Patents

Literature

140results about How to "Reduce gas flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

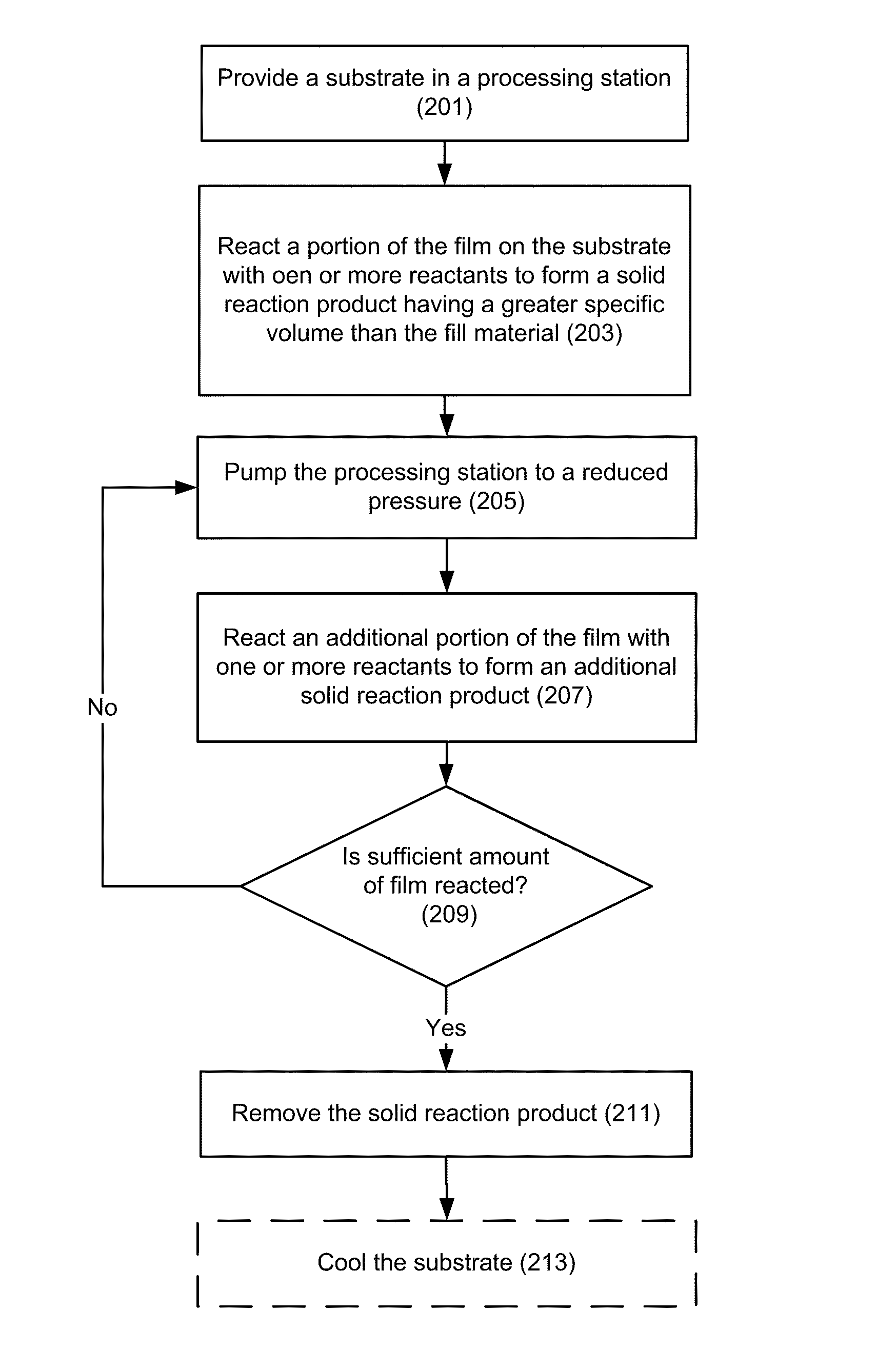

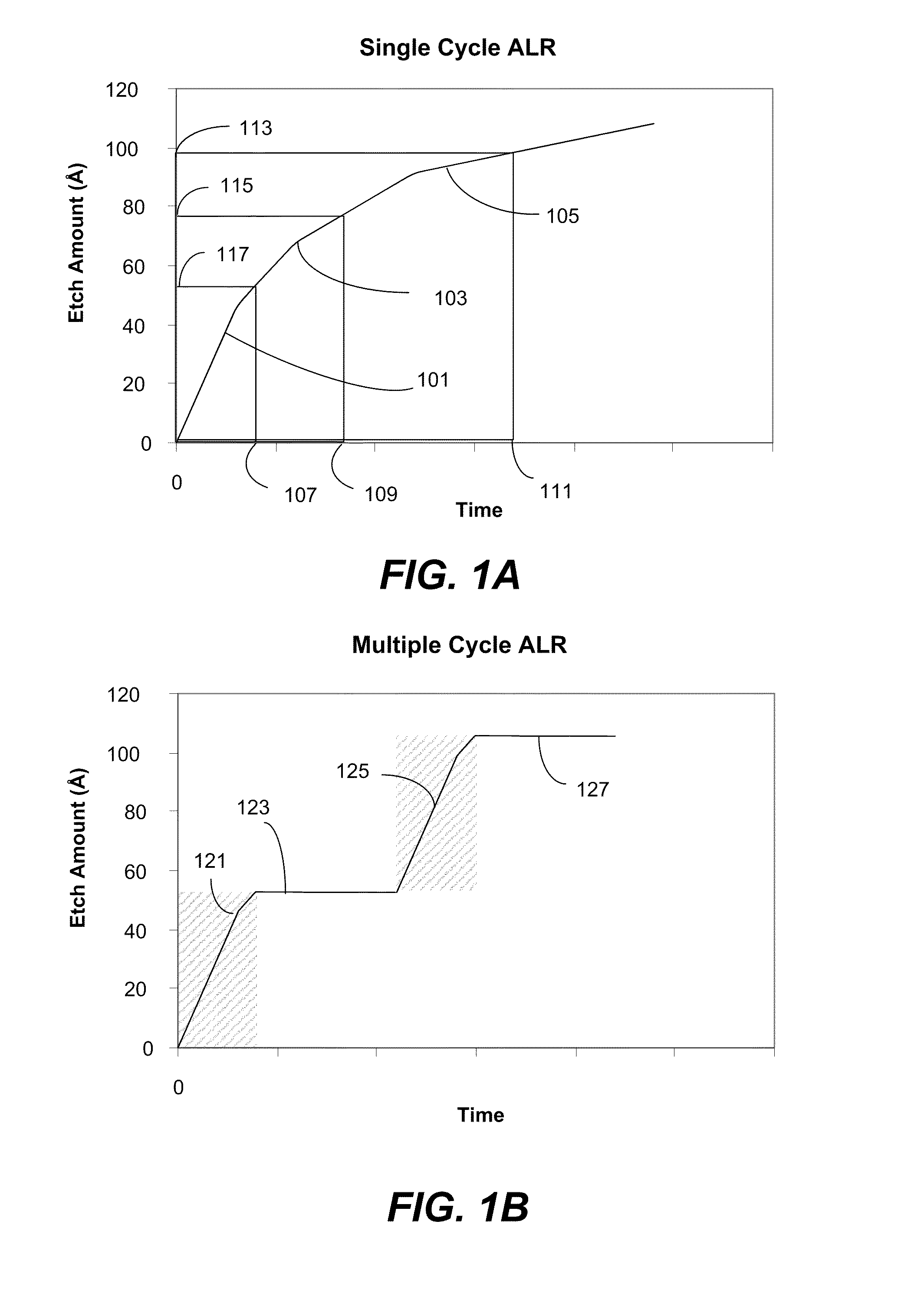

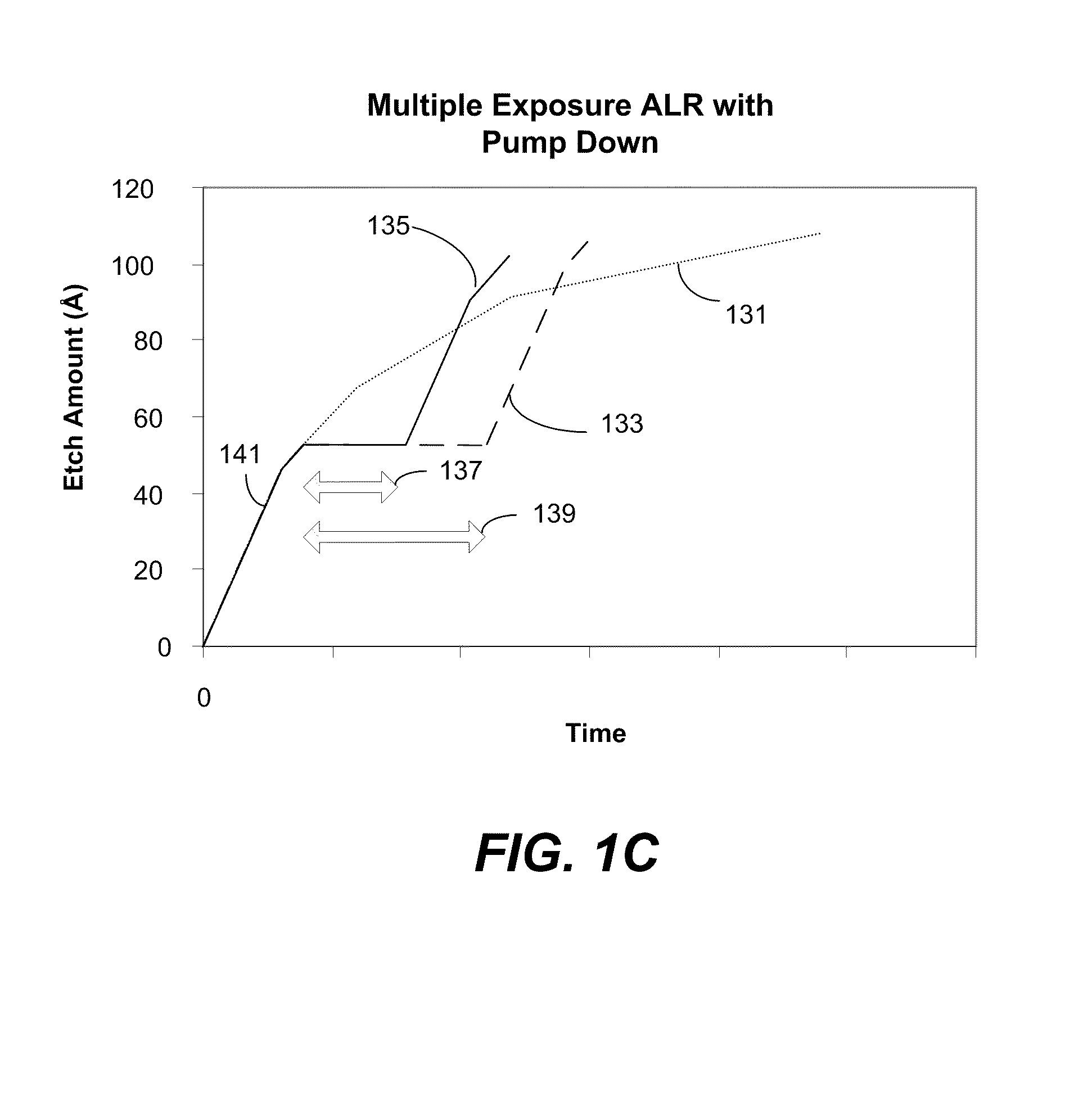

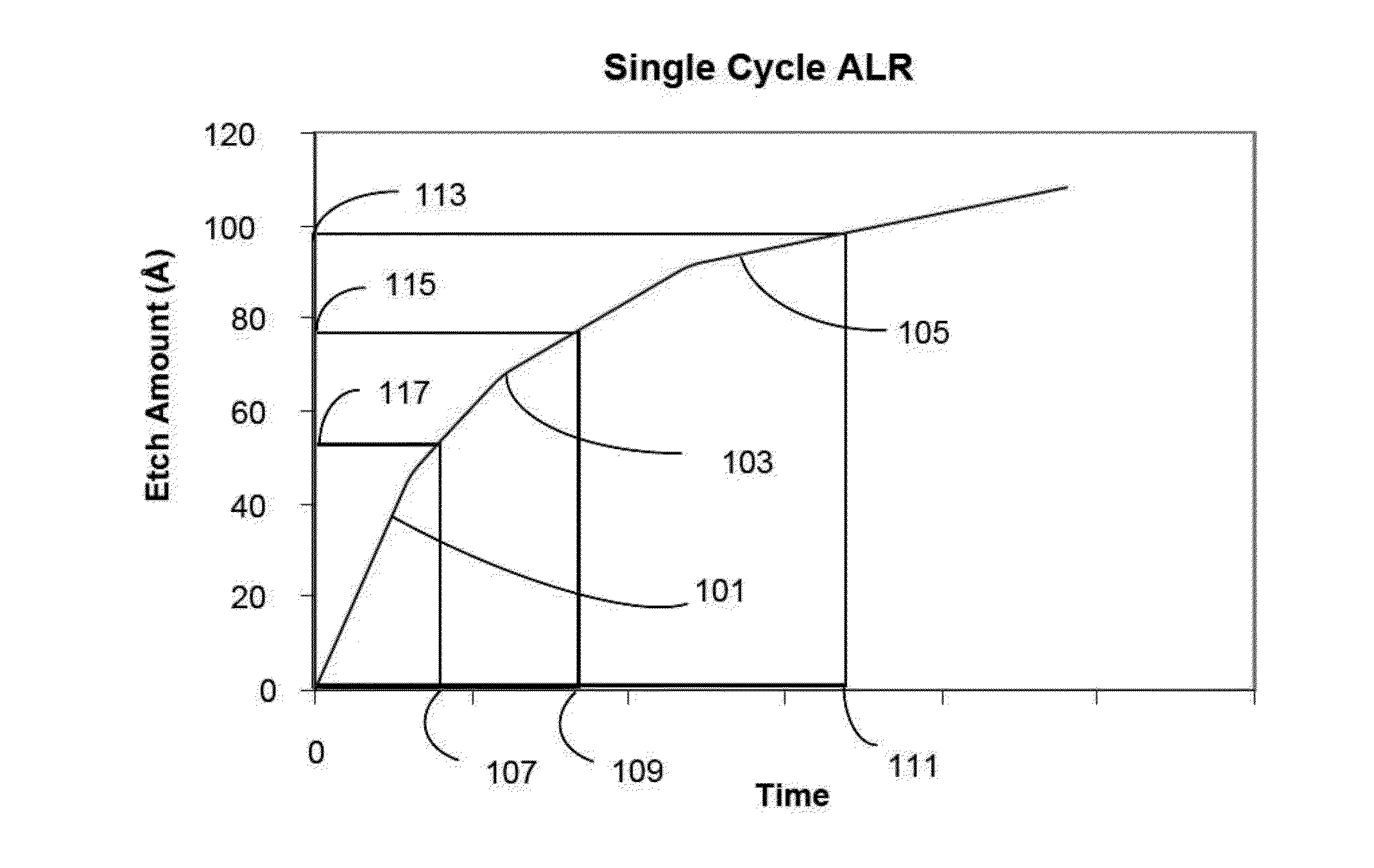

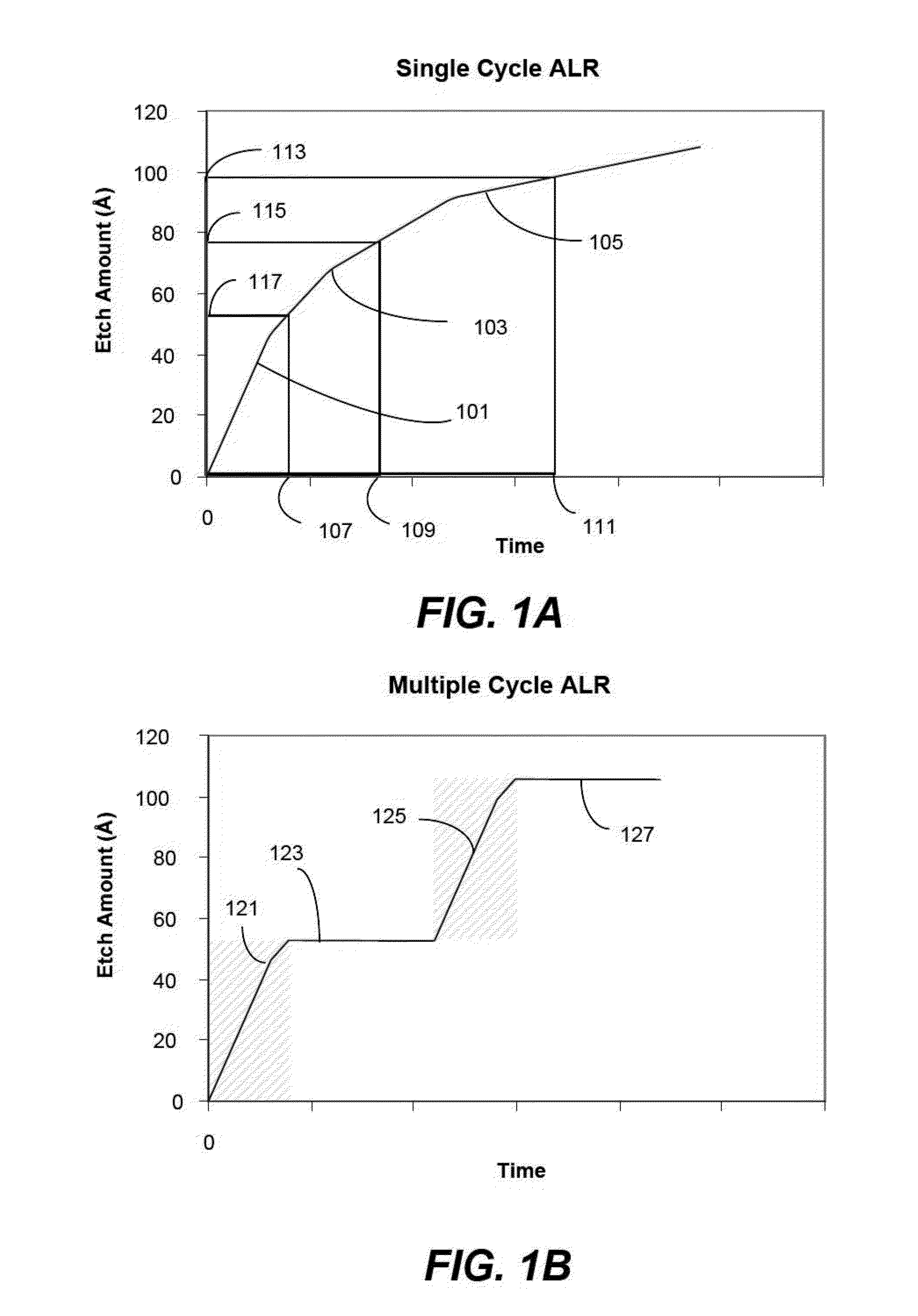

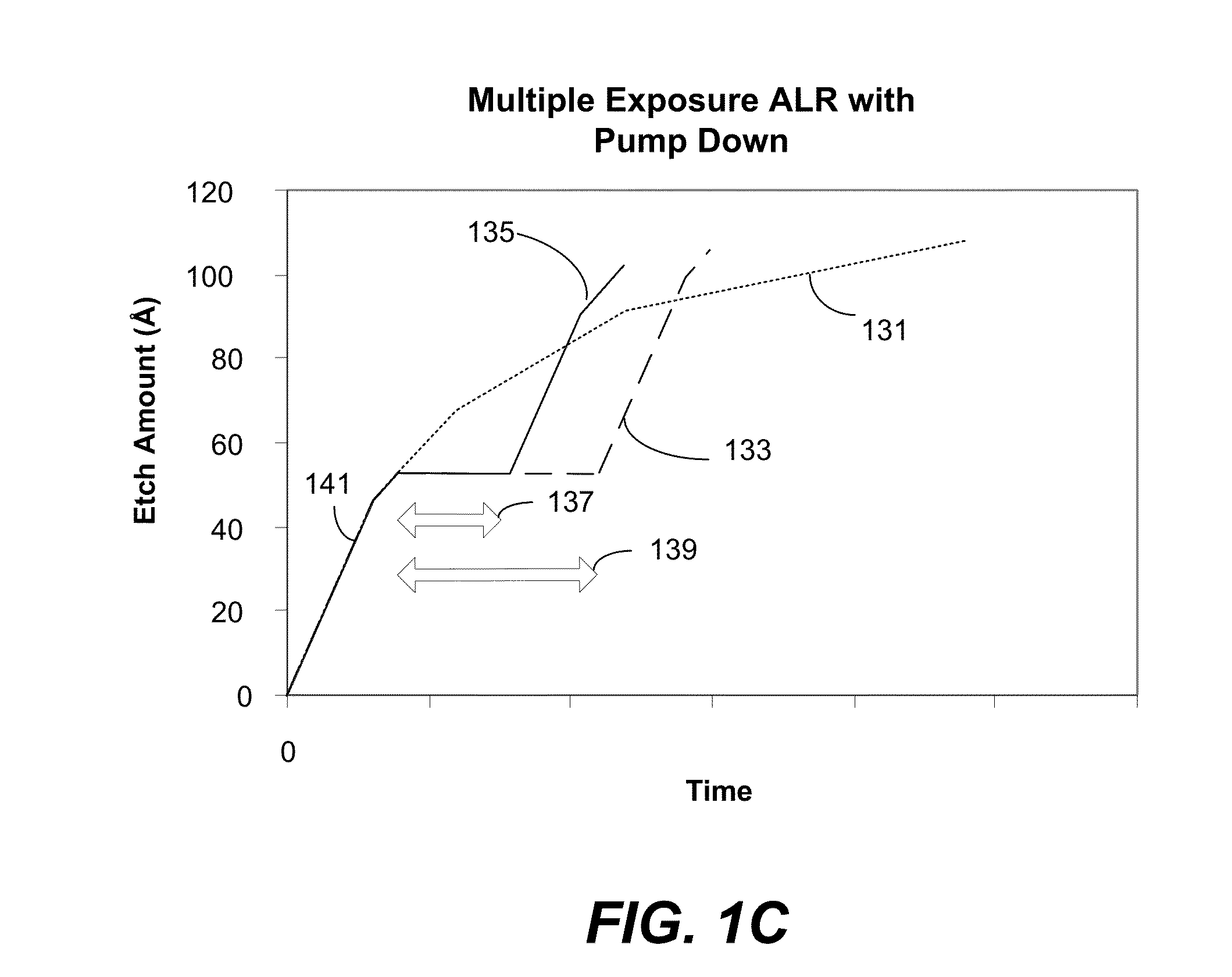

Atomic layer removal process with higher etch amount

InactiveUS8058179B1Easy to controlLimit amount of materialSemiconductor/solid-state device manufacturingSelf limitingLayer removal

Higher overall etch rate and throughput for atomic layer removal (ALR) is achieved. The reaction is a self-limiting process, thus limiting the total amount of material that may be etched per cycle. By pumping down the process station between reacting operations, the reaction is partially “reset.” A higher overall etch rate is achieved by a multiple exposure with pump down ALR process.

Owner:NOVELLUS SYSTEMS

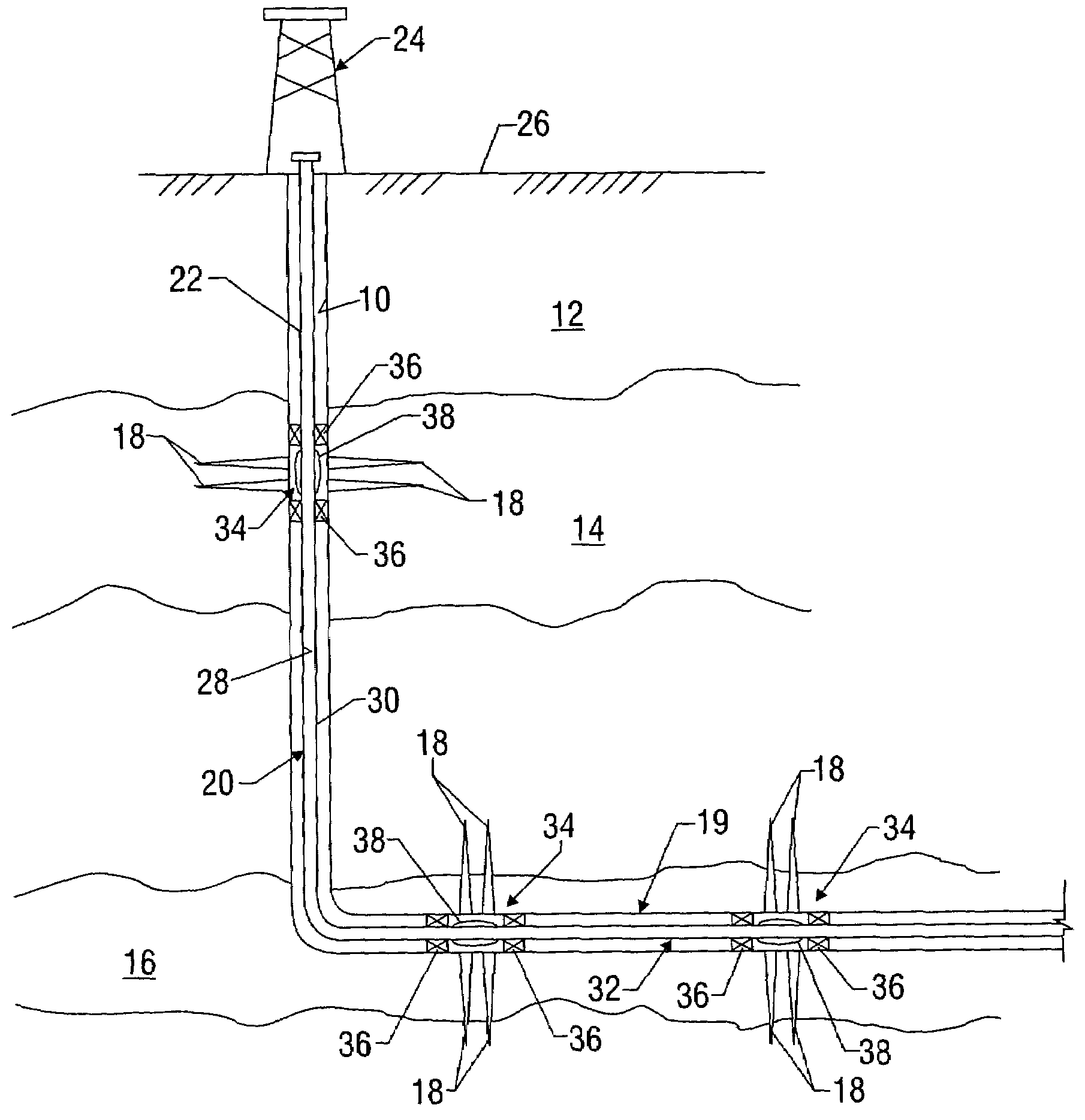

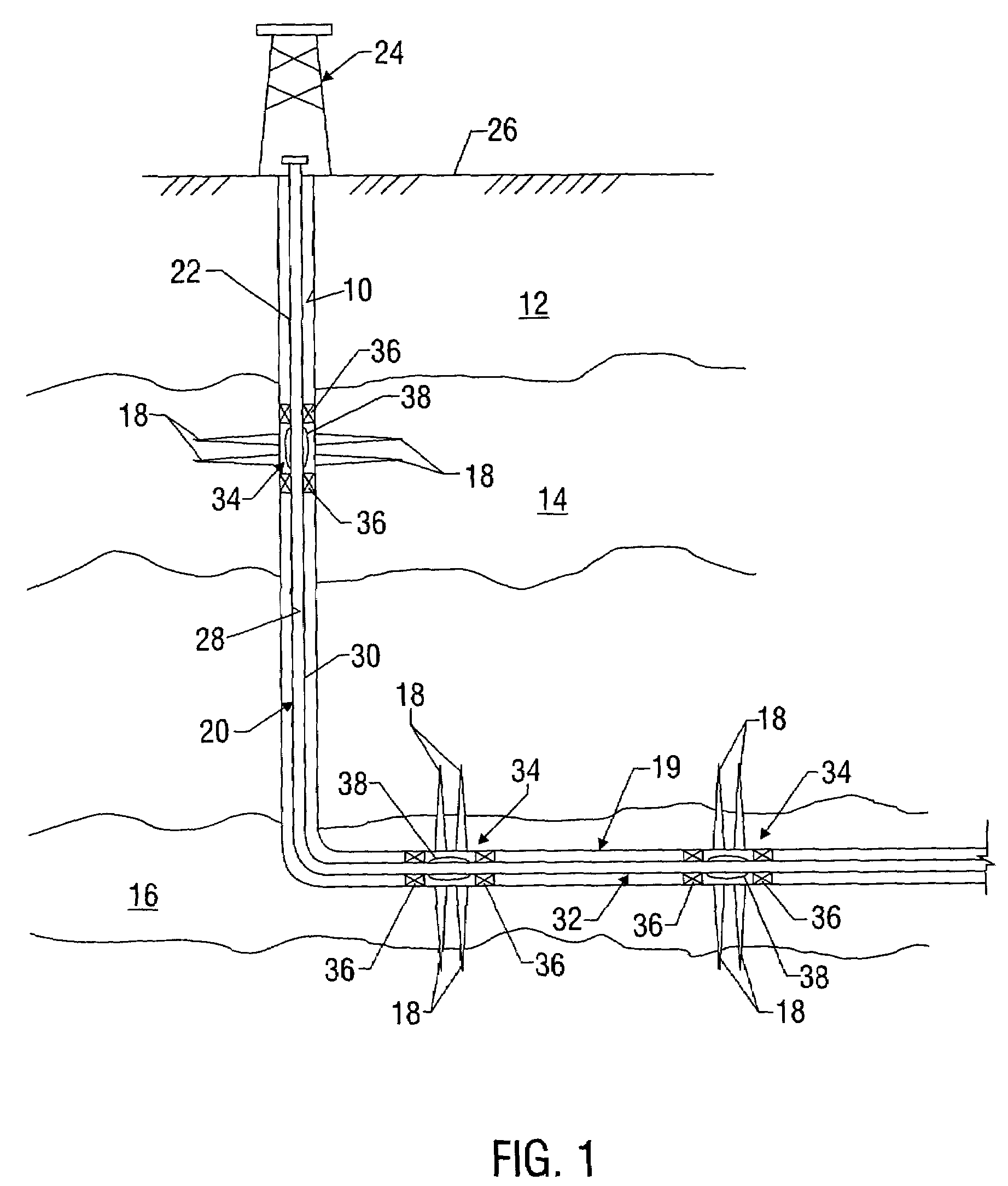

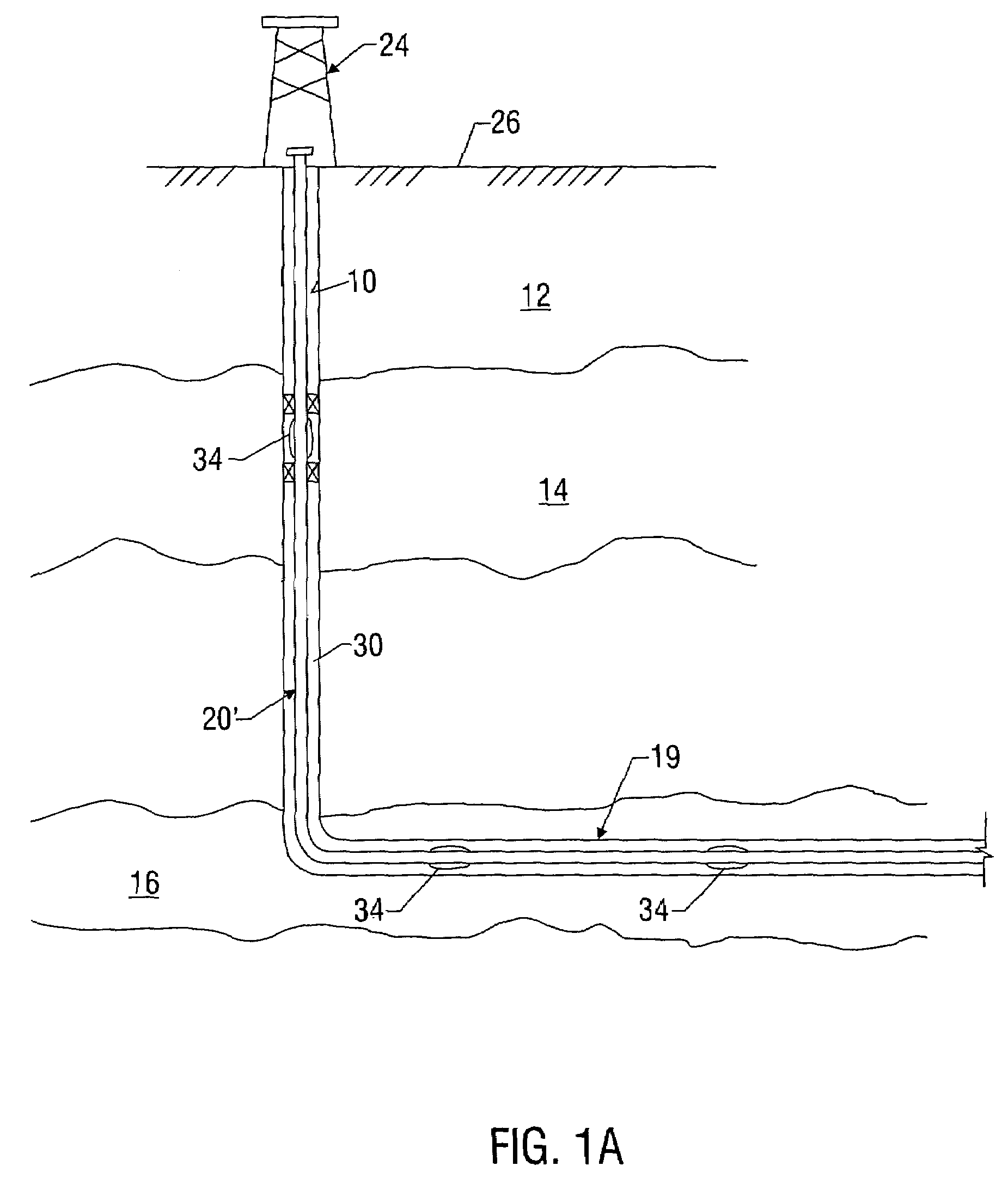

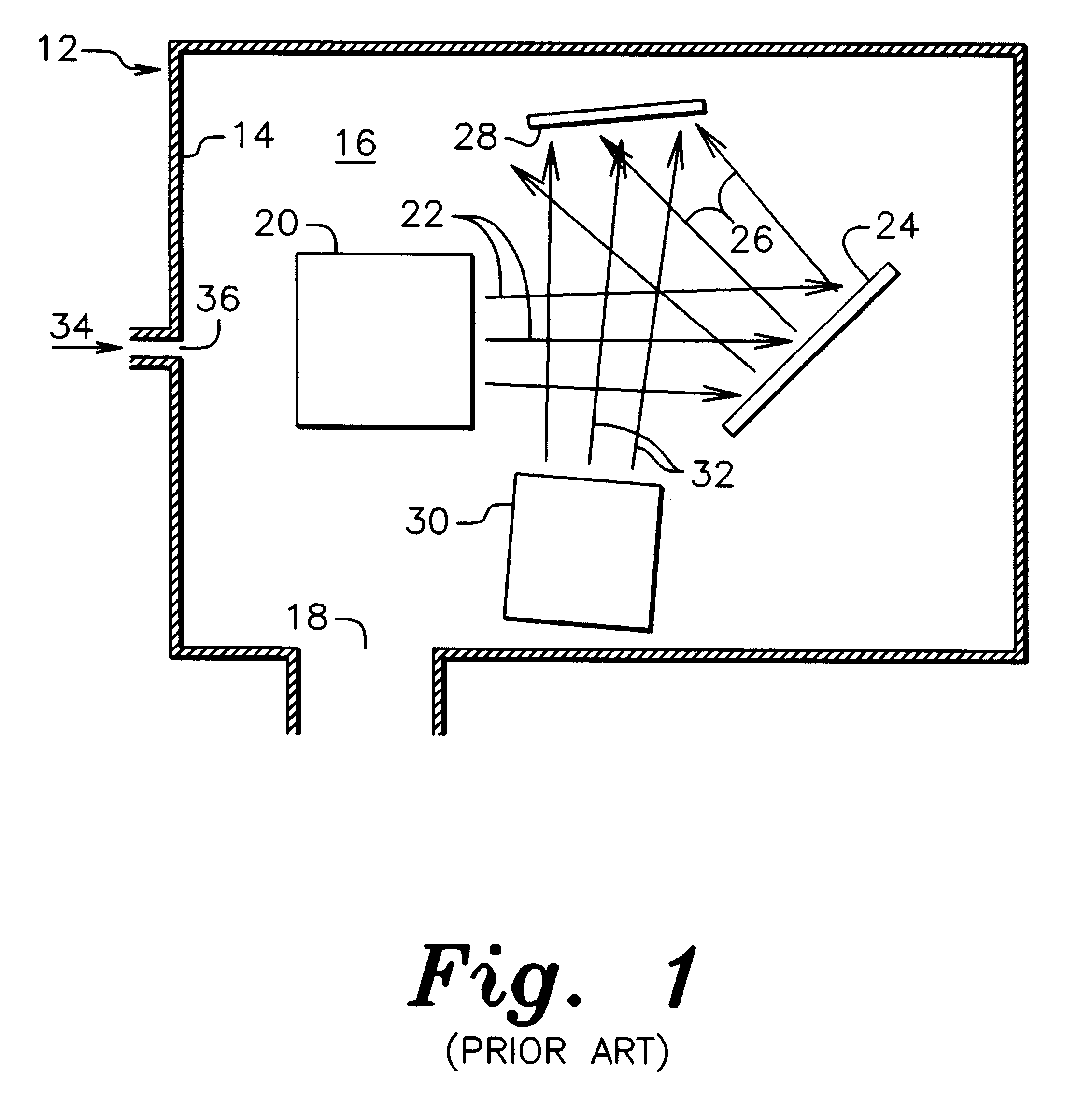

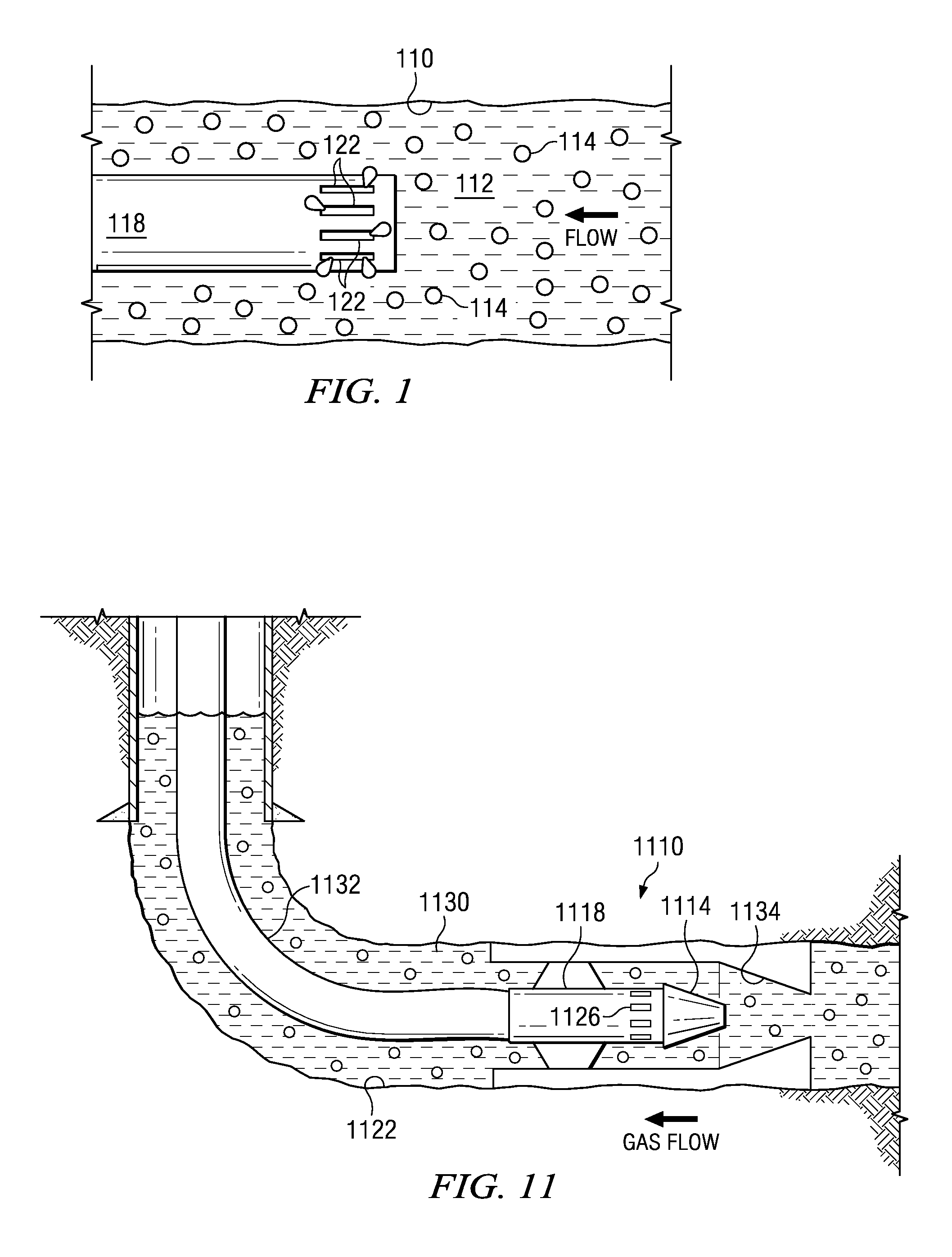

Inflow control device with passive shut-off feature

InactiveUS7290606B2Reduce gas flowConsistent service lifeSurveyConstructionsControl flowControl signal

Devices and methods for control flow of formation fluids respect to one or more selected parameter relating to the wellbore fluid. In one embodiment, a flow control device for controlling fluid flow into the production tubular uses a flow restriction member that is actuated by a character change of the formation fluid, such as liquid to gas or oil to water. The flow restriction member can be sensitive to a change in density of the formation fluid. The flow restriction member is passive, self-regulating and does not need any power source or control signal to control fluid flow. In one embodiment, the flow control device automatically rotates into a predetermined orientation upon being positioned in the wellbore. A seal disposed on the flow control devices expands into sealing engagement with an enclosure after the flow control device assumed the desired predetermined position.

