Sterilization and disinfection purification device and method for air in livestock shed

A sterilization, air purification technology, applied in the direction of disinfection, atomization, deodorization, etc., can solve the problem of insufficient exchange of polluted air and ozone water, water and air circulation loops are not separated independently, and poor purification and sterilization effects. and other problems, to achieve the effect of increasing average daily gain, promoting feed intake, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

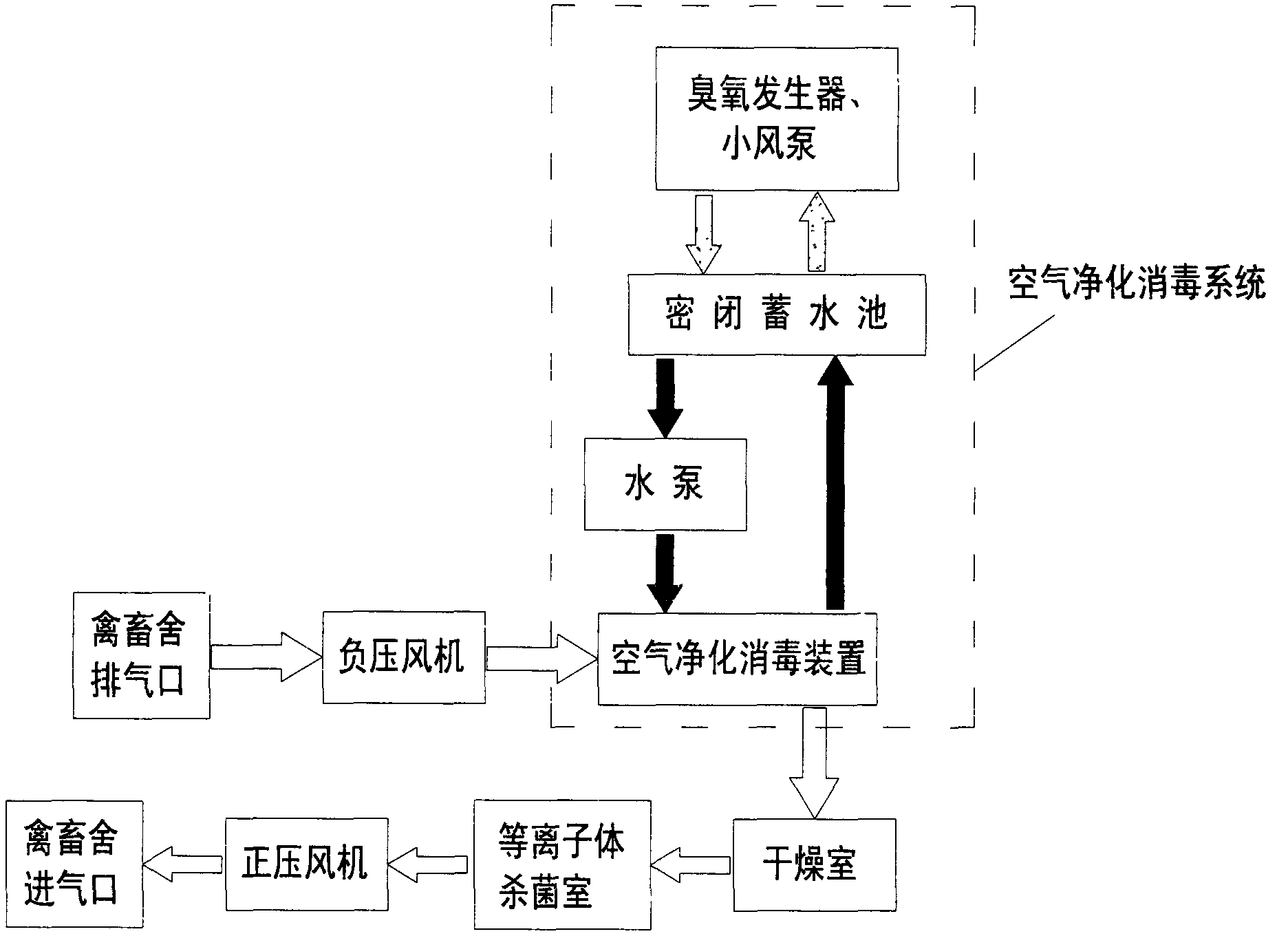

[0020] Embodiment 1: with reference to attached figure 1 . A sterilizing, disinfecting and purifying device for the air in a poultry breeding house, which includes a PLC-controlled negative pressure fan, a positive pressure fan, an air purification and disinfection system, a dryer and a plasma sterilizing device; The exhaust port of the house is connected, and the outlet port is connected with the air purification and disinfection system; the air pollutants in the poultry house are drawn out into the air purification and disinfection system through the exhaust port under the action of the negative pressure fan; the air The outlet end of the purification and disinfection system communicates with the dryer; the outlet end of the dryer communicates with the plasma sterilization chamber; the inlet end of the positive pressure fan communicates with the plasma sterilization chamber, and the outlet end communicates with the air inlet of the poultry house; The purified air pollutants...

