Patents

Literature

190results about "Purification using adsorption agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

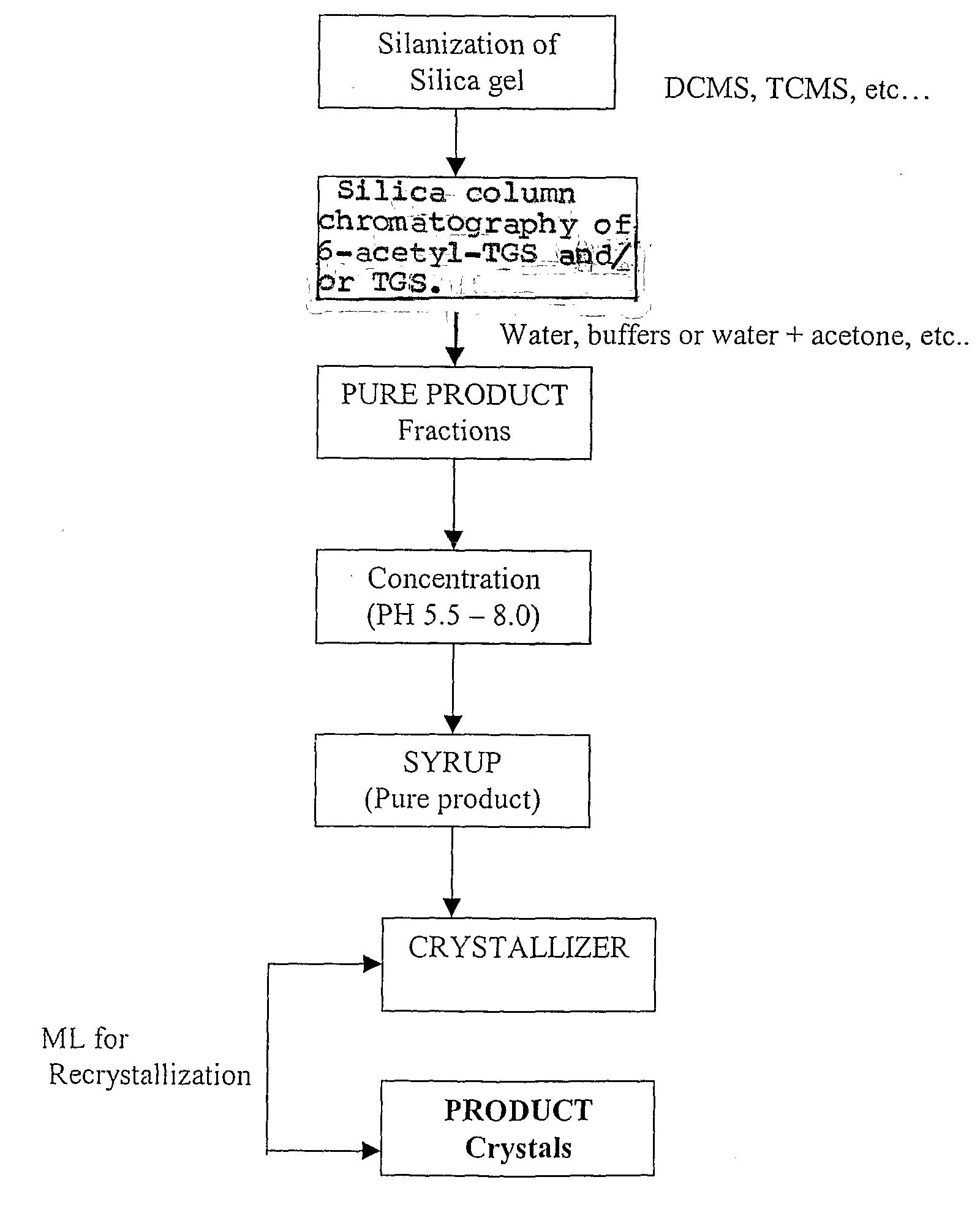

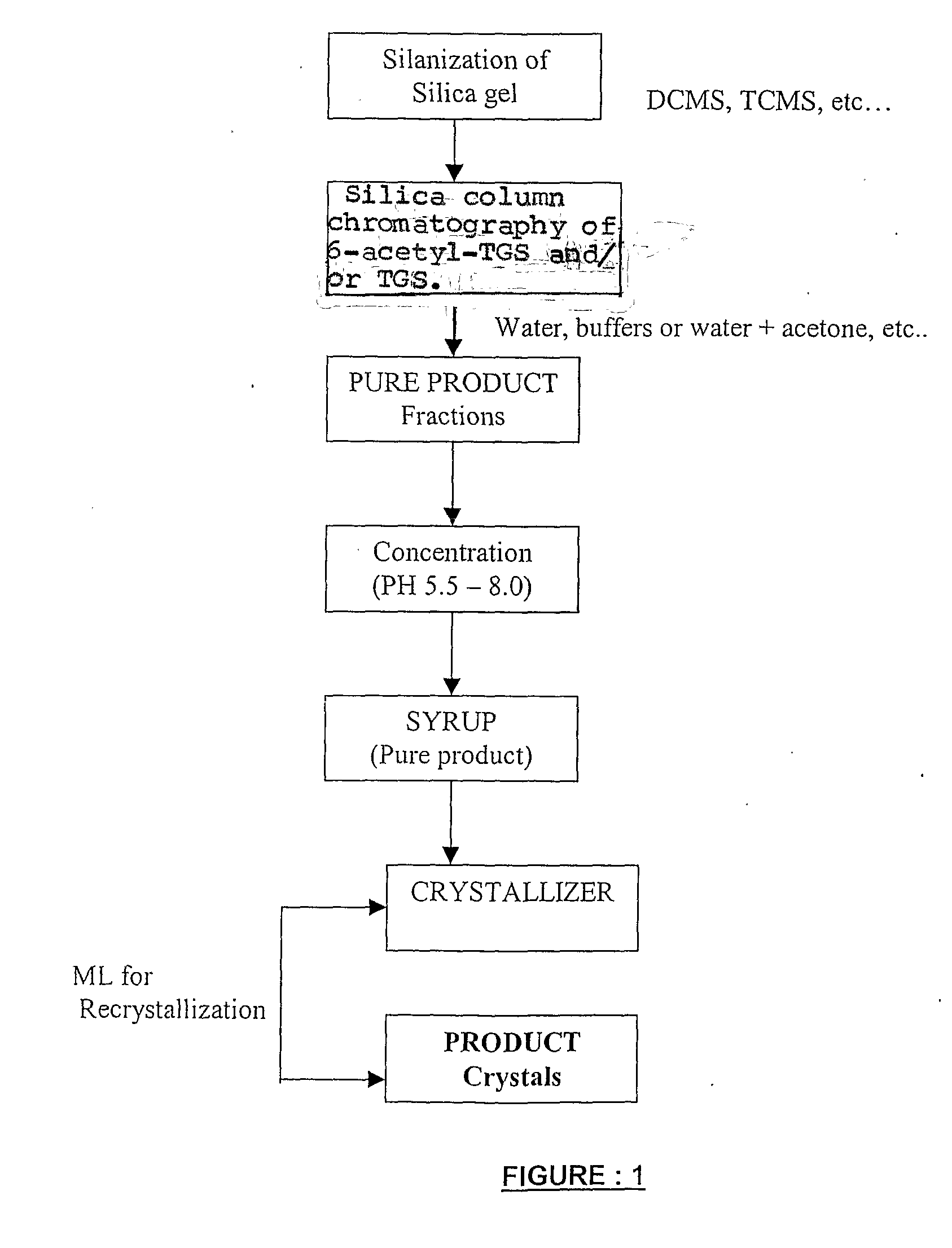

Process for Purification of 6 Acetyl 4,1', 6' Trichlorogalactosucrose and 4,1', 6' Trichlorogalactosucrose by Chromatography on Silanized Silica Gel

InactiveUS20070270583A1Purification using adsorption agentsSugar derivativesStationary phaseOrganic solvent

A reverse phase column chromatographic process of purification of 6-acetyl-4,1′,6′trichlorogalactose and 4,1′,6′trichlorogalactose is described which uses silanized silica as stationary phase and water or predominatly aqeous mixture derived from water and small proportion of organic solvents as a mobile phase.

