Patents

Literature

6228results about How to "Reduce flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

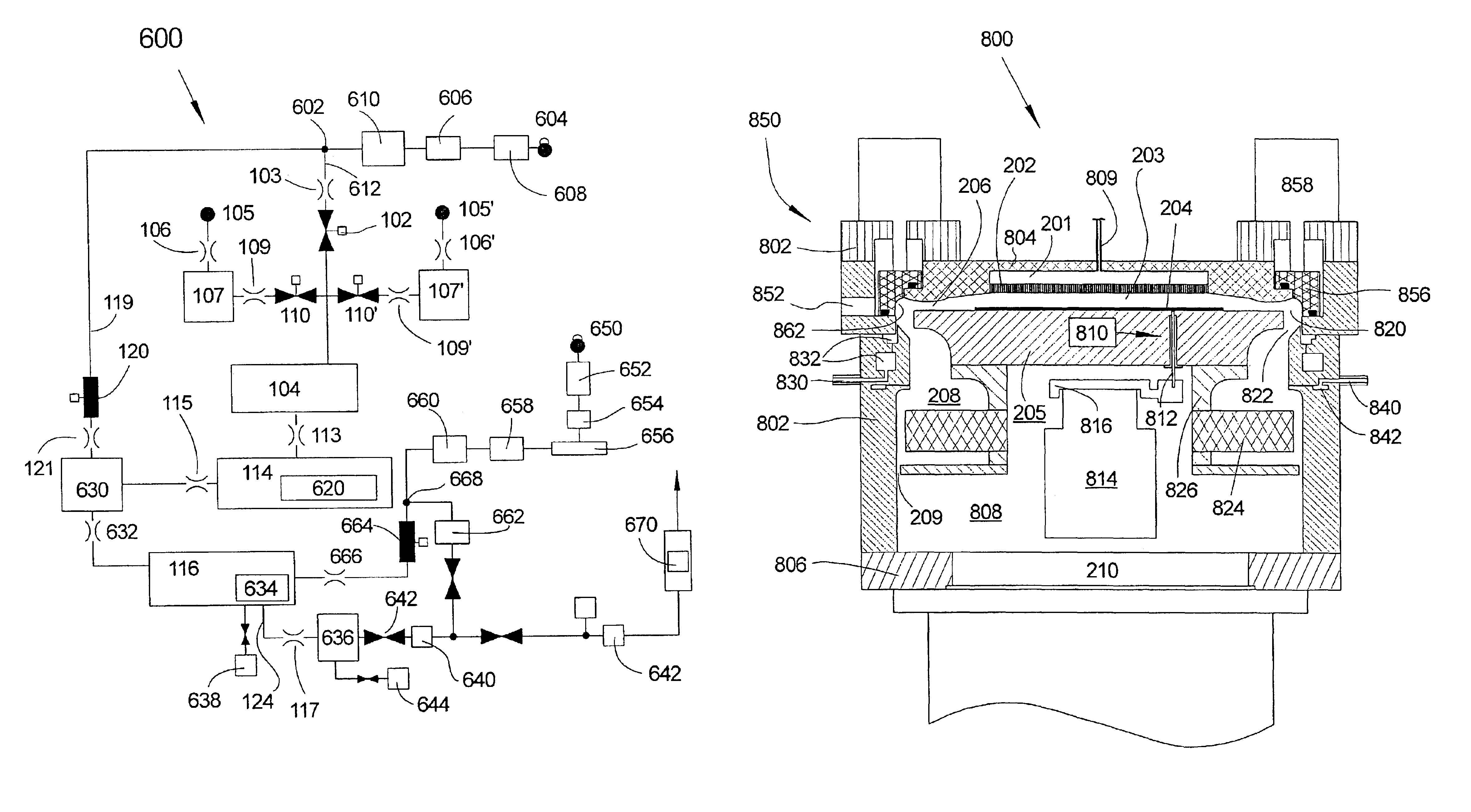

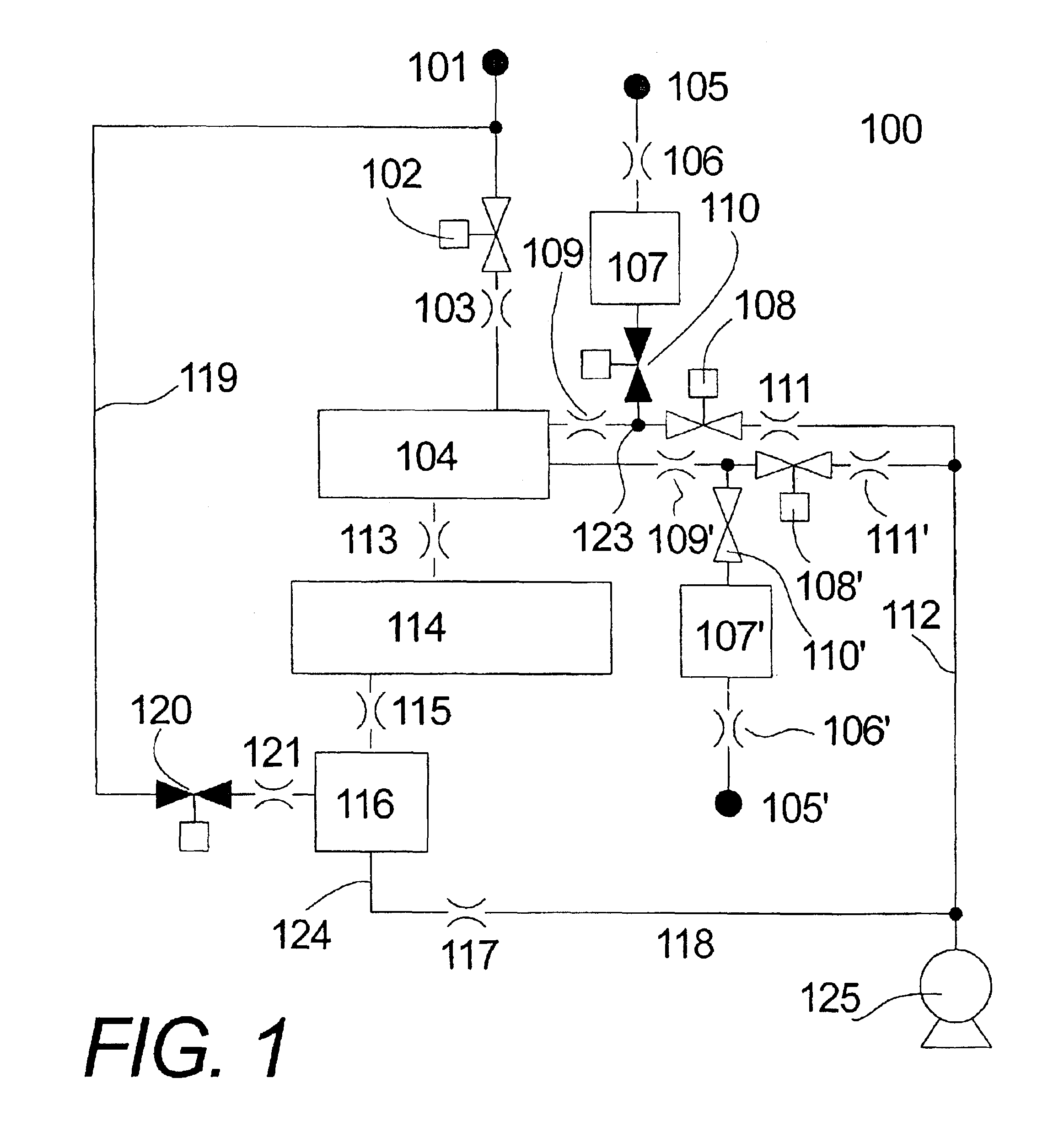

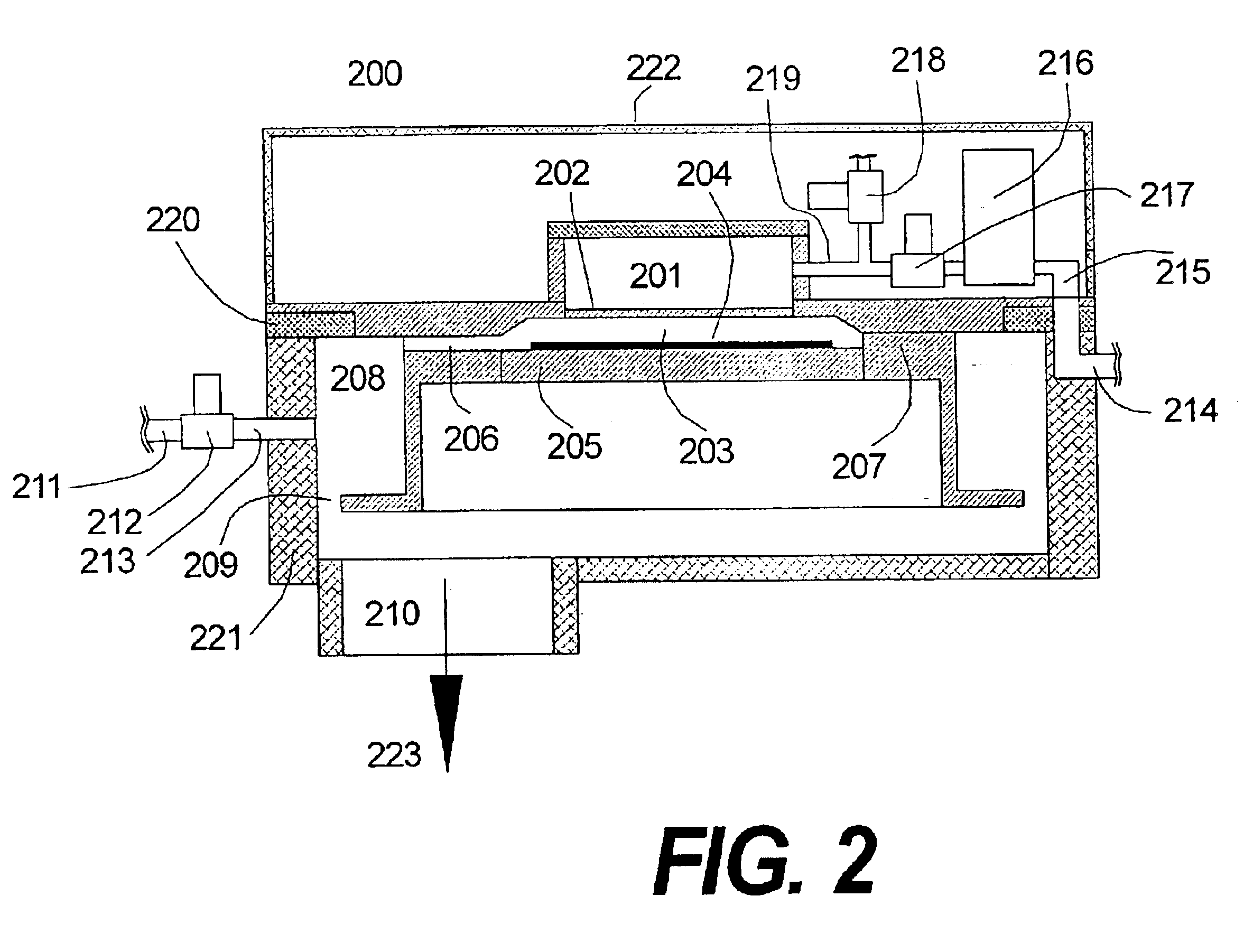

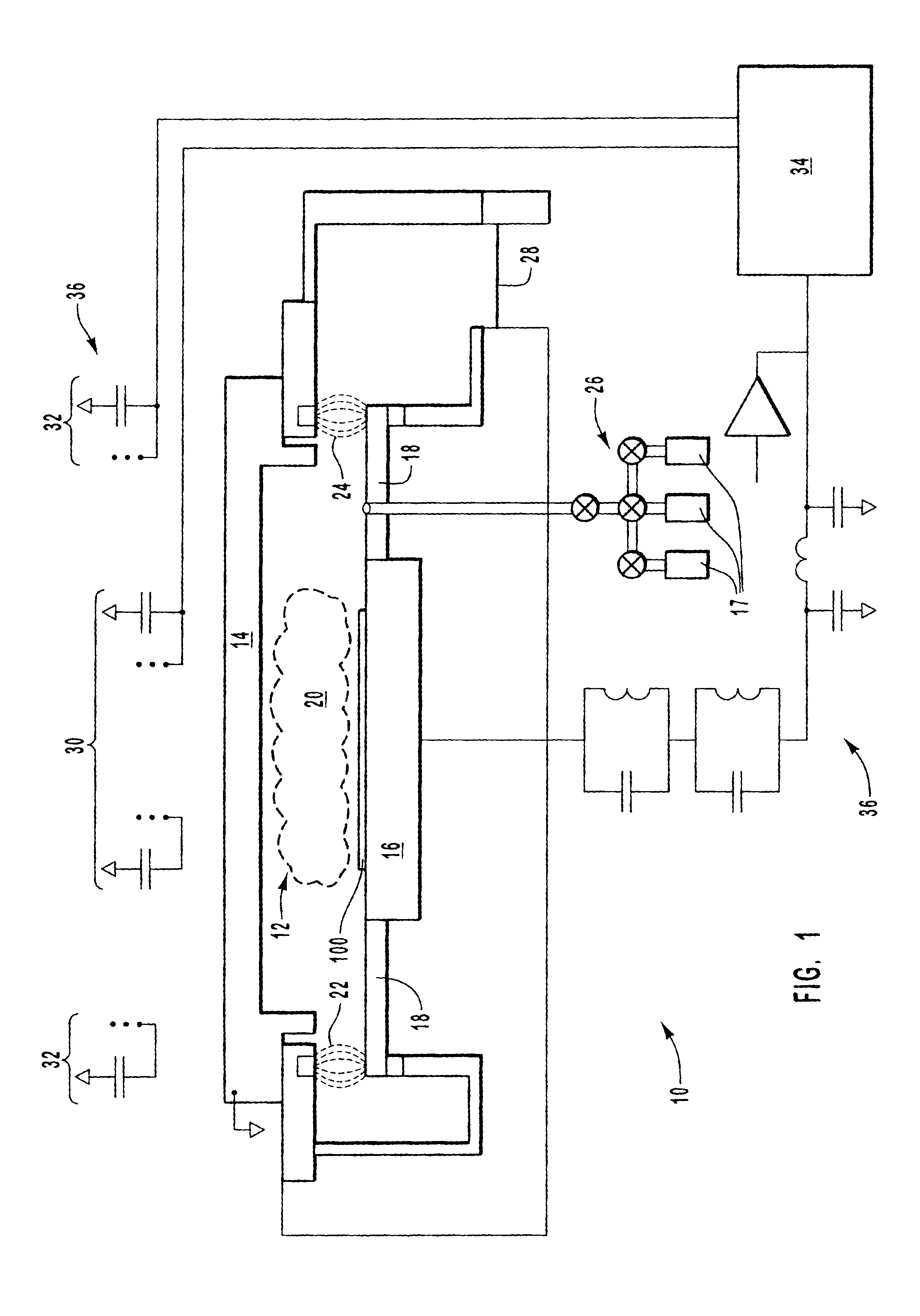

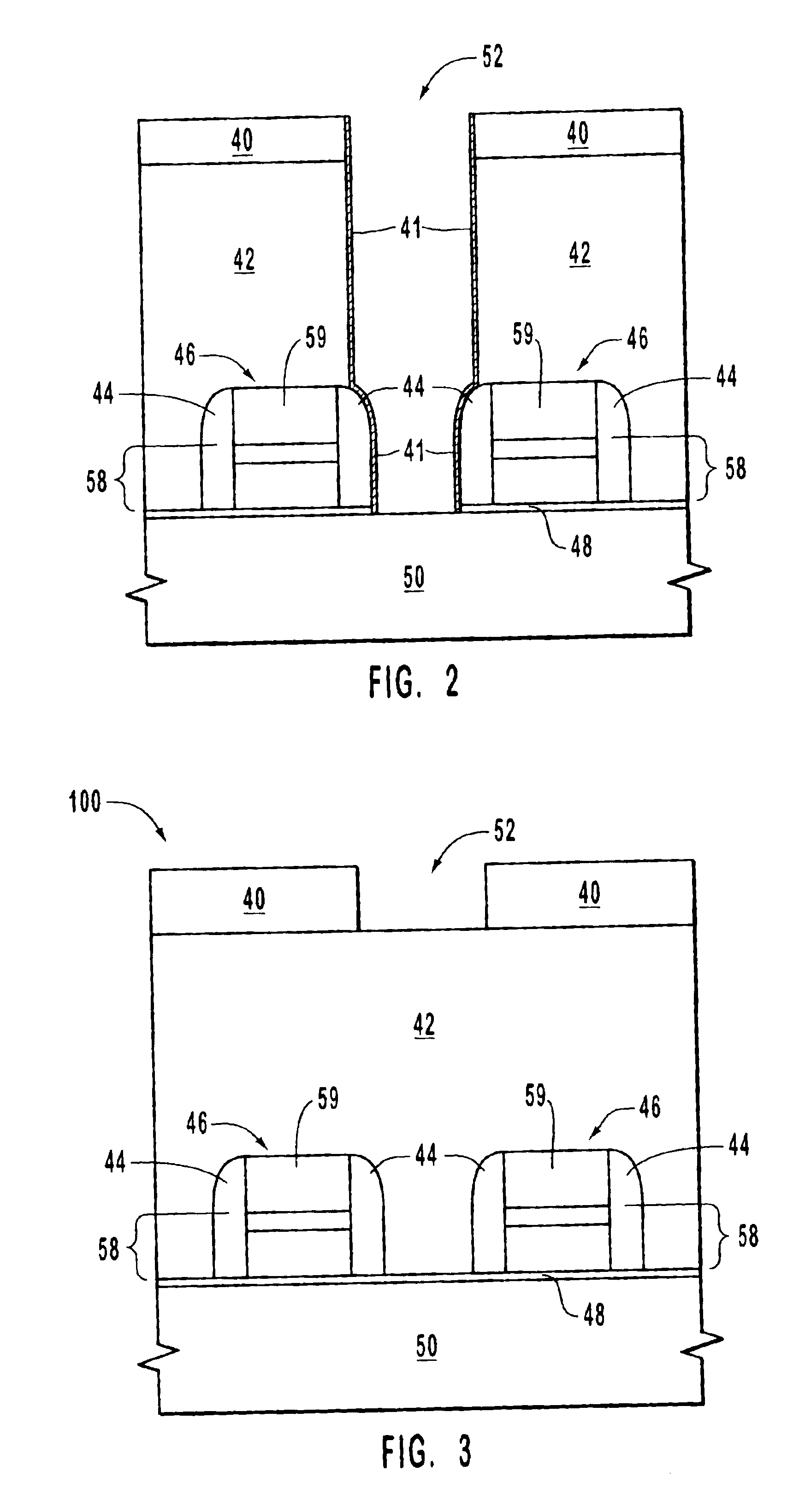

ALD apparatus and method

InactiveUS6911092B2Increase flow rateReduce flow rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringMechanical engineering

An apparatus and method for atomic layer deposition with improved efficiency of both chemical dose and purge is presented. The apparatus includes an integrated equipment and procedure for chamber maintenance.

Owner:SUNDEW TECH

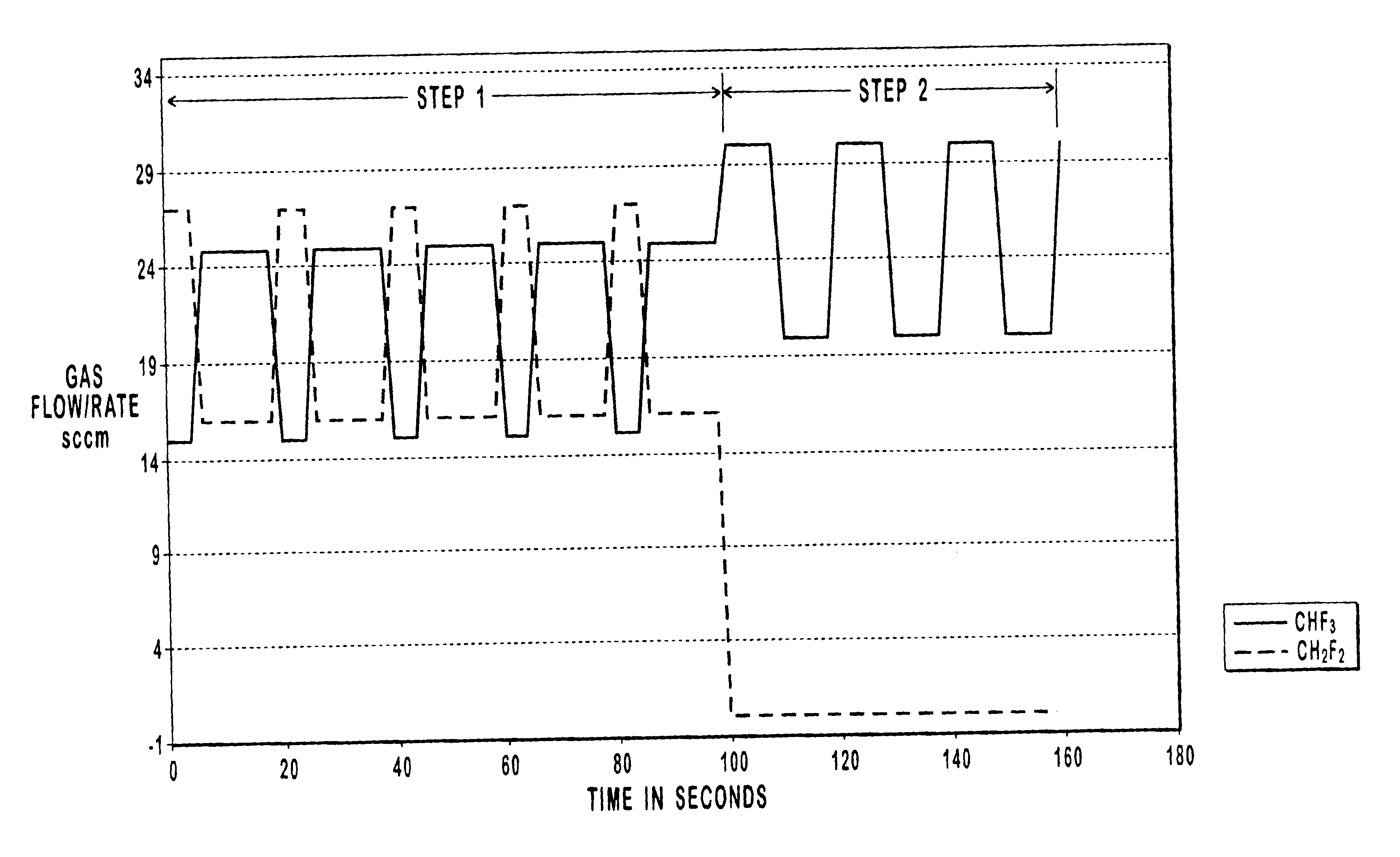

Gas pulsing for etch profile control

InactiveUS6784108B1Increase flow rateReduce flow rateElectric discharge tubesDecorative surface effectsEngineeringAnisotropic etching

Etch profile control with pulsed gas flow and its applications to etching such as anisotropic etching of high aspect ratio features and etching of self-aligned contact structures in various processes. Pulsing can be applied according to this invention to the flow rate of a gas such as an etchant gas, a gas that leads to the deposition of a protective layer, a gas that modifies the deposition of a protective layer, and a gas that modifies etching.

Owner:MICRON TECH INC

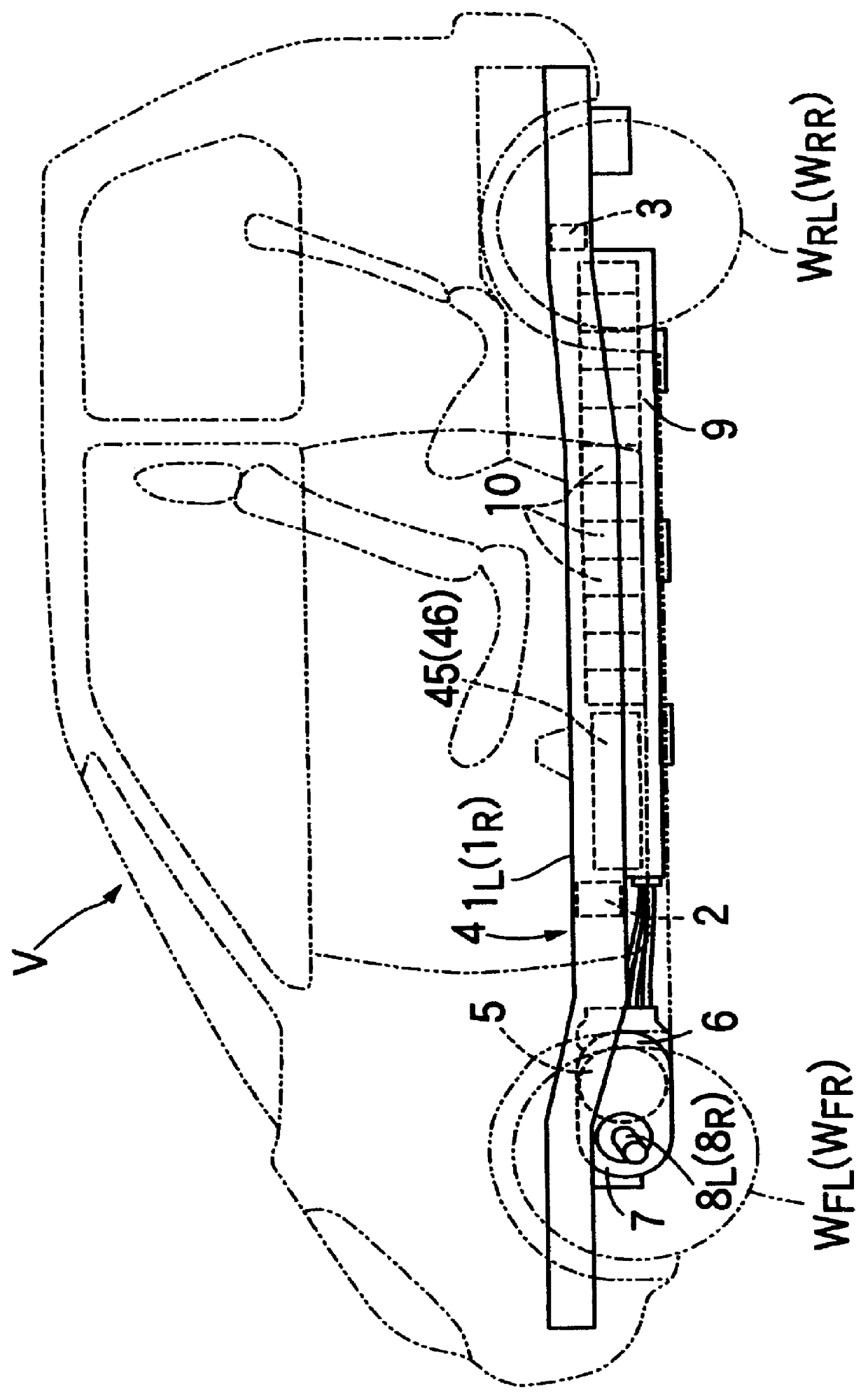

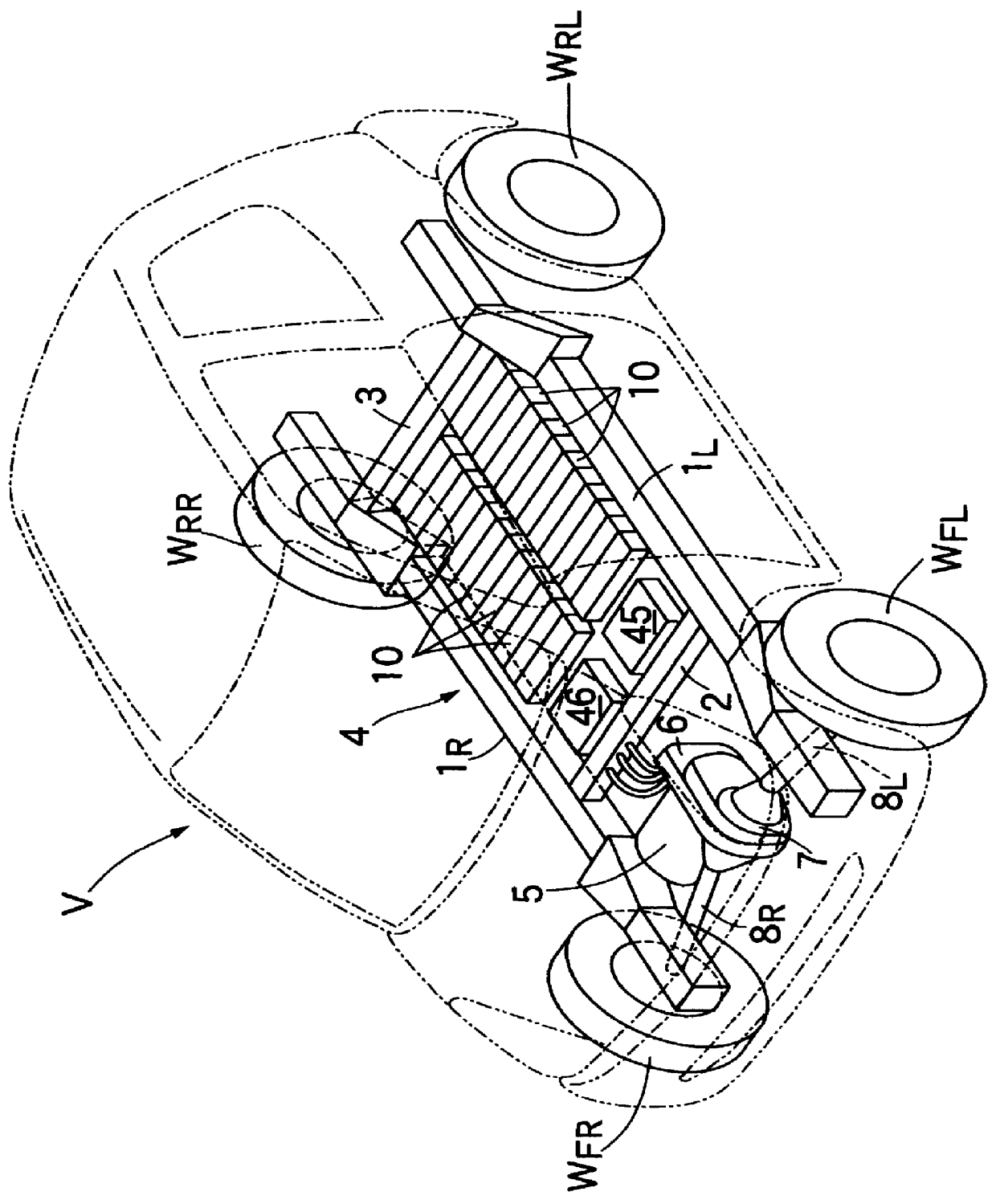

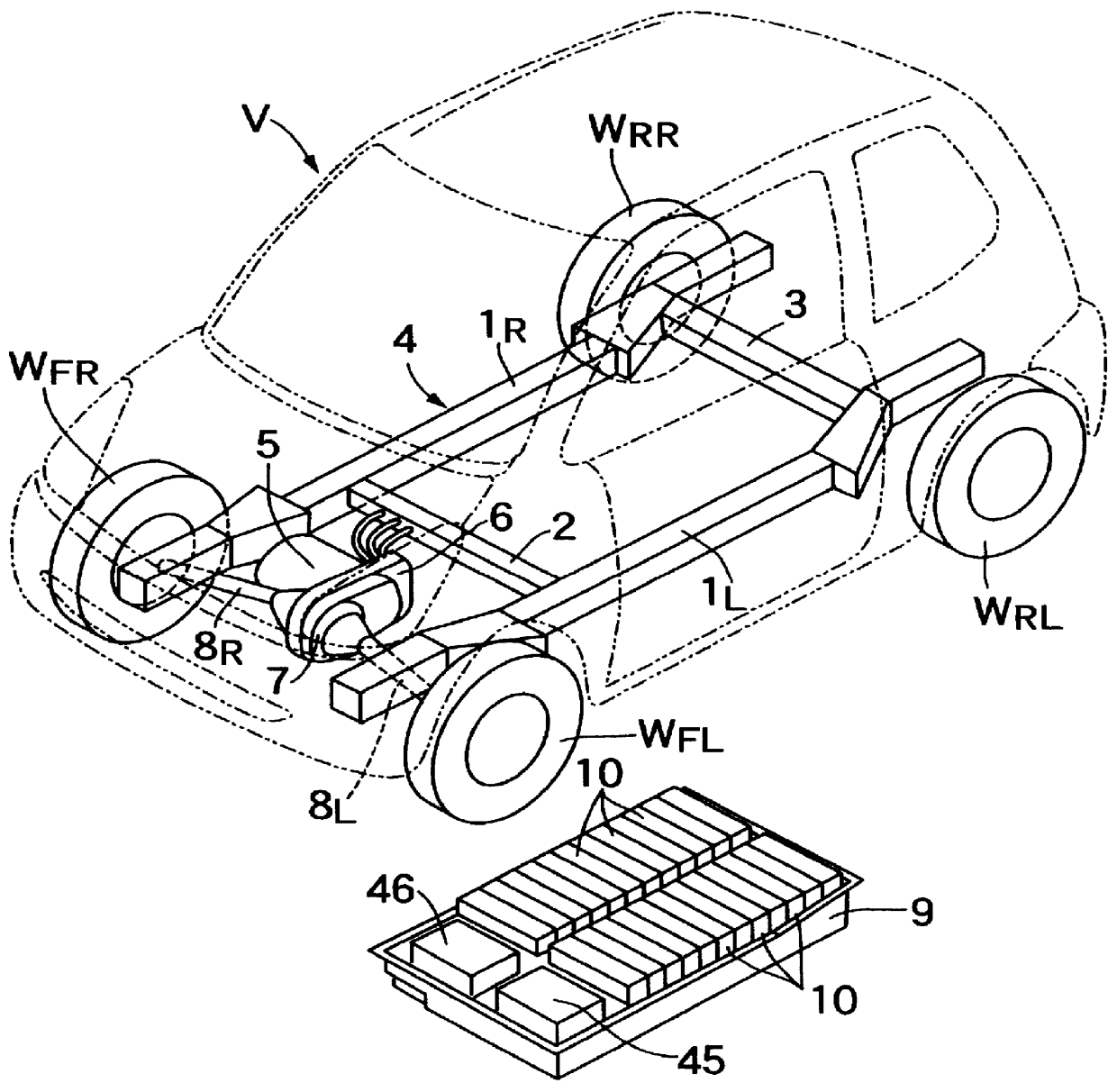

Cooling structure an electric vehicle

InactiveUS6094927AReliable coolingImprove cooling effectDomestic cooling apparatusLighting and heating apparatusAirflowThermal resistance

An electric vehicle includes plurality of batteries accommodated in a rear portion of a battery box, and an electric part is accommodated in an electric part accommodating chamber provided in a front portion of the battery box. Cooling air supplied from a cooling fan to the rear portion of the battery box cools the batteries having a large thermal resistance, while being passed through a first cooling air passage around outer peripheries of the batteries at a low flow rate. A second cooling air passage having a smaller sectional area than that of the first cooling air passage is provided below the electric part accommodating chamber, and cooling fins protruding downwards from the electric part are exposed within the second cooling air passage. The second cooling air passage extends continuously the first cooling air passage in a downstream direction of airflow, so that cooling air which has first cooled the batteries then cools the electric part having a smaller thermal resistance, while being passed through the second cooling air passage at a higher flow rate than that in the first cooling air passage.

