Patents

Literature

93results about How to "Reduce gas concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

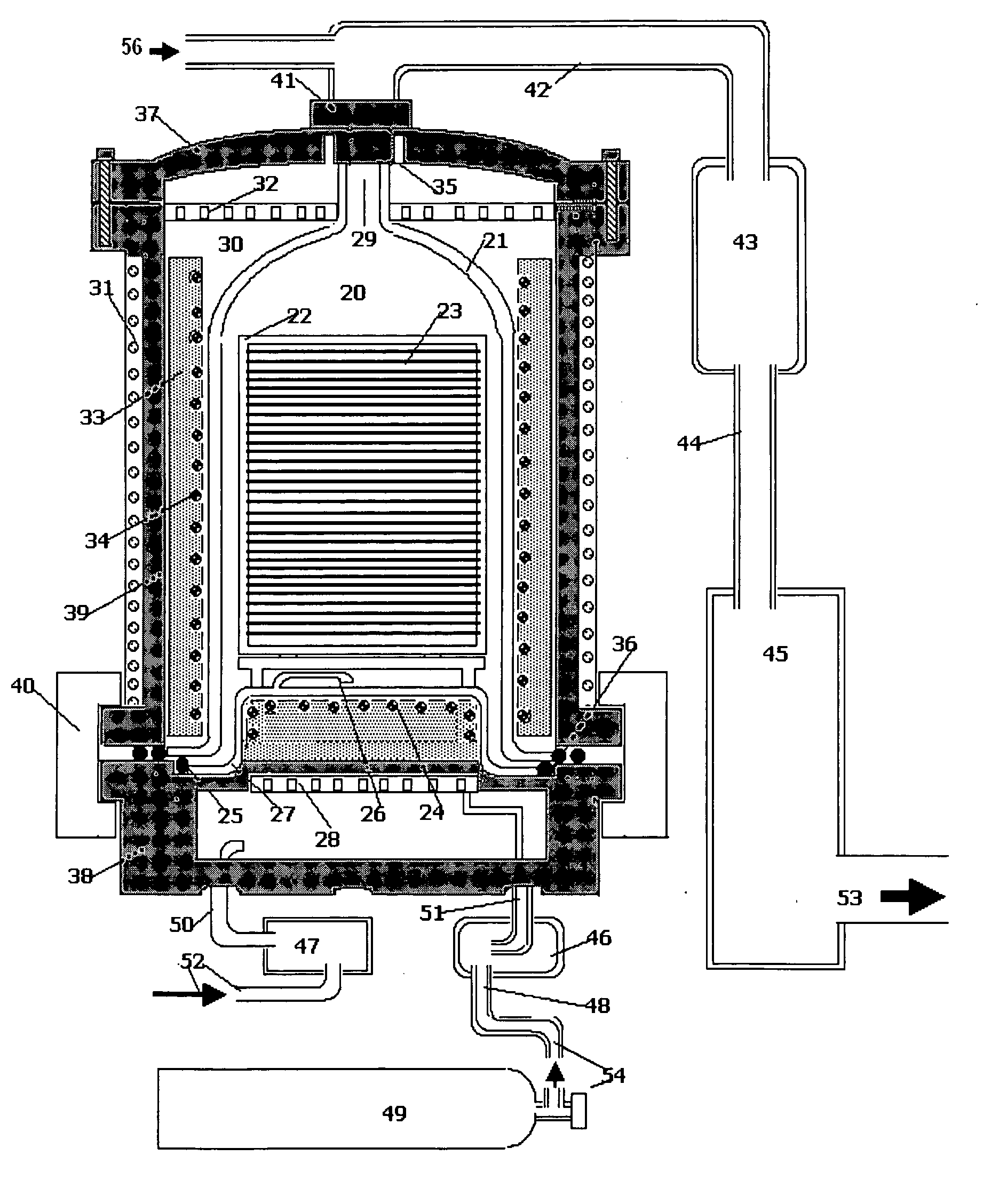

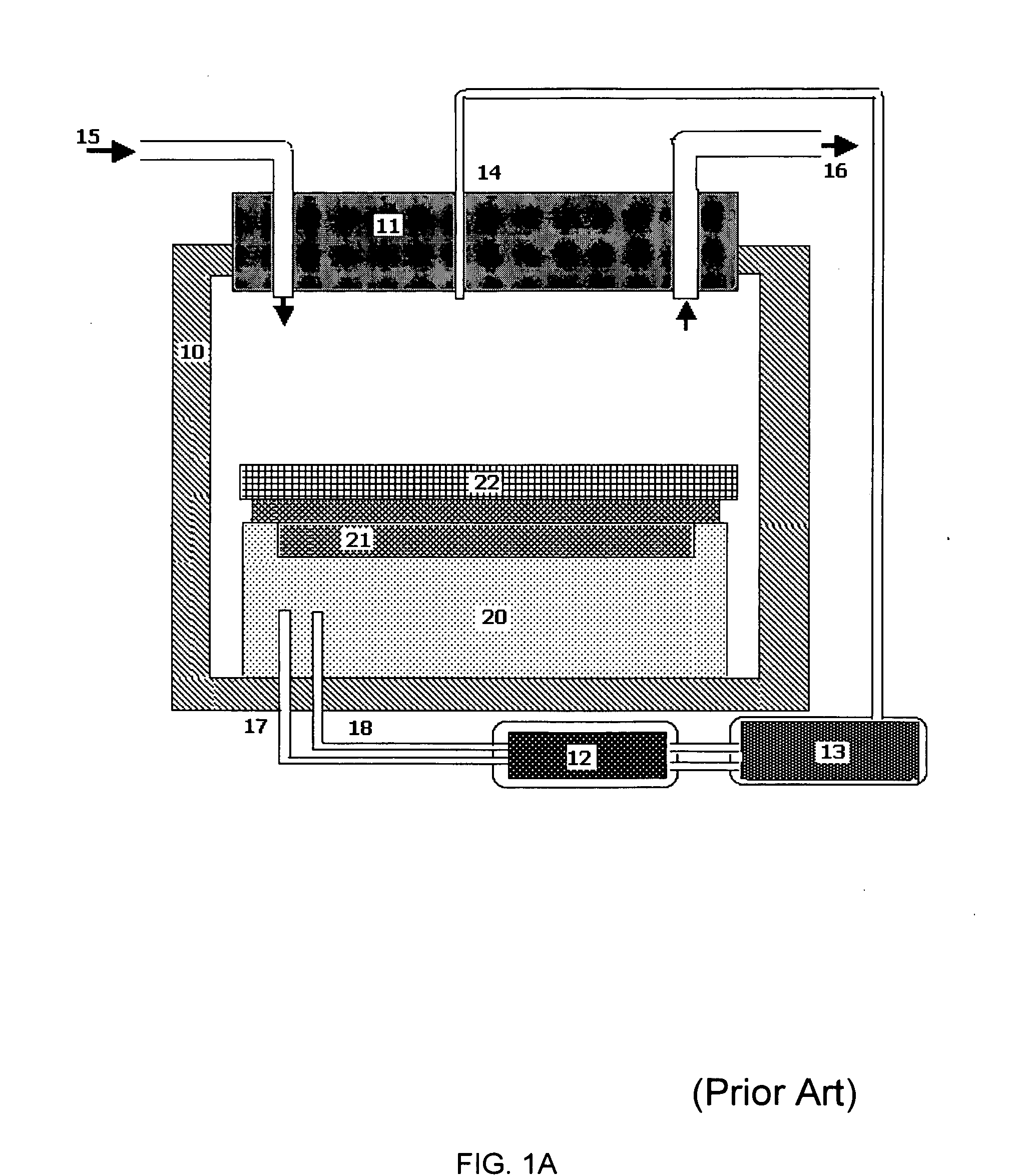

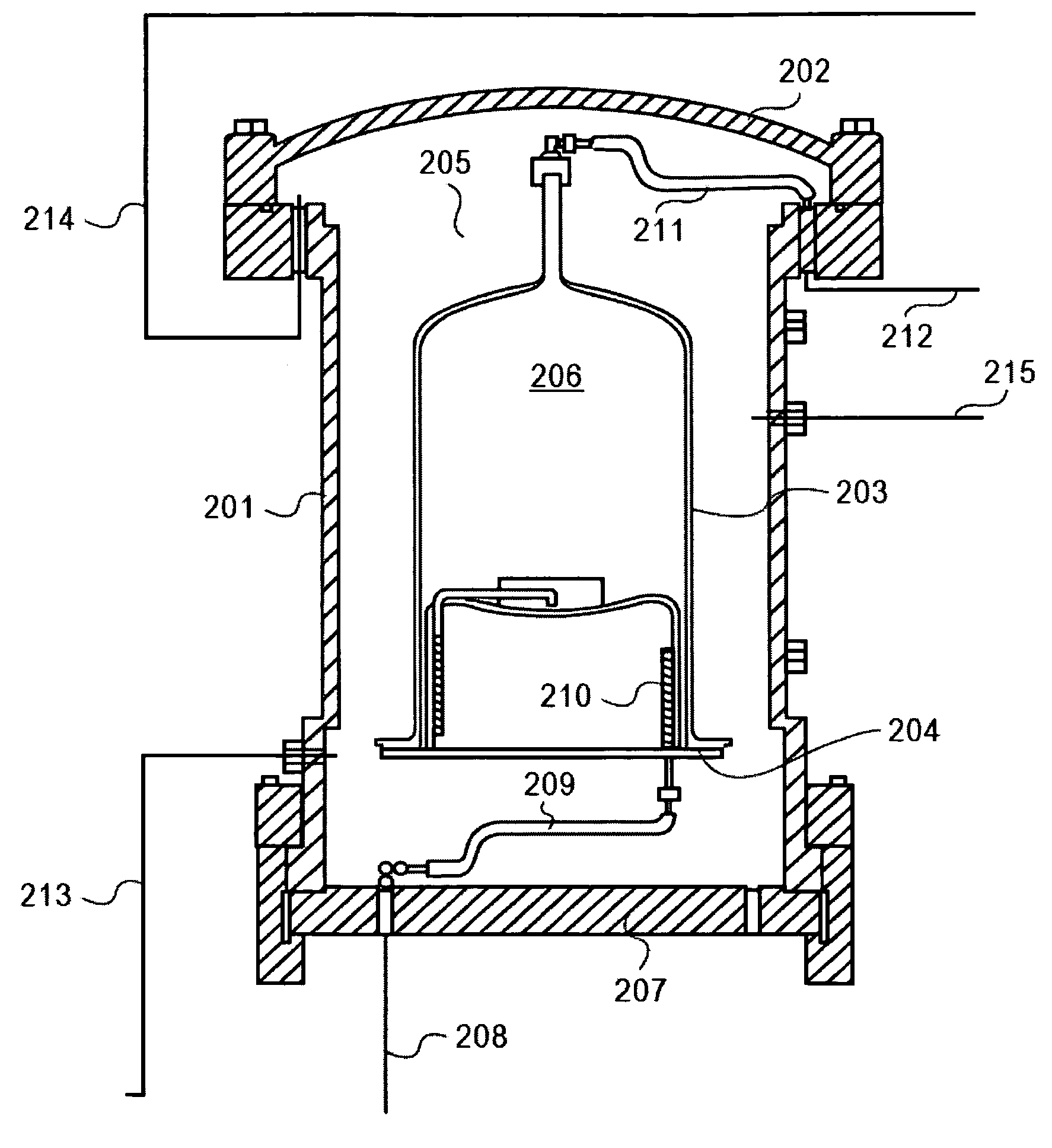

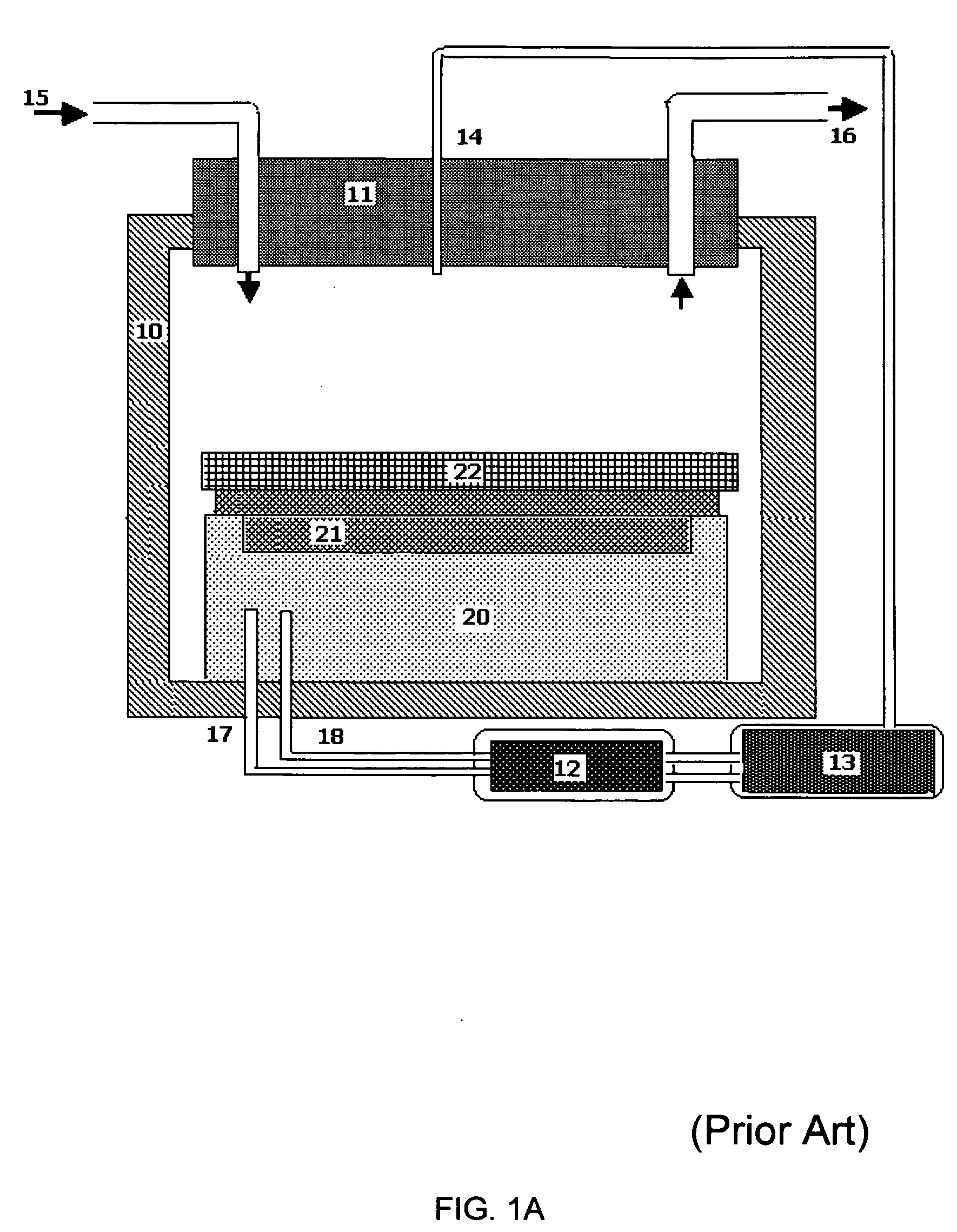

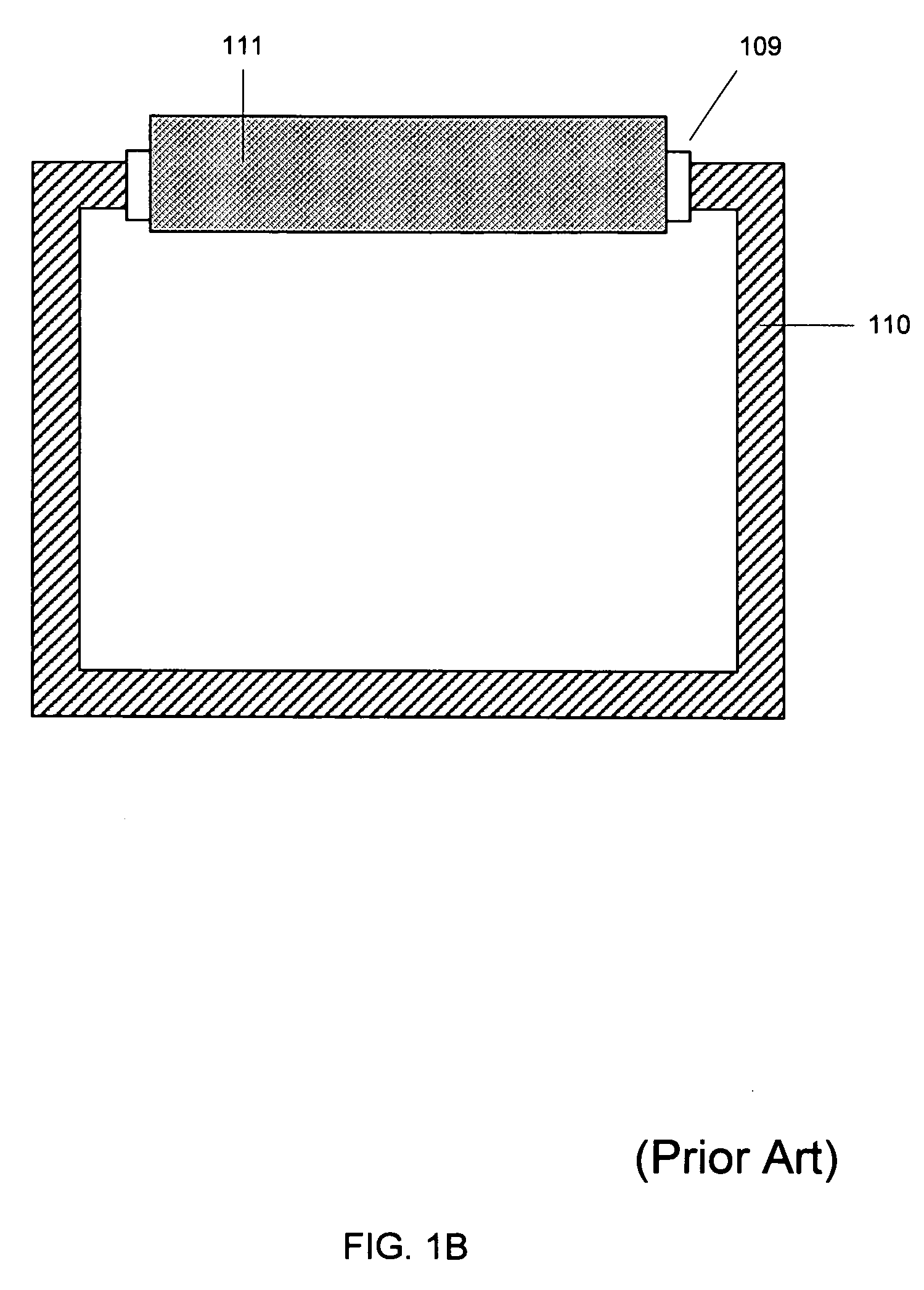

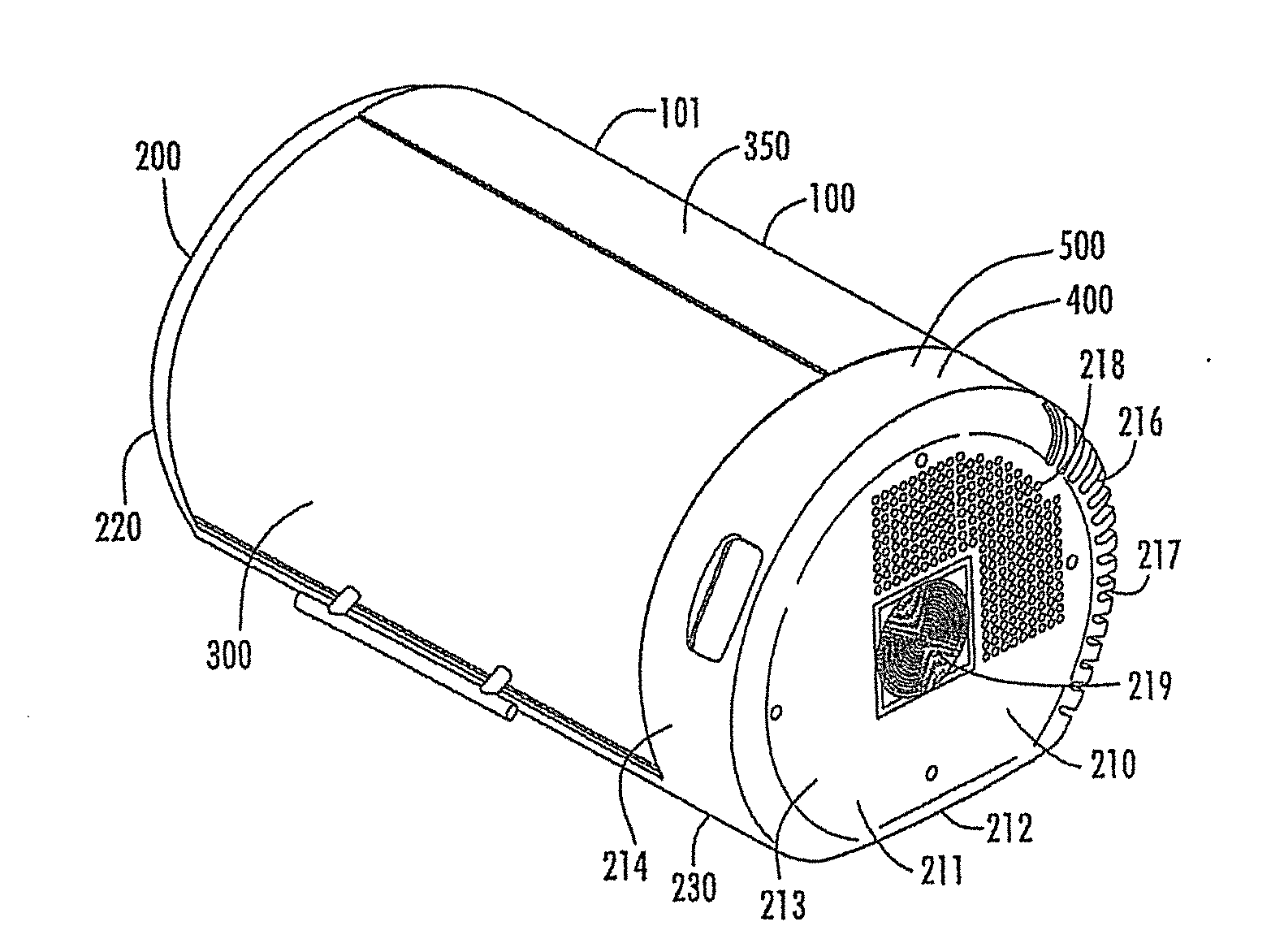

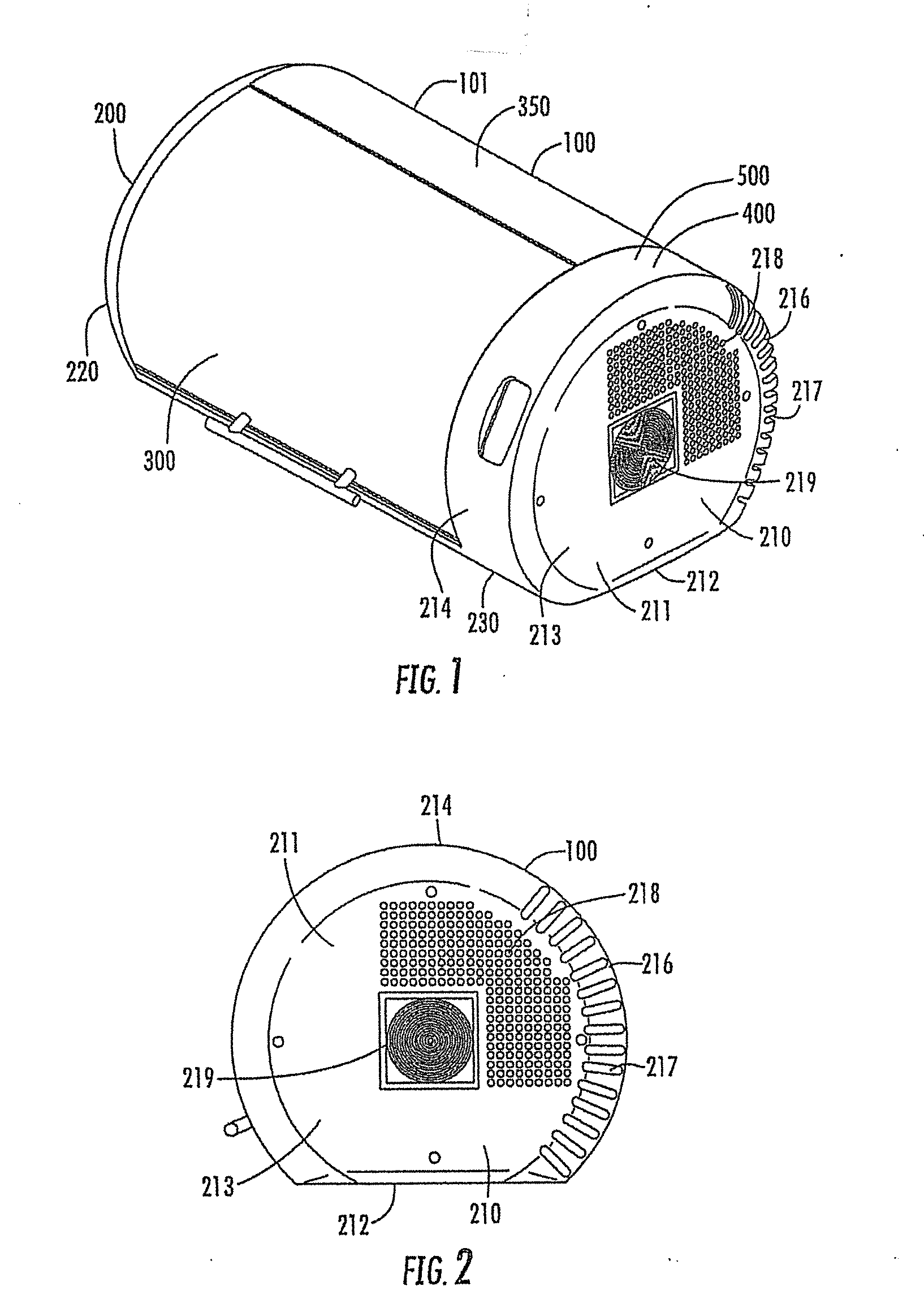

Methods and apparatuses for high pressure gas annealing

InactiveUS20070187386A1Improve device performanceIncrease device 's lifetimeSemiconductor/solid-state device testing/measurementSolid-state devicesForming gasGate dielectric

Novel methods and apparatuses for annealing semiconductor devices in a high pressure gas environment. According to an embodiment, the annealing vessel has a dual chamber structure, and potentially toxic, flammable, or otherwise reactive gas is confined in an inner chamber which is protected by pressures of inert gas contained in the outer chamber. The incoming gas delivery system and exhaust gas venting system are likewise protected by various methods. Embodiments of the present invention can be used, for example, for high-K gate dielectric anneal, post metallization sintering anneal, and forming gas anneal in the semiconductor manufacturing process.

Owner:PSMC

Method and apparatuses for high pressure gas annealing

ActiveUS20090148965A1Reduce in quantityImprove device performanceSemiconductor/solid-state device testing/measurementSolid-state devicesGate dielectricForming gas

Novel methods and apparatuses for annealing semiconductor devices in a high pressure gas environment. According to an embodiment, the annealing vessel has a dual chamber structure, and potentially toxic, flammable, or otherwise reactive gas is confined in an inner chamber which is protected by pressures of inert gas contained in the outer chamber. The incoming gas delivery system and exhaust gas venting system are likewise protected by various methods. Embodiments of the present invention can be used, for example, for high-K gate dielectric anneal, post metallization sintering anneal, and forming gas anneal in the semiconductor manufacturing process.

