Patents

Literature

830 results about "Rice bran oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rice bran oil is the oil extracted from the hard outer brown layer of rice called chaff (rice husk). It is known for its high smoke point of 232 °C (450 °F) and mild flavor, making it suitable for high-temperature cooking methods such as stir frying and deep frying. It is popular as a cooking oil in several Asian countries, including Bangladesh, Japan, India, and China.

Food spreads

The present invention is of a food spread containing a mixture of at least one edible oil of natural or synthetic origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, nut oils, walnut oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil, palm oil, sesame oil, wheatgerm oil, jojoba oil or corn oil. More preferably an oil such as avocado oil, fish oil, palm oil or olive oil is used and most preferably the oil is olive oil and fish oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The oil is present preferably in an amount of from about 85 to about 98 percent and most preferably in an amount of from about 93 to about 96 percent. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

Process for the pre-treatment of vegetable oils for physical refining

ActiveUS20040005399A1Speed up the processFatty acids production/refiningTea extractionMicroorganismActivated carbon

The present invention relates to a simple and economically attractive process for the pretreatment of vegetable oils which involves (a) enzymatic degumming with commercially available phospholipase A1 from the sources like Aspergillus oryzae microorganism, (b) bleaching of the enzymatically degummed oil using bleaching earth and activated carbon, and (c) dewaxing (in case of rice bran oil) of degummed and bleached oil at lower temperature to obtain oil with less than 5 ppm of residual phosphorus which is amenable for physical refining.

Owner:COUNCIL OF SCI & IND RES

Healthy food spreads

InactiveUS6117476AGreat degree of solidityUnlimited shelf lifeEdible oils/fats with aqeous phaseFood borneMonoglyceride

The present invention is of a food spread containing a mixture of an edible oil of natural origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil or corn oil. More preferably an oil such as avocado oil or olive oil is used and most preferably the oil is olive oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The ratio of oil to monoglyceride is preferably from about 9 to about 1 to from about 49 to about 1 and most preferably from about 15 to about 1 to from about 24 to about 1. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

Rice bran first-level oil refinement production method

ActiveCN101455242ARealize large-scale productionReduce pollutionEdible oils/fatsFood preparationSocial benefitsO-Phosphoric Acid

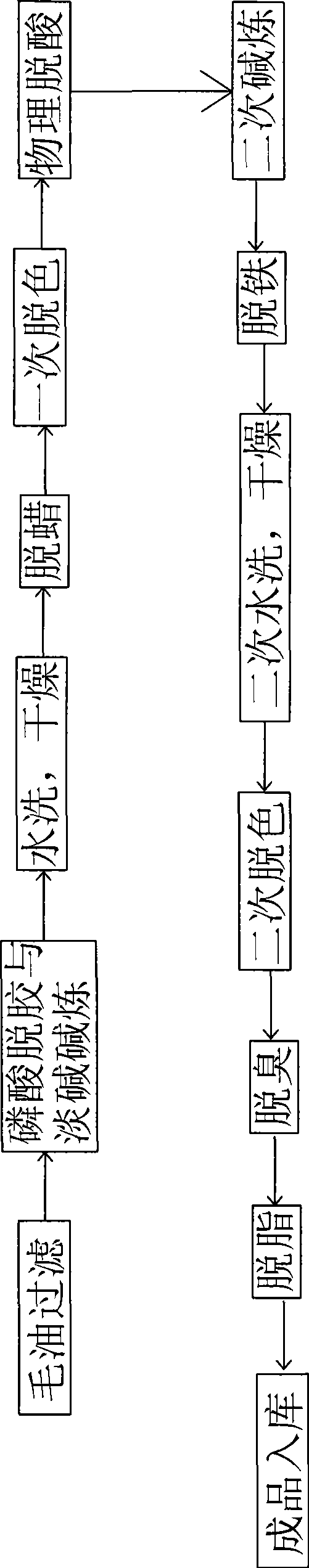

The present invention relates to a manufacturing method of refining rice bran top oil, which can effectively refining top oil from the rice bran and satisfy the people requirement to the health dieting. The invention includes the following steps: (1) crude oil filtering; (2) phosphoric acid degumming and light alkali alkali refining; (3) washing, drying; (4) dewaxing; (5) a primary decolorizing; (6) physical deacidification; (7) secondary alkali refining; (8) iron removing; (9) washing; (10) drying; (11) secondary decolorizing; (12) deodorization; (13) degreasing. The invention adopts a mode of combining the physical refining and chemical refining to realize a large-scale production of the rice bran top oil, provides a favorable technique to the rice bran deep-processing, improves the extraction rate from traditionally 55-60% to 75-80%, saves materials and reduces environmental pollution, has huge economic and social benefits. The invention is a major innovation to the edible rice bran oil production.

Owner:河南华泰粮油机械股份有限公司

Edible mixed oil

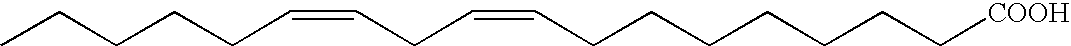

ActiveCN101422200AReduce chronic diseaseEdible oils/fatsFood preparationVegetable oilOMEGA-3 POLYUNSATURATED FATTY ACIDS