Owner:V B MEDICARE PVT LTD

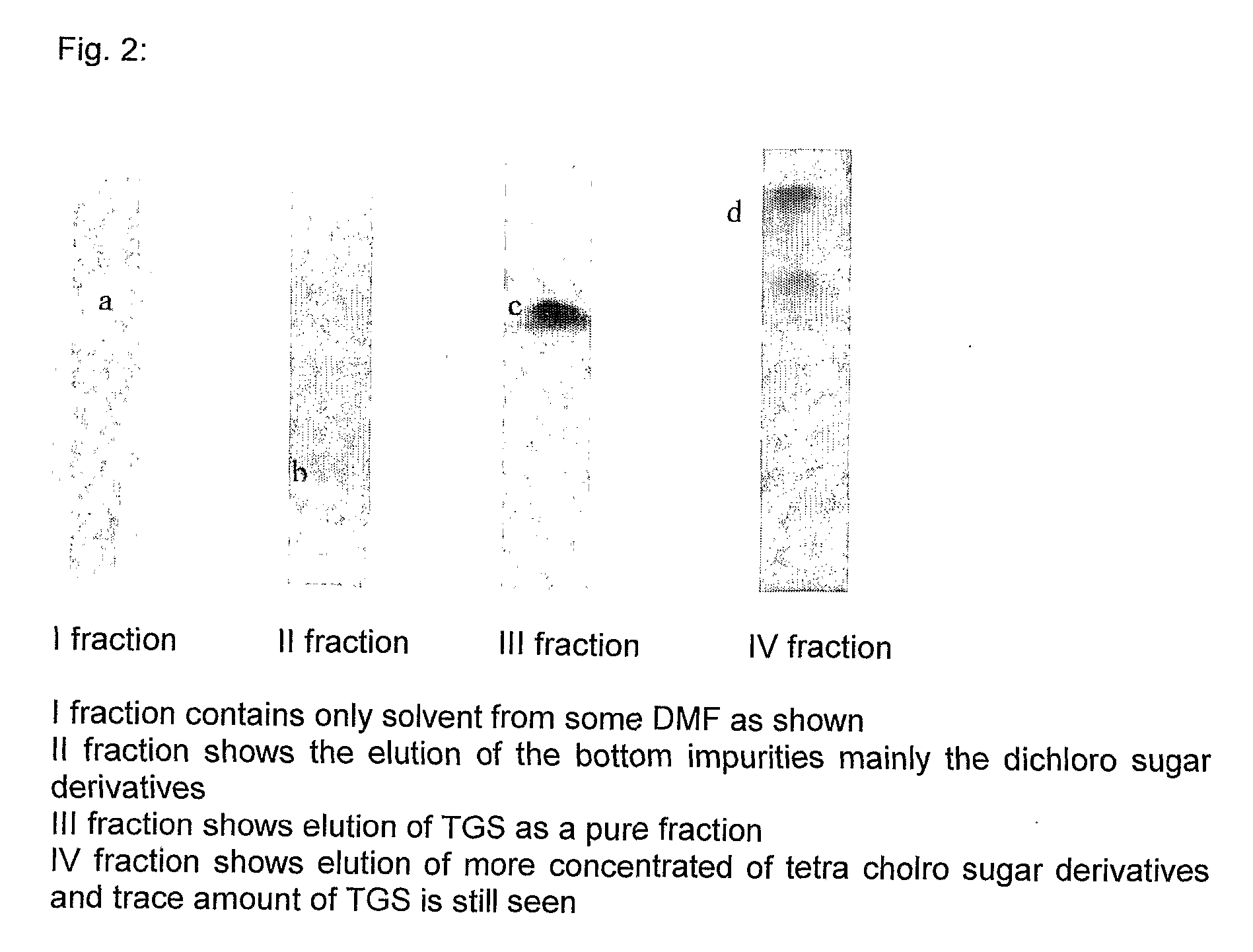

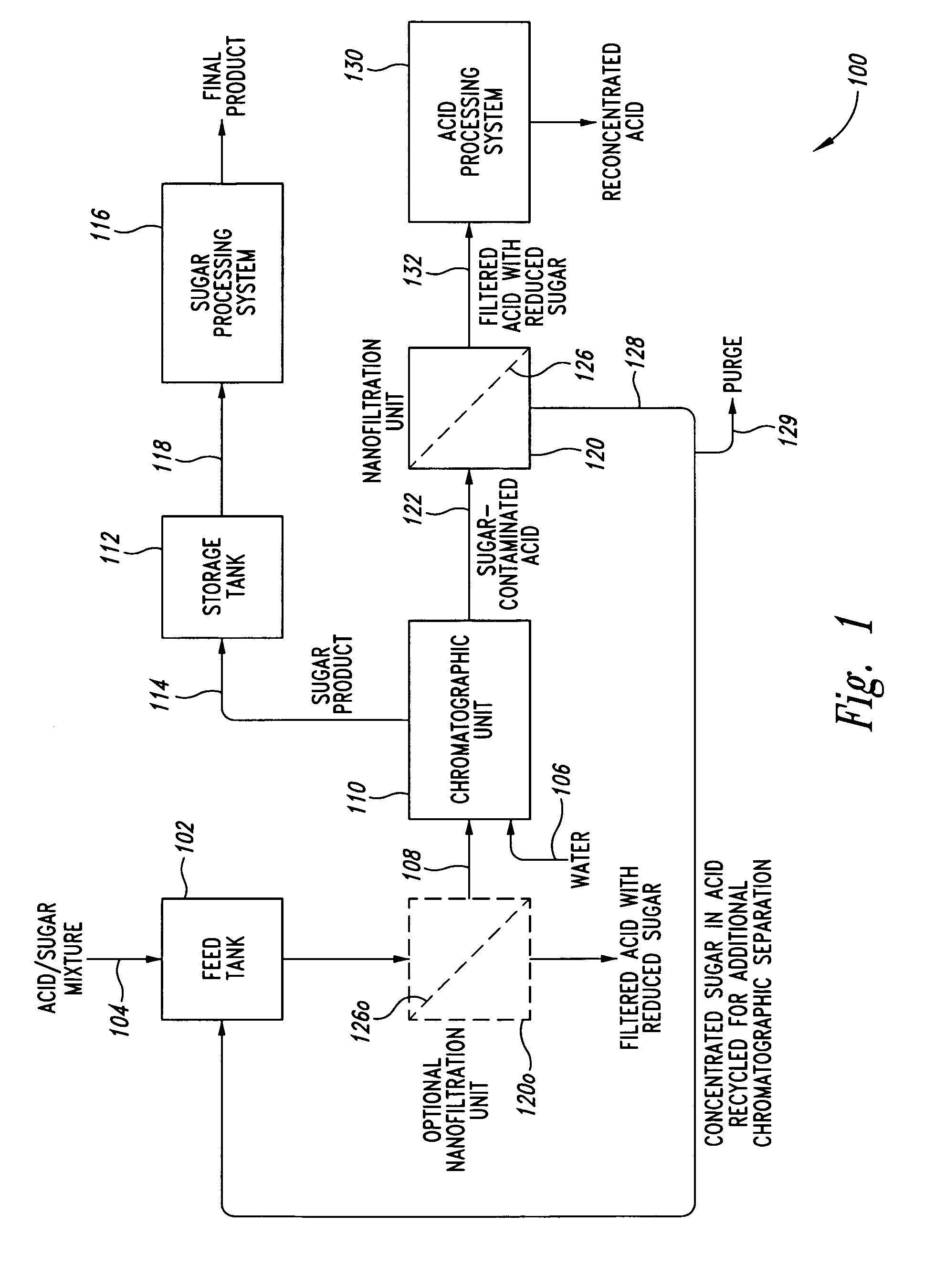

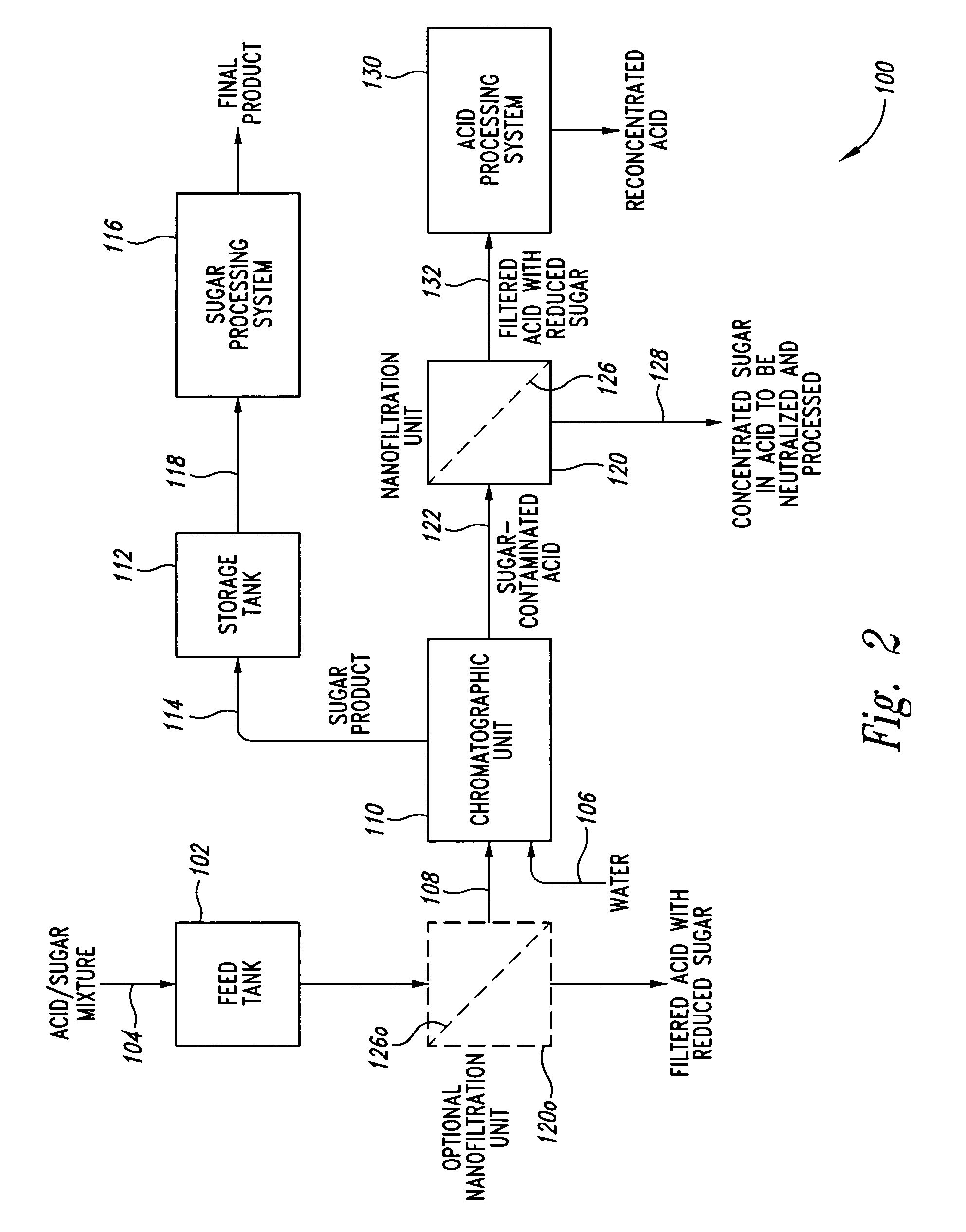

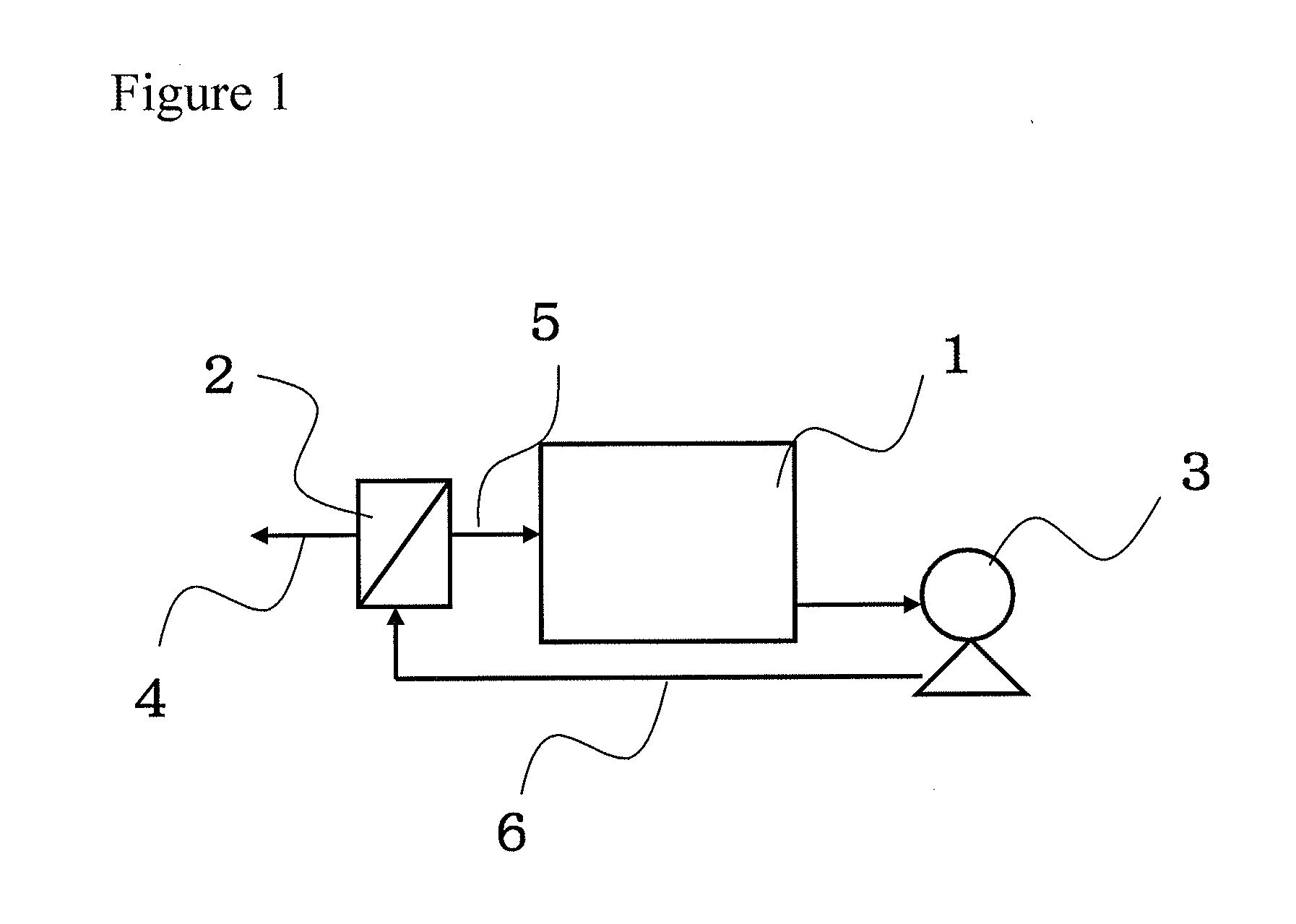

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

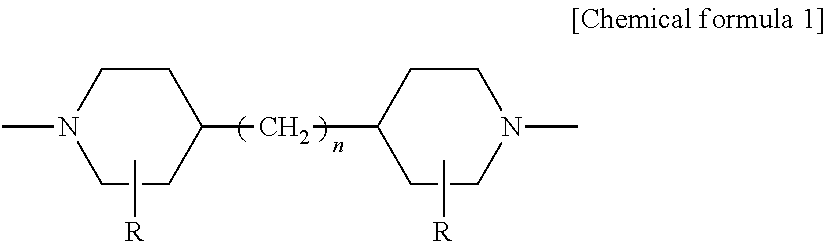

Separation of sugars, sugar alcohols, carbohydrates and mixtures thereof

InactiveUS7361273B2Efficient separationCation exchanger materialsIon-exchanger regenerationChromatographic separationAlcohol sugars

The present invention relates to a method of separating sugars and sugar alcohols from each other. More particularly the present invention relates to the use of a weakly basic anion exchange resin in a chromatographic separation process. The advantage of the present invention compared with the prior art is that it is especially suitable for separating reducing sugars in acidic conditions as well as for example in weakly acidic conditions. The method using chromatographic separation comprises at least one step where a weakly basic anion exchange resin is used in a chromatographic column or in a part of a column.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Separation process

