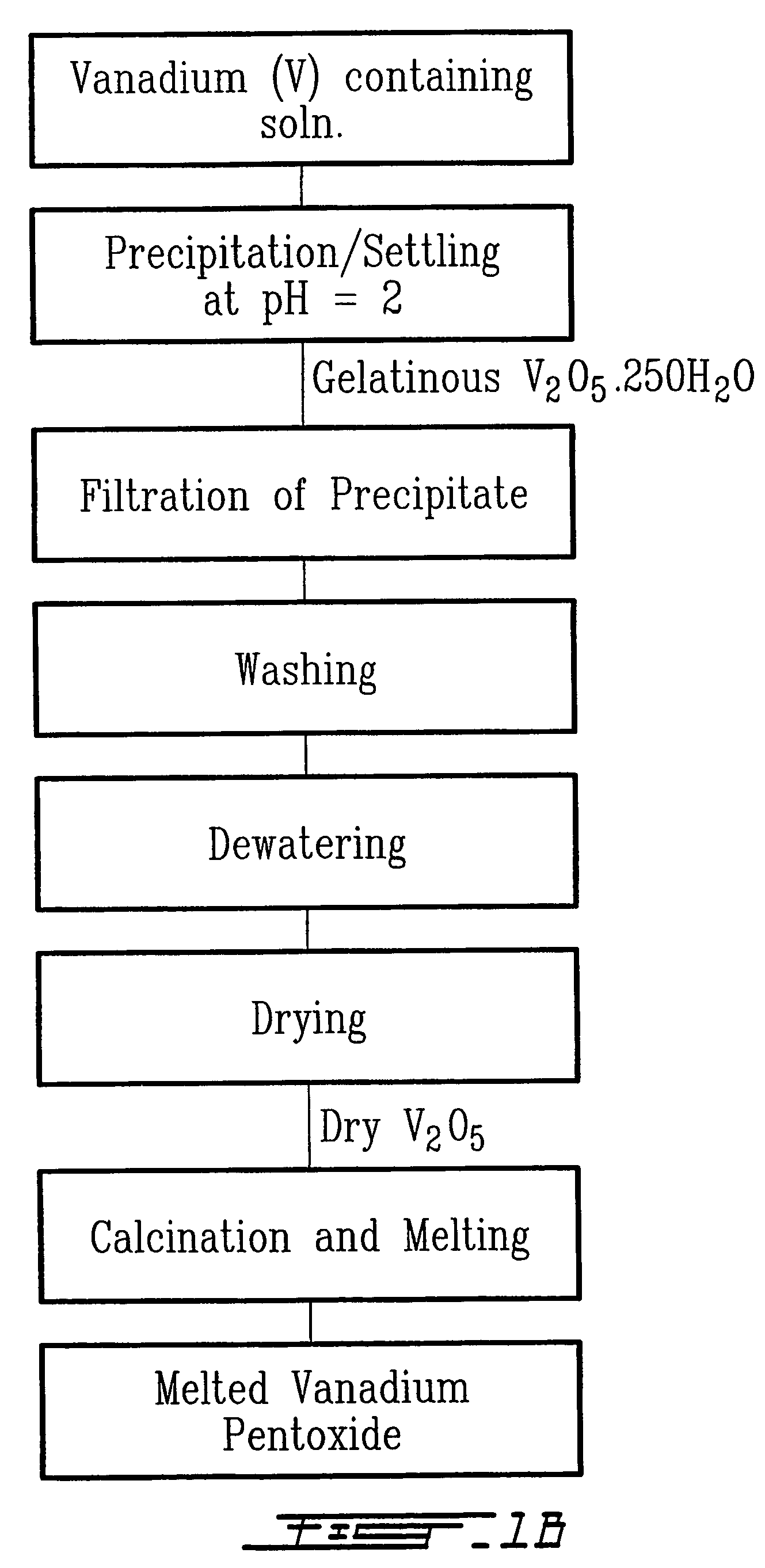

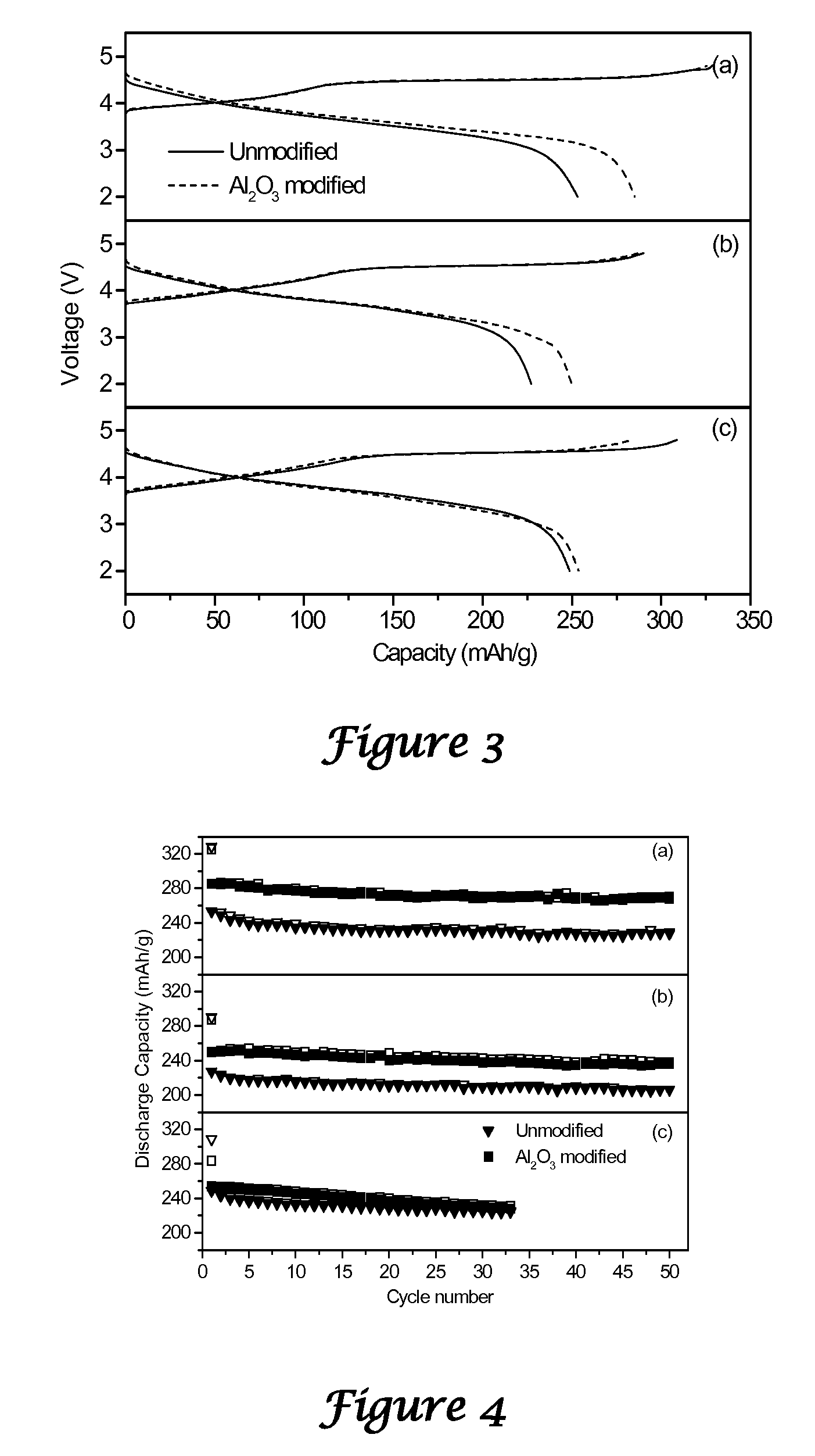

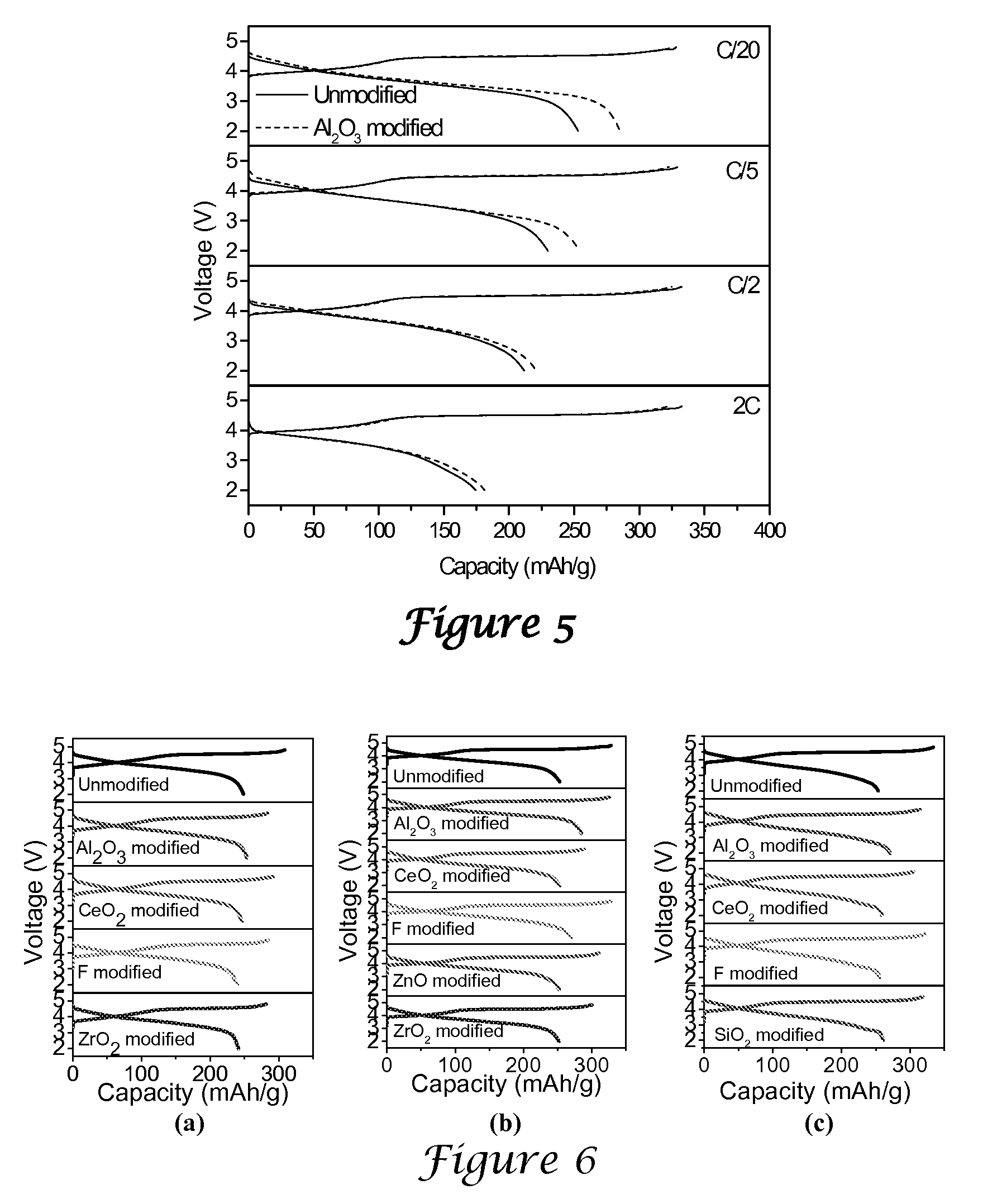

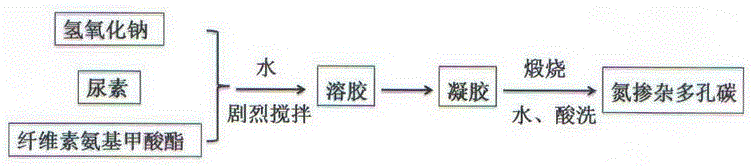

Surface and Bulk Modified High Capacity Layered Oxide Cathodes with Low Irreversible Capacity Loss

InactiveUS20090224212A1Large capacityLow costNon-metal conductorsConductive materialCapacity lossCrystal structure

The present invention includes compositions, surface and bulk modifications, and methods of making of (1−x)Li[Li1 / 3Mn2 / 3]O2.xLi[Mn0.5-yNi0.5-yCo2y]O2 cathode materials having an O3 crystal structure with a x value between 0 and 1 and y value between 0 and 0.5, reducing the irreversible capacity loss in the first cycle by surface modification with oxides and bulk modification with cationic and anionic substitutions, and increasing the reversible capacity to close to the theoretical value of insertion / extraction of one lithium per transition metal ion (250-300 mAh / g).