Embodiment 2

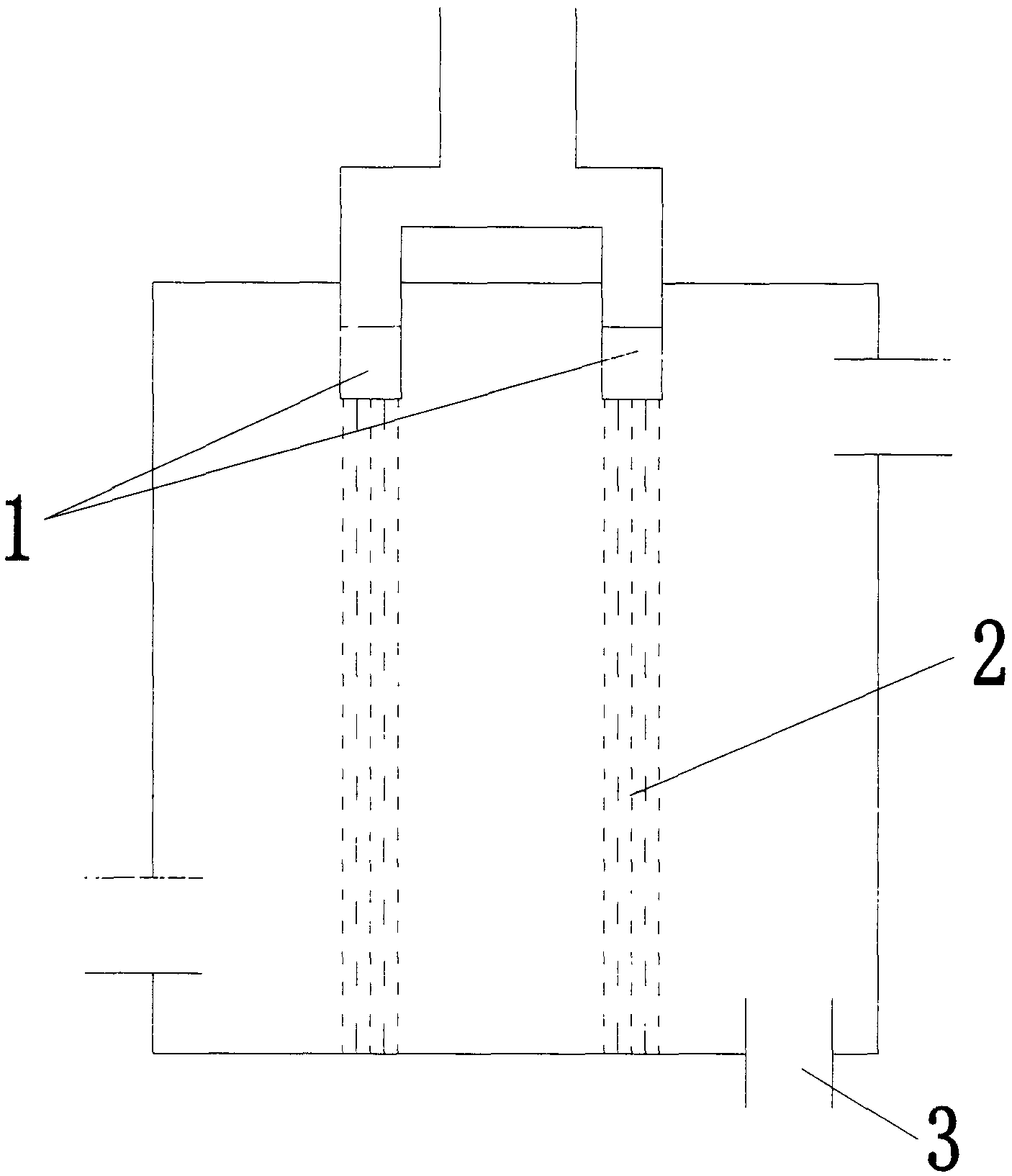

[0022] Embodiment 2: on the basis of embodiment 1, with reference to appended figure 2 . A device for sterilizing, disinfecting and purifying air in poultry and livestock breeding houses, which has two copper nozzles 1; the two copper nozzles 1 are installed on the top of the air purification and disinfection device, and the nozzles 1 spray vertically downwards Water screen 2; the air pollutants are discharged after passing through two water screens 2 in sequence; the air purification and disinfection device is provided with a drainage pipe 3, and the drainage pipe 3 is connected to a closed reservoir.

Embodiment 3

[0023] Embodiment 3: a kind of sterilizing and purifying method of the air in poultry breeding house, it adopts the sterilizing and purifying device described in embodiment 1, comprises the following steps:

[0024] ①The air pollutants in the livestock house are discharged into the air purification and disinfection device of the air purification and disinfection system through the exhaust port under the action of the negative pressure fan.

[0025] ②In the air purification and disinfection system, the ozone generated by the ozone generator is continuously pumped into the closed reservoir through the small air pump. After the ozone is dissolved in water, it is continuously pumped into the air purification and disinfection device by the water pump. The ozone bubbles that are not dissolved in water It can be circulated back to the ozone generator through another pipeline, which can ensure that the water in the reservoir is rich in ozone and has no excess ozone bubbles. The water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com