Patents

Literature

242 results about "Oil palm" patented technology

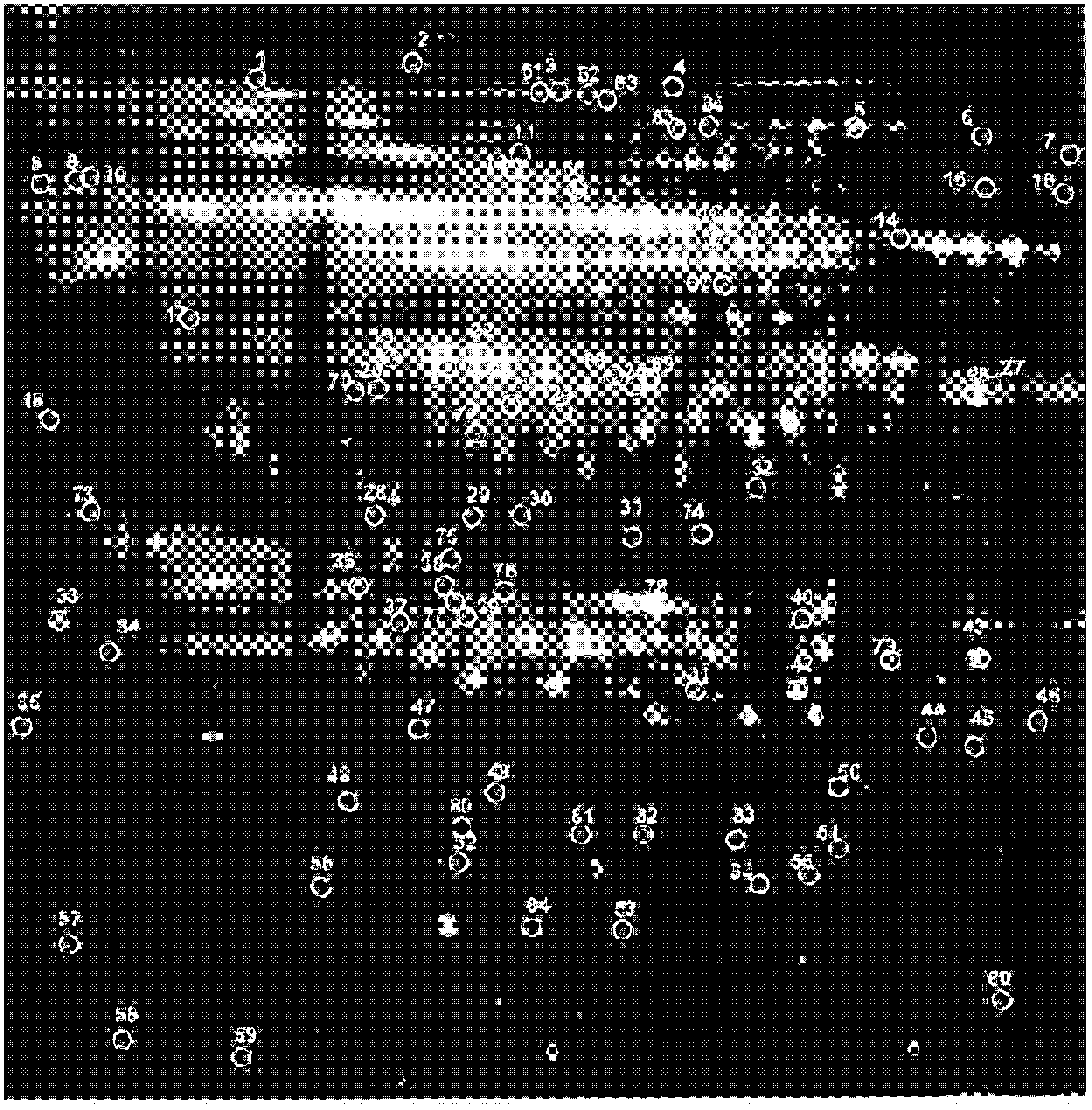

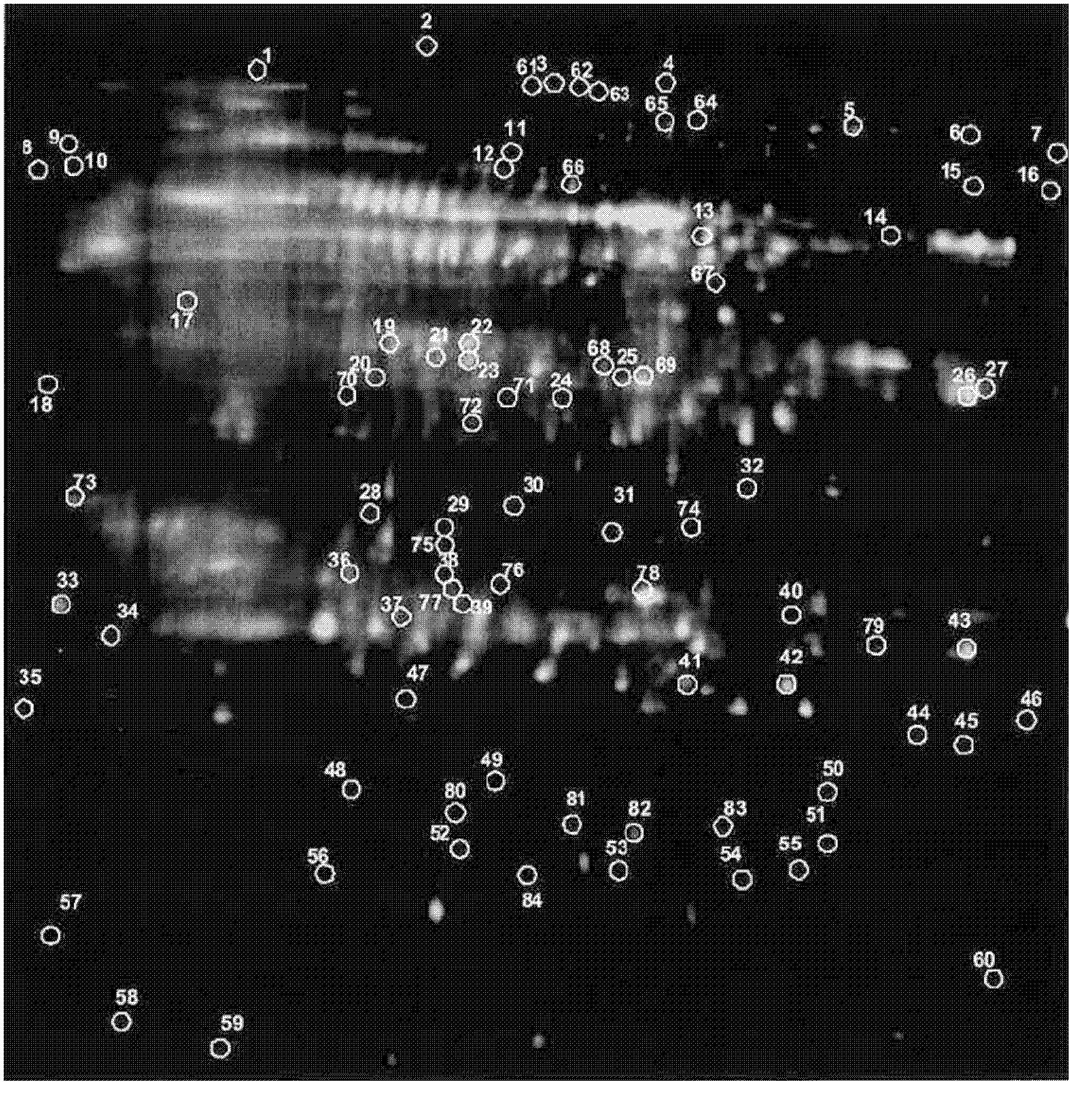

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

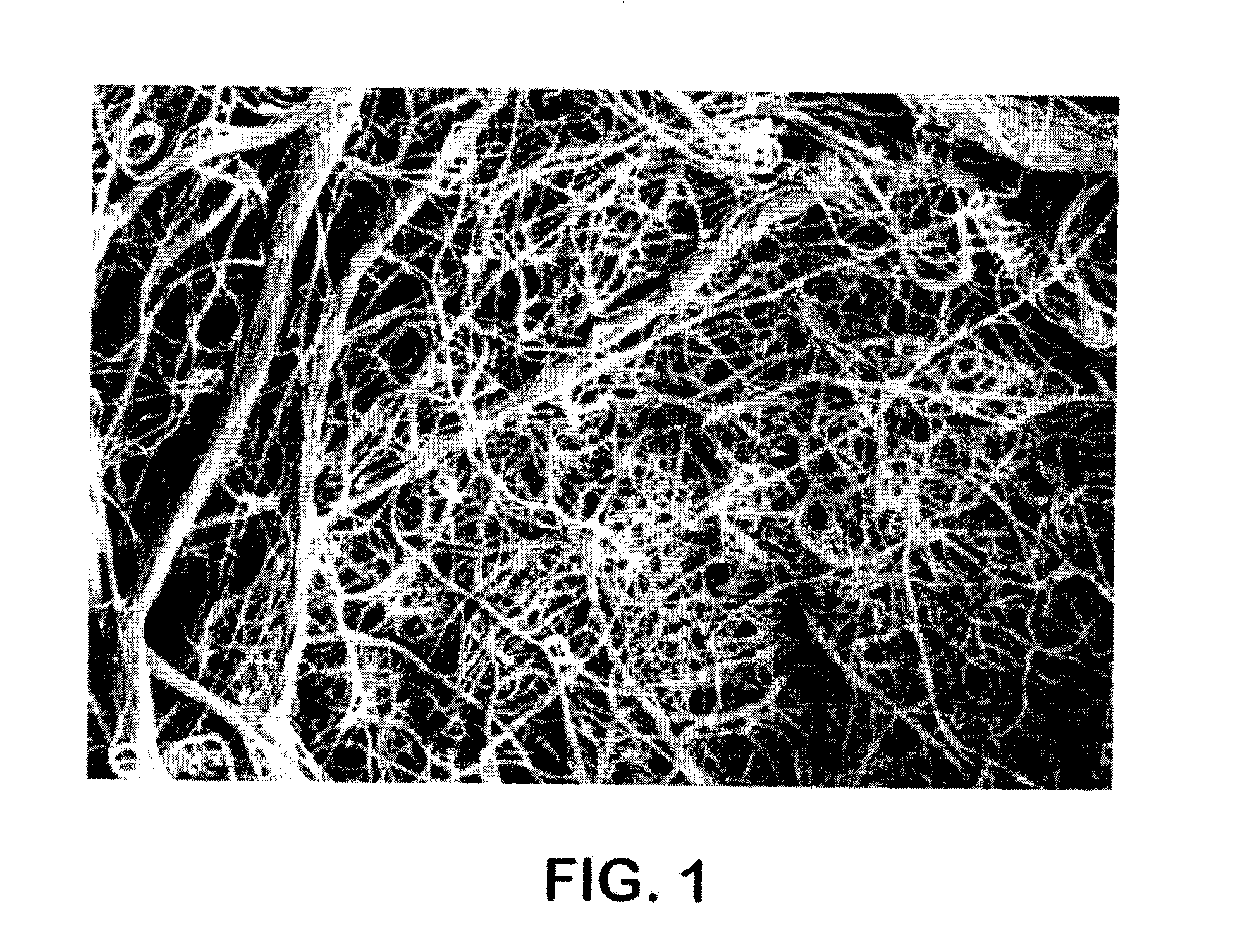

Endophytic fungus and uses therefor

The present invention provides novel microorganisms, compositions and methods of use thereof, for treating, inhibiting or preventing the developing of a plant pathogenic disease and for killing or inhibiting growth of a variety of pests or pathogens. Provided are compositions comprising a novel endophytic fungal organism effective to inhibit the growth of or kill pests and pathogenic microbes, including Ganoderma boninense. Invention compositions are especially useful in preventing and treating basal stem rot in the oil palm, and can be applied on or in the vicinity of the plant or used to sterilize the plant growth medium prior to or concurrent with plant growth therein. The disclosure further provides substantially purified polynucleotides and polypeptides encoded thereby, together with methods of using those products, for example for making transgenic organism.