Owner:BAKER HUGHES INC

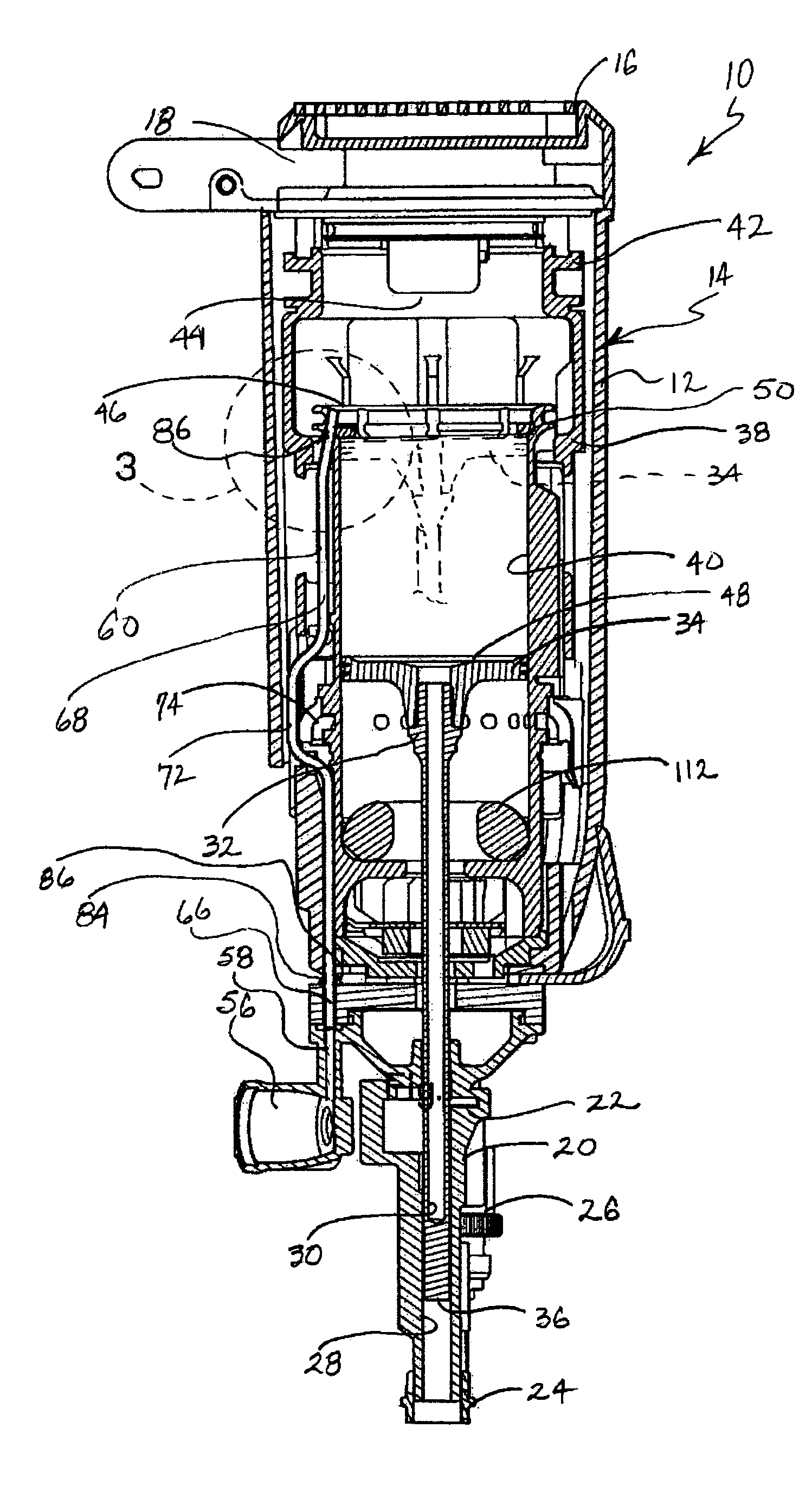

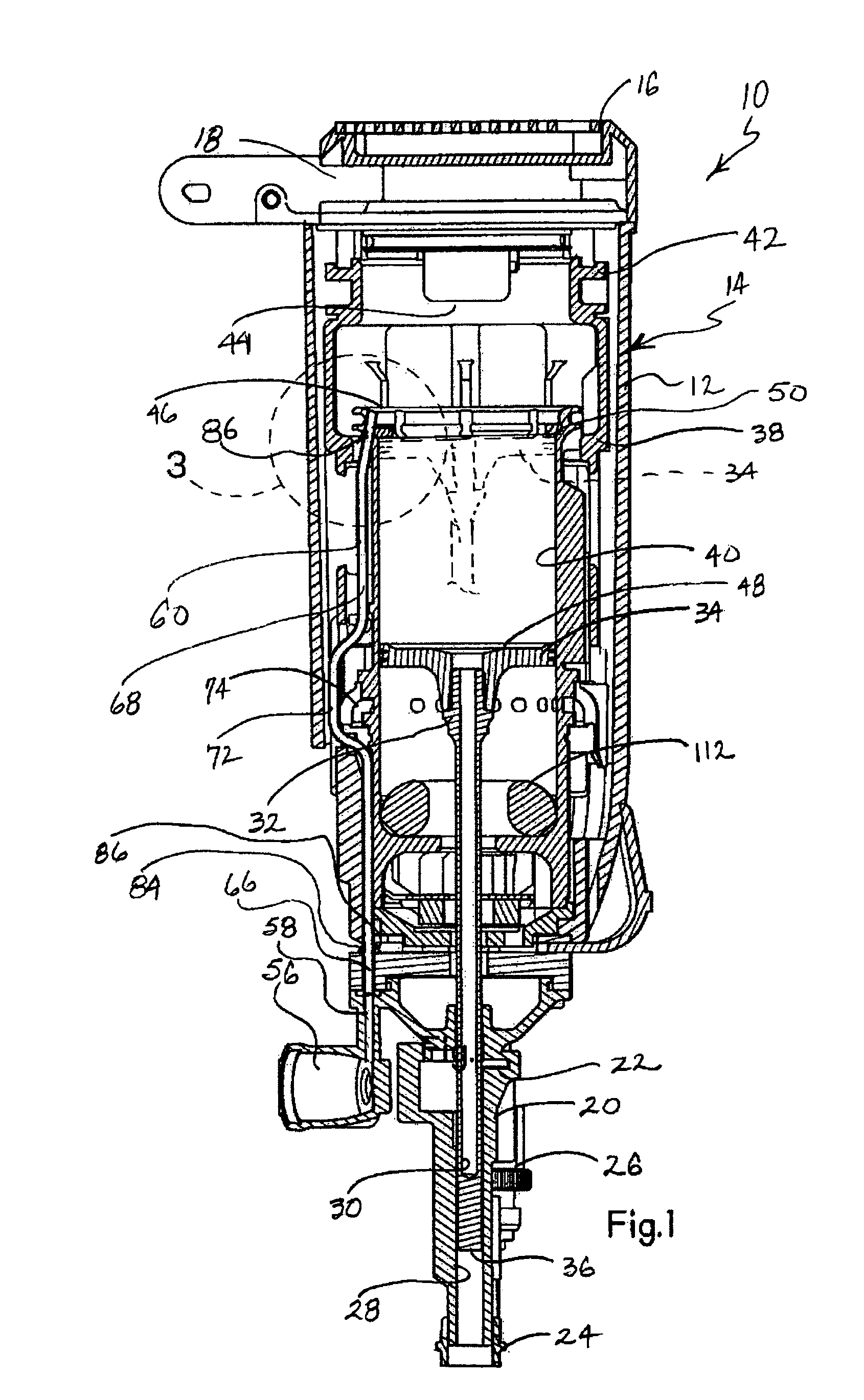

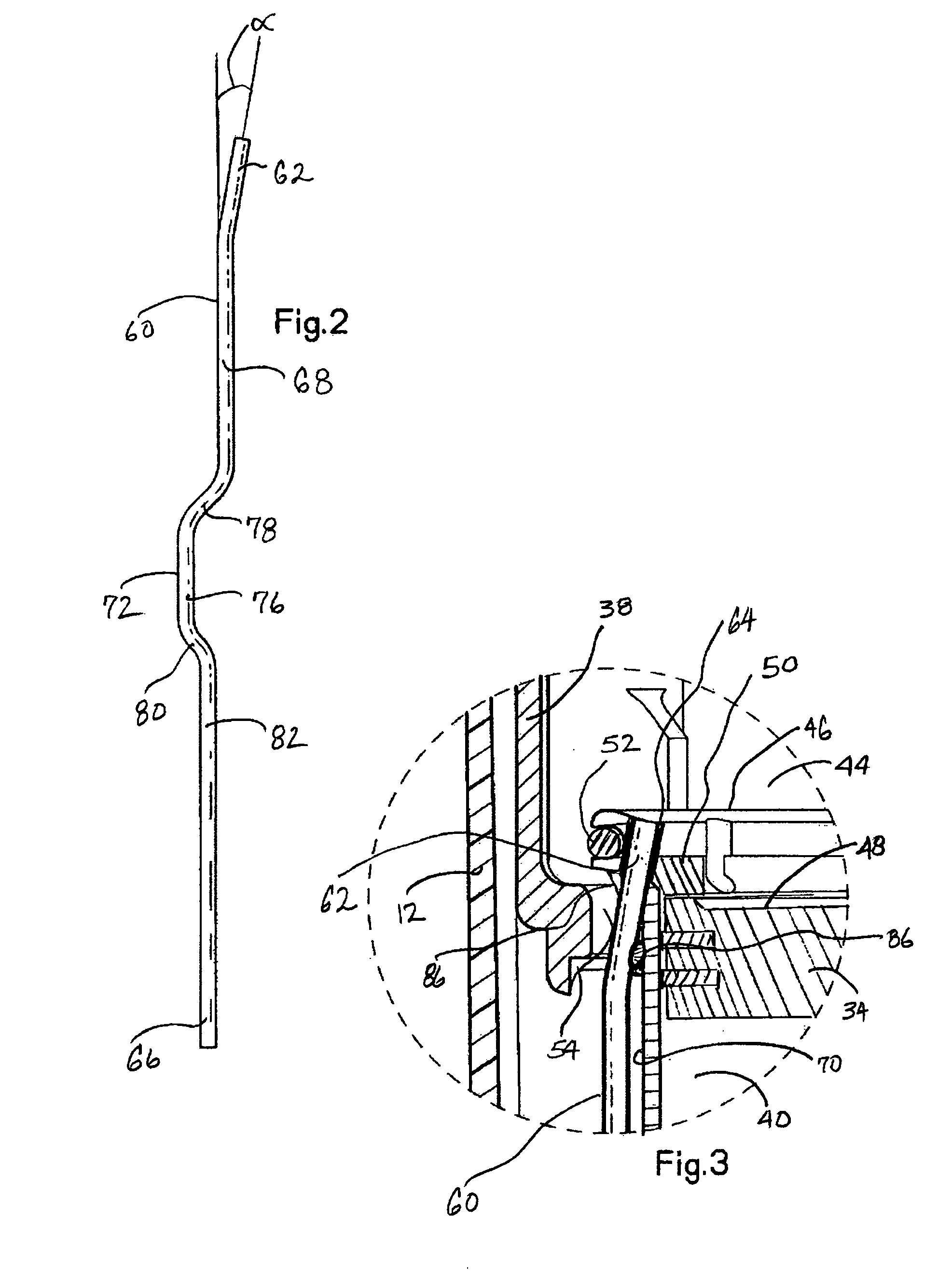

Gas driven actuation feed tube for combustion powered fastener-driving tool

ActiveUS7040521B2Reduce gas flowIncrease powerStapling toolsPortable percussive toolsCombustion chamberReciprocating motion

A combustion tool having a gas actuated magazine advance includes a combustion chamber defined in part by a cylinder, a valve sleeve axially reciprocating relative to the cylinder and an upper surface of a piston, a pneumatically actuated magazine fastener mechanism, and an exhaust driven actuation feed tube having a first end configured for insertion into an opening in the cylinder in fluid communication with the combustion chamber and a second end connected to the magazine fastener advance mechanism.

Owner:ILLINOIS TOOL WORKS INC

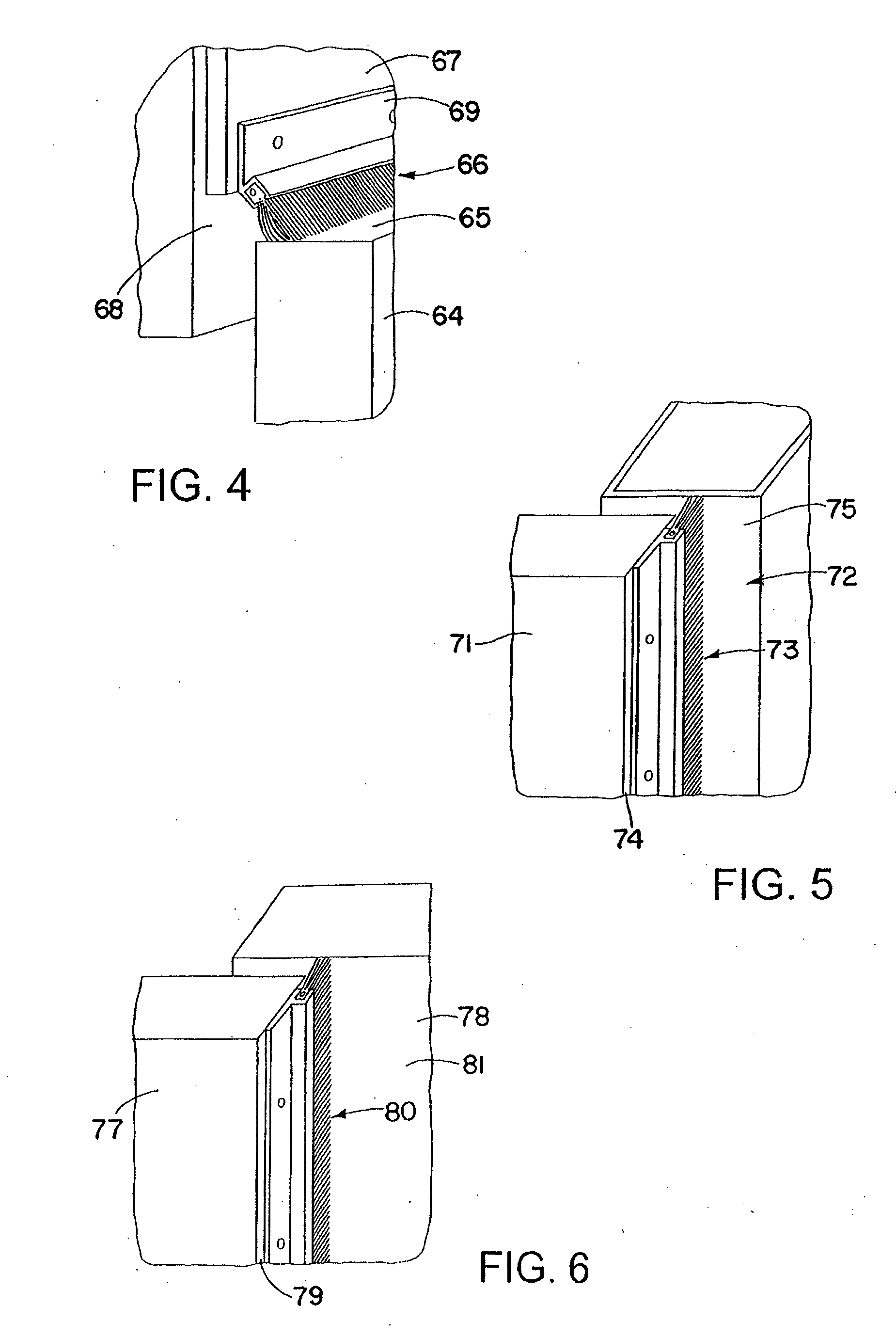

Ion assisted deposition source

InactiveUS6238537B1Minimize damageReduce gas flowCellsElectric discharge tubesElectronAtomic physics

In accordance with one specific embodiment of the present invention, the ion assisted deposition source for thin films comprises an axially symmetric discharge region into which an ionizable gas is introduced, a sputter target at one end of that region, an axially symmetric magnetic field within and extending out the opposite and open end of that region, an anode around the circumference of that region, and an electron emitting cathode located near the open end of that region. Particles are sputtered from the sputter target, pass through the discharge region, and are deposited on a deposition substrate located exterior of both the discharge region and the deposition source. A beam of energetic ions from the discharge region bombards the film being deposited to improve the adhesion, density, and other properties of that film. The density of the plasma can be controlled with the emission from the cathode, the emission of sputtered particles from the sputter target can be controlled with the negative potential of that target, while the energy of the ions used to assist in the deposition can be controlled with the positive potential of the anode. The deposition source thus simultaneously generates a flux of sputtered material with which to deposit a film on a substrate and a beam of energetic ions to assist in that deposition, and does so with a simple and economical apparatus.

Owner:KAUFMAN & ROBINSON

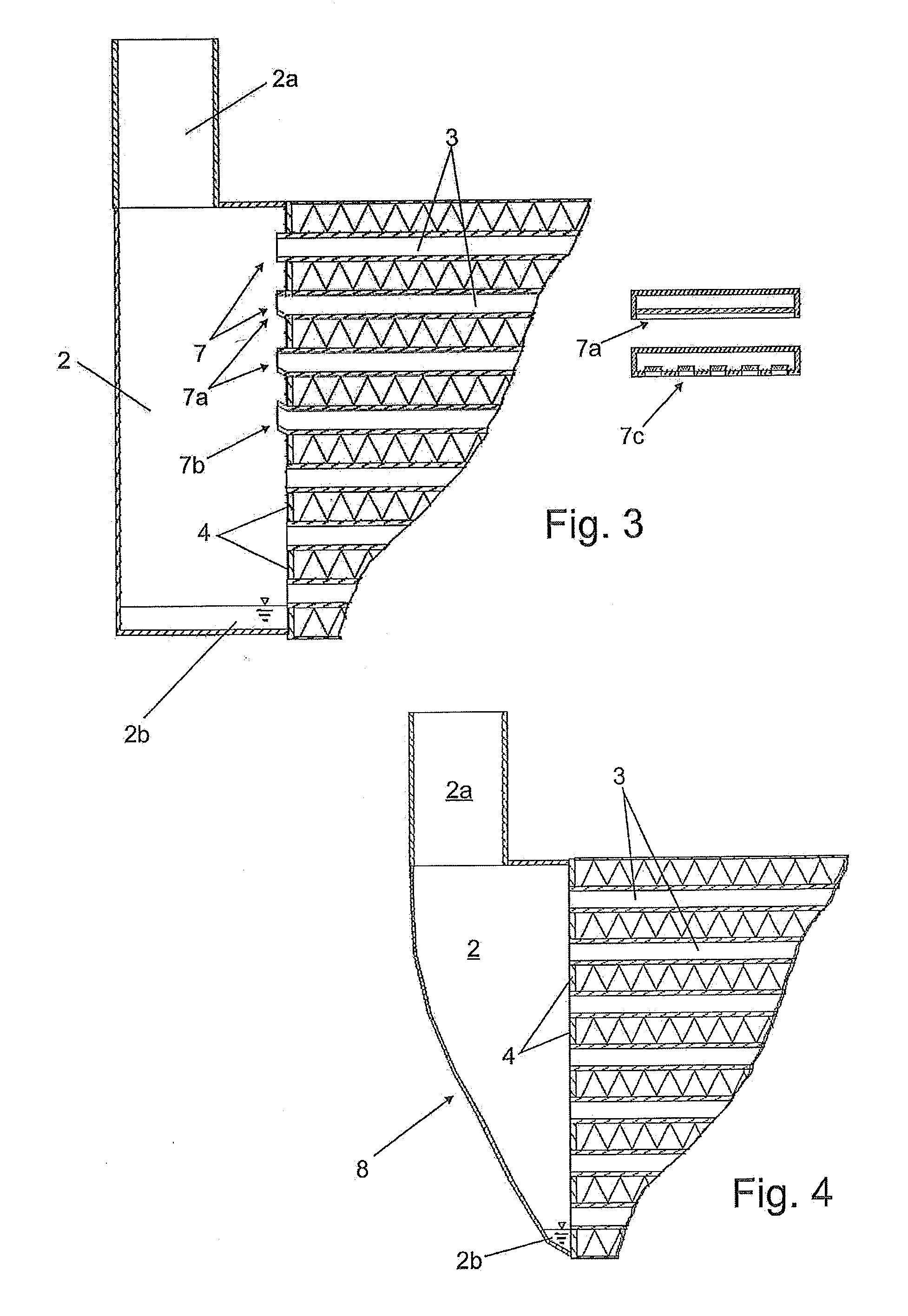

Heat exchanger

InactiveUS20100300647A1Promote atomizationReduce gas flowRecuperative heat exchangersMachines/enginesExternal combustion engineProcess engineering

A heat exchanger, in particular a charge air cooler or an exhaust gas cooler for an internal combustion engine, comprising a plurality of essentially parallel tubes and at least one collector box on the output side, the tubes each emptying into the collector box on the output side, and a gas flow flowing from the tubes into the collector box and from the collector box into an outlet of the collector box, a structure for interacting with the gas flow being provided at least one of the tubes or collector box, a condensation being transported to the outlet with the aid of the structure.

