Patents

Literature

116results about "Sucrose extraction by chemical means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superabsorbent surface-treated carboxyalkylated polysaccharides and process for producing same

Owner:ARCHER DANIELS MIDLAND CO

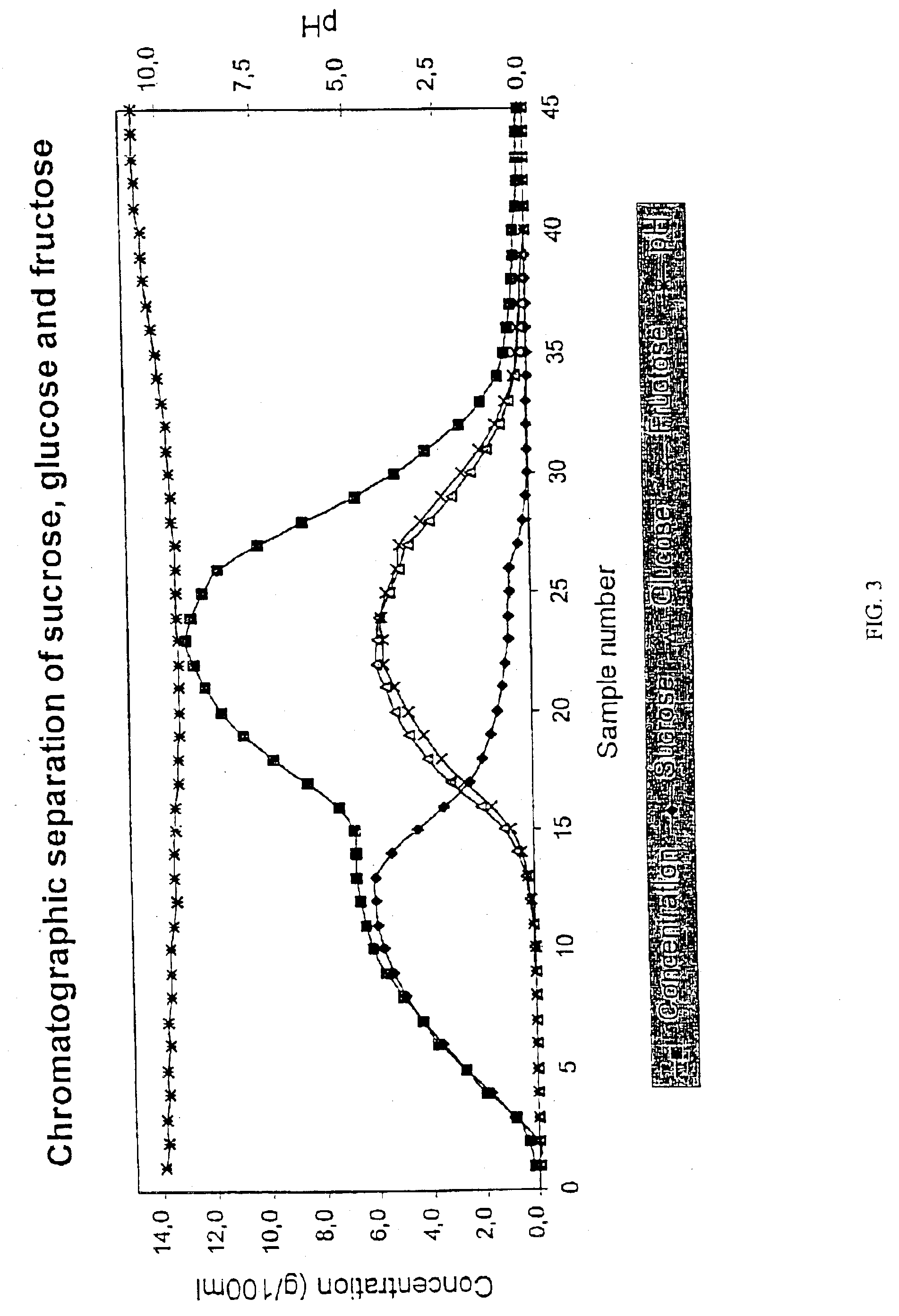

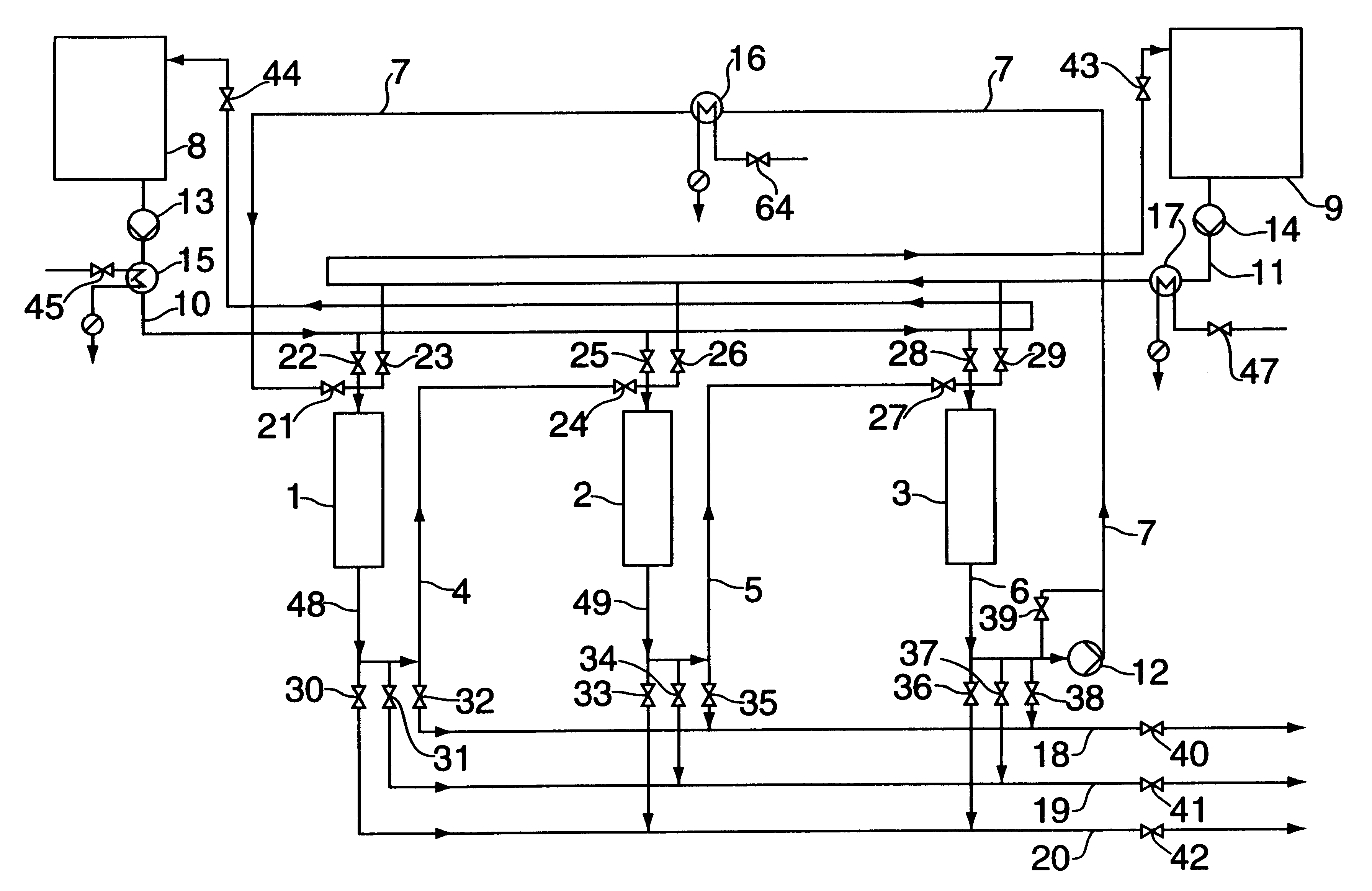

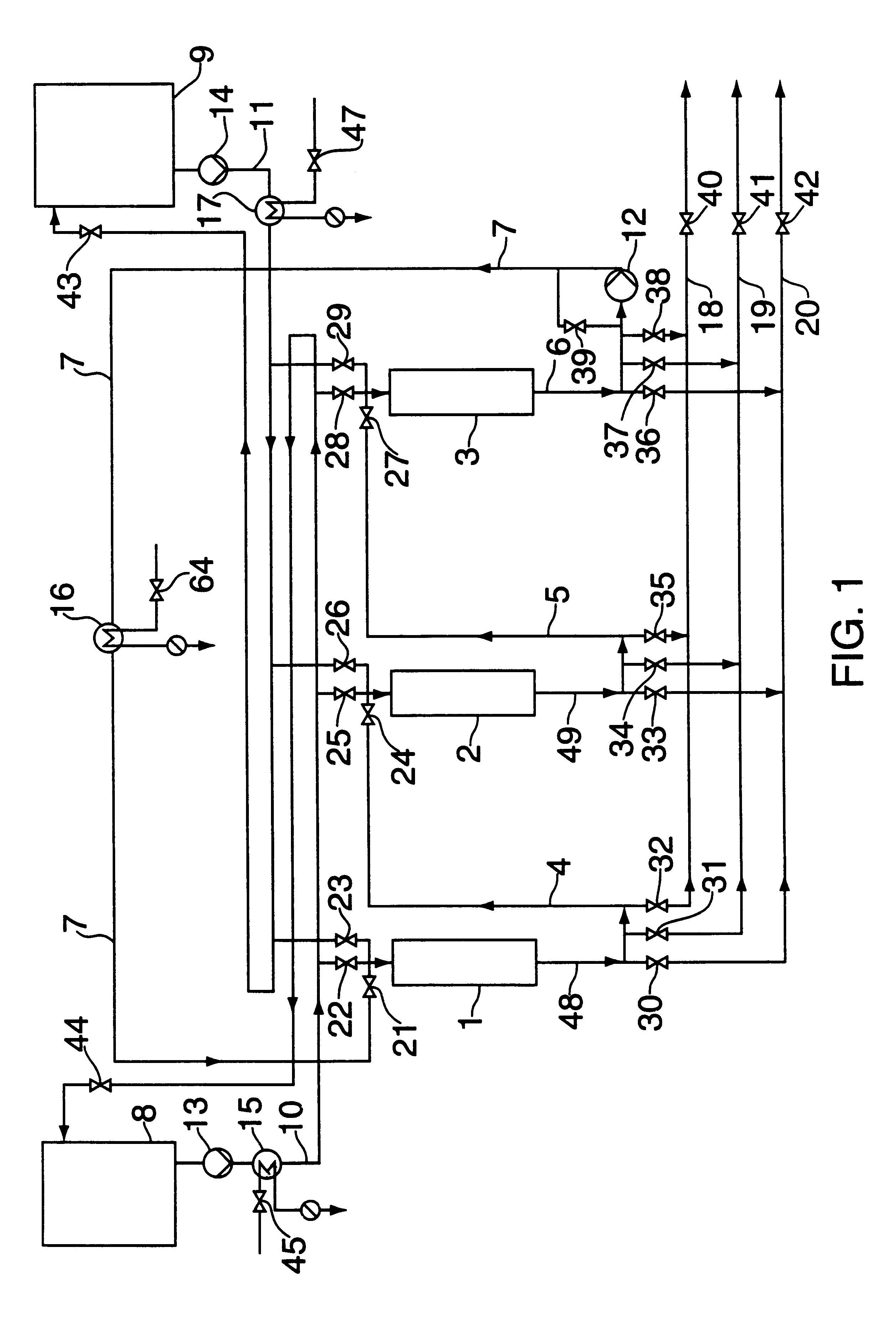

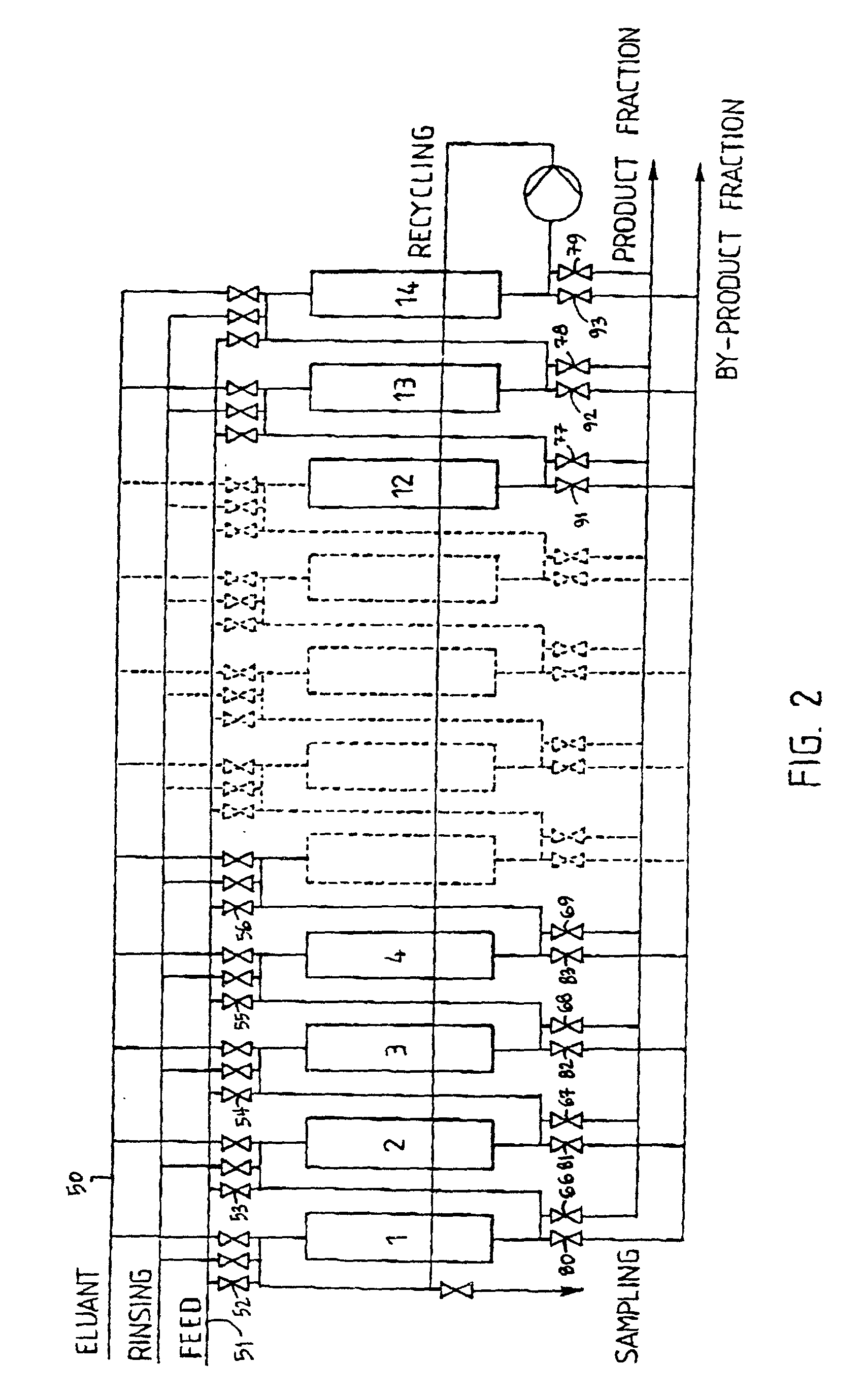

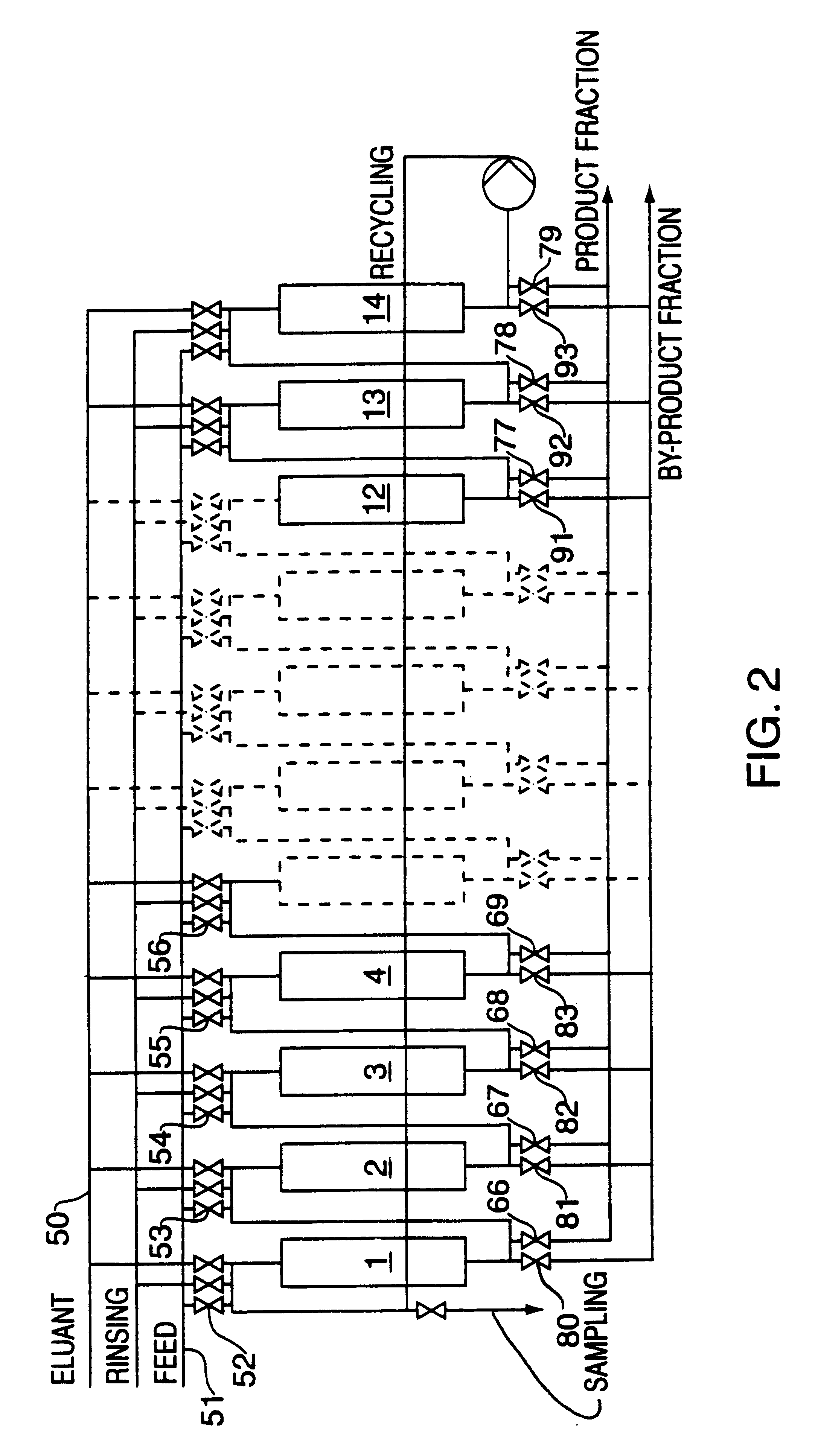

Method of displacement chromatography

InactiveUS6379554B1Efficient separationLower requirementIon-exchange process apparatusComponent separationChromatographic separationBetaine

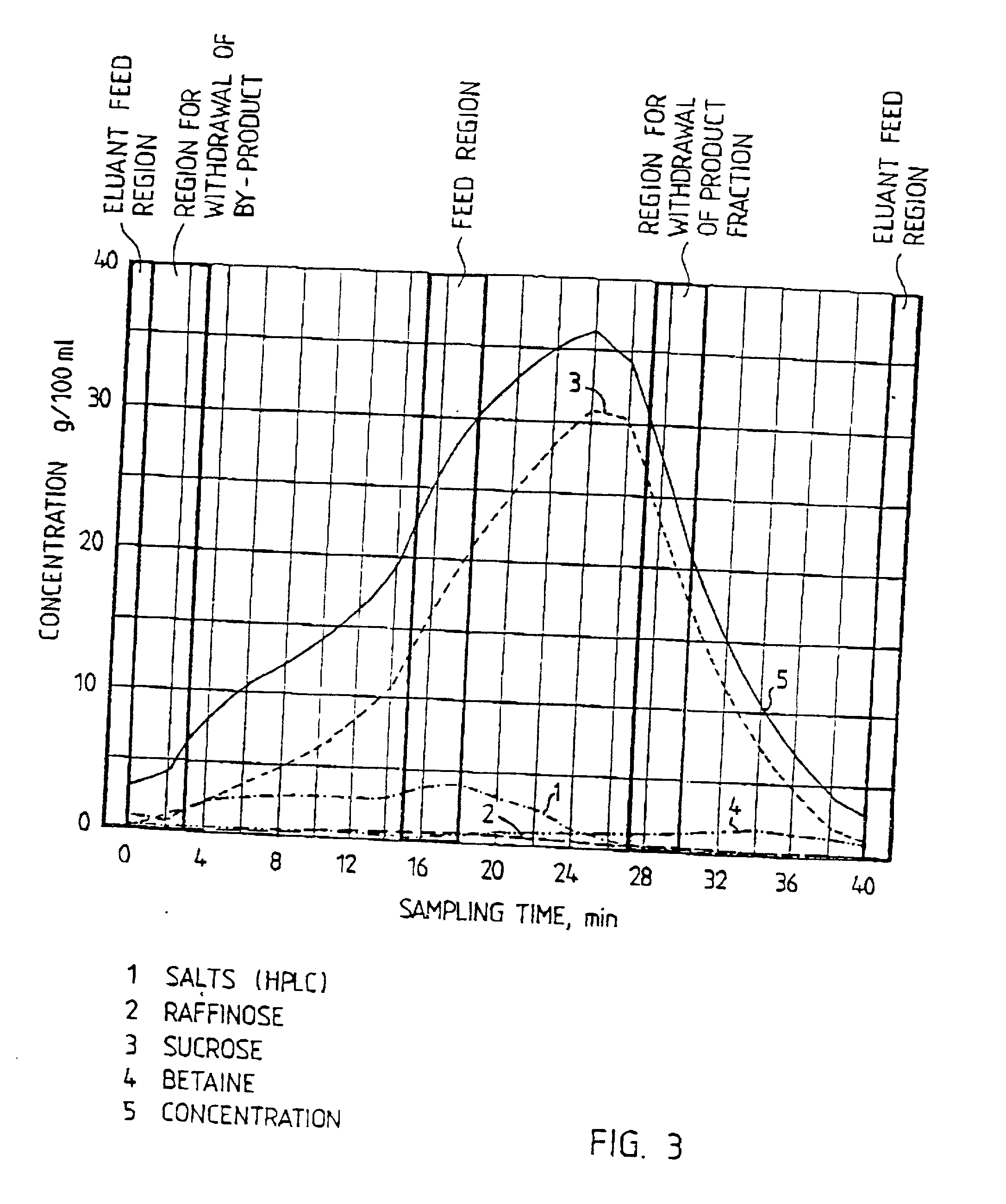

A plurality of chromatographic separation operations, including a first simulated moving bed operation, are coupled into a process which functions, preferably through the application of continuous displacement chromatography, to recover a fraction rich in small organic molecules, notably betaine and / or invert from sucrose solutions, enabling the subsequent production of a high purity sucrose product.