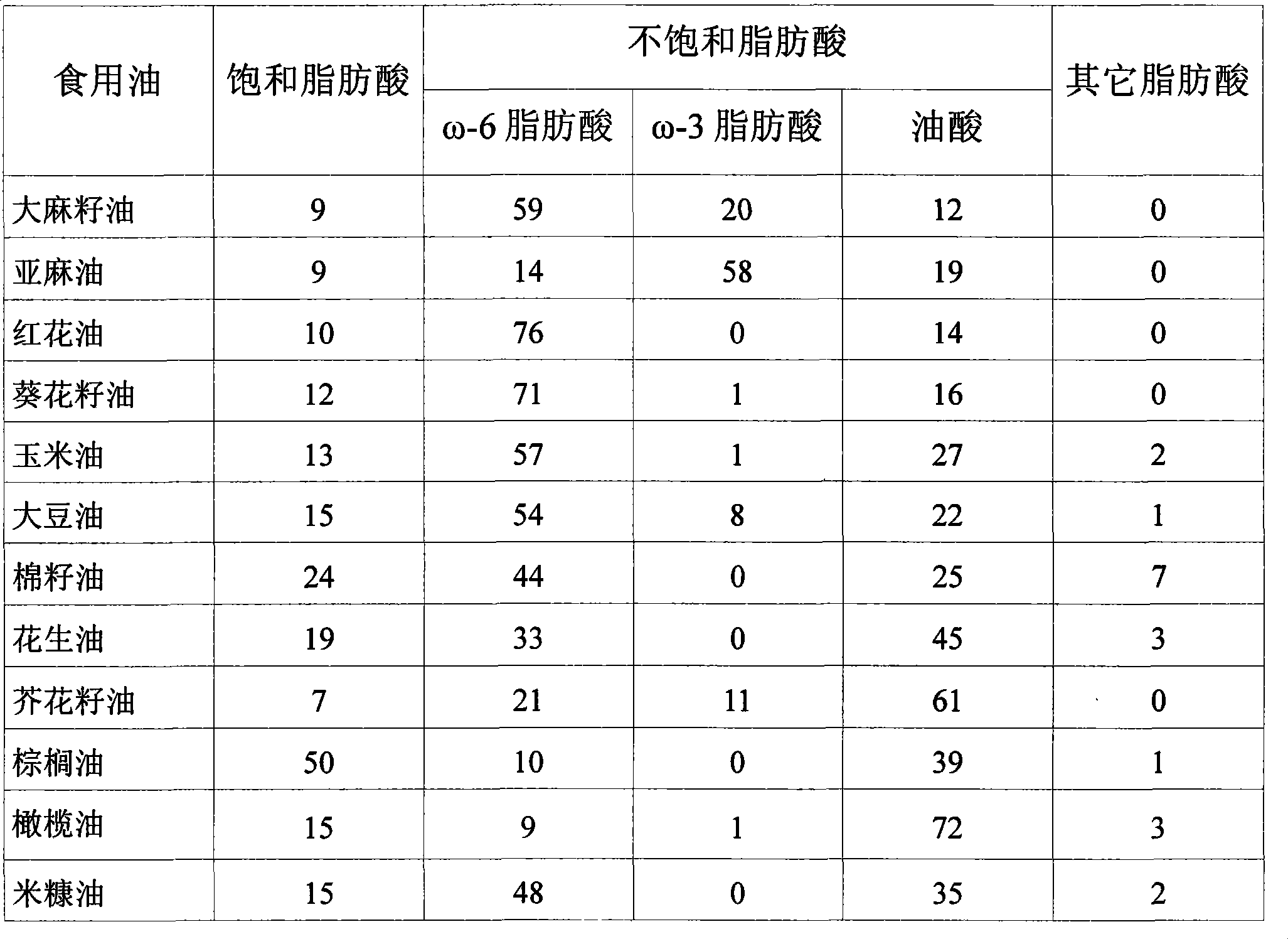

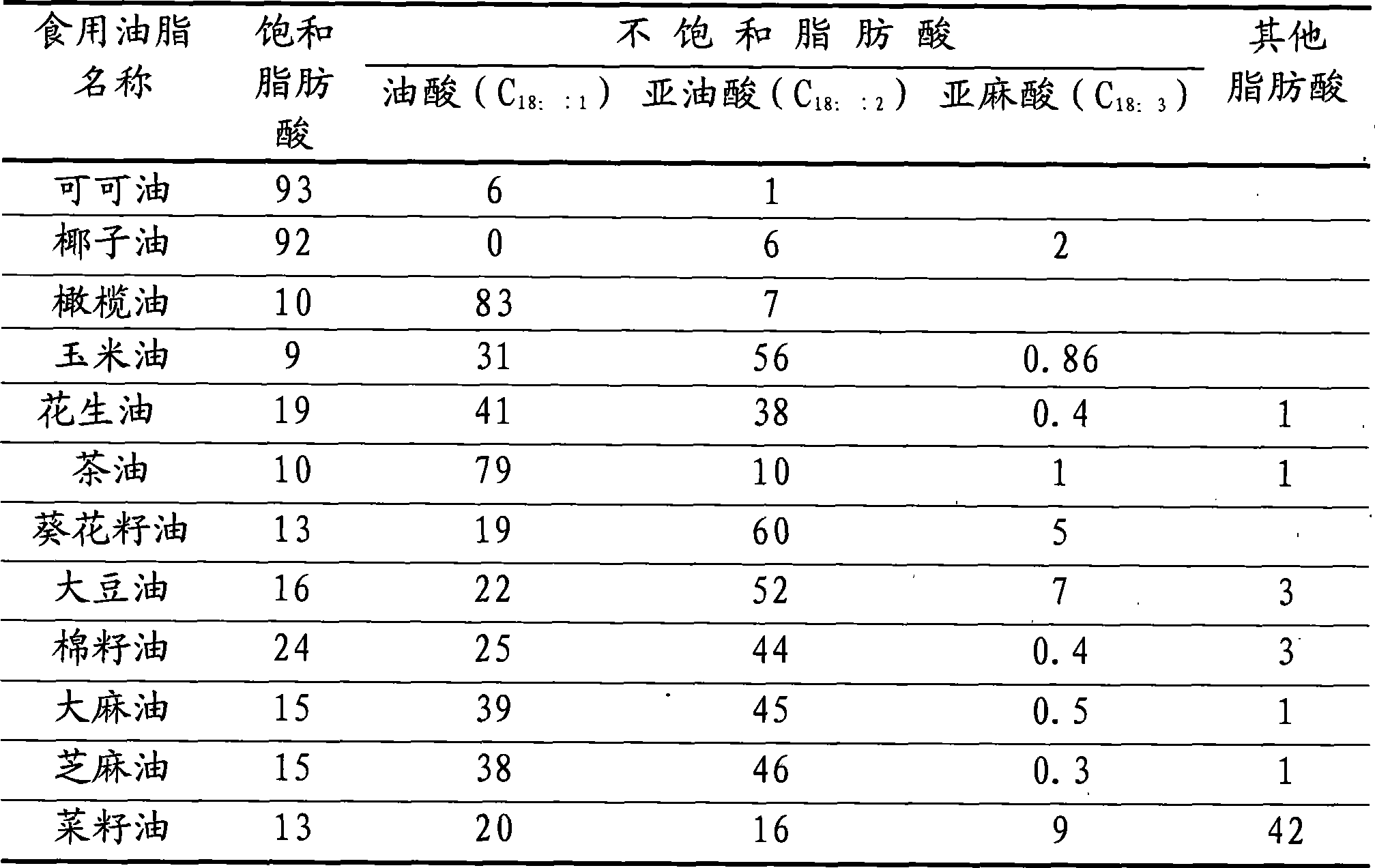

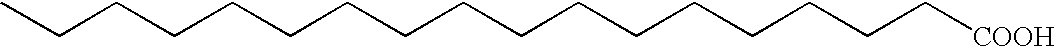

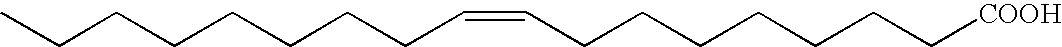

The invention relates to an edible blend oil, which aims at solving the problem of the improper ratio between Omega-6 polyunsaturated fatty acid and Omega-3 polyunsaturated fatty acid in the current single plant edible oil and provides an edible plant blend oil with the ratio between Omega-6 polyunsaturated fatty acid and Omega-3 polyunsaturated fatty acid being the best, meeting the health need of Chinese residents and simultaneously being capable of controlling the amount and stability of saturated fatty acids. The technical keys are as follows: the edible blend oil is prepared with a hemp seed oil and another edible plant oil or other edible plant oils according to weight percentage; wherein, the hemp seed oil is 8 to 85 and the edible plant oil is 15 to 92; and the other edible plant oil can be as follows: grape seed oil, olive oil, camellia oil, rice bran oil, safflower oil, canola oil, sunflower oil, corn oil, linseed oil, sesame oil, rapeseed oil, soybean oil, peanut oil and other edible plant oils. The content of the saturated fatty acids does not exceed 15 percent and the ratio between Omega-6 and Omega-3 is 4-6:1.

Owner:淮安市淮安区综合检验检测中心

Blend oil, preparation method and application thereof

InactiveCN101766235AImprove stabilityFix stability issuesEdible oils/fatsFood preparationBeef TallowRice bran oil

The invention provides a blend oil, a preparation method and application thereof. The blend oil, counted in 100 parts by weight, comprises 0.1-5 parts of phytosterol ester, 0.01-5 parts of microalgae DHA and 90-99.8 parts of other oil components; the other oil components are sorted from three or more than three of soybean oil, colza oil, maize oil, sunflower oil, peanut oil, sesame oil, tea seed soil, palm oil, cottonseed oil, rice bran oil, olive oil, safflower oil, linseed oil, cannabis oil, pig tallow, beef tallow, or microalgae oil.

Owner:嘉里特种油脂(上海)有限公司

Chinese herbal medicine lactagogue feed for sow and preparation method of feed

ActiveCN103141706AMeeting nutritional needsImprove immunityFood processingAnimal feeding stuffBiotechnologyAngelica Sinensis Root

The invention relates to a Chinese herbal medicine lactagogue feed for a sow. The Chinese herbal medicine lactagogue feed comprises the following components: wheat, corn, bean pulp, tofu skin, calcium hydrophosphate, rice bran oil, mountain flour, salt, lysine, antioxidant, potassium chloride, magnesium sulfate, vitamin premix, microelement premix and traditional Chinese medicine additive, wherein the traditional Chinese medicine additive comprises the following bulk drugs: cowherb seed, ligusticum wallichii, hawthorn, herba epimedii, pericarpium citri reticulatae, radix ophiopogonis, astragalus mongholicus, dandelion, angelica sinensis, bighead atractylodes rhizome, akebiaquinata, madder, honeysuckle, elecampane, medicated leaven and medlar. By adopting a new formula and the traditional Chinese medicine additive, the nutritional requirement of milking sows is met, the palatability is good, the immunity, milk yield and milk quality of the sows are improved, the productivity of piglets is improved, and the hurt on the sows and the piglets by chemical medicine is avoided. The Chinese herbal medicine lactagogue feed has the advantages of little toxic and side effect, no drug tolerance, no residue and the like, and the side effect on the food safety is reduced.

Owner:SHANDONG NEW HOPE LIUHE GROUP

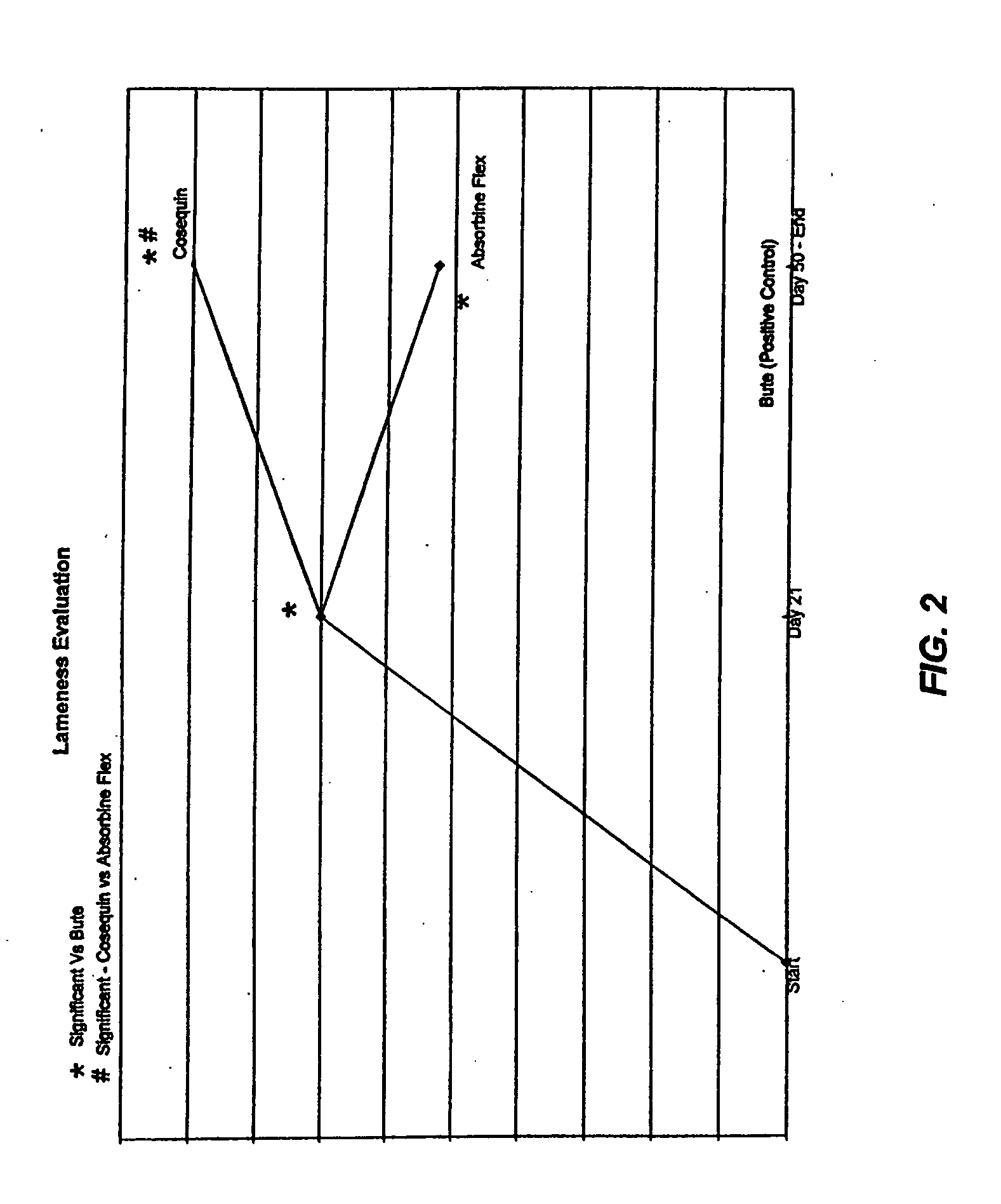

Methods for treating joint inflammation, pain, and loss of mobility

This invention provides methods and formulations for treating an inflammatory disease or reducing an inflammatory reaction comprising administering a fortified formulation comprising stabilized rice bran derivative and a fortification agent. Preferred rice bran derivatives are rice bran oil and the solubilized fraction of rice bran. Preferred fortification agents are glucosamine derivative, methylsulfonylmethane, yucca concentrate, and grape seed extract.

