Patents

Literature

221results about How to "Reduce steam consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

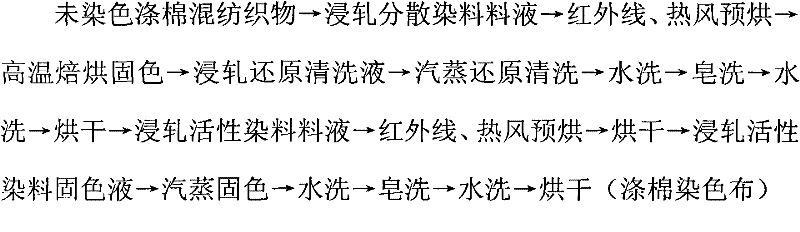

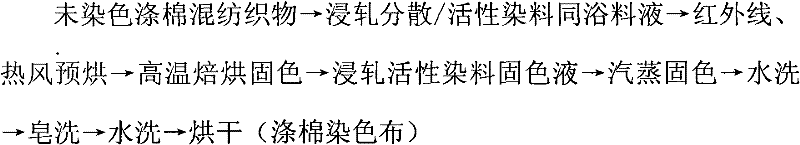

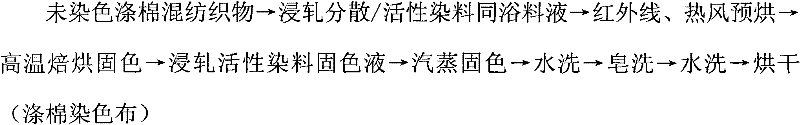

One-bath one-step process for dispersing/reactive dye of cotton-polyester blended fabric

InactiveCN102409565AReduce contentReduce consumptionSolvent-treatmentLiquid/gas/vapor removalFiberPolyester

The invention relates to a one-bath one-step process for a dispersing / reactive dye of a cotton-polyester blended fabric. The one-bath one-step process mainly comprises the following steps performed on the cotton-polyester blended fabric: dispersing / reactive dye one-bath pad dyeing; infrared and hot-air drying in advance; high-temperature baking fixation; padding in a reactive dye fixation solution; steam fixation; water washing; soaping; water washing; drying; terylene dyeing; and obtaining finished cloth. The one-bath one-step process is characterized by fully padding an unstained cotton-polyester blended fabric in a dispersing / reactive dye one-bath solution, introducing infrared and hot air so as to dry 60-70% of water in the fabric in advance, baking at high temperature so as to dye and fix color for polyester fibers, fully padding in the reactive dye fixation solution, performing steam fixation so as to dye and fix color for cotton fibers, and performing the processes of water washing, soaping and water washing so as to fully develop color on the fabric and fully wash off the surface dyeing on the fabric, thereby finishing a dyeing process. The dry and wet grinding fastness can fully meet the customer demand.

