Daily ration for partridges

A quail and corn technology, applied in the application, animal feed, animal feed and other directions, can solve the problems of high production cost, impact on egg production, environmental pollution, etc., achieve the same production performance of livestock and poultry, improve economic benefits, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

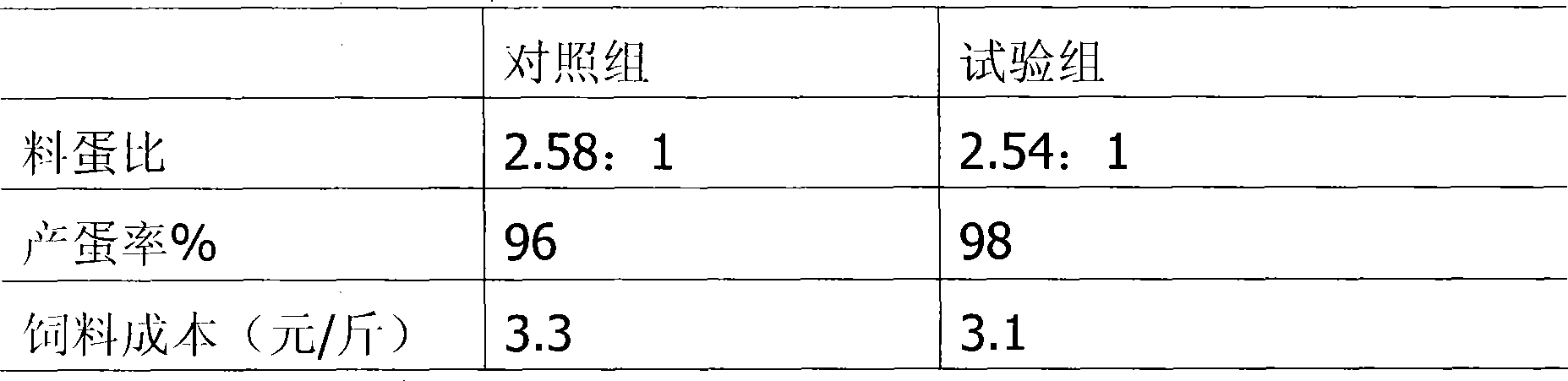

Image

Examples

example 1

[0022] The quail diet of the present invention is composed of the following components by weight: corn: 10.6, wheat: 30, rice bran: 30, rice bran oil: 2.2, soybean meal: 4, cotton meal: 4, rapeseed meal: 2, corn gluten meal: 5. Fish meal: 2.5, salt: 0.21, stone powder: 8.2, calcium hydrogen phosphate: 0.2, lysine: 0.25, methionine: 0.13, threonine: 0.11, premix: 0.6.

[0023] The above components are crushed and passed through an 80-mesh sieve, and mixed evenly.

example 2

[0025] The quail diet of the present invention is composed of the following components by weight: corn: , wheat, rice bran: , rice bran oil: 3.2, soybean meal: 4, cotton meal: 3.5, rapeseed meal: 2.5, corn gluten meal: 8, fish meal: 2.0, table salt: 0.11, stone powder: 5.2, calcium hydrogen phosphate: 0.3, lysine: 0.4, methionine: 0.26, threonine: 0.11, premix: 1.0.

[0026] The above components are crushed and passed through an 80-mesh sieve, and mixed evenly.

example 3

[0028] Quail diet of the present invention is made up of following components by weight: corn: 12.6, wheat: 28, rice bran:, rice bran oil: 1.2, soybean meal: 7, cottonseed meal: 1, corn gluten meal: 2, fish meal: 5, Salt: 0.31, stone powder: 11.2, calcium hydrogen phosphate: 0.1, lysine: 0.1, threonine: 0.22, premix: 0.2.

[0029] The above components are crushed and sieved for 80 days, and mixed evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com