Owner:RICEBRAN TECH

Process for producing corn germ oil and table oil made by products produced thereby

InactiveCN1523094AReduce lossesReduce production consumptionFatty-oils/fats refiningEdible oils/fatsOil and greaseVegetable oil

The present invention provides a production process of maize germ oil, at the same time discloses a table oil made up by its product. It is characterized by that it makes the maize germ raw material oil undergo the processes of degumming, deacidification, water-washing, decolouring, dewaxing and deodorization so as to obtain the refined edible finished oil. According to the physicochemical properties and nutrient components of other plant oil said maize germ oil and other plant oil can be made into the table oil using maize germ oil as main component. The described plant oil can be one of rice oil, carthamus oil, walnut oil, scabish oil, pine seed oil, sesame oil, peanut oil, wheat-germ oil, sunflower oil and soybean oil or their mixture.

Owner:高元财 +1

Plant blend oil and method for preparing same

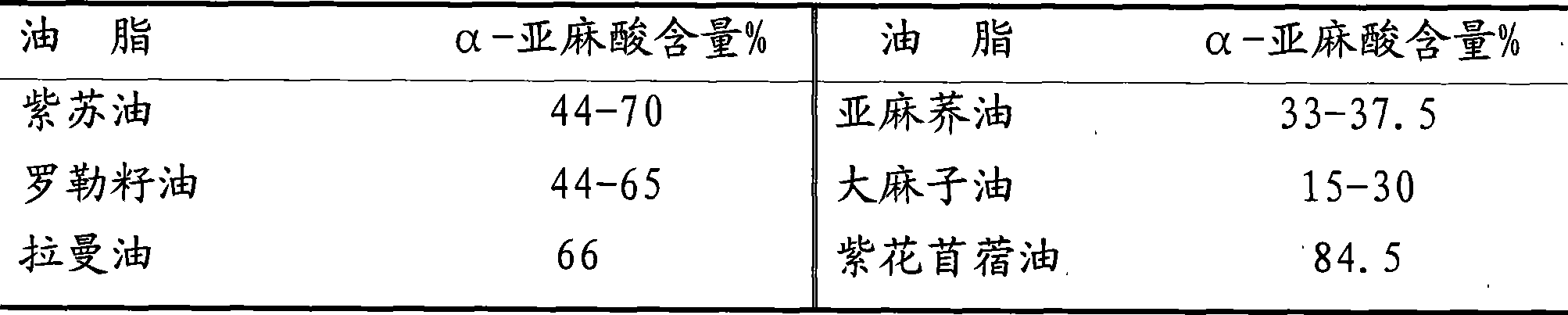

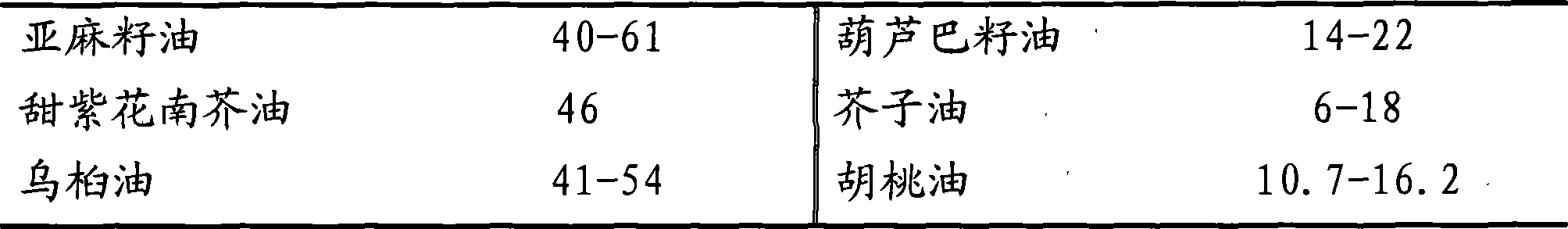

The invention belongs to the field of edible oil products and in particular relates to plant blend oil with balanced nutrition and a method for preparing the same. The technical proposal comprises: the plant blend oil comprises the following compositions in portion by weight: 7.5 to 23 weight portions of maize oil, 8.6 to 20.7 weight portions of soybean oil, 7.7 to 21.8 weight portions of peanut oil, 7.5 to 19.7 weight portions of sunflower seed oil, 6.5 to 18.8 weight portions of rice bran oil, 2.1 to 15.6 weight portions of perilla oil, 2 to 13.5 weight portions of safflower seed oil, 4.9 to 12 weight portions of flaxseed oil, 5.2 to 12 weight portions of walnut oil , 2 to 11.5 weight portions of wheat germ oil, 6.5 to 15 weight portions of tea seed oil and 0.2 to 8 weight portions of evening primrose oil. The invention also provides the method for preparing the plant blend oil; and the blend oil highlights reasonableness of the proportional composition of various unsaturated fatty acids, namely the ratio of oleic acid to linoleic acid to linolenic acid is 5:4:1 and also highlights the trophic function of a product.

Owner:邹平三星油脂工业有限公司

Shortening composition

ActiveUS20050214436A1Improve stabilityImprove the organoleptic and physical propertiesDough treatmentBakery productsBiotechnologyVegetable oil

The present invention relates to a shortening system, for use as dough fat or filling fat; for instance, a shortening system containing, consisting essentially of, or consisting of, unhydrogenated or non-hydrogenated vegetable oil, such as a highly unsaturated, non-hydrogenated or unhydrogenated vegetable oil, e.g., soybean oil, sunflower oil, corn oil, ricebran oil, or cottonseed oil and a minimum or minor amount (e.g., by weight about 3-10%, advantageously about 3-7%, more advantageously about 3-6% or about 3-5% or less than about 6% or less than about 8%) of an emulsifier composition comprising a monoglyceride and / or diglyceride, an alpha tending emulsifier and an ionic emulsifier as well as to methods for making and using such a shortening system and products from the use of such a shortening system.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Process for the preparation of rice bran oil low in phosphorous content

InactiveUS6706299B2Simple and economical and fast processReduce processing stepsFatty-oils/fats refiningCheese manufacturePhosphoric acidPulp and paper industry

Owner:COUNCIL OF SCI & IND RES

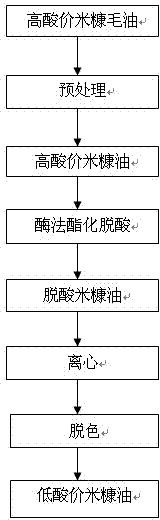

A kind of preparation method of rice bran oil with low acid value

InactiveCN102295986ALow acid valueSimple processFatty-oils/fats refiningFatty-oils/fats productionAcid valueRice Bran Extract

The invention provides a preparation method of rice bran oil with the low acid value, which comprises the following steps: fresh-keeping the rice bran, extracting the rice bran oil, degumming, de-waxing, decolouring, deacidifying and deodorizing. The invention has the advantages of simple technology and low production cost; since the extracted crude rice bran oil is performed a fresh-keeping treatment, the acid value is relative low. The final finished product rice bran oil treated by the above steps is detected by a method prescribed by GB / T5530-2005, the acid value is between 1.0-3.0 (KOH) (mg / g).

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Refining method of rice bran oil

The invention relates to a refining method of rice bran oil, which adopts crude rice bran oil as raw oil. The rice bran oil is obtained through the procedures such as degumming, oil-foot separation, dewaxing, decoloration, high-temperature deacidification and deodorization, freezing and degreasing. The weaknesses of the traditional refining method that during the degumming, the neutral oil loss is large, partial neutral oil is neutralized by NaOH during the deacidification process and free-fatty acid process yield of the oil grease is reduced are overcame. A combination-type deacidification is adopted during the high-temperature deacidification process, and the acid value can be reduced to 3 through one-time physical deacidification. The utilization rate of the raw material and the product yield are improved, and the environmental pollution caused by the chemical refining can be greatly reduced. The deacidification process is free from the chemical reaction, so the loss of the oil grease is reduced, and the refining rate of the oil grease is improved. The consumption of the auxiliary raw materials and the labor can be reduced, and the price of the distilled fatty acid is better than that of the acidification oil; therefore, not only the production cost is reduced, but also the economic benefit is improved.