Owner:HPSP CO LTD

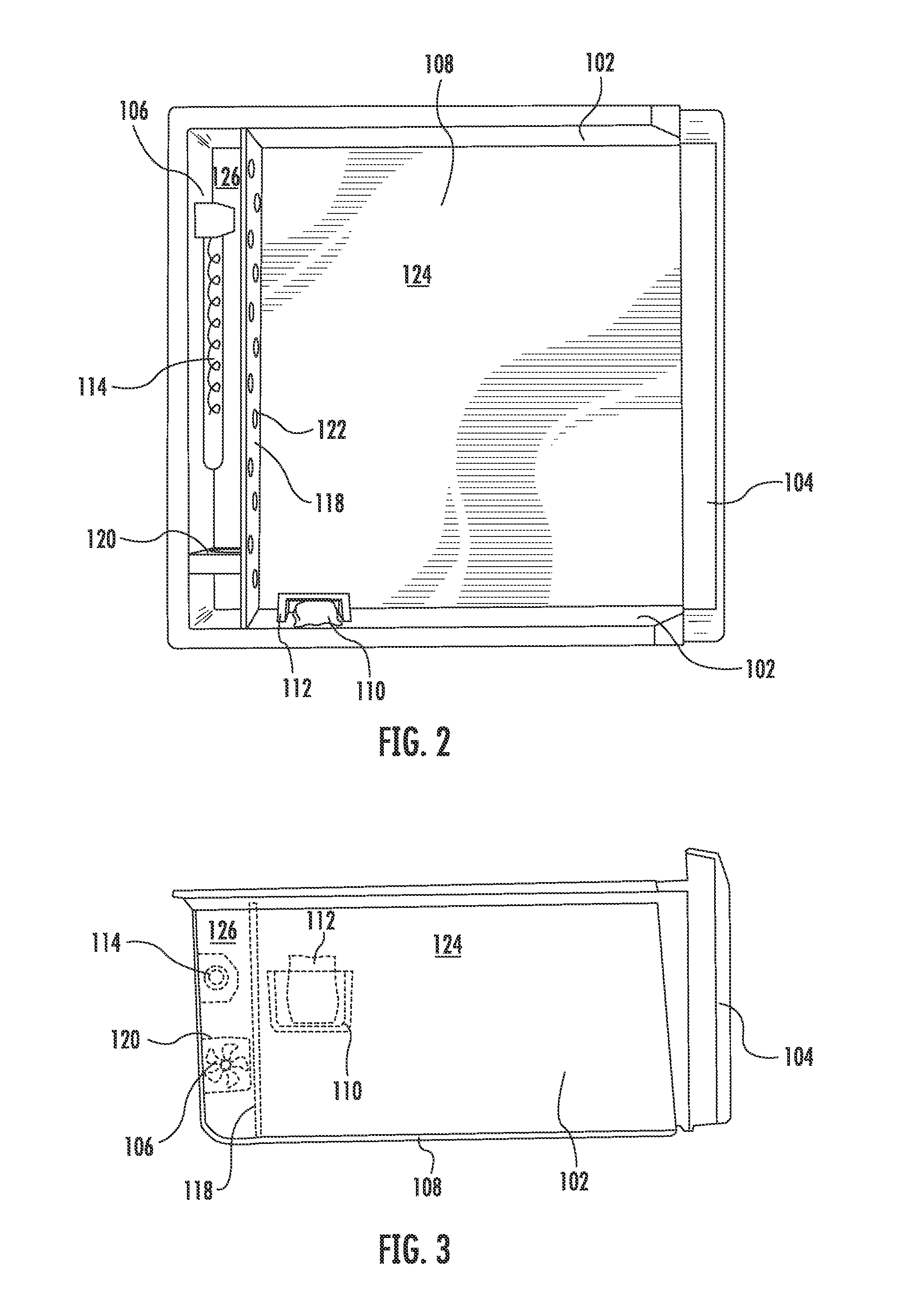

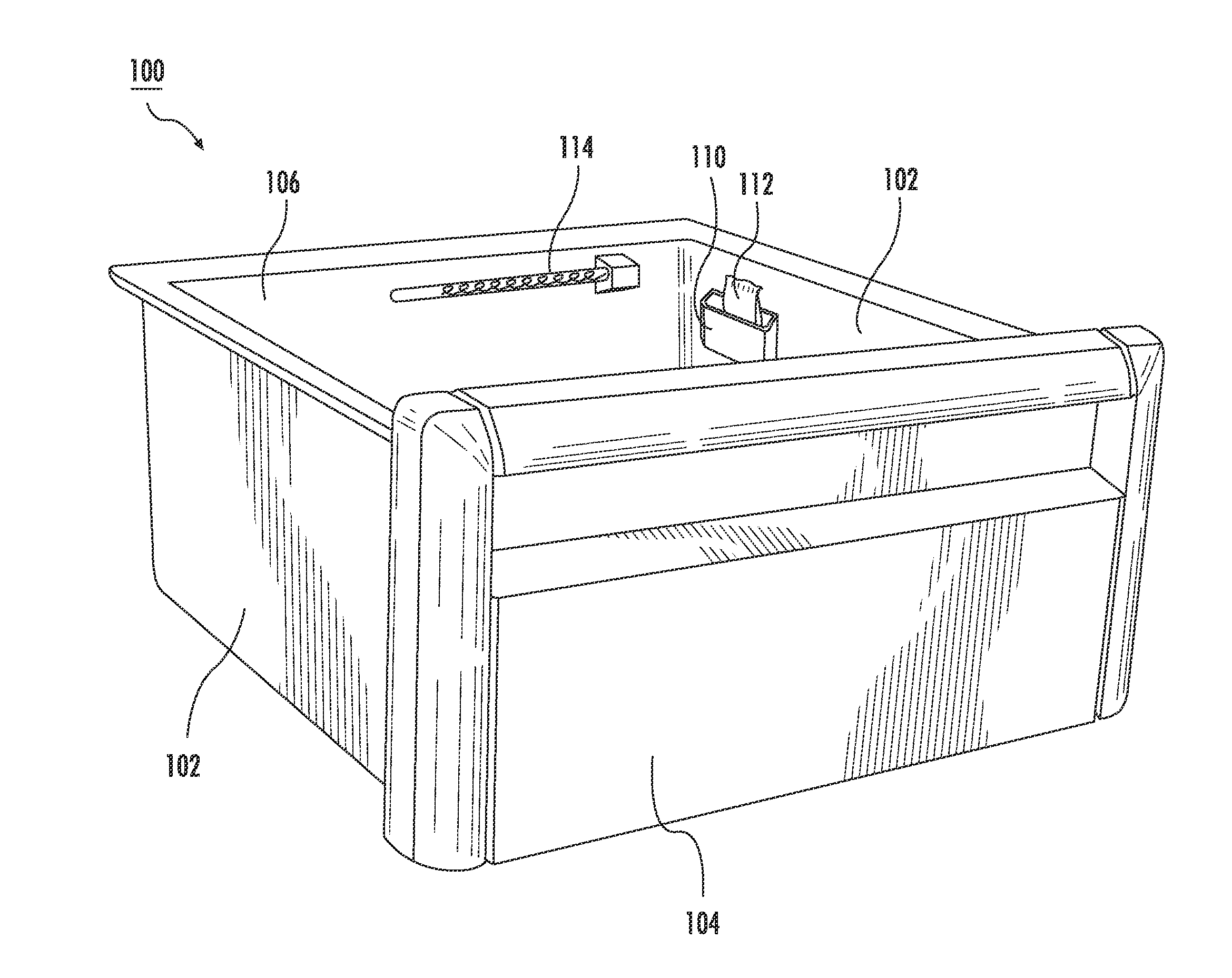

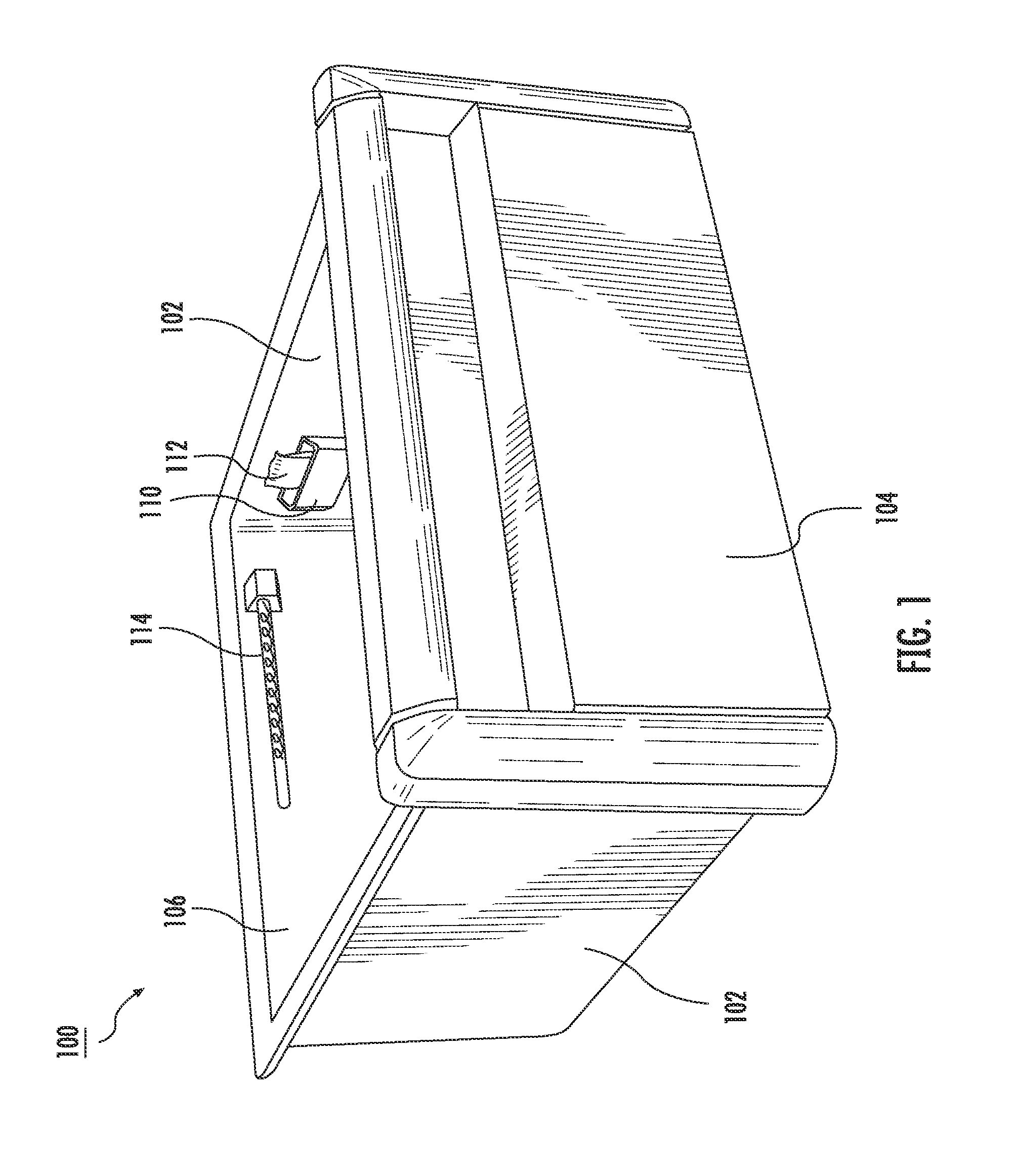

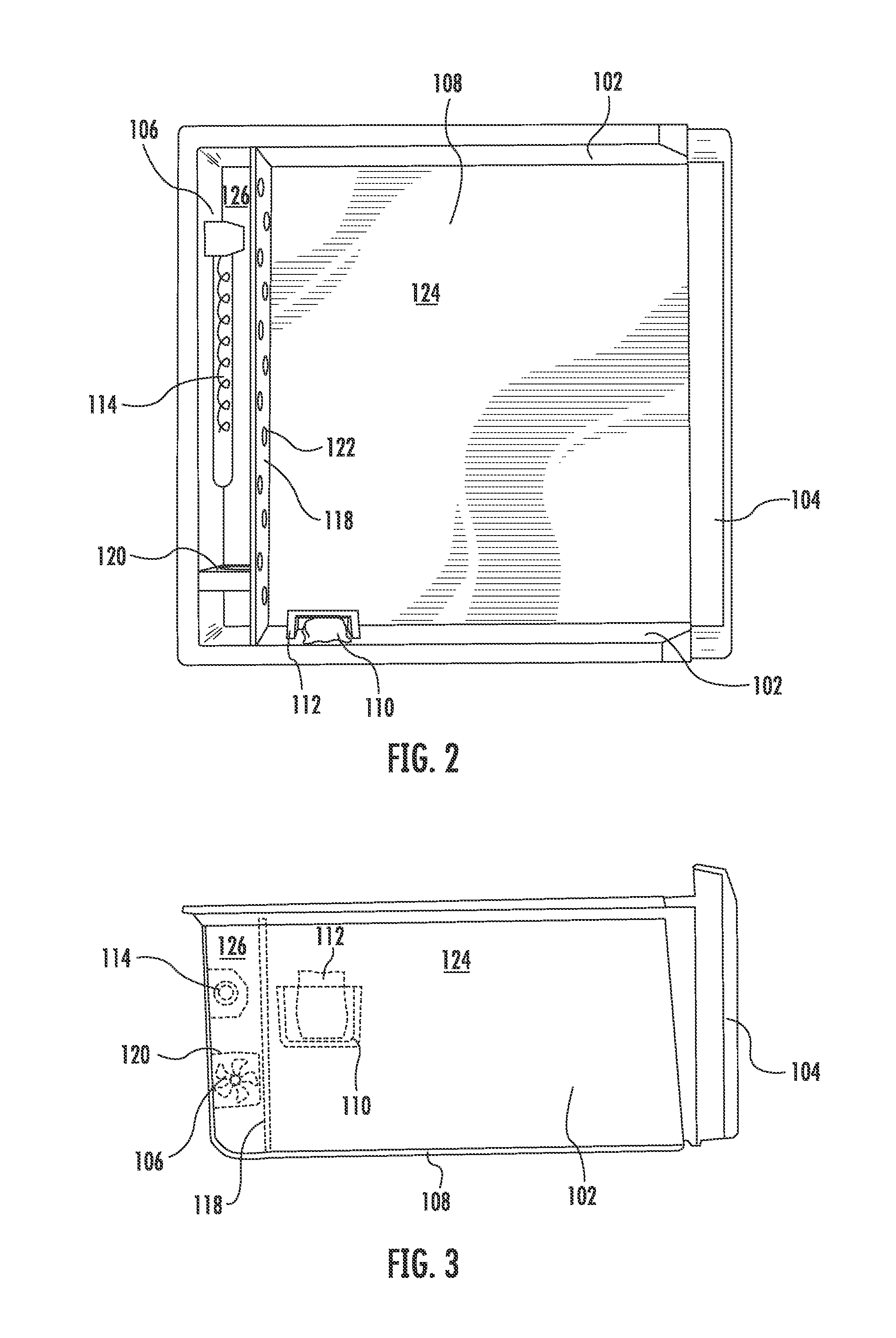

Refrigerator Crisper Ozonation System and Related Method

InactiveUS20130059047A1Delaying postharvest produce deteriorationSufficient sizeMechanical apparatusFruit and vegetables preservationOzone generatorEnvironmental engineering

A crisper drawer for postponing postharvest produce deterioration having a drawer housing that substantially defines the size and shape of the crisper drawer and fits within a residential refrigerator. A chamber within the drawer housing is cooled by the refrigerator. An ozone generator provides gaseous ozone to the chamber, and an ethylene scrubber reduces levels of ethylene in the chamber. An ozone level control with the ozone generator controls ozone levels.

Owner:ARRIGO VINCENT M

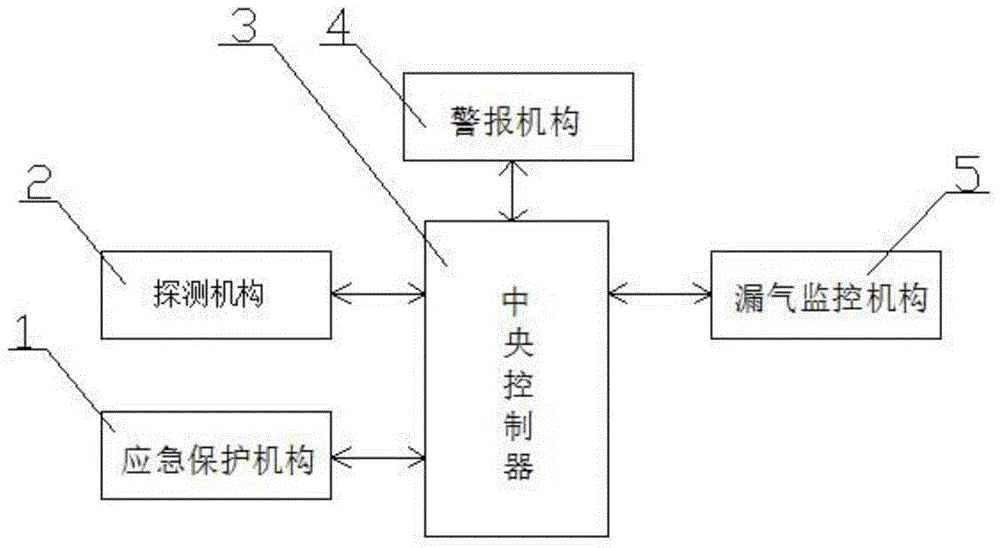

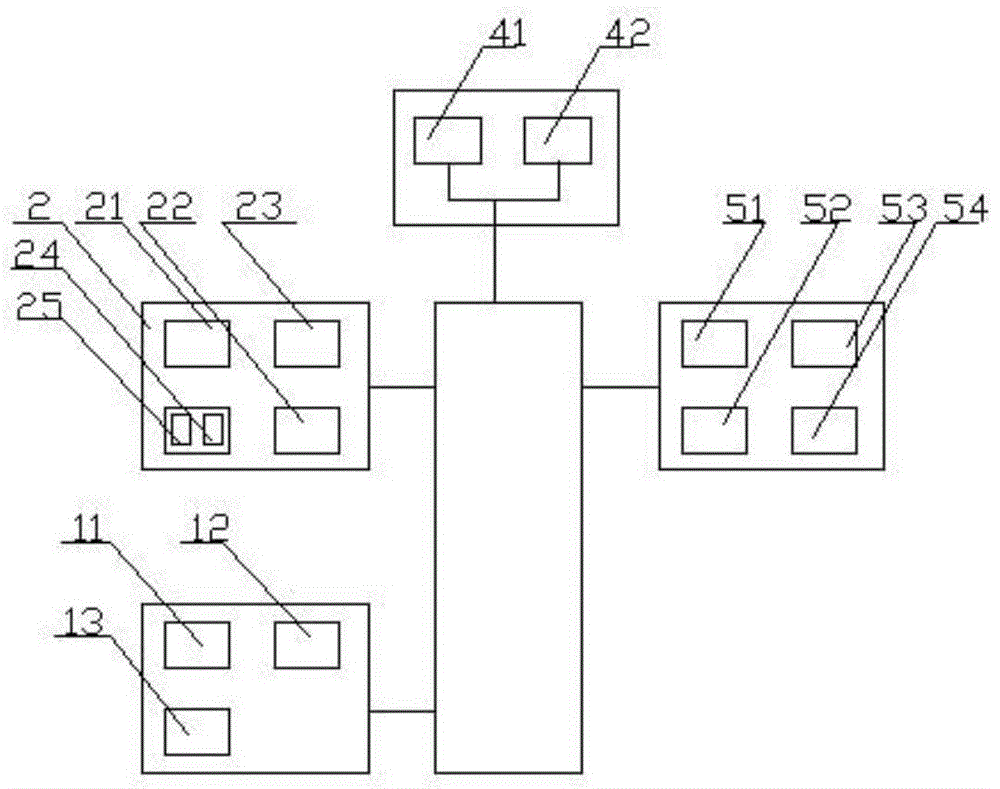

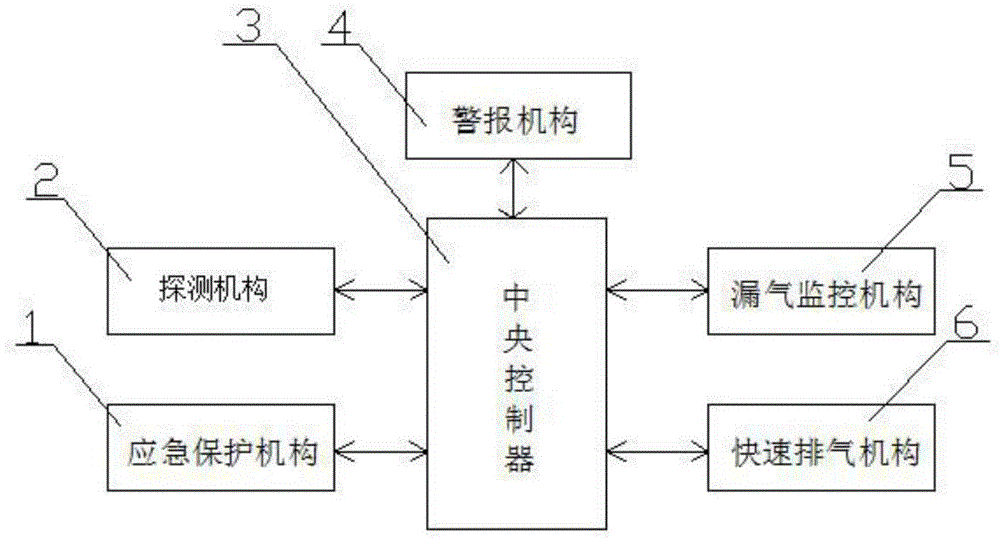

Combustion gas leakage alarm control system

ActiveCN105701985AEnsure safetyRealize intelligent controlPipeline systemsAlarmsControl systemProtection mechanism

The invention discloses a combustion gas leakage alarm control system comprising a central controller, a gas leakage monitoring mechanism disposed on a combustion gas pipeline, and a detection mechanism disposed on a combustion gas appliance. The gas leakage monitoring mechanism and the detection mechanism are connected with the central controller. The central controller is provided with an emergency protection mechanism and an alarm mechanism. The combustion gas leakage alarm control system ensures combustion gas safety by multiple protections, prevents living property losses caused by manual factors, combustion gas leakage, or aged pipelines, and is simple in structure, high in intellectualized degree, and worth applying and generalizing.

Owner:湖南天联城市数控有限公司

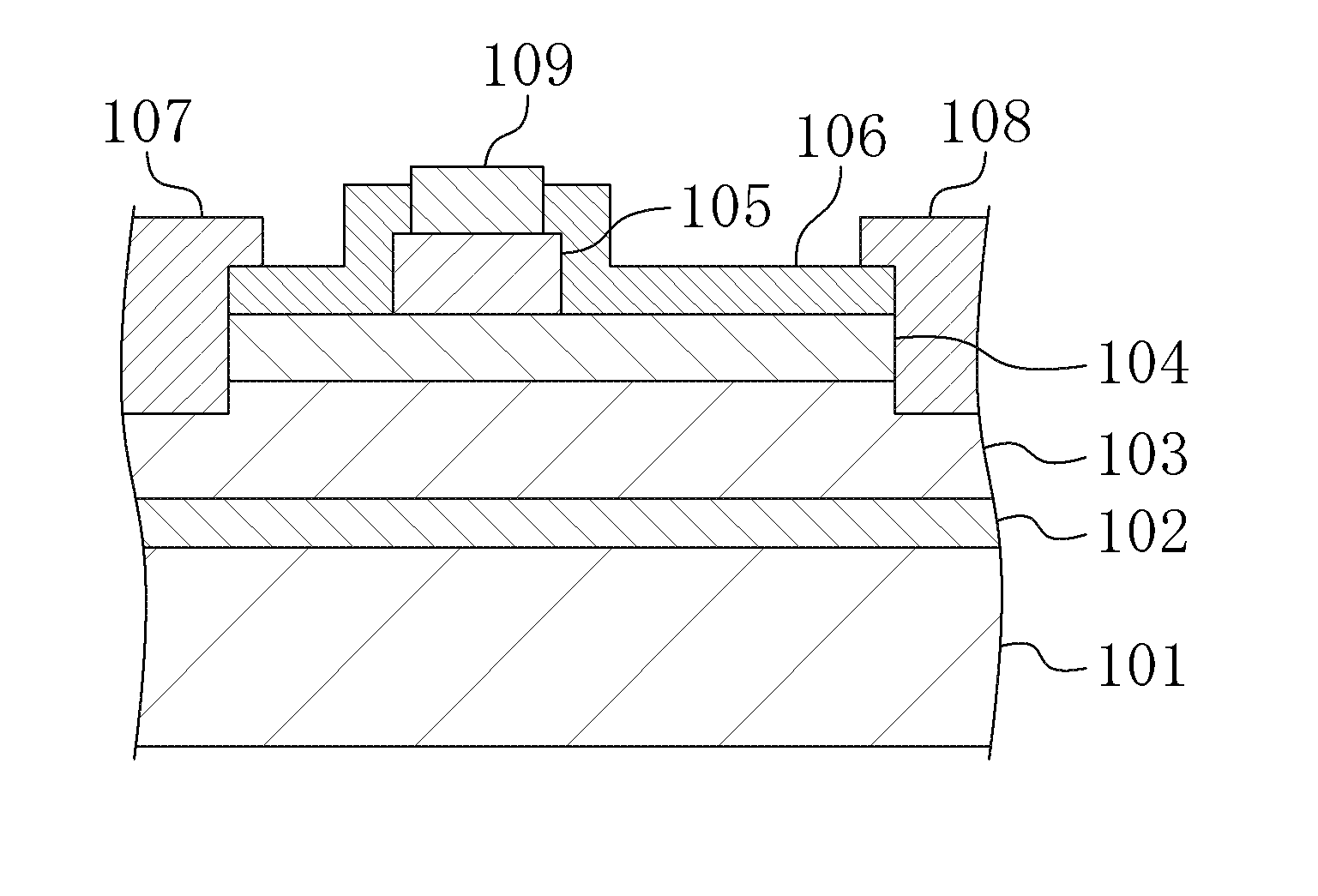

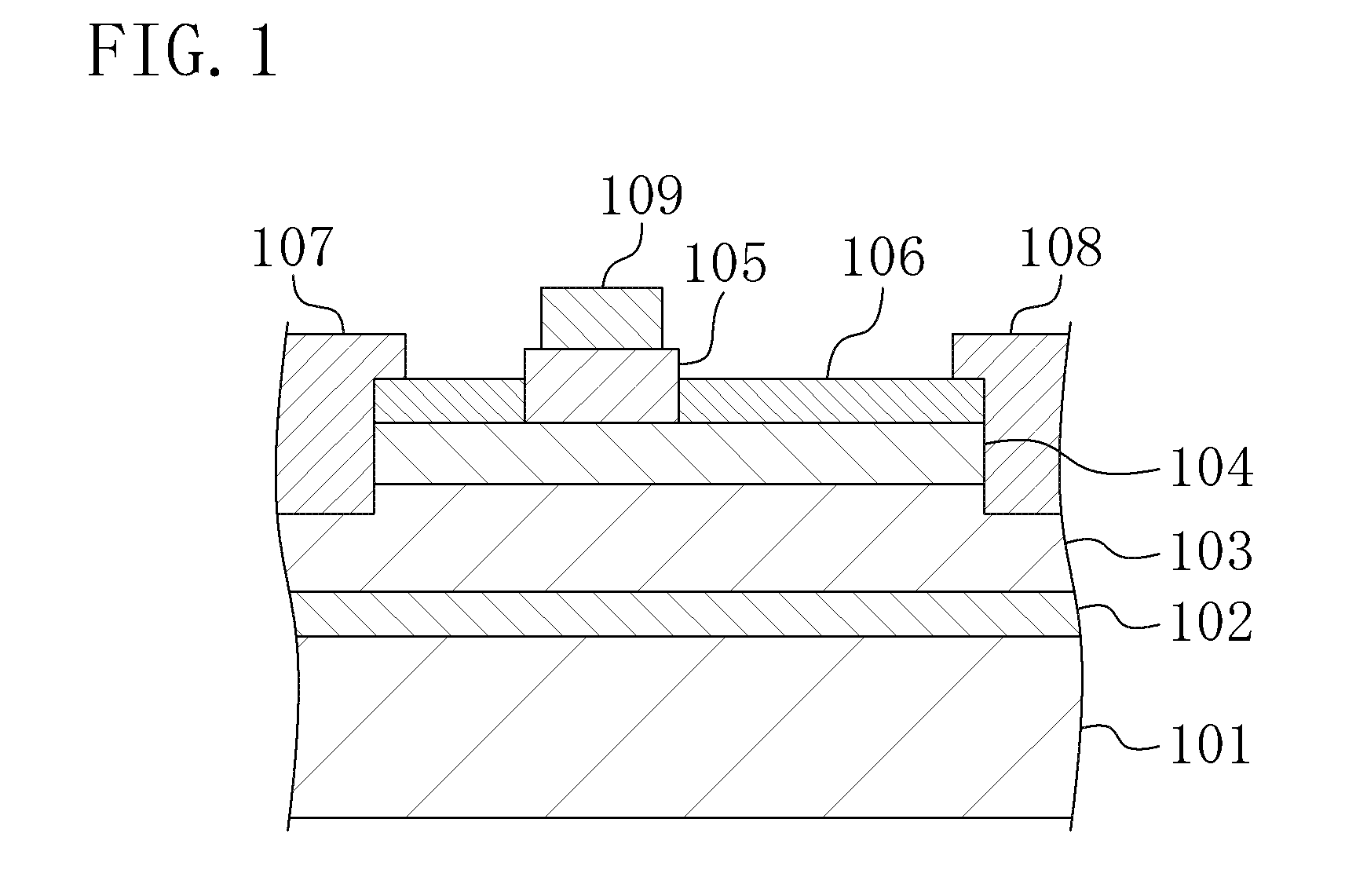

Semiconductor device and method of manufacturing the device

ActiveUS20110266554A1Lower on-resistanceReduce gas concentrationSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorDevice material

In a manufacturing method of a semiconductor device, first, a first semiconductor layer, a second semiconductor layer, and a p-type third semiconductor layer are sequentially epitaxially grown on a substrate. After that, the third semiconductor layer is selectively removed. Then, a fourth semiconductor layer is epitaxially grown on the second semiconductor layer. Then, a gate electrode is formed on the third semiconductor layer.

Owner:PANASONIC CORP

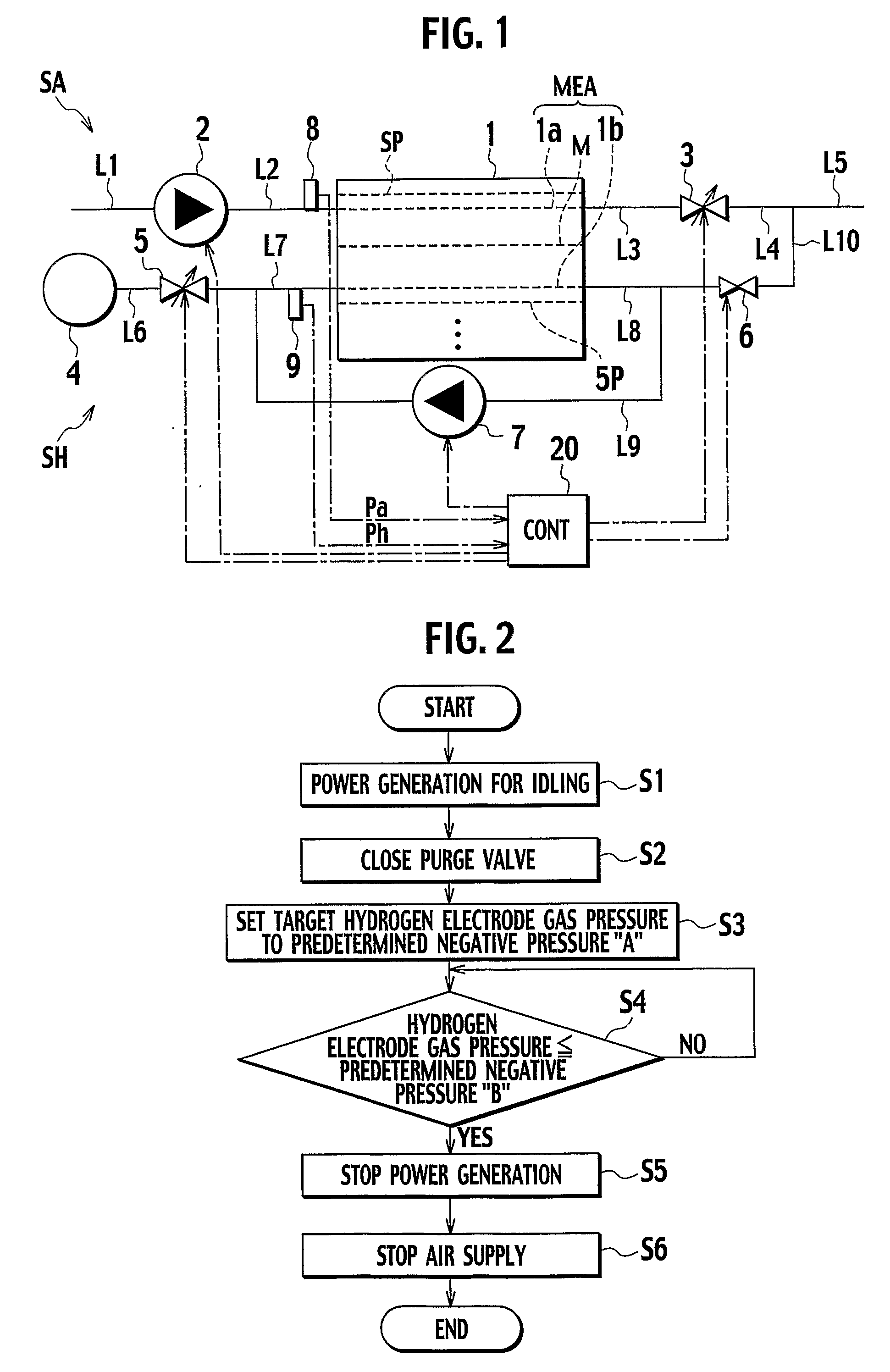

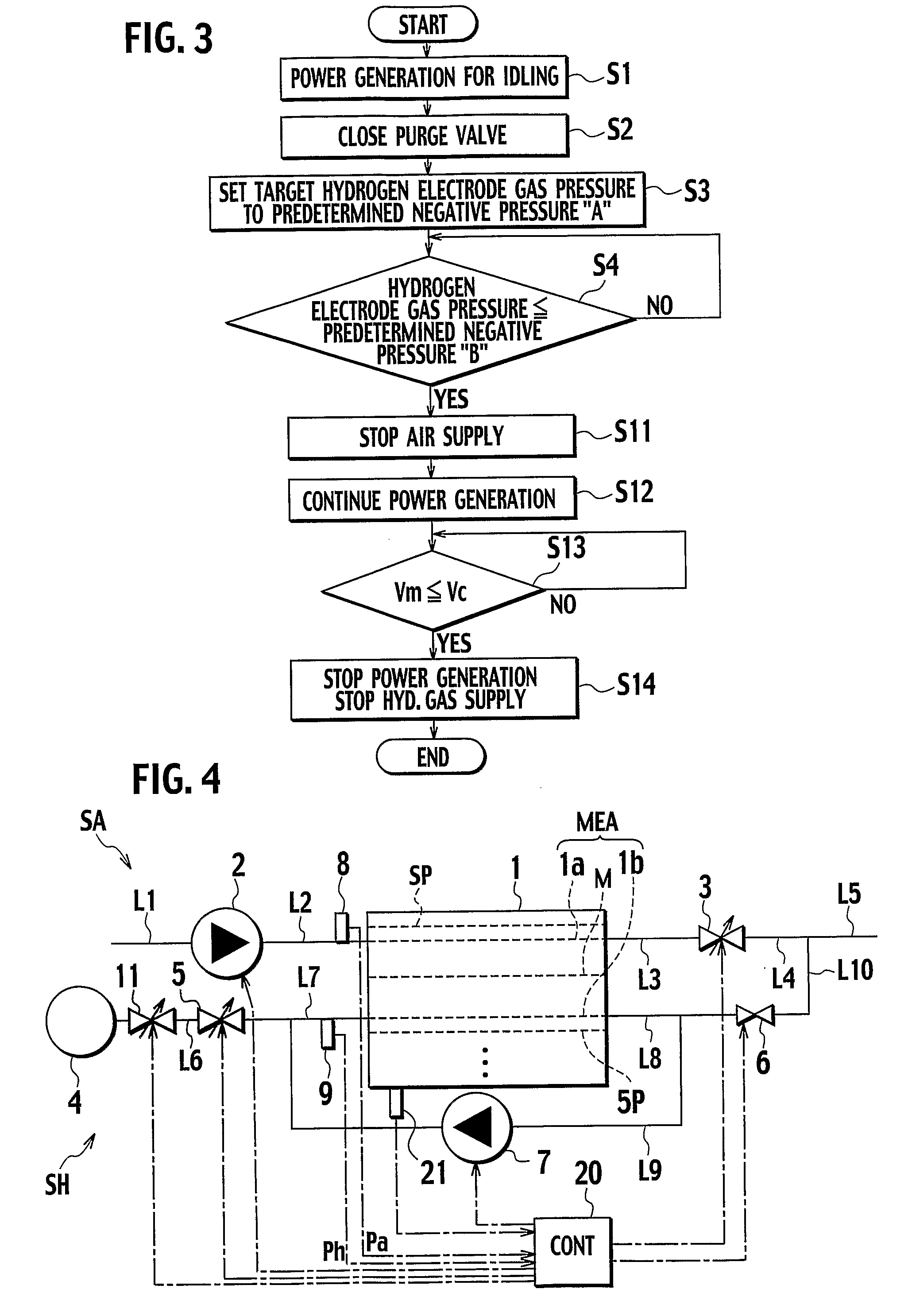

Fuel Cell System

ActiveUS20080187790A1Reduce hydrogen concentrationPower generation stopFuel cell controlFuel cellsExhaust valve

A fuel cell system including: a fuel cell supplied with a fuel gas to a fuel electrode thereof and air to an air electrode thereof; a fuel gas supplying device which supplies the fuel gas to the fuel electrode; an air supplying device which supplies air to the air electrode; a fuel gas pressure regulator which regulates fuel gas pressure at the fuel electrode; a purge valve which discharges exhaust fuel gas from the fuel electrode to the outside; and a controller. The controller continues power generation of the fuel cell, controlling the fuel gas pressure regulator to lower the fuel gas pressure at the fuel electrode, having the air supplying device continuing supplying air to the air electrode with the purge valve closed; and after the fuel gas pressure at the fuel electrode becomes equal to or lower than the atmospheric pressure, stops power generation of the fuel cell.

