Patents

Literature

328 results about "Milking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milking is the act of removing milk from the mammary glands of cattle, water buffalo, humans, goats, sheep and more rarely camels, horses and donkeys. Milking may be done by hand or by machine, and requires the animal to be currently or recently pregnant. The milker may refer either to the animal that produces the milk or the person who milks said animal.

Device and method for determining teat positions

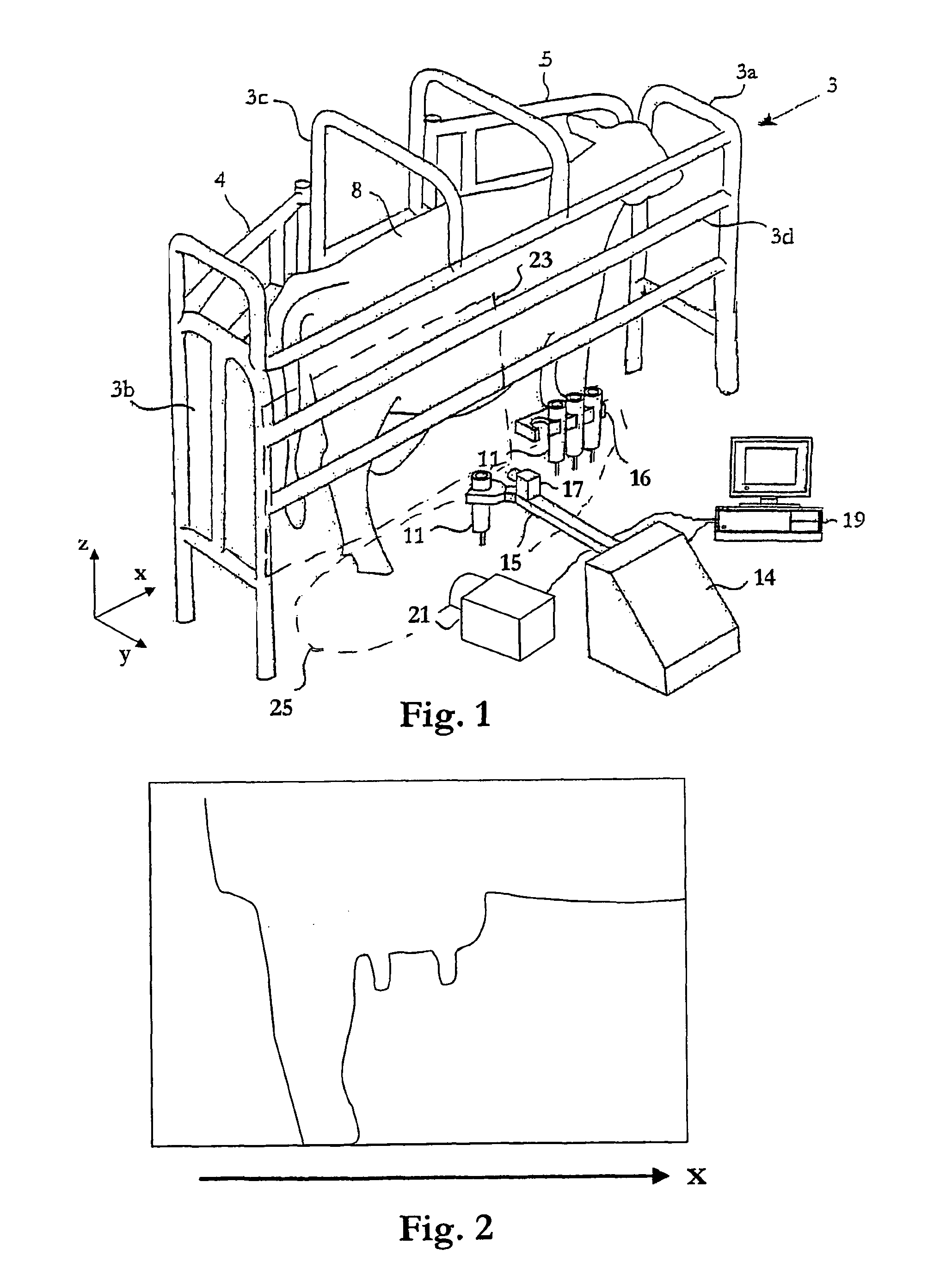

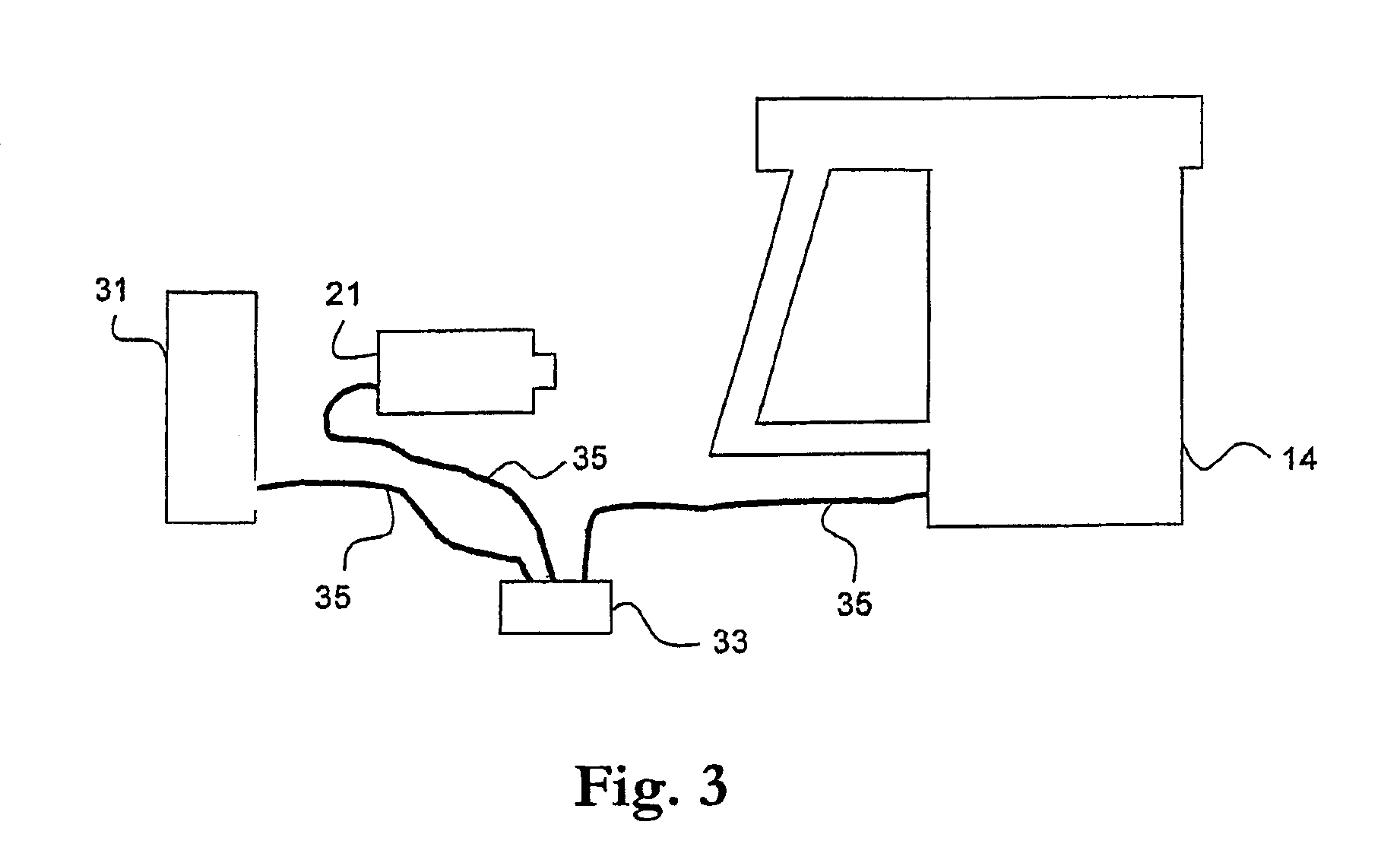

A device for determining the teat positions of a dairy animal after milking. The device is provided with at least one position-measuring device for determining a position of a teat prior to the milking of the dairy animal and for emitting a position signal corresponding to the teat position. The position-measuring device generates individual teat position signals and a control unit determines on the basis of the teat position signals determined before the milking, planes of symmetry extending substantially parallel to the teats. The expected positions are calculated with respect to the planes of symmetry.

Owner:LELY ENTERPRISES

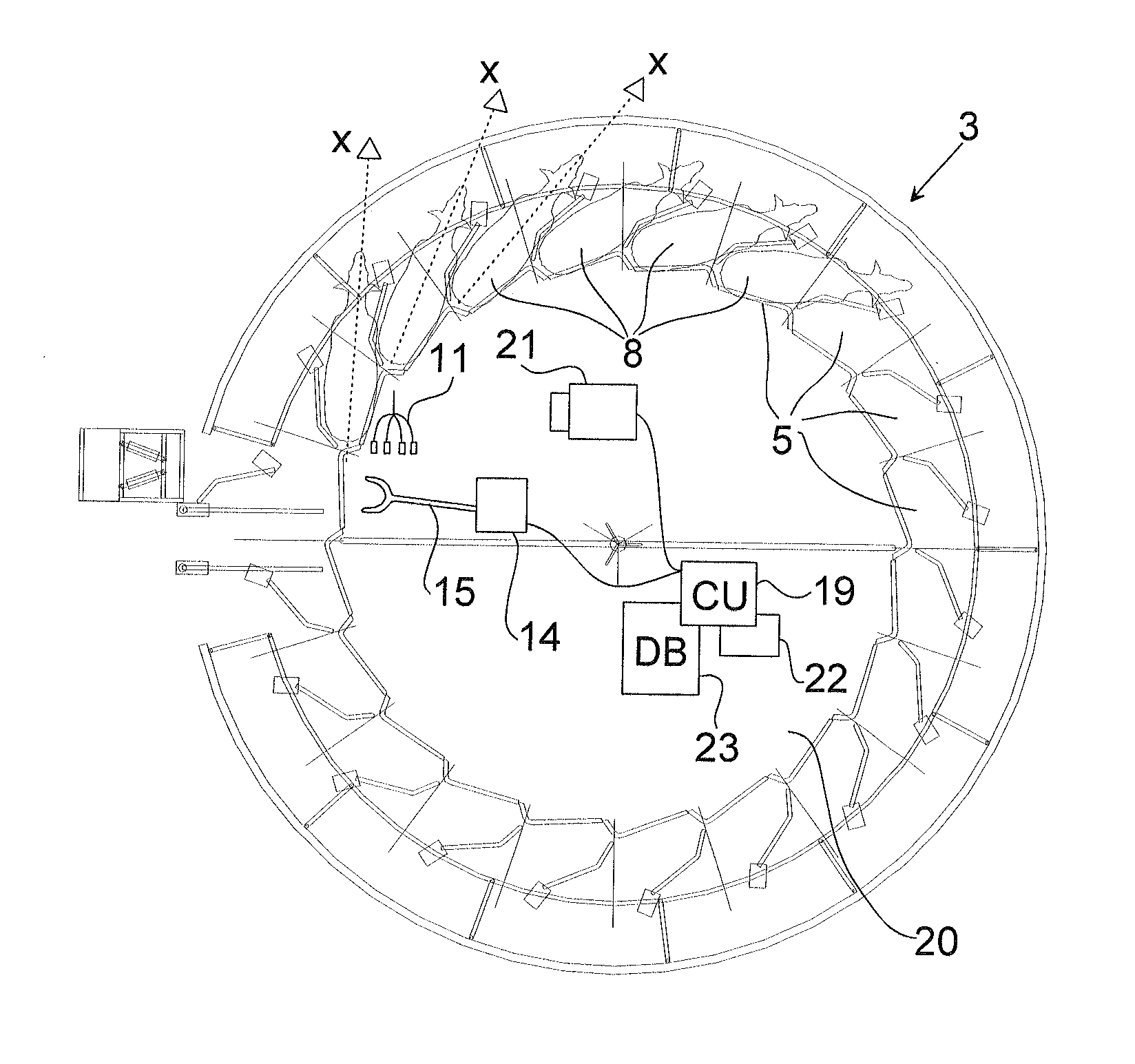

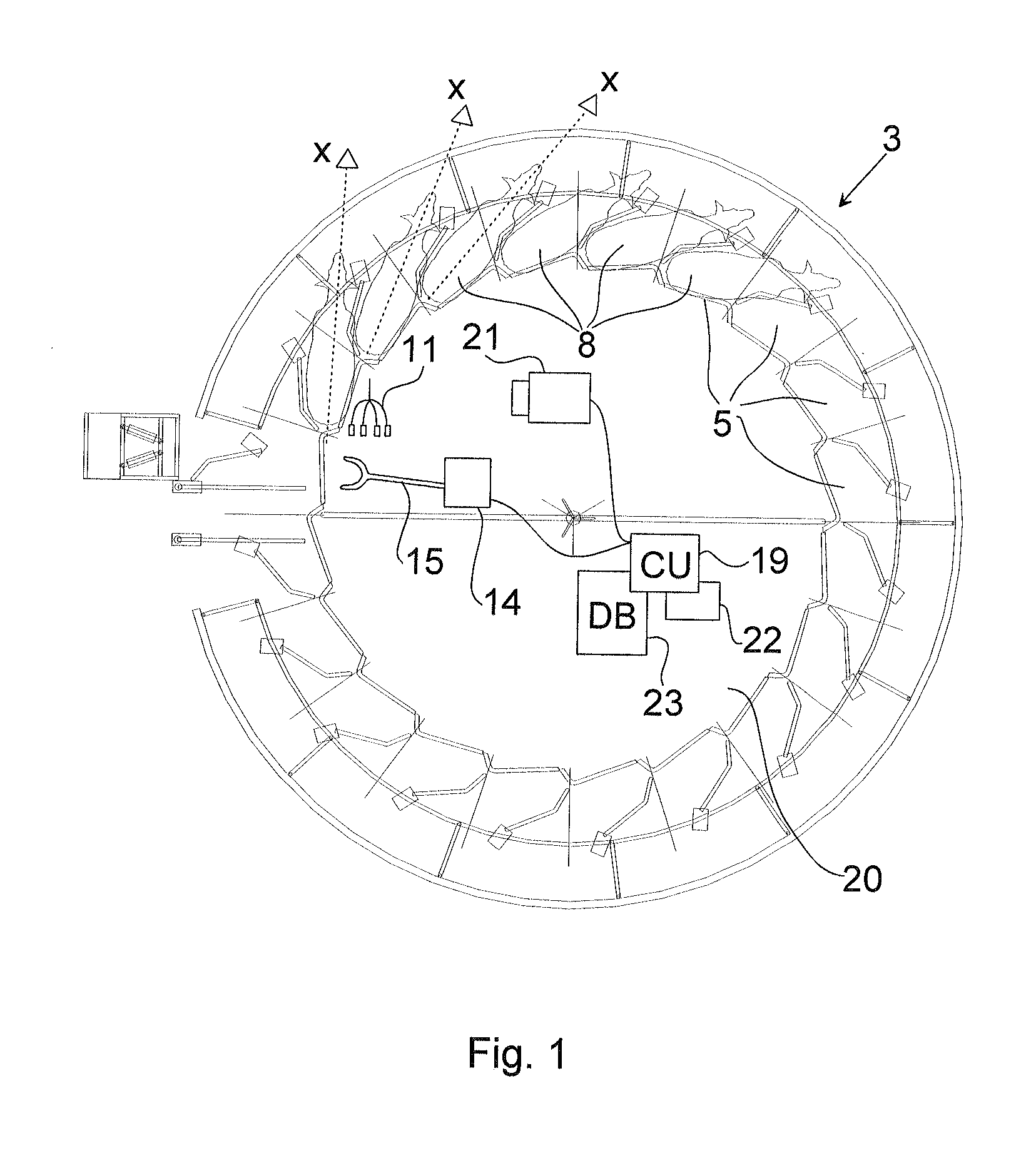

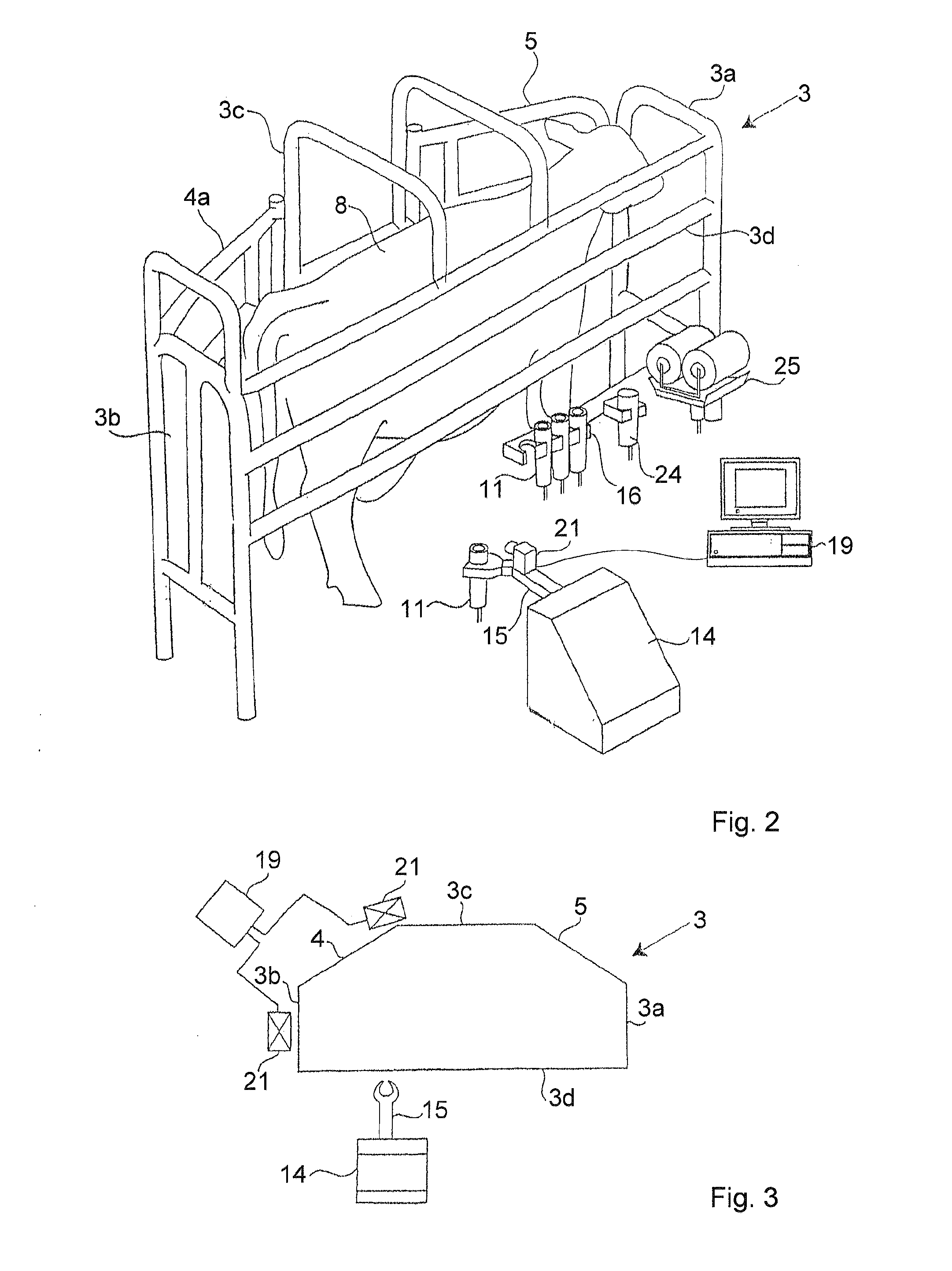

Arrangement and Method for Determining Positions of the Teats of A Milking Animal

ActiveUS20100289649A1Determination of the positions of the teats of an animalRapid determinationCathetersPosition fixationImaging processingEngineering

An arrangement is provided for attaching teat cups to teats of a milking animal in a rotary milking system having a milking stall for housing the milking animal during milking. The arrangement comprises a three-dimensional camera configured to be directed towards the udder of the milking animal in the milking stall and to repeatedly record three-dimensional images of the udder of the milking animal in real time. The three-dimensional camera is further configured to be directed towards the teat cups located in a magazine and to repeatedly record three-dimensional images of the teat cups in real time. The arrangement also includes an image processing device configured to repeatedly detect the teats of the milking animal and determine the positions of the teats in three spatial dimensions based on said repeatedly recorded three-dimensional images of the teats. The image processing device is also configured to repeatedly detect the plurality of teat cups and determine the positions of the teat cups in three spatial dimensions based on said repeatedly recorded three-dimensional images of the teat cups located in the magazine. The arrangement also includes a control device configured to control a robot arm, based on the determined positions of the teats of the milking animal and the determined positions of the teat cups, to automatically attach at least one teat cup to at least one teat of the milking animal in the milking stall.

Owner:DELAVAL HLDG AB

Device and method for determining teat positions

InactiveUS20070245964A1Improve accuracyEasy to detectCathetersPosition/course control in three dimensionsEngineeringControl unit

A device for determining the teat positions of a dairy animal after milking. The device is provided with at least one position-measuring device for determining a position of a teat prior to the milking of the dairy animal and for emitting a position signal corresponding to the teat position. The position-measuring device generates individual teat position signals and a control unit determines on the basis of the teat position signals determined before the milking, planes of symmetry extending substantially parallel to the teats. The expected positions are calculated with respect to the planes of symmetry.

