Patents

Literature

401results about How to "Lower volume resistivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

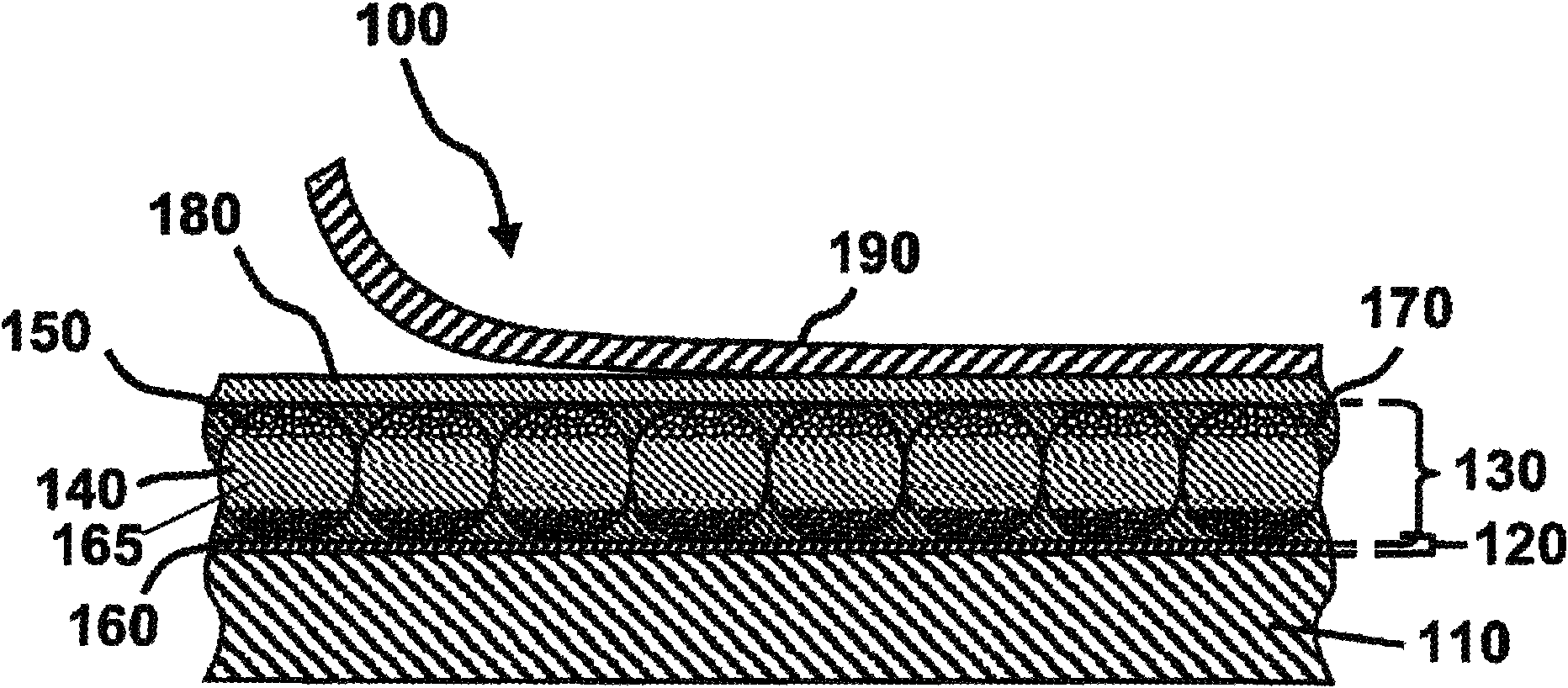

Electro-optic assemblies, and adhesives and binders for use therein

InactiveUS20090122389A1Lower volume resistivityLayered productsPolyureas/polyurethane adhesivesOrganic matterAdhesive materials

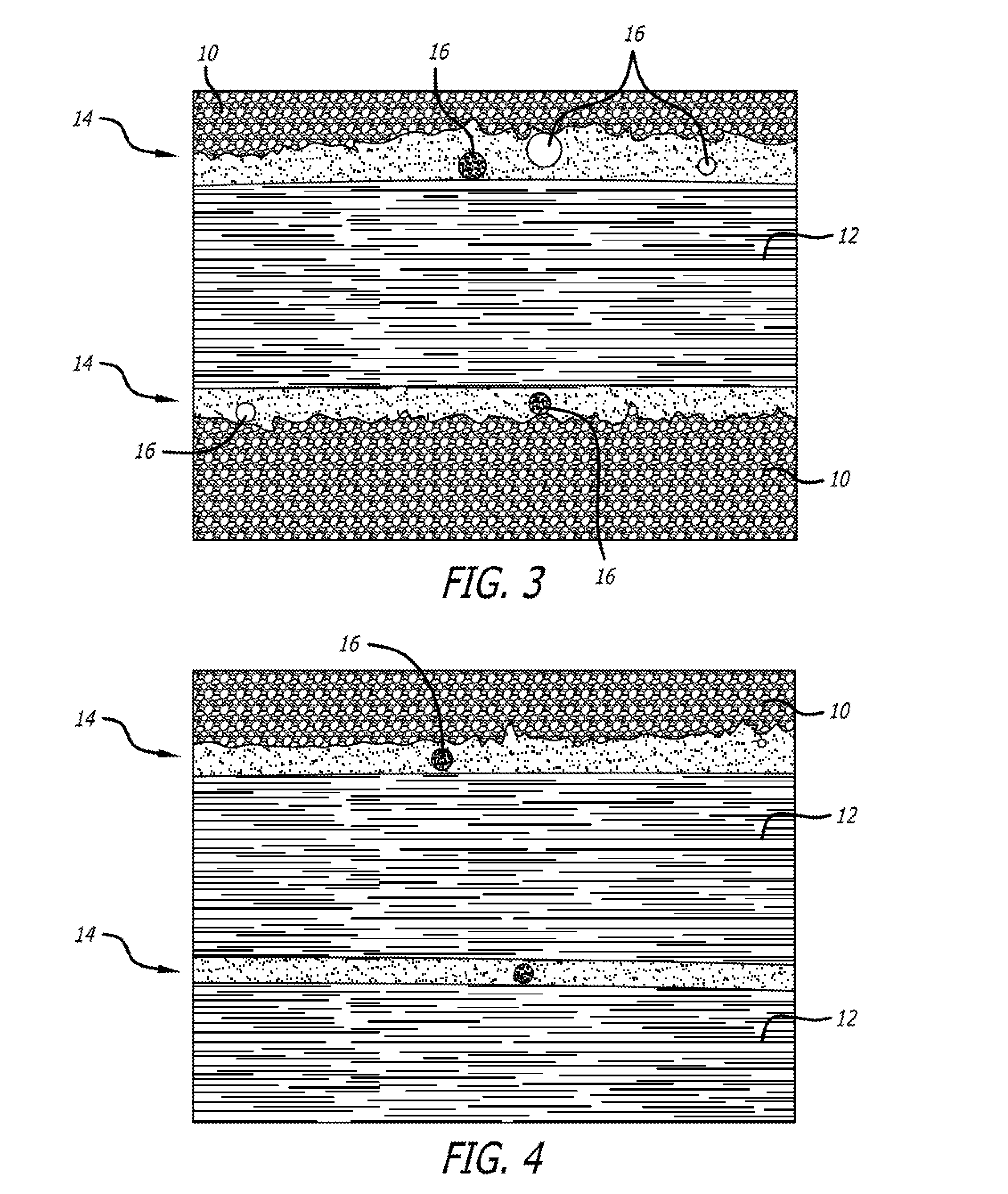

An electro-optic assembly comprises an adhesive layer and a layer of electro-optic material. The adhesive layer comprises a polymeric adhesive material and an ionic material having either its cation or its anion fixed to the polymeric adhesive material. The ionic material reduces the volume resistivity of the polymeric adhesive material and is not removed upon heating to 50° C. In a similar electro-optic assembly comprising an adhesive layer and a layer of electro-optic material, the adhesive layer comprises a polymeric adhesive material which has been subjected to dialysis or diafiltration to remove organic species having a molecular weight less than about 3,500, so that the adhesive material has a content of N-methylpyrrolidone not exceeding 500 ppm based upon the total weight of the adhesive layer and layer of electro-optic material.