Owner:AMALGAMATED RES

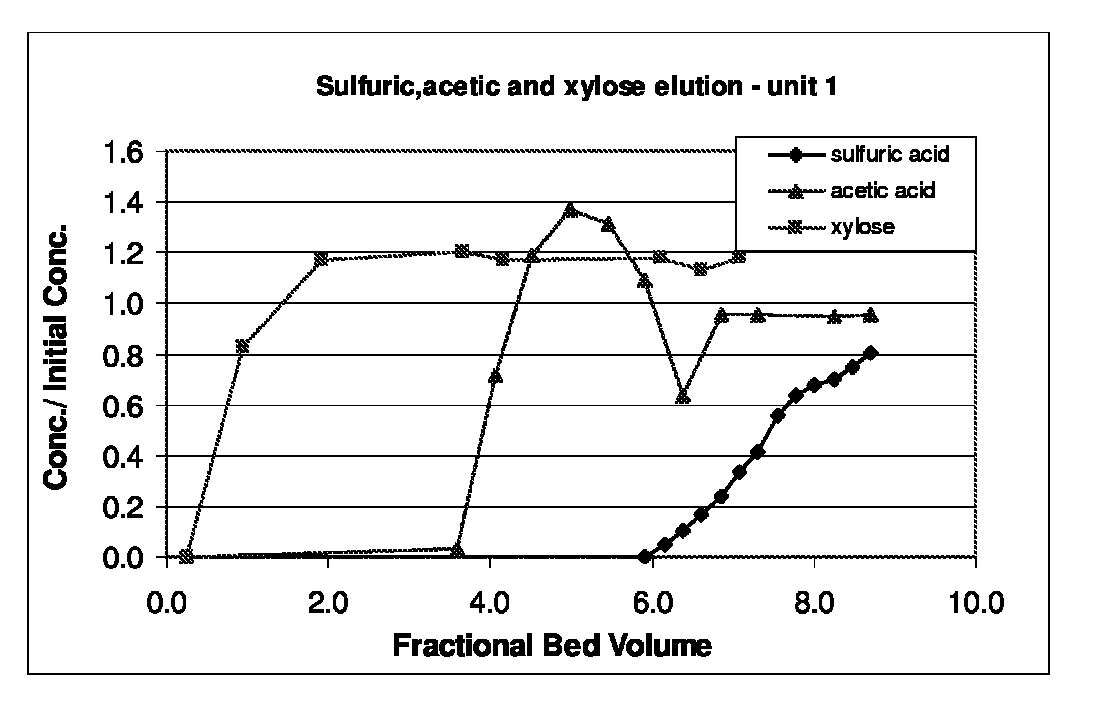

Method of obtaining an organic salt or acid from an aqueous sugar stream

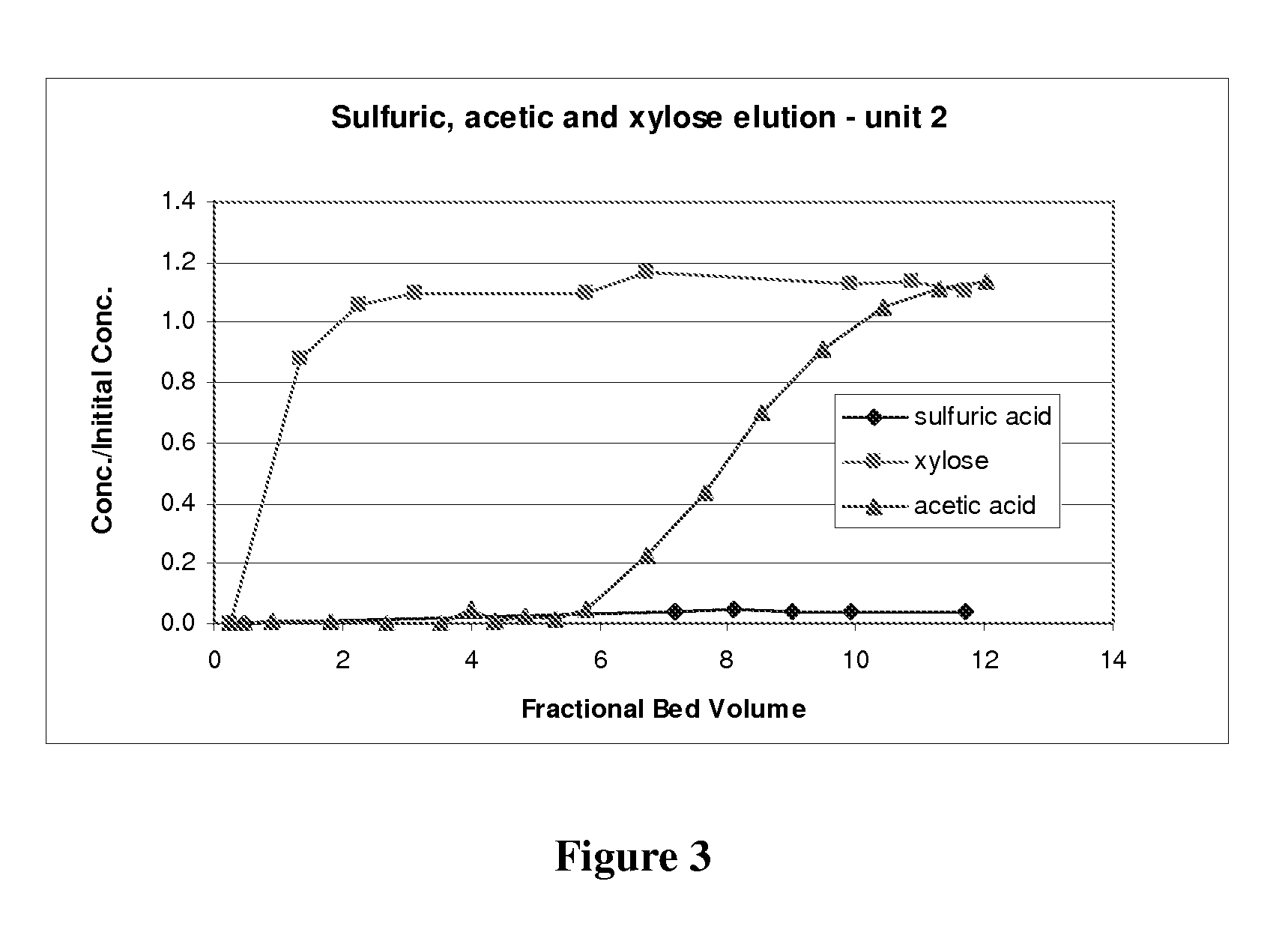

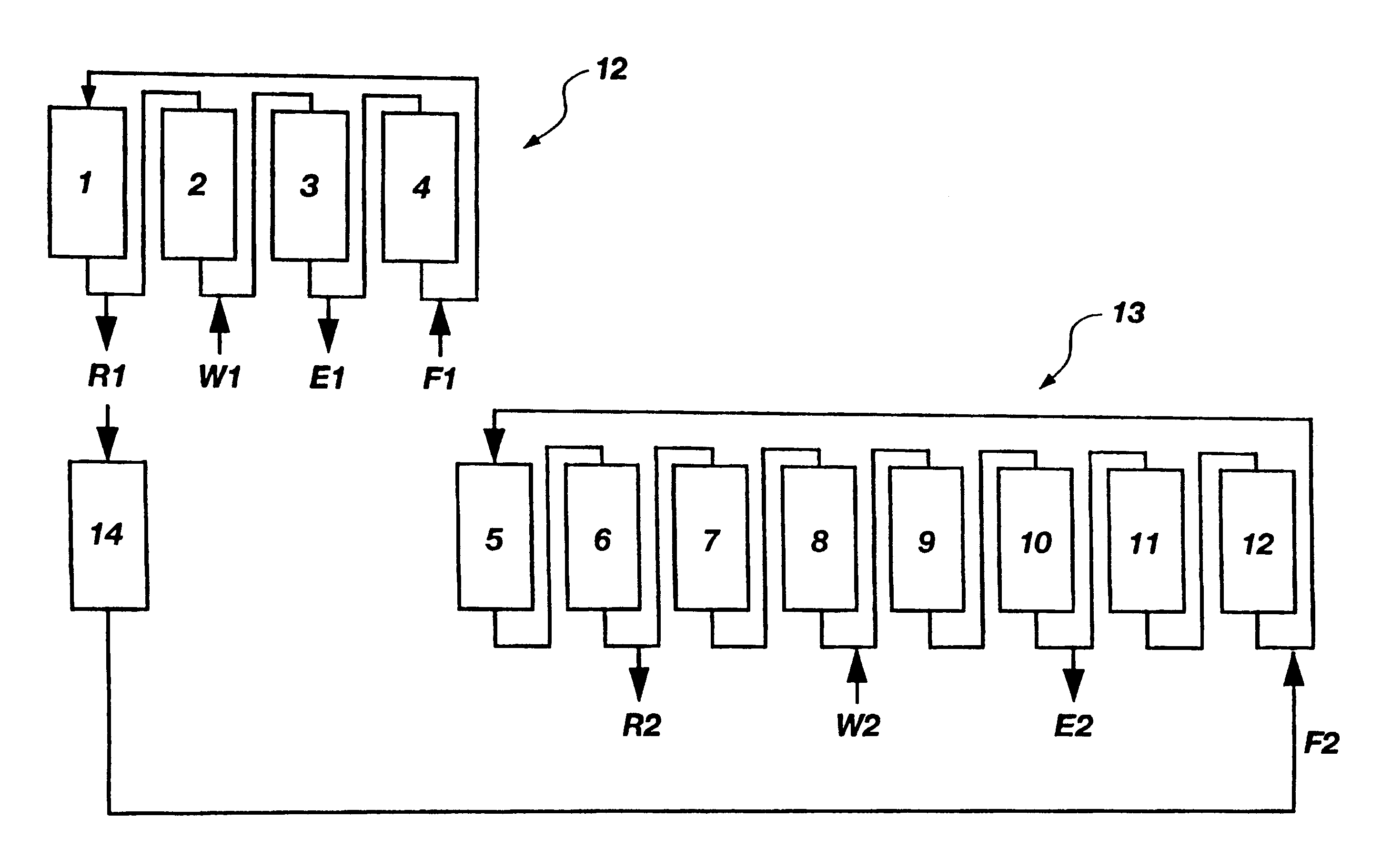

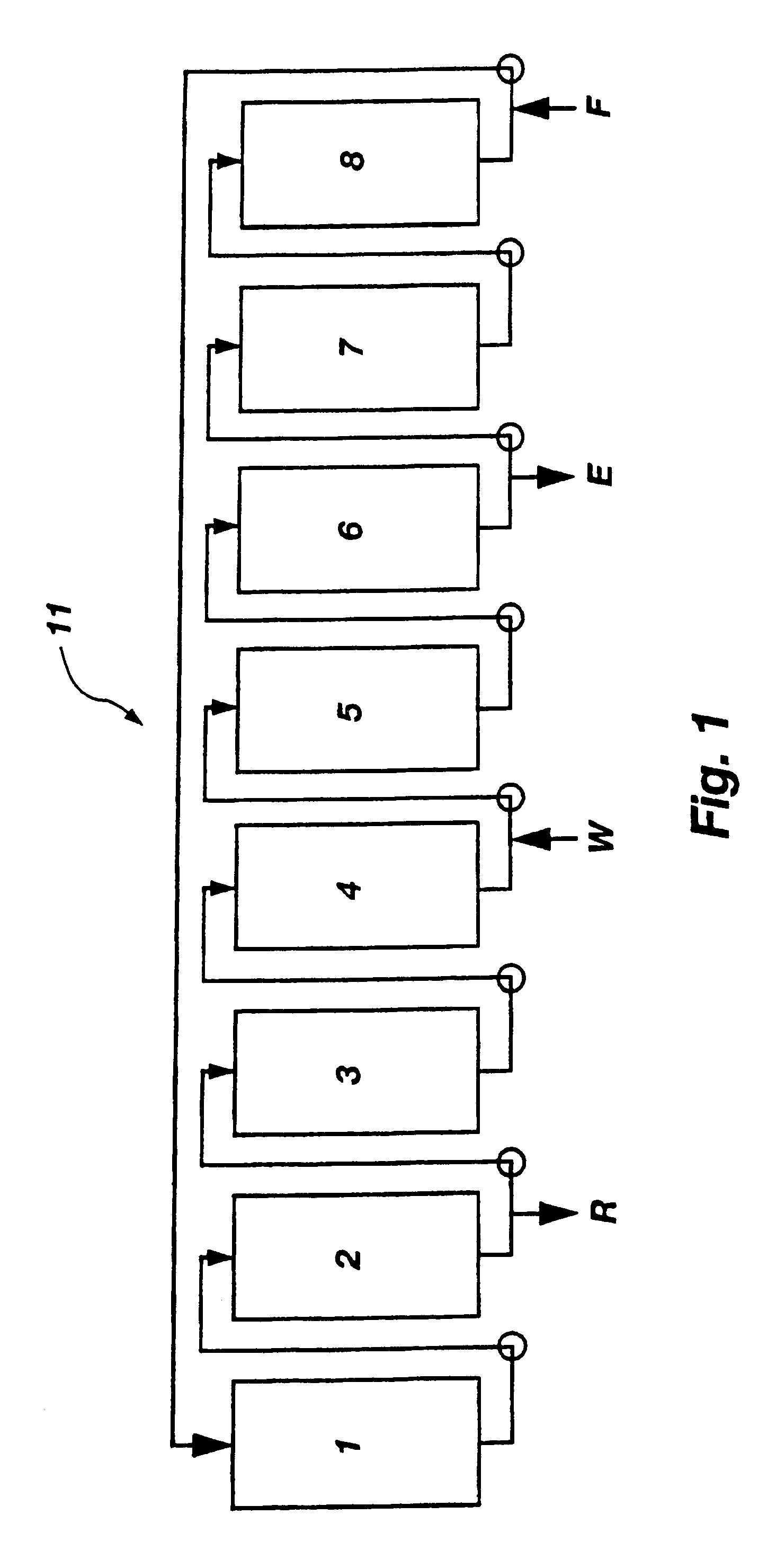

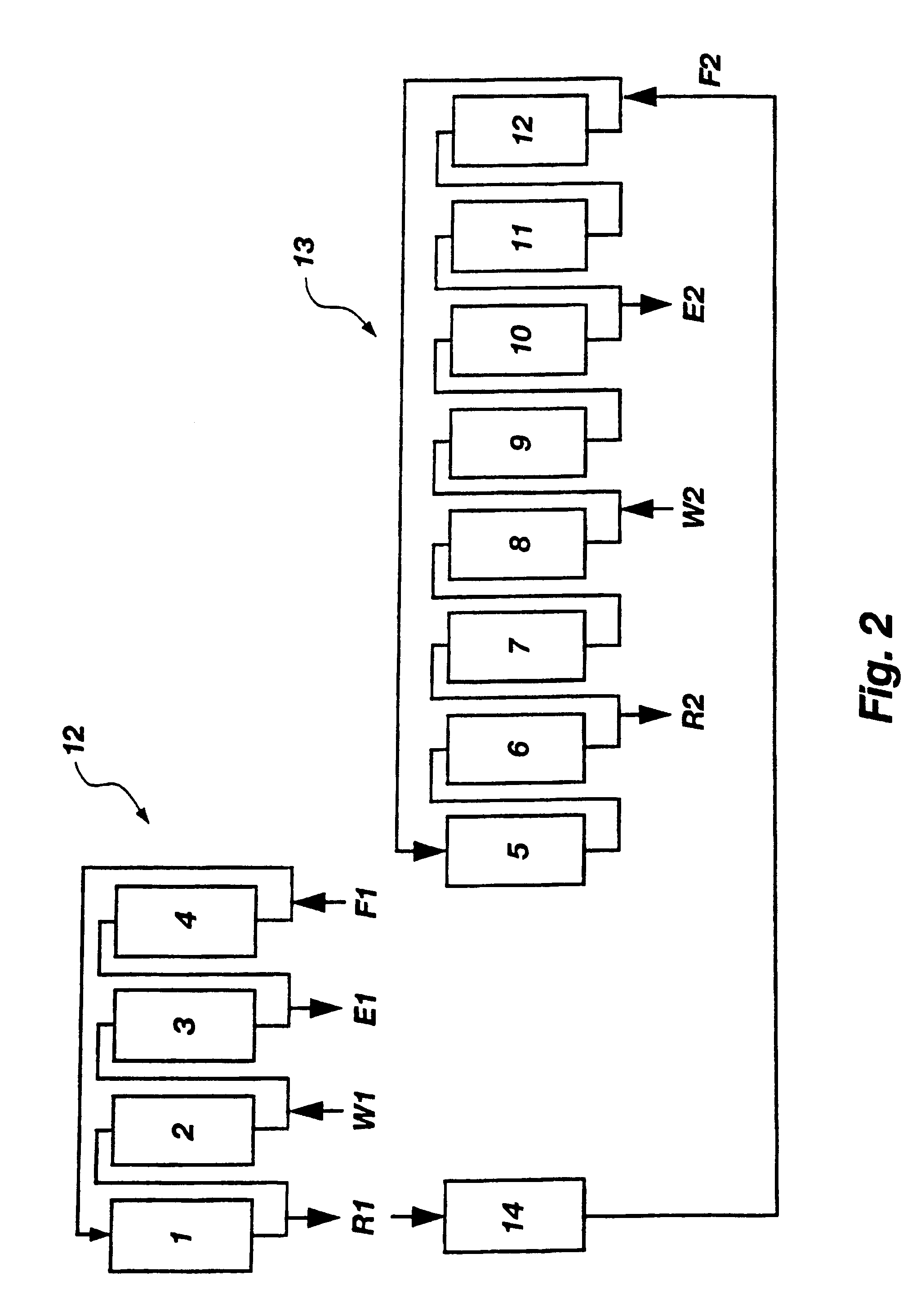

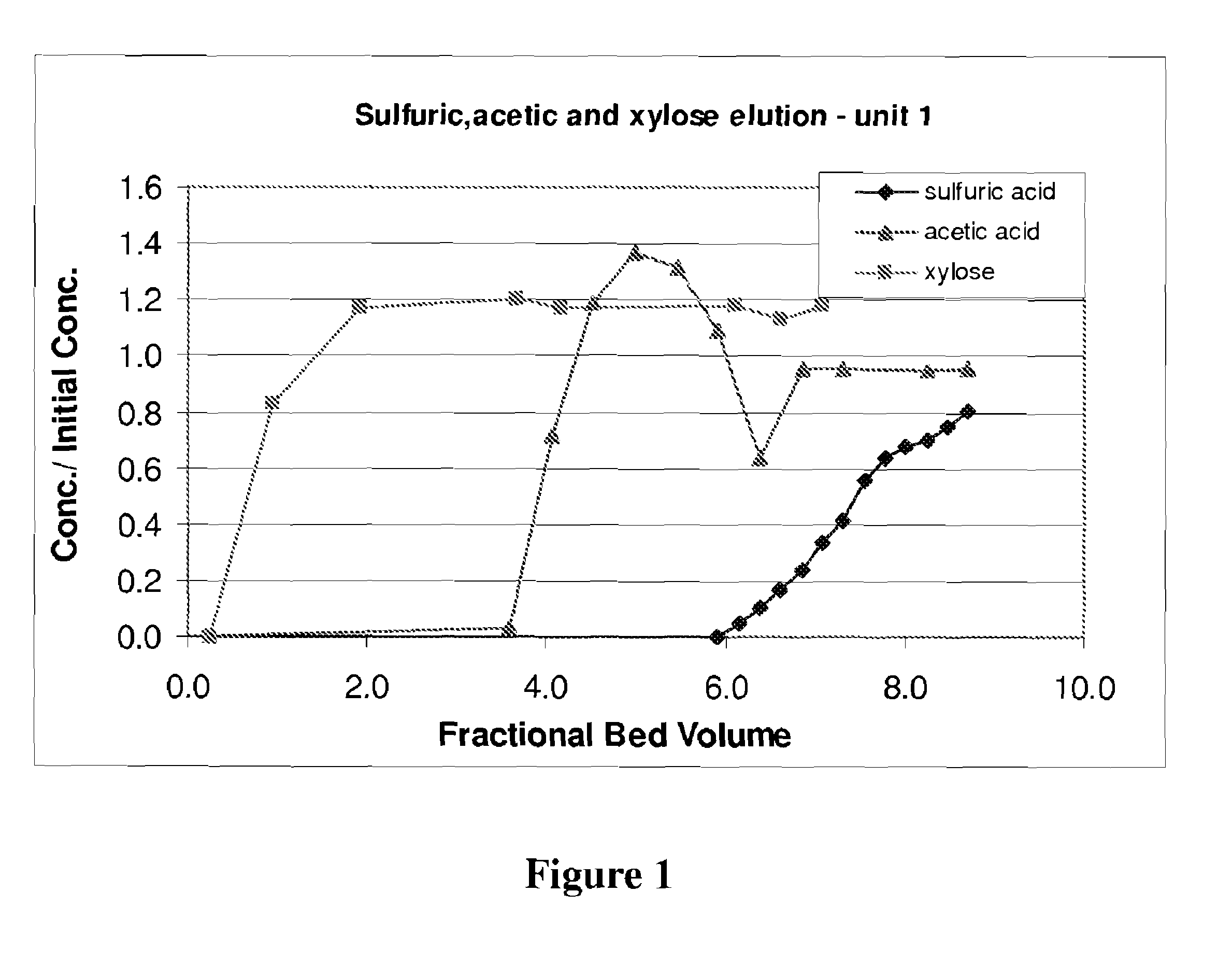

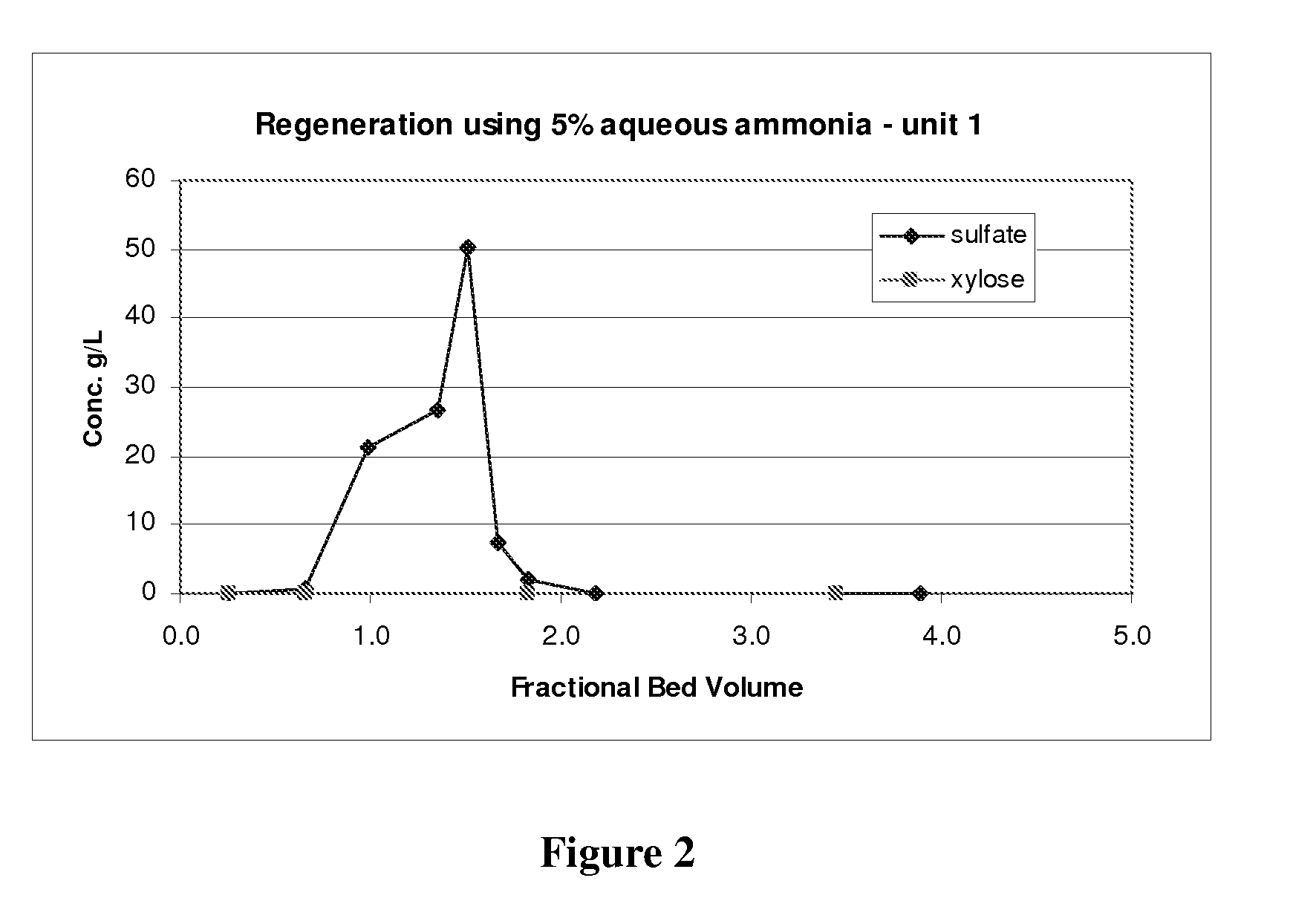

InactiveUS20080041366A1Low costPromote recoverySugar derivativesComponent separationOrganic acidOrganic Ester

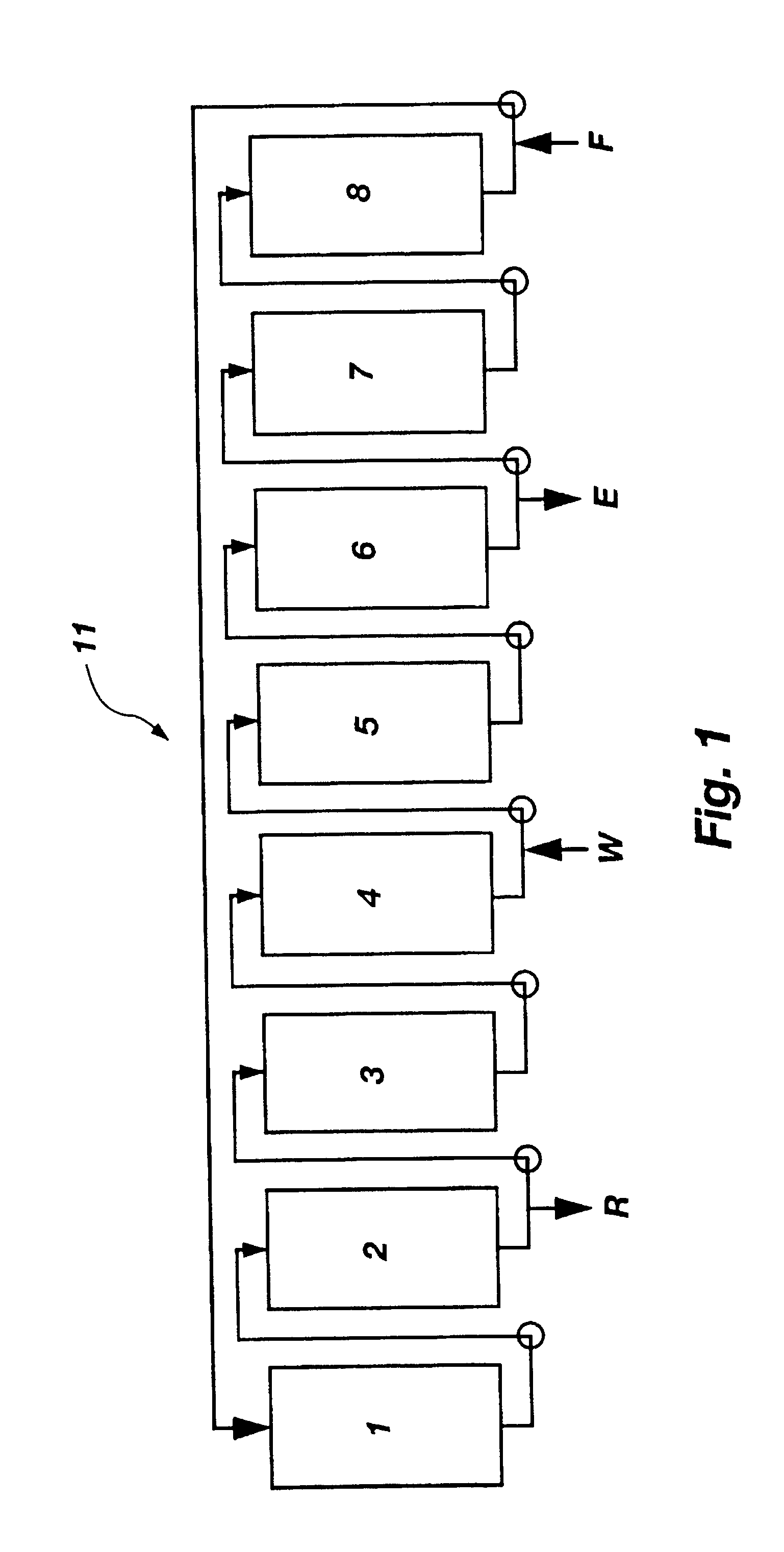

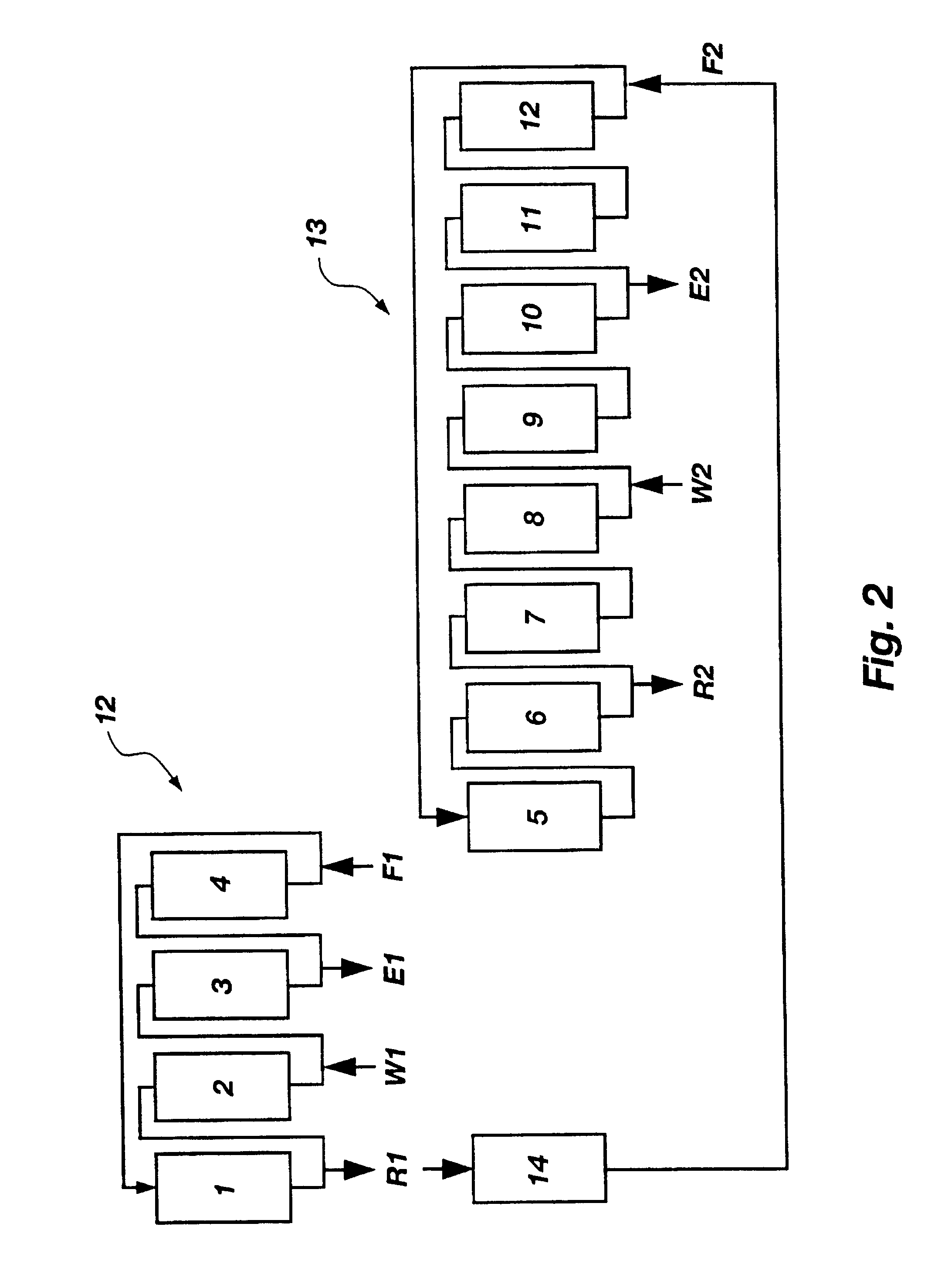

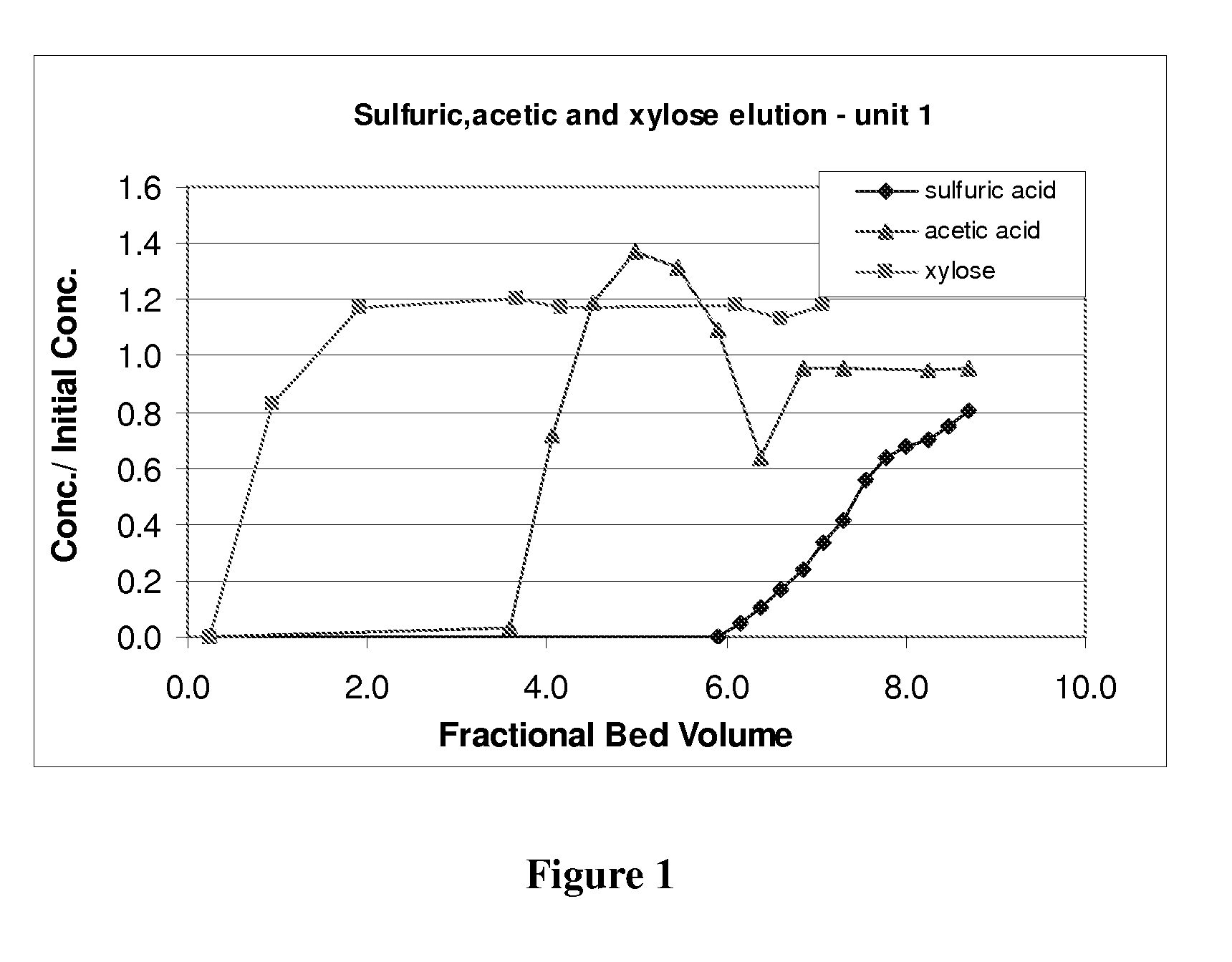

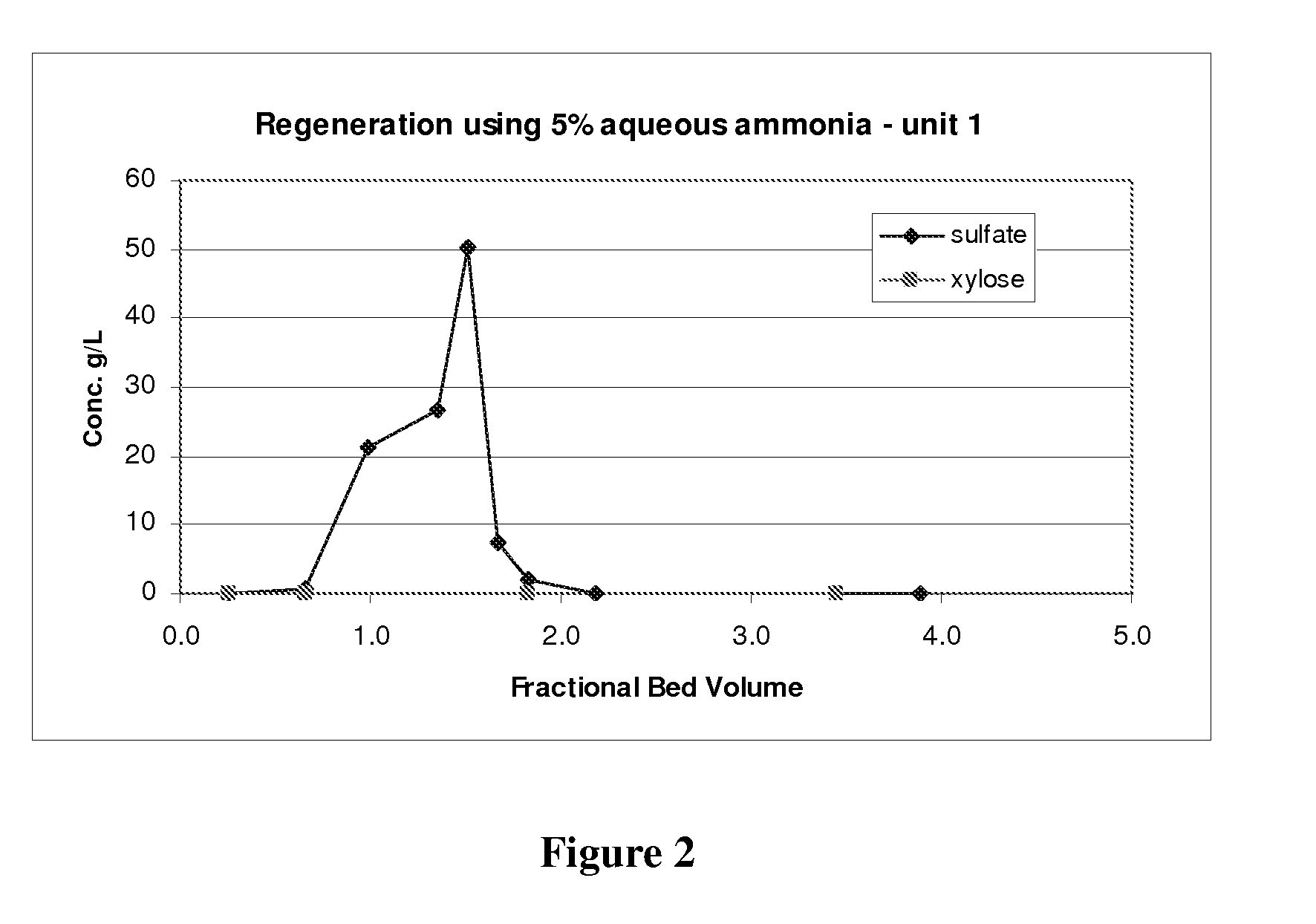

A process for obtaining one or more than one salt of an organic acid(s), or organic acid(s), from an aqueous sugar stream comprising one or more than one mineral acid and the organic acid(s) is provided. The process comprises introducing the aqueous sugar stream to a separation system comprising one or more beds of anion exchange resin and obtaining a stream therefrom comprising the sugar. The one or more beds of anion exchange resin are then regenerated in one or more stages to produce at least one product stream comprising the organic acid, a salt of the organic acid, or a combination thereof, and a separate outlet stream comprising the mineral acid, a salt of the mineral acid, or a combination thereof. The product stream is then recovered. The separation may be conducted with two separation units, or using a single anion exchange unit.