Owner:LELY ENTERPRISES

Milking and application teat cup, system, and method

Owner:DELAVAL INC

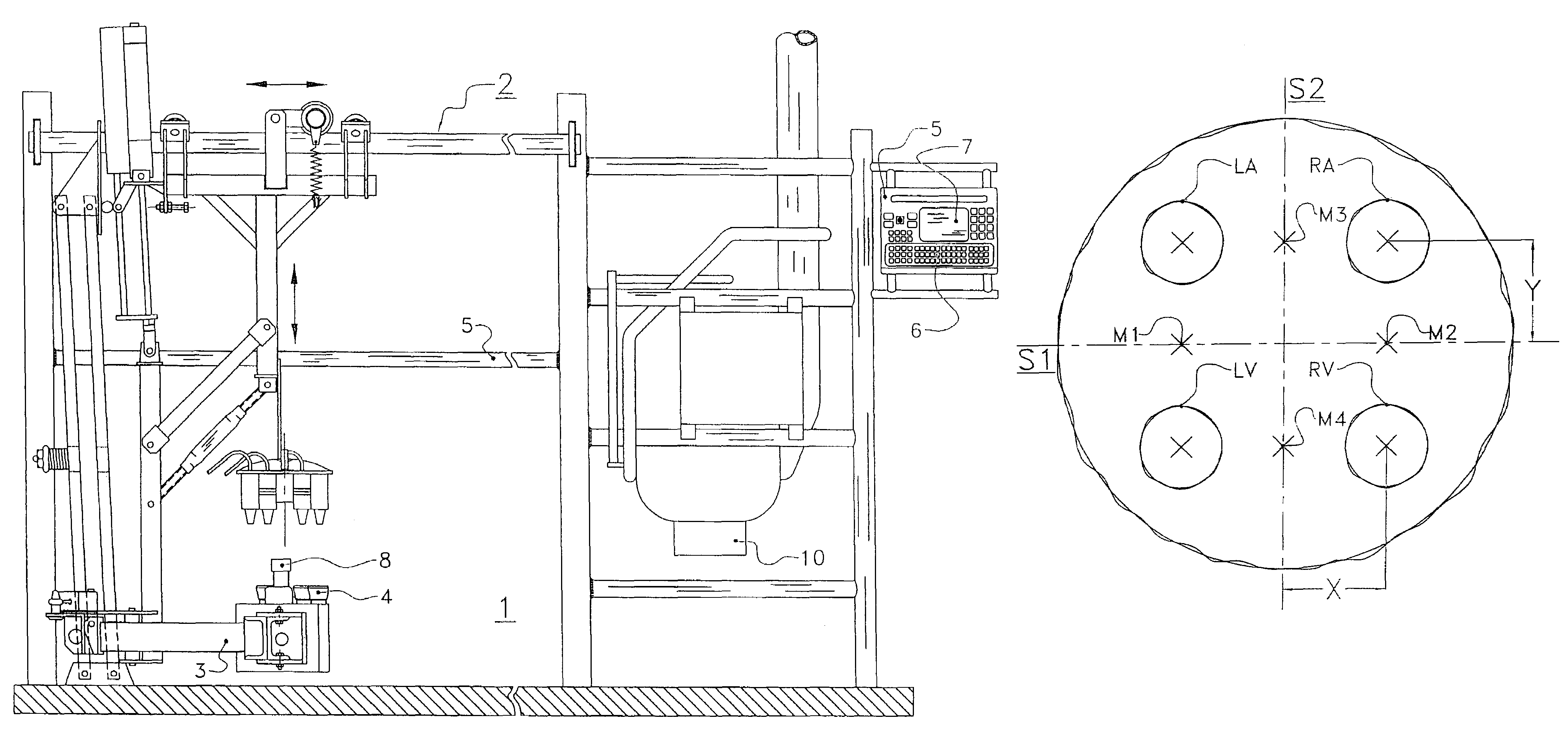

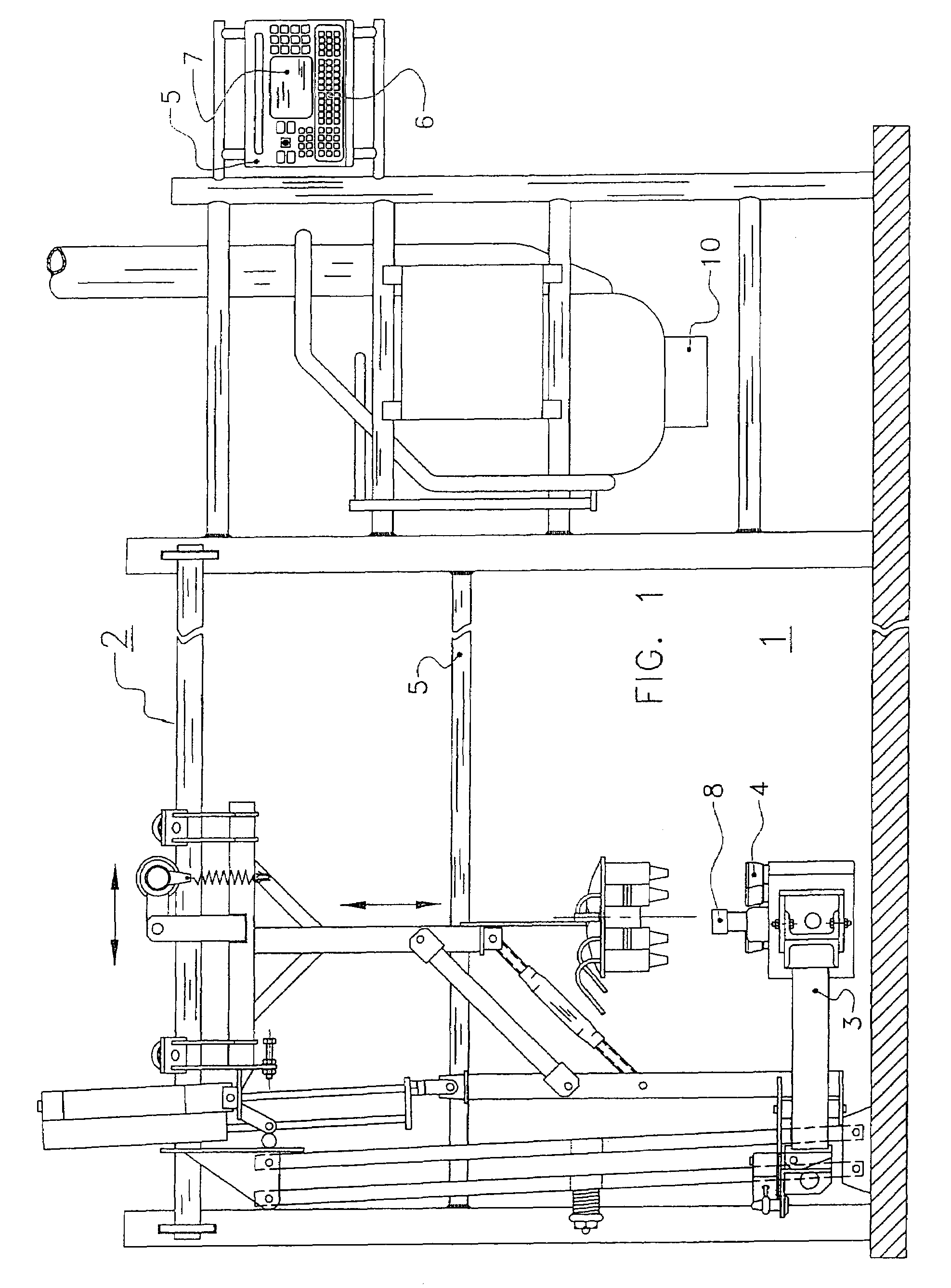

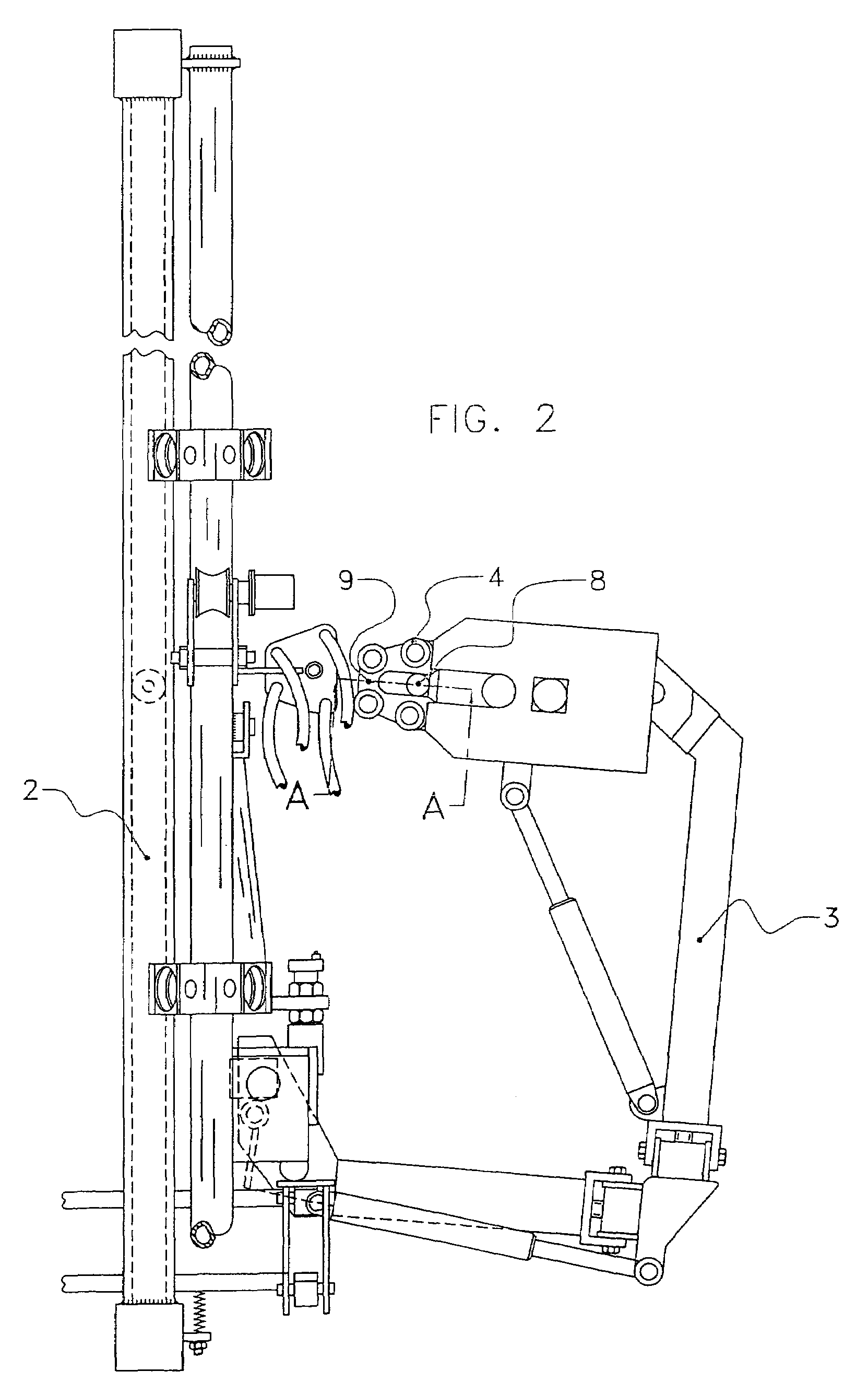

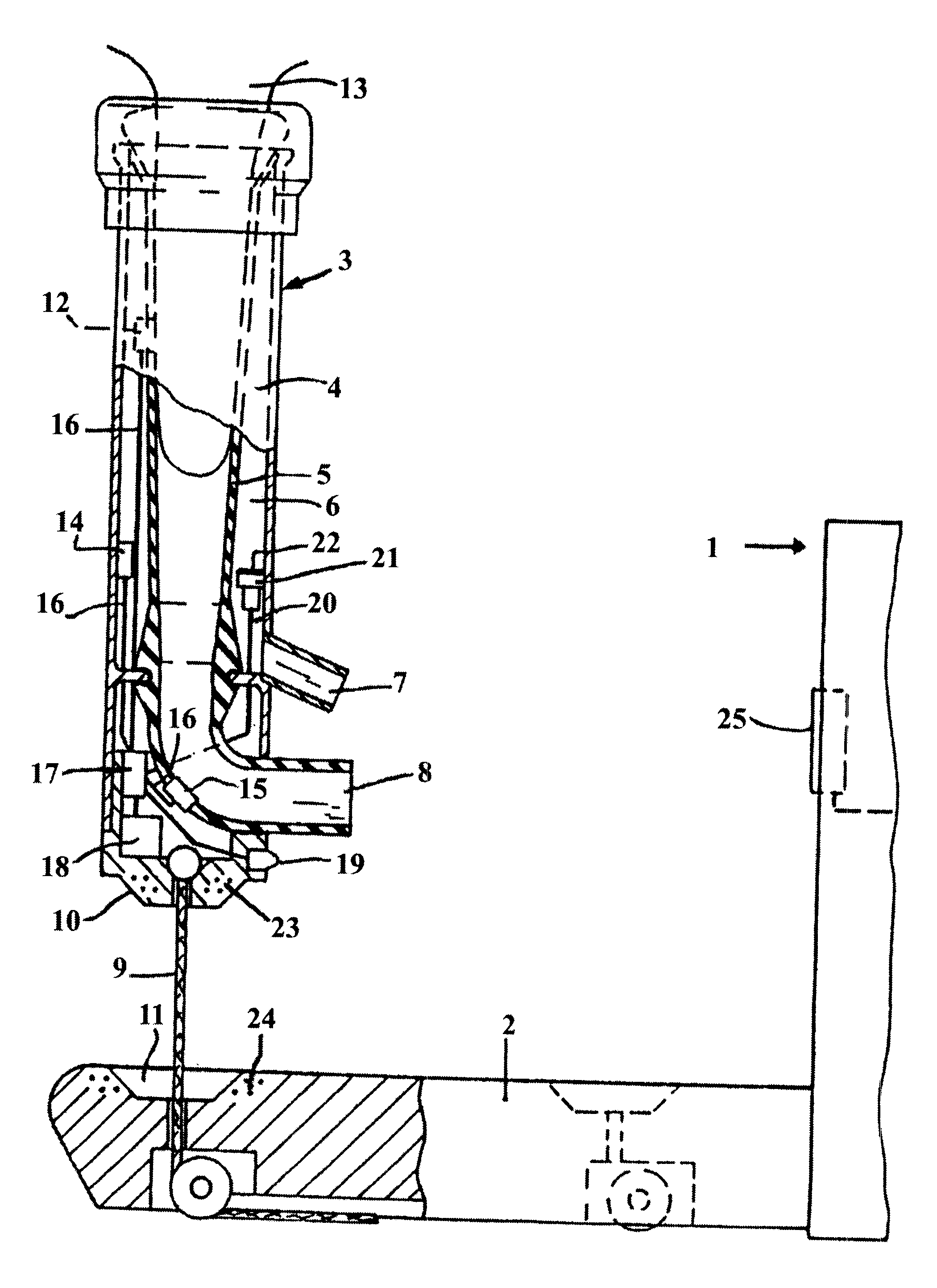

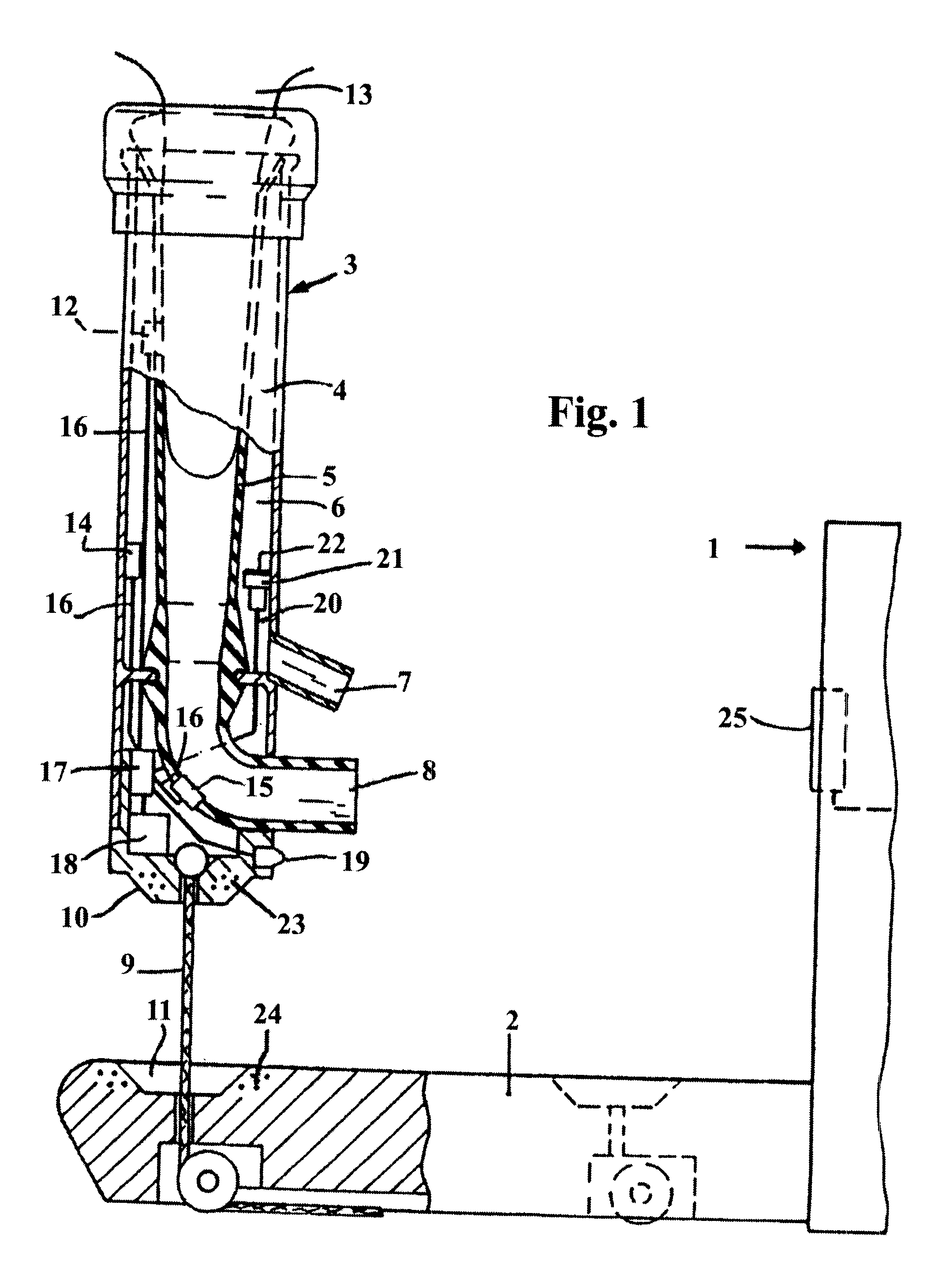

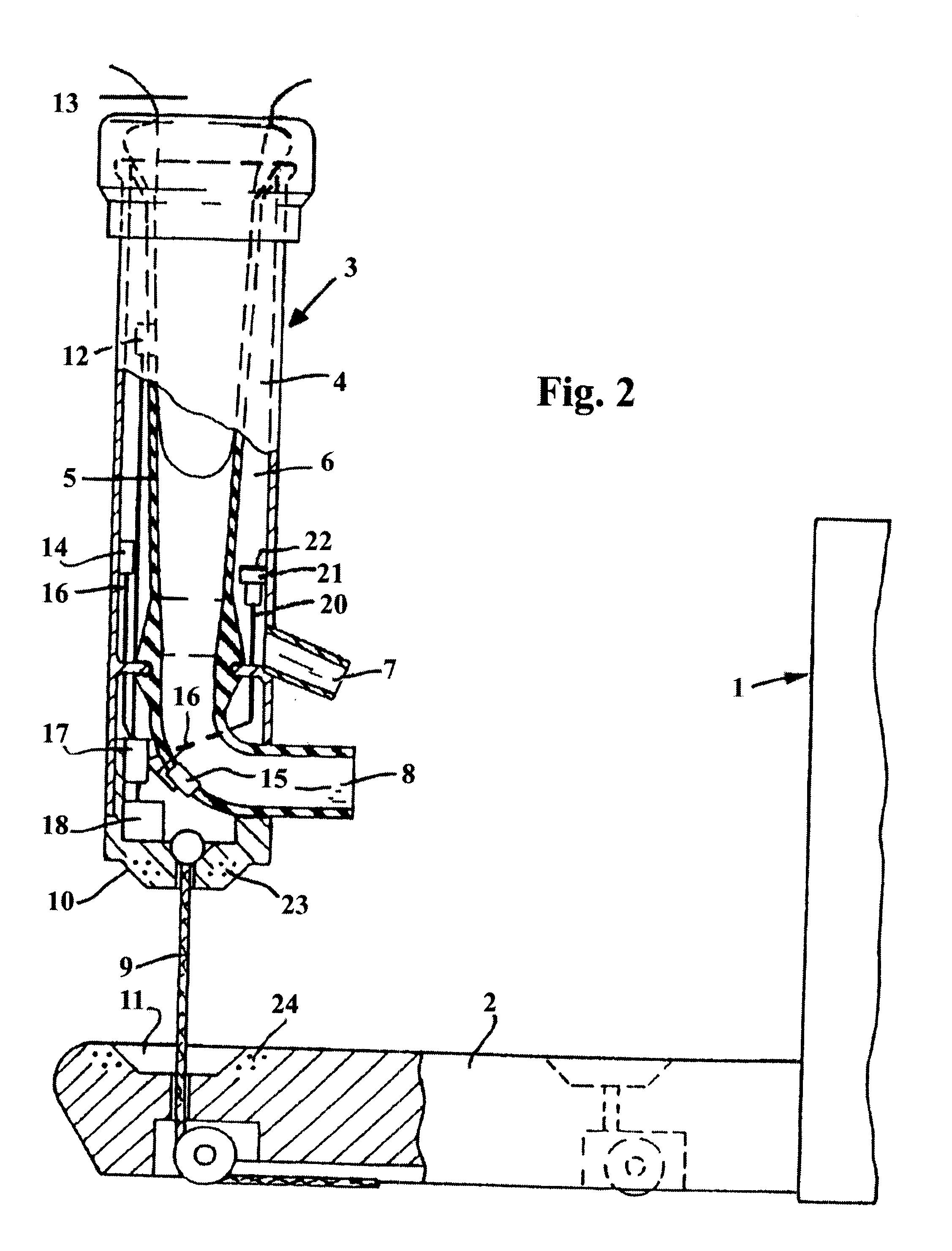

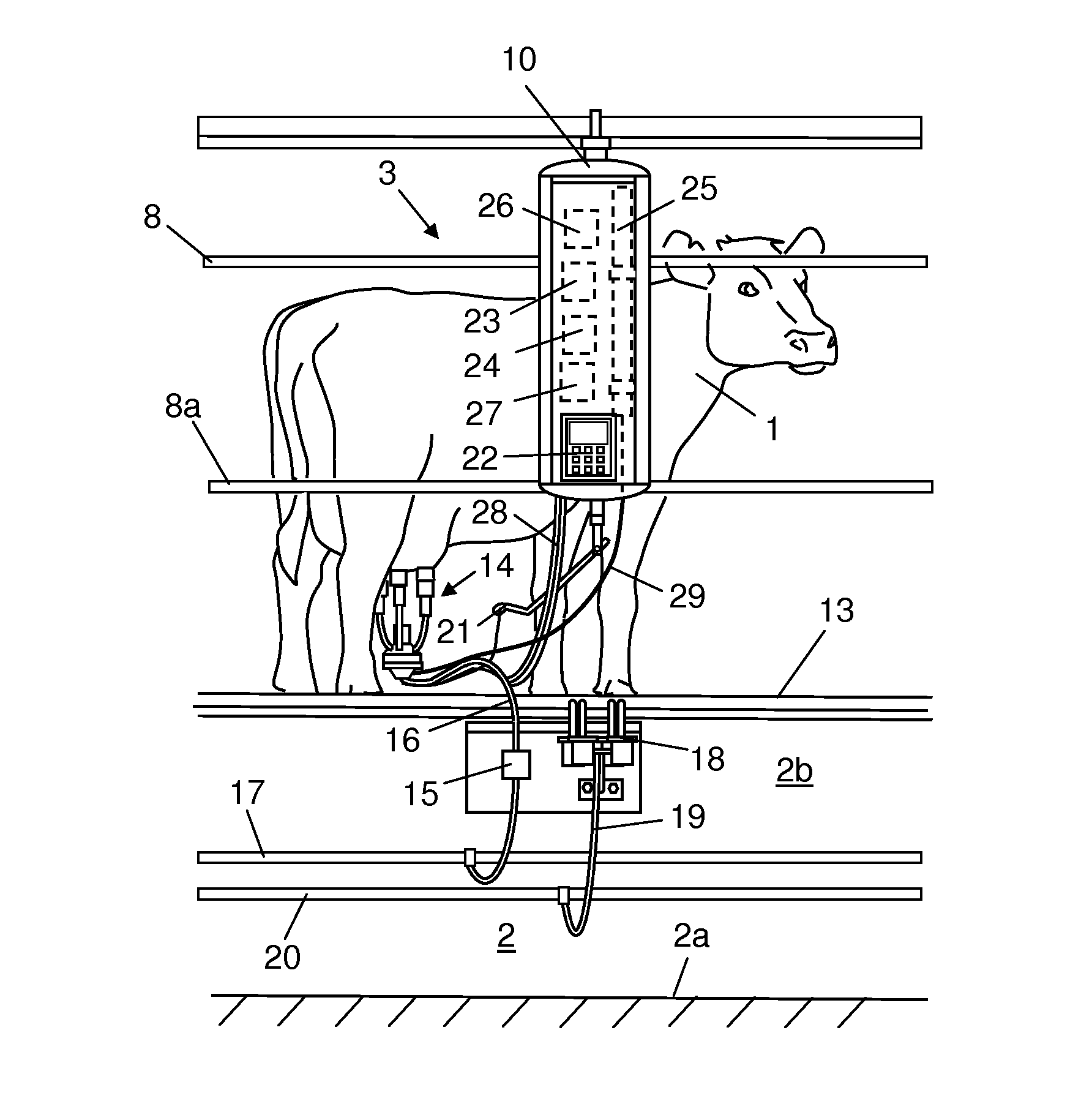

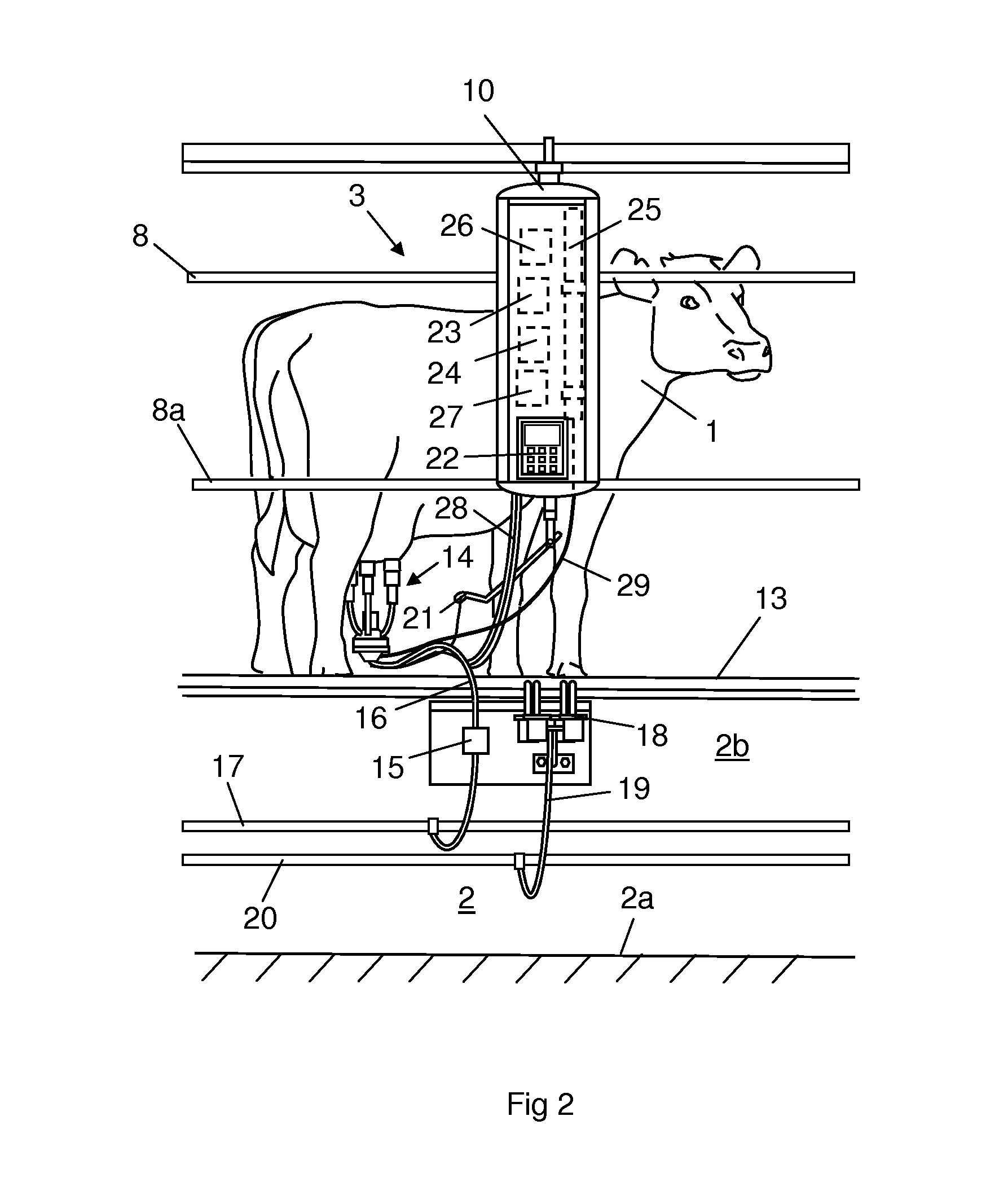

Implement for milking animals, such as cows

This invention relates to an Apparatus for milking animals, such as cows, and comprising a milking machine with teat cups and sensors which govern the milking process, examine the milk obtained and the physical condition of the animal being milked. The apparatus also includes a processing unit such as a computer for processing signals received from the sensors. The signals from the sensors are wirelessly transmitted via a transmitter to the processing unit. The sensors may be incorporated in each teat cup or only one teat cup. Energy for the sensors is generated by movements of magnets in coils, which are incorporated in each teat cup or in at least one of the feed cups, the movements of the magnets being provided by vacuum pulsations on each teat cup or one of the teat cups, or from another energy sources such as solar cells.

Owner:LELY ENTERPRISES

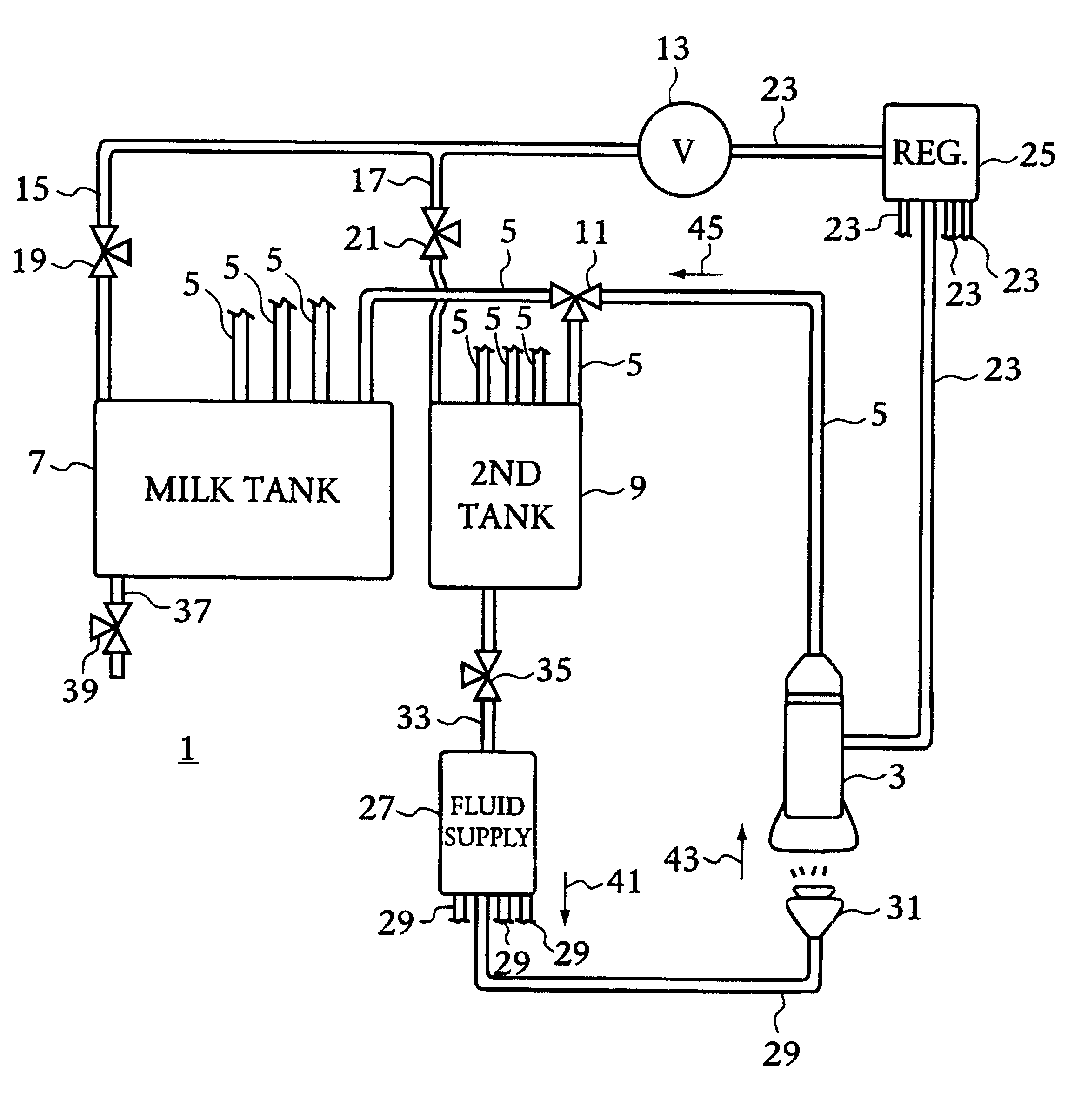

Method and apparatus for teat cup cleaning

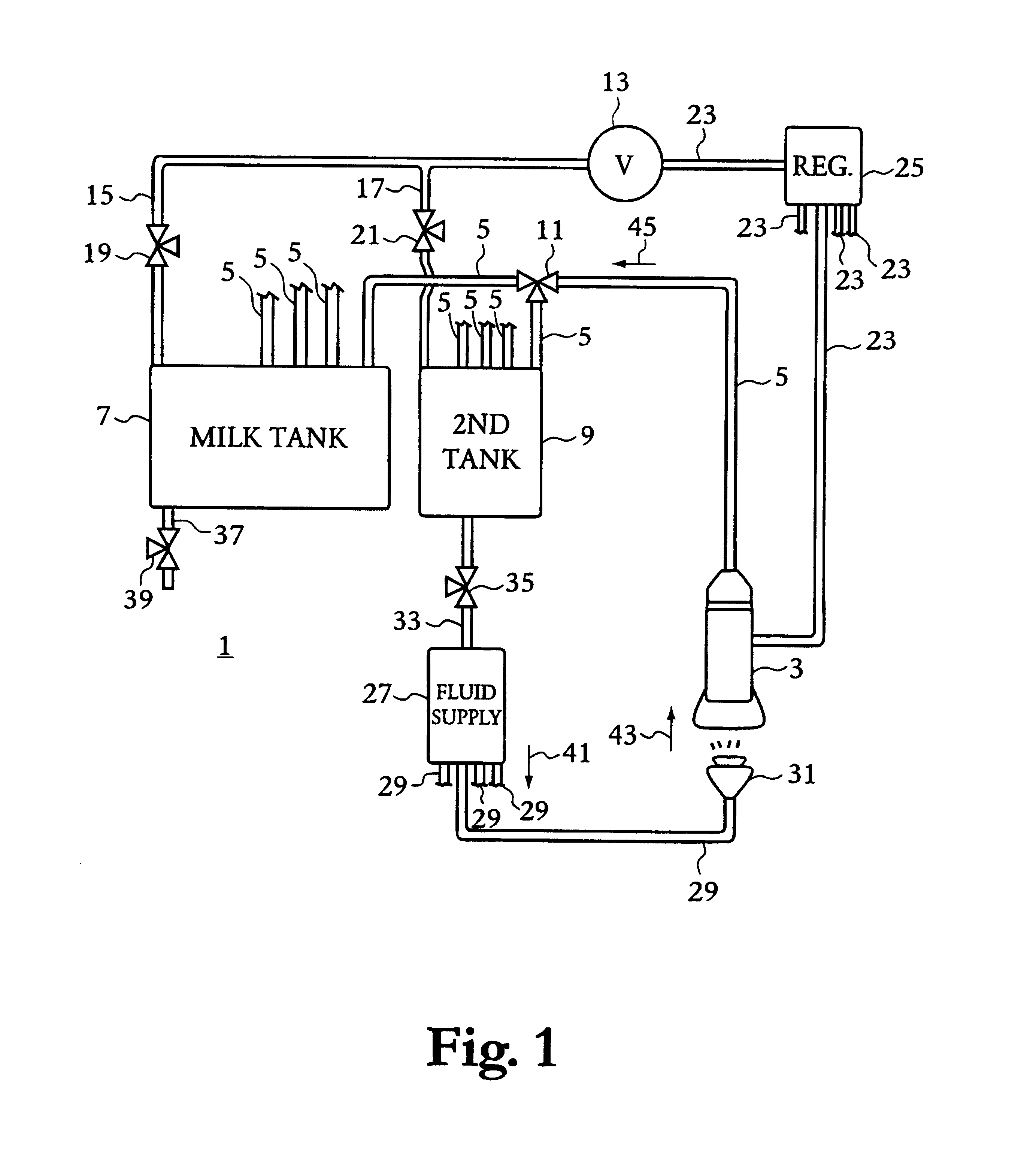

The present invention refers to teat cup cleaning in an automated milking system comprising a plurality of teat cups, each connected to a first end of a respective milk line (5), and the second end of each milk line being individually and automatically connectable to a first (7) or a second container (9), respectively, wherein, during milking of the teats of a milking animal, the plurality of teat cups are attached to the teats of the animal, the second ends of the milk lines are connected to said first container and vacuum is supplied to said first container in order to draw milk through the milk lines into said first container. The cleaning comprises supplying (41, 43) a cleaning fluid to at least a first (3) of said plurality of teat cups; connecting the second end of the milk line (5) connected to the first teat cup (3) to said second container (9); and supplying vacuum to said second container in order to suck cleaning fluid through the milk lines into said second container (9), while keeping said first container (7) at substantially atmospheric pressure.

Owner:DELAVAL HLDG AB

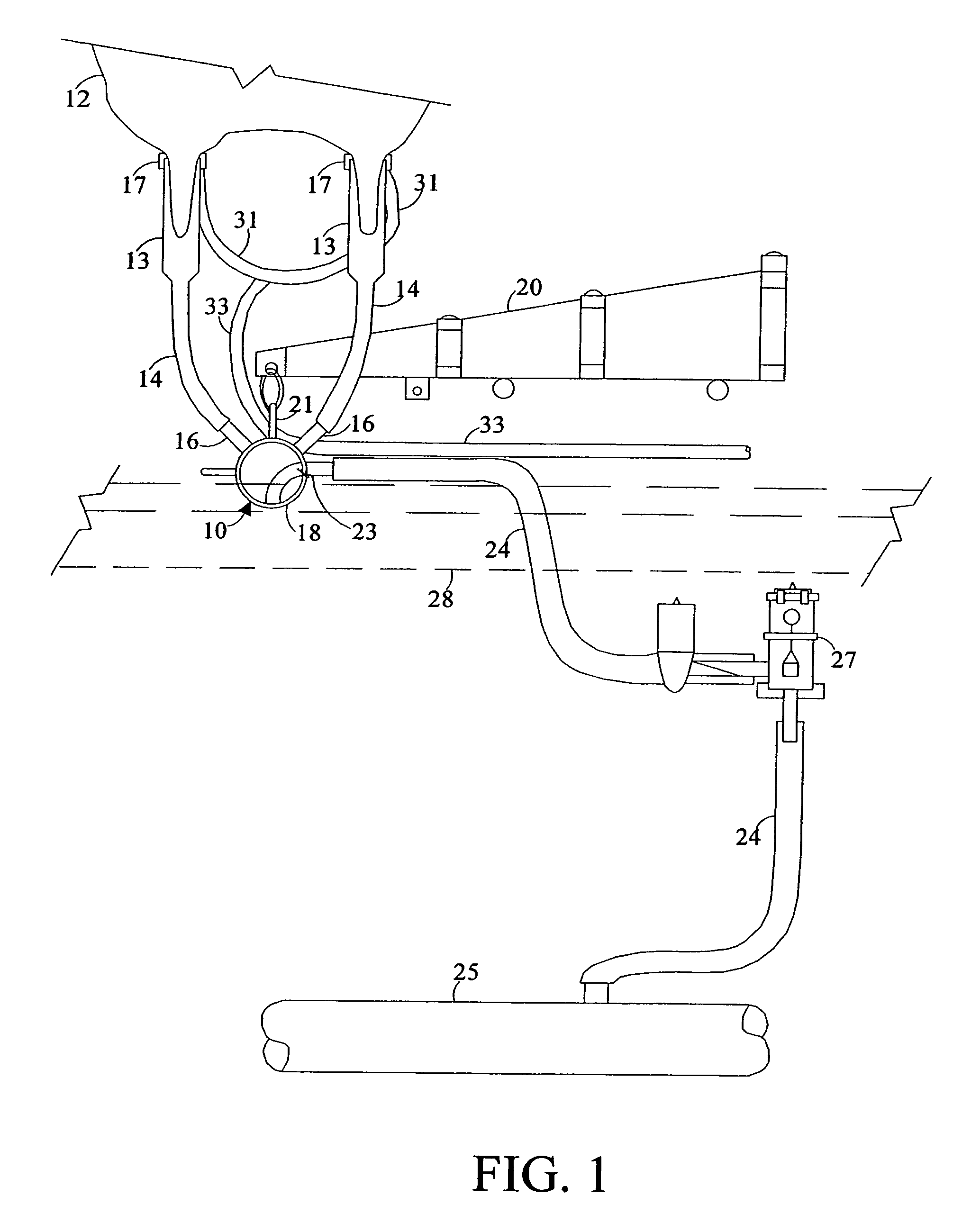

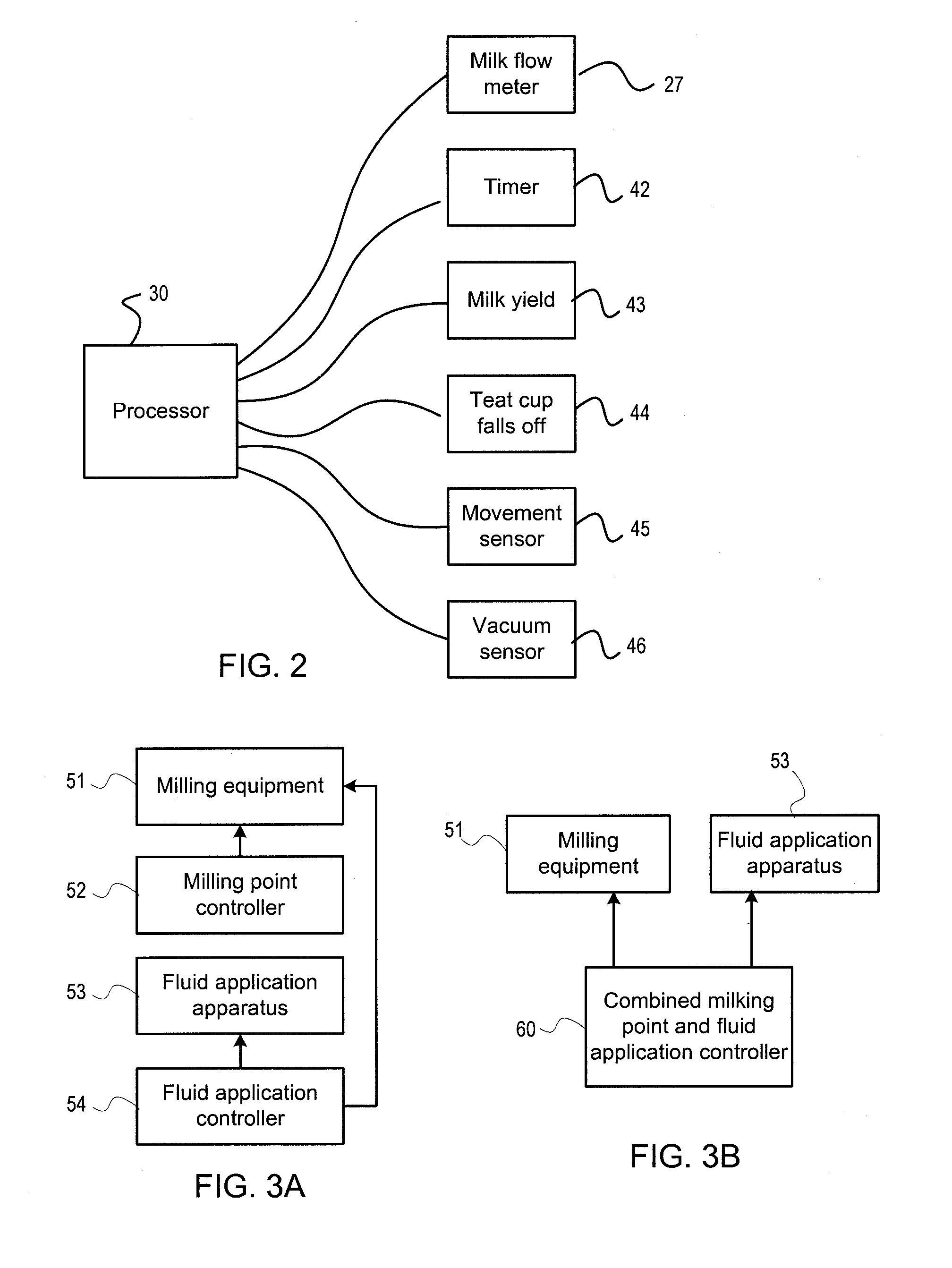

Fluid application systems and methods and milking systems and methods

ActiveUS20080314322A1Avoid applicationEfficient and accurate and preciseComputer controlSimulator controlEngineeringMilking

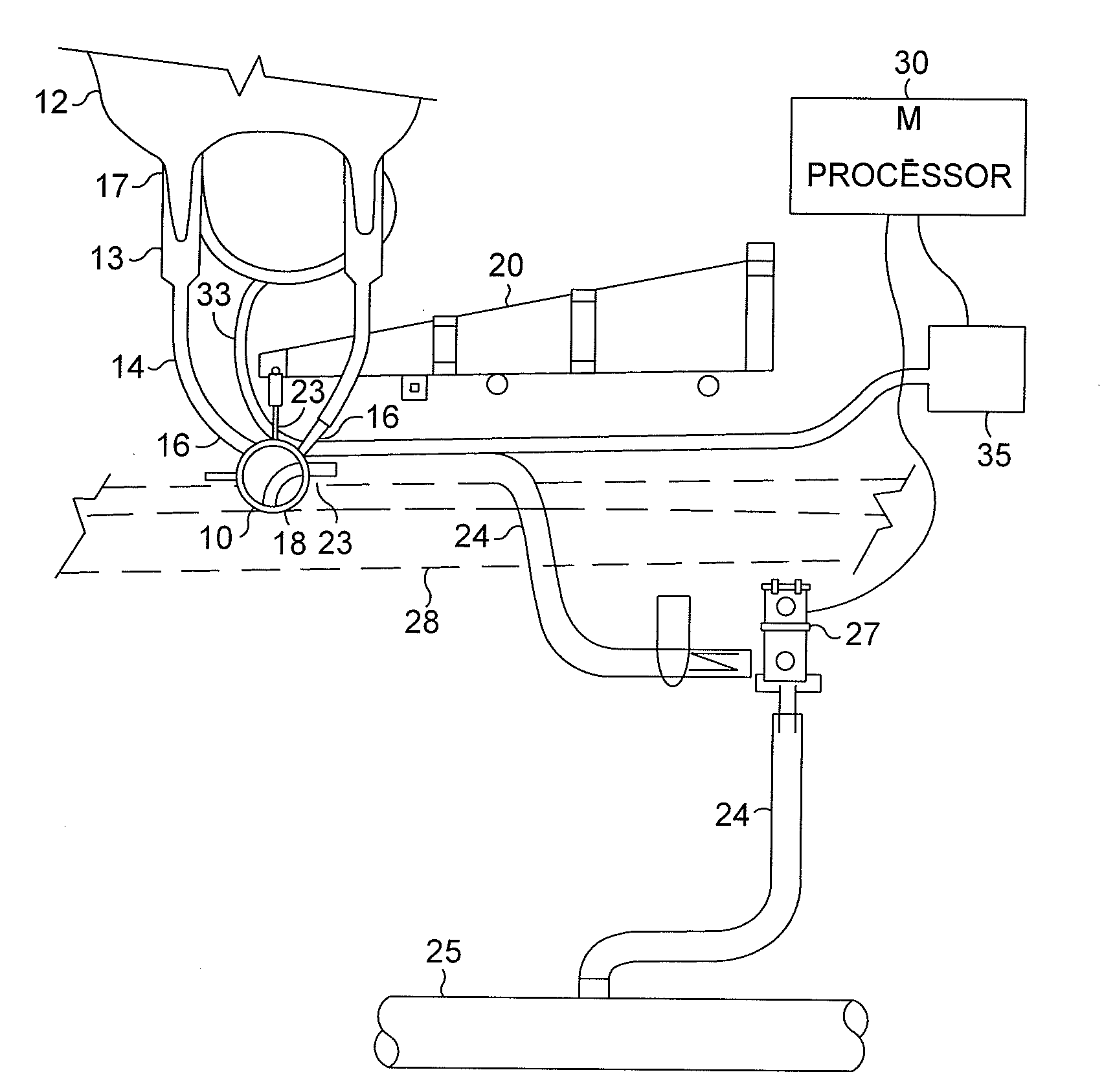

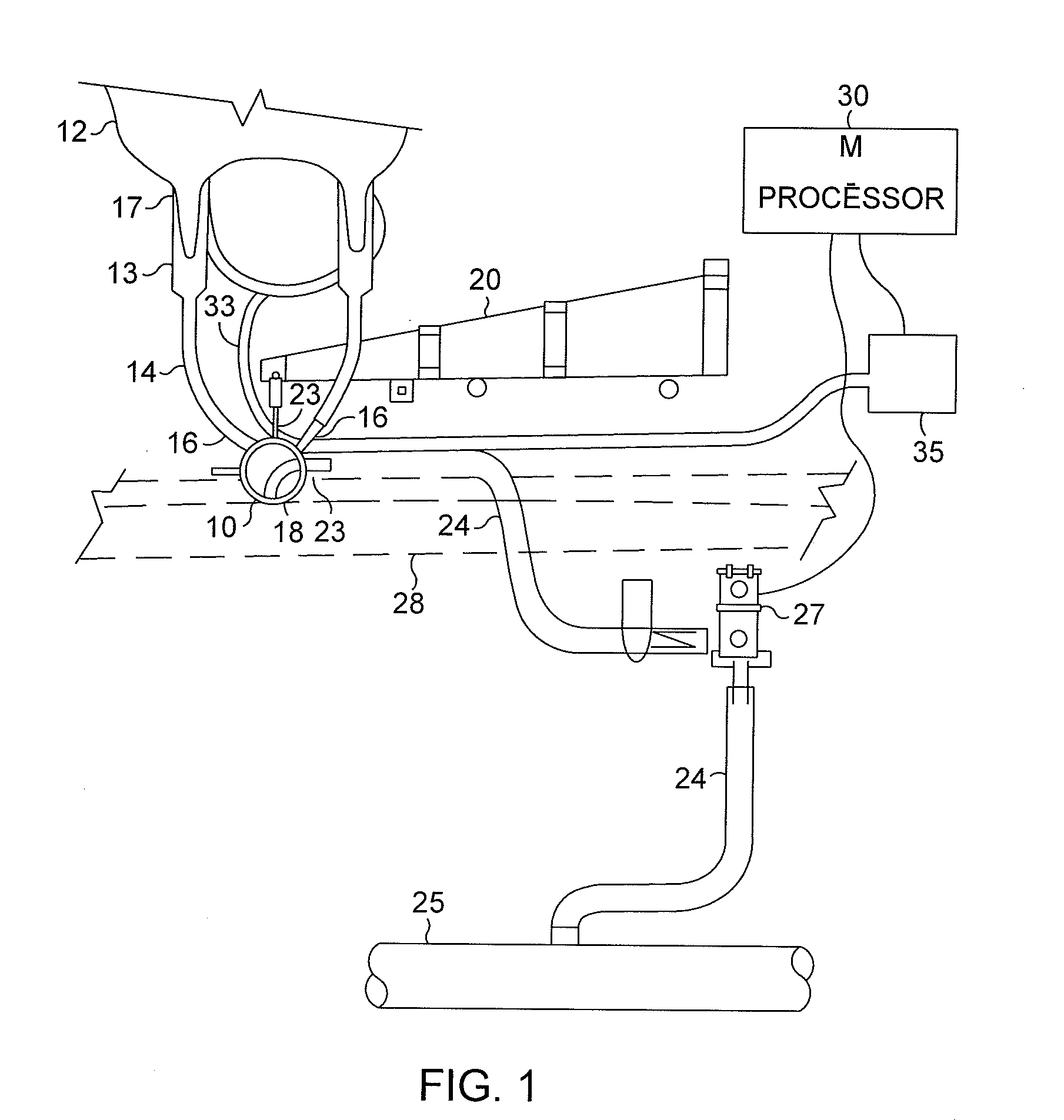

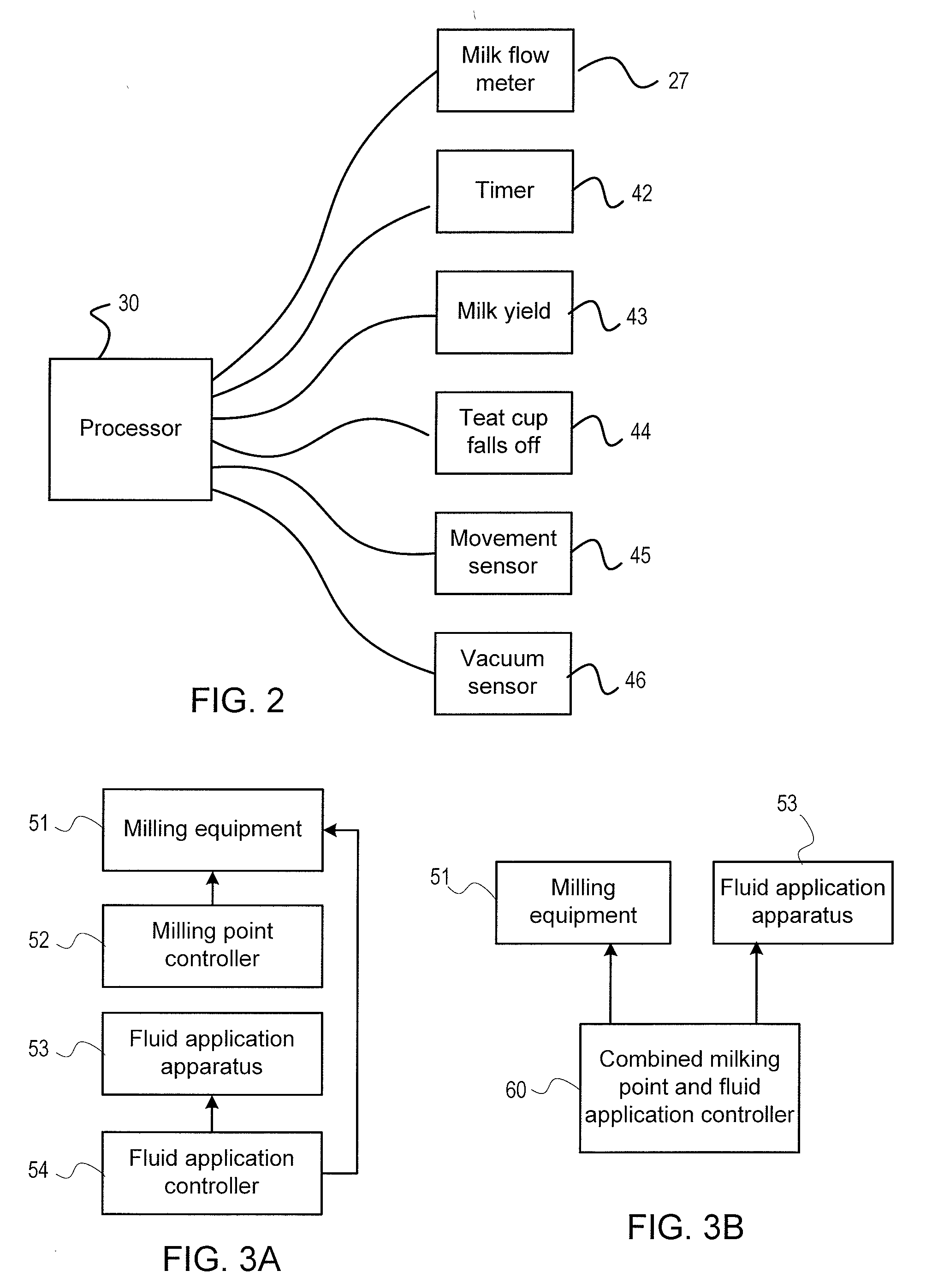

A fluid application system for automatically applying a fluid to the teats of an animal subsequent to the milking of the animal comprises a fluid delivery arrangement comprising a plurality of applicators, wherein each of the applicators is arranged in connection with a respective teat cup and is provided for applying the fluid to a teat of the animal, to which the respective teat cup is attached during the milking of the animal, in connection with a detachment of the teat cup from the teat. A control arrangement is provided for (i) determining, for a detachment of a teat cup from a teat, whether that detachment is a normal detachment or an abnormal detachment, and (ii) controlling, for the detachment of the teat cup from the teat, the applicator arranged in connection with that teat cup to apply the fluid provided that the detachment is a normal detachment and to not apply the fluid provided that the detachment is an abnormal detachment.