Owner:E INK CORPORATION

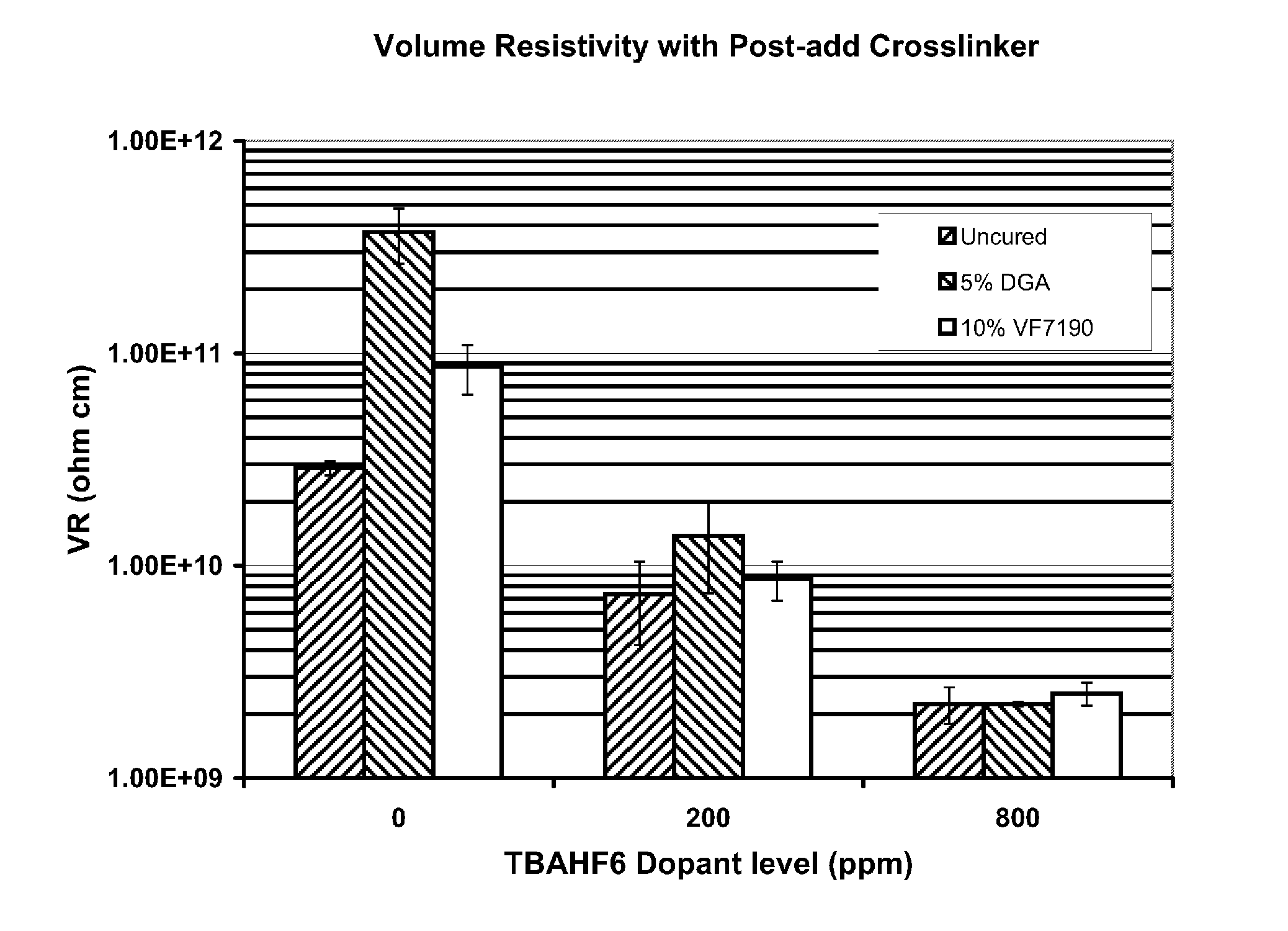

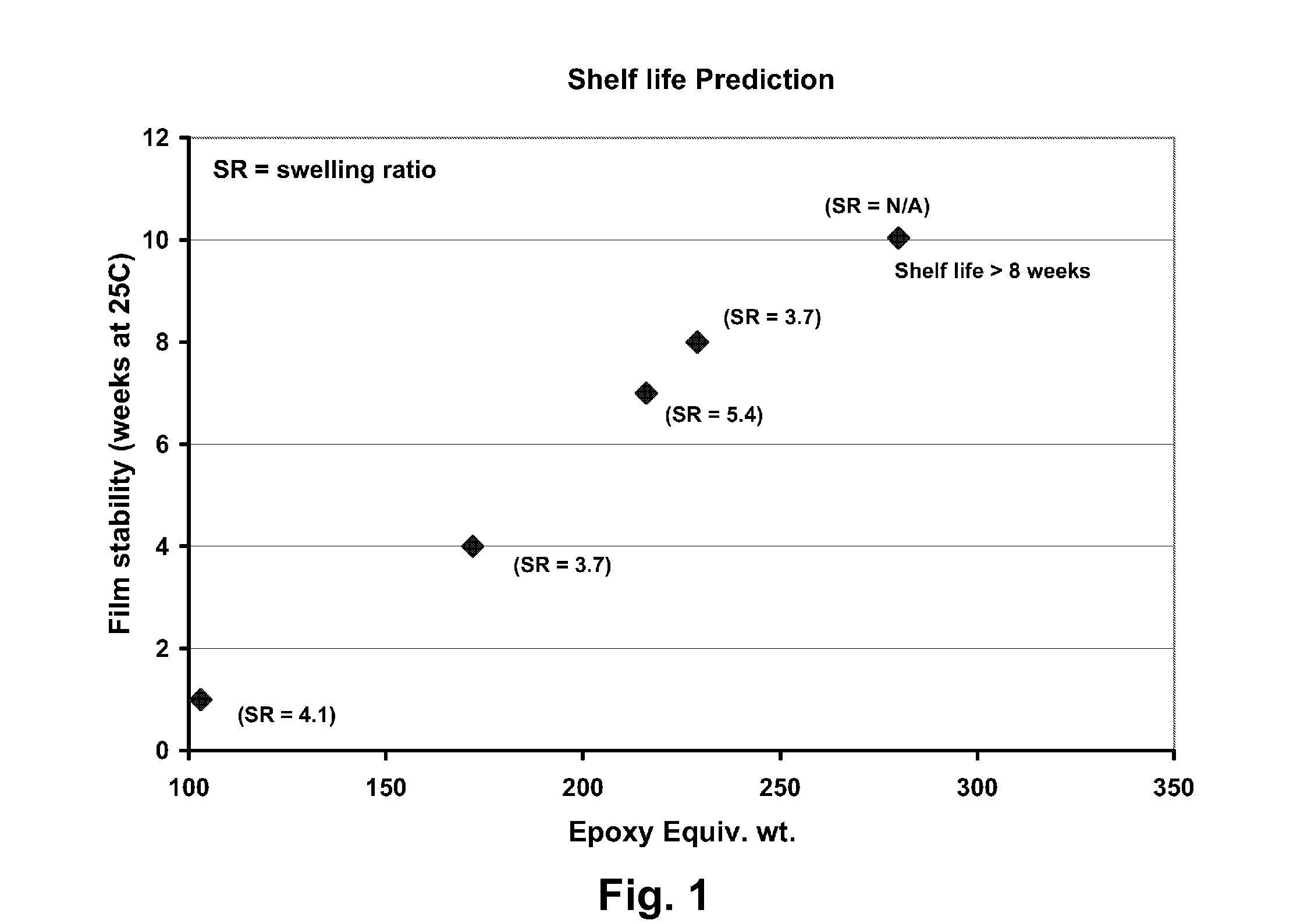

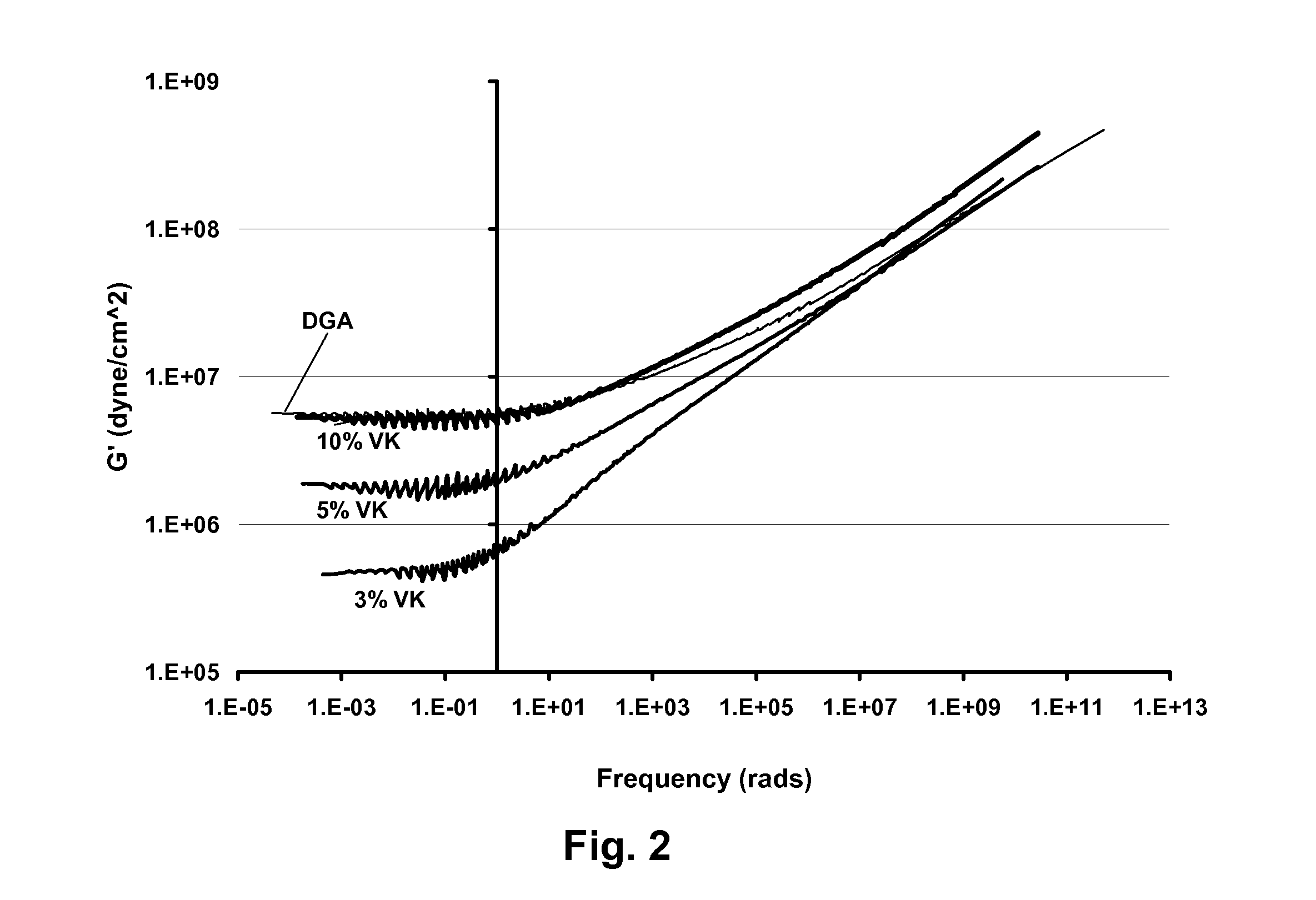

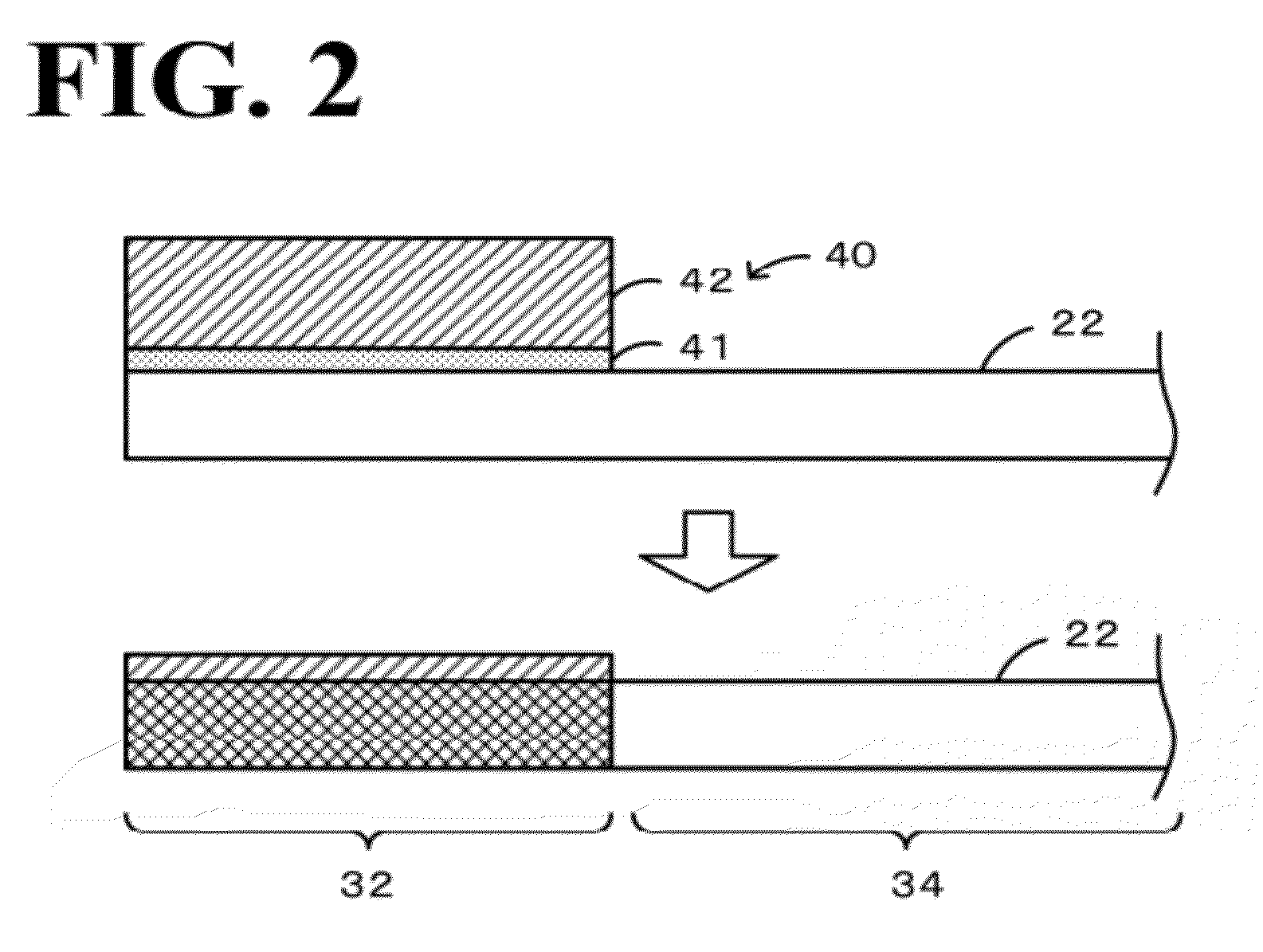

Electro-optic displays, and materials for use therein

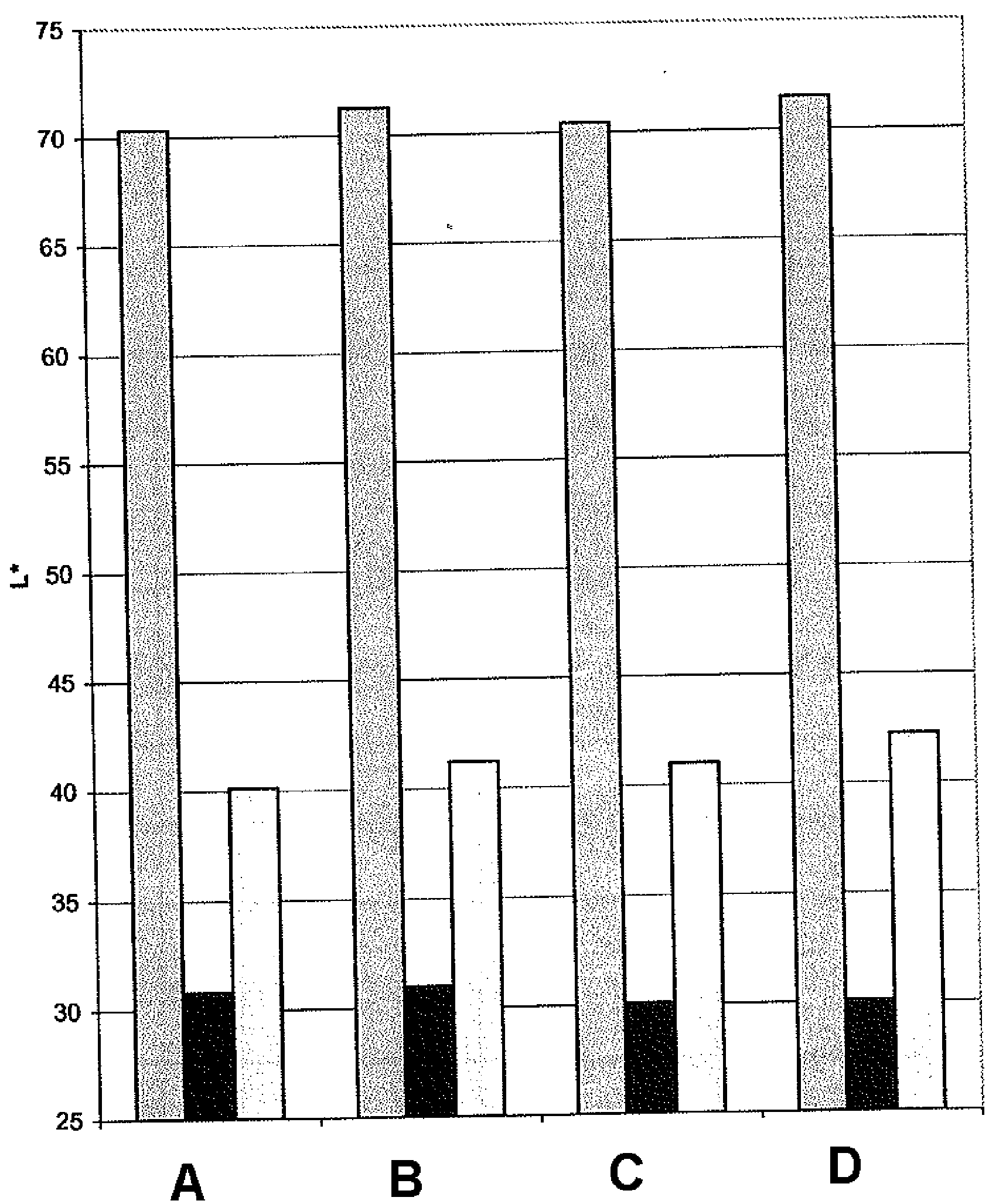

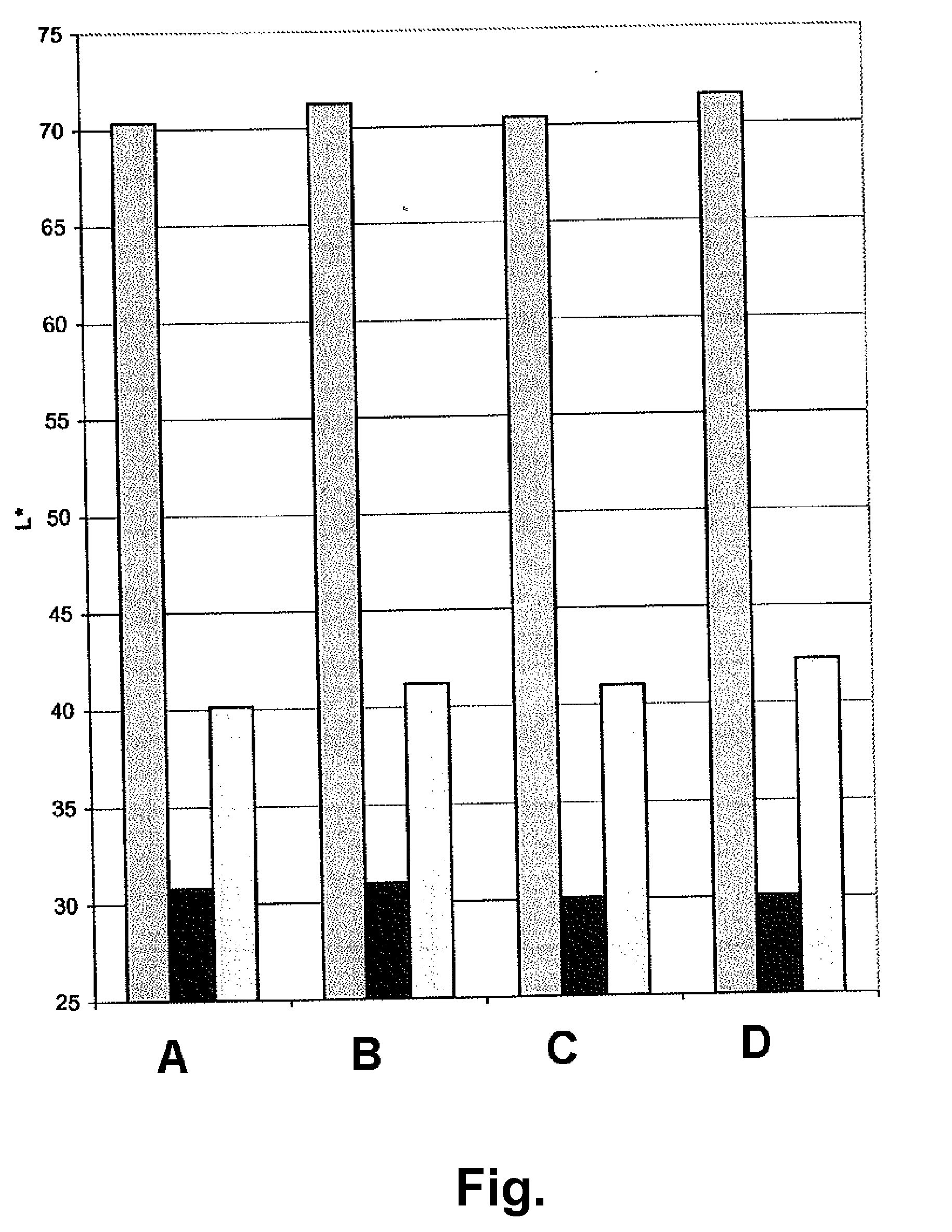

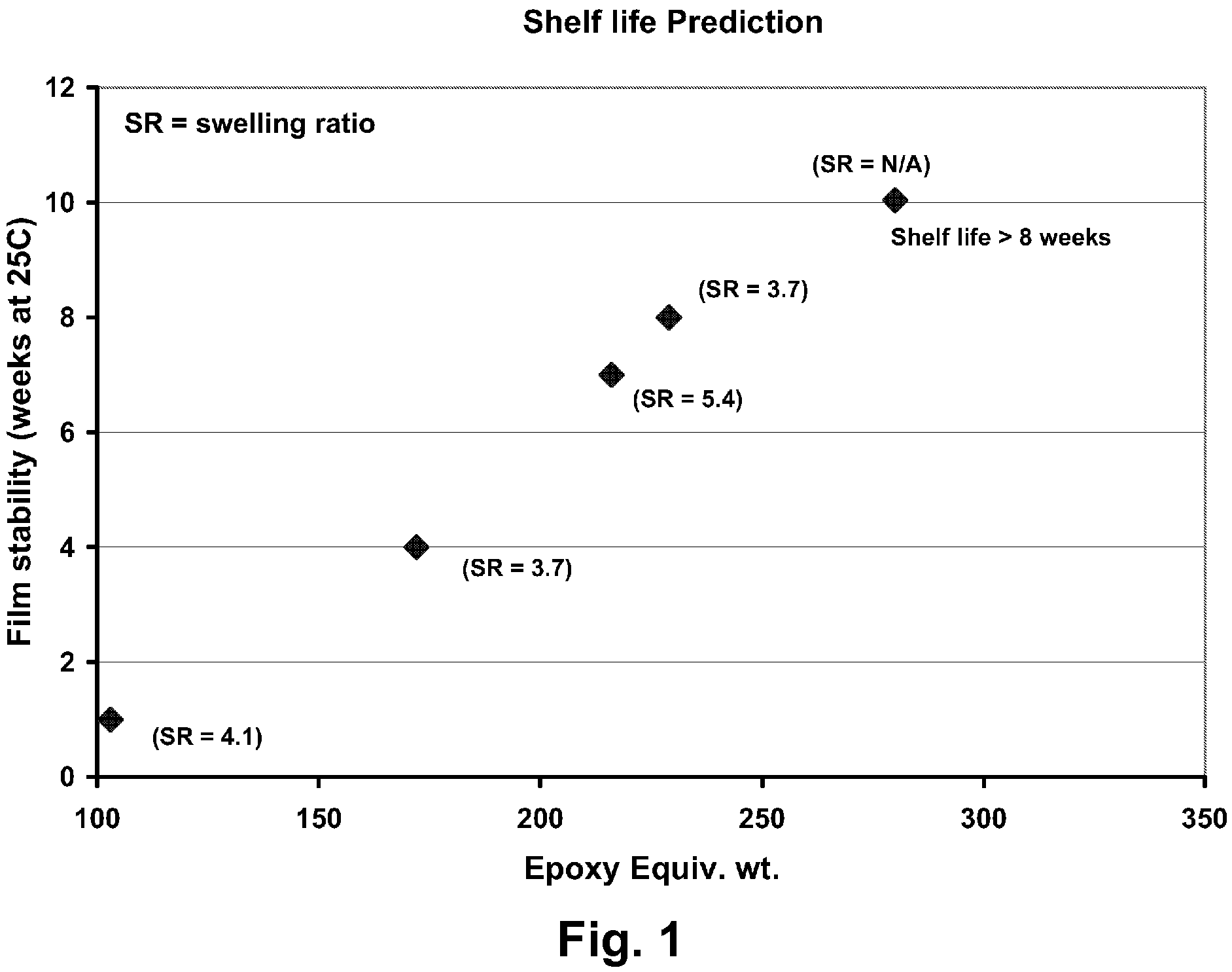

ActiveUS7551346B2Lower volume resistivityPolyureas/polyurethane adhesivesThin material handlingCross-linkVegetable oil

An electro-optic display comprises a layer of solid electro-optic material; a backplane comprising at least one electrode; and an adhesive layer disposed between the layer of electro-optic material and the backplane and adhesively securing the layer of electro-optic material to the backplane, the adhesive layer comprising a thermally-activated cross-linking agent comprising an epoxidized vegetable oil fatty acid or an epoxidized ester of such a fatty acid. The cross-linking agent reduces void growth when the display is subjected to temperature changes.

Owner:E INK CORPORATION +1

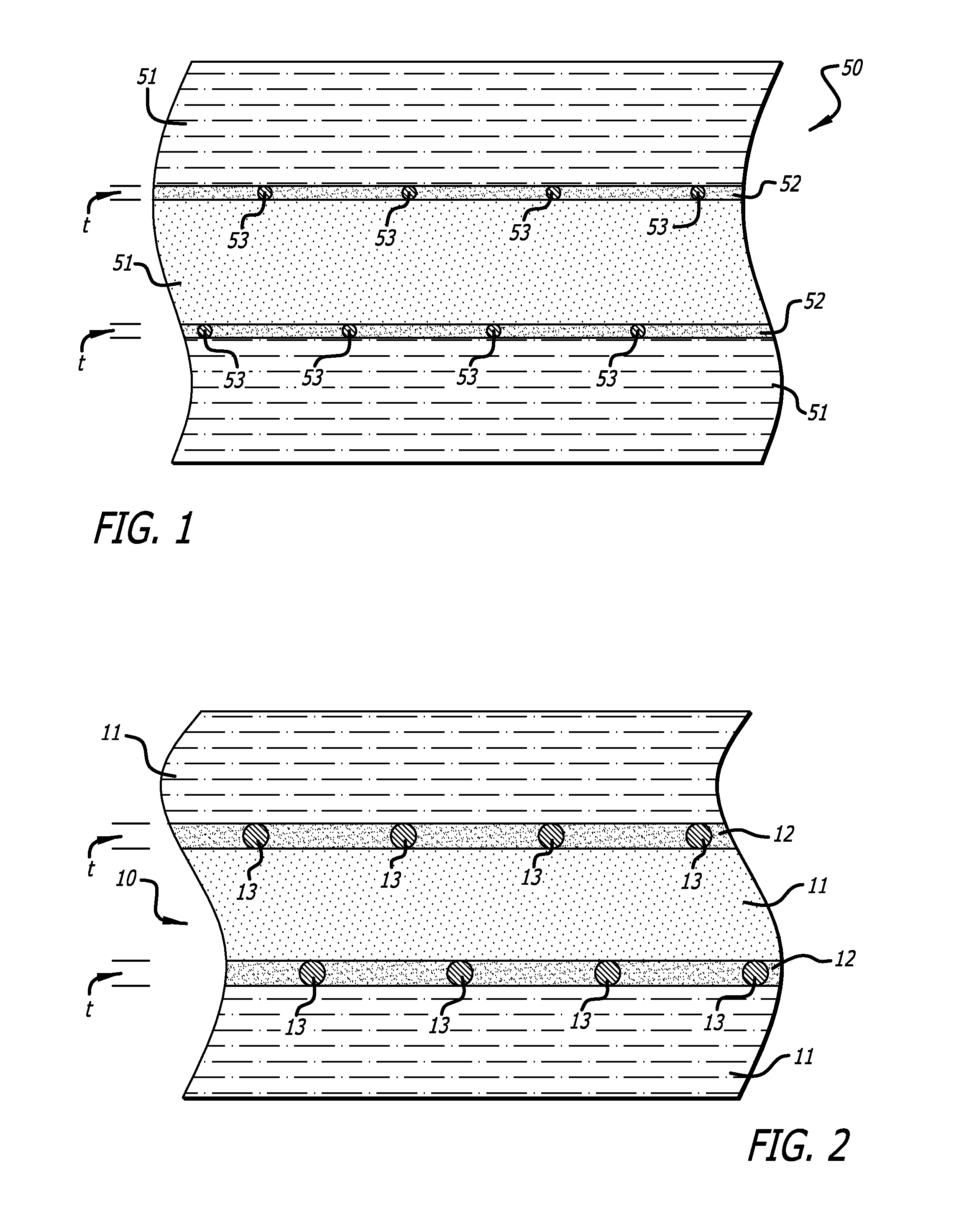

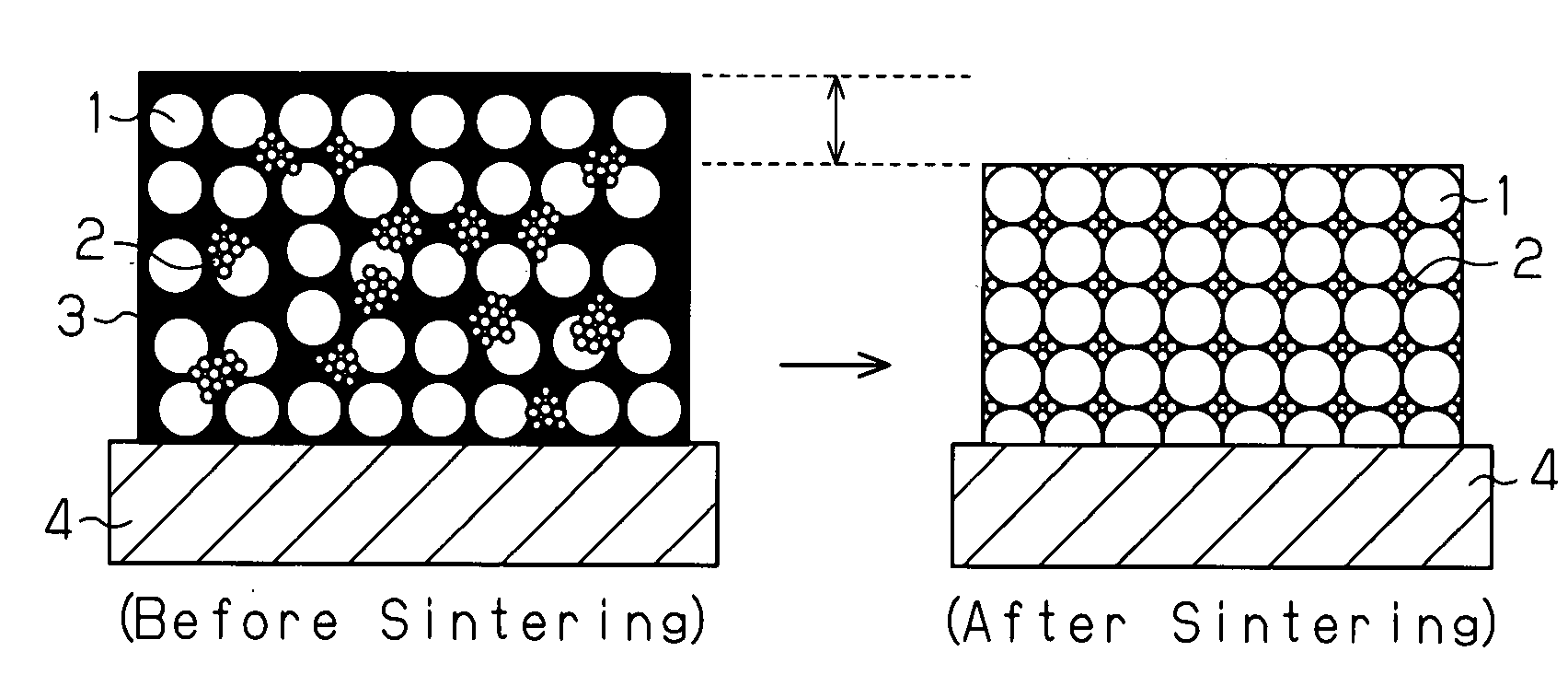

Composite materials

ActiveUS20080295955A1Improve conductivityLittle and no additional weightMaterial nanotechnologyBaby linensFiberPolymer science

A composite material, the composite material comprising at least one prepreg, said prepreg comprising at least one polymeric resin and at least one fibrous reinforcement; and conducting particles dispersed in the polymeric resin.

Owner:HEXCEL COMPOSITES LTD (GB)