Owner:IOGEN ENERGY CORP

Method of displacement chromatography

InactiveUS6602420B2Efficient separationLower requirementIon-exchange process apparatusComponent separationChromatographic separationBetaine

A plurality of chromatographic separation operations, including a first simulated moving bed operation, are coupled into a process which functions, preferably through the application of continuous displacement chromatography, to recover a fraction rich in small organic molecules, notably betaine and / or invert from sucrose solutions, enabling the subsequent production of a high purity sucrose product.

Owner:AMALGAMATED RES

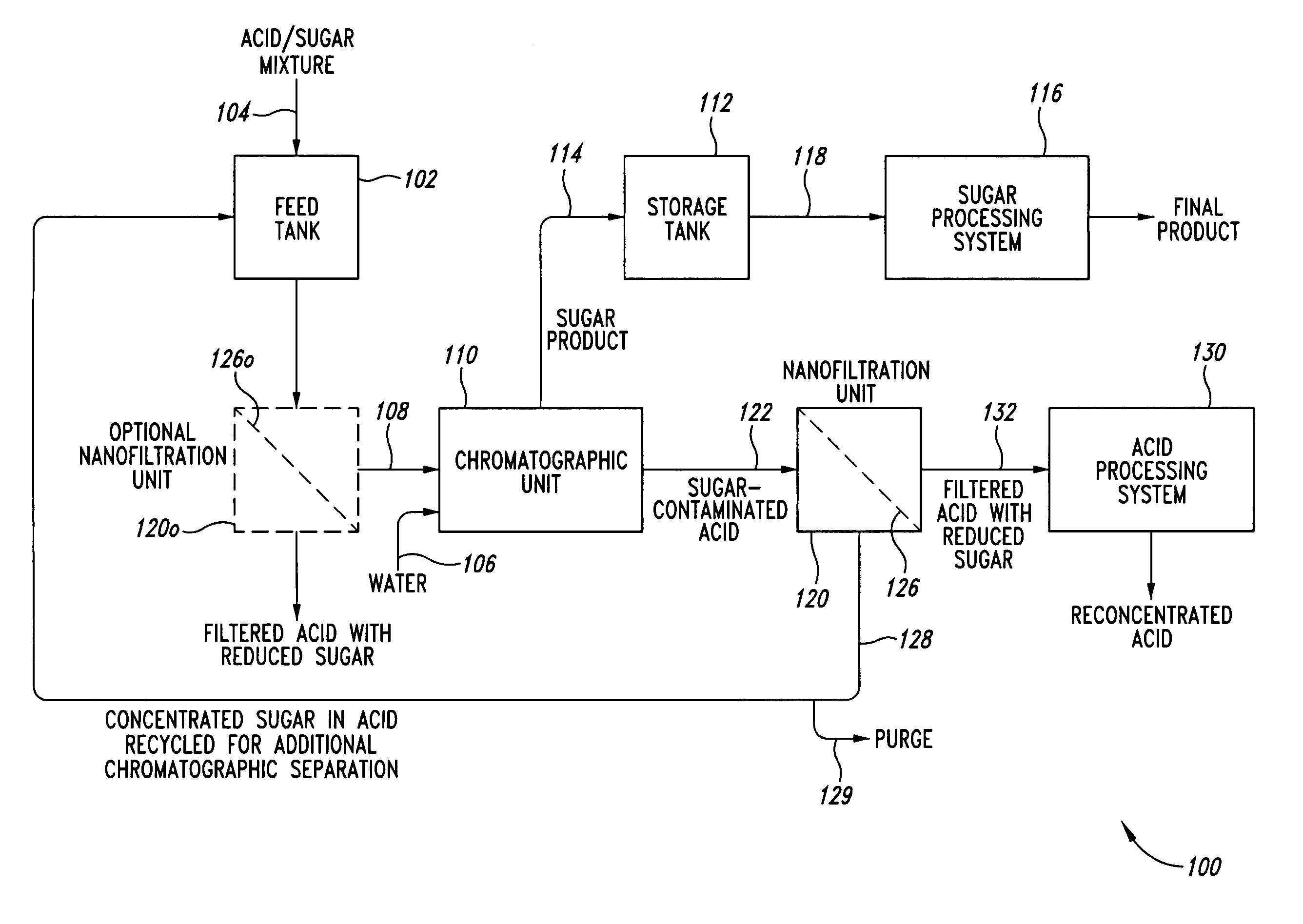

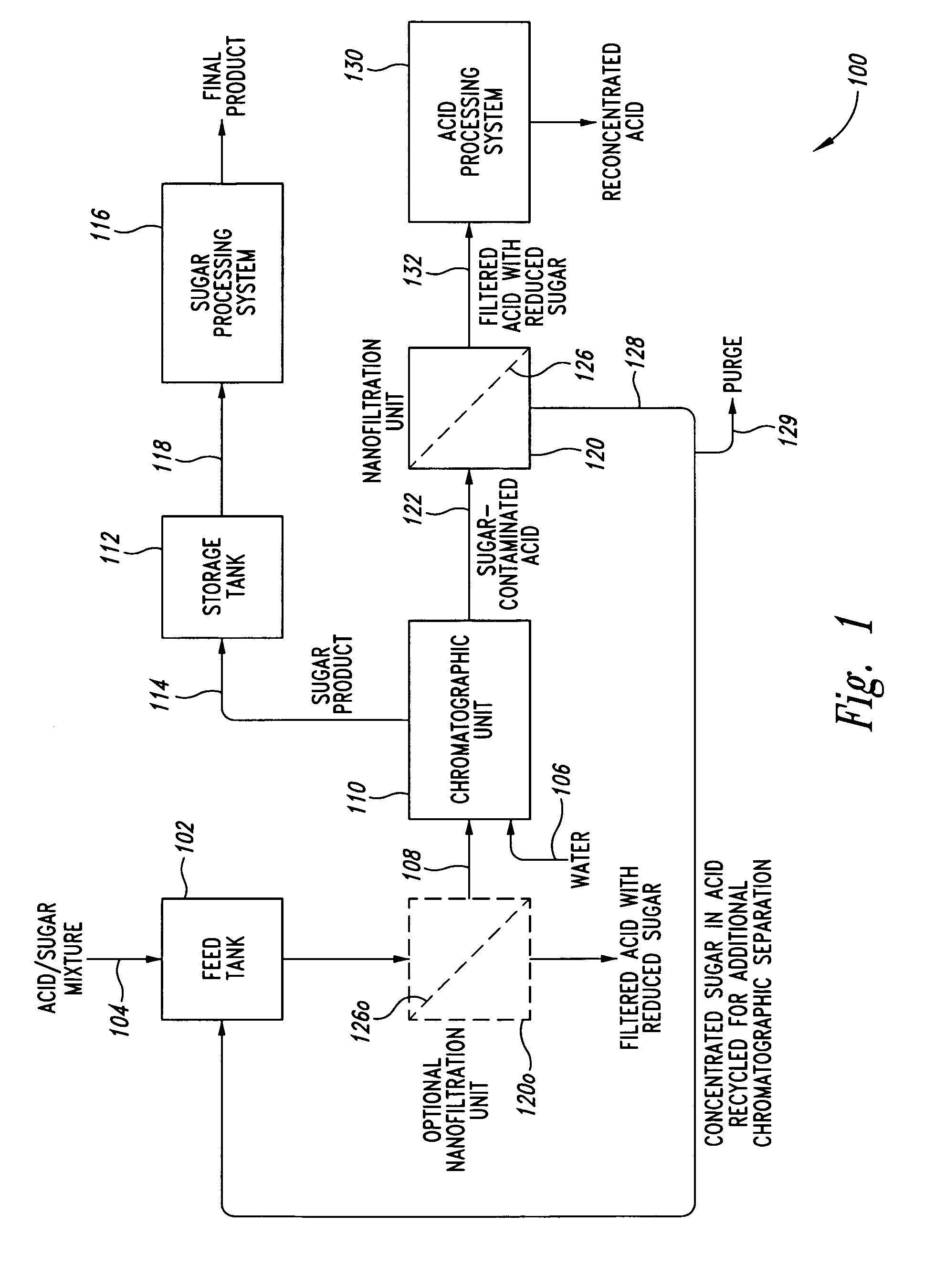

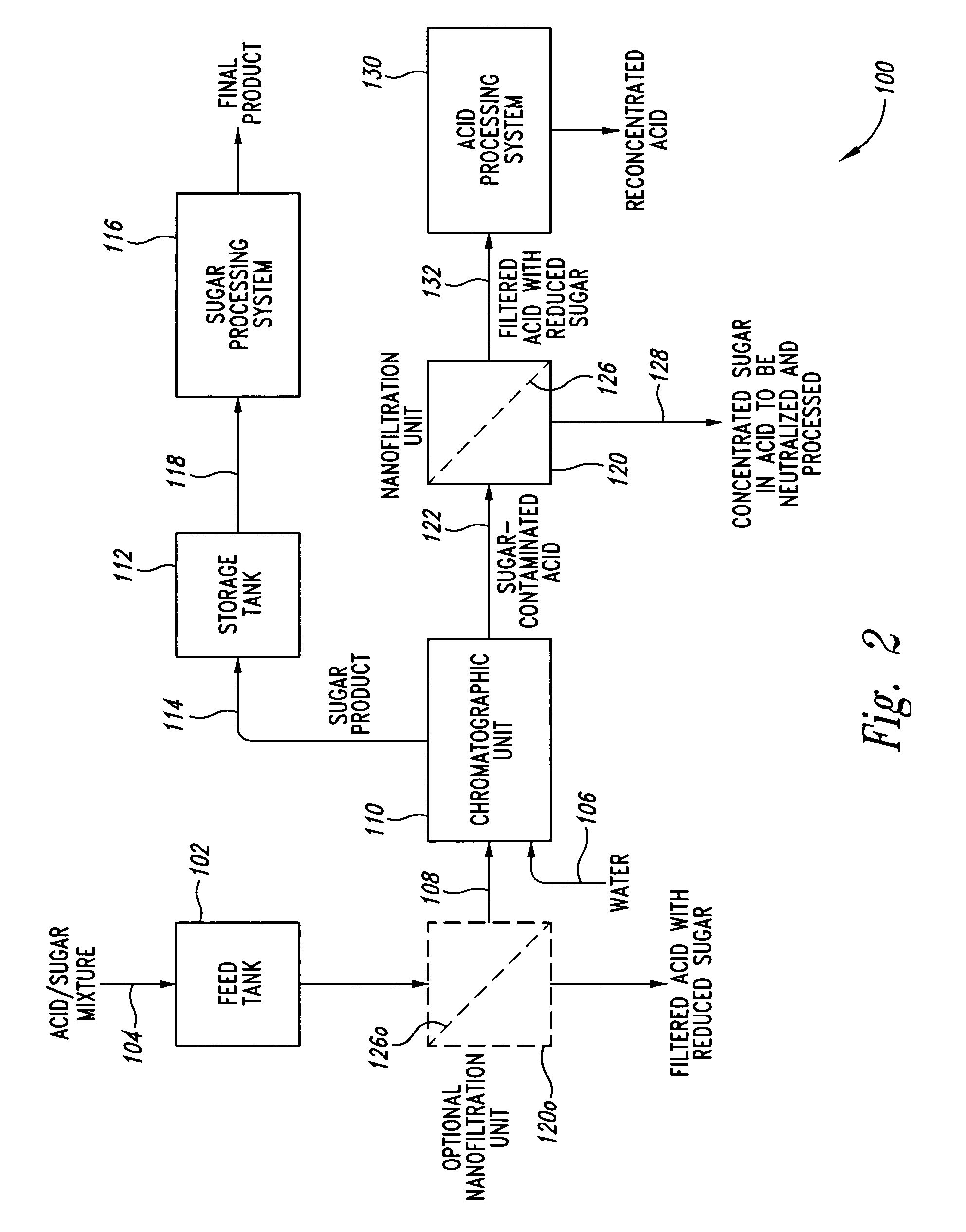

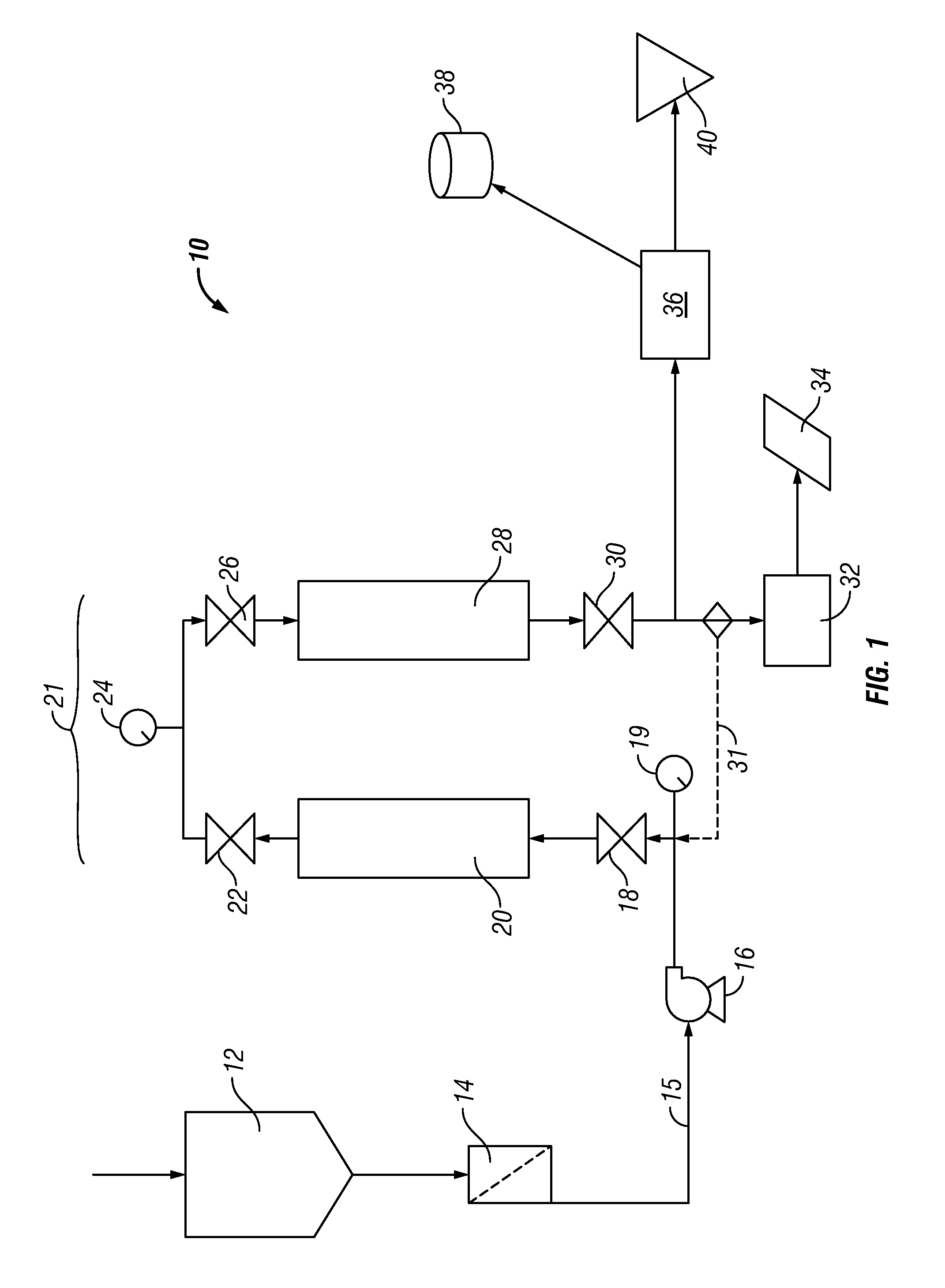

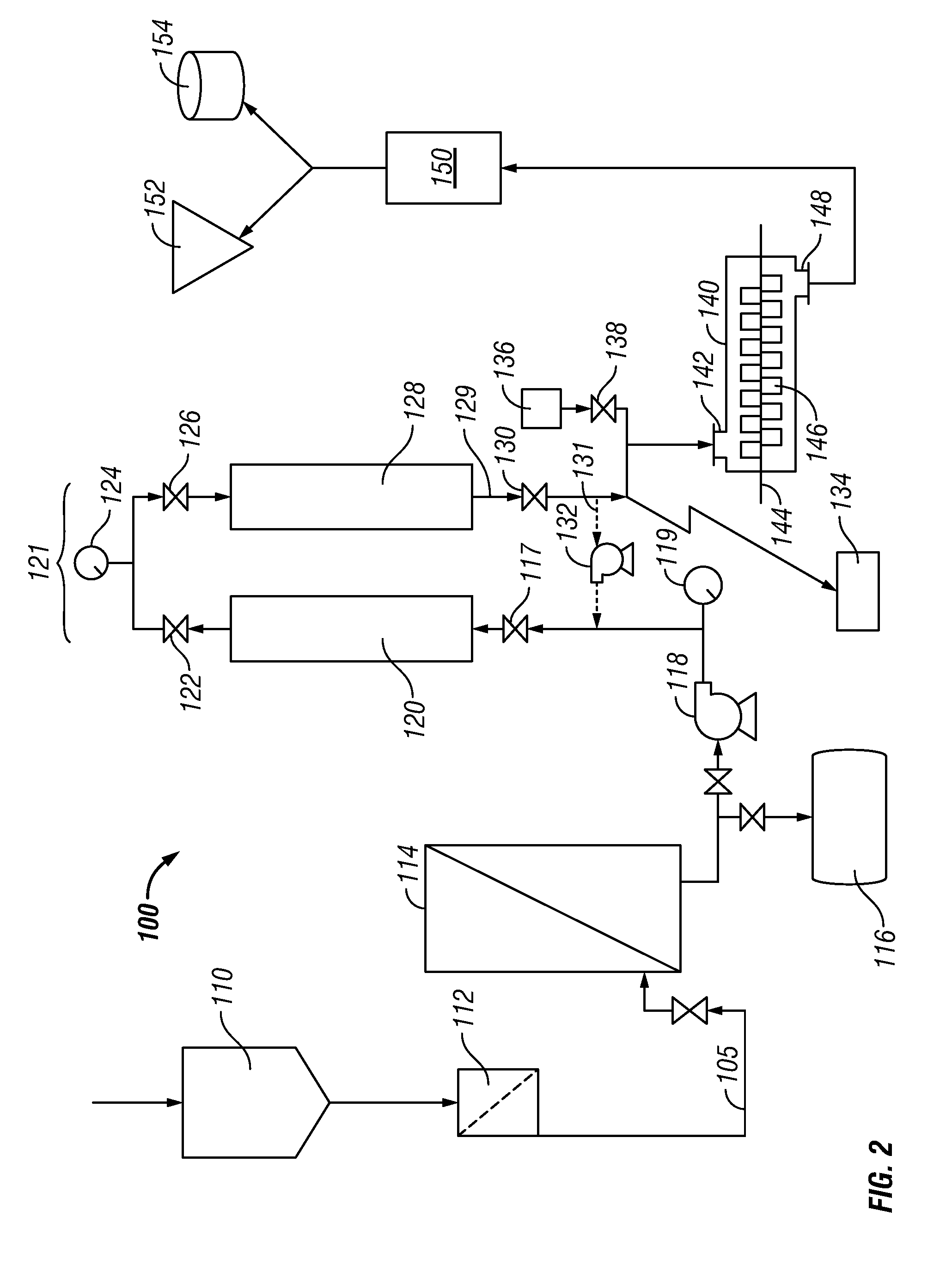

Nanofilter system and method of use

An acid recovery system used in a hydrolysis operation includes a chromatographic unit to provide initial separation of sugar and acid. The sugar product provided by the chromatographic unit is processed to produce higher value products, such as ethanol. The remaining acid is contaminated by sugar. A nanofiltration unit containing a nanofilter membrane processes the sugar contaminated acid. The acid is allowed to permeate across the nanofilter membrane while sugar is rejected. The permeate is provided to a conventional acid recovery system and recycled for use in the hydrolysis process.

