Patents

Literature

217results about How to "Avoid surface defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

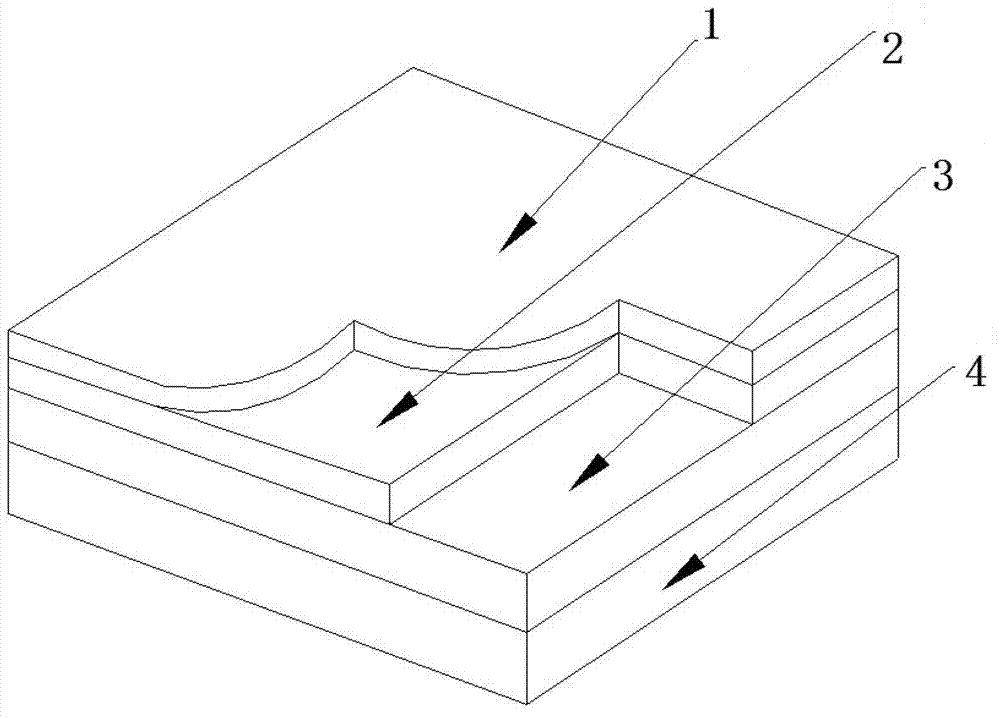

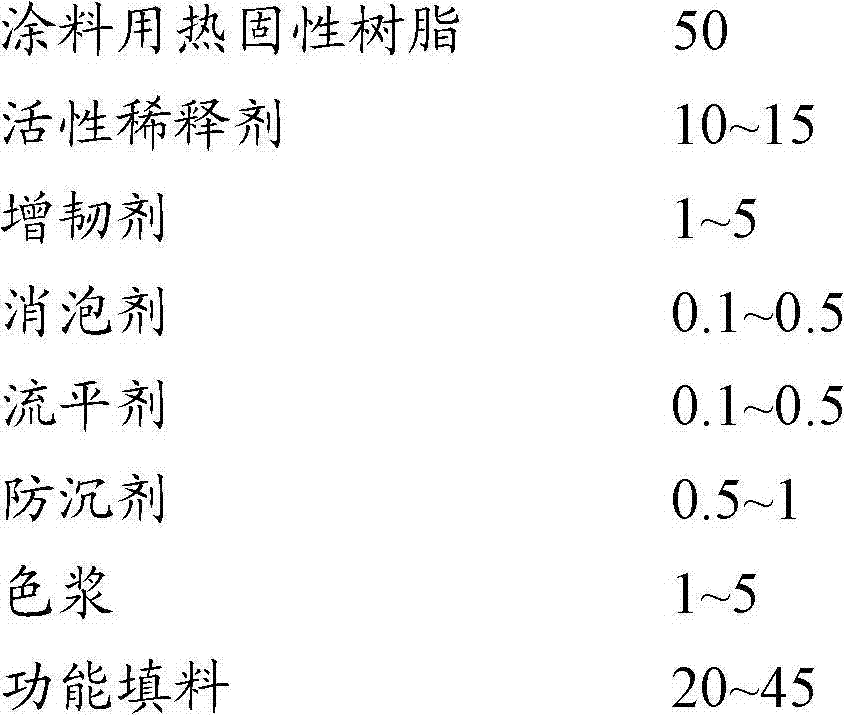

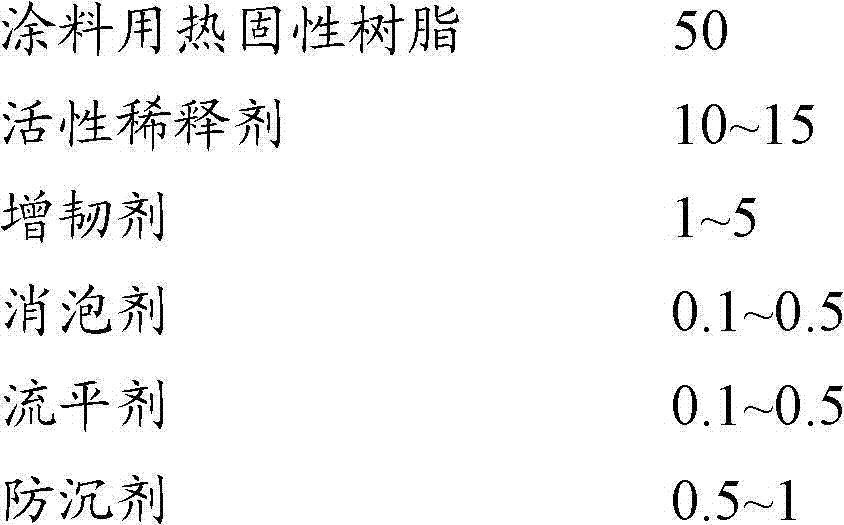

Thermosetting resin composite facing material and preparation method thereof

ActiveCN102808334AIncrease the physical and chemical properties of instant noodlesImprove scratch resistanceSynthetic resin layered productsTextiles and paperResin coatingHigh integrity

The invention discloses a thermosetting resin composite facing material, which comprises a fiber reinforced layer, and a decorative layer and a basic layer which are respectively coated on the upper surface and the lower surface of the fiber reinforced layer. The decorative layer and the basic layer are made of functional thermosetting resin coating. By using the thermosetting resin composite facing material, the organic combination of a thermosetting resin coating layer and a fiber fabric layer is realized, and the obtained material has the advantages of high integrity, uniform performance, convenience in field laying, fewer gap and excellent performance. The excellent physical and chemical performance of thermosetting resin is inherited, the toughness of the material is increased, the material is more convenient and rapid to install and the application scope is wider. The invention additionally discloses a preparation method of the thermosetting resin composite facing material.

Owner:HANGZHOU JIUHE NEW MATERIAL

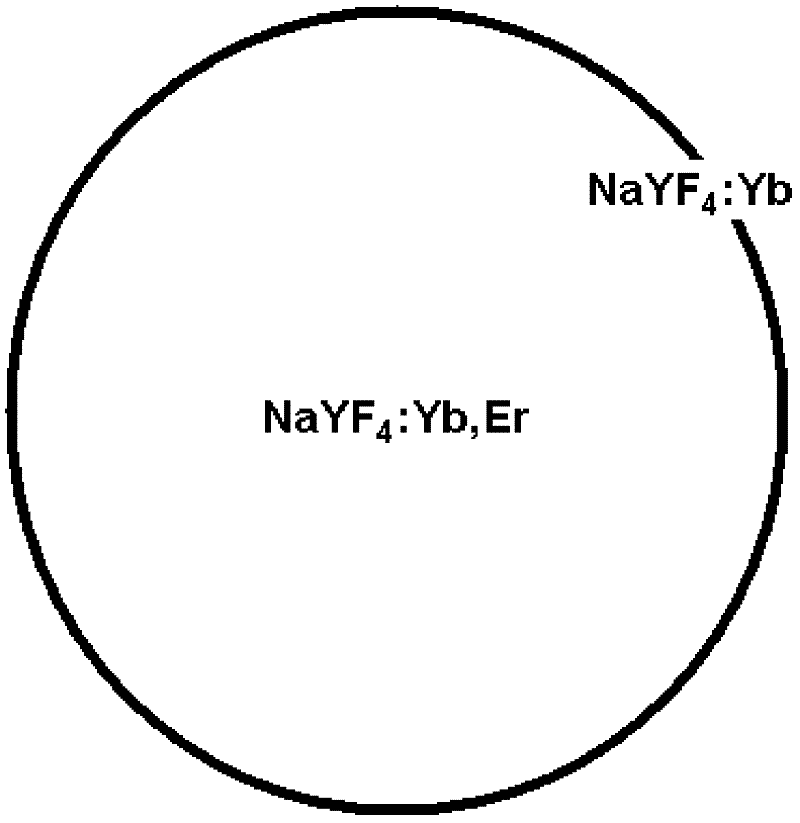

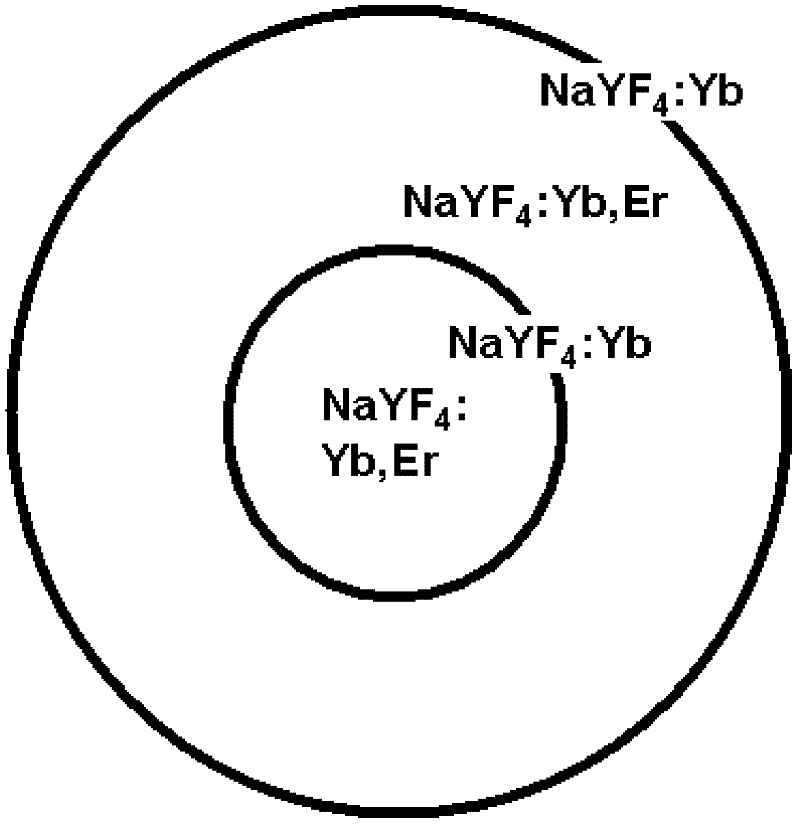

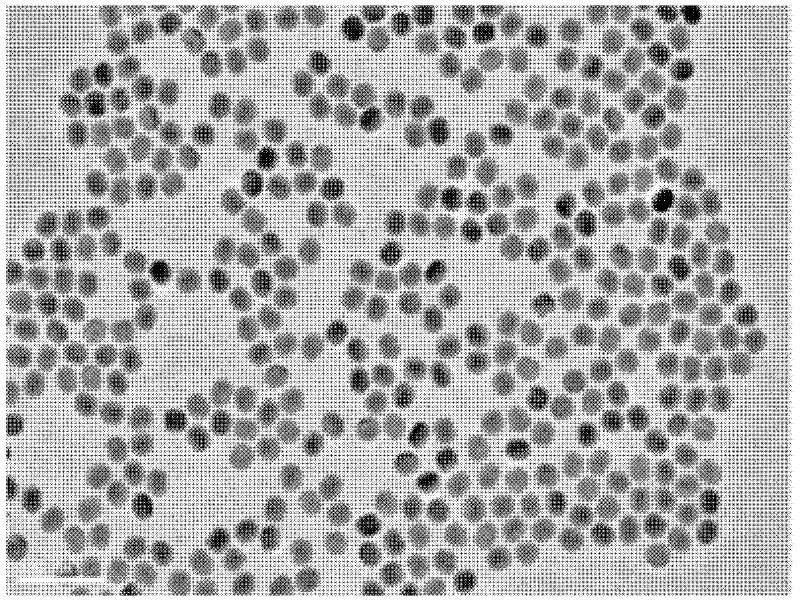

Rare earth up-conversion fluorescent material doped with luminescent center in different regions and preparation method thereof

The invention discloses a luminescent centre regionally doped rare earth upconversion luminescent material and a preparation method thereof, which relates to the technical field of structural design and preparation of luminescent materials. For solving the problems of small doping amount in the luminescent center and low luminescent efficiency of the rare earth upconversion luminescent material, the conventional materials of the same kind take NaYF4 as a matrix, are doped with rare earth sensitized ions and rare earth luminescent ions and has a core / shell structure and nanocrystalline micro structure, wherein a luminescent shell layer is coated outside the core / shell structure, and a sensitized layer is the outmost layer. The preparation method of the rare earth upconversion luminescent material comprises: after a trifluoroacetate thermal decomposition method is implemented, adding a luminescent shell layer precursor into solution of nanoparticle colloid with the luminescent core / shell structure, heating, and reacting to form the luminescent shell layer; cooling the product obtained by the previous step, adding a sensitized shell precursor layer, heating, reacting and obtaining a sensitized shell layer on the outside of the luminescent shell layer; and thus, obtaining the luminescent centre regionally doped rare earth upconversion luminescent material.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

