Patents

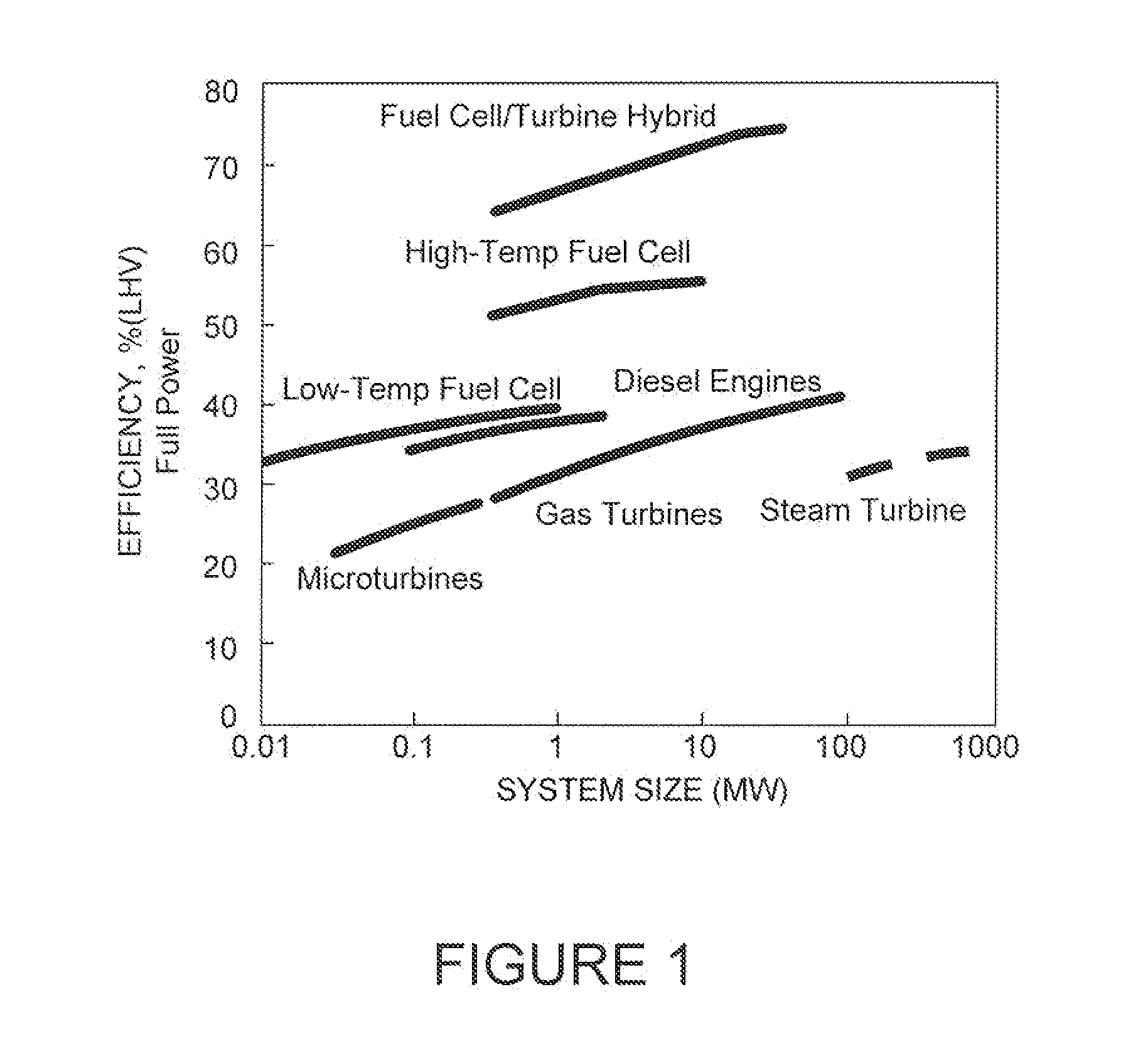

Literature

73results about How to "Efficiently oxidized" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Layered SOx tolerant NOx trap catalysts and methods of making and using the same

InactiveUS20050164879A1Minimize conversionMaintain activityDispersed particle separationCatalyst activation/preparationExhaust gasPollutant

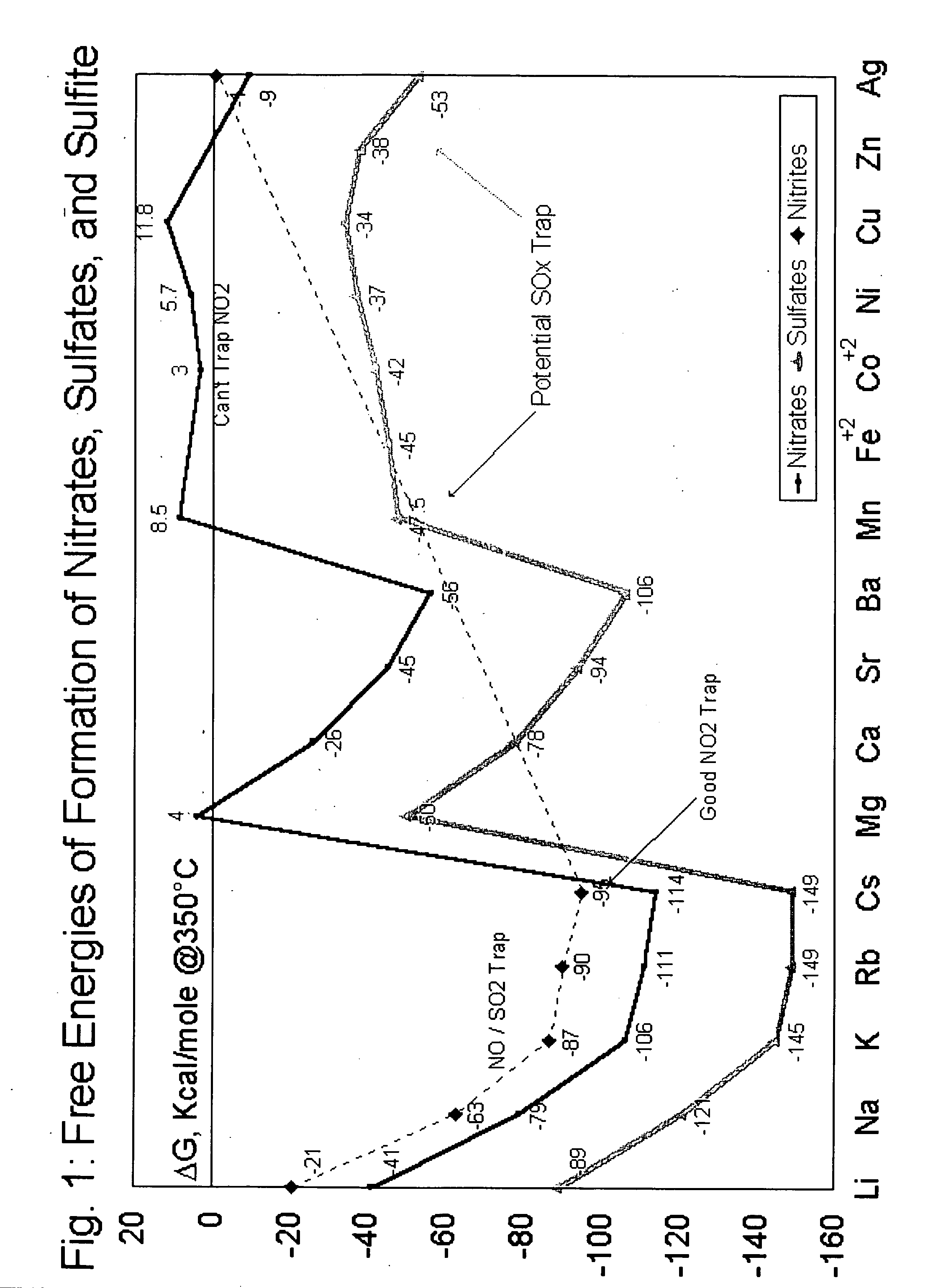

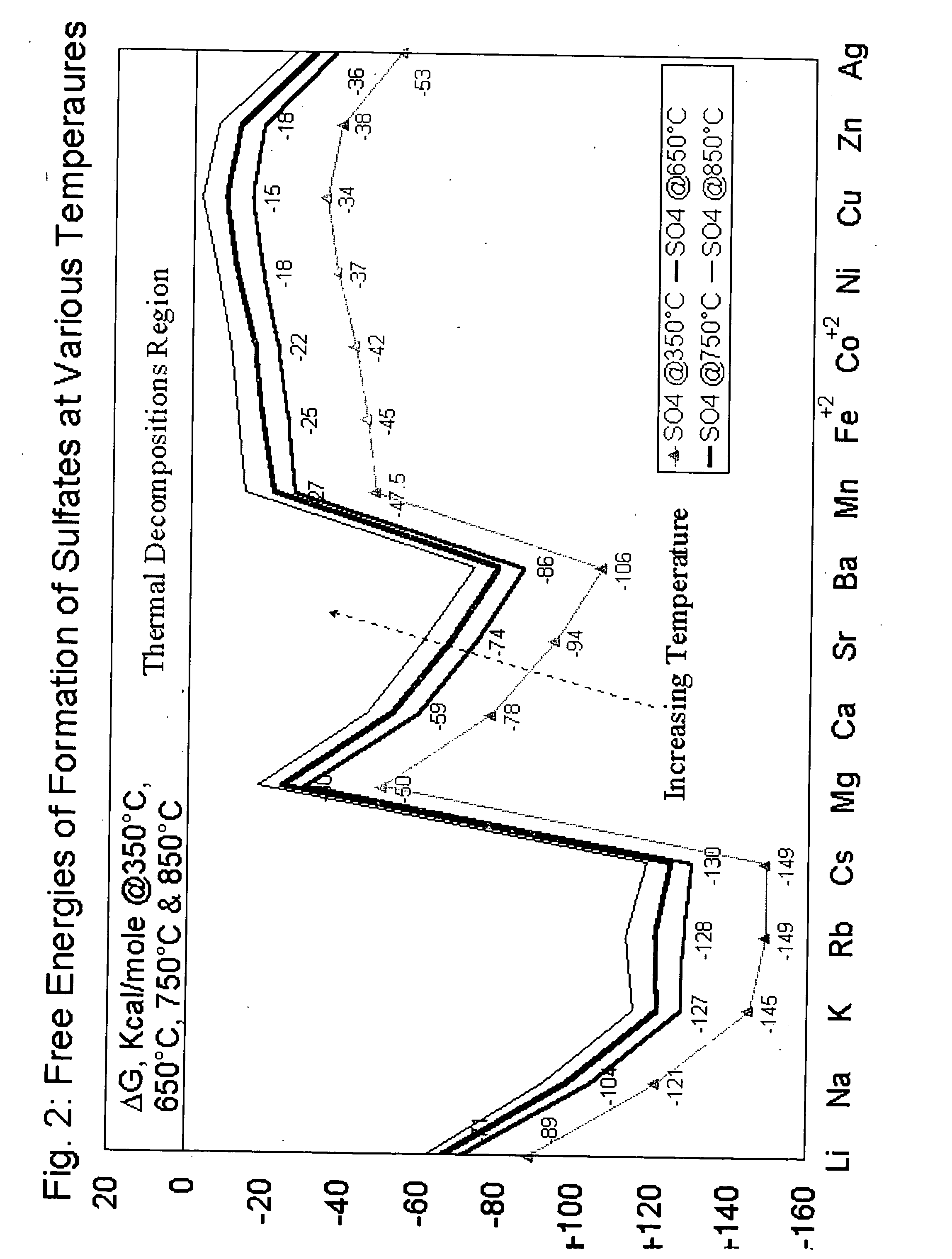

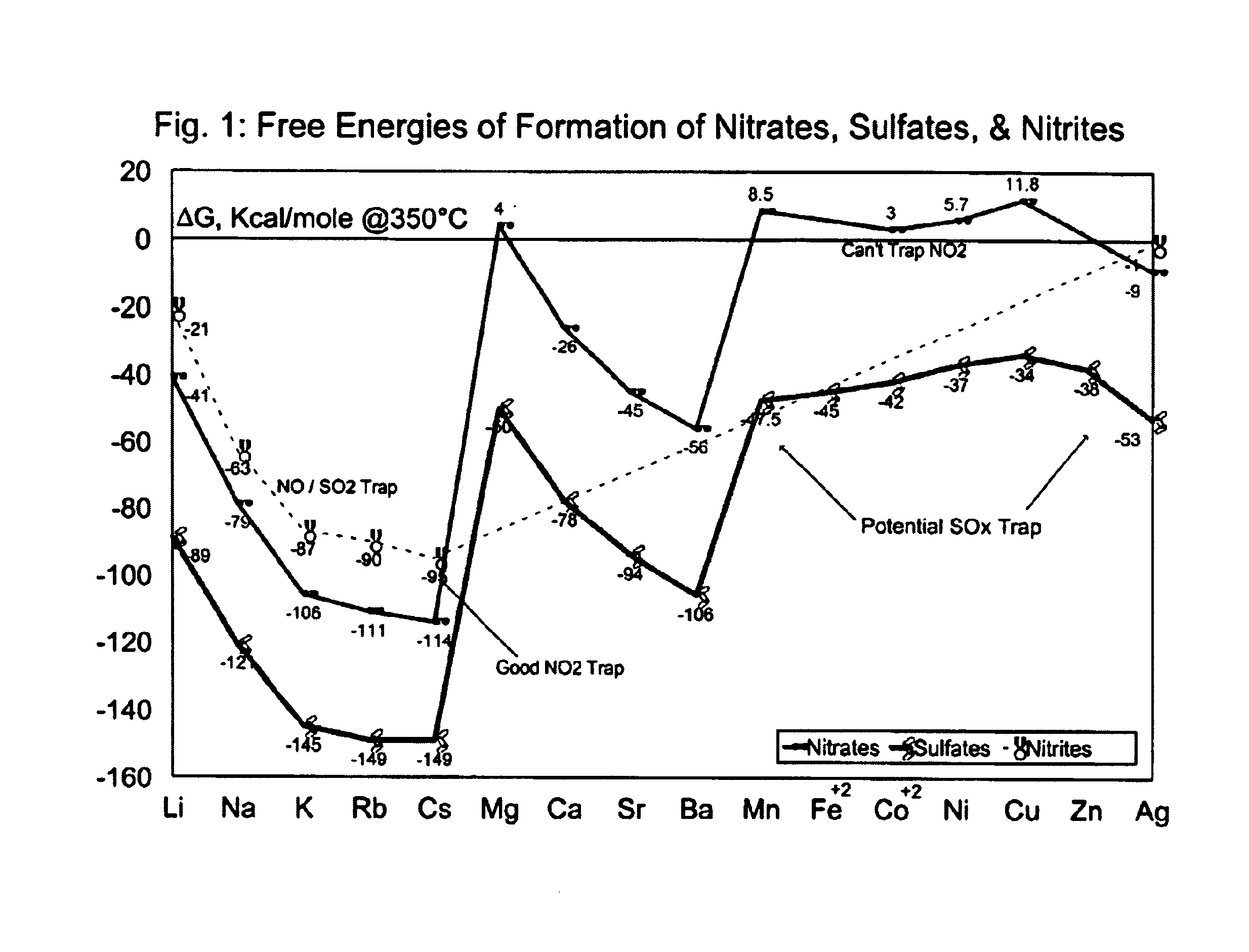

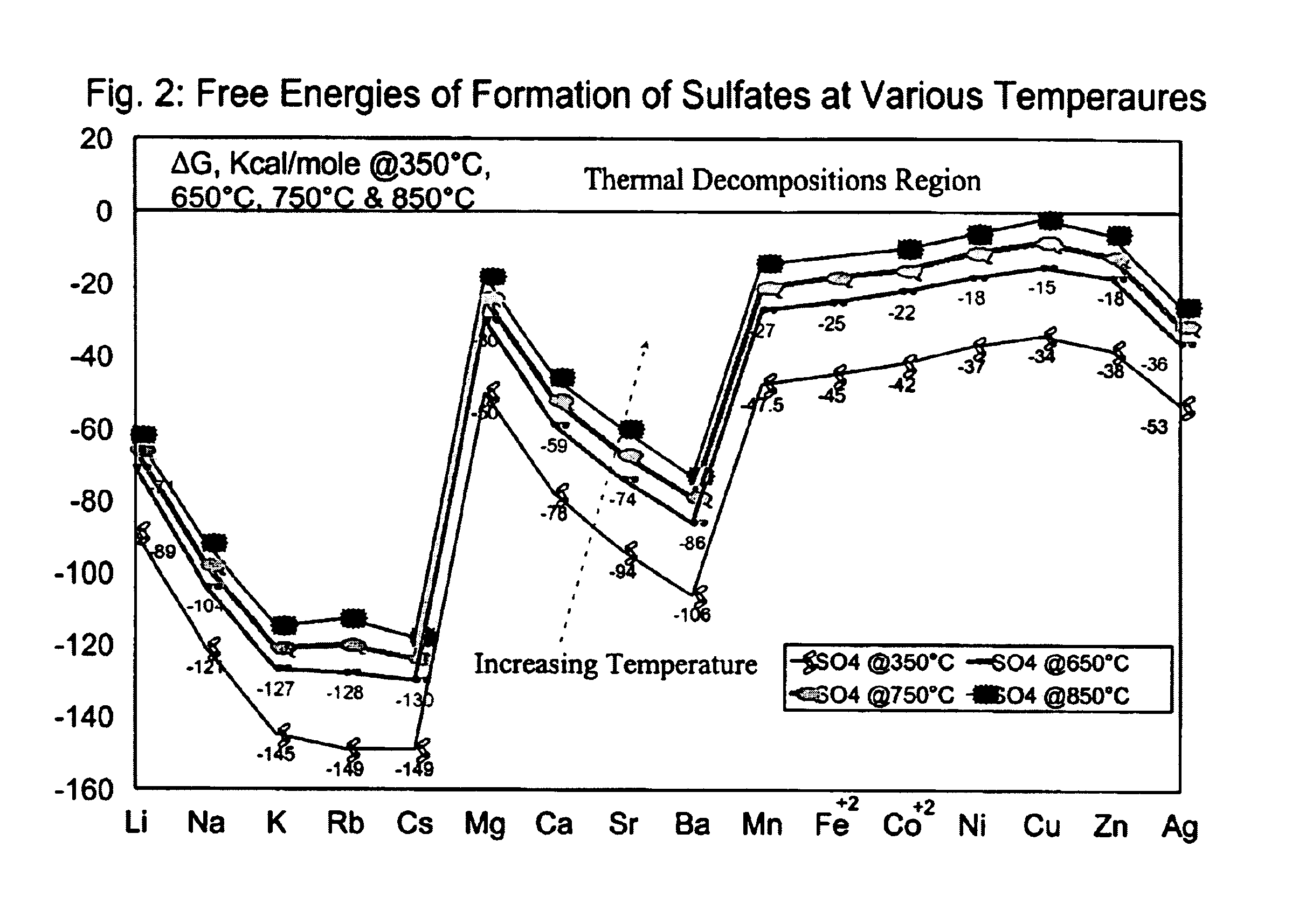

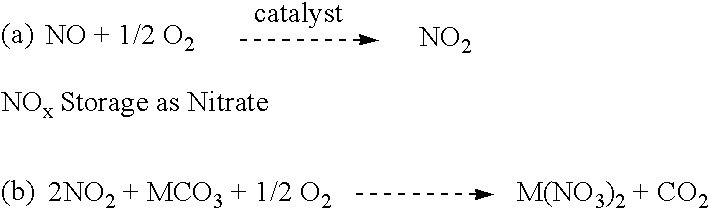

The present invention relates to a layered catalyst composite useful for reducing contaminants in exhaust gas streams, especially gaseous streams containing sulfur oxide contaminants. More specifically, the present invention is concerned with improved catalysts of the type generally referred to as “three-way conversion” catalysts. The layered catalysts trap sulfur oxide contaminants, which tend to poison three-way conversion catalysts used to abate other pollutants in the stream. The layered catalyst composites of the present invention have a sulfur oxide absorbing layer before or above a nitrogen oxide absorbing layer, and / or normal three-way catalytic layers. The layered catalyst composite comprises a first layer and a second layer. The first layer comprises a first support and at least one first platinum component. The second layer comprises a second support and a SOx sorbent component after forming its reaction product with SOx having a free energy of formation from about 0 to about −90 Kcal / mole at 350° C. The sulfur oxide absorbing layer selectively and reversibly absorbs sulfur oxides over nitrogen oxides and prevents or alleviates sulfur oxide poisoning of the nitrogen oxide trap.

Owner:ENGELHARD CORP

Cellulose oxidation by nitrogen dioxide in a perfluorinated tertiary amine solvent

ActiveUS7645874B2Efficiently oxidizedReduce usageBiocideOrganic active ingredientsAqueous alcoholNitrogen dioxide

This invention relates to a process for preparing bioabsorbable oxidized cellulose comprising combining cellulose material, with nitrogen dioxide and a nonaqueous solvent chosen from the class of perfluorinated tertiary amines. This invention also relates to a method of oxidizing cellulose material comprising introducing a solvent into the vessel, circulating the solvent through the cellulose material, adding nitrogen dioxide to said vessel containing the solvent and cellulose in the required amounts, circulating the solution for 7 to 24 hours while controlling the reaction temperature, and isolating the oxidized material. Preferably, isolation of the oxidized product is followed by first washing the oxidized cellulose material with cold water, then washing the oxidized cellulose material with an aqueous alcohol solution several times, then washing the material with 100% alcohol several times, and finally drying the oxidized material.

Owner:DEPUY SYNTHES PROD INC

Cellulose oxidation by nitrogen dioxide in a perfluorinated tertiary amine solvent

ActiveUS20070054880A1Efficiently oxidizedReduce usageBiocideOrganic active ingredientsNitrogen dioxideAqueous alcohol

This invention relates to a process for preparing bioabsorbable oxidized cellulose comprising combining cellulose material, with nitrogen dioxide and a nonaqueous solvent chosen from the class of perfluorinated tertiary amines. This invention also relates to a method of oxidizing cellulose material comprising introducing a solvent into the vessel, circulating the solvent through the cellulose material, adding nitrogen dioxide to said vessel containing the solvent and cellulose in the required amounts, circulating the solution for 7 to 24 hours while controlling the reaction temperature, and isolating the oxidized material. Preferably, isolation of the oxidized product is followed by first washing the oxidized cellulose material with cold water, then washing the oxidized cellulose material with an aqueous alcohol solution several times, then washing the material with 100% alcohol several times, and finally drying the oxidized material.

Owner:DEPUY SYNTHES PROD INC

Layered SOX tolerant NOX trap catalysts and methods of making and using the same

InactiveUS6923945B2Alleviates sulfur oxide poisoningMaintain long-term activityNitrogen compoundsInternal combustion piston enginesPlatinumFree energies

The present invention relates to a layered catalyst composite useful for reducing contaminants in exhaust gas streams, especially gaseous streams containing sulfur oxide contaminants. More specifically, the present invention is concerned with improved catalysts of the type generally referred to as “three-way conversion” catalysts. The layered catalysts trap sulfur oxide contaminants which tend to poison three-way conversion catalysts used to abate other pollutants in the stream. The layered catalyst composites of the present invention have a sulfur oxide absorbing layer before or above a nitrogen oxide absorbing layer. The layered catalyst composite comprises a first layer and a second layer. The first layer comprises a first support and at least one first platinum component. The second layer comprises a second support and a SOx sorbent component having a free energy of formation from about 0 to about −90 Kcal / mole at 350° C. The sulfur oxide absorbing layer selectively and reversibly absorbs sulfur oxides over nitrogen oxides and prevents or alleviates sulfur oxide poisoning of the nitrogen oxide trap.

