Patents

Literature

799 results about "Aqueous alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The volume (density) of the aqueous alcohol solution, as well as any other fluid, is temperature dependent.The density of the solution decreases with increase in temperature (the volume increases), the change is not linear, as well as the behavior of water density with the temperature change.

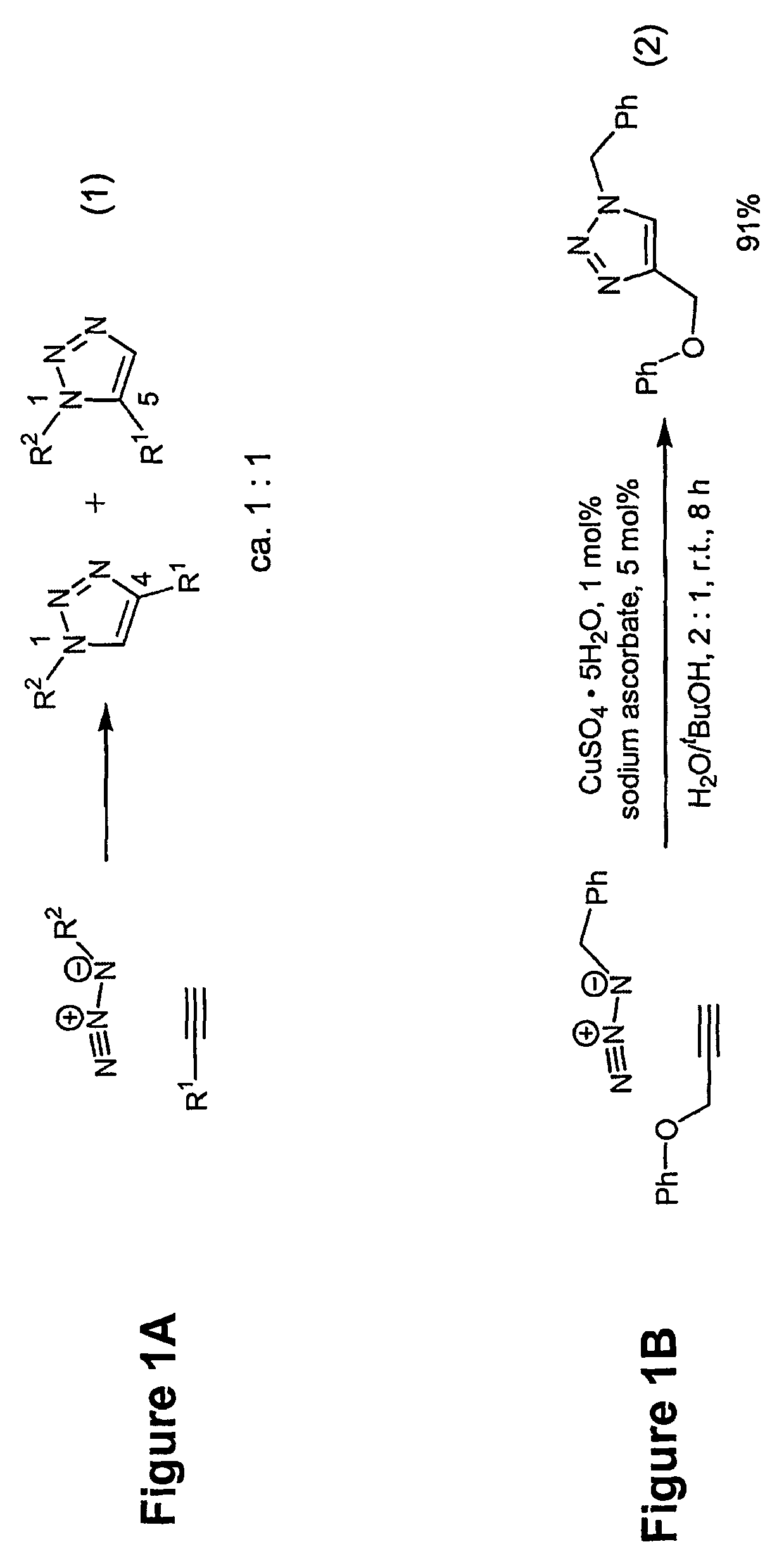

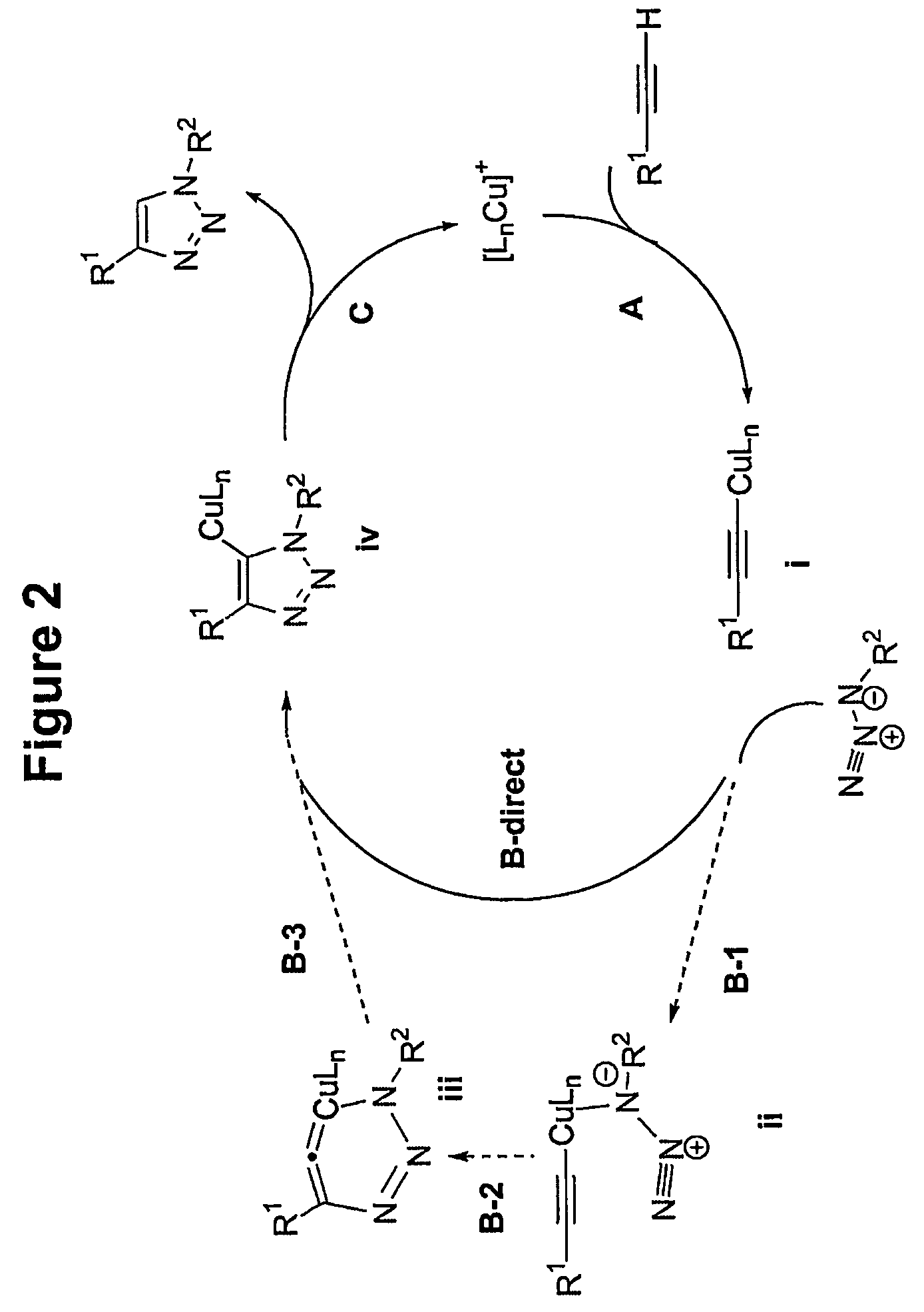

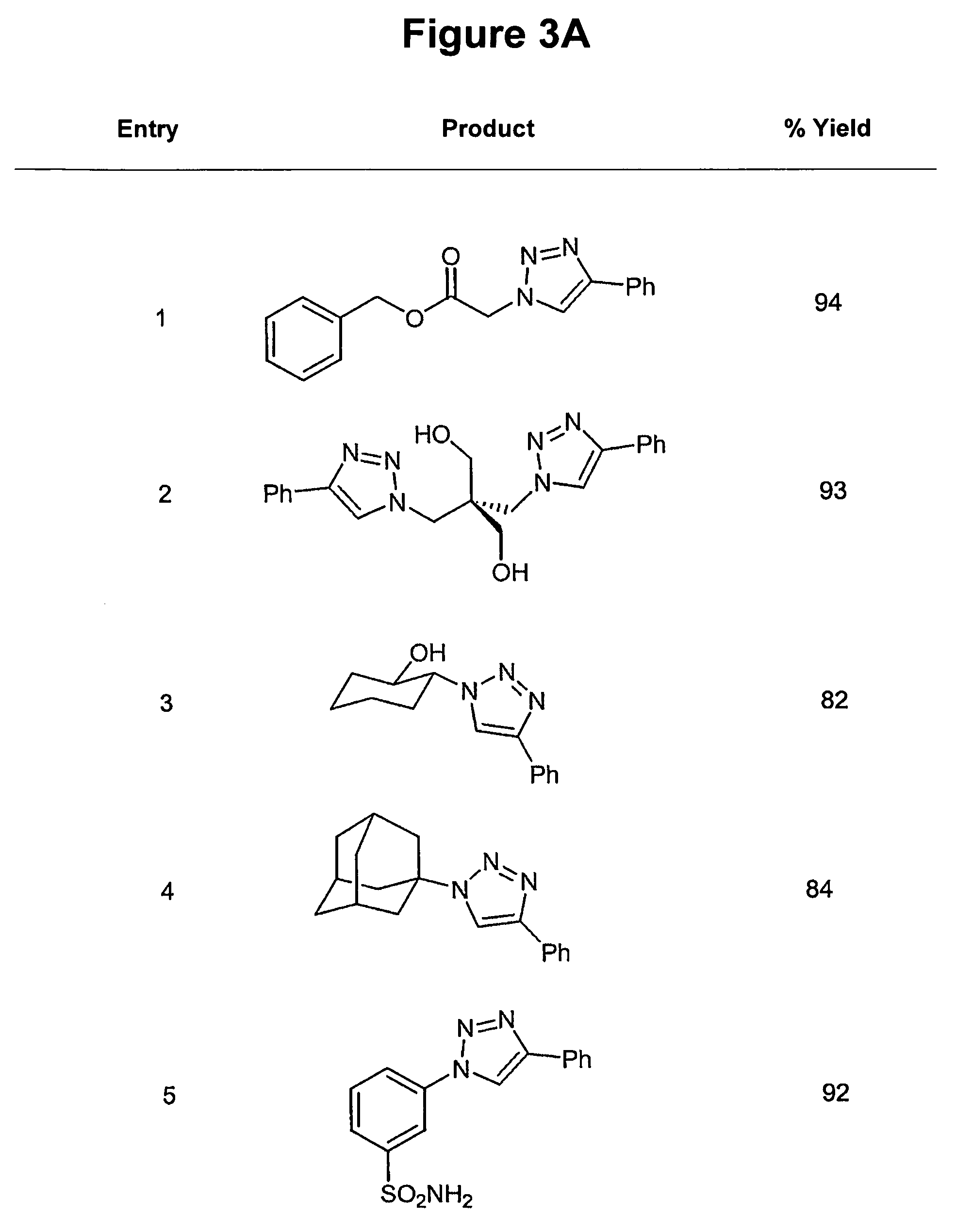

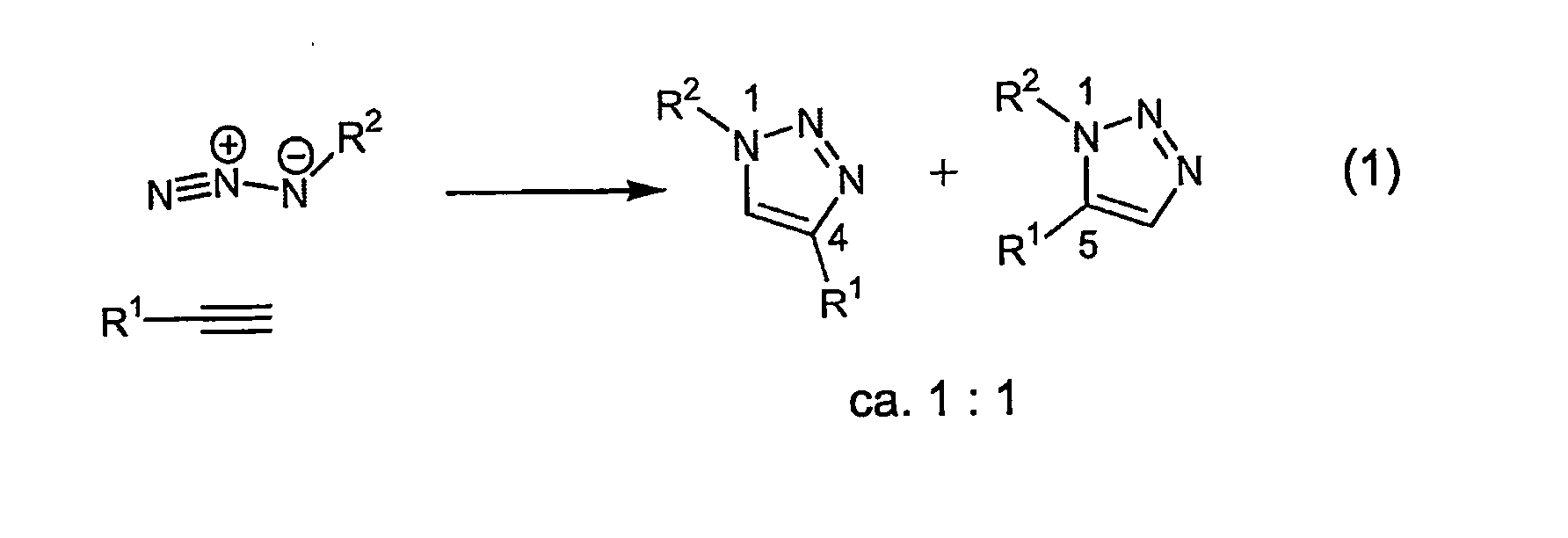

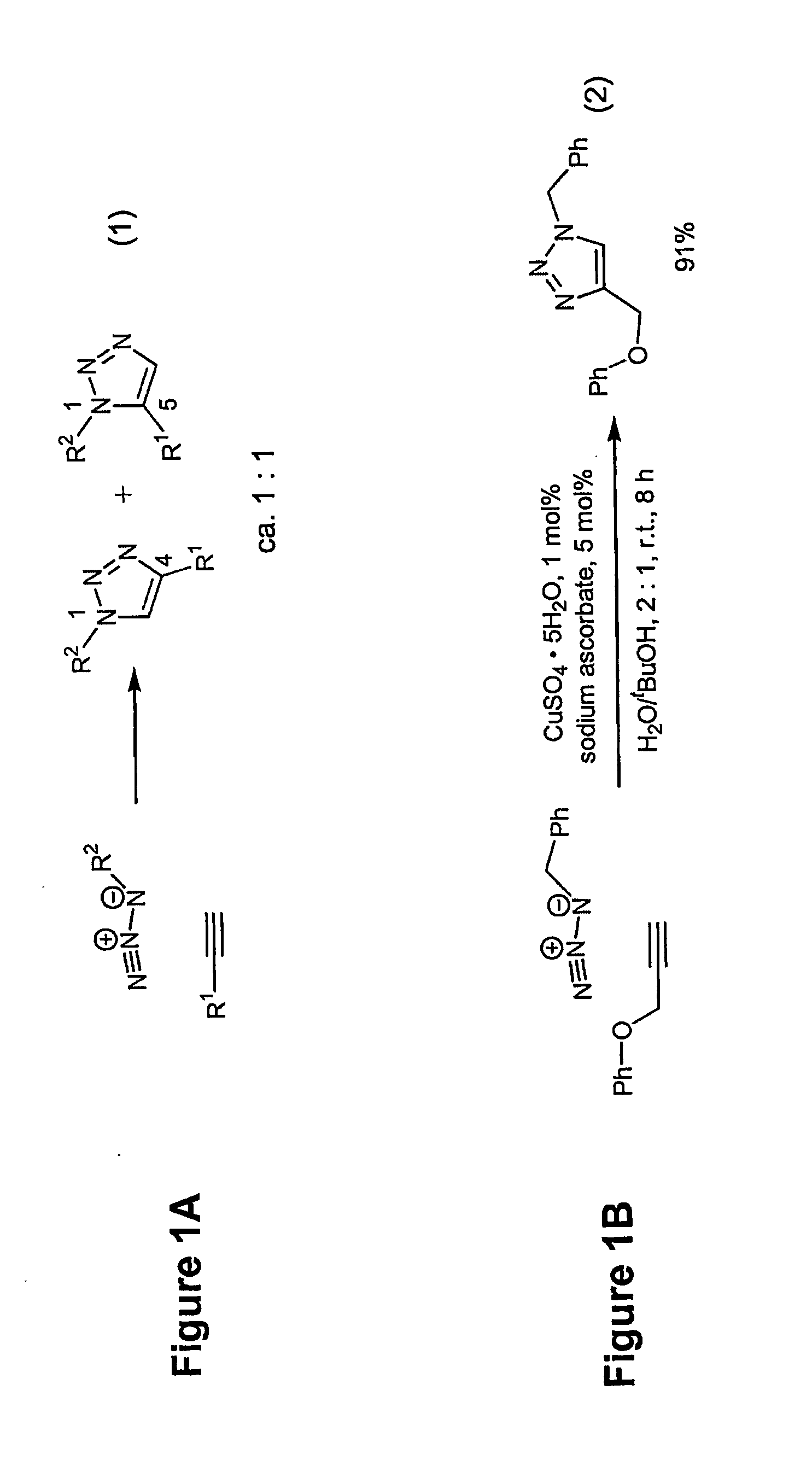

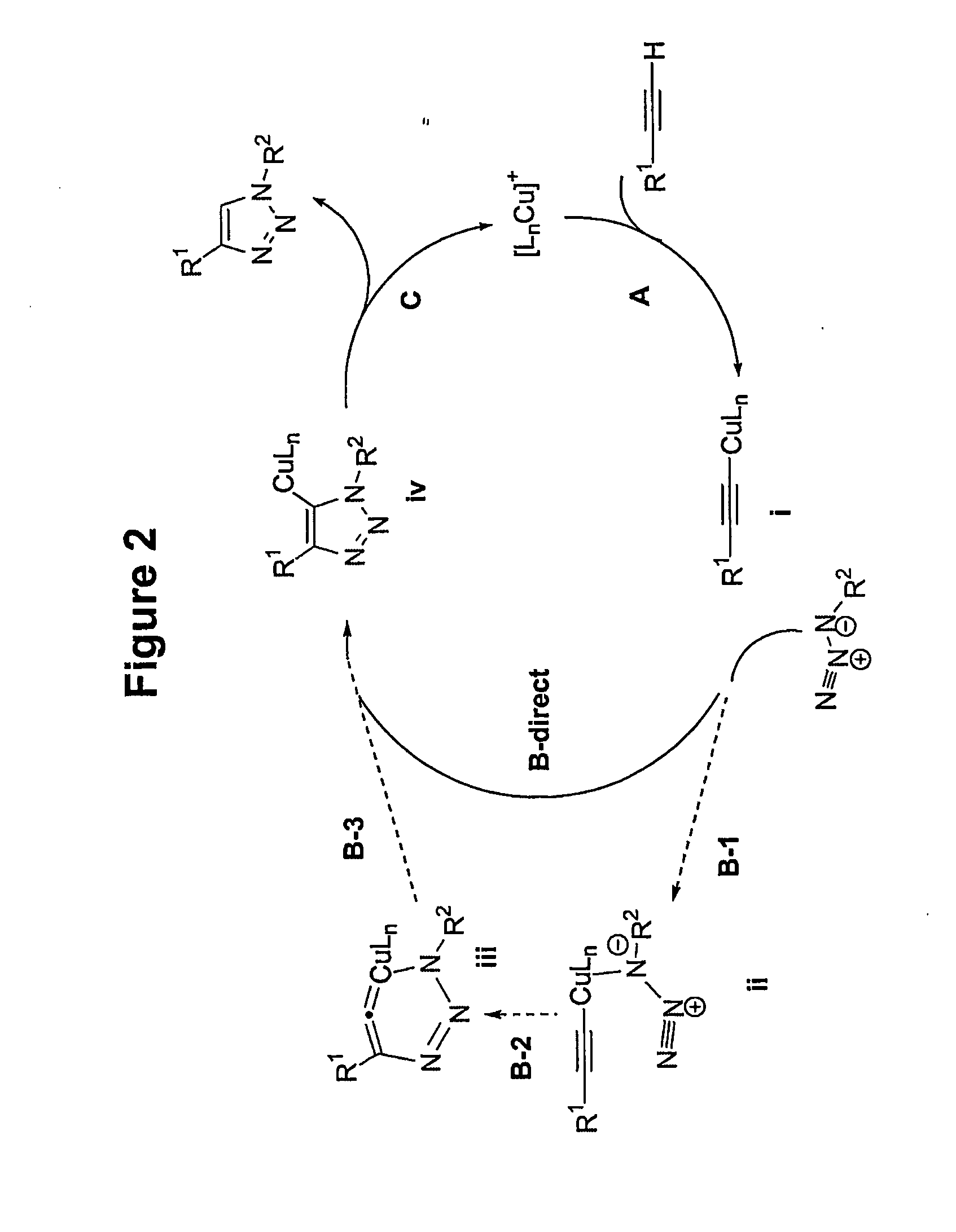

Copper-catalysed ligation of azides and acetylenes

InactiveUS7763736B2Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsChemical ligationAqueous alcohol

A copper catalyzed click chemistry ligation process is employed to bind azides and terminal acetylenes to provide 1,4-disubstituted 1,2,3-triazole triazoles. The process comprises contacting an organic azide and a terminal alkyne with a source of reactive Cu(I) ion for a time sufficient to form by cycloaddition a 1,4-disubstituted 1,2,3-triazole. The source of reactive Cu(I) ion can be, for example, a Cu(I) salt or copper metal. The process is preferably carried out in a solvent, such as an aqueous alcohol. Optionally, the process can be performed in a solvent that comprises a ligand for Cu(I) and an amine.

Owner:TETARD INC

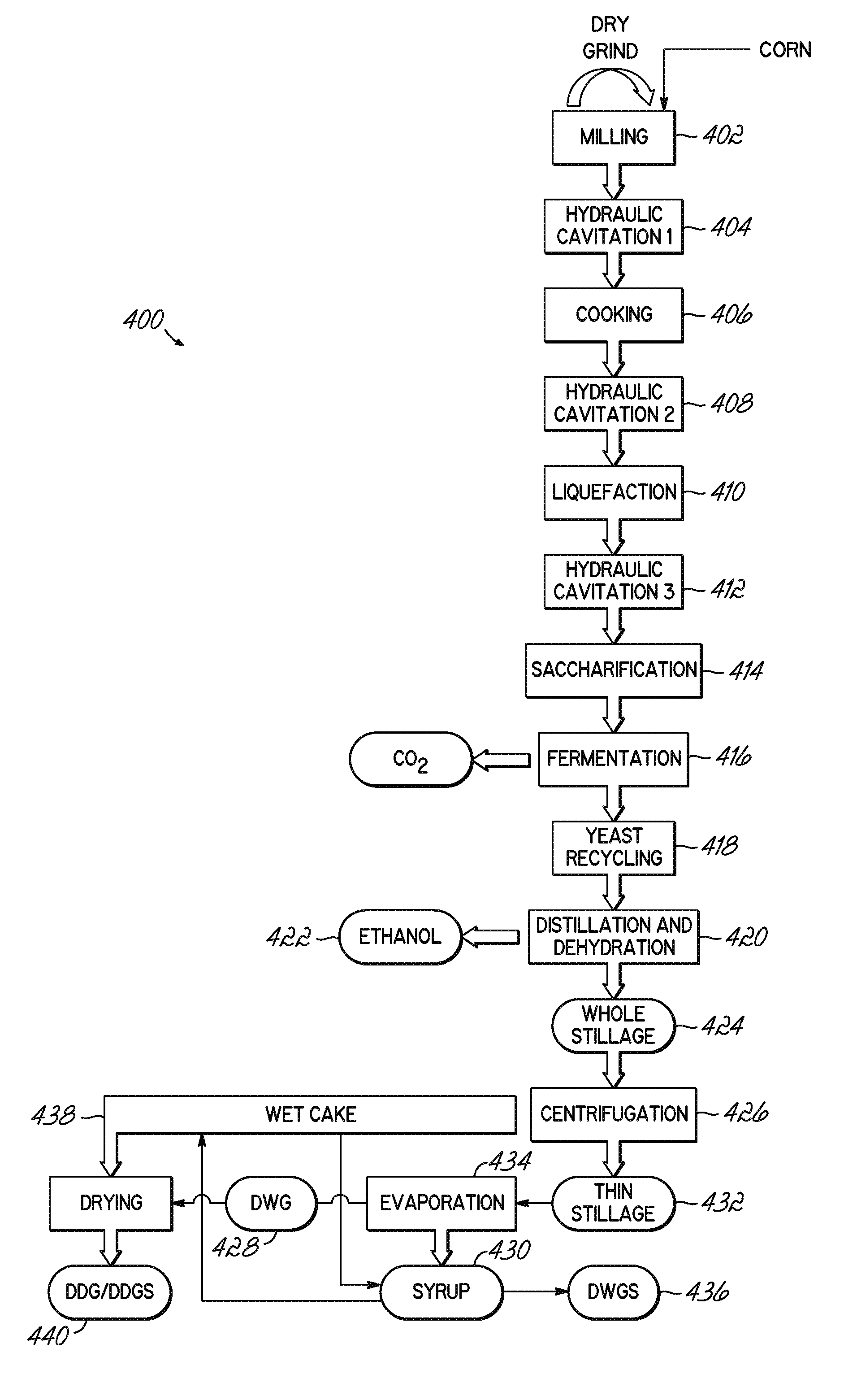

Alcohol production using hydraulic cavitation

InactiveUS20080277264A1Increase speedHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsCavitationLiquid medium

