Patents

Literature

190results about "Drawing mandrels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

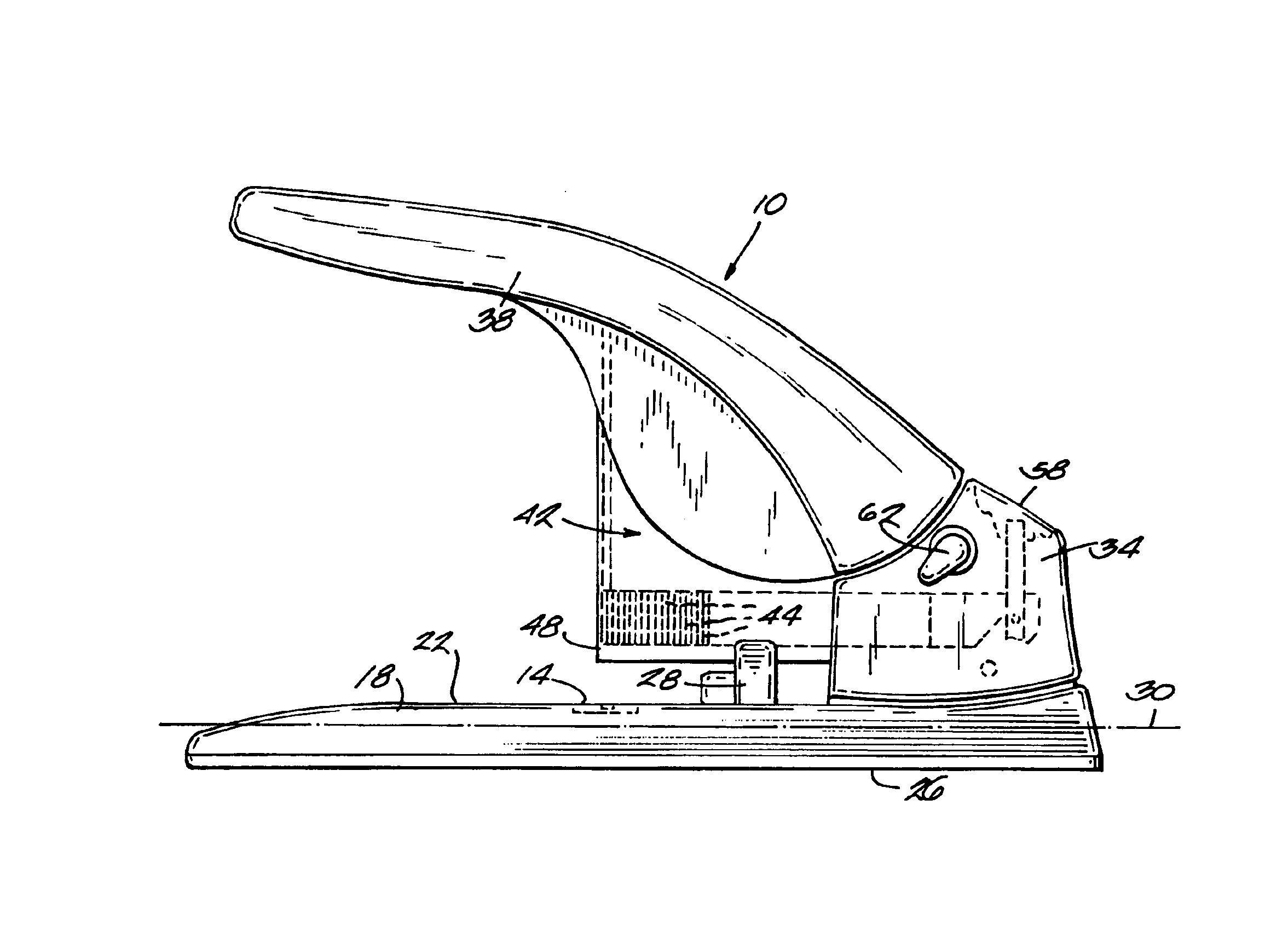

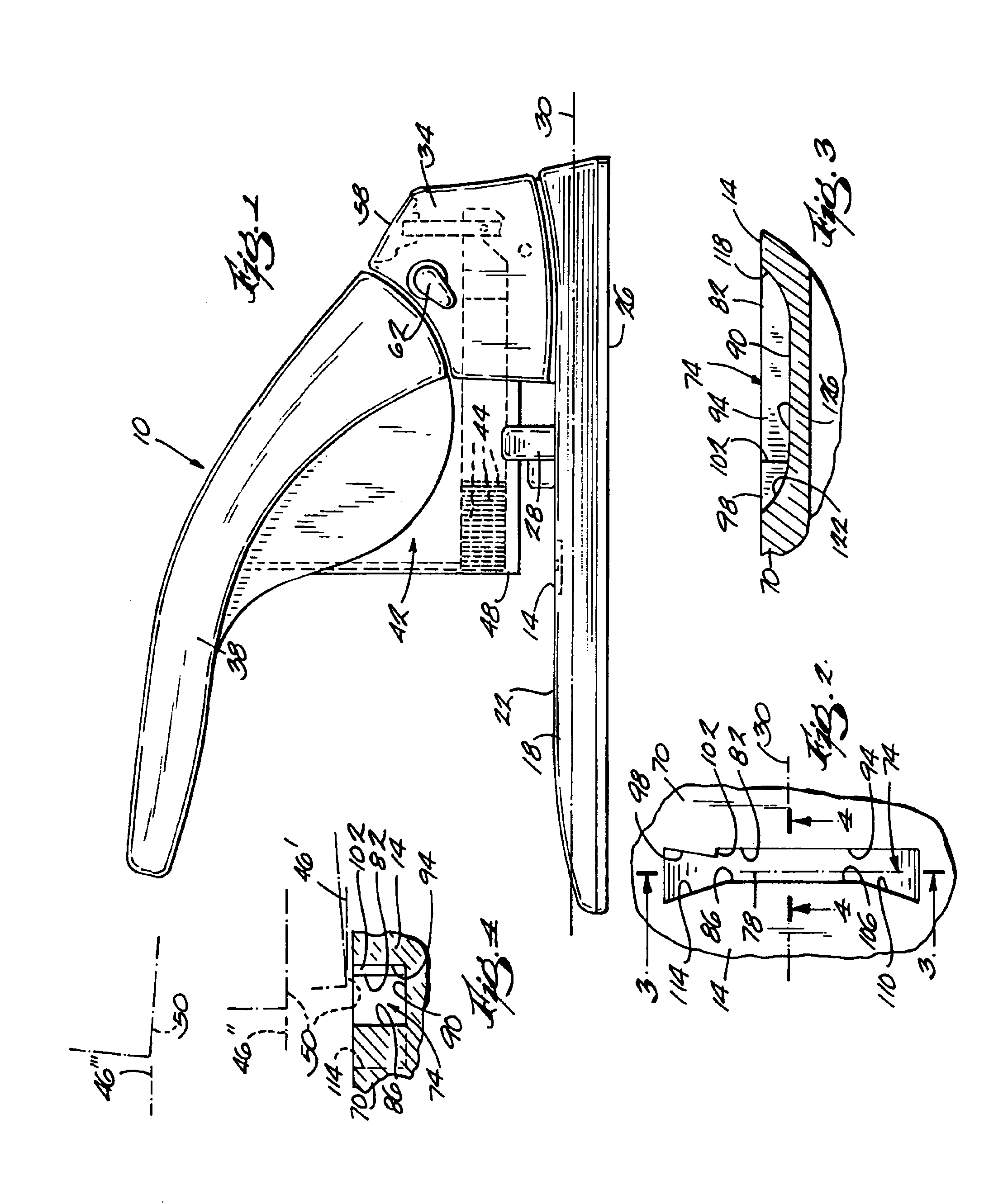

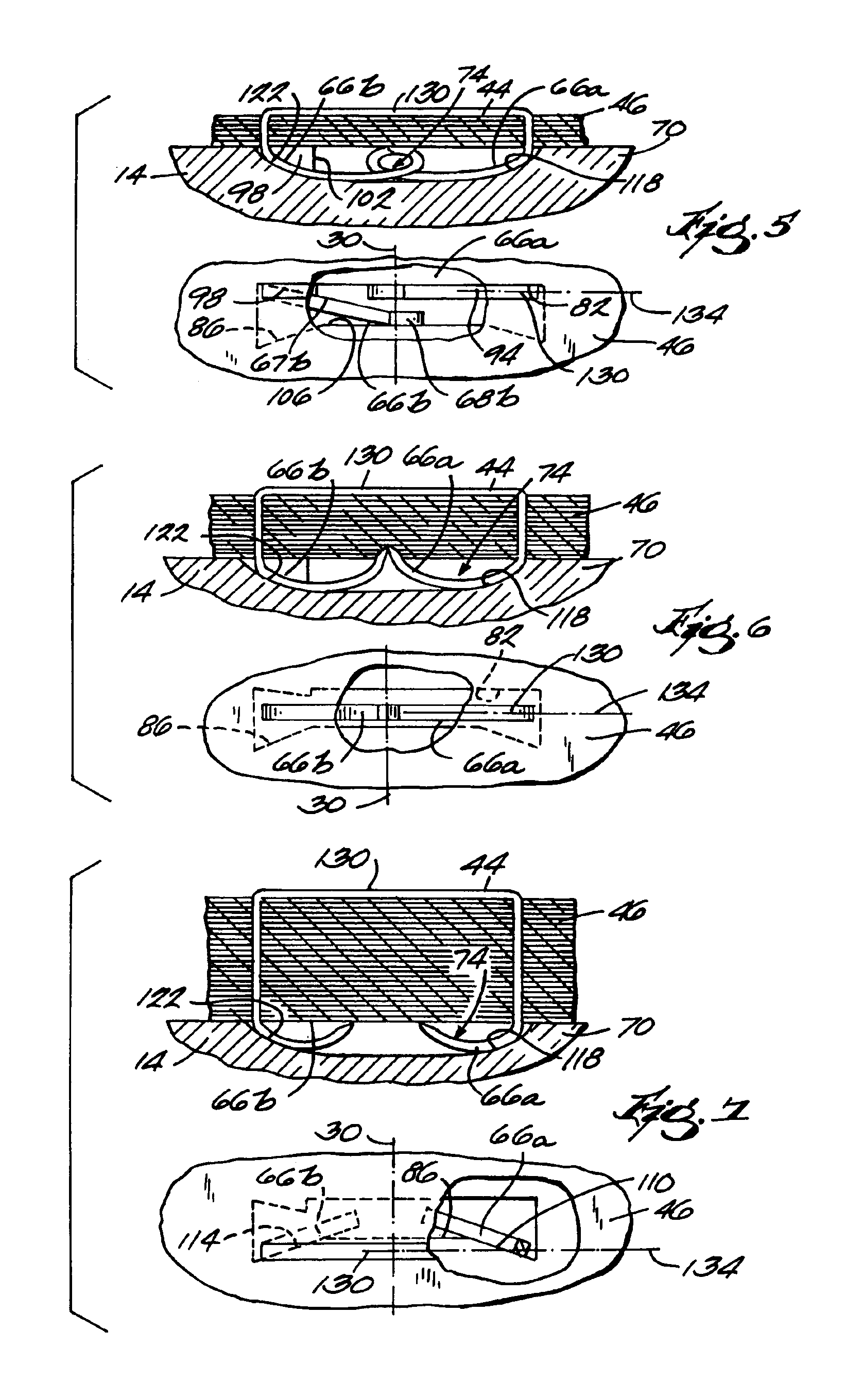

Stapler anvil

InactiveUS6925849B2Prevents staple jammingFacilitates staple removalDrawing mandrelsStapling toolsEngineering

Owner:ACCO BRANDS USA LLC

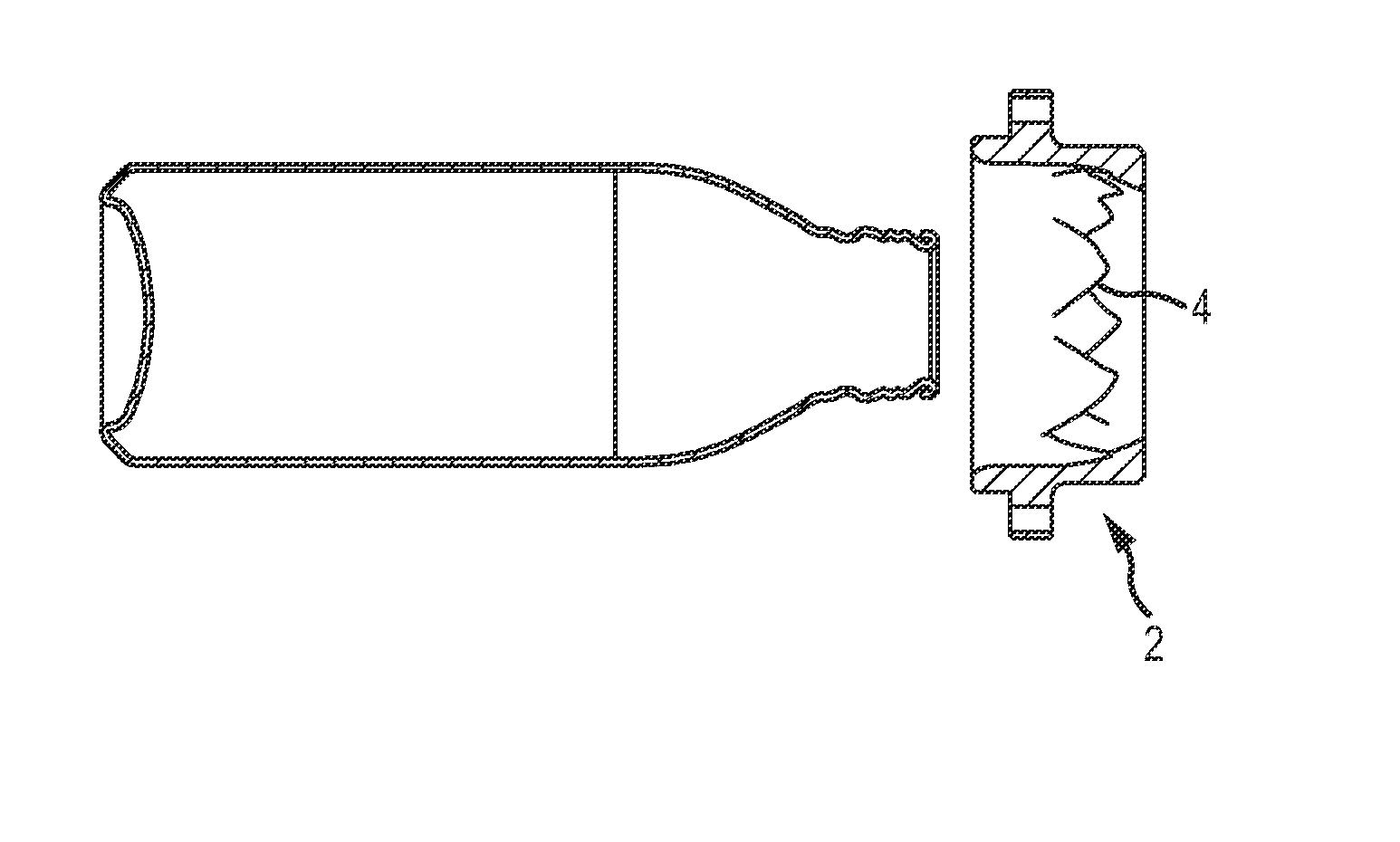

Elongated member/radially expandable member assembly and methods of assembling the same

At least one embodiment generally relates to using an installation tool to pass an expansion mandrel through an elongated member to at least locally, radially expand at least a portion of the elongated member and achieve an interference fit with a radially expandable member located about an outer surface of the elongated member. In one embodiment, the elongated member is radially expanded over its entire length and may include a stepped feature so that only a portion of the elongated member achieves the interference fit with the radially expandable member. During the radial-expansion process, both the radially expandable member and the elongated member may be at the same or approximately the same temperature. Before the radial-expansion process, the radially expandable member may be assembled using press-fit techniques, shrink fit techniques, clearance fitting techniques, or combinations thereof.

Owner:FATIGUE TECH

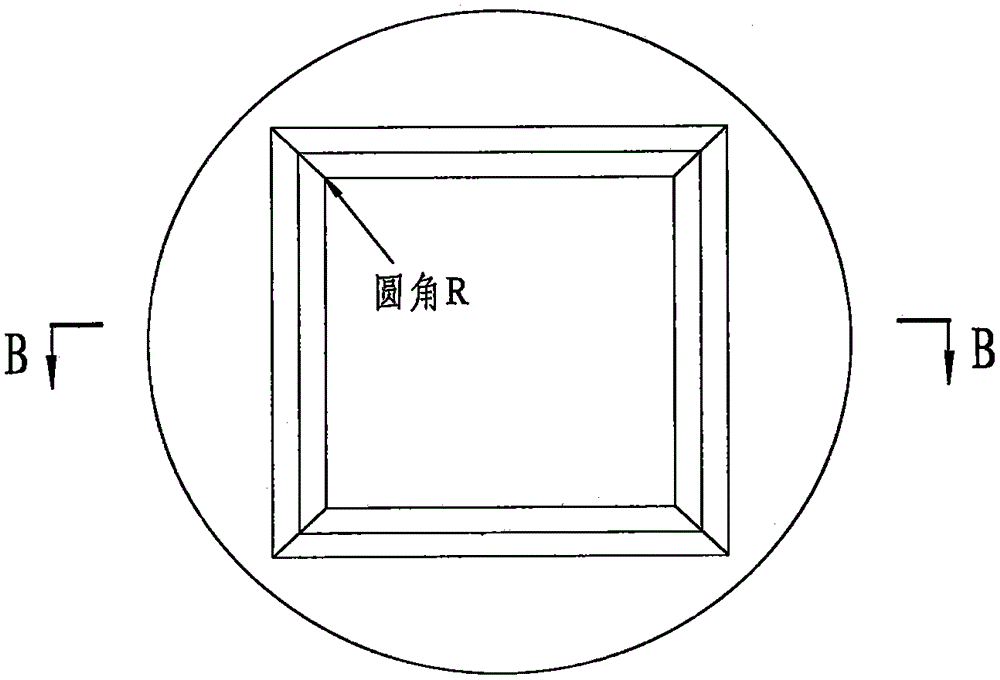

Preparation process of red copper square pipe material

ActiveCN105562456APrevent oxidationReduce operational processingDrawing mandrelsDrawing diesSurface oxidationChain type

The invention provides a preparation process of a red copper square pipe material. The process comprises the following flow processes of casting, cast ingot sawing and cutting, water seal extrusion, sawing and cutting, straightening, rolling, chain type drawbench circular drawing, circular transition to square pipe material hollow pulling, square pipe material hollow pulling, shaping drawing, finishing, bright annealing and packaging; the diameter shaping drawing is firstly performed after the rolling; the transition to the square pipe material is realized; the diameter shaping hollow pulling is performed; finally, a finished product is fed onto a core head to be subjected to shaping drawing; the goal that the radius R of the circular corner is gradually reduced until the radius R conforms to the requirement is achieved; the outer dimension center part back arching is avoided; the inner dimension is enabled to conform to the requirements; the water seal decrustation processing mode is used in the extrusion process; the pipe blank surface oxidation can be prevented; the process processing process is reduced; the product quality is further ensured.

Owner:中铝洛阳铜加工有限公司

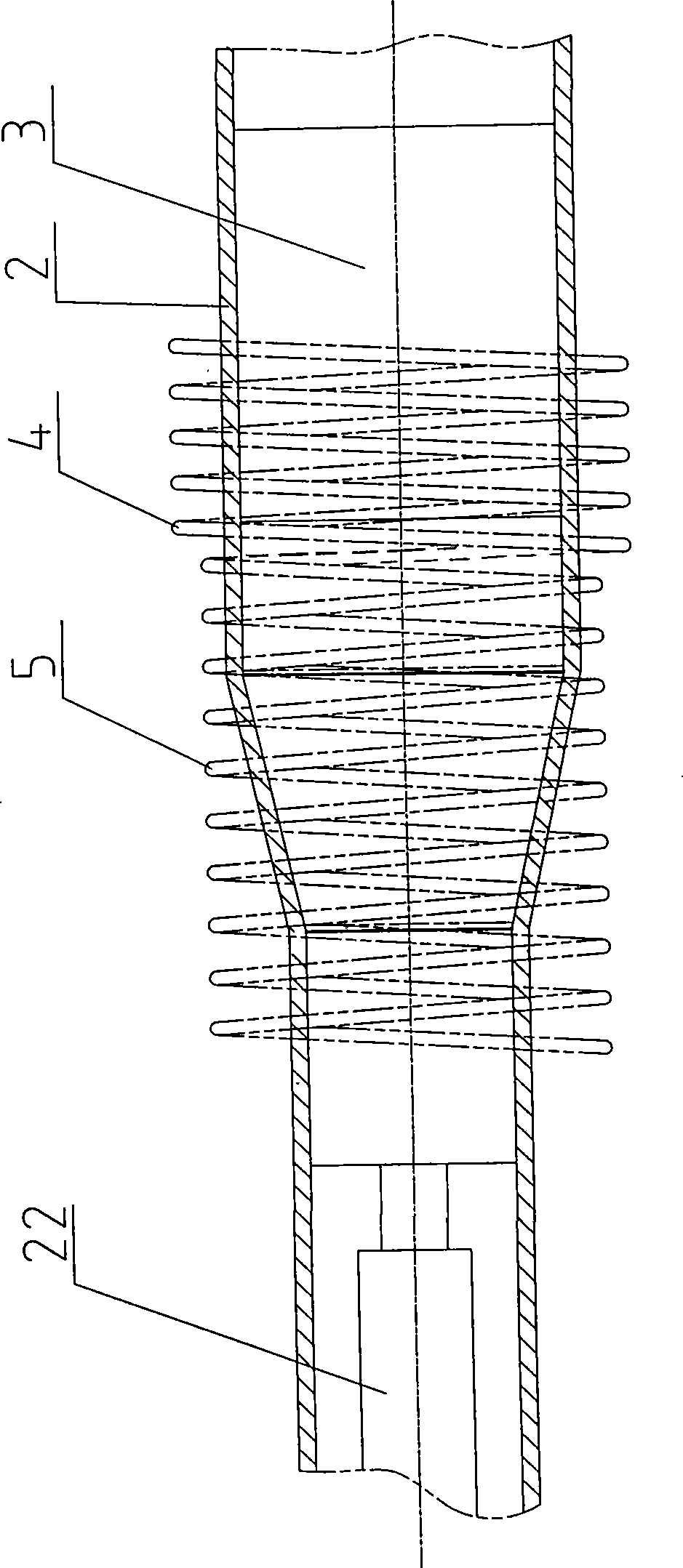

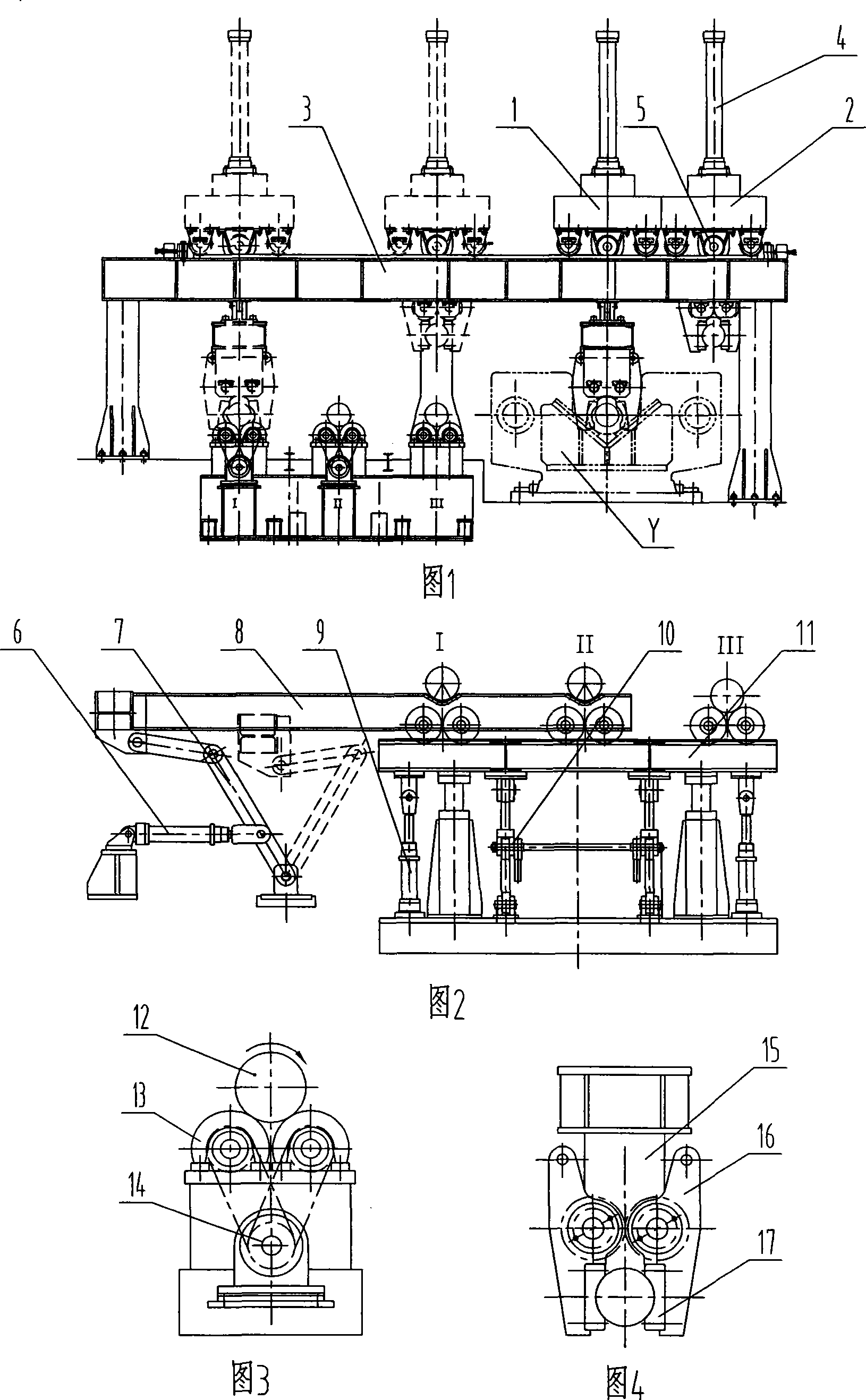

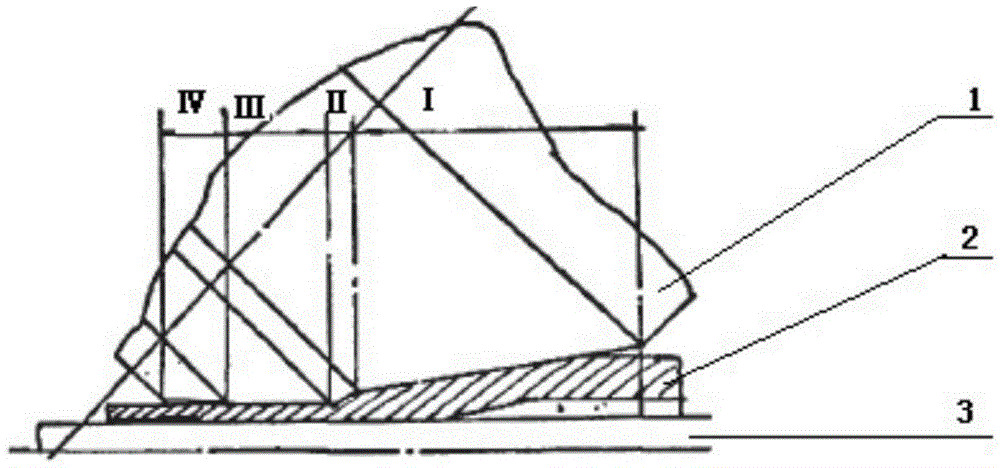

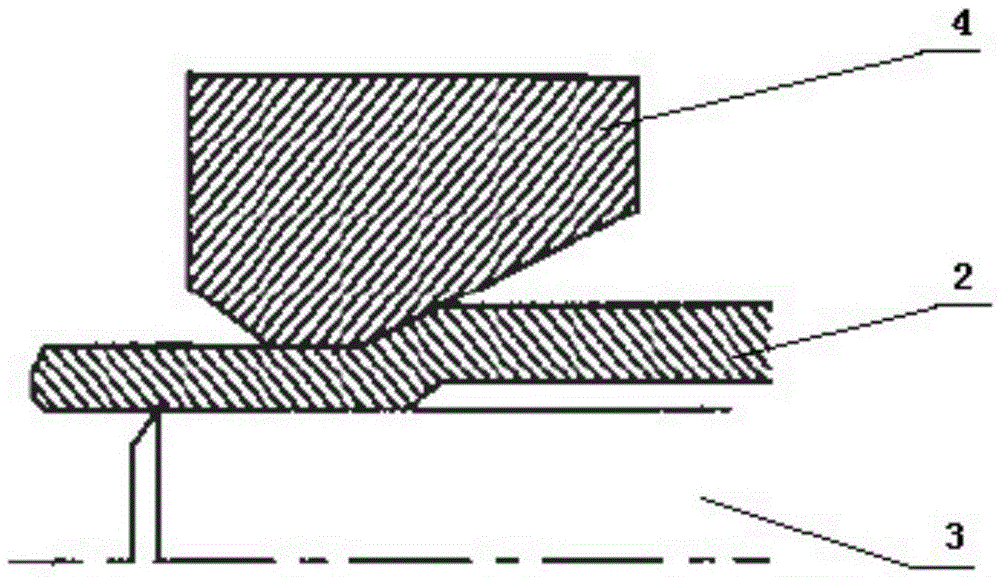

Thermal expansion machine for producing stainless steel tube

InactiveCN101468364AThe material remains the sameConstant wall thicknessDrawing mandrelsShaping toolsIntermediate frequencyNational standard

The invention provides a tube manufacturing machine for thermal diameter expansion of a stainless steel tube, and belongs to a steel tube processing device. The tube manufacturing machine comprises a bracket, a supporting plate, a rear push plate, a front push plate and a front supporting plate arranged on a stand sequentially from rear to front; an intermediate frequency heating coil of an intermediate frequency induction heating coil device consists of an induction heating coil section and a heat insulating coil section; a core head mould consists of a guide section, a diameter variation section, a diameter sizing section, a tapered section, and an alignment section from rear to front; and in the tube manufacturing machine for the thermal diameter expansion of the stainless steel tube, the structures of the core head mould and the intermediate frequency heating coil and a material of the core head mould are suitable for requirements on the thermal tube expansion of the stainless steel tube; the diameter of the stainless steel tube is arbitrarily enlarged and shaped, and the material and the wall thickness of the stainless steel tube after diameter expansion is unchanged. Simultaneously, the stainless steel tube after the diameter expansion reaches the requirement on normalizing, and improves a metallographic phase structure of the original stainless steel tube so as to improve the physical performance of the stainless steel tube after the diameter expansion and fully reach or exceed various indexes regulated by national standard.