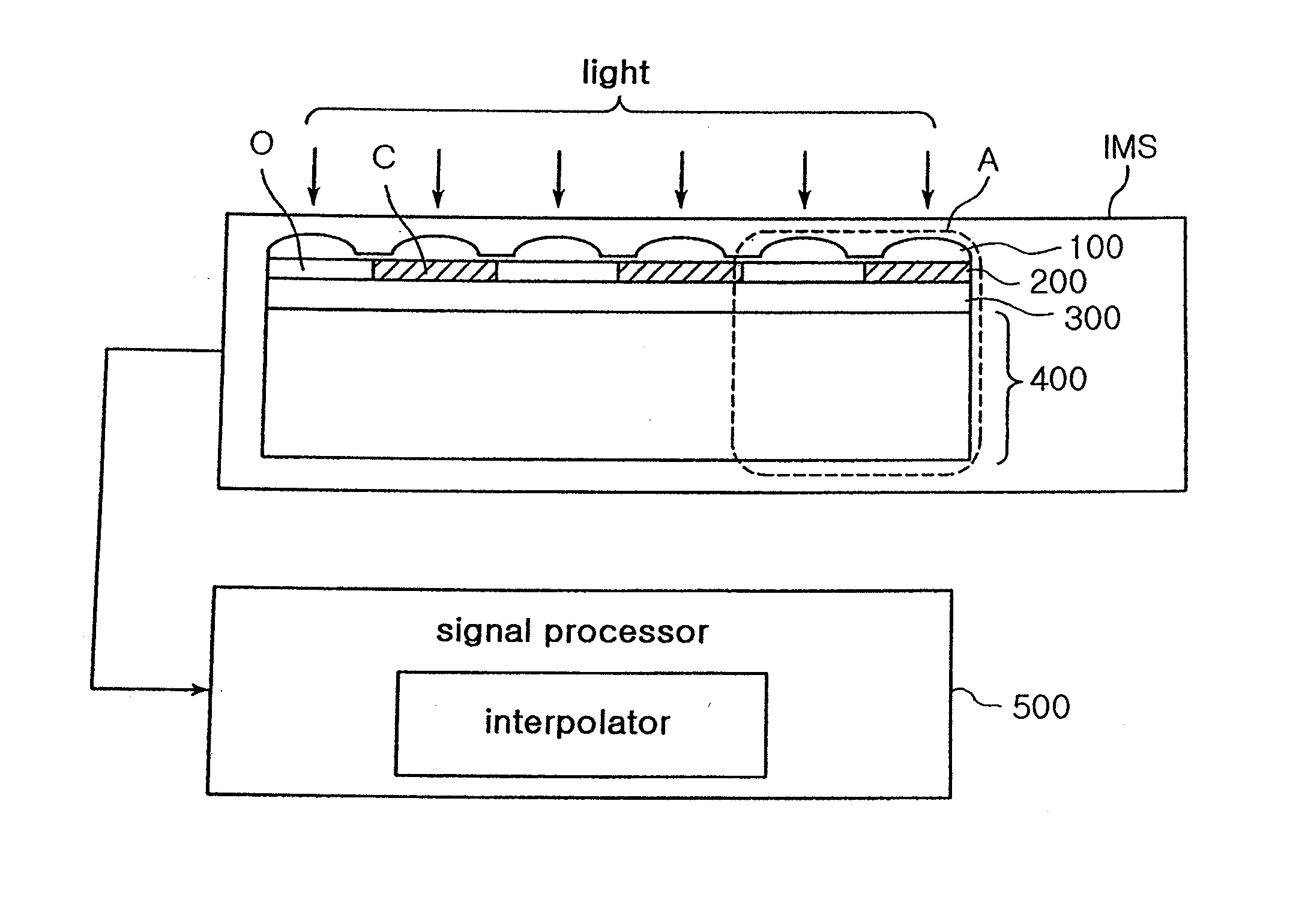

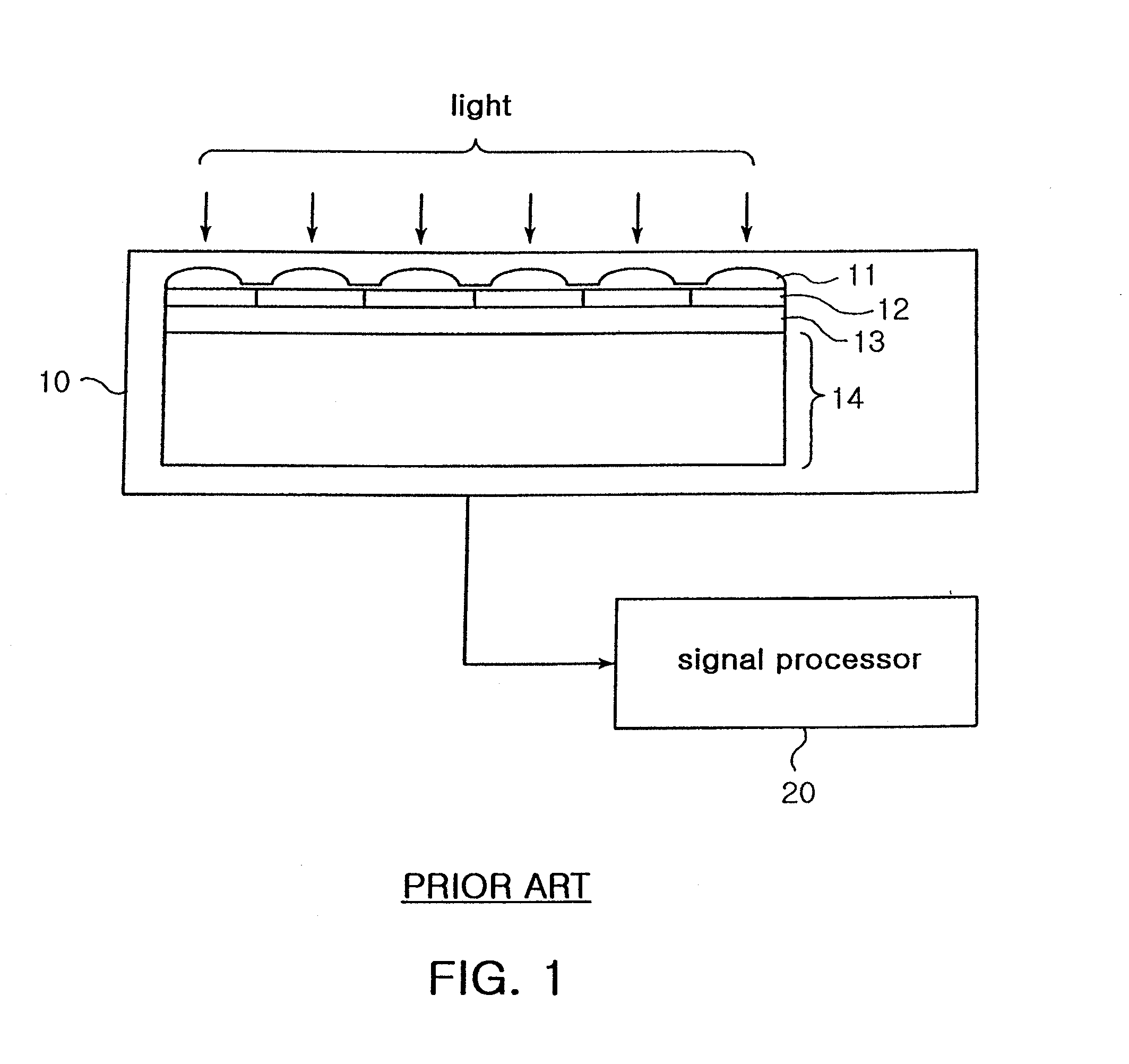

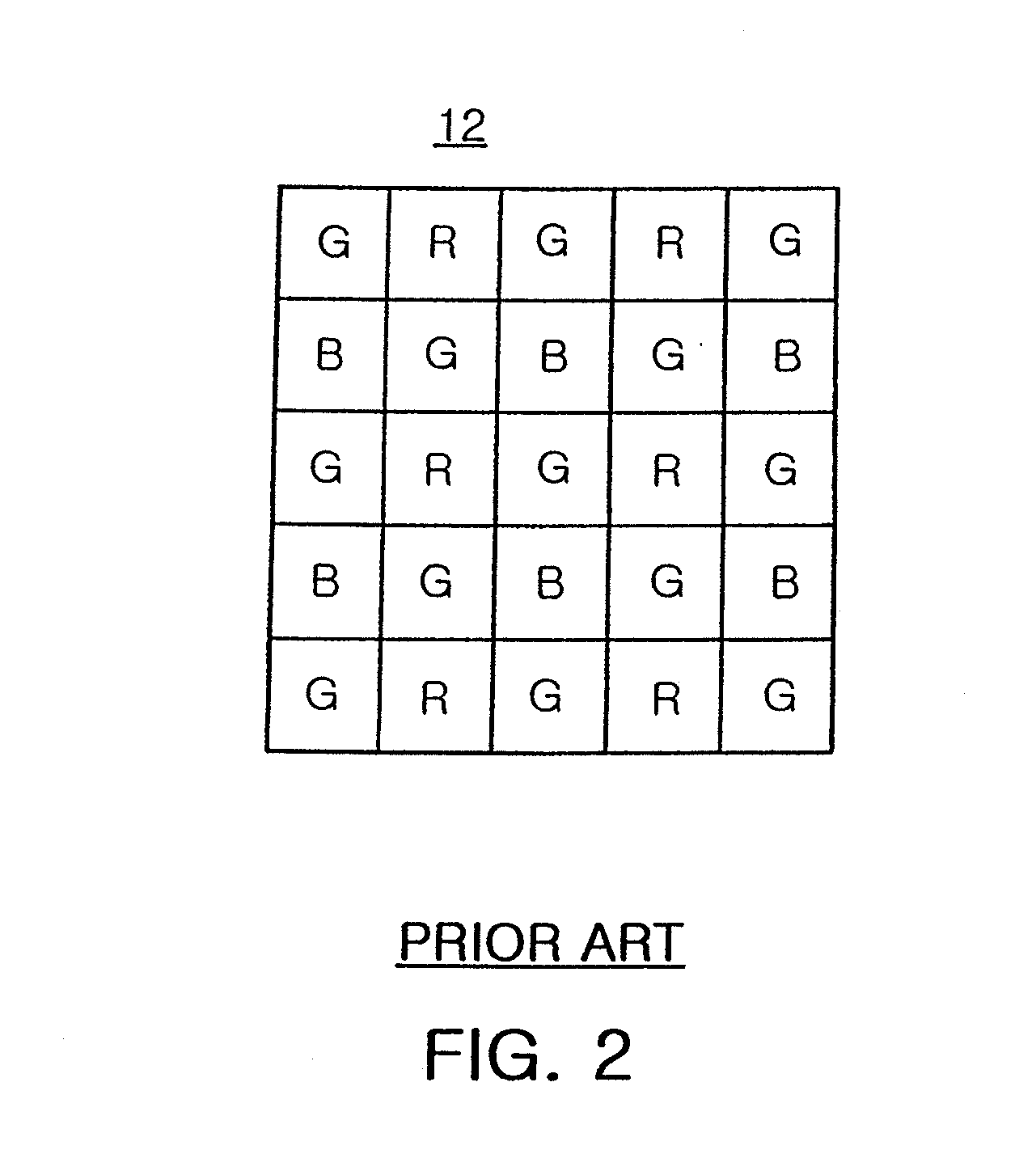

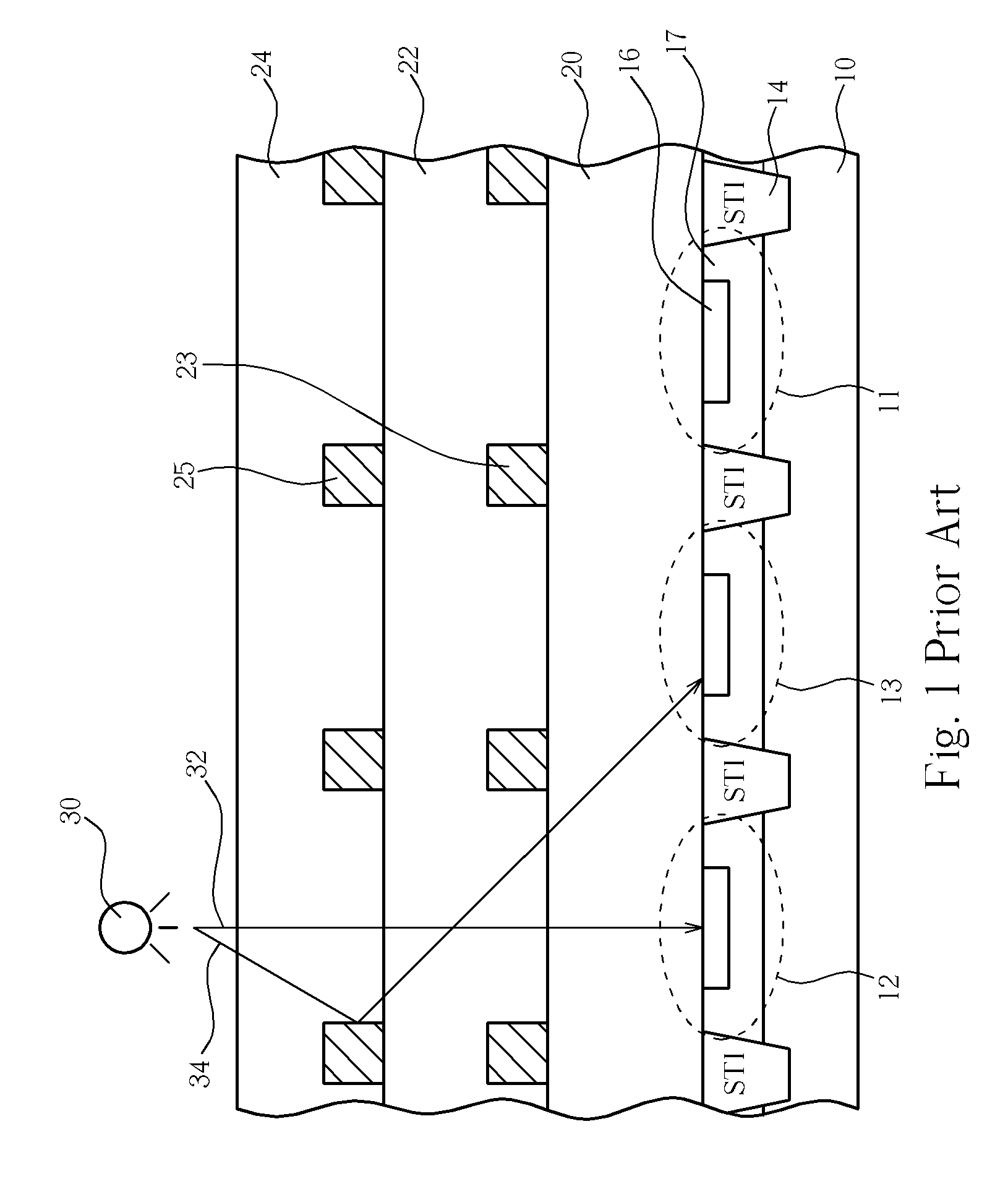

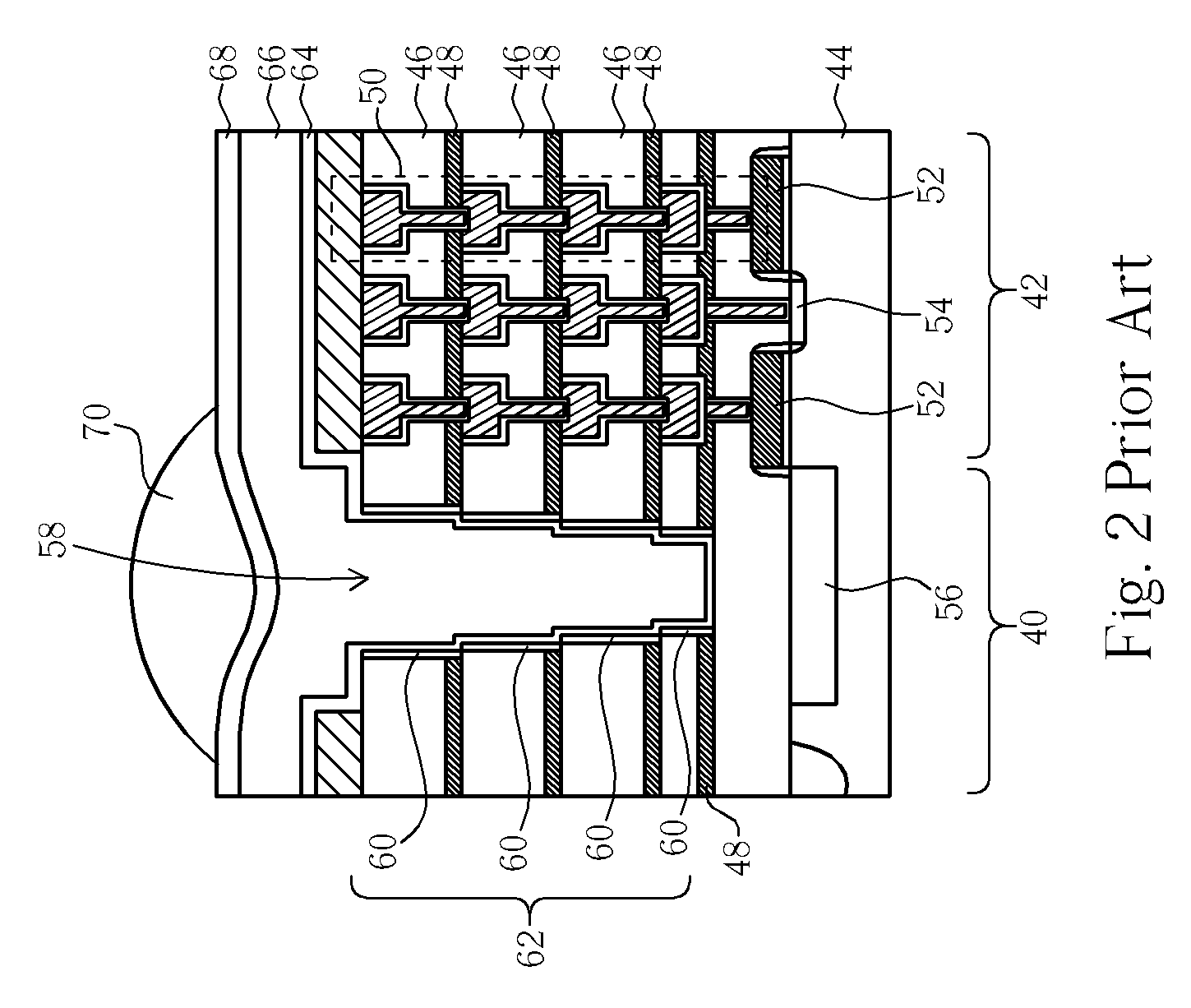

Image sensor for semiconductor light-sensing device and image processing apparatus using the same

InactiveUS20060266921A1Minimize impactAccurate interpolationTransistorRadiation pyrometrySensor arrayImaging processing

The invention relates to an image sensor and an image processing apparatus using the same having a color filter array with open window cells alternating with single color filter cells. The image sensor includes a lens array containing a plurality of microlenses, a color filter array having a plurality of open window cells and color filter cells, each corresponding to each microlens. The image sensor also includes a protection layer, and a pixel sensor array having a first photosensor sensing a first light passed through each color filter cell, a second photosensor formed under the first photosensor, sensing a second light passed through each color filter cell, a third photosensor sensing a third light passed through each open window cell, and a fourth photosensor formed under the third photosensor, sensing a fourth light passed through each open window cell.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

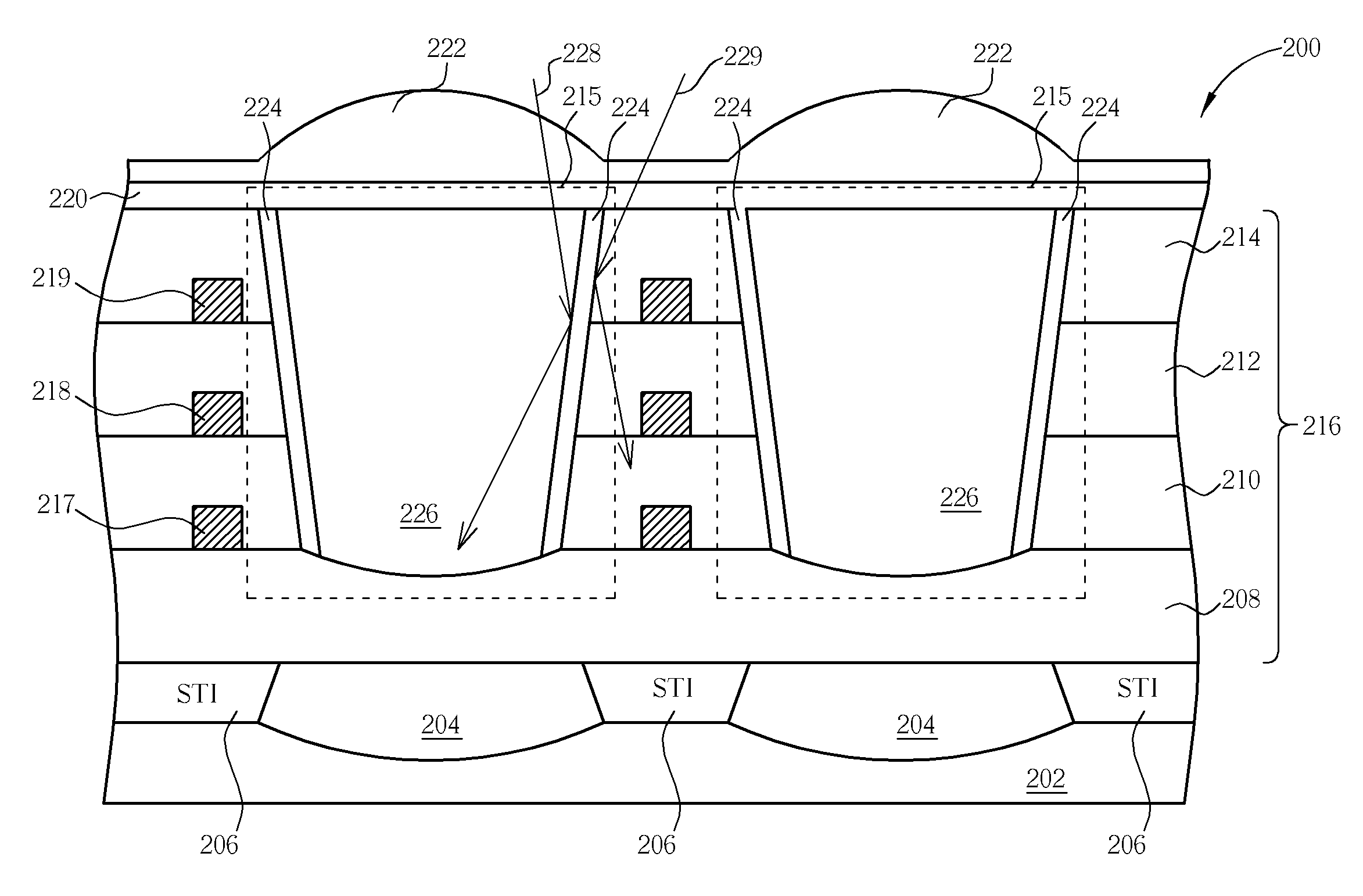

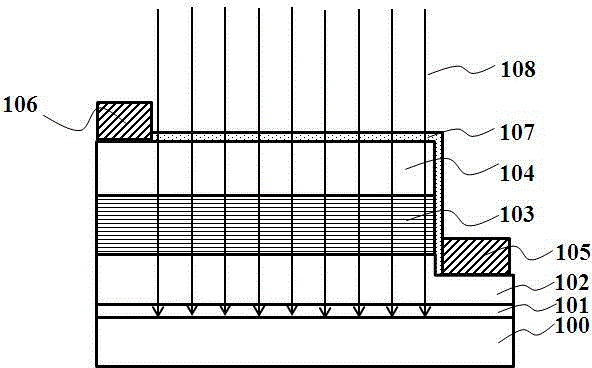

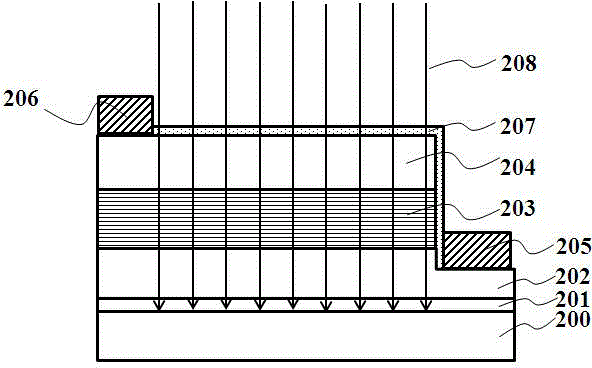

Image sensor with a waveguide tube and a related fabrication method

ActiveUS7524690B2Avoid Crosstalk EffectsHigh sensitivitySolid-state devicesSemiconductor/solid-state device manufacturingWaveguideDielectric layer

An image sensor includes a substrate, at least an optical device, at least a dielectric layer, and at least a wave-guide tube disposed upon the optical device. The wave-guide tube has an optical barrier disposed on a sidewall thereof and a filter layer filled in the wave-guide tube. The structure of the wave-guide tube has the advantages of shortening light path, focusing, and preventing undesirable crosstalk effect between different optical devices.