Owner:NISSAN MOTOR CO LTD

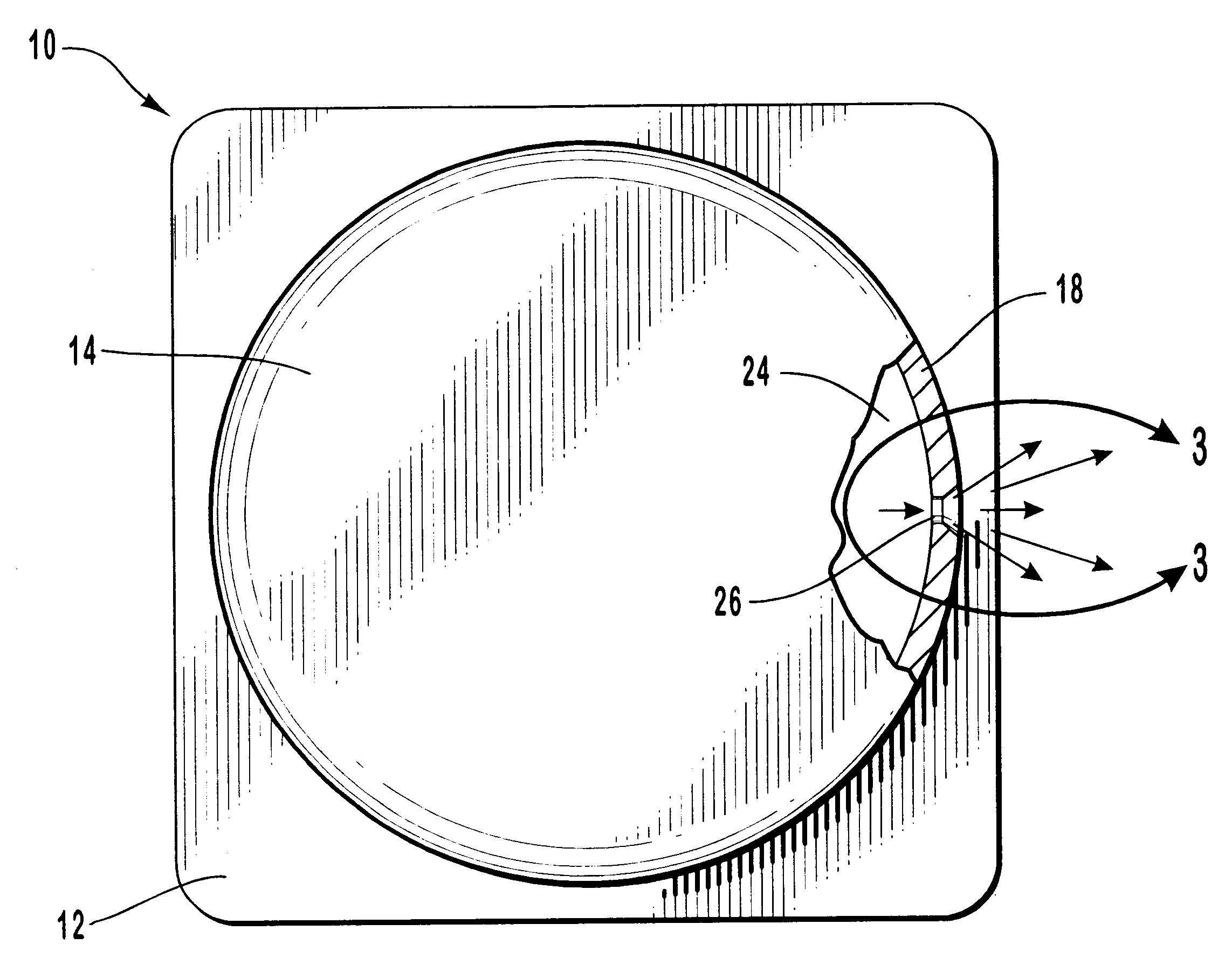

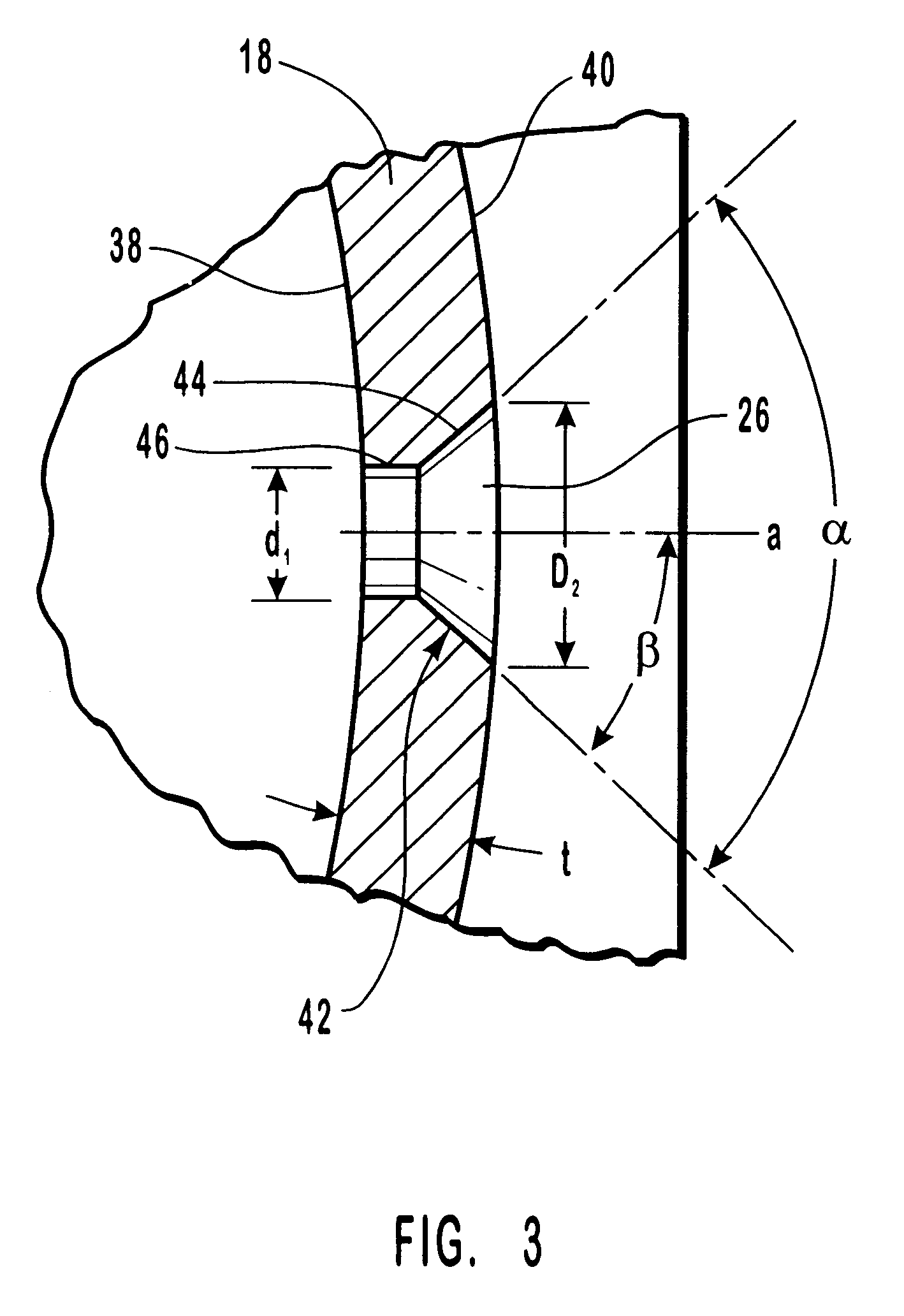

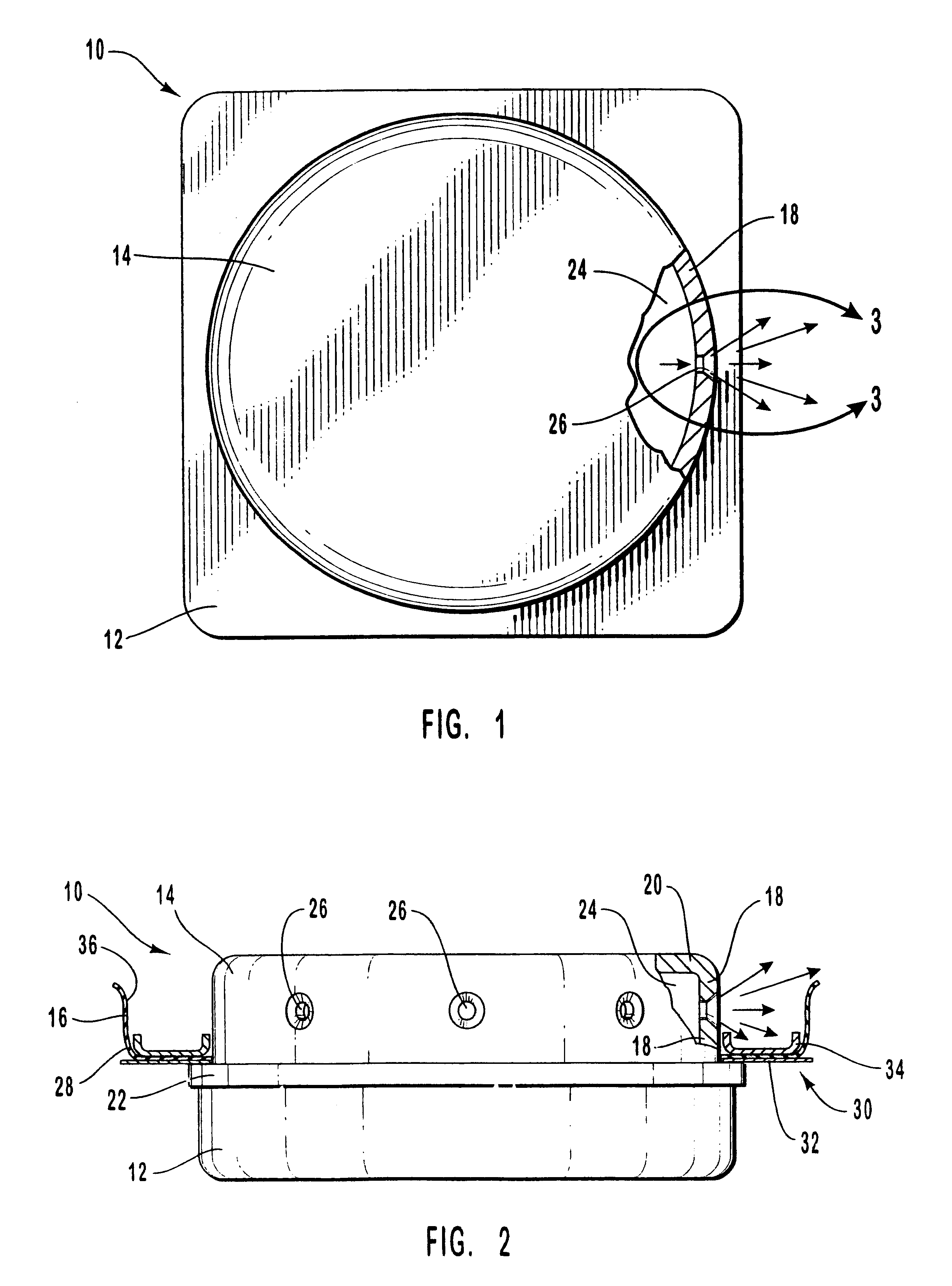

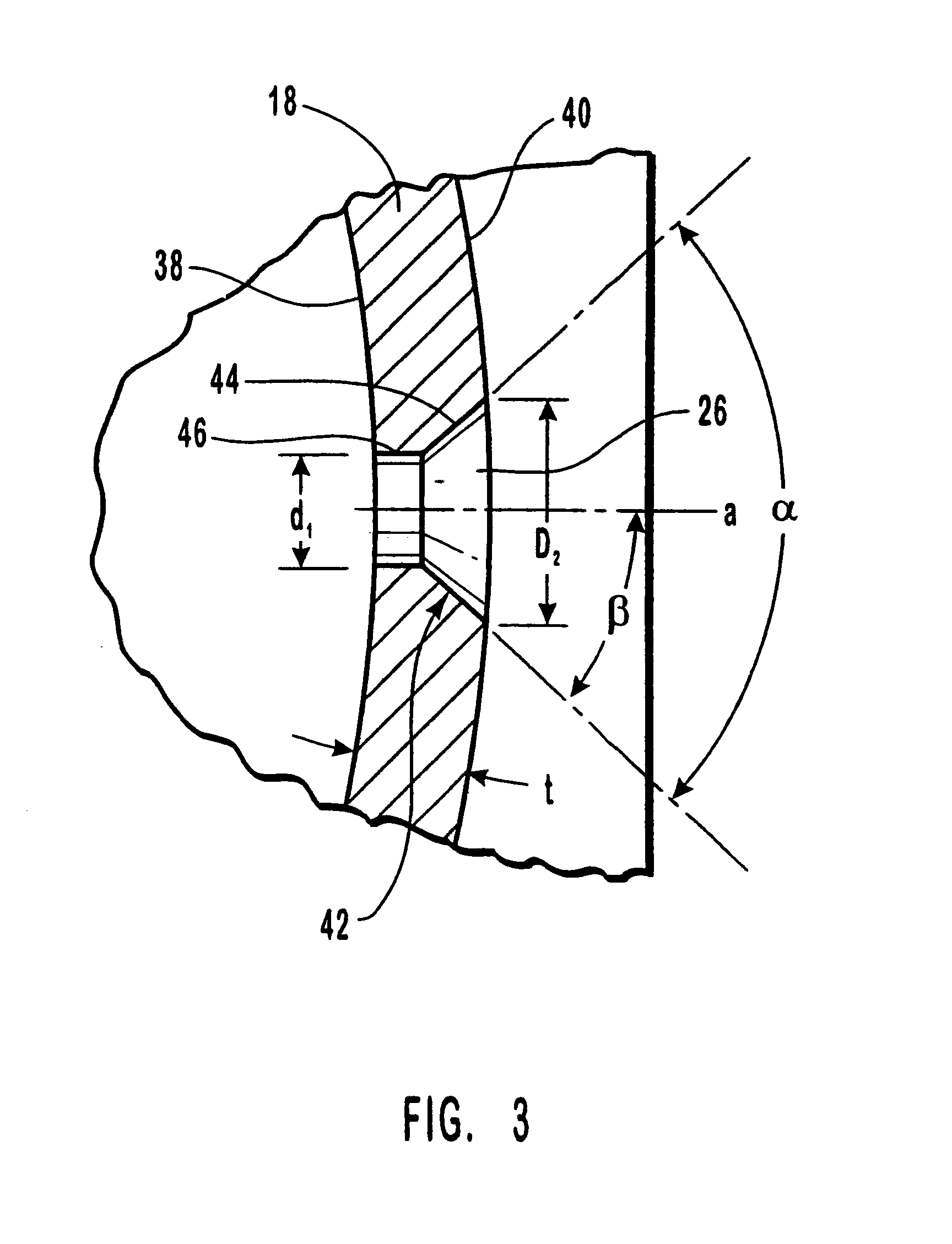

Air bag inflator exit gas dispersion features

InactiveUS6206417B1Reduce thicknessReduce gas concentrationPedestrian/occupant safety arrangementInterior spaceEngineering

An air bag device that includes an air bag cushion, a diffuser canister, and a gas generation inflator. The diffuser canister is attached to the air bag cushion and has walls configured to define an interior space therein. The walls of the diffuser canister have an interior surface, an exterior surface, and a wall thickness t. At least one of the walls has an aperture formed therethrough in communication with the interior of the air bag cushion. The gas generation inflator is configured to rapidly create a gas that exists the diffuser canister through the aperture so as to fill the air bag cushion. The aperture is defined by an edge extending between the interior and said exterior surfaces of the wall that is configured to diffuse the gas exiting the diffuser canister through the aperture. The edge of the aperture is configured such that the cross-sectional area of the aperture that is proximate to the exterior surface of the wall is larger than the cross-sectional area of the aperture proximate to the interior surface of wall. The edge includes an angled portion configured such that opposing sides of the aperture have an angle alpha therebetween in the range of about 20 degrees to about 145 degrees. The aperture has a diameter d1 proximate to the interior surface of the wall and is configured so that the diameter d1 and wall thickness t have a ratio d1 to t in the range of about 0.5 to about 4.

Owner:AUTOLIV ASP INC

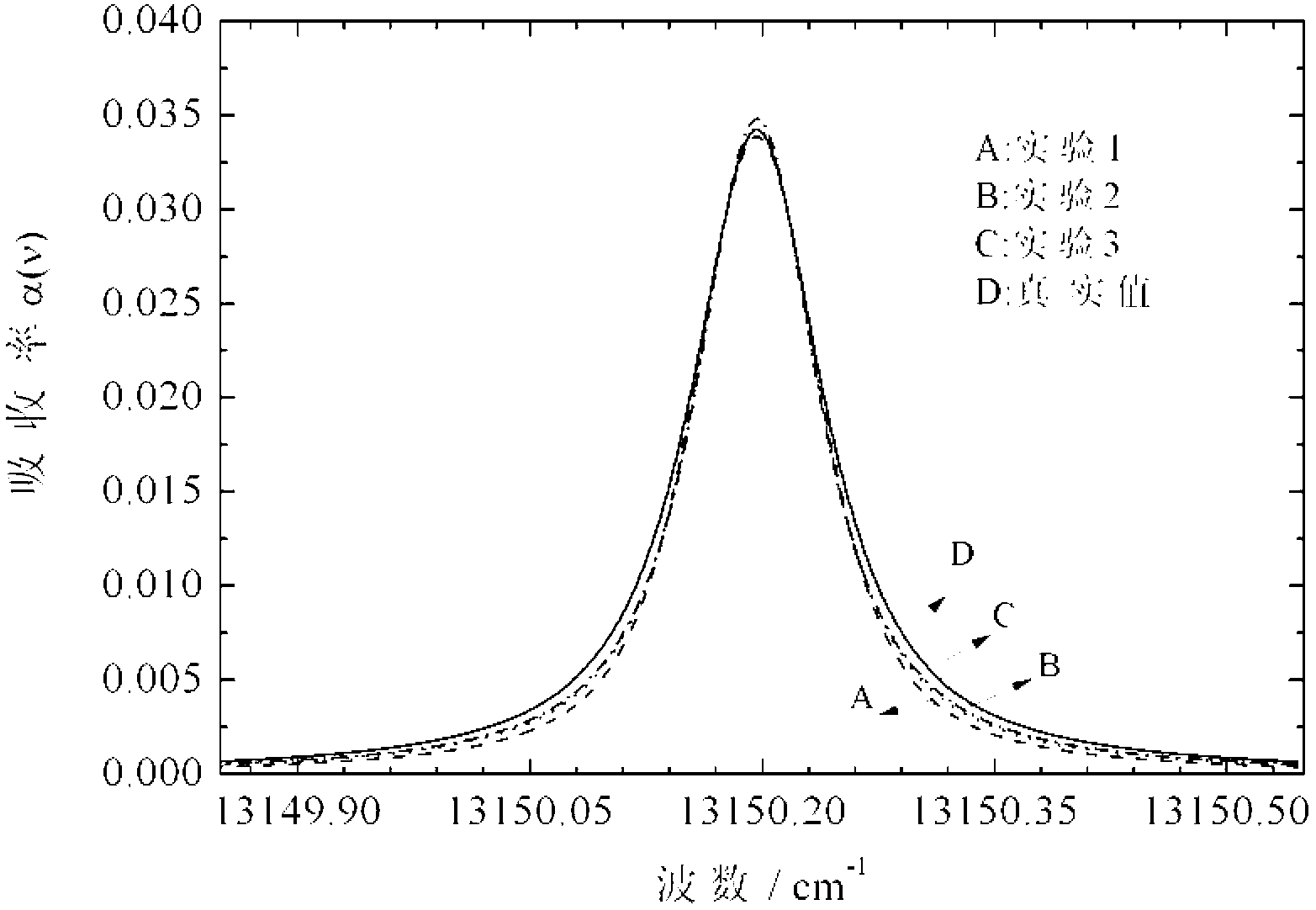

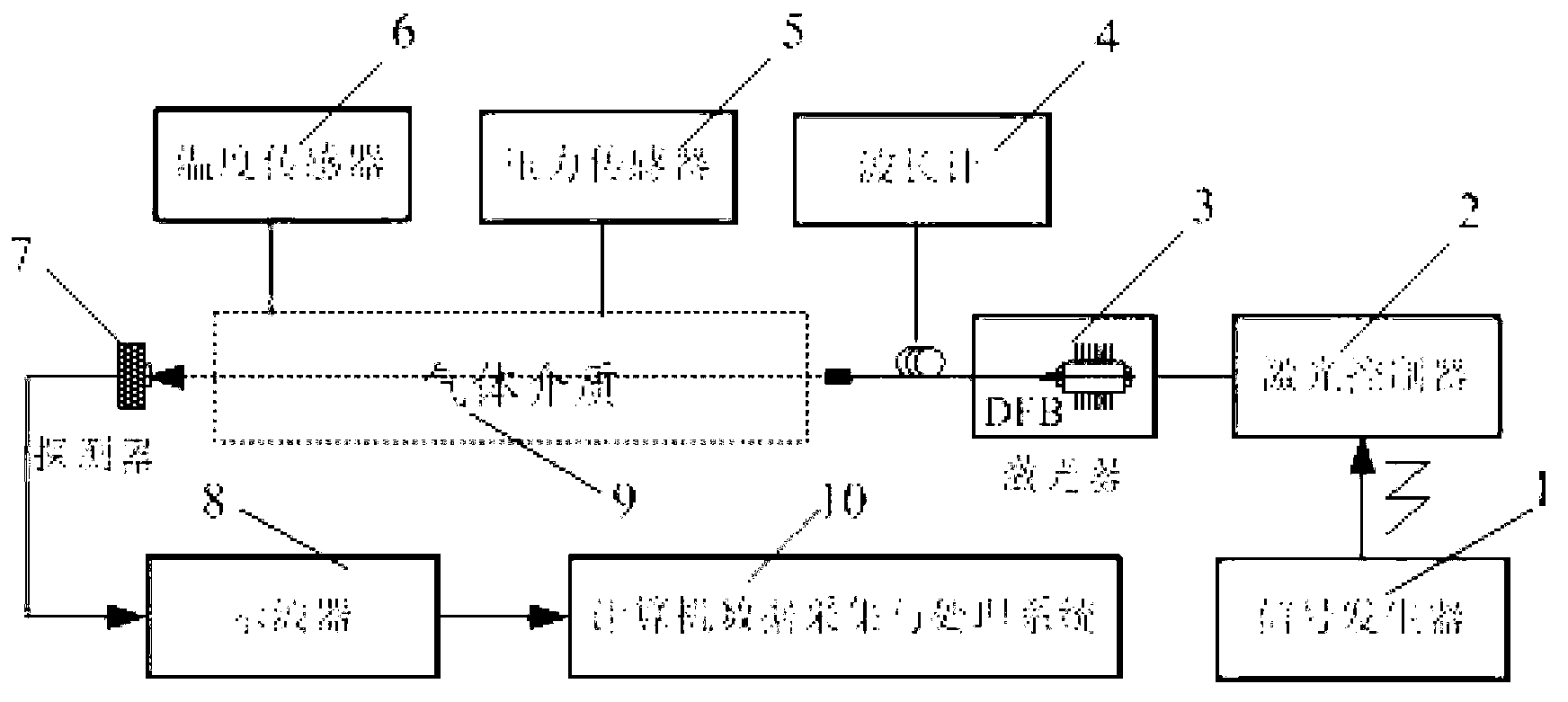

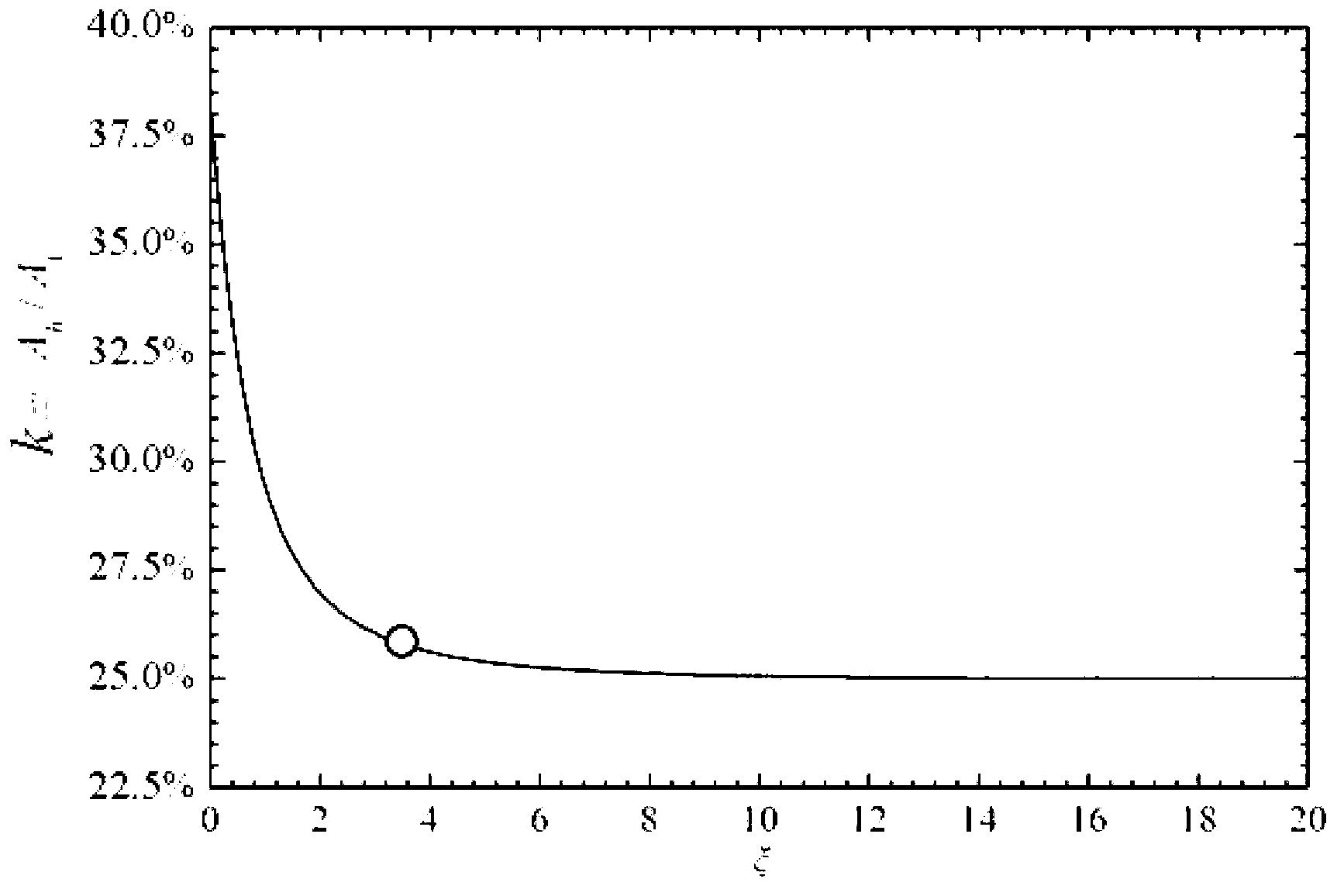

Gas concentration on-line measurement method based on full-width-at-half-maximum integral method

ActiveCN102798610AEliminate random errorsEliminate Fitting ErrorColor/spectral properties measurementsFull width at half maximumAbsorption rate

The invention discloses a gas concentration on-line measurement method based on a full-width-at-half-maximum integral method and belongs to the technical field of tunable diode laser absorption spectroscopy (TDLAS). According to the method, a gas absorption rate curve which is fitted by a direct absorption method is integrated in a full-width-at-half-maximum range near the central frequency of a spectral line, and the concentration of gas to be measured is determined according to an iterative algorithm. The method has the advantages that the problem of concentration measurement errors caused by inaccurate fitting of the gas absorption rate curve of the direct absorption method under the condition of weak absorption can be effectively solved, the measurement accuracy of gas concentration is improved, and an application range of a TDLAS technology is expanded.

Owner:北京新叶科技有限公司

Method for processing liquid fuel oil by using waste oil

InactiveCN101805644AMeet the use requirementsWell mixedTreatment with plural serial refining stagesLiquid carbonaceous fuelsMetalworkingAntioxidant

The invention relates to a method for processing liquid fuel oil by using waste oil. The method comprises the following steps of: in part by weight, weighing 40 to 50 parts of waste metal processing oil, 20 to 30 parts of waste emulsifying oil and 20 to 40 parts of waste lubricating oil, and stirring the components uniformly and sufficiently to obtain mixed oil; adding a cationic surfactant and concentrated sulfuric acid into the mixed oil, performing emulsion breaking, and filtering the mixture to eliminate heavy metals and other impurities; adding diatomaceous earth into the mixture to perform adsorption bleaching, and performing filter pressing to separate liquid and a solid mixture; adding isopropanol to separate out oil and water; and adding a flash point modifier and an antioxidant into the separated oil, and modulating the mixture to obtain the liquid fuel oil. The method has a simplified process, can be performed at normal temperature and generates fewer waste products; the waste oil can be combusted sufficiently after being processed, and an exhaust gas contains few harmful gases; and the fuel oil can be widely used as a fuel for power generation by electric power plants, ship boilers, heating furnaces, metallurgical furnaces and other industrial furnaces. The method realizes the full utilization of the waste oil and has good economic and social benefits.

Owner:GONGYI OASIS WASTE TREATMENT

Method for preparing novel carbon pottery composite adsorption material

InactiveCN101234330AAchieve the purpose of reusingReduce gas concentrationOther chemical processesSpontaneous combustionHigh intensity

The invention relates to a preparation method for a novel carbon pottery composite absorption material, comprising raw material preparation, kneading and forming, drying, high temperature activation and post treatment. By adopting a coke burning process to replace the present burning ceramic technology to prepare carbon pottery, the preparation method for a novel carbon pottery composite absorption material shortens the process period greatly as the temperature rising rate is improved and the activation temperature is reduced, thus being good for transforming the charcoal into activated carbon as well as for improving the yield and performance of the product and reducing the cost simultaneously. The prepared novel carbon pottery complex absorption material also has the advantages of water resistance, no spontaneous combustion, high intensity and large specific surface area.

Owner:FUJIAN AGRI & FORESTRY UNIV

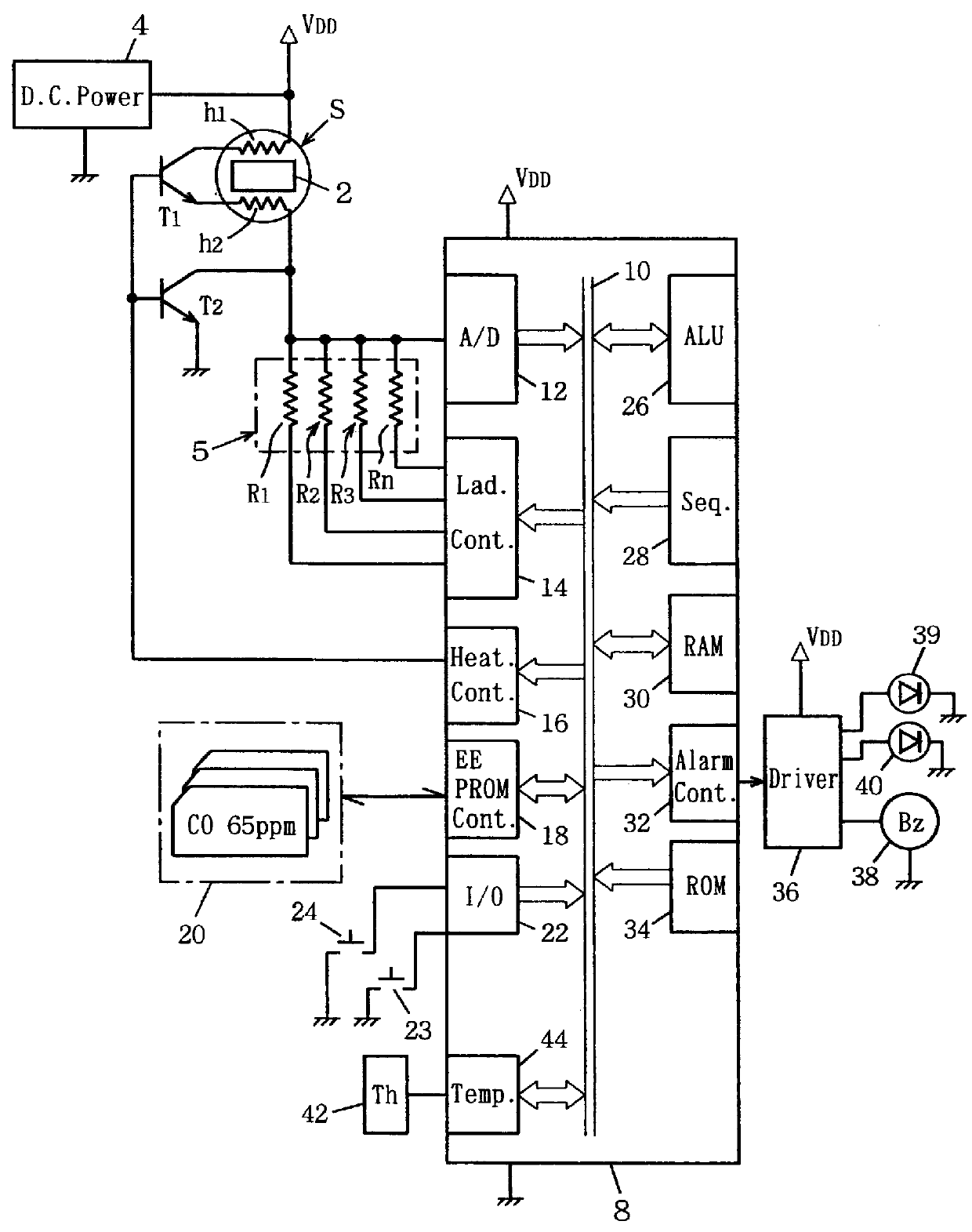

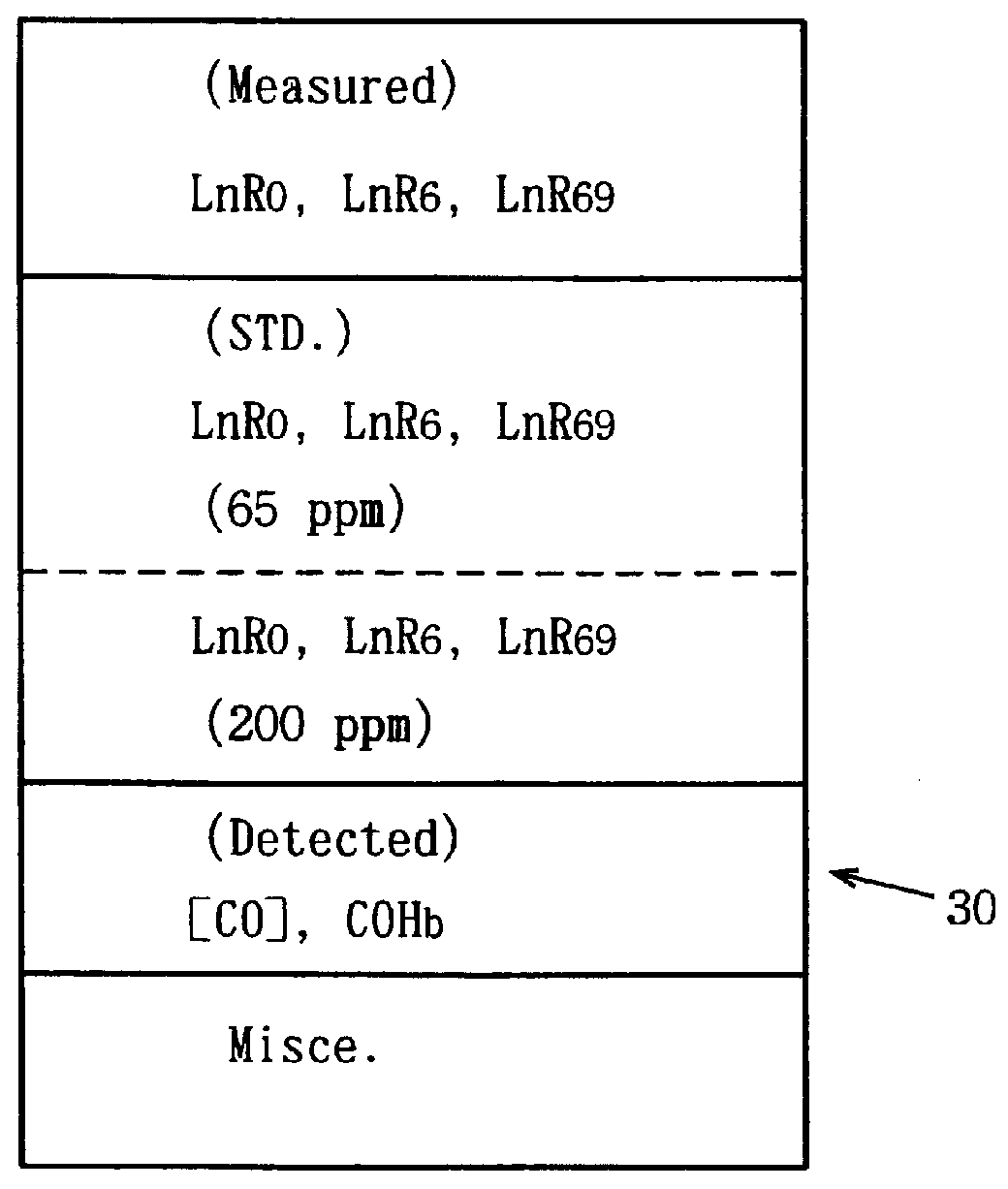

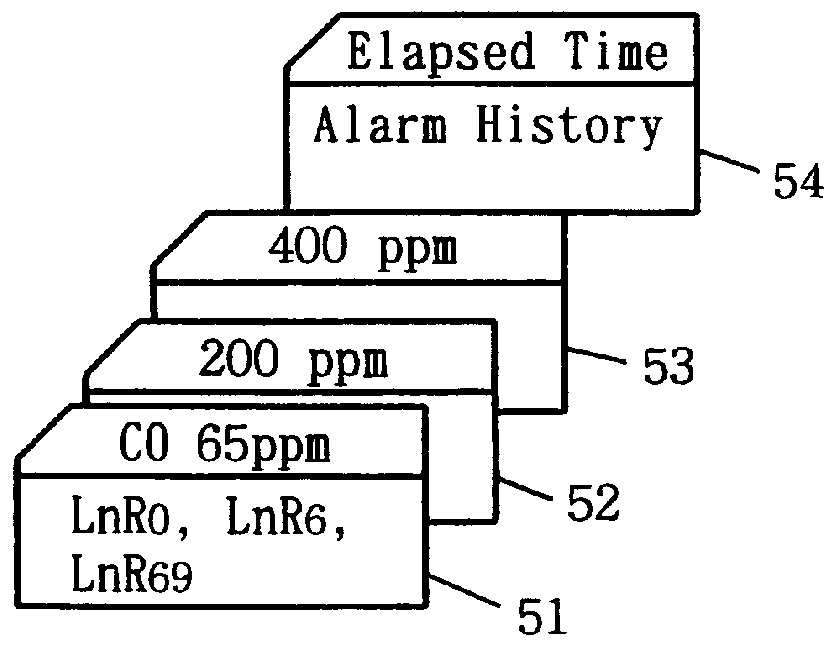

Gas detecting method and its detector

InactiveUS6128945AGood compensationReduce gas concentrationUsing mechanical meansGas analyser construction detailsOxide semiconductorPhysics

A metal oxide semiconductor is subjected to a temperature change, and signals measured at two timings in the course of the temperature change are used to define a two-dimensional topological space. In the topological space, two axis, an axis indicating the concentration of the gas to be detected and an axis corresponding to drift are defined, and the topological space is represented by an oblique coordinate system. The gas concentration is determined from projection of measured data onto the gas concentration axis.