Polyvinylidene fluoride composites and methods for preparing same

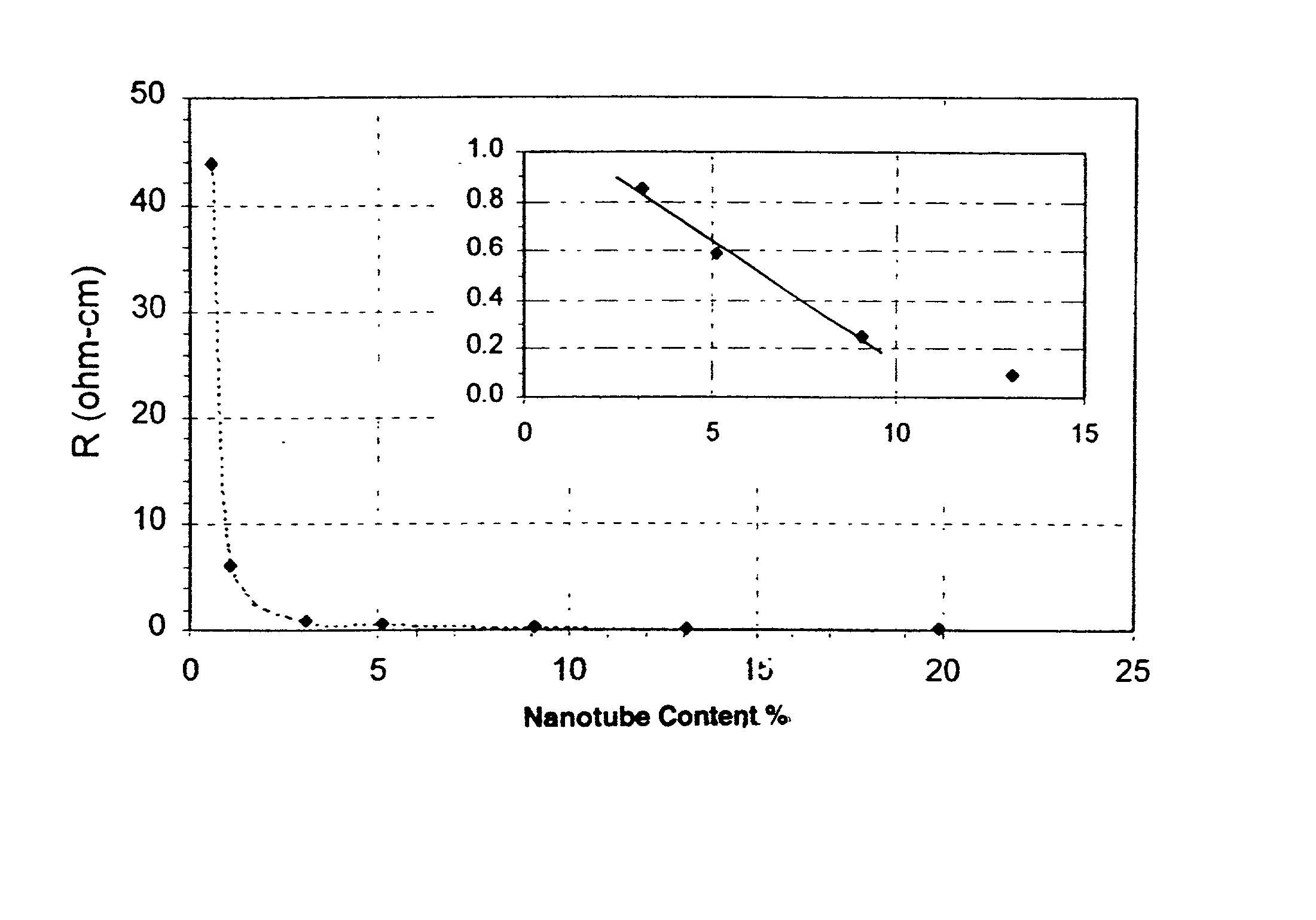

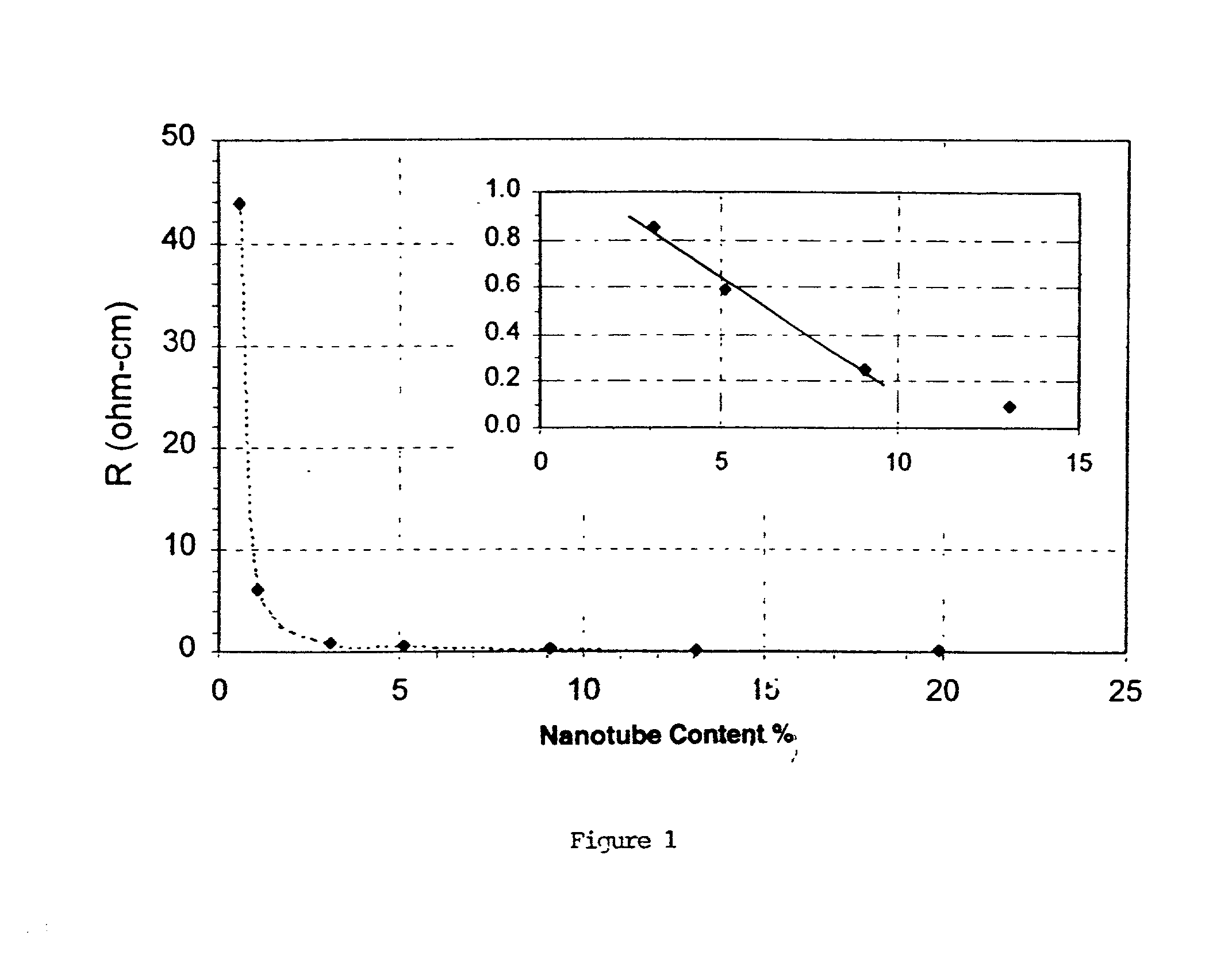

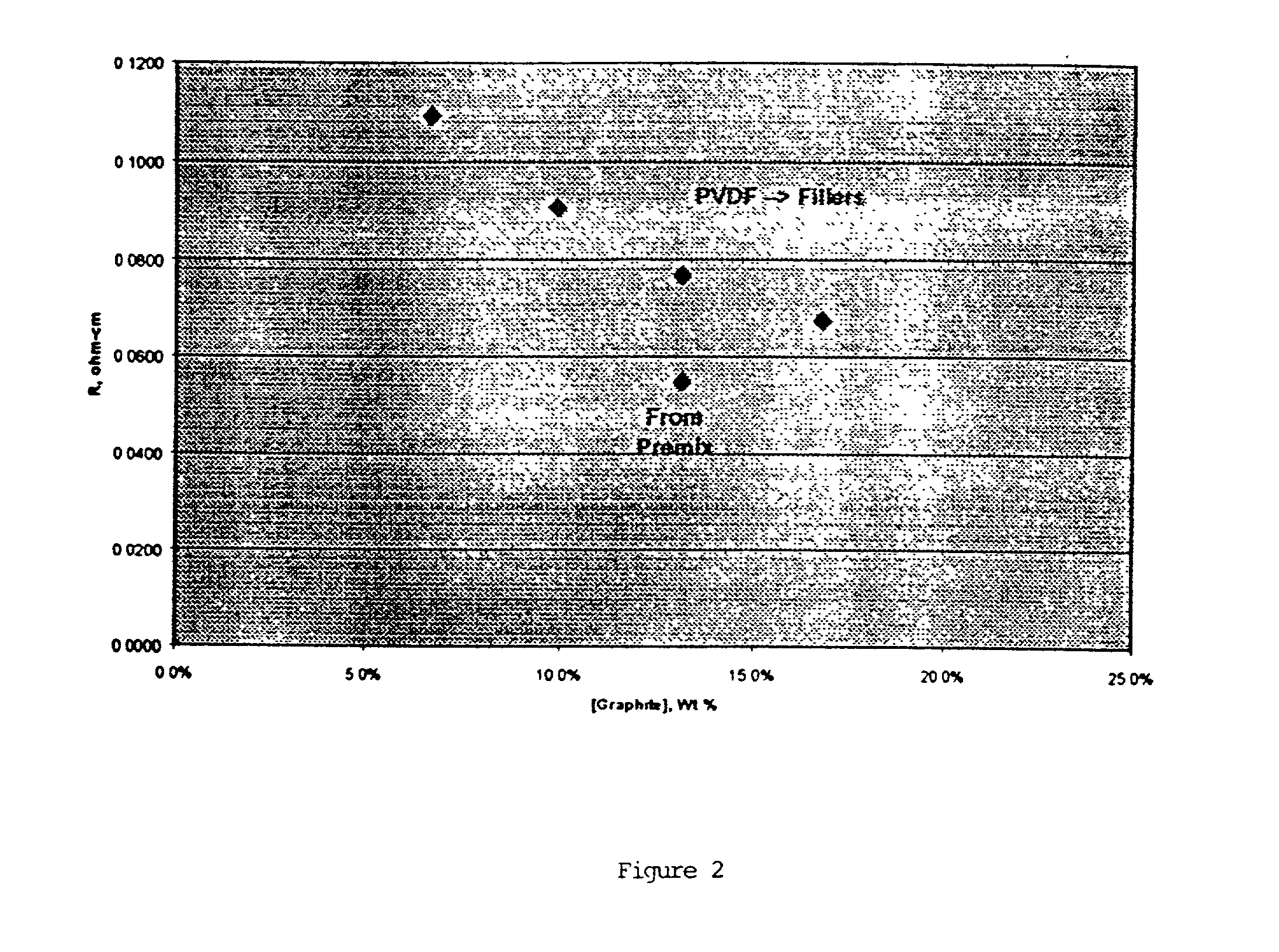

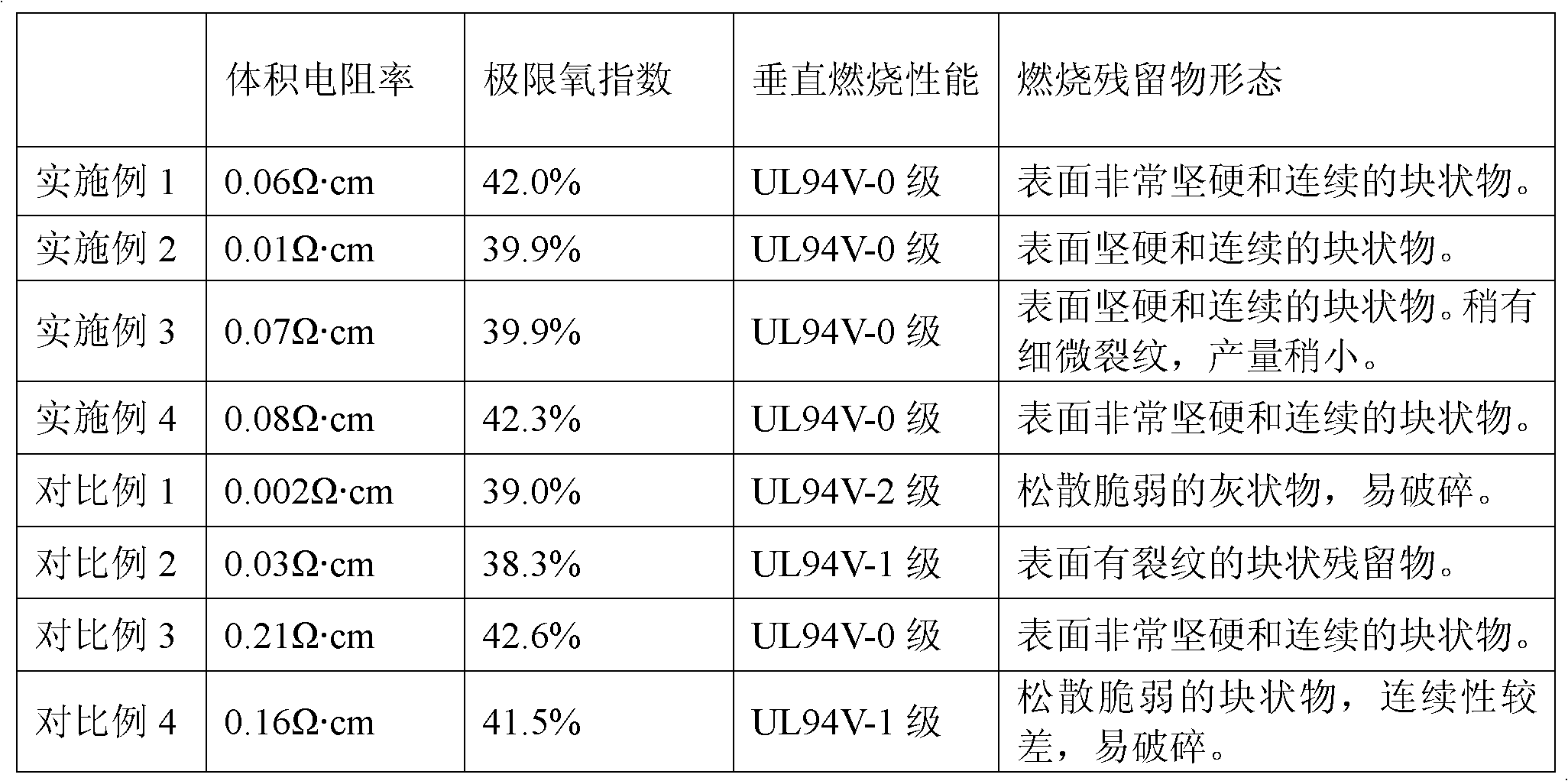

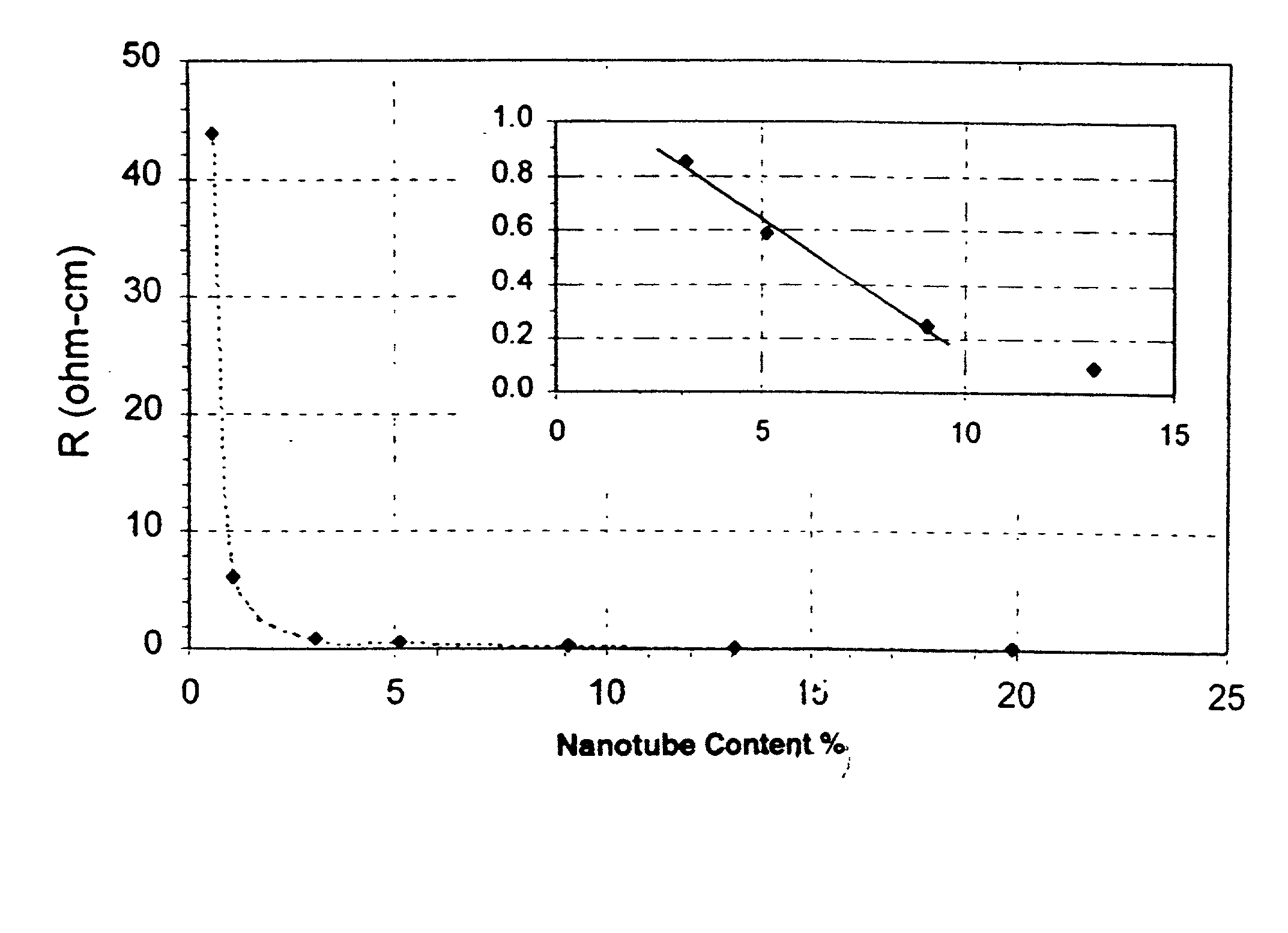

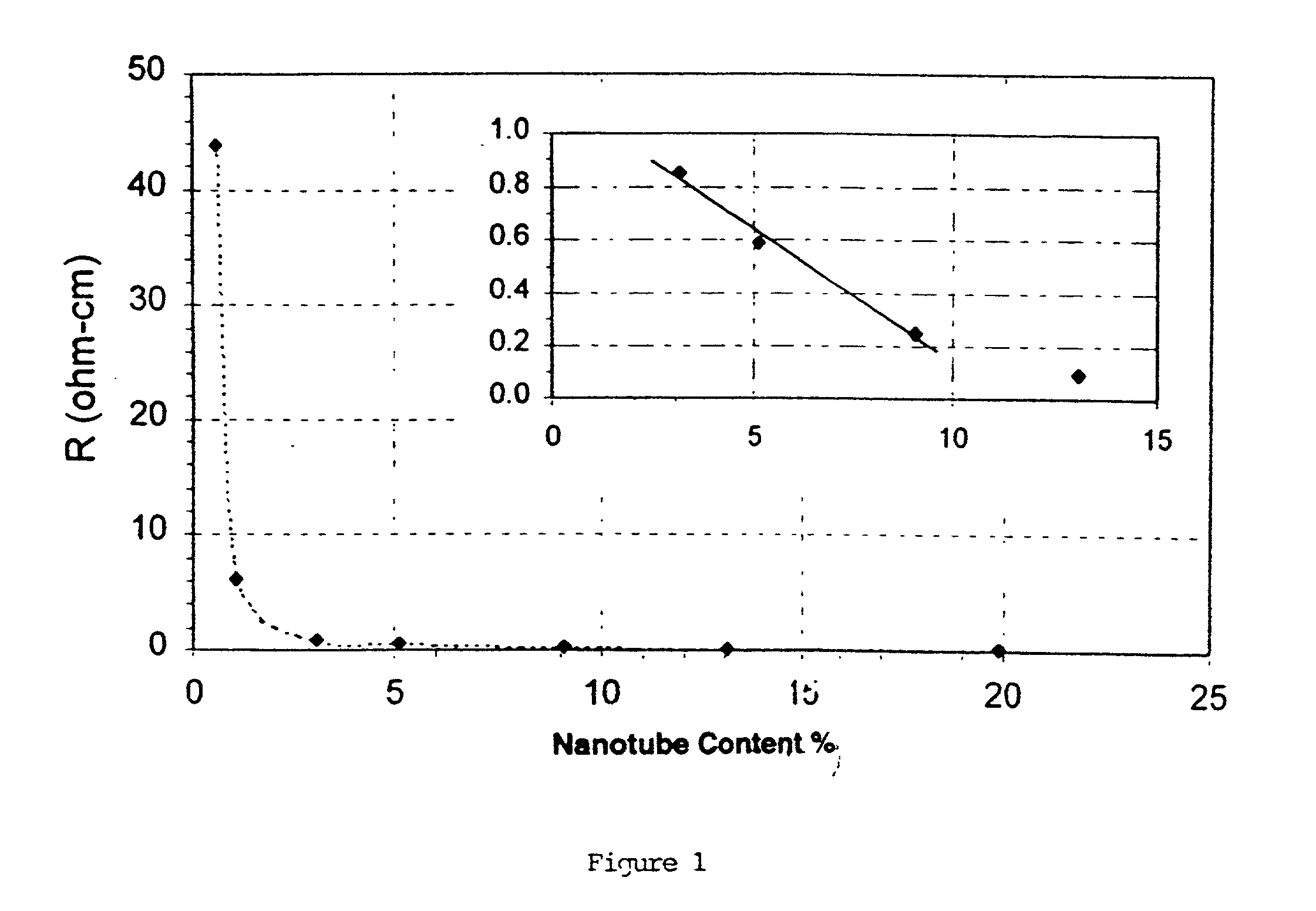

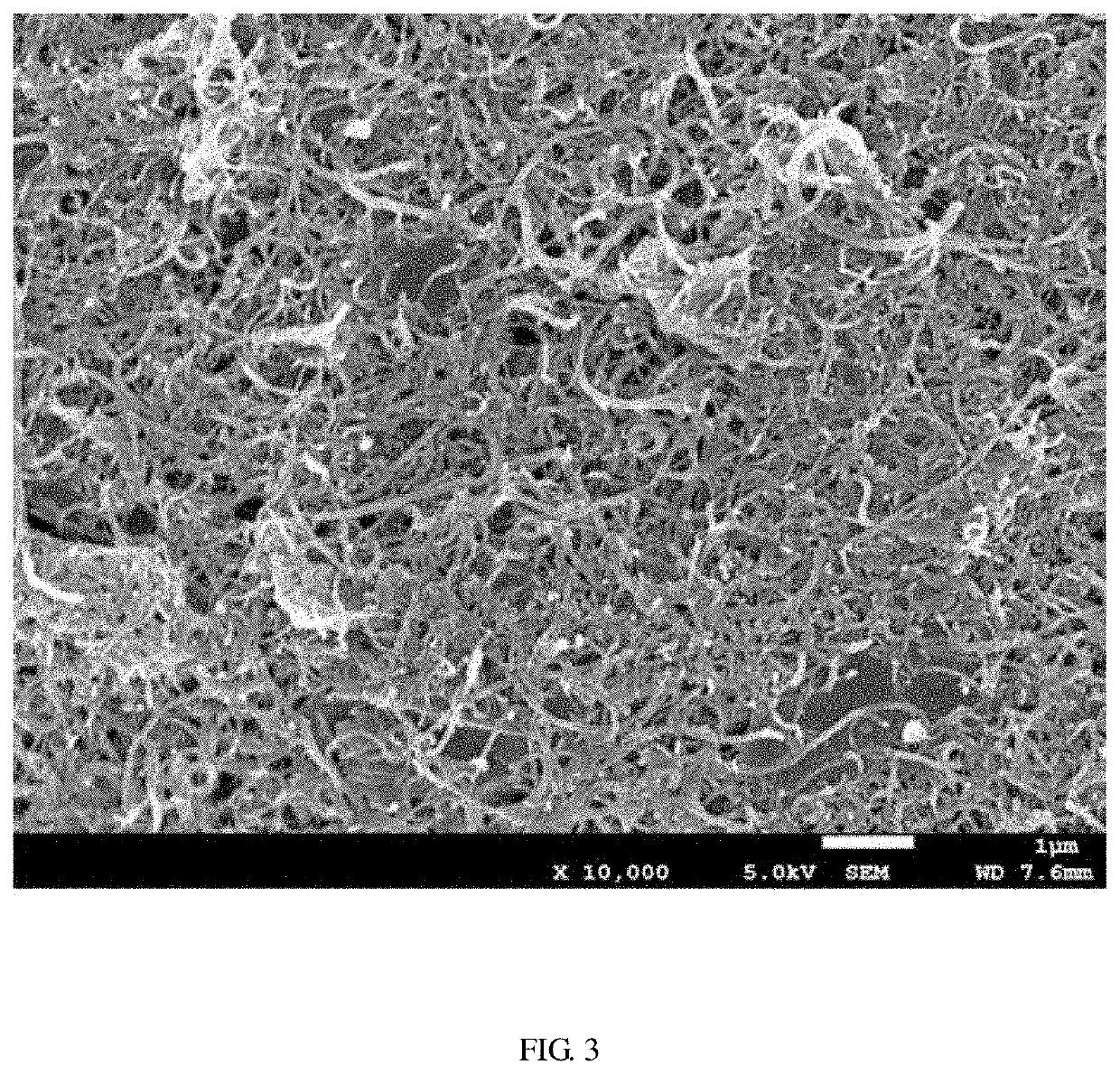

InactiveUS20030089890A1Low bulk resistivityGood distributionMaterial nanotechnologyNanoinformaticsSolventPolyvinylidene fluoride

An electrically conductive composite comprising a polyvinylidene fluoride polymer or copolymer and carbon nanotubes is provided. Preferably, carbon nanotubes may be present in the range of about 0.5-20% by weight of the composite. The composites are prepared by dissolving the polymer in a first solvent to form a polymer solution and then adding the carbon nanotubes into the solution. The solution is mixed using an energy source such as a sonicator or a Waring blender. A precipitating component is added to precipitate out a composite comprising the polymer and the nanotubes. The composite is isolated by filtering the solution and drying the composite.