Owner:付朋

System for compression relief shaping

ActiveUS20150360279A1Easy to controlReduces “Drawing mandrelsDecorative surface effectsEngineeringMechanical engineering

Owner:BALL CORP

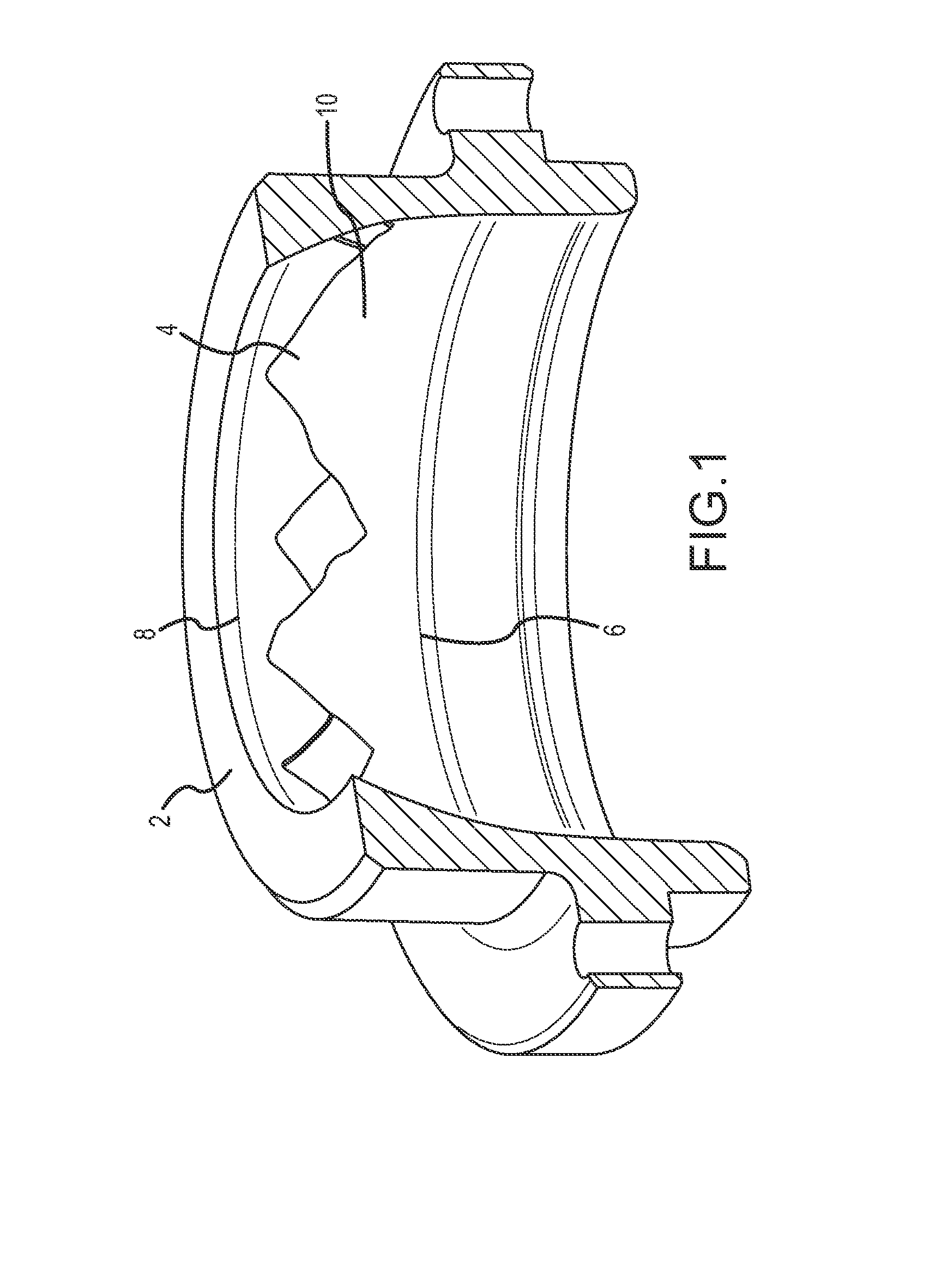

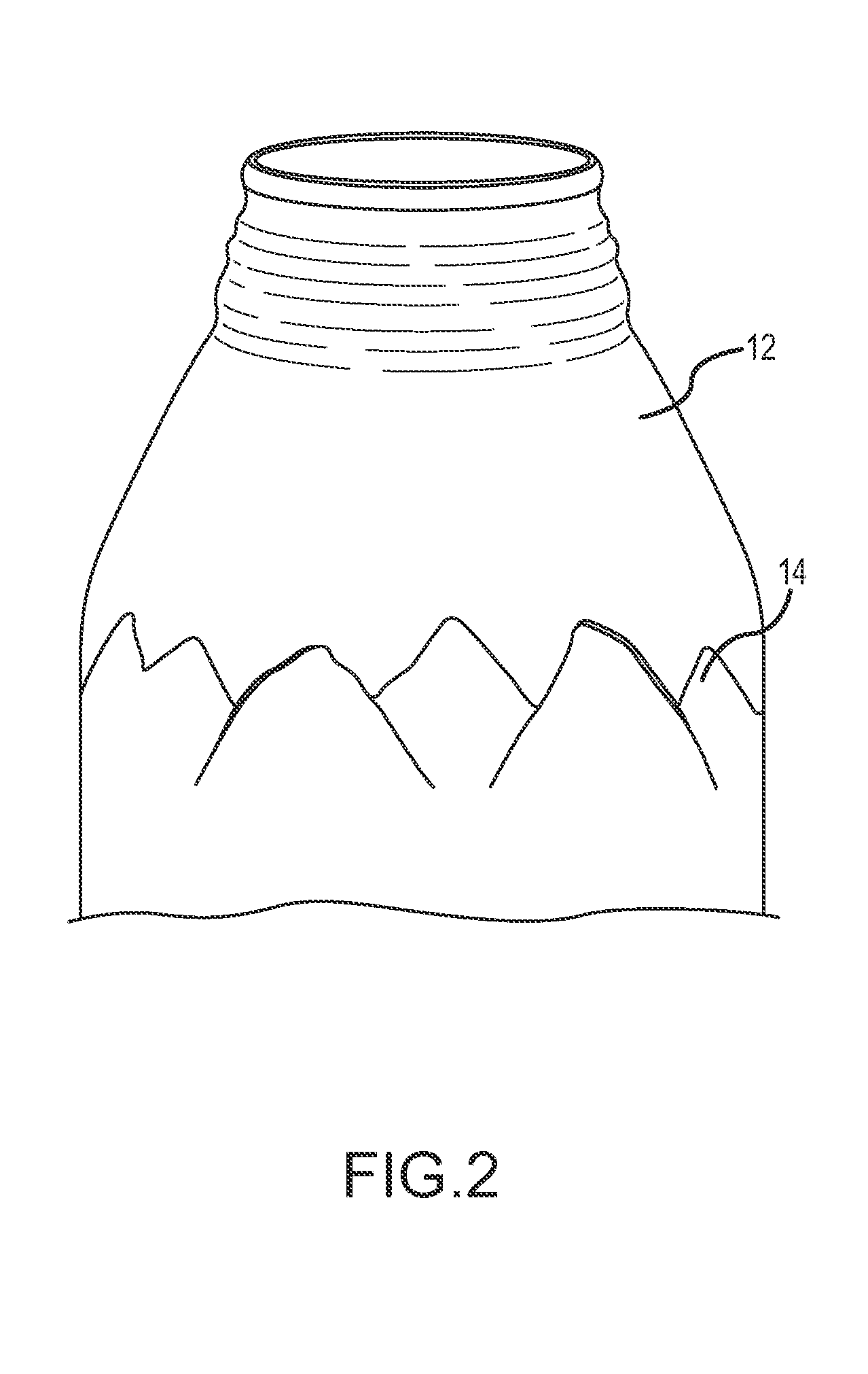

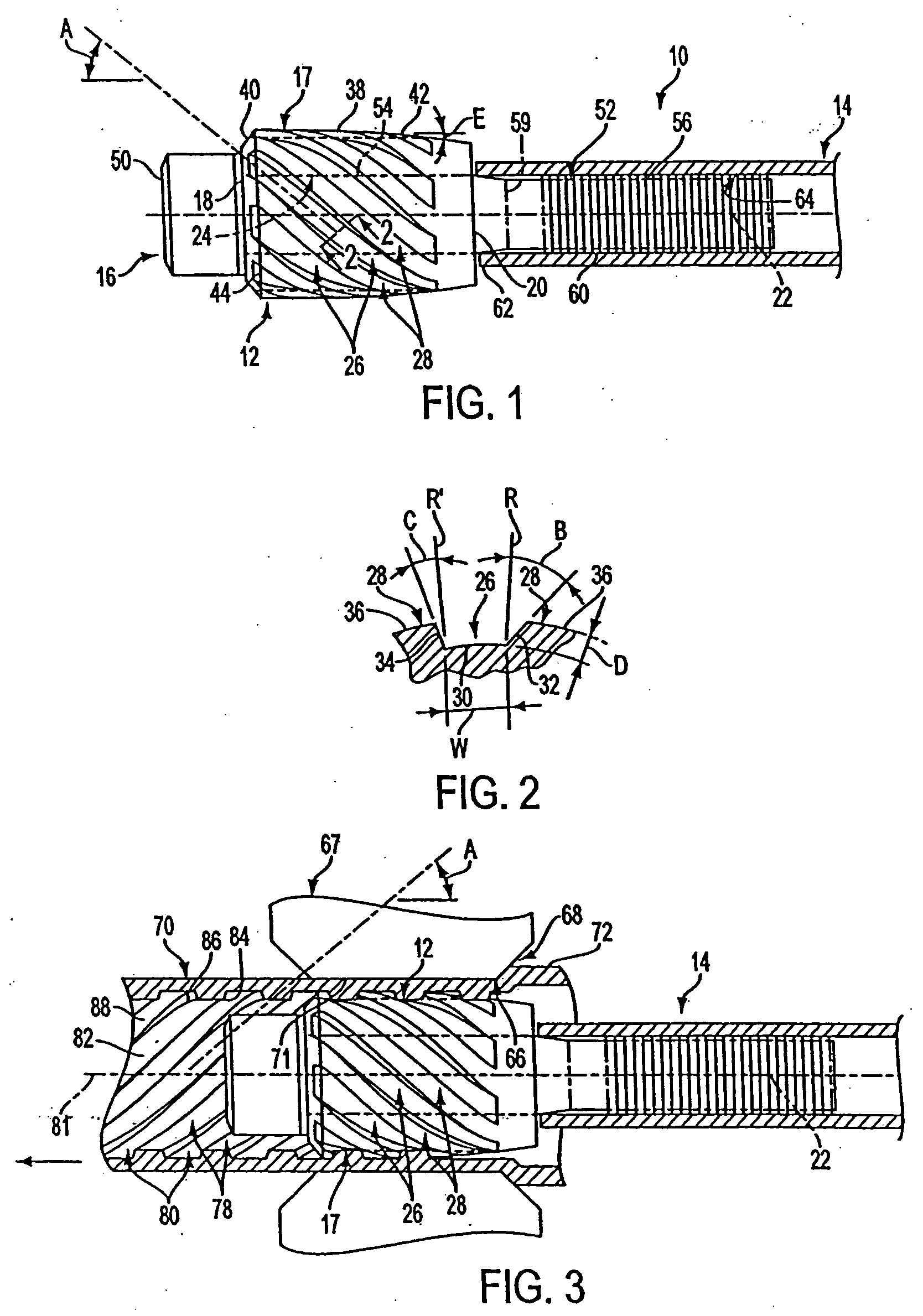

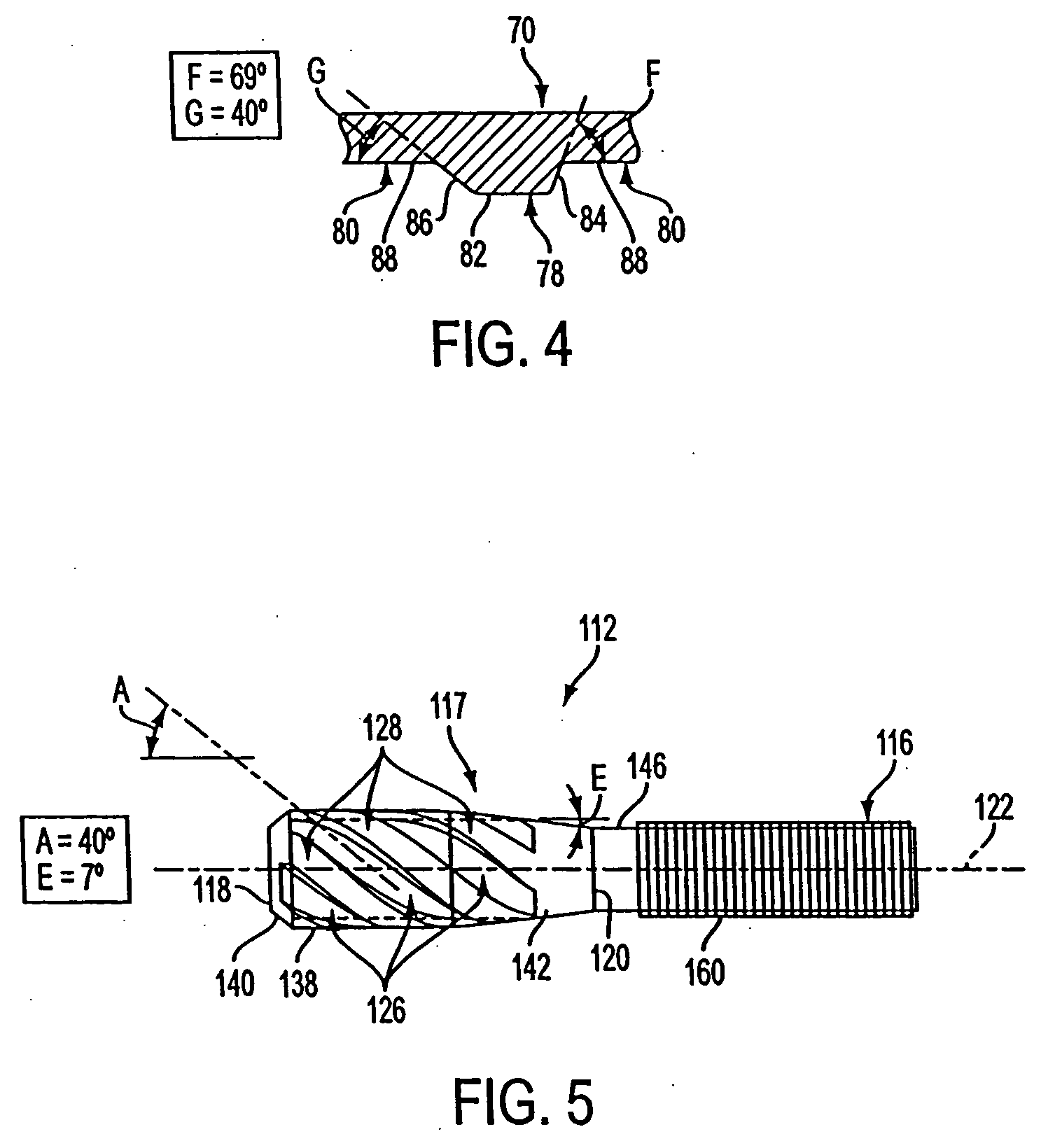

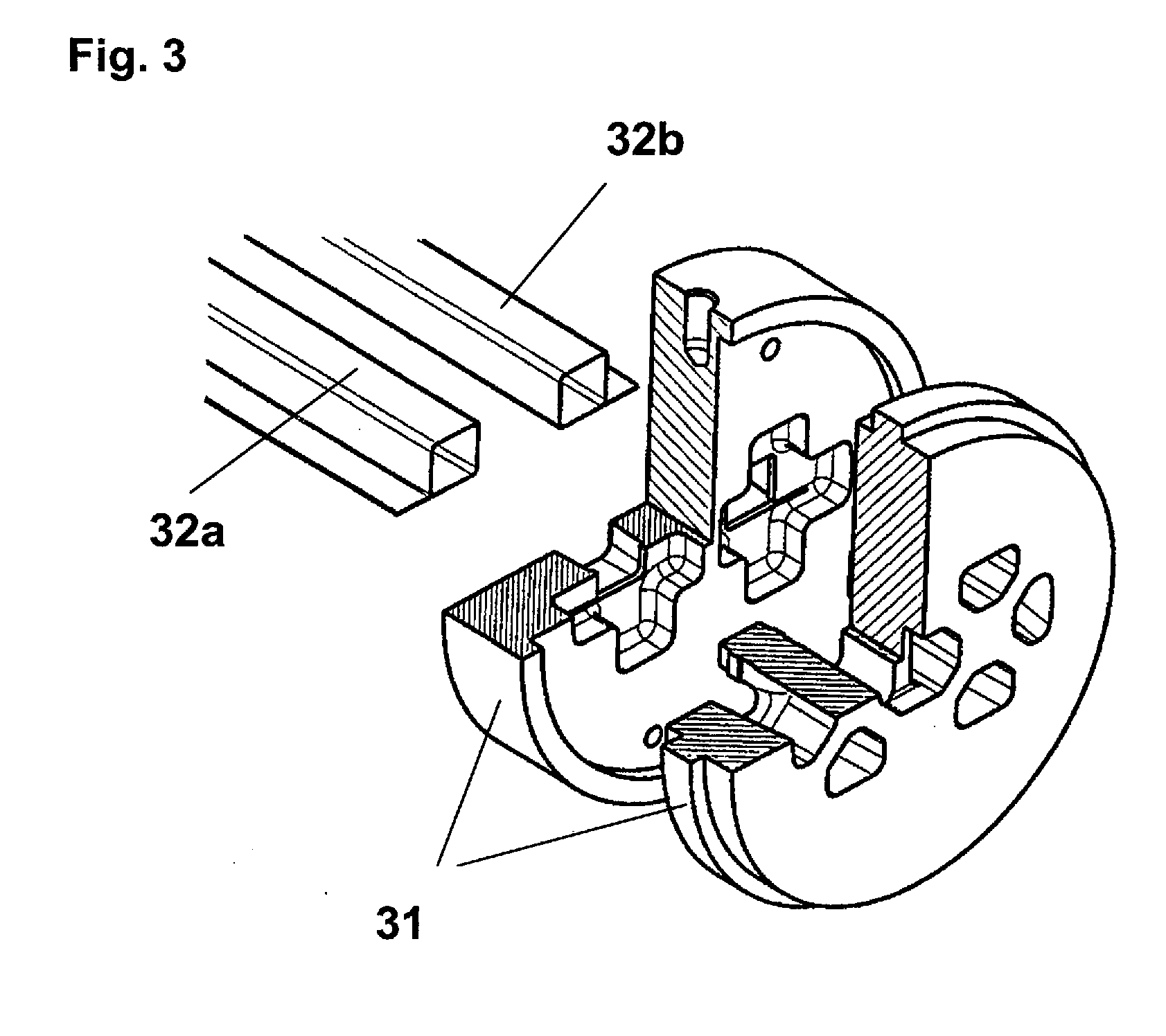

Apparatus and method for forming internally ribbed or rifled tubes

ActiveUS20050229667A1Improve productivityImprove tool lifeDrawing mandrelsMetal rolling stand detailsEngineeringHelix

A plug tool for forming internally helically ribbed tube comprises a plug body for being rotatably disposed in a die orifice of a drawing die. The plug body has a central longitudinal axis, a plurality of external grooves equally spaced about the axis and a plurality of external lands in alternating arrangement with the grooves. The grooves extend along the plug body at a helix angle to the axis. Each groove has a normal cross-section defined by a root surface and opposing flank surfaces extending angularly outwardly from the root surface to adjacent land surfaces. The flank surfaces extend angularly outwardly from the root surface in opposite directions at different angles from one another. A method for forming internally helically ribbed tube involves drawing a length of tubing over the plug body rotatably disposed in a die orifice of a drawing die and constricting the tubing in the drawing die to force the tubing into the grooves of the plug body to form a plurality of internal helical ribs in the tubing in correspondence to the grooves.

Owner:DOOSAN BABCOCK ENERGY AMERICA

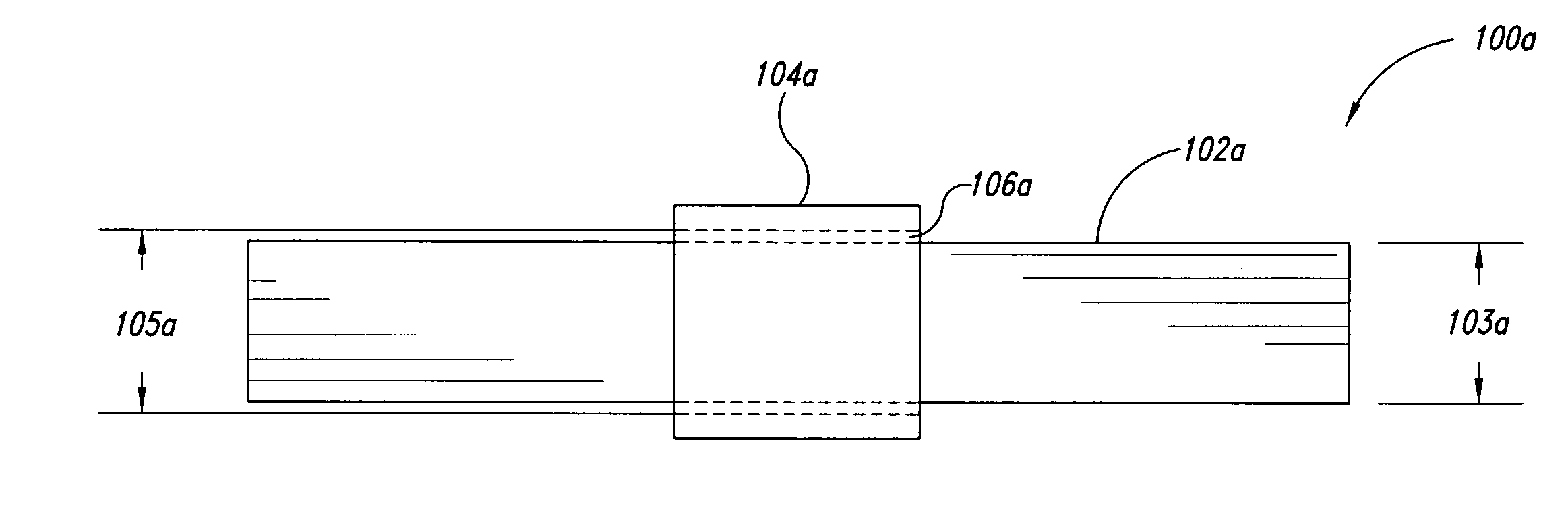

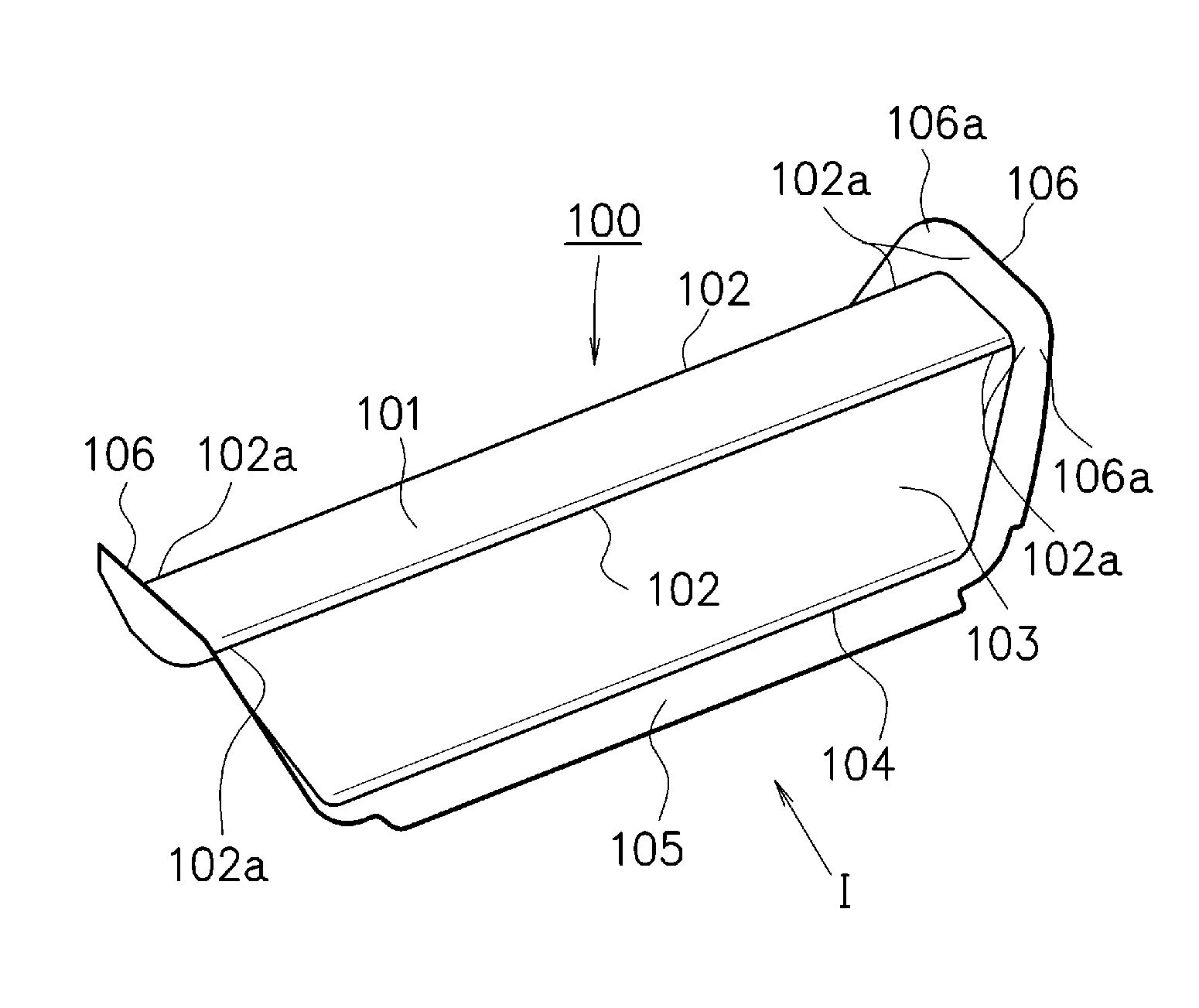

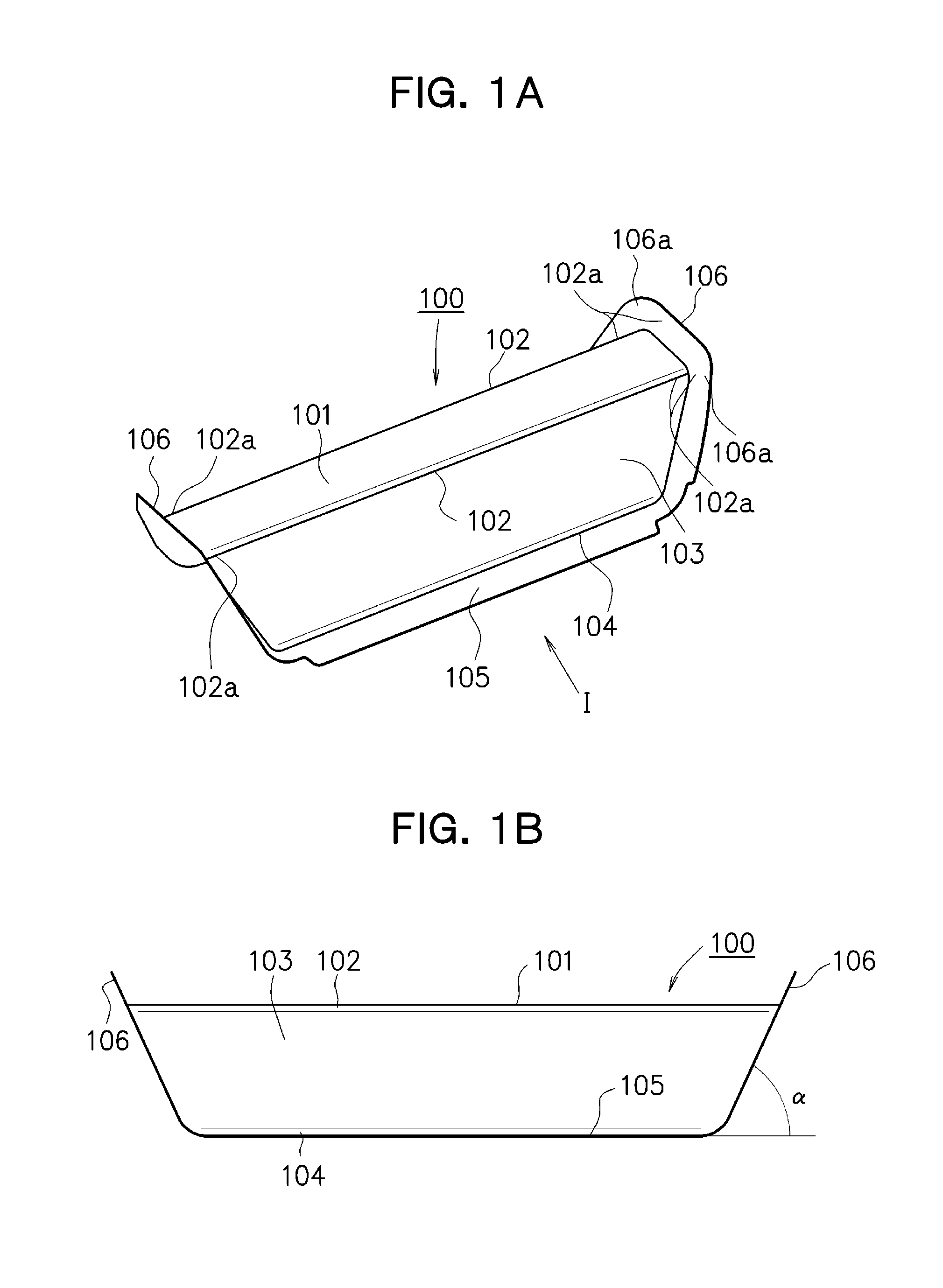

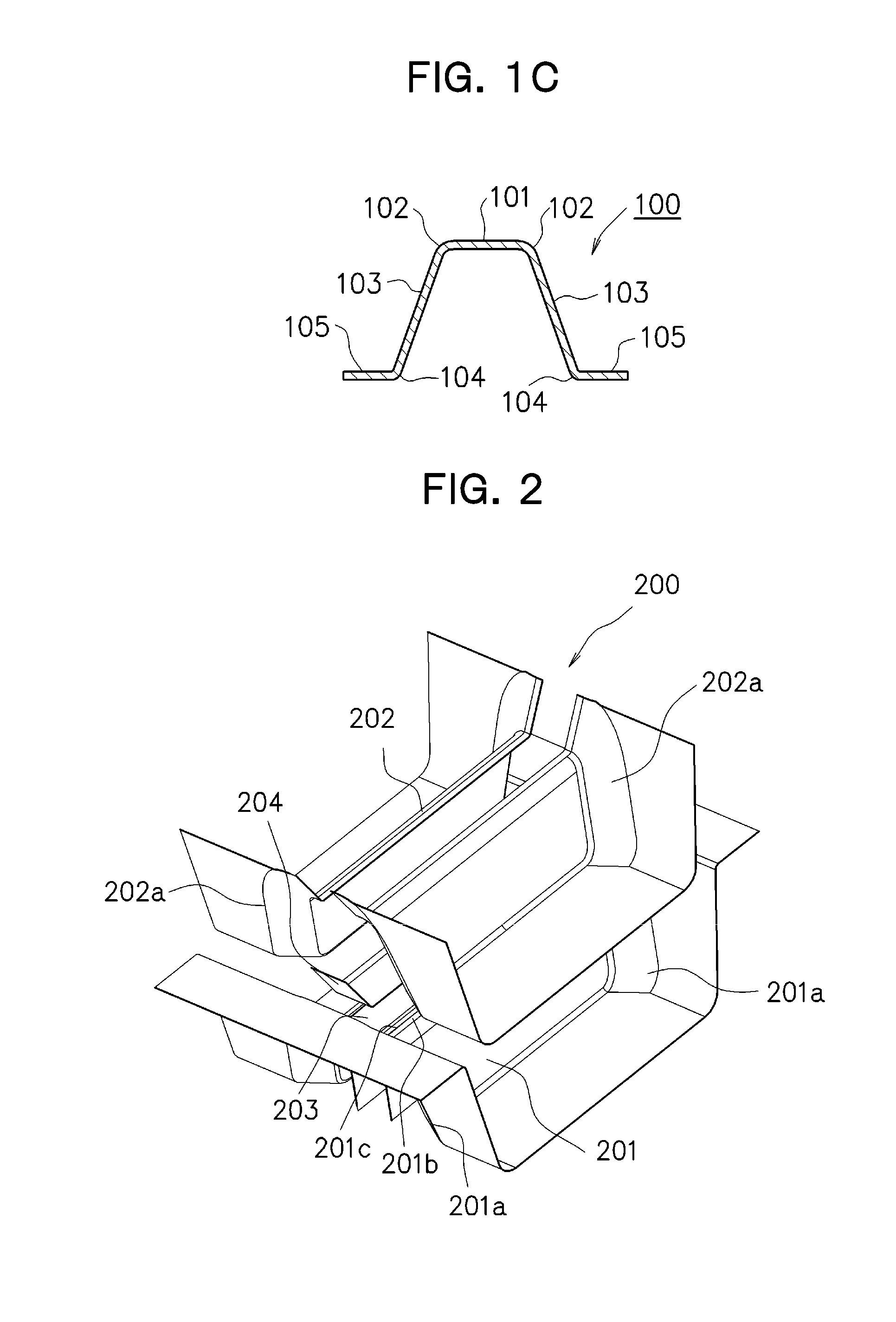

Manufacturing method of press-formed member and press forming apparatus

ActiveUS20150367392A1Improve rigidityImprove noiseDrawing mandrelsVehicle componentsEngineeringFlange