Owner:SYNTHETIC GENOMICS INC

Treatment of vegetation liquors derived from oil-bearing fruit

InactiveUS7387802B2Effect separationIncrease contentBiocideSemi-permeable membranesPhytochemicalPhenolic acid

The present invention relates to processes for the treatment of liquors derived from oil-bearing fruit, for example from oil palm fruit, and to products therefrom. Typically a process involves removal of undissolved solids, oleaginous parts, colloids and higher weight molecules from the vegetation liquor to give an aqueous fraction containing phytochemicals, for example, flavonoids, phenolic acids and hydroxy acids. Subsequently, pH adjustment and solvent extraction upon said aqueous fraction realise an extract rich in hydroxy acids or phenolic acids or flavonoids or any combination thereof Applications of the substances subject of this invention are to be found in drinks, edible products, tonics, health supplements, antioxidant additives, cosmetics, soaps, shampoos, detergents, drugs or medicinal products.

Owner:MALASIAN PALM OIL BOARD

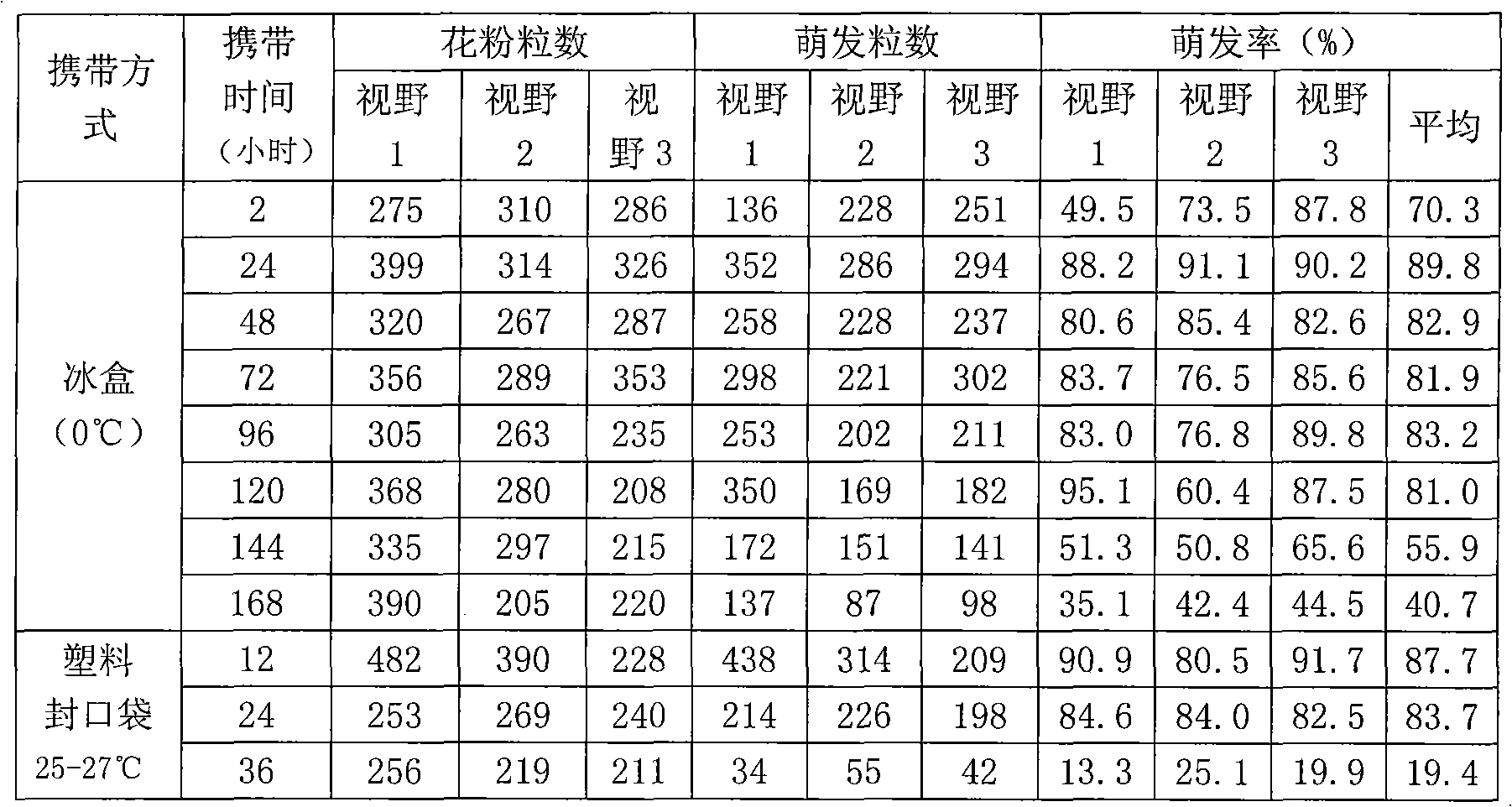

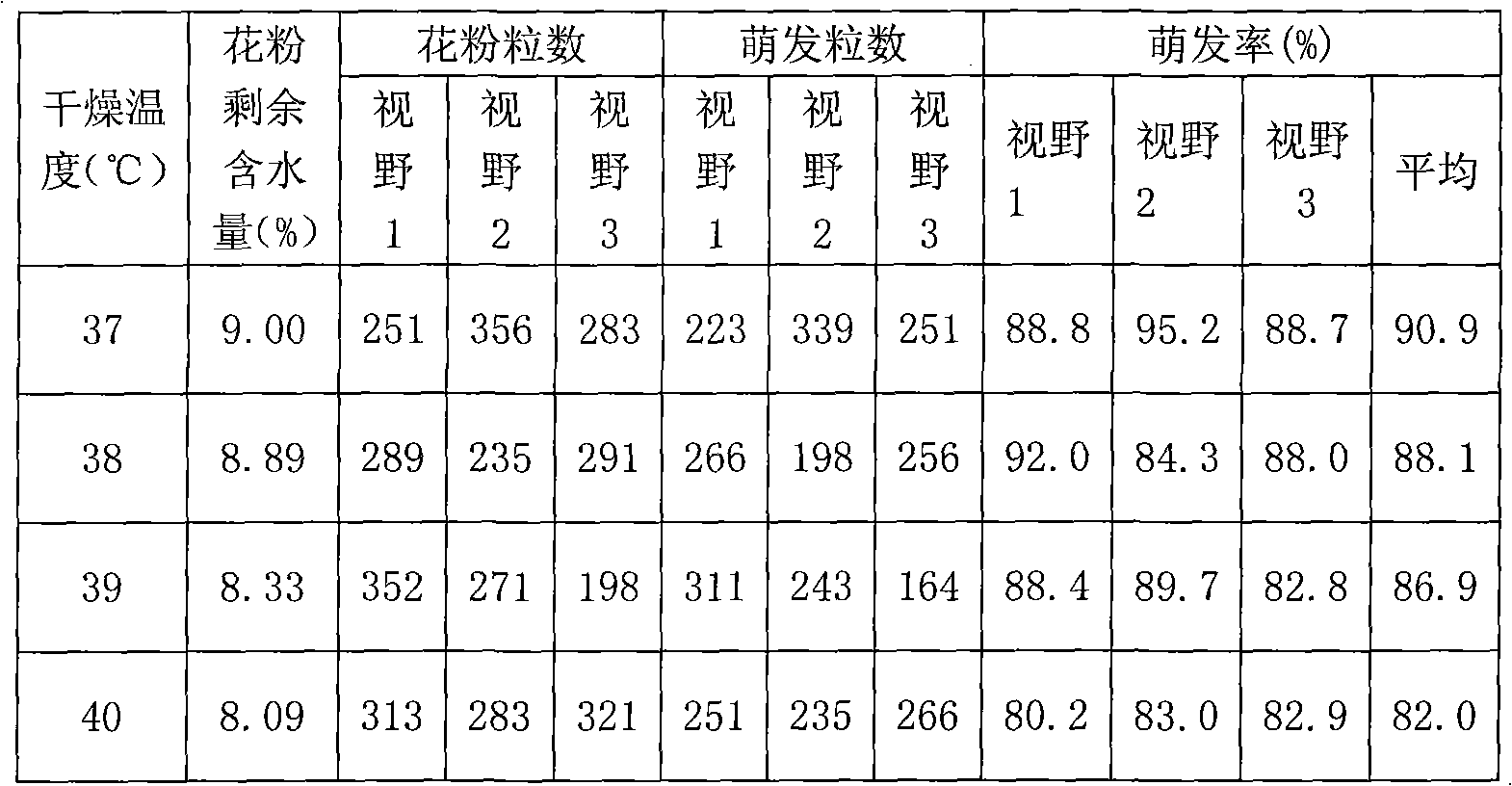

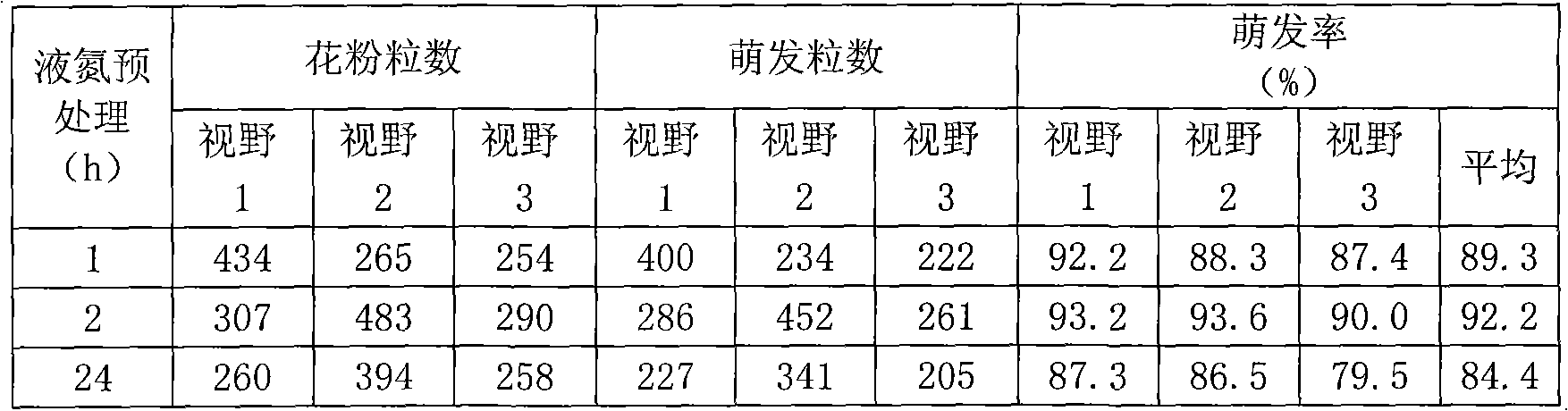

Ultra-low temperature preservation method for oil palm pollen

InactiveCN101926323AImprove germination rateAchieve long-term preservationDead plant preservationUltra Low Temperature FreezerPollen

The invention relates to an ultra-low temperature preservation method for oil palm pollen, which comprises the following steps of: drying the collected fresh oil palm pollen after impurity removal to control the residual moisture content of the oil palm pollen to between 8 and 9 percent; filling the dried oil palm pollen into a freezing pipe, directly putting the freezing pipe into liquid nitrogen to perform pre-freezing treatment, then transferring the freezing pipe to an ultra-low temperature refrigerator for preservation, and flushing the ultra-low temperature preserved oil palm pollen by using normal-temperature tap water during de-freezing. The method has simple process and low cost, effectively realizes long-term preservation of the oil palm pollen by preserving the oil palm pollen at the ultra-low temperature on the premise of controlling the residual moisture content of the pollen, and has the advantages of low preservation cost, long storage time, high pollen germination rateand the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

