Purification and decolouring agent cane juice, syrup and its preparation method and application in sugar refining technology

A decolorizing agent and syrup technology, which is applied in the direction of using adsorbent purification, etc., can solve the problems that ion exchange resins are easily polluted, difficult to recycle and process, and the number of resin regeneration is too many, so as to reduce fouling and reduce costs. Small size, improved heat transfer performance and throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

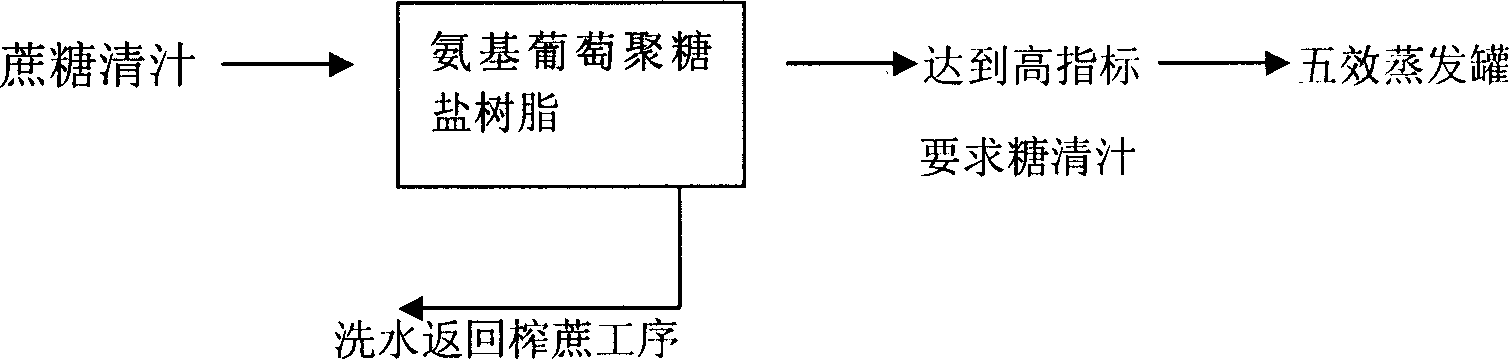

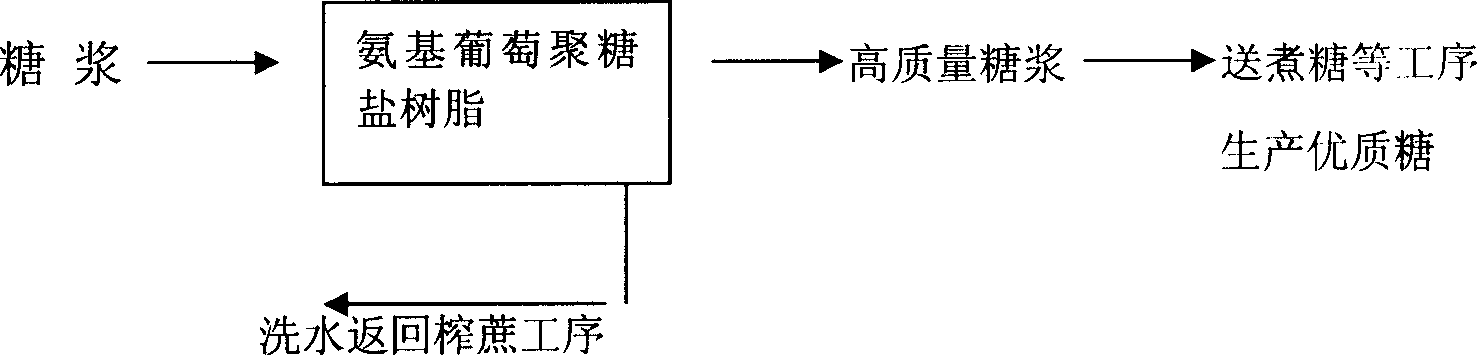

Method used

Image

Examples

Embodiment 1-1

[0034] Embodiment 1-1. put 100 kilograms of chitosan (particle size 1-3mm) into 200 kilograms of concentrations and be 30% acetic acid solution, stir evenly, normal temperature airtight reaction 6-8 hour, (when the reaction is completed, the particle is translucent shape and soluble in water). Then it is sealed and stored for 35 days, so that strong hydrogen bonds are formed inside and outside the macromolecular chain molecules, and it presents a crystalline phase state, thereby cross-linking to form a three-dimensional network structure, and polymerizing to form an insoluble water-soluble aminodextran acetate resin. The gum is baked at ℃ until the water content is 50%, crushed into 1-3mm colloidal particles, and packaged as a finished product.

[0035] Note: Another method is to react the reactant at room temperature for 6-8 hours, then dry it at 40°C-60°C for 24-48 hours, and then crush it into 1-3mm solid resin particles. In this method, the crystallinity and The degree of...

Embodiment 1-2

[0036] Embodiment 1-2. put 100 kilograms of chitosan (particle size 1-3mm) into 300 kilograms of concentration and be 45% citric acid solution, stir well, normal temperature airtight reaction 18-24 hour, (when the reaction is completed, the particle is half transparent and soluble in water). Then it is sealed and stored for 50 days, so that strong hydrogen bonds are formed inside and outside the polymer chain molecules, and it presents a crystalline phase state, thereby cross-linking to form a three-dimensional network structure, forming an insoluble water-soluble aminodextran citrate resin, which is heated at 60°C Bake the gum until the water content is 40%, crush it into 1-3mm colloidal particles, and pack the finished product.

[0037] Note: Another method is to react the reactant at room temperature for 18-24 hours, then dry it at 40°C-60°C for 24-48 hours, and then crush it into 1-3mm solid resin particles. The degree of cross-linking is not high.

Embodiment 1-3

[0038] Embodiment 1-3. put 350 kilograms of chitosan (particle size 1-3mm) into 700 kilograms of concentration and be 20% hydrochloric acid solution, stir well, normal temperature airtight reaction 4-8 hour, (when the reaction is completed, the particle is translucent shape and soluble in water). Then it is sealed and stored for 35 days, so that strong hydrogen bonds are formed inside and outside the macromolecular chain molecules, and it presents a crystalline phase state, thereby cross-linking to form a three-dimensional network structure, and forming an insoluble water-soluble aminodextran hydrochloride resin. Bake the gum until the water content is 50%, crush it into 1-3mm colloidal particles, and pack the finished product.

[0039] Note: Another method is to react the reactants at room temperature for 4-8 hours, then dry them at 40°C-60°C for 24-48 hours, and then crush them into 1-3mm solid resin particles. The degree of cross-linking is not high.

[0040] Two, use ami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com