Patents

Literature

251results about How to "Inhibition resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

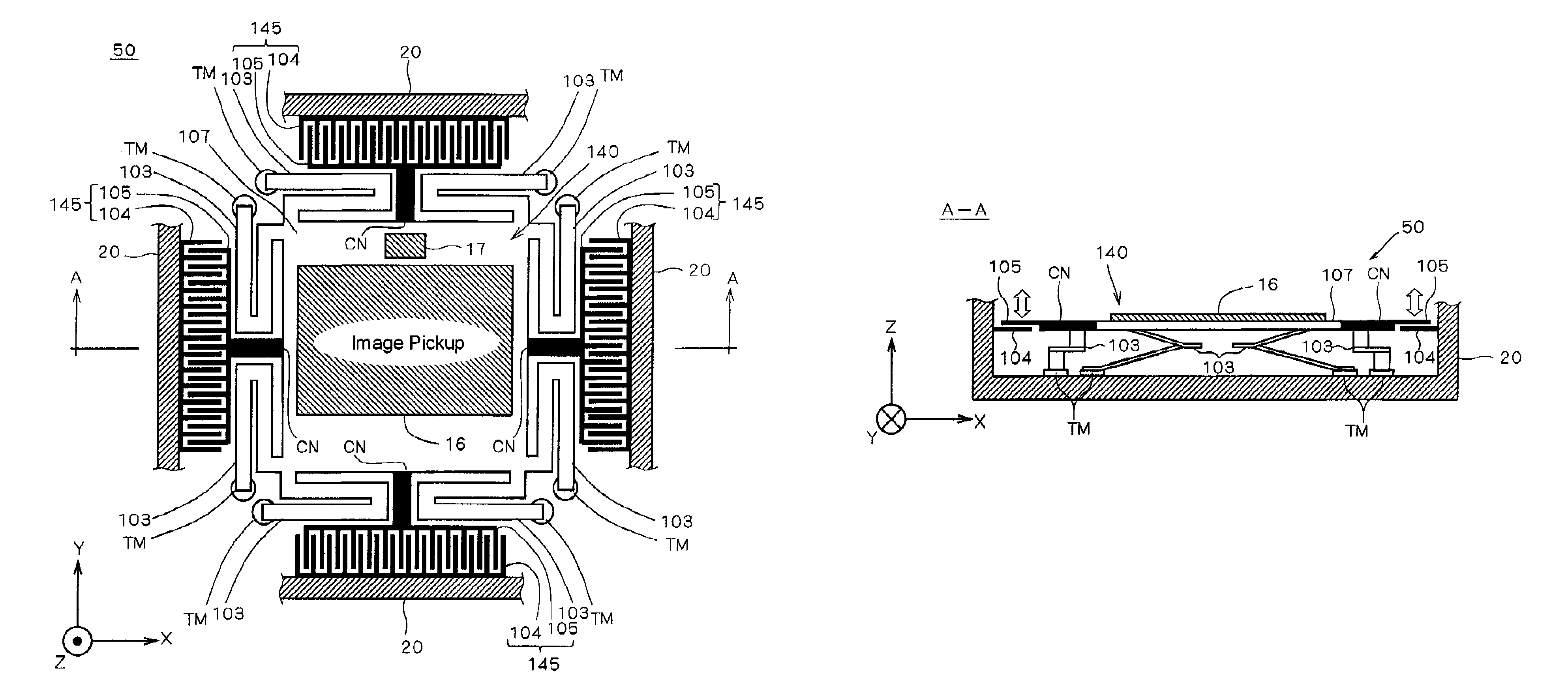

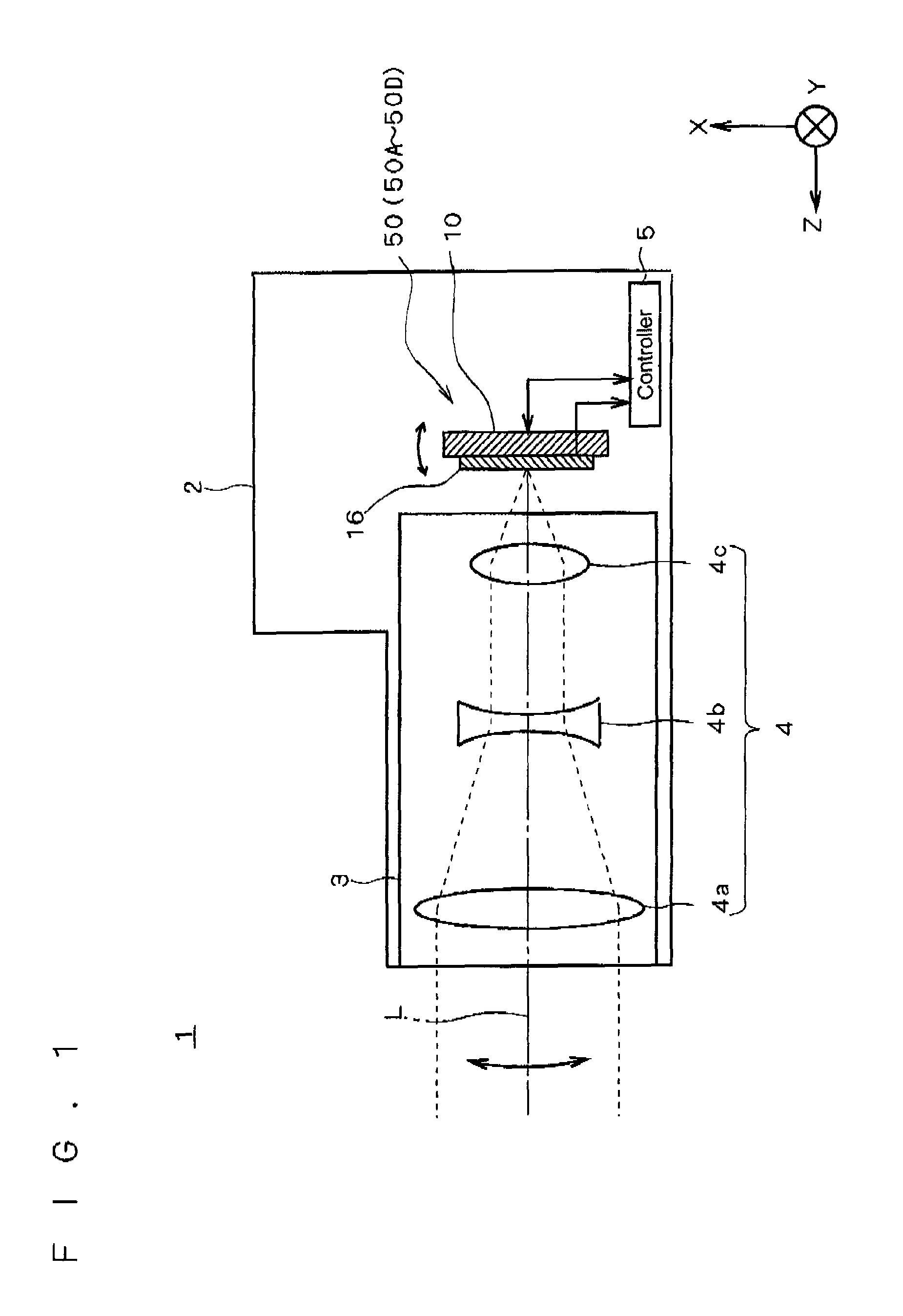

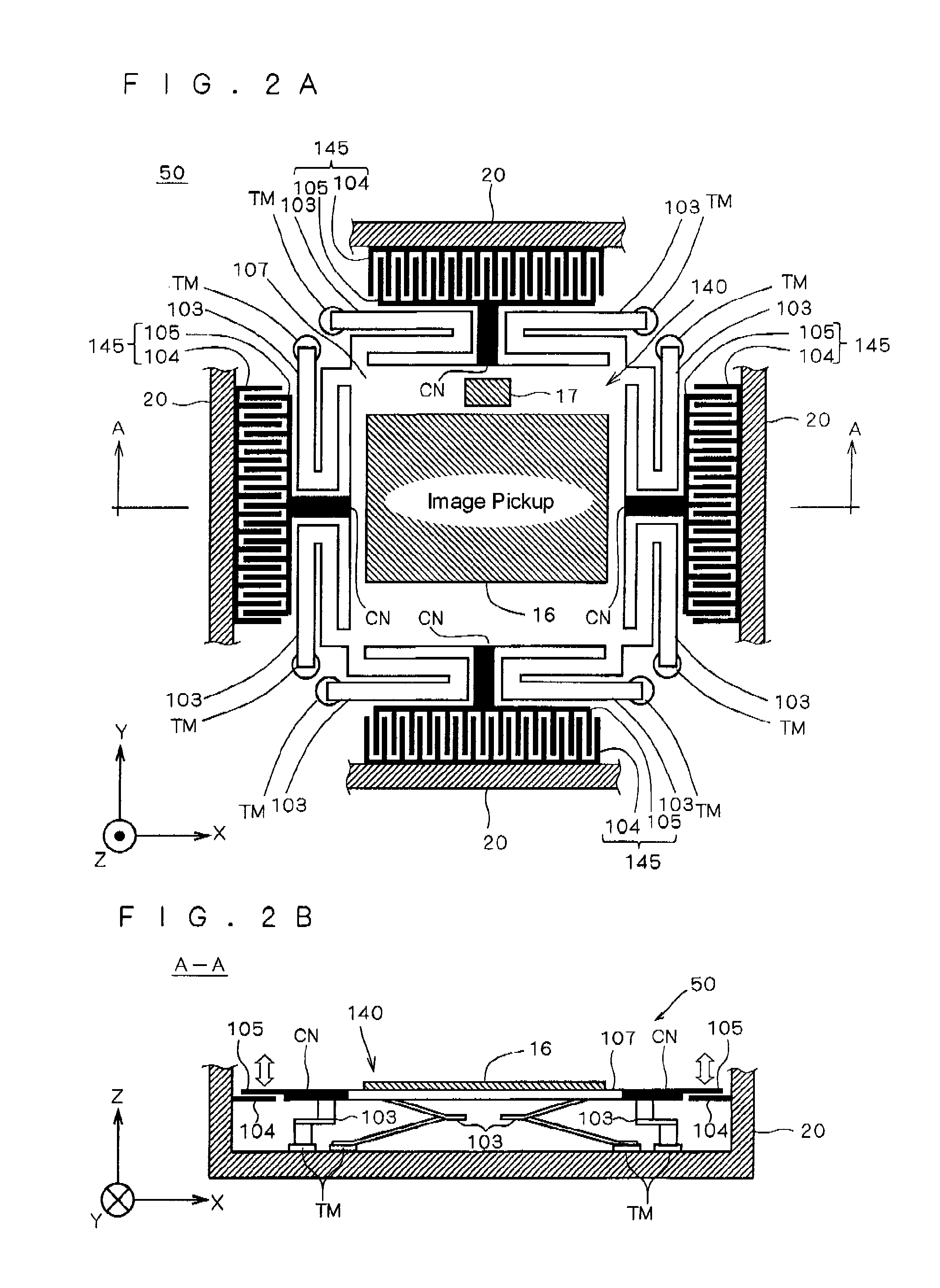

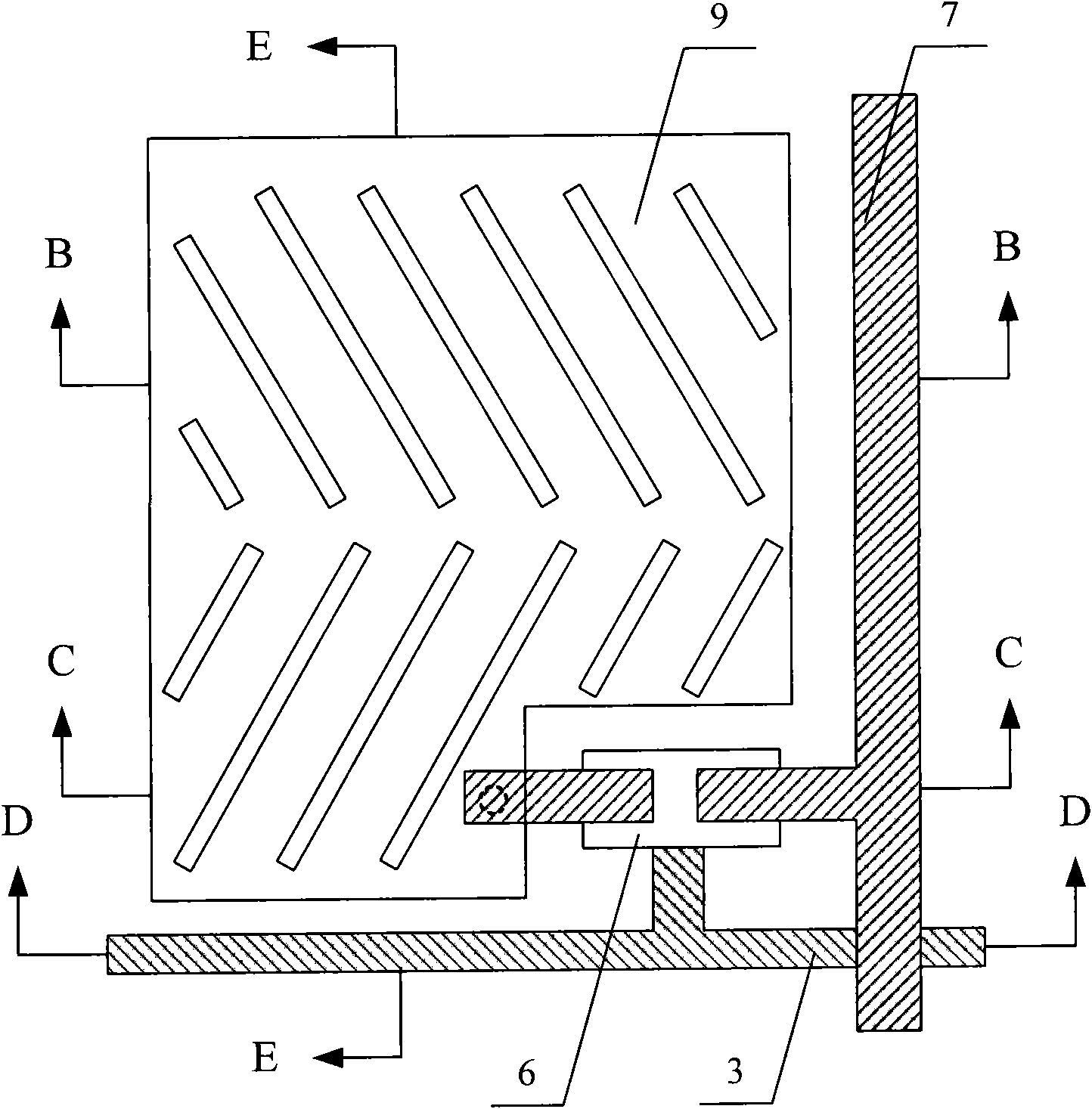

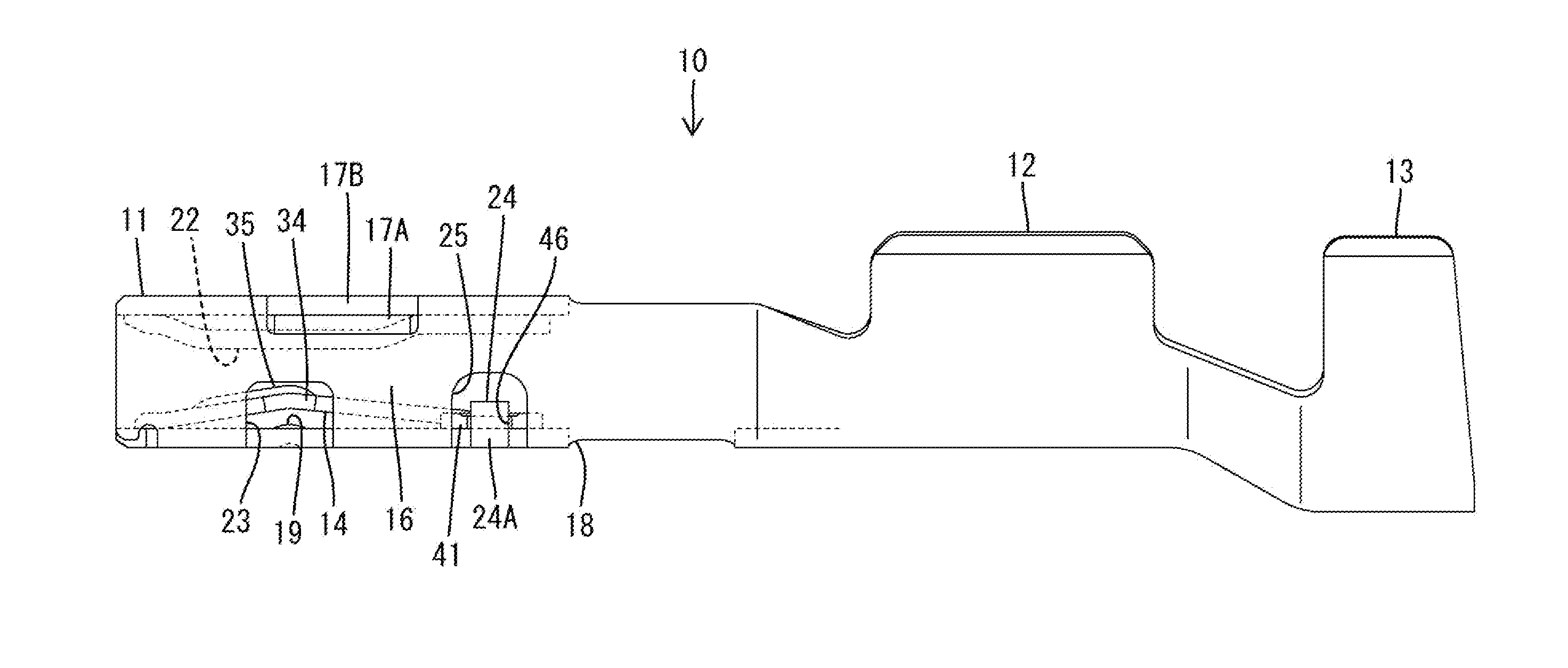

Image sensor device

InactiveUS20080198249A1Improve accuracyInhibition resistanceTelevision system detailsTelevision system scanning detailsElectricityEngineering