Owner:桃源县博睿粮油加工有限公司

Nutritional blend oil with balanced fatty acid component and active component for middle and old aged

The invention relates to a nutritional blend oil with balanced fatty acid components and active components for the middle and old aged, which is prepared by a plurality of plant oils selected from flaxseed oil, walnut oil, double-low rapeseed oil, soybean oil, wheat germ oil, corn oil, teal oil, peanut oil, grape seed oil, rice bran oil, camellia oil, evening primrose seed oil, sunflower seed oil and the like, wherein, Omega 6 serial polyunsaturated fatty acids (PUFA) and Omega 3 serial PUFA are contained to enable the ratio of saturated fatty acid (SFA) to monounsaturated fatty acid (MUFA) to PUFA to be 0.6-0.8:1:1, the ratio of Omega 6 to Omega 3 to be 4:1 in the comprehensive evaluation of the blend oil absorbed by the middle and old aged and the fat from other sources, thereby meeting the recommended value of Chinese Nutrition Society; the nutritional blend oil contains 2% of gama-linolenic acid, thereby beneficial to improving the contents of DH-gama-linolenic acid and arachidonic acid; the total content of lauric acid, myristic acid and palmitic acid contained in the nutritional blend oil is below 8.5% in order to avoid over rising the level of Low density lipoprotein (LDL) in the plasm of the middle and old aged; in addition, the nutritional blend oil also comprises a plurality of active components with oxidation resistant property, so other antioxidants do not need to be added in the blend oil.The blend oil provided by the invention is characterized by low cost, balanced fatty acid nutrition, a plurality of abundant active components and higher security, thereby better improving the health and intelligence of eaters, preventing cardiovascular and cerebrovascular diseases, and avoiding fatness, hyperlipidemia, thrombotic diseases and the like caused by unbalanced fatty nutrition.

Owner:ZHEJIANG OIL MASTER

Process for extracting high-grade rice bran oil by physical method

InactiveCN101805666AImprove retentionEmission reductionFatty-oils/fats refiningWater vaporFatty acid

The invention relates to a process for extracting high-grade rice bran oil by a physical method, which utilizes the partial pressure of water vapor to reduce the partial pressure of free fatty acids in the oil and also reduce the boiling point temperature of the free fatty acids under high vacuum conditions, so that the free fatty acids can also be gasified at a lower temperature (240 DEG C) lower and further be separated from the oil. The chemical refining aims to further reduce the acid value, and ensure the oil color; while the process adopts the three-time bleaching and deodorization combining method to achieve the purpose. The three-time bleaching is that a mixing bleaching agent is used to remove 'blue' and other pigments produced in the deacidification process, and the deodorization is that the water vapor distillation principle is utilized to further remove the free fatty acids in the oil, so that the acid value and the like meet the requirements of product quality standards. Compared with the existing refining process, the process has high yield increasing by about 2-3% under the same conditions, and large micronutrient retention capacity, greatly retains nutrients, and significantly reduces the discharge amount of sewage.

Owner:ANHUI SIRUN GRAIN OIL REFINERY

Method for preparing rice bran oil from rice bran

InactiveCN1935963AImprove stabilityReduced activityFatty-oils/fats productionRice Bran ExtractRice bran oil

The invention relates to rice bran oil preparing method. It includes the following steps: processing the rice bran by micro wave with 800W power, 60s, 60mm height of layer, 7.4% humidity after processing; using supercritical carbon dioxide to extract rice bran oil at 25-60 degree centigrade, 10MPa-40MPa pressure, 15L / h-90L / h rate of CO2 flow for 30-150min. The prepared rice bran oil will not be rancidity and resolved by lipase to increase its stability. The product is easy to store. The rice bran oil yield is 20-22%.

Owner:南京远望富硒农产品有限责任公司 +1

Process for the isolation of glycolipids

InactiveUS6953849B2Simple methodEsterified saccharide compoundsFatty substance recovery/refiningSludgeRice Bran Extract