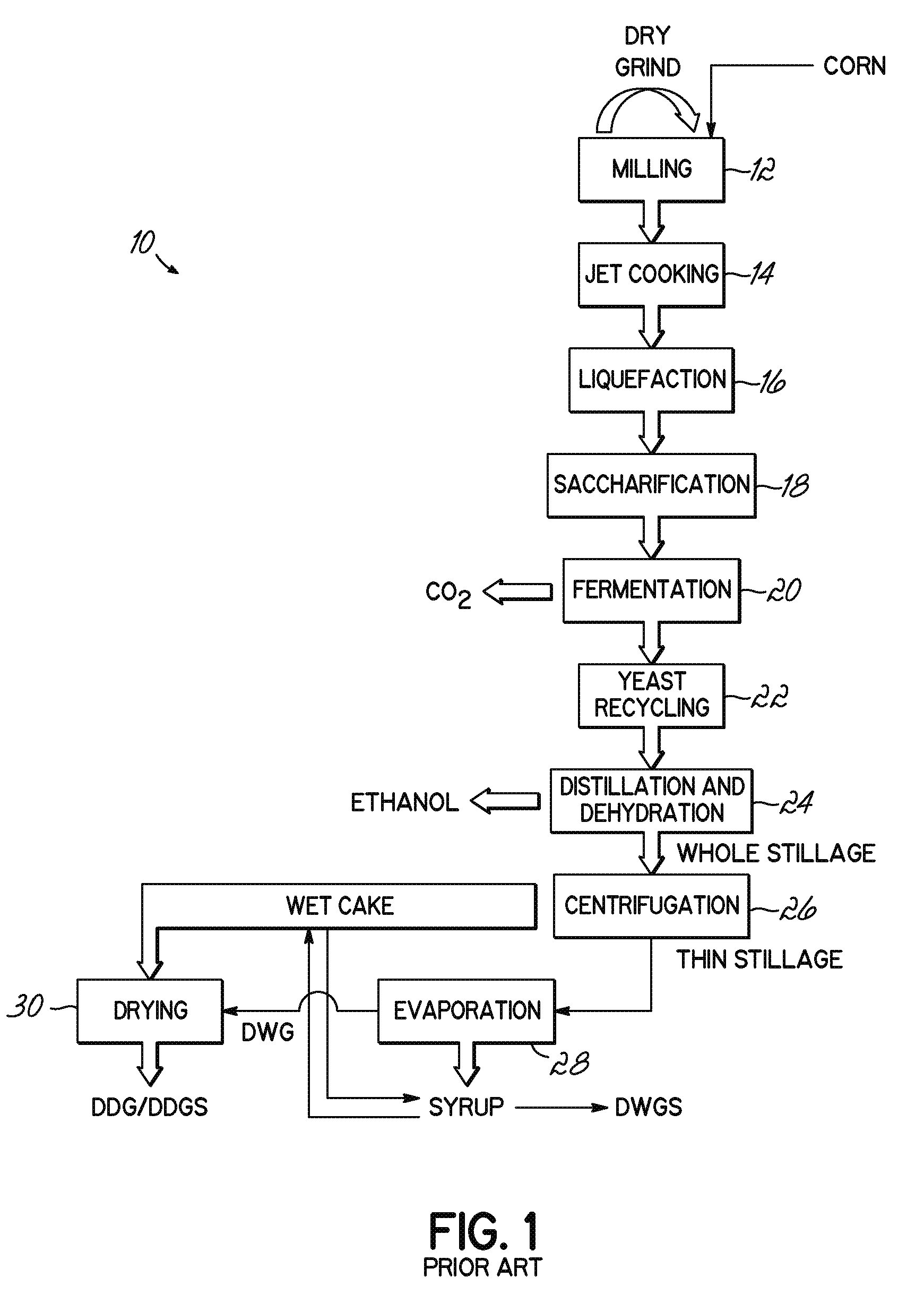

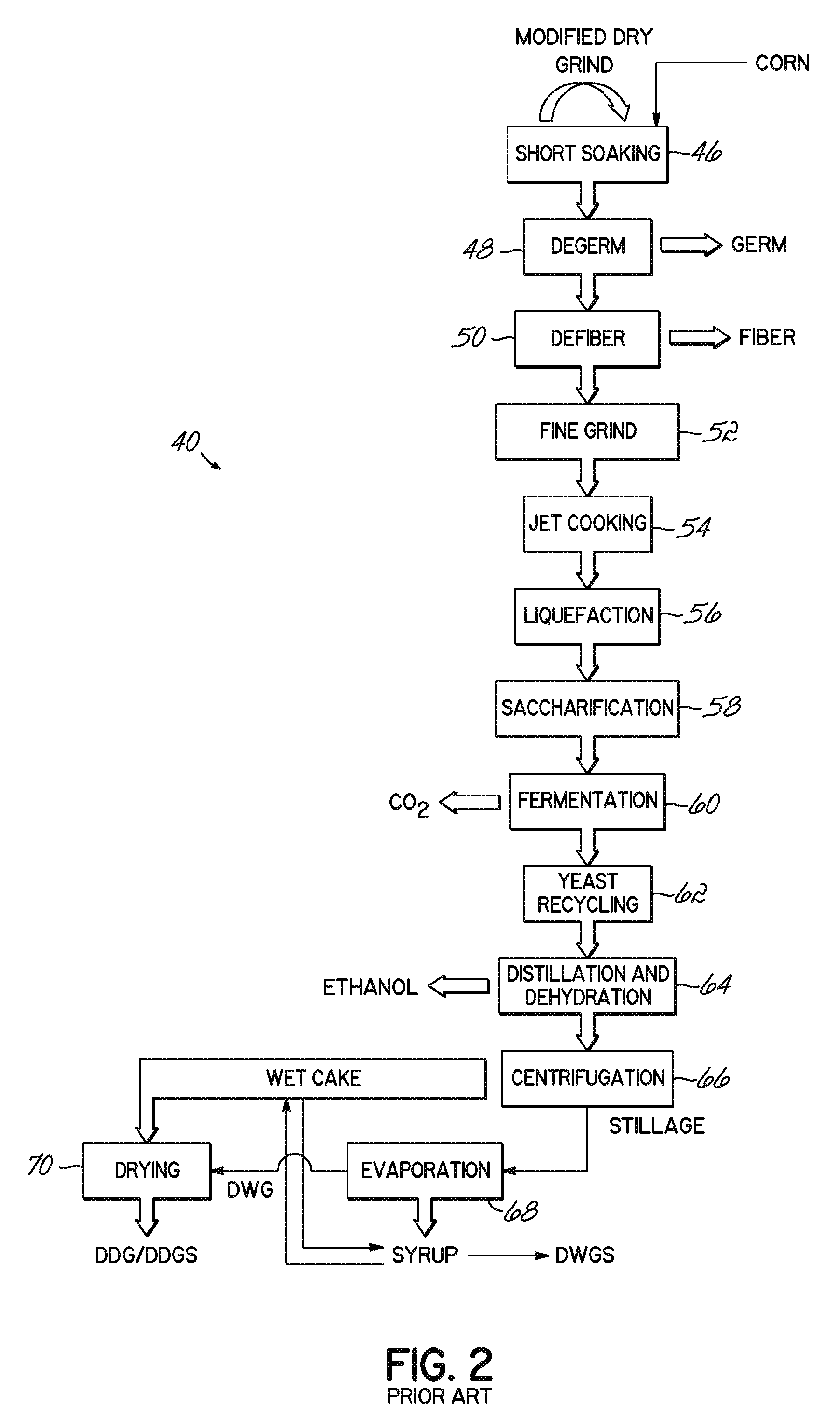

A system and method is provided which includes using a liquid treatment apparatus, which is equipped with cyclonettes, for example, to subject a liquid medium processing stream in an alcohol production process to hydraulic cavitation, i.e., to shear under vacuum, at one or more locations. The liquid treatment apparatus, in one embodiment, is directed to the formation of a central axial jet and a vacuum chamber that can be sealed by the exiting jet. Cavitation is generated by directing a high velocity jet of liquid medium processing stream through a volume of vapor under a vacuum created in the chamber through which the jet travels. This can reduce the production cost of alcohol, such as ethanol, by improving alcohol yield per bushel, among other benefits. In one embodiment, the alcohol production process is a dry grind process, a modified dry grind process, or a wet mill process. In one embodiment the alcohol production process utilizes grain as a starting material.

Owner:FLUID QUIP INC

Cellulose oxidation by nitrogen dioxide in a perfluorinated tertiary amine solvent

ActiveUS7645874B2Efficiently oxidizedReduce usageBiocideOrganic active ingredientsAqueous alcoholNitrogen dioxide

This invention relates to a process for preparing bioabsorbable oxidized cellulose comprising combining cellulose material, with nitrogen dioxide and a nonaqueous solvent chosen from the class of perfluorinated tertiary amines. This invention also relates to a method of oxidizing cellulose material comprising introducing a solvent into the vessel, circulating the solvent through the cellulose material, adding nitrogen dioxide to said vessel containing the solvent and cellulose in the required amounts, circulating the solution for 7 to 24 hours while controlling the reaction temperature, and isolating the oxidized material. Preferably, isolation of the oxidized product is followed by first washing the oxidized cellulose material with cold water, then washing the oxidized cellulose material with an aqueous alcohol solution several times, then washing the material with 100% alcohol several times, and finally drying the oxidized material.

Owner:DEPUY SYNTHES PROD INC

Cellulose oxidation by nitrogen dioxide in a perfluorinated tertiary amine solvent

ActiveUS20070054880A1Efficiently oxidizedReduce usageBiocideOrganic active ingredientsNitrogen dioxideAqueous alcohol

This invention relates to a process for preparing bioabsorbable oxidized cellulose comprising combining cellulose material, with nitrogen dioxide and a nonaqueous solvent chosen from the class of perfluorinated tertiary amines. This invention also relates to a method of oxidizing cellulose material comprising introducing a solvent into the vessel, circulating the solvent through the cellulose material, adding nitrogen dioxide to said vessel containing the solvent and cellulose in the required amounts, circulating the solution for 7 to 24 hours while controlling the reaction temperature, and isolating the oxidized material. Preferably, isolation of the oxidized product is followed by first washing the oxidized cellulose material with cold water, then washing the oxidized cellulose material with an aqueous alcohol solution several times, then washing the material with 100% alcohol several times, and finally drying the oxidized material.

Owner:DEPUY SYNTHES PROD INC

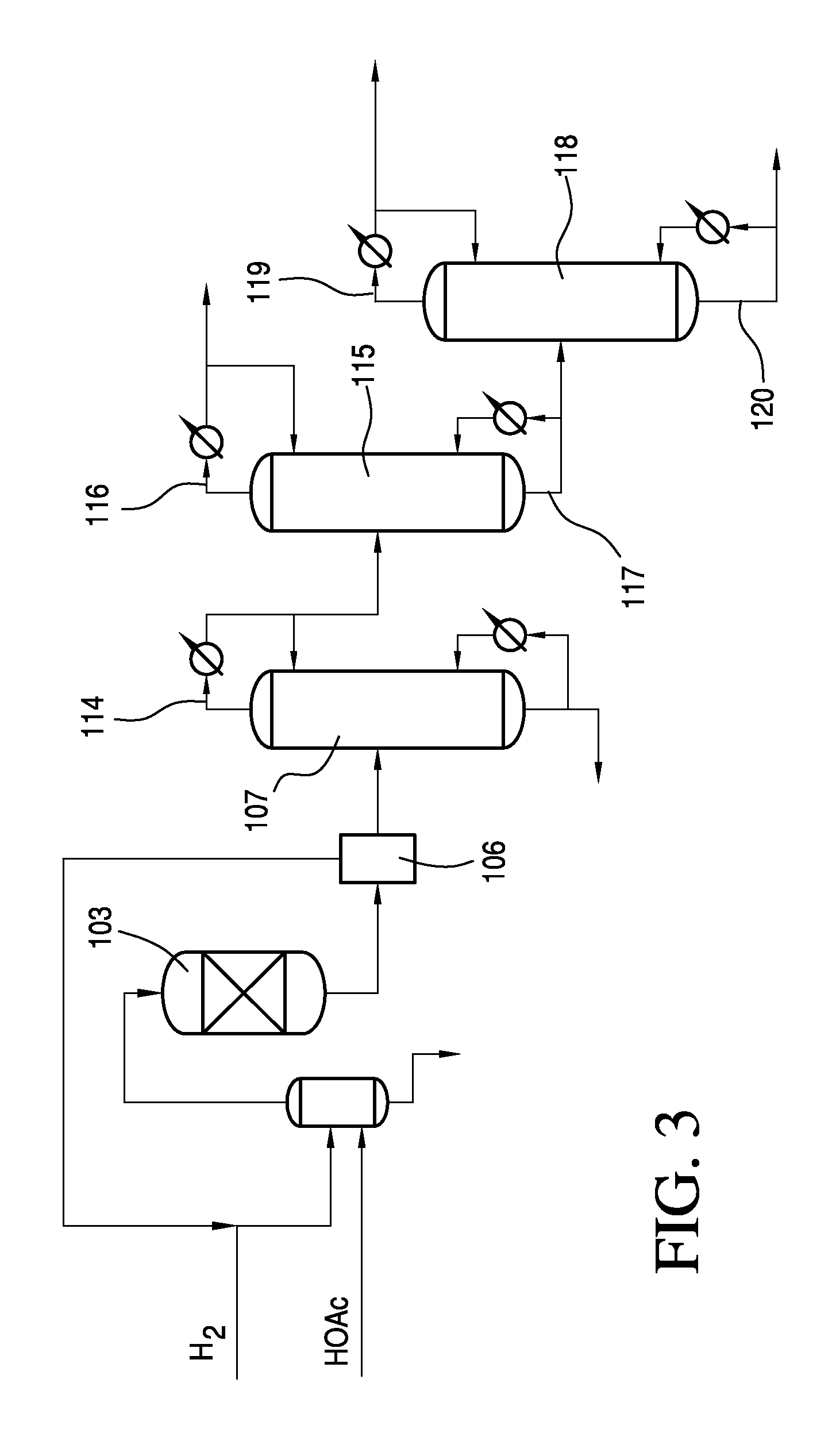

Reduced Energy Alcohol Separation Process

InactiveUS20120010438A1Fermented solutions distillation/rectificationOrganic compound preparationAcetic acidAqueous alcohol

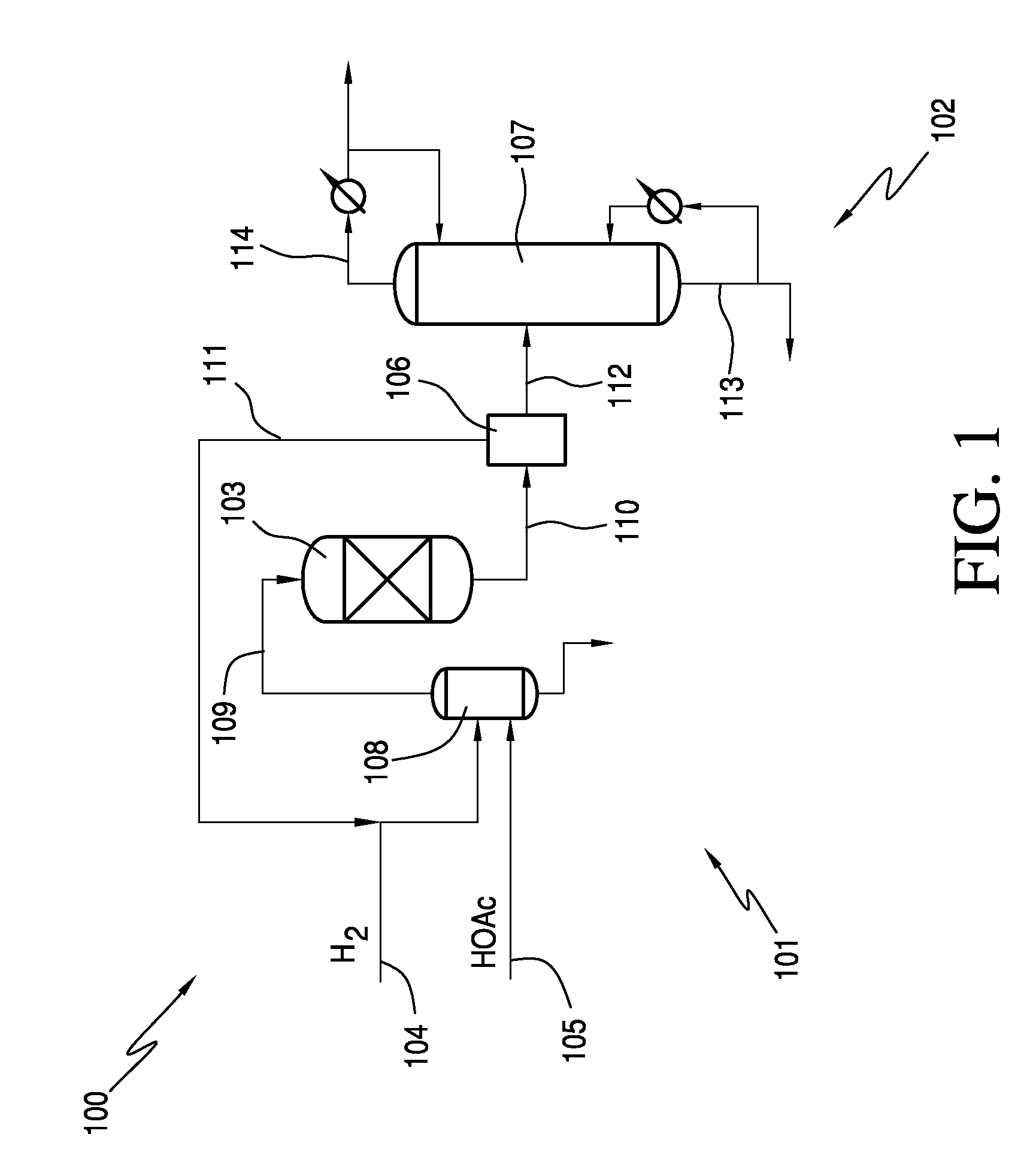

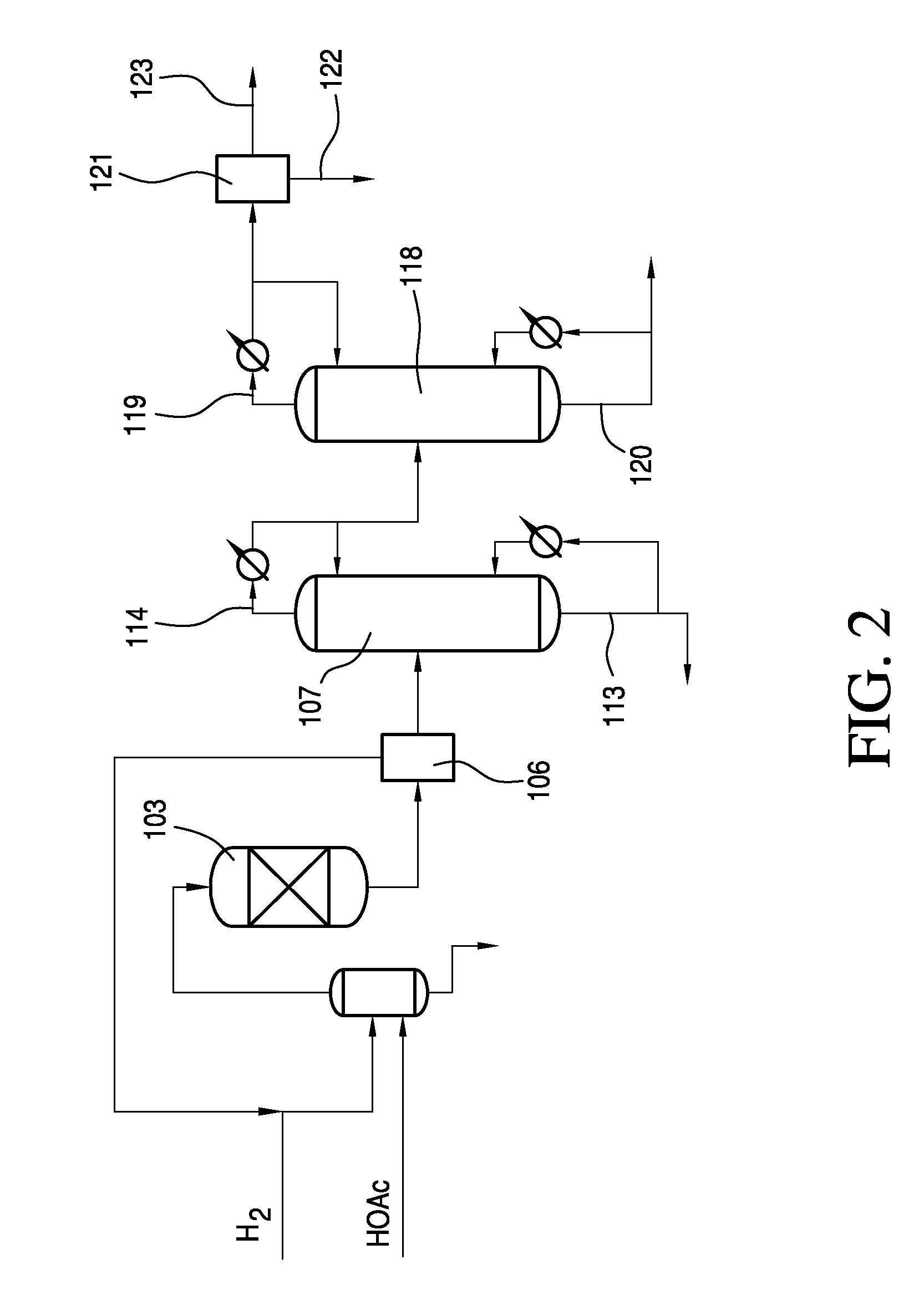

Recovery of alcohols, in particular ethanol, from a crude ethanol product obtained from the hydrogenation of acetic acid using a reduced energy process. The crude ethanol product may be fed to a distillation column in which a substantial portion of the water is removed with the acetic acid in the residue. The ethanol product is obtained from the distillate.