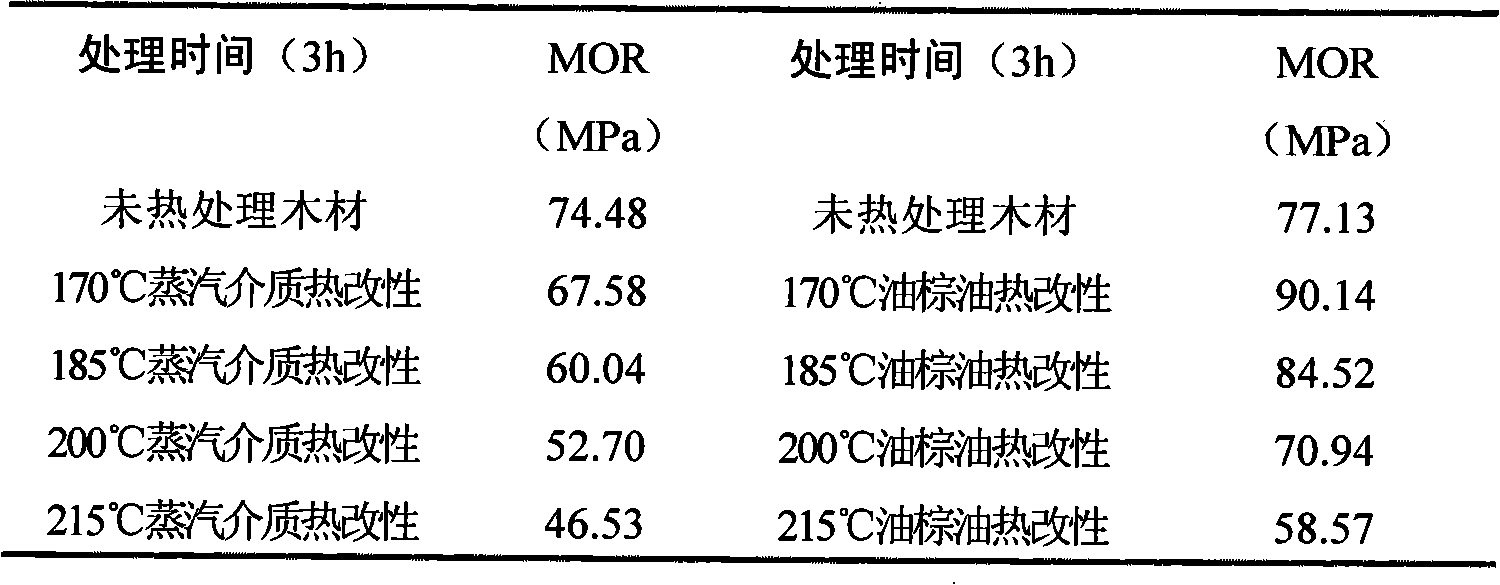

Method for thermally modifying wood by oil palm oil

ActiveCN102152361AFast heat transferHigh boiling pointWood treatment detailsIncrease sizeRoom temperature

The invention relates to a method for thermally modifying wood by oil palm oil. The method comprises the following steps of: stacking the wood stably, and then placing the wood stack in a treating tank; heating up the oil palm oil and then filling to the treating tank, completely covering the wood by the oil palm oil, heating up the wood, and keeping the temperature for 0.5-3 hours for thermally modifying the wood when the temperature of the wood reaches 200-215 DGE C; and stopping heat supply, then discharging the oil palm oil immediately, filling atomized water into the treating tank to gradually cool the wood, and then naturally cooling the wood to the room temperature (30 DEG C) so as to complete the treatment. The method in the invention is simple in process; the wood is isolated from the air by the oil palm oil; the wood is effectively prevented from oxidation and degradation; the thermal treatment features in fast heating speed, short treating period and low cost; the treated wood features in increased size stability, small bending resistance intensity loss, high corrosion resistance, high intensity, good durability and the like; and the wood is convenient for industrial application, and can be widely used for the indoor and outdoor furniture, landscapes, finishing materials and the like.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

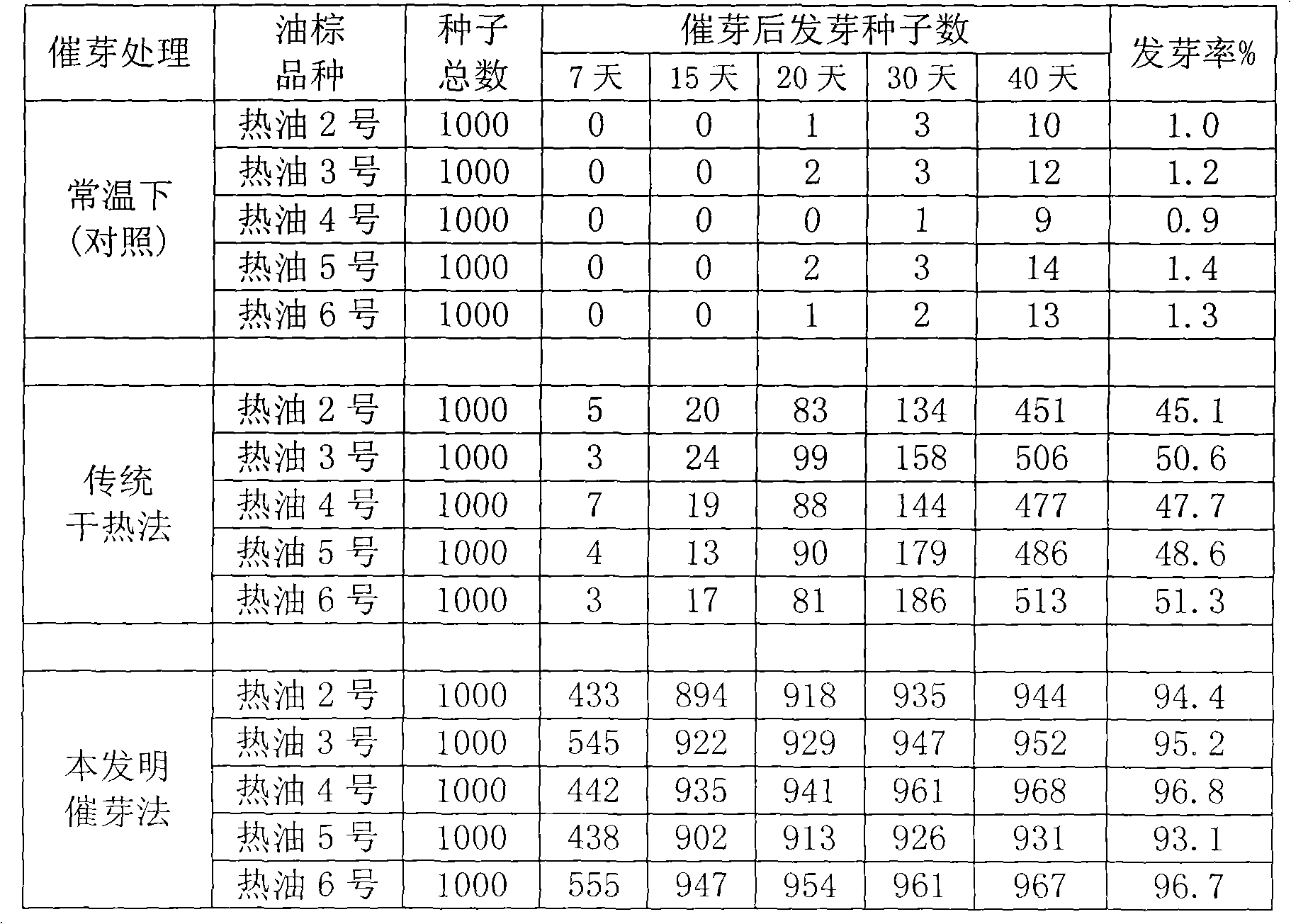

Method for raising seedling of oil palm seed

InactiveCN102084774ASpeed up germinationImprove germination rateSeed and root treatmentHorticultureAgricultural scienceOil palm

The invention belongs to the technical field of plant sprout breeding, in particular to a method for raising a seedling of an oil palm seed, which comprises the following steps of: (1) seed harvesting and accelerating germination; (2) seedbed preparing; (3) sowing and seedling-growing managing; and (4) transplanting. The invention has a simple process, is convenient for operation, increases the oil palm seed germinating speed, the germinating rate and the uniformity through combining accelerating germination with seedling-growing manners, improves the sprout quality, cultivates robust sprouts, shortens the oil palm period of immaturity, and provides a high-efficiency method for mass sprouts required by the oil palm planting industry.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

Compositions of volatile organic compounds and methods of use thereof

InactiveUS20100255124A1Prevent and inhibit developmentGrowth inhibitionBiocideMicroorganismsMicroorganismDisease

The present invention provides compositions and methods for treating, inhibiting or preventing the developing of a plant pathogenic disease. The compositions comprise volatile organic compounds effective to inhibit the growth of, or kill pathogenic microbes, including Ganoderma boninense. Invention compositions are especially useful in preventing and treating basal stem rot in the oil palm, and can be applied in the vicinity of the plant or used to sterilize the plant growth medium prior to or concurrent with plant growth therein.

Owner:SYNTHETIC GENOMICS INC

Method for processing oil palm fiber

ActiveCN101476164AEasy to handleLow costDry-cleaning apparatus for textilesVegetable materialOil and greasePlant fibre

The invention discloses a method for treating oil palm fiber which has characteristics that: dipping oil palm fiber in water with temperature 40-90 DEG. C, PH value 7-8, washing, natural insolating or drying after dehydration. The method is summed up by experiments that is simple and has low cost for washing grease layer and impurity on the oil palm fiber. The method includes steps as follows: placing the oil palm fiber into hot water with temperature 40-90 DEG. C, PH value 7-8 to dip that has better effect than normal temperature and does not need turning and stirring the oil palm fiber for avoiding knotting or breaking, adding surface active agent for treating more cleanly and reducing dipping time. Oilness rate of the treated oil palm fiber reduces 0.5%, sugar rate of the treated oil palm fiber reduces lower than 0.3%, odor degree special for the oil palm fiber reduces properly that is suitable for producing a plant fibre spring-mattress contained with fragrance special by the oil palm, and reduces possibility of mildewed and insert living greatly.