Owner:DELAVAL HLDG AB

Method of controlling a milking implement, a software program for and an implement performing the method

ActiveUS8286583B2Testing is superfluousOrientation of the teat cup relative to the udder can be improvedCathetersObstetricsMilk cow's

A method of controlling a milking implement for automatically milking a dairy animal with an udder, such as a cow, which milking implement includes a camera and a teat cup. More particularly, the method includes attaching the teat cup to a teat of the udder, followed by producing by the camera an image of at least a part of the udder and of at least a part of the teat cup, making an analysis of the image of the udder with the teat cup, and performing at least one control action by the milking implement, based on the analysis.

Owner:MAASLAND

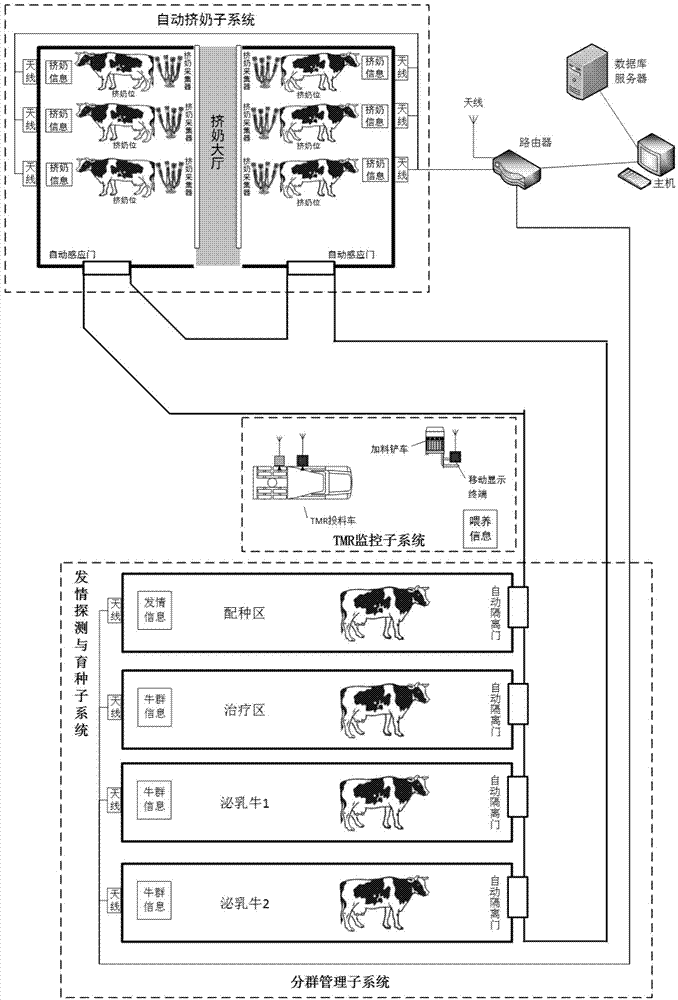

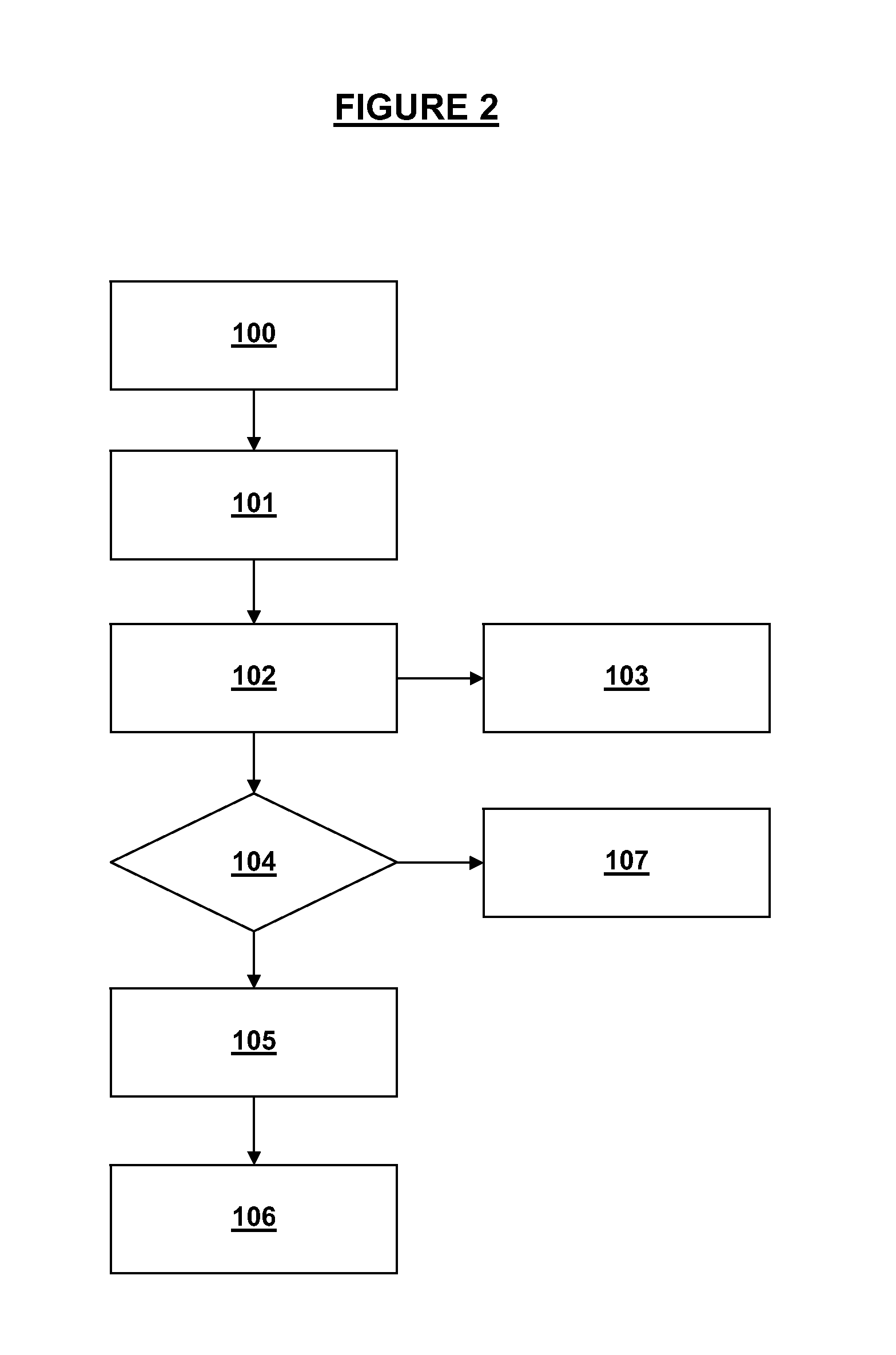

Cow fine breeding method based on RFID technology

ActiveCN103782954AImplement dynamic configurationImprove efficiencyClimate change adaptationCo-operative working arrangementsAgricultural scienceBusiness function

The invention discloses a cow fine breeding method based on the RFID technology. The method includes the following steps that 1, the milk production of cows is recorded through an automatic milk production recording subsystem where the RFID technology and milking are combined; 2, automatic clustering management is performed on the cows through an automatic cow isolation door based on the RFID technology; 3, appropriate nutritious daily ration is prepared for cow groups through a TMR monitoring subsystem based on the RFID technology; 4, cow movement and oestrus sensors are installed on cow neckbands so as to monitor movement conditions of the cows in real time. In the cow fine breeding method, the cow breeding management business relates to various fields of milking management and fodder management, and the cow fine breeding method is applied and deployed from the aspects of automatic milk production counting, clustering management, fodder management and oestrus hybridization management according to different business functions of cow farms.

Owner:GUANGDONG YANTANG DAIRY

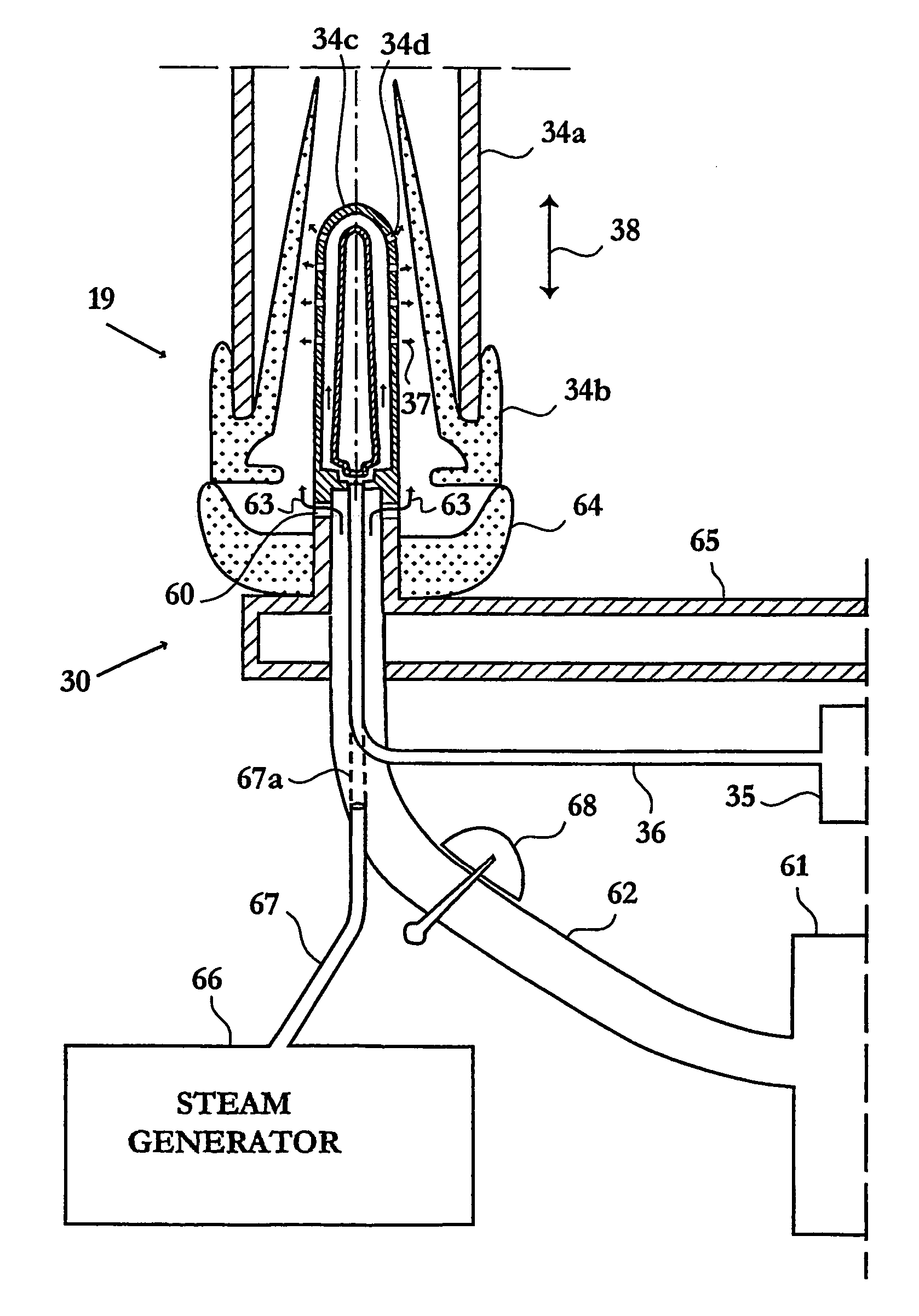

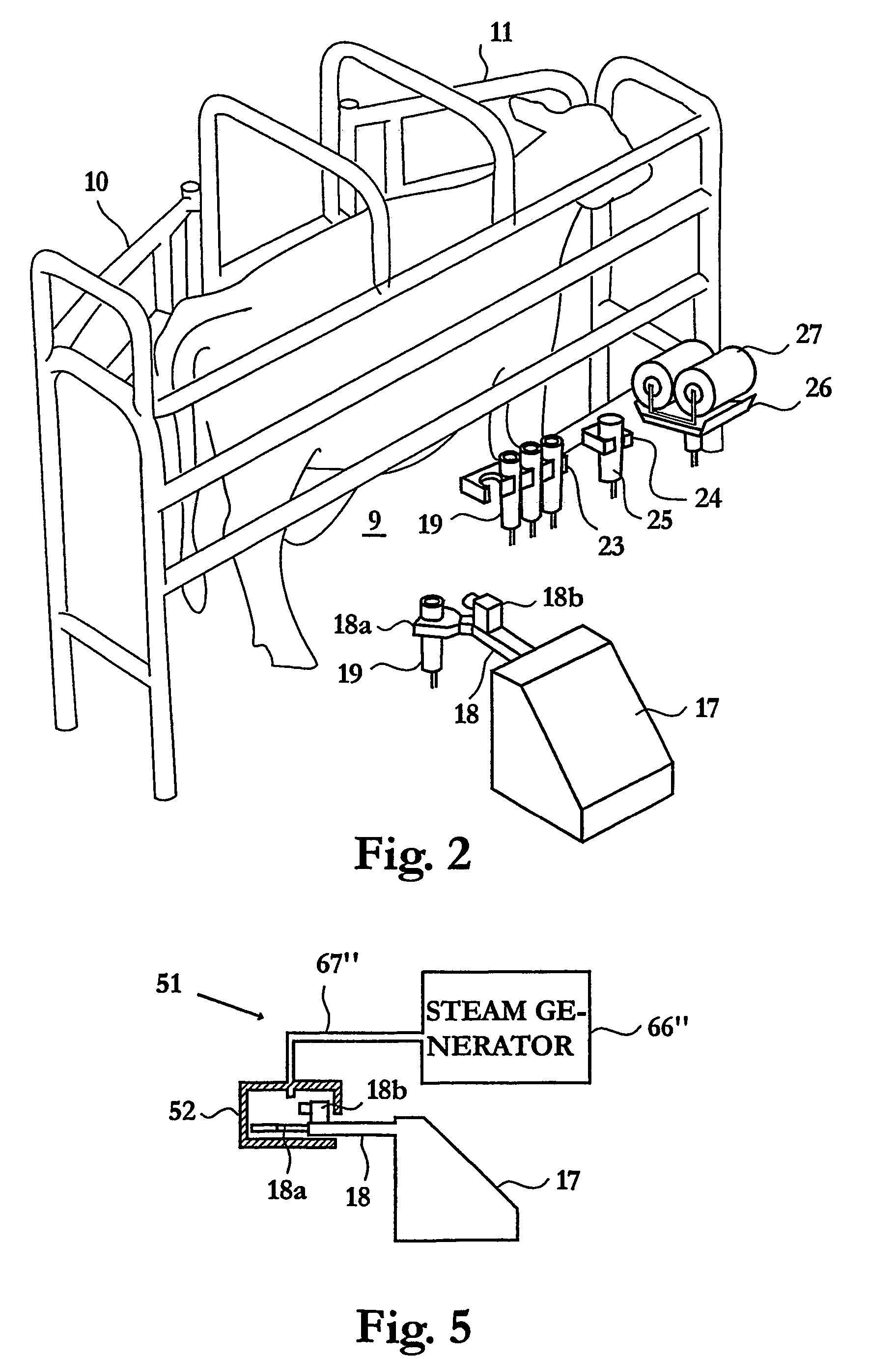

Method and an arrangement at a dairy farm

InactiveUS7263948B2Effective and accurate and reliable and safeLow costCathetersDairy farmingEngineering

The present invention refers to a cleaning method in a milking system (9) comprising a plurality of teat cups (19), each of which is connected to a respective milk line, wherein, during milking of the teats of a milking animal, the plurality of teat cups (19) are attached to the teats of the animal, and vacuum is supplied to the respective milk lines in order to draw milk from the teats of the milking animal. The cleaning comprises the steps of removing milk or other residues present at each of said plurality of teat cups by means of flushing (37) each of said plurality of teat cups with a cleaning fluid supplied via a supply line (36, 34c); evacuating cleaning fluid from each of said plurality of teat cups or from the supply line; and disinfecting at least one of said plurality of teat cups by means of exposing (60) said at lest one of said plurality of teat cups to steam.

Owner:DELAVAL HLDG AB

Milking sow concentrated feed

ActiveCN101579062AImprove lactation performanceImprove reproductive performanceAnimal feeding stuffAccessory food factorsPhytaseAdditive ingredient

The invention relates to a milking sow concentrated feed, mainly comprising the main components such as fat powder, fish meal, puffed corn powder, natural plant extract, lysine, phytase, electrolytic mixture, choline, composite vitamin supplement, salt, rock powder, calcium hydrogen phosphate, mineral elements such as iron, zinc, copper, manganese, iodine, cobalt, selenium, chromium and the like, and accessories such as antioxidant, mildewproof agent, feed carrier and the like. The feed has multiple nutritional components, which can improve synergistically the lactation ability and proliferation ability of milking sows. Meanwhile, the content of the concentrated feed provided by the invention in daily ration is 10 % (according to weight percentage), the concentrated feed is easy to mix evenly and conducive to solve the problems that the methods for preparing feeds and controlling quality are not enough.

Owner:河南雄峰科技股份有限公司

Fluid Application Systems And Methods And Milking Systems And Methods

A fluid application system for automatically applying a fluid to the teats of an animal subsequent to the milking of the animal comprises a fluid delivery arrangement comprising a plurality of applicators, wherein each of the applicators is arranged in connection with a respective teat cup and is provided for applying the fluid to a teat of the animal, to which the respective teat cup is attached during the milking of the animal, in connection with a detachment of the teat cup from the teat. A control arrangement is provided for (i) determining, for a detachment of a teat cup from a teat, whether that detachment is a normal detachment or an abnormal detachment, and (ii) controlling, for the detachment of the teat cup from the teat, the applicator arranged in connection with that teat cup to apply the fluid provided that the detachment is a normal detachment and to not apply the fluid provided that the detachment is an abnormal detachment.

Owner:DELAVAL HLDG AB

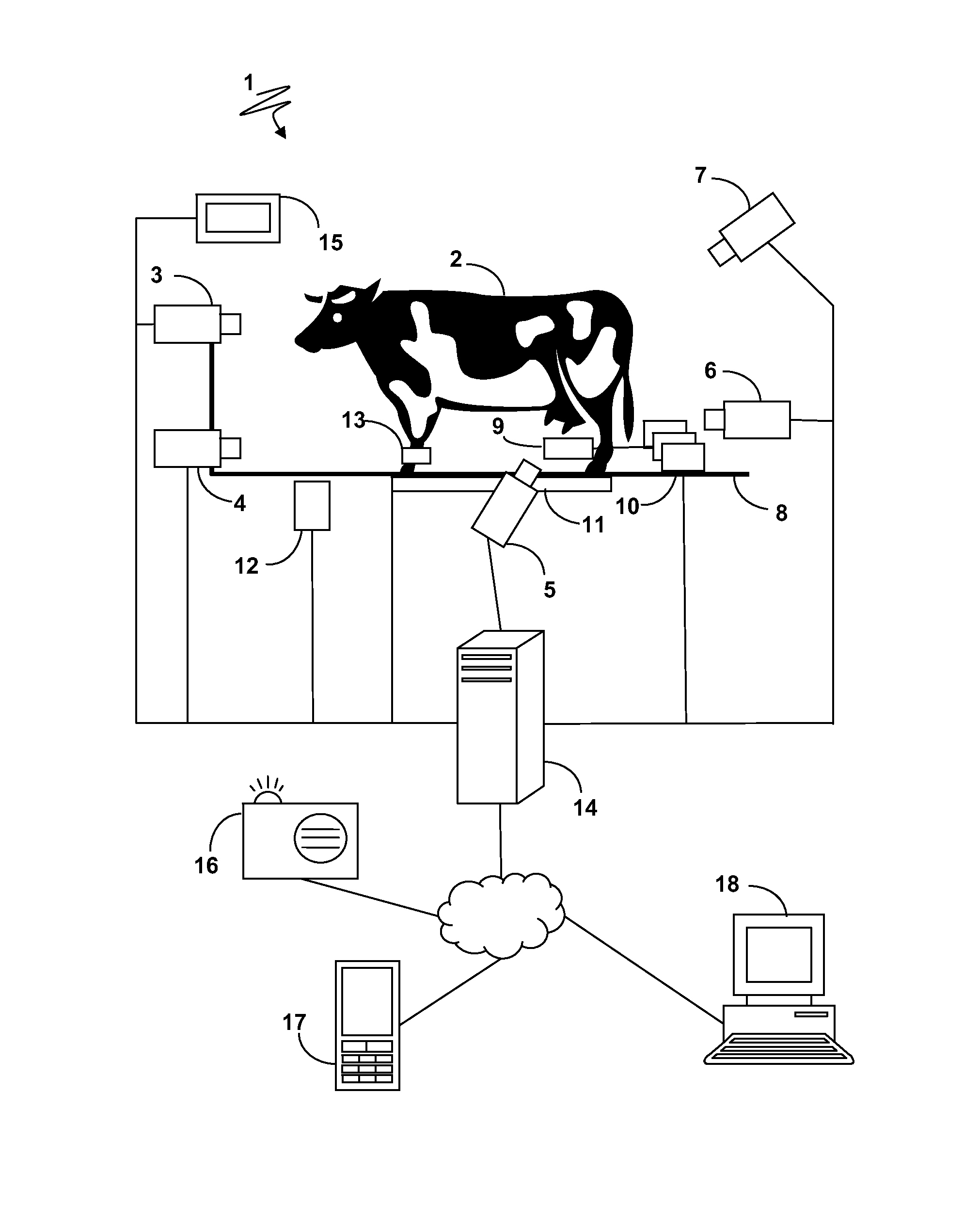

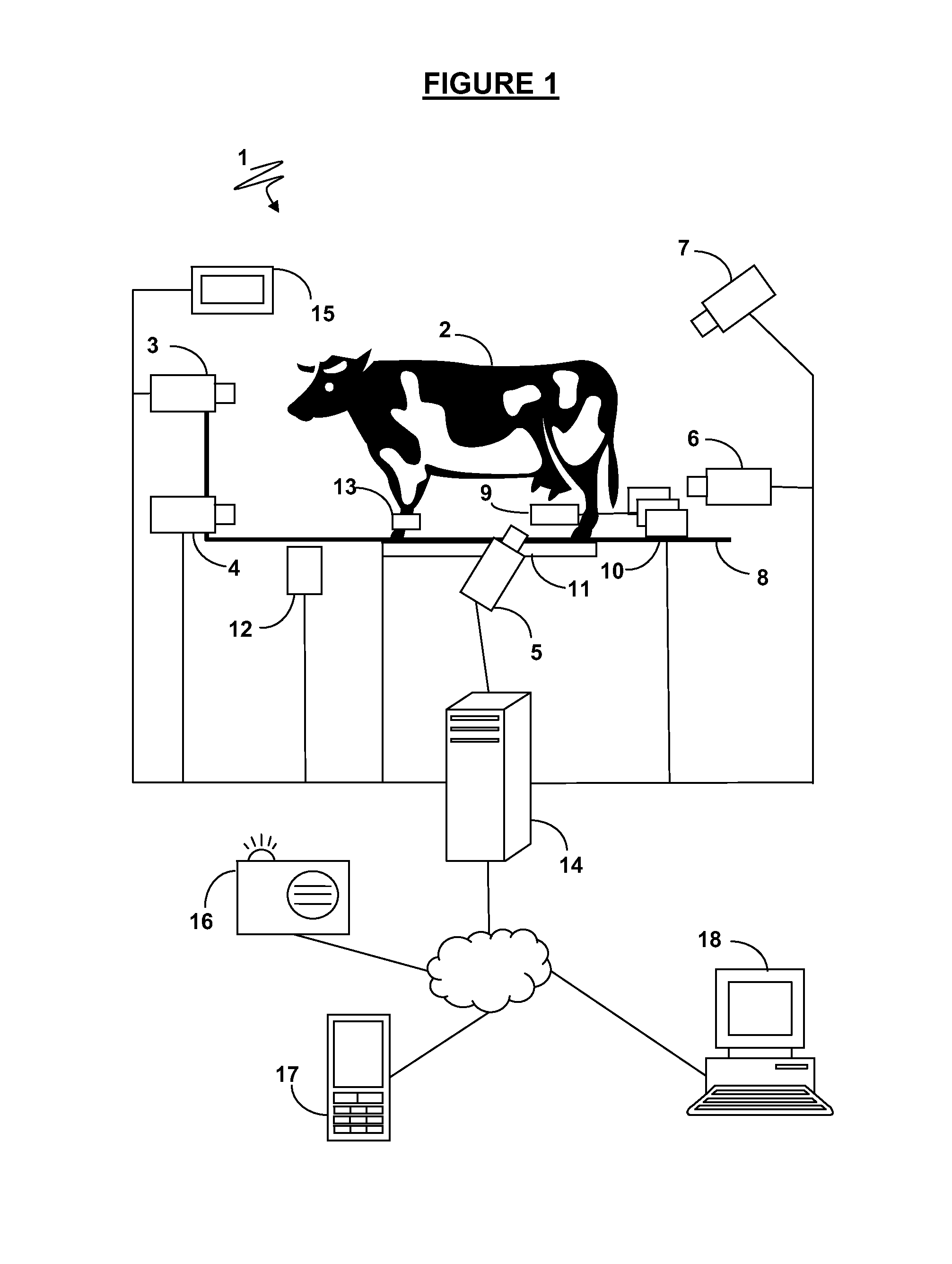

Detection apparatus for the monitoring of milking animals

ActiveUS20130319336A1Accurate measurementImproved oddsAnimal reproductionCathetersProduction rateThermographic camera

An apparatus is provided for monitoring a milking animal during milking of the animal. The apparatus includes a number of productivity sensors, each measuring at least one indicator of productivity of the animal. A number of temperature sensors, including at least two thermographic cameras, measure heat output from different processing areas of the milking animal. A processor receives the heat outputs and productivity indicators, and uses a combination of these to determine a condition of the milking animal. The condition is then indicated in real time at the monitoring apparatus.