Owner:CELANESE INT CORP

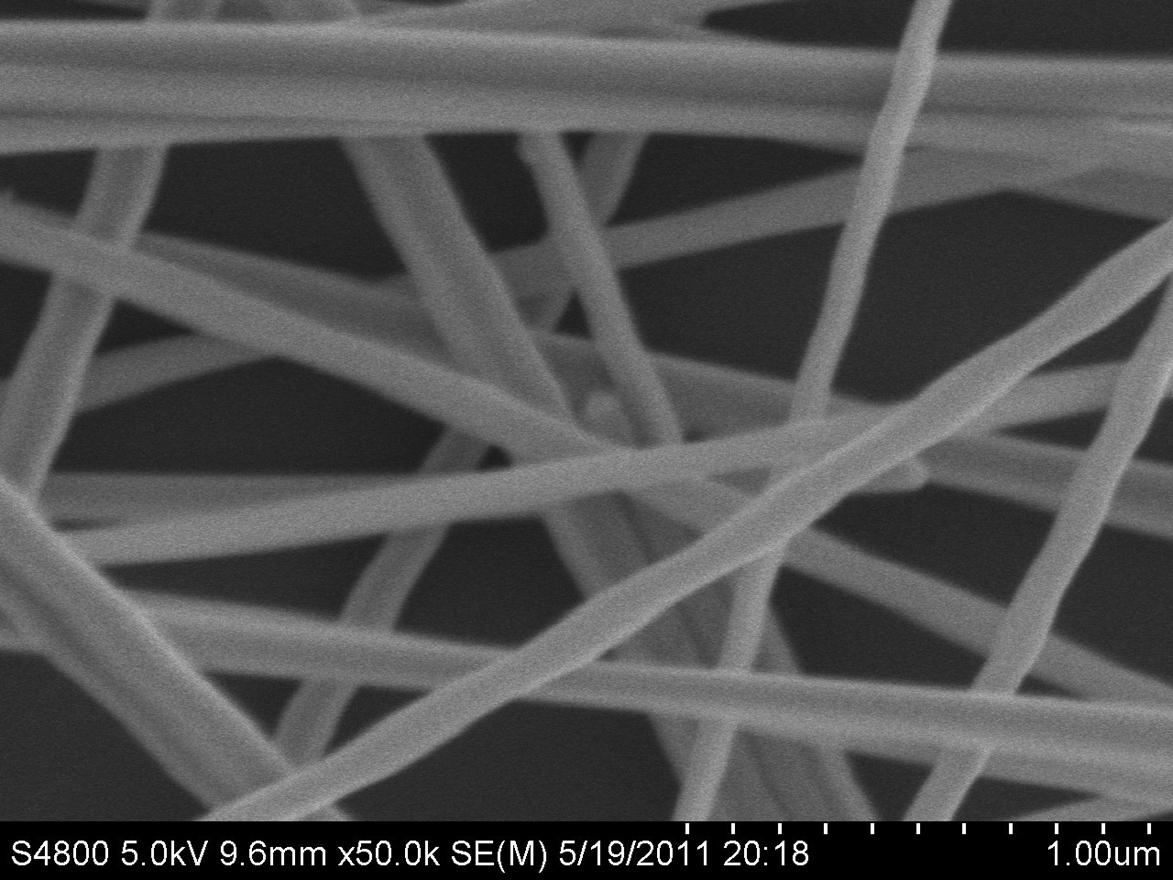

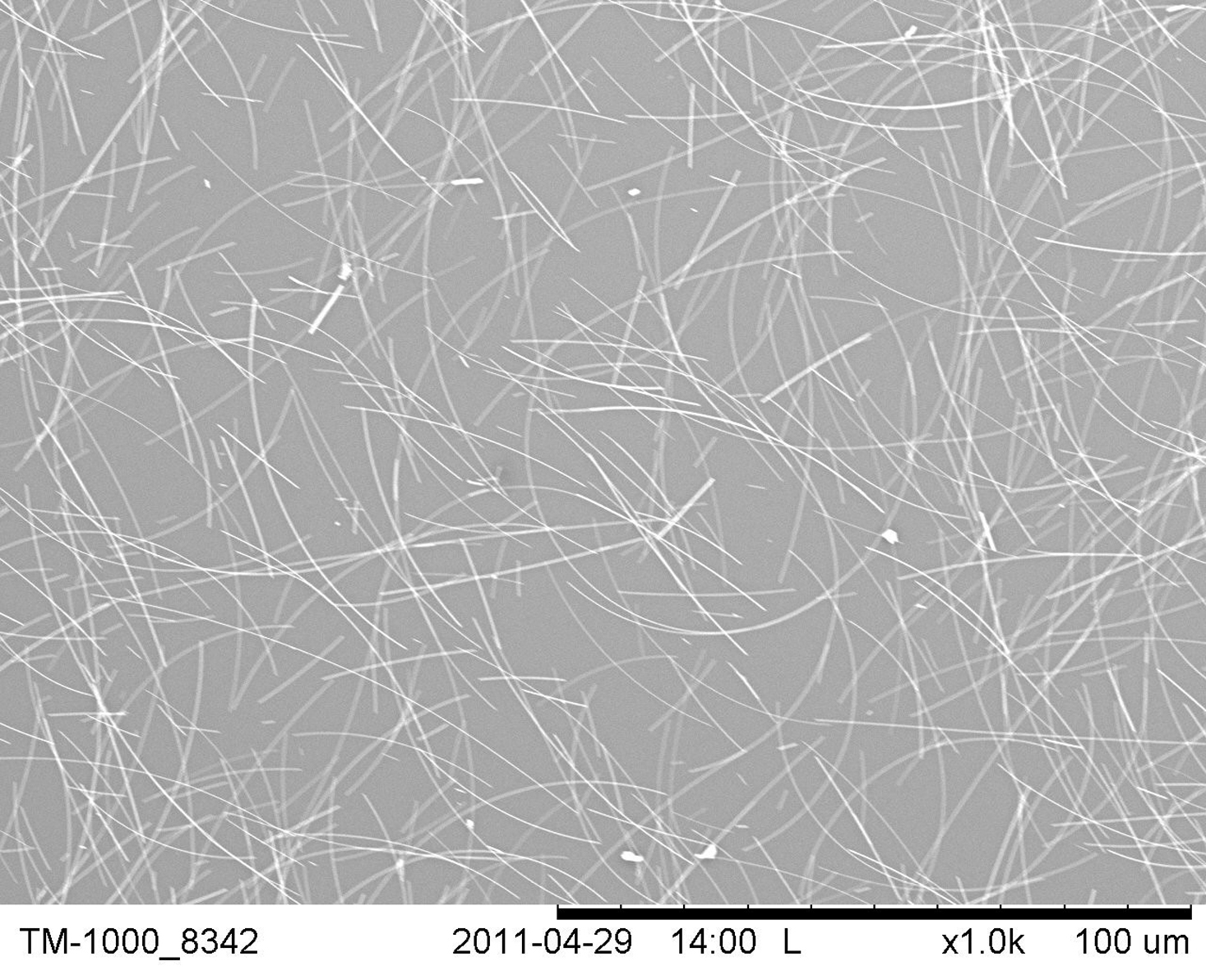

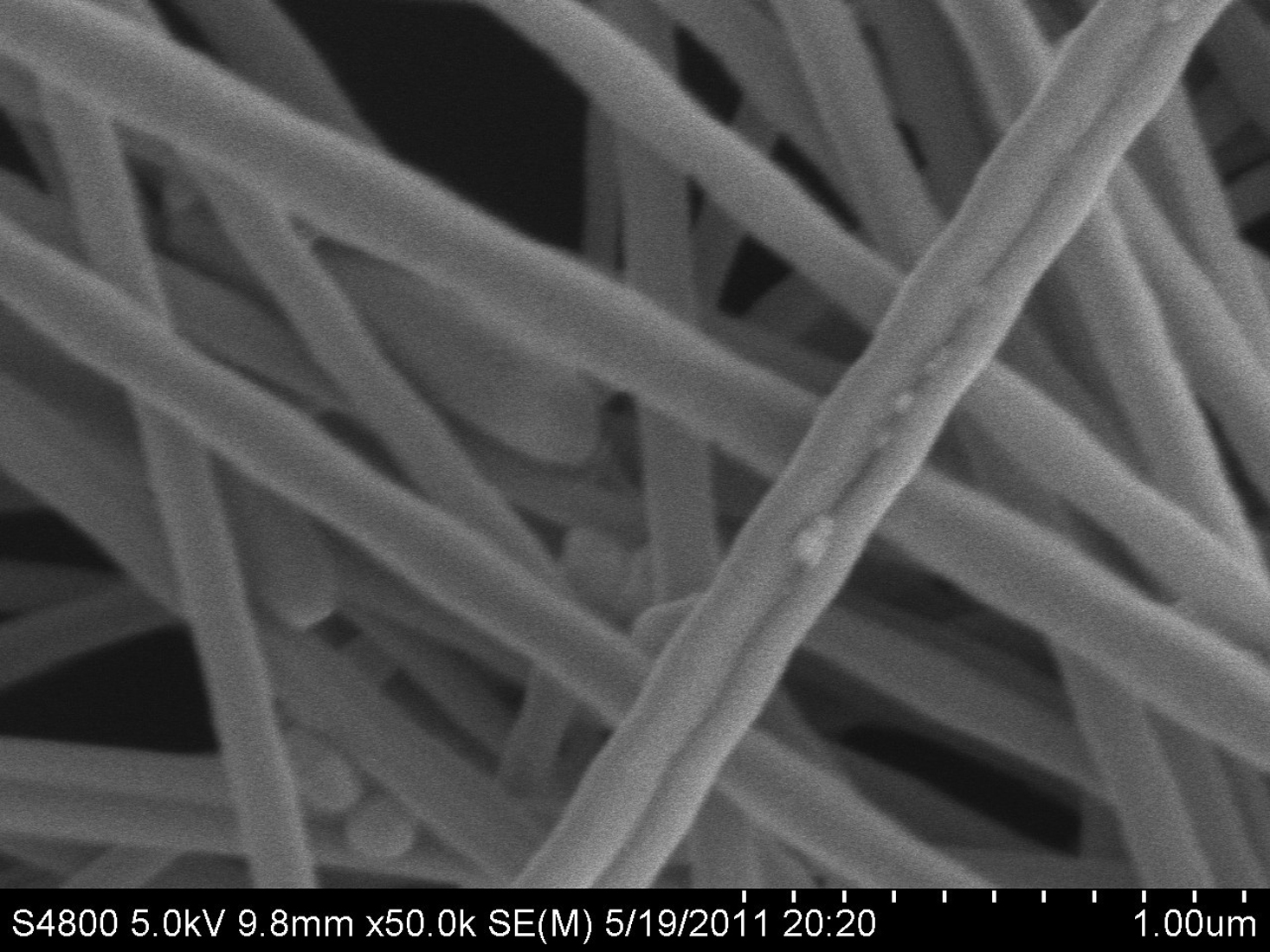

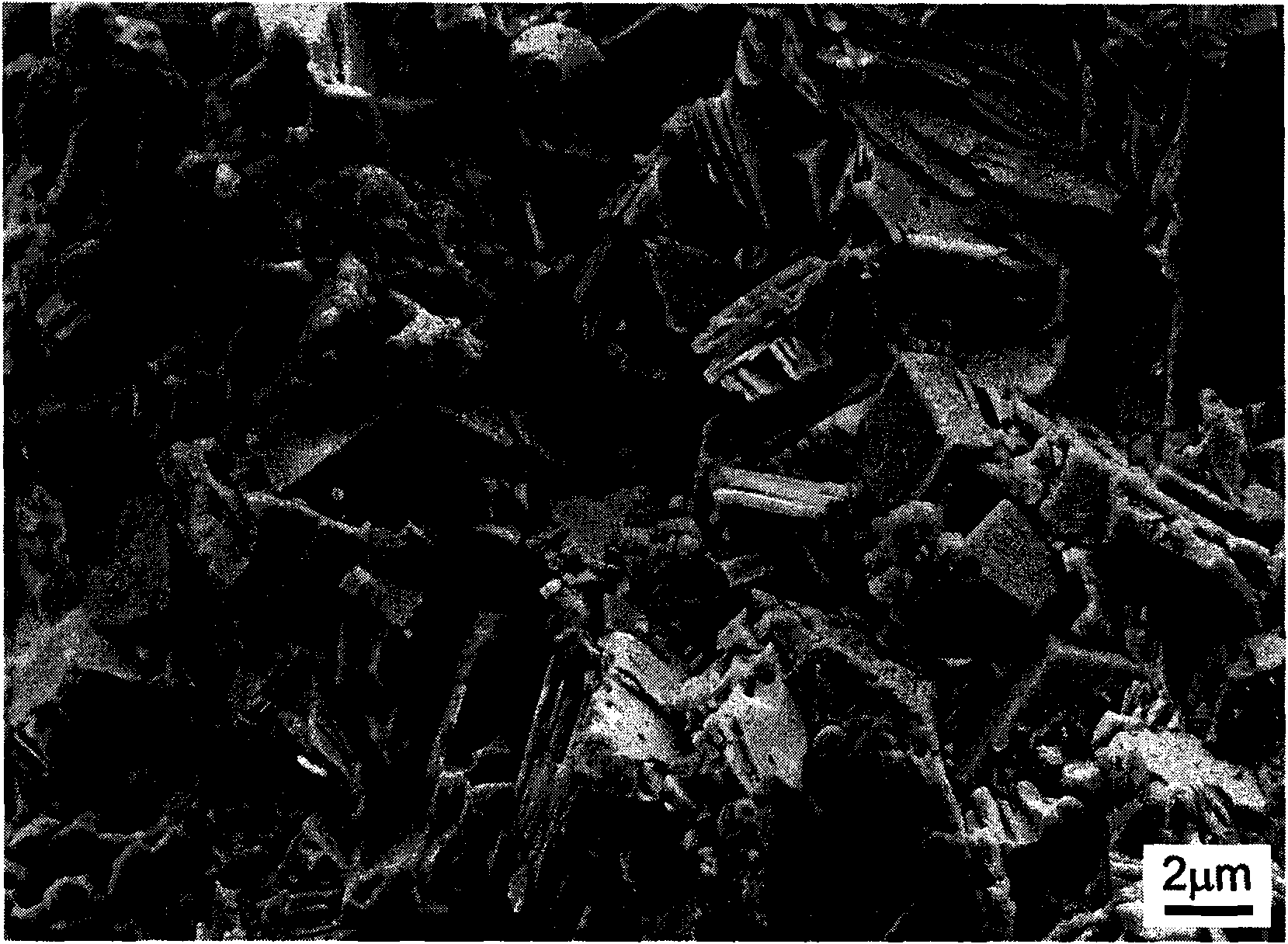

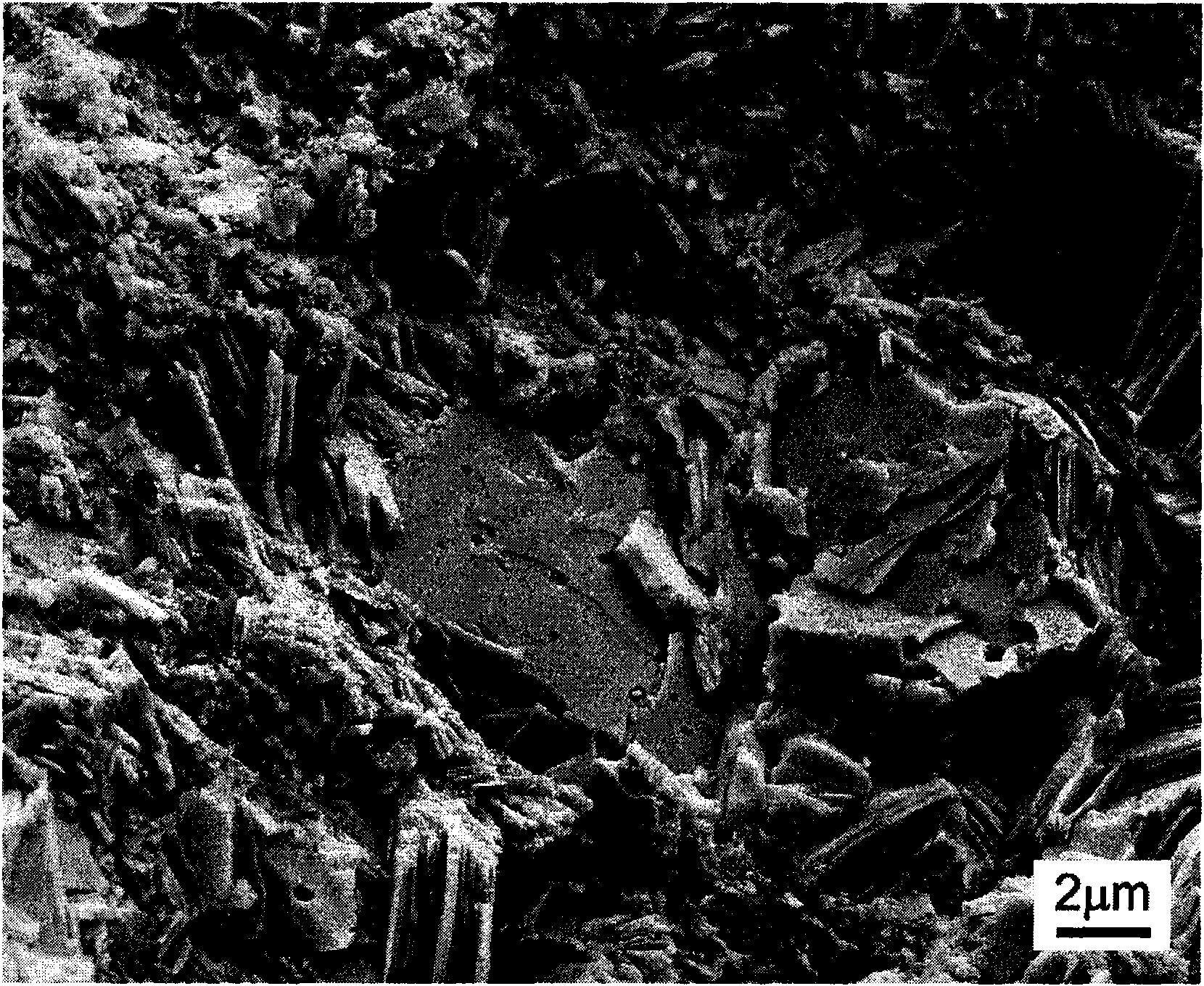

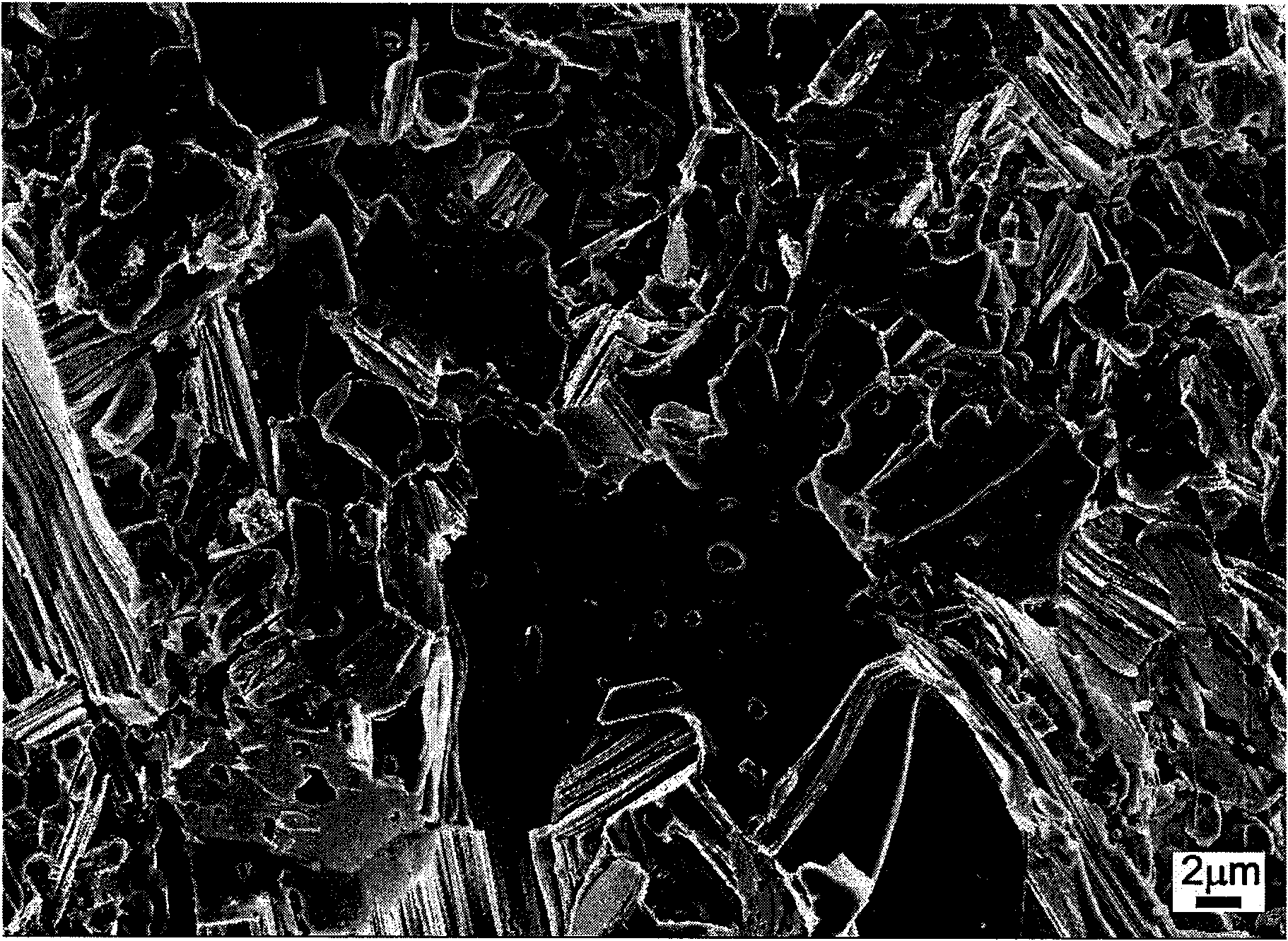

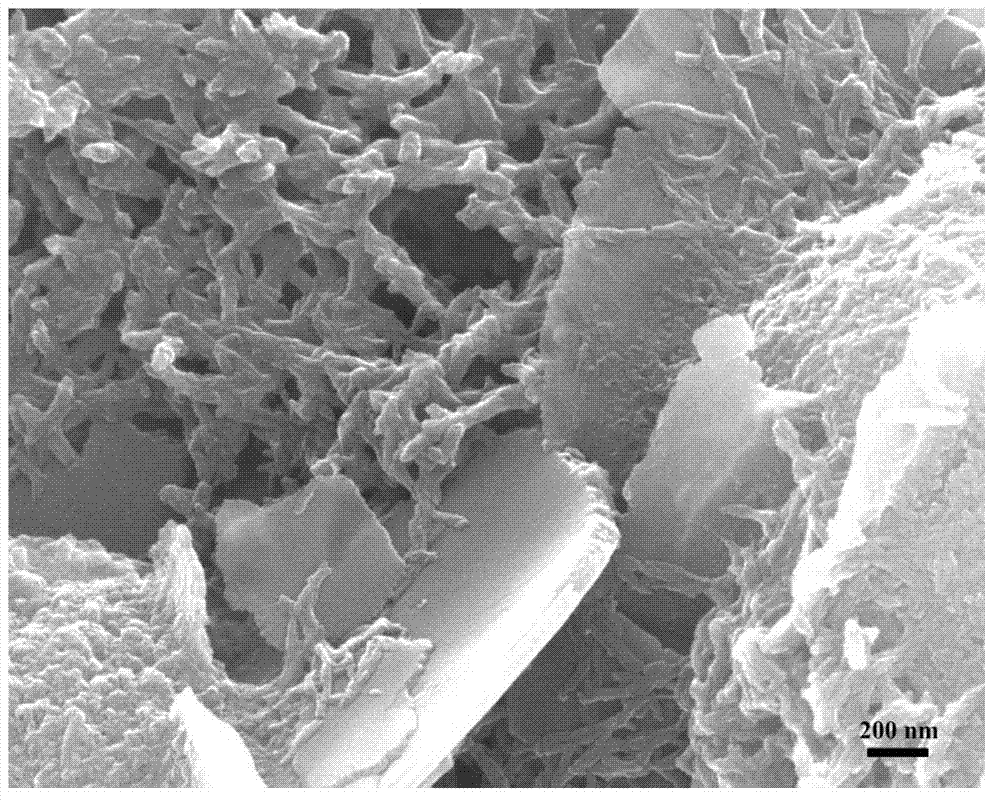

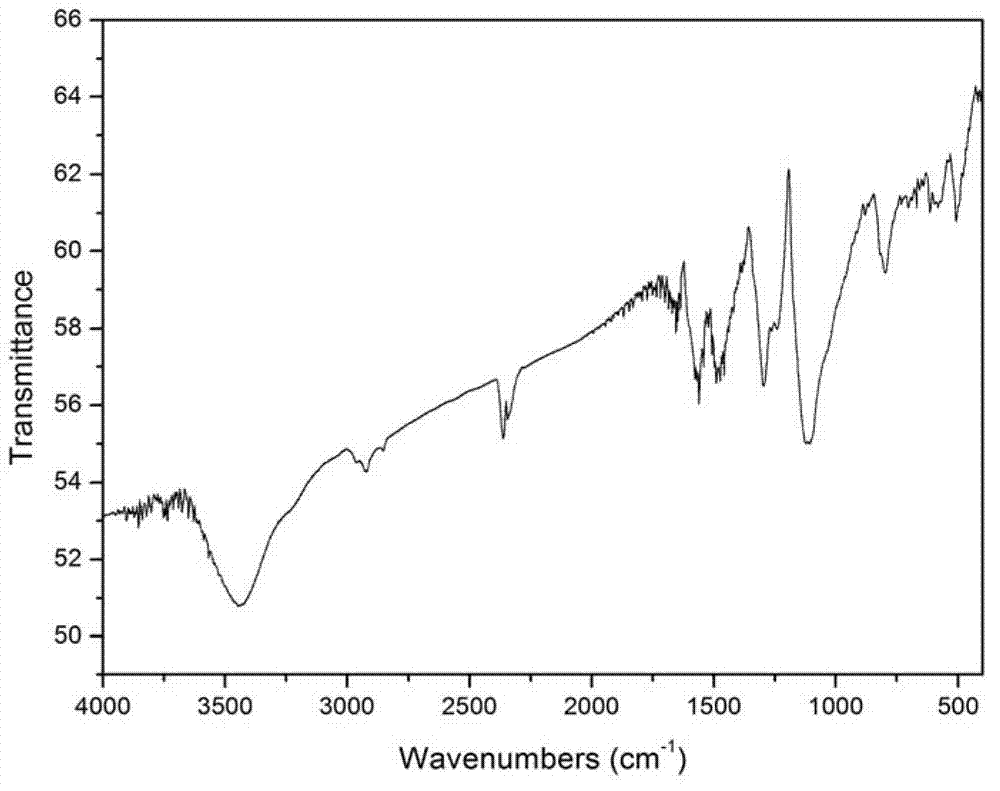

Method for preparing length-diameter-ratio nano-silver wire by pH-value regulation solvothermal method

The invention relates to a method for preparing a length-diameter-ratio nano-silver wire by a pH-value regulation solvothermal method. The method comprises the following steps of: preparing the following ethylene glycol solution, namely an ethylene glycol solution A of silver nitrate or silver acetate, an ethylene glycol solution B of polyvinyl pyrrolidone (PVP), an ethylene glycol solution C of water-soluble chloride and concentrated acid D; mixing the components according to a certain amount and fully stirring to form a final mixed solution; moving the final mixed solution into a reaction kettle; placing in an oven for reaction for a certain time; taking the reaction kettle out and cooling to room temperature to obtain mother liquid of the nano-silver wire; adding alcohol into the mother liquid for diluting, and removing supernatant liquor to obtain a precipitate; and repeatedly performing centrifugal separation, and thus obtaining nano-silver wire dispersion liquid uniformly dispersed in the alcohol. The method is simple, high in efficiency and low in cost, and can prepare high-quality nano-silver wires within a wider range of reaction condition; and prepared products are high in length-diameter ratio, good in length uniformity and low in impurity content.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

Alcohol-free fountain solution with high viscosity and low surface tension

InactiveCN103935150AHigh effective contentReduce pollutionPrinting pre-treatmentAlcohol freeAqueous alcohol

The invention discloses alcohol-free fountain solution with high viscosity and low surface tension. The alcohol free fountain solution with high viscosity and low surface tension comprises the following components by weight, 30-55 parts of alcohol solvents, 2-6 parts of buffer agents, 3-8 parts of wetting agents, 1-4 parts of surface active agents, 0.3-2.2 parts of antifoaming agents, 0.5-3 parts of thickening agents, 0.5-1.2 parts of anticorrosion and bactericidal agents, 1-3 parts of penetrating agents, 0-2 parts of electrolyte and 20-45 parts of viscosity modifier water. The fountain solution is free of volatile solvents containing alcohol and isopropyl alcohol and pollution to the environment, the surface tension ranges from 4*10-2N / m to 7*10-2N / m, pH ranges from 4.8 to 5.5, the heat conduction rate ranges from 800mus / cm to 1200mus / cm, and therefore, quality requirements of the fountain solution can be met better.

Owner:苏州禾川化学技术服务有限公司

High-Purity Mogrosides And Process For Their Purification

The present invention provides a process for preparation of highly purified mogrosides mixture from low purity mogrosides mixture. The process comprises providing a mixture of low purity mogrosides, dissolving the low purity mogrosides mixture in water or an aqueous alcohol solution to form an initial solution of mogrosides, passing the initial solution through a column system, wherein the column system comprises a plurality of columns, and each column is packed with a sorbent having different affinities to impurities and mogrosides so that one or more columns retains more mogrosides than other columns, washing the columns to remove impurities with an acidic aqueous solution, a basic aqueous solution, and an aqueous alcoholic solution successively, eluting the columns with an aqueous alcohol solution that contains higher alcohol content than the aqueous alcohol solution used in the washing step, wherein the eluate from the columns with high content of mogrosides are combined, and drying the combined eluate to obtain high purity mogrosides with the content of the total mogrosides are more than 70% (w / w). The present invention also provides a sweetener mixture and product comprising high purity mogrosides.

Owner:PURECIRCLE SDN BHD

Enhanced cell preservative solution and methods for using same

InactiveUS20060088814A1Maintain structural integrityImprove solubilityDead animal preservationPreservativeAqueous alcohol

Owner:CYTYC CORP

Copper-catalysed ligation of azides and acetylenes

InactiveUS20080214831A1Organic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMetalloleSufficient time

A copper catalyzed click chemistry ligation process is employed to bind azides and terminal acetylenes to provide 1,4-disubstituted 1,2,3-triazole triazoles. The process comprises contacting an organic azide and a terminal alkyne with a source of reactive Cu(I) ion for a time sufficient to form by cycloaddition a 1,4-disubstituted 1,2,3-triazole. The source of reactive Cu(I) ion can be, for example, a Cu(I) salt or copper metal. The process is preferably carried out in a solvent, such as an aqueous alcohol. Optionally, the process can be performed in a solvent that comprises a ligand for Cu(I) and an amine.

Owner:TETARD INC

Method for preparing multilevel pore carbon electrode material of super capacitor

InactiveCN101774567AIncrease energy densityImproved power output characteristicsElectrolytic capacitorsHybrid/EDL manufactureNitrogen gasBiological activation

The invention provides a method for preparing a multilevel pore carbon electrode material of a super capacitor, comprising the following steps: (1) preparing the mixing solution of ethyl alcohol and water, adding a surfactant and a phenol compound into the mixture, stirring until the mixture is dissolved, adding concentrated hydrochloric acid into the solution, stirring until the solution is pink, then adding methanal, stirring to generate solid phenolic resin at the bottom of the solution, aging the phenolic resin in the solution, taking out, and then aging at 100 DEG C; (2) carbonizing aged phenolic resin under the protection of nitrogen at 850 DEG C to obtain a mesoporous carbon material; (3) smashing the mesoporous carbon material to less than 50 meshes, and then activating by an activating agent under the protection of nitrogen; and (4) washing the activated product by deionized water and drying to obtain the microporous-mesoporus multilevel pore carbon electrode material. In the invention, mesoporus carbon with even pore size distribution is prepared firstly, and then micropores are produced on the pore wall of the mesoporus carbon in the activation process to obtain the multilevel pore carbon electrode material with directly communicated mircropores and mesopores.