Owner:HONDA MOTOR CO LTD

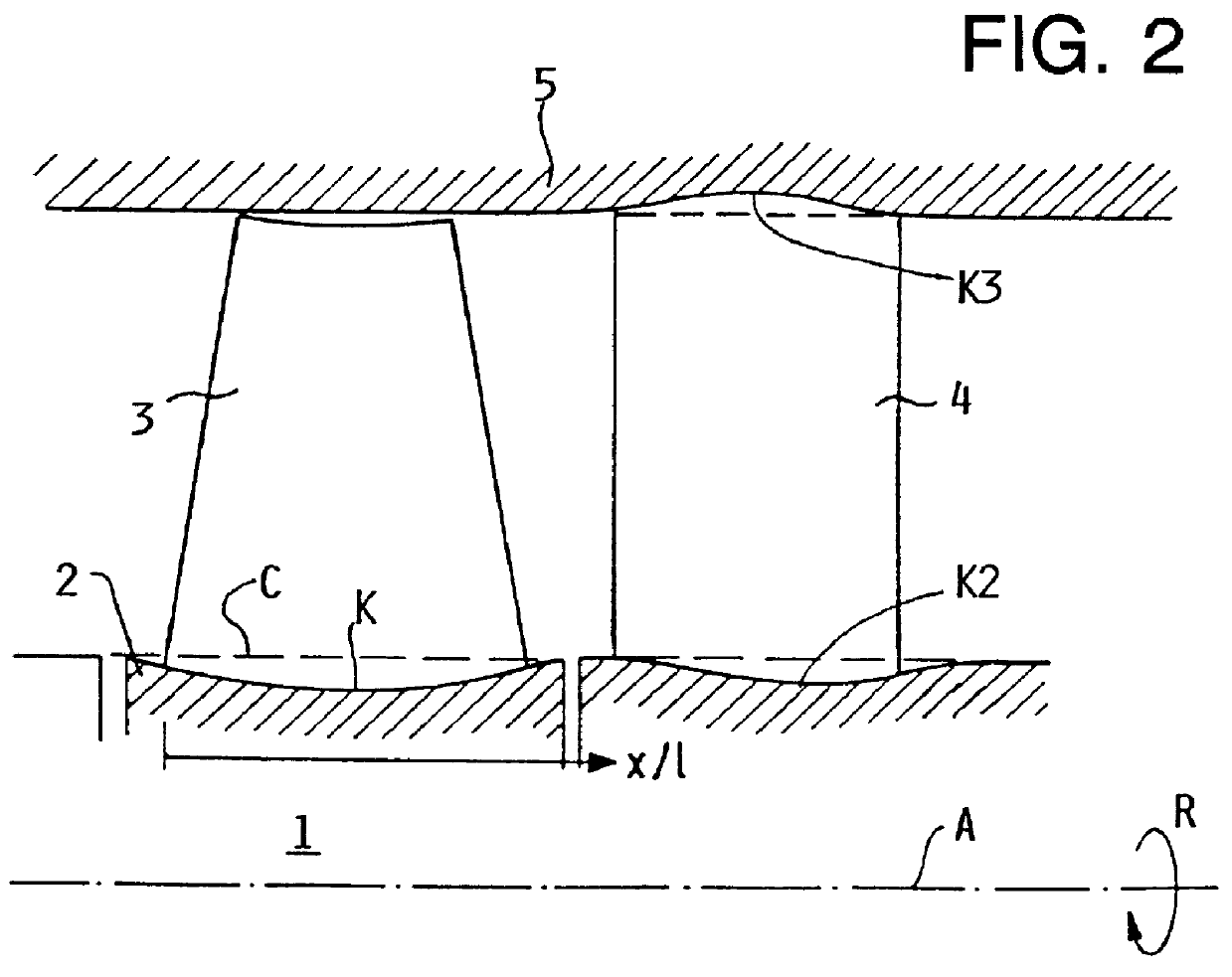

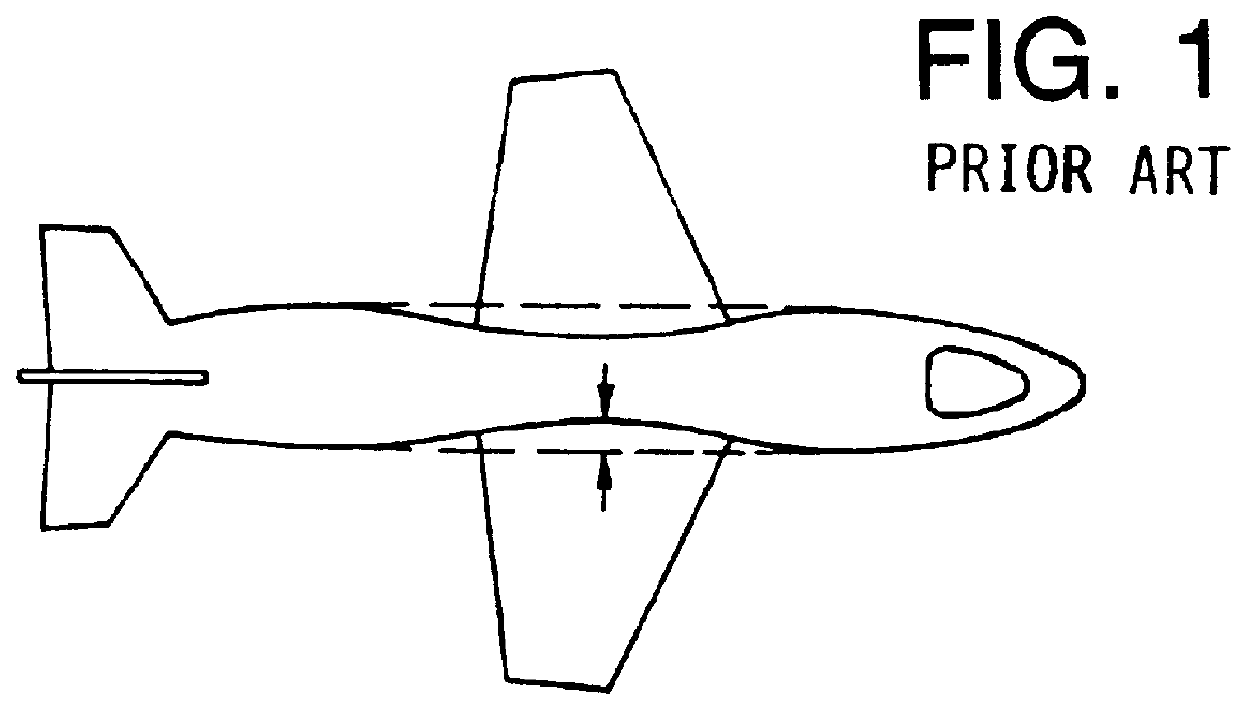

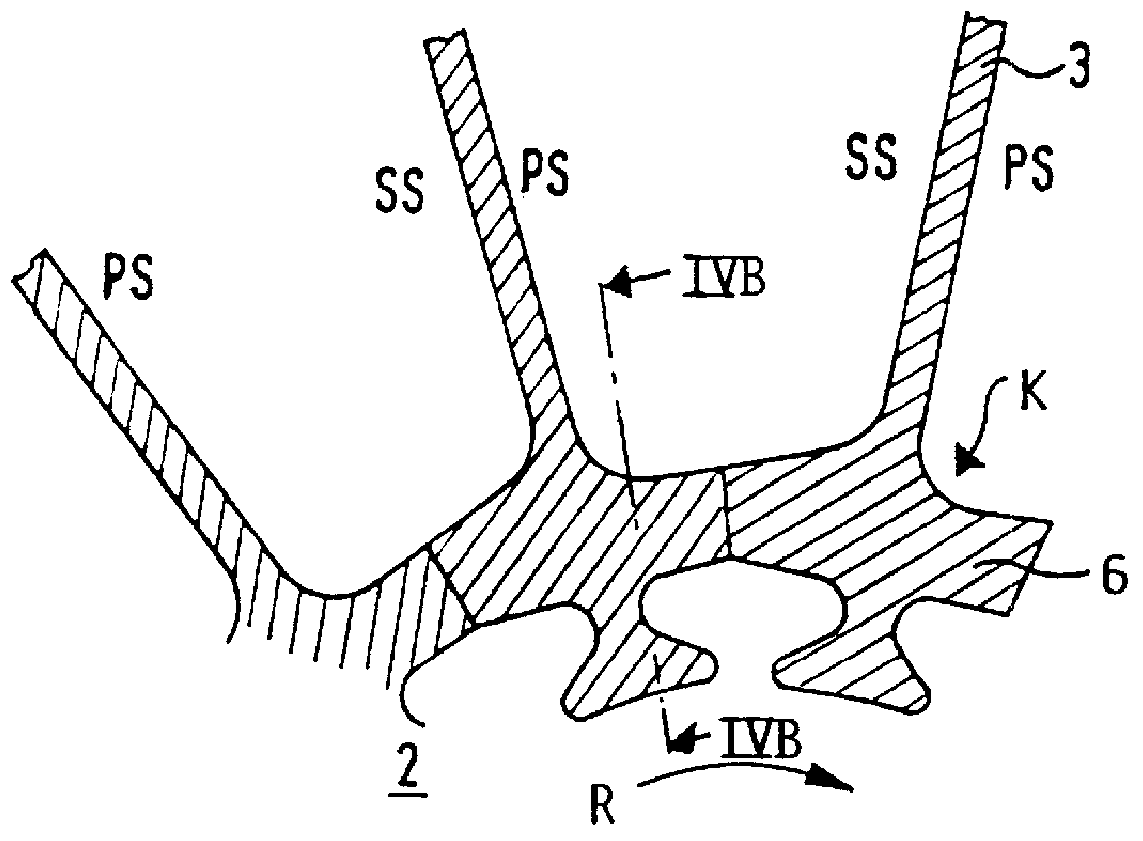

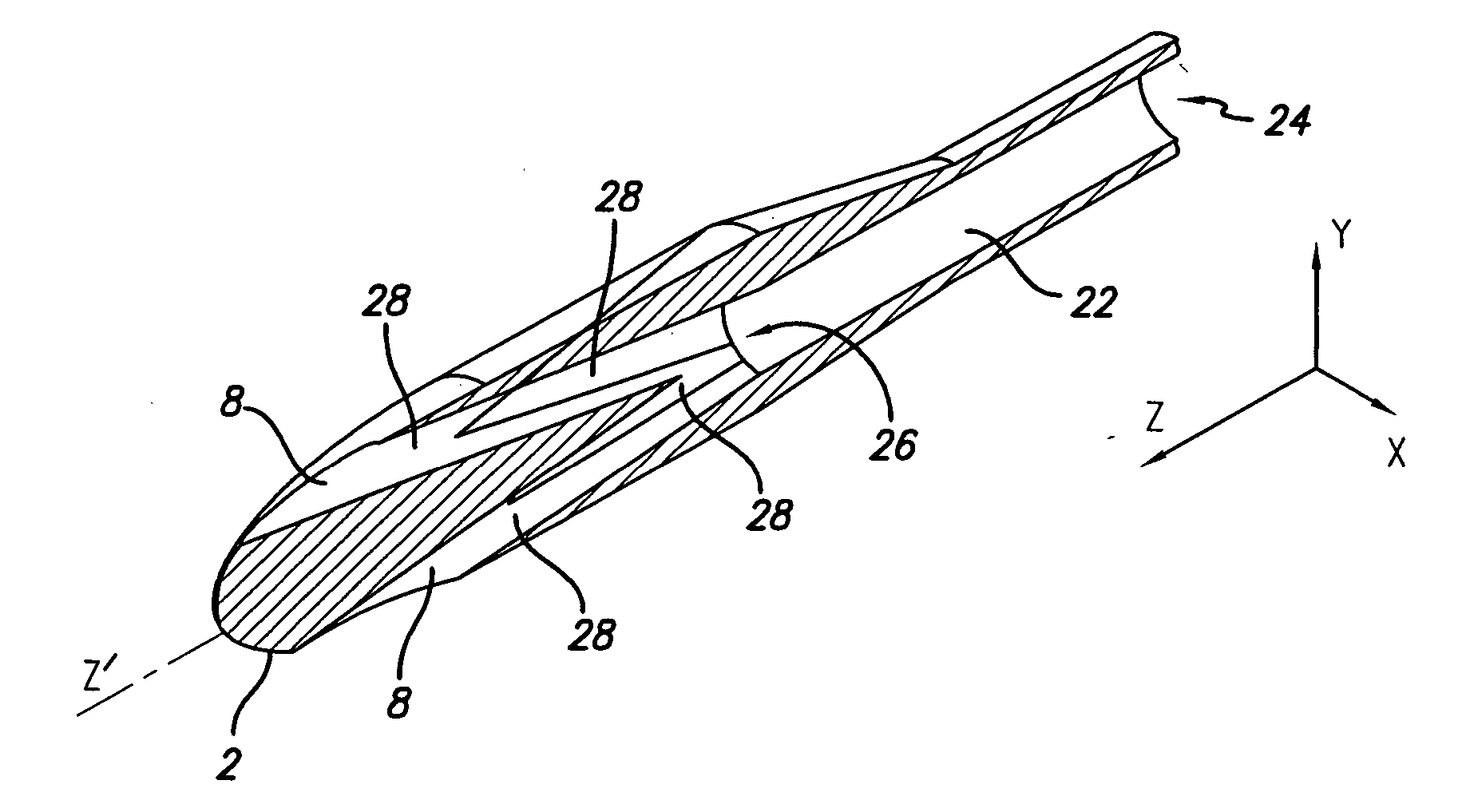

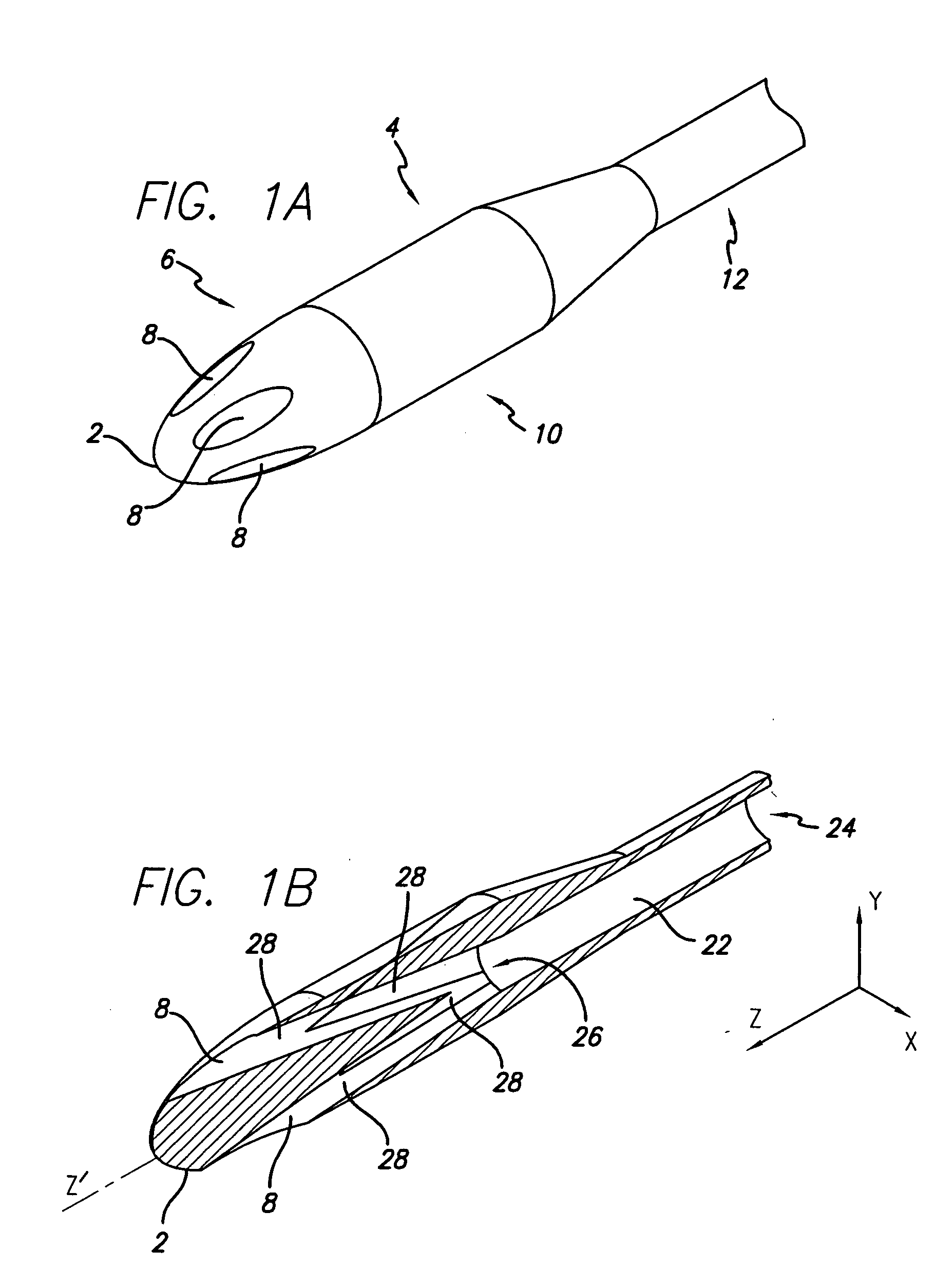

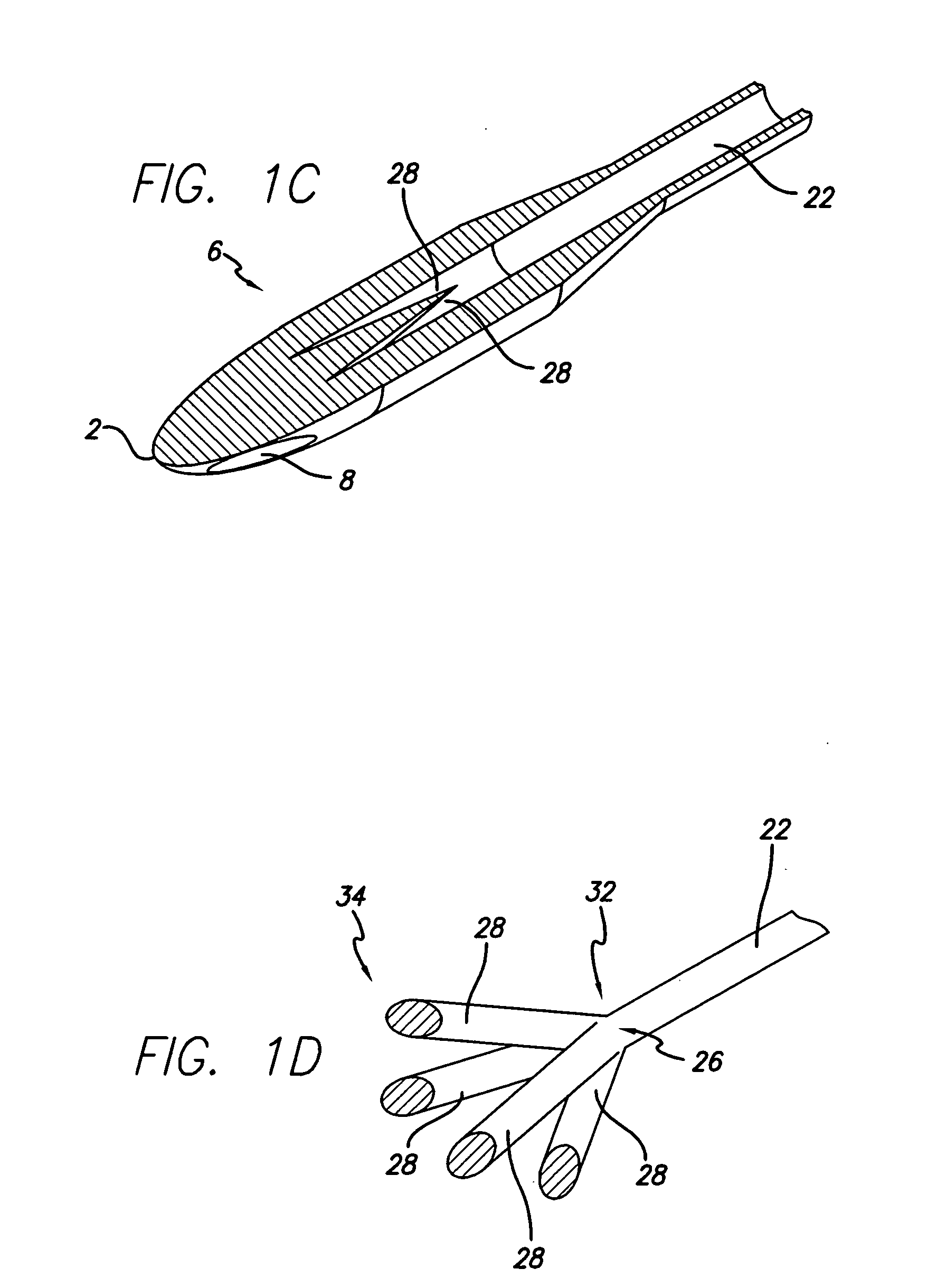

Rotary turbomachine having a transonic compressor stage

InactiveUS6017186AReduce flow rateReduce flowPropellersSupersonic fluid pumpsTransonic compressorStator

A rotary turbomachine, and particularly a turbojet engine, has a compressor stage that is especially adapted for operation in the transonic region. The compressor stage includes a rotor (1) having a hub (2) and a plurality of compressor blades (3) extending radially therefrom, and a stator having a plurality of compressor blades extending radially between a stator hub and a housing. The hub (2) of the rotor (1), and / or the hub of the stator, and / or the housing of the stator, have a circumferential surface contour that is not continuously rotationally symmetrical. Namely, a concave contour (K) is provided in the circumferential surface of the hub near the base of each blade (3) on the pressure side (PS) thereof, while the circumferential surface on the suction side (SS) of the base of each blade has a contour that is linear, slightly convex, convex / concave, or slightly concave to a lesser degree than the concave contour (K) on the pressure side of each blade. The hub contour slopes and transitions smoothly radially outwardly from the concave contour (K) on the pressure side to the flatter or convex contour on the suction side. In this manner, fluid flow velocities on both the pressure side and the suction side of each blade are reduced, especially under transonic operating conditions, and compression shock losses can be minimized.

Owner:MOTOREN UND TURBINEN UNION MUNCHEN GMBH

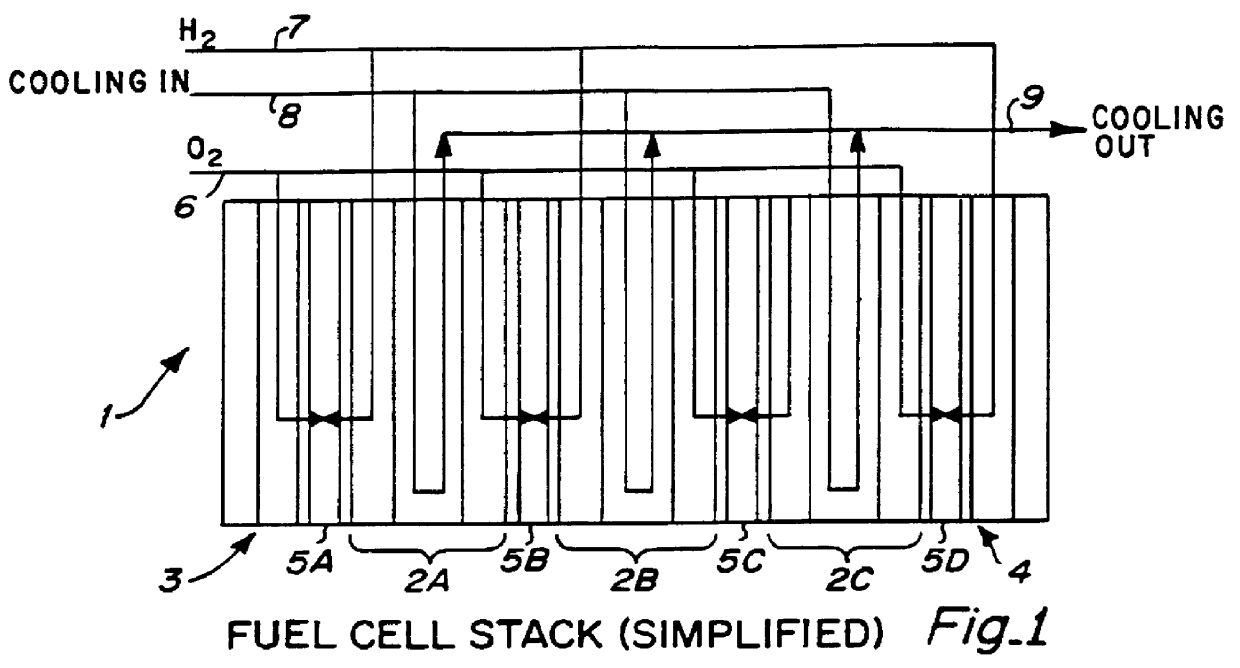

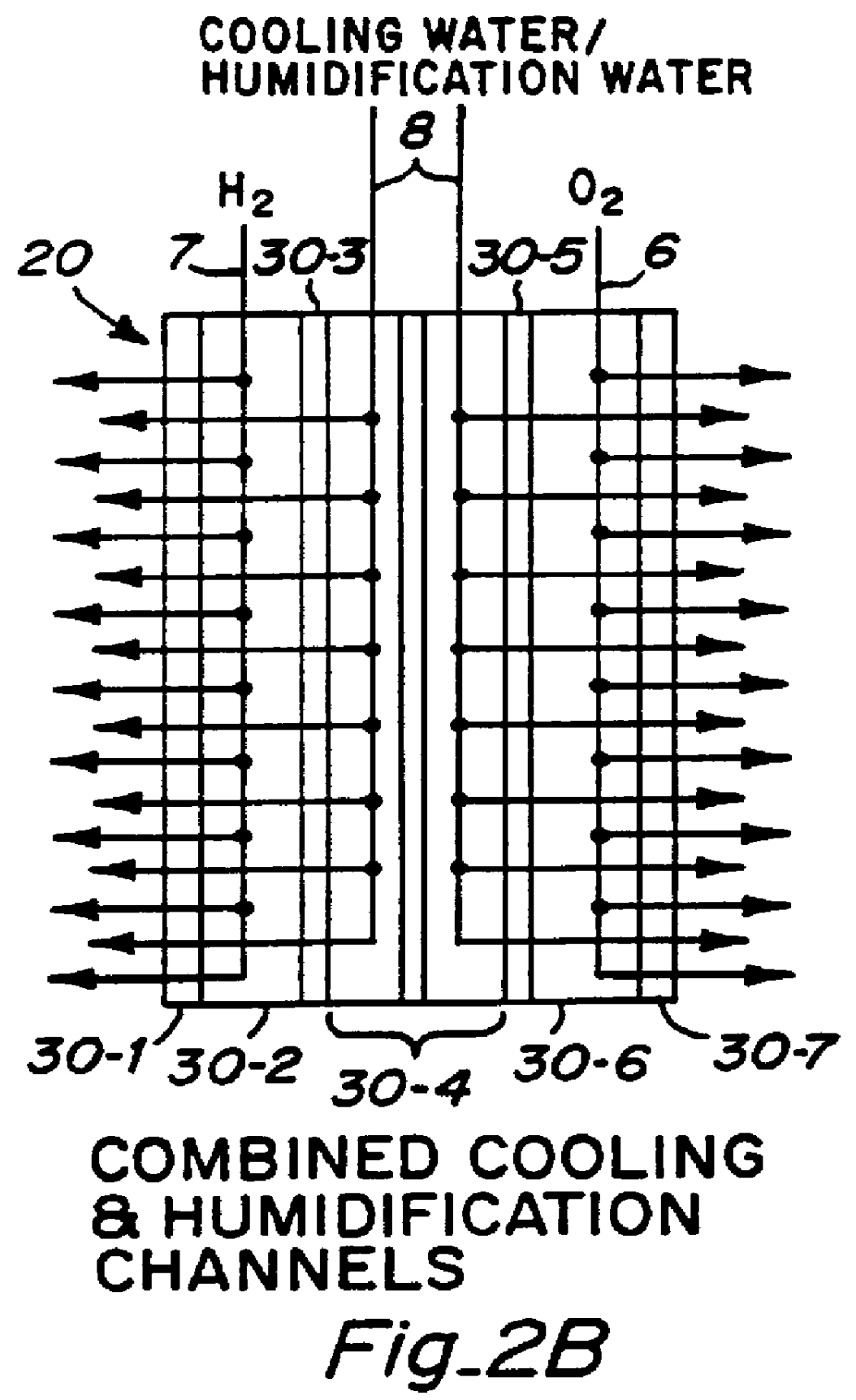

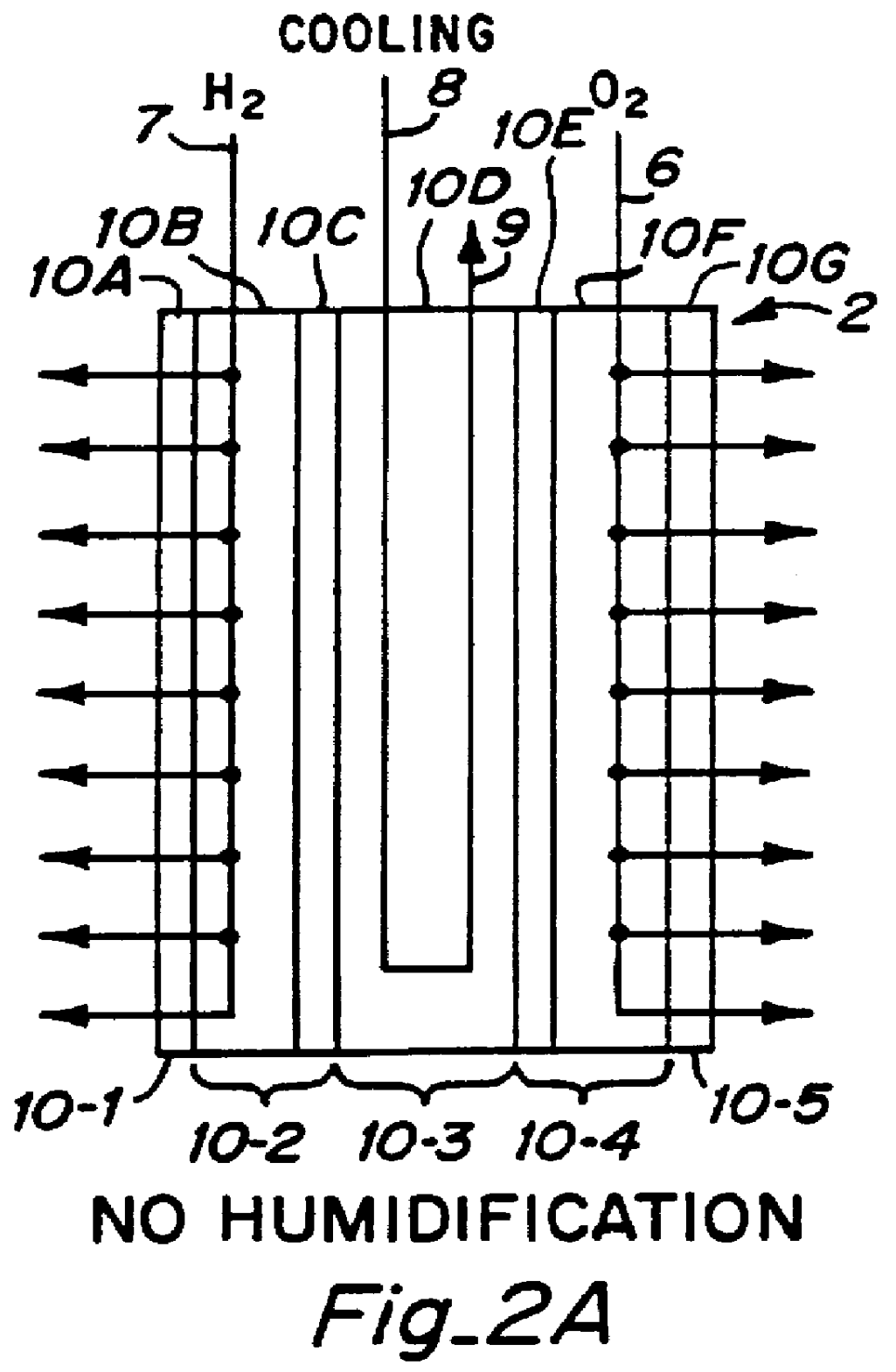

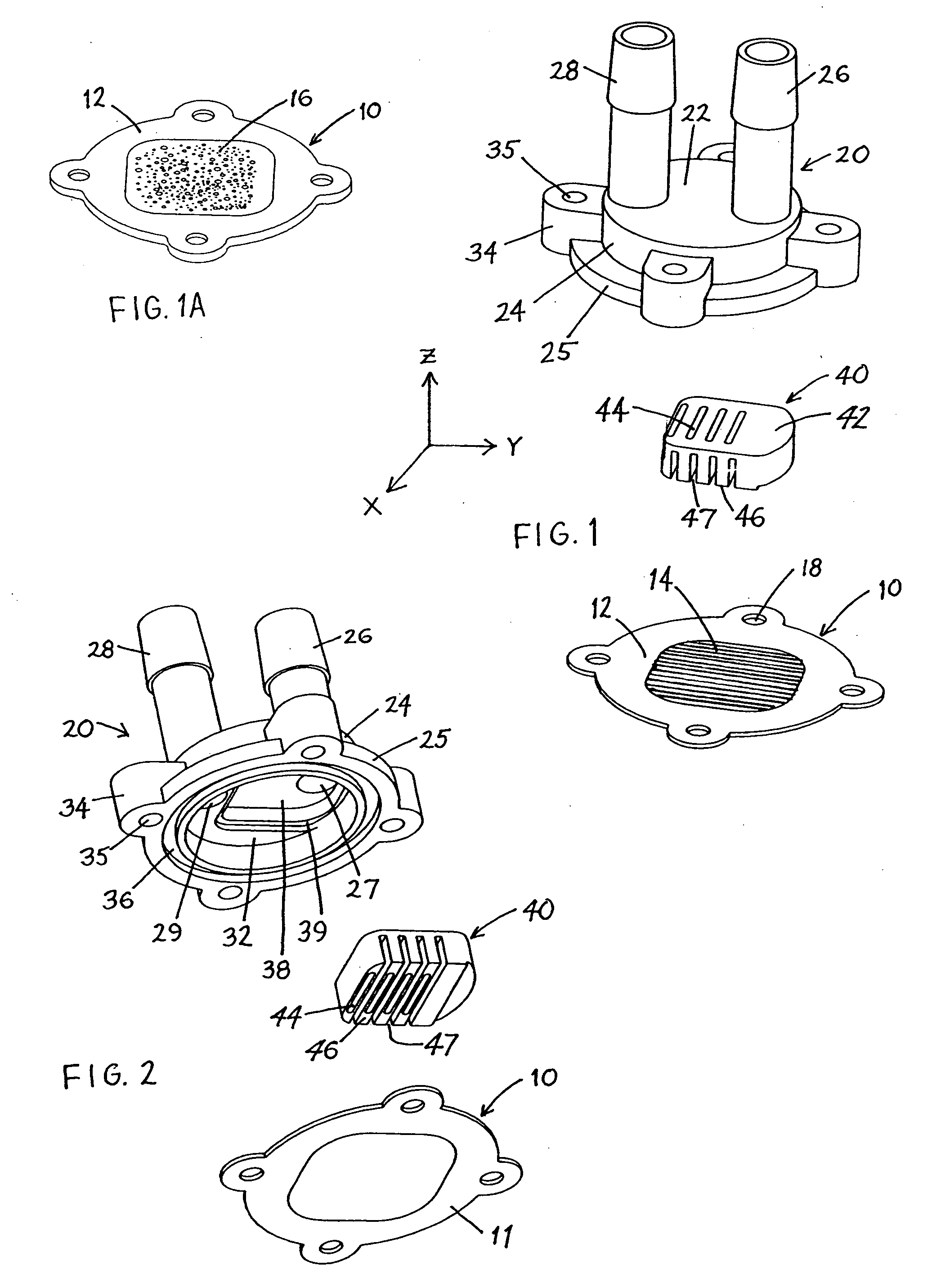

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

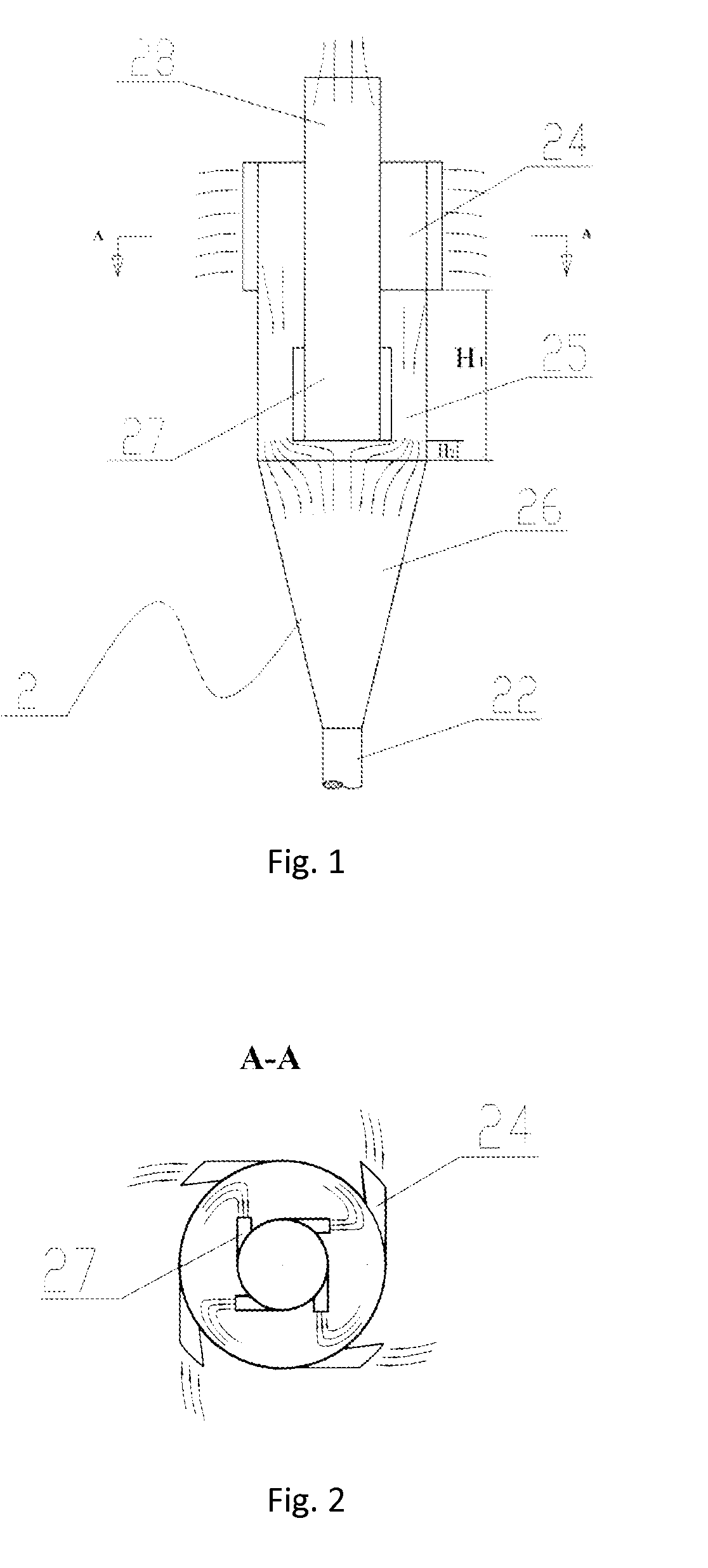

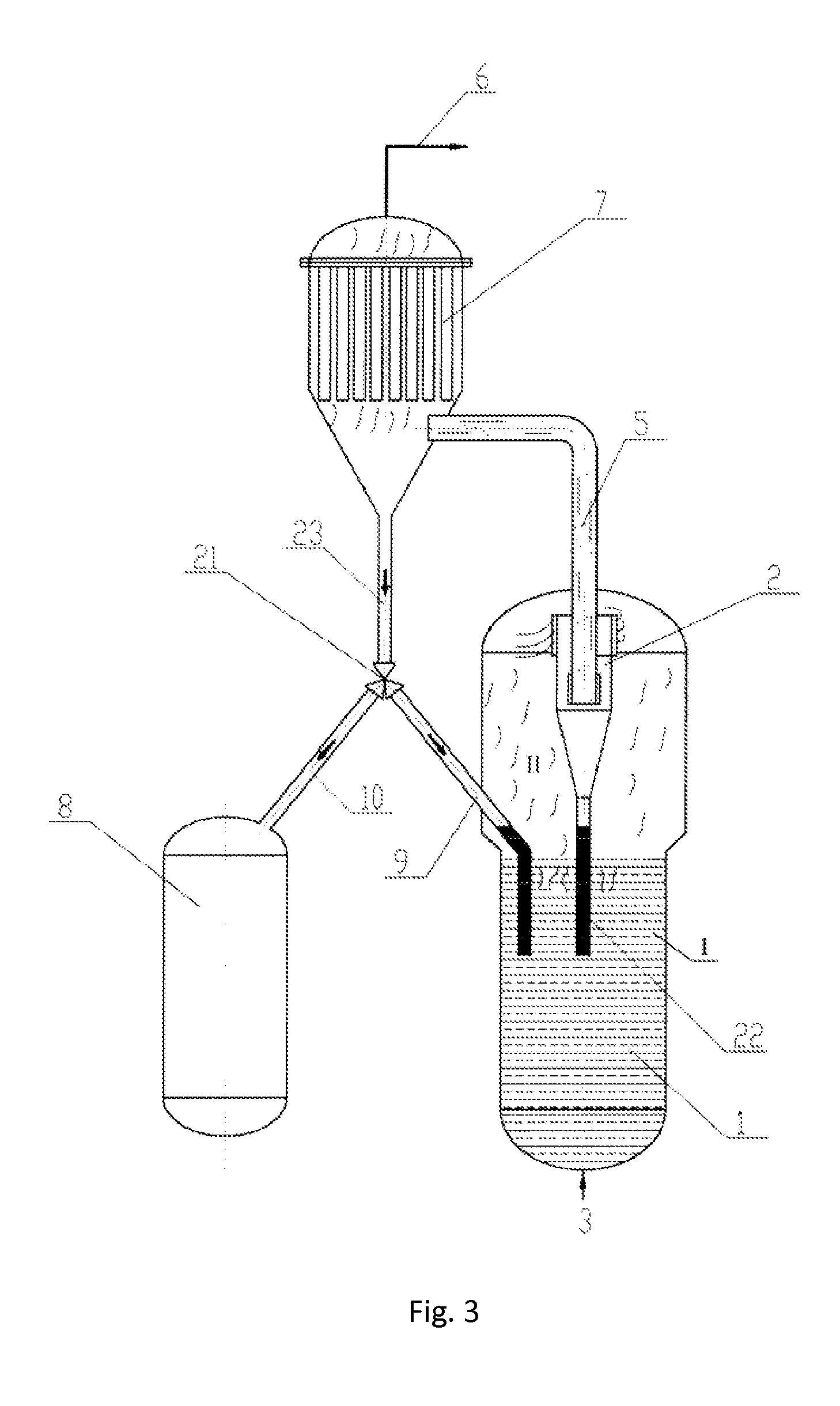

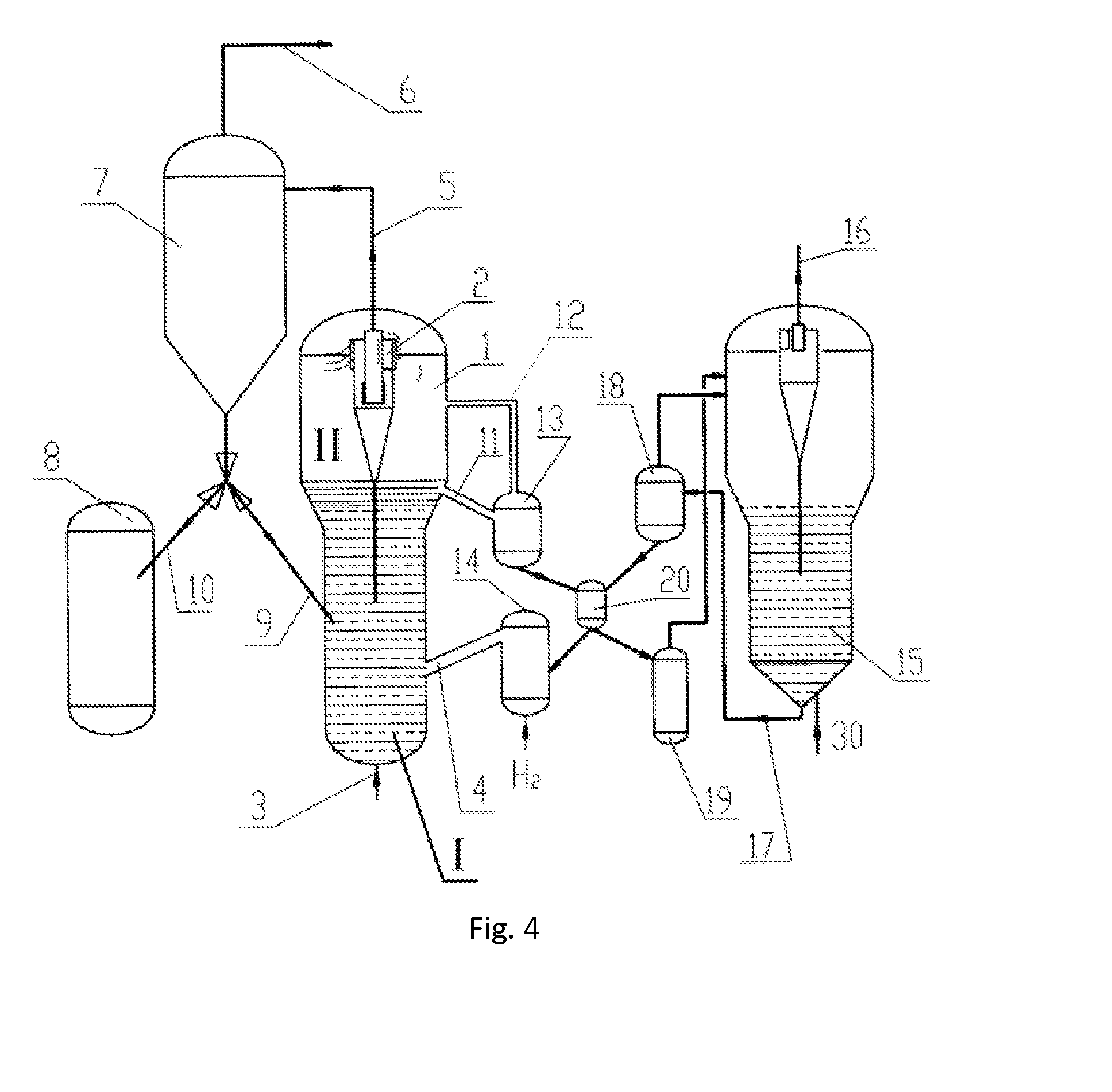

Adsorption Desulfurization Process for Hydrocarbons and a Reaction Apparatus Therefor

ActiveUS20140121438A1Efficient removalReduce flow rateReversed direction vortexHydrocarbonsFluidized bedStraight tube

The present invention relates to an airflow particle sorter, comprising: a top-sealed sorter main body, a discharge port, an outtake tube and at least one directing-intake port; the inner space of the sorter main body, from the above to the bottom, includes, a straight tube zone and a cone zone, the conical bottom of the cone zone is connected to the straight tube zone; the discharge port is located at the bottom of the cone zone; the directing-intake port is installed in the upper part of the straight tube zone in a tangential direction of the straight tube zone, and is communicated with the inner space of the sorter main body; the outtake tube is hermetically inserted into the top of the sorter main body, and extends downwardly to the lower part of the straight tube zone, and the outtake tube has a sealed bottom end; the lower part of the outtake tube is installed with at least one directing-outtake port, which communicates the outtake tube with the inner space of the sorter main body, the directing-outtake port is installed in a tangential direction of the outtake tube. The present invention further relates to a fluidized bed reactor and an adsorption desulfurization reaction apparatus as well as an adsorption desulfurization process.