Owner:FIGARO ENG INC

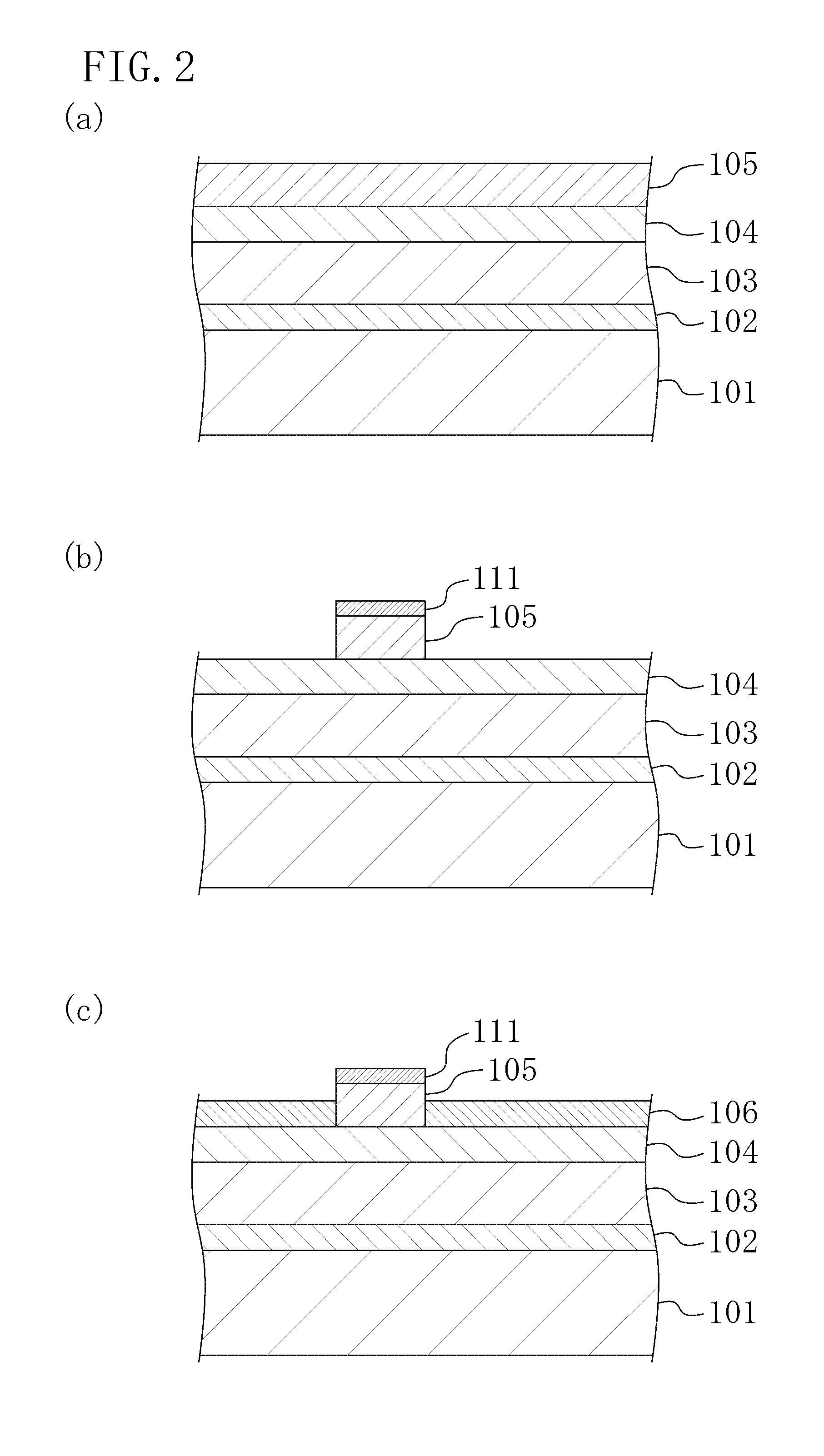

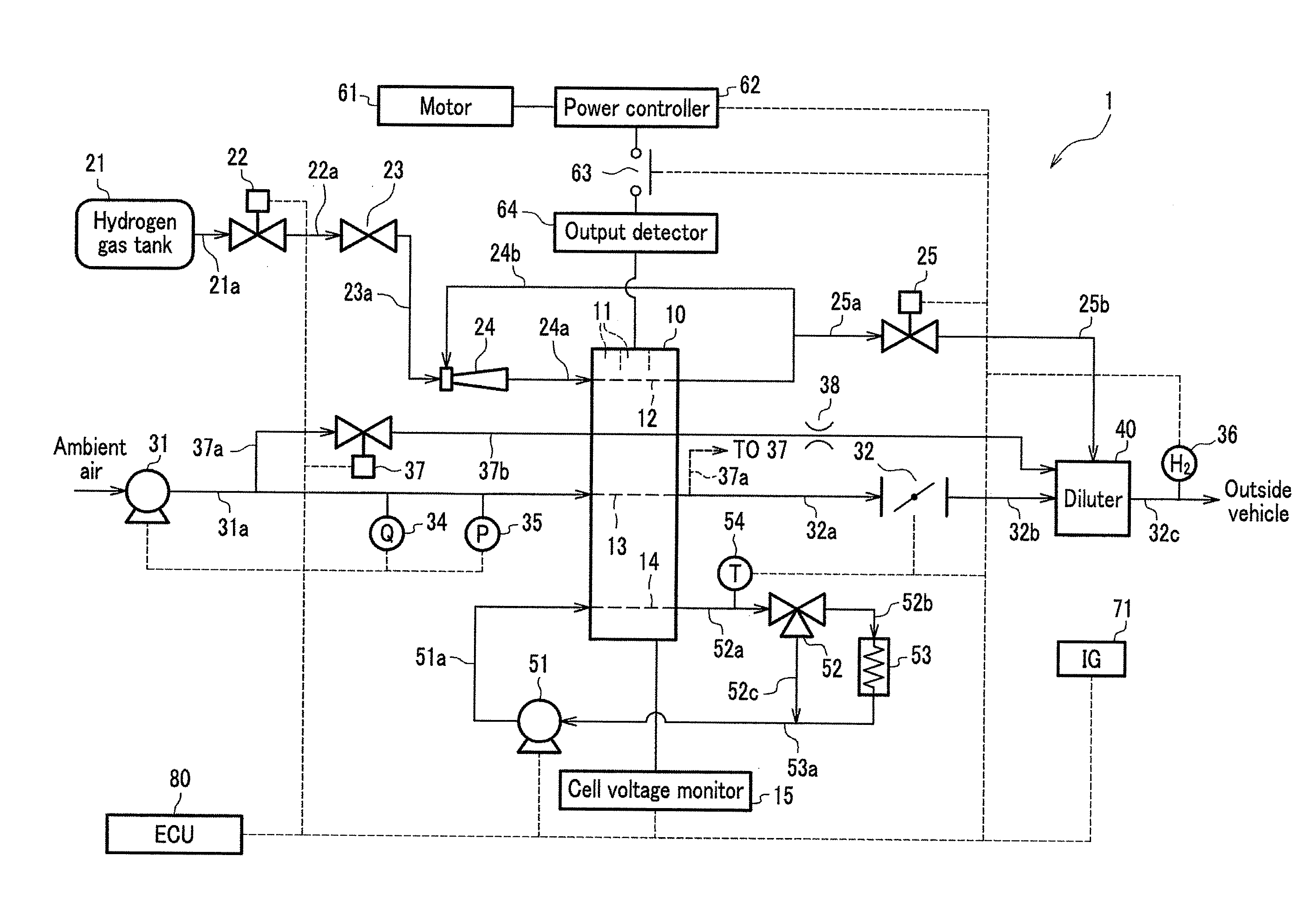

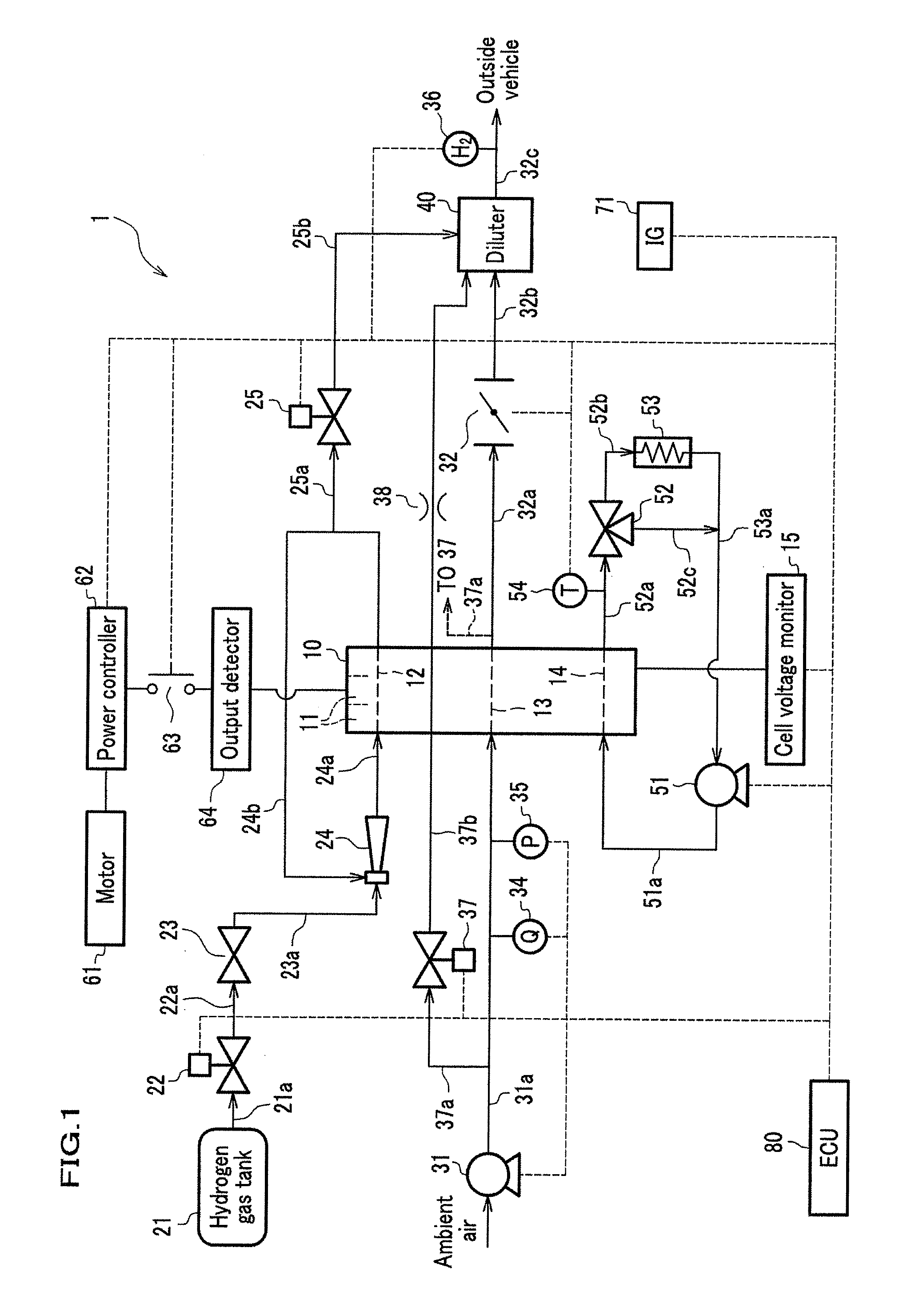

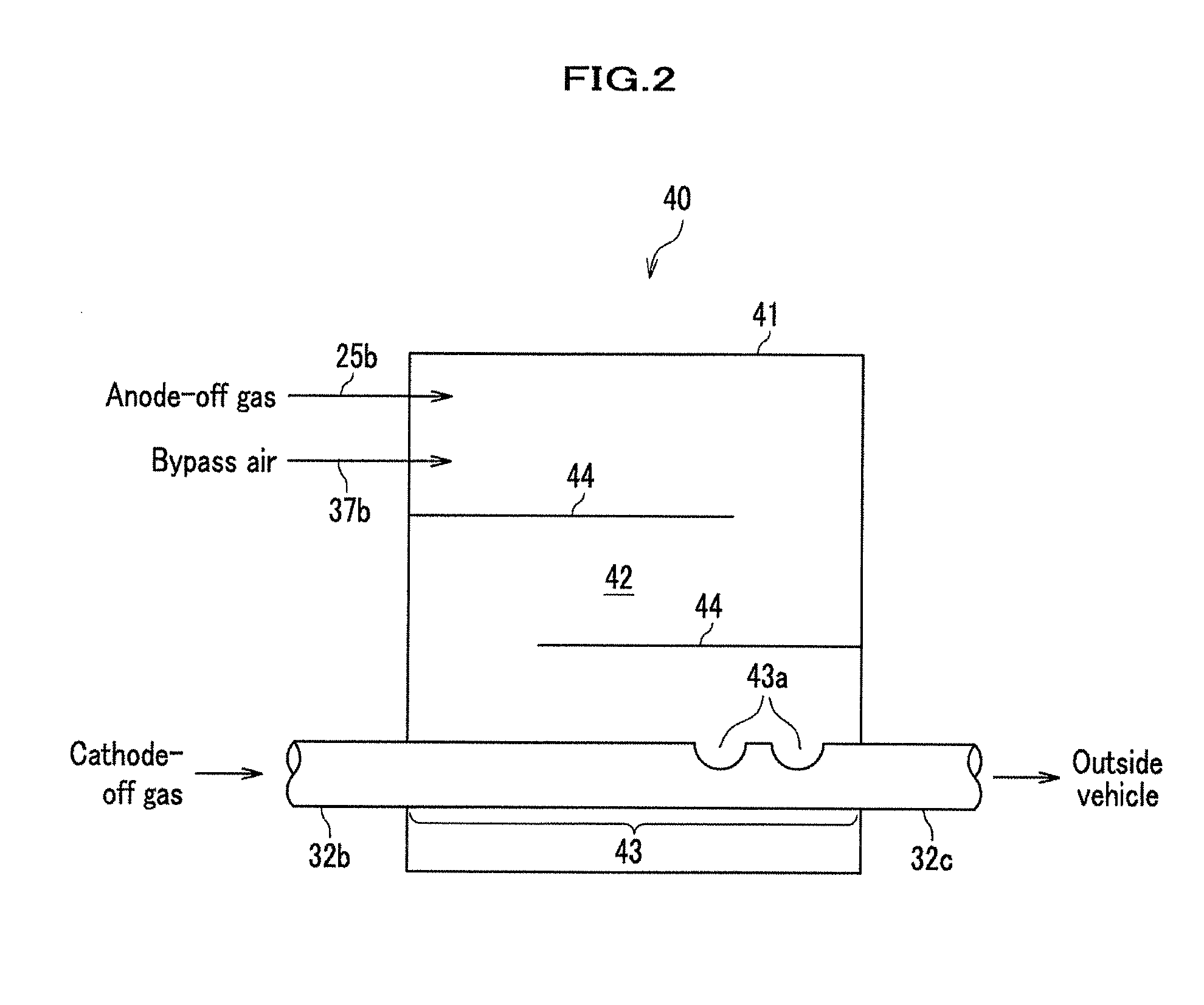

Fuel cell system and method of operating fuel cell system

A fuel cell system includes: a fuel cell stack, a hydrogen gas tank, a compressor, an oxidant gas supplying flow passage, an oxidant off-gas discharge flow passage, a diluter for diluting an anode off-gas with a cathode off-gas, a branched gas flow passage through which a branched gas is directed to the diluter, a back pressure valve for controlling a pressure of branched gas, an OCV determining unit, and an I-V characteristic decreasing unit for starting power generation of the fuel cell stack and decreasing an I-V characteristic of the single cell by decreasing a stoichiometric ratios. In a low temperature start-up, the back pressure valve decreases a pressure of the branched gas introduced into the diluter when the I-V characteristic of the single cell is decreased by the I-V characteristic decreasing unit. An operation method of operating the fuel cell system is also disclosed.

Owner:HONDA MOTOR CO LTD

Counter-top produce refrigeration and ozonation system and method

InactiveUS20120198862A1Delaying postharvest produce deteriorationReduce gas concentrationFruit and vegetables preservationContainer filling methodsTemperature controlProcess engineering

A produce storage chamber comprising a chamber capable of encasing produce, a refrigeration system, at least one ozone generation units, and at least one ethylene scrubbers. The chamber is capable of delaying postharvest produce deterioration using at least one of temperature control, ozone generation, and ethylene scrubbing.

Owner:ARRIGO VINCENT M

Method and sensor system for measuring gas concentrations

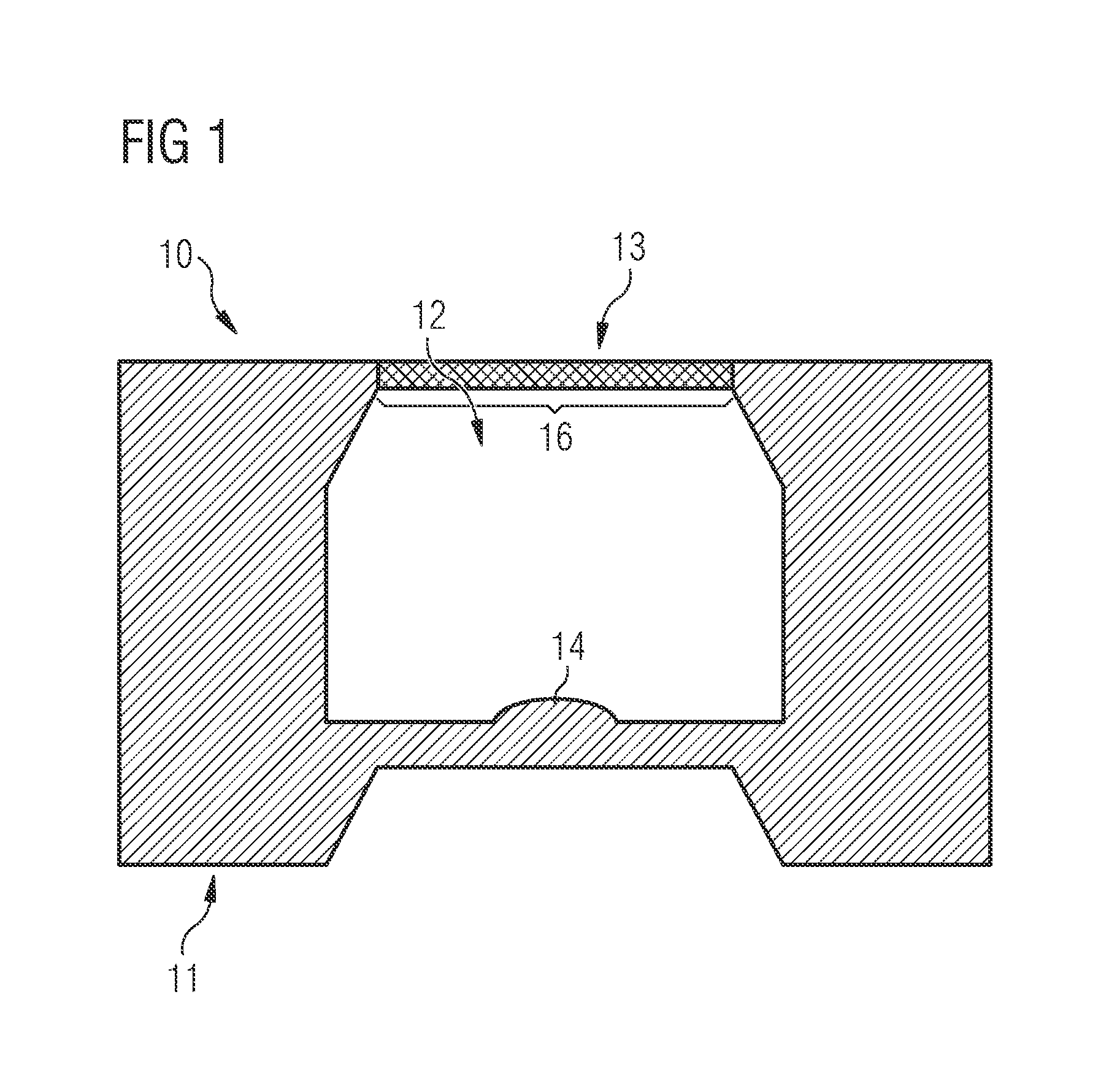

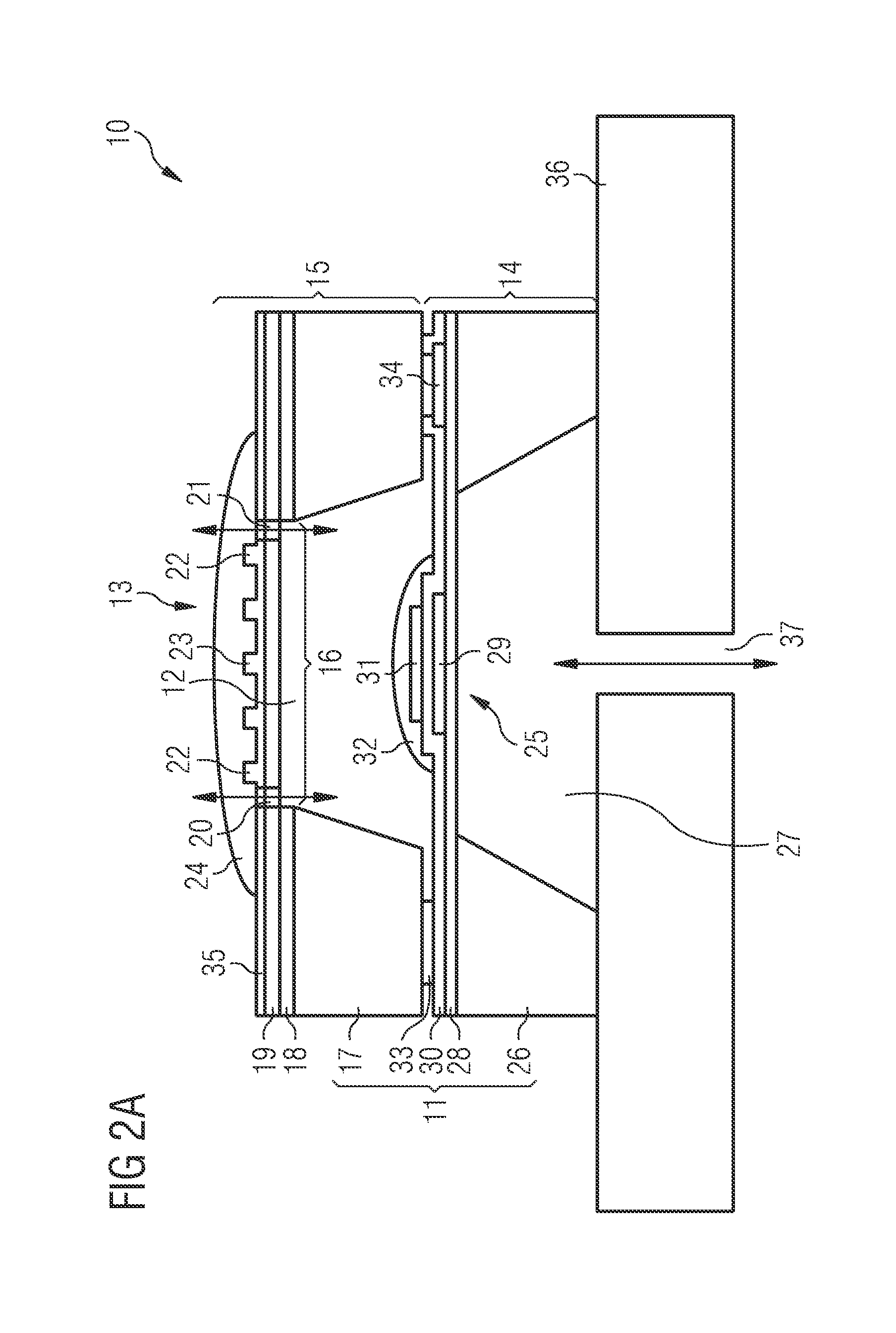

ActiveUS20160349201A1Improve sensor sensitivityReduce gas concentrationMaterial resistanceGas concentrationSensor system

A method for measuring the concentration of at least one gas from a gas sample by a sensor system (10) which has a measuring area (12) with at least one gas sensor (14), wherein the inlet of the measuring area (12) being closed by a gas-permeable structure (13) such that the volume of the measuring area (12) is initially heated up, the heating is then switched off and the change in resistance of the at least one gas sensor (14) is measured.

