Alcohol quinque-towel differential pressure distilling arrangement and technique thereof

A distillation device and differential pressure technology, applied in distillation separation, chemical instruments and methods, separation methods, etc., can solve problems such as shutdown and maintenance, economic loss, blockage, etc., to save steam consumption, improve heat exchange effect, and improve heat exchange The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

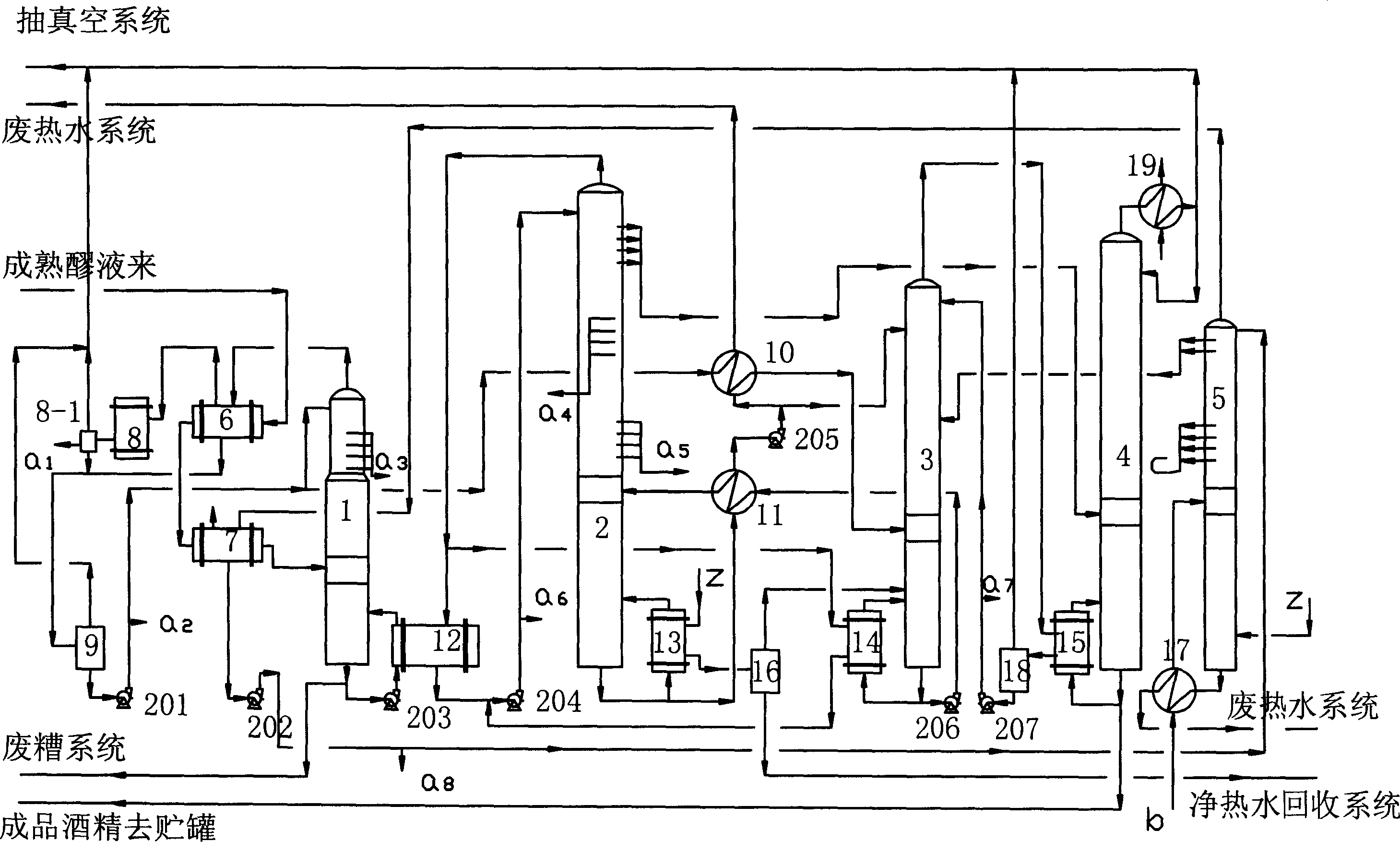

[0026] Example: as attached figure 1 As shown, the five-tower differential pressure distillation device comprises a crude distillation tower 1, a rectification tower 2, a water washing tower 3, a methanol tower 4 and a recovery tower 5, wherein the top of the rectification tower 2 is connected to the crude distillation tower reboiler 12 respectively through pipelines. The shell-side inlet port is connected to the shell-side inlet port of the reboiler 14 of the water washing tower, and the shell-side outlet port of the crude distillation tower reboiler 12 and the shell-side outlet port of the reboiler 14 of the water washing tower are respectively connected to the rectification tower reflux pump 204 through pipelines. The inlet port is connected; the bottom of rectification tower 2 is connected with the shell-side inlet port of light wine preheater 11 through pipeline, and the shell-side outlet port of light wine preheater 11 is connected with the residual water pump 205 inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com