Owner:CHINA PETROCHEMICAL CORP +1

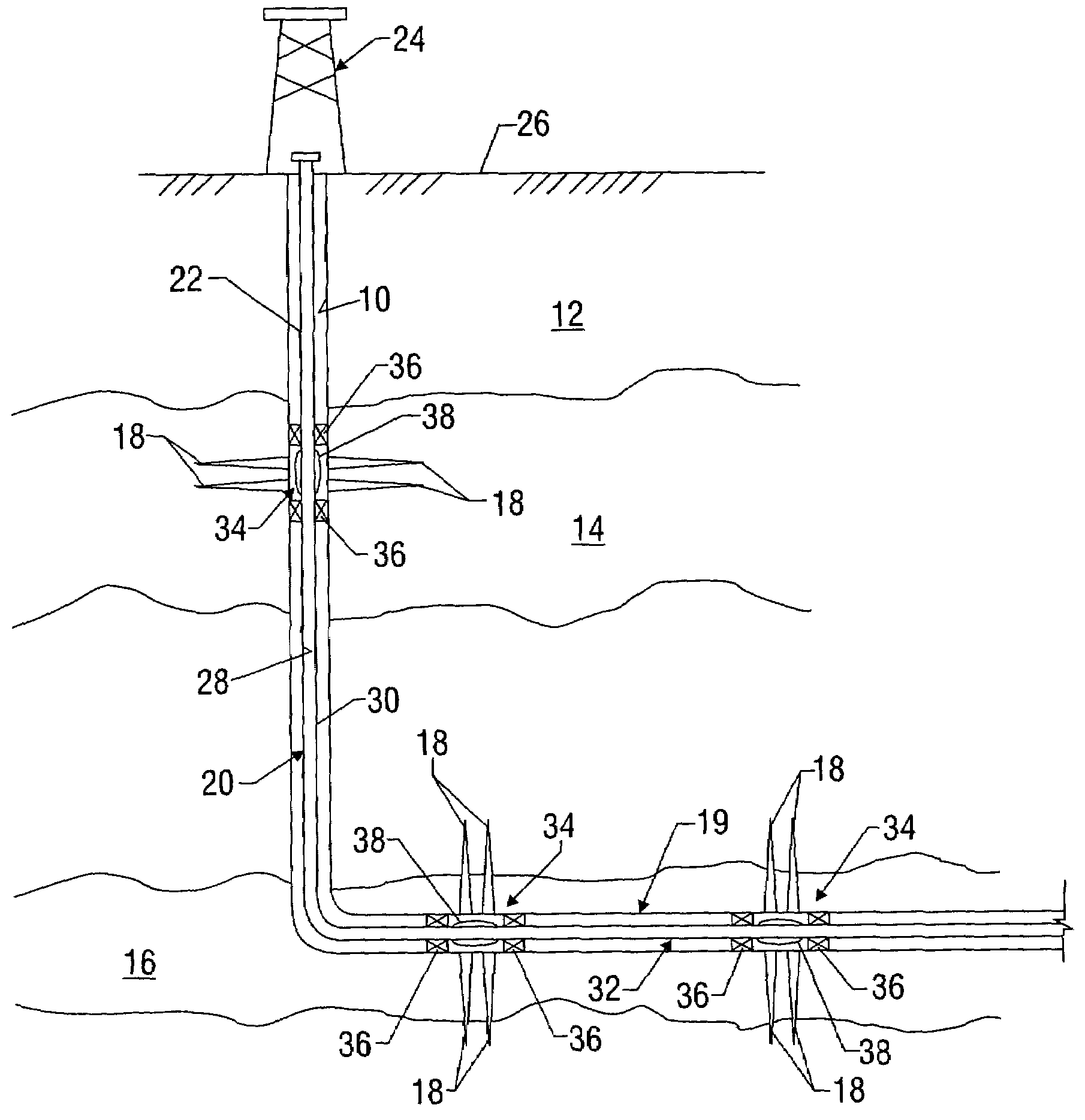

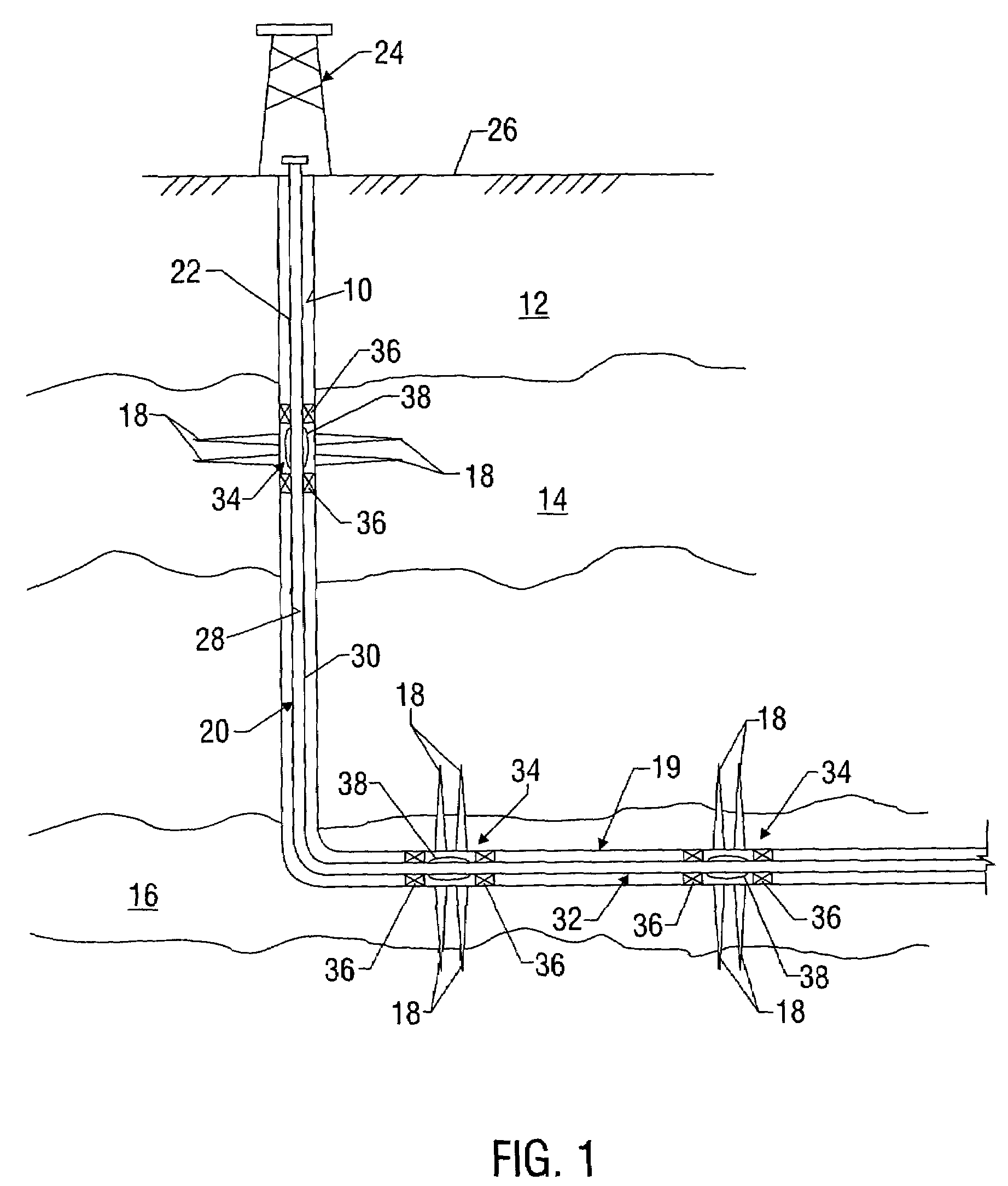

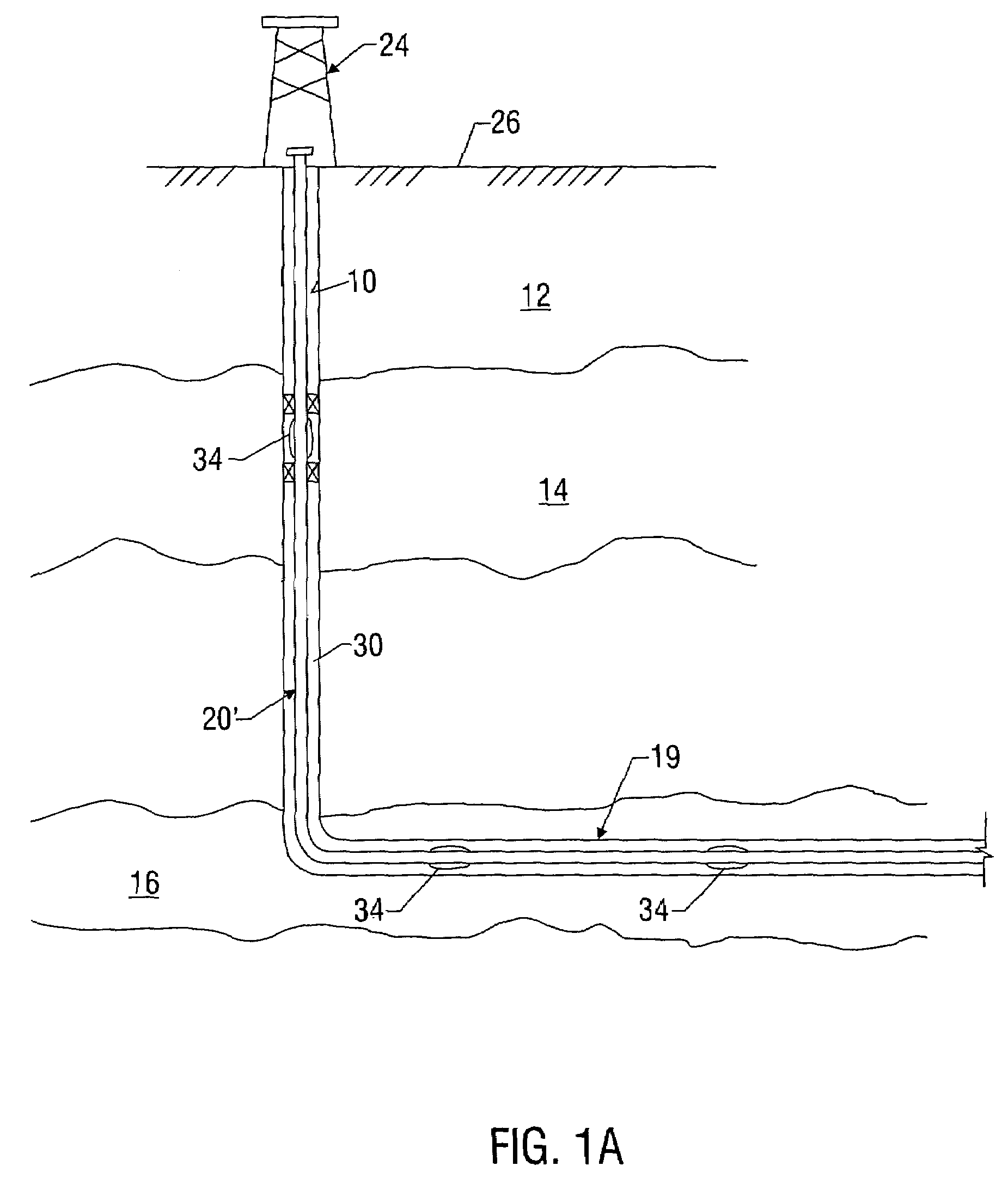

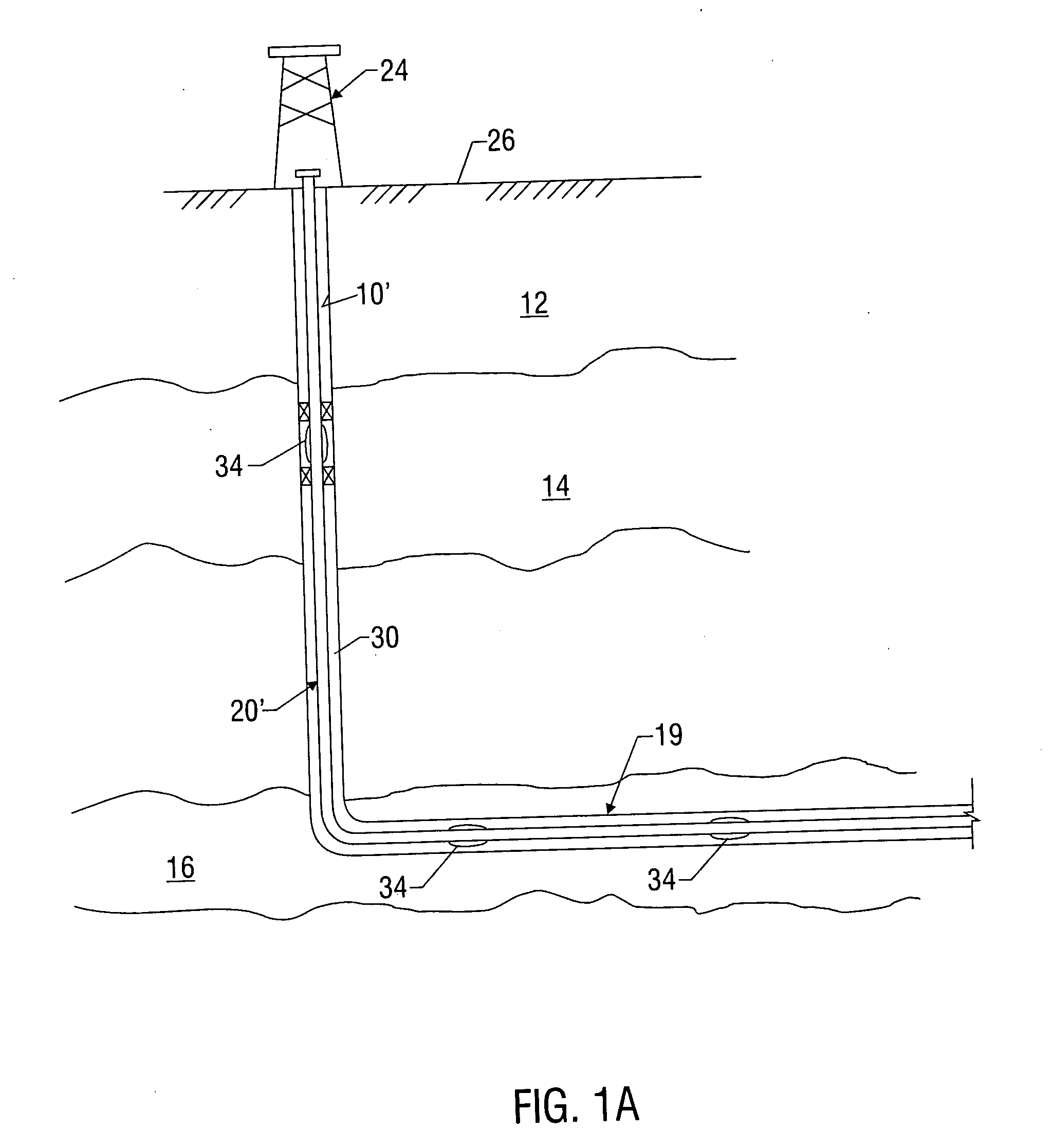

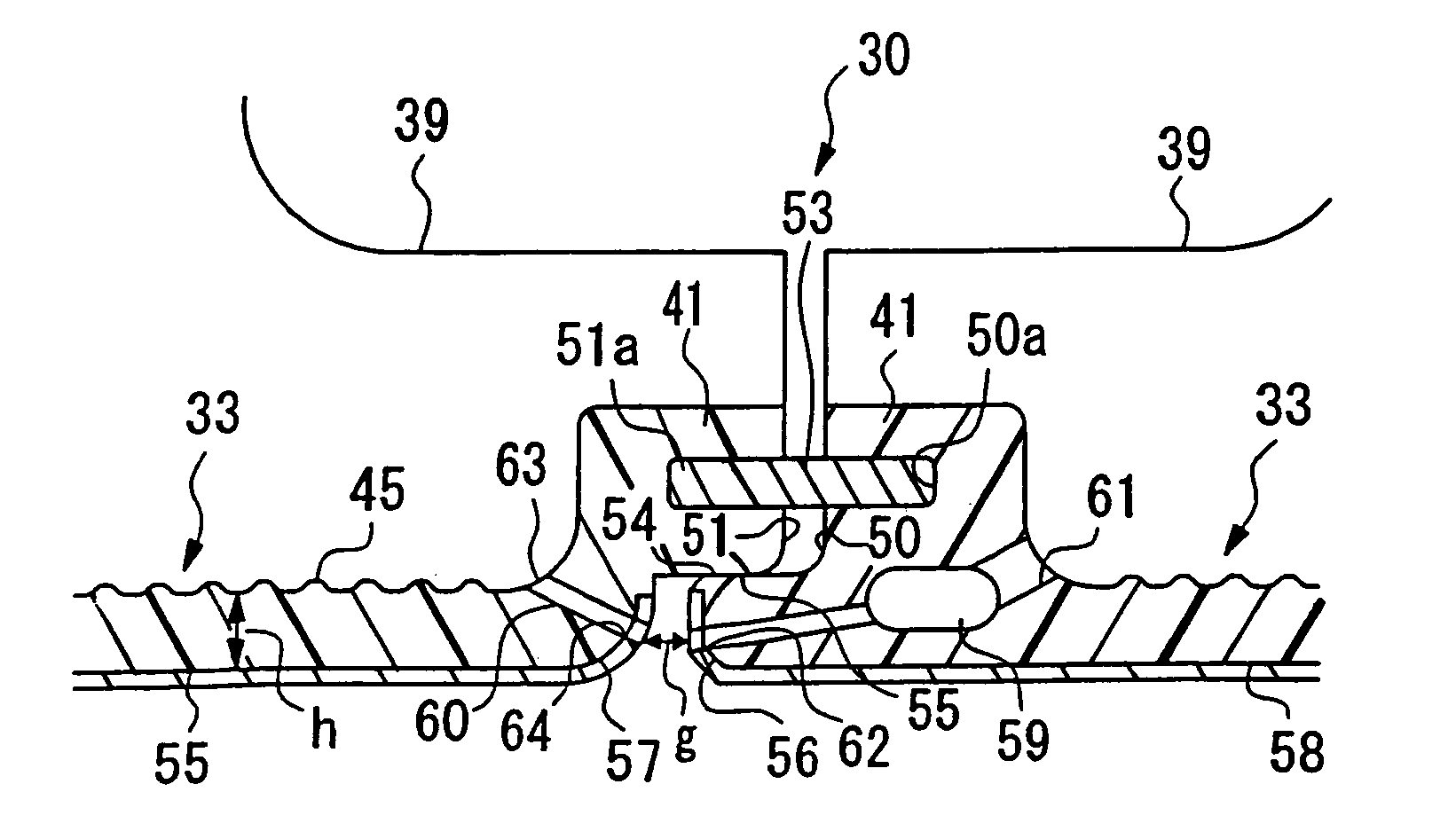

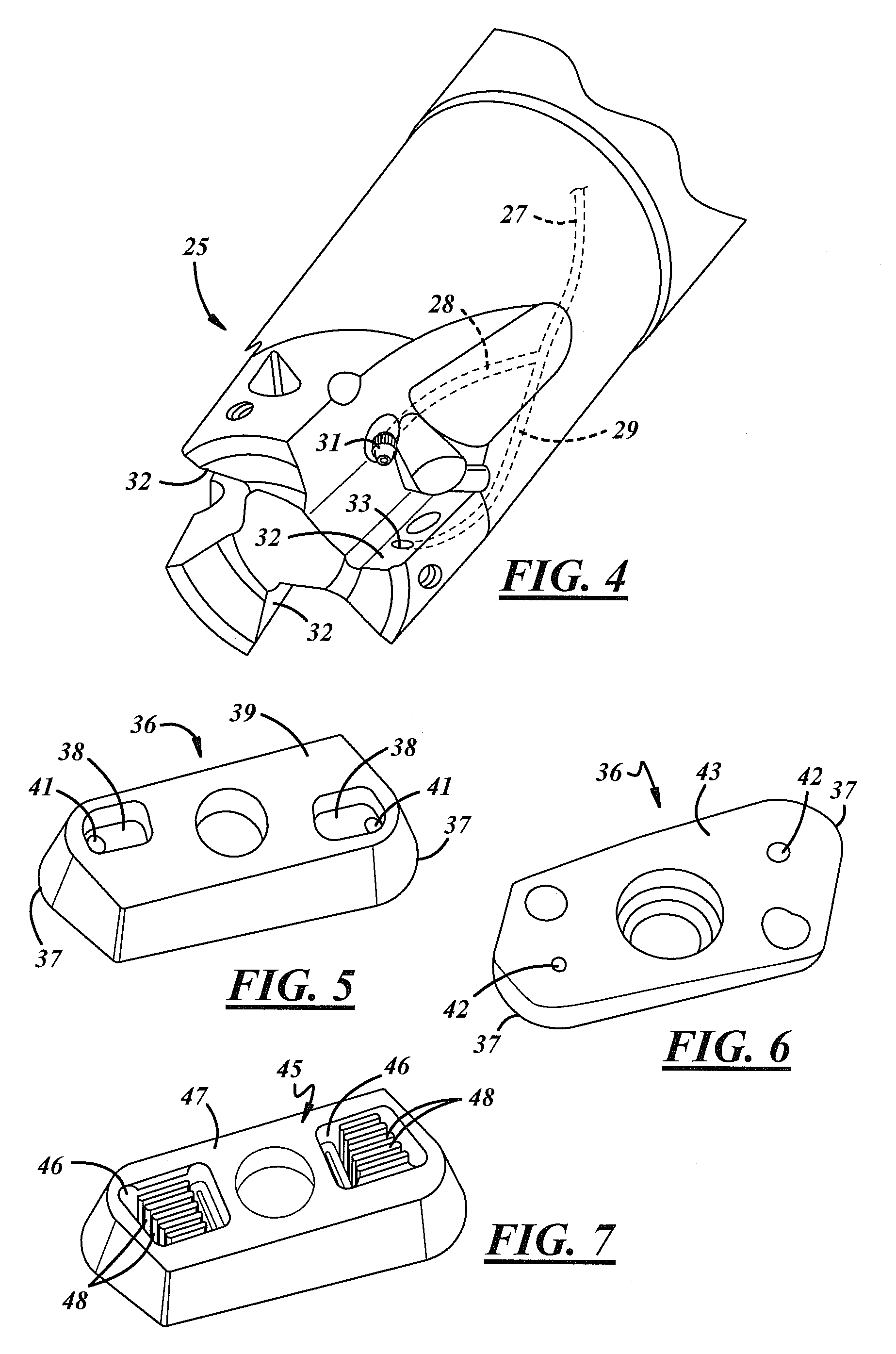

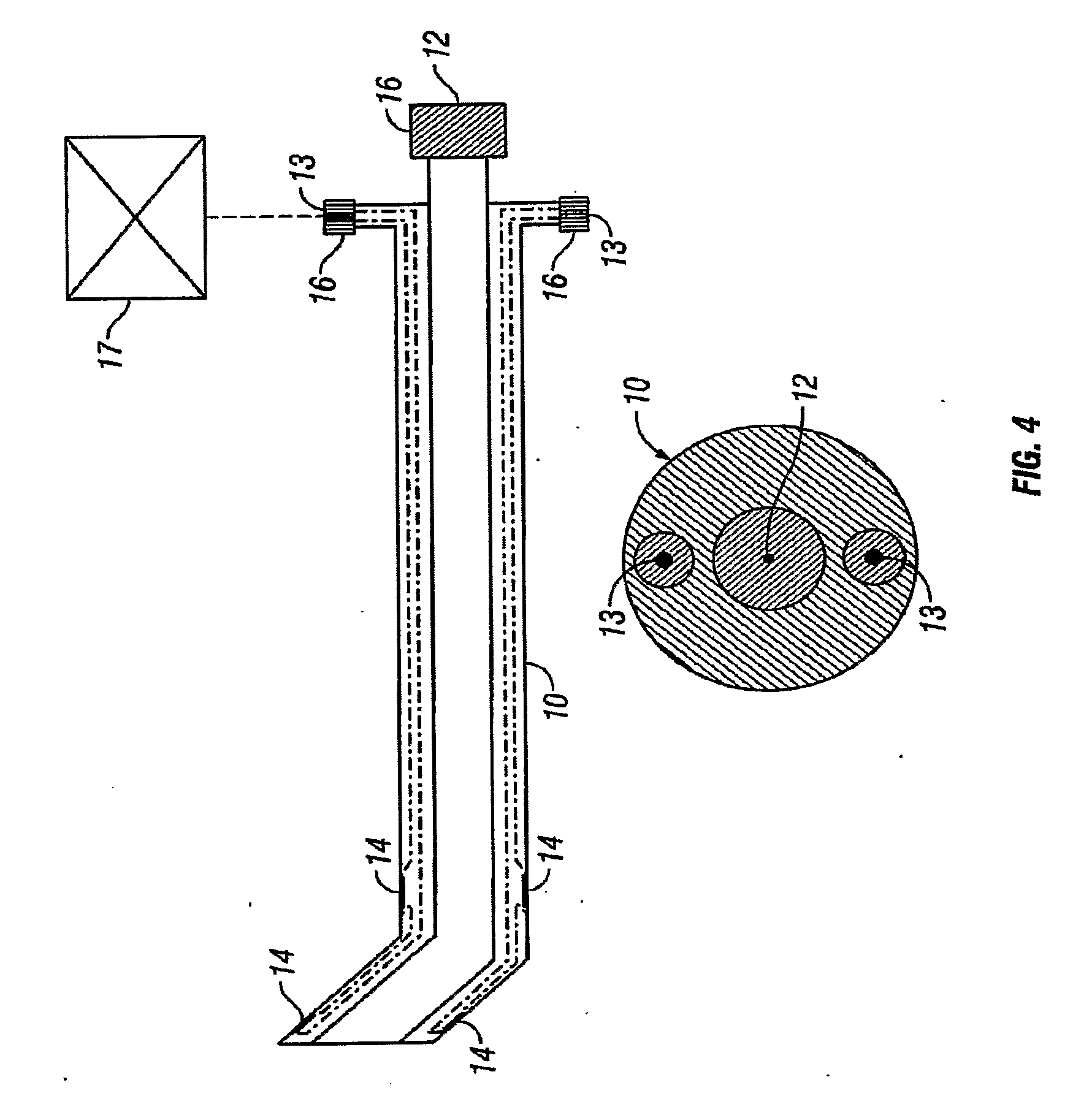

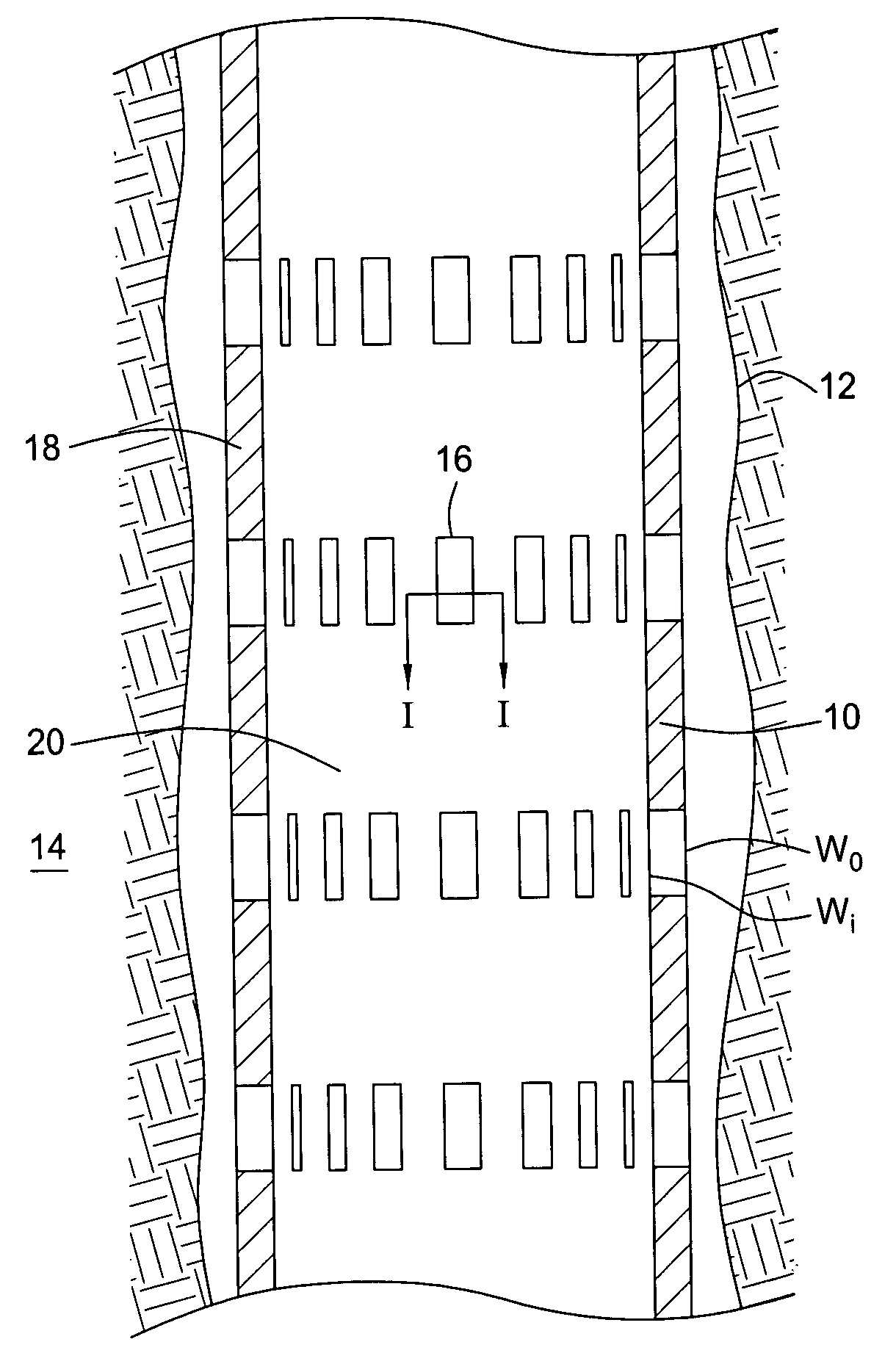

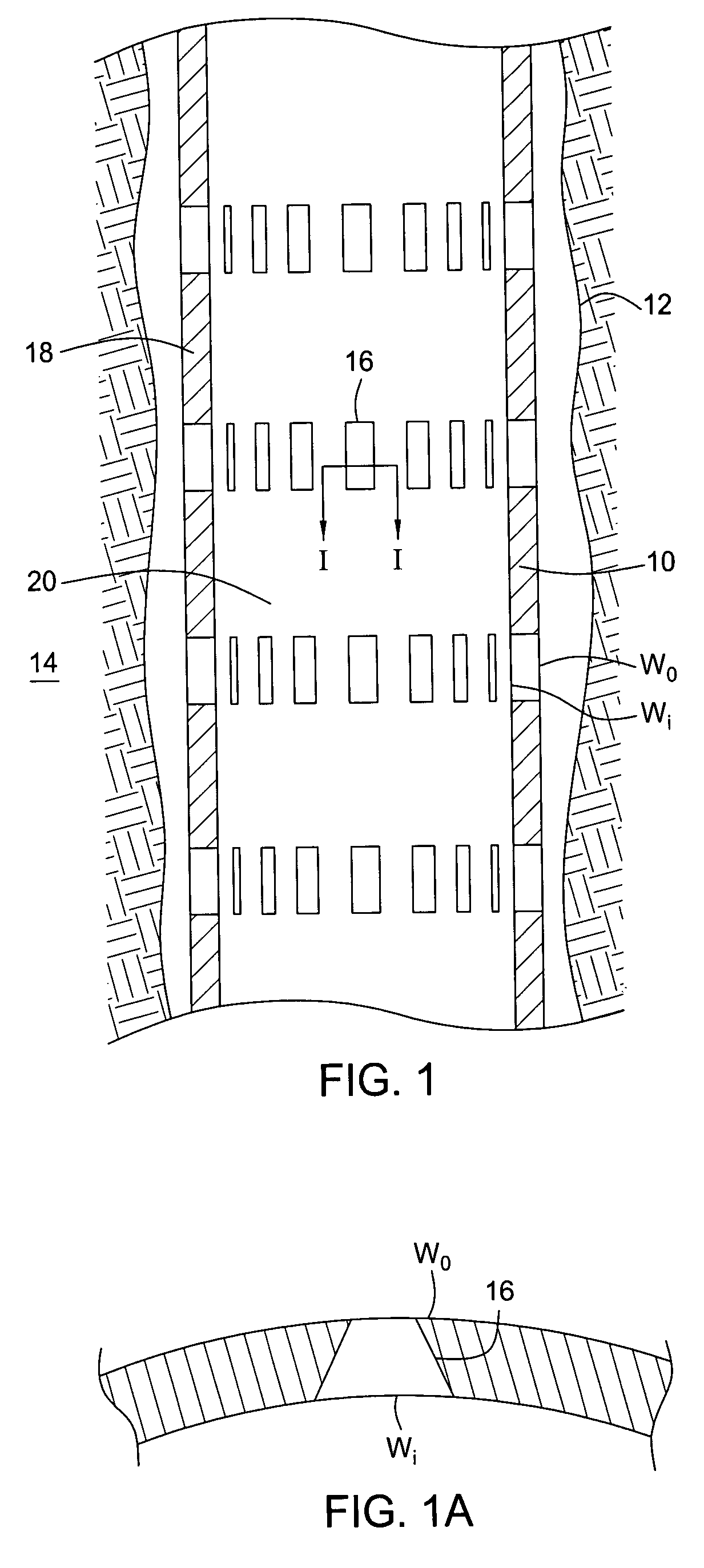

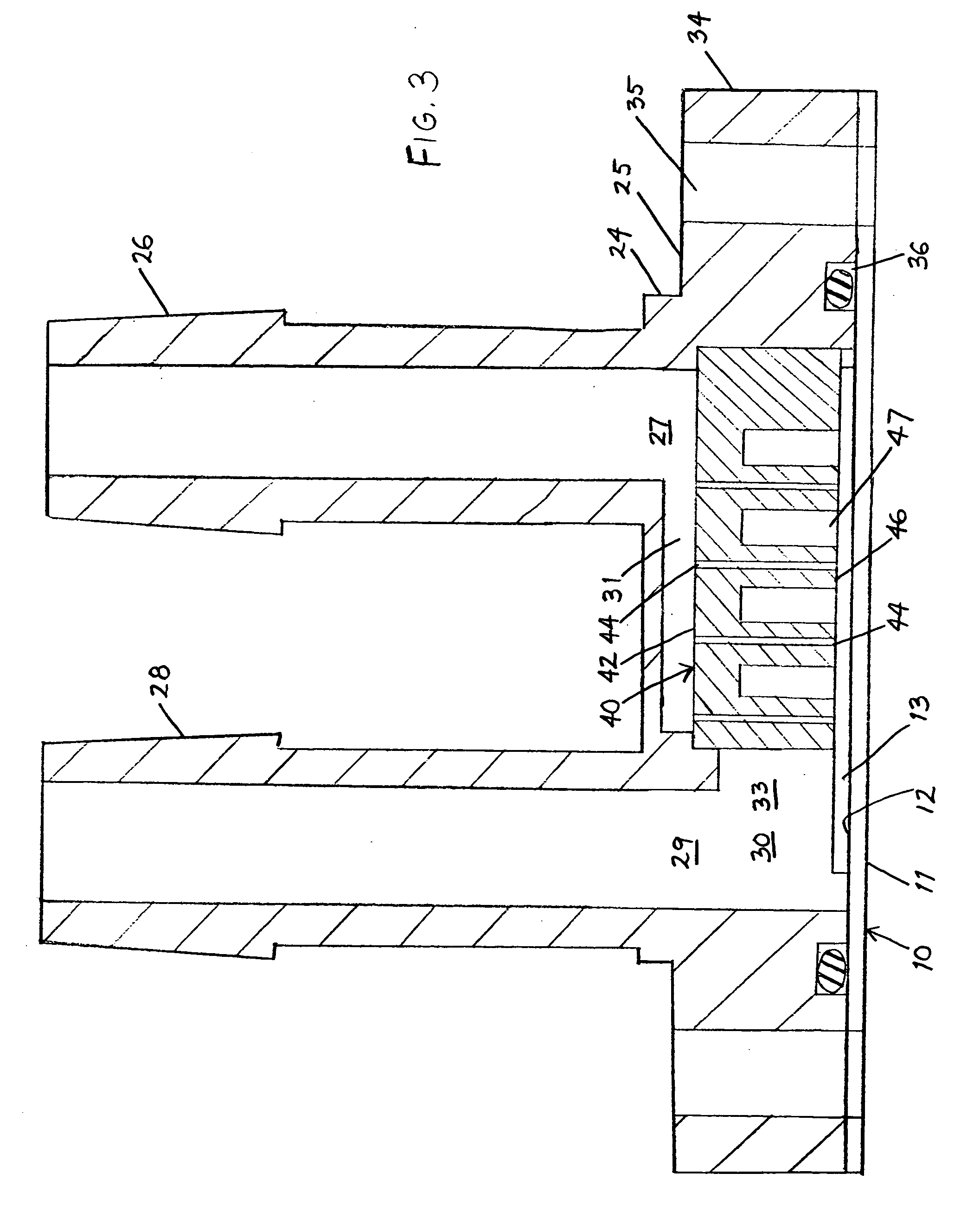

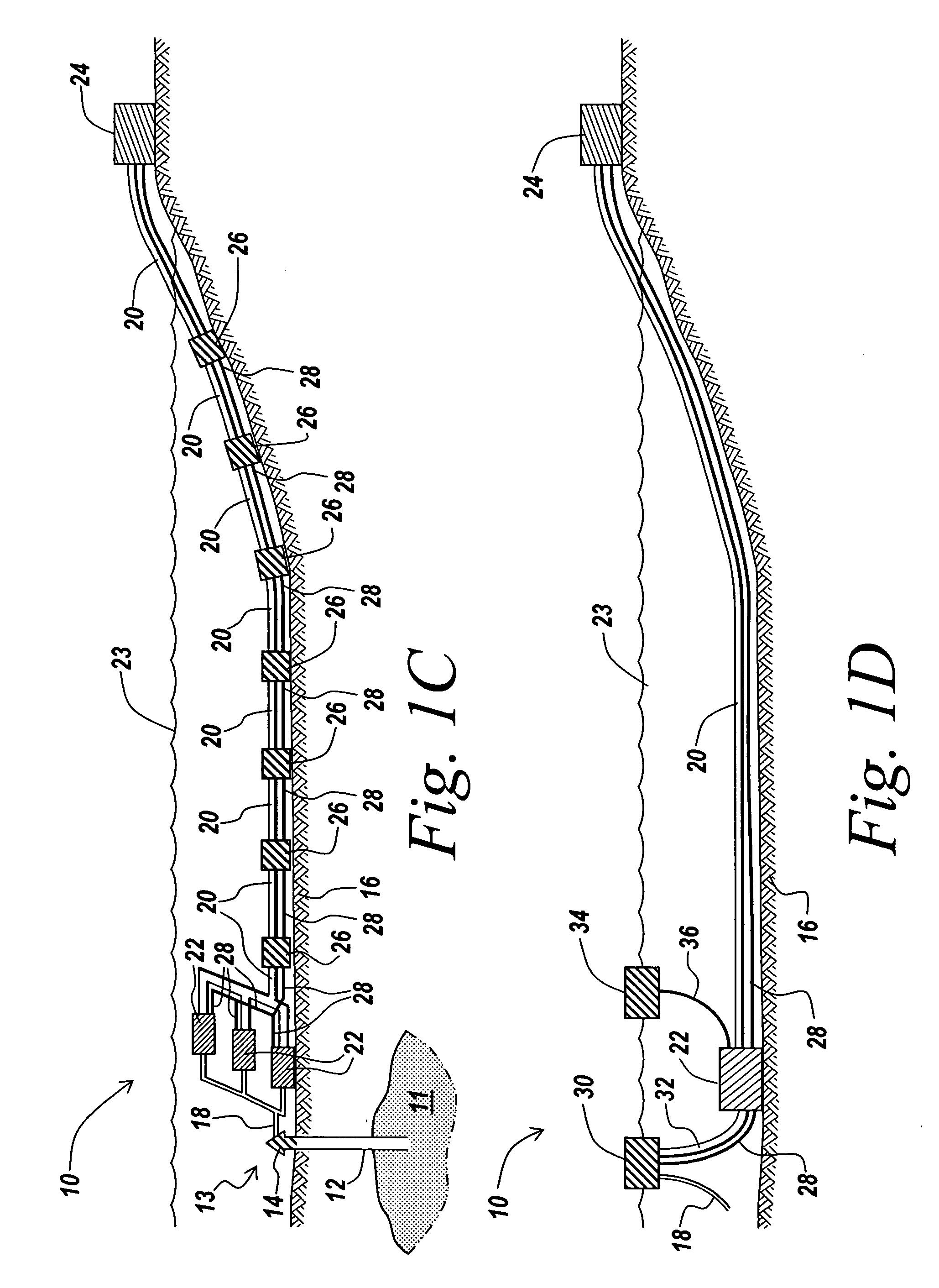

Inflow control device with passive shut-off feature

InactiveUS7290606B2Reduce gas flowConsistent service lifeSurveyConstructionsControl flowControl signal

Devices and methods for control flow of formation fluids respect to one or more selected parameter relating to the wellbore fluid. In one embodiment, a flow control device for controlling fluid flow into the production tubular uses a flow restriction member that is actuated by a character change of the formation fluid, such as liquid to gas or oil to water. The flow restriction member can be sensitive to a change in density of the formation fluid. The flow restriction member is passive, self-regulating and does not need any power source or control signal to control fluid flow. In one embodiment, the flow control device automatically rotates into a predetermined orientation upon being positioned in the wellbore. A seal disposed on the flow control devices expands into sealing engagement with an enclosure after the flow control device assumed the desired predetermined position.