Owner:ENGELHARD CORP

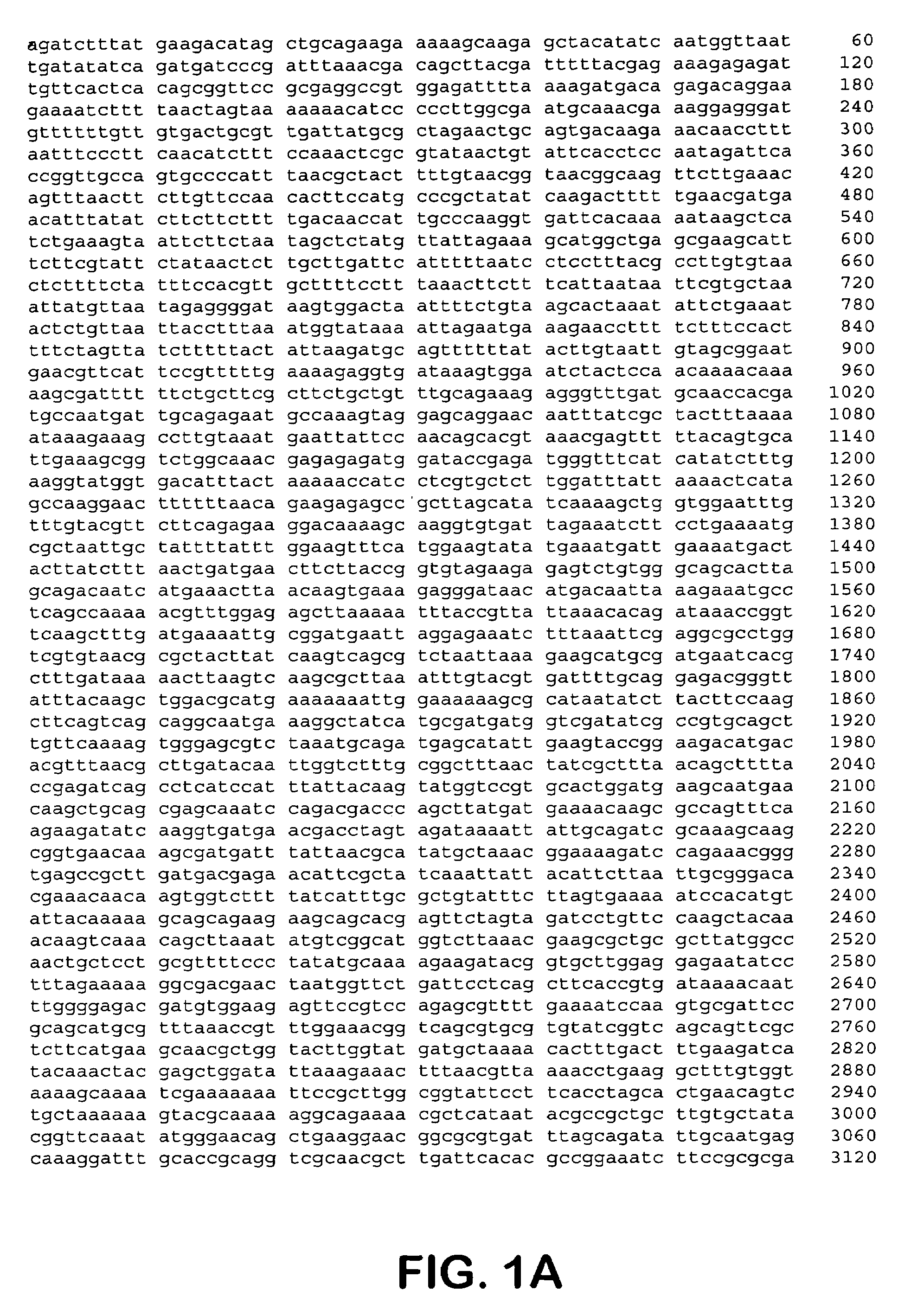

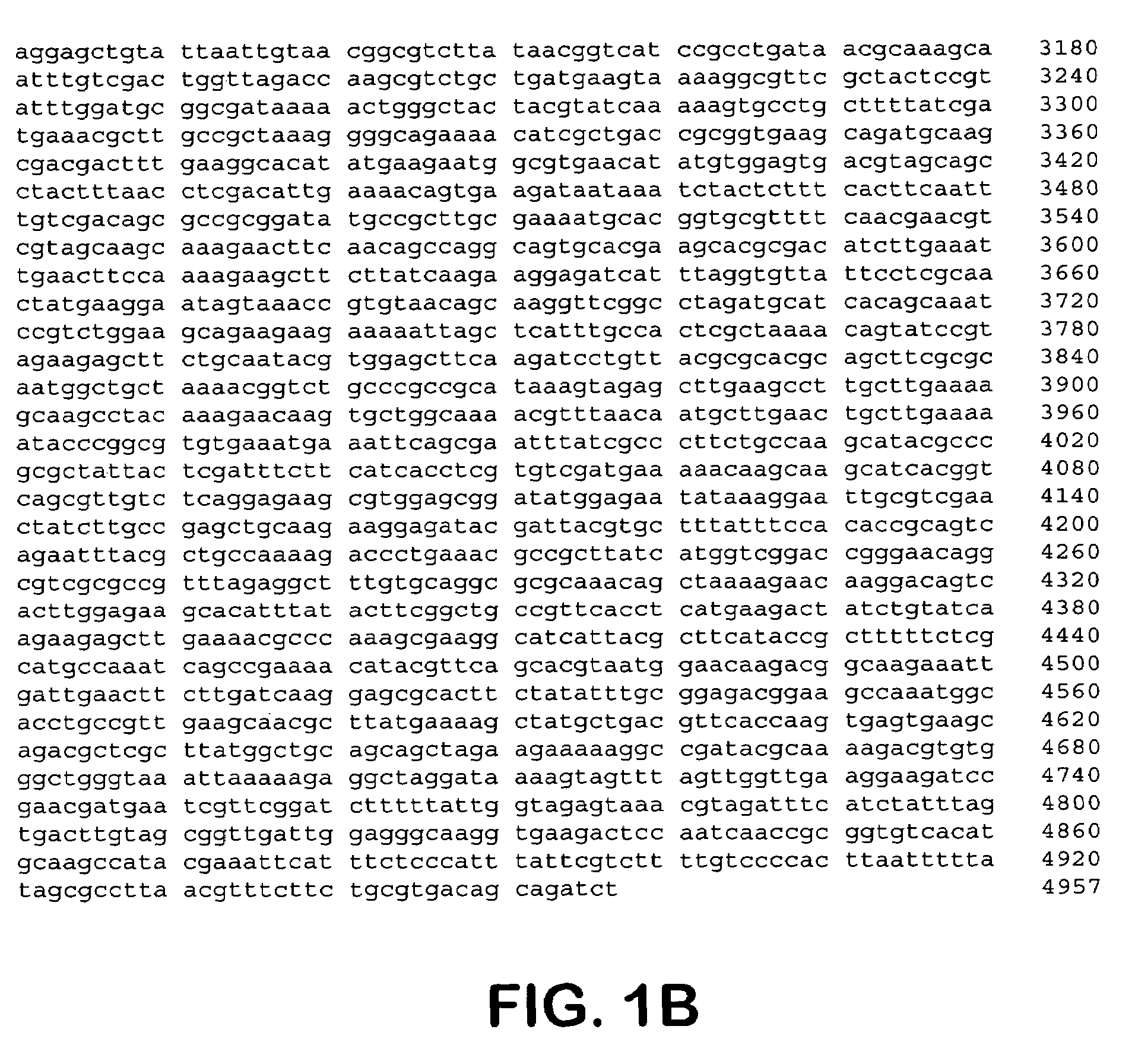

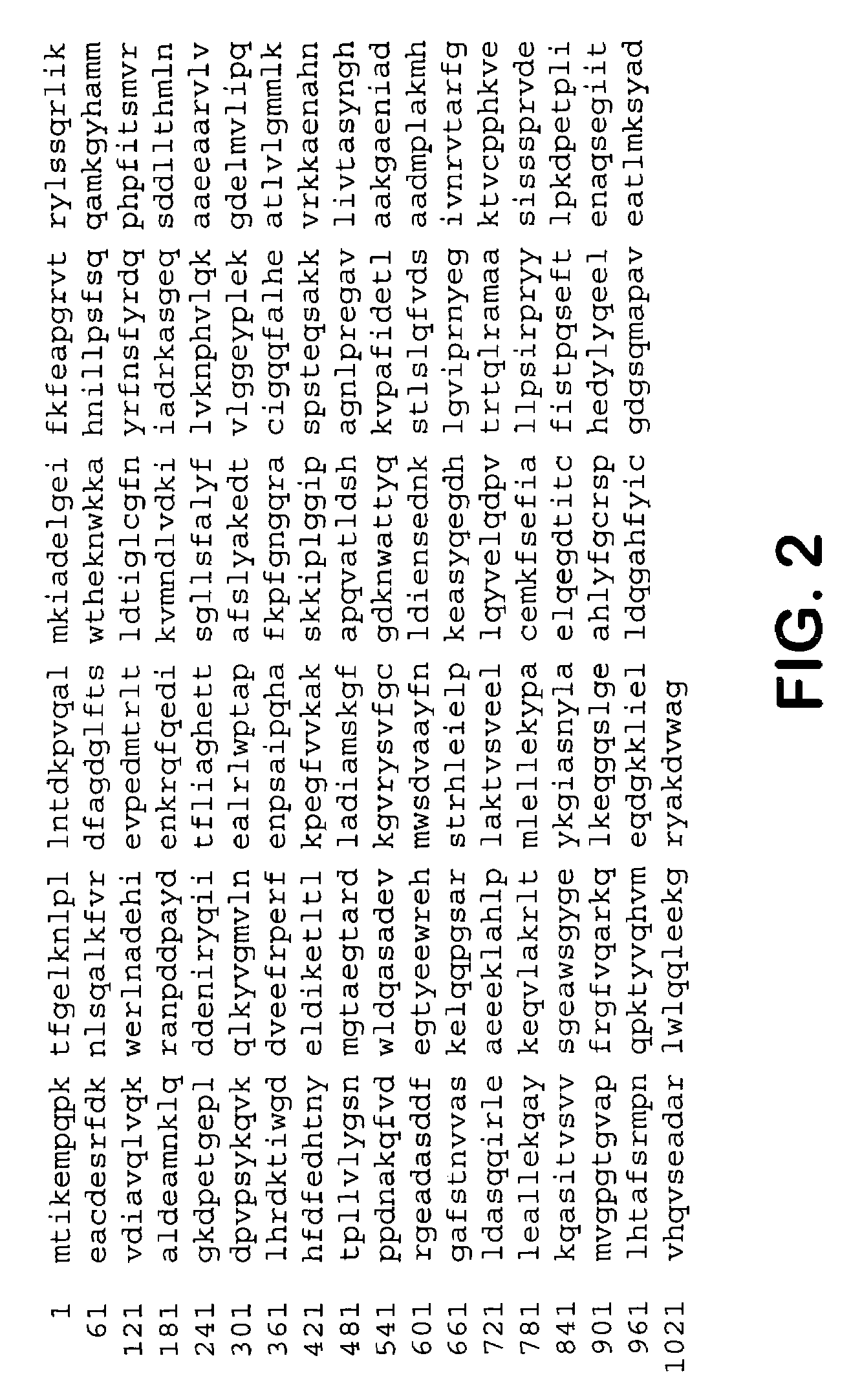

Peroxide-driven cytochrome P450 oxygenase variants

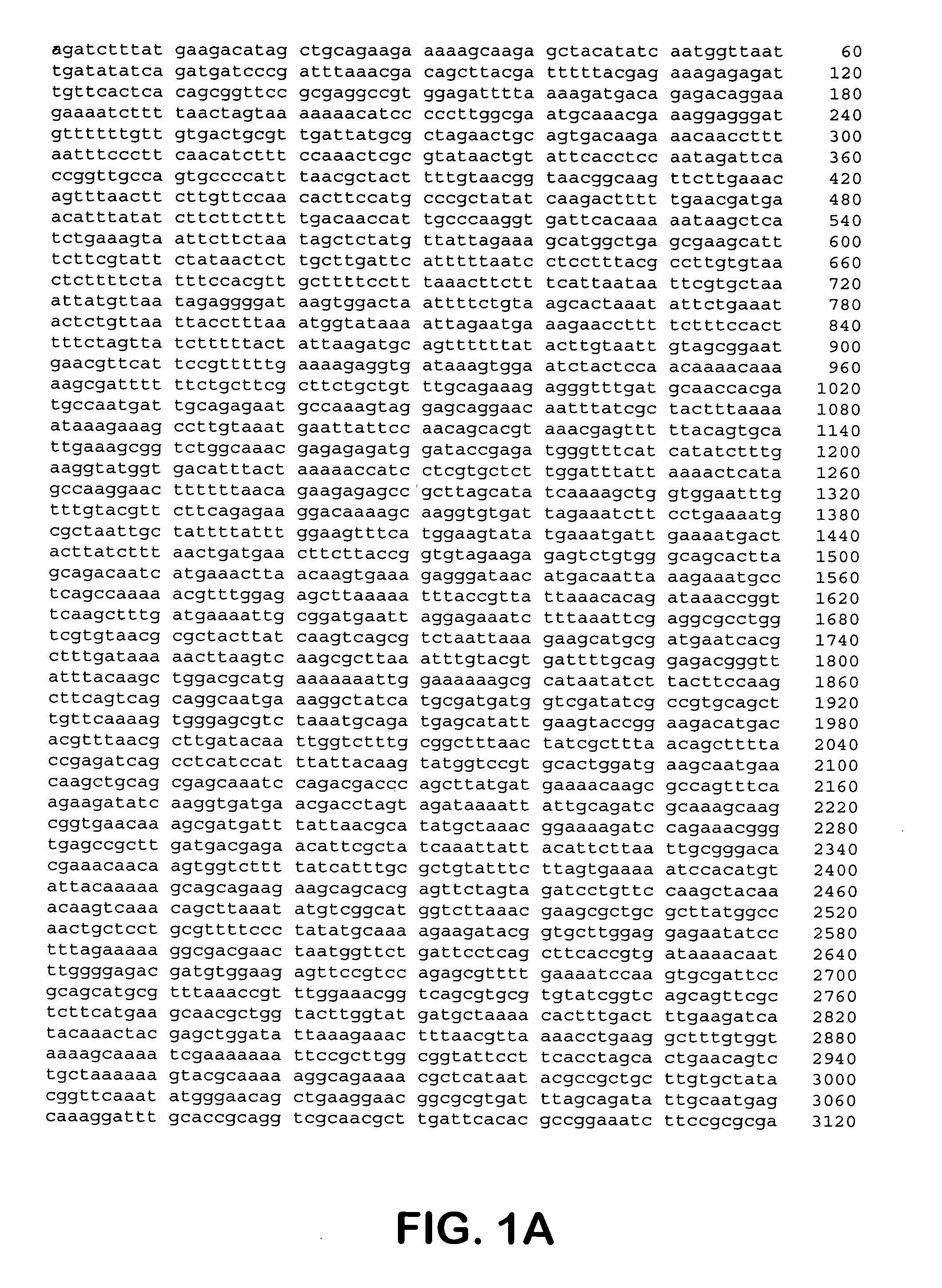

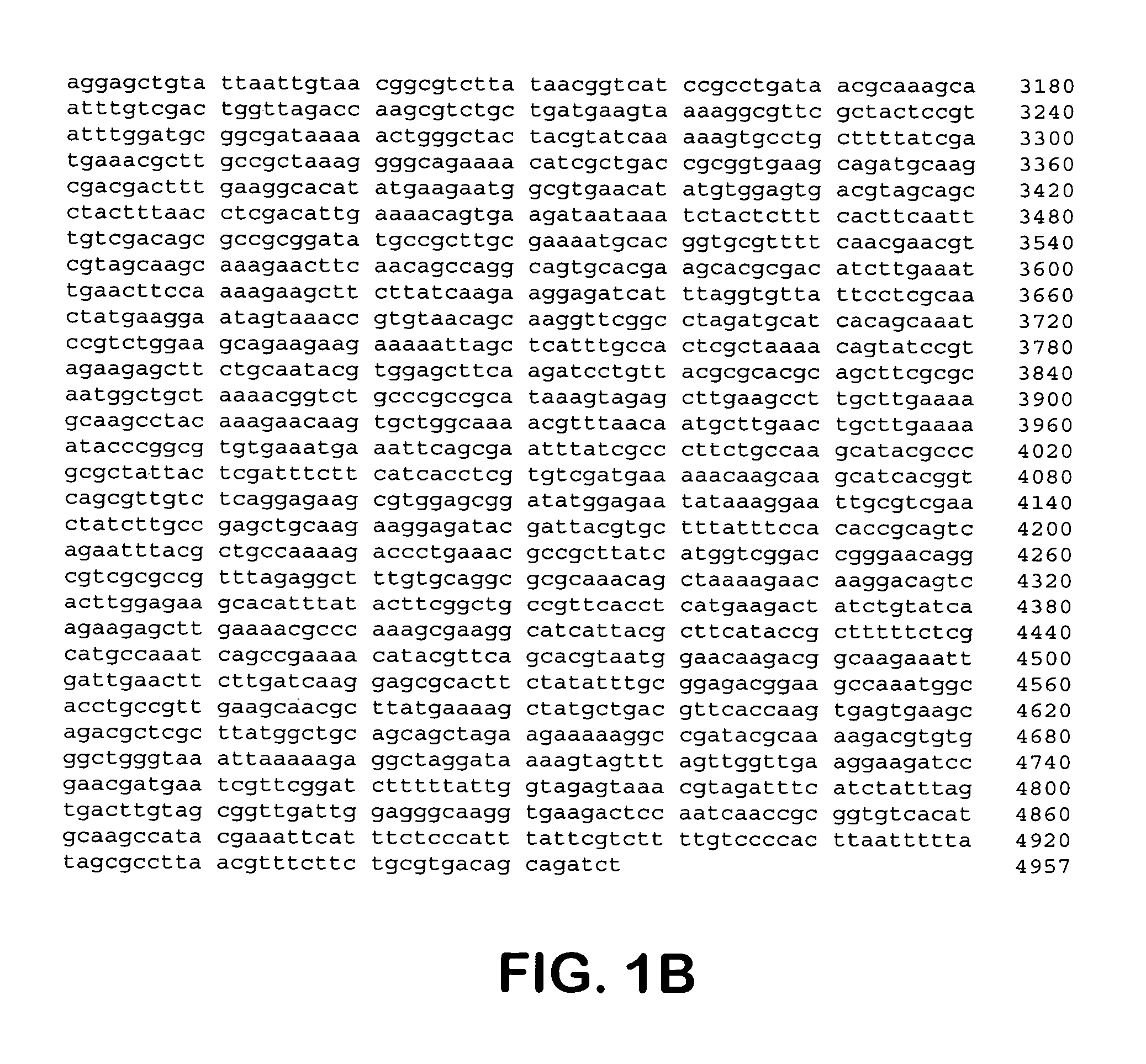

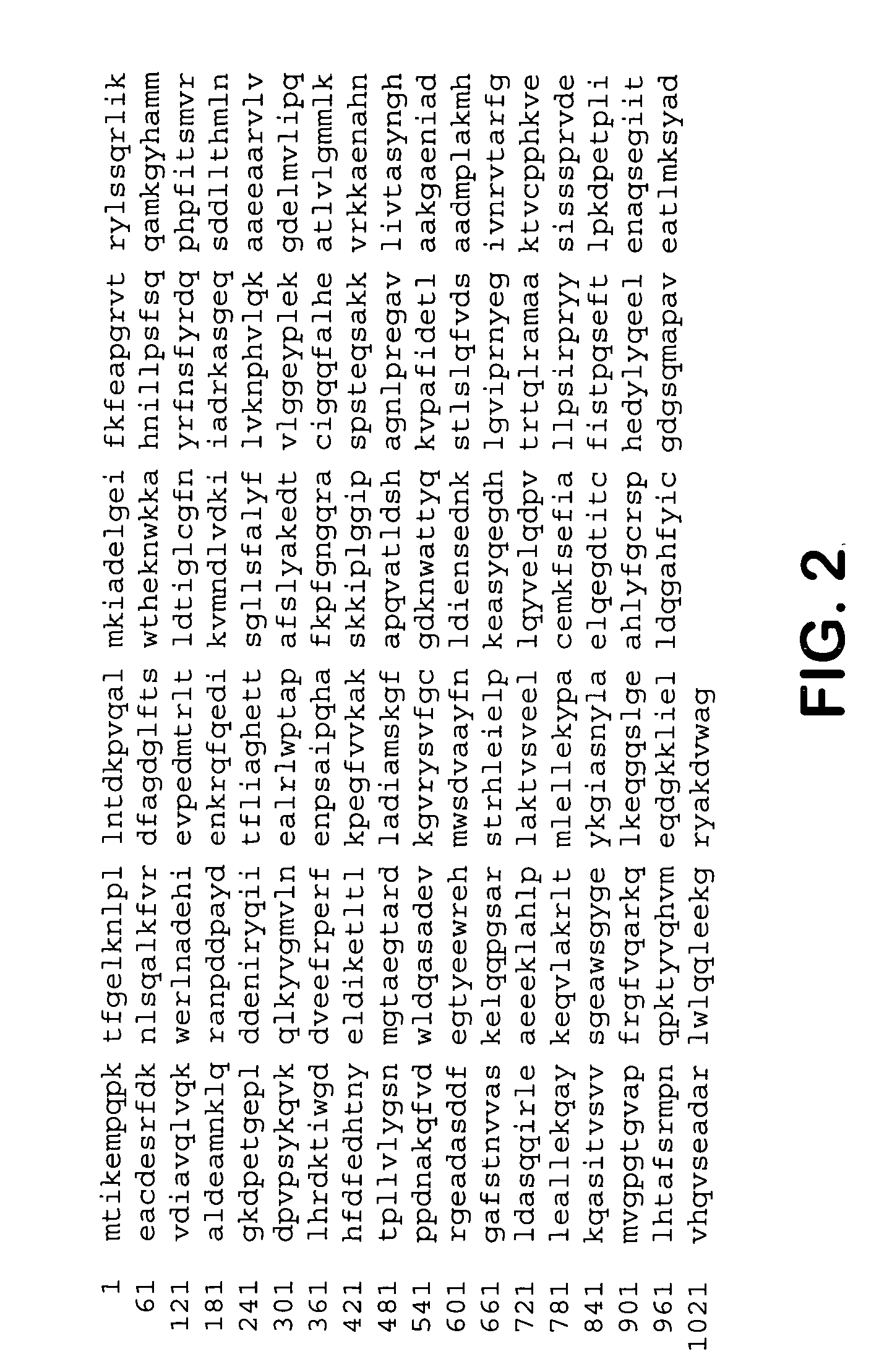

InactiveUS20050202419A1Improve abilitiesImprove thermal stabilityBacteriaSugar derivativesOxygenaseHeme

The invention relates to novel variants of cytochrome P450 oxygenases. These variants have an improved ability to use peroxide as an oxygen donor as compared to the corresponding wild-type enzyme. These variants also have an improved thermostability as compared to the cytochrome P450 BM-3 F87A mutant. Preferred variants include cytochrome P450 BM-3 heme domain mutants having I58V, F87A, H100R, F107L, A135S, M145A / V, N239H, S274T, L324I, I366V, K434E, E442K, and / or V446I amino acid substitutions.

Owner:CALIFORNIA INST OF TECH

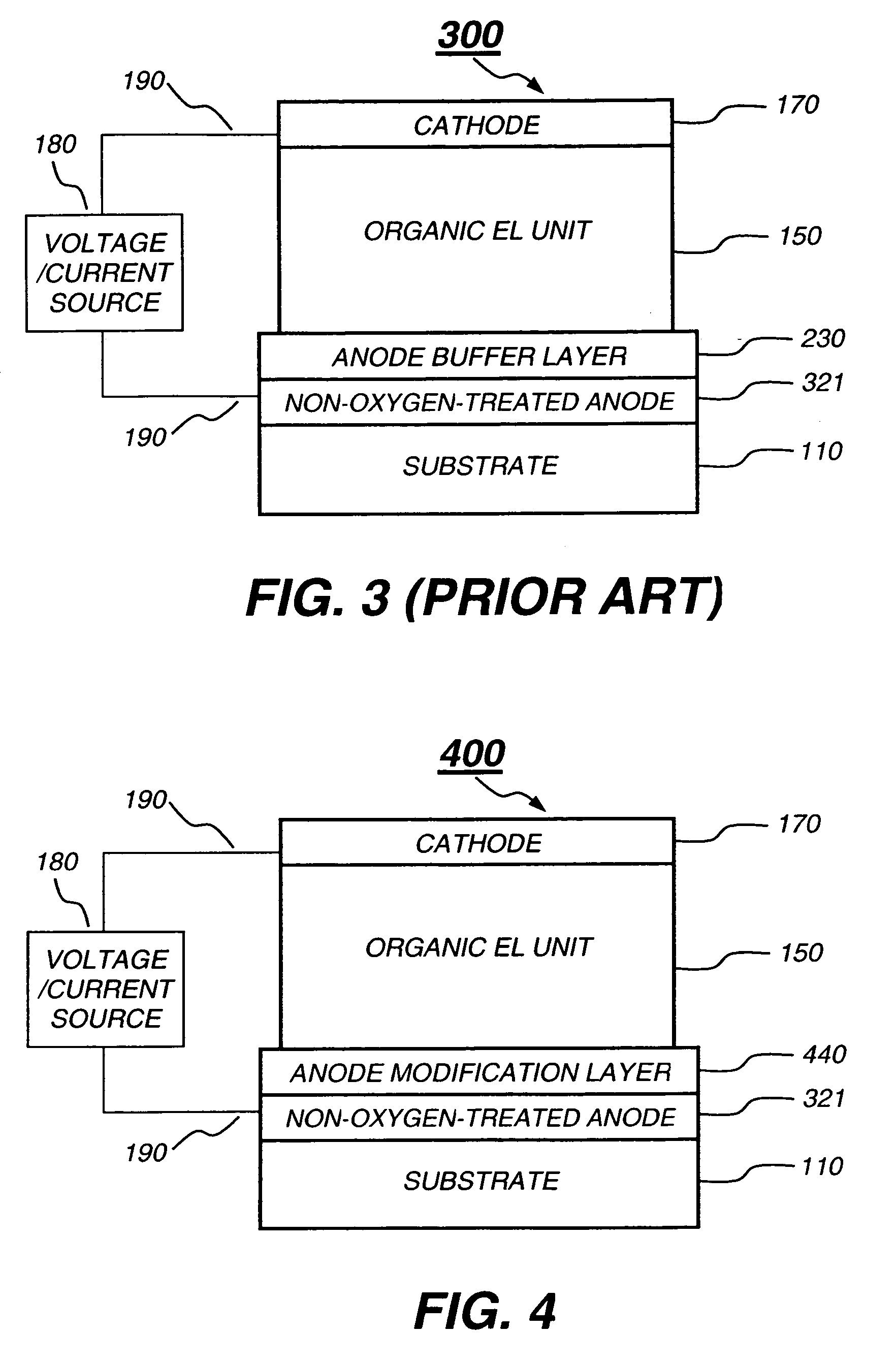

Catalytic filter for removing soot particulates from diesel engine exhaust and method of preparing the same

Owner:SK ENERGY CO LTD (KR)

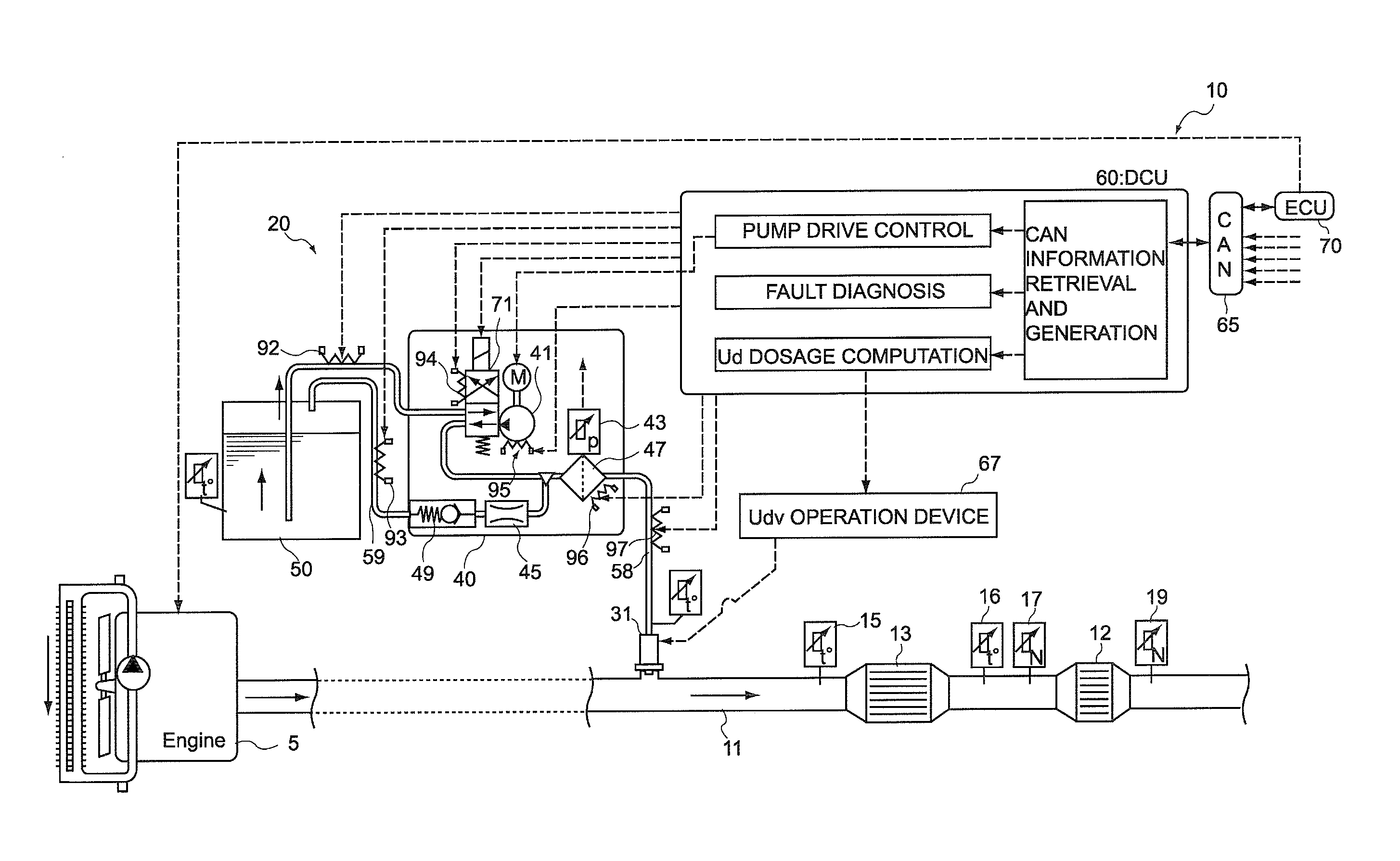

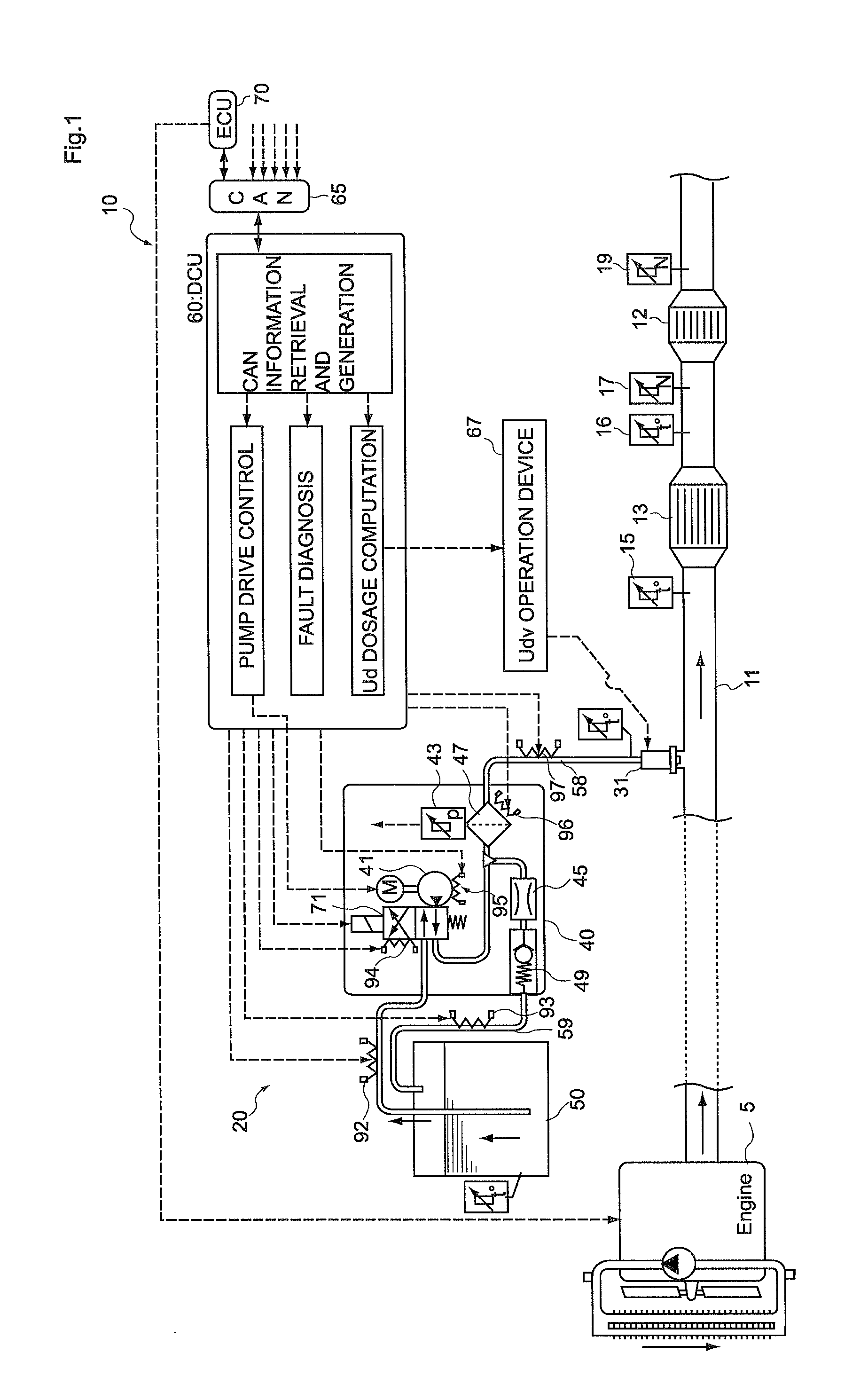

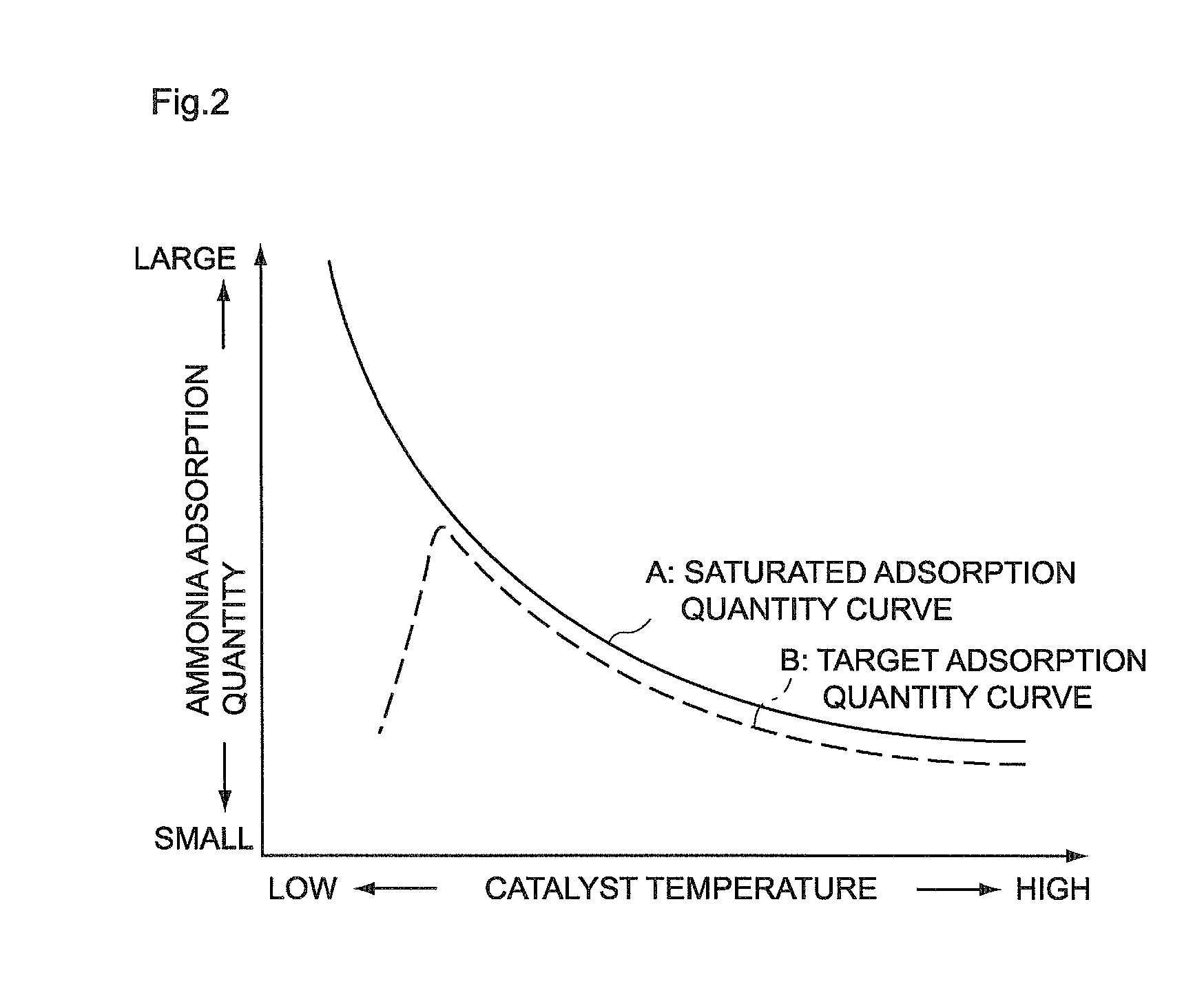

Oxidation catalyst fault diagnosis unit and oxidation catalyst fault diagnosis method and internal combustion engine exhaust purification apparatus

InactiveUS20100319316A1Good precisionPrevent releaseInternal combustion piston enginesExhaust apparatusDiagnosis methodsProcess engineering

To provide an oxidation catalyst fault diagnosis unit and fault diagnosis method that can perform fault diagnosis of an oxidation catalyst with good precision in a desired time period and an internal combustion engine exhaust purification apparatus equipped with the oxidation catalyst fault diagnosis unit.An oxidation catalyst fault diagnosis unit which, in an exhaust purification apparatus of an internal combustion engine that delivers a reducing agent capable of generating ammonia to an exhaust passage on the upstream side of a reduction catalyst and selectively reduces and purifies NOx in exhaust with the reduction catalyst, is for performing fault diagnosis of an oxidation catalyst placed on the downstream side of the reduction catalyst, the oxidation catalyst fault diagnosis being equipped with a reducing agent dosage calculating portion that sets a dosage of the reducing agent such that a predetermined quantity of the ammonia flows out to the downstream side of the reduction catalyst, an oxidation efficiency calculating portion that obtains the efficiency with which the predetermined quantity of ammonia flowing out to the downstream side of the reduction catalyst is oxidized by the oxidation catalyst when the predetermined quantity of ammonia passes through the oxidation catalyst, and a fault determining portion that performs determination of whether or not the oxidation catalyst is faulty by comparing the oxidation efficiency with a predetermined reference value.

Owner:BOSCH CORP

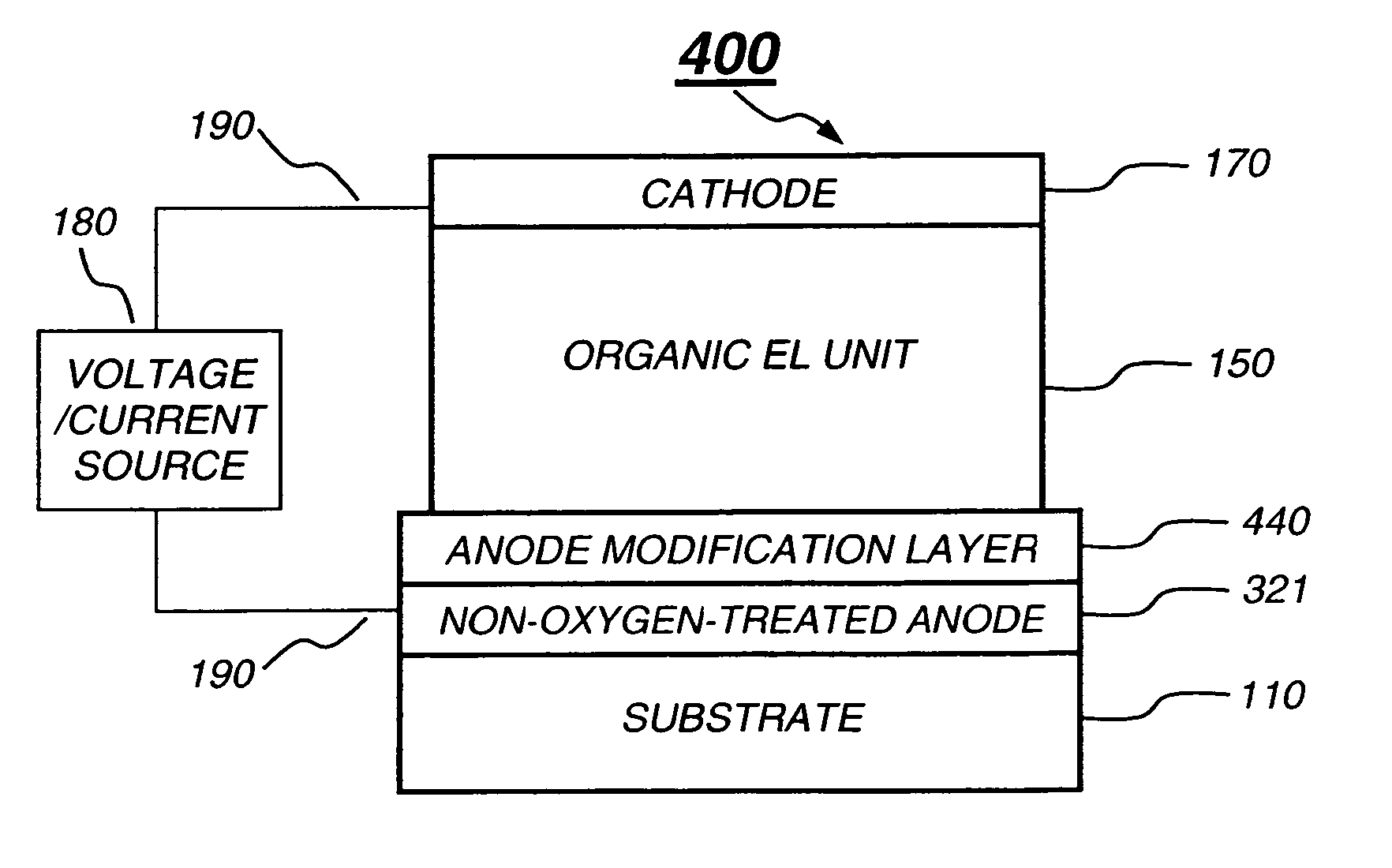

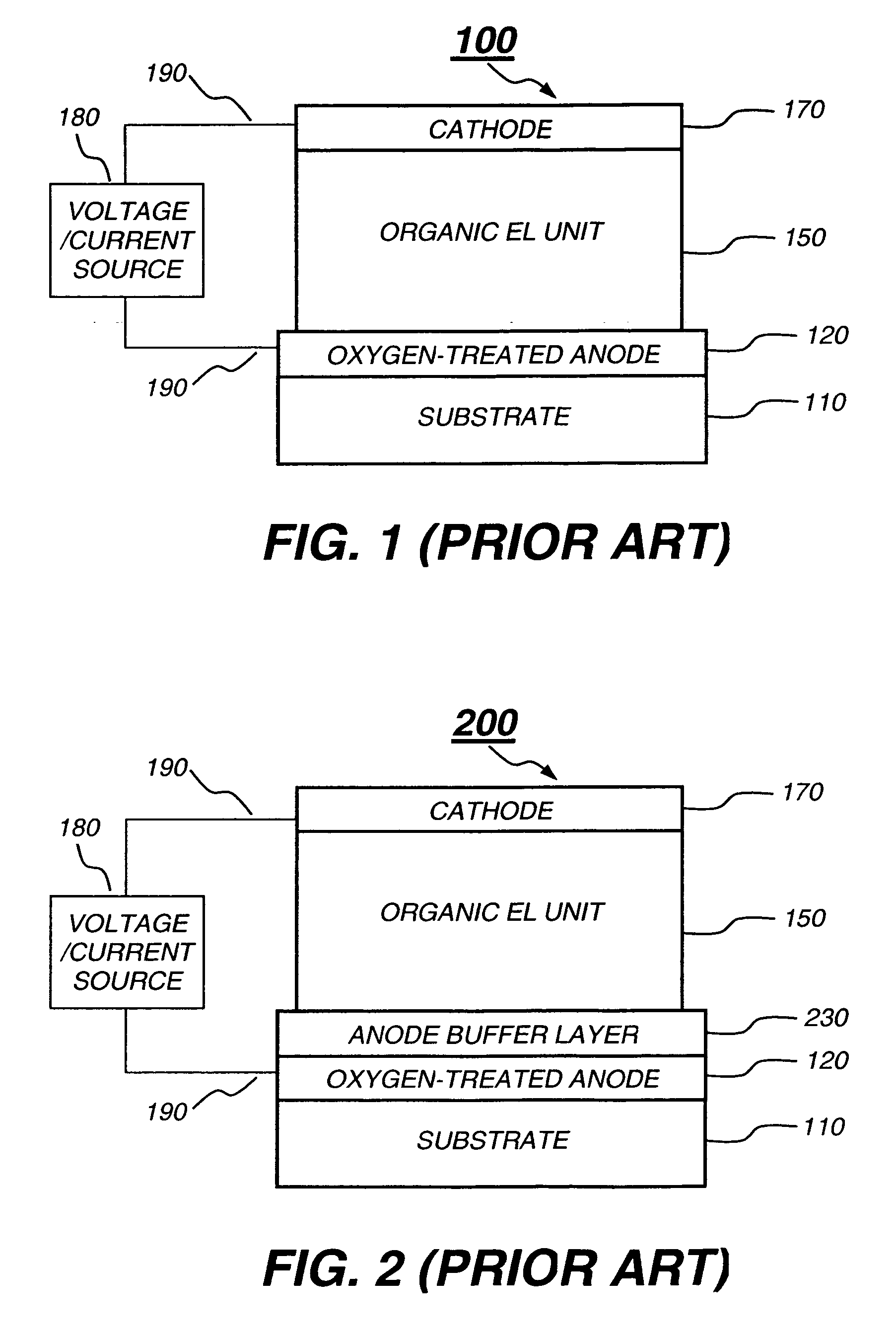

OLED anode modification layer

InactiveUS20060240280A1Efficiently oxidizedQuality improvementDischarge tube luminescnet screensElectroluminescent light sourcesContact formationOxygen

An OLED includes an anode formed over a substrate, wherein the anode is a non-oxygen-treated anode and an anode modification layer formed in direct contact with the anode, wherein the anode modification layer includes one or more organic materials, each having an electron-accepting property and a reduction potential greater than 0.0 V vs. a Saturated Calomel Electrode, and wherein the one or more organic materials provide more than 50% by mole ratio of the anode modification layer. The OLED also includes an organic electroluminescent unit formed over the anode modification layer, wherein the organic electroluminescent unit includes at least a hole-transporting layer and a light-emitting layer, and a cathode formed over the organic electroluminescent unit.

Owner:EASTMAN KODAK CO

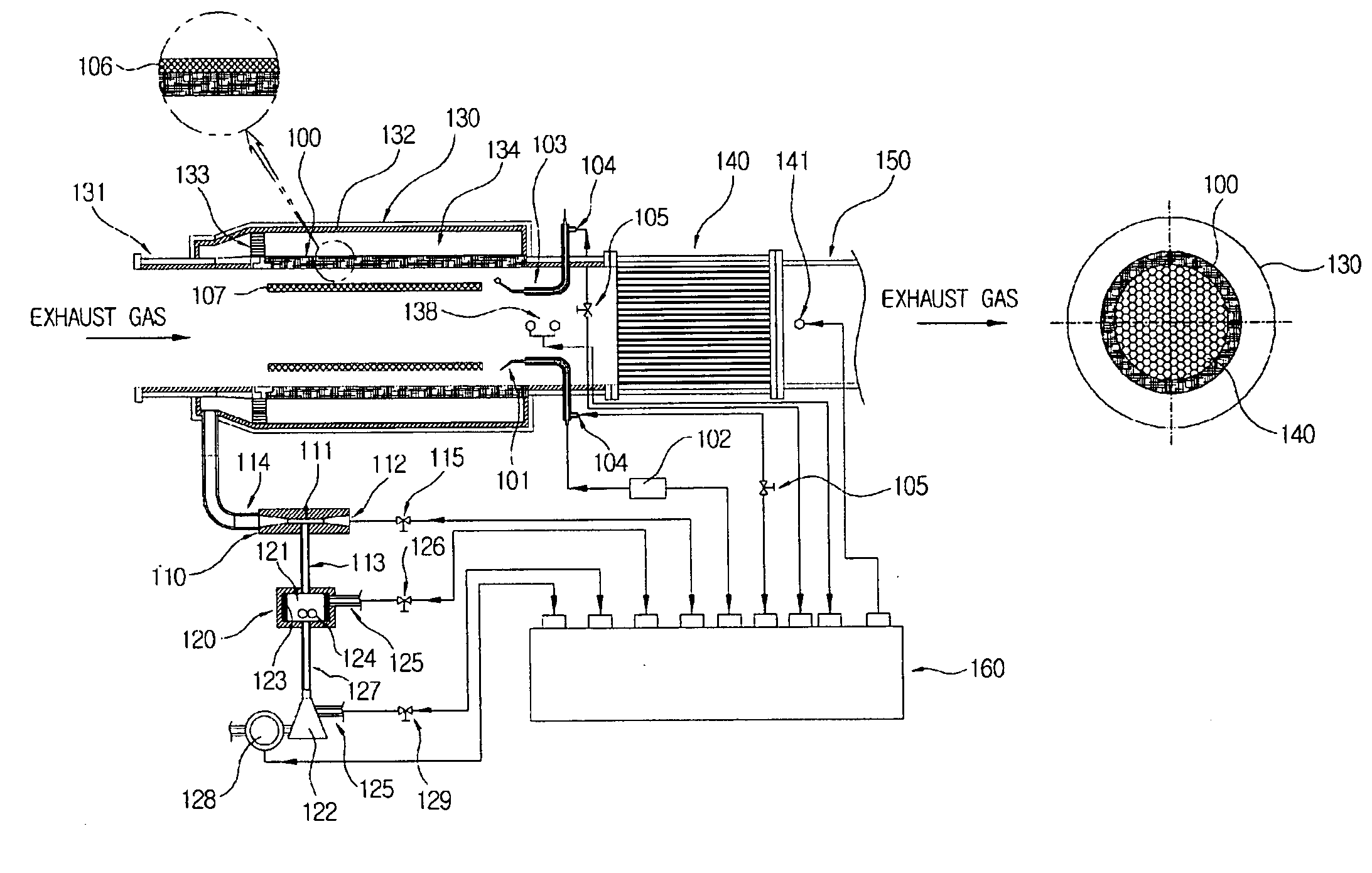

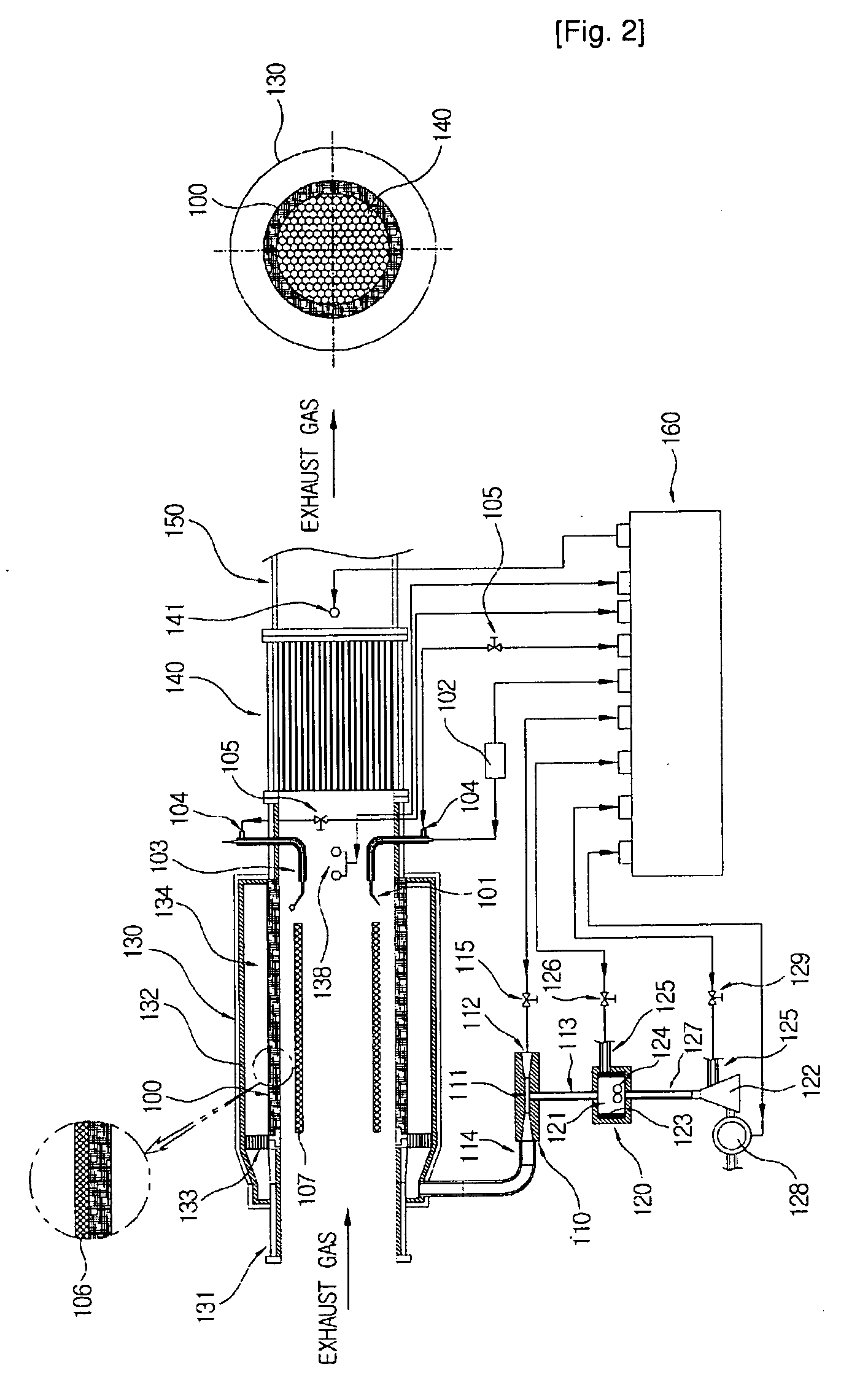

Inner flame burner for regeneration of diesel particulate filter

InactiveUS20100146939A1Quick heat transferLarge surfaceExhaust apparatusSilencing apparatusDiesel particulate filterCombustion chamber

Provided is a burner for regenerating a diesel engine particulate filter. The burner includes: a combustion chamber for receiving exhaust gas from a diesel engine; a carburetor for gasifying liquid fuel; a mixed gas supplying unit for mixing the gasified fuel with an external air, and supplying the mixed gaseous fuel to the combustion chamber; a mixed gas storing chamber disposed in the combustion chamber for receiving the mixed gaseous fuel and instantly storing the received mixed gaseous fuel; an inner flame combustor made of porous material for injecting the mixed gaseous fuel toward the inside of the inner flame combustor, and disposed in the combustion chamber to allow an exhaust gas to flow through the inner flame combustor; an igniter for igniting the mixed gaseous fuel; and a flame sensor for sensing the flame on the inner flame combustor.