Owner:COUNCIL OF SCI & IND RES

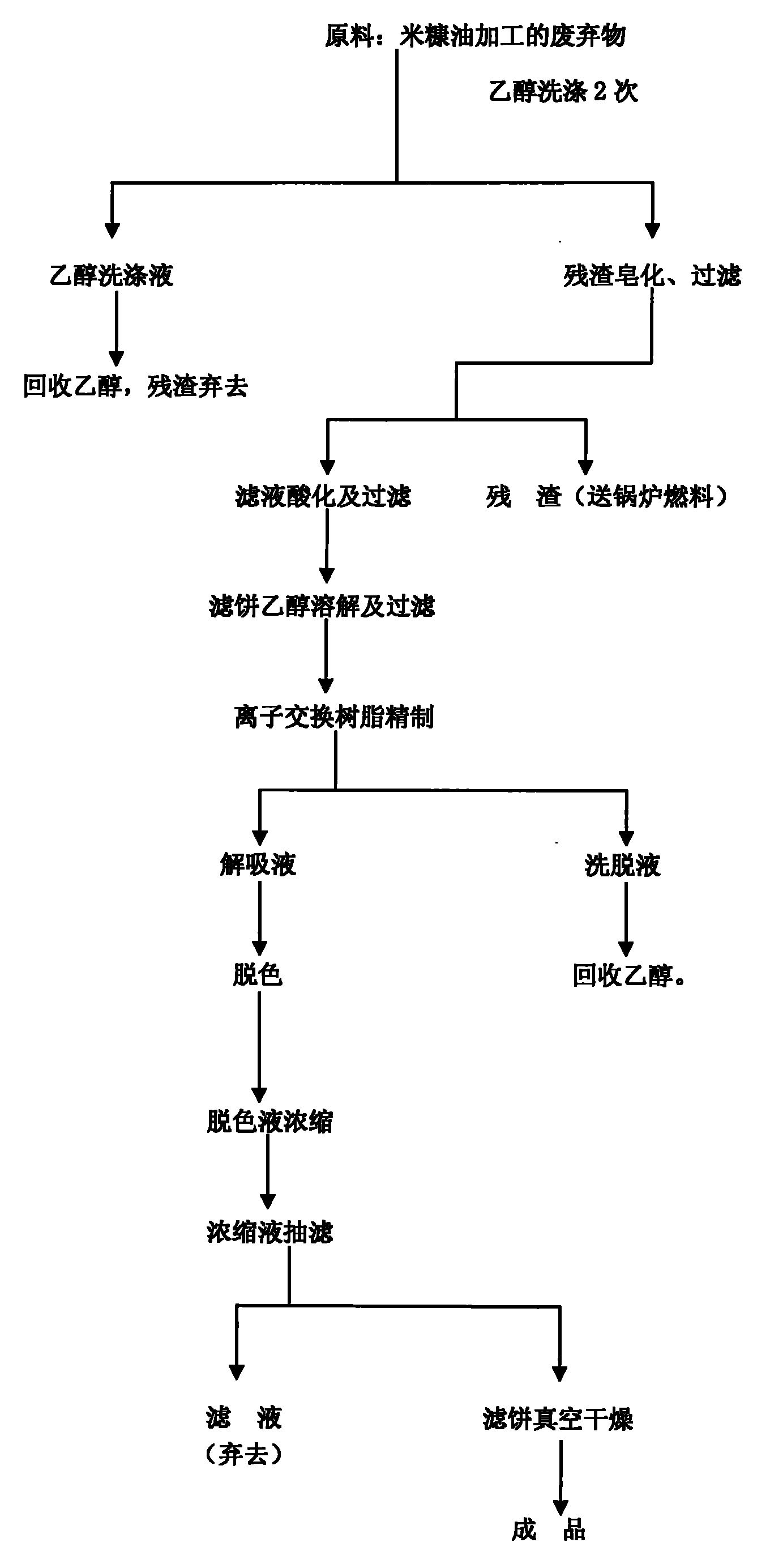

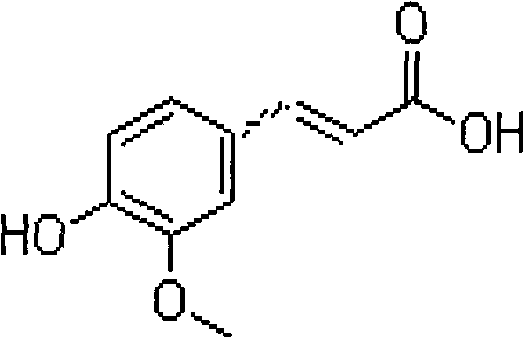

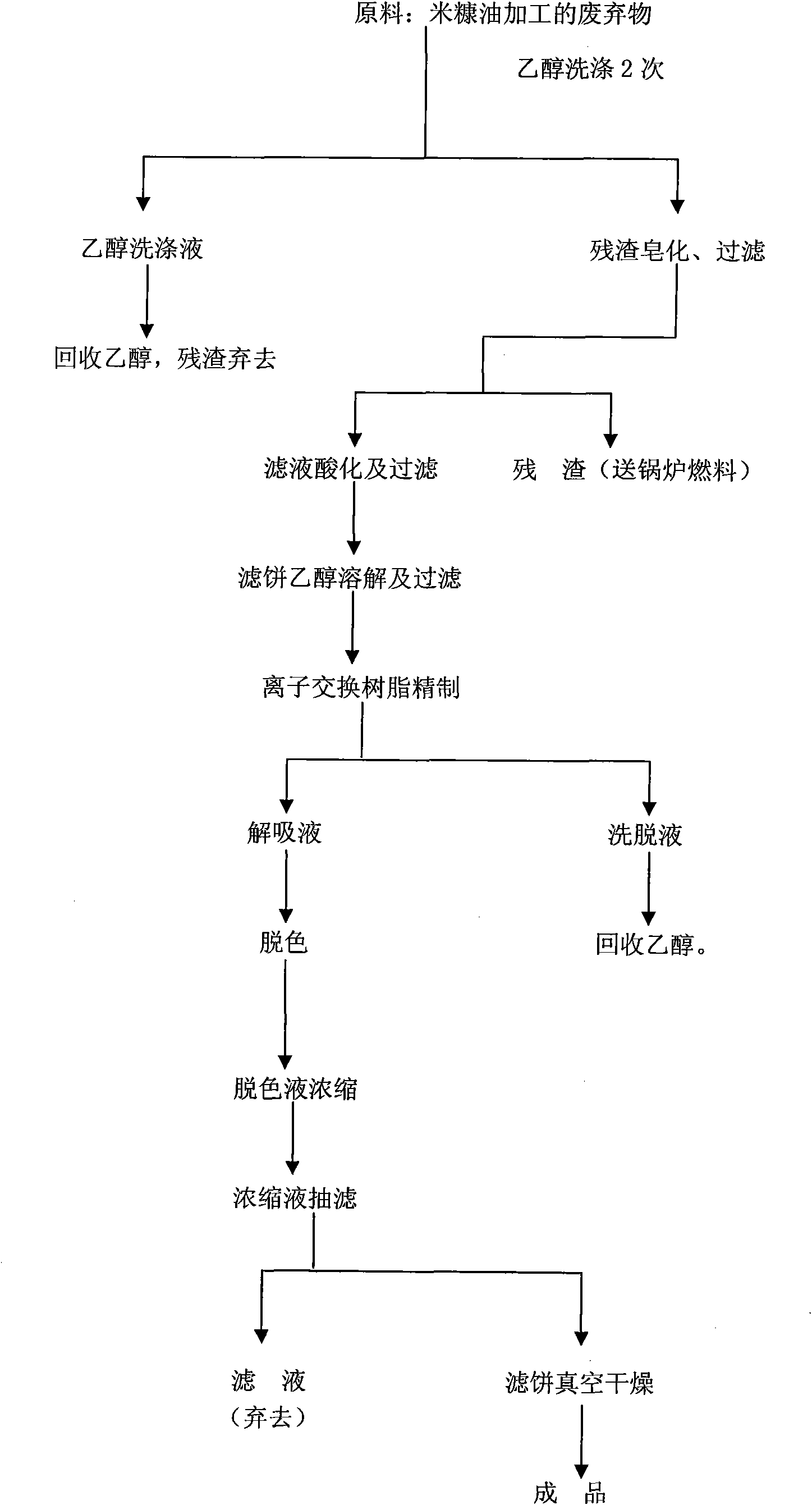

Process for separating and extracting natural ferulic acid with content not more than 98% from wastes in rice bran oil processing

InactiveCN101811958ARaw materials are easy to getSimple processOrganic compound preparationCarboxylic compound separation/purificationAlcoholWhite powder

The invention discloses a process for separating and extracting natural ferulic acid with the content not more than 98% from wastes in rice bran oil processing. The process is characterized in that the wastes generated in the rice bran oil processing method are used as raw materials; the process comprises the following steps of: washing by using alcohol, saponificating and filtering, acidifying and filtering, dissolving by using alcohol and filtering, refining by using ion exchange resin, decoloring, concentrating, pumping and filtering, and drying by vacuum to obtain the white powder product with the natural ferulic acid content not more than 98%. The invention has the advantages of easy obtainment of raw materials, utilization of wastes, simple and process, high purity of product by more than 98%, and industrial production.

Owner:GUANGXI DAIYUAN VEGETABLE PROD

Lactation compound feed for sows and preparation method thereof

ActiveCN102763784AMeeting nutritional needsImprove immunityFood processingAnimal feeding stuffPhytaseAntioxidant

The invention discloses lactation compound feed for sows and a preparation method thereof. The lactation compound feed for sows is made from wheat, corn in northeast China, 46% soybean meal, soybean hull, calcium hydrophosphate, rice bran oil, liquid phytase, liquid compound enzyme, limestone flour, salt, 65% lysine, threonine, 60% choline chloride, antioxidant, plasma protein, potassium chloride, magnesium sulfate, vitamin prefix, and trace mineral premix. The preparation method include: weighing all materials by percent weight, and adding the materials into a crusher for crushing under the crushed size of 25-40 mesh; and adding the crushed materials into a pelletizer to make pellets at 85 DEG C with gelatinization degree reaching more than 90%. The lactation compound feed for sows has the advantages that the lactation compound feed for sows meets requirements of nursing sows for nutrition and is high in palatability, immunity, milk yield and milk quality are increased for the sows, and productivity of piglets is further improved.

Owner:SHANDONG NEW HOPE LIUHE GROUP

Health-care nutrition non-washing rice, and its prodn. method

A nutritive health-care rice without washing is prepared from fragrant rice, rich long-grained non-glutinous rice, glutinous rice, fragrant black rice, buckwheat chip, corn chip, mung bean, red bean, black bean and rice bran oil through conventional technology.

Owner:ANHUI YANZHIFANG FOOD

Process for the pre-treatment of vegetable oils for physical refining

ActiveUS7494676B2Speed up the processFatty acids production/refiningTea extractionMicroorganismActivated carbon

The present invention relates to a simple and economically attractive process for the pretreatment of vegetable oils which involves (a) enzymatic degumming with commercially available phospholipase A1 from the sources like Aspergillus oryzae microorganism, (b) bleaching of the enzymatically degummed oil using bleaching earth and activated carbon, and (c) dewaxing (in case of rice bran oil) of degummed and bleached oil at lower temperature to obtain oil with less than 5 ppm of residual phosphorus which is amenable for physical refining.

Owner:COUNCIL OF SCI & IND RES

Pomegranate peel feed for chicken

InactiveCN102845630ACompatibility is reasonableAnti-disease and growth-promotingFood processingAnimal feeding stuffFeed conversion ratioAnimal science

The invention discloses a pomegranate peel feed for chicken. The feed is prepared from the following raw materials in parts by weight: 50-55 parts of cornmeal, 15-20 parts of cottonseed meal, 5-8 parts of rice bran meal, 5-8 parts of wheat meal, 22-26 parts of soybean meal with content of crude proteins being more than 48%, 3-6 parts of corn protein meal, 0.5-1 part of fish meal, 1-2 parts of apple leaf meal, 1-2 parts of feed-grade dicalcium phosphate, 0.3-0.8 part of rice bran oil, 0.2-0.4 part of salt, 0.1-0.3 part of choline chloride, 0.1-0.2 part of lysine, 0.1-0.2 part of methionine, 2-4 parts of oil residues, 0.4-0.8 part of multi-vitamin, 0.5-1 part of seabuckthorn oil, 0.1-0.5 part of loofah lyophilized meal, 15-25 parts of fresh brewer's grains, 2-5 parts of Muyu stone meal, 3-5 parts of pomegranate peel meal, 0.1-0.4 part of zeolite meal pickled in vinegar, 0.5-1 part of bitter orange petal meal, 1-2 parts of peanut kernel meal and 4-6 parts of traditional Chinese medicine additives. The feed has the beneficial effects that the utilization rate of the feed is improved, the feed conversion ratio is reduced and growth is promoted.

Owner:BENGBU DACHENG FOOD

Methods for treating joint inflammation

InactiveUS20050158406A1Good effectImprove actionBiocidePowder deliveryJoints inflammationExtracted grape seeds

Owner:NUTRACEA

High-oryzanol rice bran oil two-phase extraction de-acidification refining technology

InactiveCN101984028AReduce refining consumptionGreat tasteFatty-oils/fats refiningEdible oils/fatsDistillationPhosphoric acid

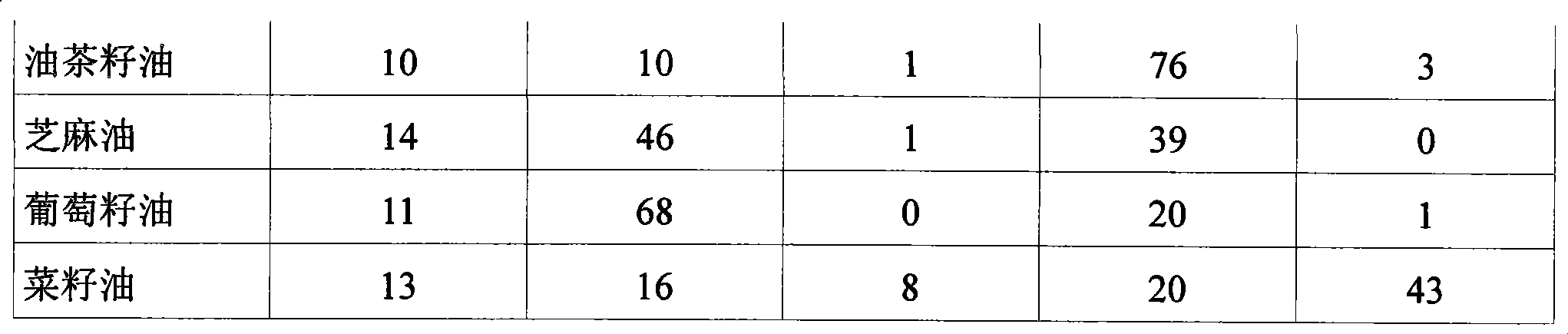

A high-oryzanol rice bran oil two-phase extraction de-acidification refining technology includes processes of degumming with phosphoric acid, centrifugal separation, two-phase extraction de-acidification, separatory distillation for solvent removal, vacuum drying, adsorptive de-coloration, deodorization, de-waxing and the like. The refined rice bran oil produced by the technology is clear, transparent and odour free, and has good tastes, Physical and Chemical characters of acid value and the like of the refined rice bran oil are in accordance with the second grade of national edible oil standard, and simultaneously, content of the produced rice bran oil is more than 1.5%. The whole technology is simply, few devices are invested for the technology, the rice bran oil products have high yield and purity, product quality can be easily controlled, and a new way for producing high-quality nutritious rice bran oil is provided.