Owner:SCIOSENSE BV

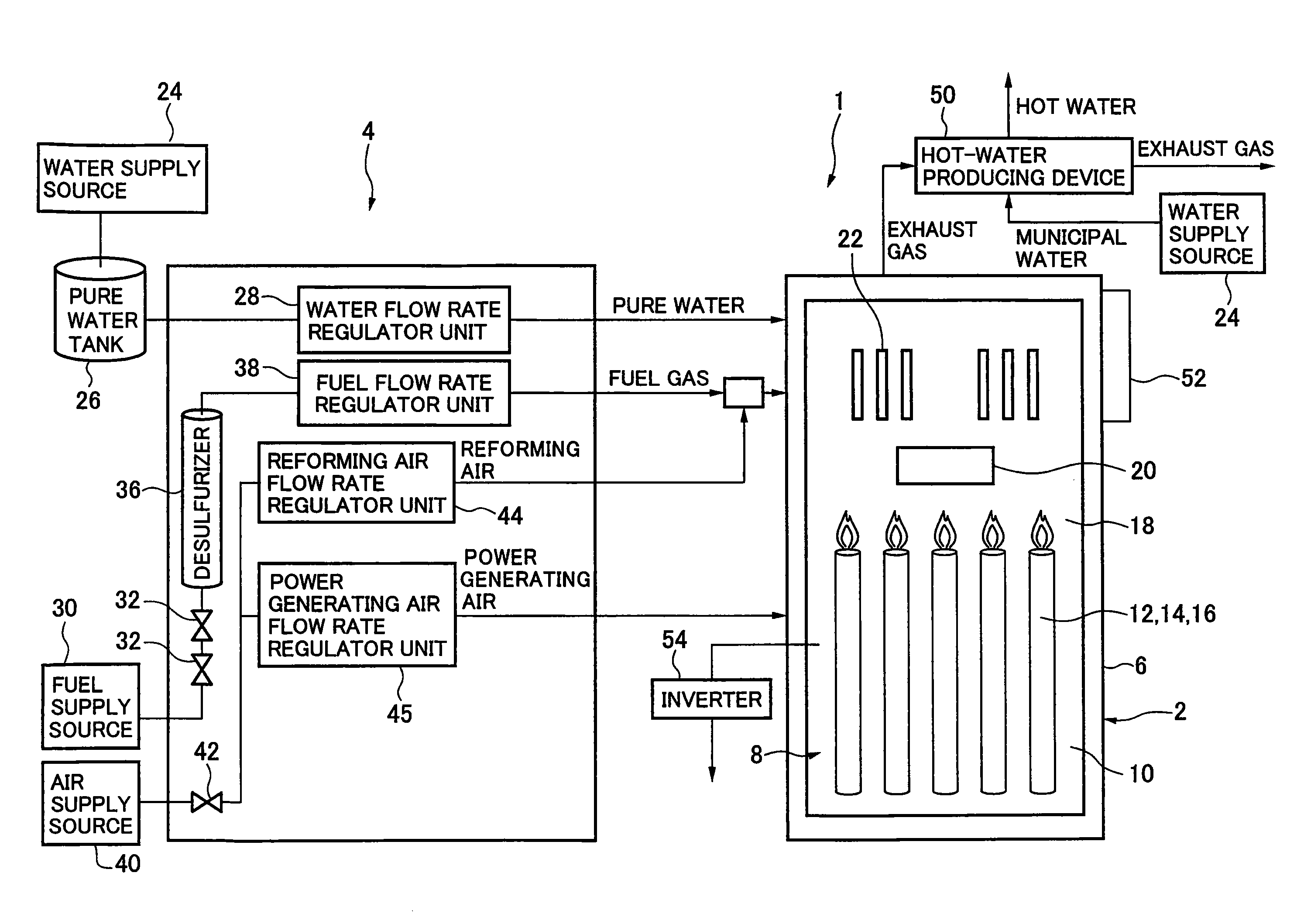

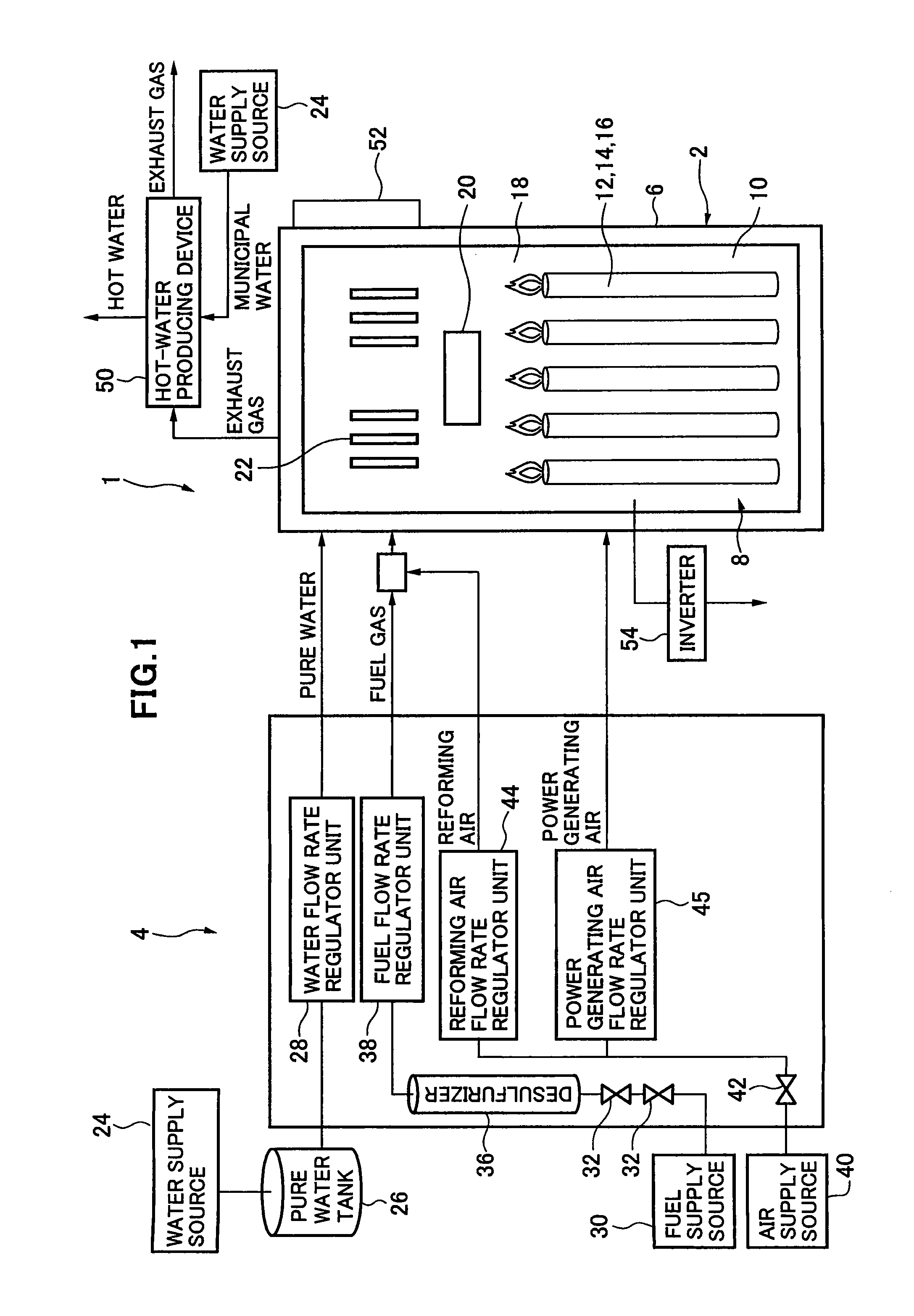

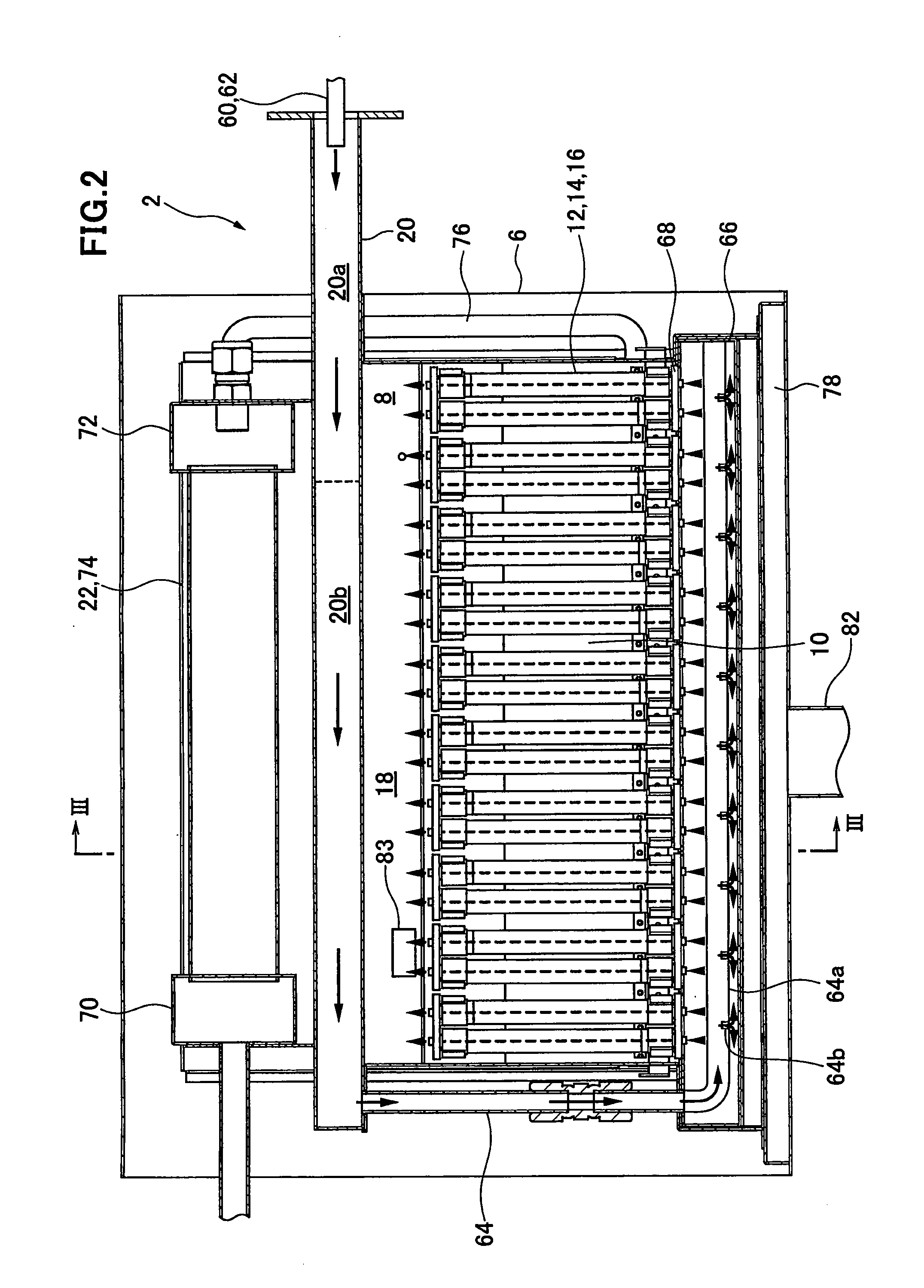

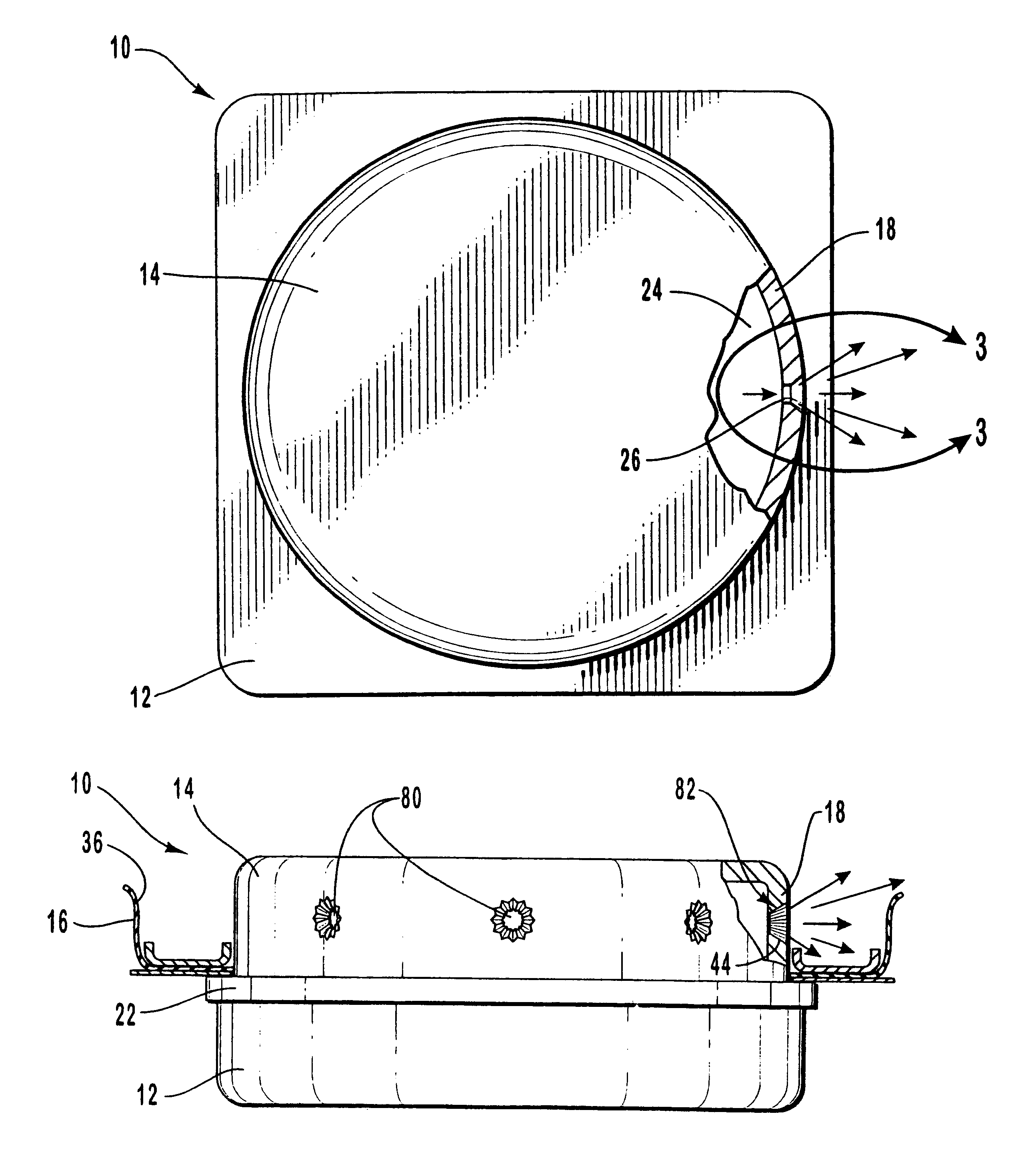

Solid oxide fuel cell device

InactiveUS20100304235A1Reliable ignition characteristicReduce concentrationHydrogenHydrogen/synthetic gas productionSteam reformingPartial oxidation

A solid oxide fuel cell (SOFC) device comprises a fuel cell assembly, a reformer, a fuel gas supply device, a water supply device, a reforming air supply device, a power generating air supply device, an ignition device, and a control device, the control device controls the fuel gas supply device, the water supply device, the reforming air supply device, the power generating air supply device, and the ignition device to conduct a combustion operation, then supply the fuel gas and the reforming air into the reformer to conduct a partial oxidation reforming reaction (POX) operation, then supply the fuel gas, the reforming air and water into the reformer to conduct an auto-thermal reforming reaction (ATR) operation, and then supply the fuel gas and water into the reformer to conduct a steam reforming reaction (SR) operation, thereby starting the solid oxide fuel cell device, and the control device controls the fuel gas supply device to hold constant the supply flow rate of fuel gas during a predetermined interval, controls the ignition device to ignite the fuel gas at the middle of the predetermined interval, and controls the fuel gas supply device to reduce the supply flow rate of fuel gas after an elapse of the predetermined interval.

Owner:TOTO LTD

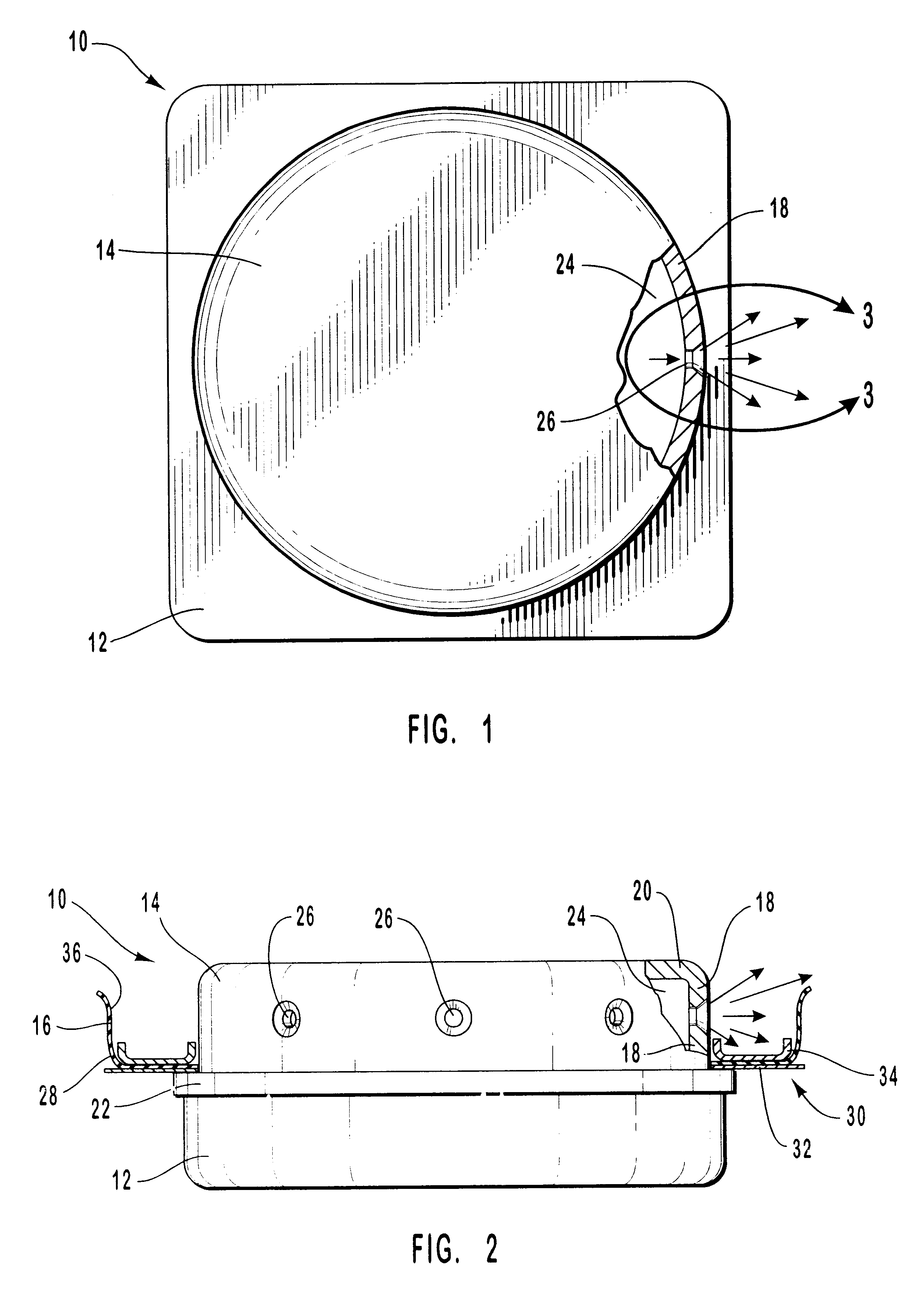

Air bag inflation exit gas dispersion features

InactiveUS6394491B2Reduce thicknessReduce gas concentrationPedestrian/occupant safety arrangementInterior spaceEngineering

An air bag device that includes an air bag cushion, a diffuser canister, and a gas generation inflator. The diffuser canister is attached to the air bag cushion and has walls configured to define an interior space therein. The walls of the diffuser canister have an interior surface, an exterior surface, and a wall thickness t. At least one of the walls has an aperture formed therethrough in communication with the interior of the air bag cushion. The gas generation inflator is configured to rapidly create a gas that exits the diffuser canister through the aperture so as to fill the air bag cushion. The aperture is defined by an edge extending between the interior and said exterior surfaces of the wall that is configured to diffuse the gas exiting the diffuser canister through the aperture. The edge of the aperture is configured such that the cross-sectional area of the aperture that is proximate to the exterior surface of the wall is larger than the cross-sectional area of the aperture proximate to the interior surface of wall. The edge includes an angled portion configured such that opposing sides of the aperture have an angle alpha therebetween in the range of about 20 degrees to about 145 degrees. The aperture has a diameter d1 proximate to the interior surface of the wall and is configured so that the diameter d1 and wall thickness t have a ratio d1 to tin the range of about 0.5 to about 4. An alternate embodiment of the air bag device comprises an aperture defined by an edge that is configured so that the cross-section of aperture is non-smooth and causes turbulence in the gas stream.

Owner:AUTOLIV ASP INC

Method for preparing fireproof and explosion suppression pulverized fuel ash carbon dioxide material

InactiveCN101787289APrevent spontaneous combustionReduce the probability of ignitionDust removalFire preventionSpontaneous combustionSodium bicarbonate

The invention relates to a method for preparing fireproof and explosion suppression pulverized fuel ash carbon dioxide material, which comprises the steps of: mixing 70-80% of water and 20-30% of pulverized fuel to prepare pulverized fuel ash slurry liquid according to the mass percent; mixing 94-98% of water and 2-6% of industrial sodium hydrogen carbonate to prepare industrial sodium hydrogen carbonate solution according to the mass percent; mixing 77-92% of water, 5-15% of industrial aluminum sulfate and 3-8% of polyvinyl alcohol to prepare mixed solution of the industrial aluminum sulfate and the polyvinyl alcohol according to the mass percent; and mixing the prepared pulverized fuel ash slurry liquid, the industrial sodium hydrogen carbonate solution and the mixed solution of the industrial aluminum sulfate and the polyvinyl alcohol according to the proportion of 1: 1: 1, mutually reacting to generate a great deal of carbon dioxide, and forming a great deal of foam. The foam pulverized fuel ash has good effect of preventing and extinguishing fire, releases carbon dioxide on gas phase, reduces the oxygen concentration and gas density in a mined out space, leads the mined out space for inerting, and inhibits spontaneous combustion of coal and gas explosion; the pulverized fuel ash on solid phase covers the coal body, blocks an air leakage channel and achieves the aim of preventing the spontaneous combustion of coal; and water on liquid phase can reduce the temperature of the coal body, thus reducing the ignition rate of the spontaneous combustion of coal.

Owner:CHINA UNIV OF MINING & TECH

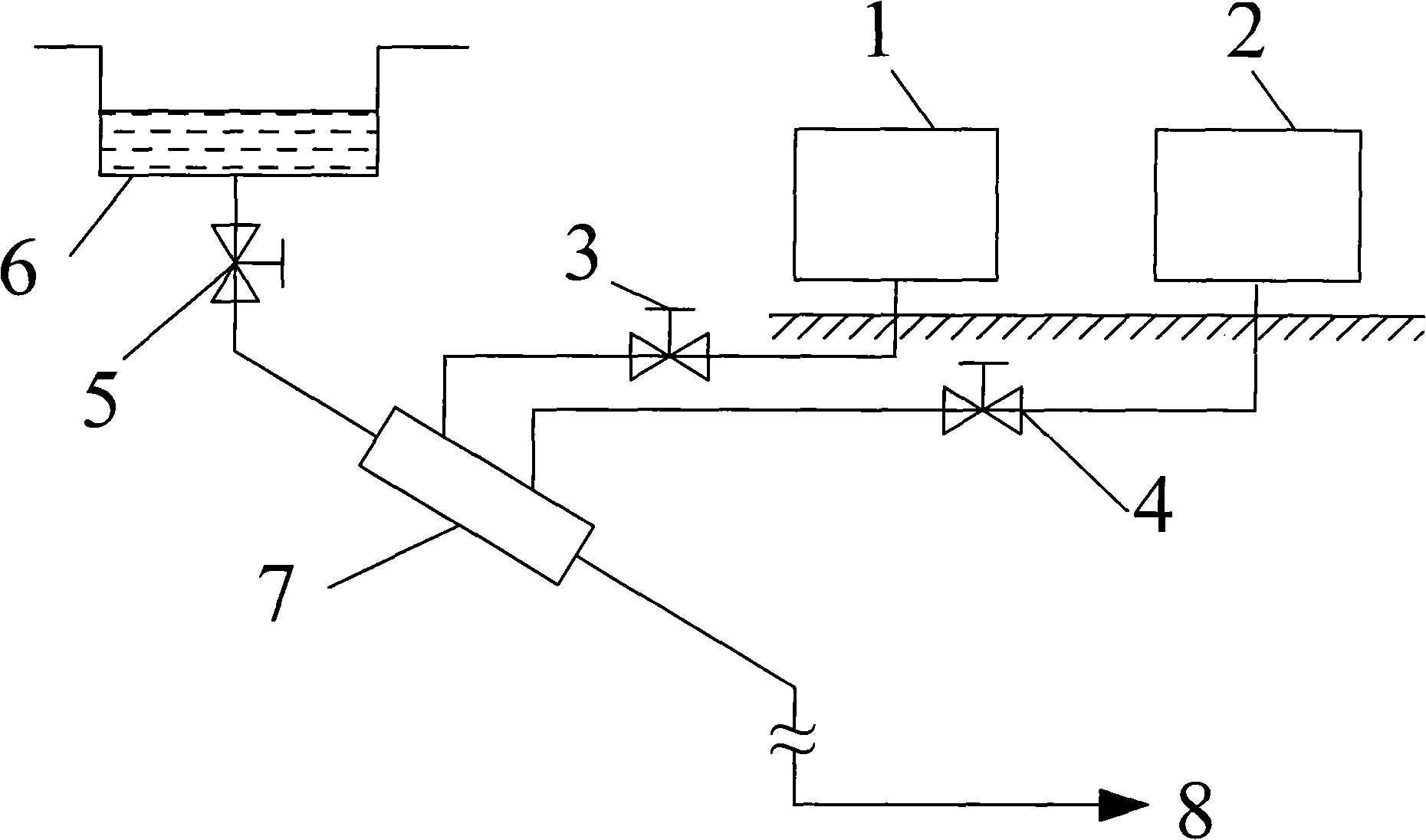

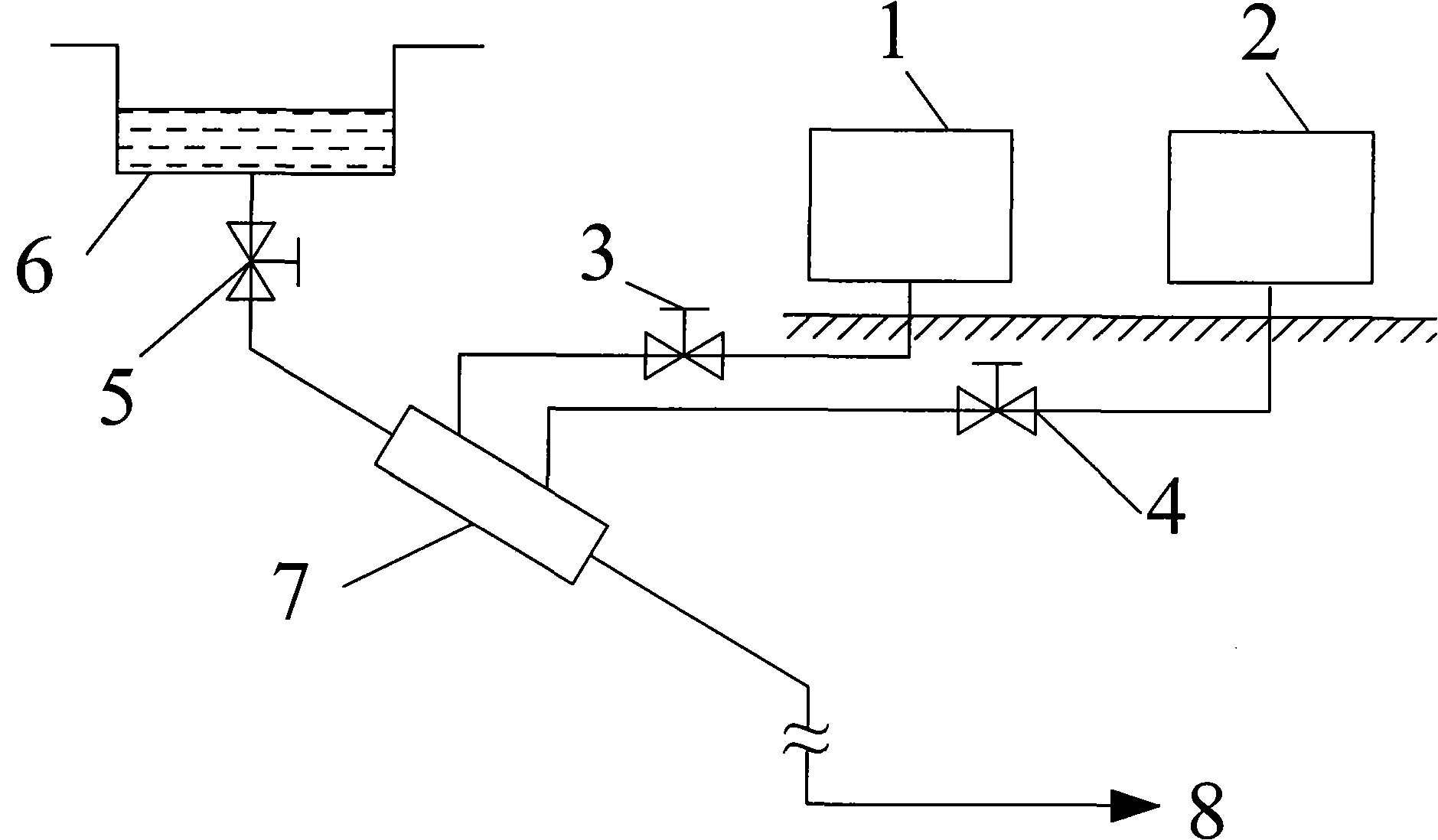

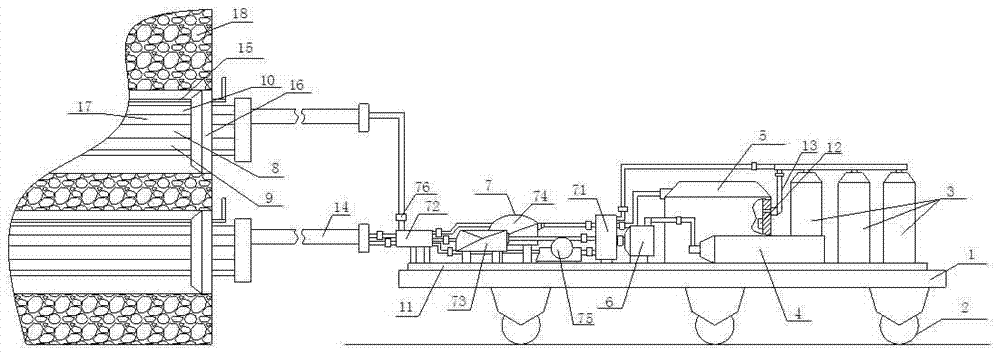

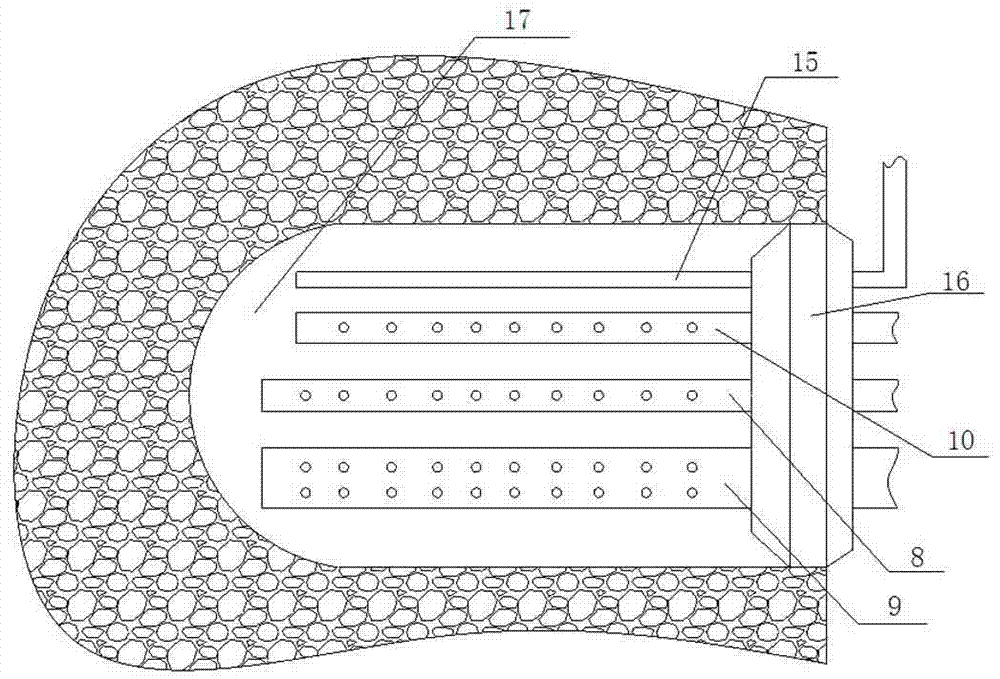

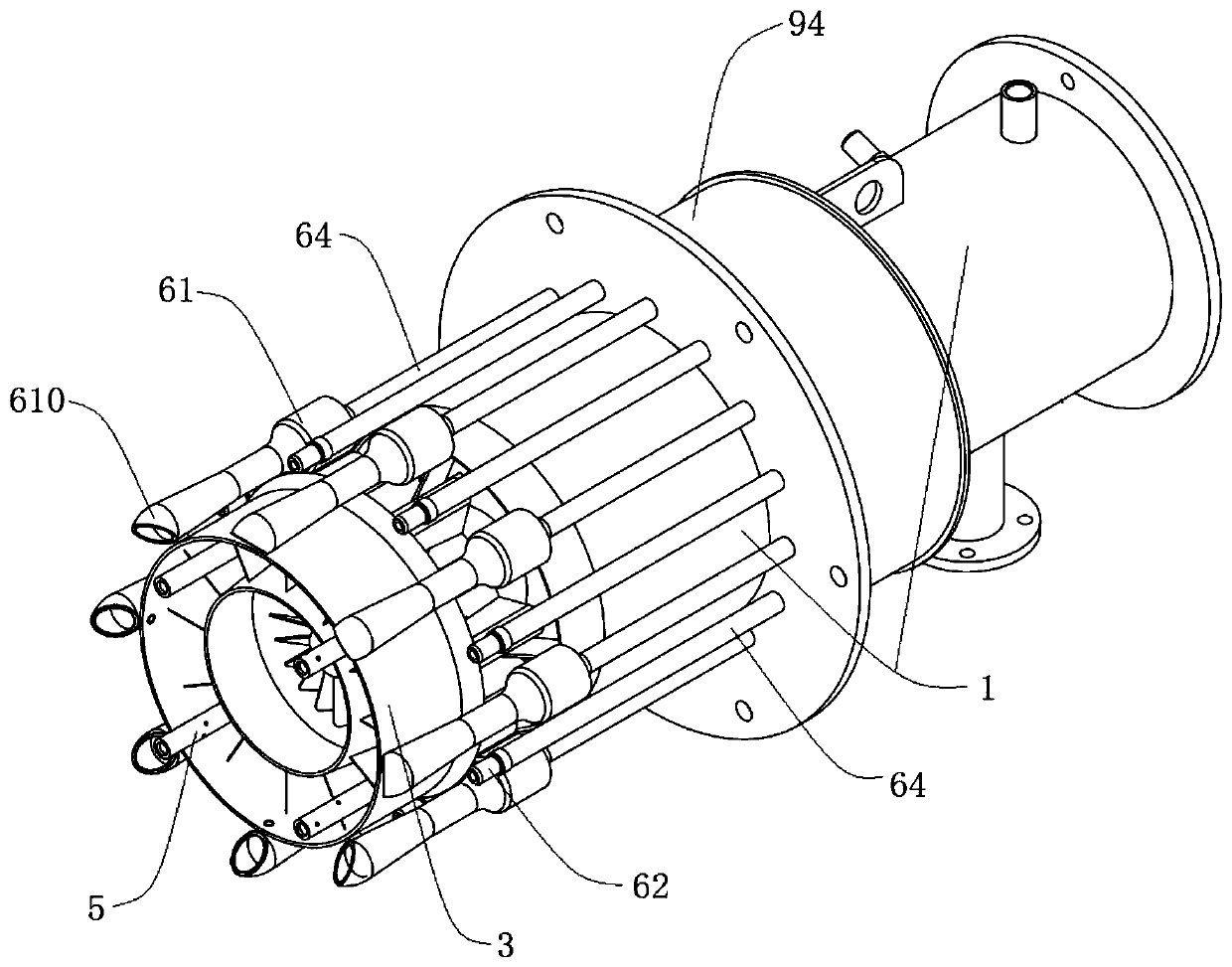

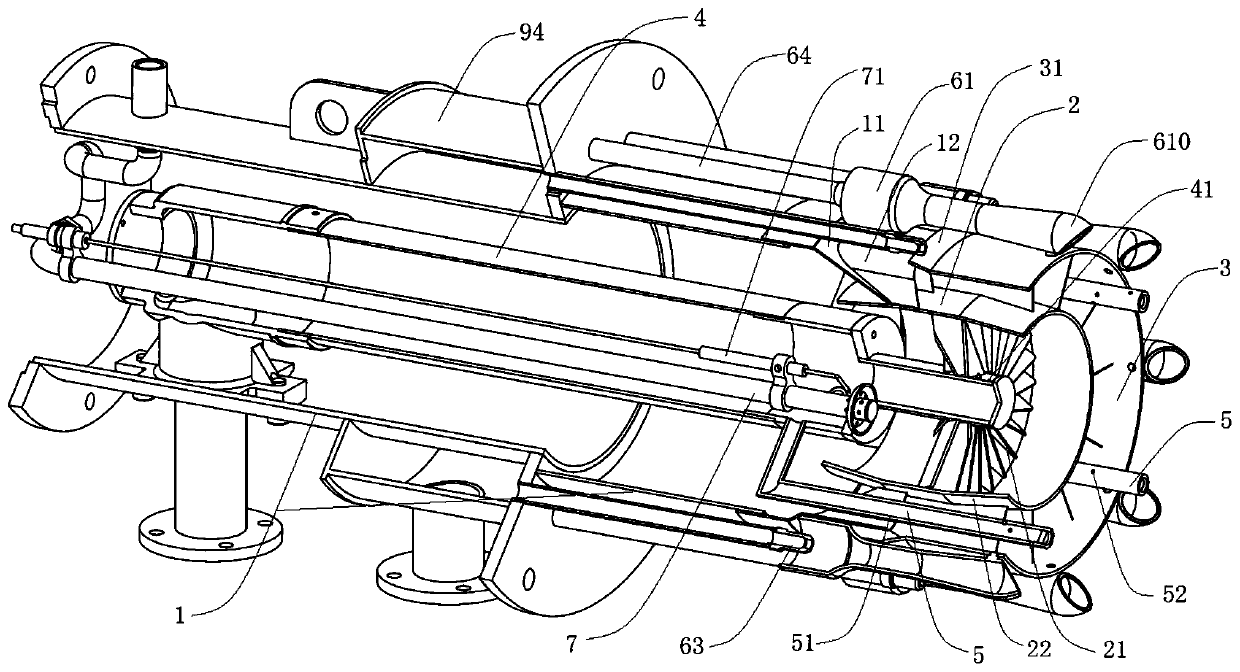

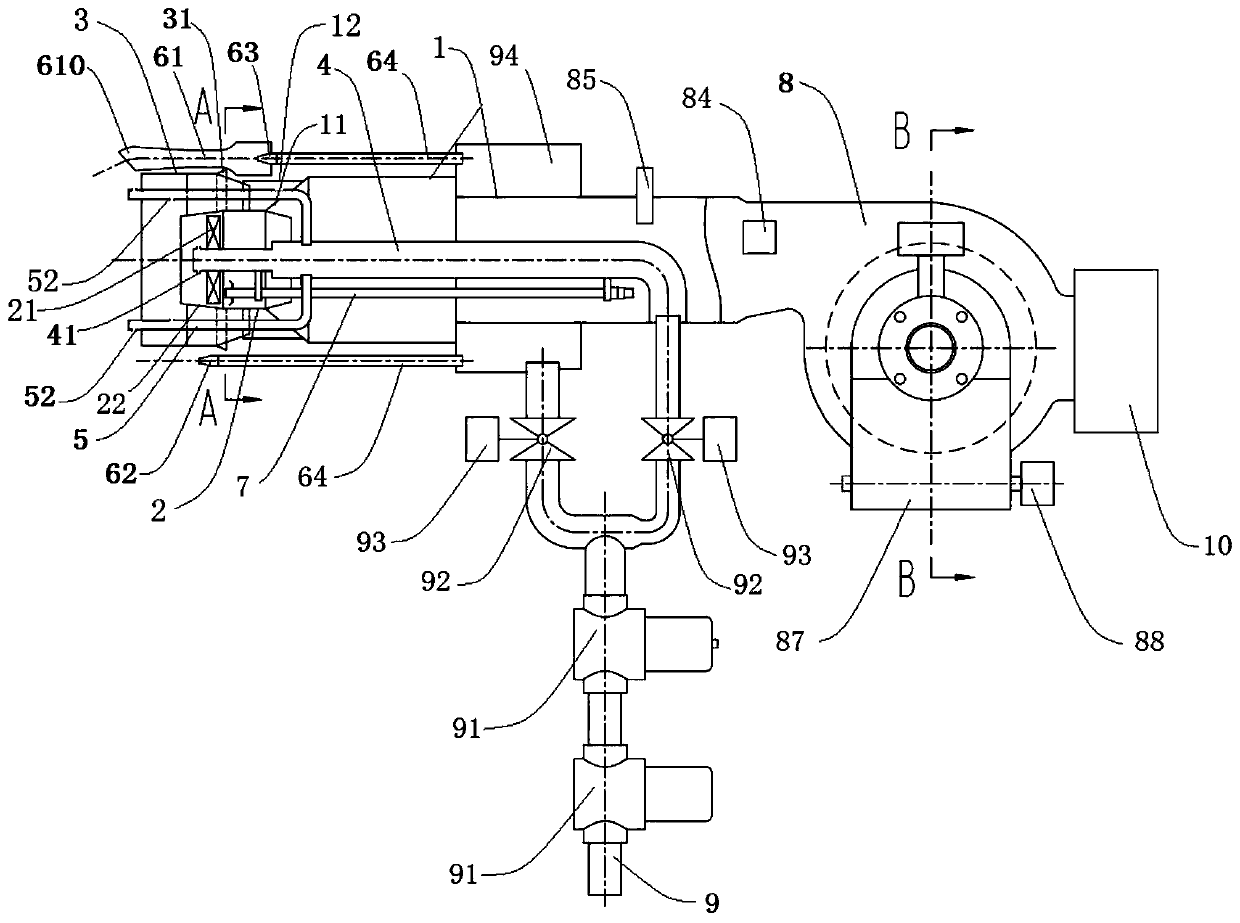

Coal seam extraction drilling hot-cold impacting coal-breaking permeability-increasing device and permeability-increasing method

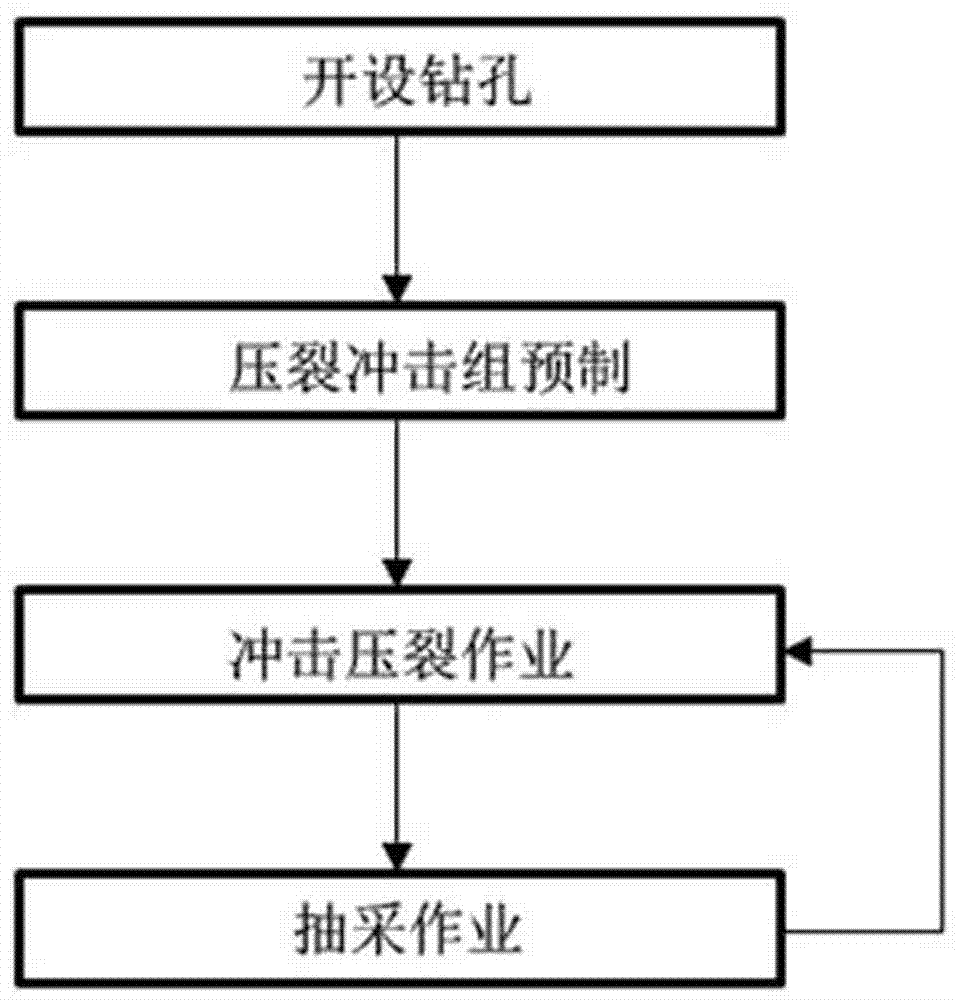

ActiveCN106968705AImprove drainage flowImprove extraction efficiencyGeothermal energy generationFluid removalWater storage tankLiquid nitrogen cooling

The invention relates to a coal seam extraction drilling hot-cold impacting coal-breaking permeability-increasing device. The coal seam extraction drilling hot-cold impacting coal-breaking permeability-increasing device comprises a bearing base, a traveling mechanism, a liquid nitrogen storage steel bottle, a gaseous nitrogen storage steel bottle, a water storage tank, a hot-air blower, booster pump assemblies, nitrogen heating pipes, water cooling pipes and liquid nitrogen cooling pipes. The lower surface of the bearing base is connected with the traveling mechanism, and the liquid nitrogen storage steel bottle, the gaseous nitrogen storage steel bottle, the water storage tank, the hot-air blower and the booster pump assemblies are slidably connected with the upper surface of the bearing base through a slide rail. A fracture impacting assembly is formed by each nitrogen heating pipe, the corresponding water cooling pipe and the corresponding liquid nitrogen cooling pipe. The fracture impacting assemblies communicate with the two booster pump assemblies. A permeability-increasing method of the coal seam extraction drilling hot-cold impacting coal-breaking permeability-increasing device comprises the steps such as drill hole forming, fracture impacting assembly prefabricating, impacting fracture operation and extraction operation. According to the coal seam extraction drilling hot-cold impacting coal-breaking permeability-increasing device and the permeability-increasing method, on the one hand, drilling gas extraction efficiency is improved, gas extraction cost is reduced, and on the other hand, safety and reliability of gas extraction operation are improved.