Owner:UNITED MICROELECTRONICS CORP

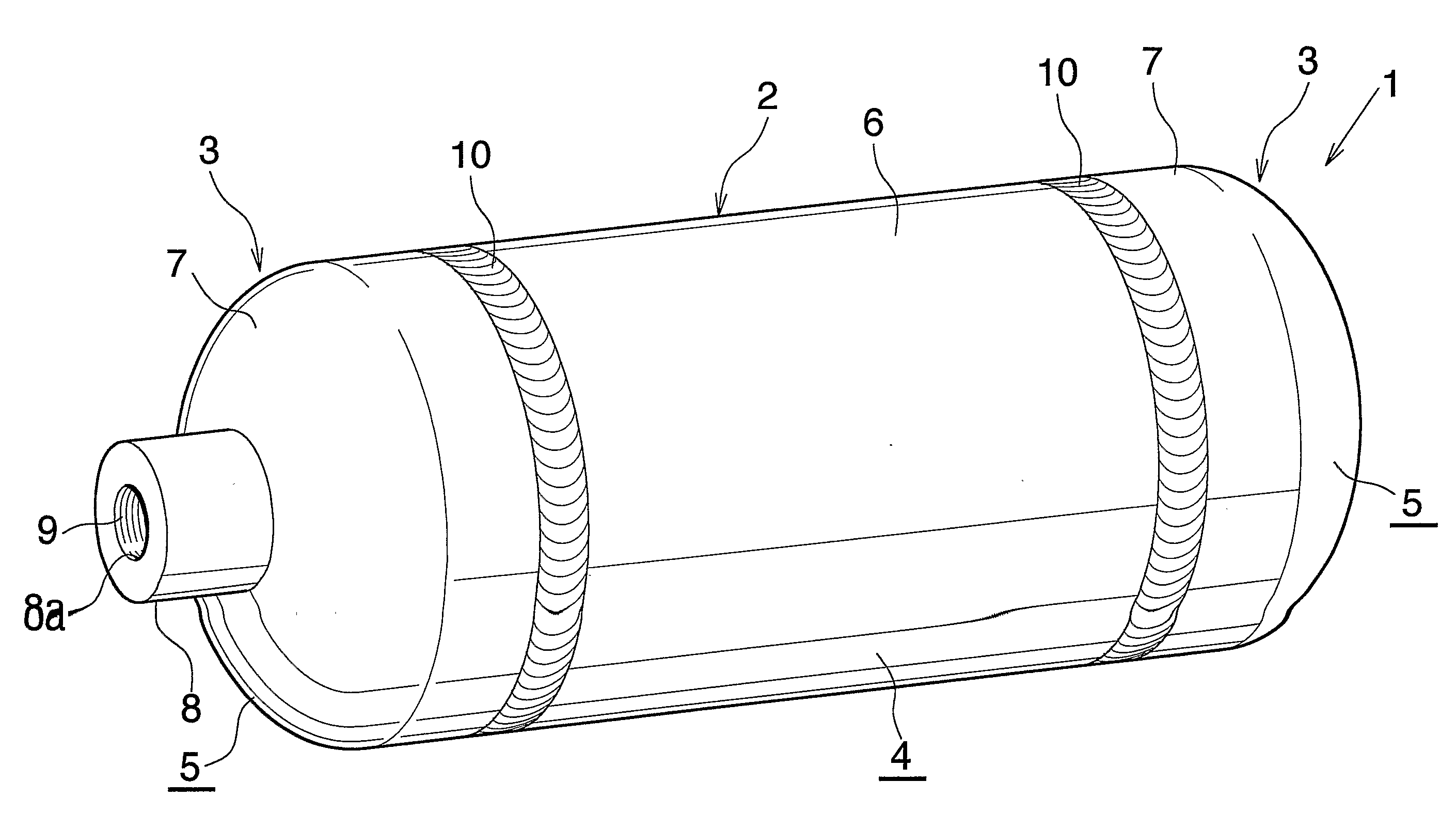

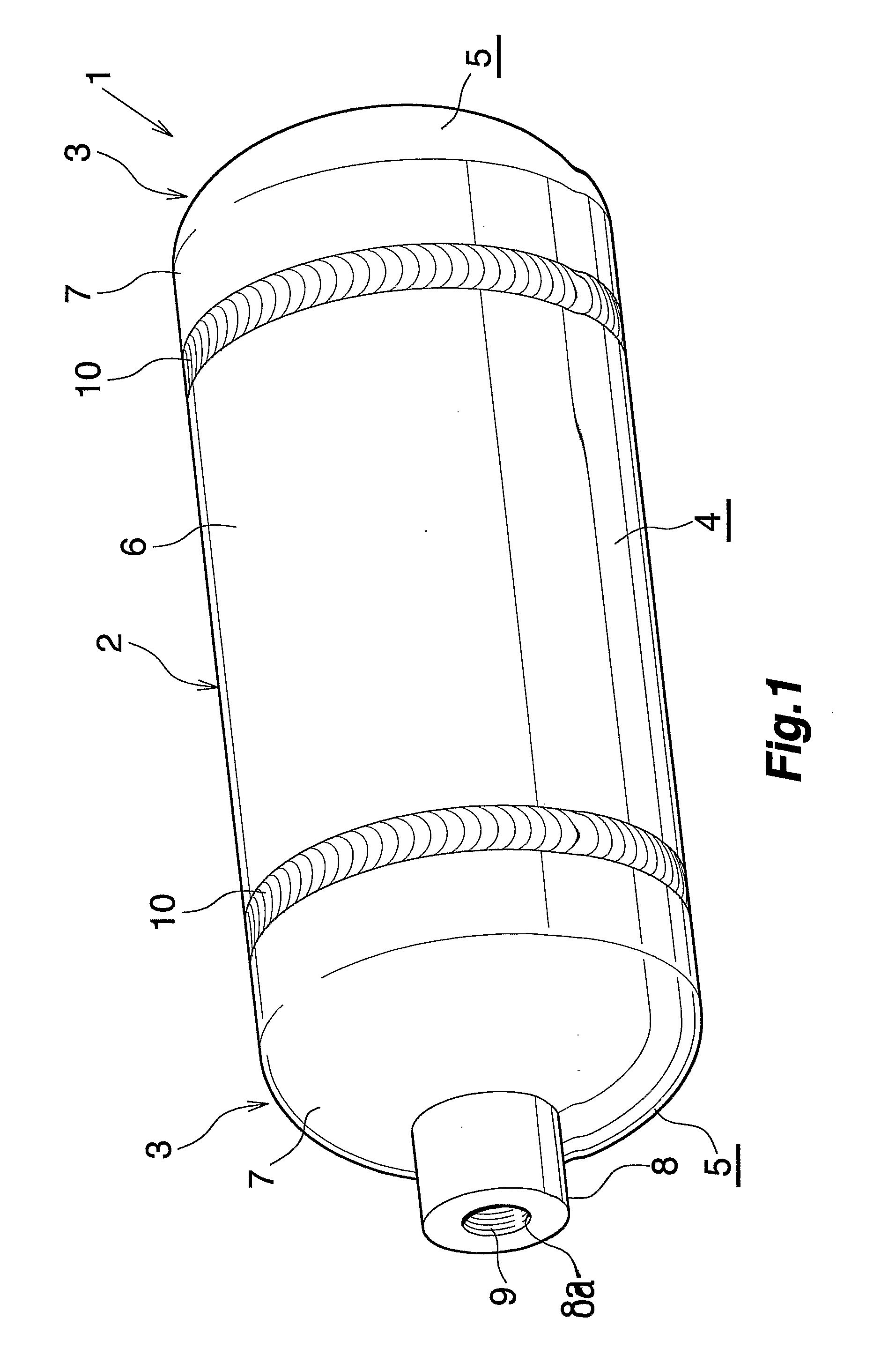

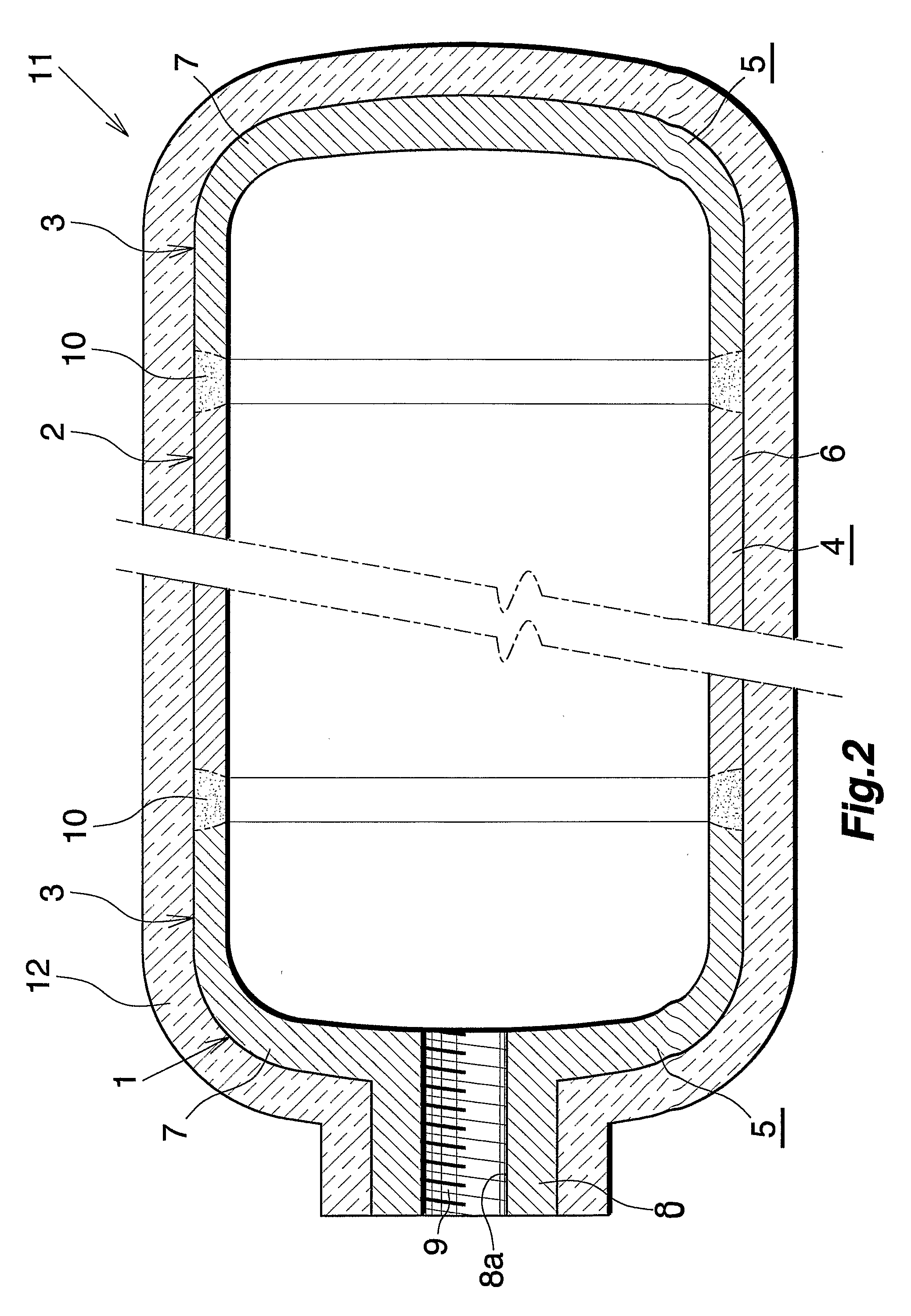

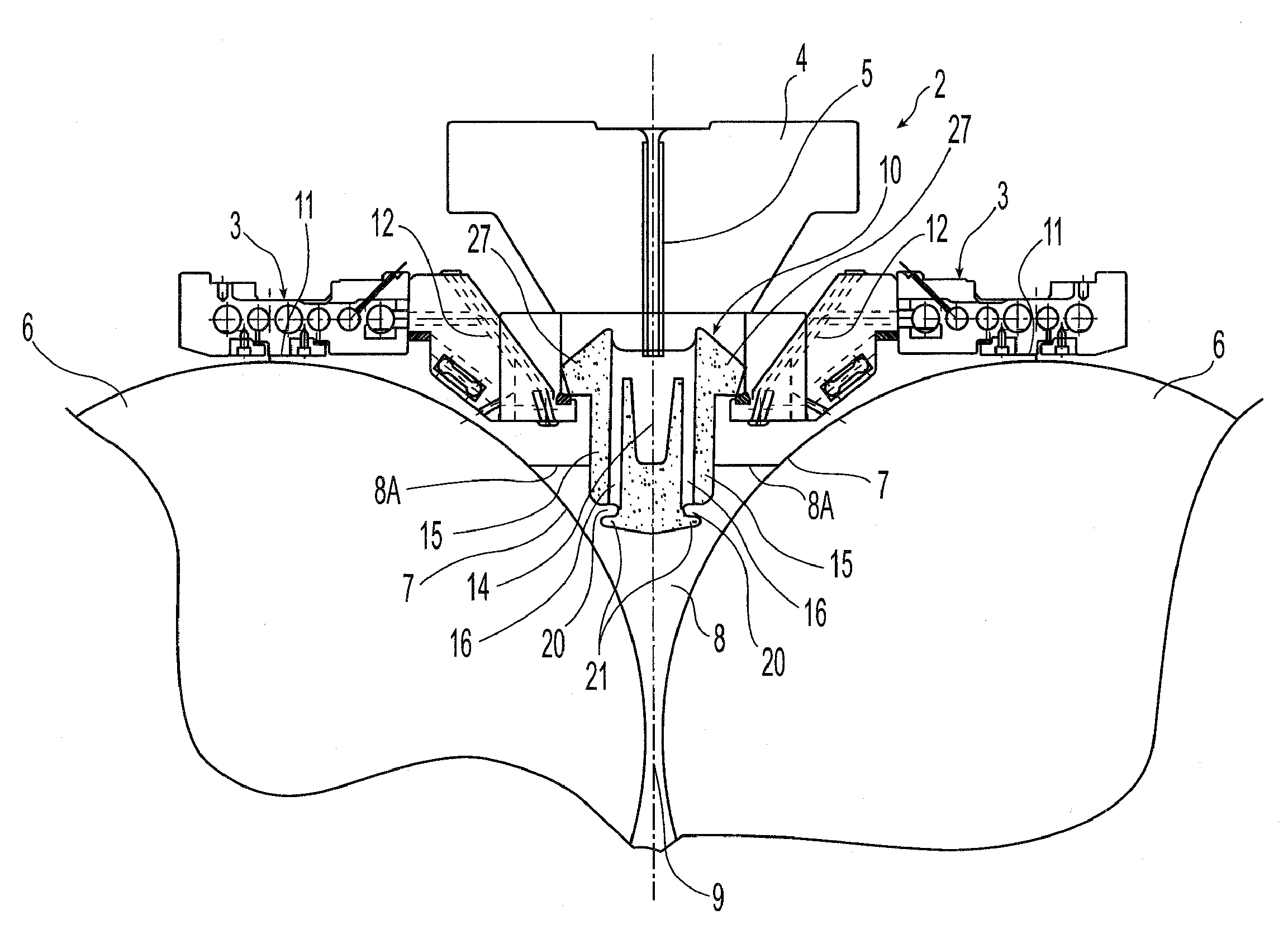

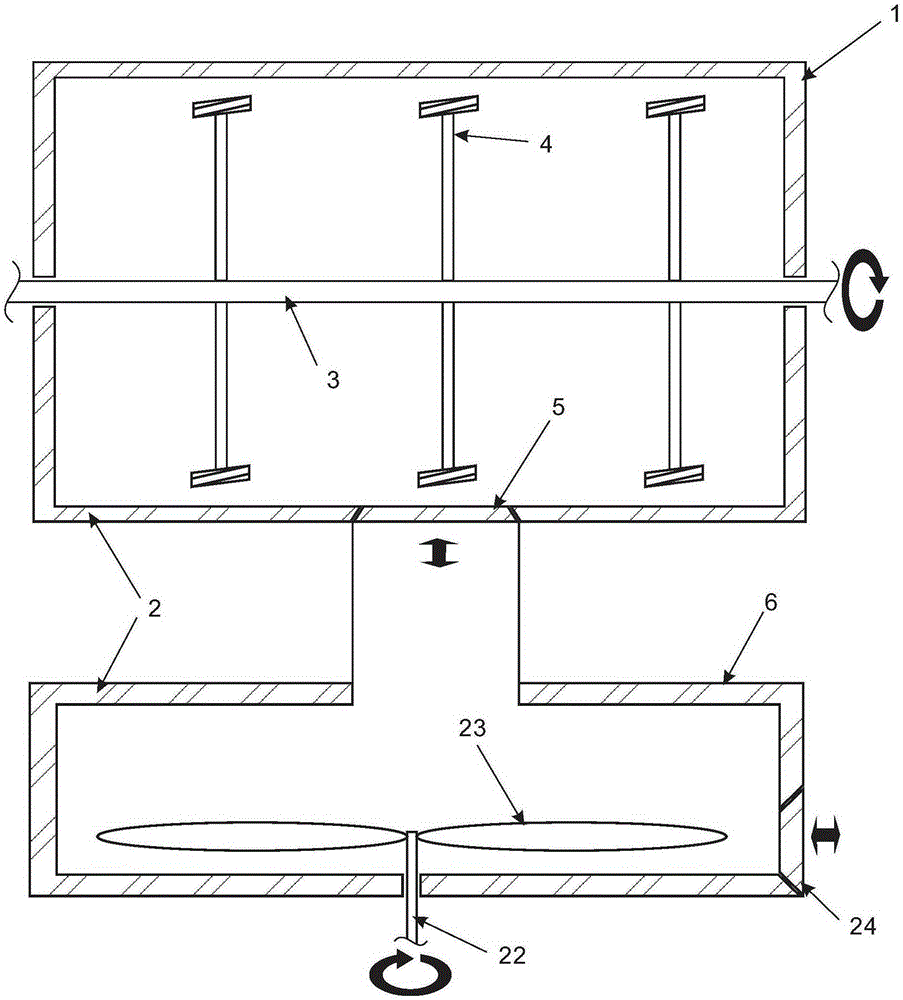

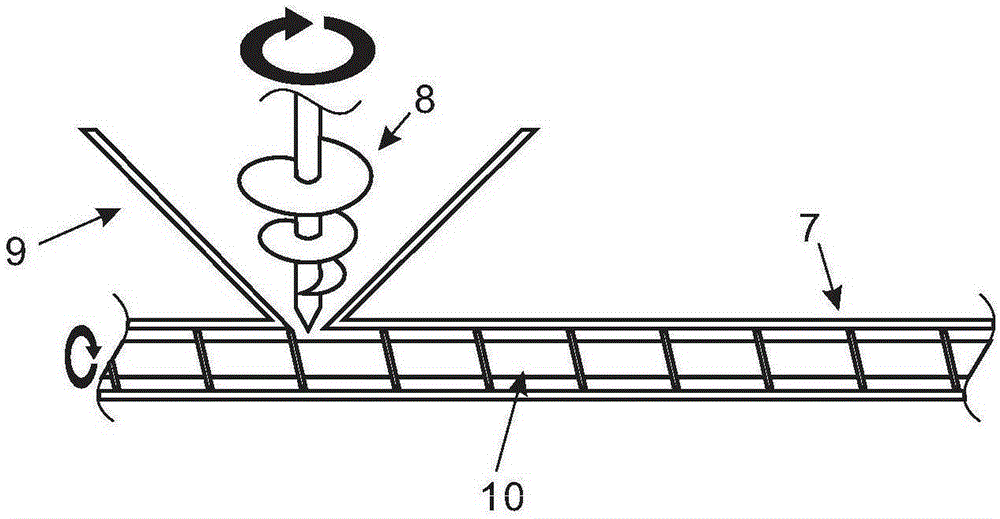

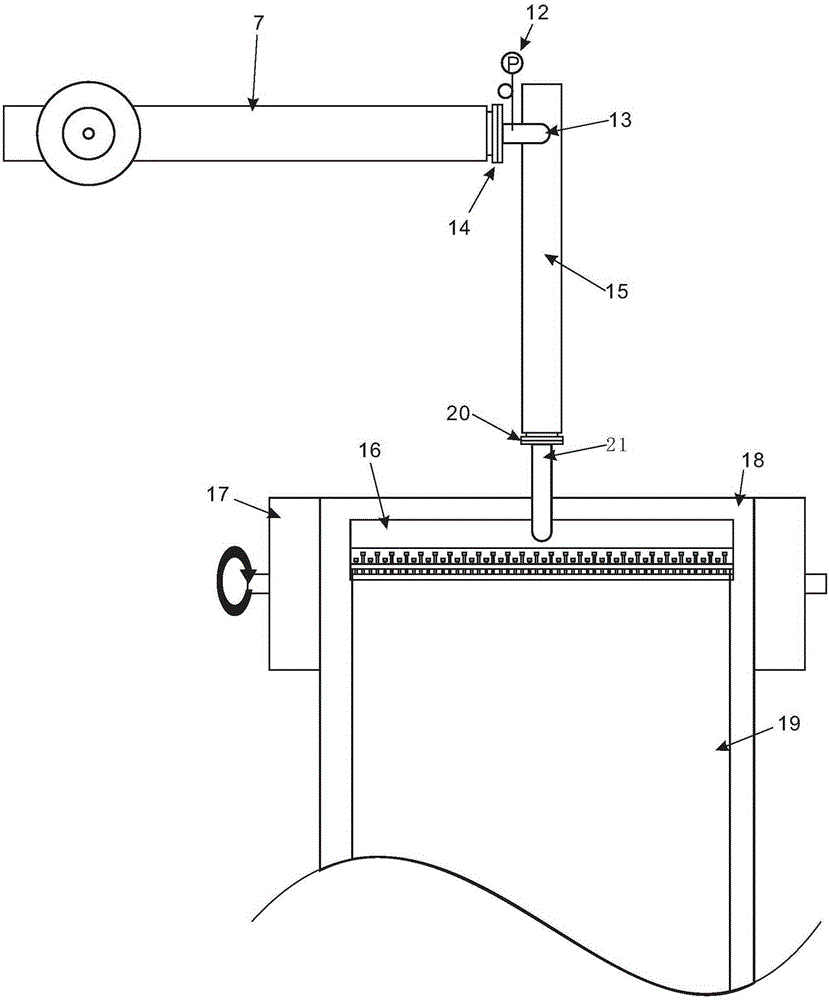

Process for Fabricating Pressure Vessel Liner

InactiveUS20080274383A1Avoid deformationCost of apparatus can be reducedGas handling applicationsFuel cellsProduction rateEngineering

A process prevents a reduction in the strength of the joint between the liner components, and assures high productivity without impairment. The peripheral walls (6, 7) of the liner component (4) and each of the second liner components (5) are brought into contact with each other, a probe (22) of friction agitation joining tool (20) is placed into the two liner components across the contact portions thereof, and the probe (22) in rotation is thereafter moved relative to the two liner components (4, 5). Assuming that the number of revolutions of the probe (22) is R rpm and that the speed of joining of the two liner components (4, 5) is V mm / min, R / V is in the range of 2≦R / V≦12.

Owner:SHOWA DENKO KK

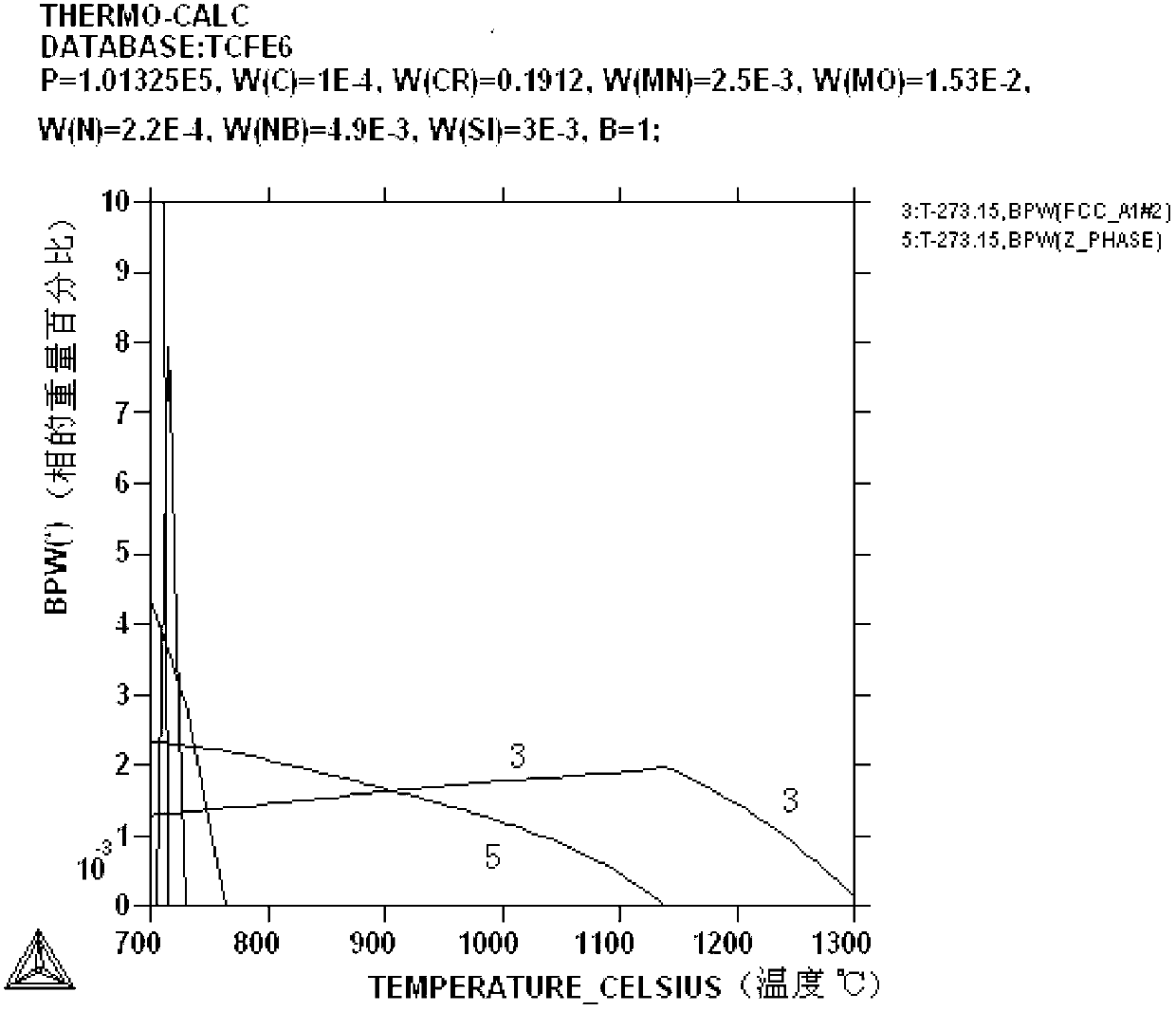

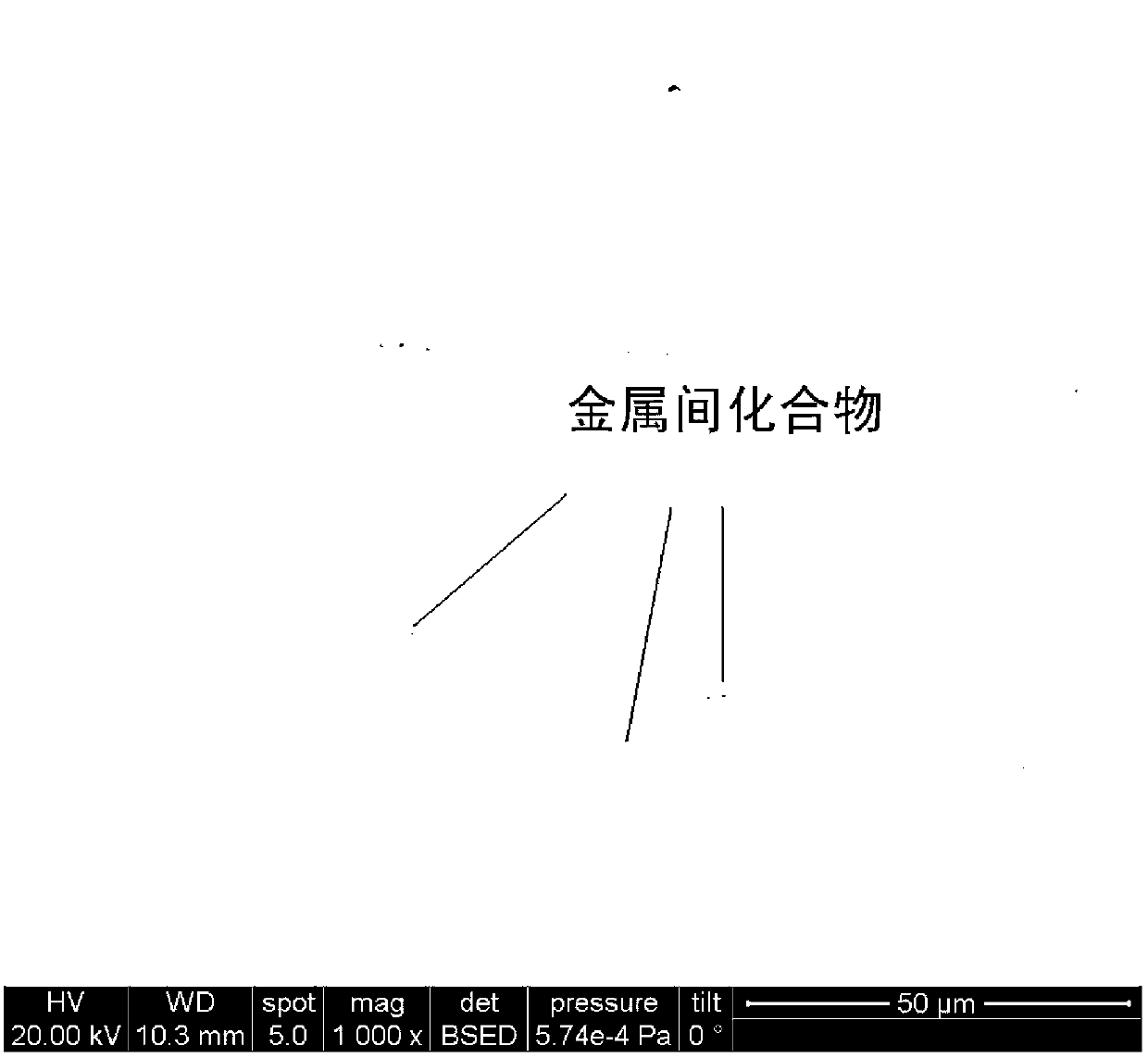

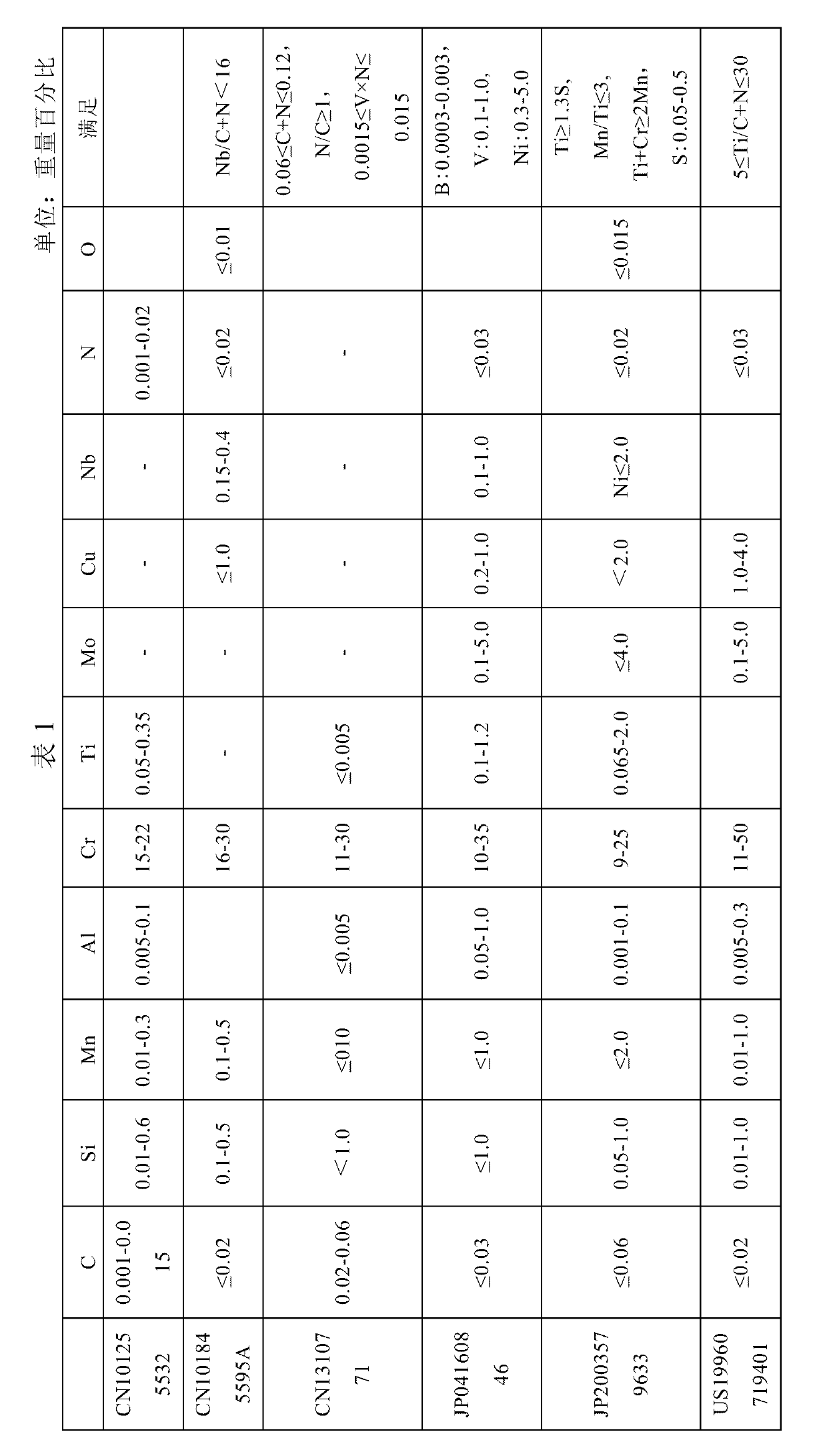

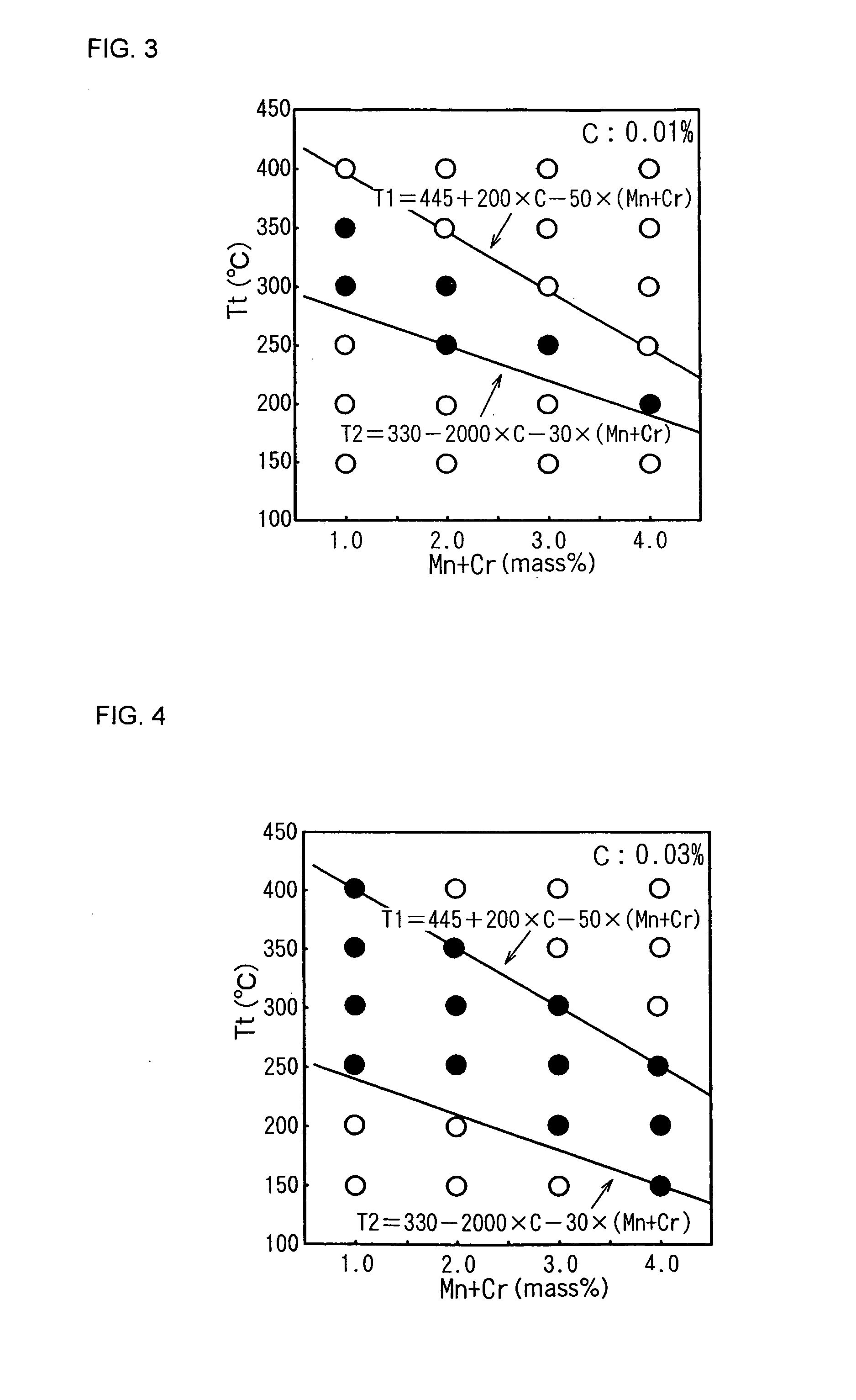

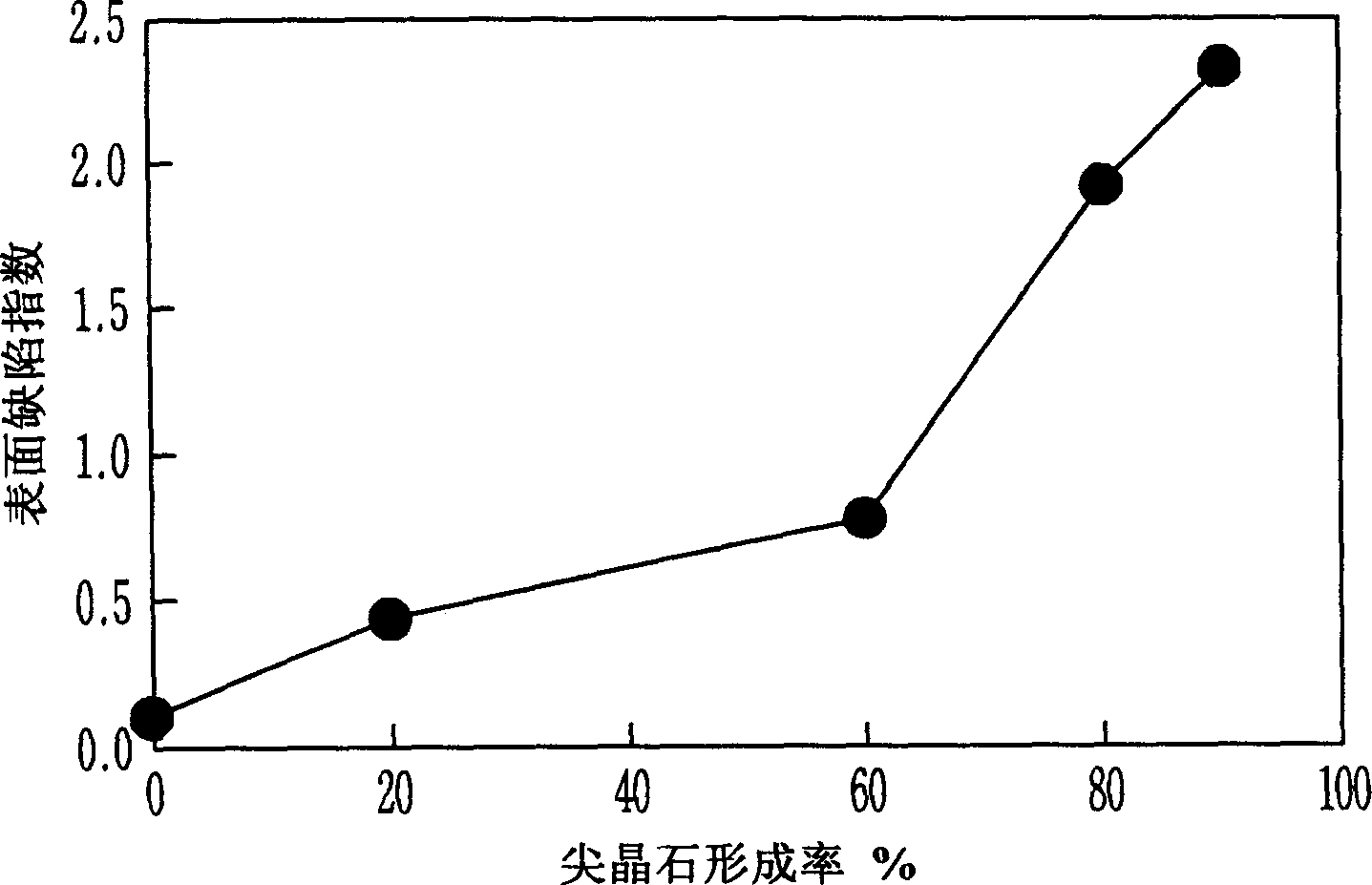

High-surface quality ferrite stainless steel plate and manufacturing method thereof