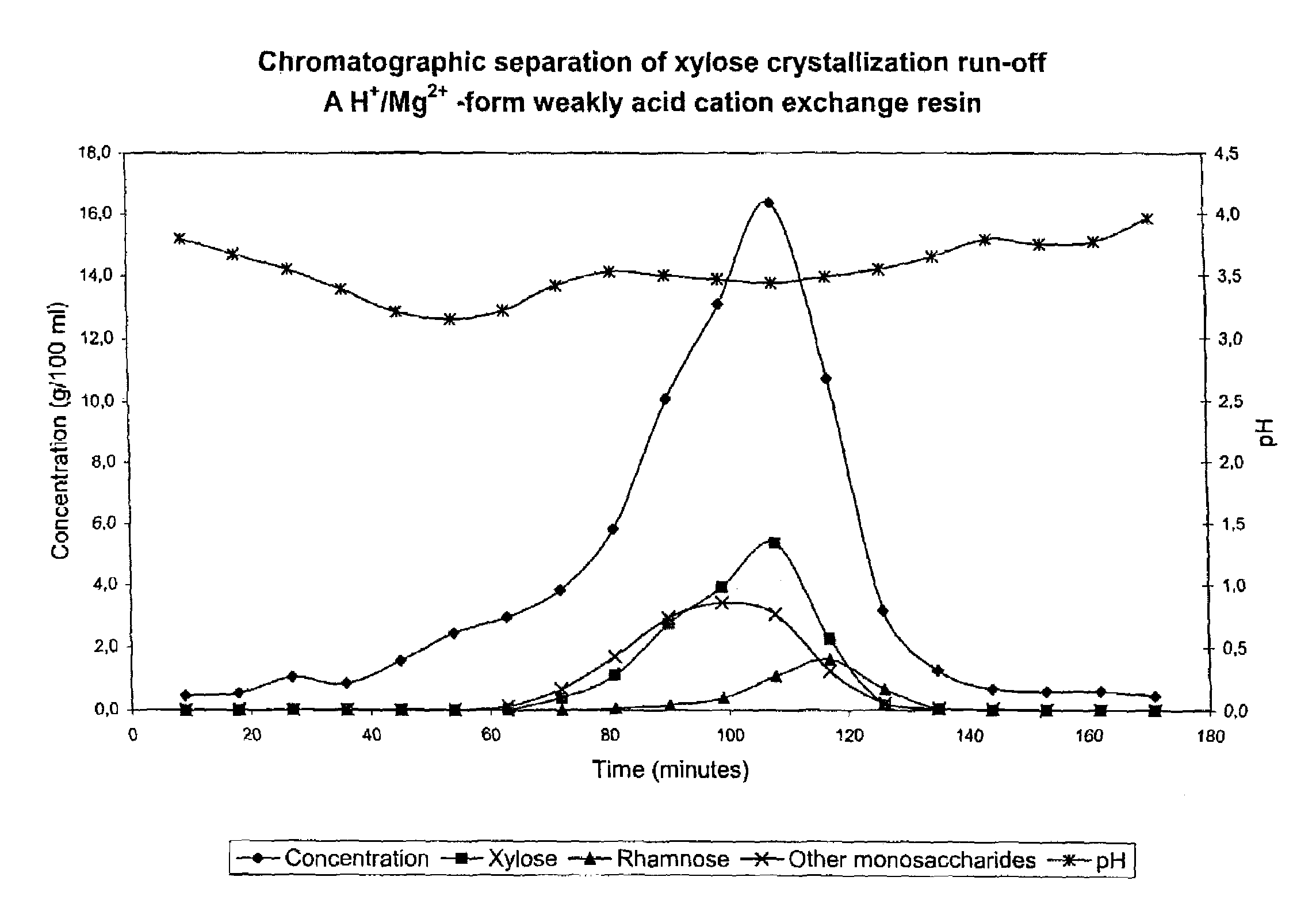

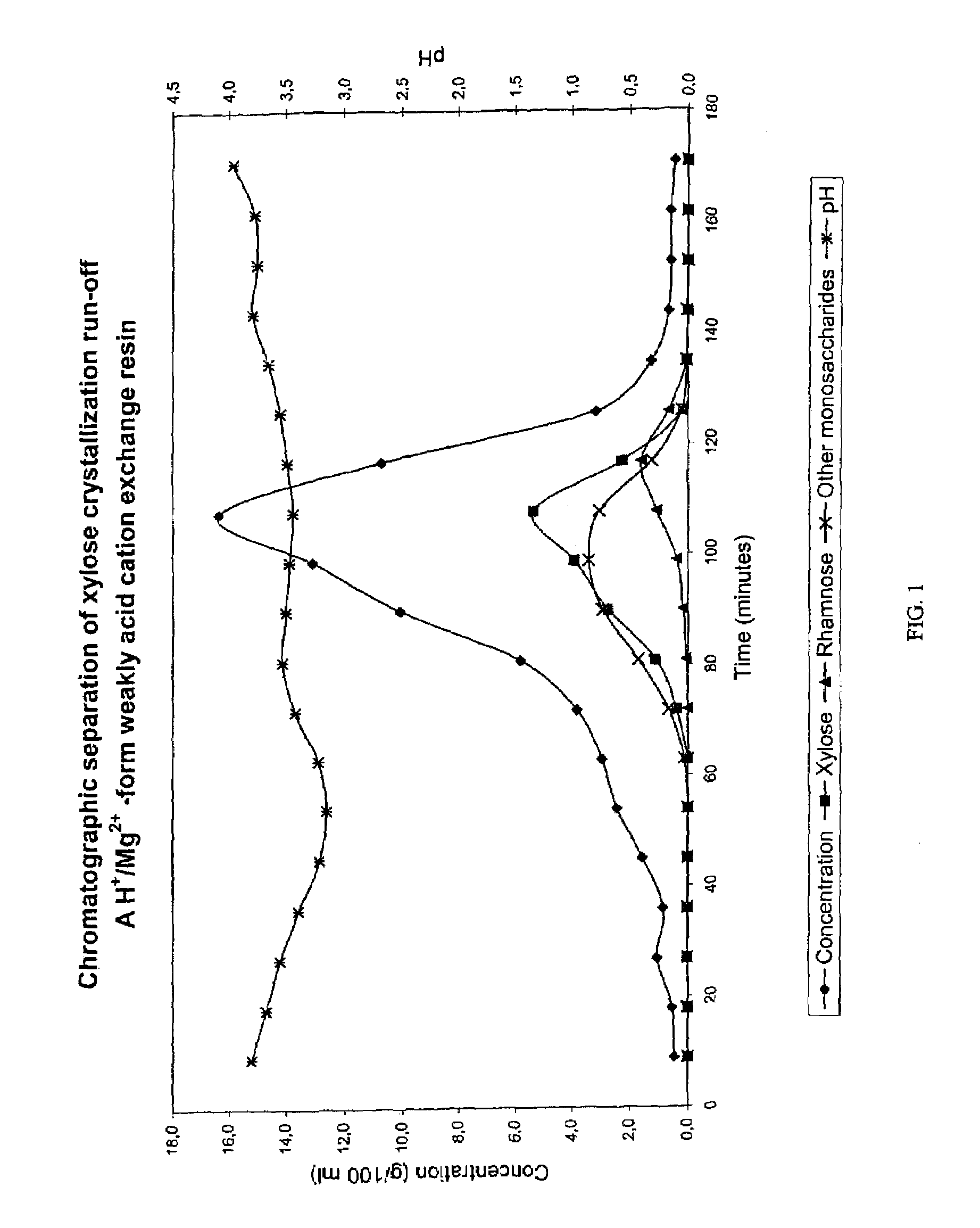

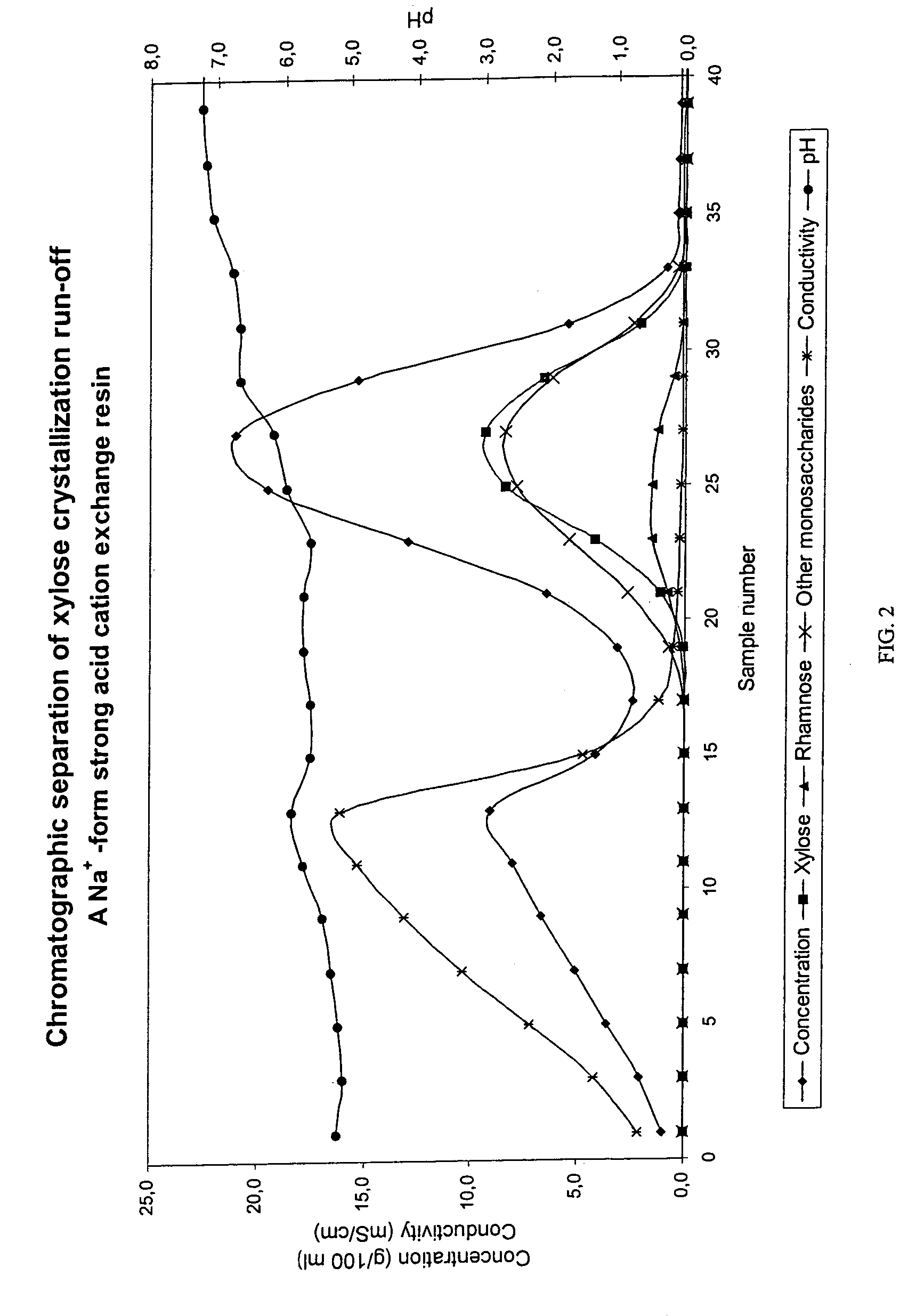

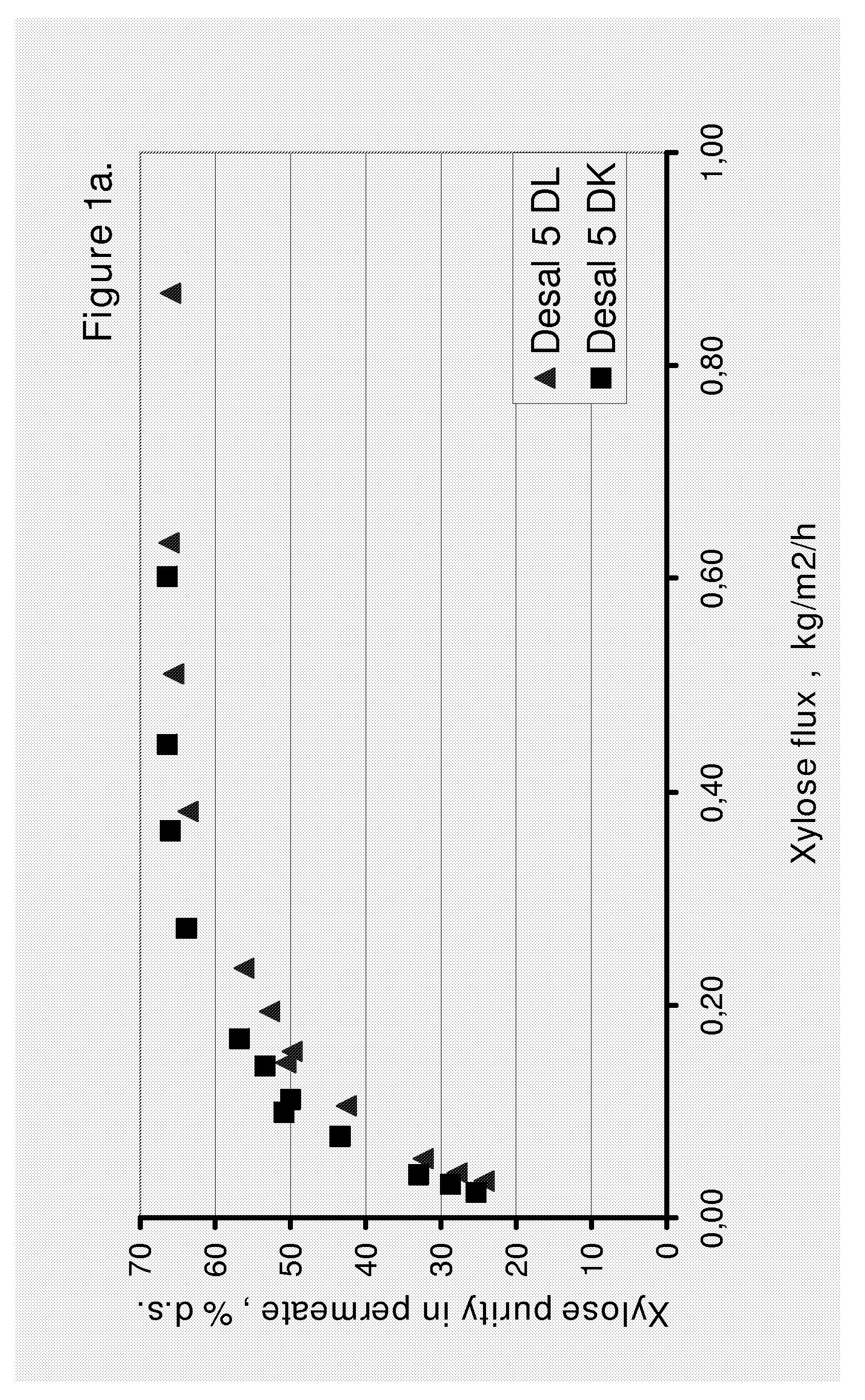

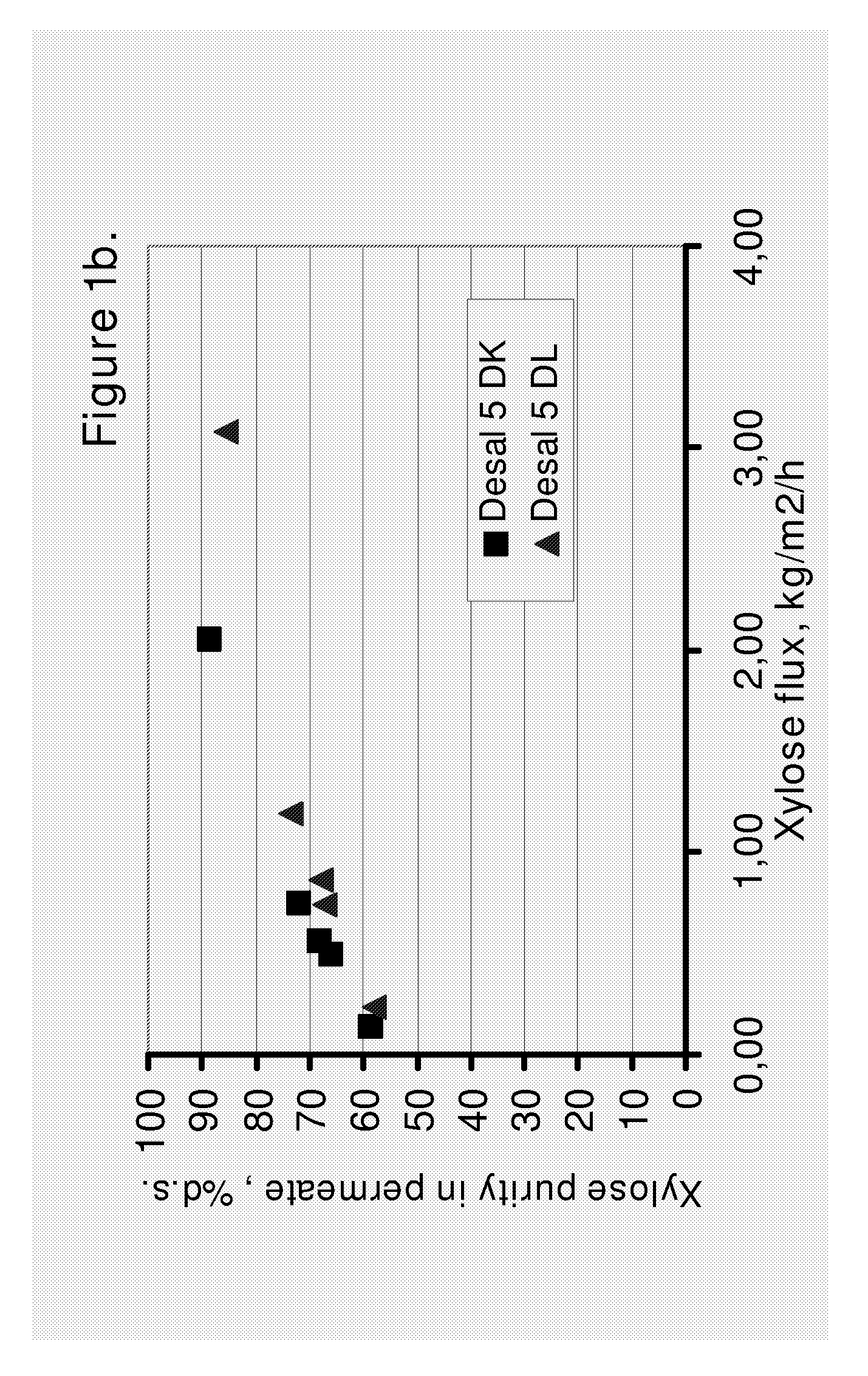

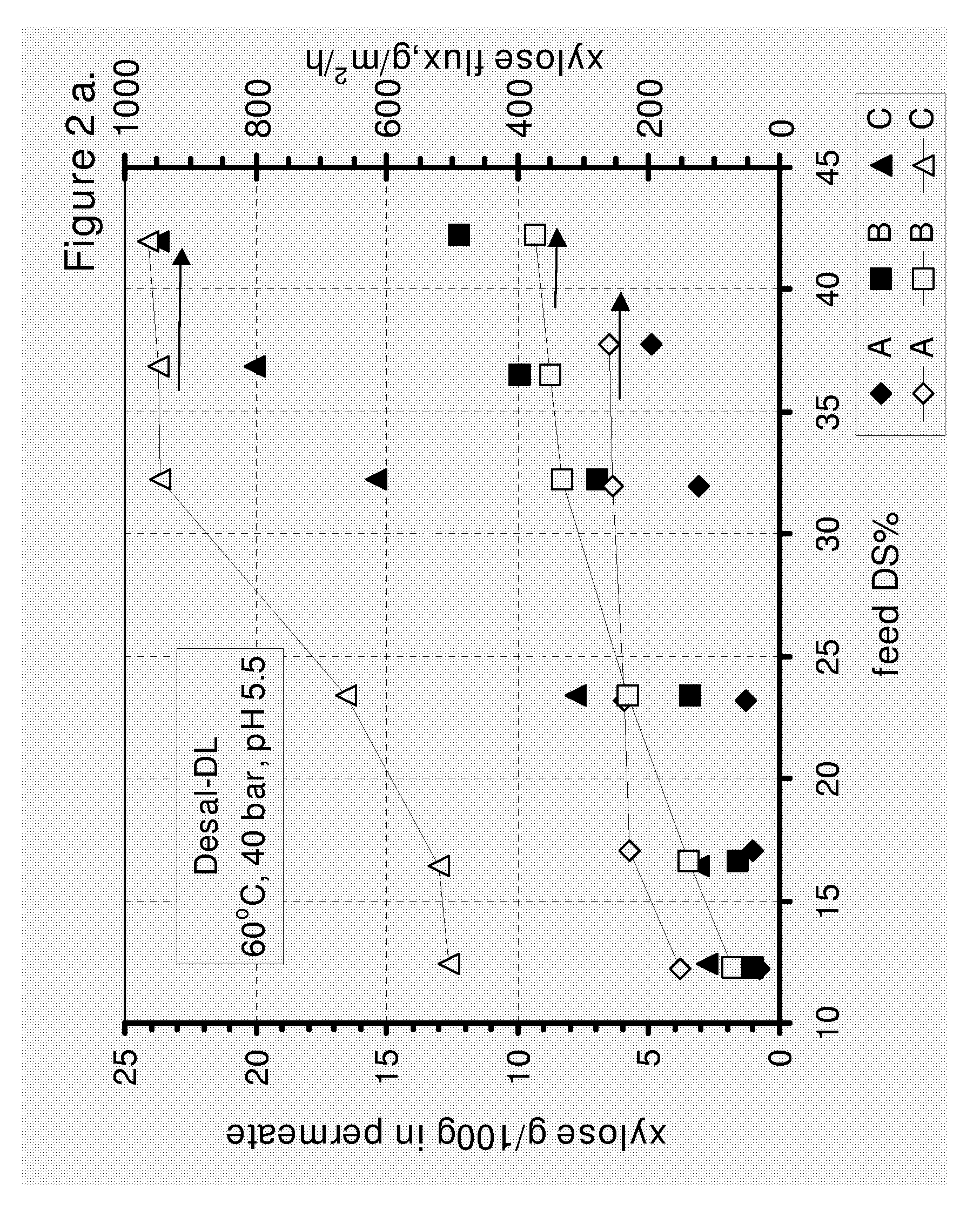

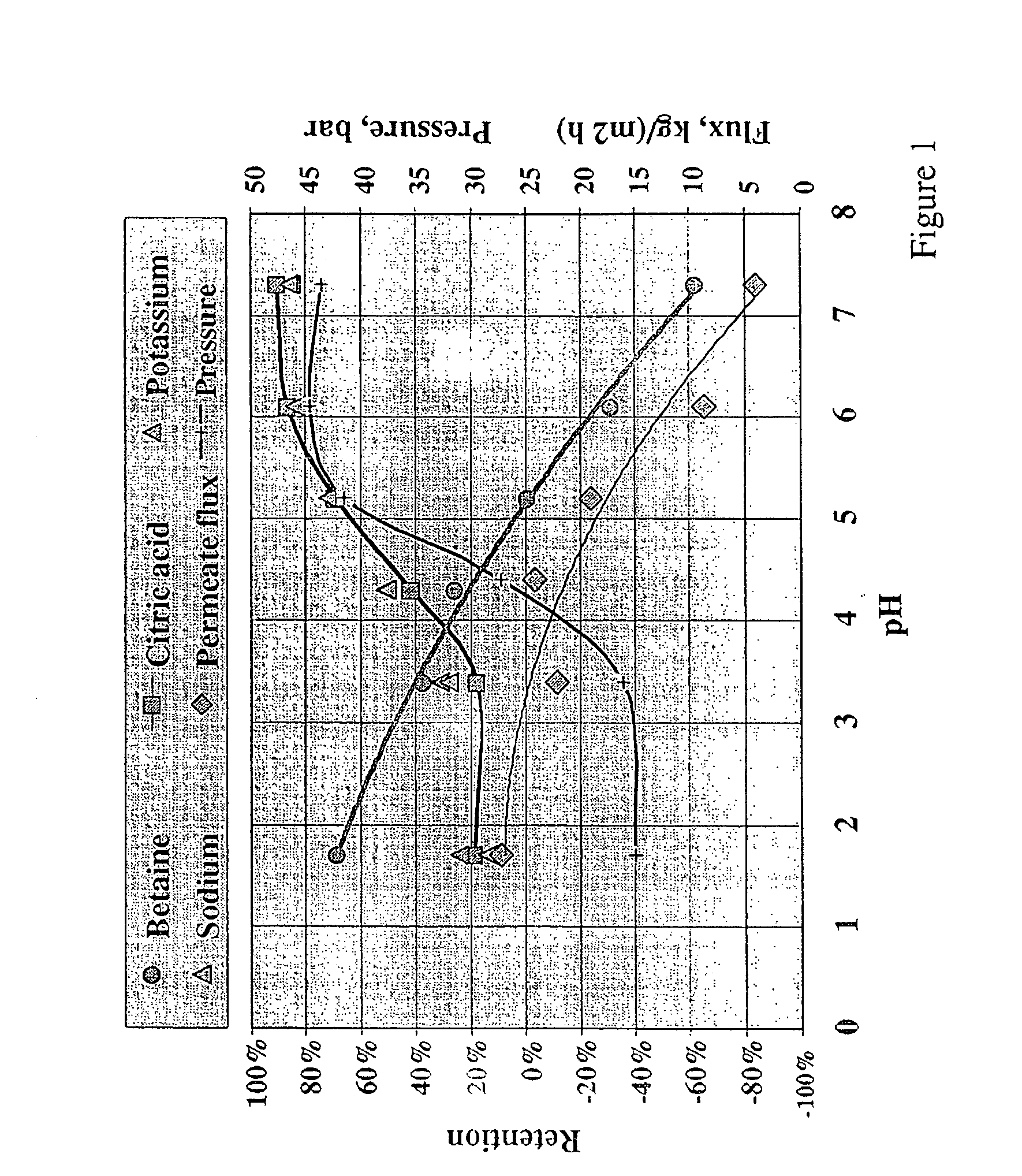

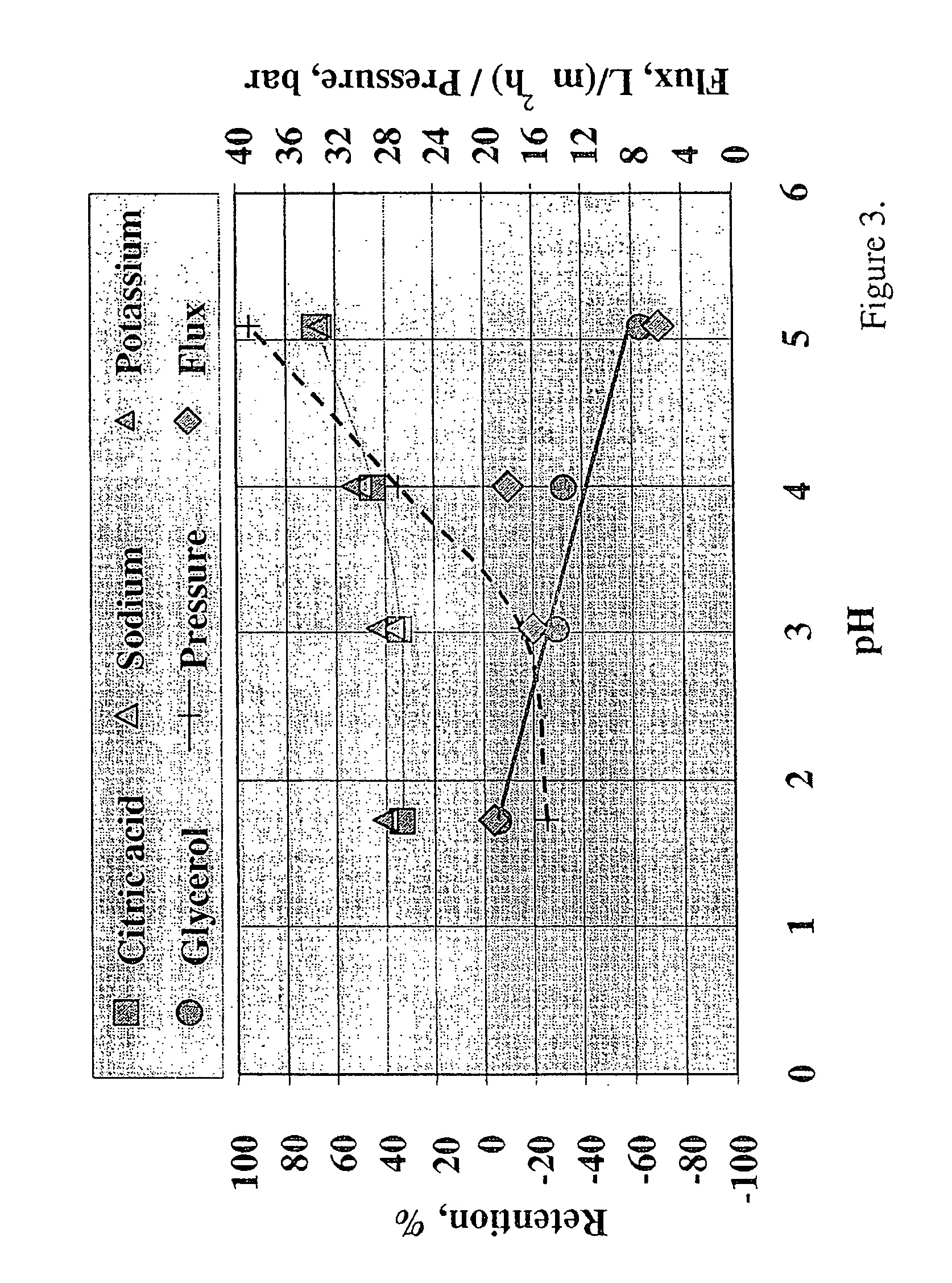

ActiveUS20090173339A1Improve performanceFavorable enrichment factor of xyloseMembranesPurification using adsorption agentsHydrolysateNanofiltration