Owner:BAKER HUGHES INC

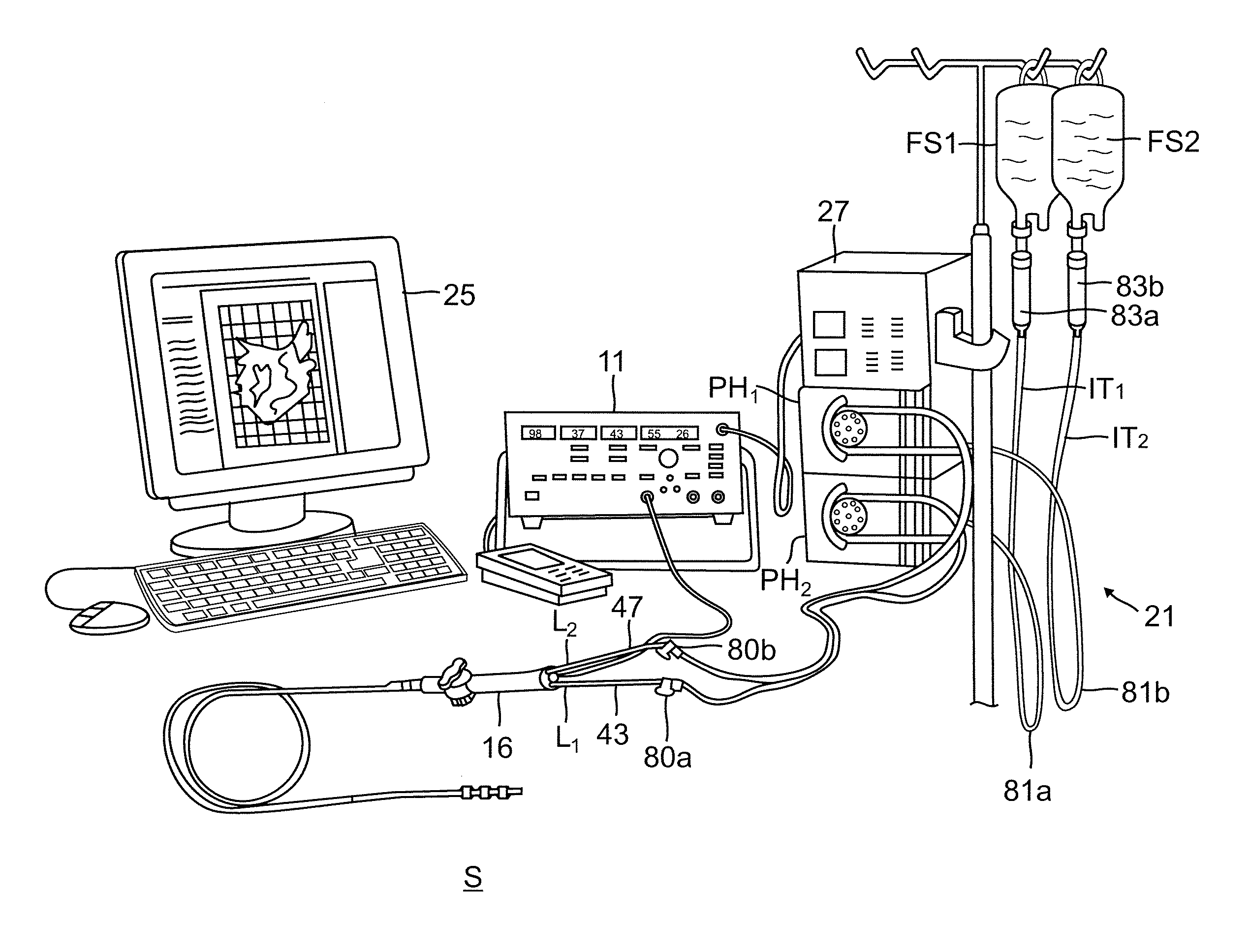

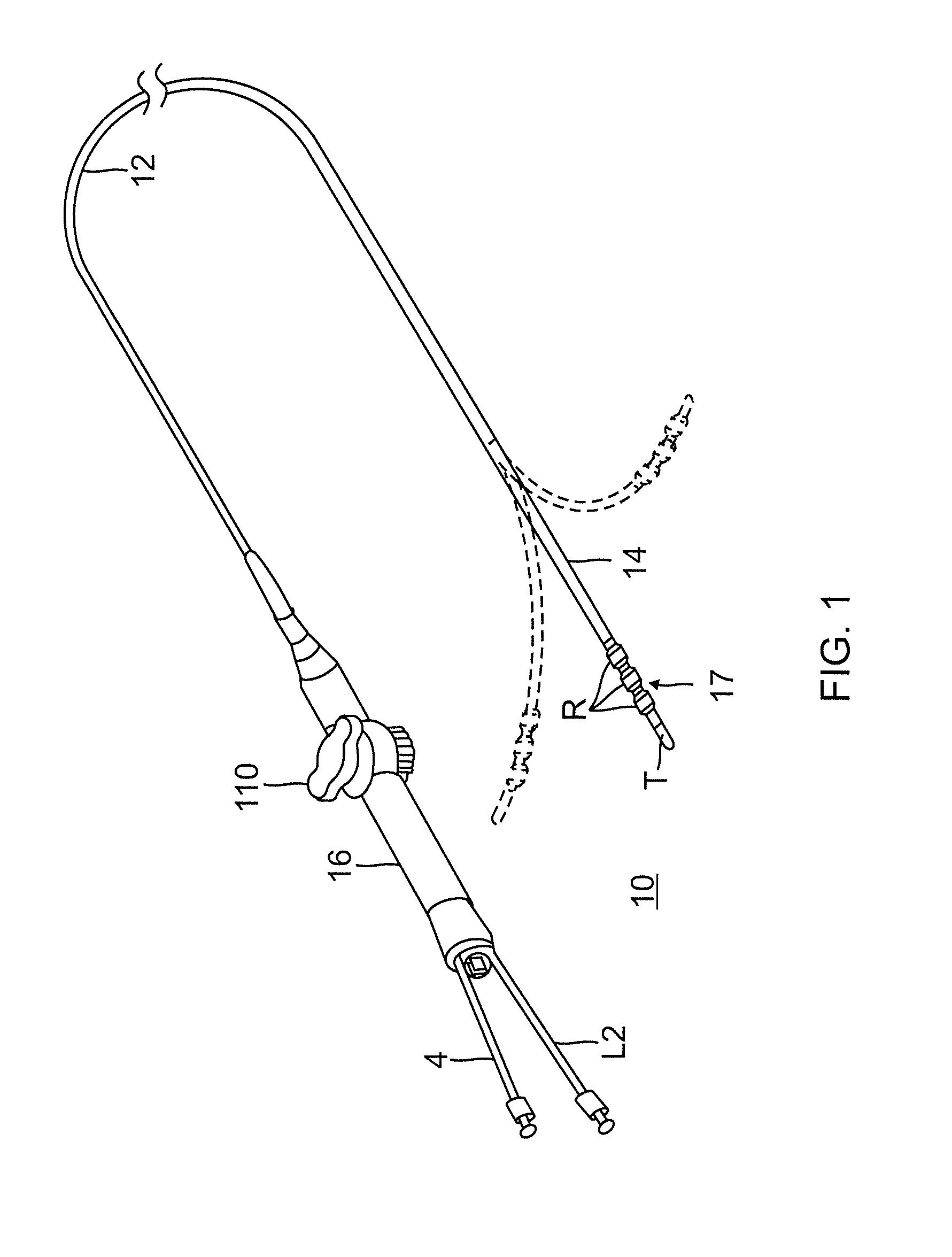

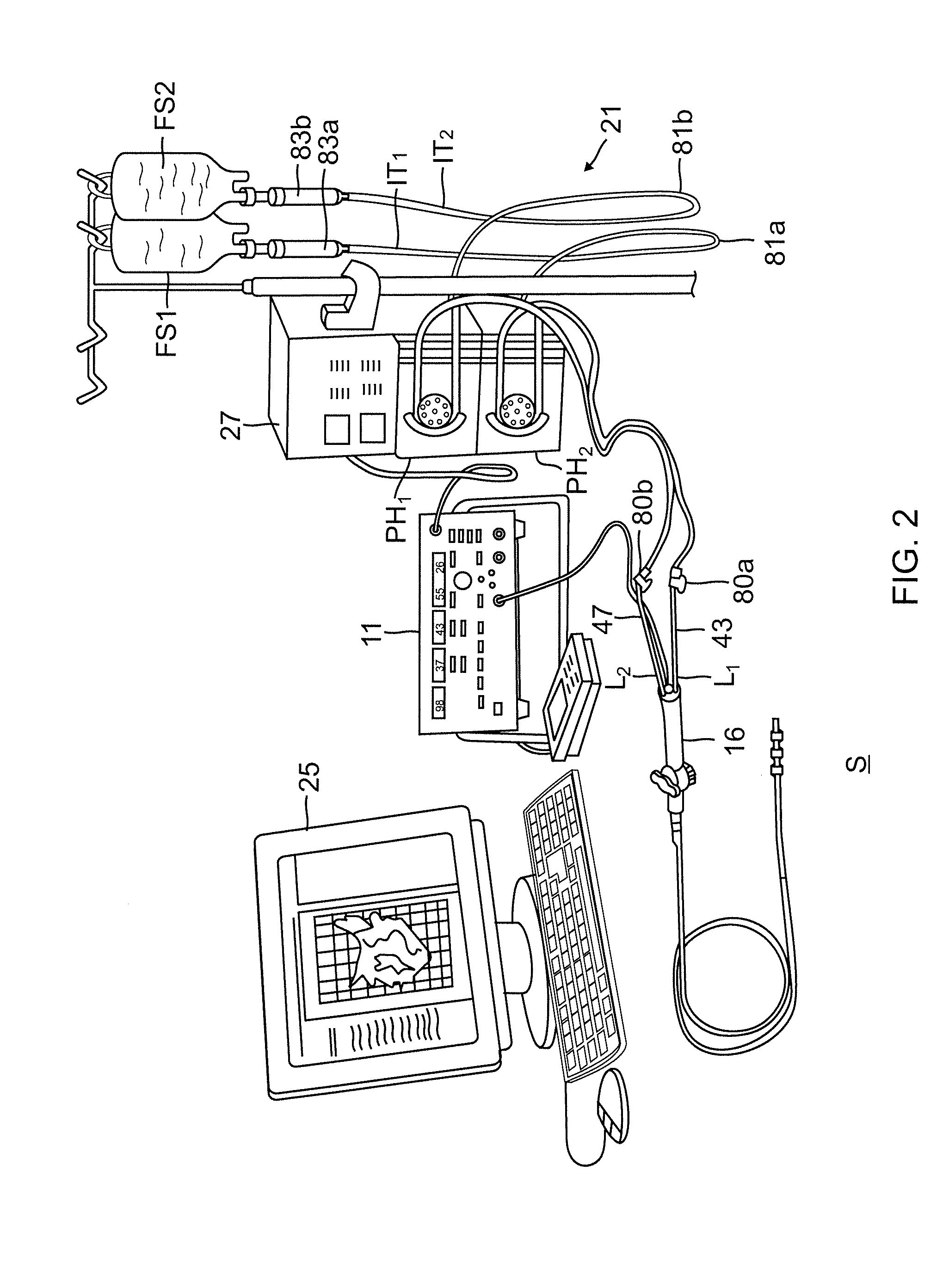

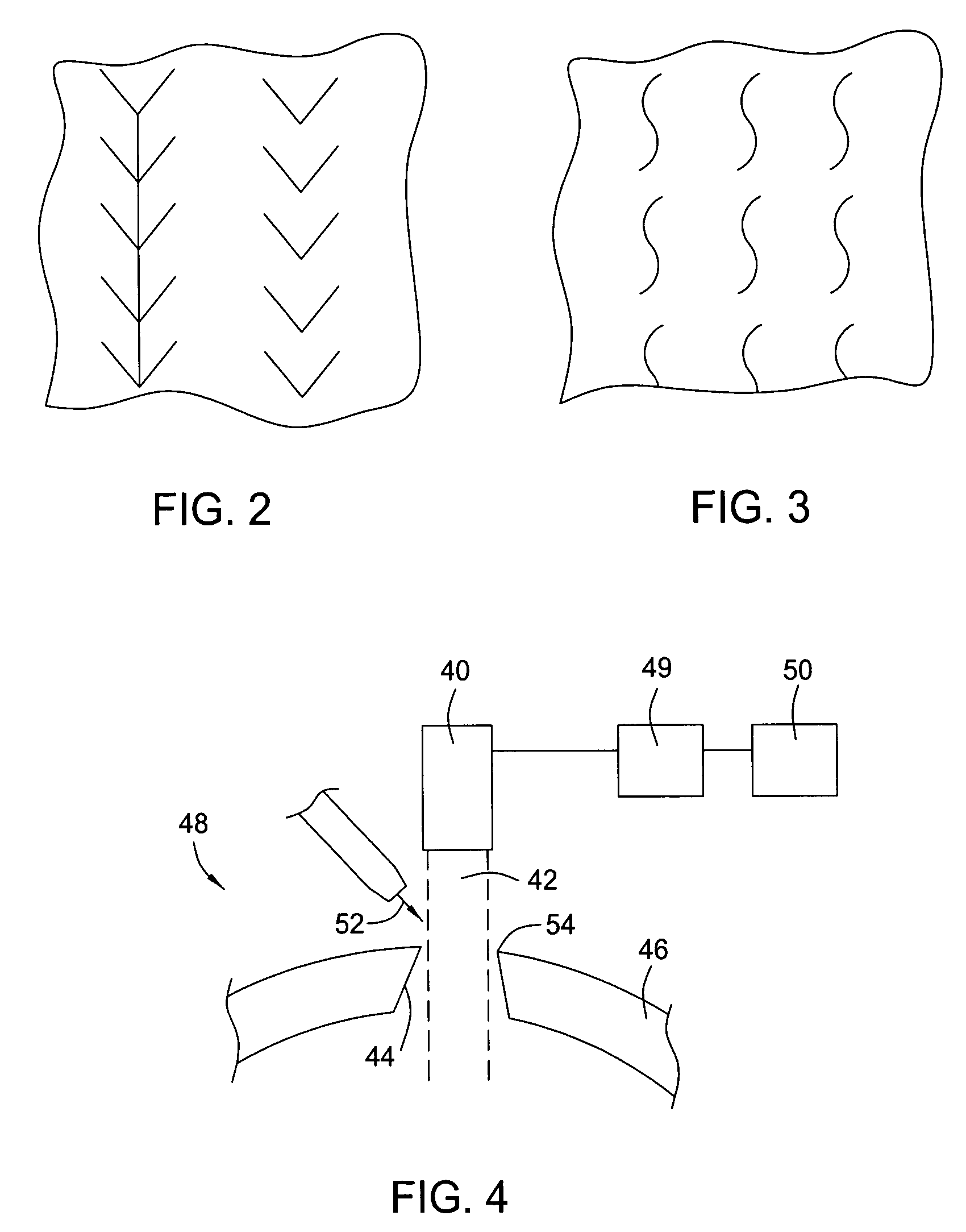

Integrated ablation system using catheter with multiple irrigation lumens

ActiveUS20130030426A1Limiting fluid loadingReduce driving stressDiagnosticsSurgical instruments for heatingPump headIrrigation fluids

A catheter adapted for ablation has multiple dedicated irrigation tubings to supply fluid to their respective electrode or set of electrodes. The tubings provide parallel flow pathways through the catheter where irrigation fluid is delivered to irrigated tip and / or ring electrodes which can accomplish uni-polar or bi-polar ablation. Such separate and dedicated fluid pathways allow fluid to be delivered to the corresponding electrode or set of electrodes at different flow rates. An integrated ablation system using such catheter has an ablation energy source and an irrigation pump with multiple pump heads that can operate independently of each other. An integrated irrigation tubing set is included to extend between the fluid source and the catheter, with each pump head being able to act on a different tubing that delivers fluid to a different electrode or set of electrodes.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

Inflow control device with passive shut-off feature

InactiveUS20060076150A1Reduce gas flowConsistent service lifeSurveyConstructionsControl flowStream flow

Devices and methods for control flow of formation fluids respect to one or more selected parameter relating to the wellbore fluid. In one embodiment, a flow control device for controlling fluid flow into the production tubular uses a flow restriction member that is actuated by a character change of the formation fluid, such as liquid to gas or oil to water. The flow restriction member can be sensitive to a change in density of the formation fluid. The flow restriction member is passive, self-regulating and does not need any power source or control signal to control fluid flow. In one embodiment, the flow control device automatically rotates into a predetermined orientation upon being positioned in the wellbore. A seal disposed on the flow control devices expands into sealing engagement with an enclosure after the flow control device assumed the desired predetermined position.

Owner:BAKER HUGHES INC

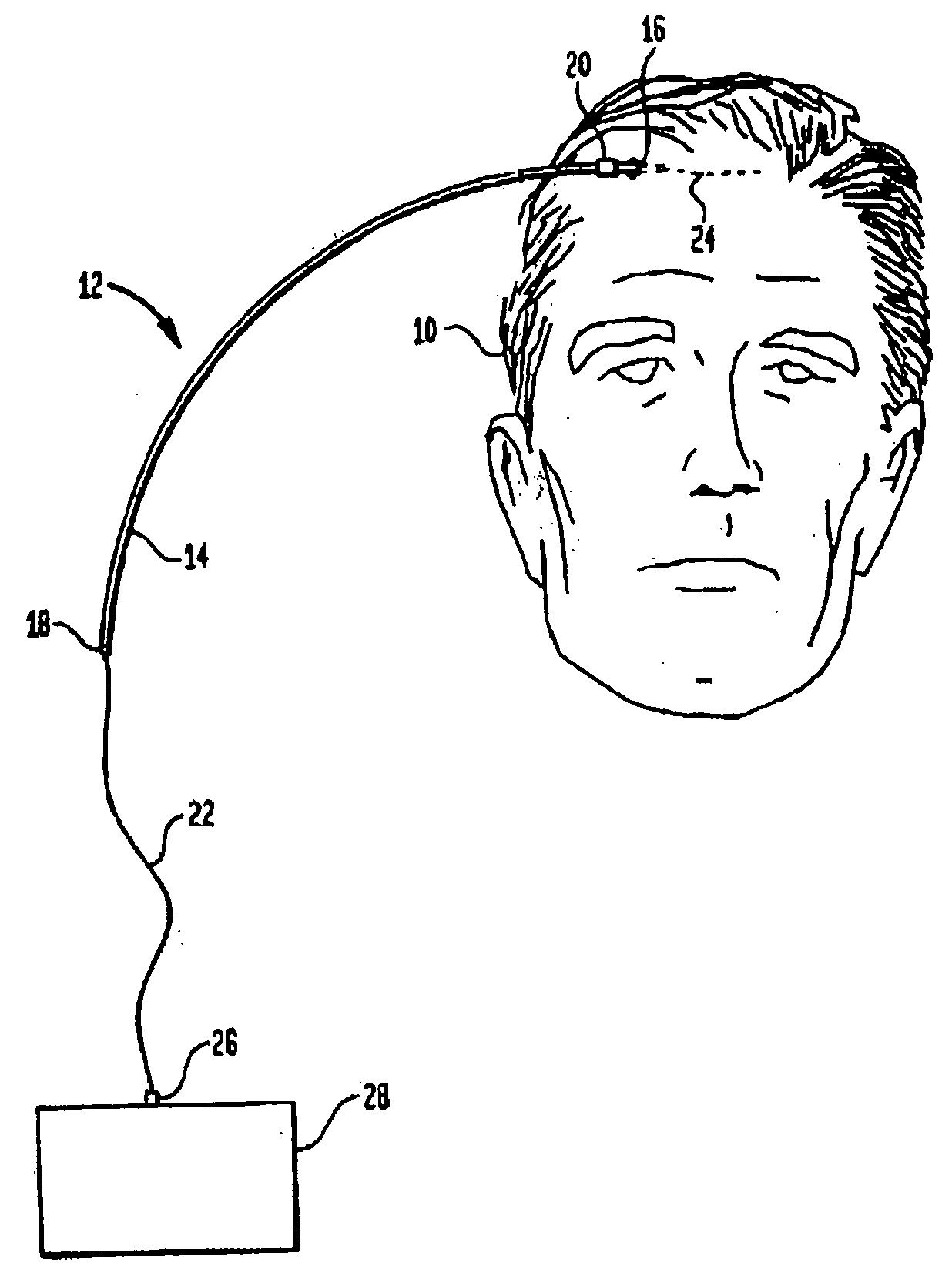

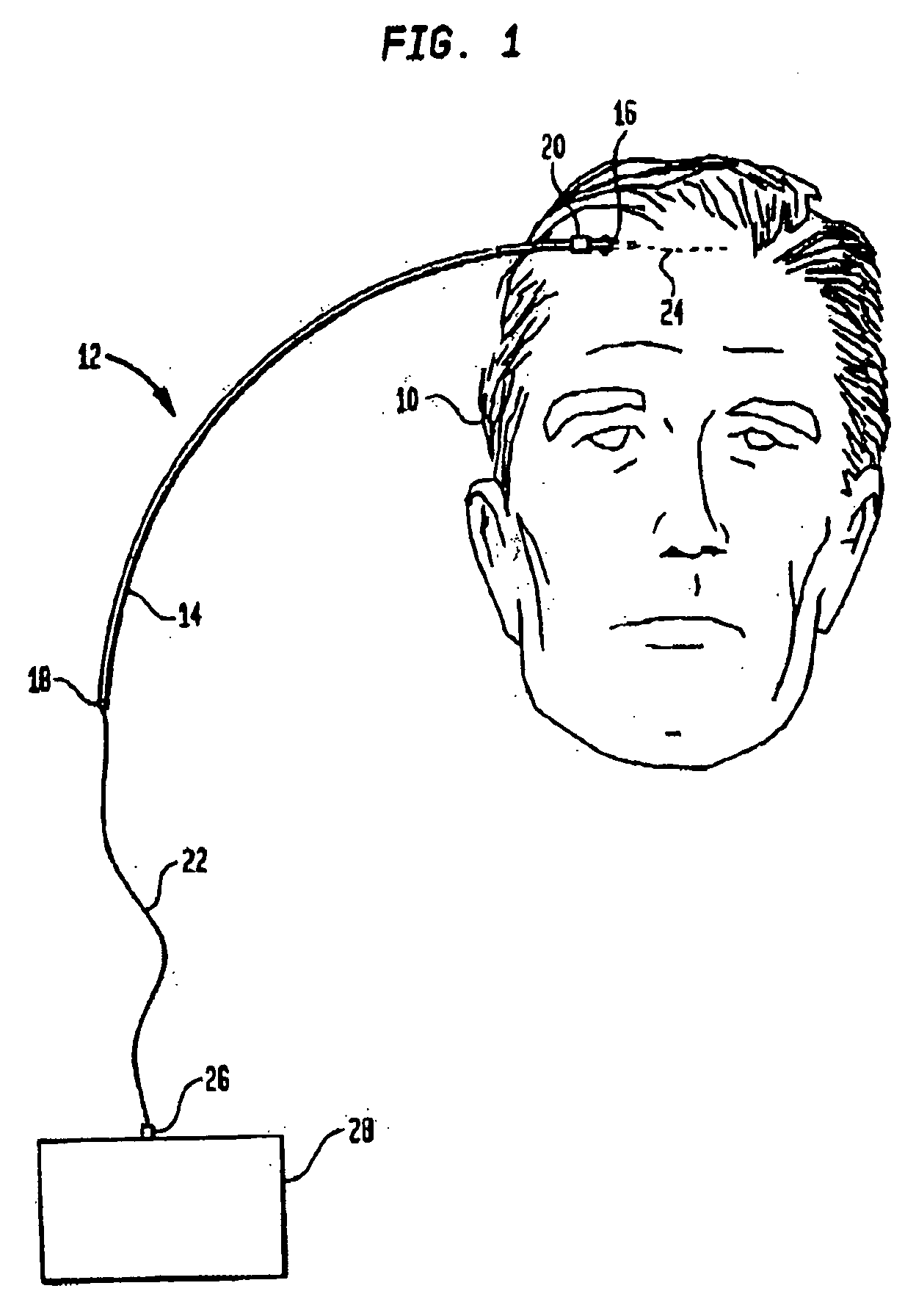

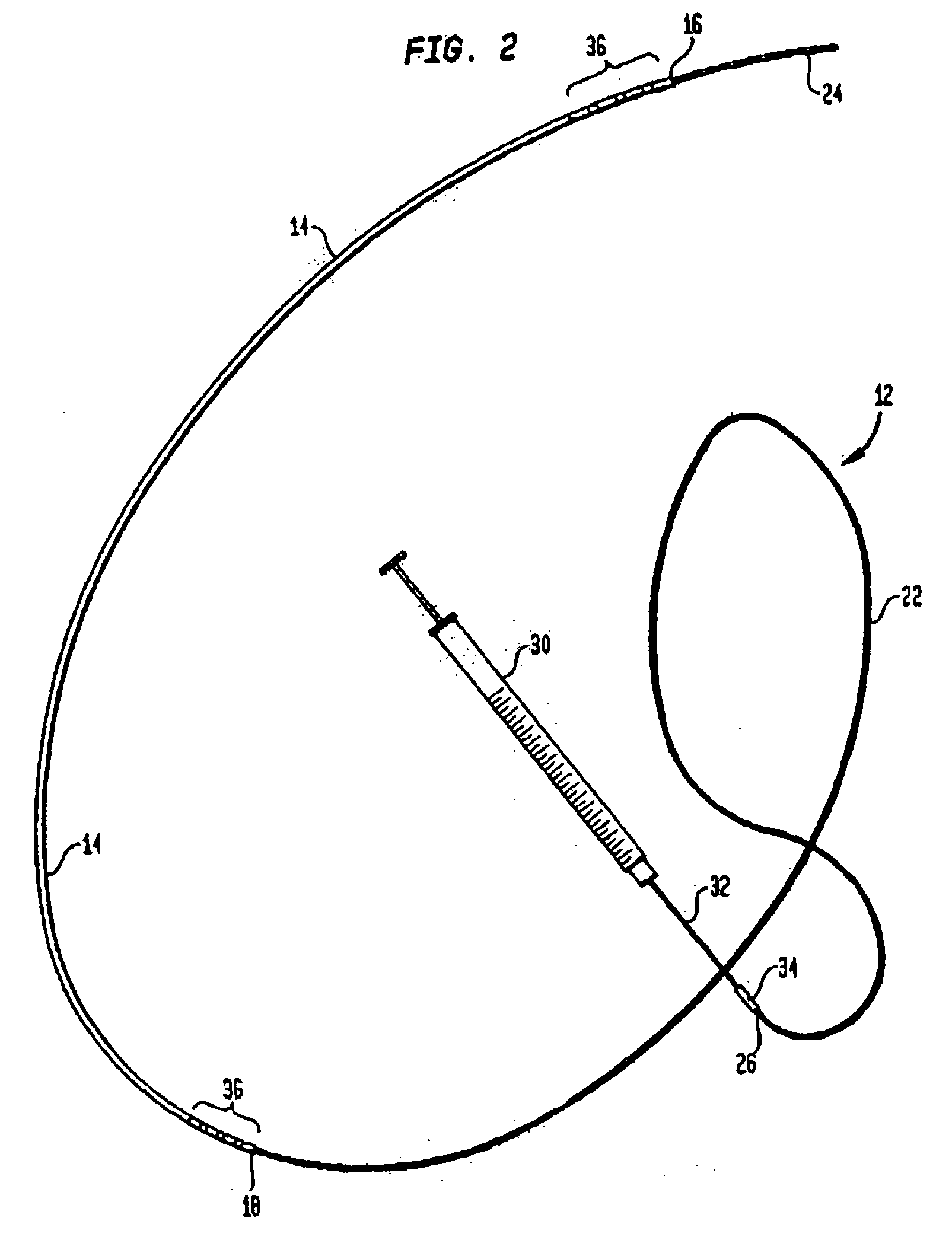

Infusion device and method for infusing material into the brain of a patient

InactiveUS20060129126A1Utilized effectively and accuratelyReduce flow rateGuide needlesMulti-lumen catheterFluid infusionGuide tube

A fluid infusion device and a method of using the same. The device includes an outer, flexible guide catheter having a distal end for introduction beneath the skull of a patient and a proximal end remaining external of the patient. A flexible infusion fiber is located within the guide catheter and has a distal end extending outwardly from the guide catheter to be located in a target area within the patient's brain. The infusion fiber can be fixed or axially movable within the guide catheter. In the latter embodiment, the proximal end of the infusion fiber extending outwardly from the guide catheter can be manipulated to locate the distal end of the infusion fiber in the target area. An infusion pump is connected to the proximal end of the infusion fiber to infuse a minute quantity of fluid at an extremely low flow rate into the brain of the patient.

Owner:MEDTRONIC INC

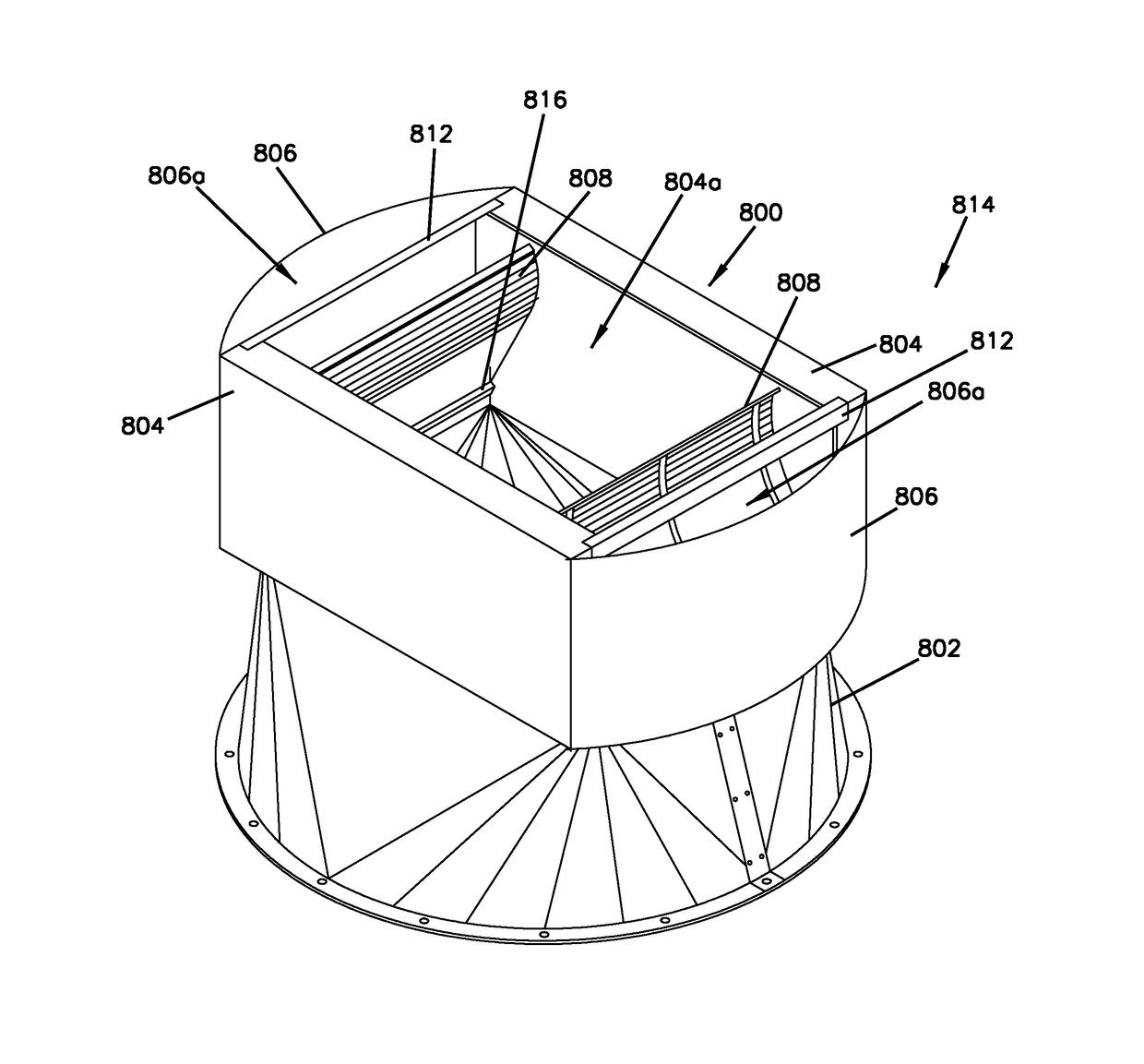

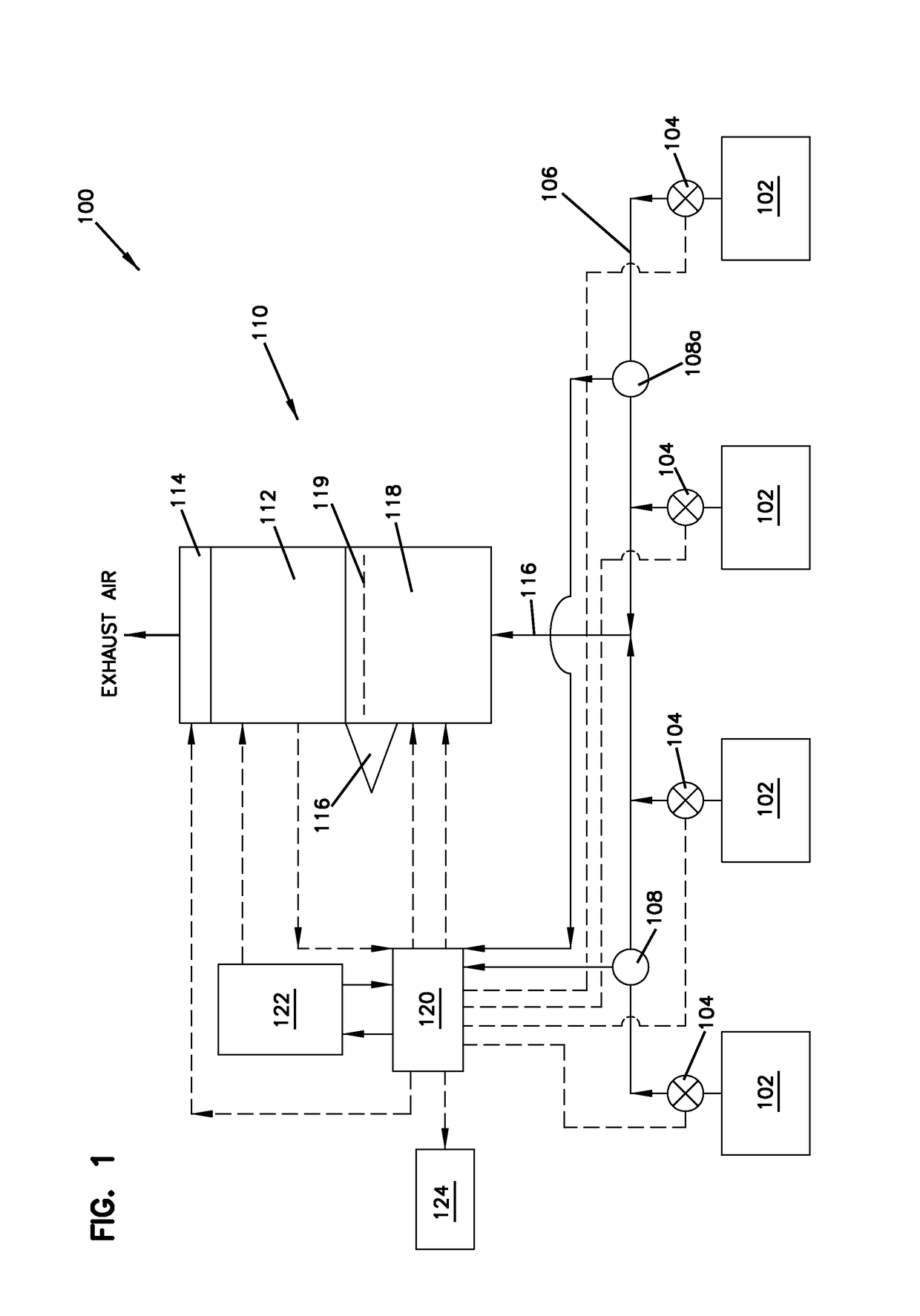

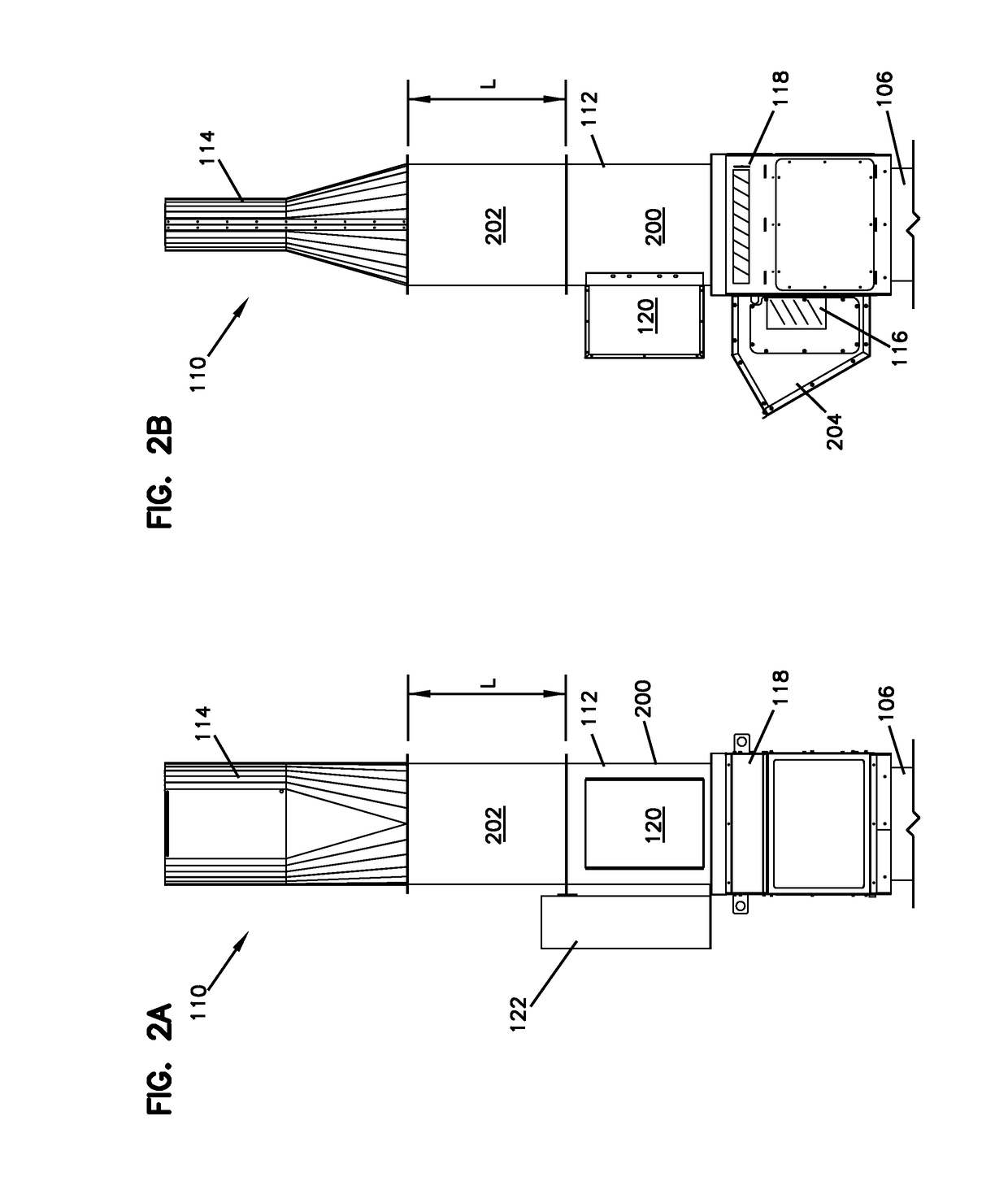

Variable-volume exhaust system

ActiveUS10029289B2Reduce energy consumptionReduce flow ratePump componentsSpace heating and ventilation safety systemsControl systemShock absorber

Owner:GREENHECK FAN

Reduction of recirculation in catheters

InactiveUS20060004316A1Decrease outflow velocity of fluidPrevent sprayingMedical devicesCatheterDistal portionNose

A catheter tip designed to reduce the outflow velocity and / or directional momentum of fluid being infused by a catheter having such a tip. In one variation, a plurality of channels is provided at the distal portion of the catheter to increase the outflow cross-sectional area. In another variation, the diameter of the catheter at its distal portion where the fluid exits is increased. In yet another variation, a bullet-shaped nose is implemented which may decrease turbulence at the distal end of catheter tip. The low velocity outflow catheter tip may also be implemented on a dual lumen catheter, such as a hemodialysis catheter, to reduce recirculation rate. Various device configurations and methods for such implementations are also disclosed.

Owner:CR BARD INC

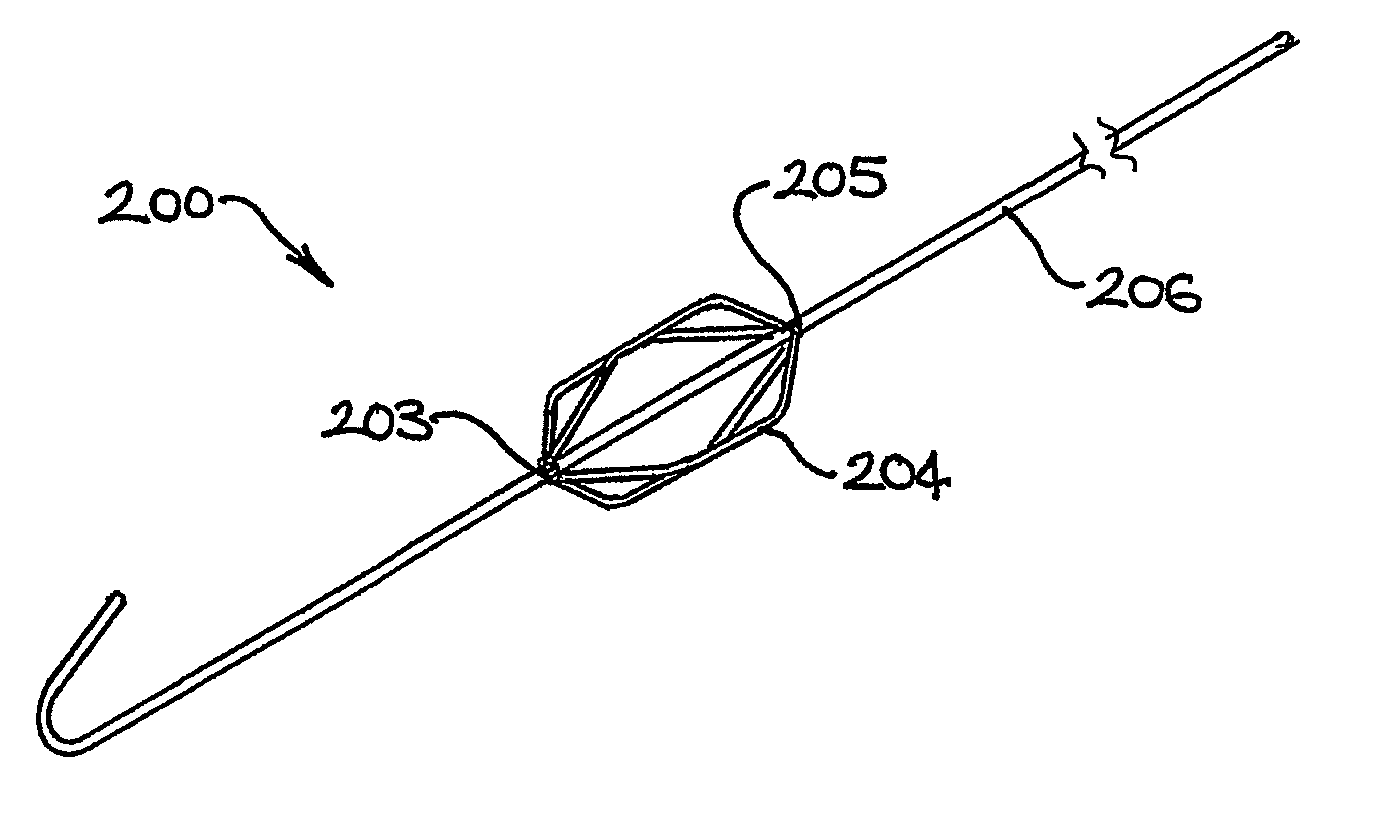

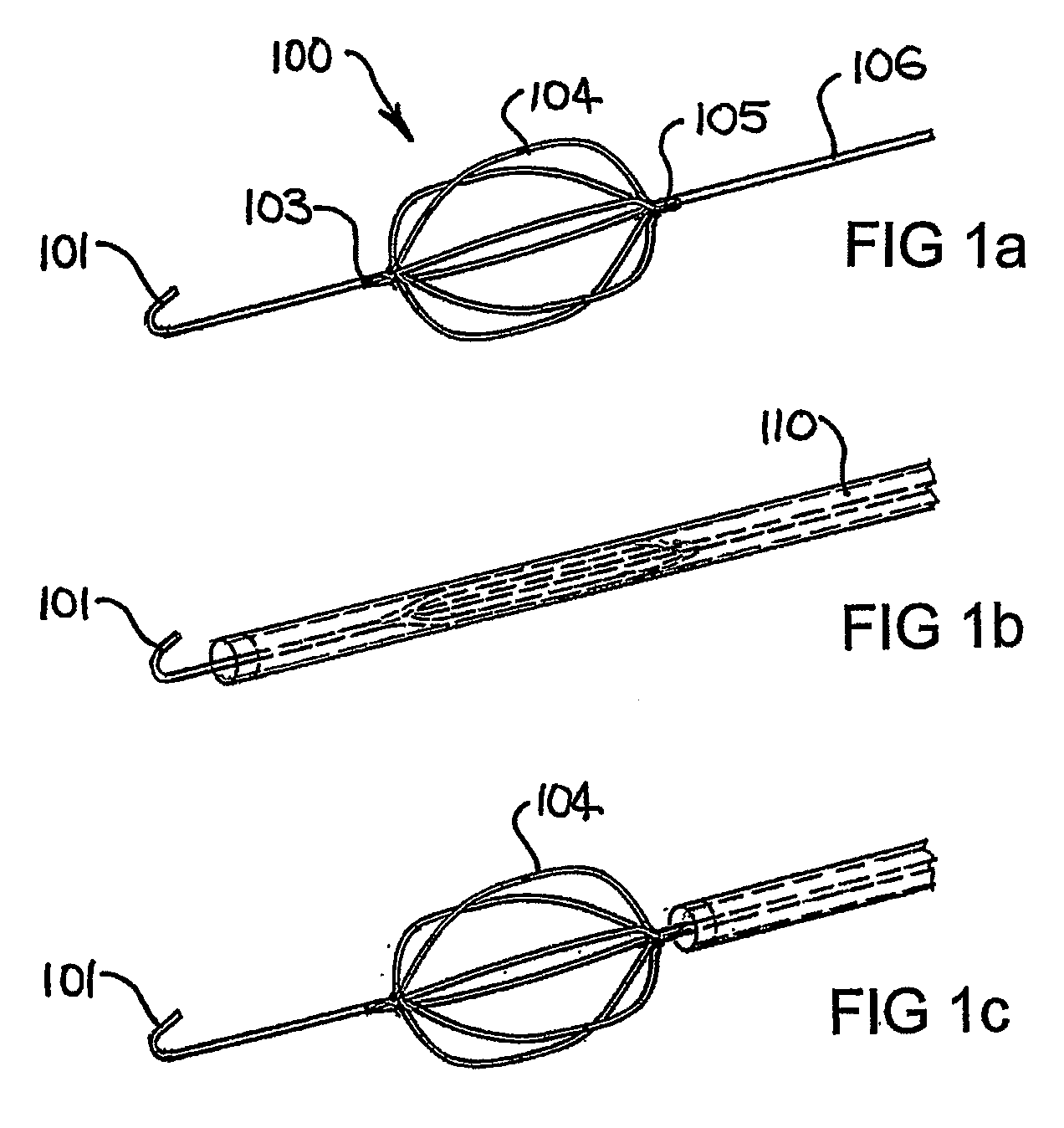

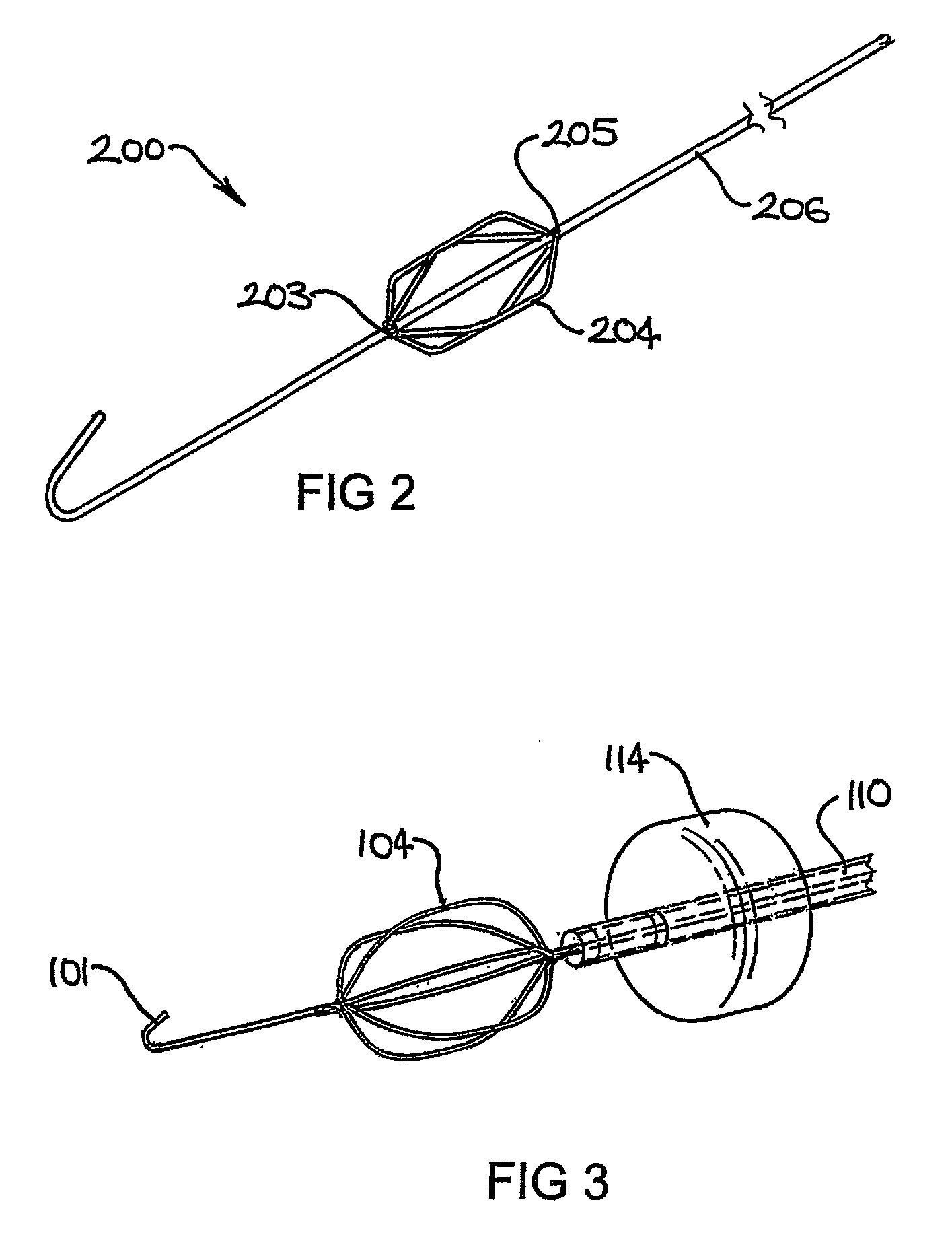

Devices and Methods for Perfusing an Organ

The present invention provides devices and methods for use in the perfusion of organs and anatomical regions. In one aspect the present method provides a percutaneously deliverable device for supporting a vessel in a human or animal subject including means for supporting the vessel during delivery of a fluid thereto or collection of a fluid therefrom. In another aspect the invention provides a method for delivery or collection of a fluid to or from an organ or anatomical region in a human or animal subject, the method including the step of supporting a vessel associated with the organ or anatomical region. The devices and methods may be used to deliver, remove or recirculate a therapeutic agent to an organ or anatomical region.