Owner:HYPERION CATALYSIS INT

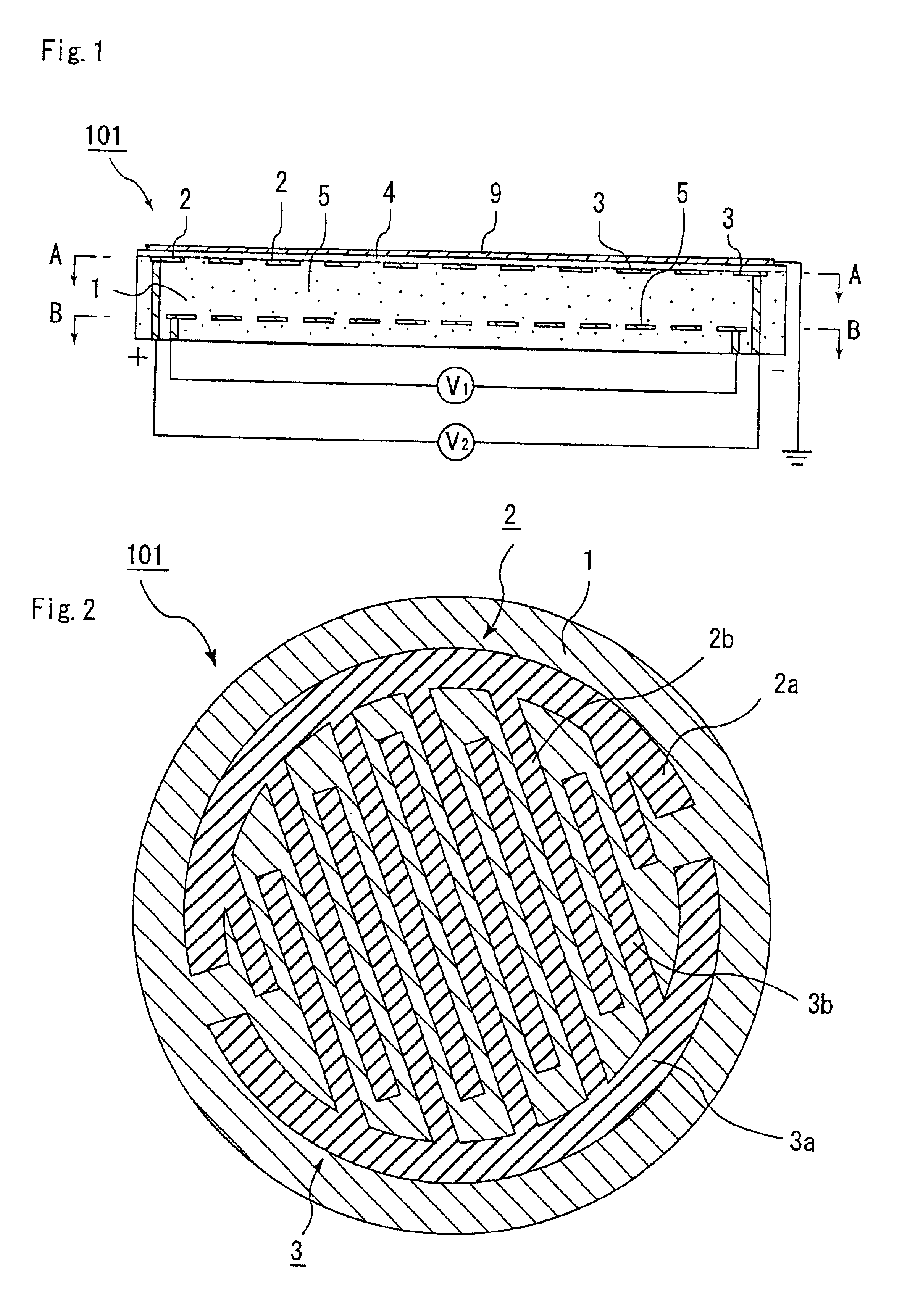

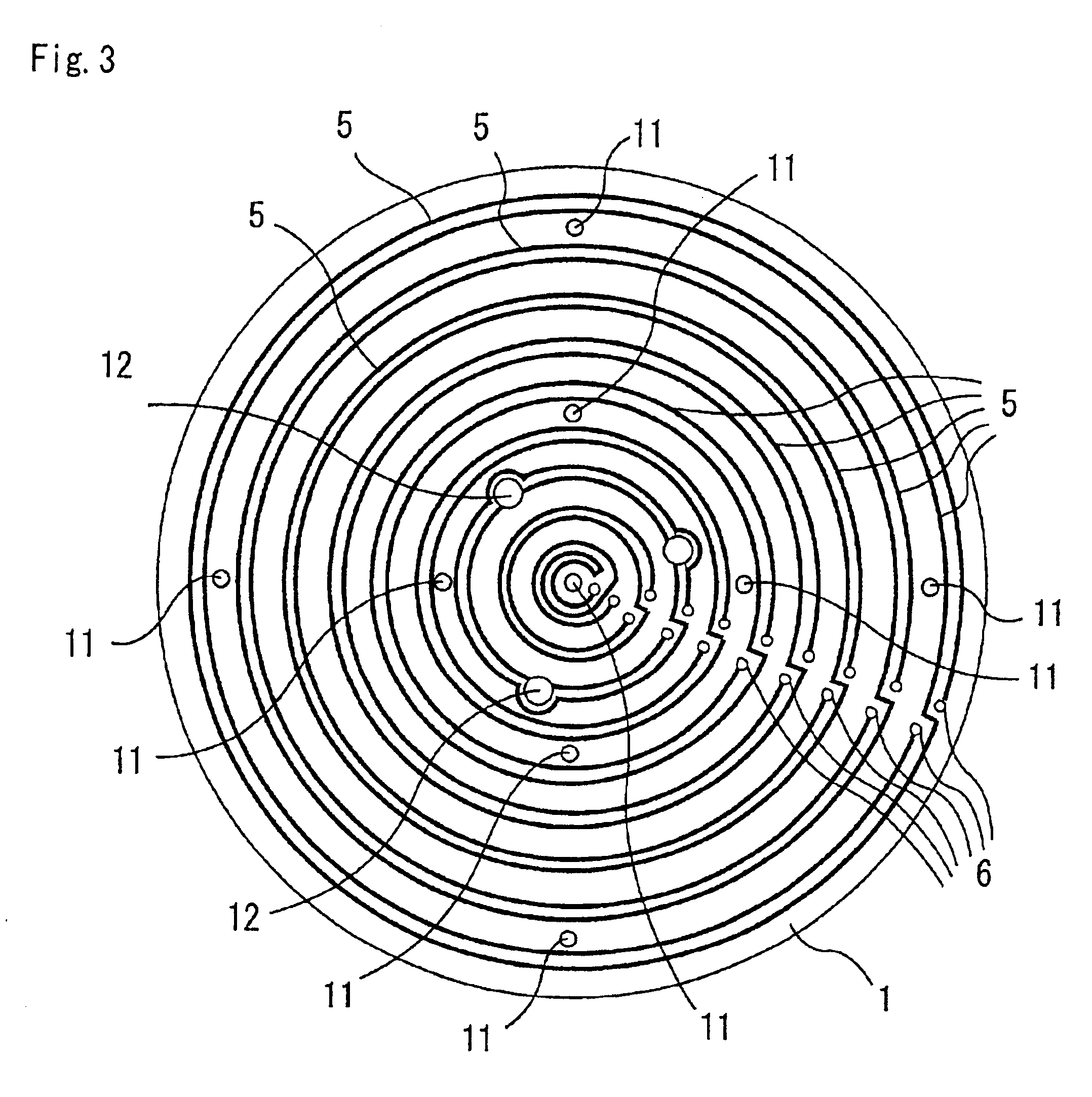

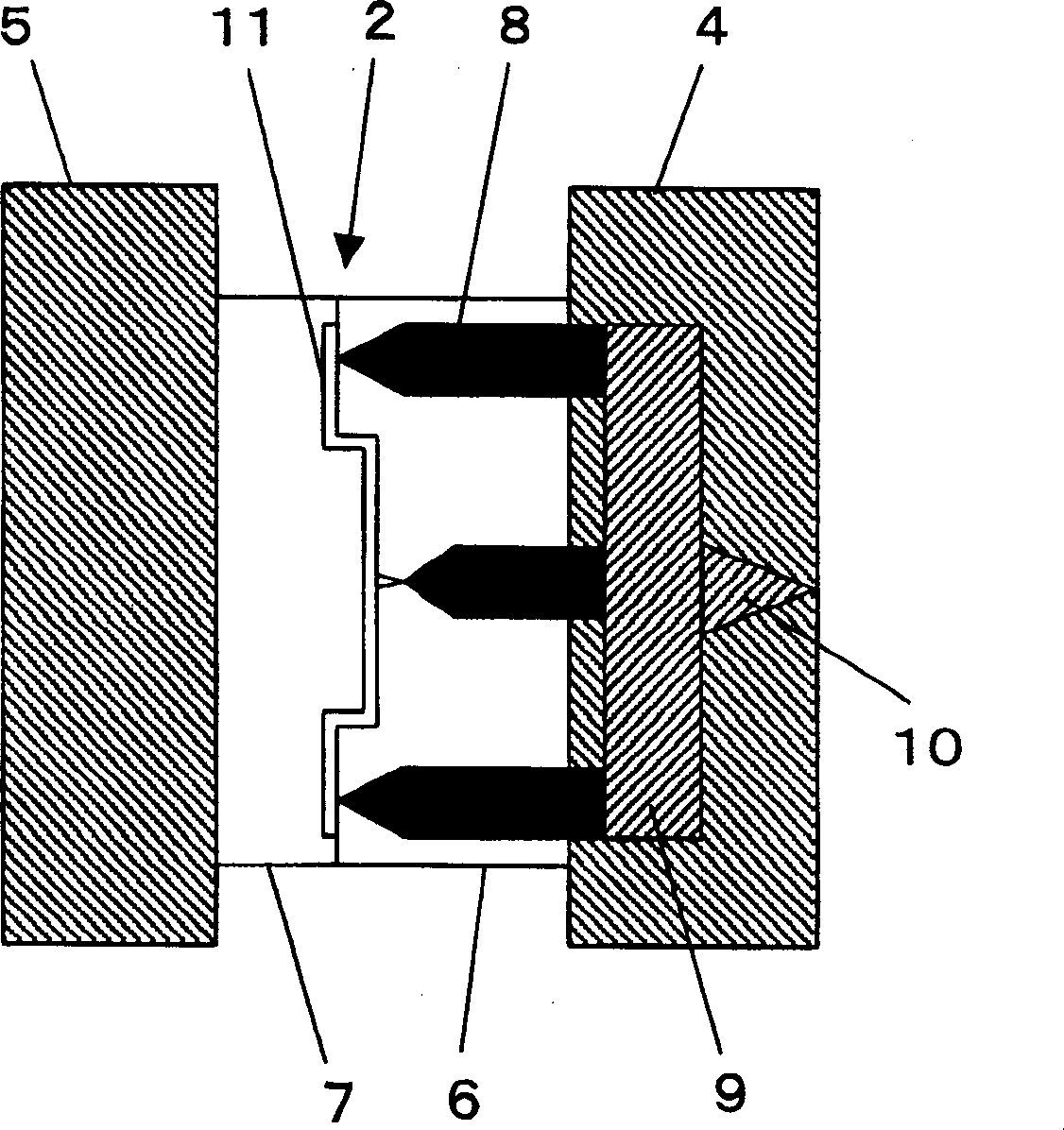

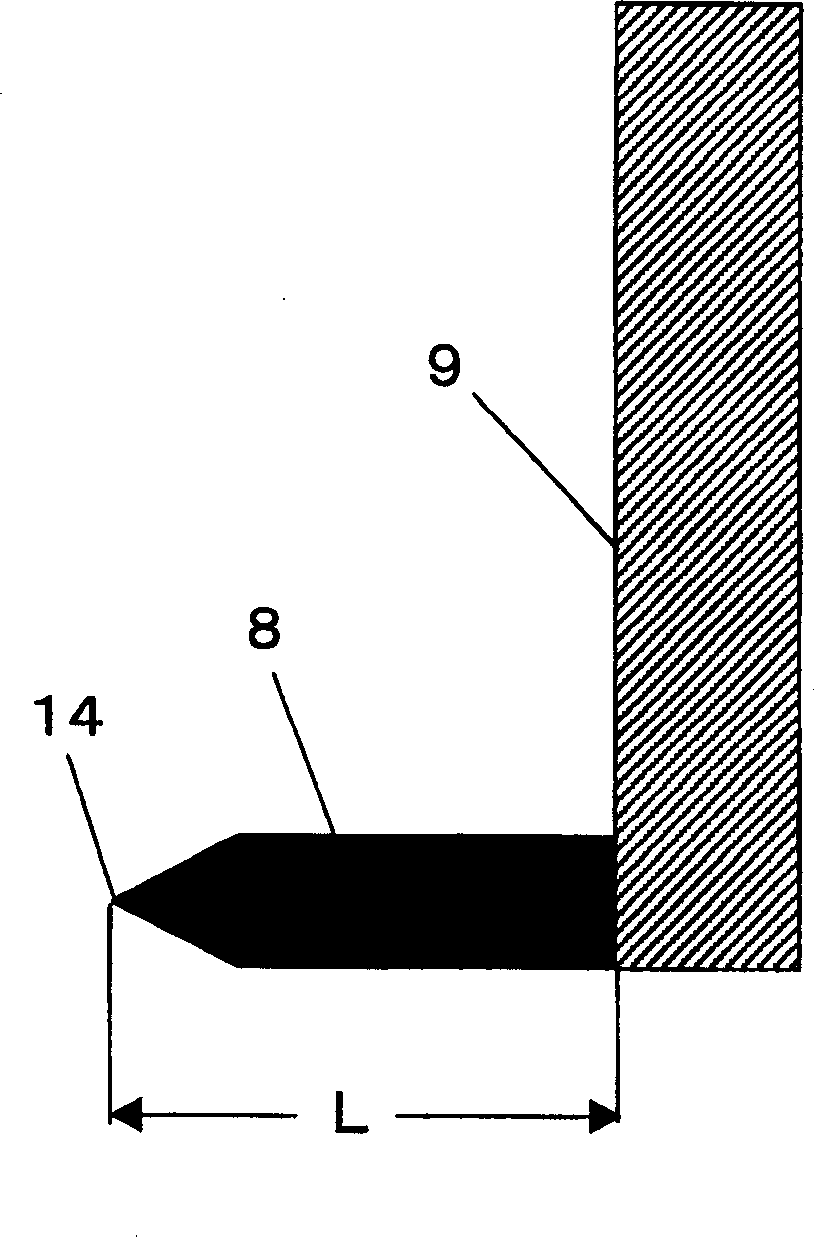

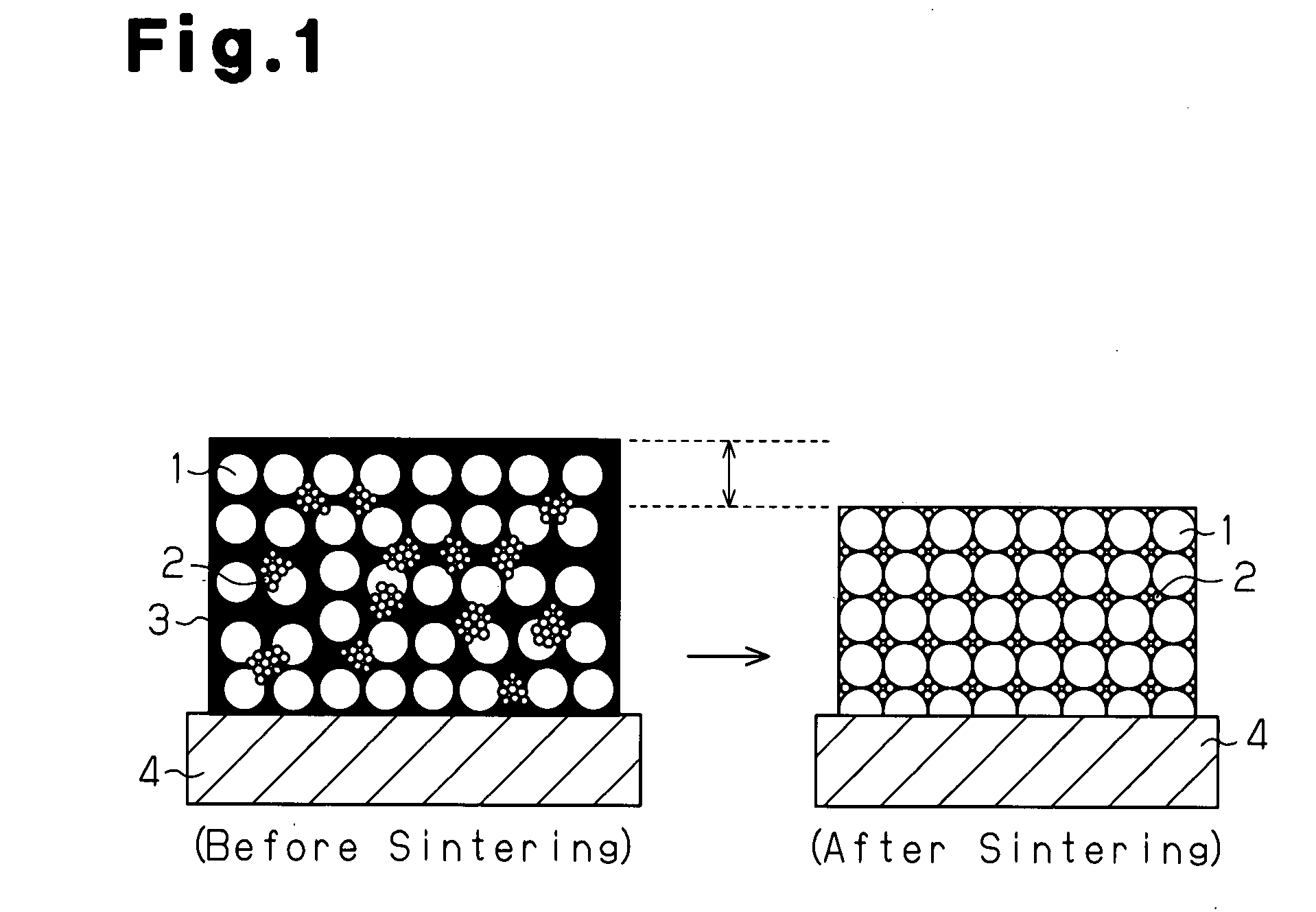

Ceramic substrate for a semiconductor production/inspection device

InactiveUS6891263B2Increase the number ofLower volume resistivitySemiconductor/solid-state device detailsSolid-state devicesNon oxide ceramicsElectrical conductor

The present invention provides a ceramic substrate which can keep a sufficiently large breakdown voltage even if the pore diameter of its maximum pore is 50 μm or less to be larger than that of conventional ceramic substrates, can give a large fracture toughness value because of the presence of pores, can resist thermal impact, and can give a small warp amount at high temperature. The ceramic substrate of the present invention is a ceramic substrate for a semiconductor-producing / examining device having a conductor formed on a surface of the ceramic substrate or inside the ceramic substrate, wherein: the substrate is made of a non-oxide ceramic containing oxygen; and the pore diameter of the maximum pore thereof is 50 μm or less.

Owner:IBIDEN CO LTD

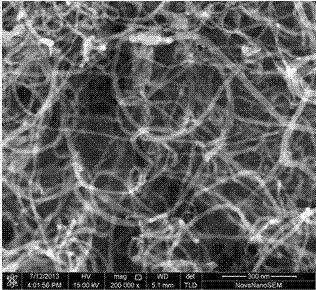

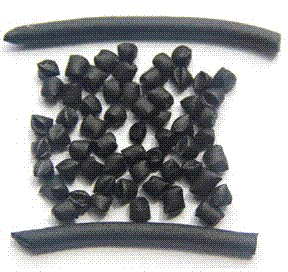

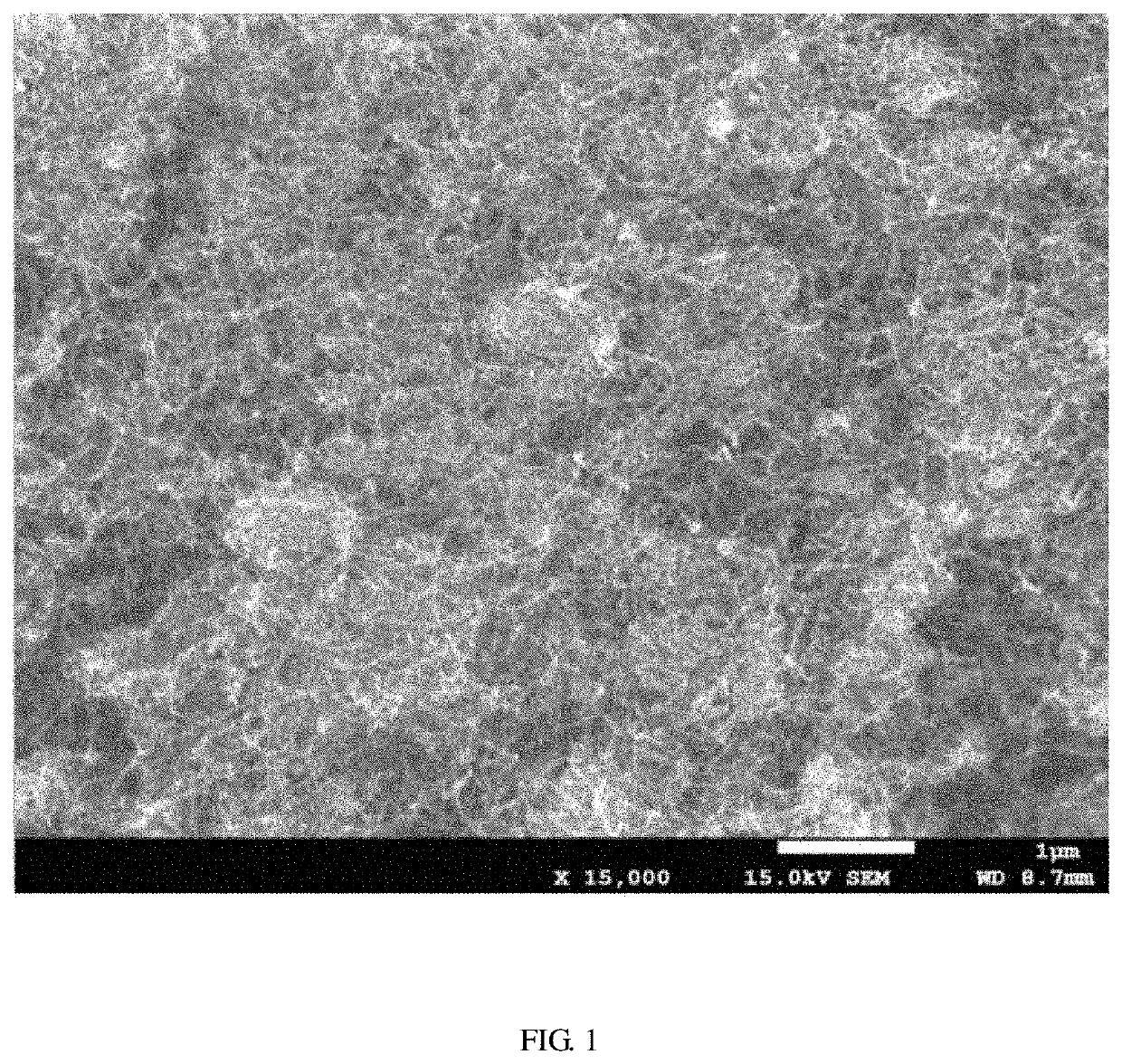

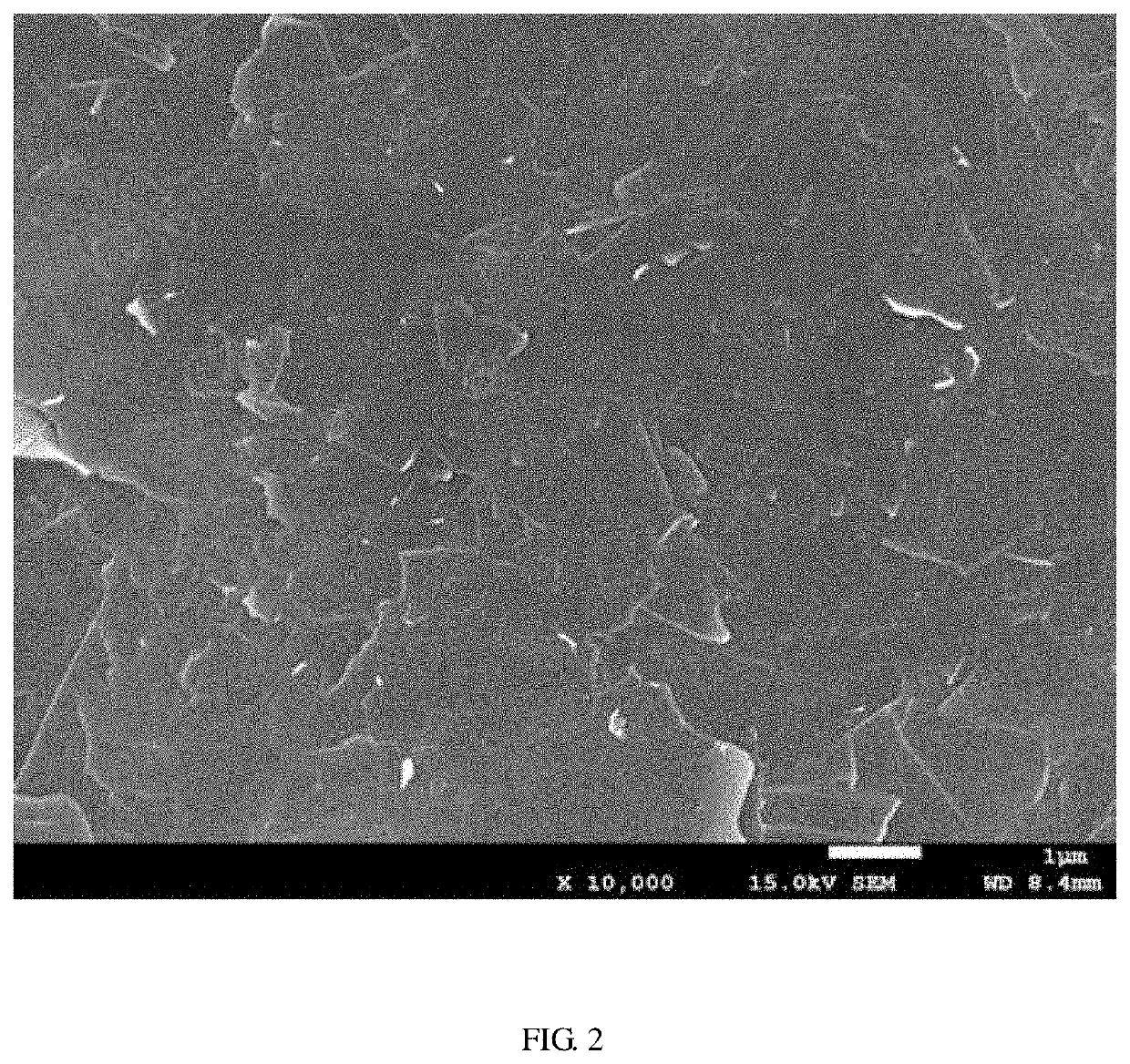

Preparation method of pre-dispersed carbon nano-tube rubber masterbatches

ActiveCN104513410AHigh tear strengthWear volume reductionSpecial tyresMicron scaleHigh concentration

The invention belongs to the field of materials and specifically relates to a preparation method of pre-dispersed carbon nano-tube rubber masterbatches. The method is characterized in that the rubber masterbatches comprise the following ingredients, by weight, 5-100 parts of carbon nano-tube, 5-100 parts of rubber, 5-100 parts of wax, 0.5-50 parts of a dispersing aid, 0.5-5 parts of an anti-aging agent and 0.1-10 parts of an activator. The preparation method of the rubber masterbatches comprises the following specific steps: carrying out high-speed shearing on the above ingredients, mixing, carrying out in situ activated modification on carbon nano-tube such that carbon nano-tube is uniformly dispersed and has no micron-scale aggregate, and pelleting so as to obtain the pre-dispersed high-concentration carbon nano-tube rubber masterbatches. By the use of the pre-dispersed carbon nano-tube rubber masterbatches prepared by the above formula and method, tear strength of tire tread rubber can be raised by about 5-10% and even more, wear volume of Akron is reduced by about 30% and even more, volume resistivity is minimized by two orders of magnitudes, and mechanical properties such as tensile strength, elongation at break and the like are basically unchanged or increased a little.

Owner:SHANDONG DAZHAN NANO MATERIALS

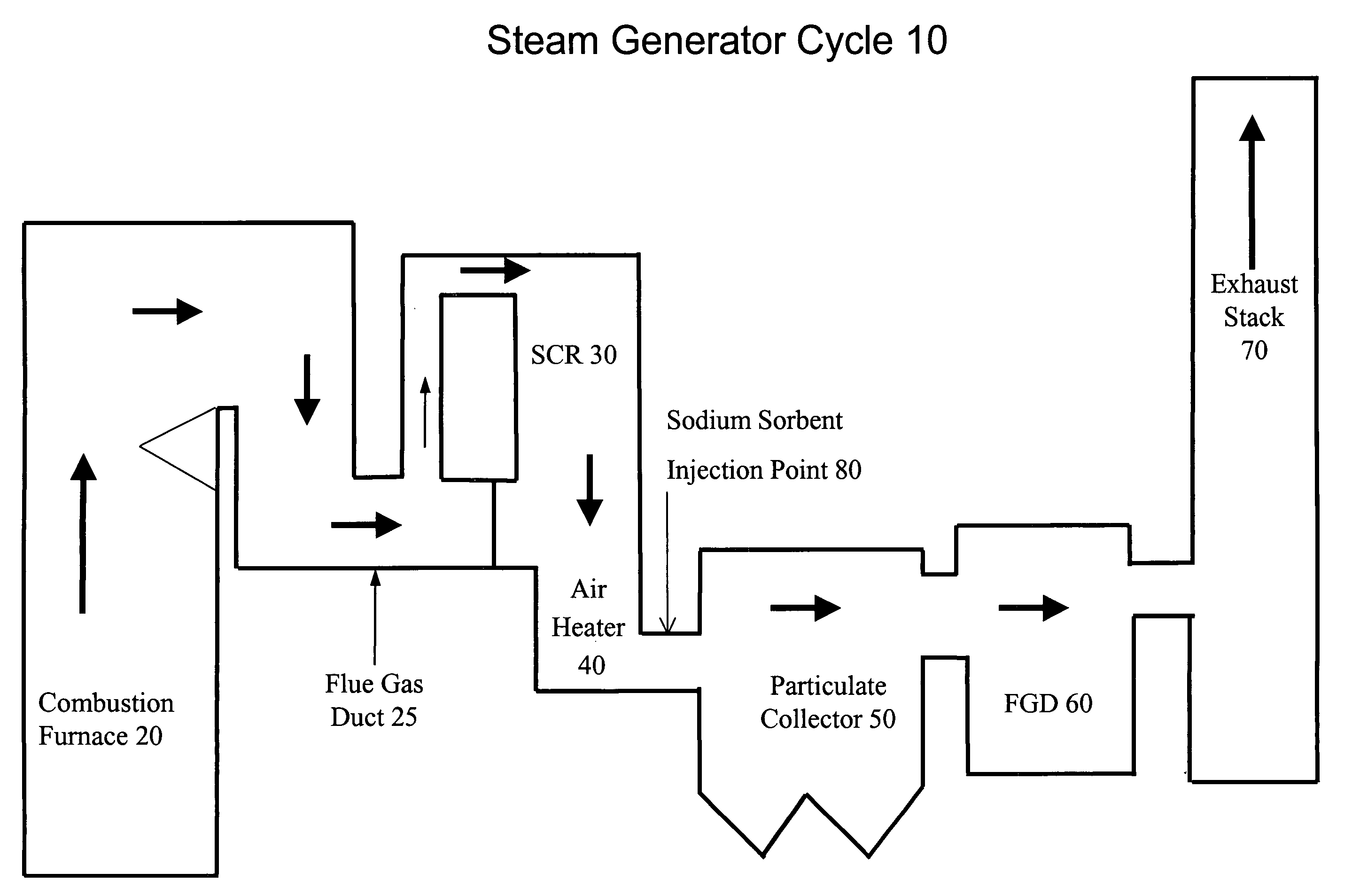

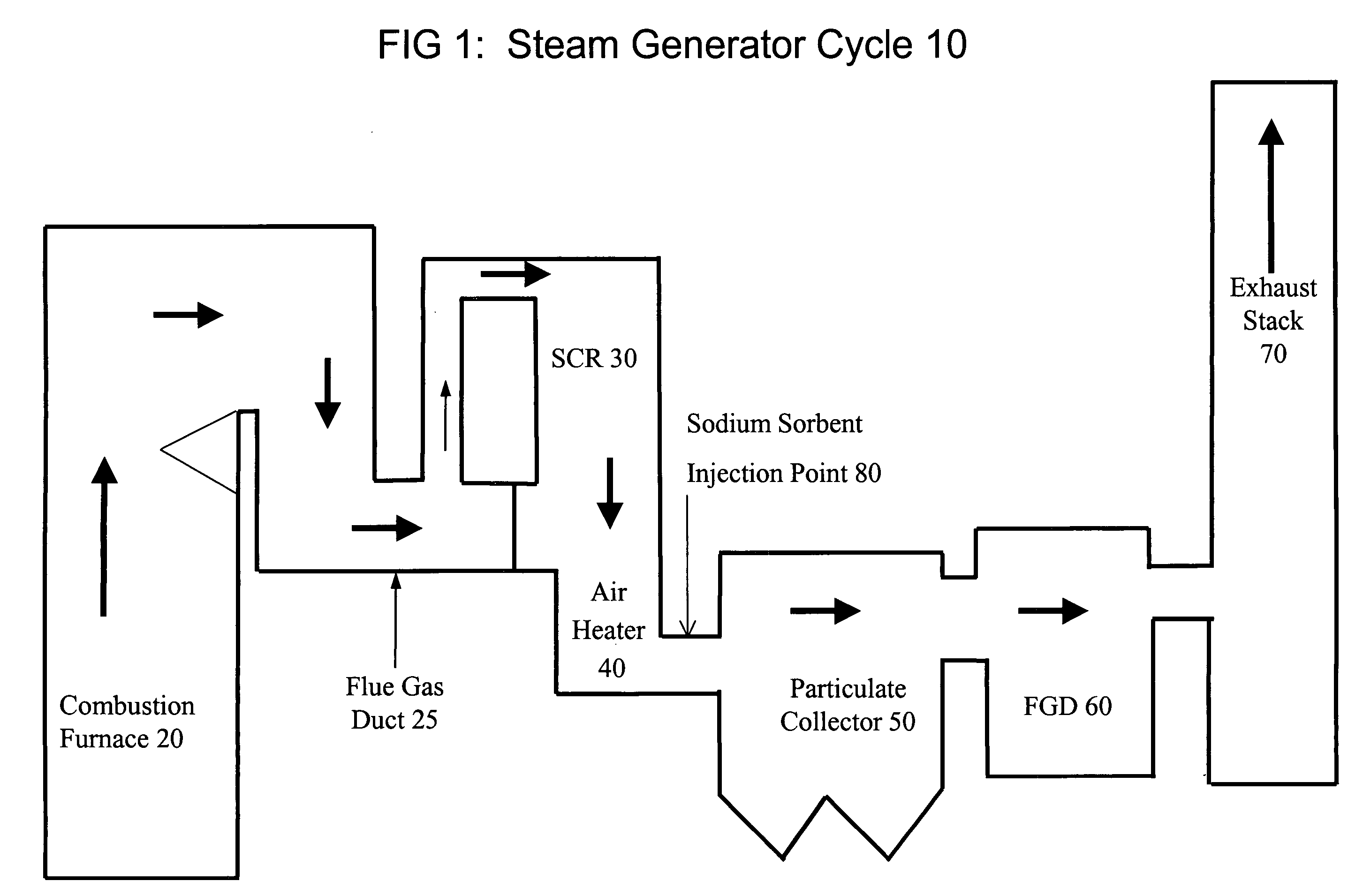

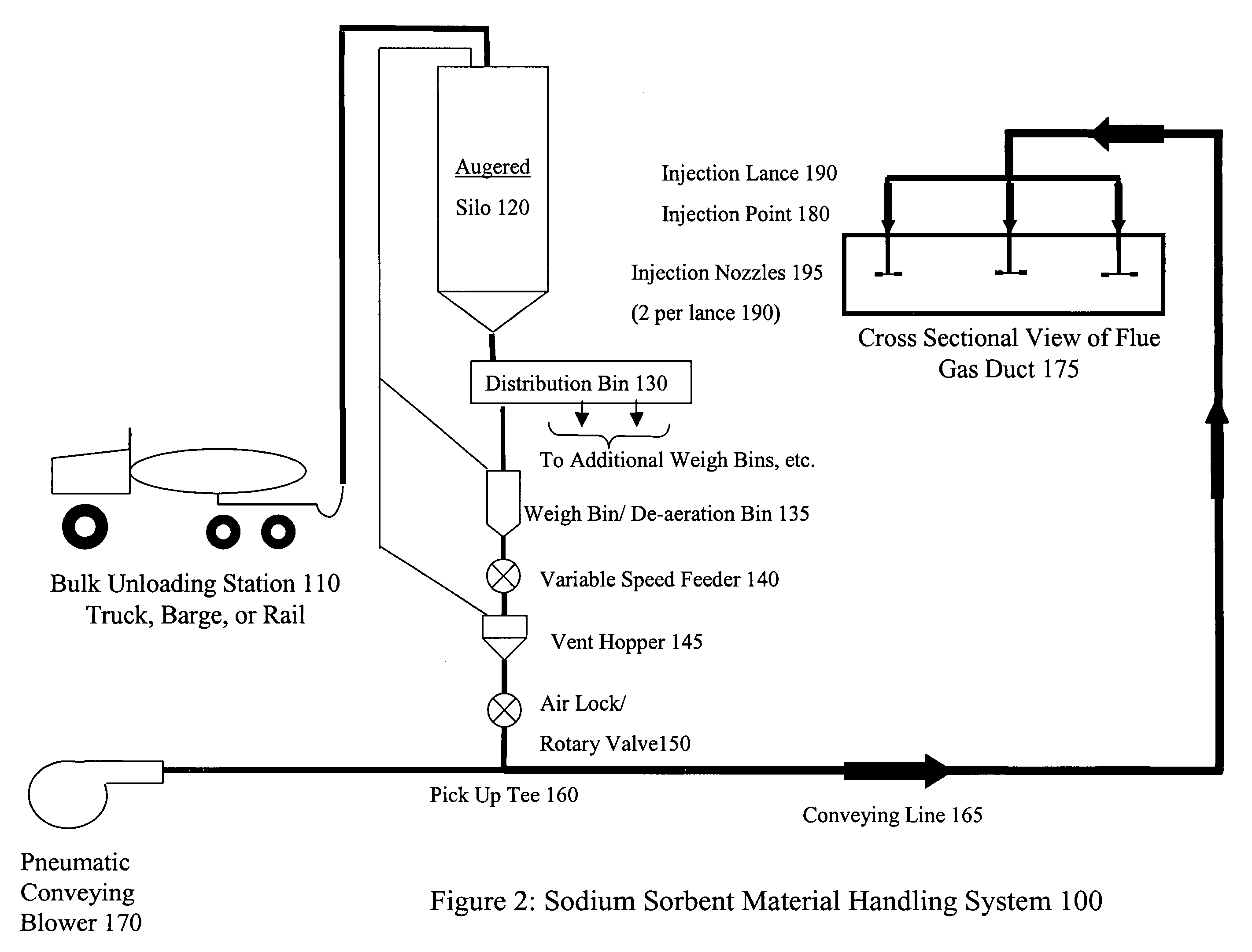

System and method for treating a flue gas stream

PendingUS20050201914A1Lower volume resistivityEfficient removalCombination devicesGas treatmentParticulatesDicarbonate

The present invention is a system and method for treating a flue gas stream to remove strong acid compounds selected from the group consisting of hydrofluoric acid (HF), hydrochloric acid (HCl), sulfuric acid (H2SO4), and sulfur trioxide (SO3) by injecting a sodium sorbent selected from the group consisting of sodium sesquicarbonate, sodium carbonate-bicarbonate, trona ore, mechanically refined trona ore, and trona into the flue gas stream, calcining substantially all of the sodium sorbent in the presence of the flue gas stream to form a soda ash, reducing the concentration of the at least one strong acid compound in the flue gas stream by reacting the at least one strong acid compound with the soda ash to form a sodium based by-product; and changing the chemistry of the flue gas stream to reduce the overall average resistivity of the particulate matter.