Owner:XIANGFAN NEW NO 45 PRINTING & DYEING

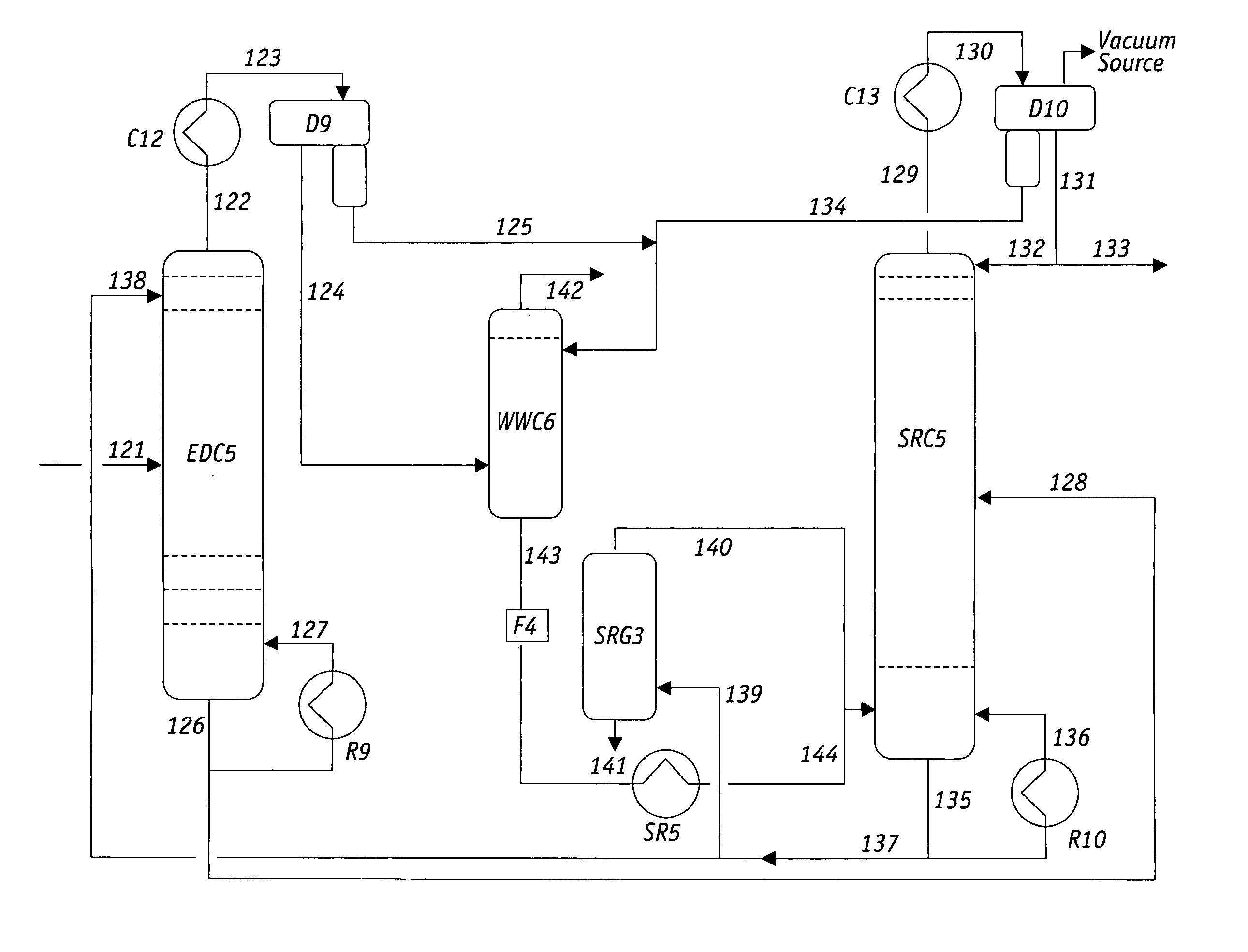

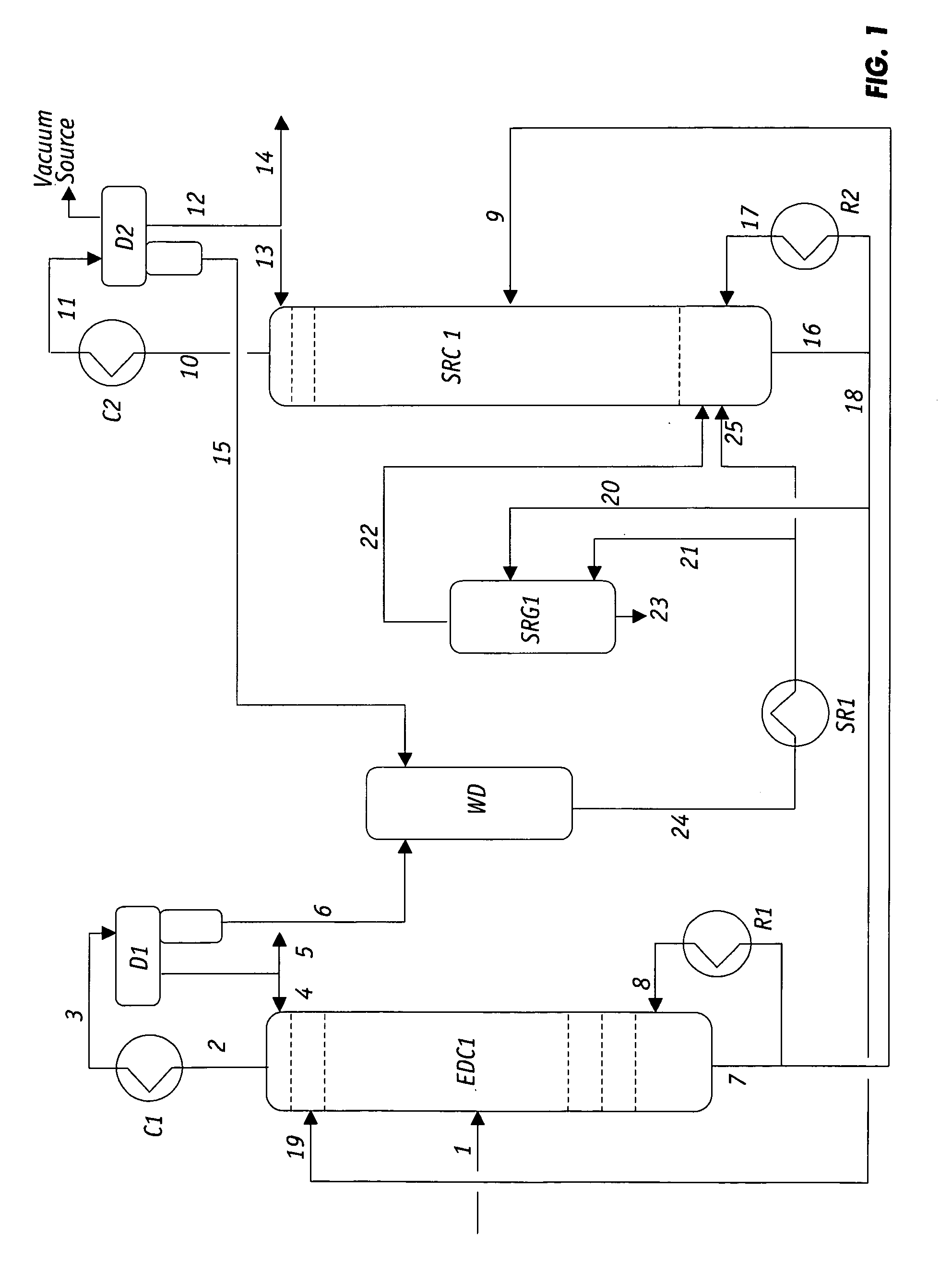

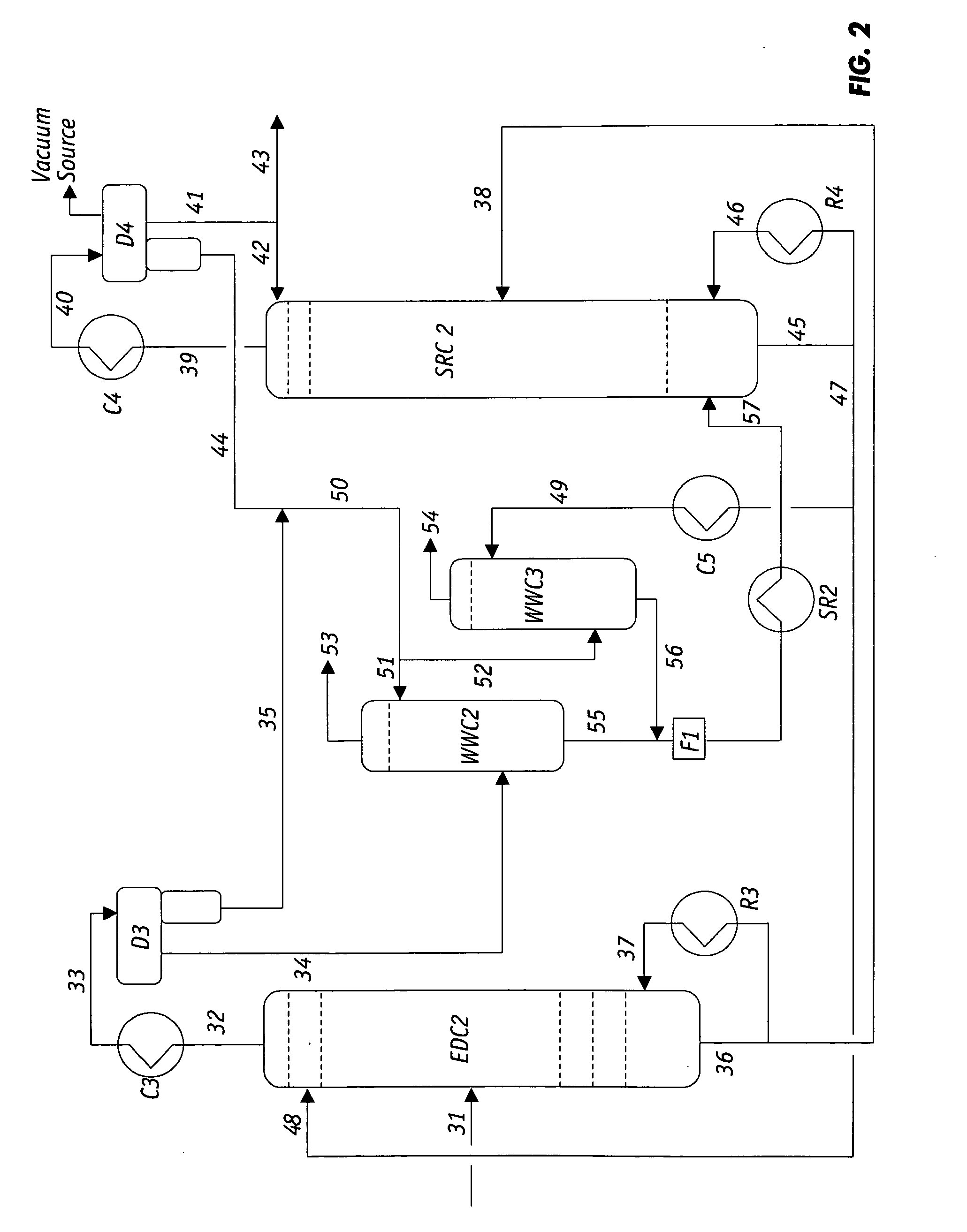

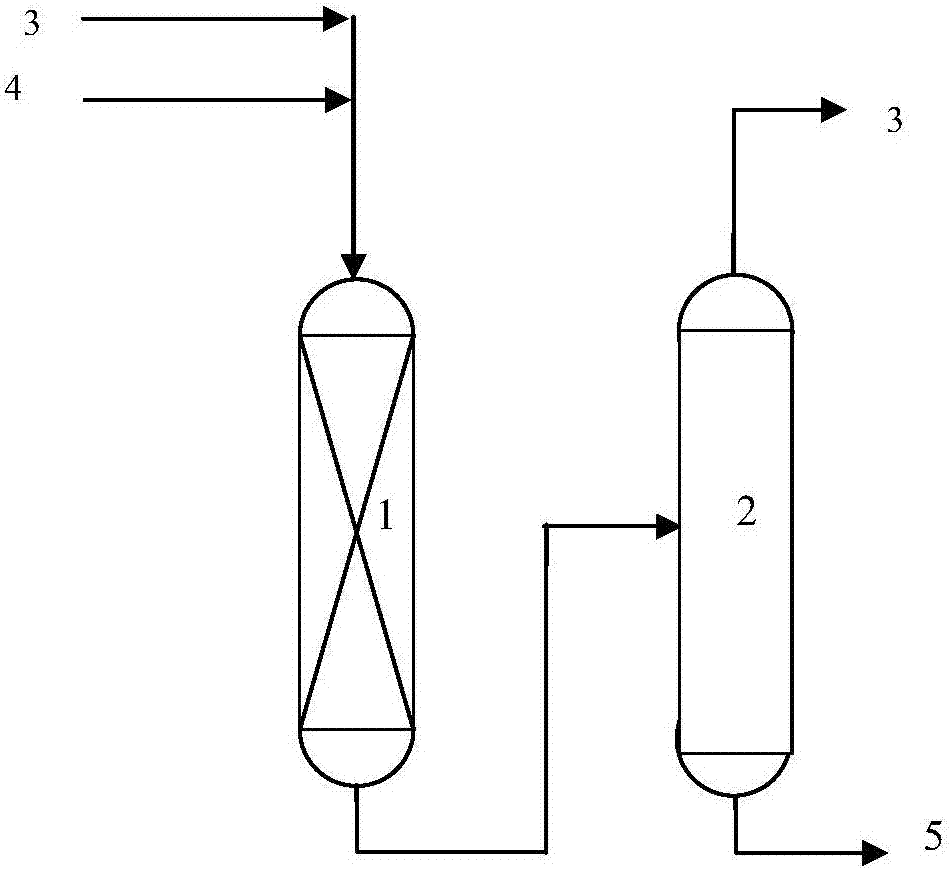

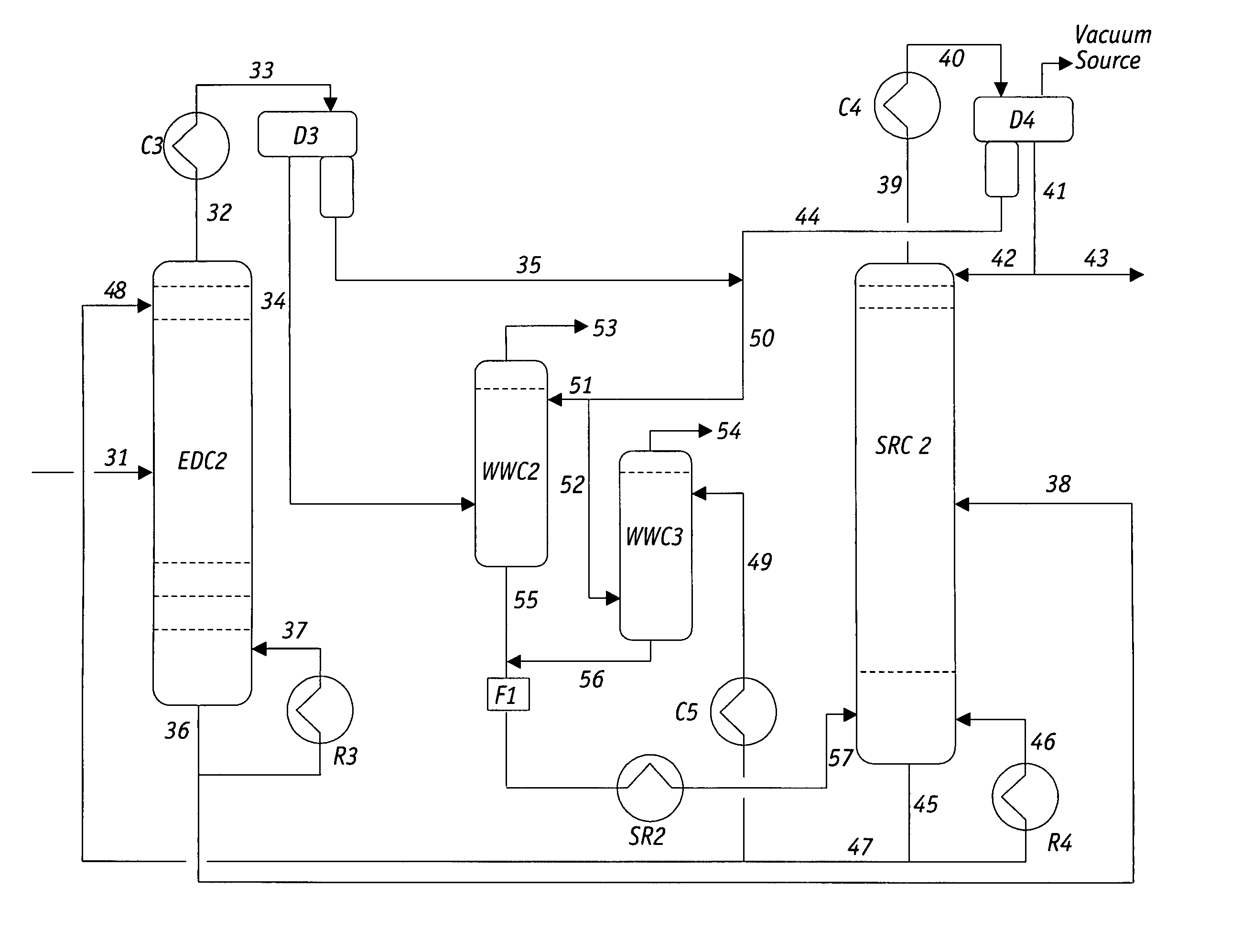

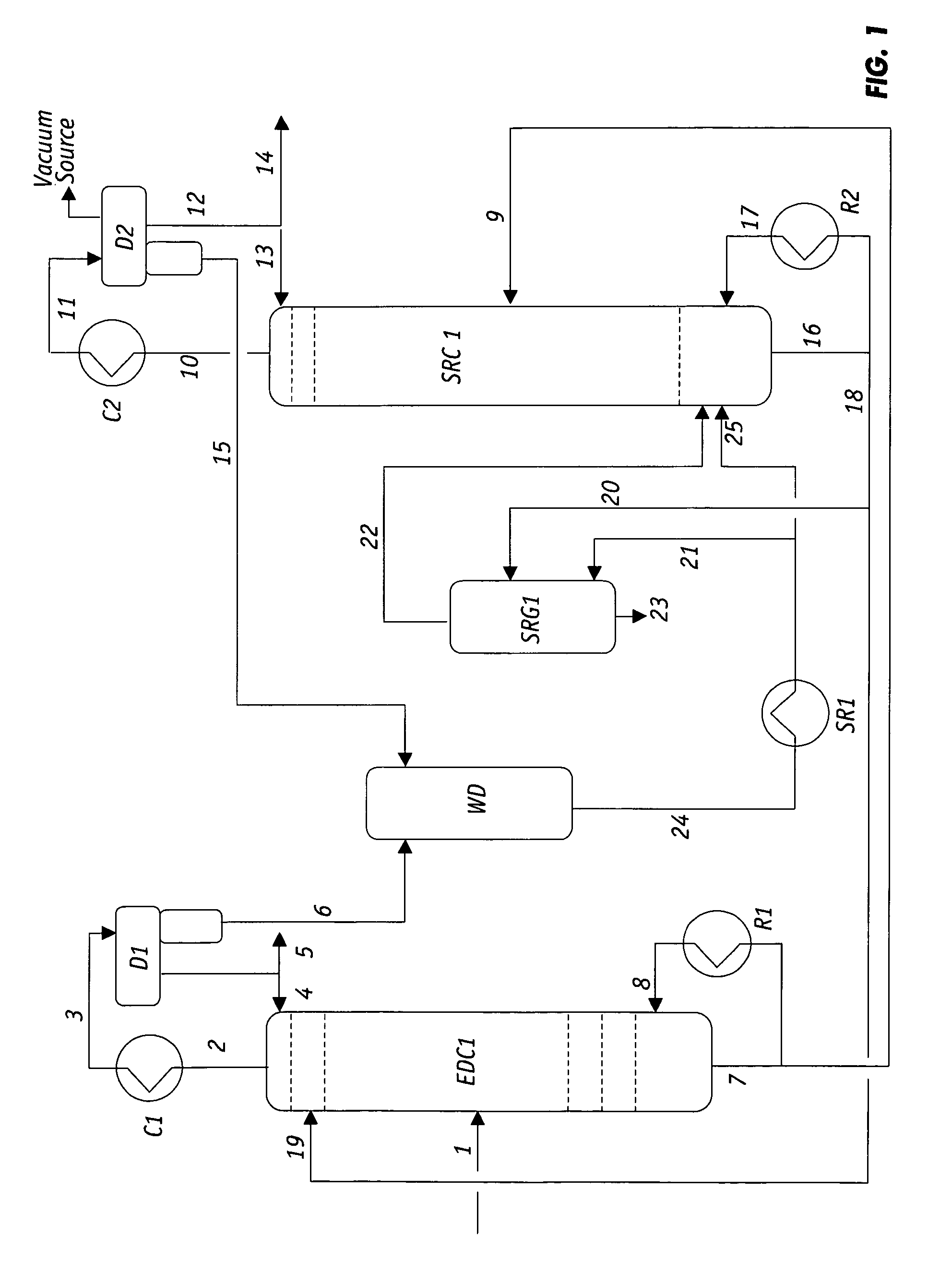

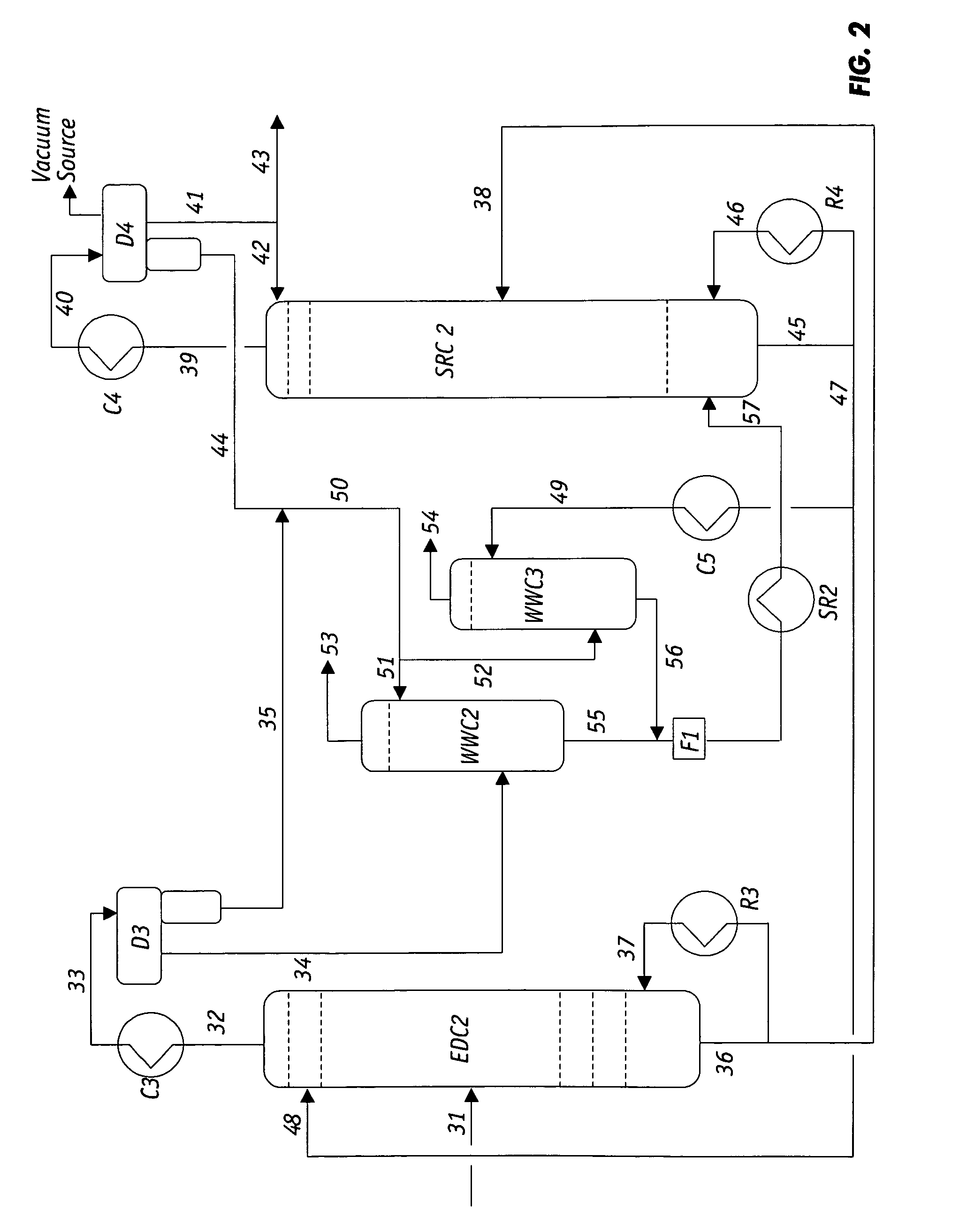

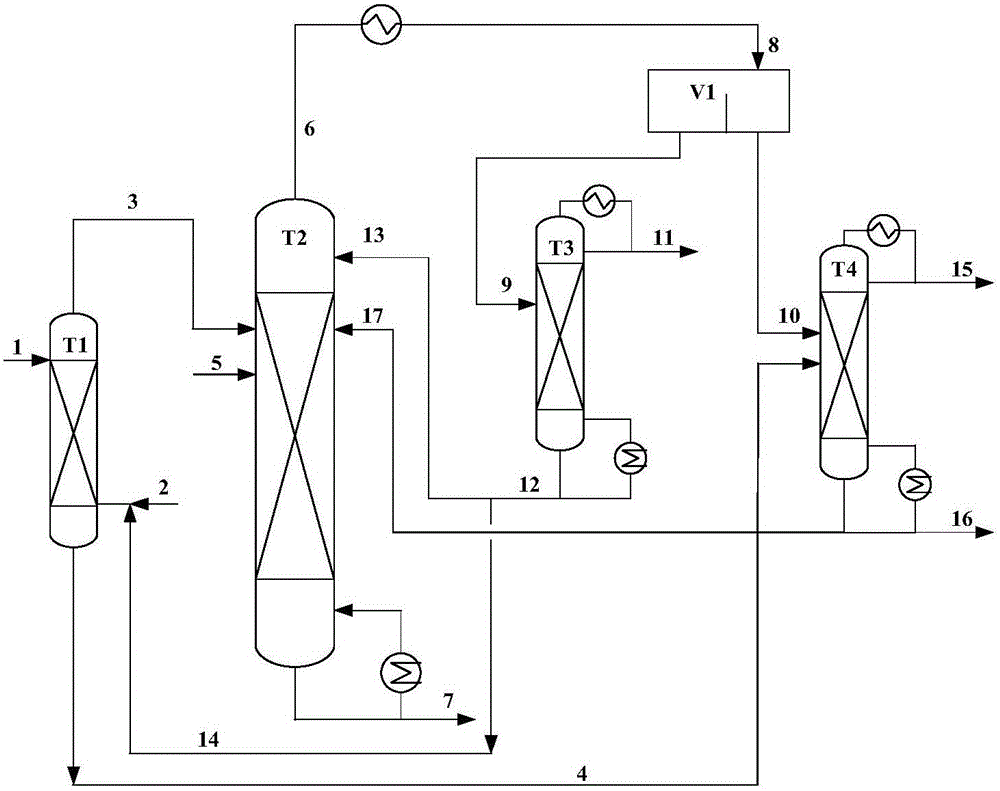

Extractive distillation processes using water-soluble extractive solvents

ActiveUS20090105514A1Reduce steam consumptionGood solvent resistanceHydrocarbon purification/separationHydrocarbonsExtractive distillationWater soluble

Extractive distillation processes whereby water-soluble extractive distillation (ED) solvents are regenerated and recovered employ improved operations of the extractive distillation column (EDC) so that polar hydrocarbons are recovered and purified from mixtures containing polar and less polar hydrocarbons and measurable amounts of hydrocarbons that are heavier than intended feedstock and / or polymers that are generated in the ED process. The improved process can effectively remove and recover the heavy hydrocarbons and / or remove polymer contaminants from the solvent in a closed solvent circulating loop through mild operating conditions with no additional process energy being expended. With the improved process, the overhead reflux of the EDC may be eliminated to further reduce energy consumption and to enhance the loading and performance within the upper portion of the EDC, especially when two liquid phases exists therein.