Owner:OSPREY MEDICAL

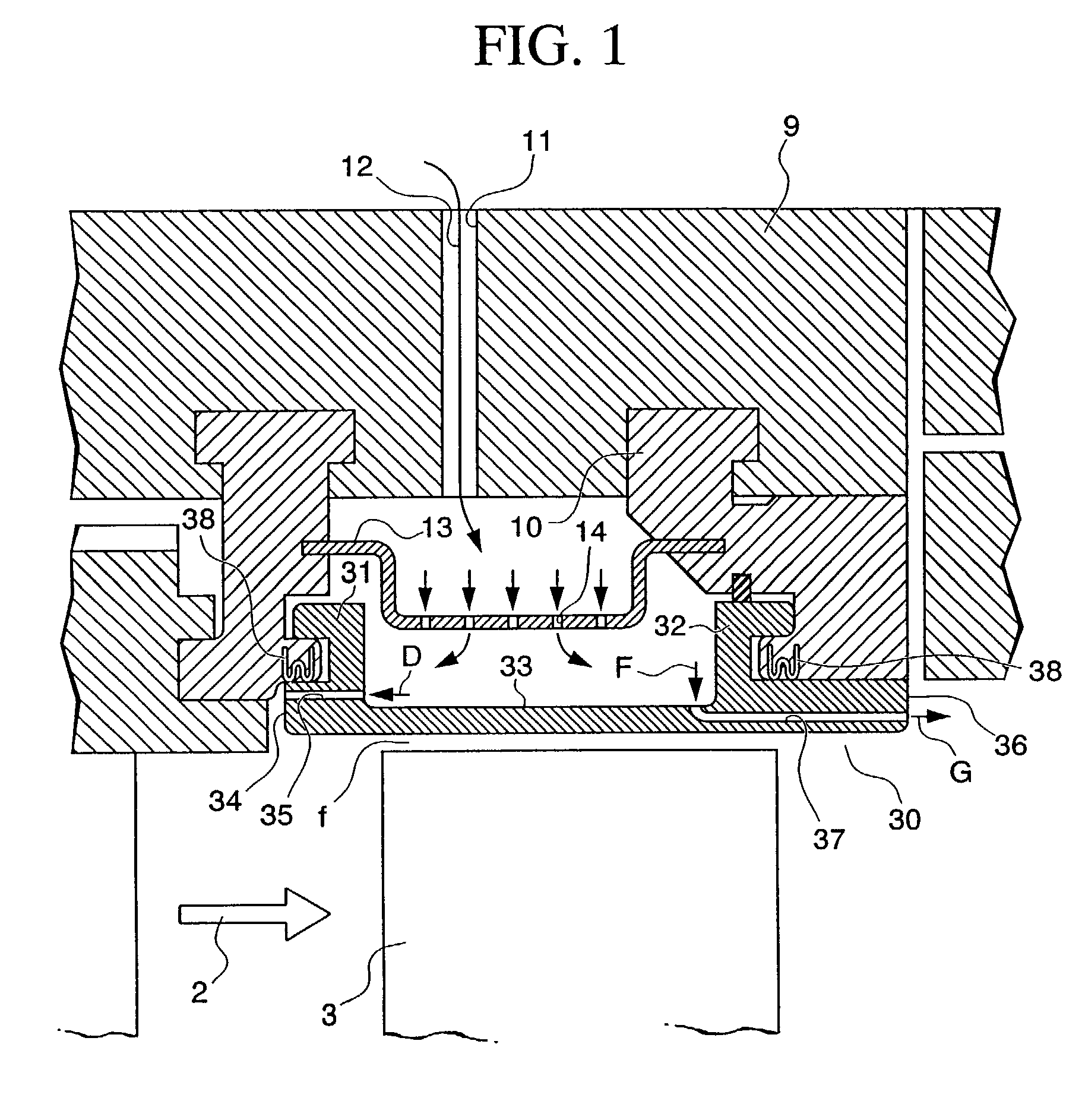

Ring segment of gas turbine

An object of the present invention is to provide a ring segment of a gas turbine in which the temperature is maintained low, damage due to high temperature oxidation is prevented, and high temperature deformation is prevented. In order to achieve the object, the present invention provides a ring segment of a gas turbine which comprises a blade ring, a main shaft and moving blades comprising a plurality of individual units which define an annular form by being arranged around the peripheral direction of the main shaft, and disposed so that its inner peripheral surface is maintained at a constant distance from the tips of the moving blades, wherein grooves which extend along the axial direction of the main shaft of the turbine are formed upon of the individual units so as mutually to confront one another; a seal plate which is inserted into each mutually confronting pair of the grooves so as to connect together the adjacent pair of individual units; and contact surfaces which are formed at positions more radially inward than the seal plates, which extend in the axial direction and the peripheral direction and which mutually contact one another.

Owner:MITSUBISHI HEAVY IND LTD

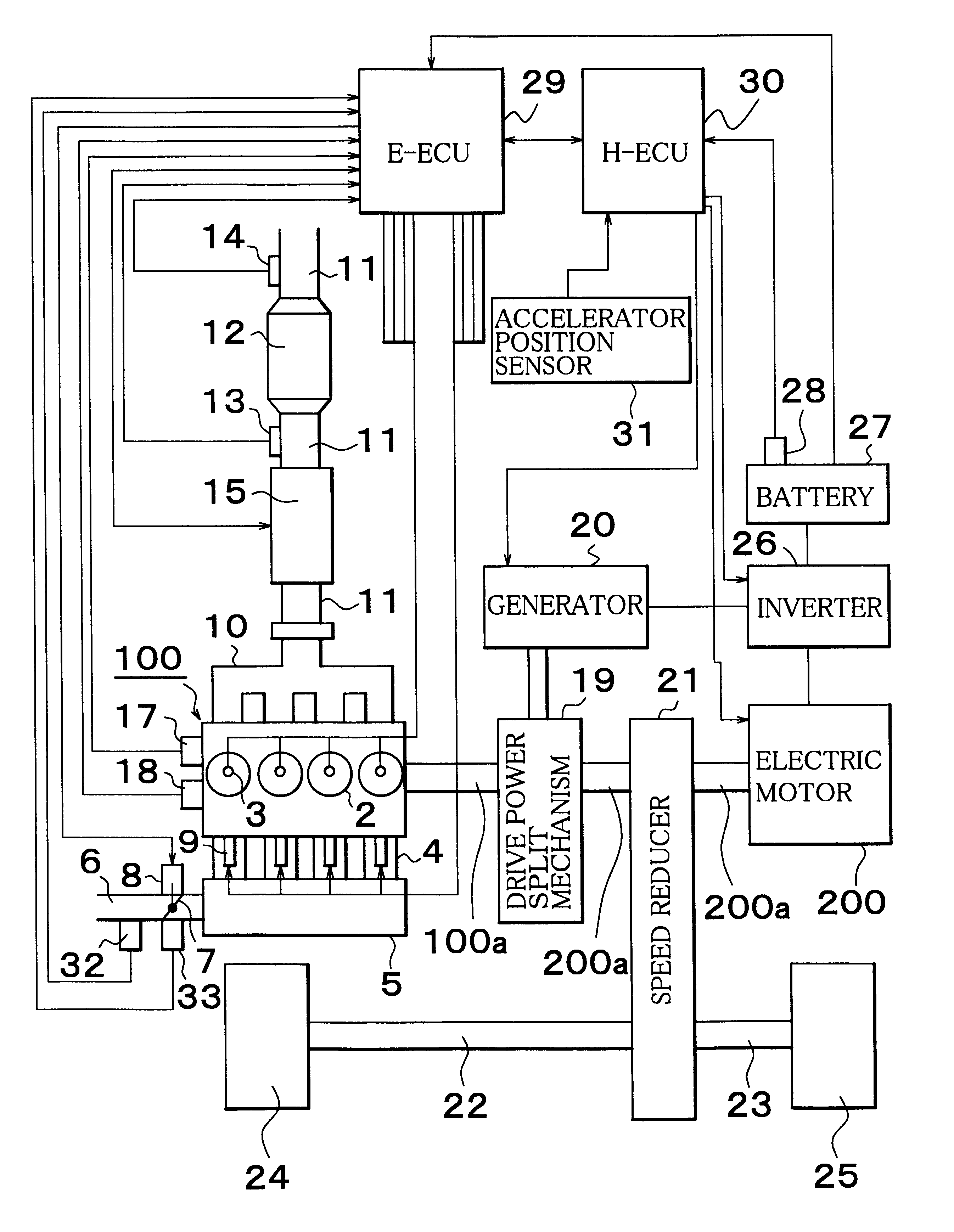

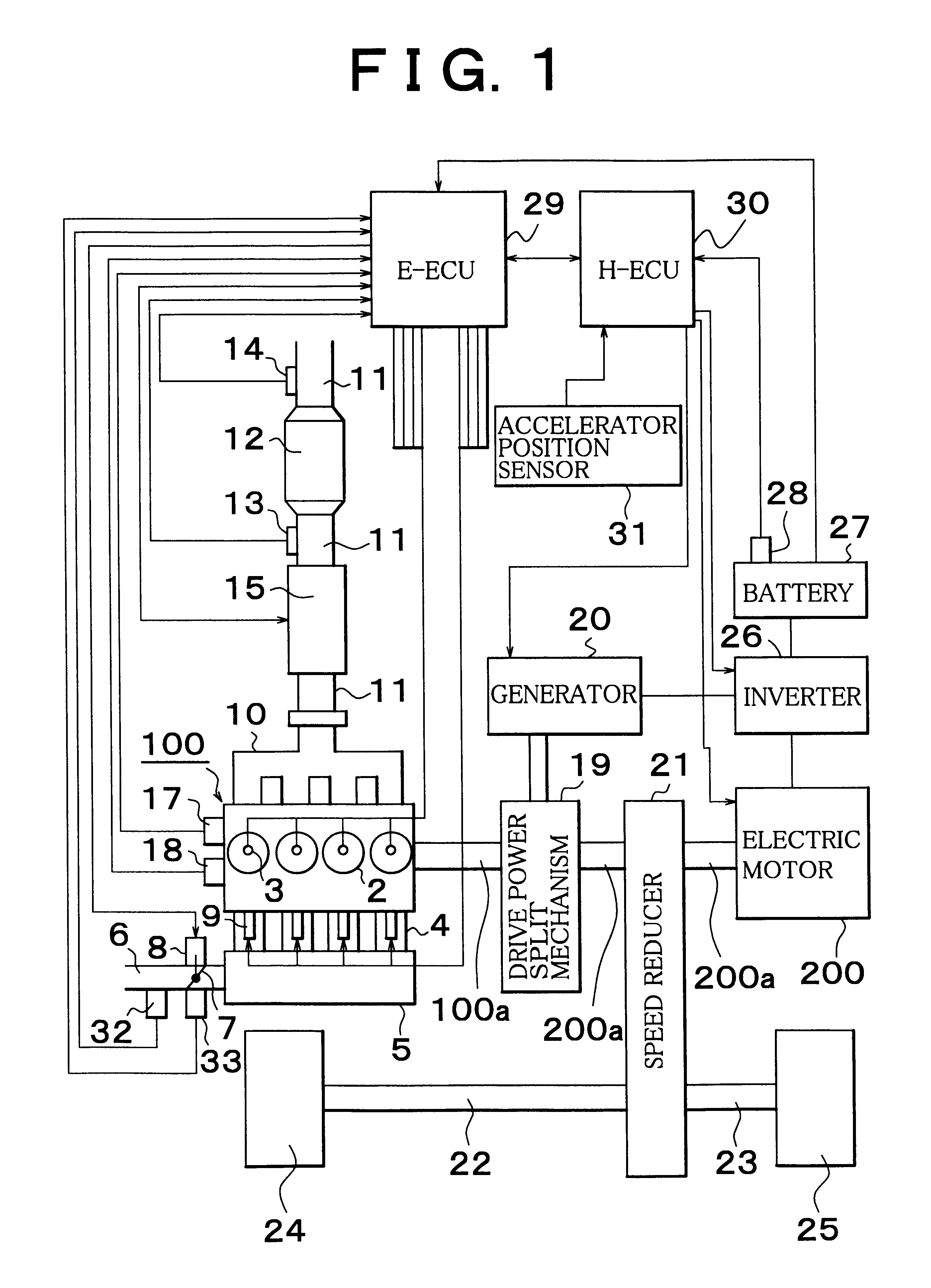

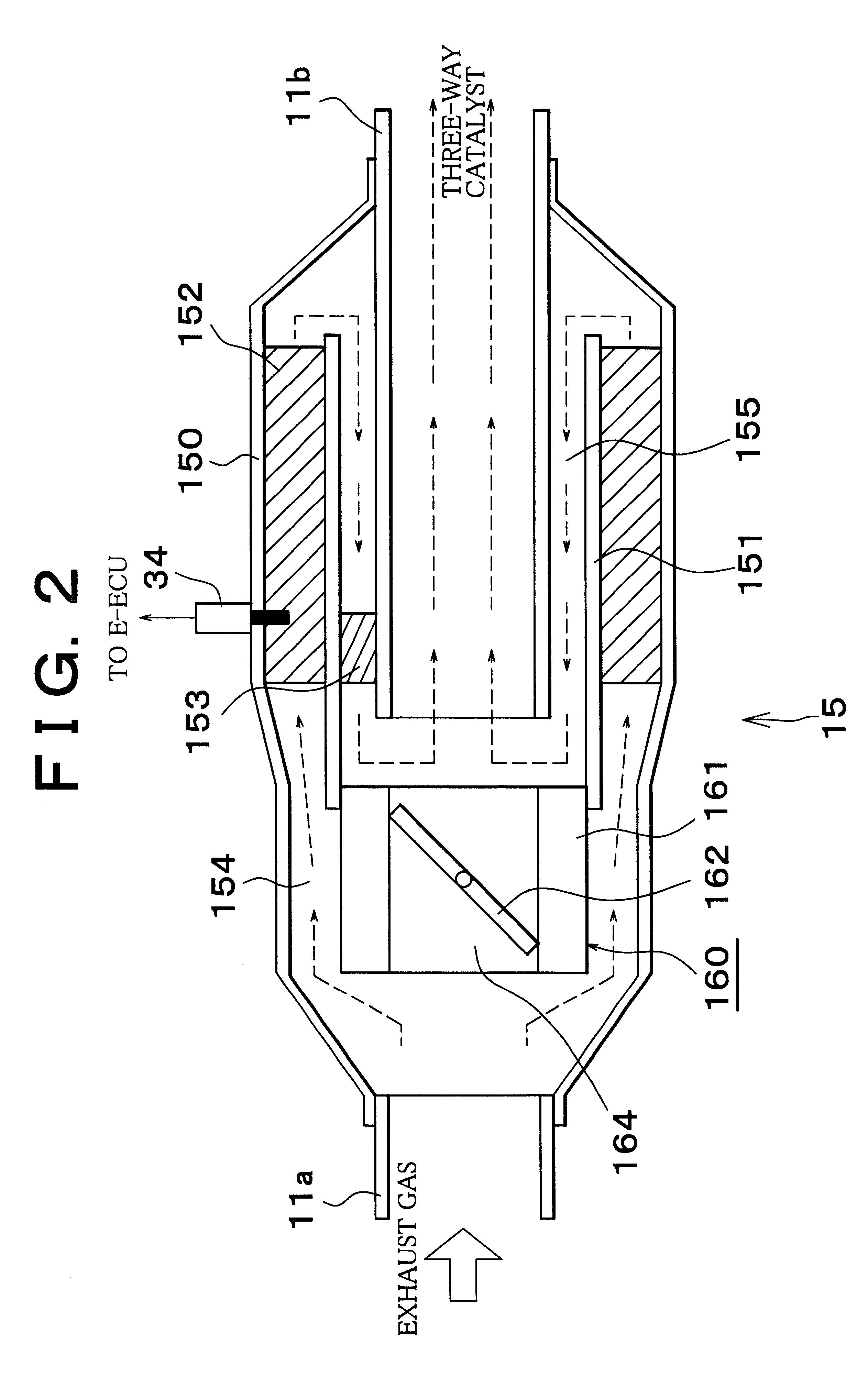

Exhaust gas emission control apparatus of hybrid vehicle

InactiveUS6327852B1Increase slowlyLower exhaust gas temperatureHybrid vehiclesElectrical controlSorbentExhaust fumes

An exhaust gas emission control apparatus is provided in an exhaust passage of a hybrid mechanism driven by an internal combustion engine and an electric motor. The apparatus has an adsorbent that adsorbs unburned fuel contained in exhaust gas when the temperature of the adsorbent is lower than a predetermined temperature, and that releases adsorbed unburned fuel therefrom when the temperature is at least the predetermined temperature. When the temperature of the adsorbent is lower than the predetermined temperature, the apparatus controls the hybrid mechanism to delay an increase in the temperature of the adsorbent.

Owner:TOYOTA JIDOSHA KK

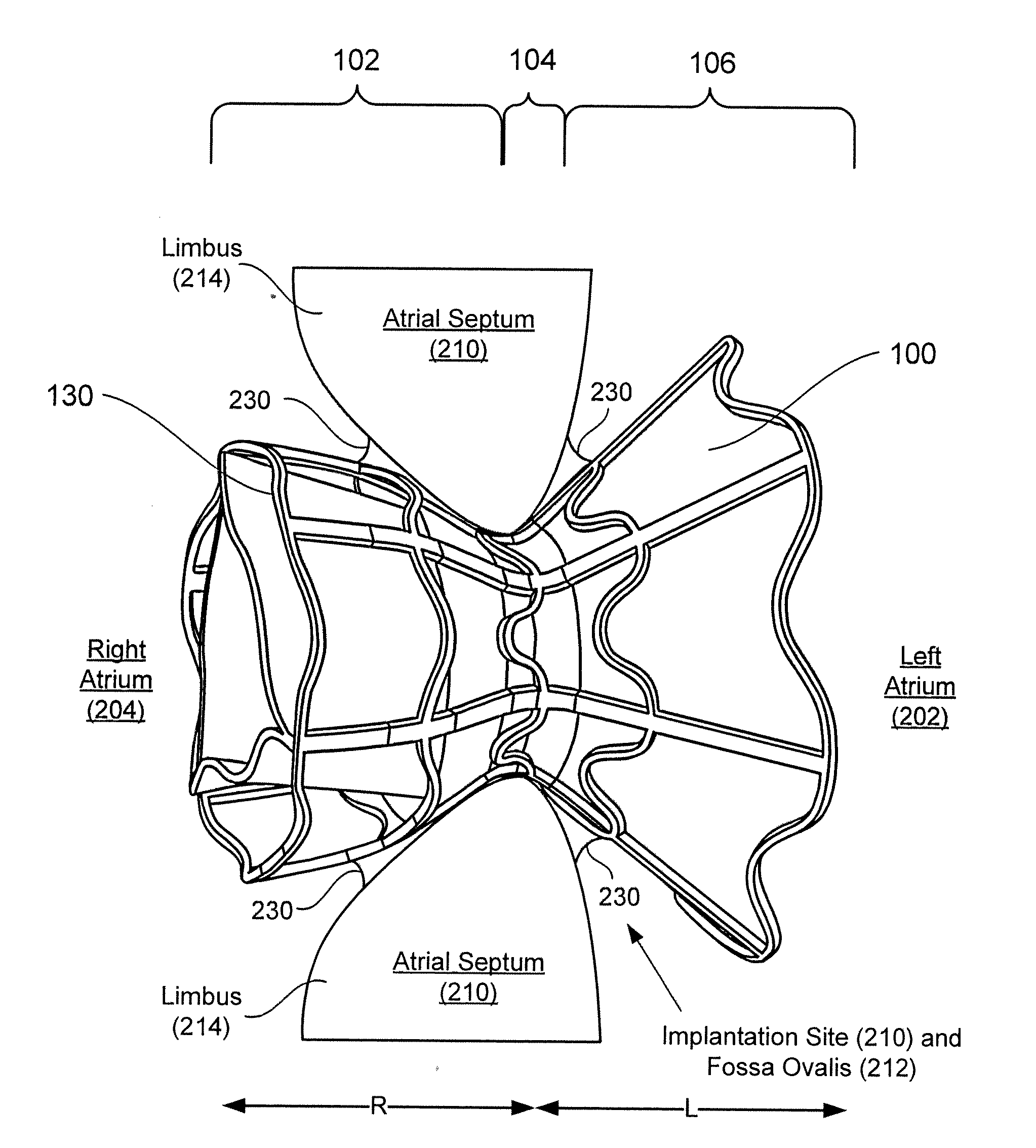

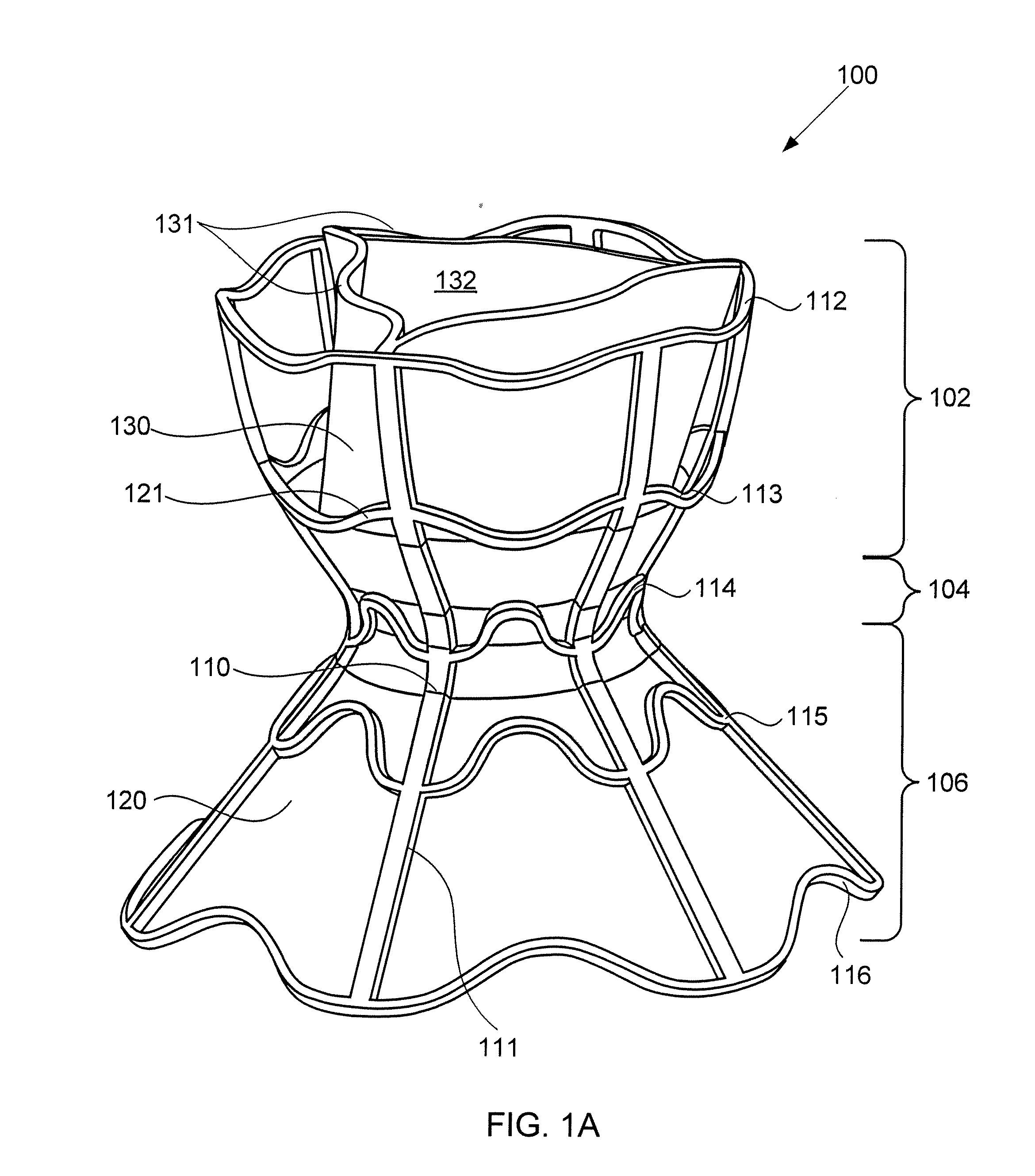

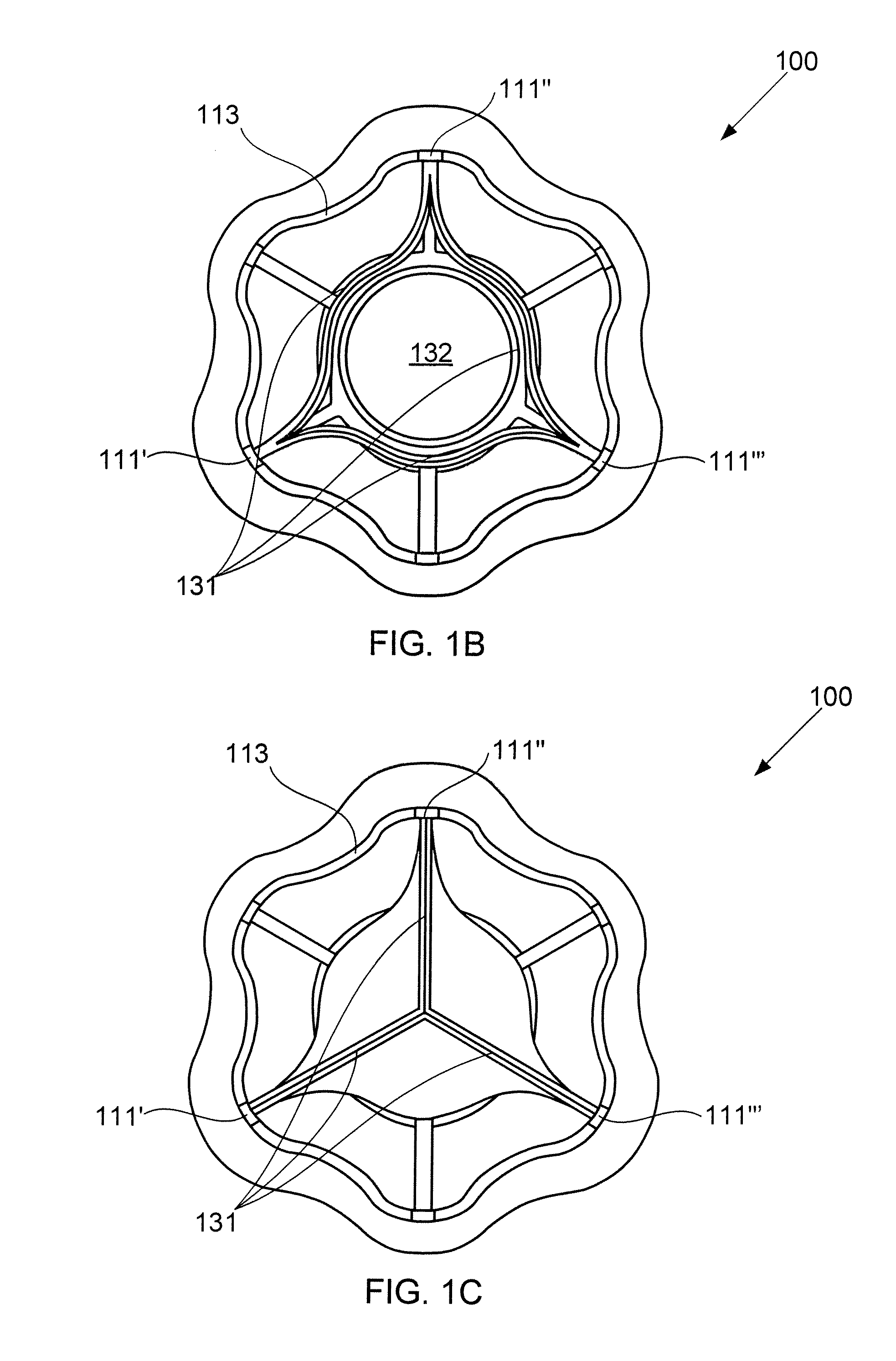

Devices for reducing left atrial pressure having biodegradable constriction, and methods of making and using same

ActiveUS20130030521A1Reducing left atrial pressureIncrease cardiac outputHeart valvesSurgeryLeft ventricular sizeLeft atrial pressure

A device for regulating blood pressure between a patient's left atrium and right atrium comprises an hourglass-shaped stent comprising a neck region and first and second flared end regions, the neck region disposed between the first and second end regions and configured to engage the fossa ovalis of the patient's atrial septum; and a one-way tissue valve coupled to the first flared end region and configured to shunt blood from the left atrium to the right atrium when blood pressure in the left atrium exceeds blood pressure in the right atrium. The inventive device may include a biodegradable material that biodegrades to offset flow changes caused by tissue ingrowth. The inventive device may reduce left atrial pressure and left ventricular end diastolic pressure, and may increase cardiac output, increase ejection fraction, relieve pulmonary congestion, and lower pulmonary artery pressure, among other benefits.

Owner:WAVE LTD V

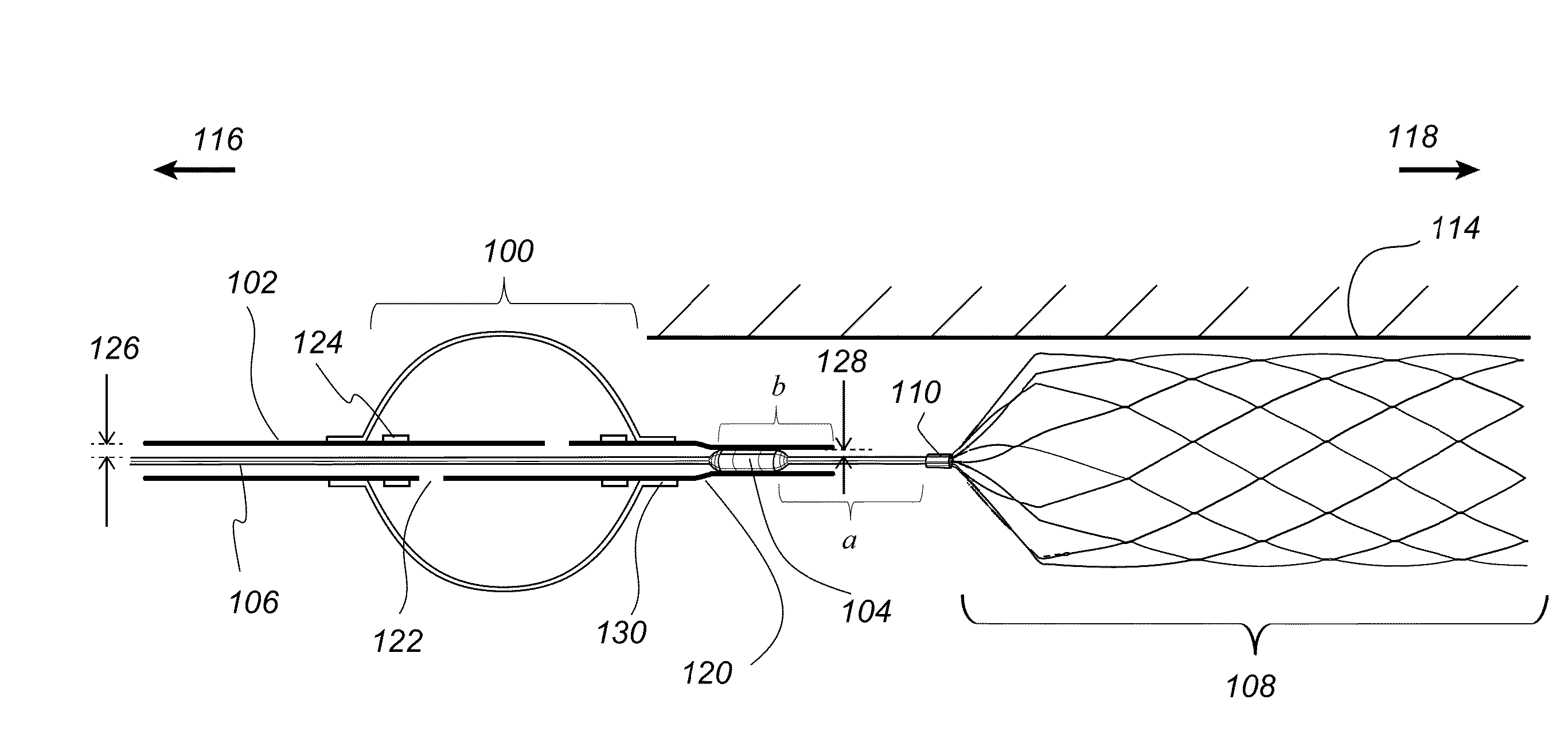

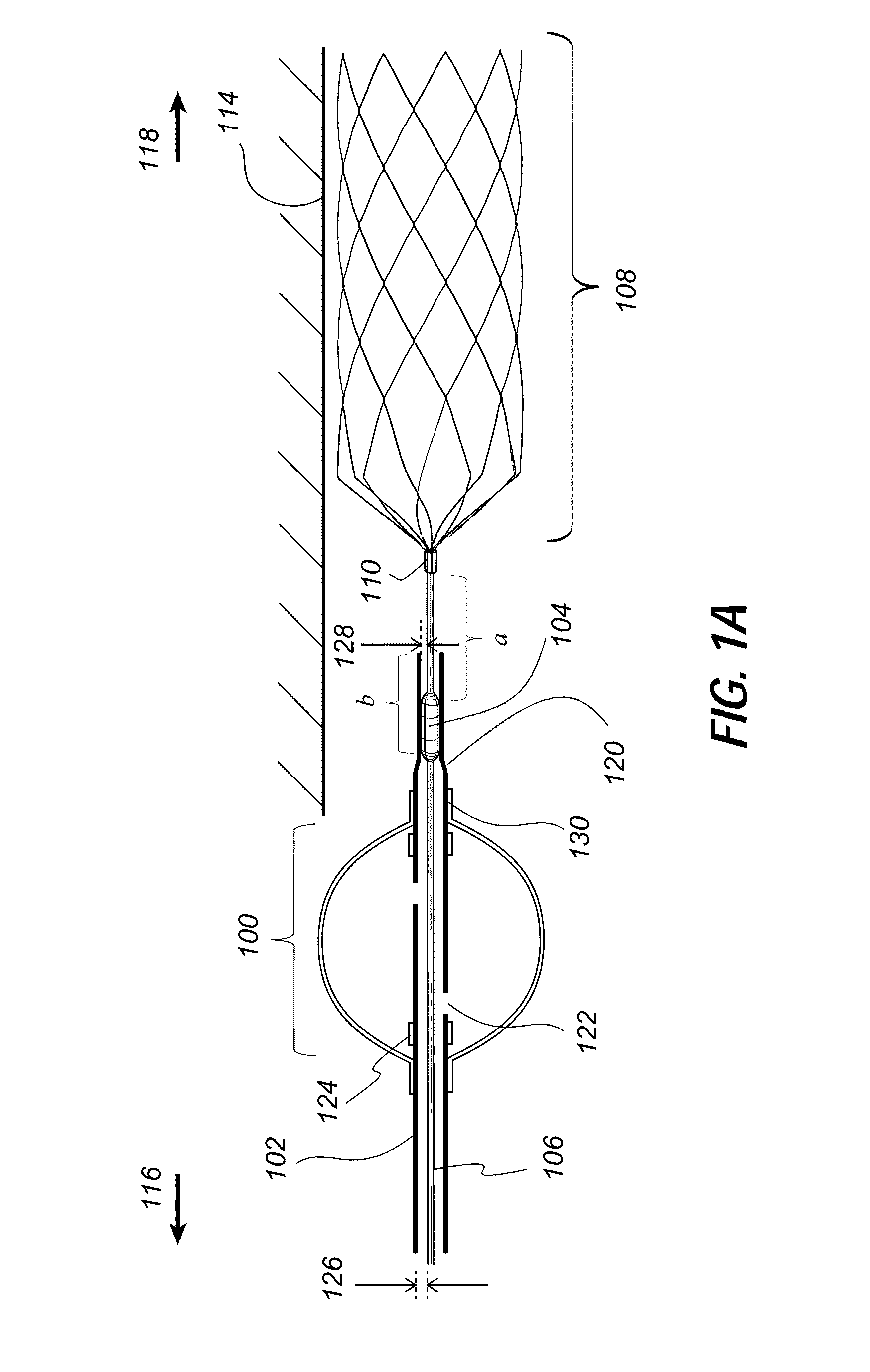

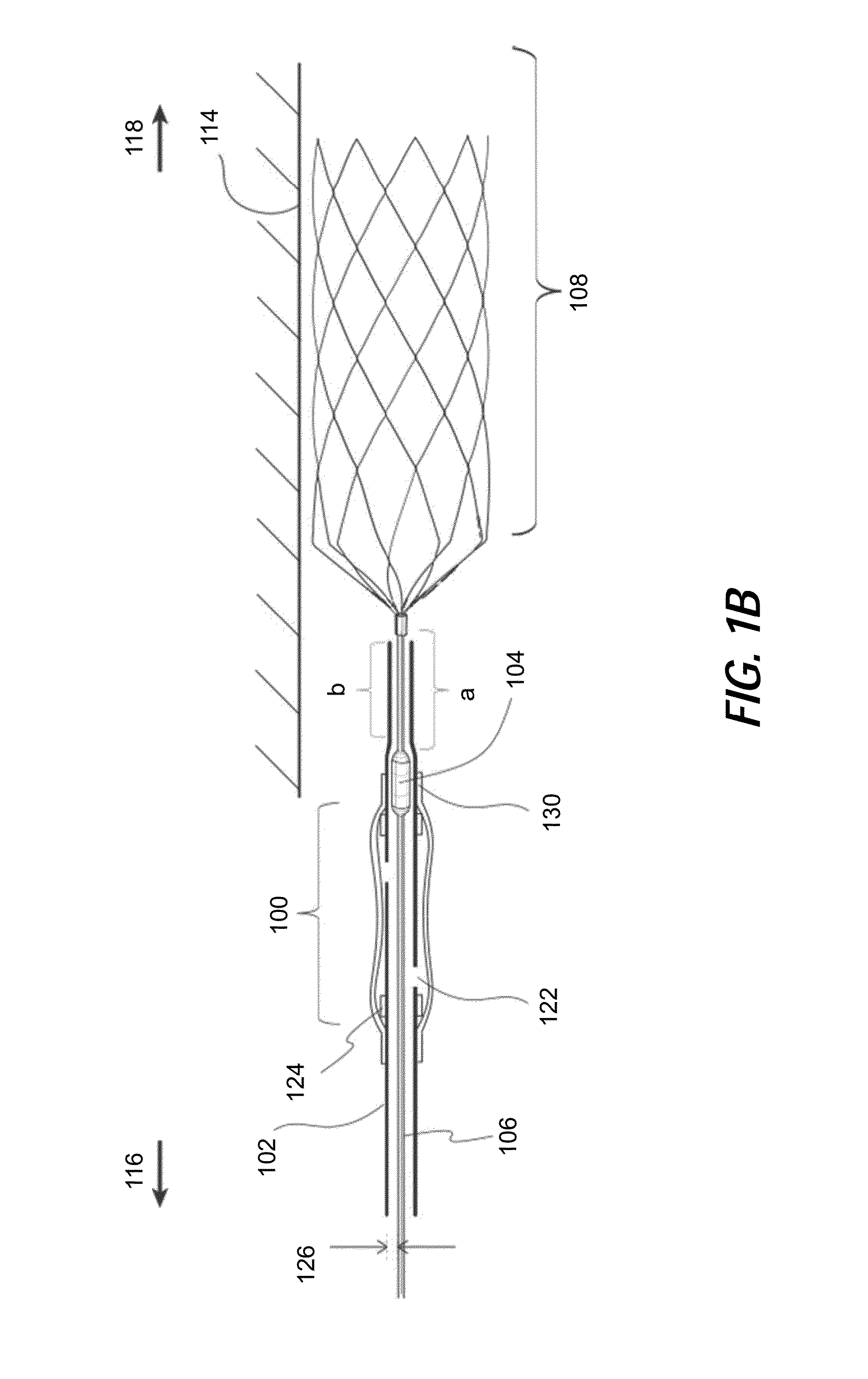

Methods, devices, and systems for postconditioning with clot removal

ActiveUS20140155980A1Reduce volumetric flow rateImprove fluid flowStentsBalloon catheterReperfusion injuryThrombus

New devices, systems, and methods are disclosed for preventing, treating, and / or at least minimizing ischemia and / or reperfusion injury by restoring and / or modulating blood flow, particularly in the cerebral vasculature where blood vessels are narrow and tortuous. These devices, systems, and methods make it possible for a clinician to adequately and systematically restore blood flow to ischemic tissue while simultaneously modulating the blood flow to minimize reperfusion injury. New thrombectomy devices and systems, which, for example, expand with greater radial force, further enable improved binding with clots and restoration of blood flow.