Owner:HENAN POLYTECHNIC UNIV

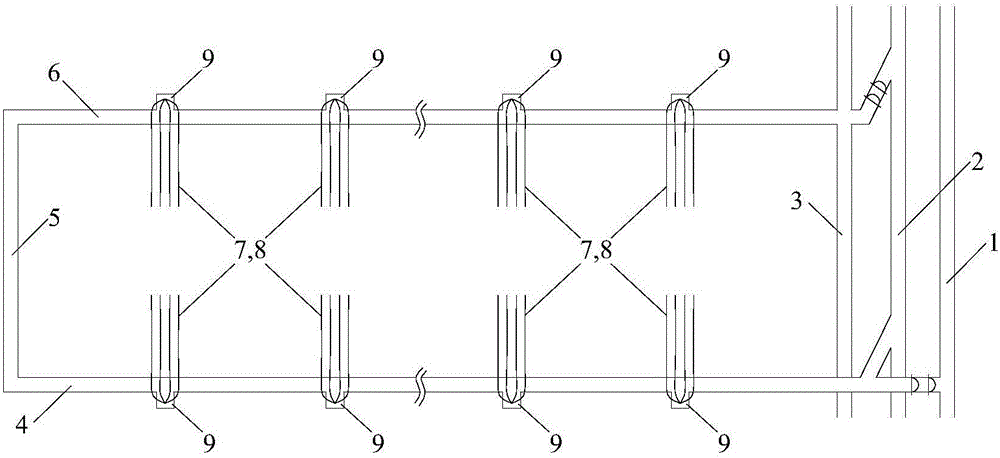

High-gas coal bed group dip orientation drilling cluster and gas extracting method

InactiveCN106014475AEfficient extractionReduce gas concentrationFluid removalGas removalCoalDrill hole

The invention discloses a high-gas coal seam group inclination directional drilling cluster and a gas extraction method, which mainly consists of a transport lane, an air return lane, an inclination directional bendable drilling cluster and a drilling field. It is characterized in that a group of drilling sites are respectively constructed in the transportation lane and the air return lane of the working face of the coal seam, and a cluster of roof inclined and oriented bendable drilling holes and a cluster of bottom plate inclined and oriented bendable drilled holes are respectively constructed in each drilling site. Each cluster of boreholes is composed of 4 inclination-oriented bendable boreholes. After the borehole construction is completed, the holes are sealed, and gas drainage pipelines are installed in each borehole, and then merged into the gas drainage of the return airway and the transportation roadway respectively. The system pipeline is used to drain the gas released from the coal seam. The invention has the characteristics of short construction time, easy construction, low construction cost and large extraction range, and can improve the extraction efficiency of pressure-relieving gas in high-gas coal seam groups, especially the extraction of gas in gas-enriched areas in fracture zones.

Owner:ANHUI UNIV OF SCI & TECH

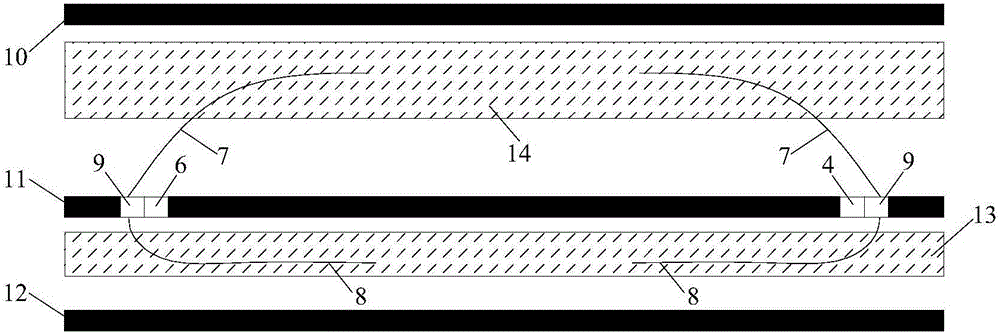

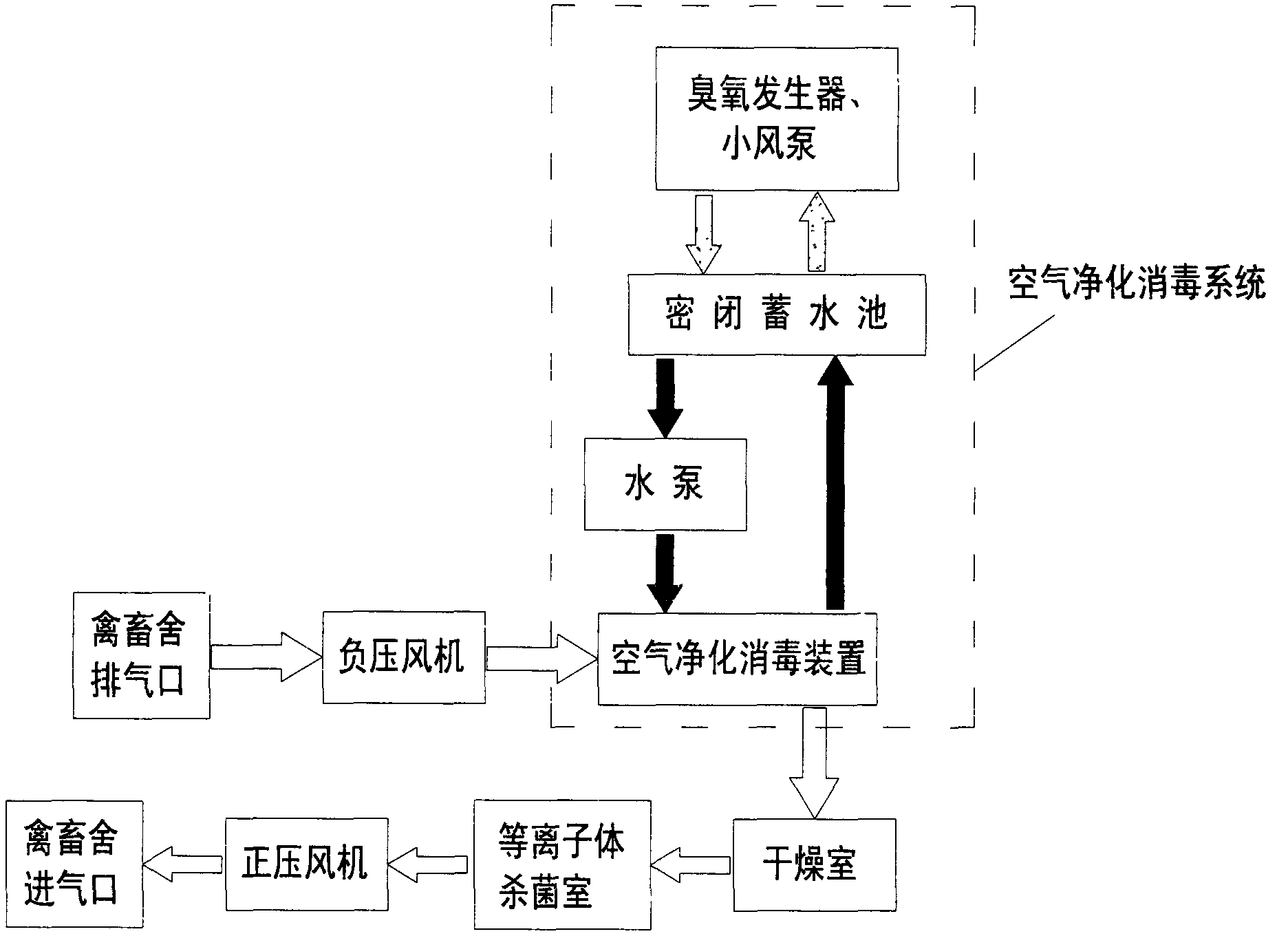

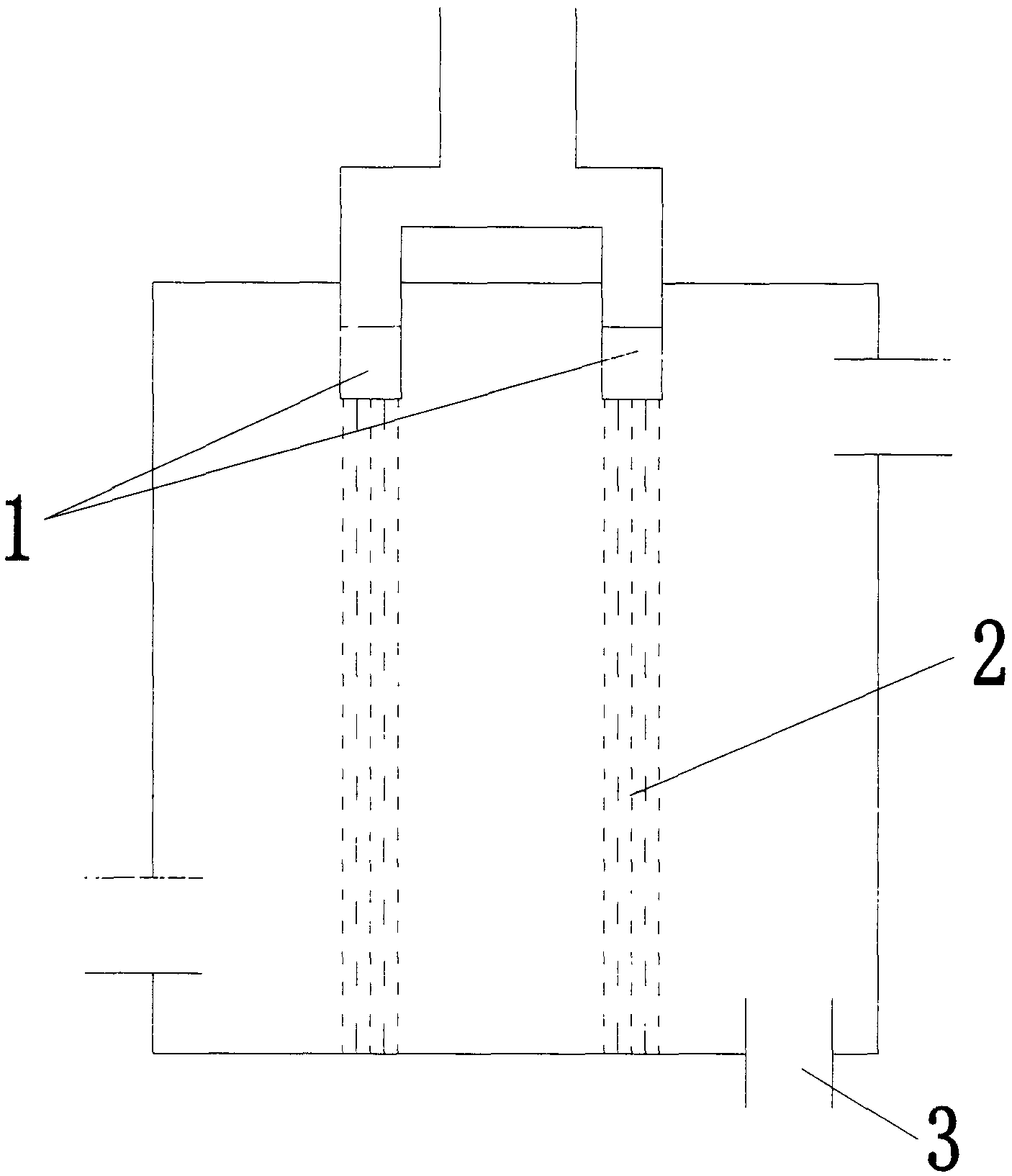

Sterilization and disinfection purification device and method for air in livestock shed

InactiveCN103845754AExtended service lifePromote repairDeodrantsAtomized substancesProgrammable logic controllerPositive pressure

The invention relates to a low-cost sterilization and disinfection purification device and method for air in a livestock shed, which can be used for rapidly and effectively purifying, sterilizing and disinfecting air pollutants in a large-scale livestock shed. The sterilization and disinfection purification device comprises a negative-pressure fan, a positive-pressure fan, an air purification and disinfection system, a dryer and a plasma sterilization device which are controlled by a PLC (Programmable Logic Controller), wherein the inlet end of the negative-pressure fan is communicated with an air outlet of the livestock shed while the outlet end of the negative-pressure fan is communicated with the air purification and disinfection system; the outlet end of the air purification and disinfection system is communicated with the dryer; the outlet end of the dryer is communicated with a plasma sterilizing chamber; and the inlet end of the positive-pressure fan is communicated with the plasma sterilizing chamber while the outlet end of the positive-pressure fan is communicated with an air inlet of the livestock shed. When the device is used for purifying air, the negative-pressure fan is used for extracting polluted air out of the livestock shed, then the polluted air is sequentially introduced into the air purification and disinfection system, the dryer and the plasma sterilization device for sterilization and disinfection, then the treated air is introduced into the livestock shed via the positive-pressure fan; and therefore, the polluted air in the livestock shed is sequentially and circularly treated.

Owner:黄磊

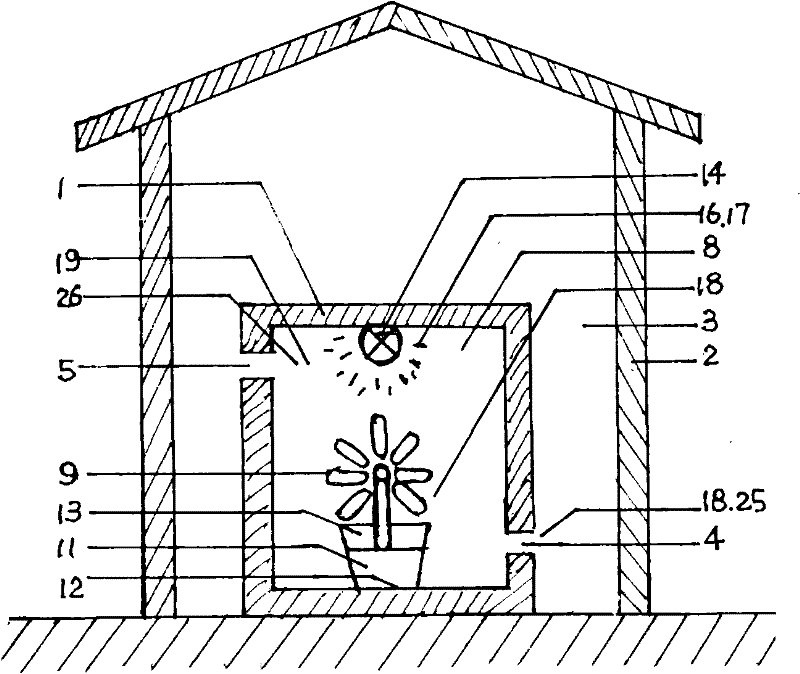

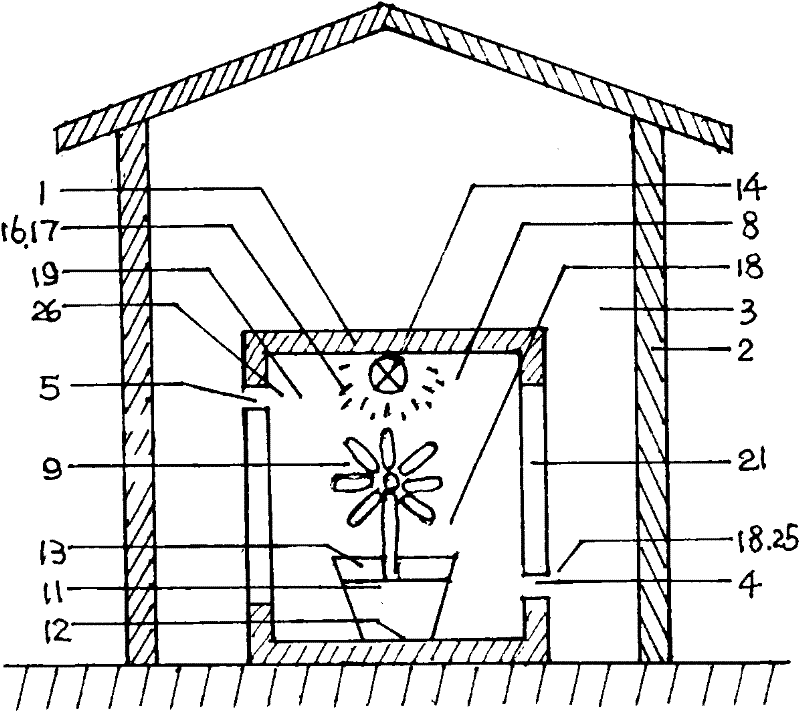

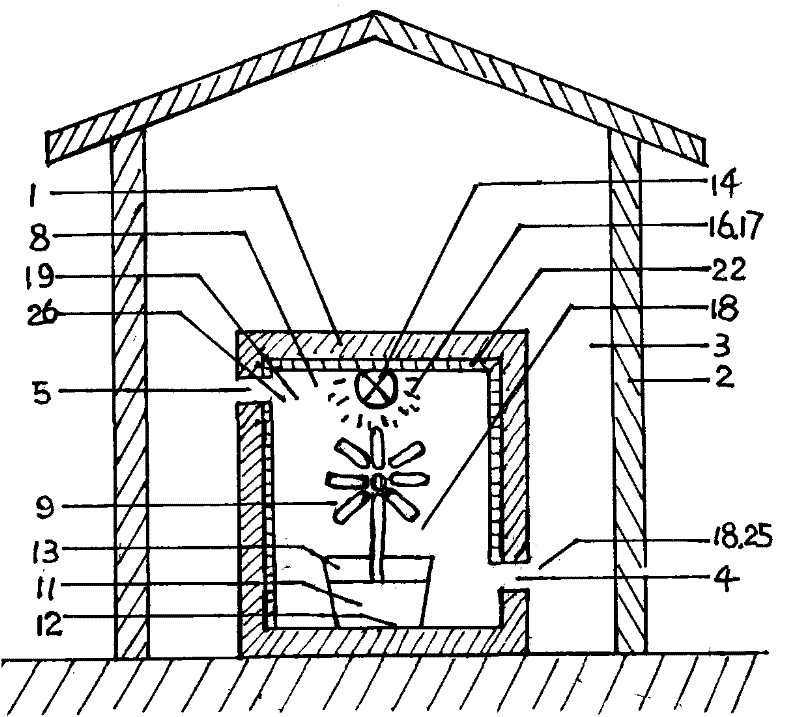

Plant light carbon synthesis oxygen release device

InactiveCN102233236AReduce gas concentrationKeep healthyDispersed particle separationAir quality improvementChemistryCarbon dioxide

The invention provides a plant light carbon synthesis oxygen release device for reducing the concentration of carbon dioxide in a crowd intensive space, a closed personnel space and a human respiratory tract space, increasing the content of oxygen, reducing carbon dioxide discharge of automobile exhaust, reducing the discharge of industrial carbon dioxide and promoting yield and income increment of agriculture and forestry by using the property that green plants absorb the carbon dioxide under an illumination condition to synthesize carbohydrate and release oxygen. A lamp house 1 is positioned in the exterior 27 of a space 2, the heat radiation 34 of sunlight 33 at daytime passes through a lamp house wall 21 to supply energy to the interior 8 of the lamp house, a lamp 15 at night supplies illumination 16 and heat radiation 17 to the interior 8 of the lamp house, carbon dioxide gas 18 in a space 3 and cold air 25 enter the interior 8 of the lamp house through an inlet ventilated window 4, green plants 9 and 10 catch the carbon dioxide 18 under the illumination condition to generate carbohydrate and release oxygen 19, and the oxygen 19 and the heated air 26 enter the space 3 through an outlet ventilated window 5, so that the tasks of reducing the concentration of the carbon dioxide in the space and increasing the content of the oxygen are completed.

Owner:余蜀翔

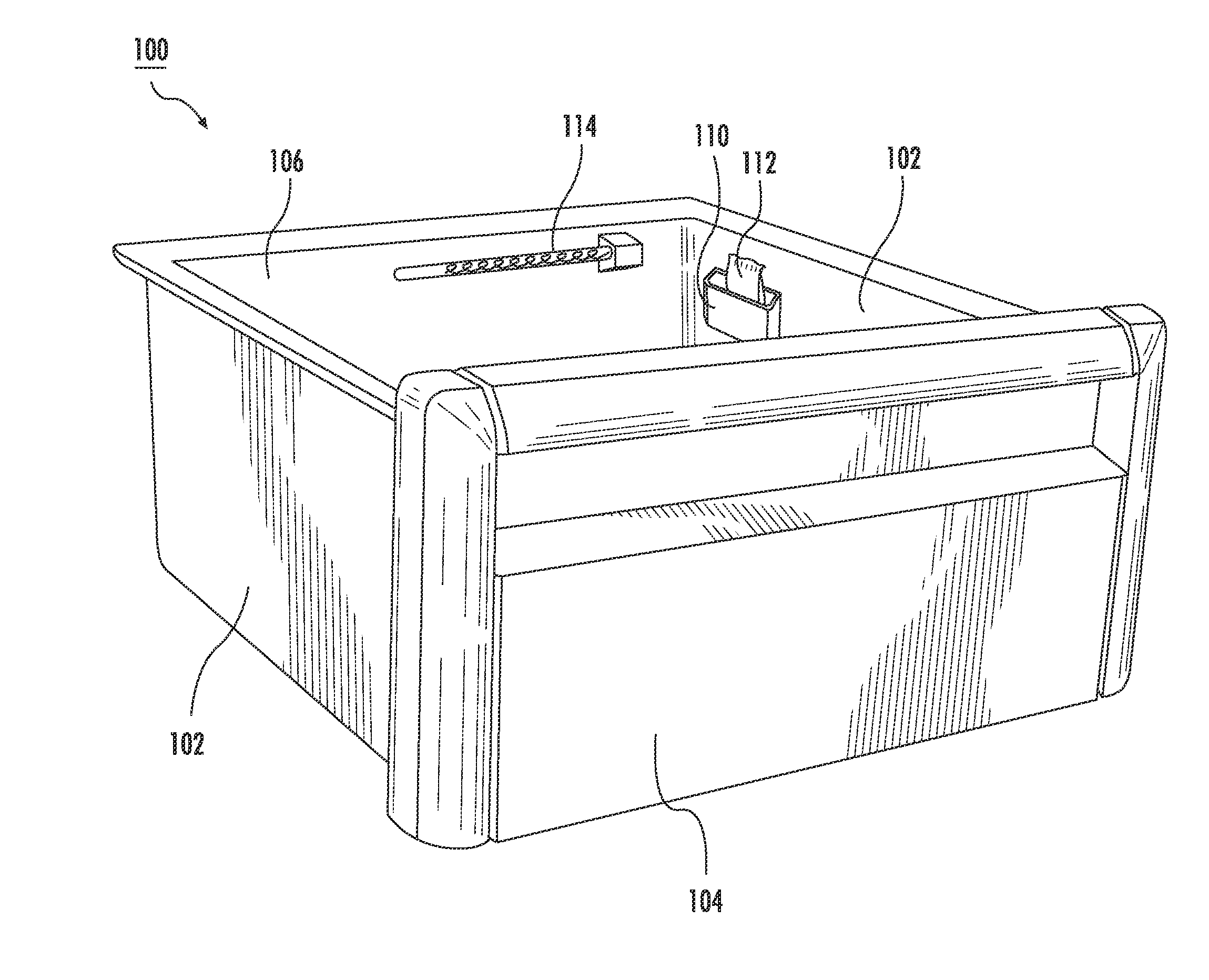

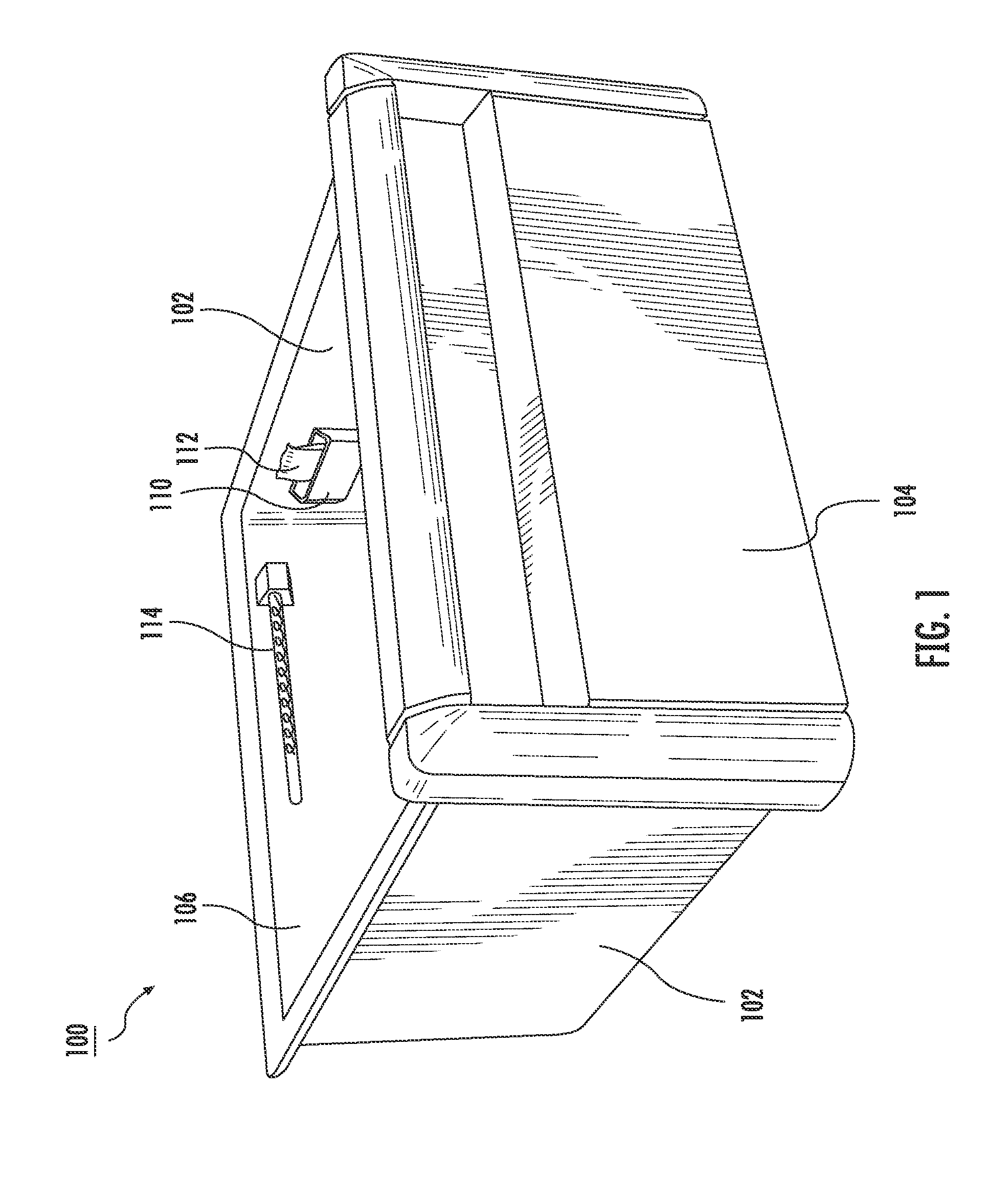

Refrigerator Crisper and Ozonation System and Method

ActiveUS20140342064A1Delaying postharvest produce deteriorationSufficient sizeFruit and vegetables preservationMilk treatmentOzone generatorEnvironmental engineering

A crisper drawer for postponing postharvest produce deterioration having a drawer housing that substantially defines the size and shape of the crisper drawer and fits within a residential refrigerator. A chamber within the drawer housing is cooled by the refrigerator. An ozone generator provides gaseous ozone to the chamber, and an ethylene scrubber reduces levels of ethylene in the chamber. An ozone level control with the ozone generator controls ozone levels.