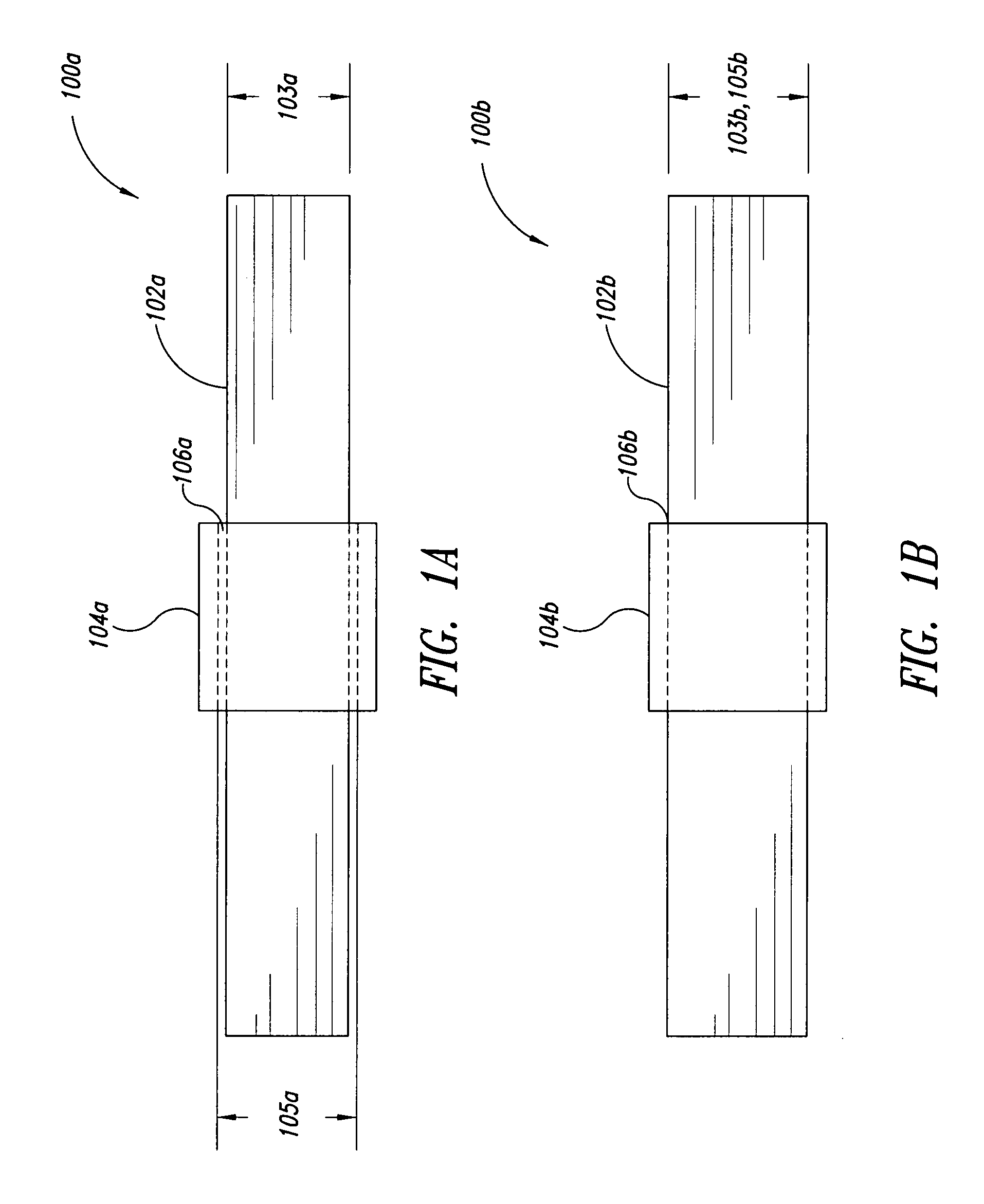

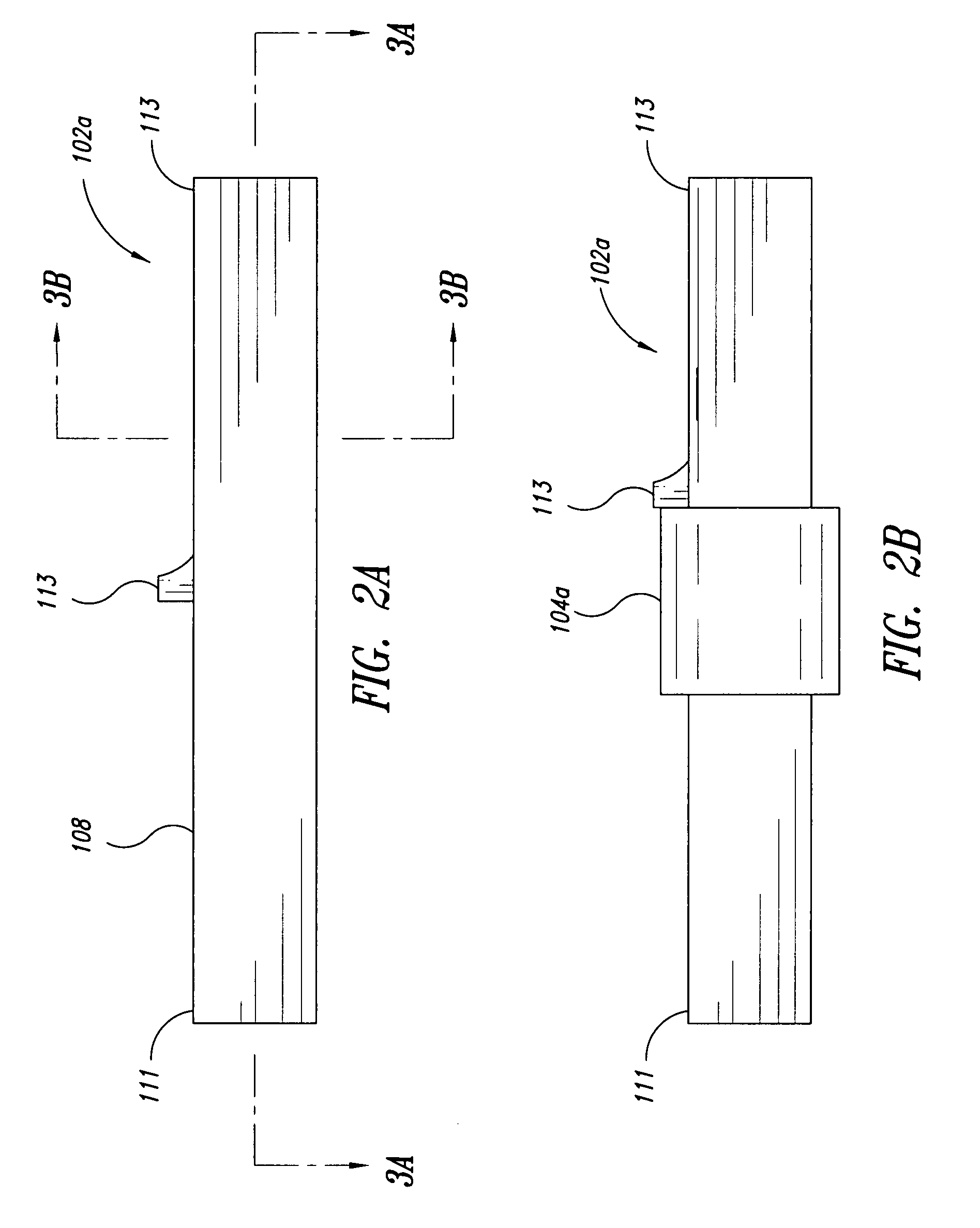

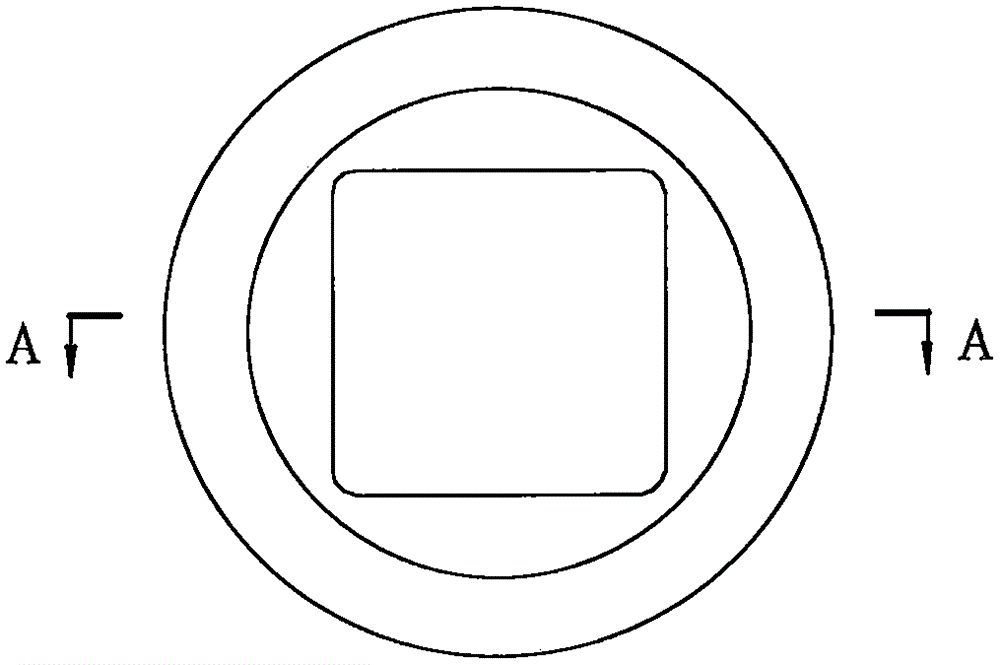

In a press forming step of obtaining, from a blank (300) of high-tensile strength steel sheet of 390 MPa or more, a press-formed product with a shape of cross section having at least a groove bottom part (101), ridge line parts (102), and vertical wall parts (103), and in which an outward flange (106) including parts (106a) along the ridge line parts (102) is formed at an end part in a longitudinal direction, forming of parts to be formed to the ridge line parts (102) is started by creating a state where a region (300a) positioned at least at an end portion in a longitudinal direction of a part to be formed to the groove bottom part (101) of the blank (300) is separated from a punch top part (201b), and at that time or thereafter, the region (300a) is made to approach the punch top part (201b). Accordingly, when the forming of the ridge line parts (102), and in accordance with that, the forming of the parts (106a) of the outward flange (106) are conducted, the parts are formed relatively moderately from the start to the middle of the press forming, to thereby reduce or prevent an occurrence of stretch flange fracture and a generation of wrinkling.

Owner:NIPPON STEEL CORP

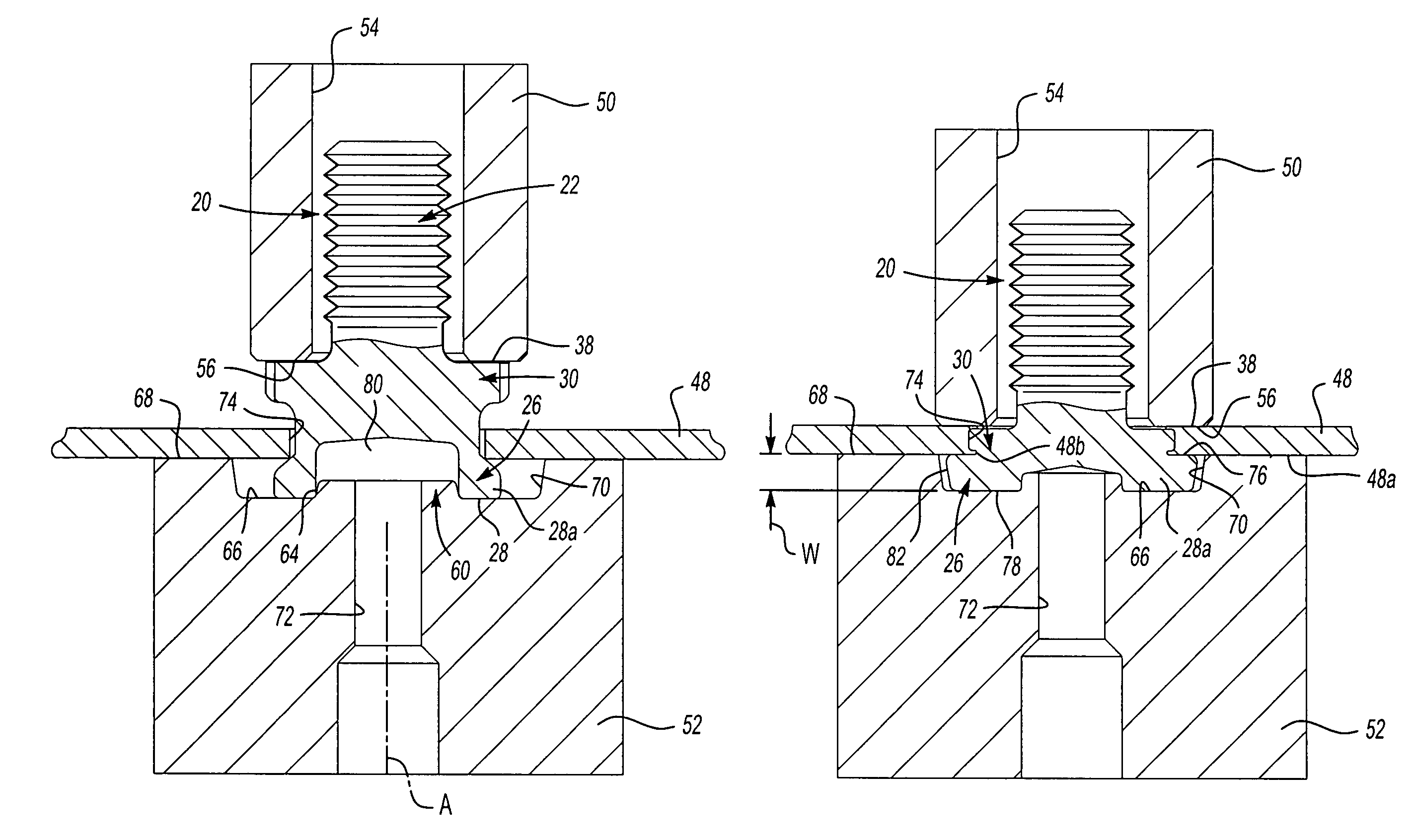

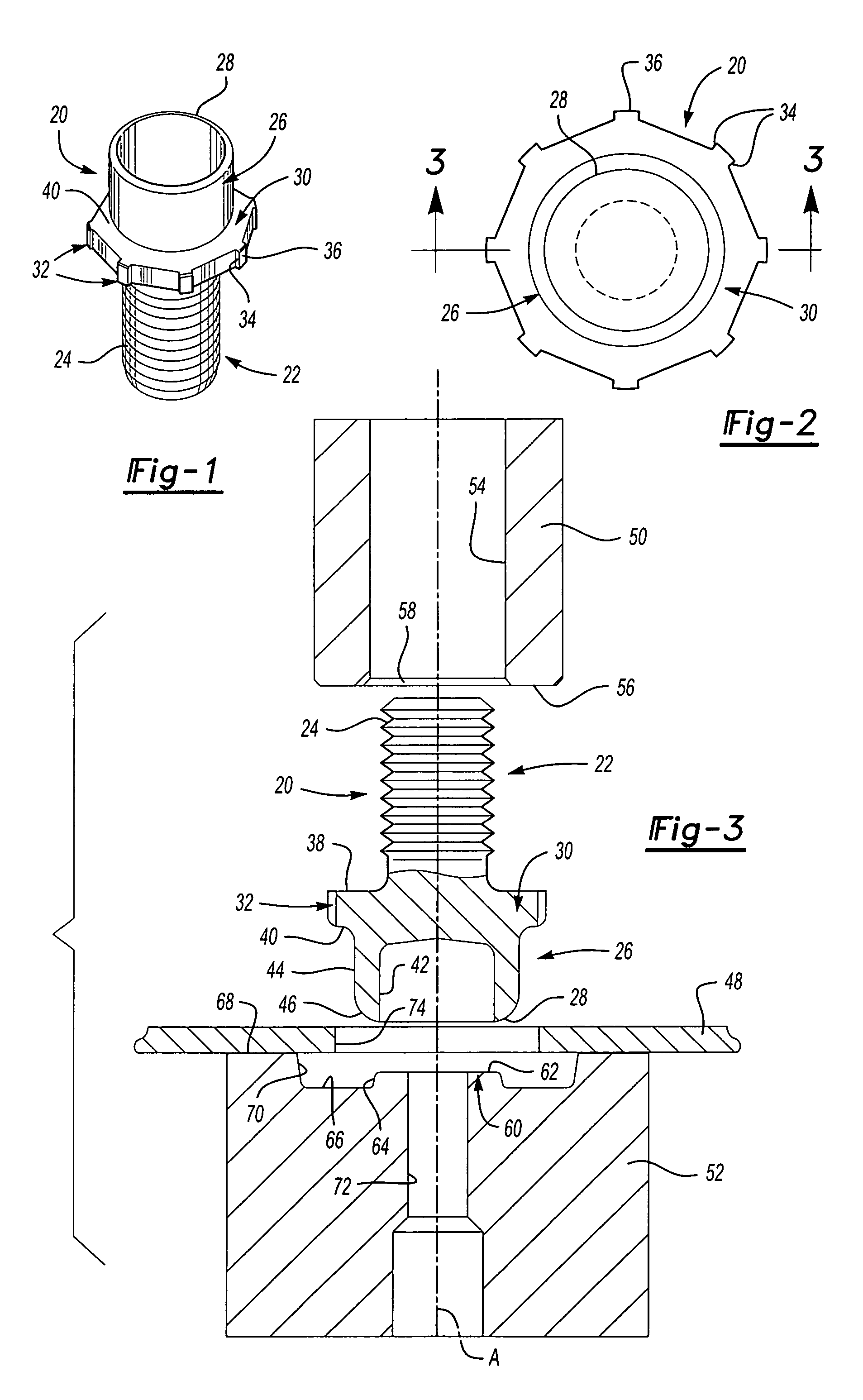

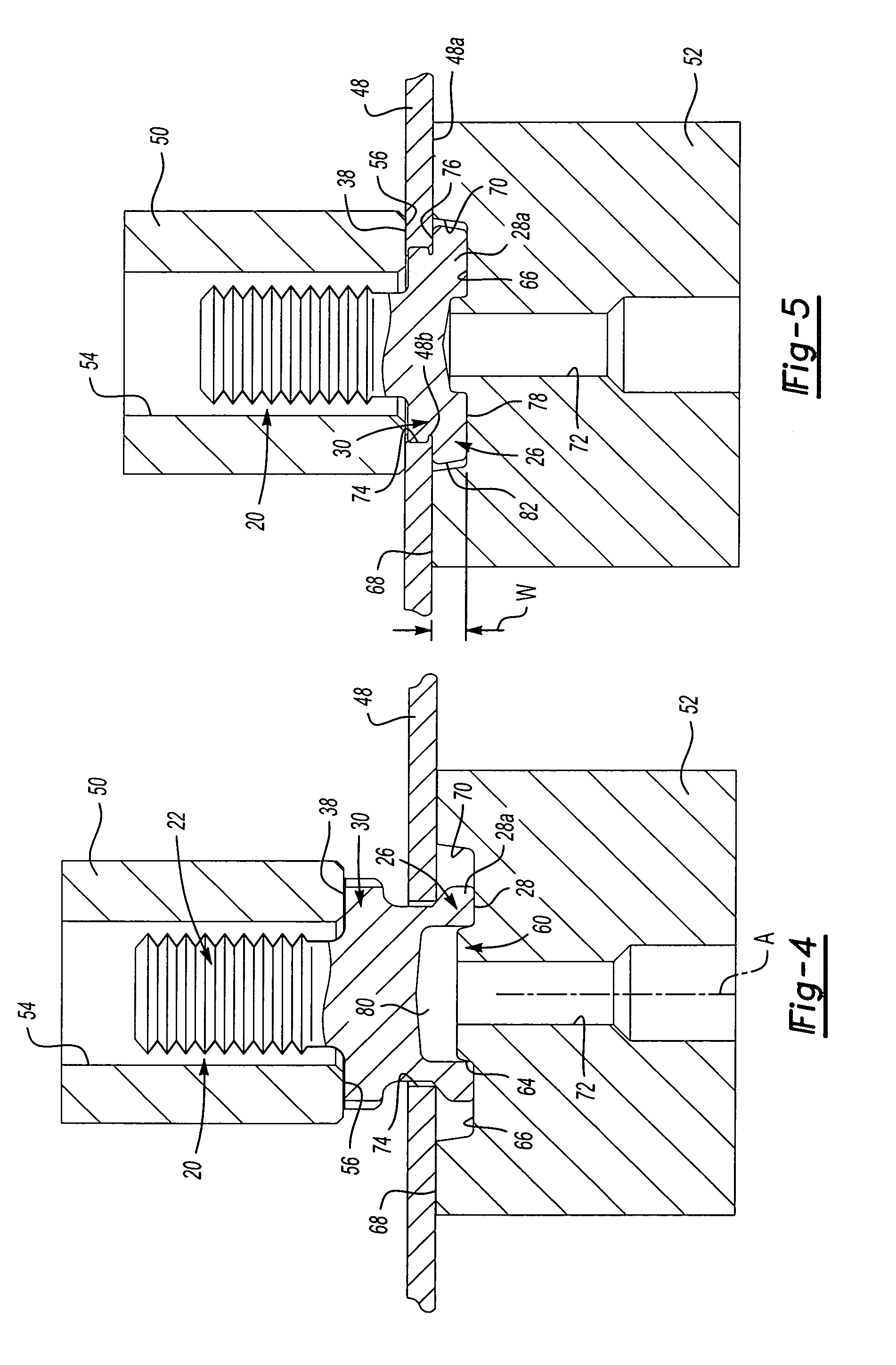

Method of attaching a self-attaching fastener to a panel

ActiveUS7380326B2Eliminate cracksWell formedDrawing mandrelsRopes and cables for vehicles/pulleyFace sheetBearing surface

A self-attaching fastener and panel assembly wherein the free end of the tubular barrel portion is coined and deformed axially and radially outwardly against a planar die face into an annular shape having a planar annular bearing surface supporting the panel and a flat end face. The die includes a central post and an annular planar die surface extending substantially perpendicular to the longitudinal axis of the die member. The method of installation includes coining and deforming the barrel portion axially and radially eliminating cracking of the barrel, frictional resistance and hoop-stress.

Owner:PENN AUTOMOTIVE INC

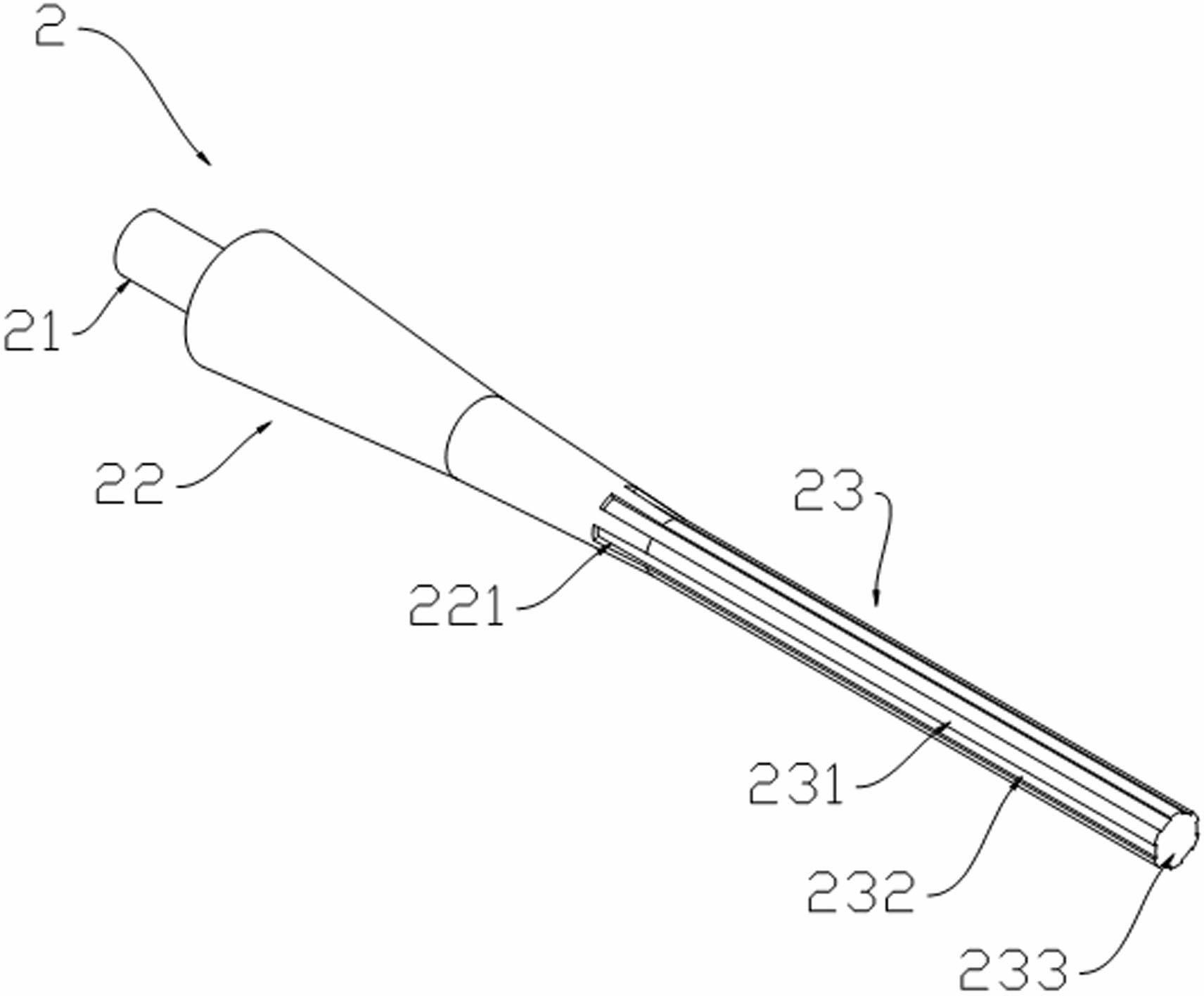

Forming Tool

InactiveUS20080209976A1Fine deterministic structureReduce thicknessDrawing mandrelsShaping toolsPolymerExtrusion

A forming tool (20) it comprises a substrate (21) and a metallic glass layer (23) on at least the working surface (22) of the forming tool (20) wherein the forming tool is one of:a) a forming tool of an extrusion press;b) a die of a wire-drawing machine;c) a roll of a polymer processing unit.

Owner:ENGINEERED PRODS SWITZERLAND

Method of making an internal grooved tube

Owner:FURUKAWA ELECTRIC CO LTD

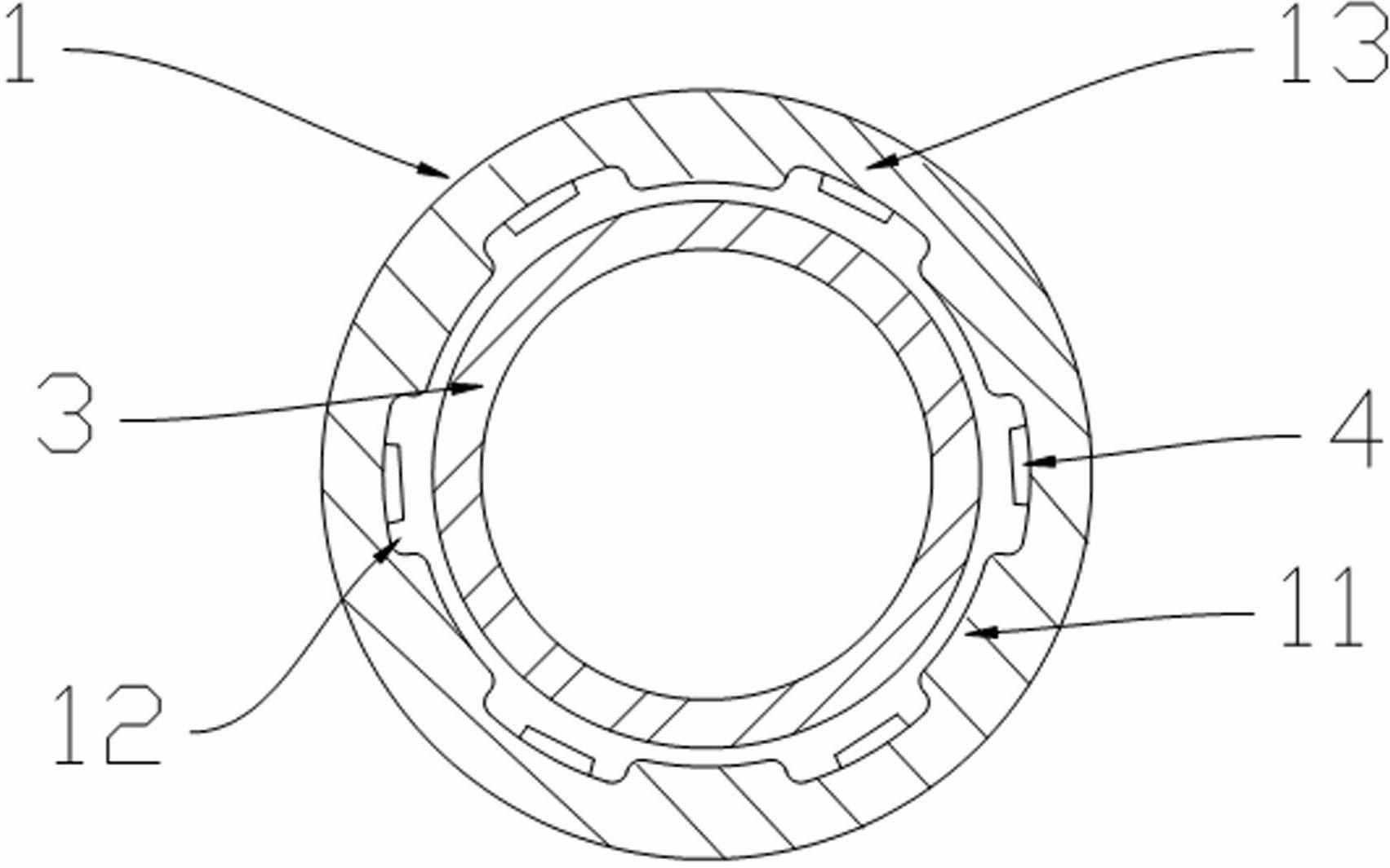

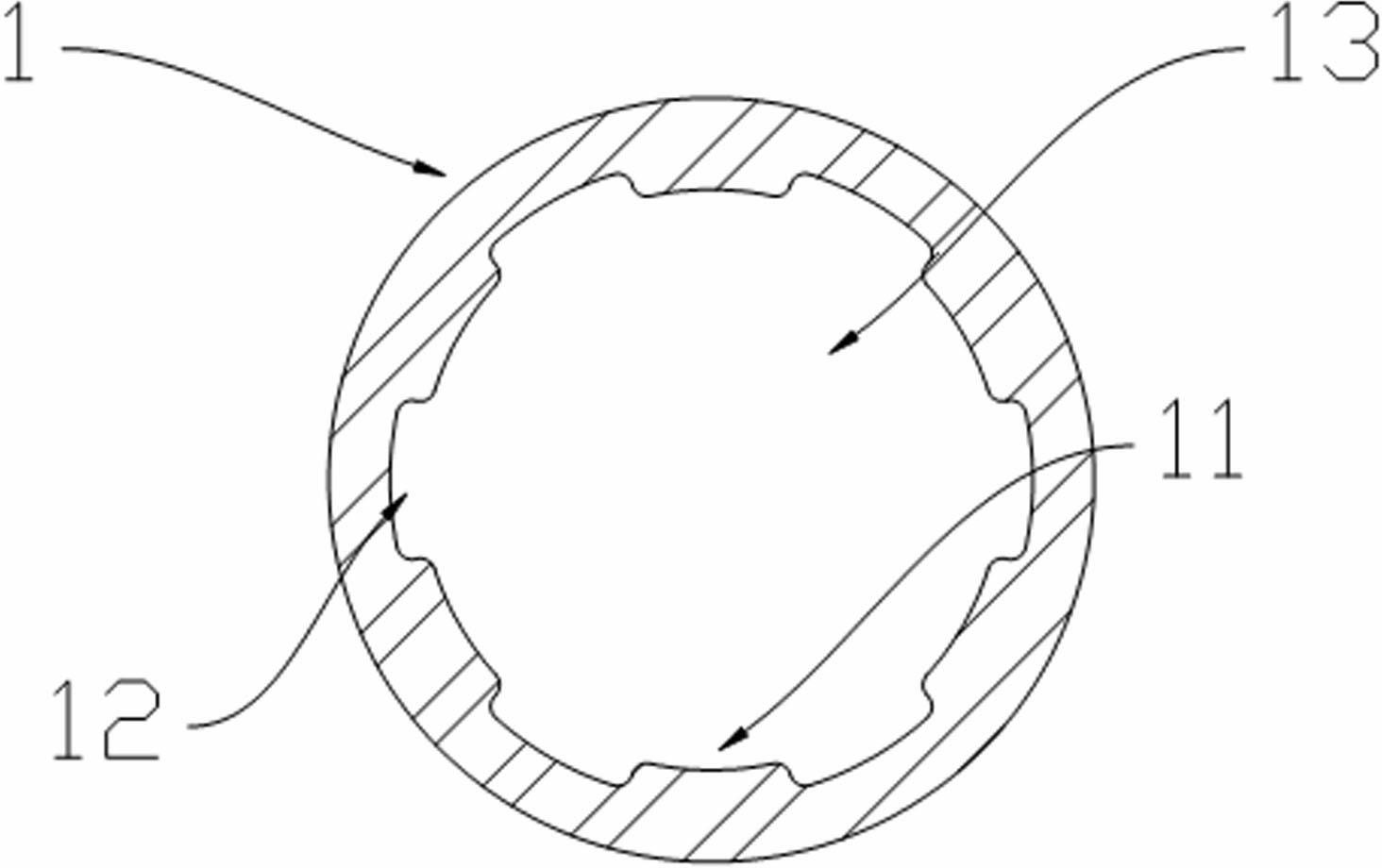

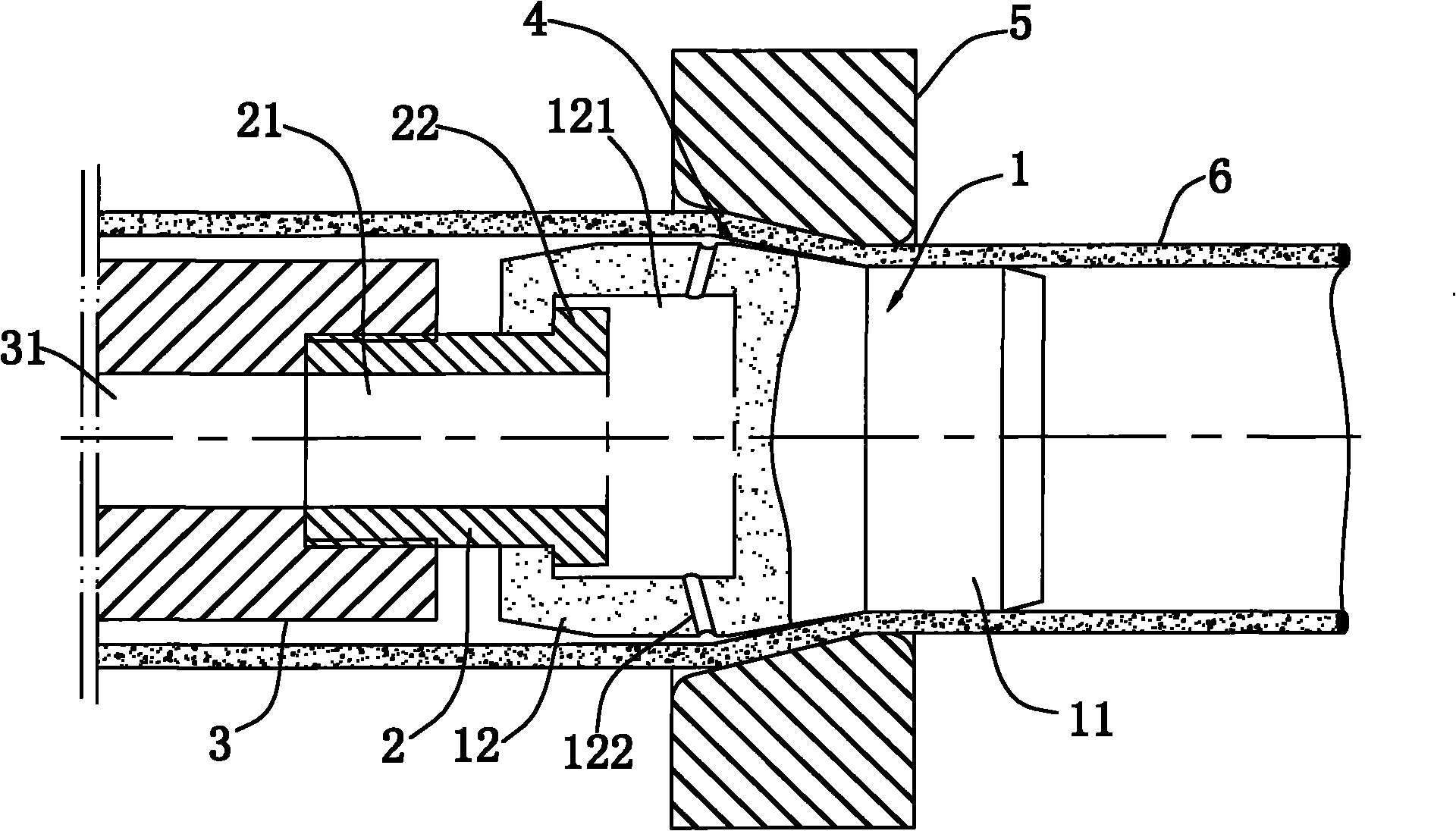

Ship oil way protection device, processing method of protection sleeve and core rod for processing

InactiveCN102606841AGuaranteed uptimeHigh strengthDrawing mandrelsMandrelsMarine engineeringProtection KIT

The utility model discloses a ship oil way protection device, which comprises an oil pipe and a protection sleeve sleeved outside the oil pipe. The protection sleeve comprises a first body and a plurality of first protrusions arranged on the inner wall of the first body, the first protrusions are distributed around the axis of the first body on the section perpendicular to the axis of the first body, a first recessed portion is formed between two adjacent first protrusions and the first body, and a pressure sensor device is arranged on the first recessed portion. The processing method of the protection sleeve comprises hot penetrating, cold drawing and cold rolling. The core rod for processing the protection sleeve comprises a connection section, a transition section and a working section which are sequentially connected. The working section comprises a cylindrical second body and a plurality of second protrusions arranged on the outer wall of the second body, the second protrusions are arranged around the axis of the second body circumferentially on the section perpendicular to the axis of the second body. Adjacent second protrusions and the second body form a second recessed portion respectively, and a groove communicated with the second recessed portion is arranged on the transition section.