Owner:KOREA INST OF MASCH & MATERIALS

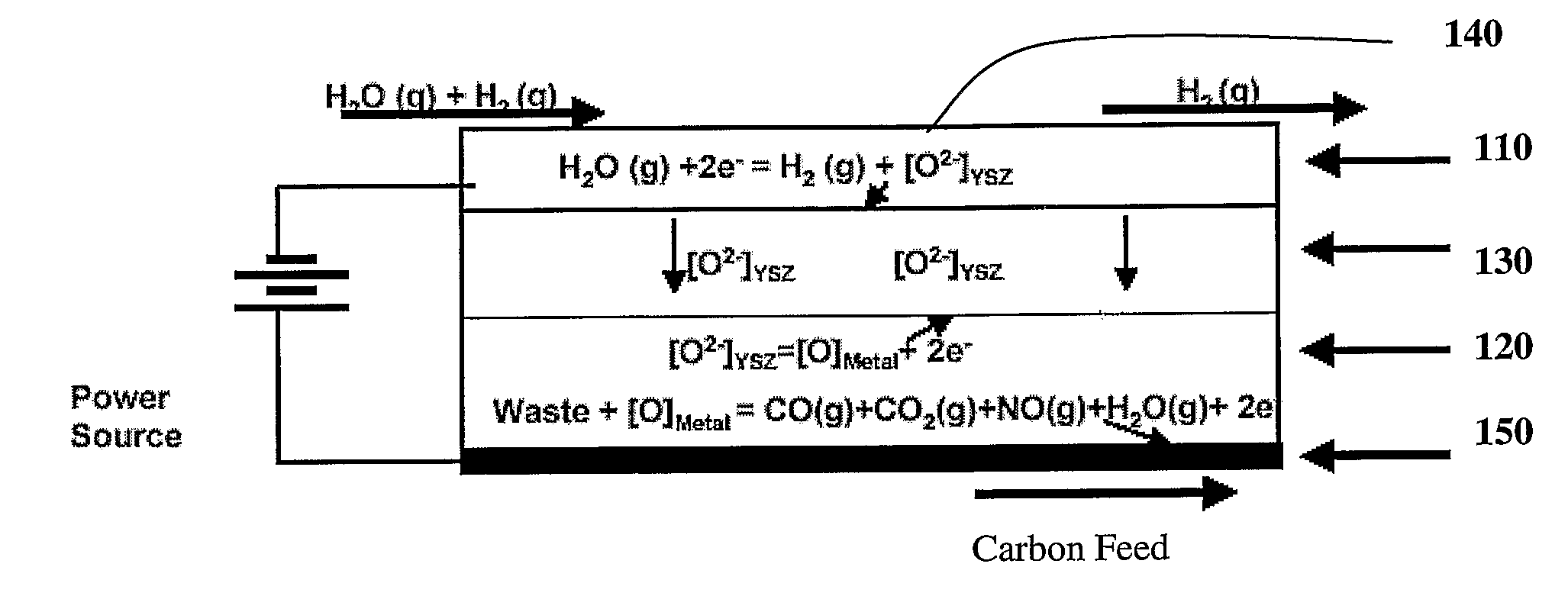

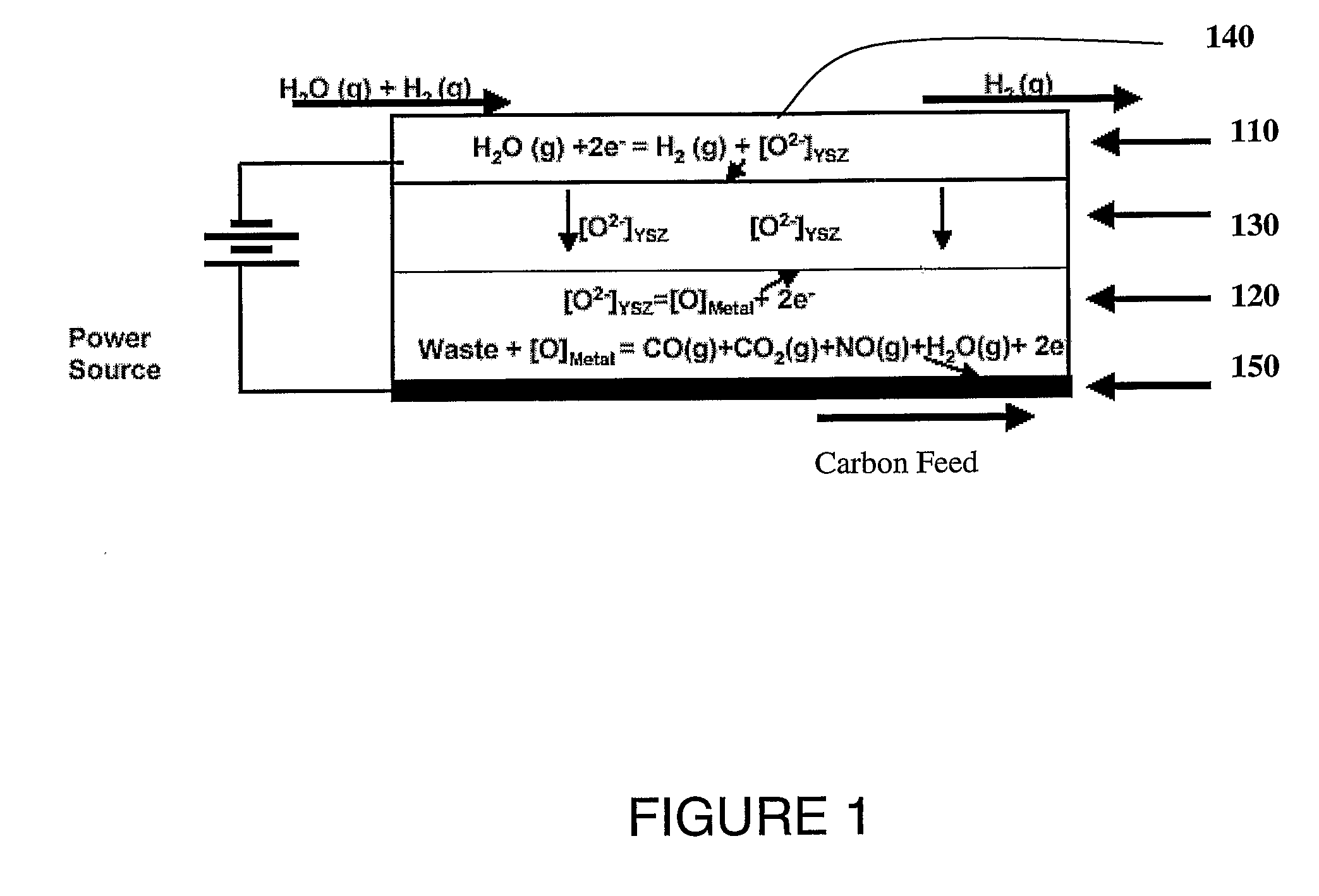

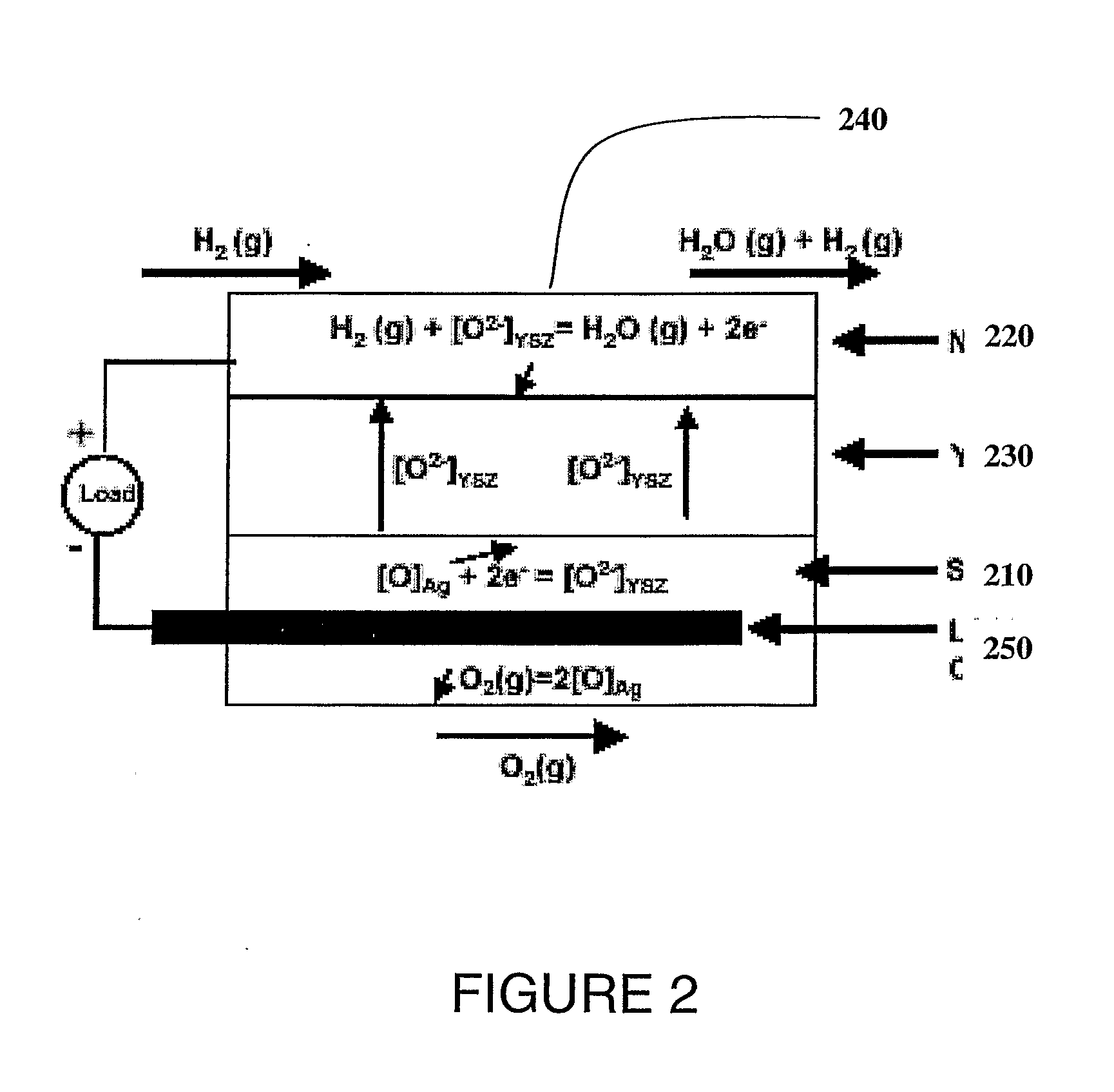

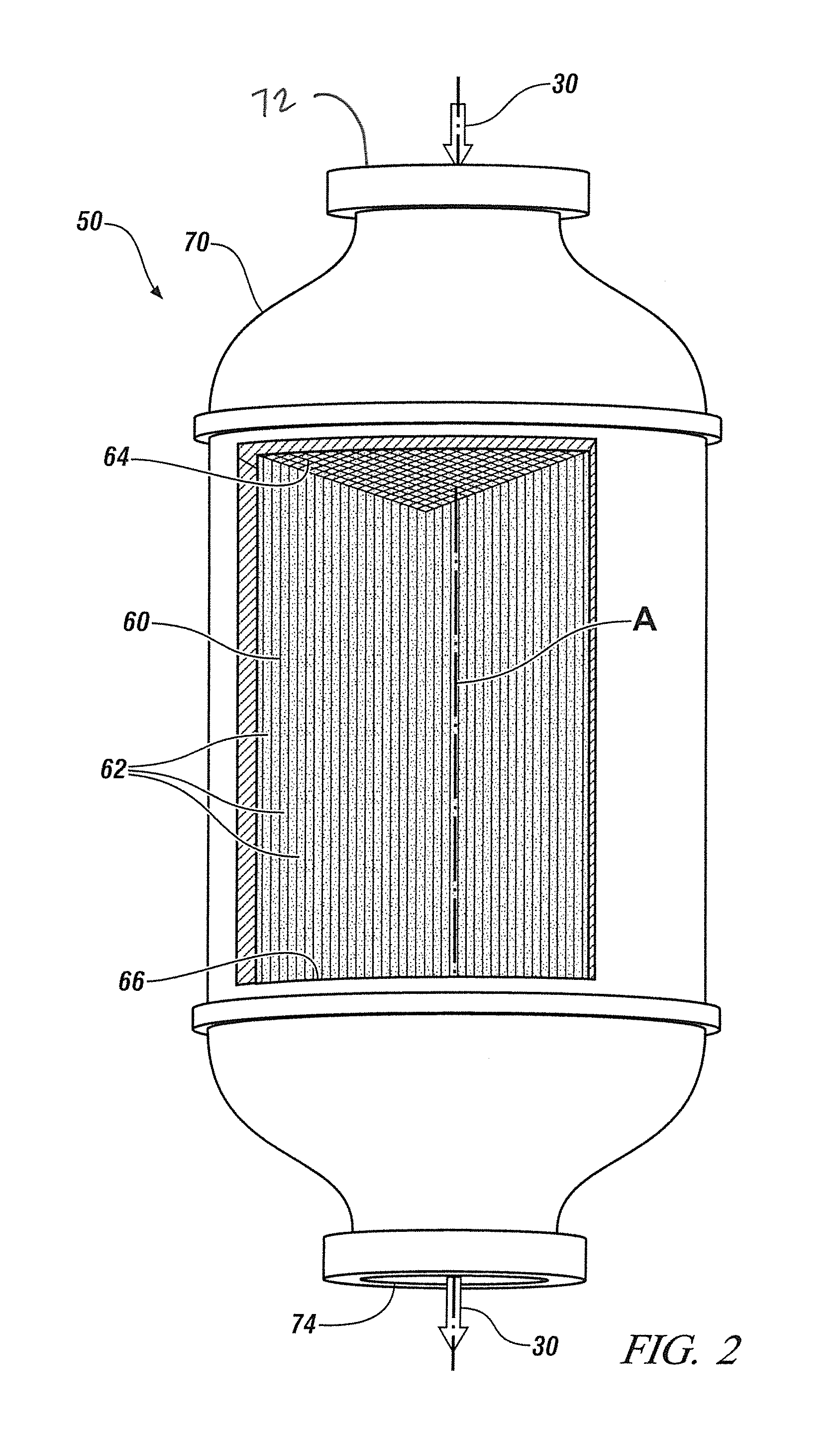

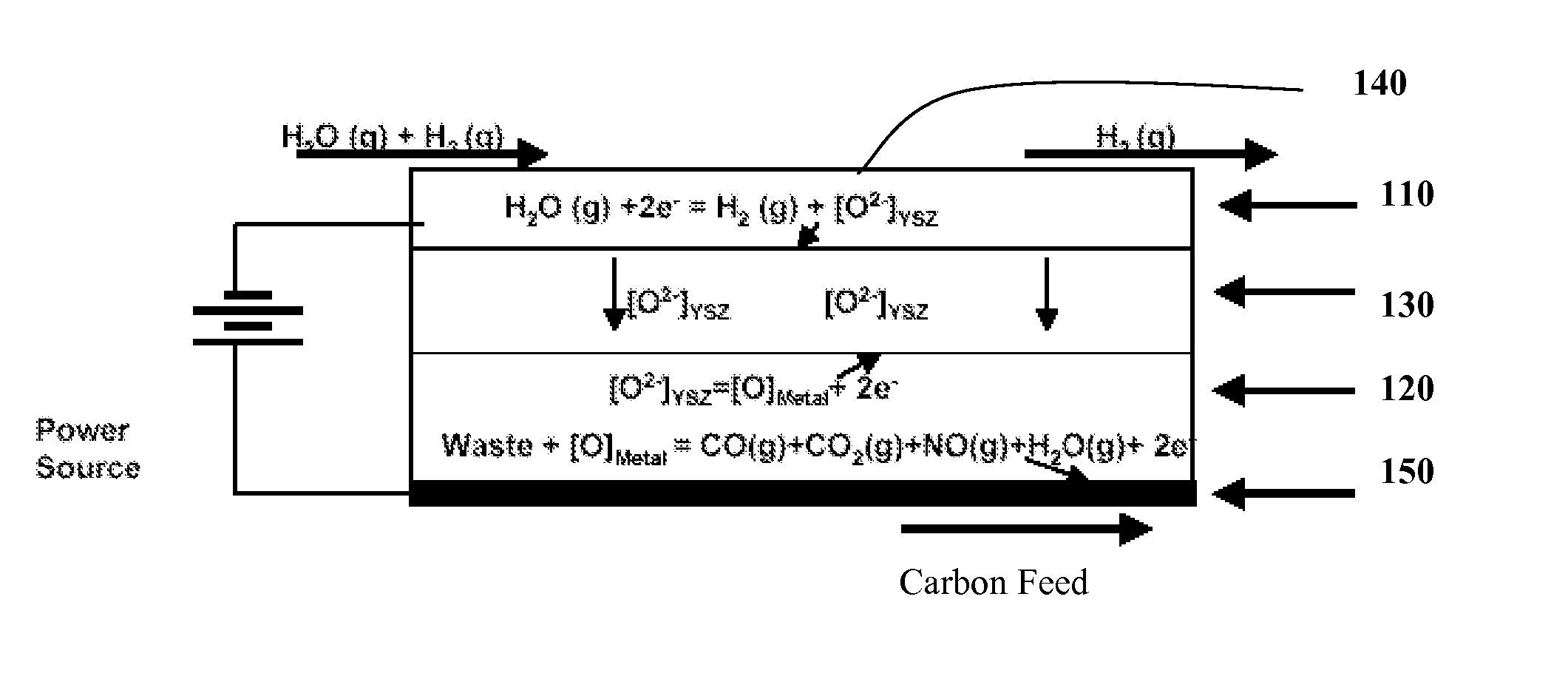

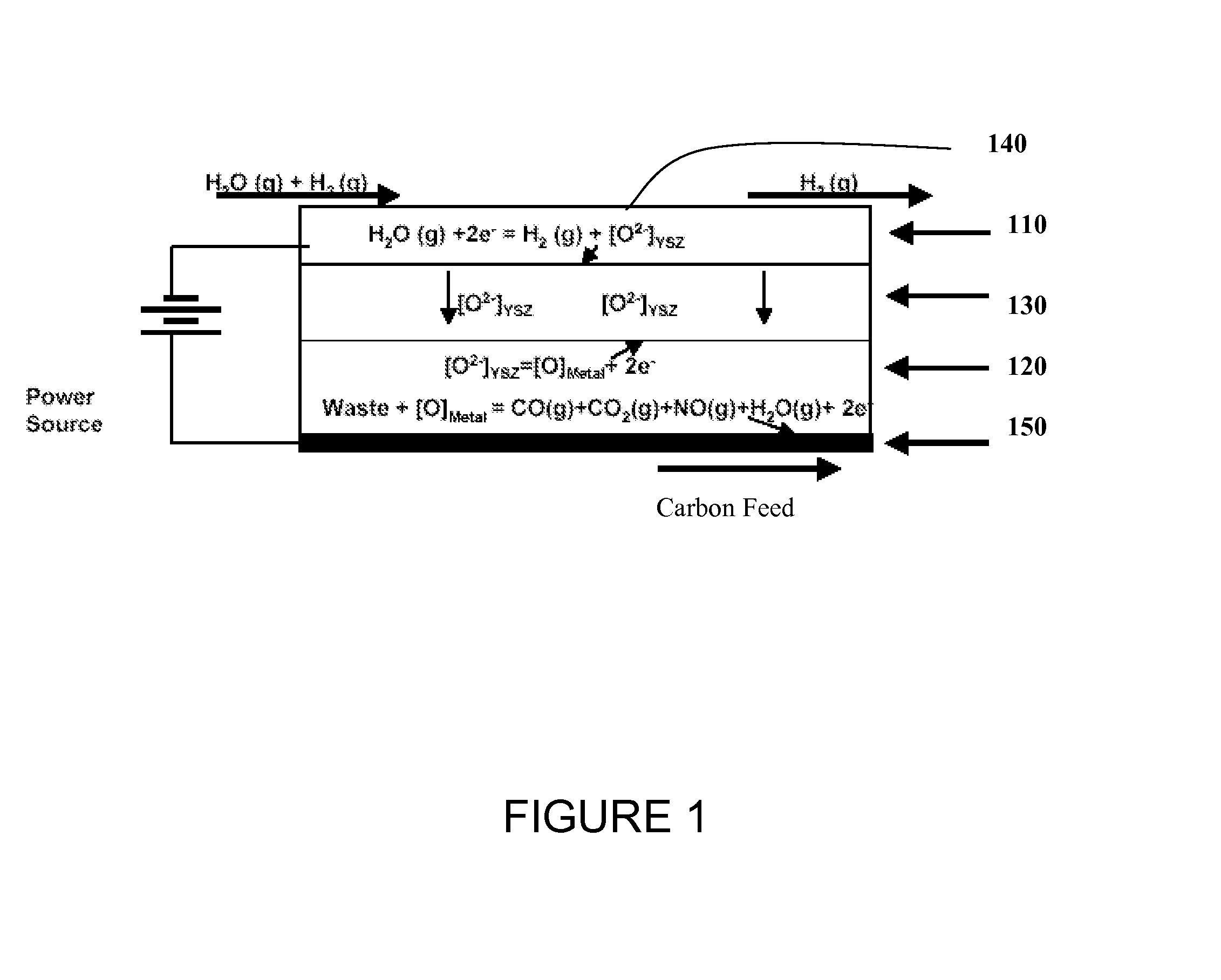

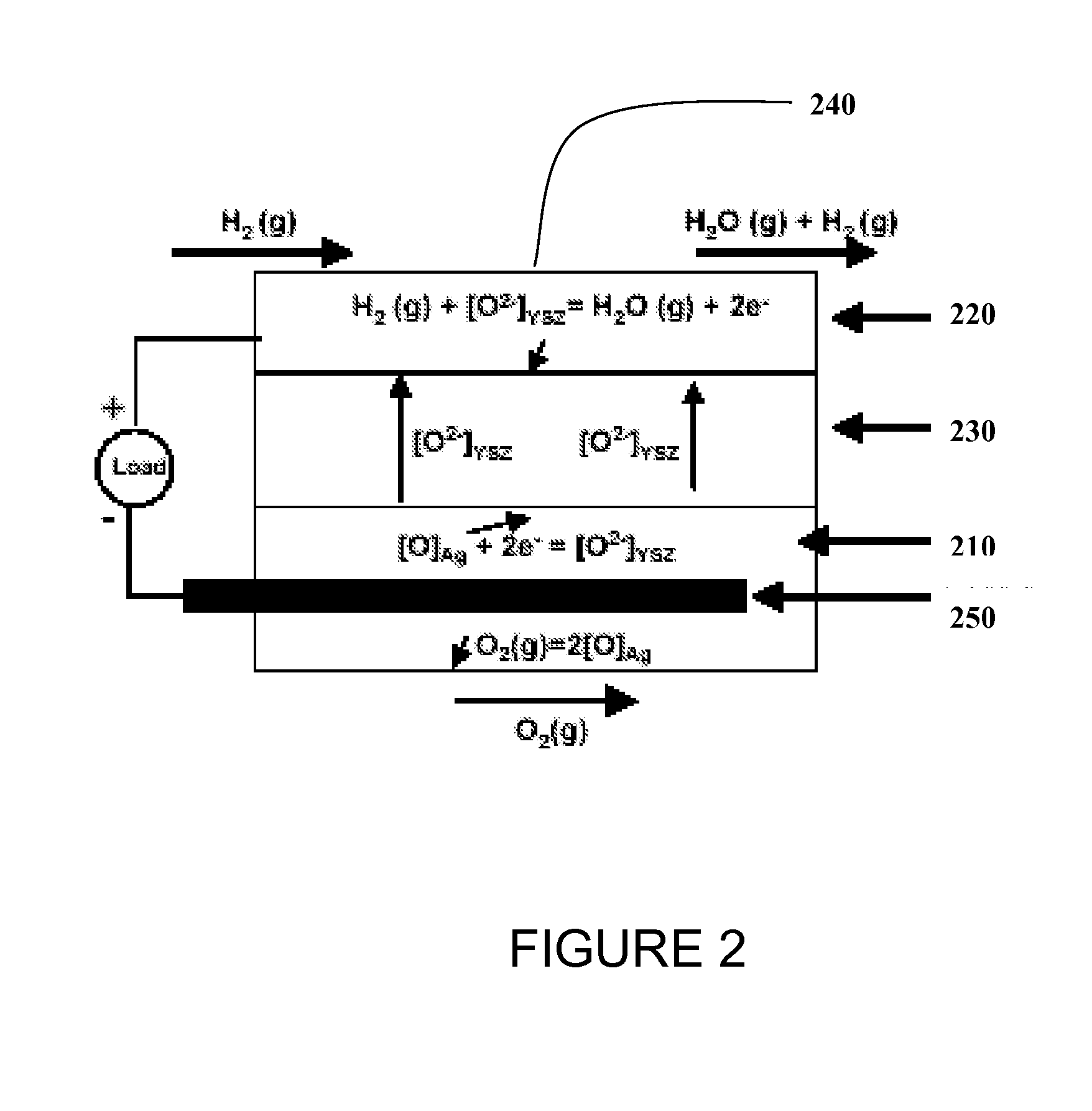

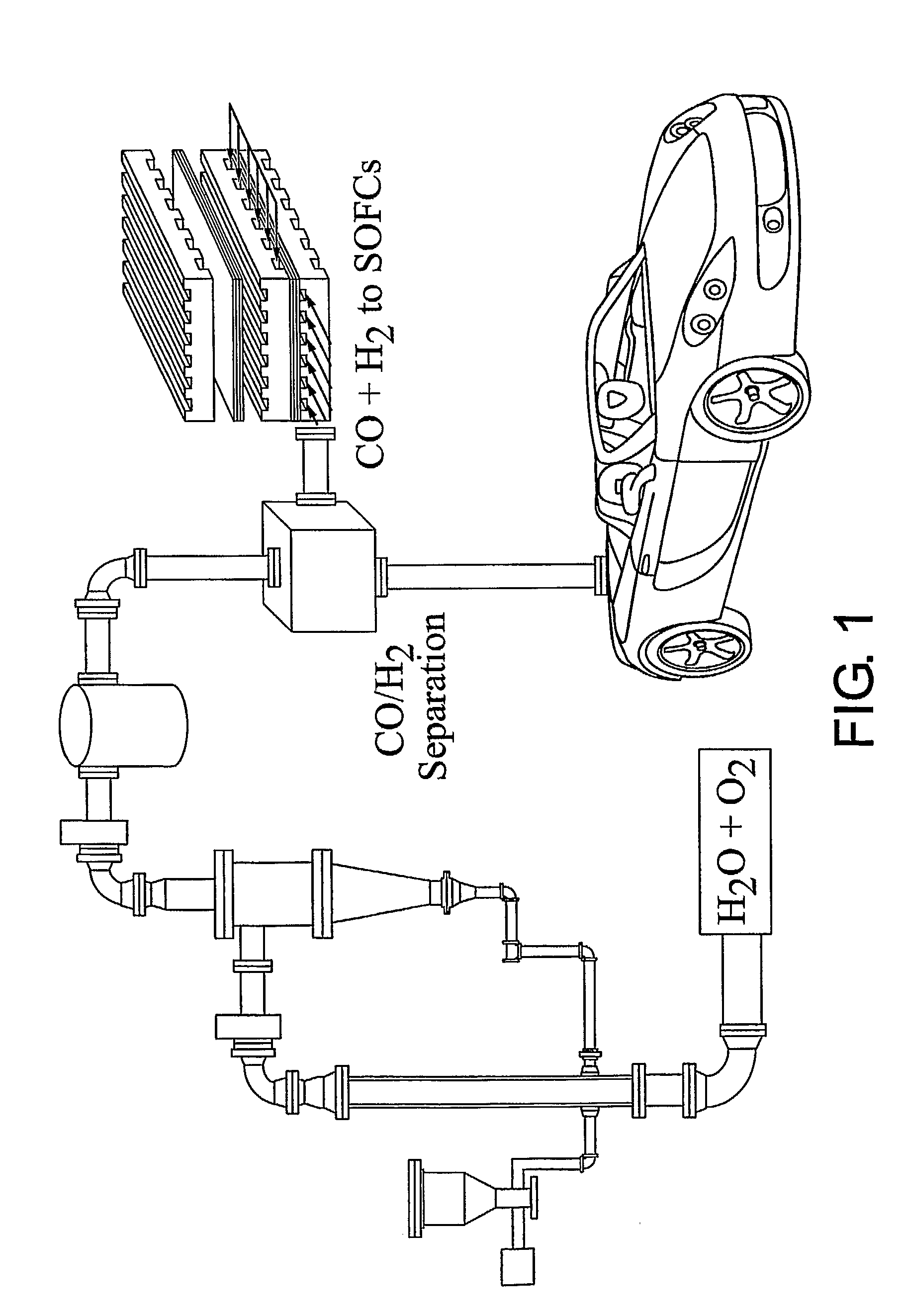

Waste to hydrogen conversion process and related apparatus

InactiveUS20090071841A1Efficiently reduce steamEfficient decompositionCellsHydrogen separationElectrolysisSilver electrode

A reversible electrochemical system includes a first electrode comprising liquid silver metal and a second electrode, said first and second electrodes separated by a oxygen ion-conducting solid electrolyte; a conduit for directing a first reactive material across the second electrode; and a conduit for contacting second reactive material with the first liquid silver electrode, wherein the cell is capable of steam electrolysis when the polarity of the electrodes is selected such that the liquid silver is an anode and the cell is capable of electrical energy generation when the polarity of the electrodes is selected such that the liquid silver is a cathode.

Owner:TRUSTEES OF BOSTON UNIV

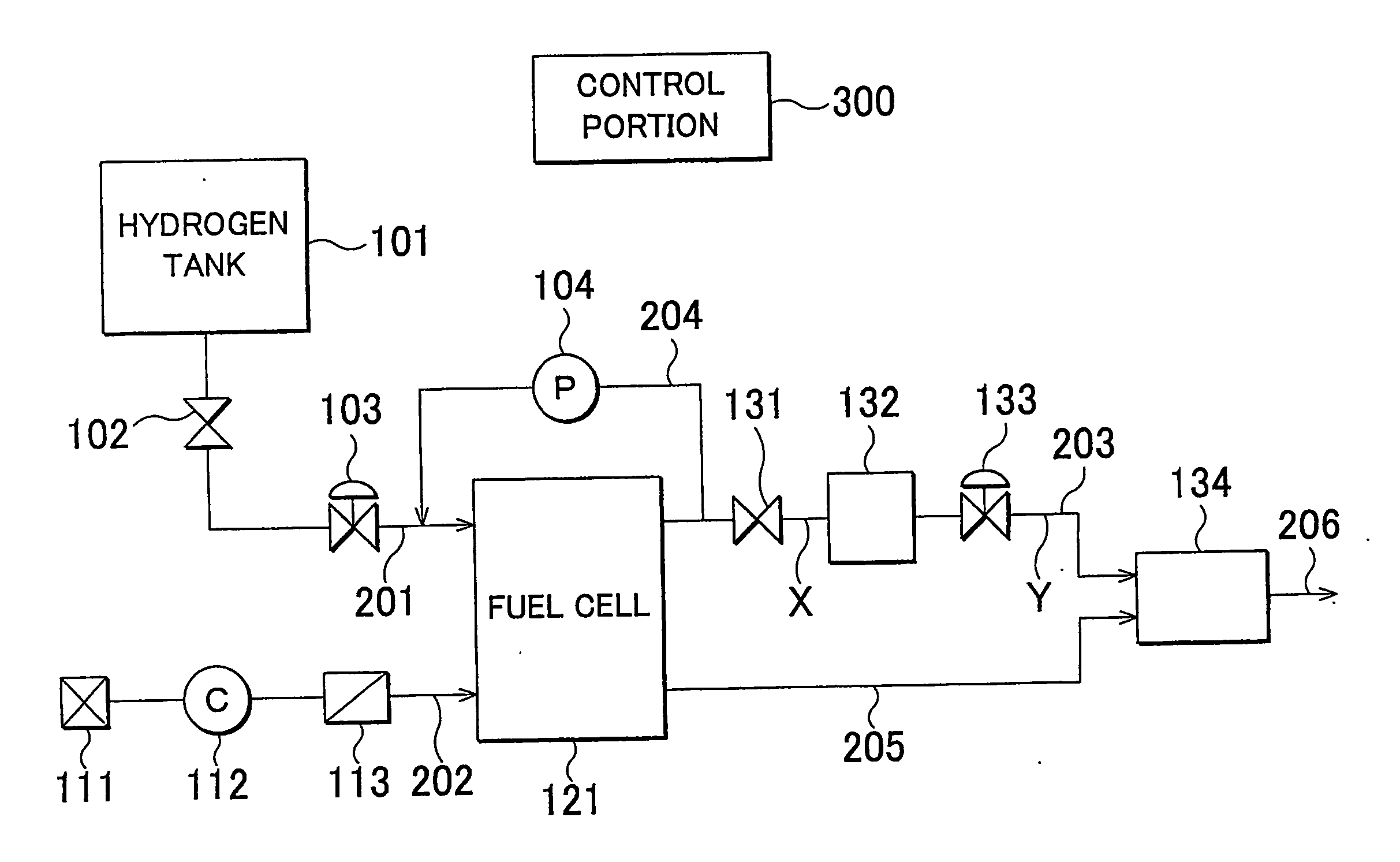

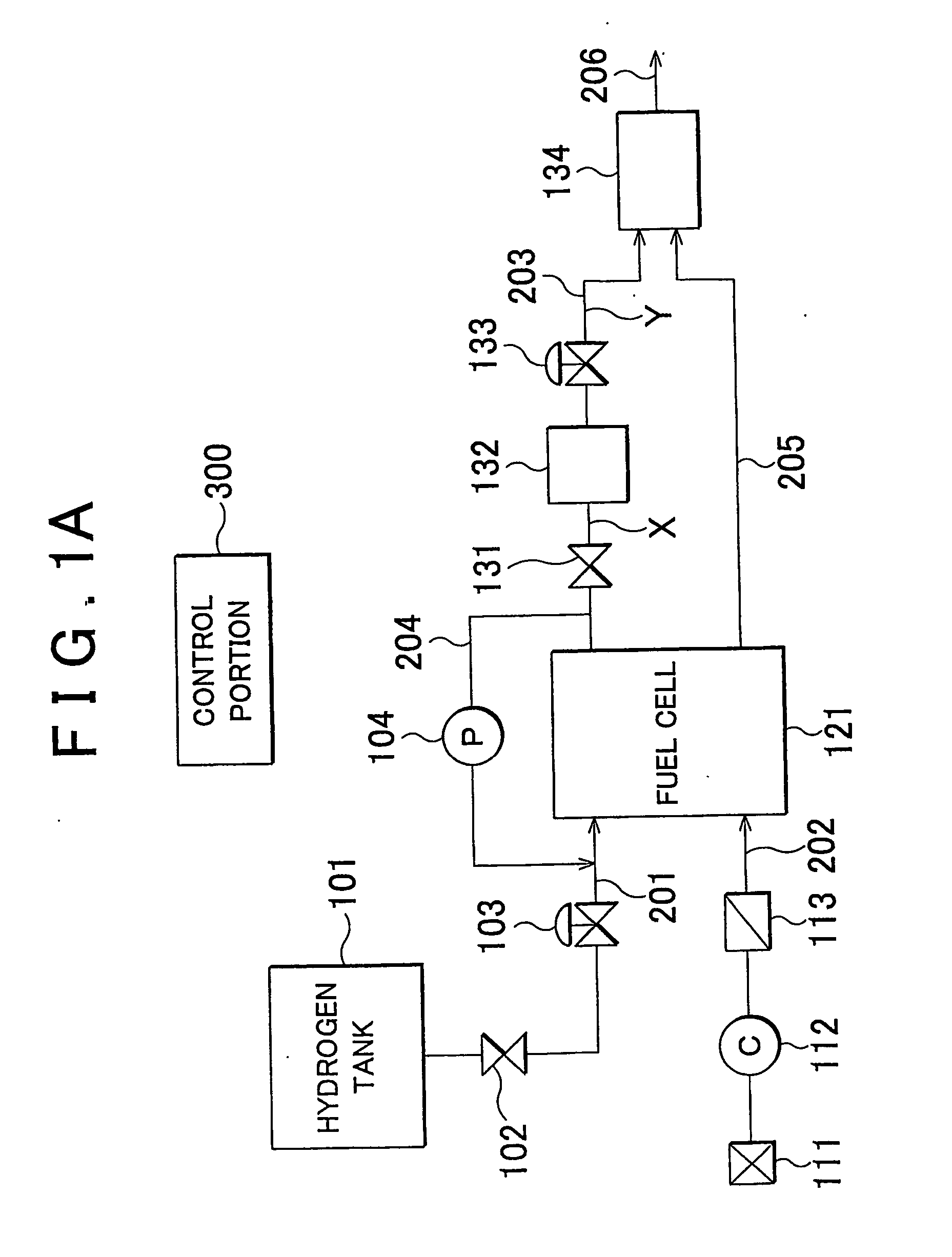

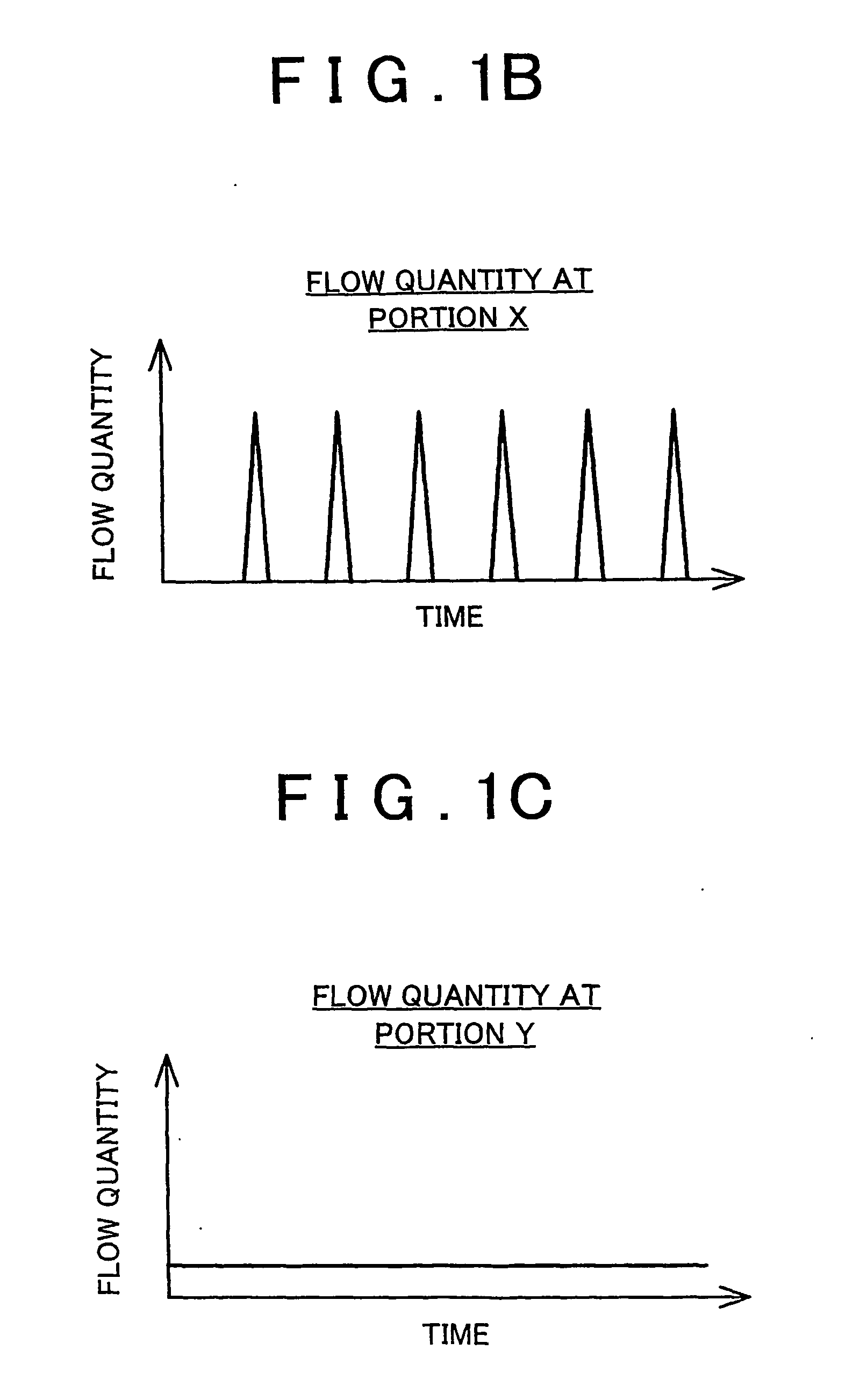

Fuel cell system

InactiveUS20060263658A1Reduce usageGood effectFuel cell auxillariesTransportation fuel cell technologyFuel cellsHydrogen