Owner:SMART FARM TECH

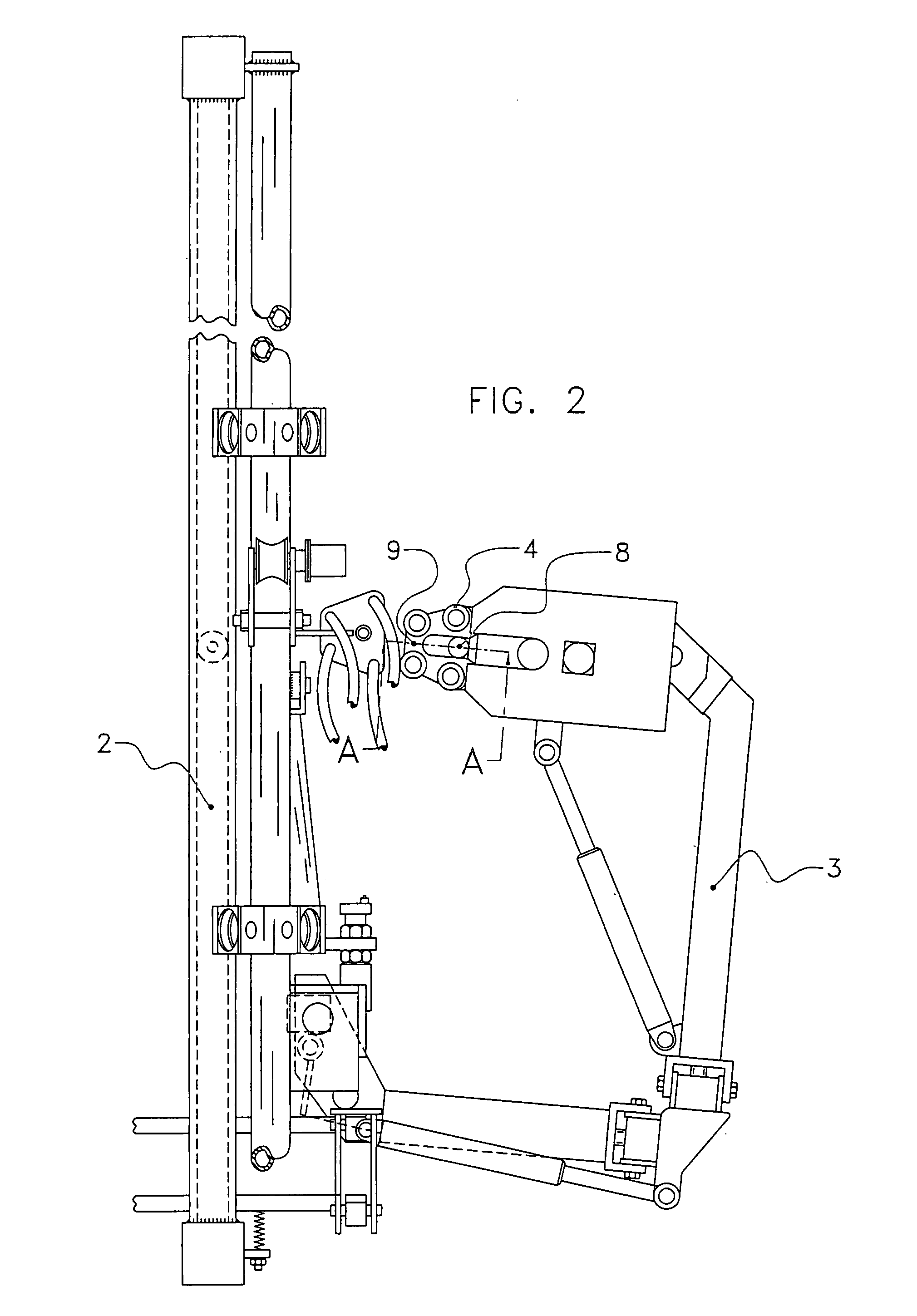

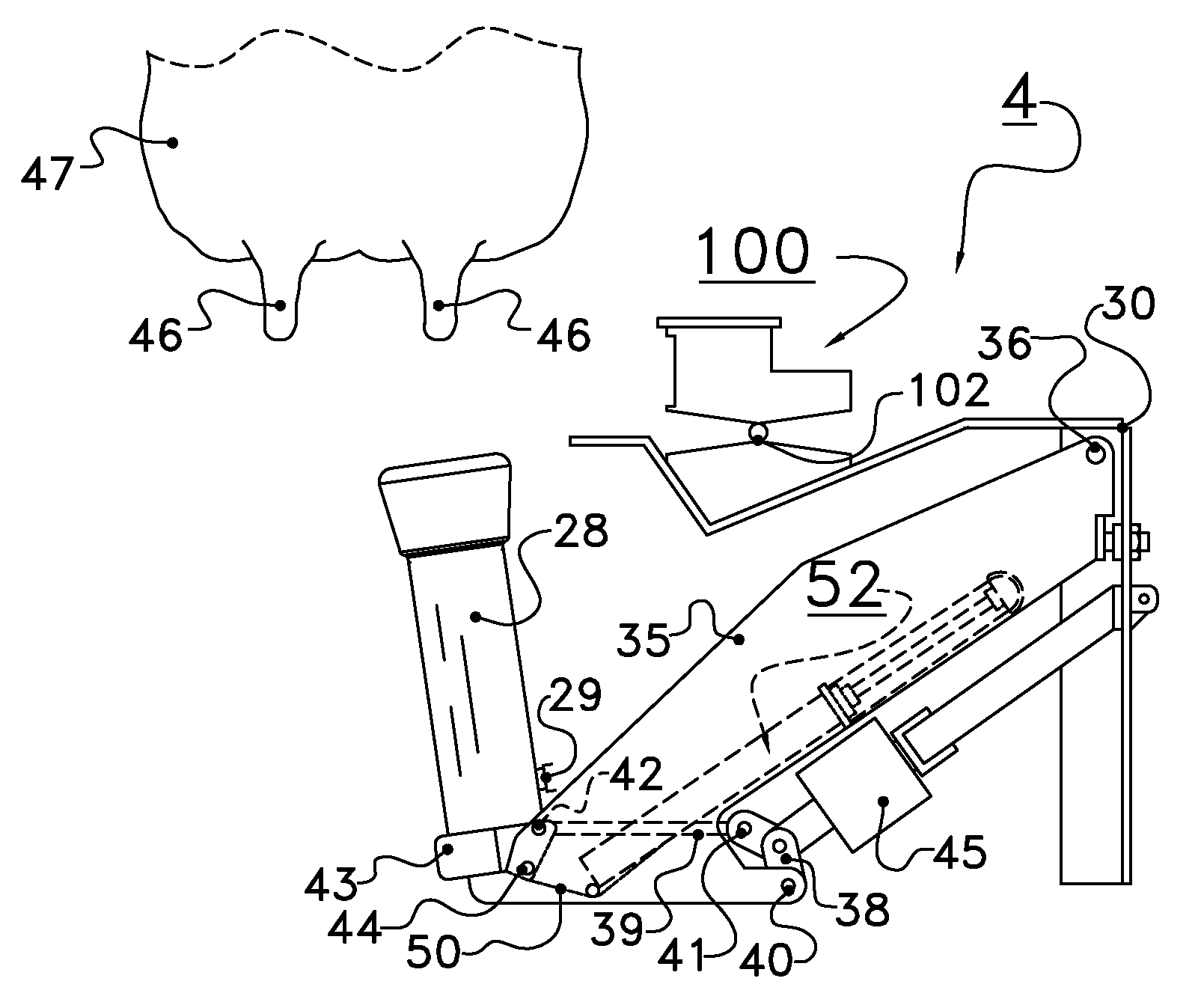

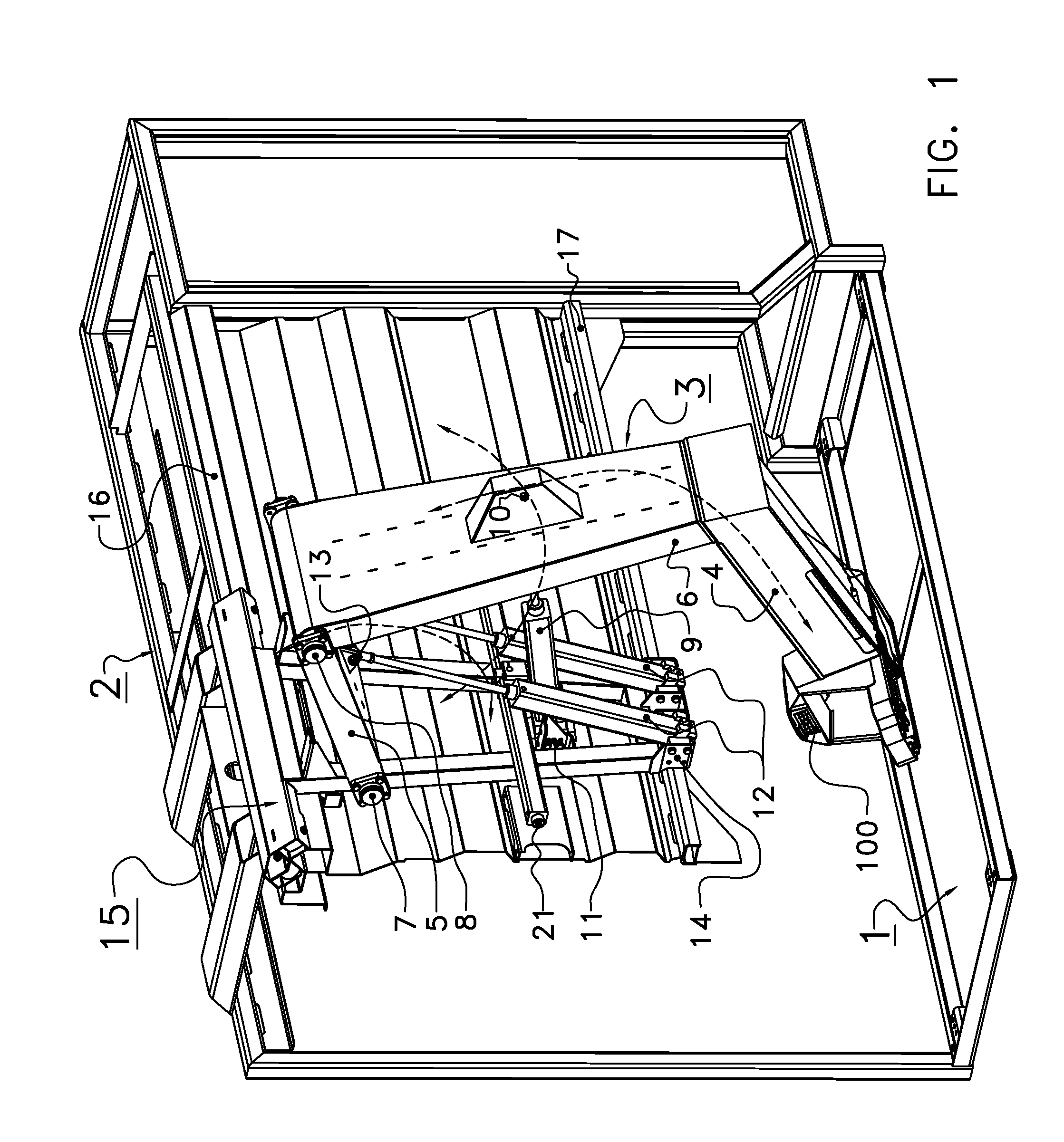

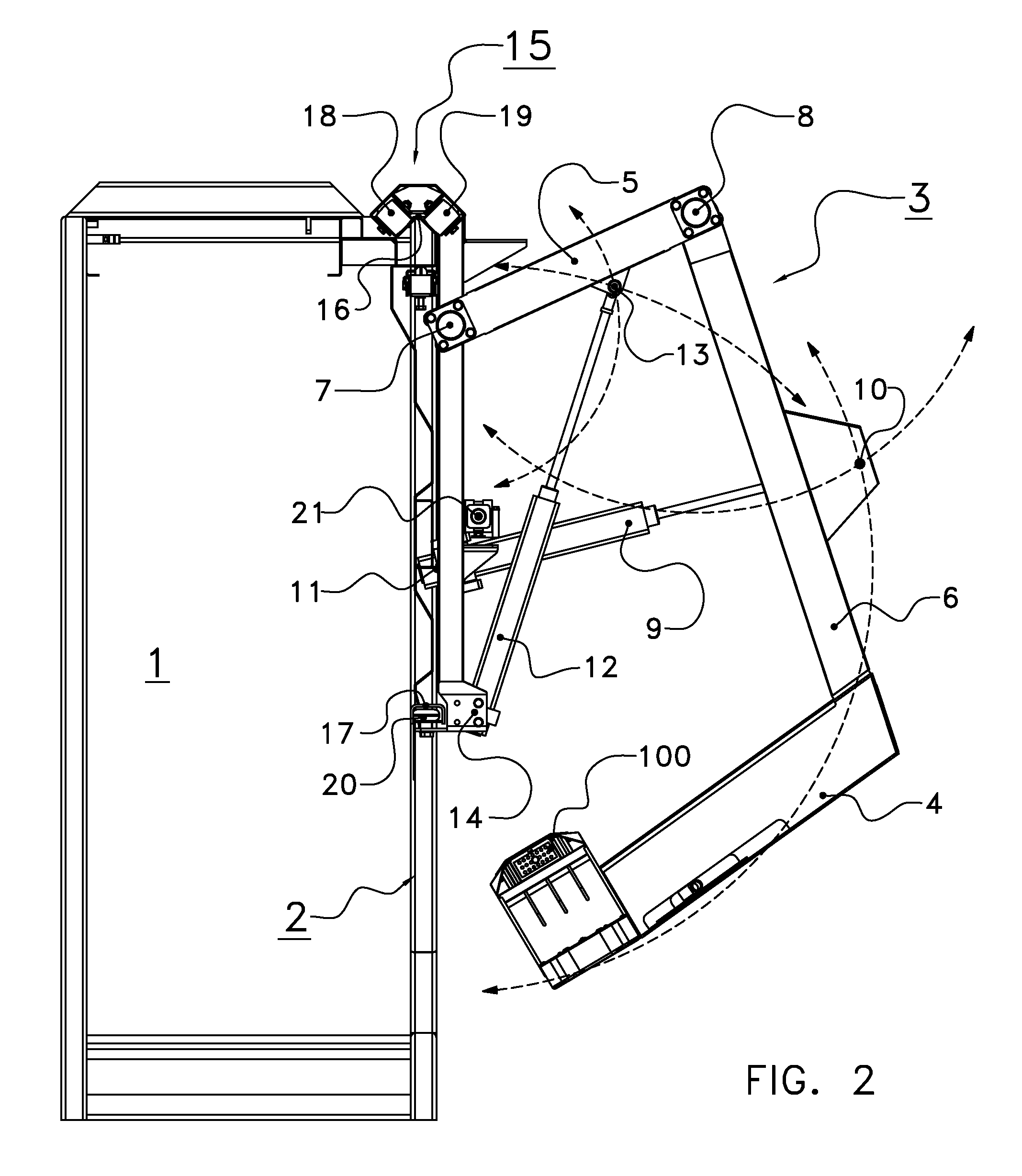

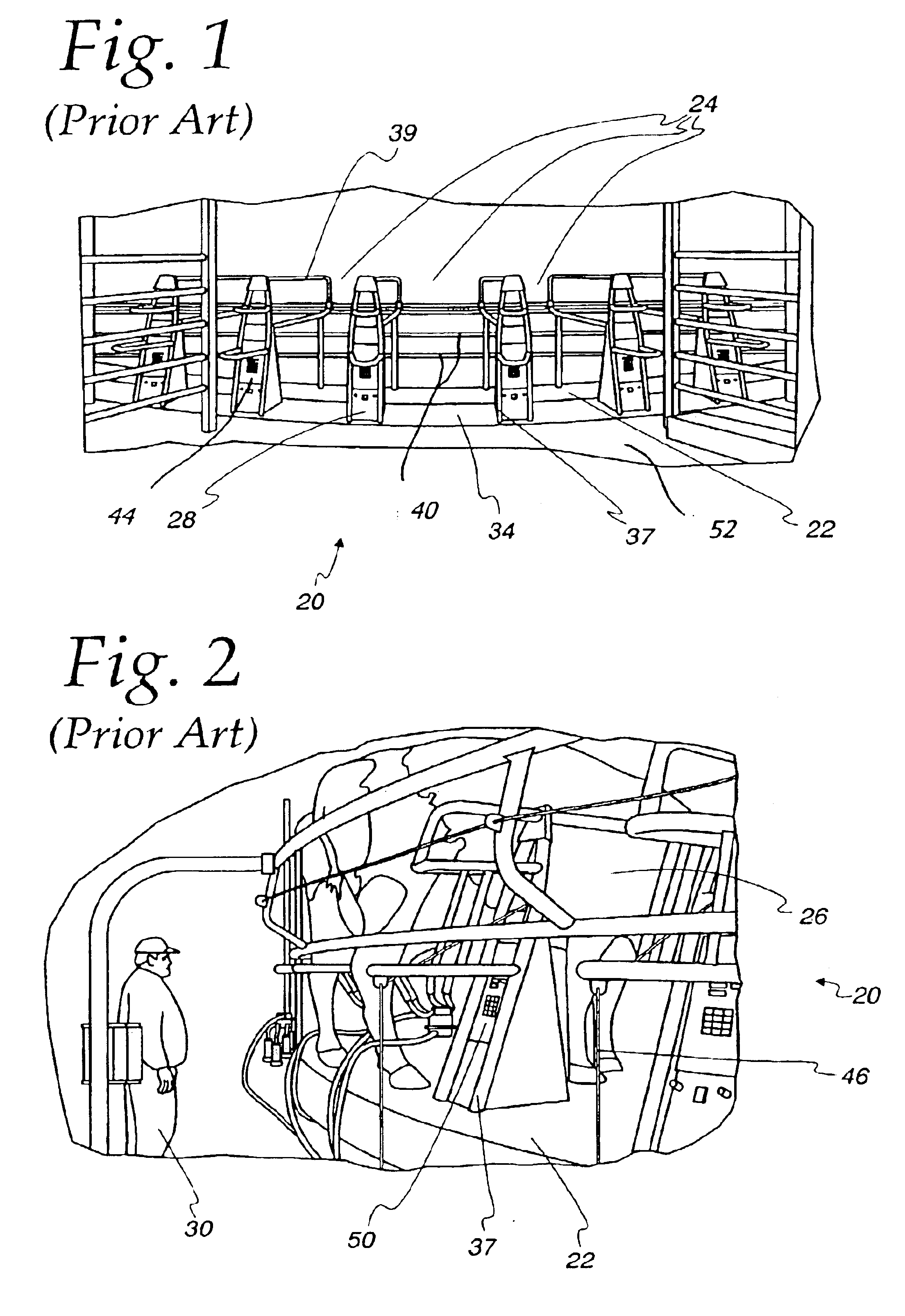

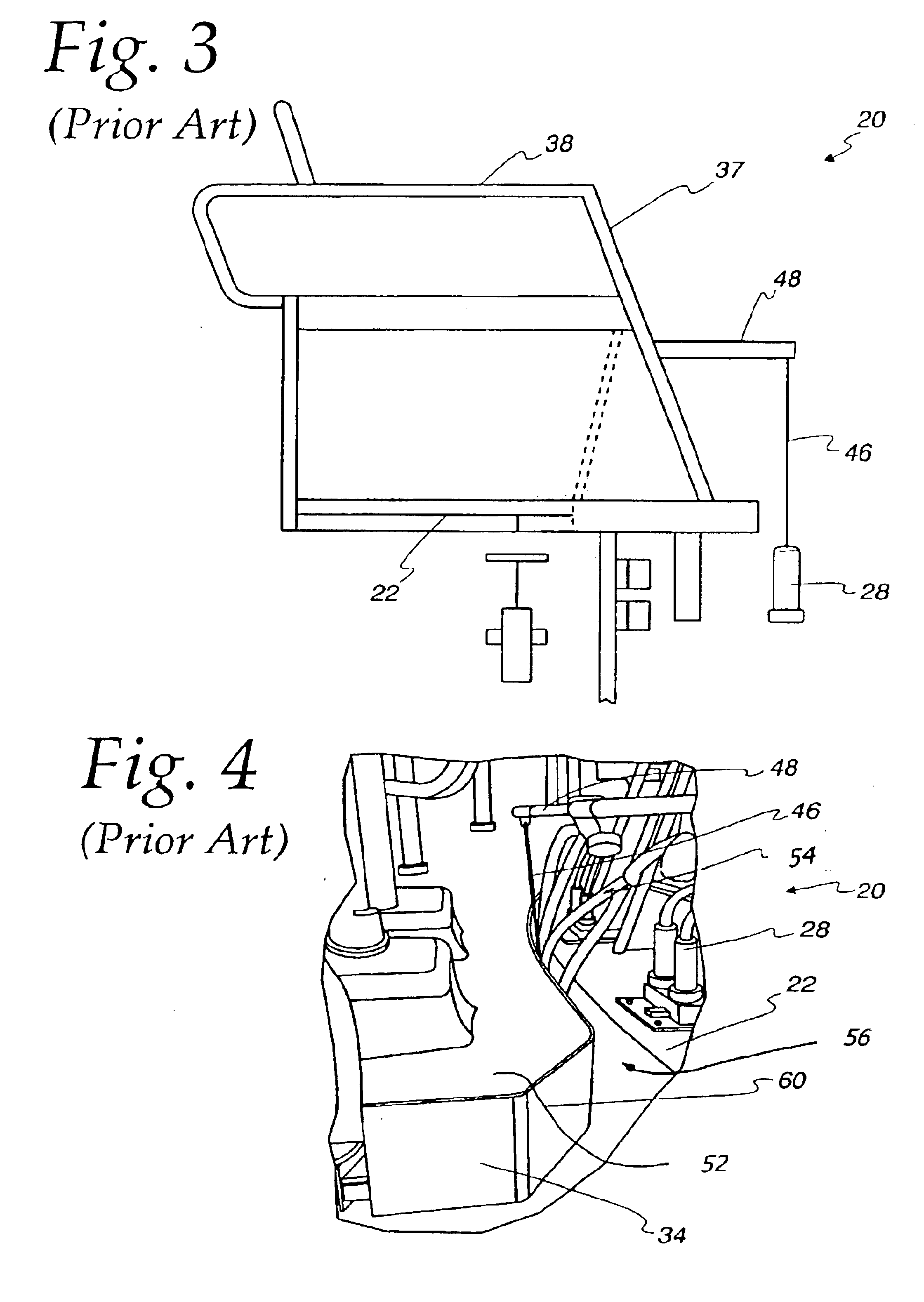

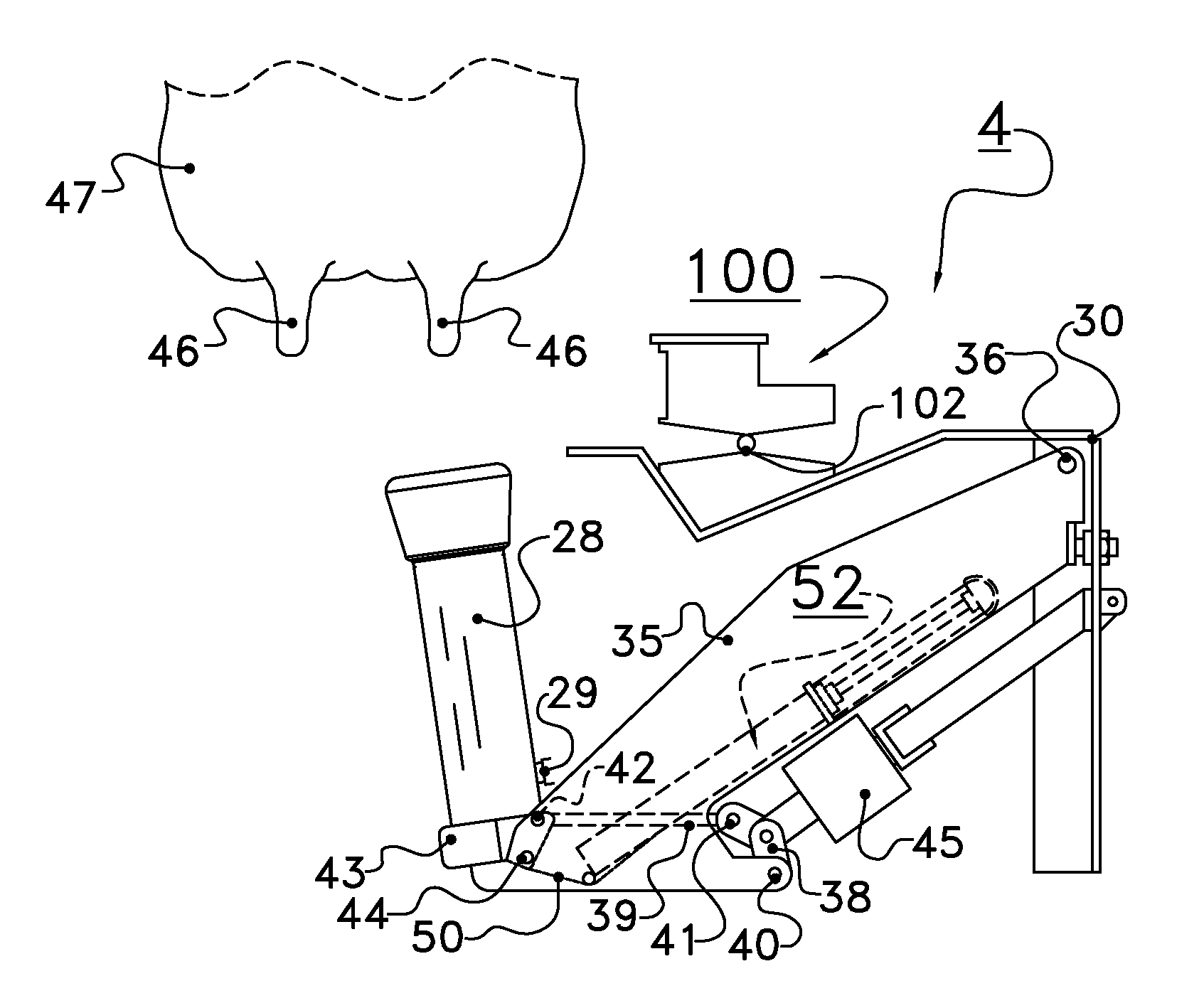

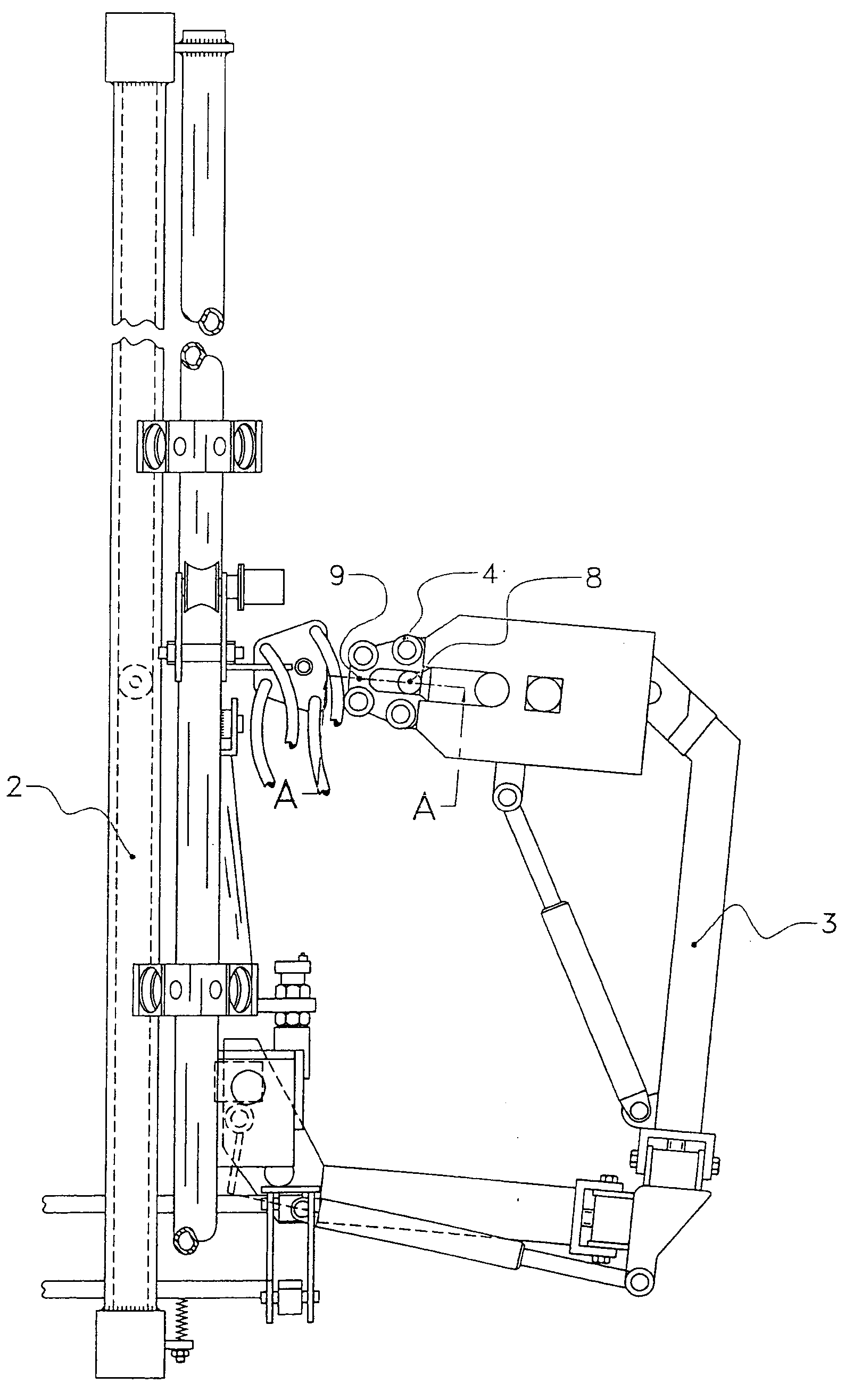

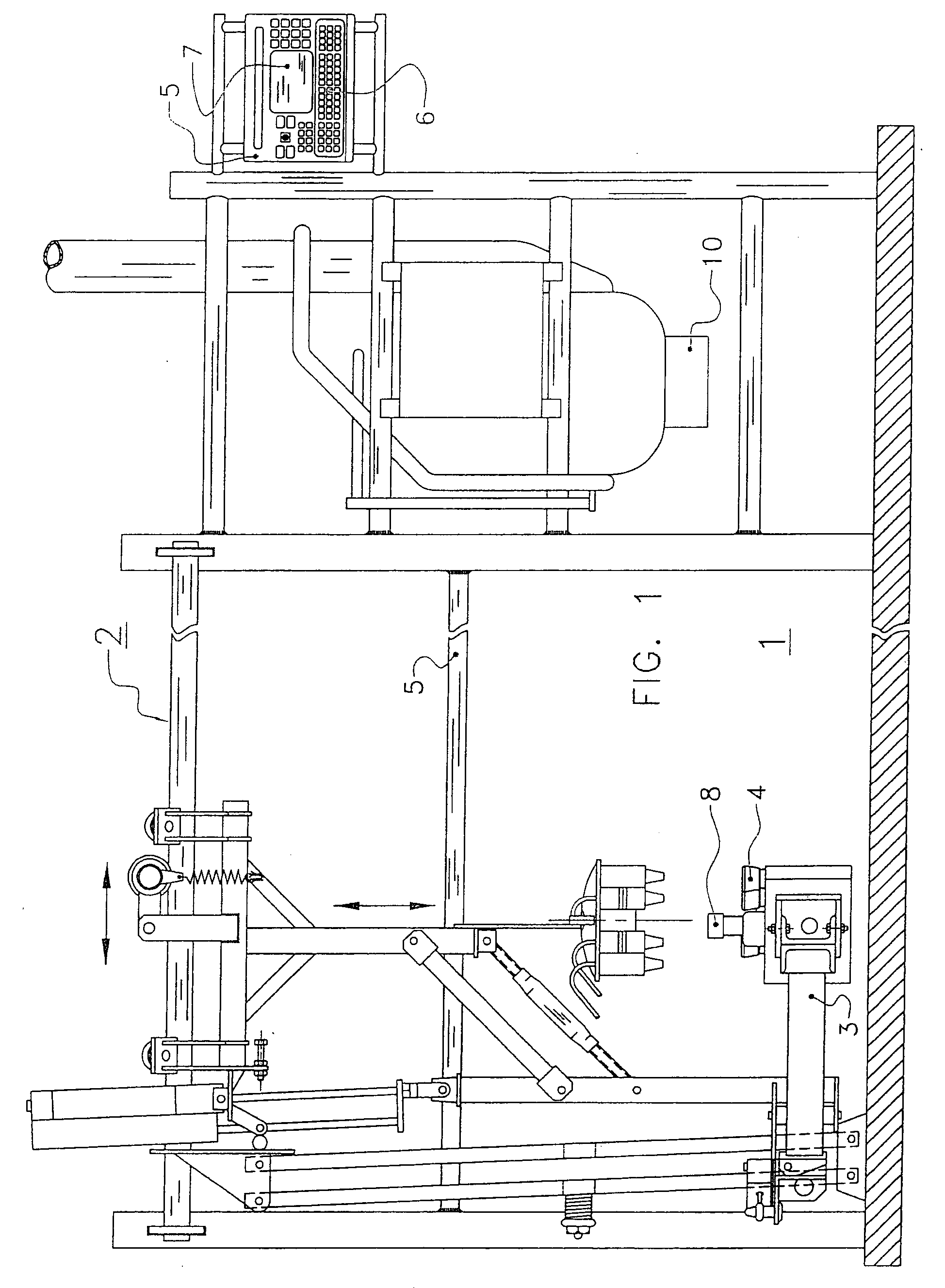

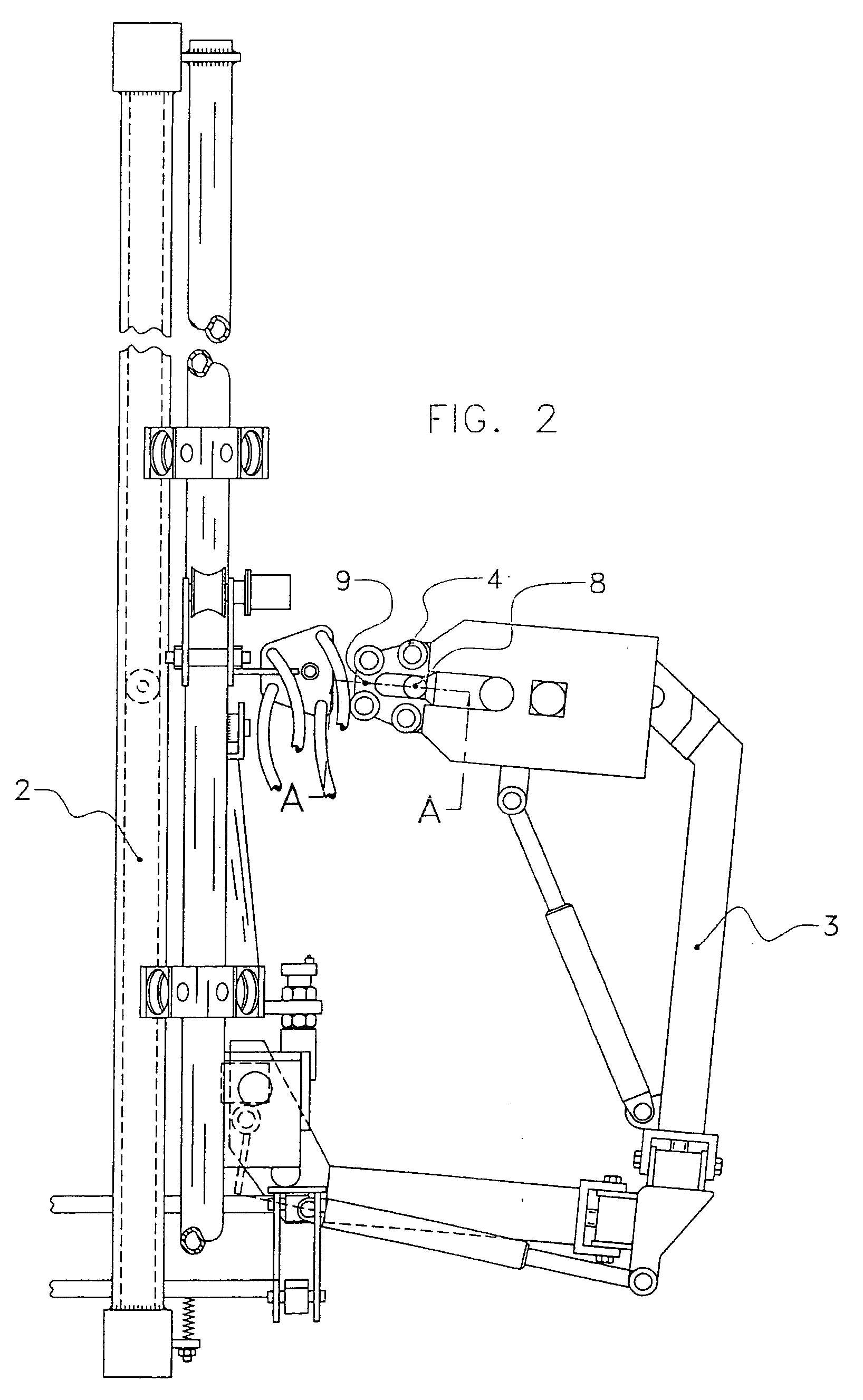

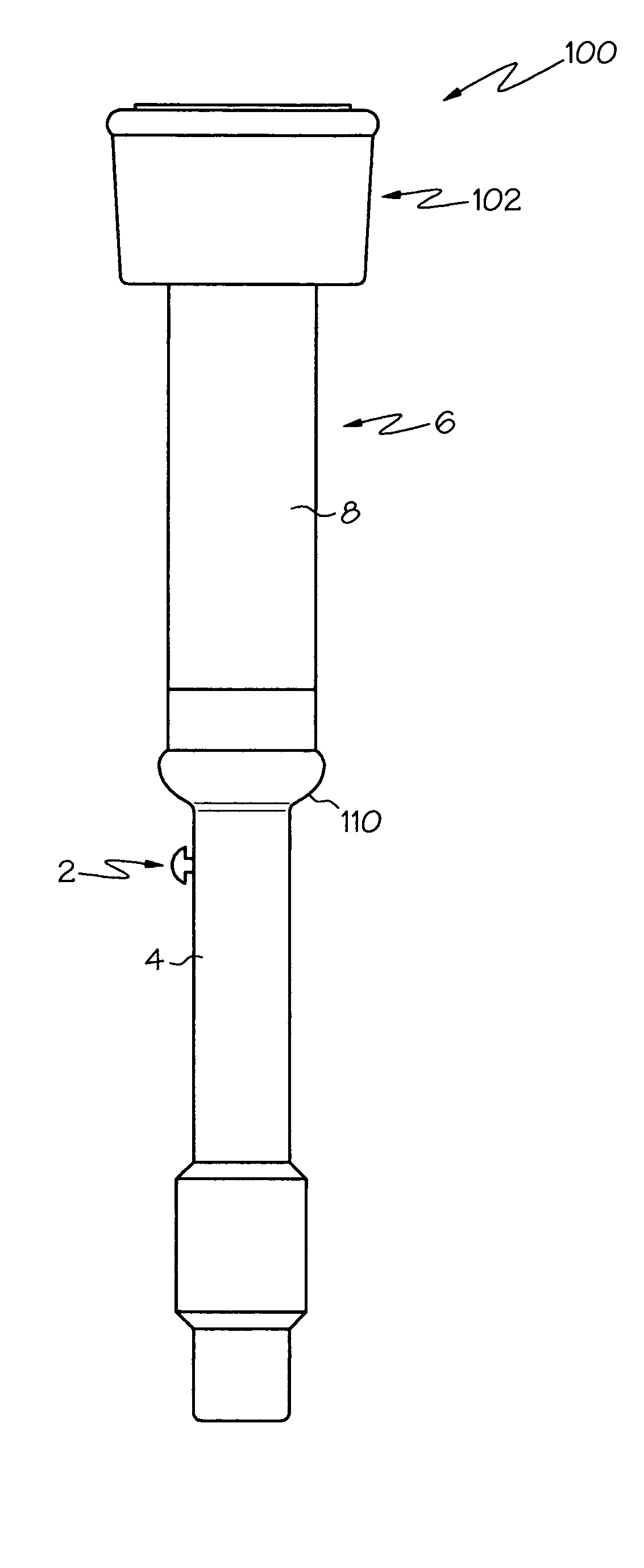

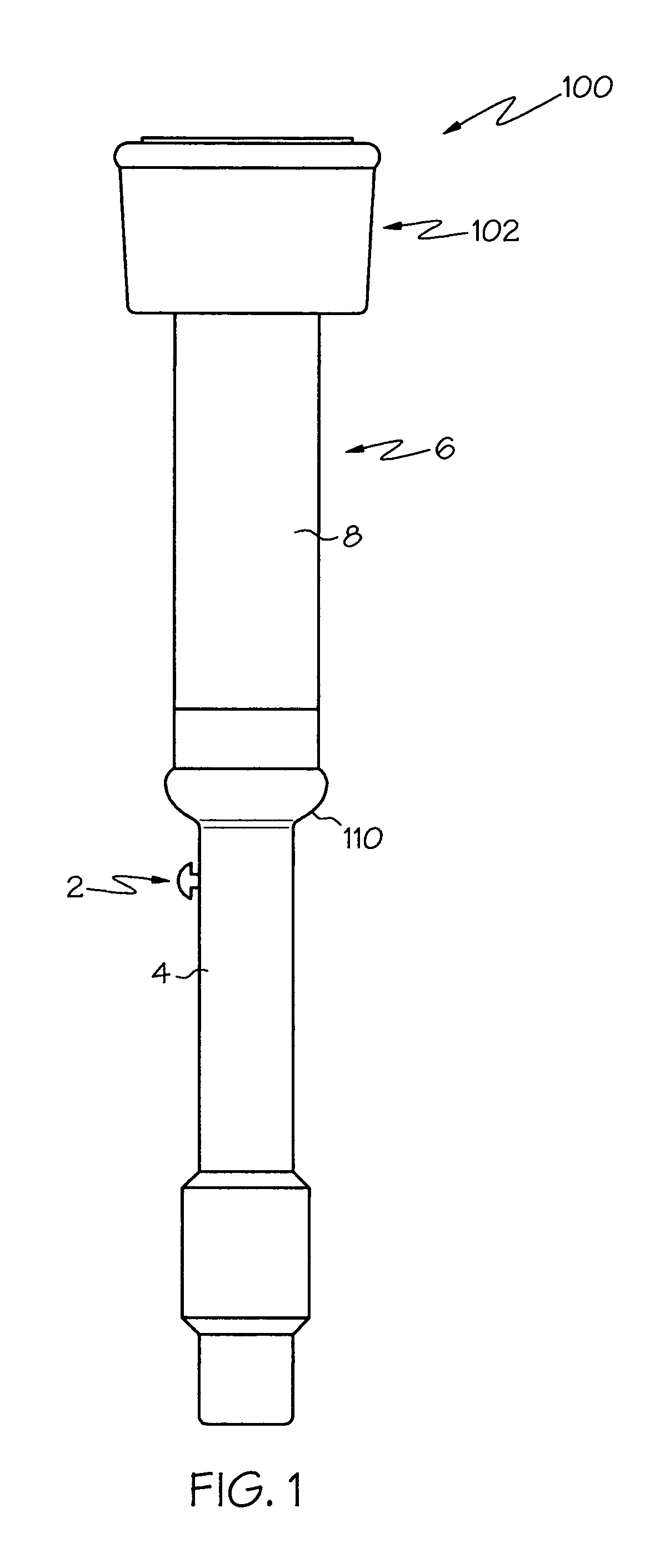

Milker unit detacher for rotary milking parlor

A rotary milking parlor milker detacher having a pivoting support arm and retracting chain arrangement that is synchronized with a rotating platform position to move the detacher between a storage position, a presentation position, and a milking position to protect the detacher from damage and provide a superior ergonomic design that reduces operator fatigue and turnover.

Owner:GEA FARM TECH

Method of controlling a milking implement, a software program for and an implement performing the method

ActiveUS20110048329A1Testing is superfluousOrientation of the teat cup relative to the udder can be improvedCathetersComputer scienceSoftware

Method of controlling a milking implement for automatically milking a dairy animal with an udder, such as a cow, which milking implement comprises a camera and a teat cup, which method comprises the following steps:attaching the teat cup to a teat of the udder, followed byproducing by means of the camera an image of at least a part of the udder and of at least a part of the teat cup,making an analysis of the image of the udder with the teat cup, and performing at least one control action by means of the milking implement, based on the analysis.

Owner:MAASLAND

Control system and a method for milking members in a milking parlour

ActiveUS20130199449A1Simplifying routineShorten the timeCathetersAnimal housingControl systemEngineering

A control system and a method for milking members in a milking parlour having plural milking stalls. The control system includes a local control unit in each milking stall automatically preparing the milking member for a milking operation by setting a vacuum valve in an open position when the milking member is moved from a storage position, and a control unit setting the milking stalls in the milking parlour in a pre-cleaning mode when a milking operation is still in progress in at least one other of the milking stalls. In this case, the local control units prepare the milking members for a cleaning operation instead of a milking operation by maintaining the vacuum valve in a closed position when the milking member is moved from a storage position, until the cleaning operation of the milking member is started.