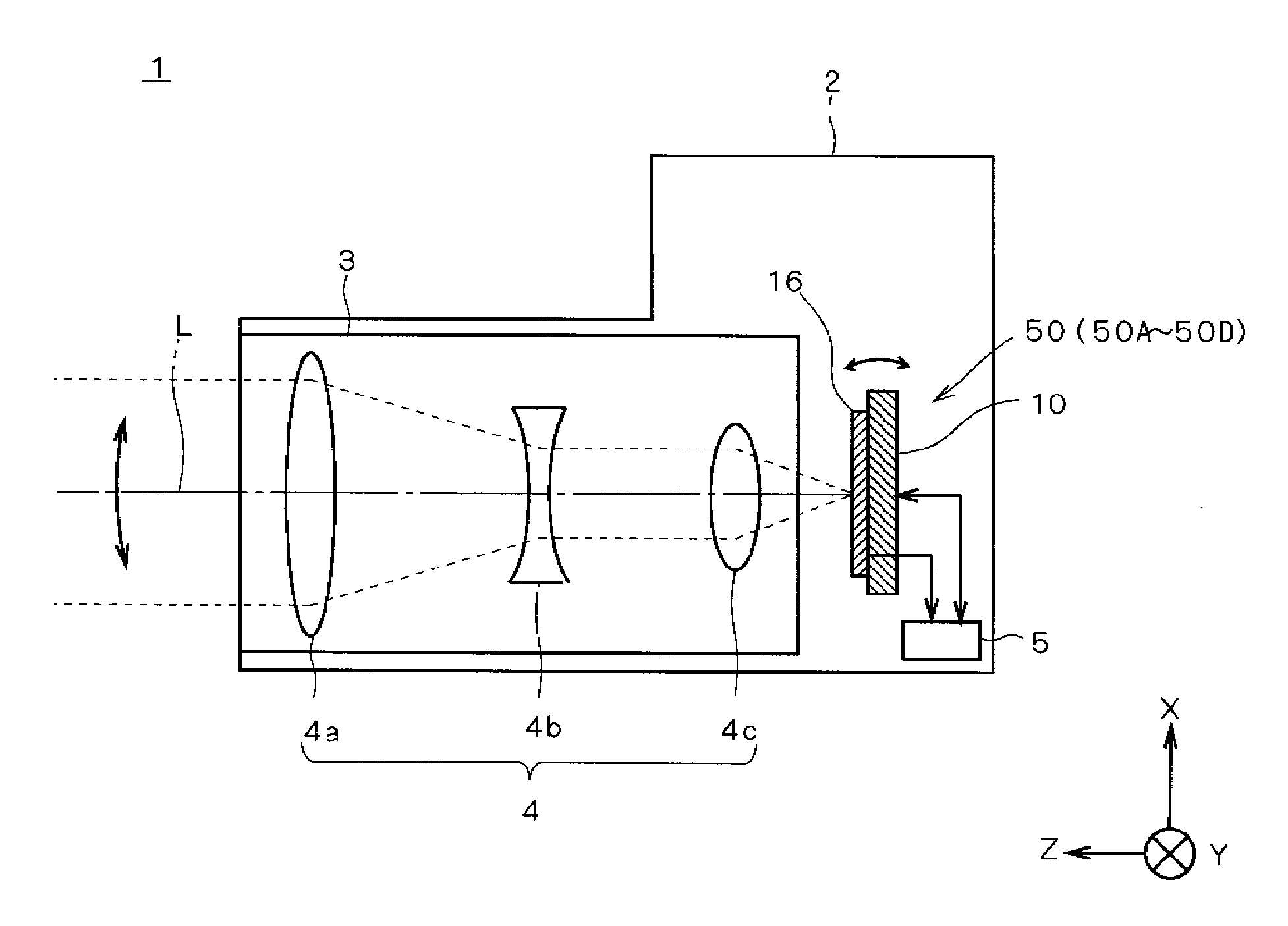

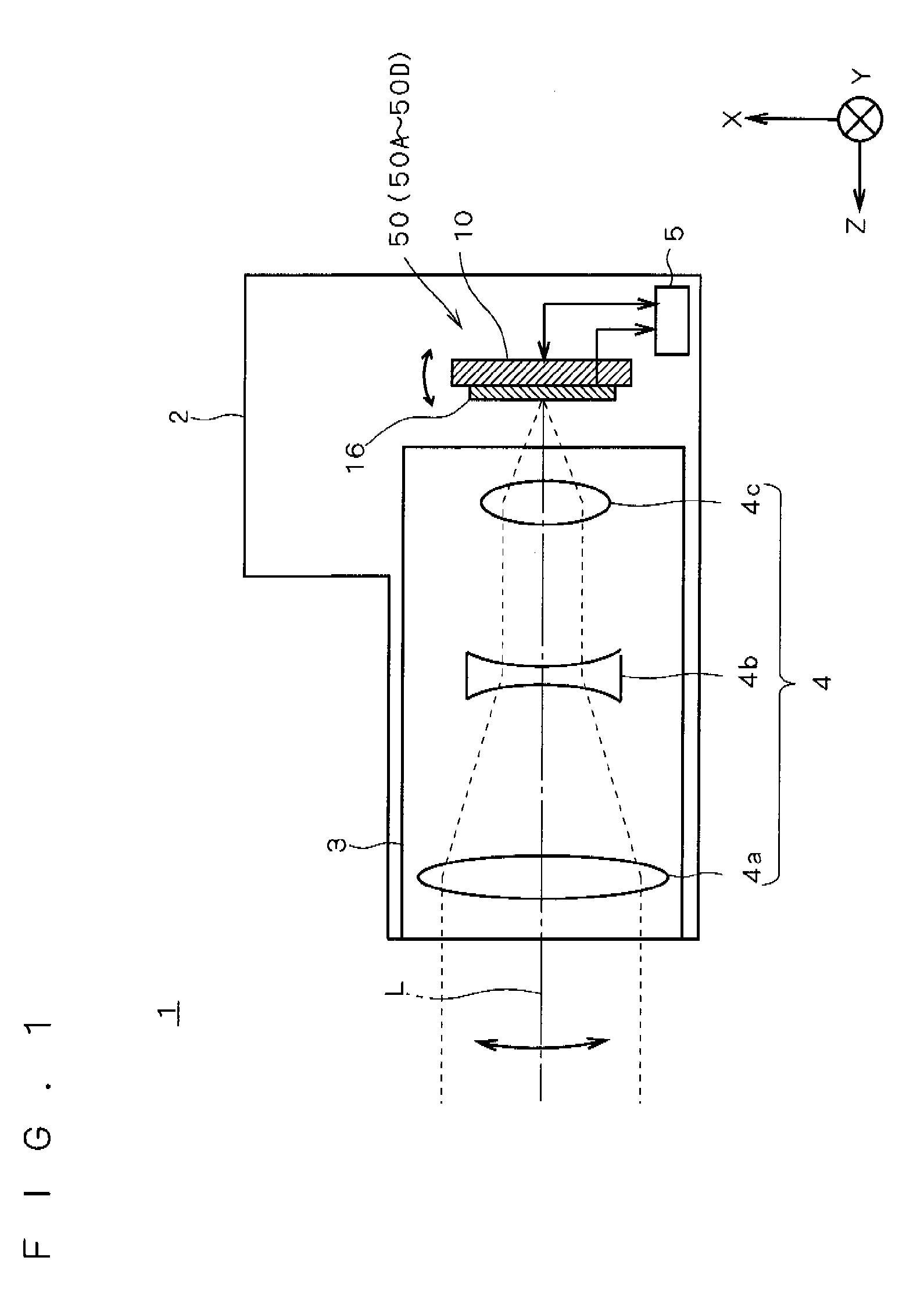

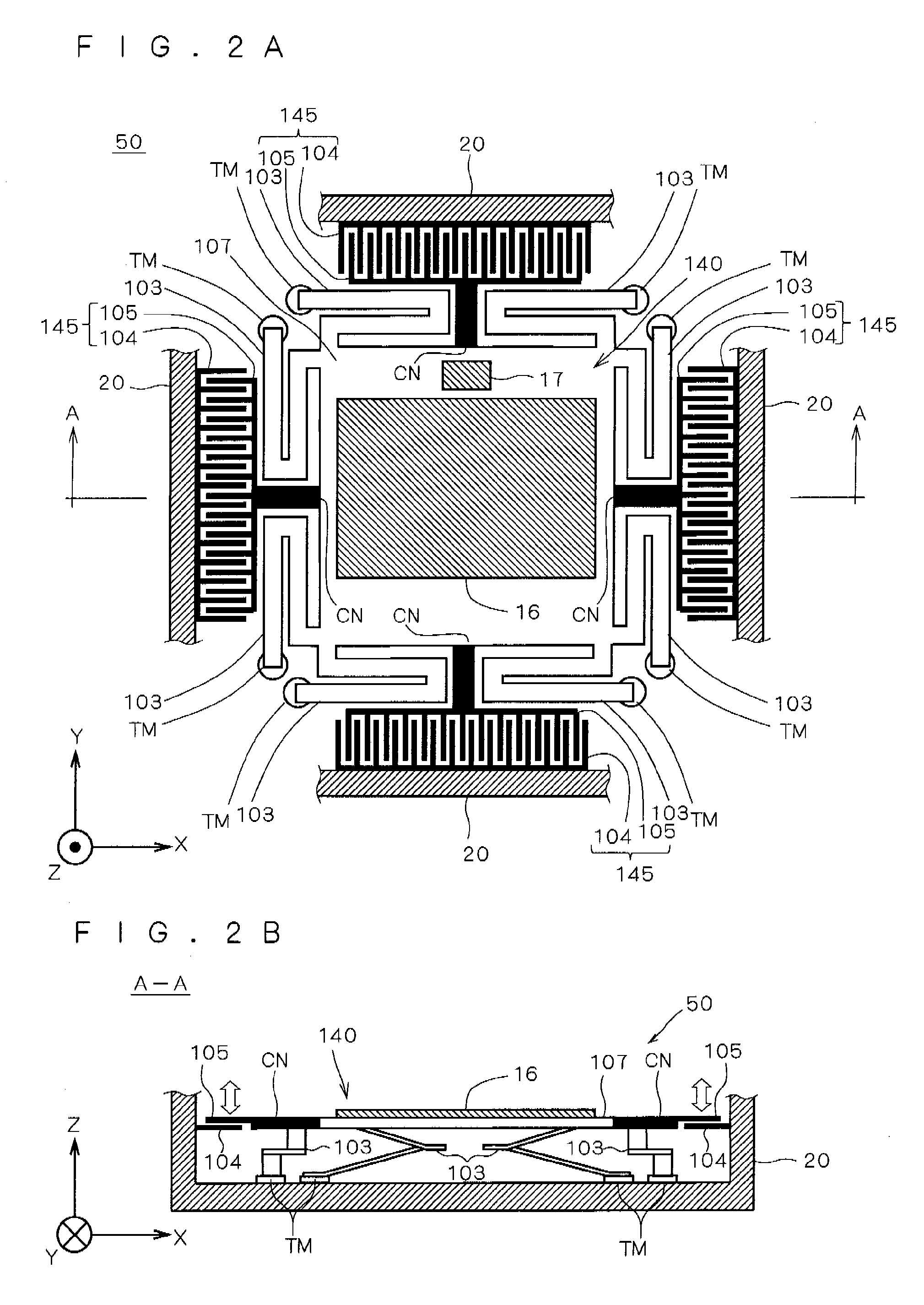

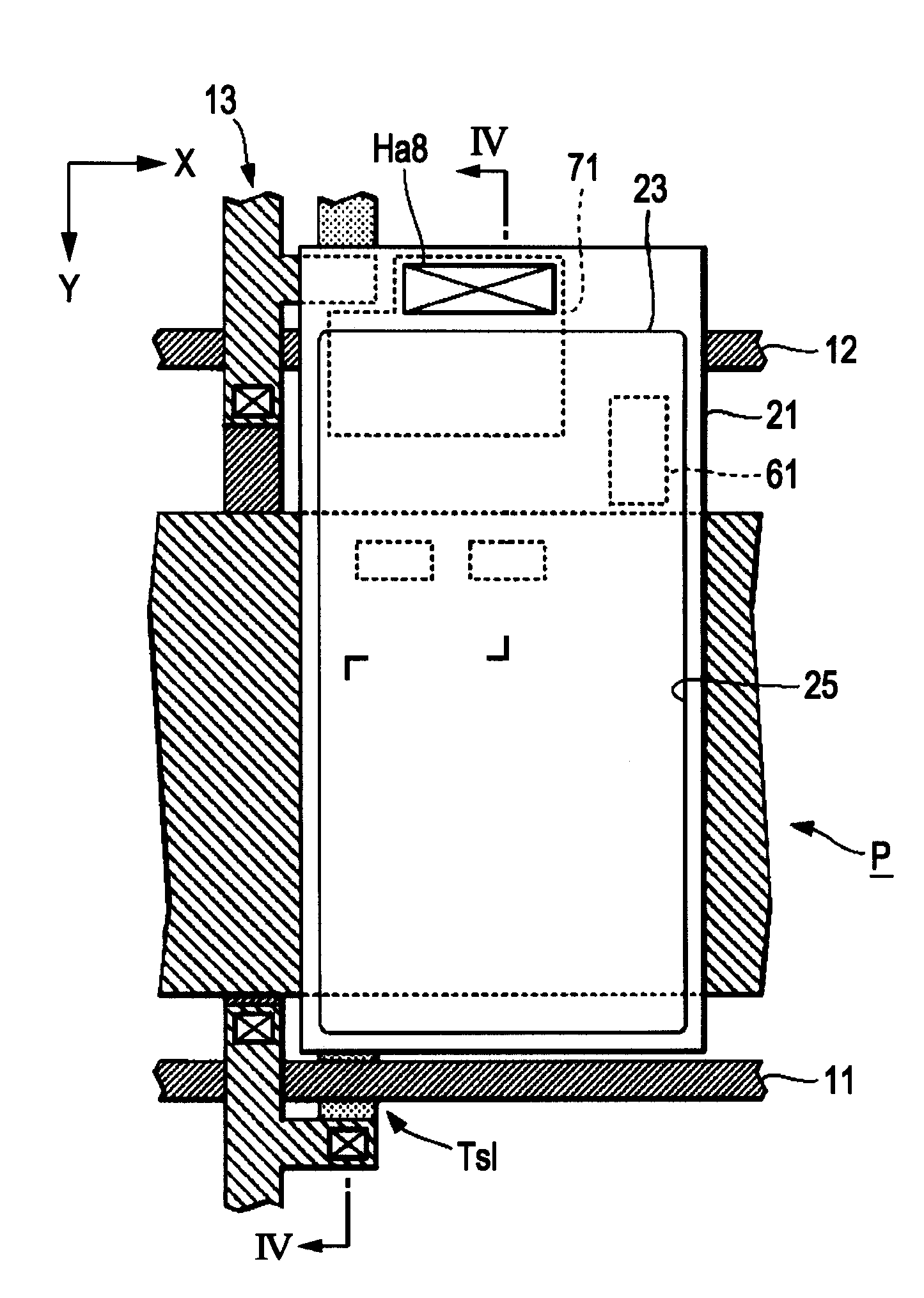

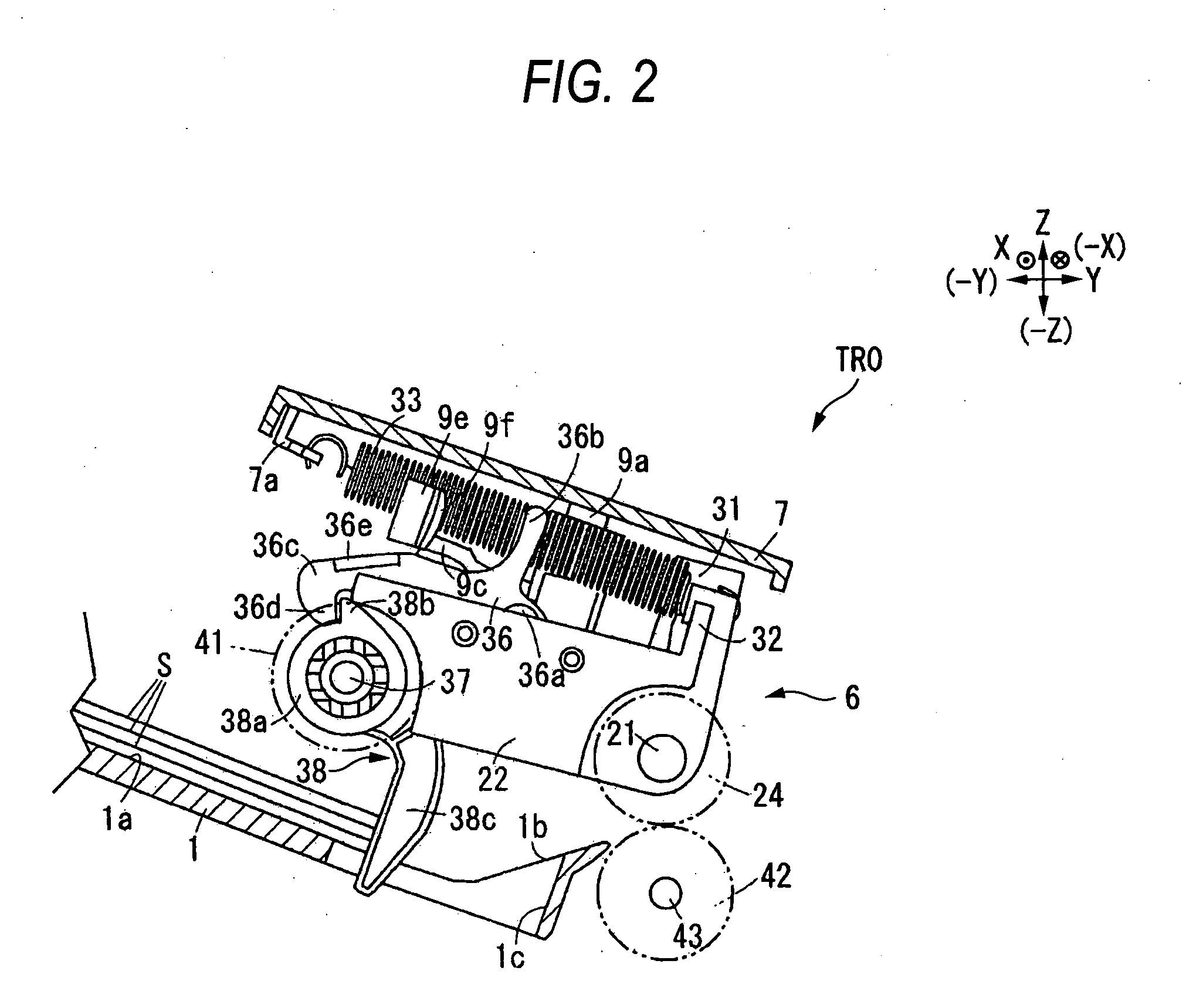

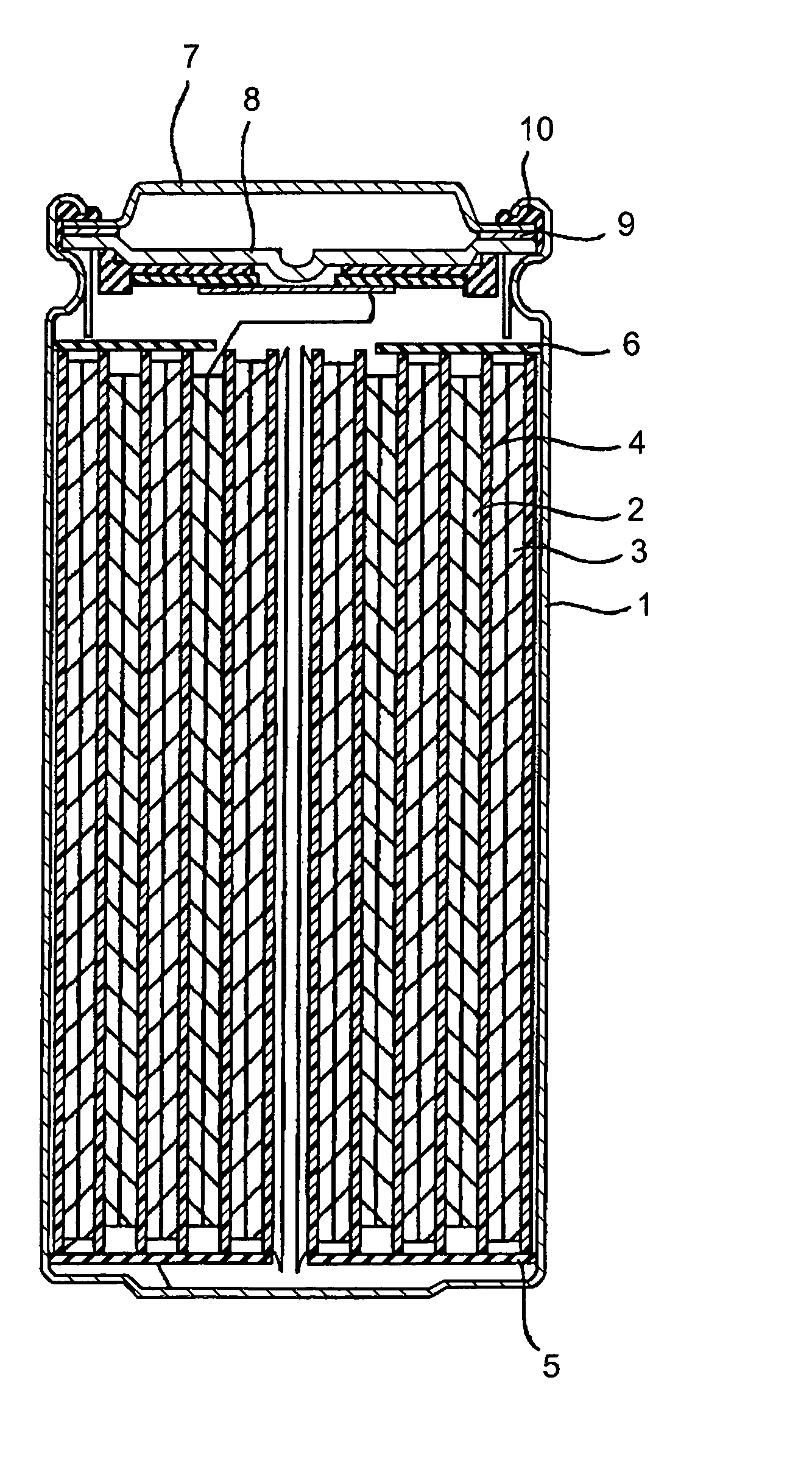

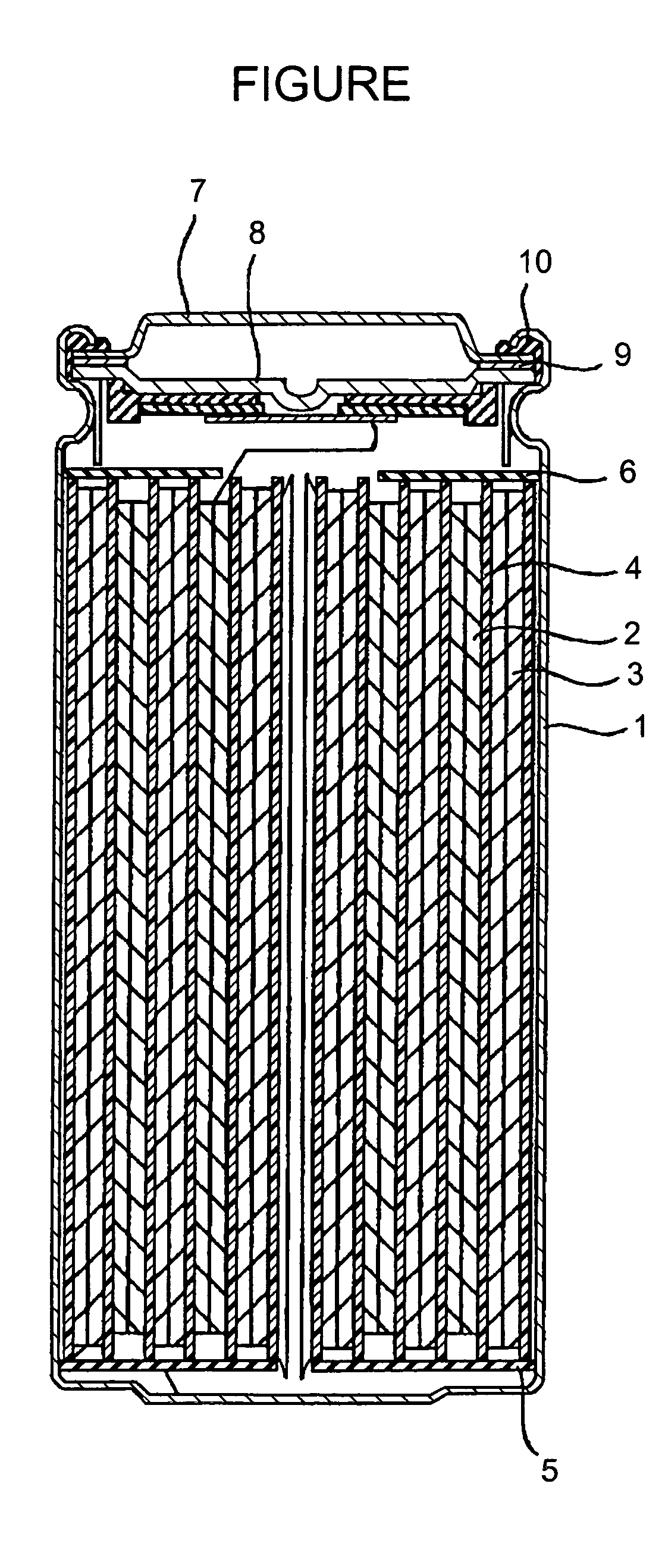

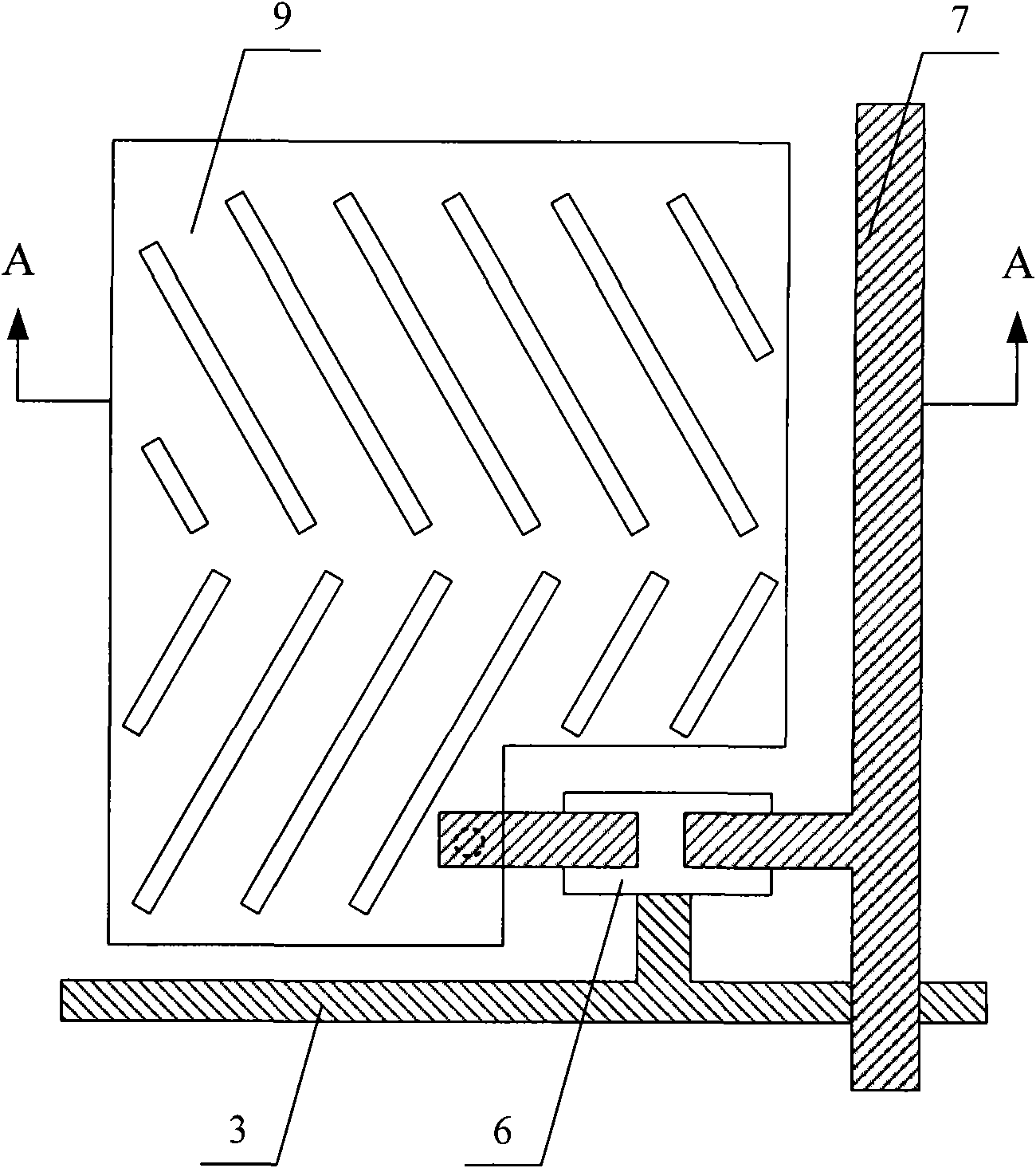

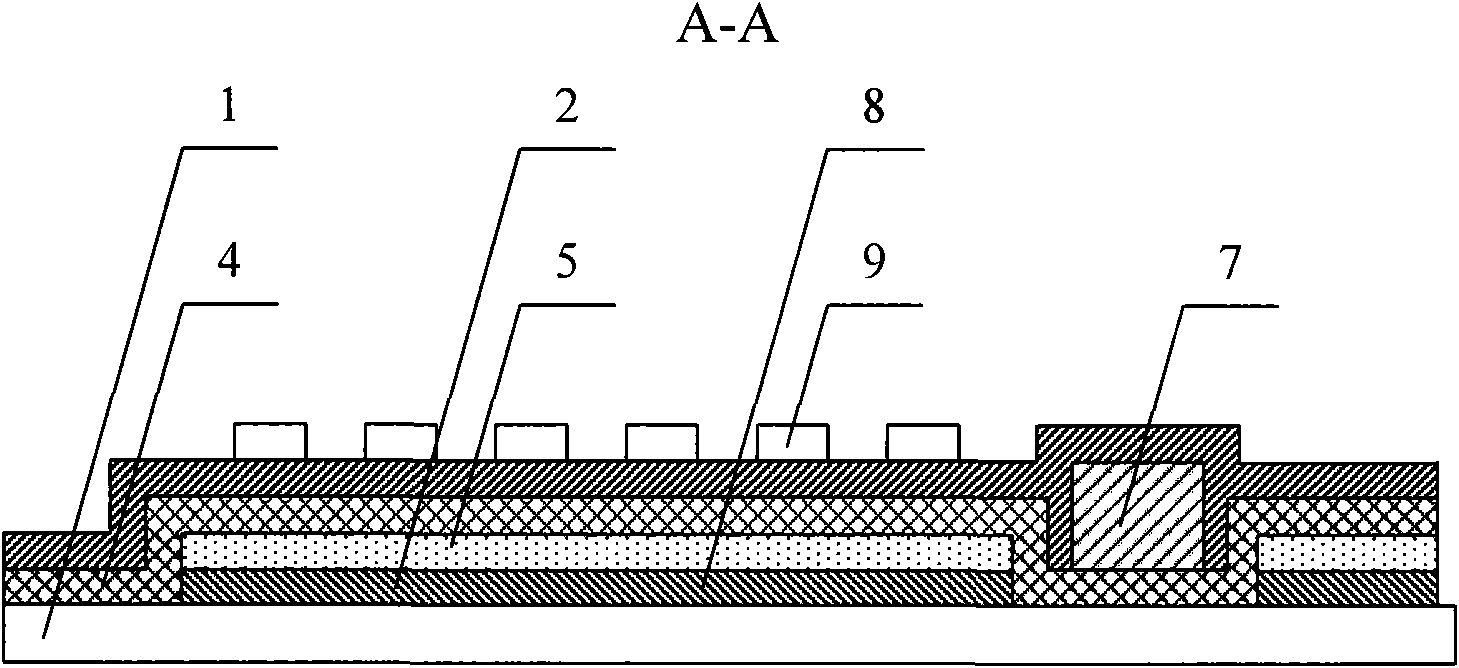

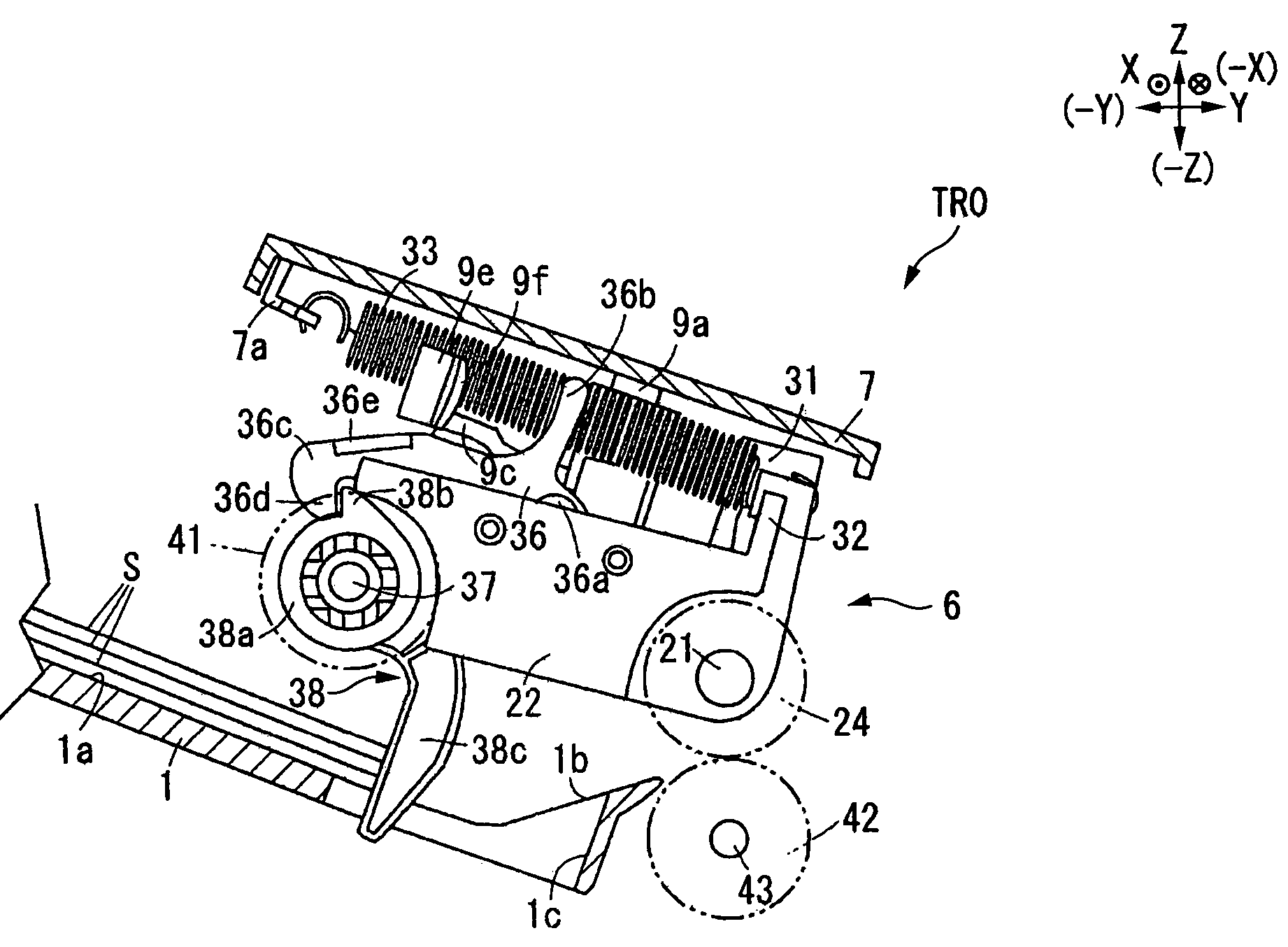

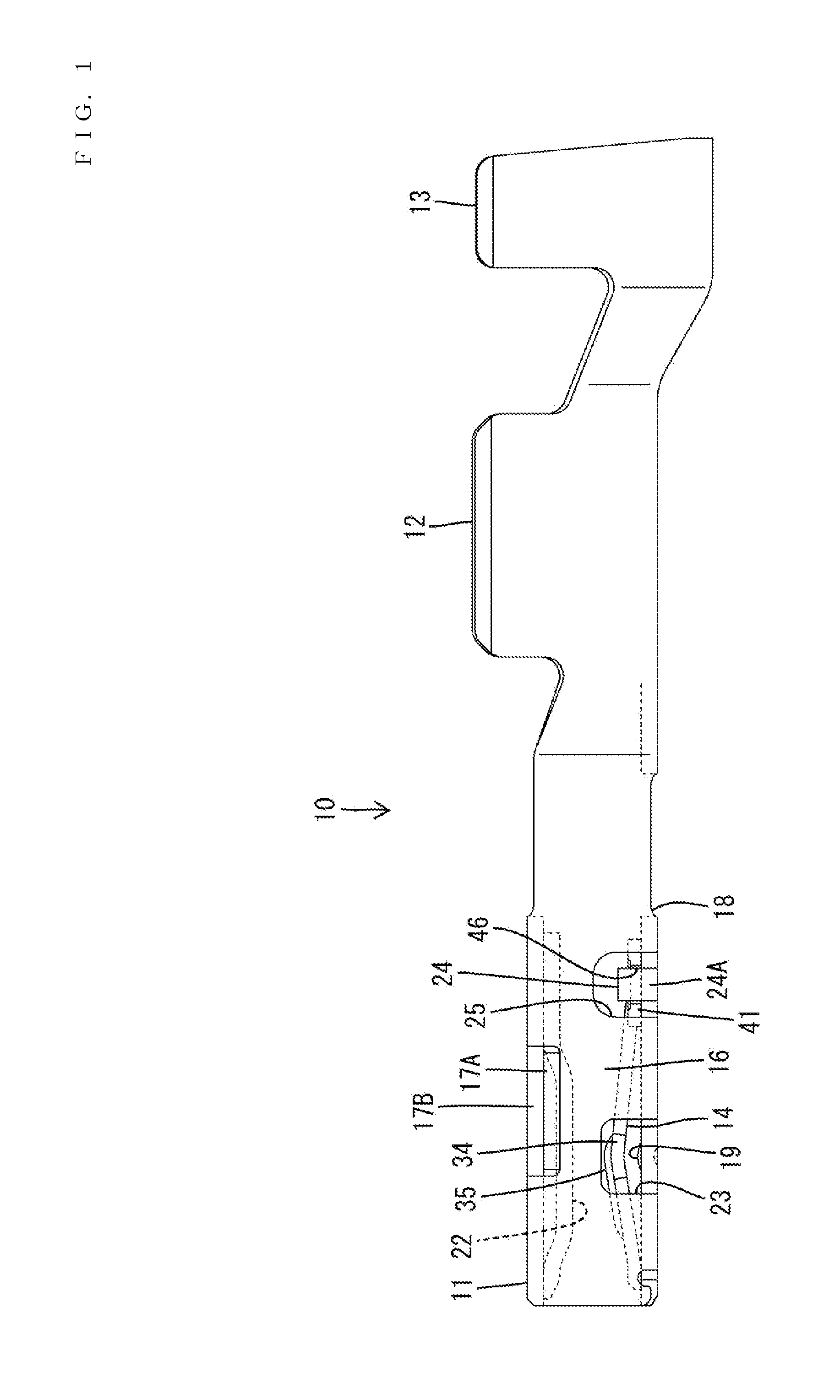

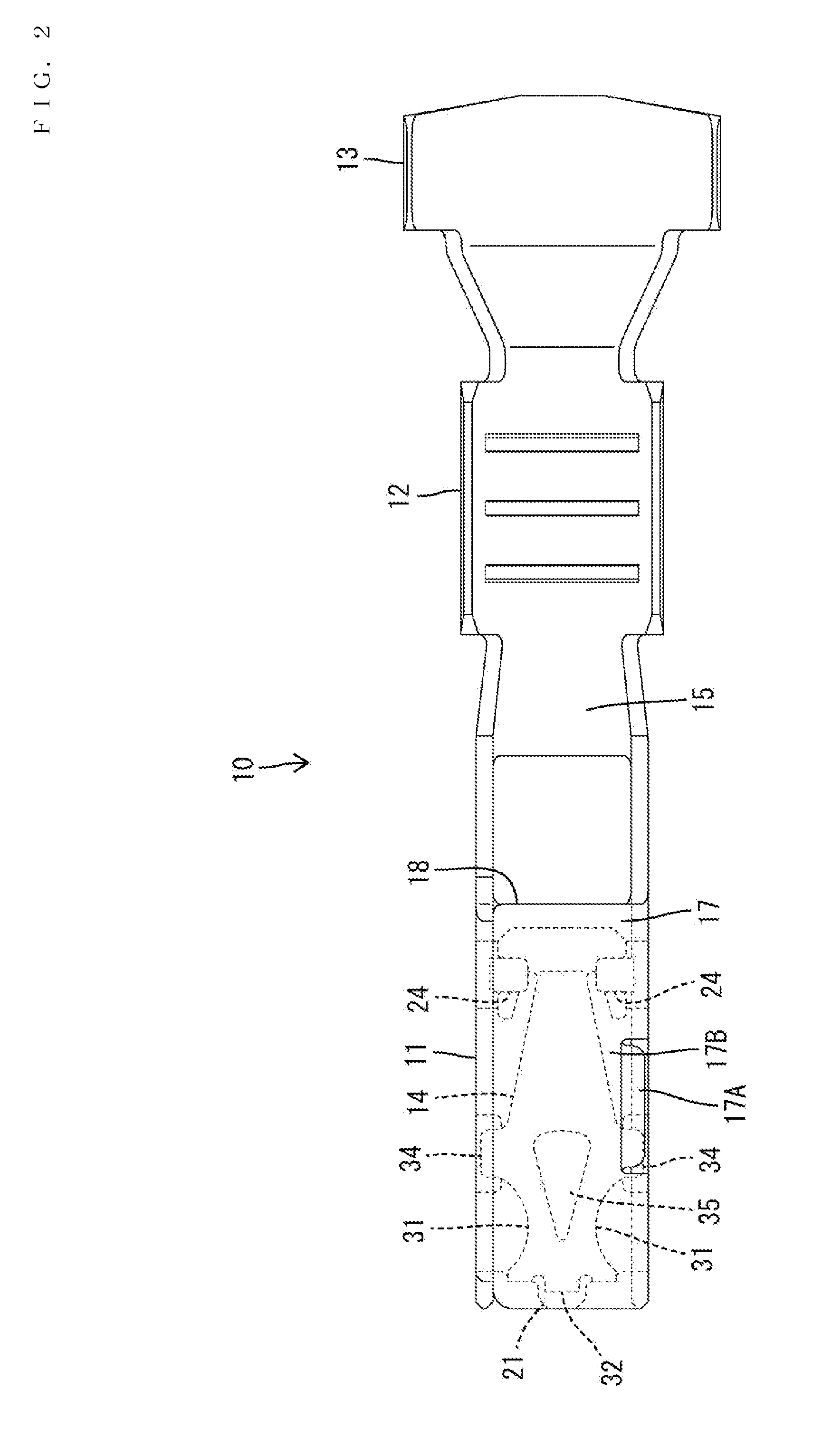

An object of the present invention is to provide a small-sized image sensor device having high precision of moving an object to be moved. The image sensor device includes: a fixed unit; a movable unit including an image sensor; a beam unit fixed to the fixed unit and movably supporting the movable unit; a driving unit for applying a driving force for moving the movable unit; and a wire unit provided for the beam unit and electrically connecting the image sensor and an external circuit.