A fuel cell system which reduces a quantity of hydrogen in hydrogen off-gas discharged from a fuel cell, and then discharges the hydrogen off-gas to atmosphere, includes an adjusting valve that suppresses a pulsed change in a flow quantity of hydrogen off-gas, which is intermittently discharged from the fuel cell to an exhaust passage and therefore flows in the exhaust passage in a pulse manner, such that the flow quantity becomes constant (stable).

Owner:TOYOTA JIDOSHA KK

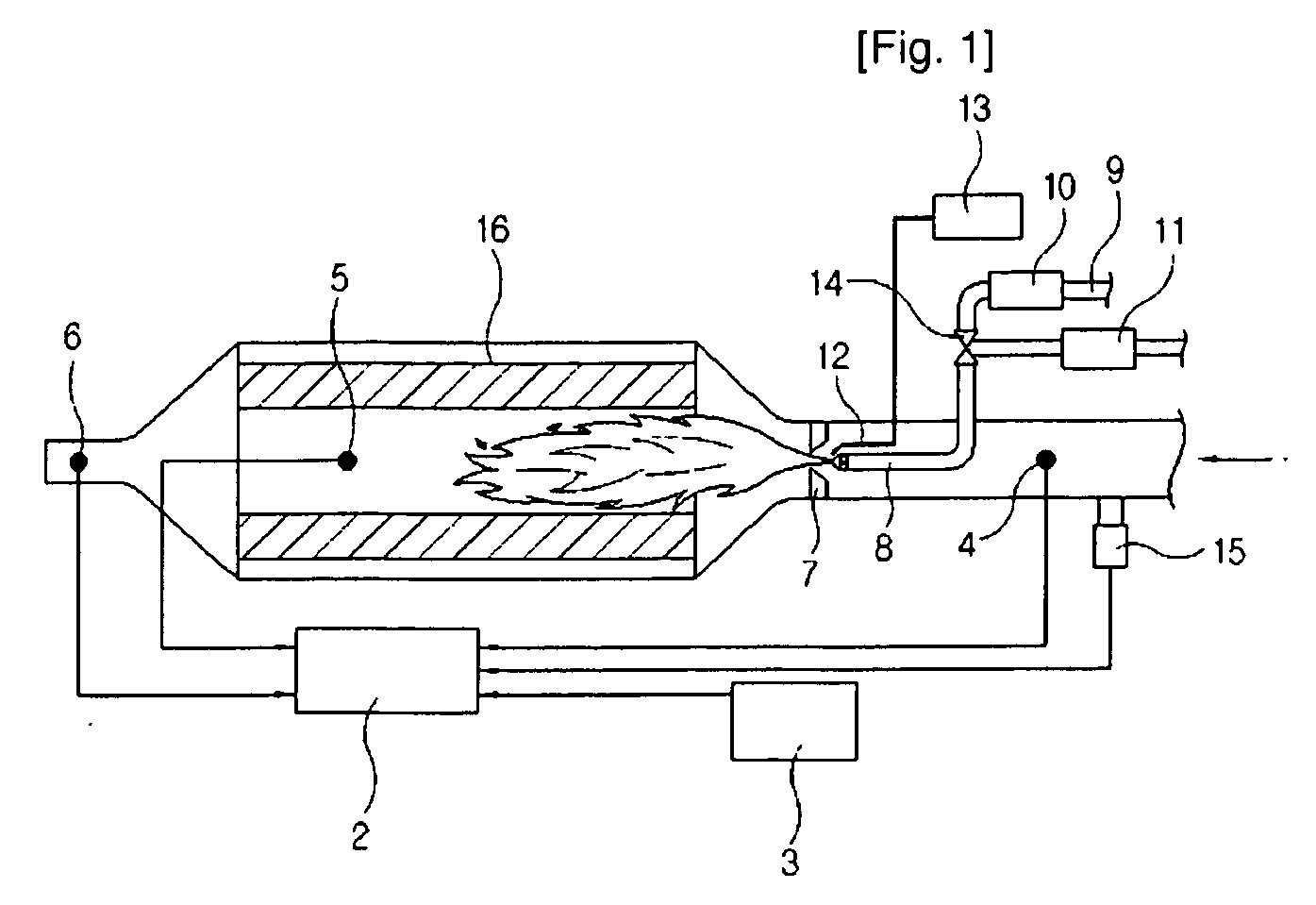

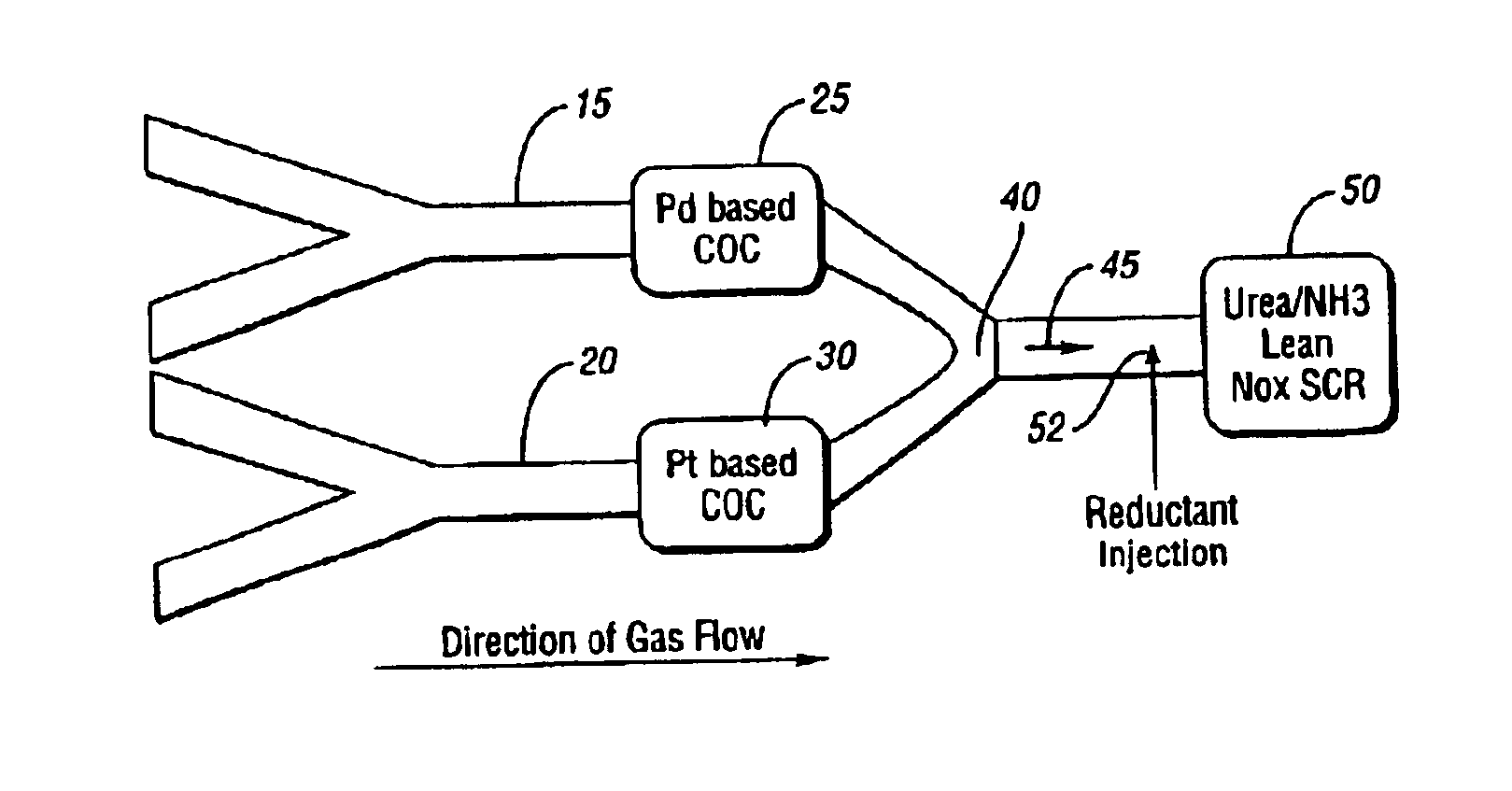

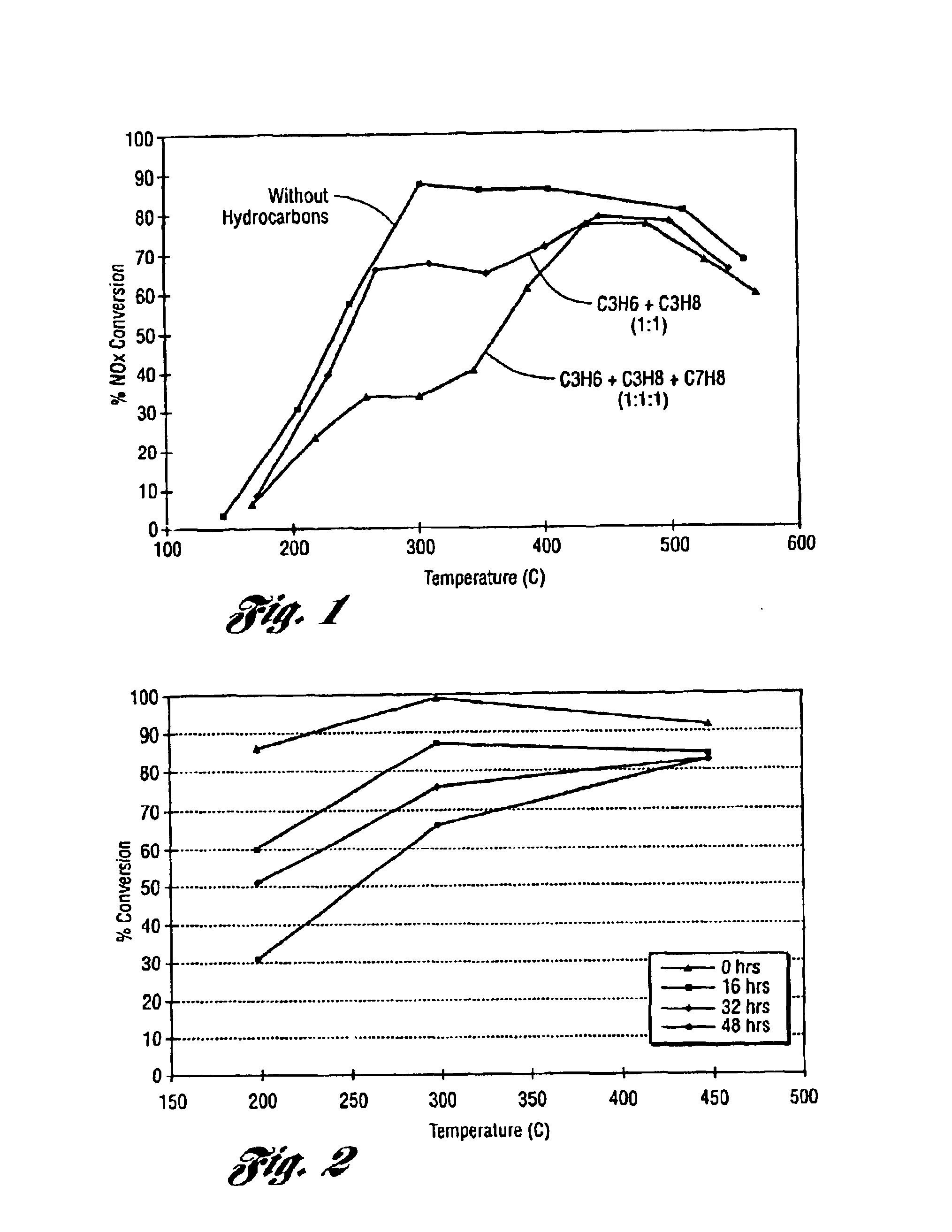

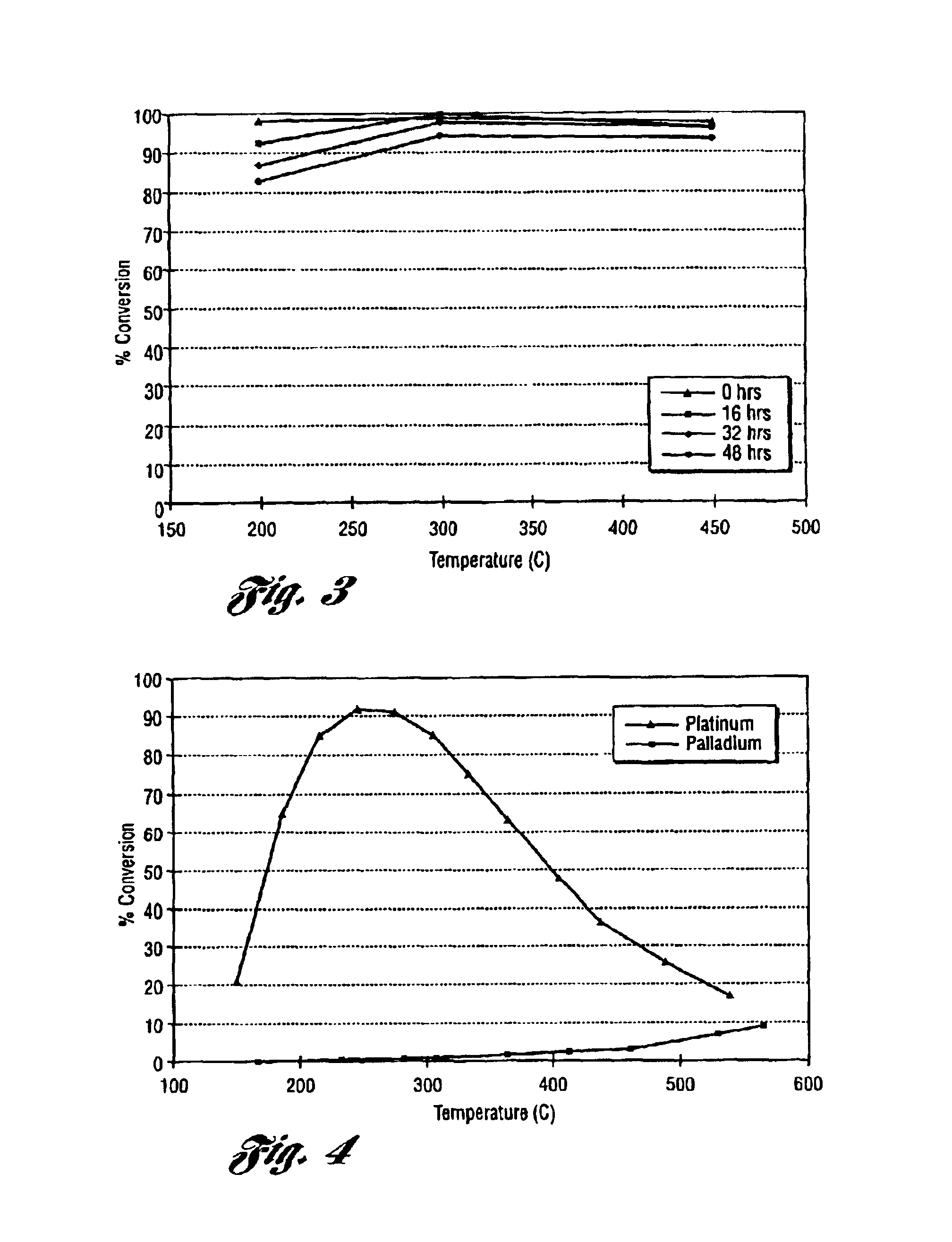

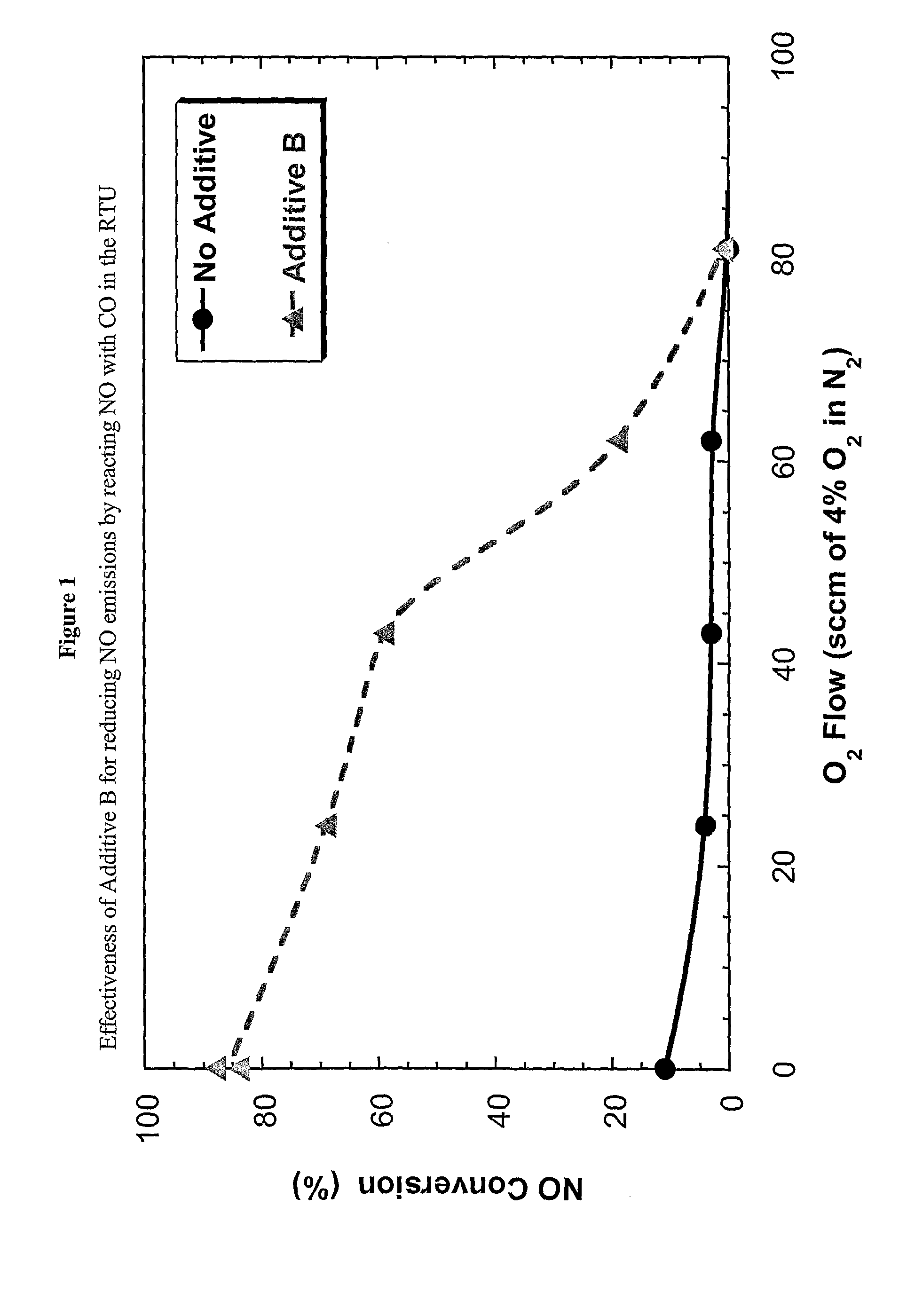

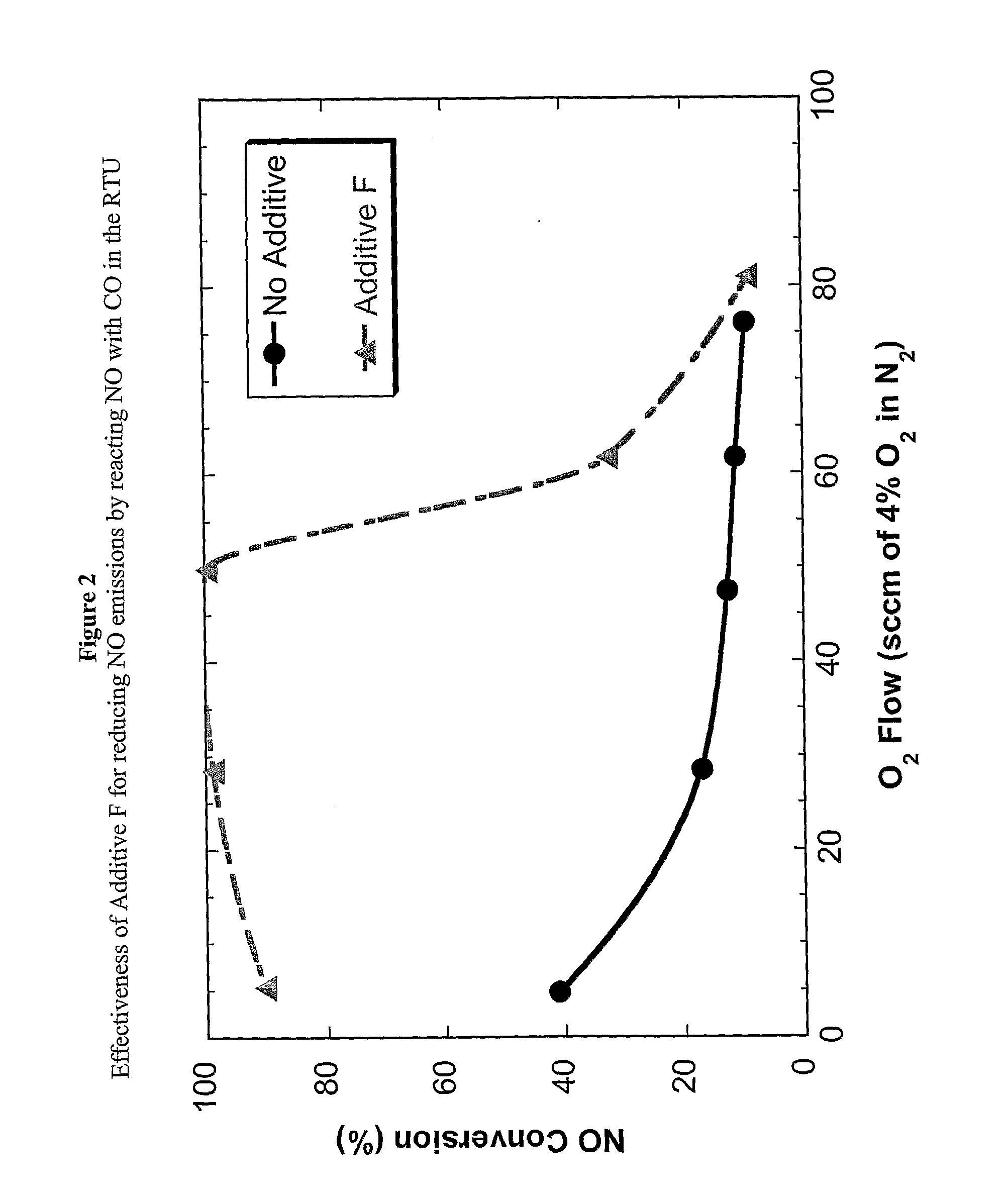

Bimodal catalyst-urea SCR system for enhanced NOx conversion and durability

InactiveUS6846464B2Efficiently oxidizedRapidly and efficiently reducedNitrous oxide captureCombination devicesEngineeringAmmonia

The present invention discloses a method for reducing NOx in exhaust gases of an internal combustion engine. The purpose of this invention is to convert engine out NOx (approximately 90% NO in diesel exhaust) into roughly a 50:50 mixture of NO and NO2, while simultaneously oxidizing engine-out hydrocarbons which interfere with the reduction of NOx by urea or ammonia. The present invention demonstrates that a 50:50 blend of NO and NO2 is reduced more rapidly and with higher efficiency than a gas stream which is predominantly NO. In addition, catalyst in an engine exhaust that is a 50:50 mixture of NO and NO2 is far more resistant to hydrothermal deterioration than using NO alone. In another embodiment of the present invention, a vehicle exhaust system utilizing the method of the present invention is provided.

Owner:FORD GLOBAL TECH LLC

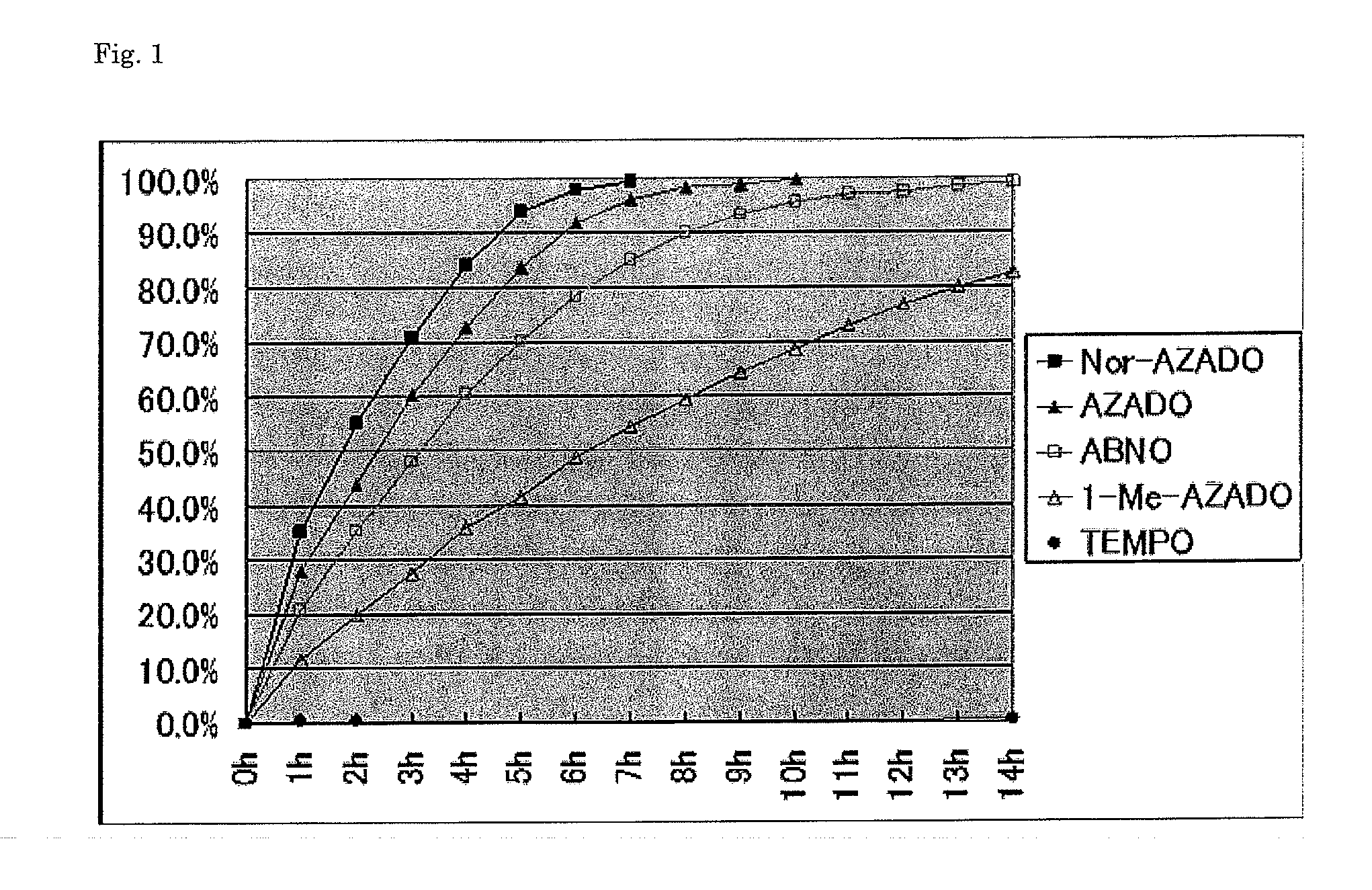

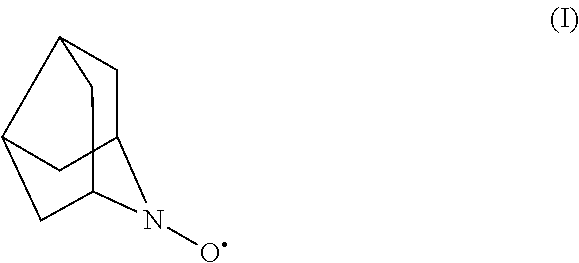

Method for oxidizing alcohols

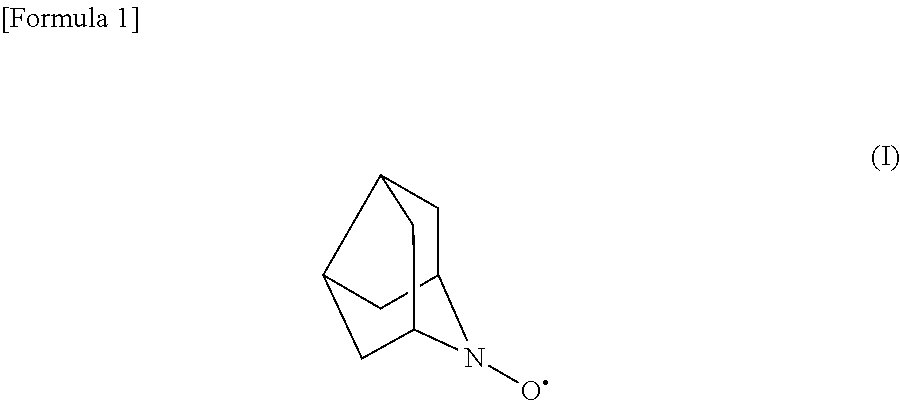

InactiveUS20130172543A1Efficiently oxidizedLow costCarbamic acid derivatives preparationSugar derivativesAlcoholPrimary alcohol

A method for oxidizing an alcohol, wherein oxidation is performed in the presence of a compound represented by the following formula (I) and a bulk oxidant, which enables efficient oxidation of secondary alcohols as well as primary alcohols, and can attain high reaction efficiency even when air is used as a bulk oxidant.

Owner:TOHOKU UNIV

Catalyst for oxidation of metal mercury

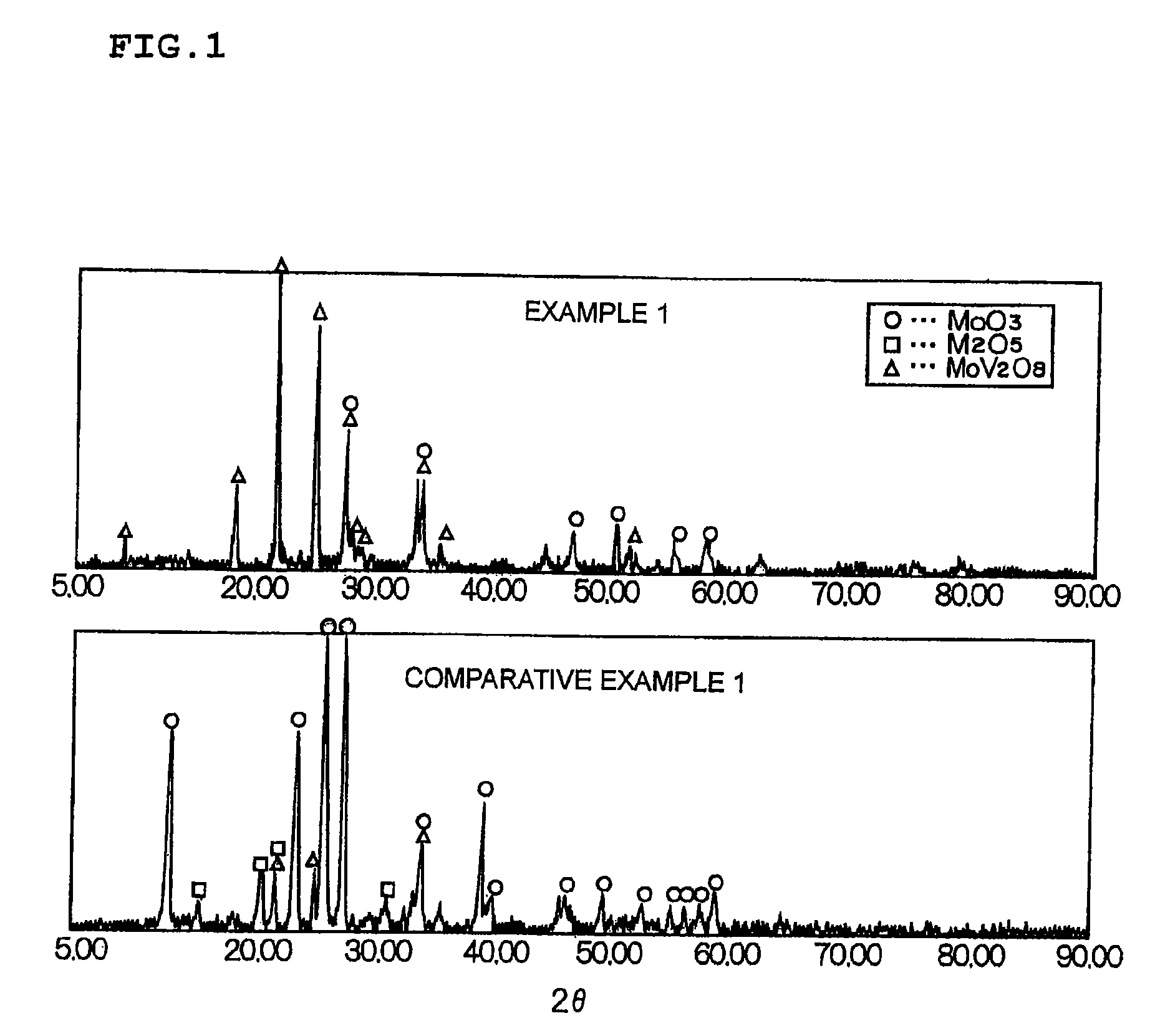

ActiveUS7842644B2Efficiently oxidizedImprove performanceDispersed particle filtrationElectrostatic separationHoneycomb likeMercury oxidation

A catalyst is provided having higher mercury oxidation performance than a conventional catalyst without increasing catalyst quantity or enhancing SO2 oxidation performance and constitutes an oxidation catalyst for metal mercury, which contains a molybdenum and vanadium complex oxide, for example, MoV2O8, as a main component having a catalytic activity and is formed by placing the molybdenum and vanadium complex oxide in layers only on the surface of a plate-like or honeycomb-like porous carrier. The porous carrier contains Ti and W and has a function of an NOx removal catalyst as a whole.