Owner:HARRIS GROUP

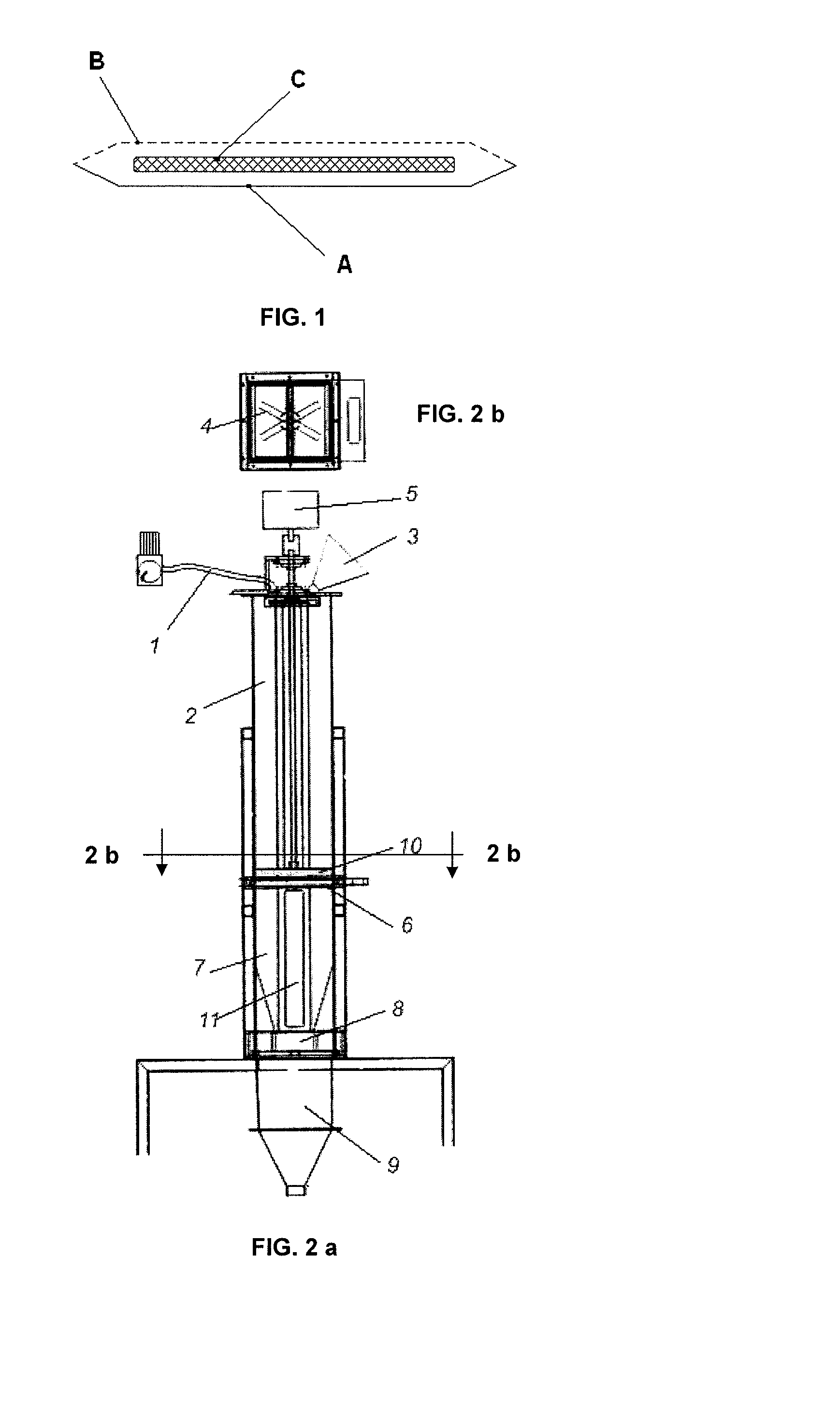

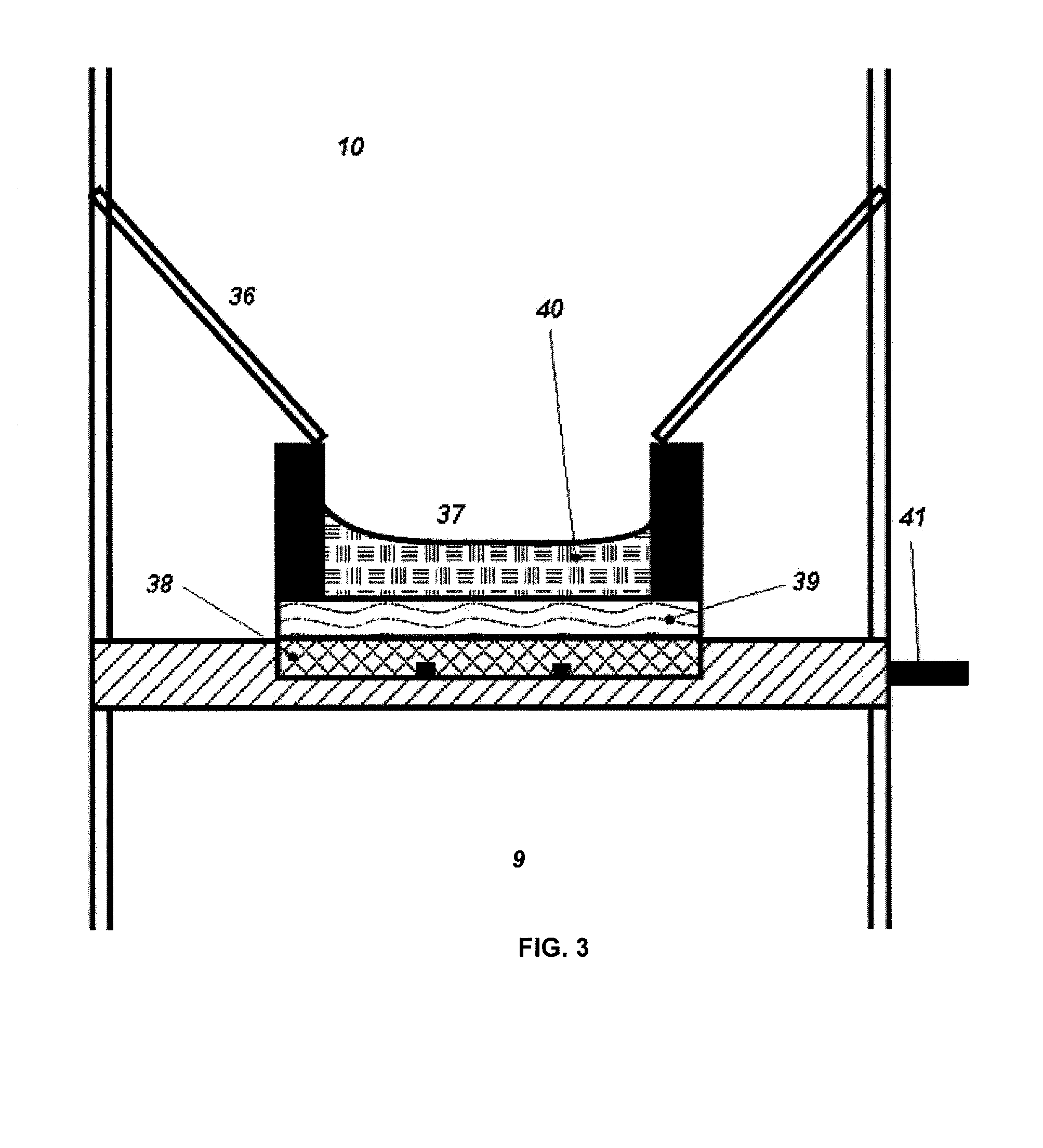

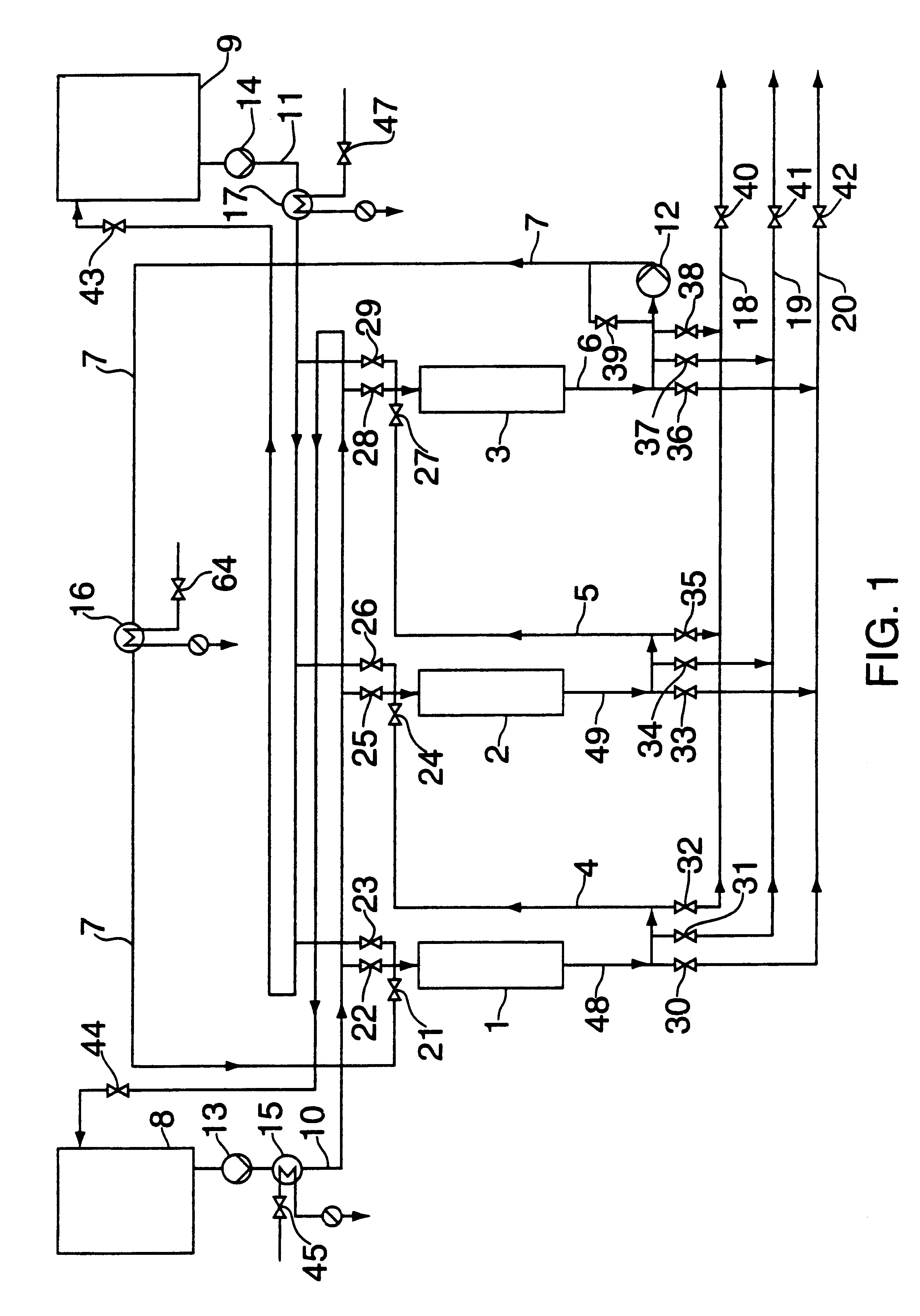

Separation system and process

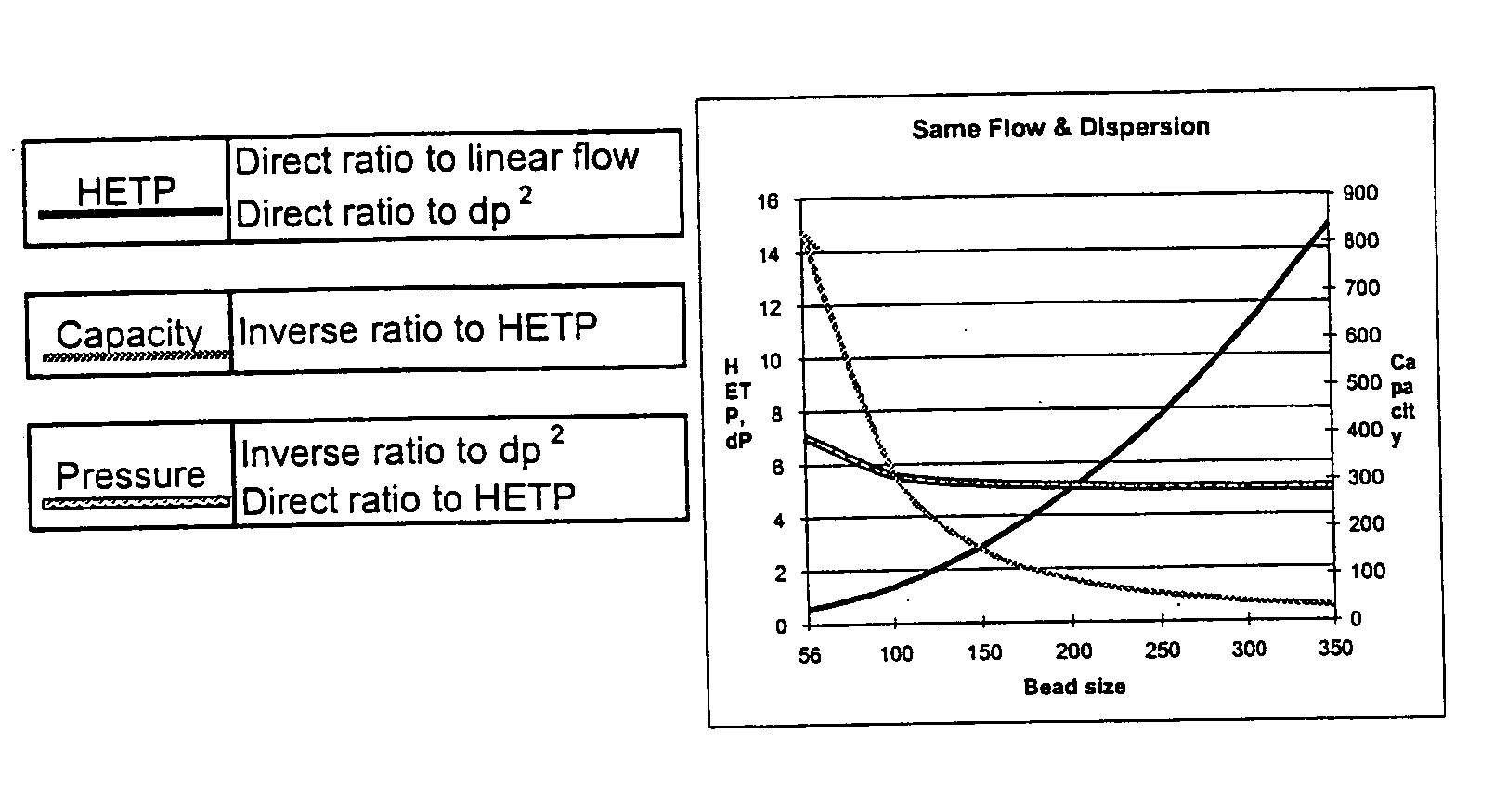

InactiveUS20040251204A1Cation exchanger materialsIon-exchanger regenerationIon-exchange resinSeparation system

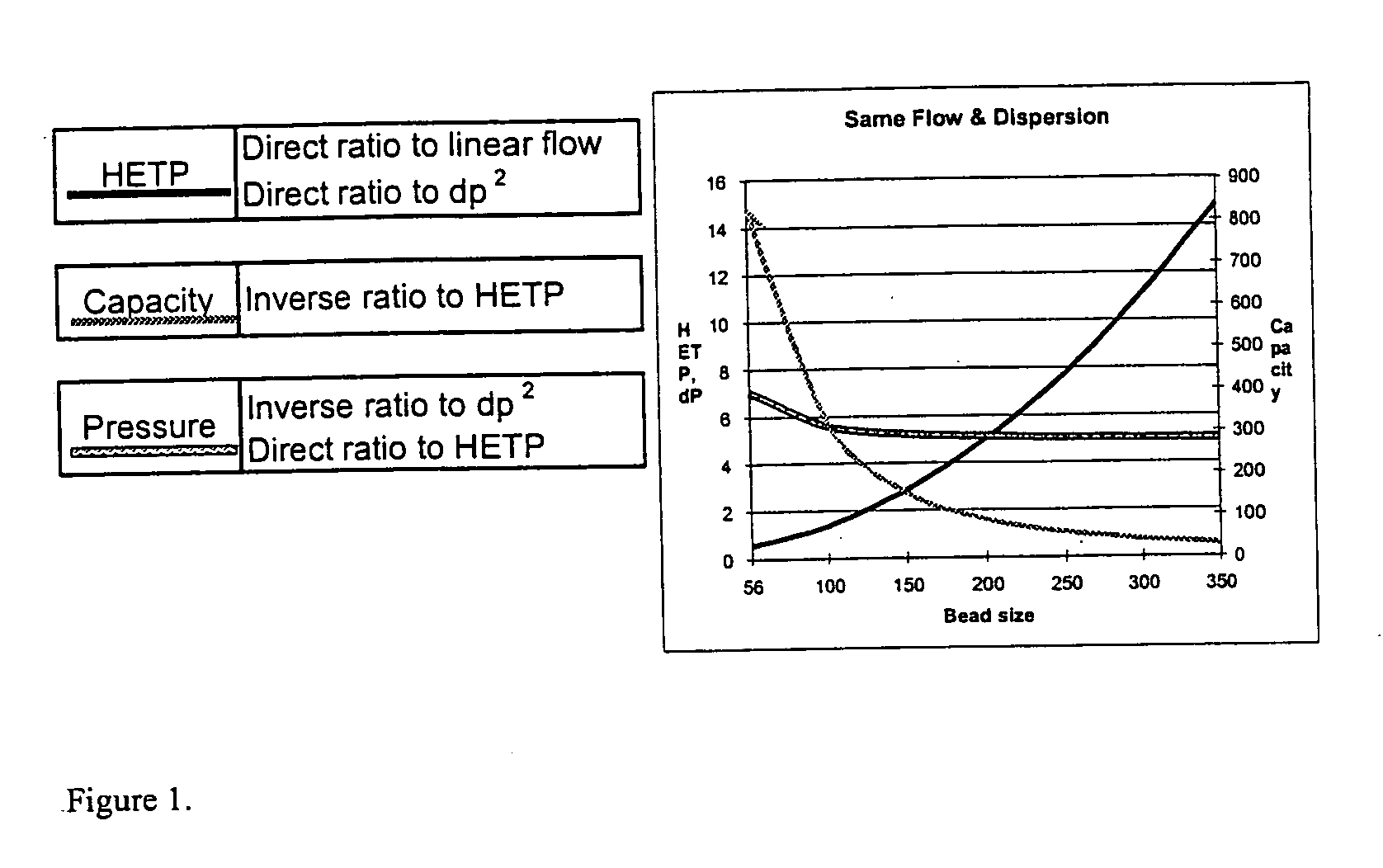

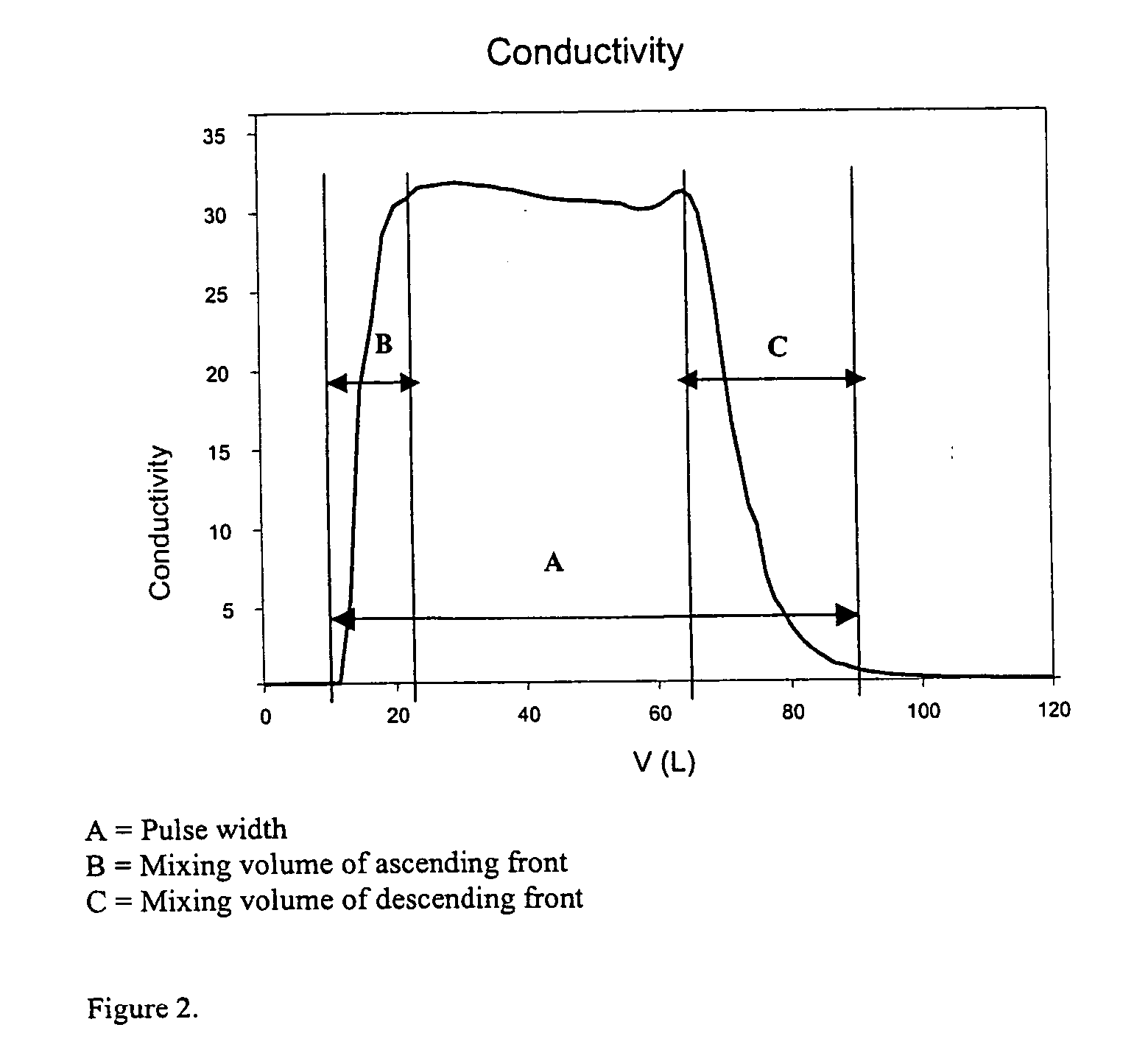

The invention relates to a system and a process for fractionating a solution into two or more fractions. The system of the invention comprises at least two compartments having a diameter of at least about one meter and including a uniform packing of a polymer-based ion exchange resin with a bead size in the range of about 50 to about 250 mum. The mixing volume of the fluid fronts in the system of the invention is not more than 5% of the volume of the compartment.

Owner:FINPHIDE

Separation of sugars, sugar alcohols, carbohydrates and mixtures thereof

InactiveUS7361273B2Efficient separationCation exchanger materialsIon-exchanger regenerationChromatographic separationAlcohol sugars

The present invention relates to a method of separating sugars and sugar alcohols from each other. More particularly the present invention relates to the use of a weakly basic anion exchange resin in a chromatographic separation process. The advantage of the present invention compared with the prior art is that it is especially suitable for separating reducing sugars in acidic conditions as well as for example in weakly acidic conditions. The method using chromatographic separation comprises at least one step where a weakly basic anion exchange resin is used in a chromatographic column or in a part of a column.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Superabsorbent surface-treated carboxyalkylated polysaccharides and process for producing same

Owner:ARCHER DANIELS MIDLAND CO

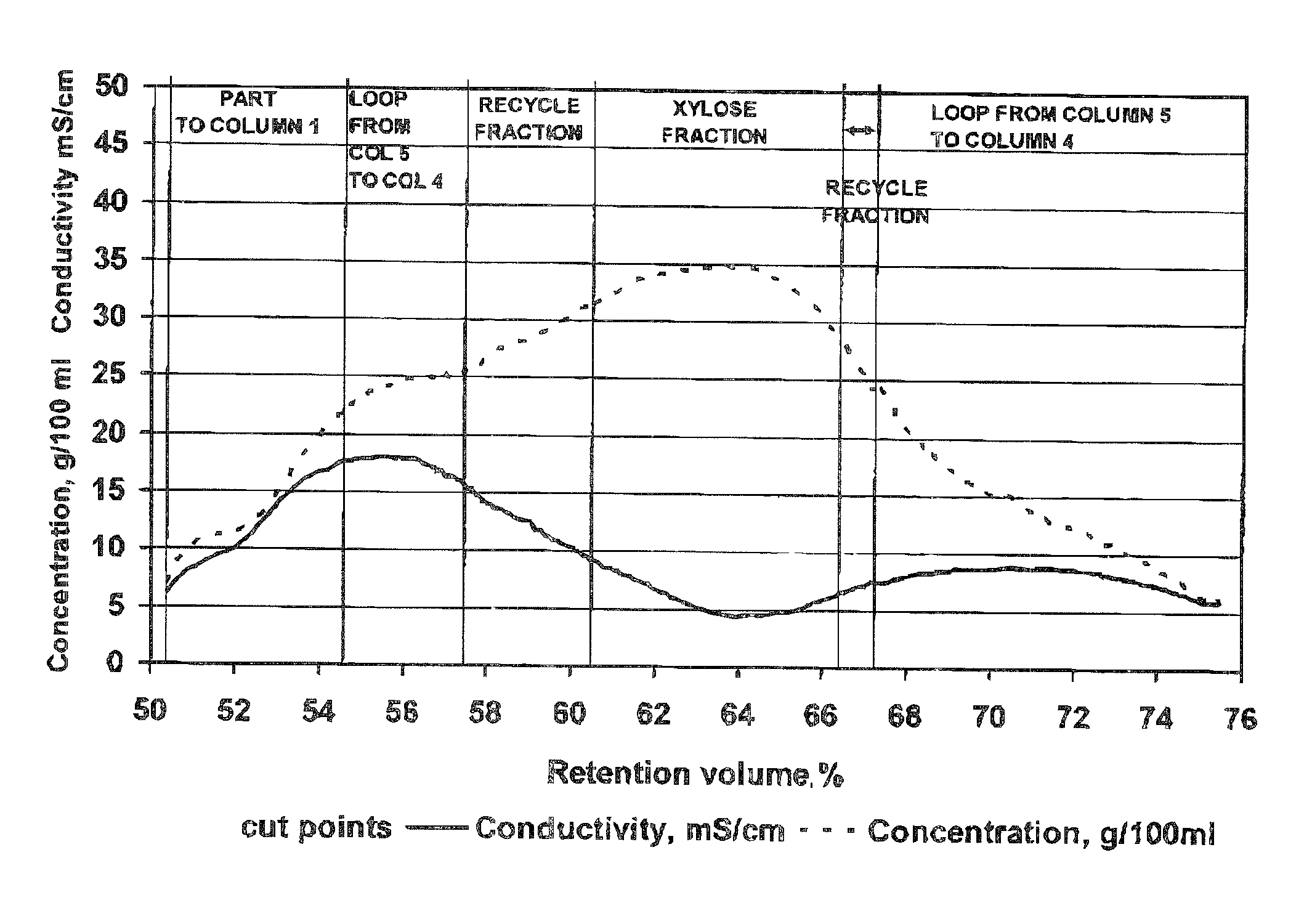

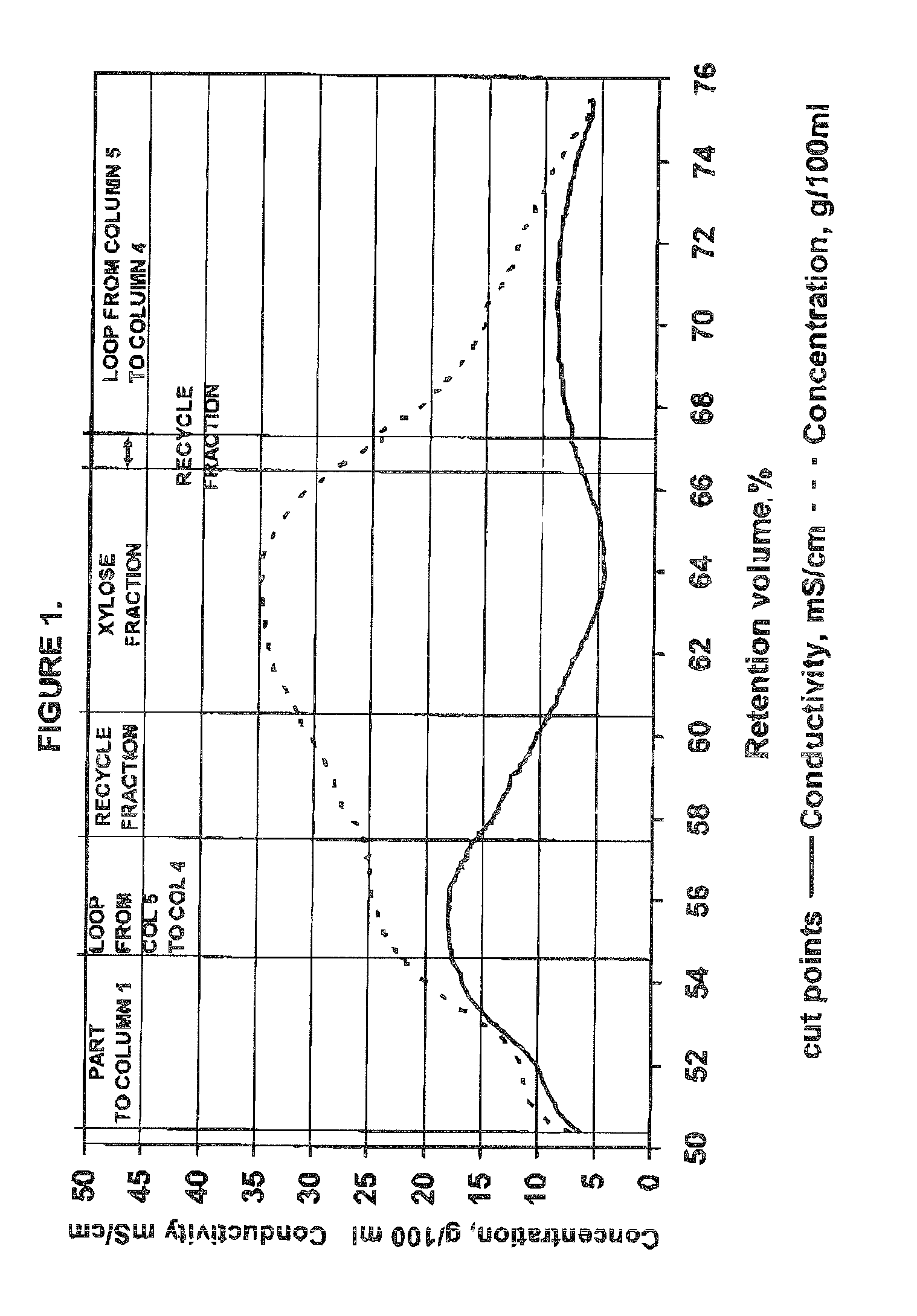

Separation process

ActiveUS7959811B2Disturb separation efficiency of separationLower the volumeIon-exchange process apparatusSugar derivativesChromatographic separationBetaine

The present invention relates to a chromatographic separation process for fractionating solutions containing sugars, sugar alcohols, sugar acids and / or betaine by utilizing fractions comprising parts of the separation profile as a substituent of the eluent in a novel and inventive manner. The starting solutions are typically multicomponent plant-based extracts and hydrolysates, stillages, and fermentation products and derivatives thereof. The process prow vides improved separation capacity and separation efficiency without affecting the yield or purity of product components, such as sugars, sugar alcohols, sugar acids, and betaine. The process can especially be applied to sequential SMB separation systems.