The invention discloses a high-surface quality ferrite stainless steel plate and a manufacturing method thereof. The high-surface quality ferrite stainless steel plate comprises, by weight, less than or equal to 0.03% of C, 0.20 to 1.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.03% of P, less than or equal to 0.01% of S, 16 to 20% of Cr, 0.75 to 2.0% of Mo, 0.42 to 0.7% of Nb, less than or equal to 0.03% of N, less than or equal to 0.005% of Al, less than or equal to 0.005% of O and the balance Fe and unavoidable impurities, wherein based on Nb content, C content and N content respectively represented by Nb, C and N, Nb-20*C-7*N is greater than or equal to 0.15% and less than or equal to 0.7% and 1.2*C+N is less than or equal to 0.04%. Through smelting, hot rolling, two-rolling process cold rolling, bright annealing and flattening, the high-surface quality ferrite stainless steel plate which is a high-glossiness high-brightness low-roughness high-surface quality mirror material is obtained, has excellent corrosion resistance, cold deformation wrinkling resistance, high yield strength and high surface hardness and is suitable for automobile outer-decoration bright strips (pieces) and furniture decoration bright strips having high surface quality requirements.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

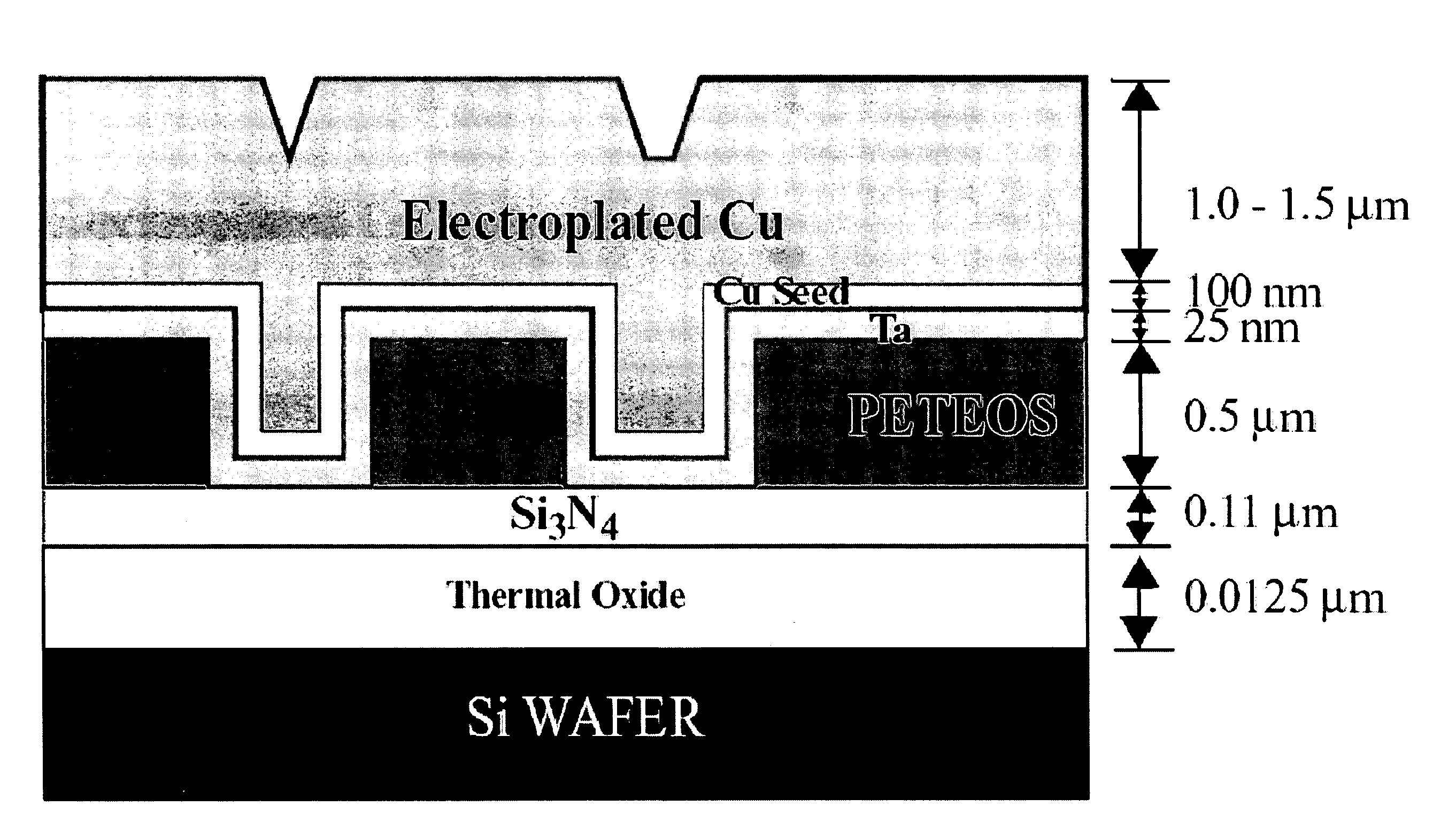

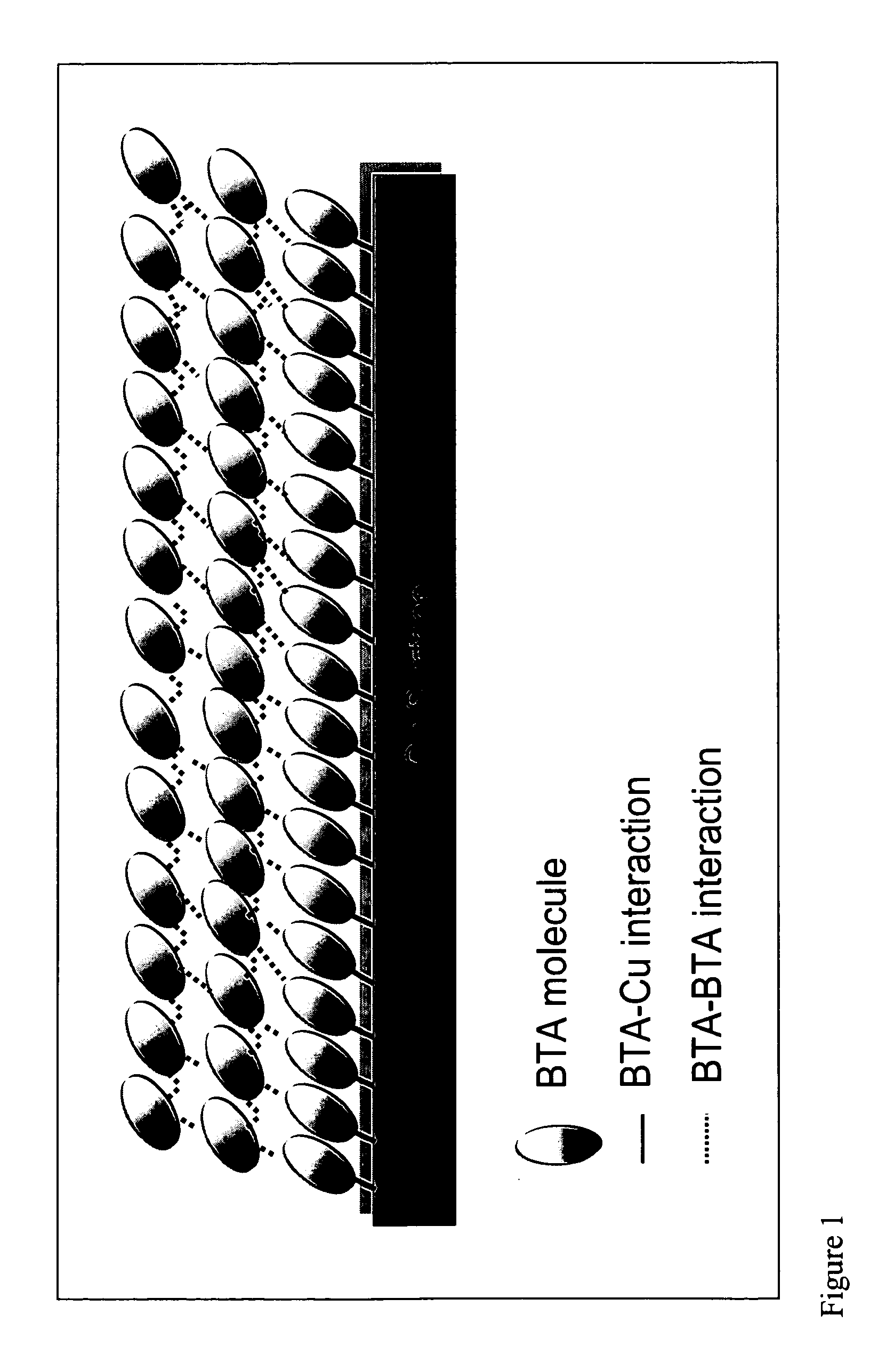

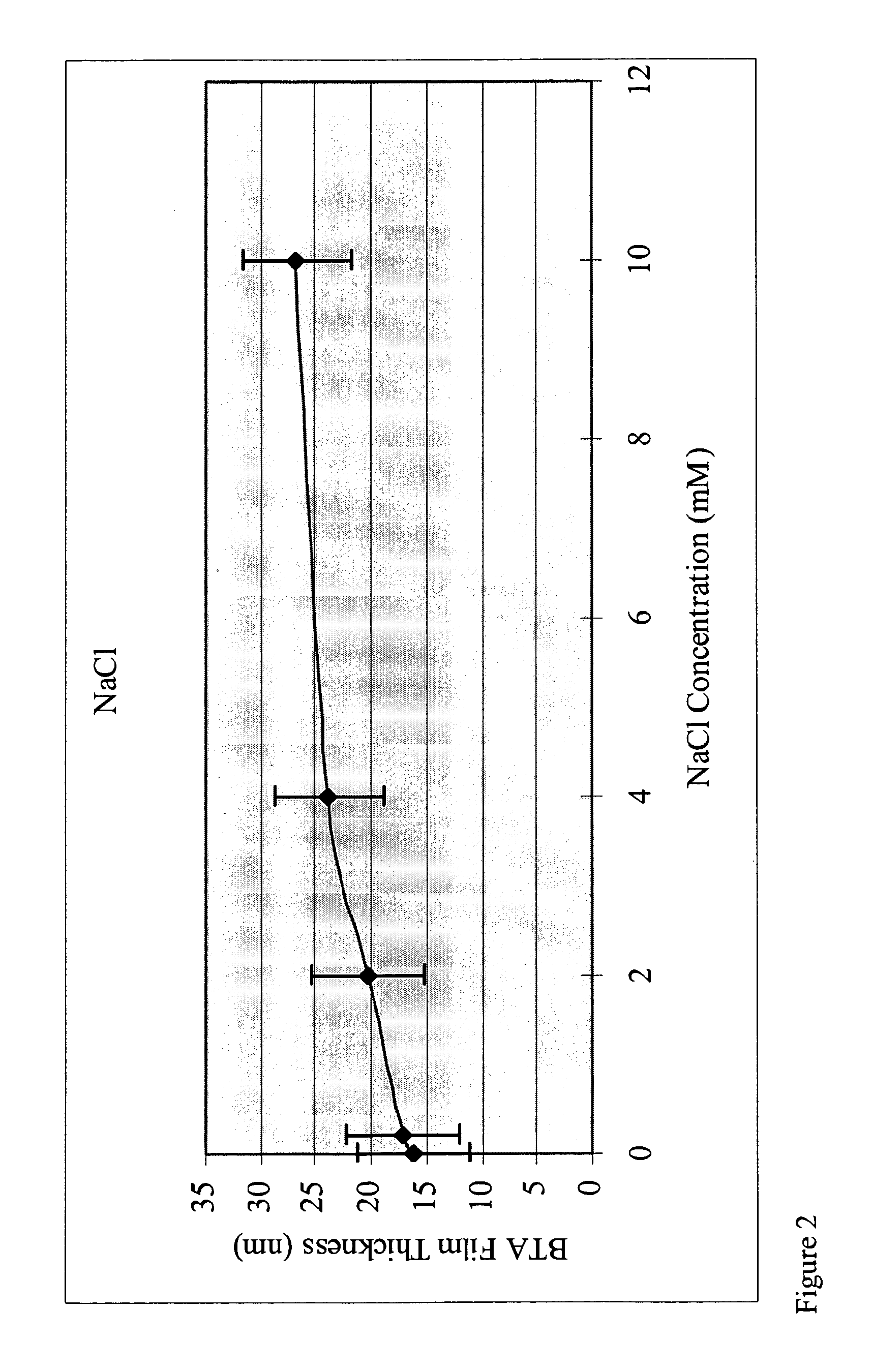

Controlling passivating film properties using colloidal particles, polyelectrolytes, and ionic additives for copper chemical mechanical planarization

InactiveUS20100178768A1Increase static etch rateLower static etch ratePigmenting treatmentOther chemical processesSlurryCopper

The present invention provides for a copper CMP slurry composition which comprises a complexing agent, an oxidizer, an abrasive and a passivating agent. The present invention also provides for a method of chemical mechanical planarization of a copper conductive structure which comprises administering the copper CMP slurry composition during the planarization process.

Owner:BASF AG

Lubricating oil composition for wide steel strip hot continuous mill rolling process

A lubricating oil composition for hot tandem rolling of wide steel band contains a component (d) composed of a surface layer which is dialkylbithiophosphoric acid or monocarboxy fatty acid, and a kernel which is the nano TiO2 particle. Its advantages are excellent lubricating performance, high resistance to emulsifying, and no deposition and demixing.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation method for photoelectric device

ActiveCN104638070AReduce pollutionAvoid surface defectsFinal product manufactureSemiconductor devicesUltraviolet lightsEngineering

The invention discloses a preparation method for a photoelectric device. The preparation method comprises the following steps: performing UVLED (ultraviolet light-emitting diode) processing on a substrate after loading the substrate into a reaction chamber and before growing an epitaxial layer, thereby effectively reducing surface organic or / and inorganic substance pollution caused by processes of putting the substrate into a slide glass plate and loading the substrate into the reaction chamber, enabling the surface to be clean before growing the epitaxial layer and avoiding surface defects after growing the epitaxial layer; growing N-type, active and P-type epitaxial layers on the substrate subjected to the UVLED processing and performing UVLED processing in each epitaxial layer growing process, thereby effectively reducing point defects in each of doped or non-doped AlInGaN, AlGaInP, AlGaInAs multi-element epitaxial layers, improving the crystal quality and breaking Mg-H passivated bonds of the P-type layer. Therefore, free carrier concentration and migration rate of the N-type and P-type layers can be effectively increased, the active region efficiency is improved, and the performances of the photoelectric device is improved. The preparation method is suitable for a semiconductor photoelectric device.

Owner:TIANJIN SANAN OPTOELECTRONICS

Method for metal parts surface defects restoring and antiseptic treatment

ActiveCN101113508AAvoid surface defectsSimple processing technologyMolten spray coatingSlagDefect repair

The invention relates to a surface defects repairing and anti-corrosion treatment method for metal parts, which is characterized in that: the method is carried out according to the steps of: the sorting of coming material sorting and the finding of the defect places; cleaning and pretreatment, i.e. the surfaces of the workpieces are cleaned and shielded and defect places are only exposed; repair and anti-corrosion treatment of the surface defects by combining method of a first peening, coating and a second peening.. The surface defects repairing and anti-corrosion treatment method for metal parts of the invention solves the surface defects for casting and forging processing parts, such as the surface defects of car wheel hub and large motorcycle wheel hub, for example, the repairing of slag hole, pin hole, scratching, eroded point, shrinkage porosity and external damage, and the repairing for the abrasion of copper shaft and copper roofing; the invention can also be widely applied to the anti-corrosion treatment for the surfaces of iron and steel processing parts, gas storage tanks, boiler parts. The invention has the advantages of simple processing technology, low expenses, short time consumption and excellent performance and quality.

Owner:海城三鱼泵业有限公司

Silicone stabilizers for rigid polyurethane or polyisocyanurate foams

ActiveCN102604106AAvoid surface defectsDomestic cooling apparatusLighting and heating apparatusPolymer sciencePolyisocyanurate

The invention provides partially endcapped polyether siloxanes, the use of these polyether siloxanes as foam stabilizers and also rigid polyurethane or polyisocyanurate foams obtained using the polyether siloxanes.

Owner:EVONIK OPERATIONS GMBH

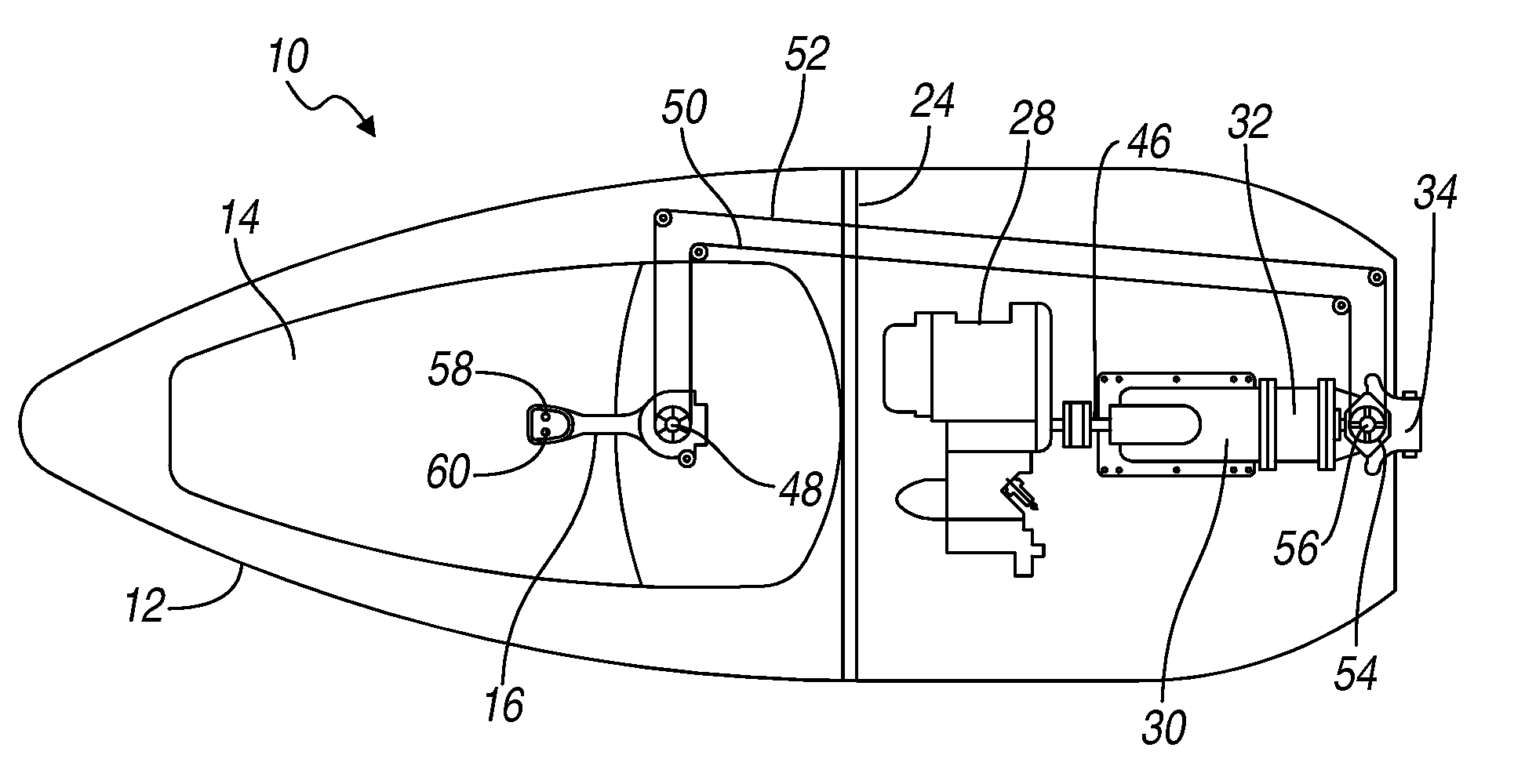

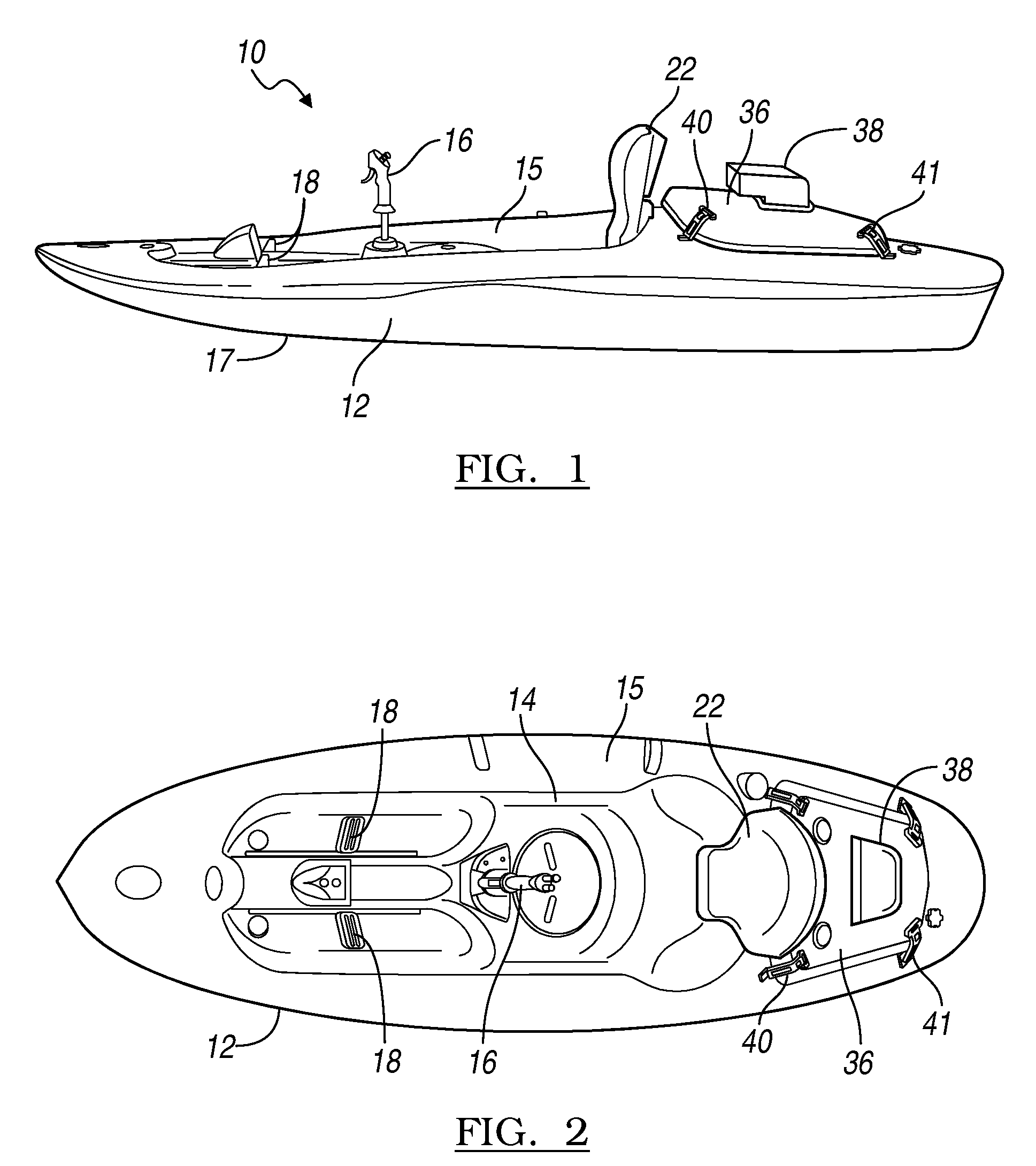

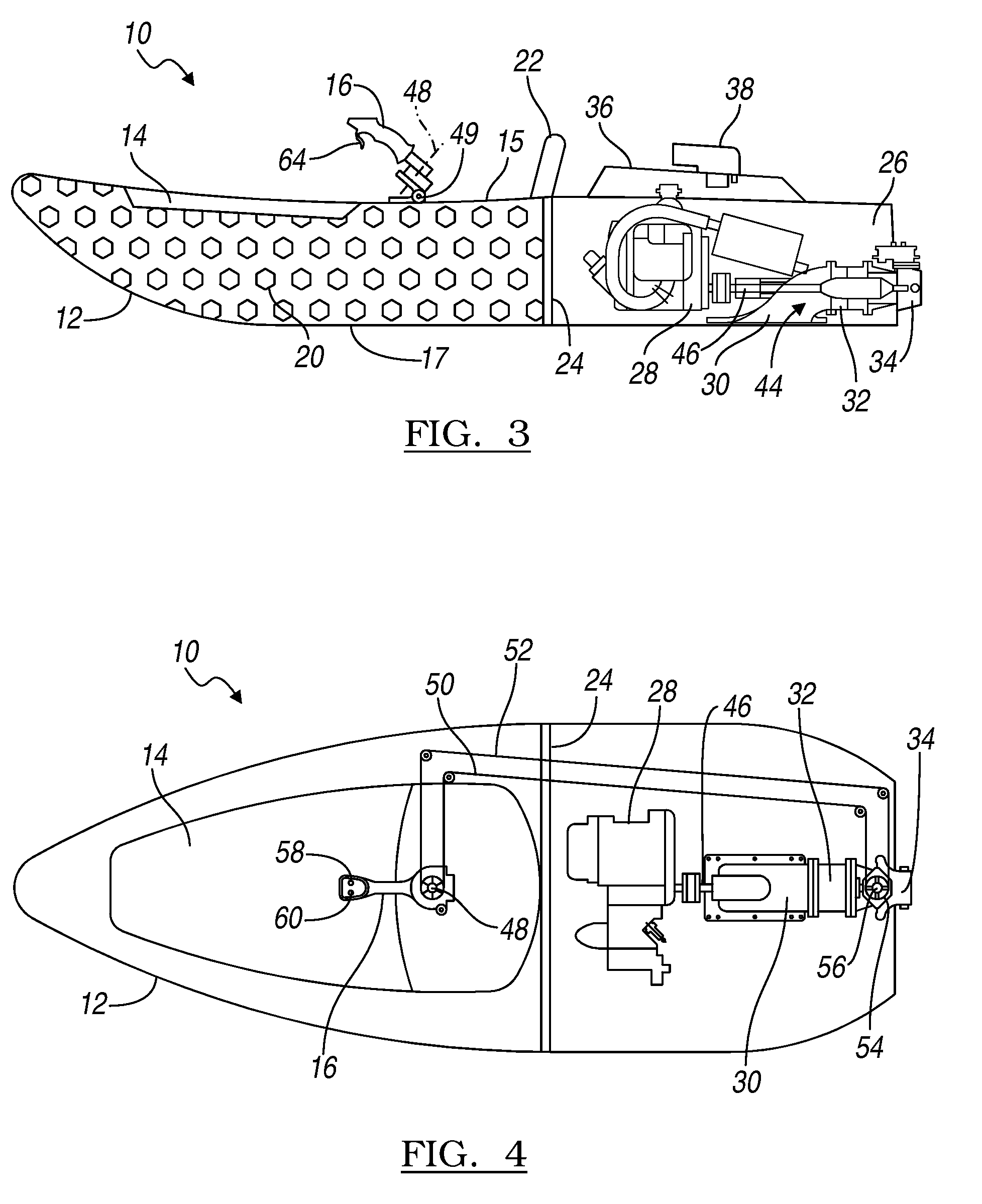

Watercraft Propelled By a Water Jet

InactiveUS20090093174A1Easy to restartAvoid surface defectsWater sport boardsPropulsive elementsThrottle controlImpeller

A watercraft propelled by a water jet includes an sealed hull portion including an upper deck and a bottom surface, an engine compartment located behind the sealed hull portion and containing a propulsion and steering system including an engine, a bladed impeller driven by the engine for inducting water and forcing the inducted water away from the craft through a directionally displaceable nozzle, and a control lever located on the upper deck including an engine throttle control and a steering control for adjusting the directionally displacement of the nozzle.