Owner:GUIZHOU DAZIRAN TECH

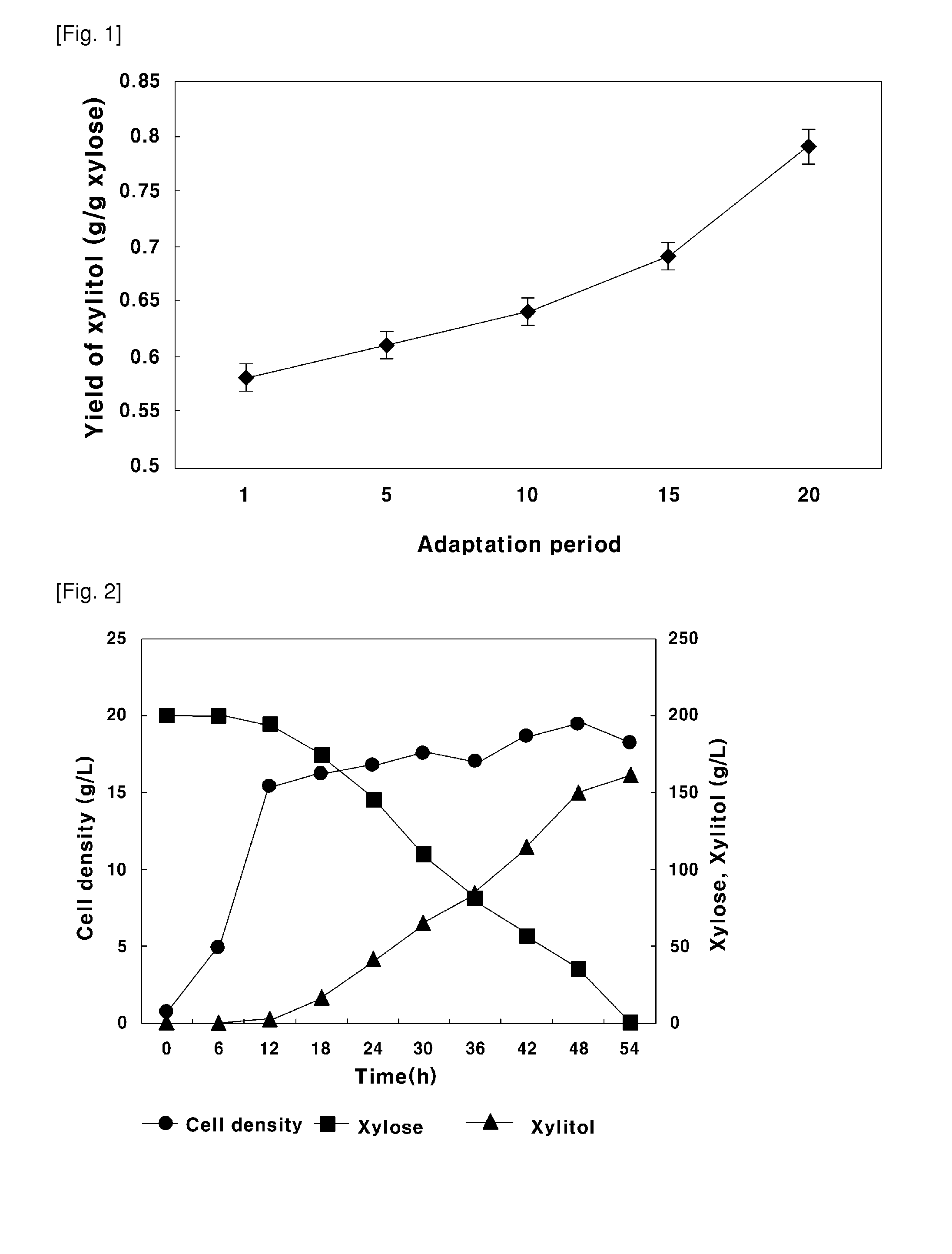

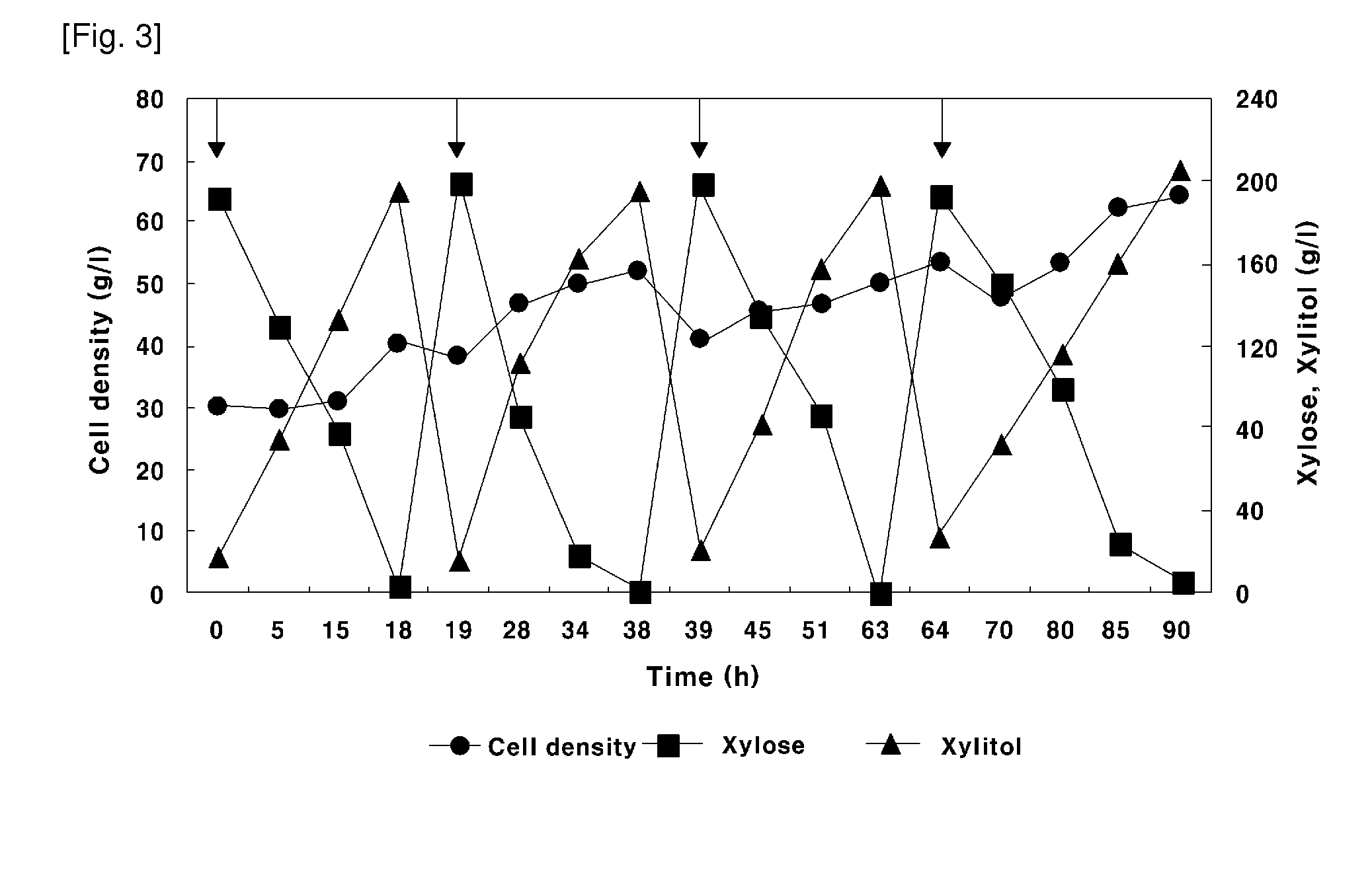

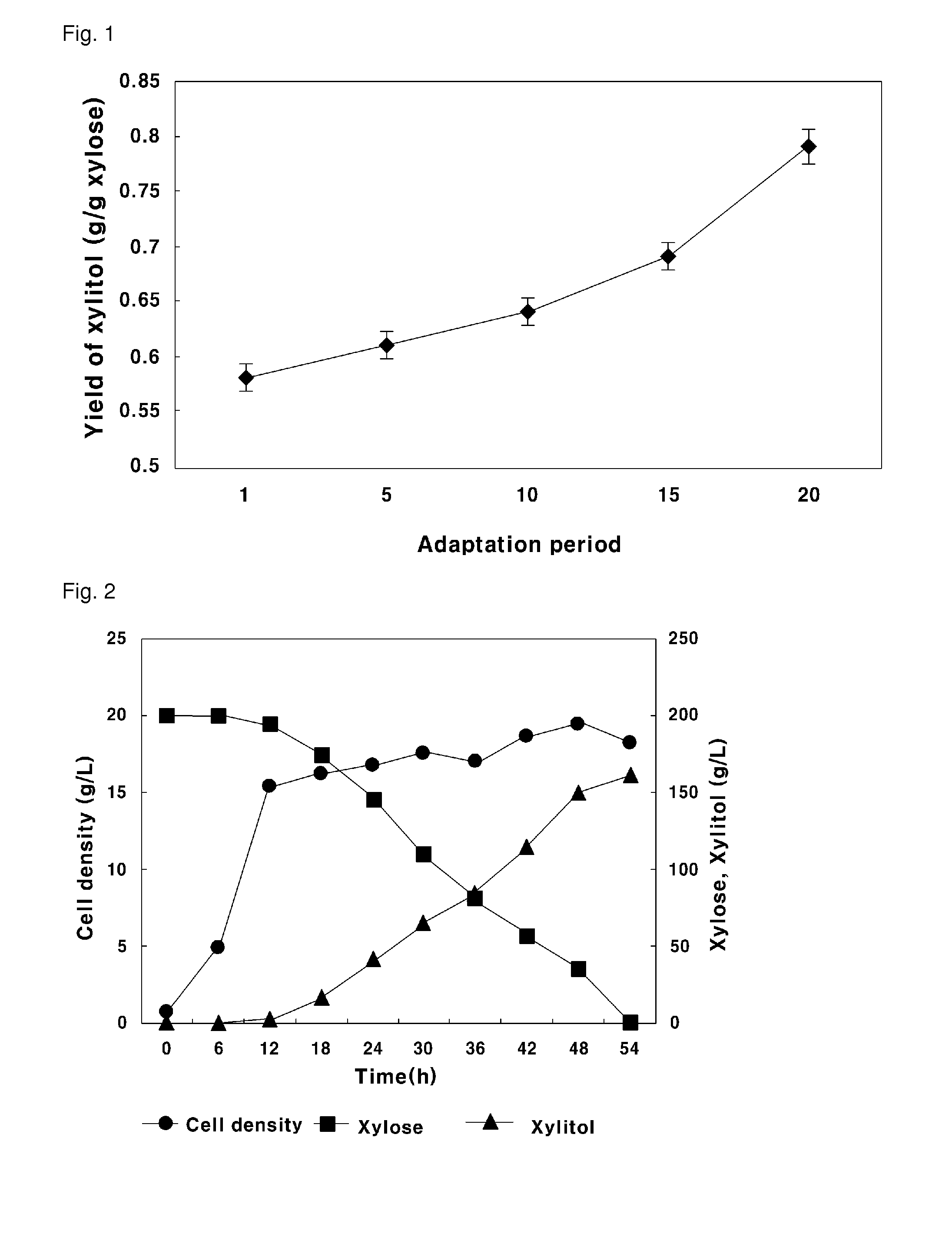

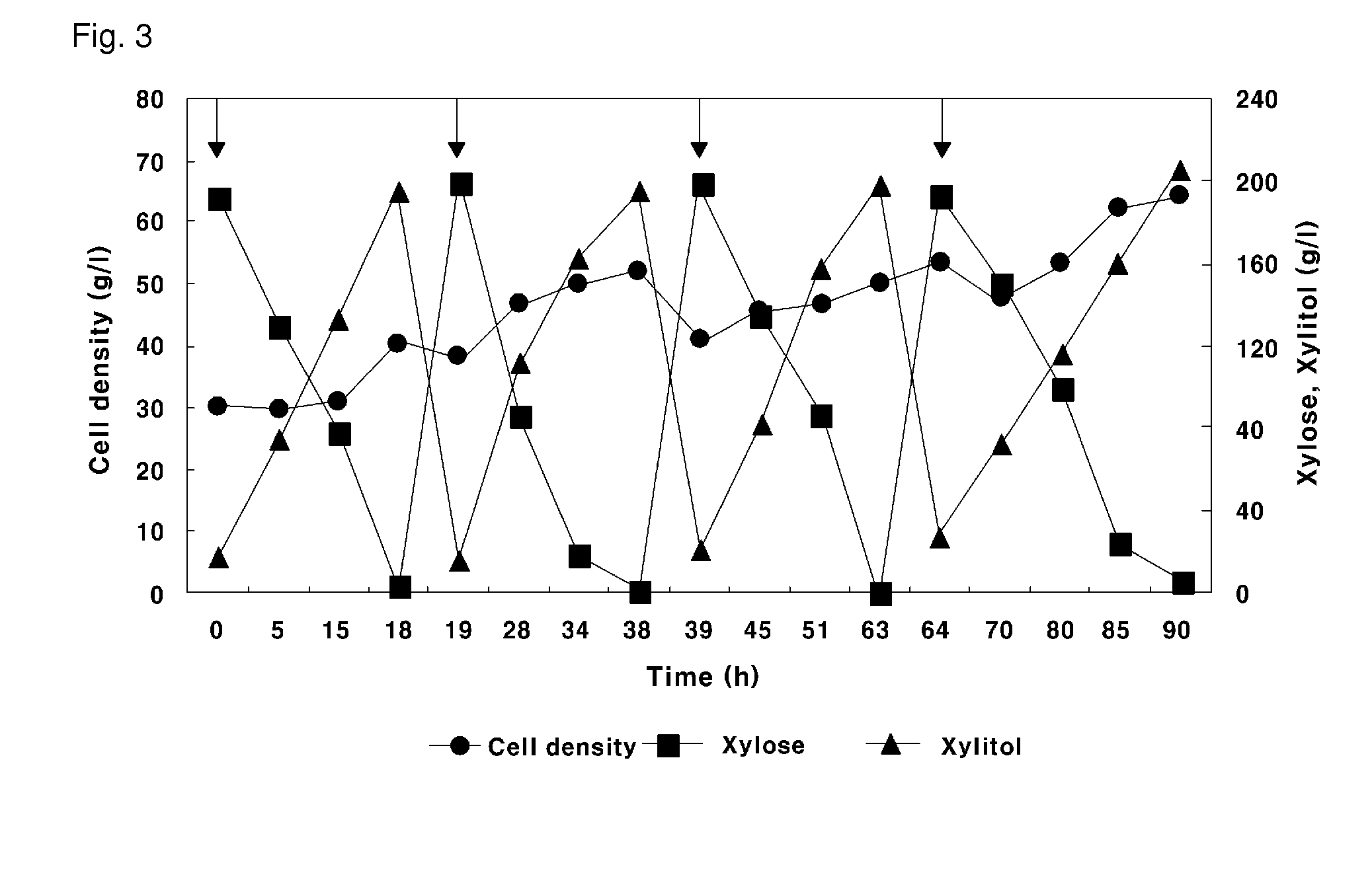

Method of Producing Xylitol Using Hydrolysate Containing Xylose and Arabinose Prepared from Byproduct of Tropical Fruit Biomass

ActiveUS20100068121A1Easy to useDecrease productivitySemi-permeable membranesCarbon compoundsHydrolysateCarbonization

Disclosed is a method of producing xylitol using a hydrolysate containing xylose and arabinose prepared from byproducts of tropical fruit biomass and more precisely, a method of producing xylitol which includes the steps of producing xylose and arabinose by the pretreatment of tropical fruit biomass byproducts including coconut shell, palm shell and oil palm empty fruit bunch (OPEFB) via acid (0.2-5%) hydrolysis and an electrodialysis and an ionic purification; and producing xylitol with high yield based on repeated batch fermentation using a hydrolysate containing xylose and arabinose as a carbon source. In addition, the present invention relates to an active carbon produced by carbonization and activation of a hydrolysate remainder of a tropical fruit shell, the byproduct of xylose and arabinose production, at a certain temperature and a preparation method of the same.