Owner:HUNAN AGRICULTURAL UNIV +1

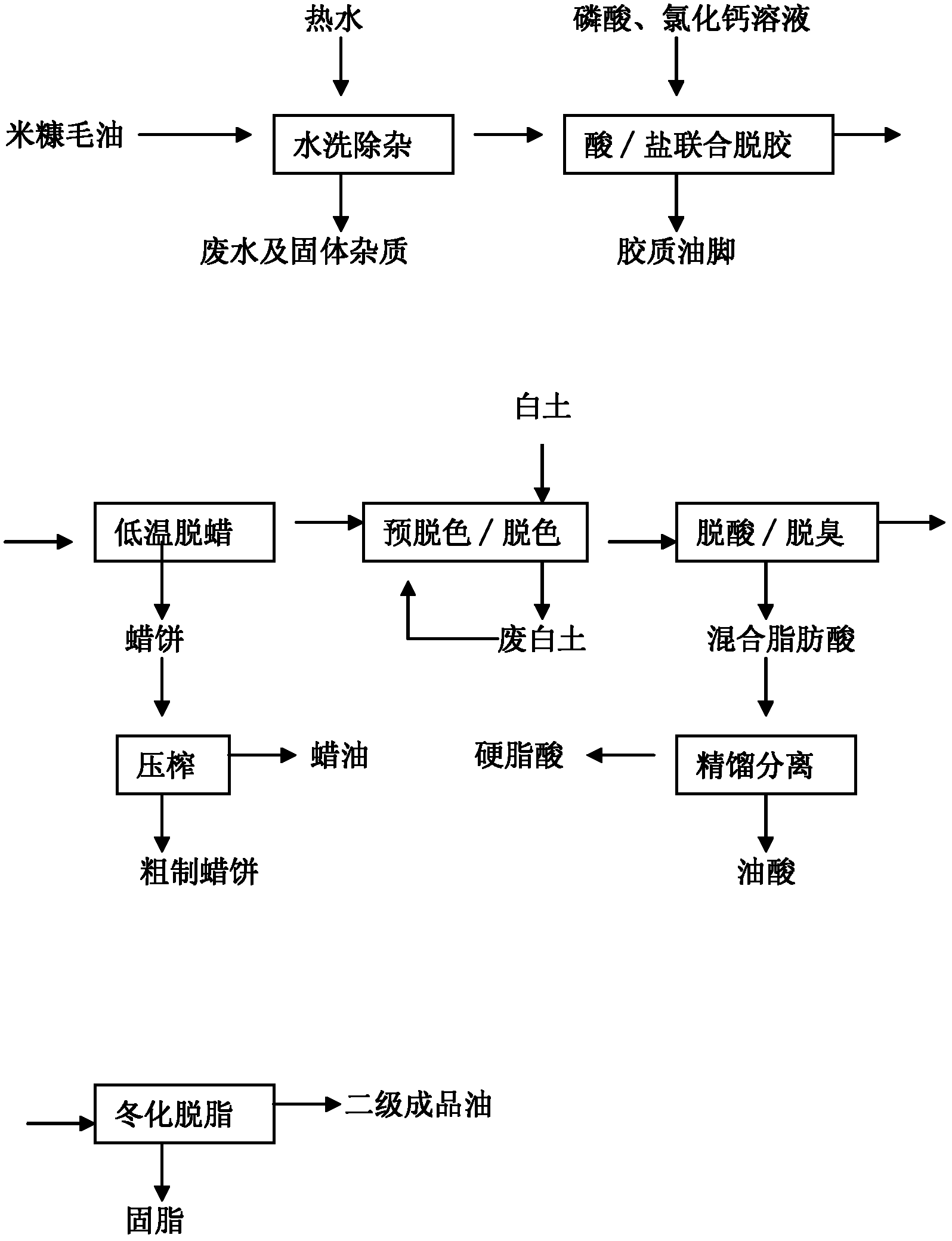

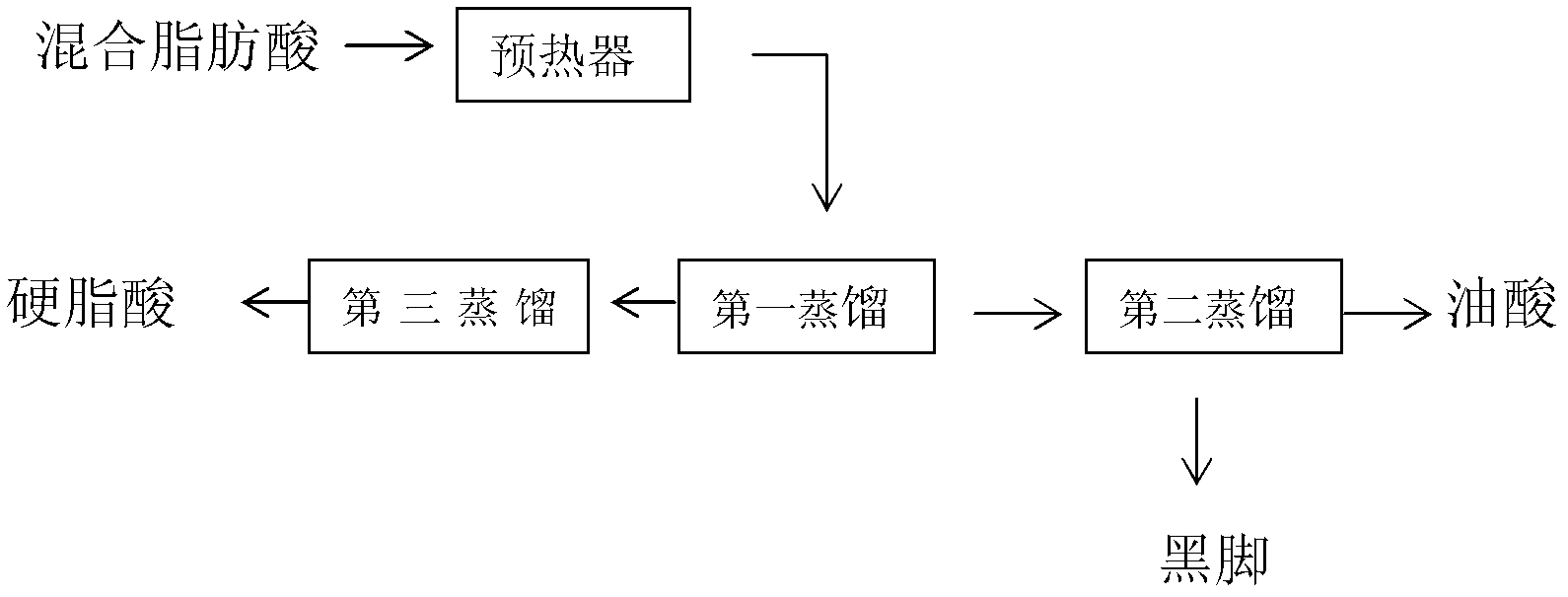

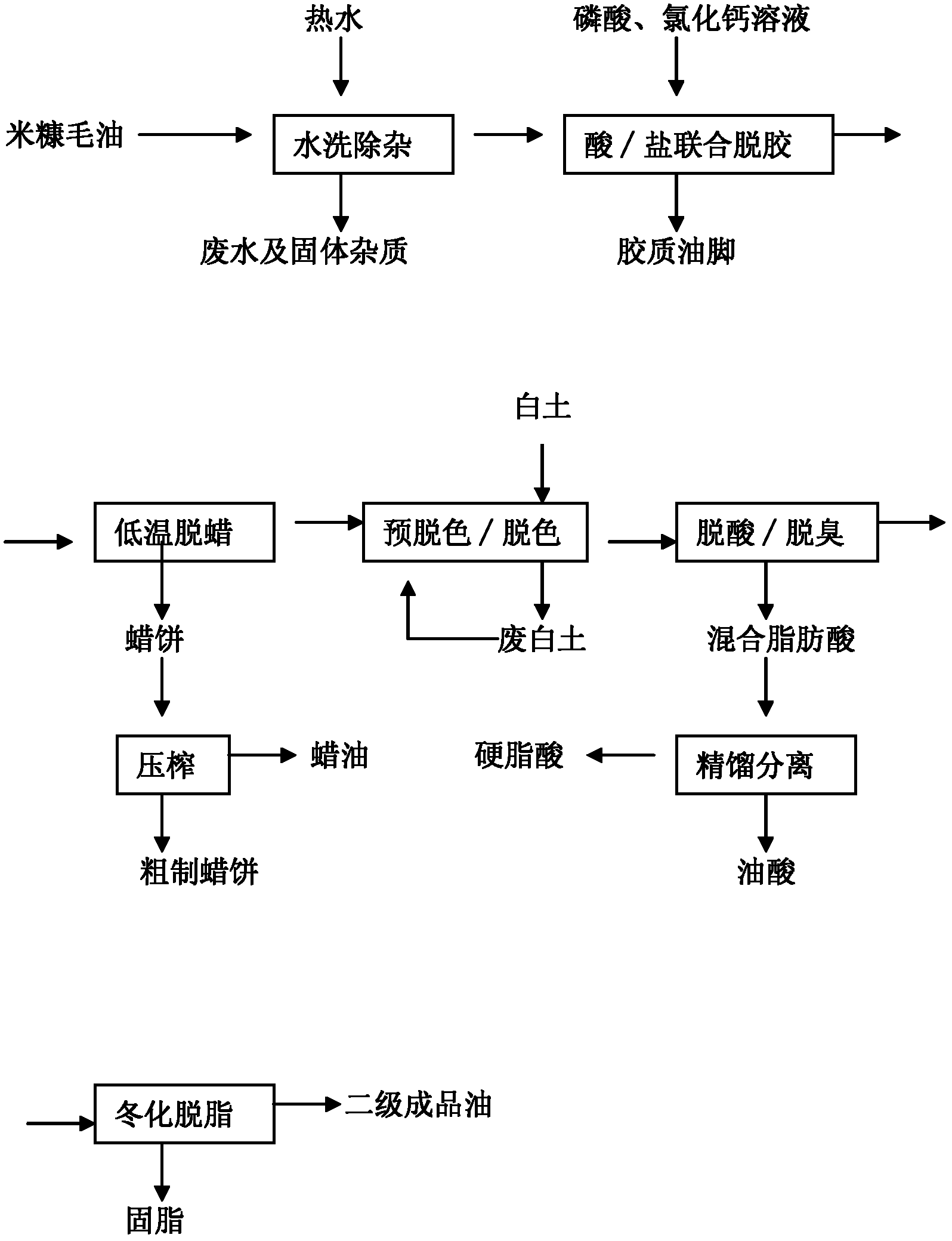

Rice bran oil refinement and byproduct production method

InactiveCN102492546AOvercome efficiencyOvercome the cycleFatty substance recovery/refiningFatty acids production/refiningWaxMixed fatty acid

The invention relates to a rice bran oil refinement and byproduct production method, and solves the problems of poor quality, low product and byproduct yield, low purity, complex technique, small production scale and the like in the existing product oil refined from rice bran oil. The technical scheme is as follows: the method comprises the following steps: carrying out acid / salt combined degumming on rice bran raw oil, dewaxing at low temperature, decolorizing, deacidifying / deodorizing, and degreasing by winterization to obtain tertiary rice bran oil and byproducts (crude wax cake, mixed fatty acids and solid grease). The technique provided by the invention is simple to control, can stably obtain Chinese standard tertiary rice bran oil and byproducts thereof, and can implement large-scale production.