Owner:DELAVAL HLDG AB

Arrangement and method for visual detection in a milking system

Owner:DELAVAL HLDG AB

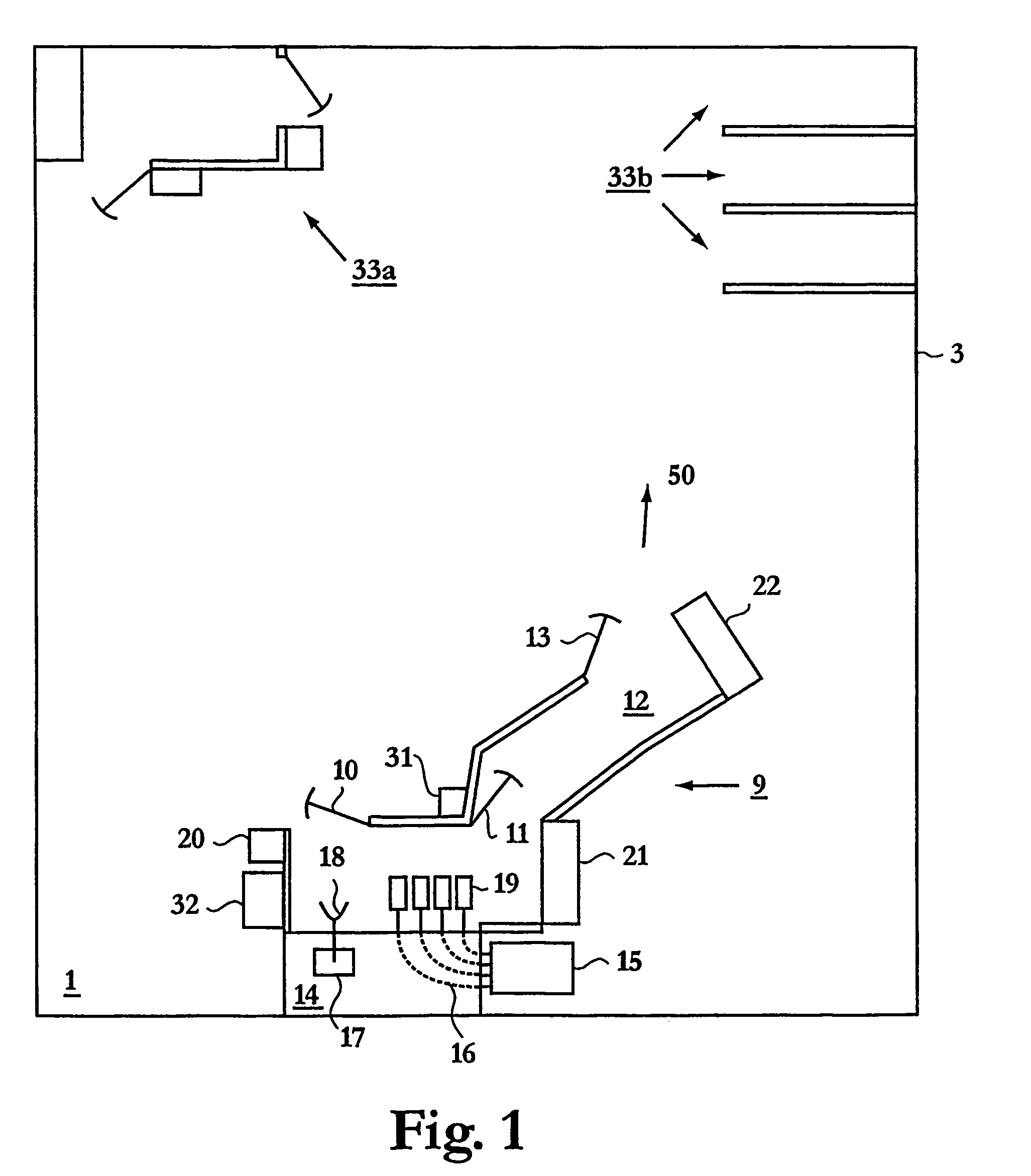

Method and device at a dairy farm

ActiveUS20050223998A1Effective and accurate and reliable and safeLow costCathetersLavatory sanitoryEngineeringMilking

The present invention refers to a method of disinfecting or sterilizing at least a portion of any of a resting, a milking, or a feeding station (3, 24, 26) provided with an animal identification device (18) and located in an area (1), in which milking animals are allowed to move. Each of the animals visiting the resting, the milking, or the feeding station is identified and is admitted to enter the station depending on the identification. The inventive method comprises the steps of retrieving information regarding the health of each of the animals entering the station; and automatically disinfecting or sterilizing the portion of the station only if the information retrieved reveals that an animal entering the station has an infection that is capable of being transmitted to other animals. The disinfection or the sterilization is performed after that said infectious milking animal has left the station.

Owner:BAYER CROPSCIENCE AG +1

Milker unit detacher for rotary milking parlor

A rotary milking parlor milker detacher having a pivoting support arm and retracting chain arrangement that is synchronized with a rotating platform position to move the detacher between a storage position, a presentation position, and a milking position to protect the detacher from damage and provide a superior ergonomic design that reduces operator fatigue and turnover.

Owner:GEA FARM TECH

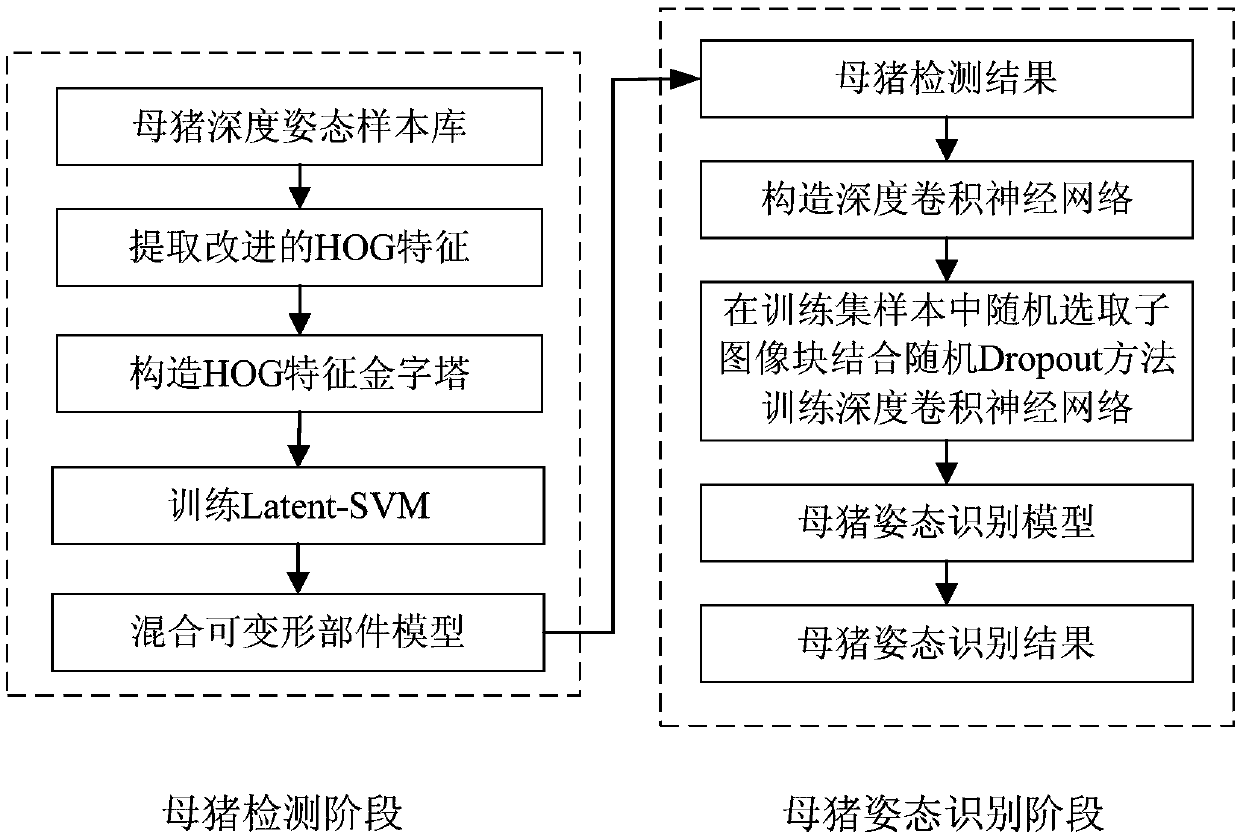

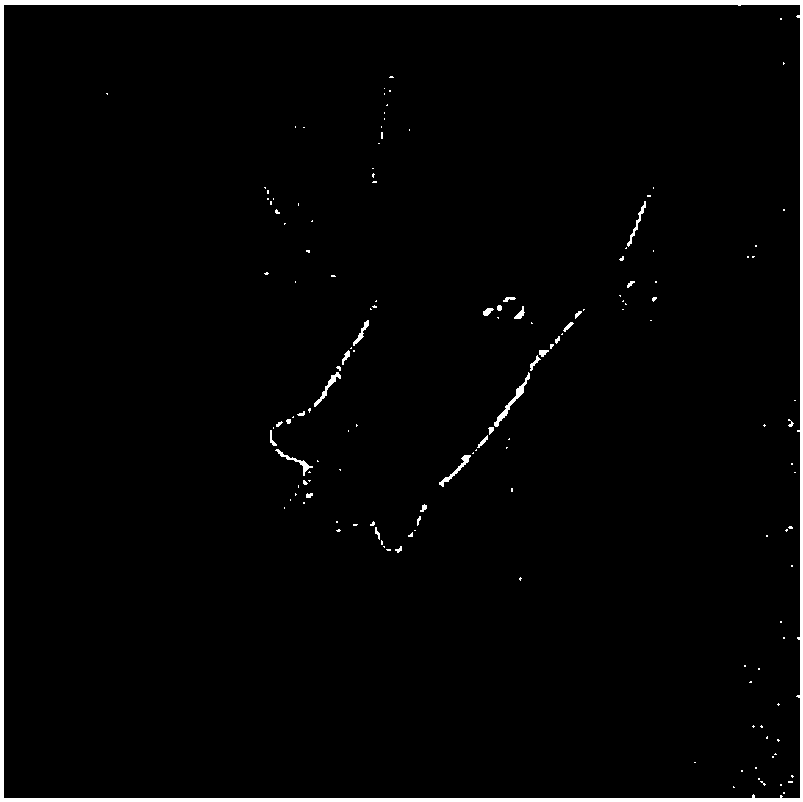

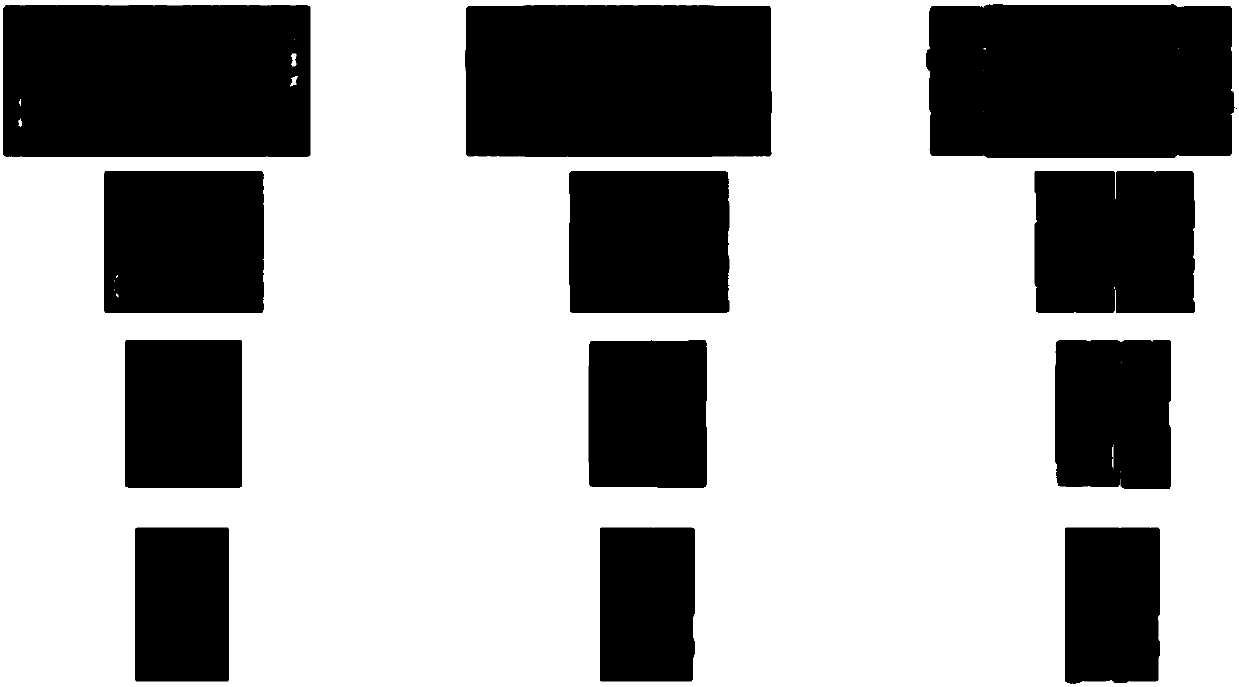

Automatic identification method for milking sow gesture on the basis of depth image

InactiveCN107844797AOvercome the difficult problem of identification and analysis at nightPrecise positioningCharacter and pattern recognitionNeural architecturesManual annotationRgb image

The invention discloses an automatic identification method for a milking sow gesture on the basis of a depth image. The method comprises the following steps that: collecting original depth image data,carrying out preprocessing, and carrying out manual annotation to form a milking sow gesture identification dataset; designing and training a milking sow hybrid deformable component model based on animproved HOG (Histogram of Oriented Gradient) feature; constructing a milking sow gesture identification deep convolutional neural network, utilizing an annotation frame and annotated gesture category training set information, and combining with a random Dropout method to train the network; inputting the test set into the milking sow hybrid deformable component model to obtain the target area ofthe milking sow; and inputting a target area result into the milking sow gesture identification deep convolutional neural network to identity the milking sow gesture. By use of the automatic identification method for the milking sow gesture on the basis of the depth image, the problem that an RGB (Red, Green and Blue) image is likely to be affected by the changes of factors, including outside illumination, shades and the like is overcome, the problem that the milking sow gesture is difficult in identification at night is solved, and the practical application requirement of all-weather milkingsow gesture monitoring can be met.

Owner:SOUTH CHINA AGRI UNIV

Device and method for determining teat positions

A device for determining the teat positions of a dairy animal after milking. The device is provided with at least one position-measuring device for determining a position of a teat prior to the milking of the dairy animal and for emitting a position signal corresponding to the teat position. The position-measuring device generates individual teat position signals and a control unit determines on the basis of the teat position signals determined before the milking, planes of symmetry extending substantially parallel to the teats. The expected positions are calculated with respect to the planes of symmetry.

Owner:LELY ENTERPRISES

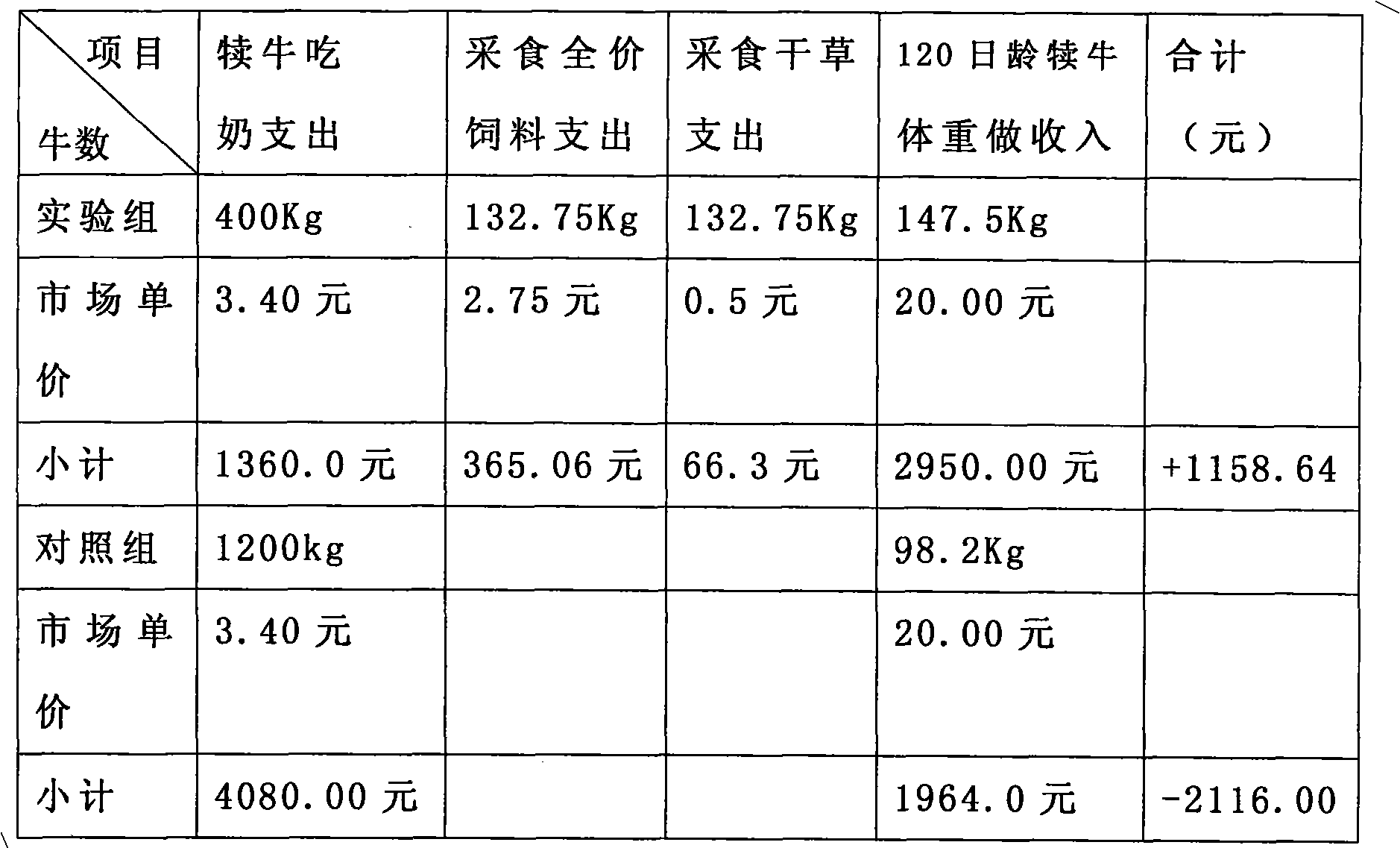

Concentrated calf fodder and use method thereof

InactiveCN101623059APromote growth and developmentComprehensive nutritionFood processingAnimal feeding stuffWeight gainingManganese

The invention relates to fodder and a use method, in particular to concentrated calf fodder and a use method thereof. The fodder comprises protein fodder and a premix compound, wherein the protein fodder is prepared from raw materials of bean cakes, corn protein powder, cotton dregs, complex enzymes, and the like; and the premix compound is prepared from common salt, fluorspar powder, magnesium sulfate, sodium diacetate, calcium hydrogen phosphate, soda, sodium humate, monensin, vitamins and trace elements of copper, iron, manganese, zinc, cobalt, and the like. The use method comprises the following steps: manually feeding calves at age of 3-5 days with a mixture of the concentrated calf fodder and a certain amount of milk; and stopping feeding the milk when the calves are at age of 60 days; and coming into a fatting period when the calves are at age of 120 days. The calf fodder has complete nutrients, reasonable proportion and low cost and is fed to the calves in a suckling period to substitute a great amount of milk, improve the commodity rate of the milk, facilitate the growth and the development of the calves, shorten the suckling period by 50 percent, increase the weight-gaining speed by about two times, shorten the deliver time by one half, increase the current fertility rate of milk cows by about two times, realize perennial milking, facilitate mechanical milking and scaled stabling management and remarkably improve the economic benefits, the social benefits and ecological benefits of cattle rearing in a plurality of aspects.