Owner:CPC CORPORATION +1

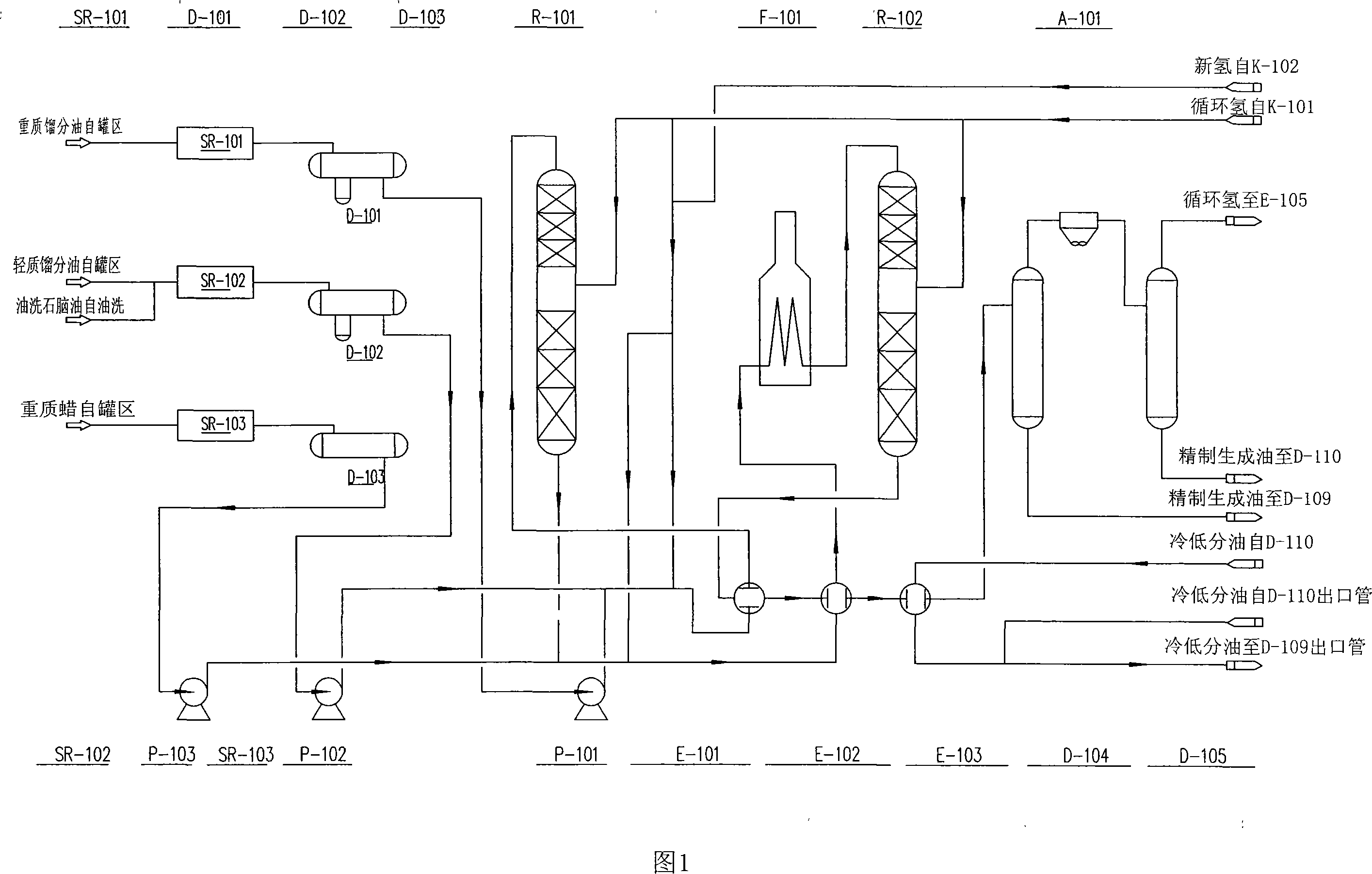

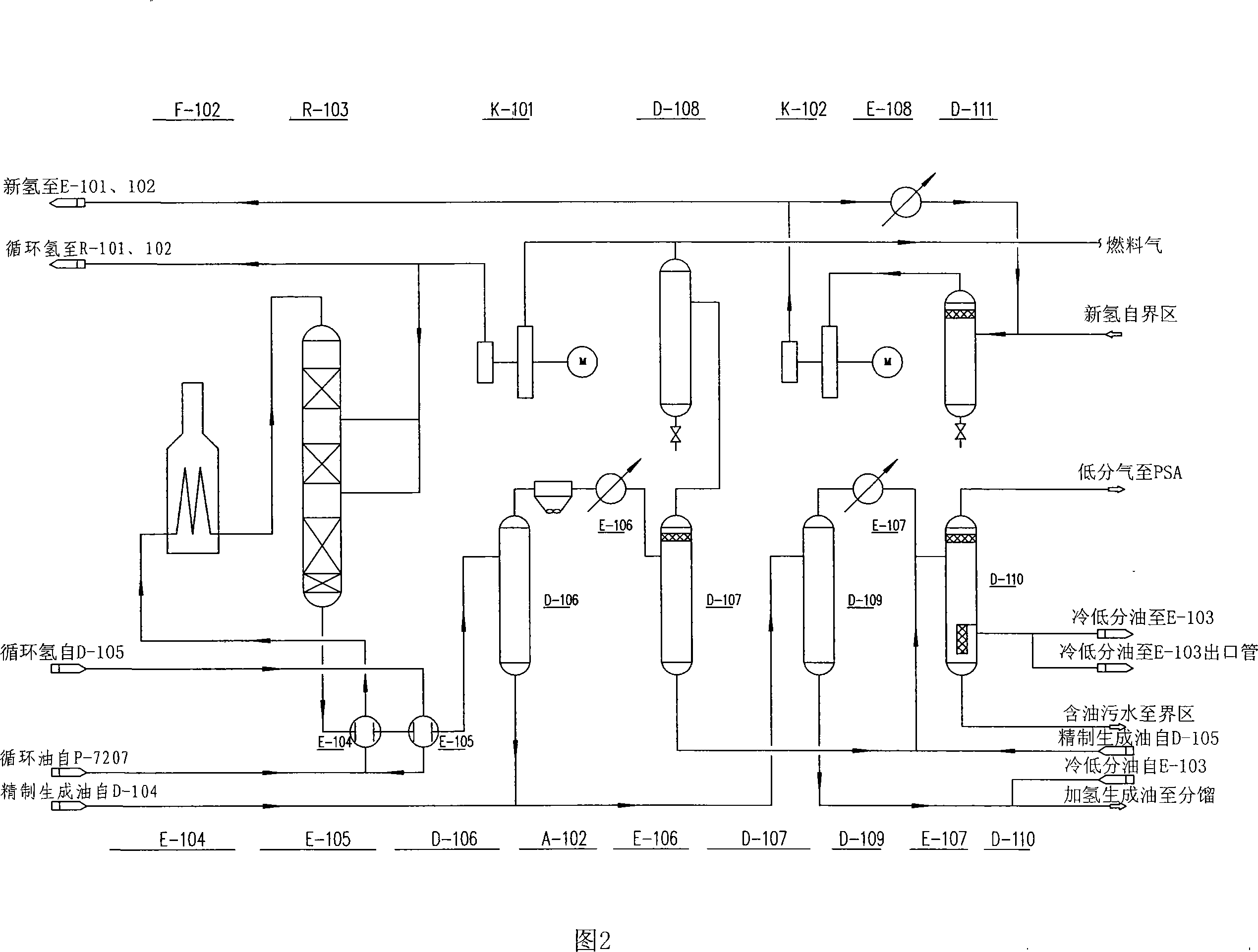

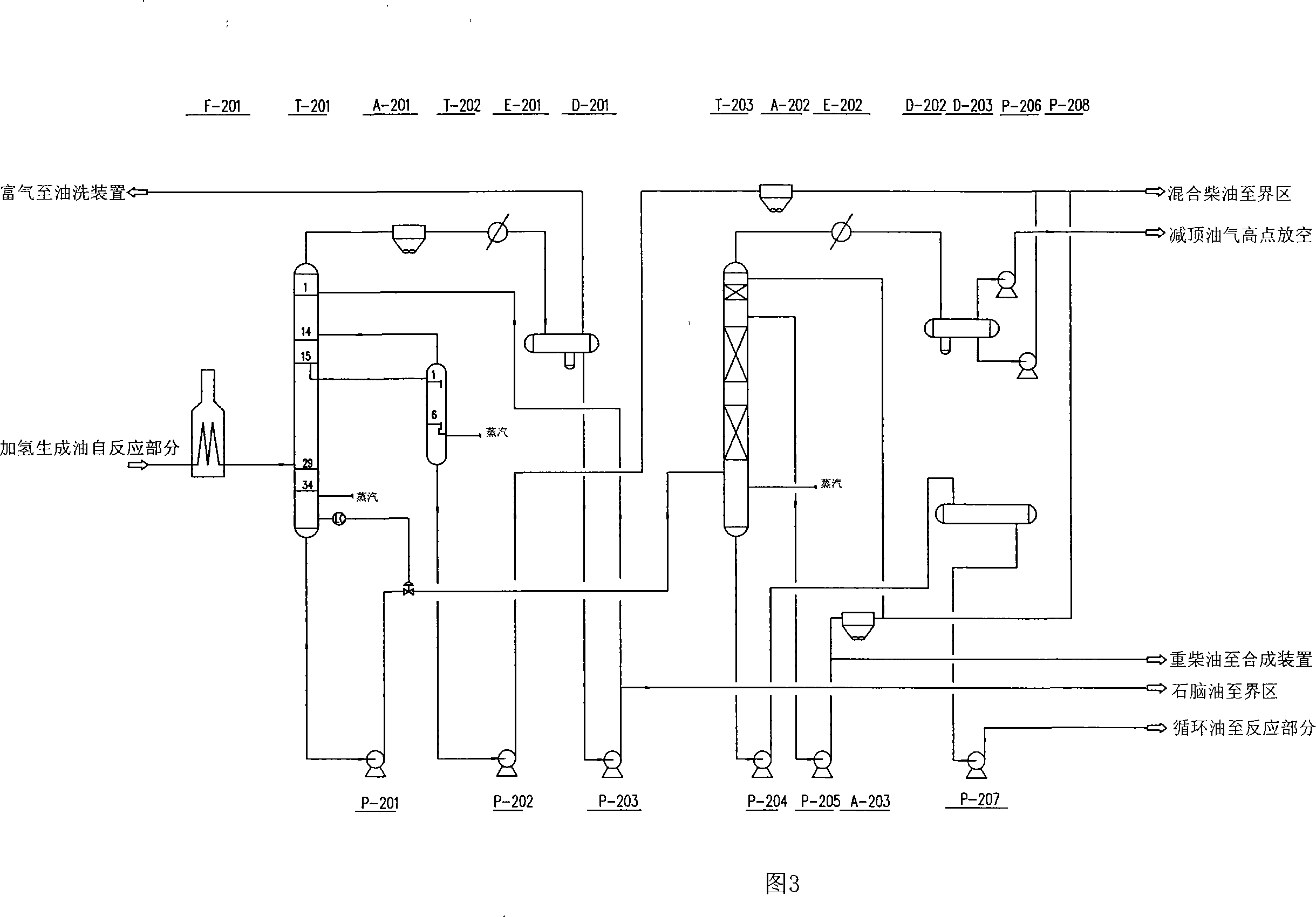

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

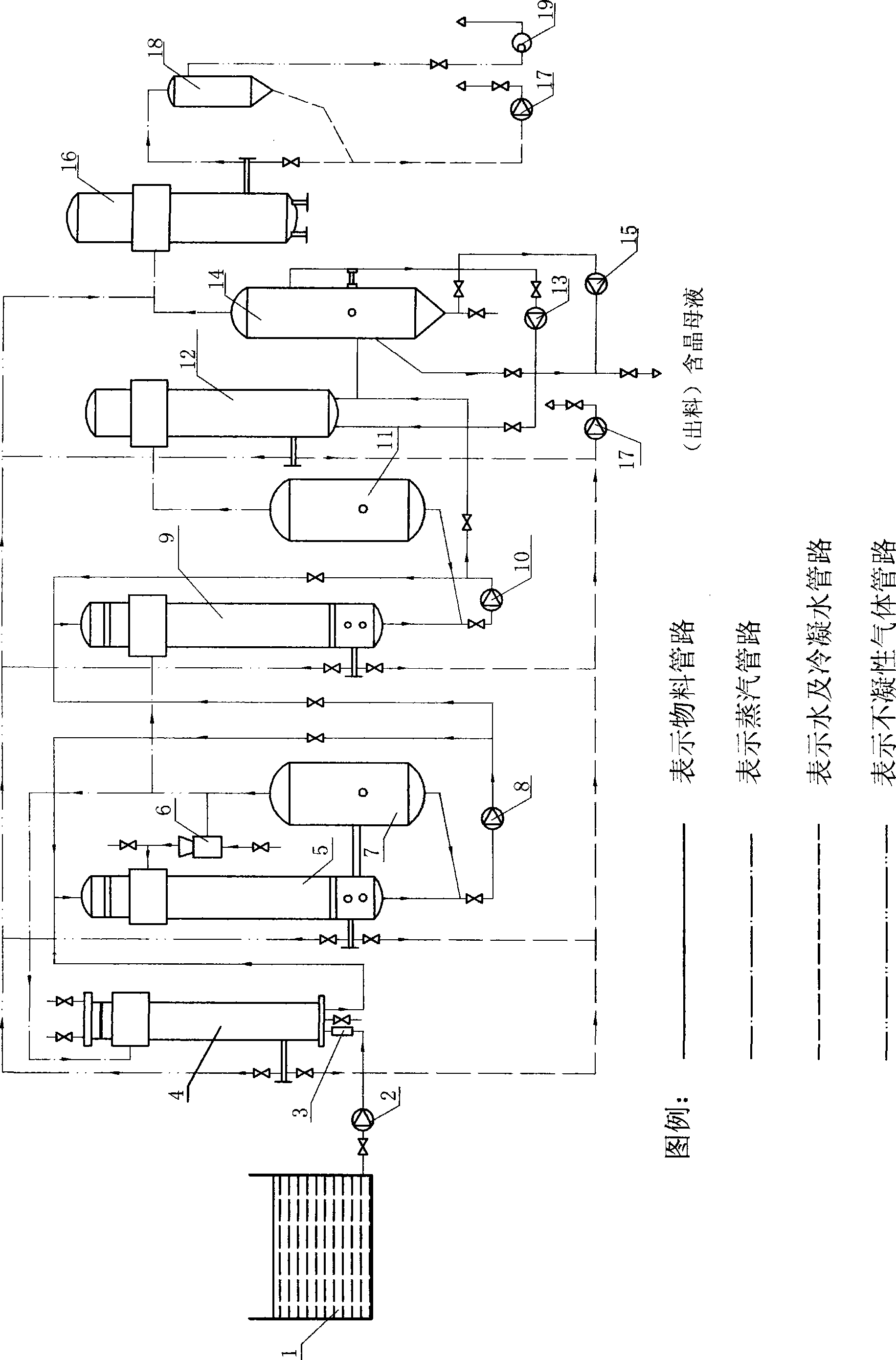

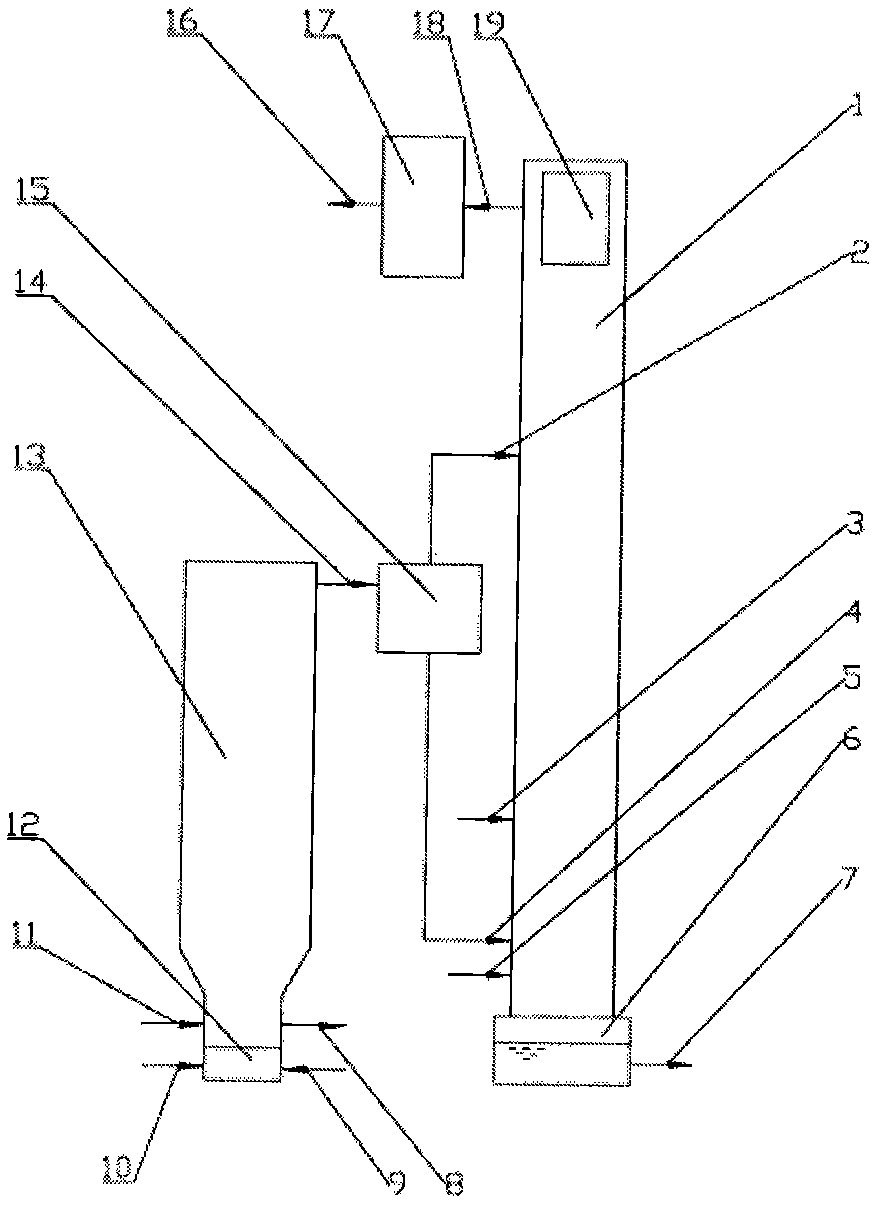

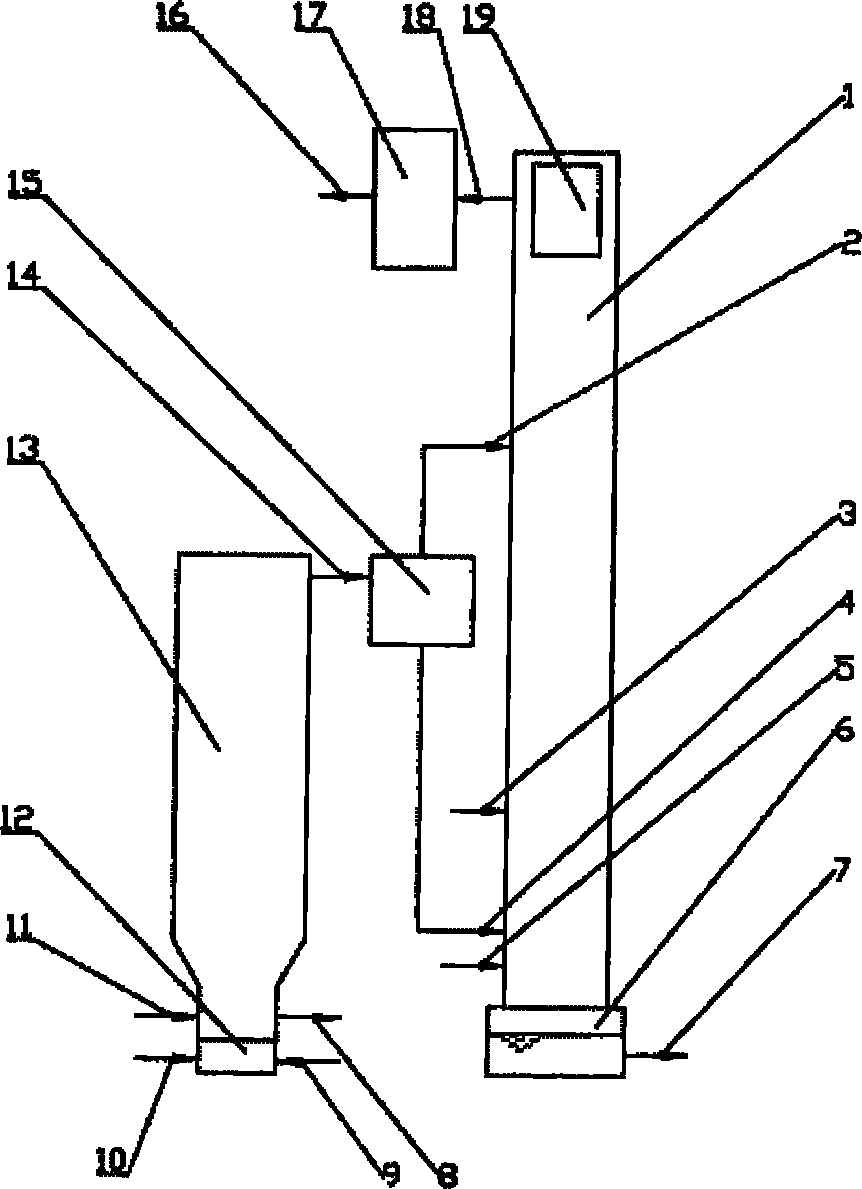

Production method and device for sodium gluconate energy-saving triple effect concentration and crystallization

InactiveCN101445449AIncrease production capacityImprove product qualityCarboxylic compound separation/purificationMoistureTriple effect

The invention discloses a production method and a device for sodium gluconate energy-saving triple effect concentration and crystallization. The continuity of sodium gluconate concentration and crystallization can be realized, that is, a raw material liquid enters a preheater continuously; the moisture can be evaporated after passing through 1st, 2nd and 3rd effect heating evaporators and 1st, 2nd and 3rd effect separators; the 2nd steam is separated continuously to heat and evaporate materials in the 1st, the 2nd and the 3rd effect heating evaporators; the crystal of sodium gluconate is separated out in the 3rd effect heating evaporator and pumped out continuously; therefore, the process of feeding, concentration and crystallization, and crystal separation at the same time is formed continuously, the 2nd steam is fully utilized, the steam consumption for evaporating moisture is 0.28 Tsteam / Twater, the crystallization rate achieves 65%, and materials can form a large amount of crystal in the 3rd effect heating evaporator. The invention can improve the productivity, reduce the steam consumption and improve the quality of products.

Owner:山东凯翔生物科技股份有限公司

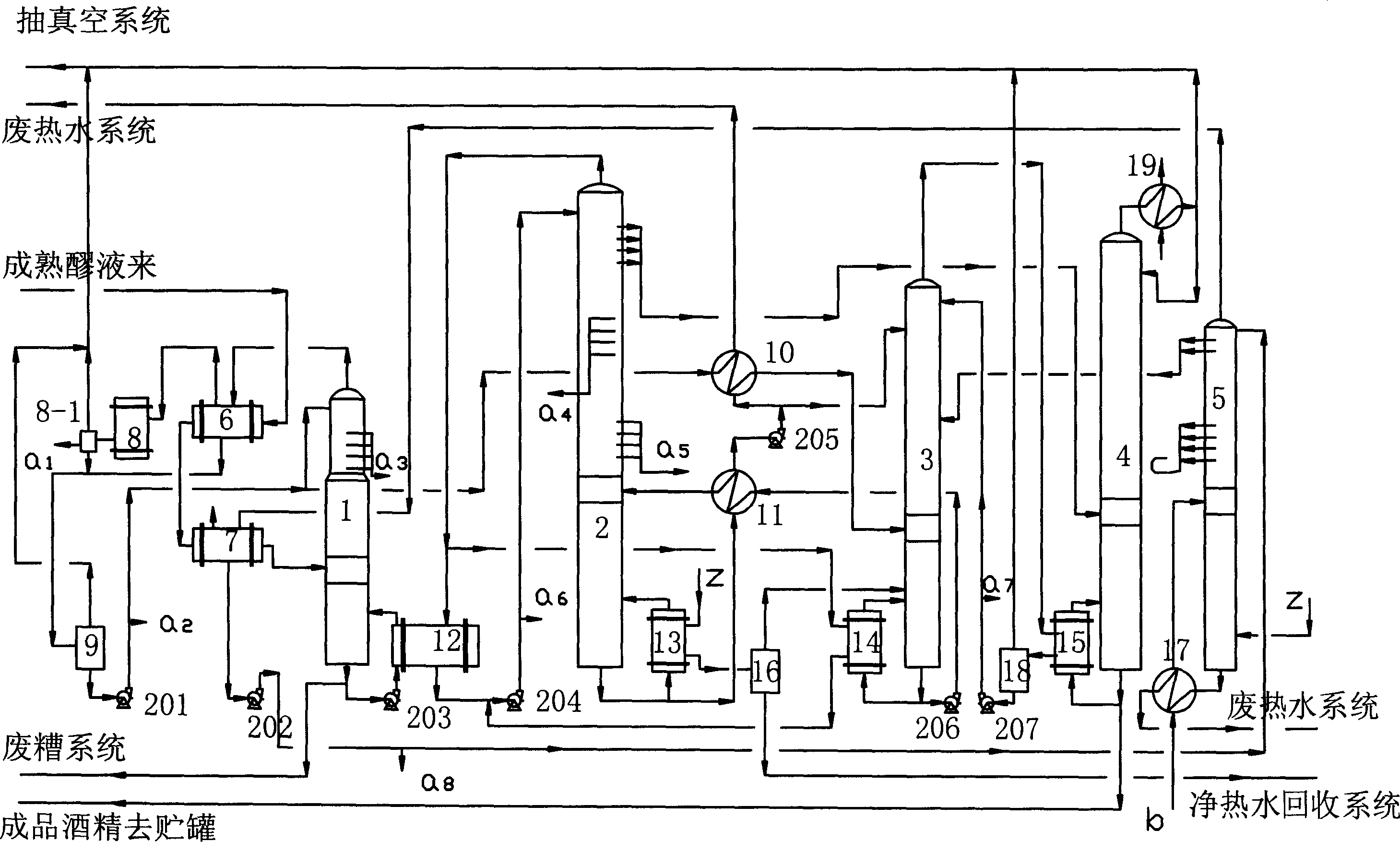

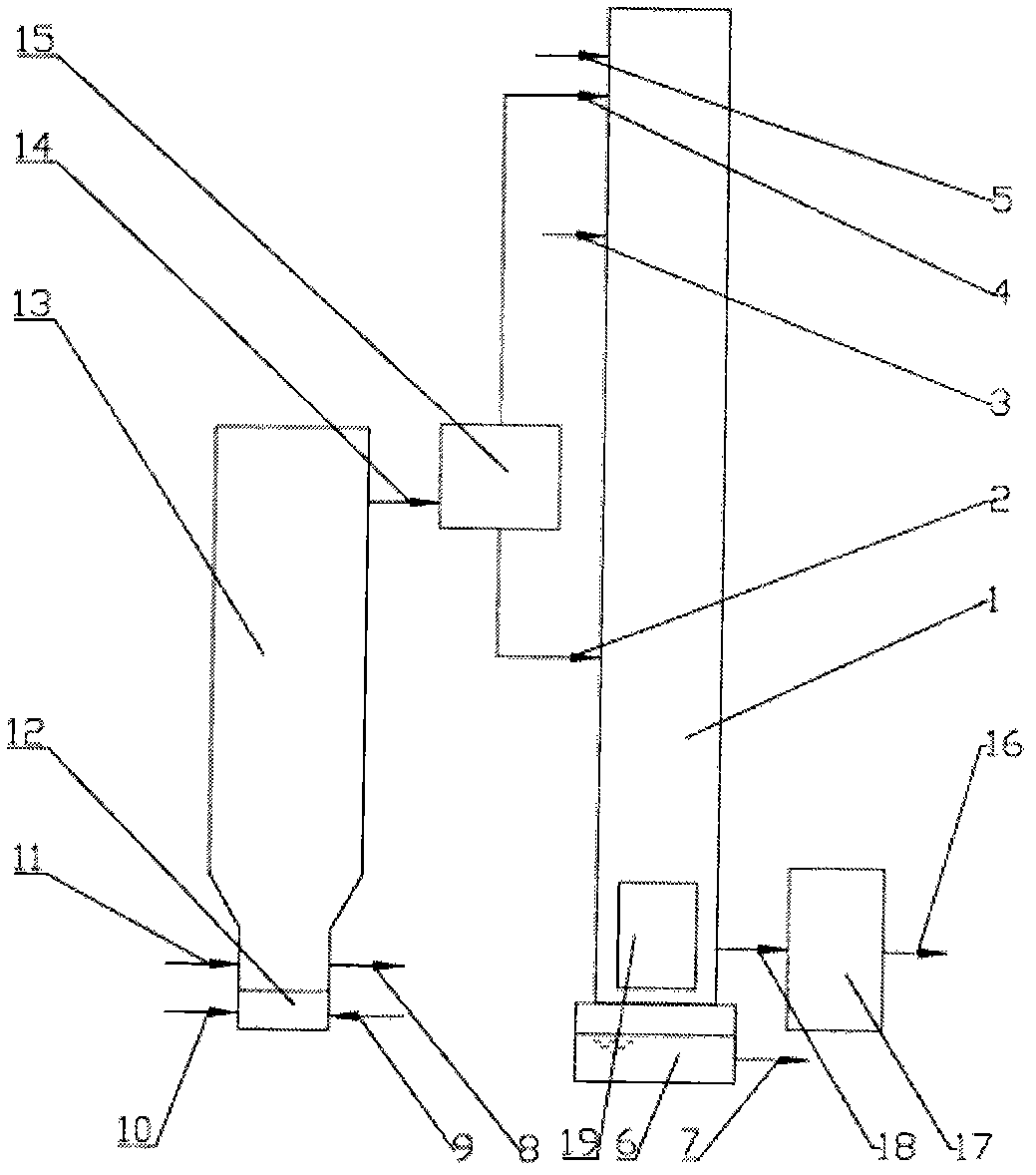

Alcohol quinque-towel differential pressure distilling arrangement and technique thereof

ActiveCN1736527APrevent scalingPrevent precipitationDistillation separationSteam condensationAqueous alcohol

The invention discloses a five-tower differential pressure distilling apparatus and the technique for alcohol: the fractionating tower operating with positive pressure, some alcohol vapor in the head tower flowing into the reboiler of crude distillation column, and the other into the reboiler of water scrubber; the leaving distilled water in the still of fractionating tower preheating the weak alcohol liquid from the bottom of water scrubber, then partly inpouring to crude alcohol preheater to preheat crude alcohol, and partly inpouring to water scrubber according to the requirement of flowmeter; by flash distillation the condensate water in the reboiler of fractionating tower generating indirect steam which enters directly into the still of water scrubber; the water scrubber operating with negative pressure, and the alcohol vapor in the head into the reboiler of the methanol heating tower. The significance effect is that: the energy saving effect is perfect when used to produce excellent edible alcohol and the vapor consuming index approaching the advanced lever of 2.3- 2.6 t / t.

Owner:广东省博罗中科天元高新技术工程有限公司

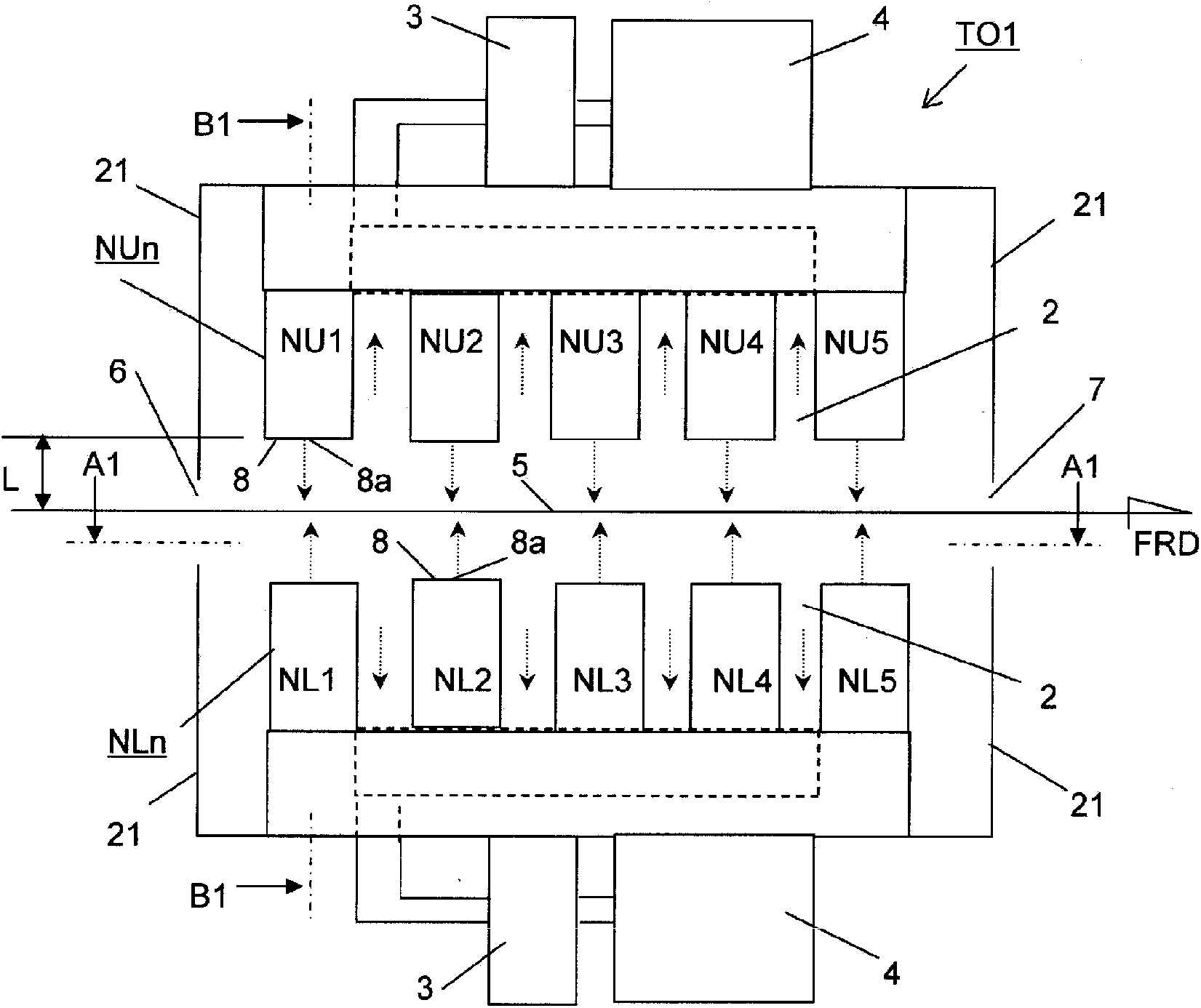

Tenter oven and manufacturing method for stretched film

ActiveCN103442879AInhibitionUniform thicknessDrying gas arrangementsDrying machines with progressive movementsProximateEngineering

The present invention provides a tenter oven for stretching a thermoplastic resin film in the width direction thereof, wherein an air blowing nozzle provided therein that blows heated air onto a film running along a film passing surface is a proximate nozzle in which an air blowing opening provided on the air blowing surface thereof is formed as a slit, a distance L between the air blowing surface and the film passing surface and a slit width (B) of the slit satisfy the relationship expressed by the equation, (L / B)<=10, and the distance L is 150 mm or less.