Owner:AMERICAN ELECTRIC POWER CO INC

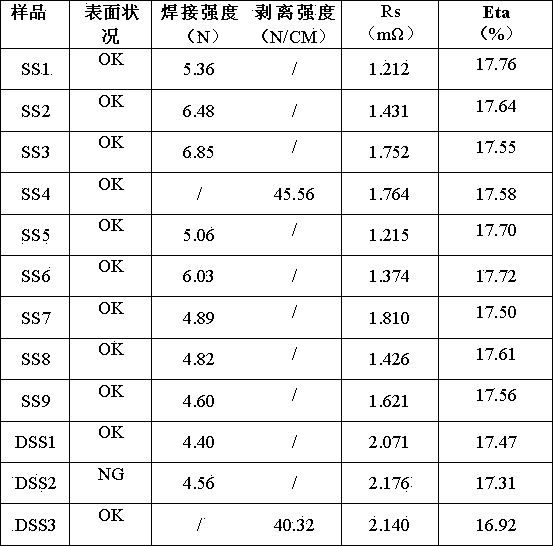

Conductive paste for crystalline silicon solar cell and preparation method of conductive paste

ActiveCN104078090AHigh tear strengthImprove adhesion strengthNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteConductive paste

The invention provides conductive paste for a crystalline silicon solar cell. The conductive paste comprises the following components in parts by weight: 100 parts of conductive metal powder, 1.0-10 parts of inorganic binder, 10-65 parts of organic carrier and 0.05-5.0 parts of conductive carbon. The conductive paste is excellent in conductivity; the photoelectric conversion efficiency of the cell is not influenced; and widely applied conductive paste for the crystalline silicon solar cell such as front-side silver paste, front-side seed layer silver paste, back-side silver paste and back electric field aluminum paste can be prepared.

Owner:BYD CO LTD

Electro-optic displays, and materials for use therein

ActiveUS20070286975A1Lower volume resistivityLamination ancillary operationsPolyureas/polyurethane adhesivesCross-linkPolymer science

An electro-optic display comprises a layer of solid electro-optic material; a backplane comprising at least one electrode; and an adhesive layer disposed between the layer of electro-optic material and the backplane and adhesively securing the layer of electro-optic material to the backplane, the adhesive layer comprising a thermally-activated cross-linking agent comprising an epoxidized vegetable oil fatty acid or an epoxidized ester of such a fatty acid. The cross-linking agent reduces void growth when the display is subjected to temperature changes.

Owner:E INK CORPORATION +1

Flaming retarding highly conductive silicon rubber composite material and preparation method thereof

The invention relates to an inflaming retarding highly conductive silicon rubber composite material and a preparation method thereof. The silicon rubber composite material with good electroconductibility and inflaming retarding property is obtained through the following steps: using nickel-clad graphite endowed with the certain function of promoting carbonization, modifying silicon rubber by adding superfine calcium carbonate powder, low softening point glass dust and hydrogen-containing silicone oil, and carrying out vulcanization by using a hydrosilylation vulcanization system.

Owner:BEIJING UNIV OF CHEM TECH +1

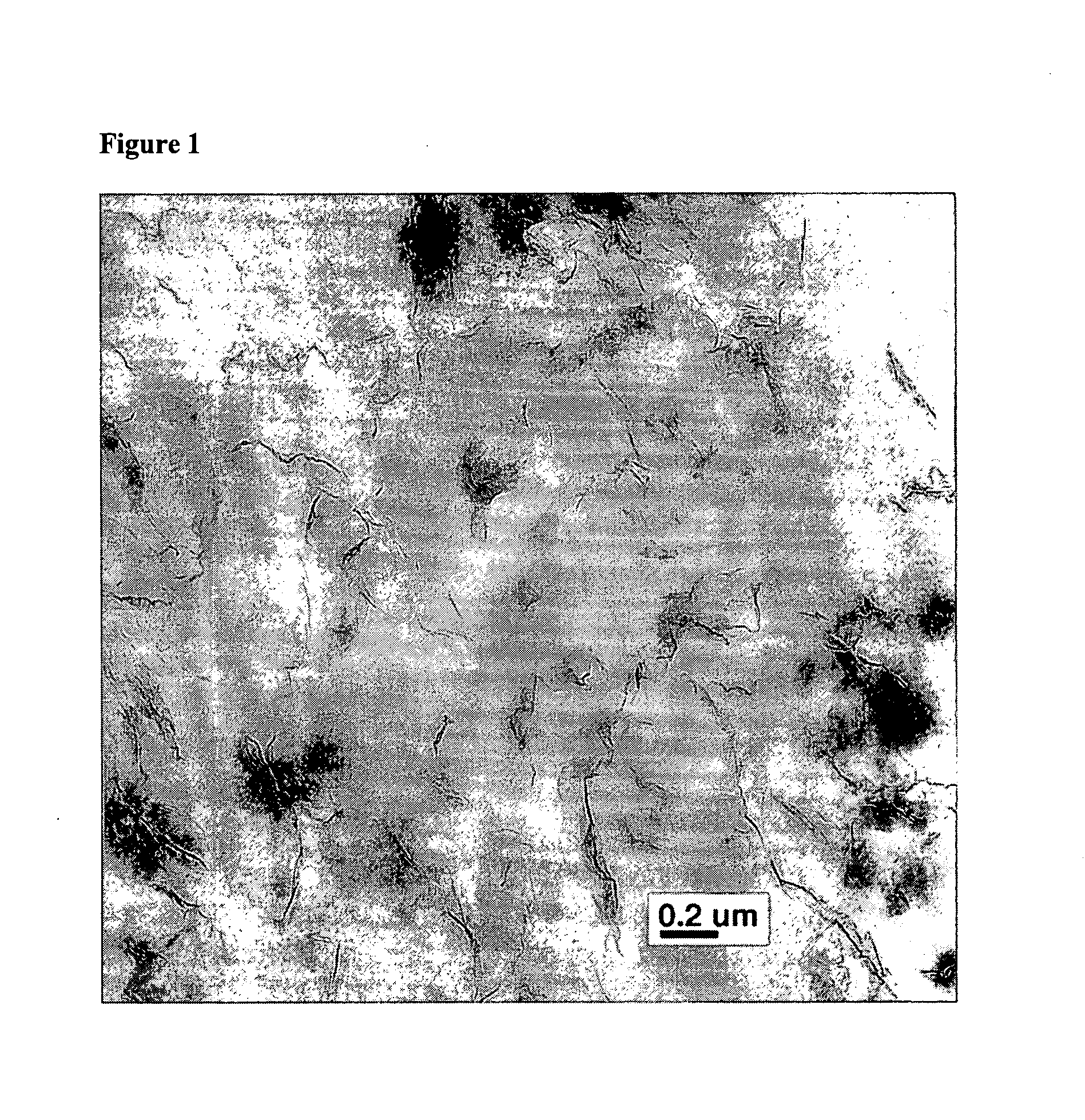

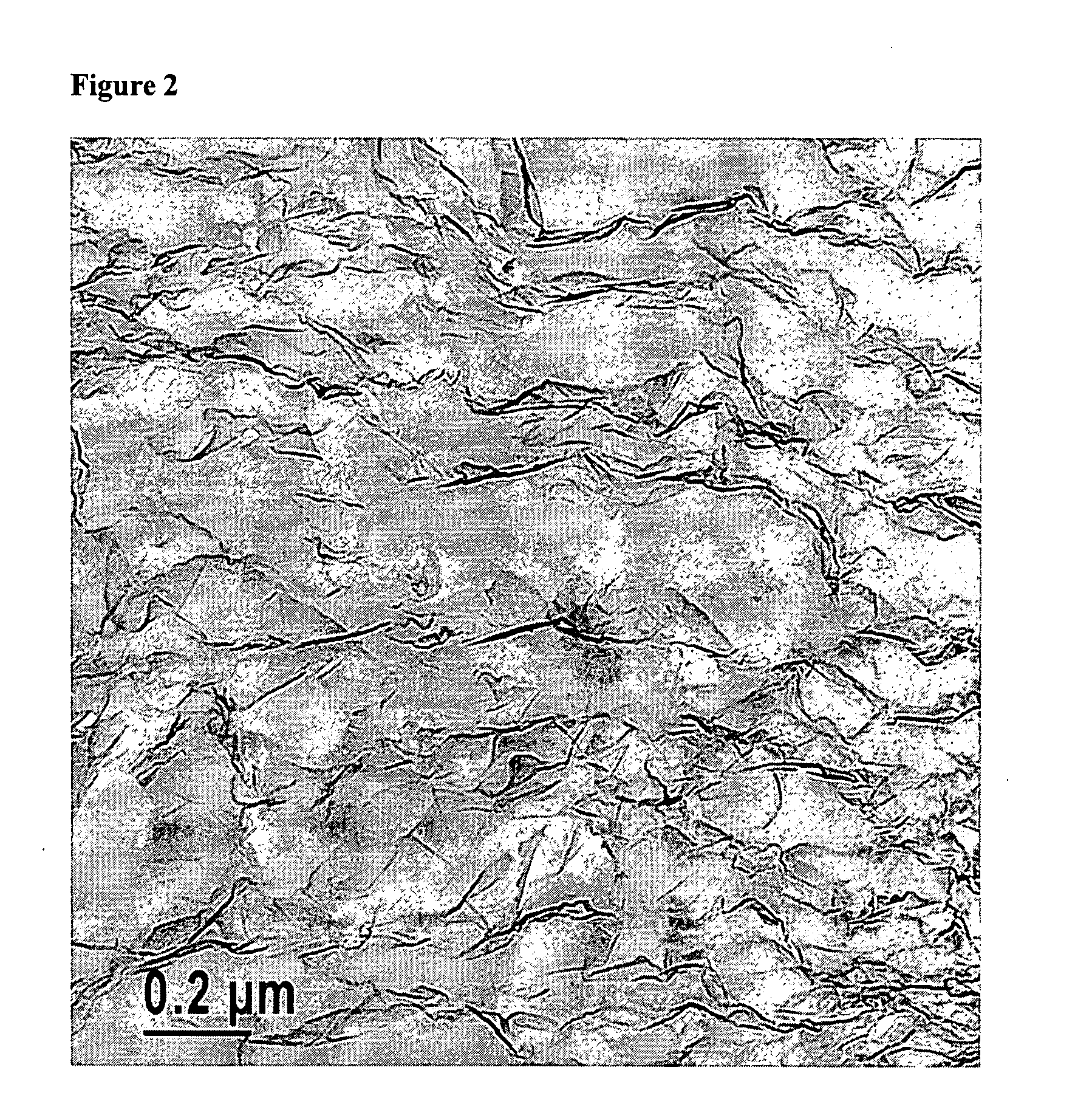

Methods for preparing polyvinylidene fluoride composites

InactiveUS20030111646A1Lower volume resistivityGood dispersionMaterial nanotechnologyNanoinformaticsPolyvinylidene difluoridePolyvinylidene fluoride

An electrically conductive composite comprising a polyvinylidene fluoride polymer or copolymer and carbon nanotubes is provided. Preferably, carbon nanotubes may be present in the range of about 0.5-20% by weight of the composite. The composites are prepared by mixing or dispersing carbon nanotubes in polymer emulsion using an energy source such as a Waring blender. The liquid in the mixture is then evaporated to obtain the composite comprising the polymer and the nanotubes.

Owner:HYPERION CATALYSIS INT

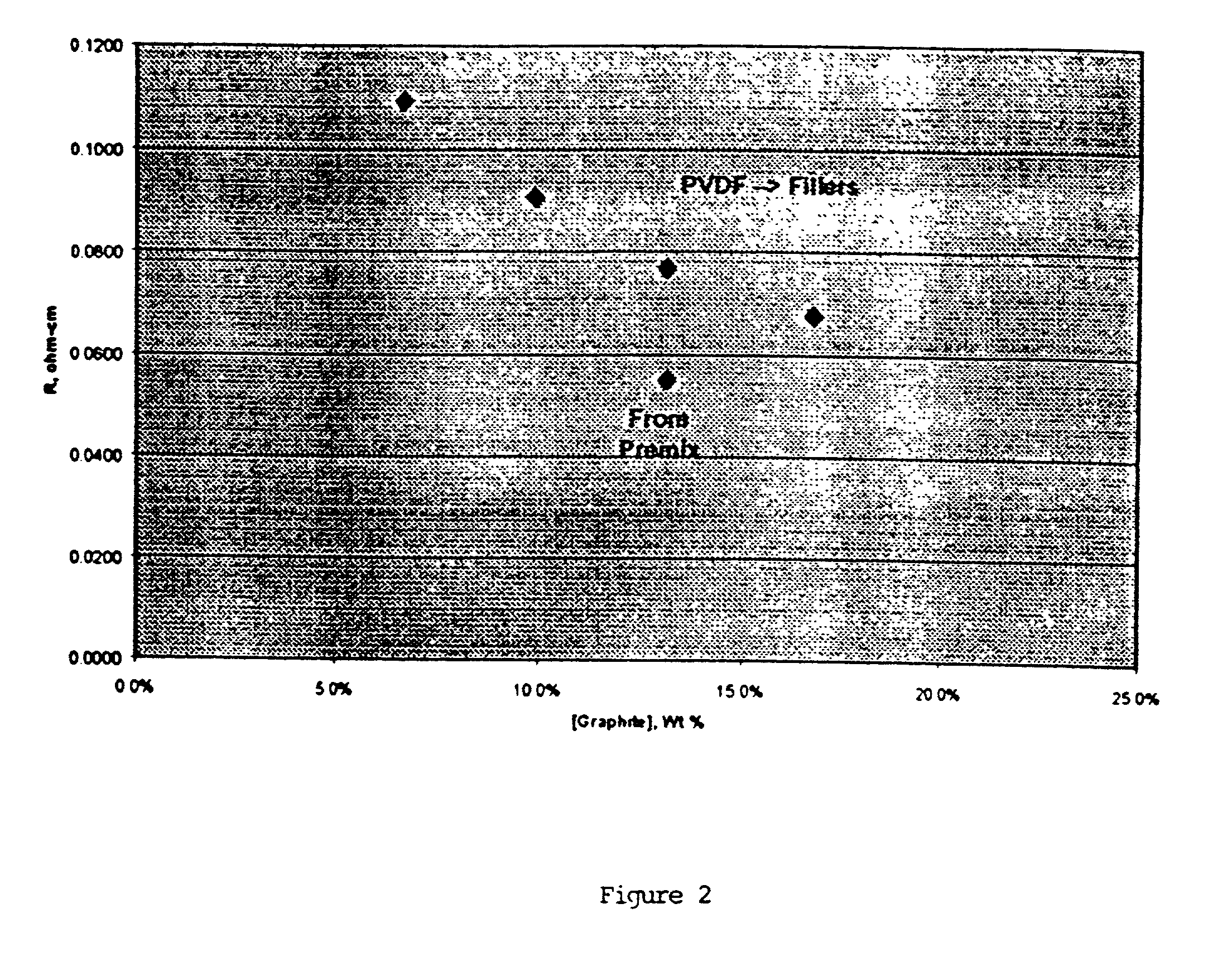

Polymers filled with highly expanded graphite

Polymers are filled with from 1 to 8% by weight of an expanded graphite having a BET surface area of at least 120 m2 / g. Processes for preparing such polymers include forming a dispersion of the expanded graphite in a polymerizable monomer or curable polymer precursor, and polymerizing or curing same in the presence of the expanded graphite. Electroconductive polymers can be prepared in this manner using low levels of the expanded graphite material.

Owner:DOW GLOBAL TECH LLC

Conductive Carbon Material Dispersing Agent and High-Conductivity Slurry for Lithium Battery

ActiveUS20200106090A1Good effectEffective dispersionElectrochemical processing of electrodesLi-accumulatorsPolyvinyl alcoholCarbon nanotube

The invention relates to the technical field of lithium battery slurry materials, in particular to a conductive carbon material dispersing agent which comprises one of modified polyvinyl alcohol, alkyl ammonium salt copolymer, olefin block maleic anhydride copolymer and pyrrolidone copolymer, or mixtures thereof, and can effectively disperse carbon nanotube, graphene and other conductive carbon materials in a solvent to obtain uniform conductive slurry; further disclosed is a high-conductivity slurry for the lithium battery, which comprises 0.5-15.0% by weight of a conductive carbon material and 0.1-3.0% by weight of a dispersing agent, and can remarkably reduce the bulk resistivity of a positive electrode system of the lithium battery and improve the conductivity of a pole piece.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

Preparation of electrostatic resistant and conductive polypropylene blend

ActiveCN1583867ALower volume resistivityLow resistivityOther chemical processesNon-conductive material with dispersed conductive materialGlass fiberEpoxy

This invention has offered a kind of antistatic and conductive polypropylene (pp) to mix the preparation method of the thing altogether. And charcoal PP mix composition of thing PP, epoxy resin, through unite glass fibre and charcoal black electric conduction that pharmaceutical deal with occasionally altogether. Join above-mentioned composition in the dense smelting machine under 170-210deg.C temperature, in the course of shearing and mixing, will form carbon black distribute among epoxy resin, epoxy resin is it cover on the glass fibre surface to wrap up spontaneous, and through joining forming the complex system that the electric conduction goes the same way among the glass fibre, can reduce the resistivity of volume of PP effectively. Preparation that invention offer this method processing technology simple, can regulate the resistivity of PP in heavy range, antistatic and conductive PP got mixes the resistivity of things altogether steadily, the reappearing is good.

Owner:上海长宁橡胶制品厂有限公司

Conductive elastomer composition and its mfg. method

InactiveCN1475865ALower volume resistivityReduce hardnessConductive materialOrganic conductorsElastomerThermoplastic elastomer

A conductive elastomer composition having rubber-like elasticity and flexibility and thermoplastic-resin-like moldability and realizing a high conductivity. The conductive elastomer composition includes a thermoplastic elastomer composition (A) containing a compound (A1) composed of a thermoplastic resin and / or a thermoplastic elastomer and a compound (A2), composed of a crosslinkable rubber and / or a crosslinkable thermoplastic elastomer, dispersed in the compound (A1) by dynamically crosslinking the compound (A2); and an ionic-conductive agent (B), containing a metal salt and a polyether-containing block copolymer resin, dispersed in the thermoplastic elastomer composition (A). The conductive elastomer composition may contain carbon black (C).

Owner:SUMITOMO RUBBER IND LTD

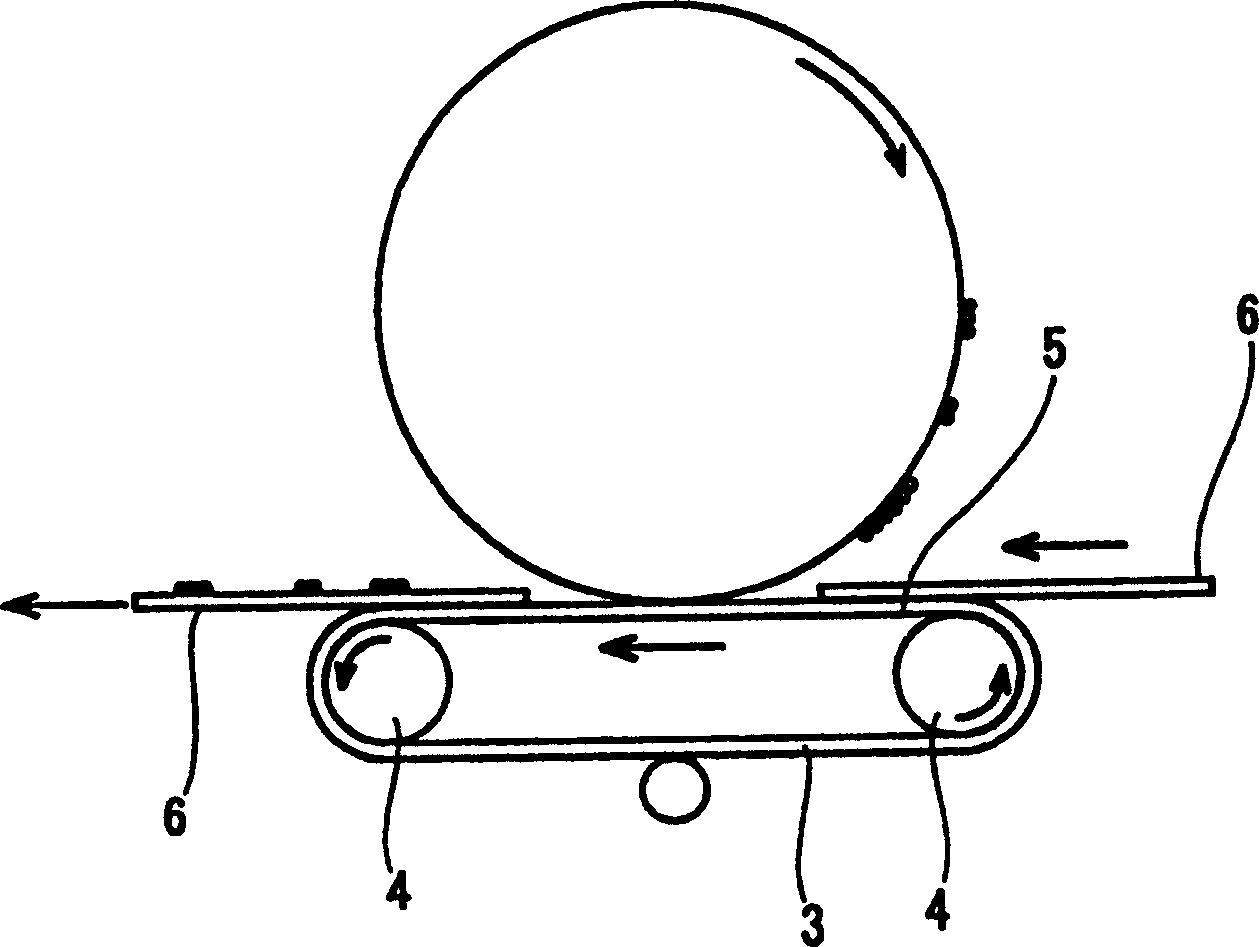

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437AReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