Owner:WUHAN POLYTECHNIC UNIVERSITY +2

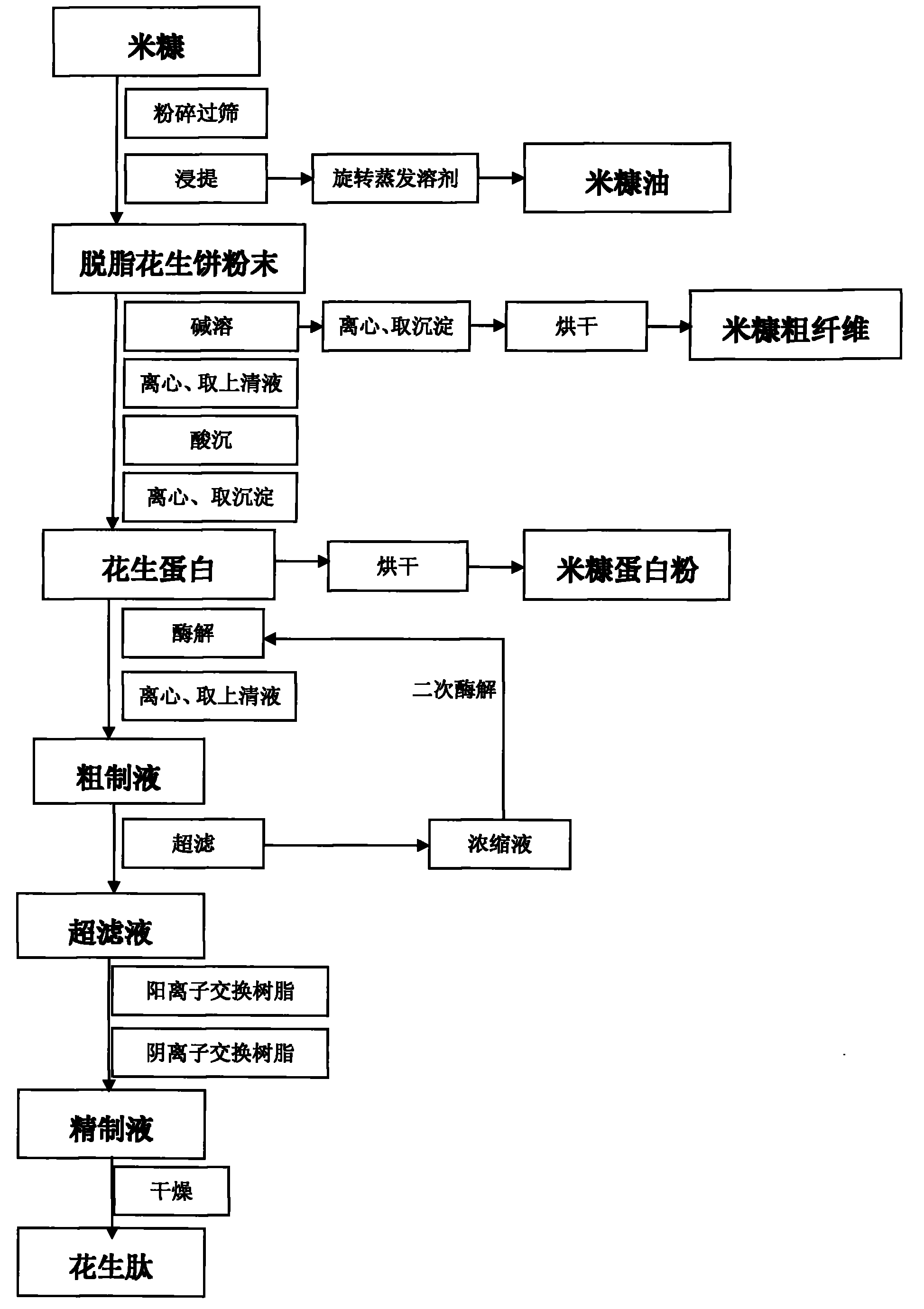

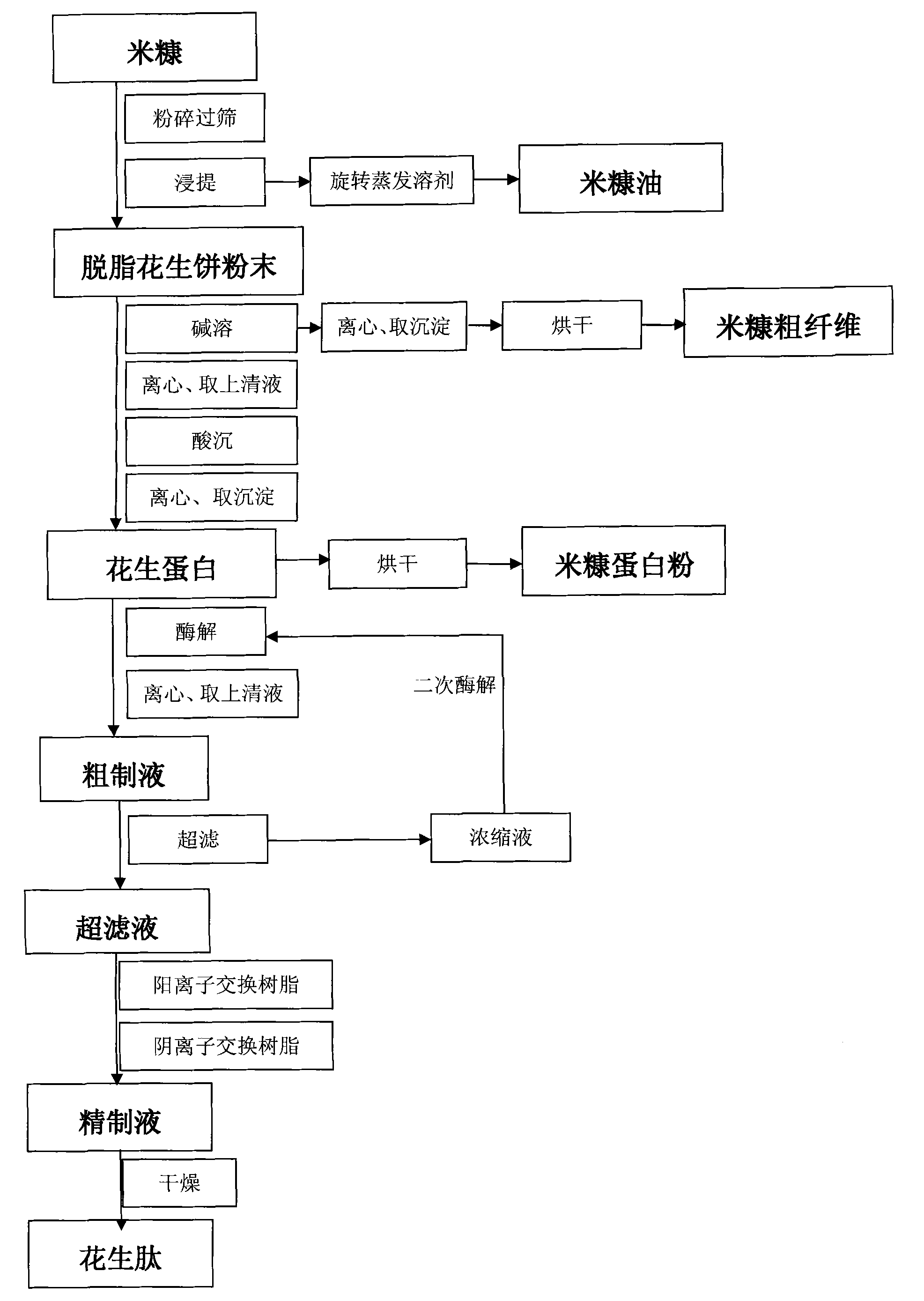

Method for comprehensively utilizing rice bran

ActiveCN102115690AGuaranteed Molecular WeightReduce salt contentPeptide preparation methodsFatty-oils/fats productionFiberUltrafiltration

The invention discloses a method for comprehensively utilizing rice bran, which can be used for preparing four types of products, namely rice bran oil, rice bran crude fiber, rice bran egg white and rice bran peptide. A preparation process comprises the following steps of: extracting grease from rice bran serving as a raw material; separating rice bran crude fiber and rice bran egg white from therice bran by using an alkali-solution and acid-isolation method; adding protease into the rice bran egg white for hydrolyzing proteins; removing salt through anion and cation exchange resins by ultrafiltration fraction; and concentrating and drying to obtain rice bran biologically active peptide.