Owner:SURFANGO

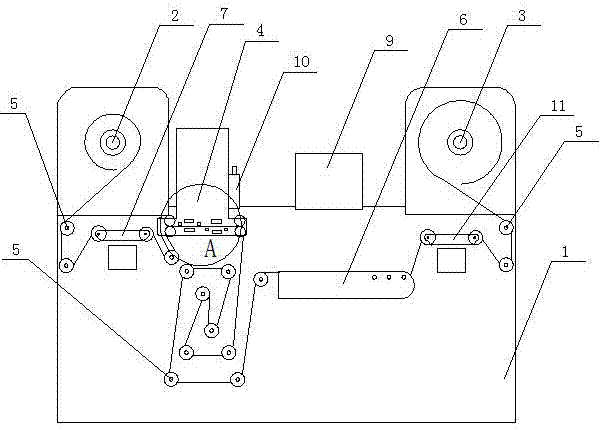

Light source arrangement method for RFID (radio frequency identification) tag automatic optical detection

InactiveCN106885810ADo visual inspectionAvoid defectsOptically investigating flaws/contaminationDisplay deviceEngineering

The invention relates to a light source arrangement method for RFID (radio frequency identification) tag automatic optical detection. The method comprises a machine frame, wherein the machine frame is provided with an unreeling roll, a reeling roll, a visual detection device, a plurality of delivery wheels, a display device and an ink-jet printer, wherein one end of an RFID tag tape formed by bonding a plurality of RFID tags to a release paper tape is wound on the unreeling roll, and the other end penetrates through the visual detection device sequentially via the delivery wheels and is wound on the reeling roll; the visual detection device comprises a first detection device and a second detection device which are arranged horizontally at an interval; the first detection device comprises a front camera, a first left reflected light source, a first right reflected light source and a first transmitted light source; the second detection device comprises a back camera, a second left reflected light source, a second right reflected light source and a second transmitted light source; and the front camera and back camera are respectively connected with the display device through signal wires. The method is advanced and scientific; and the detection combination of the front and back sets and the visual solution of reflected light-transmitted light composite mode are utilized to effectively detect various types of defects in various materials.

Owner:ARIZON RFID TECH YANGZHOU

Titanium alloy blade forging method

ActiveCN103722108AAvoid surface defectsConducive to forging formingHeating/cooling devicesTitanium alloyTechnical design

The invention belongs to the technical field of titanium alloy blade forging and discloses a titanium alloy blade forging method. The titanium alloy blade forging method includes the following steps that the machining allowance of a corresponding forged piece is determined according to part drawings and technical design parameters of a titanium alloy blade; a corresponding hot forging drawing is designed. The twist angle of the titanium alloy blade is determined according to the hot forging drawing and the following formula of theta=(alpha1+alpha2) / 2, wherein the alpha1 is the included angle between a profile chord length line of a tip of the titanium alloy blade and the chord direction of the titanium alloy blade, and the alpha2 is the included angle between the profile chord length line of a root of the titanium alloy blade and the chord direction of the titanium alloy blade. A finish forging die is made according to the hot forging drawing and the twist angle of the titanium alloy blade. A forged-piece rough profile is designed according to the hot forging drawing, and a tire mold is made according to the size and shape of the designed forged-piece rough profile. A blank is subjected to on-hammer rough profile forging through a free forging hammer to form the forged-piece rough profile; then, the forged-piece rough profile is subjected to on-hammer die forging through the finish forging die.

Owner:SHAANXI HONGYUAN AVIATION FORGING

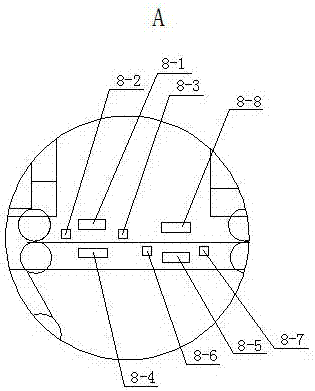

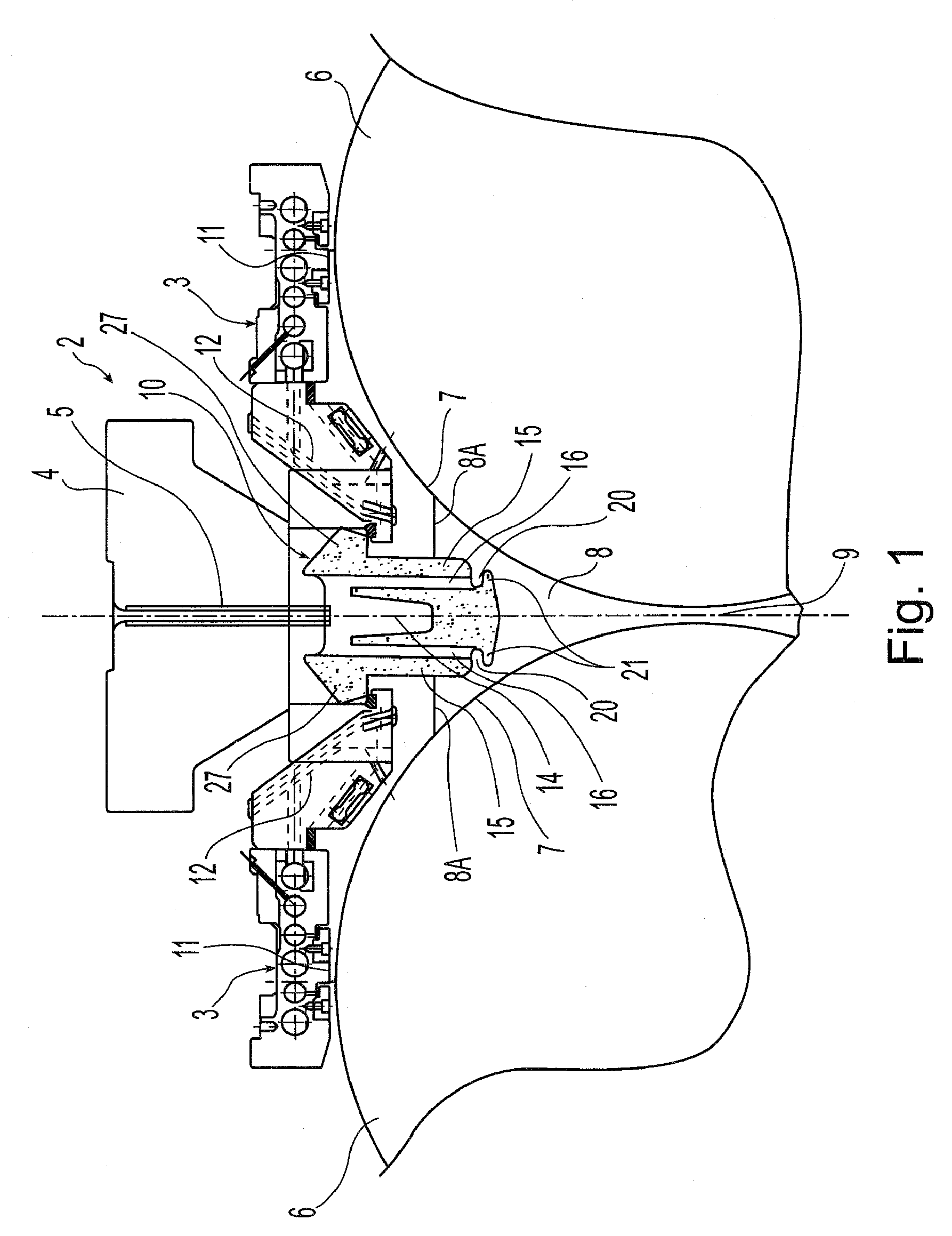

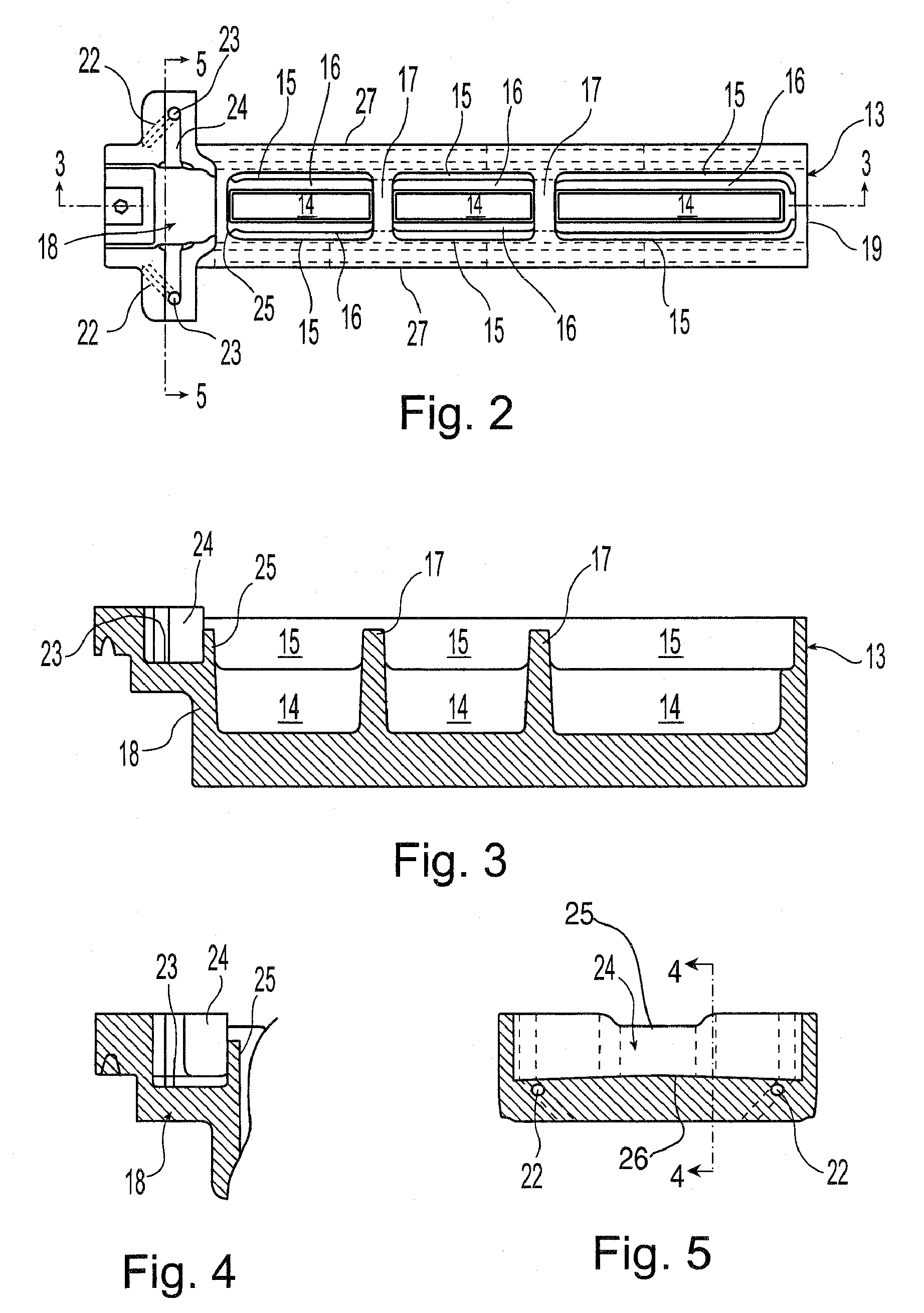

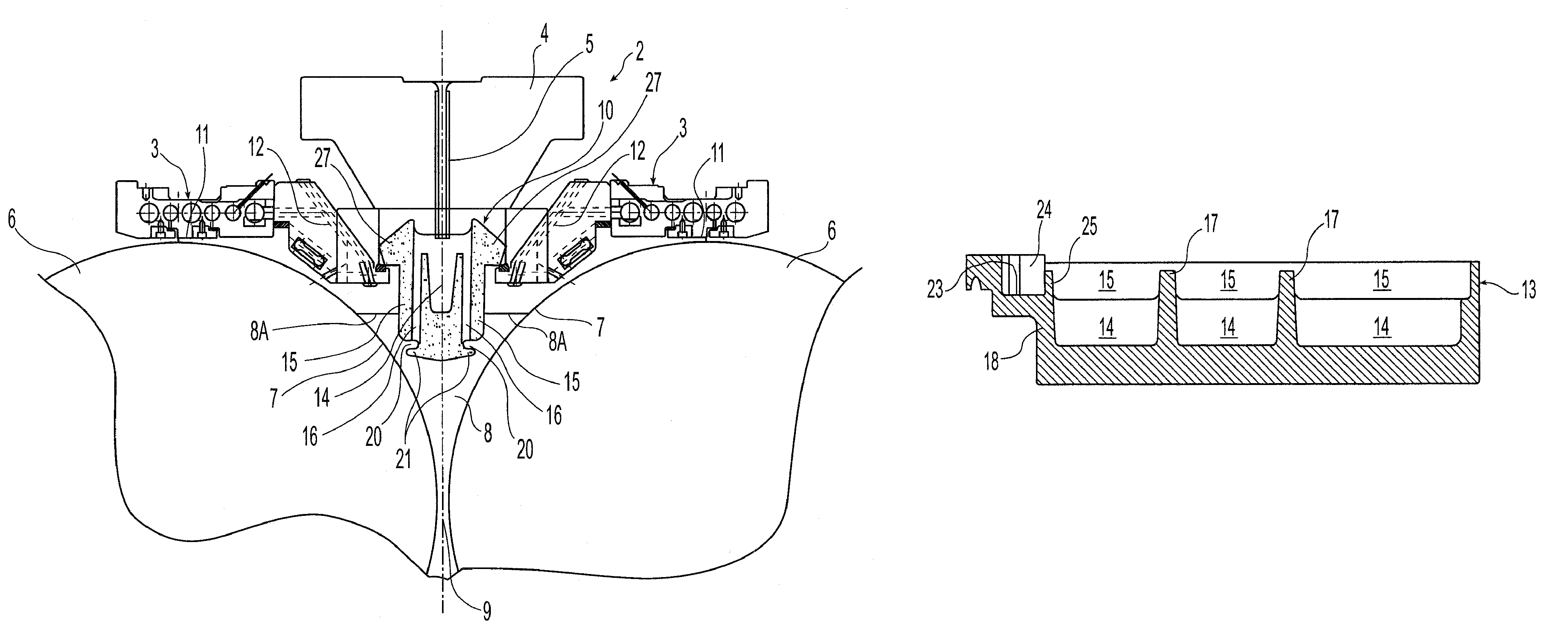

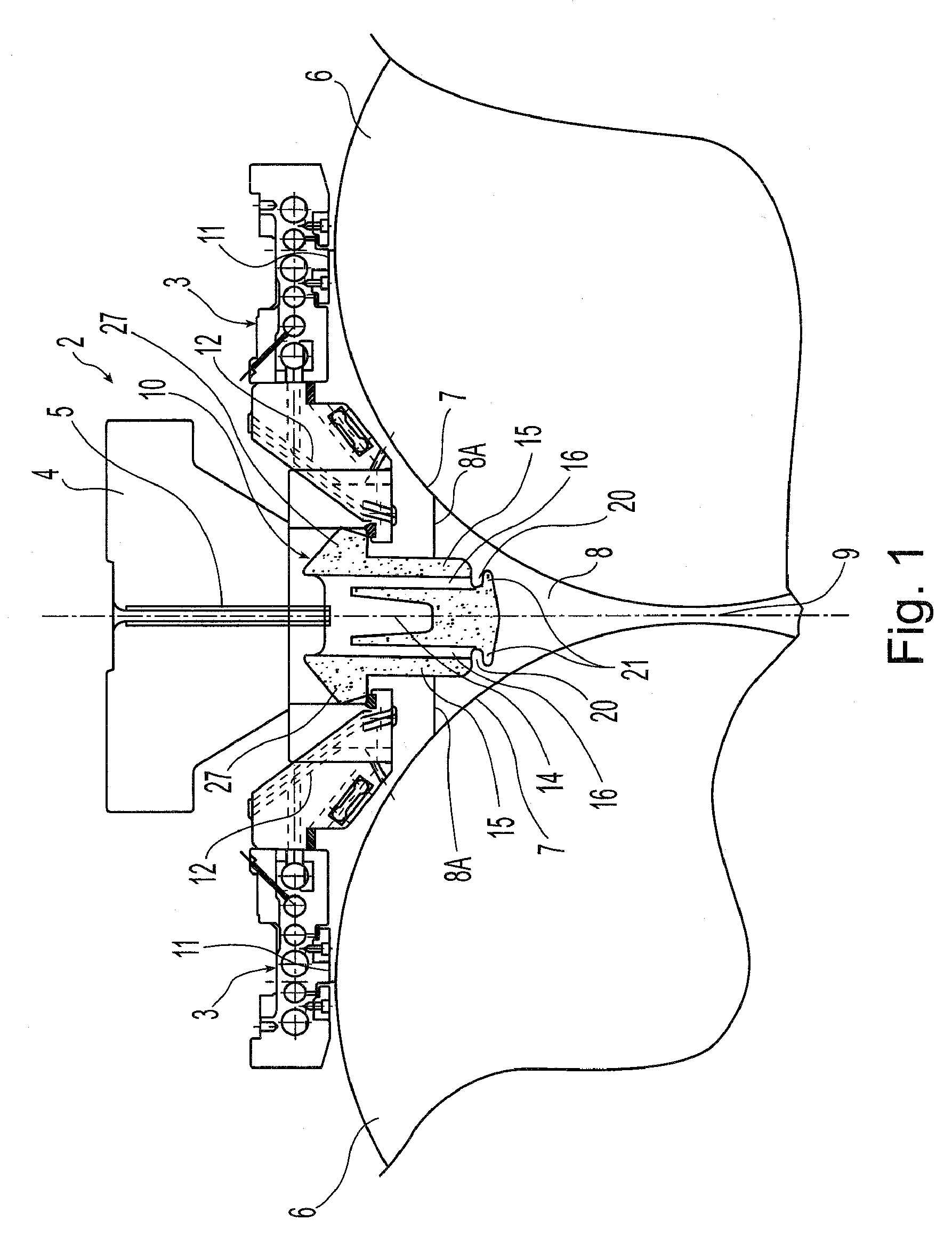

Delivery nozzle with more uniform flow and method of continuous casting by use thereof

InactiveUS20080173424A1Reduce kinetic energyLarge partMelt-holding vesselsBlast furnace componentsEngineeringMolten metal

A method of and apparatus for casting metal strip involving assembling a pair of casting rolls laterally disposed to form a nip between them, assembling an elongated metal delivery nozzle extending along and above the nip between the casting rolls, with at least one segment having opposing side walls and end walls, an inner trough extending longitudinally within between side walls and forming passages between the side walls and the inner trough and communicating with side outlets adjacent bottom portions, introducing molten metal through the elongate metal delivery nozzle to form a casting pool of molten metal supported on the casting rolls above the nip, such that molten metal is caused to flow into the inner trough of the delivery nozzle, from the inner trough through the passages between the inner trough and sidewalls, and from the passages through the side outlets in a substantially lateral direction into the casting pool, and counter rotating the casting rolls to deliver cast strip downwardly from the nip.