Owner:ARRIGO VINCENT

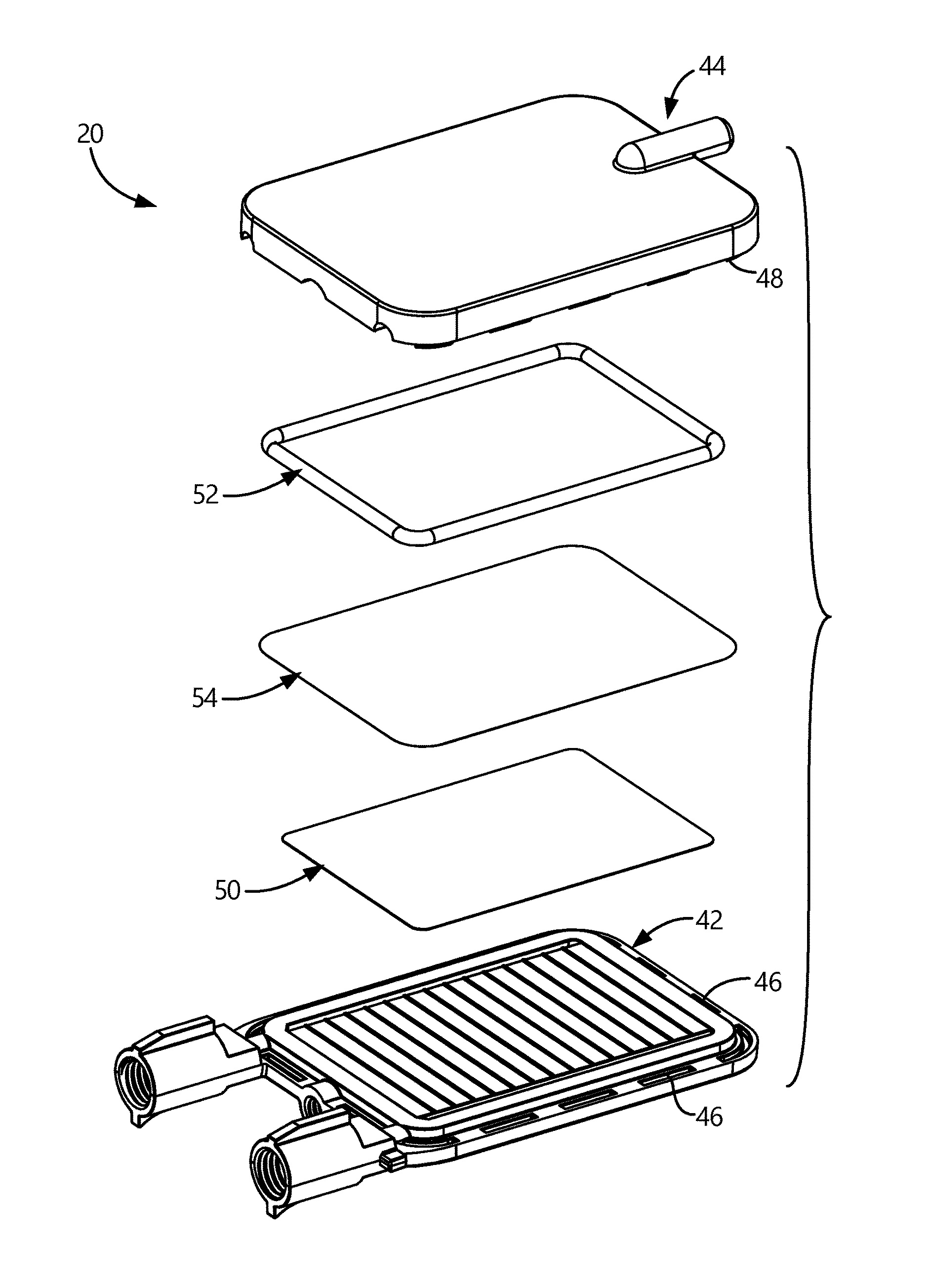

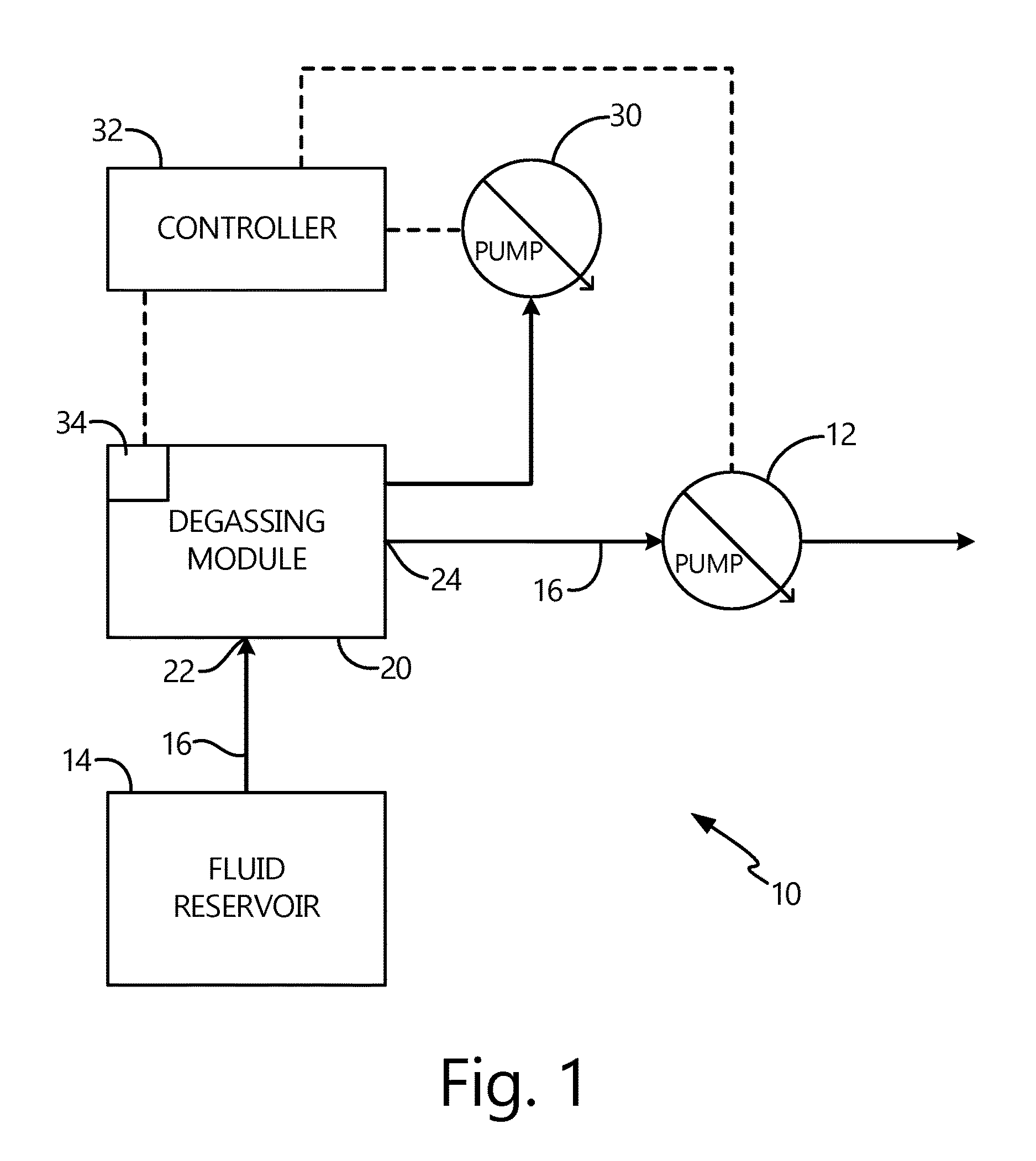

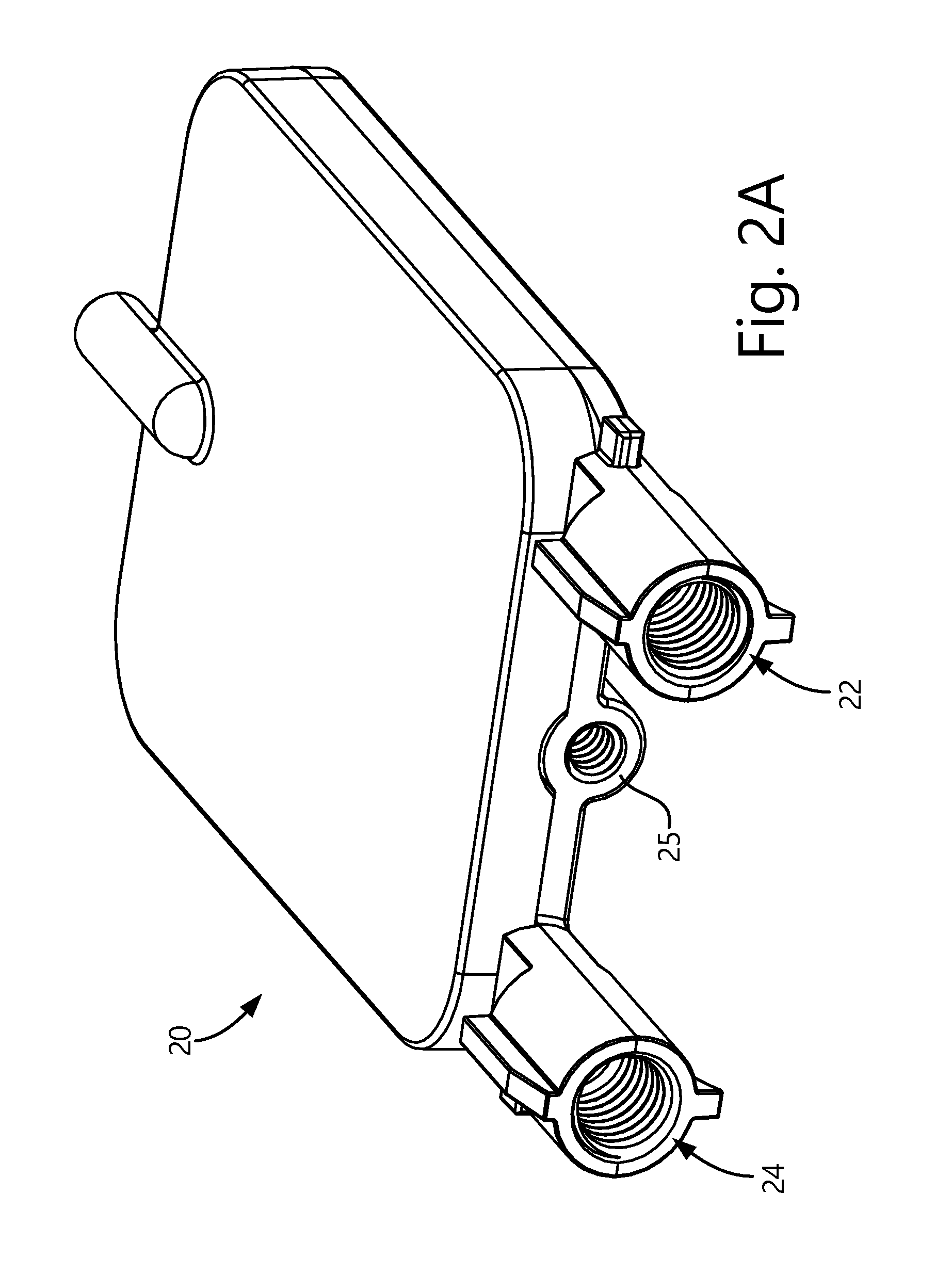

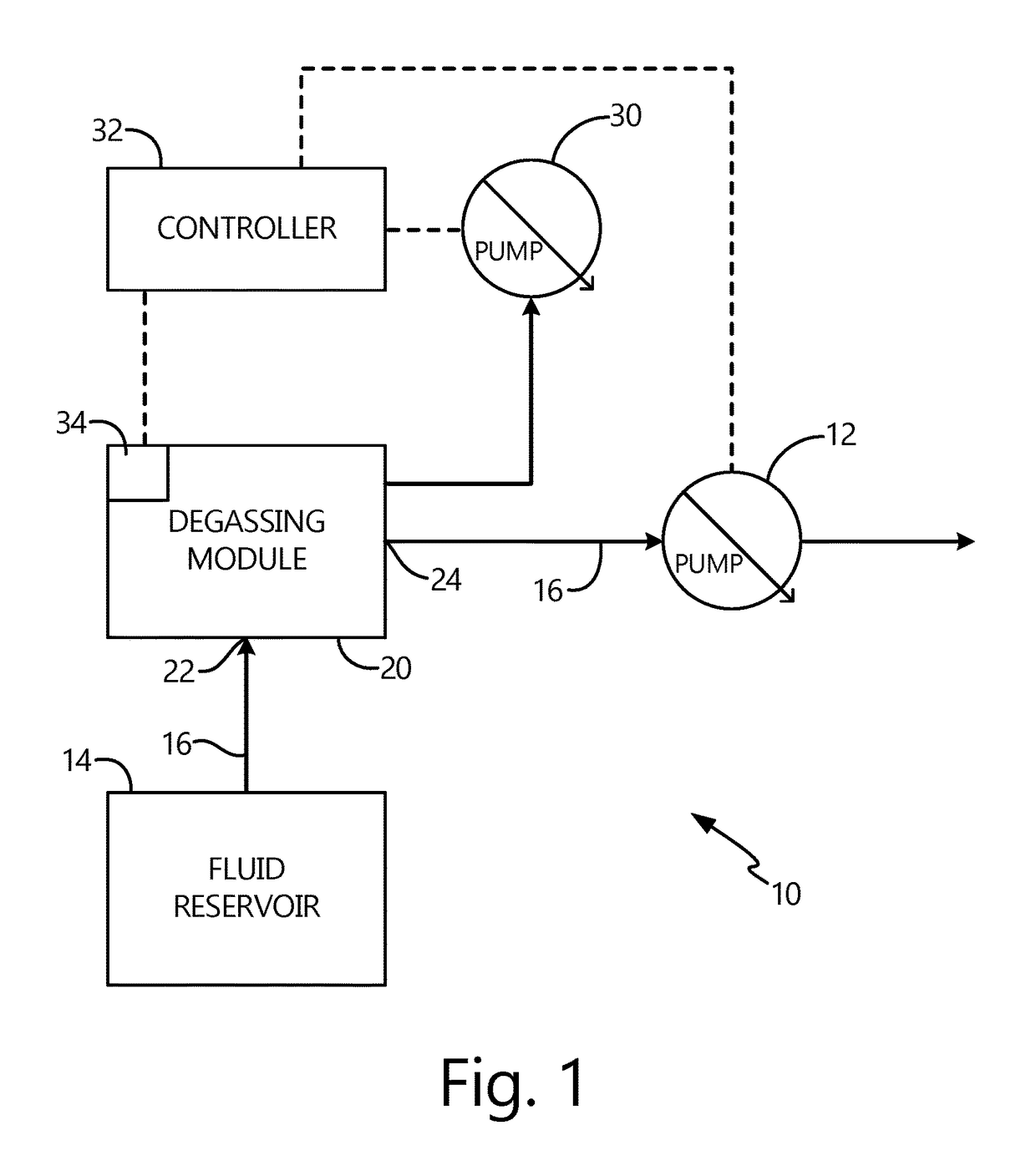

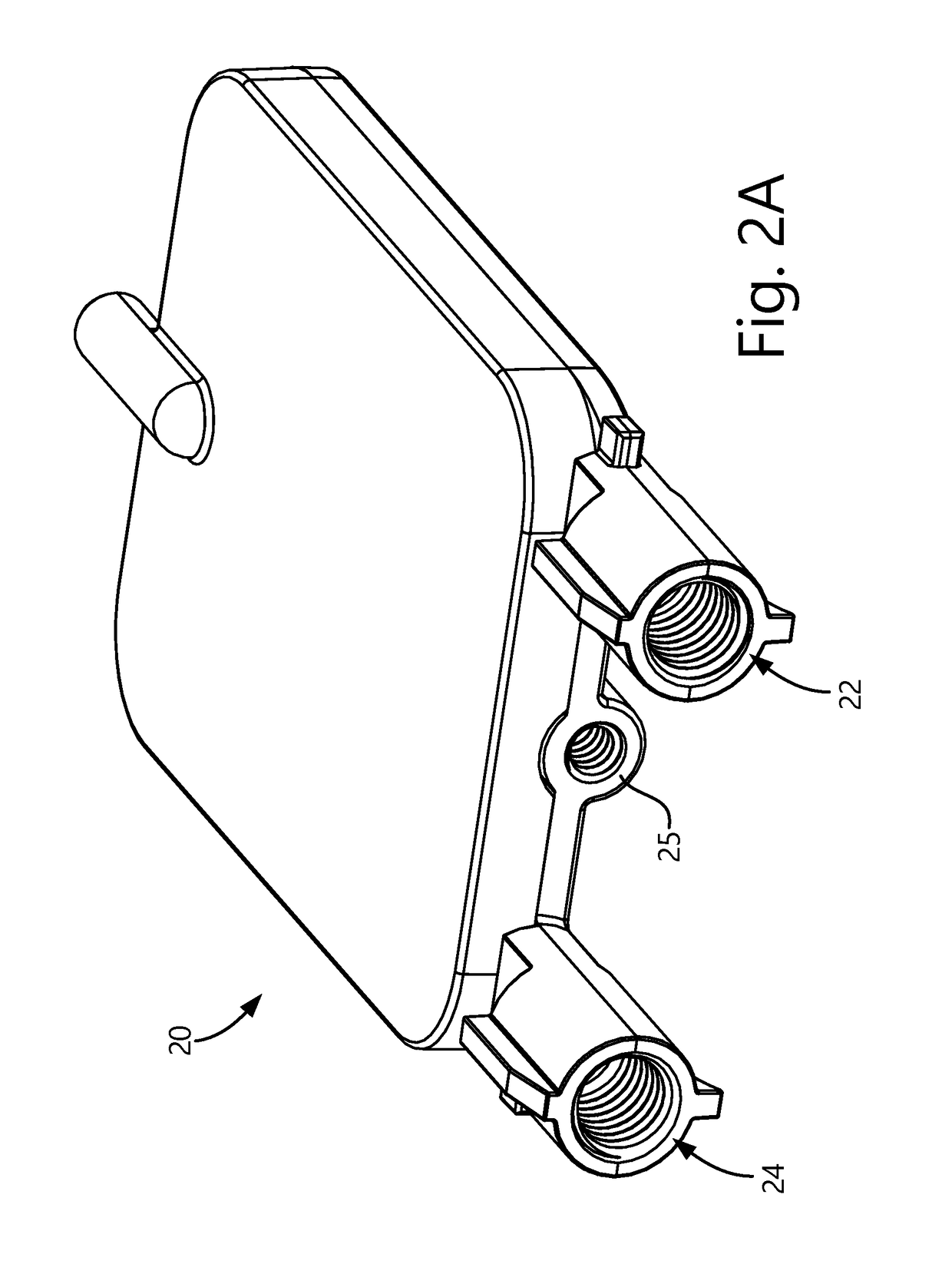

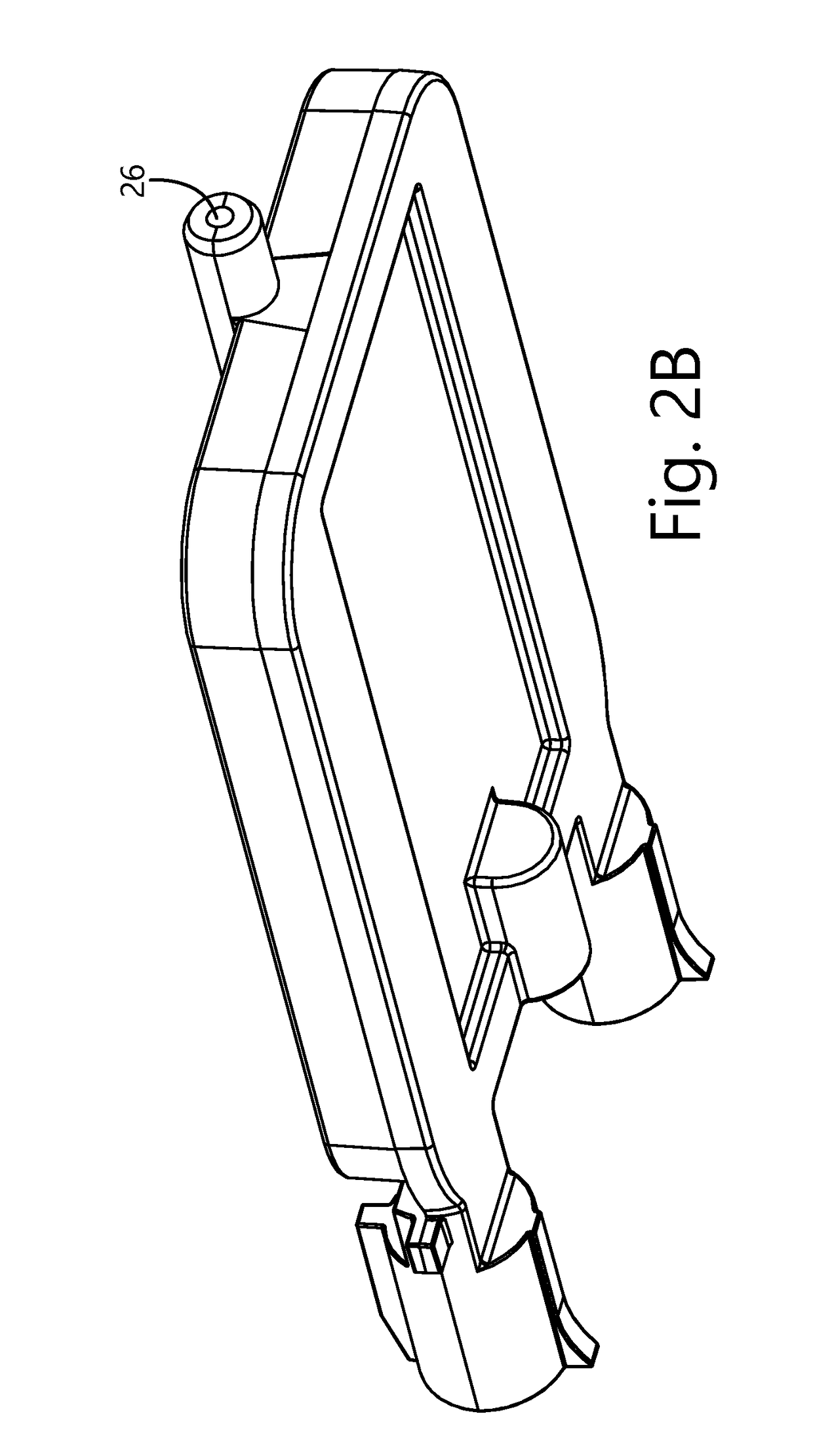

Membrane Gas/Liquid Contactor

ActiveUS20170056788A1Reduce gas concentrationSemi-permeable membranesSolid sorbent liquid separationBiomedical engineeringMembrane configuration

A membrane gas-liquid contactor is arranged to define a fluid flow path for contact with a membrane in a manner to improve degassing efficiency. A degassing module housing the membrane is arranged with flow fields for distributing the fluid flow throughout the membrane contact area. The distributed fluid flow may have a uniform membrane contact opportunity.

Owner:IDEX HEALTH & SCI

Membrane gas/liquid contactor

ActiveUS10143942B2Reduce gas concentrationSemi-permeable membranesSolid sorbent liquid separationBiomedical engineeringMembrane configuration

A membrane gas-liquid contactor is arranged to define a fluid flow path for contact with a membrane in a manner to improve degassing efficiency. A degassing module housing the membrane is arranged with flow fields for distributing the fluid flow throughout the membrane contact area. The distributed fluid flow may have a uniform membrane contact opportunity.

Owner:IDEX HEALTH & SCI

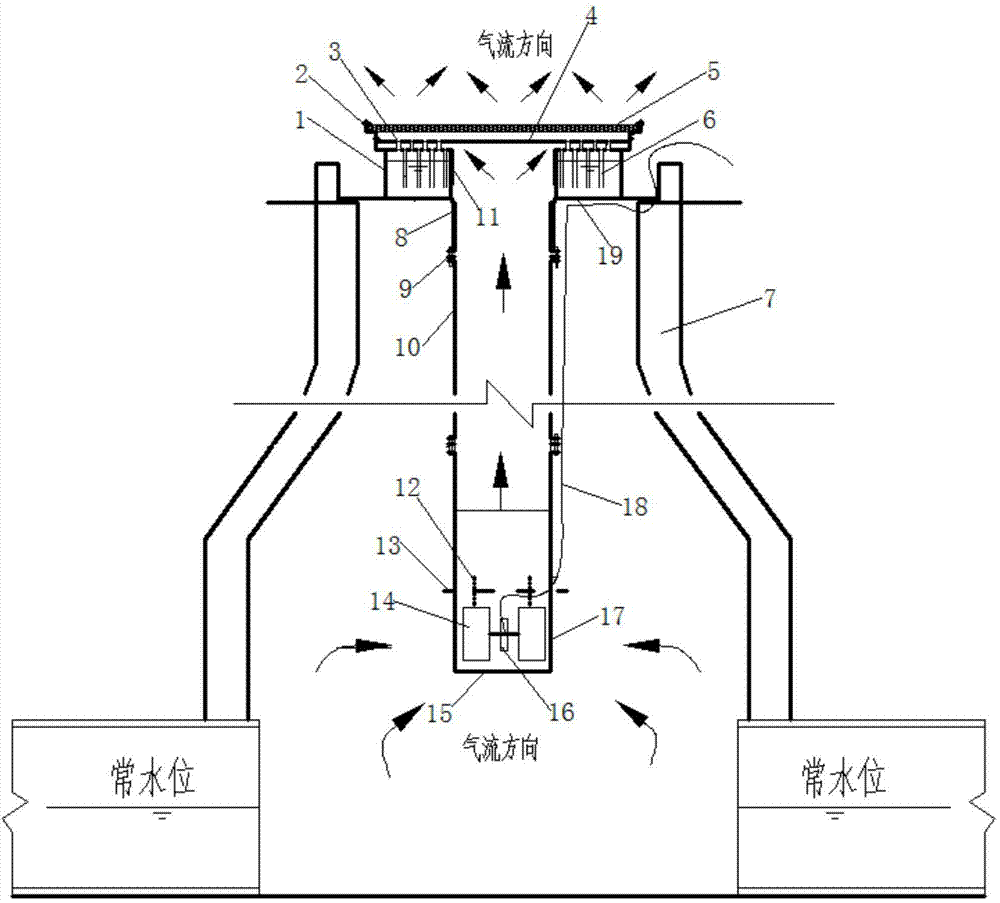

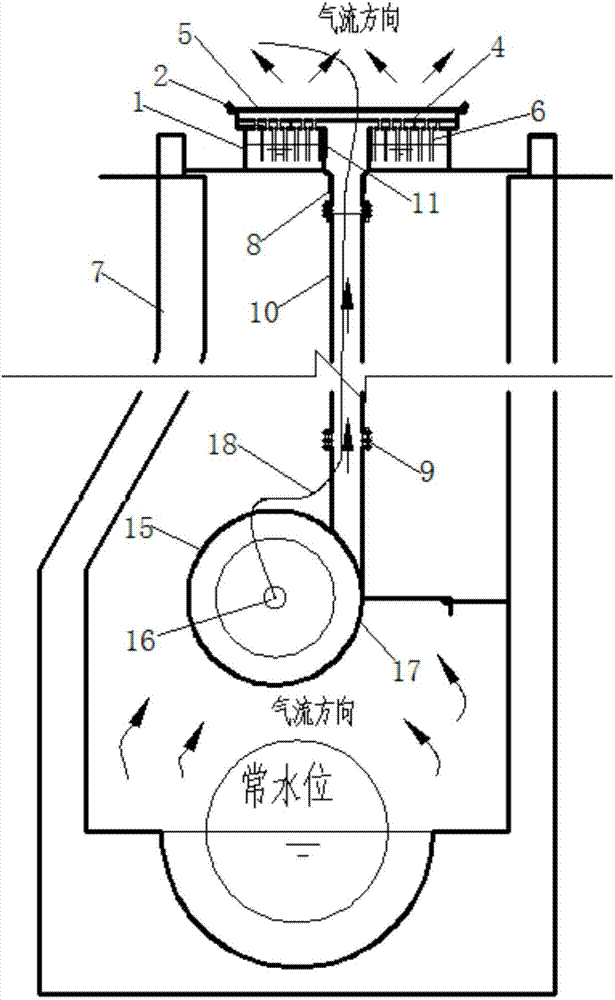

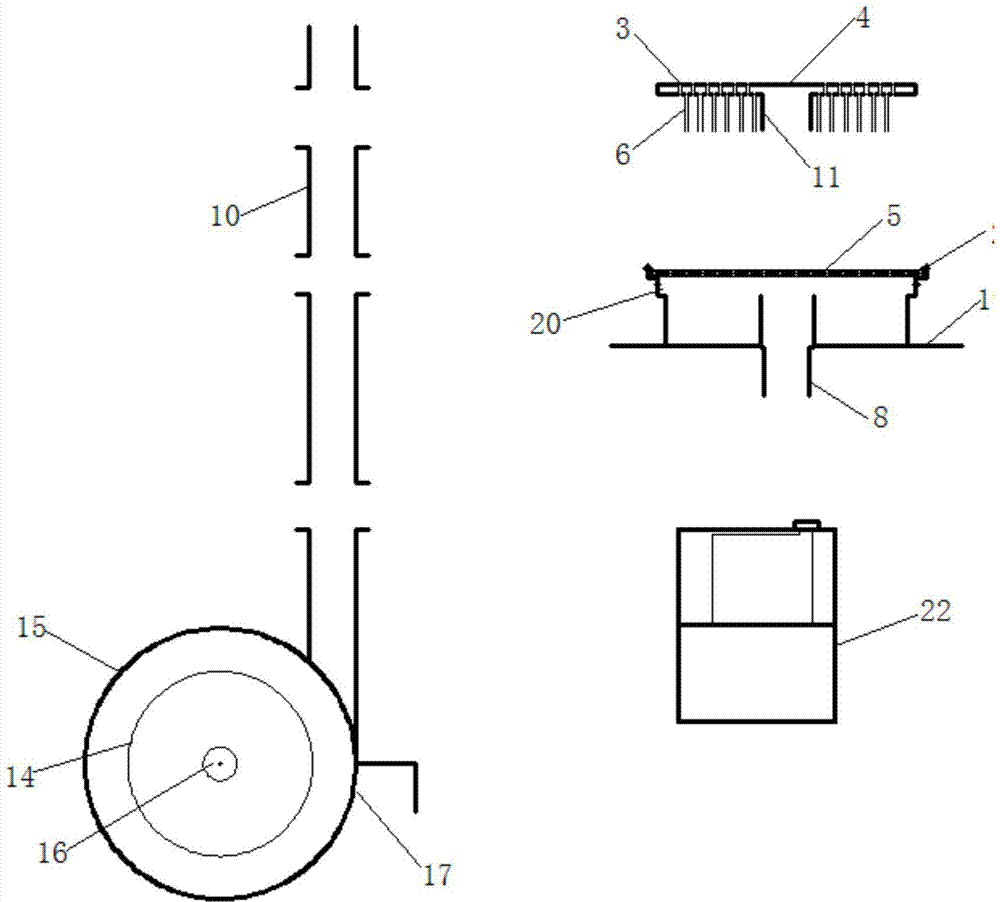

Harmlessness removal apparatus for harmful gas in city sewage pipeline

ActiveCN104492238ASimple structureEasy to assembleSewerage structuresDispersed particle separationMunicipal sewageProcess engineering

The invention discloses a harmlessness removal apparatus for harmful gas in city sewage pipeline, which comprises an air exhaust apparatus in an inspection well, the air exhaust apparatus extracts harmful gas in the inspection well, and is introduced to gas processing equipment arranged at port of the inspection well through an airduct, the gas processing equipment comprises a filtering apparatus and an adsorption apparatus, harmful gas passes through the filtering apparatus and the adsorption apparatus for processing harmful gas in order, and the processed gas is discharged in atmosphere. The harmlessness removal apparatus can be used for fast assembly and installation in the inspection well, and is capable of performing rapid and effective elimination as well as harmlessness processing on harmful gas in the well, land occupation of whole apparatus is little, the harmlessness removal apparatus has less influence on public transport, and work efficiency under well can be ensured.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