The invention relates to an improved nanofiltration process of recovering xylose from a solution of a plant-based biomass hydrolysate. The process of the present invention is based on the regulation of the xylose flux in the nanofiltration process.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Process for the manufacture of a starch hydrolysate with high dextrose content

InactiveUS6126754AAccelerates hydrolysis reactionReduce in quantityPurification using adsorption agentsOrganic compound preparationHydrolysateD-Glucose

The invention concerns a process for the manufacture of a starch hydrolysate with high dextrose content comprising the stages of: (a) liquefying starch milk with the aid of an alpha -amylase so as to obtain a liquefied starch milk; (b) saccharifying the liquefied starch milk, with the aid of a glucogenic enzyme, to obtain a raw saccharified hydrolysate; (c) separating the raw saccharified hydrolysate by nanofiltration over membranes so as to collect a nanofiltration permeate constituting said starch hydrolysate with high dextrose content and a nanofiltration retentate.

Owner:ROQUETTE FRERES SA

Method of processing whey for demineralization purposes

InactiveUS6383540B1Reduce maintenanceLess upkeepIon-exchanger regenerationSolid sorbent liquid separationProtonChloride

A method of treating whey for demineralization purposes, the method comprising a stage of separating out salts by transfer through electrodialysis or nanofiltration membranes, wherein, upstream from this separation stage, the method comprises in succession at least one step of exchanging divalent cations for protons and at least one step of exchanging divalent anions for chloride ions.

Owner:EURODIA IND SA

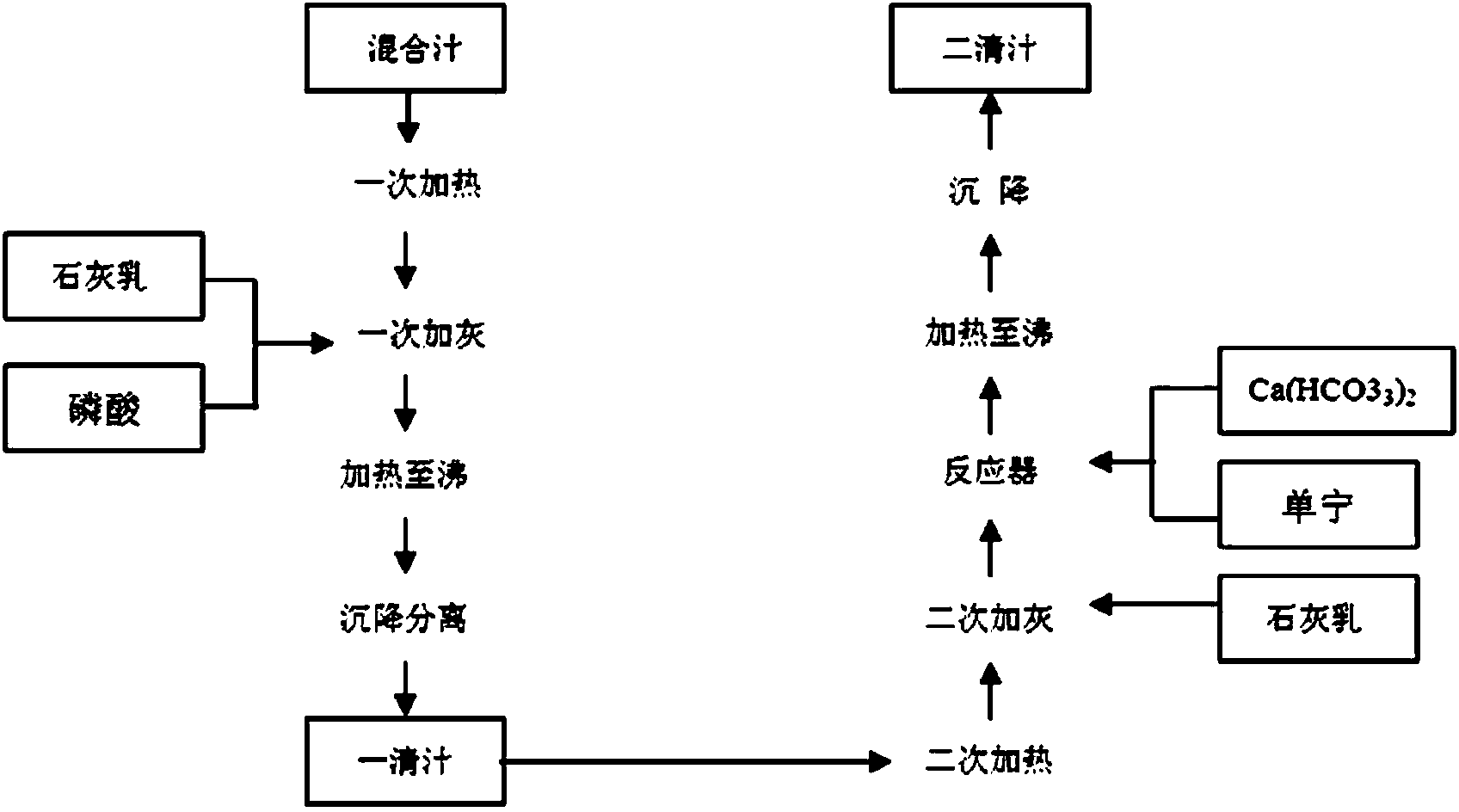

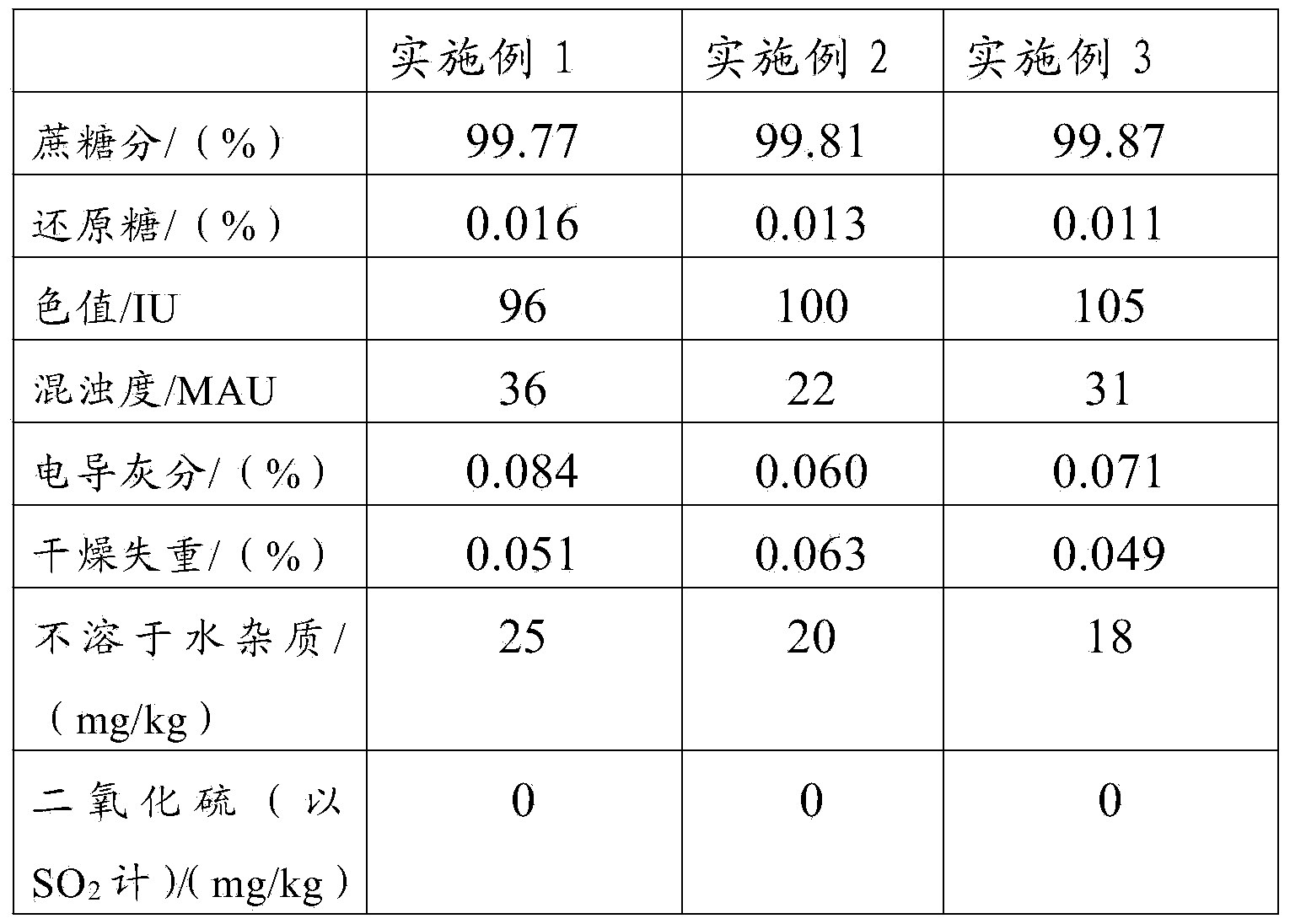

Sulfur-free clarifying method for cane sugar manufacture

ActiveCN103866052AAddress sugar containing SO

<sub>2</sub>

questionSolve containing SO

<sub>2</sub>

questionPurification using adsorption agentsCalcium bicarbonateFree sugar

The invention discloses a sulfur-free clarifying method for cane sugar manufacture. According to the method, lime milk, phosphoric acid, calcium bicarbonate and tannin are taken as clarifying agents, sugarcane mixed juice is taken as the raw material, after filtering by a sieve, primary clear juice is obtained through clarifying by a lime method, then the tannin and calcium bicarbonate are added for secondary clarifying, so as to obtain secondary clear juice. Sulfur-free sugar is produced without using SO2 in the whole process, so that the problem that domestic sugar has SO2 is solved thoroughly, the safety of the sugar is improved, and domestic sugar products are increased.

Owner:GUANGXI UNIV

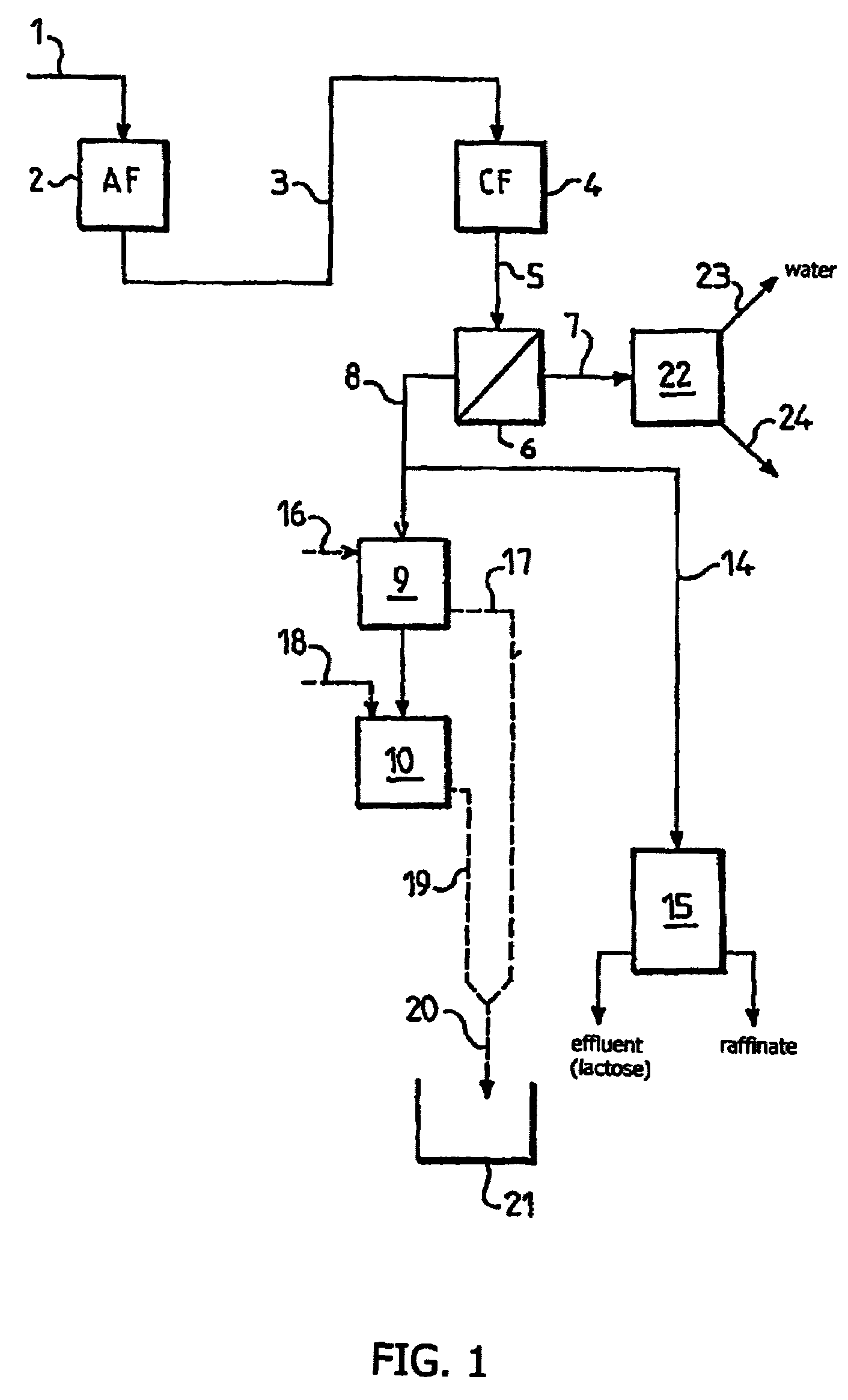

Process for fractioning vinasse

InactiveUS6022394AIncrease PotassiumPromote crystallizationIon-exchange process apparatusBy-product recoveryOrganic fractionOrganic acid

PCT No. PCT / FI95 / 00329 Sec. 371 Date Mar. 10, 1997 Sec. 102(e) Date Mar. 10, 1997 PCT Filed Jun. 7, 1995 PCT Pub. No. WO96 / 00776 PCT Pub. Date Jan. 11, 1996The invention relates to a process for fractioning vinasse, in which process the pH value of the vinasse is lowered by adding acid, and the formed precipitate is separated in order to obtain an inorganic fraction, whereupon an organic fraction remains. The invention also relates to the products obtained. The inorganic fraction mainly contains potassium salt, and it is useful for example as a fertilizer. The organic fraction mainly contains organic acids, and it is useful for example as an additive in animal feed and in producing silage.