Owner:MAHLE INT GMBH

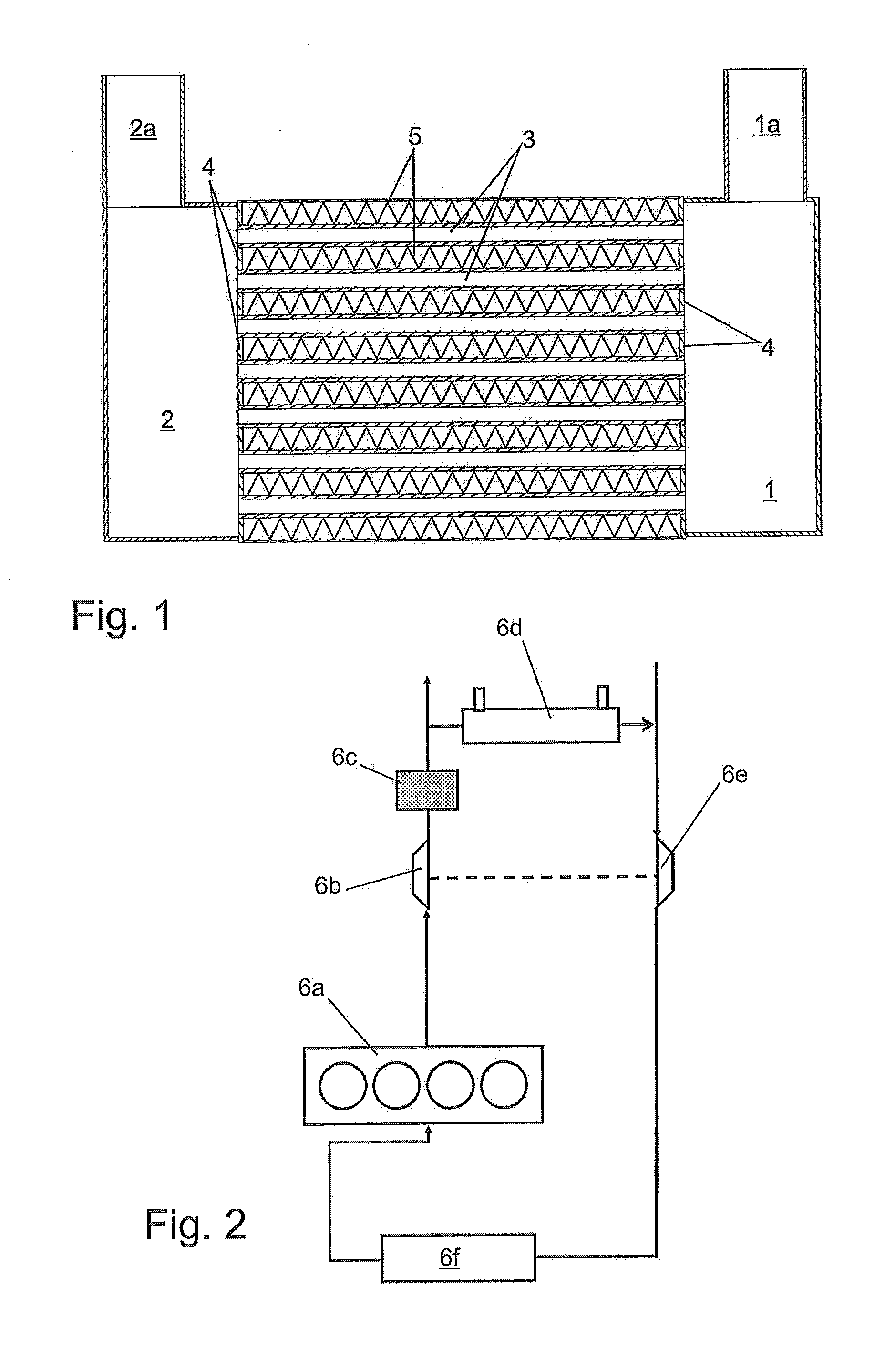

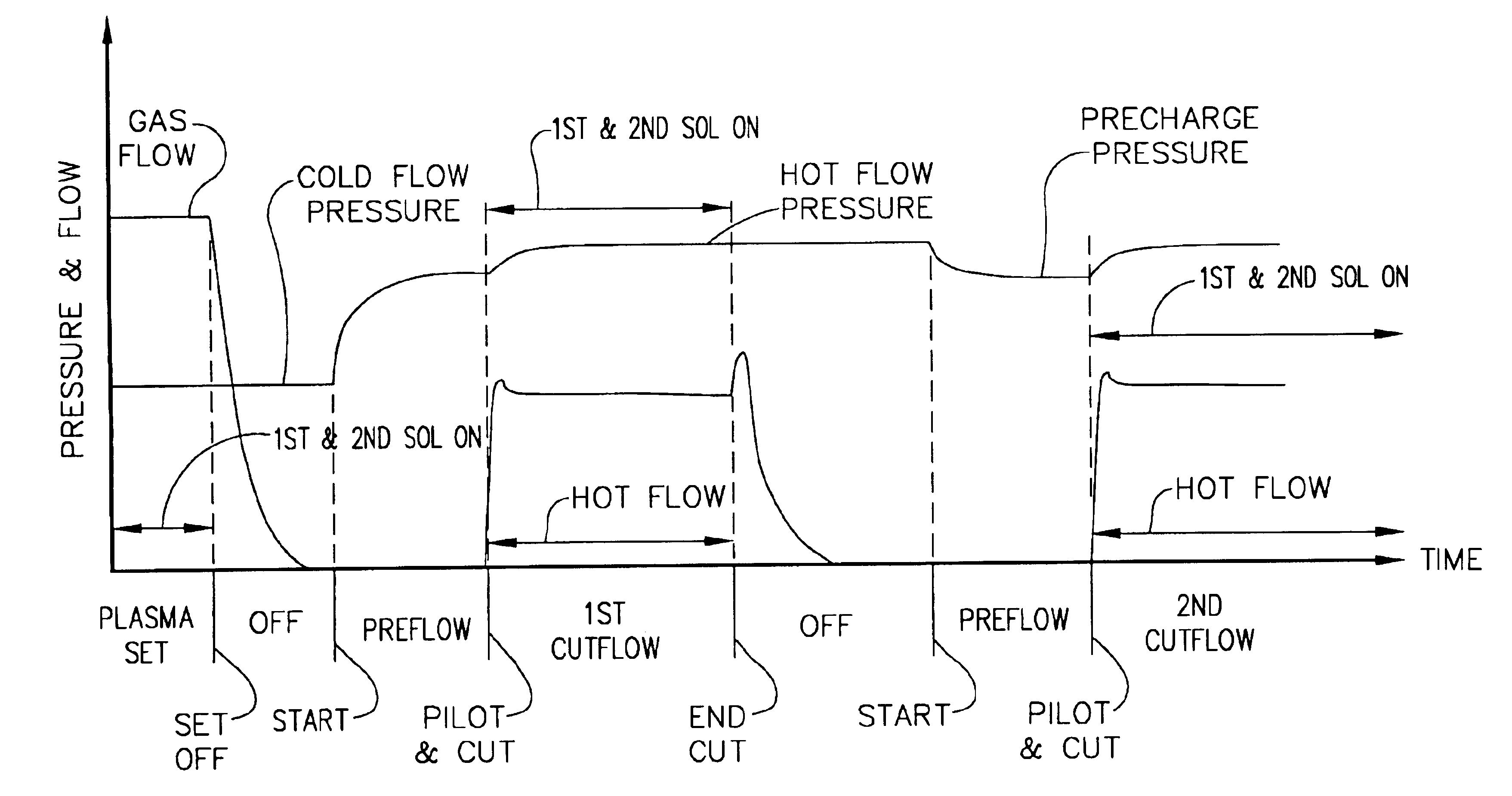

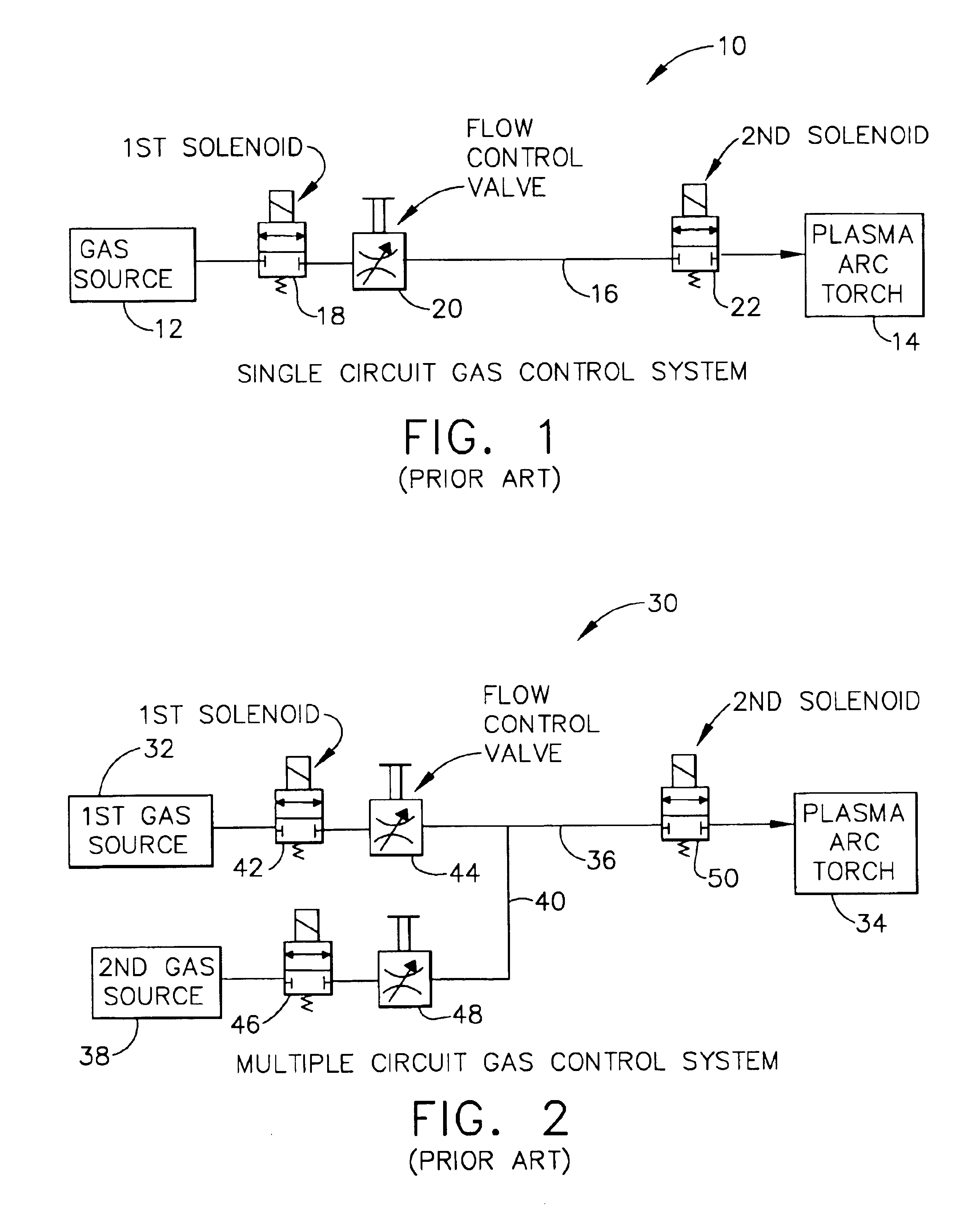

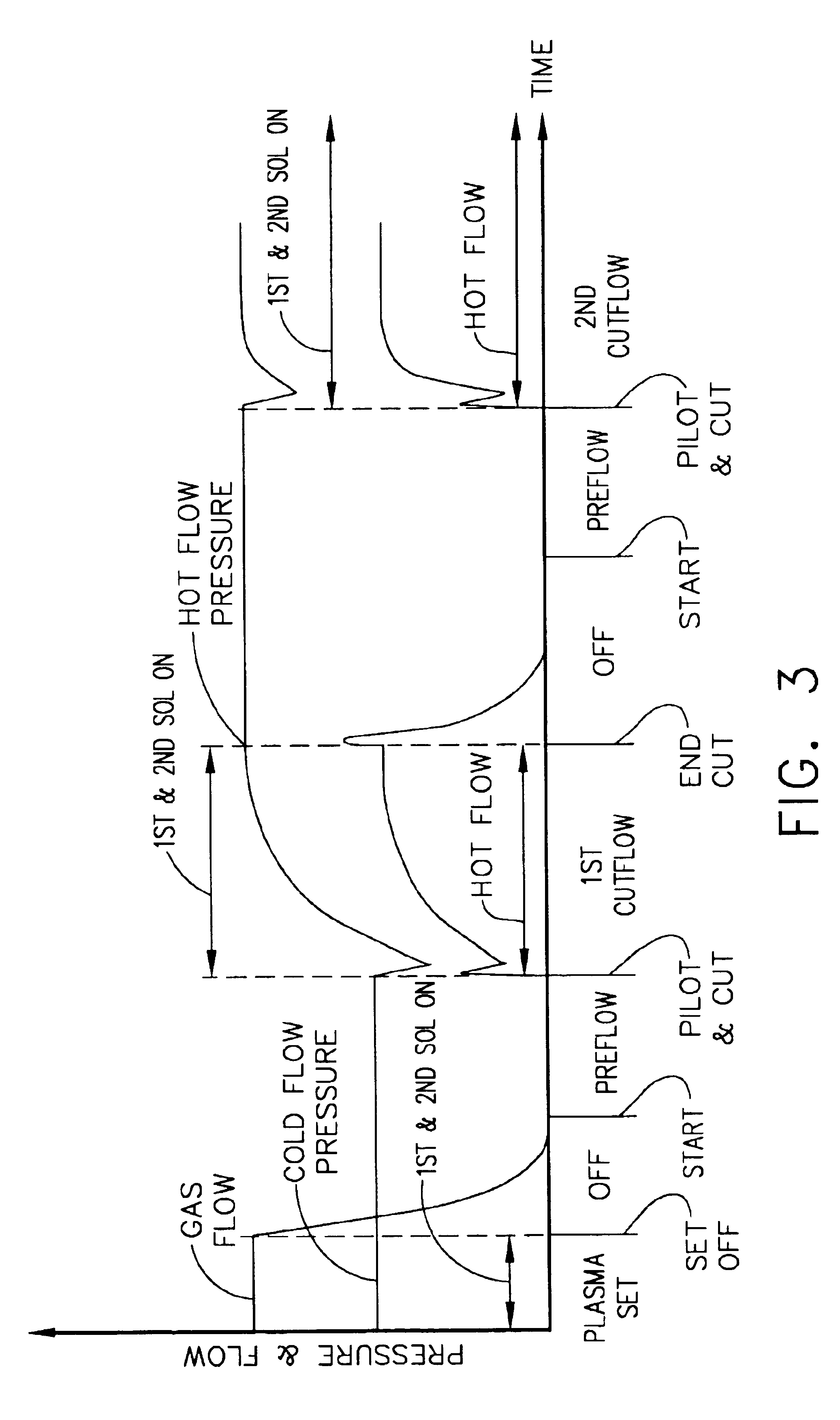

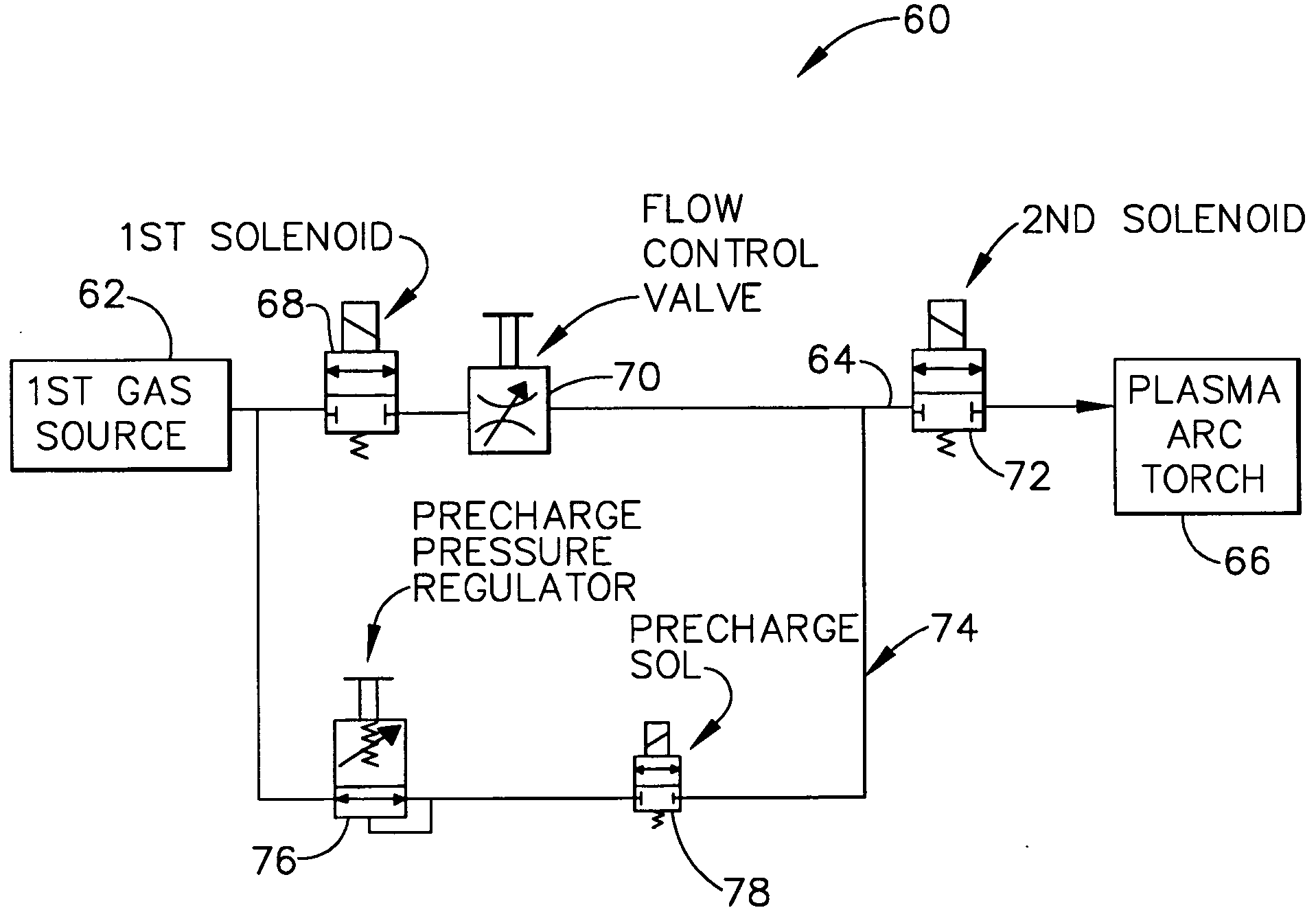

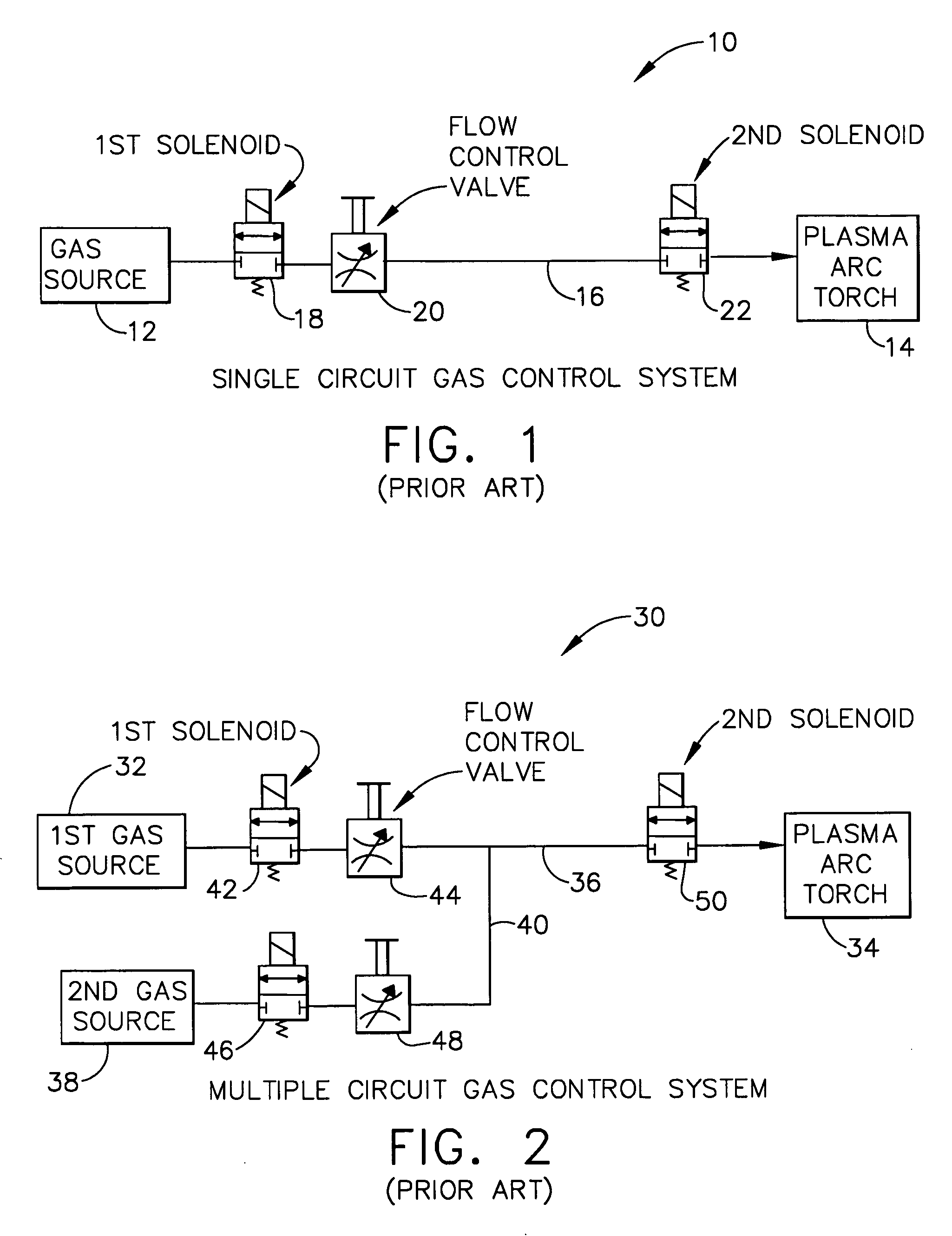

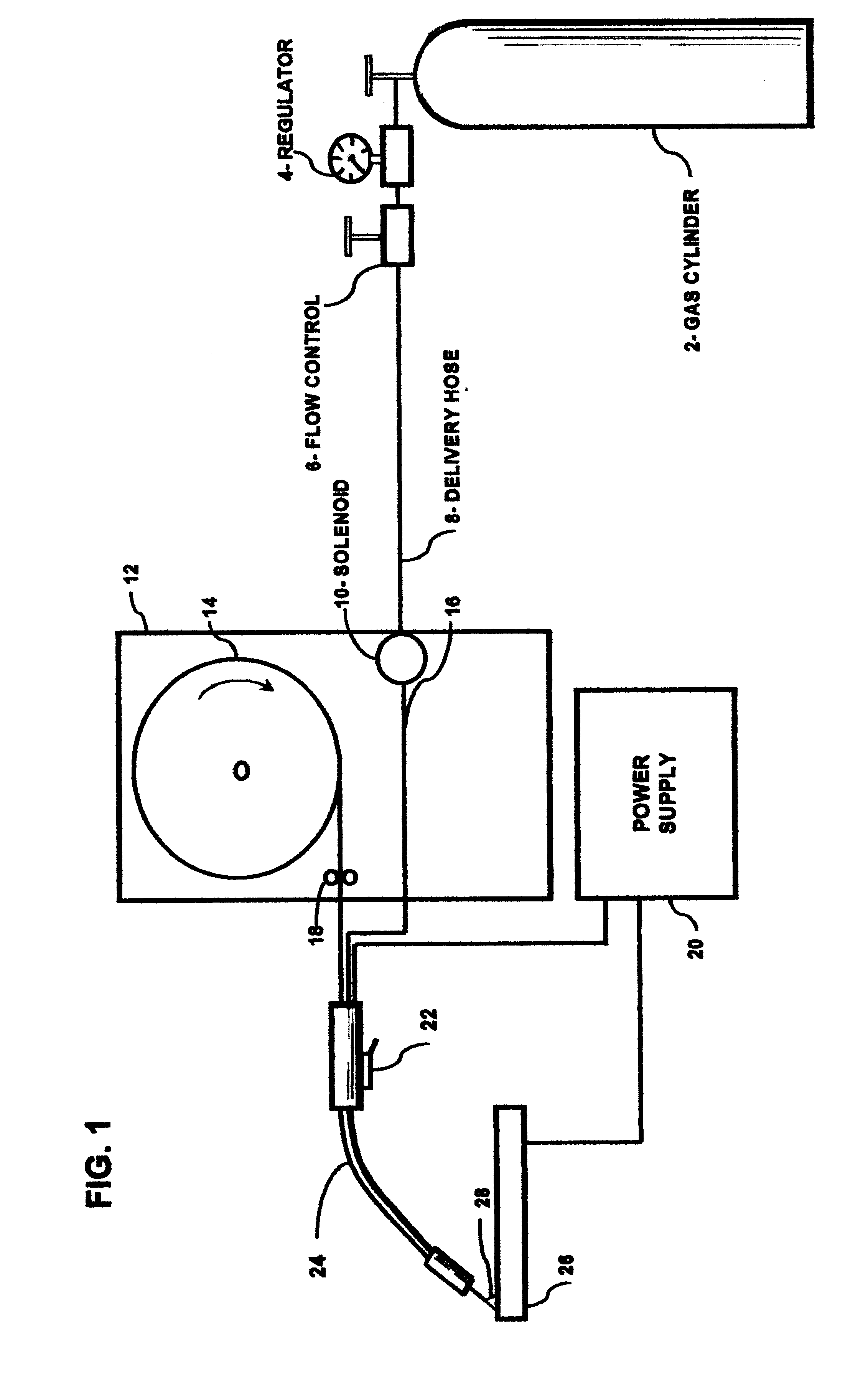

Gas flow pre-charge for a plasma arc torch

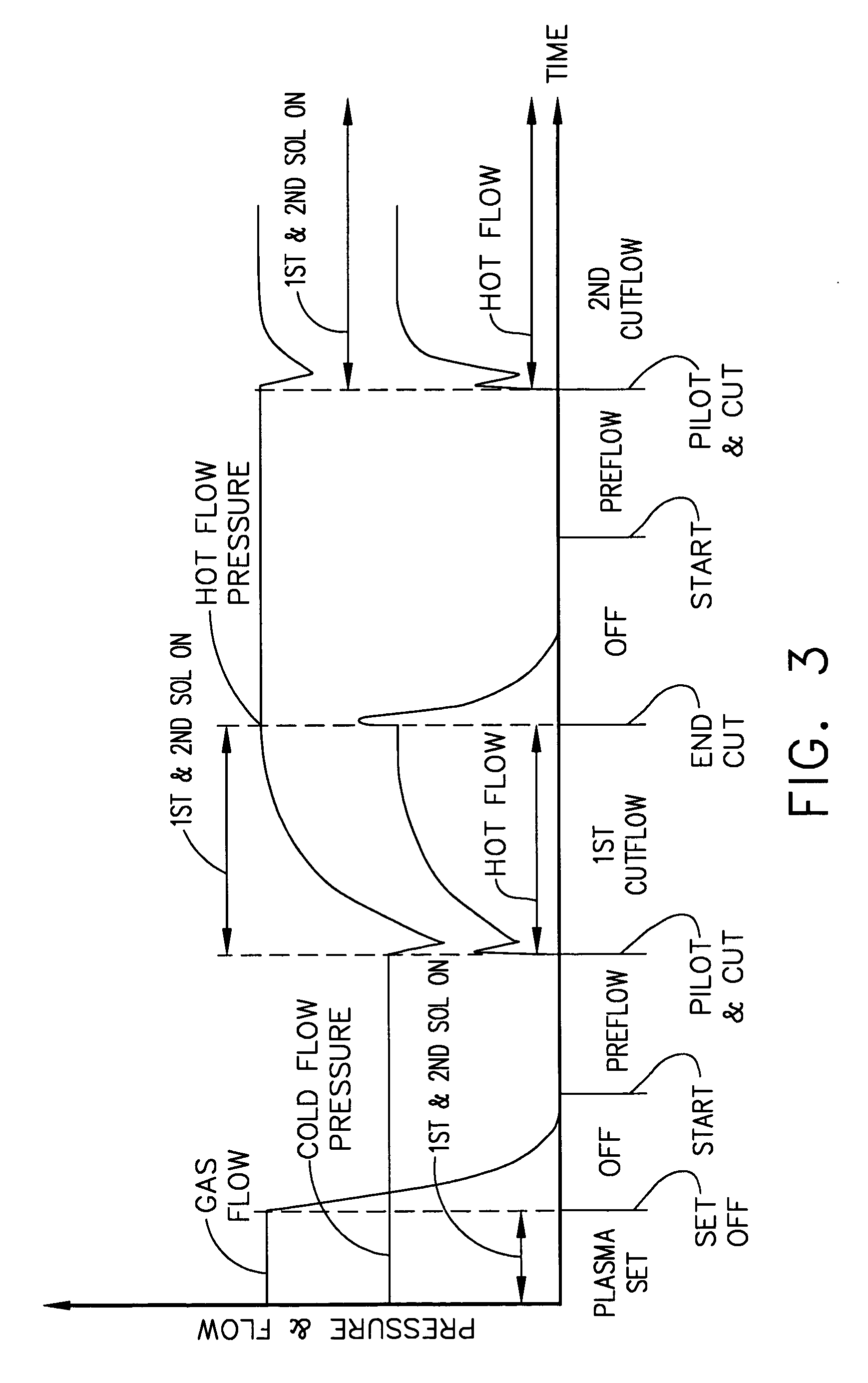

InactiveUS6960737B2Reduce gas flowArc welding apparatusPlasma welding apparatusHeat flowControl system

A system for controlling gas flow from a gas source, through a gas conduit, and to a plasma arc torch during a transition from a cold flow when no arc is present to a hot flow when an arc is provided by the present invention. The system comprises a first solenoid in communication with the gas source, a second solenoid disposed proximate the plasma arc torch, and a bypass circuit in communication with the gas source and the second solenoid. The bypass circuit comprises a bypass solenoid that controls the gas pressure within the gas conduit to reduce gas flow fluctuations when transitioning from cold flow to hot flow. Additional gas control systems and methods are also provided that cause the gas pressure to be higher during cold flow, prior to arc ignition, which overcomes the rapid drop in flow that typically occurs during the transition to hot flow.

Owner:VICTOR EQUIP

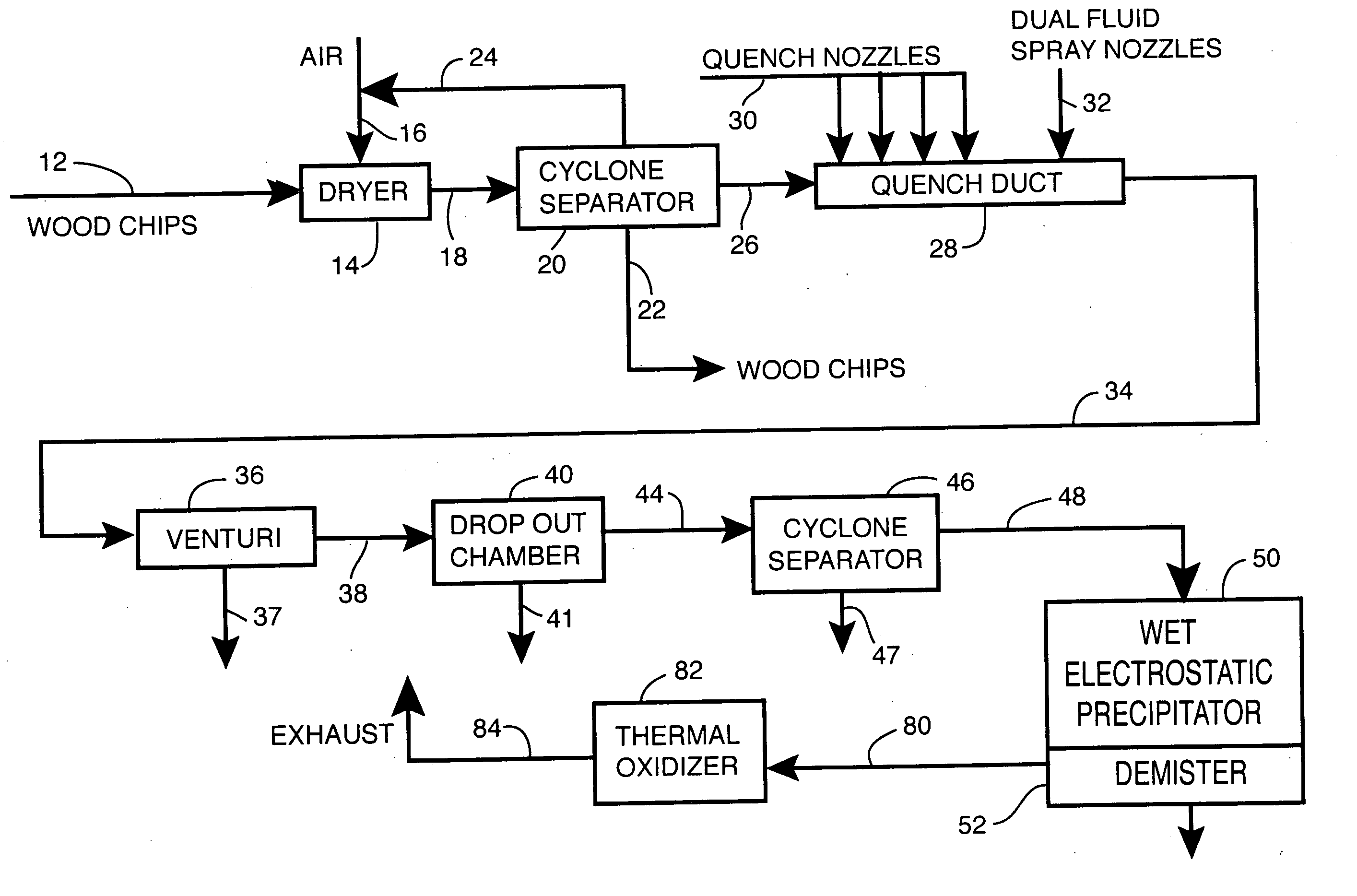

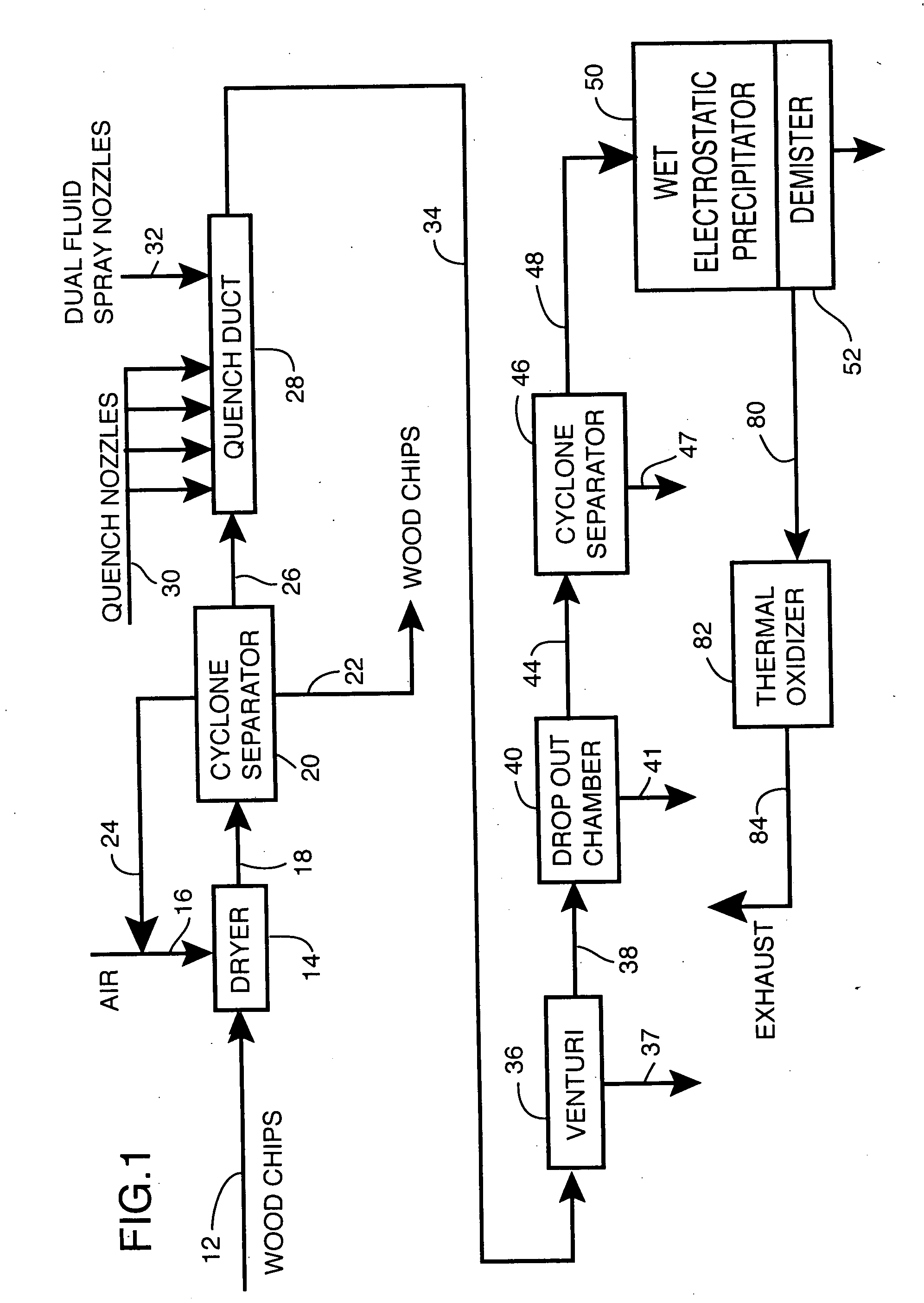

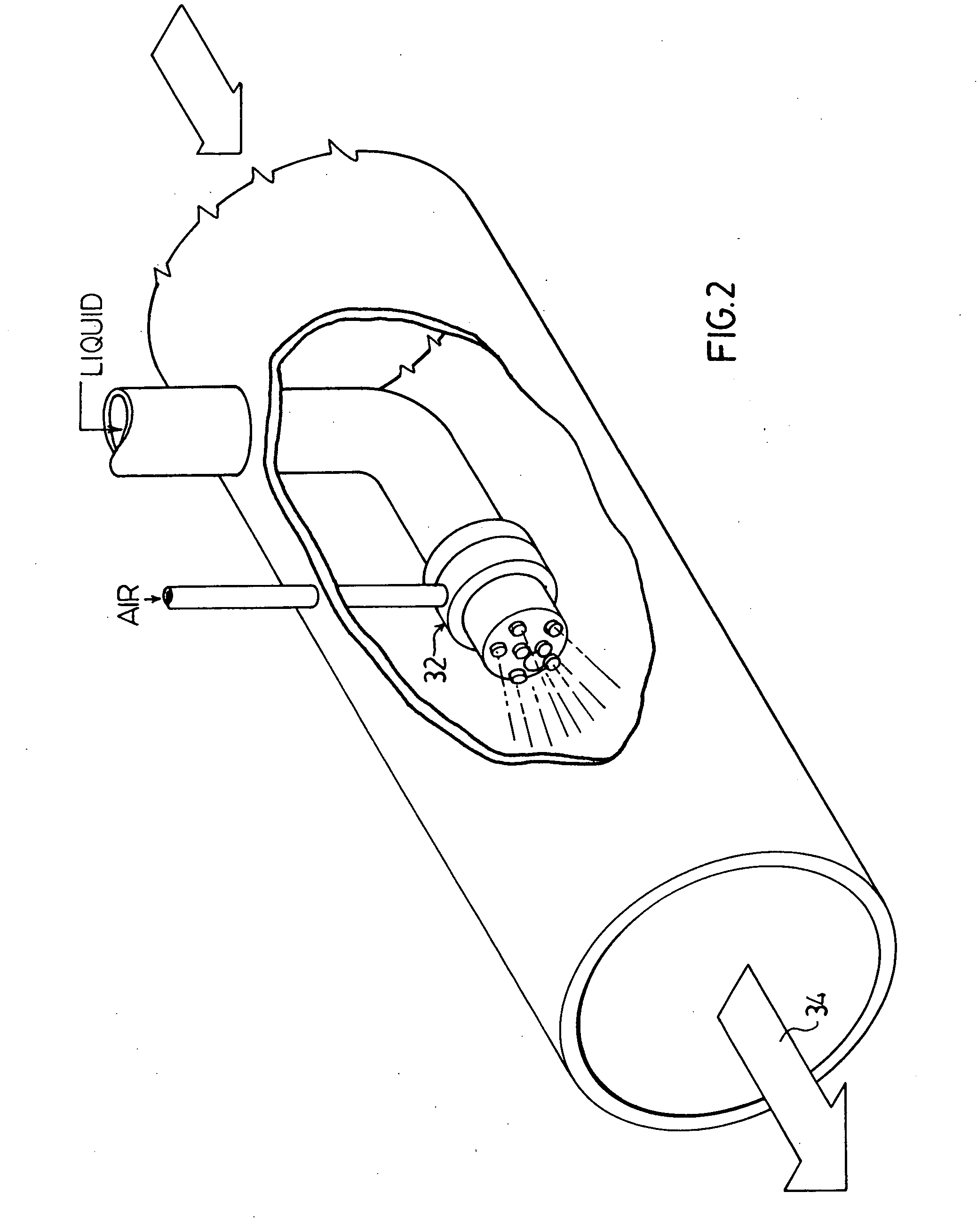

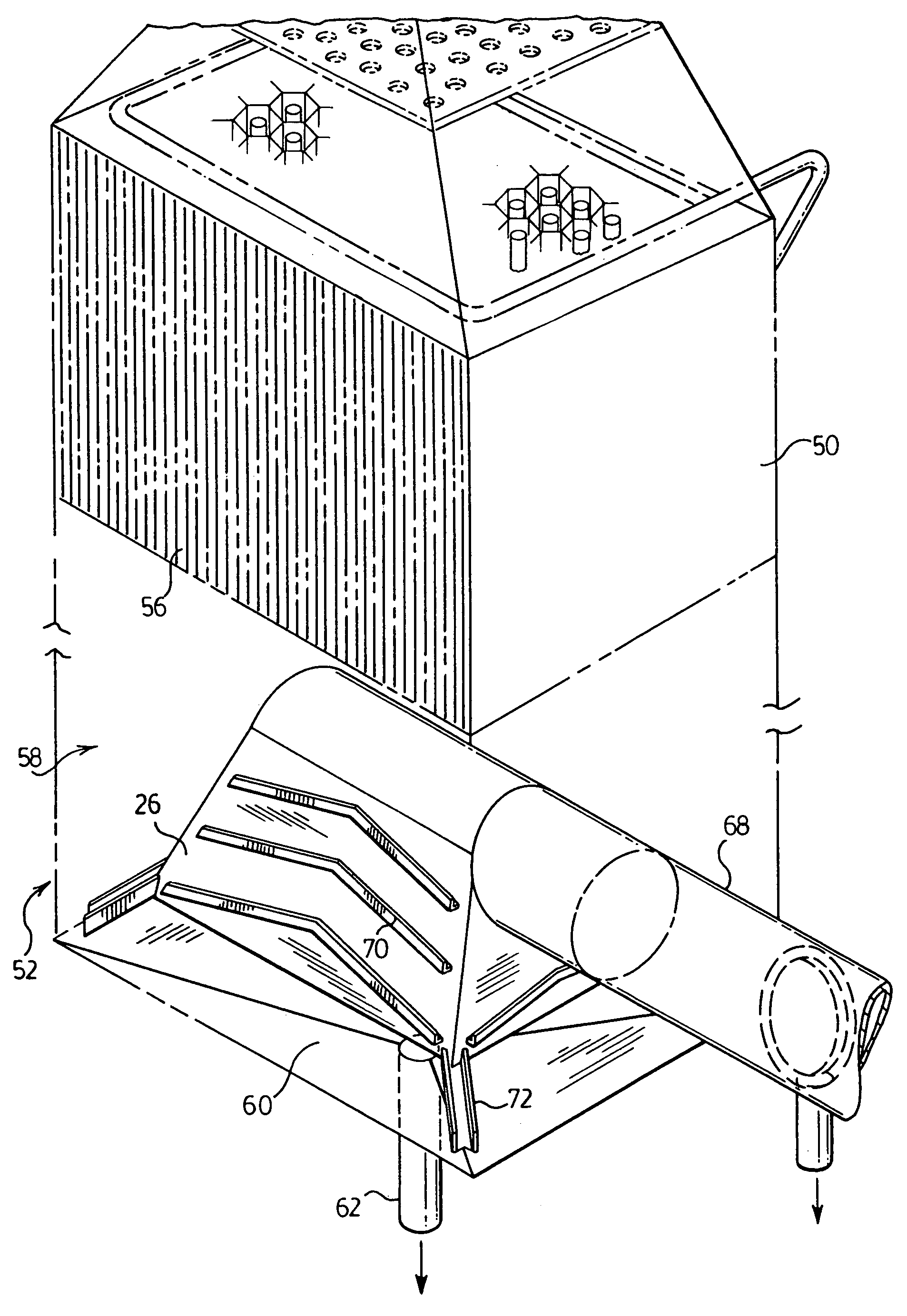

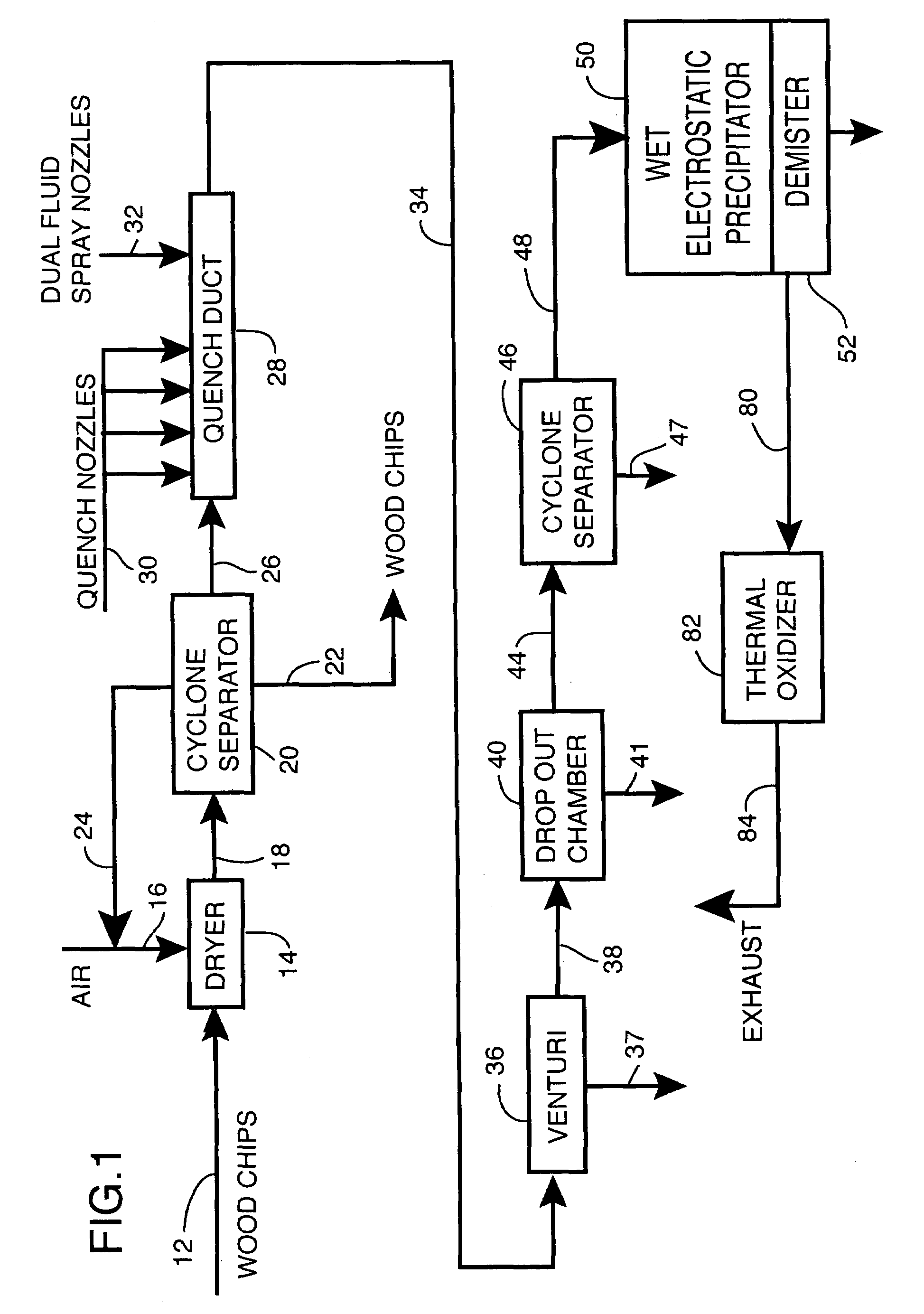

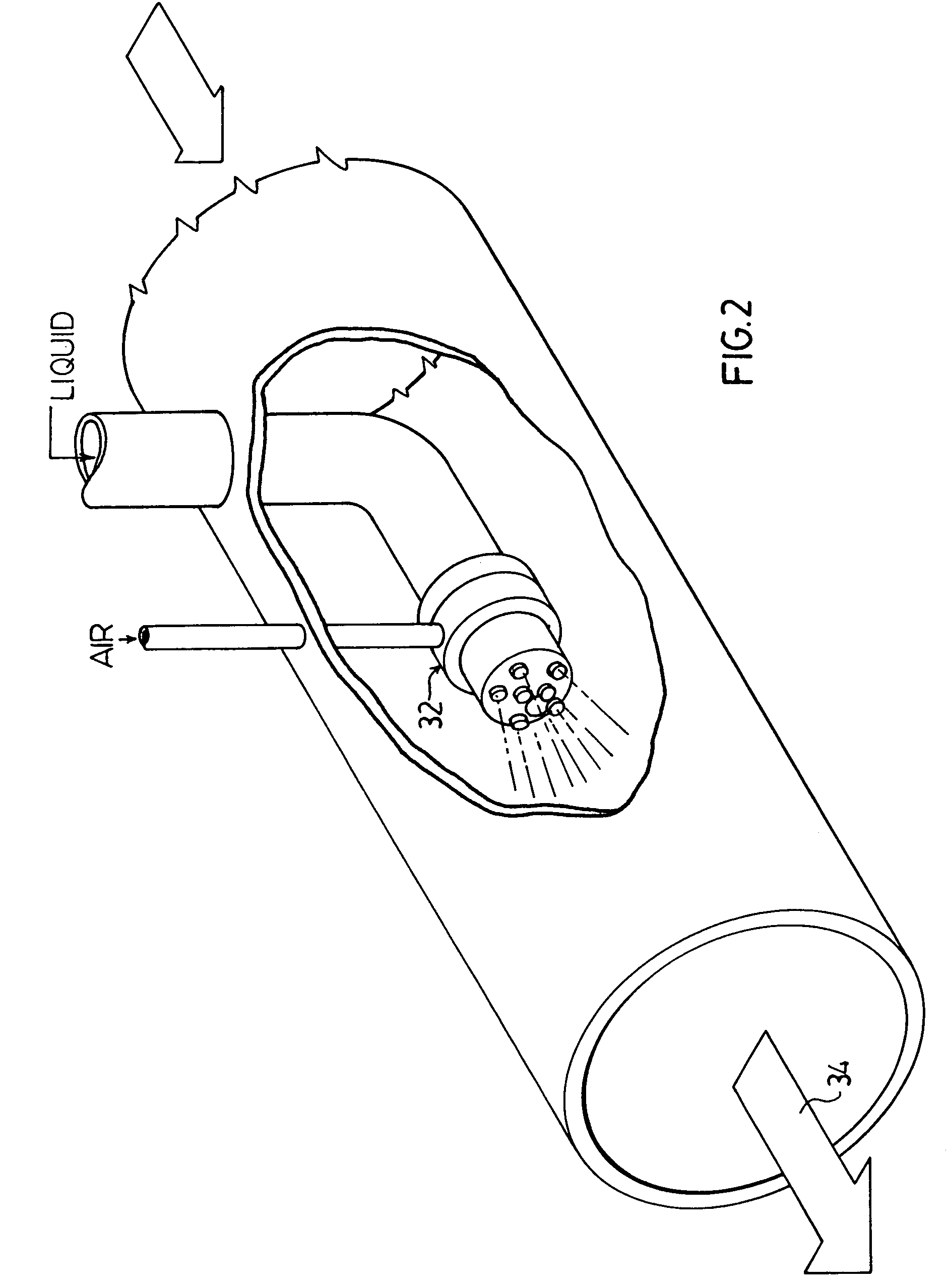

Pollution control in wood products dryer

InactiveUS20050229780A1Reduce gas flowEmission reductionCombination devicesDrying solid materials with heatParticulatesCombustor

Contaminant laden gas streams from wood product dryer operations, and other sources, are purified. The gas stream first is saturated with moisture by contacting the gas stream with fine liquid droplets which entrain particulates. The gas stream then is subjected to a plurality of separate particulate and liquid droplet removal steps before a droplet-free gas stream having substantially reduced particulate contaminant levels is passed to a burner for removal of volatile organic compounds from the gas stream.