Owner:DUPONT NUTRITION BIOSCIENCES APS

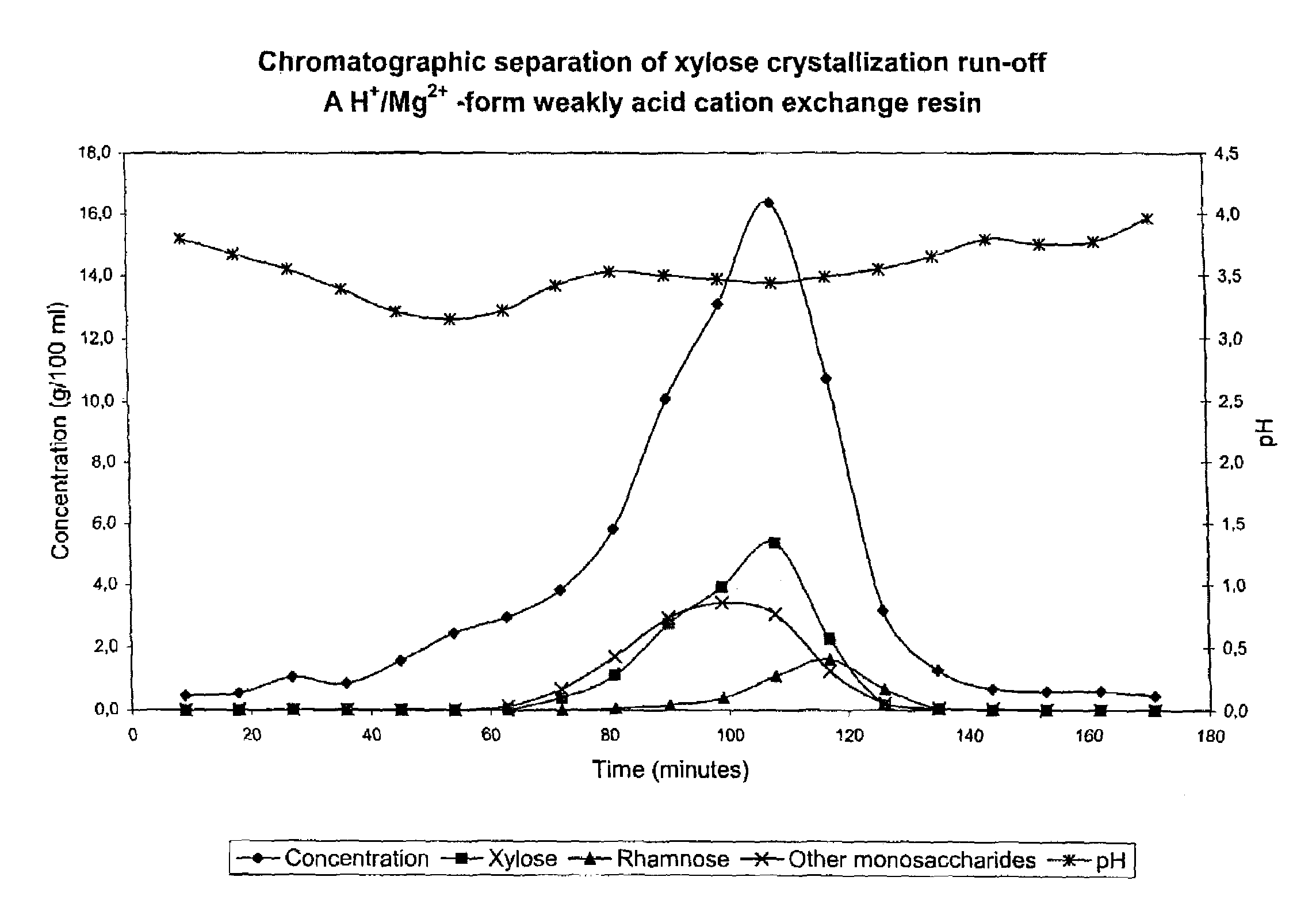

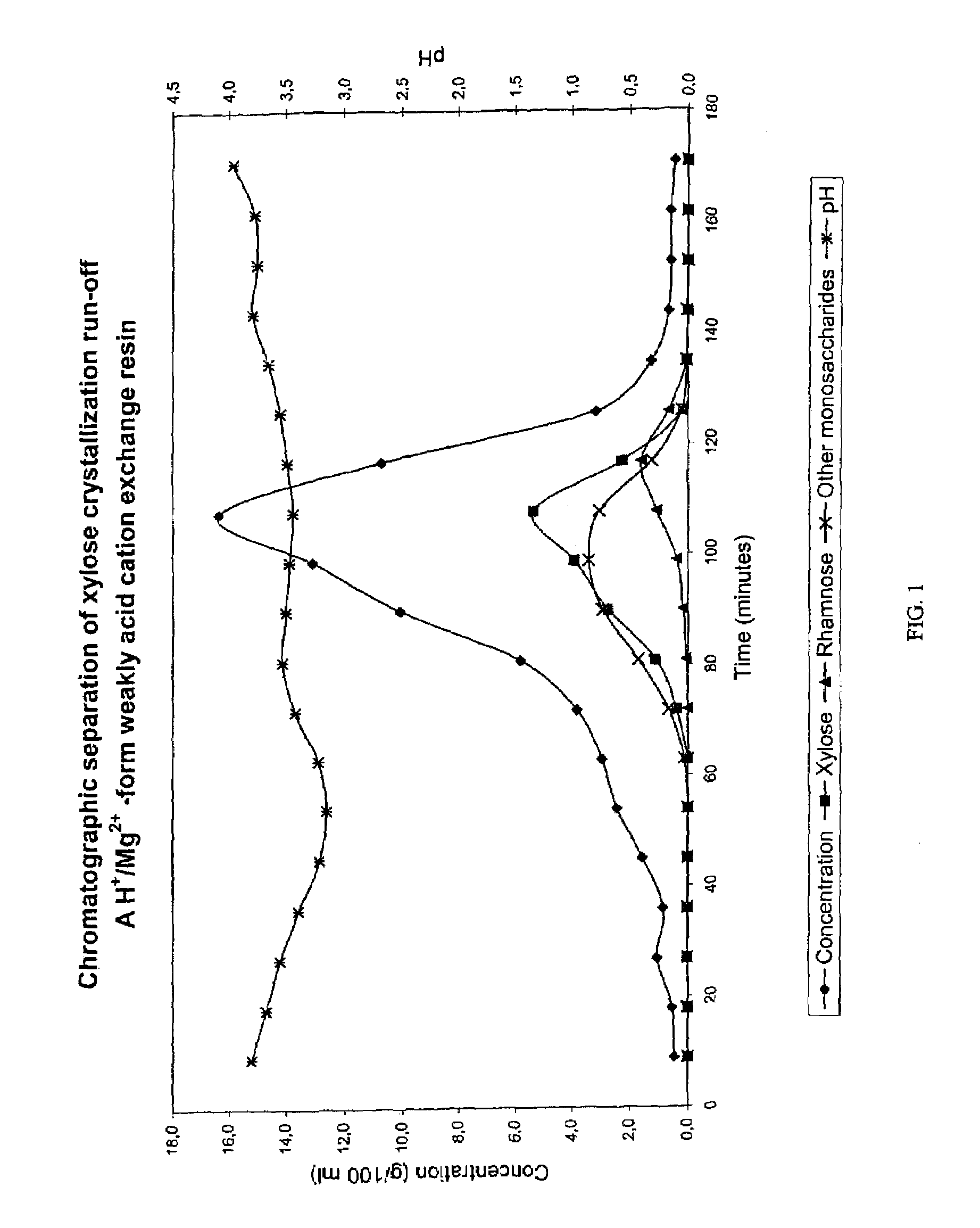

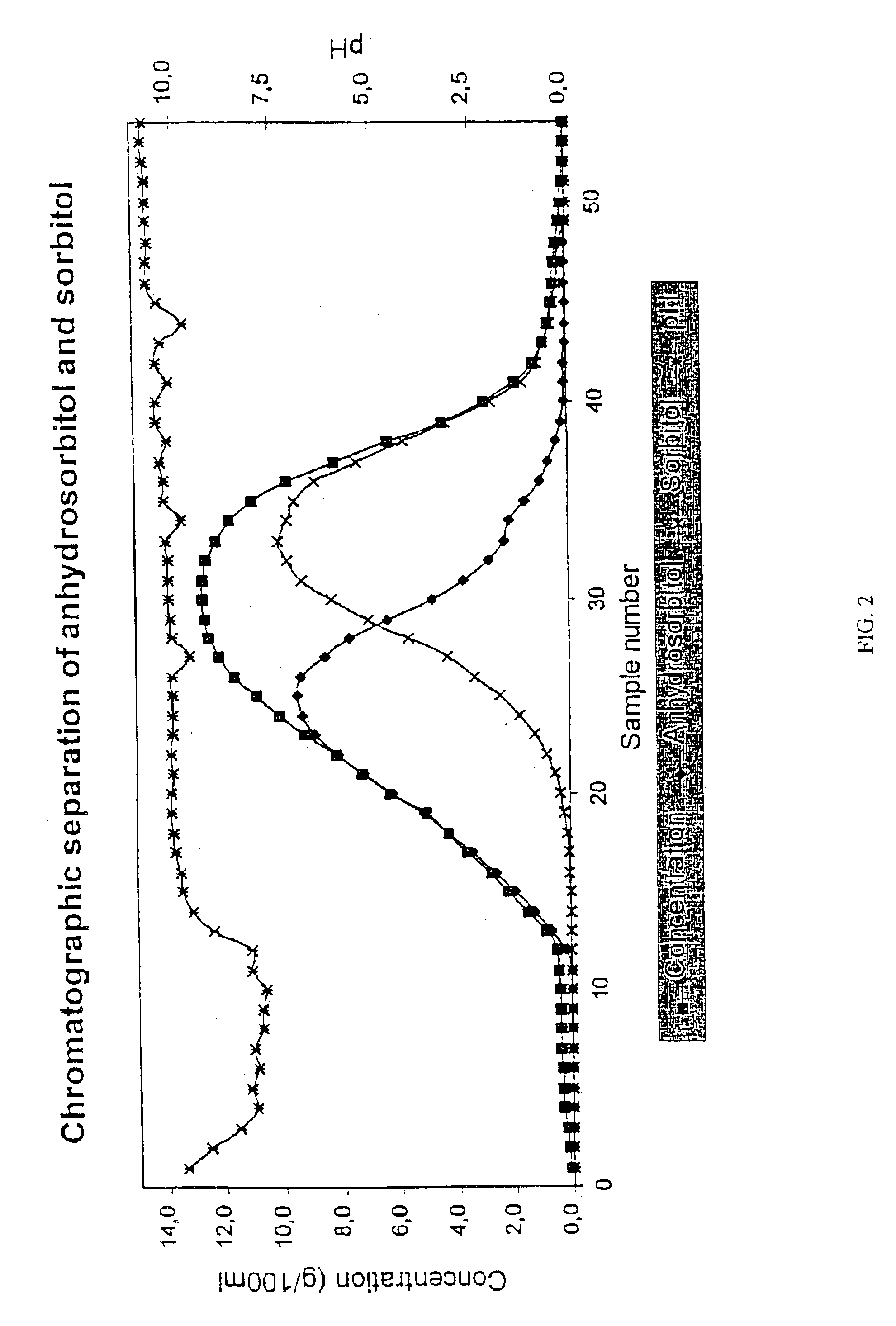

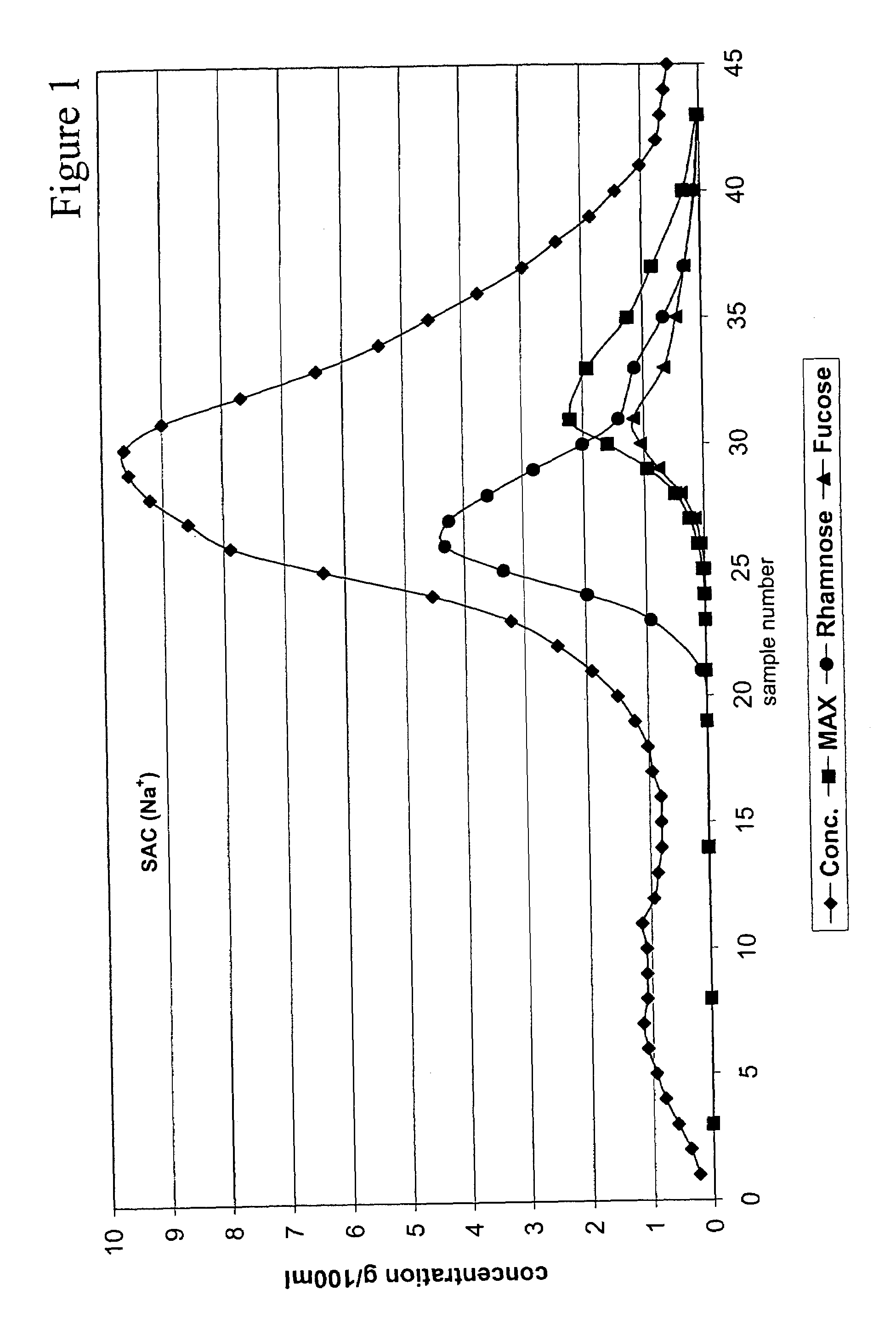

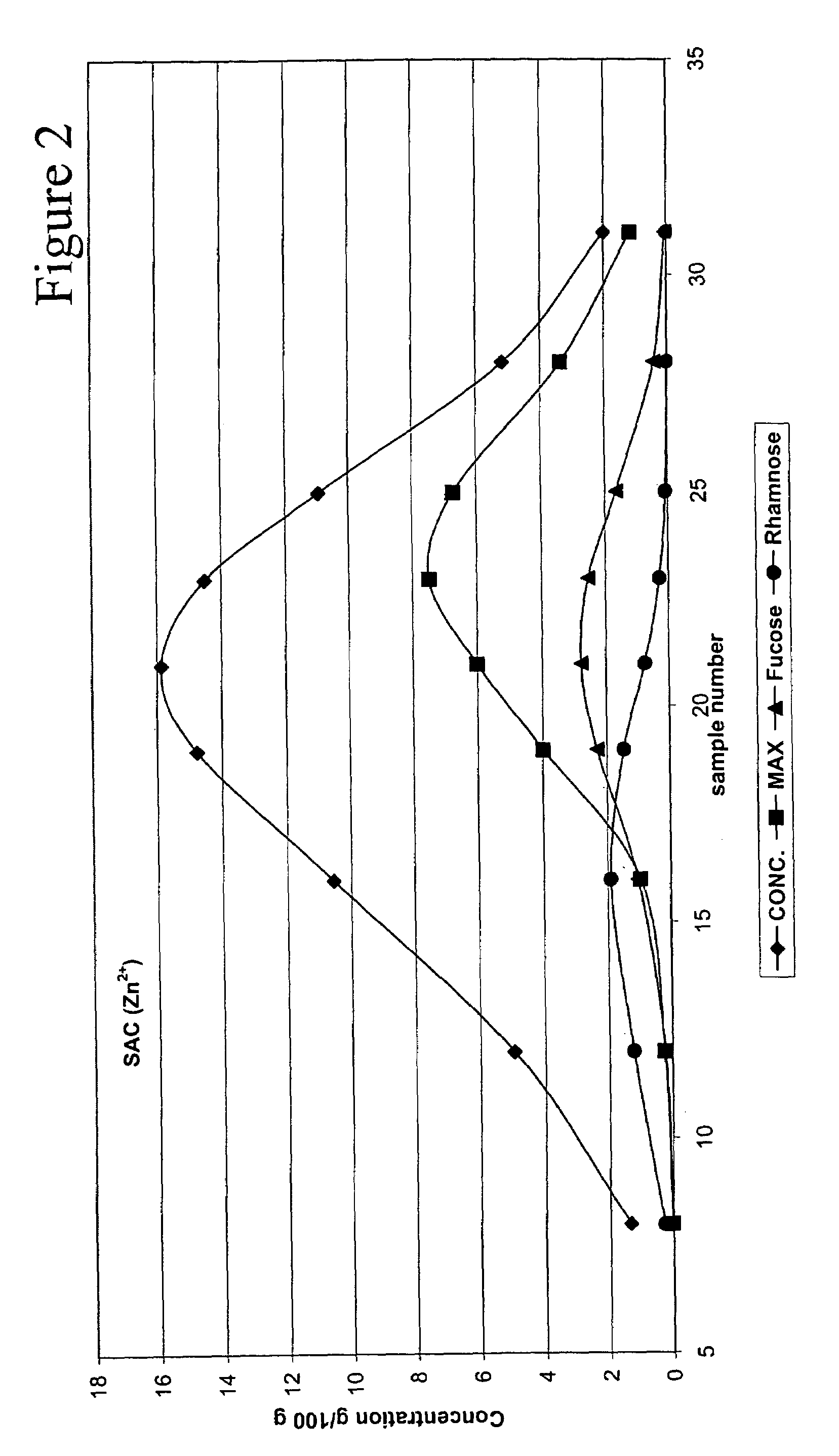

Use of a weakly acid cation exchange resin for chromatographic separation of carbohydrates

InactiveUS6924371B2High yieldEasy to separateChromatographic cation exchangersCation exchanger materialsChromatographic separationAlcohol sugars

The invention relates to the use of a weakly acid cation exchange resin for chromatographic separation of carbohydrates. In the invention the hydrophilic / hydrophobic interaction of carbohydrates, sugars and sugar alcohols with the weakly acid cation exchange resin is utilized. The weakly acid cation exchange resin is used for separation of hydrophobic saccharides, such as deoxy, methyl and anhydrosugars and anhydrosugaralcohols from more hydrophilic saccharides.

Owner:DANISCO SWEETENERS

Method of processing whey for demineralization purposes

InactiveUS6383540B1Reduce maintenanceLess upkeepIon-exchanger regenerationSolid sorbent liquid separationProtonChloride

A method of treating whey for demineralization purposes, the method comprising a stage of separating out salts by transfer through electrodialysis or nanofiltration membranes, wherein, upstream from this separation stage, the method comprises in succession at least one step of exchanging divalent cations for protons and at least one step of exchanging divalent anions for chloride ions.

Owner:EURODIA IND SA

Method of obtaining an organic salt or acid from an aqueous sugar stream

InactiveUS7718070B2Facilitates recovery and further processingLow costSugar derivativesComponent separationOrganic acidSugar

A process for obtaining one or more than one salt of an organic acid(s), or organic acid(s), from an aqueous sugar stream comprising one or more than one mineral acid and the organic acid(s) is provided. The process comprises introducing the aqueous sugar stream to a separation system comprising one or more beds of anion exchange resin and obtaining a stream therefrom comprising the sugar. The one or more beds of anion exchange resin are then regenerated in one or more stages to produce at least one product stream comprising the organic acid, a salt of the organic acid, or a combination thereof, and a separate outlet stream comprising the mineral acid, a salt of the mineral acid, or a combination thereof. The product stream is then recovered. The separation may be conducted with two separation units, or using a single anion exchange unit.

Owner:IOGEN ENERGY CORP

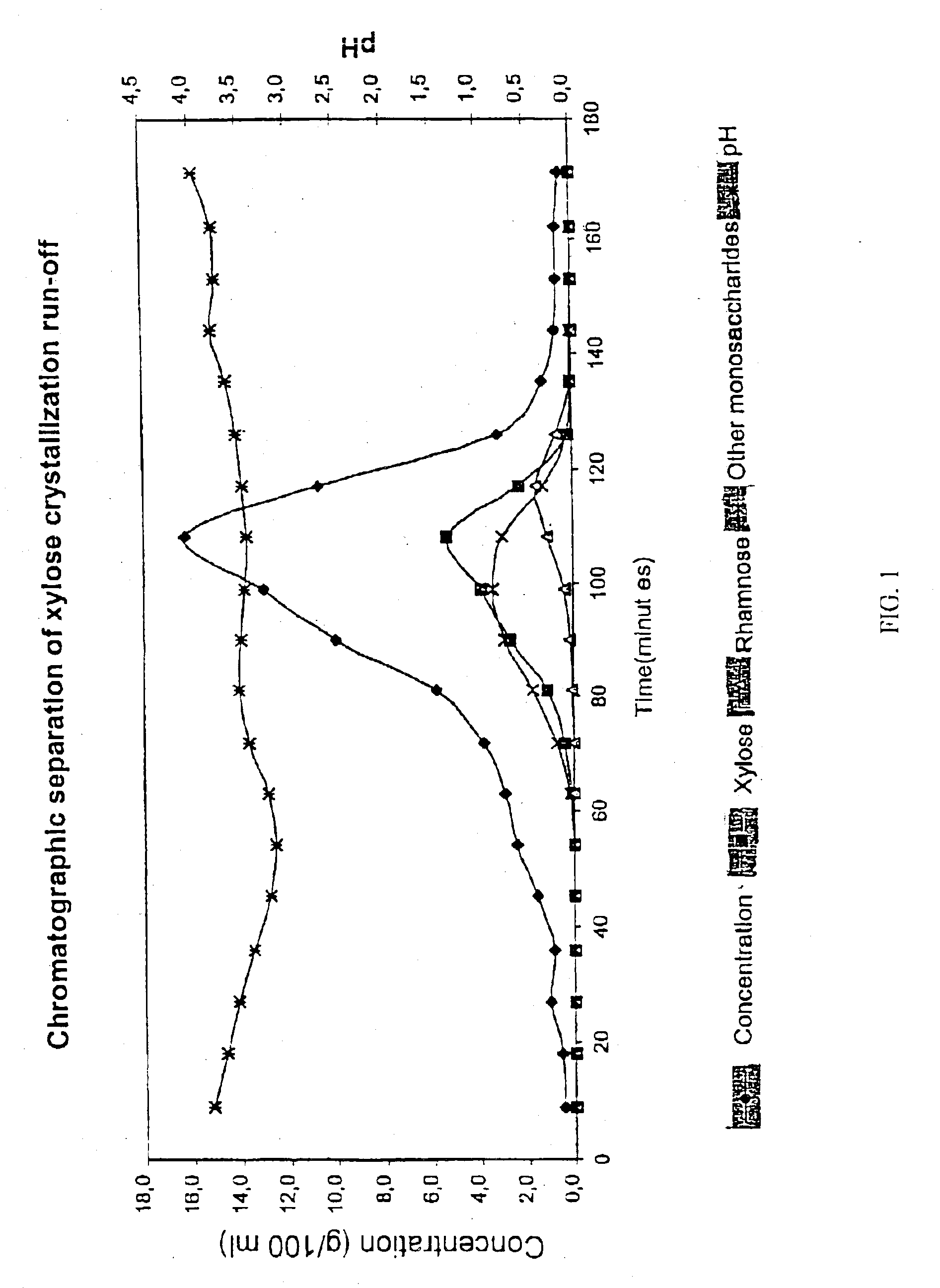

Separation of sugars

InactiveUS7037378B2Avoid insufficient puritySugar derivativesSugar productsChromatographic separationDeoxy sugar

Owner:DANISCO SWEETENERS

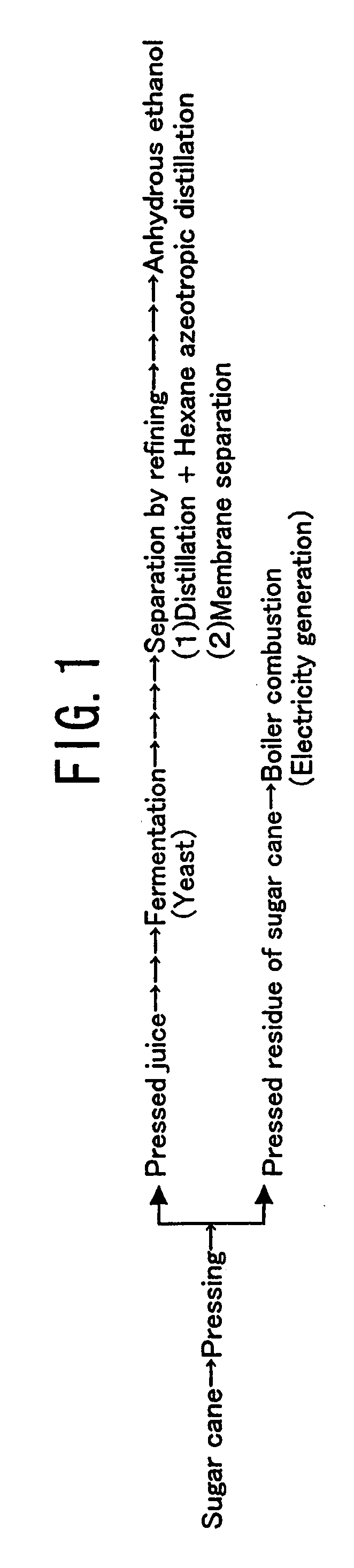

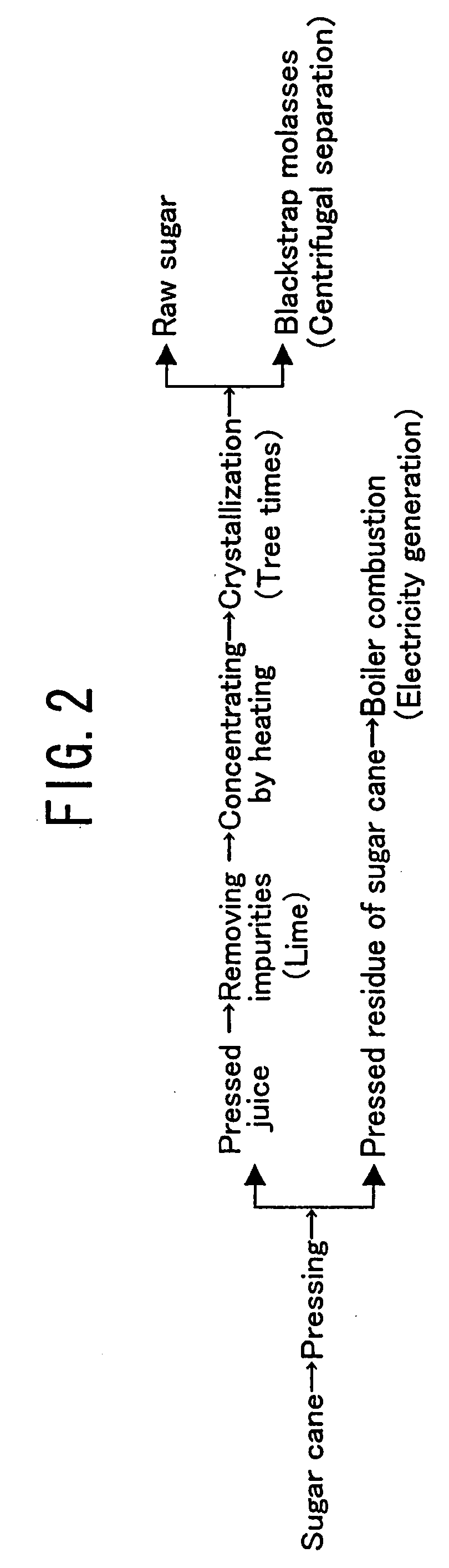

Method for producing sugar and a useful material

InactiveUS20060035355A1Increase volumeReduce productionBiofuelsSugar crystallisationBiotechnologyEngineering

An object of the present invention is to provide a method for producing sugar and ethanol from sugar cane, in which almost all of energy to be consumed in the production processes of the sugar, the ethanol and the like can be supplied by the energy obtained by burning a pressed residue of sugar cane, yet without decreasing the sugar amount to be produced. The present invention provides a method for producing sugar and a useful material from sugar cane, comprising the steps of: (a) producing from sugar cane a pressed juice and pressed residue of sugar cane; (b) producing sugar and blackstrap molasses from said pressed juice; and (c) generating an energy and a useful material by using said pressed juice, said blackstrap molasses and said pressed residue of sugar cane as source materials that have been obtained from said steps (a) and (b), wherein said sugar cane contains an amount of 15% or greater by mass of fiber component in its cane stem region and provides a dry matter yield amount per unit area of 40 t / ha / year or higher; and 90% or more of energy required for all of the steps of said production method is obtained from energy generated by burning said pressed residue of sugar cane.

Owner:ASAHI BREWERIES LTD

Method for recovering sulfuric acid from concentrated acid hydrolysate of plant cellulose material

ActiveUS8052953B2Reduce solubilityEasier the sugars precipitateSugar derivativesSugar crystallisationCelluloseOrganic solvent

Owner:CHEN PEIHAO

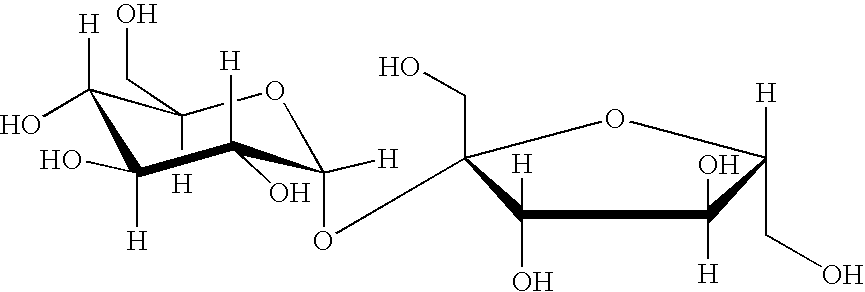

Saccharification of lignocellulosic biomass

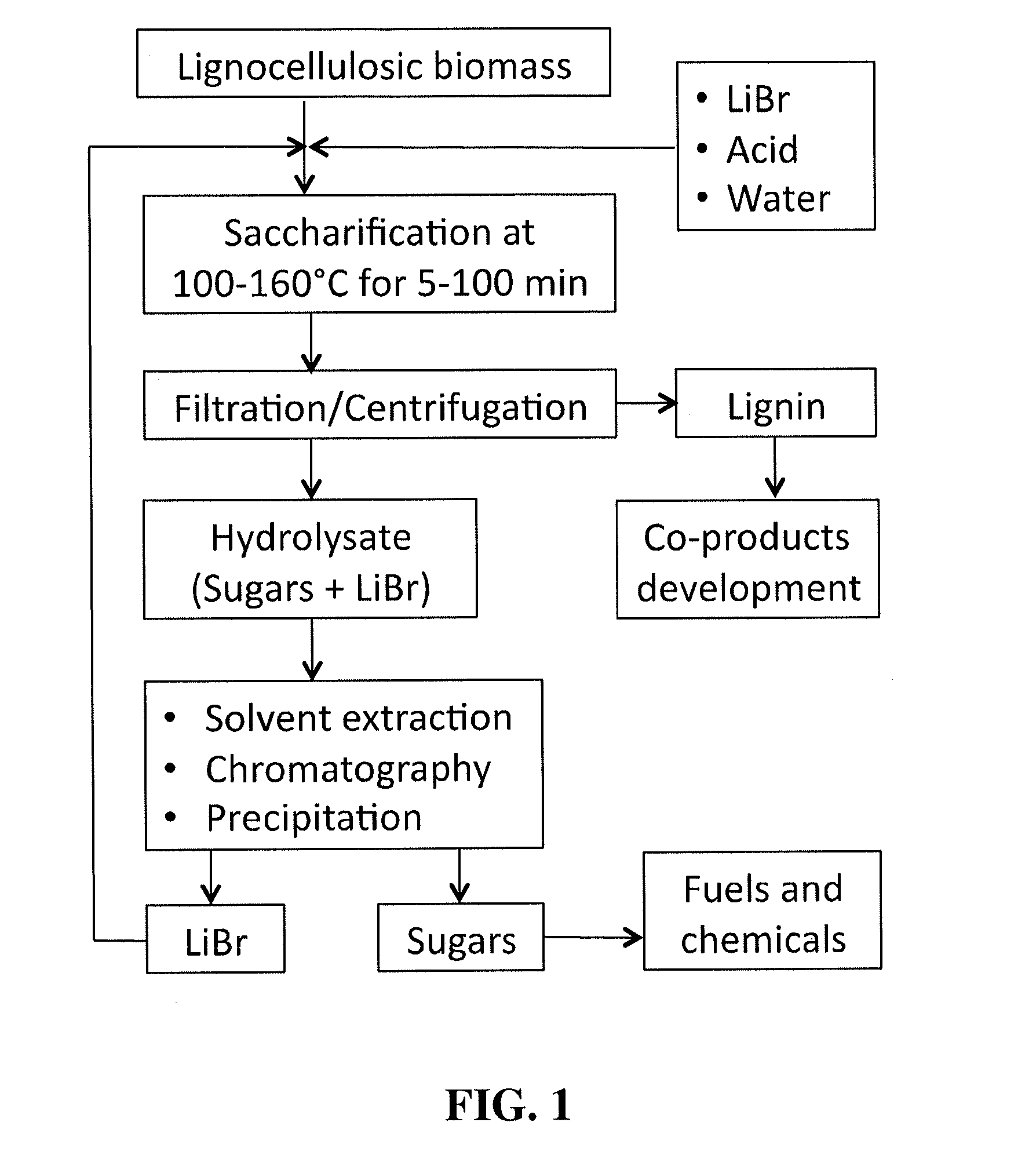

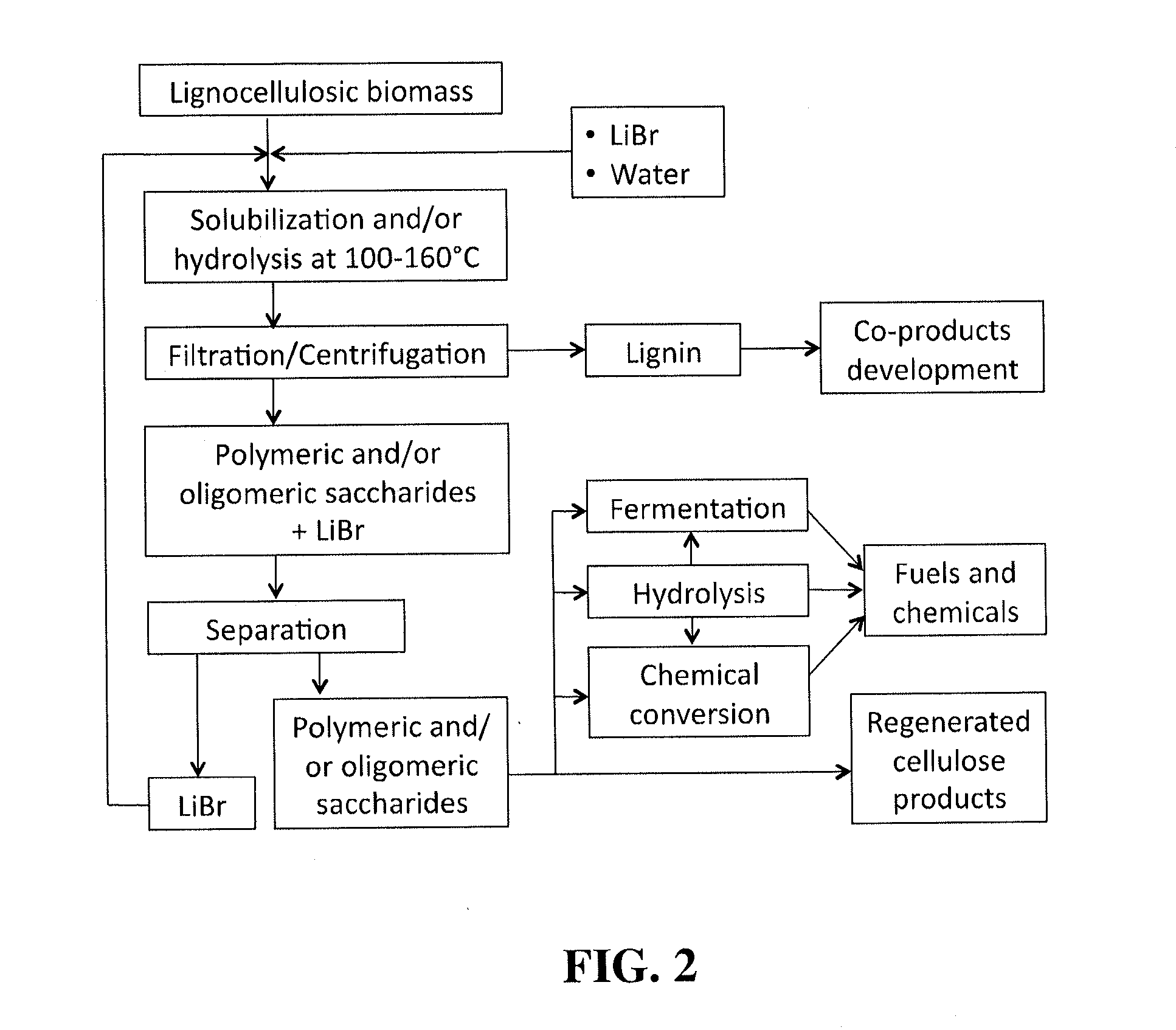

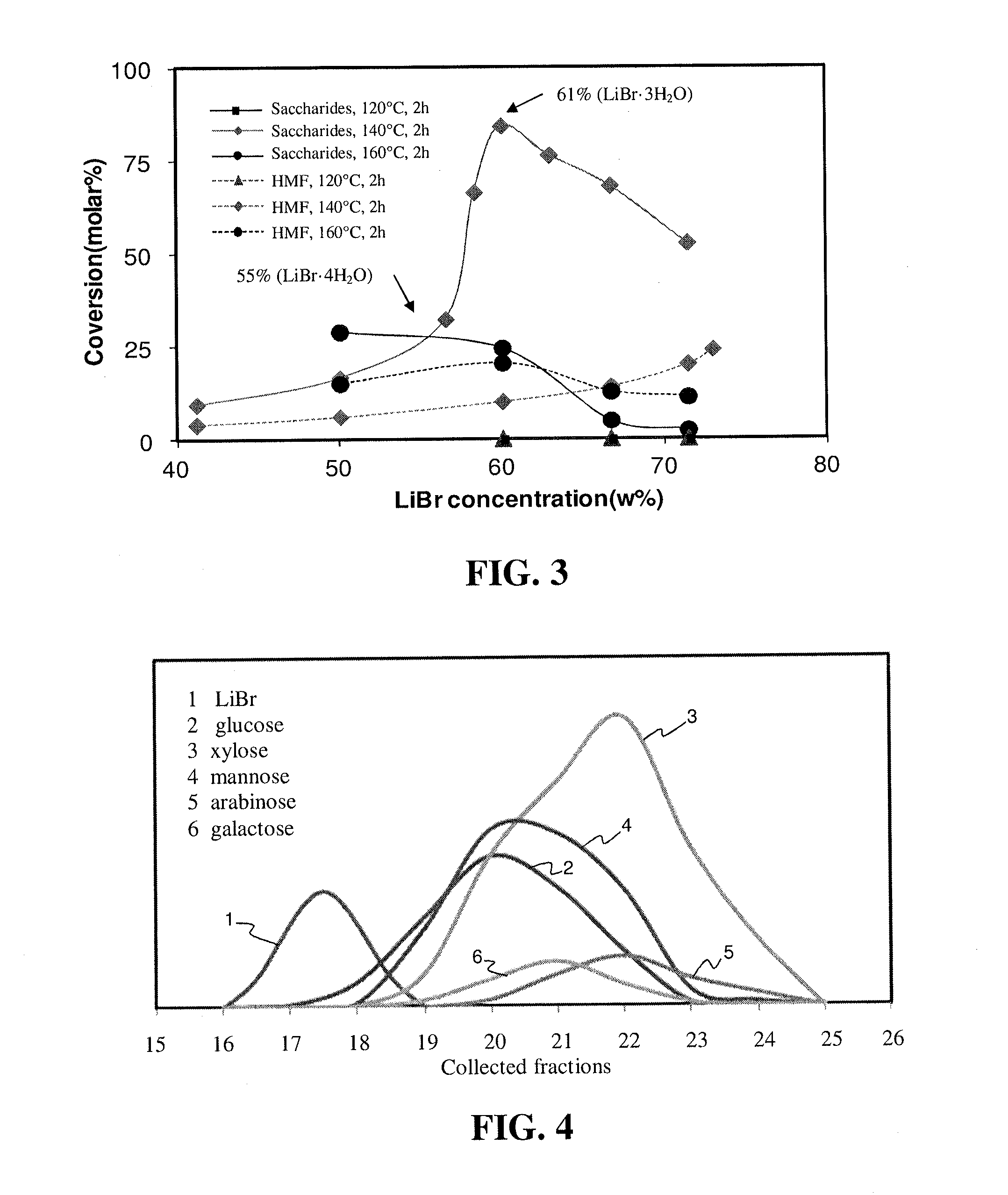

ActiveUS20130252302A1Efficient and low-cost processingPrevent degradationBiofuelsSucrose extraction by chemical meansFiltrationIon exchange