Owner:CJ CHEILJEDANG CORP

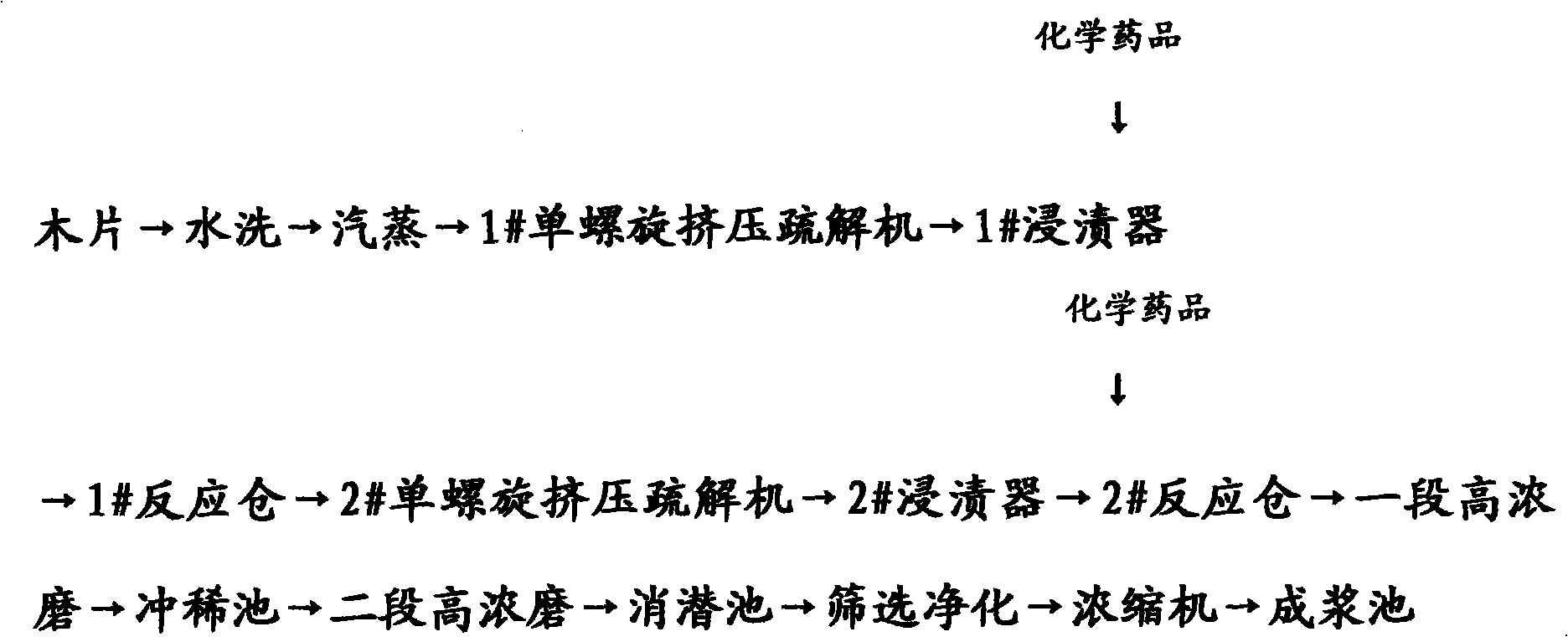

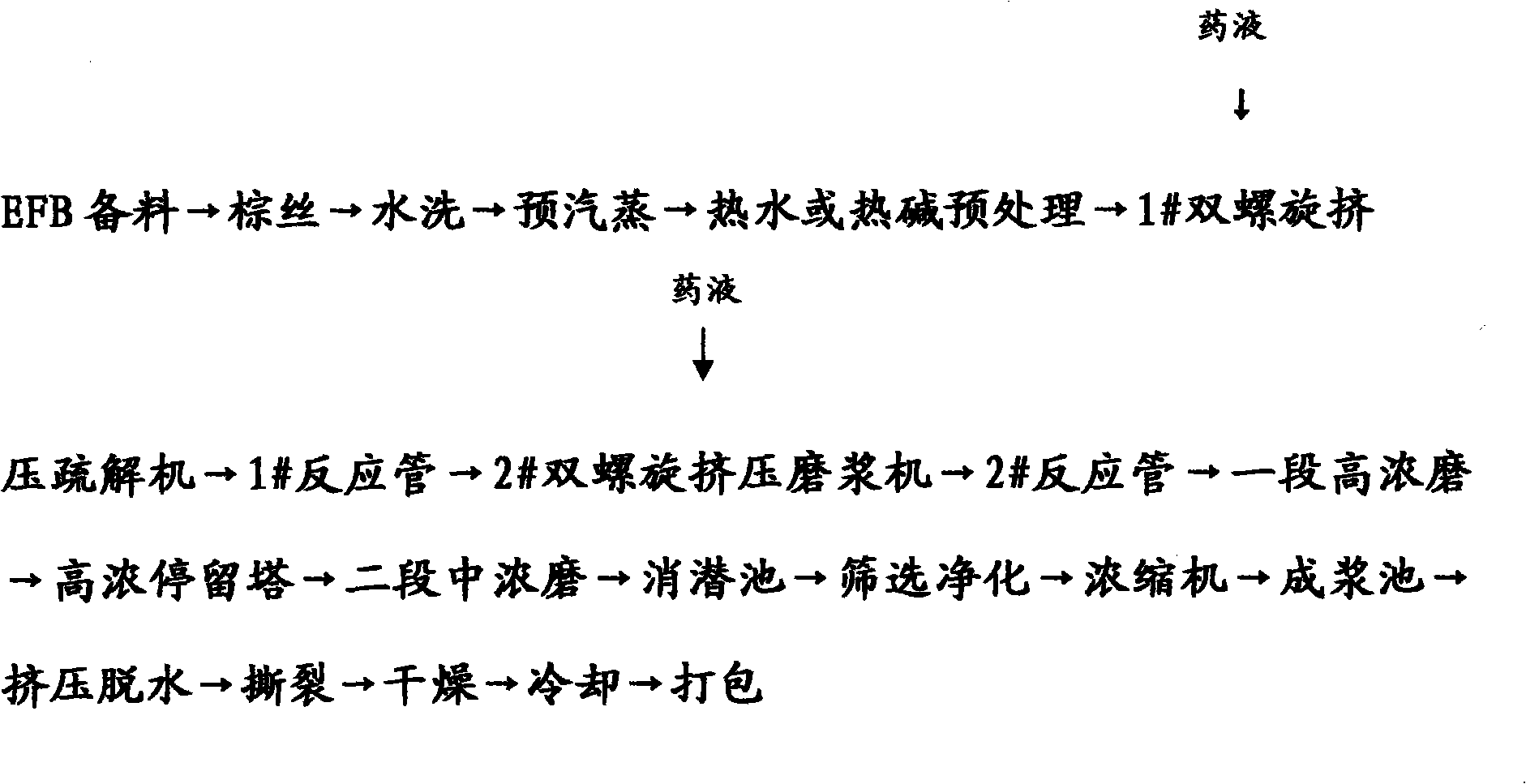

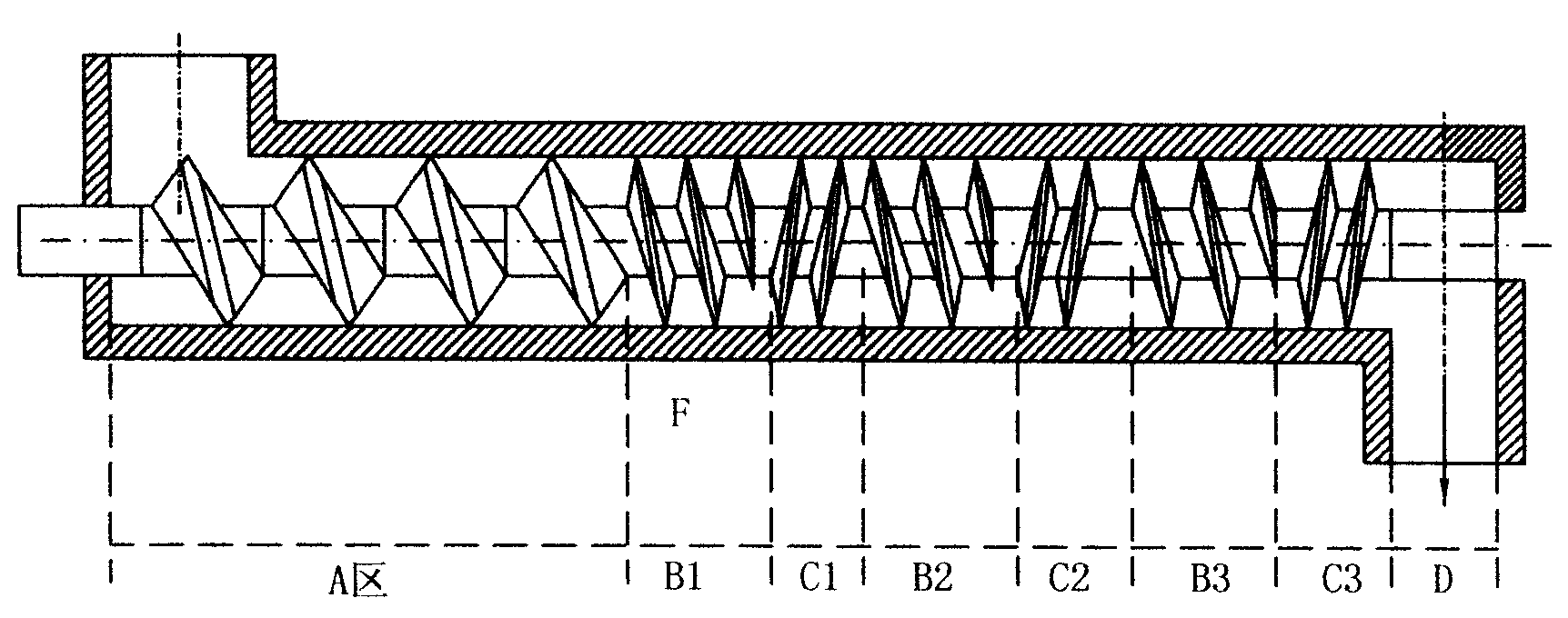

New pulping process of chemical mechanical pulp (CEMP) employing oil palm EFB high concentration extrusion displacement method

InactiveCN101638858AImprove extrusion tear effectFlexible adjustment of crushing and tearing degreePulping with inorganic basesPulp beating/refining methodsHigh concentrationFiber

The invention provides a new pulping process of chemical mechanical pulp (CEMP) employing oil palm EFB high concentration extrusion displacement method and the invention relates to a pulping process of CEMP, in particular to a pulping process of alkaline hydrogen peroxide mechanical pulp (CEMP) employing oil palm EFB high concentration extrusion displacement method. The invention adopts the following technical scheme: the process flow of the pulping process comprises the following procedures: water washing palm fibre, vapor-steaming, pretreating with hot water or hot alkali, sending to a double-screw extrusion kneader 1, sending to a reaction cabin 1, sending to a double-screw extrusion refiner 2, sending to a reaction pipe 2, high concentration grinding in first section, medium concentration grinding in second section, sending to a latency chest, screening and cleaning, sending to a thickener and a slurry-forming pool and the like; a double-screw extrusion kneader is used to completethe pulping process and the pulping and bleaching liquid medicines are separately poured in the double-screw extrusion kneader 1 and the double-screw extrusion refiner 2. By using the pulping processof the invention, the device investment can be reduced by about 40% compared with the prior art and the pulping process can save about 20% of energy, thus reducing the production cost. High concentration treatment is used to treat fiber materials so as to reduce the dosage of water for pulping and the wastewater treatment load and benefit the environment protection.