Owner:MEGTEC TURBOSONIC

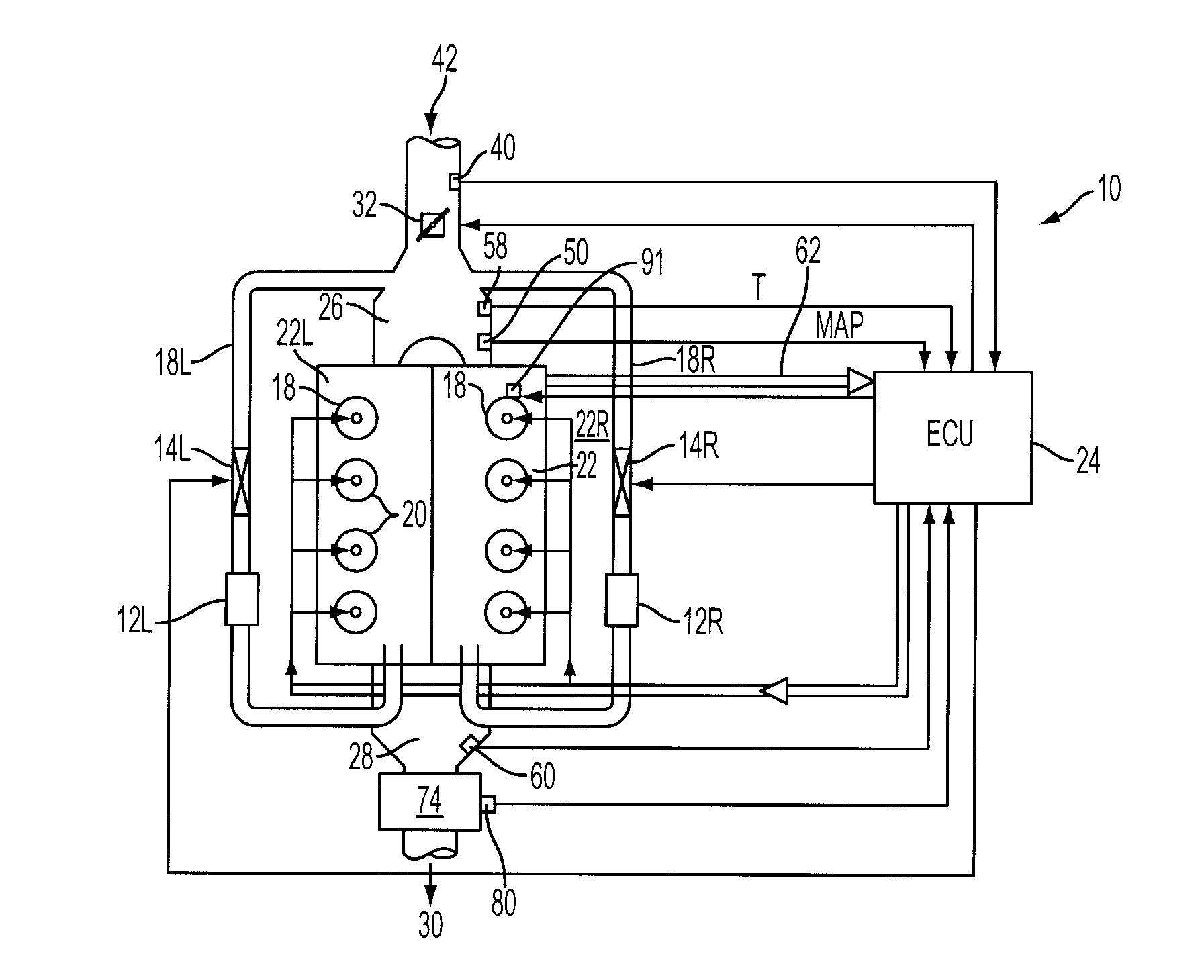

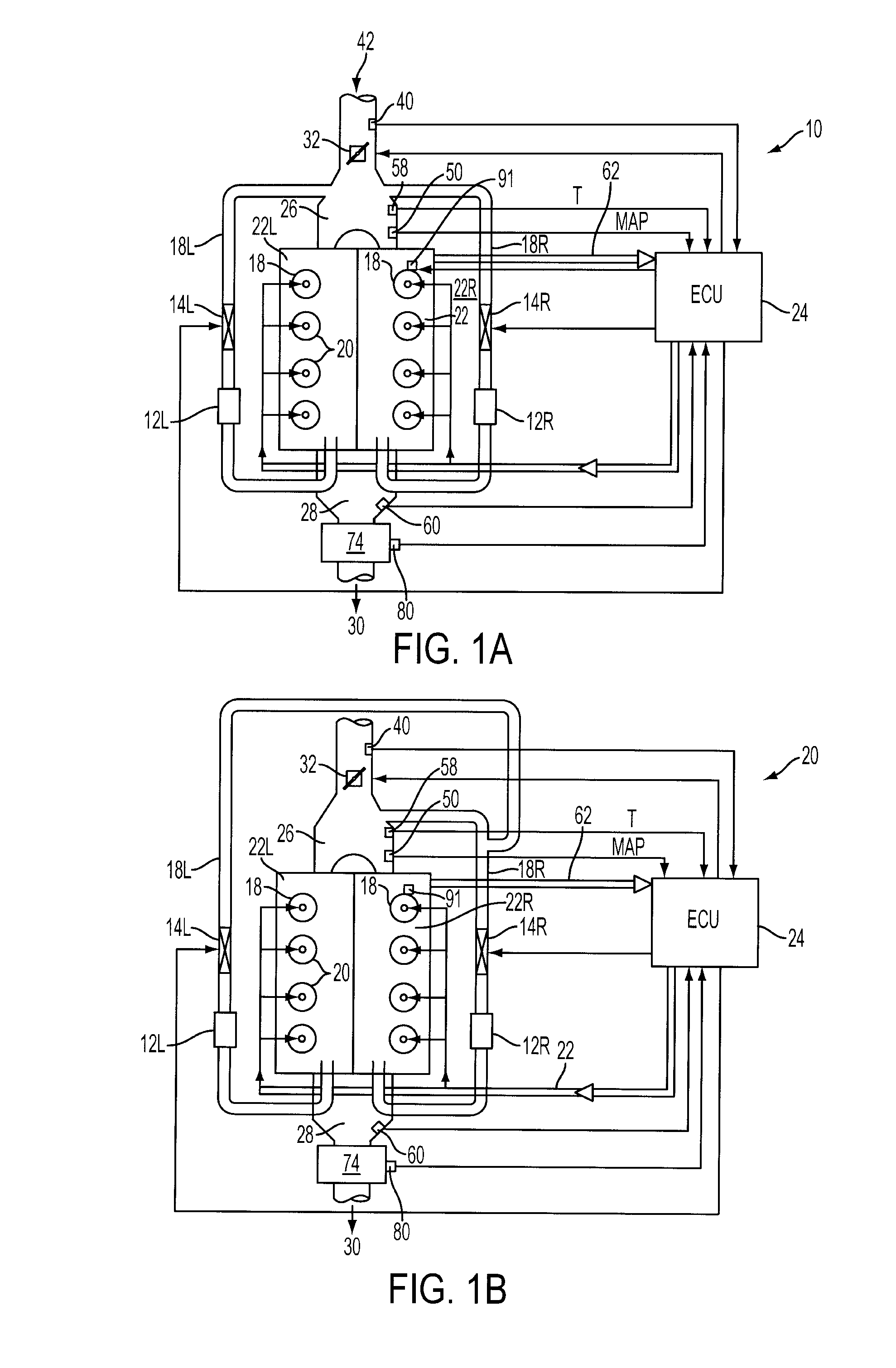

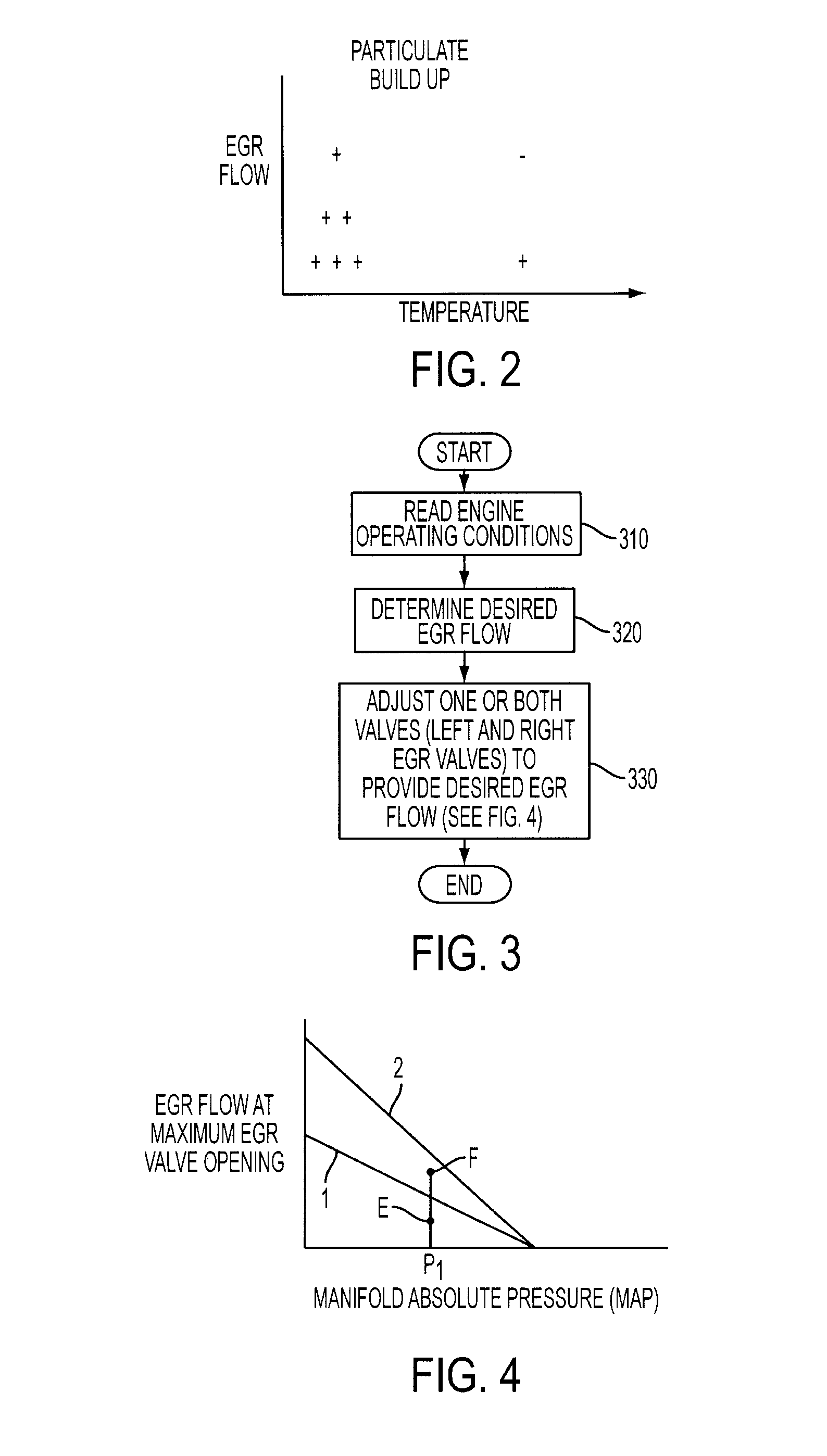

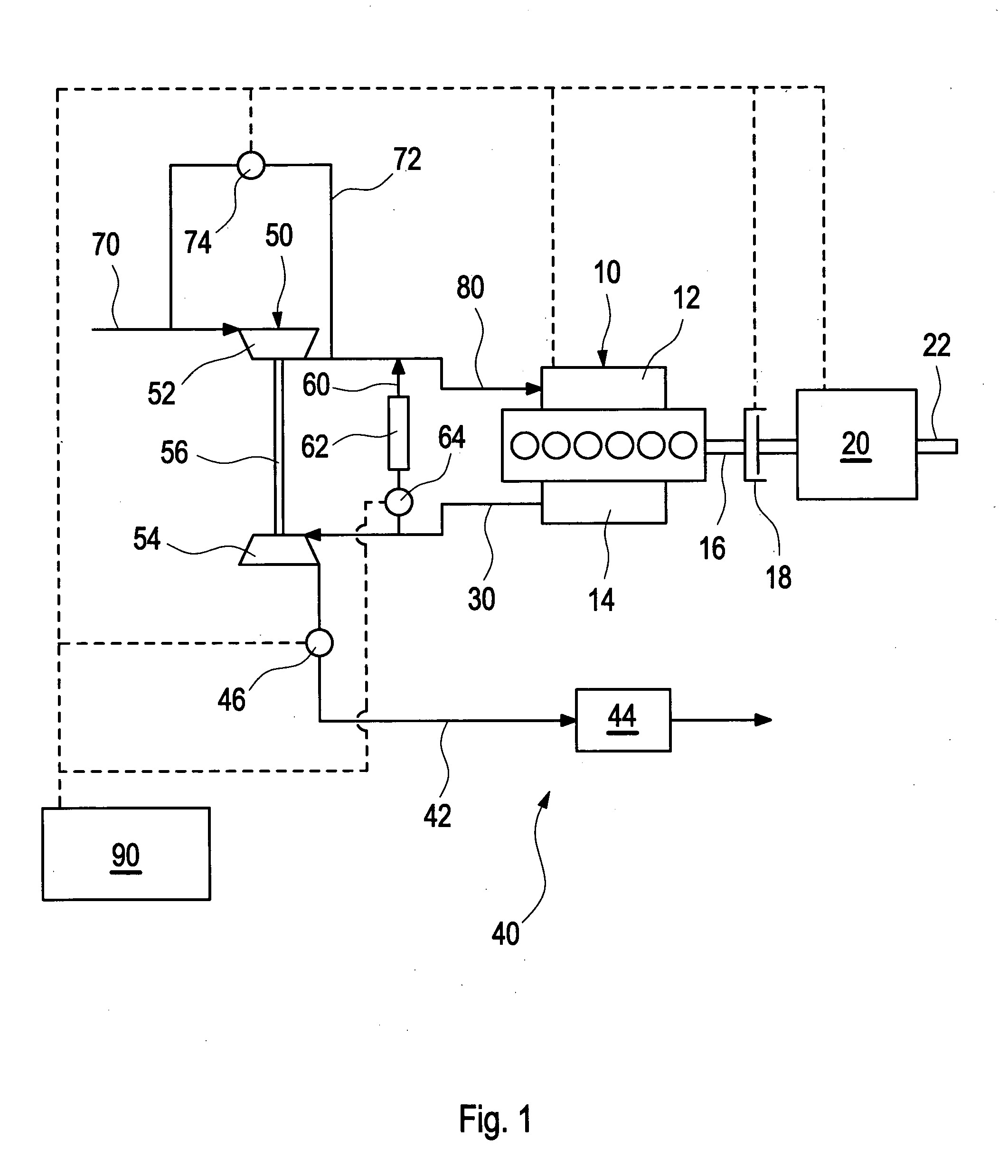

Alternative Left/Right Bank EGR Loop Operation to Improve Fouling Resistance During Low Mass Flow Engine Mode

InactiveUS20080060624A1Reduce formationReduce nitrogen oxide emissionsElectrical controlInternal combustion piston enginesControl systemDiesel engine

A system for a vehicle, comprising of a diesel engine having an intake system and an exhaust system, a first EGR loop coupled between said intake system and said exhaust system and having a first valve and a first cooler located therein, a second EGR loop coupled between said intake system and said exhaust system and having a second valve and a second cooler located therein, and a control system operating the first and second valves in a first condition where both valves provide EGR flow to the engine, and at least temporarily increasing flow in the first EGR loop and decreasing flow in the second EGR loop when EGR flow is decreased to a condition where buildup in one of said coolers is increased.

Owner:FORD GLOBAL TECH LLC

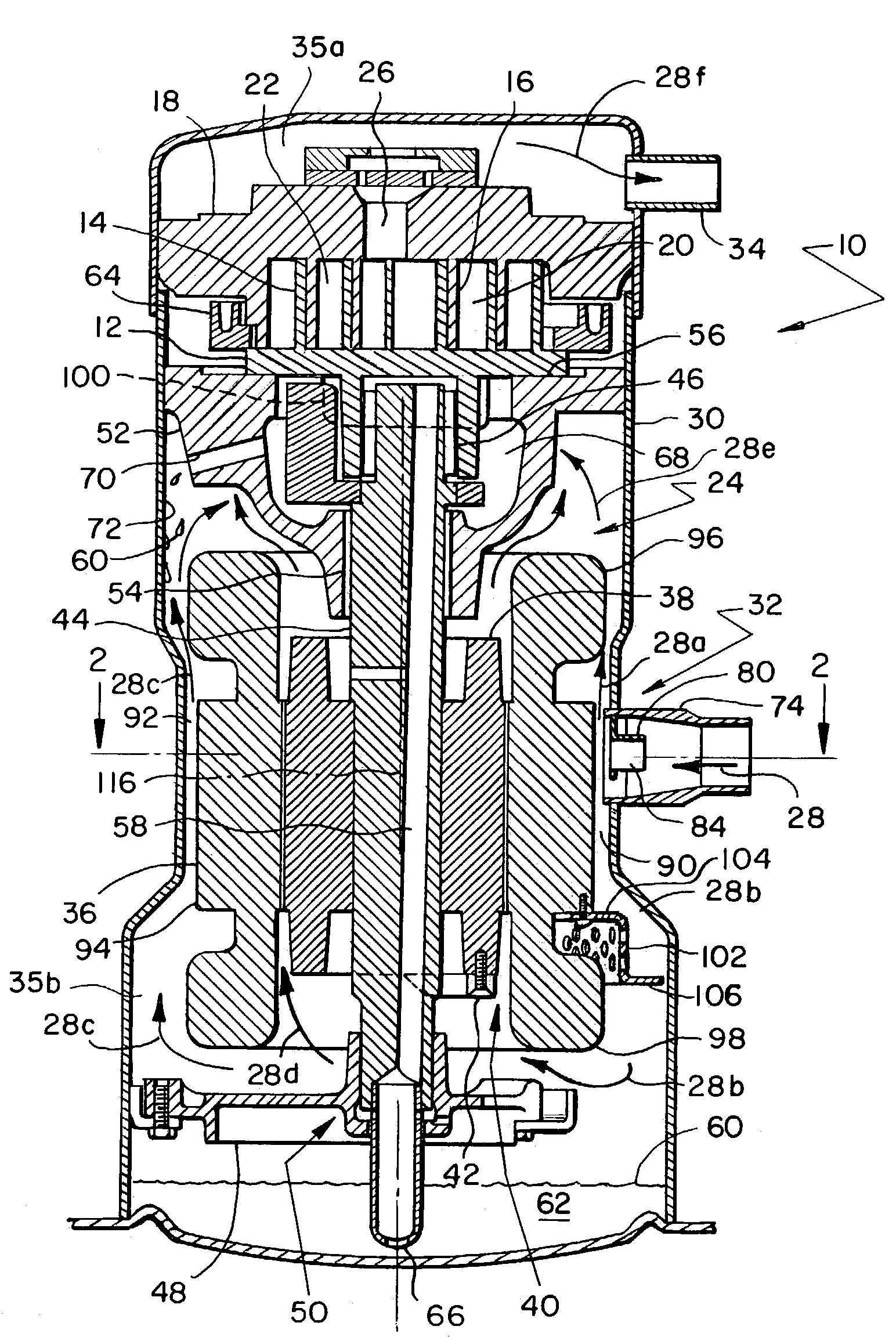

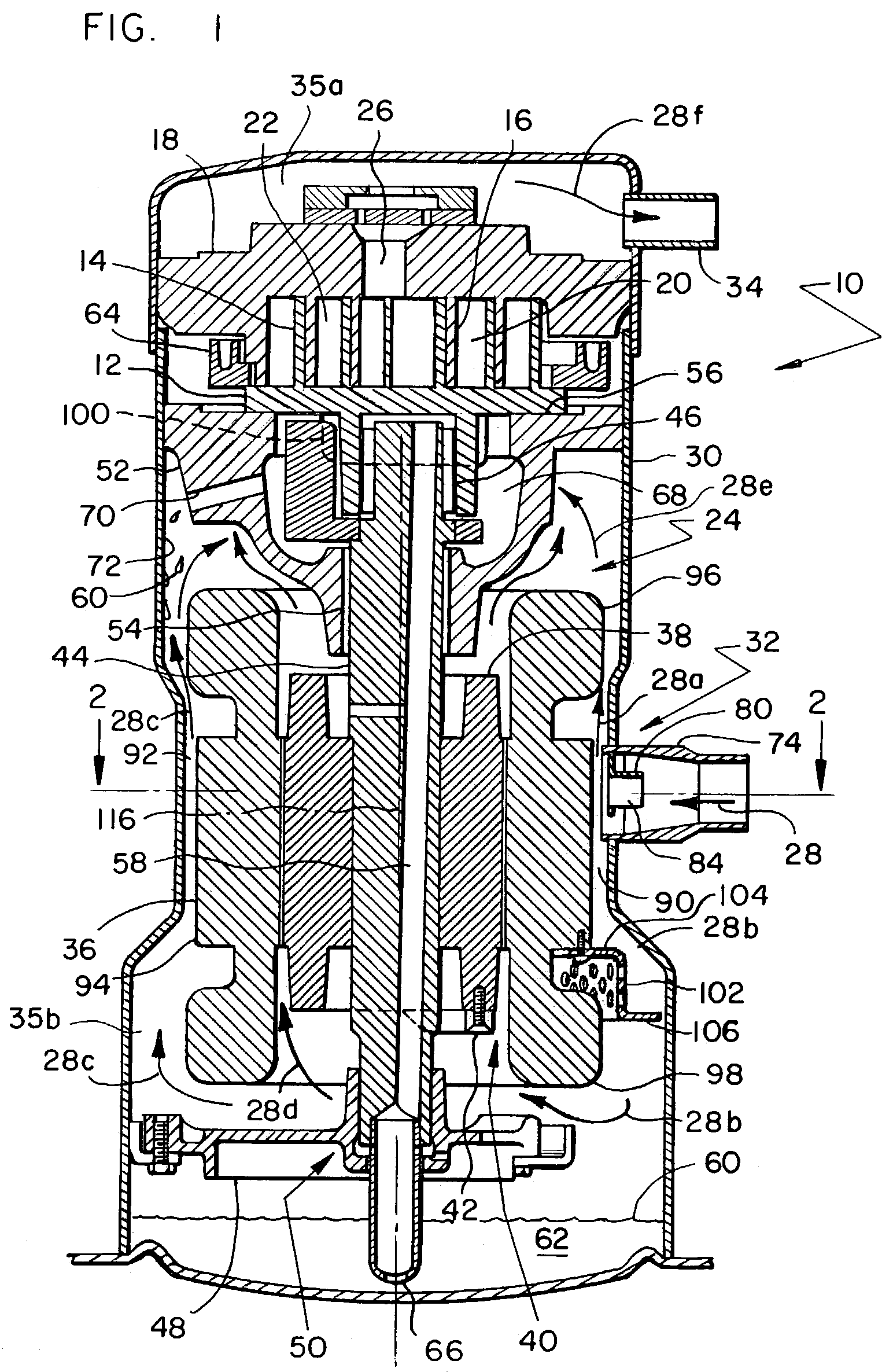

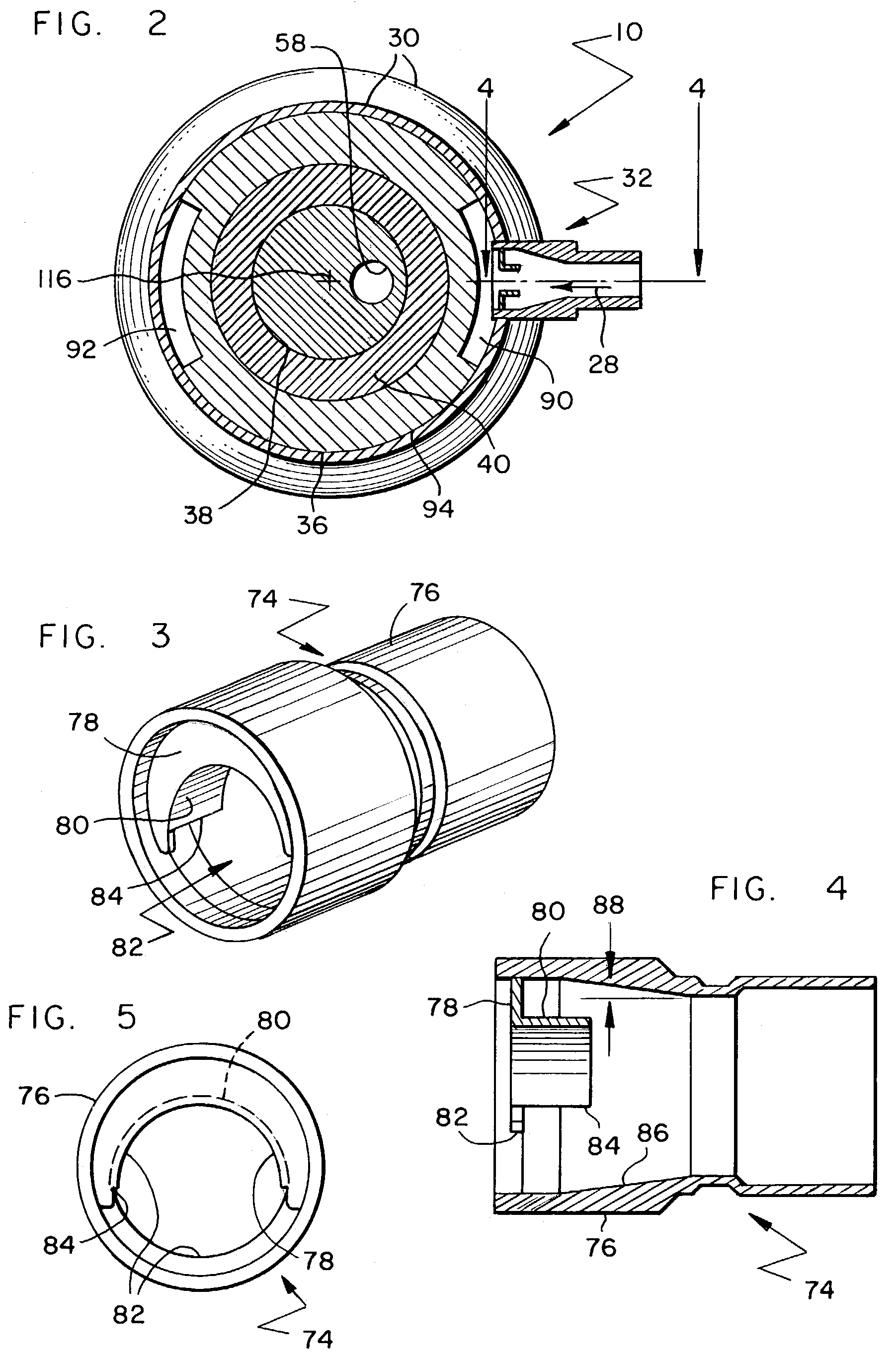

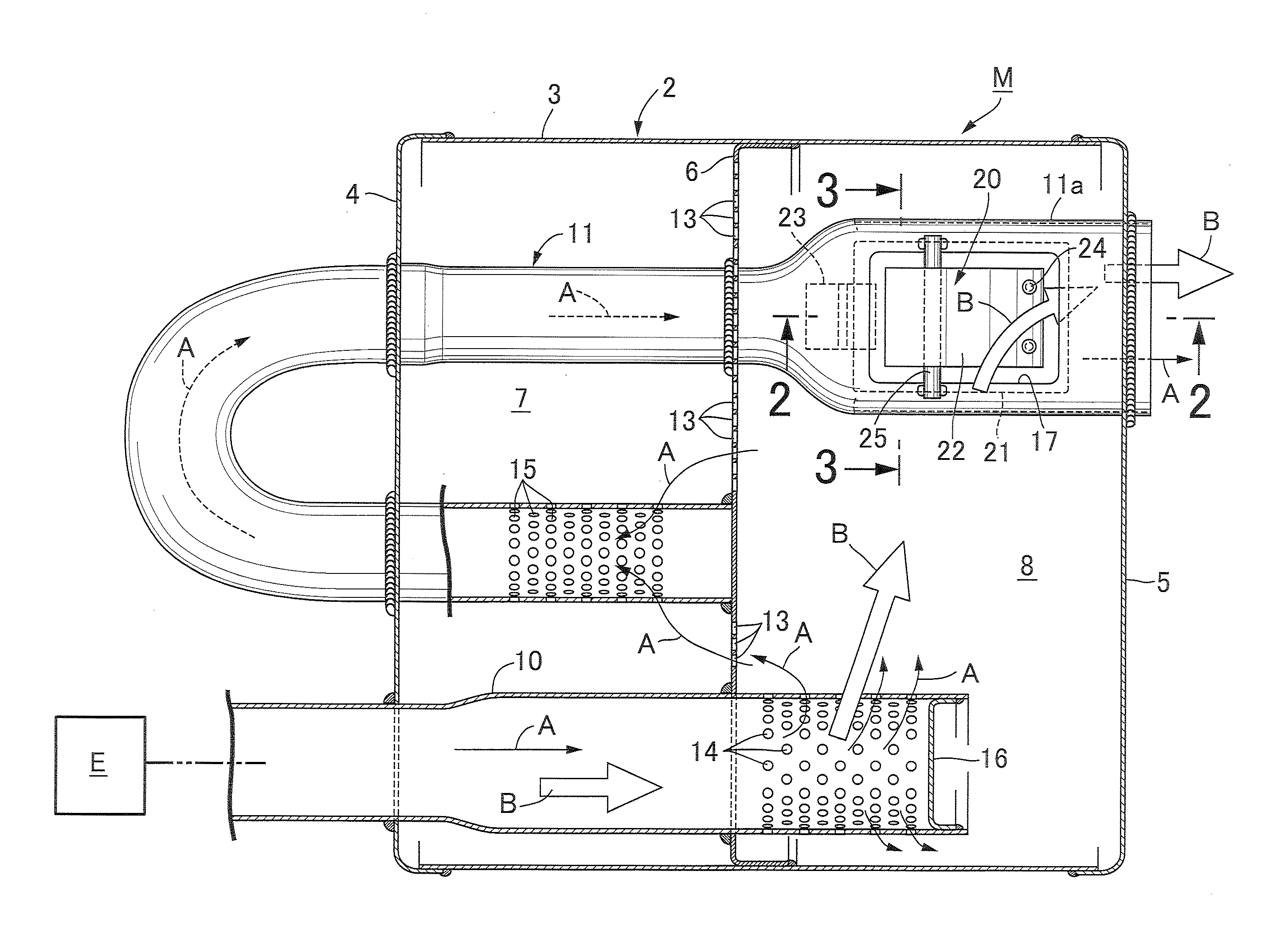

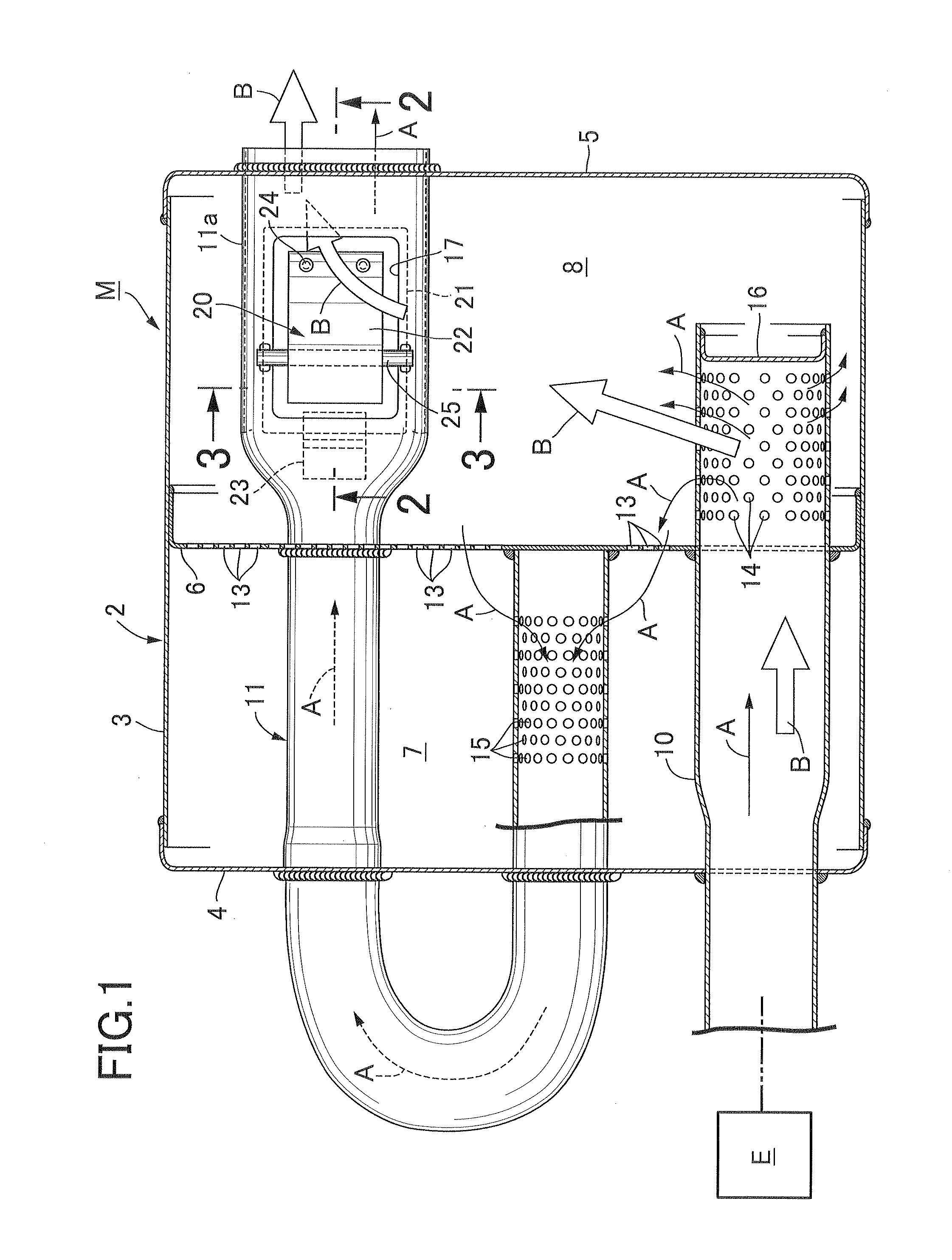

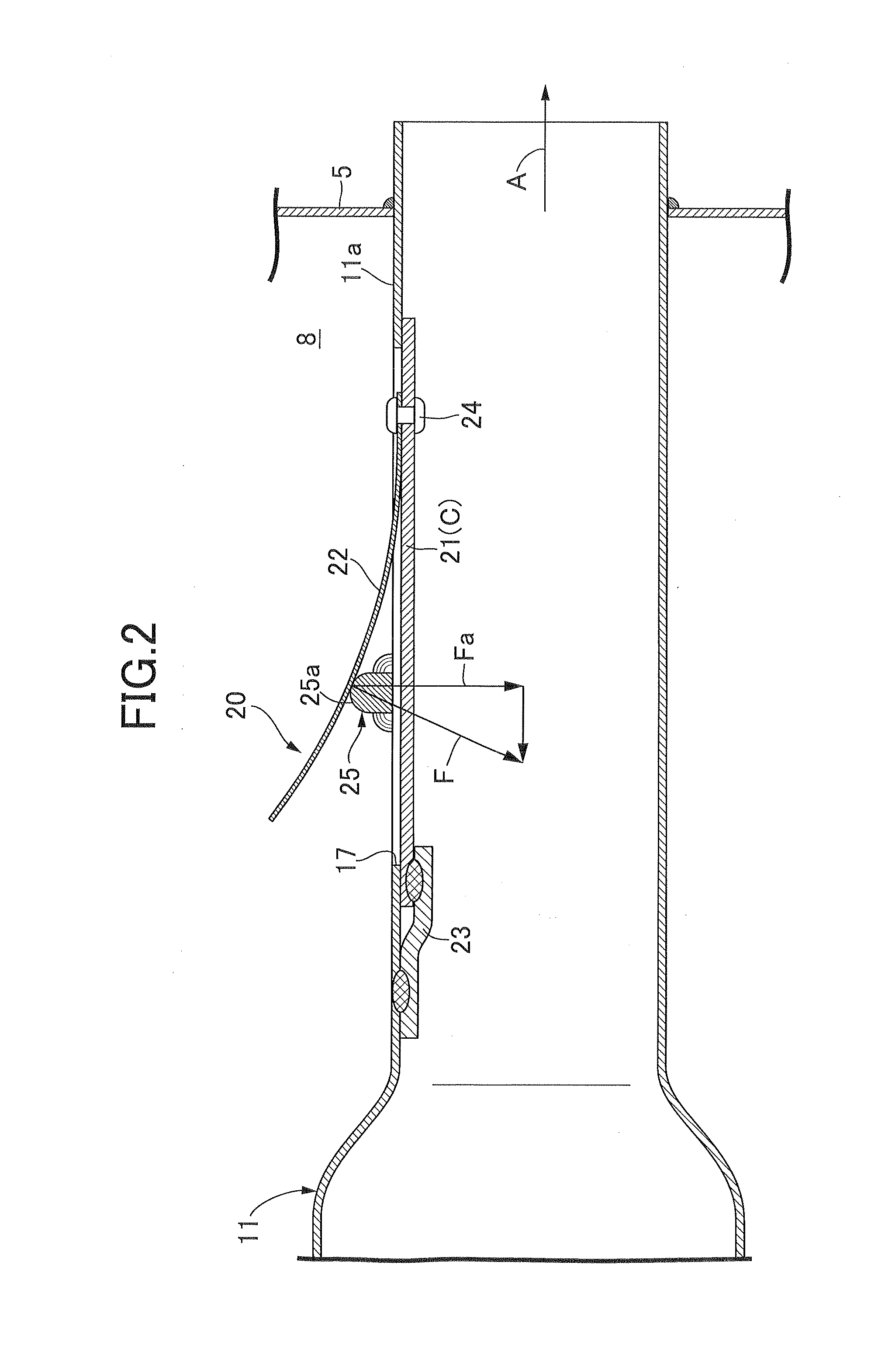

Scroll compressor with bifurcated flow pattern

ActiveUS7311501B2Reduce oilShorten speedRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsOil separationEngineering

A scroll compressor includes various features that promote a bifurcated flow pattern of gas through a compressor shell to reduce oil entrainment. After entering the shell, some gas travels upward, which reduces the volume of gas traveling downward toward an oil sump. To accomplish this, the compressor's motor can be surrounded by a sleeve having upper and lower apertures for directing the flow to the motor's upper and lower stator end turns. In some embodiments, a suction inlet is strategically positioned relative to two gas passageways that are between the stator and the compressor shell. The inlet's position is such that one passageway receives incoming gas and divides the flow in opposite directions: upward and downward. The other passageway only conveys the gas upward. In addition, a suction baffle, a diffuser, a streamlined counterweight and / or a suction line oil trap can also help promote gas / oil separation or minimize oil entrainment.