Owner:KONICA MINOLTA OPTO

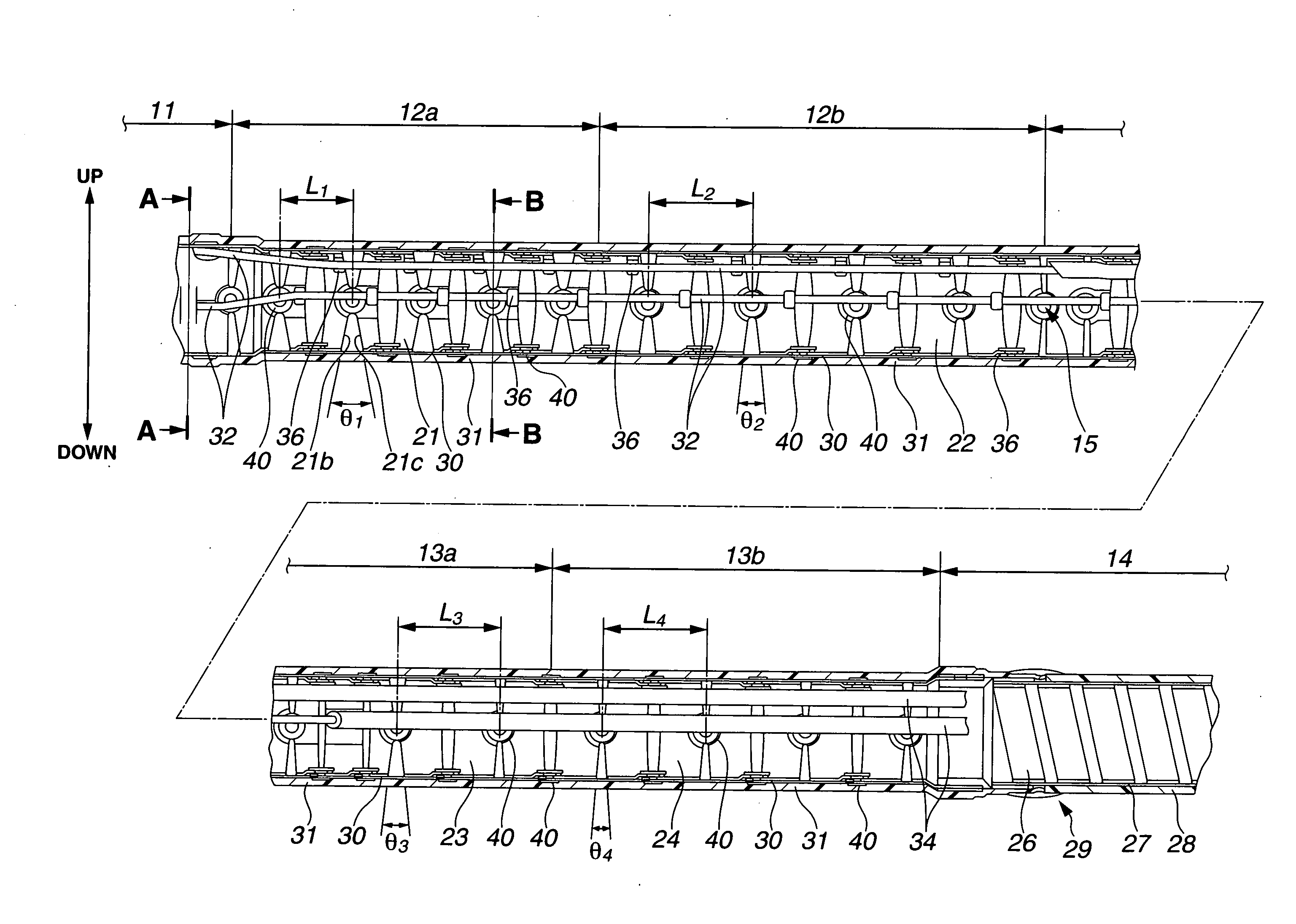

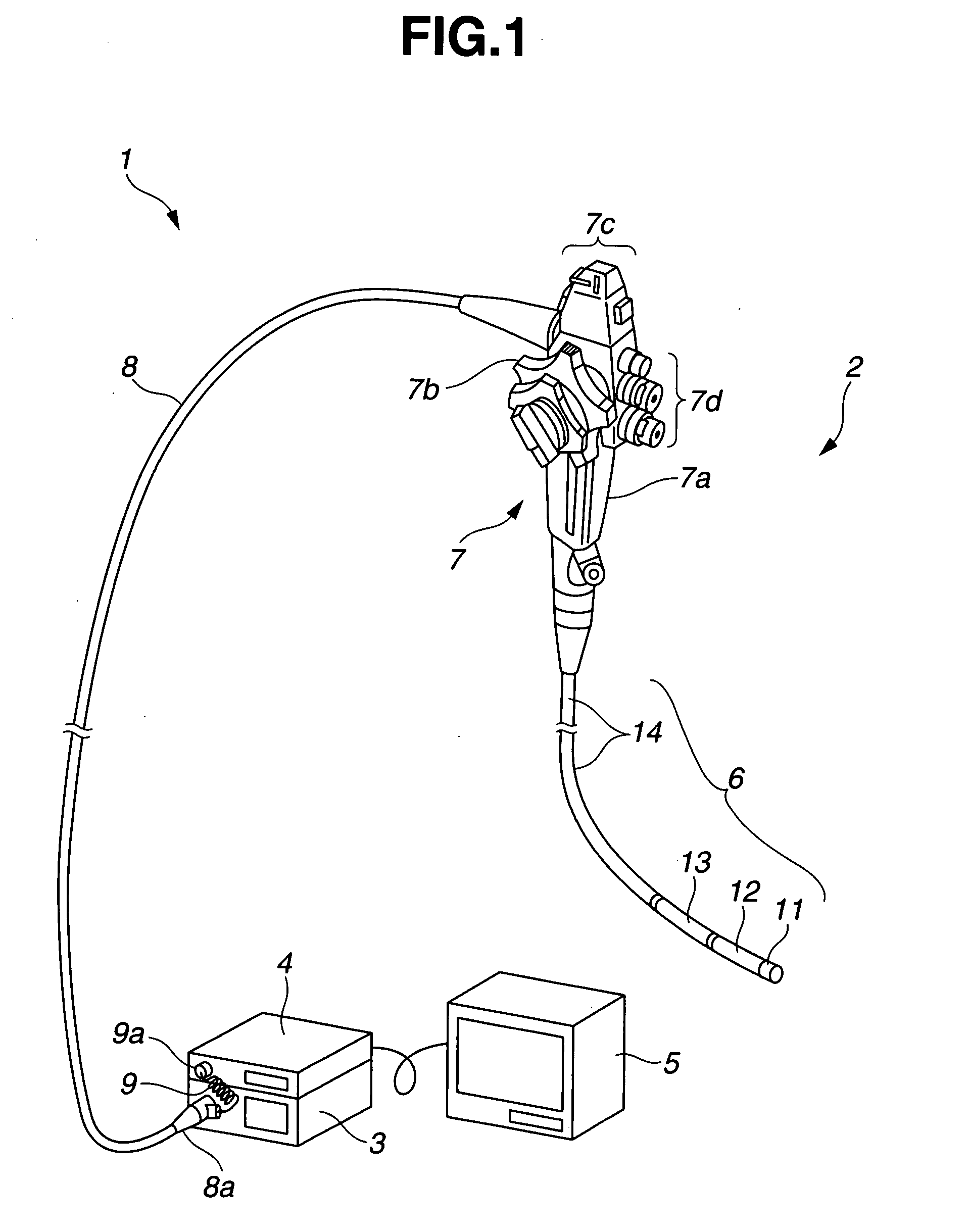

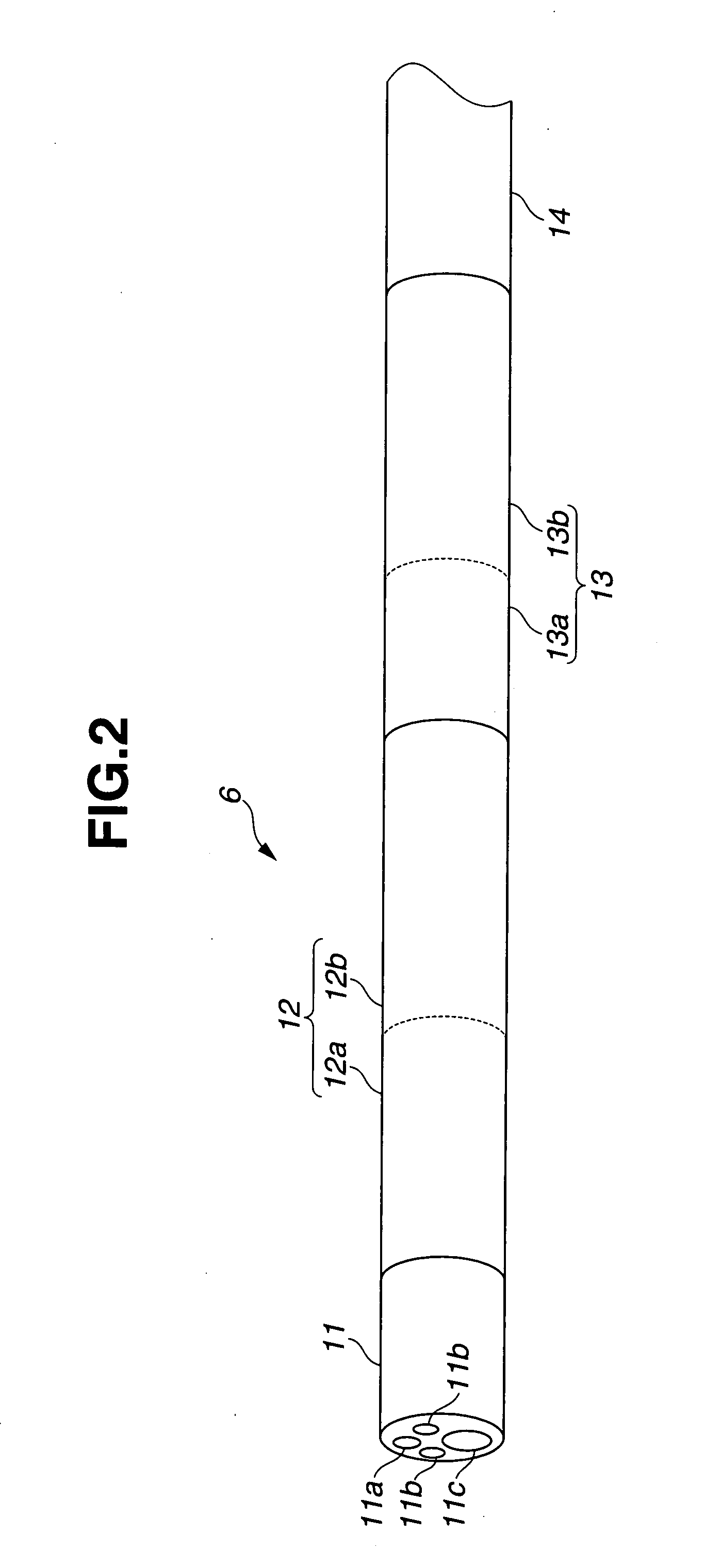

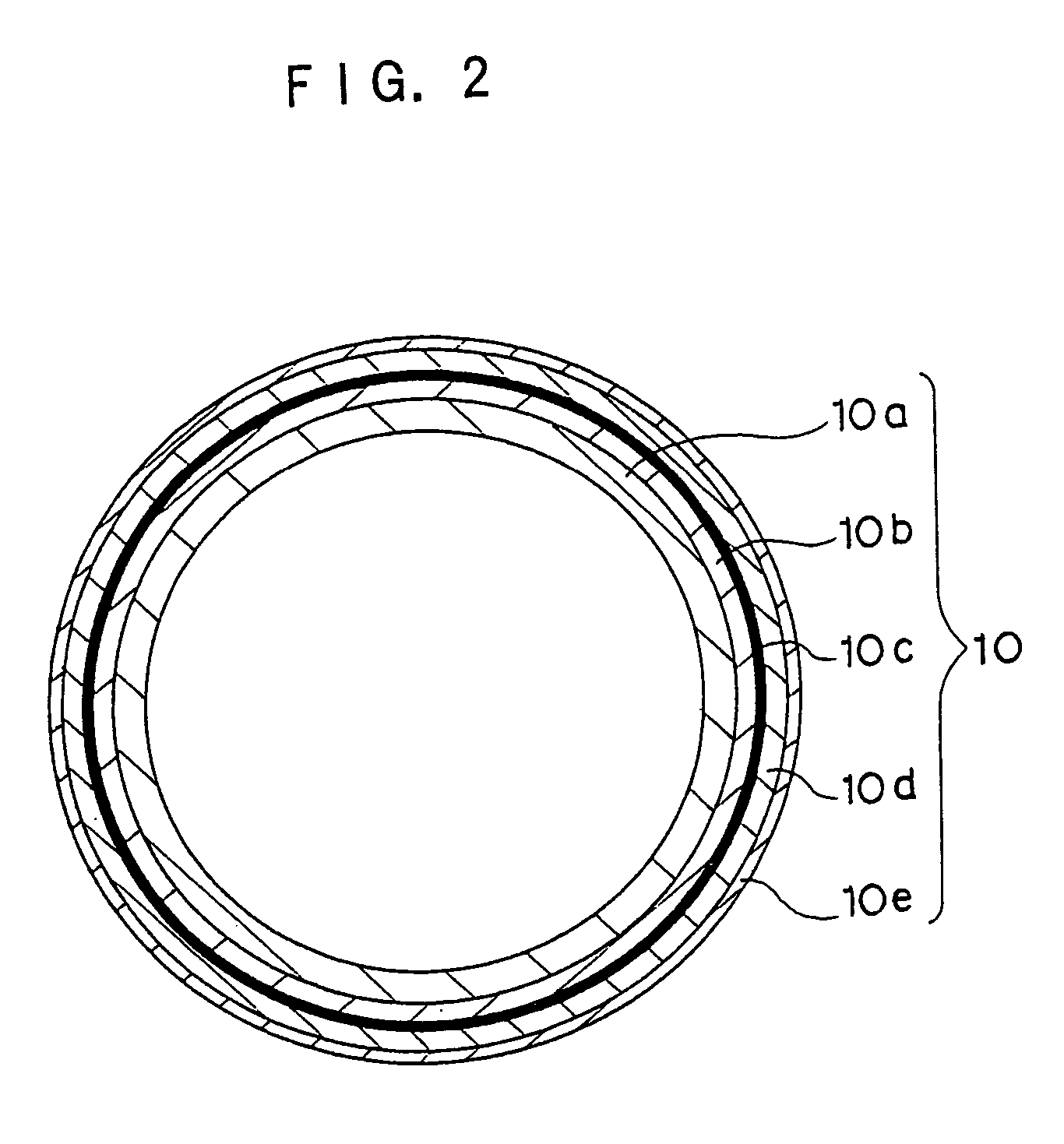

Endoscope Flexible Tube and Endoscope Device

In an endoscope flexible tube and an endoscope device of the present invention, an endoscope flexible tube which exhibits flexibility to be inserted into a body cavity includes a bending portion formed at a distal end side, a first flexible tube portion connected in series to a proximal end of the bending portion, and a second flexible tube portion connected in series to a proximal end of the first flexible tube portion. When the bending portion and the first flexible tube portion pass a flexed portion of the body cavity, a curvature radius of the first flexible tube portion which is passively bent under a predetermined force is set to be larger than a curvature radius of the bending portion in a maximum bent state.

Owner:OLYMPUS CORP

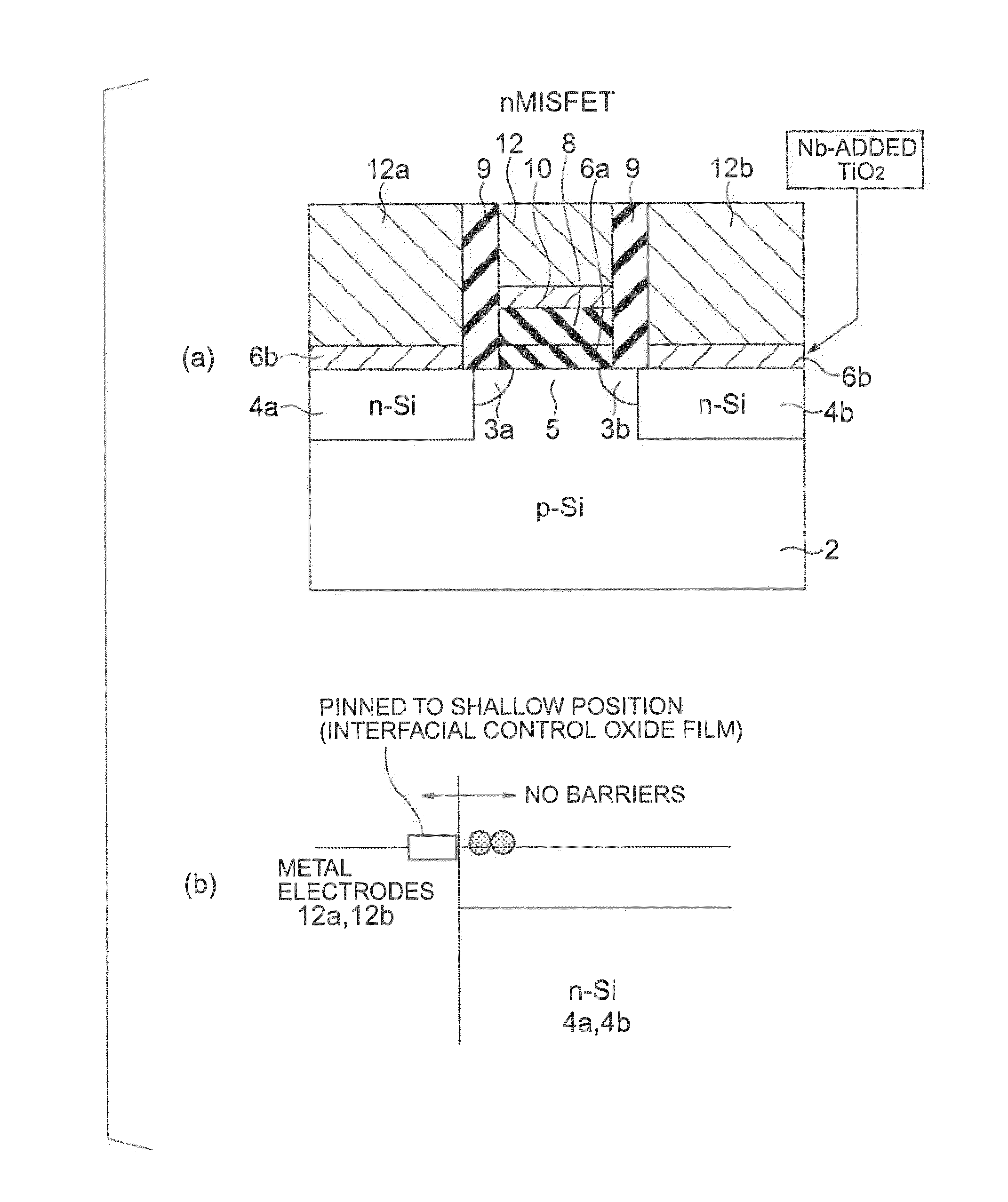

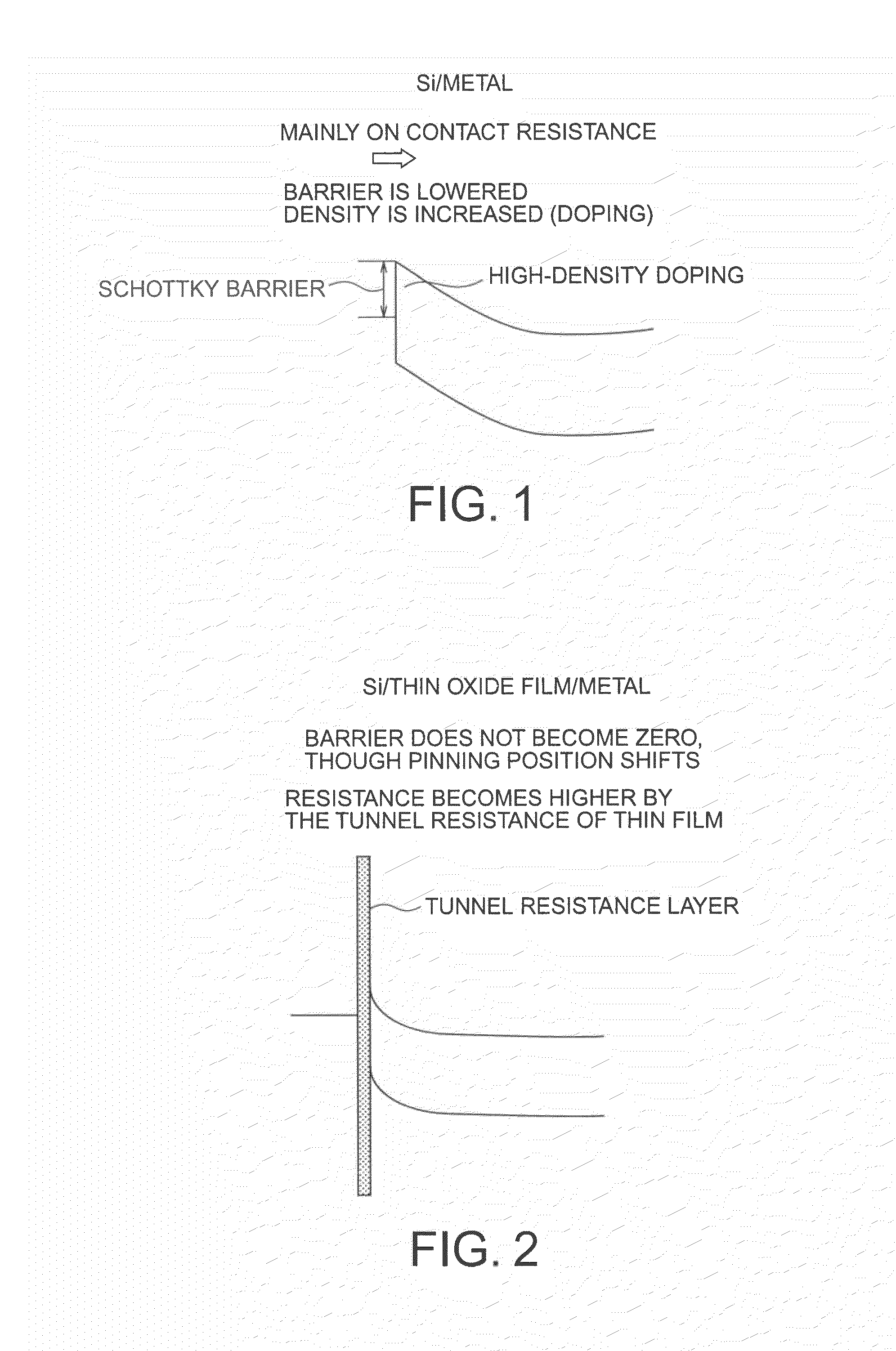

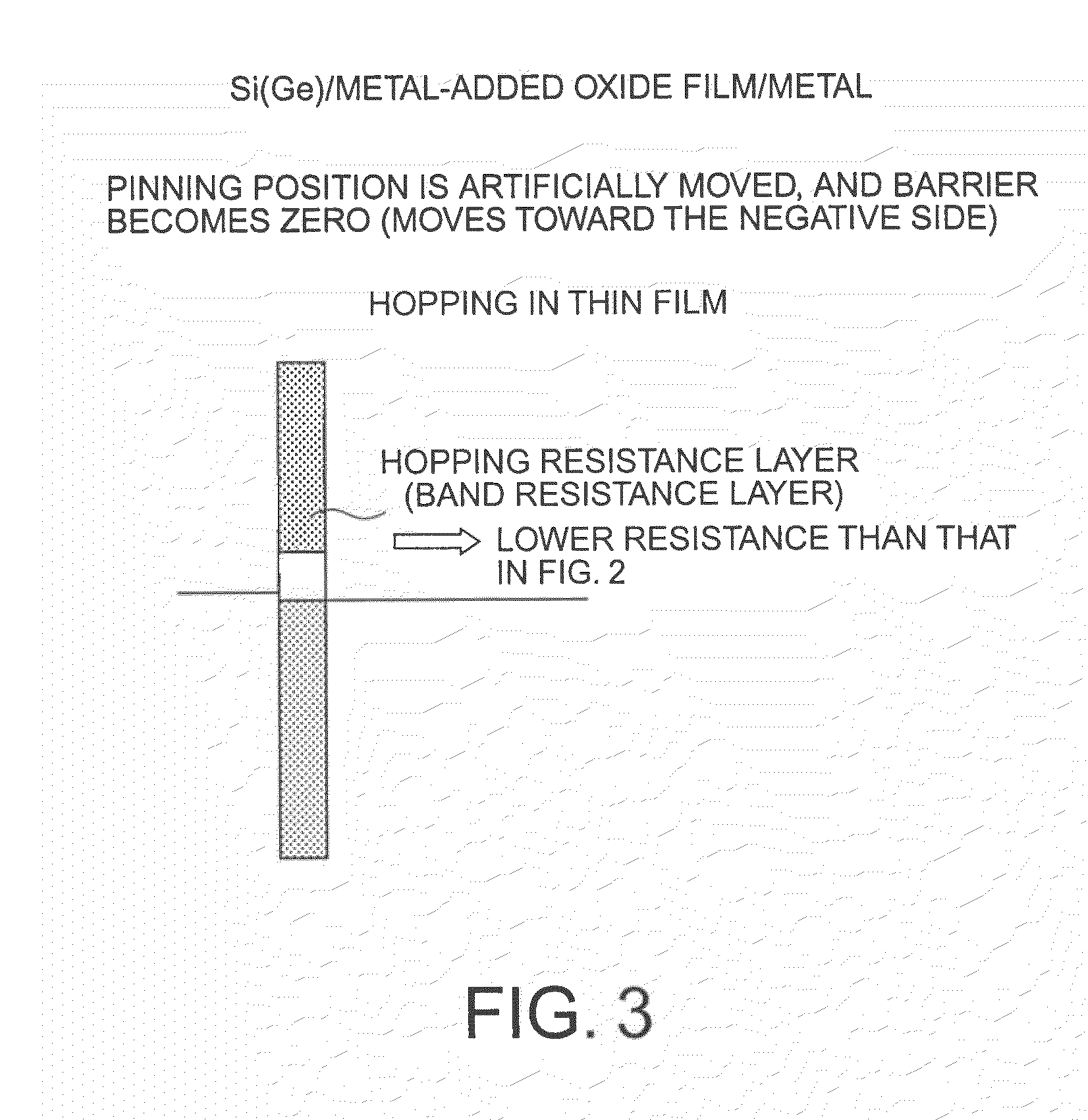

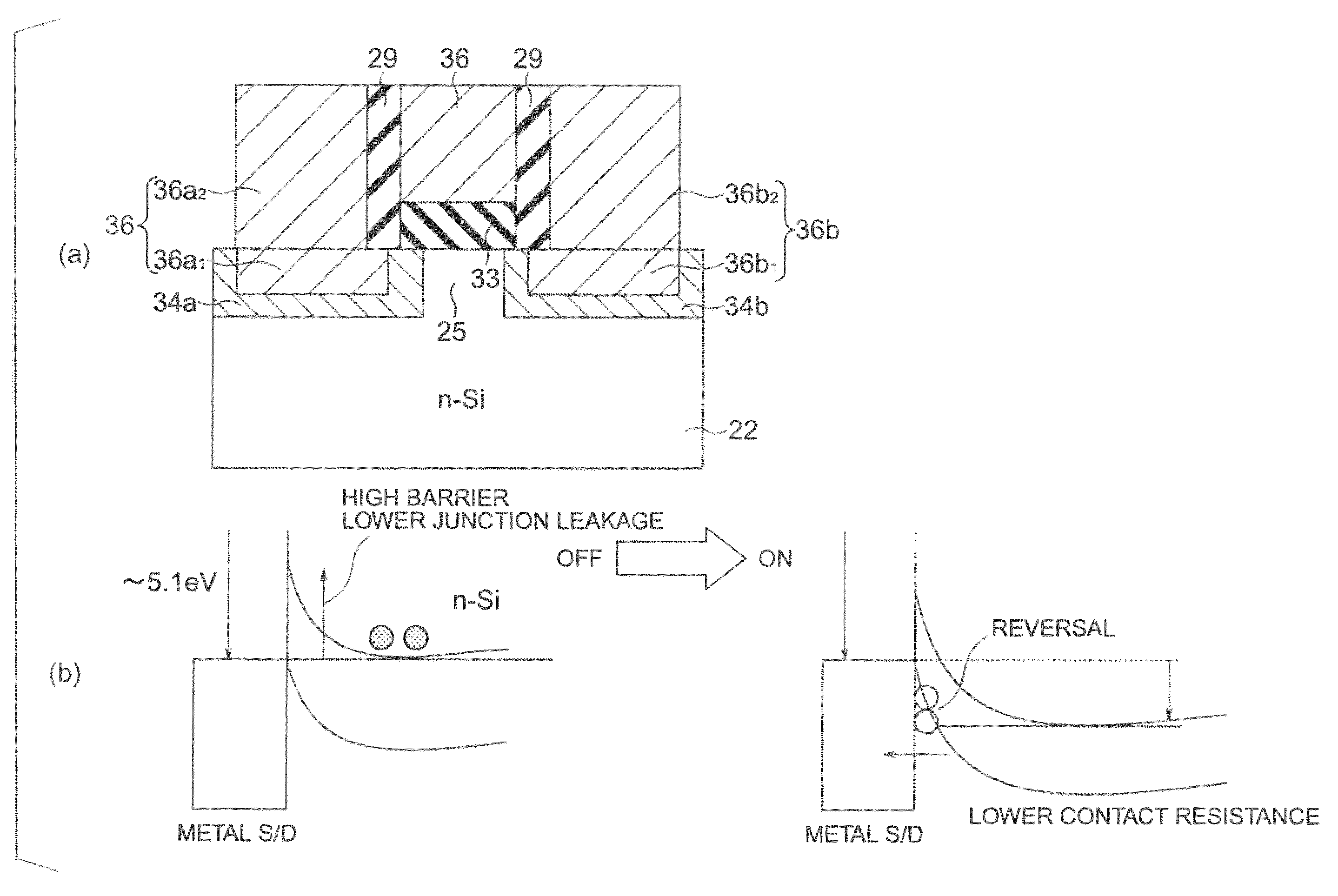

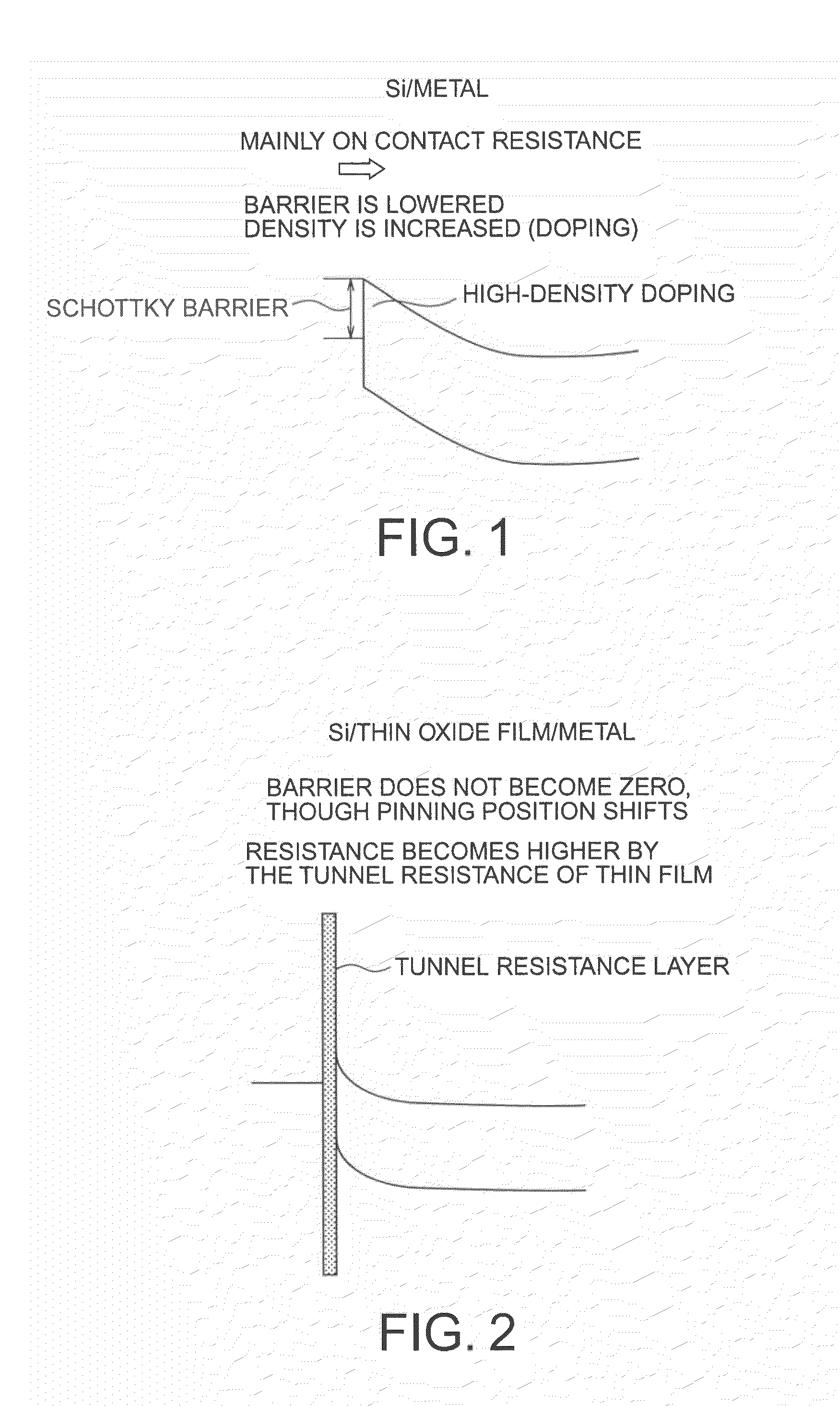

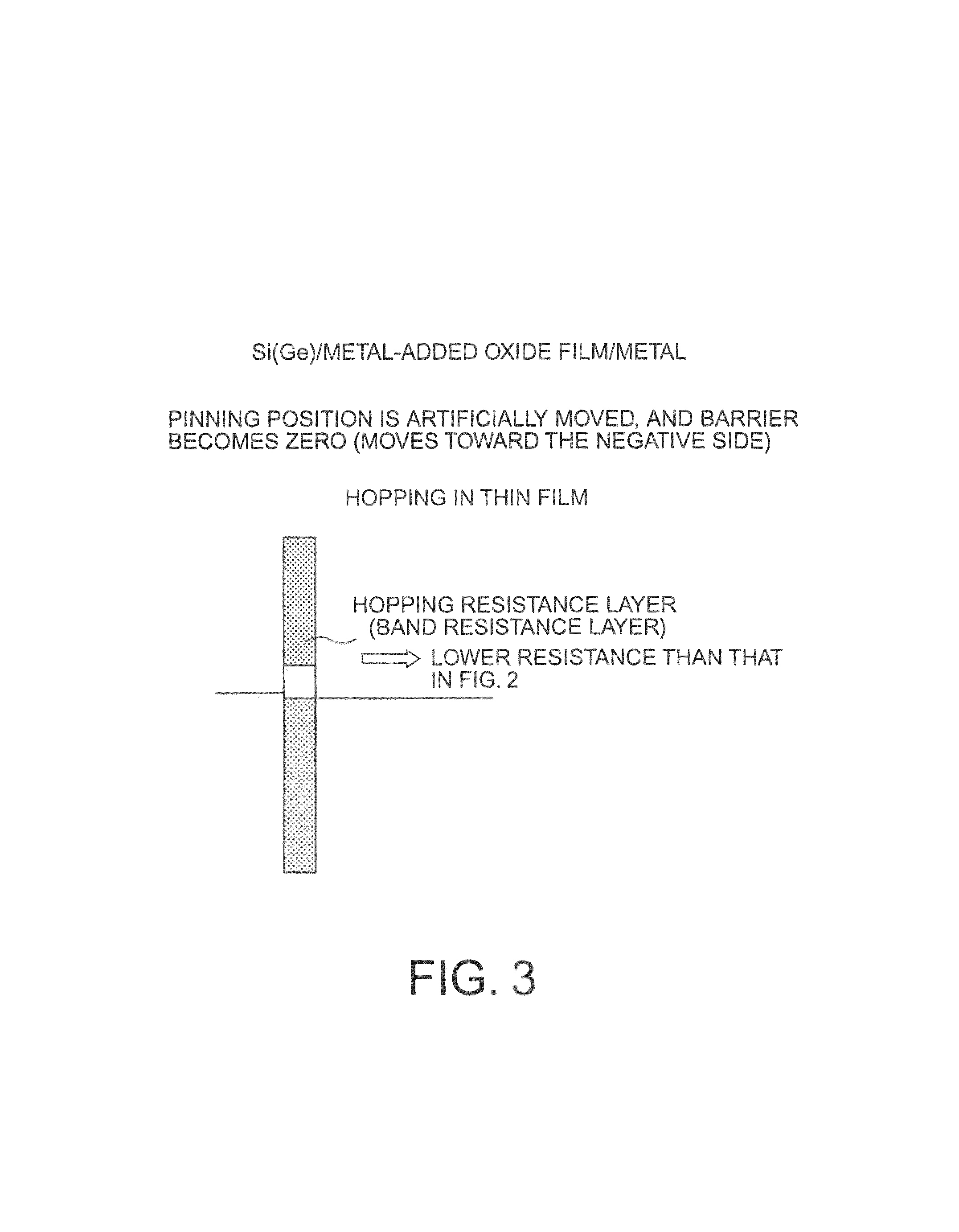

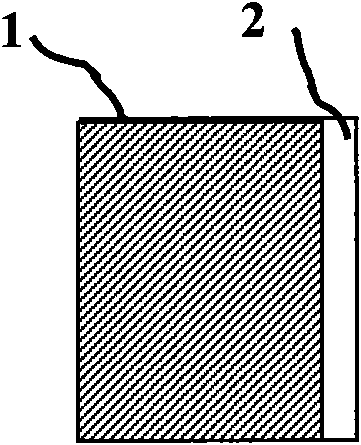

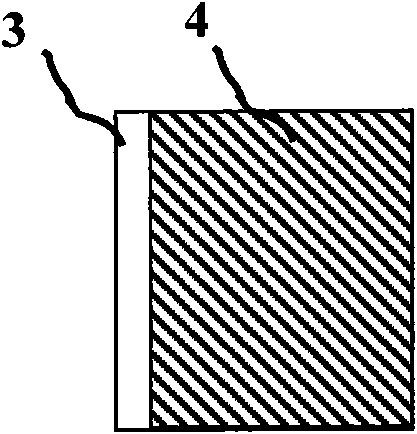

Semiconductor device

InactiveUS20100224916A1Optimize effective work functionSuppress generationTransistorSemiconductor/solid-state device detailsWork functionSemiconductor

It is made possible to optimize the effective work function of the metal for a junction and suppress the resistance as far as possible at the interface between a semiconductor or a dielectric material and a metal. A semiconductor device includes: a semiconductor film; a Ti oxide film formed on the semiconductor film, and including at least one element selected from the group consisting of V, Cr, Mn, Fe, Co, Ni, Nb, Mo, Tc, Ru, Rh, Pd, Ta, W, Re, Os, Ir, and Pt; and a metal film formed on the Ti oxide film.

