Apparatus and method for drawing metal tube

A technology for drawing devices and metal tubes, which is applied in the direction of the mandrel, etc., can solve problems such as the decline in the deflection accuracy of the drawn tubes, and achieve the effects of preventing sintering and efficient processing

Inactive Publication Date: 2012-05-23

SHOWA DENKO KK

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, for the outer surface that can be supplied with lubricating oil at any time, the inner surface sometimes has insufficient lubricating oil during drawing and sintering occurs, which reduces the deflection accuracy of the drawn tube.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

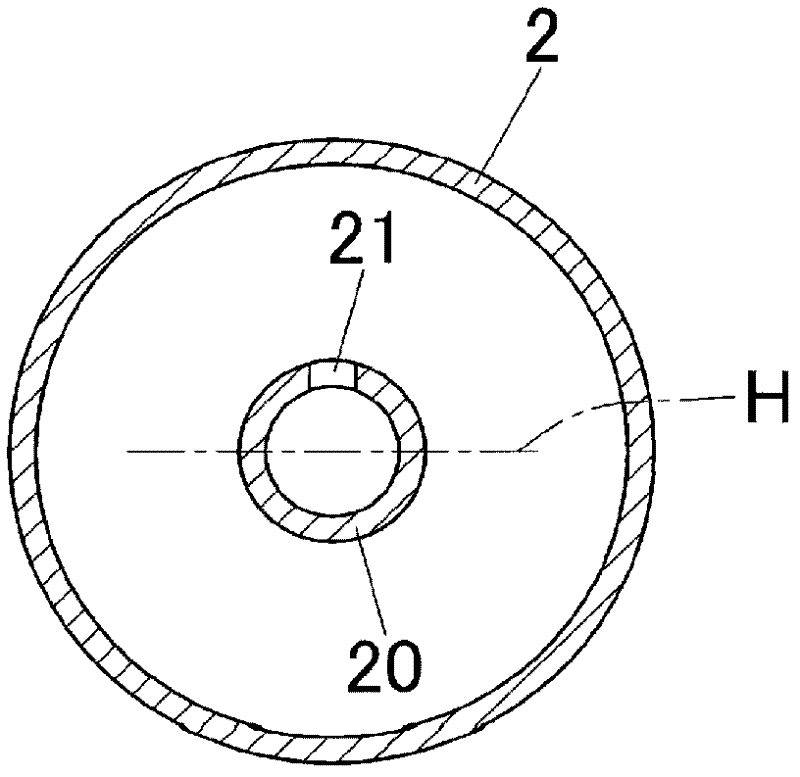

[0075] Such as figure 2 As shown, a discharge port 21 is provided at a position of θ=0°.

Embodiment 2

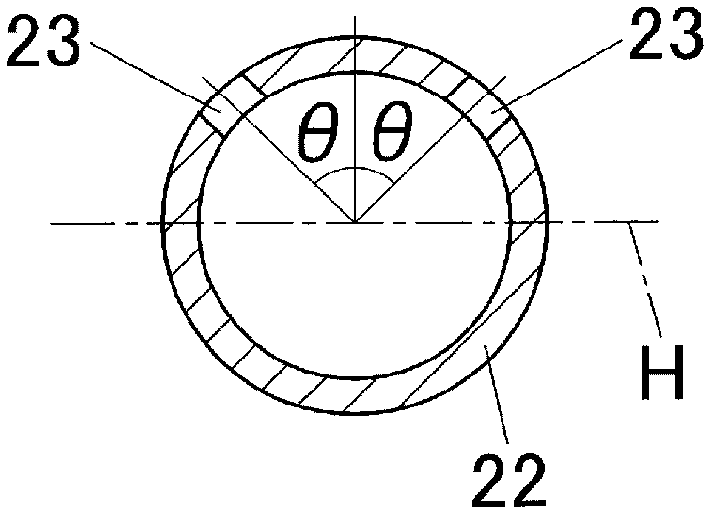

[0077] Such as image 3 As shown, two discharge ports 23 are provided at the position of θ=40°.

Embodiment 3

[0079] Such as Figure 4 As shown, one discharge port 21 is provided at a position of θ=0°, and two discharge ports 23 are provided at a position of θ=40°.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

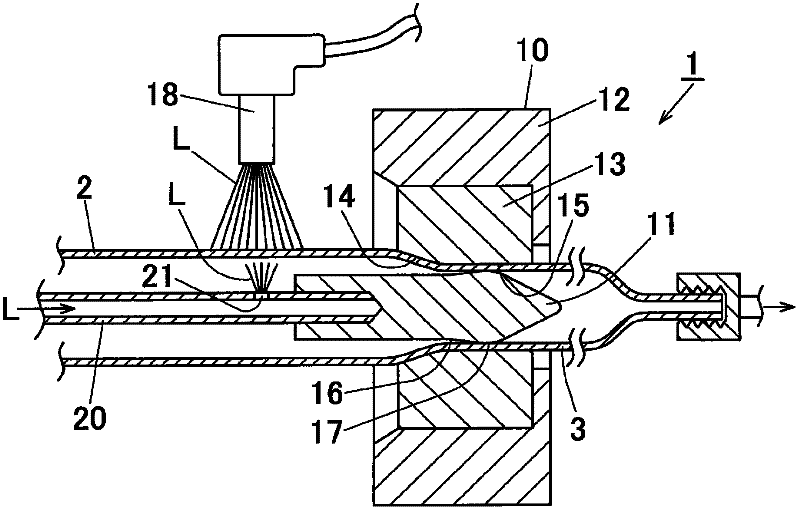

In an apparatus for drawing a metal tube, in which a lubricant is discharged from an opening formed in a hollow rod which supports a plug to apply the lubricant onto an inner surface of a tube blank, the lubricant discharging sensitivity when a discontinuous lubricant supply is performed is enhanced. In a drawing apparatus in which a metal tube blank (2) is machined by passing the same between a die (10) for forming an outer surface and a plug (11) for forming an inner surface, a discharge port (21) from which a lubricant (L) is discharged opens onto an outer peripheral surface of a hollow rod (20) which supports the plug (11). The discharge port (21) is provided only in an area of the rod (20) higher than the center thereof in the upward and downward directions.

Description

technical field [0001] The present invention relates to a drawing device and use of a metal tube capable of producing a drawn tube made of metal, such as a substrate for an OPC photosensitive drum of electrophotographic equipment such as a copier, a laser printer, and a facsimile, and having excellent dimensional accuracy. The drawing method of the drawing device. In addition, in the description of this specification, the "rear" of the drawing device and the drawing method means the direction relative to the shell side of the drawn pipe, and the "front" means the direction of the drawn pipe relative to the shell (capillary, plain pipe). direction of the tube side. Background technique [0002] In recent years, as substrates for photosensitive drums of OPCs in electrophotographic equipment such as printers, laser printers, and facsimile machines, non-cut tubes suitable for mass production are often used. [0003] As one of the non-cutting tubes, there is an ED tube that is ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21C3/16B21C1/22B21C9/00

CPCB21C9/005B21C3/16B21C1/24

Inventor 山本学张替勳境祐治

Owner SHOWA DENKO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com