Owner:TRANE INT INC

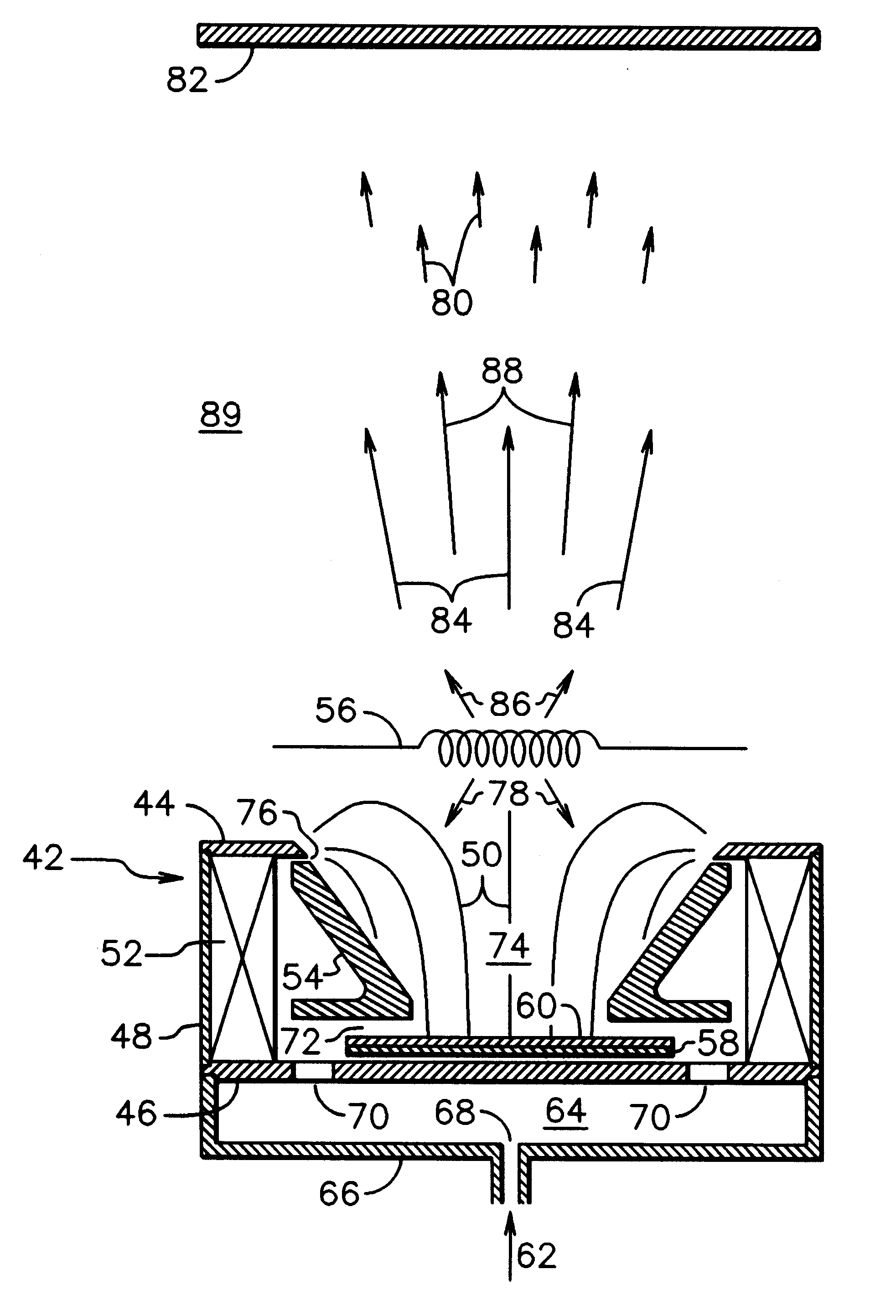

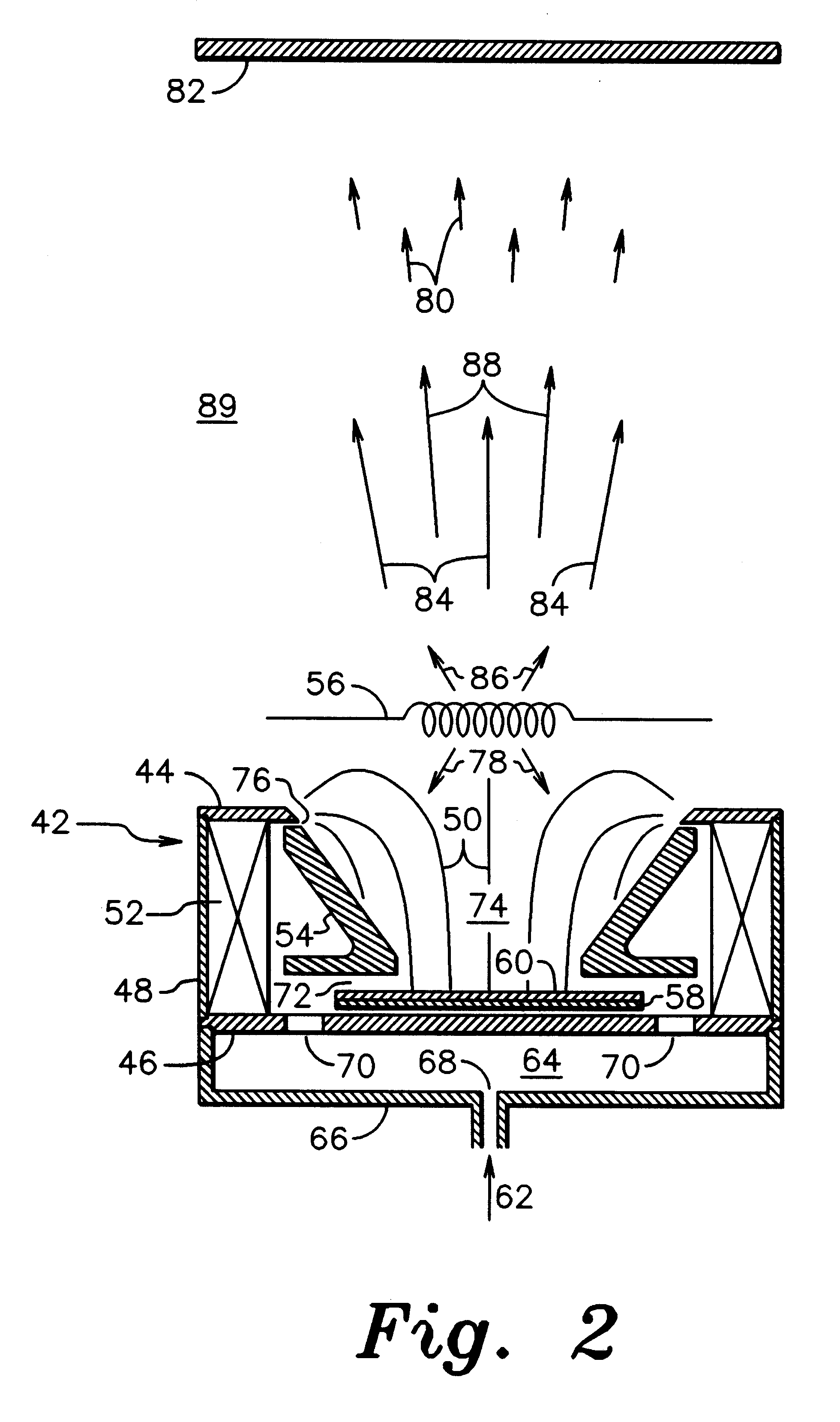

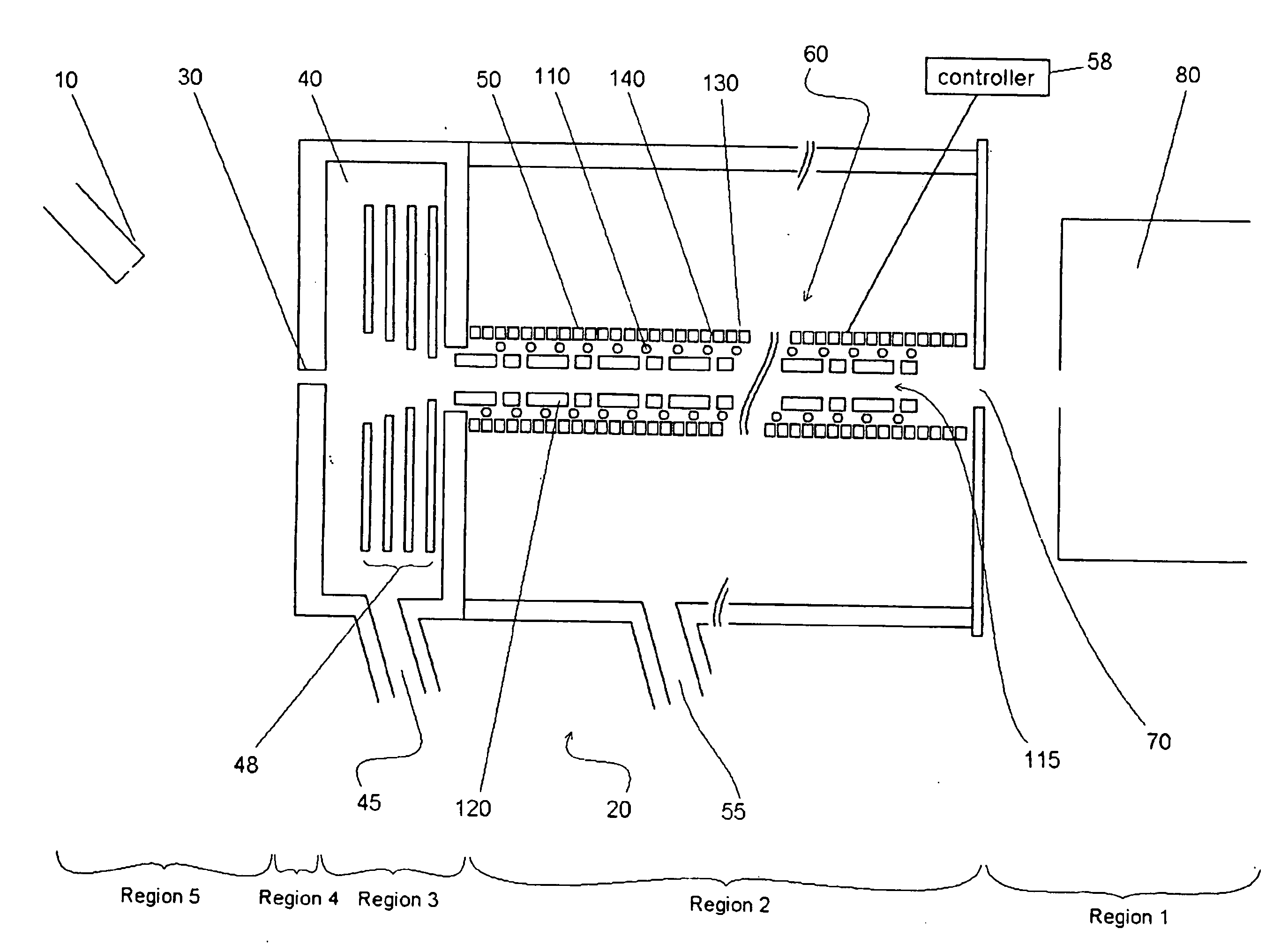

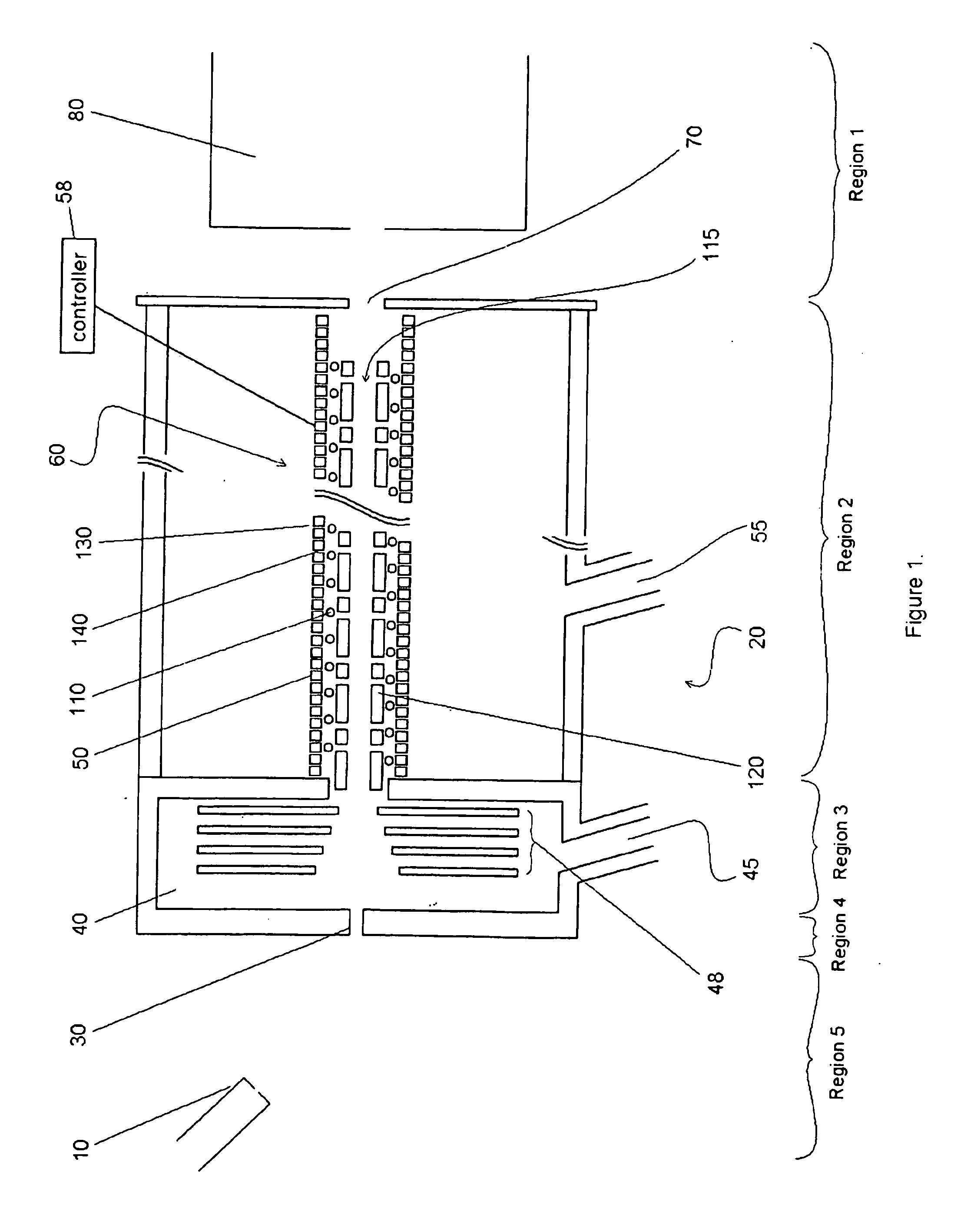

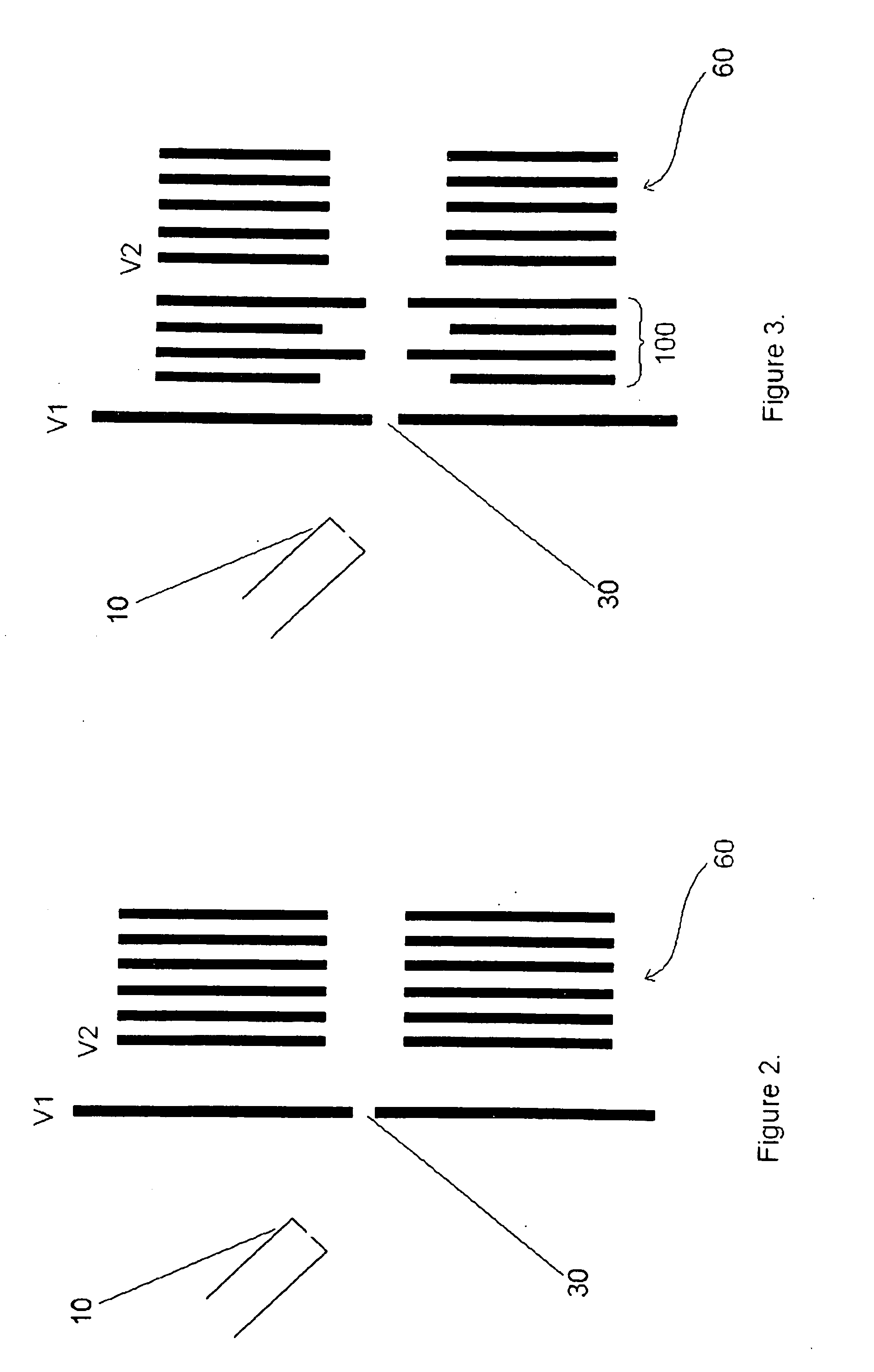

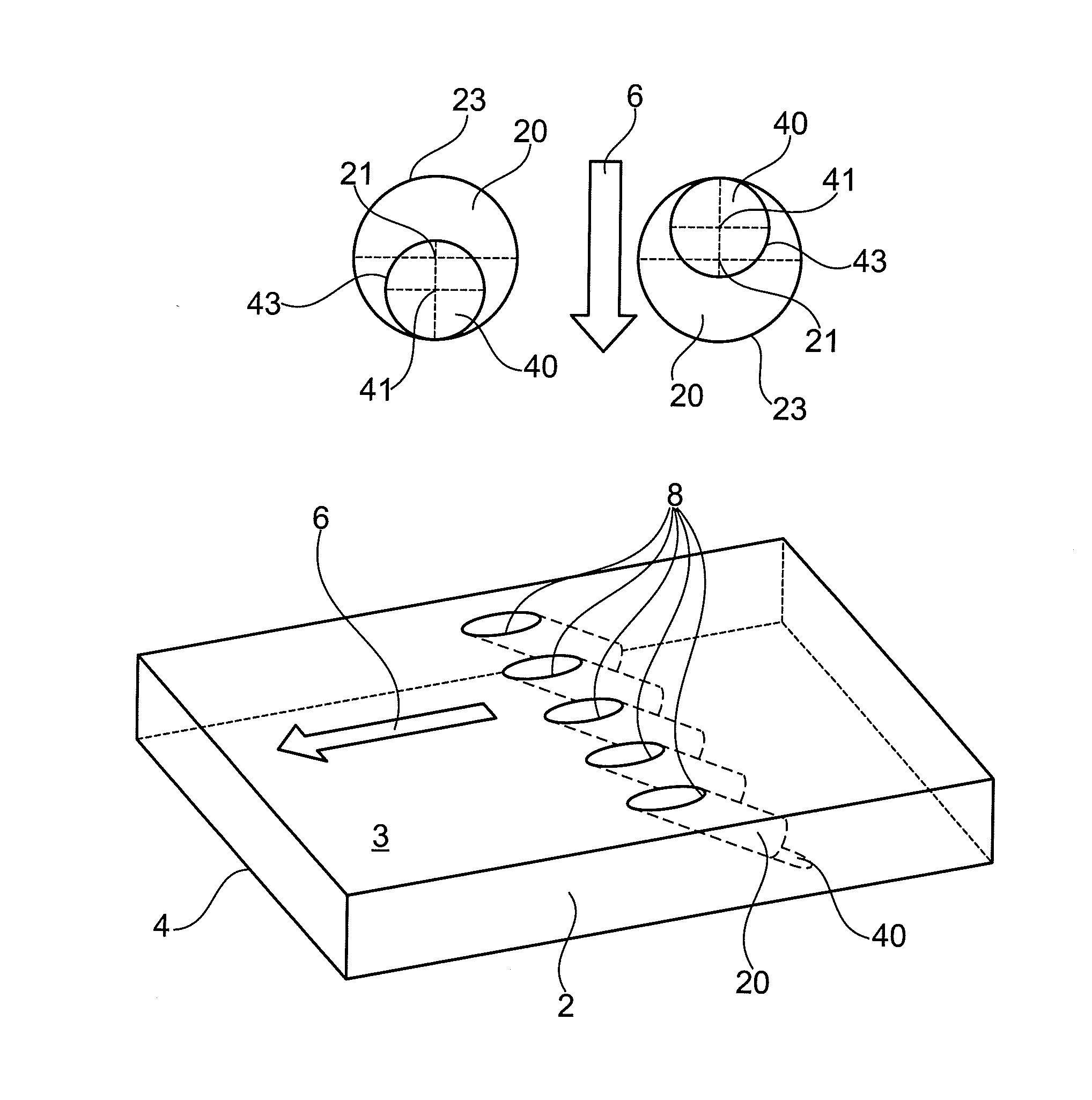

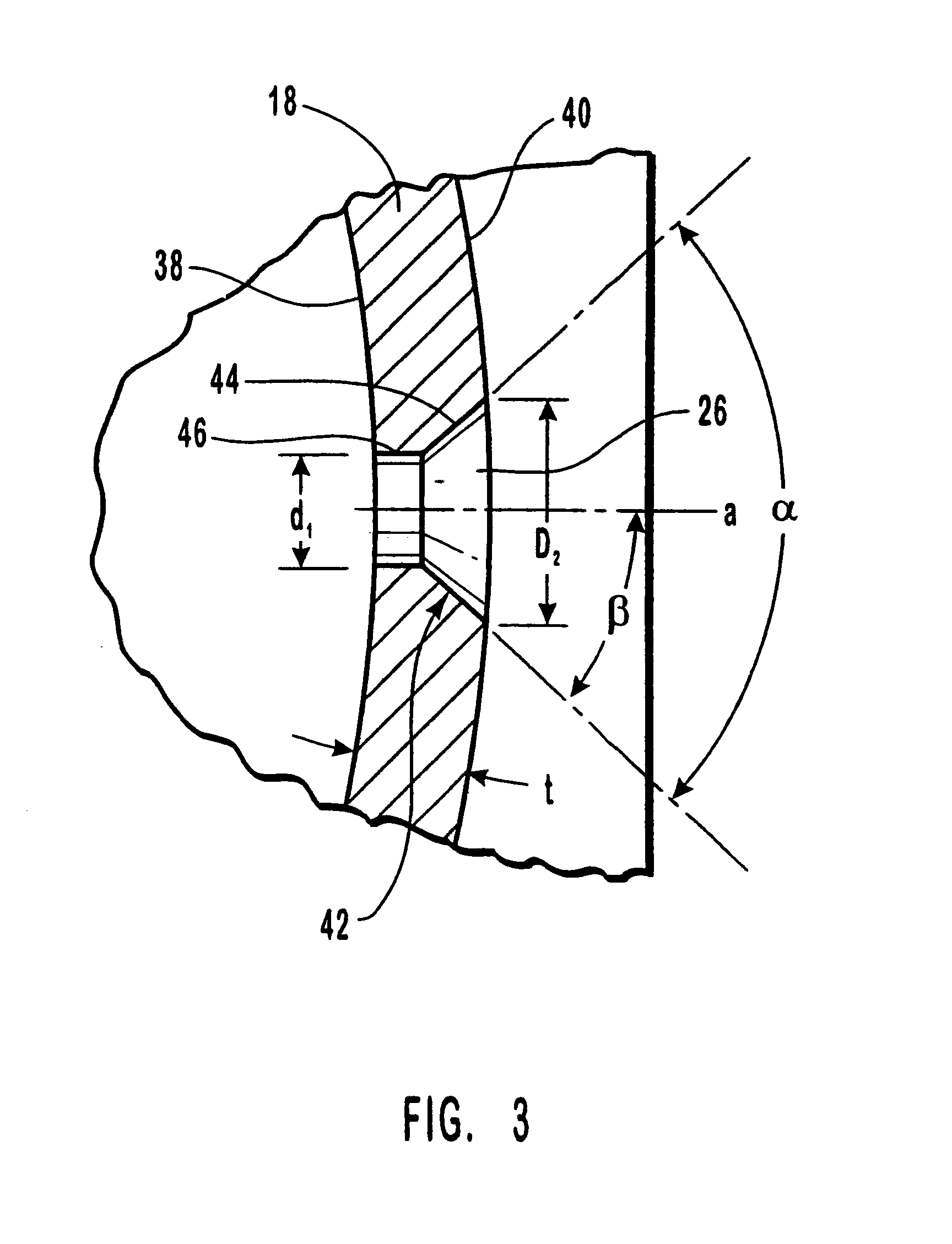

Ion Transfer Arrangement with Spatially Alternating DC and Viscous Ion Flow

ActiveUS20100038533A1Reduce gas flowWeaken energyBeam/ray focussing/reflecting arrangementsElectron/ion optical arrangementsViscous flowElectrical polarity

A method of transporting gas and entrained ions between higher and lower pressure regions of a mass spectrometer comprises providing an ion transfer conduit 60 between the higher and lower pressure regions. The ion transfer conduit 60 includes an electrode assembly 300 which defines an ion transfer channel. The electrode assembly 300 has a first set of ring electrodes 305 of a first width D1, and a second set of ring electrodes of a second width D2 (≧D1) and interleaved with the first ring electrodes 305. A DC voltage of magnitude V1 and a first polarity is supplied to the first ring electrodes 205 and a DC voltage of magnitude V2 which may be less than or equal to the magnitude of V1 but with an opposed polarity is applied to the second ring electrodes 310. The pressure of the ion transfer conduit 60 is controlled so as to maintain viscous flow of gas and ions within the ion transfer channel.

Owner:THERMO FISHER SCI BREMEN

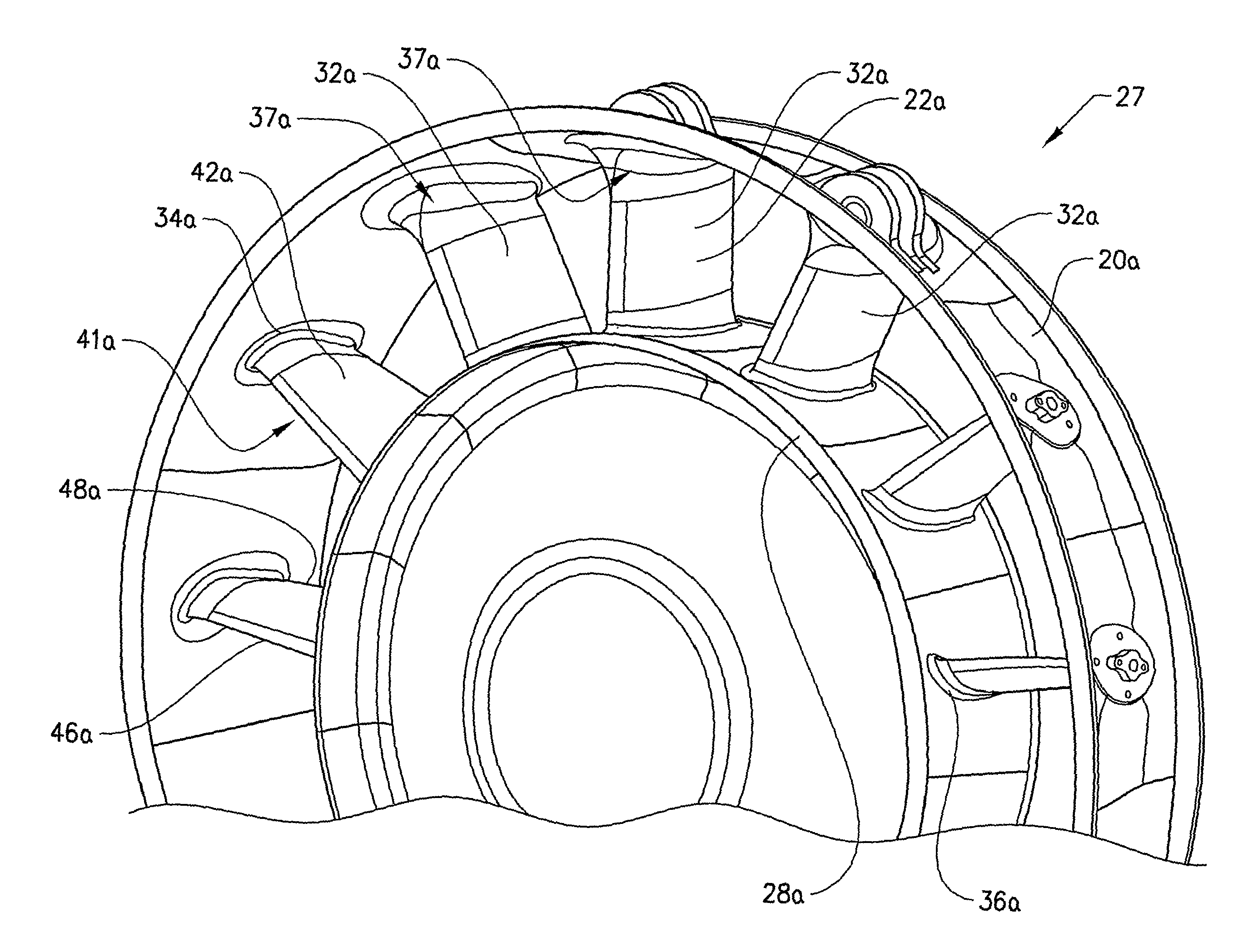

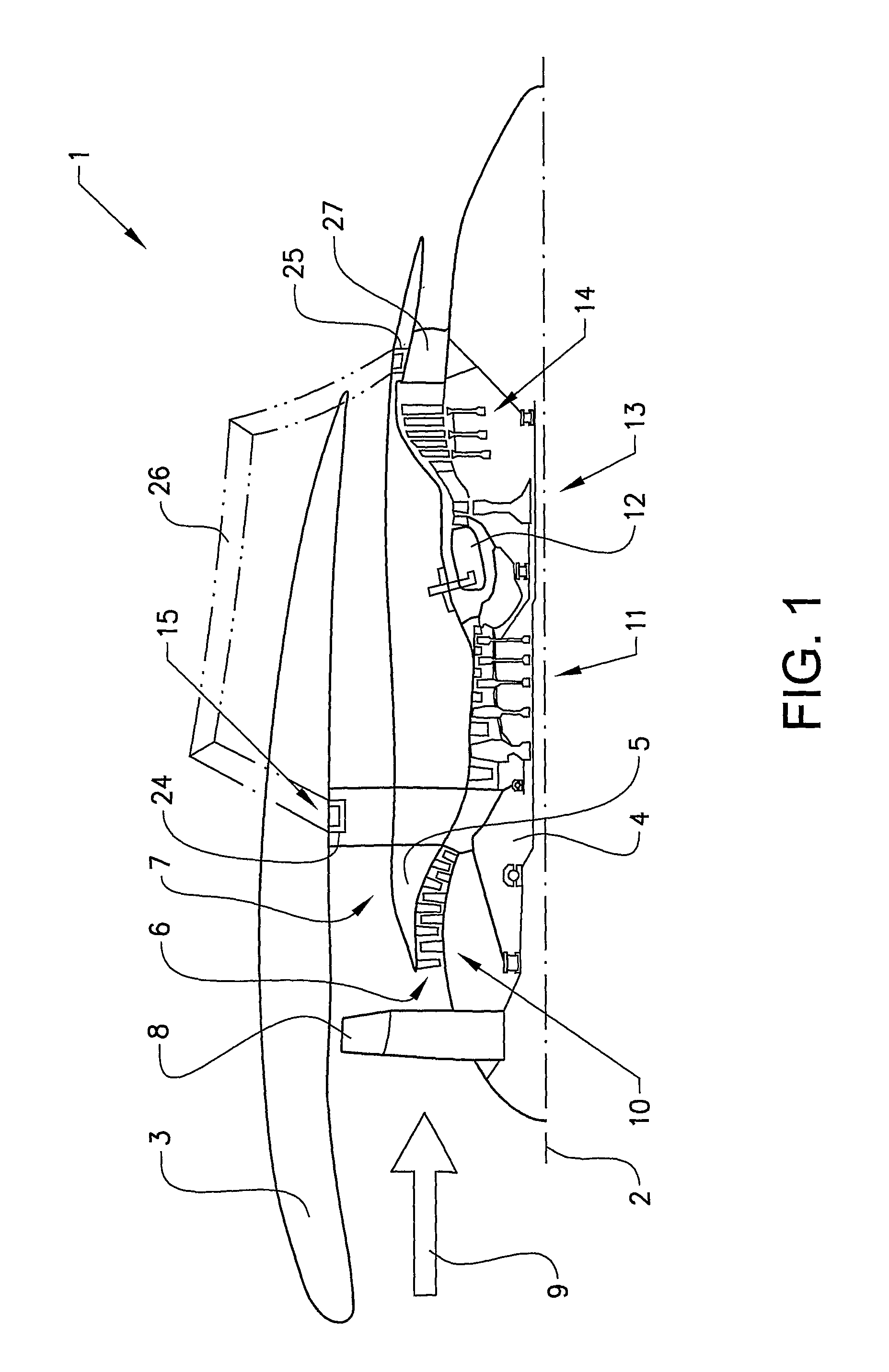

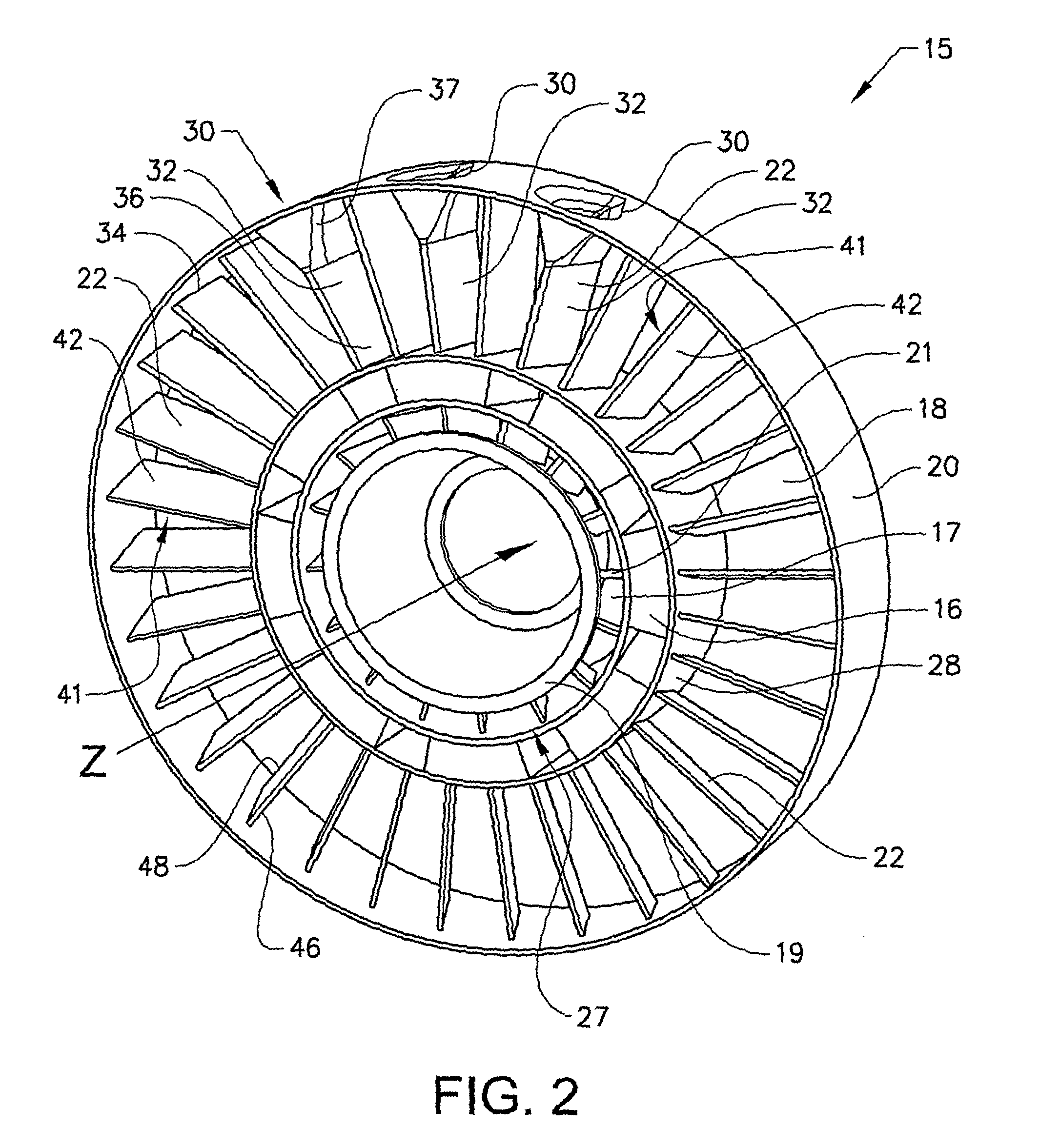

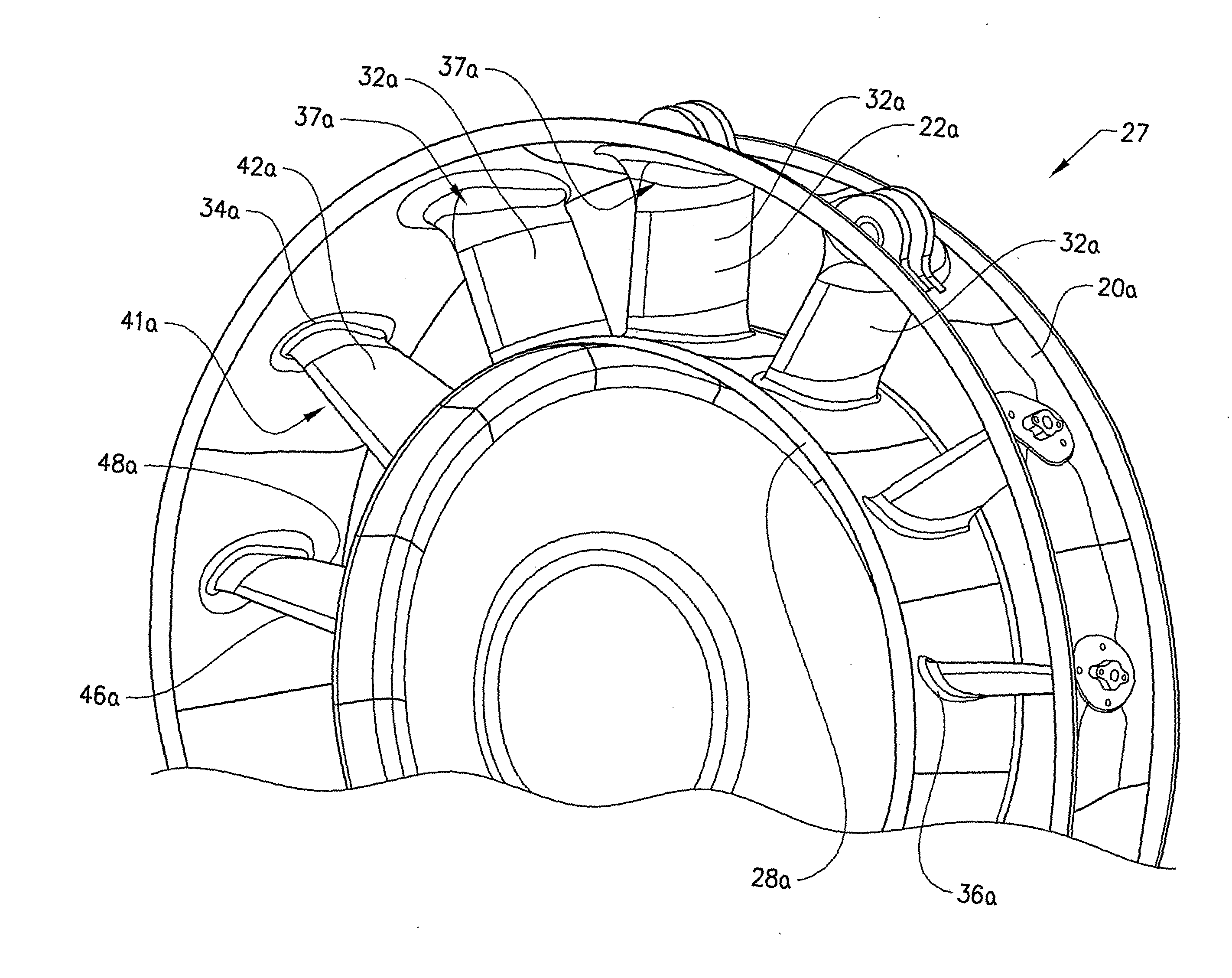

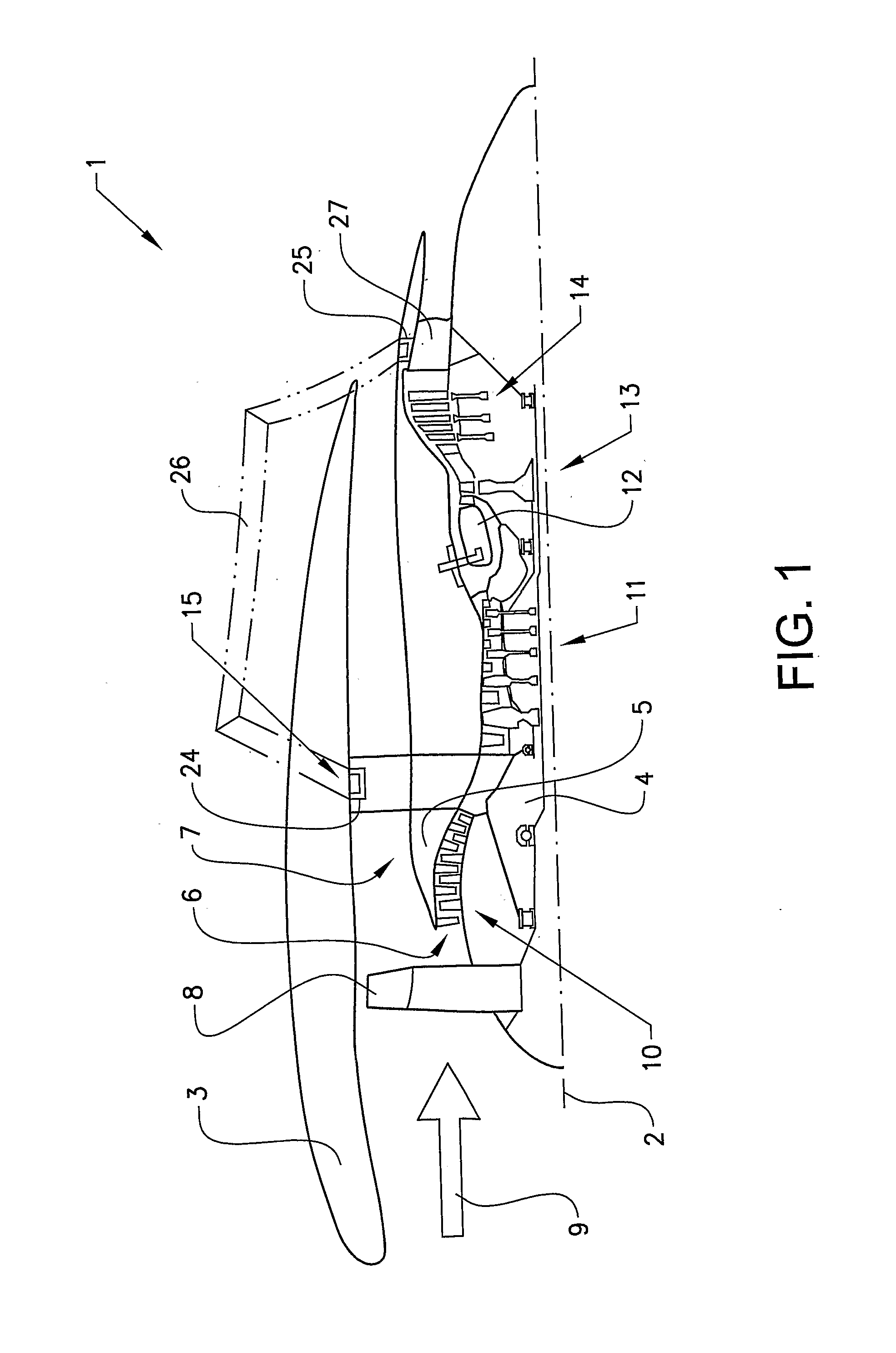

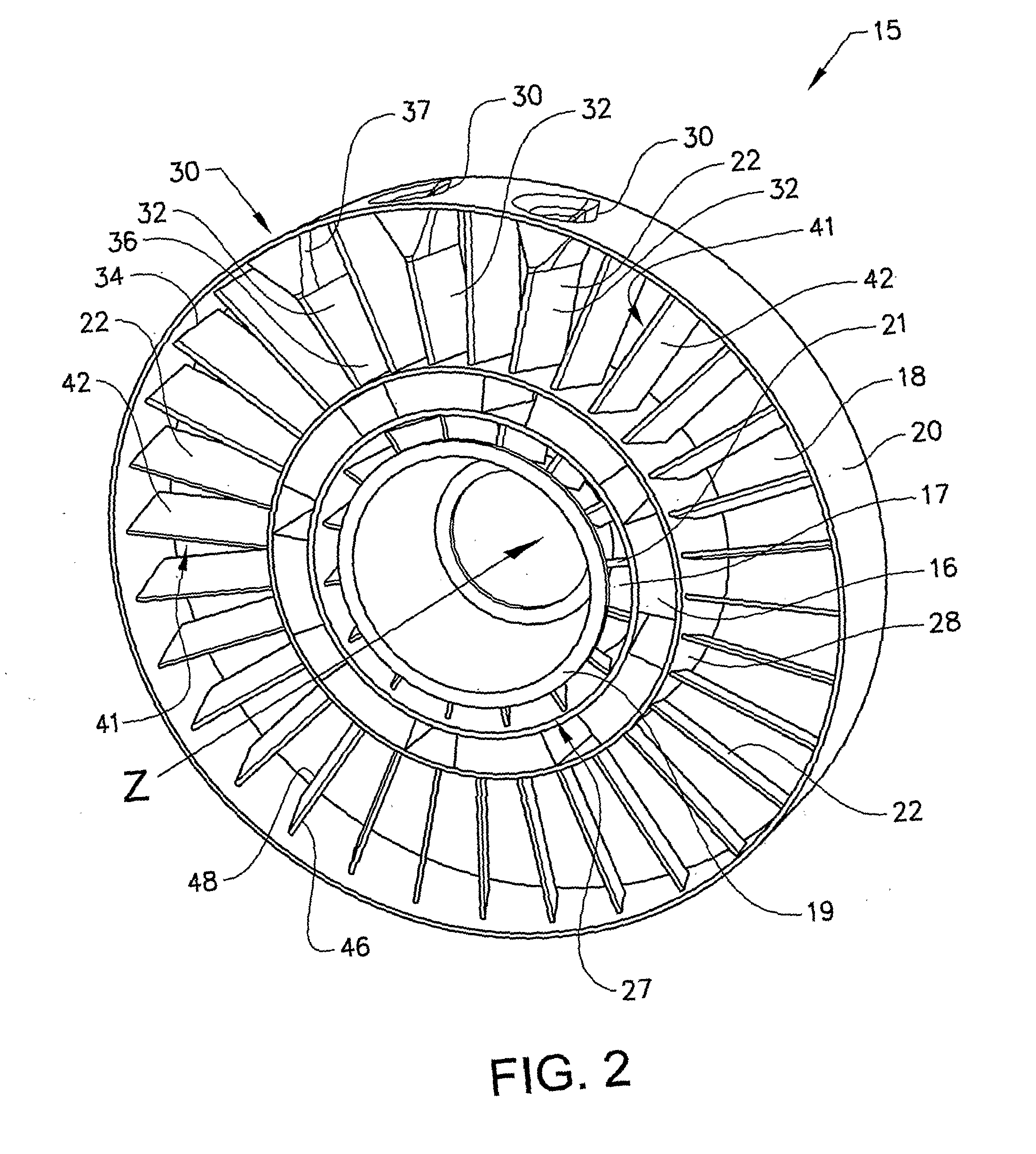

Strut and a gas turbine structure comprising the strut

ActiveUS8794912B2Low efficiencyImprove efficiencyPump componentsGas turbine plantsEngine mountGas turbines

A strut for application between an outer ring and an inner ring in a gas turbine structure and a gas turbine structure including such a strut are provided. The strut includes an end portion which has a diverging shape so that an internal space is formed in the end portion for receiving at least part of an engine mount. Engine mounting lugs can be positioned at such struts.

Owner:GKN AEROSPACE SWEDEN AB

Strut and a gas turbine structure comprising the strut

ActiveUS20120093642A1Less-effectiveReducing flow distortionPump componentsBlade accessoriesEngine mountGas turbines

A strut for application between an outer ring and an inner ring in a gas turbine structure and a gas turbine structure including such a strut are provided. The strut includes an end portion which has a diverging shape so that an internal space is formed in the end portion for receiving at least part of an engine mount. Engine mounting lugs can be positioned at such struts.