Owner:COGNITION MEDICAL

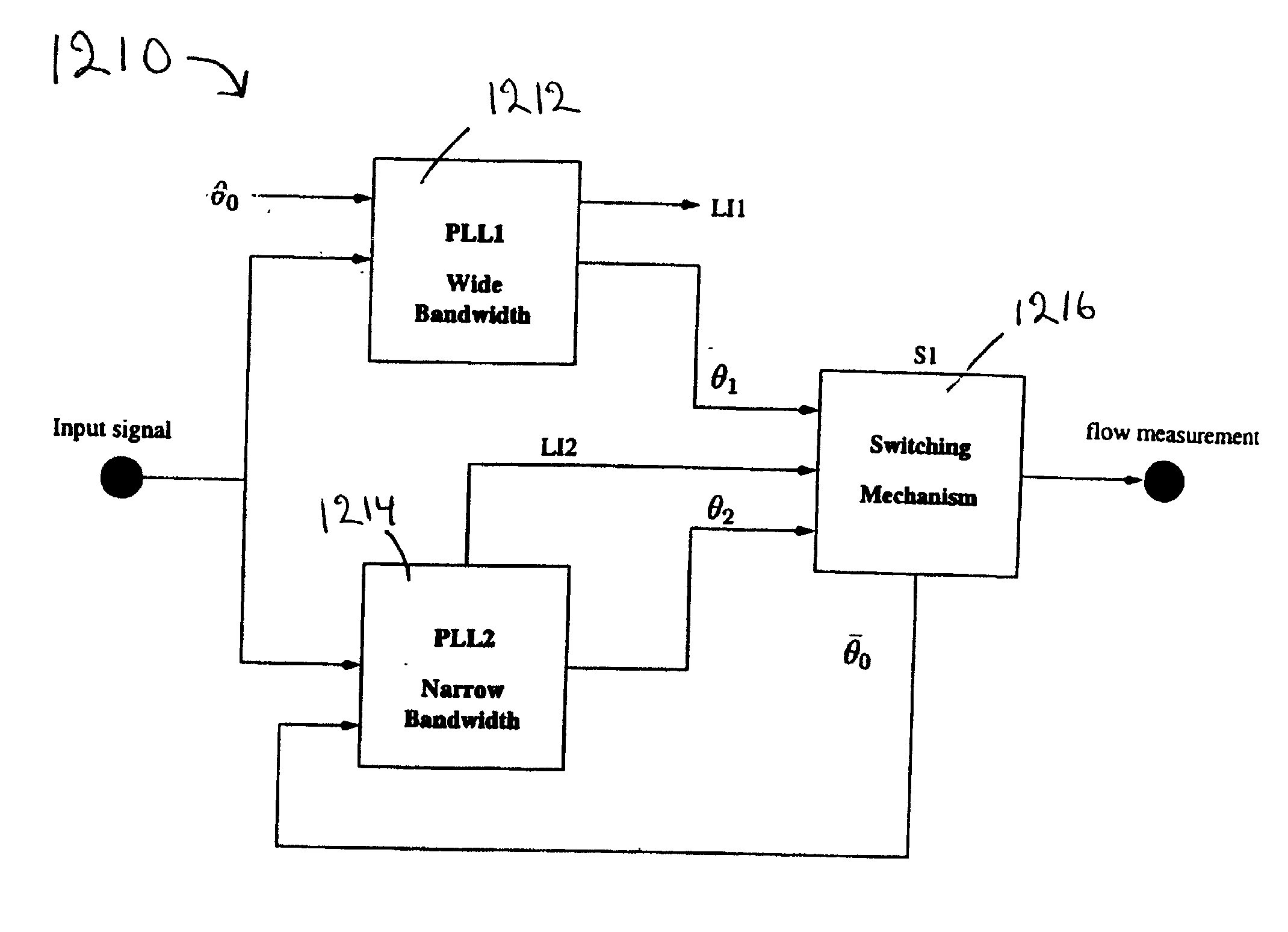

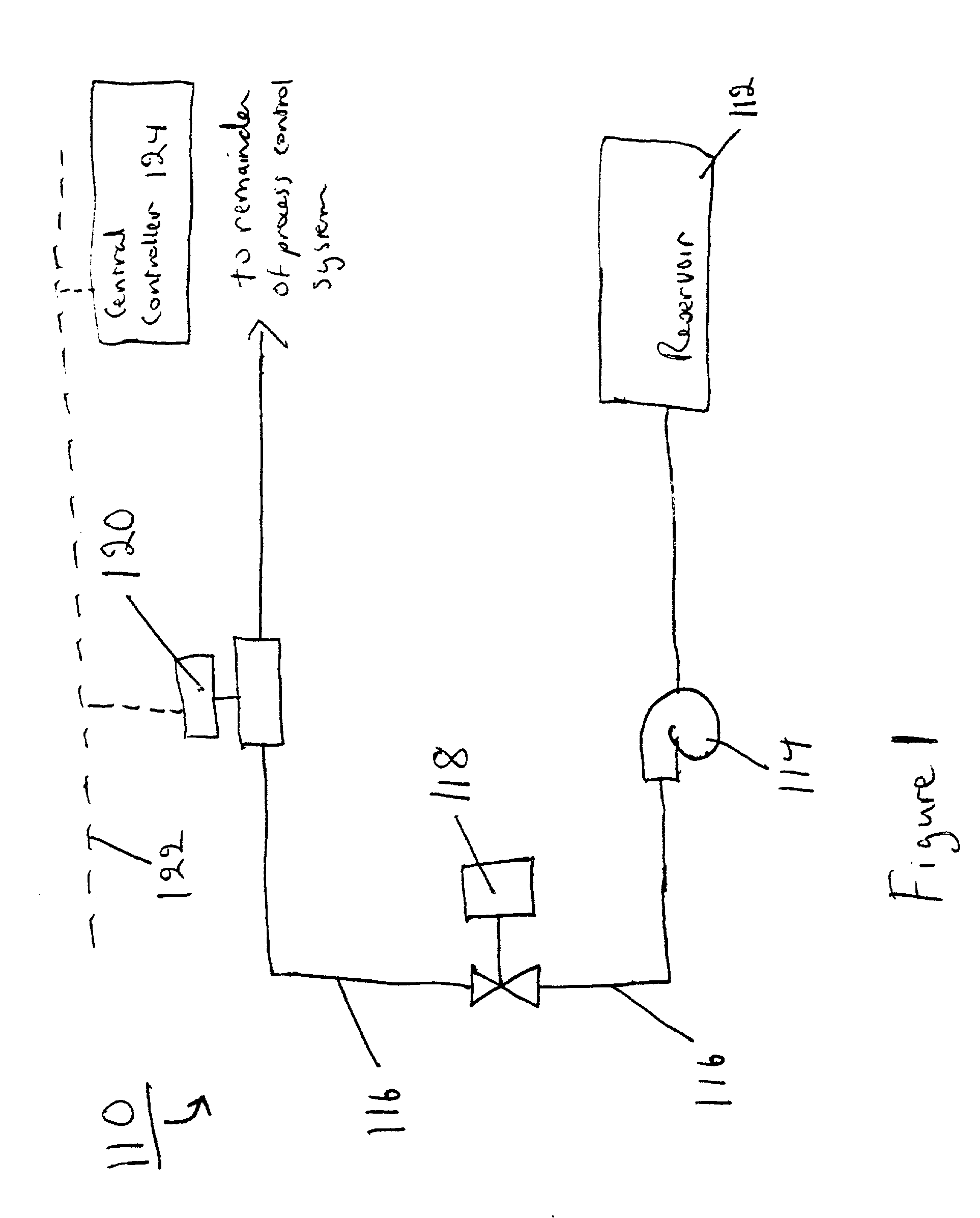

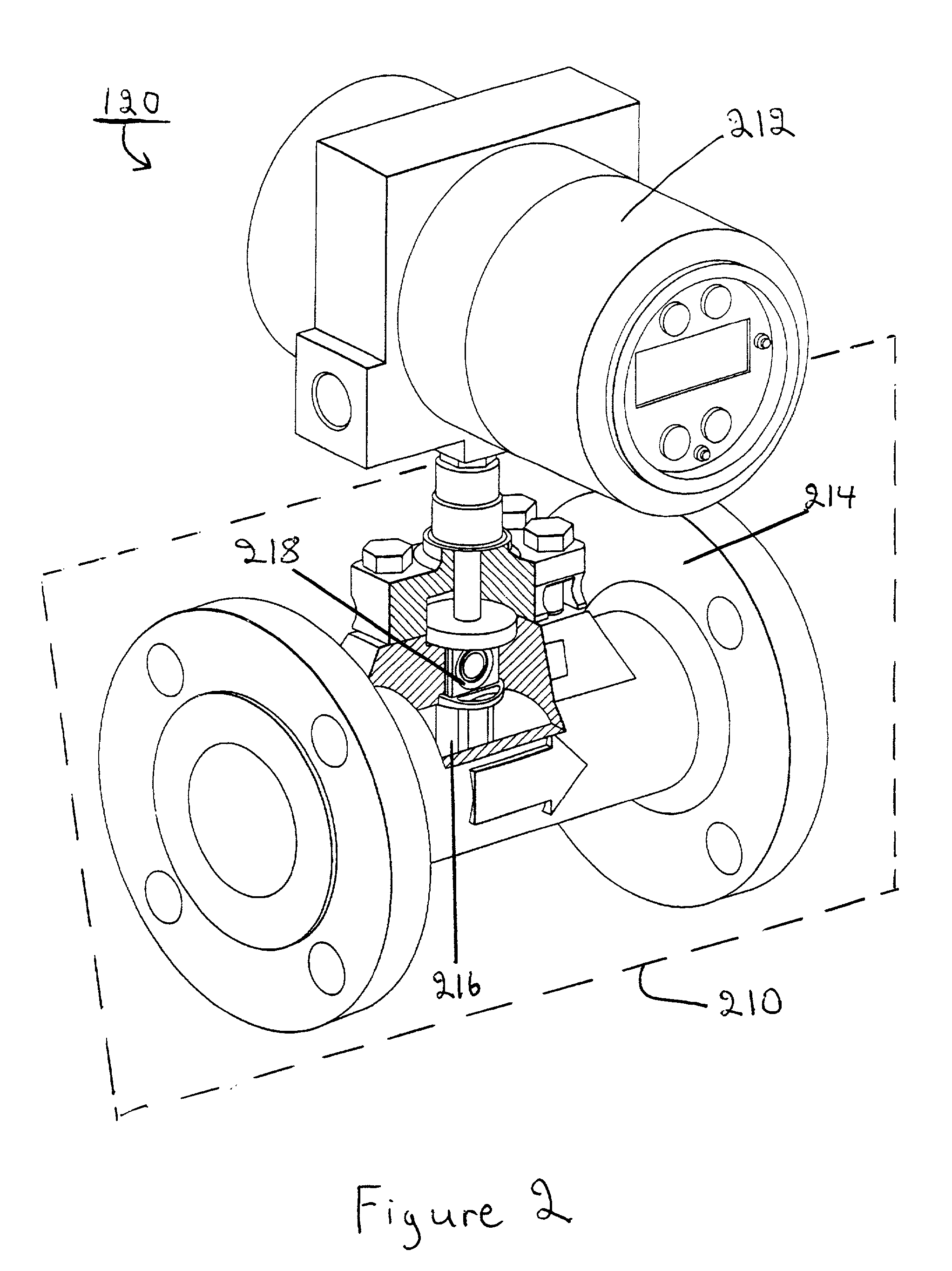

Vortex flowmeter

InactiveUS20020129661A1Improve accuracyIncrease speedElectrical measurementsVolume/mass flow by dynamic fluid flow effectEngineeringBand width

A process variable transmitter, implemented in a dual PLL structure, includes a first PLL having a first bandwidth producing a first output signal, and a second PLL having a second bandwidth narrower than the first bandwidth of the first PLL. The first and second PLLs are operable to lock into a frequency of an input signal and produce first and second output signals, respectively. The second PLL is operable to lock into the frequency of the input signal with greater accuracy and greater immunity to noise than the first PLL. A switch is operable to switch an output signal of the process variable transmitter between the first output signal and the second output signal.

Owner:SCHNEIDER ELECTRIC SYST USA INC

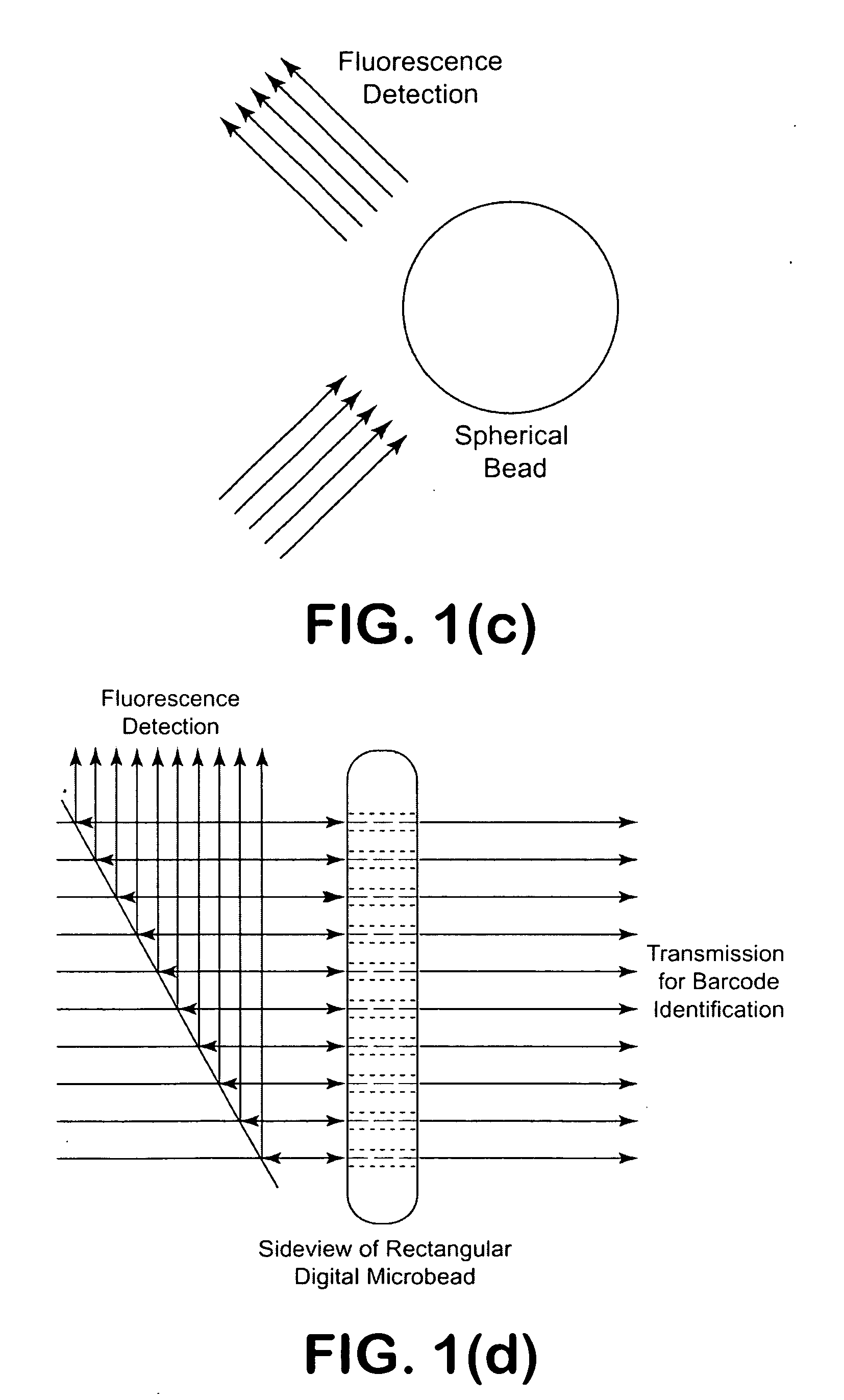

Substrate for solder joint

InactiveUS7224073B2Avoid pollutionPerformed easily and accuratelyPrinted circuit assemblingFinal product manufactureSolder maskEngineering

A substrate for solder joint is provided, including: a core layer; at least one conductive trace formed on the core layer and having a circular terminal as a pad through which a plurality of hollow portions are formed and expose predetermined portions of the core layer underneath the pad, wherein the hollow portions are arranged at equal intervals and spaced from a periphery of the circular pad; and a solder mask for covering the conductive trace and having at least one opening bordered across each of the hollow portions of the pad, such that part of the pad and part of each of the predetermined portions of the core layer are exposed via the opening, to allow a conductive element to be bonded to the exposed part of the pad and the exposed part of the predetermined portions of the core layer in the opening of the solder mask.

Owner:UTAC HEADQUARTERS PTE LTD

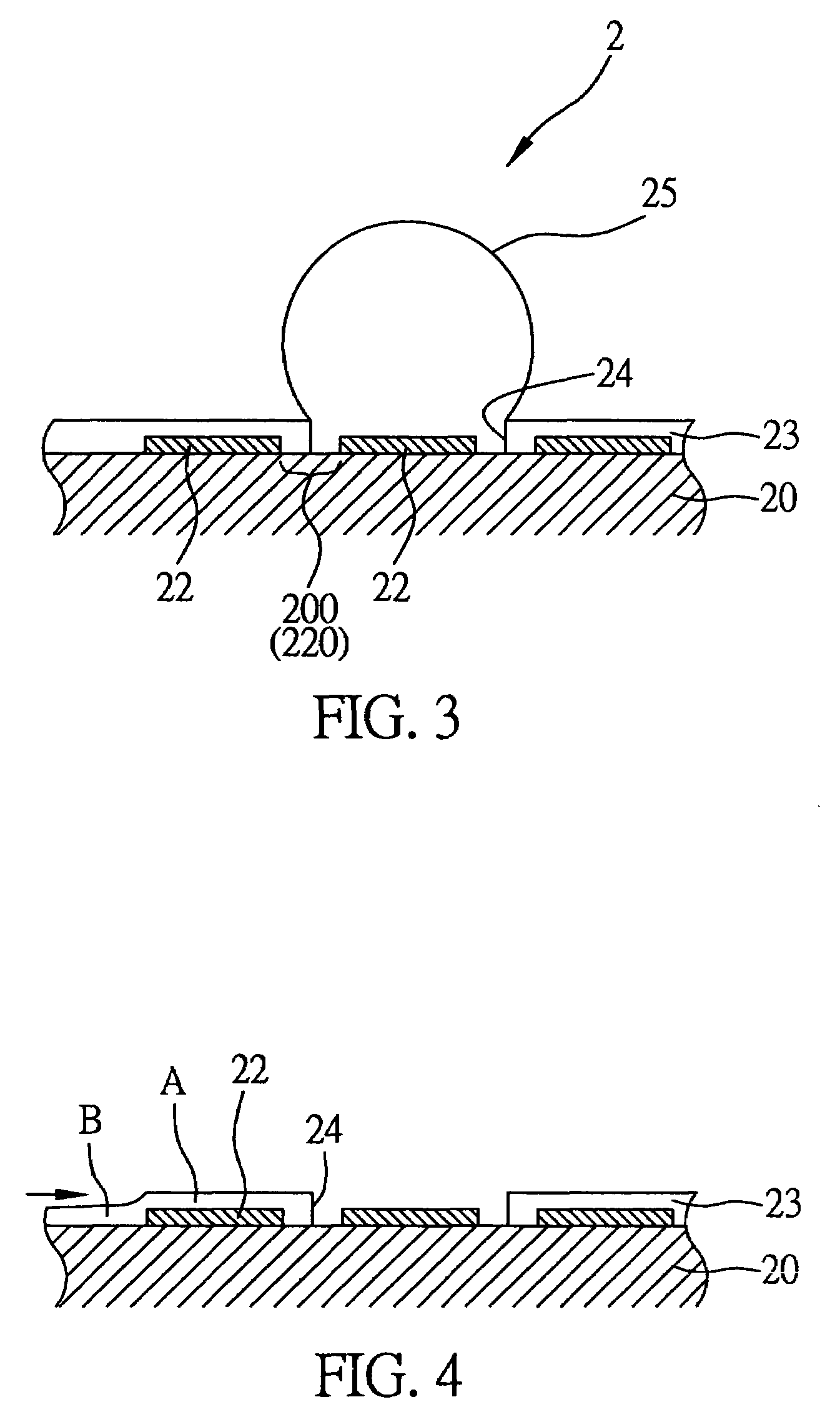

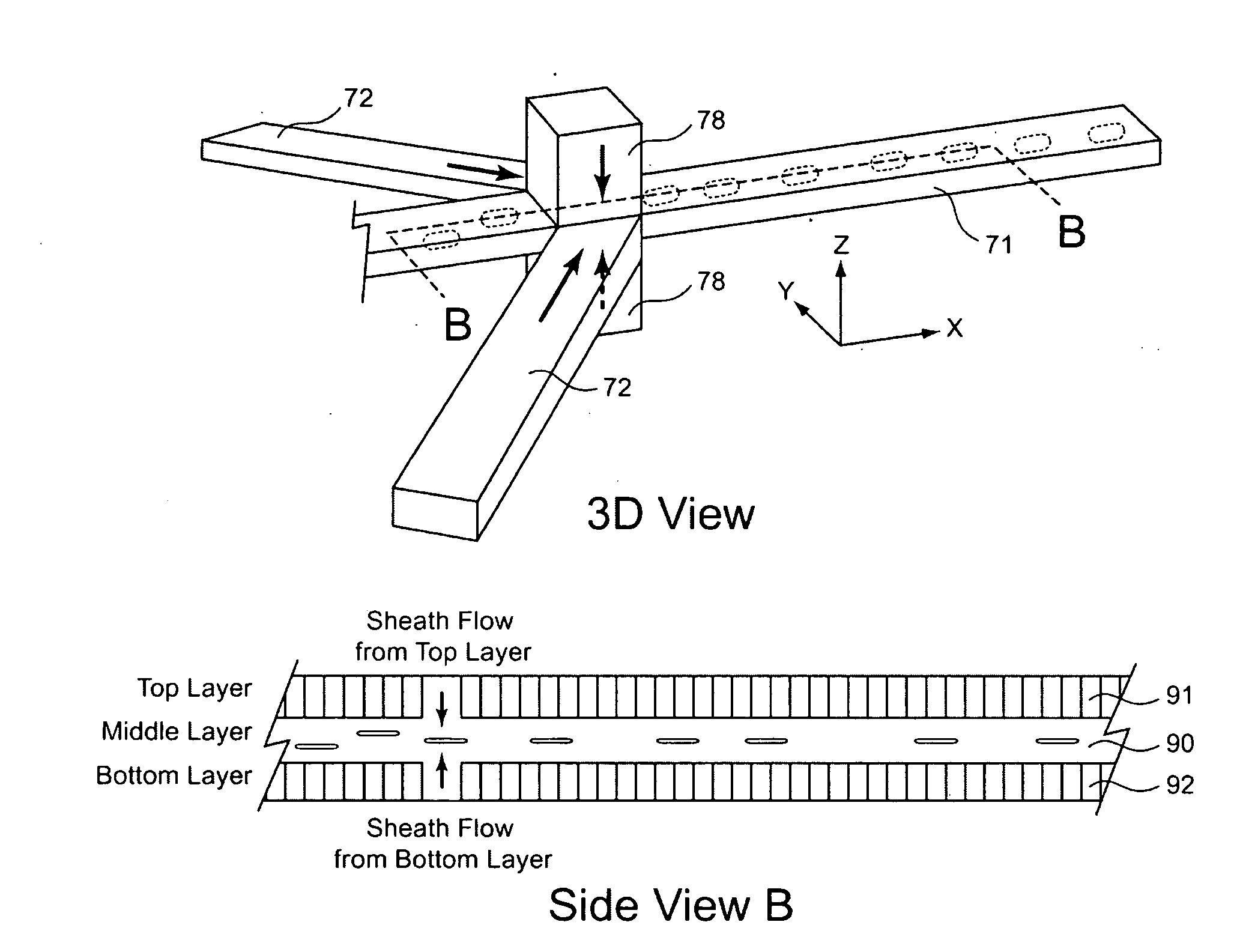

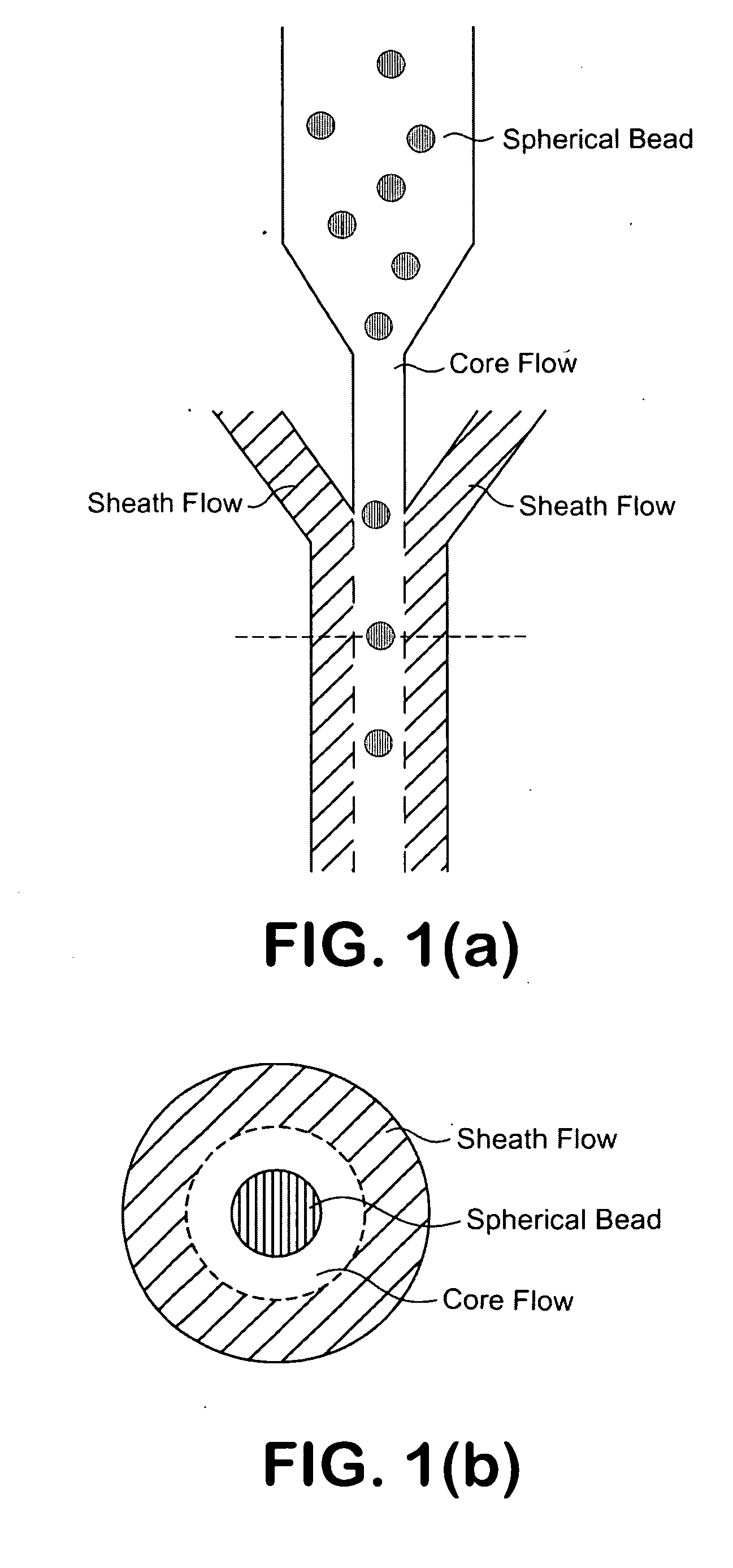

Hydrodynamic focusing for analyzing rectangular microbeads

InactiveUS20090201504A1Improve liquidityNo cloggingVolume/mass flow measurementMaterial analysis by optical meansBarcodeEngineering

A microfluidic apparatus having a one-dimensional or two-dimensional hydrodynamic flow system to control stable and proper digitally coded bead orientation through the optical detection area of a bioanalysis system. The hydrodynamic system include one core flow, which carries the rectangular barcode beads, and sheath flows, on the sides of or about or around the outer periphery of the core flow, pull the core flow into a proper orientation. The sheath flows, at much higher flow speed but lower volume flow rate, can be pushed or pulled by vacuum, gravity, or pressure. By this method, the coded bead will align themselves in line and flow reliably, without wobbling or flipping, in the core flow channel through the detection zone. By adjusting the relative flow rate of core flow and sheath flows, the coded beads flow reliably in the flow system, thus it can be decoded and detected by an optical system accurately.

Owner:MAXWELL SENSORS

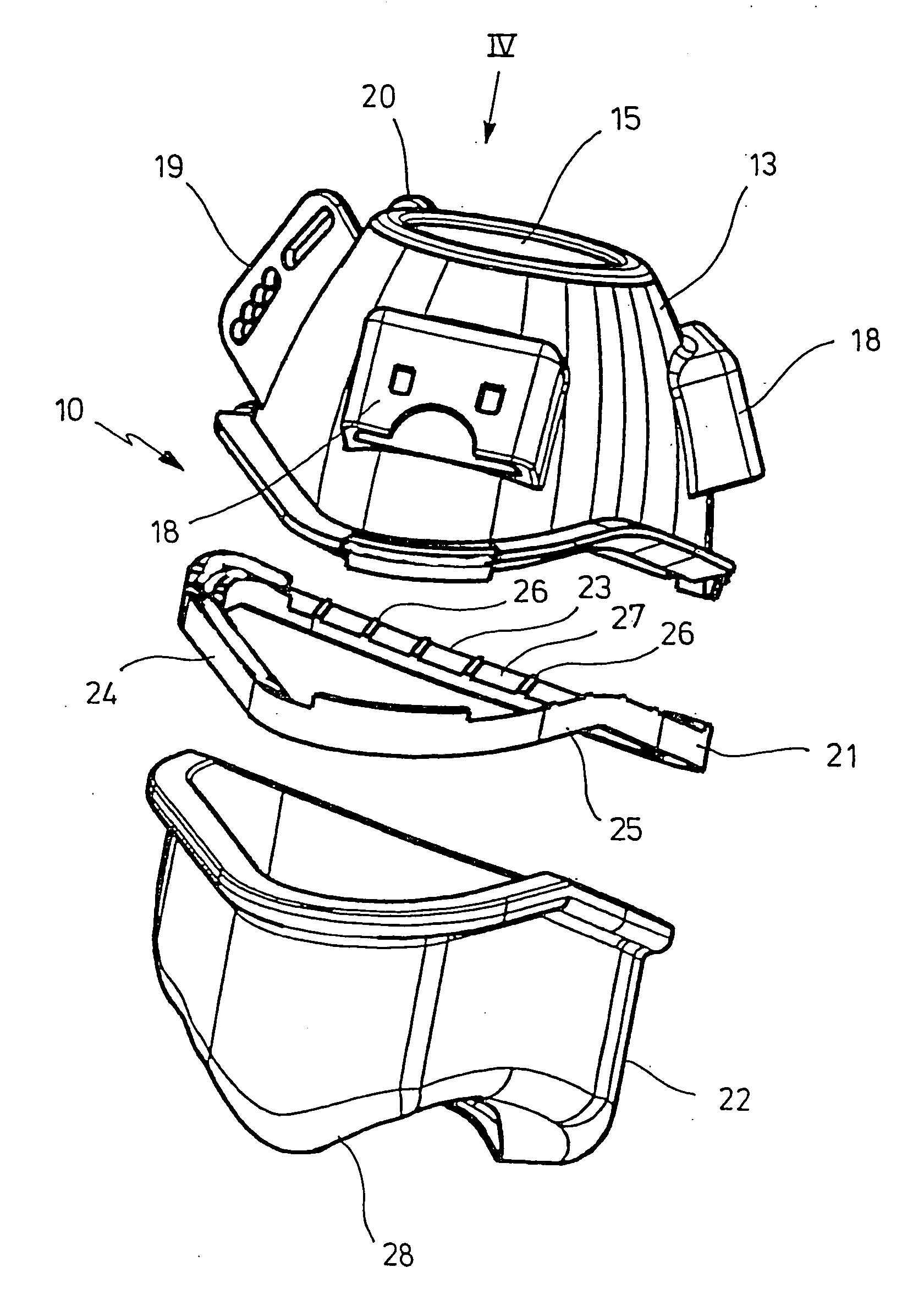

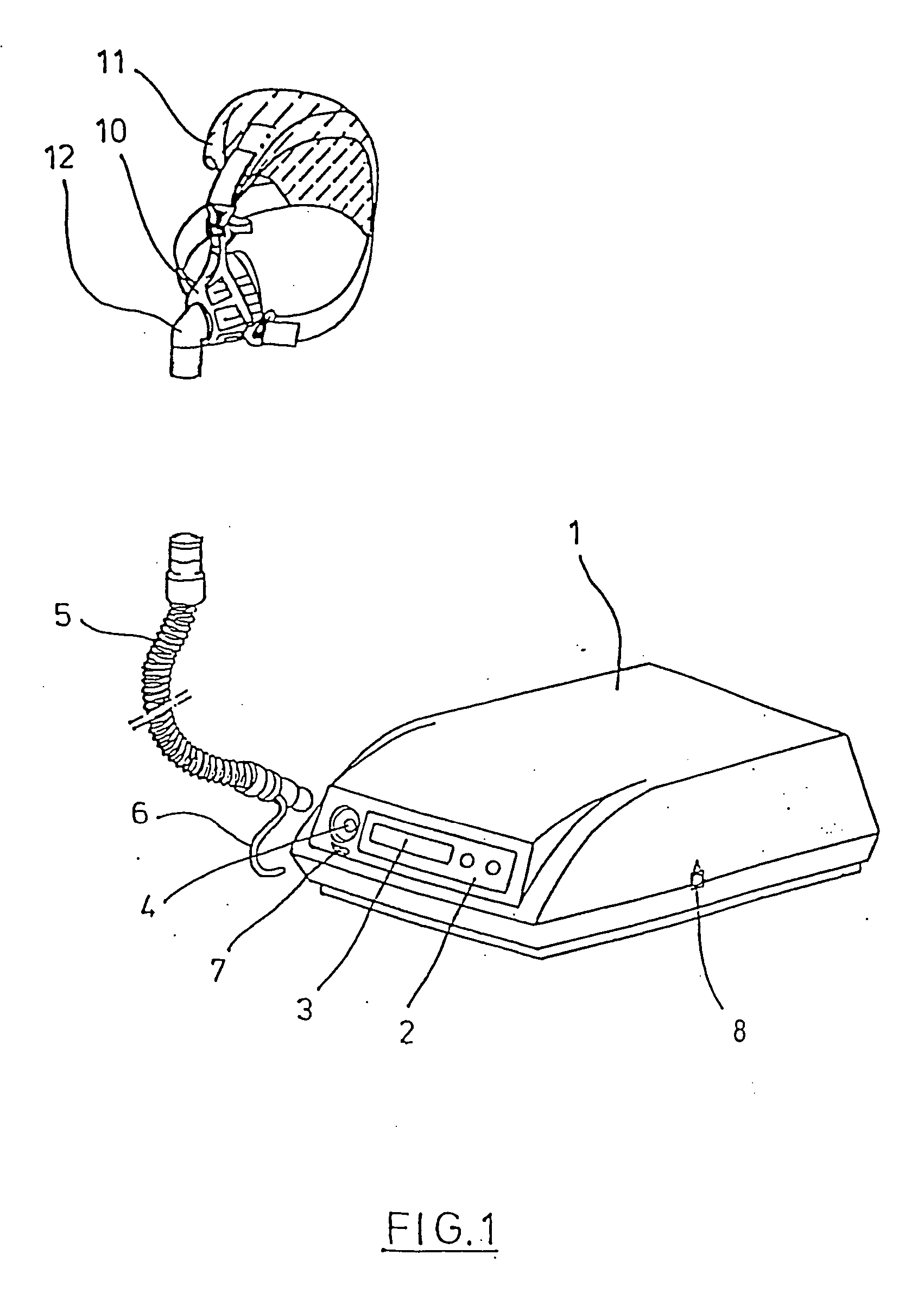

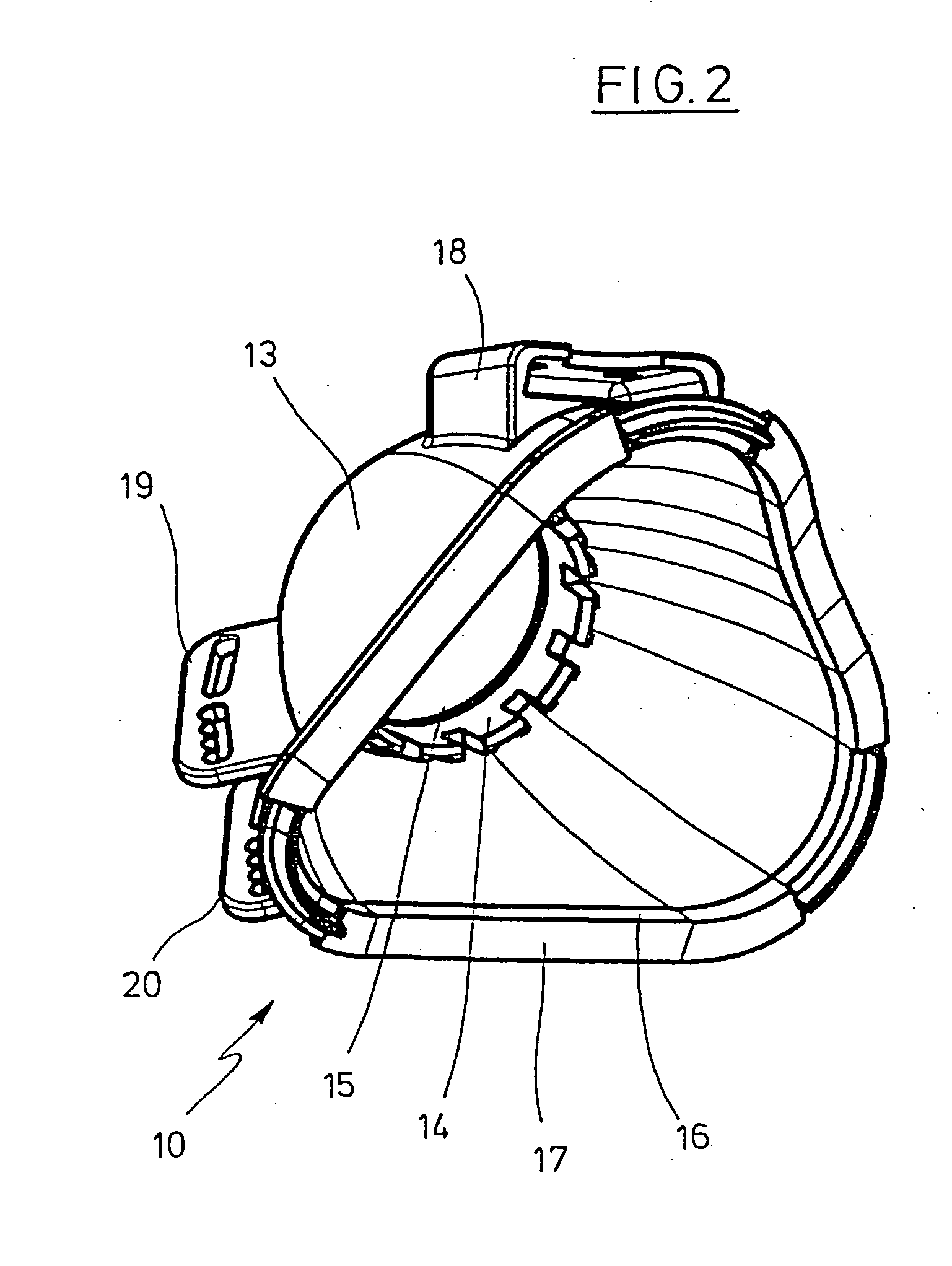

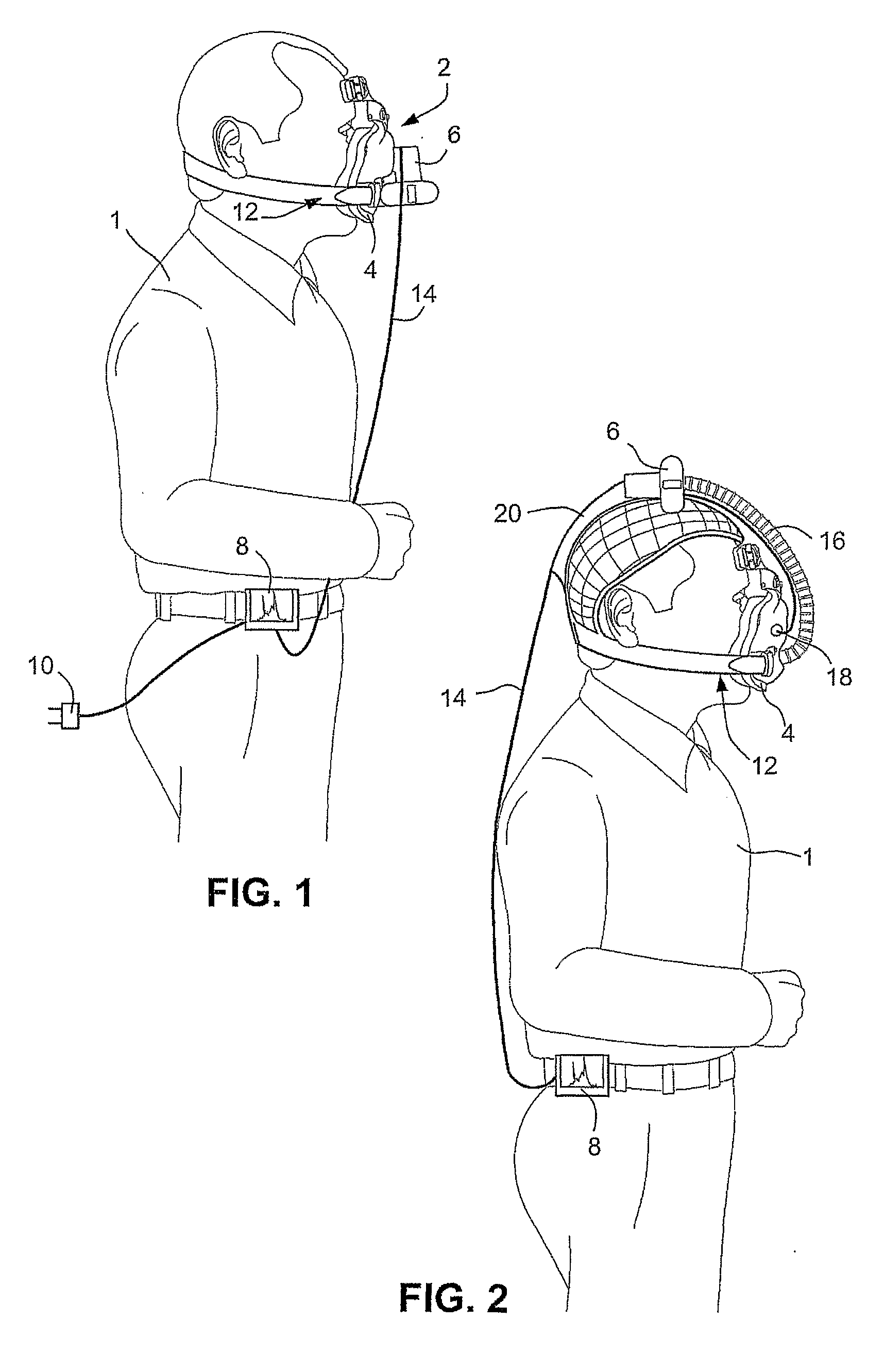

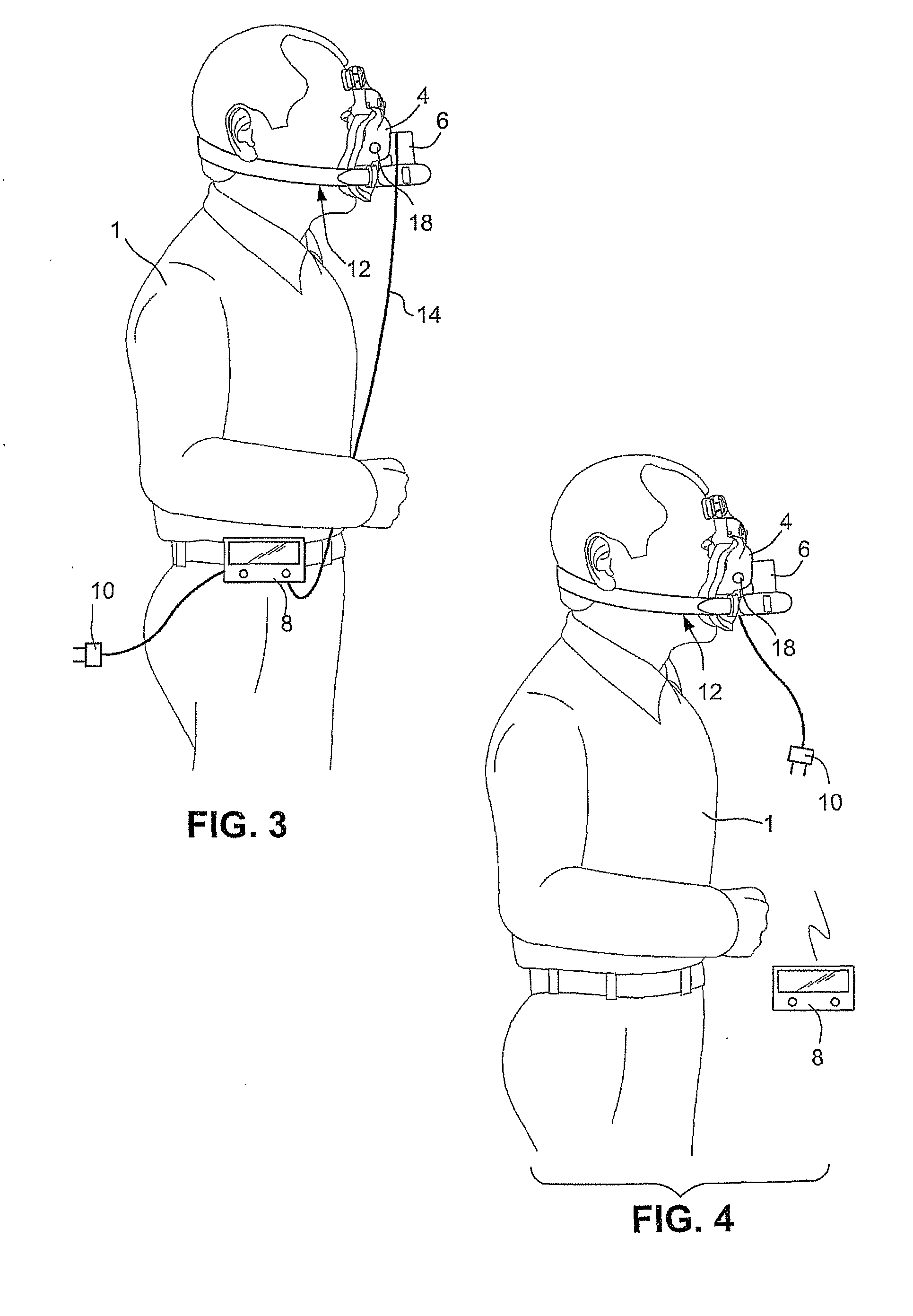

Ventilation mask

InactiveUS20060169286A1Easy to wearReduce the numberBreathing masksRespiratory masksEngineeringBreathing