Owner:TORAY IND INC

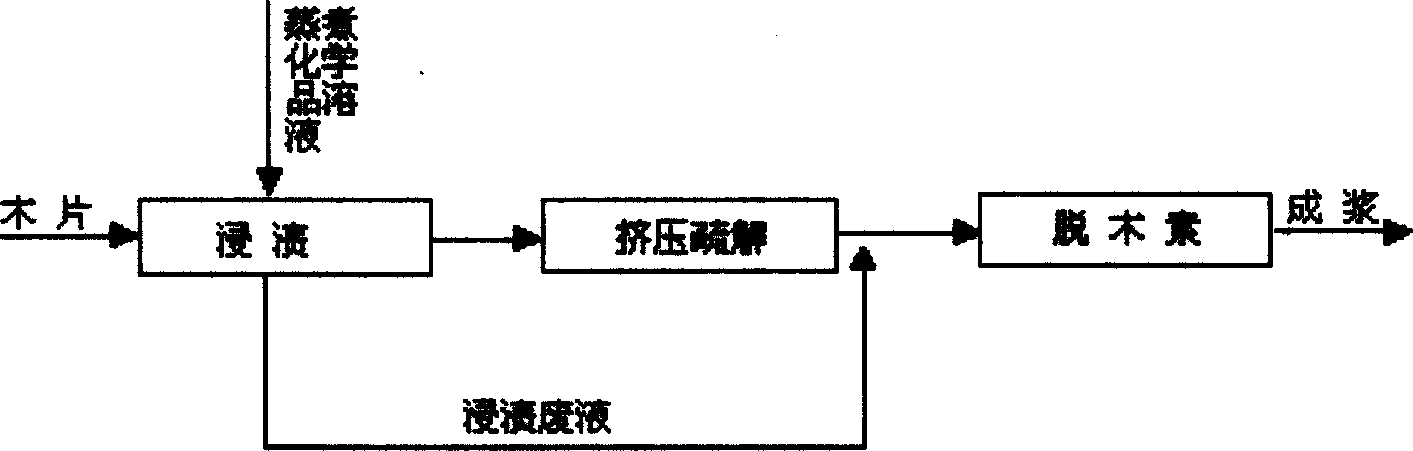

Method for producing chemical wood pulp

InactiveCN1563564AIncrease production capacityTake advantage ofCellulose material pulpingMaterials sciencePressed wood

This invention is a chemical wood pulp productive method. It contains following steps: 1) To soak, Put the thin piece wood plate into the soak liquid container, the soaking temperature is 50-90 deg.C. Soaking time is 15-50 minutes; the soak liquids use part or whole boiling liquid. 2) To relieve squeeze and press; relieve the pressed wood plate, the pressing ratio is 3-6:1. 3) To take-out lignin: put the pressing wood plate and its soak liquid into the boiler, boiling them to do the reaction of take-out lignin.

Owner:QILU UNIV OF TECH

Technology for producing diisobutylene from C4 mixture

ActiveCN107473917ASimple structureReduce energy consumptionChemical industryDistillation purification/separationChemical synthesisFixed bed

The invention belongs to the technical field of chemical synthesis, and specifically relates to a technology for producing diisobutylene from a C4 mixture. The technology comprises: pumping a C4 mixture and tert-butyl alcohol by a metering pump to a static mixer for mixing, performing pre-heating, allowing the obtained product to enter a fixed bed reactor, performing a dimerization reaction of isobutene in the function of a resin catalyst in a gas-liquid mixed phase state, allowing a diisobutylene product generated from a reactor outlet to enter a rectifying tower for separation, and obtaining the C4 mixture from the tower top and the diisobutylene product from the column bottom. The technology is low in pressure, high in reaction selectivity, simple in reactor structure, saved in energy consumption of the reactor and rectifying tower, and reduced in investment.

Owner:CHINA PETROLEUM & CHEM CORP

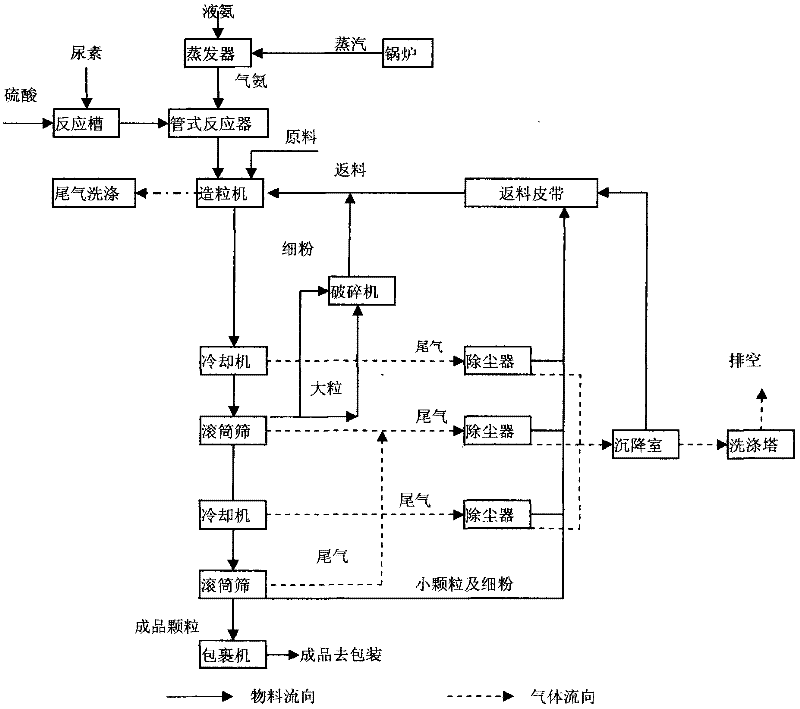

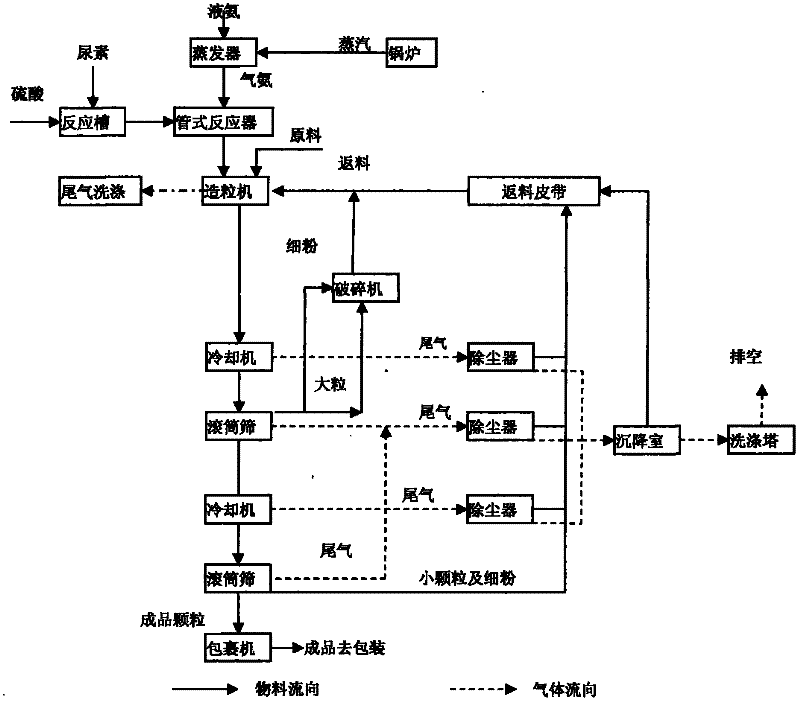

Process for producing urea sulfate ammoniated compound fertilizer

InactiveCN102503622AReduce steam consumptionReduce moisture contentFertiliser formsFertilizer mixturesAmmonium sulfateCooking & baking

The invention discloses a process for producing a urea sulfate ammoniated compound fertilizer. The process comprises the following steps of: (1) putting sulfuric acid and urea which are in a mixture ratio into a reaction vessel for producing urea sulfate; (2) preparing a 75% urea sulfate solution from the urea sulfate by using a tail gas washing solution of a pelleting machine; (3) reacting the urea sulfate solution with gas ammonia and steam in a tubular reactor so as to generate a large number of high-temperature high-pressure superheated steam and produce ammonia sulfate and urea molten slurry; (4) loading a fertilizer containing nitrogen, phosphorus and potassium and fillers in the pelleting machine, meanwhile, carrying out atomized spray pelleting on the various materials at a feed port of the pelleting machine by using the ammonia sulfate and the urea molten slurry; (5) feeding a compound fertilizer material obtained after carrying out atomized spray pelleting into the pelleting machine for flowing bonding pelleting; and (6) carrying out twice cooling and twice screening on the compound fertilizer discharged from the pelleting machine to obtain the urea sulfate ammoniated compound fertilizer. According to the invention, the drying and baking procedures are omitted, so that raw materials and energy can be saved, and a product is high in pelletization rate and good in quality.

Owner:山东金山化肥有限公司

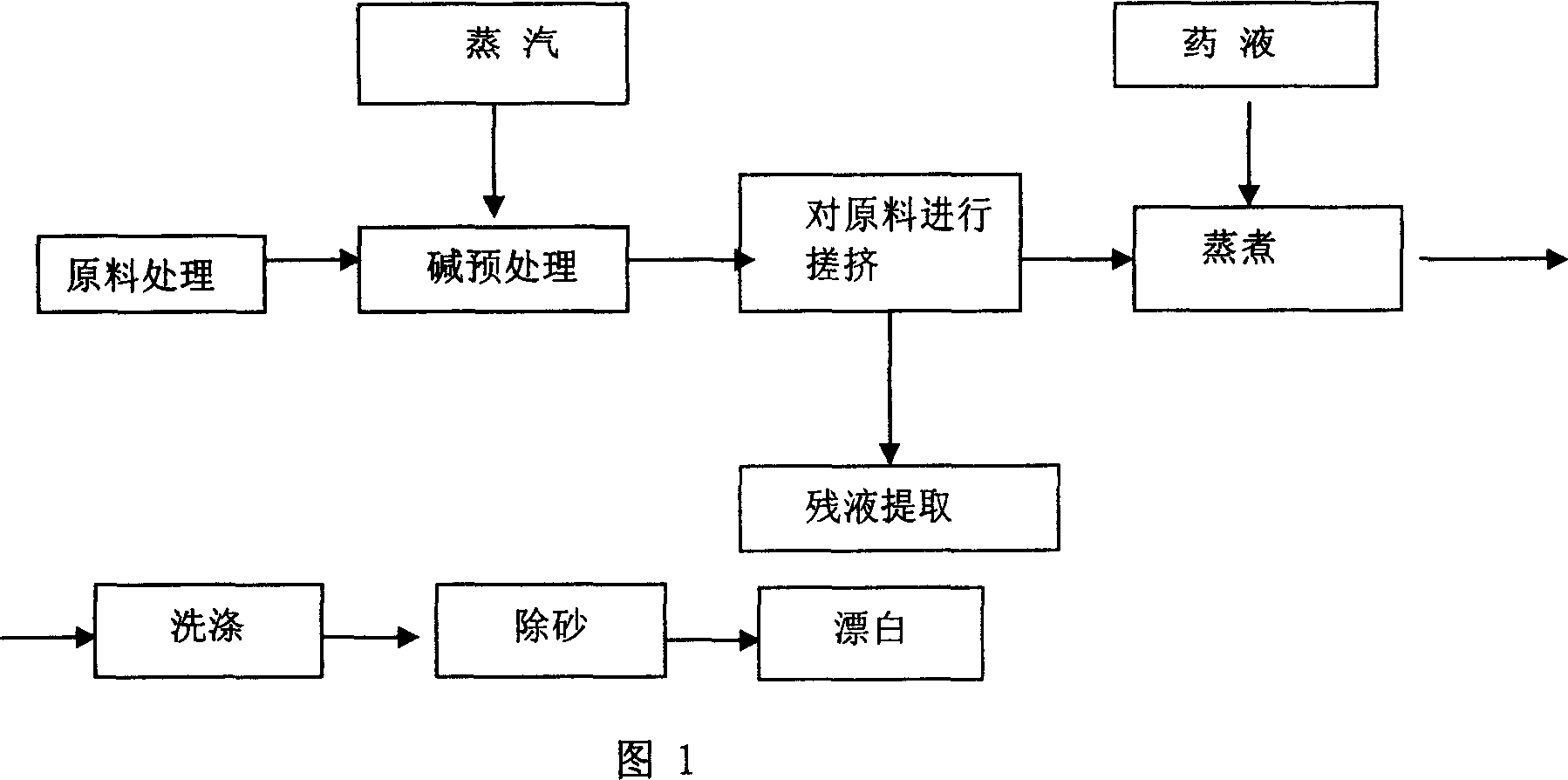

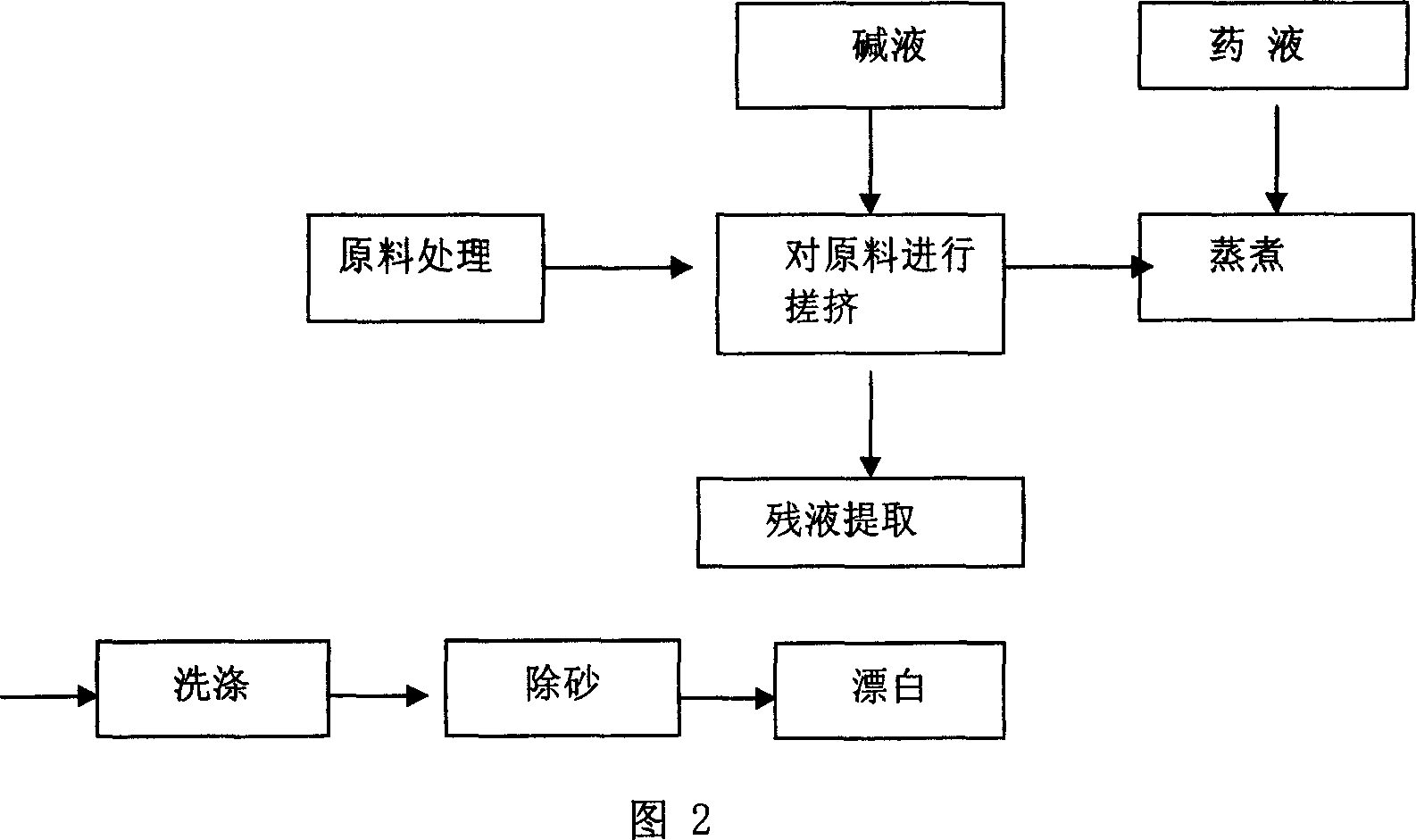

Method for producing chemical fiber pomace with fiber as raw material

InactiveCN1974922APerformance activationImprove impregnation effectCellulosic pulp after-treatmentDigestersBlack liquorPlant fibre

The present invention relates to a method for producing chemical fibre pulp by using plant fibre as raw material. Said method includes the following several steps: raw material treatment, making the treated raw material undergo the processes of rubbing and extruding, cooking, washing, removing sand and bleaching treatment. It is characterized by that in the preparation process of said chemical fibre pulp a screw extruding machine and a rubbing-extruding machine are adopted.

Owner:湖南吉湘生物科技有限公司

Coal gasification method

InactiveCN102373089ALow investment costLow running costGranular/pulverulent flues gasificationFluidized bedOxygen

The invention provides a fluidized bed-entrained flow bed gas gasification method. The method comprises the following steps: 1) carrying out reaction on raw material coal and a mixture of air and steam or a mixture of oxygen and steam to obtain gas containing incompletely reacted coal and ash; 2) separating the gas obtained from the step 1) to obtain condensed fine coal air-flow and light fine coal air-flow, and carrying out reaction on the condensed fine coal air-flow with air or oxygen to obtain gas containing coal and ash; 3) carrying out reaction on the gas obtained from the step 2) and steam to obtain gas containing coal and ash; 4) carrying out reaction on the gas obtained from the step 3), the light fine coal air-flow separated from the step 2) and a mixture of steam and carbon dioxide to obtain final gas containing coal and ash. The method lowers investment and operating cost of a traditional pulverizing system by an entrained flow bed gasification method and has a substantially increased gasification temperature than a traditional fluidized bed gasification method, so as to reduce equipment cost and increase gasification efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