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

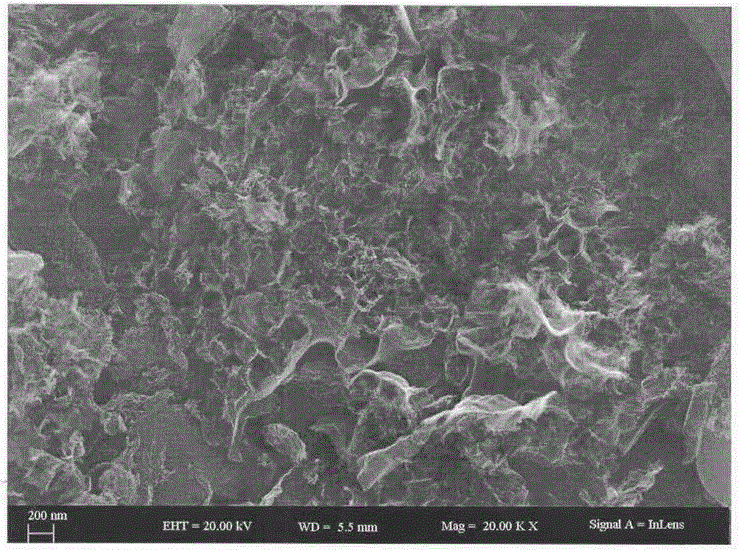

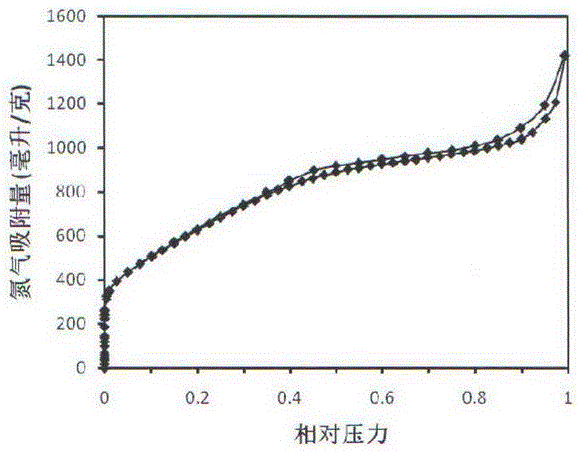

Application and preparation method of biomass-based nitrogen-doped porous carbon

InactiveCN106629655ASimple processImprove stabilityHybrid capacitor electrodesCarbon preparation/purificationCelluloseCarbamate

The invention discloses application and a preparation method of biomass-based nitrogen-doped porous carbon. The method includes: taking cheap cellulose carbamate as a raw material and urea as a nitrogen source, well mixing with sodium hydroxide solution, drying to form sol, and performing high-temperature calcination to obtain the porous-structure biomass-based nitrogen-doped porous carbon high in specific surface area and pore volume. According to electron microscopy images, the prepared material is in a three-dimensional inner-crosslinked porous structure; according to XPS and elemental analysis, nitrogen is successfully doped into a carbon substrate, the nitrogen content is 7.7-15.5%, and the specific surface area is 700-3700m<2> / g; according to supercapacitor experiments, the biomass-based nitrogen-doped porous carbon is great in electrochemical performance; according to pollutant adsorption experimental data, the material is high in adsorption rate and adsorption capacity in adsorption of dye pollutant methylene blue, and the adsorption capacity reaches 1520mg / g. The method is simple in preparation, the raw materials are renewable, and low cost is realized. In addition, sodium carbonate which is a by-product is obtained by washing of calcined samples, so that cost can be effectively reduced, and economic benefits are increased.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