Owner:CULTOR LTD +1

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

Separation Process

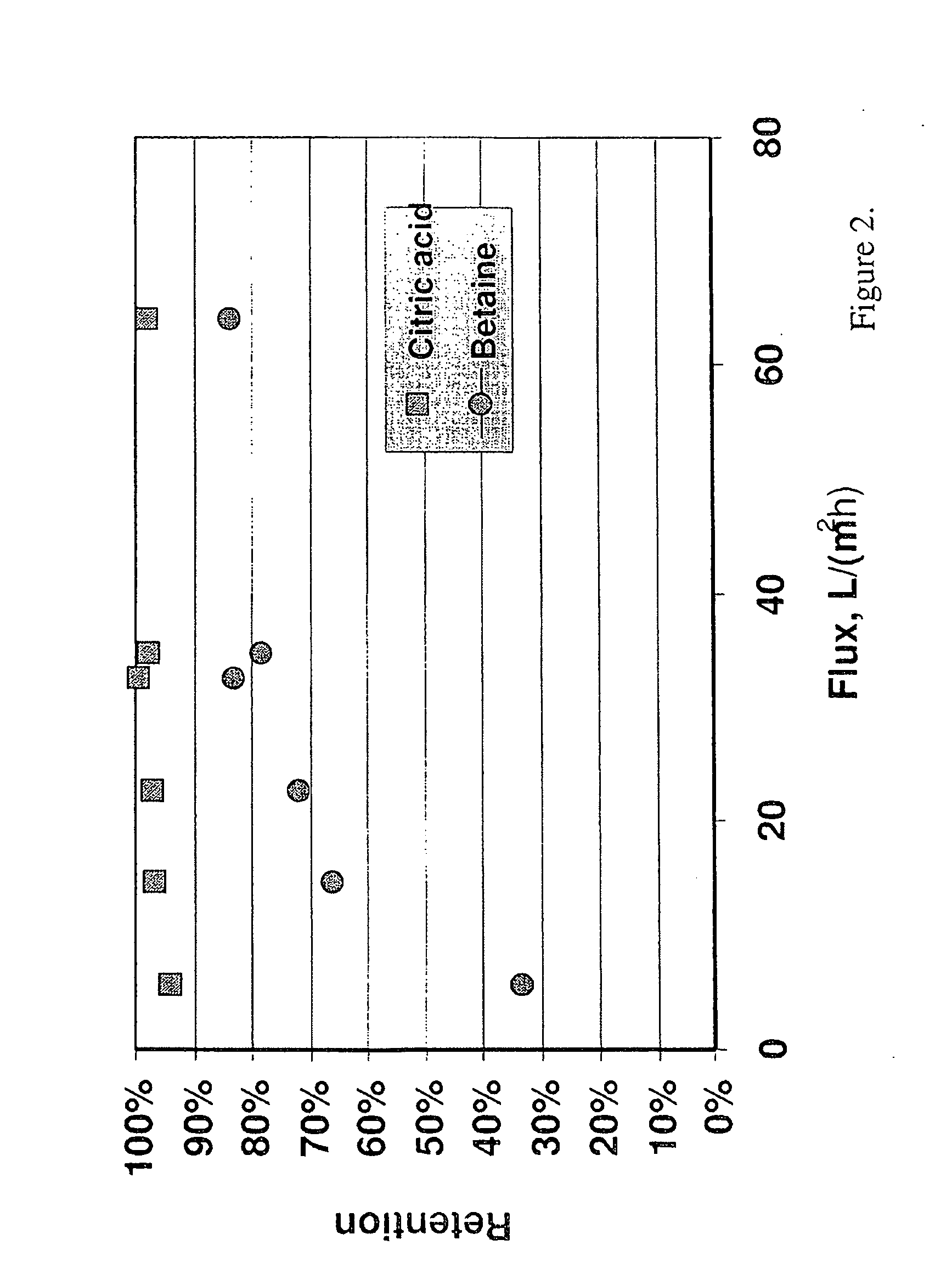

ActiveUS20090014386A1Product yield is lowReduce disadvantagesLiquid separation auxillary apparatusMembranesNanofiltrationOrganic compound

The invention relates to a nanofiltration process for enriching and concentrating a neutral organic compound into the permeated liquid with negative retention.

Owner:DUPONT NUTRITION BIOSCIENCES APS

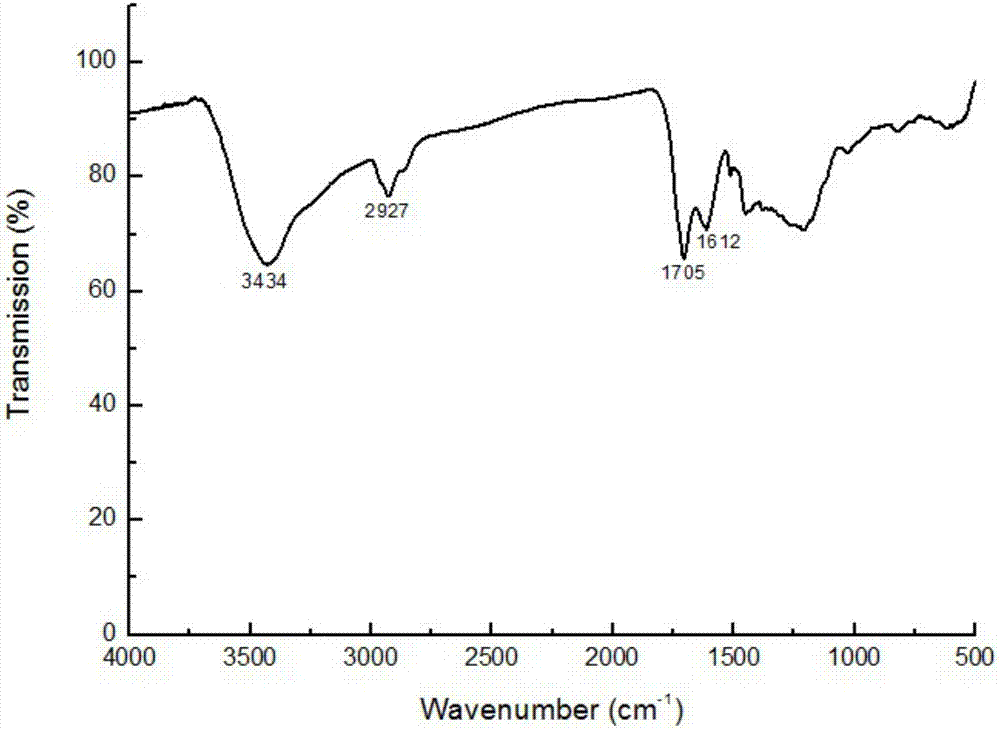

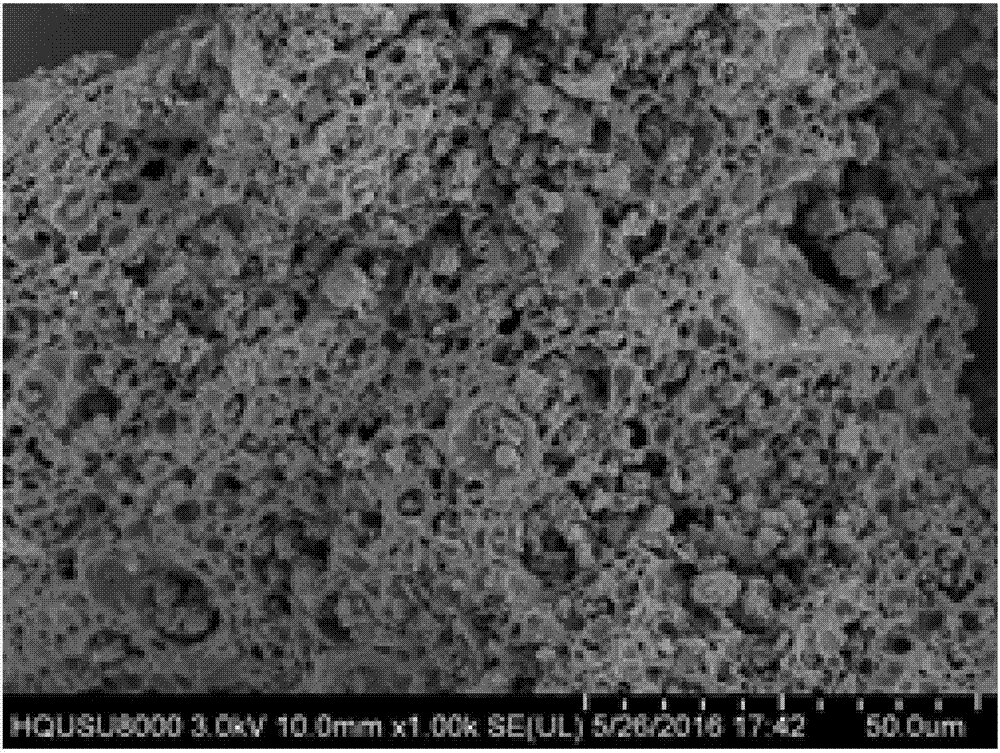

Method for preparing bagasse carbon material by hydrothermal method and application thereof

InactiveCN106904589AEasy accessThe process is simple and convenientPurification using adsorption agentsWater contaminantsSocial benefitsEconomic benefits

The invention relates to the field of preparing carbon materials by using bagasse and its application. The residual bagasse after juicing is collected and cleaned, dried, pulverized and sieved, then hydrothermally carbonized, and then carbonized in a hydrothermal medium with oxyacids added, washed and dried to obtain multifunctional and efficient adsorption Carbon material - bagasse hydrothermal carbon. The preparation process has easy-to-obtain raw materials, low cost, simple operation, and environmental friendliness; the surface of the prepared carbon material is loose and porous, rich in oxygen-containing functional groups or has a large specific surface area, and can be used in wastewater containing dyes and heavy metals or in the sugar industry The high-efficiency treatment of the decolorization of medium sugar liquid has realized the greening of the sugar making process, and has good economic, social and environmental benefits.

Owner:HUAQIAO UNIVERSITY

Carbohybrate purification using ultrafiltration, reverse osmosis and nanofiltration

InactiveCN1242776APurification using adsorption agentsSugar derivativesEnzymatic synthesisUltrafiltration

The invention provides methods for purifying carbohydrates, including oligosaccharides, nucleotide sugars, and related compounds, by use of ultrafiltration, nanofiltration and / or reverse osmosis. The carbohydrates are purified away from undesired contaminants such as compounds present in reaction mixtures following enzymatic synthesis or degradation of oligosaccharides.

Owner:NEOSE TECH

Chemical Regeneration of Activated Carbon

A simple, economical process is disclosed for regenerating granular activated carbon, using a combination of alcohol, alkali, and oxidant, preferably ethanol, sodium hydroxide, and hydrogen peroxide. The regeneration process employs inexpensive compounds, is well-suited to be implemented on-site, and does not require spent carbon to be transported to a specialized facility for regeneration. The need for thermal regeneration of carbon, and its high energy consumption, are avoided.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

Process for cleaning sugar cane juice in sugar production from sugar cane

InactiveCN1629320ASatisfy the requirement of boiled sugarPurification using adsorption agentsPhosphorSugar cane

The invention discloses a novel process for cleaning sugar cane juice in sugar production which comprises the steps of, low-temperature phosphor floating treatment, pre-decolorizing with diatomaceous earth and activated charcoal, then loading to boil the sugar. The neutral filtering mud produced in the low-temperature phosphor floating method can be directly used as fertilizer. The process can eliminate the generation of alkaline sieving mud in sugar production.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