Owner:好毕斯嘎拉吐 +2

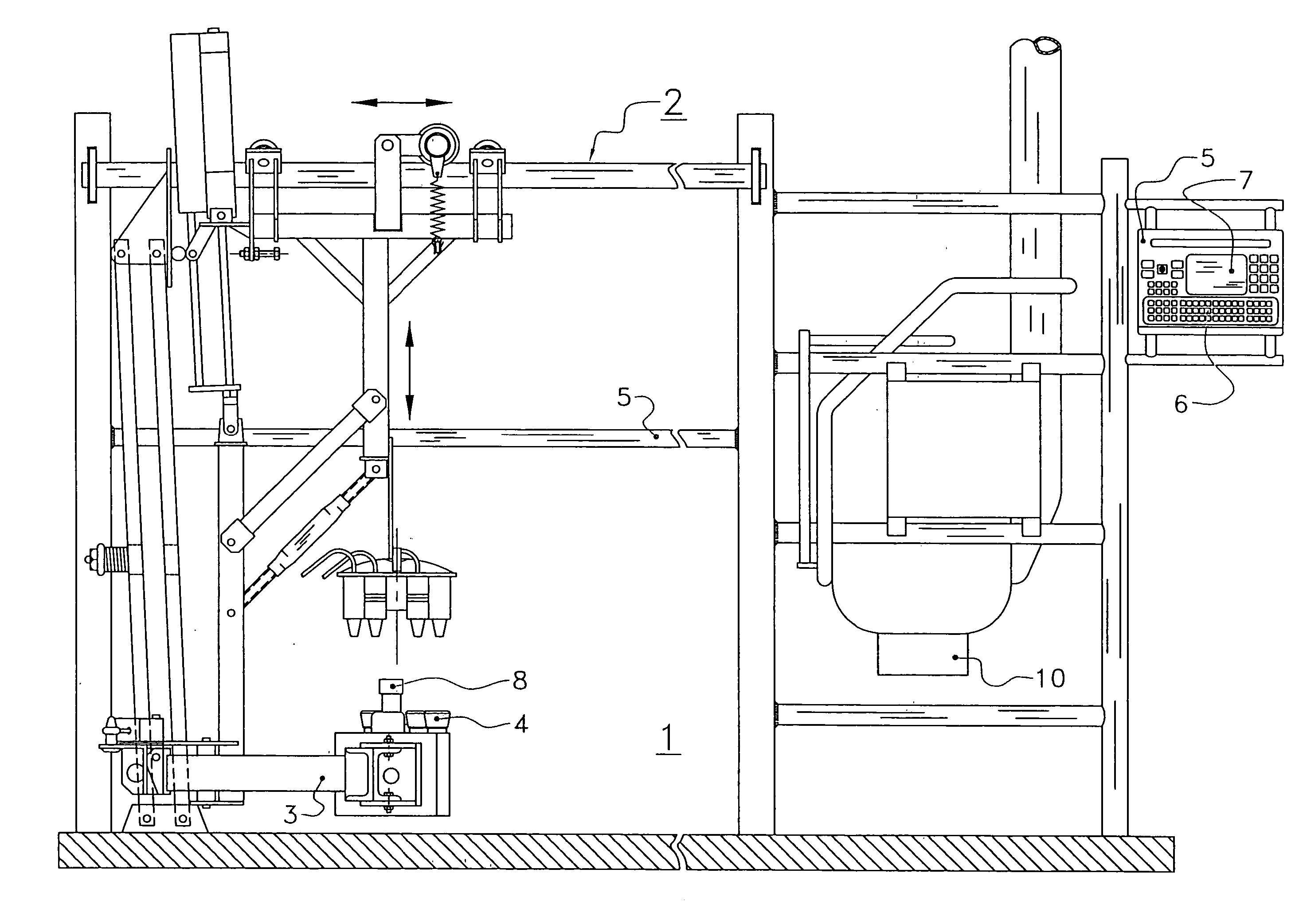

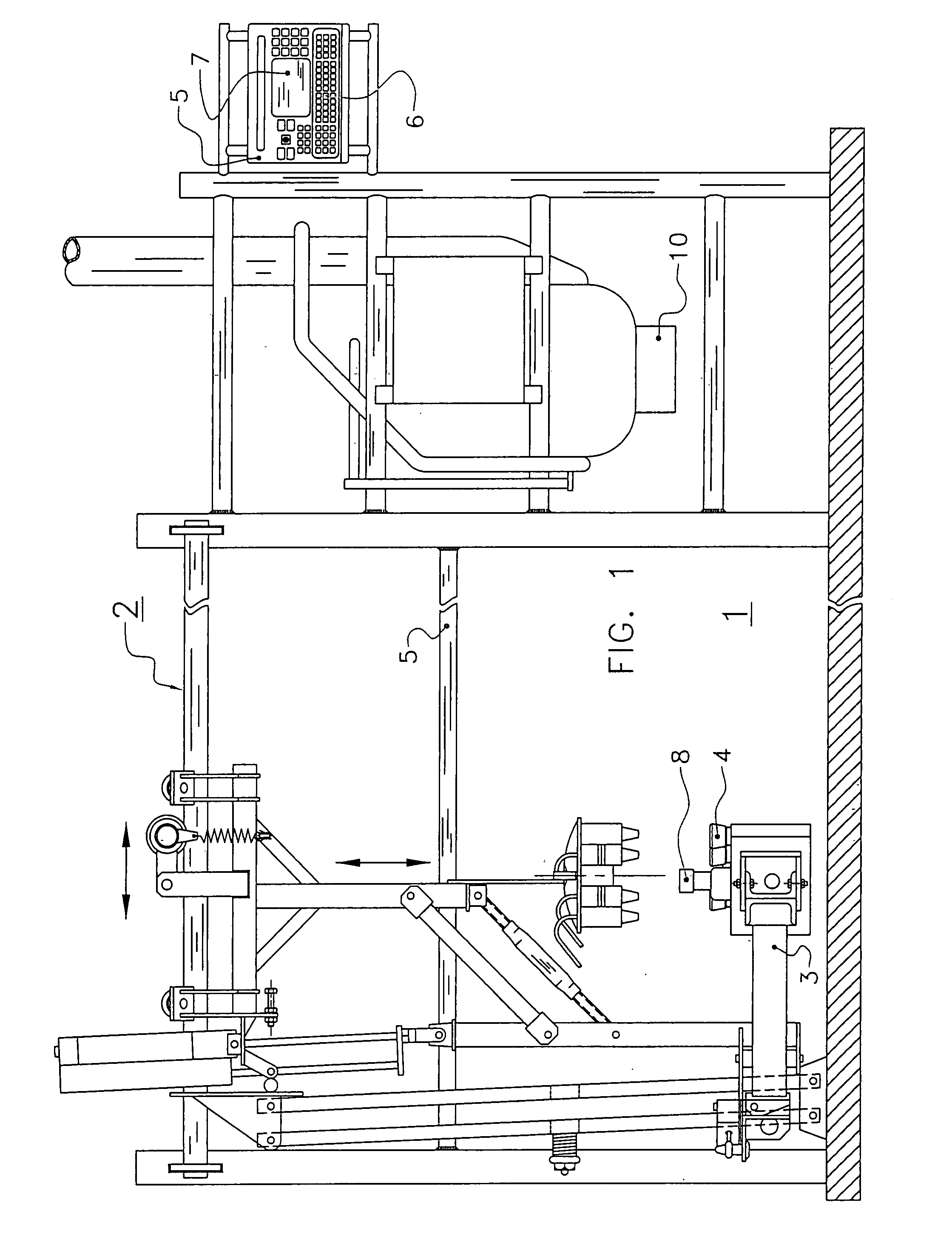

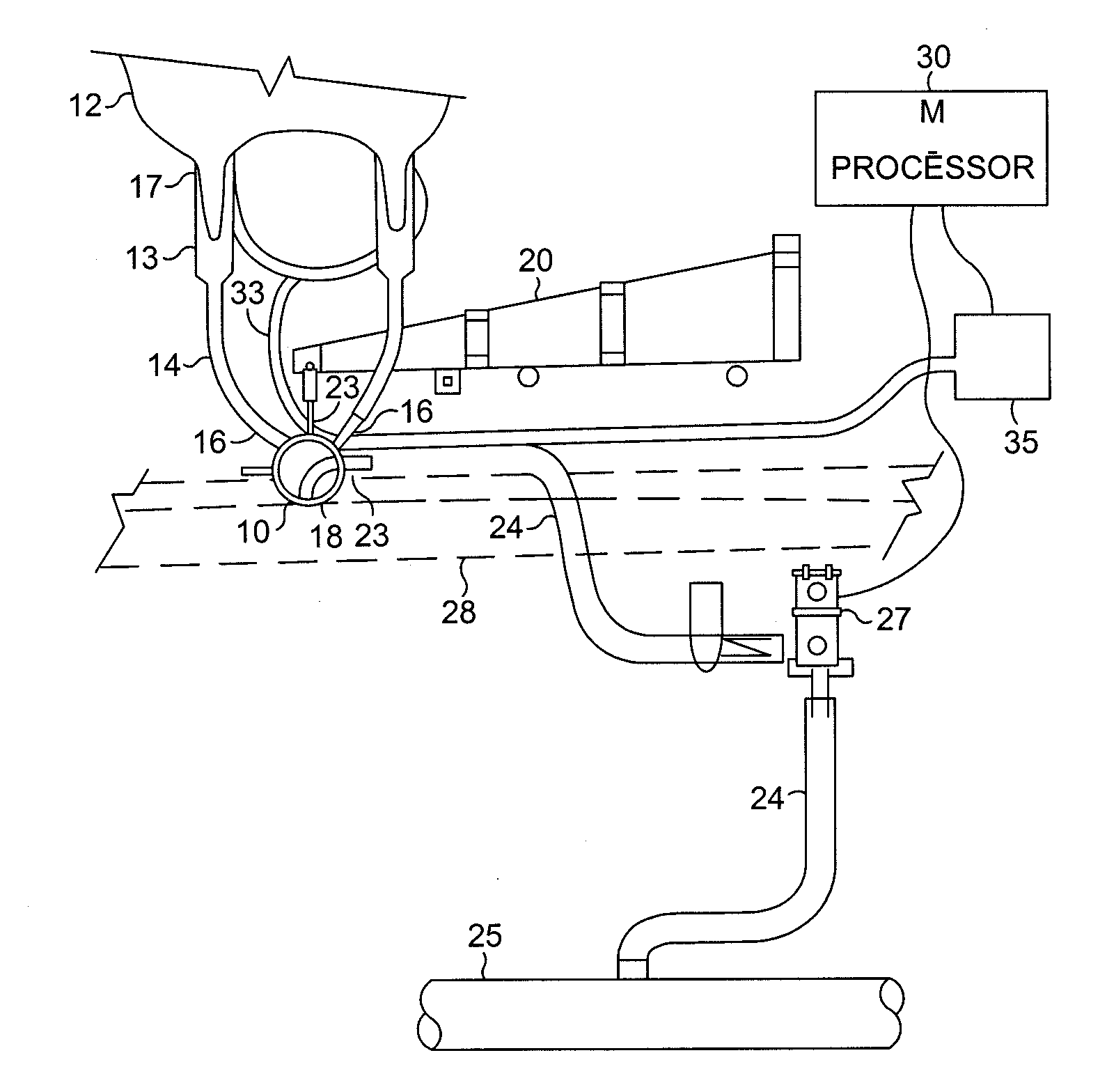

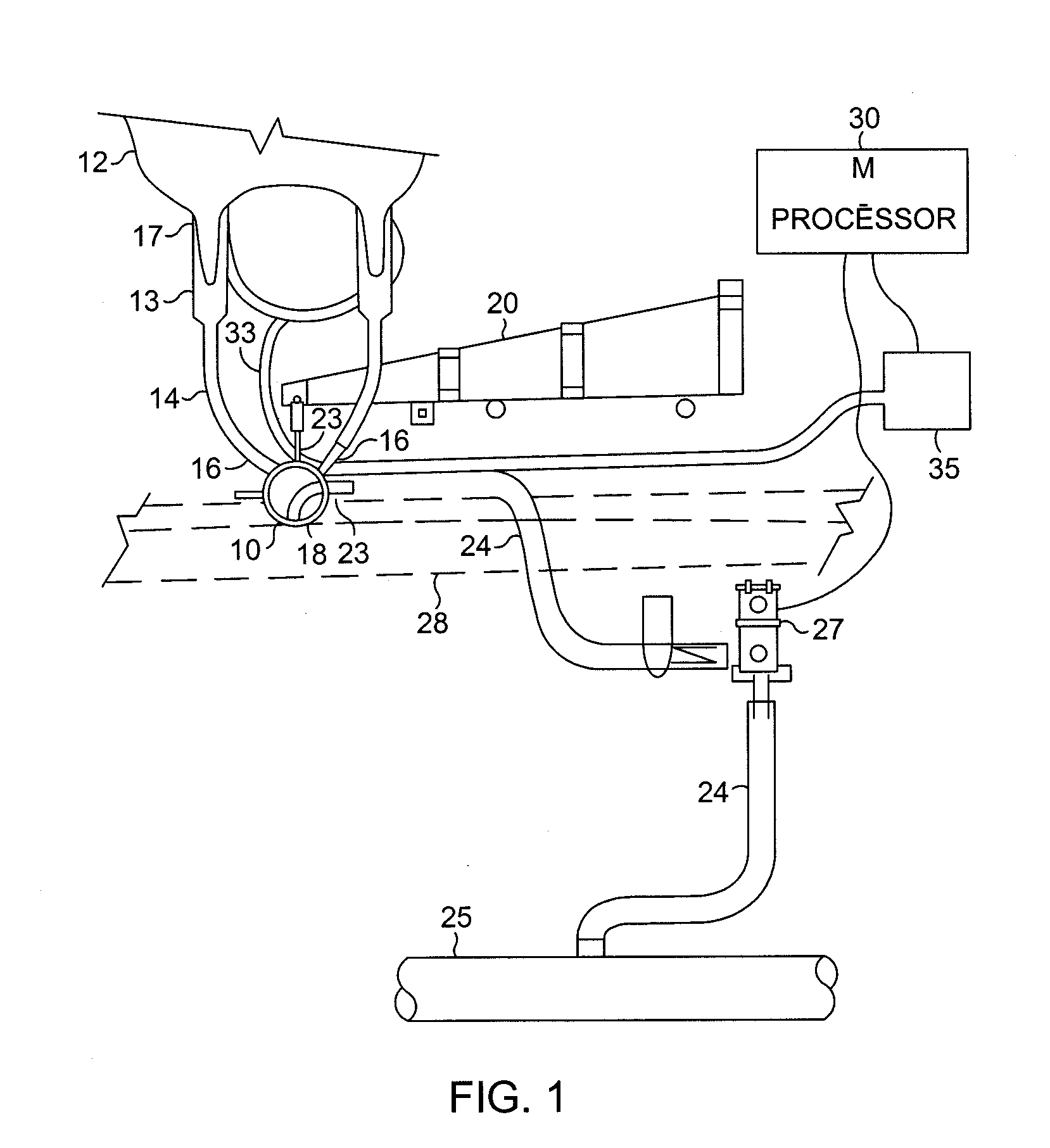

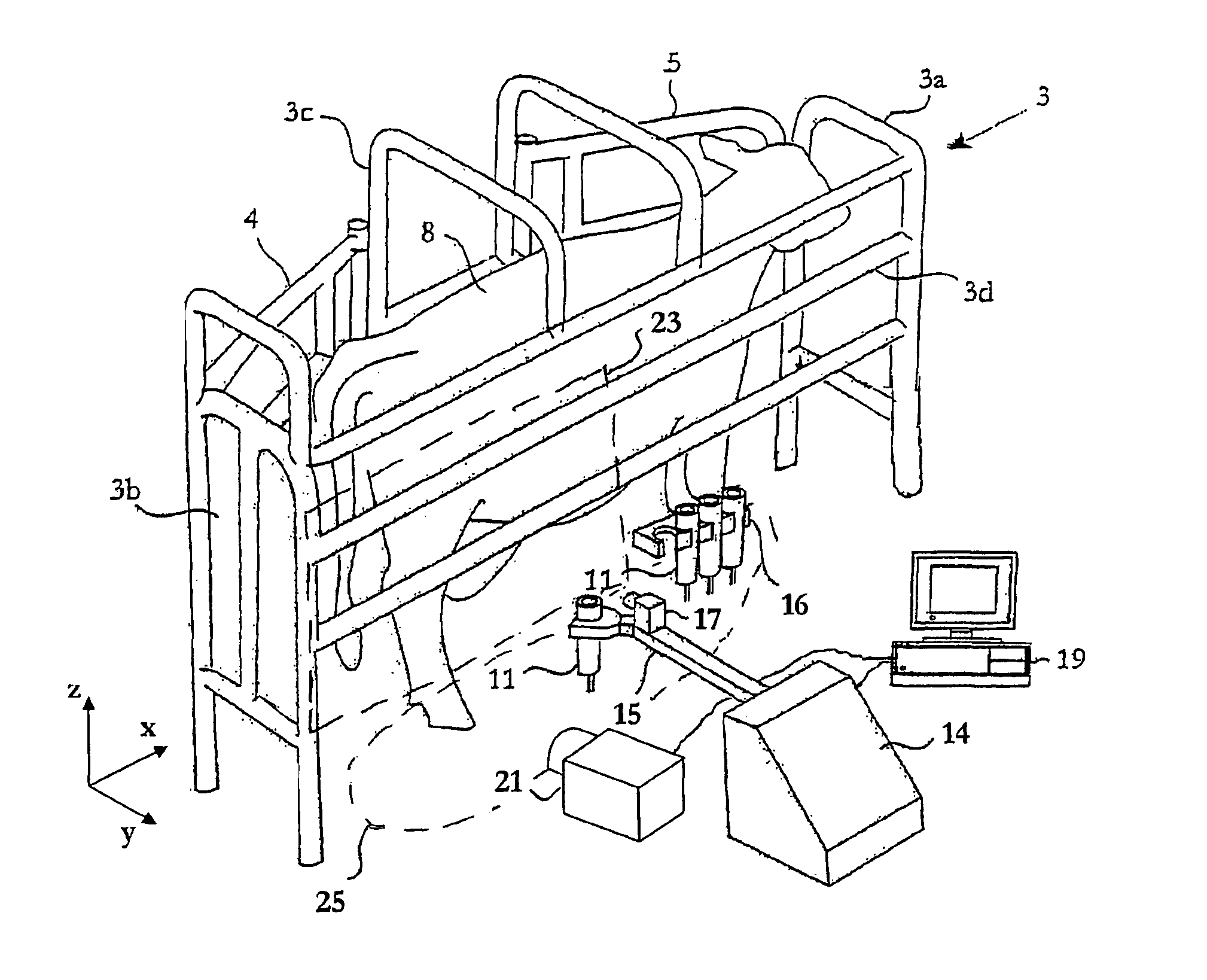

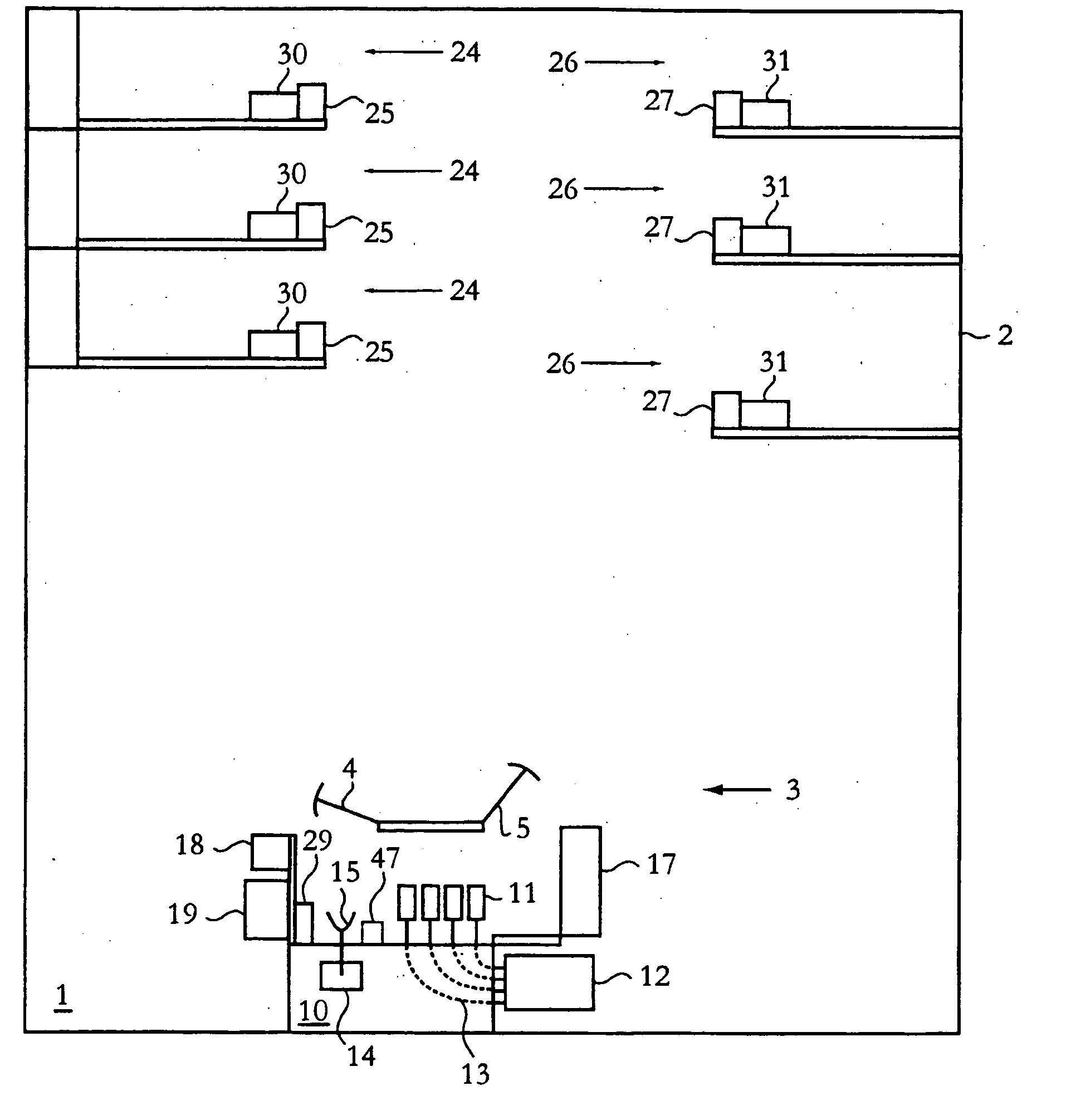

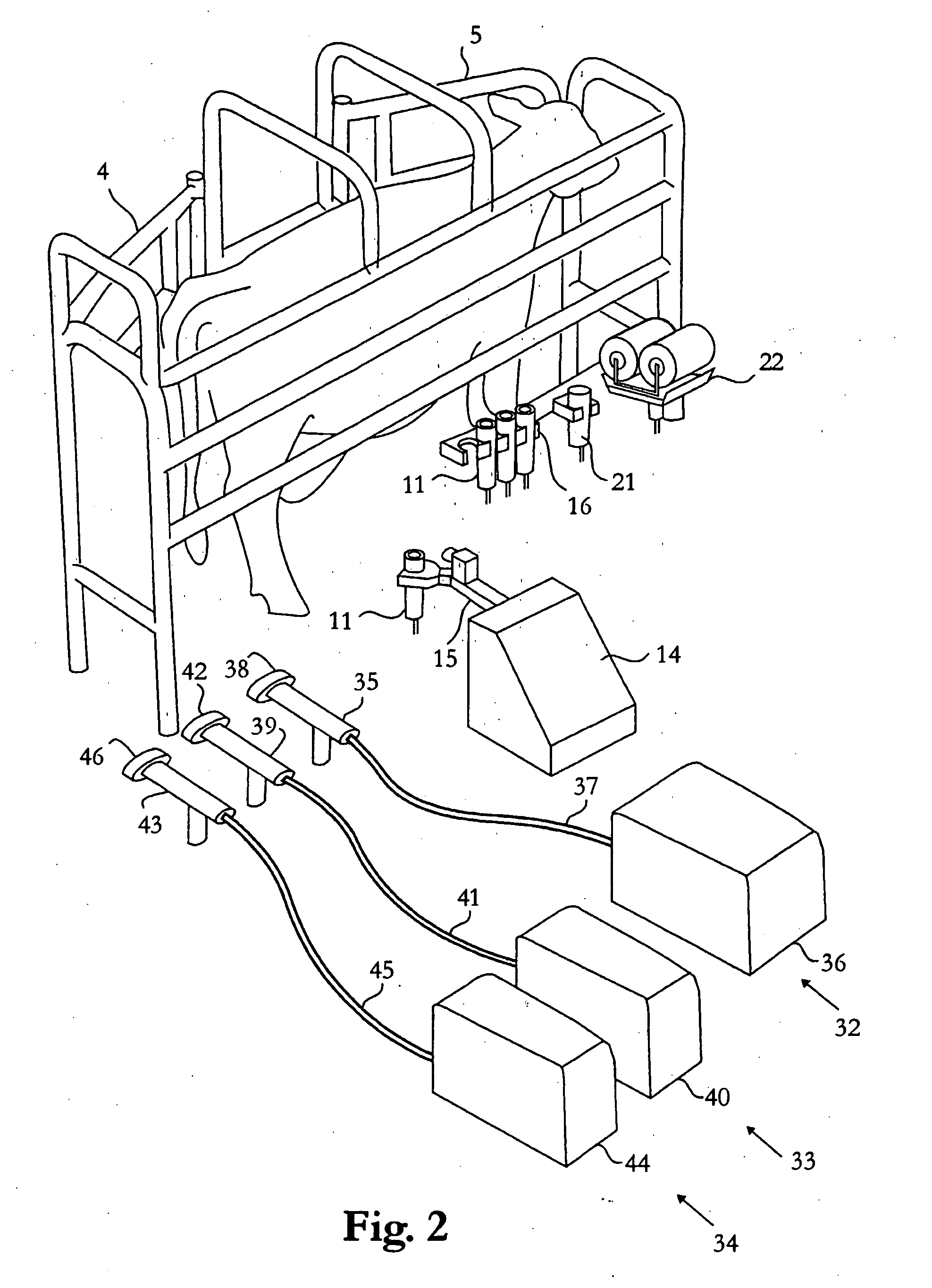

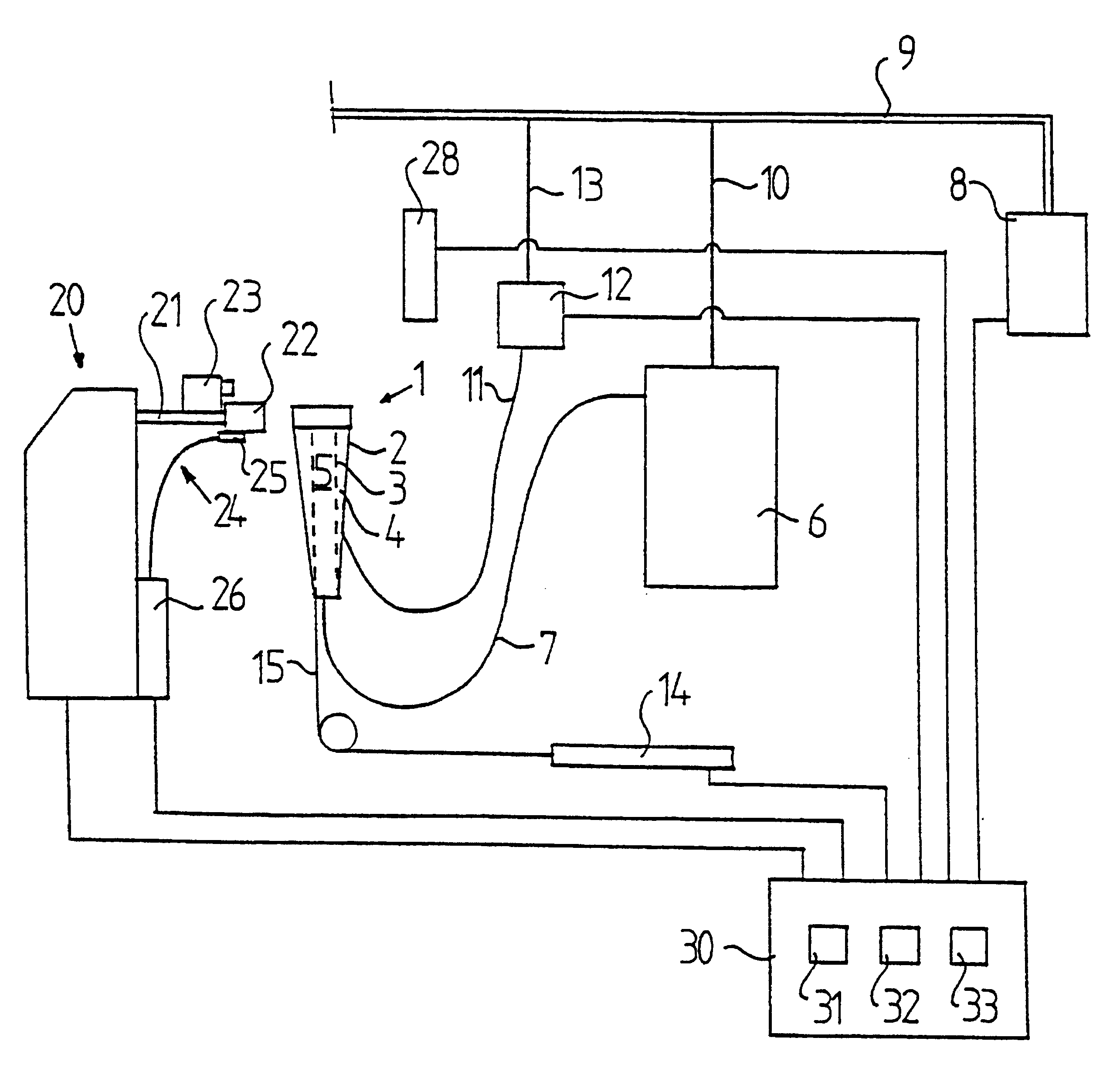

Method and a device for milking an animal

The invention refers to a method and a device for milking an animal. The device comprises a milking machine arranged to permit milking of the animal according to a milking process being determined by a number of adjustable parameters defining the intensity of the milking process. The value of a variable related to the time period from at least one first milking operation to a following second milking operation is determined for the animal by determining means (31, 32). The animal is milked during the second milking operation by means of the milking machine, wherein at least one of said parameters is adjusted in response to said determined value by control means (30, 31).

Owner:DELAVAL HLDG AB

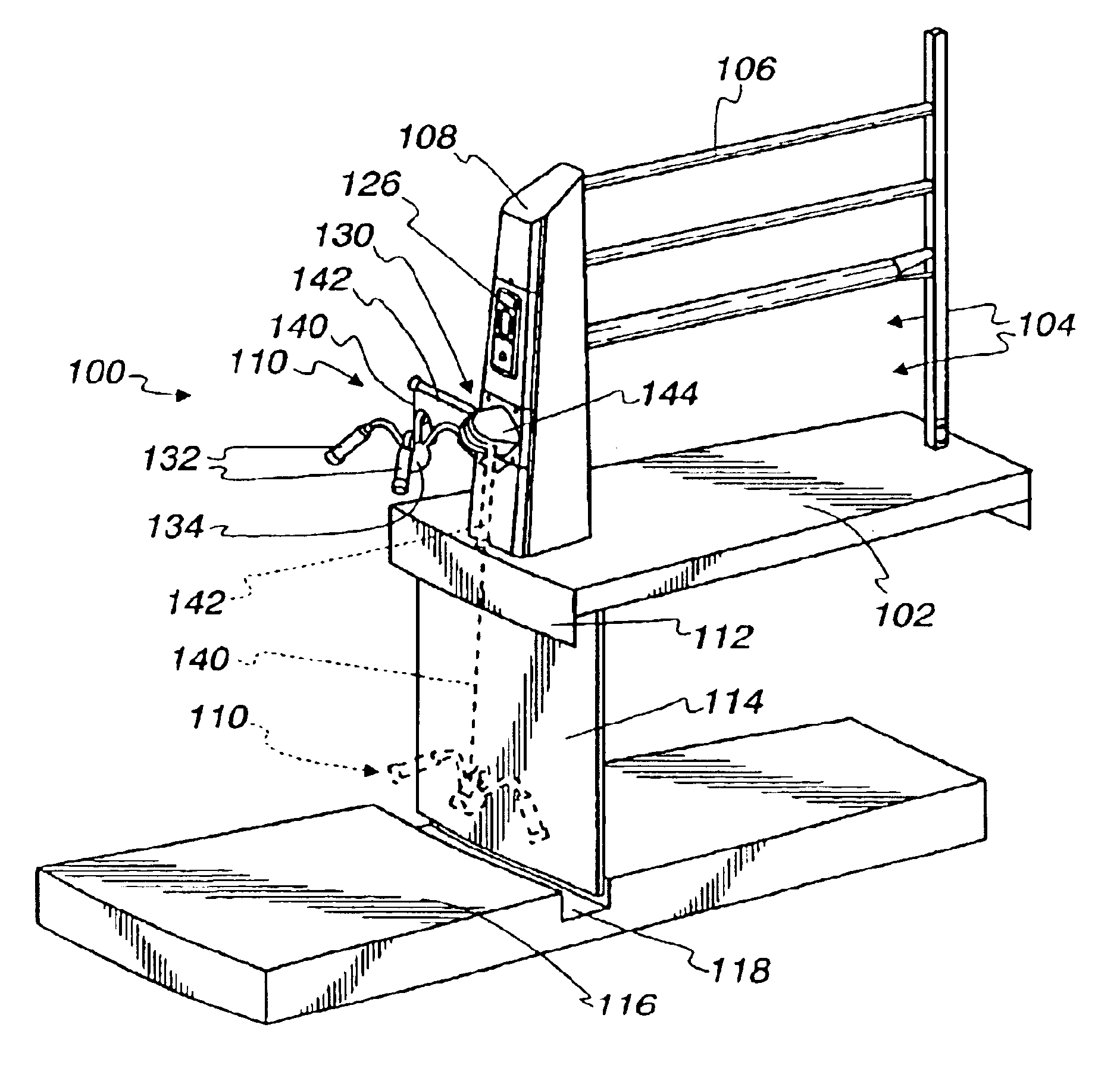

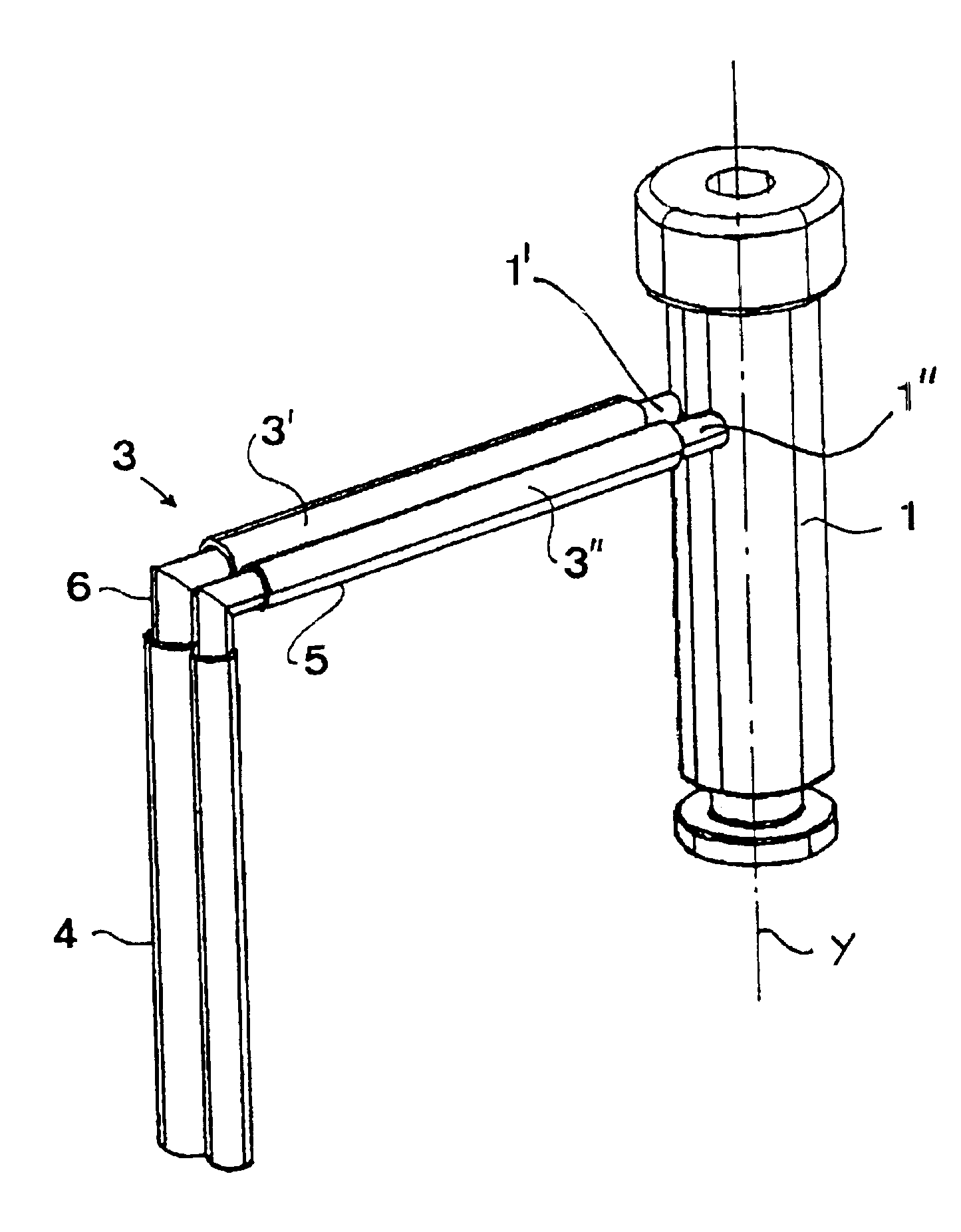

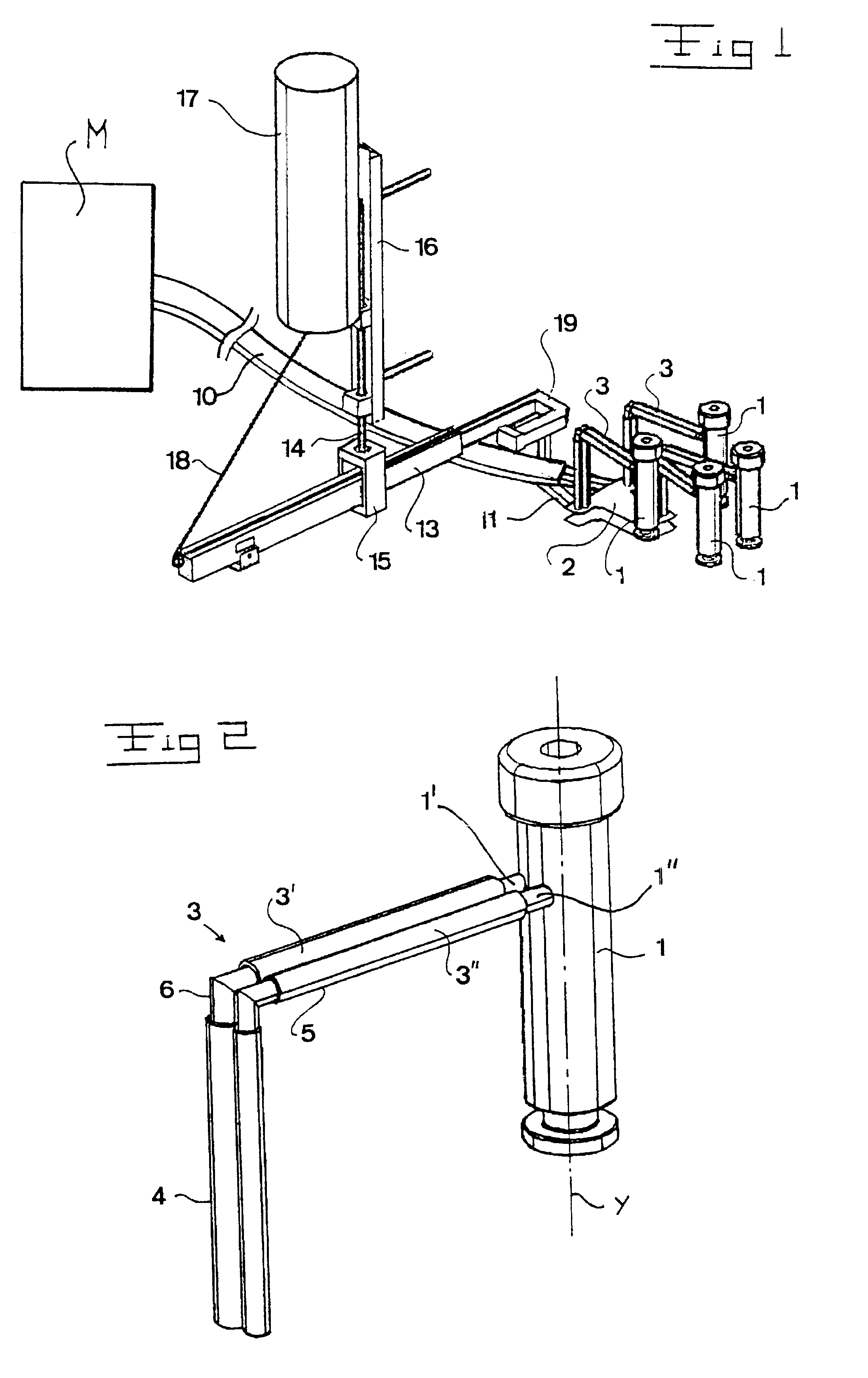

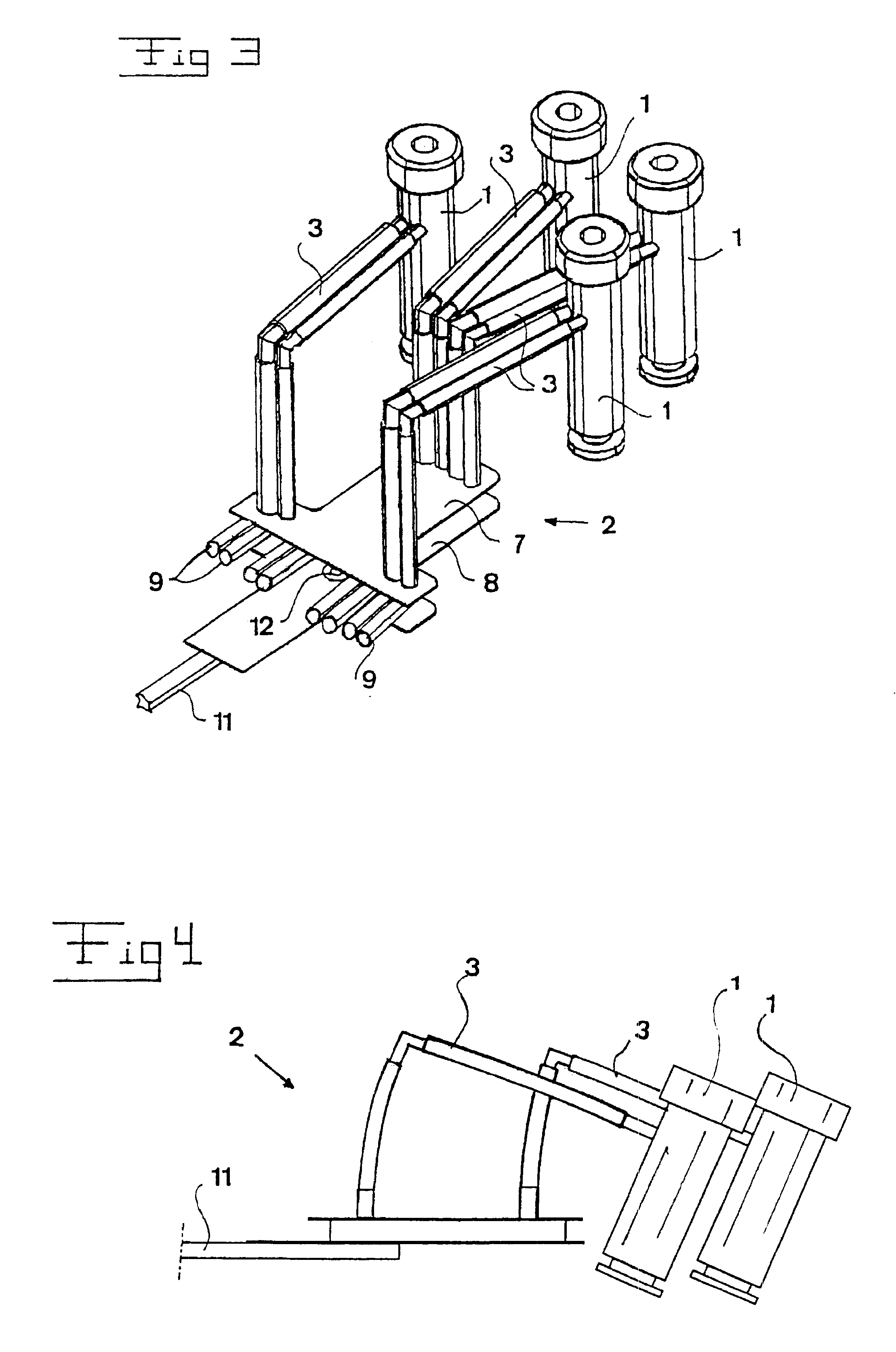

Device arranged to carry a set of teatcups

The invention refers to a device which is arranged to carry a set of teatcups arranged to be attached to a respective teat. The device includes a carrying member, which is displaceable between at least a first inactive position beside the animal to be milked and a second active milking position and on which the teatcups are mounted via a respective flexible conduit member. The conduit member includes at least a milk conduit and is designed to permit a certain movability of the teatcup in relation to the carrying member. Each conduit member extends upwardly from the carrying member and connects to a side portion of the respective teatcup.