Owner:SHANDONG UNIV OF TECH

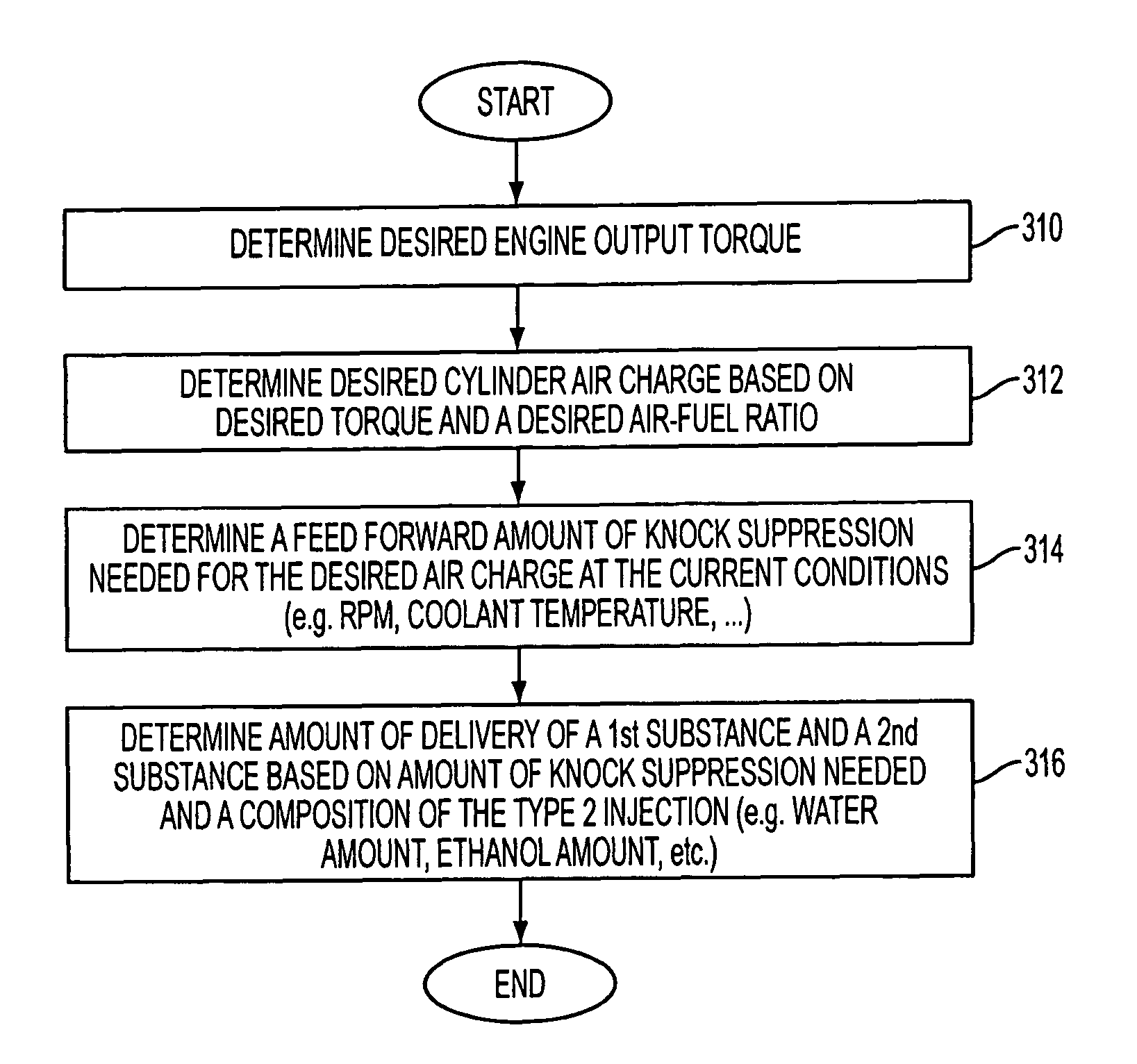

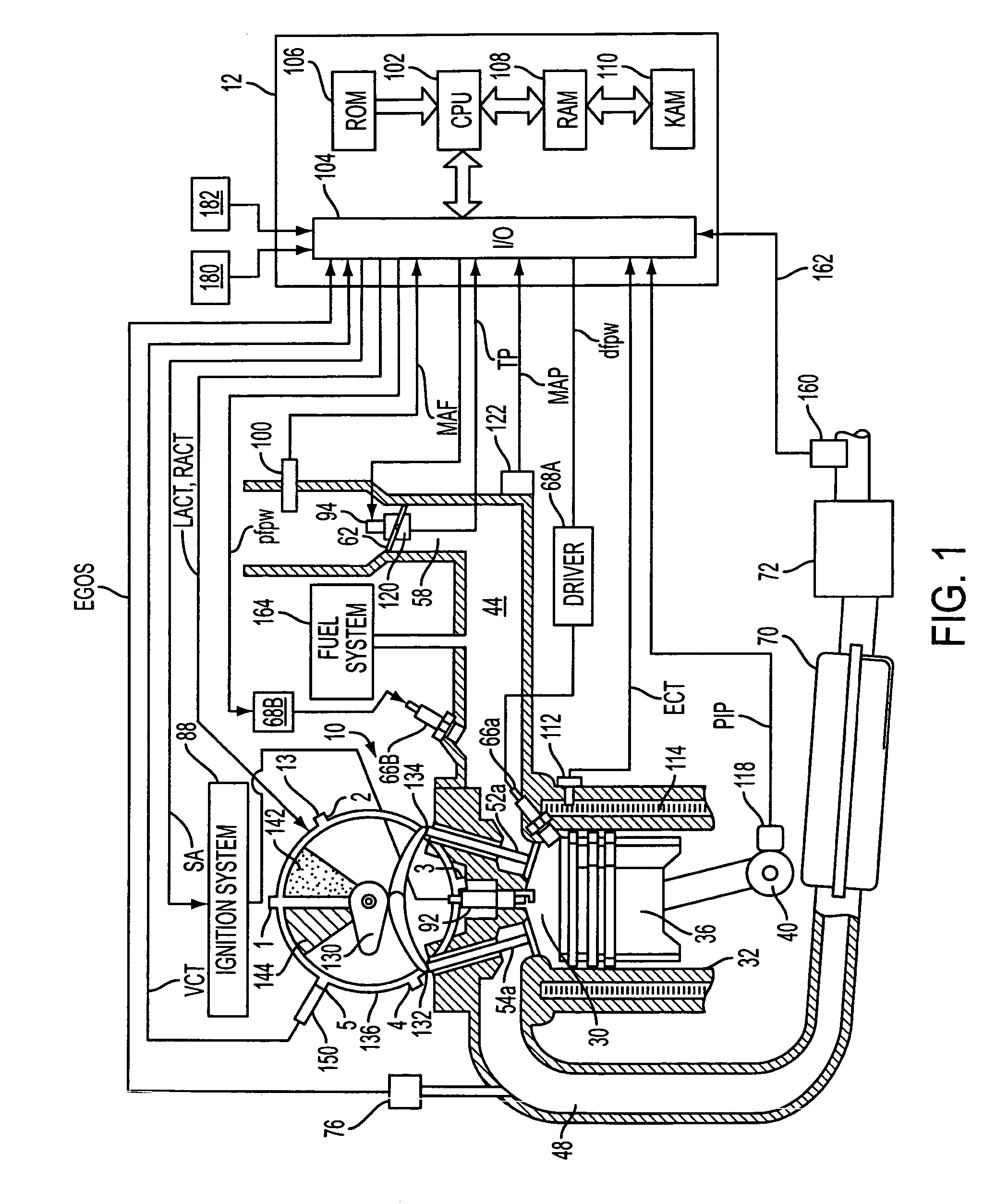

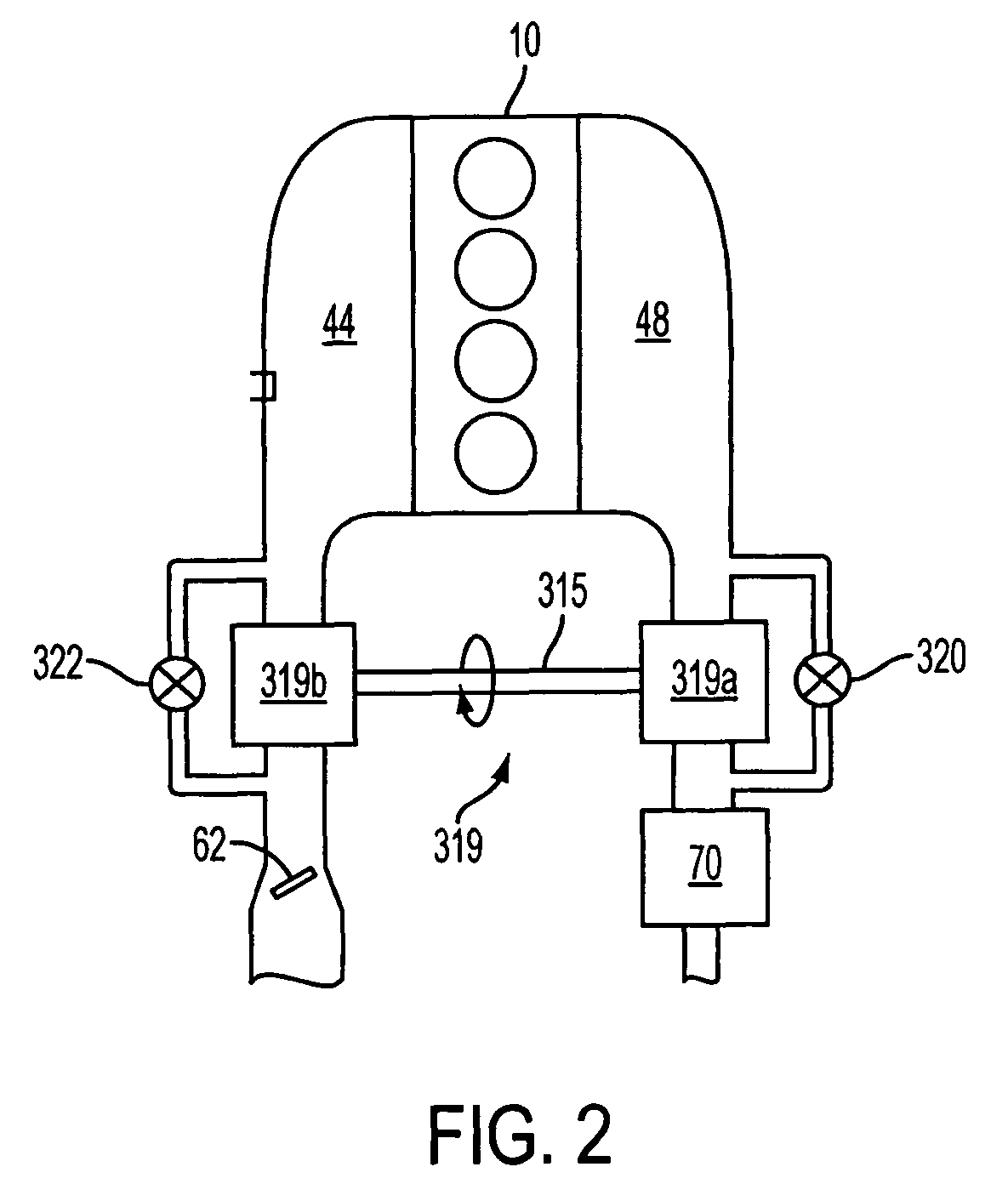

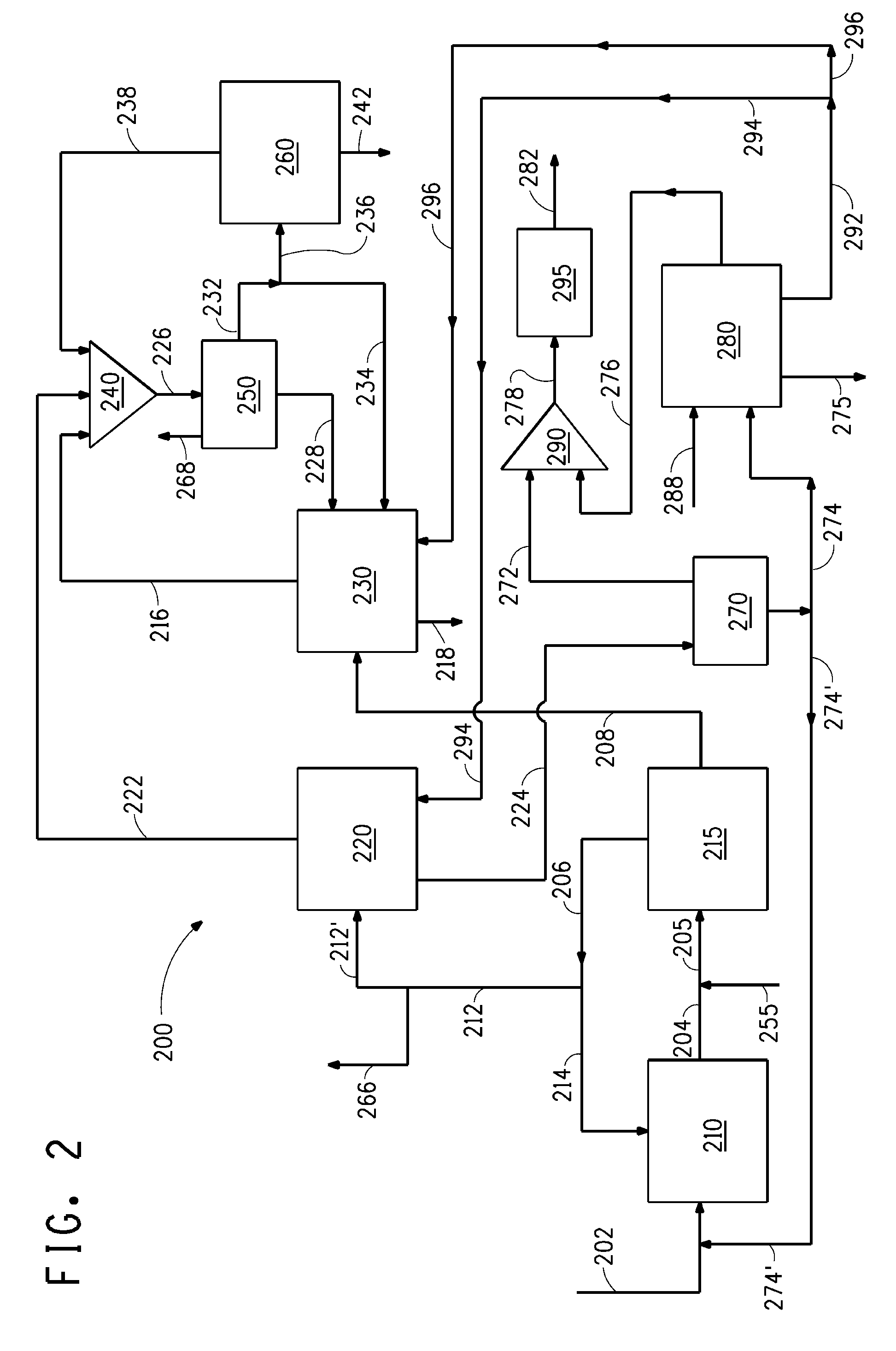

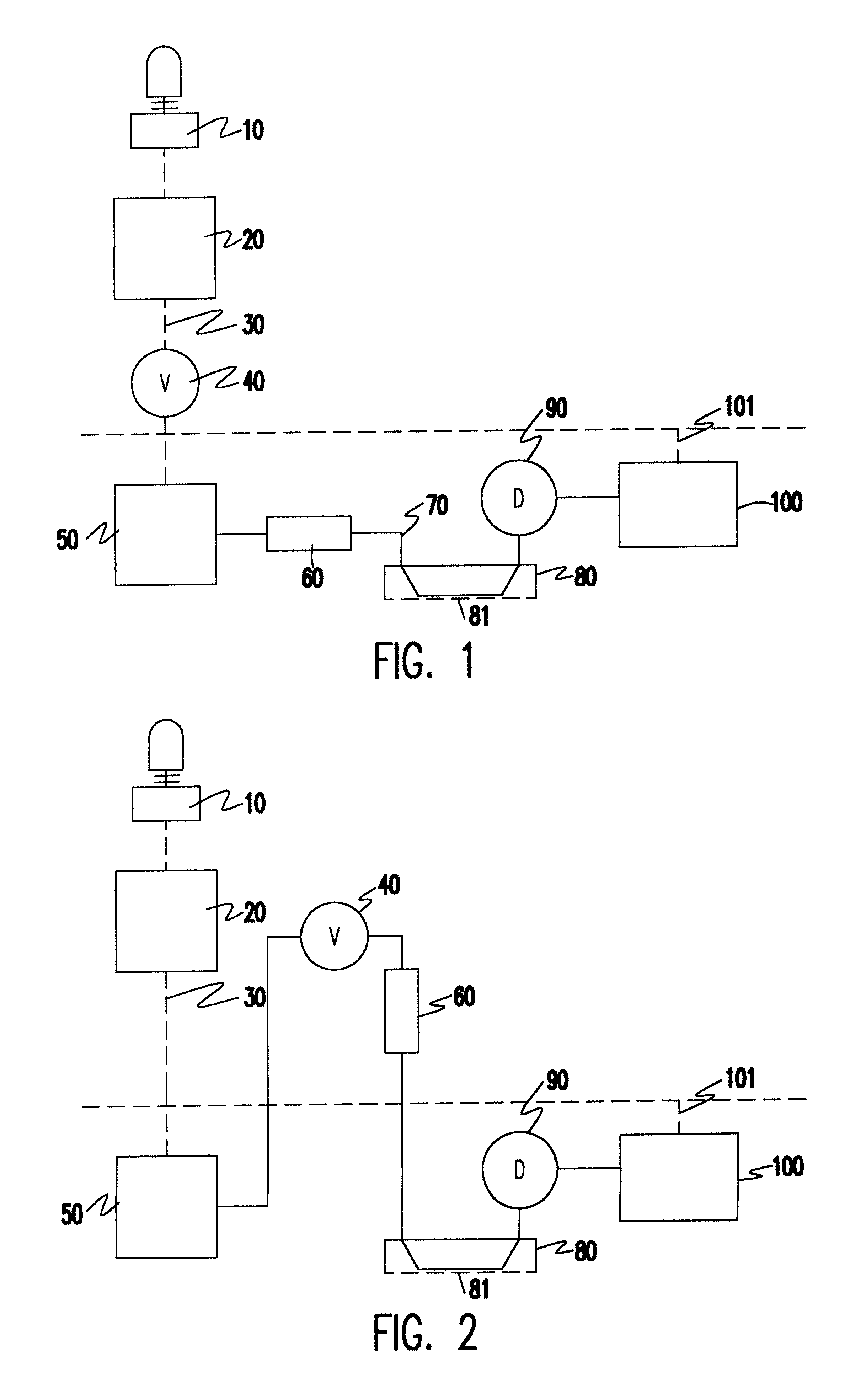

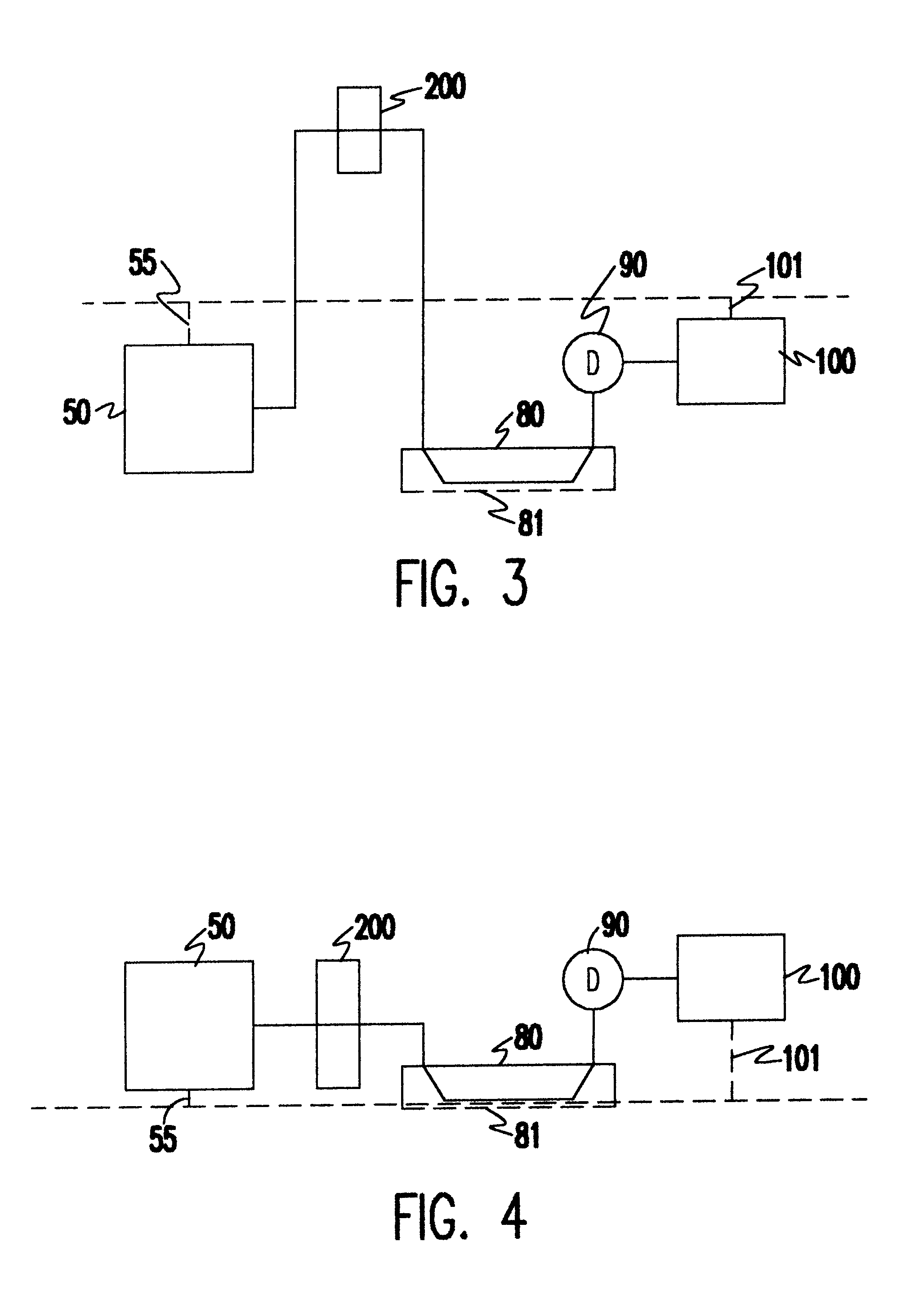

Control for alcohol/water/gasoline injection

ActiveUS8434431B2Increase profitLow costInternal combustion piston enginesNon-fuel substance addition to fuelAqueous alcoholGasoline

A system for controlling an engine is described. In one example, fuel and a fluid are delivered to the engine cylinder, the fluid including at least some water. The amount of fuel and fluid delivered is adjusted in different ratios as a condition varies to address both pre-ignition and knock.

Owner:FORD GLOBAL TECH LLC

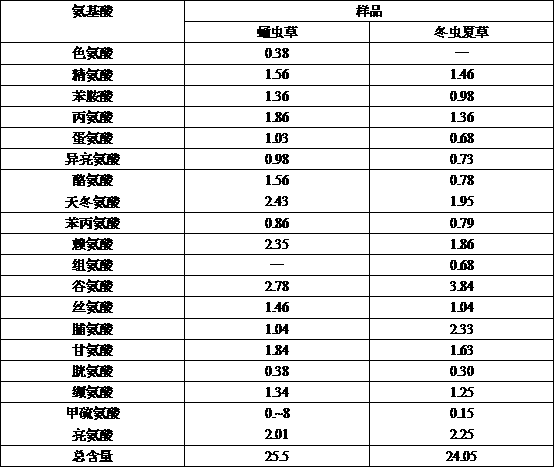

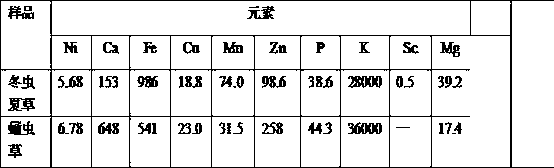

Method for preparing health food capsules by using cordyceps militaris and cocoon extracts

The invention discloses a method for preparing health food capsules by using cordyceps militaris and cocoon extracts, and aims to extract various nutrient substances with natural activities from the cordyceps militaris and cocoon to produce different types of nutrient health products, so that the utilization rate of the cordyceps militaris and cocoon is fully improved, and the market demand is met. The method is characterized by comprising the steps of extracting the nutrient substances from the cordyceps militaris and cocoon by performing freeze thawing, combined enzymolysis and aqueous alcohol precipitation sub-step extracting methods; adding a proper quantity of auxiliary materials into the nutrient substances to fully and evenly stir and sieve to prepare the particles; filling the particles into the capsules; wiping off residual powder adhered to the capsule shells; waxing; polishing; and sterilizing the capsules in a radiation mode after the capsules are packaged so as to obtain the finished product.