Owner:KK TOSHIBA

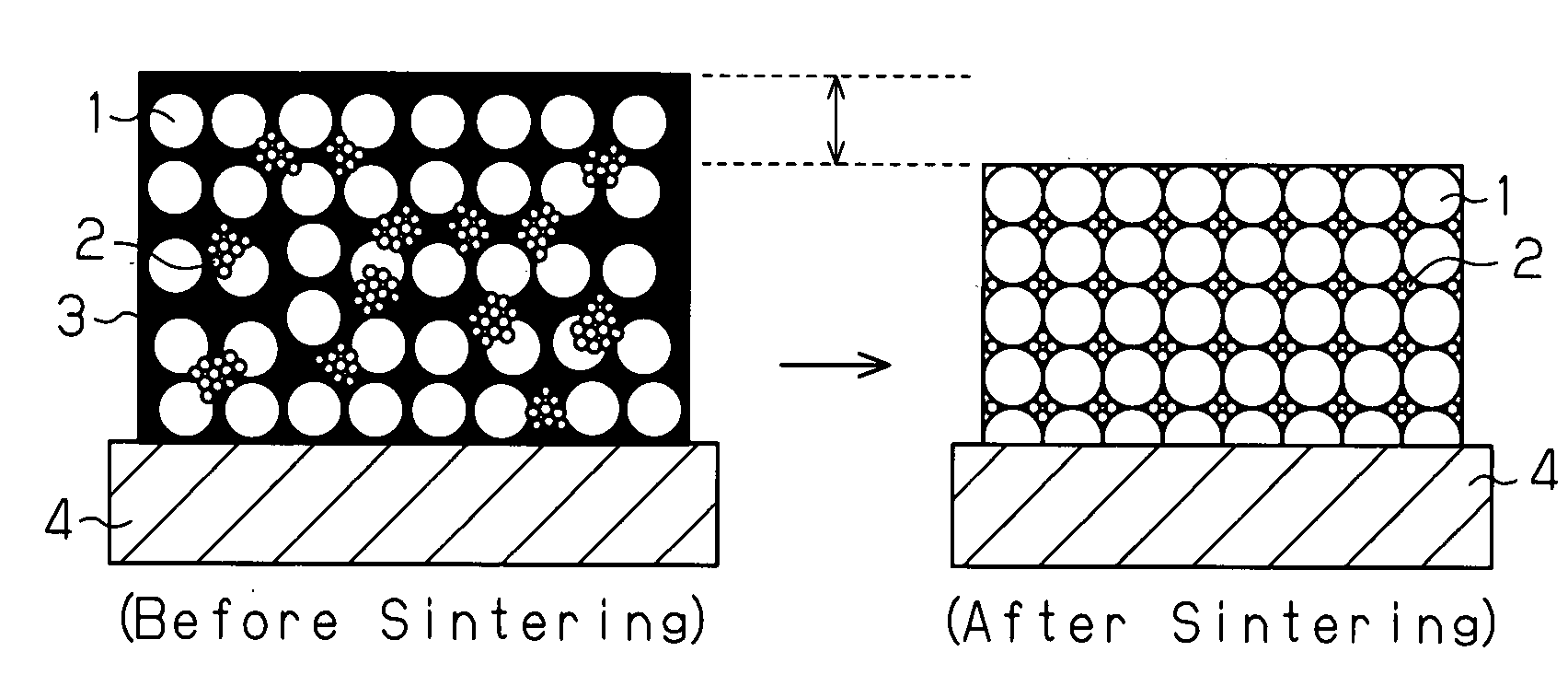

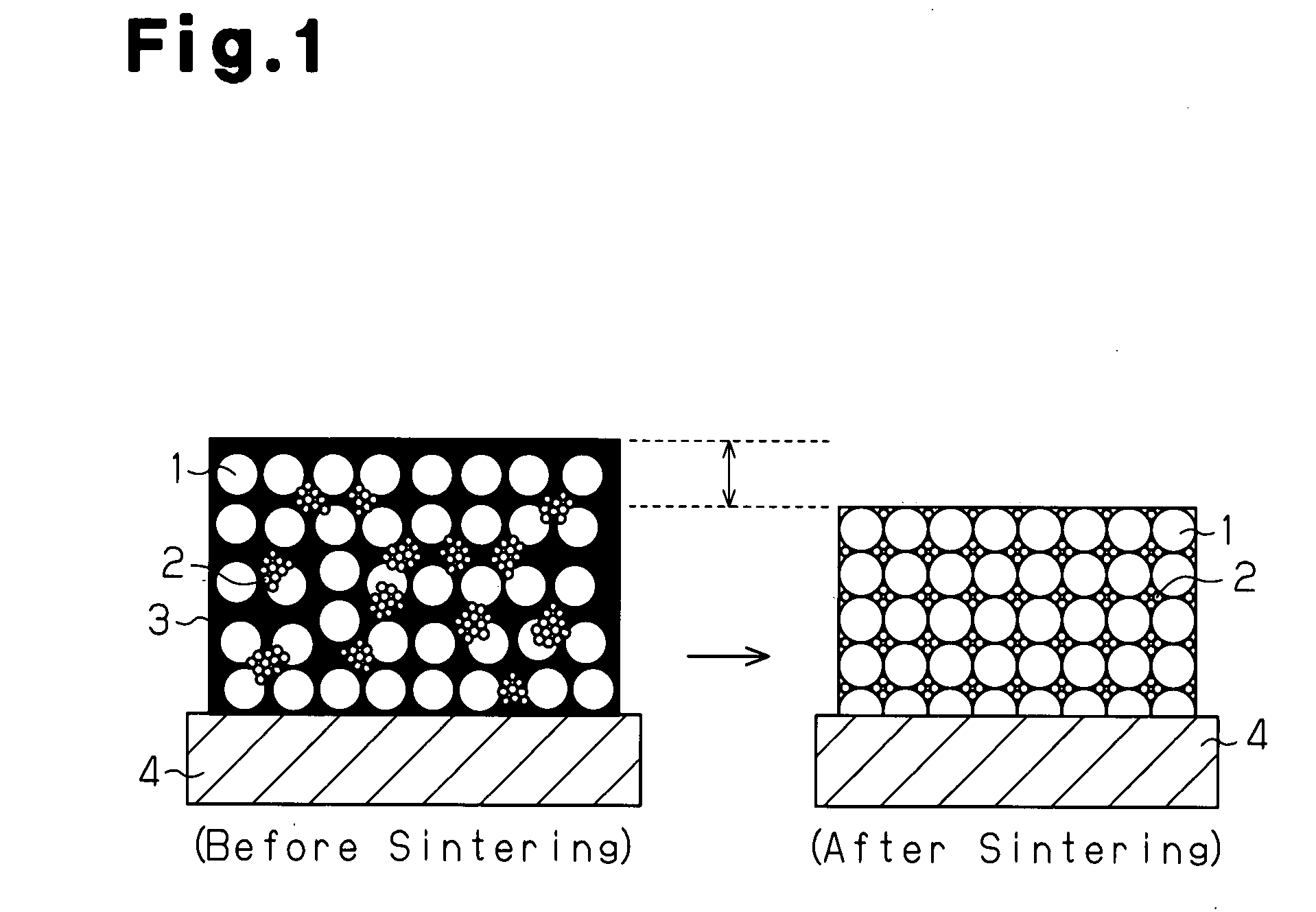

Aluminum alloy of excellent machinability and manufacturing method thereof

An aluminum alloy containing Si: 1.5-12% (mass % here and hereinafter), Mg: 0.5-6% and, optionally, at least one of Mn: 0.5-2%, Cu: 0.15-3% and Cr: 0.04-0.35% and, further, containing Ti: 0.01-0.1% and the balance of Al and inevitable impurities, in which the average grain size of crystallized grains of Si system compounds is from 2 to 20 mu m and an area ratio thereof is from 2 to 12%. The alloy is melted to obtain a cast ingot having DAS (Dendrite Arm Spacing) of 10 to 50 mu m, which is then put to a soaking treatment at 450 to 520 DEG C. and then to extrusion molding. The aluminum alloy has excellent machinability with no addition of low melting metals.

Owner:KOBE STEEL LTD

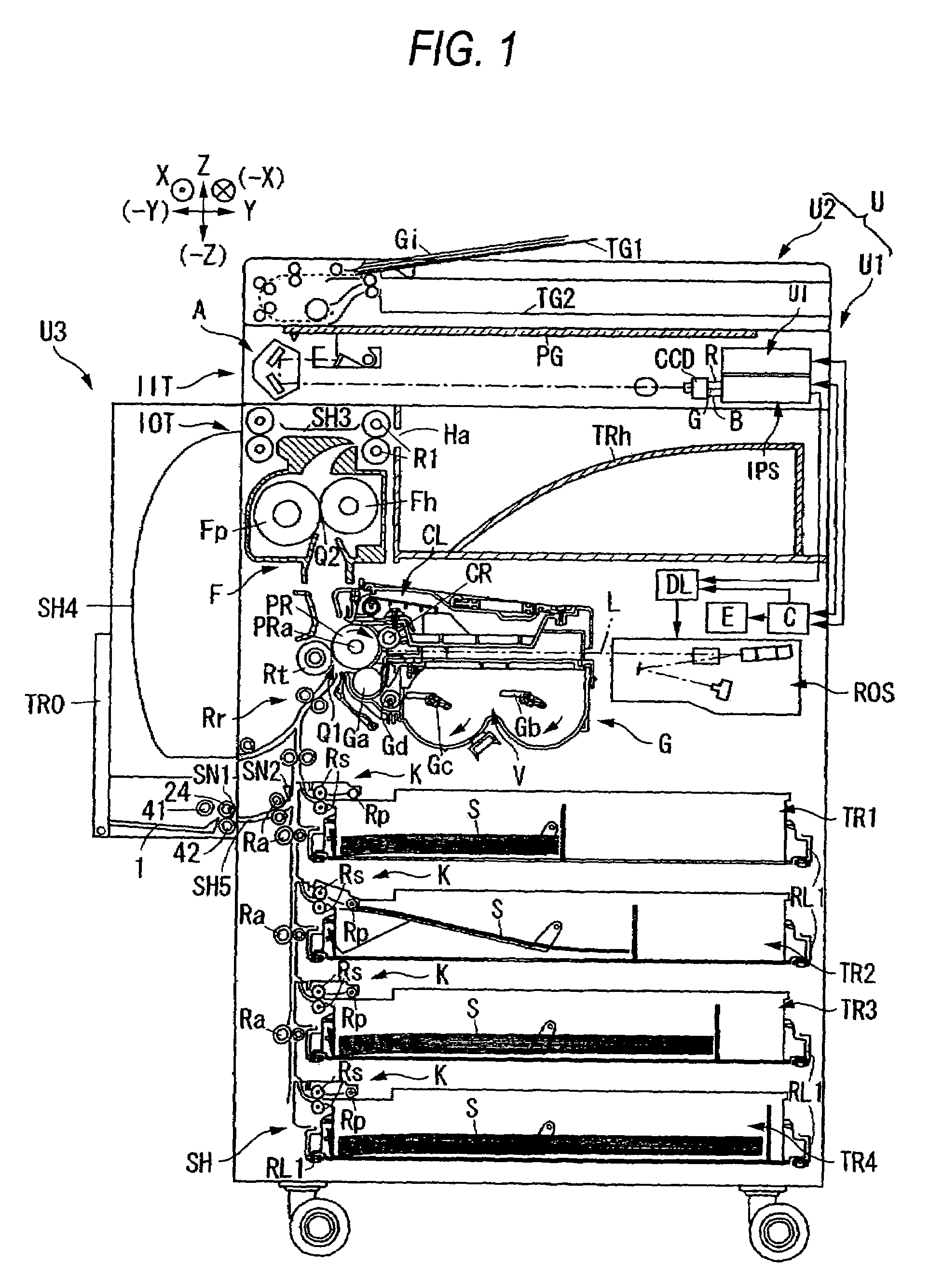

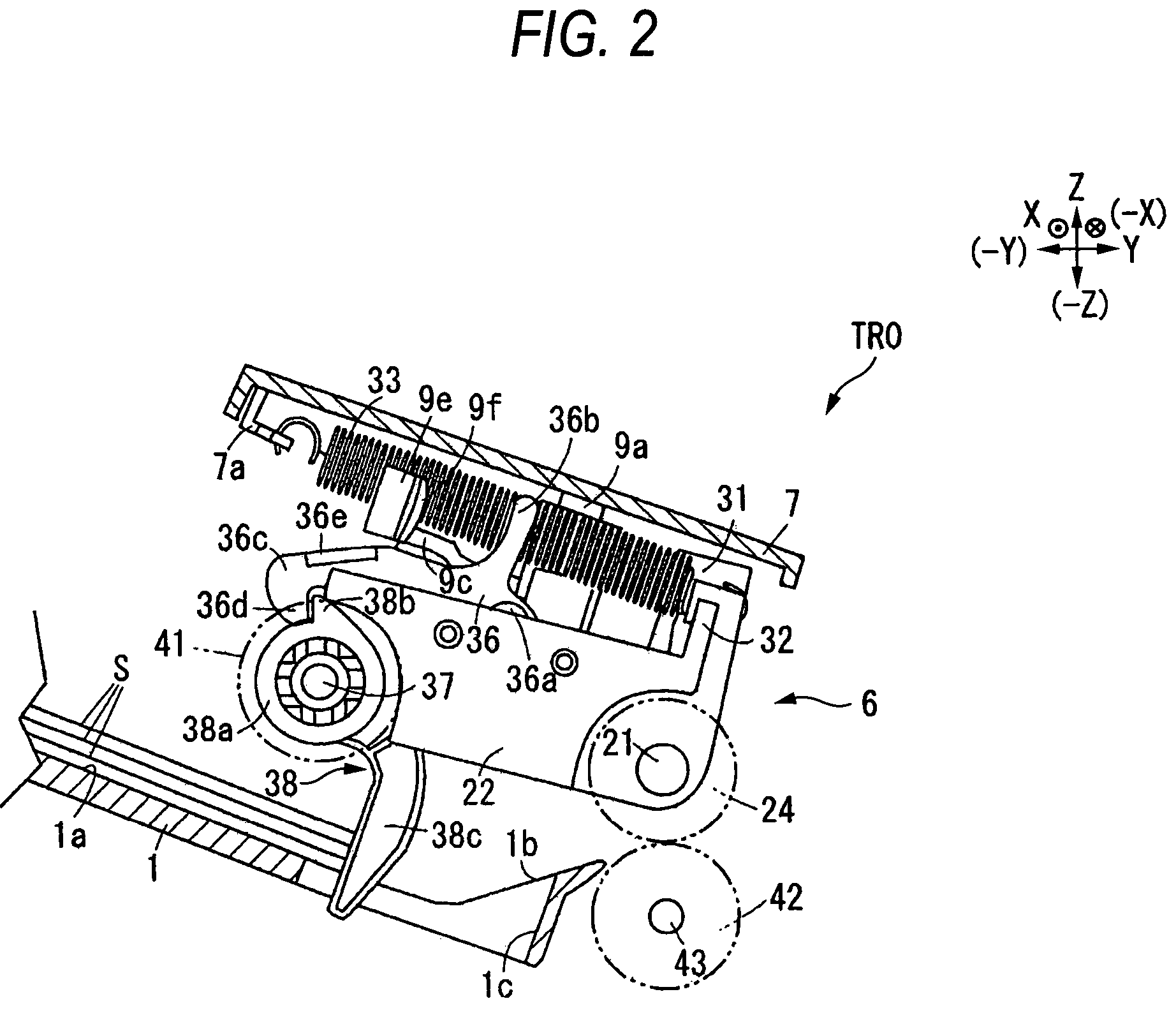

Image sensor device with movable sensor

InactiveUS8248497B2Improve accuracyInhibition resistanceTelevision system detailsTelevision system scanning detailsEngineeringExternal circuit

Owner:KONICA MINOLTA OPTO

Electrode for secondary battery, slurry for secondary battery electrode, and secondary battery

ActiveUS20120107690A1Improve mobilityNot suppress depositionElectrode manufacturing processesHybrid capacitor electrodesLithiumPolymer

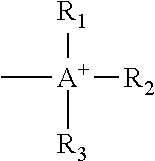

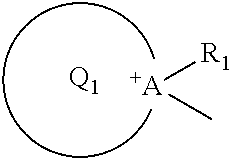

A secondary battery electrode which suppresses decrease in capacity and lithium deposition at low temperatures is provided. An electrode for a secondary battery includes an electrode active material layer containing a polymer having a cationic group, an anion corresponding to the cationic group, and an electrode active material, and the cation density in the polymer is 0.1 to 15 meq / g.

Owner:ZEON CORP

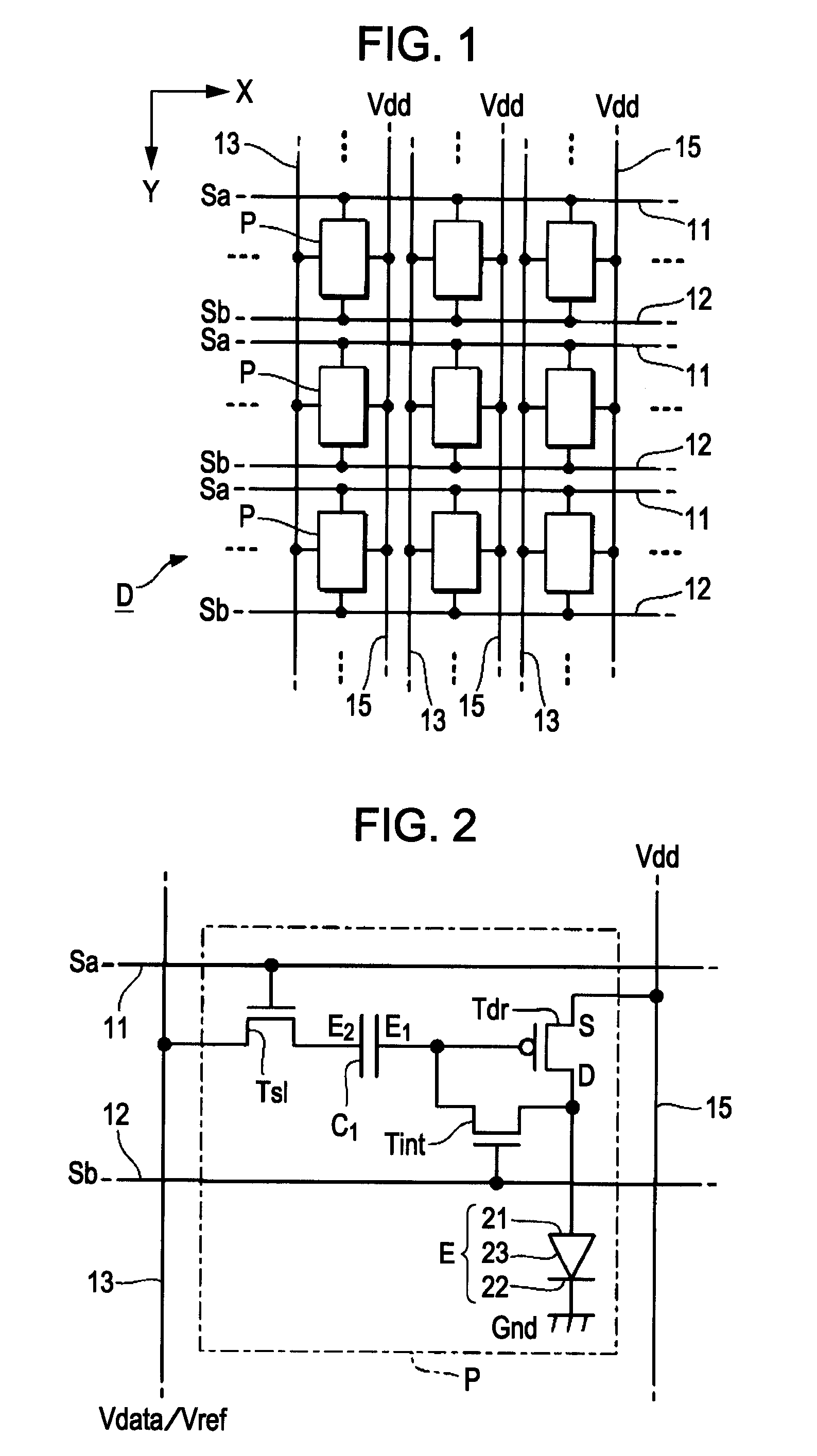

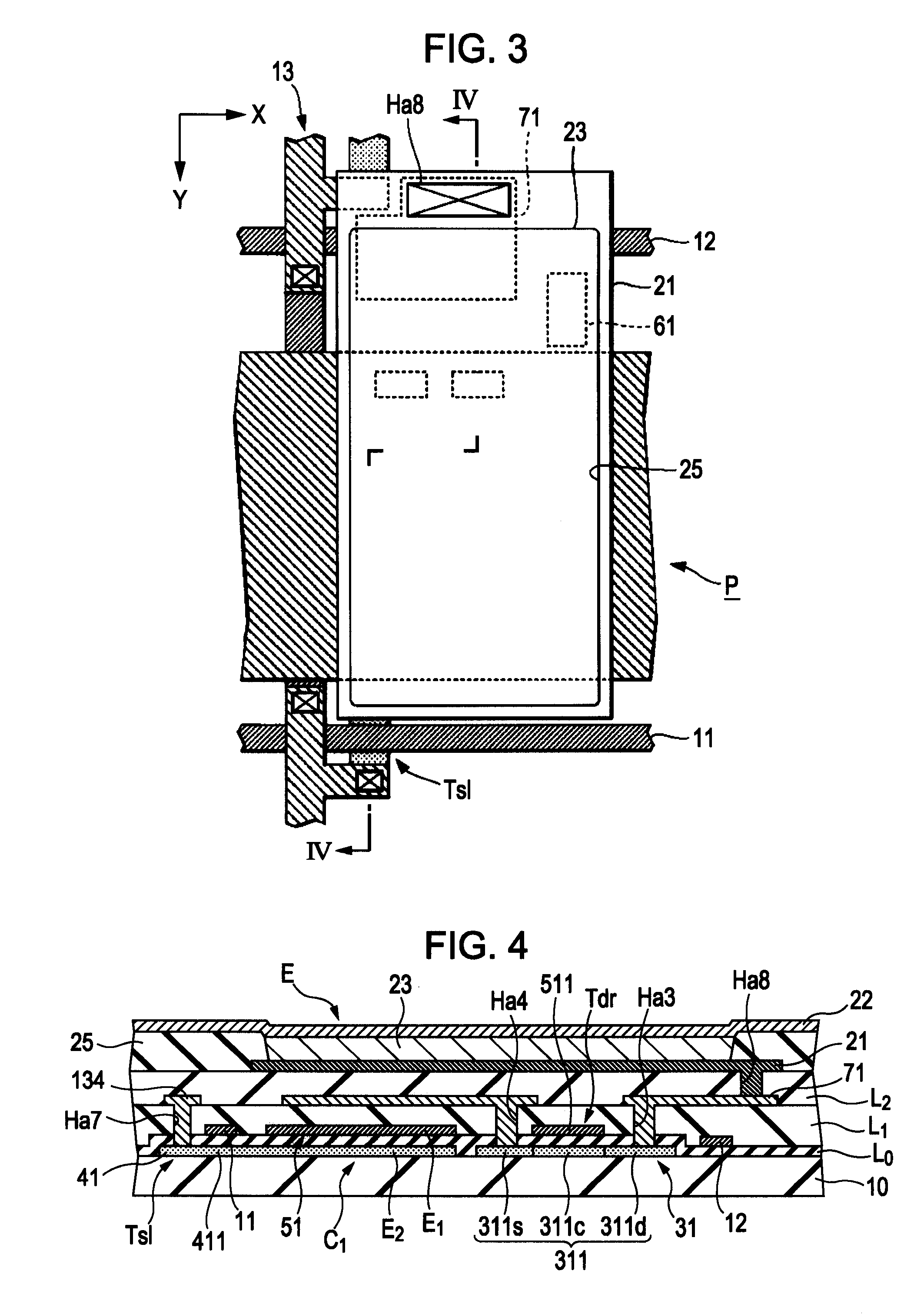

Light-emitting device and electronic apparatus

ActiveUS20070120188A1Inhibition resistanceSimple manufacturing processElectroluminescent light sourcesSolid-state devicesEngineeringLight emitting device

A light-emitting device includes a drive transistor that controls a current to be supplied to a light-emitting element from a power supply line, an electrical continuity portion that electrically connects the drive transistor with the light-emitting element, an initializing transistor that is turned ON to diode-connect the drive transistor, and a connecting portion that electrically connects the drive transistor with the initializing transistor. The power supply line includes a first portion extending in a predetermined direction. The electrical continuity portion and the connecting portion are formed from the same layer as that of the power supply line and are located on one side along the width of the first portion across the drive transistor.