Owner:常熟市异型钢管有限公司

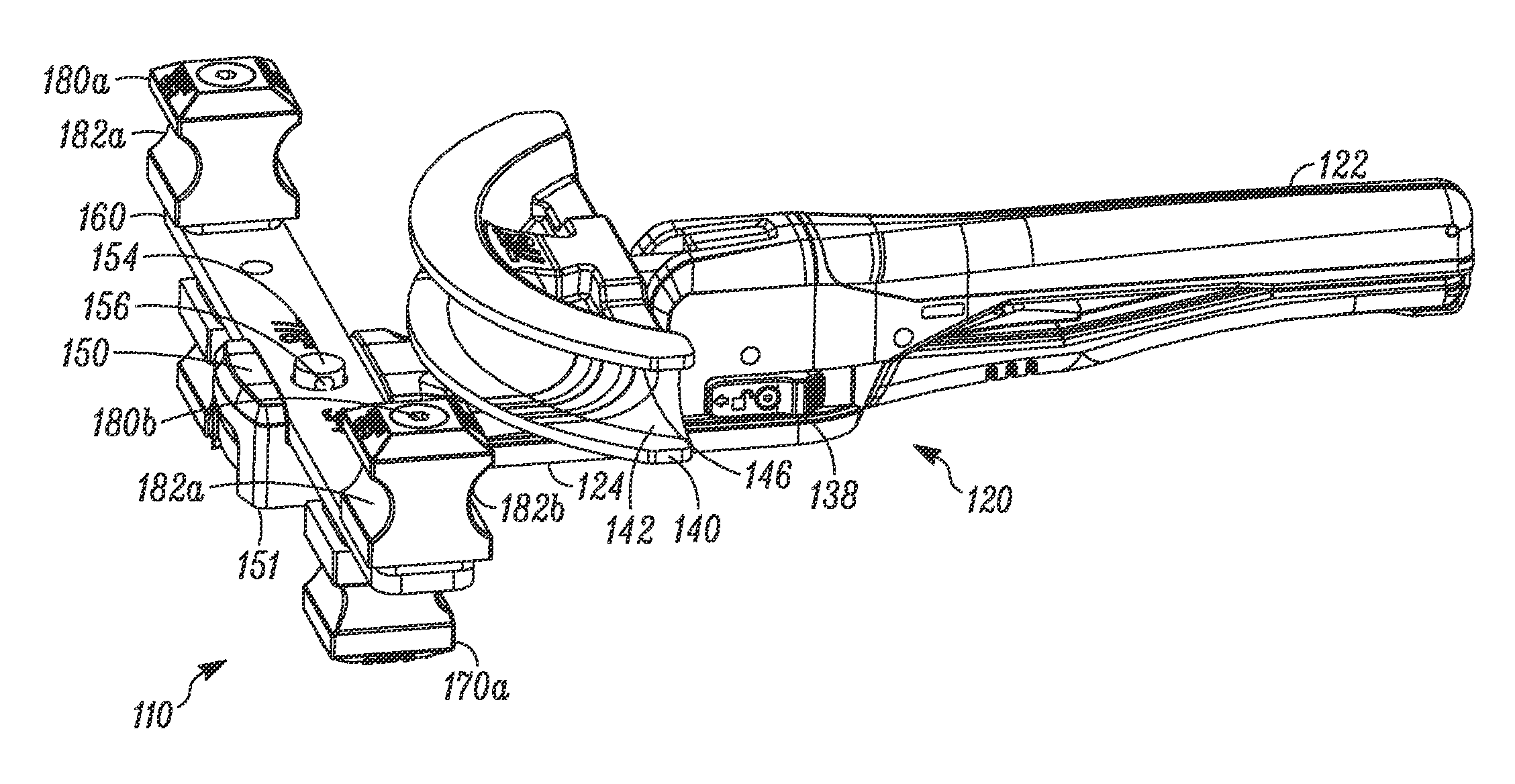

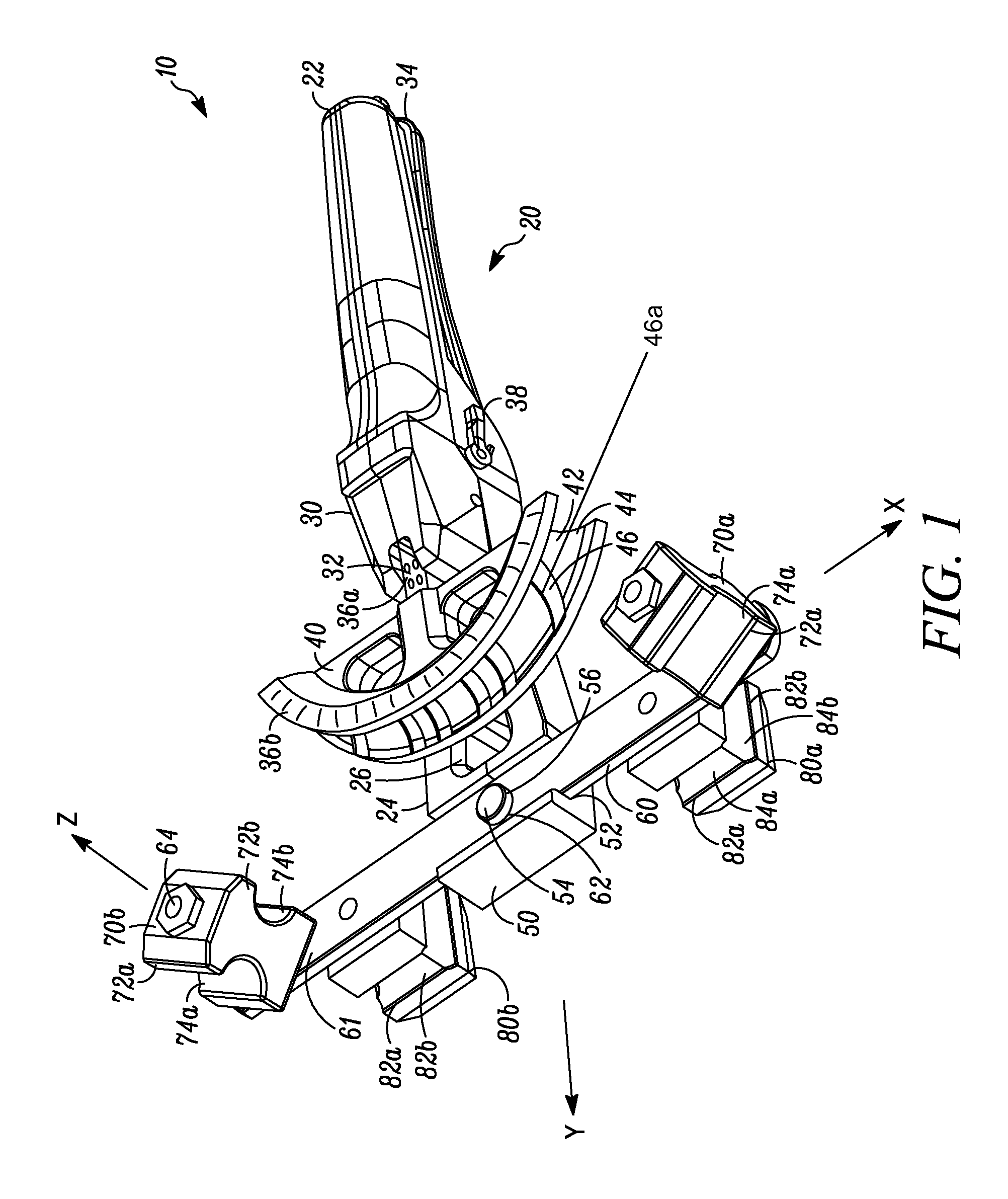

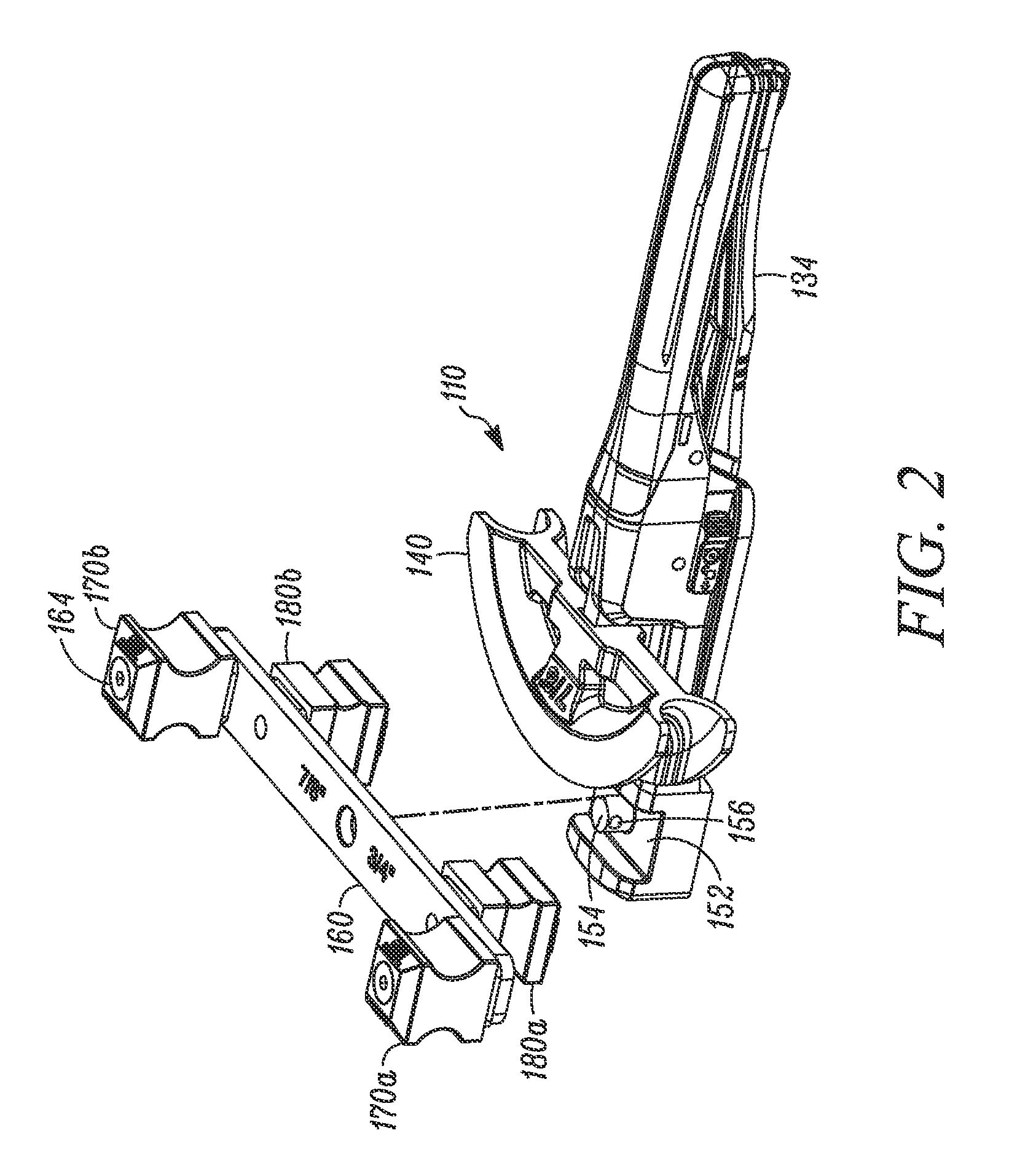

Tube and pipe benders and methods of bending same

ActiveUS9144835B2Reduce frictionEliminate cumbersomenessDrawing mandrelsShaping toolsMechanical engineering

Owner:DIVERSITECH

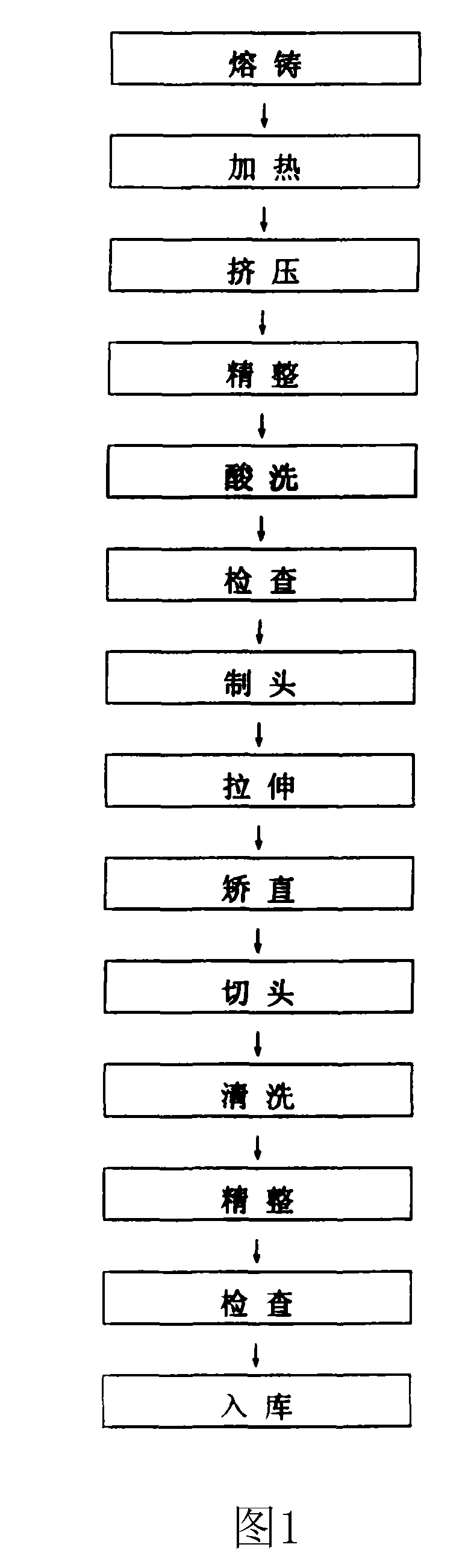

Manufacturing and processing method of D-type copper pipe

The invention discloses a producing method for a D-shaped copper tube, comprising: fusion casting, heating, extrusion pressing, final finishing, acid washing, examining, head making, drafting, straightening, cropping, washing, final finishing, examining, and storing; wherein the extrusion pressing process and drafting process are: replacing extrusion pressing and drafting process in the processing of circular copper tubes in prior art with extrusion pressing and drafting of D-shaped tubes with analogical transitivity and termination product drafting. D-shaped tubes are not-exclusively symmetrical tubes with strict technical index, and the production thereof is difficult. The invented method solves the technique problem in prior art and the D-shaped tubes are not dependent on importation.

Owner:中铝洛阳铜加工有限公司

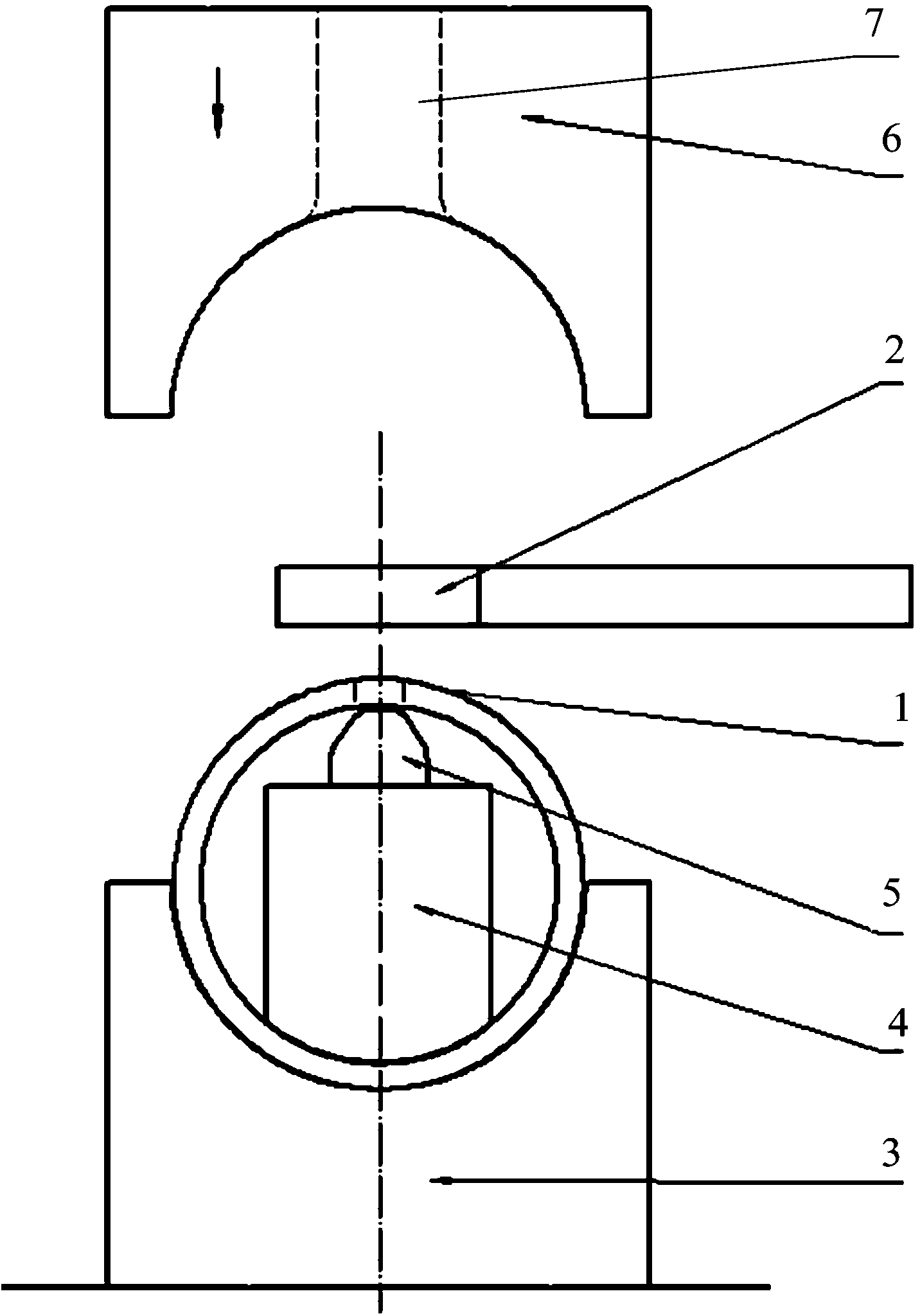

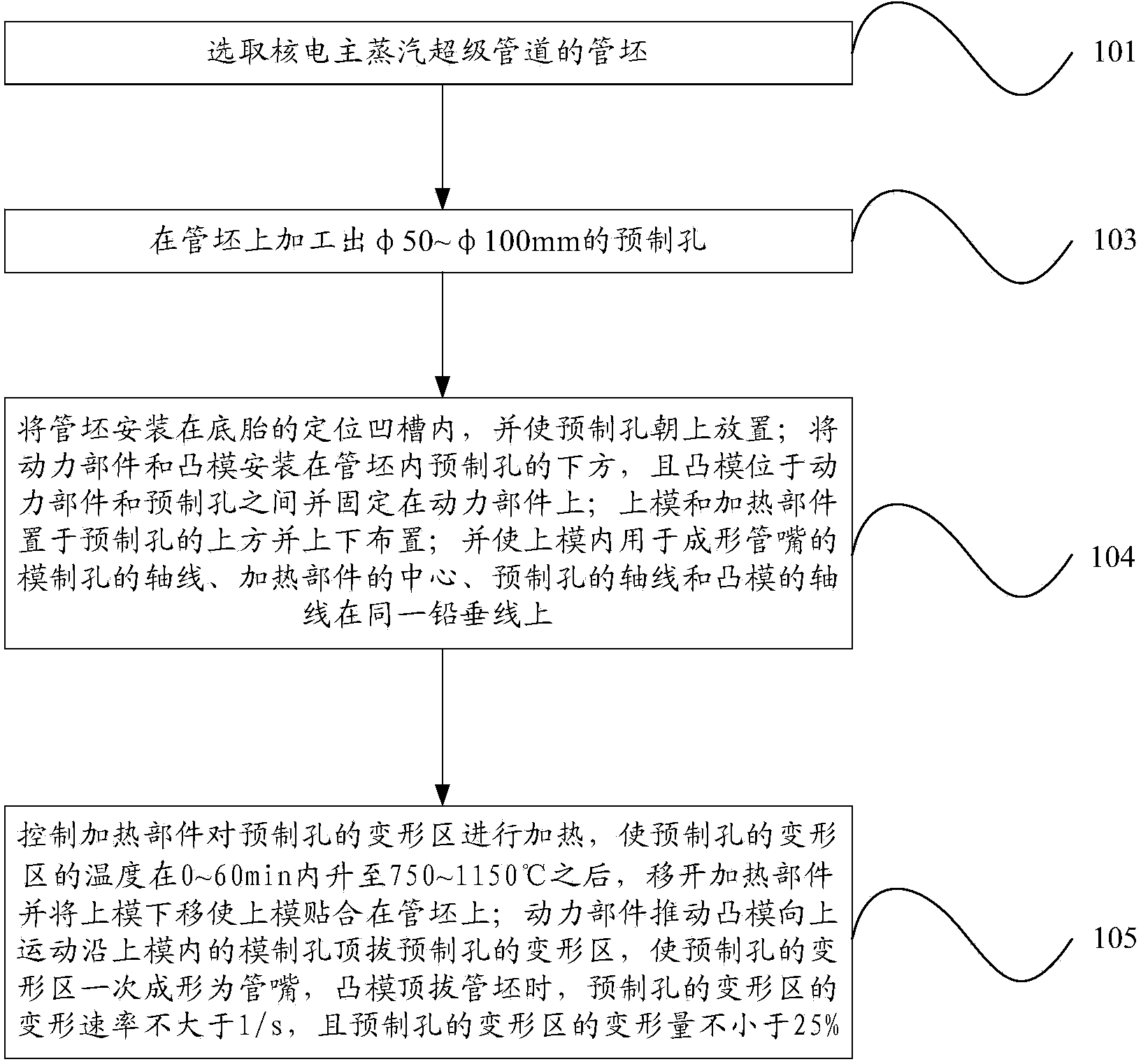

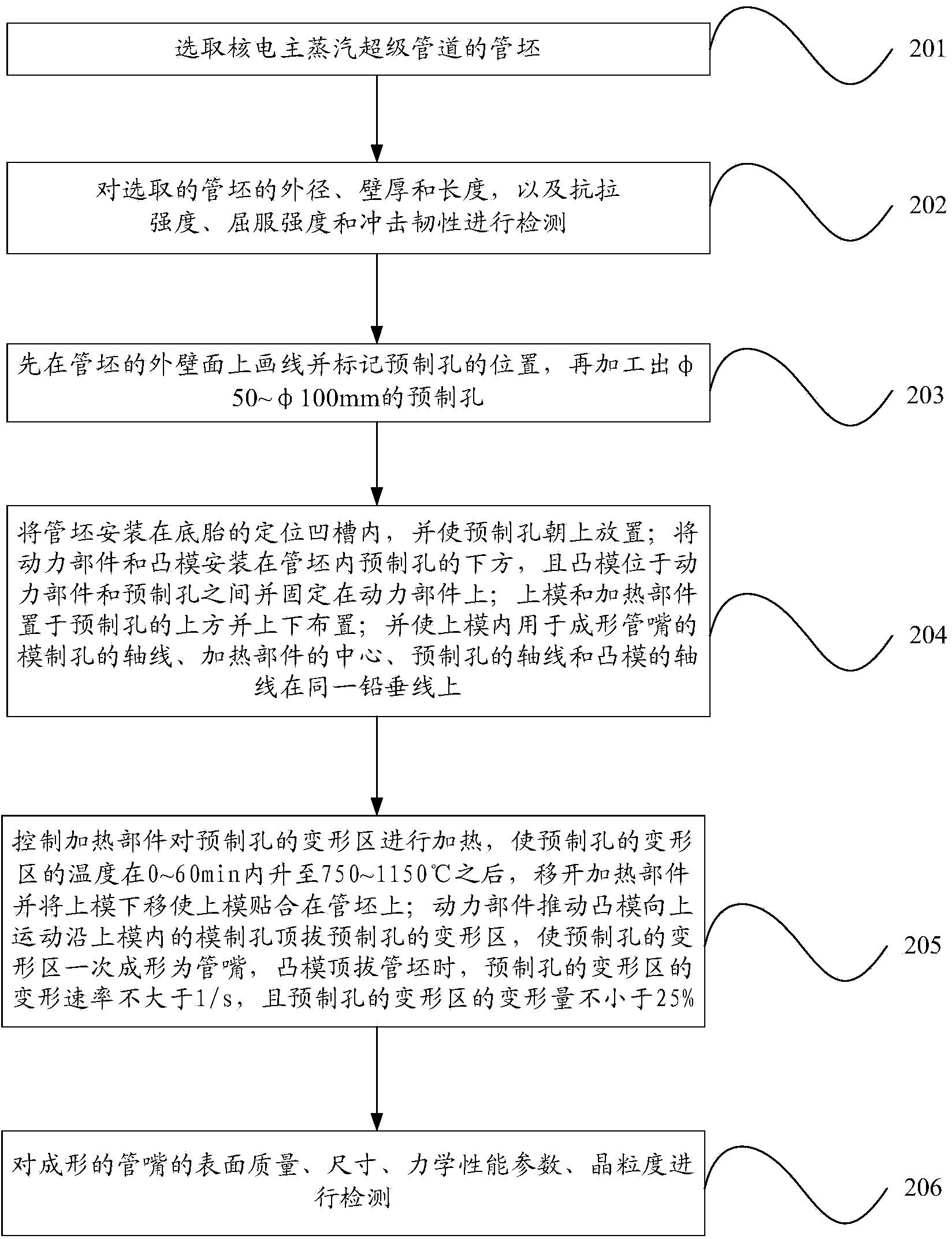

One-step forming technology of nozzle of nuclear power main-steam super pipeline

InactiveCN103658208ADoes not affect impact toughnessHigh precisionDrawing mandrelsNuclear powerEngineering

The invention provides a one-step forming technology of a nozzle of a nuclear power main-steam super pipeline. The technology comprises the steps as follows: a pipe blank of the nuclear power main-steam super pipeline is selected; prefabricated holes are formed in the pipe blank; the pipe blank is mounted in a positioning groove of a bottom base, and the prefabricated holes are placed upwards; a power unit, a male die, an upper die and a heating part are mounted, and an axis of a molding hole for forming the nozzle in the upper die, the center of the heating part, axes of the prefabricated holes and an axis of the male die are located on the same plumb line; the heating part is controlled to heat a deforming area of the prefabricated holes and is removed after the deforming area is heated to a certain temperature, and the upper die is moved downwards to be attached onto the pipe blank; and the power unit pushes the male die to move upwards, so that the deforming area is jacked and pulled to form the nozzle by one step. With the adoption of the one-step forming technology of the nozzle of the nuclear power main-steam super pipeline, the nozzle can be manufactured on the pipe blank within one hour, and the nozzle forming efficiency is effectively improved.

Owner:BEIJING SHOUHONGGANG HEAVY EQUIP TECH

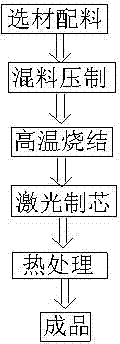

Manufacturing method of high-performance wire-drawing die core

InactiveCN103480848AImprove mechanical propertiesProper selectionDrawing mandrelsCemented carbideMechanical property

The invention discloses a manufacturing method of a high-performance wire-drawing die core. The manufacturing method comprises the following steps that a), material selecting and compounding are conducted; b), material mixing and pressing are conducted; c), high-temperature sintering is conducted; d) laser core manufacturing is conducted; e) heat treatment is conducted. The manufacturing method of the high-performance wire-drawing die core is reasonable in procedure arrangement, easy and convenient to implement, and modest in cost, the material of the die core is selected and compounded reasonably, pressing, sintering, heat treatment and other procedures are arranged orderly and proper to implement, the comprehensive mechanical property of the die core is improved to the maximum degree, and particularly abrasion-resistance performance reaches the property level of cemented carbide.

Owner:SUZHOU YIQUN MOLD

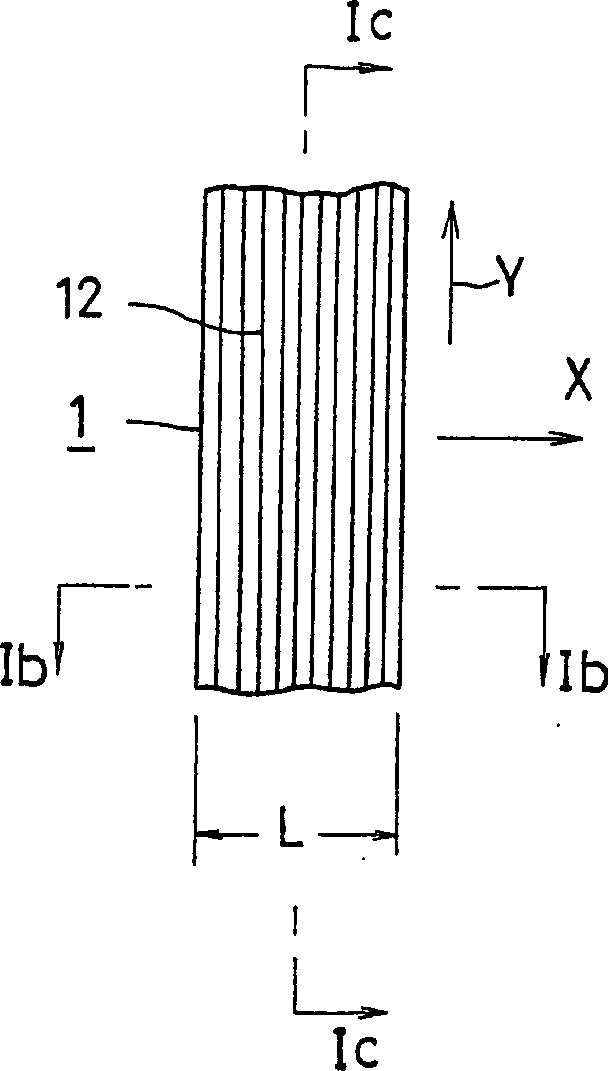

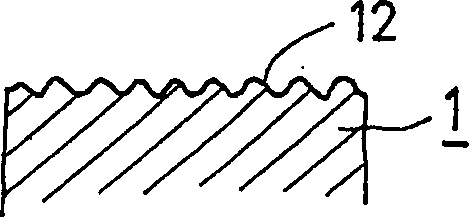

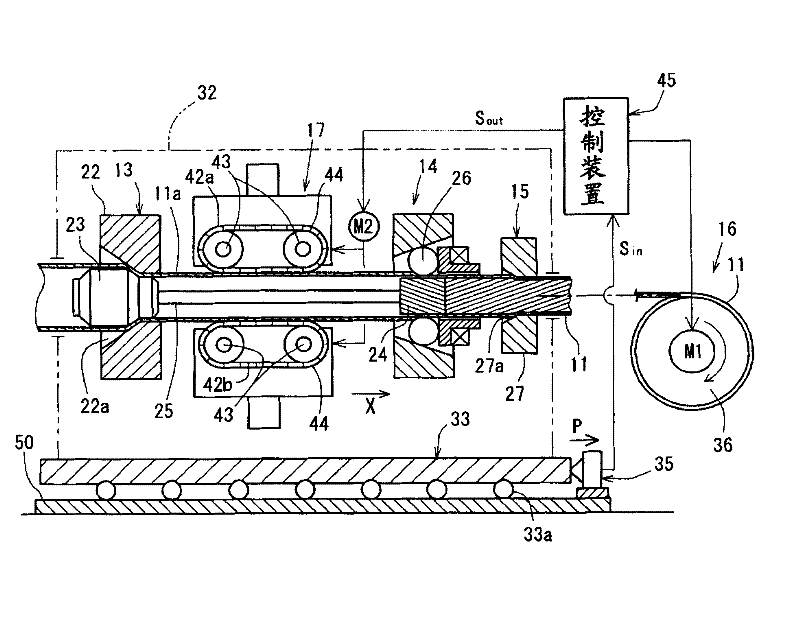

Aluminum pipe having excellent surface quality, method and apparatus for manufacturing the aluminum pipe, and photosenstive drum base body

InactiveCN1819879AEfficient preparationPrevent heat stickingDrawing mandrelsDrawing diesMaterials scienceAluminium

In a manufacturing method in which an aluminum bullet is extruded to obtain an extruded raw pipe 4 and then the extruded raw pipe 4 is subjected to a drawn process, the aluminum extruded raw pipe 4 is cut at a position within 10m from a discharge position M of an extruding die to obtain an aluminum extruded raw pipe 4 with a length of 10m or shorter, and the extruded raw pipe 4 is subjected to a drawing process. With this, an aluminum pipe excellent in surface quality having no surface defect such as white peeling can be manufactured at high manufacturing efficiency.