Owner:XUZHOU HONGYU AGRI TECH

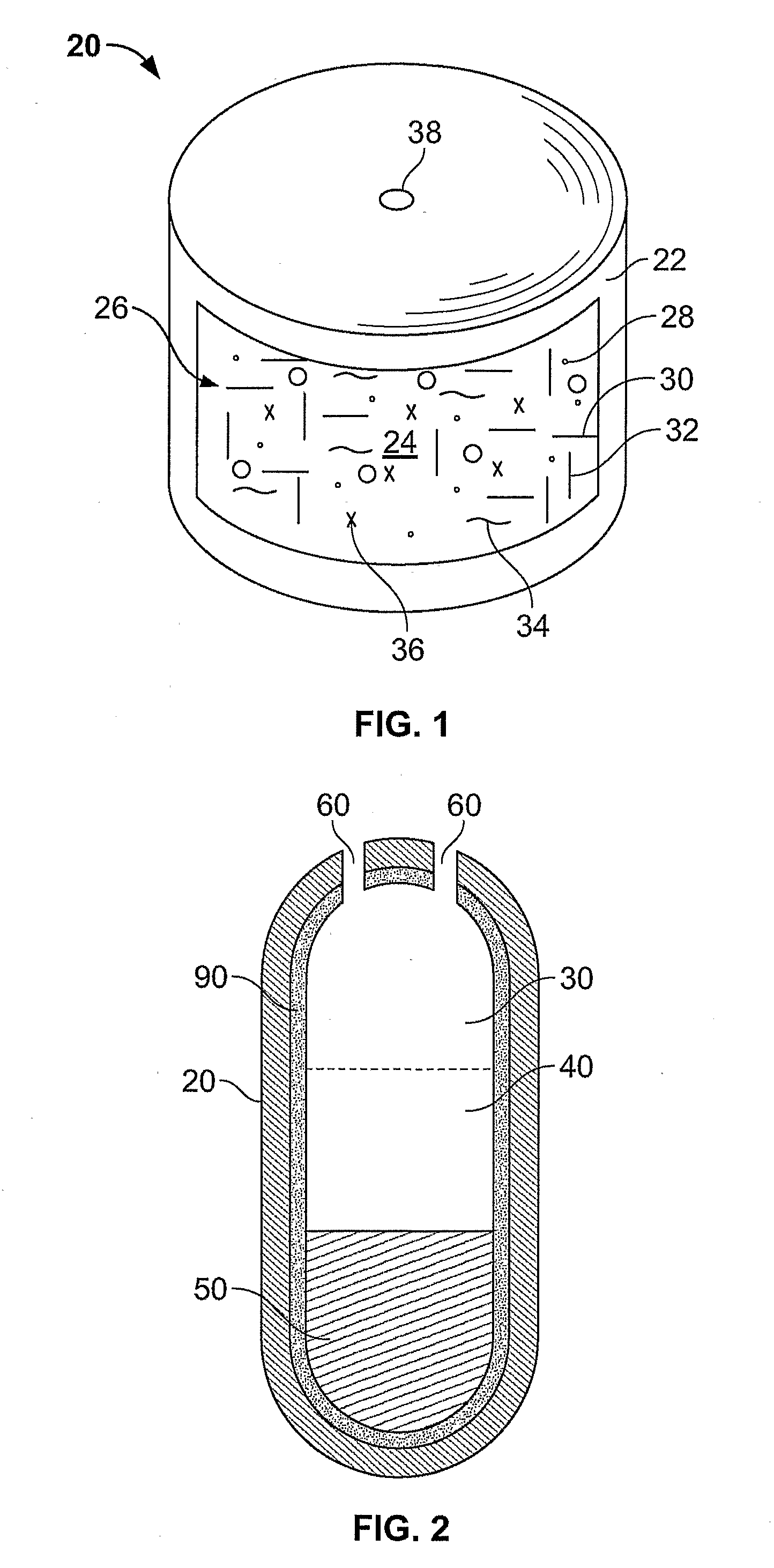

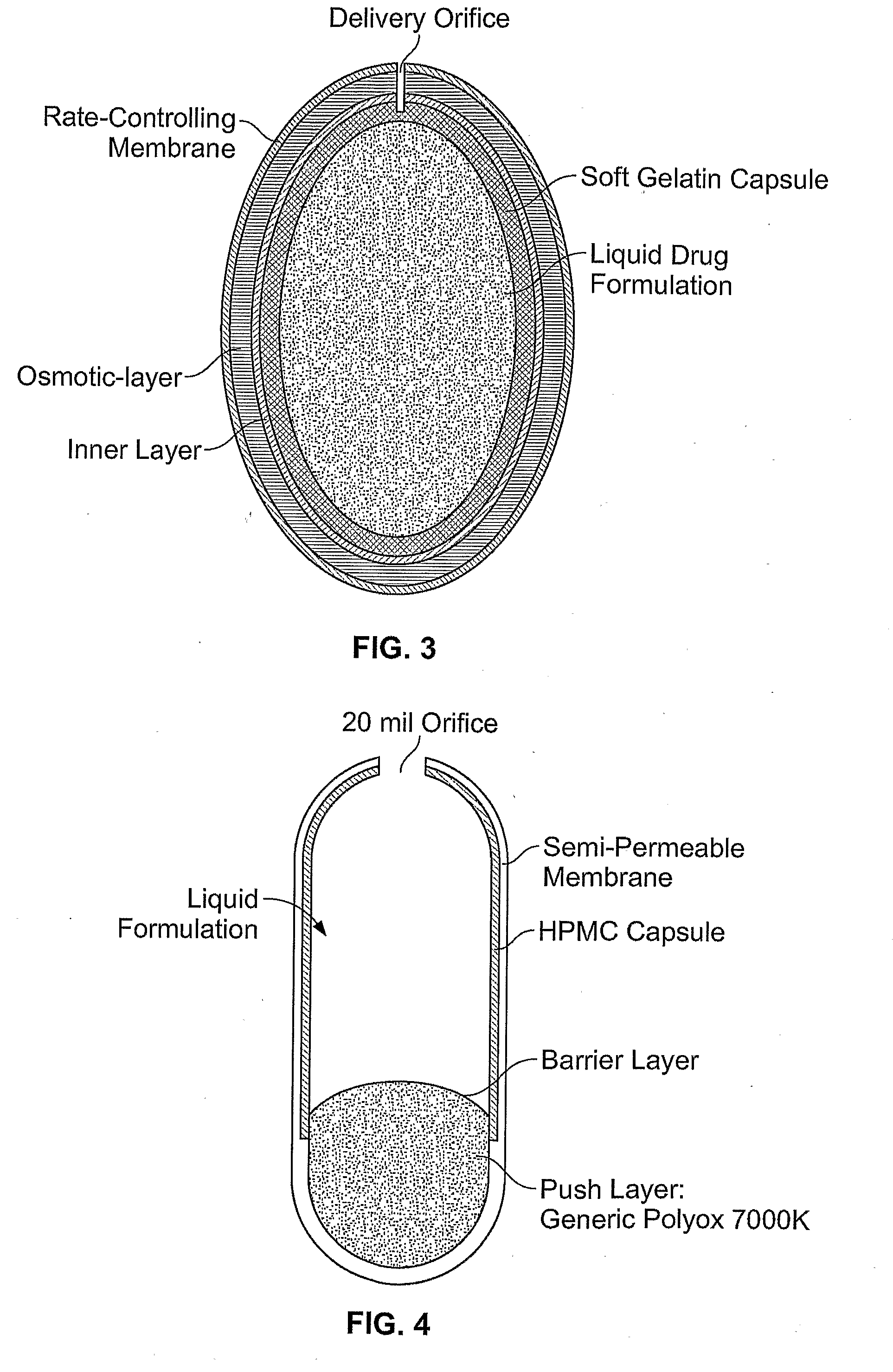

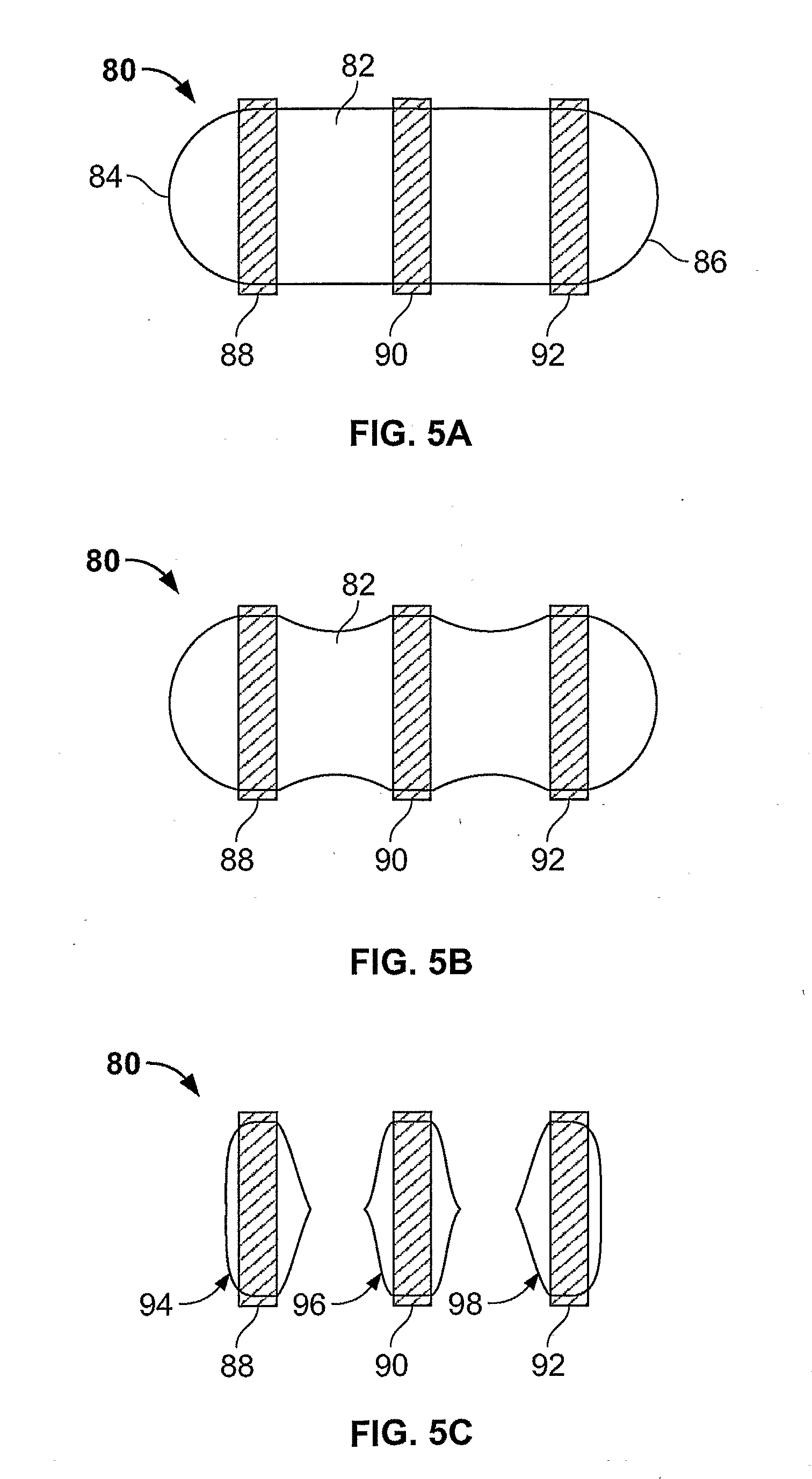

Methods of Reducing Alcohol-Induced Dose Dumping for Opioid Sustained Release Oral Dosage Forms

Disclosed are methods of sustained release administration of opioids, including but not limited to hydromorphone and oxycodone, that exhibit improved properties with respect to co-ingestion with aqueous alcohol.

Owner:ALZA CORP

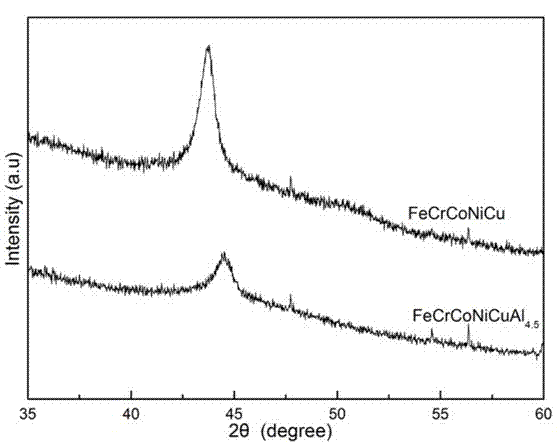

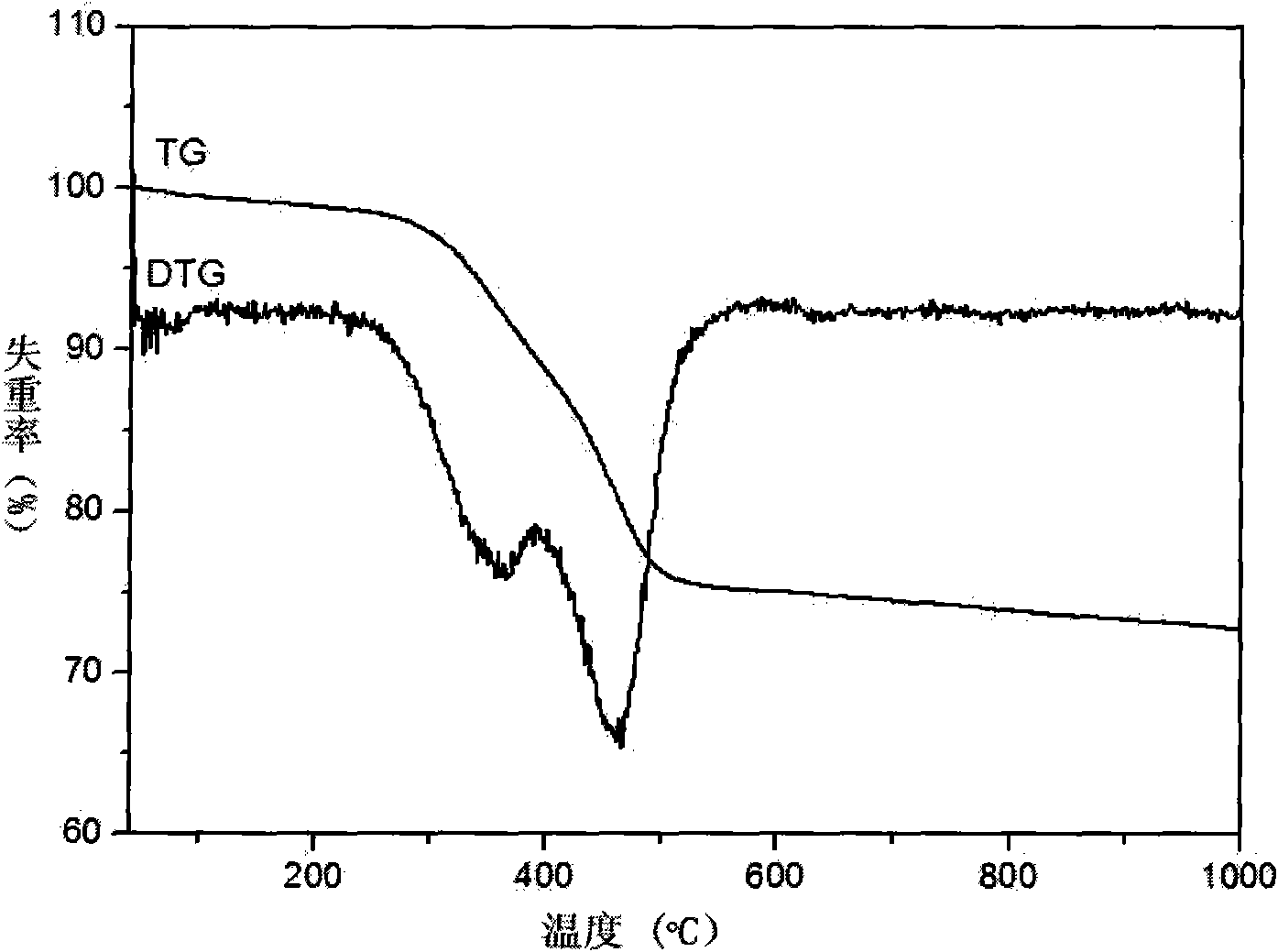

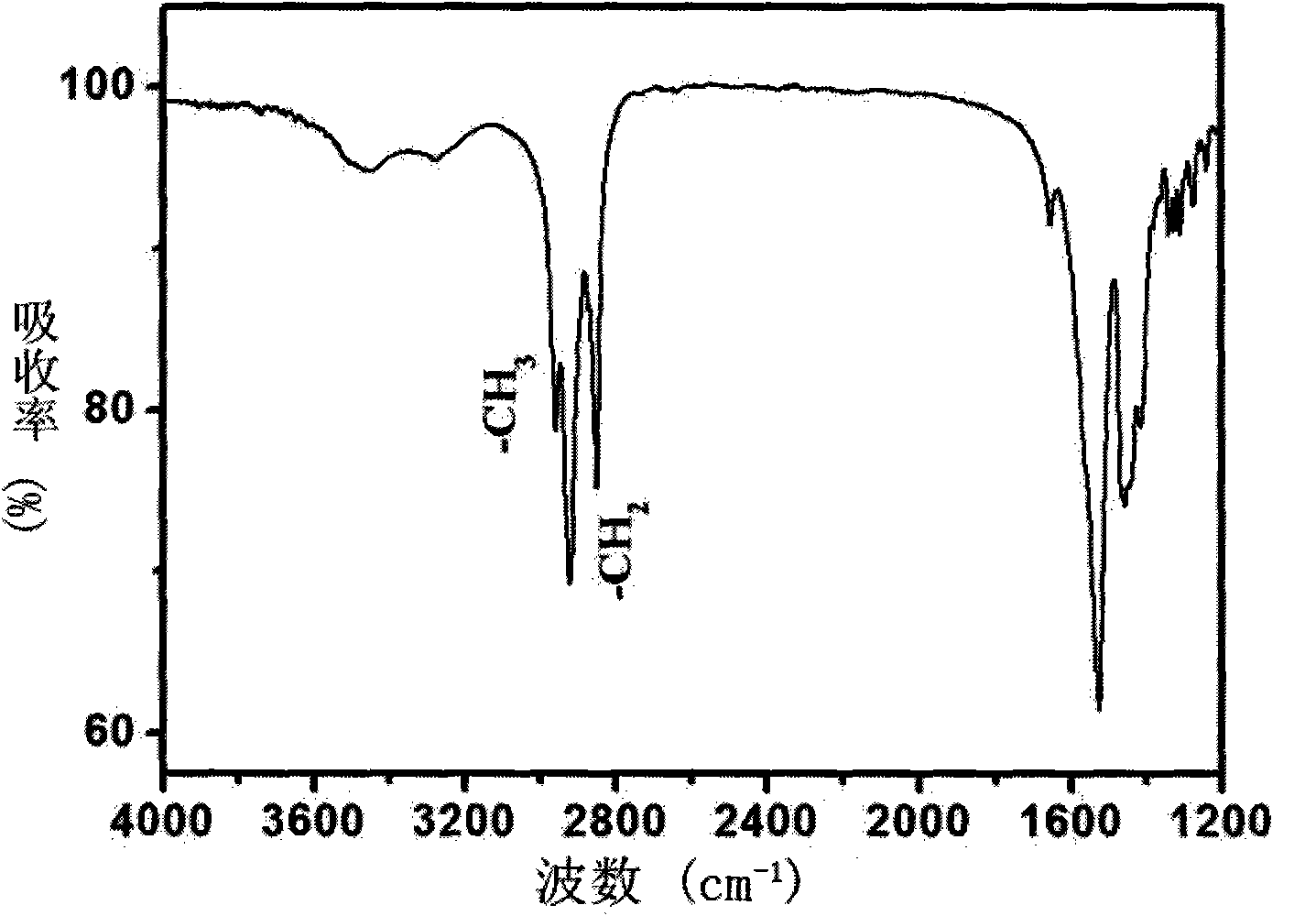

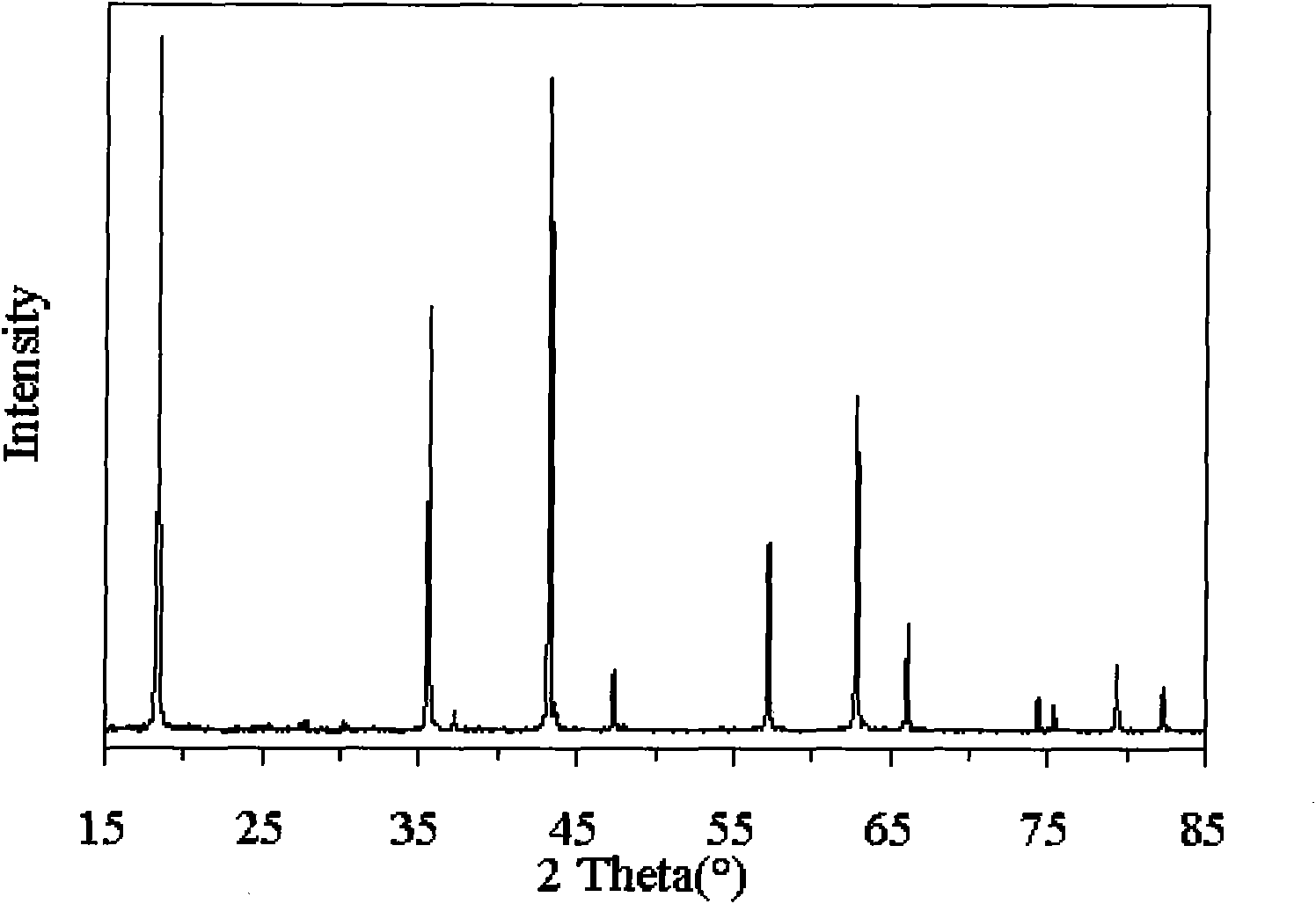

Multi-element high-entropy alloy film and preparation method thereof

ActiveCN103898463AUniform thicknessInhibition formationVacuum evaporation coatingSputtering coatingHigh entropy alloysEvaporation