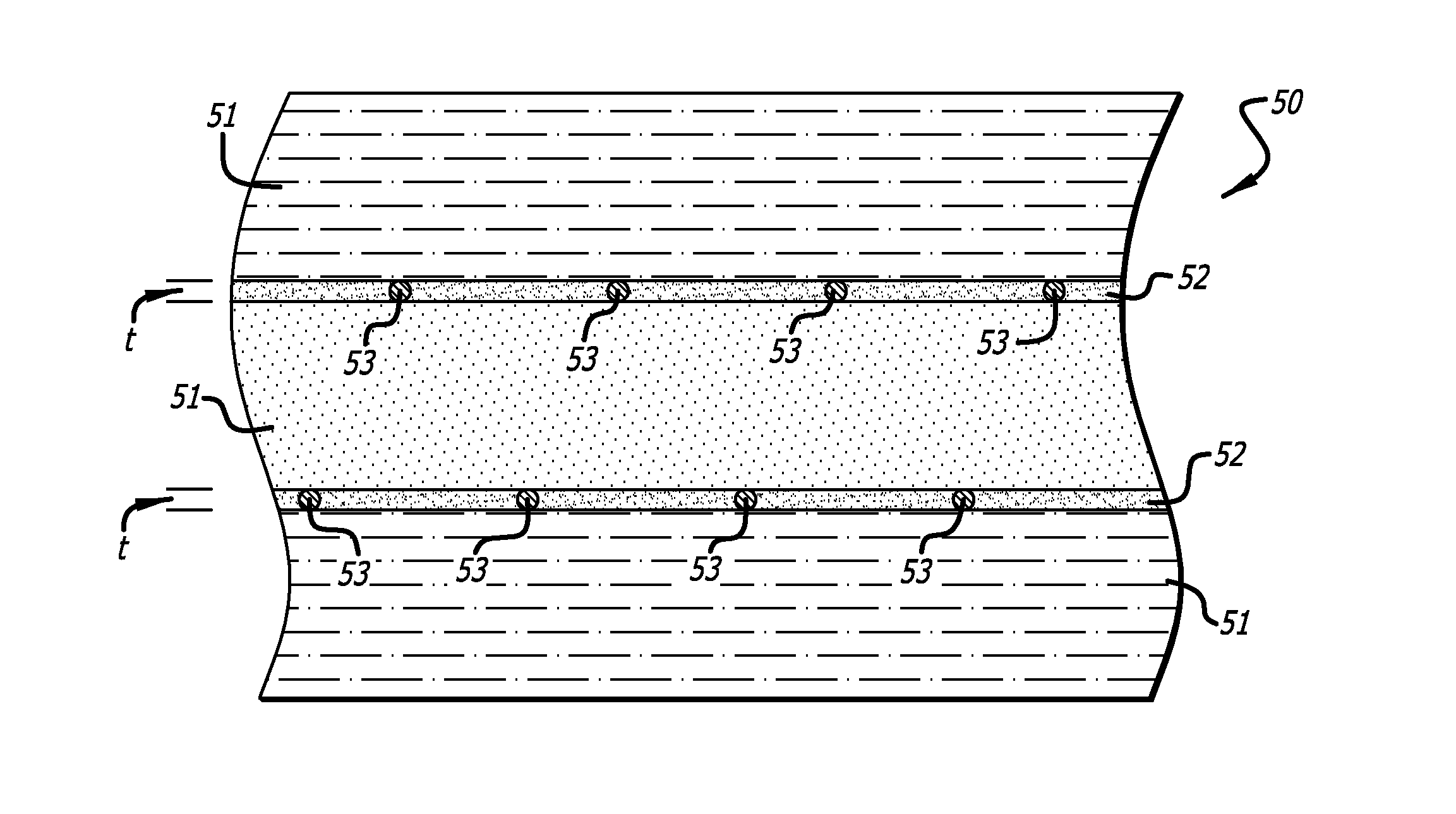

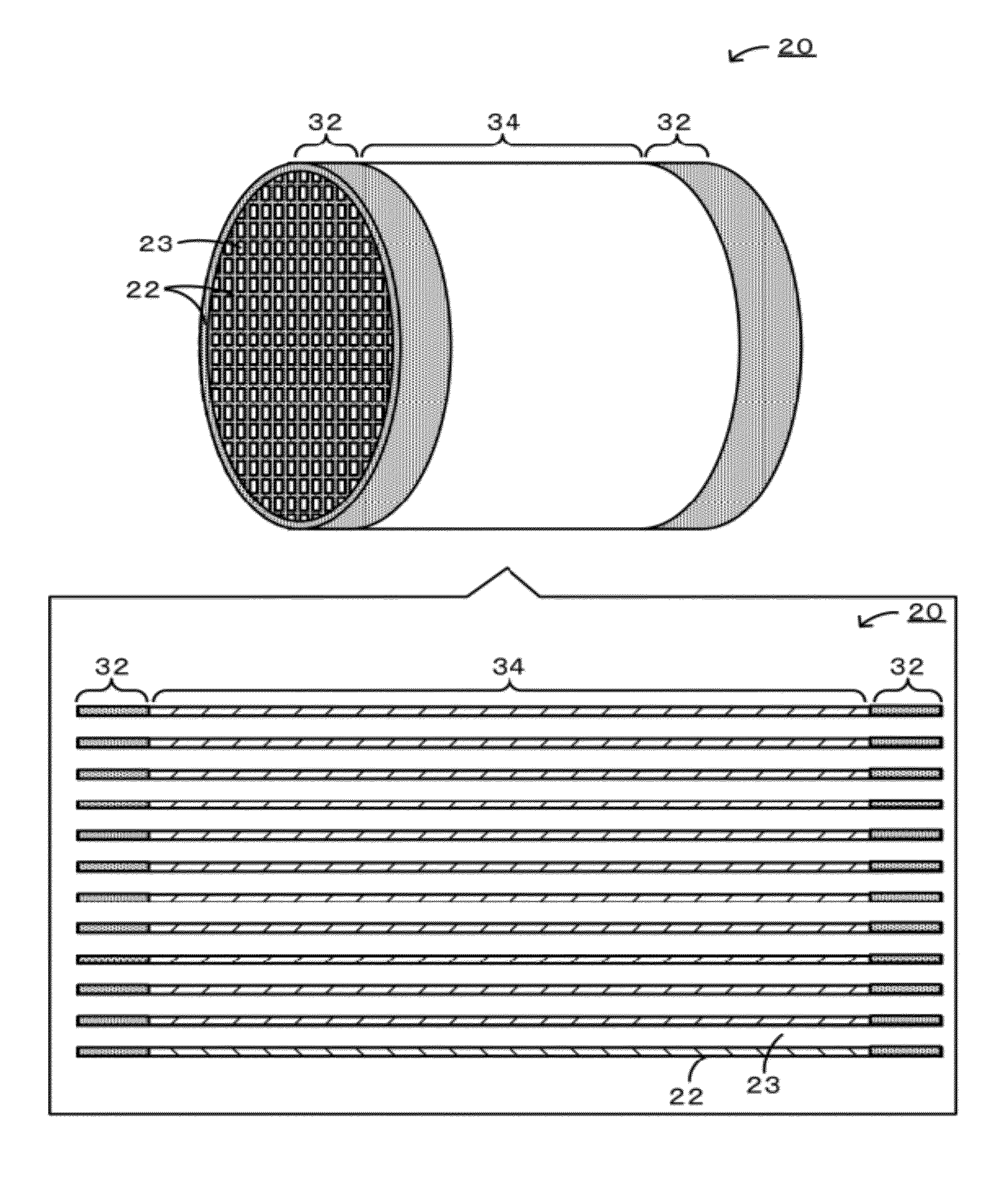

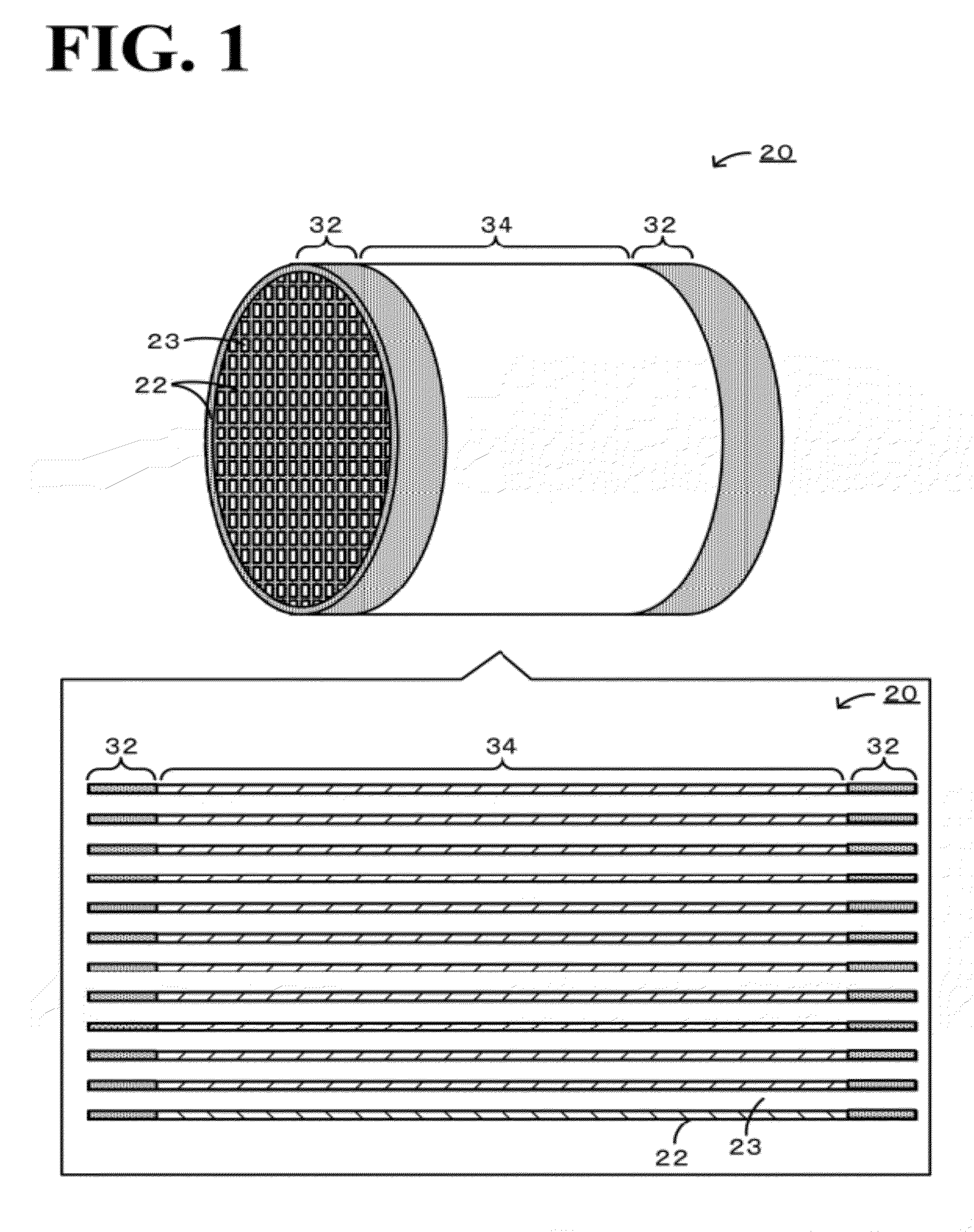

Composite materials

InactiveUS20150210039A1Improve conductivityLittle and no additional weightMaterial nanotechnologyLayered productsFiberPolyresin

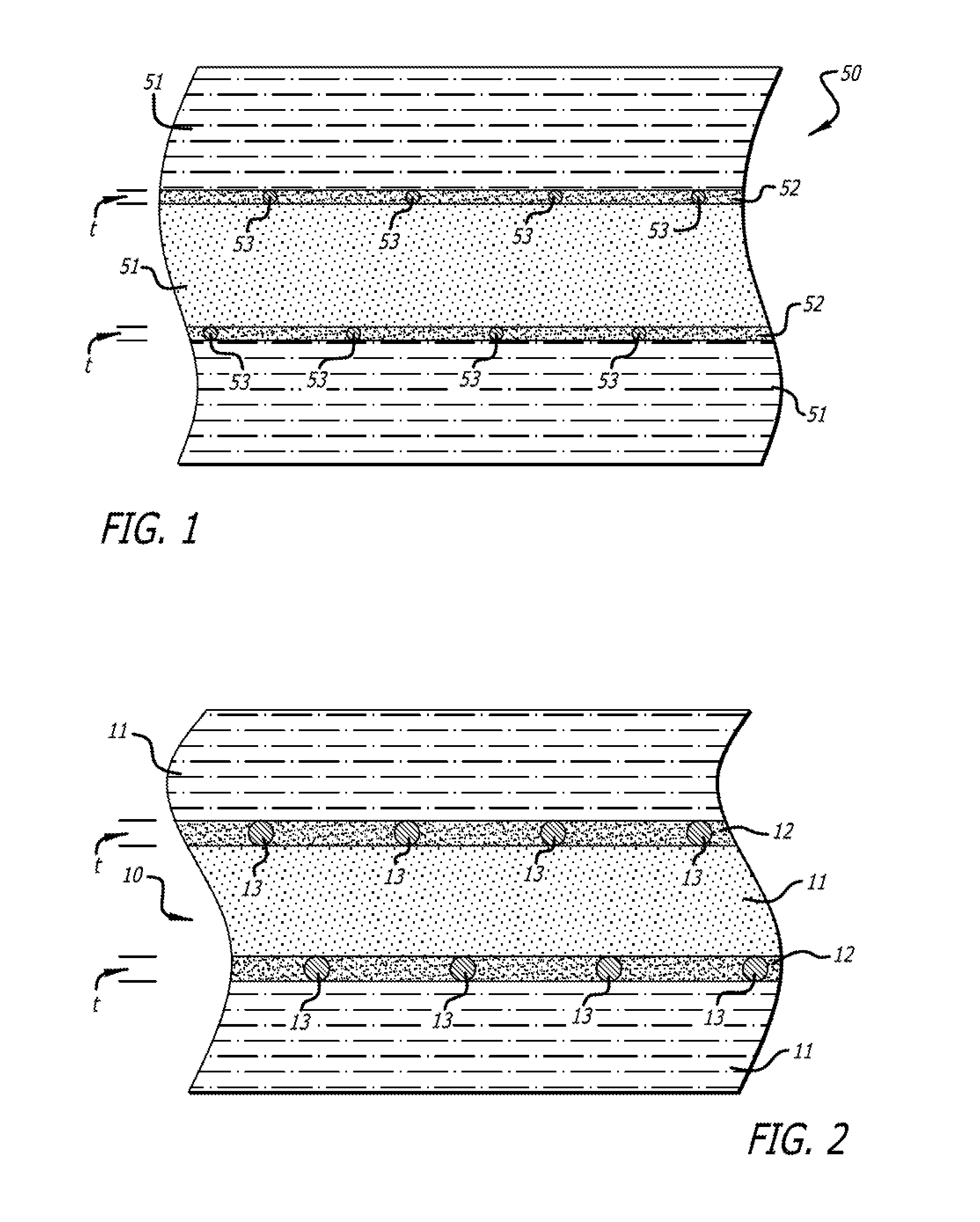

A prepreg comprising a single structural layer of electrically conductive unidirectional fibres and a first outer layer of curable resin substantially free of structural fibres, and optionally a second outer layer of curable resin substantially free of structural fibres, the sum of the thicknesses of the first and second outer resin layers at a given point having an average of at least 10 micrometres and varying over at least the range of from 50% to 120% of the average value, and wherein the first outer layer comprises electrically conductive particles.

Owner:HEXCEL COMPOSITES LTD (GB)

Composite materials

InactiveUS20130330514A1Improve conductivityLittle and no additional weightSynthetic resin layered productsLaminationFiberPolymer resin

A composite material, the composite material comprising at least one prepreg, said prepreg comprising at least one polymeric resin and at least one fibrous reinforcement; and glassy carbon particles dispersed in the polymeric resin.

Owner:HEXCEL COMPOSITES LTD (GB)

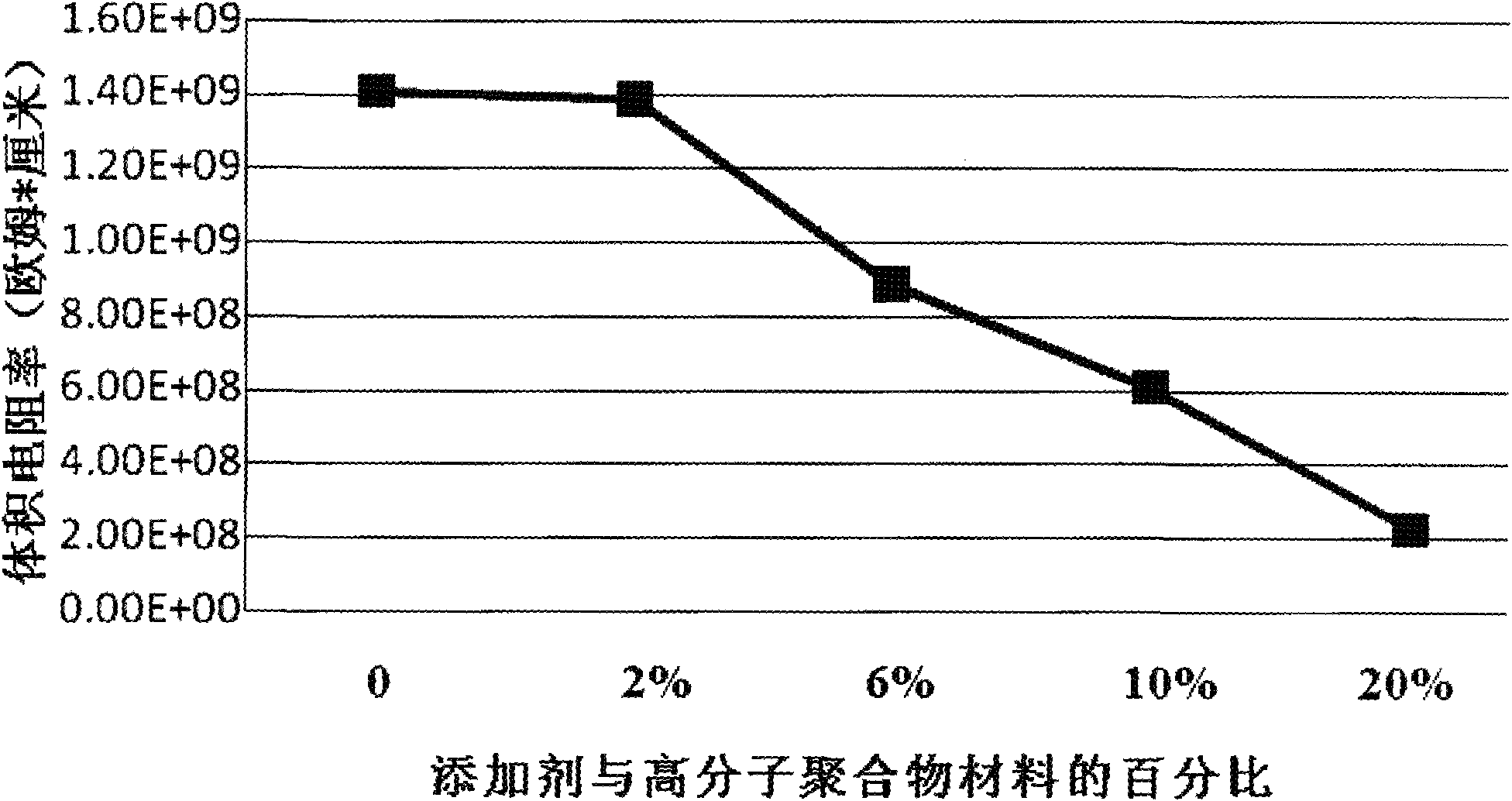

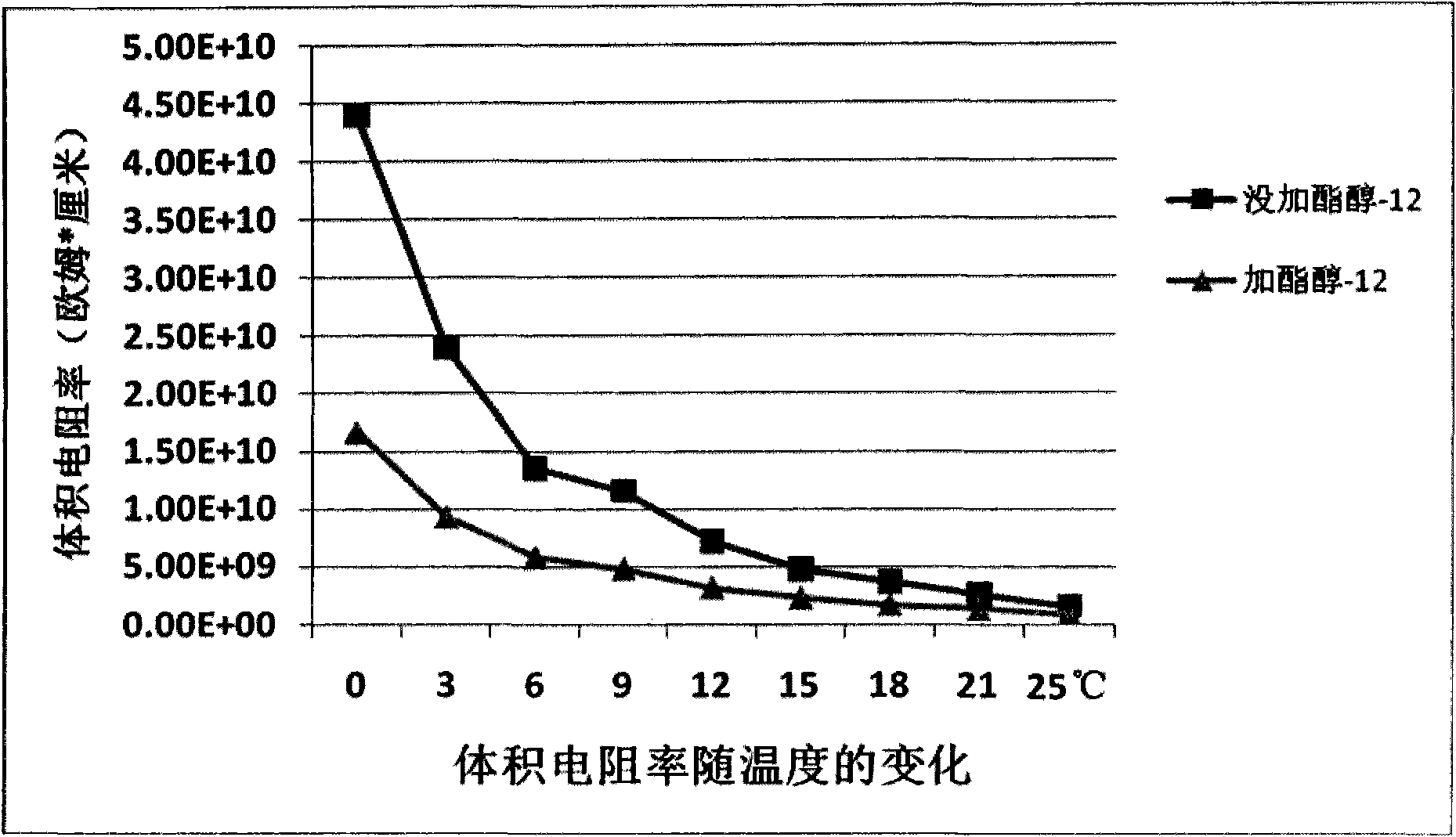

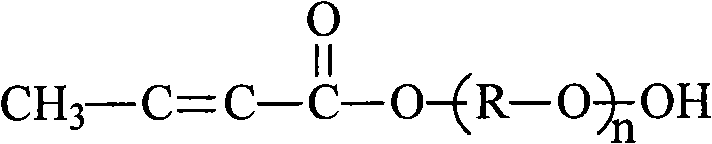

Bonding agent and electro-optic assembly and electrophoretic medium thereof

InactiveCN102253502ALower volume resistivityImproved electro-optical performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAlcoholElectrophoresis

The invention discloses a bonding agent and an electro-optic assembly and an electrophoretic medium thereof. The electro-optic assembly comprises a first substrate, a second substrate, a boning agent layer positioned between the first substrate and the second substrate, and an electro-optic material layer positioned between the first substrate and the second substrate; and the bonding agent layer comprises a polymer boning agent material and an additive agent, wherein the additive agent is selected from propylene glycol ether, butyl carbitol, methoxyl methanol, ethylene glycol, propanediol, propanetriol, Texanol, adipate, phthalandione, lusolvan, FBH, Coasol, DBE-IB, DPnB, Dowanol PPh, alcohol ester-12, hexamethylene glycol, commercialization compositions thereof and combinations thereof. The invention further discloses the bonding agent layer, a double-stripping sheet and use of the bonding agent layer and the double-stripping sheet. The bonding agent layer has the advantages shown in specifications.

Owner:GUANGZHOU OED TECH INC

Spraying-free nano nylon 6 composite material

The invention discloses a spraying-free nano nylon 6 composite material. The spraying-free nano nylon 6 composite material is prepared from the following raw materials in parts by mass: 70 to 94 partsof a nano nylon 6 composite material, 4 to 10 parts of metal master batch, 1 to 10 parts of an antistatic agent and 1 to 10 parts of an antibacterial agent; the nano nylon 6 composite material is prepared from the following raw materials in parts by mass: 81 to 87 parts of caprolactam and 3 to 6 parts of montmorillonite. The composite material disclosed by the invention does not need to be sprayed, so that coating is saved and the working mount in a production process is reduced; the spraying-free nano nylon 6 composite material has an environment protection effect and also has the advantagesof good color and luster, high strength, strong wear resistance, antistatic performance, antibacterial performance and the like.

Owner:GUANGDONG XINHUI MEIDA NYLON

Carbon nano-tube / unsaturated polyester composite material and preparation thereof

The invention belongs to the technical field of nano materials, and particularly relates to a carbon nano tube / unsaturated polyester composite material and a preparation method thereof. The preparation method comprises the following steps: carboxylic acid and chloroformylation are carried out to the carbon nano tube, the carbon nano tube is modified by amino or hydroxyl acrylic ester compound, and the carbon nano tube which can carry polymerizable double bond. The modified carbon nano tube is dispersed in unsaturated polyester substrate, and cobalt iso-octoate and methyl ethyl ketone peroxide are adopted as an accelerating agent and a curing agent so as to prepare the carbon nano tube / unsaturated polyester composite material. The obtained composite material has higher heat stability and chemical stability. Compared with unsaturated polyester condensate which has same compositions and does not add the carbon nano tube, the volume resistivity of the cured composite material is reduced to 3 to 9 order of magnitude, and the surface resistivity is reduced to 3 to 8 order of magnitude. The invention has simple technique and more practicability. The composite material can be applied to the shell or coating of the equipment in the fields of manufacturing motors of electric appliances, chemical machines and the like.