Owner:SEIKO EPSON CORP

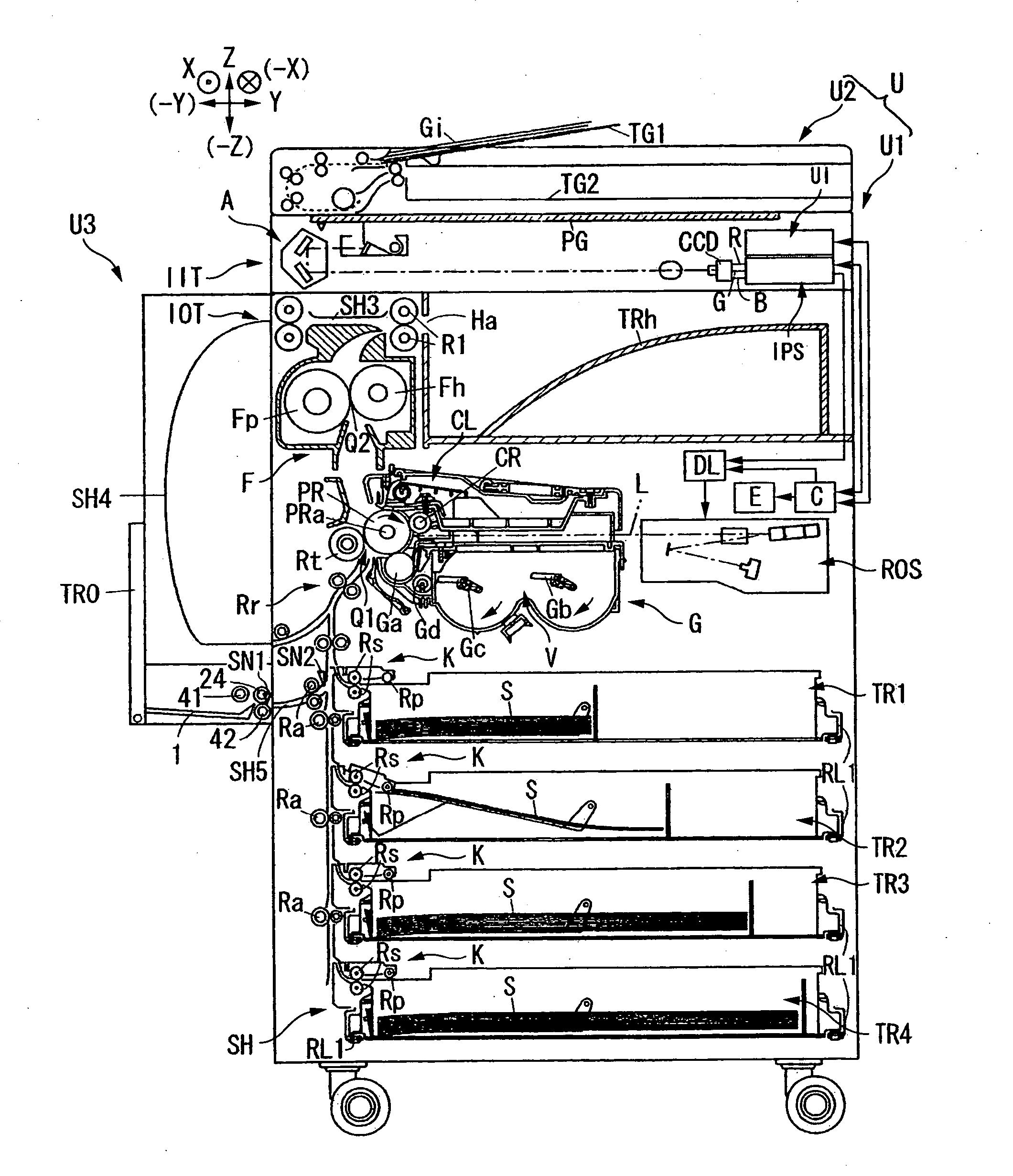

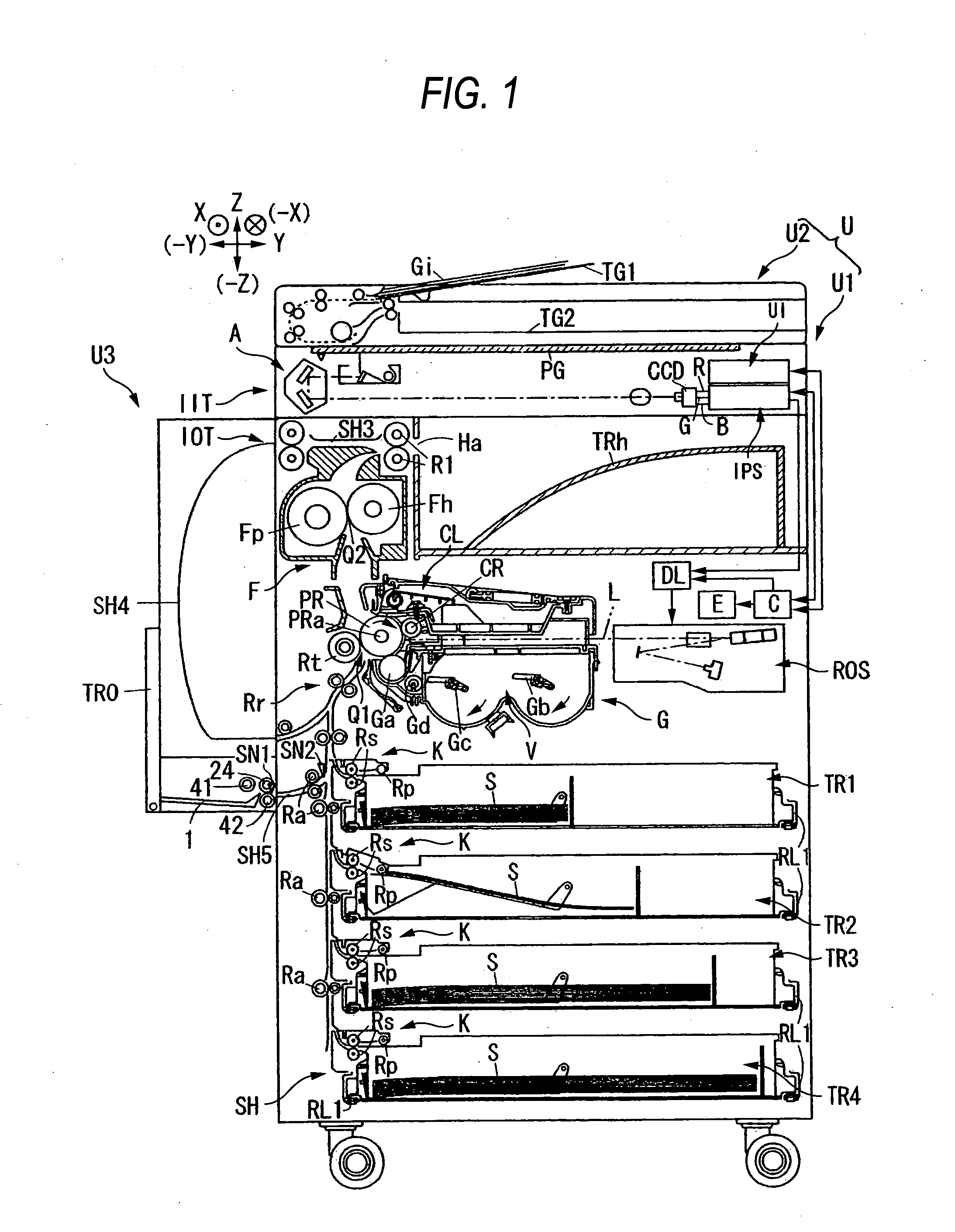

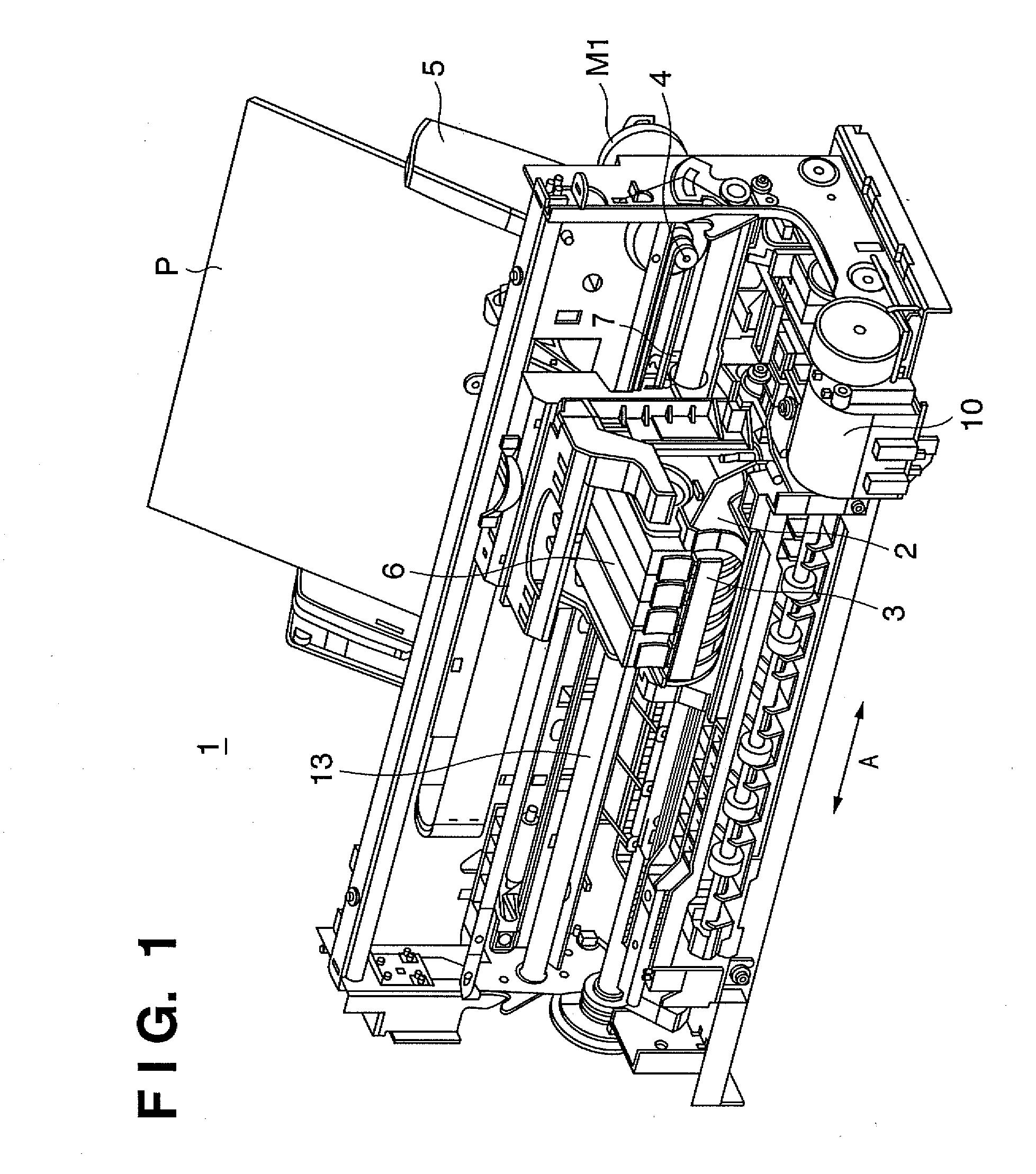

Sheet conveyance device

Owner:FUJIFILM BUSINESS INNOVATION CORP

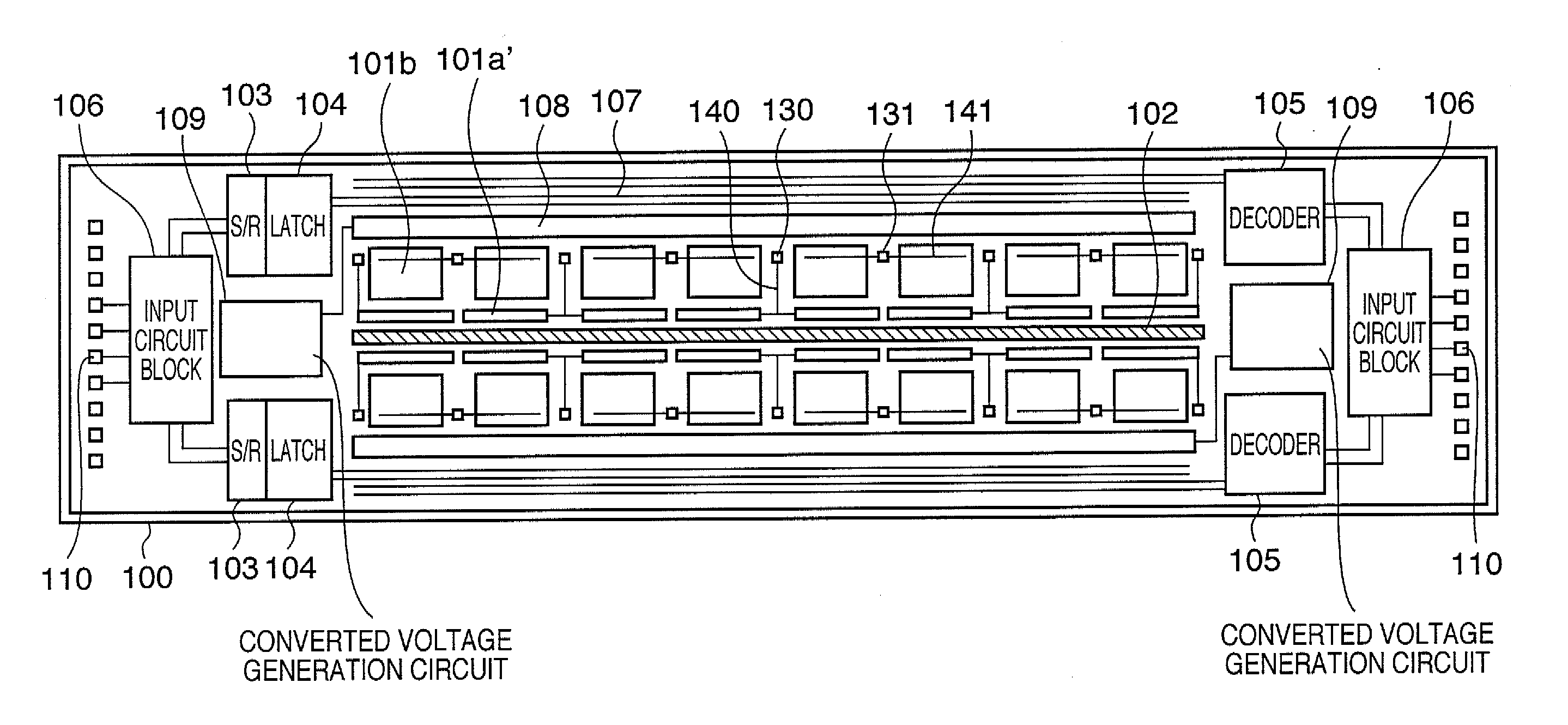

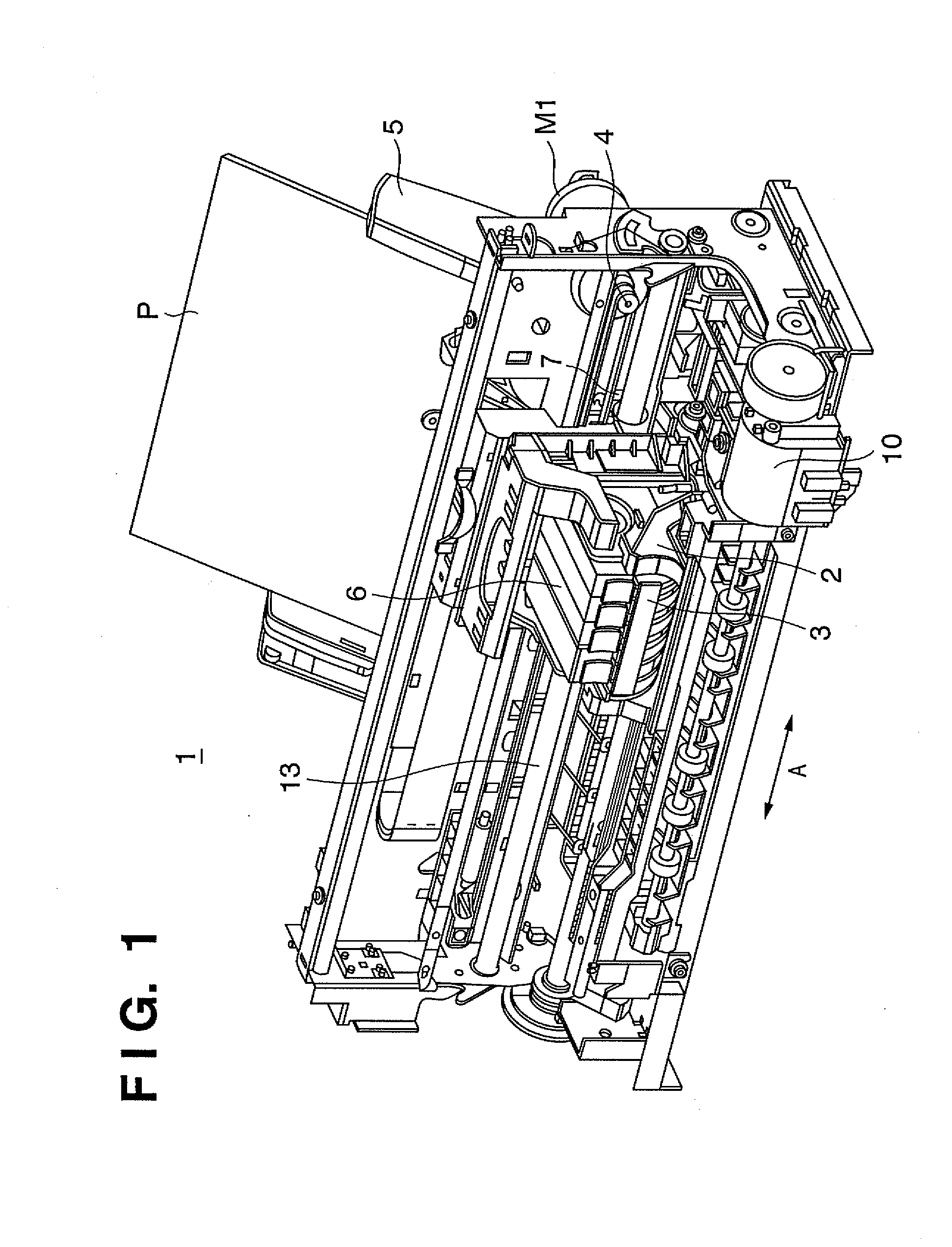

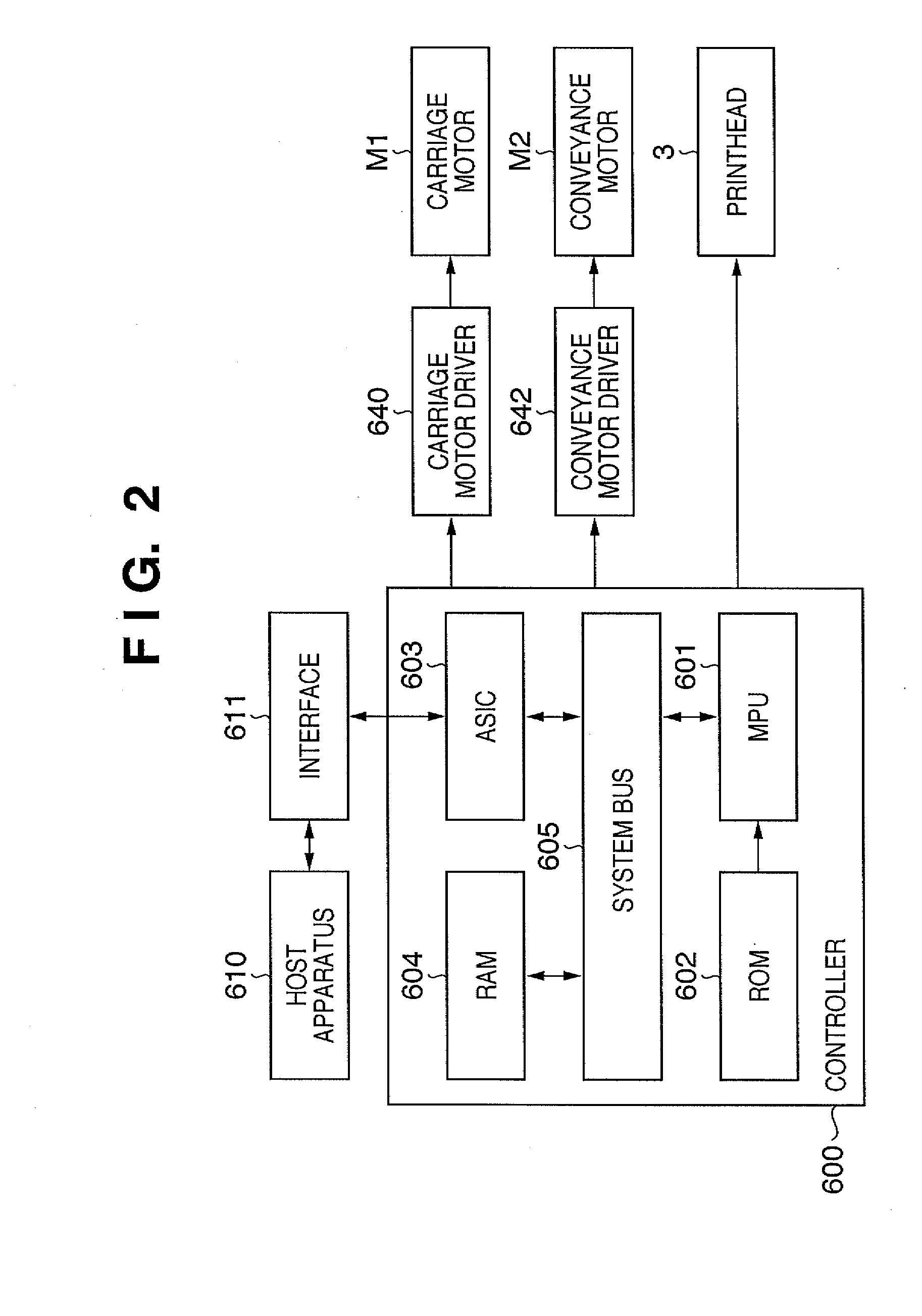

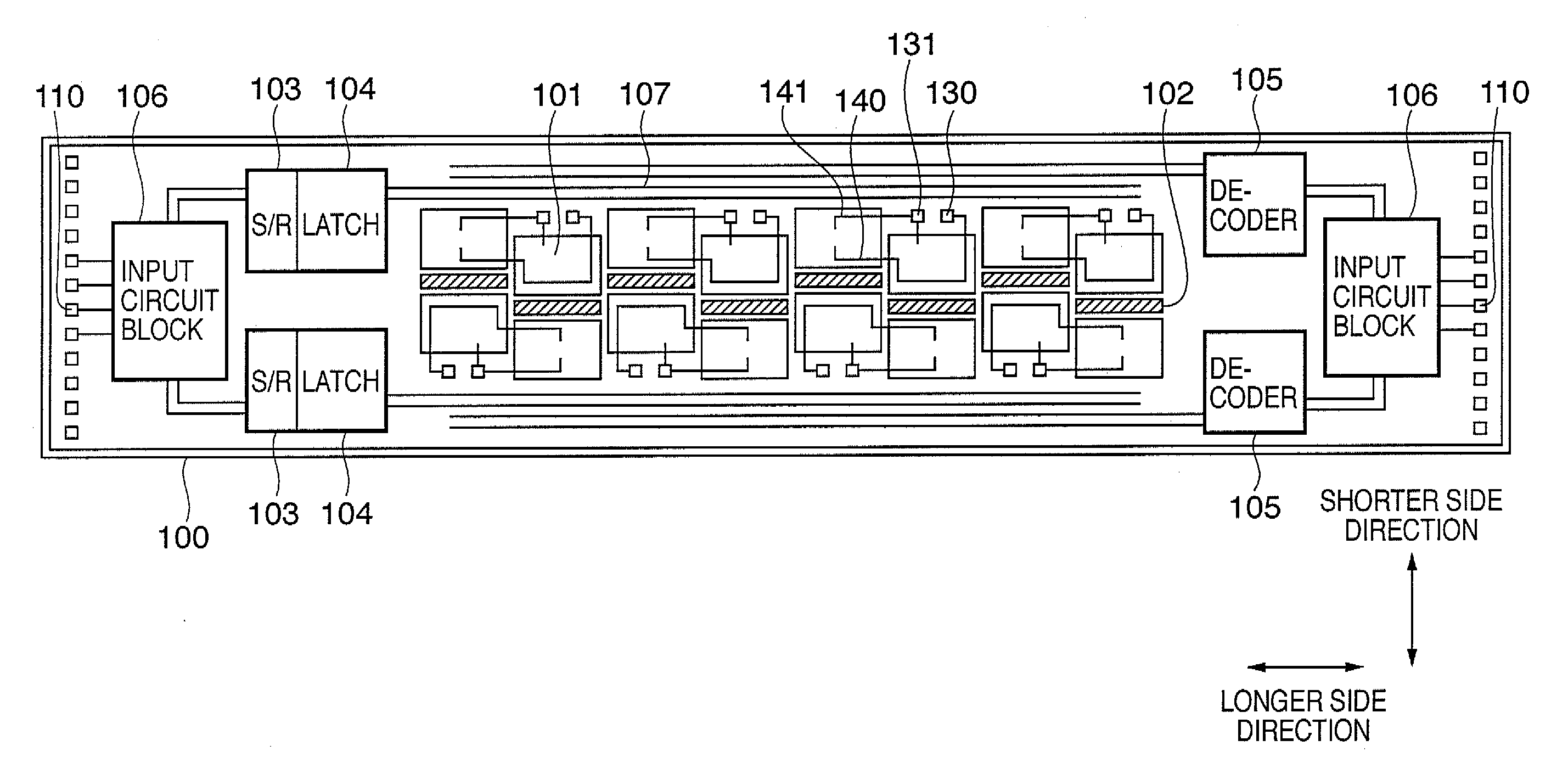

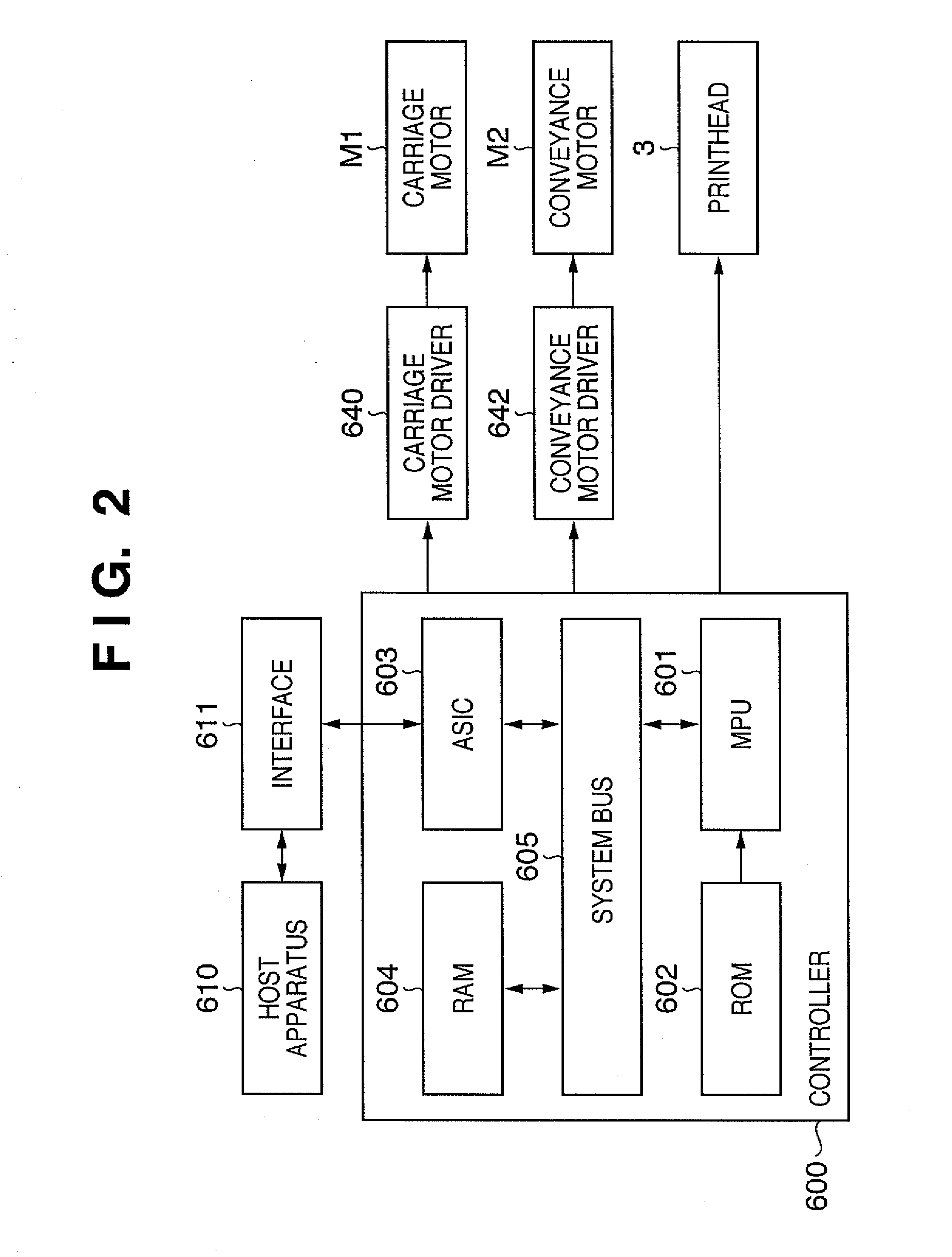

Head substrate, printhead, head cartridge, and printing apparatus

InactiveUS20080129791A1Reduce power lossShortening of durable service life can be preventedInking apparatusOther printing apparatusEngineeringDriven element

The purpose of this invention is to provide a head substrate capable of increasing layout efficiency. To achieve this purpose, an ink supply channel is arranged, and a plurality of printing element arrays are arranged on at least one side of the ink supply channel, and a plurality of driving element arrays are arranged adjacent to the plurality of printing element arrays. A plurality of power supply pads and a plurality of ground pads are arranged in areas between the plurality of driving element arrays.

Owner:CANON KK

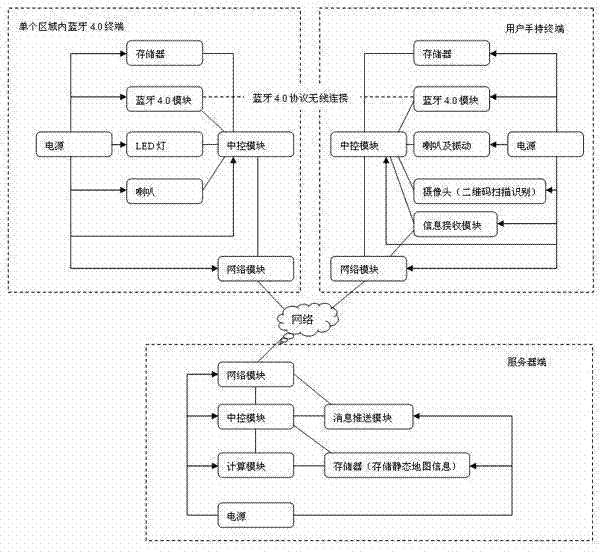

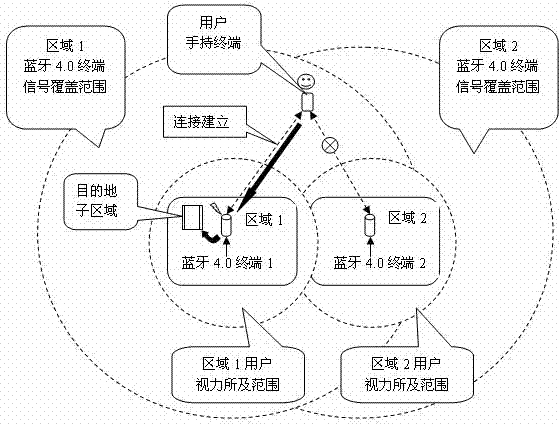

Position identification and guide method based on bluetooth and two-dimension code

InactiveCN103199898AEasy to findNot affectedNear-field transmissionRoad vehicles traffic controlHand heldComputer terminal

The invention relates to a position identification and guide method based on bluetooth and a two-dimension code. The method comprises a bluetooth 4.0 terminal, a user hand-held terminal and a server end, wherein the bluetooth 4.0 terminal, the user hand-held terminal and the server end are connected through wireless communications, and the user hand-held terminal is provided with a bluetooth 4.0 module. The method includes the following steps: step one, conducting regional division and enabling the bluetooth 4.0 terminal to be mounted in a region; step two, conducting subregion division; step three, appointing a destination; step four, appointing an original place; step five, guiding a path from the original place to the destination; and step six, guiding the position of a subregion of the destination. By means of the position identification and guide method based on the bluetooth and the two-dimension code, position guiding can be achieved swiftly.