An efficient process for saccharifying lignocellulosic biomass in concentrated aqueous solutions of certain bromine salts, particularly LiBr and CaBr2. Real lignocellulose biomass, such as corn stover, switchgrass, waste paper, hardwood, and softwood, can be hydrolyzed without the need for any prior pretreatment. Complete saccharification of both cellulose and hemicellulose is achieved within 5-200 min at temperatures ranging from about 100 to about 160° C. Residual lignin is readily separated from product sugars by filtration or centrifugation and can be used to prepare beneficial coproducts. The bromine salt can be recovered and separated from product sugars (predominantly monosaccharides) by any art-known method and in particular solvent extraction, anti-solvent precipitation, ion-exclusion chromatography and / or ion-exchange chromatography can be employed. Hydrolysis product containing sugars can be employed for in fermentation for the production of value added products or useful fuels.

Owner:WISCONSIN ALUMNI RES FOUND

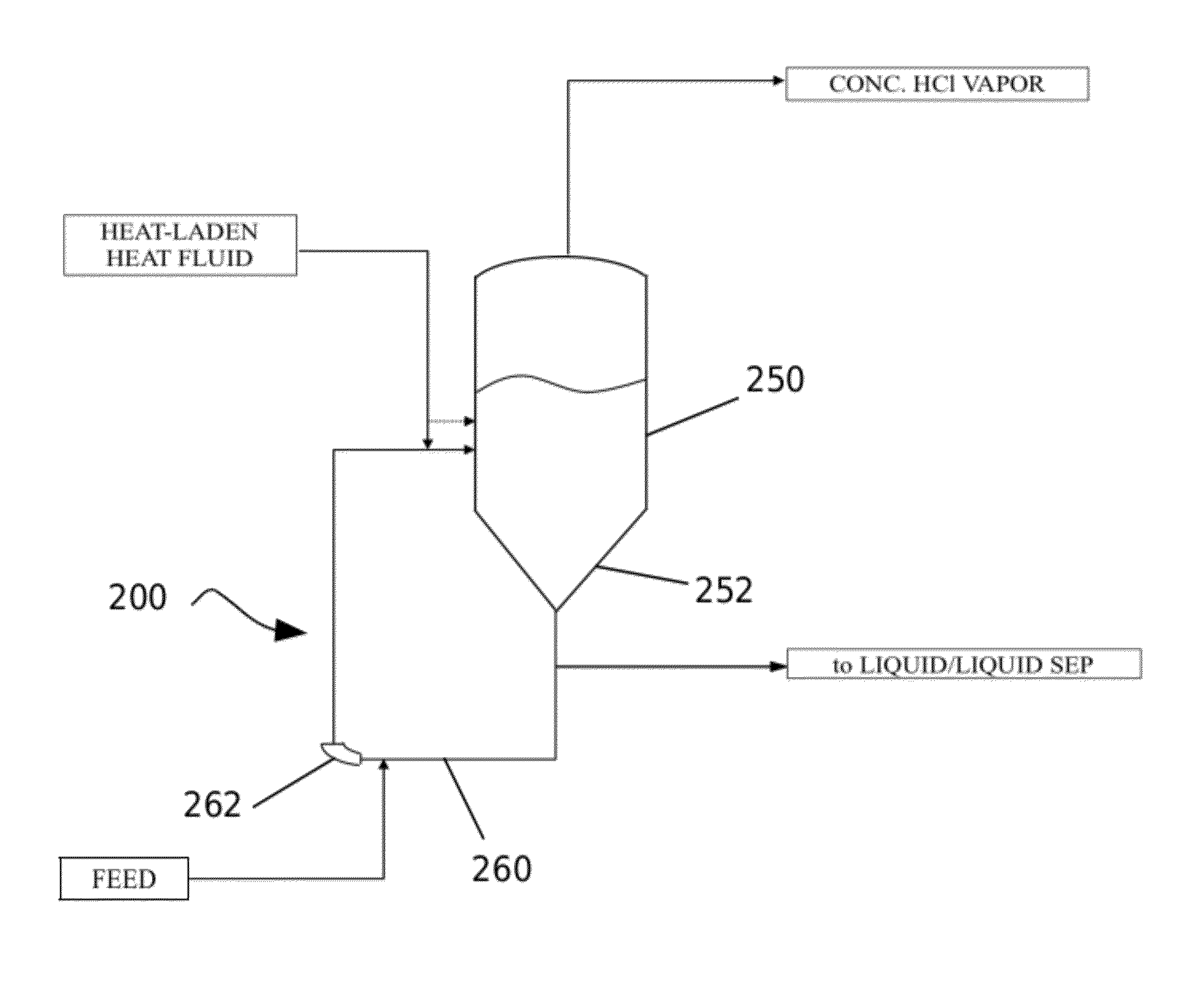

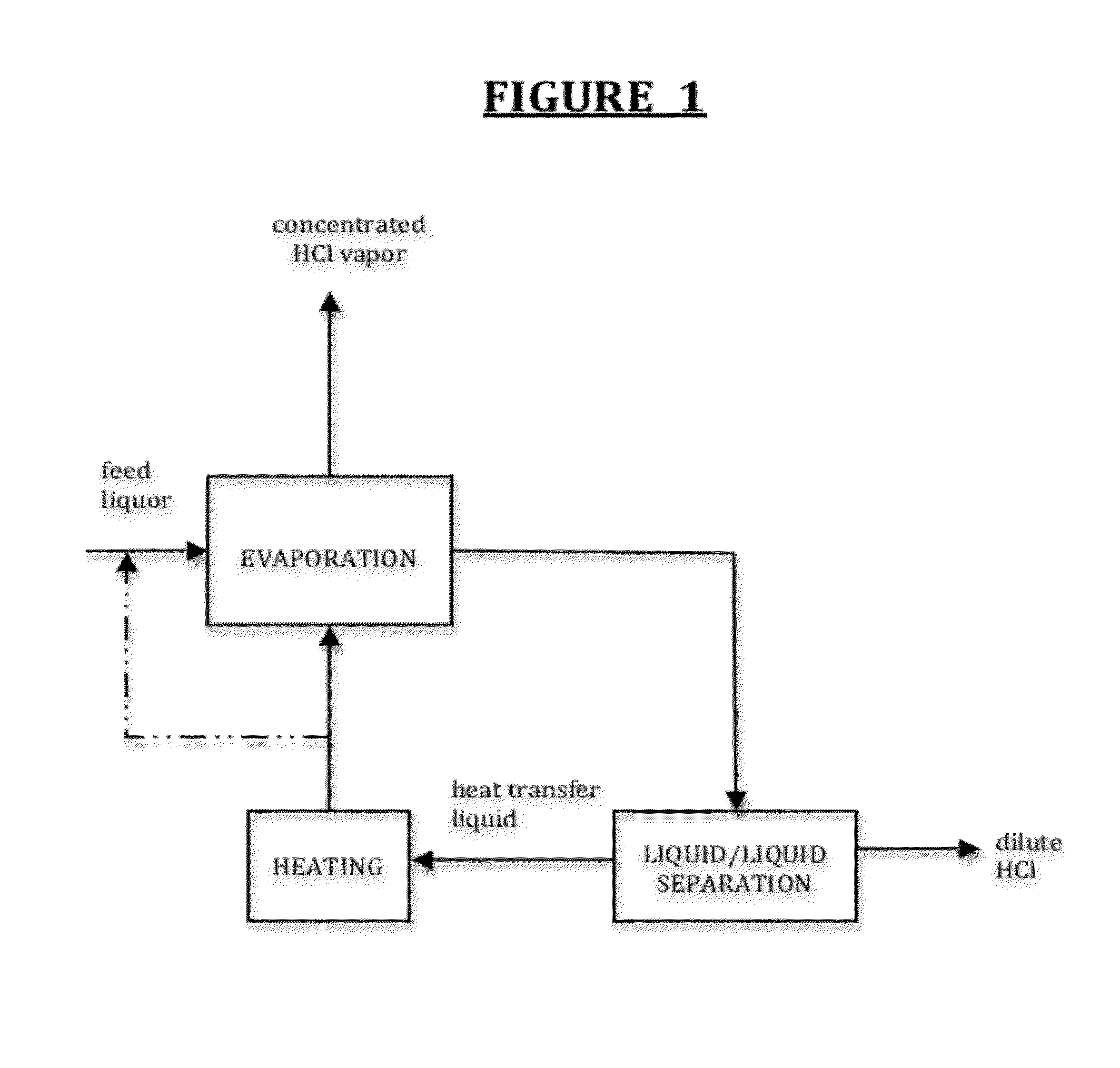

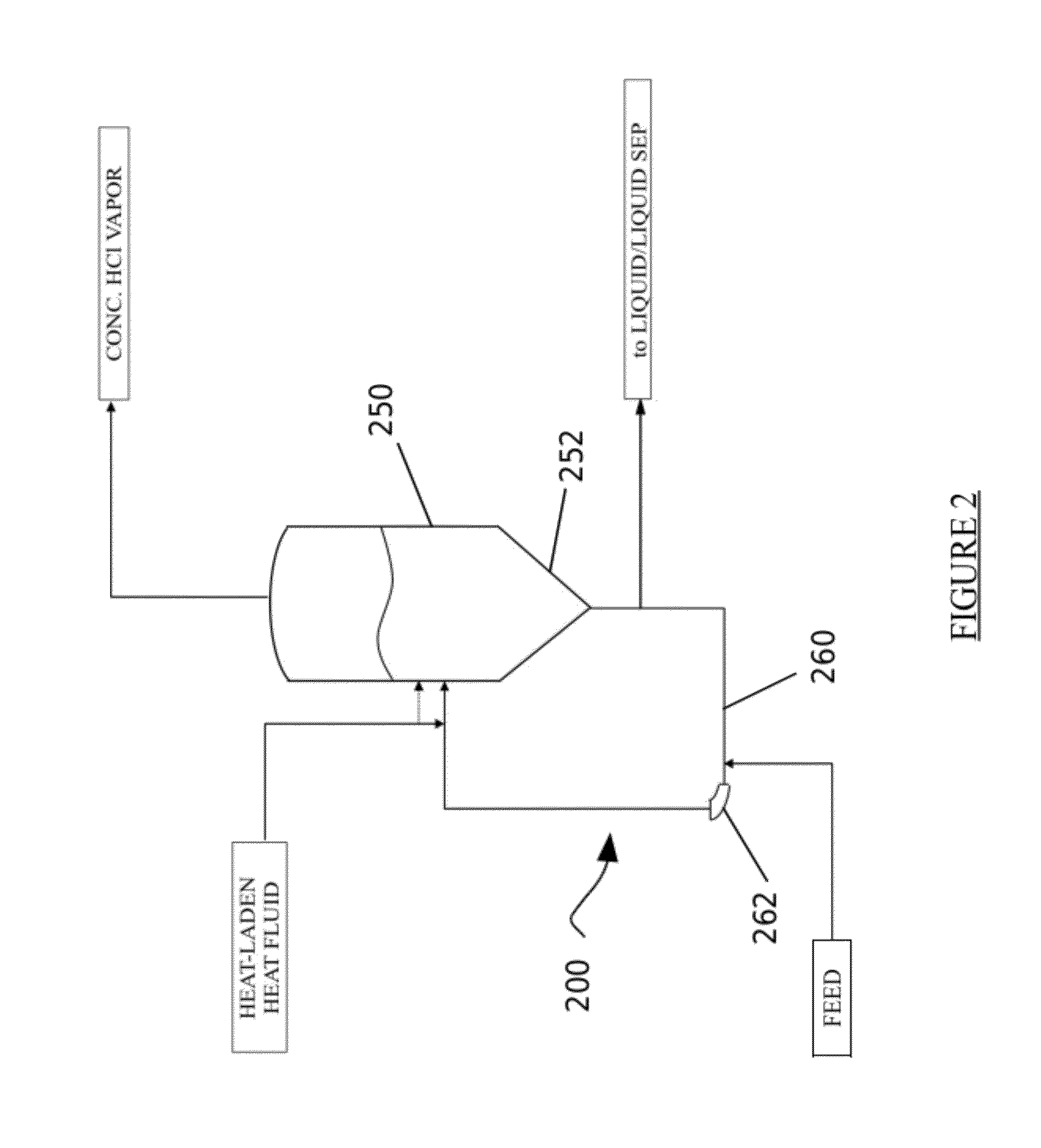

Method of concentrating hydrochloric acid

InactiveUS8163092B2Chlorine/hydrogen-chloride purificationOther chemical processesHeat transfer fluidAqueous solution

A method for producing concentrated HCl vapor from an aqueous solution of HCl, including: (a) introducing an aqueous feed liquor to an evaporation chamber containing a mother liquor, the feed liquor having an initial, super-azeotropic HCl concentration; (b) directly contacting a liquor of these liquors with a heat-laden heat transfer fluid, to transfer heat from the fluid; (c) utilizing the heat to evaporate HCl, within the chamber, to produce the concentrated HCl vapor and to produce the mother liquor, the mother liquor including an aqueous phase having a reduced concentration of HCl, with respect to the initial HCl concentration; (d) subjecting the mother liquor to a liquid-liquid separation to produce a liquid phase containing HCl, and another liquid phase containing the heat transfer fluid in a heat-depleted state, with respect to the heat transfer fluid in step (b); (e) heating the heat transfer fluid in the heat-depleted state, to regenerate the heat-laden heat transfer fluid, and (f) returning this heat transfer fluid to step (b).

Owner:VIRDIA

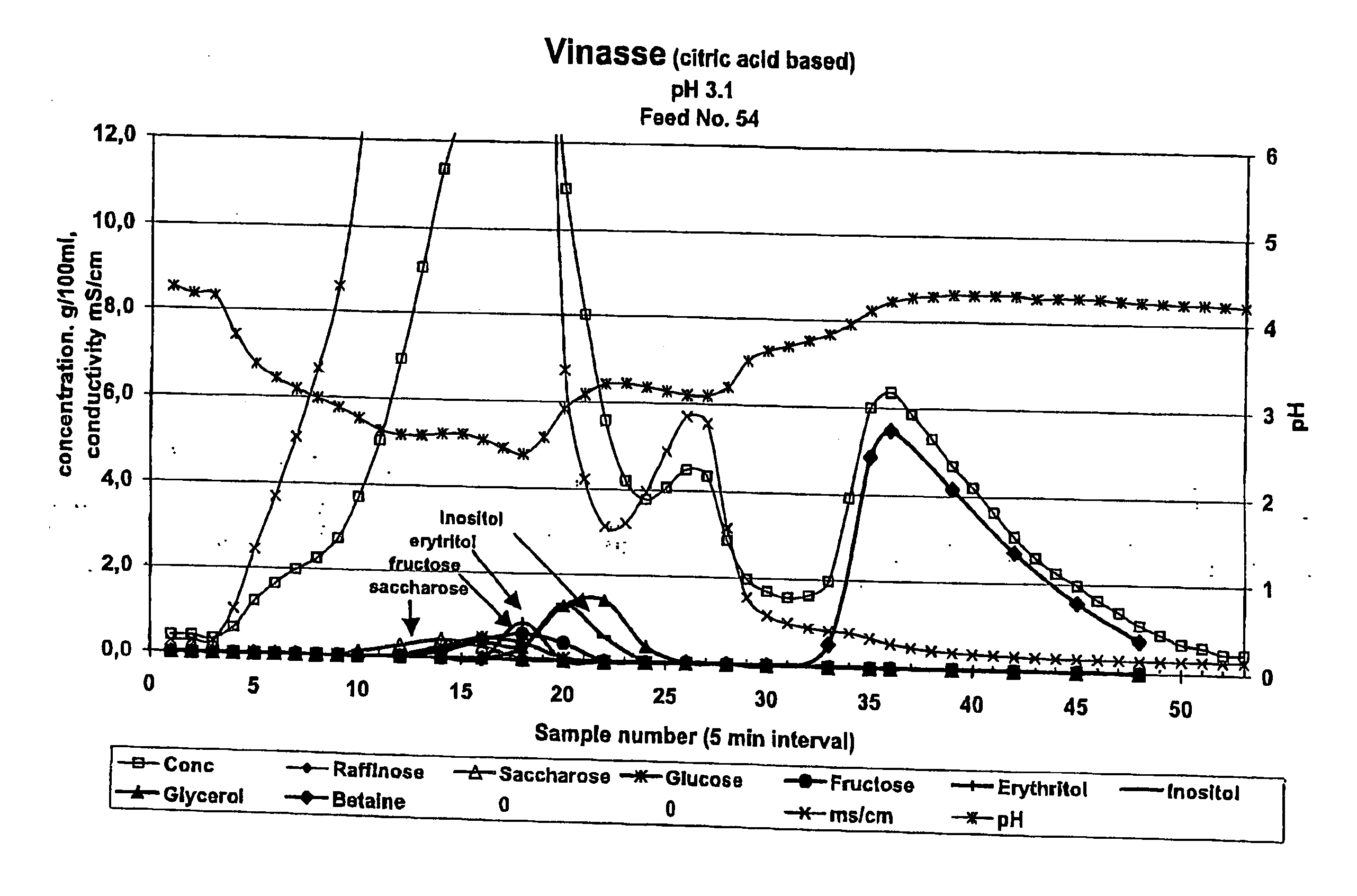

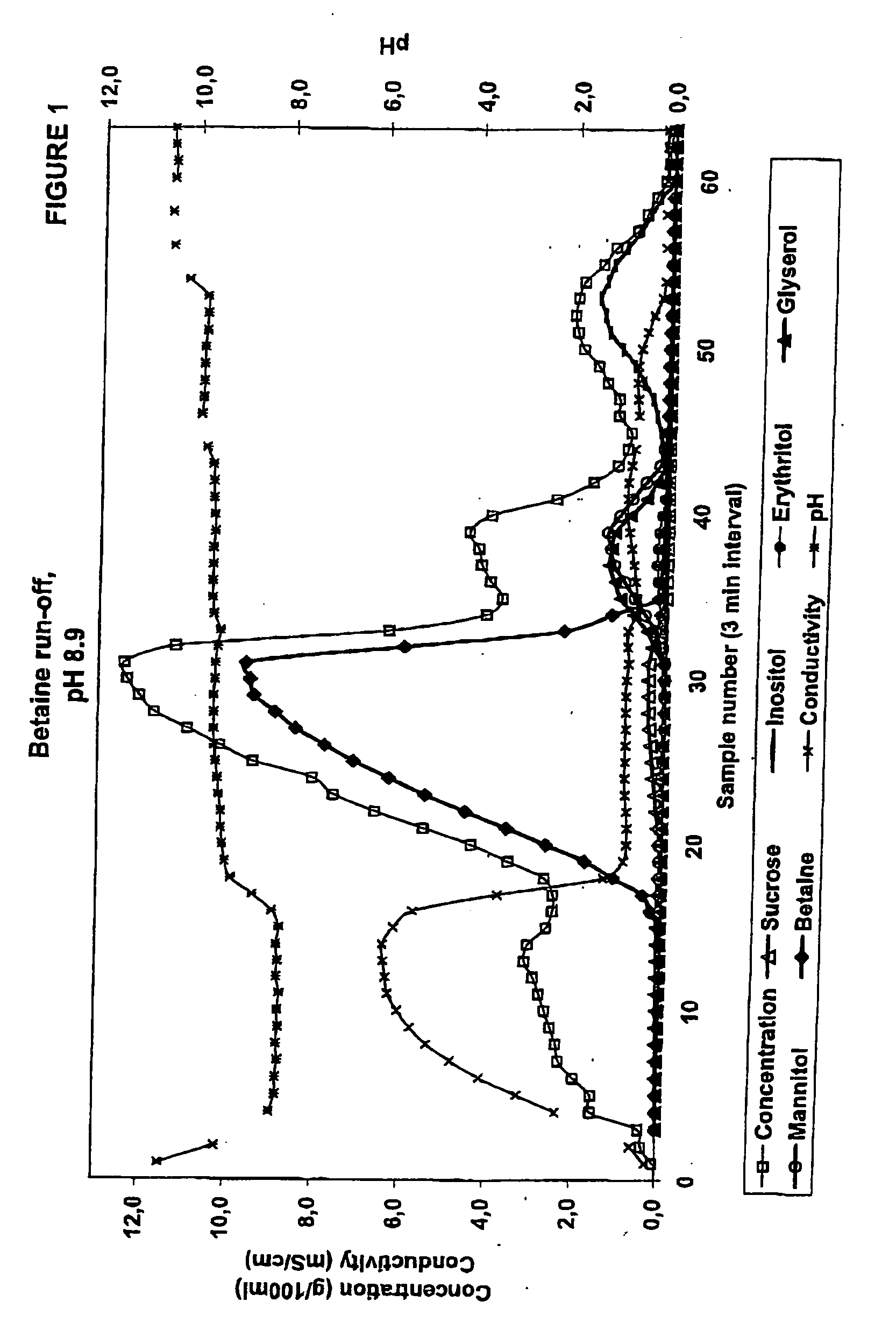

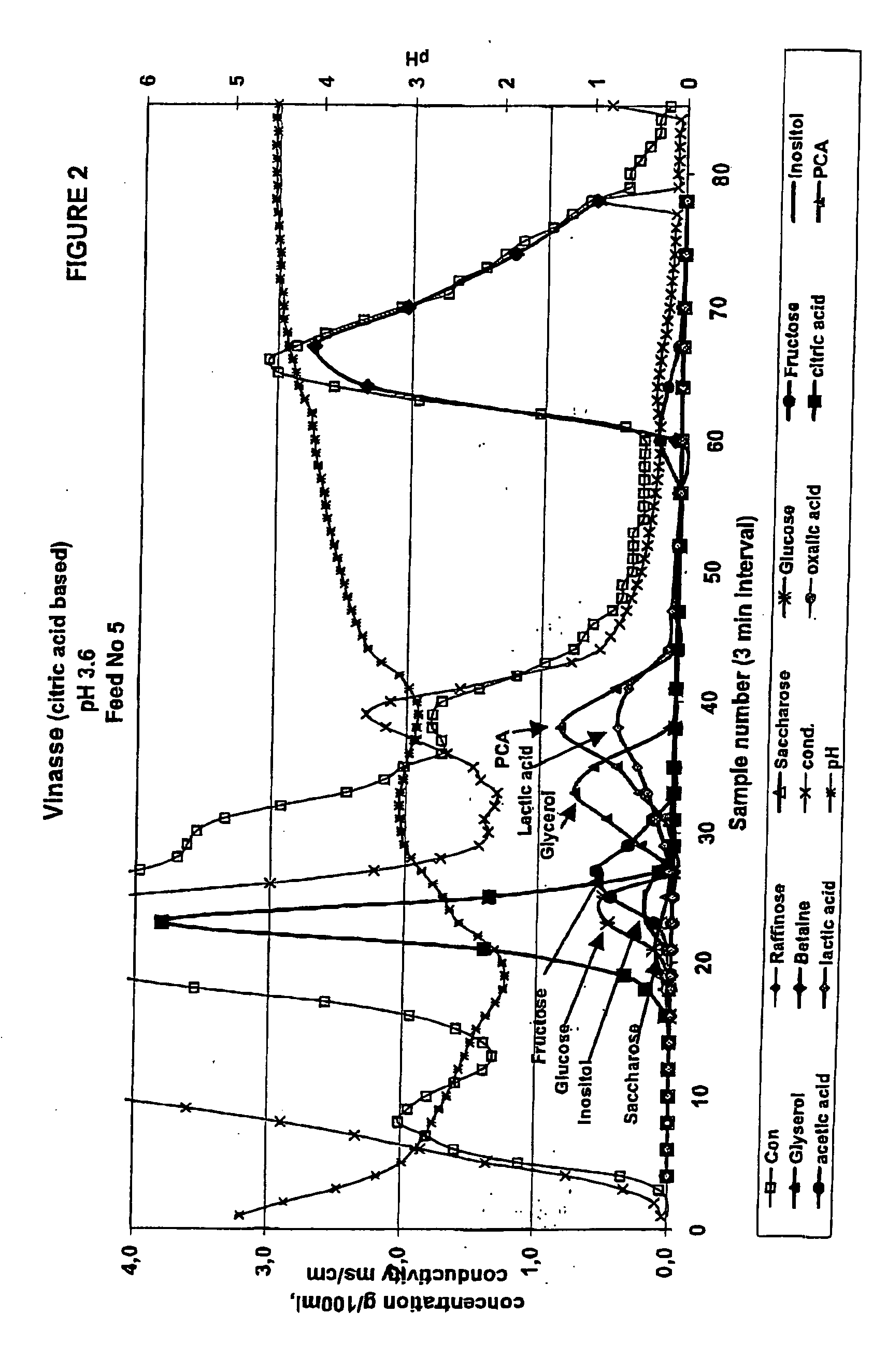

Process for fractioning vinasse

InactiveUS6022394AIncrease PotassiumPromote crystallizationIon-exchange process apparatusBy-product recoveryOrganic fractionOrganic acid

PCT No. PCT / FI95 / 00329 Sec. 371 Date Mar. 10, 1997 Sec. 102(e) Date Mar. 10, 1997 PCT Filed Jun. 7, 1995 PCT Pub. No. WO96 / 00776 PCT Pub. Date Jan. 11, 1996The invention relates to a process for fractioning vinasse, in which process the pH value of the vinasse is lowered by adding acid, and the formed precipitate is separated in order to obtain an inorganic fraction, whereupon an organic fraction remains. The invention also relates to the products obtained. The inorganic fraction mainly contains potassium salt, and it is useful for example as a fertilizer. The organic fraction mainly contains organic acids, and it is useful for example as an additive in animal feed and in producing silage.