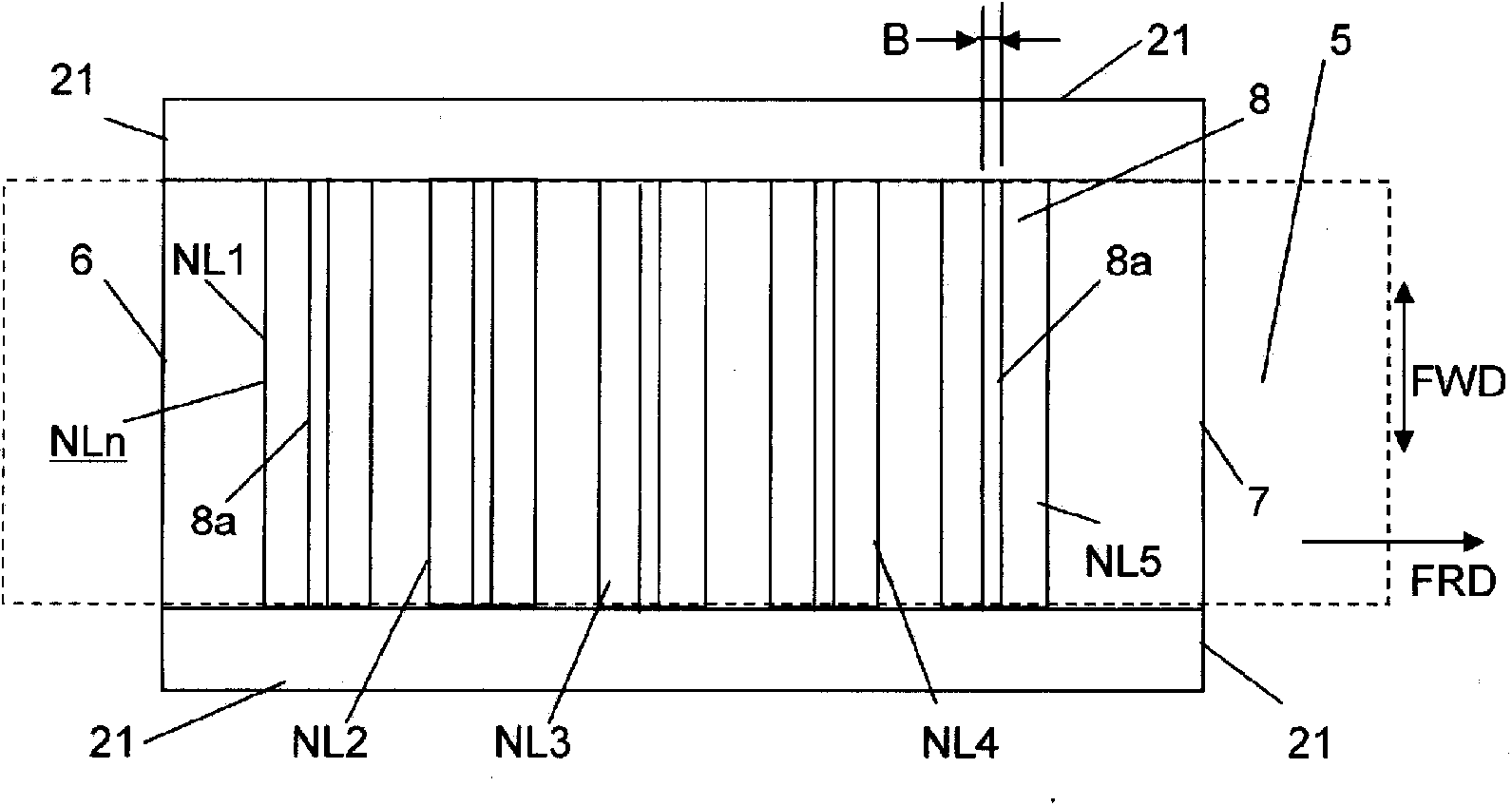

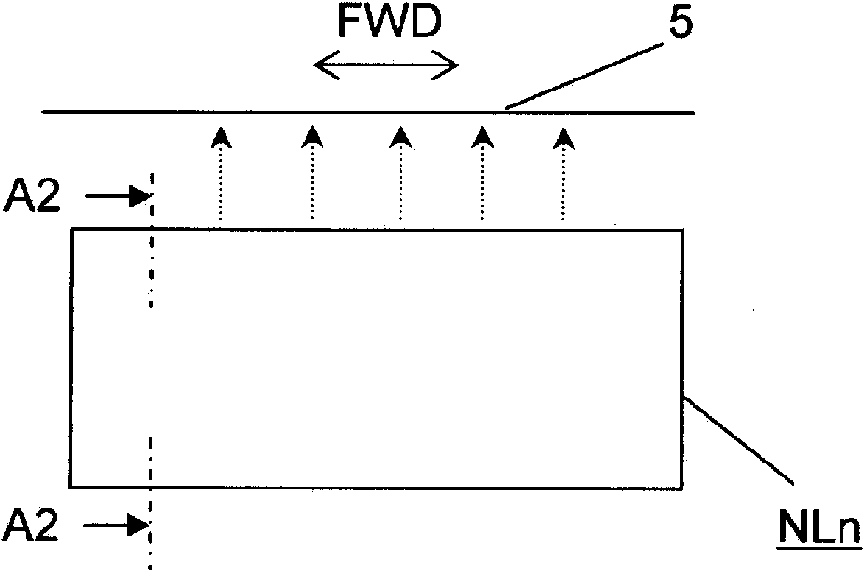

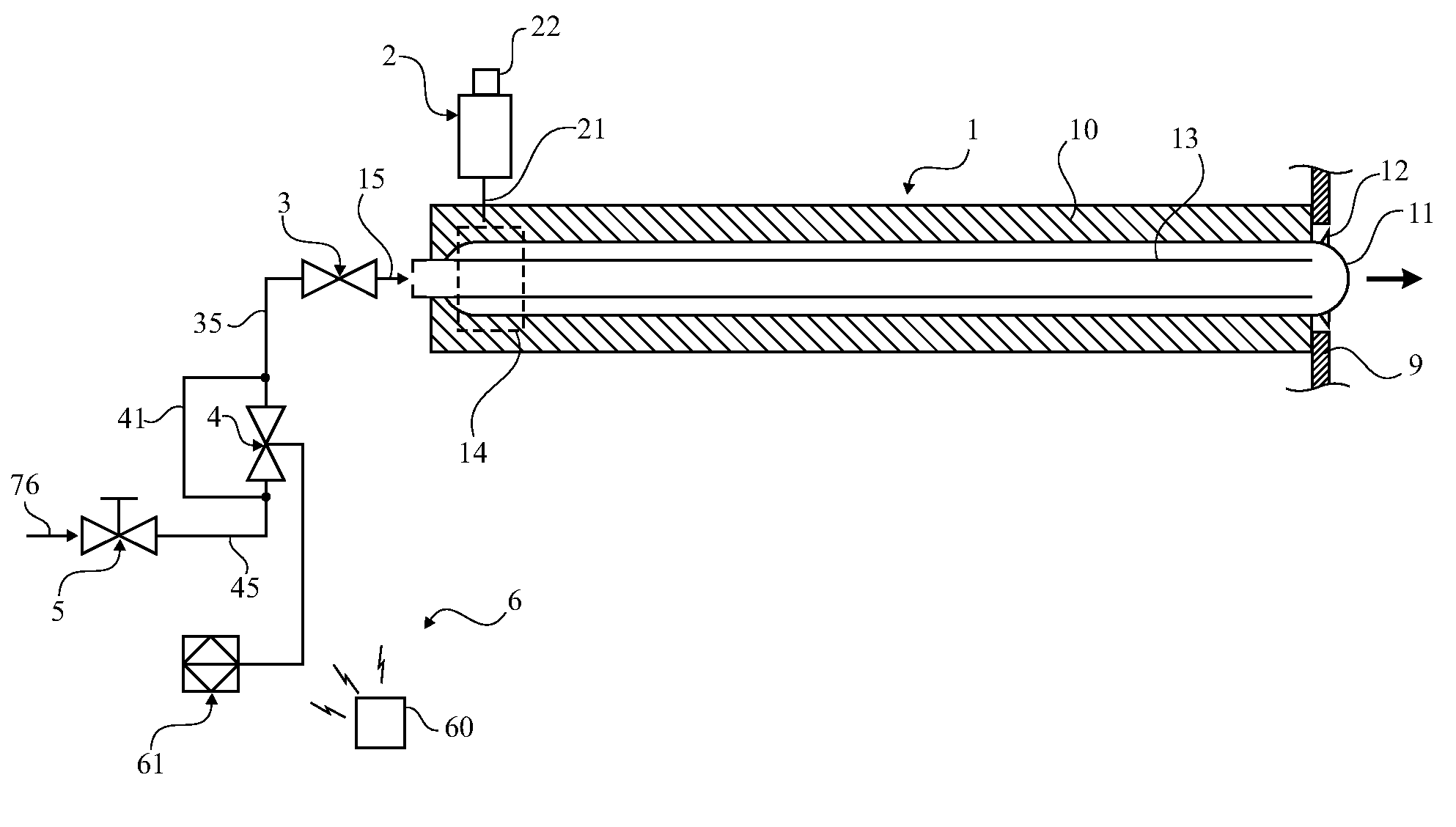

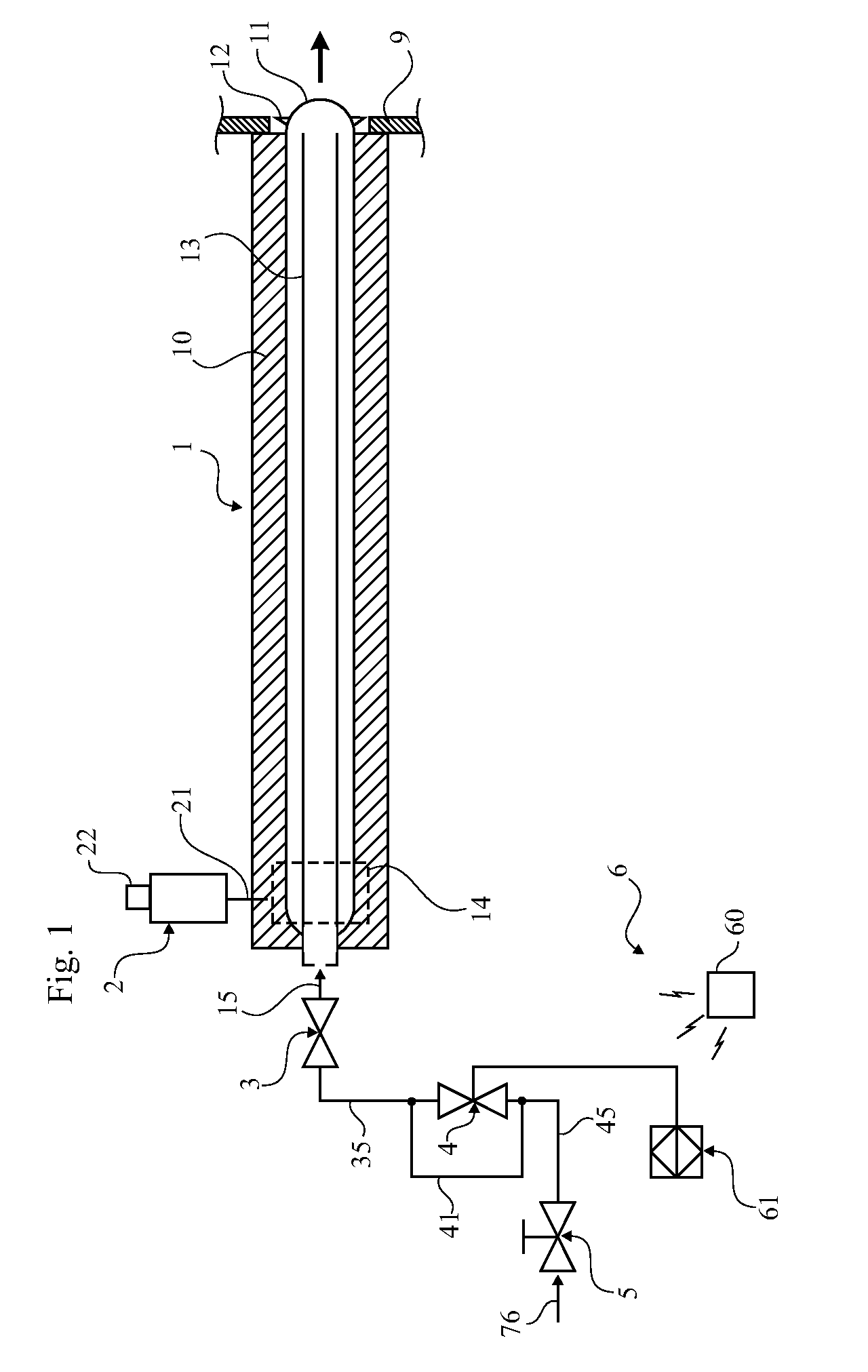

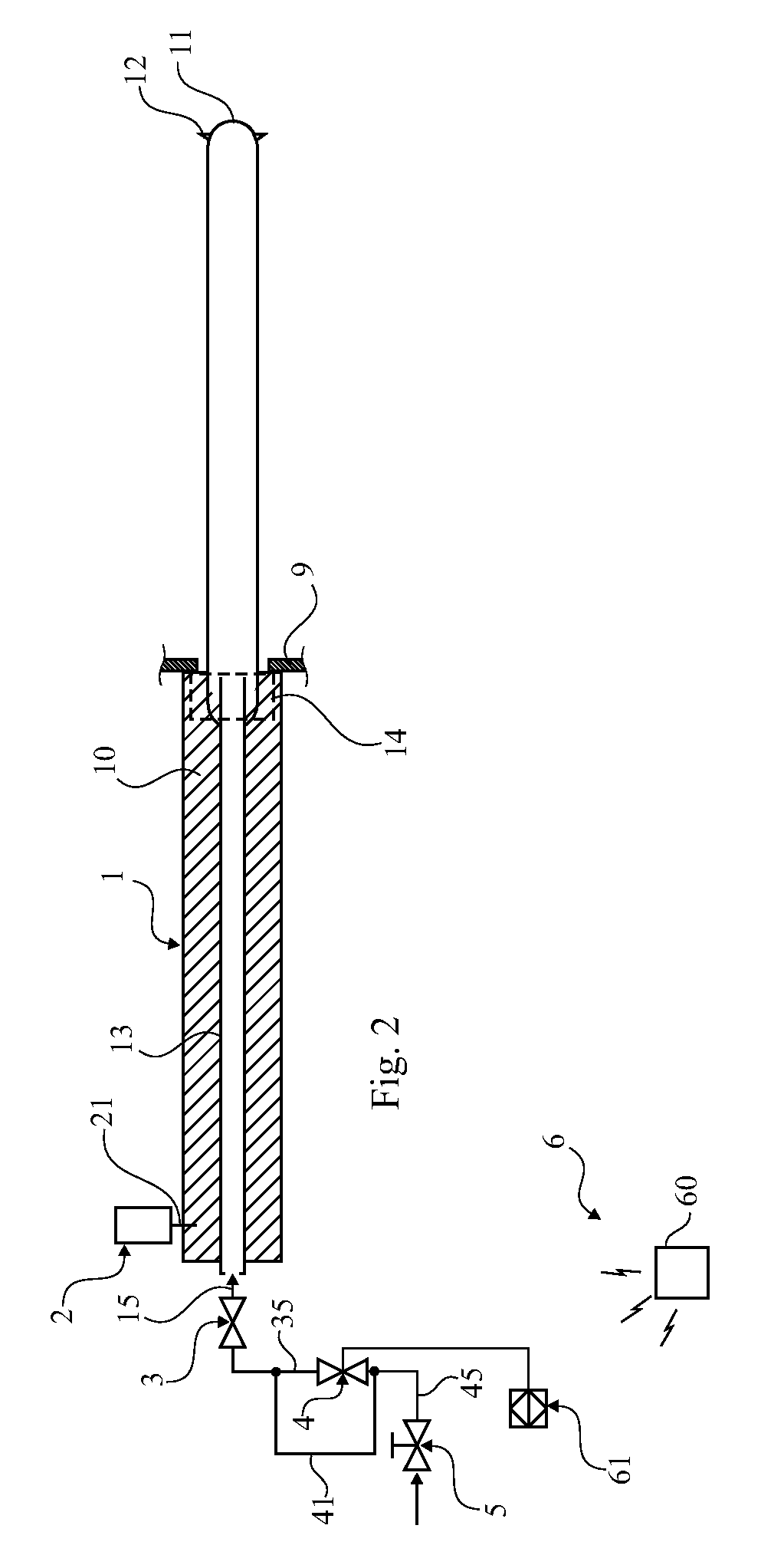

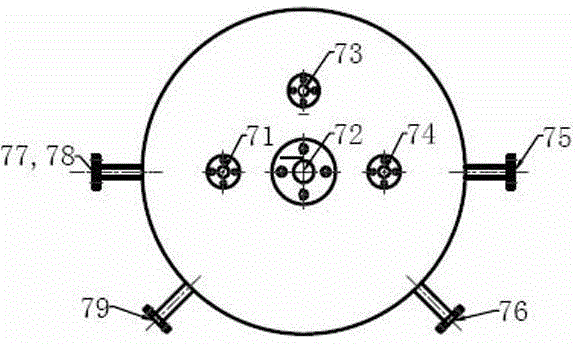

Method of rebuilding a sootblowing system of a recovery furnace, a sootblower for a recovery furnace, and a sootblowing system including a plurality of sootblowers

ActiveUS20100064470A1Reduce steam consumptionWithout reducing soot removal efficiencyMechanical cleaningPressure cleaningEngineeringFeeding tube

This invention relates to a method of rebuilding a sootblowing system of a recovery furnace, said sootblowing system including a plurality of sootblowers (1), and each sootblower (1) including a frame (10), a moveable carriage (14) supported by the frame (10), a motor (2) for moving the carriage (14), a lance tube (11) mounted on the carriage (14) to be insertable into and retractable from the recovery furnace (8), said lance tube (11) having at least one nozzle (12), and a steam feed tube (45, 35, 15) connected to the lance tube (11) for feeding sootblowing steam to be ejected through said at least one nozzle (12) into the recovery furnace, said steam feed tube (45, 35, 15) having a first valve (3) arranged to admit steam through said at least one nozzle (12) only when the carriage with the lance tube (11) is in an activated position, i.e. during retraction and introduction of the lance tube (11), wherein further providing means (4, 30) to arrange for controlled steam supply merely during a limited time period, e.g. merely during introduction.

Owner:SOOTTECH AB

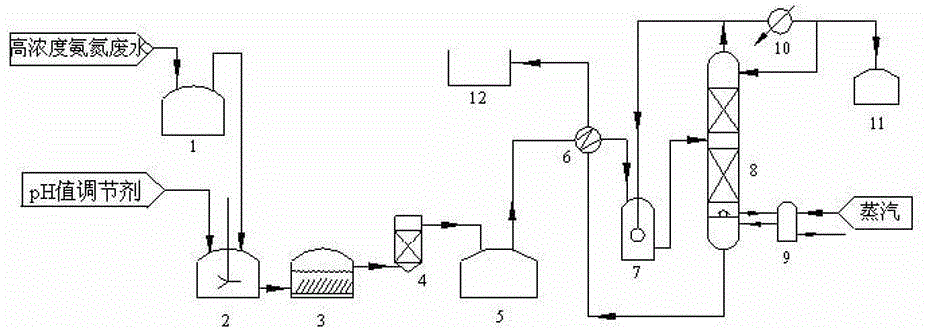

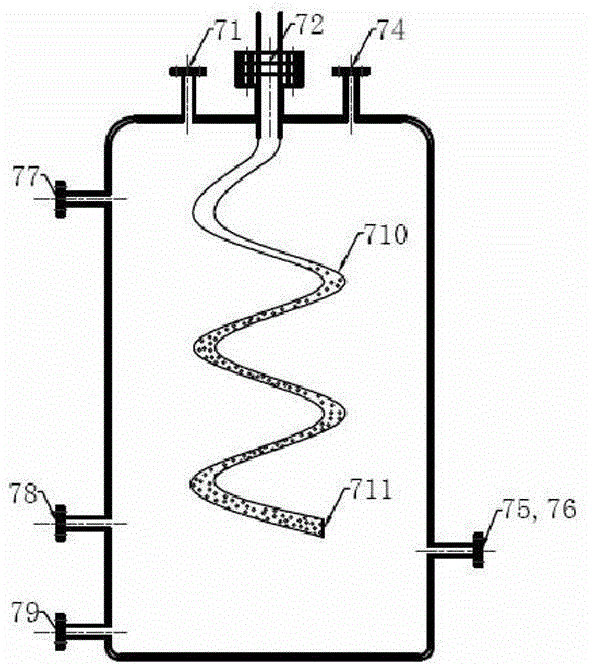

Treatment process for high-concentration ammonium-nitrogen waste water

ActiveCN104926012ALow running costImprove economic efficiencyMultistage water/sewage treatmentPre treatmentEnvironmental chemistry

The invention discloses a treatment process for high-concentration ammonium-nitrogen waste water. The treatment process includes the following steps: (1), pre-treating the high-concentration ammonium-nitrogen waste water; (2), performing heat exchange treatment and densification heating treatment on the ammonium-nitrogen waste water after being pre-treated sequentially; (3), adopting stripping steam to perform steam stripping treatment on the ammonium-nitrogen waste water after densification heating to obtain ammonium-containing steam and deammoniated waste water; (4), subjecting part of the ammonium-containing steam to densification heating treatment of step (2), performing densification heating on the ammonium-nitrogen waste water after heat exchange treatment, condensing the other part of the ammonium-containing steam, enabling part of condensed liquid to flow back into steam stripping treatment of step (3), and taking the other part of the condensed liquid as a finished ammonia water product for storage. The treatment process is simple in step, small in equipment investment, high in ammonium-nitrogen removing efficiency and low in steam single consumption of ammonium-nitrogen waste water treatment, standard reaching emission can be realized through only one-time treatment by the treatment process, and the finished ammonia water product having economic value can be recycled.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