Owner:GKN AEROSPACE SWEDEN AB

Pollution control in wood products dryer

InactiveUS7160358B2Reduce gas flowEmission reductionCombination devicesDrying solid materials with heatParticulatesCombustor

Owner:MEGTEC TURBOSONIC

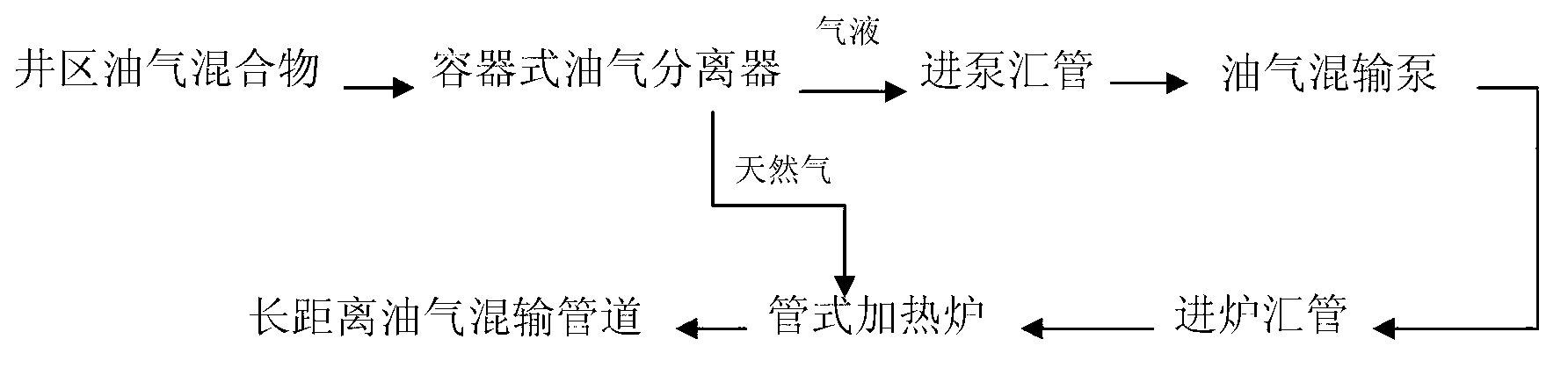

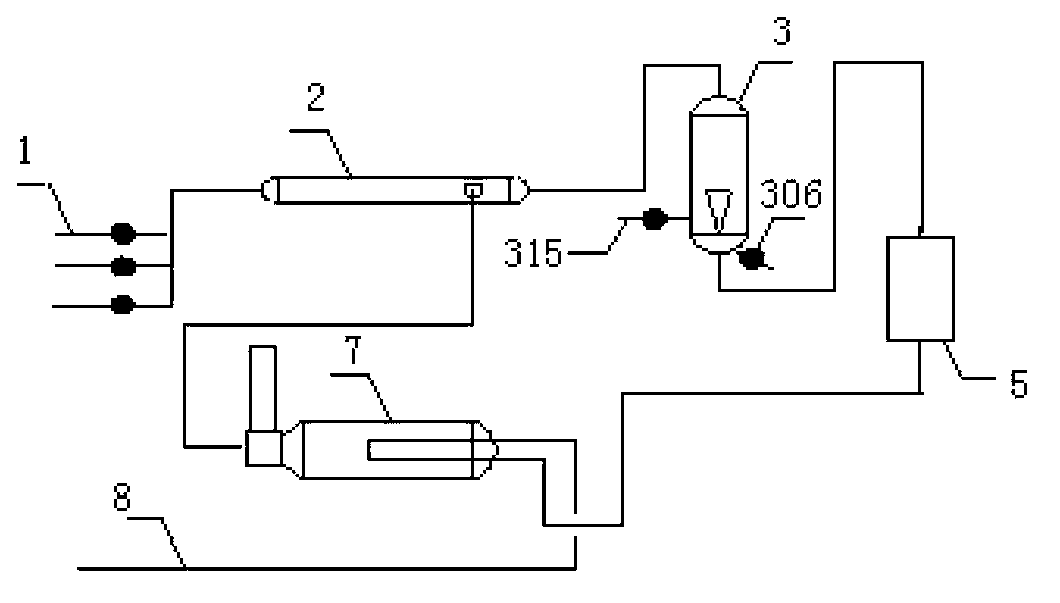

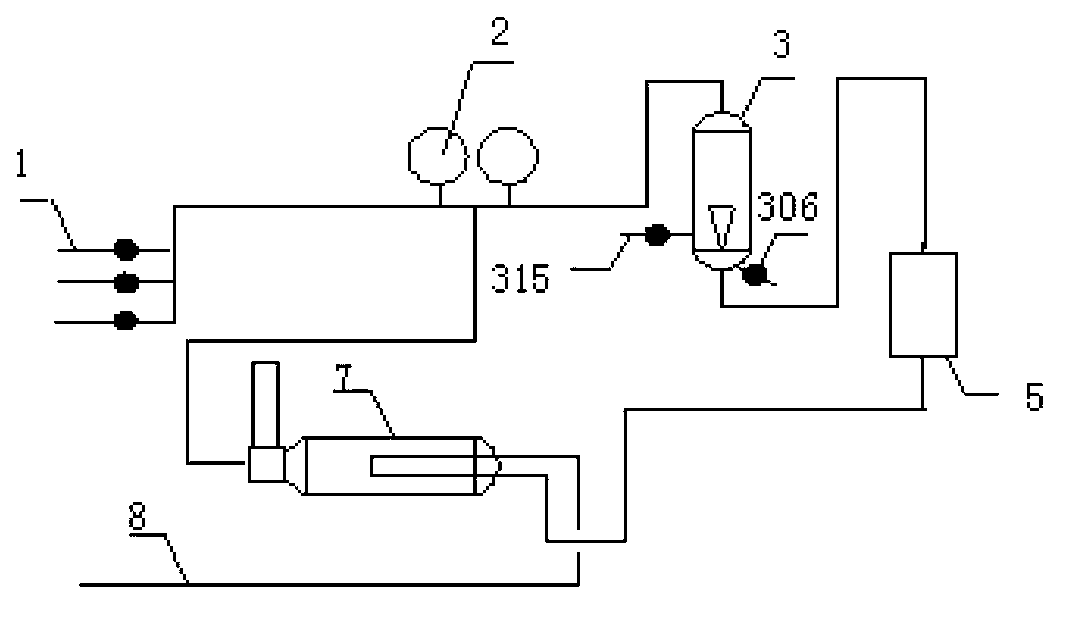

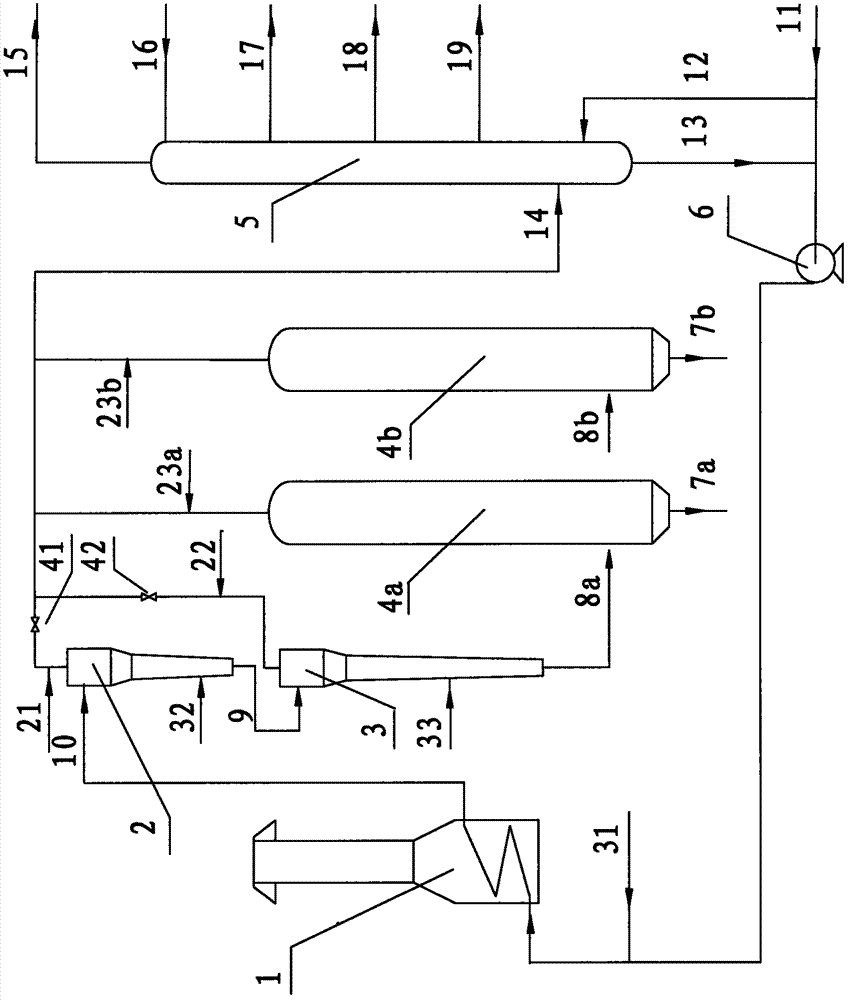

Pressurizing heating oil gas mixing transportation system and method

The invention relates to a pressurizing heating oil gas mixing transportation system and method. The system comprises an in-station valve group, a fuel gas separator, an oil gas mixing transportation pump, a pipe type heating furnace and a long-distance oil gas mixing transportation pipe which are sequentially communicated through a pipe. A multi-phase shock excitation sand remover, a multi-phase mixing transportation pump group inlet uniform flow device and a gas liquid separation flow divider. Gas and liquid mixture from an oil field well area enters the pipe type fuel gas separator, a part of natural gas is separated to serve as fuel of the heating furnace, surplus gas liquid mixture enters the multi-phase shock excitation sand remover to be subjected to sand removing, enters the multi-phase mixing transportation pump group inlet uniform flow device to be subjected to uniform flow distribution and is delivered to the gas liquid separation flow divider through the oil gas mixing transportation pump, and the separated liquid enters the pipe type heating furnace to be heated and is mixed with the separated gas to enter the long-distance oil gas mixing transportation pipe. Safe stable high-efficiency operation of the system is guaranteed, service life of devices is prolonged, and project investment, energy consumption, operation maintenance and operation cost are reduced.

Owner:PETROCHINA CO LTD +2

Gas flow pre-charge for a plasma arc torch

ActiveUS20050045600A1Reduce airflow fluctuationsReduce gas flowArc welding apparatusPlasma welding apparatusHeat flowControl system

A system for controlling gas flow from a gas source, through a gas conduit, and to a plasma arc torch during a transition from a cold flow when no arc is present to a hot flow when an arc is provided by the present invention. The system comprises a first solenoid in communication with the gas source, a second solenoid disposed proximate the plasma arc torch, and a bypass circuit in communication with the gas source and the second solenoid. The bypass circuit comprises a bypass solenoid that controls the gas pressure within the gas conduit to reduce gas flow fluctuations when transitioning from cold flow to hot flow. Additional gas control systems and methods are also provided that cause the gas pressure to be higher during cold flow, prior to arc ignition, which overcomes the rapid drop in flow that typically occurs during the transition to hot flow.

Owner:VICTOR EQUIP

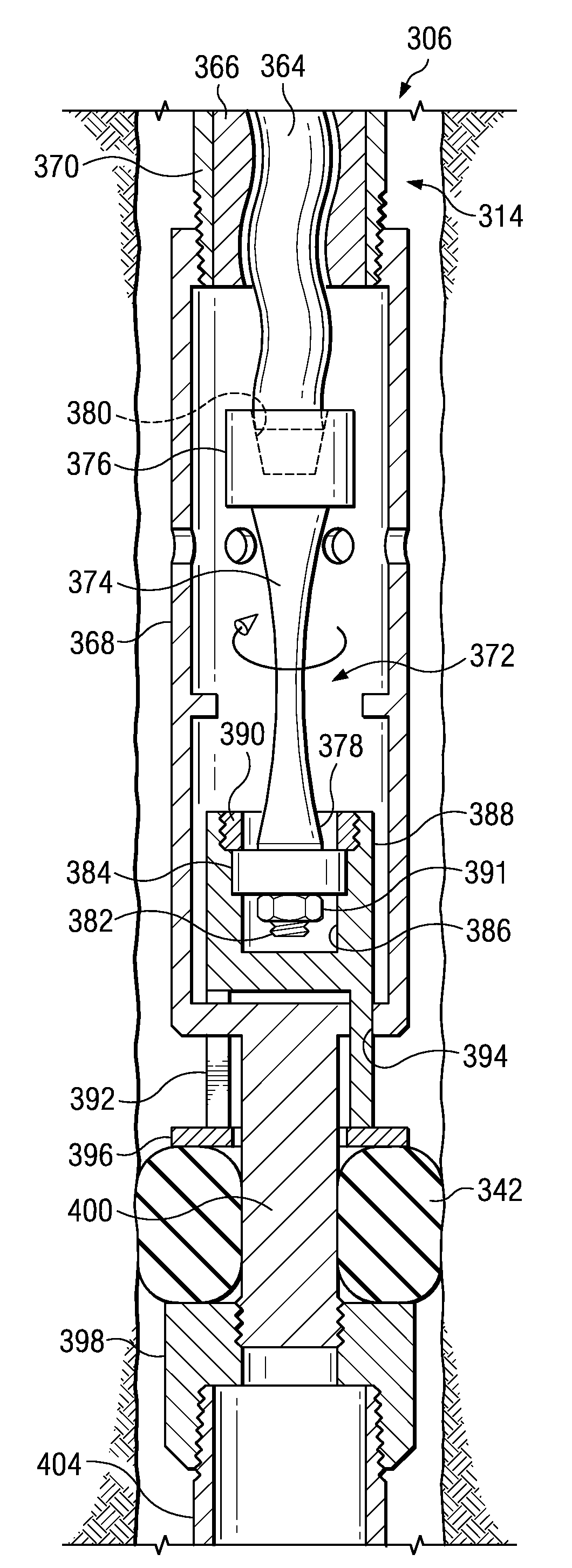

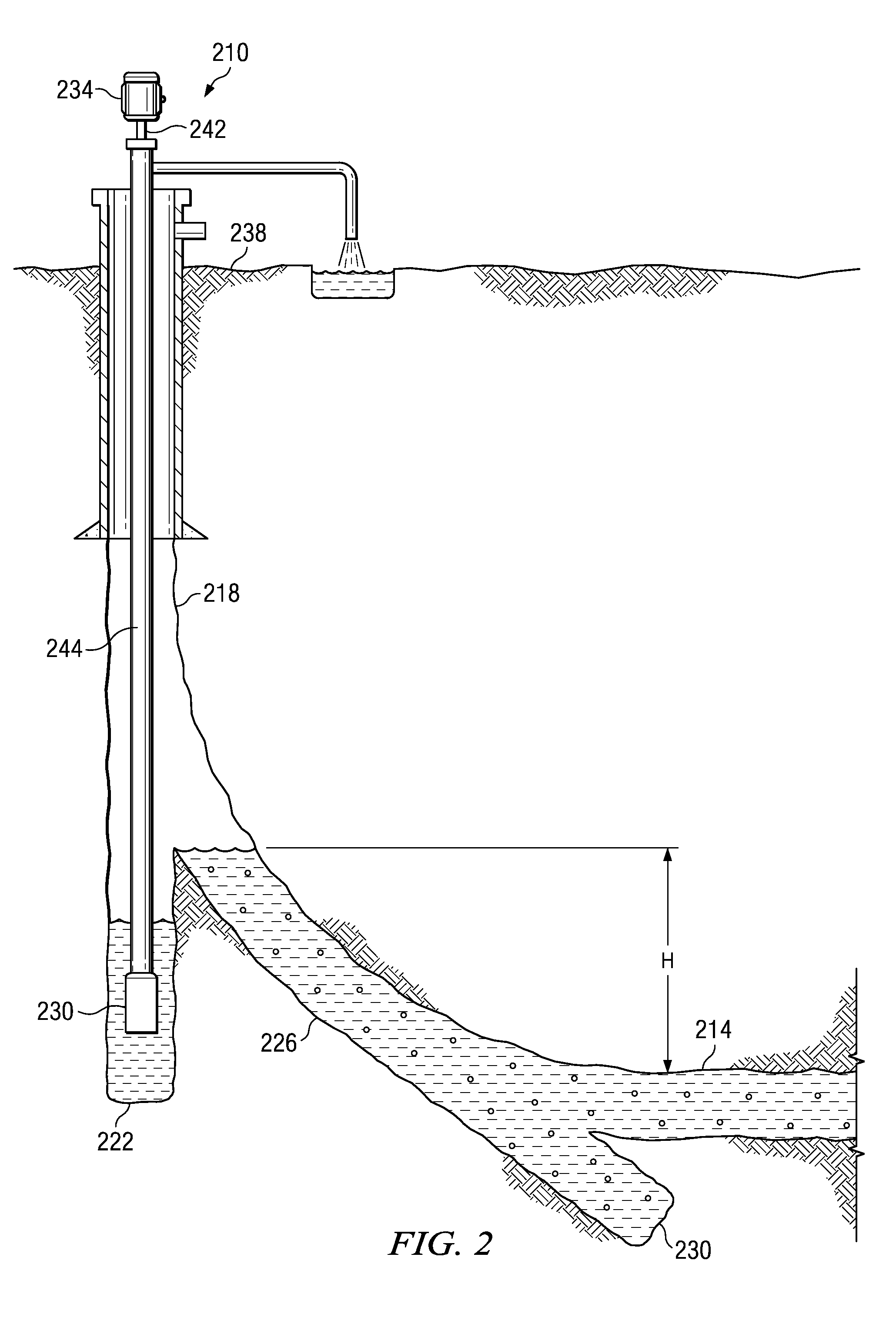

Flow control system having an isolation device for preventing gas interference during downhole liquid removal operations

InactiveUS20090032262A1Avoid flowReduce gas flowFluid removalRotary piston pumpsControl systemEngineering

A flow control system includes a pump positioned in a wellbore to remove liquid from the wellbore. An isolation device is positioned downhole of the pump and is expandable within the wellbore between a sealed position and an unsealed position. The isolation device in the sealed position substantially reduces gas flow at the pump during removal of the liquid.

Owner:PINE TREE GAS

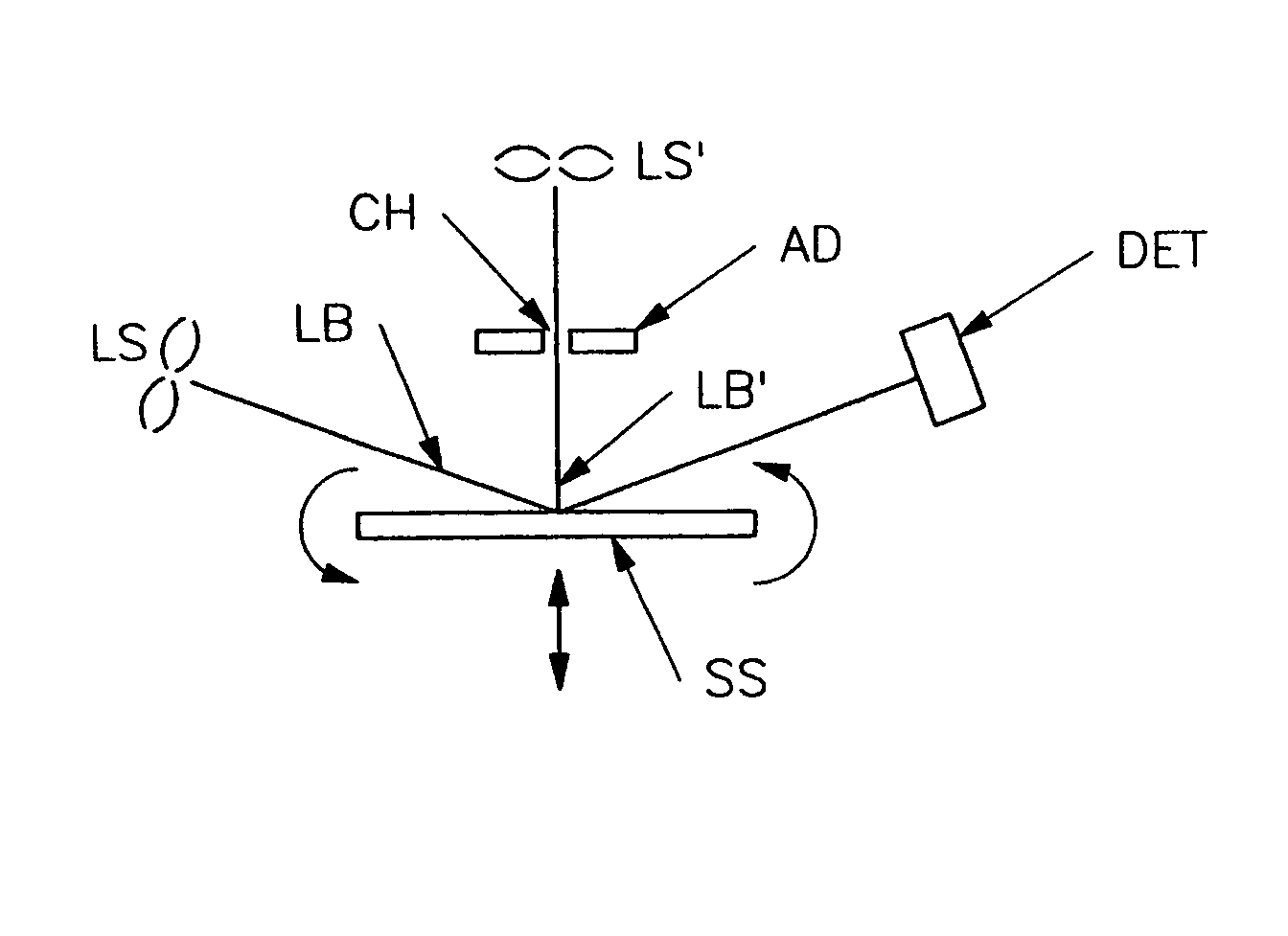

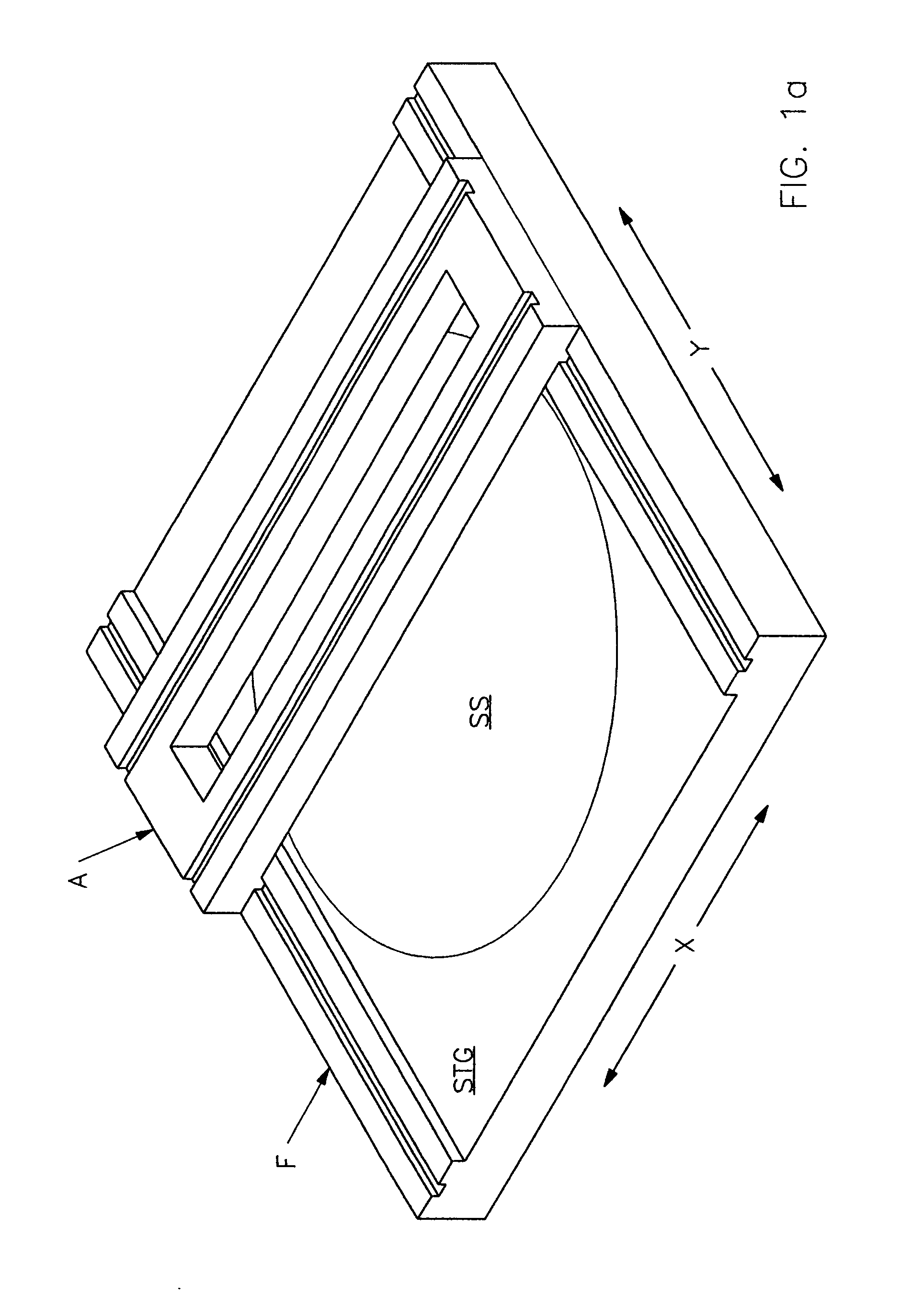

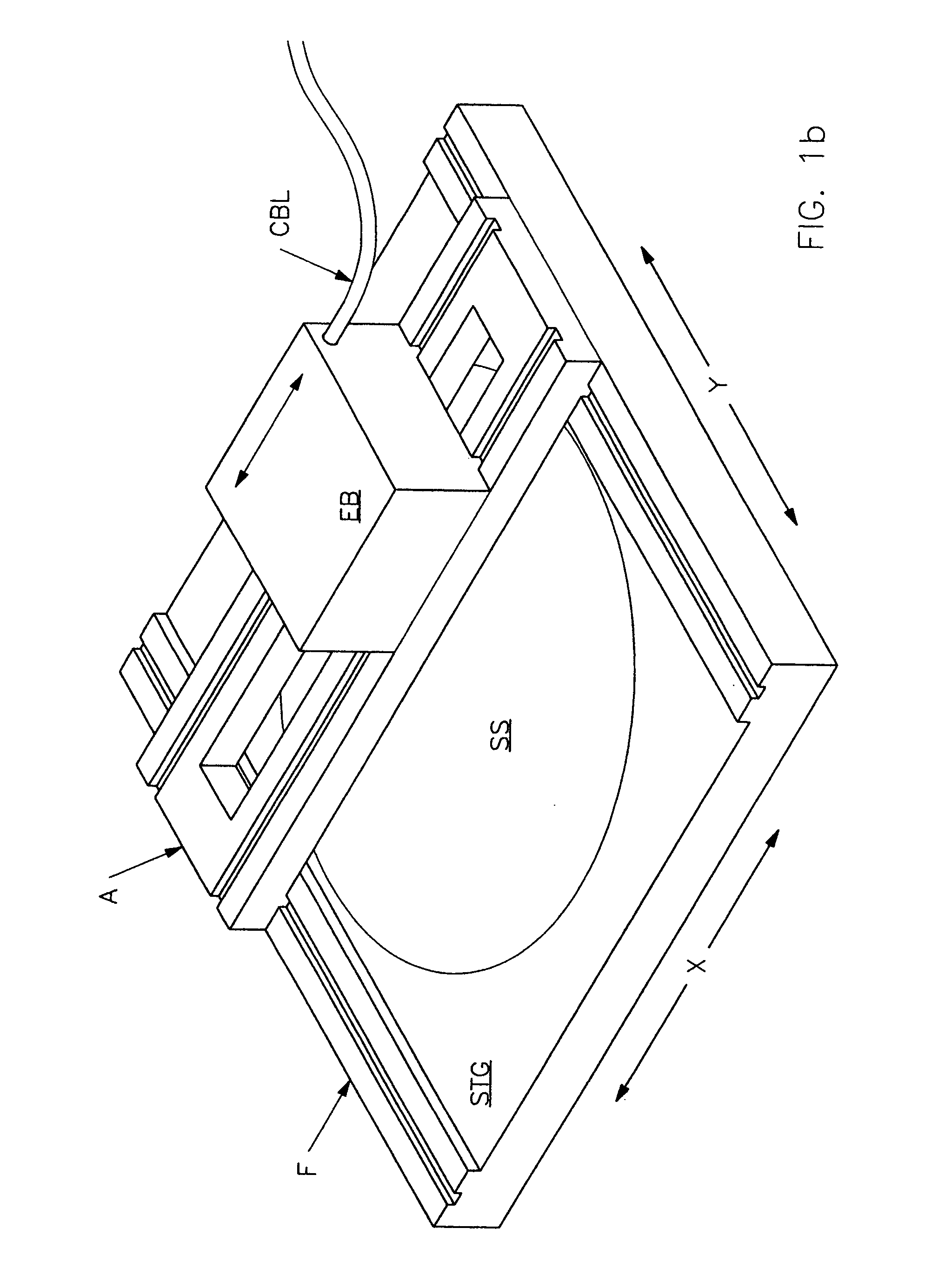

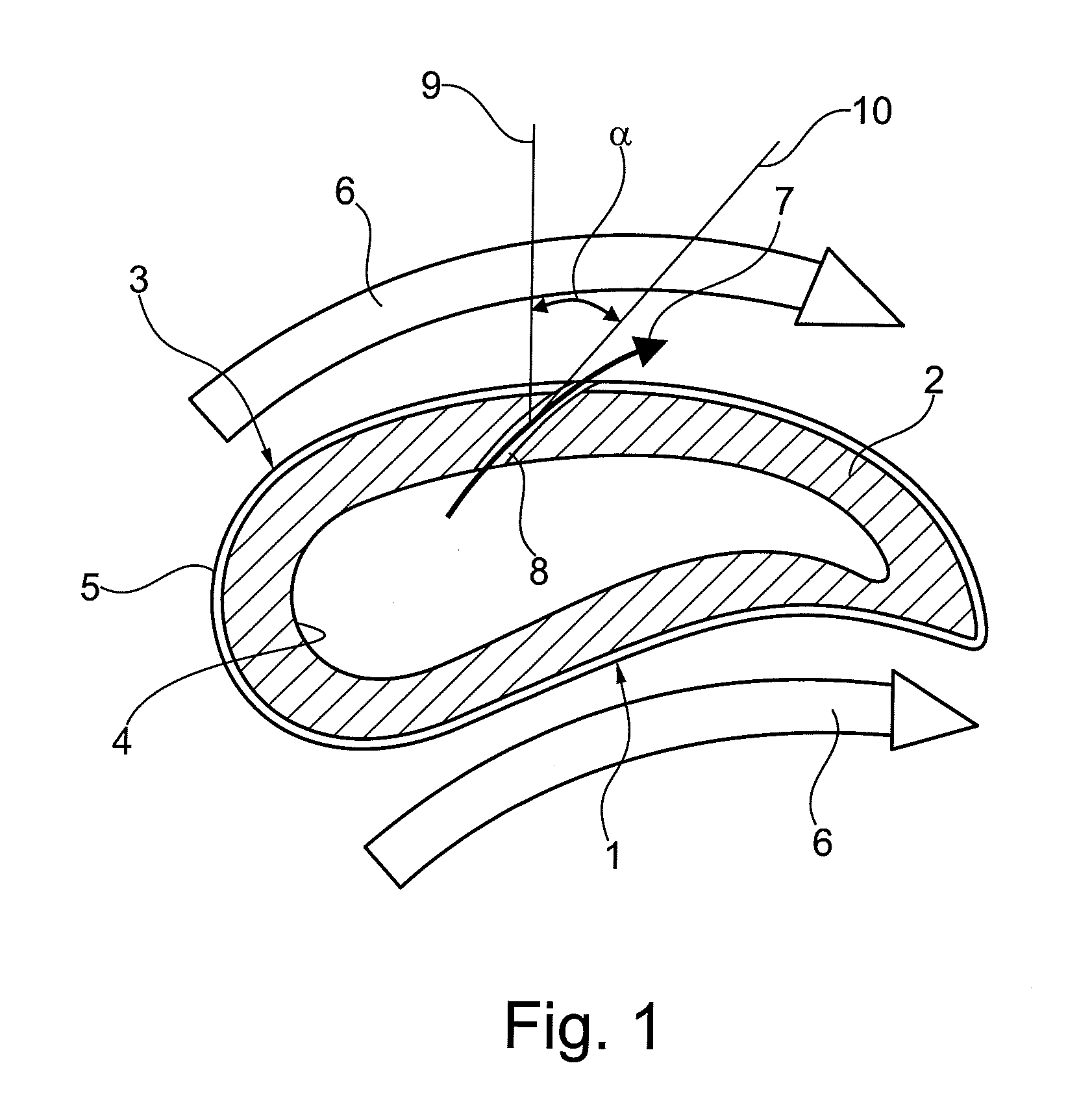

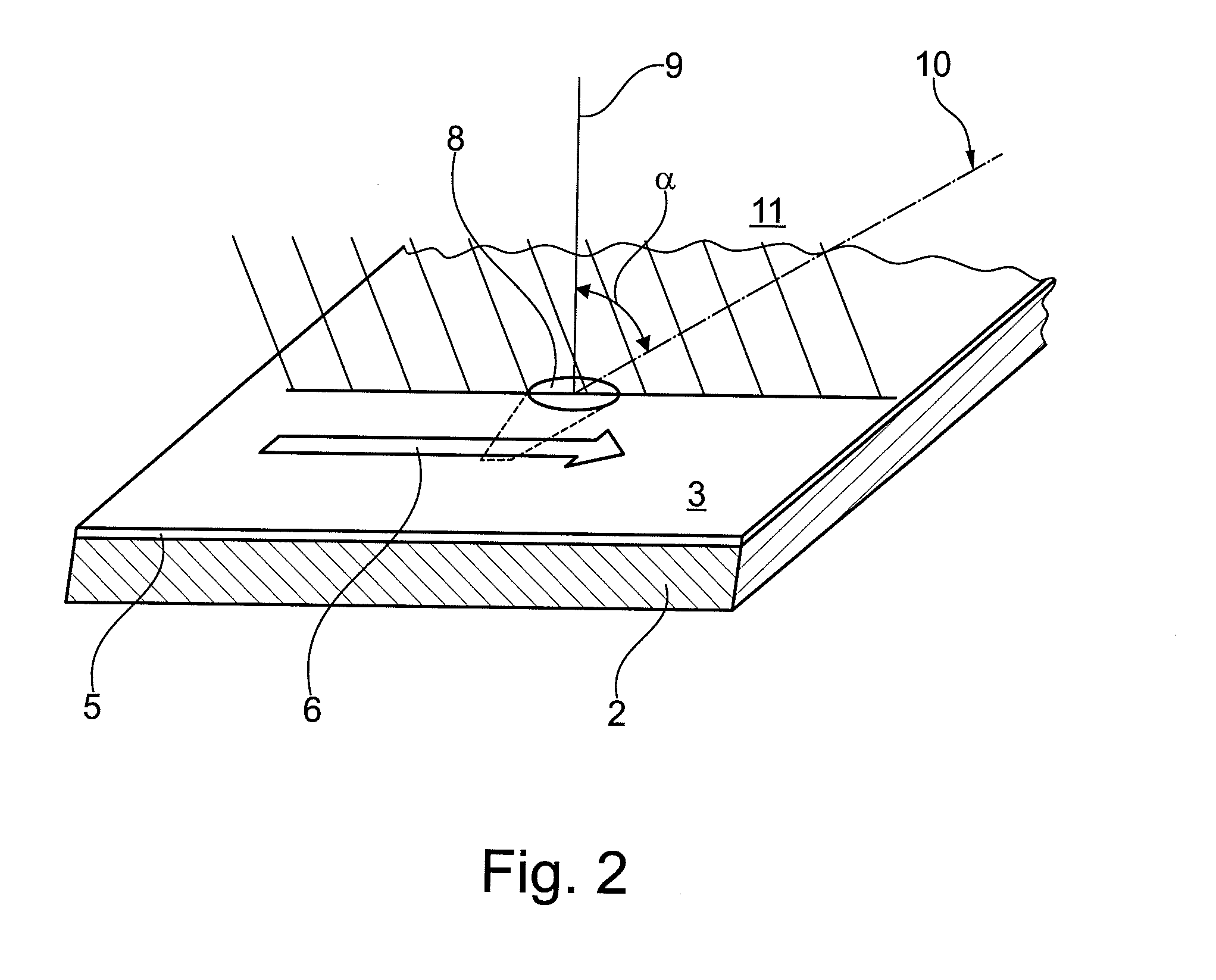

Flying mobile on-board ellipsometer, polarimeter, reflectometer and the like systems

InactiveUS7746471B1Efficiently useReduce gas flowPolarisation-affecting propertiesScattering properties measurementsAirflowOn board

A substantially self-contained “on-board” material system investigation system for effecting relative translational and rotational motion between a source and detector of electromagnetic radiation and a sample, which system is functionally mounted on a three dimensional locational system to enable positioning at desired locations on, and distances from, the surface of a sample, including the capability to easily and conveniently effect rotation and / or to change the angle-of-incidence of a beam of electromagnetic radiation onto a sample surface and / or to provide gas flow confined in a mini-chamber near the surface of a sample, at a location at which a beam having UV, VUV, IR and / or NIR wavelengths of electromagnetic radiation is caused to be impinged thereupon.

Owner:J A WOOLLAM CO

Method for producing contoured holes

InactiveUS20160193667A1Fast and inexpensive methodAvoid disadvantagesTurbinesContinuous combustion chamberEngineering

Owner:ANSALDO ENERGIA IP UK LTD

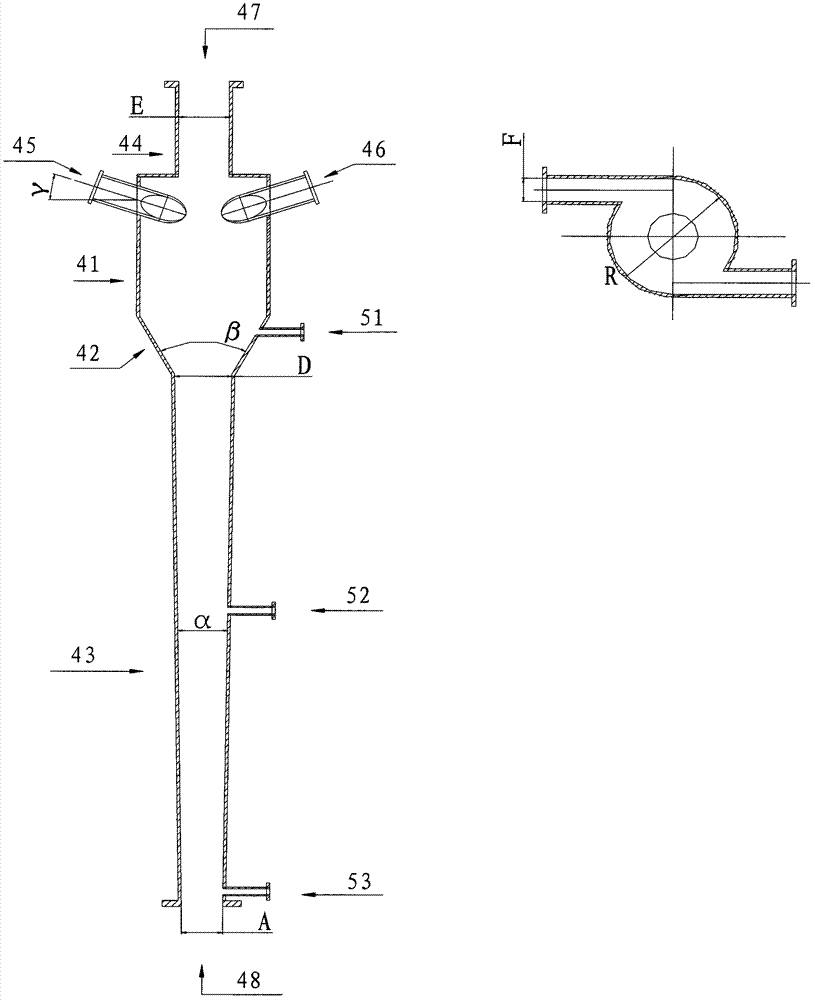

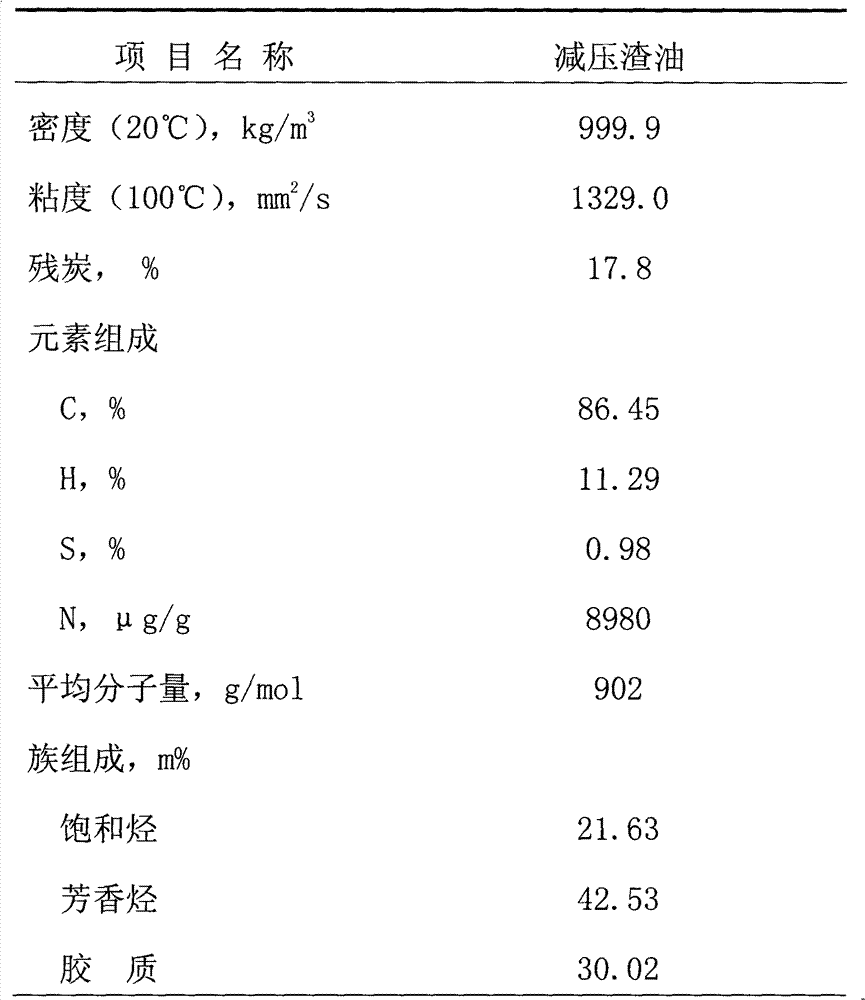

Delayed coking method

InactiveCN103087769ASave operating costsSave processHydrocarbon oils treatmentGas phaseFractionation

The invention aims at solving defects such as low light oil yield, high foam layer, and high coke yield of prior arts, and discloses a delayed coking method. The method is characterized in that: a mixed raw material is heated in a heating furnace; the heated hot material flow enters a primary hydrocyclone, such that a gas phase (1) and a mixed liquid phase (1) are obtained; the gas phase (1) is quenched and is delivered into a fractionation column; high-temperature steam is injected into the mixed liquid phase (1), and the mixture is delivered into a secondary hydrocyclone; the secondary hydrocyclone separates the mixed liquid phase (1) into a gas phase (2) and a mixed liquid phase (2). The gas phase (2) is delivered into a fractionation column; high-temperature steam is injected into the mixed liquid phase (2), and the mixture is delivered into a coke column; coke is discharged from the bottom of the coke column, and reaction oil gas is delivered into the fractionation column.

Owner:CHINA PETROLEUM & CHEM CORP +1

Exhaust flow control device for exhaust muffler

ActiveUS20120055734A1Increase pressureReduce back pressureSilencing apparatusMachines/enginesEngineeringControl valves

An exhaust flow control valve includes: a valve plate hinged to a downstream exhaust pipe to be pivotable, inside the pipe, between a fully closed position where a short-cut hole is closed and a fully open position where the short-cut hole is opened, the valve plate having a tip end directed toward a downstream side of the downstream exhaust pipe when at the fully open position; a spring receiving member provided to the downstream exhaust pipe to traverse the short-cut hole; and a valve spring having one end portion fastened to a tip end portion, which is located on the downstream side of the downstream exhaust pipe with respect to the spring receiving member, of the valve plate, and having an opposite end side being slidably in pressure contact with the spring receiving member, thereby generating a repulsive force to bias the valve plate toward the fully closed position.