Owner:上海网罗电子科技有限公司

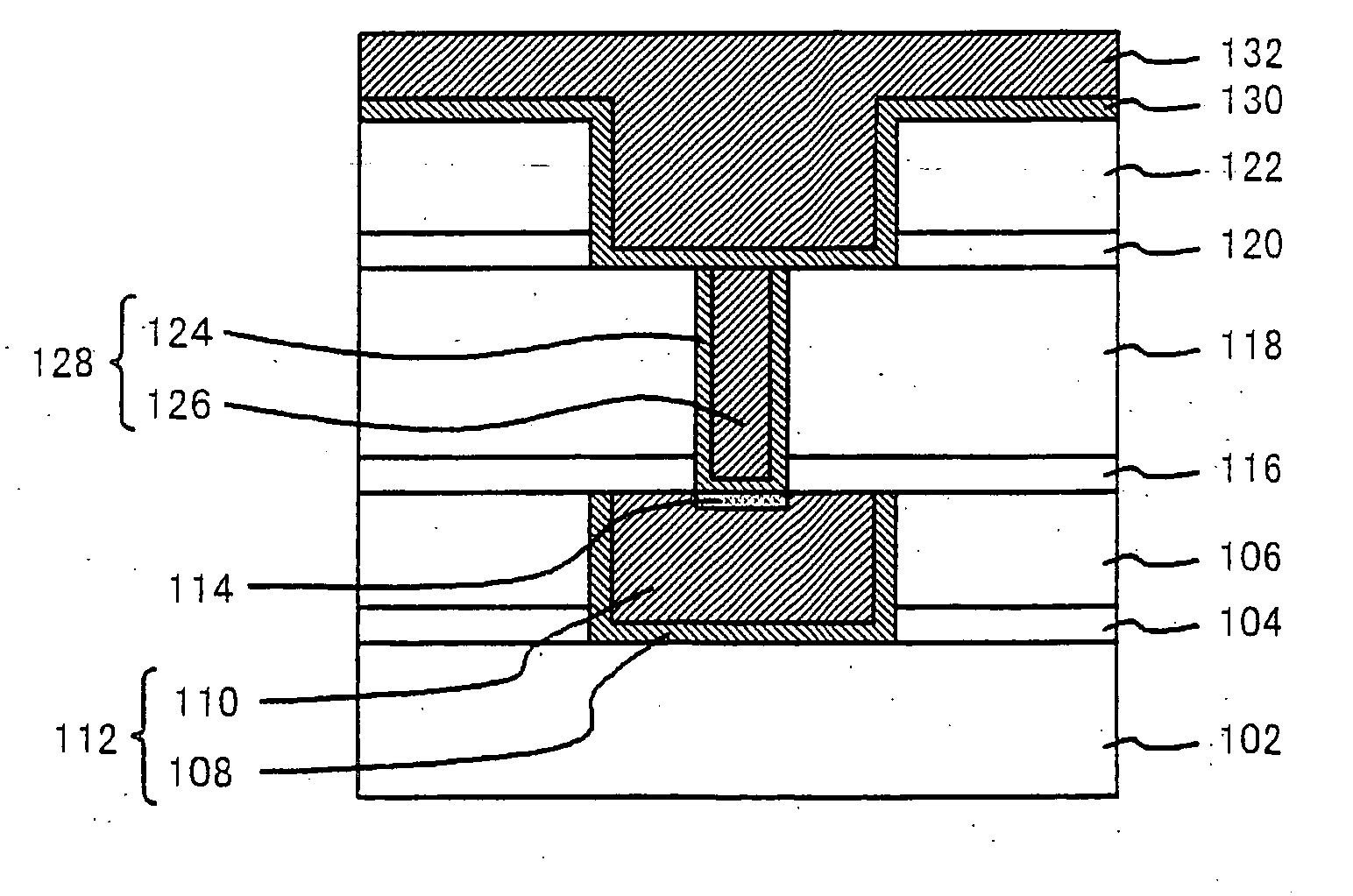

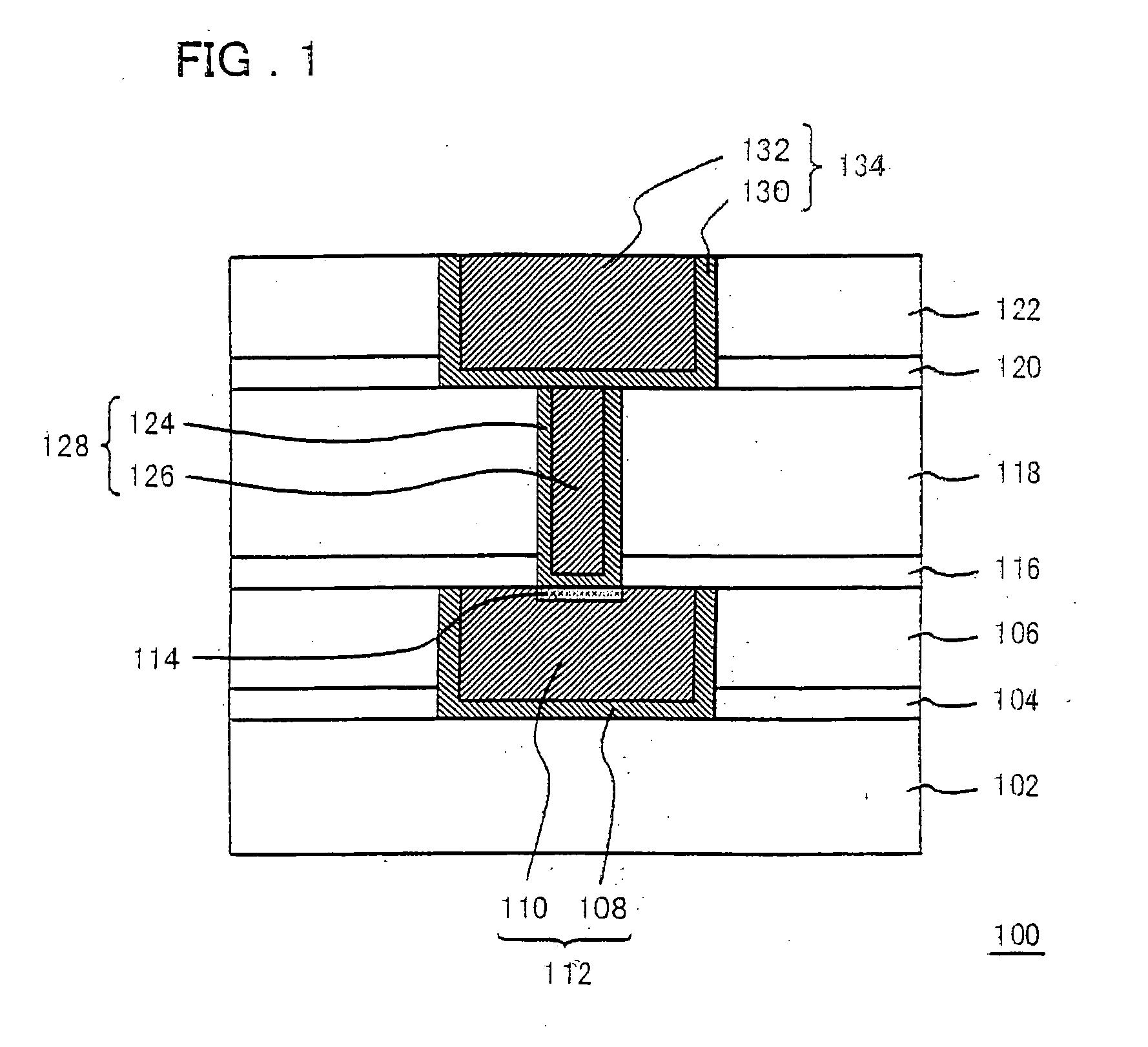

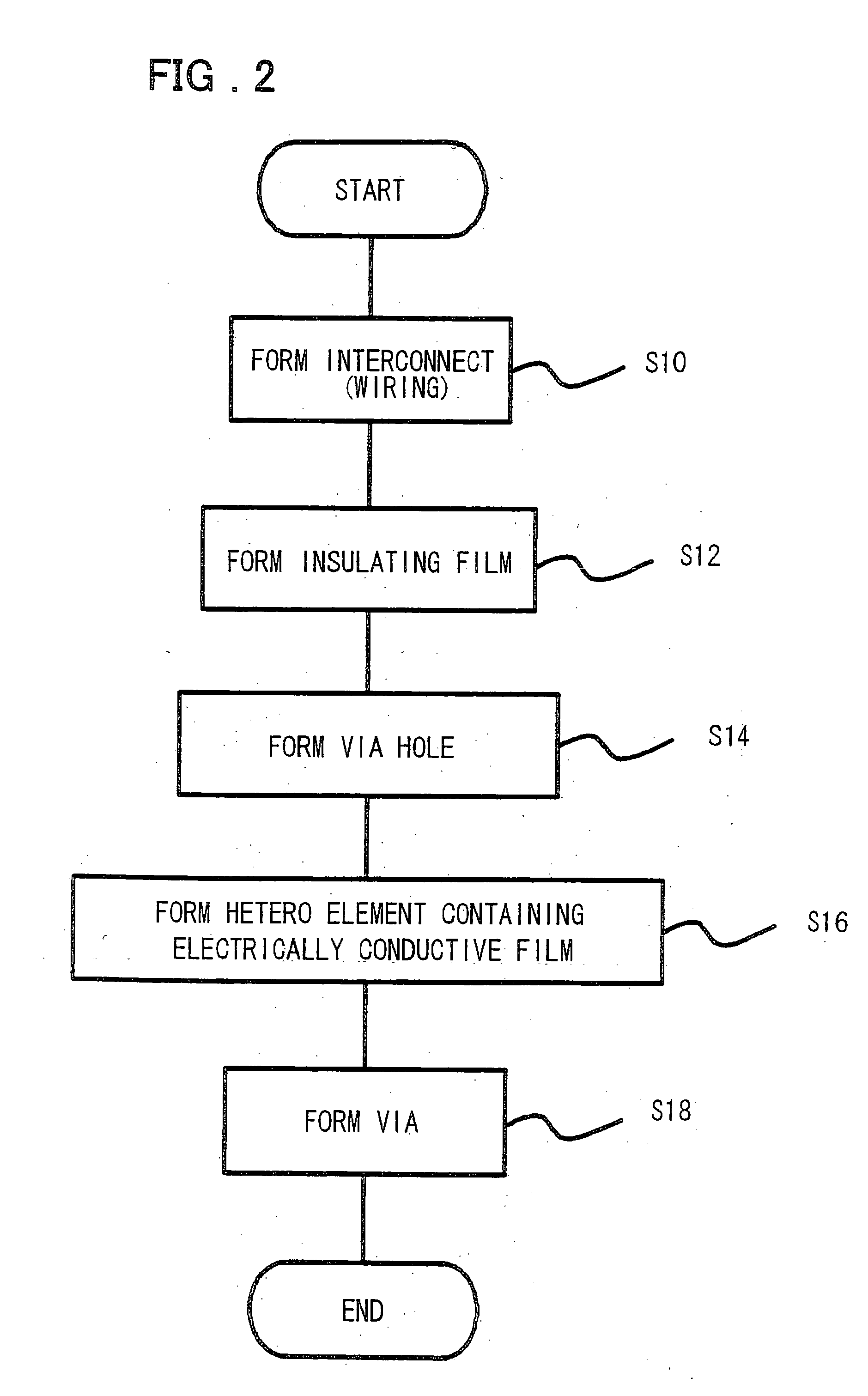

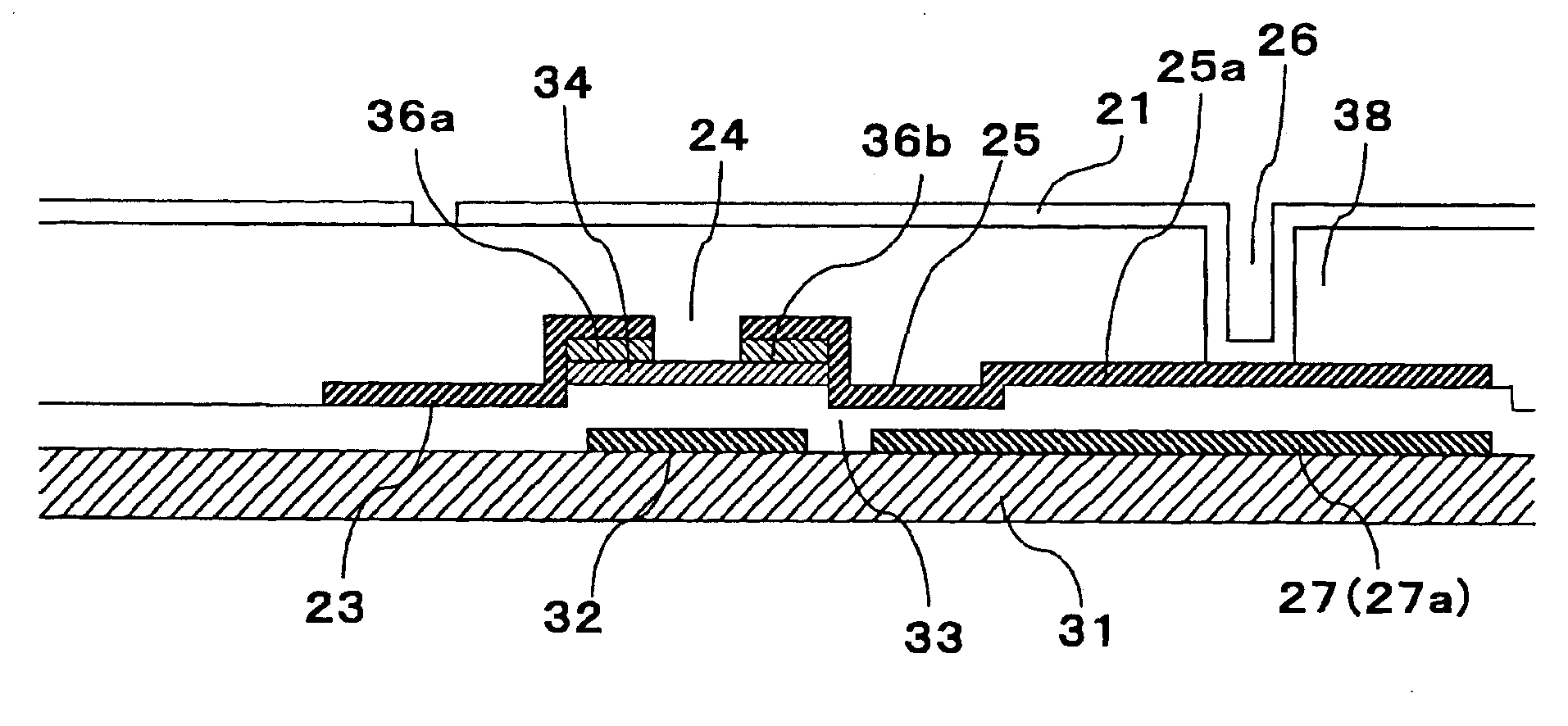

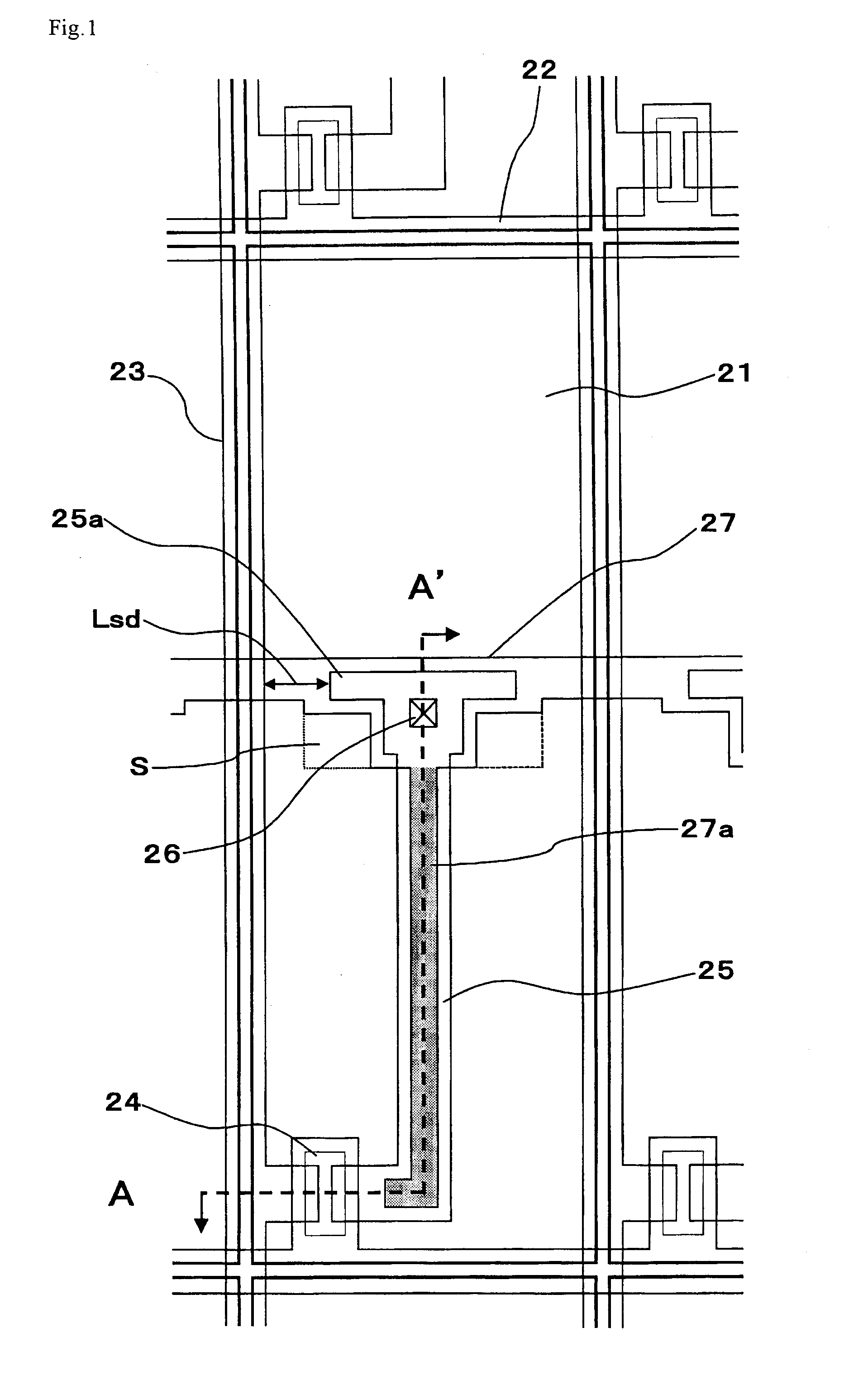

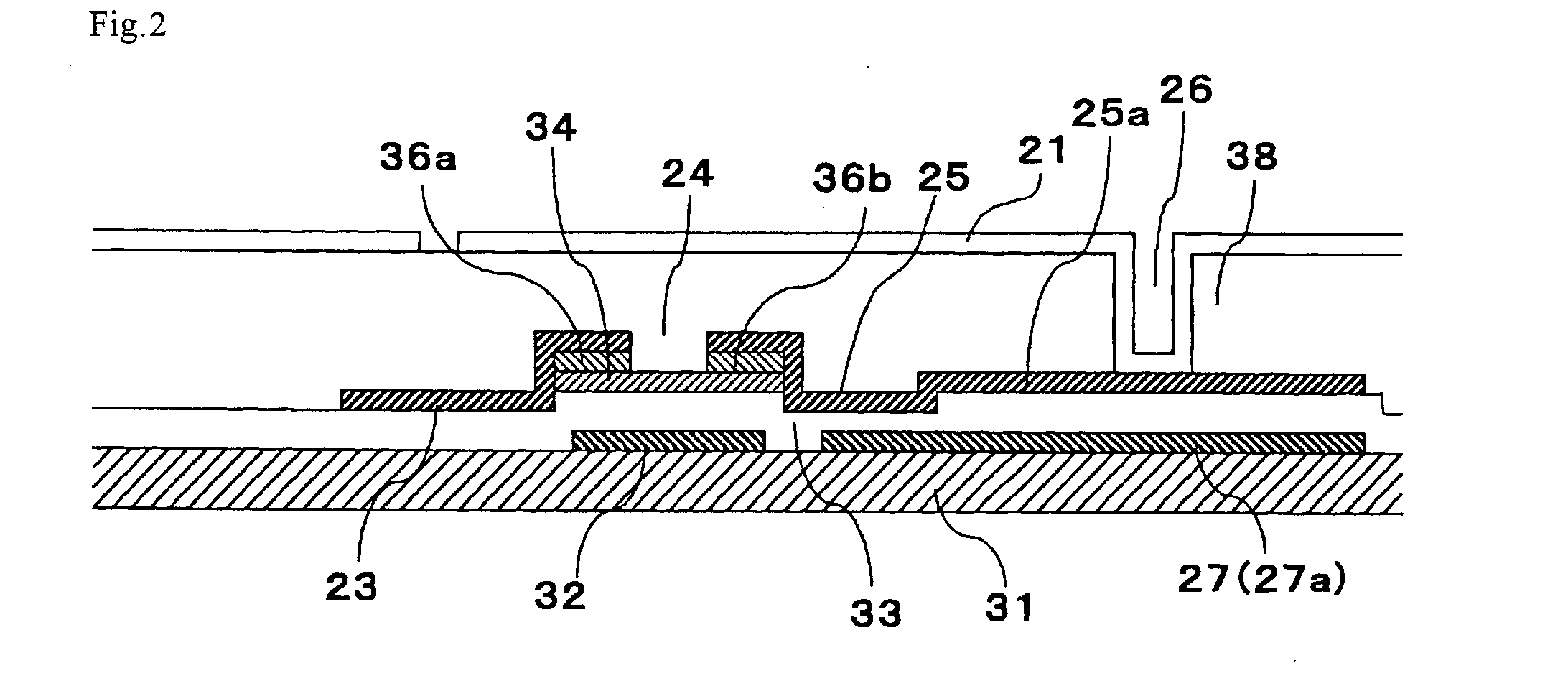

Semiconductor device and manufacturing method thereof

ActiveUS20070082488A1Raise resistance against migrationIncrease productionSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

A semiconductor device has a multi-layer wiring in which resistance against migration of the semiconductor device is raised to improve the yield. Semiconductor device 100 includes a first interconnect (wiring) 112, formed in a first interlayer insulating film 106 on a semiconductor substrate, not shown, a via 128 provided on the first interconnect (wiring) 112 so that the via is connected to the first interconnect (wiring) 112, and a different element containing electrically conductive film 114. The different element containing electrically conductive film is formed selectively on a site on the top of the first interconnect (wiring) 112 where the first wiring is contacted with the bottom of the via 128. The different element containing electrically conductive film contains a metal of a main component of the first interconnect (wiring) 112 and a different element different from the metal of the main component.

Owner:RENESAS ELECTRONICS CORP

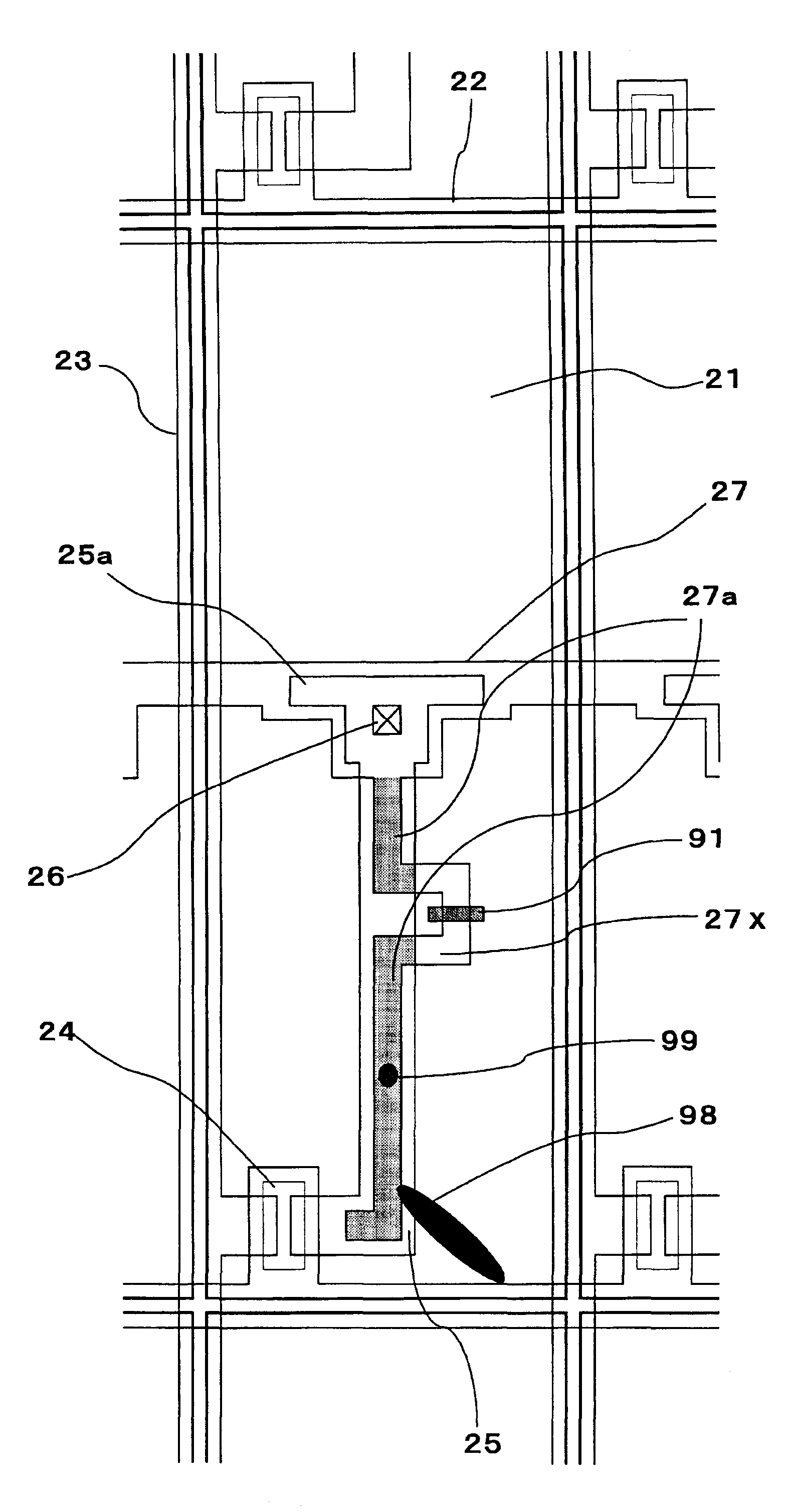

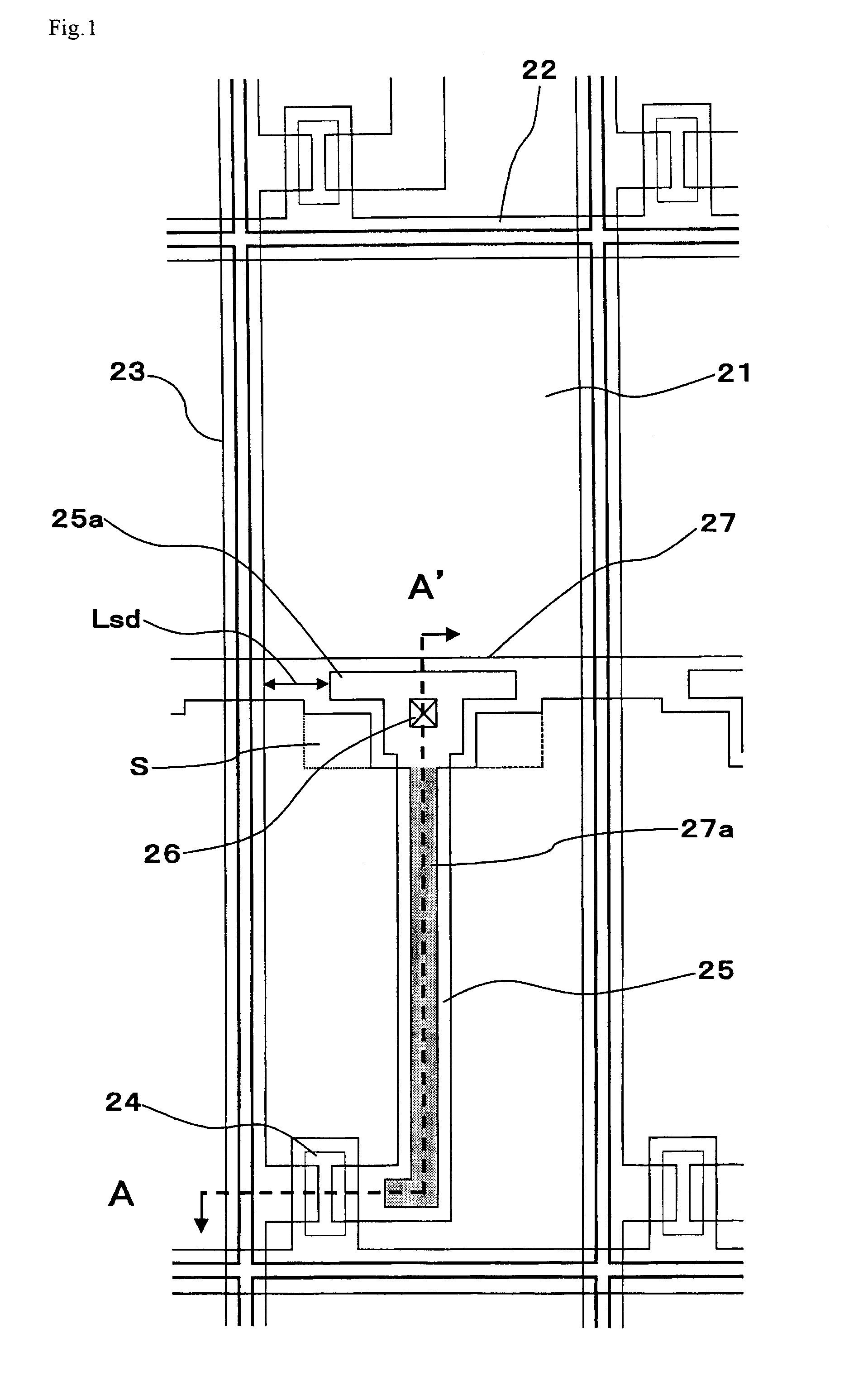

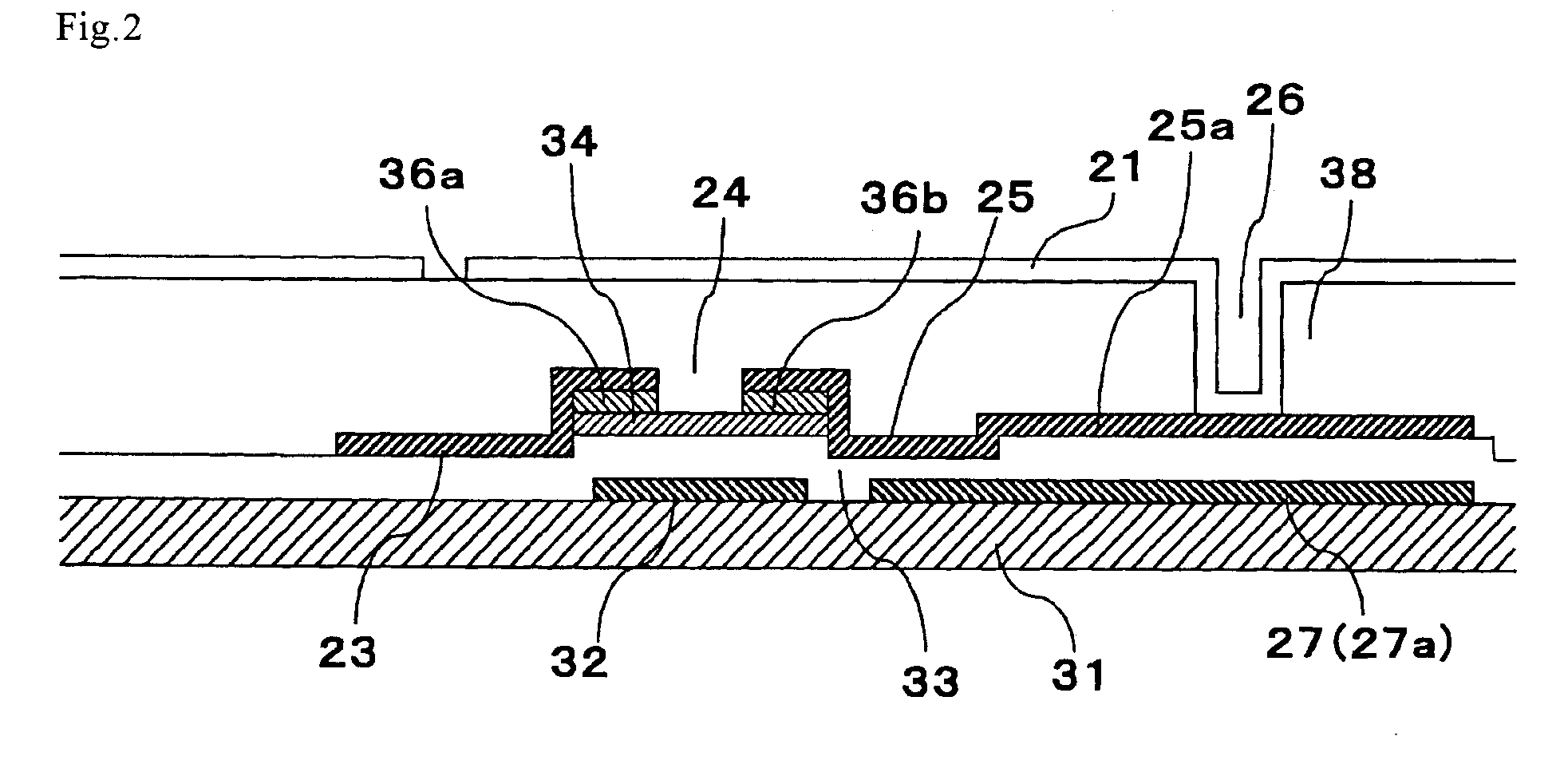

Active matrix substrate and display device

InactiveUS20090073335A1Solve insufficient storage capacityIncrease the aperture ratioNon-linear opticsSemiconductor devicesActive matrixDisplay device

An active matrix substrate suppresses reduction in production yield and increase in production steps and simultaneously permits both sufficient securing of a storage capacity and improvement of an aperture ratio of a pixel. The active matrix substrate is an active matrix substrate and includes a thin film transistor disposed at an intersection of a scanning signal line with a data signal line on a substrate, the thin film transistor including a gate electrode connected to the scanning signal line, a source electrode connected to the data signal line, and a drain electrode connected to a drain lead-out wiring; a storage capacitor upper electrode connected to the drain lead-out wiring and a pixel electrode; and a storage capacitor wiring overlapping with the storage capacitor upper electrode through an insulating film, wherein the storage capacitor wiring has an extending portion overlapping with the drain lead-out wiring through the insulating film.

Owner:SHARP KK

Positive electrode active material and non-aqueous electrolyte secondary cell

ActiveUS20050181279A1Reduces ionic conductivityImprove the immunityNon-aqueous electrolyte accumulatorsFinal product manufactureDecompositionComposite oxide

A non-aqueous electrolyte secondary cell having superior high temperature-operation properties and excellent large current-discharge properties is provided. The non-aqueous electrolyte secondary cell has a positive electrode composed of a positive electrode collector and positive electrode active material layers formed thereon. A positive electrode active material contained in the above layer is formed of a first composite oxide and a second composite oxide mixed therewith. The first composite oxide is formed of grains of a first lithium transition metal composite oxide containing at least nickel as a transition metal and a cover layer formed on at least part of the surface of each of the grains for suppressing decomposition of an electrolyte caused by the first lithium transition metal composite oxide. The second composite oxide is composed of grains of a second lithium transition metal composite oxide.

Owner:MURATA MFG CO LTD

Array substrate of liquid crystal display device

ActiveCN101561602ALower the altitudeLower resistanceSolid-state devicesNon-linear opticsLiquid-crystal displayEngineering

The invention relates to an array substrate of a liquid crystal display device, comprising a substrate, a grid line arranged on the substrate, a data wire intersected with the grid line, a thin film transistor which is electrically connected with the grid line and the data wire, and a pixel electrode which is electrically connected with the thin film transistor and positioned in an area defined by a crossed array of the grid line and the data wire; a section difference supplementation layer is arranged between the substrate and the grid line; and the section difference supplementation layer which corresponds to the data wire is provided with a first groove. By the first groove arranged on the section difference supplementation layer, the array substrate reduces the height of the data wire area and ensures that the height of the data wire area is equal to the height of the pixel area, thereby overcoming the defect of unfavorable friction of an oriented film on the surface of the prior array substrate.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Head substrate, printhead, head cartridge, and printing apparatus

InactiveUS20080129781A1Efficient use ofReduce power lossInking apparatusElectrical and Electronics engineeringHemt circuits

The objective of this invention is to provide a head substrate capable of increasing the layout efficiency by arranging circuit elements in a free area of the head substrate on which ink supply channels are staggered. More specifically, the circuit elements connected to a plurality of element arrays are arranged on the free area.

Owner:ABLYNX NV +1

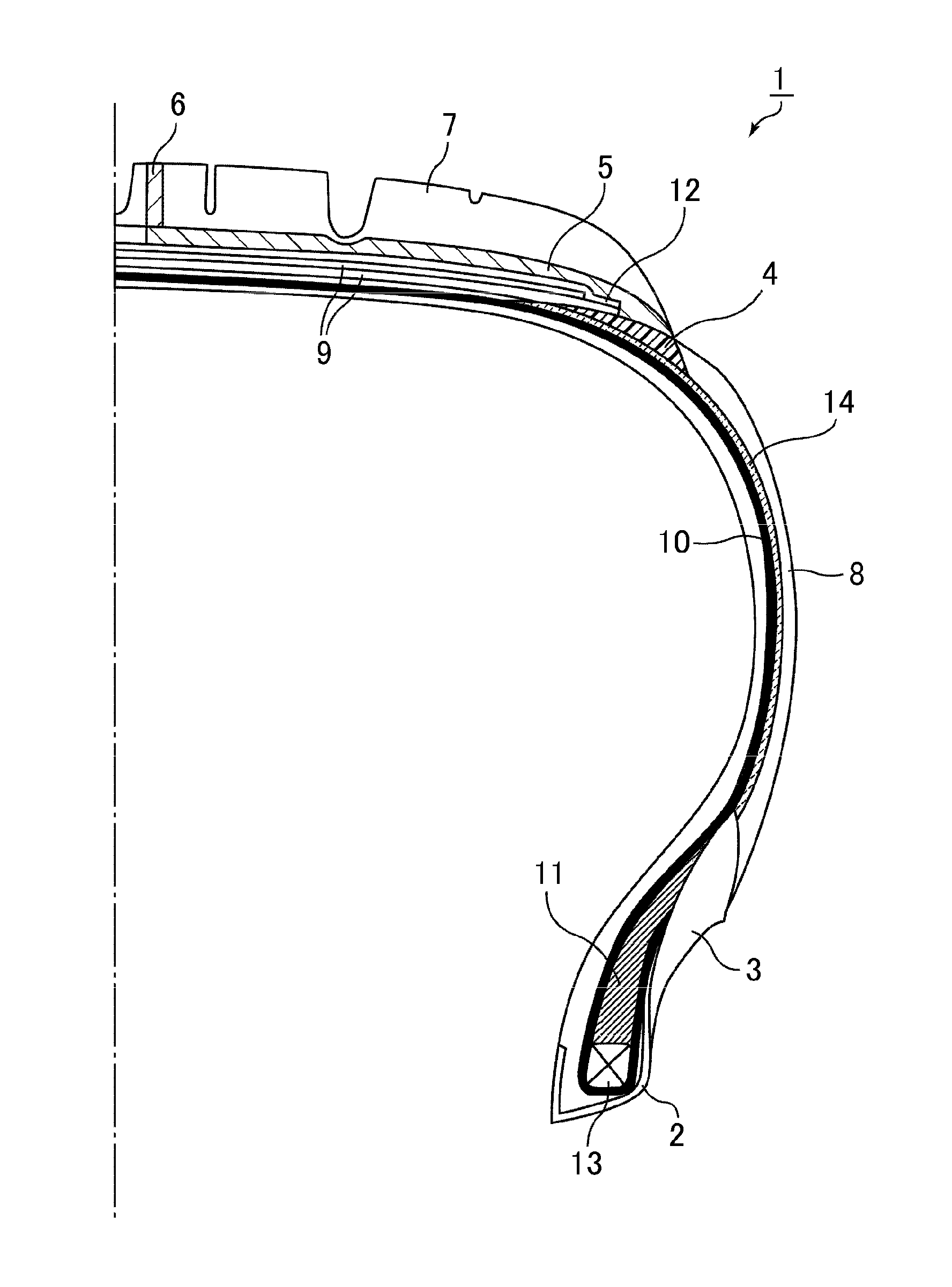

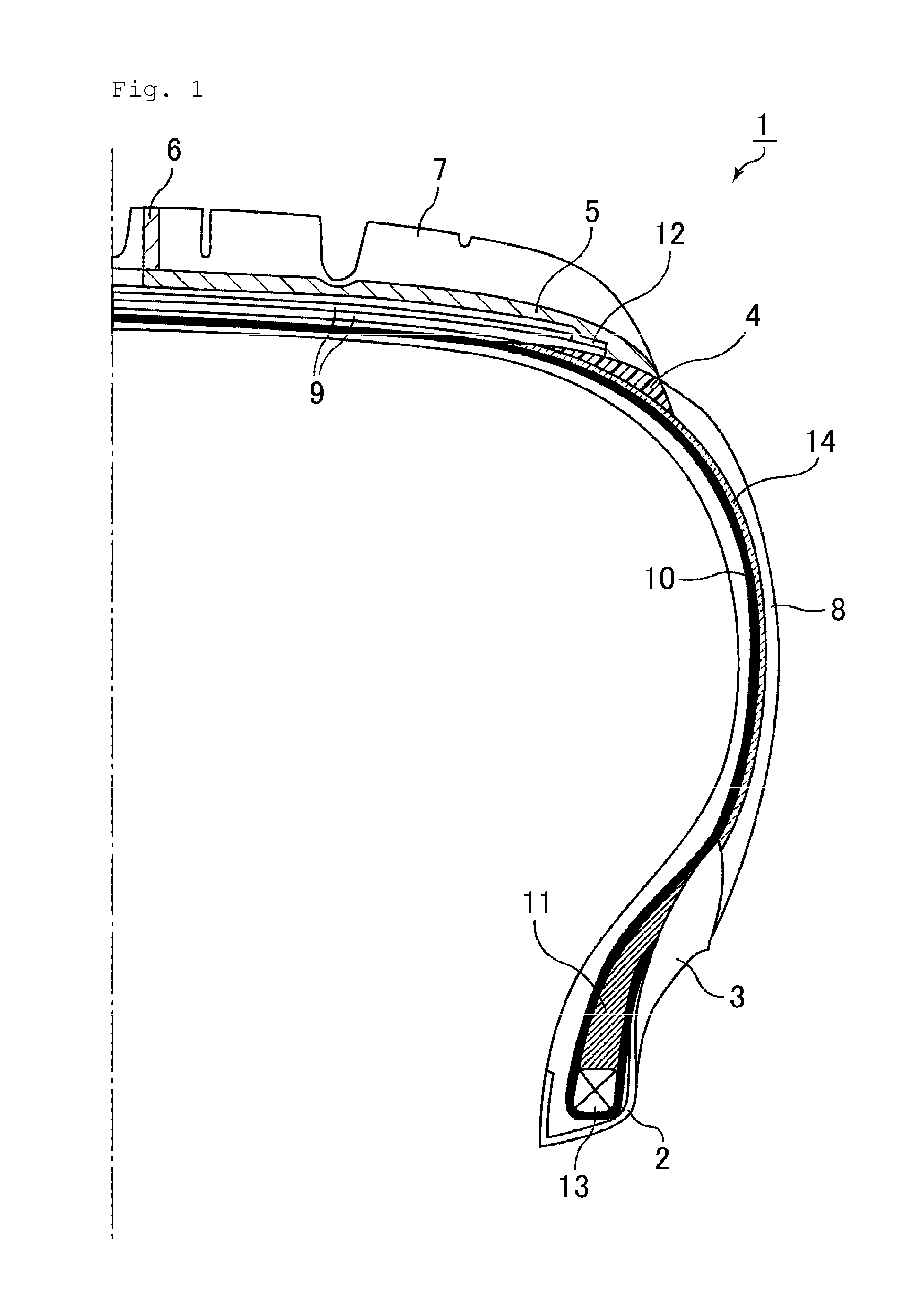

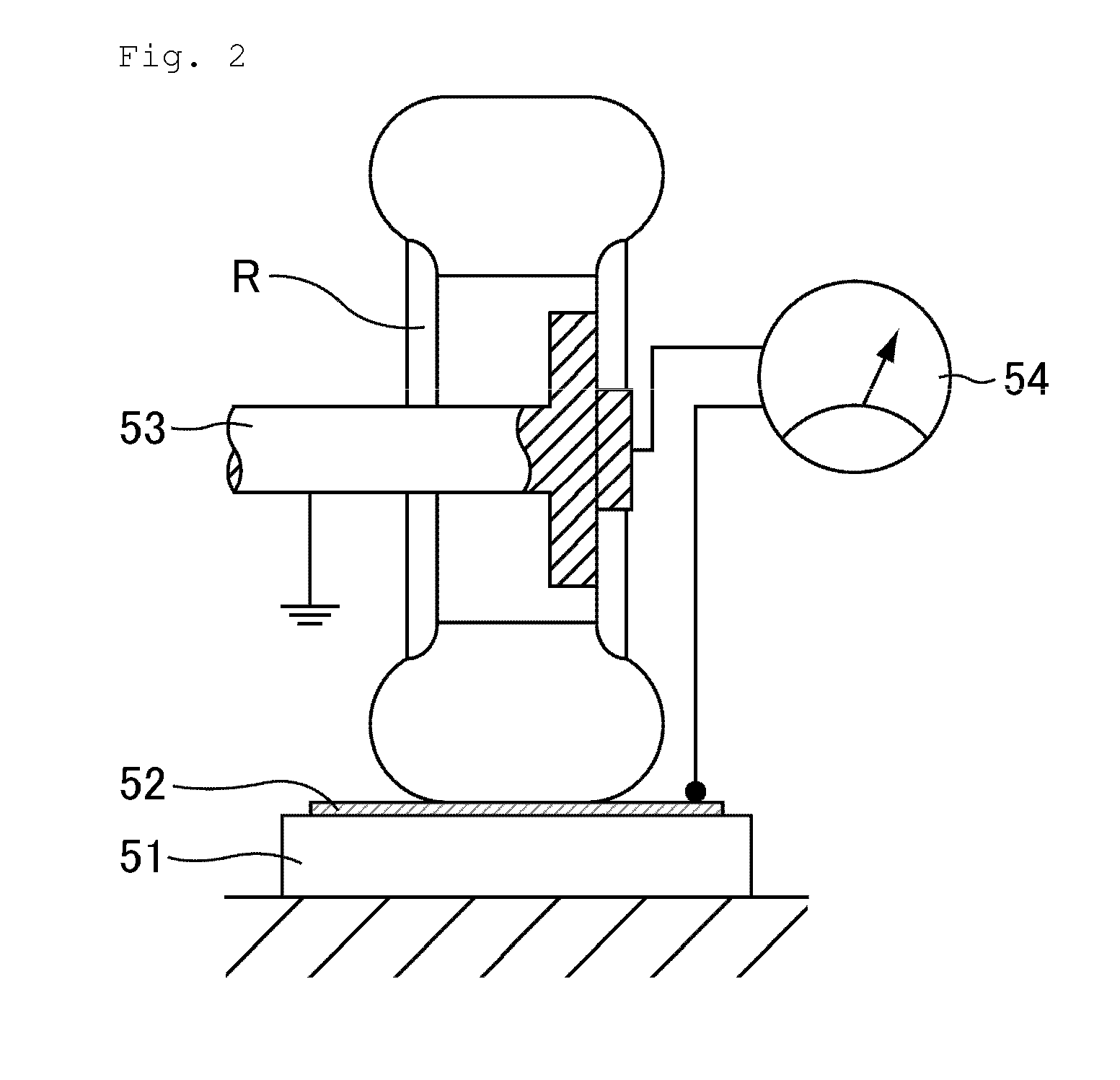

Rubber composition for tire, and pneumatic tire

InactiveUS20130180637A1Avoid accumulationSuppress increaseWithout separate inflatable insertsSpecial tyresElectrical resistance and conductancePolyolefin

Provided is a pneumatic tire using a rubber composition which makes it possible to keep rolling resistance low, prevent the accumulation of static electricity during the running of the tire, suppress an increase over time in electrical resistance of the tire, and improve durability. The present invention relates to a rubber composition, including: a rubber component including two or more diene rubber; and carbon black having a nitrogen adsorption specific surface area of 400 m2 / g or more in an amount of 5 to 30 parts by mass per 100 parts by mass of the rubber component, wherein the rubber composition has a degree of carbon black dispersion determined by counting agglomerates based on JIS K 6812 “Method for the assessment of the degree of pigment or carbon black dispersion in polyolefin pipes, fittings and compounds” of 90% or more.