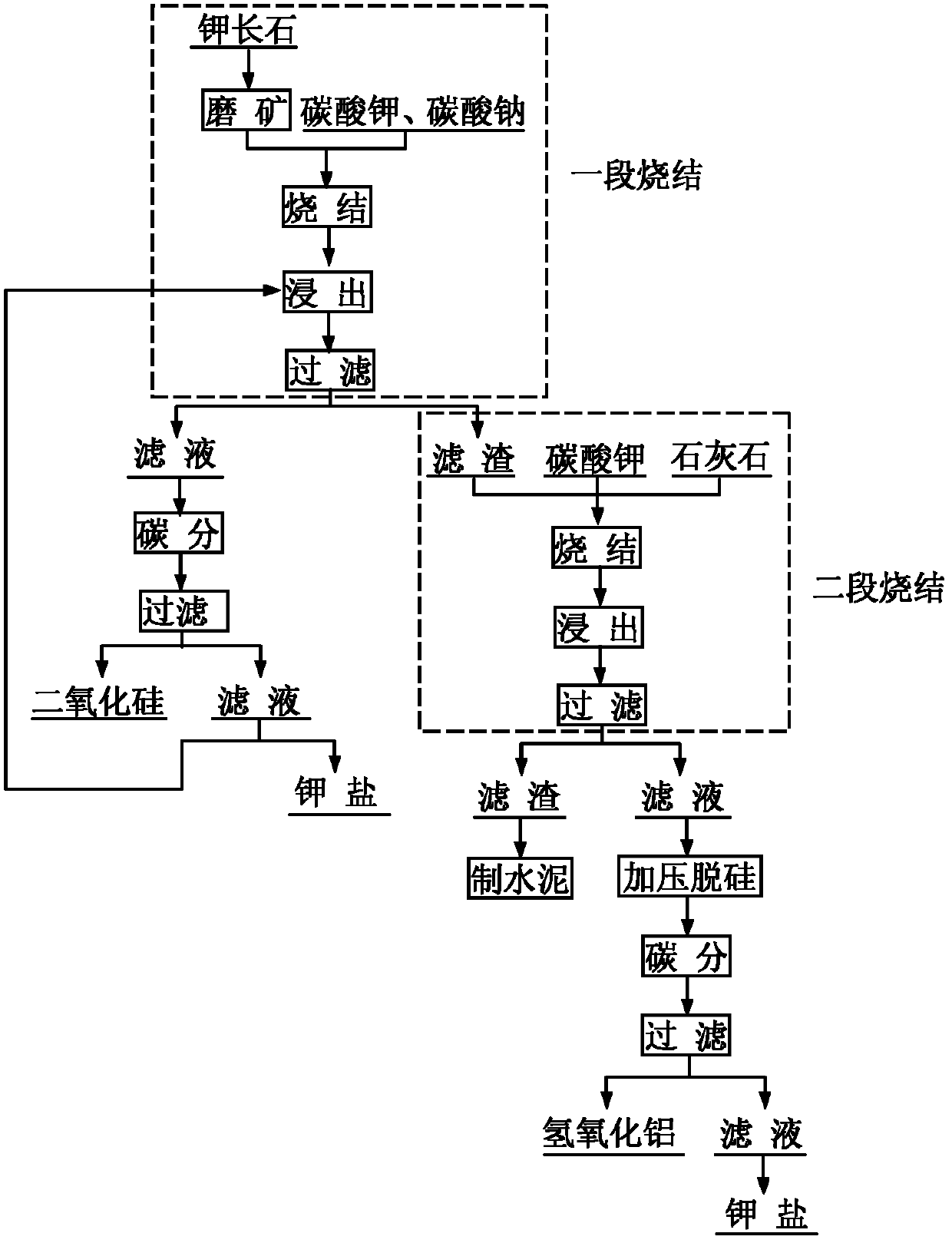

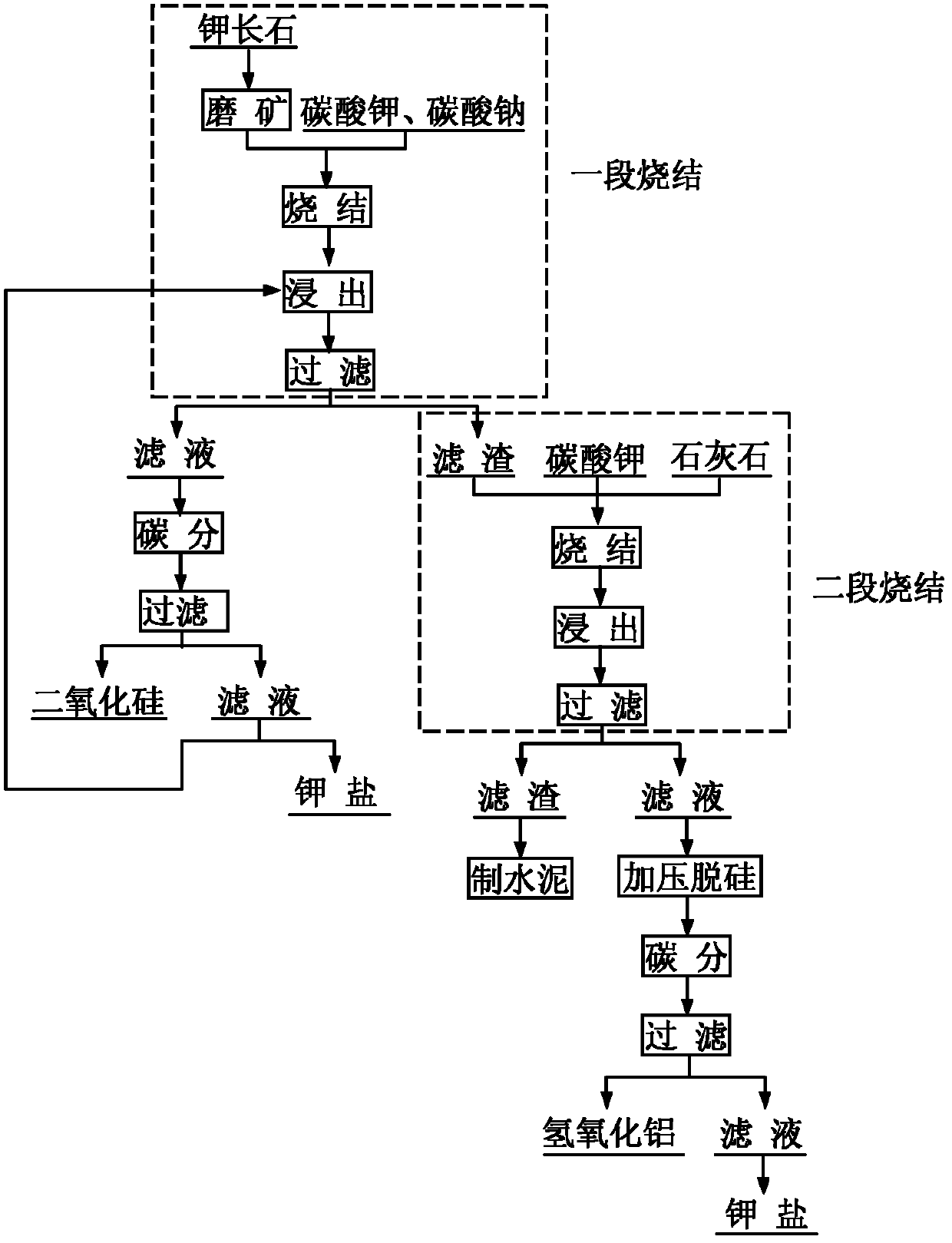

New process for comprehensively utilizing potassium feldspar

InactiveCN102557050AMaximize the value of silicon resourcesResource value maximizationSilicaCement productionDecompositionFiltration

The invention discloses a new process for comprehensively utilizing potassium feldspar. The new process comprises the following steps of: performing primary sintering on the potassium feldspar added with potassium carbonate or sodium carbonate, leaching the sintering clinker in a mixed solution of potassium hydroxide and potassium carbonate, and filtering, wherein the obtained filter residue is araw material for secondary sintering, the obtained filtrate is subjected to carbon decomposition and filtration, partial silicon dioxide is recovered from filter residue for producing white carbon black, part of the filtrate is used for producing potassium salt and part of the filtrate returns to the primary leaching procedure; and performing secondary sintering, namely sintering primary sintering clinker leaching residue added with