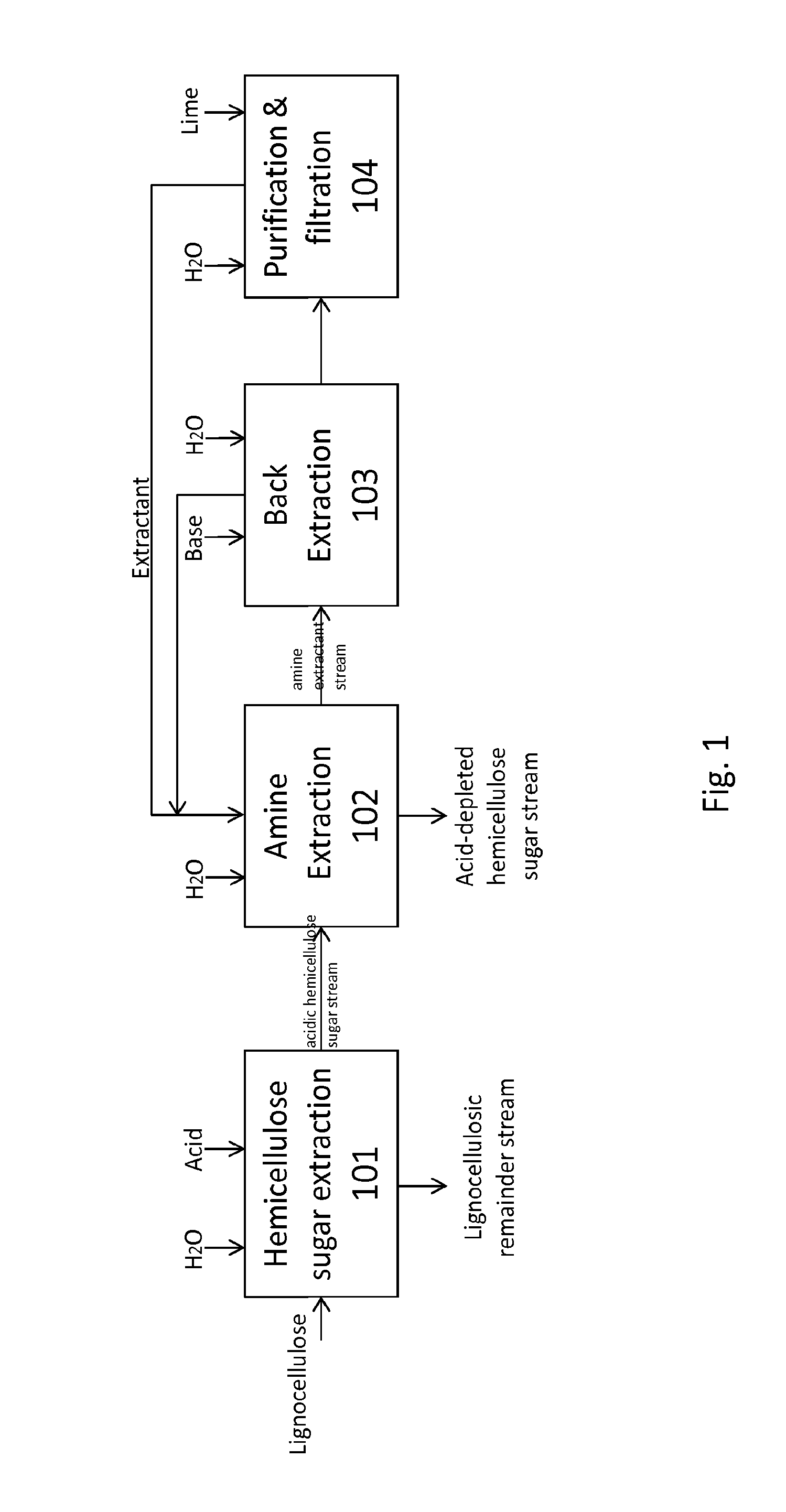

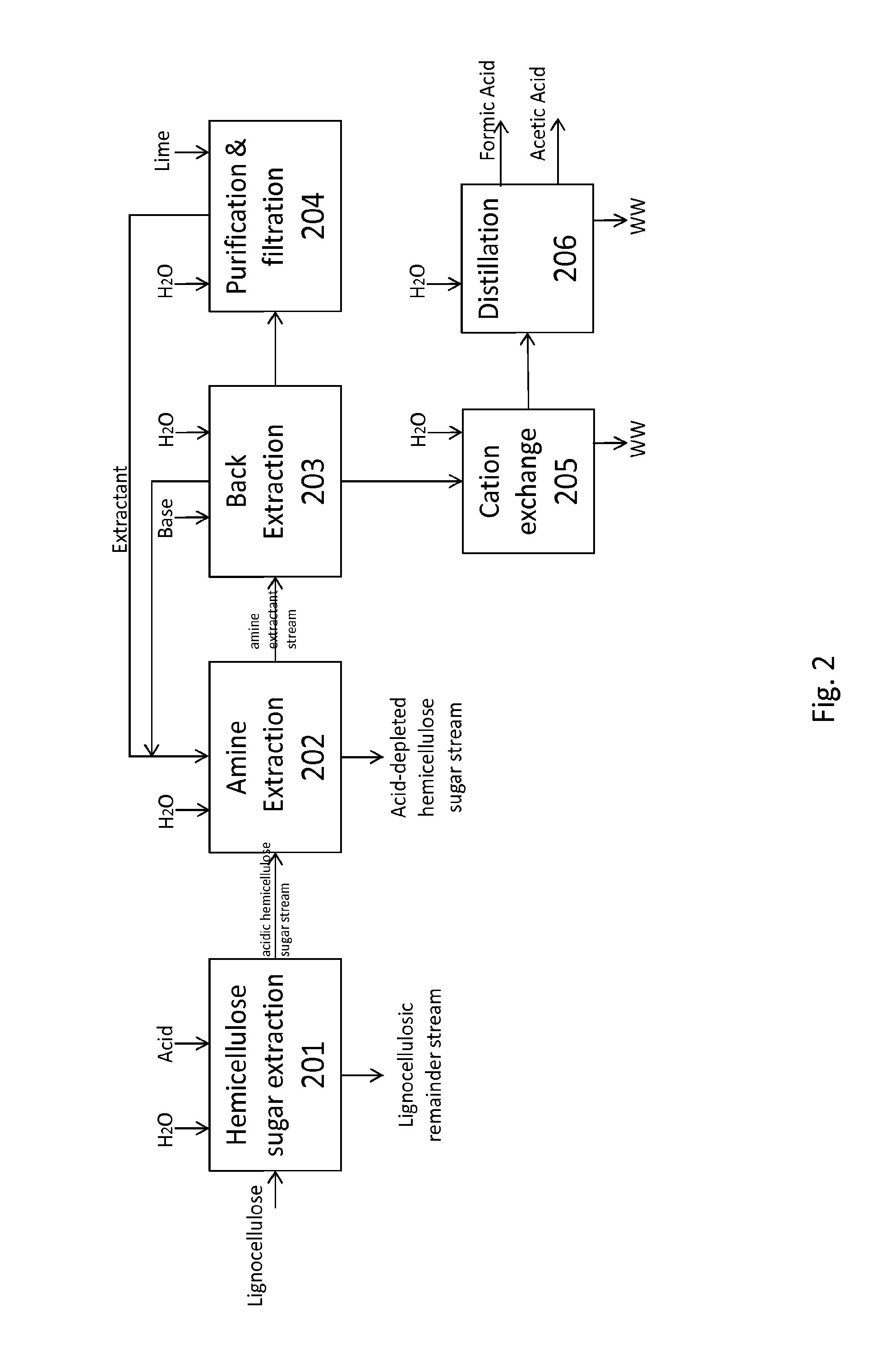

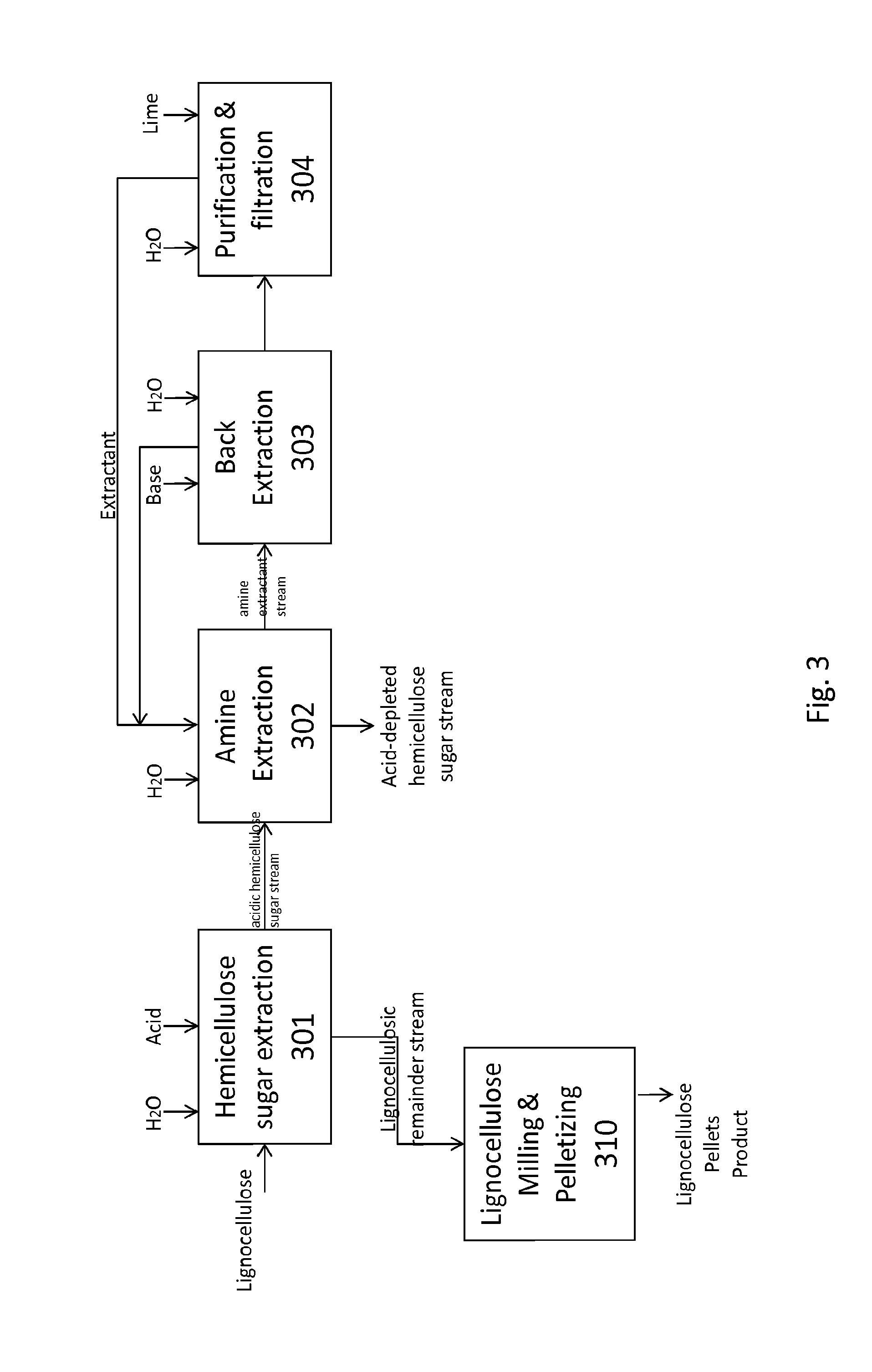

Methods for treating lignocellulosic materials

ActiveUS20150136121A1Increase acid concentrationChromatographic cation exchangersPurification using adsorption agentsSugarHemicellulose

The present invention relates to methods of processing lignocellulosic material to obtain hemicellulose sugars, cellulose sugars, lignin, cellulose and other high-value products. Also provided are hemicellulose sugars, cellulose sugars, lignin, cellulose, and other high-value products.

Owner:VIRDIA

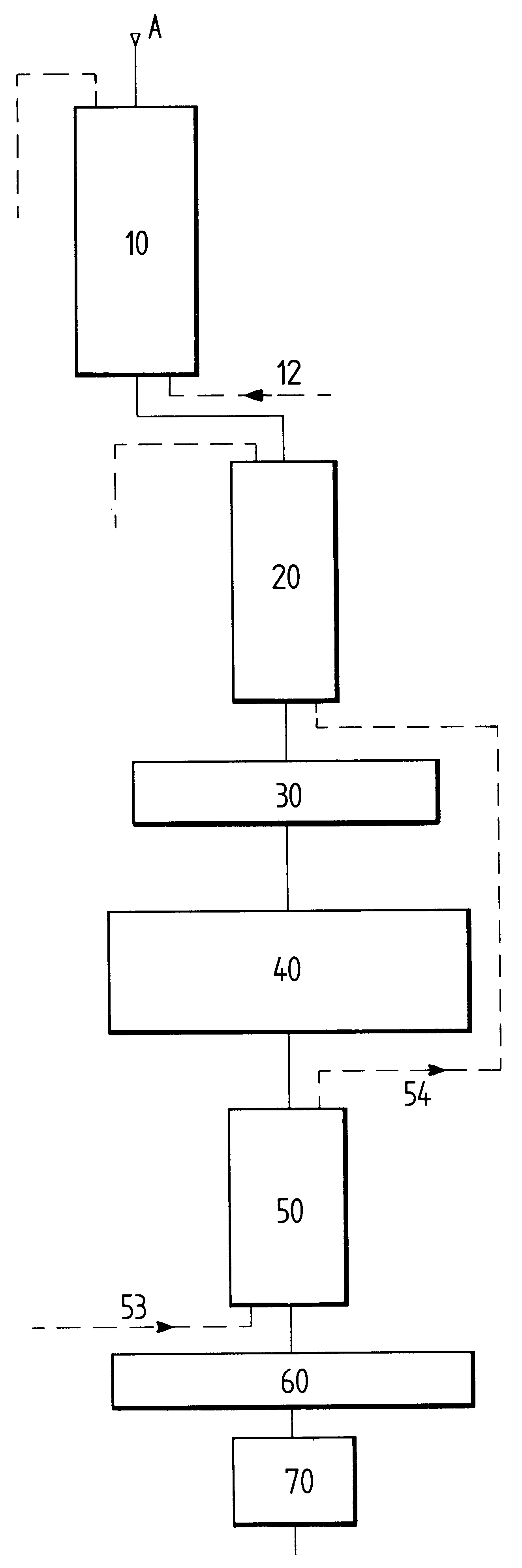

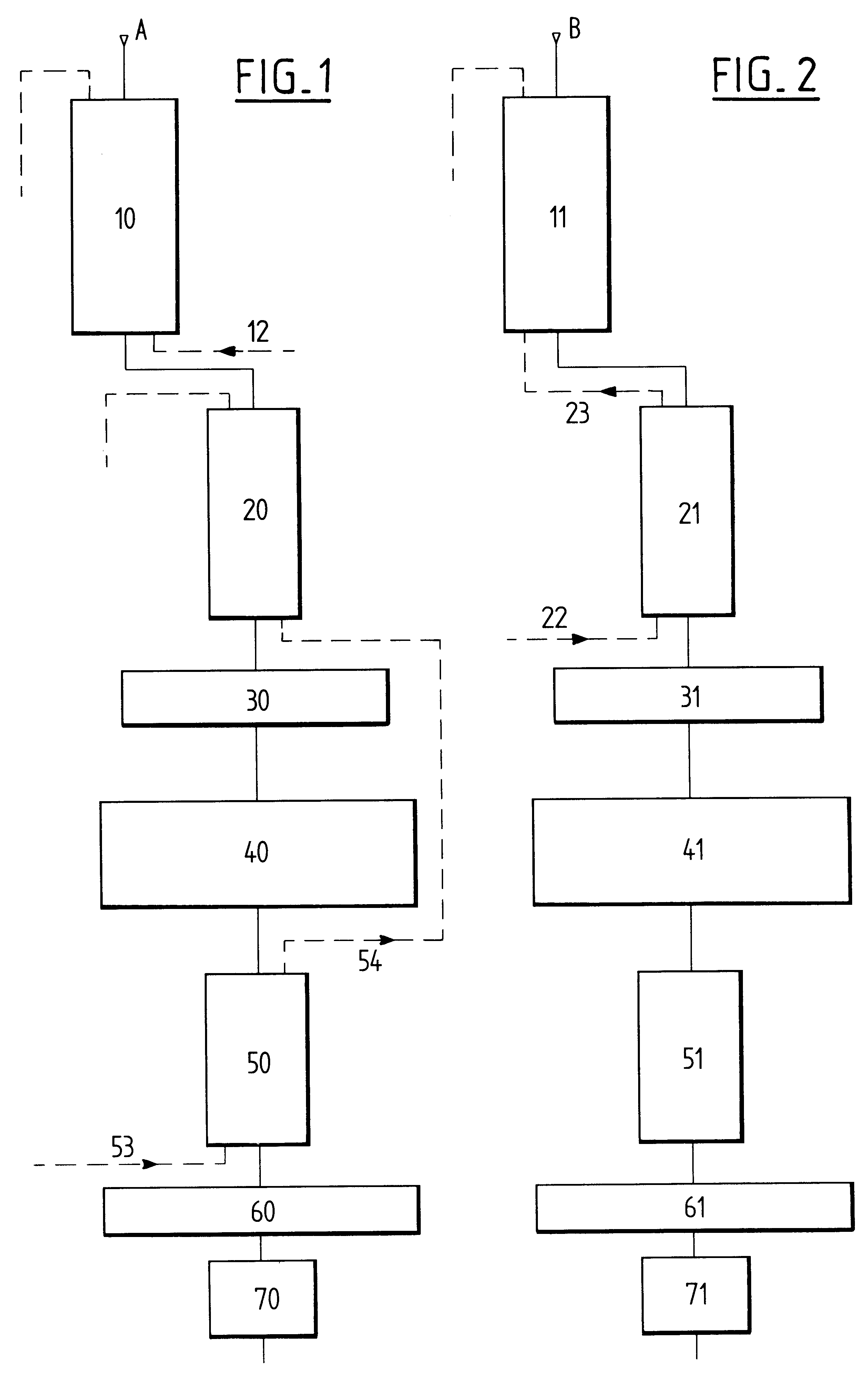

Method for Obtaining White Sugar from Cane Juice

InactiveUS20120216799A1Requires low equipmentReduce the amount requiredPurification by oxidation/reductionPurification using adsorption agentsFruit juicePhosphoric acid

The invention relates to a method for obtaining white sugar from cane juice, characterized in that it involves: obtaining sugar colors of between 300 and 150 ICUMSA units, with a sulphite content no greater than 5 ppm and an ash content no greater than 0.2% in the case of white sugar and in the case of refined sugar with colors less than 40 UI, less than 5 ppm sulphites and less than 0.04% ash, using fewer chemical products and devices and comprising the formation of reducing sugars; as well as optimizing the production time, reducing deterioration, making the process and the chemical products more efficient and preventing SO2 contamination. The method is characterized in that it simplifies the traditional method of obtaining white sugar using elemental sulfur, eliminating prealkalinization and sulphiting and the respective machinery and equipment and reducing the number of chemical products, such as lime, phosphoric acid, sulfur and activated carbon, in order to aggregate only sodium metabisulphite optionally complemented with monosodium phosphate in juice with pH values of 4 to 6.6 prior to any process involving the clarification of juice, cane syrup or molten liquor.