Owner:DELAVAL HLDG AB

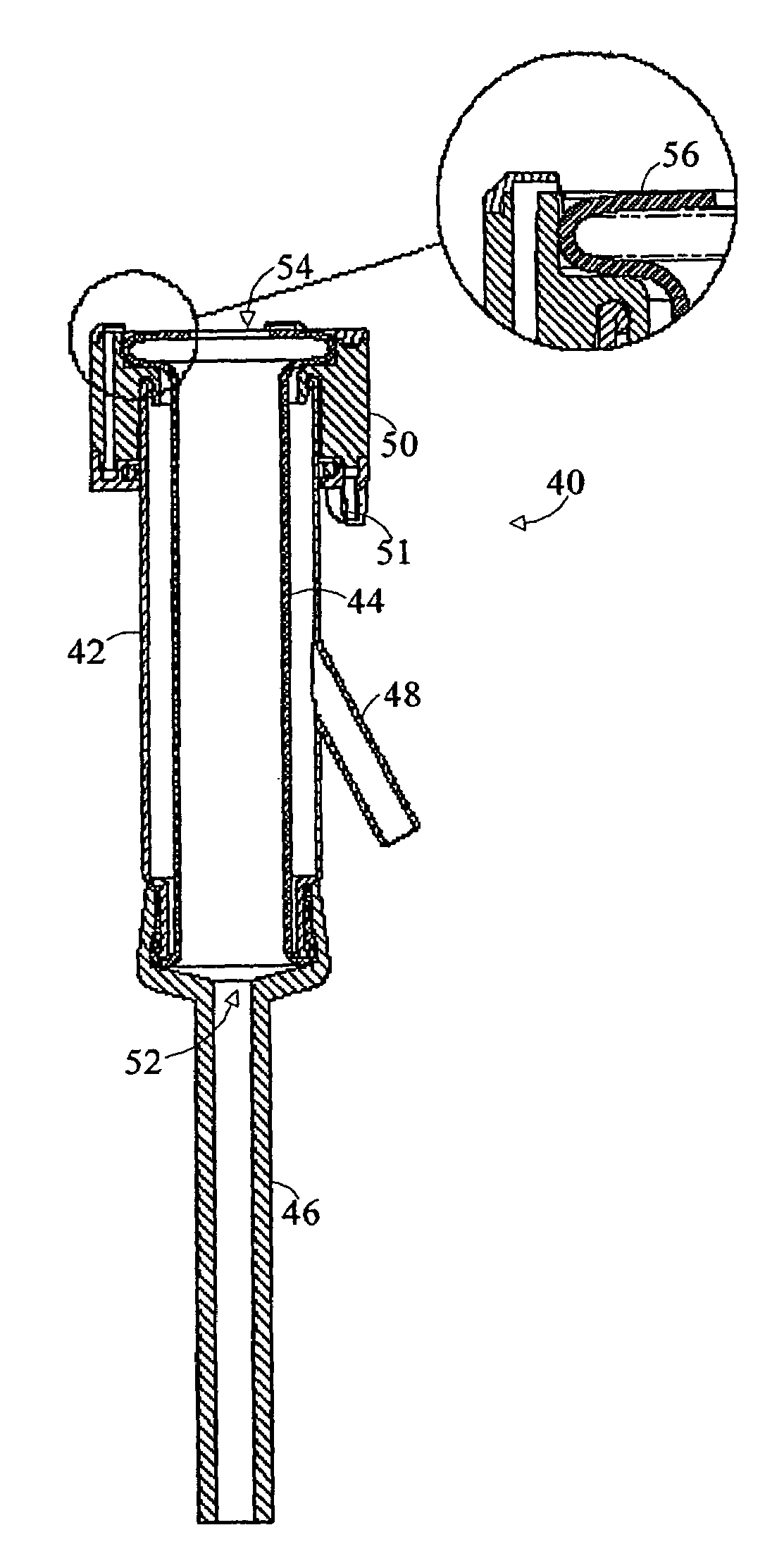

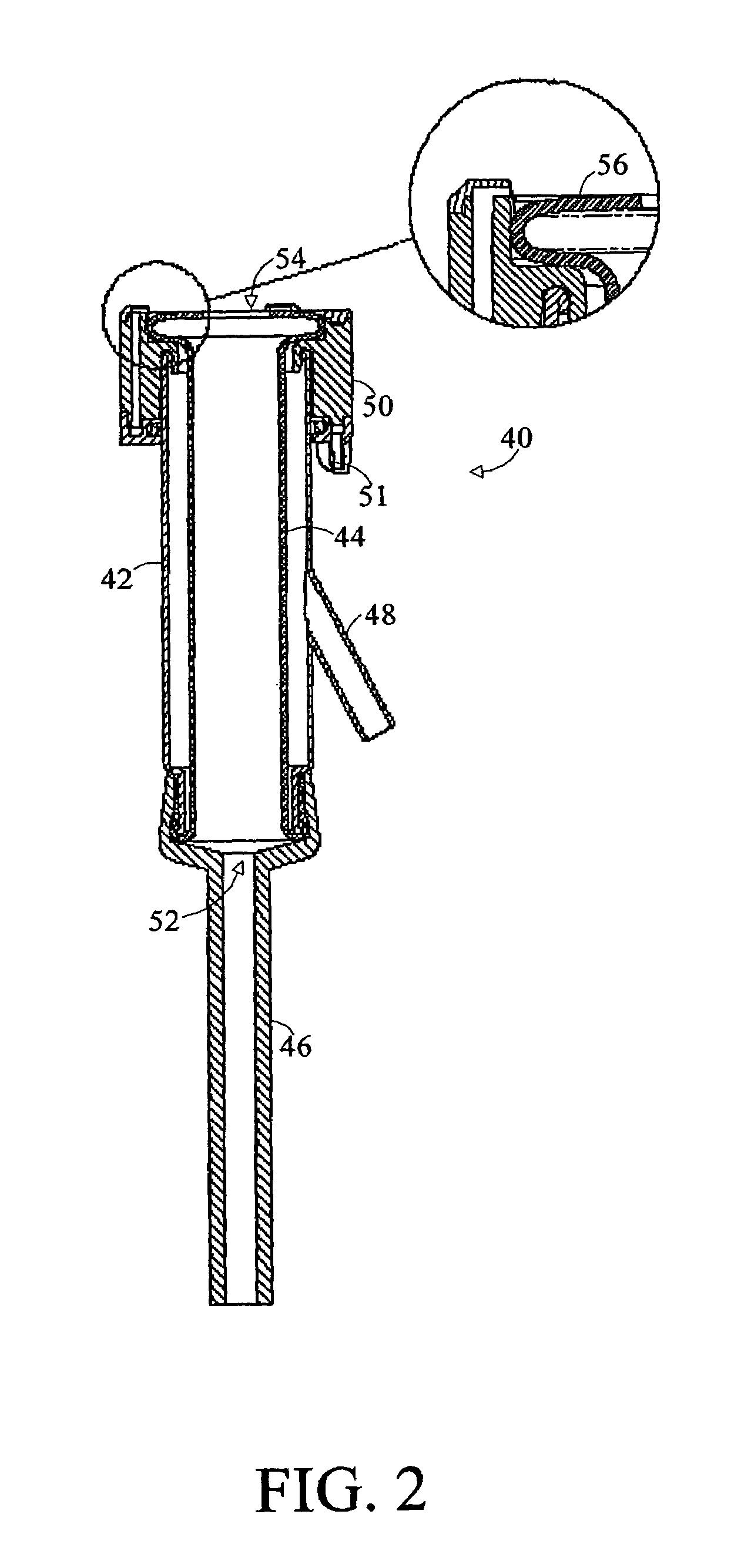

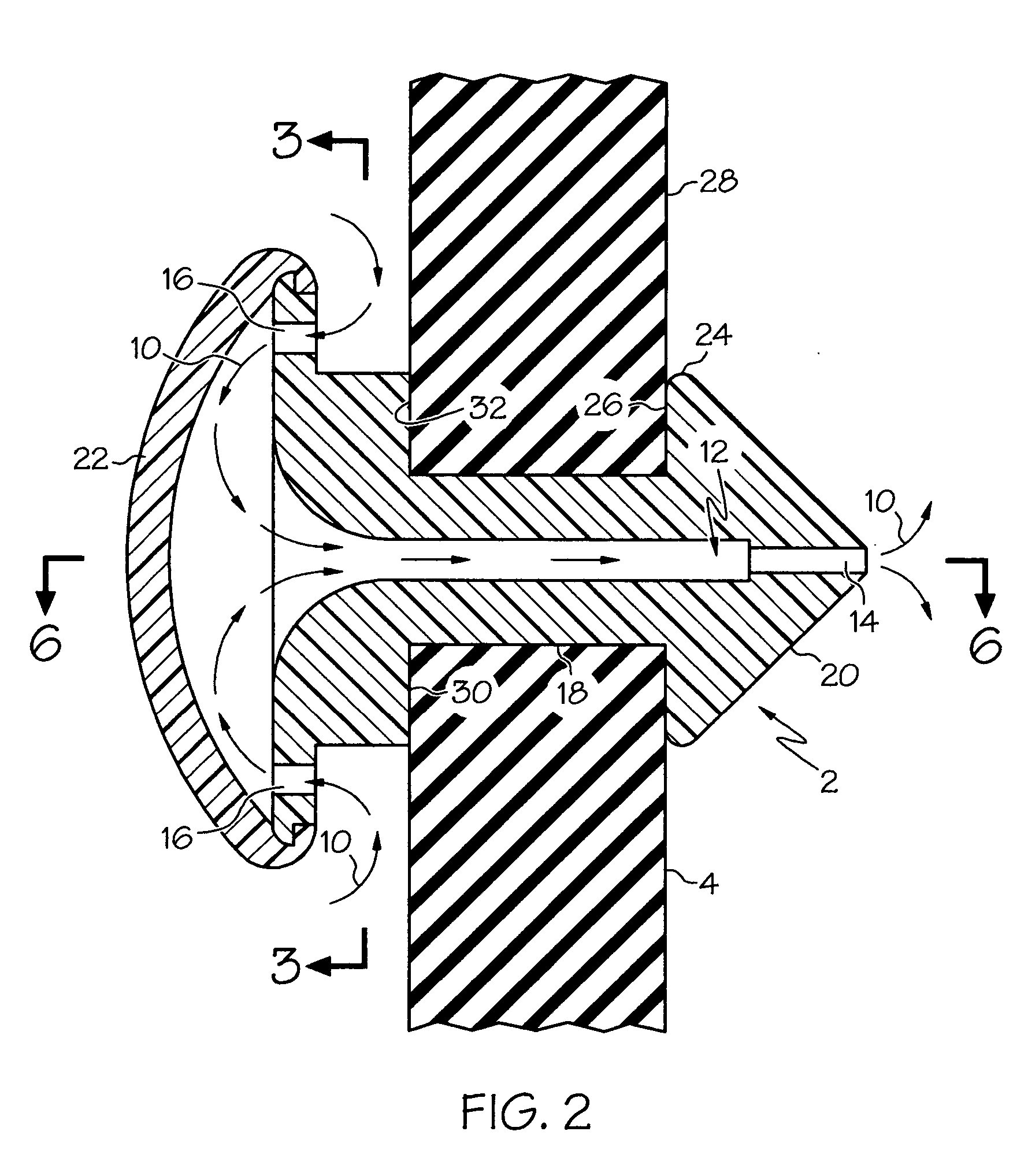

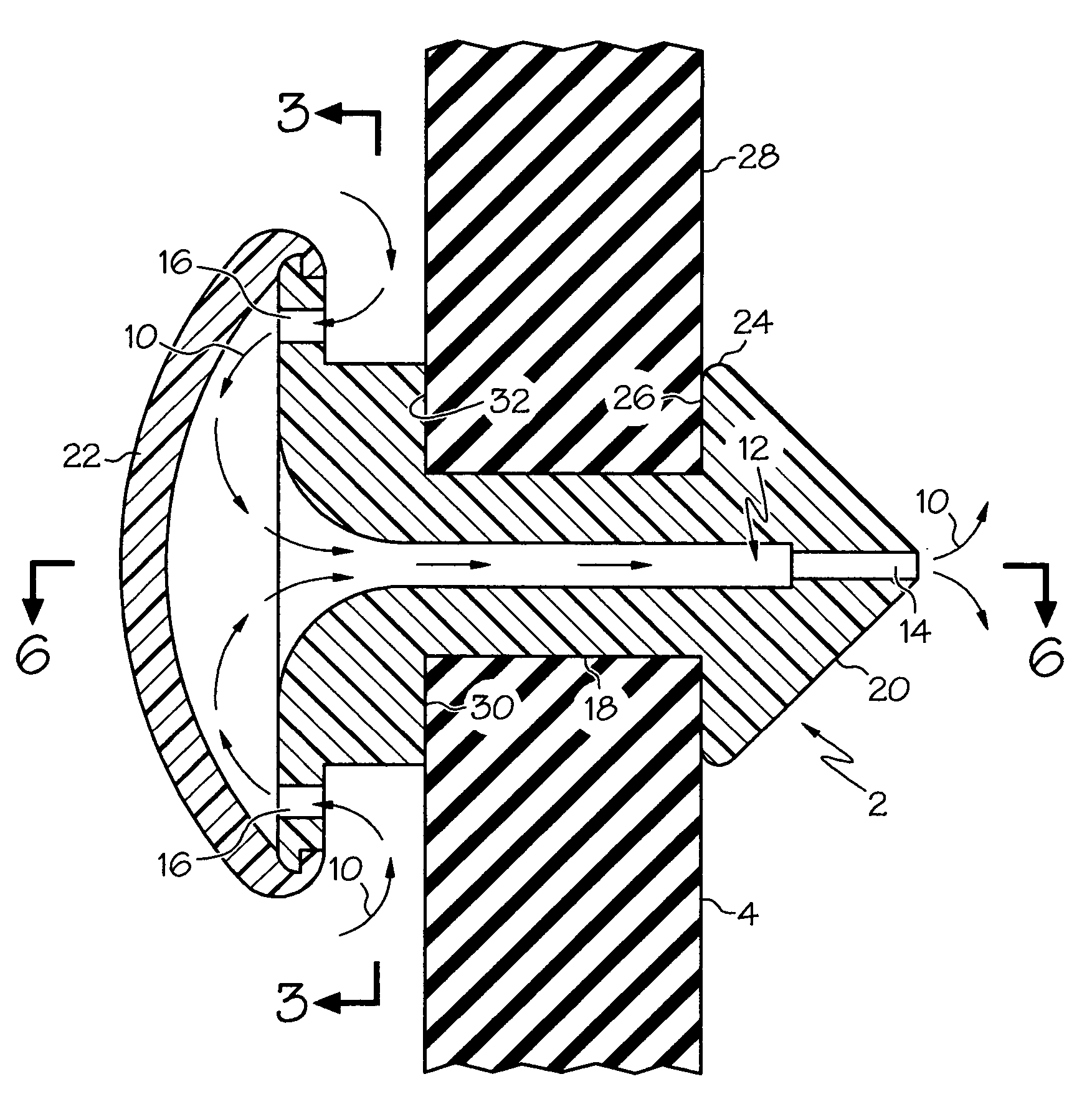

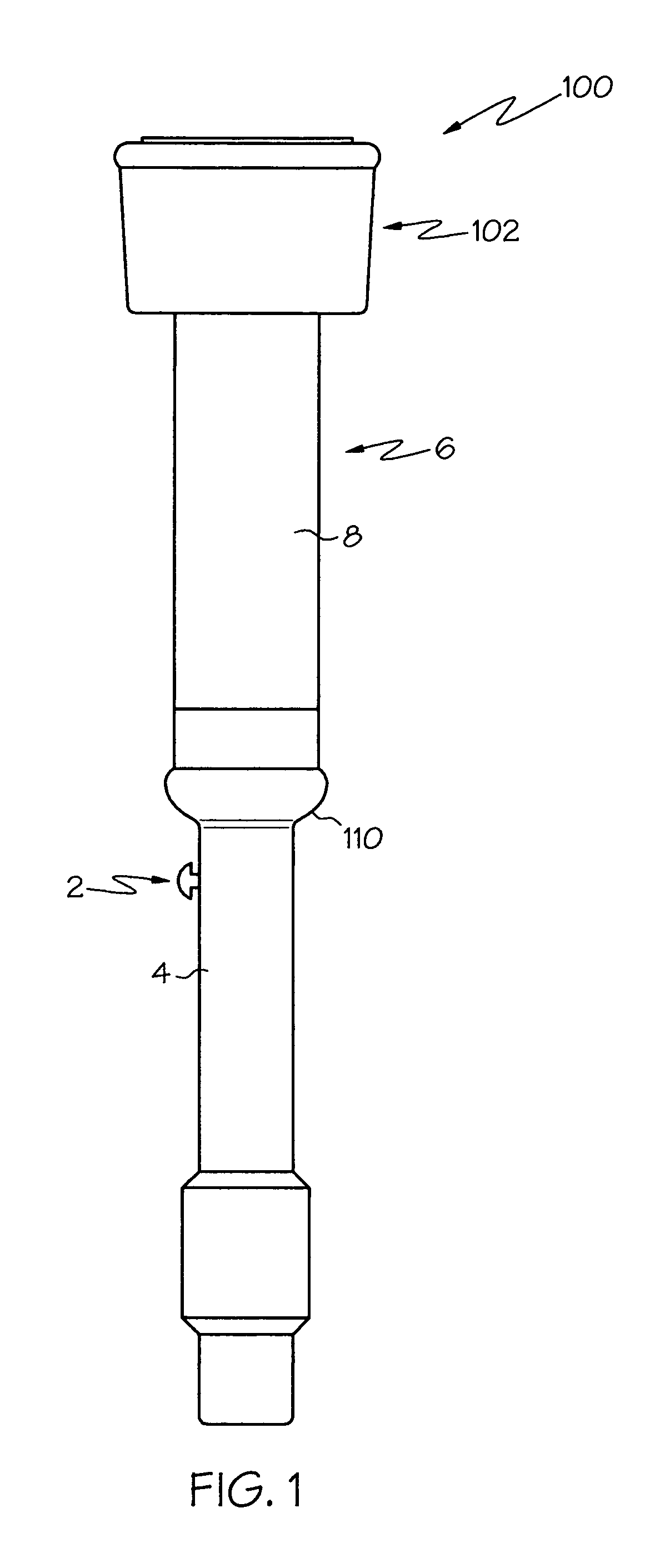

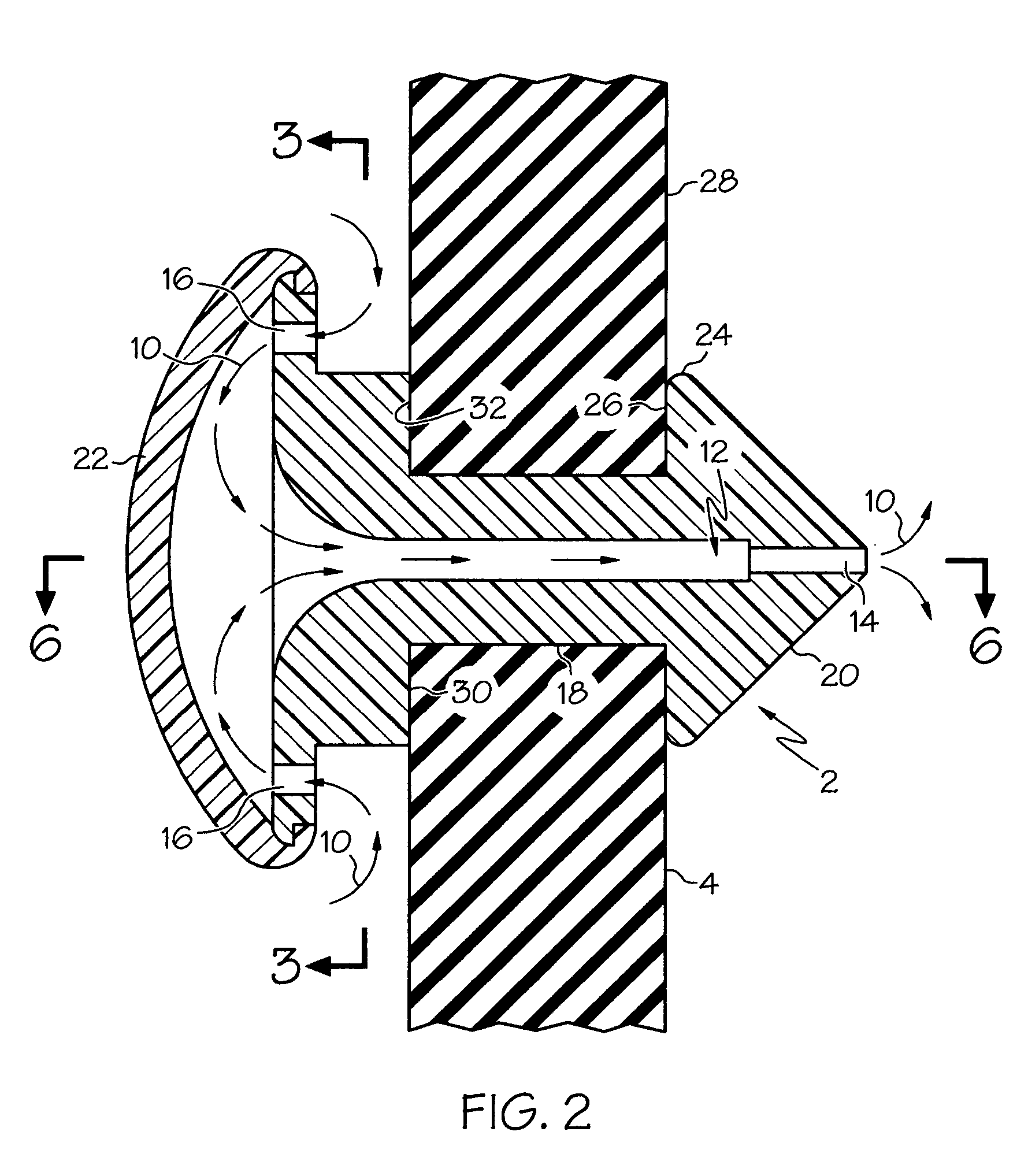

Vent plug for milking liner

A vent plug for a milking liner has a shielded inlet that reduces the likelihood that it will become clogged with debris from the floor of the milking parlor. In one embodiment, the vent plug has a plurality of redundant inlets that allow the vent plug to function if one of the inlets becomes clogged. In another embodiment, the inner flange of the body of the vent plug is at least twice the thickness of the body tube to help secure the vent plug in the milking liner.

Owner:LAUREN AGRISYST

Vent plug for milking liner

A vent plug for a milking liner has a shielded inlet that reduces the likelihood that it will become clogged with debris from the floor of the milking parlor. In one embodiment, the vent plug has a plurality of redundant inlets that allow the vent plug to function if one of the inlets becomes clogged. In another embodiment, the inner flange of the body of the vent plug is at least twice the thickness of the body tube to help secure the vent plug in the milking liner.

Owner:LAUREN AGRISYST

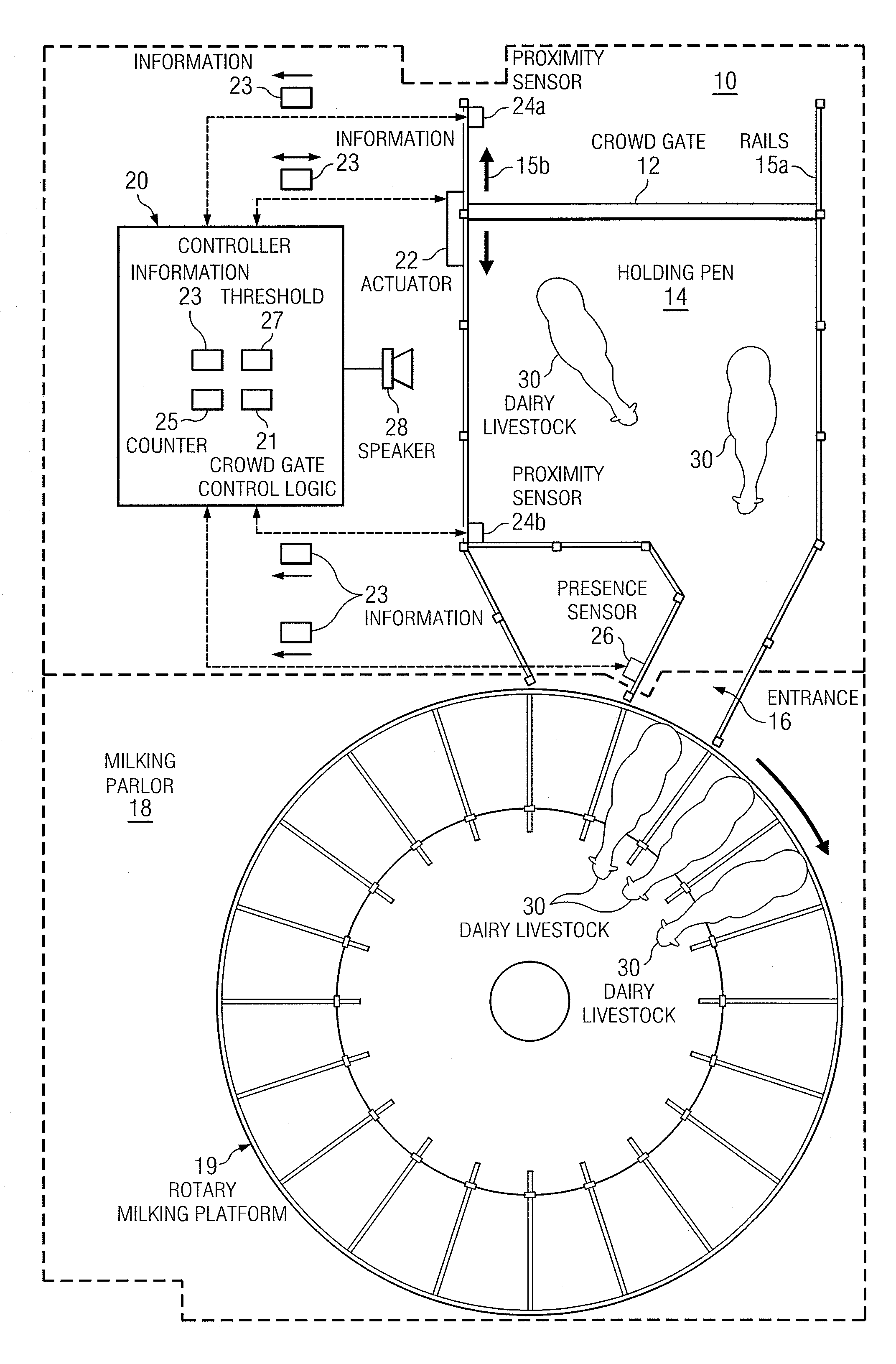

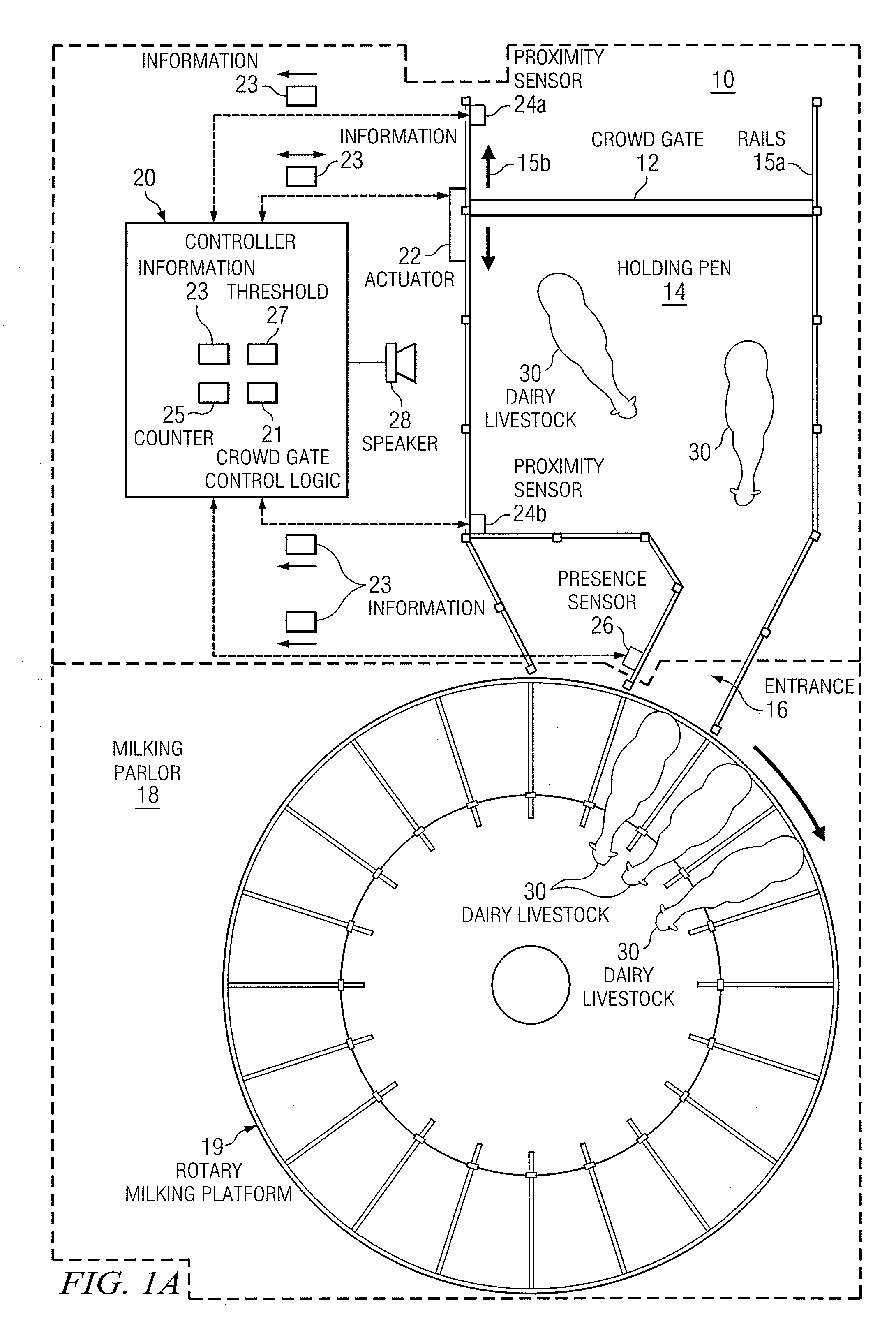

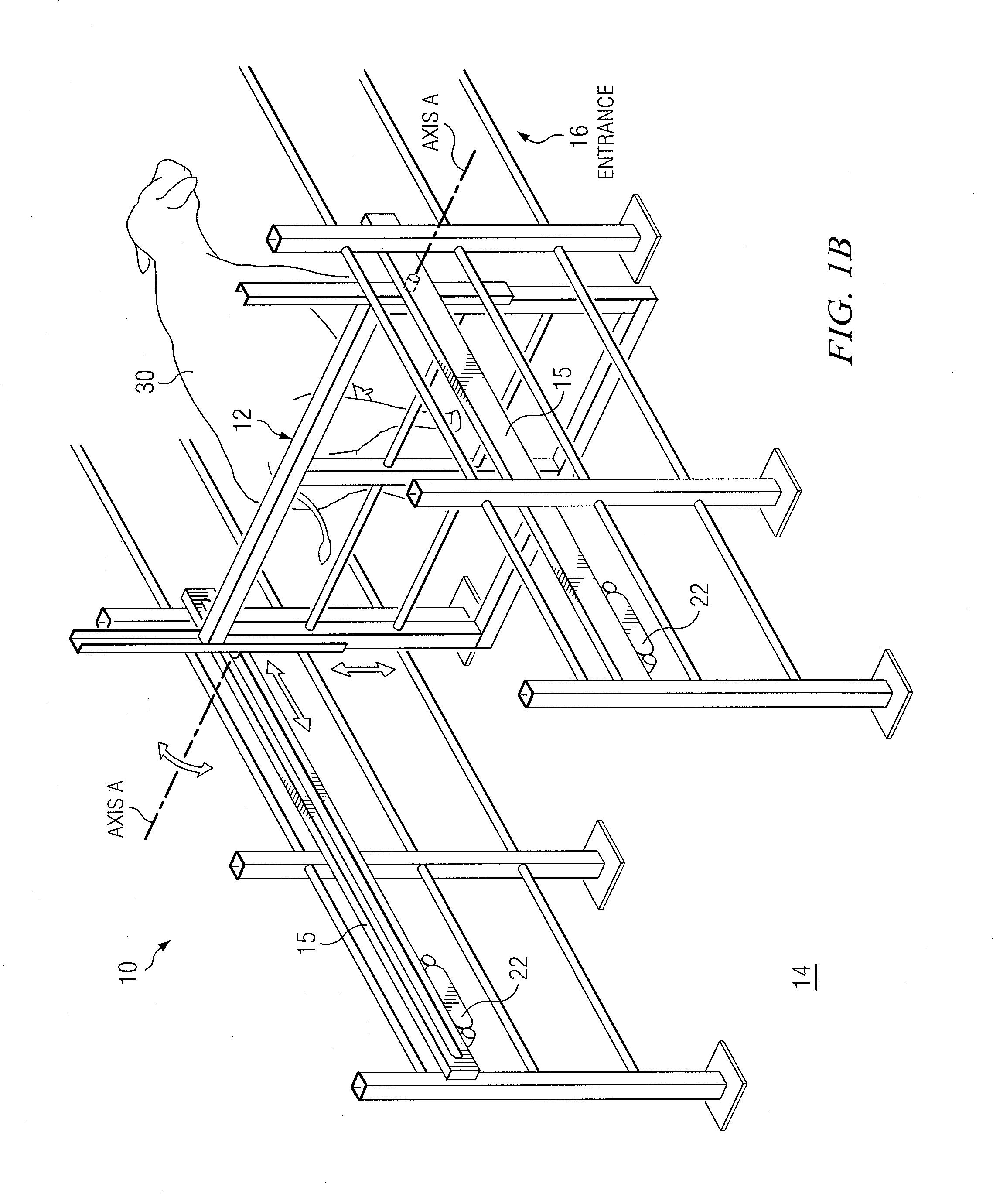

Crowd Gate Control System and Method

A crowd gate control system includes a holding pen for dairy livestock, a crowd gate, and a controller. The holding pen is adjacent to an entrance to a milking parlor. The crowd gate is operable to form a side of the holding pen and move in relation to the entrance to the milking parlor along an axis substantially parallel to two other sides of the holding pen. The controller is operable to store a triggering threshold associated with a counter related to the milking parlor, determine whether the counter has reached the triggering threshold, and initiate a first mode of operation of the crowd gate in response to determining that the counter has reached the triggering threshold.