Owner:MITSUBISHI POWER LTD

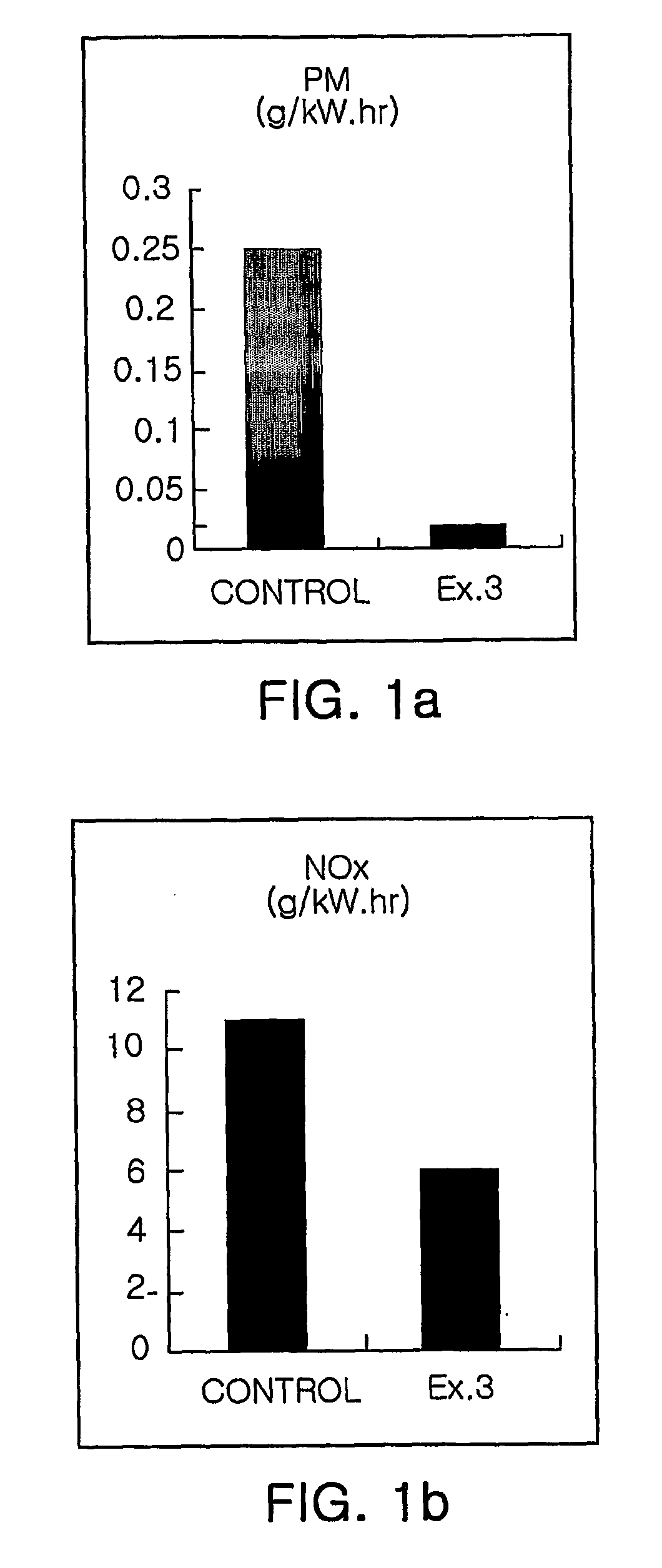

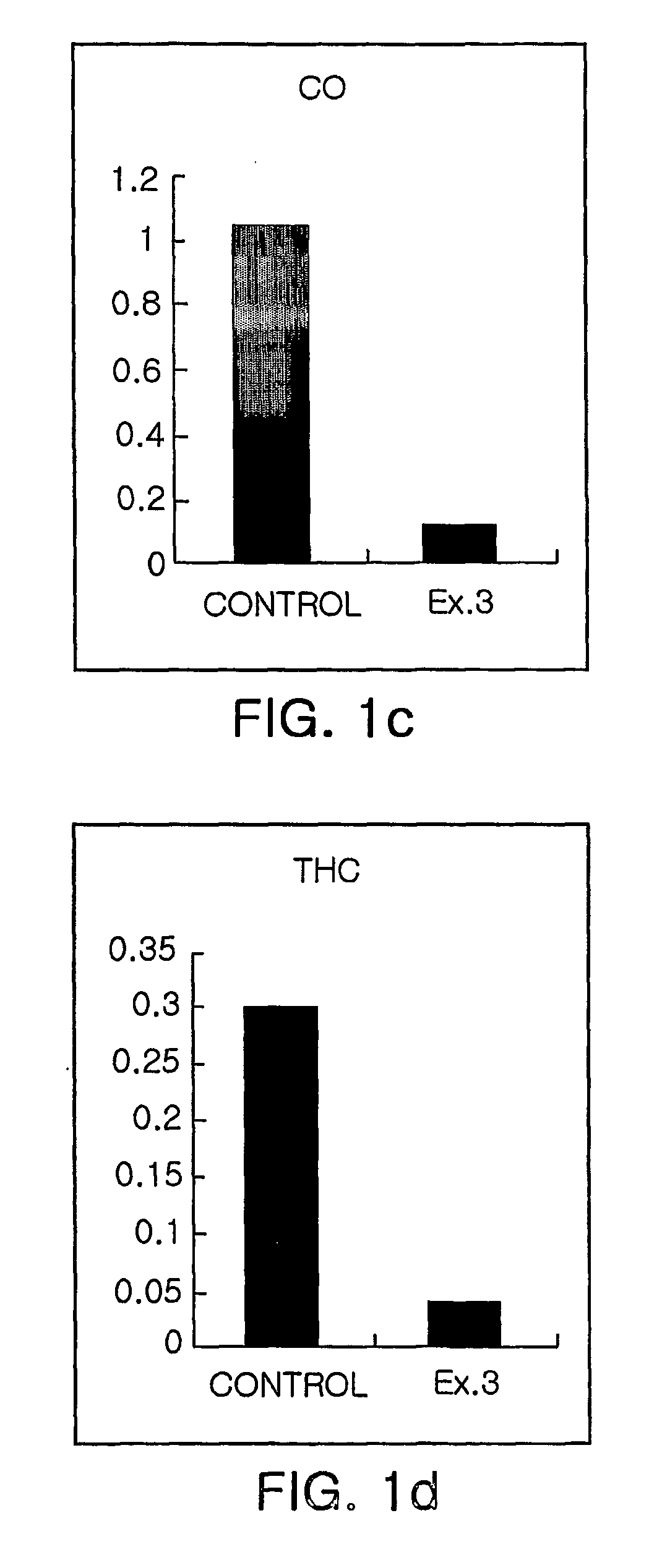

Catalytic filter for removing soot particulates from diesel engine exhaust and method of preparing the same

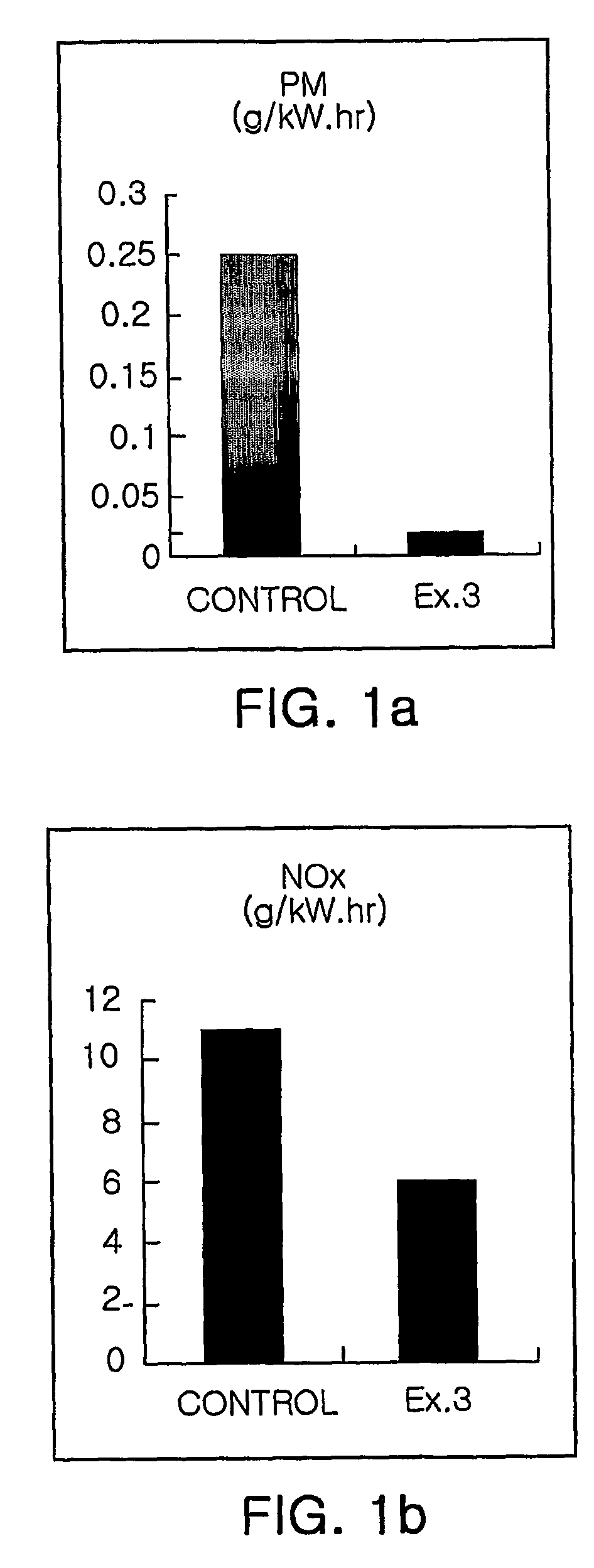

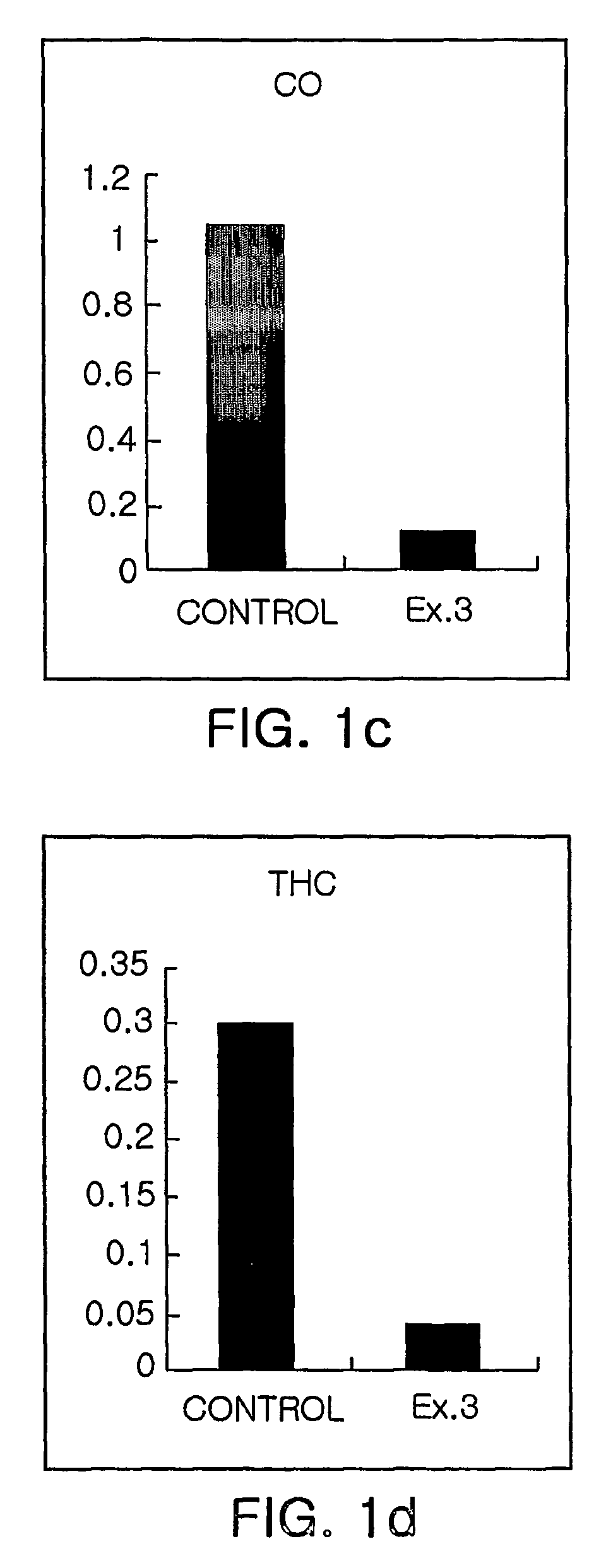

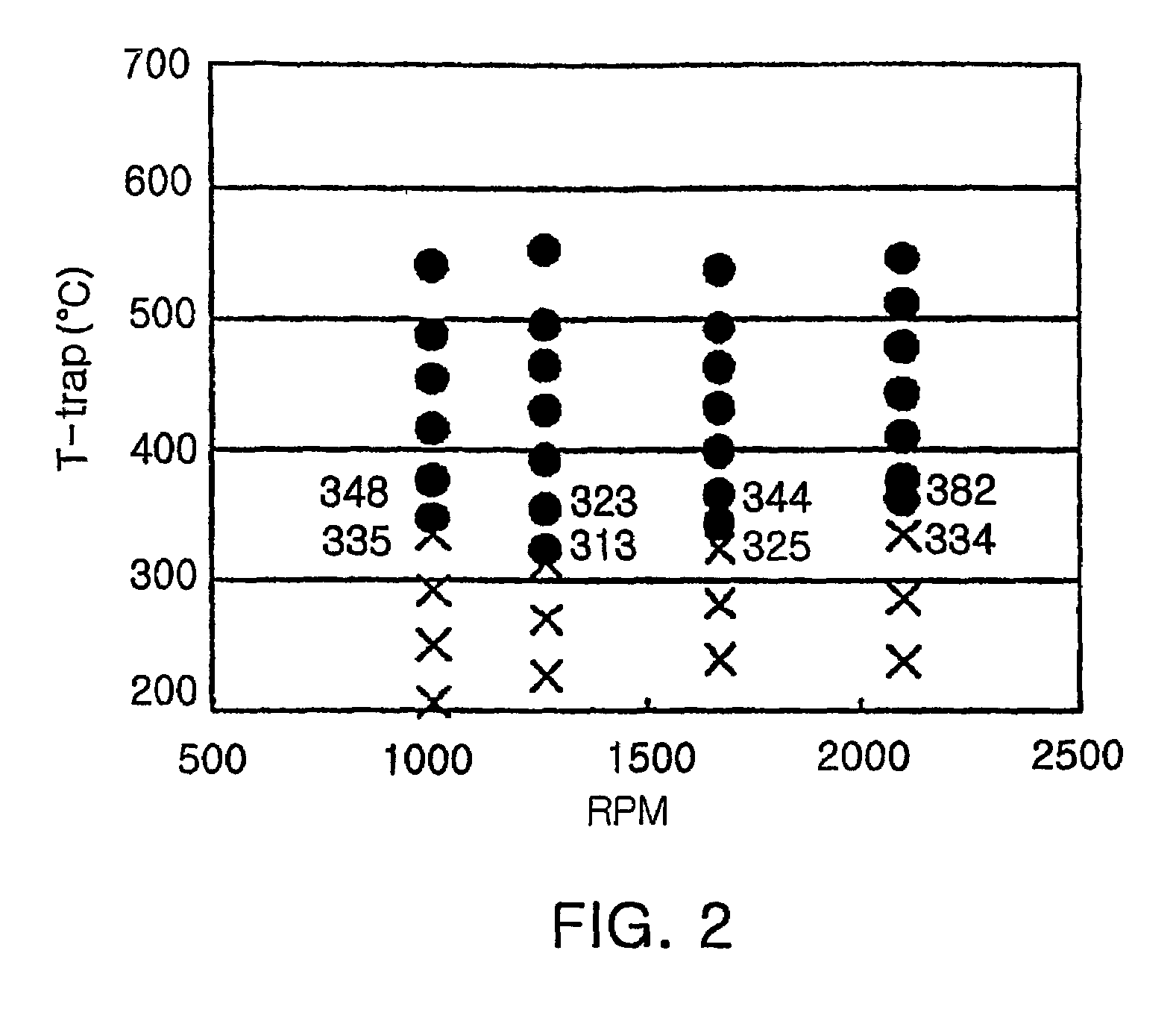

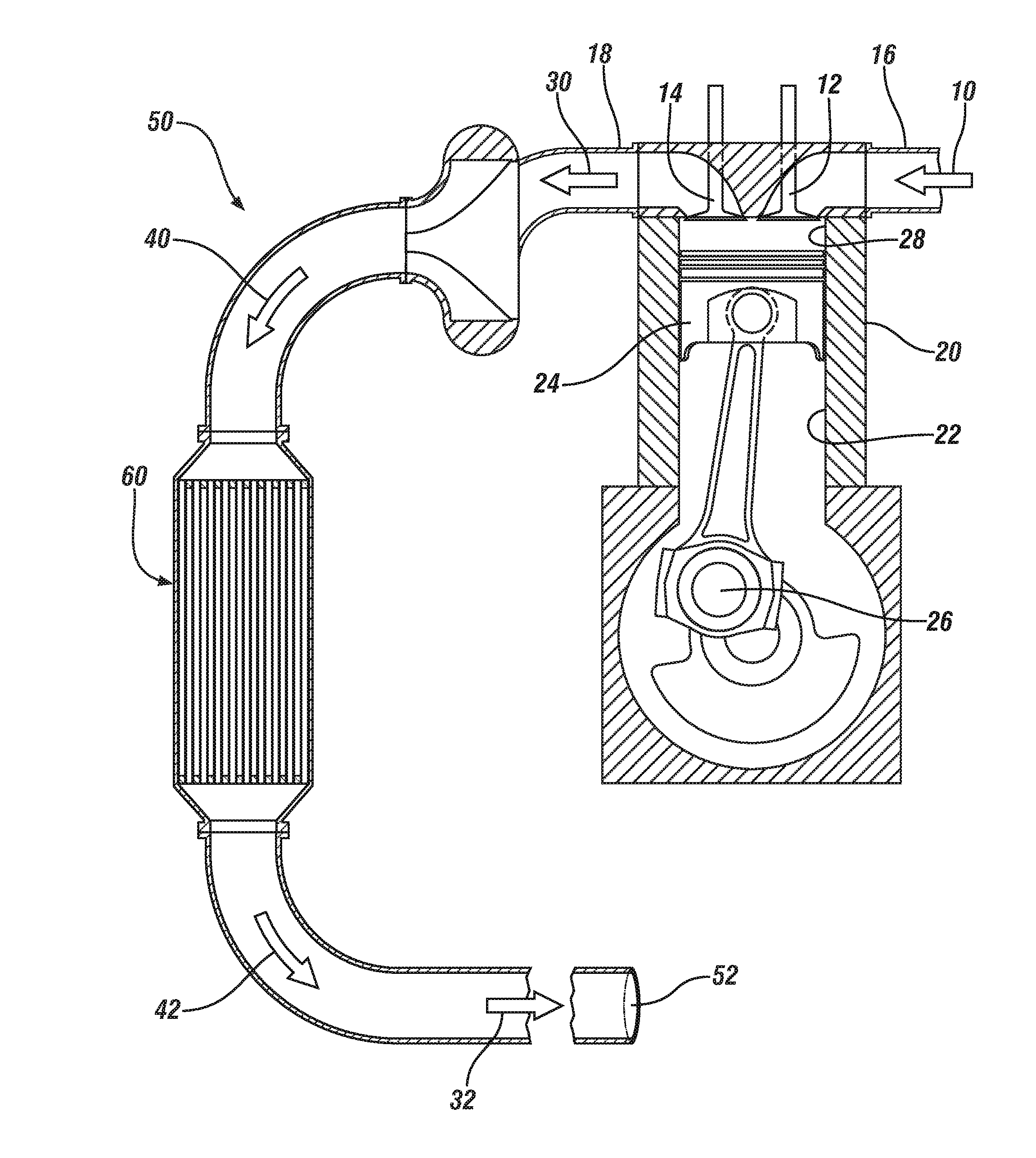

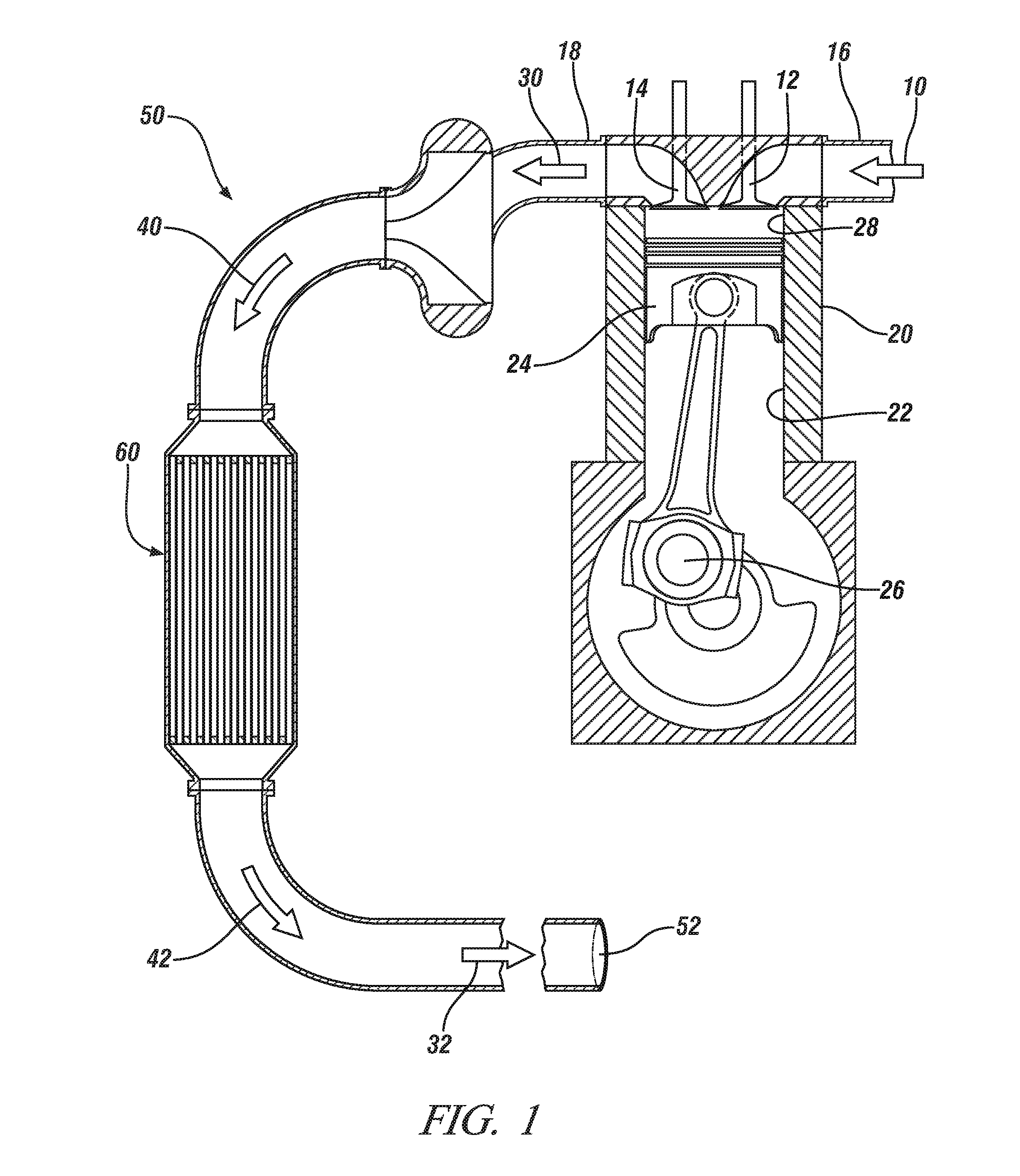

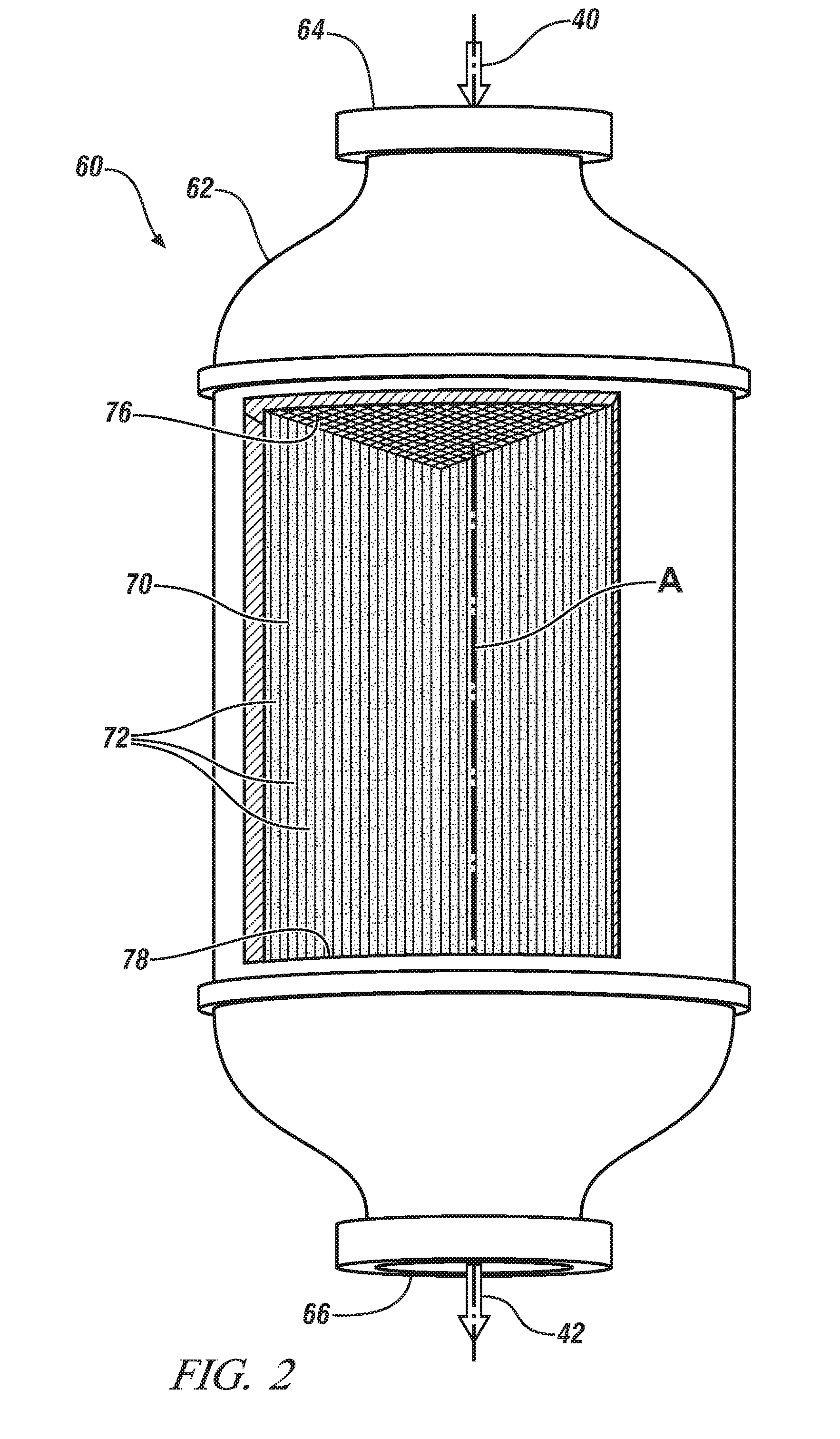

ActiveUS20050239642A1Efficiently oxidizedCombination devicesAuxillary pretreatmentReducing agentMetal salts

Disclosed is a catalytic filter for removing soot particulates from diesel engine exhaust, which is comprised of monolithic oxidation catalyst upstream of the catalytic filter, which effectively oxidize gaseous pollutants and volatile organic fractions, and a catalyzed wall-flow filter downstream serving to low temperature combustion of soot particulates collected on the filter. Also, the preparation method of the catalytic filter is provided, including the colloidal mixture solution of platinum group metal salts and other metal salts with a water-soluble polymer and a reducing agent, which is then impregnated on a catalyst support, followed by calcining at high temperatures. In the present invention, use of the catalytic filter provides effective means of abating diesel exhaust pollutant emissions, that is, particulate matter (PM) and gaseous pollutants (HC, CO, NOx).

Owner:SK ENERGY CO LTD (KR)