Owner:YUTAKA GIKEN CO LTD

Method for controlling an exhaust gas temperature

ActiveUS20120059572A1Improve efficiencyConsume energyAnalogue computers for vehiclesElectrical controlOperation modeFuel supply

A method is provided for controlling an exhaust gas temperature of an engine of a vehicle during interruption of fuel supply to the engine, wherein the engine drives a driveline of the vehicle. The method involves alternating between two or more operational modes, wherein at least one of the operational modes maintains a higher exhaust temperature than the one or more other operational modes.

Owner:VOLVO LASTVAGNAR AB

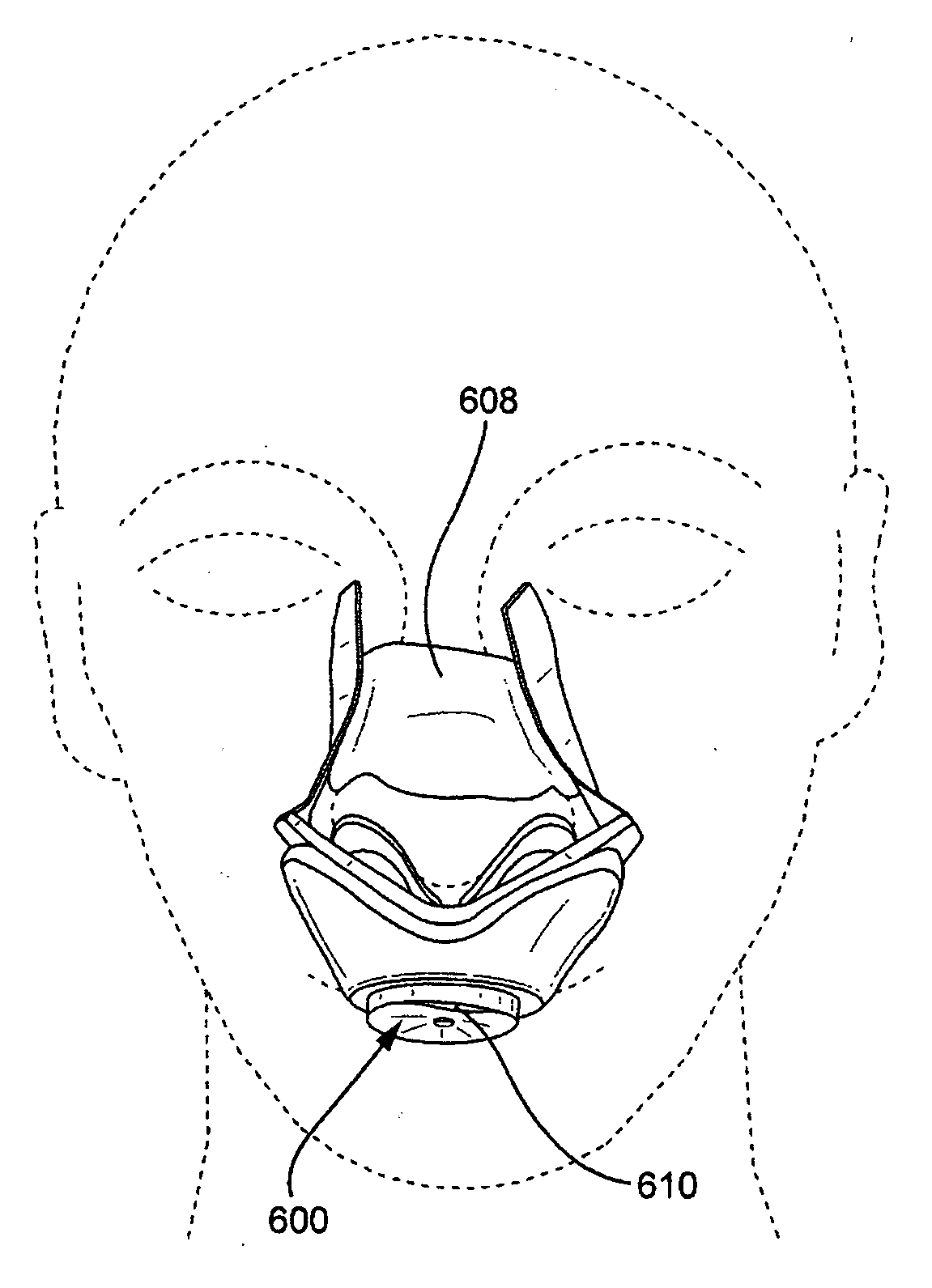

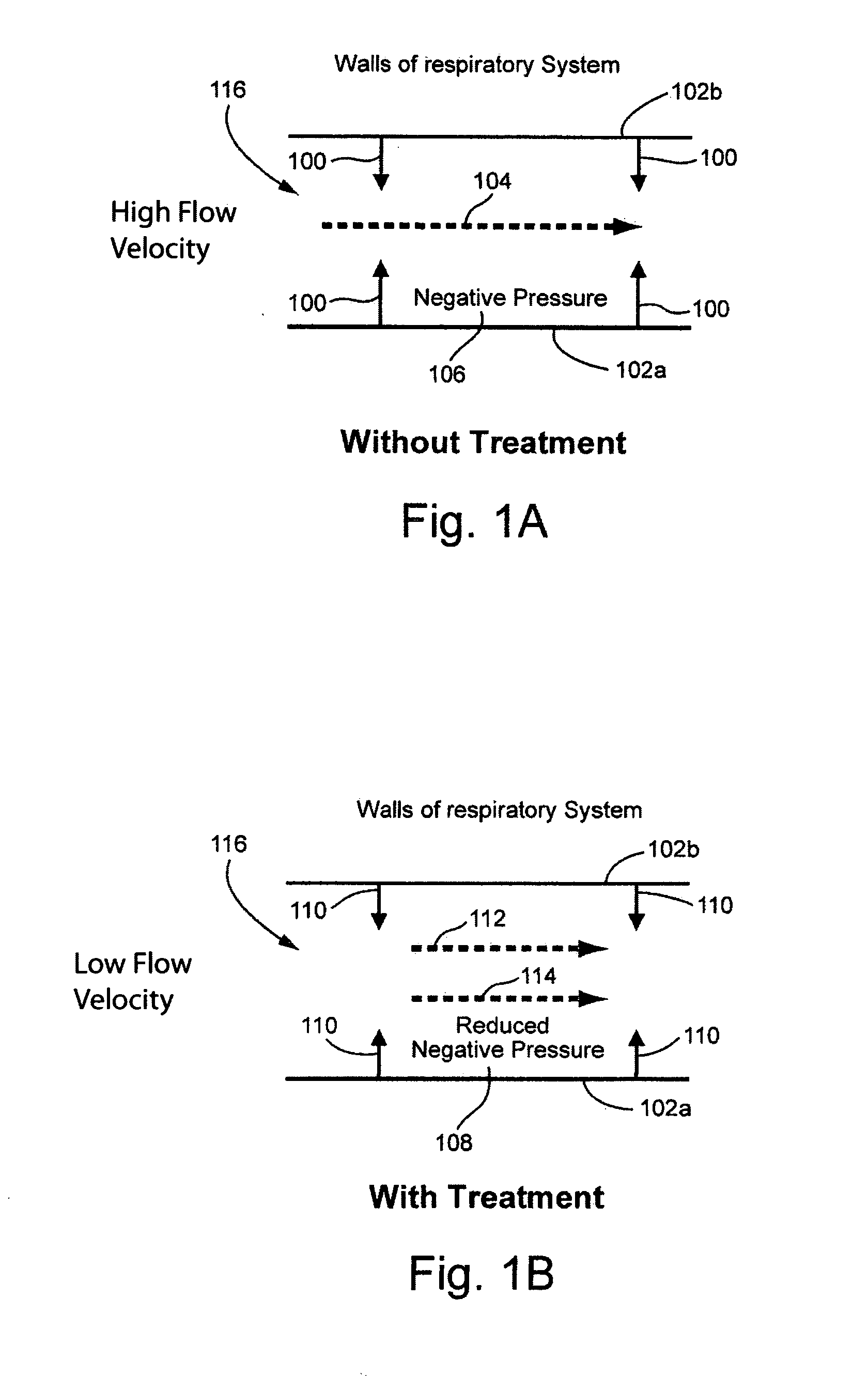

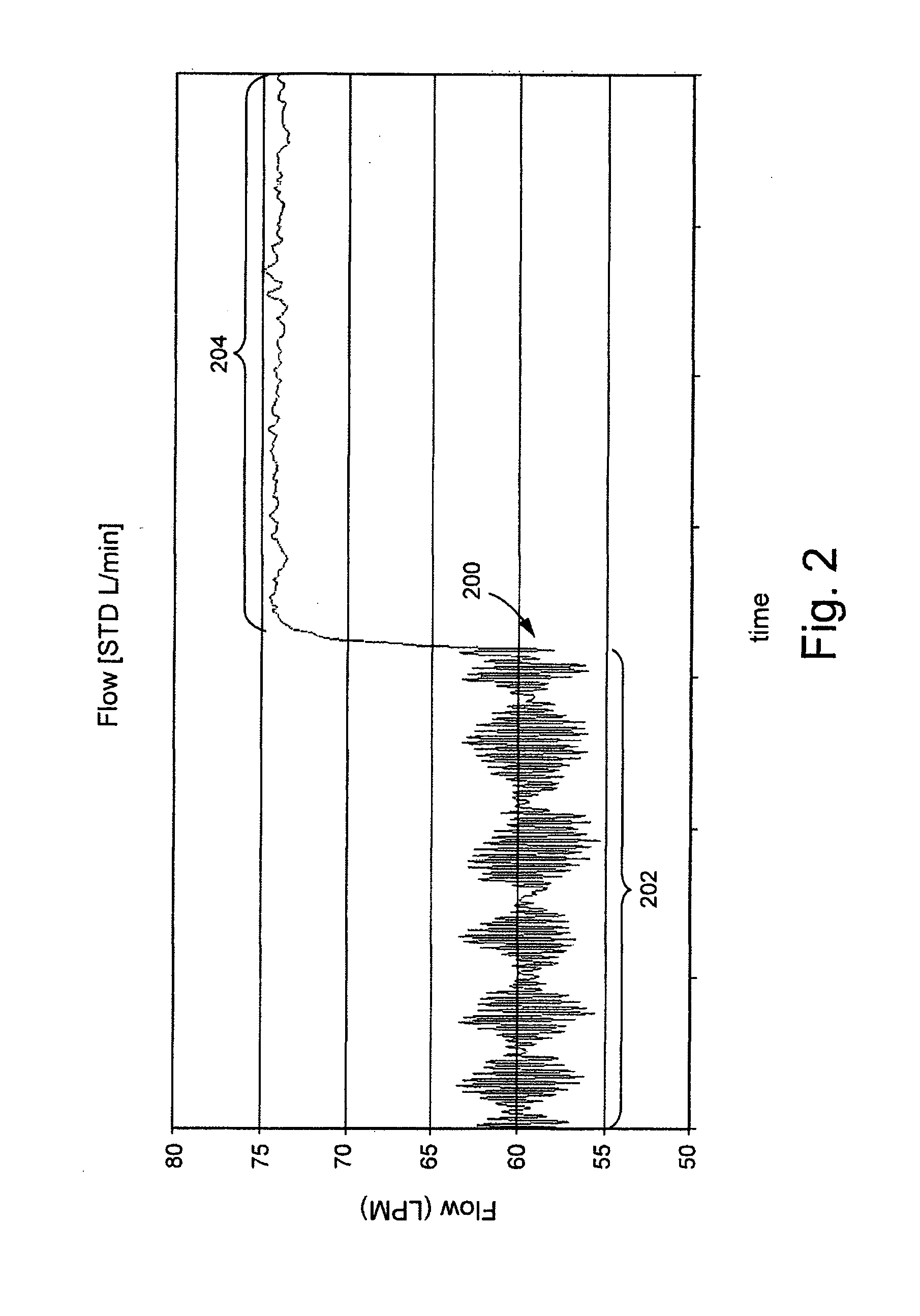

Respiratory resistance systems and methods

InactiveUS20130000647A1Reduce gas flowPrevents and reduces collapseRespiratory masksBreathing masksAirflowIntensive care medicine

A patient interface includes a mask configured to communicate with at least one airway of a patient, the mask including at least one aperture (402) configured to deliver gas to the at least one airway of the patient; and an airflow resistance member (400) provided to the mask to control the airflow through the at least one airway.

Owner:RESMED LTD

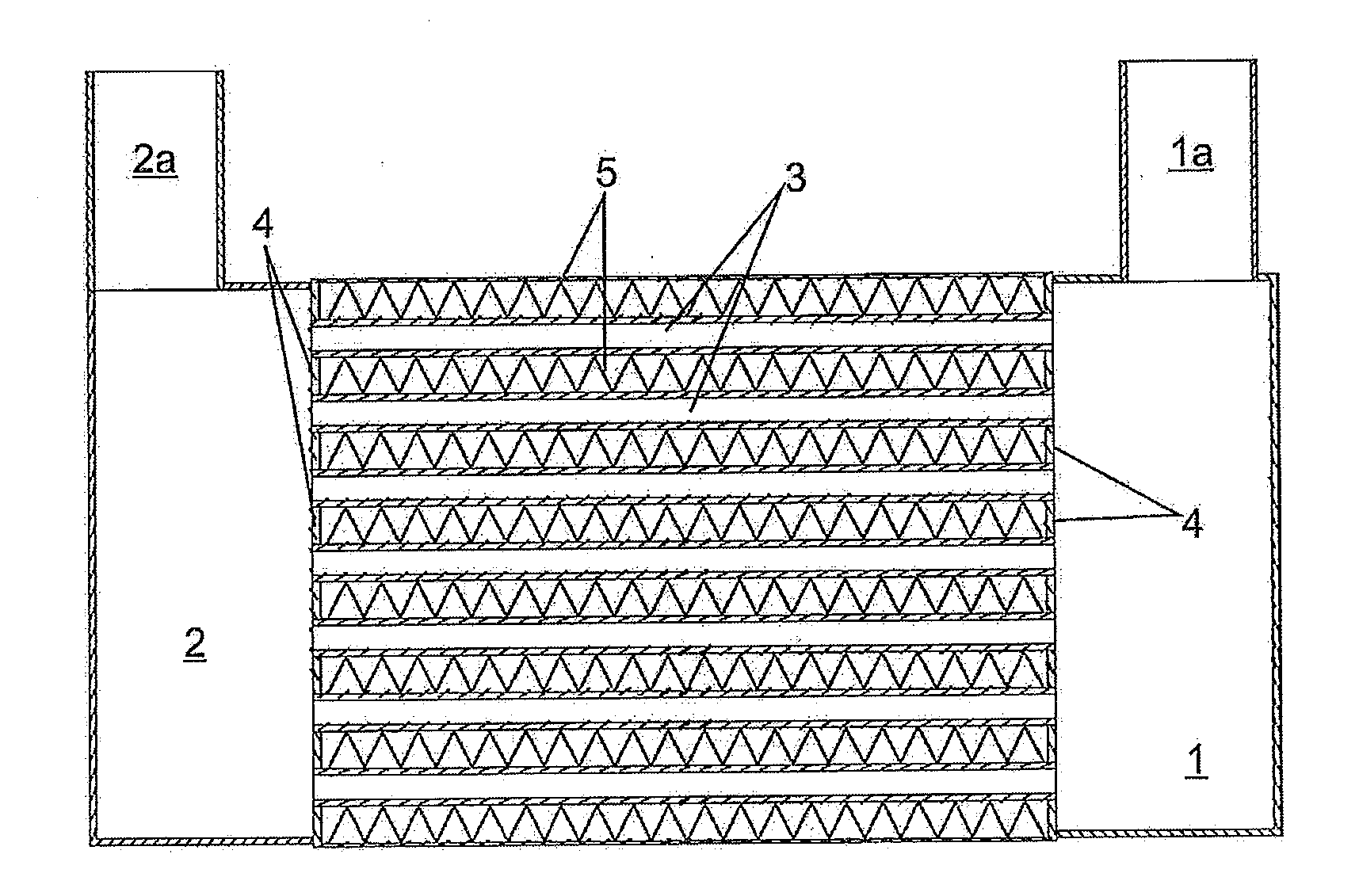

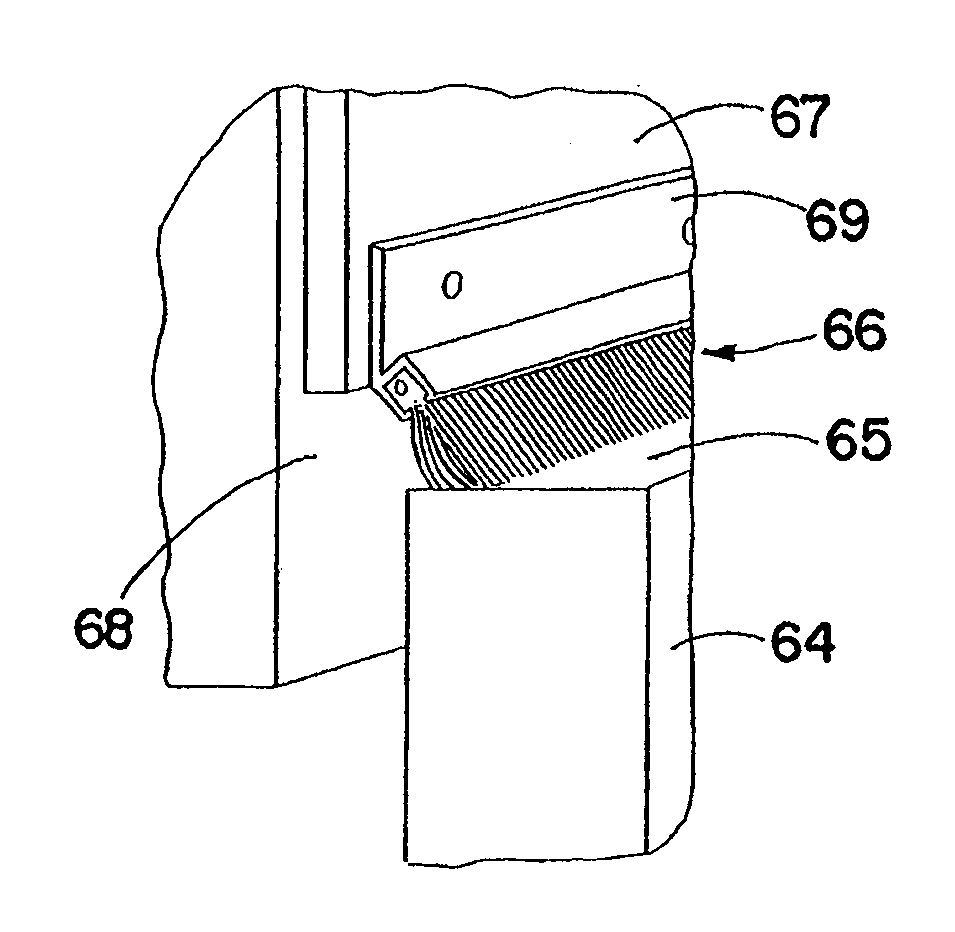

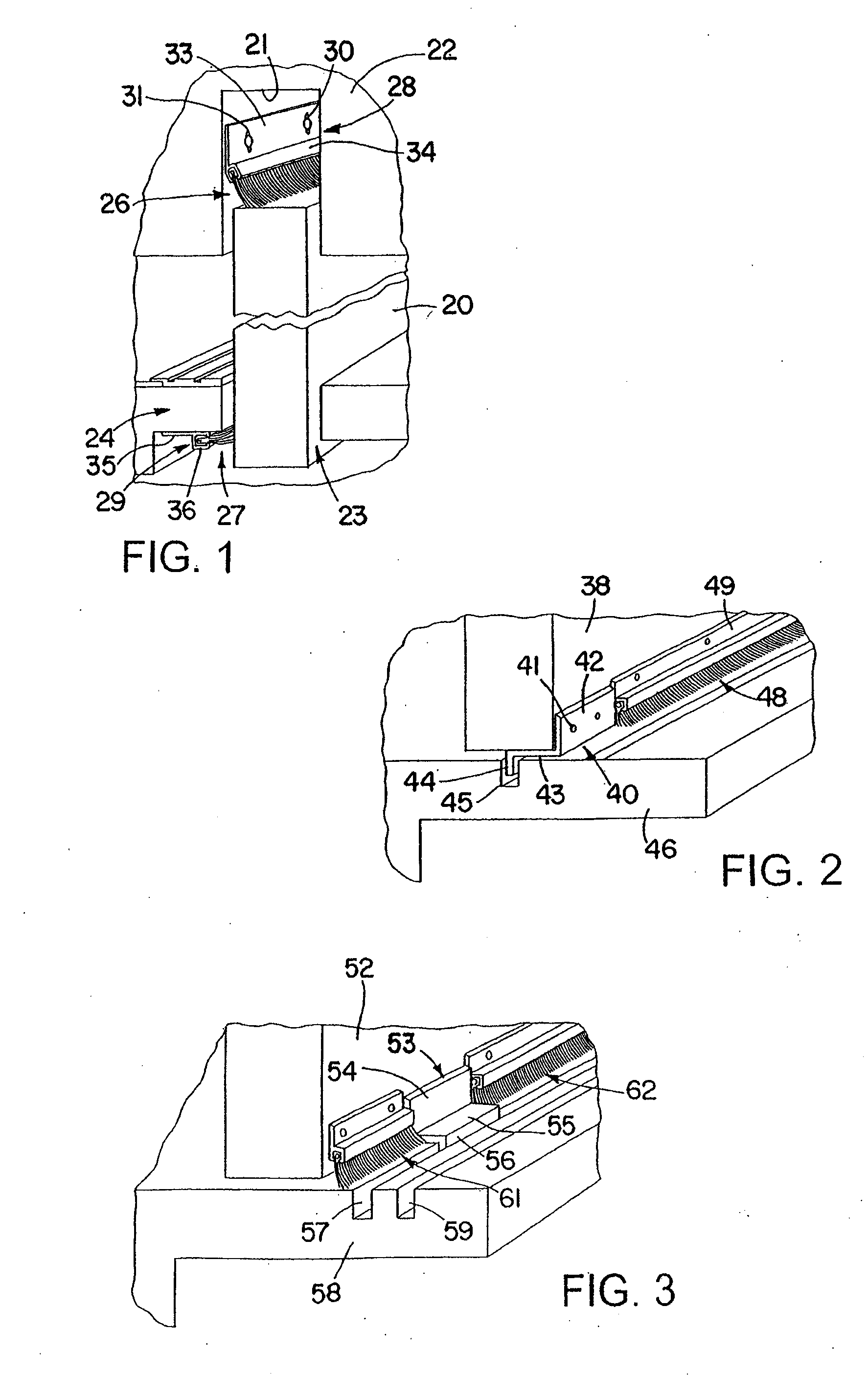

Environmental brush seal

InactiveUS20100083581A1Improve sealingHigh pressureEngine sealsElectrical apparatusEngineeringBand pattern

A passive brush seal effectively to limit conditioned air such as humidity, temperature or filtered air, or contaminated air such as smoke or fumes from an area of greater pressure to one of lower pressure. The passive brush seal is in the form of a strip brush with triangular filaments that provide an improved block to the flow of gases. The shape of the filaments is such that they inter-fit or interlock and separate less readily. Important applications are as elevator seals or clean room or computer room seals.

Owner:MATTICE DOUGLAS A

Atomic layer removal process with higher etch amount

InactiveUS20150118848A1Limit amount of materialEasy to controlSemiconductor/solid-state device manufacturingSelf limitingLayer removal

Higher overall etch rate and throughput for atomic layer removal (ALR) is achieved. The reaction is a self-limiting process, thus limiting the total amount of material that may be etched per cycle. By pumping down the process station between reacting operations, the reaction is partially “reset.” A higher overall etch rate is achieved by a multiple exposure with pump down ALR process.

Owner:NOVELLUS SYSTEMS

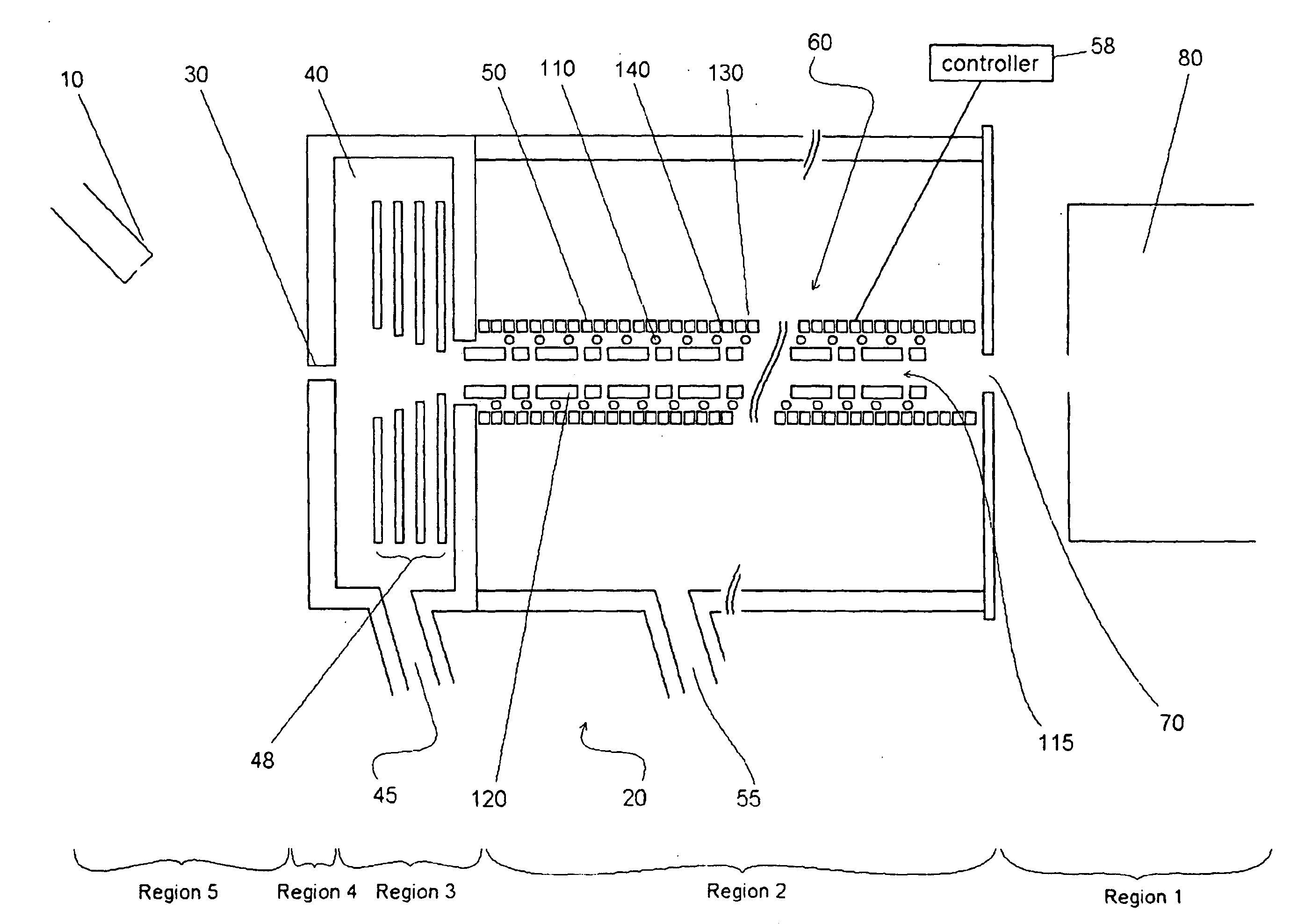

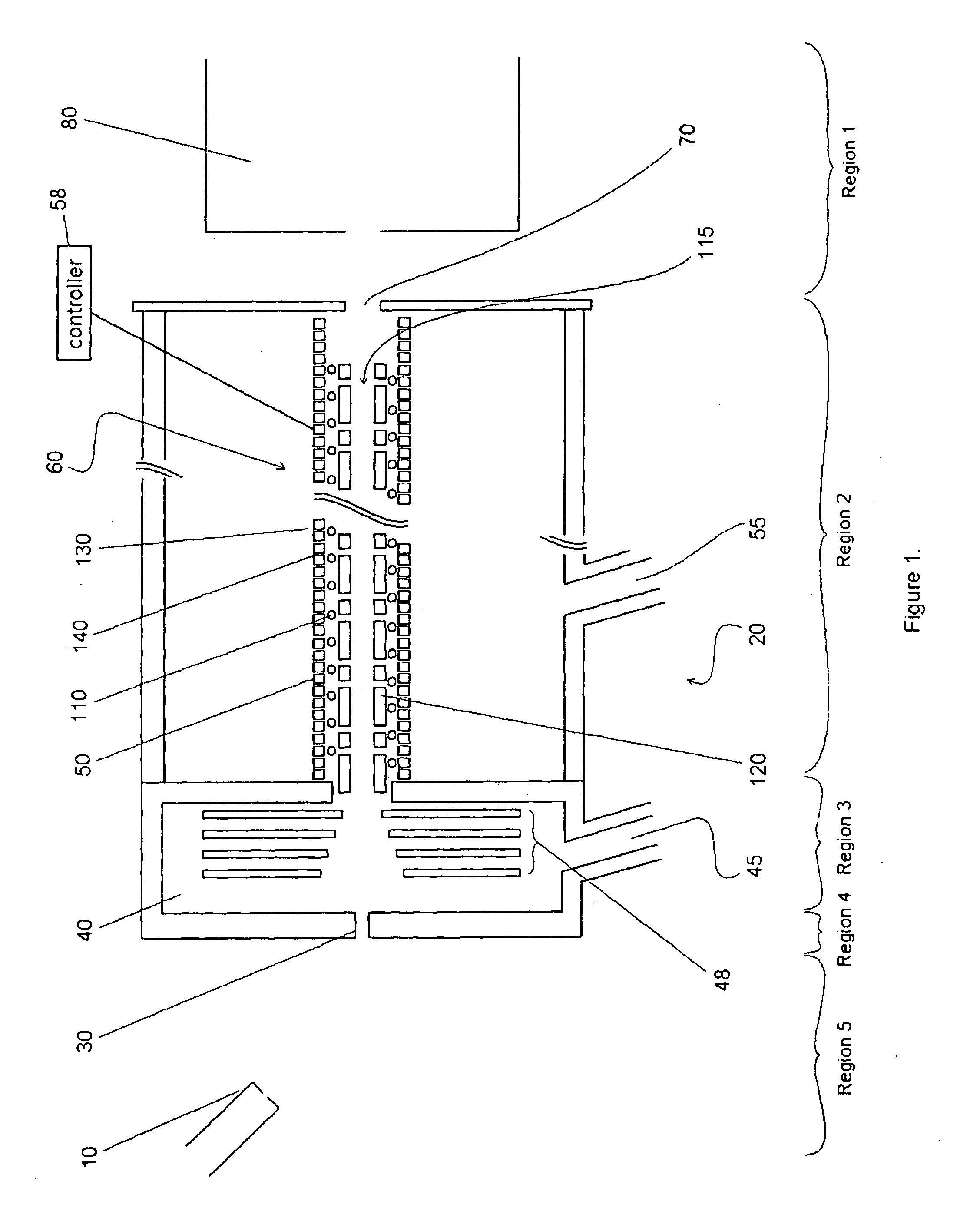

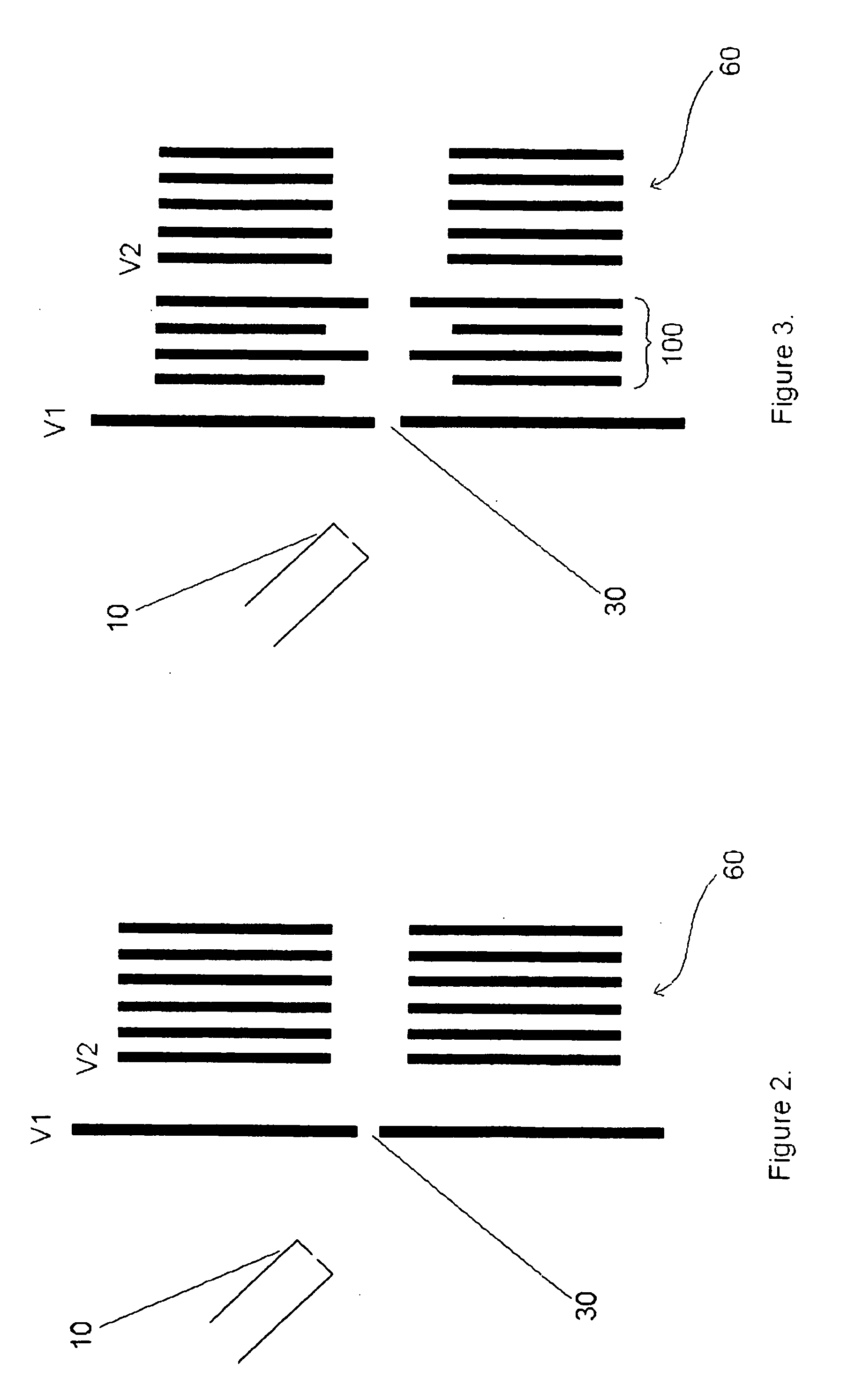

Efficient Atmospheric Pressure Interface for Mass Spectrometers and Method

ActiveUS20100038532A1Reduce gas flowWeaken energyBeam/ray focussing/reflecting arrangementsSamples introduction/extractionIon transferMass analyzer

An ion transfer arrangement for transporting ions between higher and lower pressure regions of the mass spectrometer comprises an ion transfer conduit 60. The conduit 60 has an inlet opening towards a relatively high pressure chamber 40 and an outlet 70 opening towards a relatively low pressure chamber. The conduit 60 also has at least one side wall surrounding an ion transfer channel 115. The side wall includes a plurality of apertures 140 formed in the longitudinal direction of the side wall so as to permit a flow of gas from within the ion transfer channel 115 to a lower pressure region outside of the side wall of the conduit 60.

Owner:THERMO FISHER SCI BREMEN

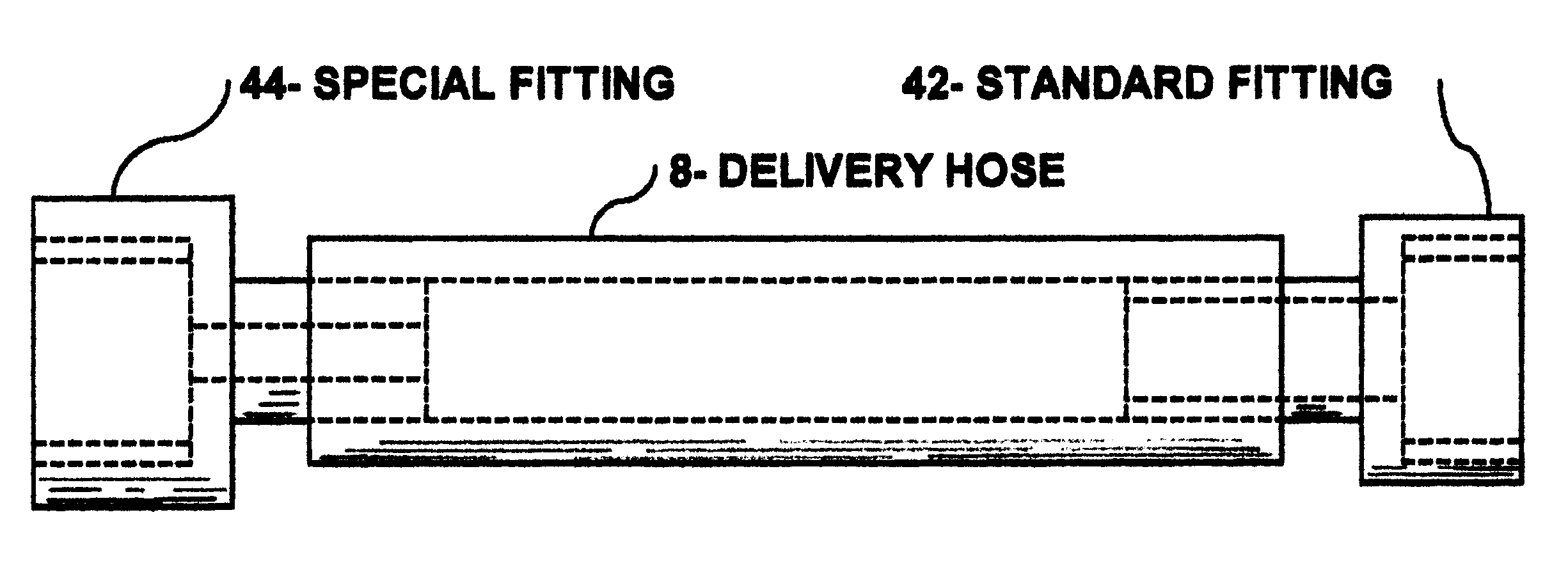

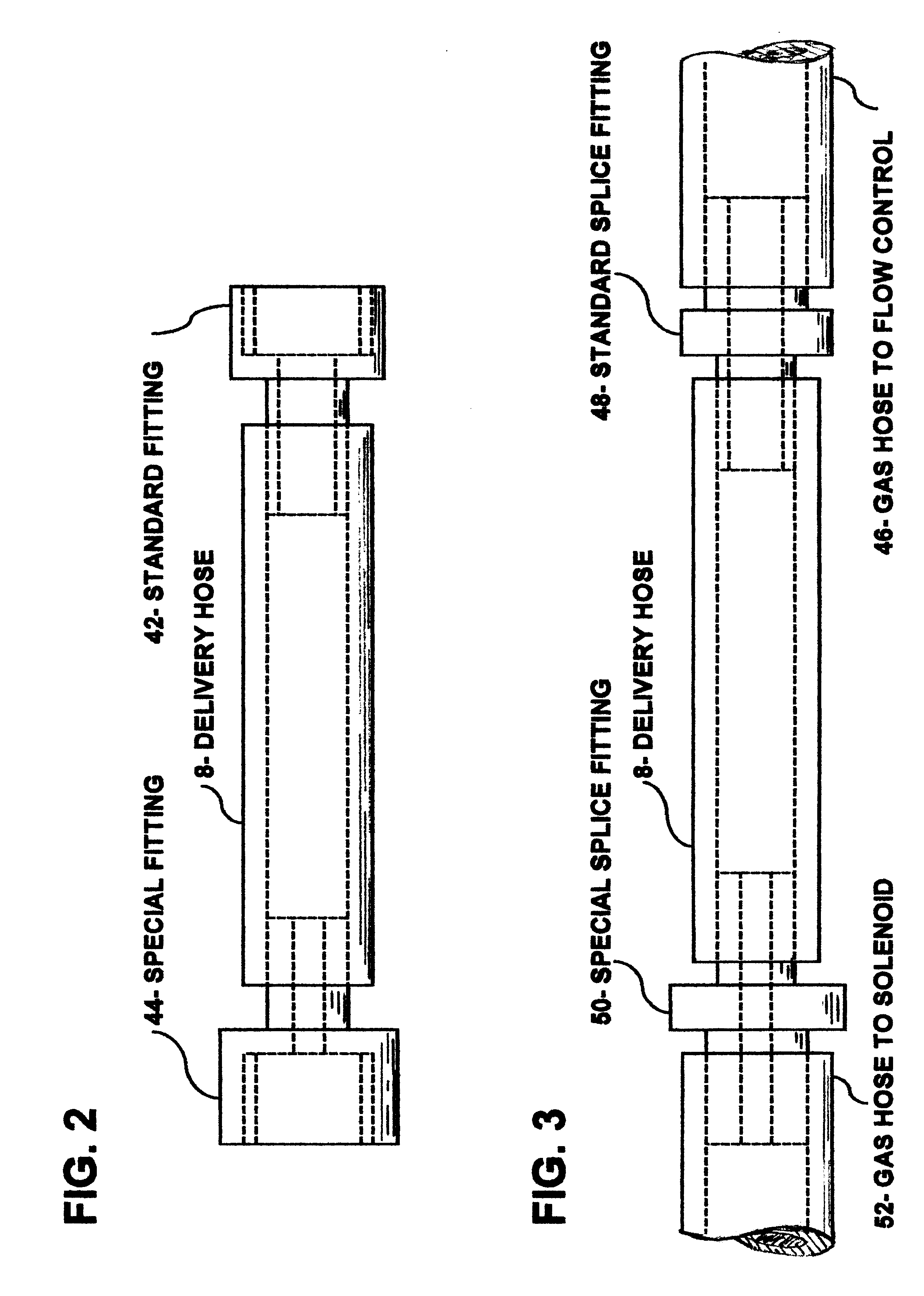

Welding shielding gas saver device

InactiveUS6610957B2Minimize storageAvoid wastingShielding gas supply/evacuation devicesWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

This device significantly reduces major reasons for shielding gas waste primarily in metal inert gas welding. Excess shielding gas stored at the end of each weld in the shielding gas delivery hose connecting the gas source to the welding machine creates a shielding gas flow-surge at the next weld start. This gas flow-surge creates shielding gas waste and can cause poor weld start performance. Other methods employed over the years to reduce shielding gas waste have been either complex, leaked, were not sufficiently robust for the environment, provided only partial solutions or did not provide shielding gas savings for welds longer than about 3 seconds. This device includes a delivery hose connecting the shielding gas supply to the welding machine, which has a small internal volume and a gas surge-restricting orifice at the gas solenoid end of the hose.