Owner:WEINMANN GERATE FUR MEDIZIN

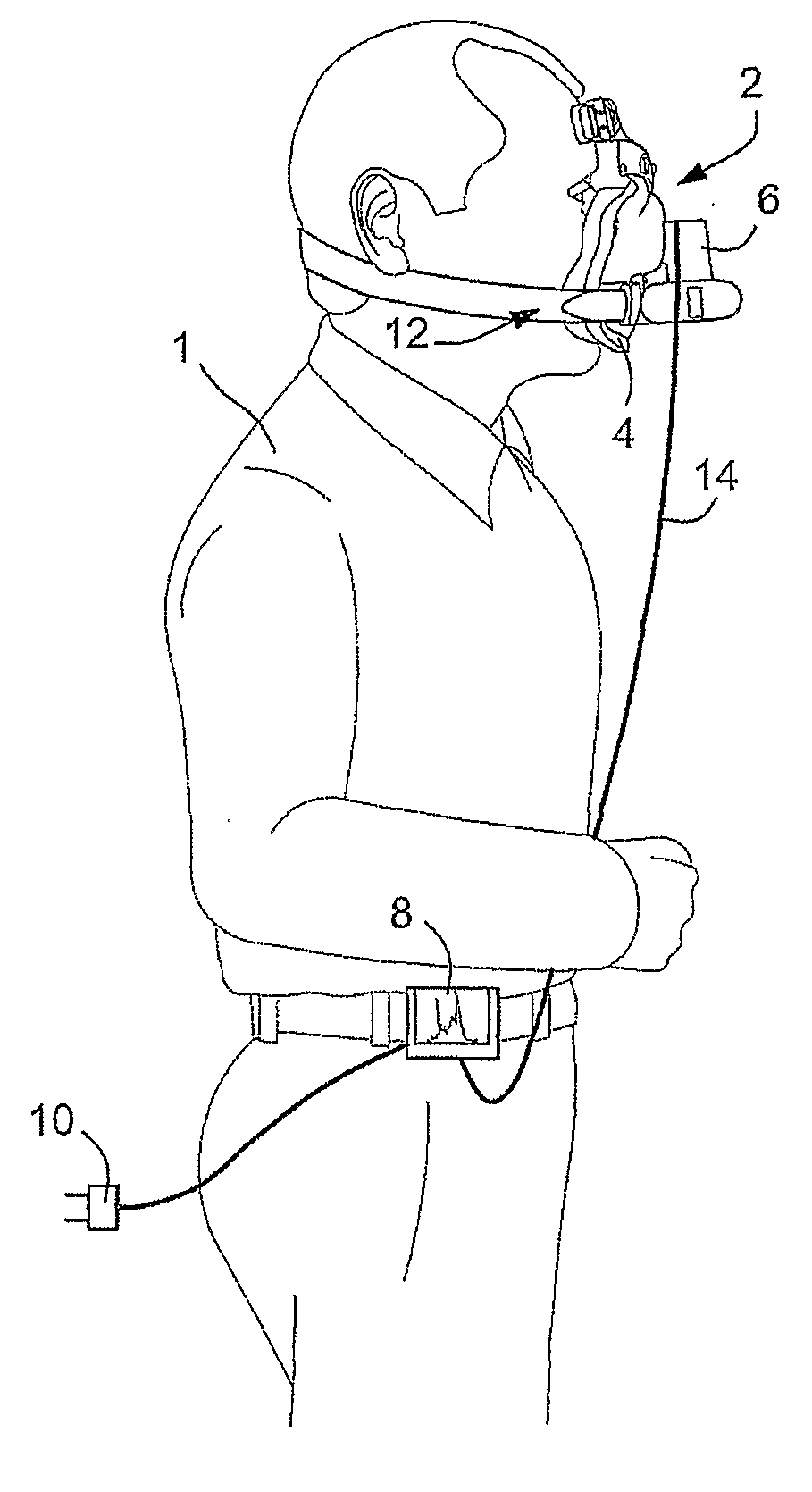

Mask and flow generator system

InactiveUS20090320842A1Reduction in functional dead spaceReduce functional dead spaceOperating means/releasing devices for valvesRespiratory masksBreathing gasEngineering

A system for delivering a pressurized flow of breathable gas to a patient includes a patient interface configured to contact the patient's head. The patient interface includes a frame, a cushion supported by the frame and configured to sealingly connect the patient interface to the patient's face and form a chamber between the frame and the wearer's face, and an inlet port in the frame to receive the pressurized flow of breathable gas. A flow generator is configured to generate the pressurized flow and is capable of creating a pressure of about 2-40 cm H20 in the chamber. A flow generator housing is provided to house the flow generator. The flow generator housing is mounted on the patient interface and configured to reduce the transmission of vibration and / or noise generated by the flow generator to the patient interface.

Owner:RESMED LTD

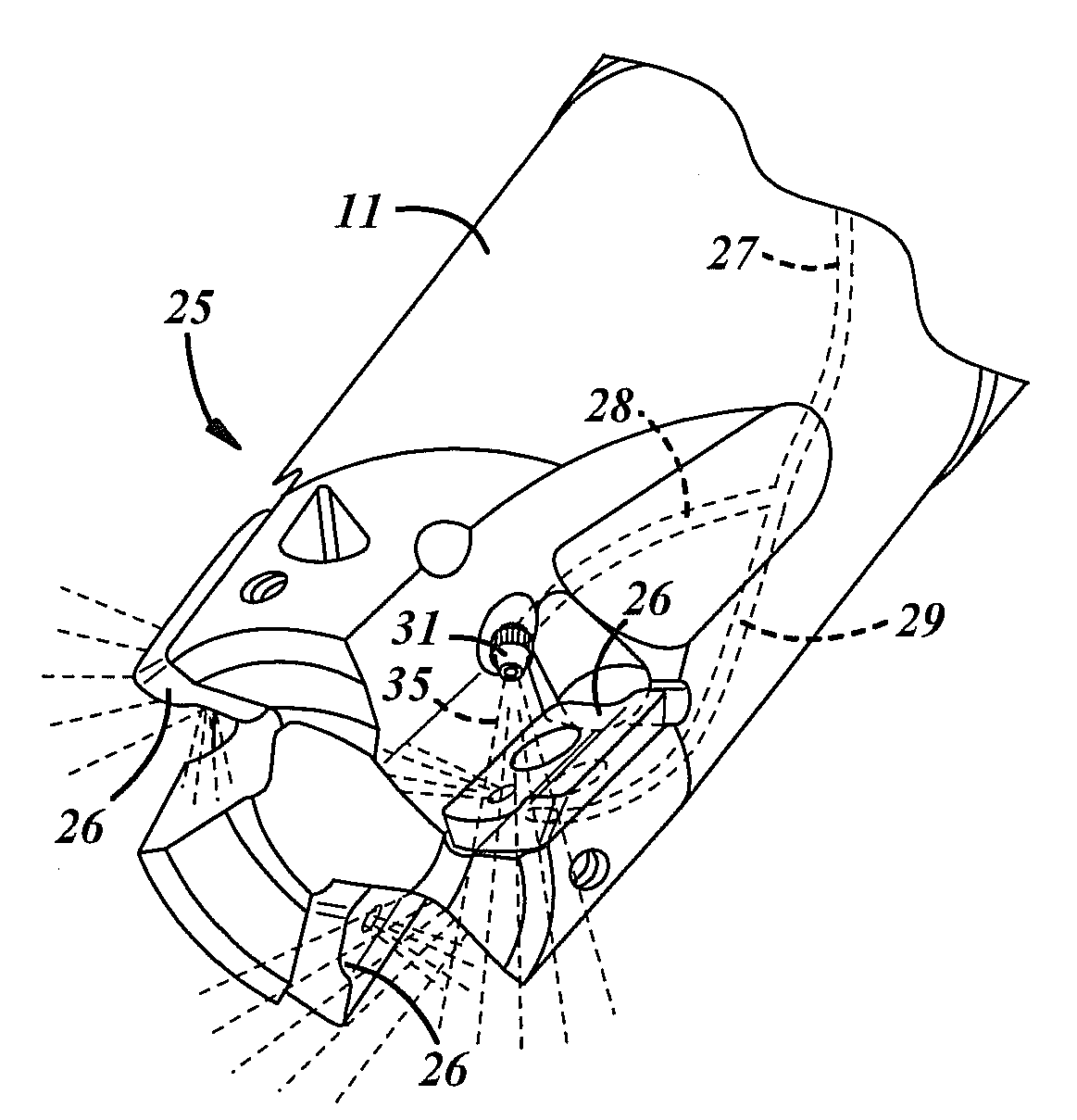

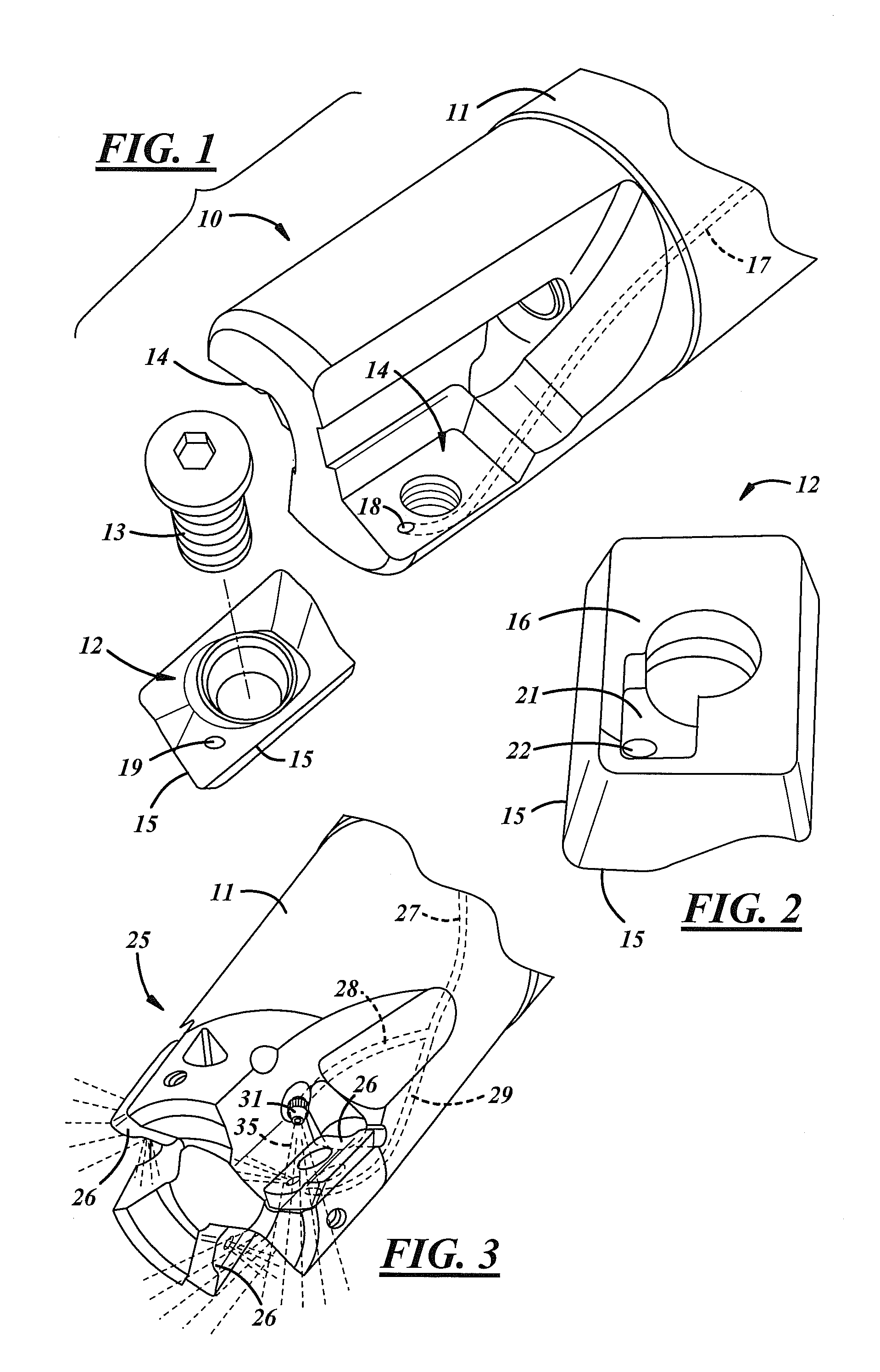

Indirect Cooling of a Rotary Cutting Tool

ActiveUS20100272529A1Dissipate energyMinimization requirementsTransportation and packagingMilling cuttersWorking fluidEngineering

An indirect cooling system for a rotating cutting tool uses a cryogenic coolant that is delivered to a cavity formed on the back surface of the cutting element, providing cooling near the cutting edge of the element. Because the total flow rate of the working fluid is low (less than 0.08 Liters / min / cutting edge), the fluid can be safely vented to atmosphere from the cavity, and as a result, no specialized coolant recovery or ventilation equipment is needed. The cavity may be formed with fins to enhance the heat transfer between the cutting element and the coolant, and coolant may additionally be sprayed directly onto the exterior surface of the element to cool the tool-chip interface. The indirect cooling system may be used for hard to machine metals and composites, as well as the machining of conventional materials without the use of traditional cutting fluids.

Owner:5ME LLC

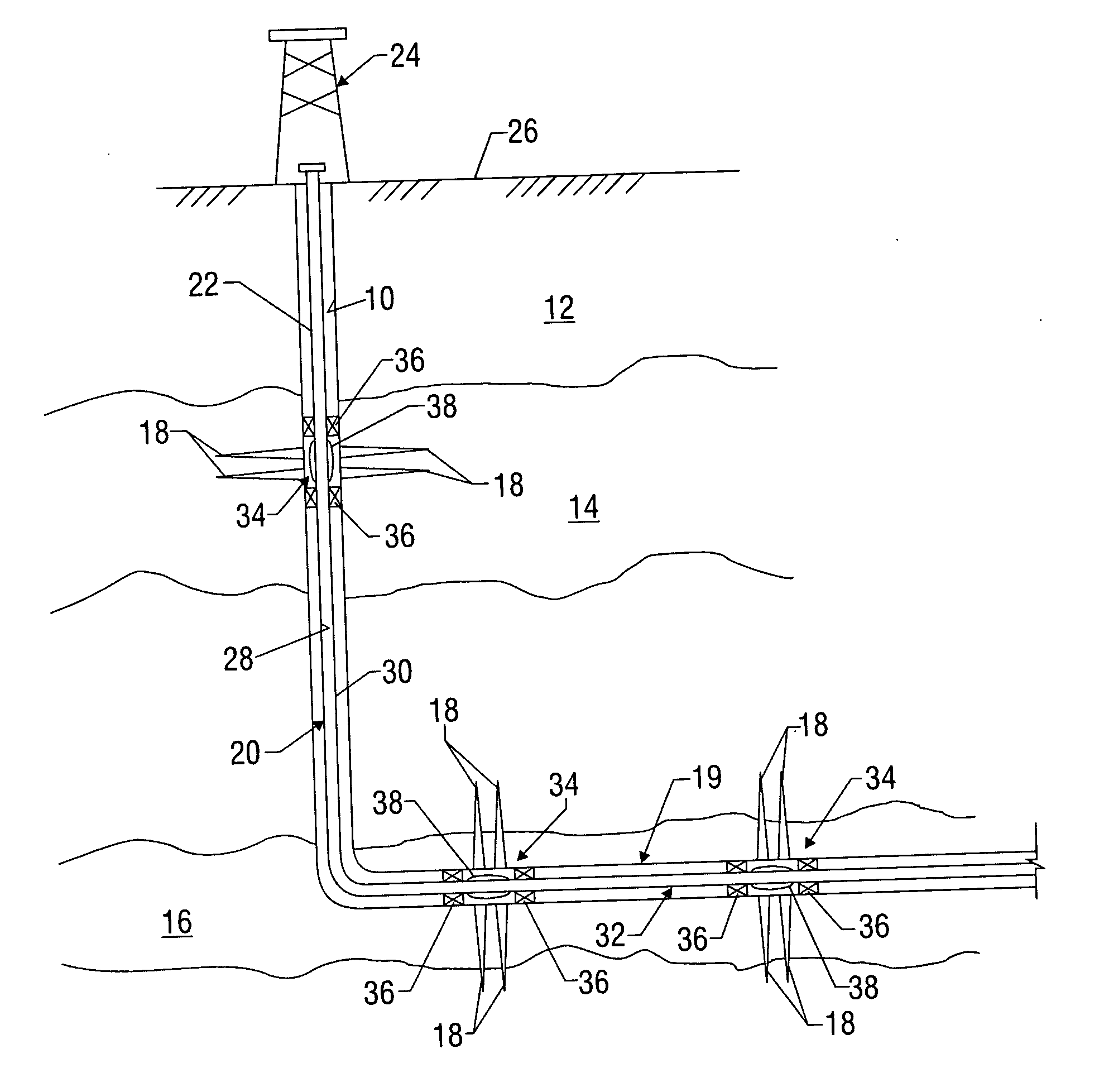

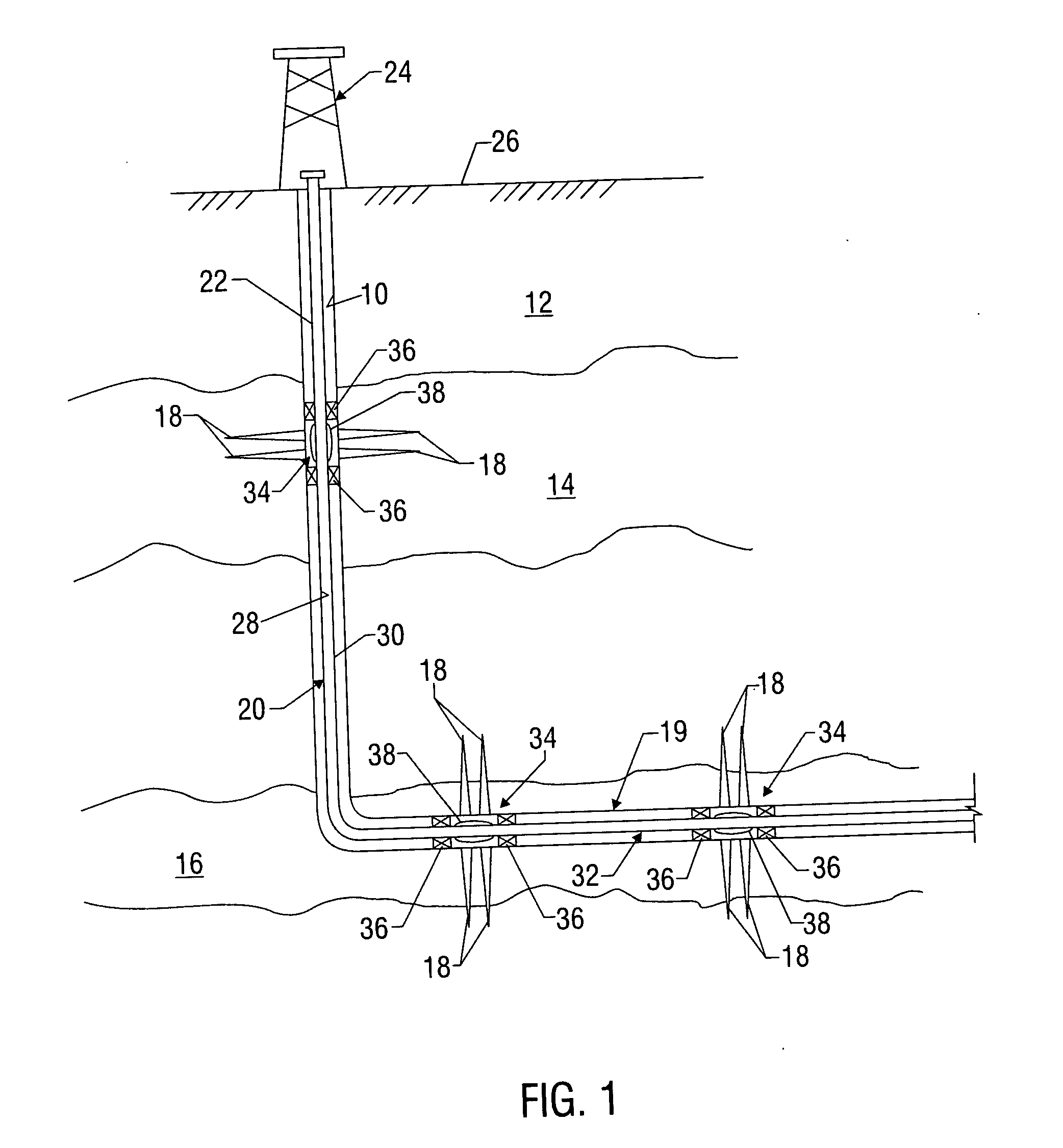

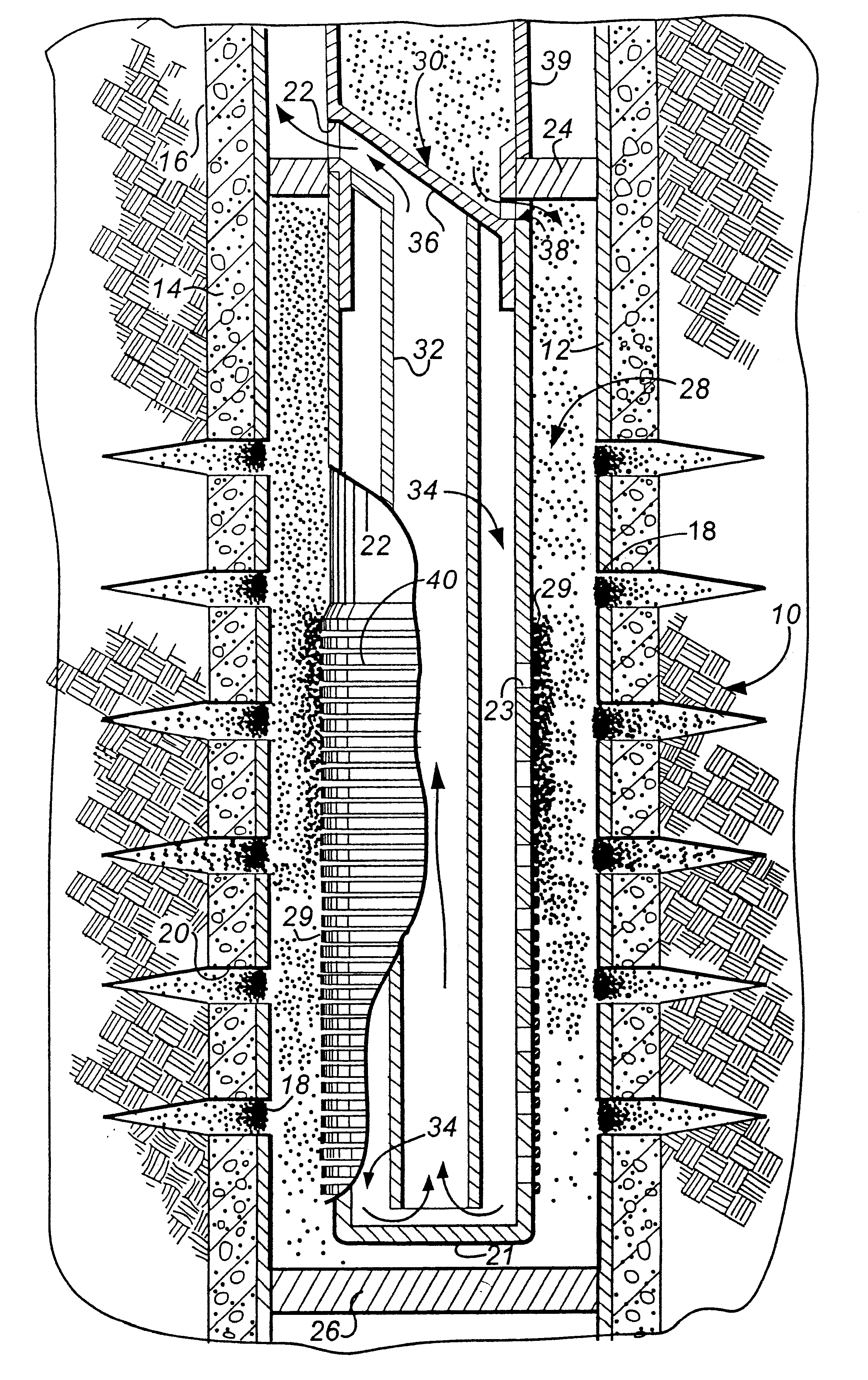

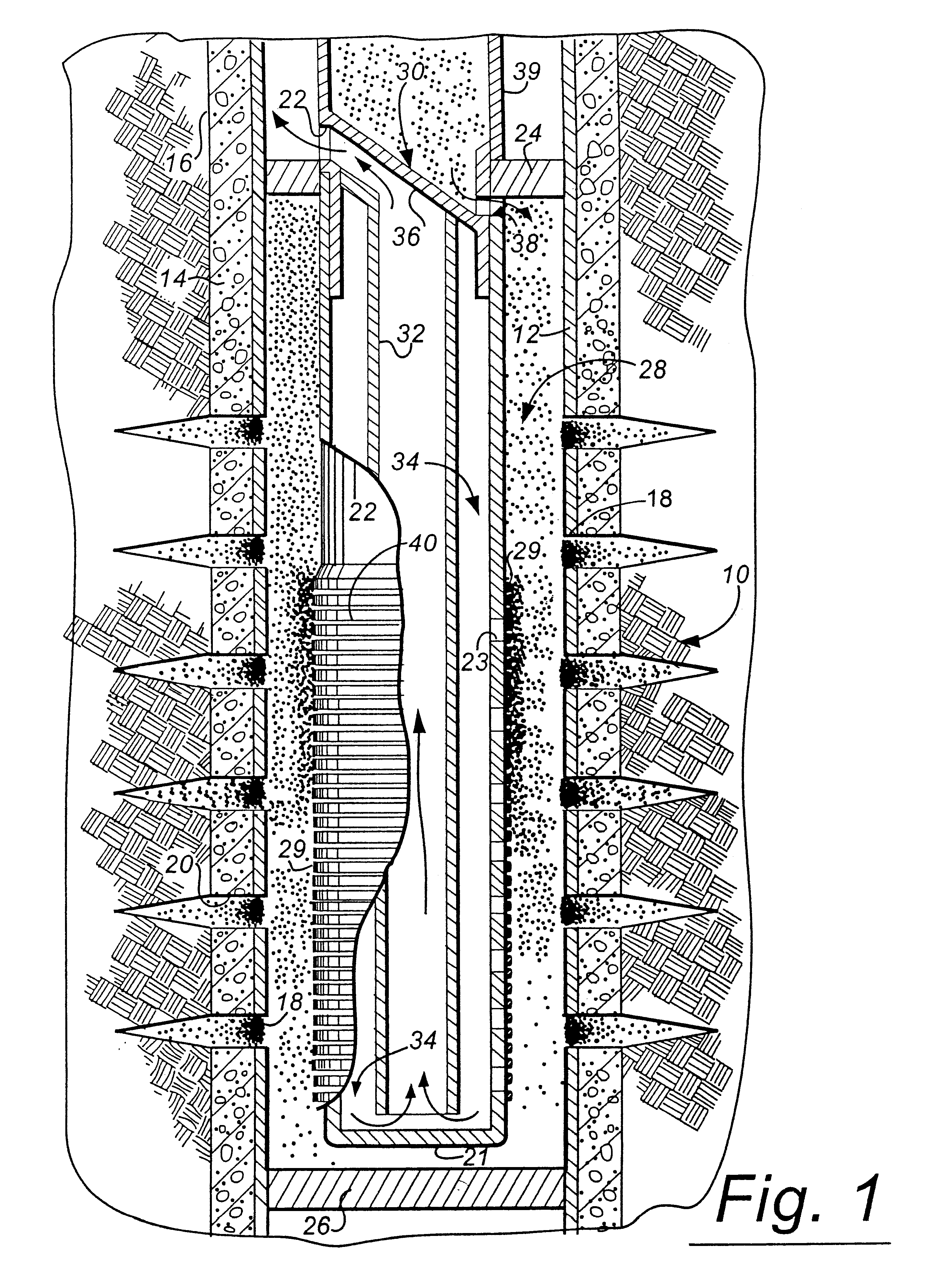

Method of completing a well

InactiveUS6253851B1Reduce flow rateSufficient distanceFluid removalHydraulic fracturingMaterial Perforation

This invention relates to a method of completing a well that penetrates a subterranean formation and more particularly to a method for screen placement during proppant packing of formation perforations or fractures created by hydraulic fracturing techniques. The top of the screen is placed at a sufficient distance below the top of the perforations such that the frac pack pumping rate does not bridge off at the top of the screen when the frac pack is being pumped.