Owner:ZHEJIANG UNIV

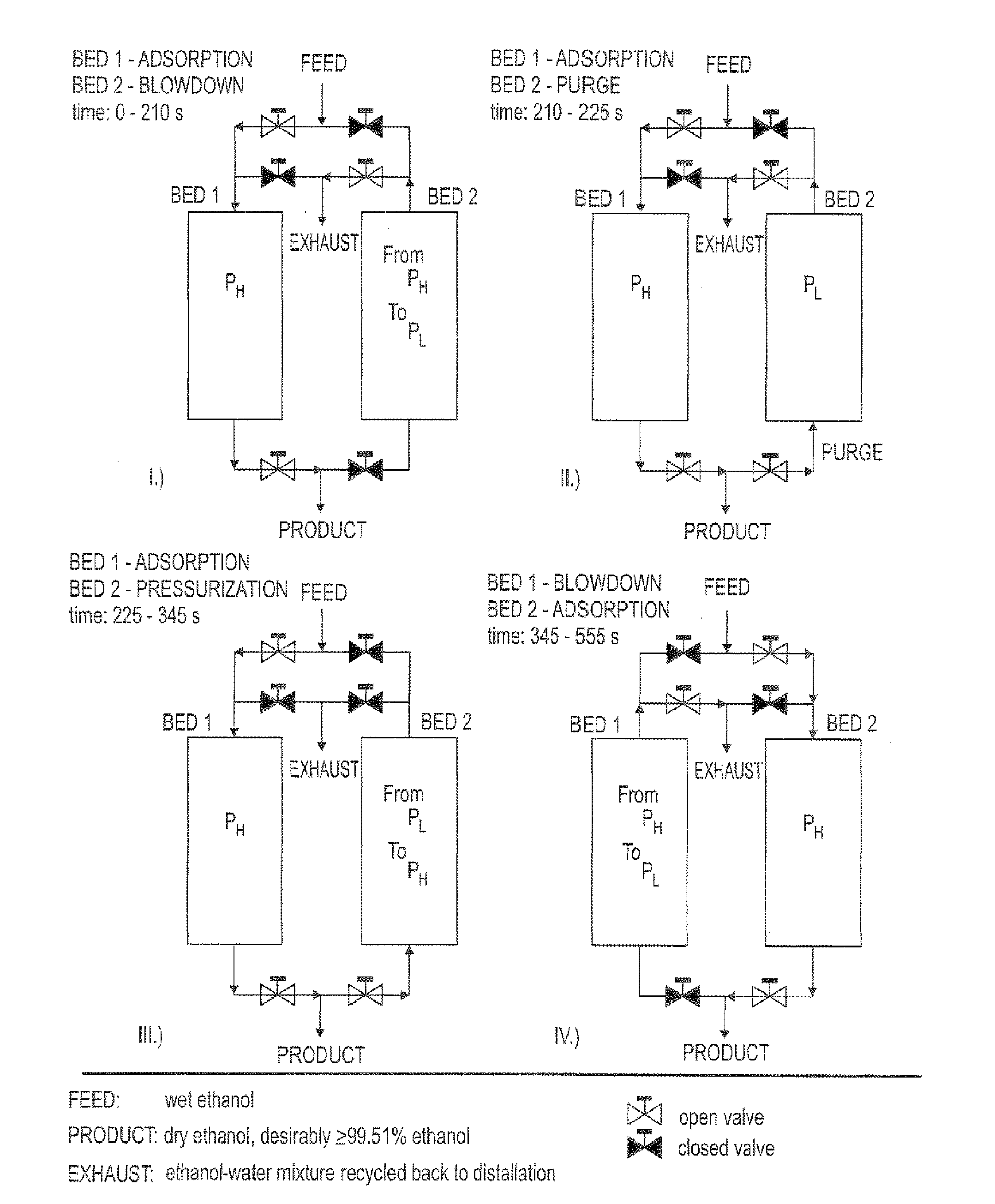

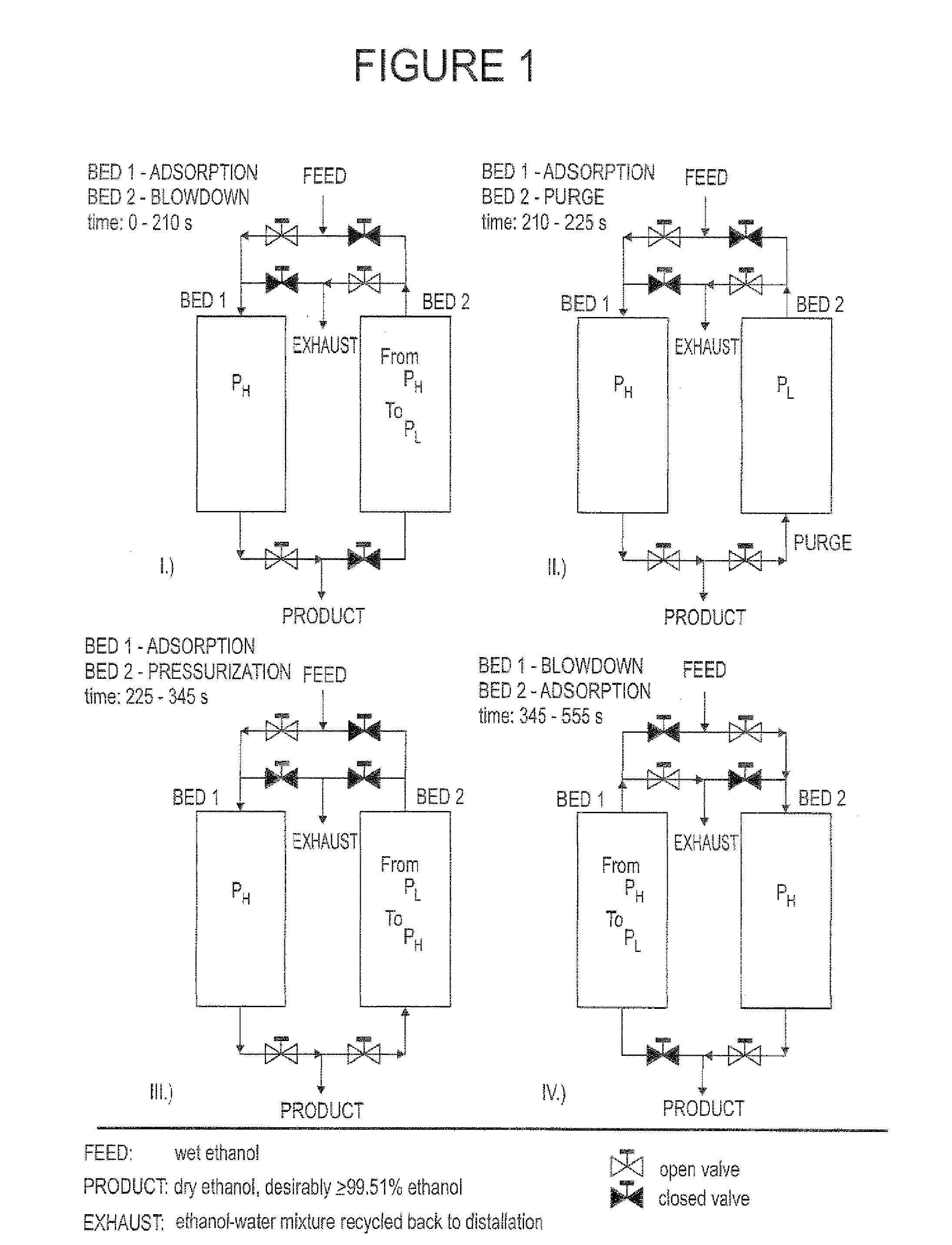

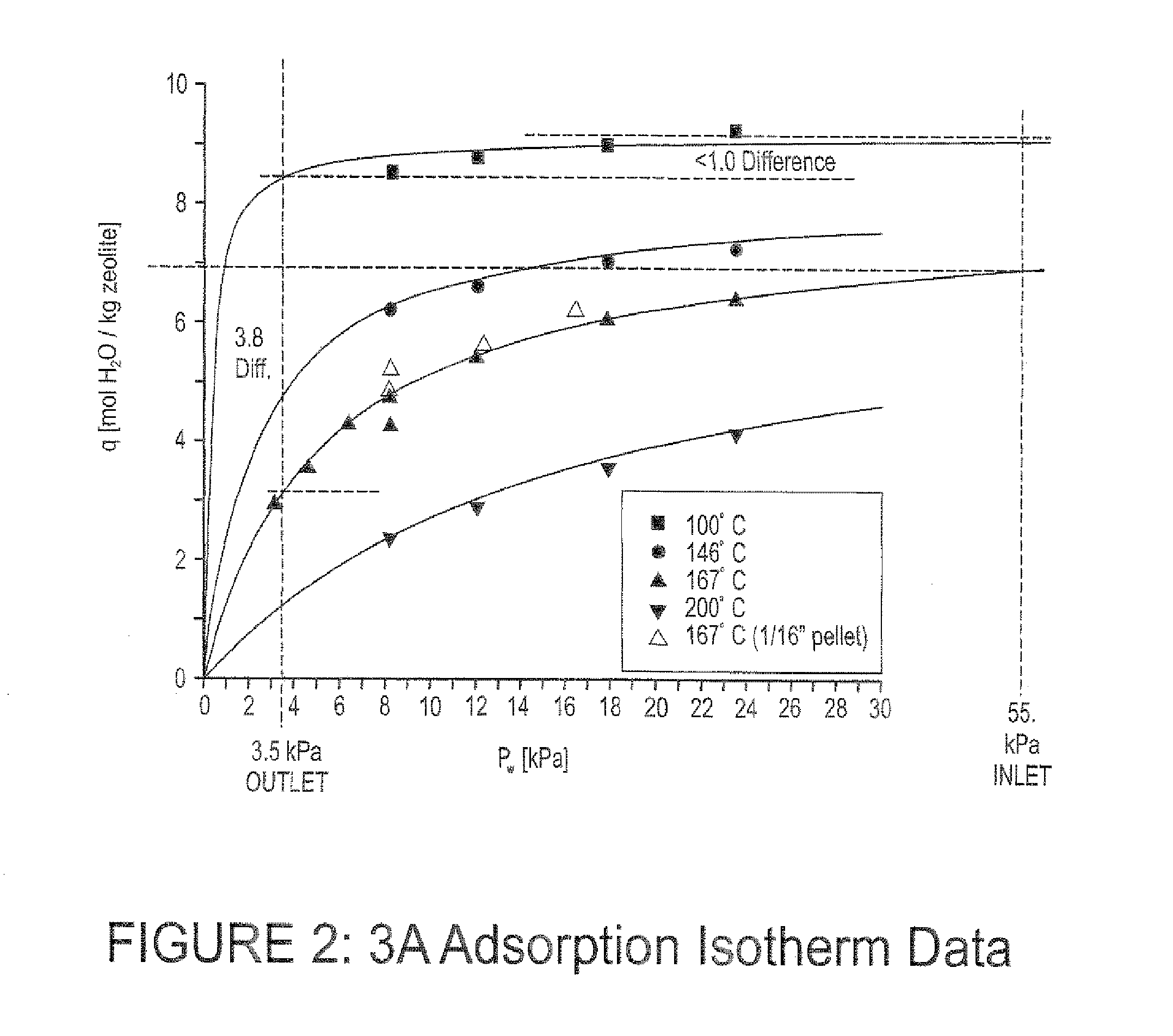

Adsorption process for the dehydration of alcohol

ActiveUS20130225880A1Increase productivityImprove performanceGas treatmentOrganic compound preparationAqueous alcoholHigh pressure

The present invention includes a process for the dehydration of ethanol by adsorption of water at elevated pressure and for the regeneration (purging) of adsorbent at a lower pressure than the pressure used for the adsorption of water where the ratio of the duration of the regeneration (purge) step to the duration of the water adsorption step is higher than 0.1 and the temperature of adsorption is greater than 260 degree Fahrenheit.

Owner:RCM TECH USA INC

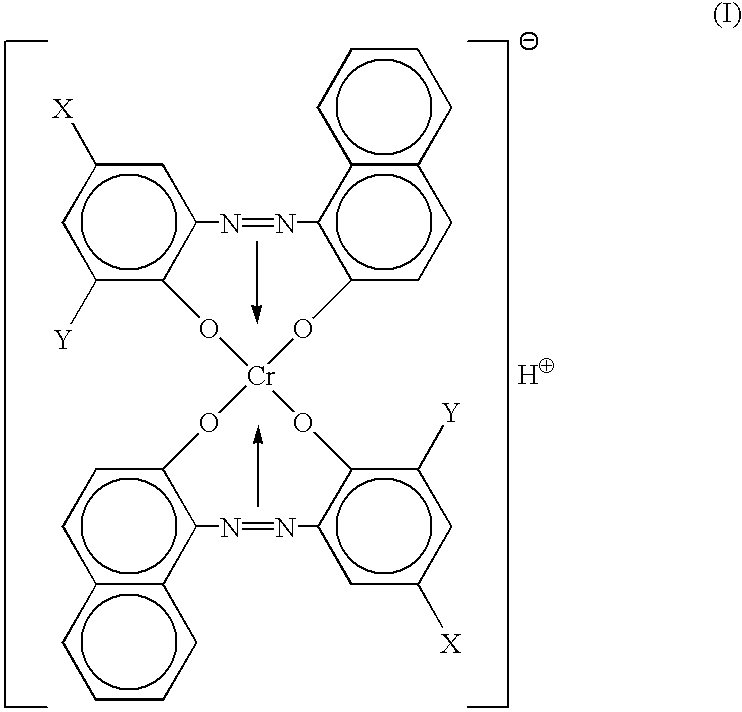

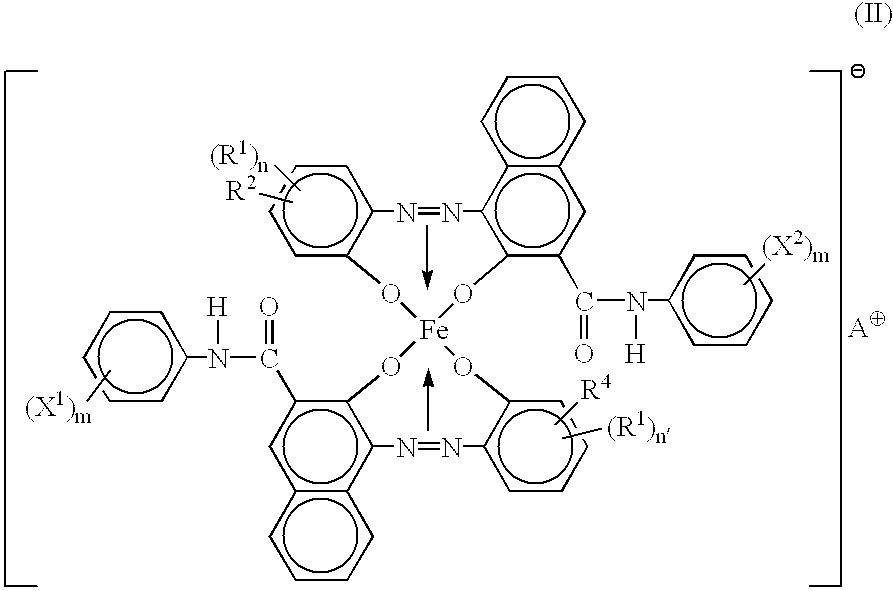

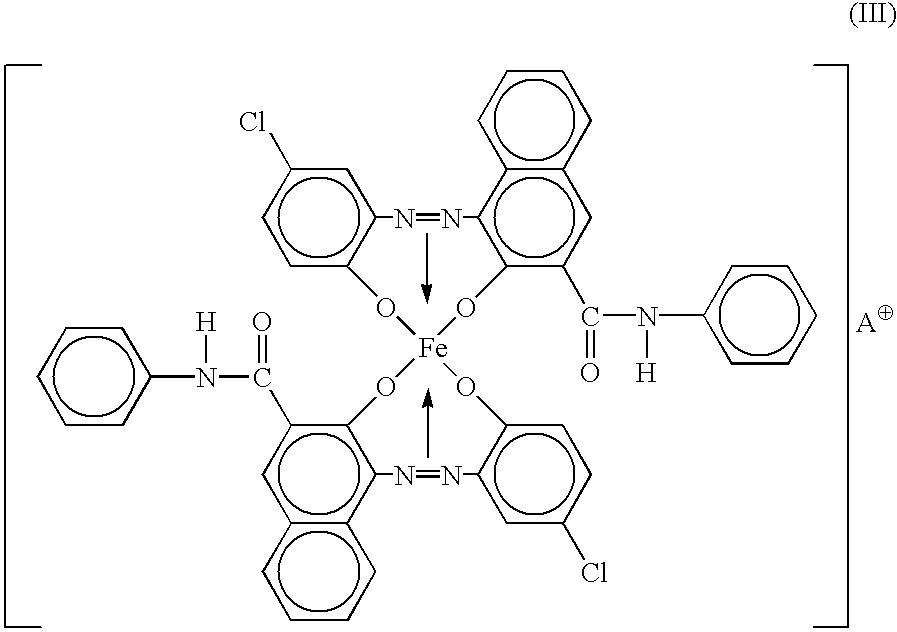

Magnetic toner with negative polarity for developing latent electrostatic images, and image forming apparatus using the same

A magnetic toner with a negative polarity for developing latent electrostatic images is made of toner particles, each toner particle containing a binder resin, a magnetic powder, and a charge control agent, the surface of the magnetic toner satisfying the relationship of 2x10-7<=C / Sw<=10x10-7, provided C<=8x10-3, wherein C is an amount (g / g) of the charge control agent dissolved in a solvent comprising water and methanol, and Sw is a specific surface area (cm2 / cm3) of the toner particles determined from a weight-average particle diameter of the toner particles. An image forming apparatus has an electrostatic image bearing member, and a unit for developing the electrostatic image with the above magnetic toner, the unit having a developer holding member provided with a magnet, and a developer container. A method for measuring the amount of a charge control agent extracted from the surface of magnetic toner particles employs an aqueous alcohol solvent of water and an alcohol.

Owner:RICOH KK

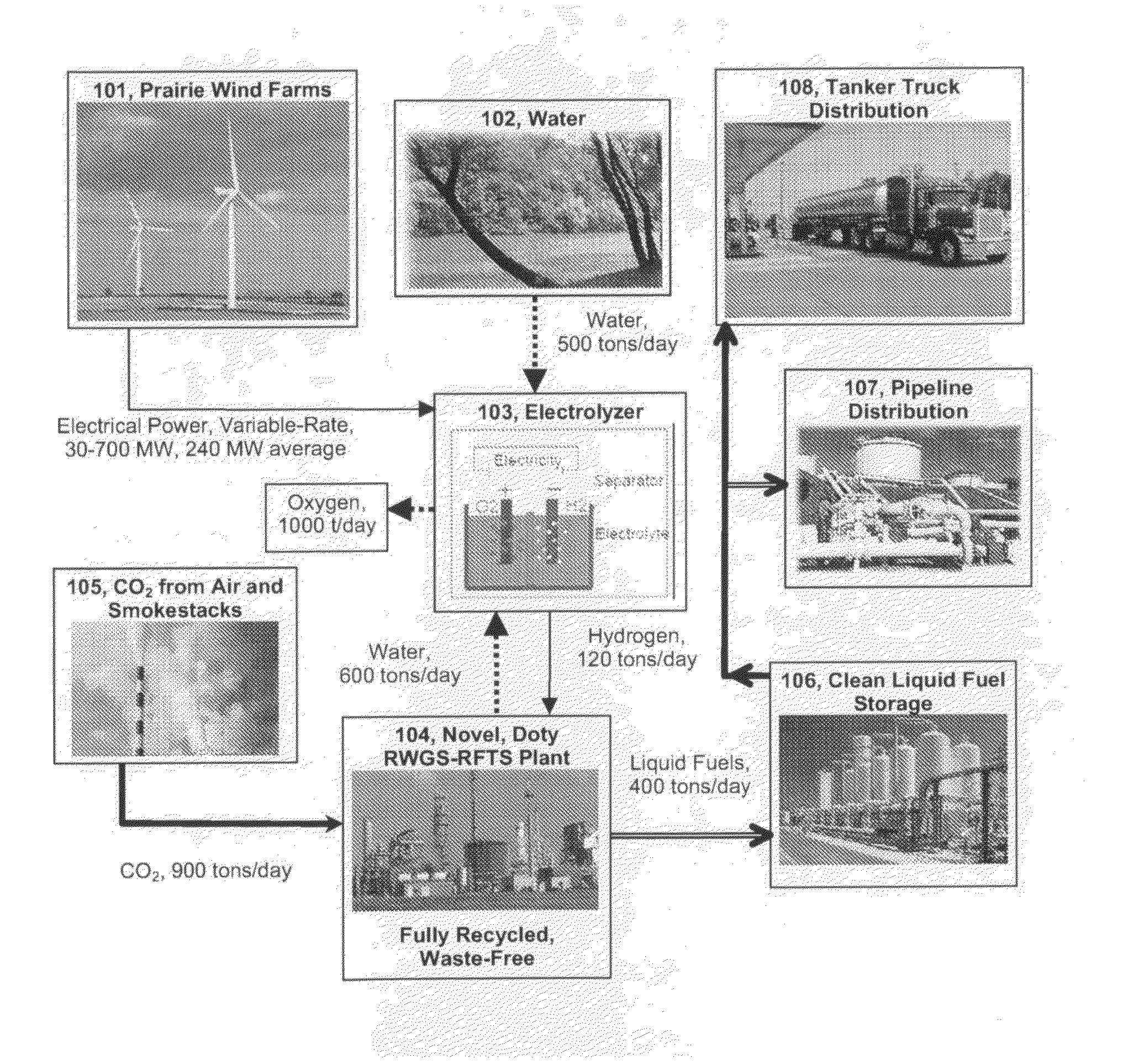

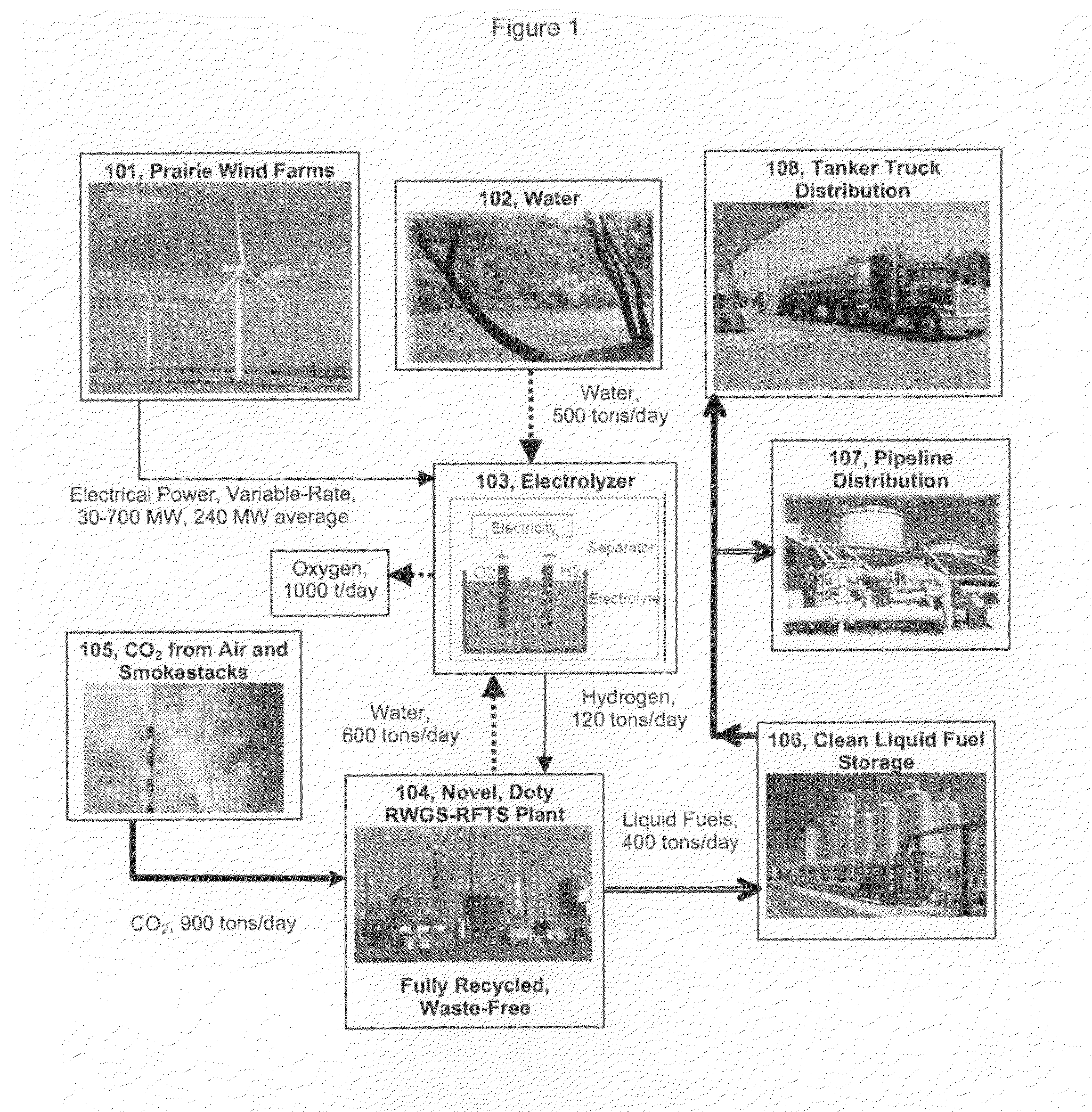

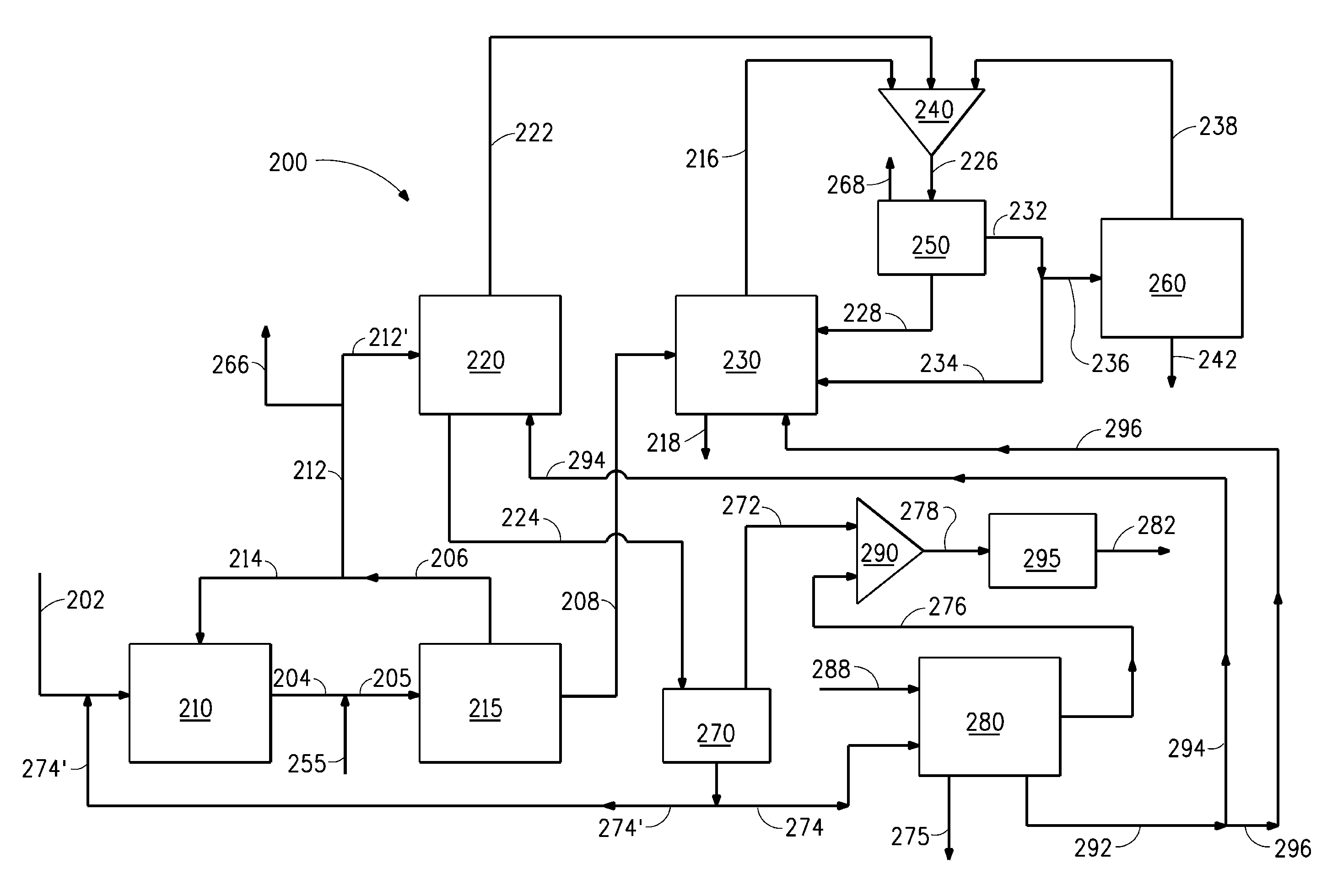

Hydrocarbon and alcohol fuels from variable, renewable energy at very high efficiency

InactiveUS20100280135A1Less power consumptionHigh work pressureLiquid hydrocarbon mixture productionHydrogen productionElectrolysisOrganic Rankine cycle

A Renewable Fischer Tropsch Synthesis (RFTS) process produces hydrocarbons and alcohol fuels from wind energy, waste CO2 and water. The process includes (A) electrolyzing water to generate hydrogen and oxygen, (B) generating syngas in a reverse water gas shift (RWGS) reactor, (C) driving the RWGS reaction to the right by condensing water from the RWGS products and separating CO using a CuAlCl4-aromatic complexing method, (D) using a compressor with variable stator nozzles, (E) carrying out the FTS reactions in a high-temperature multi-tubular reactor, (F) separating the FTS products using high-pressure fractional condensation, (G) separating CO2 from product streams for recycling through the RWGS reactor, and (H) using control methods to maintain temperatures of the reactors, electrolyzer, and condensers at optima that are functions of the flow rate. The RFTS process may also include heat engines, a refrigeration cycle utilizing compressed oxygen, and a dual-source organic Rankine cycle.