Owner:UTTRACHI GERALD DANIEL

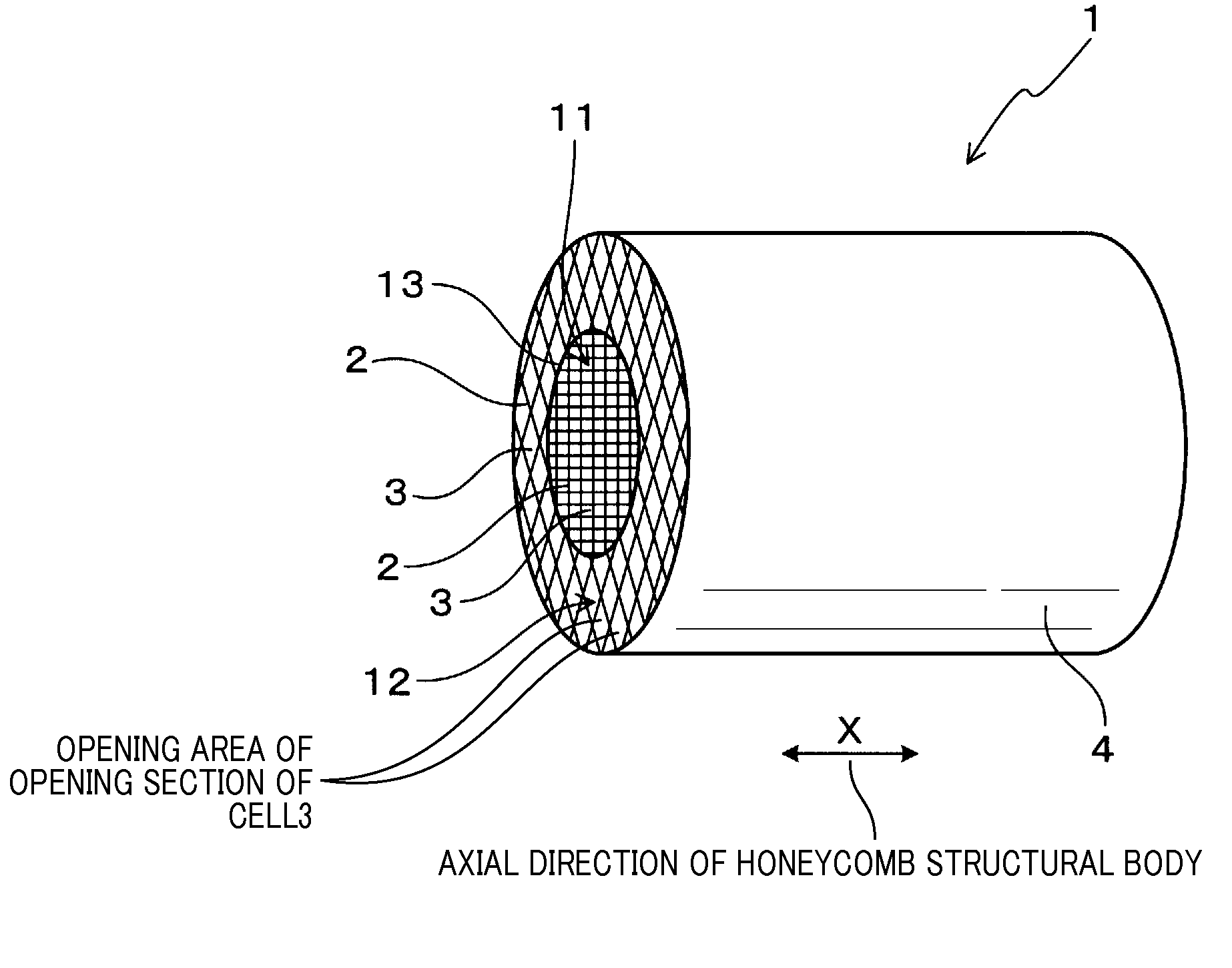

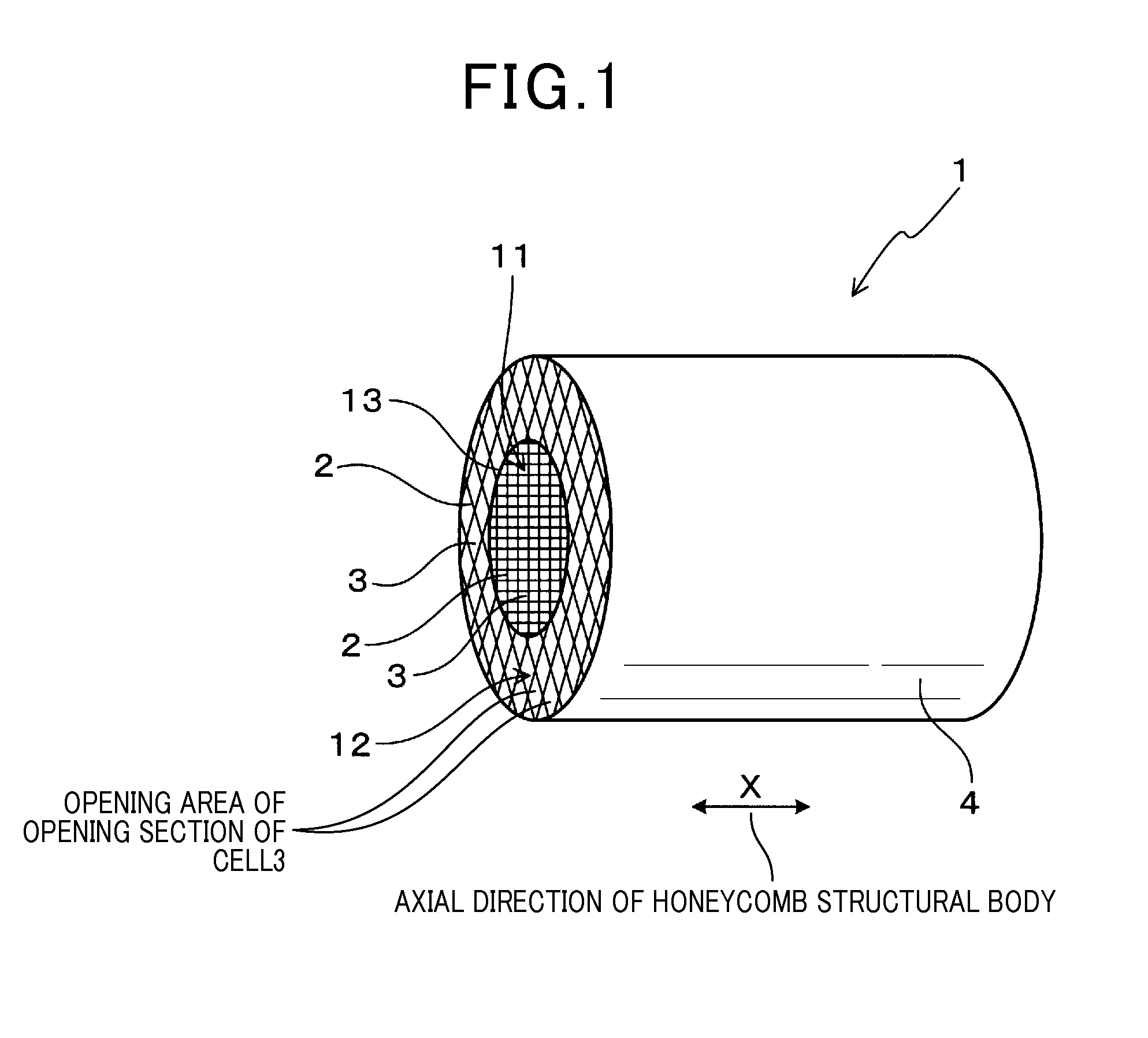

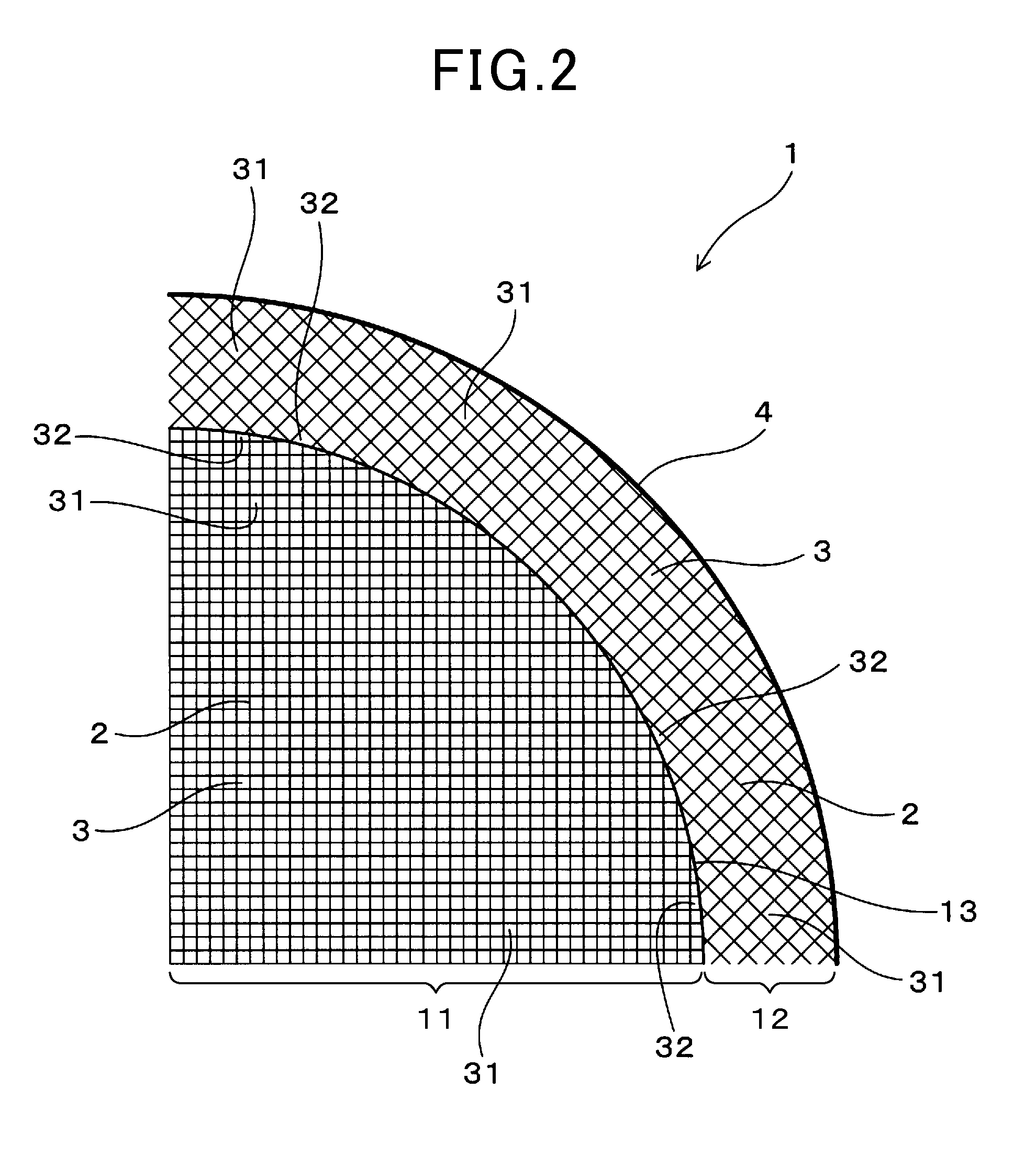

Honeycomb structural body

ActiveUS20140287192A1Suppress generationHigh strengthDispersed particle filtrationLayered productsEngineeringCell wall

A honeycomb structural body has cells surrounded by cell walls arranged in a lattice-like shape. A cross section is divided into a central section and an outer peripheral section. The outer peripheral section surrounds the central section through a boundary partition wall. The outer peripheral section is lower in a cell density than the central section. The cells contain imperfectly shaped cells in contact directly with the boundary partition wall. In the imperfectly shaped cells, first specific imperfectly shaped cells are smaller in opening area than second specific imperfectly shaped cells. Each first specific imperfectly shaped cells has an opening area of not more than a predetermined area S=(P−T)2 / 8. P and T indicate a cell pitch and a thickness of each cell wall, respectively. The opening section of the first specific imperfectly shaped cells is closed by the same raw material of the cell walls.

Owner:DENSO CORP

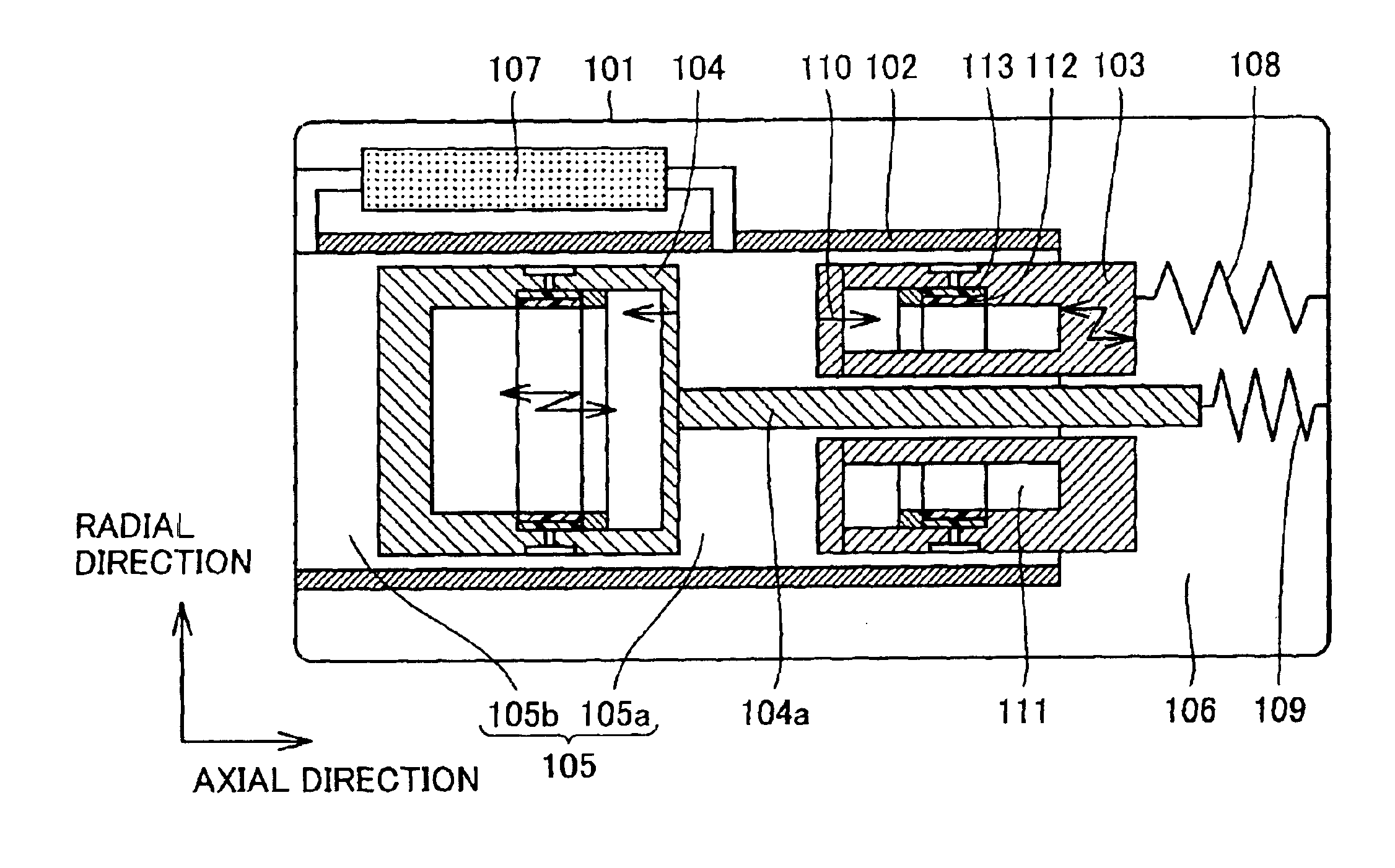

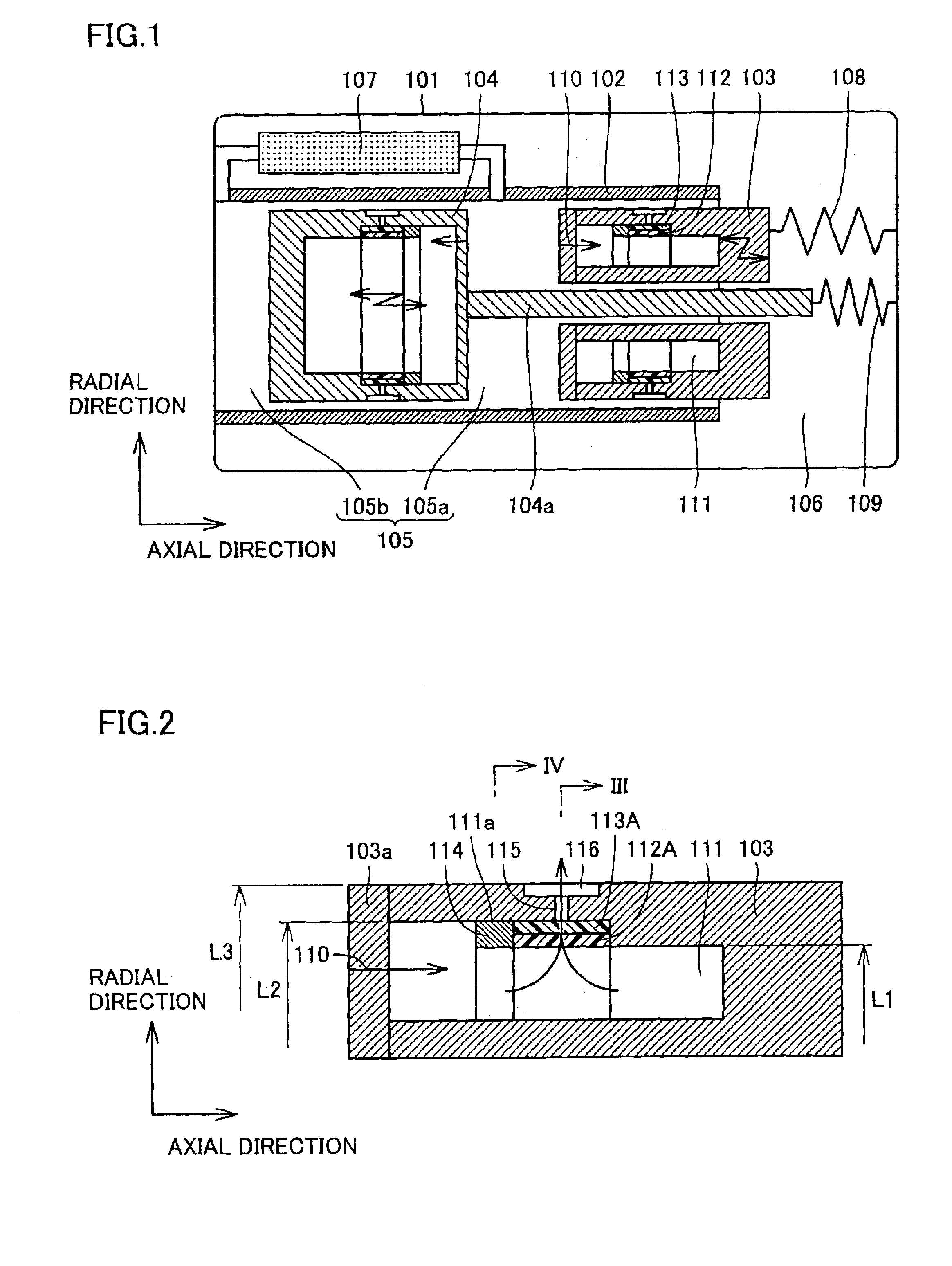

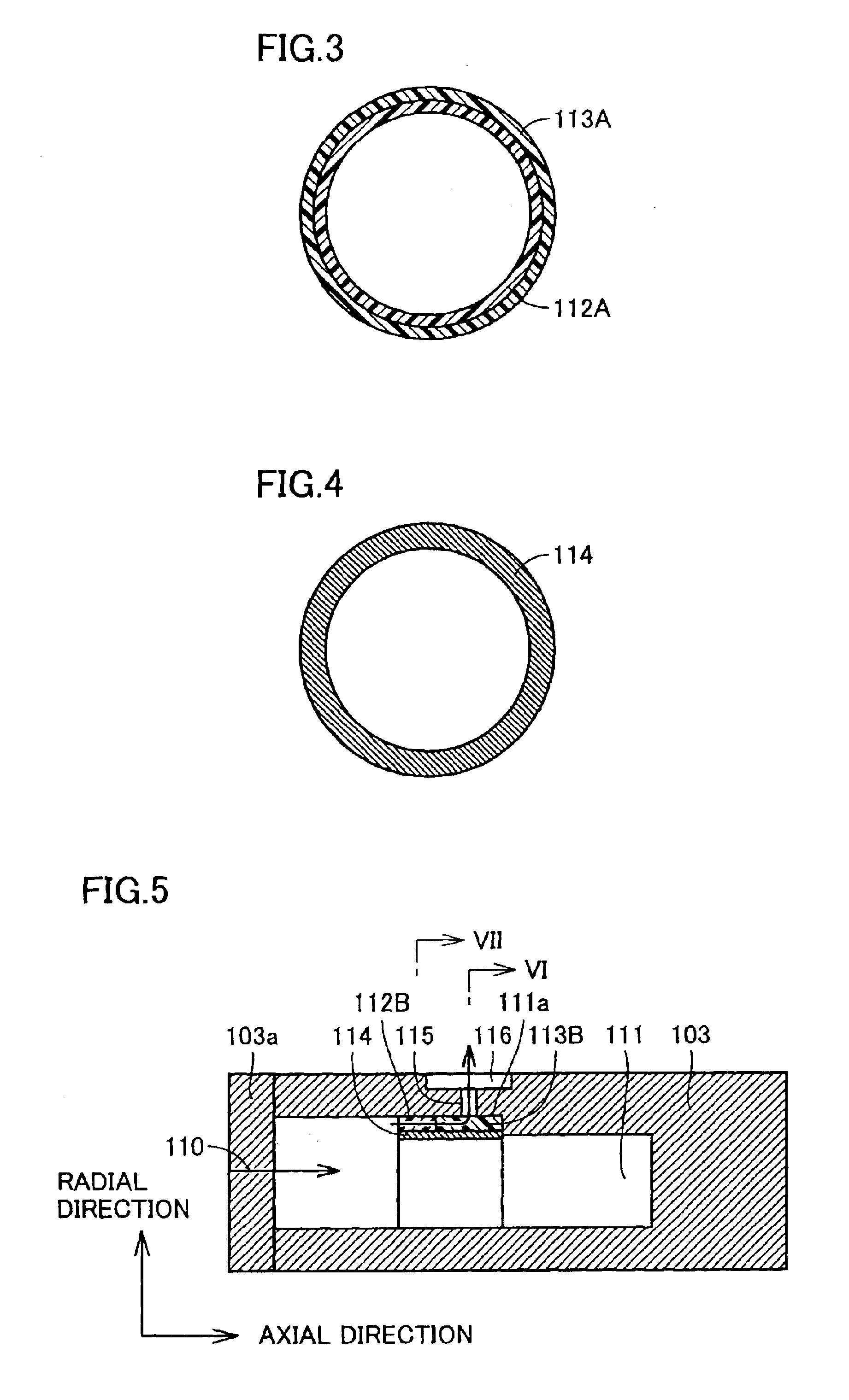

Stirling engine, and stirling refrigerator

InactiveUS6945043B2Increase manufacturing costInternal capacity is reducedCompression machinesGas cycle refrigeration machinesEngineeringRefrigerated temperature

A Stirling engine comprises a first porous body having a large hole diameter, a second porous body having a small hole diameter and a ring for fixing the first porous body and the second porous body in a pressurization chamber inside a gas outlet closer to the pressurization chamber.

Owner:SHARP KK

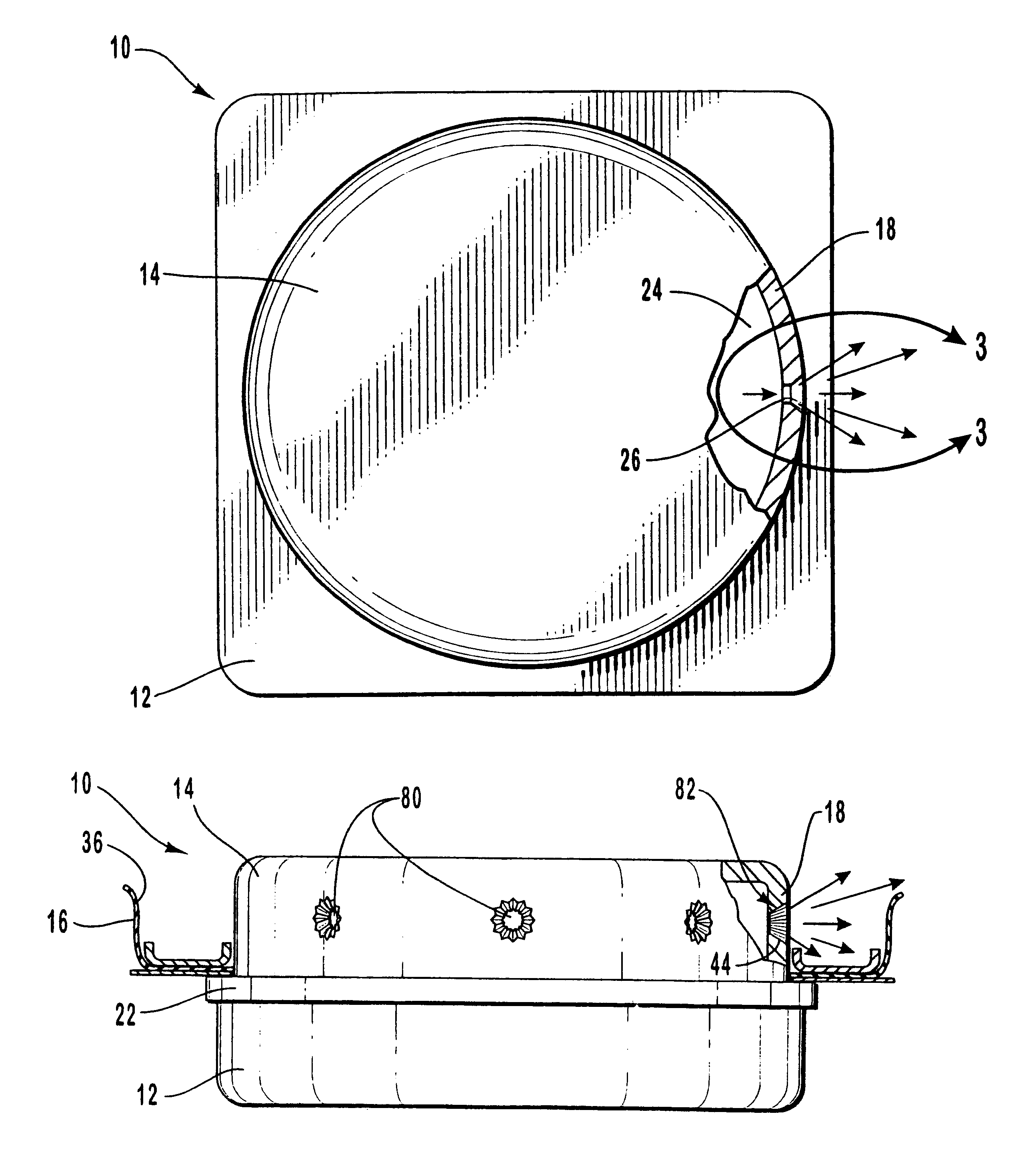

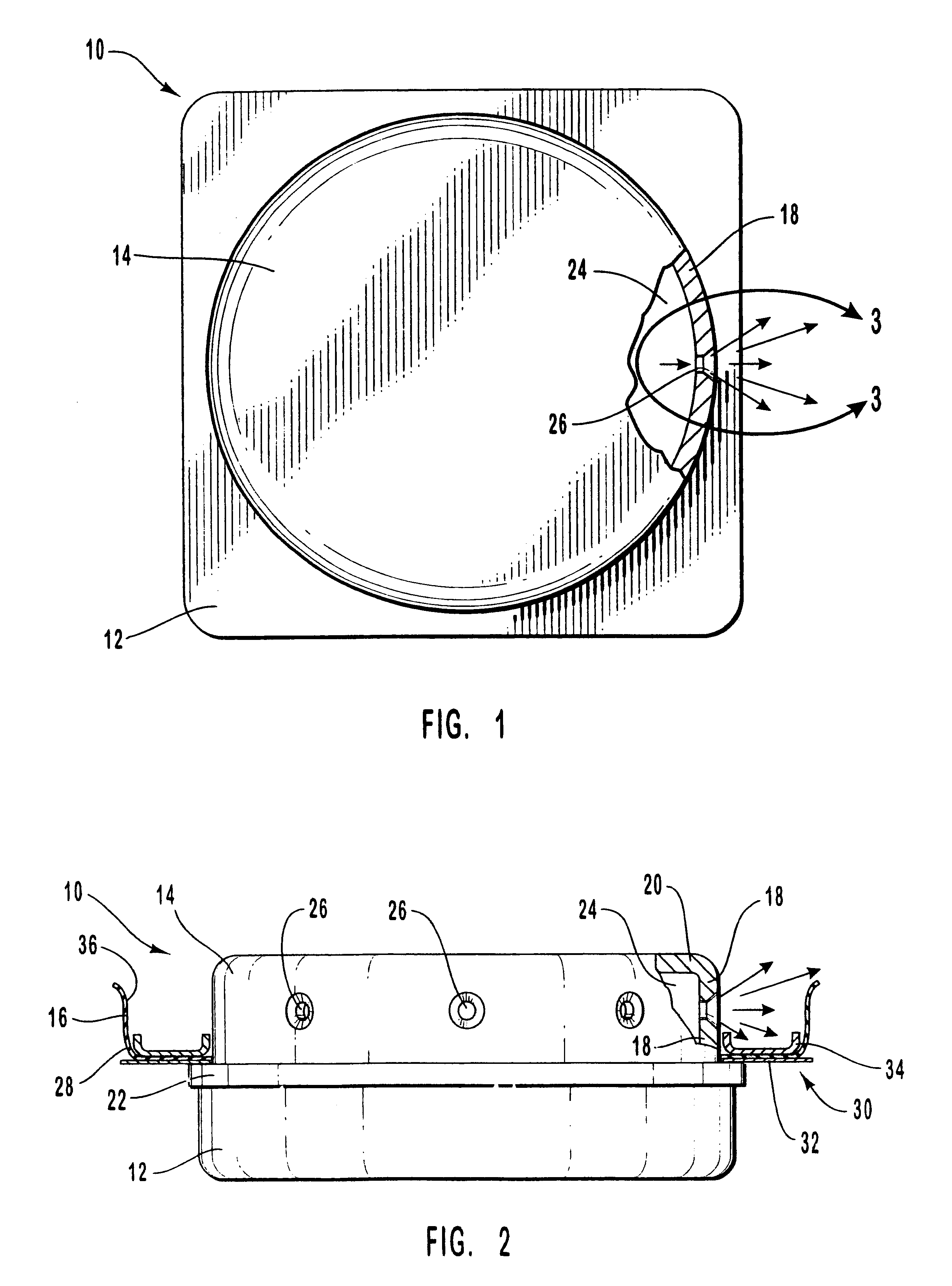

Air bag inflation exit gas dispersion features

InactiveUS6394491B2Reduce thicknessReduce gas concentrationPedestrian/occupant safety arrangementInterior spaceEngineering

An air bag device that includes an air bag cushion, a diffuser canister, and a gas generation inflator. The diffuser canister is attached to the air bag cushion and has walls configured to define an interior space therein. The walls of the diffuser canister have an interior surface, an exterior surface, and a wall thickness t. At least one of the walls has an aperture formed therethrough in communication with the interior of the air bag cushion. The gas generation inflator is configured to rapidly create a gas that exits the diffuser canister through the aperture so as to fill the air bag cushion. The aperture is defined by an edge extending between the interior and said exterior surfaces of the wall that is configured to diffuse the gas exiting the diffuser canister through the aperture. The edge of the aperture is configured such that the cross-sectional area of the aperture that is proximate to the exterior surface of the wall is larger than the cross-sectional area of the aperture proximate to the interior surface of wall. The edge includes an angled portion configured such that opposing sides of the aperture have an angle alpha therebetween in the range of about 20 degrees to about 145 degrees. The aperture has a diameter d1 proximate to the interior surface of the wall and is configured so that the diameter d1 and wall thickness t have a ratio d1 to tin the range of about 0.5 to about 4. An alternate embodiment of the air bag device comprises an aperture defined by an edge that is configured so that the cross-section of aperture is non-smooth and causes turbulence in the gas stream.

Owner:AUTOLIV ASP INC

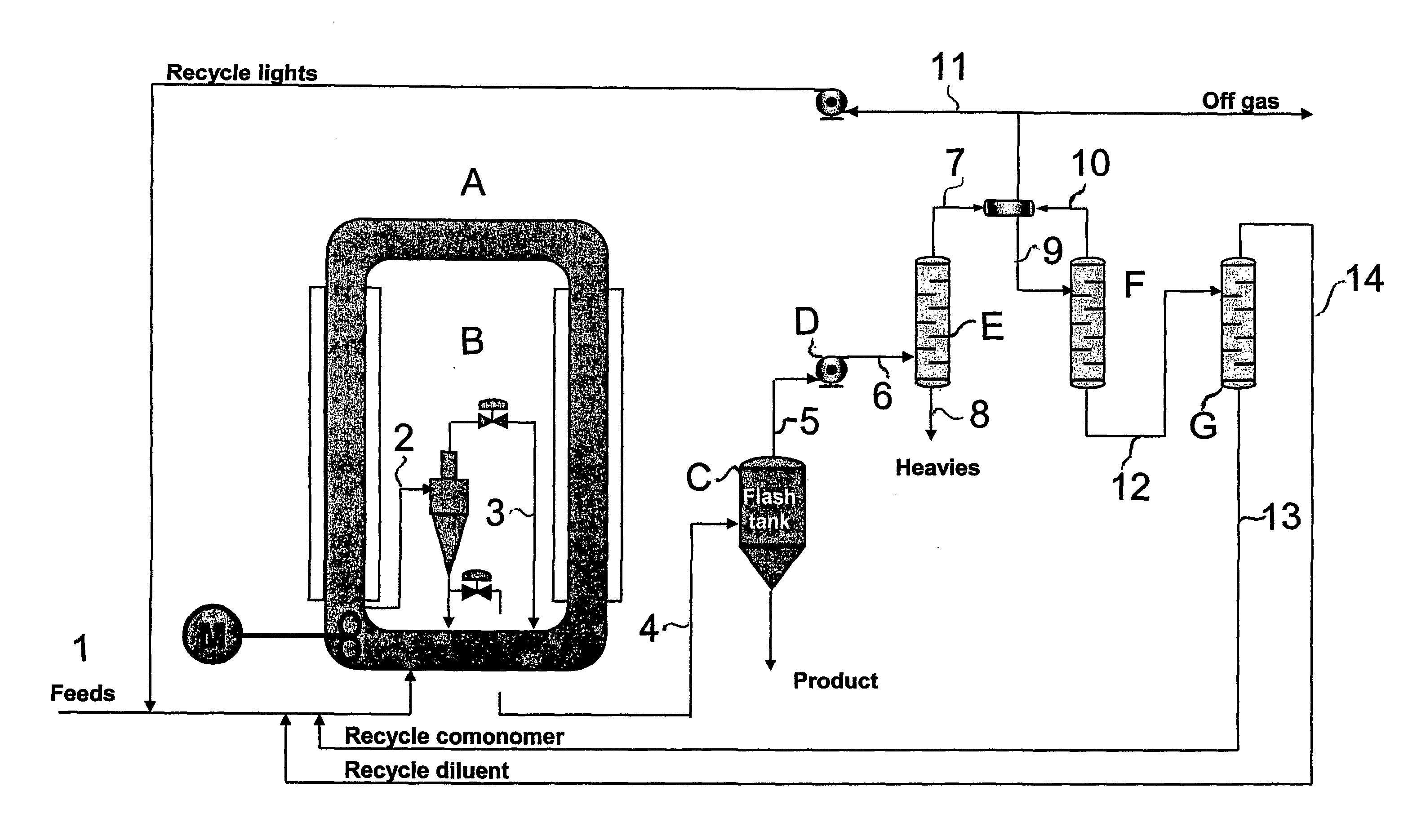

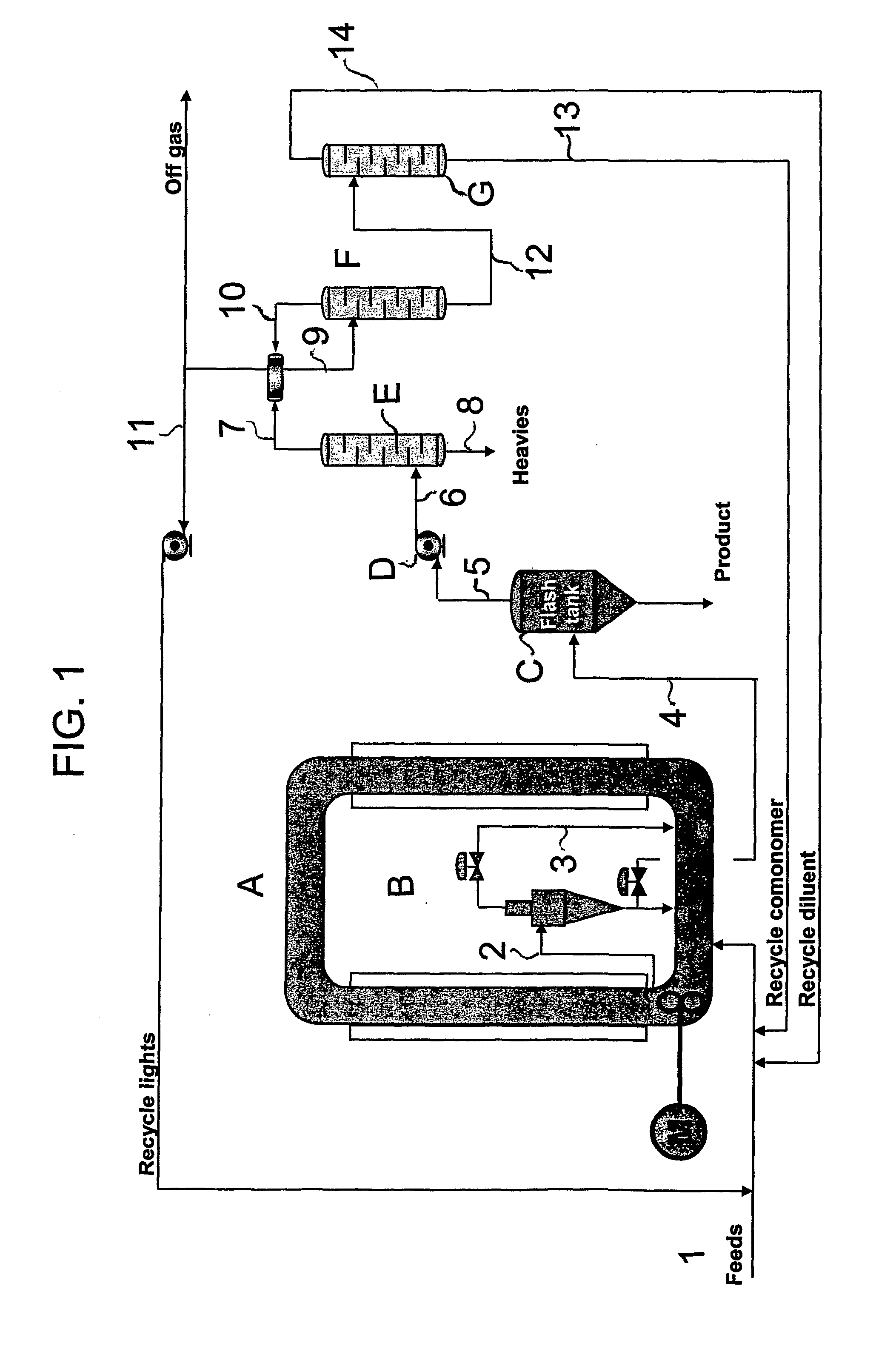

Process And Apparatus For Producing Olefin Polymers

ActiveUS20080039597A1Eliminate disadvantagesReduce capacityChemical/physical/physico-chemical stationary reactorsFluid phaseDistillation

The present invention concerns a process and an apparatus for continuous polymerisation of olefin monomers. In particular, the present invention concerns a process and an apparatus for continuous polymerisation olefin monomers like ethylene and other monomers, wherein an olefin monomer is polymerised in slurry phase in an inert hydrocarbon diluent in at least one loop reactor. According to the invention, a polymer slurry is continuously withdrawn from the loop reactor and concentrated. The concentrated slurry is conducted to a flash unit in order to remove the remaining fluid phase, and gas obtained is compressed in a flash gas compressor before it is being fed to a distillation section. By means of the present invention it is possible reduce the size of the flash gas compressor and the capacity of the distillation sections. This significantly reduces investment cost for a continuously operated polymerization apparatus.

Owner:BOREALIS TECH OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com