Owner:TONGJI UNIV

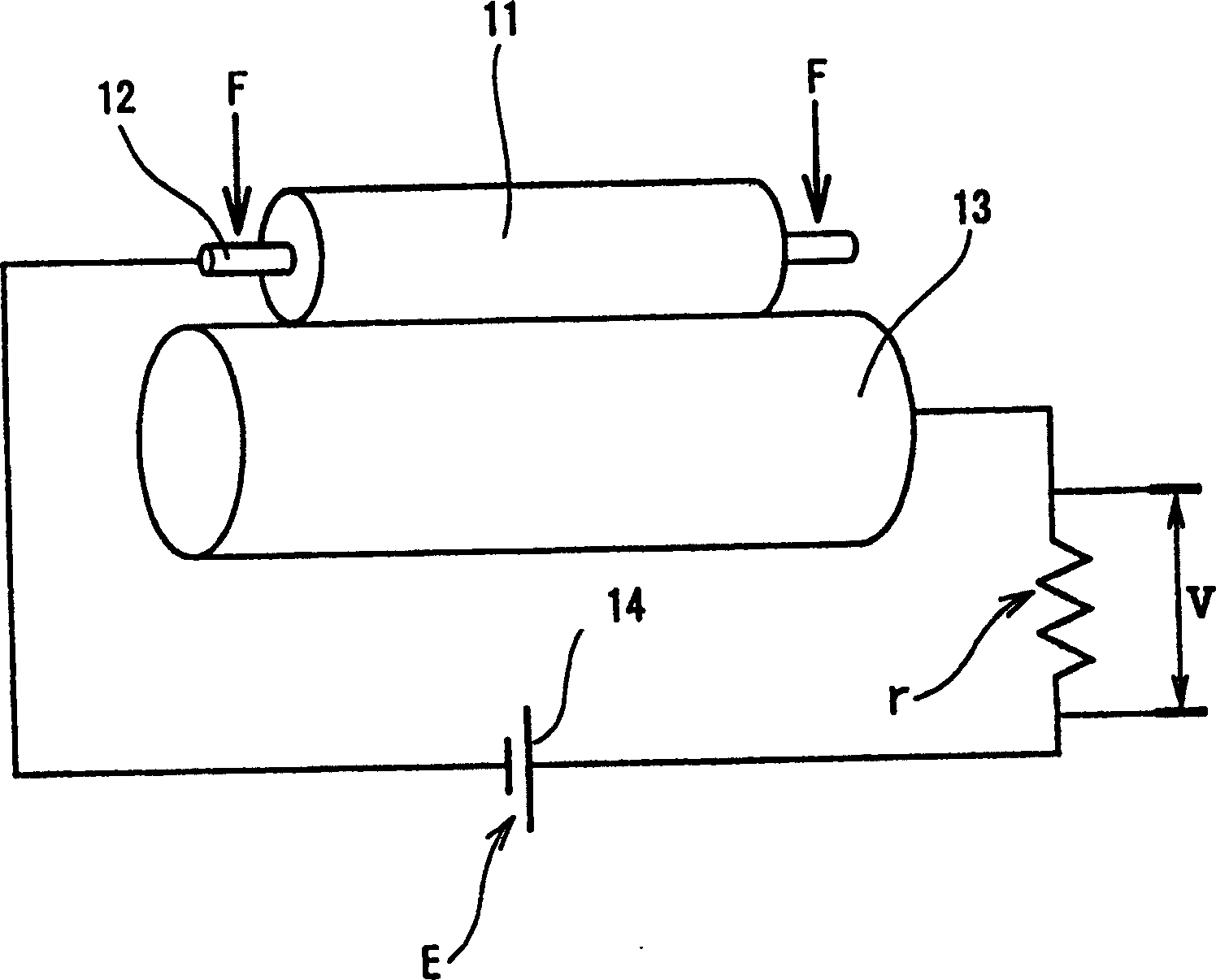

Polymeric-type electric resistance control agent and polymer composition containing the same

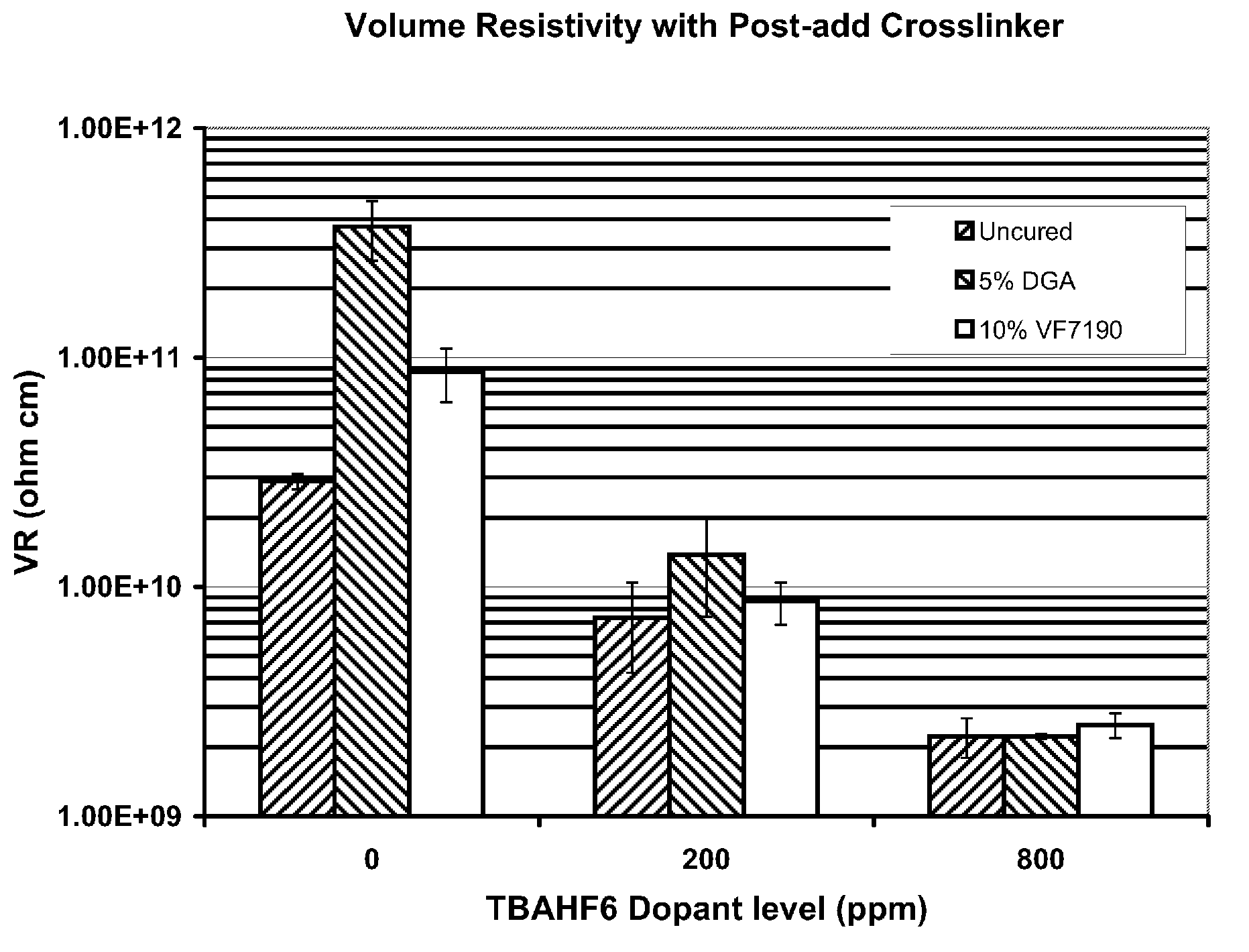

InactiveUS20070021548A1Significant dimensional changeSmall compression setAntibacterial agentsOther chemical processesElastomerAntistatic agent

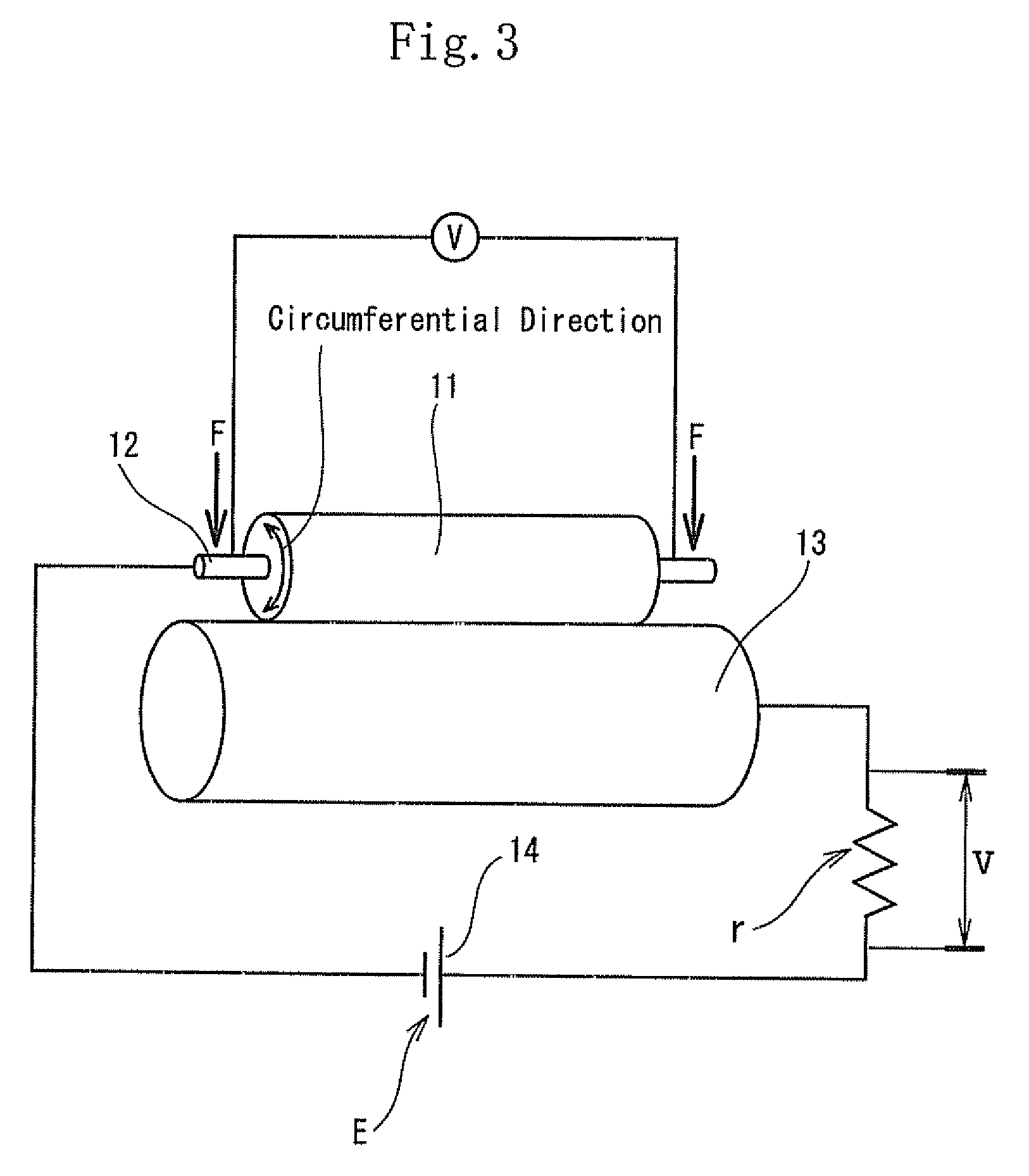

The present invention provides a polymeric-type antistatic agent containing a polymer composition consisting of a polymeric-type antistatic agent containing a resin or / and an elastomer as a main component thereof; or / and a thermoplastic resin having a polar group or / and an elastomer having the polar group. At least one kind of an anion-containing salt, having a fluoro group and a sulfonyl group, is added to the polymer composition without intermediary of a medium consisting of a low-molecular-weight polyether-containing compound or a low-molecular-weight polar compound whose number-average molecular weight is not more than 5000. The present invention also provides a composition, for a conductive roller or the like, containing polymer components and the polymeric-type antistatic agent dispersed in the polymer components.

Owner:SUMITOMO RUBBER IND LTD

Negative electrode active material for nonaqueous electrolyte secondary batteries and method for producing same

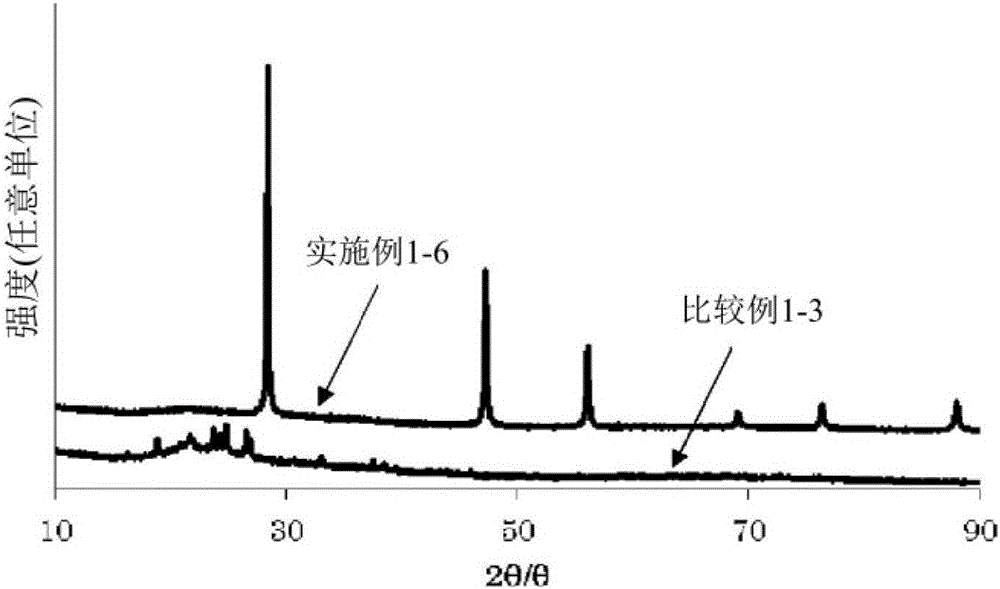

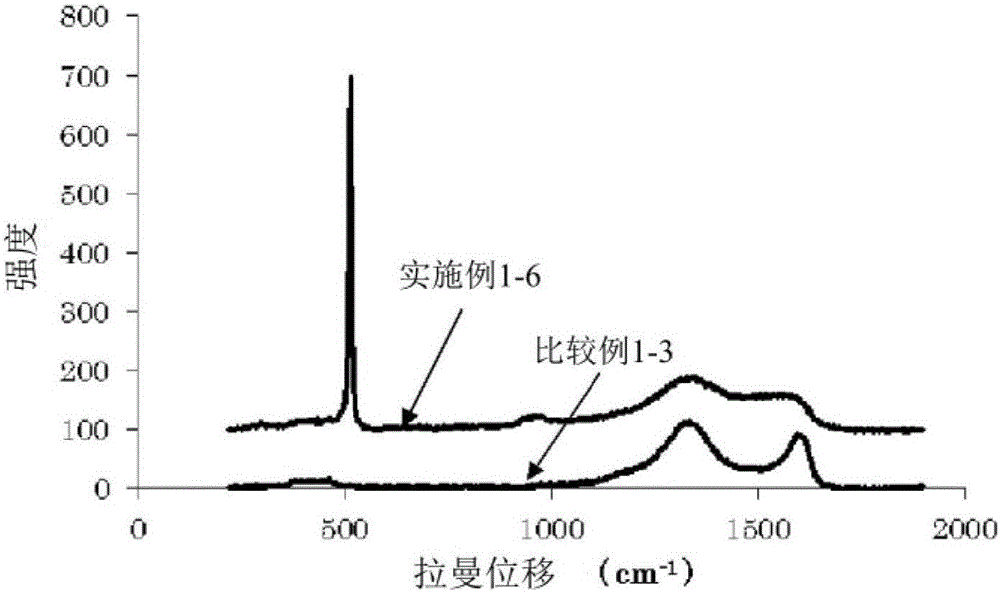

ActiveCN105849953ACollapseReduce irreversible capacityElectrode thermal treatmentFinal product manufactureElemental compositionAlkaline earth metal

The present invention relates to: a negative electrode active material for nonaqueous electrolyte secondary batteries, which is represented by elemental composition formula Met1-Si-O-C-H (wherein Met1 represents one alkali metal element or a mixture of alkali metal elements), and which contains a silicate salt that is composed of a silicon-based inorganic compound and the alkali metal, while having fine particles that are composed of silicon, a silicon alloy or silicon oxide dispersed within the silicate salt; and a negative electrode active material for nonaqueous electrolyte secondary batteries, which is represented by elemental composition formula Met2-Si-O-C-H (wherein Met2 represents one alkaline earth metal element or a mixture of alkaline earth metal elements), and which contains a silicate salt that is composed of a silicon-based inorganic compound and the alkaline earth metal.

Owner:SHIN ETSU CHEM CO LTD

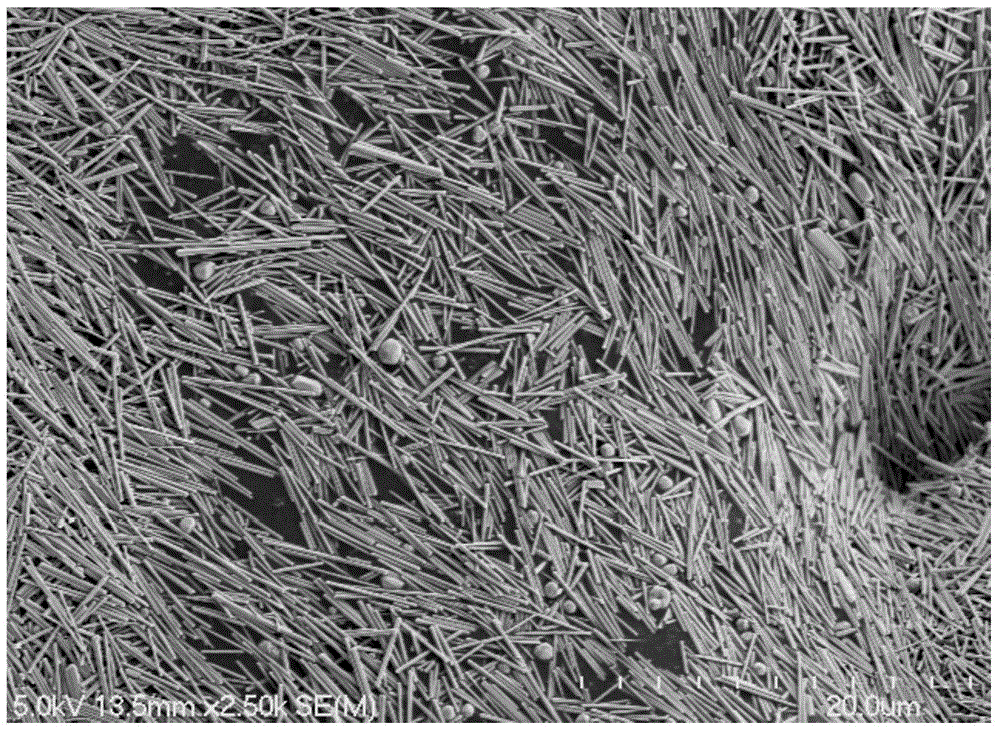

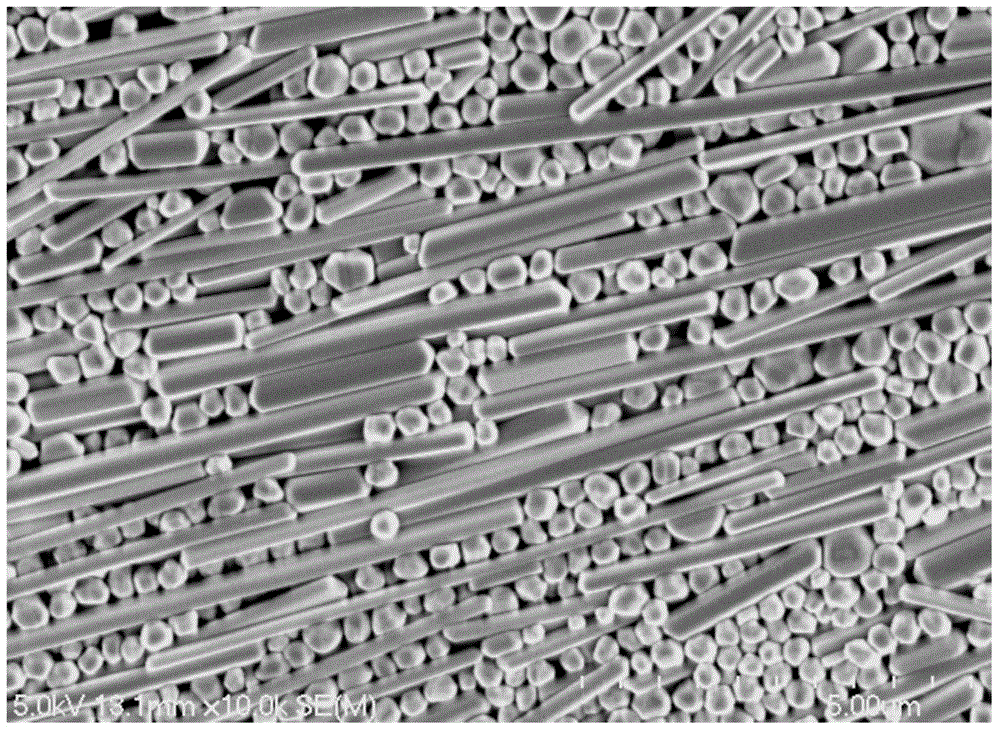

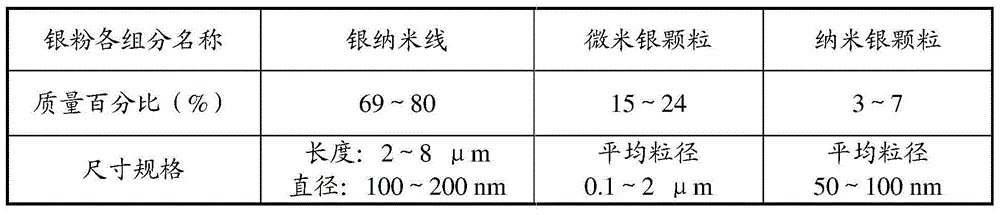

Solar cell electrode slurry, preparation method, cell electrode and solar cell

InactiveCN105280265AReduce material costsThe preparation process is stableFinal product manufactureNon-conductive material with dispersed conductive materialMicrometerSlurry

The invention discloses one kind of solar cell electrode slurry comprising an organic carrier and silver powder, glass powder and an antifoaming agent which are dispersed in the organic carrier. The silver powder comprises micrometer silver particles, nanometer silver particles and silver nano wires which are 2-8 [mu]m in length and 100-200 nm in diameter, and silver nano wires account for 50-80% of the total mass of the silver powder. According to the invention, the silver powder mostly is prepared by the silver nano wires which are stable in preparation process and lower in cost relative to nanometer silver particles, so that the material cost of the electrode slurry is effectively lowered; in addition, gaps of the silver power can be filled by silver nano wires, micrometer silver particles and nanometer silver particles, so that conductive paths are added and a conductive network is formed, and the volume resistivity of the electrode material is lowered. At the same time, the invention further discloses a preparation method of the electrode slurry, and a cell electrode and a solar cell using the electrode slurry.