Owner:DOTY SCI

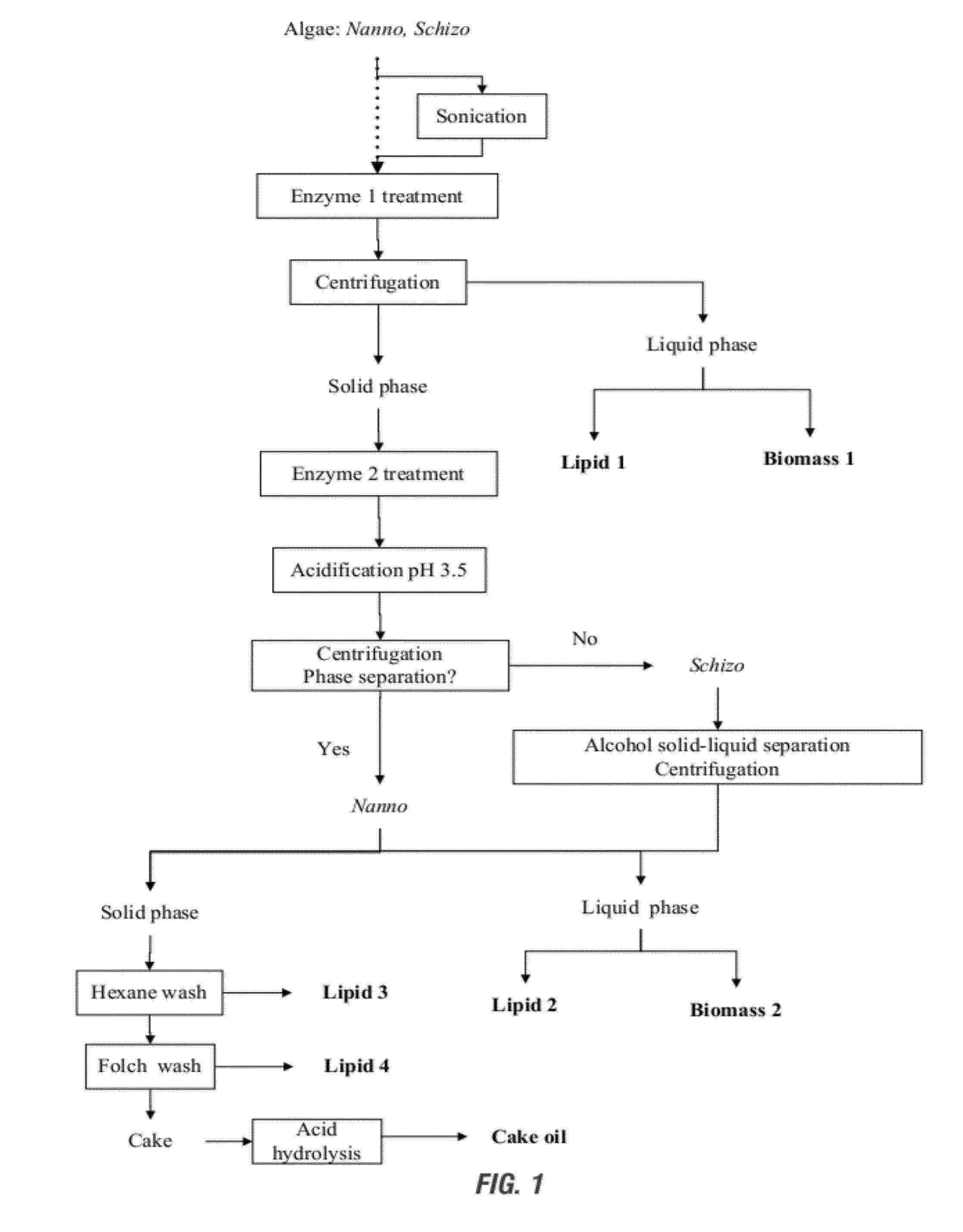

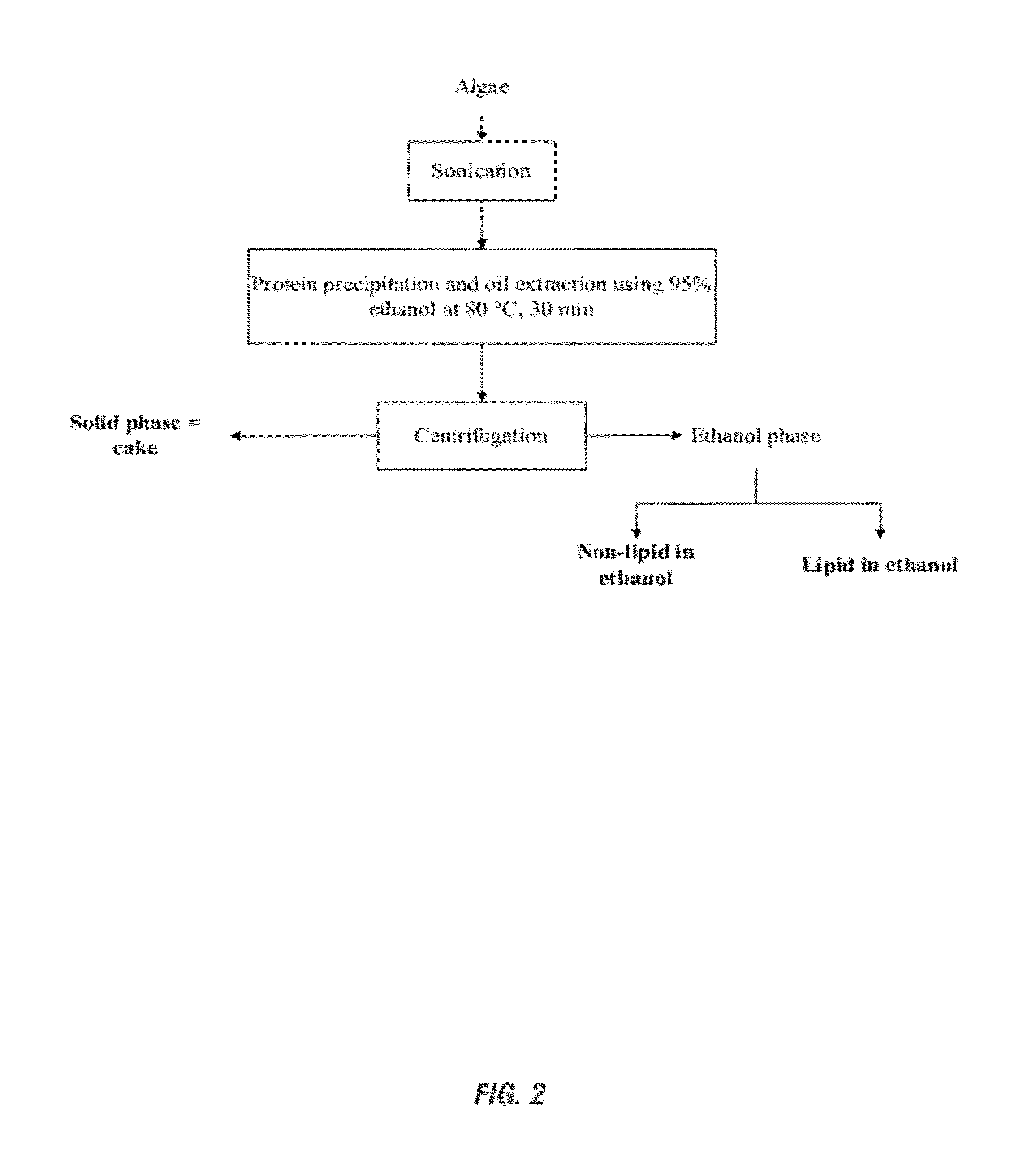

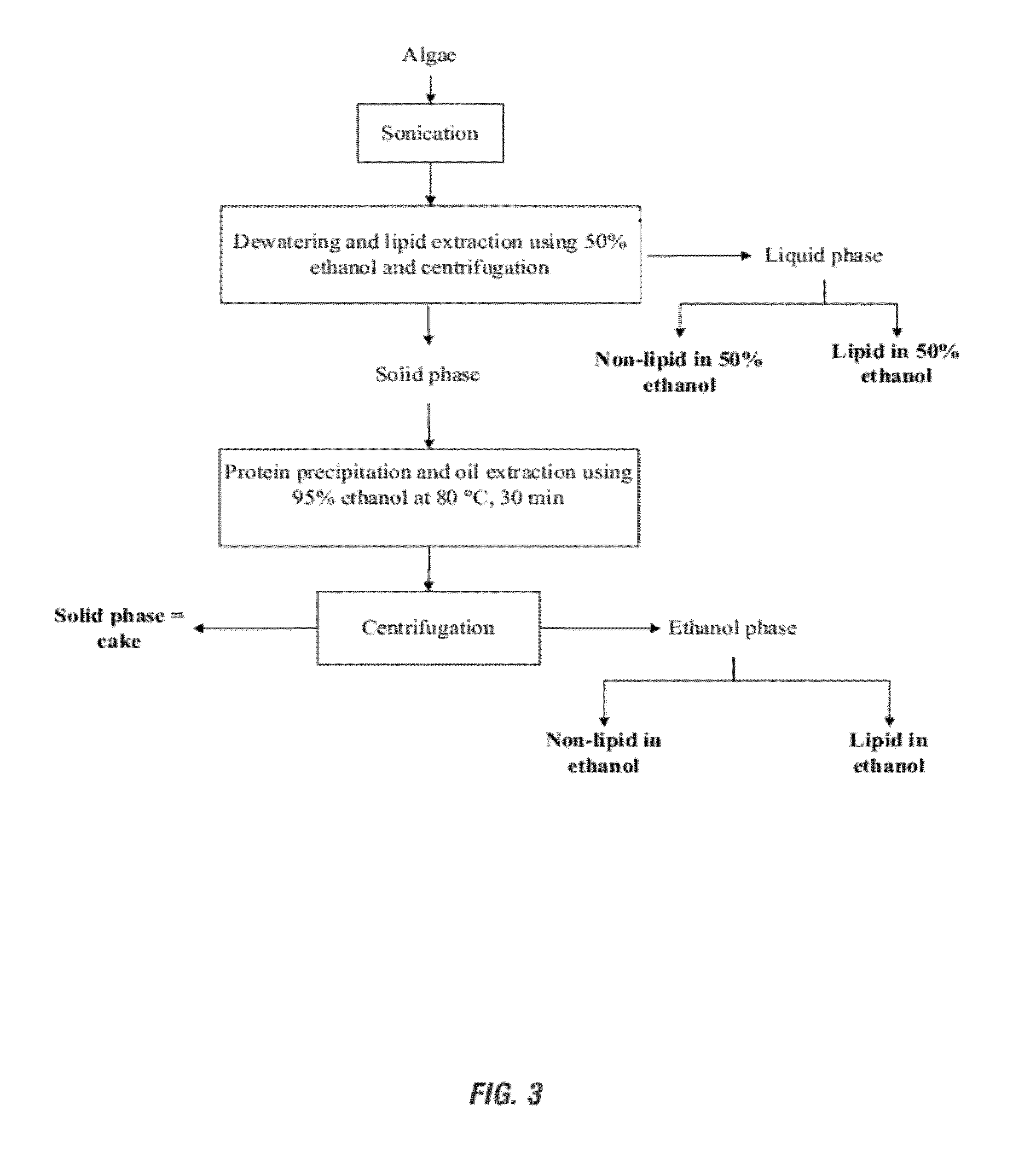

Oil extraction from microalgae

InactiveUS20120238732A1Costly and energy intensivePeptide preparation methodsDepsipeptidesAqueous alcoholOlive oil extraction

A method of oil extraction and biomass recovery from microalgae is disclosed. Methods according to the invention extract lipids from a biomass source and concentrate protein in the solid biomass source by alcohol processing. Aqueous alcohol processing methods provide extraction and separation techniques for lipids and protein-rich biomass suitable for biofuels.

Owner:IOWA STATE UNIV RES FOUND

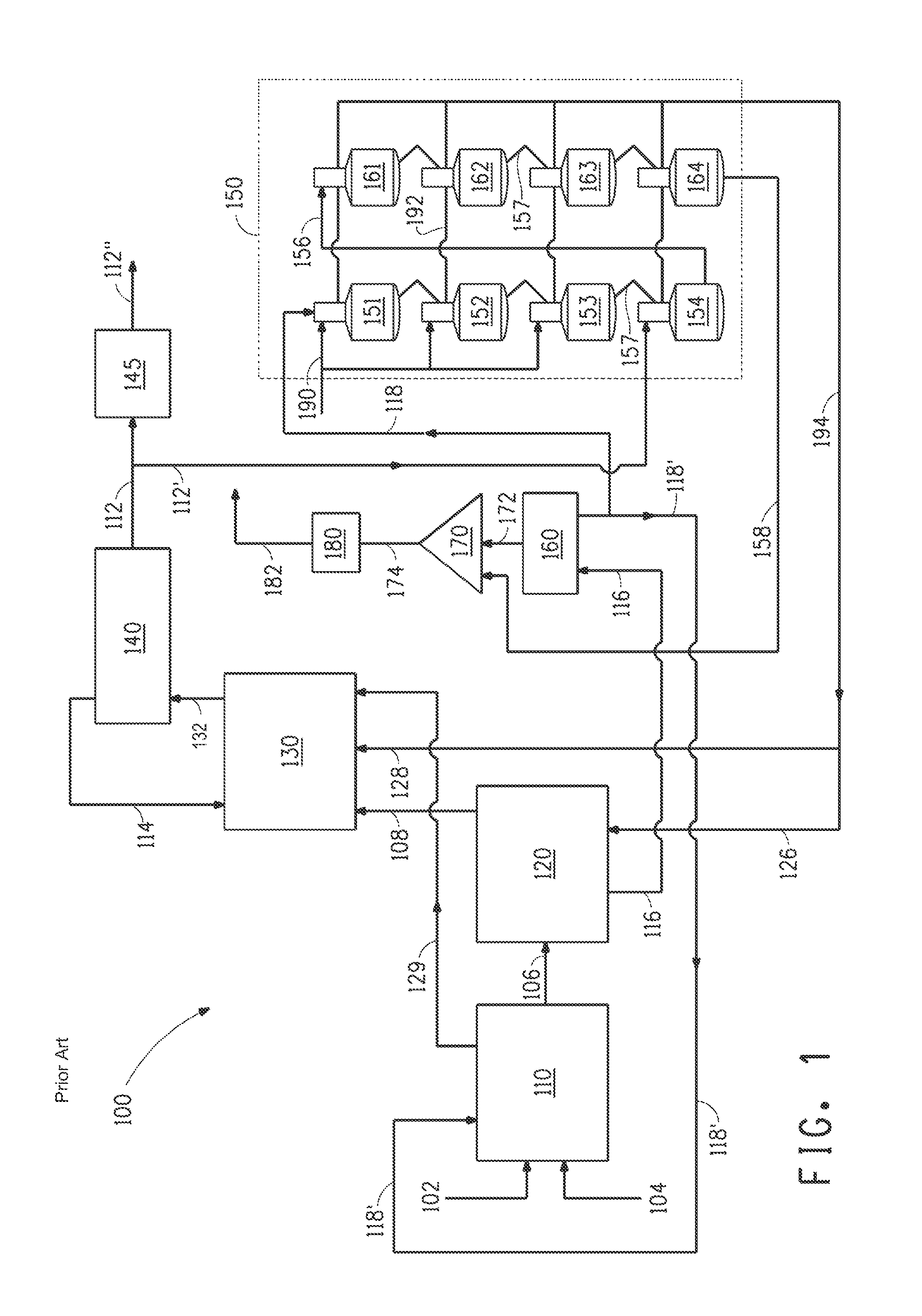

Methods for alcohol recovery and concentration of stillage by-products

ActiveUS8906204B2Efficient use ofHydrocarbon purification/separationAlcoholic beverage preparationAqueous alcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

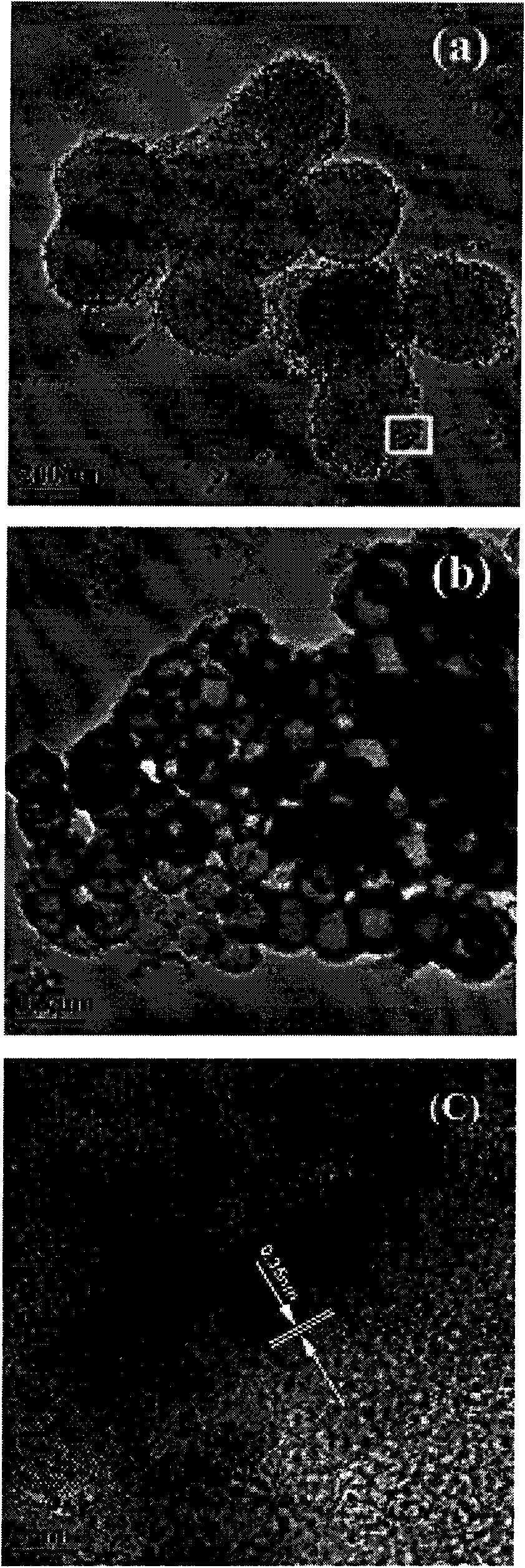

Preparation of core/shell structural polystyrene/titanium dioxide composite photo catalyst

InactiveCN101537349AImprove photocatalytic activityLow densityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPhotocatalytic reactionMicrosphere

The invention relates to preparation of core / shell structural polystyrene / titanium dioxide composite photo catalyst, comprising the steps of: (1) dissolving titanium alkoxide in absolute lower alcohol to be prepared into aqueous alcohol solution of titanium alkoxide with the concentration of titanium alkoxide in the lower alcohol being 0.004-0.100mL / Ml; (2) adding polystyrene microballs into the aqueous alcohol solution of titanium alkoxide to experience ultra-sound and stirring to obtain a uniform mixture; (3) placing a crucible holding, the polystyrene microballs and the aqueous alcohol solution of titanium alkoxide in a closed container, heating the closed container to 70-200 DEG C for heat treatment and preserving temperature for 1-96 hours; washing and drying to obtain the core / shell structural polystyrene / titanium dioxide composite photo catalyst. The photo catalyst prepared by the invention maintains the characteristic of high catalytic activity of titanium dioxide nano crystal grain, and has the photo catalytic activity similar to the photo catalytic activity of nano titanium dioxide prepared by gas phase method in the majority of photo catalysis reactions.

Owner:DONGHUA UNIV

Dry type manufacturing method of animal specimen

InactiveCN1971663AImprove qualityAdequate perfusionDead animal preservationEducational modelsHigh concentrationGlycerol

The invention relates to a dry type making method for animal specimen that includes six steps: collecting material, reshaping antisepsis fix and tube cavity cast, alcohol dewatering fix, glycerol process, turpentine impregnation and air drying, material repairing tinction preservation or seal up for keeping. Thereinto, in step 1, the animal material is bleed and killed via health quarantine, in step 2, potting it with the formalin with colorless glycerin and phenol or alcohol solution, in step 3, controlling the concentration of every step and fixed time, in step 4, marinating it with glycerol moisture absorption soften liquid, and transfer it from low concentration to high concentration of glycerin, and the time is prolonged gradually, in step 5, treating it with turpentine continually, in step 6, printing it. The invention improves the present technique, the quality of specimen is improved greatly, and that can keep the original state of material, the color and the luster. The dried specimen is sanitation without peculiar smell, and good at handle and quality.

Owner:王荣林

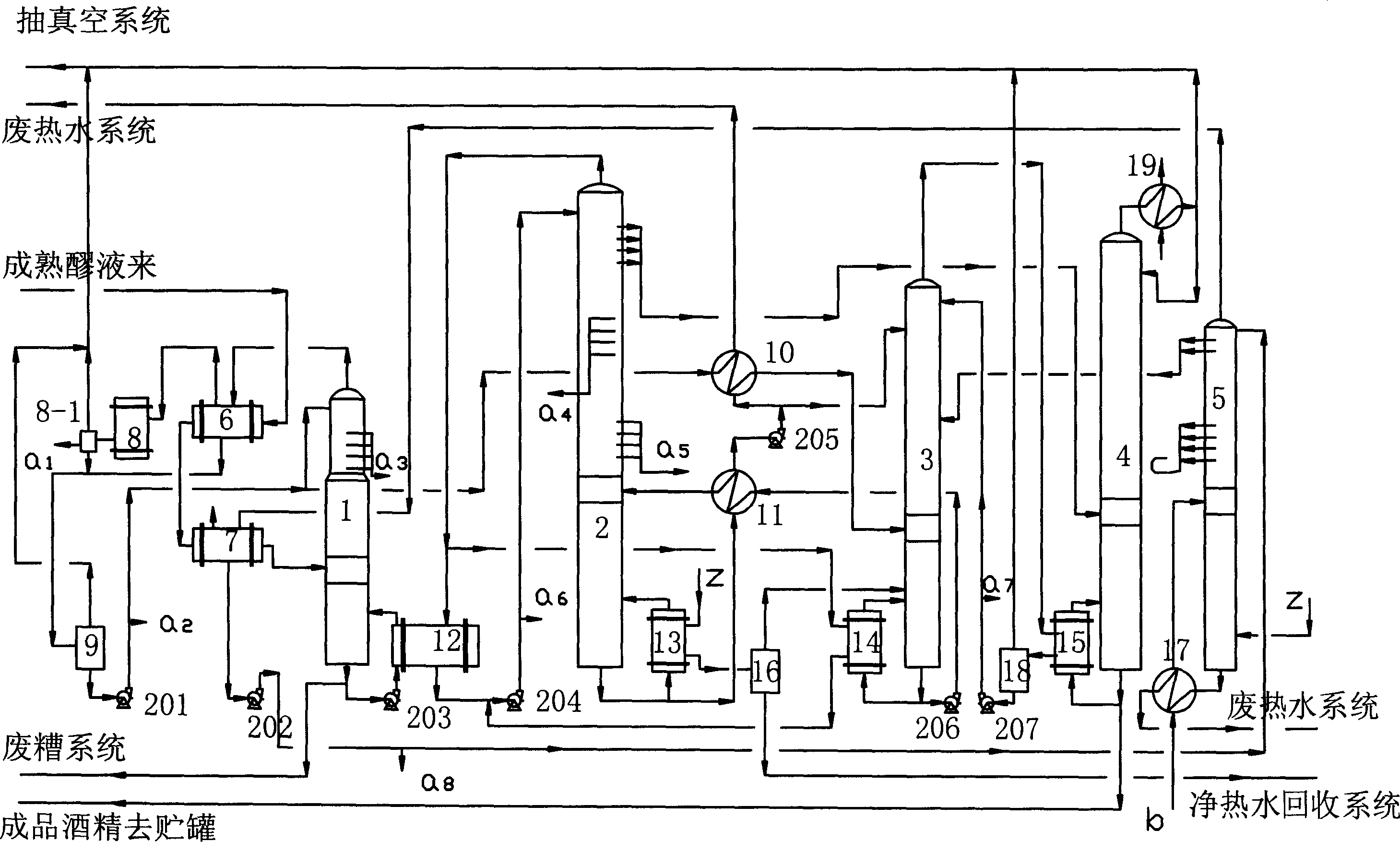

Alcohol quinque-towel differential pressure distilling arrangement and technique thereof

ActiveCN1736527APrevent scalingPrevent precipitationDistillation separationSteam condensationAqueous alcohol

The invention discloses a five-tower differential pressure distilling apparatus and the technique for alcohol: the fractionating tower operating with positive pressure, some alcohol vapor in the head tower flowing into the reboiler of crude distillation column, and the other into the reboiler of water scrubber; the leaving distilled water in the still of fractionating tower preheating the weak alcohol liquid from the bottom of water scrubber, then partly inpouring to crude alcohol preheater to preheat crude alcohol, and partly inpouring to water scrubber according to the requirement of flowmeter; by flash distillation the condensate water in the reboiler of fractionating tower generating indirect steam which enters directly into the still of water scrubber; the water scrubber operating with negative pressure, and the alcohol vapor in the head into the reboiler of the methanol heating tower. The significance effect is that: the energy saving effect is perfect when used to produce excellent edible alcohol and the vapor consuming index approaching the advanced lever of 2.3- 2.6 t / t.

Owner:广东省博罗中科天元高新技术工程有限公司

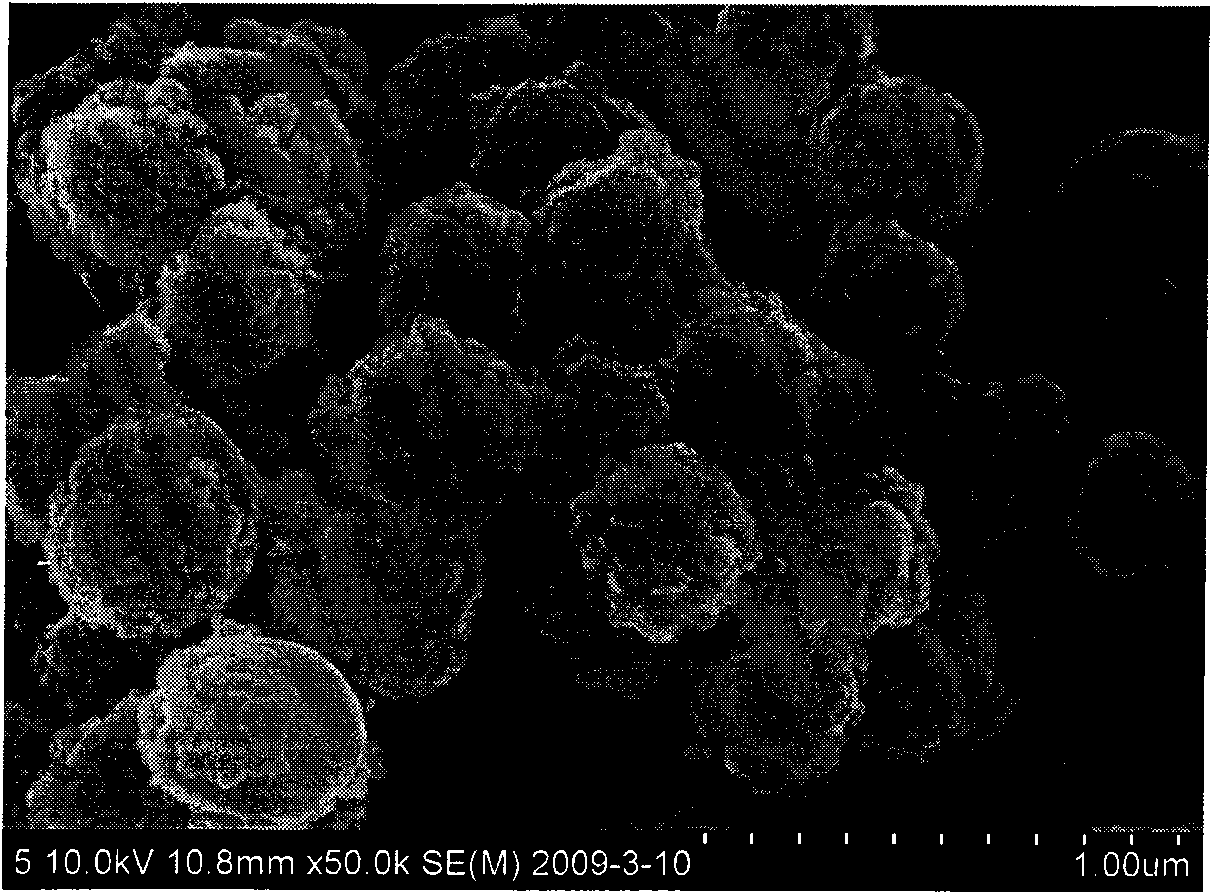

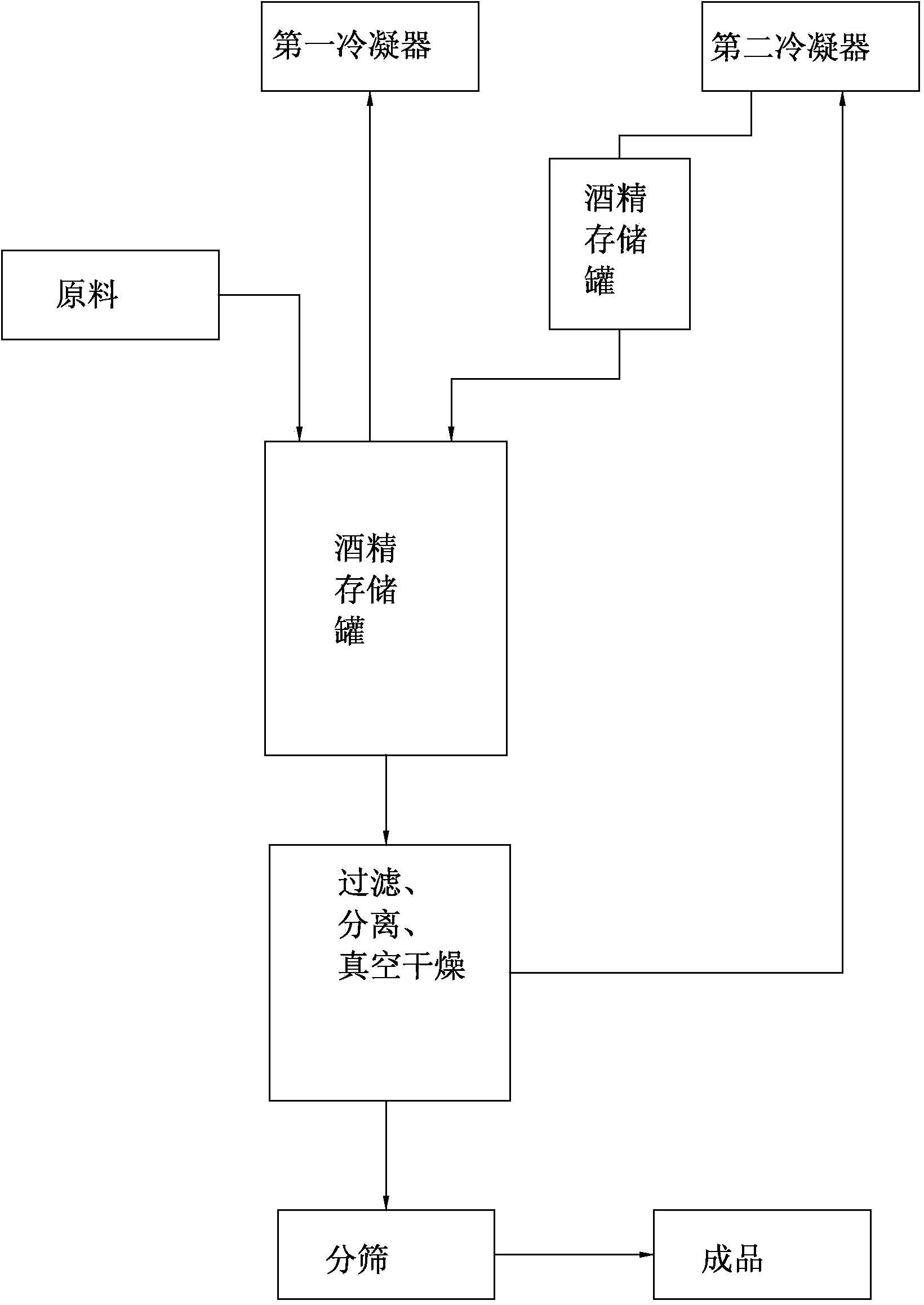

Preparation method of high-molecular nylon powder material used for 3D printing

The invention discloses a preparation method of a high-molecular nylon powder material used for 3D printing. The method comprises the following steps: 1)placing a nylon material, a nucleating agent and alcohol in a high pressure reaction vessel; 2)operating the high pressure reaction vessel for stirring, introducing nitrogen for protection, heating the material in the high pressure reaction vessel to 130-160 DEG C; 3)insulating and dissolving, insulating the reaction vessel for 2-3 hours, fully stirring, dissolving the nylon material; 4)cooling, depositing and precipitating, controlling the stirring speed of the high pressure reaction vessel, slowly cooling, and gradually completing the precipitation and moulding of the nylon powder; 5)filtering, cooling the material in the high pressure reaction vessel to less than 70 DEG C, transferring the mixture to a filter tank, separating the solvent from the solid; 6)centrifuging, transferring the filter residue to a centrifuge for removing the solvent; 7)drying under vacuum; thoroughly removing the solvent in a vacuum drying machine; and 8)sieving the dried nylon powder, and controlling the particle size of nylon powder at 35-50 mum to obtain the required material.

