Array substrate of liquid crystal display device

A technology of a liquid crystal display device and an array substrate, which is applied in the field of array substrates, and can solve the problems of high step difference between the data line area and the pixel area, and high anti-friction resistance, and achieve the effects of reducing resistance, improving quality, and overcoming the phenomenon of poor friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

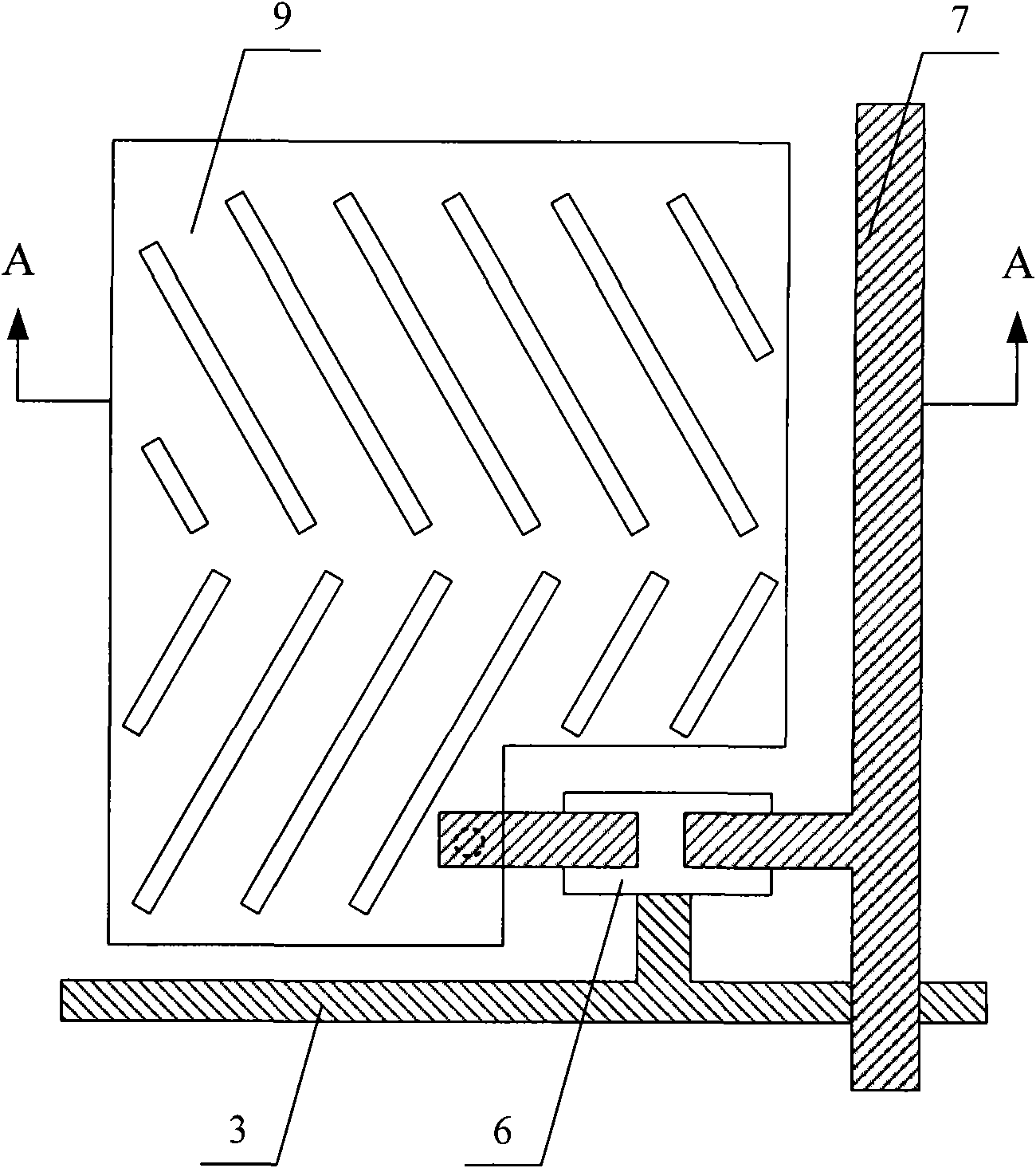

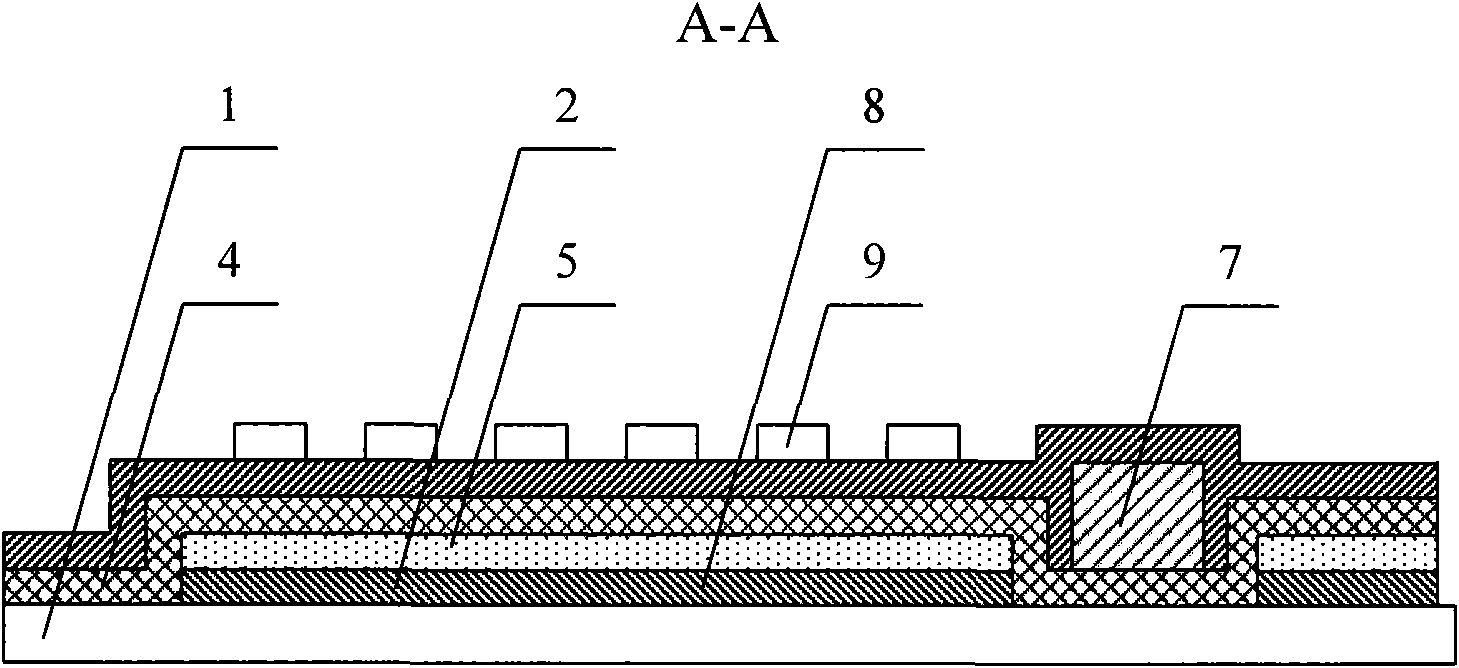