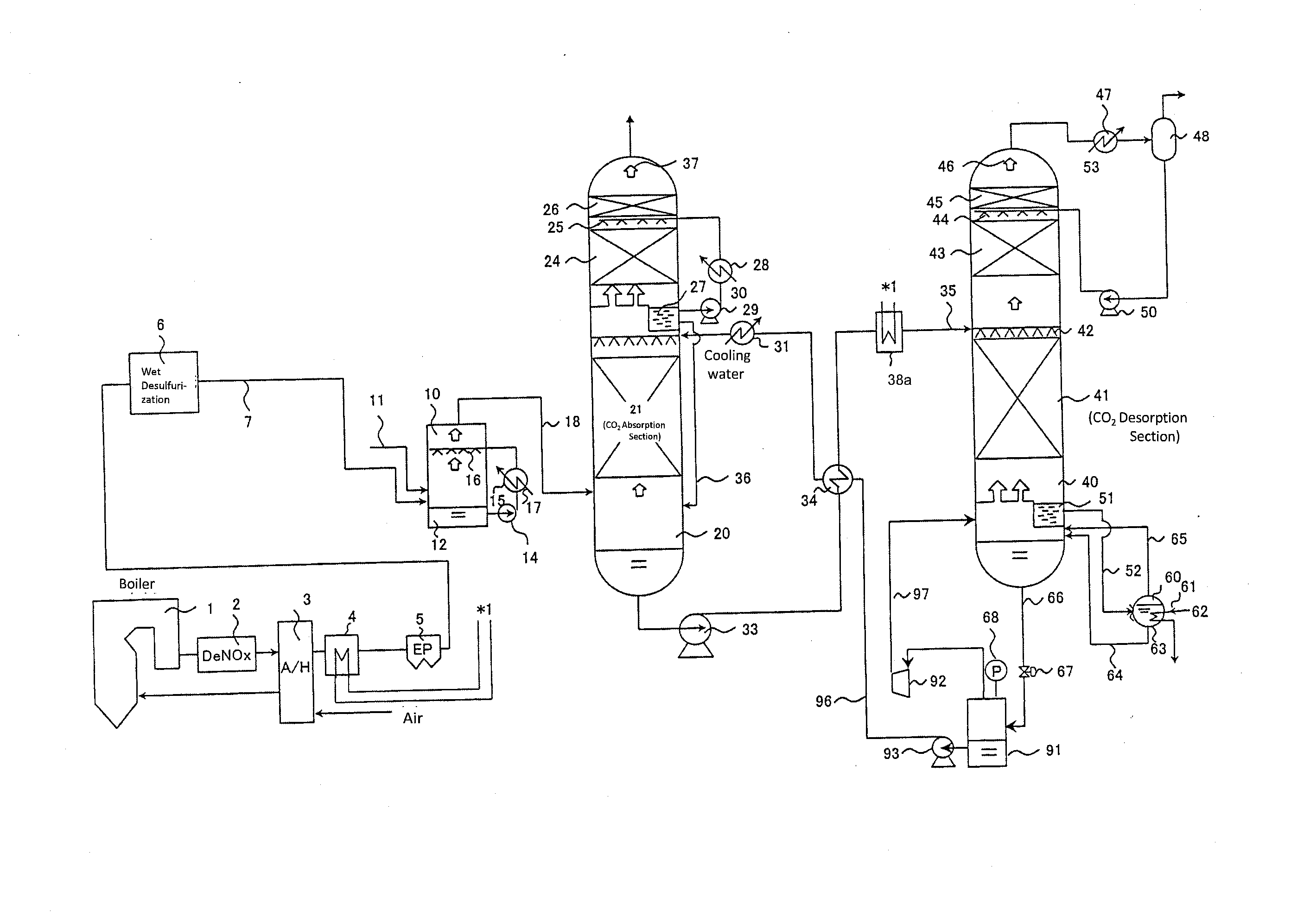

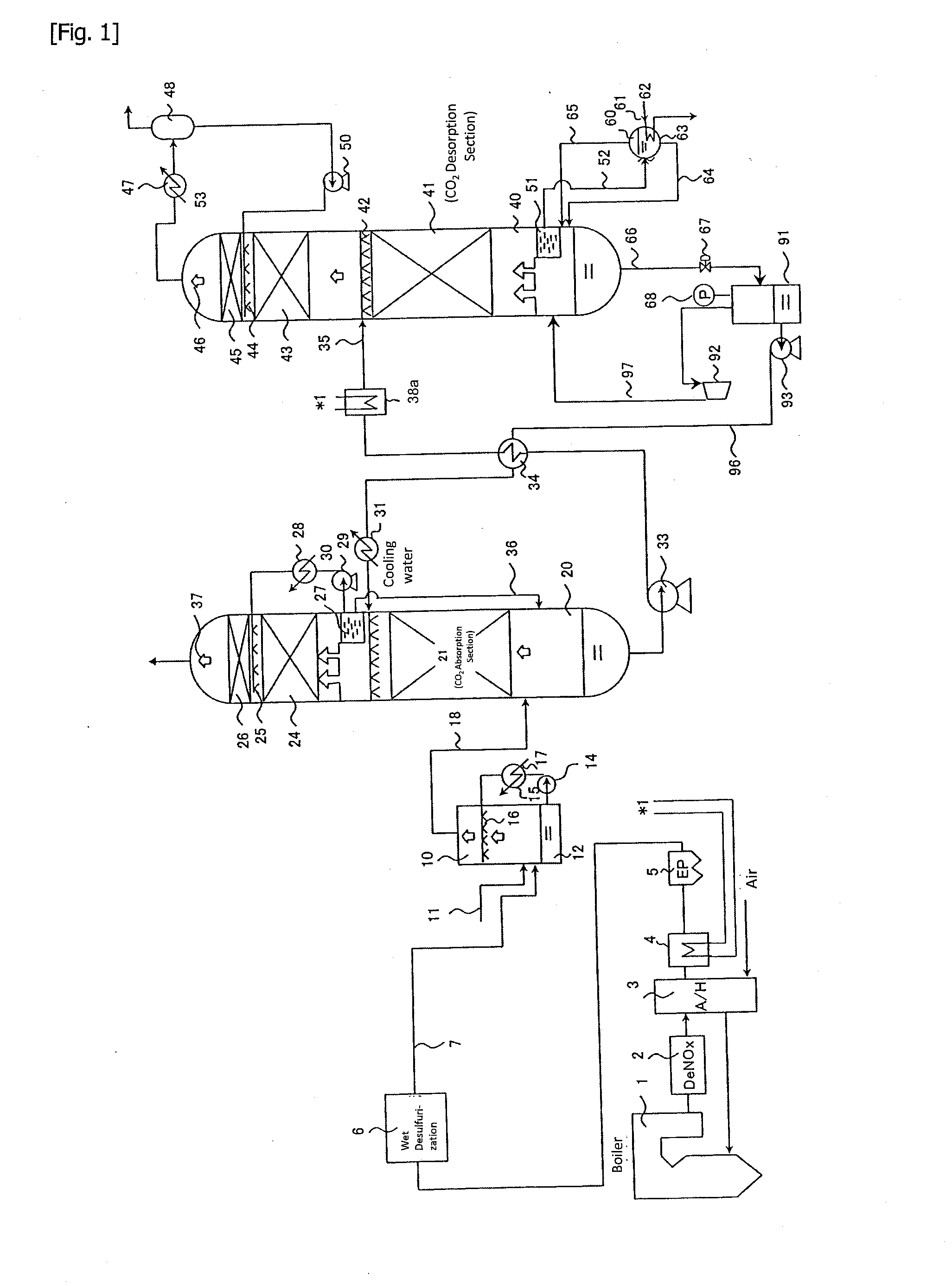

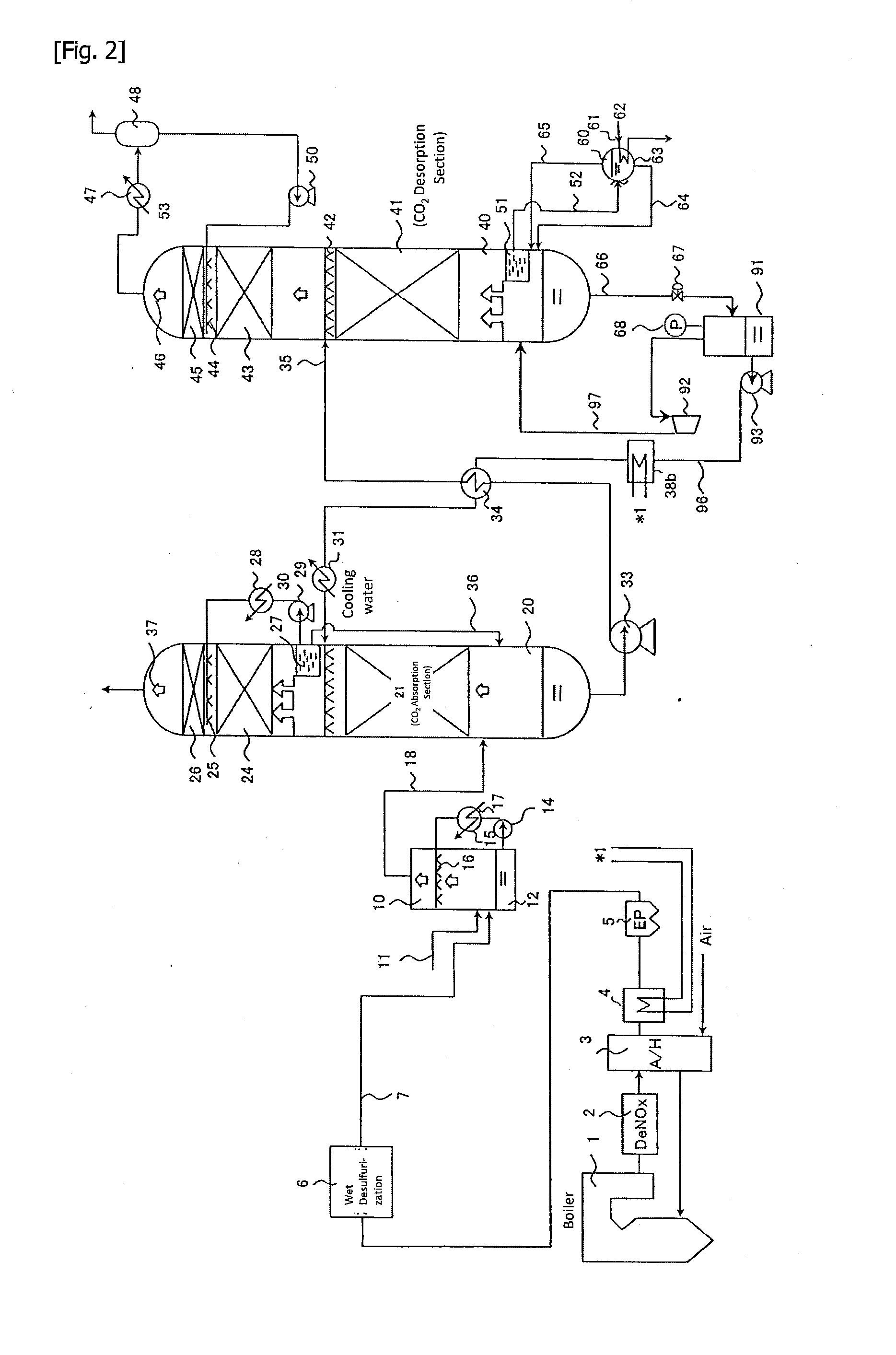

Combustion exhaust gas treatment system and method of treating combustion exhaust gas

A combustion exhaust gas treatment system comprising: a heat exchanger (A) for recovering heat contained in the combustion exhaust gas into heat medium, an absorption column for obtaining CO2 removed gas by absorbing CO2 in the combustion exhaust gas into absorbent, a heat exchanger (B) for applying heat recovered by heat medium to the CO2 absorbed absorbent, a desorption column for desorbing the absorbent by removing CO2 from the CO2 absorbed absorbent, a flash tank for flash vaporizing the desorbed absorbent and a heat exchanger (E) for transferring heat from the desorbed absorbent to the CO2 absorbed absorbent, wherein the CO2 absorbed absorbent can be supplied from the absorption column to the desorption column via the heat exchanger (E) and the heat exchanger (B) in this order, and the desorbed absorbent can be supplied from the desorption column to the absorption column via the flash tank and the heat exchanger (E) in this order.

Owner:MITSUBISHI POWER LTD

Extractive distillation processes using water-soluble extractive solvents

ActiveUS7871514B2Reduce amountGood solvent performanceHydrocarbon purification/separationHydrocarbonsFluid phaseExtractive distillation

Extractive distillation processes whereby water-soluble extractive distillation (ED) solvents are regenerated and recovered employ improved operations of the extractive distillation column (EDC) so that polar hydrocarbons are recovered and purified from mixtures containing polar and less polar hydrocarbons and measurable amounts of hydrocarbons that are heavier than intended feedstock and / or polymers that are generated in the ED process. The improved process can effectively remove and recover the heavy hydrocarbons and / or remove polymer contaminants from the solvent in a closed solvent circulating loop through mild operating conditions with no additional process energy being expended. With the improved process, the overhead reflux of the EDC may be eliminated to further reduce energy consumption and to enhance the loading and performance within the upper portion of the EDC, especially when two liquid phases exists therein.

Owner:CPC CORPORATION +1

Technology for immersing corn in a corn starch production process

The invention discloses a technology for immersing corn in a corn starch production process, wherein the technology uses a seven-can immersing method, and comprises a seventh into fragmentation grinding and a first can where new core is added, new-prepared acid is added into a sixth can before into fragmentation grinding, and concentration of sulfurous acid in the new-prepared acid is 0.15-0.17%; before the new-prepared acid is added, a can-inversing method is used, that is opposite to the direction in which the core is fed, a immersion liquid in the first to sixth cans is orderly poured form a can with a bigger sequence number to a can with a smaller sequence number, the liquid is poured until a liquid level that the immersed core is not exposed, and the immersion liquid level in each can is same; and the a total immersion time of the core is controlled in a range from 25h to 29h. The technology for immersing corn in the corn starch production process, strictly controls the immersion concentration and temperature, needs short immersion time, can effectively immerse out effective components in the corn, and has advantages of high yield, low concentration of sulfurous acid, short immersion time, and low power consumption and steam consumption.

Owner:MENGZHOU GOLDEN CORN

Process for recycling ammonium chloride waste water

InactiveCN102020389AReduce steam consumptionLow running costMultistage water/sewage treatmentAmmonium salt fertilisersTriple effectFertilizer

The invention provides a process for recycling ammonium chloride waste water, which comprises the steps of pre-heating ammonium chloride waste water and performing triple effect evaporation on feed liquid by using a plate type evaporator in turn. The process has the advantages that: triple effect downstream evaporation is adopted, pressure is kept between normal pressure and low vacuum, and evaporation temperature is lowered with the increase in the ammonium chloride concentration in waste water to reduce the corrosion of a medium by ammonium chloride, and the enough gas heat generated by steam-liquid separation at the previous effect evaporation is used as the heat source for later effect evaporation, so that the heating medium is fully utilized and steam consumption and operation cost are reduced; the first effect evaporation and second effect evaporation are falling film evaporation which has high evaporating capacity; the third effect evaporation is forced circulation evaporation; and the concentration of ammonium chloride solution after triple effect evaporation is controlled to be saturated, cooling and crystallizing can be performed subsequently, and the dried material can be used as a fertilizer directly and has a high commercial value.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

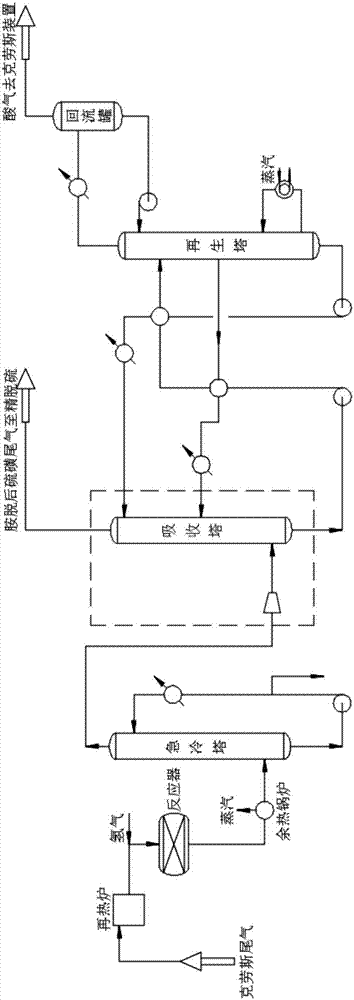

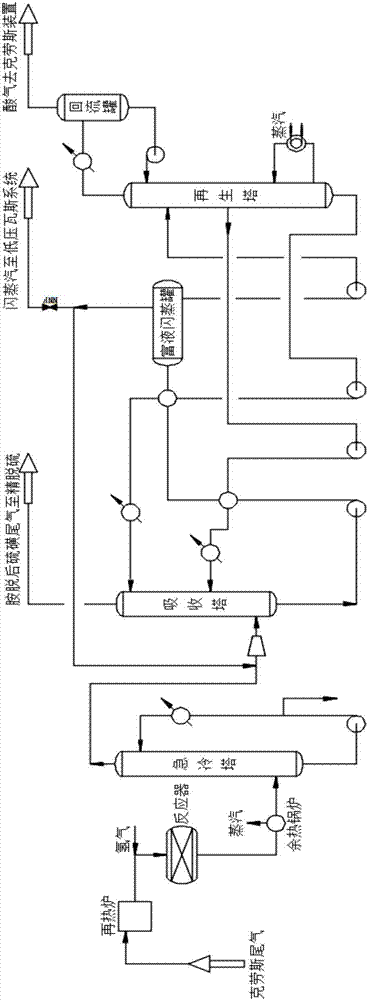

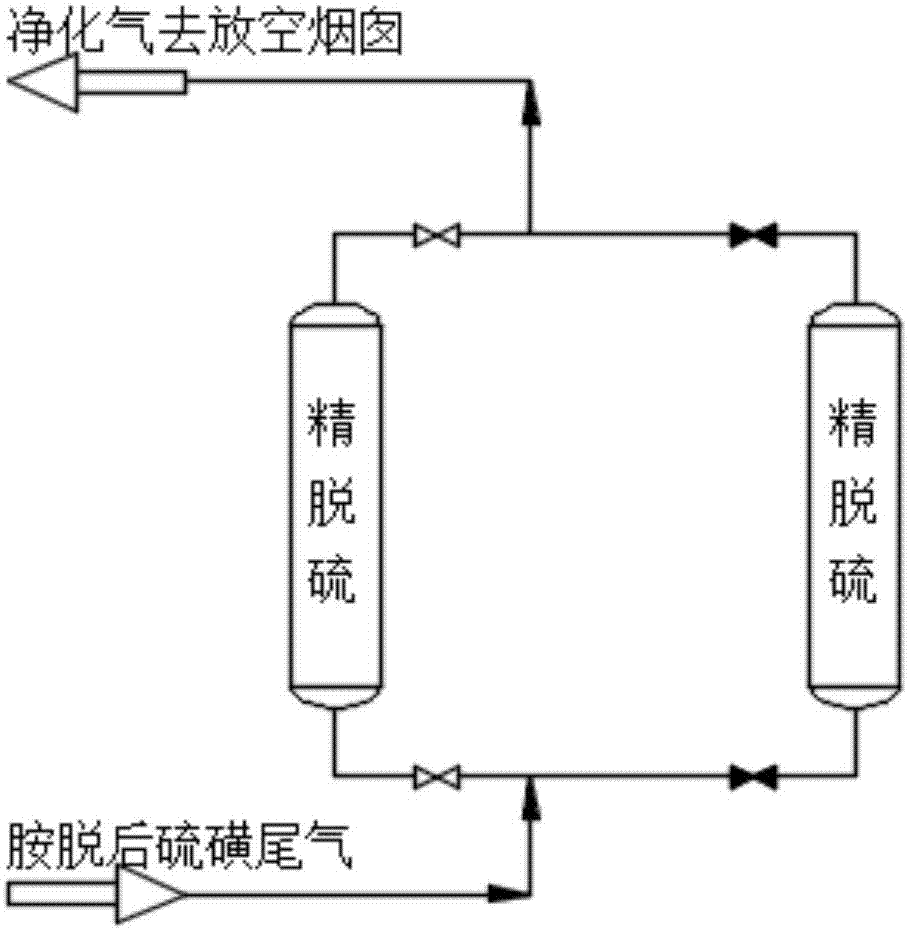

Sulfur tail gas purification process for direct discharge after treatment

ActiveCN106881021AGuaranteed absorptionReduce steam consumptionDispersed particle separationProtonationSulfur

The invention provides a sulfur tail gas purification process for direct discharge after treatment. On the basis of a conventional Super-SCOT process, the absorption pressure inside an absorbing tower is 0.05-0.25MPa; the absorption grade inside the absorbing tower is not smaller than that of an actual tower plate of 18 layers; a desulfuration solvent for deamination comprises the following components in percentage by weight: 20-50% of N-methyldiethanolamine (MDEA), 0-30% of diisopropanolamine (DIPA), 10-50% of sulfolane, 1-2% of a protonation agent and the balance of water; a semi lean solution is sucked out from 1-5 layers above a middle layer in the middle of a regeneration tower and is moved upwards along with increase of the content of CO2 in a deamination raw material gas; two semi lean solution inlets are longitudinally formed in the middle of the absorbing tower; when the content of the CO2 in the deamination raw material gas is higher than 10% (mol / mol), the semi lean solution is fed into the feeding hole above, or else the semi lean solution is fed into a feeding hole below; COS is hydrolyzed into H2S and CO2 by using a fine desulfurization process, H2S is adsorbed and reacts to generate sulfide, and a treated purified gas can be directly discharged. The purified gas treated by using the method can be directly discharged without incineration, and thus relatively low sulfur discharge standards can be met with relatively low energy consumption.

Owner:HEBEI REFINING TECH CO LTD

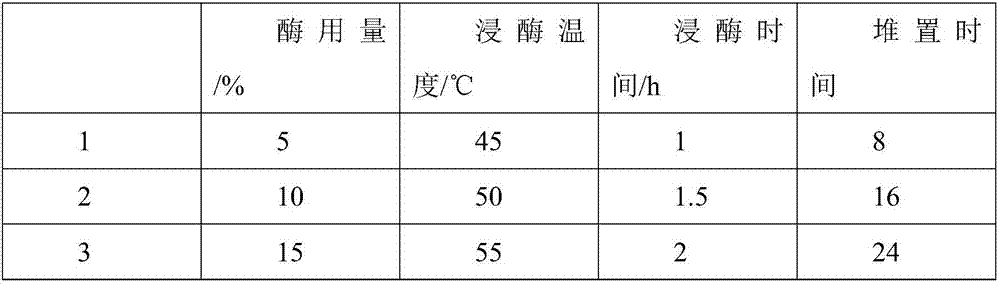

Preparation method of linen flat-strip fabric

ActiveCN107419403AAchieve productionBig cost energy advantageBiochemical treatment with enzymes/microorganismsDyeing processEngineeringWeft yarn

The invention discloses a preparation method of linen flat-strip fabric. The preparation method comprises the following steps that raw flax with a disintegration degree larger than or equal to 250 count is selected and made into linen roving; bio-enzymatic treatment is conducted, and degumming treatment is conducted on the linen roving; the linen roving treated with bio-enzymes is made into linen S twist yarn and linen Z twist yarn, and the count of both the linen S twist yarn and the linen Z twist yarn is 36 metric count; the linen S twist yarn is put into a humidification storehouse for humidification curing; warping and drawing-in treatment is conducted on the linen Z twist yarn in sequence; the linen Z twist yarn is regarded as warp yarn, the linen S twist yarn is regarded as weft yarn, a loom is used for weaving, and fabric dyeing is conducted on woven gray cloth to obtain the linen flat-strip fabric. According to the preparation method, the prepared linen fabric has the advantages that dyeing is even, colors are beautiful, and the design and color and the cloth type are novel and fashionable.

Owner:JIANGSU HUAXIN LINEN TEXTILE

Method for preparing cyanoacetic acid through continuous dehydration

ActiveCN102336685AReduce steam consumptionReduce the solid-to-liquid ratioPreparation by cyanide reactionCarboxylic acid nitrile purification/separationMulti effectAqueous solution

The invention discloses a method for preparing cyanoacetic acid through continuous dehydration. After chloroacetic acid is neutralized, cyanided and acidized to obtain cyanoacetic acid water solution, multi-effect evaporation and forced circulation evaporation are adopted and coupled for continuous dehydration, in addition, continuously separated sodium chloride is removed in the dehydration process for preparing the cyanoacetic acid, when the multi-effect evaporation is used for preparing the cyanoacetic acid, the steam consumption is reduced, and in addition, the sodium chloride is filtered during the proceeding of each effect, so the separated sodium chloride can be filtered and removed in time, the solid-liquid ratio is reduced, filter equipment can be more favorably selected, the operation is simple, the equipment utilization rate is high, the steam consumption is low, in addition, the dehydration time is short, and the cyanoacetic acid yield is high.

Owner:WEIFANG BAILI CHEM

Energy-saving efficient glass jelly preparation method capable of retaining natural flavor

ActiveCN102919833AReduce steam consumptionShorten production timeFood preparationPectinaseEngineering

The invention discloses an energy-saving efficient glass jelly preparation method capable of retaining natural flavor. Firstly, selected dried grass jelly is smashed so as to enlarge contact area of enzyme and substrate, enzymolysis effect is improved, then water is added and boiled to perform sterilization, and cooling is performed. Cellulose, dextranase and pectinase are added at a specific PH range, enzymolysis is performed for a period, a settling centrifugal machine is used for filtering grass jelly dregs to obtain clear feed liquid, at last starch is added to be mixed, the starch is stirred and heated till to be gelatinized fully, and the glass jelly is formed after being cooled. No high-temperature infusion is not needed in a whole process, steam consumption in production is saved greatly, production time is shortened, the time is reduced from traditional 3-4 hours to 2 hours, yield of the glass jelly is improved above 40%, loss of glass jelly flavor substances is avoided further, no plenty of edible alkali needs to be added, and natural flavor of the glass jelly is retained.