limestone and potassium carbonate, leaching the sintering clink in a mixed solution of potassium hydroxide and potassium carbonate, and filtering, wherein filter residue is taken as a cement production raw material, filtrate is added with calcium oxide for pressure desilication treatment, a solution subjected to desilication is subjected to carbon decomposition and filtration, and aluminum hydroxide is recovered from filter residue for producing diversified alumina. In the process of primary sintering and secondary sintering, the filtrate subjected to carbon decomposition and filtration is subjected to desilication, concentration and other processes, and the potassium carbonate can be recovered. By the process, the potassium feldspar value resource canbe utilized maximally, the potassium carbonate can be recycled, and environment is protected.

Owner:KUNMING METALLURGY INST

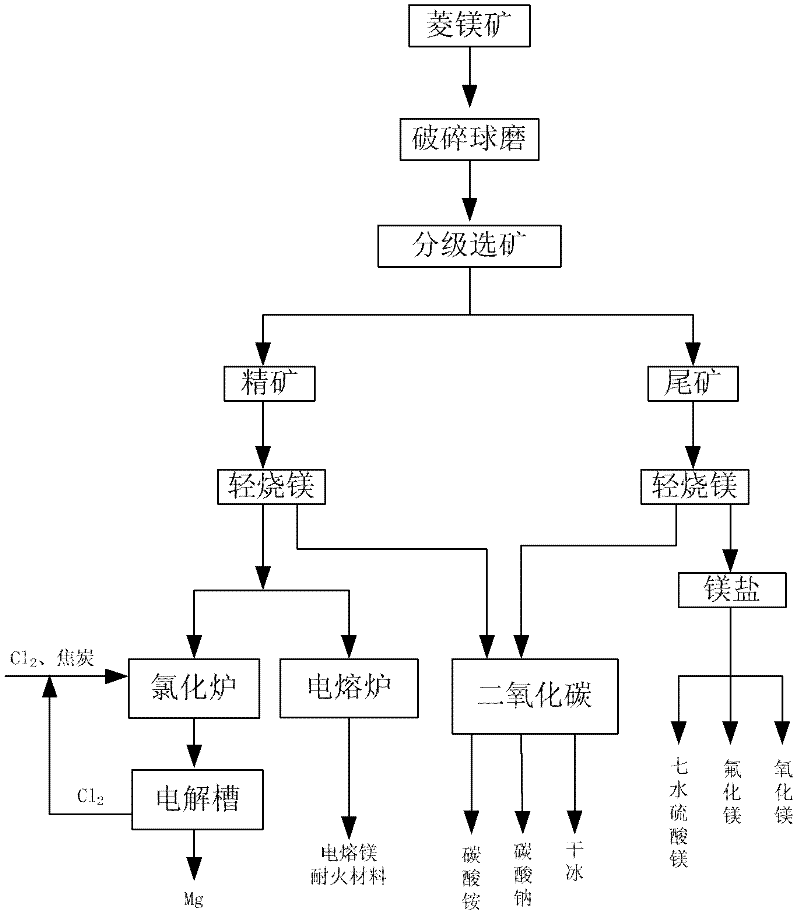

Integrated utilization method of low grade magnesite

InactiveCN102515213ASave raw materialsSimple processCarbon compoundsAmmonium carbonates/bicarbonatesElectrolysisMagnesium salt