Owner:NUCOR CORP

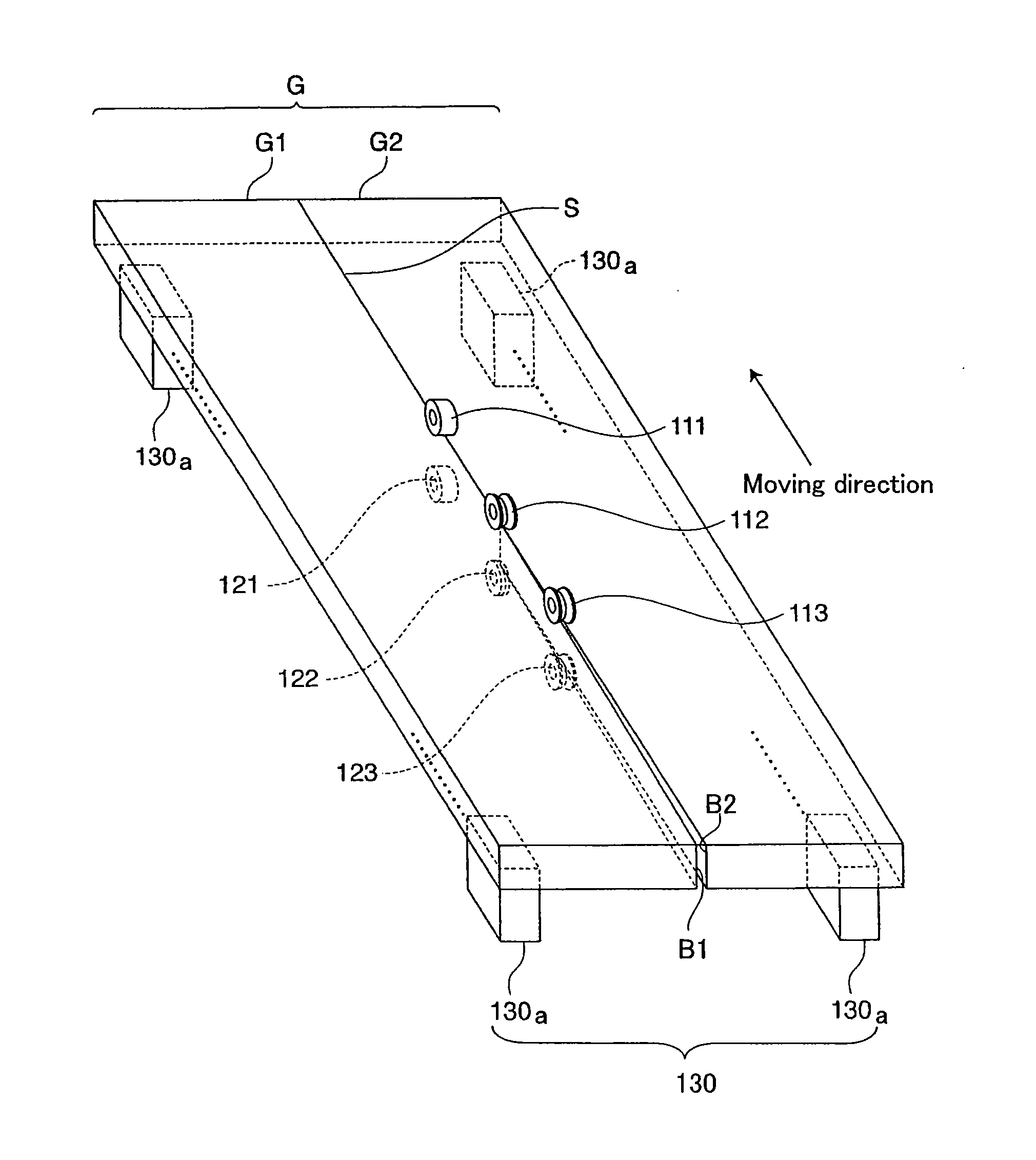

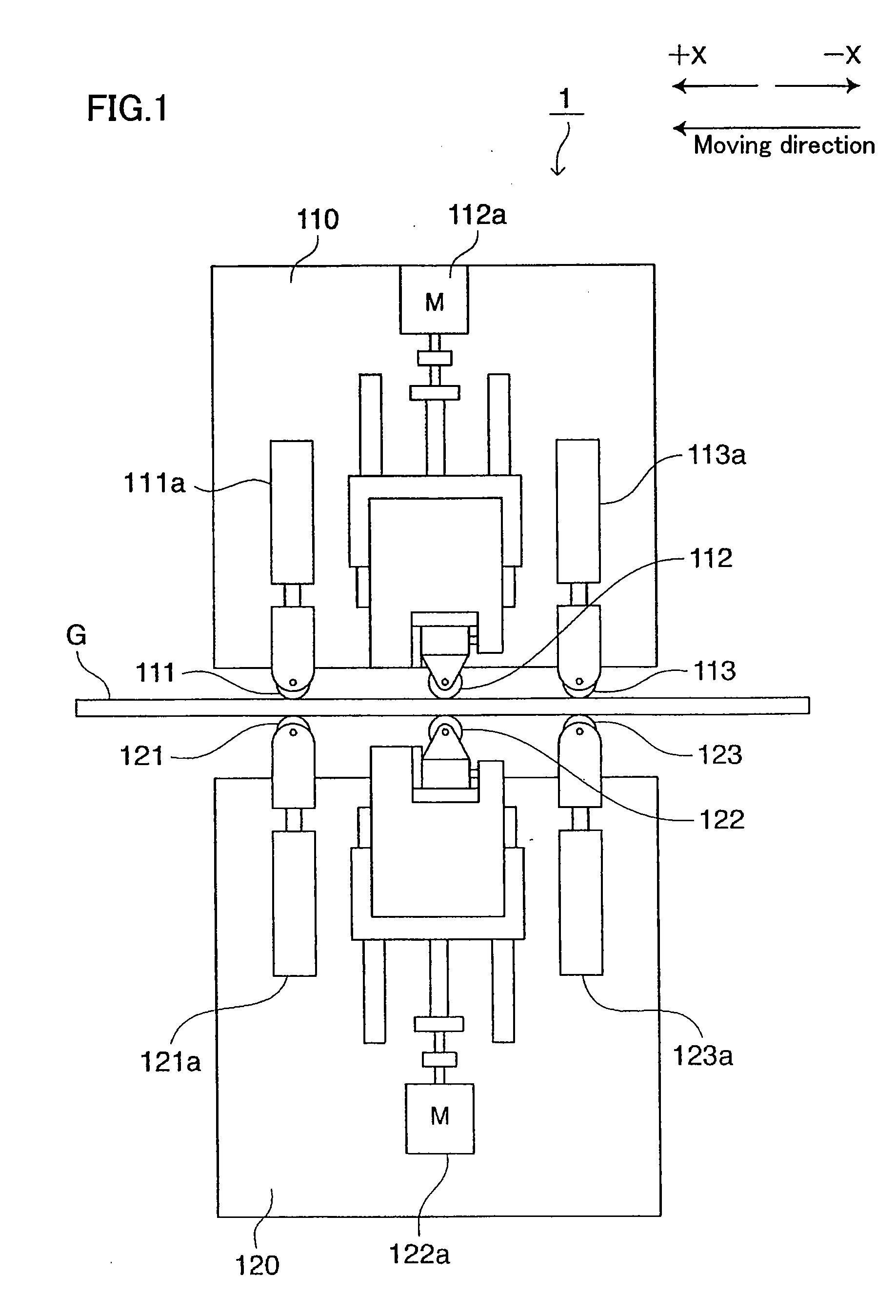

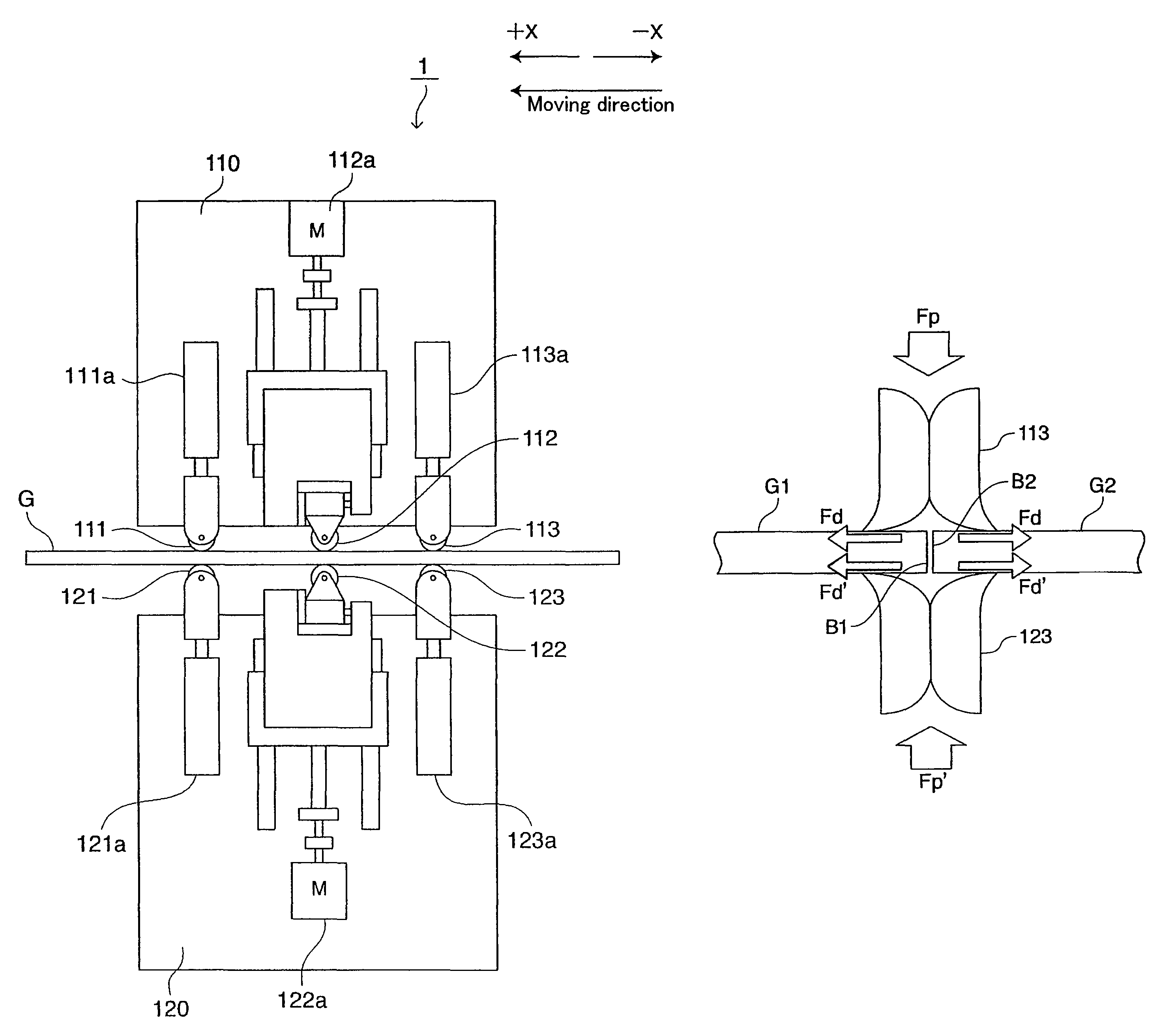

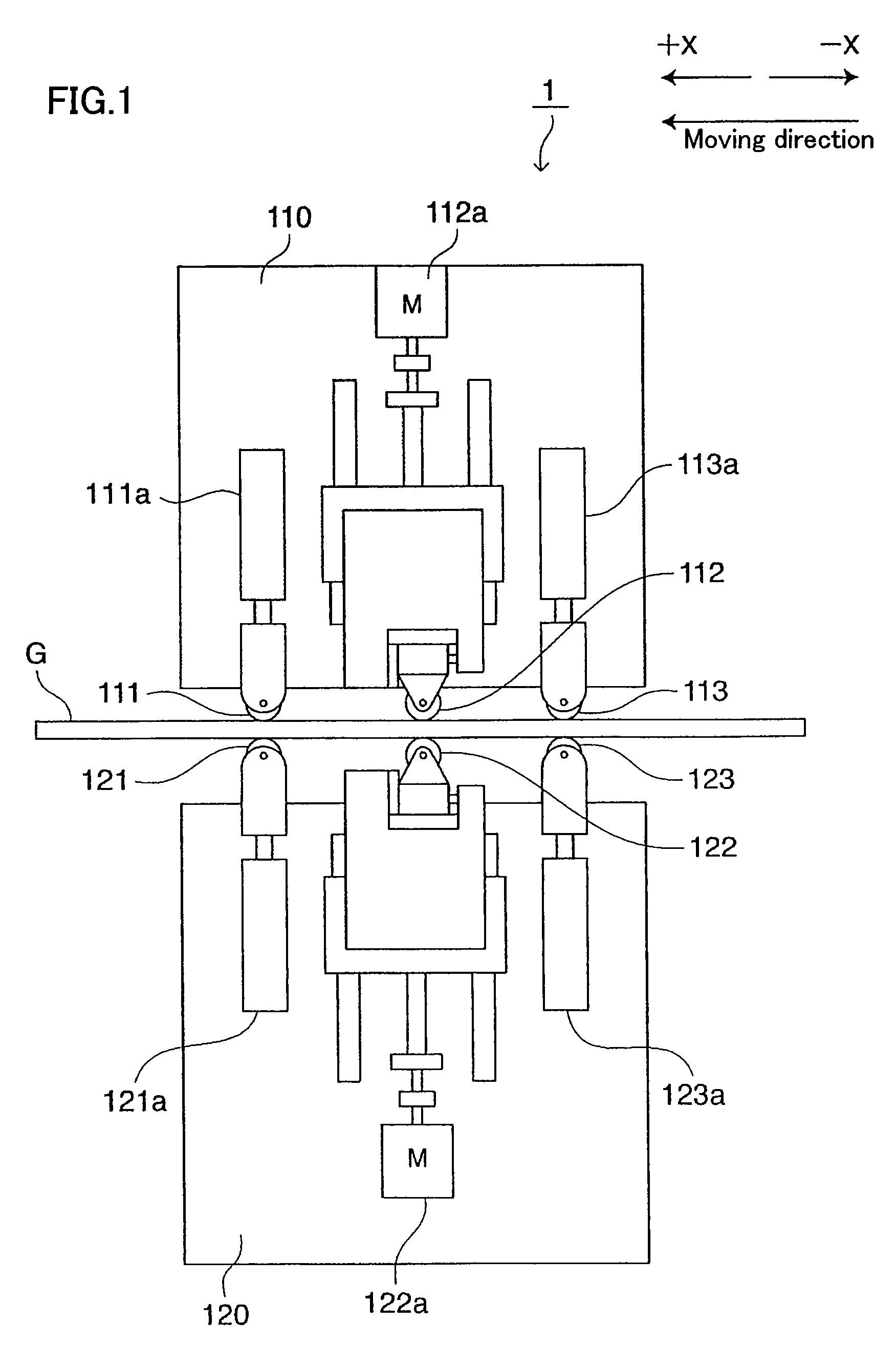

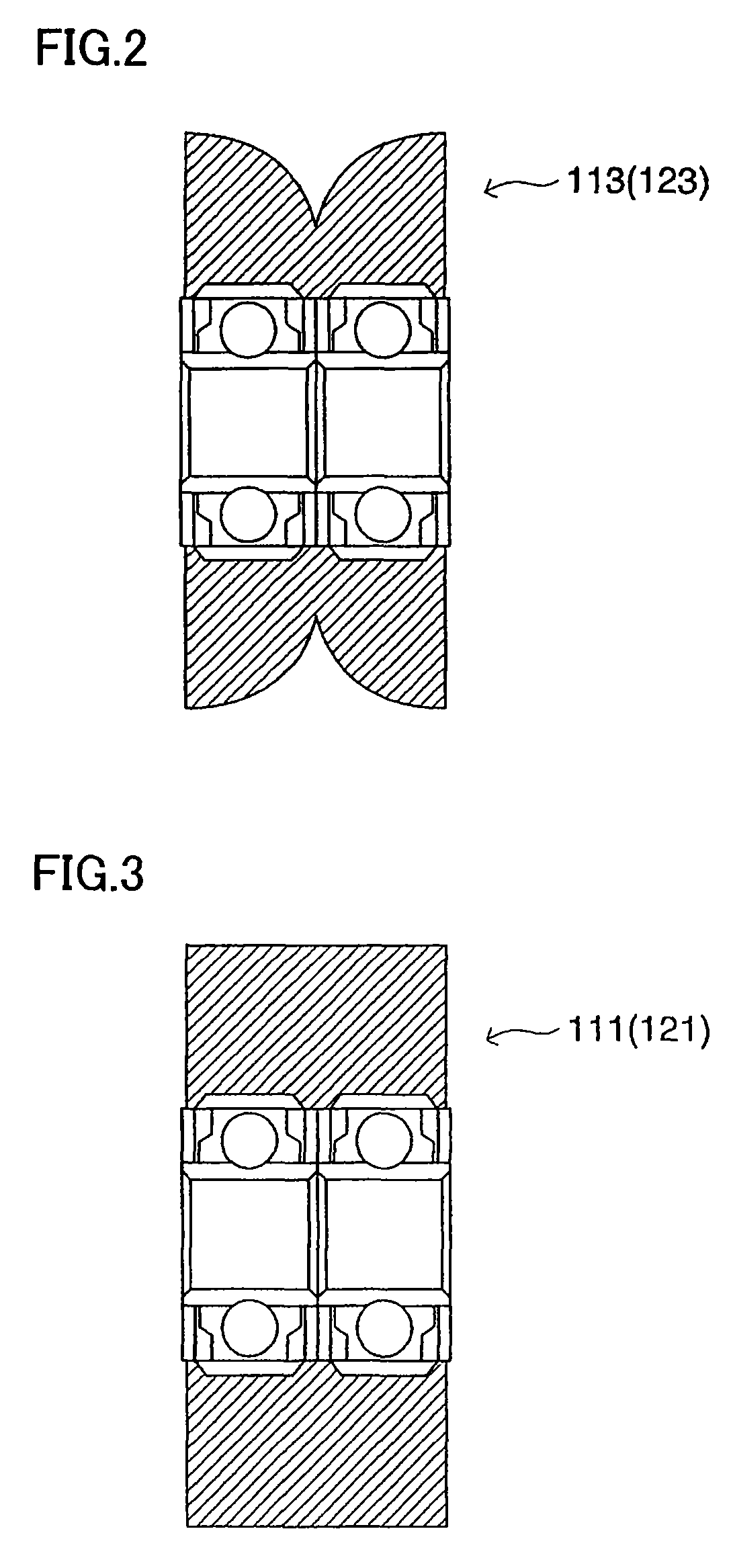

Device and method for cutting off substrate of fragile material

InactiveUS20100065599A1Reduce yieldAvoid surface defectsConveyorsPaper-makingEngineeringMechanical engineering

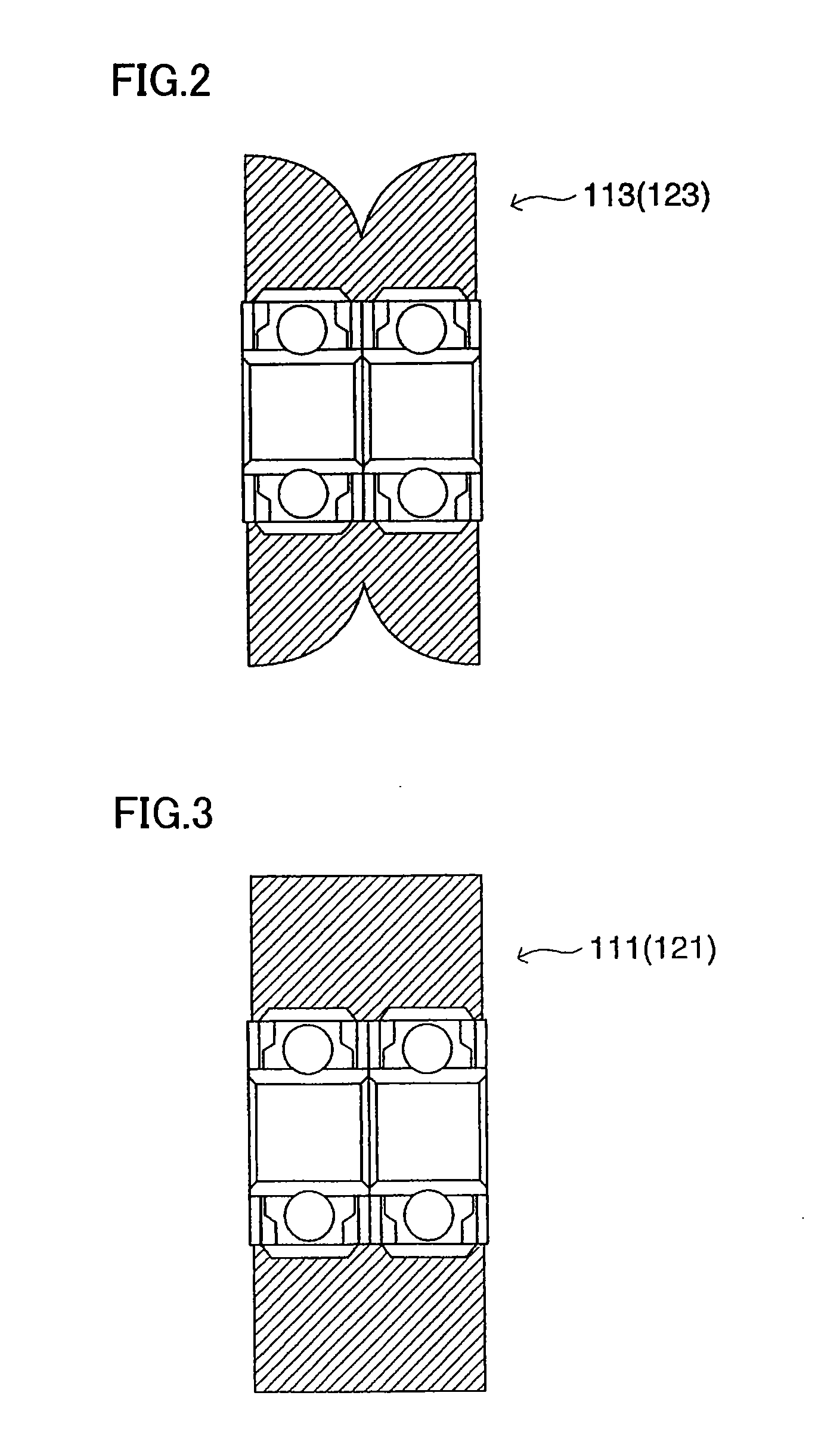

A brittle material substrate cutting method and cutting apparatus are provided, which prevent cut faces of a brittle material substrate from contacting each other after the cutting in a break step of continuously cutting the brittle material substrate, so that a damage or contamination on the brittle material substrate due to the contact can be prevented. A brittle material substrate cutting apparatus includes: a cutting section (112, 122) for applying a pressing force in a vicinity of a scribe line S formed on a substrate G and cutting the pressed portion of the substrate G; and a holding section moving parallel to the scribe line S while holding the cutting section. The brittle material substrate cutting apparatus continuously cuts the substrate G along the scribe line S. The brittle material substrate cutting apparatus further includes: a cut-face separating section (113, 123), provided in the holding section, for holding and pressing at least one part of cut substrate portions of the substrate G, wherein the cut substrate portions are generated as a result of the cutting and they oppose each other, and moving cut faces of the cut substrate portions approximately parallel to a main face of the substrate G and in directions to separate the cut faces from each other.

Owner:MITSUBOSHI DIAMOND IND CO LTD

High-strength cold-rolled steel sheet, high-strength plated steel sheet, and methods for their manufacture

InactiveUS20080202638A1Sufficient formabilityNot develop surface defectHot-dipping/immersion processesFurnace typesRoom temperatureHigh intensity

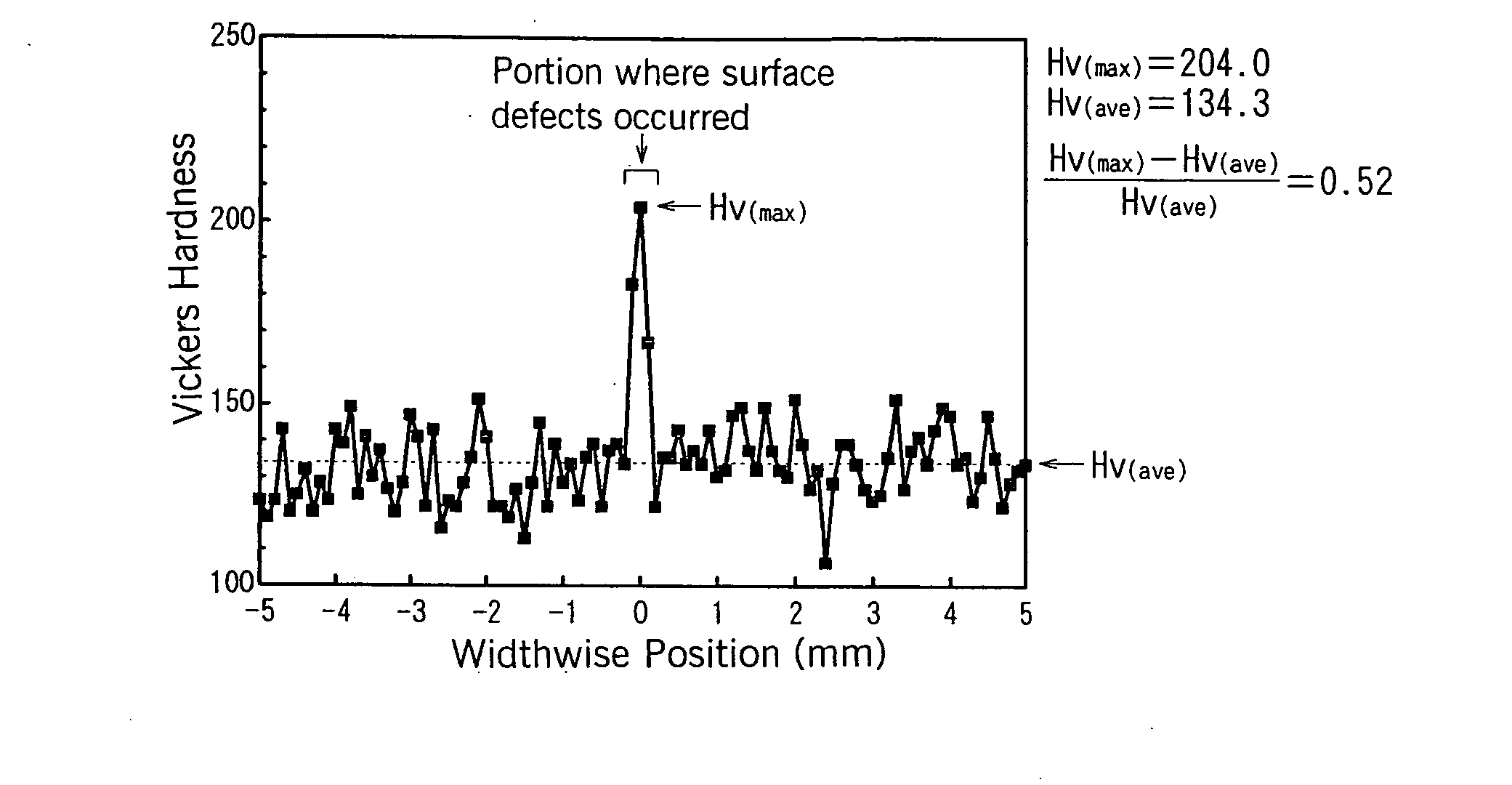

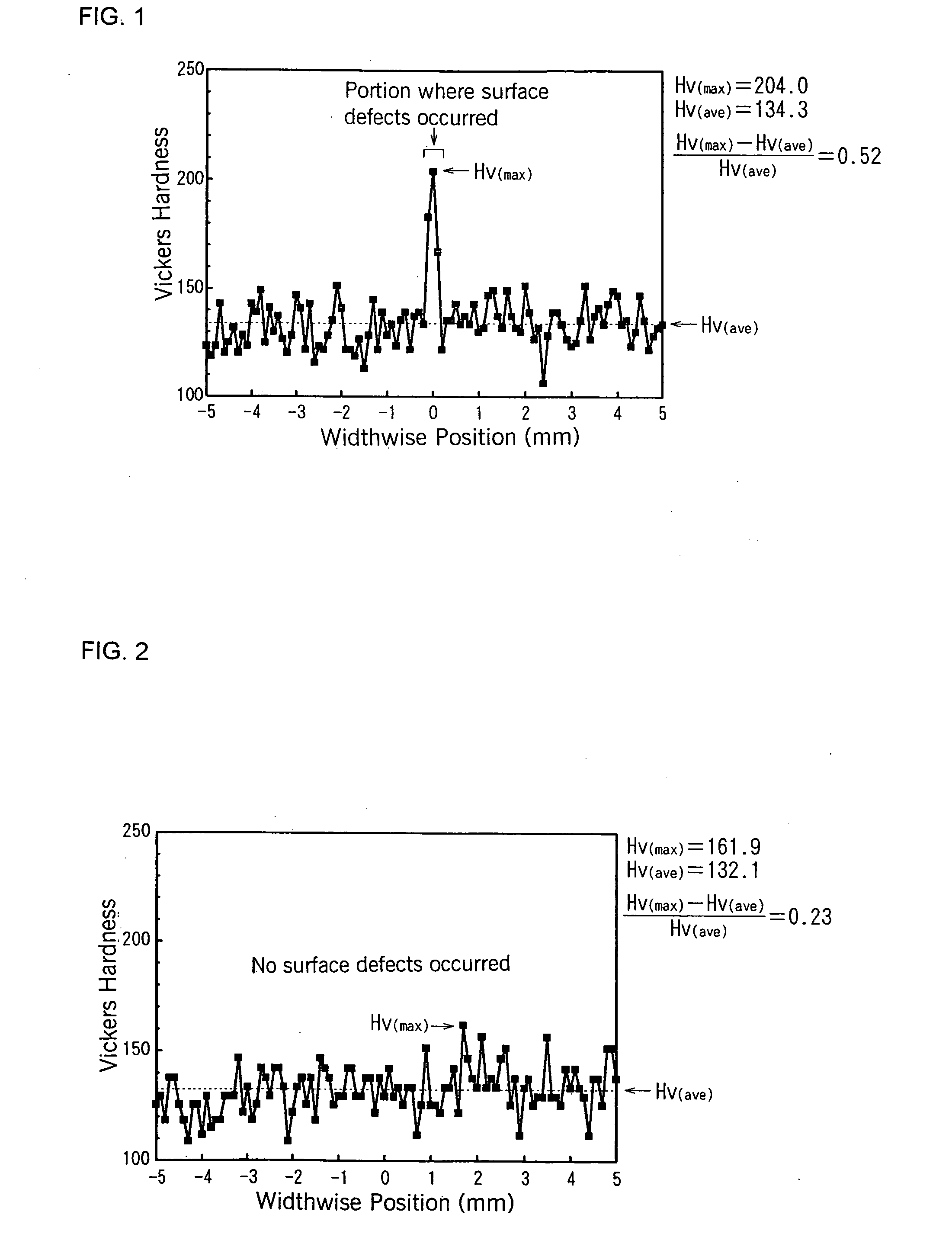

A high-strength cold-rolled steel sheet providing a product with a good surface condition after press forming, having excellent bake hardenability and anti room temperature aging property, and having a dual phase structure with a tensile strength of at least 340 MPa is provided.A high-strength cold-rolled steel sheet has a structure comprising a main phase which is a ferrite and a secondary phase which is a low temperature transformation product including a martensite and has a hardness distribution of the ferrite phase in an arbitrary cross section having a length of 10 mm in the widthwise direction of the sheet which satisfies the relationship prescribed by (Hv(max)−Hv(ave))<0.5×(Hv(ave). Hv(max) is the maximum Vickers hardness of ferrite grains in a region at a distance of from (⅛)t to (¼)t in the thickness direction from the surface when the thickness of the high-strength cold-rolled steel sheet is t, and Hv(ave) is the average Vickers hardness of ferrite grains in this region.