Owner:RESONAC HOLDINGS CORPORATION

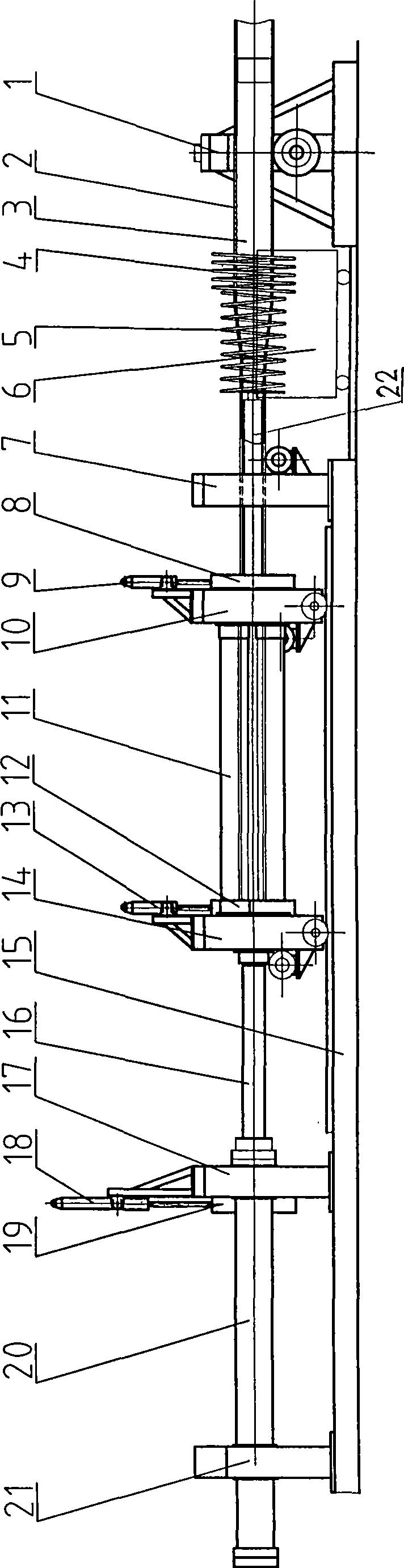

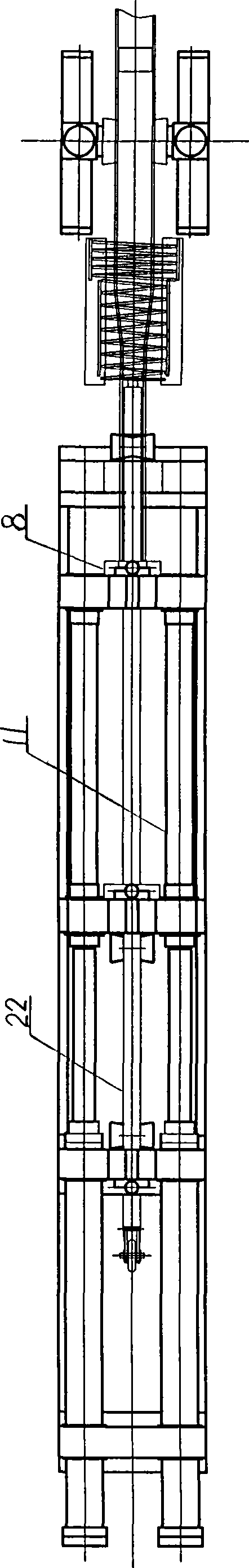

Core rod cycle device for drawing and extending hydraulic machine

ActiveCN101204719AHigh degree of mechanical automationEvenly lubricatedDrawing mandrelsEngineeringLubricant

A mandril circulation device used for pulling and extending a pressing machine relates to an auxiliary device for pulling and extending the pressing machine. The mandril cooling and lubricating of the prior art has the disadvantages of production time occupying, long period, low efficiency, short continuous service life of the mandri, uneven manual lubricant coating as well as time and labor waste. The invention comprises a carrier roller supporting device, two machine trays and a stepping mechanism. Three mandril stations are arranged outside the pressing machine and the mandril of each station is supported by the carrier roller. The mandril on the cooling and lubricating stations can rotate. Two track beams are arranged on the upward side of the mandril and the two machinery trays operate on the track beams. A lifting device provided with a gripper is arranged on the machinery tray. Four sets of vertical lifting cylinders of the stepping mechanism are connected with the tracks and a stepping beam, thus being able to lead the tracks and the stepping beam to life vertically. The stepping beam is driven by a horizontal stepping cylinder and can move horizontally along the tracks. The invention has the advantages of shortening the manufacture period, improving the working efficiency, prolonging the service life of the mandril and improving the machinery automatization of the pressing machine.

Owner:TAIYUAN HEAVY IND

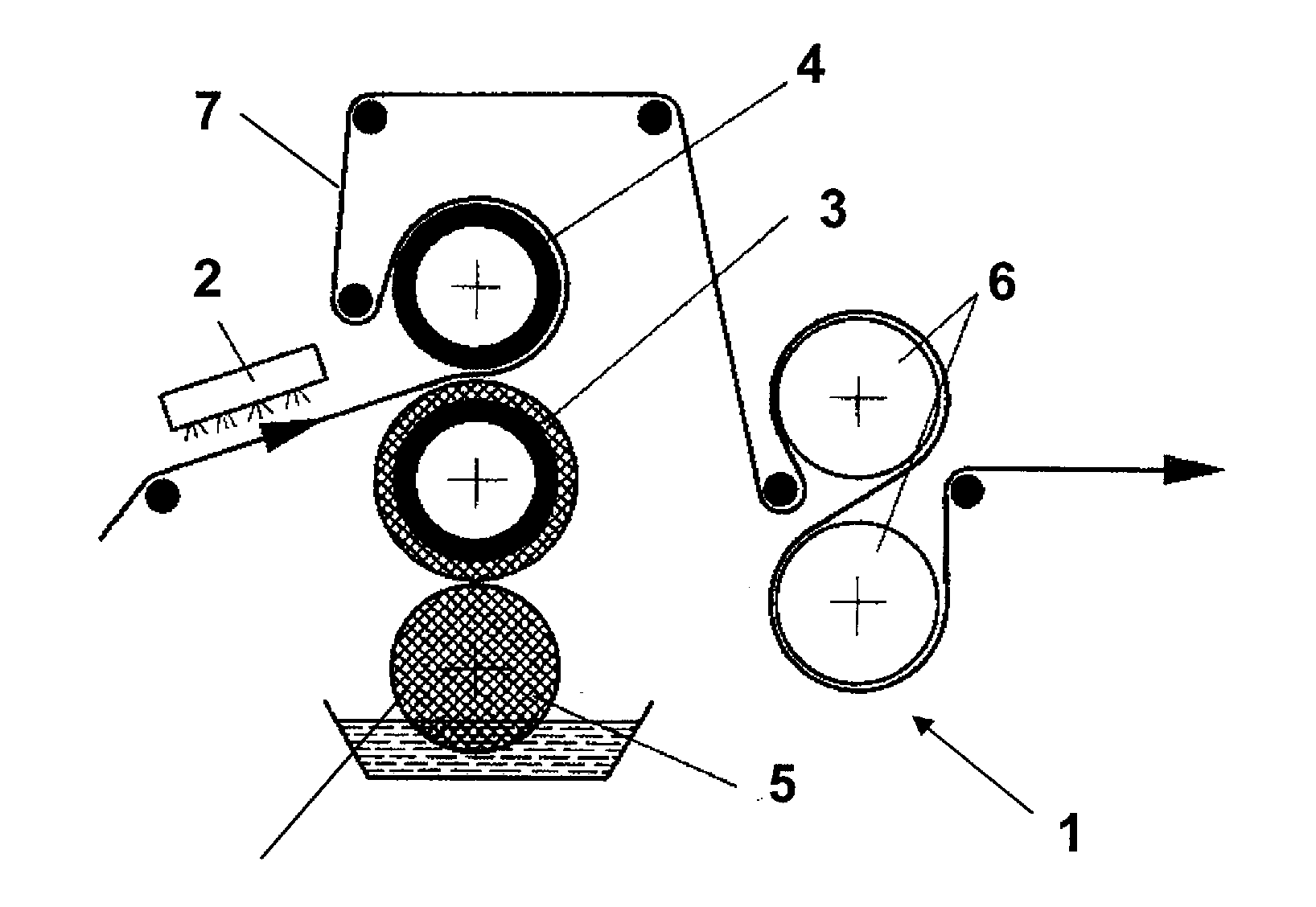

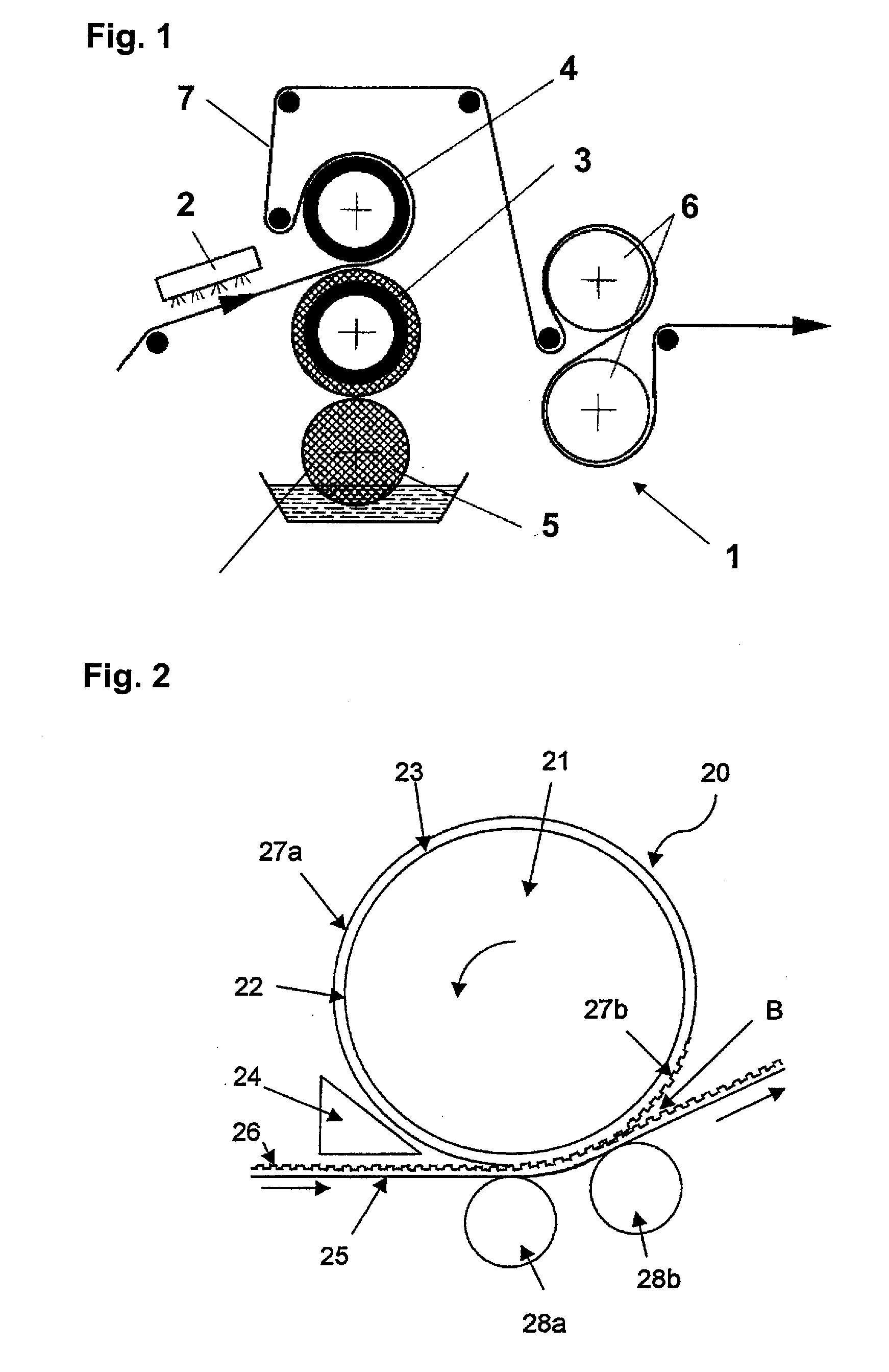

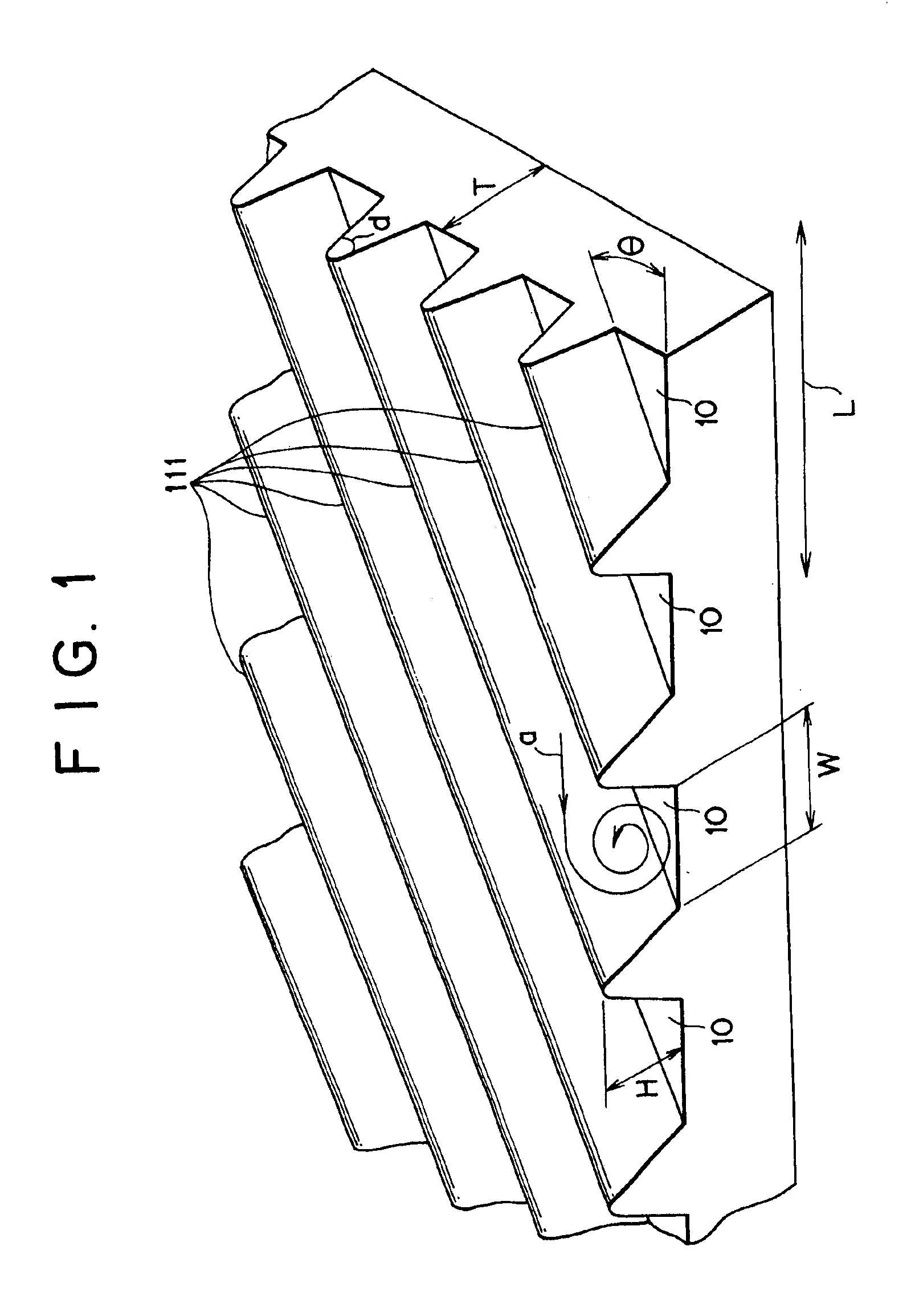

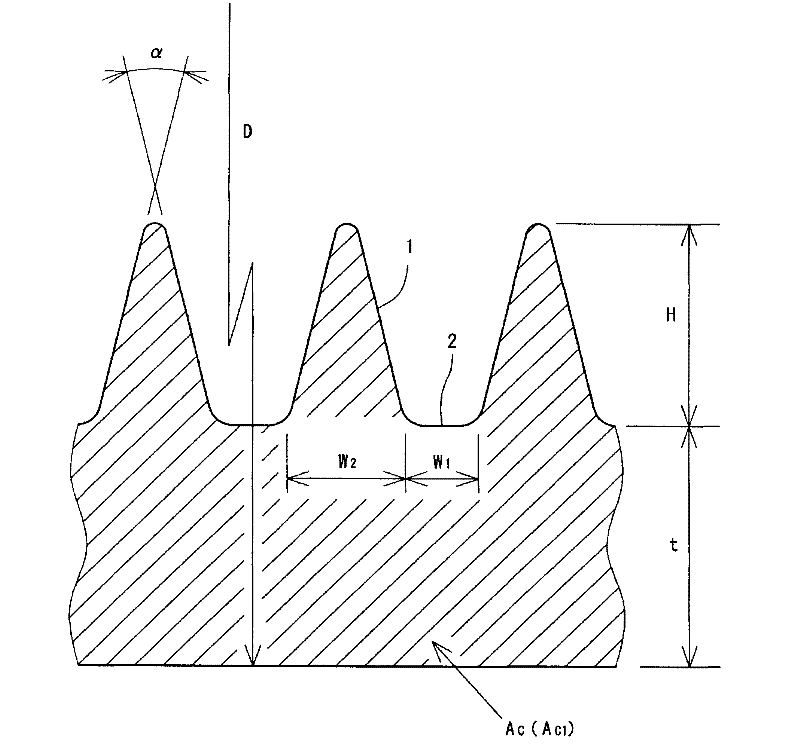

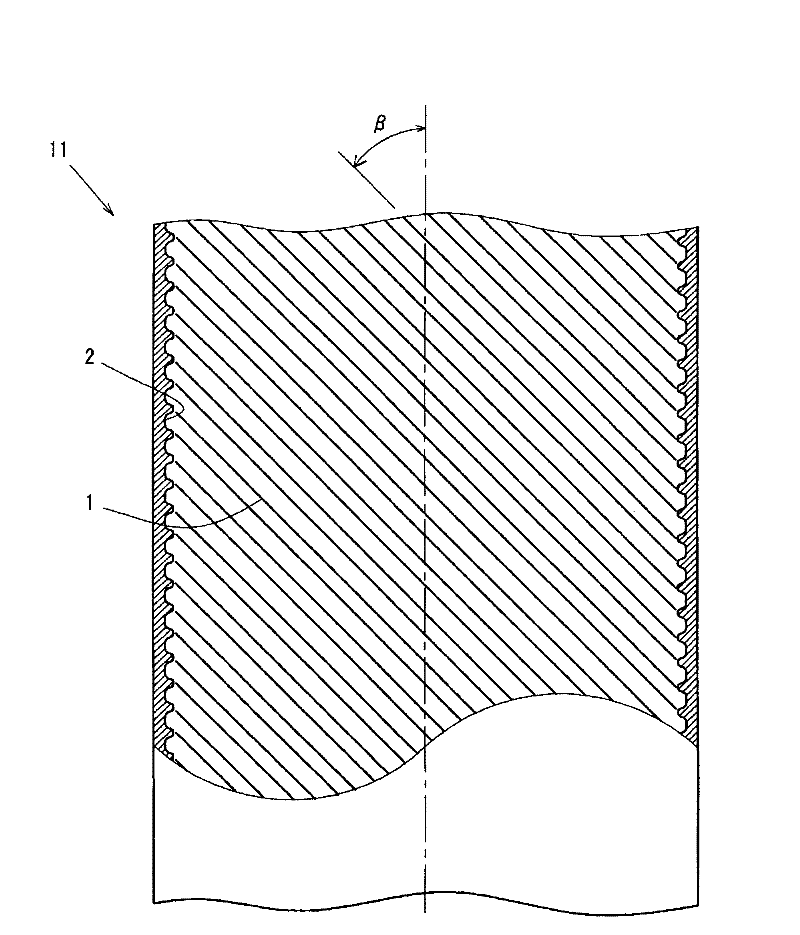

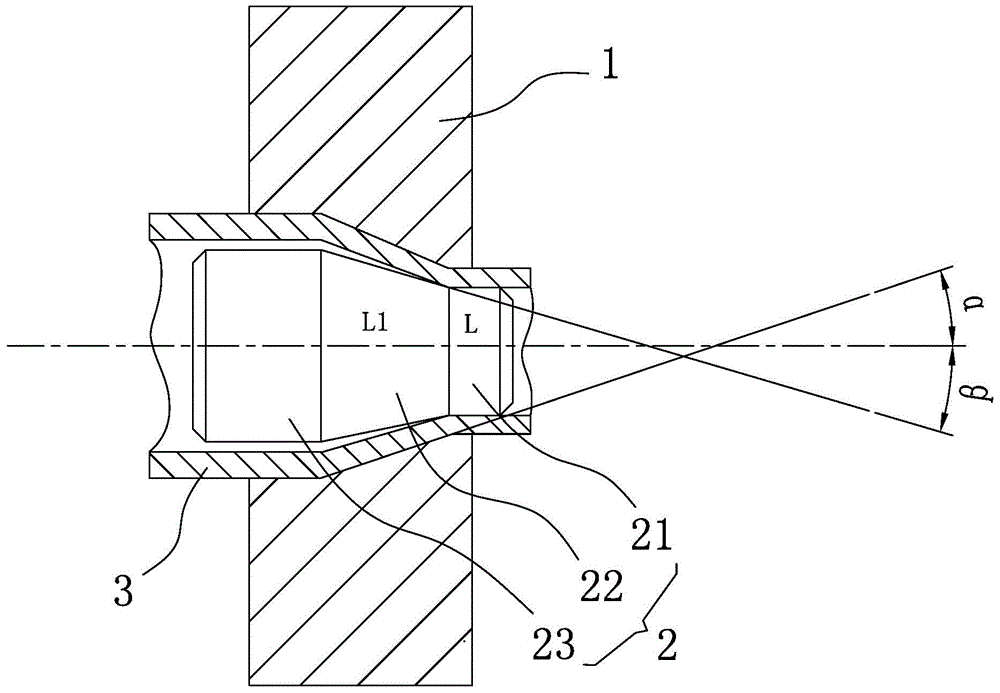

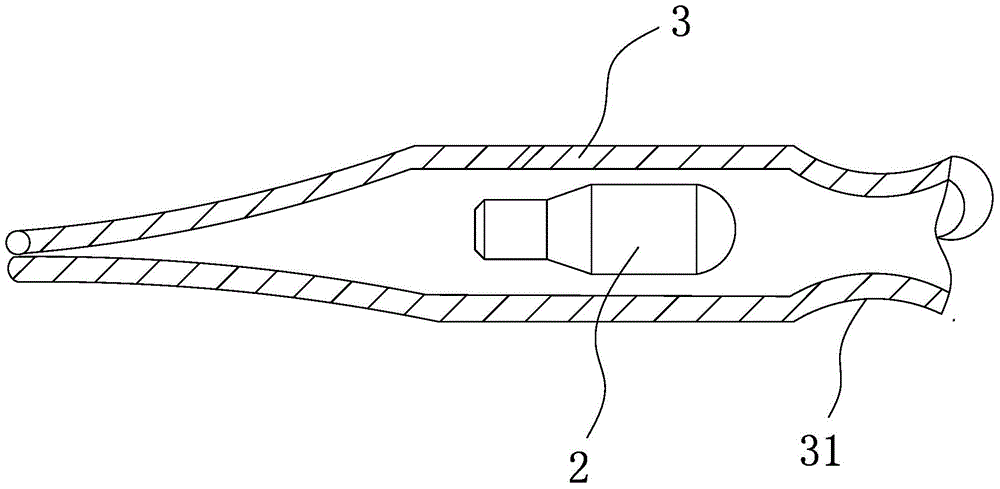

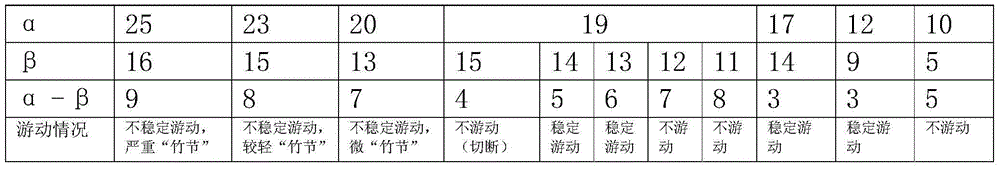

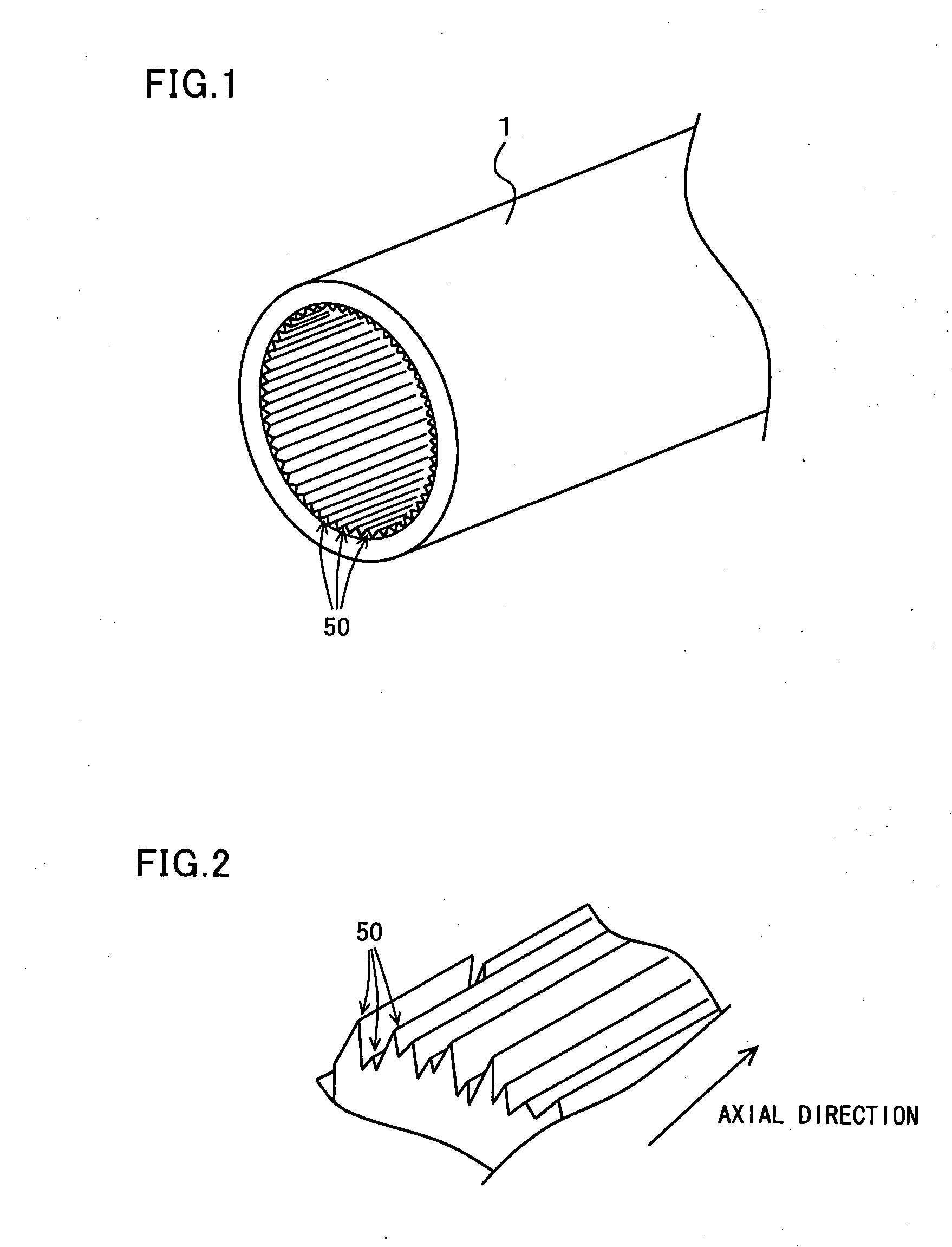

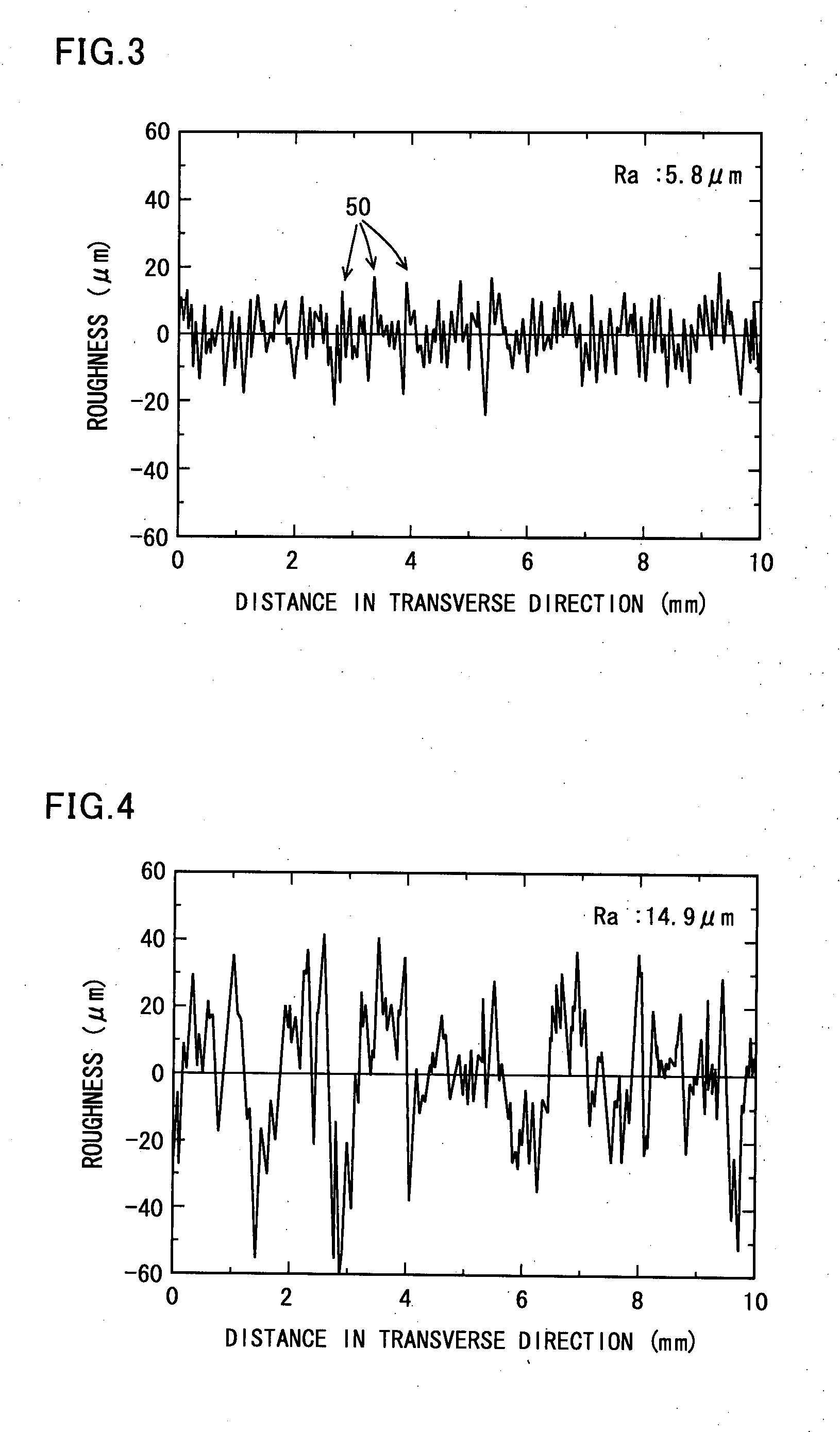

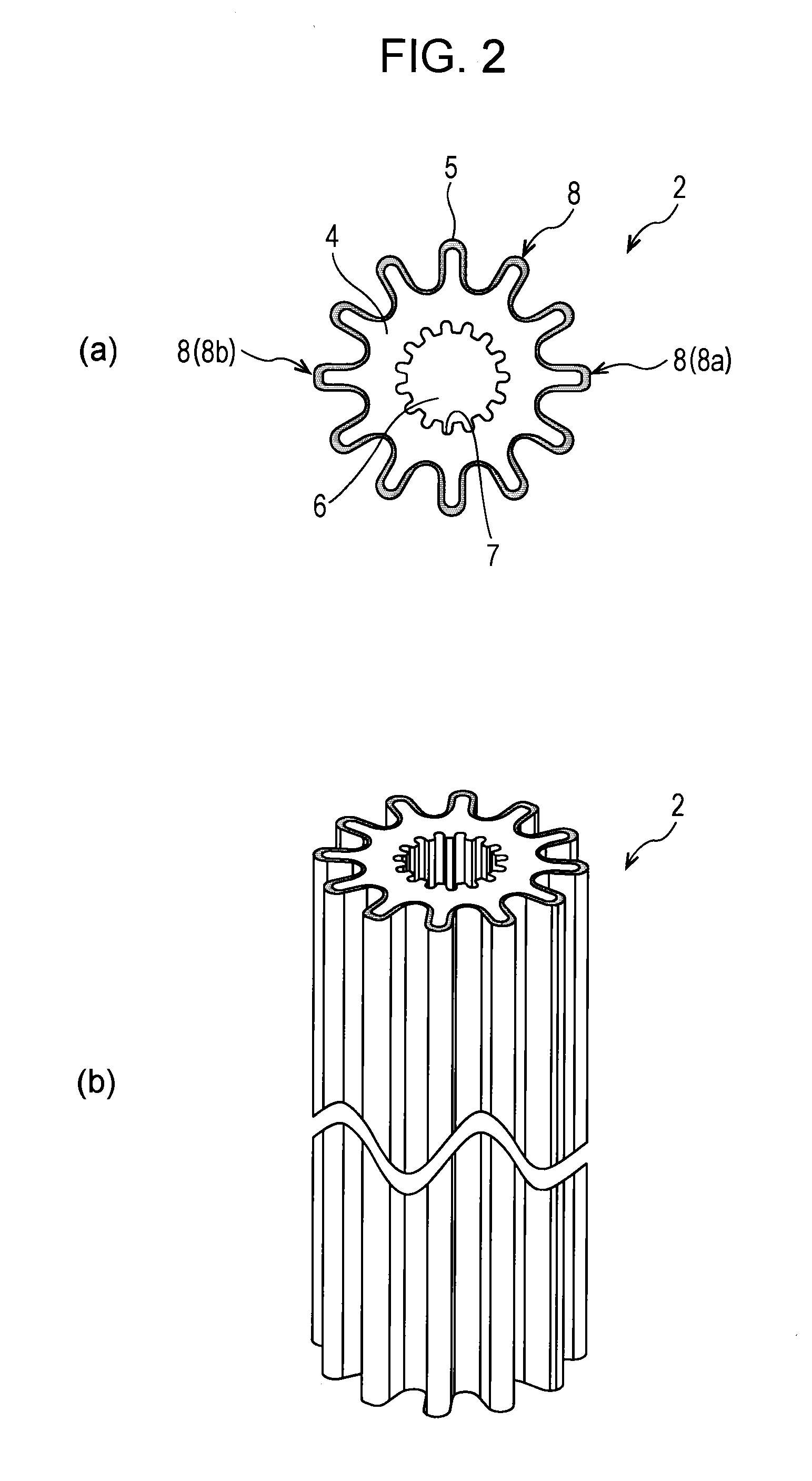

Pipe having grooved inner surface, apparatus for producing the same and method for producing the same

InactiveCN102245323AEasy broken tube detectionReliable identificationDrawing mandrelsDrawing diesCENBOLEngineering

Provided is a pipe having a grooved inner surface, which has excellent thermal conduction properties, can be made compact and lightweight, and allows resources to be conserved. Also provided are a method and apparatus for producing this pipe having a grooved inner surface, which allow efficient and stable production thereof. The apparatus which is used for producing the pipe having a grooved inner surface is provided with: diameter-reducing means for drawing a base pipe in order to reduce the diameter thereof, and groove-forming means for forming a large number of grooves on the inner surface of the base pipe. If, for example, the angle of twist of a groove with respect to the centre axis of the pipe is beta (DEG) and the apex angle of a fin which is formed between adjacent grooves is alpha (DEG), then beta is between 30 and 60 and alpha is between 5 and 20. If the outer diameter is D (mm), the groove depth is H (mm), and the cross-sectional area with respect to the axial direction of the pipe is Ac (mm<2>), then D is no greater than 6, H is at least 0.07, and Ac is less than 0.8*D.