Owner:QINGDAO ZHISEN SCI & TECH DEVCO

Treatment of vegetation liquors derived from oil-bearing fruit

Owner:MALASIAN PALM OIL BOARD

Method for extracting fiber from oil palm fruit bundle and fiber obtained thereby

The invention discloses a method for extracting fiber yarns from palm fruit clusters of oil palm. The palm fruit clusters of the oil palm are cooked by steam with a temperature of between 100 and 200 DEG C for 0.5 to 1.5 hours, oil palm fruit pericarps are separated to obtain empty fruit clusters, then the empty fruit clusters are extruded and torn to obtain fiber blocks, the fiber blocks are washed and then are extruded to ensure that the water content of the fiber blocks is between 30 and 80 percent, then the selection is performed, the selected fiber blocks are subjected to silk fetching treatment to obtain the fiber yarns, and then the fiber yarns are dried, screened and bagged. The applicator aims at the requirement on an elastic material to process and select the fiber yarns in the palm fruit clusters so as to be suitable to process natural oil palm silk mattresses. Natural fiber yarns of the palm fruit clusters obtained by the method can substitute mountain palm fiber yarns to produce various natural palm mattresses, cushions, and products such as fiberboards and sound insulation boards for buildings and so on.

Owner:GUIZHOU DAZIRAN TECH

Method for producing and bleaching slasher sizing with oil windmill palm empty fruit fibre

InactiveCN101492891AHigh mechanical strengthReduce manufacturing costNon-fibrous pulp additionPulp bleachingFiberHigh concentration

The invention discloses a method for using oil palm hollow fruit fibers for the production of bleaching machine pulp, comprising: step 1, subjecting the oil palm hollow fruit fiber raw material to water scrubbing to remove oil stains, sands and dusts; step 2, adding a penetrant for pre-penetration treatment; step 3, extruding and dehydrating by a polishing splitting machine and pressing to filaments to then feed into a first thermofiner for rough grinding so that the fibers are split into coarse pulp; step 4, watering to dilute the coarse pulp roughly-grinded by the thermofiner in order to sieve out the coarse pulp and screened pulp which are extruded and filtered, respectively; step 5, Introducing the sieved coarse pulp into a second thermofiner for continuous thermal grinding, and mixing the grinded size with the screen pulp by a pulp screen in the fourth step; step 6, watering to dilute the grinded size followed by screening via a screen net, delivering the coarse pulp to the second thermofiner for regrinding, concentrating the screened pulp to prepare for bleaching; step 7, employing a high-concentration high-temperature chlorine-free hydrogen peroxide bleaching method to reach 75%-80%ISO of the whiteness of the bleached pulp, and obtaining the bleaching machine pulp via washing, filter-pressing and drying for the papermaking.

Owner:SHAANXI UNIV OF SCI & TECH

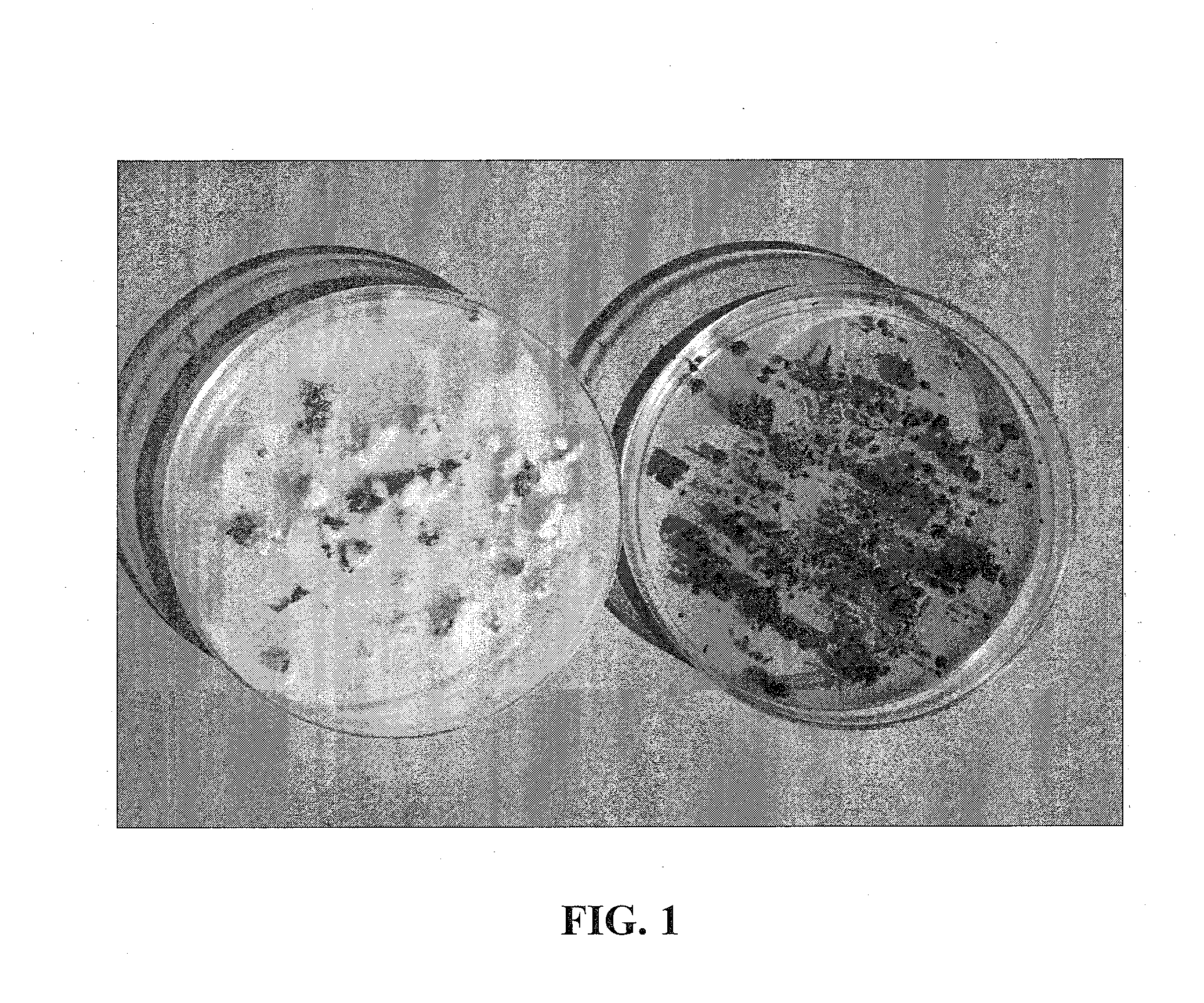

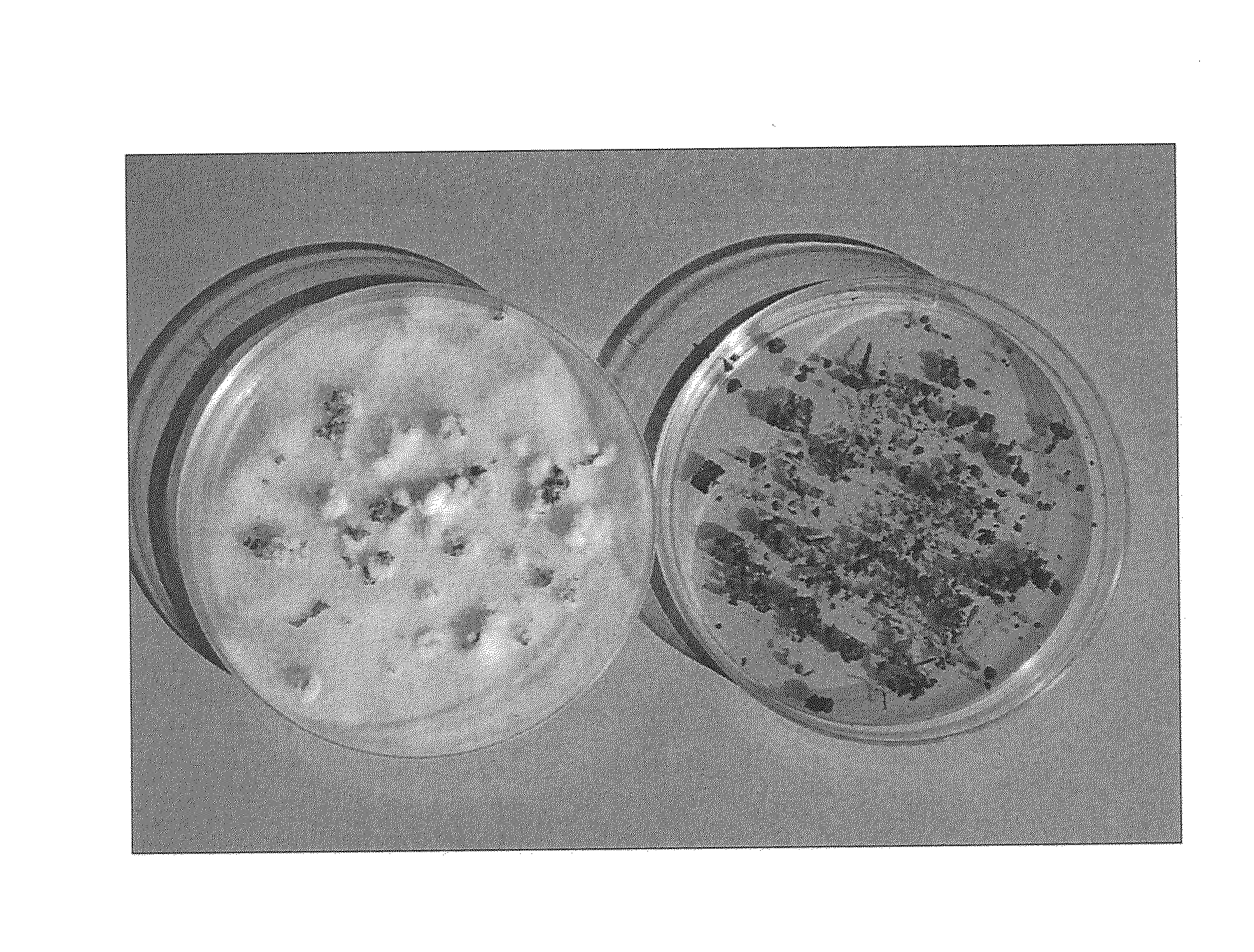

Compositions of Volatile Organic Compounds and Methods of User Thereof

InactiveUS20130224315A1Prevent and inhibit developmentGrowth inhibitionBiocideOrganic active ingredientsDiseaseStem rot

The present invention provides compositions and methods for treating, inhibiting or preventing the developing of a plant pathogenic disease. The compositions comprise volatile organic compounds effective to inhibit the growth of, or kill pathogenic microbes, including Ganoderma boninense. Invention compositions are especially useful in preventing and treating basal stem rot in the oil palm, and can be applied in the vicinity of the plant or used to sterilize the plant growth medium prior to or concurrent with plant growth therein.

Owner:VIRIDOS INC

Compositions of volatile organic compounds and methods of use thereof

InactiveUS8425946B2Prevent and inhibit developmentGrowth inhibitionBiocideMicroorganismsDiseaseGrowth plant

The present invention provides compositions and methods for treating, inhibiting or preventing the developing of a plant pathogenic disease. The compositions comprise volatile organic compounds effective to inhibit the growth of, or kill pathogenic microbes, including Ganoderma boninense. Invention compositions are especially useful in preventing and treating basal stem rot in the oil palm, and can be applied in the vicinity of the plant or used to sterilize the plant growth medium prior to or concurrent with plant growth therein.

Owner:SYNTHETIC GENOMICS INC

Bone collagen-rich corn porridge

InactiveCN104366292AFull of nutritionAlleviate Liver and Kidney Yin DeficiencyFood ingredient functionsFood preparationBiotechnologyPhospholipid

The invention discloses bone collagen-rich corn porridge. The bone collagen-rich corn porridge is prepared from the following raw materials in parts by weight: 550-600 parts of waxy corn, 2-3 parts of rice bran oil, 8-9 parts of sesame, 10-11 parts of sea weed, 20-22 parts of oilseed rape, 1-2 parts of oil palm fruit pericarp, and 5-6 parts of apple blossom. The added Eclipta prostrate has the efficacies on relieving the deficiency of liver-yin and kidney-yin and insomnia, organic substances in sheep bone contain bone collagen, bone mucinoid and elasticin and also contain neutral fat, phospholipid, a small amount of glycogen and the like, and the organic substances in sheep bone are sweet and warm in property and flavor and have the effects of tonifying kidney and strengthening tedons; and the bone collagen-rich corn porridge is also added with wheat germ powder, black peanut, waxy corn, sesame and other auxiliary materials with rich nutrition and specific taste, so that the corn porridge has good mouthfeel and is suitable for people of all ages.