Owner:龙岩嘉麒生物科技有限公司

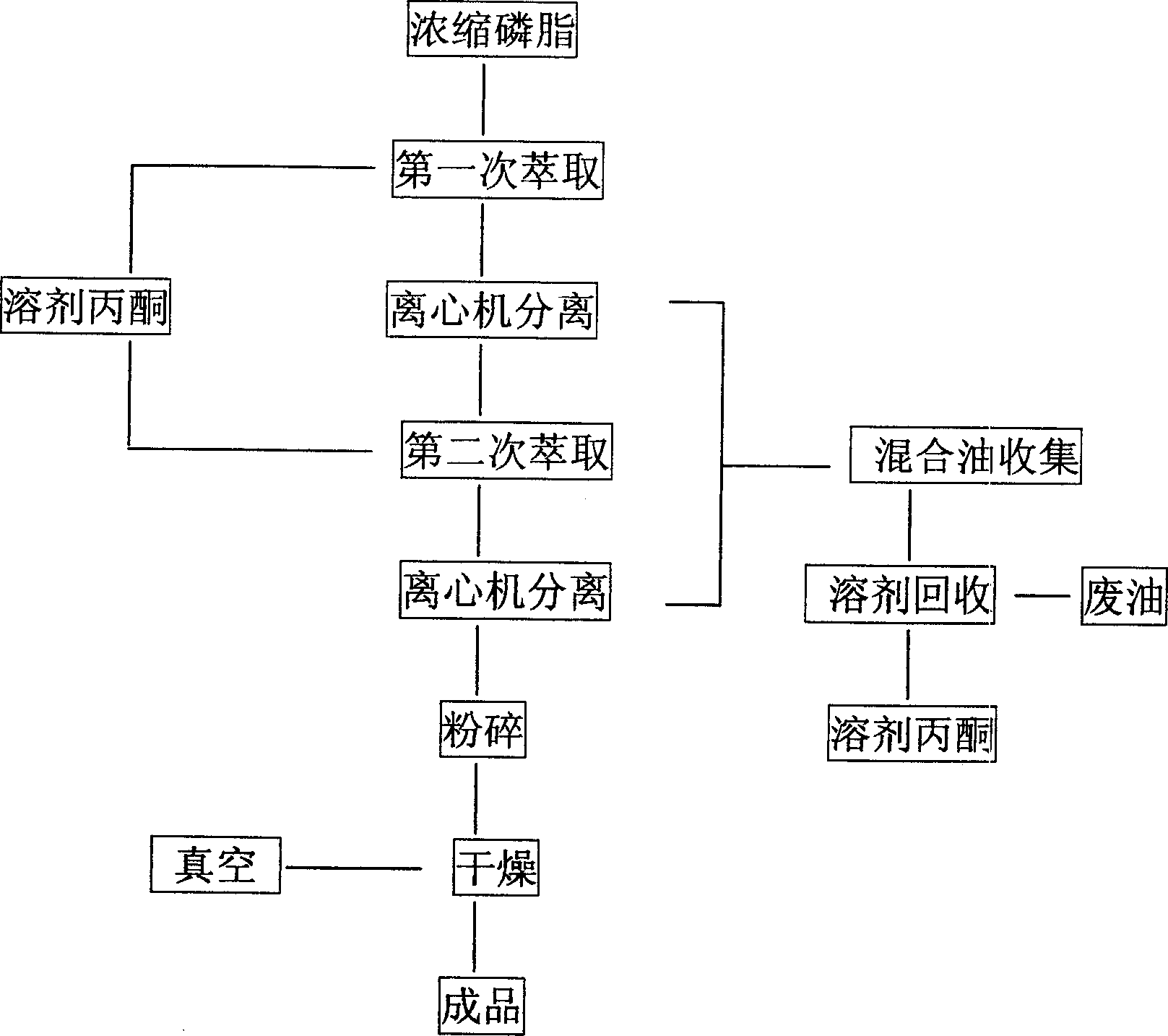

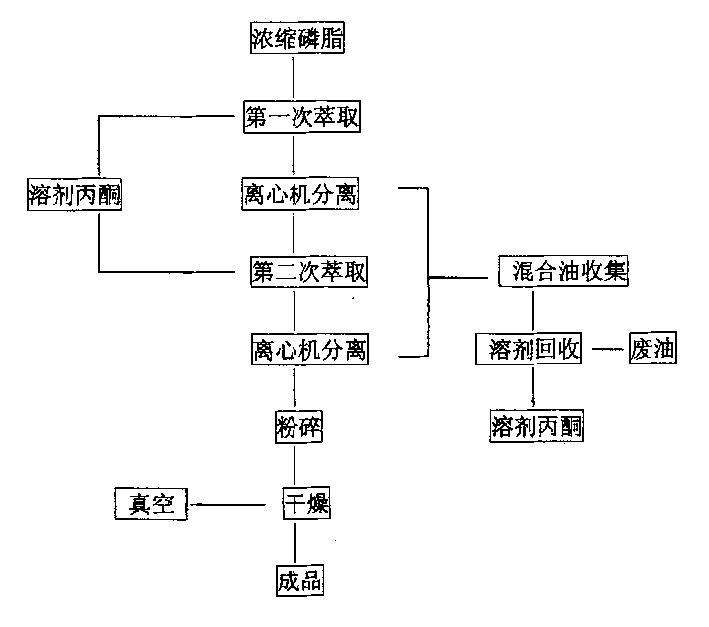

Process for preparing powdered soy bean phosphatide

InactiveCN1408716AReduce lossRealize continuous sealingPhosphatide foodstuff compositionsPhospholipidSolvent

The present invention relates to the preparation process and is especially the preparation process of powdered soybean phosphatide. The preparation process includes the steps of: mixing concentrated soybean phosphatide material with acetone of 2-30 times volume and the first homogeneous extraction to make soybean phosphatide dissolve in the solvent; solid-liquid separation to make liquid phase enter mixed oil tank and solid phase phosphatide second extracted; extraction in the second extractor with acetone; the second separation of mixed liquid after the second extraction in centrifuge; powdering solid soybean phosphatide; vacuum heating to dry soybean phosphatide; and recovering mixed oil in mixed oil tank. The present invention is used in producing high-quality medical soybean phosphatide.

Owner:上海金伴药业有限公司

Replacement cooking pulping method

InactiveCN102154874AIncrease productionReduce outputPulp liquor regenerationCellulose material pulpingThermal energyProcess engineering

The invention discloses a replacement cooking pulping method. The method comprises the following steps of: filling warm black liquid into a pan; filling the warm black liquid; replacing and raising temperature; filling hot white liquid; raising temperature; preserving heat; before emptying materials, replacing heat; and emptying the materials. In the method, the black liquid replaced by a high-temperature-section distilling pan is subjected to heat exchange by a heat exchanger and then is fed into a low-temperature-section distilling pan, the temperature and the pressure of the black liquid are reduced before the black liquid enters the low-temperature-section distilling pan, a water attack phenomenon is avoided, a production process is easy to control, and the production cost is obviously reduced. The heat of the black liquid discharged before the materials are emptied is recovered, so when the materials are emptied, the temperature in the material emptying process is very low, the discharged flash steam is very few, and the method is favorable for protecting environment.

Owner:白福安

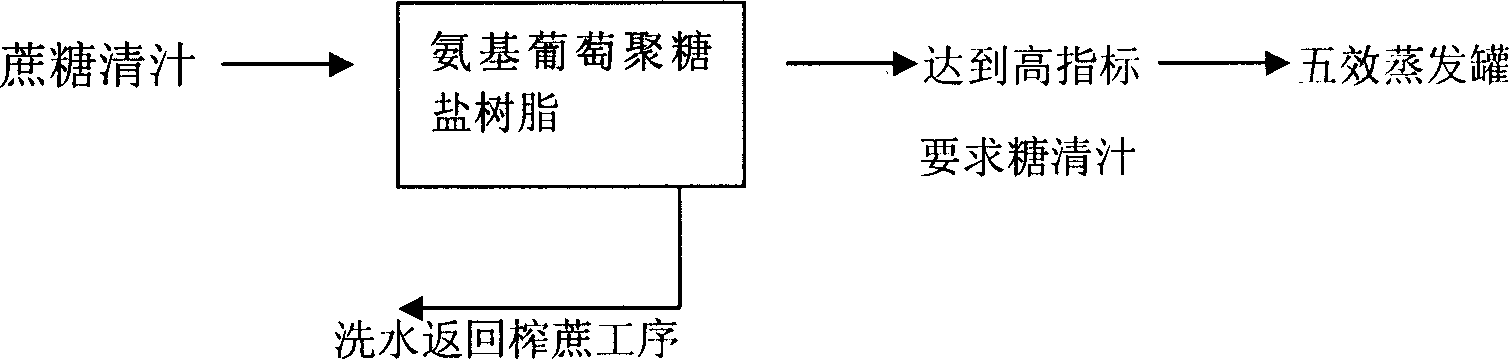

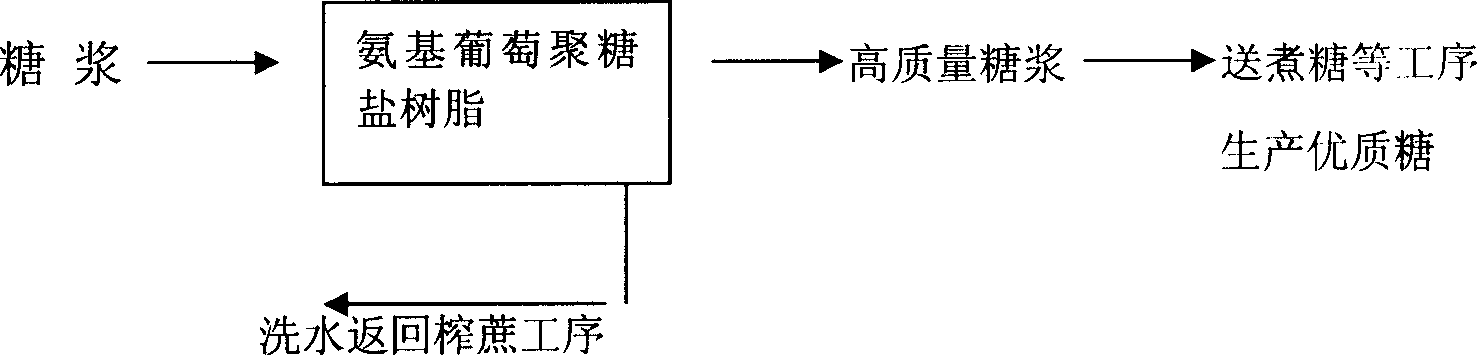

Purification and decolouring agent cane juice, syrup and its preparation method and application in sugar refining technology

InactiveCN1757756AEasy to handleEasy to operatePurification using adsorption agentsAcetic acidSugar refining

A purifying and decoloring agent for the cane juice or syrup in sugar refinery is prepared from chitosan through catalytic reaction between chitosan and the solution of acetic acid, citric acid or hydrochloric acid to obtain the polyose aminogluconate, and polymerizing to obtain aminoglucosan salt insoluble in water and deluted acid.

Owner:张永达 +3

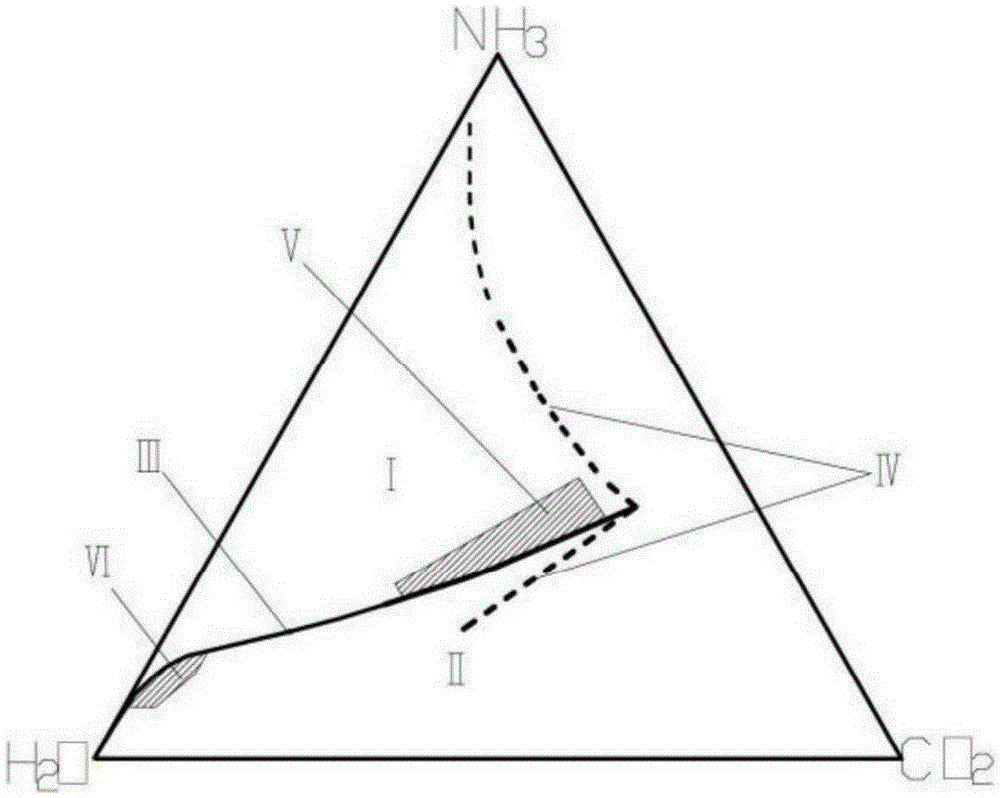

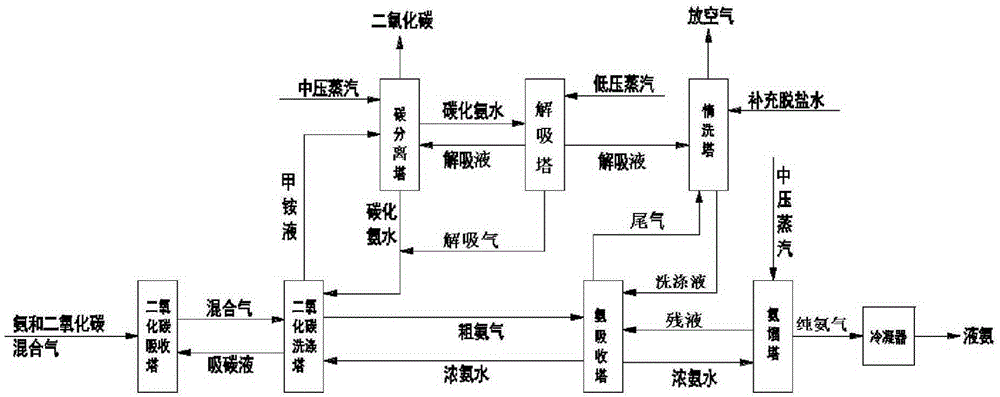

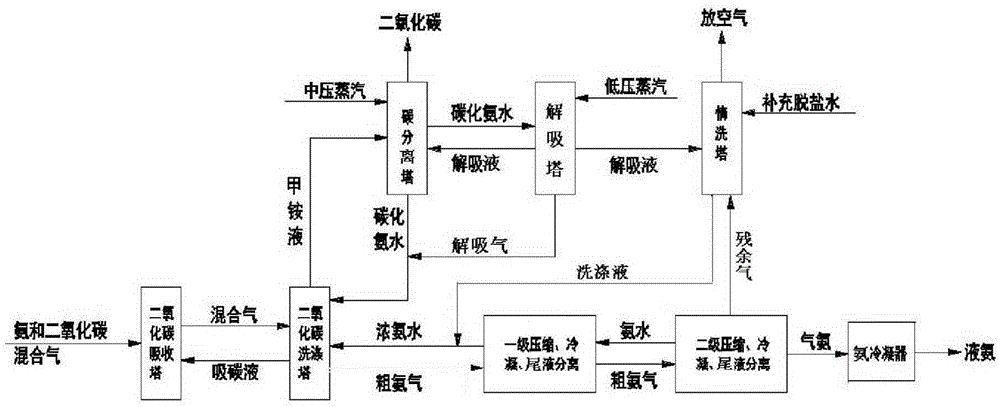

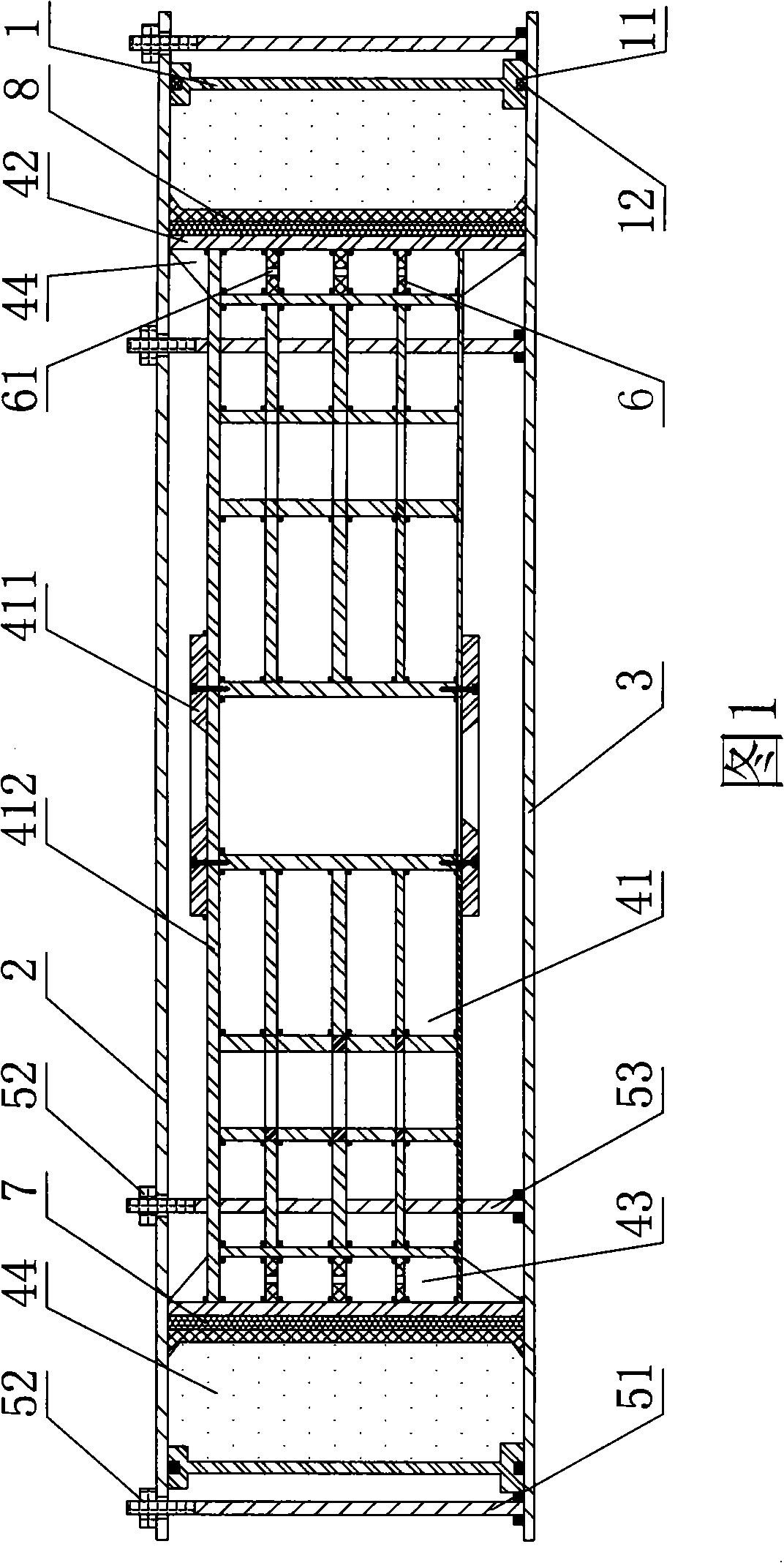

Ammonia-carbon separation process

ActiveCN105289210AEasy to separateReduce circulationProductsCarbon compoundsCo2 absorptionEconomic benefits

The invention provides an ammonia-carbon separation process. The process comprises the step of carbon dioxide absorption, wherein a gas mixture sequentially makes contact with carbonized ammonia water and strong ammonia water in a carbon dioxide washing tower, carbon absorbing liquid is formed, the carbon absorbing liquid makes contact with a gas mixture in a carbon dioxide absorption tower, and ammonium carbamate liquid is obtained. According to the process, synergism of the carbon dioxide absorption tower and the carbon dioxide washing tower is initiatively utilized, carbon dioxide is separated from the gas mixture to the greatest extent, to be specific, the carbon dioxide absorption tower adopts the carbon absorbing liquid for absorbing carbon dioxide in the gas mixture, while carbon dioxide washing tower adopts carbonized ammonia water as the main medium and strong ammonia water as the auxiliary medium for precisely absorbing carbon dioxide, therefore the content of carbon dioxide in obtained coarse ammonia gas can be controlled below 50 ppm, then ammonia is separated from the coarse ammonia gas, and finally pure ammonia containing no carbon dioxide or water is obtained. By means of the ammonia-carbon separation process, thorough separation of ammonia and carbon dioxide is achieved in real sense, the ammonia-carbon separation effect is improved, and it is helpful to increase economic benefits.