Owner:SUMITOMO METAL IND LTD

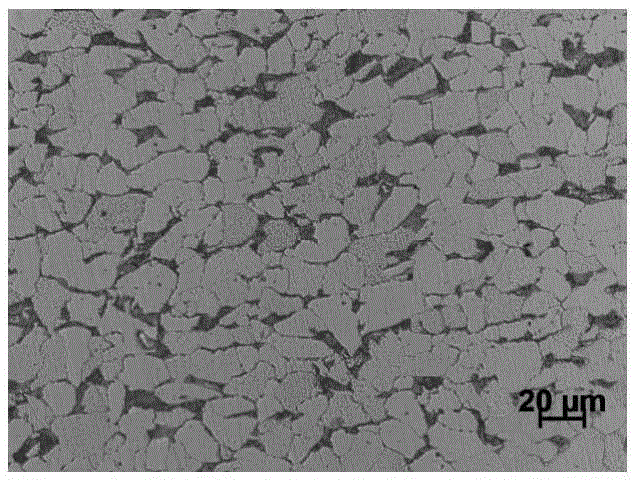

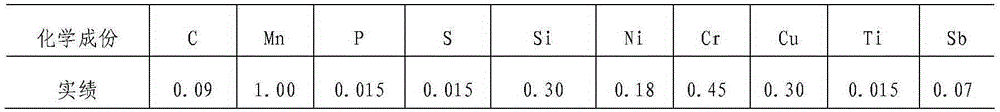

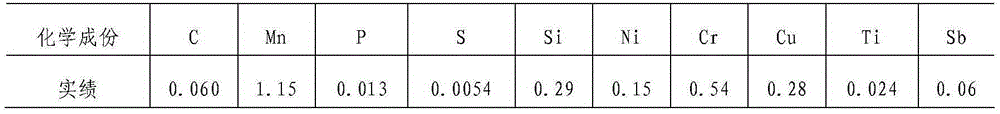

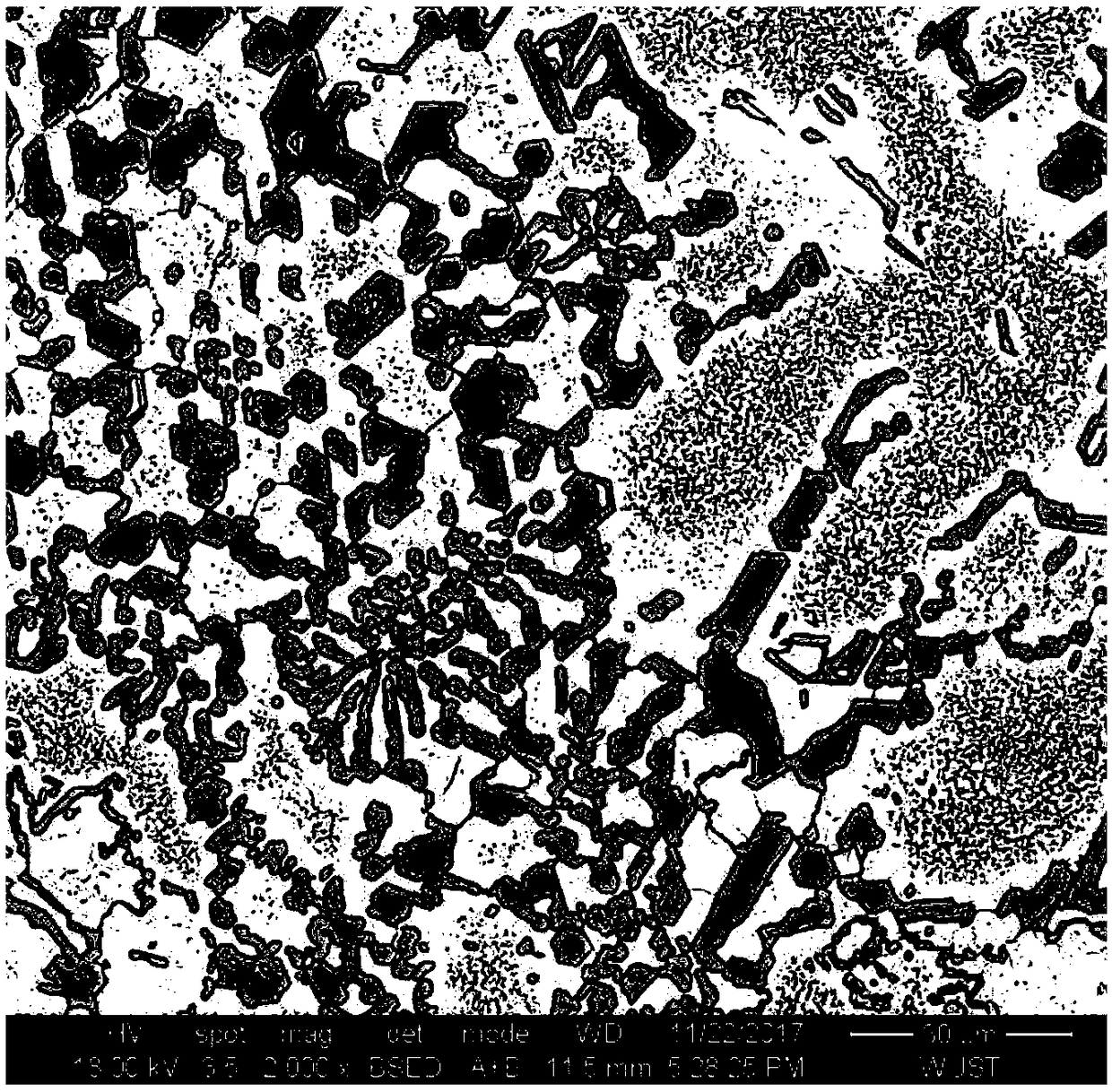

Low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel and production method thereof

InactiveCN105349911AGuaranteed Performance RequirementsGuaranteed production costHigh pressure waterHigh pressure

The invention provides low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel. The steel is characterized by comprising the following elements in percentage by mass: smaller than or equal to 0.12% of C, smaller than or equal to 0.55% of Si, 0.75% to 1.20% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.025% of S, 0.50% to 1.2% of Cr, 0.20% to 0.50% of Cu, smaller than or equal to 0.25% of Ni, 0.05% to 0.15% of Sb, smaller than or equal to 0.025% of Ti, smaller than or equal to 0.010% of V, 0.020% to 0.050% of Alt and 0.0005% to 0.0035% of Ca. The tissues of the steel disclosed by the invention are ferrite and pearlite; the heating temperature is increased; generation of relatively thick iron oxide scale is facilitated; transient temperature reduction of the surface iron oxide scale is increased during descaling of high-pressure water, so that shrinkage of the surface iron oxide scale is intensified, the iron oxide scale is easier to remove from a base body, the descaling efficiency is improved, and iron oxide scale residues are fundamentally reduced.

Owner:NANJING IRON & STEEL CO LTD

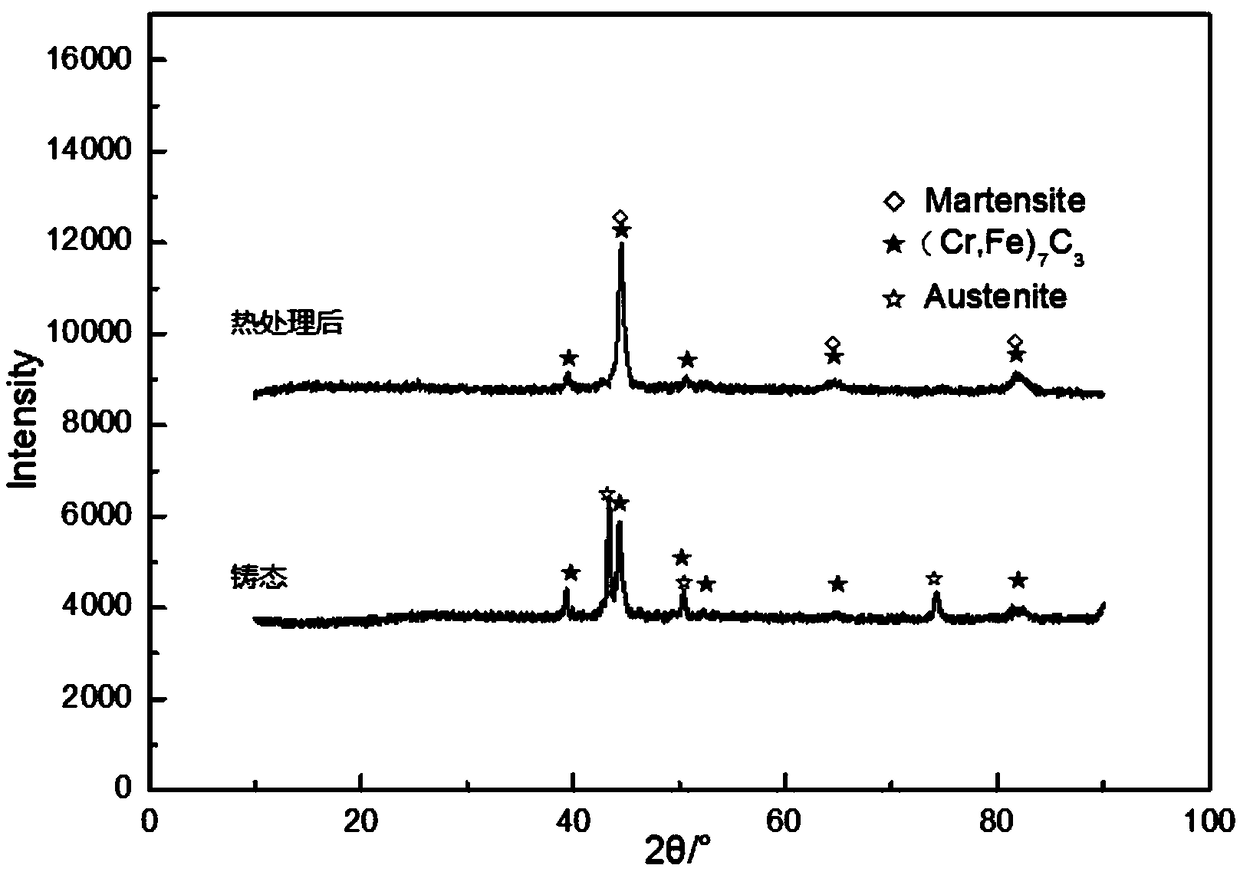

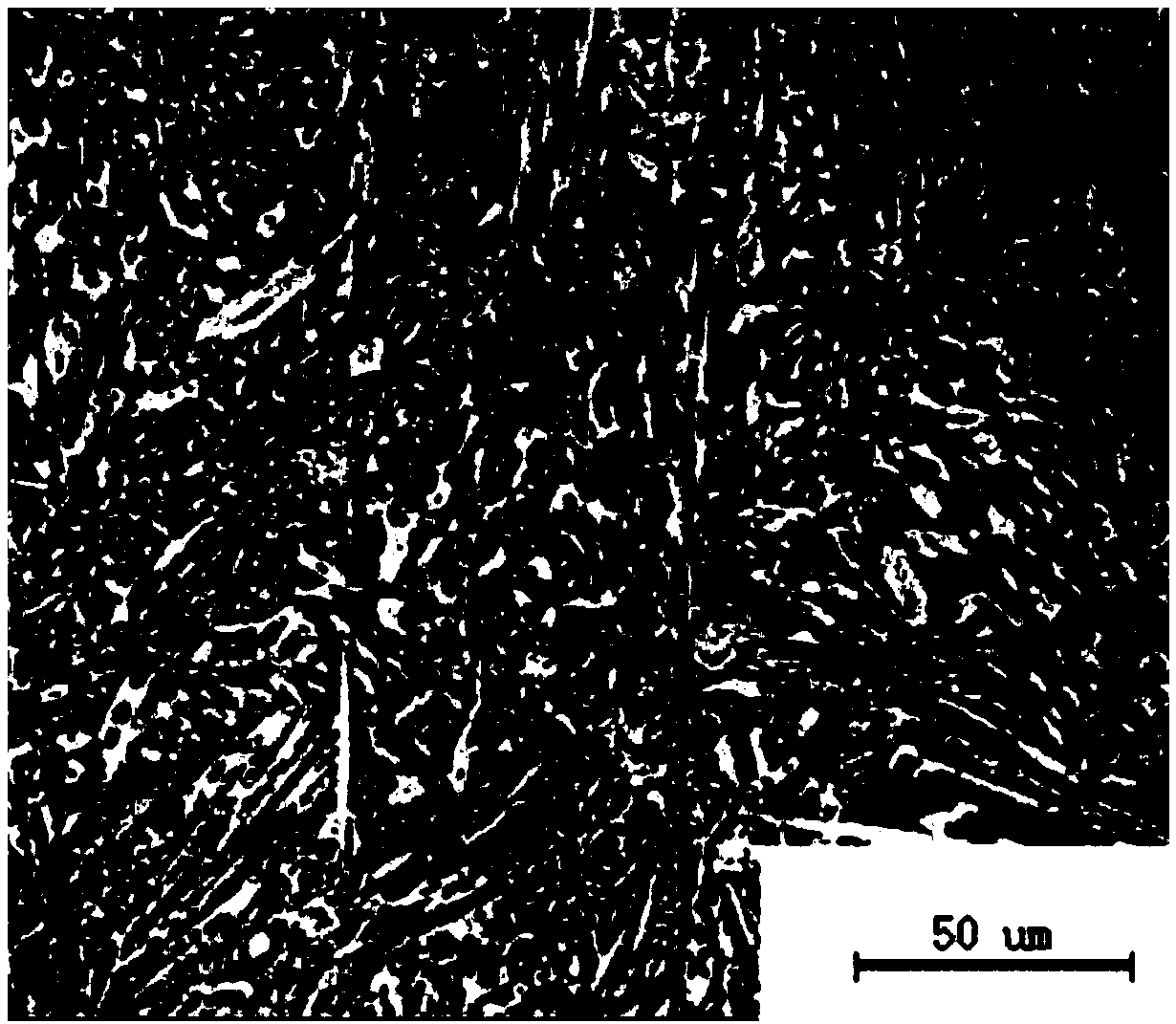

Chemical high-chromium cast iron roller and preparation method thereof

ActiveCN108723091AReduce C contentGood uniformity of refinementFurnace typesRollsChemical compositionCentrifugation

The invention discloses a chemical high-chromium cast iron roller which comprises a high-chromium cast iron work layer and a nodular cast iron roller core. Chemical components of the high-chromium cast iron work layer comprise, by mass percent, 2.1%-2.9% of C, 0.4%-0.8% of Si, 0.5%-08% of Si, 0.5%-0.8% of Mn, 15%-20% of Cr, 0.5%-2% of Ni, 0.5%-2% of Mo, 0.2%-3.0% of V, 0.1%-0.4% of Ti, 0.2%-0.8% of Cu, 0.01%-0.03% of RE, smaller than 0.15% of P, smaller than 0.15% of S and the balance iron. During preparation, a composite centrifugation method is adopted for casting; during heat treatment, thetemperature of a forming roller is increased to range from 920 DEG C to 960 DEG C at the speed ranging from 9 DEG / h to 12 DEG / h, heat preservation is carried out, after quenching, the temperature isincreased to range from 200 DEG C to 250 DEG C for tempering, and heat preservation is carried out for 8 h to 10 h. Laser strengthening treatment is carried out, tempering is carried out at the temperature ranging from 200 DEG C to 250 DEG C, and after heat preservation is carried out for 2 h to 3 h, the chemical high-chromium cast iron roller is obtained. According to the chemical high-chromium cast iron roller, no chip off-falling phenomenon happens in the use process, the roller has good corrosion resistance and high hardness and wear resistance, and the service life of the roller is prolonged.

Owner:HUBEI GOLD STANDARD GENERAL ROLLER

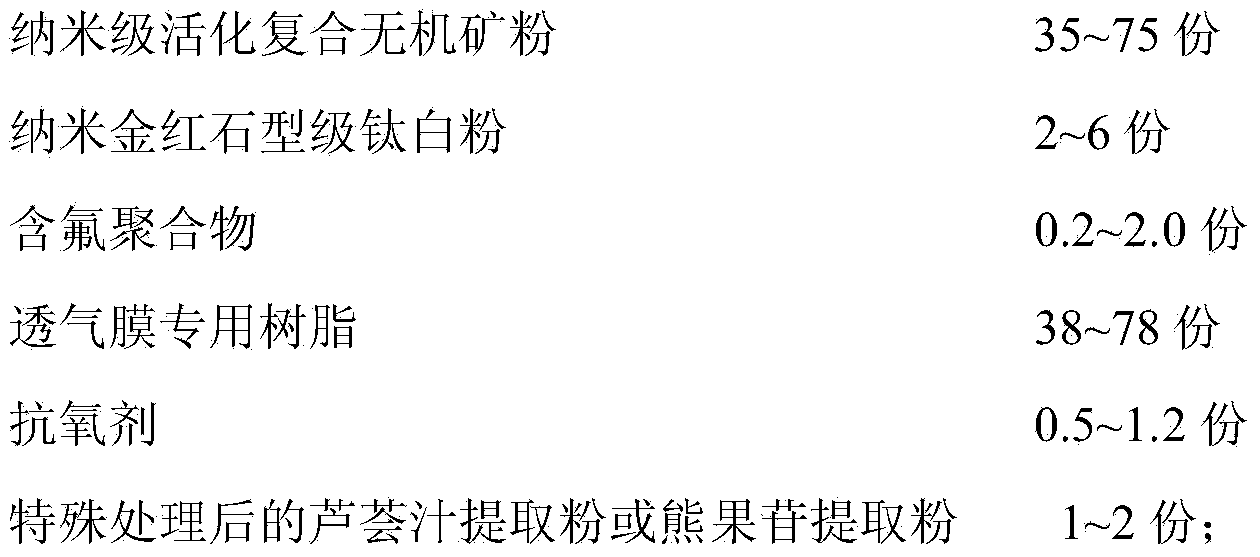

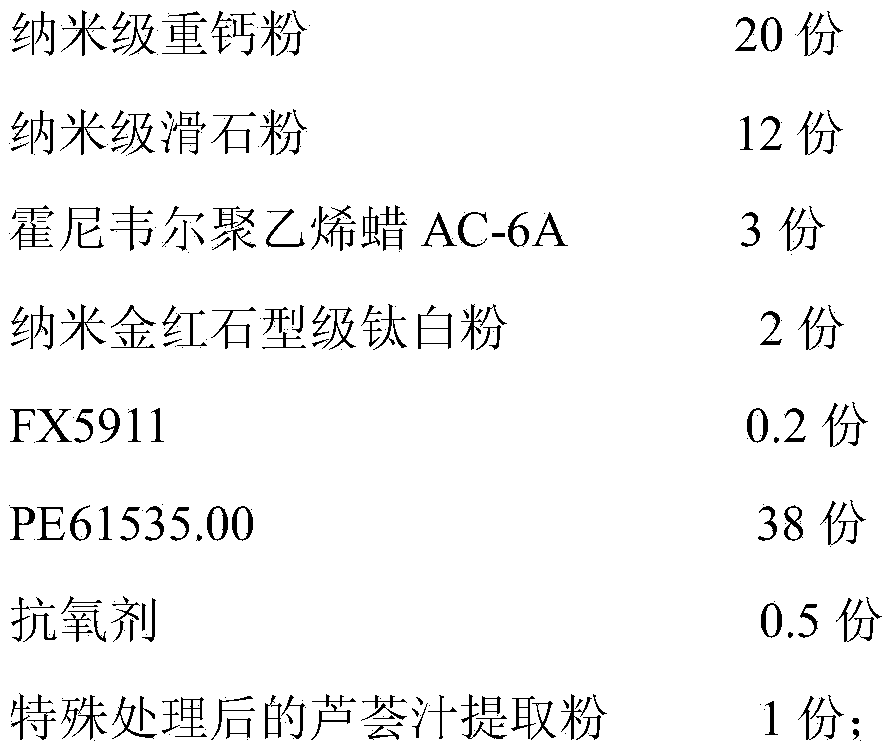

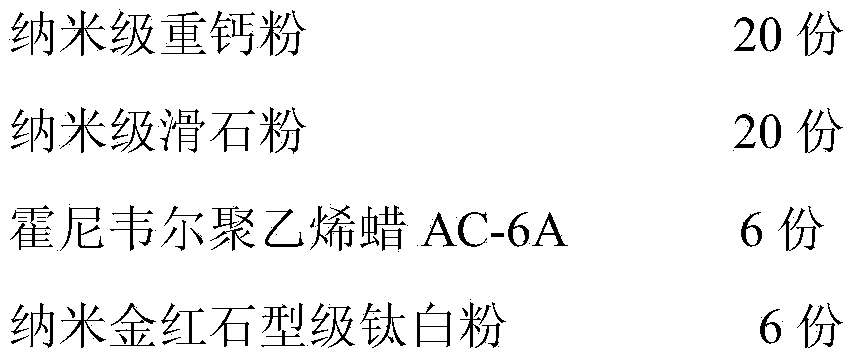

Medical grade gas-permeable membrane special material and preparation method thereof

The invention discloses a medical grade gas-permeable membrane special material. The medical grade gas-permeable membrane special material is prepared from the following components in parts by weight: 35-75 parts of nanoscale activated composite inorganic mineral powder, 2-6 parts of nano rutile type titanium dioxide, 0.2-2.0 parts of fluorine-containing polymer, 38-78 parts of gas-permeable membrane special resin, 0.5-1.2 parts of antioxidant and 1-2 parts of specially treated aloe juice extract powder or arbutin extract powder, wherein the nanoscale activated composite inorganic mineral powder comprises nanoscale ground calcium carbonate powder, nanoscale talcum powder and a surface active agent. A preparation method of the medical grade gas-permeable membrane special material comprises the following steps: firstly carrying out high-speed mixing on the nanoscale activated composite inorganic mineral powder for removing water; secondly, preparing a gas permeable membrane special material mixture; and thirdly, preparing a gas permeable membrane special material finished product. The medical grade gas-permeable membrane special material has the advantages that raw materials are simple, source of the raw materials is rich, a technology is simplified and cost is low.

Owner:广西工程技术研究院有限公司

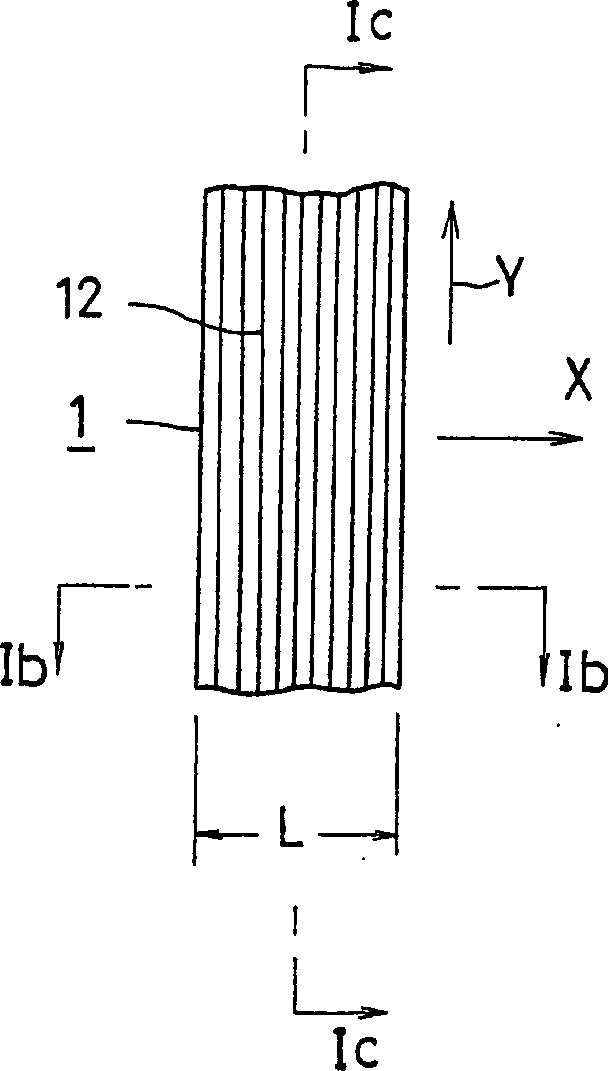

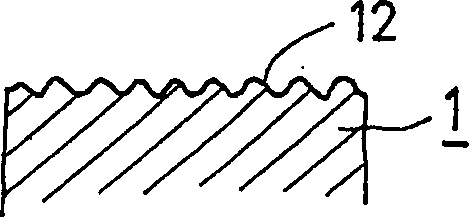

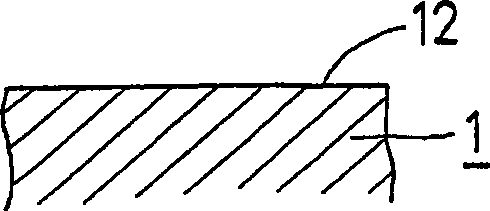

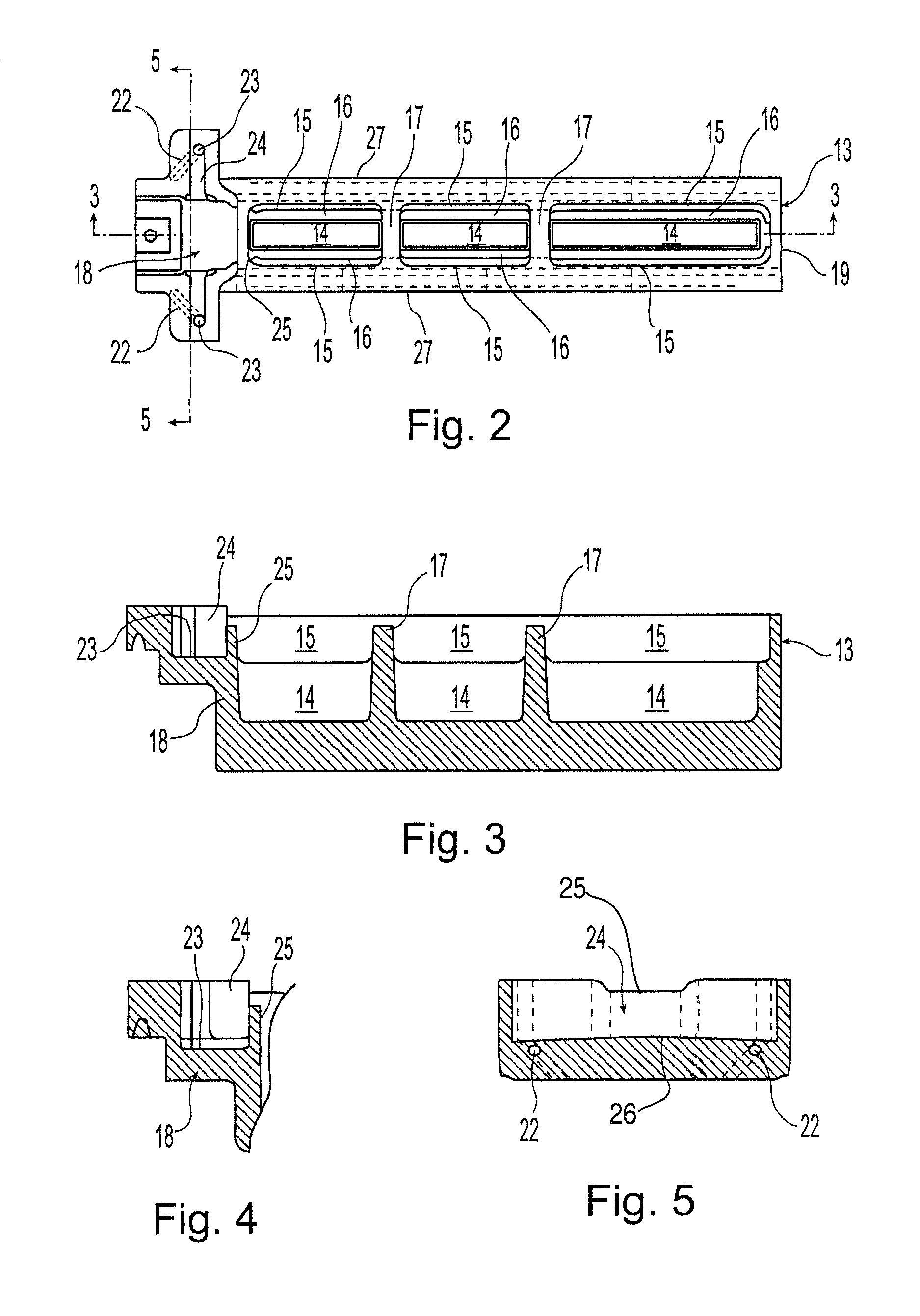

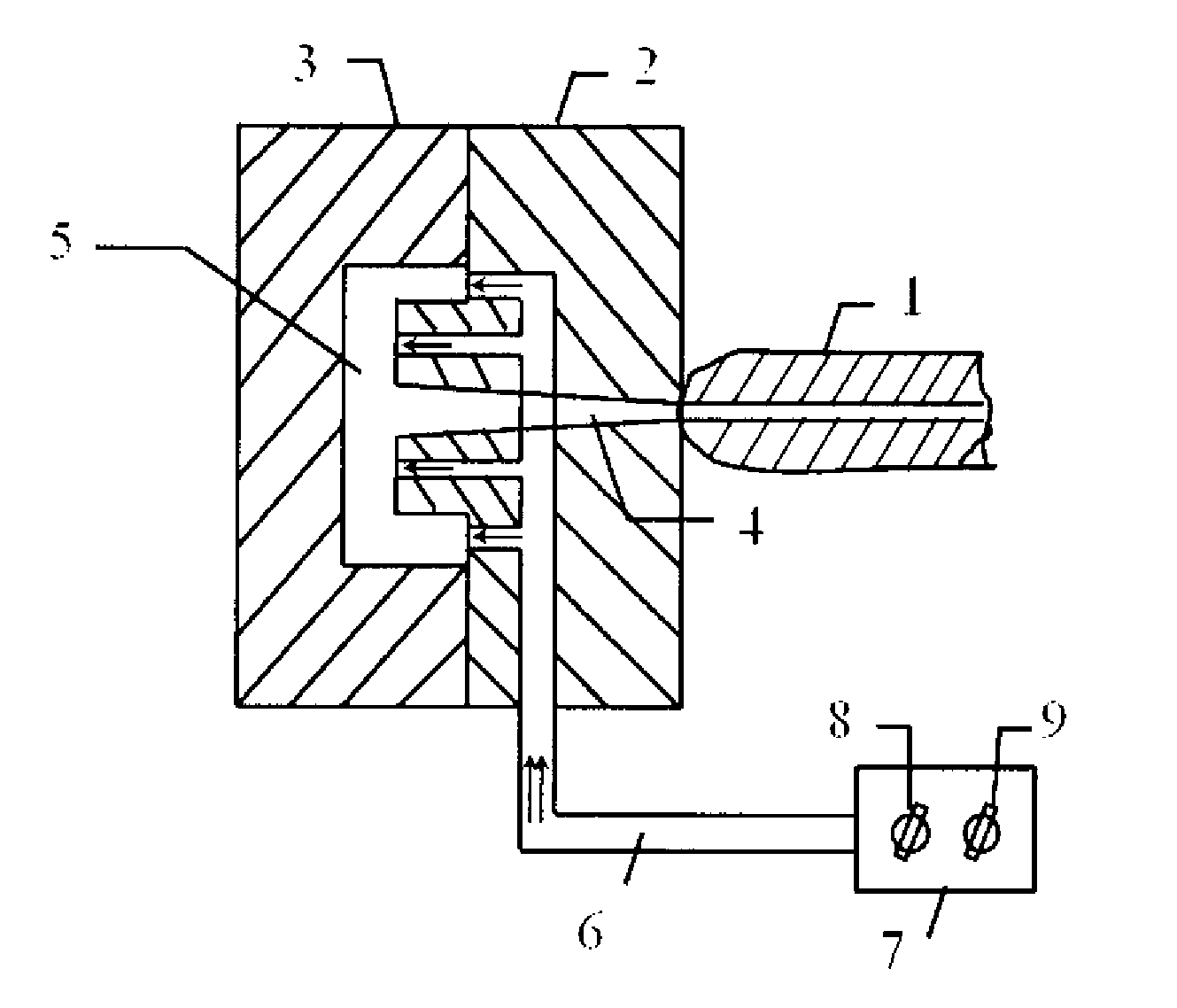

Aluminum pipe having excellent surface quality, method and apparatus for manufacturing the aluminum pipe, and photosenstive drum base body

InactiveCN1819879AEfficient preparationPrevent heat stickingDrawing mandrelsDrawing diesMaterials scienceAluminium

In a manufacturing method in which an aluminum bullet is extruded to obtain an extruded raw pipe 4 and then the extruded raw pipe 4 is subjected to a drawn process, the aluminum extruded raw pipe 4 is cut at a position within 10m from a discharge position M of an extruding die to obtain an aluminum extruded raw pipe 4 with a length of 10m or shorter, and the extruded raw pipe 4 is subjected to a drawing process. With this, an aluminum pipe excellent in surface quality having no surface defect such as white peeling can be manufactured at high manufacturing efficiency.