Owner:CULTOR LTD +1

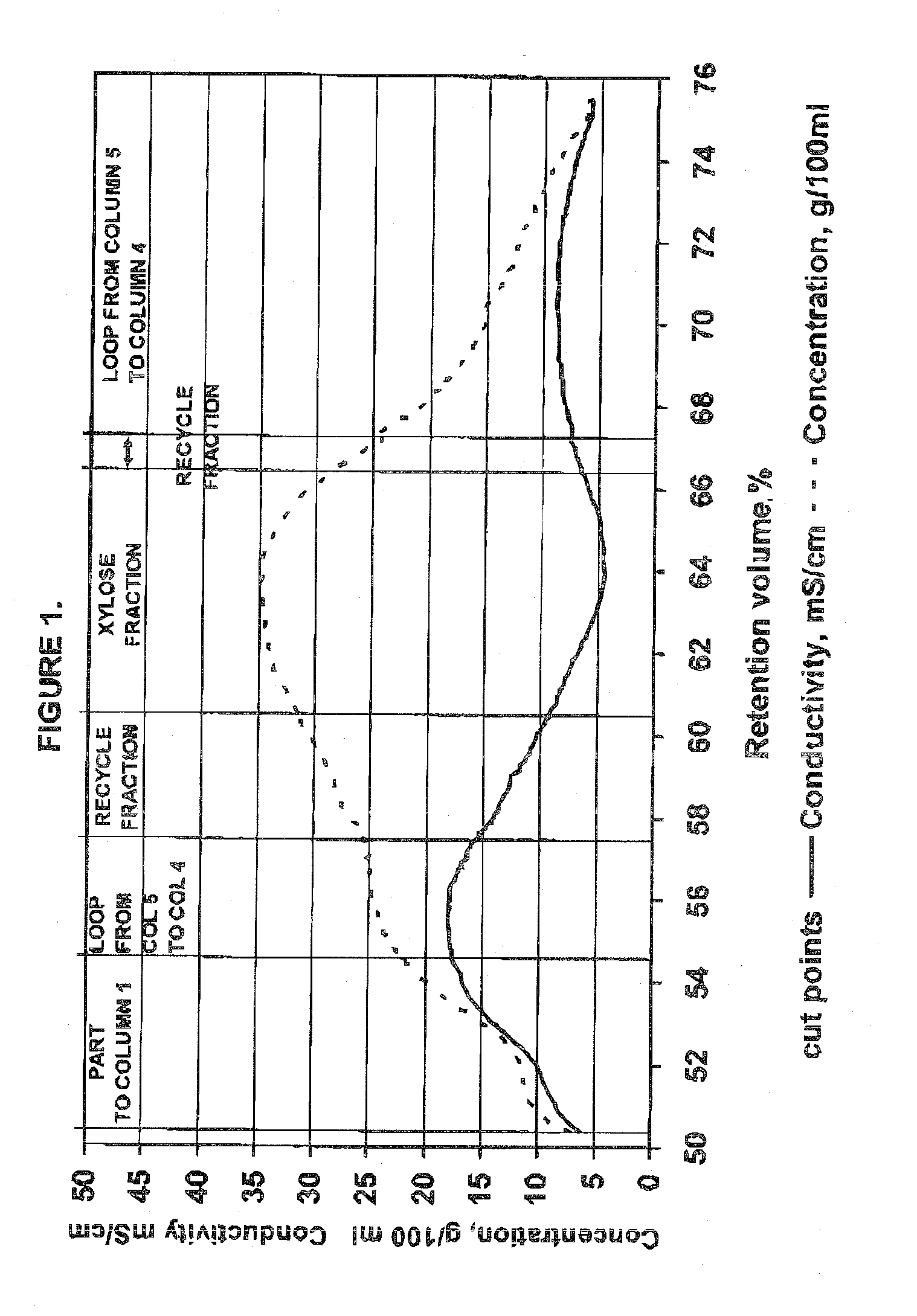

Separation process

ActiveUS20100213130A1Lower the volumeLower energy requirementsIon-exchange process apparatusSugar derivativesChromatographic separationBetaine

The present invention relates to a chromatographic separation process for fractionating solutions containing sugars, sugar alcohols, sugar acids and / or betaine by utilizing fractions comprising parts of the separation profile as a substituent of the eluent in a novel and inventive manner. The starting solutions are typically multicomponent plant-based extracts and hydrolysates, stillages, and fermentation products and derivatives thereof. The process prow vides improved separation capacity and separation efficiency without affecting the yield or purity of product components, such as sugars, sugar alcohols, sugar acids, and betaine. The process can especially be applied to sequential SMB separation systems.

Owner:DUPONT NUTRITION BIOSCIENCES APS

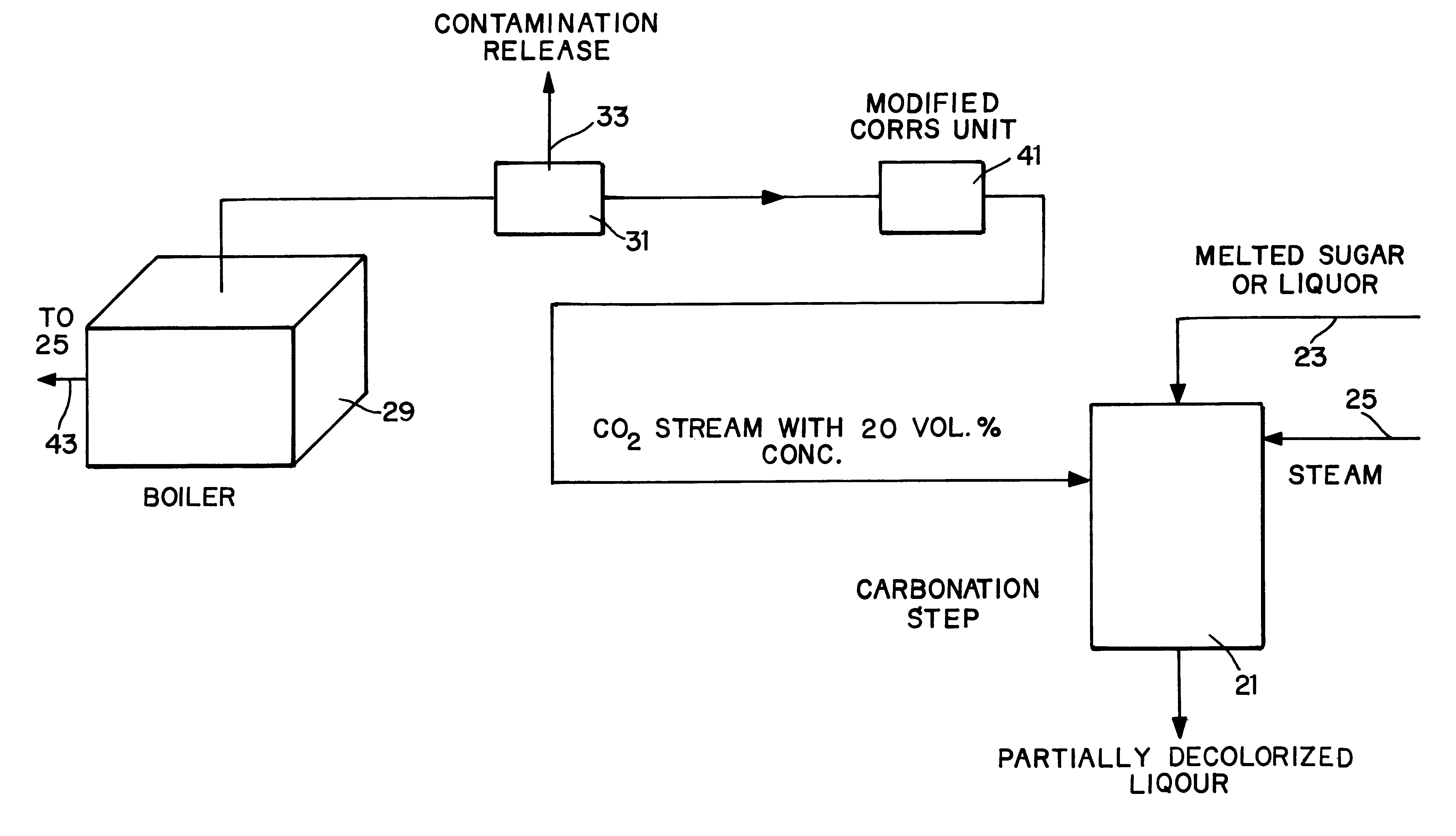

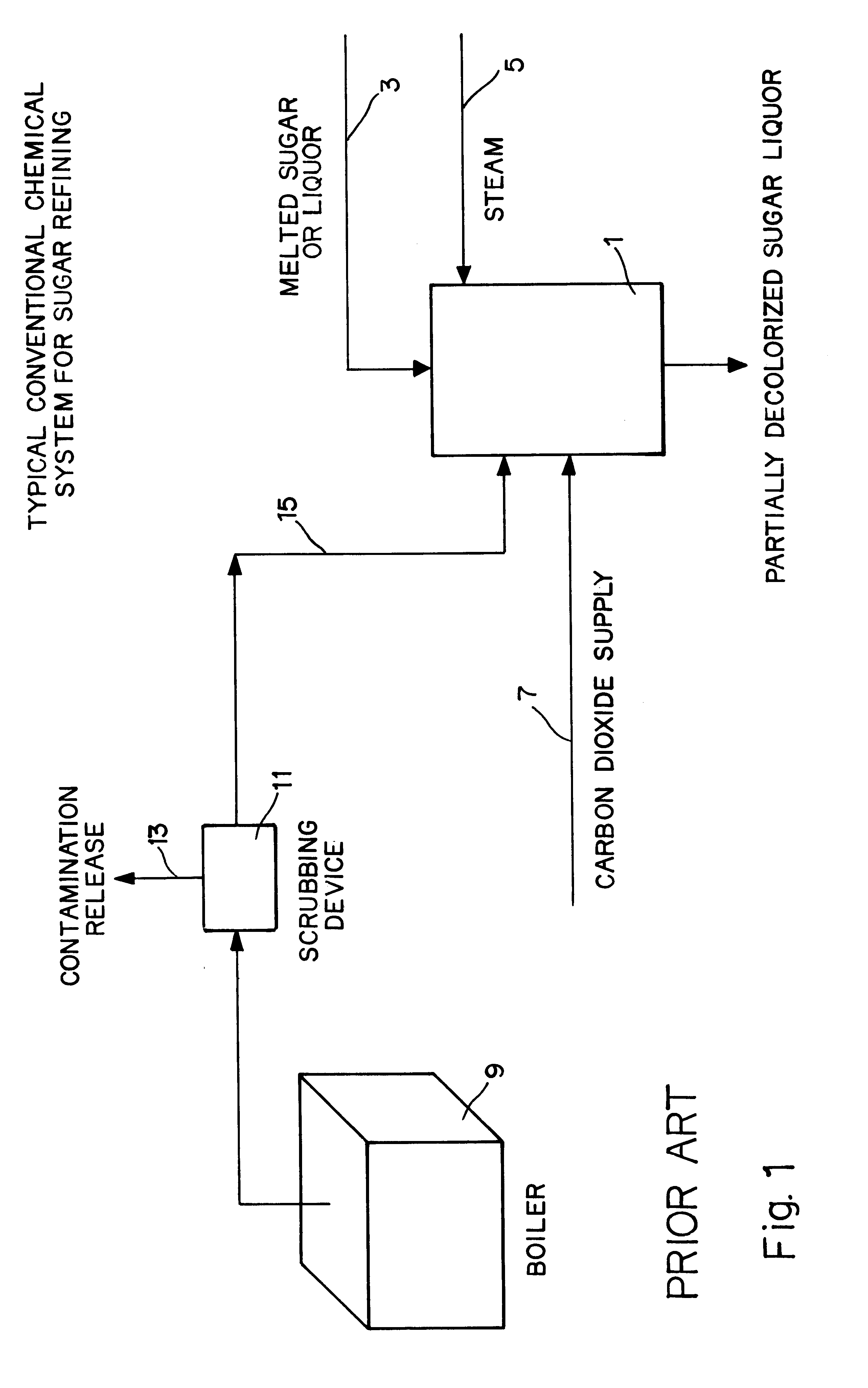

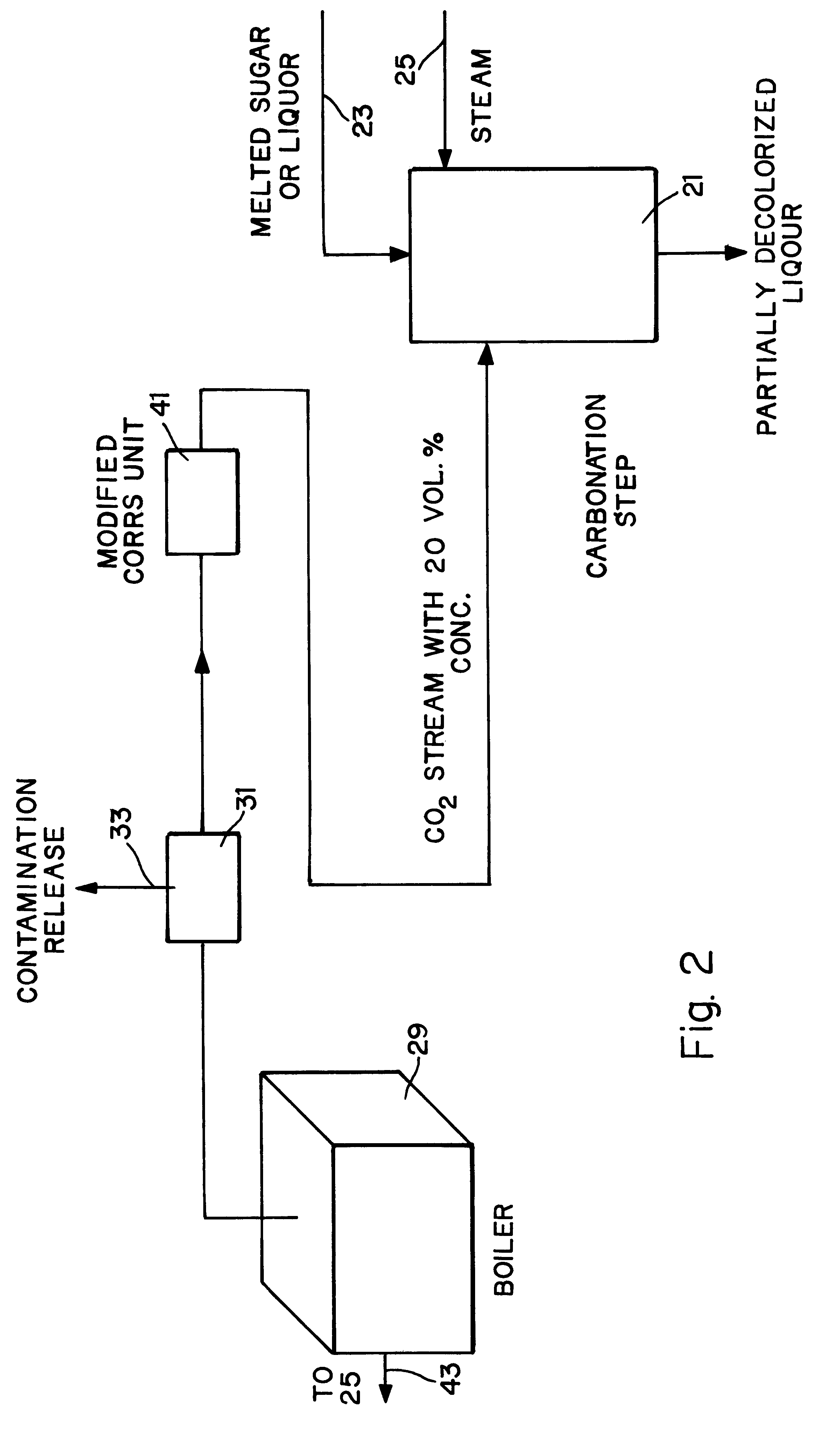

System and method for refining sugar

InactiveUS6176935B1Speed up the processEasily incorporated into existing refineryPurification using alkaline earth metal compoundsSugar crystal separationFlue gasSugar refining

A sugar refining process uses carbon dioxide obtained from a module containing a plurality of gas-permeable polymeric membranes. Flue gas from a boiler is scrubbed, and then passed through the gas-separation module. The output of the module contains an enhanced concentration of carbon dioxide, in the range of about 20% by volume. The carbon dioxide enhanced gas is then directed into a reactor in which raw sugar is exposed to carbon dioxide to cause carbonation, an essential step in the decolorization of the raw sugar. The same boiler used to produce the carbon dioxide is also used to produce steam which drives the reaction. The present invention provides carbon dioxide for carbonation in a highly efficient manner, as the gas separation membrane has no moving parts and requires little maintenance. The invention is especially suited for retrofitting existing sugar refining plants, to improve their efficiency, at a relatively small cost.

Owner:AIR LIQUIDE AMERICA INC +1

Crystallization of sugars

The invention relates to removing crystallization inhibitors from a solution comprising one or more reducing sugars by nanofiltration, hydrolysis and / or chromatography. The reducing sugars are typically selected from fructose and xylose.

Owner:DANISCO SWEETENERS

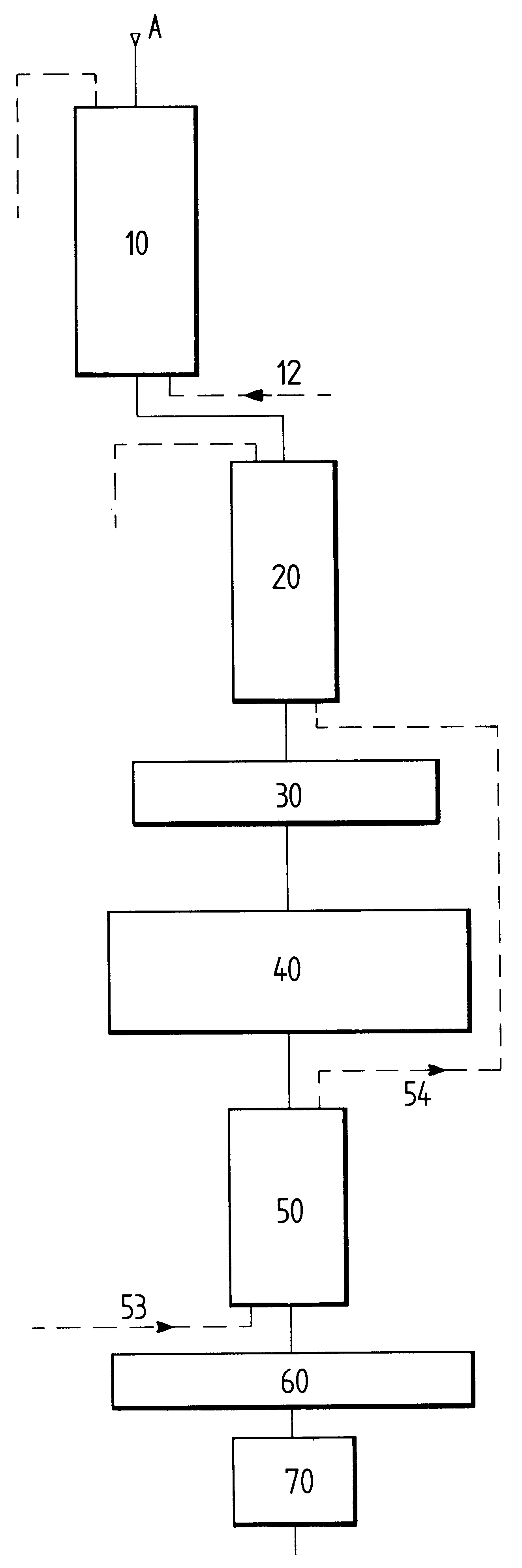

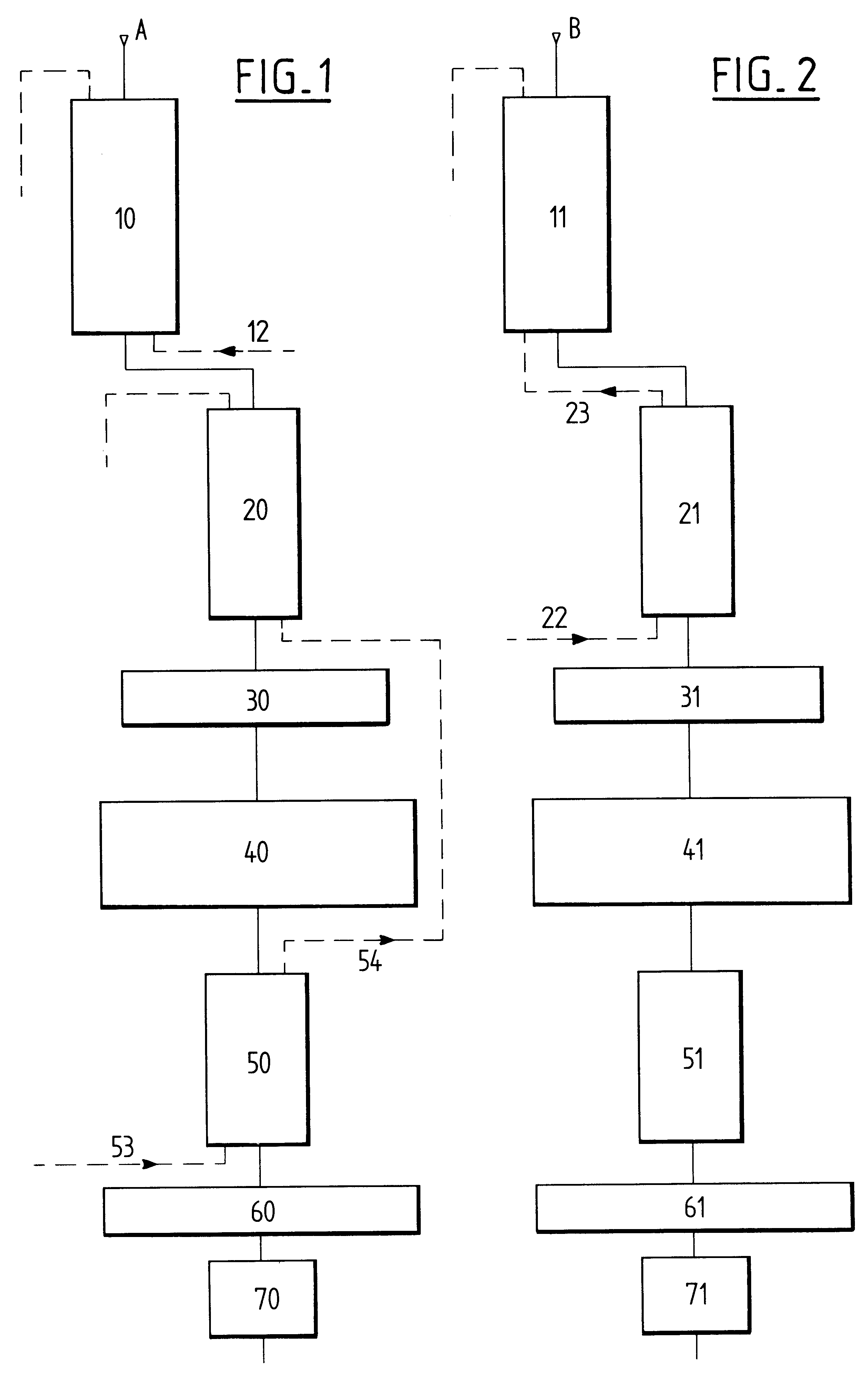

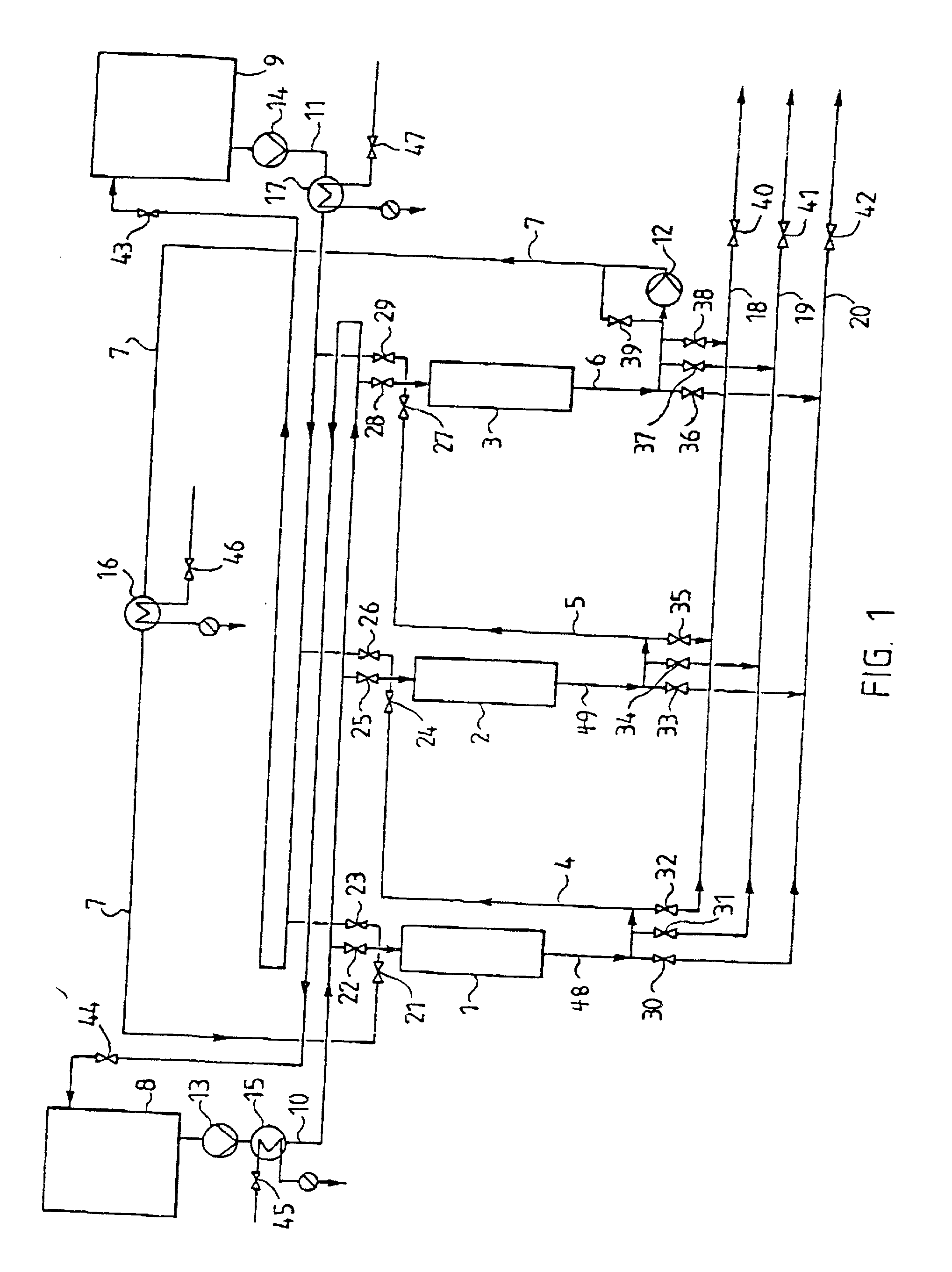

Fractionation method for sucrose-containing solutions

InactiveUS6214125B1High yieldEquivalent purityIon-exchange process apparatusIon-exchanger regenerationSimulated moving bedSaccharophagus degradans

A method for separating sucrose and a second dissolved component from a sucrose-containing solution, preferably a beet-derived sucrose-containing solution, wherein the solution is subjected to a first fractionation by a continuous or sequential chromatographic simulated moving bed process to yield a sucrose-enriched fraction and a fraction enriched with the second dissolved component. The resulting fraction enriched with the second component is subjected to a second chromatographic fractionation that is a simulated moving bed or batch type process, to yield a second sucrose-enriched fraction and a second fraction enriched with the second dissolved component wherein both fractions have an improved yield or purity.

Owner:DANISCO FINLAND OY

Natural Sweetener

ActiveUS20080045464A1Improve gutLowering GIOrganic active ingredientsSugar food ingredientsPhytochemicalWaste product

Owner:POLY GAIN PTE LTD

Method for separating betaine

ActiveUS20070158269A1Ion-exchange process apparatusIon-exchanger regenerationChromatographic separationBetaine

The invention relates to a method for separating betaine from fermentation process solutions, vinasse and other sugar beet based solutions on a weakly acid cation exchange resin in H+-form in the chromatographic separation process. The present invention relates also to use of a weakly acid cation exchange resin in H+-form for the chromatographic separation of betaine.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Process for Producing High-Purity Sucrose

InactiveUS20100160624A1Sugar productsPurification using ion-exchange materialsSucrose solutionRefined sugar

Improved processes for the purification of raw or refined sugar, or sucrose, to produce sucrose and sucrose-related products having substantially no inorganic impurities are described, wherein the processes include the use of both cation and anion exchange resins. In accordance with the process, a sucrose starting material, such as refined sugar or invert syrup, is dissolved in water at a temperature sufficient to dissolve the sucrose product and produce a low visicosity sucrose solution having not more than about 76 wt. % solids. Thereafter, the process includes contacting the low viscosity sucrose solution with one or more ion exchange resin beds, which can be separate or mixed, for a time sufficient to yield a highly-purified sucrose product that is substantially free of inorganic elemental impurities.

Owner:RAGUS HLDG

Fractionation method for sucrose-containing solutions

InactiveUS20010001956A1Equivalent purityHigh yieldSolid sorbent liquid separationPurification using ion-exchange materialsSimulated moving bedSaccharophagus degradans

A method for separating sucrose and a second dissolved component from a sucrose-containing solution, preferably a beet-derived sucrose-containing solution, wherein the solution is subjected to a first fractionation by a continuous or sequential chromatographic simulated moving bed process to yield a sucrose-enriched fraction and a fraction enriched with the second dissolved component. The resulting fraction enriched with the second component is subjected to a second chromatographic fractionation that is a simulated moving bed or batch type process, to yield a second sucrose-enriched fraction and a second fraction enriched with the second dissolved component wherein both fractions have an improved yield or purity.