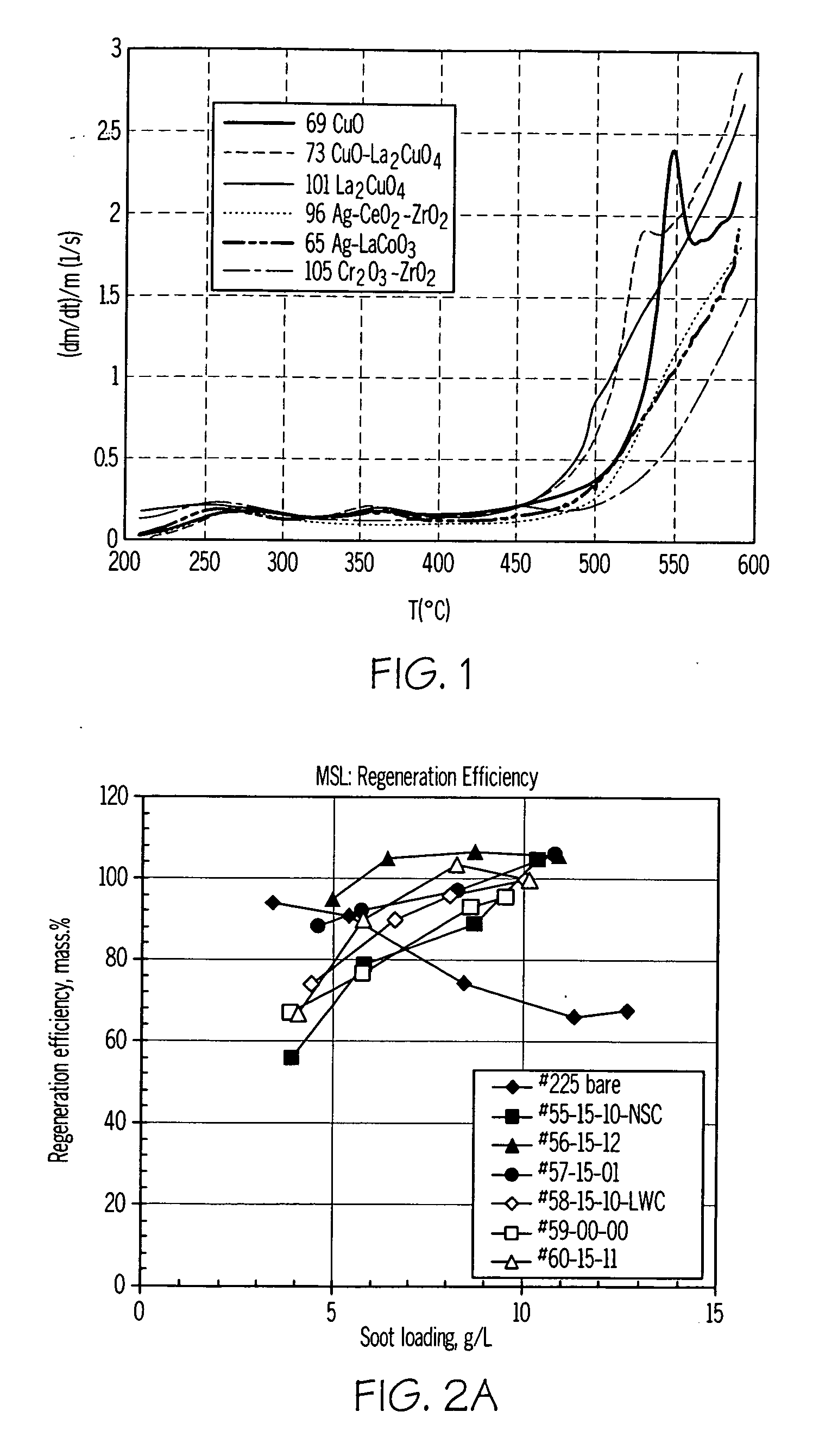

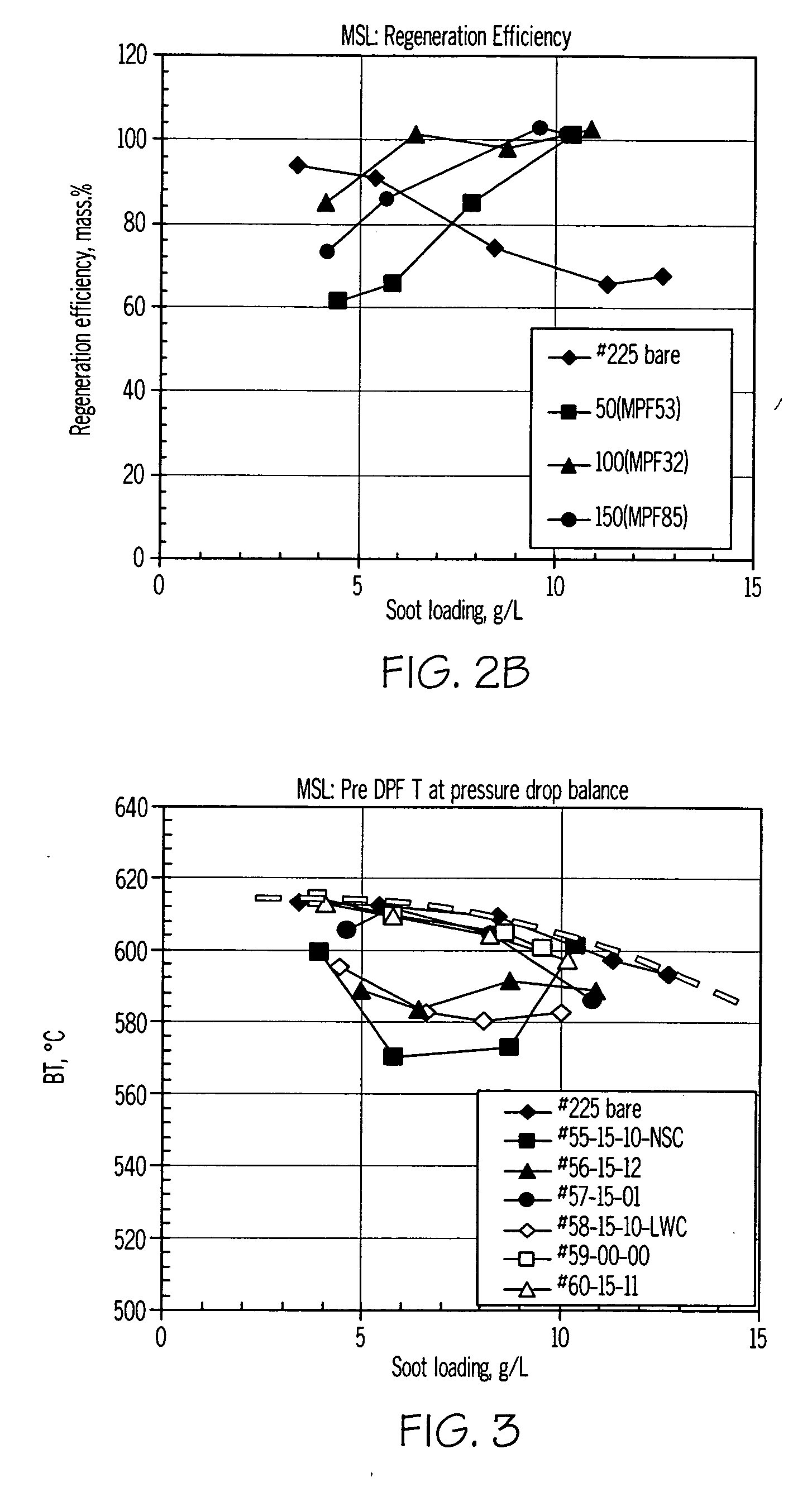

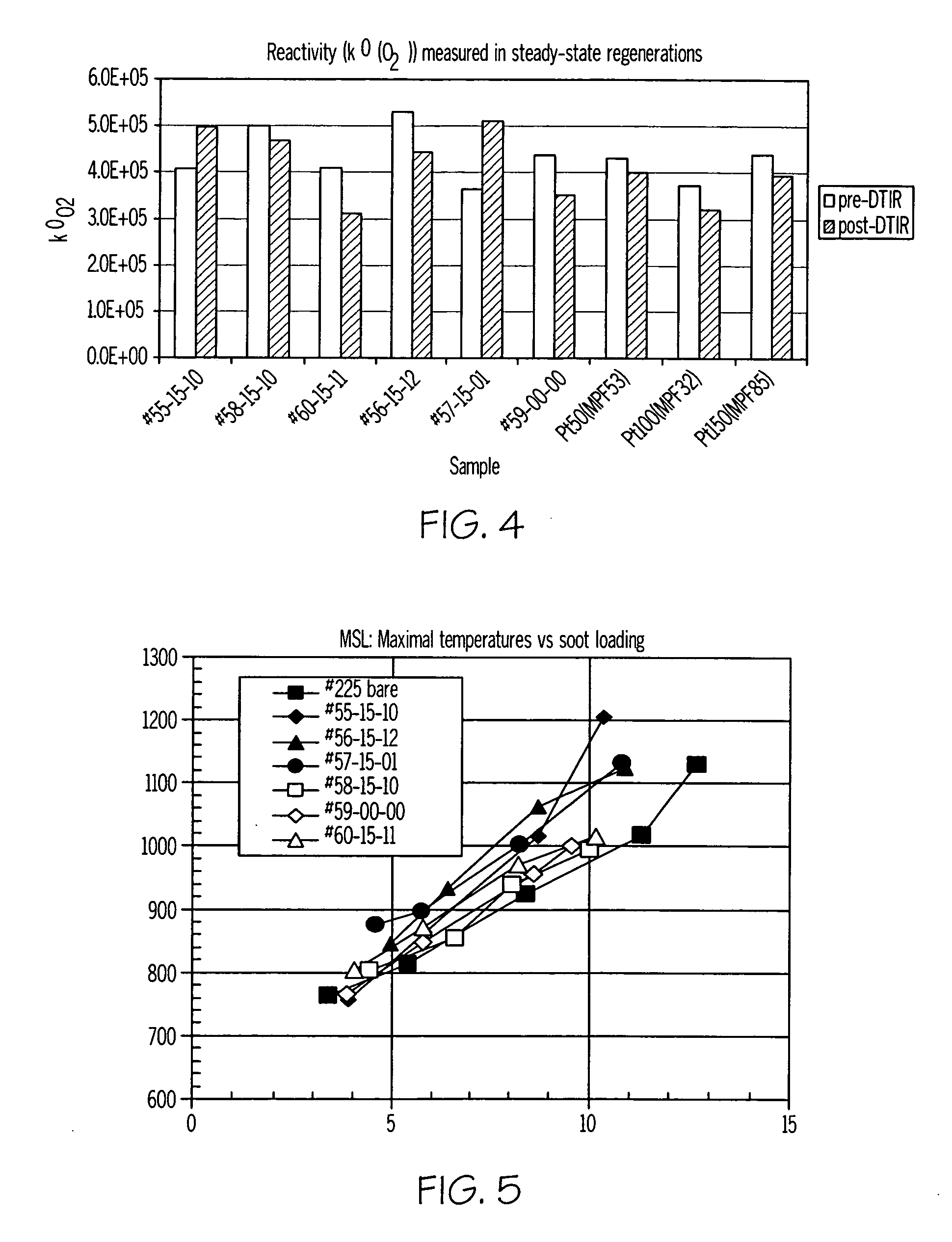

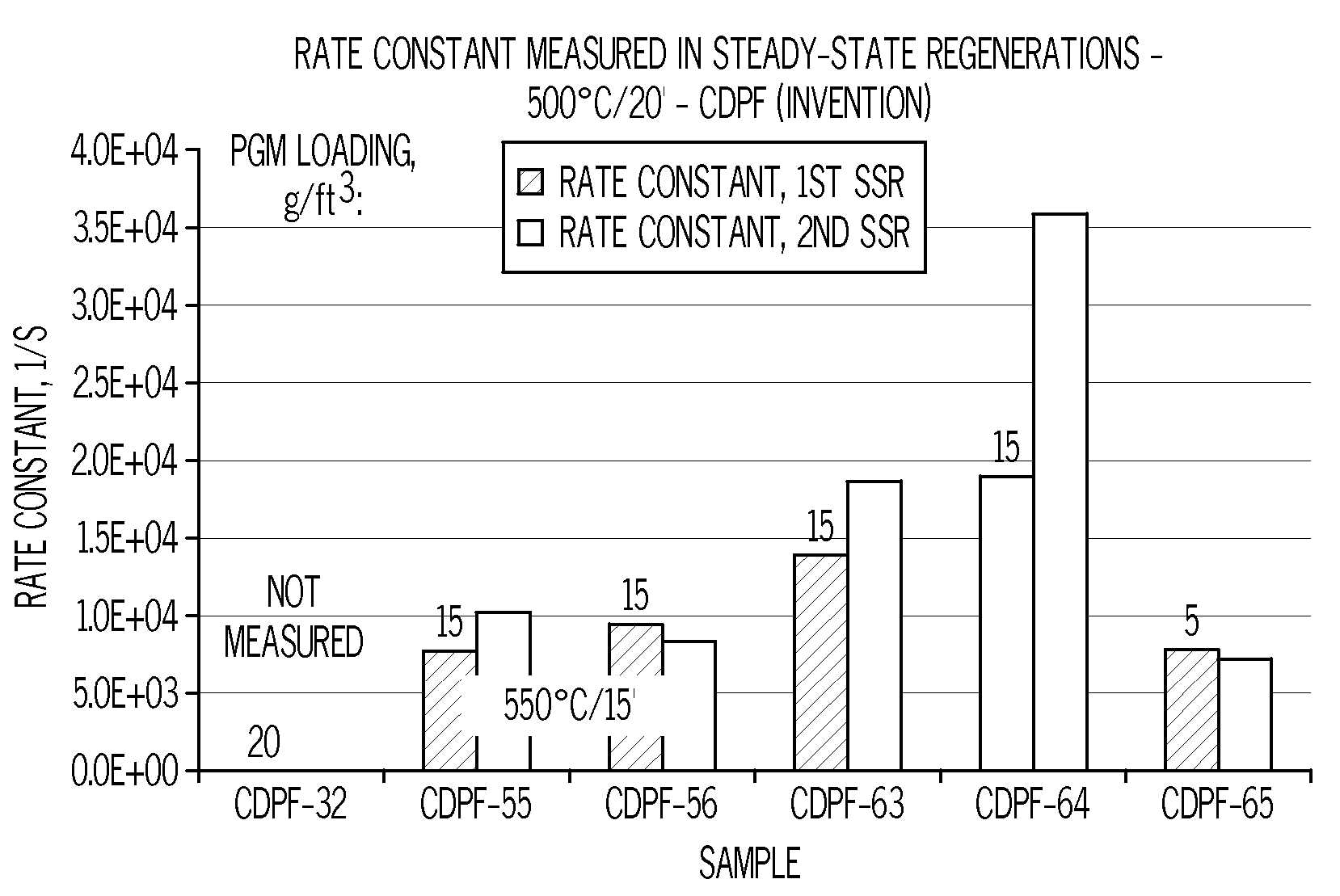

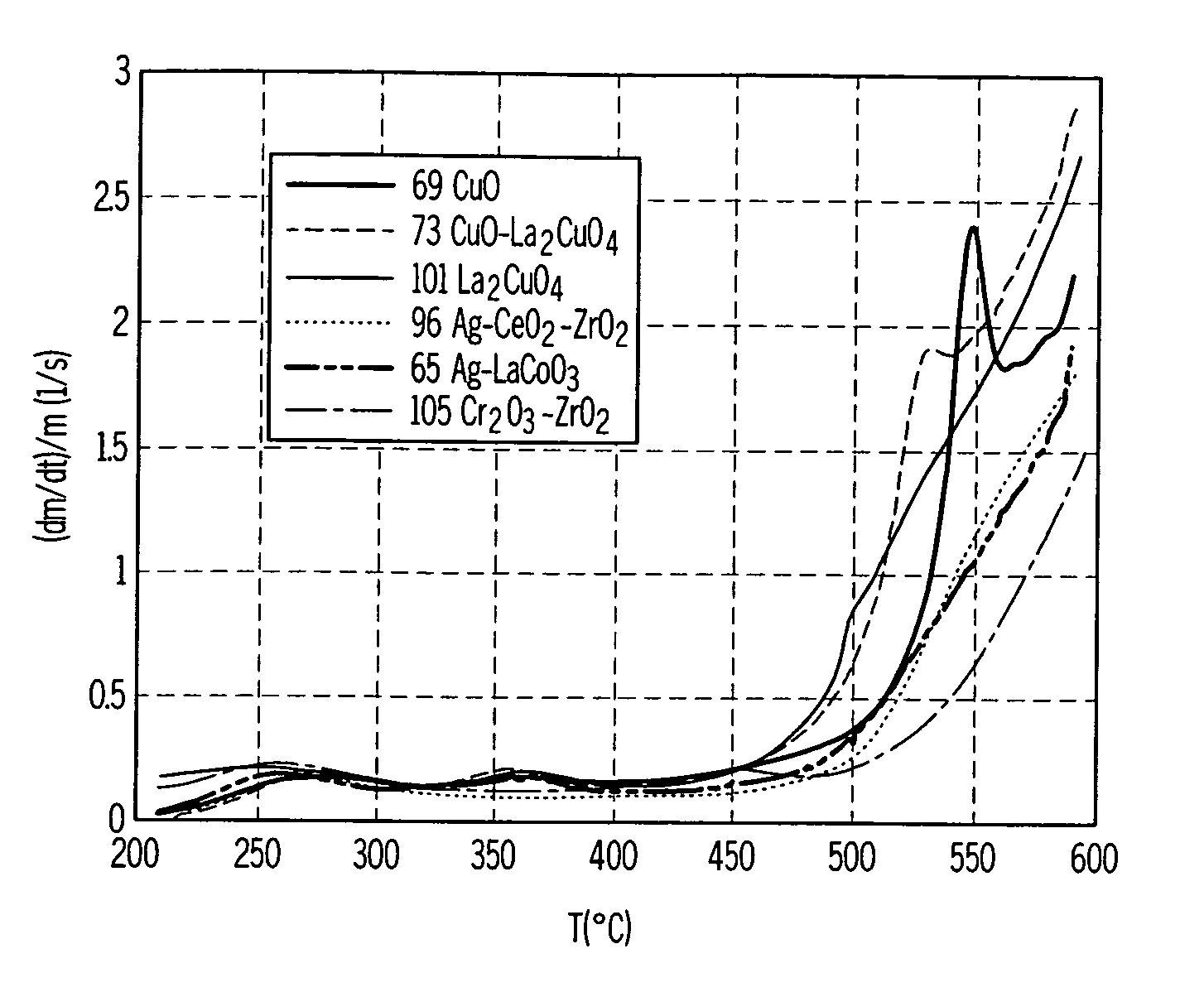

Soot oxidation catalyst and method of making

InactiveUS20070219088A1Efficiently oxidizedPrevent materialCombination devicesNitrogen compoundsDiesel particulate filterGlycerol

A catalyst composition for facilitating the oxidation of soot from diesel engine exhaust is provided. The catalyst composition includes a catalytic metal selected from Pt, Pd, Pt—Pd, Ag, or combinations thereof, an active metal oxide component containing Cu and La, and a support selected from alumina, silica, zirconia, or combinations thereof. The platinum group metal loading of the composition is less than about 20 g / ft3. The catalyst composition may be provided on a diesel particulate filter by impregnating the filter with an alumina, silica or zirconia sol solution modified with glycerol and / or saccharose, impregnating the filter with a stabilizing solution, and impregnating the filter with a solution containing the active metal oxide precursor(s) and the catalytic metal precursor(s). The resulting catalyst coated diesel particulate filter provides effective soot oxidation, exhibits good thermal stability, has a high BET surface area, and exhibits minimal backpressure.

Owner:FORD GLOBAL TECH LLC

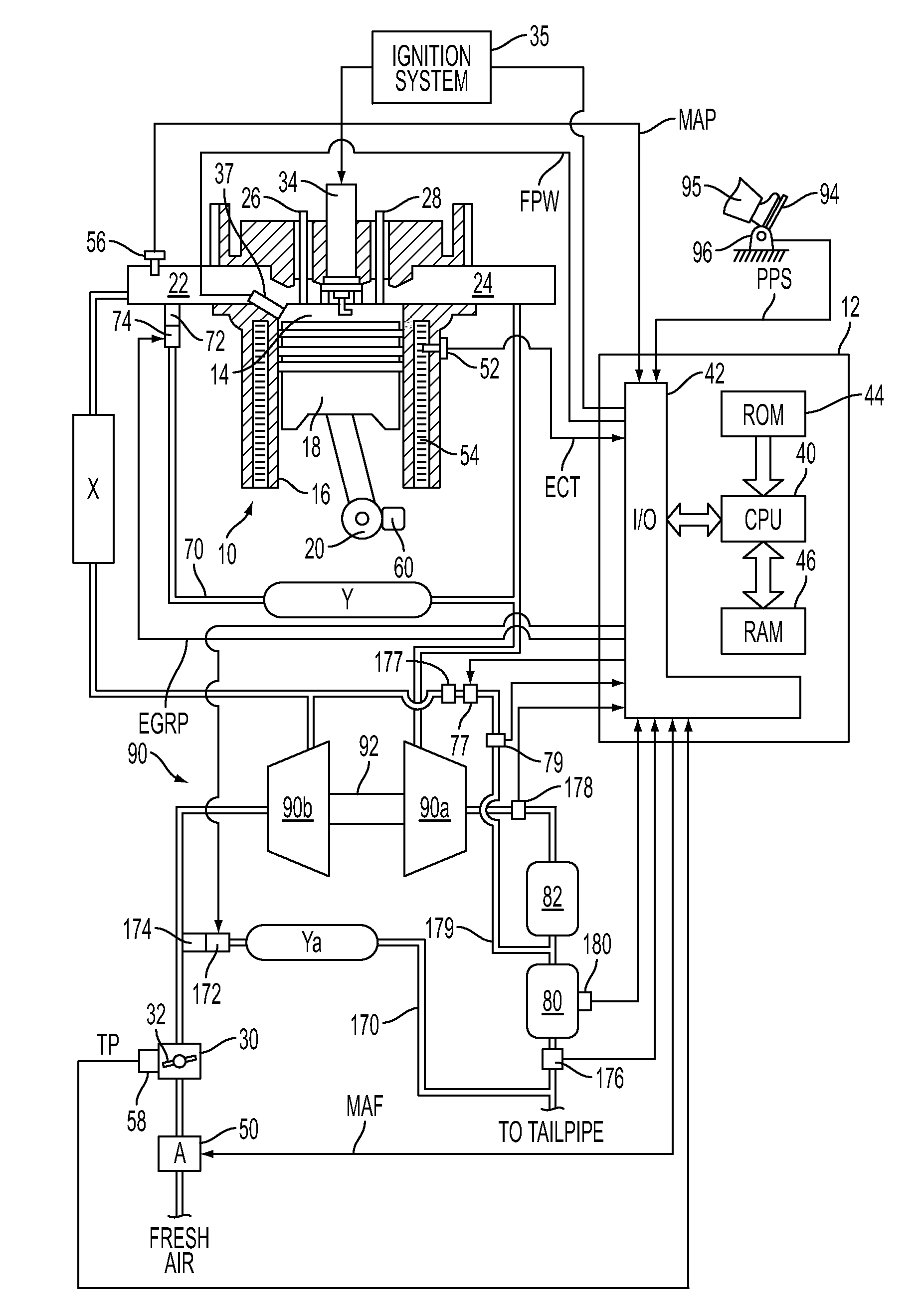

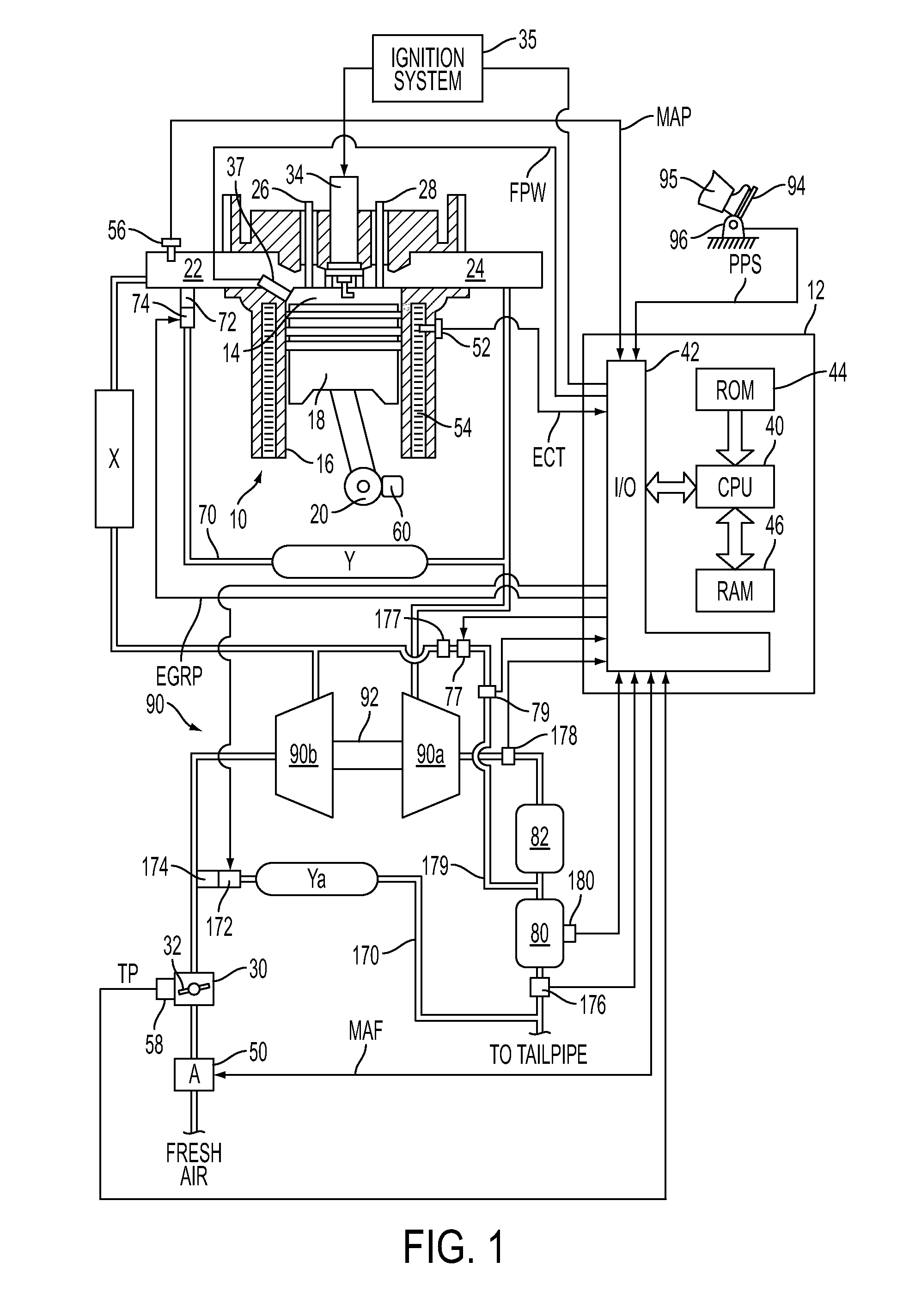

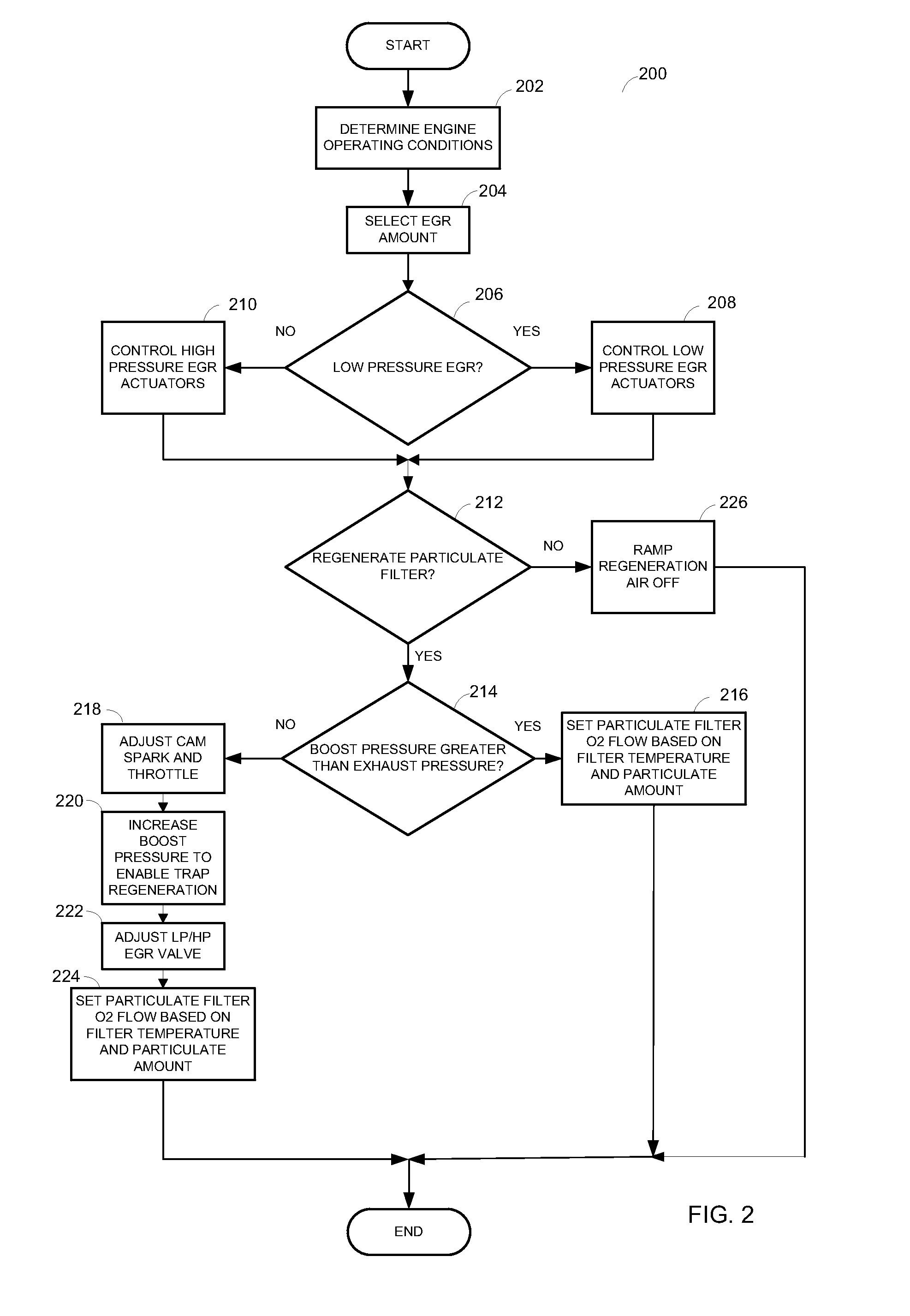

Method for adjusting boost pressure while regenerating a particulate filter for a direct injection engine

ActiveUS20110072803A1Emission reductionReduce engine pumping lossElectrical controlInternal combustion piston enginesGasolineEngineering

A method for regenerating a particulate filter is disclosed. In one example, oxygen is pumped from the intake system of a direct injection turbocharged gasoline engine to the exhaust system by a compressor. The oxygen is introduced to a particulate filter at a location upstream from the particulate filter and downstream of a three-way catalyst. The oxygen may be regulated in part by adjusting compressor boost pressure in response to a state of particulate filter regeneration. Further, in one embodiment, engine NOx can be controlled by EGR.

Owner:FORD GLOBAL TECH LLC

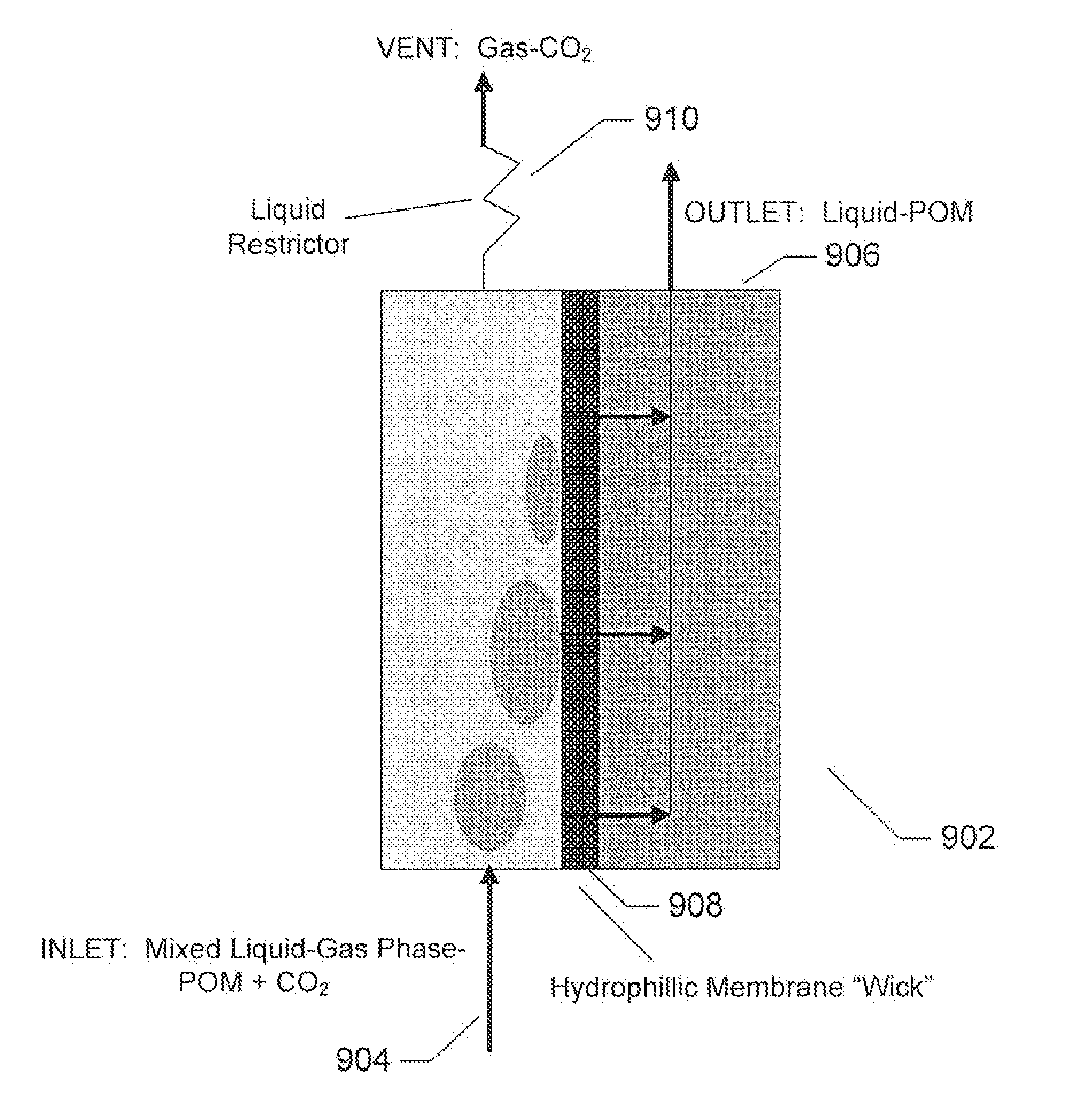

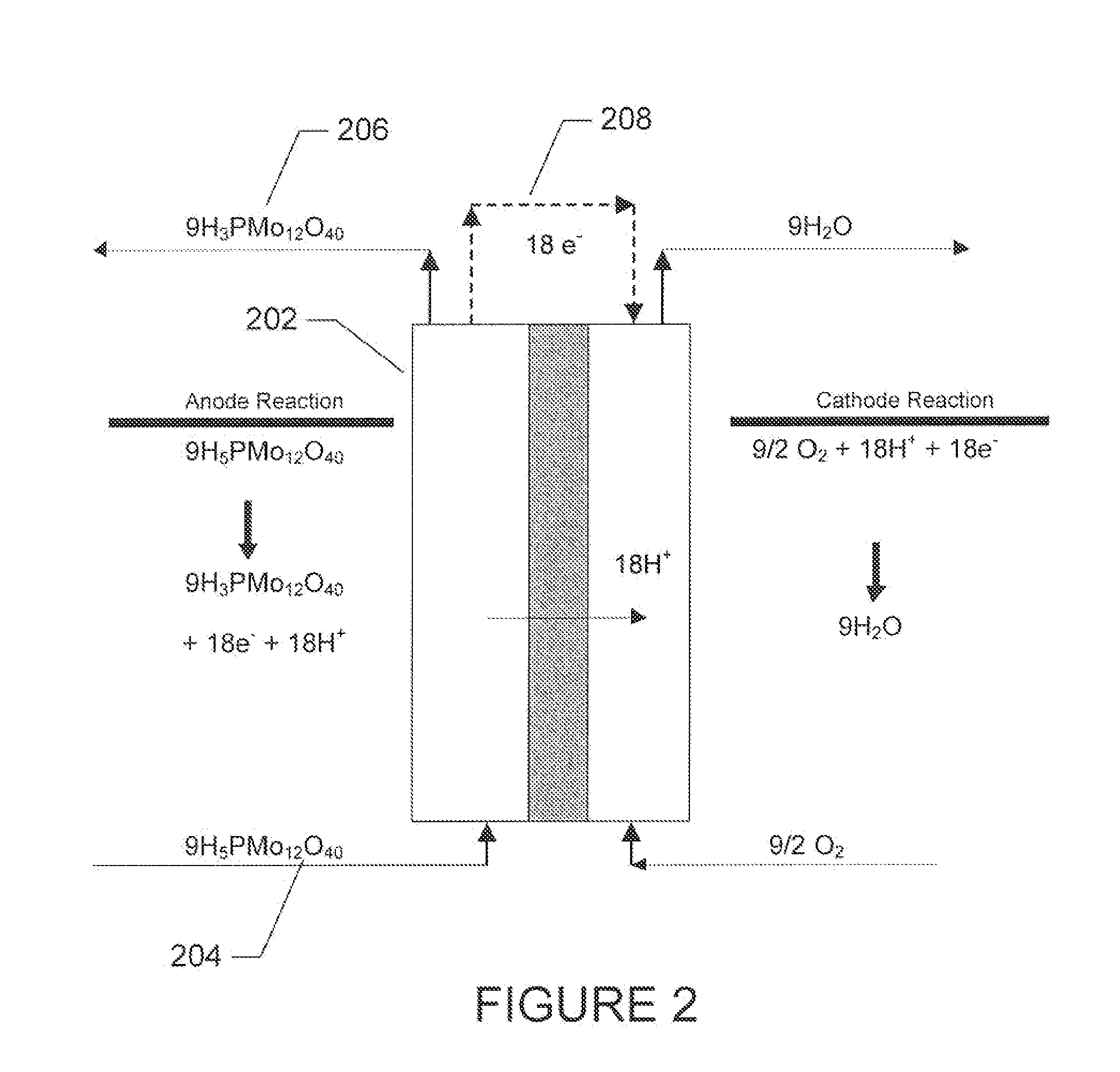

Polyoxometalate flow-cell power system

InactiveUS20110014527A1Improve electronic conductivityEfficiently oxidizedFuel and secondary cellsCell electrodesElectrochemical responseLiquid product

Embodiments of the present invention relate generally to redox flow batteries and, more specifically, to flow batteries that employ electron-ferrying redox compounds made from polyoxometalates (“POMs”). Embodiments of the present invention employ flow-battery technology that combines the fast electrochemical reaction of a battery with the fuel flexibility of a fuel cell to meet next-generation energy needs of a variety of power applications, including portable electronics used in military and commercial applications and large power modules that provide 550 W or more. To obtain a high-power-density stack, a reduced form of liquid POM is fed to the stack of cells, in certain embodiments of the present invention, where the reduced form of liquid POM is efficiently oxidized into liquid products at the anodes. Air is fed and reduced at the cathodes, generating water as a byproduct.

Owner:FC & ASSOC

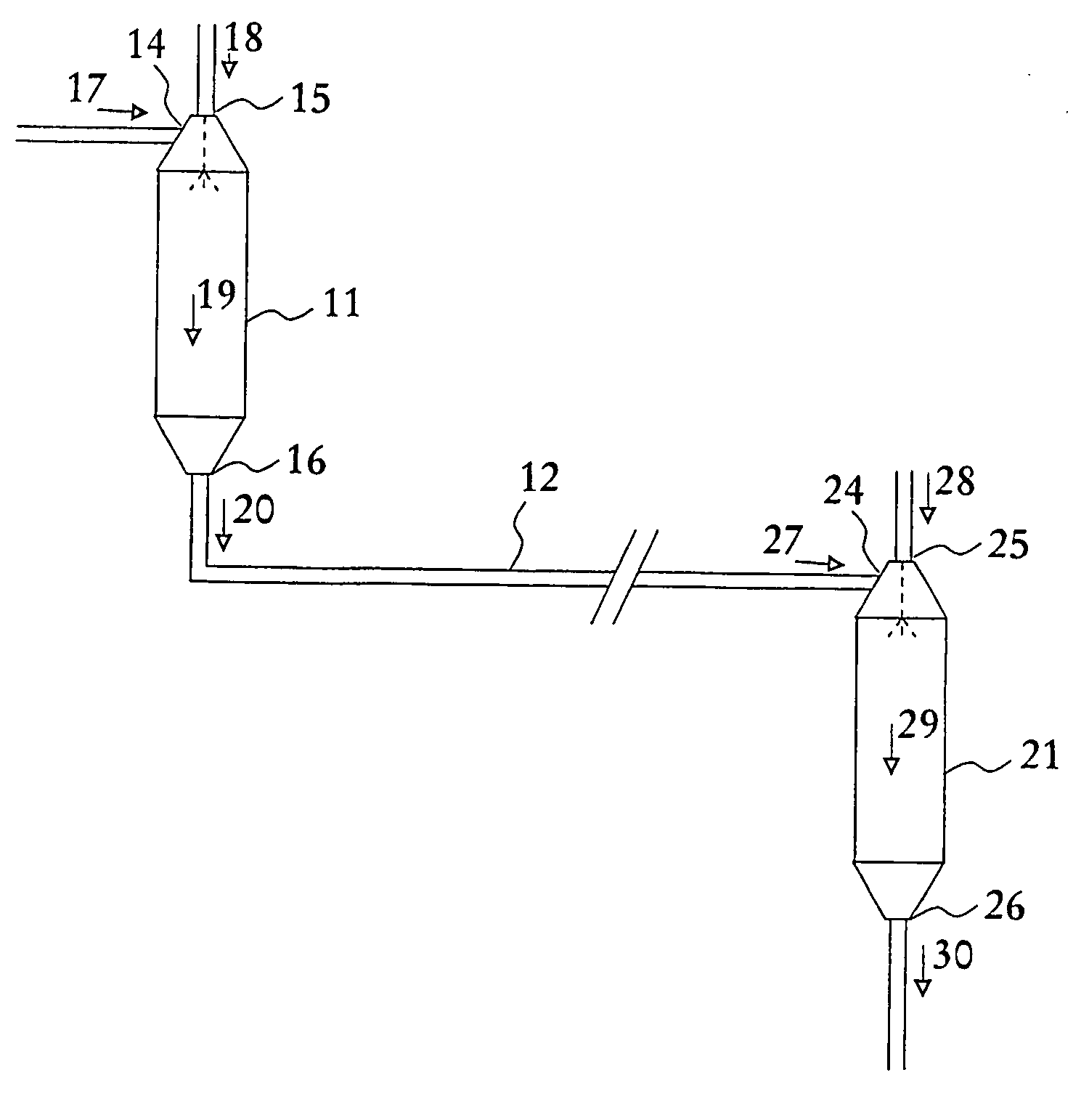

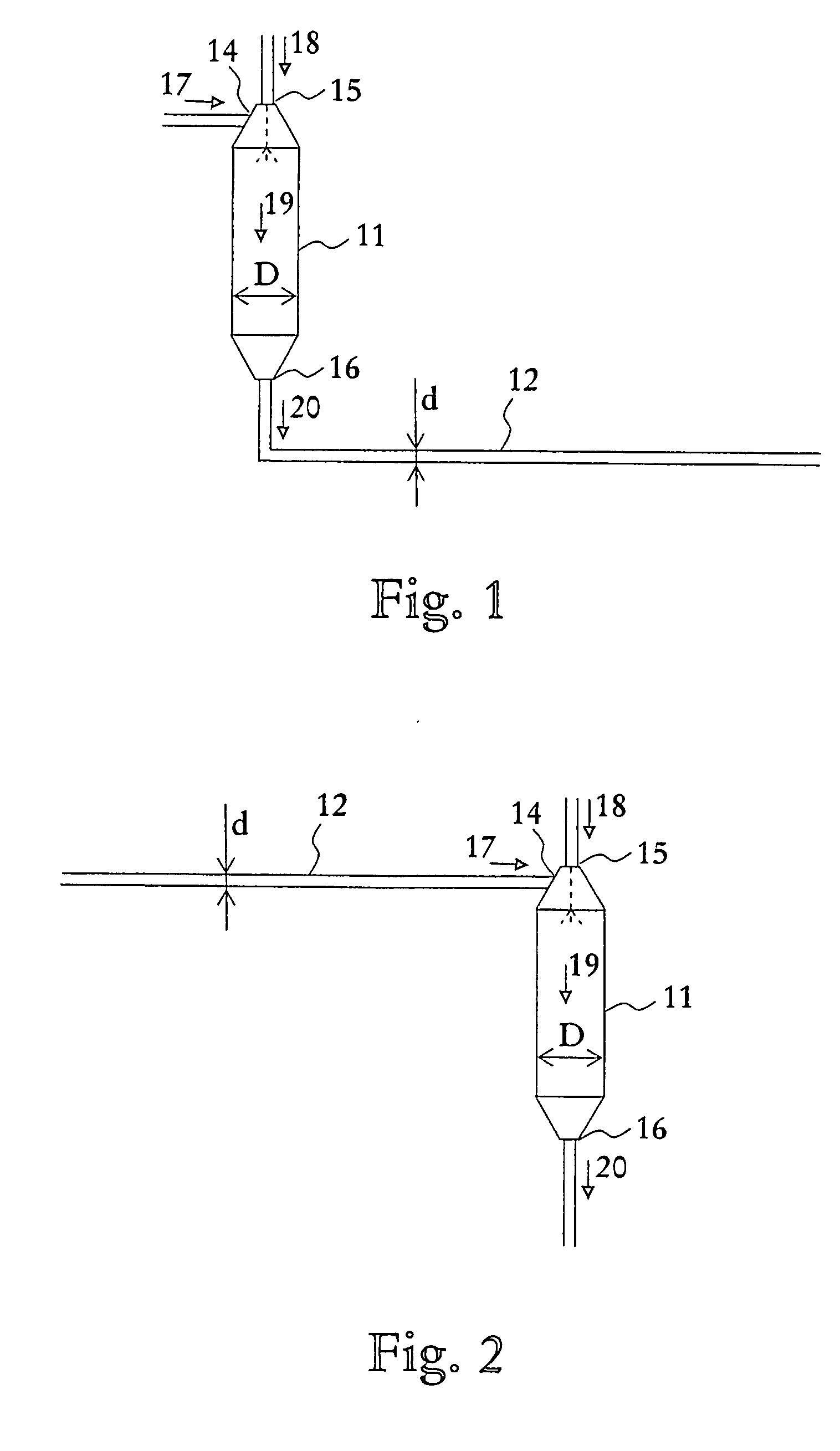

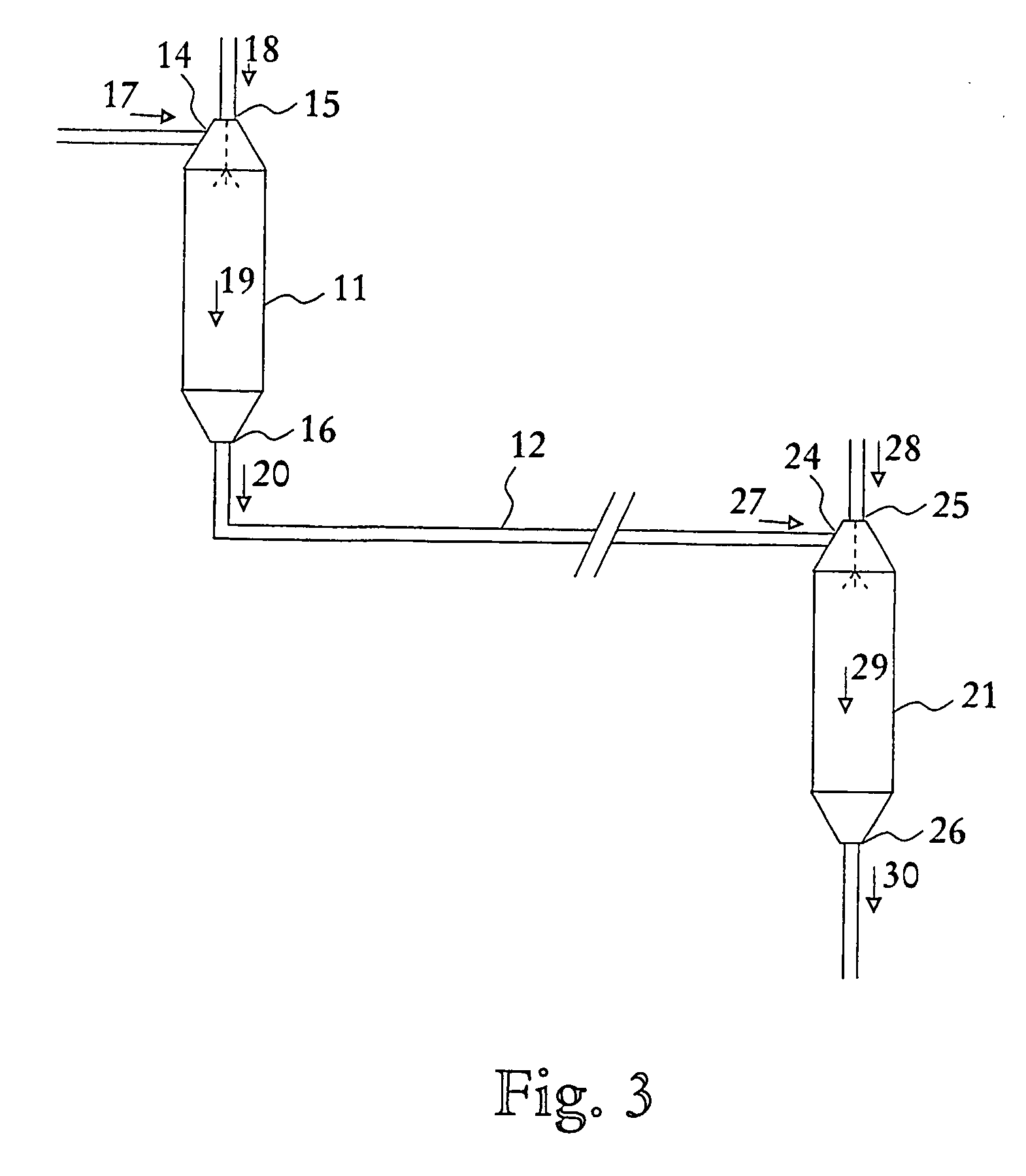

Reactor and Method for Supercritical Water Oxidation

InactiveUS20080073292A1Increase the cross-sectional areaInhibition formationSludge treatment by oxidationChemical/physical/physico-chemical stationary reactorsNuclear engineeringOrganic matter

A reactor for supercritical water oxidation comprises an essentially vertical reactor section (11) and an essentially non-vertical reactor section (12), wherein the vertical reactor section has a cross-sectional area which is substantially larger than the cross-sectional area of the non-vertical reactor section. The vertical reactor section has an inlet (14) in an upper portion thereof for receiving (17) a flow containing organic material and water, and an outlet (16) in a lower portion thereof for outputting (20) the flow. Both the vertical and the non-vertical reactor sections are configured to oxidize organic material in the flow through supercritical water oxidation.