Owner:东莞方易达三维科技有限公司 +1

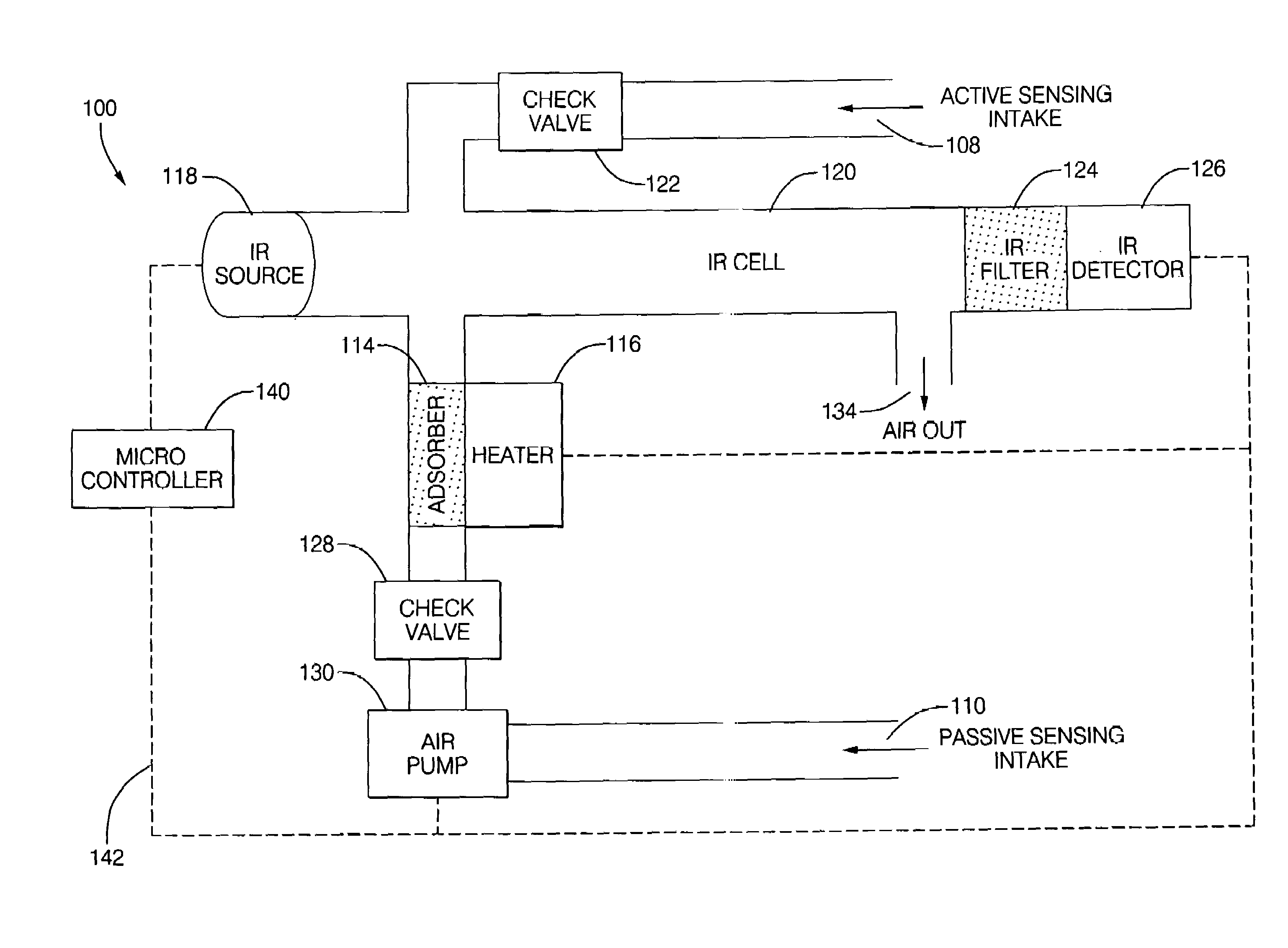

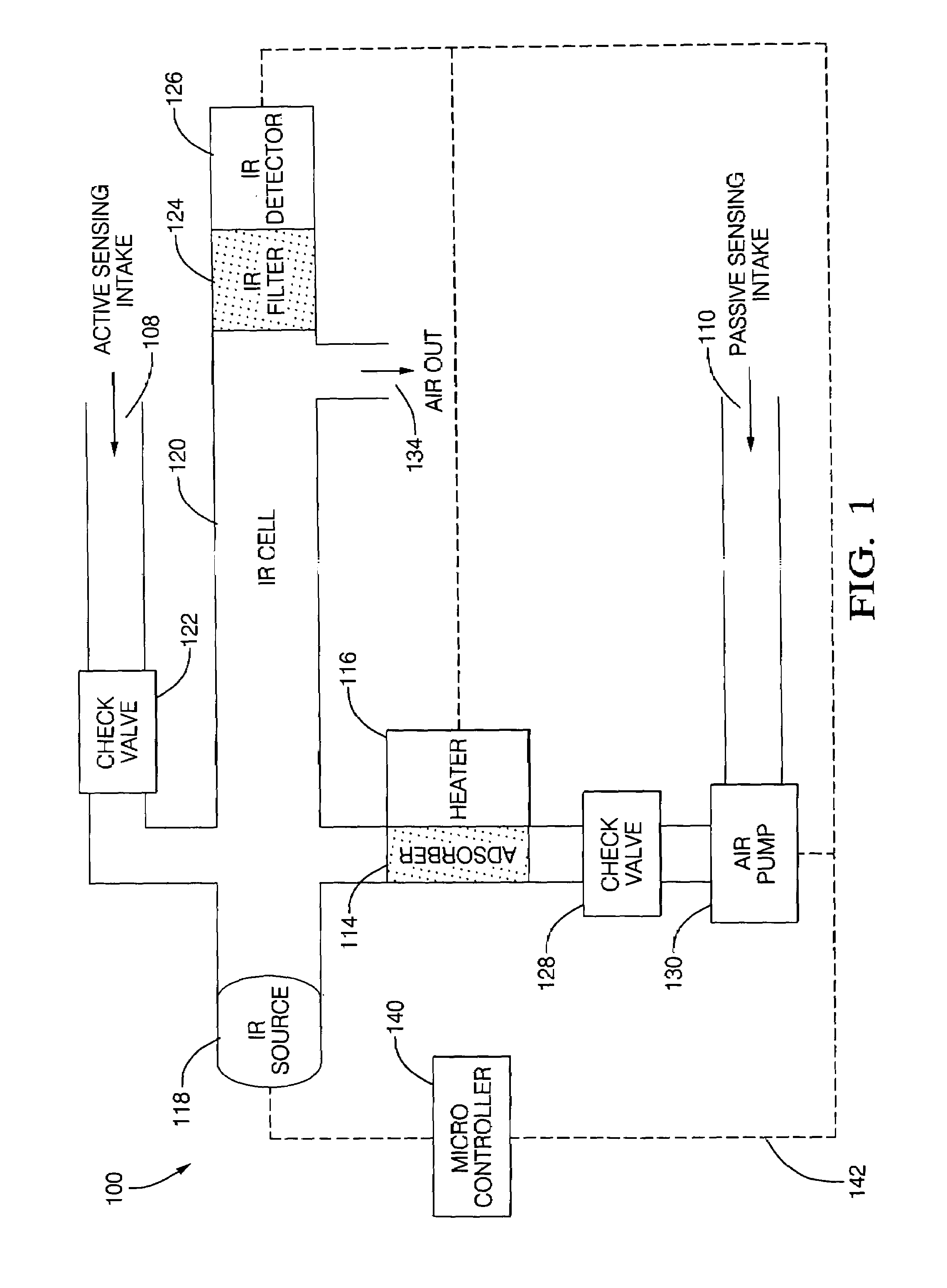

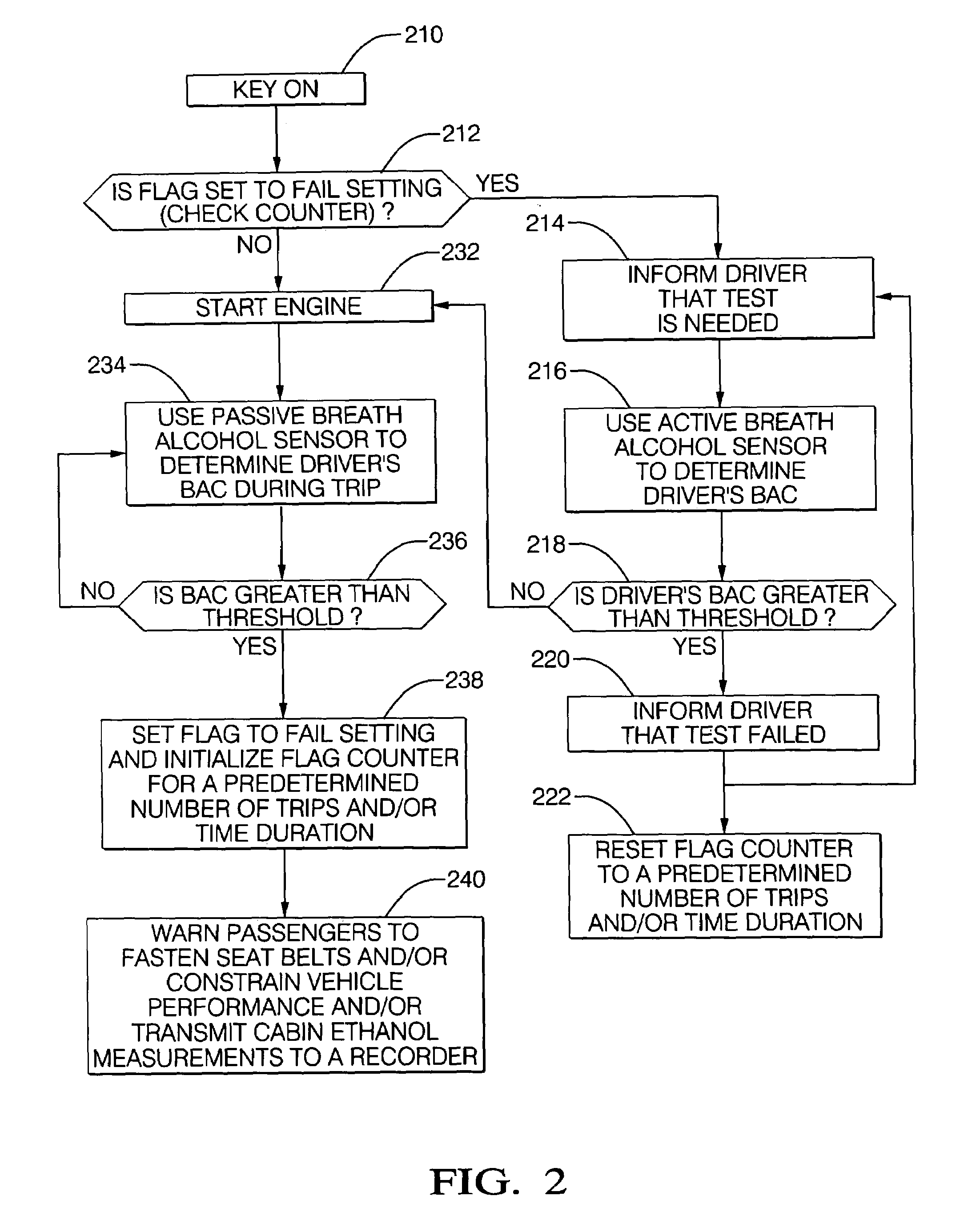

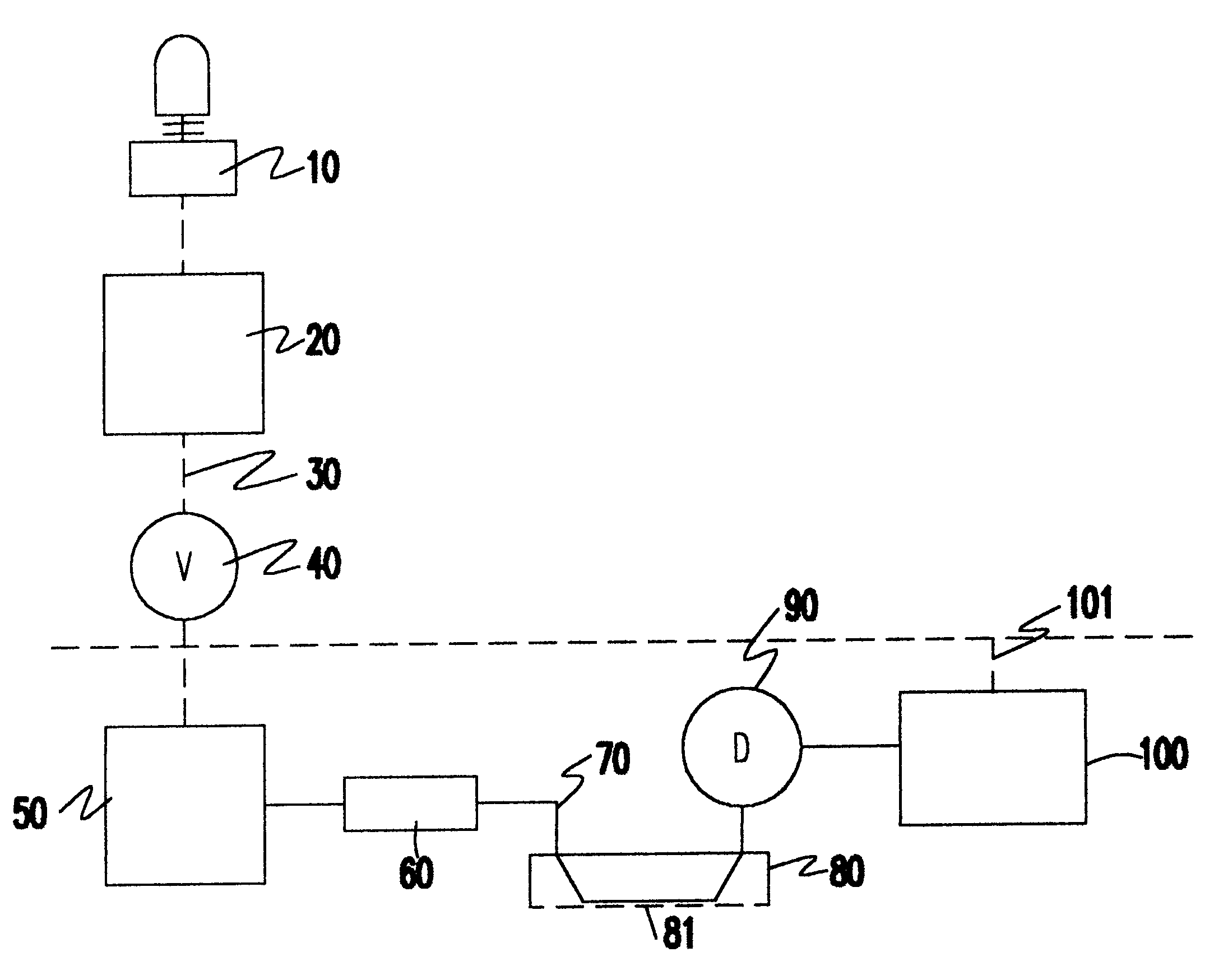

Chemical vapor sensor having an active and a passive measurement mode

ActiveUS7279132B2High detection sensitivityMinimize time inconvenienceAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationDriver/operatorChemical vapors

A chemical vapor sensor is provided that measures a chemical species of interest with high sensitivity and chemical specificity. In an aspect, an ethanol vapor sensor is provided, sized for being inconspicuous and on-board a vehicle, having a passive measurement mode and an active breathalyzer mode, for detecting a motor vehicle driver that exceeds a legal limit of blood alcohol concentration (BAC), for use with vehicle safety systems. For the passive mode, a vapor concentrator is utilized to amplify a sampled vapor concentration to a detectible level for use with an infrared (IR) detector. In an aspect, ethanol vapor in a vehicle cabin is passively measured and if a predetermined ethanol level is measured, a countermeasure is invoked to improve safety. In an aspect, an active breathalyzer is used as a countermeasure. The active breathalyzer can be imposed for a number of vehicle trips or for a predetermined time period.

Owner:APTIV TECH LTD

High-per formance carbon material preparing method by water-base curtain coating technology

InactiveCN1472833AGood electrical and thermal conductivityReduced electrical and thermal conductivityCell electrodesFuel cellsFiberCarbon composites

A method of water-base casting technological preparation of the carbon material with advanced property, it belongs to the field of fuel cell, adopt intermediate phase carbon powder as raw materials, take short carbon fiber or grahpite as the enhanced modified material, the solution of casting slurry adopts the mixture of the water and alcohol, through the water-base cast techniques prepare the carbon / carbon composite green compacts, press the multiplayer casting green compacts to gain the laminating green compacts which have air interval channel, then through the high temperature sintering technique and the resin impregnation sealing of hole, finally get the bipolar plate of fuel cell of proton exchange membrane. This invention adopts firstly the casting forming technique to prepare the carbon / carbon composite bipolar plate.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method for bismuth-tellurium nano-porous thermoelectric material

InactiveCN101656292AImprove performanceUniform sizeThermoelectric device manufacture/treatmentThermoelectric materialsCrystal system

A preparation method for bismuth(Bi)-tellurium(Te) nano-porous thermoelectric semiconductor material is disclosed, belonging to the technical field of the thermoelectric material. The preparation method comprises the following step: Bi-Te-based nano-powders Bi[2-x]Sb[x]Te[3-y]Se[y] (x=0-1.9, y=0-0.5) are placed in alcohol solution with a pore-forming agent sufficiently dissolved therein, in orderto be mixed by a method which combines ultrasonic wave with magnetic suspension agitation, the powders are sintered into bulk material by means of a discharge plasma sintering technology after being dried, and during the sintering, the pore-forming agent is utilized for sublimation and evaporation at the particular temperature so that the bulk material can form nano-sized pore structure therein inthe process of sintering in order to form the nano-porous material. The Bi-Te-based alloy belongs to rhombohedral crystal system structure. The preparation method has the advantages of simple preparation, easy operation, lower cost, accurate ingredient control, relatively uniform size and distribution of the nano pores and the like.

Owner:UNIV OF SCI & TECH BEIJING

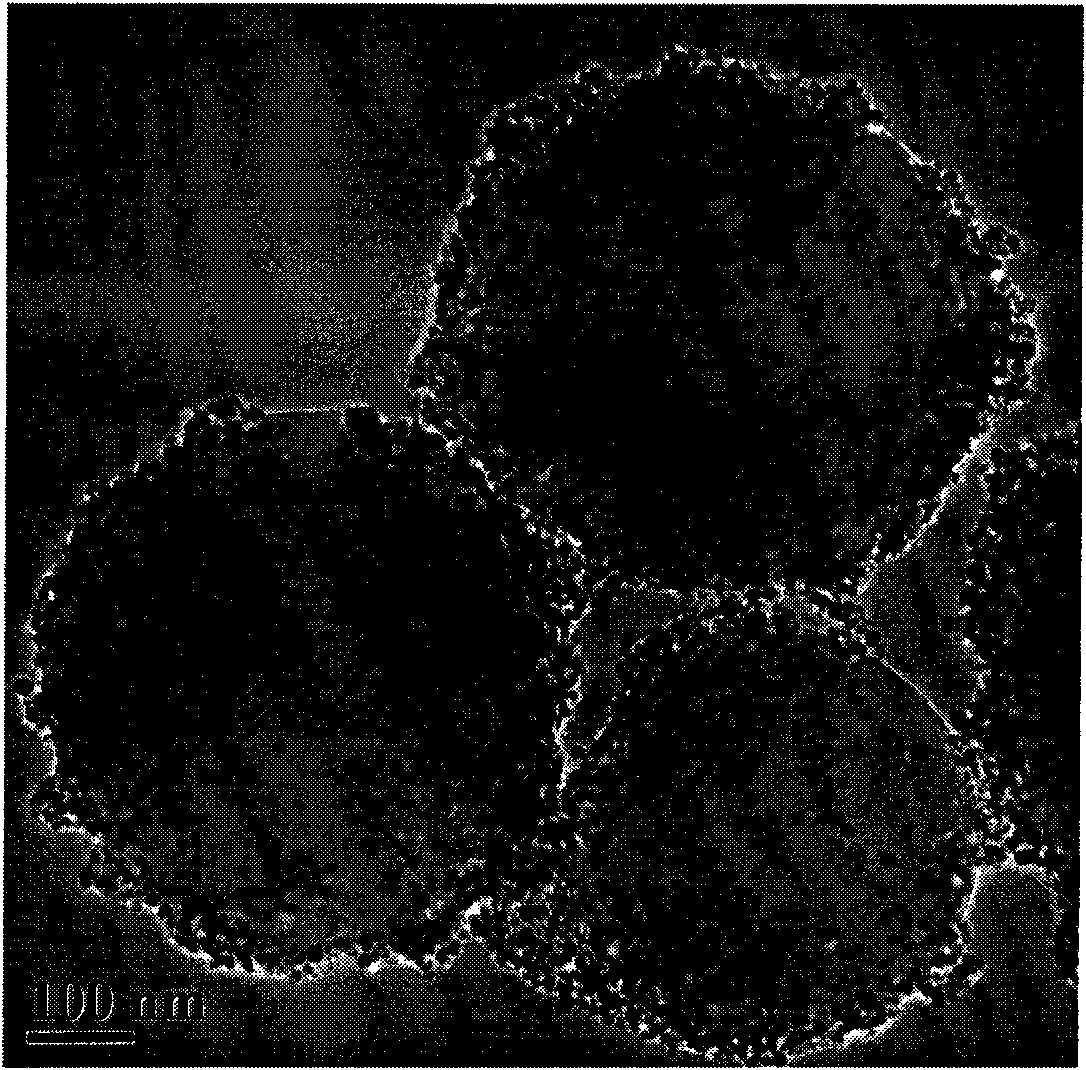

Preparation method of carbon-coated lithium titanate

The invention discloses a preparation method of carbon-coated lithium titanate, comprising the following steps of: 1) weighing and dispersing lithium source and titanium source in distilled water or deionized water; 2) adding long-chain aliphatic carboxylic acid to the water, heating the water to 30 to 100 DEG C, followed by uniform stirring and dispersion in order to obtain suspension; 3) transferring the suspension into a closed reaction container for being heated so that the suspension is subjected to reaction at constant temperature; 4) cooling reaction products to room temperature upon the end of the reaction, repeatedly washing with mixed liquid of alcohol and water, centrifuging and drying the reaction products, and collecting precursor; and (5) putting the collected precursor in an atmosphere furnace filled with non-oxidative gas to be roasted, and then cooling the roasted precursor to result in the carbon-coated lithium titanate. Compared with the prior art, the preparation method according to the invention achieves the formation of uniform carbon-coated layers under the protection of non-oxidative gas by means of surface coordination of long-chain aliphatic carboxylic acid and lithium titanate, thus the conductivity of lithium titanate can be improved and the high-rate and high temperature performances of lithium ion secondary battery can also be enhanced.

Owner:DONGGUAN AMPEREX TECH +1

Process and measuring system for detection of substances emitted or perspired through the skin

InactiveUS6183418B1Minimize impactInexpensive productionTesting beveragesPreparing sample for investigationDiffusionQuantitative determination

The process for detection and for quantitative determination of substances emitted or perspired through the skin is derived from flow diffusion analysis. The measuring system conceived for this purpose uses a diffusion half cell through which an acceptor medium flows and which is closed by a membrane. For the duration of the measurement, the membrane is brought into contact with the skin or a closed gas volume formed over the skin. With the process and the related measuring system, the blood alcohol level can be determined with a good degree of precision indirectly via the quantity of (gaseous) ethanol emitted through the skin.

Owner:MOLLER MEDICAL +2

Preparation method of nanometer composite film ammonia gas sensor

InactiveCN102788822AMild conditionsRaw materials are easy to getMaterial resistanceComposite filmIce water

A preparation method of a nanometer composite film ammonia gas sensor comprises the following steps: 1, taking 18-20 parts by weight of aniline monomers, dispersing the aniline monomers into deionized water, adding 0.1-3 parts by weight of graphene, and uniformly stirring; 2, adding 700-1000 parts by weight of 1mol / L hydrochloric acid to the mixed solution obtained in step 1, placing the obtained solution in an ice water bath, continuously stirring for 20-40min, adding a solution containing 456 parts by weight of ammonium persulfate, placing in the ice water bath, and reacting for 14-18h under stirring; 3, filtering, taking the obtained precipitate, respectively washing with the deionized water and alcohol, drying for 24-72h to obtain dry powder, dispersing the powder in an alcohol solution with the concentration of 15-40% (v / v), and carrying out ultrasound for 3-5h to obtain a uniform dispersion; and 4, coating the dispersion on an interdigital electrode, and obtaining the nanometer composite film ammonia gas sensor after the alcohol solution volatilizes. The sensor prepared through the preparation method has the advantages of high detection sensitivity, good stability, no need of a heating part, and realization of working at room temperature.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com