Owner:张晓艳

Method for producing wrapping paper by oil palm empty fruit bunches mechanical pulping

InactiveCN101503867AHigh strengthLow costNon-fibrous pulp additionPulp beating/refining methodsCardboardCarton

The invention provides a method for producing wrapping paper by pulping of hollow nuts of oil palms with a mechanical process, which comprises that: step one, raw materials are washed by water to remove residual oil, sand grains and dust; step two, a penetrant is added for prepenetration treatment; step three, the raw materials are extruded for dehydration and pressed into filaments, and the filaments are sent into a first pass of thermofiner for coarse grinding and separated into unscreened pulp; step four, the unscreened pulp is added with water for dilution, and respectively screened into the unscreened pulp and screened pulp which are then respectively extruded and filtered; step five, the unscreened pulp enters a second pass of thermofiner for hot grinding after being condensed, and the ground pulp and the screened pulp from a pulp cleaner of the step four are mixed together; step six, the ground pulp is mixed evenly and undergoes pulp screening after pulp dilution, the unscreened pulp enters the second pass of pulping machine for pulping again, and the screened pulp is condensed and ready for a third pass of fine pulping; step seven, the mixed pulp is further ground finely; and step eight, the pulp is put onto a net by a paper machine for paper making to produce carton boards or high strength corrugating paper. The method is characterized by high yield, low cost and small pollution.

Owner:SHAANXI UNIV OF SCI & TECH

Catalyst for preparing alkane of diesel oil fraction from synthetic gas and its preparation

InactiveCN1190267CHydrocarbon from carbon oxidesLiquid hydrocarbon mixture recoveryAlkanePore distribution

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Methods of producing haploid and doubled haploid oil palms

InactiveCN101688238AMicrobiological testing/measurementPlant genotype modificationBiotechnologyAtypical phenotype

The present invention relates to haploid oil palm plants and homozygous doubled haploid oil palm plants. The invention also relates to methods for producing and selecting haploid and doubled haploid plants. More particularly, but not exclusively, the method may be used for selecting haploid and doubled haploid oil palm plants. Haploid and doubled haploid plants are selected by a large-scale screening based on a combination of the phenotype with the use of molecular methods combined with flow cytometry techniques to identify haploid and doubled haploid plants. More particularly, a method for selecting haploid and doubled haploid plants is described comprising: (a) germinating seeds; (b) selecting seedlings with atypical phenotype; (c) assessing heterozygosity using markers; (d) isolating cells from the seedlings and determining the DNA content of the cells; and (e) isolating and purifying the DNA and using defined molecular markers to characterise the genotype of the plant. The haploidoil palm plants may be used for producing homozygous doubled haploid oil palms: doubled haploids may be intercrossed to produce uniform F1 hybrids of superior properties.

Owner:SUMATRA BIOSCI PTE

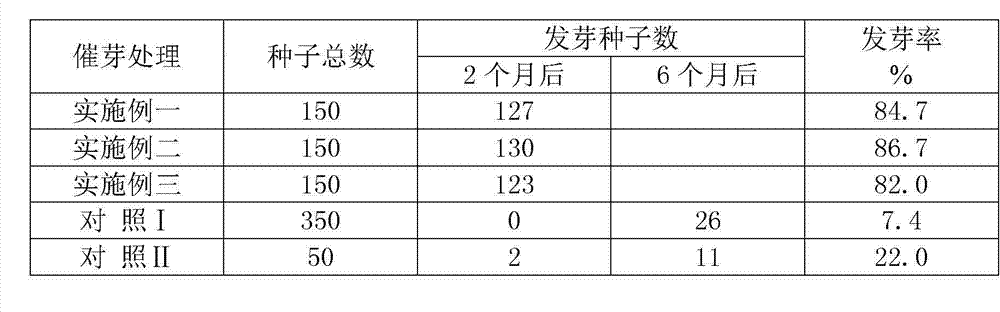

Oil palm seed pregermination method

The invention relates to an oil palm seed pregermination method. The method comprises the following steps: collecting fresh oil palm seeds; removing the epicarp and fiber on the surfaces of the seeds; cleaning surface grease for standby; treating by chemical reagents, disinfecting, packaging, carrying out cold treatment and heat treatment, and then soaking in clean water; and placing at normal temperature until germinating. The oil palm seed pregermination method has the advantages of simple technology and low cost. The mode of soaking by chemical reagents and processing at changed temperature and constant temperature can effectively break through the dormancy of the recalcitrant seeds of the oil palm, accelerate oil palm seeds to quickly and tidily germinate, improve the seed culture planting percent of the oil palm, reduce disease infection on seeds and buds and improve the planting percent and the quality of seedlings.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Oil palm tissue culture method

InactiveCN102860256AEfficient reproductionConsistent genetic traitsHorticulture methodsPlant tissue culturePlant stemEmbryo

The invention belongs to a culture medium for plant tissue culture, particularly relates to an oil palm tissue culture method. An oil palm stem section on an oil palm stock plant stem growing point is cut, and then oil palm tender leaves are pruned into plates and inoculated onto a callus induction culture medium, an embryonic callus culture medium and an embryoid culture medium to be cultured to obtain oil palm somatic embryos; and the somatic embryos are inoculated into a bud induction culture medium, a rooting culture medium and a liquid rooting culture medium to be cultured to obtain oil palm test-tube plantlets. Oil palm tender leaves are used as explant material, a tissue culture technique is utilized to rapidly propagate oil palm without the limitation of seasons and weather, oil palm descendants can be effectively propagated largely, the propagation cycle of ordinary breeding is greatly shortened, the genetic characters of descendants are highly consistent to those of the parents, and an effective path is provided for the wide popularization and application of oil palm fine breeds.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Method for decomposing oil-palm into fibre filament and fibre filament therefrom

ActiveCN101074496APromote decompositionEasy to separateFibre rougheningVegetable materialNatural fiberOil palm

This invention discloses one fiber wire and its method of decomposing oil palm into fiber wire. Its character is: pick off the petiole of oil palm and dry it, cook the petiole after drying in the water with PH 5-9, Roll again, carding into silk. The creativity of this invention is the usage of the petiole of oil palm, which results in increasing the economic value of oil palm plants and providing a new environmentally friendly natural fiber material. Compared with existing technology, this invention has advantages of using resources rationally, enhancing the economic value of oil palm and providing the new all-natural silk fibers.

Owner:GUIZHOU DAZIRAN TECH

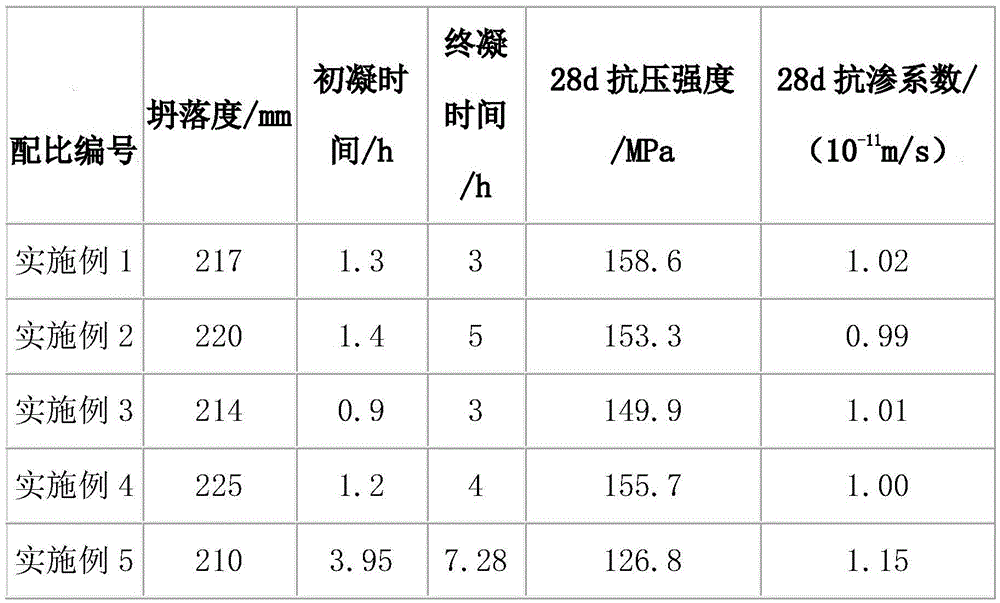

Process for using latter admixing method to produce green concrete

The invention discloses a process for using a latter admixing method to produce green concrete. According the process, microorganism modified oil palm fruit shell ash is used for replacing parts of cement to prepare a new concrete reinforcing additive, then the latter admixing method is adopted to produce the green concrete, and the produced concrete is short in setting time, high in strength, long in service life and stable in quality and is resistant to abrasion, pressure and seepage.

Owner:ZHEJIANG TIANLI NEW MATERIAL CO LTD

Accelerating germination method for shell-free type oil palm seeds

InactiveCN102812804AOvercome drynessOvercome the disadvantage of susceptibility to germ infectionSeed and root treatmentDisinfectantSeedling

The invention relates to an accelerating germination method for shell-free type oil palm seeds. The accelerating germination method comprises using abluent solution to soak the shell-free type oil palm seeds, and cleaning and airing the seeds; using a disinfectant to rinse the seeds, placing the seeds into a plump transparent sealing bag filled with air, adding pure water of 2-4ml into every 10 seeds, transferring sprouting seeds to a sand bed, enabling a sand layer with the thickness of 1-2cm to be covered on the sprouting seeds, maintaining moist, transplanting the seeds into a seedling growing bag filled with nutrition soil when the seedlings grow to 9-12cm on the sand bed, and enabling the seedlings to grow into strong seedlings. The accelerating germination method is simple in process, convenient to operate, low in cost and high in efficiency, and can effectively overcome the shortcomings that the shell-free seeds are easy to dry and are subjected to germ infection easily. Germination time is short, the germination rate, the seedling emergency and the strong seedling rate are high, and the method is efficient for accelerating germination and seedling growing of the shell-free type oil palm seeds.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Rice bran oil with qi-benefiting and kidney-tonifying effects

InactiveCN103651953AImprove the value of food therapy and health careNutritional diversityFatty-oils/fats refiningFatty-oils/fats productionGrape seedSpleen

The invention relates to the field of health food, specifically to rice bran oil with qi-benefiting and kidney-tonifying effects. The rice bran oil is prepared from the following raw materials by weight: 1350 to 1500 parts of rice bran, 38 to 40 parts of oil palm fruit pericarp, 45 to 50 parts of grape seed, 15 to 17 parts of celery seed, 10 to 12 parts of common fenugreek seed, 14 to 16 parts of eucommia bark, 15 to 18 parts of wolfberry, 6 to 8 parts of large-fruited hodgsonia seed, 16 to 20 parts of sweet osmanthus and 8 to 12 parts of fleece-flower root. According to the invention, the rice oil is prepared by using carbon dioxide subcritical extraction technology, production process is environment friendly and highly efficient, extraction temperature is low, and a plurality of beneficial biologically-active components in the raw materials are not destroyed; rice bran and oil plants like the oil palm fruit pericarp are used as carriers, active substances like volatile oils and liposoluble constituents in Chinese herbal medicines are extracted into oil, so the rice bran oil provided by the invention has comprehensive nutrients and rich fragrance, can nourish the kidney, build up the body, tonify qi, invigorate the spleen and the stomach, etc., and is applicable to daily health care of consumers.

Owner:XUZHOU FENGRUN BIOLOGICAL ORGANIC FERTILIZER TECH DEV CO LTD

Method for planting oil palms

InactiveCN107950268ASuitable for growthImprove fruit setting rateSuperphosphatesExcrement fertilisersHand-pollinationOrchard

The invention discloses a method for planting oil palms. The method comprises the following steps of 1 land selecting, 2 planting hole digging, 3 base fertilizer applying, 4 sapling planting, 5 management after planting, 6 soybean interplanting and 7 oil palm flowering and fruit bearing stage management. According to the method, fertilizer and water management is reasonable, the method is suitablefor growth of the oil palms, hand pollination is adopted during flowering, and the fruit bearing rate is increased; meanwhile, soybeans and other crops are interplanted in an oil palm orchard, the acre yield of planting land is further increased, and the economic income of farmer households is increased.