Owner:HOLLINGFORD

Peroxide-driven cytochrome P450 oxygenase variants

The invention relates to novel variants of cytochrome P450 oxygenases. These variants have an improved ability to use peroxide as an oxygen donor as compared to the corresponding wild-type enzyme. These variants also have an improved thermostability as compared to the cytochrome P450 BM-3 F87A mutant. Preferred variants include cytochrome P450 BM-3 heme domain mutants having I58V, F87A, H100R, F107L, A135S, M145A / V, N239H, S274T, L324I, I366V, K434E, E442K, and / or V446I amino acid substitutions.

Owner:CALIFORNIA INST OF TECH

Oxidation catalysts for engines producing low temperature exhaust streams

ActiveUS20120291420A1Low temperatureEfficiently oxidizedCombination devicesHeterogenous catalyst chemical elementsDiesel engineAluminium oxide

The oxidation of carbon monoxide (CO) and hydrocarbons (HC) in an oxygen-containing gas stream, such as the exhaust stream from a diesel engine, or other lean-burn engine, may be catalyzed using a combination of mixed oxide particles of cerium, zirconium and copper, and discrete particles of an alumina-supported platinum group metal catalyst. The catalyzed oxidation of CO and HC by this combination of oxidation catalyst particles is effective at temperatures below 300° C.

Owner:GM GLOBAL TECH OPERATIONS LLC

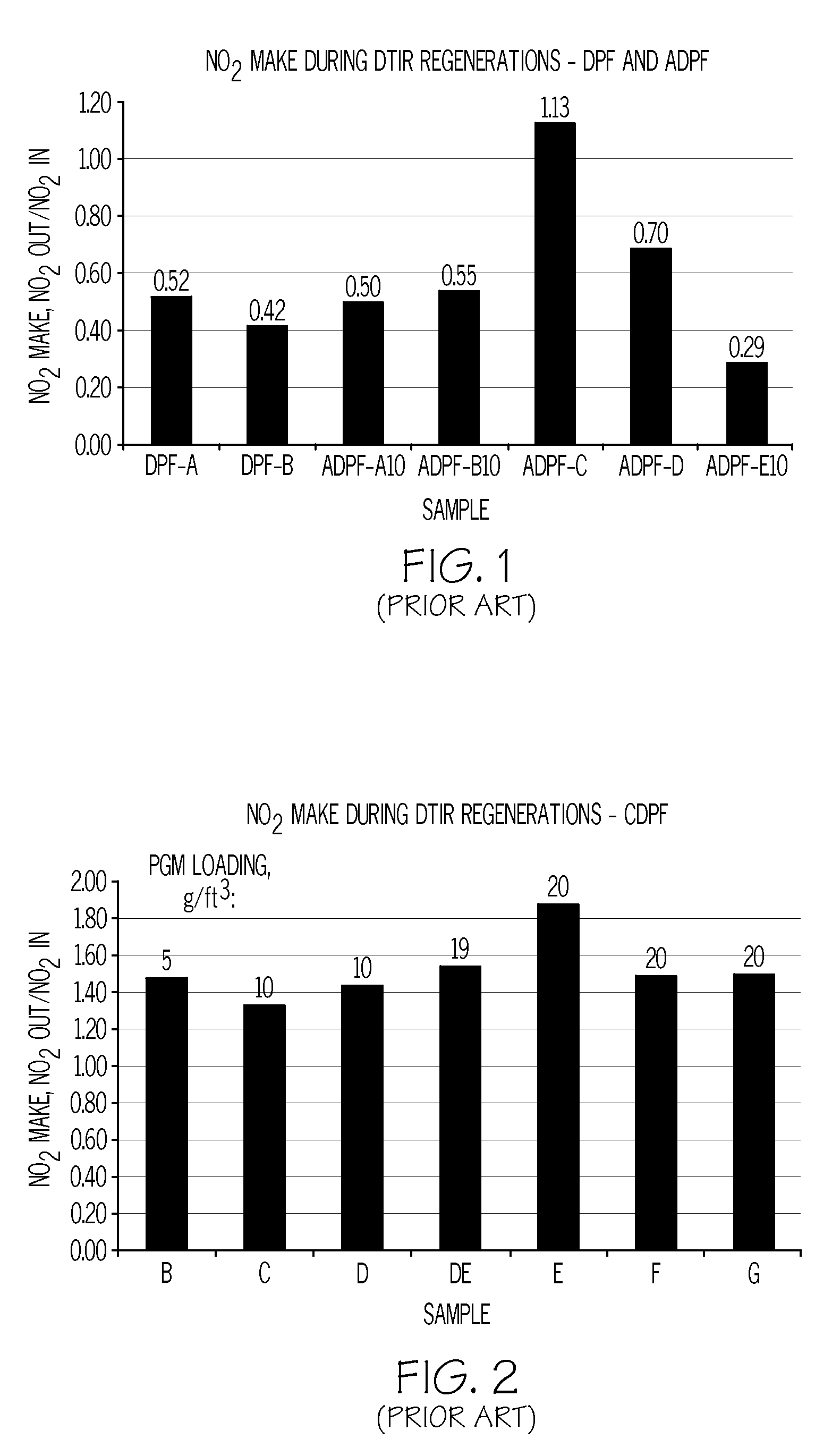

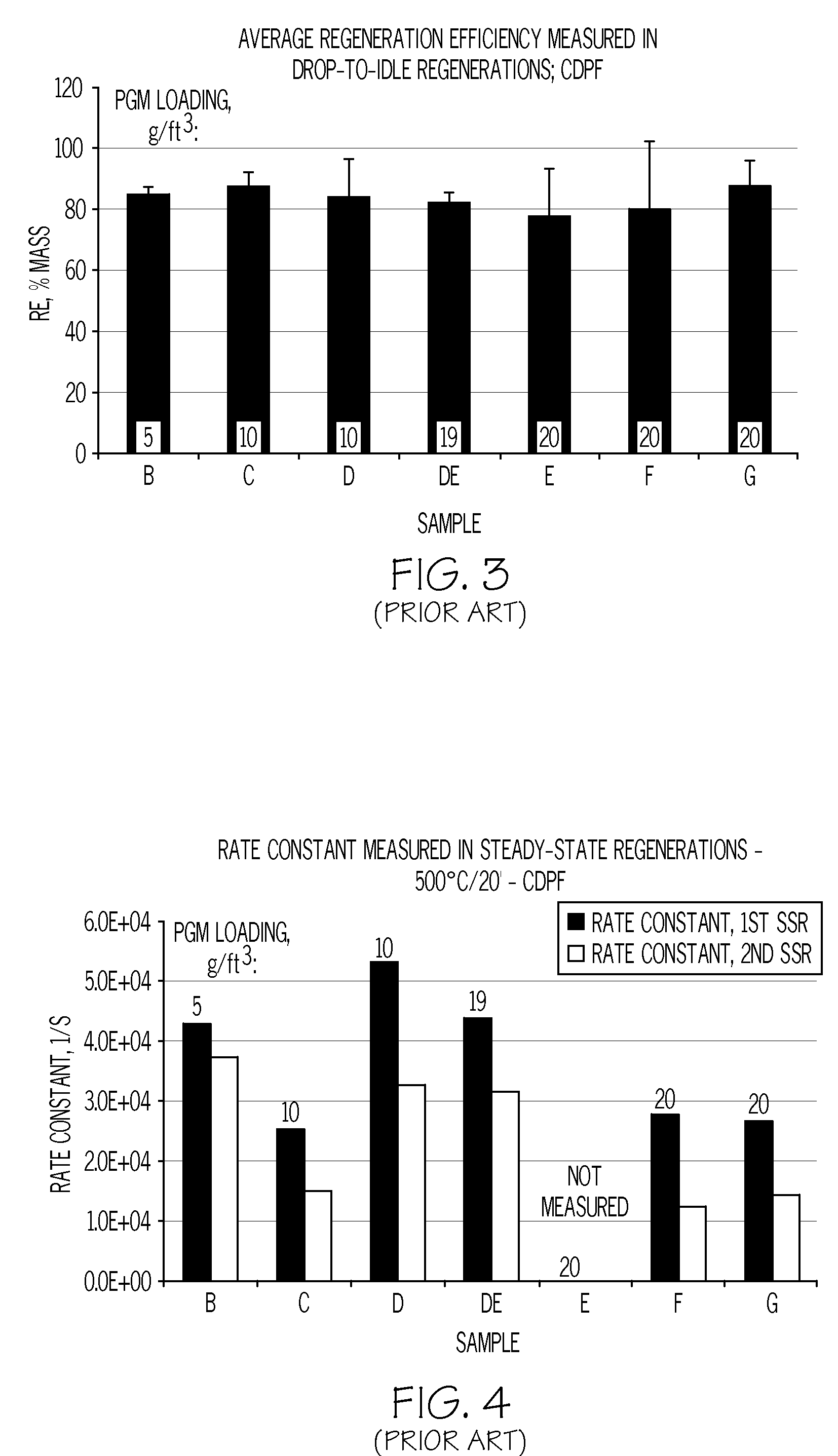

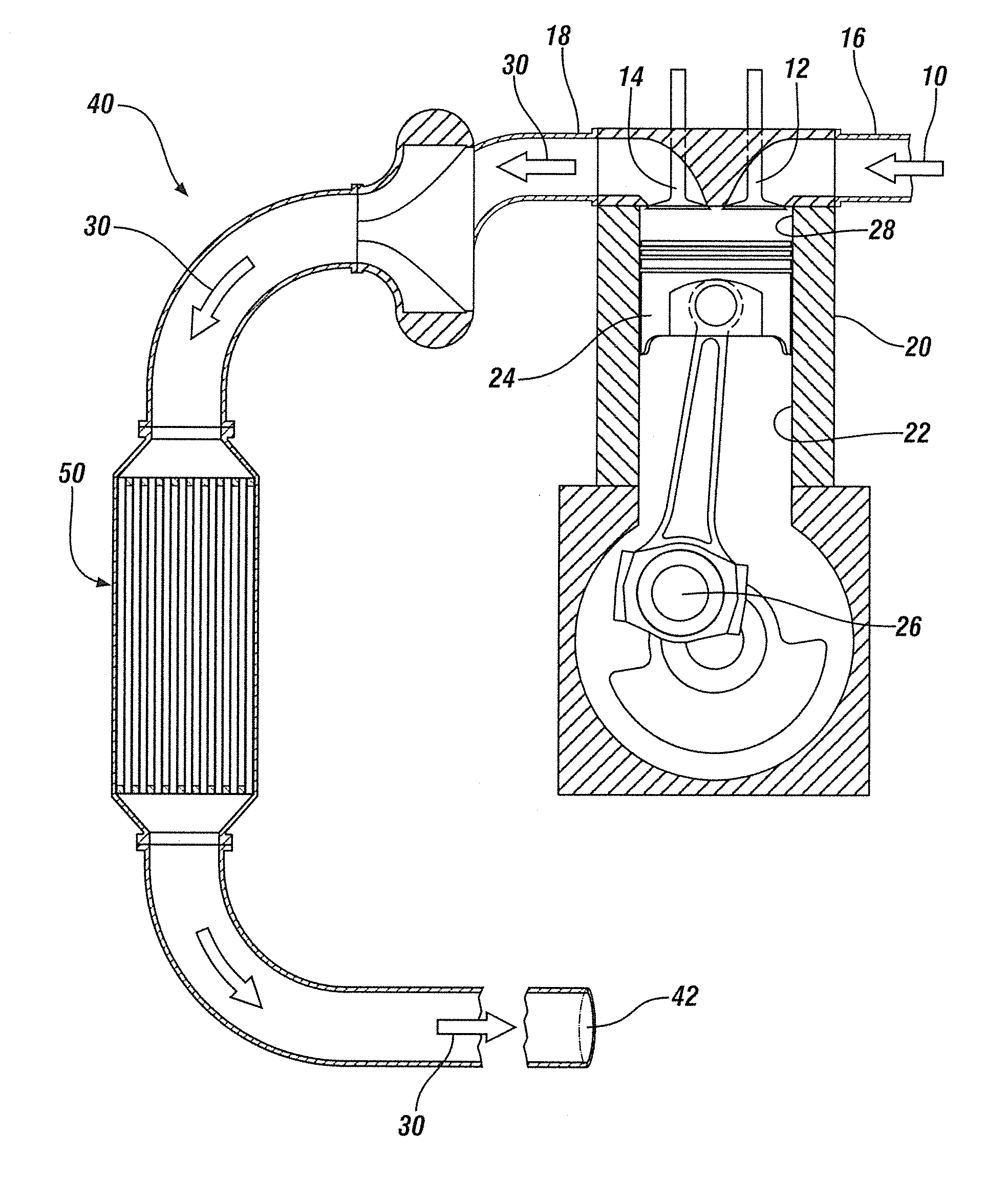

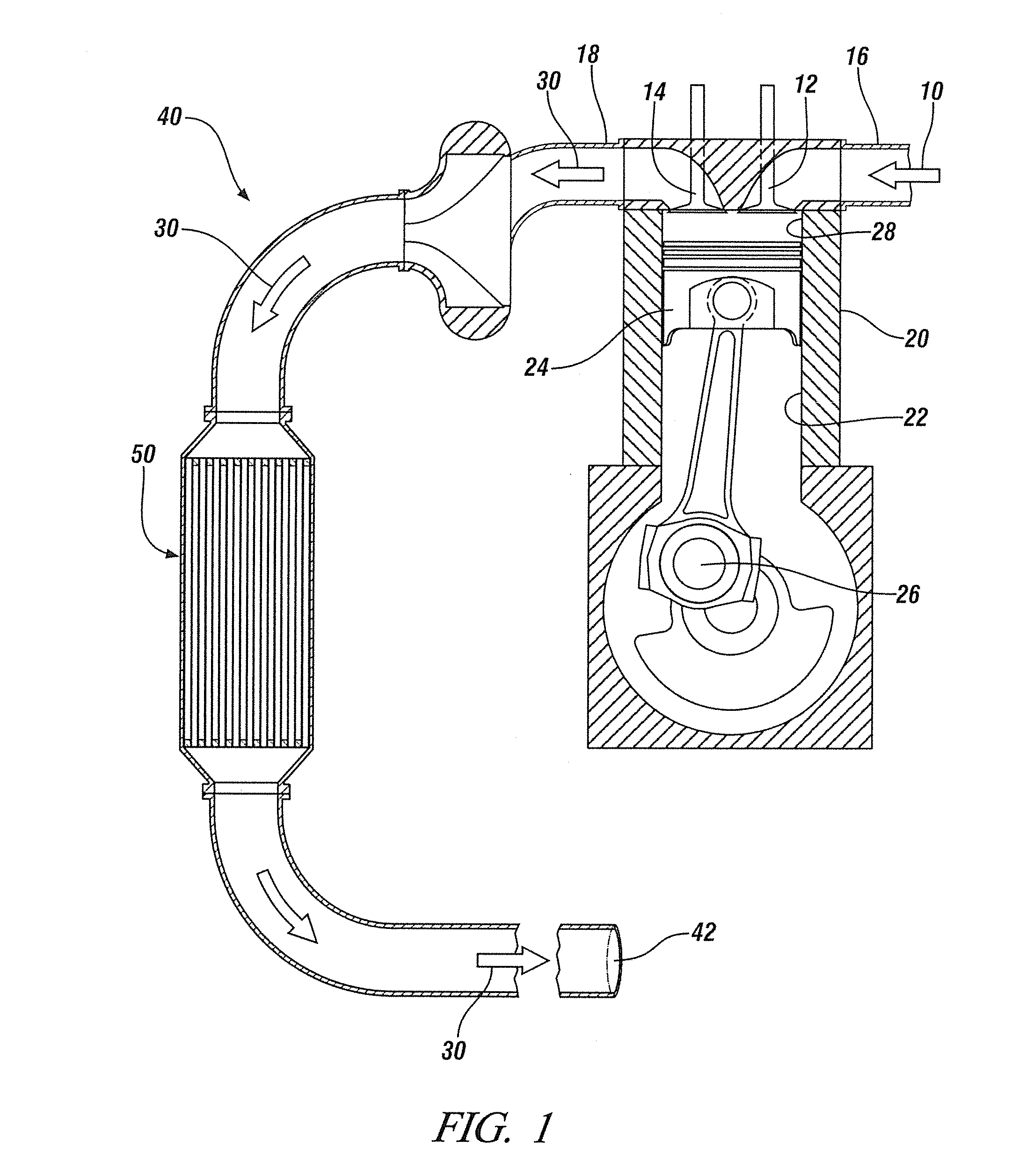

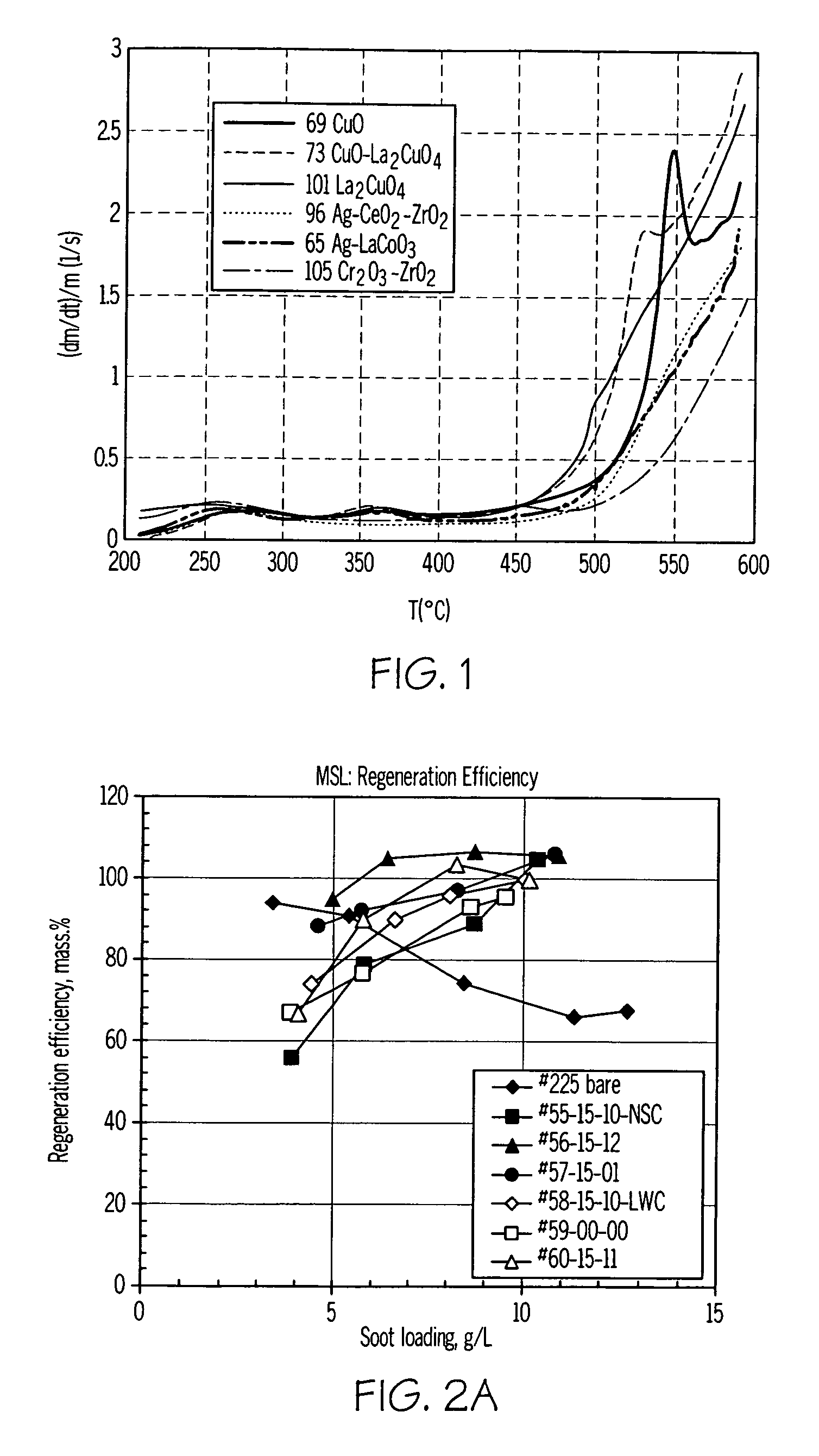

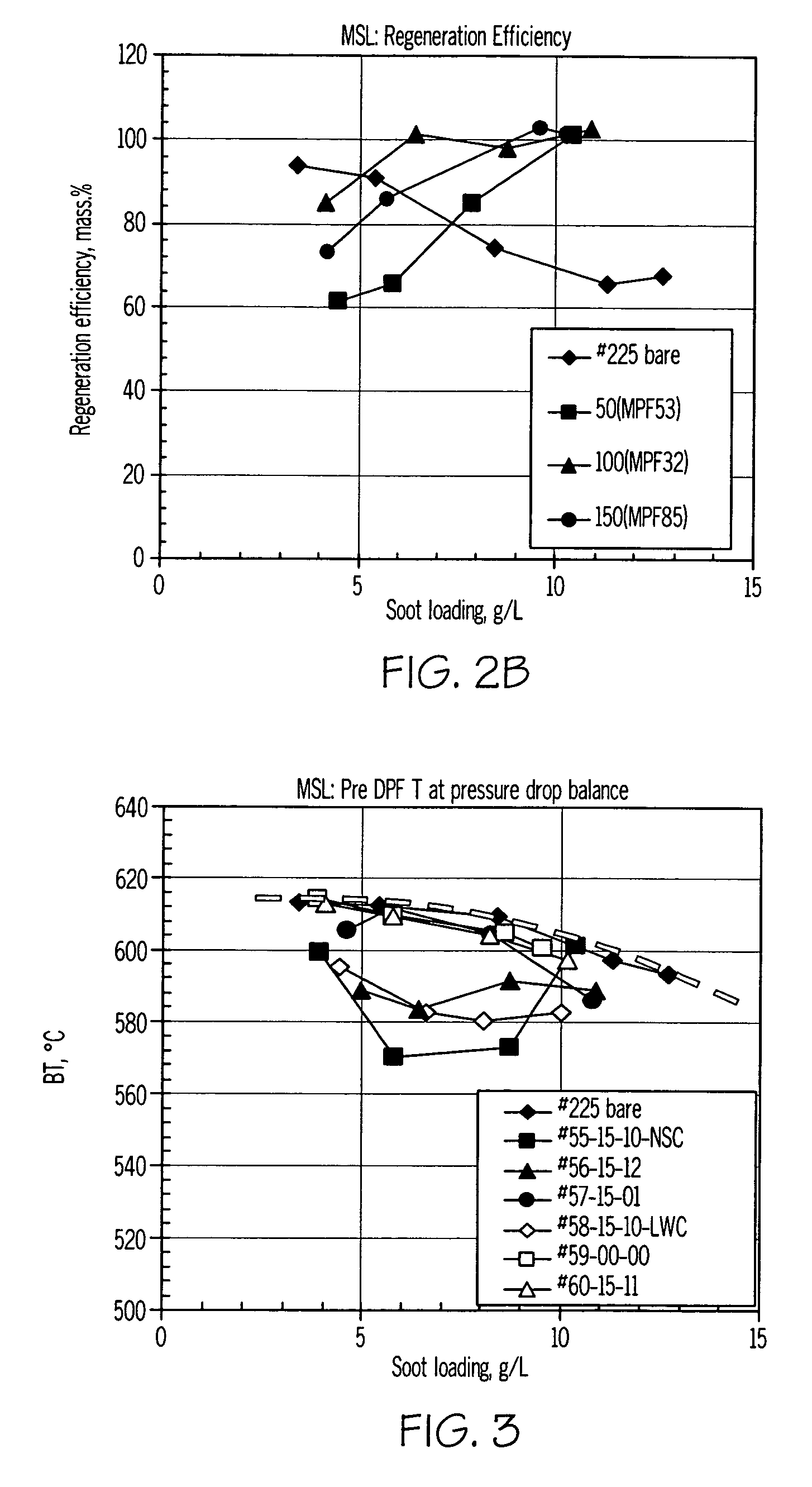

Catalyst composition for diesel particulate filter

InactiveUS7797931B2Efficiently oxidizedReduce decreaseOrganic chemistryNitrogen compoundsGlycerolCatalytic metal

A catalyst composition is provided for use on a diesel particulate filter which facilitates the oxidation of soot from diesel engine exhaust and which generates low NO2 emissions during regeneration of the filter. The catalyst composition includes a catalytic metal comprising a platinum group metal selected from Pt, Pd, Pt—Pd, or combinations thereof, an active metal oxide component containing Cu and La; and an oxide component selected from oxides of Co, Fe, or combinations thereof. The catalyst composition includes a support selected from alumina, silica, zirconia, or combinations thereof. The catalyst composition may be provided on a diesel particulate filter by impregnating the filter with an alumina, silica or zirconia sol solution modified with glycerol and / or saccharose, impregnating the filter with a stabilizing solution, and impregnating the filter with a solution containing the catalyst metal precursor(s), the active metal oxide precursor(s) and the Co or Fe oxide(s). The resulting catalyst coated diesel particulate filter provides effective soot oxidation, exhibits good thermal stability, has a high BET surface area, exhibits minimal backpressure, and produces low NO2 emissions during filter regeneration.

Owner:FORD GLOBAL TECH LLC

Mn, Ce and Zr MIXED OXIDES OXIDATION CATALYST

ActiveUS20120036834A1Great proportionImprove performanceOrganic chemistryMachines/enginesMixed oxideSulfur

The oxidation of nitrogen oxide (NO) in an oxygen-containing exhaust gas flow from a diesel or other lean-burn engine may be catalyzed using particles of co-precipitated and calcined manganese (Mn), cerium (Ce) and zirconium (Zr) mixed oxides. In preferred embodiments, the molar ratios of Mn, Ce and Zr to the total amount of base metals in the ternary mixed oxide catalyst are in the range of 0.25-0.35, 0.40-0.50 and 0.20-0.25, respectively. Further, this ternary mixed oxide catalyst is less susceptible to sulfur poisoning than previously-disclosed binary mixed oxide catalysts. The ternary mixed oxide catalyst may also be regenerated—and the inhibiting effect of SO2 reversed—by briefly exposing the catalyst to a reducing exhaust gas environment.

Owner:GM GLOBAL TECH OPERATIONS LLC

Waste to hydrogen conversion process and related apparatus

InactiveUS20130026032A1Efficiently reduce steamEfficient decompositionCellsHydrogen separationElectrolysisSilver electrode

A reversible electrochemical system includes a first electrode comprising liquid silver metal and a second electrode, said first and second electrodes separated by a oxygen ion-conducting solid electrolyte; a conduit for directing a first reactive material across the second electrode; and a conduit for contacting second reactive material with the first liquid silver electrode, wherein the cell is capable of steam electrolysis when the polarity of the electrodes is selected such that the liquid silver is an anode and the cell is capable of electrical energy generation when the polarity of the electrodes is selected such that the liquid silver is a cathode.

Owner:TRUSTEES OF BOSTON UNIV

Soot oxidation catalyst and method of making

InactiveUS7771669B2Efficiently oxidizedPrevent materialCombination devicesNitrogen compoundsGlycerolCatalytic metal

A catalyst composition for facilitating the oxidation of soot from diesel engine exhaust is provided. The catalyst composition includes a catalytic metal selected from Pt, Pd, Pt—Pd, Ag, or combinations thereof, an active metal oxide component containing Cu and La, and a support selected from alumina, silica, zirconia, or combinations thereof. The platinum group metal loading of the composition is less than about 20 g / ft3. The catalyst composition may be provided on a diesel particulate filter by impregnating the filter with an alumina, silica or zirconia sol solution modified with glycerol and / or saccharose, impregnating the filter with a stabilizing solution, and impregnating the filter with a solution containing the active metal oxide precursor(s) and the catalytic metal precursor(s). The resulting catalyst coated diesel particulate filter provides effective soot oxidation, exhibits good thermal stability, has a high BET surface area, and exhibits minimal backpressure.

Owner:FORD GLOBAL TECH LLC

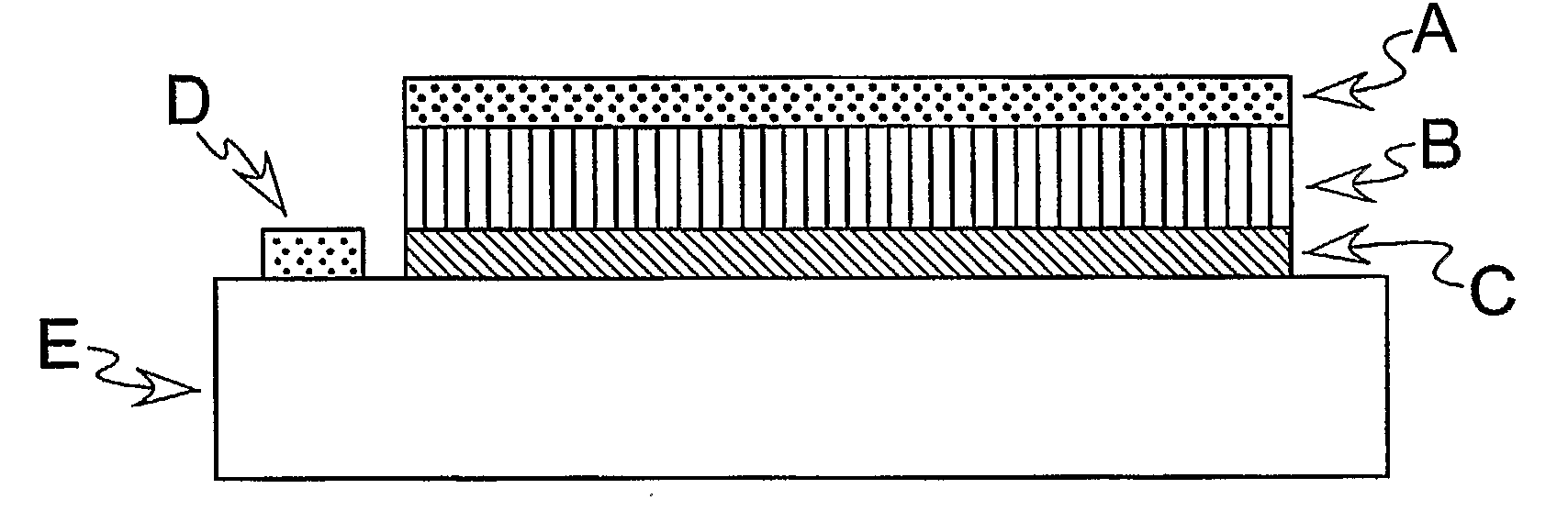

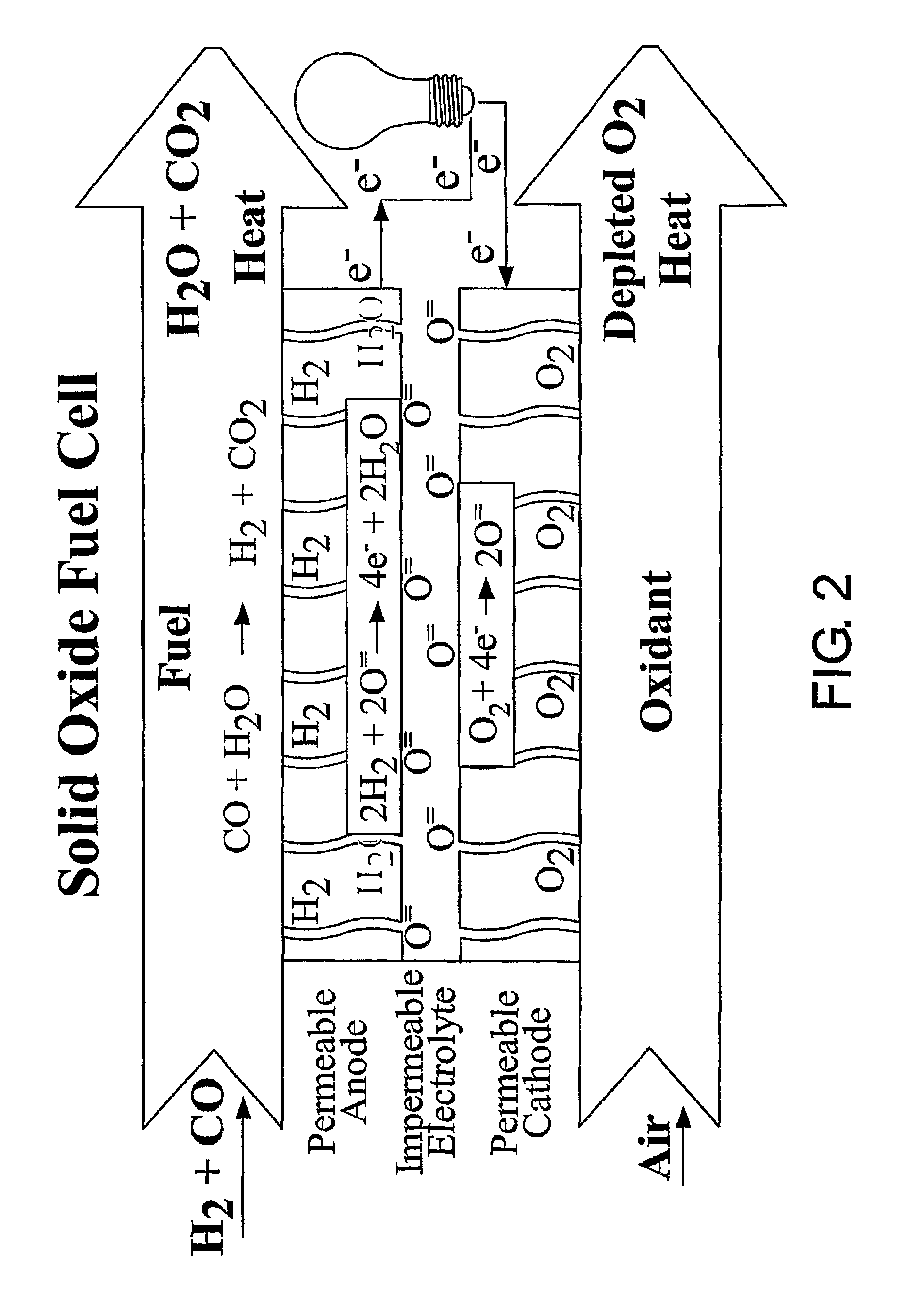

Sulphur-Tolerant Anode For Solid Oxide Fuel Cell

InactiveUS20080138669A1Efficiently oxidizedHigh densityFuel cell auxillariesNegative electrodesStrontium titanateLanthanum

An anode for a solid oxide fuel cell. The anode is not harmed by sulfur-containing compounds, nor is its resistance increased thereby. The anode has two layers, including a “protective” layer (A) and a layer (B) that oxidizes molecular hydrogen The protective layer has a diffusion rate for molecular hydrogen that exceeds its diffusion rate for sulfur-containing compounds, and has an oxidation rate for sulfur-containing compounds that exceeds its oxidation rate for molecular hydrogen. The first anode layer can be selected fro the group of Lanthanum Strontium Titanate (LST) and Lanthanum Strontium Vanadate (LSV), and the second anode layer is made of Gadolinium Doped Cerium oxide (GDC) and nickel. The first layer can include Yttria Stabilized Ziroonia (YSZ), and the second layer can include YSZ interspersed throughout the layer as a separate phase.