Owner:BOLANOS MARIO ALAVES

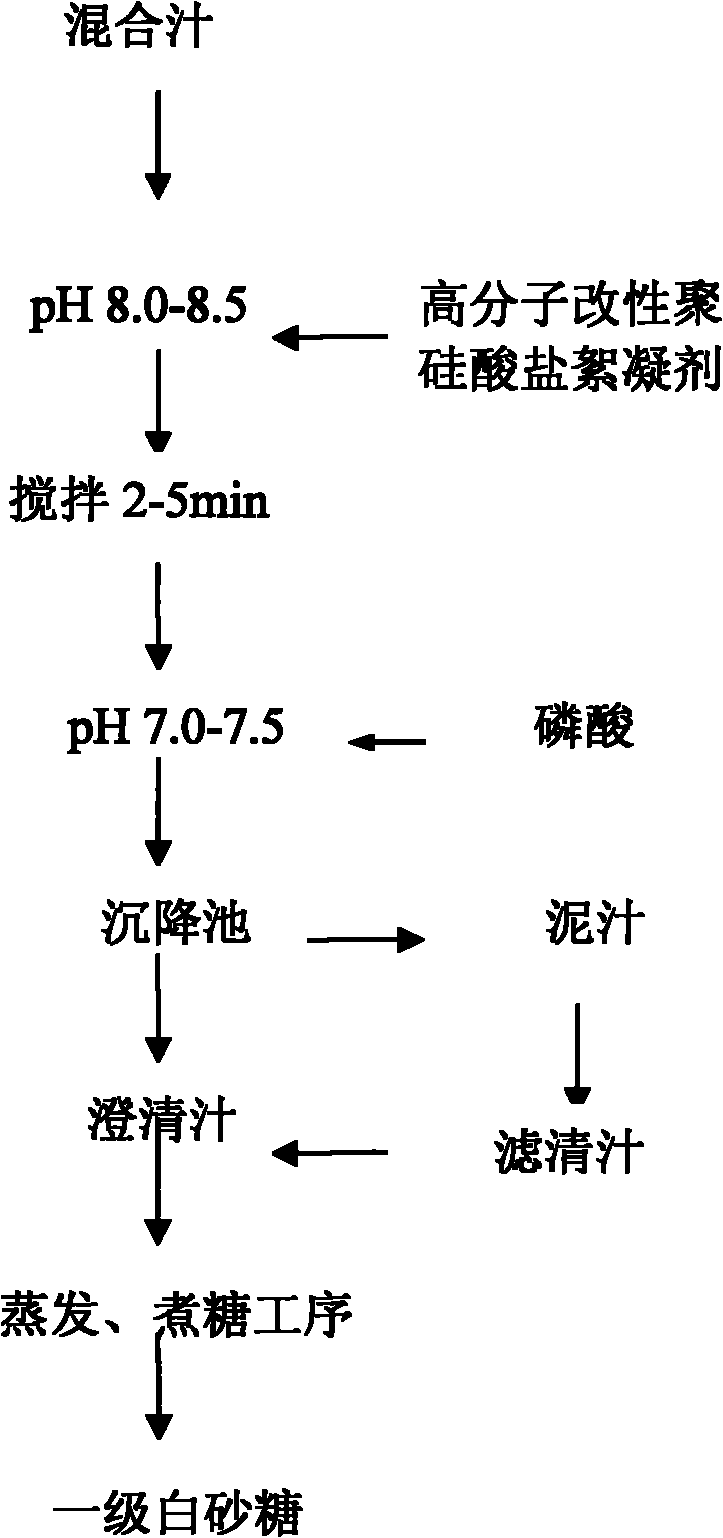

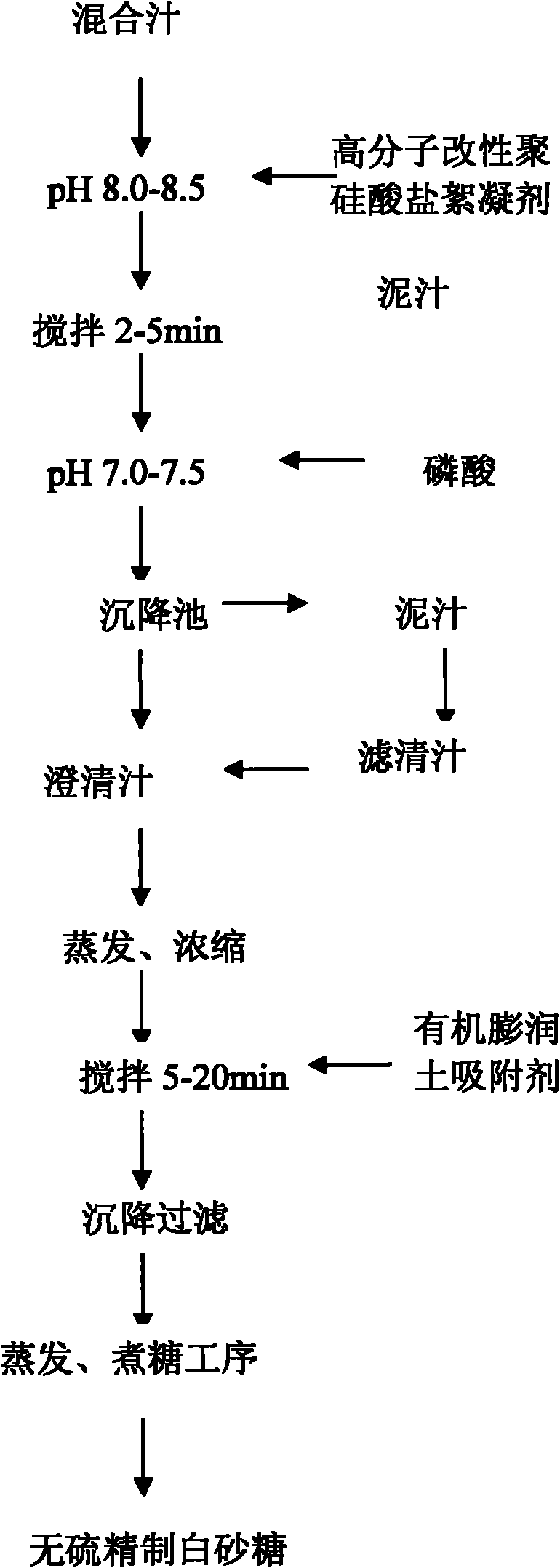

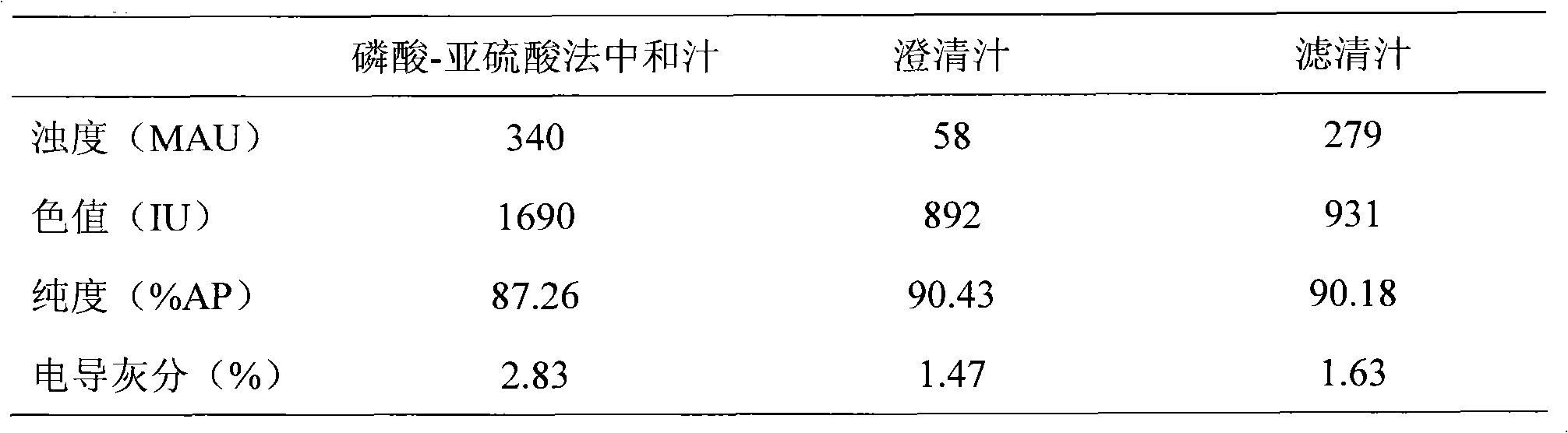

Method for producing high-quality white granulated sugar by clarifying syrup

InactiveCN102021250AReduce color valueHigh purityPurification using adsorption agentsPurification using alkaline earth metal compoundsSulfurPhosphoric acid

The invention relates to a method for producing high-quality white granulated sugar by clarifying syrup. The method comprises the following steps of: heating the syrup; adding lime milk; adjusting the pH value to be between 8.0 and 8.5; adding anionic inorganic gel serving as a flocculating agent in an amount which accounts for 0.01 to 0.05 percent of the amount of the syrup; keeping the pH value at 8.0 to 8.5 for about 2 minutes; adding phosphoric acid to reduce the pH value to be between 7.0 and 7.5; pouring the syrup into a sedimentation tank or a floatation tank to separate clarified juice and mud juice out; filtering the mud juice by using filtering cloth or a vacuum filter, and mixing the filtered clarified juice and the separated clarified juice; and evaporating, concentrating, boiling sugar, crystallizing and extracting the sugar to obtain the white granulated sugar of above first class; or evaporating and concentrating to obtain the syrup, adding organic bentonite in an amount which accounts for 0.2 to 1 percent of the amount of the syrup, stirring, adsorbing for 5 to 20 minutes, filtering by using the filtering cloth, boiling, crystallizing and extracting the sugar to directly produce sulfur-free refined sugar. The method has the advantages of good clarification effect, high clear juice purity, short process flow, high process operation safety and low labor intensity.

Owner:杨鲁昆

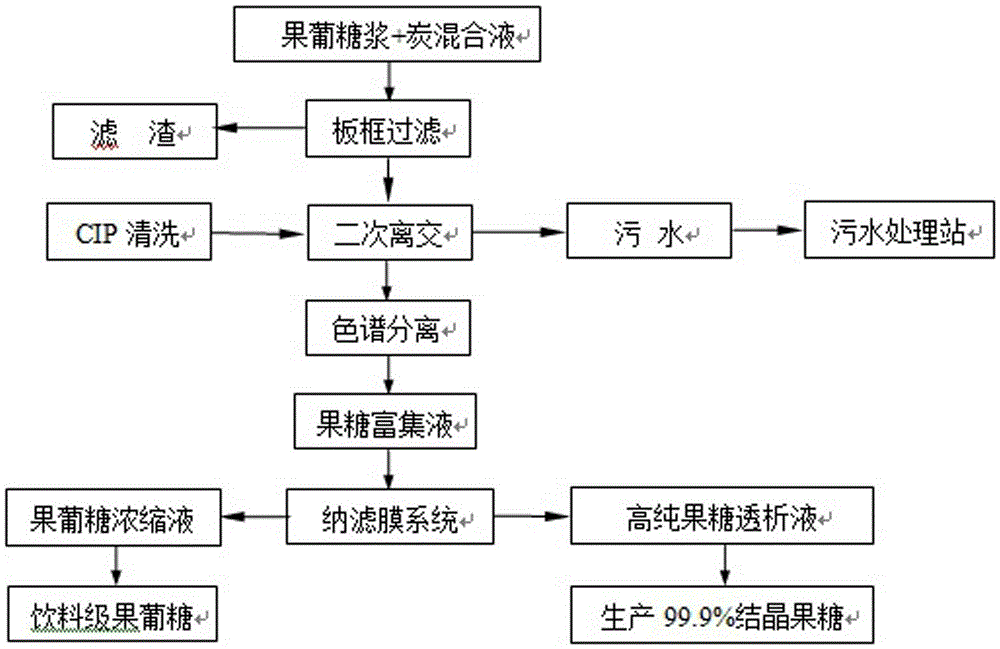

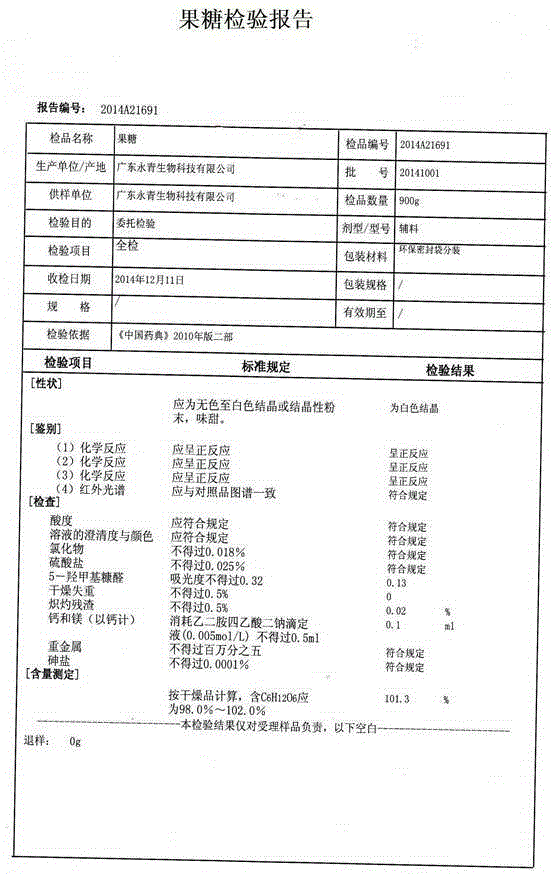

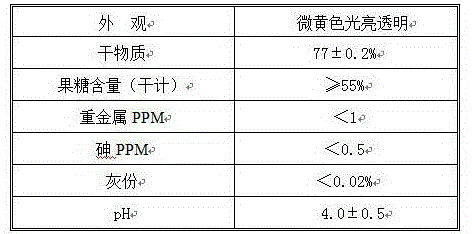

Purification method for HFCS (high fructose corn syrup) in fructose production process

InactiveCN105256079AQuality improvementImprove stabilityPurification using adsorption agentsPurification using ion-exchange materialsIon exchangeActivated carbon

The invention provides a purification method for HFCS (high fructose corn syrup) in a fructose production process. According to the purification method, the HFCS is obtained after cane juice is subjected to neutralization-hydrolysis in a medicinal anhydrous crystalline fructose production process adopting sugarcane as a raw material, the HFCS is decolorized with activated carbon, subjected to ion exchange twice and then separated through chromatography, a fructose rich liquid is obtained, the fructose rich liquid enters a nanofiltration membrane system, a high-purity fructose dialysate and a high fructose corn concentrated solution are filtered out respectively, the high-purity fructose dialysate is used for producing 99.9% crystalline fructose, and the high fructose corn concentrated solution is applied to beverage-grade high fructose corn. According to the purification method, devices and technological parameters of all working procedures are comprehensively optimized and reasonably matched to meet industrial production requirements, equipment input and production cost are greatly reduced, the one-time yield of industrially produced crystalline fructose products is up to 50%, the technical content of fructose production is increased, and the problem about the situation of heavy dependence on import of high-quality medicinal fructose is solved.

Owner:林树仁 +1

Process for the production of invert liquid sugar

InactiveUS20040255934A1Purification by oxidation/reductionPurification using adsorption agentsFruit juiceSugar

A process for the production of liquid sugar by forming a sugar solution of water and natural sugar containing juice, adjusting the pH of a sugar solution to the range of from 1.0 to 2.0 to obtain an inverted juice, filtering the inverted juice, decolorizing the inverted juice to obtain sugar syrup, demineralizing the sugar syrup, evaporating the demineralized sugar syrup, and cooling the sugar syrup to form the liquid sugar.

Owner:GRANGUILLHOME ENRIQUE R CARDENAS +2

Decolourization method for producing sucrose mix juice

InactiveCN101082065AHigh purityReduce color valuePurification using adsorption agentsSaccharumSucrose

The sucrose juice decolorizing process includes the following steps: low temperature phosphoric acid floating treatment of mixed juice in the purity of 78.19 AP and through preheating to 50 deg.c, adding phosphoric acid mixture, neutralizing with lime milk, inflating, adding flocculant and separating out neutral slime, to obtain clear juice of purity raised to 80.66 AP and color value lowered to 92.66 st deg; pre-decolorizing the clear juice heated to 75 deg.c with diatomite in 1.0 wt% of sucrose for 60 min to lower the color number to 75.23 st deg; and decolorizing the clear juice with active carbon in 1.0 wt% of sucrose for 30 min to further lower the color number to 30.70 st deg. The process has the advantages of no production of alkali slime, short technological process, high purity of obtained sucrose juice and greatly lowered color number.

Owner:TIANJIN HANGU DISTRICT FUXIANG FERTILIZER PROCESSING FACTORY

Process for production of aqueous refined sugar solution

InactiveUS20130092157A1Long-term stable productionImprove efficiencyPurification using adsorption agentsSolid sorbent liquid separationUltrafiltrationBiomass

Disclosed is a method for producing an aqueous refined sugar solution, in which a biomass residues that are formed during a step of producing a sugar from a cellulose-containing biomass is removed in a step of producing an aqueous sugar solution, thereby preventing the clogging of a microfiltration membrane and / or an ultrafiltration membrane and ensuring long-term, stable production of an aqueous refined sugar solution. Specifically disclosed is a process for producing an aqueous refined sugar solution using a cellulose-containing biomass as a raw material, which comprises the steps of: (1) decomposing cellulose-containing biomass to produce an aqueous sugar solution; (2) subjecting the aqueous sugar solution resulting from step (1) to aggregation treatment with an aggregation agent to produce an aqueous sugar solution having an average particle diameter of 2 μm or more as determined by particle size distribution measurement; and (3) filtering the aqueous sugar solution resulting from step (2) through a microfiltration membrane and / or an ultrafiltration membrane and subsequently recovering an aqueous sugar solution from the downstream side.

Owner:TORAY IND INC

Method of preparing granulated sugar from an aqueous sugar solution containing monovalent and polyvalent anions and cations

InactiveUS7338561B2Economical in energy and in chemicalLimiting quantity and numberIon-exchanger regenerationOrganic anion exchangersOrganic acidPurification methods

A purification method employs nanofiltration of an aqueous solution containing one or several sugars, multivalent cations, monovalent metal cations, monovalent anions and multivalent inorganic anions and / or organic acid anions. The method includes replacement of at least a part of said multivalent cations and / or said multivalent inorganic anions and organic acid anions respectively by monovalent metal cations and / or monovalent anions to produce a solution. Nanofiltration of the solution is carried out to obtain a retentate, and at least part of the retentate is subject to crystallization.

Owner:NOVASEP PROCESS SOLUTIONS

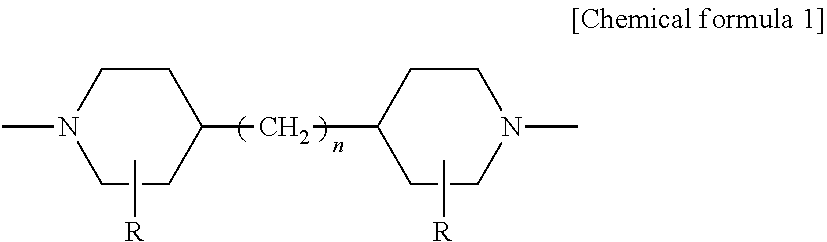

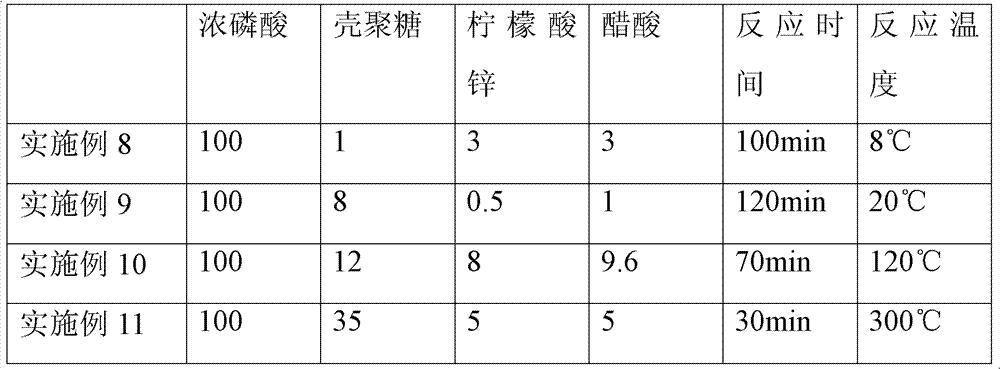

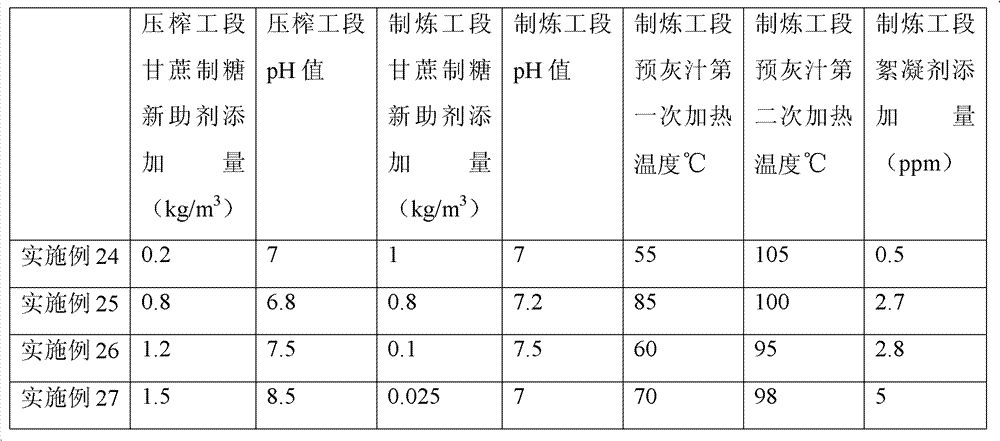

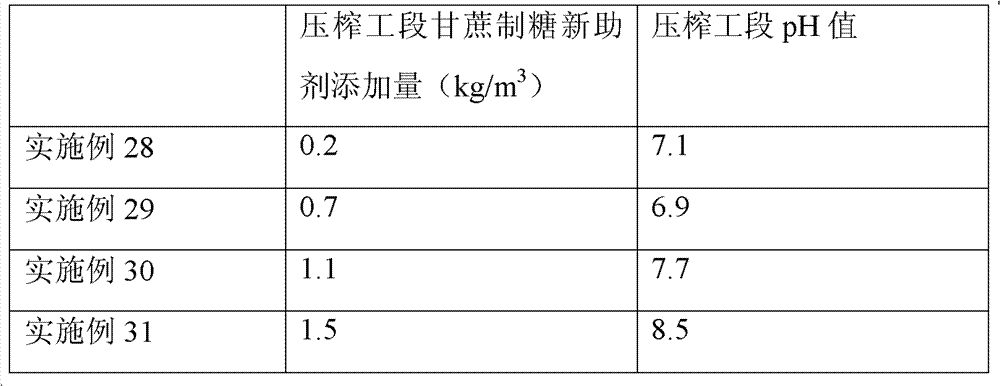

New additive for producing sugar from sugarcane, preparation method thereof and application method thereof in sugar production

ActiveCN102952904ARich choiceImprove qualityPurification by oxidation/reductionPurification using adsorption agentsFiberEnvironmental resistance

The invention discloses a new additive for producing sugar from sugarcane, a preparation method thereof and an application method thereof in a sugar production. The new additive comprises the following raw materials by weight parts: 100 parts of concentrated phosphoric acid, 0.5 to 50 parts of chitosan and 15 to 90 parts of diatomite used as a carrier raw material. The preparation method comprises adding 0.5 to 50 parts of the chitosan into 100 parts of the concentrated phosphoric acid, reacting for 30 to 120 minutes under a temperature of 8 to 300 DEG C, generating a new sugar-production additive of polyphosphate polymer compound with a strong positive charge and a high fiber after complete reaction, and absorbing the above reaction product with 15 to 90 parts of the diatomite to prepare the new additive with relatively high performance. The new additive, completely instead of sulfur dioxide, is used in cane sugar manufacture industries to decolorize and clarify sugarcane juice, mixed juices thereof and pre-heated and pre-limed juice, and as well can be used to re-treat clear juice or syrup. According to the invention, safe, green, environmental-protection and high-quality sugar products is ensured to produce.