Owner:BEIJING EDGEIN TECH +1

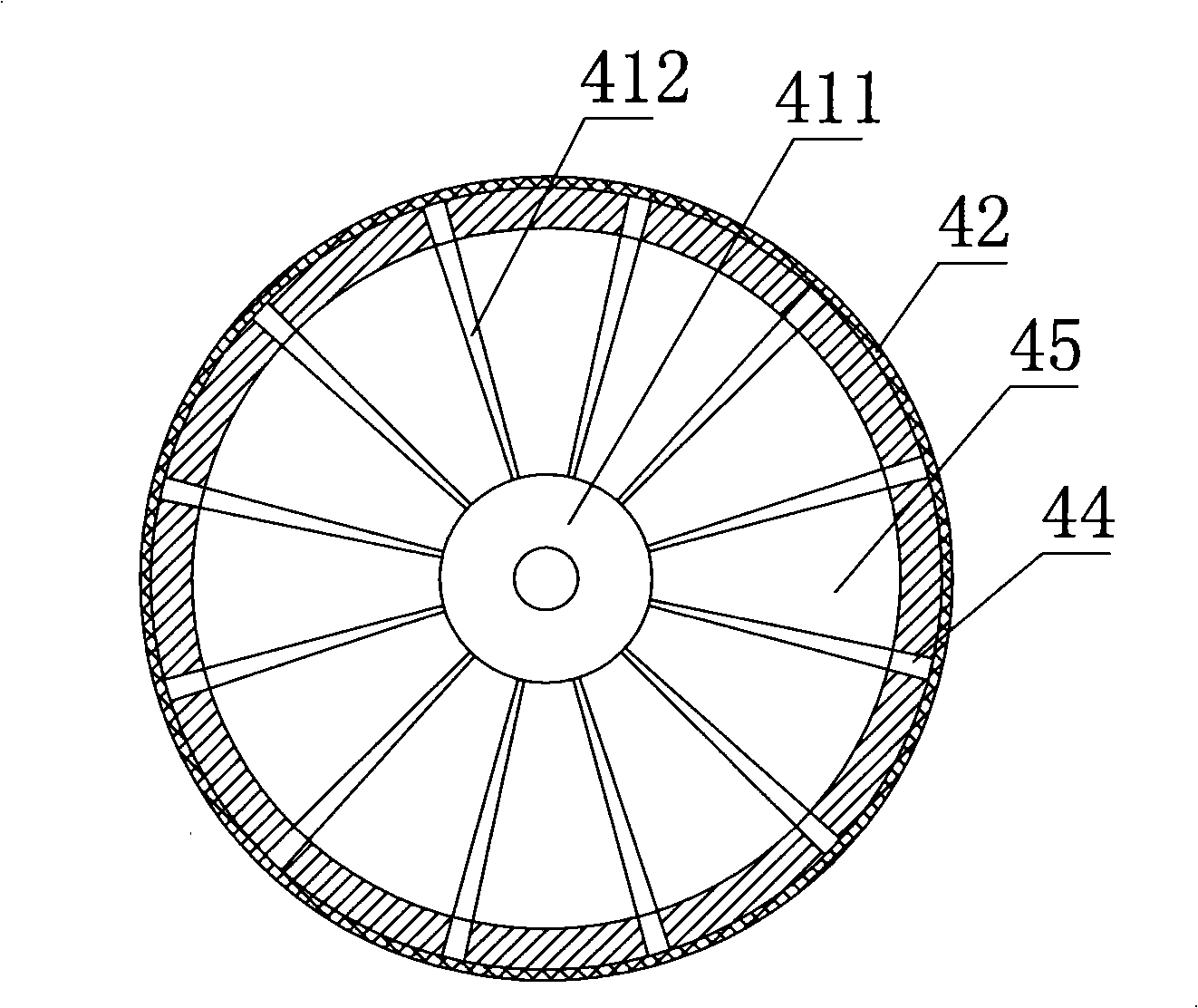

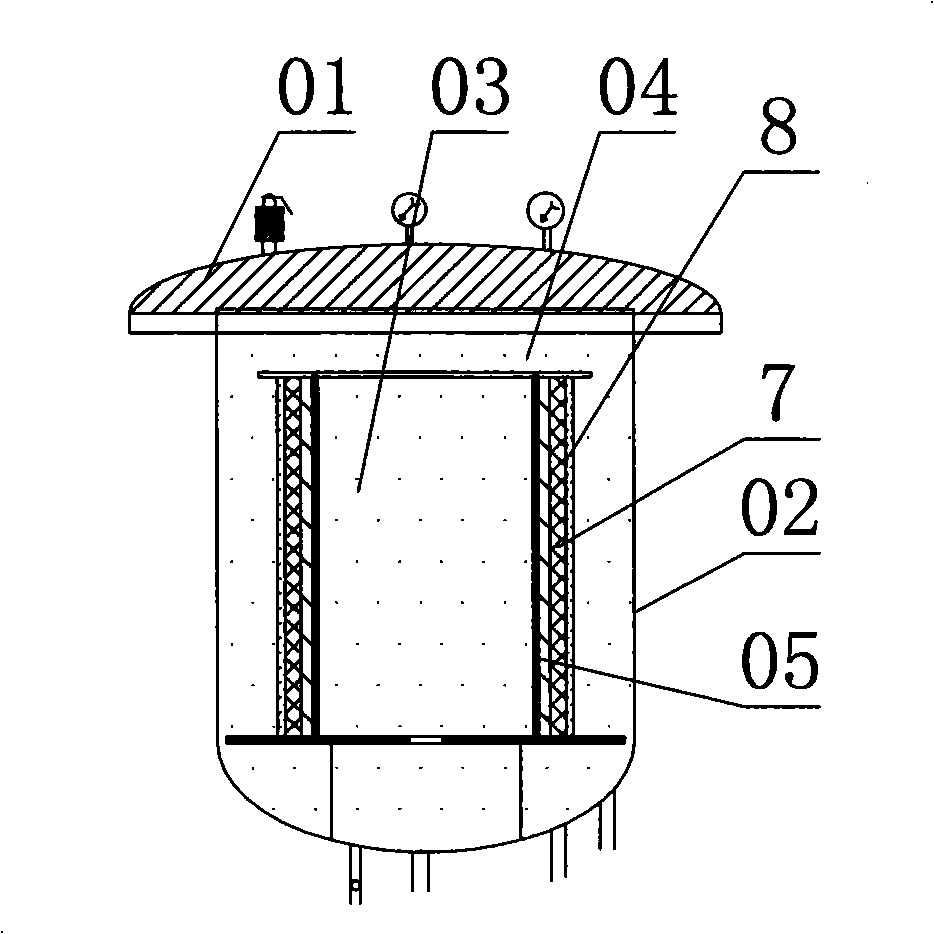

Rubber transmission belt vulcanizing device and vulcanizing method thereof

The invention discloses a rubber driving belt vulcanizing device which comprises an outer sleeve, and an upper cover plate, a lower bottom plate and a die component which are connected with the upper end surface and the lower end surface of the outer sleeve in a sealing manner. The die component comprises a pivot holder body and a die arranged at the outer ring end of the pivot holder body, a circularly communicated steam chamber is arranged on the inner surface of the die and close to the pivot holder body, an external pressure cavity is formed between the outer sleeve and the die, and the upper cover plate is adjustably connected with the lower bottom plate through a locking bolt, an inner locking bolt and a locking nut. The vulcanizing medium in the external pressure cavity is mixed with high-pressure compressed air through saturated steam, which can ensure the vulcanizing pressure and a certain temperature, the steam chamber is arranged between the die and the outer ring end of the pivot holder body, the volume of the steam chamber is greatly reduced than the volume of the internal pressure air chamber of the prior vulcanizing boiler, so that the consumption of saturated steam is greatly reduced; therefore, the steam consumption for the boiler is low, and the energy consumption is low. The device does not need a special vulcanizing boiler, so that the equipment investment is saved.

Owner:杭州金瀚能源科技有限公司

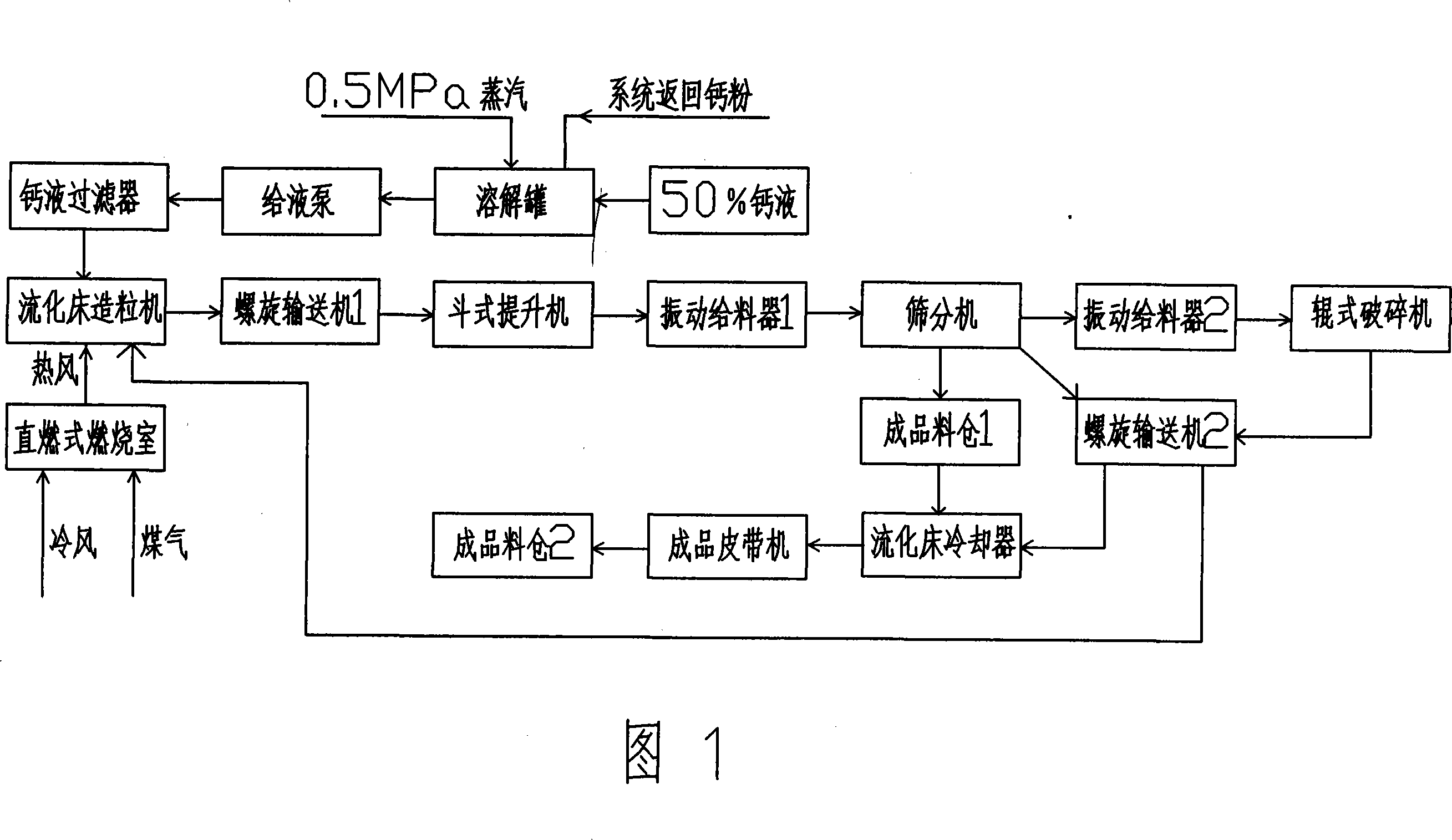

Method for directly producing anhydrous spherical calcium chloride from ammonia-soda process waste liquid

InactiveCN101125674ASimple processEasy to operateCalcium/strontium/barium chloridesFluidized bedChloride

The invention relates to a production method of calcium chloride, in particular to a method to directly produce anhydrous spherical calcium chloride with ammonia-soda process waste liquid. The method is that: calcium liquid containing about 50 percent of CaCl2 is sent to a dissolving tank by an evaporating truck to absorb system calcium fly and heated directly by primary steam to obtain more concentrated calcium liquid; after being filtered, the concentrated calcium liquid enters a fluidized bed prilling machine to inject and granulate, then is heated by hot air, evaporated and dried to obtain calcium granules more than or equal to 94.5 percent and the superfluous calcium liquid goes back to the dissolving tank; the calcium granules from the fluidized bed enter a screening machine through a screw conveyor, a bucket elevator and a vibration feeder to be two-stage screened, qualified granules enter finished product silo, comparatively larger granules enter the vibration feeder, are crushed by a roll crusher and sent to the fluidized bed by the screw conveyor and the small granules screened directly enter the screw conveyor and go back to the fluidized bed. The invention has simple process, convenient operation, high production efficiency and good quality.

Owner:唐山三友志达钙业有限公司

Method for dewatering solvent during aromatic acid production process

InactiveCN106397184AReduce loadReduce steam consumptionCarboxylic preparation by oxidationCarboxylic compound separation/purificationSolventAqueous solution

The invention discloses a method for dewatering a solvent during an aromatic acid production process. According to the present invention, an aromatic hydrocarbon for aromatic acid production is adopted as a solvent, the acetic acid in the acetic acid aqueous solution produced during the aromatic acid production process is recovered through an extraction-azeotropic coupling process, and the used equipment in the whole process comprises an extraction tower, an azeotropic rectification tower, an oil-water separation tank, an azeotropic agent refining tower, and a methyl acetate recovery tower; and with the method of the present invention, the load of the acetic acid azeotropic rectification tower can be effectively reduced and the steam consumption of the acetic acid azeotropic rectification tower can be reduced, and the PTA production capacity can be increased.

Owner:SINOPEC YANGZI PETROCHEM +1

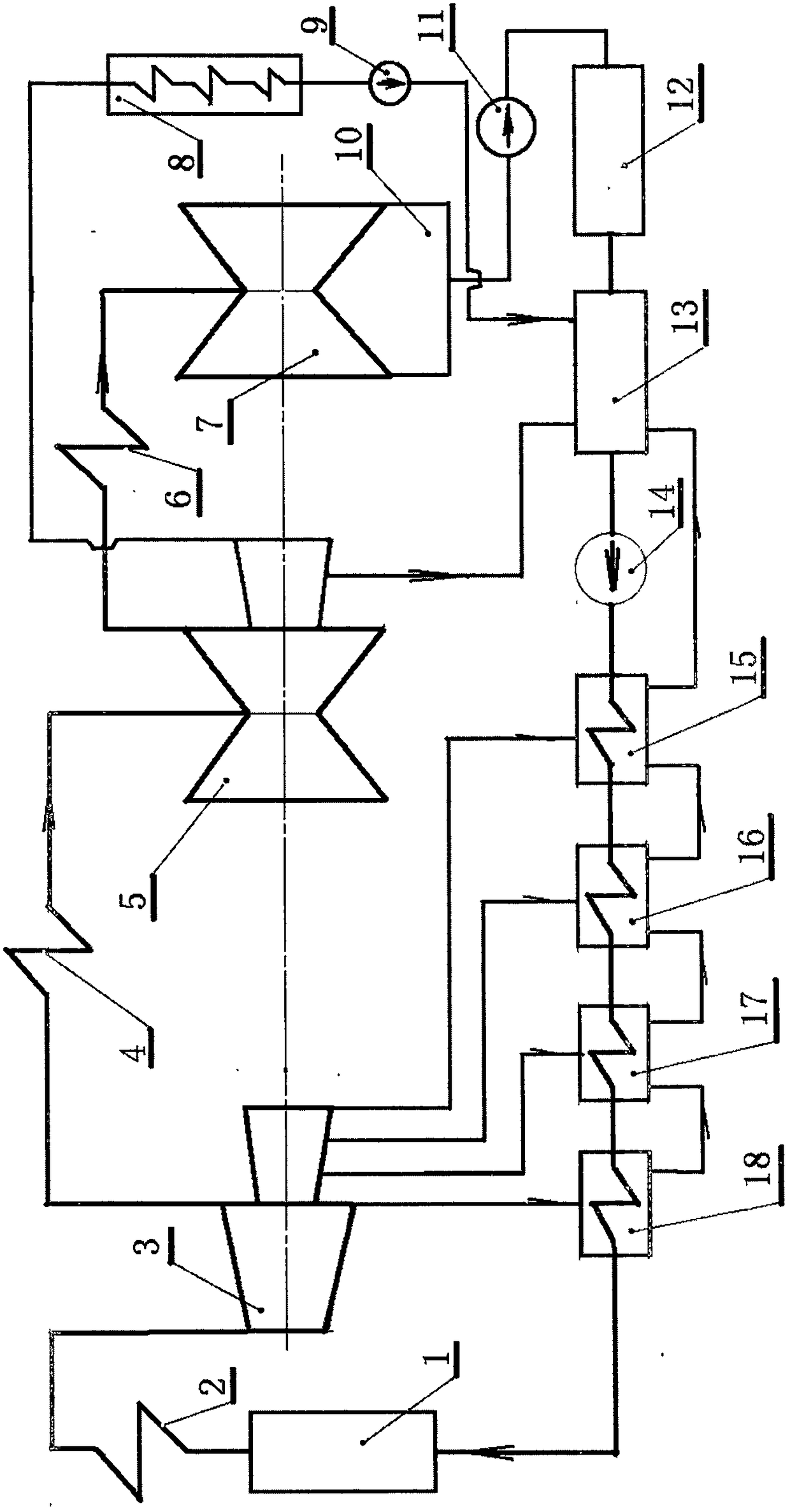

Secondary reheating unit with ultrahigh pressure cylinder and high-intermediate pressure cylinder both provided with additional heat regeneration stages

ActiveCN108643980ARaise the inlet air temperatureReduce heat consumptionSteam usePower stationEngineering

The invention discloses a secondary reheating unit with an ultrahigh pressure cylinder and a high-intermediate pressure cylinder both provided with additional heat regeneration stages, and relates toa secondary reheating unit in the fire coal power station ultra-supercritical stage. In particular, the ultrahigh pressure cylinder and the high-intermediate pressure cylinder are both provided with the additional heat regeneration stages, a heat regeneration system is further optimized, main steam, primary reheating steam and secondary reheating parameters are further optimized, the heat consumption of the secondary reheating unit in the ultra-supercritical stage can be obviously reduced, and the greenhouse gas discharge can be obviously reduced.

Owner:章礼道

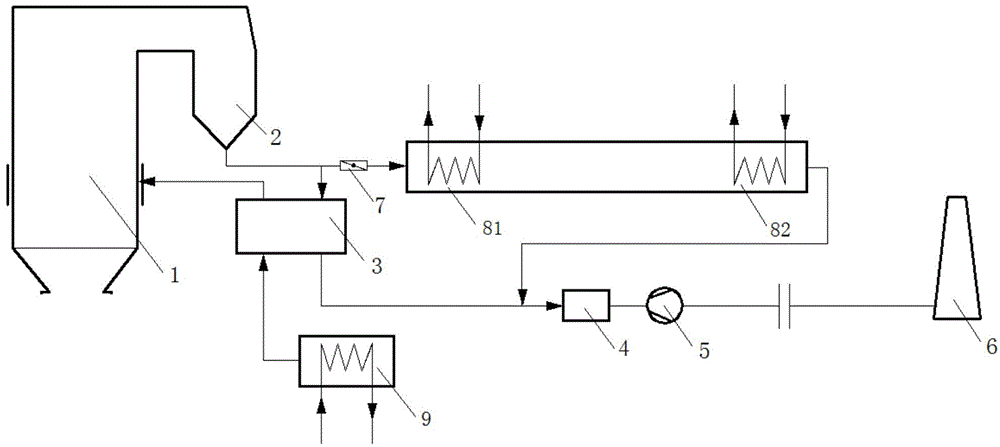

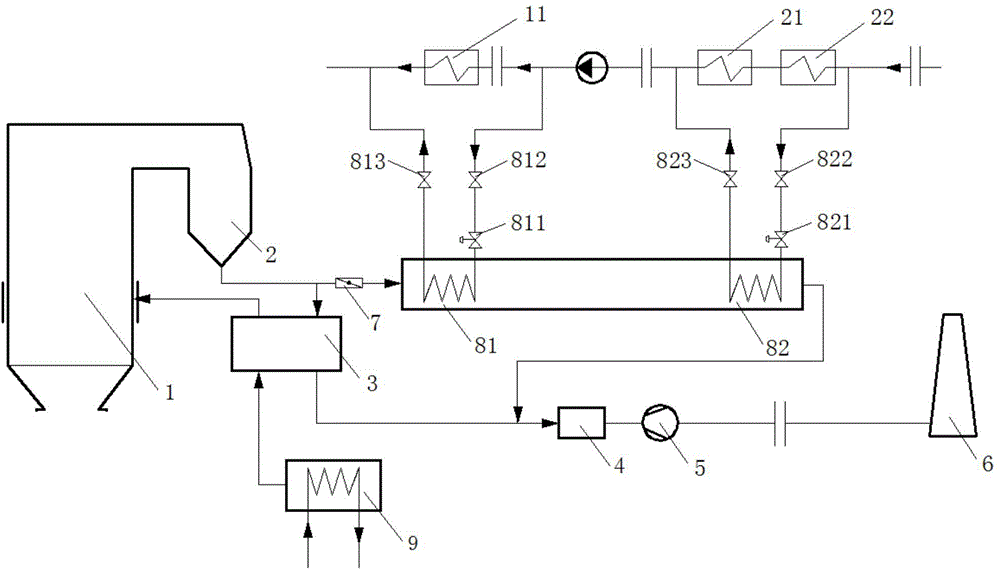

Medium-temperature coal economizer system and method thereof for recovering smoke afterheat

The invention provides a medium-temperature coal economizer system. The medium-temperature coal economizer system comprises at least one smoke-water heat exchange device, a first flue and a second flue, wherein a smoke inlet of the smoke-water heat exchange device and a flue in an inlet of an air preheater are connected through the first flue; a smoke outlet of the smoke-water heat exchange device and a flue in an outlet of the air preheater are connected through the second flue; and the medium-temperature coal economizer system further comprises a heat exchange device for heating inlet air of the air preheater. The medium-temperature coal economizer system, provided by the invention, shunts part smoke in the inlet of the air preheater, heats water in the smoke-water heat exchange device, heats the inlet air of the air preheater through an air-steam / water heat exchange device, can recover the smoke afterheat, can reduce the smoke temperature, can satisfy the requirement of lowering the smoke temperature in the inlet of a low-temperature dust remover, can improve the dust removing efficiency, and can prevent such problems as low-temperature corrosion and blockage at a cold end of the air preheater. The invention further provides a method for recovering the smoke afterheat by adopting the medium-temperature coal economizer system.

Owner:冯伟忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com