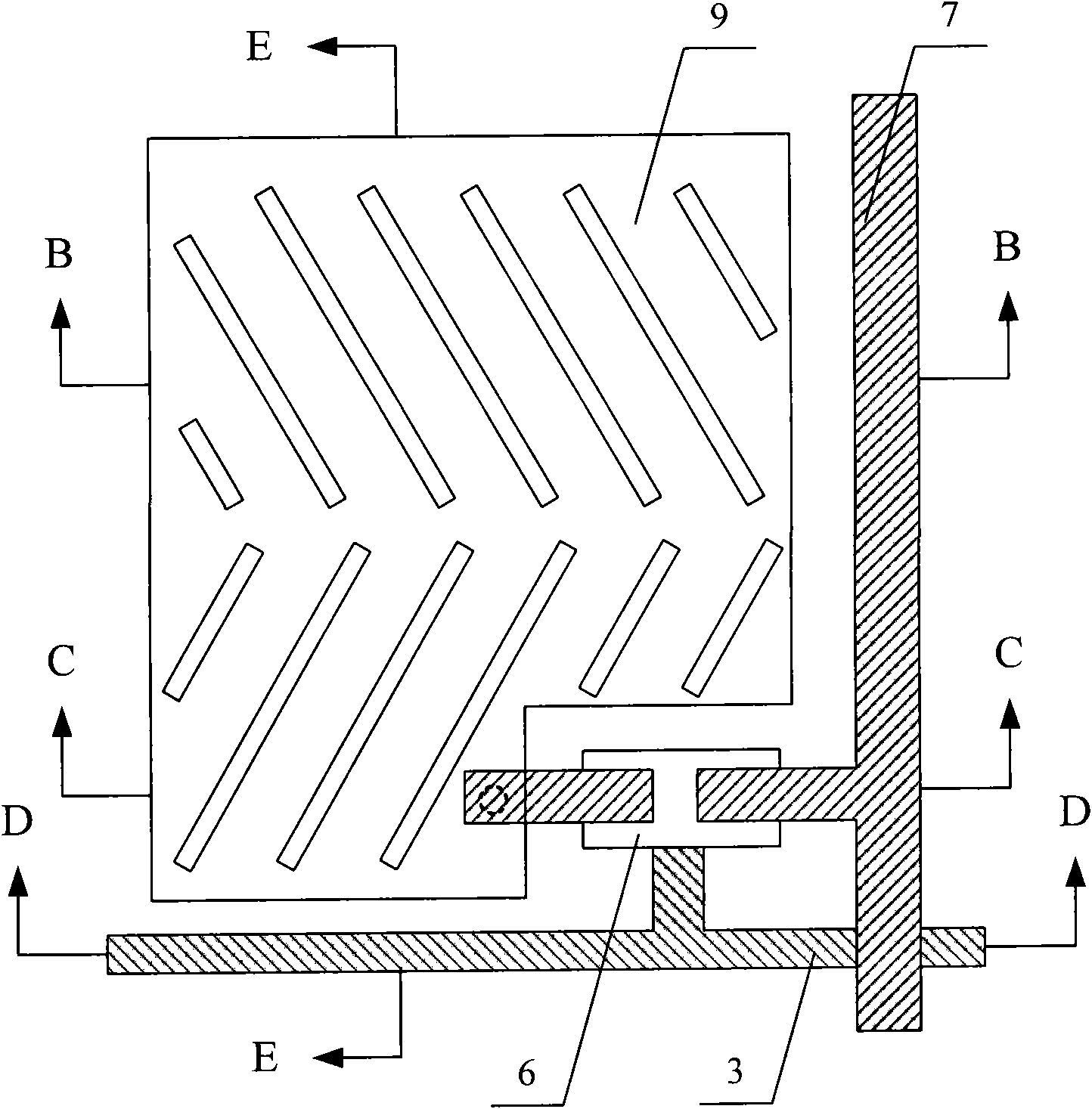

[0031] Figure 1a is a schematic structural view of the first embodiment of the array substrate of the liquid crystal display device of the present invention, Figure 1b for Figure 1a Schematic diagram of the A-A section in the middle, such as Figure 1a with Figure 1b As shown, the specific structure of the array substrate of the liquid crystal display device of the present invention includes: a substrate 1, a gate line 3 located on the substrate 1, a data line 7 crossing the gate line 3, a thin film transistor electrically connected to the gate line 3 and the data line 7 , and the pixel electrode 9 electrically connected to the thin film transistor is located in the area defined by the intersection arrangement of the gate line 3 and the data line 7, a common electrode 5 is provided under the gate insulating layer 4, and a passivation layer 8 is provided above the data line 7, The active layer 6 is located between the gate electrode (the electrode branched from the gate lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com