The invention belongs to the fields of integrated utilization technology of magnesite and environmental protection, and relates to an integrated utilization method of low grade magnesite. The method comprises steps of: magnesite fragmentation; ore grinding; ore dressing; ore dressing product calcining; conversion of calcined useful components into magnesium salt to prepare high purity magnesium oxide or direct electrolysis of the calcined useful components into magnesium metal or preparation of refractory material; and recovery utilization of gas generated by calcination. The invention comprehensively utilizes useful ingredients in the magnesite, realizes zero discharge of magnesite mine tailing, increases utilization rate of low grade magnesite and efficiently utilizes ore resource; and especially, fluidized roasting by a horizontal fluidized bed saves energy consumption and maximize economic benefit.

Owner:UNIV OF SCI & TECH BEIJING

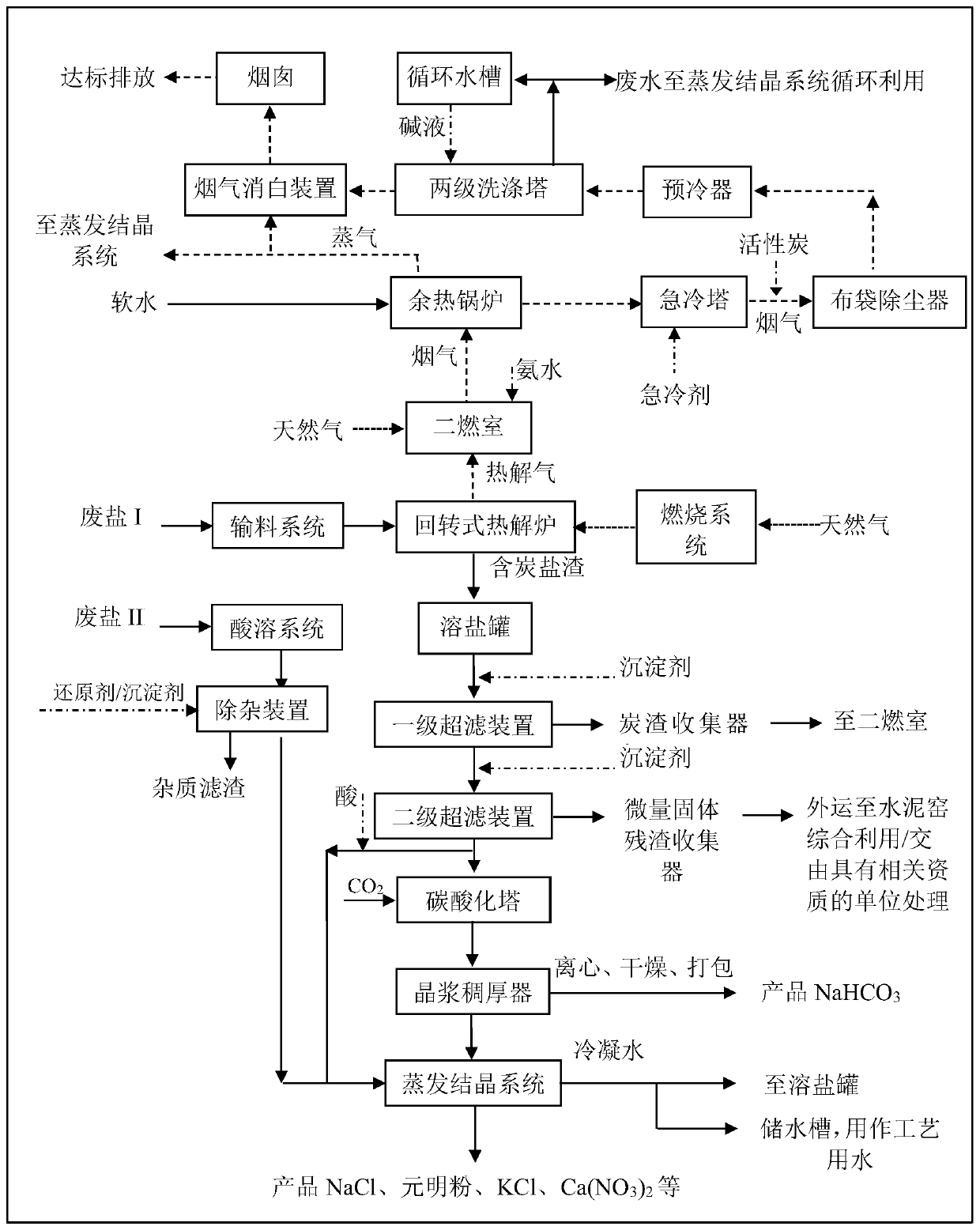

Waste salt resourceful treatment system and application

PendingCN110201975ARealize resourcesAchieve emission standardsSolid waste disposalTransportation and packagingSlagEvaporation