Owner:FURUKAWA ELECTRIC CO LTD

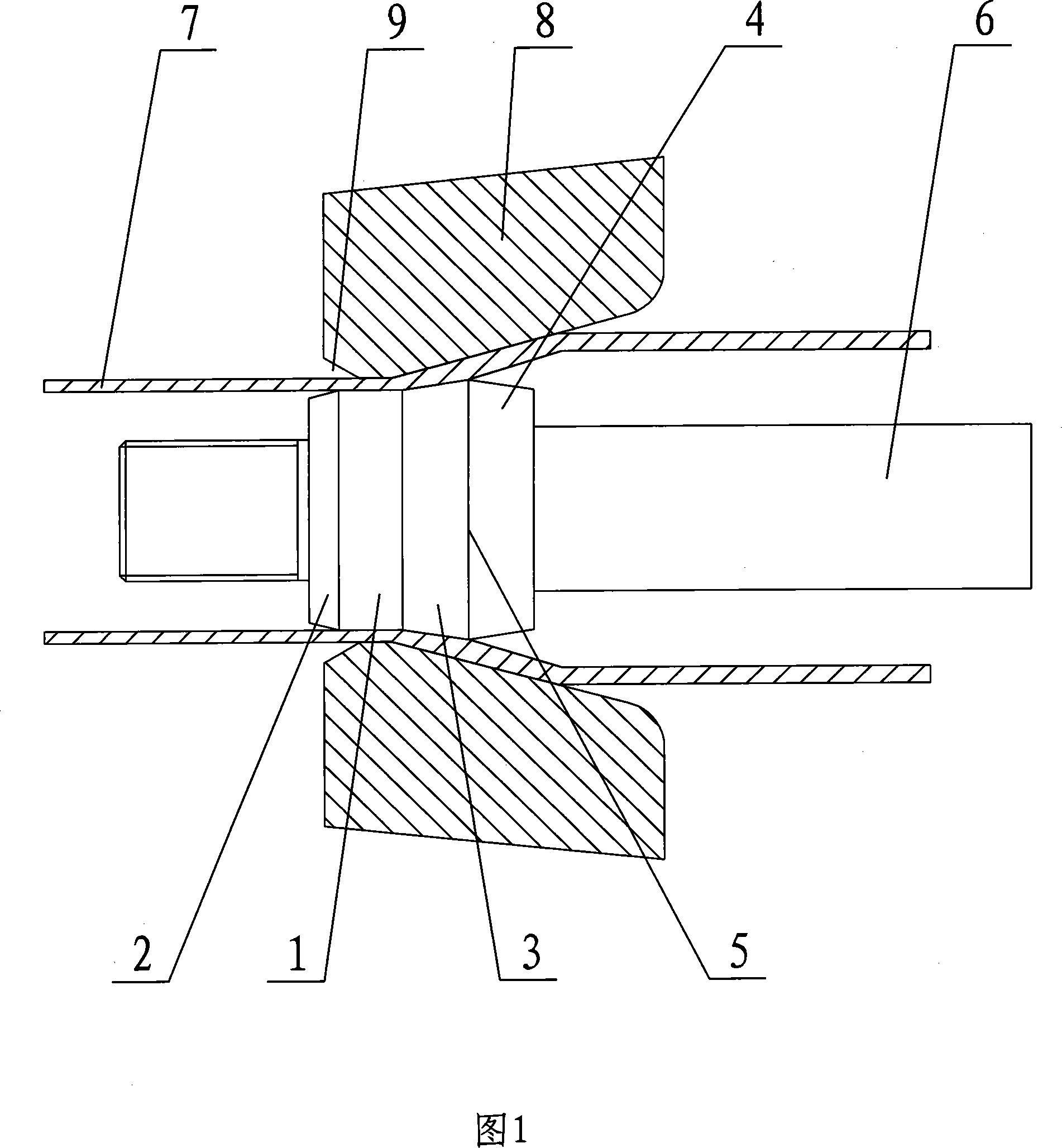

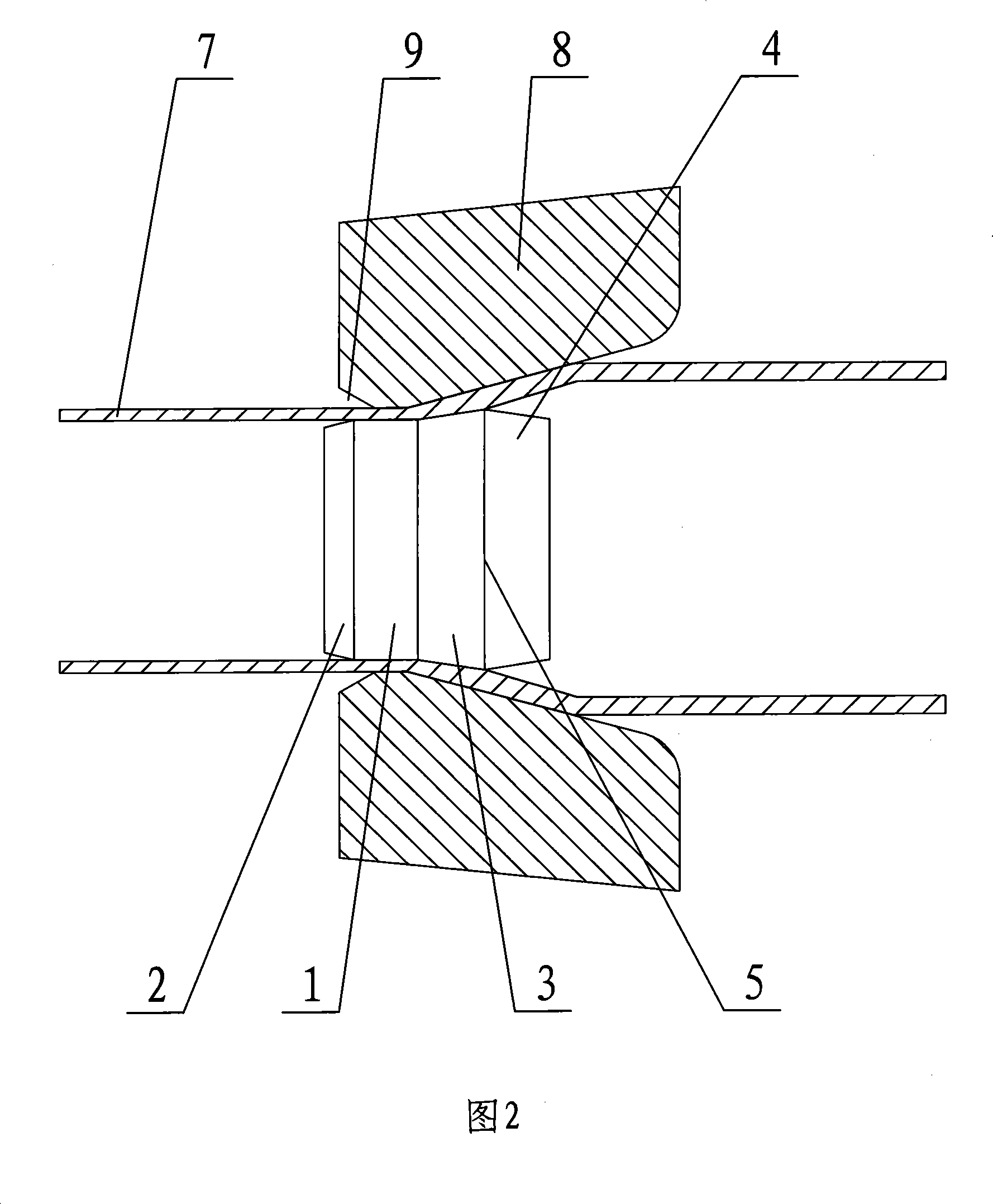

Stretching core head for hollow metal pipe

InactiveCN101121182AImprove the lubrication effectReduce resistanceDrawing mandrelsEngineeringFriction force

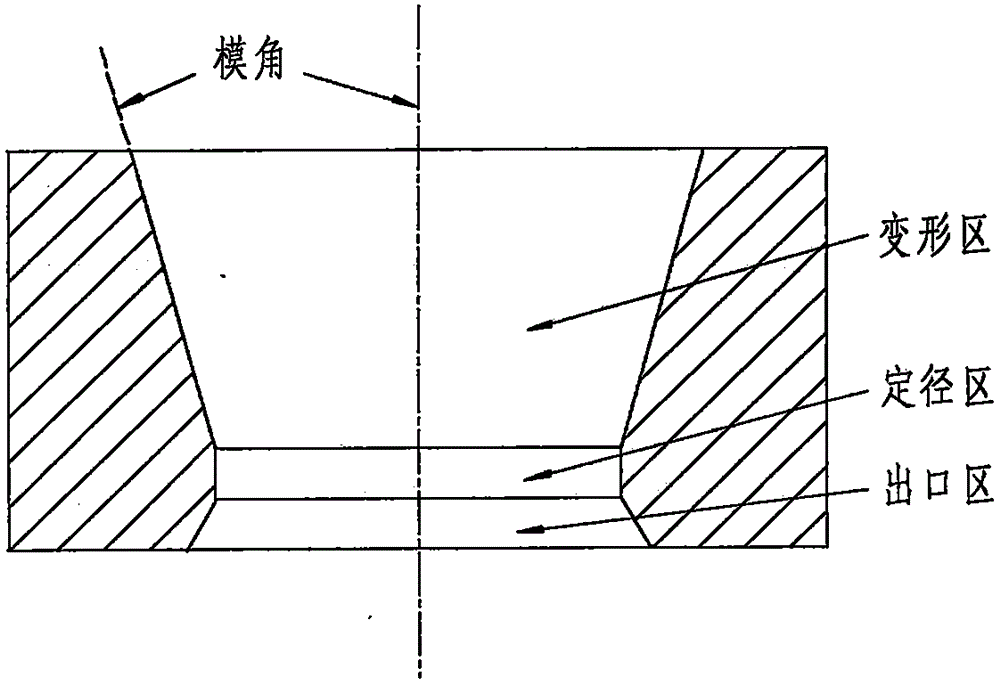

The present invention discloses a hollow metal pipe drawing core print comprising a section with fixed diameter and an outlet chamfer section equipped on one side of the section with fixed diameter; the other side of the diameter-fixed section is equipped with a deformed section tilted upwards. The hollow metal pipe drawing core print boasts of excellent lubricating performance which can reduce the friction between the drawn hollow metal pipe and the deformed section of the drawing core print and further reduce the resistance taken by the core print to ensure the size precision of the drawn metal pipe and the quality of the external surface of the drawn metal pipe; in addition, the service life of the drawing core print and the drawing processing efficiency can be increased; the present invention can be used in a wider range; the present invention can be used not only in straightening production of the hollow metal pipe but also in coiling production of the hollow metal pipe.