Owner:TECH HLDG

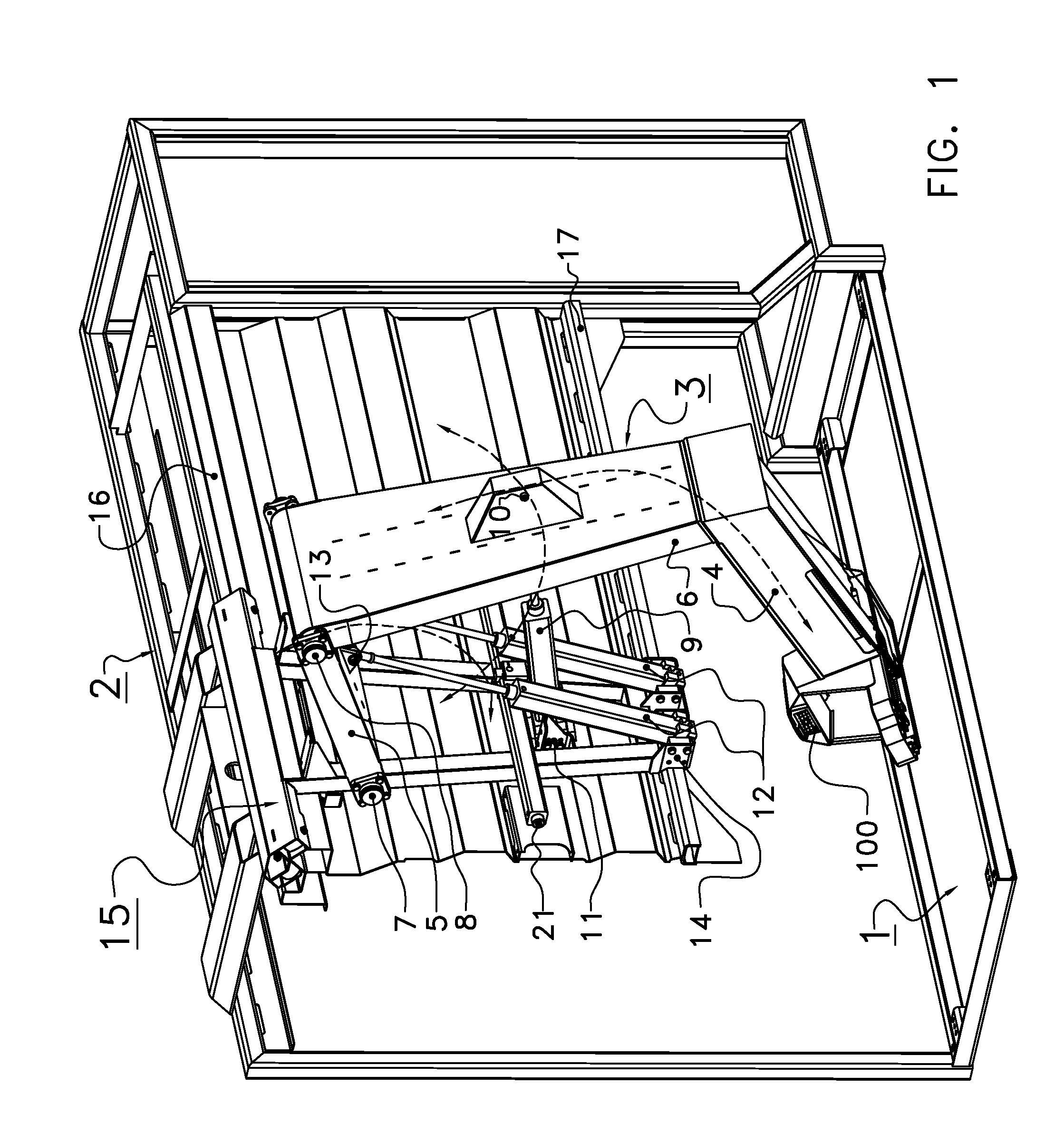

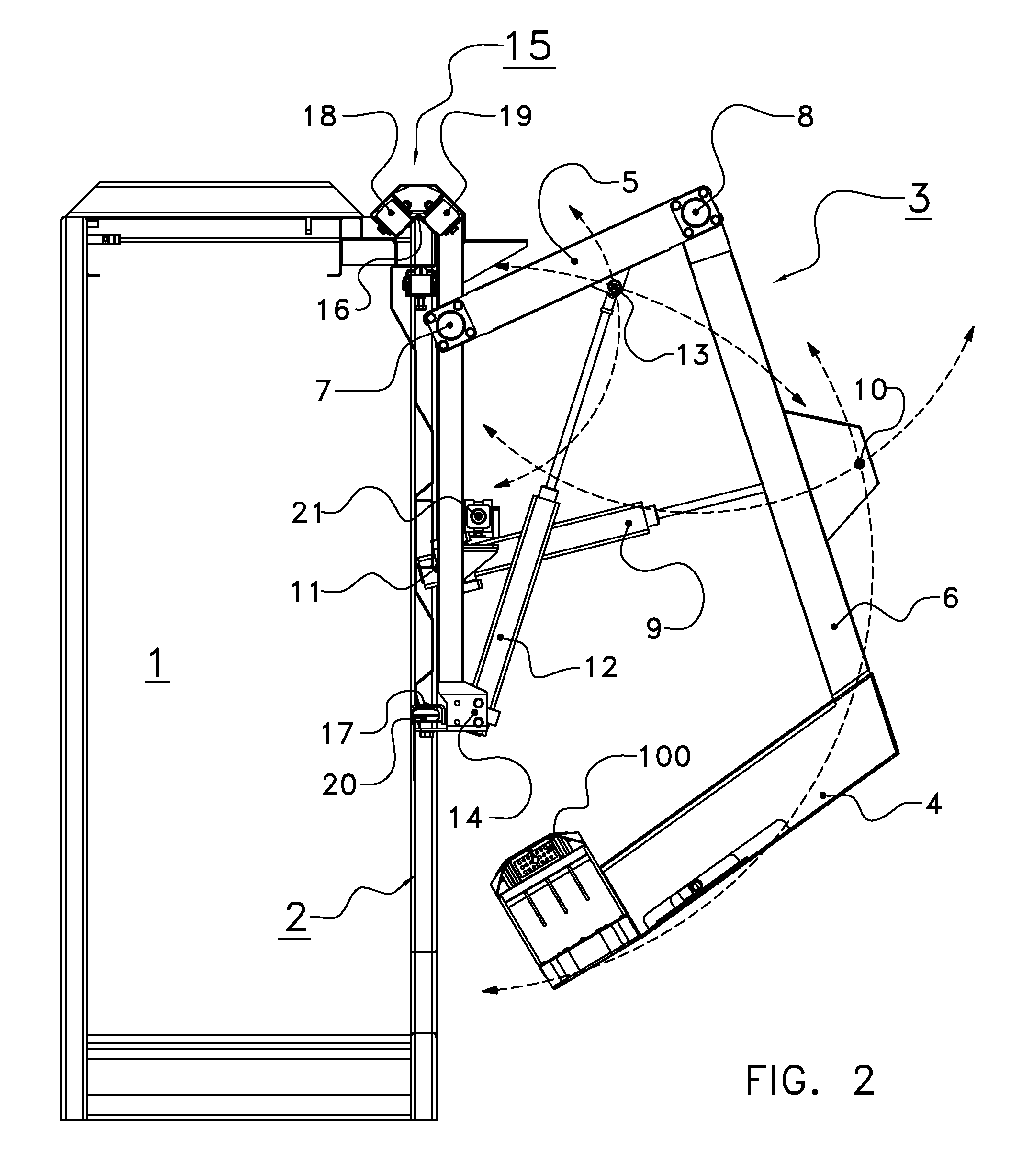

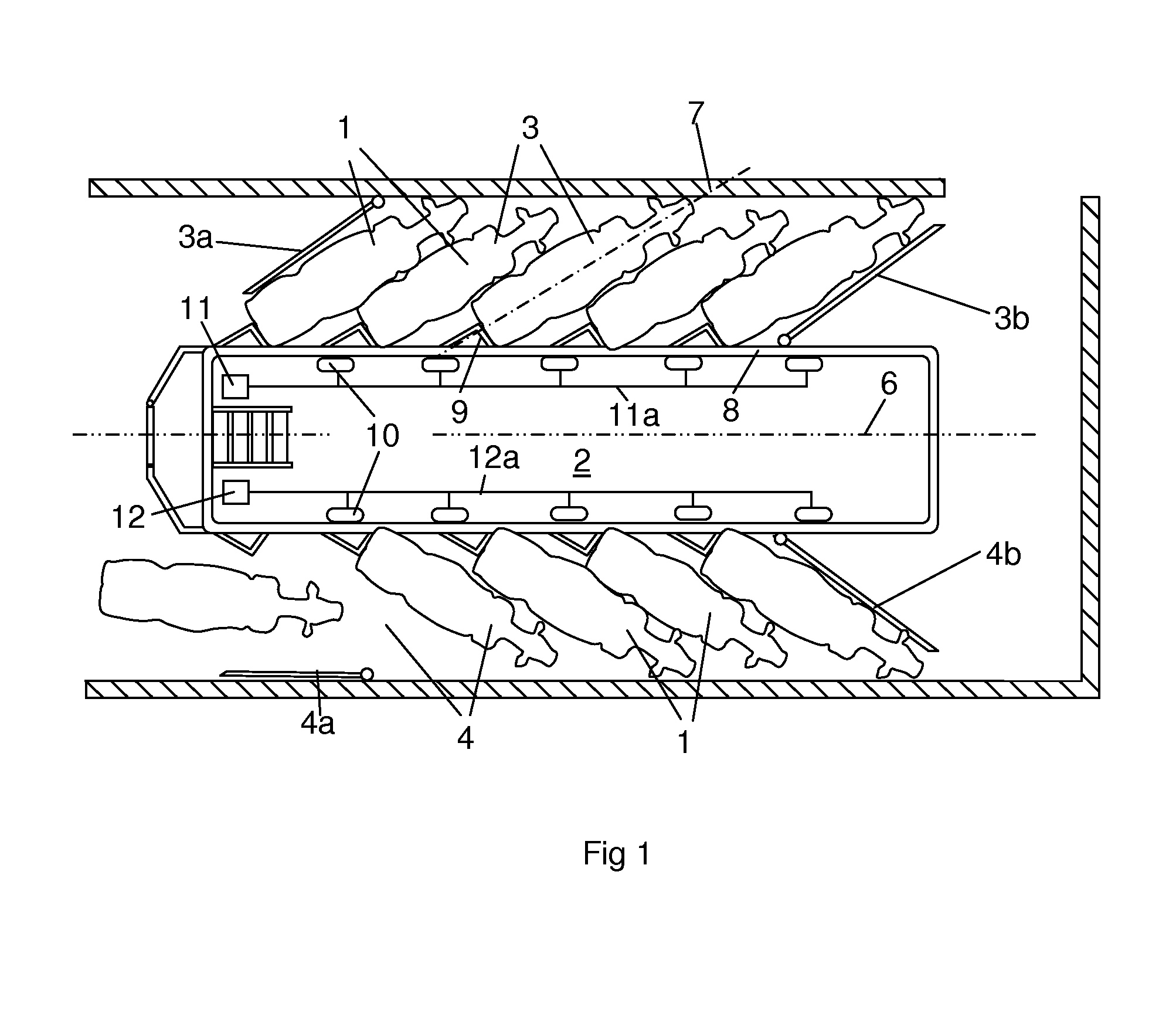

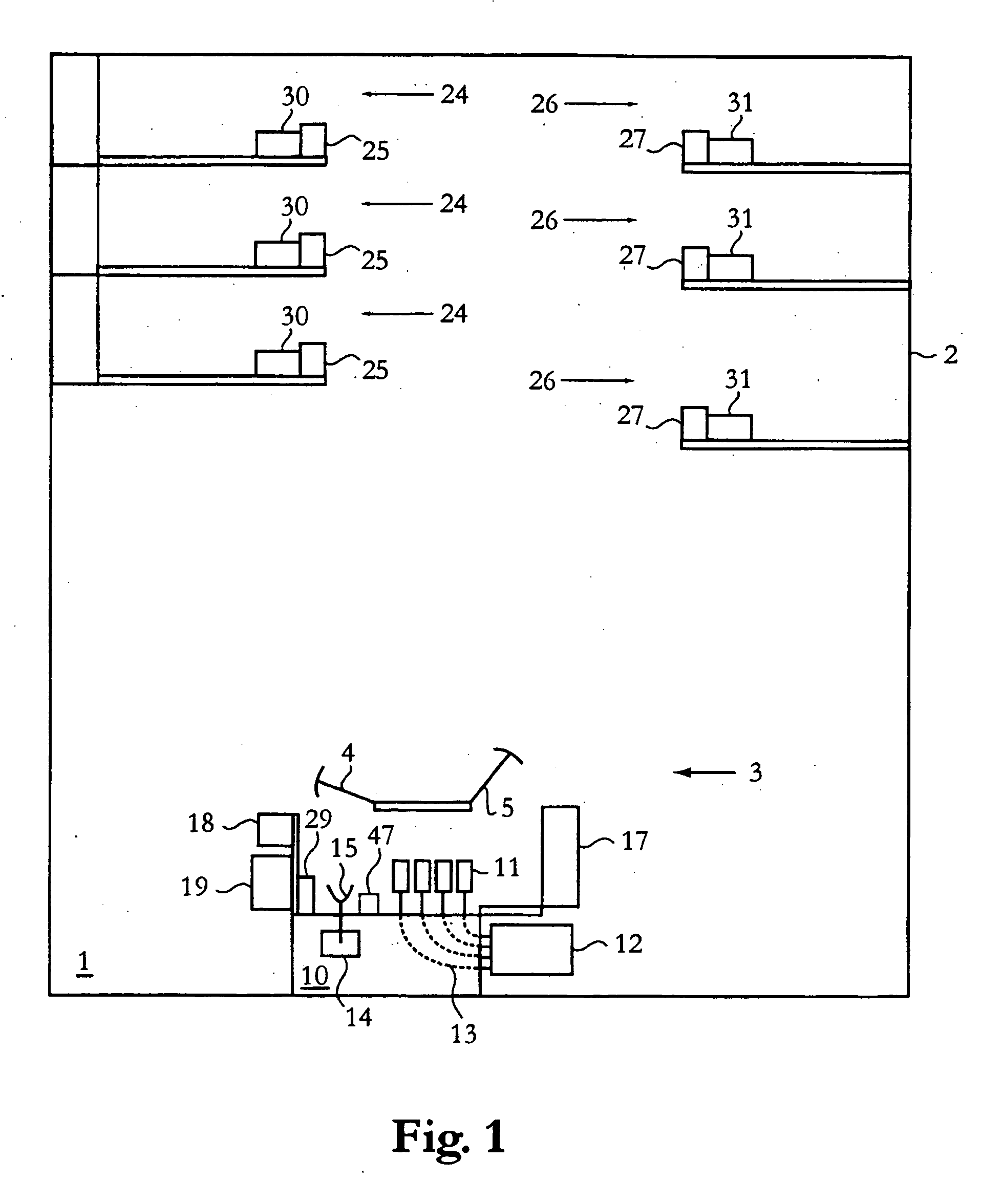

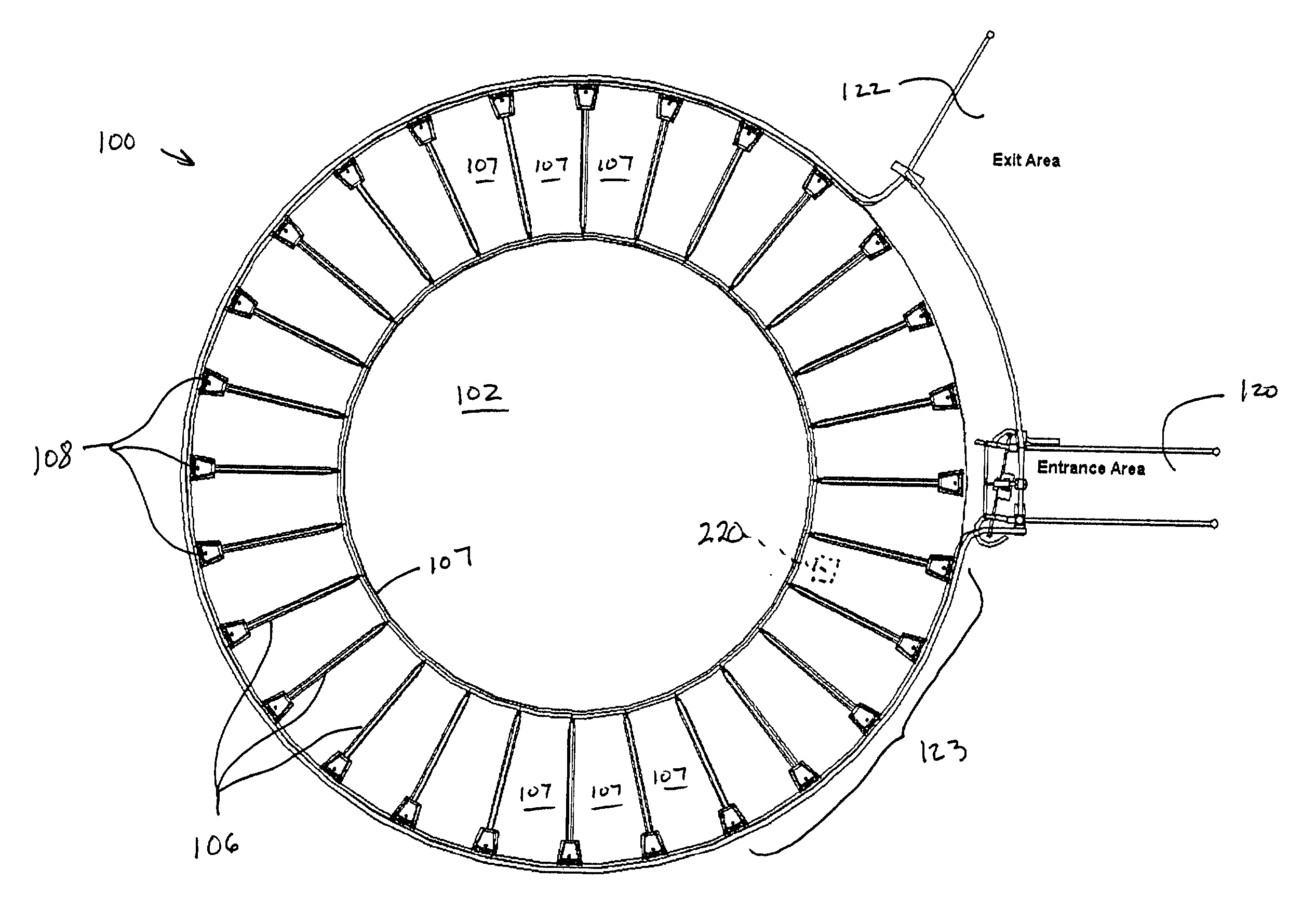

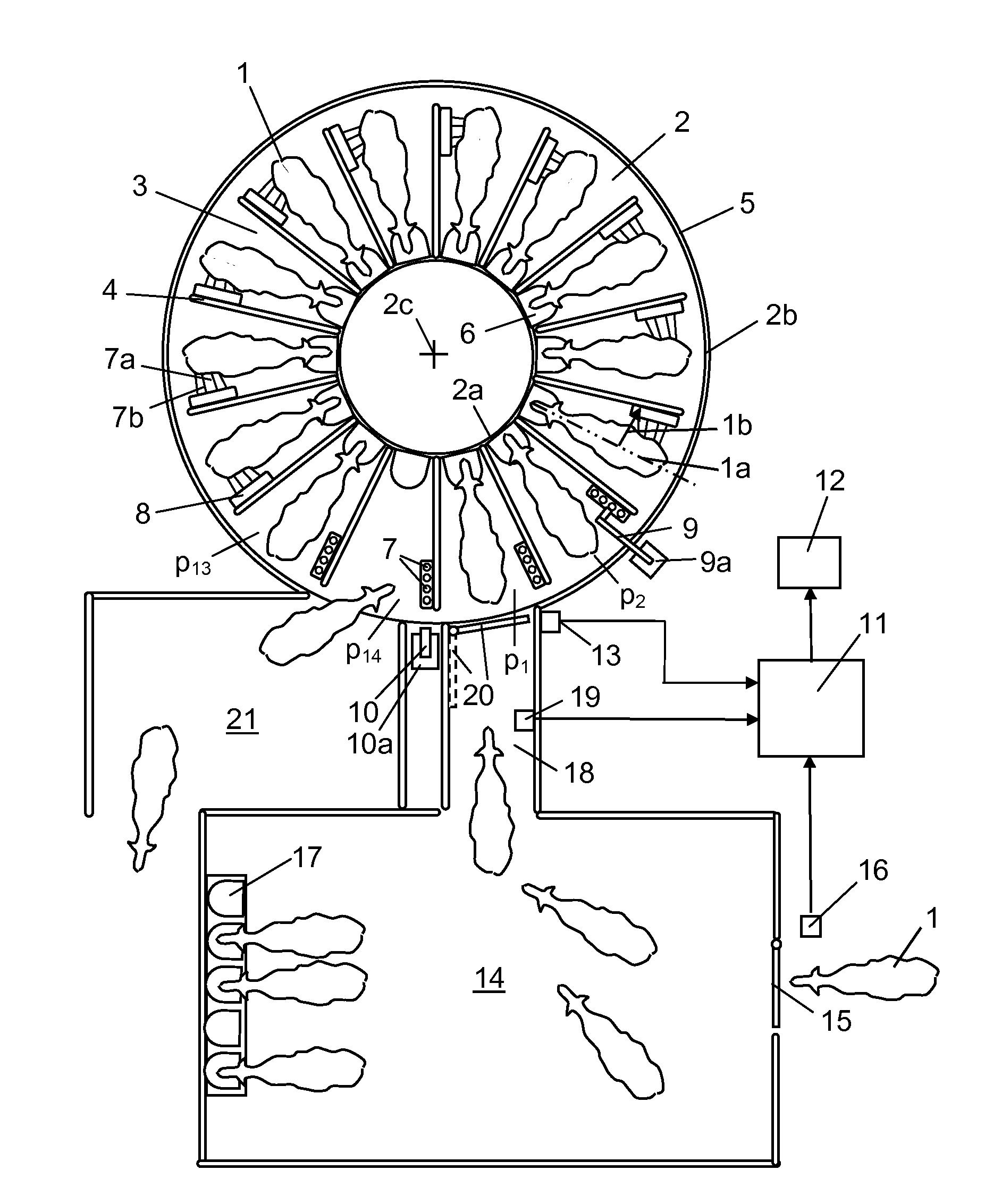

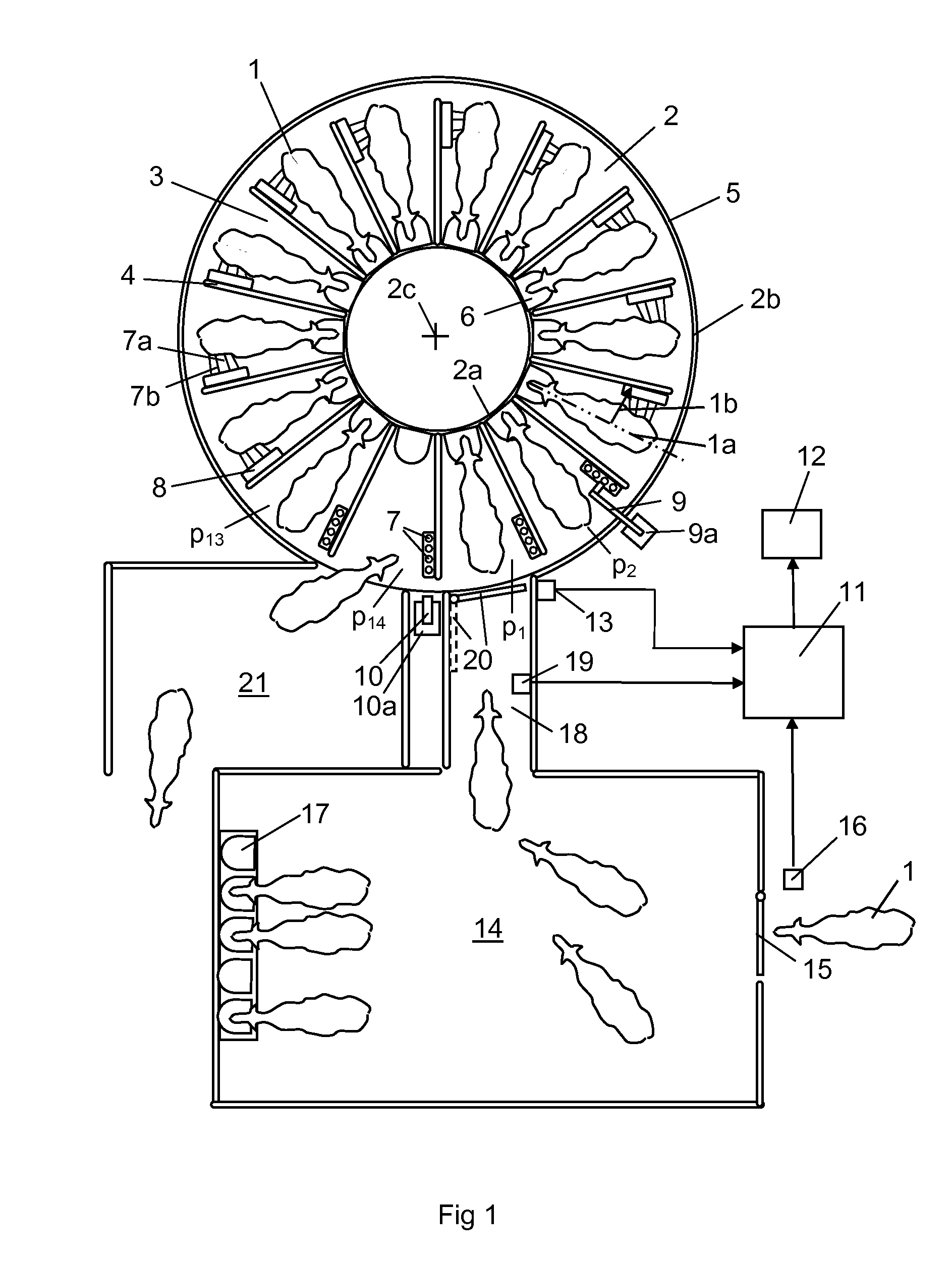

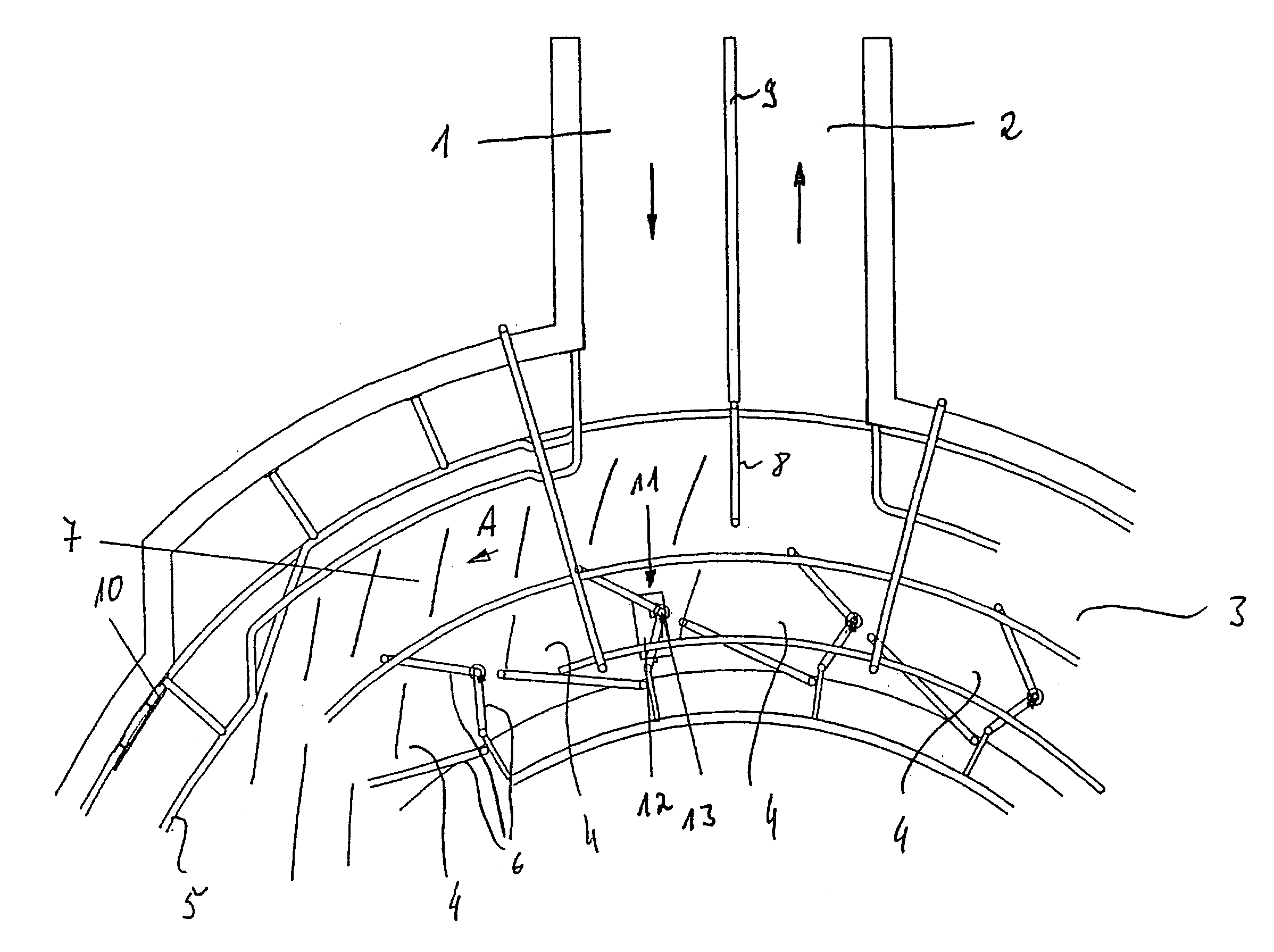

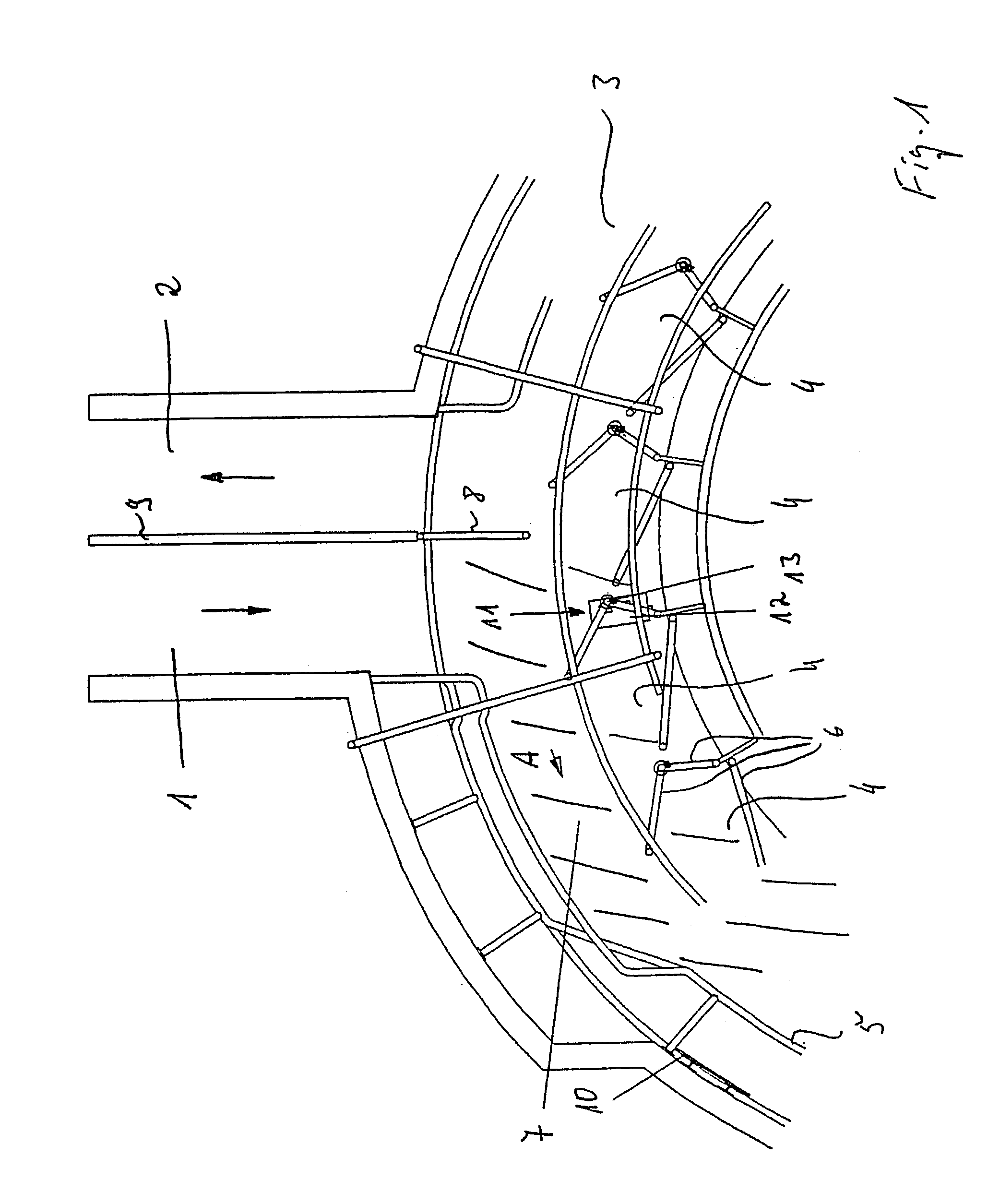

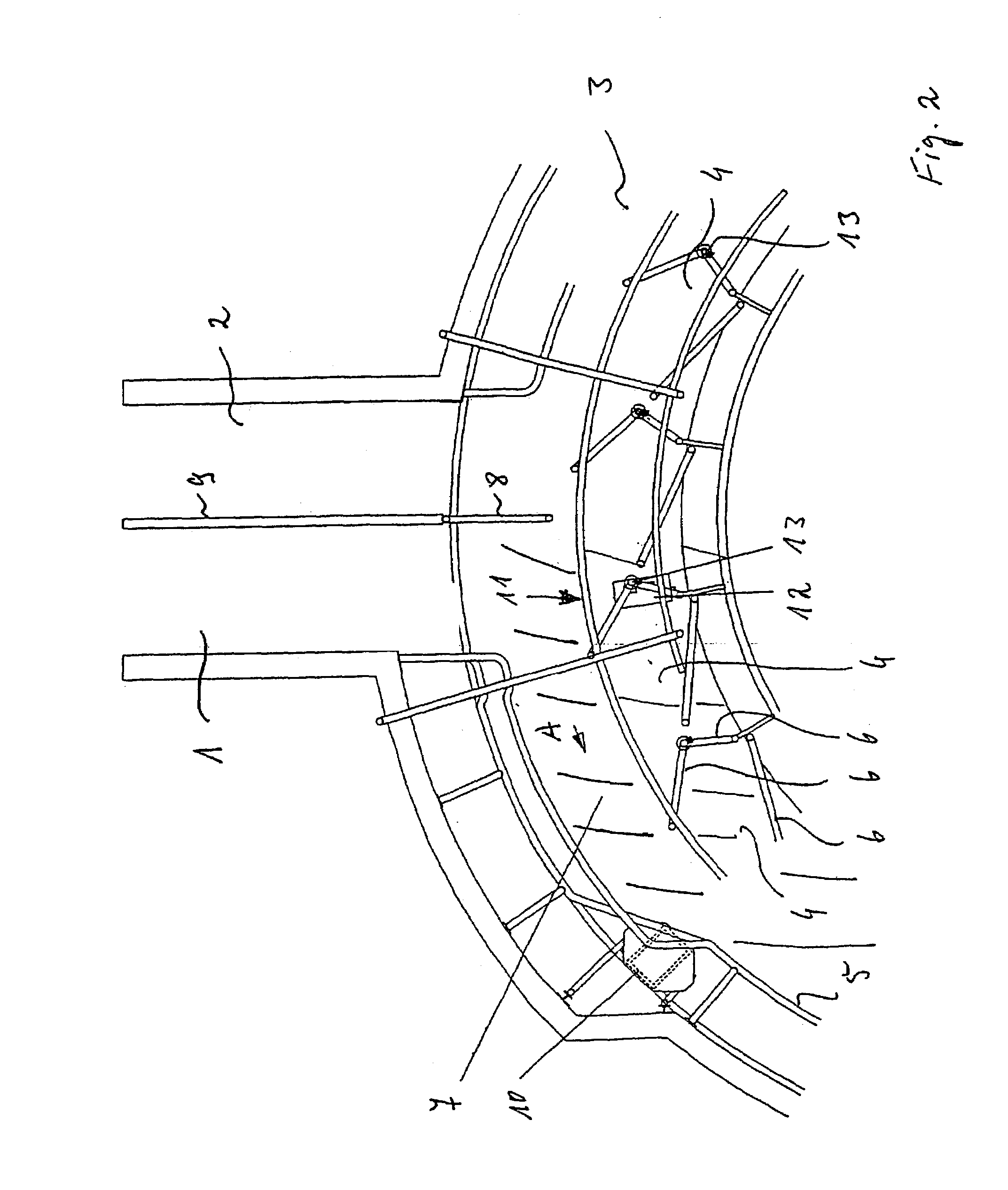

Milking arrangement for animals

A milking arrangement for animals includes rotary platform (2), a driving mechanism (12) adapted to provide a rotary motion of the platform (2), milking stalls (3) adapted to house the animals (1) to be milked on the platform (2), a blocking system (11, 20, 25) for blocking selected milking stalls (3) on the platform (1) temporarily such that the animals (1) do not have access to the blocked milking stalls (3) during a period of time and the remaining non-blocked milking stalls will be used more frequently.

Owner:DELAVAL HLDG AB

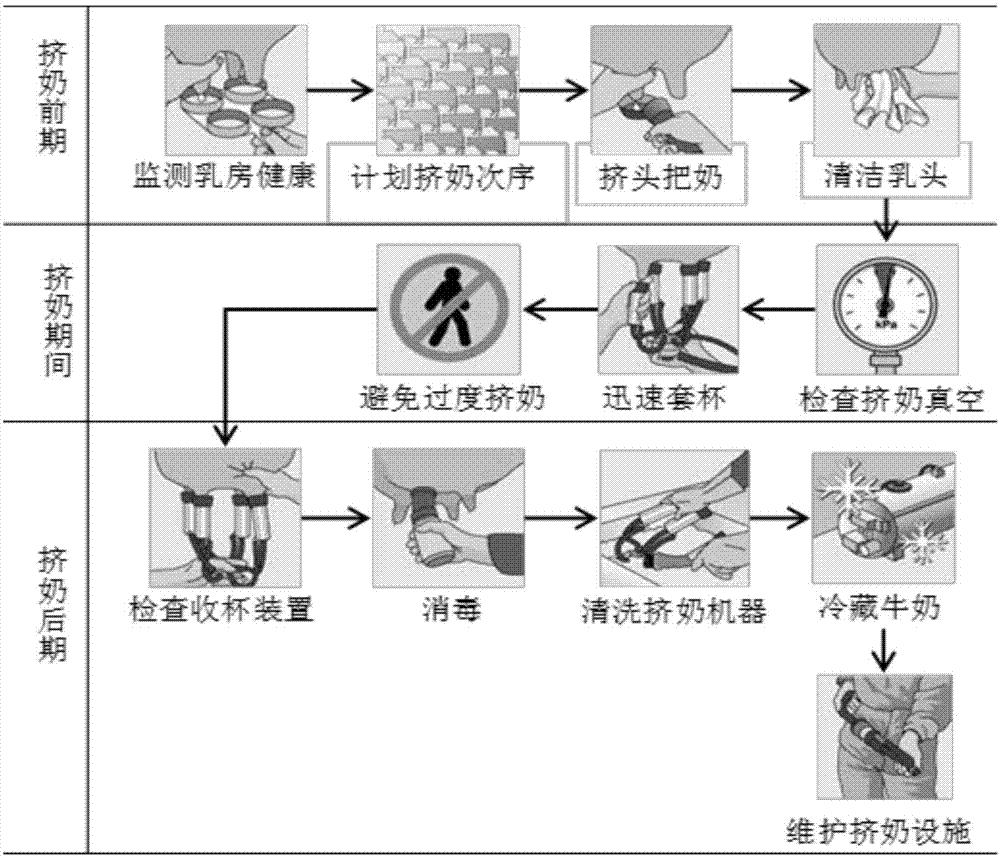

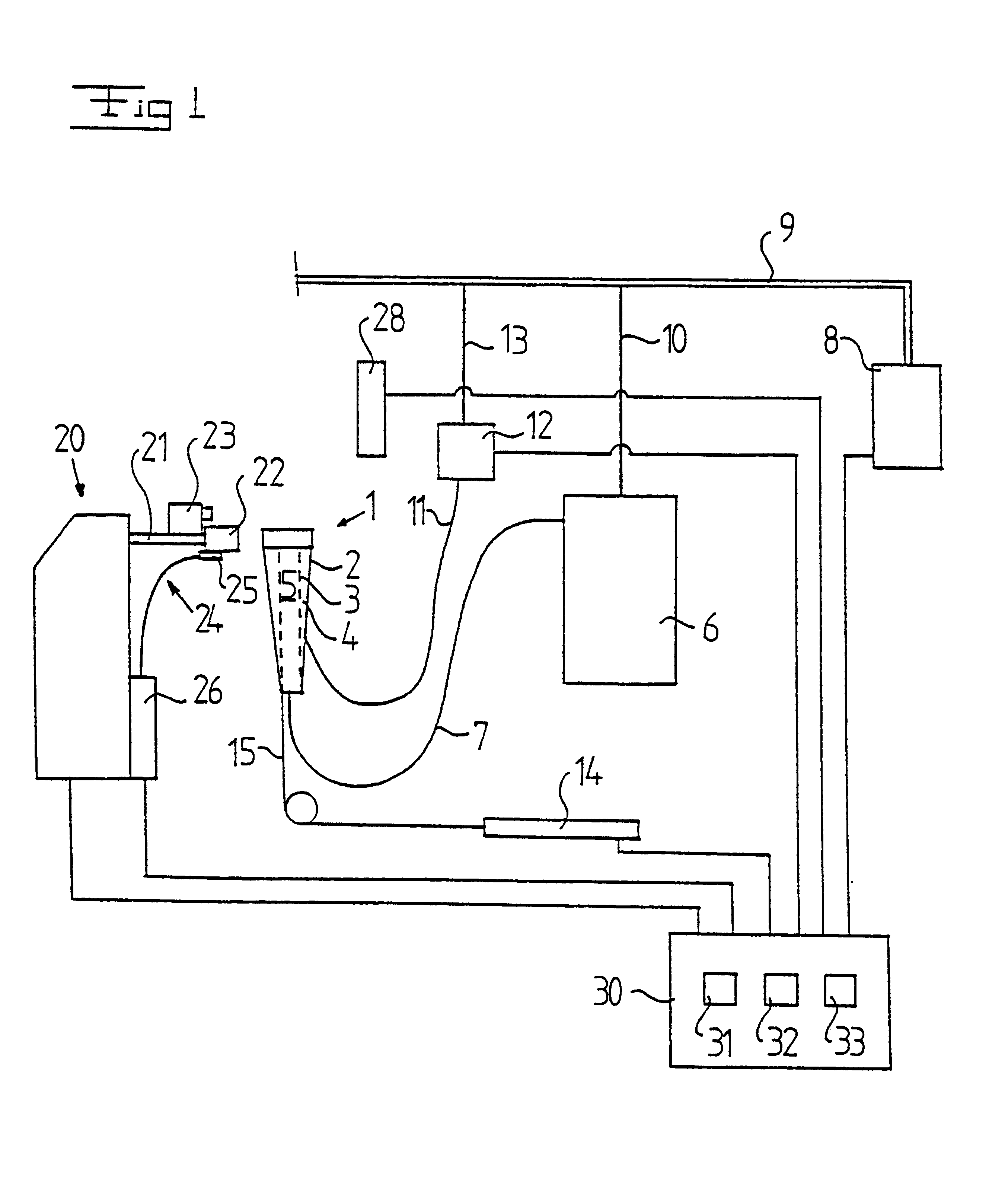

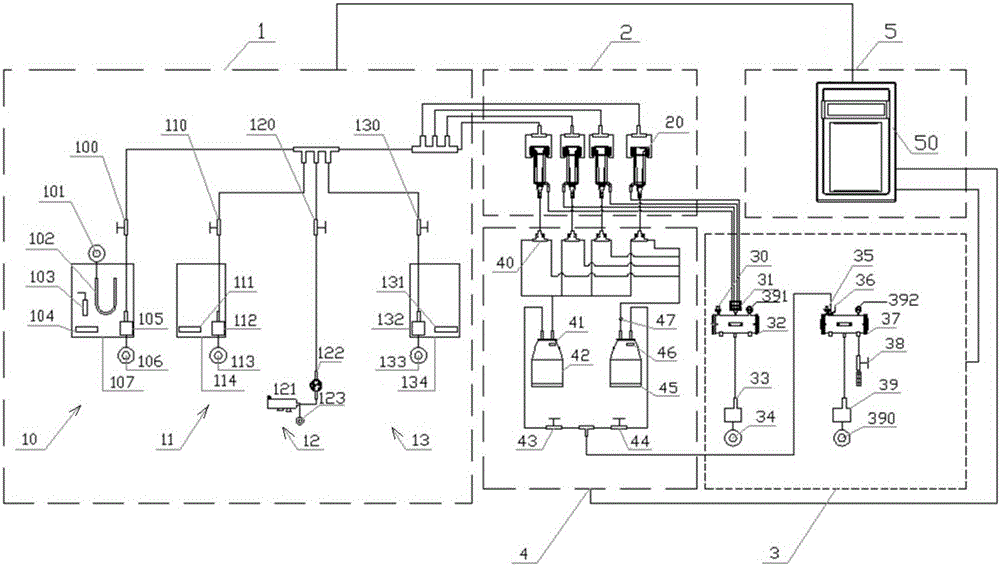

Intelligent milking system and method

ActiveCN104982338AReduce the burden onHigh degree of automationMilking devicesEngineeringAnimal husbandry

The invention discloses an intelligent milking system and an intelligent milking method. The invention relates to the field of animal husbandry automated intelligent milking equipment. The intelligent milking system comprises a liquid and gas storage and delivery system, a milk cup set, a negative pressure system, a waste liquid separation system and a control system. The liquid and gas storage and delivery system comprises a cleaning unit, a disinfection unit, a compressed gas unit and a medicated bath unit. The waste liquid separation system comprises a waste liquid collection container and a milk liquid storage container. The negative pressure system comprises a first negative pressure device and a second negative pressure device. The control system comprises a controller. The invention also discloses an intelligent milking method. With the system, cleaning, disinfection, air-drying, pre-milking, milking, medicated bath and cup-releasing works during a milking process can be automatically completed. Milk livestock nipples are effectively subjected to cleaning, disinfection, air-drying and medicated bath in time, such that mastitis occurrence and cross-infection are reduced, and milking worker burden is reduced. Also, cup releasing is realized in time, such that the milk livestock are prected from hurts caused by over-suction.

Owner:希望银蕨智能科技有限公司

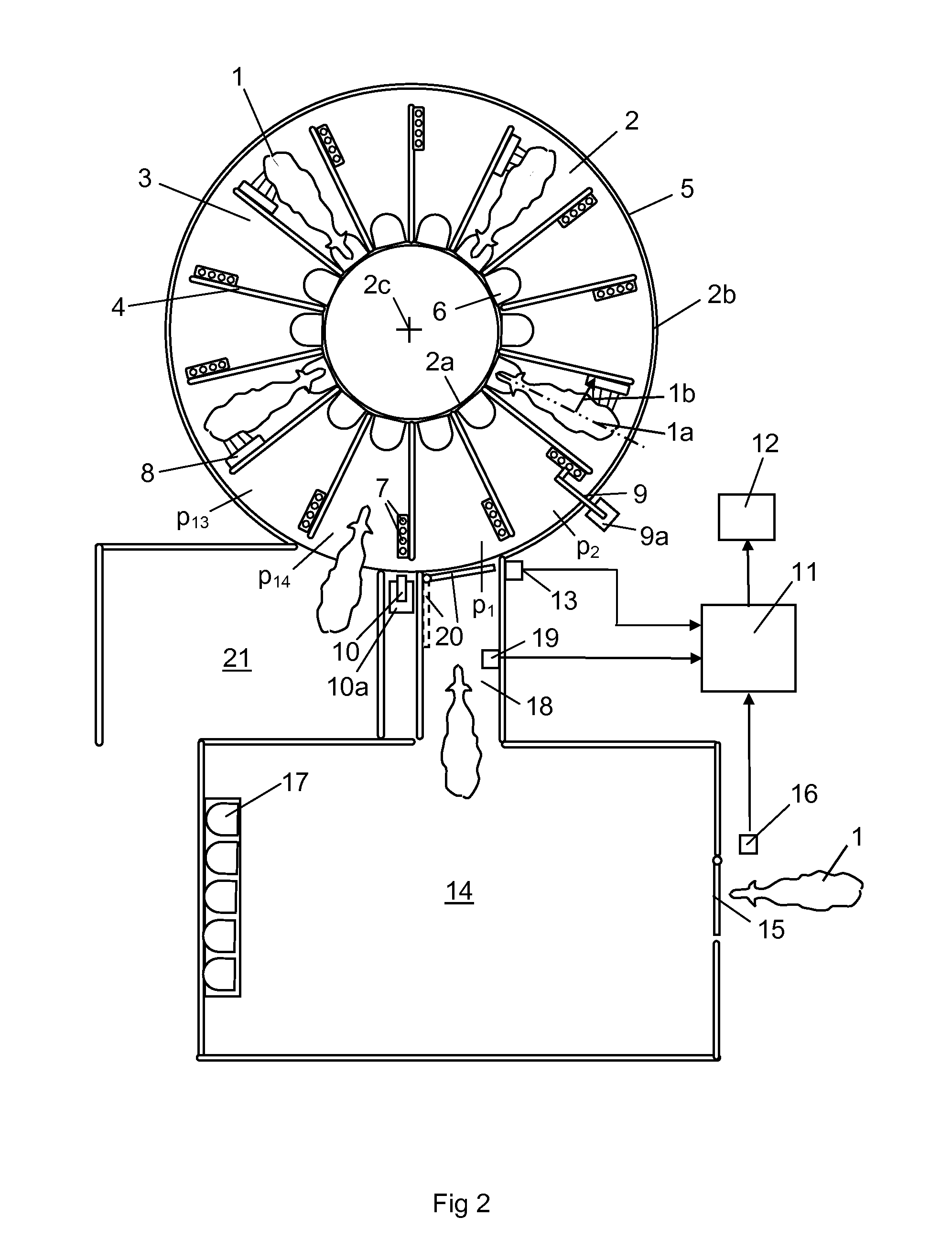

Process and rotary milking parlor for the identification of a milking stall and an animal, in particular a cow, in a rotary milking parlor

InactiveUS7104218B2Improve reliabilityIncreased throughput per unit of timeCathetersAnimal feeding devicesEngineeringMilking

For the determination of the occupancy of a milking stall by an animal, in particular a cow, in a rotary milking parlor with a plurality of milking stalls which are disposed on a rotatable milking platform, a process is proposed in which the identification of the animal only takes place after it has entered the milking stall in which it is supposed to be milked.

Owner:WESTFALIASURGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com