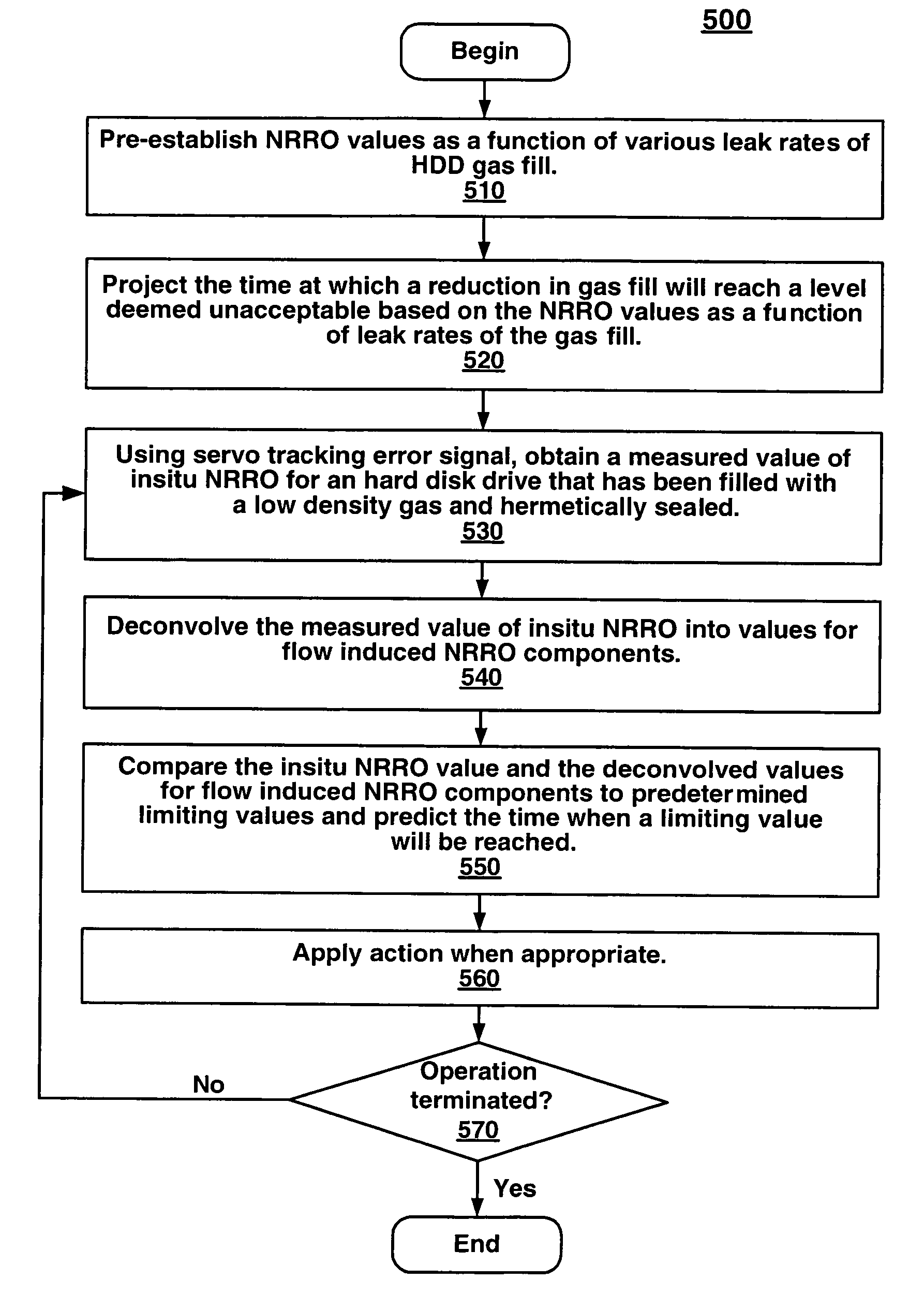

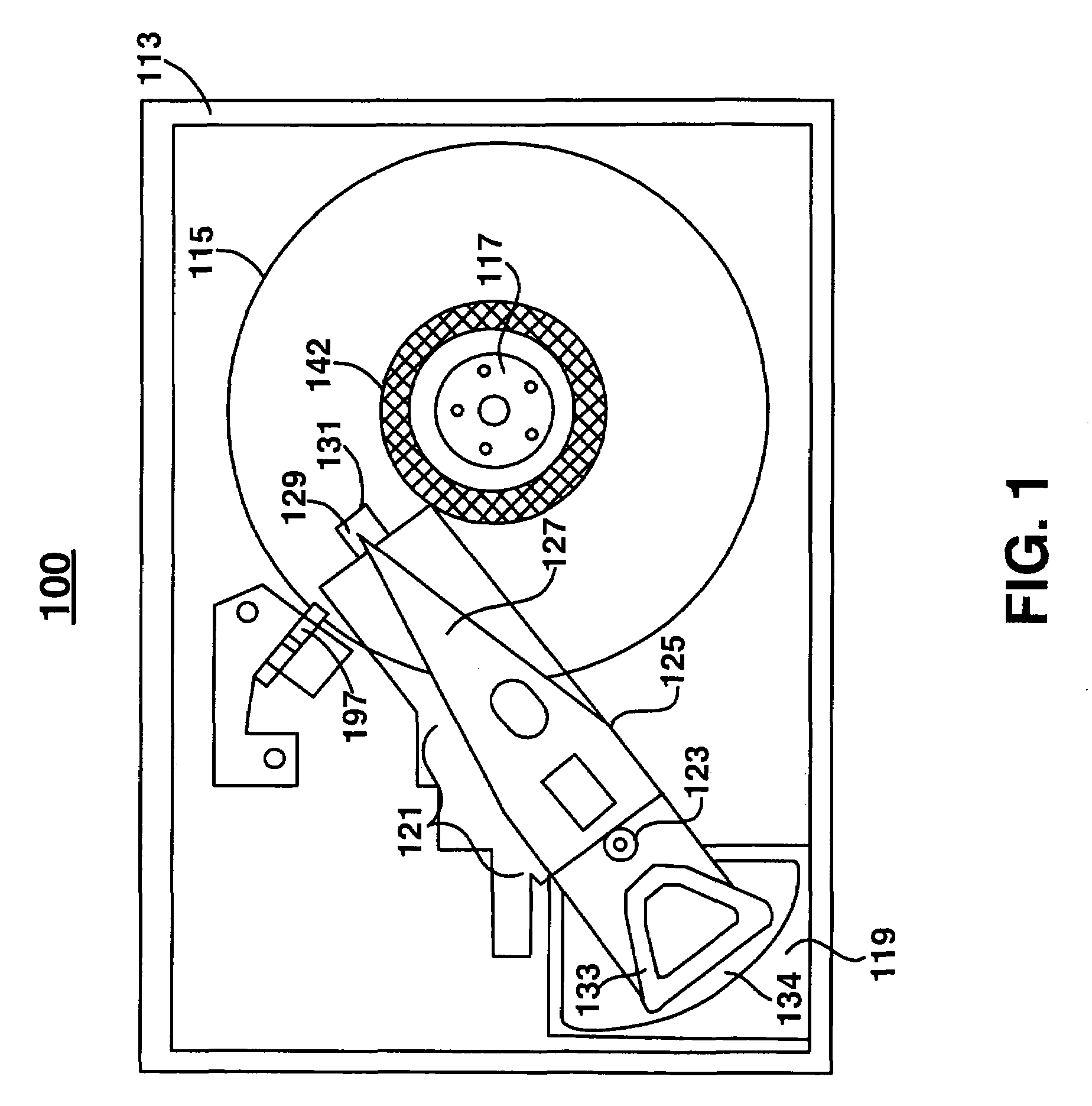

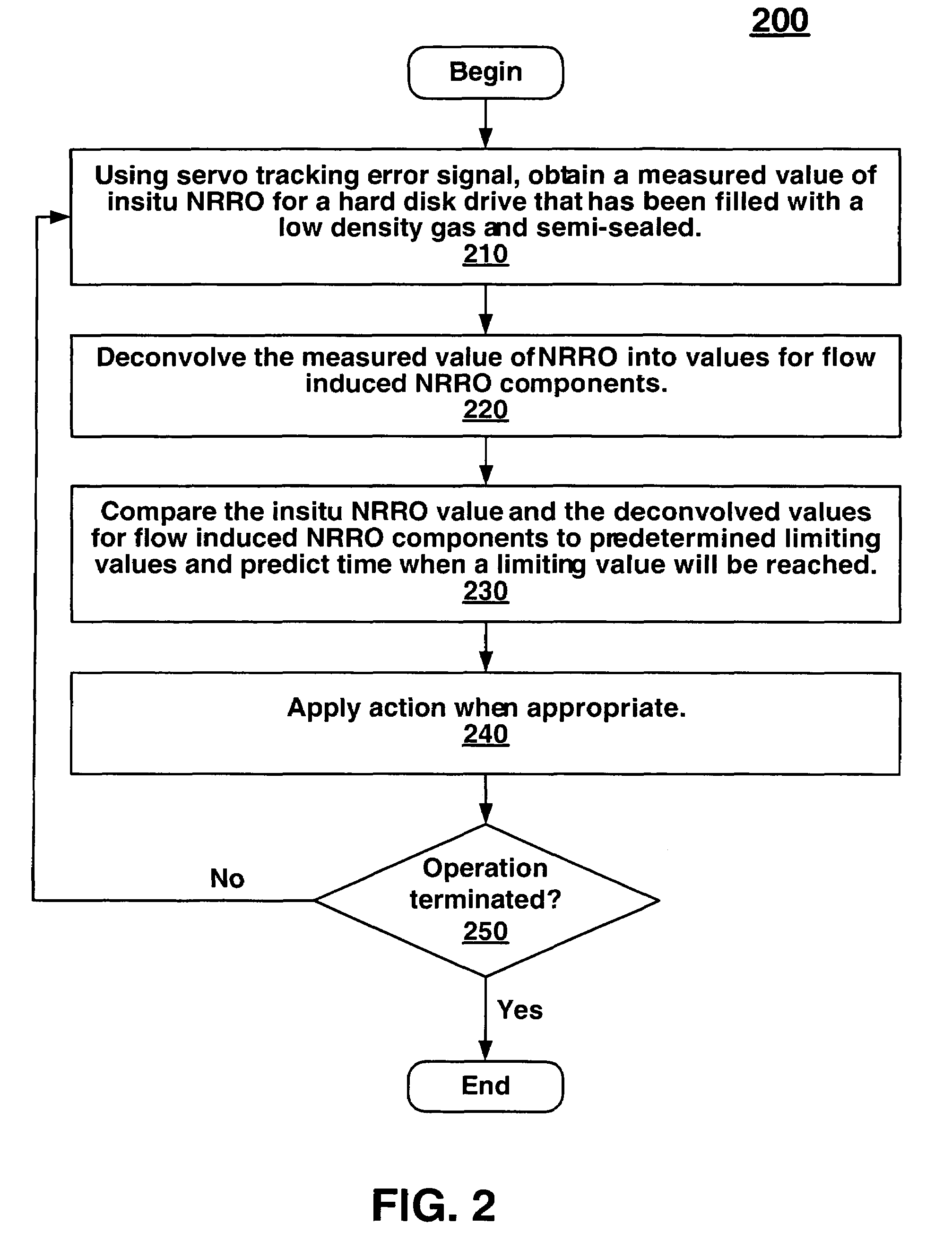

Method for preventing data loss in a hard disk drive by projecting reduction in helium concentration using insitu non-repeatable runout

InactiveUS7236321B1Preventing data loss in hardReduce gas concentrationDriving/moving recording headsFilamentary/web record carriersHard disc driveHermetic seal

A method for preventing data loss in a hard disk drive by projecting reduction in gas concentration using insitu non-repeatable runout is disclosed. The method includes using servo tracking error to obtain a measured value of insitu non-repeatable runout (NRRO) for the hard disk drive, the hard disk drive having been filled with the gas and hermetically sealed. The measured value of NRRO is then deconvolved into a plurality of values for flow induced NRRO components. These values of NRRO and of flow induced NRRO components are compared to predetermined limiting values and a time when one of the predetermined limiting values will be reached is predicted. Action is then applied as appropriate.

Owner:WESTERN DIGITAL TECH INC

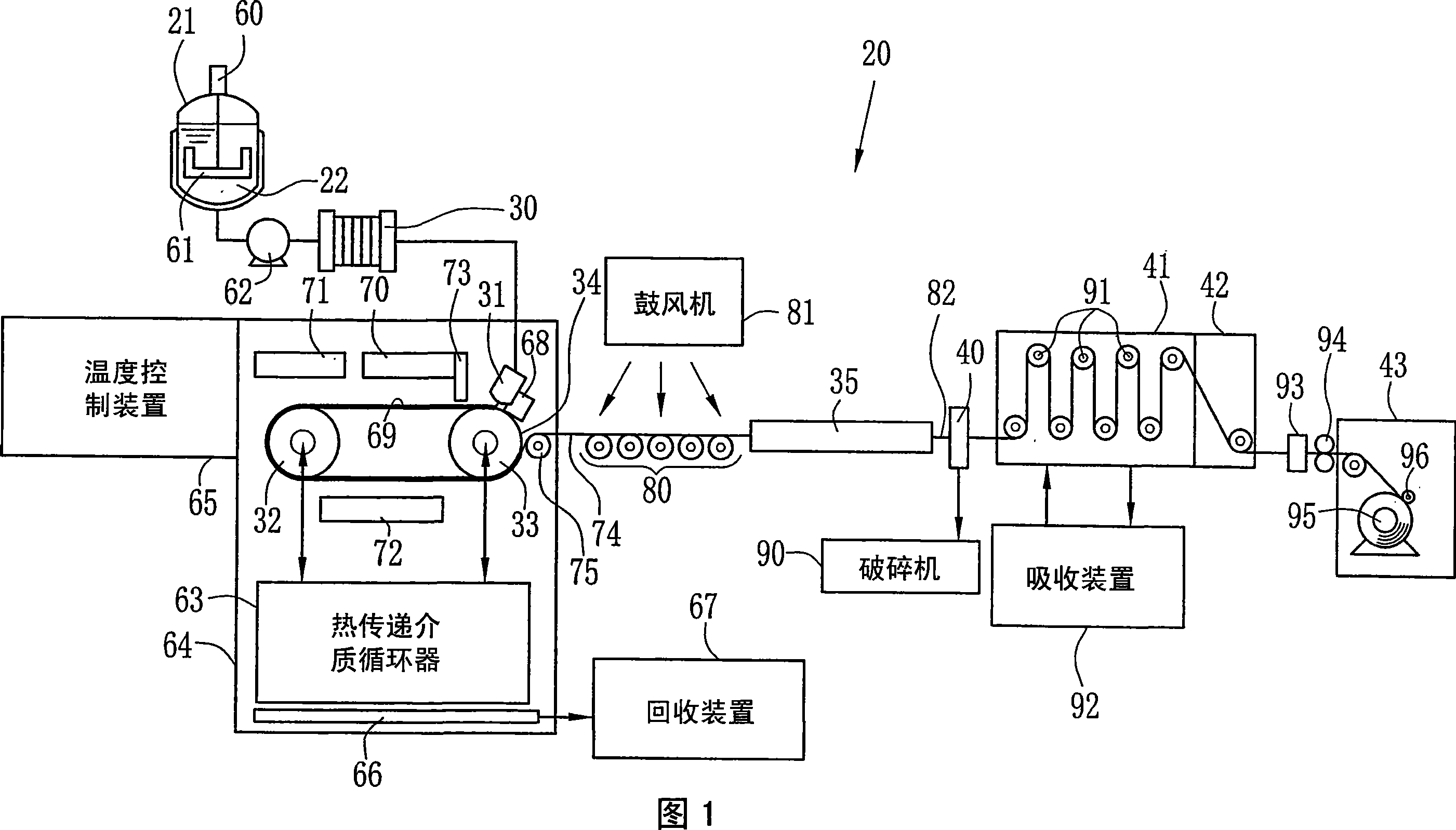

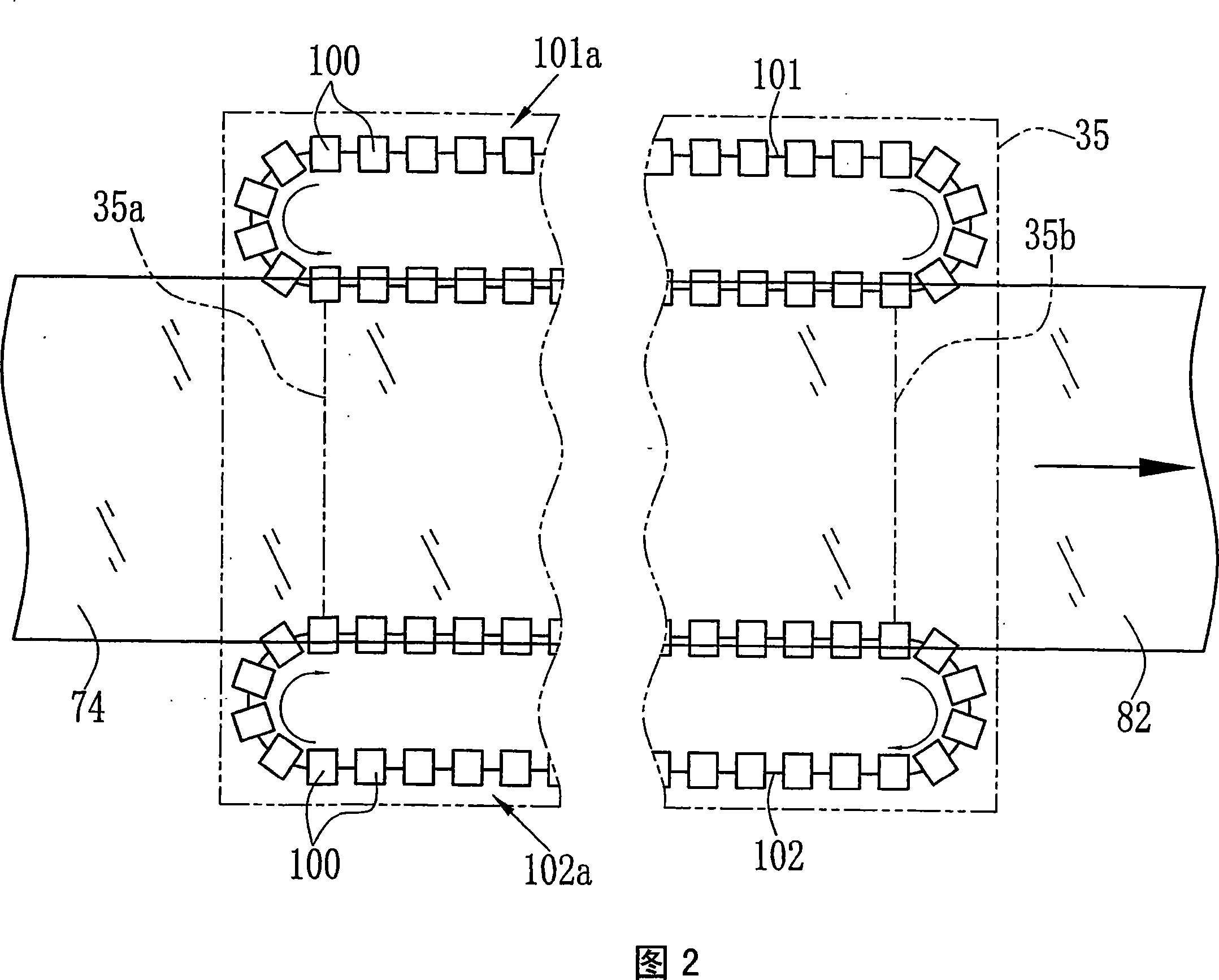

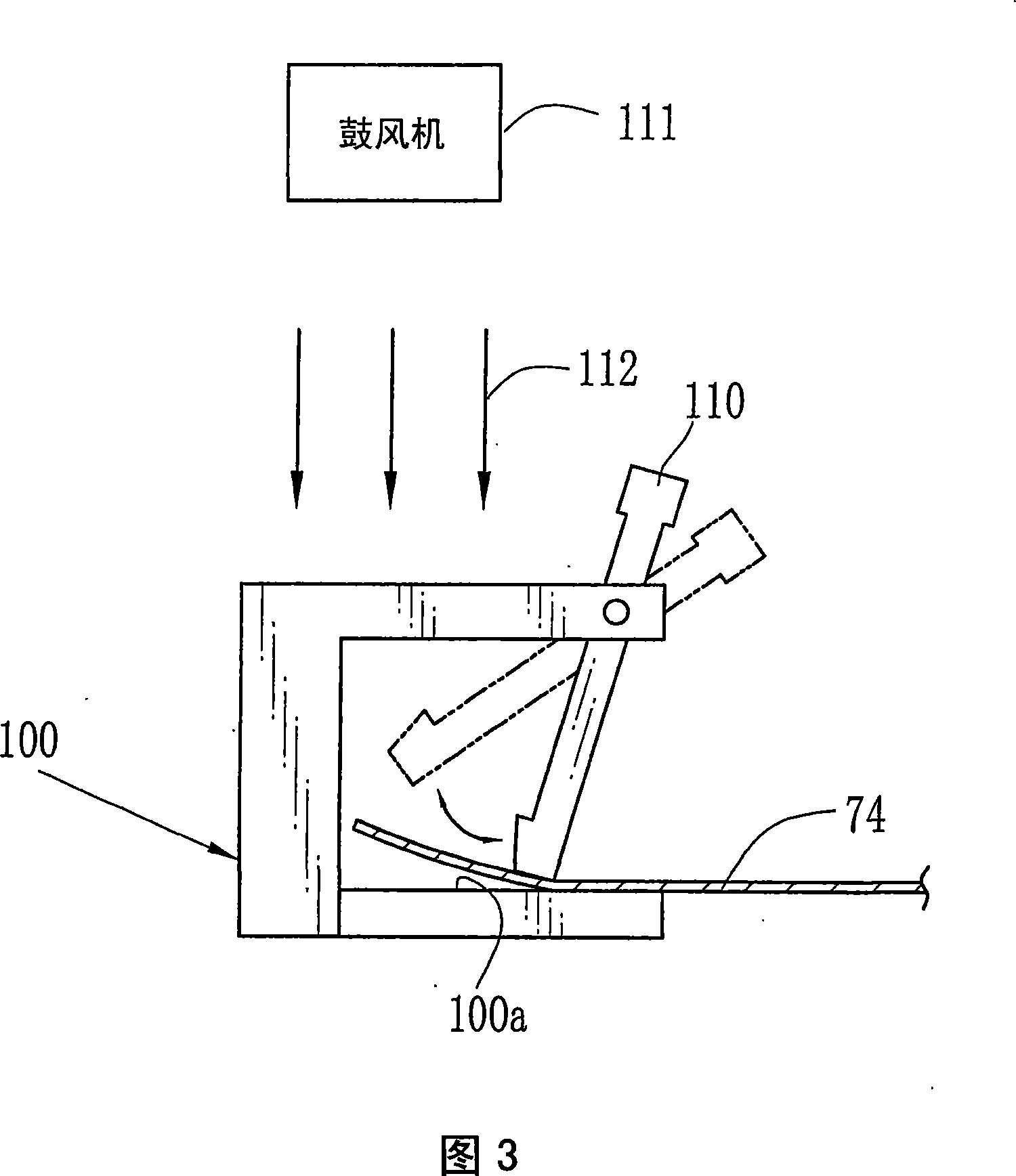

Tenter clip and solution casting method

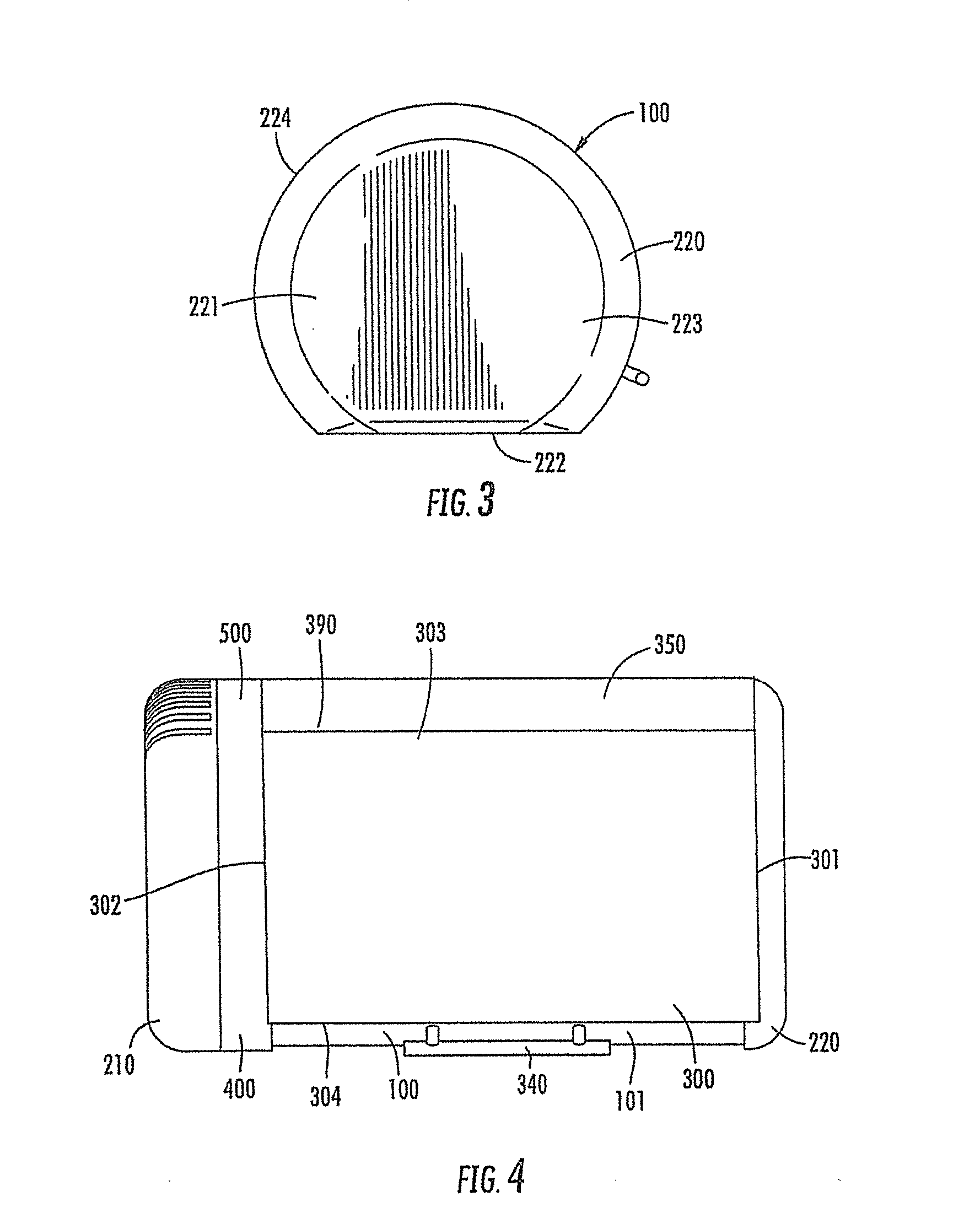

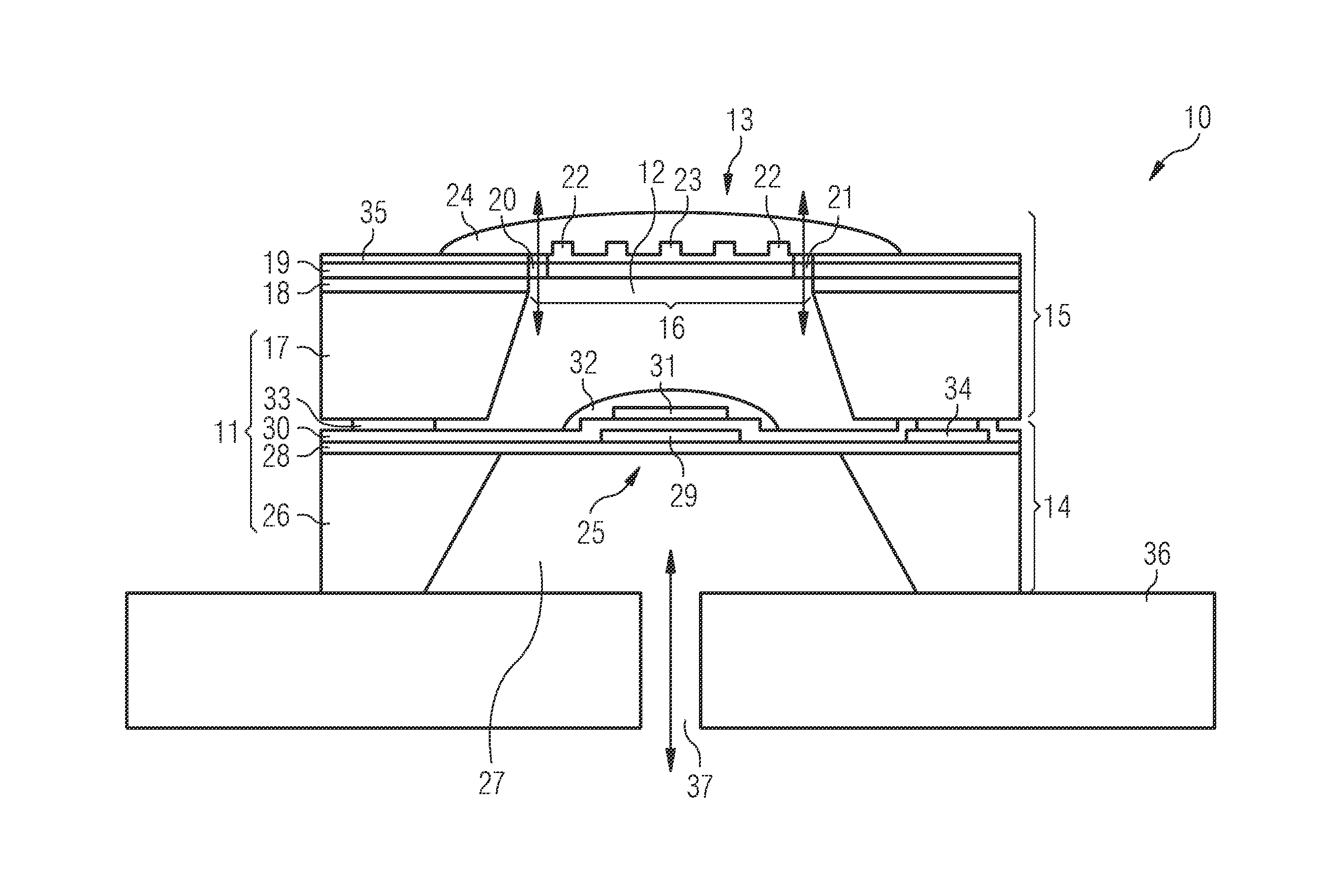

InactiveCN101166618AReduce bondingAvoid surface defectsFlat articlesCoatingsSurface roughnessHardness

A dope, prepared from cellulose triacetate (TAC), solvent and the like, is cast from a casting die onto a belt to form a casting film, which, thereafter, is peeled as a wet film (74) from the belt. The wet film (74) is transported to a tenter device, in which both side edge portions are clipped by tenter clips (100) and the firm is dried with stretching in the widthwise direction. The tenter clips (100) (temperature, 0 to 60 DEG C) has a support surface (100a) for supporting the side edge portion of the wet film (74) thereon. A surface tension of the support surface (100a) is in the range of 3.0 x 10-2 to 3. 3 x 10-2 N / m, a surface roughness Ra 0.05 to 1.0 m, and a surface hardness 400 to 800 Hv. Thus, the present invention results in reducing the adhesion of the foreign materials on the surface.

Owner:FUJIFILM CORP

Smoke internal circulation low-nitrogen gas combustor

PendingCN111442270AReduce the temperatureControl concentrationGaseous fuel burnerCombustorEngineering

The invention relates to a gas fuel combustor matched with heat energy equipment, in particular to a smoke internal circulation low-nitrogen gas combustor. The smoke internal circulation low-nitrogengas combustor comprises an air pipe, a conical air pipe, a guiding air pipe, a first-level gas pipe, a second-level gas pipe and third-level gas pipes. The outlet end of the air pipe is provided witha reducing part, and air nozzles are annularly distributed on the reducing part. The conical air pipe is sleeved with the reducing part of the air pipe, convexly stretches out of the air pipe and is internally provided with a rotational flow disc. The guiding air pipe sleeves the conical air barrel. The first-level gas pipe is located at the center of the air pipe and vertically penetrates throughthe rotational flow disc. The second-level gas pipe is connected with the first-level gas pipe and penetrates through the reducing part and the air nozzles to enter the guiding air pipe. The third-level gas spraying pipes are annularly distributed on the periphery of the air pipe. Through the arrangement of two-level combustion supporting air and three-level gas, the kinetic energy of gas and airis sufficiently utilized, high-flow smoke is mixed into air and gas, the combustion reaction speed is reduced, the flame temperature is reduced, and accordingly the NOx generation concentration is controlled.

Owner:唐山冀东石油机械有限责任公司 +1

Normally-closed GaN-based MOSFET structure with high threshold voltage and high conduction performance and fabrication method thereof

PendingCN107768252ARaise the threshold voltageImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETEngineering

The invention relates to the technical field of semiconductor, in particular to a normally-closed GaN-based MOSFET structure with a high threshold voltage and high conduction performance and a fabrication method thereof. The fabrication method of the normally-closed GaN-based MOSFET structure with the high threshold voltage and high conduction performance comprises the following steps of firstly,providing a required substrate, sequentially and epitaxially growing a stress buffer layer, a GaN buffer layer, an AIN thin layer and an AlGaN thin layer on the substrate, and reserving the AlN thin layer and the AlGaN thin layer on a grid region by etching to obtain a substrate for epitaxy of a selection region; secondly, sequentially selecting a regional epitaxial GaN channel layer, a AIN insertion layer and a AIGaN barrier layer on the substrate to form a groove structure; and finally, depositing a grid dielectric layer, covering grid metal on a groove channel grid dielectric layer, and covering two ends of the grid with metal to form a source and a drain. By the fabrication method, the threshold voltage and the grid region mobility can be effectively improved, the channel resistance isreduced, and the conduction performance of the GaN MOSFET device is improved.

Owner:SUN YAT SEN UNIV

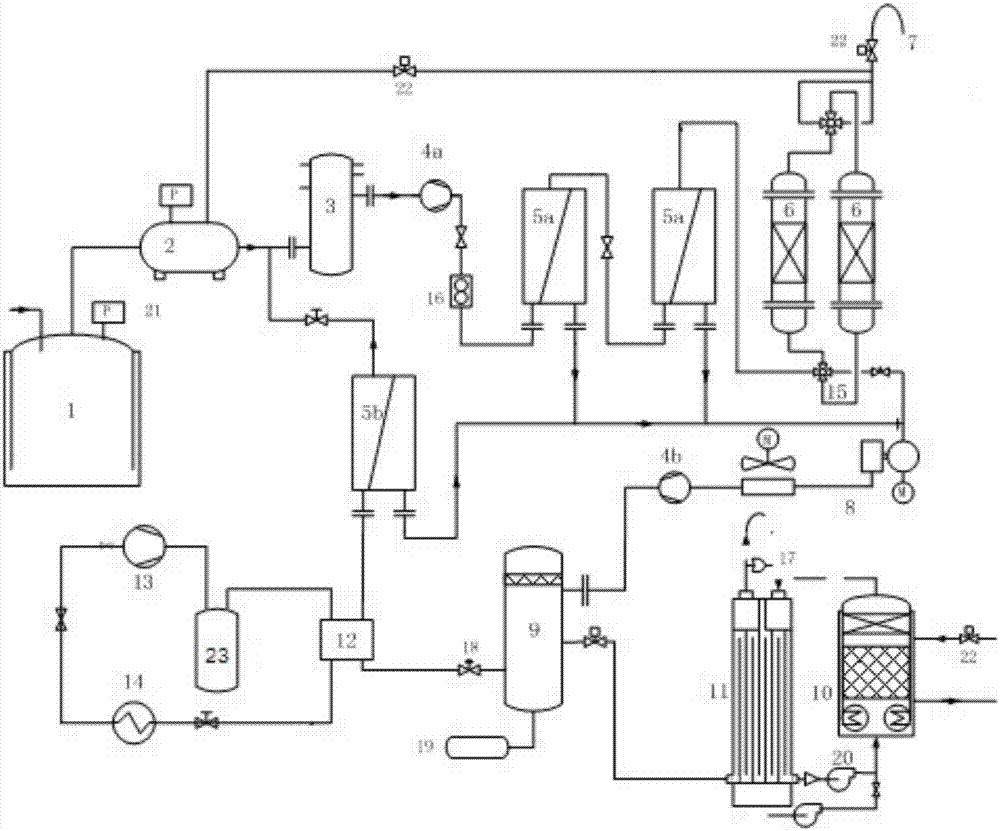

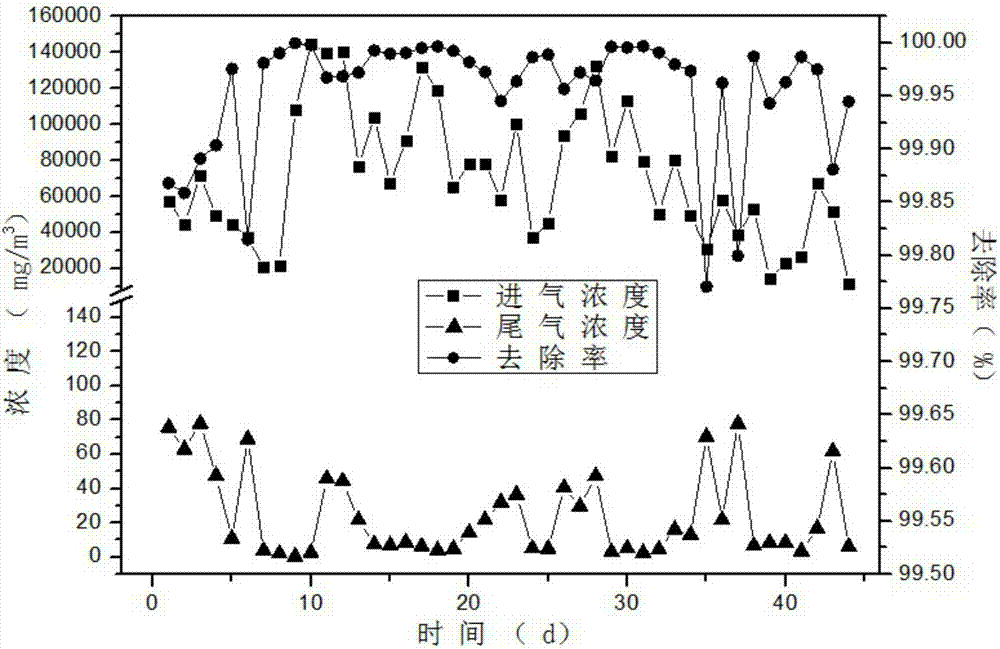

High-effective organic waste gas recovery processing method and complete equipment

ActiveCN107413173AHigh recovery rateHigh explosion-proof gradeGas treatmentDispersed particle separationHigh concentrationBuffer tank

The invention relates to a high-effective organic waste gas recovery processing method and complete equipment. The complete equipment includes: an organic waste gas collection apparatus, a gas storage tank, a buffer tank, a primary membrane unit, an active carbon adsorption unit, a vacuum pump, a gas-liquid separation tank, a compression condensing unit, a secondary membrane unit, a low temperature catalytic oxidizing reactor, and a tubular heat exchanger. Through the two-stage membrane as a core technology, advantages that a membrane process is high in efficient, is continuous, has high recover rate and high safety and is suitable for high-concentration organic waste gas are achieved, thus recovering the recoverable components in the waste gas; in addition, with the low temperature catalytic oxidization technology, an advantage of deep processing thereof is achieved, so that a problem of accumulation of light-hydrocarbon substances is overcome. The processing method and complete equipment not only high-effectively recover valuable organic substances, but also can perform deep processing to the organic waste gas with satisfaction of strict requirements on safety production in petrochemical enterprises. Through the deep processing to the organic waste gas, discharged organic waste gas can reach national emission standards.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com