Owner:GAOXIN ZHANGTONG

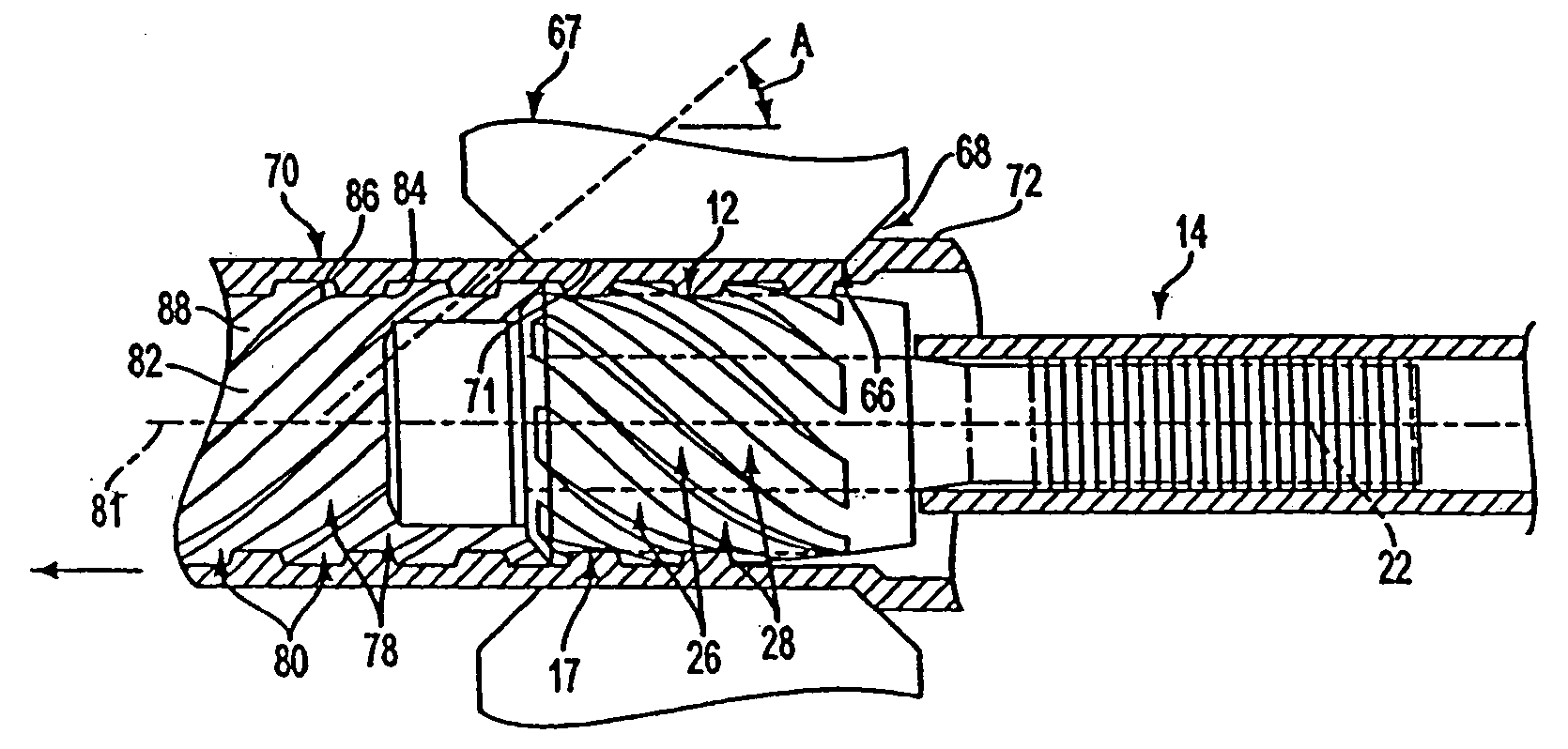

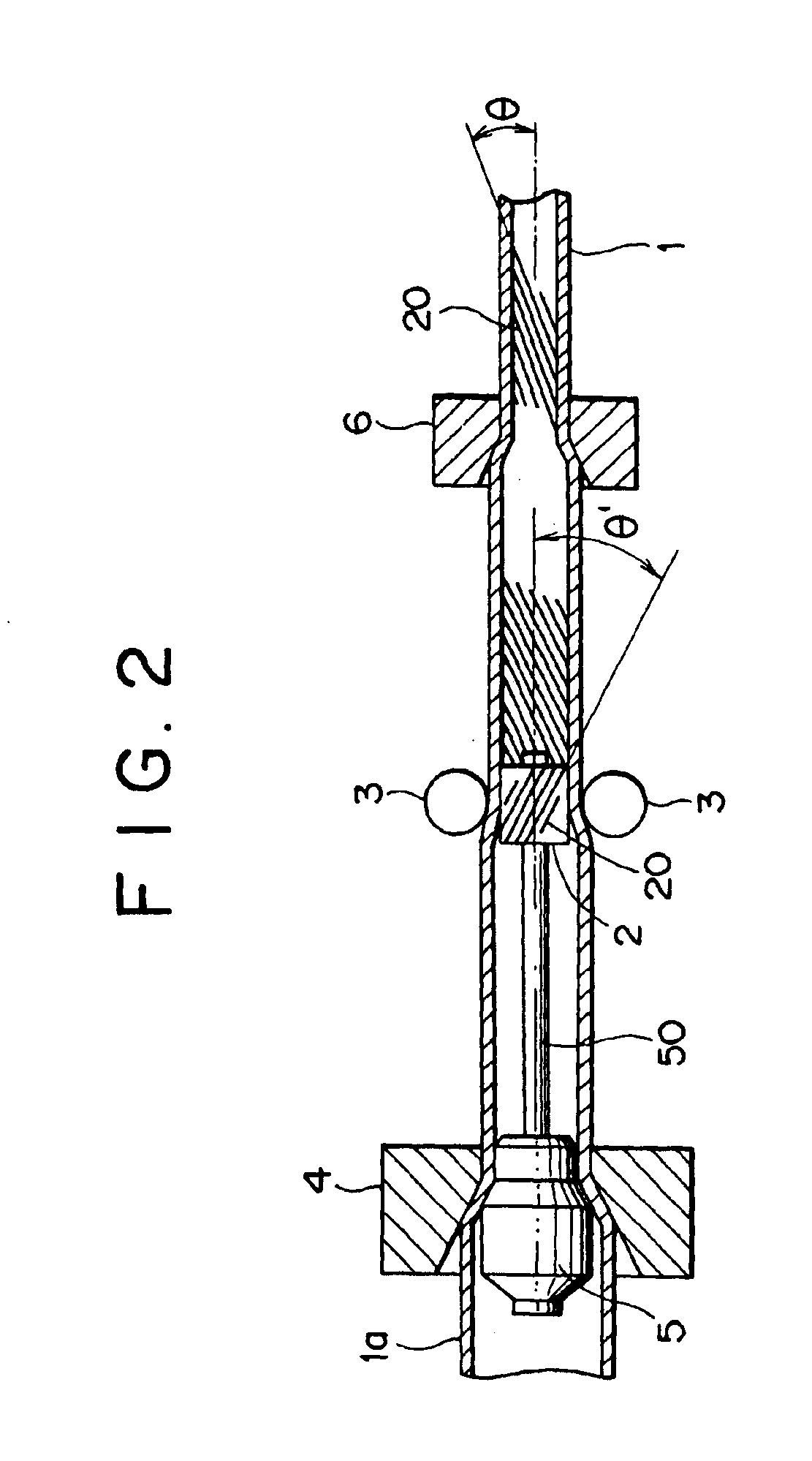

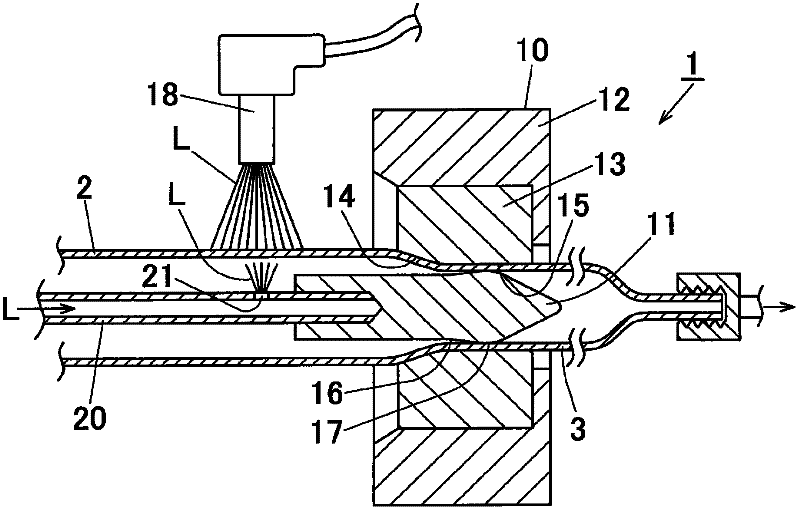

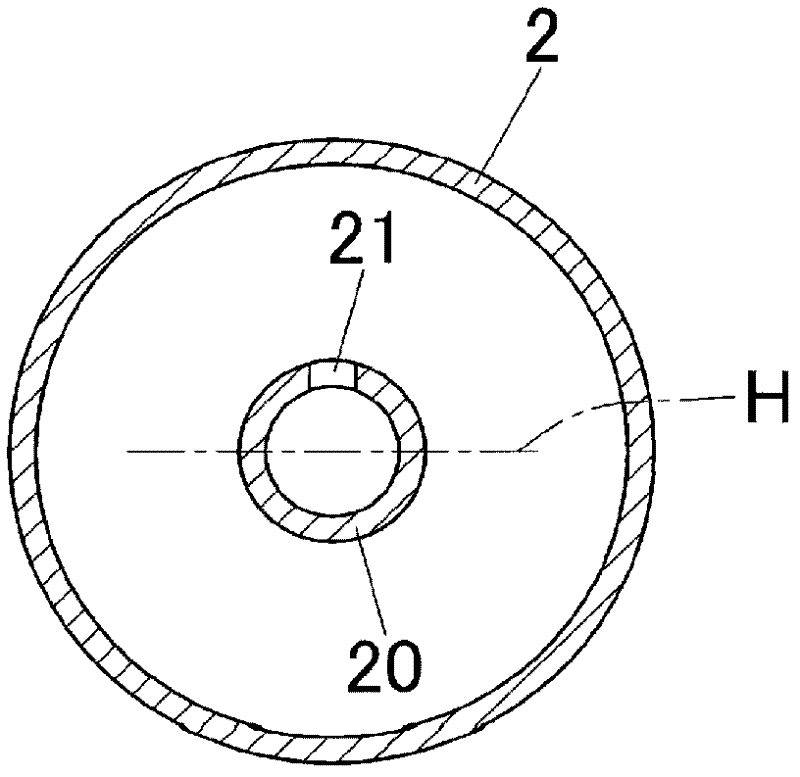

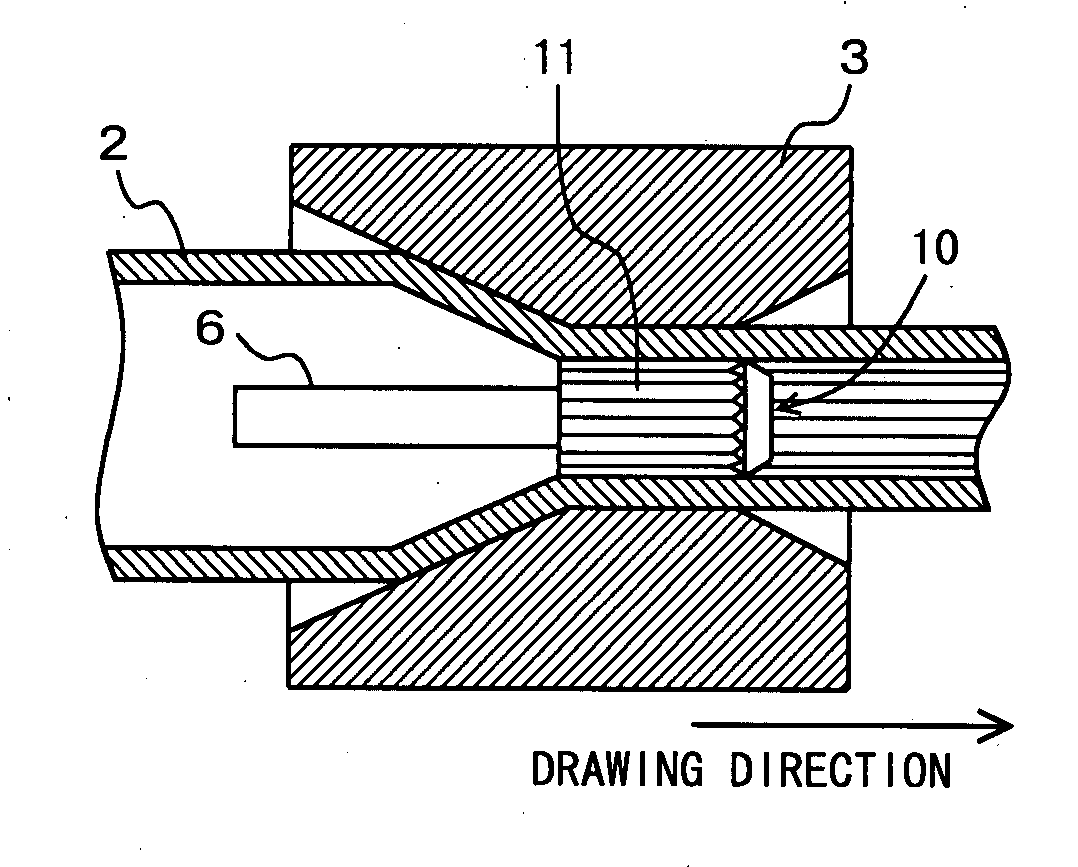

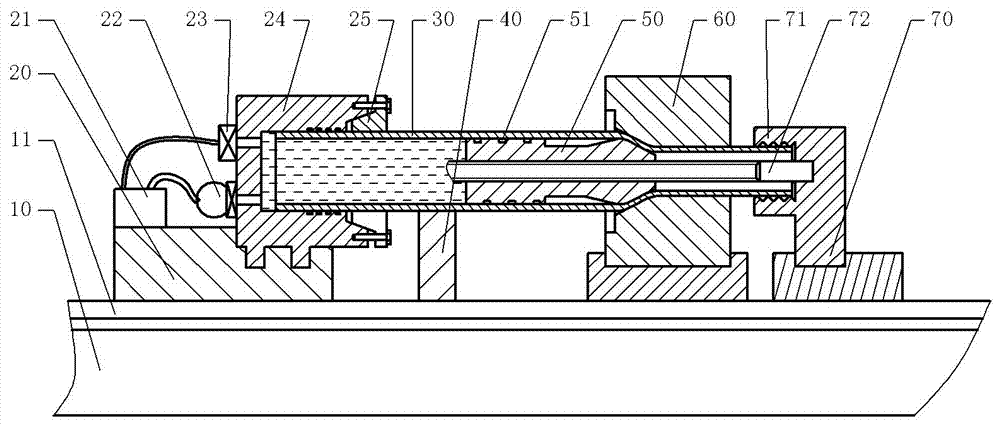

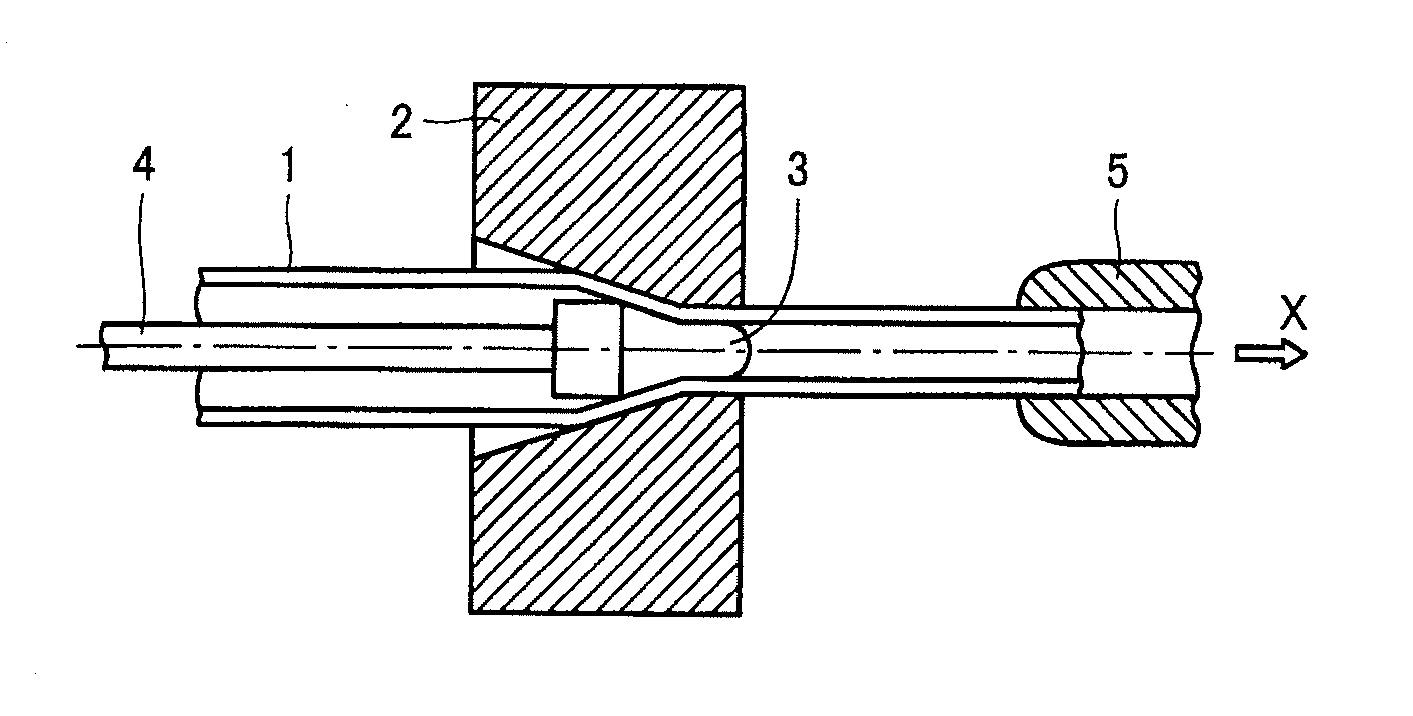

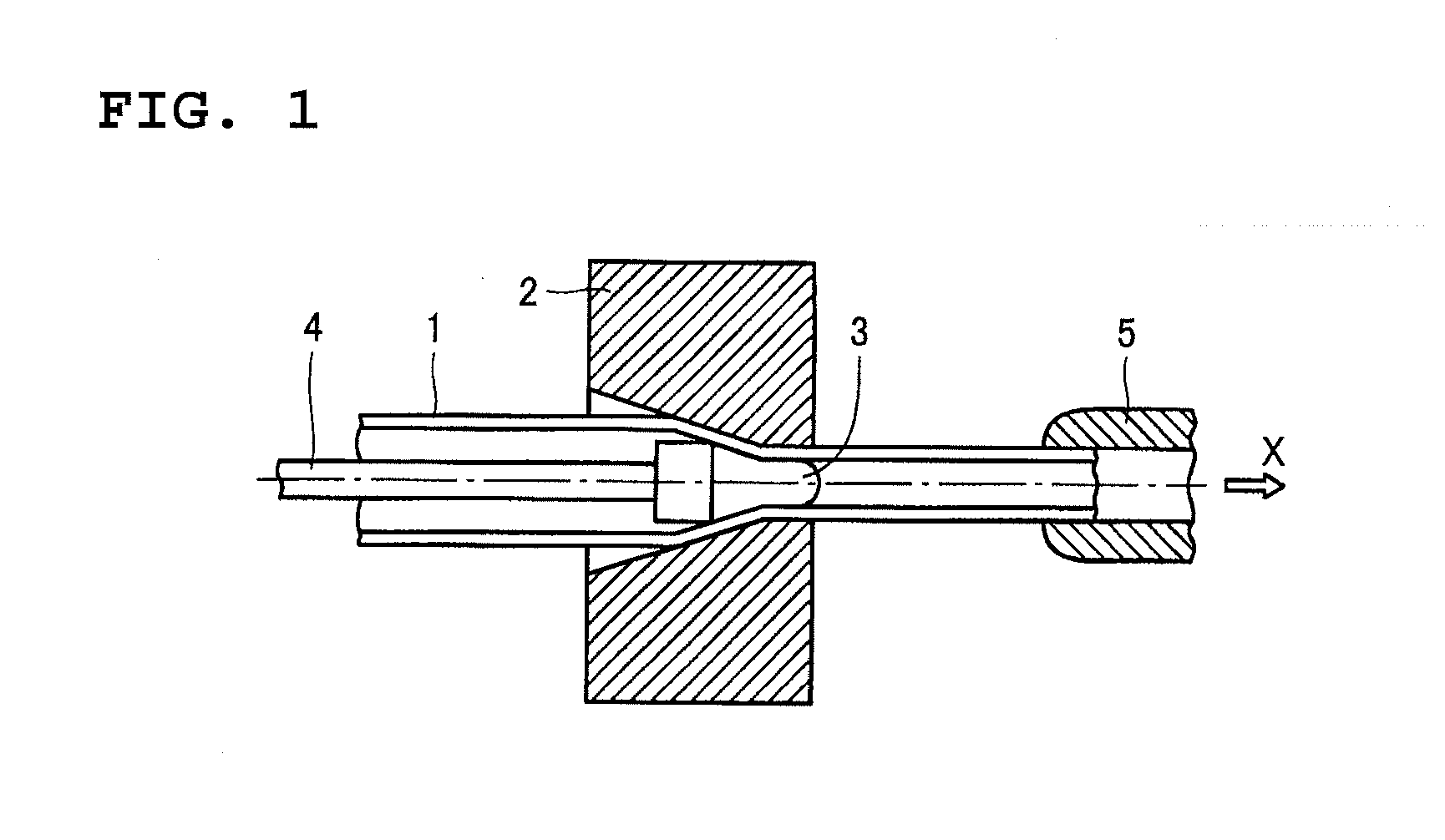

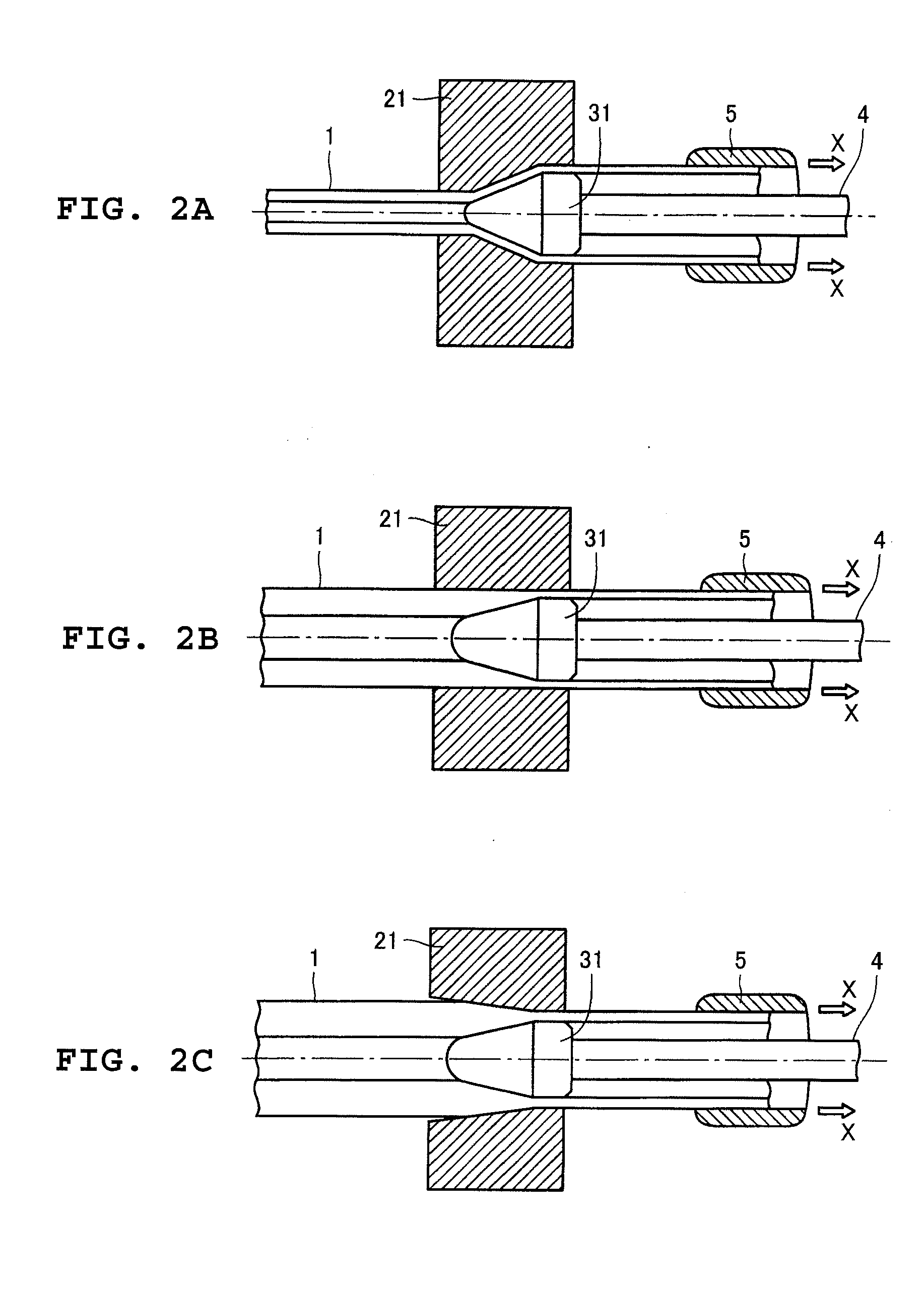

Apparatus and method for drawing metal tube

In an apparatus for drawing a metal tube, in which a lubricant is discharged from an opening formed in a hollow rod which supports a plug to apply the lubricant onto an inner surface of a tube blank, the lubricant discharging sensitivity when a discontinuous lubricant supply is performed is enhanced. In a drawing apparatus in which a metal tube blank (2) is machined by passing the same between a die (10) for forming an outer surface and a plug (11) for forming an inner surface, a discharge port (21) from which a lubricant (L) is discharged opens onto an outer peripheral surface of a hollow rod (20) which supports the plug (11). The discharge port (21) is provided only in an area of the rod (20) higher than the center thereof in the upward and downward directions.

Owner:SHOWA DENKO KK

Preparation technology for medical beta type titanium alloy capillary tubes

InactiveCN105478523AImprove rolling qualityGrain refinementDrawing mandrelsTemperature control deviceFiberHigh volume manufacturing

The invention discloses a preparation technology for medical beta type titanium alloy capillary tubes. The preparation technology comprises the steps of preparing medical beta type titanium alloy ingots through the vacuum self-consuming arc melting method, carrying out forging and cogging on the titanium alloy ingots for forming round ingots, and extruding the round ingots on an extruding machine for forming tube blanks; rolling the tube blanks twice through a three-roller planetary rolling mill, and carrying out on-line induction heating on the tube blanks in the rolling process; rolling the tube blanks further through a three-roller finish tube-rolling machine, and carrying out vacuum annealing in the middle of rolling; finally, drawing the medical beta type titanium alloy tube blanks through a precision tube drawing machine for forming the finished capillary tubes; and adopting carbon fiber rods good in tensile strength, rigidity and self-lubricating property as core rods in the drawing process, and carrying out vacuum annealing in the middle of drawing. The medical beta type titanium alloy capillary tubes obtained through the preparation technology are uniform in wall thickness, smooth in surface and high in ductility; equipment is simple, production is flexible, and the cost is low. The preparation technology is especially suitable for producing the medical beta type titanium alloy capillary tubes in an industrialized and batched mode.

Owner:宝鸡市利泰有色金属有限公司

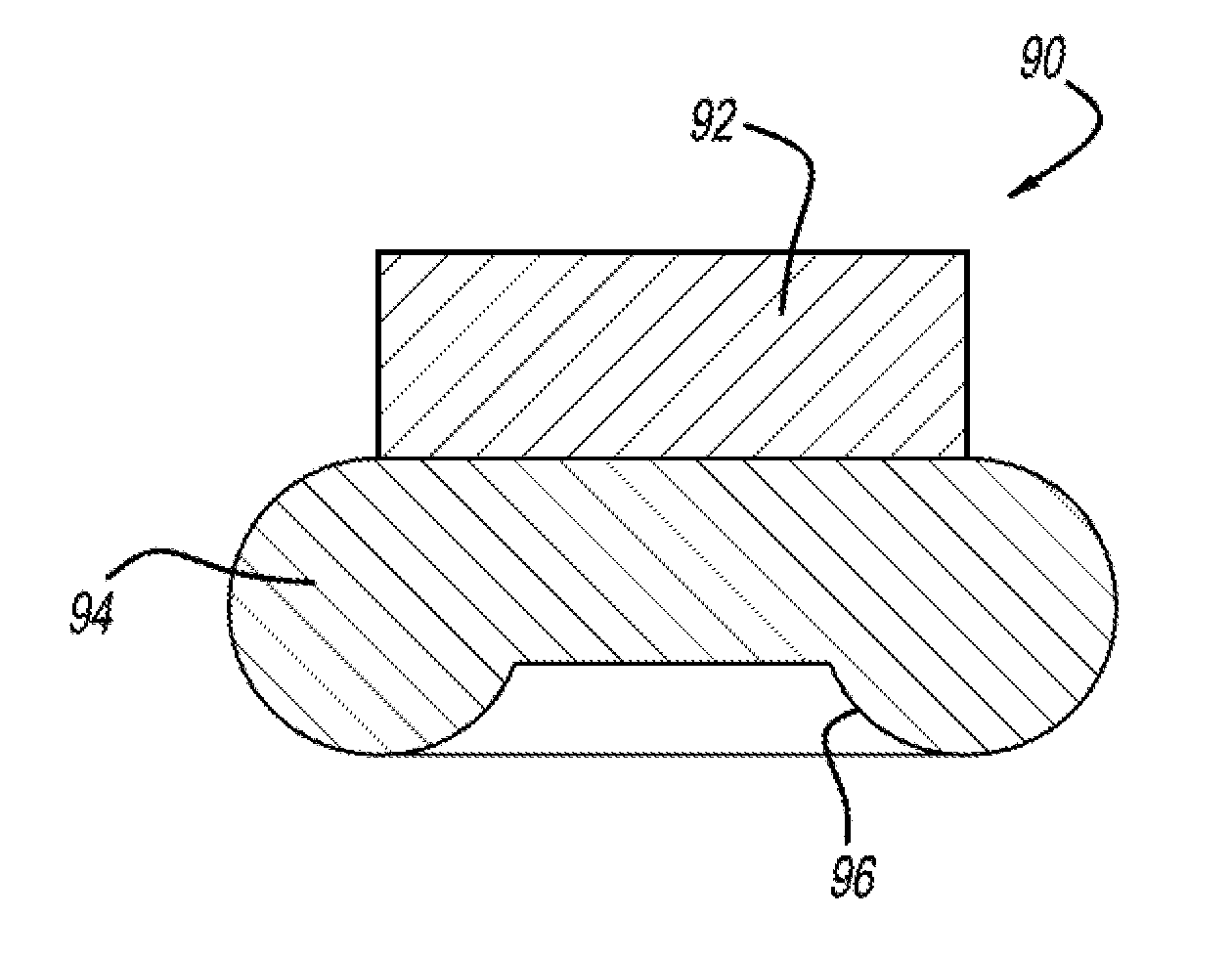

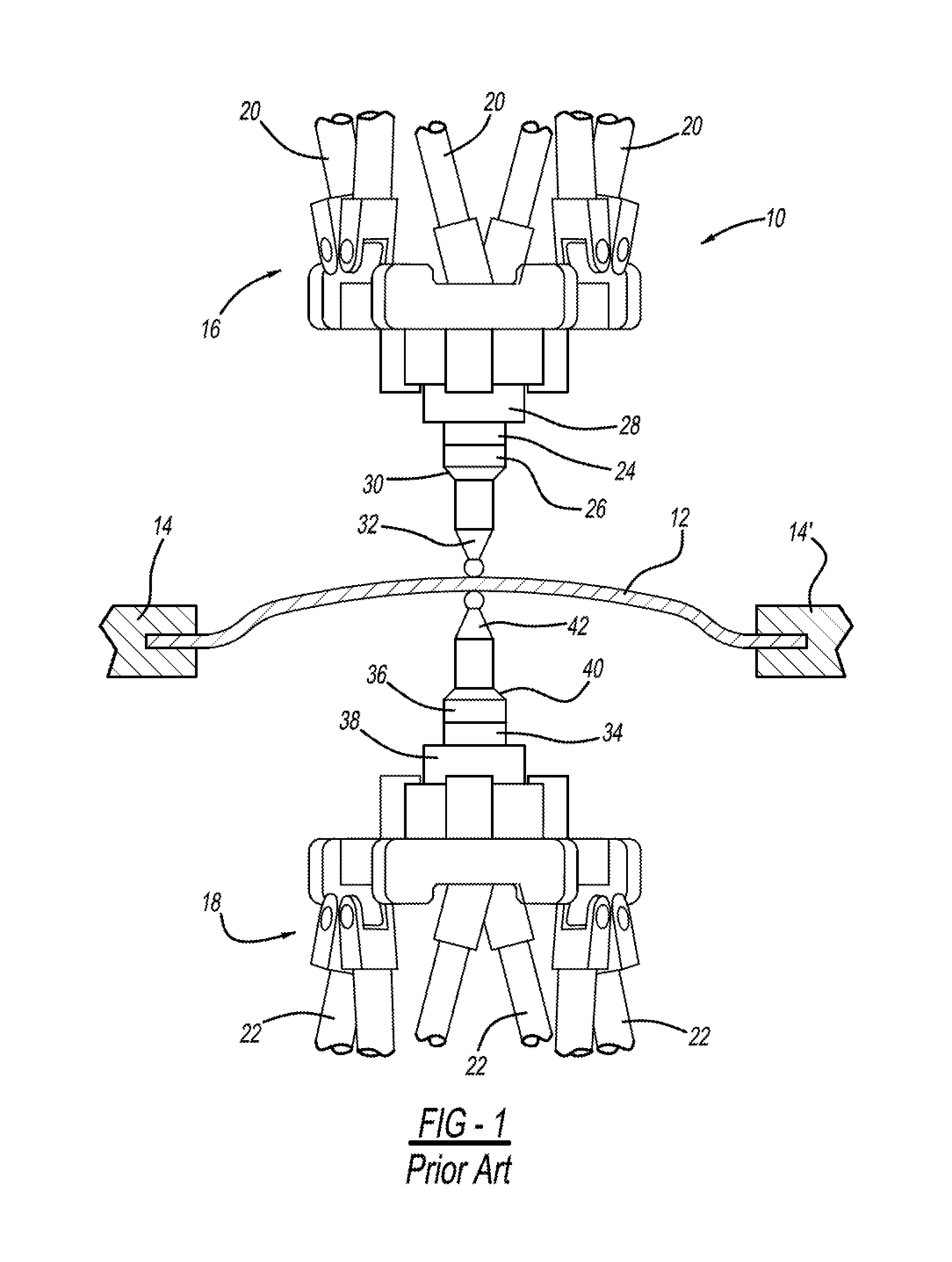

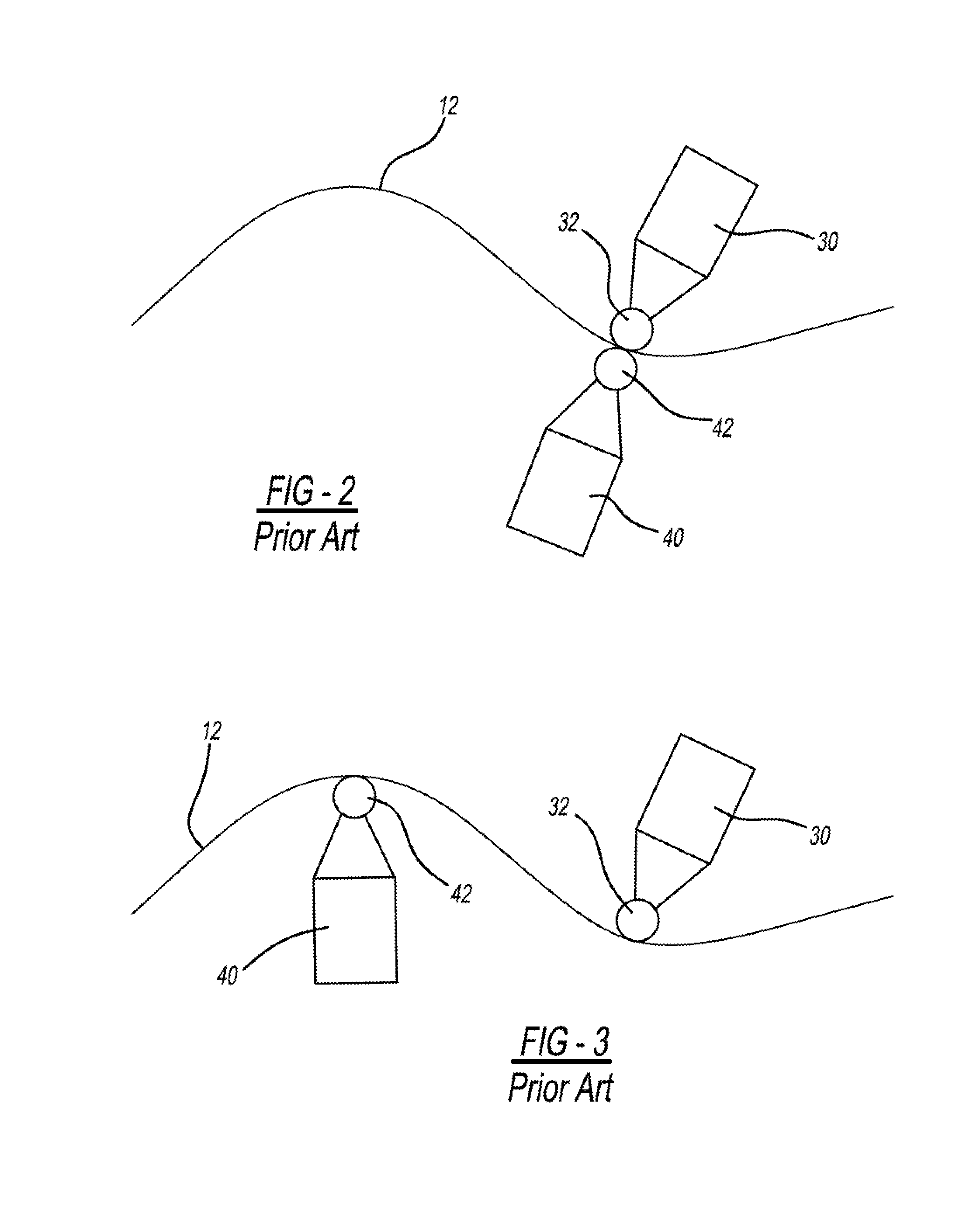

High stiffness and high access forming tool for incremental sheet forming

ActiveUS20160136714A1Avoiding tool shank-to-workpiece interferenceLacks disadvantageDrawing mandrelsShaping toolsHigh stiffnessBiomedical engineering

An tool for the incremental forming of material sheeting is disclosed. The tool comprises a forming tip, a shank, and an interface adapter positioned between the forming tip and the shank. The forming tip has a diameter and the shank has a diameter. The diameter of the forming tip is greater than the diameter of the shank. The forming tip may be of a variety of configurations. The forming tip may be donut-shaped. The donut-shaped tip may have a recessed area formed therein. The recessed area may be frustoconically shaped. As an alternative to the forming tip being donut-shaped, the forming tip may be made up of at least two forming spheres. An adapter is provided to which the spheres may be attached either directly or by arms. The diameters of the spheres may be the same or may be different diameters.

Owner:FORD GLOBAL TECH LLC

Preparation method of aluminum capillary tube of refrigerating system

The invention discloses a preparation method of an aluminum capillary tube of a refrigerating system. The preparation method comprises the following steps: drawing an aluminum parison tube by virtue of a cold drawing technique by using a drawing di, wherein the drawing die comprises an outer die and a die core matched with the outer die, the die core comprises a core head sizing part, a middle cone-shaped part and a core tail cylindrical part; and increasing drawing force of the aluminum parison tube along with increase of the length of the core head sizing part and moving the die core for drawing a parison tube to form the aluminum capillary tube of the refrigerating system. The aluminum capillary tube is developed by taking aluminum and an aluminum alloy as a material. According to a scheme of replacing copper with aluminum in the aluminum capillary tube of the refrigerating system, the welding point is reduced, the performance of a product is improved and the production cost of equipment is further lowered.