The invention relates to a waste salt resourceful treatment system which comprises a waste salt carbonization and pyrolysis system, a carbon-containing salt slag dissolving and filtering system and anevaporating and salt separating system in sequential connection, wherein the waste salt carbonization and pyrolysis system can carry out carbonization and pyrolysis treatment on waste salt I composedof sodium chloride, and sodium sulfate monomer salt or mixed waste salt and also can treat tail gas; the carbon-containing salt slag dissolving and filtering system can dissolve and filter the carbon-containing salt slag treated by the waste salt carbonization and pyrolysis system; and the evaporating and salt separating system can carry out evaporation and concentration, fractional crystallization and drying treatment on the strong brine treated by the carbon-containing salt slag dissolving and filtering system to obtain product salt. The waste salt resourceful treatment system takes industrial waste salt as the raw material, removes organic pollutant from waste salt and separates mixed inorganic salt to finally obtain an industrial second-grade salt product, so that recycling of waste salt is realized, and the flue gas generated during the production process is discharged after reaching the standard.

Owner:北京航天环境工程有限公司

Resourceful utilization method of red mud

The invention provides a resourceful utilization method of red mud. The resourceful utilization method of the red mud includes the following steps of (1) reductive transformation of slurry, specifically, the slurry is prepared from the red mud, a reductive transformation agent, lime and water, a reductive thermochemical strict reduction reaction is conducted at the temperature of 60-350 DEG C and at the pressure of 0.1013MPa-4.5Mpa, alkali combined in minerals such as aluminosilicate in the red mud is replaced to form the strong-basicity slurry, and a iron oxide mineral in the red mud is reductively transformed into ferroferric oxide in the strong-basicity slurry, and / or iron contained in the red mud is reduced synchronously with chrominum, titanium, vanadium, gallium, scandium and the like and molten into ferrite crystal lattices to form an isomorphous ferrite magnetic body of the elements like chrominum, titanium, vanadium, gallium and scandium; (2) extracting of iron through magnetic separation; (3) extracting of alkali through separation; and (4) utilization of the aluminosilicate mineral. The resourceful utilization method of the red mud has the advantages of being low in energy consumption, economical, free of secondary pollution, capable of recycling three main components in the red mud effectively and the like.

Owner:长沙紫宸科技开发有限公司

Stent With a Coating or a Basic Body Containing a Lithium Salt and Use of Lithium Salts for Prevention of Restenosis

The invention relates to a stent with in particular a coated basic body made of an implant material the use of lithium salts as a coating material or a component of an implant material for stents and the use of lithium salts in a method for restenosis prevention. The inventive stent having a basic body made of an implant material is characterized in that (i) the basic body has a coating which comprises or consists of a lithium salt, and / or (ii) the implant material is biocorrodible and the basic body contains a lithium salt.