Owner:MARATHON OIL CO

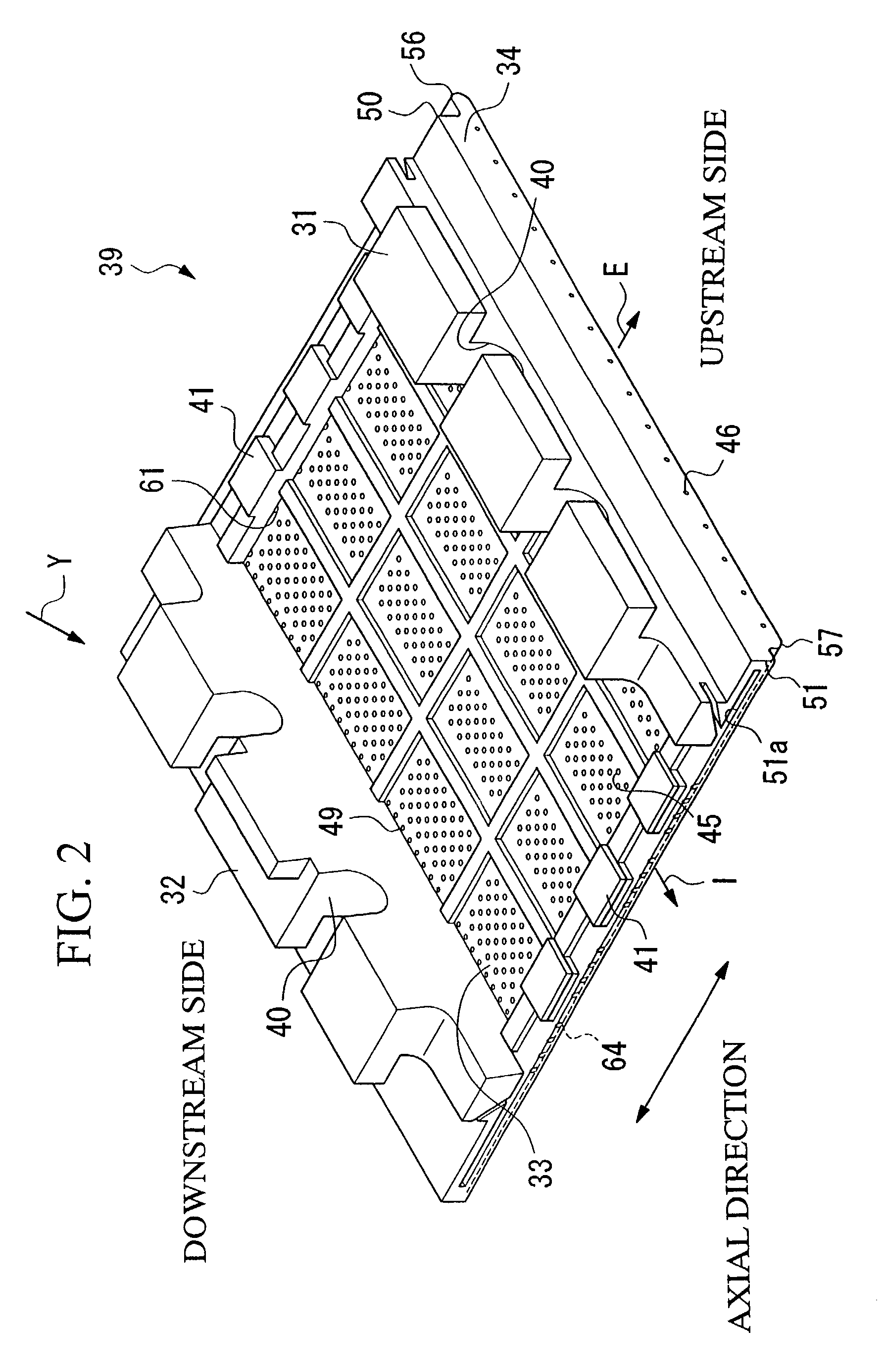

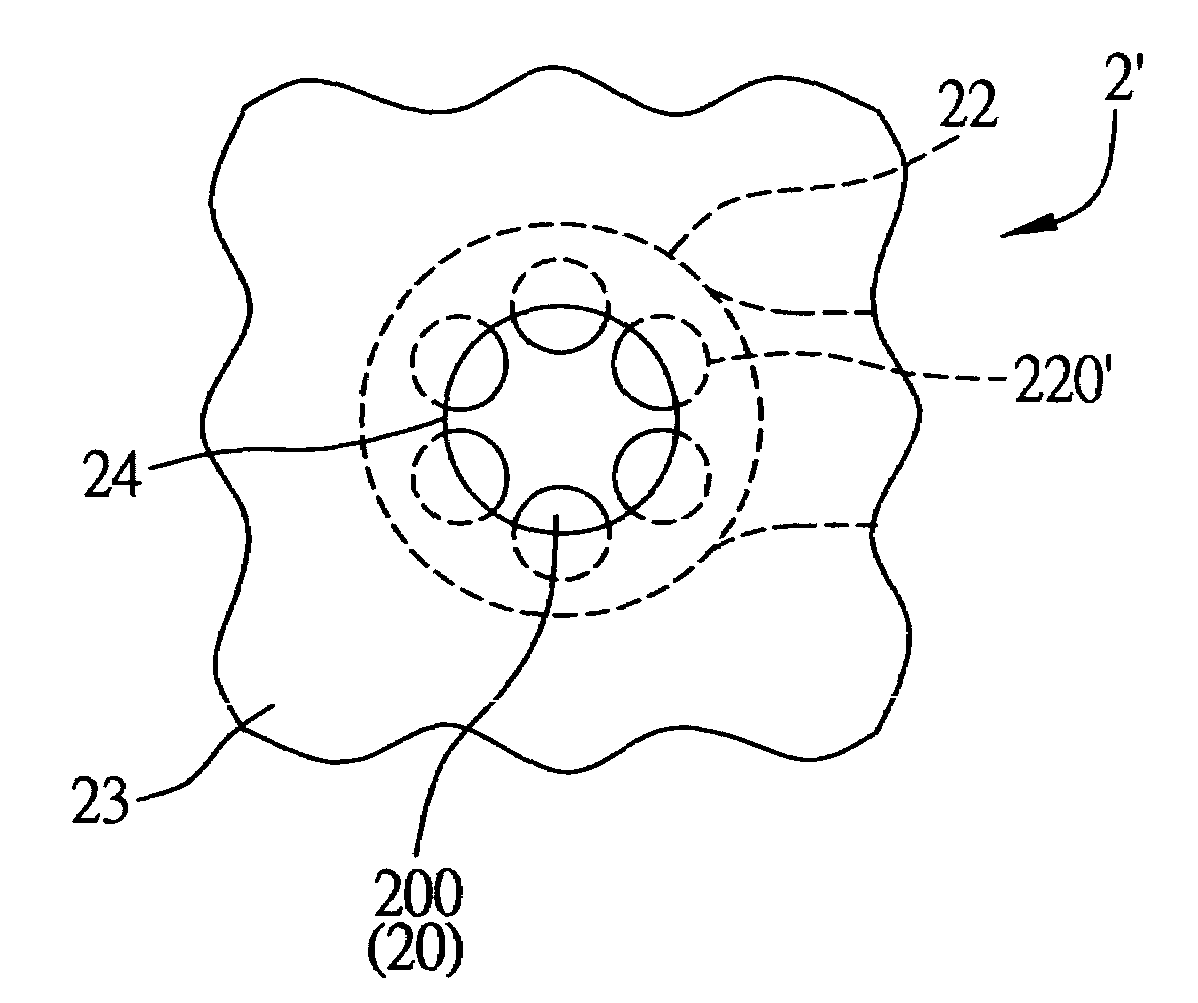

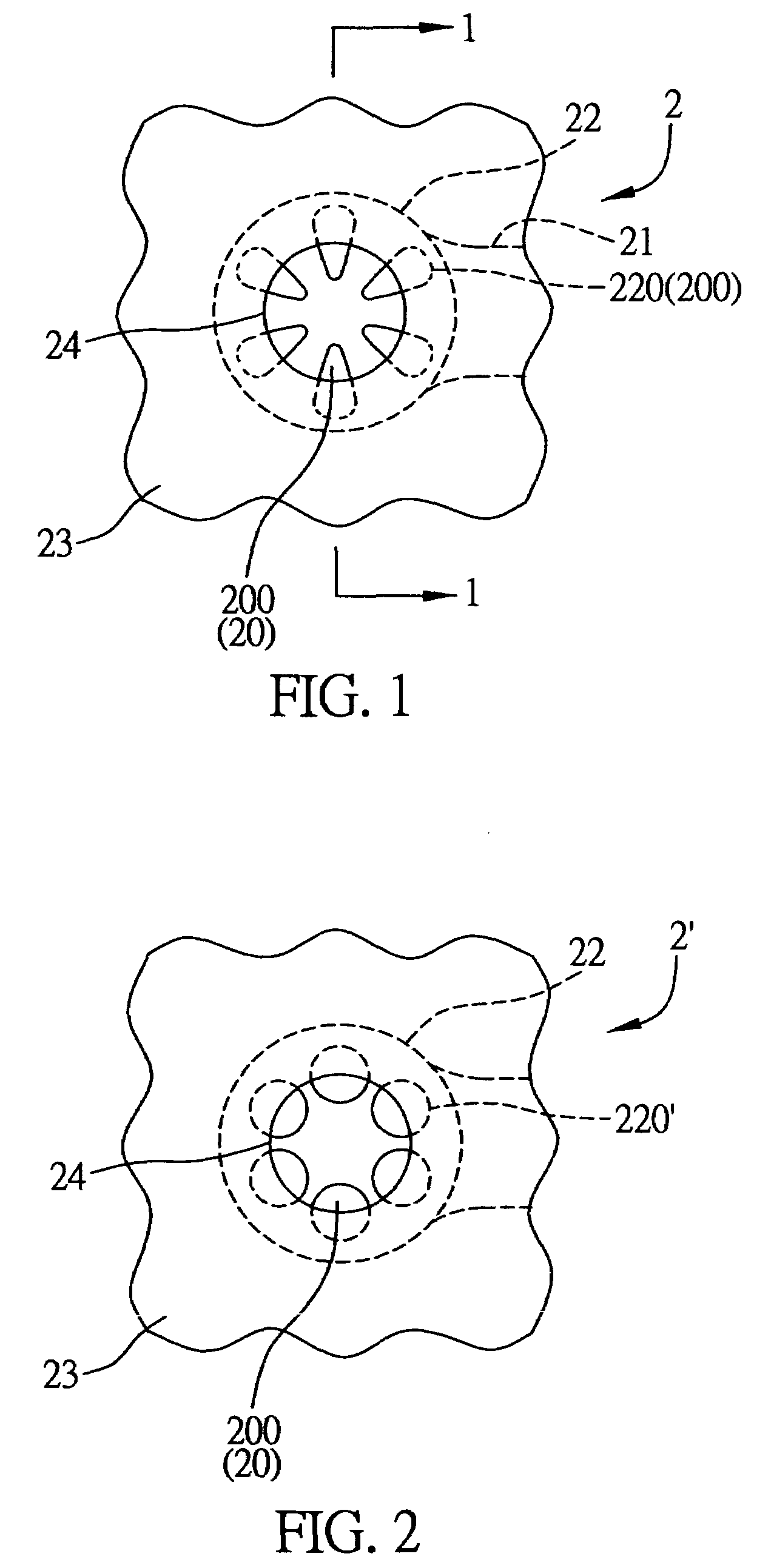

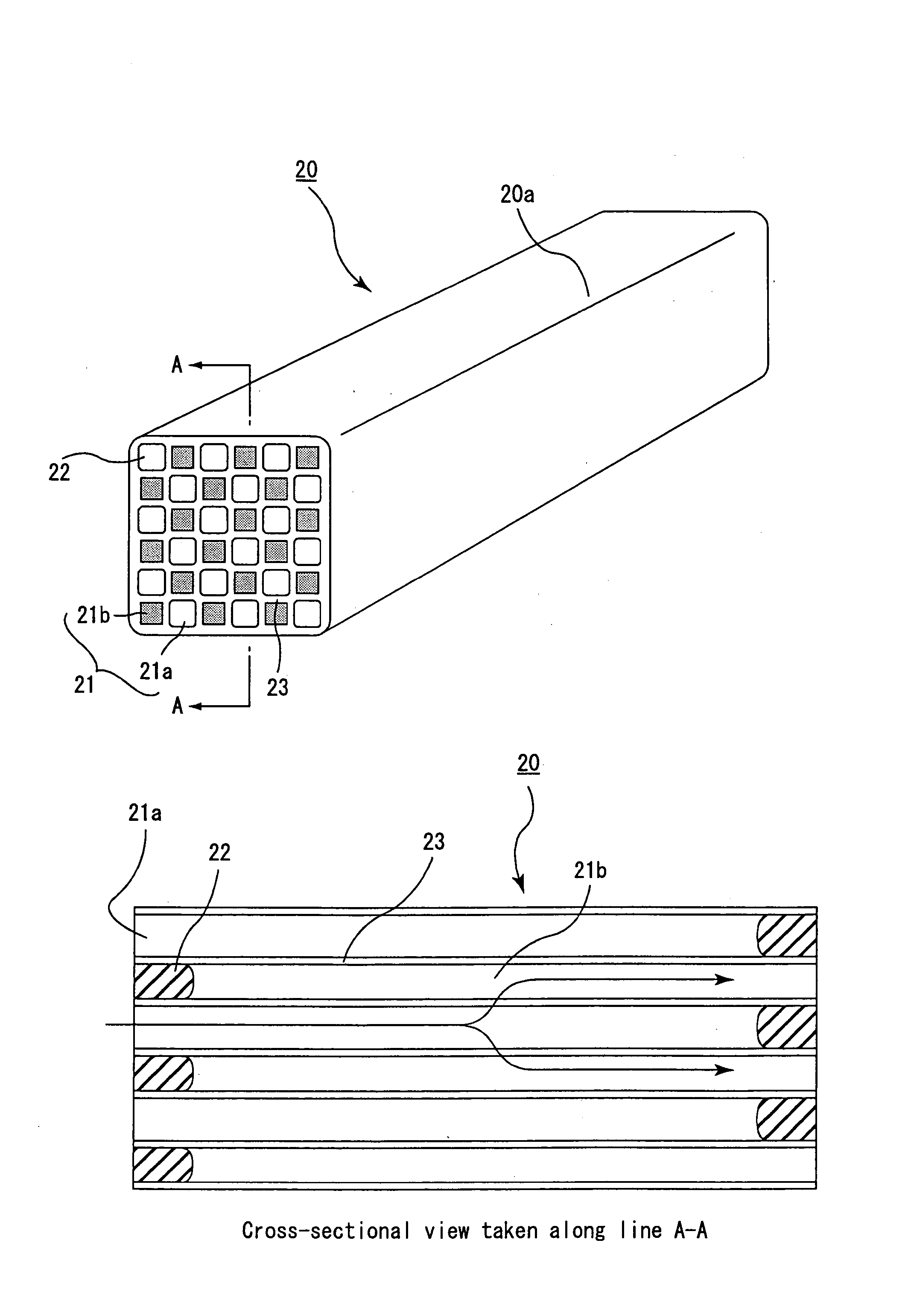

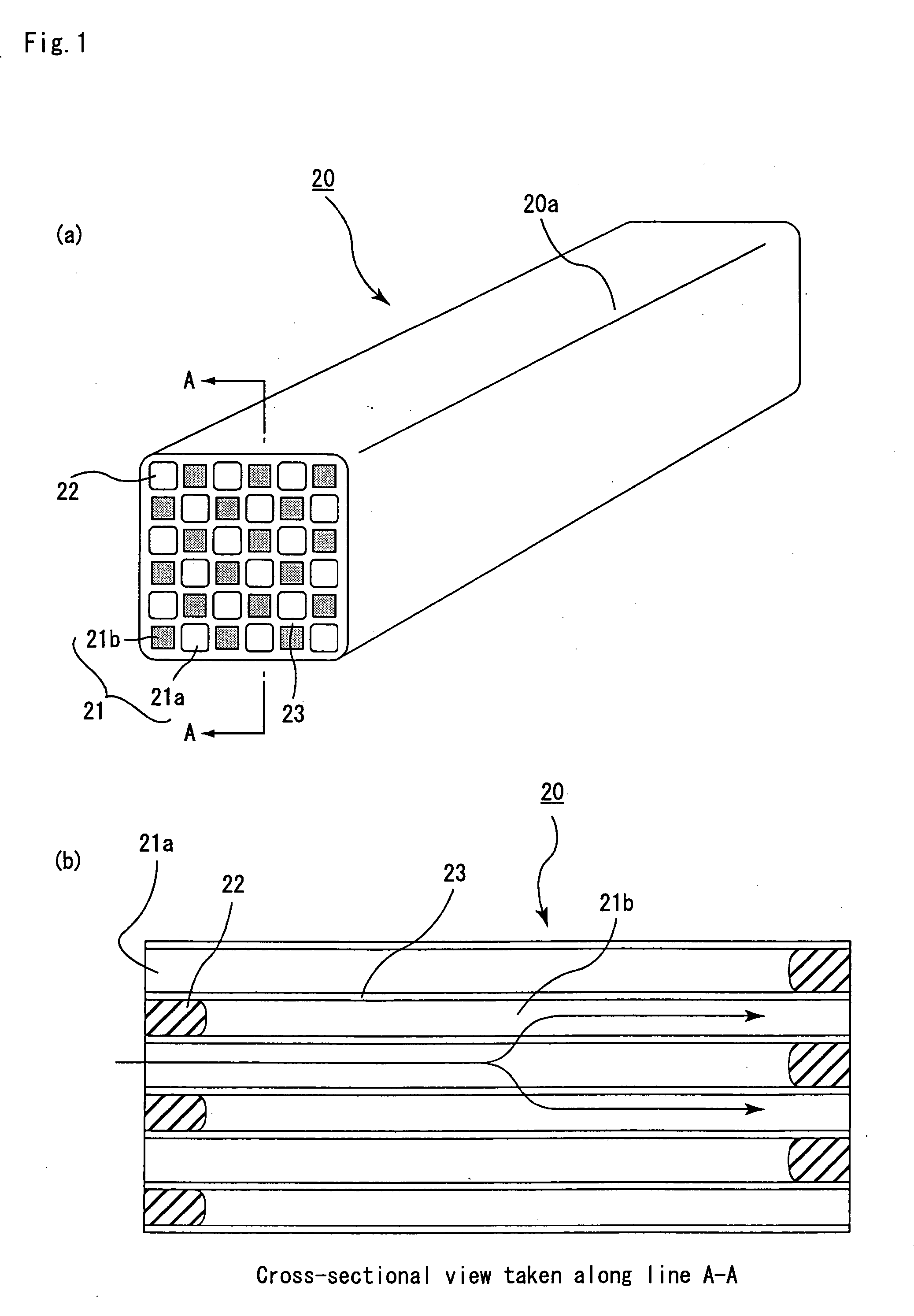

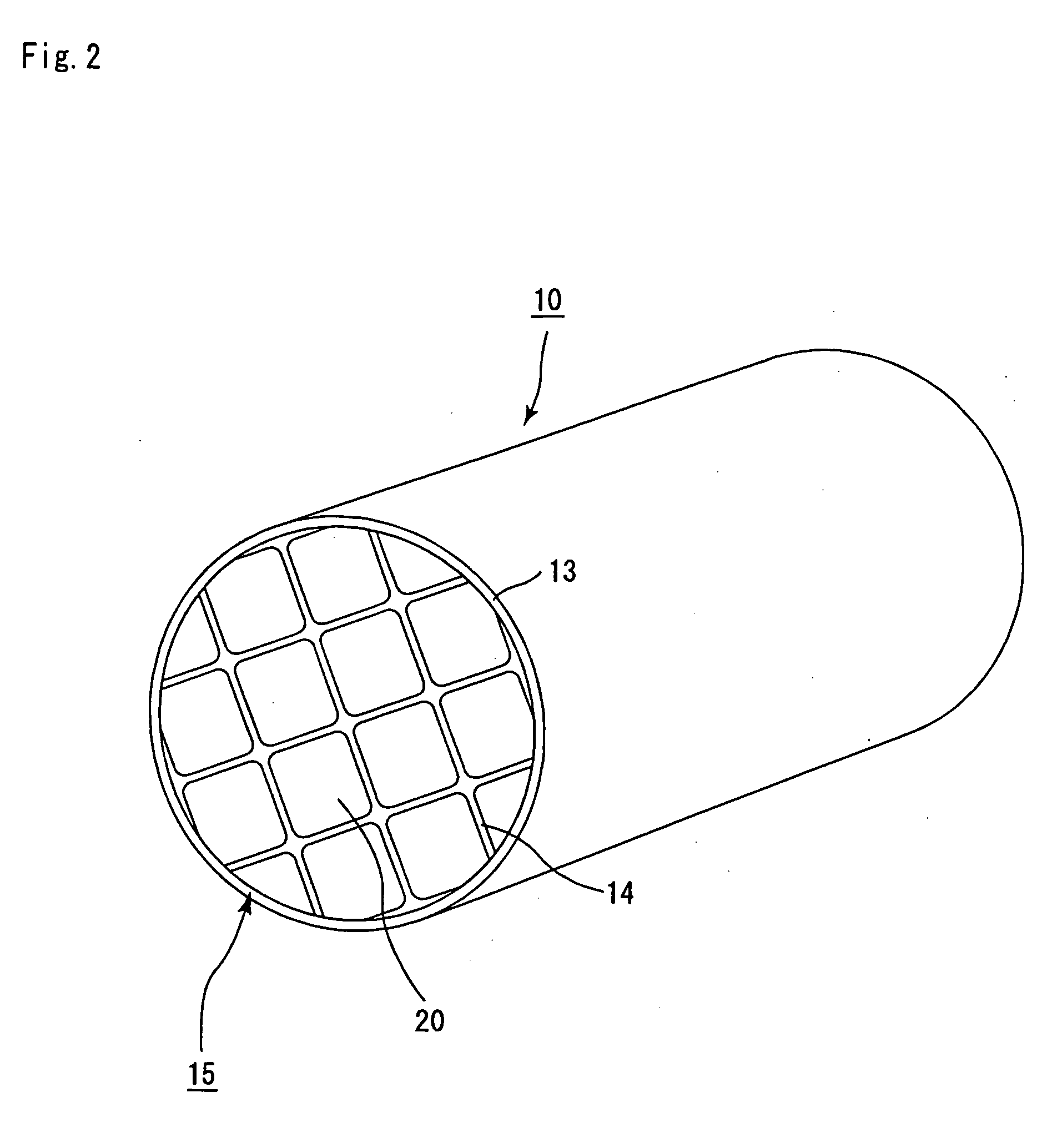

Honeycomb structure

ActiveUS20050016140A1Low pressure lossGood partitionCombination devicesAuxillary pretreatmentParticulatesEngineering

An object of the present invention is to provide a honeycomb structural body (filter) which has a low pressure loss upon collecting particulates, makes it possible to deposit a great amount of particulates and ashes, and is less likely to produce cracks. The columnar honeycomb structural body of the present invention includes a plurality of through holes placed in parallel with one another in the length direction, and wall portion that separates the plurality of through holes from one another and constitutes a circumferential face, wherein the plurality of through holes are composed of a group of large-capacity through holes, with one end thereof being sealed so as to cause the total of areas of cross-section perpendicular to the length direction to become relatively greater, and a group of small-capacity through holes, with the other end thereof being sealed so as to cause the total of areas of the above-mentioned cross-section to become relatively smaller, and the above-mentioned circumferential face of the columnar honeycomb structural body has a chamfered corner portion.

Owner:IBIDEN CO LTD

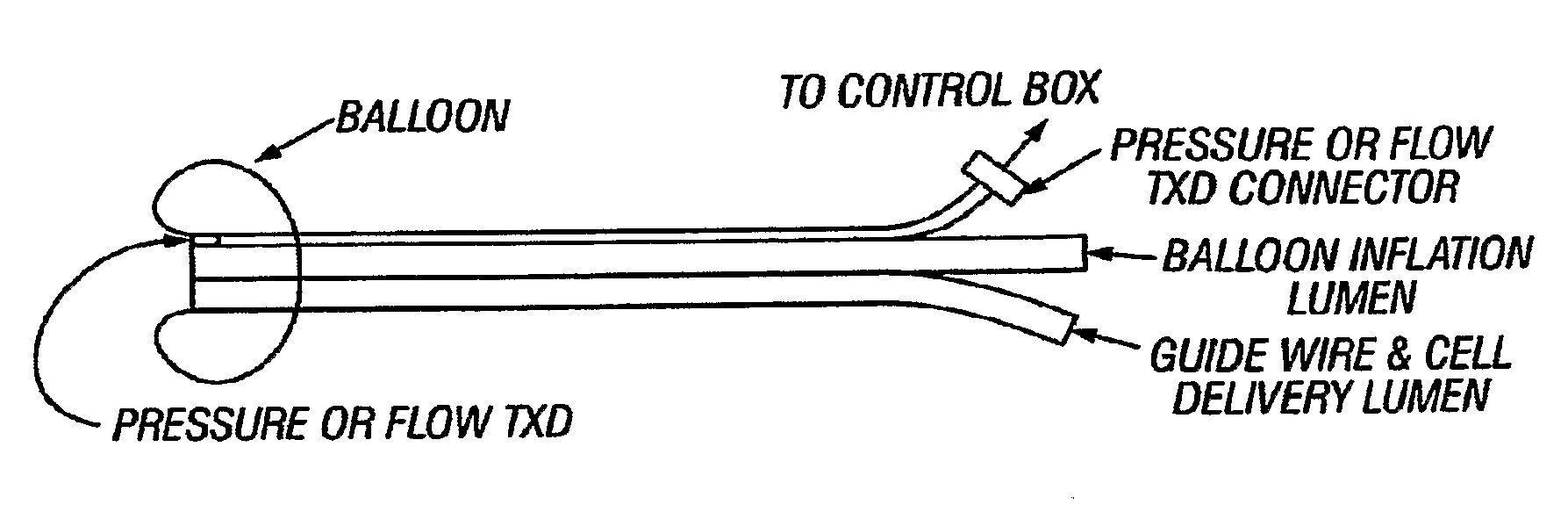

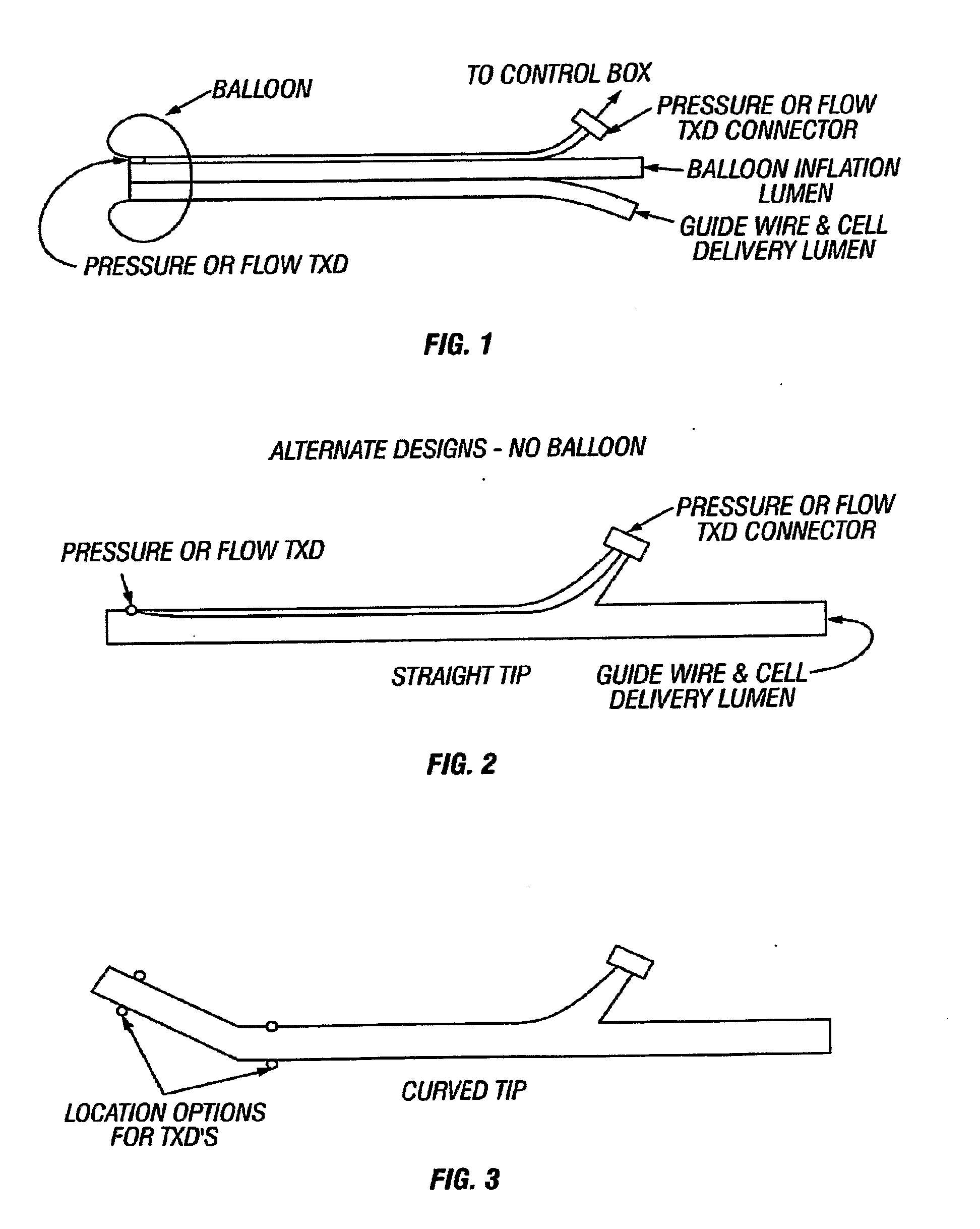

Cell delivery catheters with distal tip high fidelity sensors

InactiveUS20090177183A1Accurately determinedReduce flow rateStentsBalloon catheterTransducerCatheter device

The present invention relates to over the wire cell delivery catheters with high fidelity sensors at their distal end. These catheters are comprised of flow rate sensors and / or pressure transducer sensors. These catheters can also be comprised of occlusion balloons. The catheters of the present invention allow for administration of the highest and safest dose of therapeutic agents, e.g., adipose derived regenerative cells, on an individualized basis.

Owner:LOREM VASCULAR PTE LTD

Downhole filter

InactiveUS7188687B2Without complexityWithout expenseDrilling rodsConstructionsParticulatesEngineering

A downhole filter comprises a tubular member having a wall defining a plurality of openings. The openings have an outer width less than an inner width. The parts of the opening defining the smaller width are defined by radially outer parts of the openings, such that particulates or sand prevented from passing through the openings will tend to be retained to the outside of the tubular member. A method comprises providing a tubular string having a non-porous tubular portion and a porous tubular portion, and installing the tubular string within a wellbore such that the porous tubular portion is located adjacent a fluid-producing formation within the wellbore. In another embodiment, an apparatus comprises a drill string comprising a non-porous tubular portion and a porous tubular portion, and an earth removal member operatively connected to a lower end of the drill string.

Owner:WEATHERFORD TECH HLDG LLC

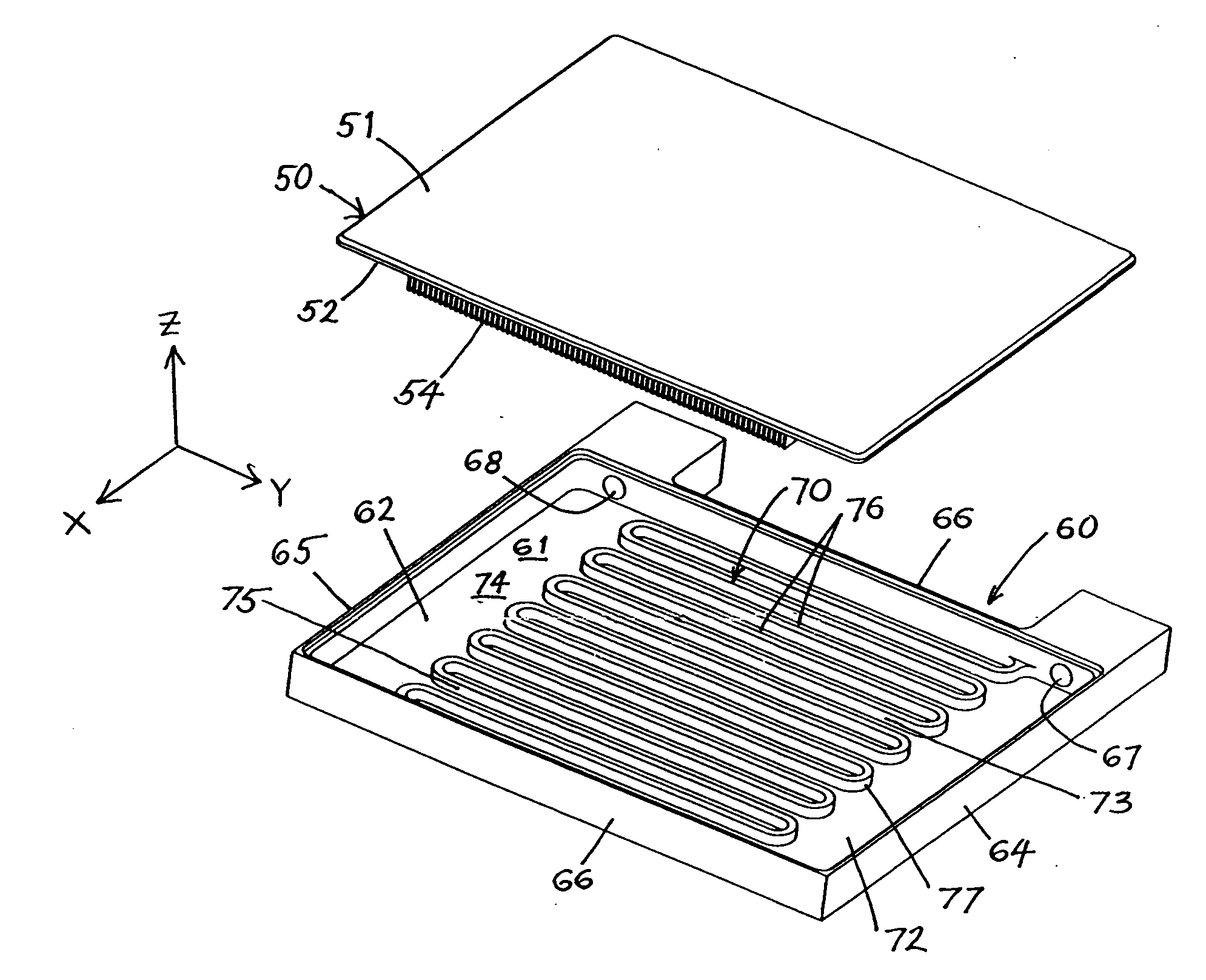

Liquid cold plate heat exchanger

InactiveUS20060096738A1Net flow rateReduce the average velocitySemiconductor/solid-state device detailsSolid-state devicesHeat transmissionCooling chamber

A heat exchanger includes a cooling plate having a heat collection surface for fixing against an object to be cooled, an opposed heat transfer surface which may be provided with fins, and a cooling chamber over the heat transfer surface, the cooling chamber having an inlet port and an outlet port for circulating a fluid through the cooling chamber via a flow path between the ports. A flow distributor in the flow path forms a plurality of inlet channels communicating with the inlet port, a plurality of outlet channels alternating with the inlet channels and communicating with the outlet port, and a plurality of flow surfaces which are spaced from the heat transfer surface by gaps. The inlet channels communicate with the gaps so that a fluid entering the inlet channels via the inlet port will flow through the gaps, into the outlet channels, and out of the chamber via the outlet port. The gaps are dimensioned to increase fluid velocity and promote mixing of the fluid, thereby improving heat transfer.

Owner:AAVID THERMALLOY LLV

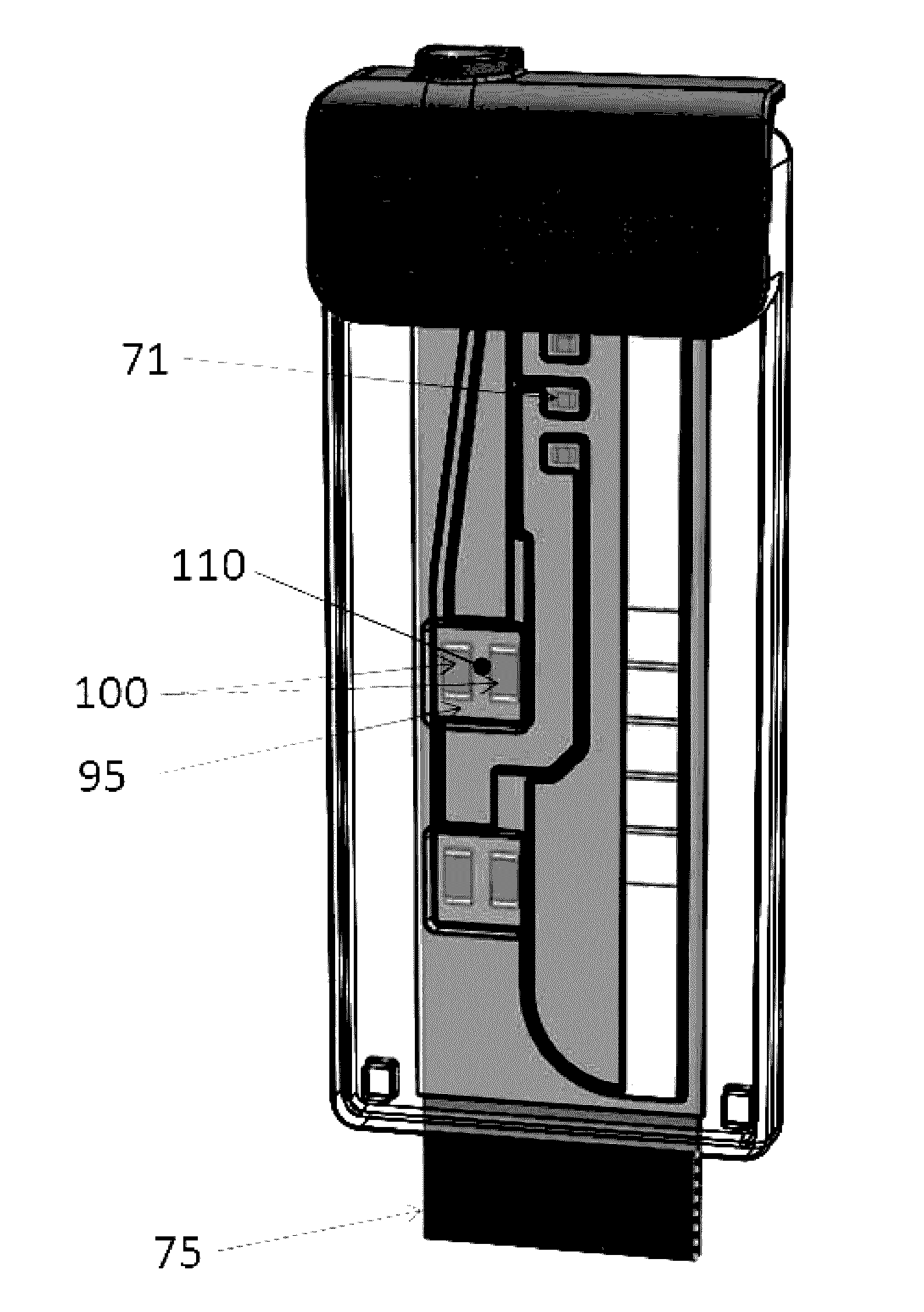

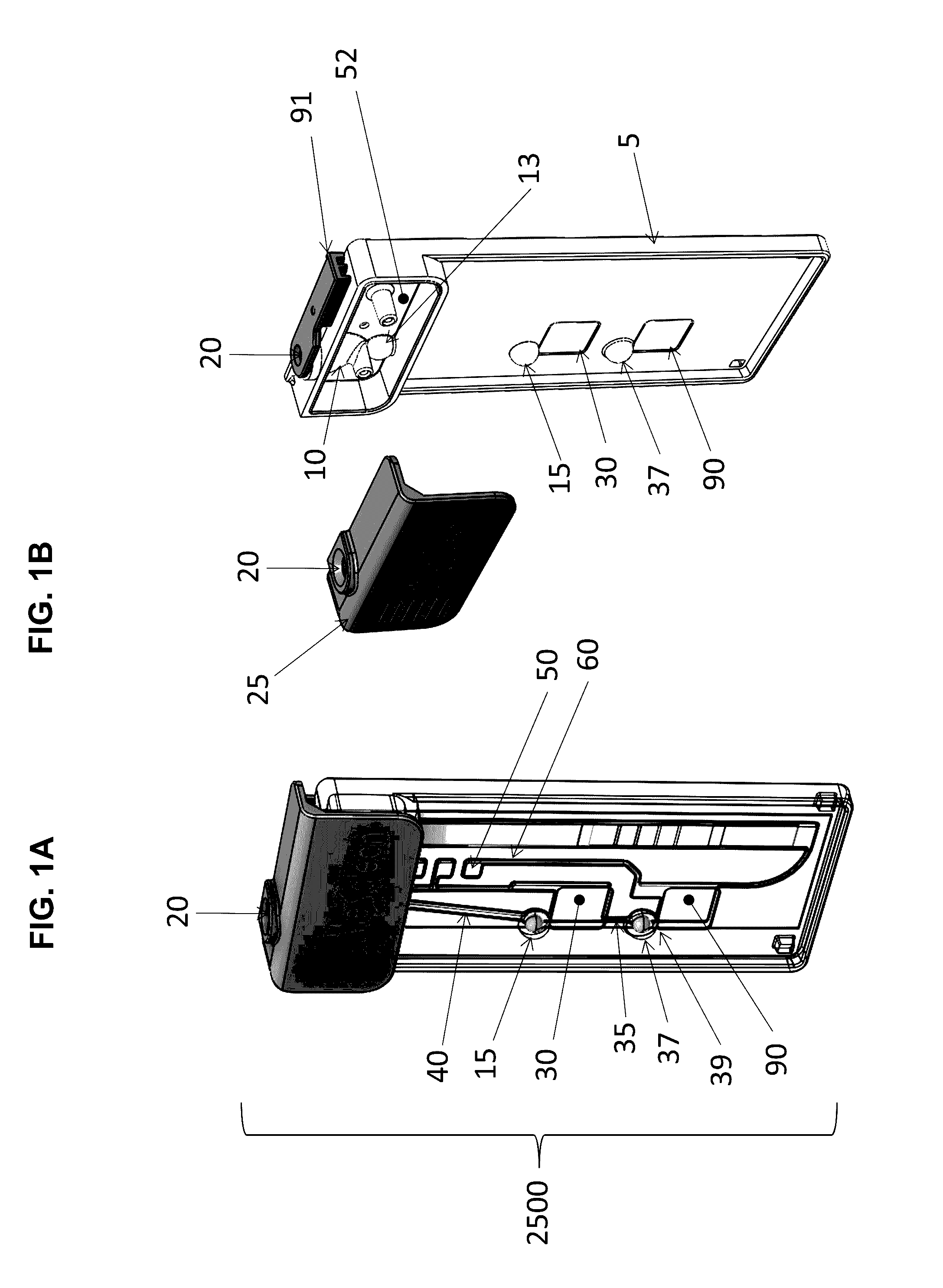

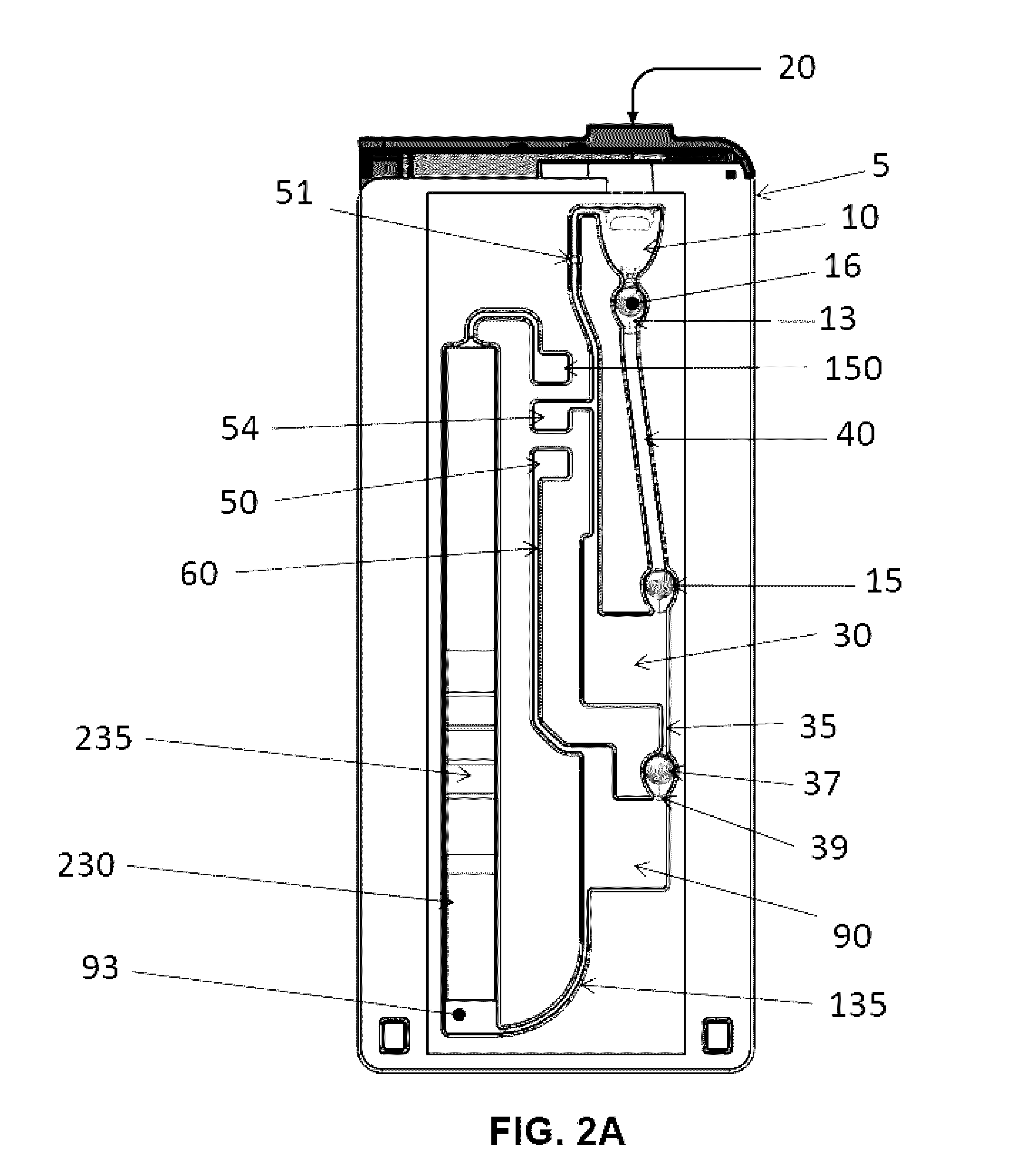

Fluidic Test Cassette

InactiveUS20160310948A1Facilitate resuspensionImproved mixing and dispersionHeating or cooling apparatusMicrobiological testing/measurementPath lengthFlexible circuits

A disposable cassette for detecting nucleic acids or performing other assays. The cassette can be inserted into a base station during use. The cassette has numerous features to ensure correct operation of the device under gravity, such as vent pockets for enabling the flow of sample fluid from one chamber to the next when the vent pocket is unsealed. The vent pockets have protrusions to help prevent accidental resealing. The cassette also can have a gasket to ensure free air movement between open vent pockets. A flexible circuit with patterned metallic electrical components disposed on a heat stable material can be in direct contact with fluid in the chambers and has resistive heating elements aligned with the vent pockets and the chambers. The detection chamber, which houses a lateral flow detection strip can have a space below the strip that has sufficient capacity to accommodate an entire volume of the sample fluid entering the detection chamber at a height that enables the fluid to flow up the detection strip by capillary action without flooding or otherwise bypassing regions of the detection strip. The space can also contain detection particles. Recesses in in the cassette channels or chambers can have structures such as ridges or grooves to direct fluid flow to enhance rehydration of lyophilized reagents disposed in the recess. Flow diverters in the chambers can reduce the flow velocity of the sample fluid and increase the effective fluid flow path length, enabling more accurate control of fluid flow in the cassette.

Owner:MESA BIOTECH

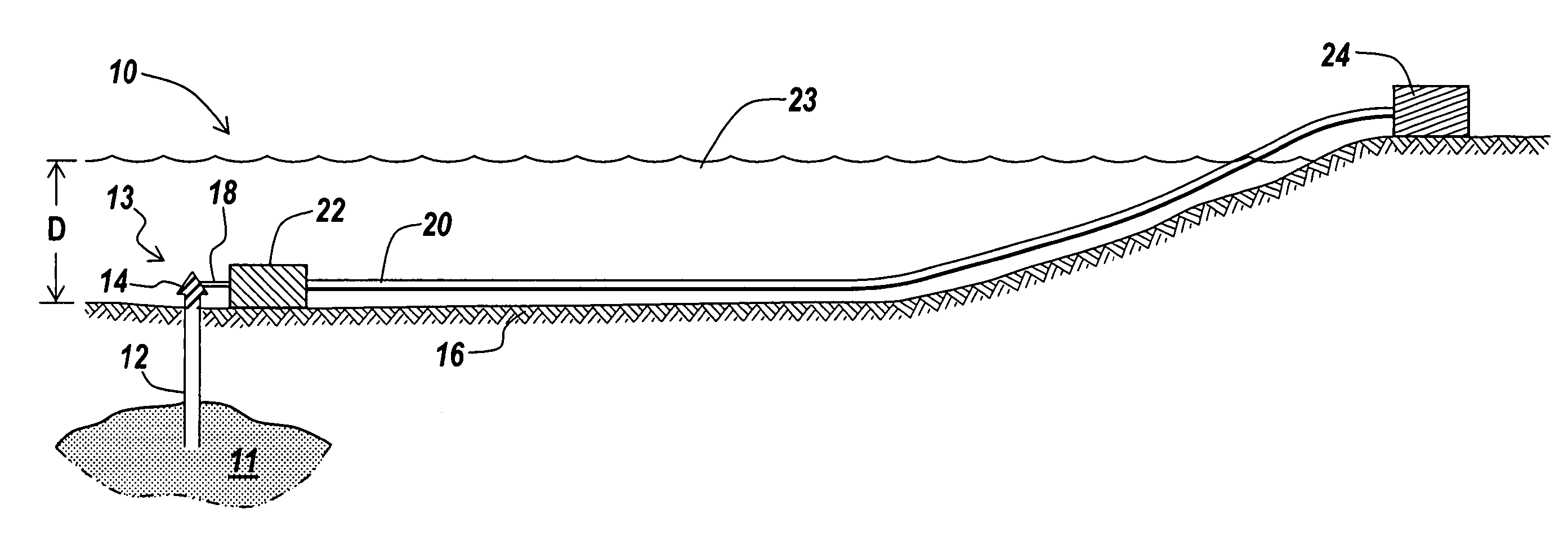

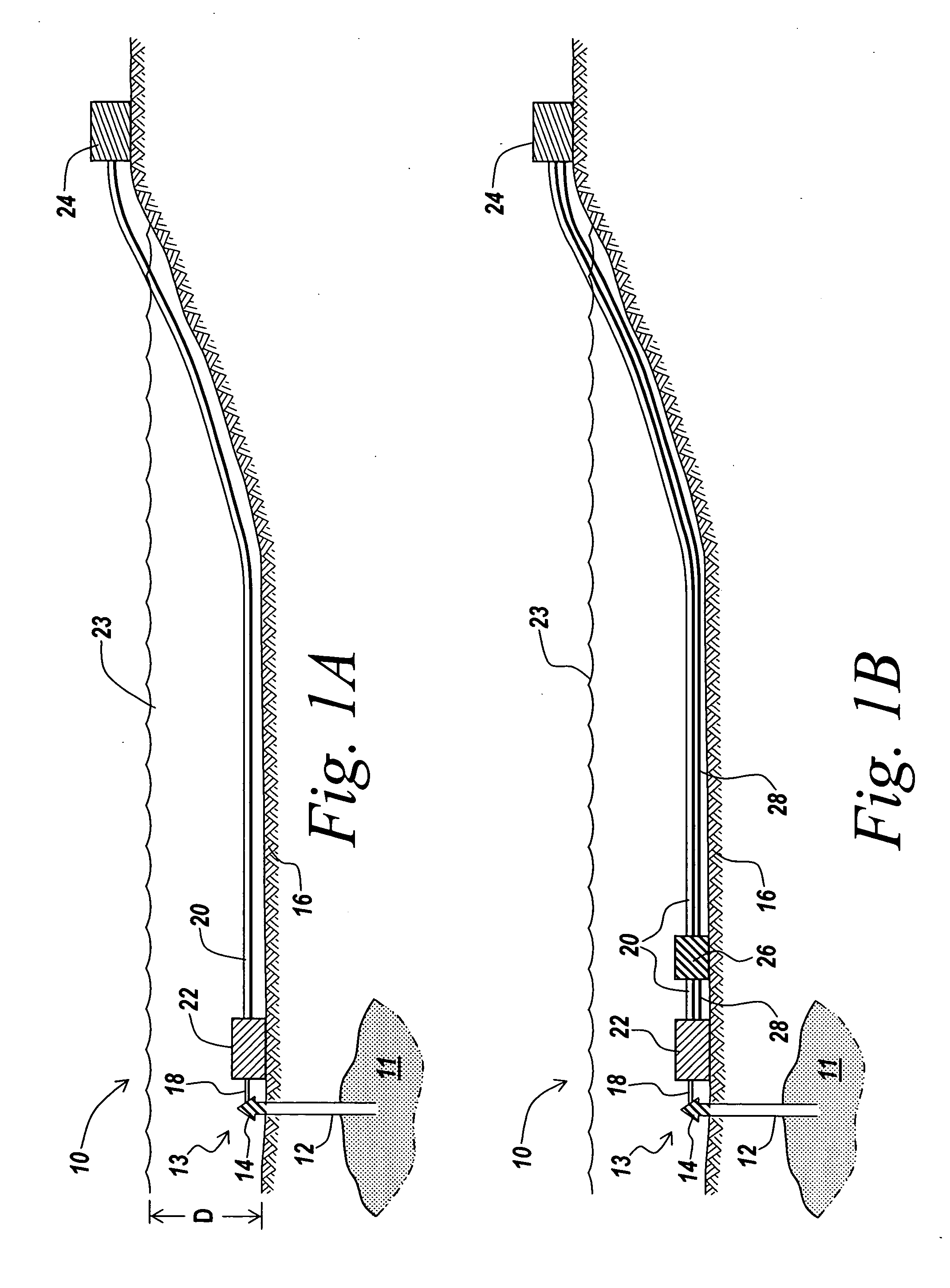

Undersea well product transport

InactiveUS20060175062A1Reduce and eliminate needEliminate and minimizeDrilling rodsInsulationHydrocotyle bowlesioidesShore

An apparatus and corresponding method of use extracts, cools, and transports effluents from subterranean, sub-sea oil formations to distant shore based processing facilities. The effluents, mostly crude oil, are conveyed rapidly to a cold flow generator near the oil wellhead on the sea bottom using the cold seawater to chill the effluents to a dispersed mixture including generated solids. The mixture is transported close to sea bottom temperatures, slowly, with small pressure drops, in low-cost submerged bare pipes over long distances to on or near shore processing facilities that can produce useful hydrocarbon products more cost effectively than at sea processing facilities. The apparatus eliminates or minimizes the need for heated or insulated pipe, the need for large floating processing structures, the need for sub-sea processing equipment, and / or the need for chemical additions to production flow.

Owner:BENSON ROBERT A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com