Owner:广西垚宇贸易有限公司

Three-dimensional cultivation method of dendrobium on oil palms

InactiveCN103918538AIncrease economic incomeOvercome spaceCultivating equipmentsSoilless cultivationOil palmDendrobium

The invention belongs to the technical field of agricultural planting, and particularly discloses a three-dimensional cultivation method of dendrobium on oil palms. According to the three-dimensional cultivation method, the live oil palms serve as planting carriers of the dendrobium; oil palm natural litters on petiole residues serve as dendrobium cultivating natural matrixes; the method that slugs and snails on the oil palms are controlled is adopted, and the oil palm natural litters on the petiole residues serve as the dendrobium cultivating natural matrixes. The three-dimensional cultivation method has the advantages that three-dimensional cultivation is achieved, the yield is high, environment-friendly production is achieved, products are high in quality and safe, the technology is simple, cost is low, and the three-dimensional cultivation method is suitable for large-area production; an oil palm garden is comprehensively used, and the benefit is high.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Method of producing xylitol using hydrolysate containing xylose and arabinose prepared from byproduct of tropical fruit biomass

ActiveUS8283139B2Easy to useDecrease productivitySemi-permeable membranesOther chemical processesHydrolysateCarbonization

Disclosed is a method of producing xylitol using a hydrolysate containing xylose and arabinose prepared from byproducts of tropical fruit biomass and more precisely, a method of producing xylitol which includes the steps of producing xylose and arabinose by the pretreatment of tropical fruit biomass byproducts including coconut shell, palm shell and oil palm empty fruit bunch (OPEFB) via acid (0.2-5%) hydrolysis and an electrodialysis and an ionic purification; and producing xylitol with high yield based on repeated batch fermentation using a hydrolysate containing xylose and arabinose as a carbon source. In addition, the present invention relates to an active carbon produced by carbonization and activation of a hydrolysate remainder of a tropical fruit shell, the byproduct of xylose and arabinose production, at a certain temperature and a preparation method of the same.

Owner:CJ CHEILJEDANG CORP

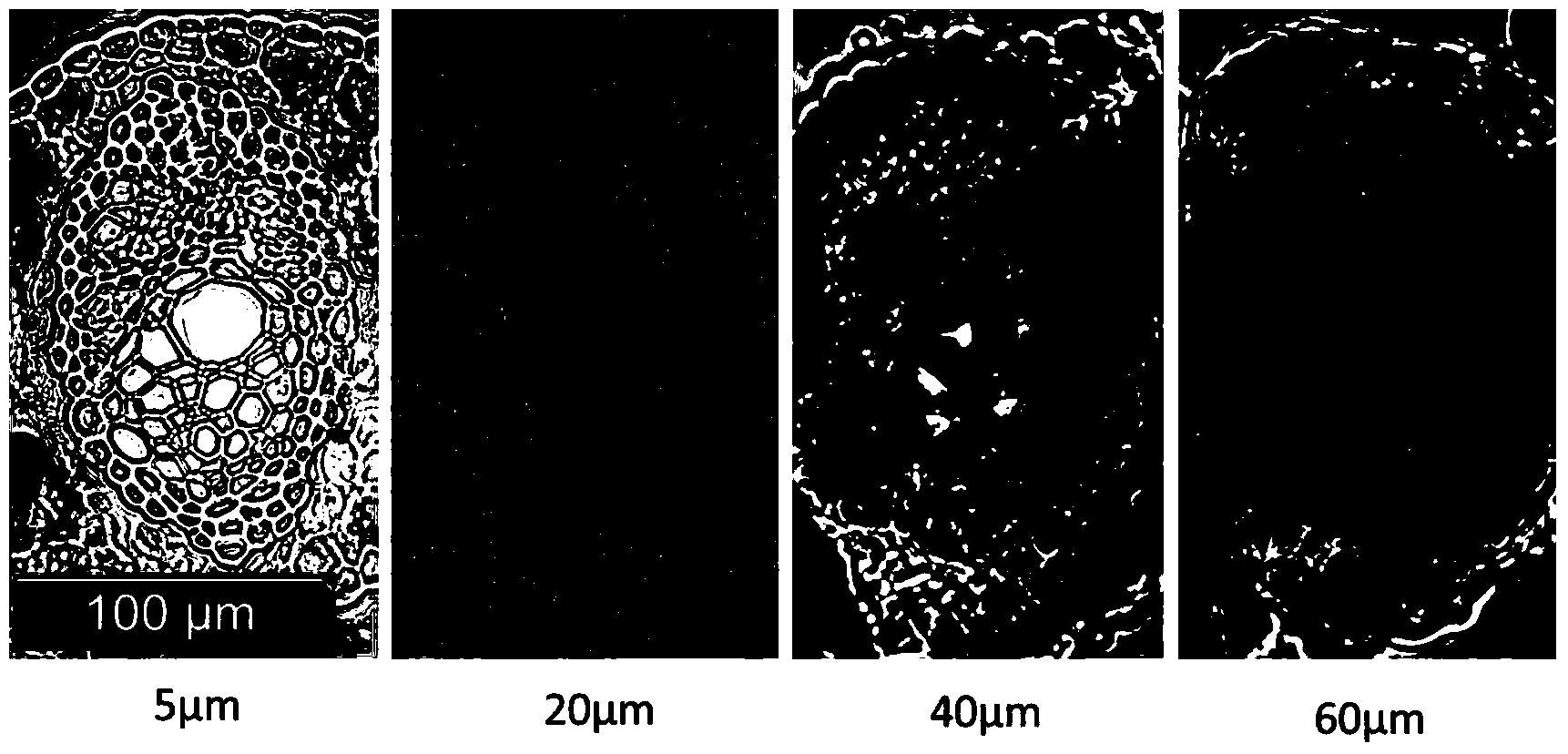

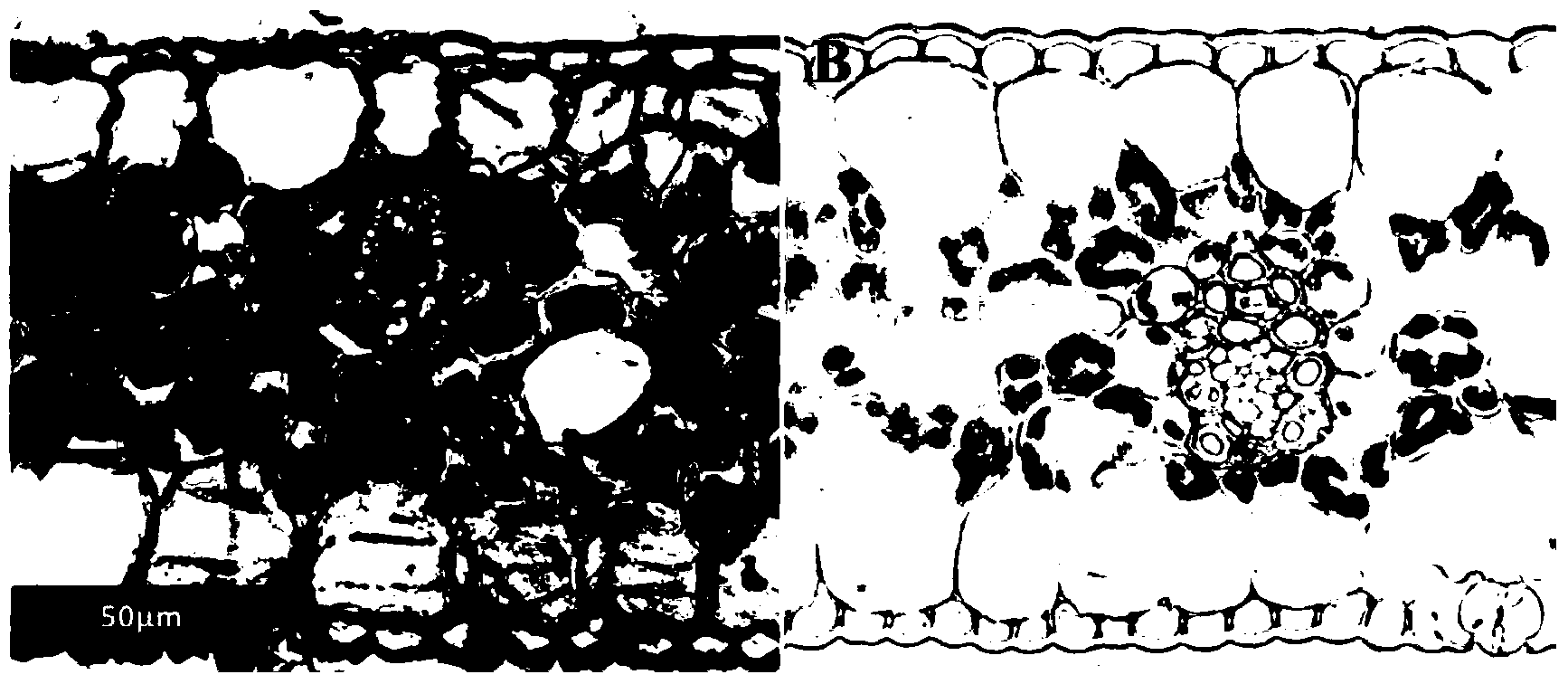

Freezing and slicing method suitable for quickly observing oil palm leaf anatomical structures

InactiveCN103926109AEasy to observeConvenient researchWithdrawing sample devicesPreparing sample for investigationAnatomical structuresWrinkle skin

The invention relates to a freezing and slicing method suitable for quickly observing oil palm leaf anatomical structures. The freezing and slicing method comprises the following steps: firstly setting temperatures of a freezing box and a sample head of a freezing microtome, manufacturing an embedding paper box and fixing the embedding paper box in a sample plate; selecting oil palm leaf material and trimming the oil palm leaf material into samples; adding an OCT (Optical Coherence Tomography) frozen embedding agent into the embedding paper box, then vertically putting the samples into the embedding agent, freezing under the condition of the temperature of 20 DEG C below zero till the frozen embedding agent is fully solidified, quickly trimming embedding blocks and then slicing and sealing to obtain a slice for observing oil palm leaf anatomical structures, observing the slice on a microscope to obtain images. By adopting the freezing and slicing technology, the frozen slice with the integrated oil palm leaf structures can be quickly obtained; the slice is smooth, free of wrinkles, uniform in thickness and clear in microscopy result; the slice facilitates the development of observation and research of the oil palm leaf anatomical structures and has great significance to the work of cultivating varieties suitable for cultivation in China or screening high-quality germplasm resource types.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

Methods for obtaining high-yielding oil palm plants

InactiveCN102998456AHigh speedImprove reproductive efficiencyBiological material analysisPlant peptidesBiotechnologyHigh yielding

Methods are provided for obtaining a high-yielding oil palm plant, comprising determining the level of a protein in mesocarp tissue of a fruit of a parental oil palm plant, determining whether there is a difference between the level of the protein in the mesocarp tissue of the fruit of the parental oil palm plant and the level of the protein in mesocarp tissue of a fruit of a reference oil palm plant, and selecting progeny of the parental oil palm plant based on the difference to obtain the high-yielding oil palm plant. Also provided are methods for predicting oil yield of a test oil palm plant and kits for obtaining a high-yielding oil palm plant.

Owner:SIME DARBY PLANTATION INTPROP SDN BHD

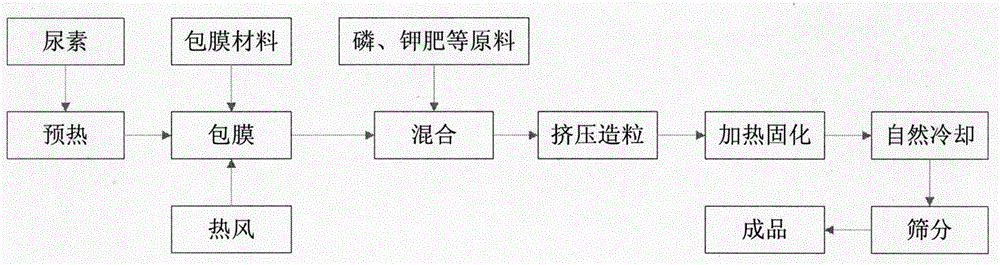

Method for producing special large-particle slow release fertilizer for oil palm

The invention discloses a method for producing a special large-particle slow release fertilizer for oil palm, belonging to the technical field of fertilizer manufacture. The method comprises the steps of: firstly, coating particular urea preheated to 50-100 DEG C by adopting a coating material in a drum coating machine; after coating is completed, adding monoammonium phosphate, magnesium oxide, potassium chloride, copper sulfate pentahydrate, sodium borate and zinc sulfate, uniformly stirring, adding a mixture into an extruding and pelleting machine for extruding and pelleting; and placing and curing the pelleted semi-finished special slow release fertilizer at a temperature of 50-80 DEG C for 20-30h, and then naturally cooling and sieving to obtain the finished product of the special large-particle slow release fertilizer. The special large-particle slow release fertilizer for oil palm, with the diameter of 10-60mm and the weight of 10-200g, can be produced according to the size of a mould of the extruding and pelleting machine. The method has the advantages of short process, less returned materials, and convenience and flexibility in operation. The special slow release fertilizer has the characteristics of high particle uniformity, high strength and no powderization.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com