Owner:OHIO UNIV

Method for Controlling Nox Emissions in the Fccu

InactiveUS20080213150A1Increase productionEfficiently oxidizedThermal non-catalytic crackingCatalytic crackingMolecular nitrogenHeterogeneous Combustion

Processes for the reduction of NOx emissions from a regeneration zone during a fluid catalytic cracking of a hydrocarbon feedstock into lower molecular weight components are disclosed. The processes comprise contacting during a fluid catalytic cracking (FCC) process where NOx emissions are released from a regeneration zone of a fluid catalytic cracking unit (FCCU) operating in a heterogeneous combustion mode under FCC conditions, a hydrocarbon feedstock with a circulating inventory of a FCC cracking catalyst and a NOx reduction composition. The NOx reduction composition comprises: (1) at least one reduced nitrogen species component having the ability to reduce the content of reduced nitrogen species to molecular nitrogen under reducing or partial burn FCC conditions and (2) at least one NOx reduction component having the ability to convert NOx to molecular nitrogen under oxidizing or full burn FCC conditions. The reduced nitrogen species and the NOx reduction components do not significantly increase the content of reduced nitrogen species or NOx under any mode of combustion during a FCC process.

Owner:WR GRACE & CO CONN

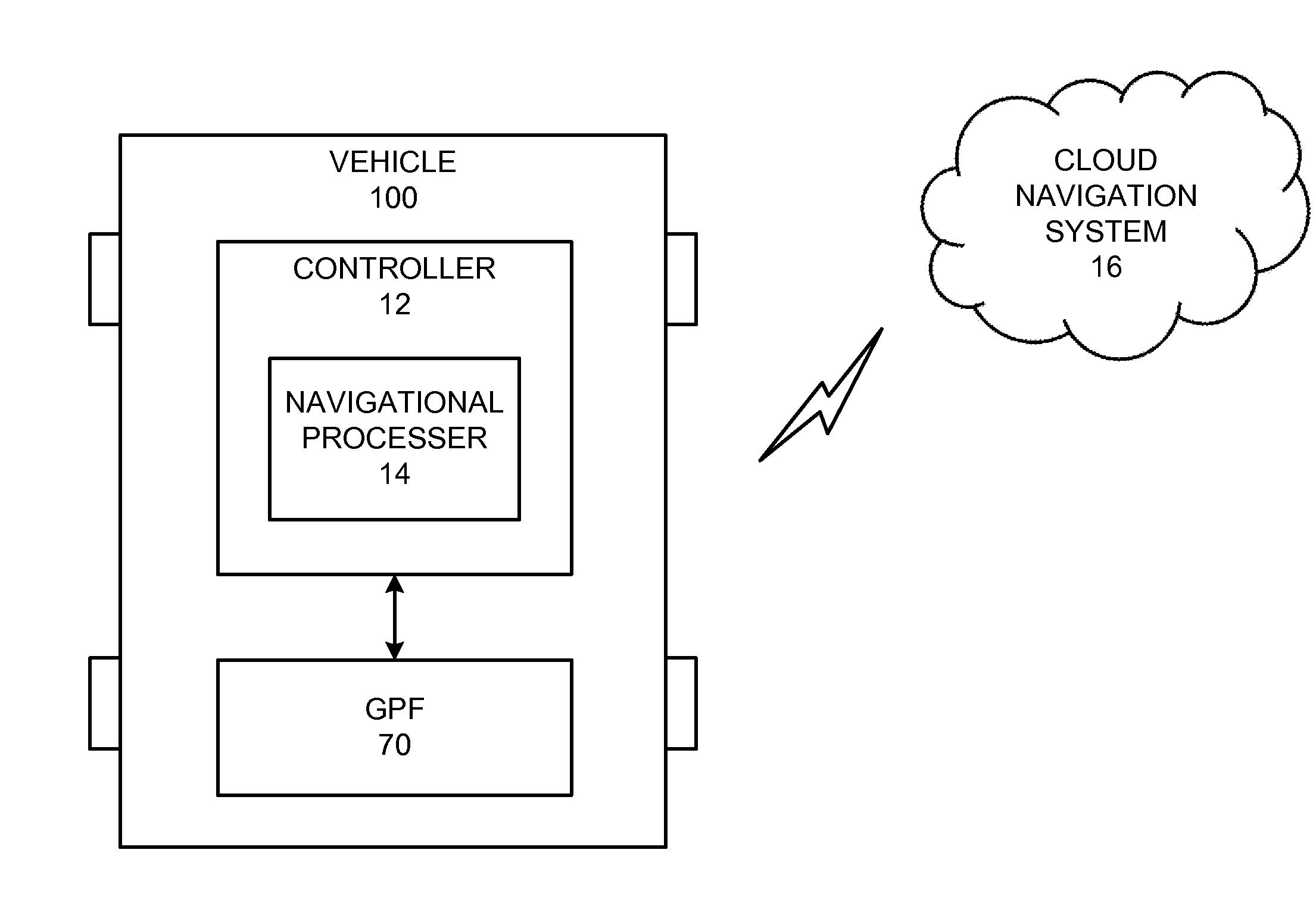

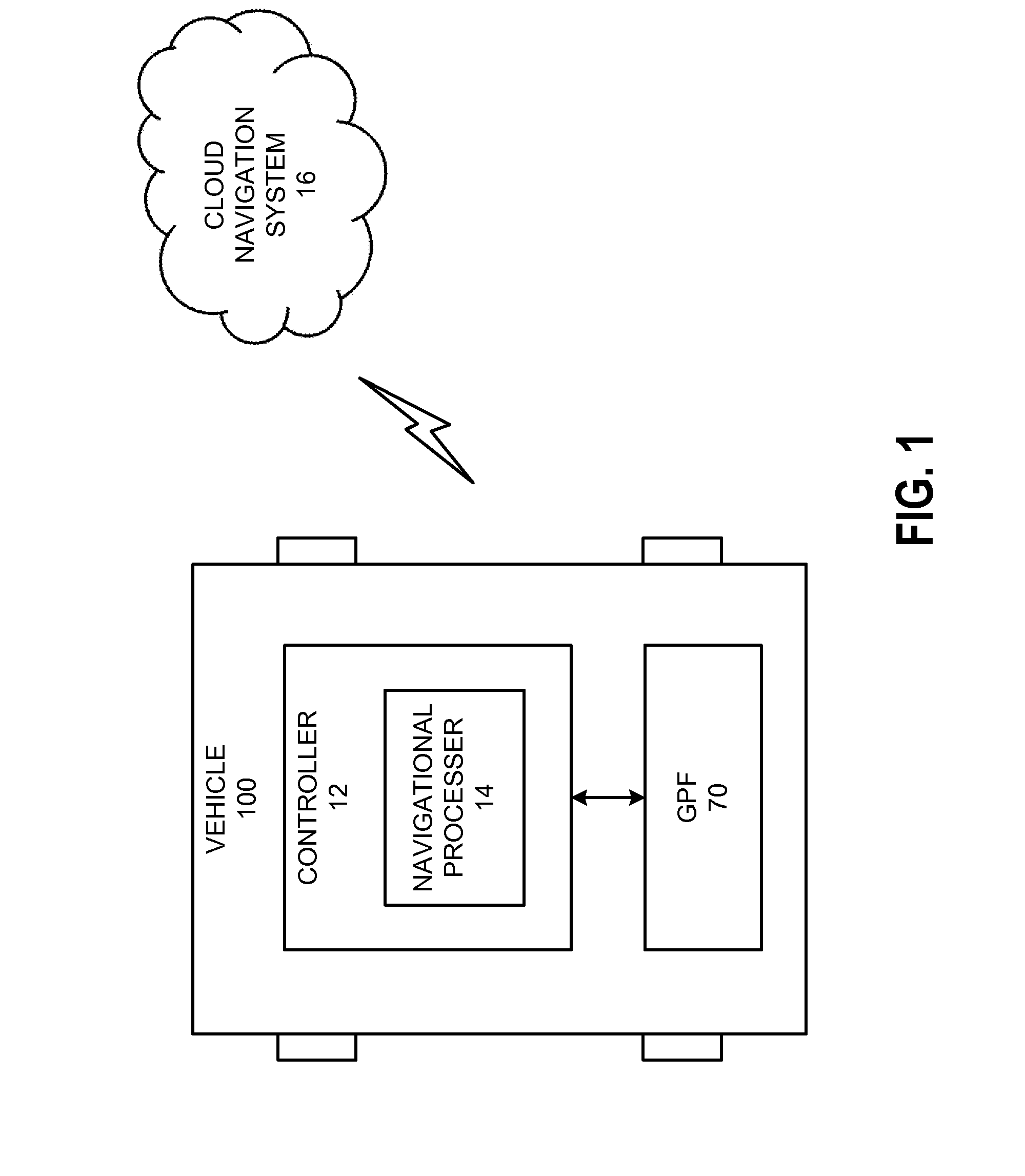

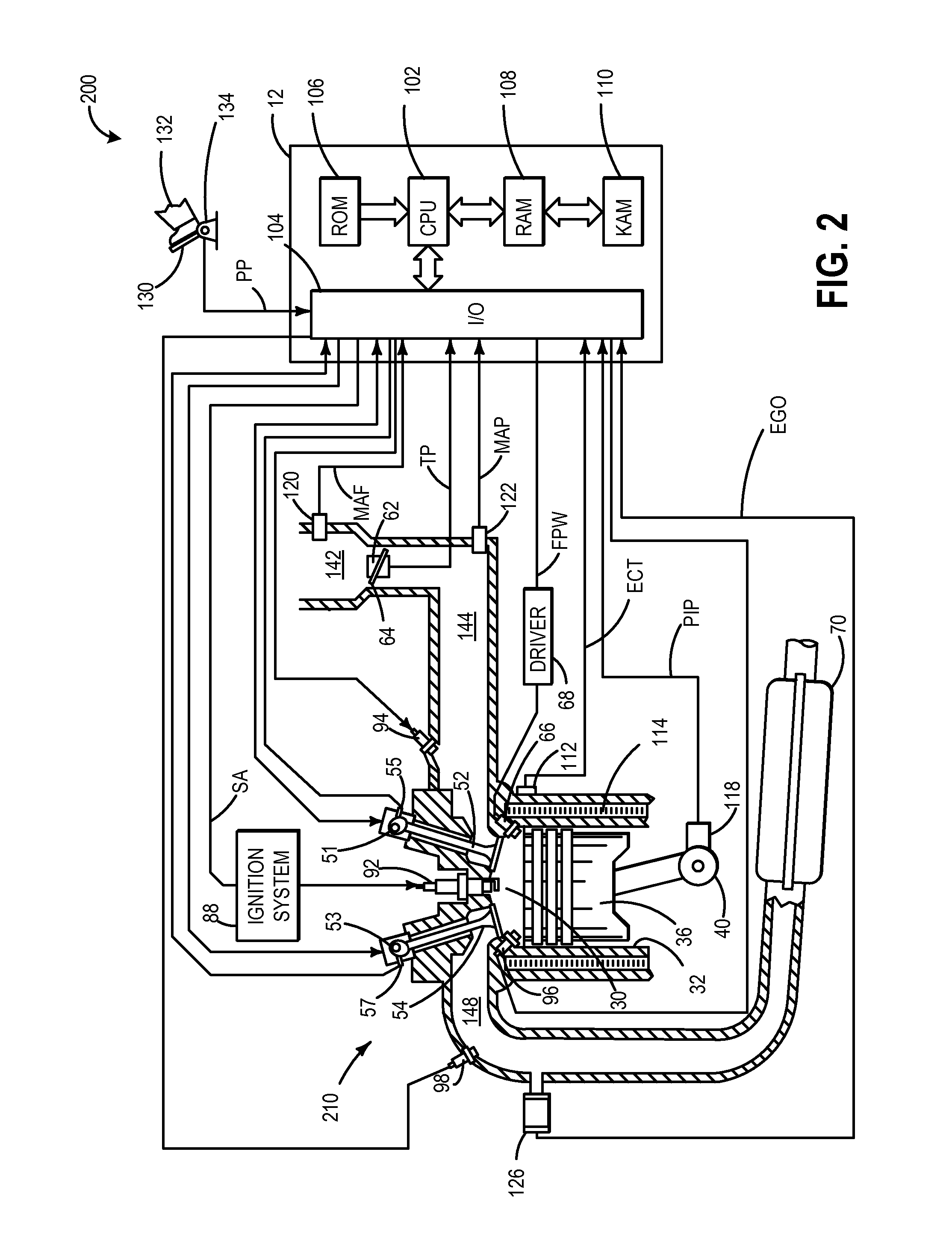

Idle speed gpf regeneration

ActiveUS20160201532A1Reduces soot loadPrevent releaseElectrical controlInternal combustion piston enginesMicro particlesElectrical and Electronics engineering

Systems and methods are described for coordinating the regeneration of a gasoline particulate filter to a time duration when engine output falls below a predetermined load threshold selected to indicate a low power state of the engine. In one particular example, the engine is configured to adjust engine operations to regenerate the particulate filter responsive to engine output falling below a predetermined low power threshold, the regeneration further based on an estimated duration that the output falls continuously below the low power threshold. The system and methods described advantageously allow for either full or partial regeneration events to be performed based on the estimated duration of the engine output below the low power threshold.

Owner:FORD GLOBAL TECH LLC

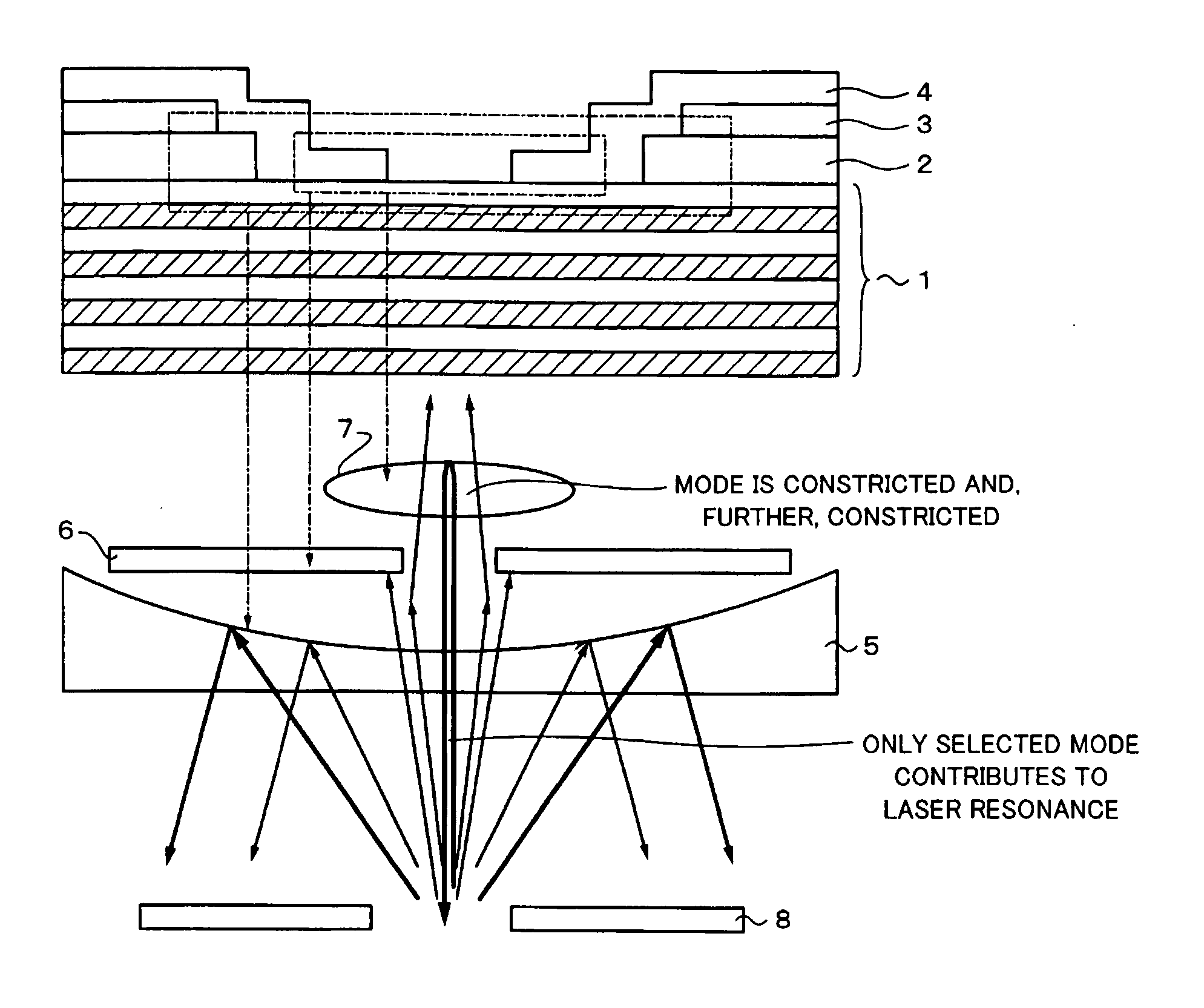

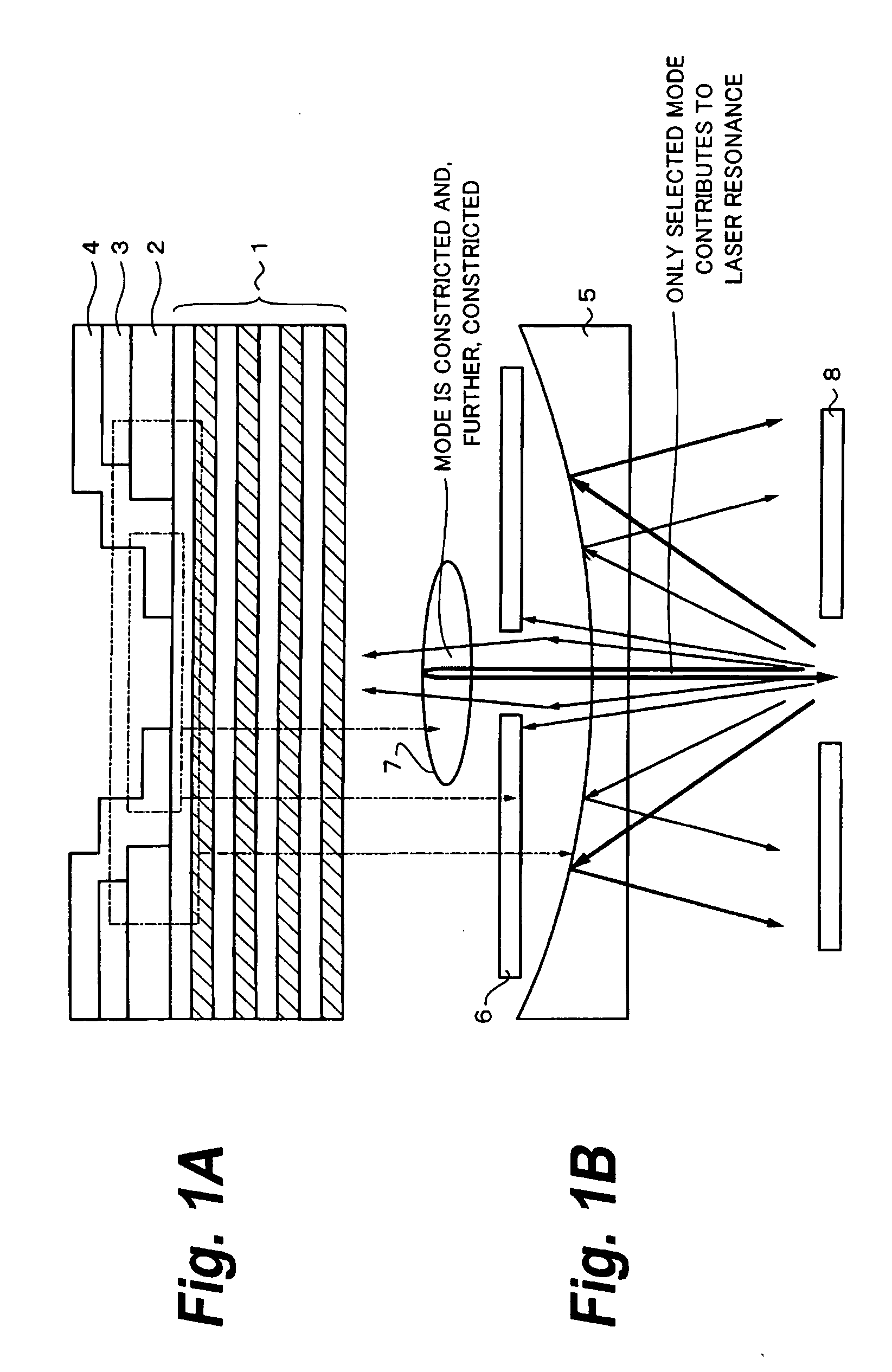

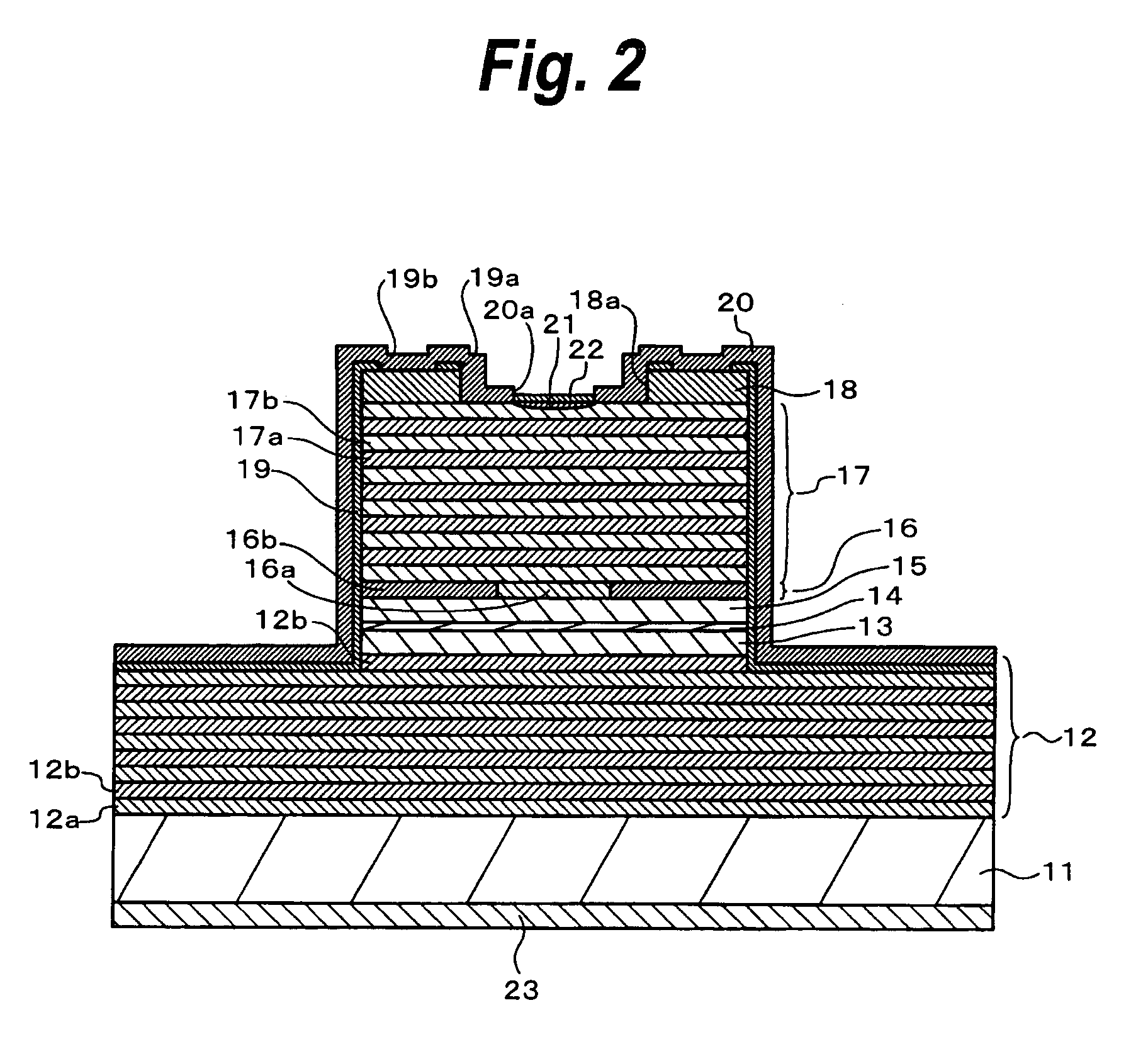

Surface emitting semiconductor laser, its manufacturing method, and manufacturing method of electron device

InactiveUS20050271106A1Reduce current constriction diameterEasy to manufactureOptical wave guidanceLaser optical resonator constructionLight beamElectron

A surface emitting semiconductor laser which can perform laser oscillation in a single peak beam like that in a single lateral mode and a manufacturing method which can easily manufacture such a laser at a high yield are provided. When a surface emitting semiconductor laser having a post type mesa structure is formed on an n-type semiconductor substrate, a mesa portion is formed and up to a p-side electrode and an n-side electrode are formed. Thereafter, a voltage is applied across the p-side and n-side electrodes and the laser is subjected to a steam atmosphere while extracting output light, thereby forming an Al oxide layer onto a p-type AlwGa1-wAs layer as a top layer of a p-type DBR layer and forming refractive index distribution like that of a concave lens.

Owner:SONY CORP

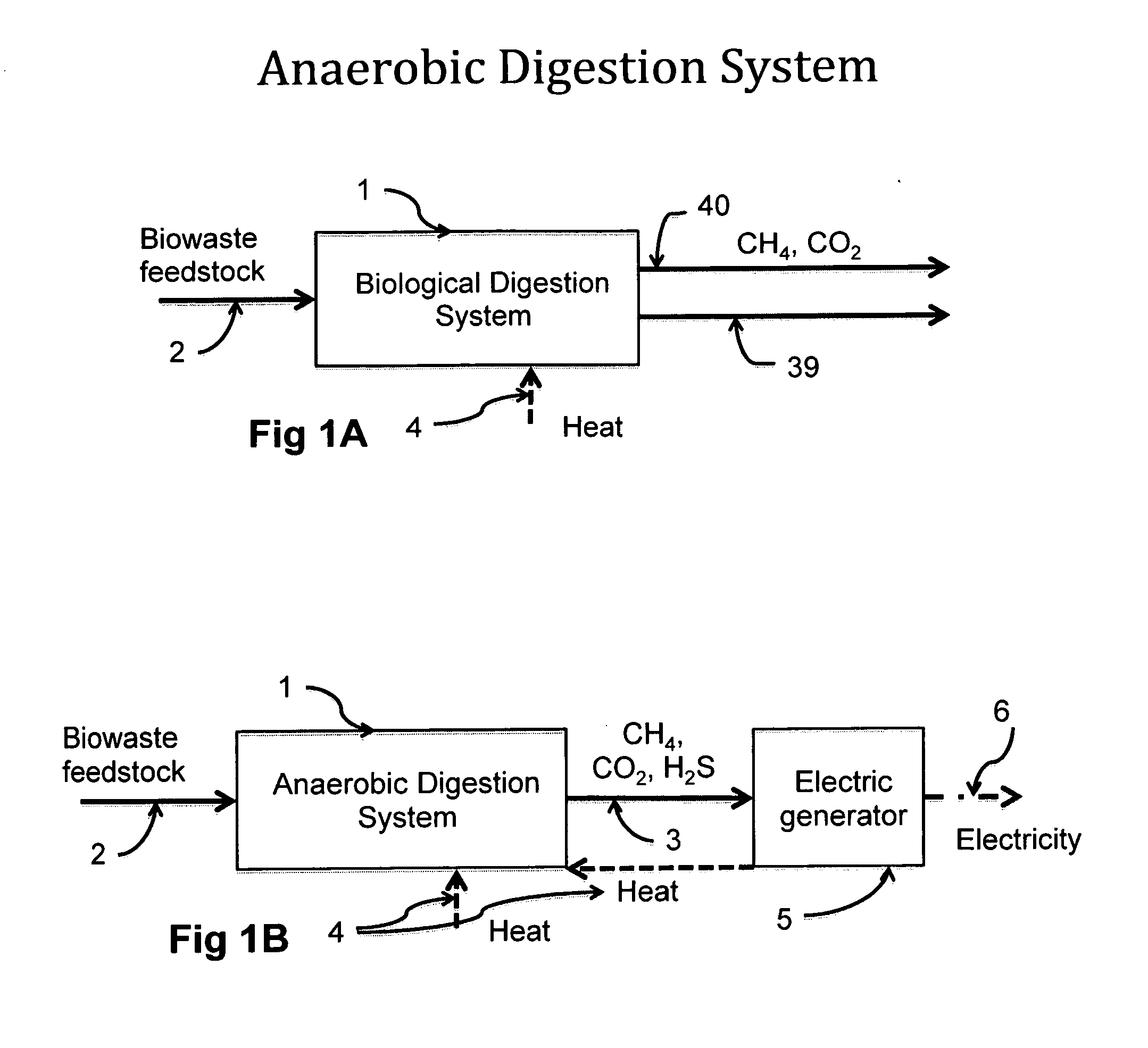

Biological solids processing system and method

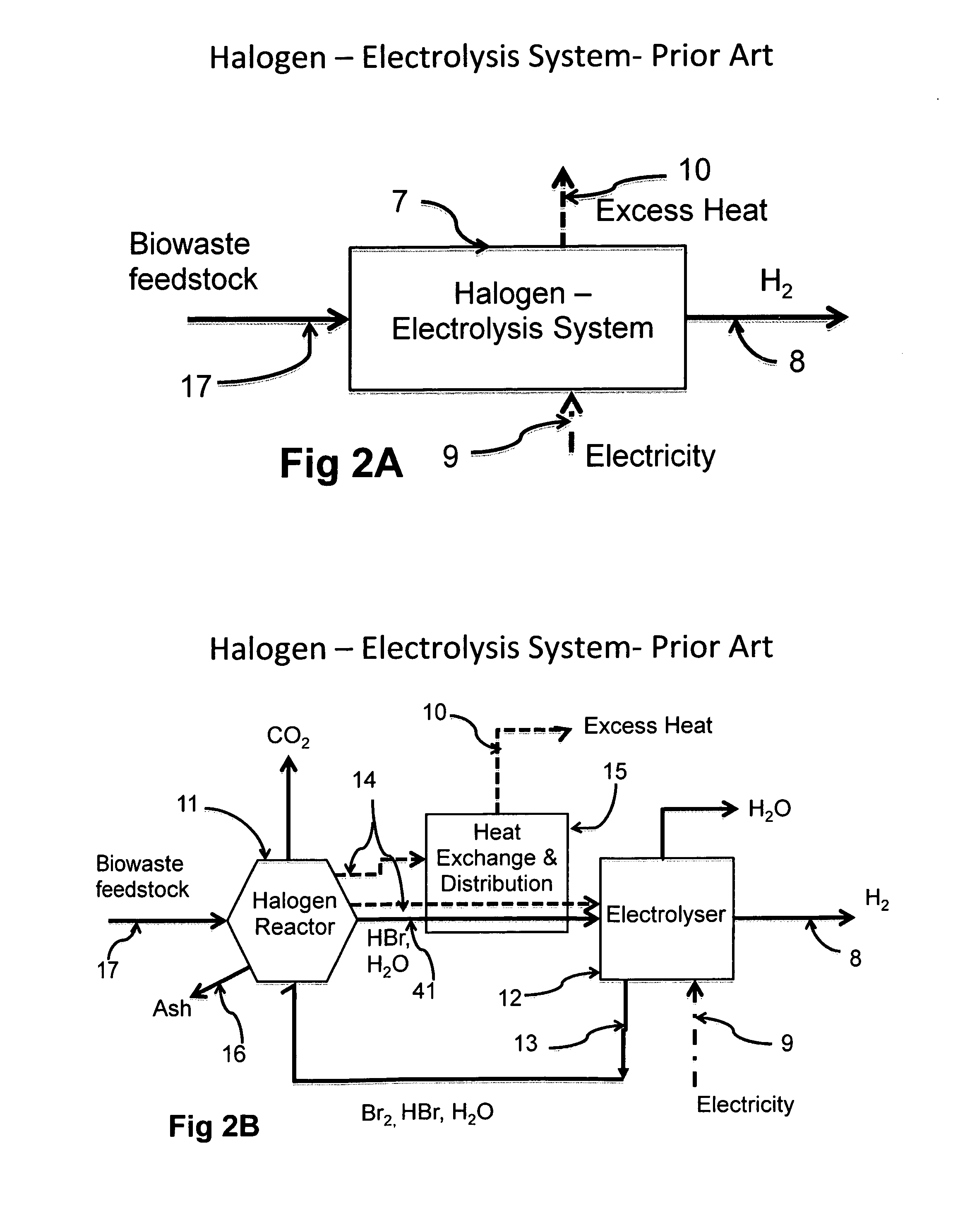

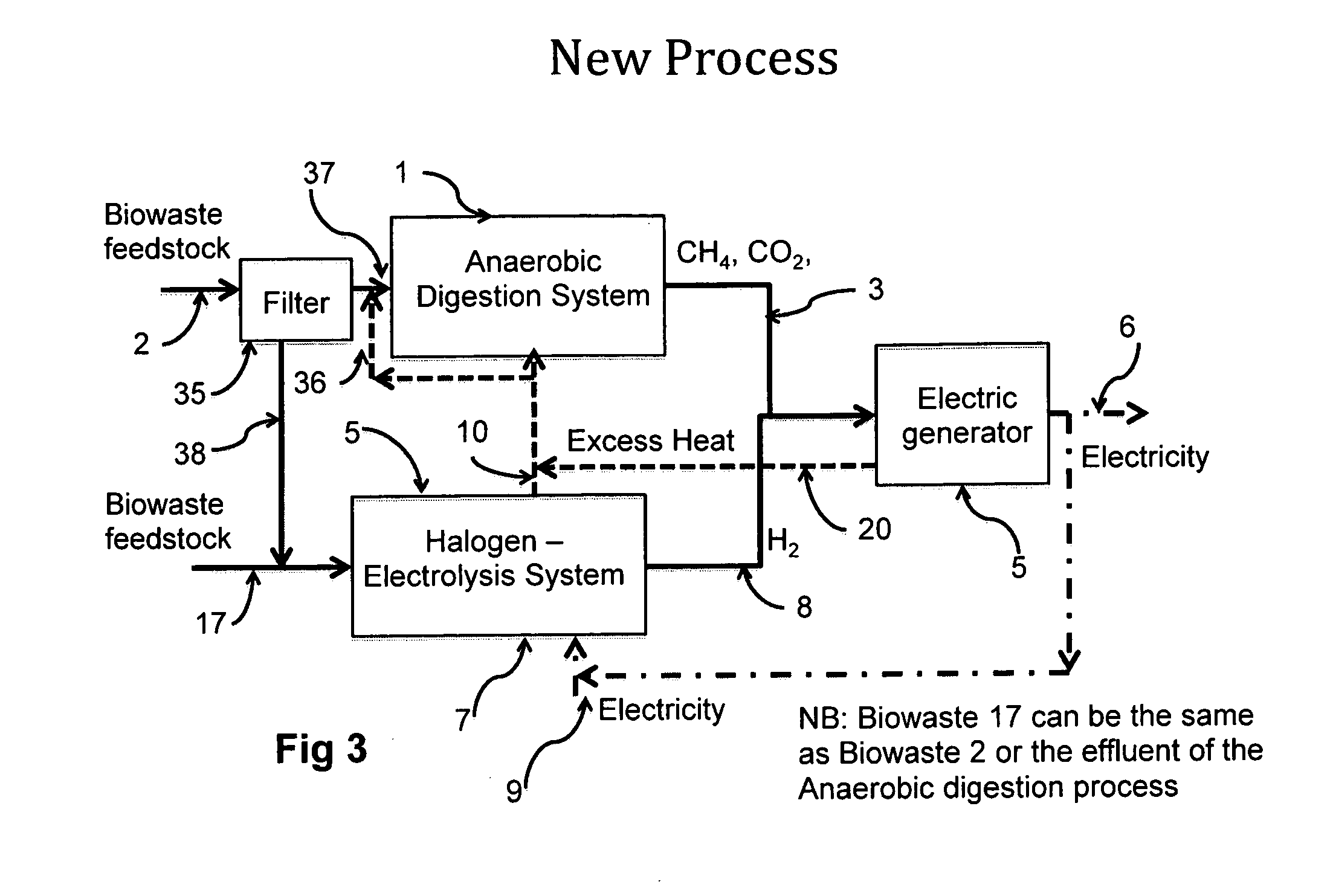

InactiveUS20110020862A1Optimizes energy extractionHigh digestionBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityHalogen

The consumption of organic solids with anaerobic digestion to generate usable gases including methane is made more efficient by maintaining the ideal digestion temperature, which is attained by combining the anaerobic digestion process with a halogen digester which produces heat energy and hydrogen gas. With a given biological feedstock four outputs can be generated (methane, hydrogen, electricity, and heat) in the ratio that makes the most economical sense. The process also provides a significant reduction in volume of output solids. The halogen oxidation process can be used on all the anaerobic digester effluent to extract more energy and oxidize a wet feedstock. If there are solids which are not easily digested with the anaerobic process, these solids can be diverted to the halogen digester to derive more energy from the feedstock. Pathogens common to other anaerobic digester effluents are removed. The mixture of methane and hydrogen gas can be compressed to produce an enriched compressed natural gas (CNG) with a variety of uses.

Owner:KAINOS POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com