Owner:BIOTRONIK AG

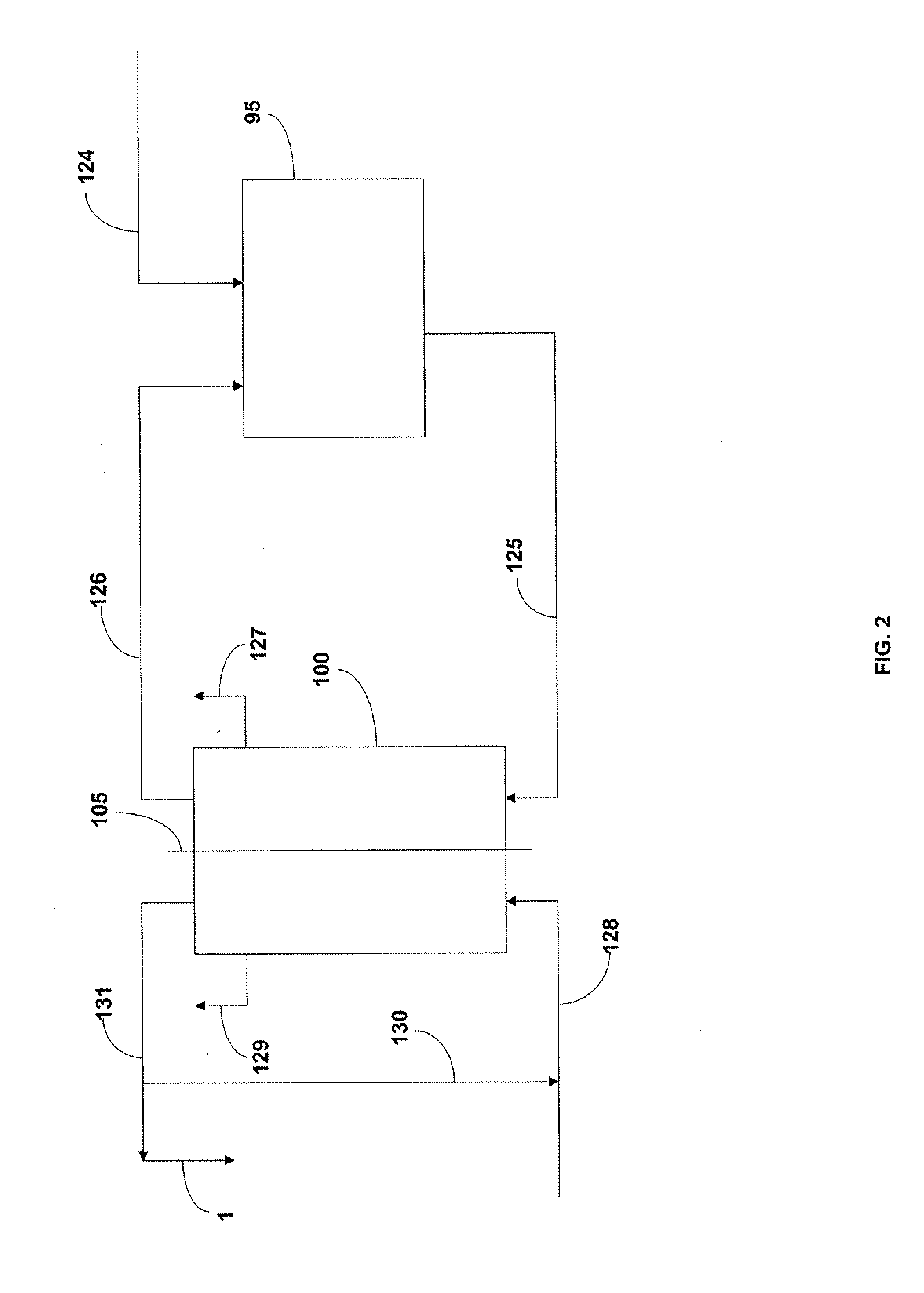

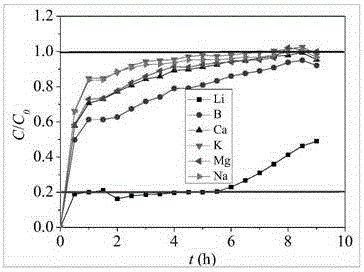

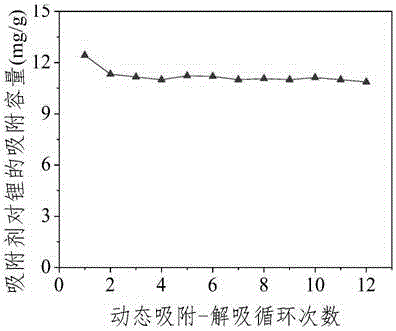

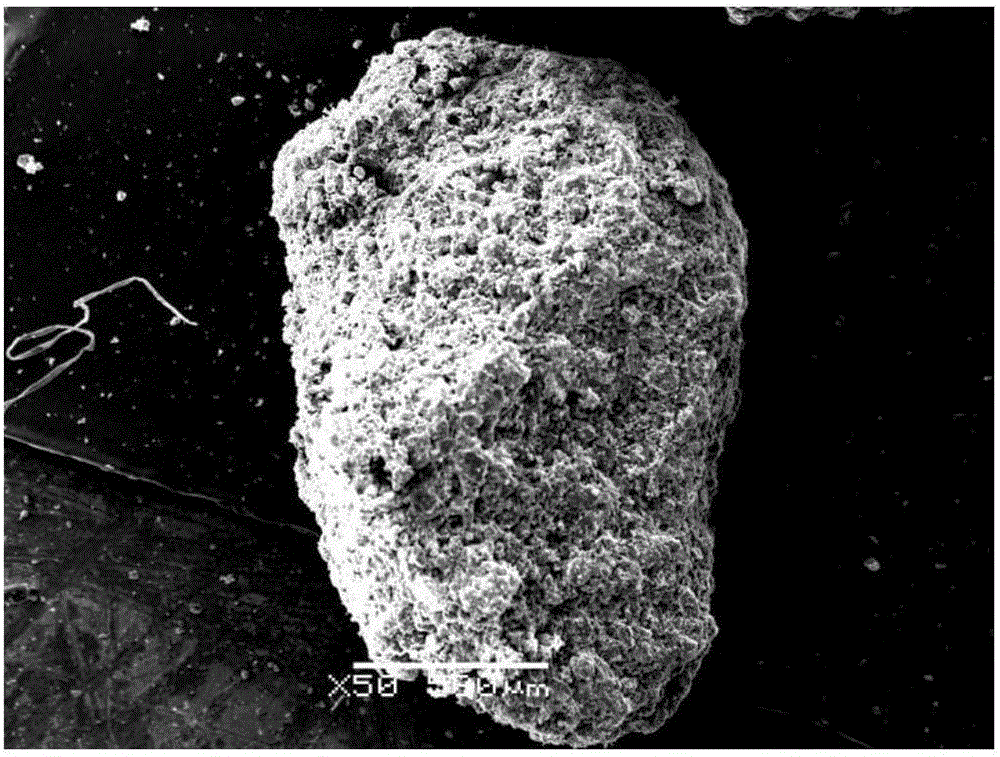

Microporous aluminum-salt lithium adsorbent, preparation method therefor, filler and lithium ion enriching method

ActiveCN106076243AOvercome the problem of high dissolution rateControl areaOther chemical processesAlkali metal oxides/hydroxidesLithiumSorbent

The invention discloses a microporous aluminum-salt lithium adsorbent, a preparation method therefor, filler containing the microporous aluminum-salt lithium adsorbent and a lithium ion enriching method. The microporous aluminum-salt lithium adsorbent disclosed by the invention has the molecular formula of LiCl.aAl(OH)3.bH2O and has micropores, of which the average pore size is smaller than 2nm, wherein a is greater than 1 and smaller than 3, and b is greater than 0.5 and smaller than 2. The preparation method disclosed by the invention is simple, and the obtained adsorbent is large in lithium ion adsorption capacity, high in selectivity, simple in eluting regeneration and long in cycle life and can be applied to the separation and extraction of lithium from lithium-containing saline lake brine, salt-field concentrated lithium-containing senescent brine, lithium-containing medicinal wastewater and a lithium-containing solution with the mineralization degree lower than 50g / L.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com