Owner:SHENZHEN HIGHWIND BIOLOGICAL TECH

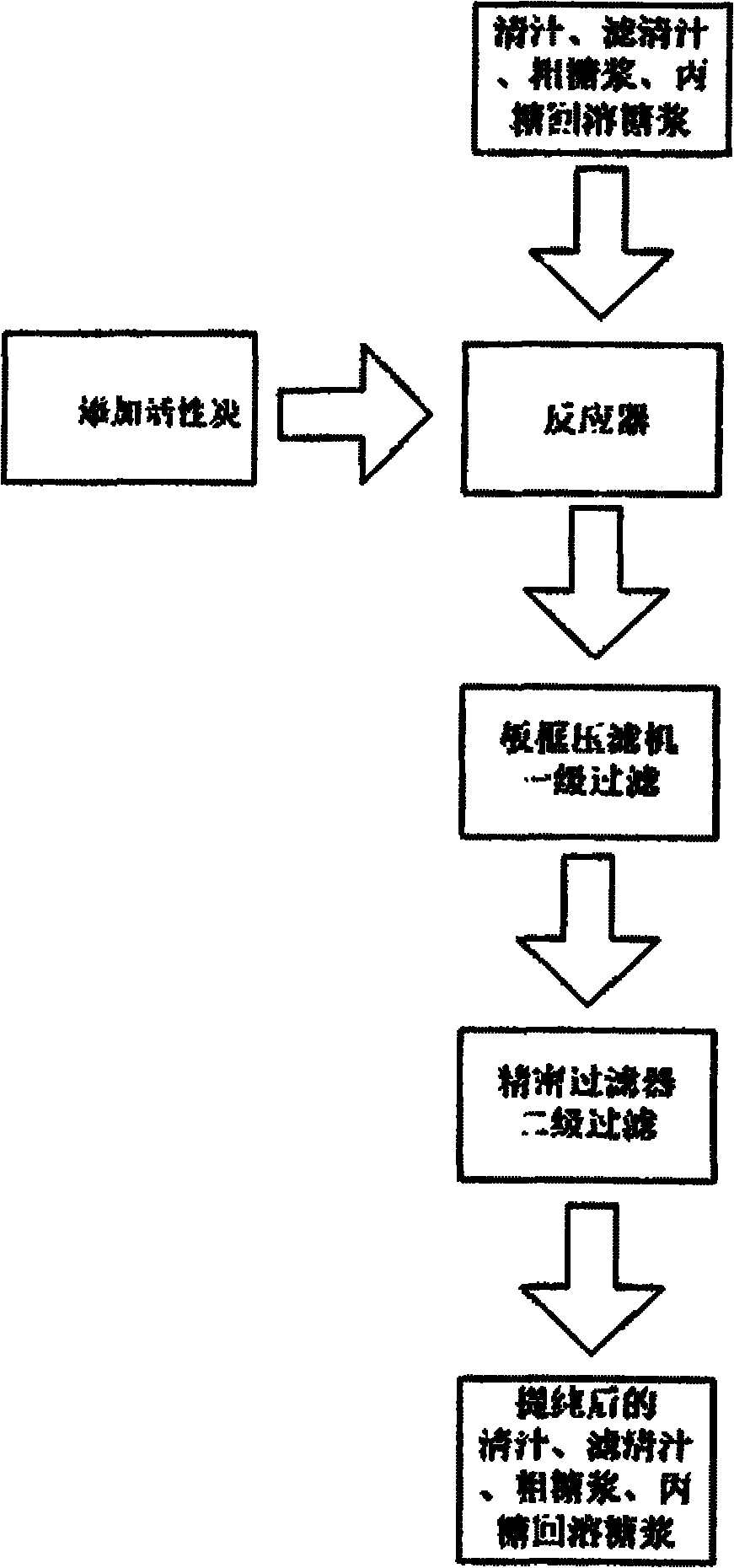

Method for improving sulfurous method production process in cane sugar factory

InactiveCN101818214AMake sure not to filter throughReduce sulfur dioxide contentPurification using adsorption agentsPurification by physical meansFiltrationImpurity

The invention discloses a method for improving a sulfurous method production process in a cane sugar factory. Active carbon is taken as an auxiliary clarifying agent to perform physical impurity removal and decoloration on serum, filtered serum, crude syrup or triose remelt syrup led out from the sulfurous method sugar production flow, and the secondary sulfur smoke process is eliminated further, so the problem of secondary sulfur smoke troubling the sugar industry for a long term is solved, the quality of whiter granulated sugar is improved fundamentally, and the high-quality whiter granulated sugar with low sulfur dioxide and low color number is produced. The method comprises the following steps of: leading the serum, filtered serum, crude syrup or triose remelt syrup out of the conventional production flow into a reactor; adding the active carbon accounting for 0.5 to 3 mass percent of the syrup in the reactor, reacting at the temperature of between 60 and 90 DEG C for 15 to 30 minutes, and performing physical adsorption, impurity removal and decoloration; and discharging sugar liquor after the adsorption from the reactor, and making purified serum, filtered serum, crude syrup or triose remelt syrup subjected to secondary filtration and solid-liquid separation by using a plate-and-frame filter press and a precision filter enter the conventional production flow again.

Owner:云南省轻工业科学研究院有限公司

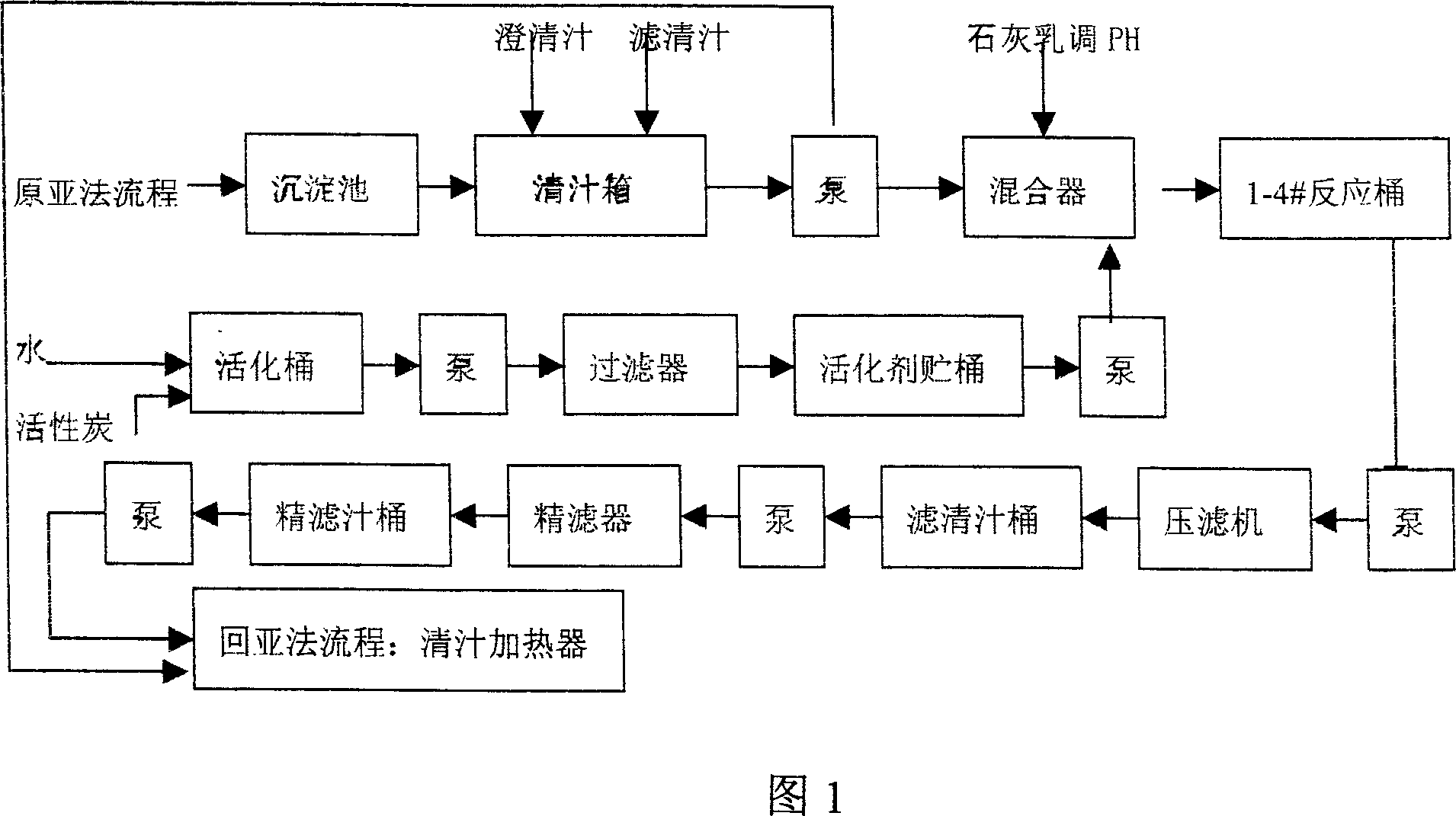

Method for producing desulfurized sugar by high efficiency active carbon improved sufurous acid method sugar producing process

InactiveCN1944684AReduce investmentExemption from the secondary sulfur fumigation processPurification by oxidation/reductionPurification using adsorption agentsActivated carbonTurbidity

The present invention is improved desulfurized sugar producing sulfurous acid process with high efficiency carbon. The process includes the first mixed sugar cane juice clarifying treatment with sulfurous acid, the subsequent adding high efficiency active carbon in the amount of 0.09-0.2 wt% of juice into the clear juice and adding lime milk to regulate pH value to 6.8-7.6 through full mixing for adsorption in 20-30 min, pressure filtering and straining to obtain high quality juice, evaporating, boiling sugar and purging to obtain high quality desulfurized sugar. The present invention has high sugar quality.

Owner:云南永德糖业集团有限公司

Method for purifying by nanofiltration an aqueous sugary solution containing monovalent and polyvalent anions and cations

InactiveUS7067014B2Economical in energyEconomical in in chemicalIon-exchanger regenerationOrganic anion exchangersOrganic acidPurification methods

A purification method employs nanofiltration of an aqueous solution containing one or several sugars, multivalent cations, monovalent metal cations, monovalent anions and multivalent inorganic anions and / or organic acid anions. The method includes replacement of at least a part of said multivalent cations and / or said multivalent inorganic anions and organic acid anions respectively by monovalent metal cations and / or monovalent anions to produce a solution. Nanofiltration of the solution is carried out to obtain a retentate, and at least part of the retentate is subject to crystallization.

Owner:NOVASEP PROCESS SOLUTIONS

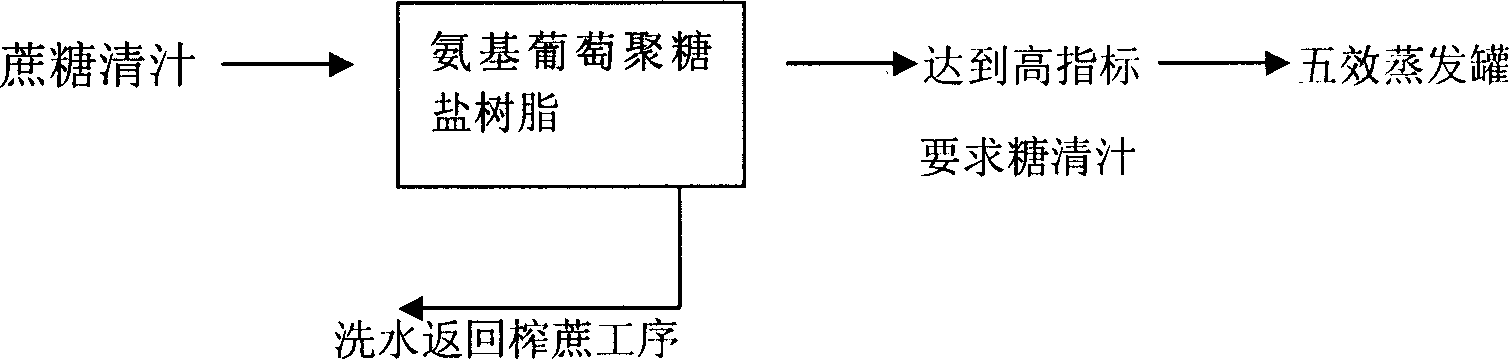

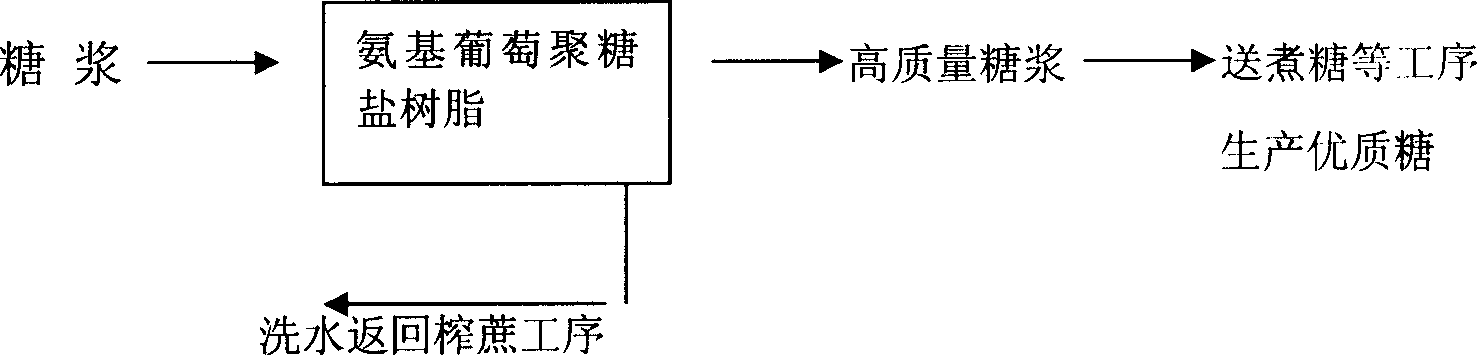

Purification and decolouring agent cane juice, syrup and its preparation method and application in sugar refining technology

InactiveCN1757756AEasy to handleEasy to operatePurification using adsorption agentsAcetic acidSugar refining

A purifying and decoloring agent for the cane juice or syrup in sugar refinery is prepared from chitosan through catalytic reaction between chitosan and the solution of acetic acid, citric acid or hydrochloric acid to obtain the polyose aminogluconate, and polymerizing to obtain aminoglucosan salt insoluble in water and deluted acid.

Owner:张永达 +3

Process for preparing a crystalline alpha anhydrous dextrose of high purity

The invention relates to a process for preparing a crystalline alpha anhydrous dextrose from a starch hydrolysate, characterized in that a starch hydrolysate is prepared, said starch hydrolysate is nanofiltered over membranes in a manner such as to obtain a nanofiltration permeate constituting a syrup with a high glucose content and a nanofiltration retentate, said syrup enriched in glucose is concentrated to a dry matter content of at least 70 wt. % of glucose and at a temperature in the range 50° C. to 110° C., said concentrated syrup is crystallized by evaporation and agitation in such a manner as to obtain a crystalline mass containing at least 30 wt. % of crystals and the crystals of alpha anhydrous dextrose thus obtained are separated, recovered and dried.

Owner:ROQUETTE FRERES SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com