Owner:SUMITOMO RUBBER IND LTD

Sheet conveyance device

InactiveUS7686291B2Simple structureRegion of handleArticle separationMechanical engineeringEngineering

Owner:FUJIFILM BUSINESS INNOVATION CORP

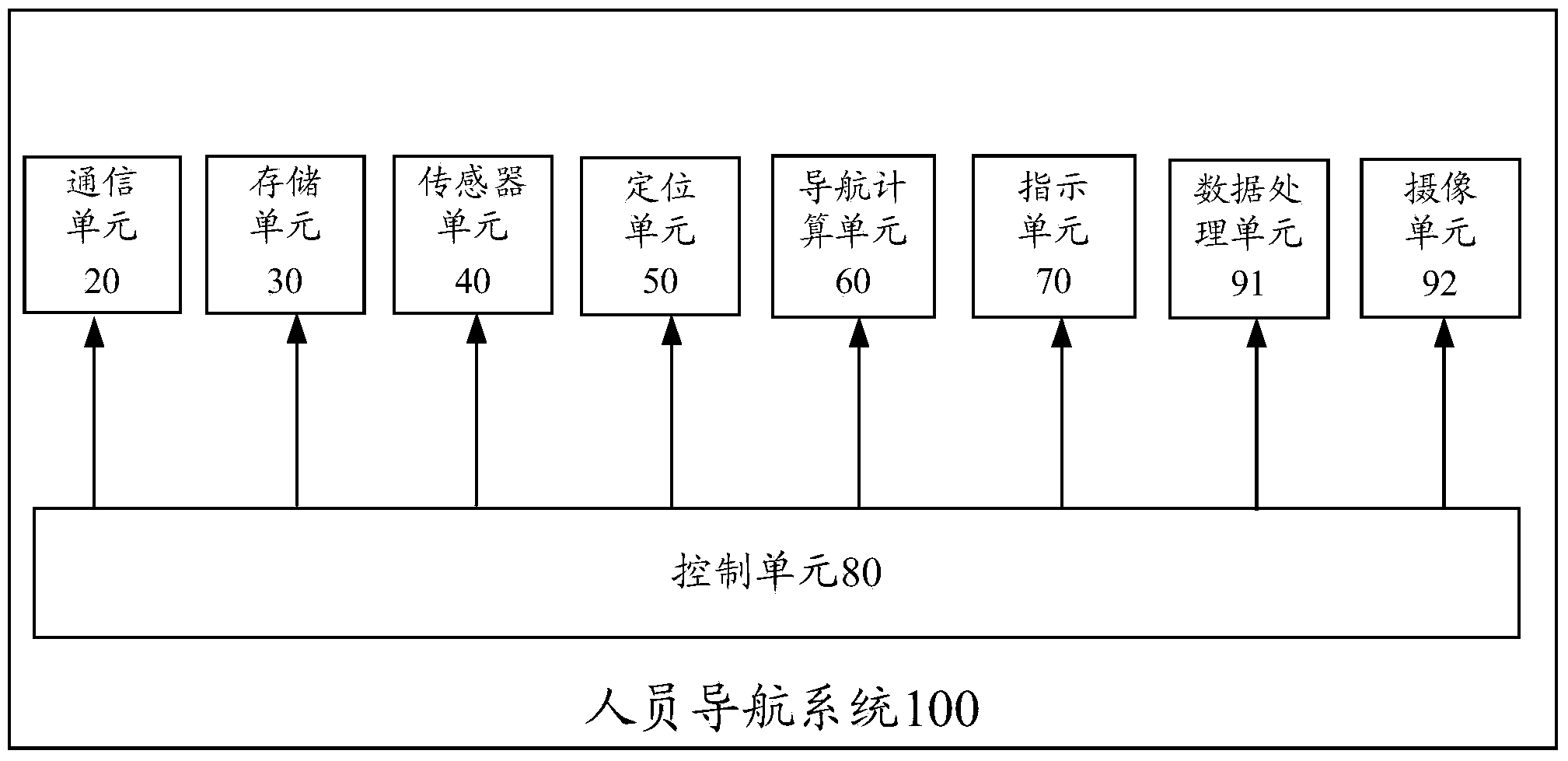

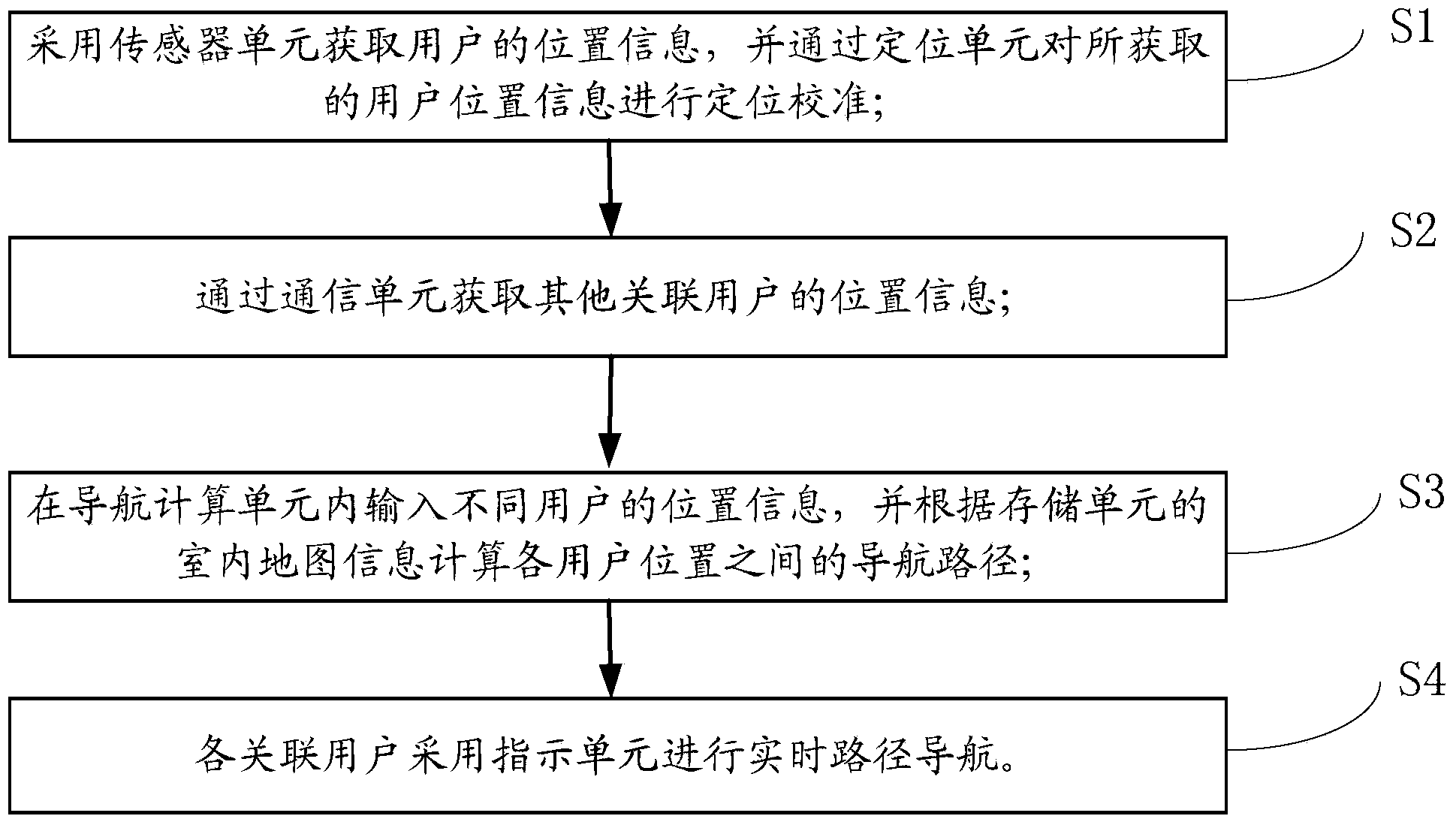

Intelligent spectacle based worker navigation system and method

InactiveCN103591958AVersatilityEasy to confirm identityNavigation by terrestrial meansNavigation by speed/acceleration measurementsCommunication unitReal time navigation

The invention provides an intelligent spectacle based worker navigation system and method. The method comprises the following steps: S1, a sensor unit is adopted to acquire user position information, and the acquired user position information is subjected to positioning calibration by a positioning unit; S2, position information of other correlated users is acquired by a communication unit; S3, position information of different users is input in a navigation calculating unit, and navigation paths between the user positions are calculated according to indoor map information of a memory unit; and S4, each correlated user adopts an indicating unit to perform real-time path navigation. Through introduction of intelligent spectacles, the whole navigation system structure is simplified, the cost is reduced, and moreover, real-time navigation can be conveniently and rapidly performed on more than two workers in an active state.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

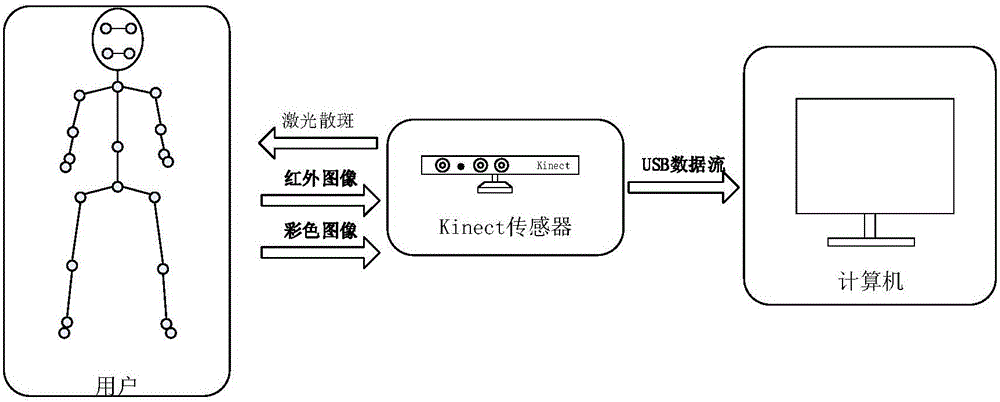

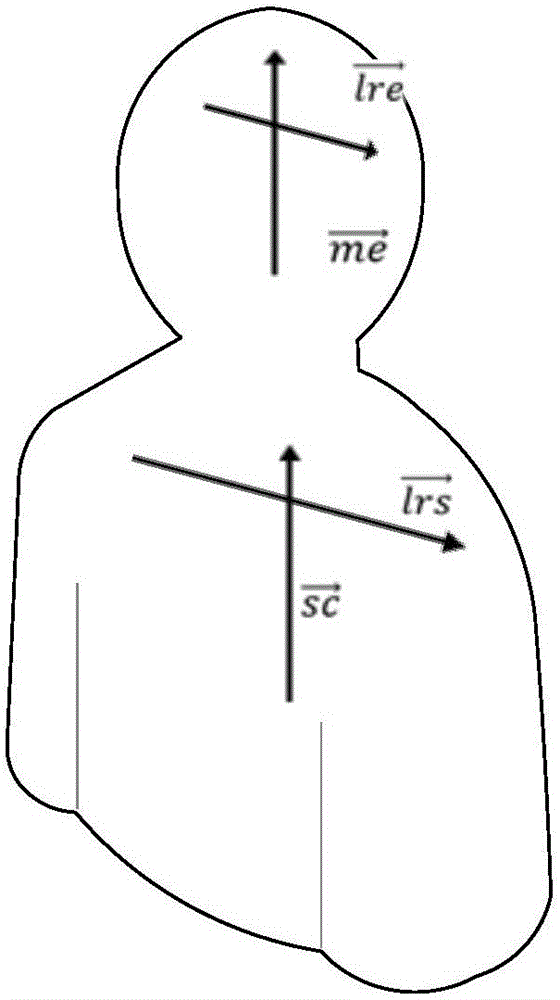

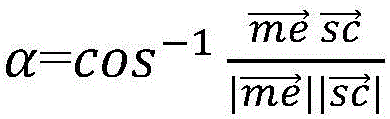

Method for measuring cervical vertebra motion degree on basis of Kinect sensor

InactiveCN105816182AImprove measurement efficiencyInhibition resistanceDiagnostic recording/measuringSensorsFeature vectorBones joints

The invention discloses a method for measuring a cervical vertebra motion degree on the basis of a Kinect sensor. The method comprises the following steps of acquiring and delivering depth data and color data in a vision field of the Kinect sensor by utilization of the Kinect sensor, then extracting three-dimensional coordinates of human face feature points and bone joint points, constructing a head feature vector and a body feature vector, calculating a cervical vertebra motion angle, then displaying the cervical vertebra motion angle, and finally recording the measured data. The method disclosed by the invention has the advantages that the human cervical vertebra motion degree can be quickly, precisely and remotely measured, and the effects of high efficiency, simplicity in operation and high reliability are achieve.

Owner:XI AN JIAOTONG UNIV

Terminal fitting

ActiveUS20140287635A1Inhibition resistanceSuppression resistanceCoupling contact membersElectric connection basesEngineeringSupport point

Owner:SUMITOMO WIRING SYST LTD

Conductive Paste and Wiring Board Using It

InactiveUS20090107707A1Inhibition resistanceLower volume resistivityConductive layers on insulating-supportsConductive materialConductive pasteFrit

A conductive paste is mainly composed of a metal powder, a glass frit, and an organic vehicle. The total content amount of the metal powder and glass frit with respect to the entire conductive paste is 85 wt % or more. The viscosity at a rotational speed of 1 rpm measured at 25° C. with an E type rotating viscometer is 100 Pa·s or more and 400 Pa·s or less.

Owner:SUMITOMO ELECTRIC IND LTD

Semiconductor device

InactiveUS8299507B2Function optimizationInhibition resistanceTransistorSemiconductor/solid-state device detailsPower semiconductor deviceWork function

It is made possible to optimize the effective work function of the metal for a junction and suppress the resistance as far as possible at the interface between a semiconductor or a dielectric material and a metal. A semiconductor device includes: a semiconductor film; a Ti oxide film formed on the semiconductor film, and including at least one element selected from the group consisting of V, Cr, Mn, Fe, Co, Ni, Nb, Mo, Tc, Ru, Rh, Pd, Ta, W, Re, Os, Ir, and Pt; and a metal film formed on the Ti oxide film.

Owner:KK TOSHIBA

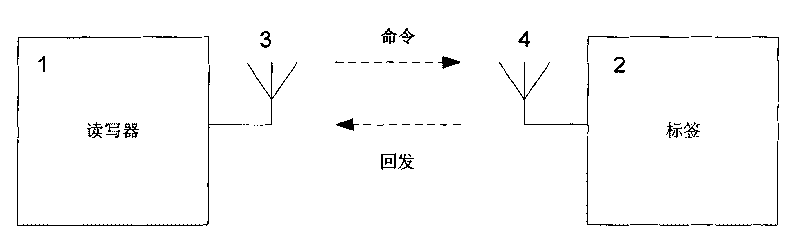

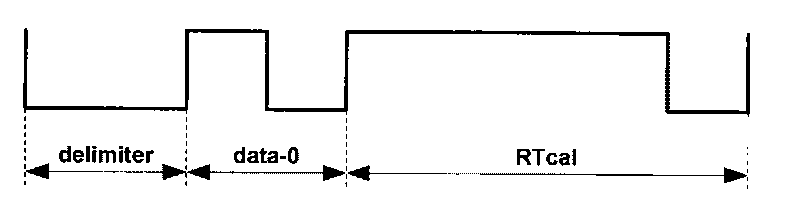

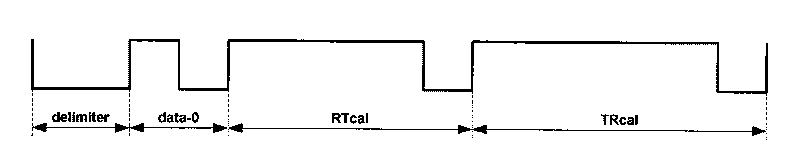

Radio frequency identification tag and method for calibrating clock signals

ActiveCN101727601AControl power consumptionIncrease reading and writing distancePulse automatic controlSensing record carriersElectricityReader writer

The invention provides a radio frequency identification (RFID) tag circuit and method for calibrating clock signals. An RFID tag circuit counts the specific duration signal emitted by a reader-writer, adjusts the clock calibration bit segment according to the counting results and writes the clock calibration bit segment into a nonvolatile memory of the tag. During next electrifying, the tag needs not to calibrate the clock again and only needs to read the clock calibration bit segment from the nonvolatile memory and adopts the clock calibration bit segment to control the circuit of an oscillator of the tag to obtain accurate clock signals. The invention ensures the clock signals generated by the tag circuit to meet the requirement of RFID protocol, correctly decodes the data sent by the reader-writer to the tag, correctly posts data back to the reader-writer, simultaneously controls the power consumption of the tag and enlarges the read-write distance of the tag.

Owner:SHANGHAI FUDAN MICROELECTRONICS GROUP

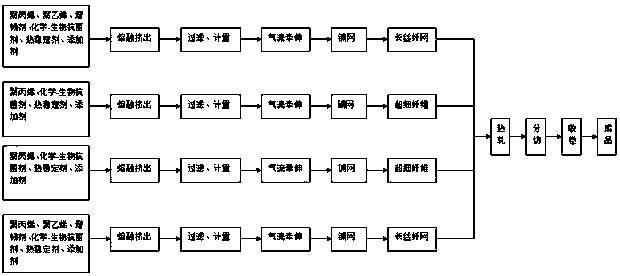

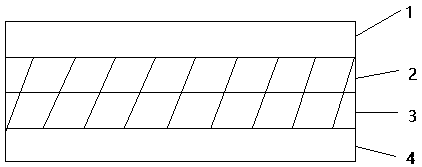

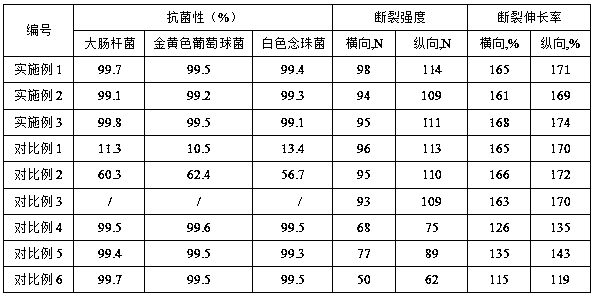

Antibacterial and bacteria-isolation SMMS composite non-woven fabric

InactiveCN110774693AWith strengthImprove tear resistanceFlame-proof filament manufactureSynthetic resin layered productsPolyhexamethylene guanidinePhysical chemistry

The invention relates to an antibacterial and bacteria-isolation SMMS composite non-woven fabric. The SMMS composite nonwoven fabric is formed by compounding a first spunbond non-woven fabric layer, afirst meltblown layer, a second meltblown layer, and a second spunbond non-woven fabric layer, wherein the first spunbond non-woven fabric layer and the second spunbond non-woven fabric layer are respectively an upper surface layer and a lower surface layer, the first meltblown layer and the second meltblown layer are intermediate layers, the spunbond non-woven fabric layers and the meltblown layers are all obtained by using polypropylene as a raw material and adding an antibacterial agent for processing, and the antibacterial agent is a chemical and biological compound antibacterial agent ofpolyhexamethyleneguanidine and gamma-polyglutamic acid. The SMMS composite non-woven fabric has the antibacterial and bacteria-isolation functions, the use of the spunbond non-woven fabric layers asthe upper and lower surfaces can ensure that the non-woven fabric has certain strength, good tear resistance, and good wear resistance, the intermediate layers adopt double-layer meltblown, permeability resistance is ensured while the air-permeability and bacteria-isolation performance are good, the resistance to bacteria is not produced, and the use is safe and reliable.

Owner:江阴金凤特种纺织品有限公司

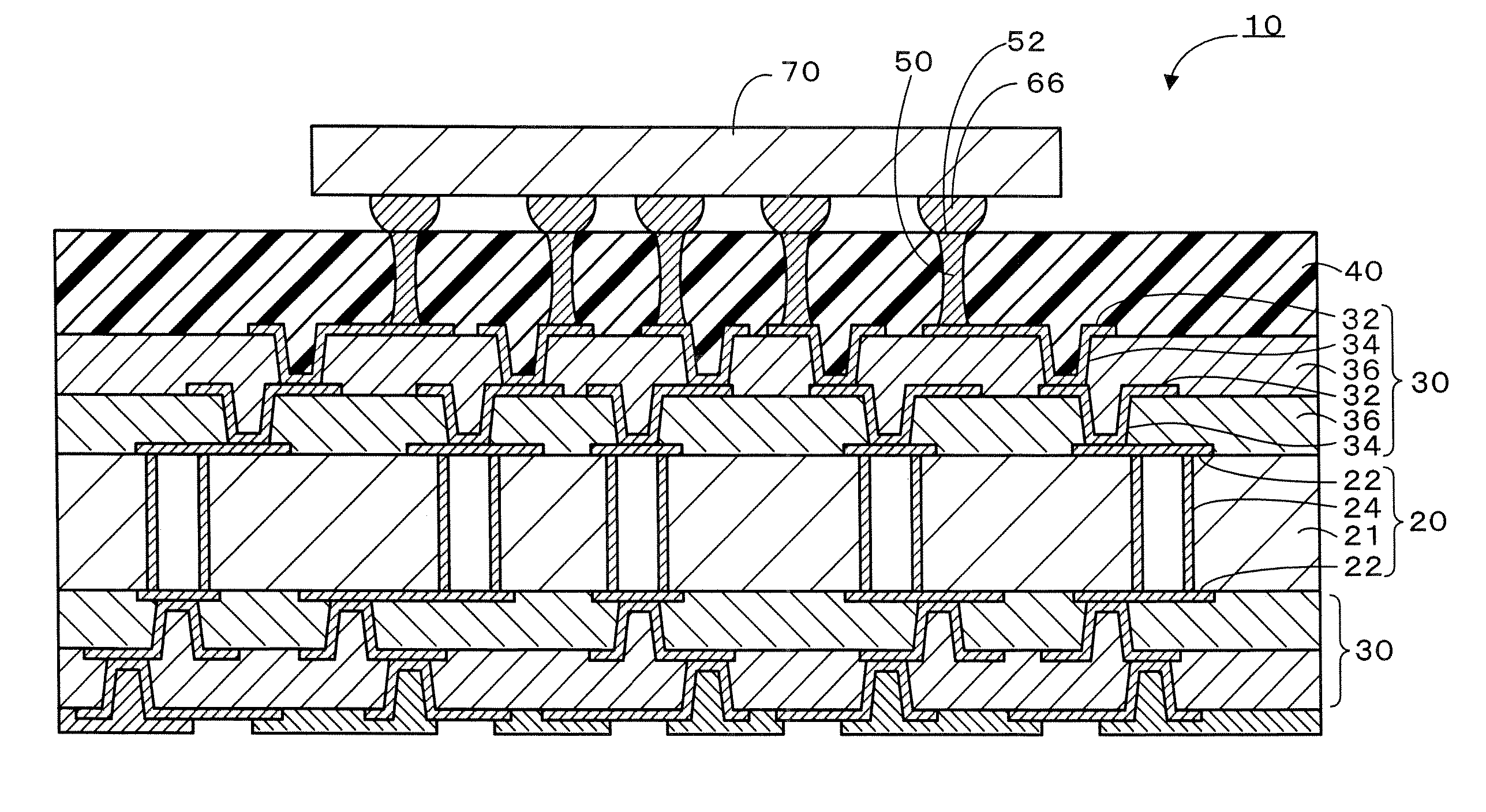

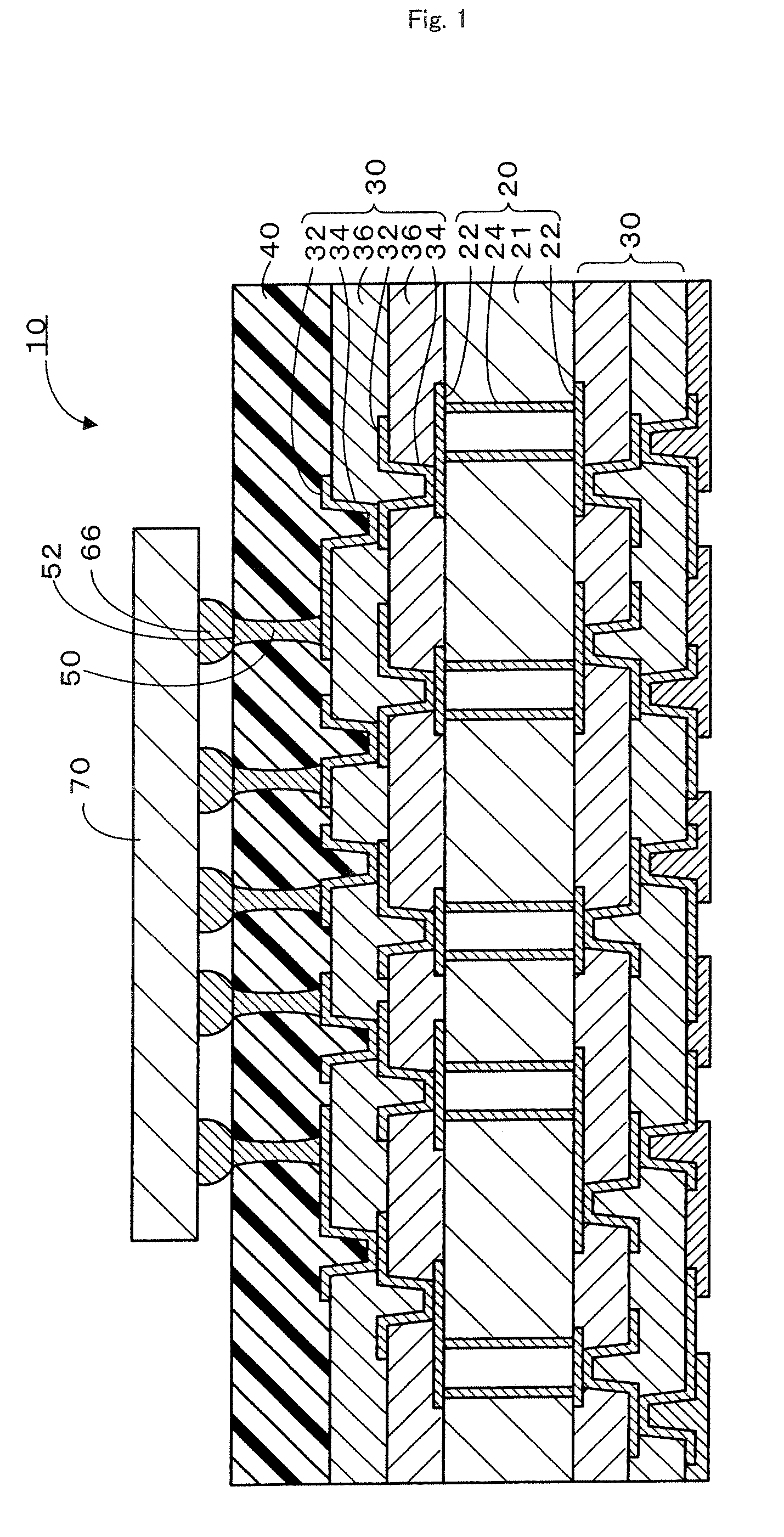

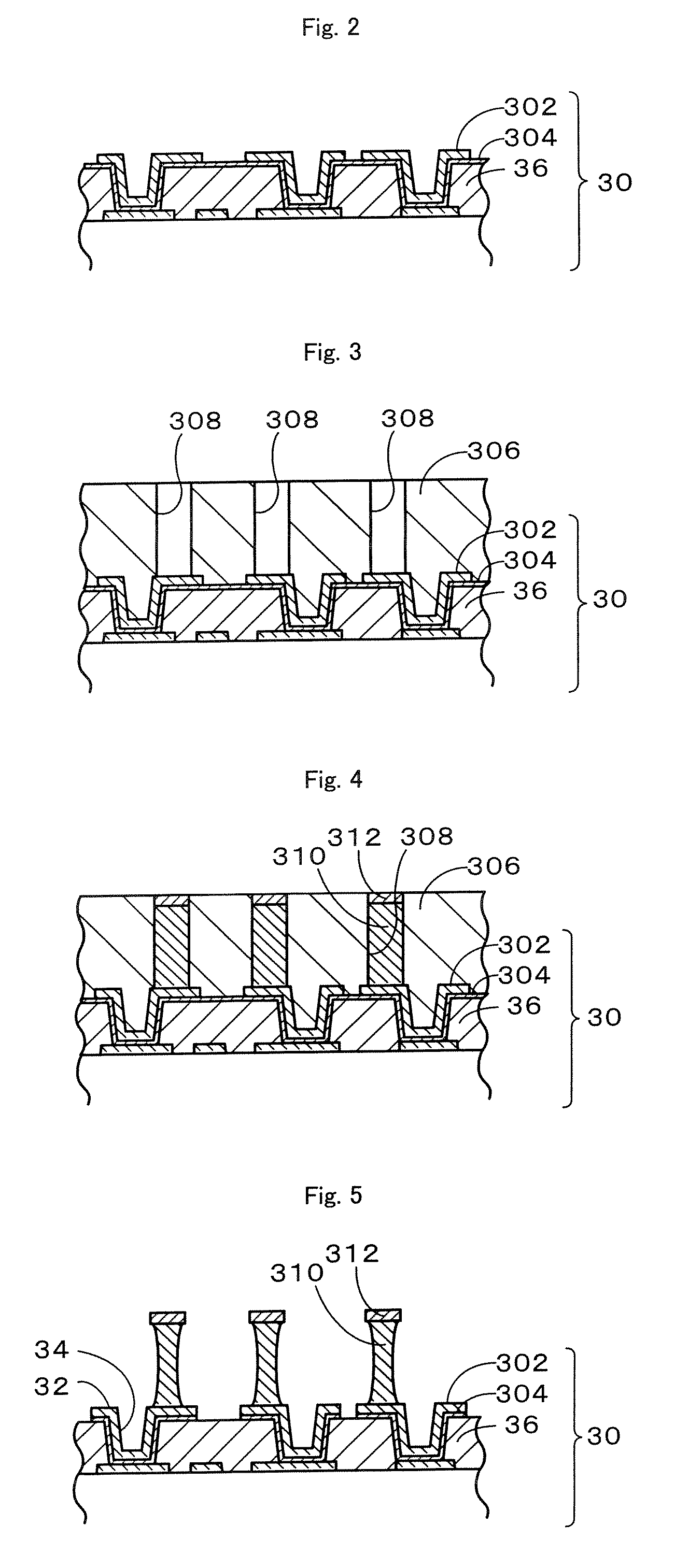

Multilayer printed wiring board

ActiveUS7495332B2Avoid separationAvoid failureSemiconductor/solid-state device detailsPrinted circuits stress/warp reductionCross-linkEpoxy

A multilayer printed wiring board is equipped with a core board 20, a build-up layer 30 formed on the core board 20 so as to have a conductor pattern 32 on the upper surface thereof, a low-elasticity layer 40 formed on the build-up layer 30, lands 52 that are provided on the upper surface of the low-elasticity layer 40 and connected to an IC chip 70 via solder bumps 66, and conductor posts 50 that penetrate through the low-elasticity layer 40 and electrically connect the lands 52 to the conductor pattern 32. The low-elasticity layer 40 is formed of resin composition containing epoxy resin, phenol resin, cross-linked rubber particles and a hardening catalyst.