Owner:WANMA TECH CO LTD

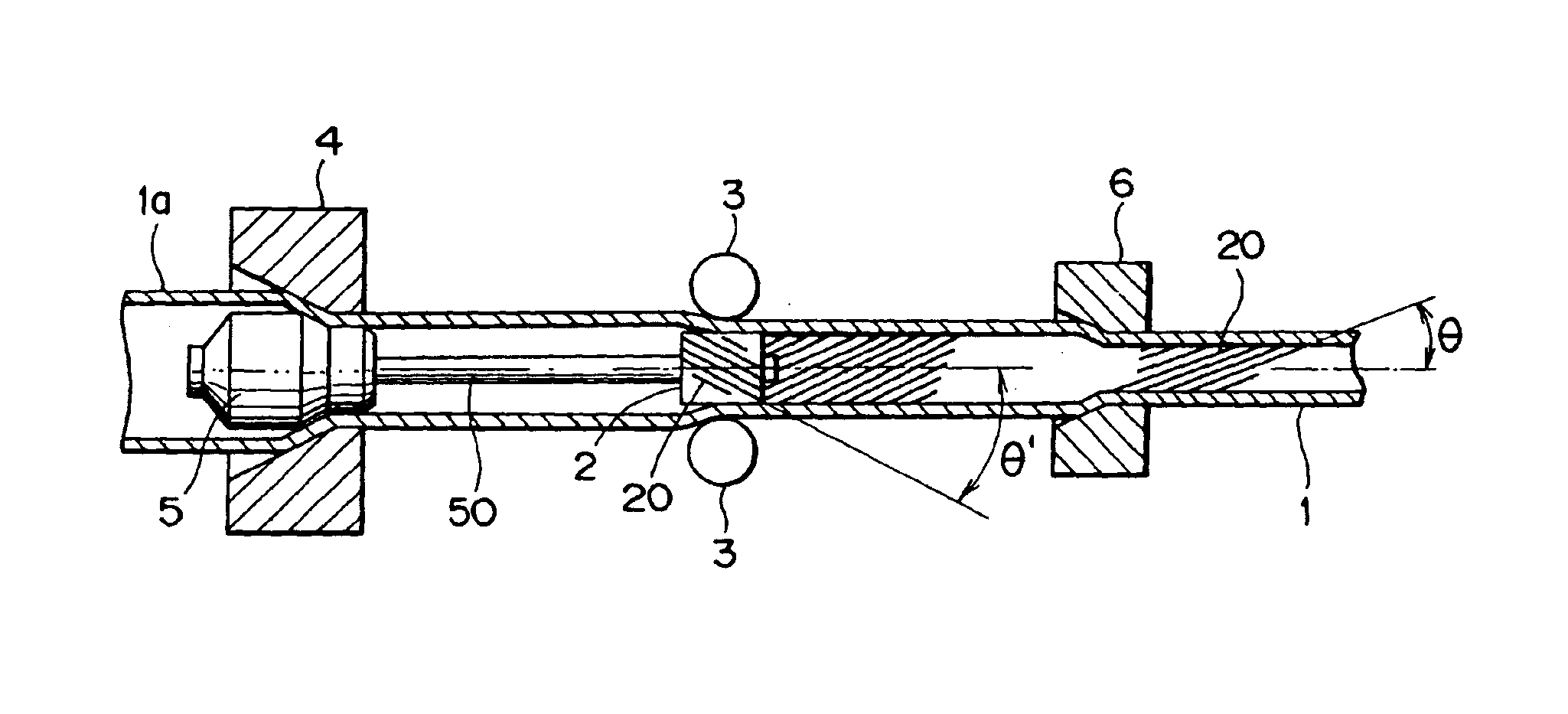

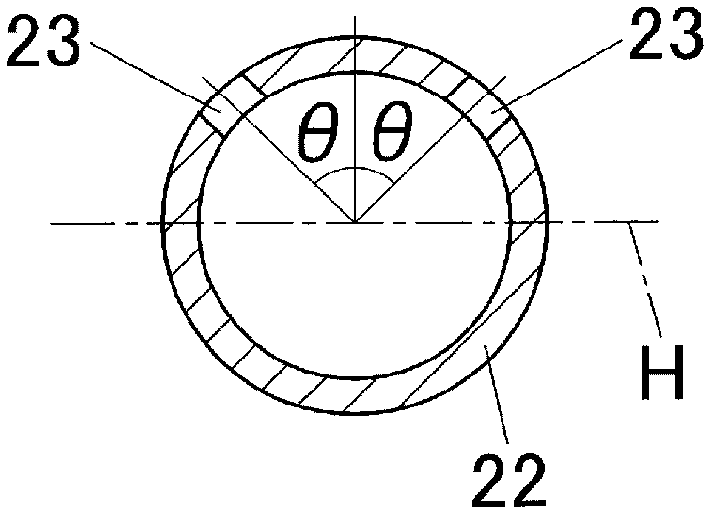

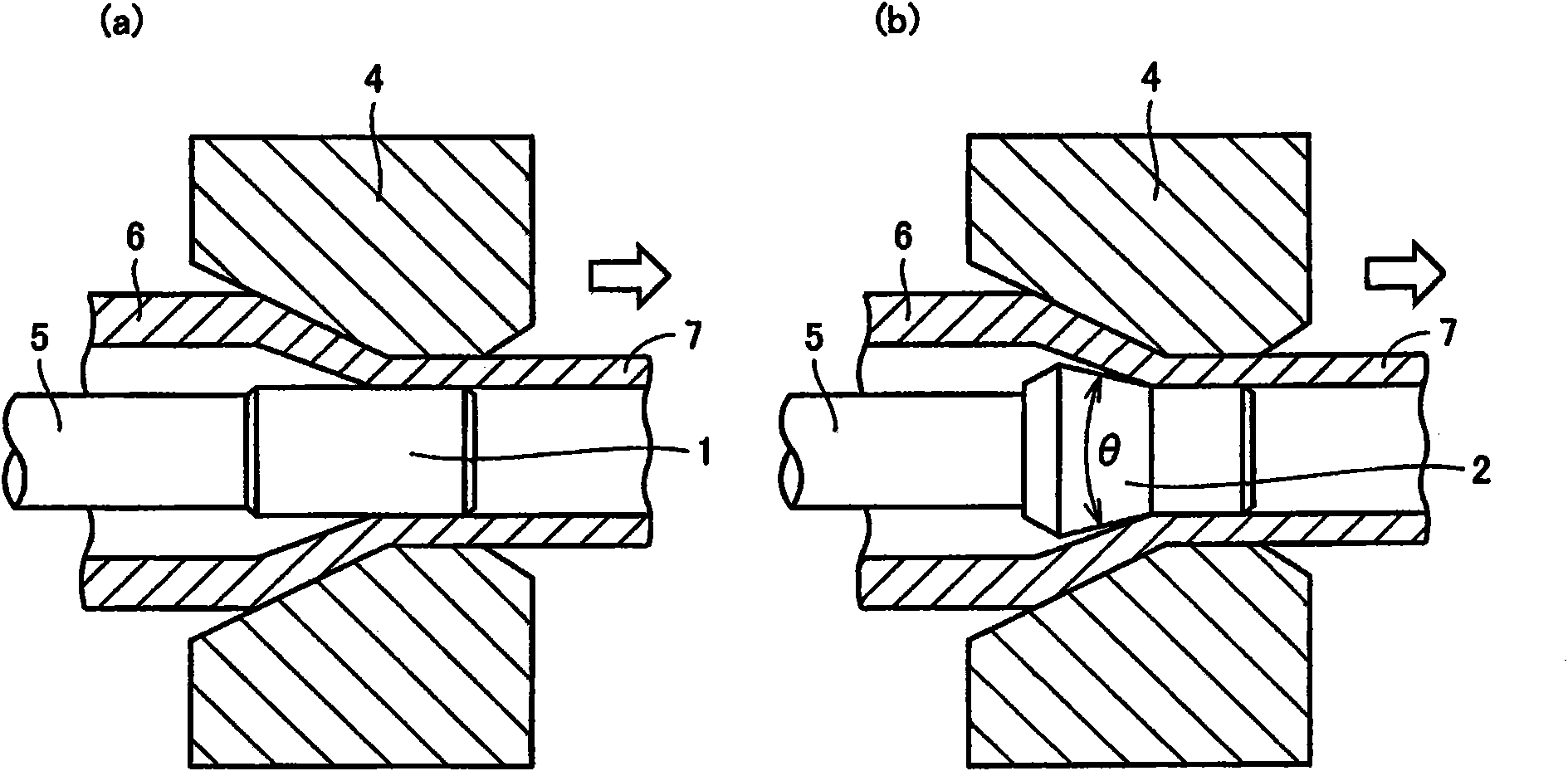

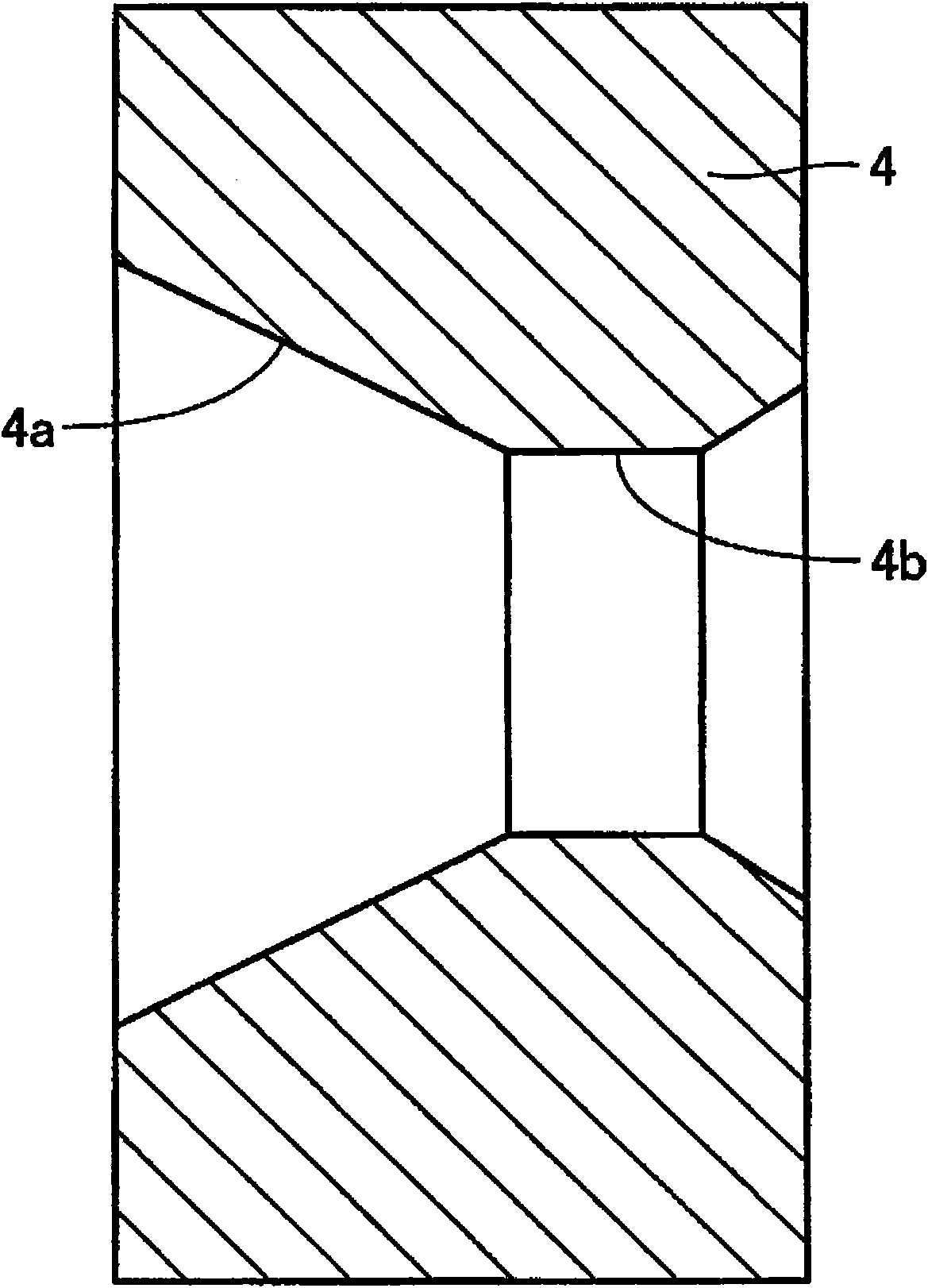

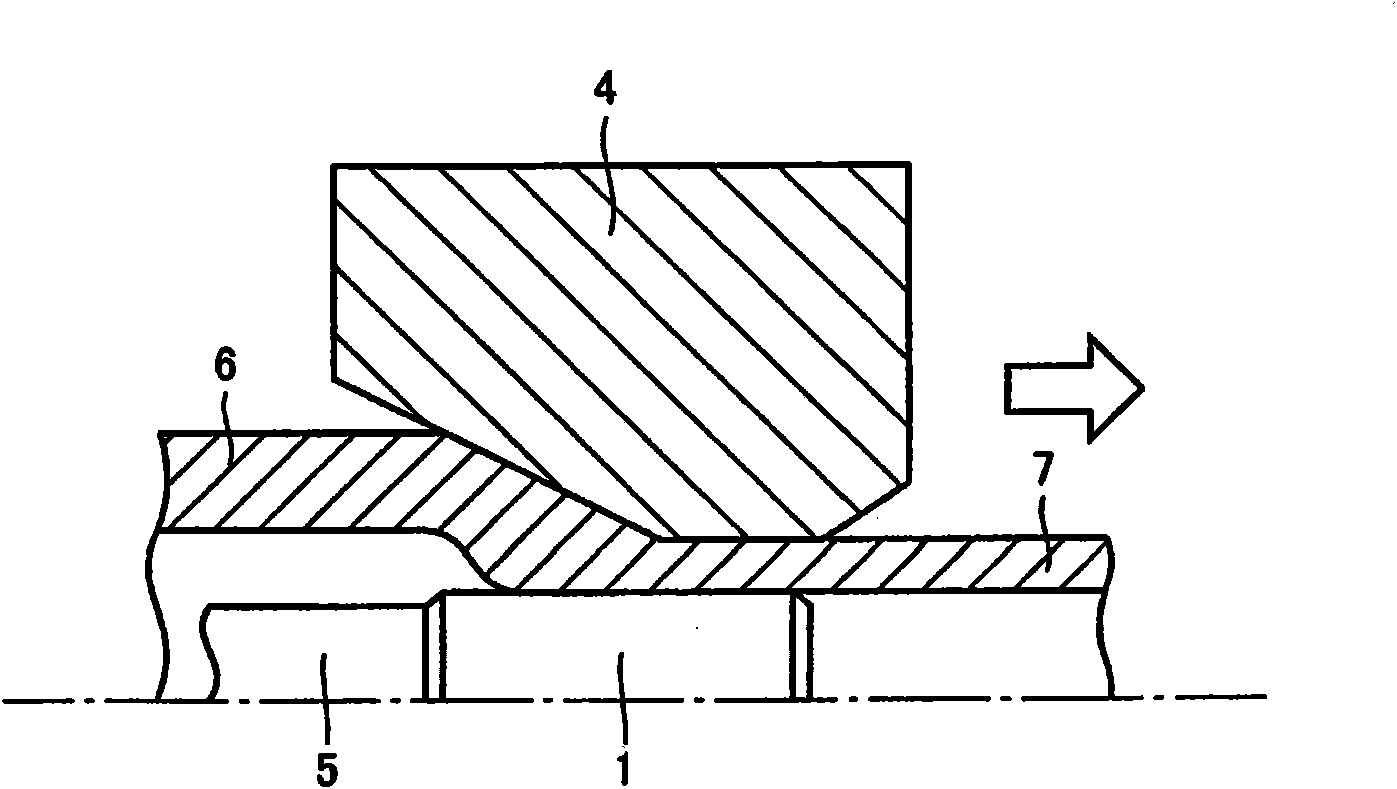

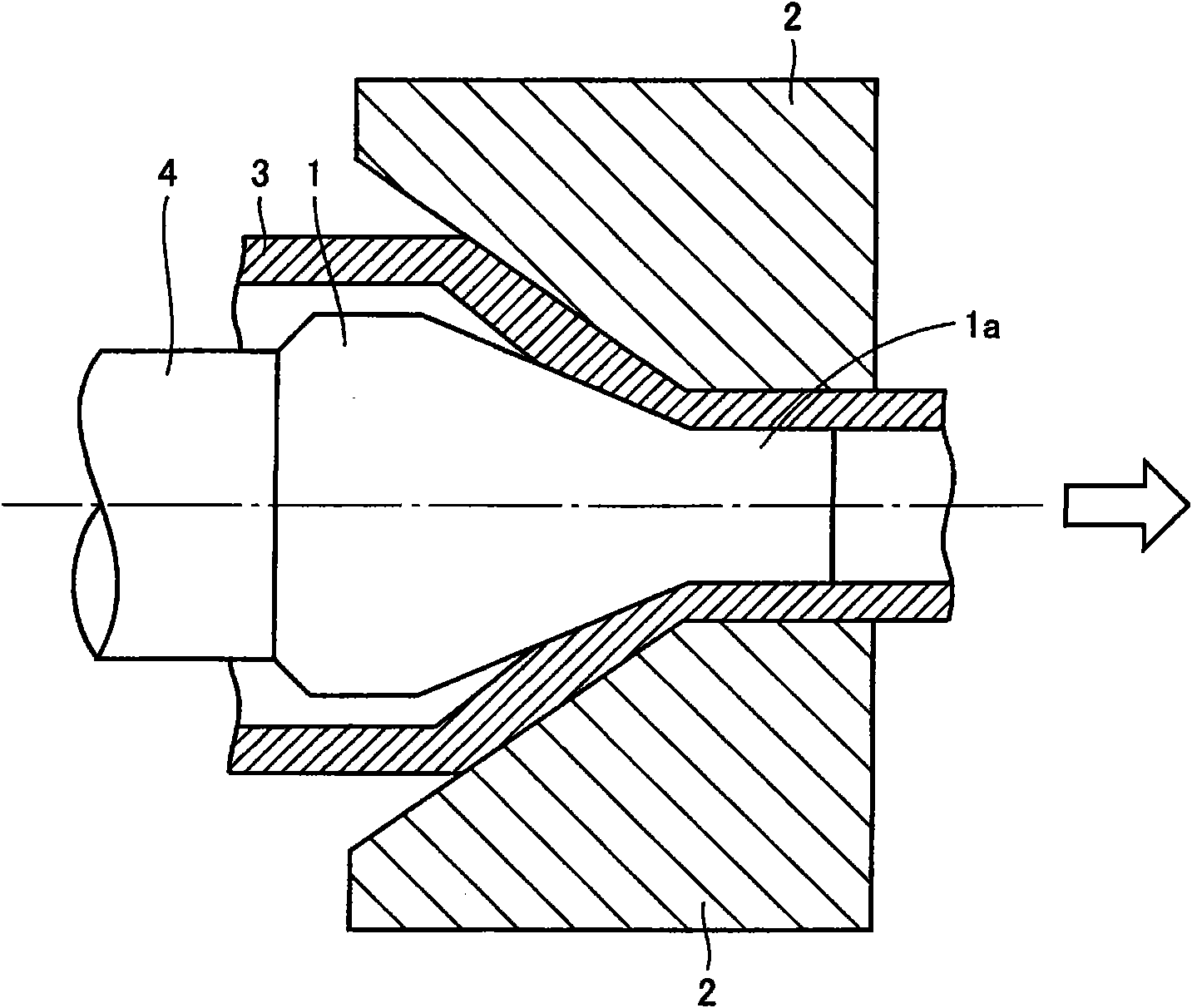

Drawing plug of pipe material and drawing method employing the plug

A drawing plug which is inserted into the inner surface of a pipe material when a thick unprocessed pipe is cold-drwan and has an outer surface having a straight portion, a first tapered portion and a second tapered portion formed sequentially from the tip of the plug, wherein the straight portion has a cylindrical outer surface, the first tapered portion is provided with a taper angle theta 1 sothat the diameter thereof increases from the straight portion toward the second tapered portion, and the second tapered portion is provided with a taper angle theta 2 so that the diameter thereof increases from the second tapered portion toward the rear end. Damage to the plug and occurrence of chattering defect can be prevented by using a plug providing the taper angles theta 1 and theta 2 that satisfy the relation theta 1 > theta 2 > 0.

Owner:NIPPON STEEL CORP

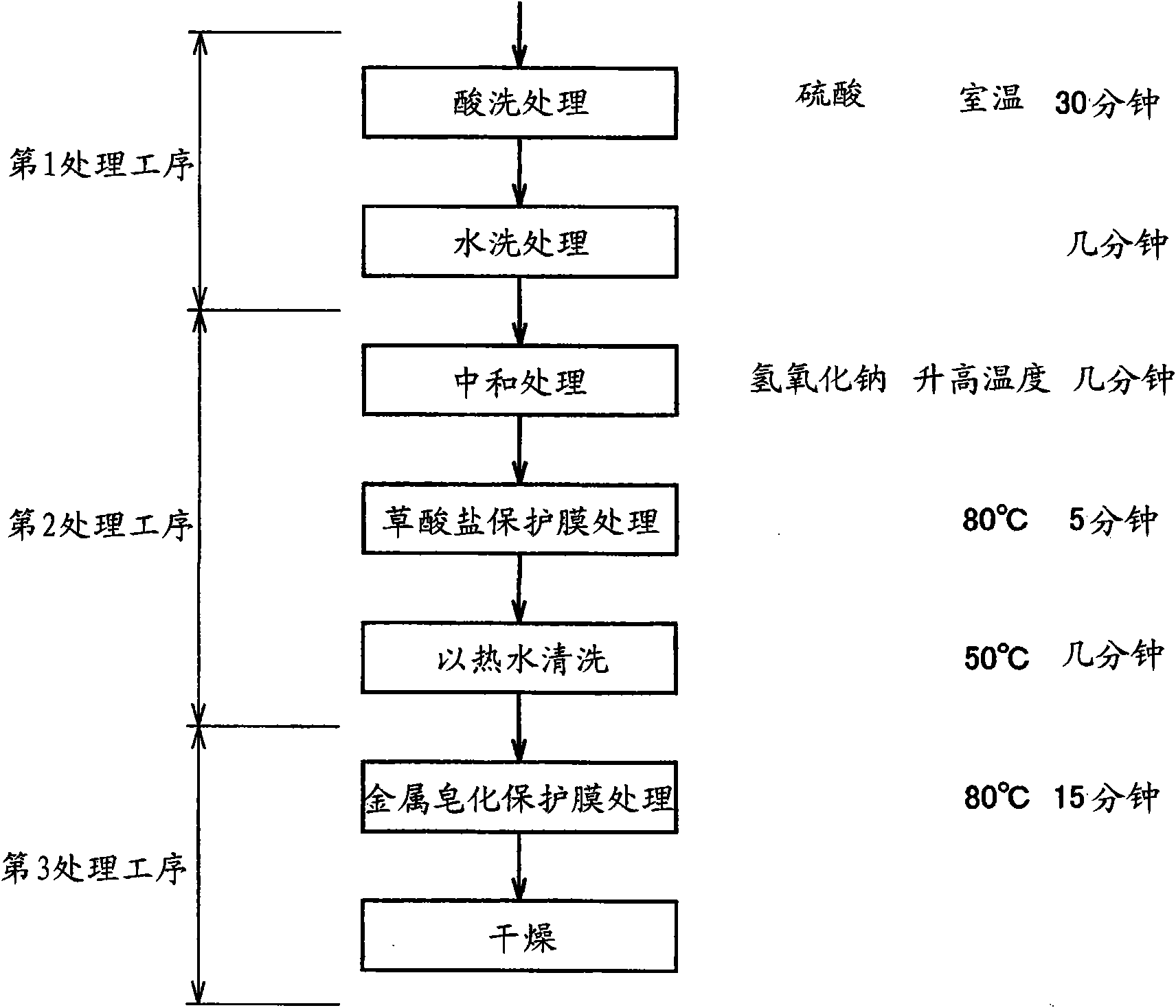

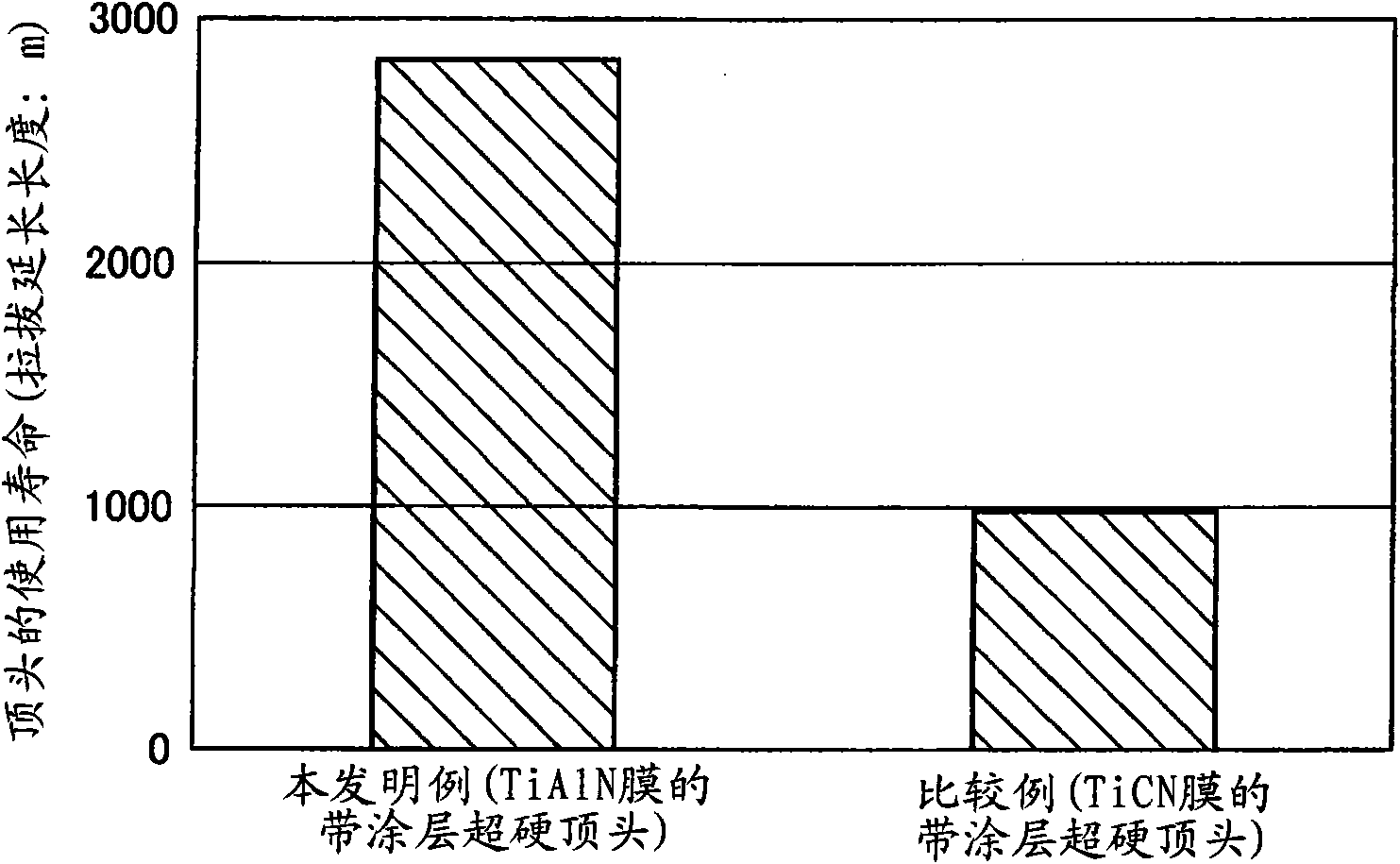

Covered carbide plug and cold drawing method using the covered carbide plug

ActiveCN101909775AExtended service lifeAvoid scratchesDrawing mandrelsHeat exchange apparatusCarbideTitanium

In cold drawing an original pipe of a Cr-base alloy steel containing not less than 5% by mass of Cr, when an original pipe with an oxalate film formed as a substrate for a lubricating film formed by conversion treatment is used while a covered carbide plug having a surface coated with titanium aluminum nitride (TiAlN) film is used as a drawing plug, the separation of the TiAlN film coated on the plug surface can be suppressed. Thus, the occurrence of seizure marks can be prevented, and the service life of the plug can be prolonged.

Owner:NIPPON STEEL CORP

Metal Pipe and Manufacturing Method Thereof

InactiveUS20090158799A1Increased durabilityReducing fluid frictionDrawing mandrelsGeothermal energy generationBiomedical engineeringMetal

A metal pipe according to the invention has a plurality of ridges that have different heights, extend in the axial direction, and are arranged in the circumferential direction at its inner circumferential surface. If the Reynolds number changes and the streak structure and the scale of a hairpin vortex change, the streak and the hairpin vortex each match any one of the ridges. Therefore, the fluid friction can be reduced in a wide Reynolds number range.

Owner:SUMITOMO METAL IND LTD

Copper pipe drawing device

InactiveCN106925621AIncrease the lengthImprove continuityDrawing mandrelsLocking mechanismHydraulic pump

Owner:CHONGQING YONGCHUAN DISTRICT YIRUI MACHINERY

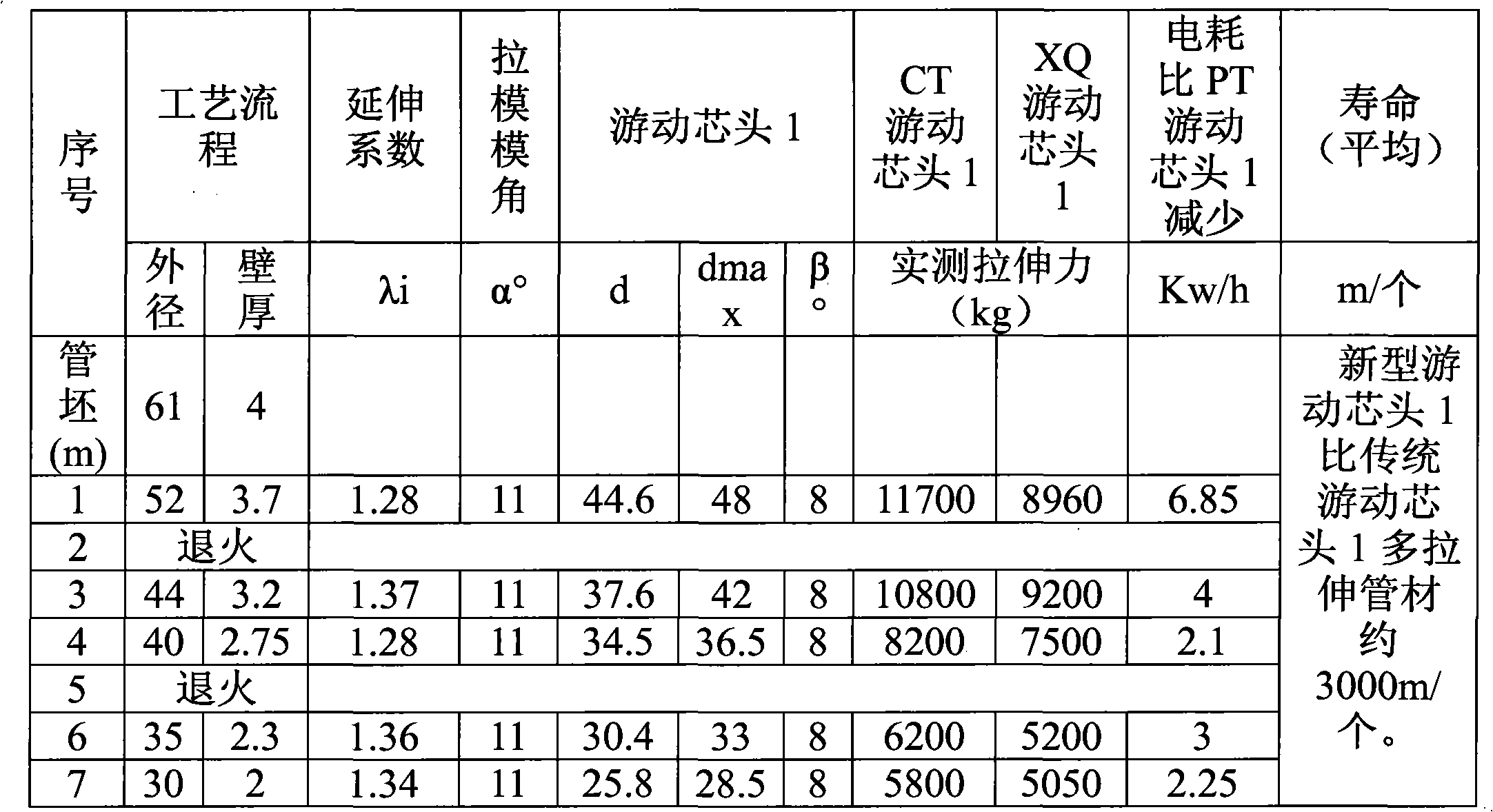

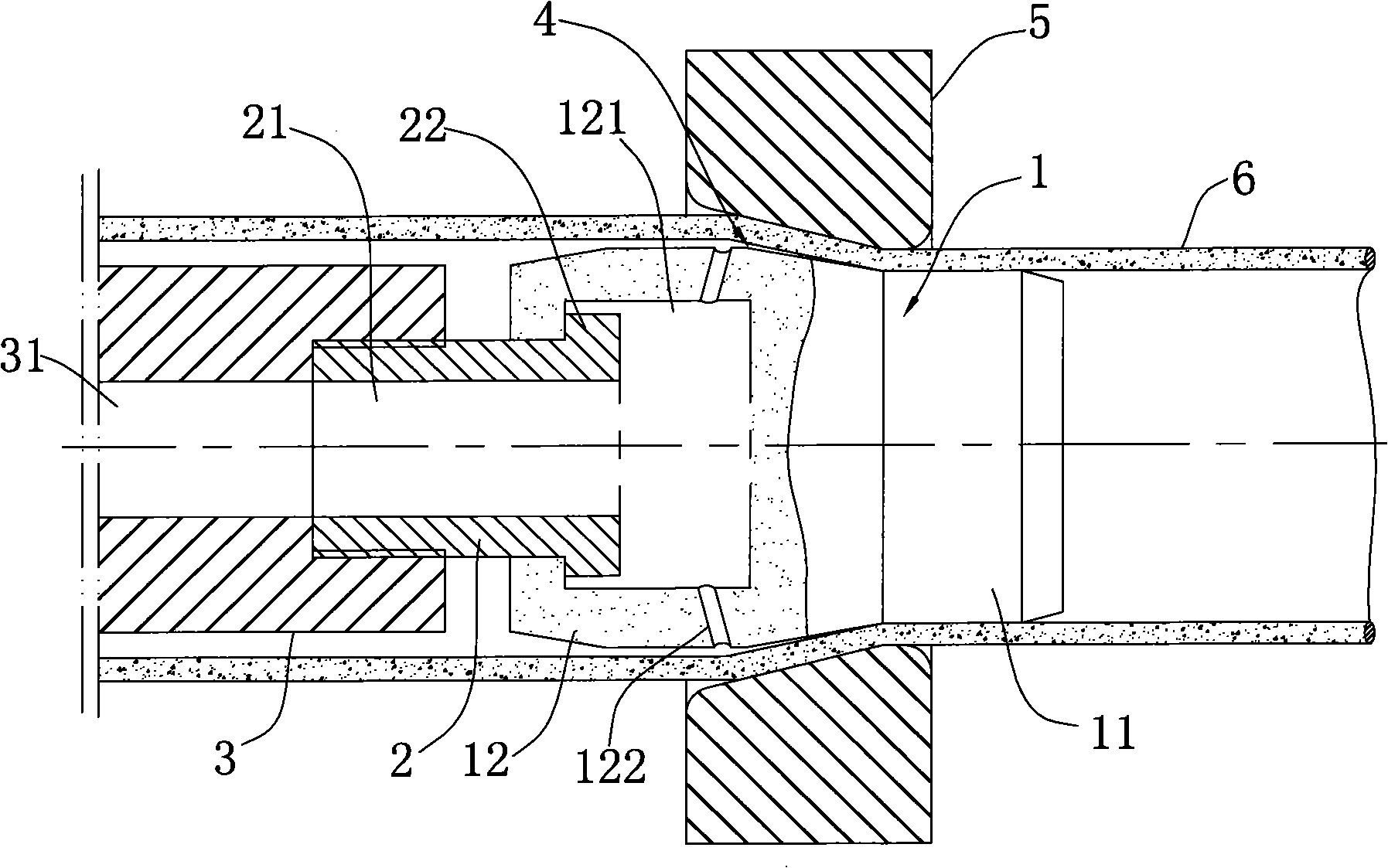

Novel strong lubrication floating core head assembly

ActiveCN101829695AAccurate and even injectionIncrease hydrodynamic pressureDrawing mandrelsLubricationHydrodynamic pressure

The invention discloses a novel strong lubrication floating core head assembly which comprises a stretching core bar, a floating core head and a connecting screw rod for connecting the stretching core bar and the floating core head, wherein an oil pore channel I is arranged in the stretching core bar; an oil storage chamber is arranged in the floating core head; an oil pore channel II which is used for communicating the oil pore channel I with the oil storage chamber is arranged in the connecting screw rod; and a plurality of oil spray through holes which are communicated with the oil storage chamber are radially and annularly distributed on the wall body of the floating core head. The structure and shape designs of the strong lubrication floating core head ensure that lubricating oil can be accurately and evenly sprayed into a lubrication wedge in the stretching process, the lubrication wedge has enough lubricating oil, and the hydrodynamic pressure in the lubrication wedge, namely, the lubrication wedge effect is improved, thereby reducing the electric energy consumption and the stretching force in the process of stretching straight pipes, improving the stretching efficiency of the pipes, prolonging the service life of the floating core head and having the advantages of energy saving and environment protection.

Owner:ZHEJIANG HAILIANG

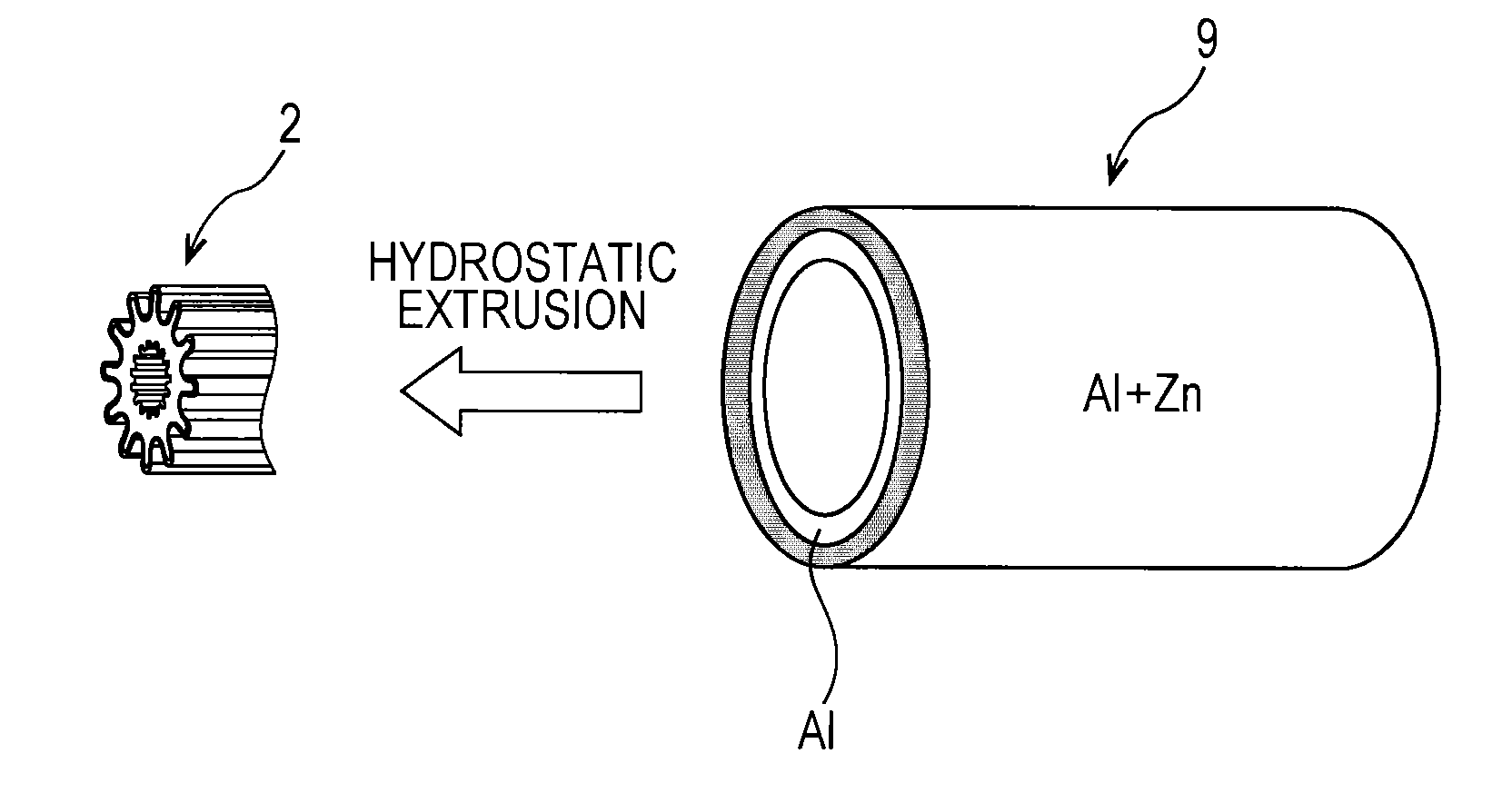

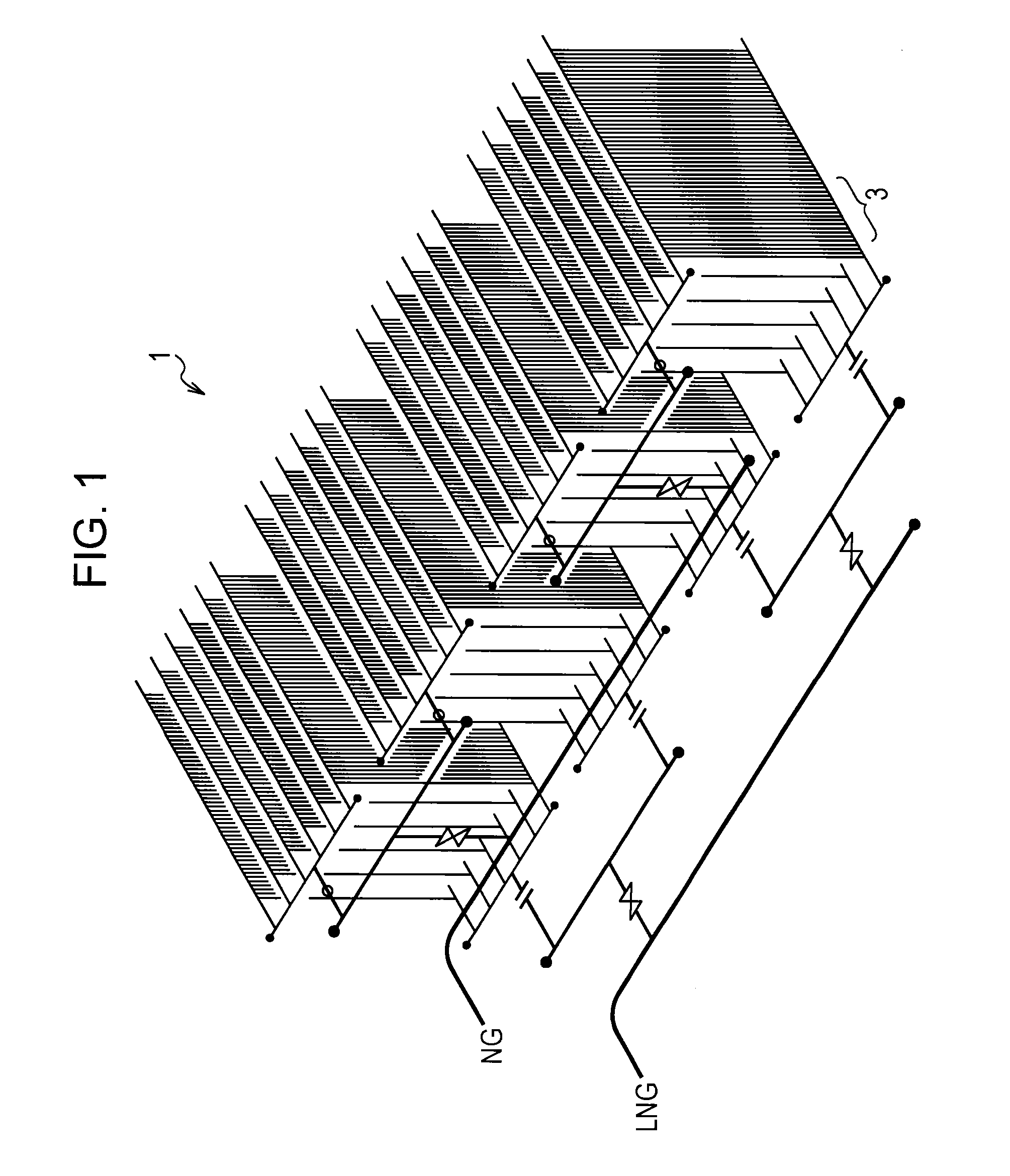

Multi-layered heat transfer tube, manufacturing method of multi-layered heat transfer tube, and forming device used in the manufacturing method

A multi-layered heat transfer tube for use in a carburetor for a liquefied gas, comprising an inner tube which is equipped with a passage through which a liquefied gas can pass and an outer tube which covers the outer peripheral surface of the inner tube, wherein each of the inner tube and the outer tube has multiple fins that extend in the direction of the length of the multi-layered heat transfer tube and are arranged along the direction of the circumference of the multi-layered heat transfer tube, at least the outer tube is composed of a fully dense material, and the outer tube covers the entire outer surface of the inner tube and is bound to the inner tube via a metallic bond.

Owner:KOBE STEEL LTD

Method of producing ultrathin-wall seamless metal tube using floating plug

Proposed is a method of producing an ultrathin-wall metal tube by a cold drawing method capable of drastically expanding an available size range toward much thinner side with respect to wall thickness of metal tubes. This is a diameter-expanding drawing method, in which an entry solid die, the diameter of which increases, remains constant or decreases from the engaging entry side toward the finishing exit side, and a delivery solid die, the diameter of which decreases at least in the vicinity of the engaging entry, are arranged in series and in an abutting relation on the same pass line, and a tapered plug, the diameter of which increases from the engaging entry side toward the finishing exit side, is caused to float along the pass line, whereby in the entry solid die region, the wall thickness is reduced while the mid-wall diameter of a hollow shell is being expanded between the solid die and the plug, and in the delivery solid die region, the tapered plug is caused to float by performing reduction working of the outside diameter. This method offers tremendously great economic advantages, because it is possible to produce ultrathin-wall seamless metal tubes and to make longer length tubes, and to realize the rationalization of processes in terms of yield, efficiency and the like.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com