Owner:武汉百信正源生物技术工程有限公司

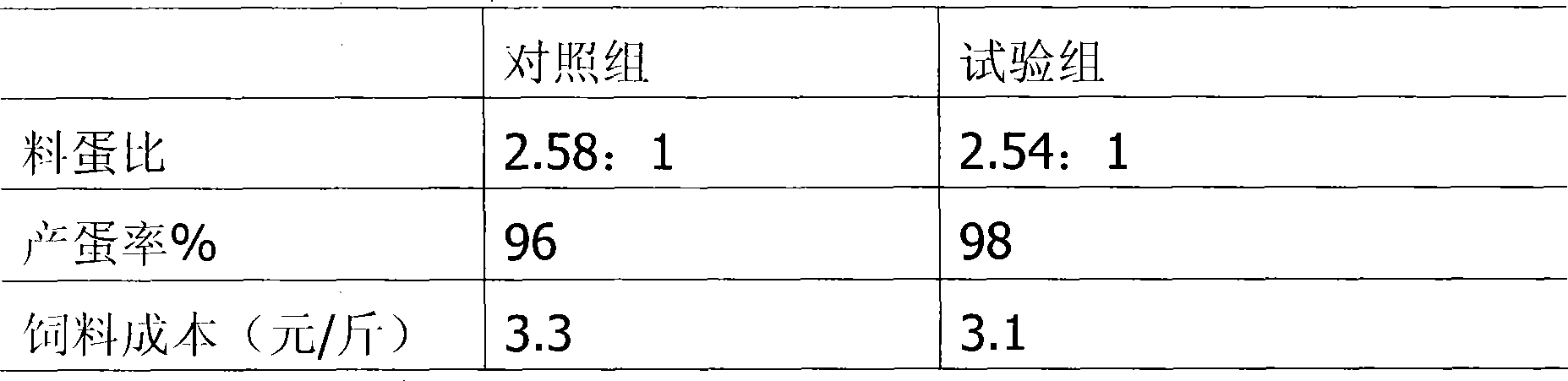

Daily ration for partridges

ActiveCN101444269AImprove conversion rateIncrease production capacityAnimal feeding stuffFeed conversion ratioRice bran oil

The invention relates to the technical field of animal feeds, in particular to a daily ration for partridges. The technical scheme of the invention is as follows: the daily ration for partridges comprises the components by part by weight as follows: 8.6 to 12.6 parts of corn; 28 to 32 parts of wheat; 26 to 34 parts of rice bran; 1.2 to 3.2 parts of rice bran oil; 1 to 7 parts of dregs of beans; 1 to 7 parts of cotton dregs; 0 to 4 parts of vegetable dregs; 2 to 8 parts of corn protein powder; 0 to 5 parts of fish meal; 0.11 to 0.31 part of salt; 5.2 to 11.2 parts of stone powder; 0.1 to 0.3 part of calcium hydrophosphate; 0.1 to 0.4 part of lysine; 0 to 0.26 part of methionine; 0 to 0.22 part of threonine; as well as 0.2 to 1.0 part of pre-mixed materials. The invention reduces the protein content of the egg laying feed of the partridges from 20 percent to 18 percent, reduces energy from 2800 to 2680, improves the feed conversion rate by 2 to 5 percent and reduces the oxygen discharge amount by 2 to 3 percent; the daily ration can reduce the production cost and the environment pollution and meanwhile maintain and improve the production performances of the egg laying partridges.

Owner:SHANDONG NEW HOPE LIUHE GROUP

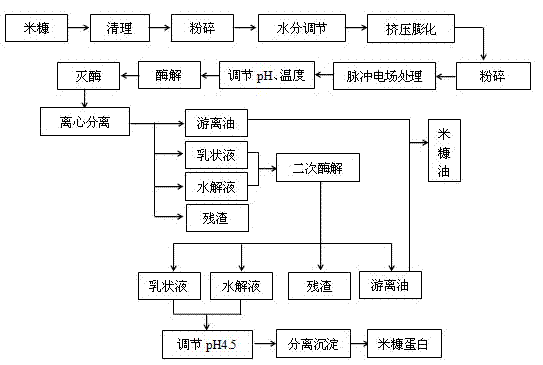

Method for synchronously preparing high-stability rice bran oil and rice bran protein

The invention relates to a method for synchronously preparing high-stability rice bran oil and rice bran protein, and belongs to a vegetable oil and protein extraction processing technology. The method comprises the steps of (1) grinding rice bran and then carrying out extrusion processing to obtain an expanded product; (2) mixing the ground expanded product with water to obtain a mixed liquid, and treating the mixed liquid by using a pulsed electric field; (3) adding alkaline protease into the mixed liquid which is treated by using the pulsed electric field, and carrying out enzymolysis to obtain enzymatic hydrolysate; carrying out enzyme deactivation on the enzymatic hydrolysate, and then carrying out centrifugal separation to obtain free oil, an emulsion, the hydrolysate and residue; separating the free oil, and standing still to obtain the rice bran oil; (4) collecting the hydrolysate and the emulsion, adding neutral protease into the collected hydrolysate and emulsion, carrying out secondary enzymolysis and centrifugal separation, and freeze-drying to obtain the rice bran protein. The method is simple in required processing equipment, low in cost and high in rice bran oil extraction rate, and the high-quality rice bran protein can be obtained at the same time.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

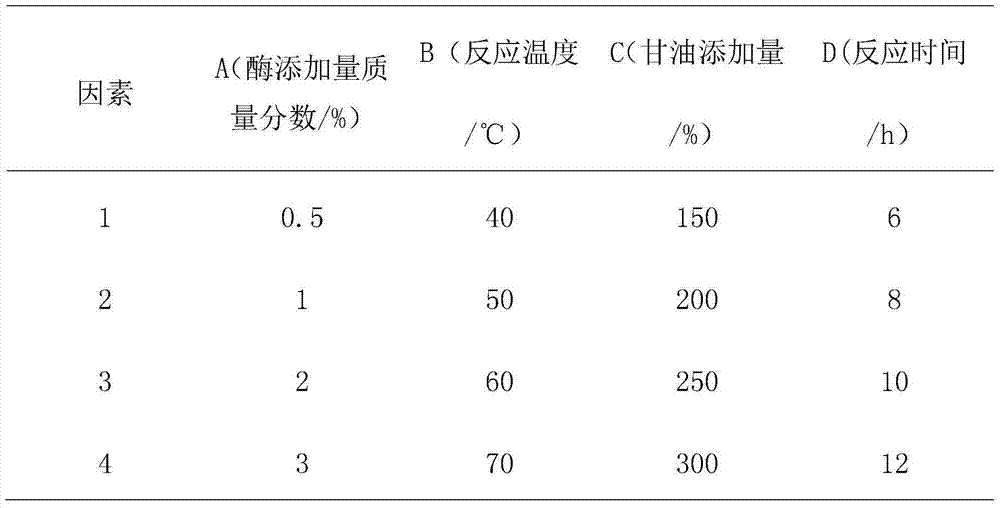

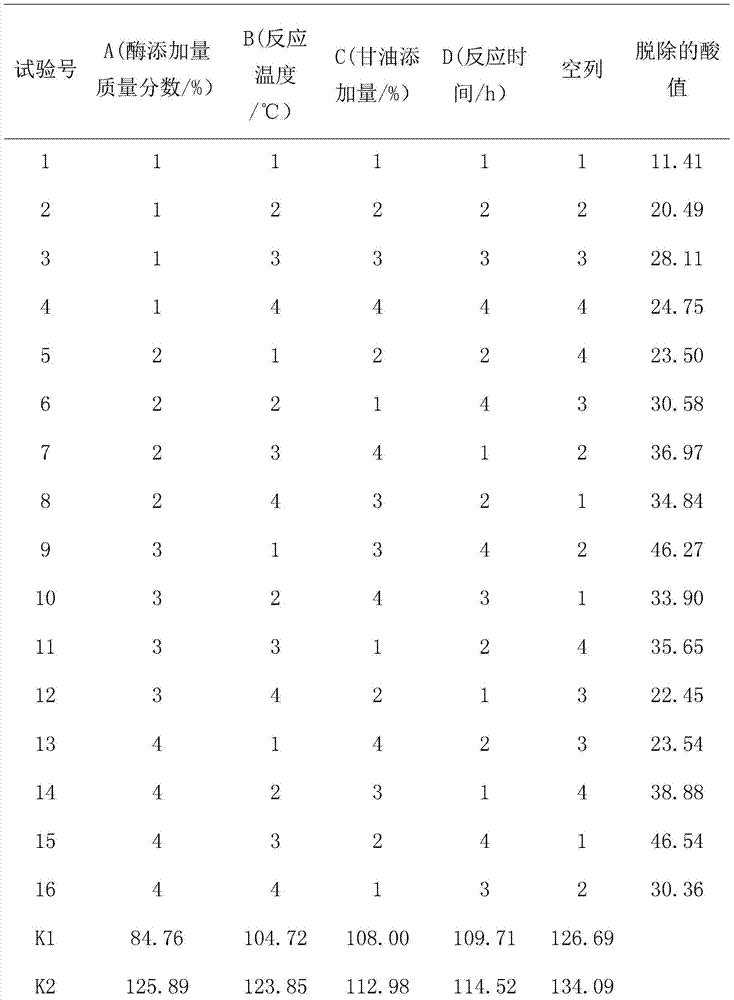

Enzyme-method esterification deacidification technology for rice bran oil with high acid value

InactiveCN104774686AIncrease the refining rateProcess safety and environmental protectionFatty acid esterificationFatty-oils/fats refiningGlycerolAcid value

The invention discloses an enzyme-method esterification deacidification technology for rice bran oil with a high acid value. The technology comprises the following steps: step one, obtaining rice bran oil with a high acid value; step two, carrying out enzyme-method esterification deacidification: heating the rice bran oil obtained in the step one under stirring in vacuum, adding glycerin and Lipozyme 435 immobilized lipase, carrying out esterification reactions between rice bran oil and glycerin in the presence of Lipozyme 435 immobilized lipase so as to obtain the de-acidified rice bran oil; step three, obtaining rice bran oil with a low acid value. In the provided technology, under a certain vacuum degree and temperature, the Lipozyme 435 immobilized lipase is used to catalyze the esterification reactions between the free aliphatic acids in rice bran oil with a high acid value and the glycerin so as to reduce the content of the free aliphatic acids, and thus the acid value of the rice bran oil can be reduced to below 3 mgKOH / g. The provided technology has the advantages of safety, environment-friendliness, low cost, and high refining yield, and is suitable for being applied to edible oil production.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com