Owner:IBIDEN CO LTD +1

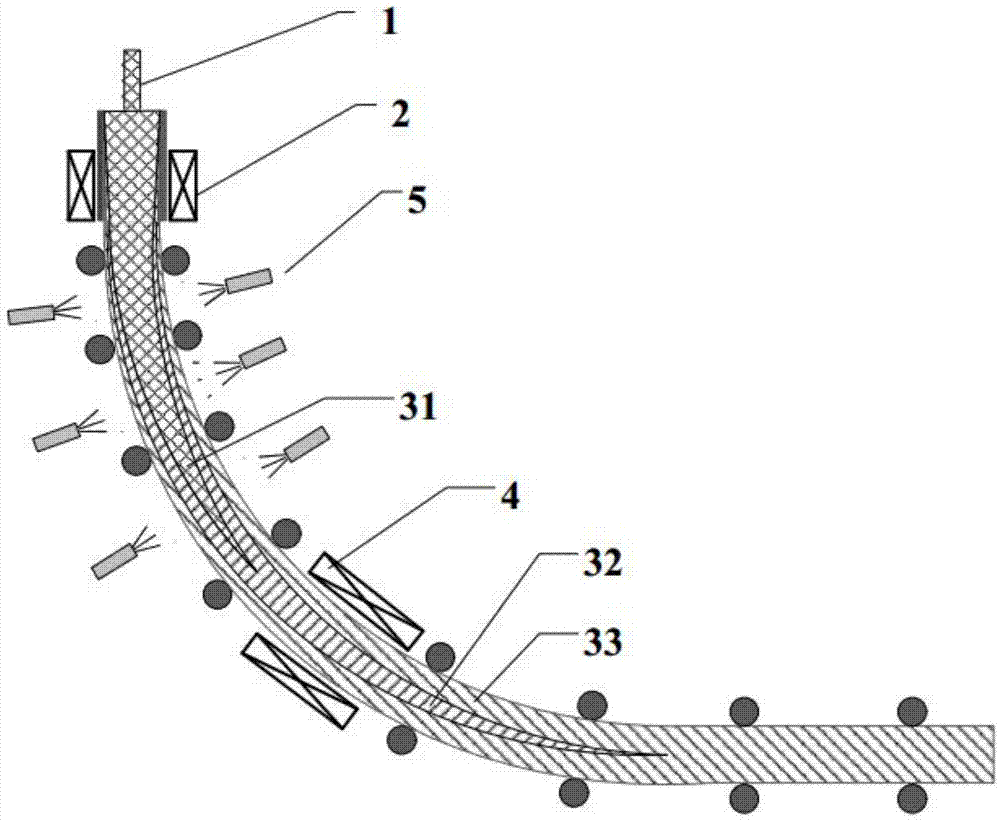

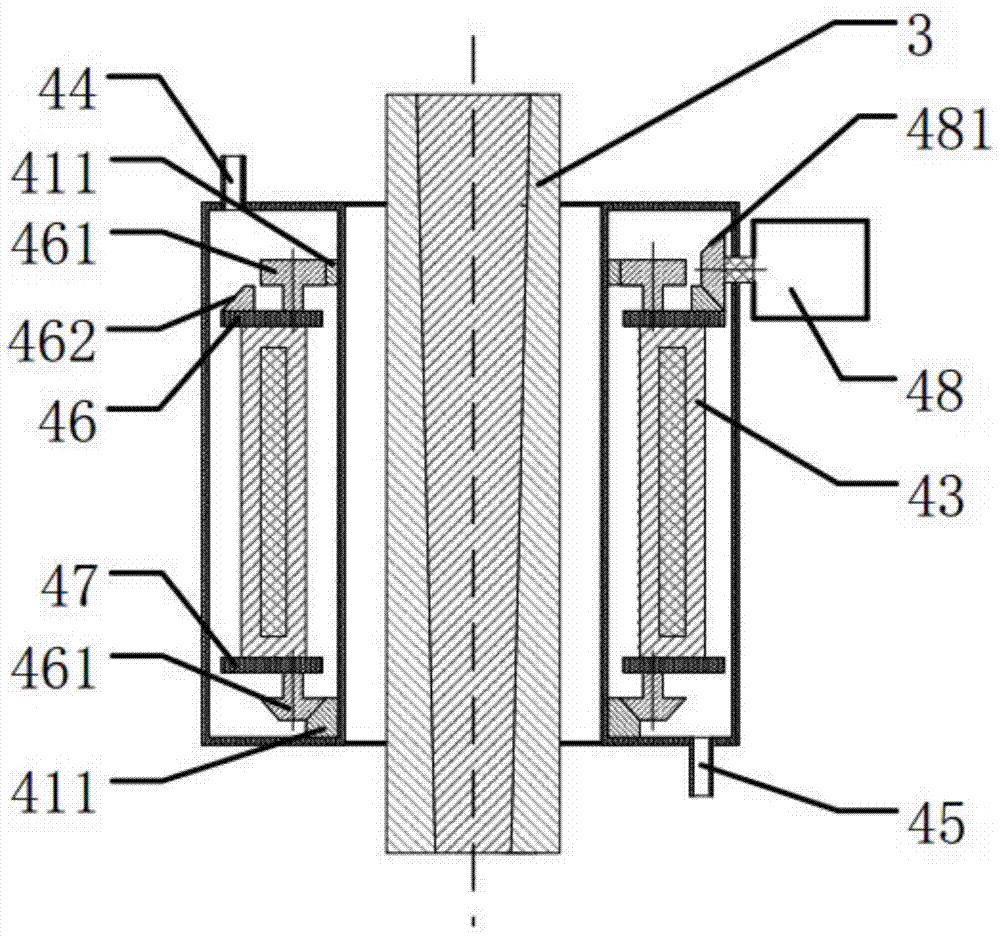

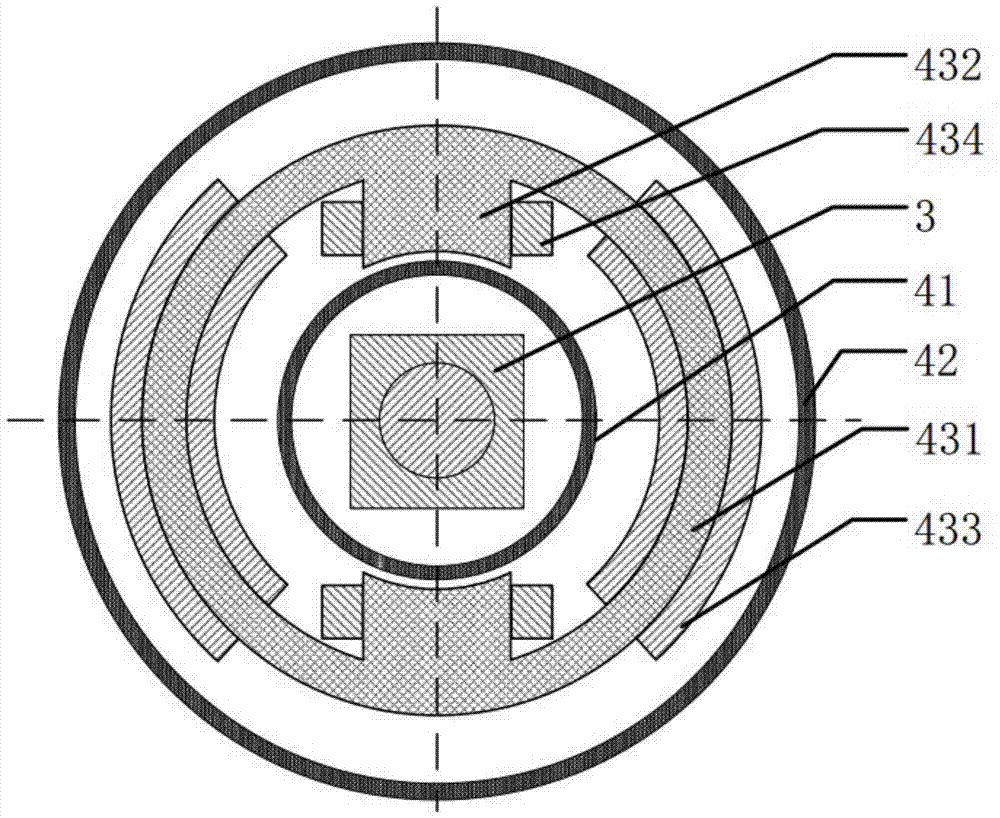

Electromagnetic stirrer for continuous casting solidification end and dynamic control method thereof

Disclosed are an electromagnetic stirrer for a continuous casting solidification end and a dynamic control method thereof. The electromagnetic stirrer for the continuous casting solidification end comprises an inner cylinder and an outer cylinder, wherein the inner cylinder is provided with a continuous casting billet, a direct current electromagnetic body is arranged between the inner cylinder and the outer cylinder, the direct current electromagnetic body is provided with an annular iron core with a salient pole and a coil which surrounds the annular iron core, the direct current electromagnetic body is driven by a drive device to rotate around the inner cylinder, an alternating magnetic field is formed in the continuous casting billet, and then an induced current is induced in the continuous casting billet, and the induced current and the alternating magnetic field interact and generate electromagnetic force so as to drive steel liquid in two phase areas to flow, accelerate redistribution of enriched solute and treelike crystals, and improve internal quality of the continuous casting billet. The dynamic control method of the electromagnetic stirrer for the continuous casting solidification end guarantees that a current stirring parameter is equivalent to the best stirring parameter so as to obtain the best stirring effects and stabilize the internal quality of the continuous casting billet.

Owner:NORTHEASTERN UNIV

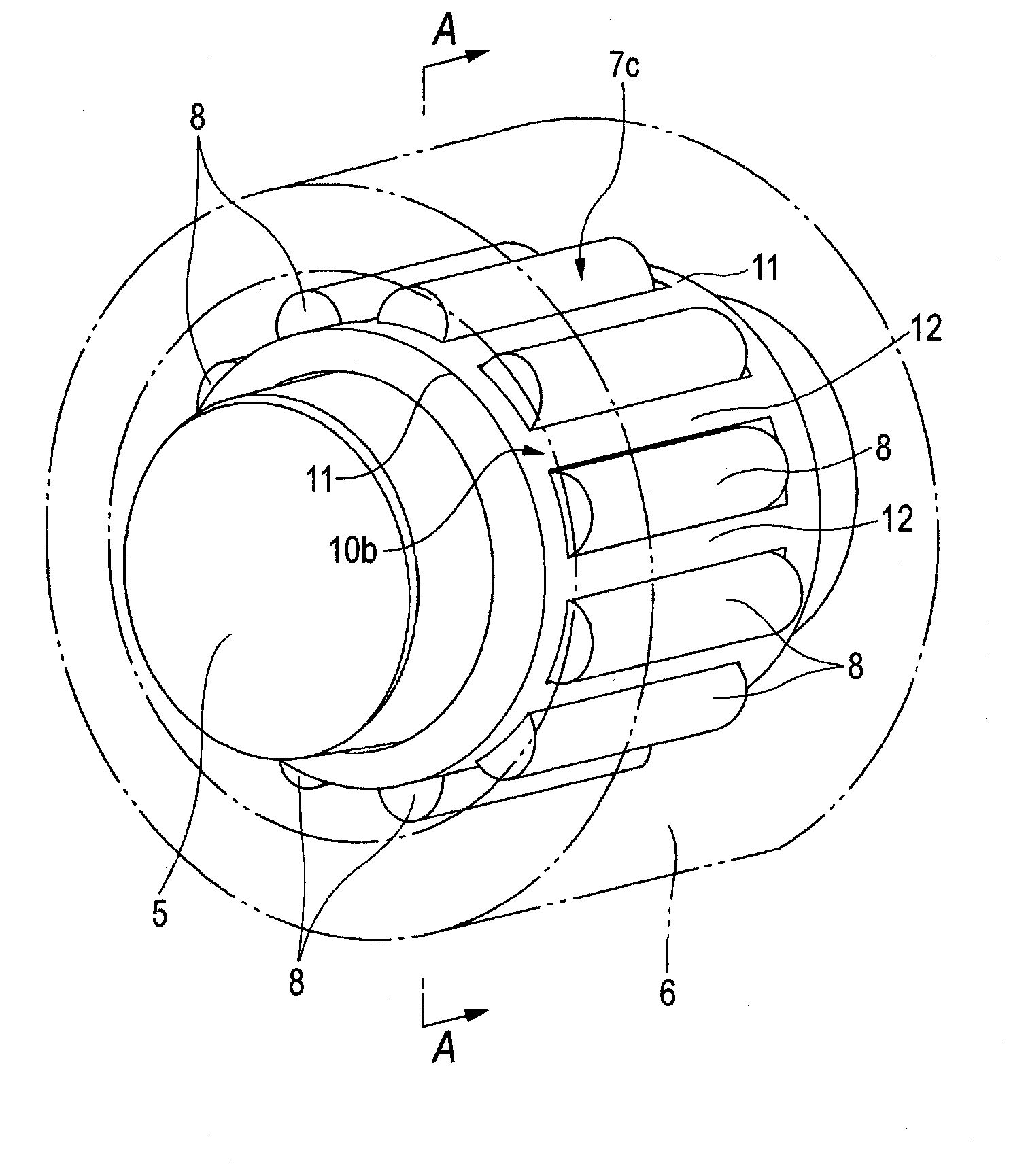

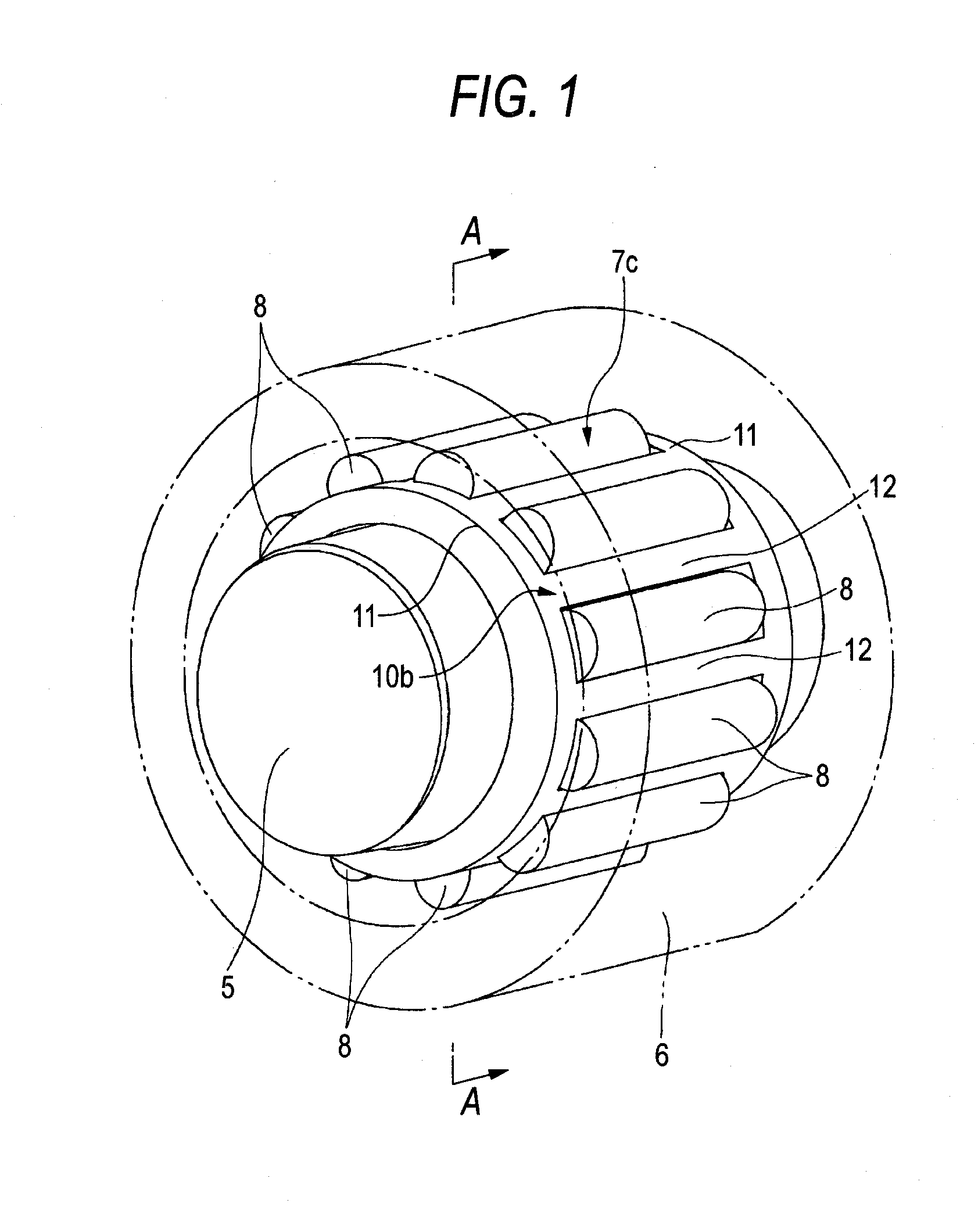

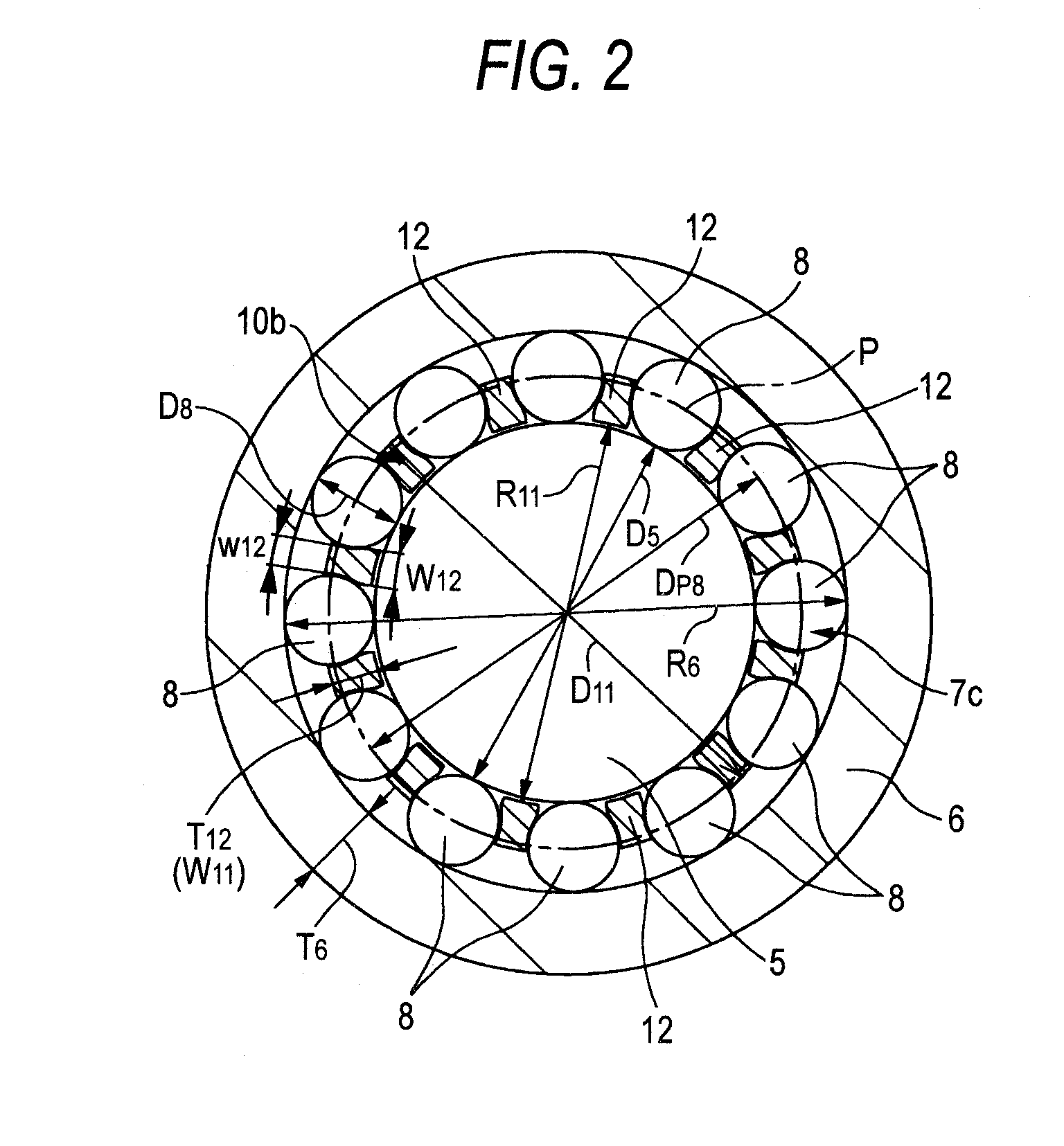

Cam follower apparatus

InactiveUS20090050091A1Reduce speedInhibition resistanceValve arrangementsRoller bearingsEngineeringTappet

As this radial needle bearing 7c, a radial needle bearing is used which includes a cage 10b. Respective pillar portions 12, 12 which make up the cage 10b are disposed more radially inwards than a circle pitch of respective needles 8, 8. In addition, the needles 8, 8 which are adjacent to each other in a circumferential direction are caused to approach each other, so as to secure the number of such needles 8, 8. As a result, no large bending stress is applied to a tappet roller 6 without increasing the thickness of the tappet roller 6.

Owner:NSK LTD

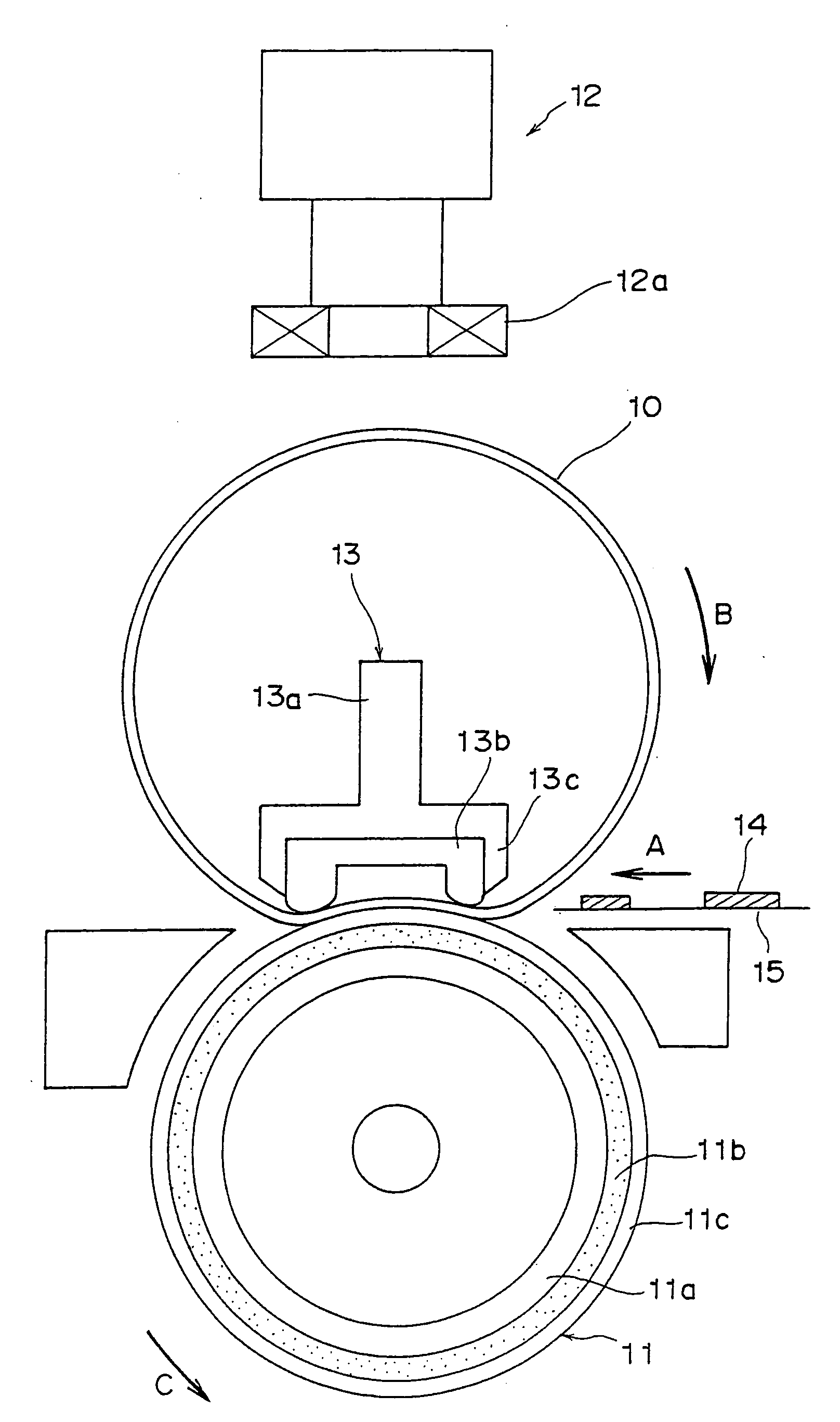

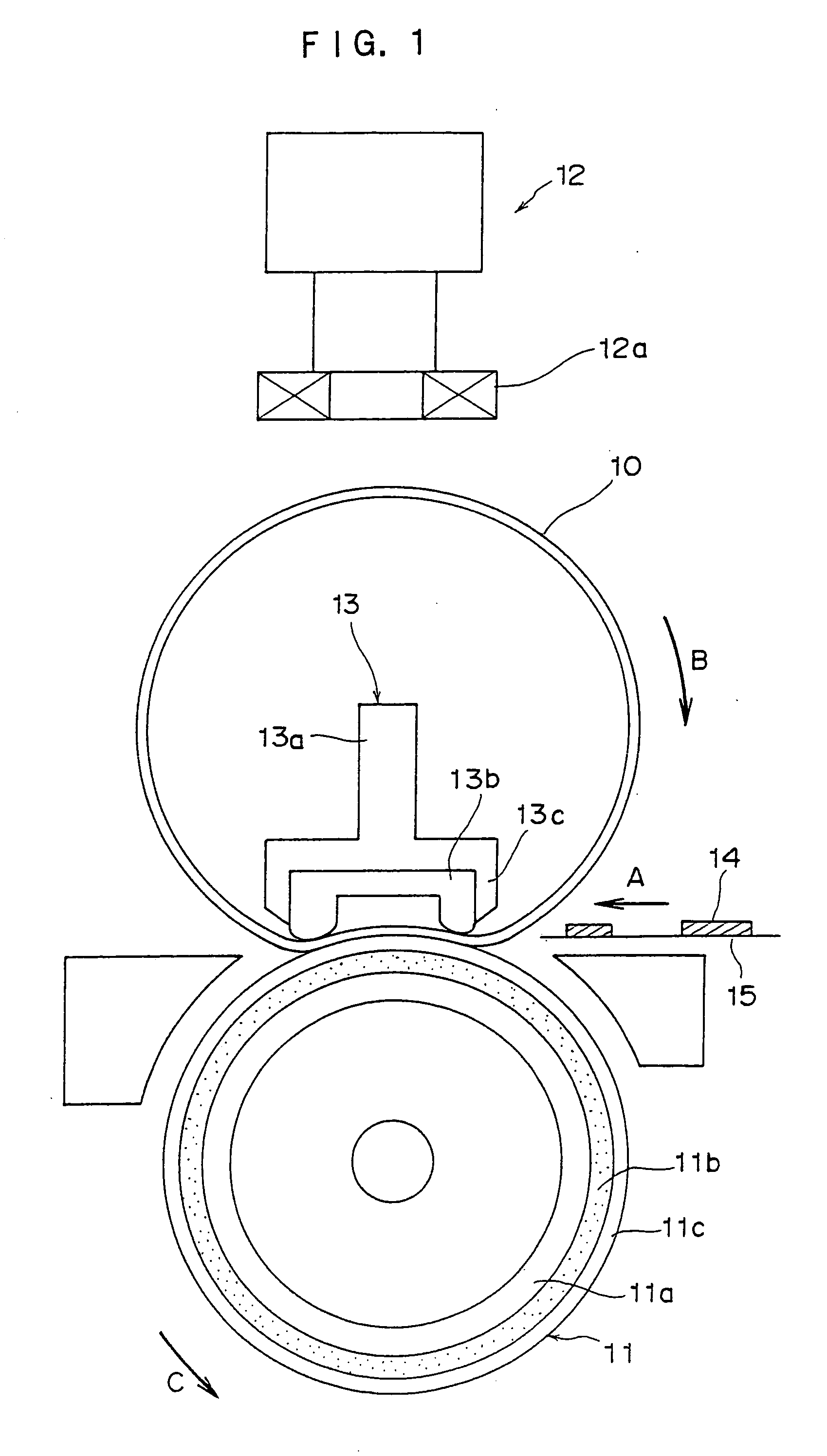

Fixing member, fixing device and image forming device

ActiveUS20060216078A1Narrow choicePrevent pressure damageElectrographic process apparatusImage formationEngineering

The present invention provides a fixing member having a heat resistant resin layer, a metal layer having two or more layers, and a releasing layer, in this order from the inner peripheral side, wherein a specific resistance of the metal layer disposed at the outer peripheral side is larger than a specific resistance of the metal layer disposed at the inner peripheral side in the at least two metal layers, and a modulus of an internal stress of the metal layer disposed at the outer peripheral side is 5 kg / mm2 or less. Further, a fixing device includes the fixing member, an electromagnetic induction heating device in which an electric field is applied to the fixing member, and a press member which press-contact the surface of a releasing layer of the fixing member. Furthermore, an image forming device having this fixing device is provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Common-current collector plate group with positive plates opposite to negative plates and common-current collector module battery

InactiveCN101556995AIncrease working temperatureImprove high temperature environment adaptabilityFinal product manufactureCell temperature controlEngineeringCharge discharge

The invention relates to a common-current collector plate group with positive plates opposite to a negative plates and a common-current collector module battery, belonging to the technical field of battery. One end of the positive plate of the common-current collector plate group with the positive plate opposite to the negative plate is provided with a naked section of conductive substrate and one end of the negative plate is provided with a naked section of conductive substrate; the naked sections of conductive substrates of all the positive plate are respectively connected with one side of a current collector, and the naked sections of all the conductive substrates of the negative plate are respectively connected with the other side of the current collector; the positive electrode of the module battery penetrates through a sealed shell and is connected with the positive plate group; the negative electrode of the module battery penetrates through a sealed shell and is connected with the negative plate group; all the positive plates are respectively wrapped by a membrane; the common-current collector plate group with the positive plates opposite to the negative plates is arranged between the positive plate group and the negative plate group in sequence; all the positive plates are respectively distributed between adjacent negative plates; and adjacent monomer batteries have a common current collector. The common-current collector plate group has simple structure and long service life, greatly improves large-current charging-discharging capability, charging-discharging efficiency, thermal environment adaptability and anti-vibration capability of the battery.

Owner:SHANGHAI JIAO TONG UNIV

Active matrix substrate where a portion of the storage capacitor wiring or the scanning signal line overlaps with the drain lead-out wiring connected to the drain electrode of a thin film transistor and display device having such an active matrix substrate

InactiveUS7812893B2Improve yieldIncrease the aperture ratioNon-linear opticsSemiconductor devicesActive matrixDisplay device

An active matrix substrate suppresses reduction in production yield and increase in production steps and simultaneously permits both sufficient securing of a storage capacity and improvement of an aperture ratio of a pixel. The active matrix substrate is an active matrix substrate and includes a thin film transistor disposed at an intersection of a scanning signal line with a data signal line on a substrate, the thin film transistor including a gate electrode connected to the scanning signal line, a source electrode connected to the data signal line, and a drain electrode connected to a drain lead-out wiring; a storage capacitor upper electrode connected to the drain lead-out wiring and a pixel electrode; and a storage capacitor wiring overlapping with the storage capacitor upper electrode through an insulating film, wherein the storage capacitor wiring has an extending portion overlapping with the drain lead-out wiring through the insulating film.

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com