Owner:DANISCO FINLAND OY

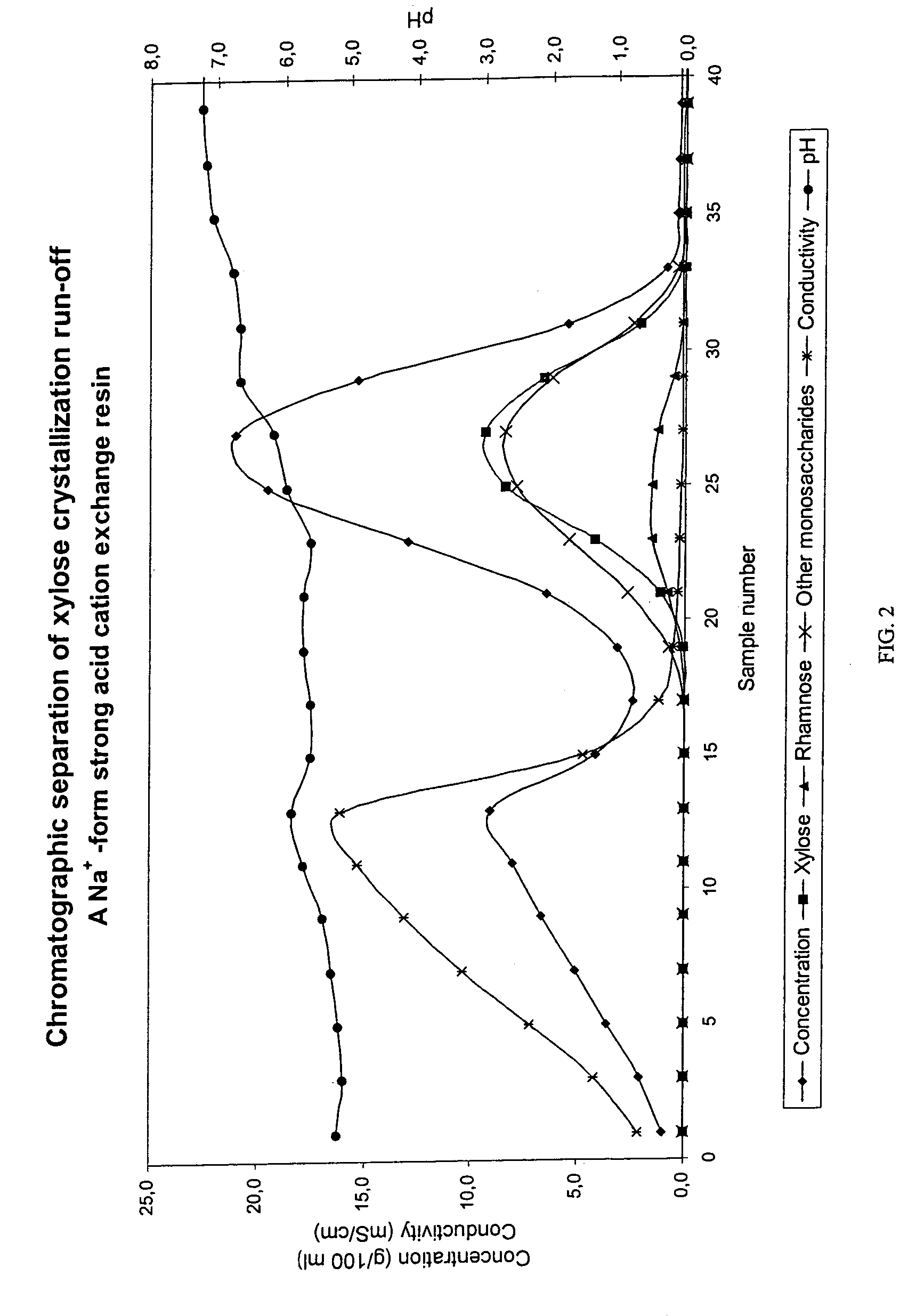

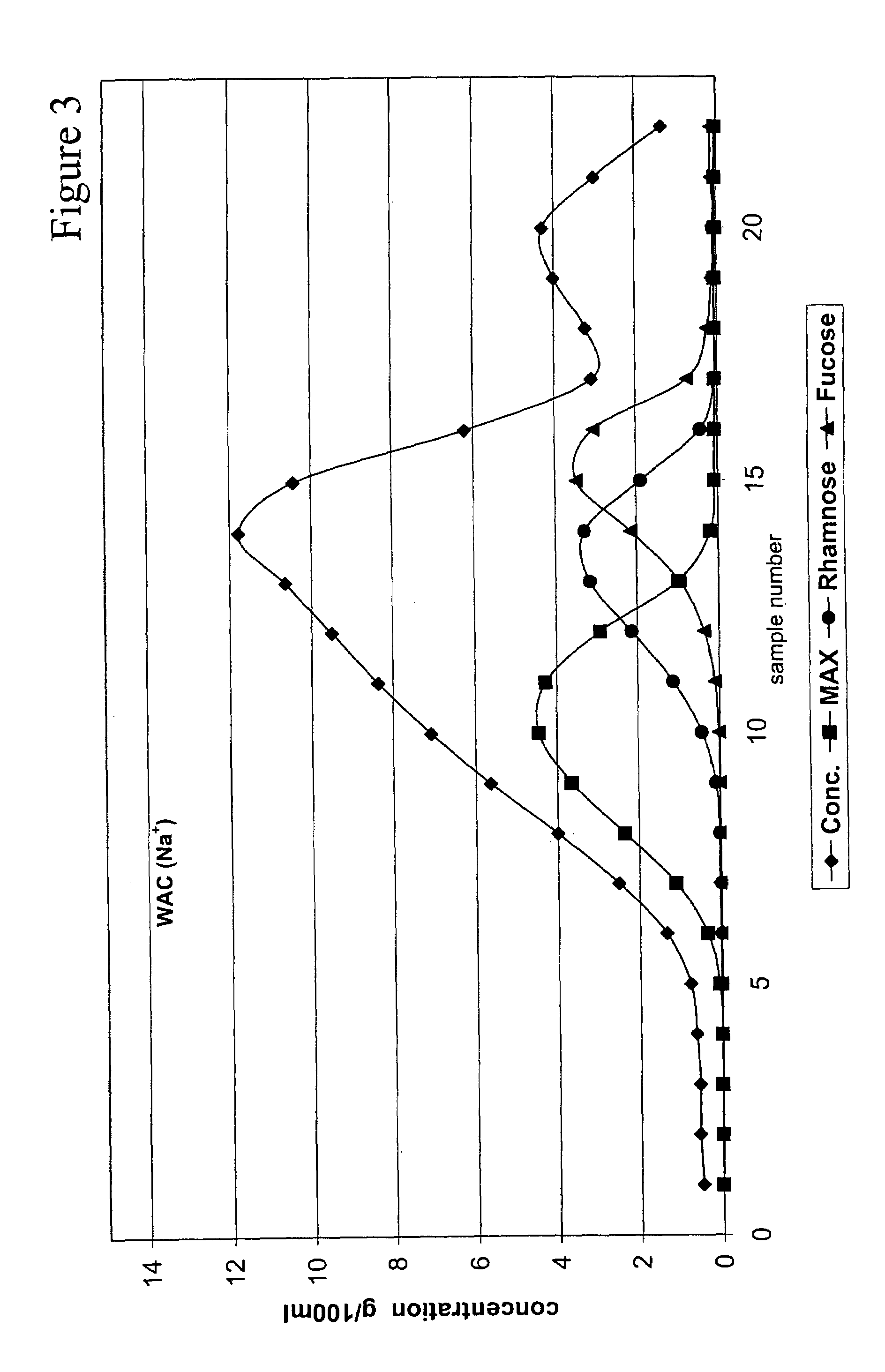

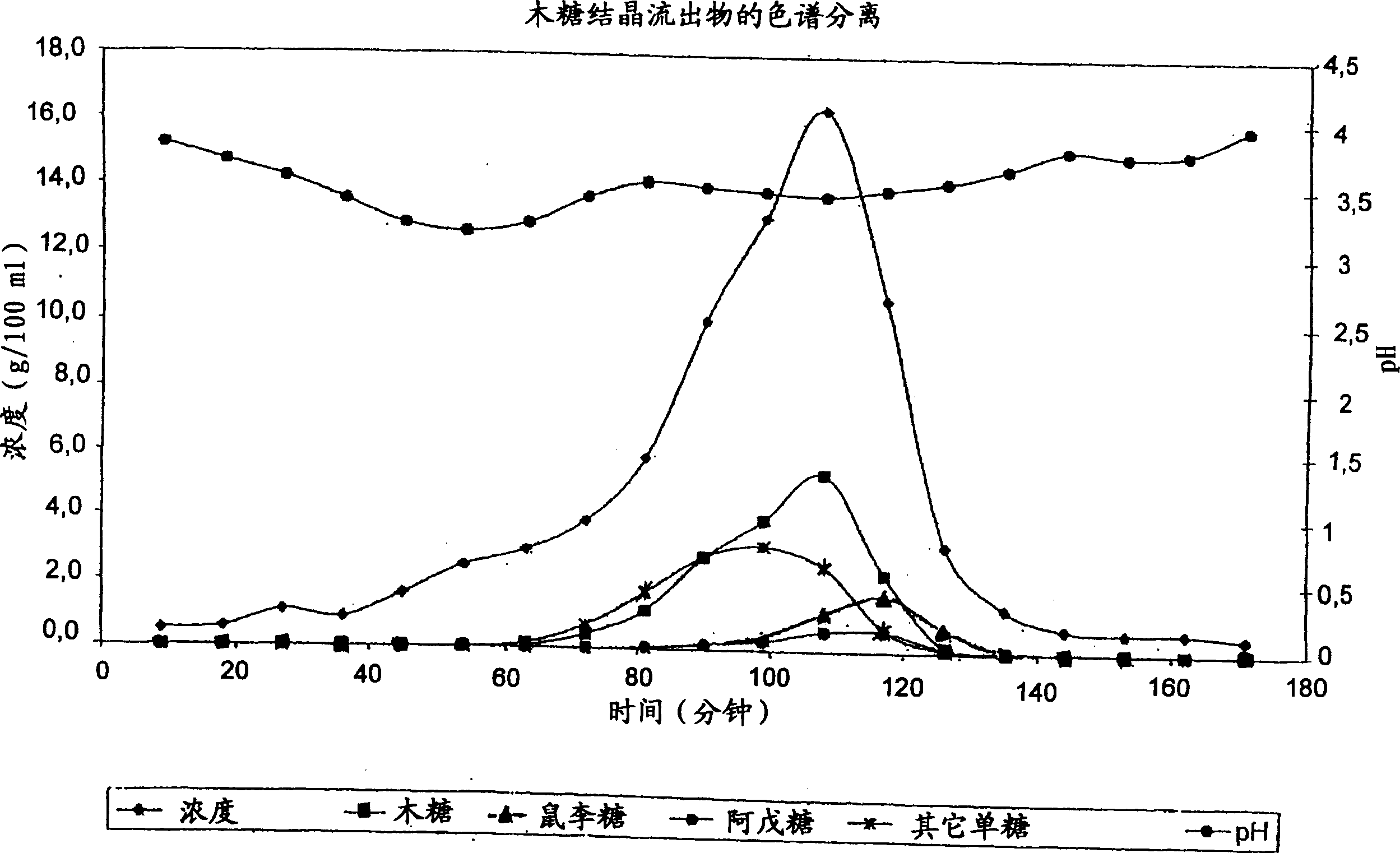

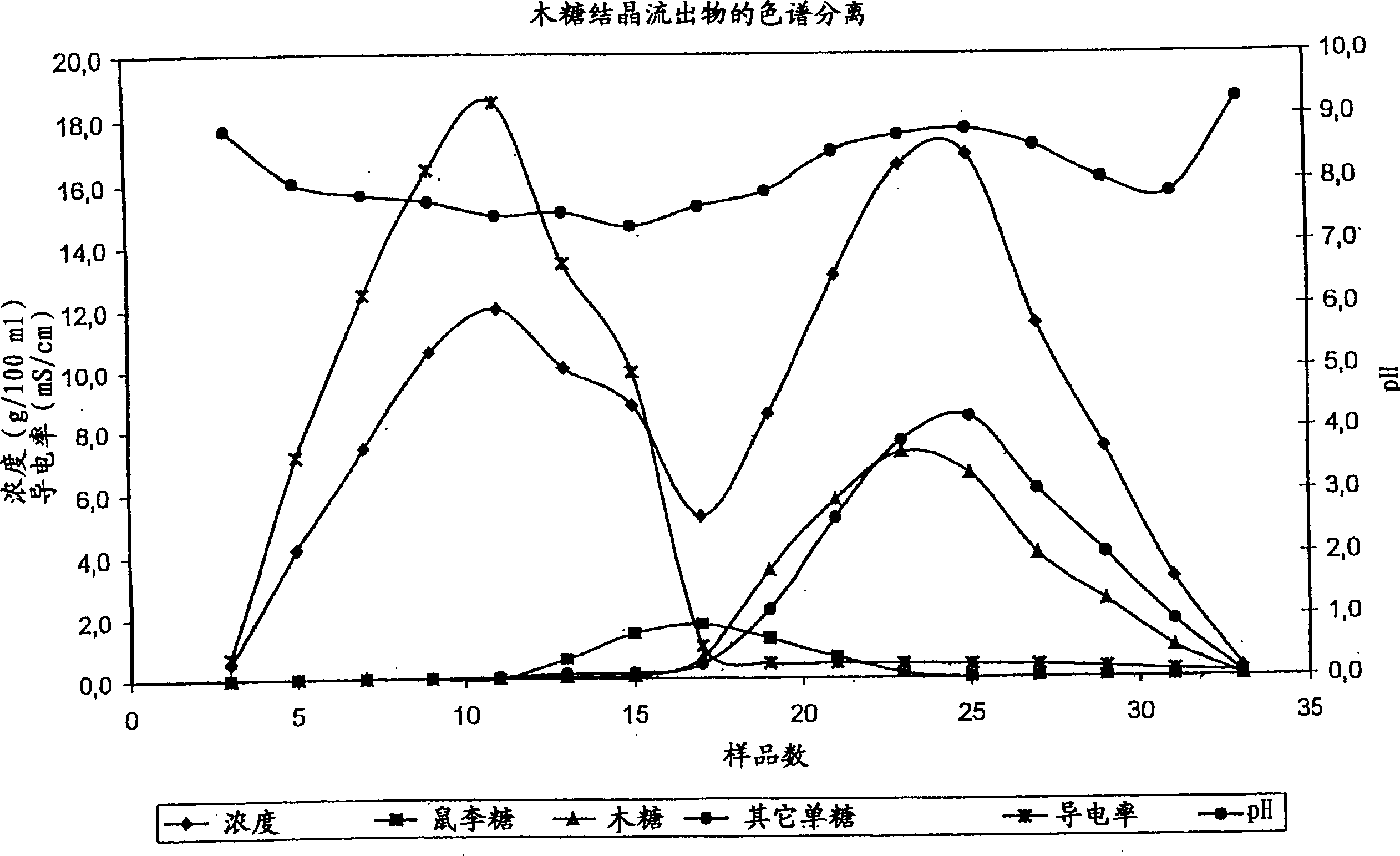

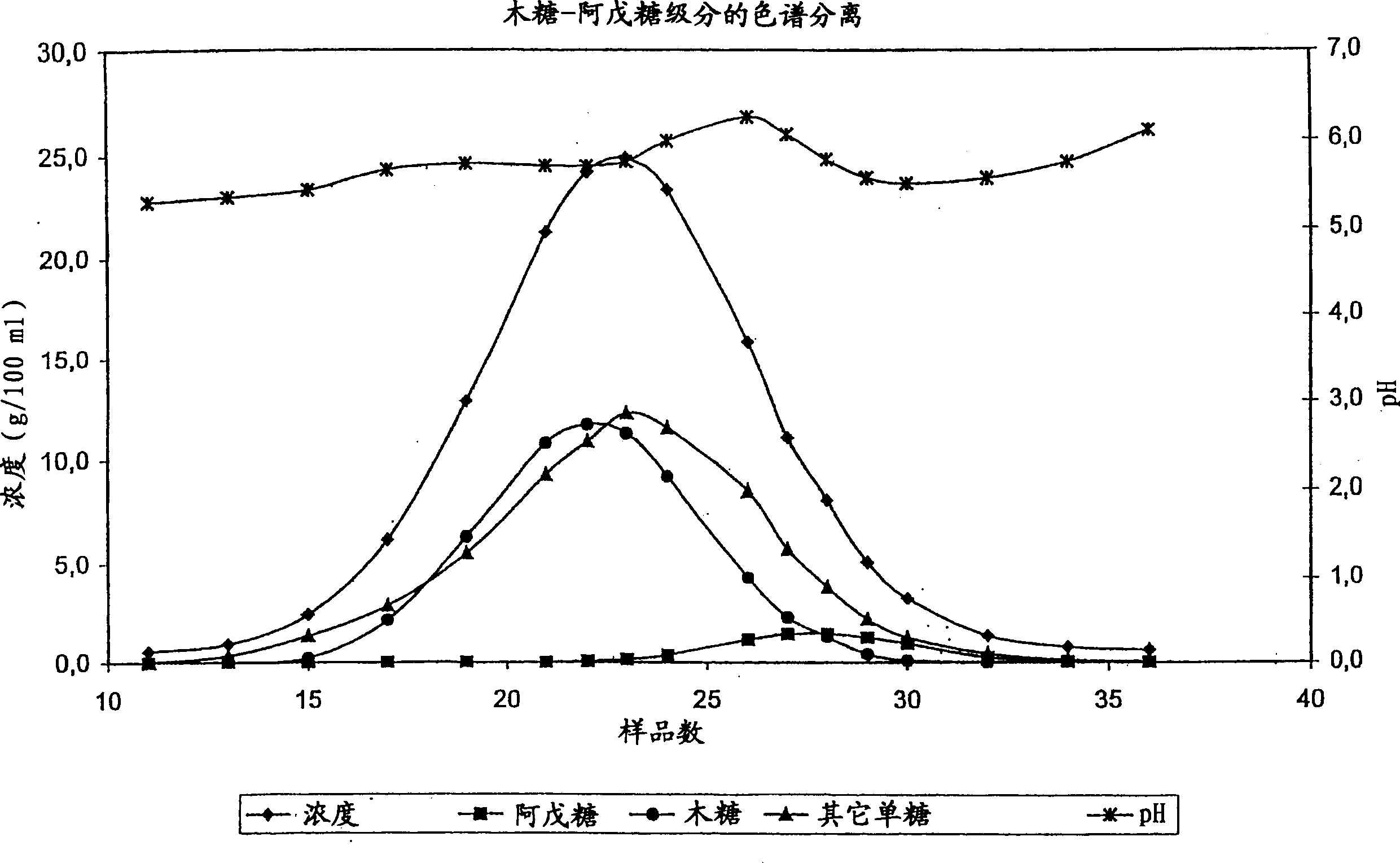

Method for recovering monosaccharide from solution using weakly acid cation exchange resin for chromatographic separation

InactiveCN1466632AChromatographic cation exchangersCation exchanger materialsChromatographic separationPhysical chemistry

The present invention relates to a method for recovering a monosaccharide selected from the group consisting of rhamnose, arabinose, xylose and mixtures thereof from a solution containing the same by a multistep process using chromatographic separation comprising at least one step, where a weakly acid cation exchange resin is used for the chromatographic separation.

Owner:DANISCO SWEETENERS

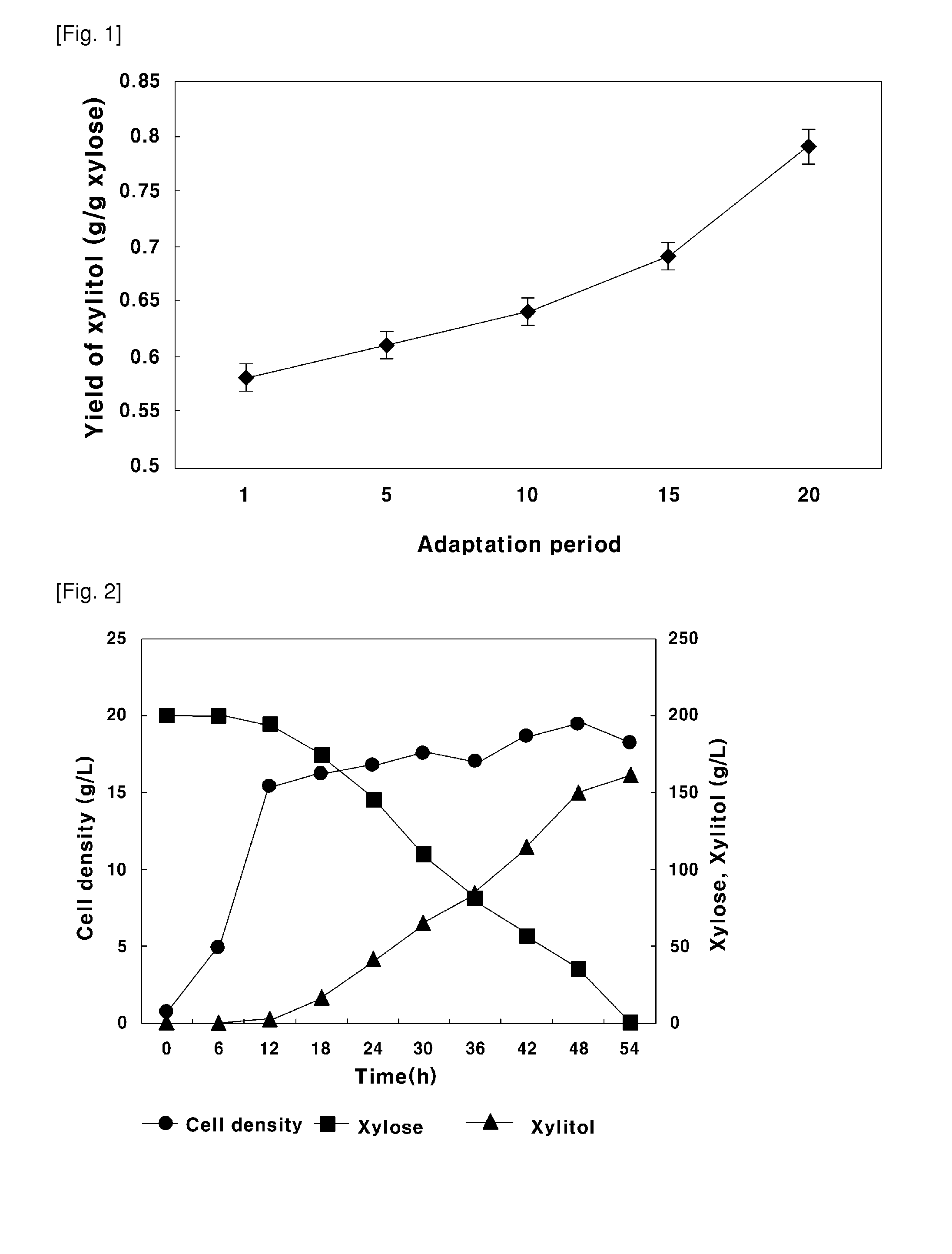

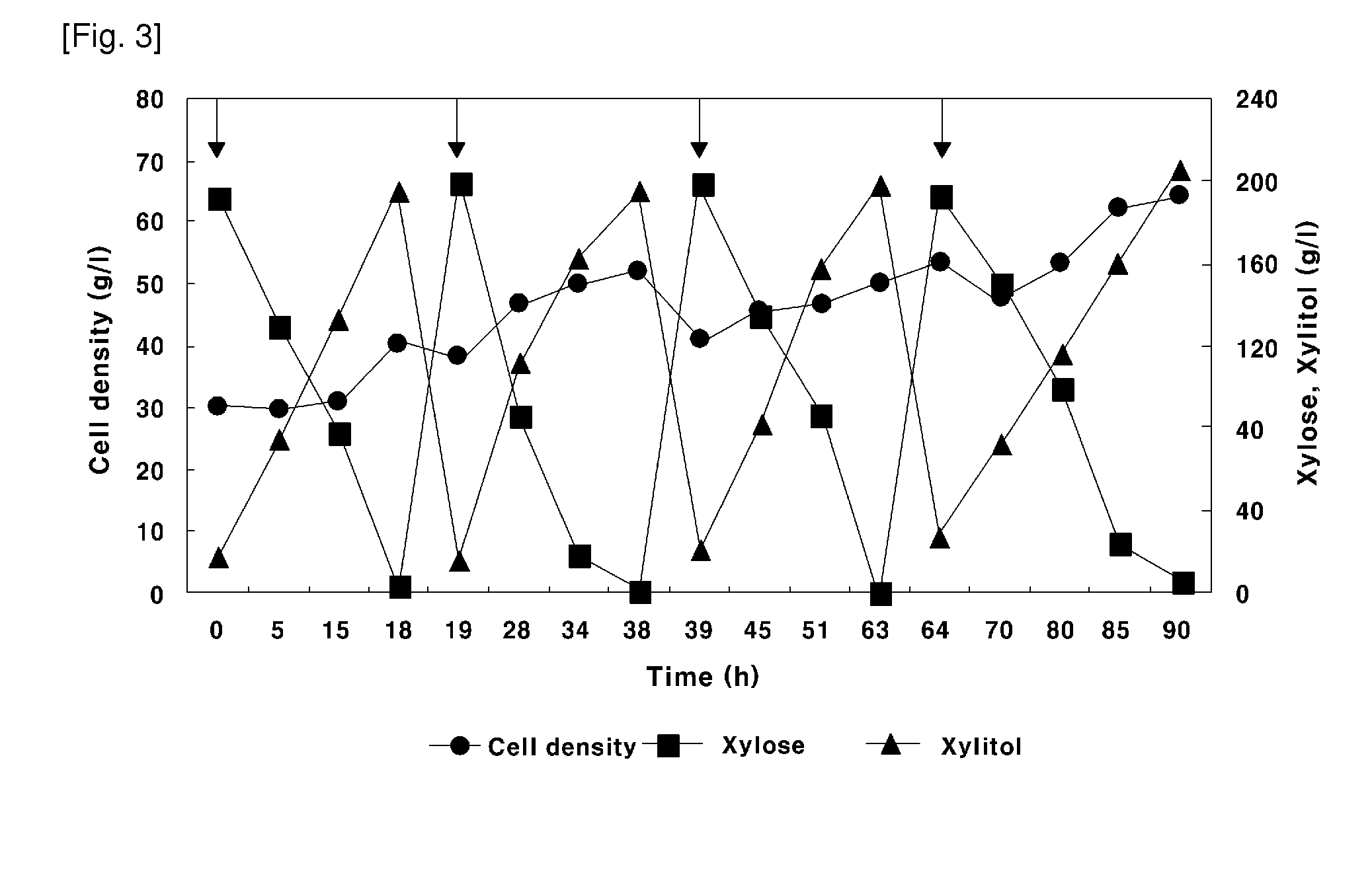

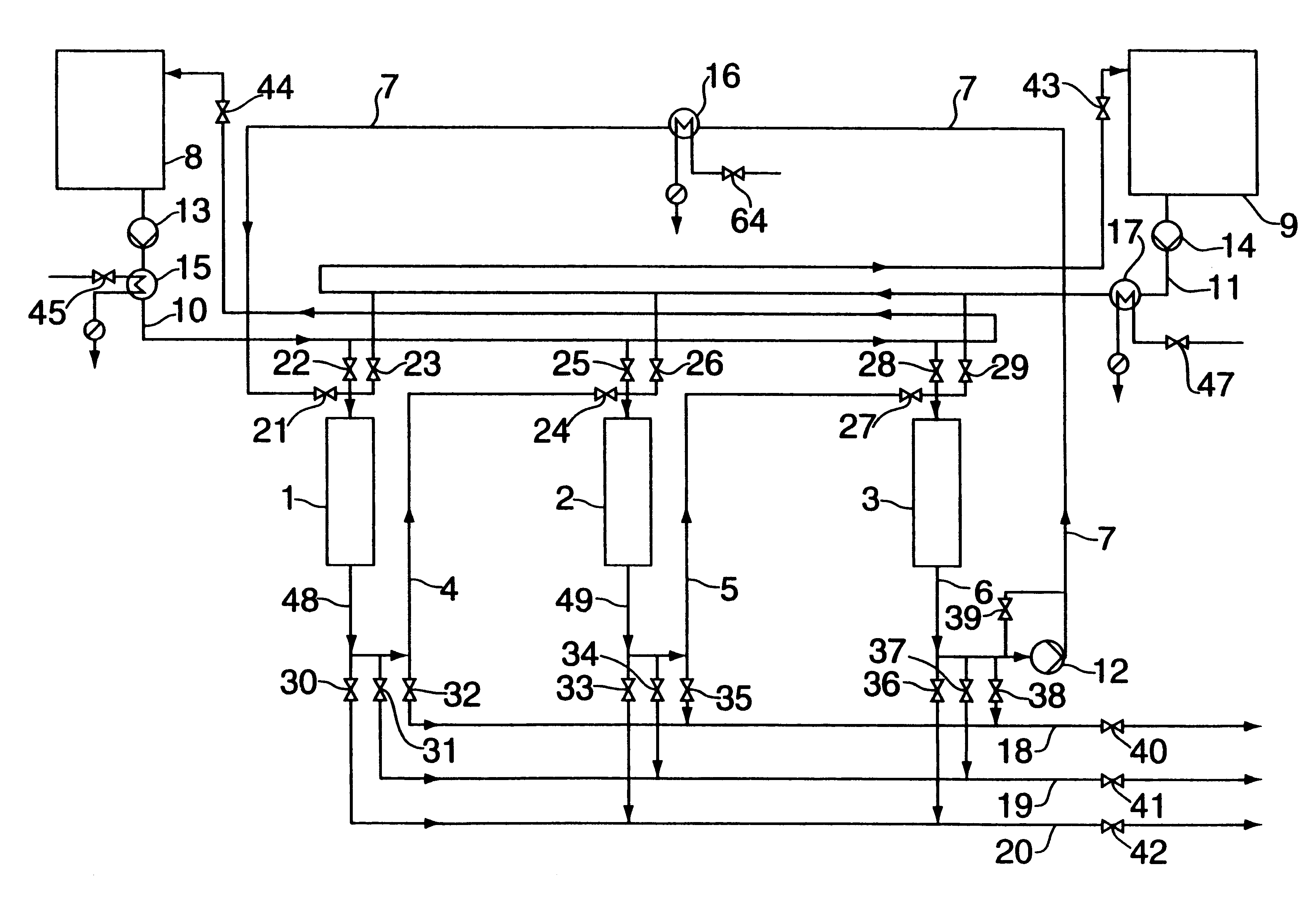

Method of Producing Xylitol Using Hydrolysate Containing Xylose and Arabinose Prepared from Byproduct of Tropical Fruit Biomass

ActiveUS20100068121A1Easy to useDecrease productivitySemi-permeable membranesCarbon compoundsHydrolysateCarbonization

Disclosed is a method of producing xylitol using a hydrolysate containing xylose and arabinose prepared from byproducts of tropical fruit biomass and more precisely, a method of producing xylitol which includes the steps of producing xylose and arabinose by the pretreatment of tropical fruit biomass byproducts including coconut shell, palm shell and oil palm empty fruit bunch (OPEFB) via acid (0.2-5%) hydrolysis and an electrodialysis and an ionic purification; and producing xylitol with high yield based on repeated batch fermentation using a hydrolysate containing xylose and arabinose as a carbon source. In addition, the present invention relates to an active carbon produced by carbonization and activation of a hydrolysate remainder of a tropical fruit shell, the byproduct of xylose and arabinose production, at a certain temperature and a preparation method of the same.

Owner:CJ CHEILJEDANG CORP

Fractionation method for sucrose-containing solutions

InactiveUS6482268B2Equivalent purityHigh yieldIon-exchange process apparatusIon-exchanger regenerationSimulated moving bedSaccharophagus degradans

A method for separating sucrose and a second dissolved component from a sucrose-containing solution, preferably a beet-derived sucrose-containing solution, wherein the solution is subjected to a first fractionation by a continuous or sequential chromatographic simulated moving bed process to yield a sucrose-enriched fraction and a fraction enriched with the second dissolved component. The resulting fraction enriched with the second component is subjected to a second chromatographic fractionation that is a simulated moving bed or batch type process, to yield a second sucrose-enriched fraction and a second fraction enriched with the second dissolved component wherein both fractions have an improved yield or purity.

Owner:DANISCO FINLAND OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com