Owner:RESONAC HOLDINGS CORPORATION

Delivery nozzle with more uniform flow and method of continuous casting by use thereof

InactiveUS7926549B2Avoid surface defectsIncrease temperatureMelt-holding vesselsBlast furnace componentsEngineeringMolten metal

A method of and apparatus for casting metal strip involving assembling a pair of casting rolls laterally disposed to form a nip between them, assembling an elongated metal delivery nozzle extending along and above the nip between the casting rolls, with at least one segment having opposing side walls and end walls, an inner trough extending longitudinally within between side walls and forming passages between the side walls and the inner trough and communicating with side outlets adjacent bottom portions, introducing molten metal through the elongate metal delivery nozzle to form a casting pool of molten metal supported on the casting rolls above the nip, such that molten metal is caused to flow into the inner trough of the delivery nozzle, from the inner trough through the passages between the inner trough and sidewalls, and from the passages through the side outlets in a substantially lateral direction into the casting pool, and counter rotating the casting rolls to deliver cast strip downwardly from the nip.

Owner:NUCOR CORP

Power schottky device barrier method

ActiveCN101051613AAvoid mutual expansionImprove positive characteristicsSemiconductor/solid-state device manufacturingEtchingAlloy

Characters of the method includes following steps: (1) oxidation; (2) first photo etching; (3) boron diffusion; (4) second photo etching; (5) sputtering barrier metal; (6) vaporizing multilayer of metal on face side; (7) third photo etching; (8) annealing; (9) thinning rear face; (10) vaporizing multilayer of metal on rear face; (11) alloying (12) testing and cutting to separate slices. Useful effects are: reducing influences from surface state, enhancing forward and backward characteristics as well as capability of inverted voltage resistant and anti burning, preventing oxidation of metal layer prolonging service life, avoiding interdiffusion between each metal and silicide, raising fatigue resistance, and reinforcing stability of parts.

Owner:JINAN JINGHENG ELECTRONICS

Manufacturing method of dual-metal seamless steel pipe with outer-layer low-carbon steel and inner-layer bearing steel

InactiveCN102728652AAvoid surface defectsAvoid stress concentrationFurnace typesHeat treatment furnacesSand blastingHigh pressure

The invention discloses a manufacturing method of a dual-metal seamless steel pipe with outer-layer low-carbon steel and inner-layer bearing steel, which relates to the technical field of heat treatment of iron-based alloy. The manufacturing method comprises the following steps of: pipe blank spheroidizing annealing; straightening; oxide layer removing by high-pressure sand blasting; cold rolling, and cold drawing; destressing and annealing; oil spot and phosphorus removing by high-pressure sand blasting; finishing; and warehousing. According to the method, scales and oil spots are removed by the sand blasting which is performed by a mixture of water and aluminum oxide sand or quartz sand, so that not only are environment pollution caused by acid liquid and surface defects caused by the nonuniform corrosion of a pipe blank are avoided, but also after the sand blasting treatment, the surface of a pipe is flat, clean and smooth, the pollution is avoided, and the pipe is safe to use. Additionally, as the pipe blank progresses uniformly and spirally on a delivery roller way, the increasing of sand blasting passages caused by intermittent removing of the scales and the oil spots is prevented, and thus the working efficiency is high.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Production process of waterproof polyving akohol film and application for obtaining waterproof polyving akohol film

ActiveCN105153608AEmission complianceNo pollution in the processSynthetic resin layered productsFlat articlesPolymer sciencePlasticizer

The invention discloses a production process of a waterproof polyving akohol film. At present, an aqueous solution salivate method for producing the polyving akohol film has the disadvantage of higher energy consumption cost, and a better waterproof film is difficult to obtain with a melt extrusion method. Polyving akohol and other raw material components are subjected to mix swelling, extrusion, salivation, drying, heat treatment, edge cutting and rolling processes sequentially to form the waterproof polyving akohol film; the mix swelling process comprises that all raw material components are stirred and mixed in a hot mixing machine with jacket heating after weighted; at mixing endpoint, obtained polyving akohol particles are swelled into an elastic, non-adhesive and transparent jelly shape, and no free moisture exists among particles. Polyving akohol resin absorbs moisture to swell through heating and mixing, so that the melting temperature of the polyving akohol resin is reduced, the energy consumption in the production process can be reduced greatly, and a plasticizer can be reduced or even isn't used.

Owner:GRI MEDICAL & ELECTRONICS TECH CO LTD

Device and method for cutting off substrate of fragile material

InactiveUS8276796B2Reduce yieldAvoid surface defectsConveyorsBox making operationsMechanical engineeringBrittleness

A brittle material substrate cutting method and cutting apparatus are provided, which prevent cut faces of a brittle material substrate from contacting each other after the cutting in a break step of continuously cutting the brittle material substrate, so that a damage or contamination on the brittle material substrate due to the contact can be prevented.

Owner:MITSUBOSHI DIAMOND IND CO LTD

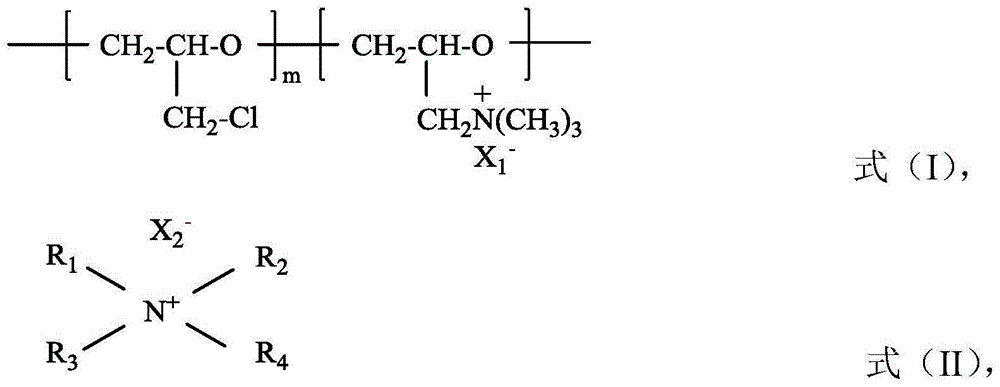

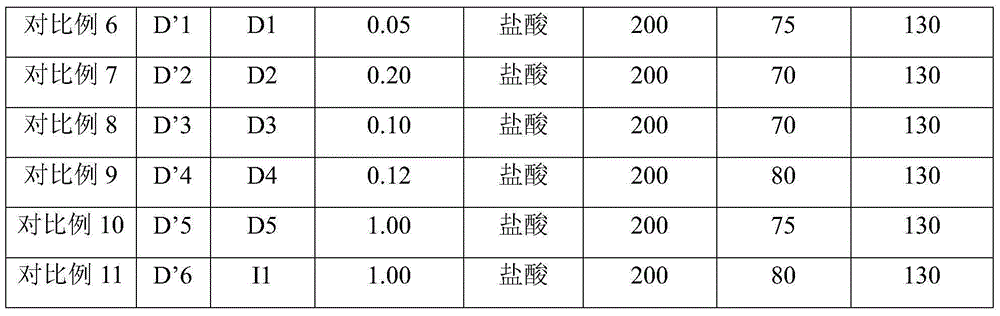

Acid pickling corrosion inhibitor and pickling method by using the same

The present invention relates to the field of corrosion inhibitor, and discloses an acid pickling corrosion inhibitor and a pickling method by using the same. The acid pickling corrosion inhibitor includes a quaternary ammonium compound, thiourea, HEDP and / or its salts, and phytic acid and / or tannic acid. The acid pickling corrosion inhibitor can be used for special steel such automobile structural steel, and has less usage amount and excellent corrosion performance; automotive structural steel hot rolled pickling plate with good surface quality can be obtained; and the method has low operation costs and good economic benefit.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for refining stainless steel with high purity

The present invention relates to a method of refining a stainless steel with high purity in where a raw material melted in an electric furnace is processed in an argon oxygen decarburization (AOD) refining furnace to be output to a ladle and then subjected to a continuous casting, wherein the occurrence of the refractory hard inclusion material is suppressed by controlling composition and basicity of the slag after the refinery surface reduction process and using the desulphurization process, so that ductility of the inclusion material can be improved and surface defects and cracks of a product can be prevented. The present invention provides a method of refining a stainless steel in where a raw material melted in an electric furnace is processed in an argon oxygen decarburization (AOD) refining furnace to be output to a ladle and then subjected to a continuous casting, wherein a basicity of a slag obtained after reduction process by using the argon oxygen decarburization (AOD) refining furnace is controlled to be in a range between 1.5 and 1.8, wherein a dolomite is used as a refractory material for the ladle, and wherein a composite (% Al2O3)+(% MgO) in the slag is less than 13.

Owner:POHANG IRON & STEEL CO LTD

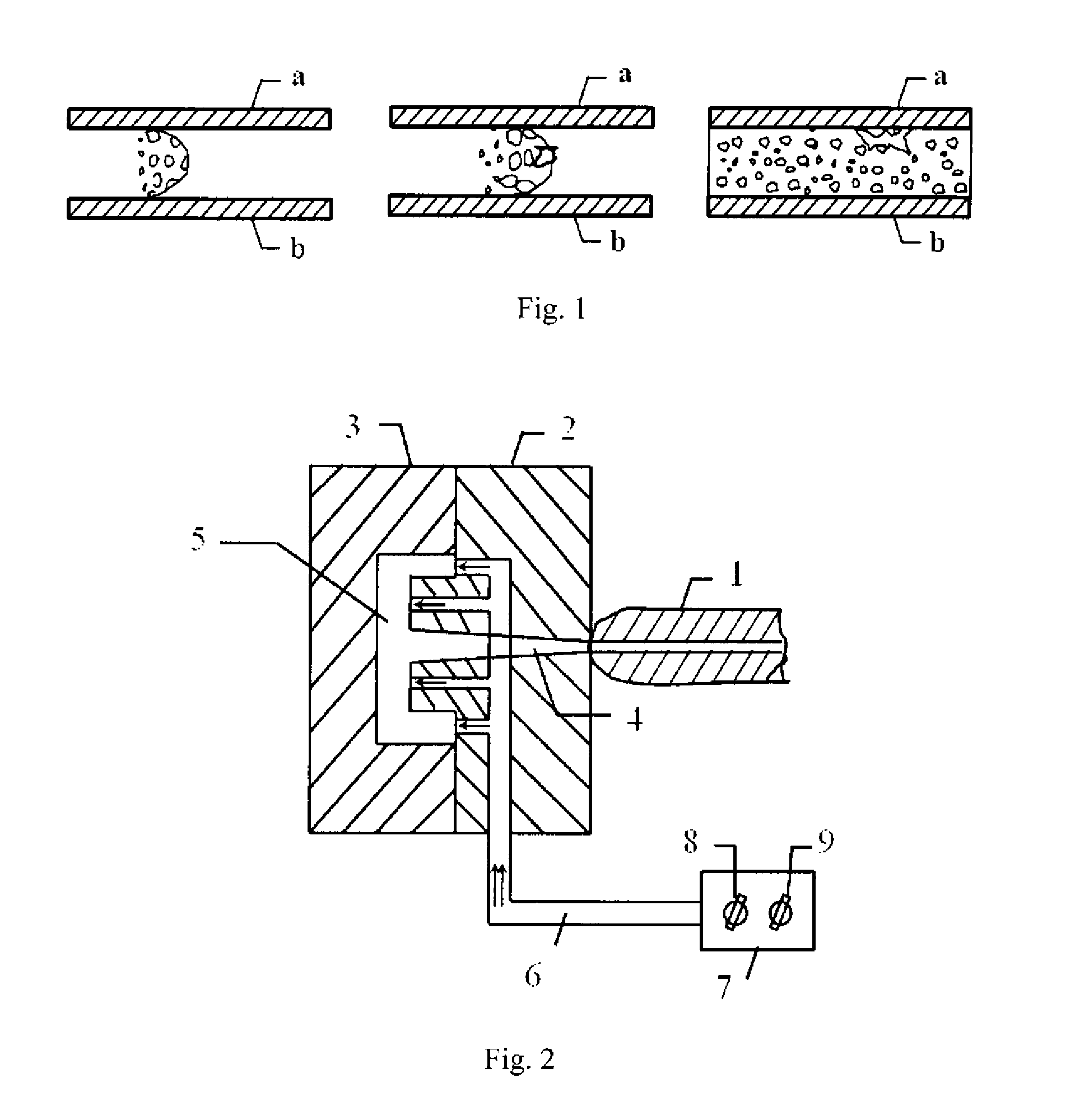

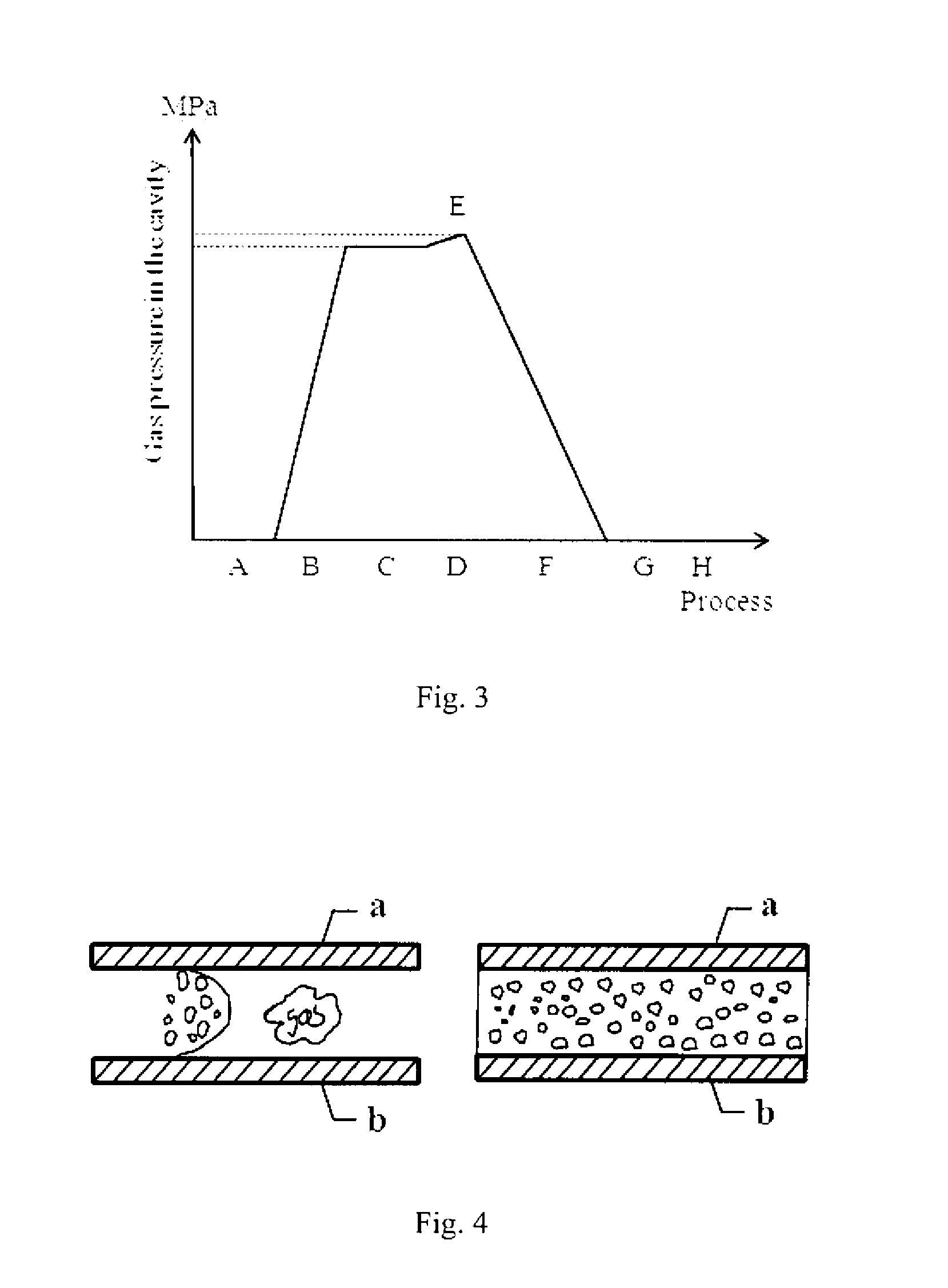

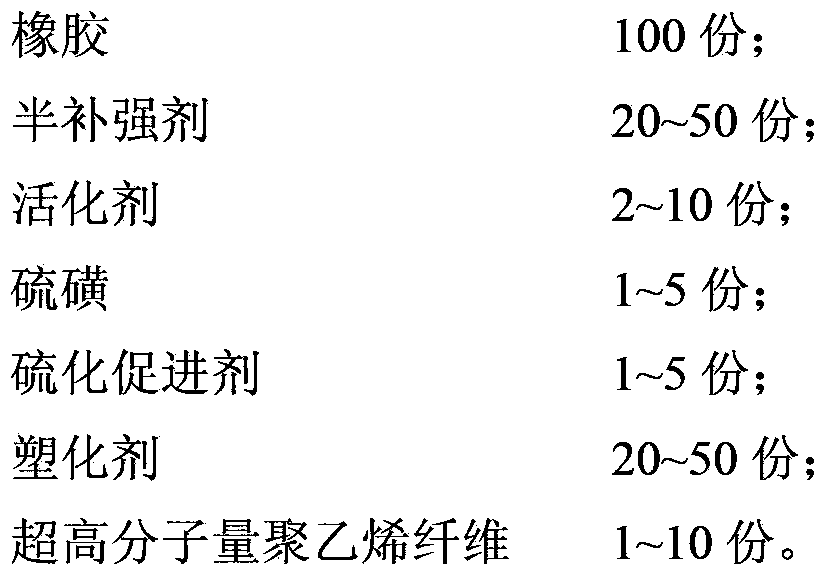

Method Of Improving The Appearance Of Injection Molding And Foaming Product

A method of improving the appearance of foaming injection molding product includes closing the moving mold and the fixed mold and setting a clamping force on the closed mold, wherein a mold cavity is formed between the moving mold and the fixed mold. The method proceeds by inflating the mold cavity with high pressure and high temperature gas until the air pressure in the mold cavity reaches 2-25 MPa and the temperature of the high pressure and high temperature gas is between 60-200° C., then injecting molten resin that contains foaming agent into the mold cavity while continuously inflating high pressure and high temperature gas. After injection completed, stopping inflating high pressure and high temperature gas and simultaneously releasing pressure, wherein the step of releasing pressure includes the step of opening the mold.

Owner:YANFENG AUTOMOTIVE TRIM SYST CO LTD

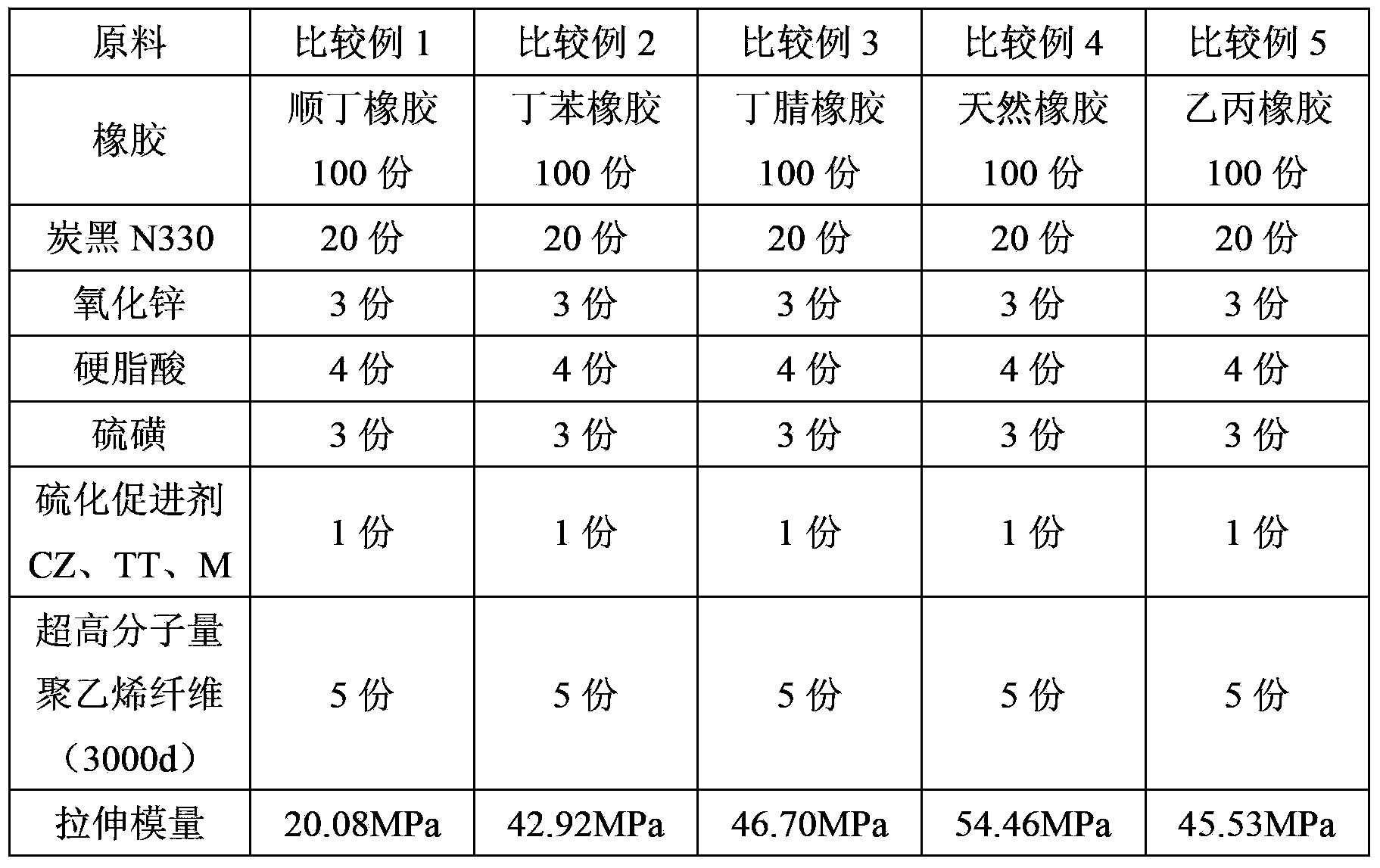

Ultrahigh molecular weight polyethylene fiber/rubber composite material and preparation method thereof

The invention relates to an ultrahigh molecular weight polyethylene fiber / rubber composite material and a preparation method thereof. The composite material comprises, by mass, 100 parts of rubber, 20-50 parts of a semi-reinforcing agent, 2-10 parts of an activator, 1-5 parts of sulfur, 1-5 parts of a vulcanization accelerator, 20-50 parts of a plasticizer , and 1-10 parts of an ultrahigh molecular weight polyethylene fiber. The preparation method comprises the steps of mixing above raw materials except the ultrahigh molecular weight polyethylene fiber in an open rubber mixing machine to obtain a semi-finished rubber product, and carrying out composite vulcanization on the semi-finished rubber product with the ultrahigh molecular weight polyethylene fiber. The composite material maintains the original mechanical properties of the rubber and the fiber, and the shear effect of the composite material improves the bonding performance of the fiber in the rubber, so the problem of difficult bonding of the fiber to the rubber due to the smooth surface of the fiber is solved; the composite material allows a matrix material to be directly firmly combined with the fiber, and is suitable for anti-aging low saturation rubber; and the preparation method has the advantages of simplicity, reduction of the raw materials and the consumption of energy in the process, cost saving, and suitableness for industrial mass production.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com