Owner:ZHUHAI ROSSINI WATCH IND

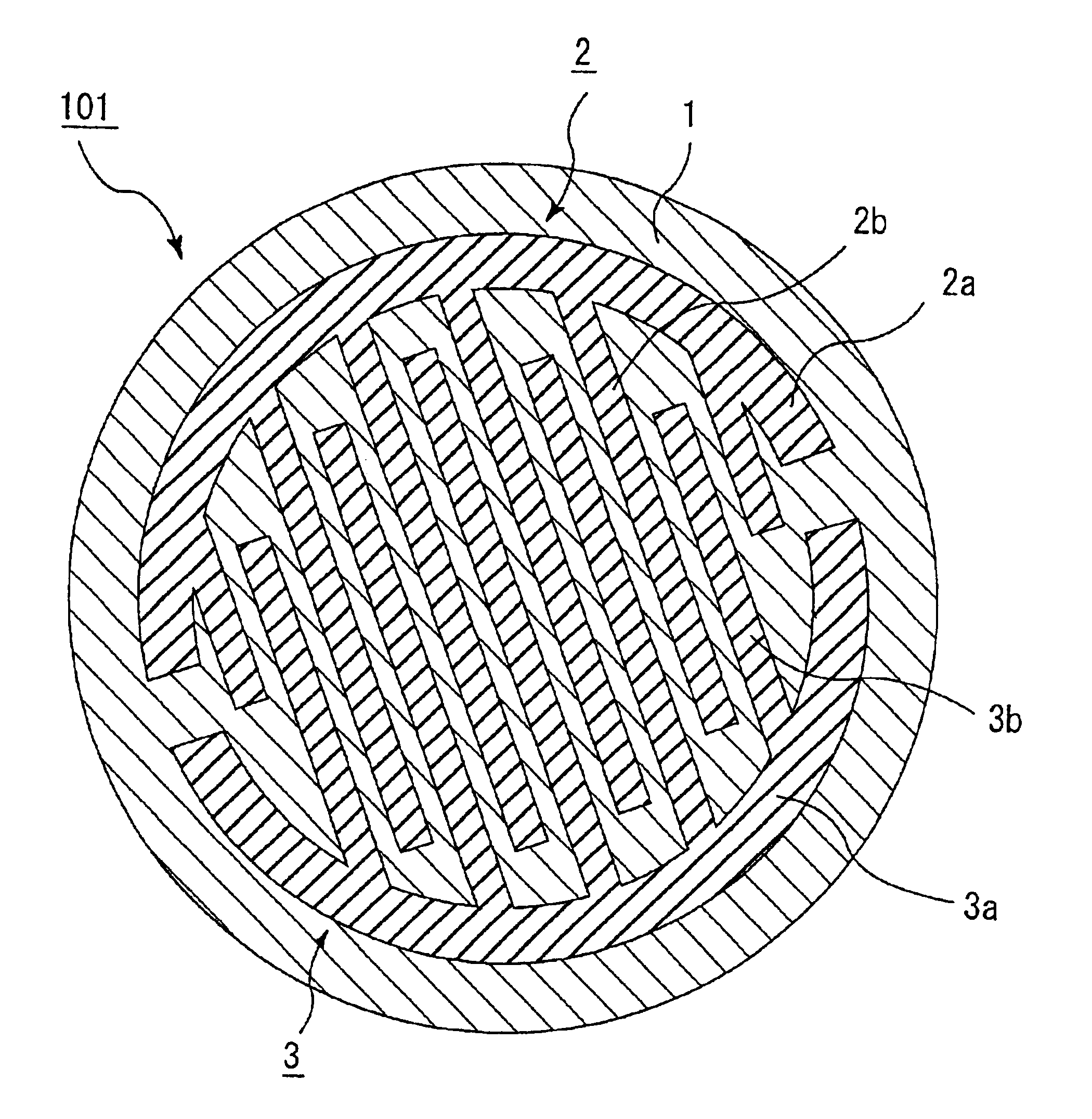

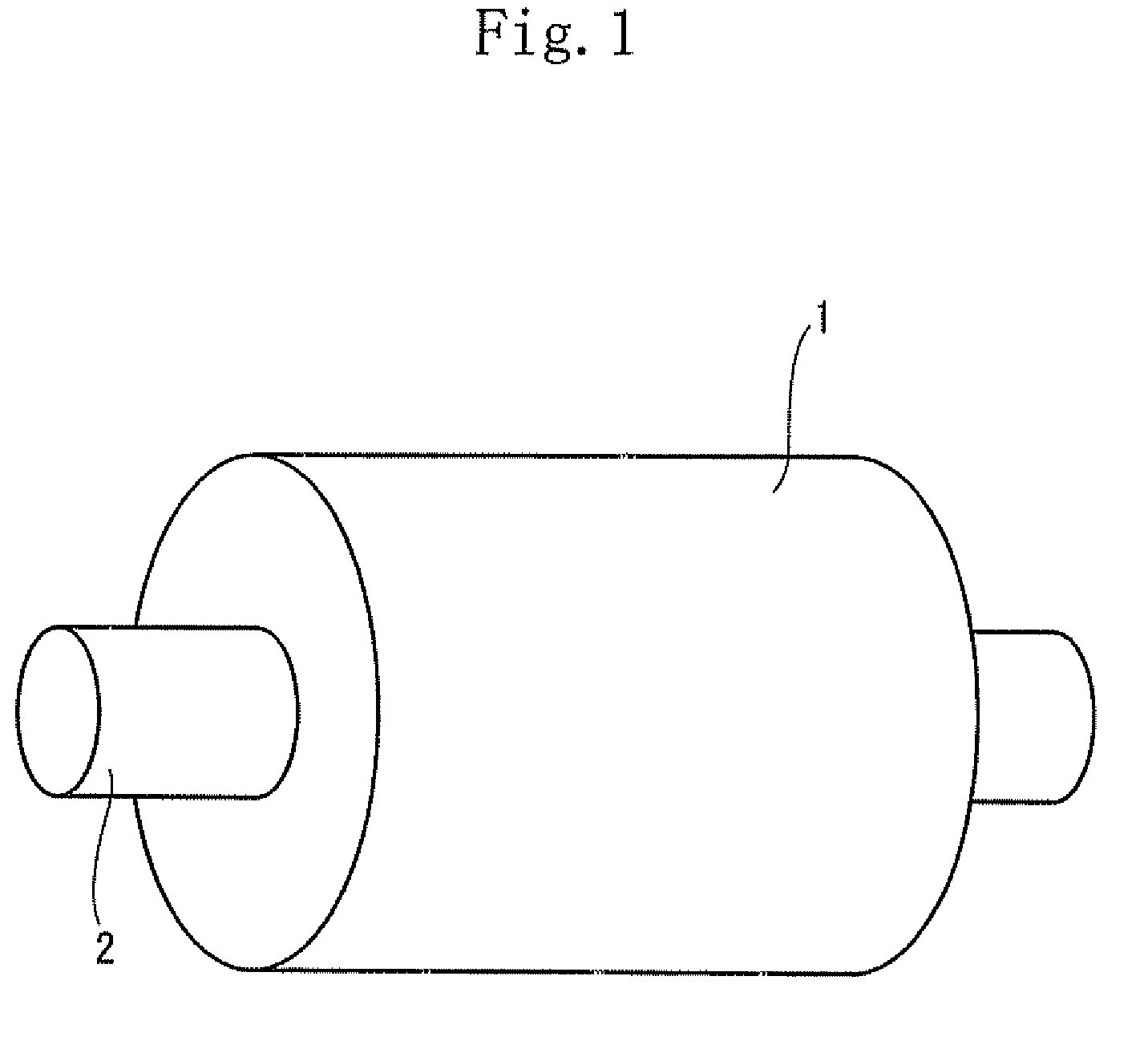

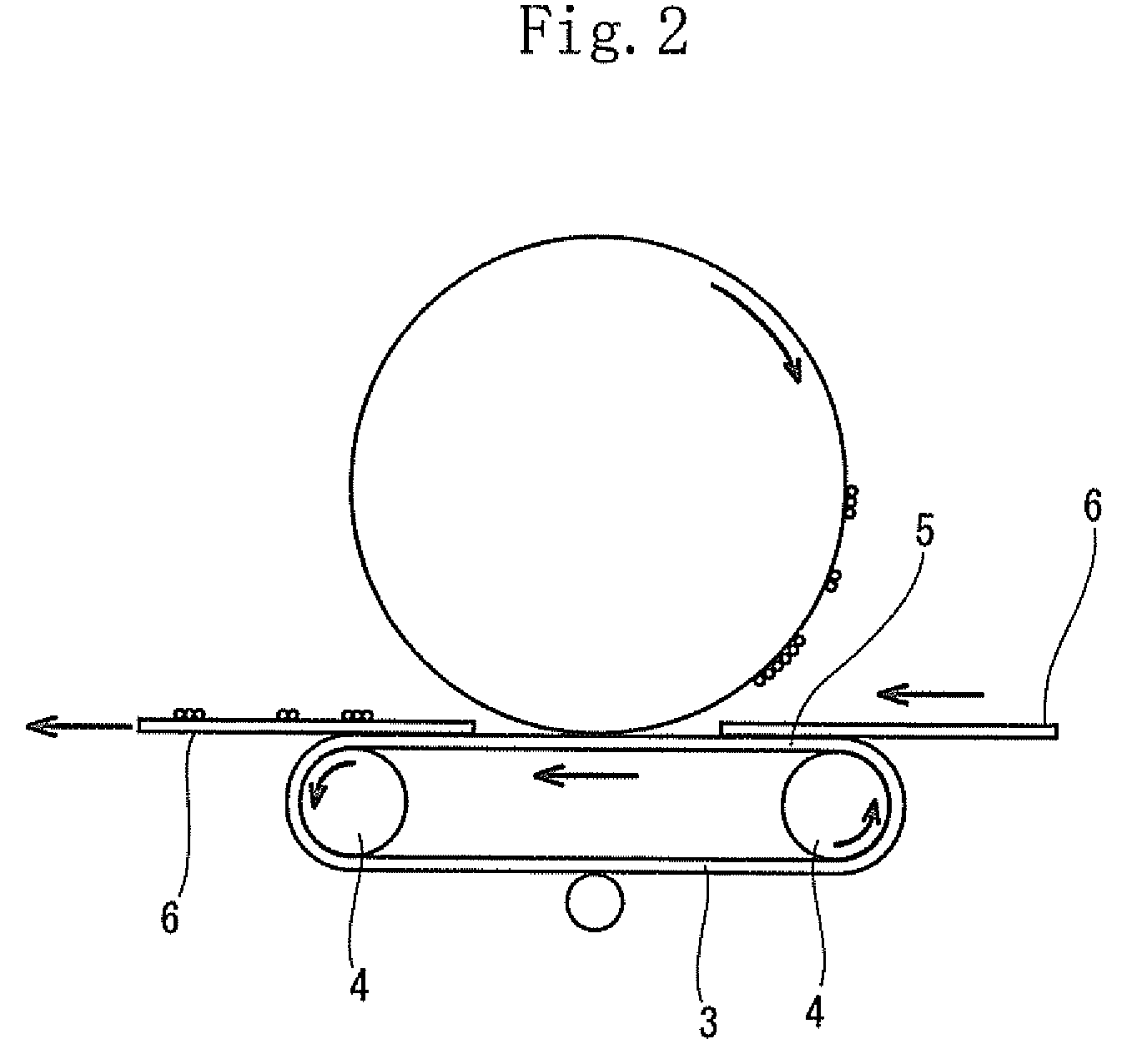

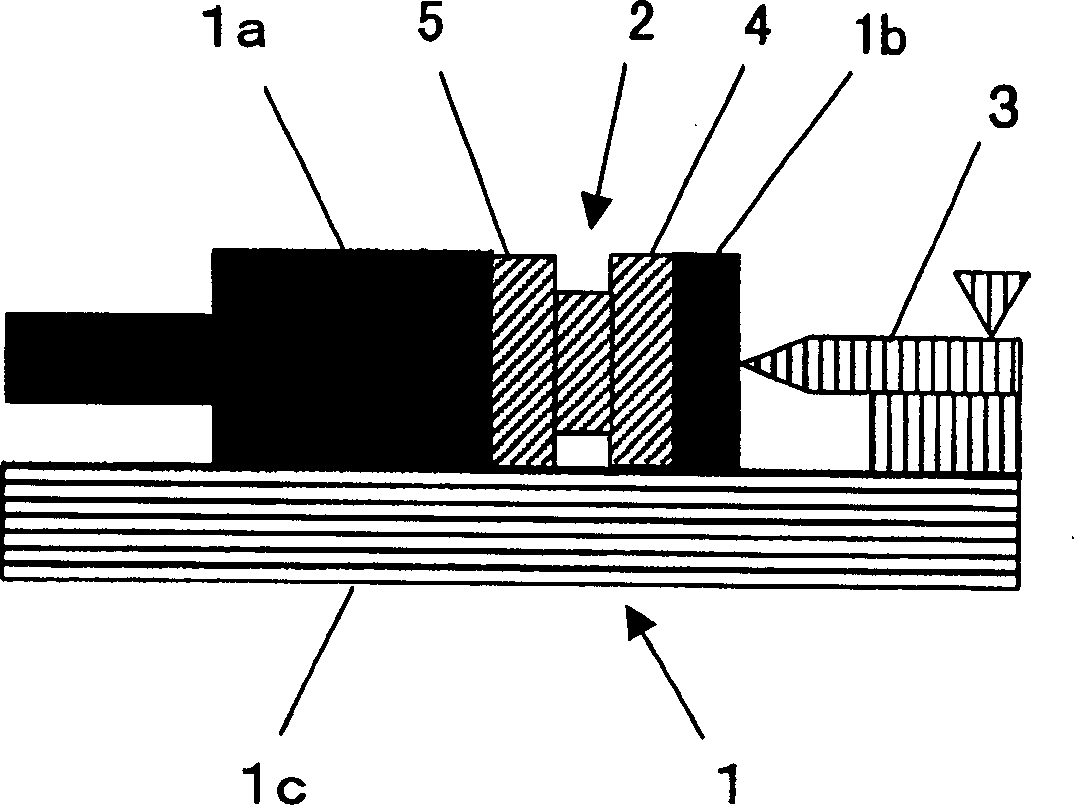

FRP molded article and method of producing same

InactiveCN1426347AImprove mechanical propertiesLower volume resistivityThin material handlingHot runnerShell molding

An FRP molded article molded by hot runner injection molding with a mixture of thermoplastic resin and resin- reinforcing fibers of 0.1-7 mm in average length dispersed in the thermoplastic resin; and a hot runner injection molding method therefor. The molded article is preferable for use as a housing for electronic terminal equipment, cellular phones, etc.

Owner:TORAY IND INC

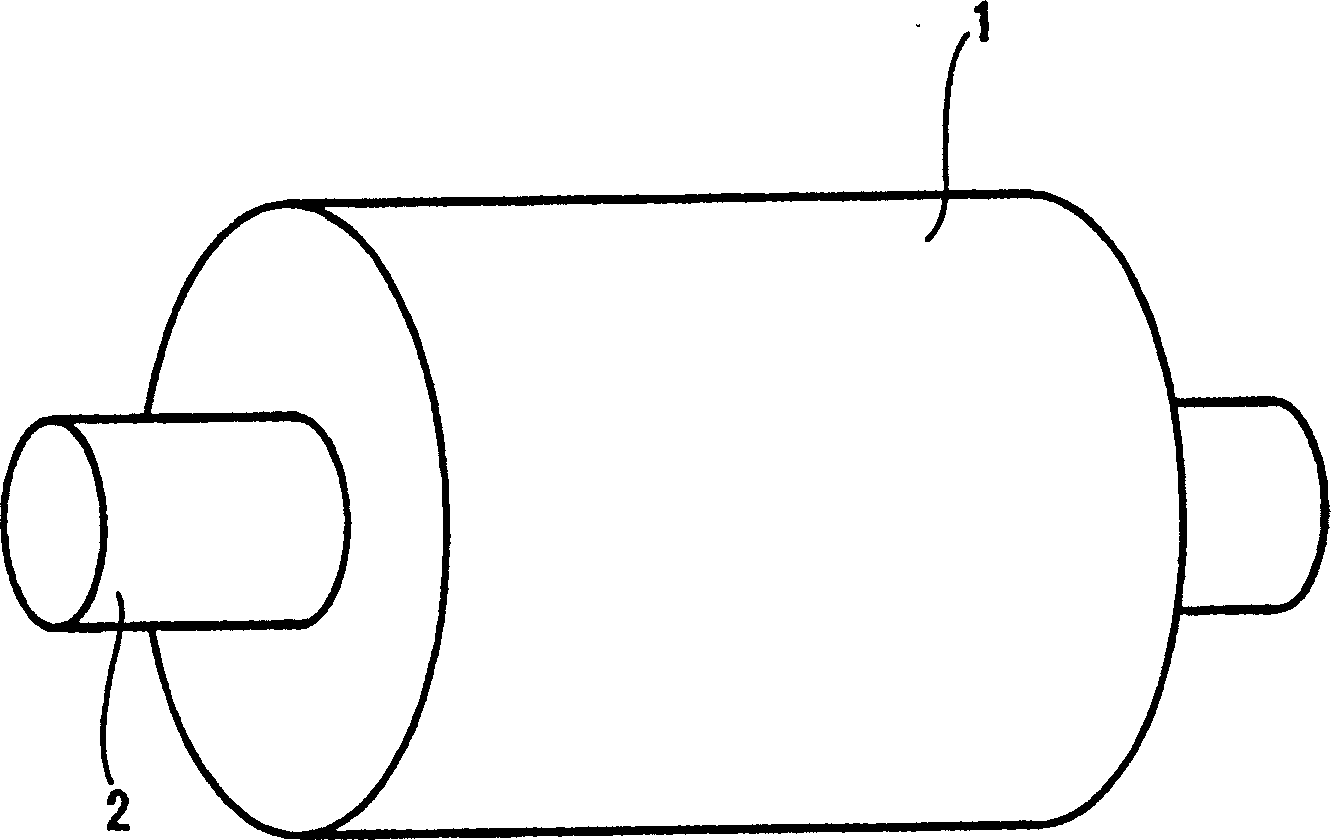

HONEYCOMB STRUCTURE, Si-SiC BASED COMPOSITE MATERIAL, METHOD FOR MANUFACTURING HONEYCOMB STRUCTURE, AND METHOD FOR MANUFACTURING Si-SiC BASED COMPOSITE MATERIAL

InactiveUS20120248090A1Lower volume resistivityWell formedPhysical/chemical process catalystsDispersed particle filtrationAlkaline earth oxidesHoneycomb structure

A honeycomb structure is provided with a partition portion constituting a plurality of cells serving as flow paths of a fluid. This honeycomb structure includes electrode portions which are disposed as parts of the partition portion and which have a SiC phase, an oxide phase containing a Si oxide, an Al oxide, and an alkaline-earth metal oxide, and a metal phase containing metal Si and metal Al, where the proportion of metal Al relative to the total amount of metal Si and metal Al is 0.001 percent by mole or more and 20 percent by mole or less and a heat generation portion which is a part of the partition portion and which has a volume resistivity higher than that of the electrode portion.

Owner:NGK INSULATORS LTD

Preparation method of electroconductive silicone rubber

The invention discloses a preparation method of electroconductive silicone rubber. Acetylene black, aluminum oxide, hydroxyl silicone oil and water accounting for 1% of the acetylene black by weight are mixed and added into a granulator to be produced into acetylene black and aluminum oxide particles for mixing. The silicone rubber has the advantages of high heat conductivity, heat resistance and low compressibility, the tensile strength is larger than 9.6 MPa, the tear strength is above 36 N / mm, and the volume resistivity is smaller than 45 omega.cm.

Owner:广东长博电子绝缘材料有限公司

Conductive Paste and Wiring Board Using It

InactiveUS20090107707A1Inhibition resistanceLower volume resistivityConductive layers on insulating-supportsConductive materialConductive pasteFrit

A conductive paste is mainly composed of a metal powder, a glass frit, and an organic vehicle. The total content amount of the metal powder and glass frit with respect to the entire conductive paste is 85 wt % or more. The viscosity at a rotational speed of 1 rpm measured at 25° C. with an E type rotating viscometer is 100 Pa·s or more and 400 Pa·s or less.

Owner:SUMITOMO ELECTRIC IND LTD

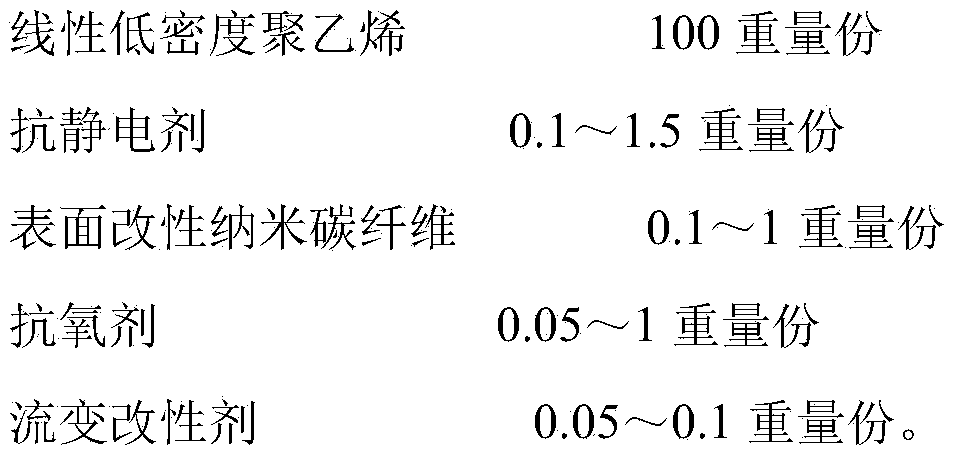

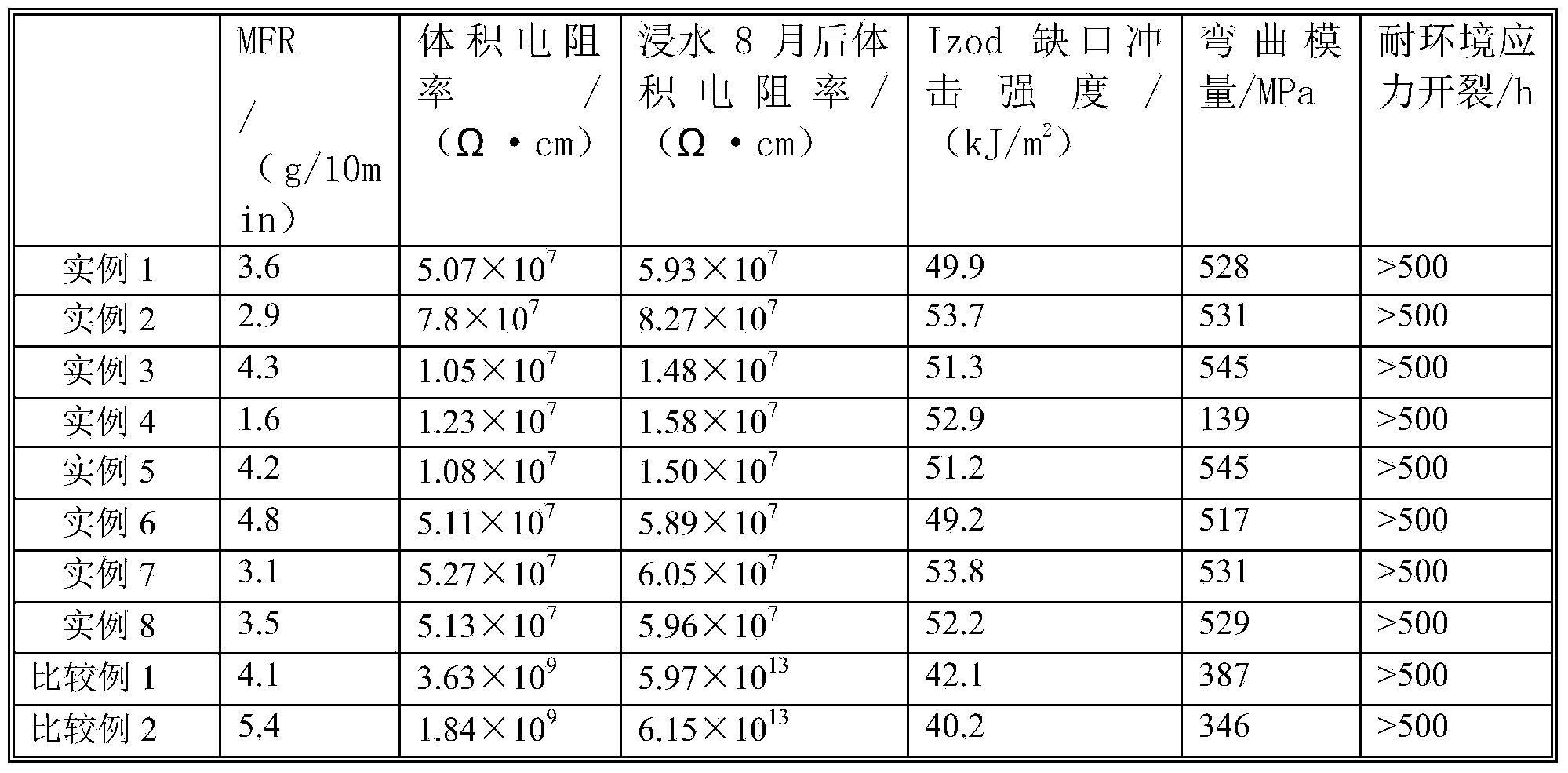

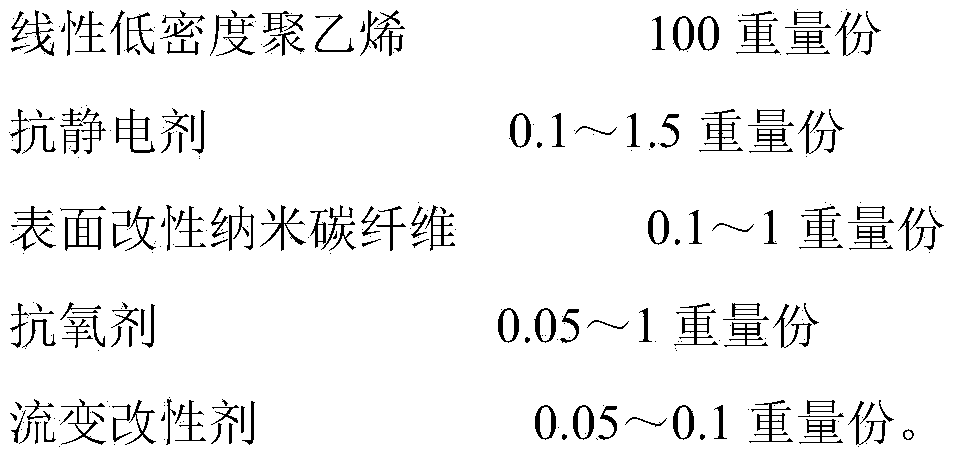

Antistatic high-rigidity rotational-moulded polyethylene composition and preparation method thereof

The invention discloses an antistatic high-rigidity rotational-moulded polyethylene composition. The antistatic high-rigidity rotational-moulded polyethylene composition comprises the following components: 100 parts by weight of linear low-density polyethylene, 0.1-1.5 parts by weight of antistatic agent, 0.1-1 part by weight of surface modified carbon nanofibers, 0.05-1 part by weight of antioxidant and 0.05-0.10 part by weight of rheology modifier. The invention also provides the preparation method of the composition. The antistatic high-rigidity rotational-moulded polyethylene composition provided by the invention has an outstanding antistatic function; the volume resistivity of the antistatic high-rigidity rotational-moulded polyethylene composition is less than 1*10<8> ohm.cm; the antistatic effect of the antistatic high-rigidity rotational-moulded polyethylene composition is lasting; the volume resistivity of the antistatic high-rigidity rotational-moulded polyethylene composition almost has no change after being soaked in water for 8 months; in addition, the composition also has better rigidity-tenacity balance; the impact strength of the composition is improved by at least 20% and the bending modulus of the composition is improved by more than 30%; simultaneously, the composition is good in environmental stress crack resistance, resin homogeneity and processability.

Owner:CHINA PETROLEUM & CHEM CORP +1

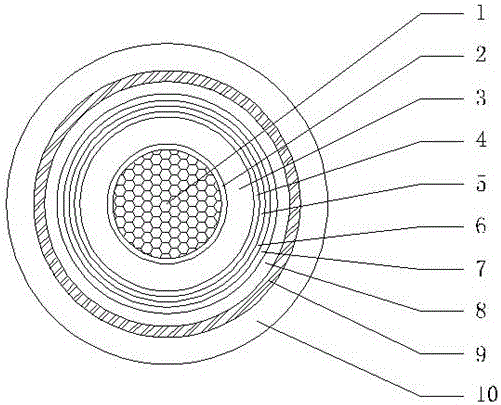

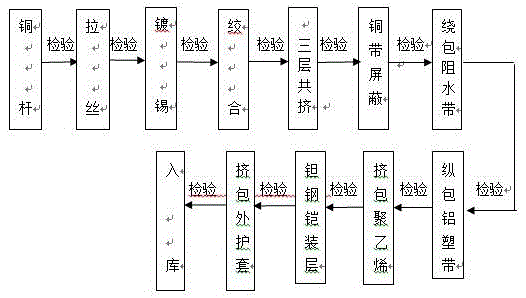

Graphene composite shielding anti-interference power cable for environment-friendly intelligent high-speed rail and fabrication method of graphene composite shielding anti-interference power cable

InactiveCN106098173AAccelerated corrosionImprove tensile propertiesPower cables with screens/conductive layersFlexible cablesCopper conductorInsulation layer

The invention discloses an environment-friendly intelligent high-speed rail graphene composite shielding anti-interference power cable and a preparation method thereof. The insulation layer and the insulation shielding layer form an insulated wire core; the outer layer of the insulating wire core is overlapped and wrapped with a metal inner shielding layer; The aluminum-plastic composite tape layer wrapped longitudinally is extruded with a polyethylene moisture barrier layer; the outer gap of the moisture barrier layer is wrapped with a double-layer tantalum steel alloy tape armor layer, and the outermost layer of the cable is extruded with an outer sheath. The invention has good insulation properties, mechanical properties, power transmission, anti-magnetic interference, lightning protection, flame retardant, halogen-free, low-smoke environmental protection, waterproof, corrosion resistance, radiation resistance and other properties; the structure is reasonable, the comprehensive performance is superior, and the product The performance index is superior to the requirements of international standards; and can produce good social and economic benefits.

Owner:WUXI CITY HENG HUI CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com