Arrangement and method for visual detection in a milking system

a technology of visual detection and milking system, which is applied in the direction of milking devices, manipulators, catheters, etc., can solve the problems of not working satisfactorily, sensor costs may not be negligible, and sensor work may not be reliably or even damaged, so as to achieve low cost or flexible implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

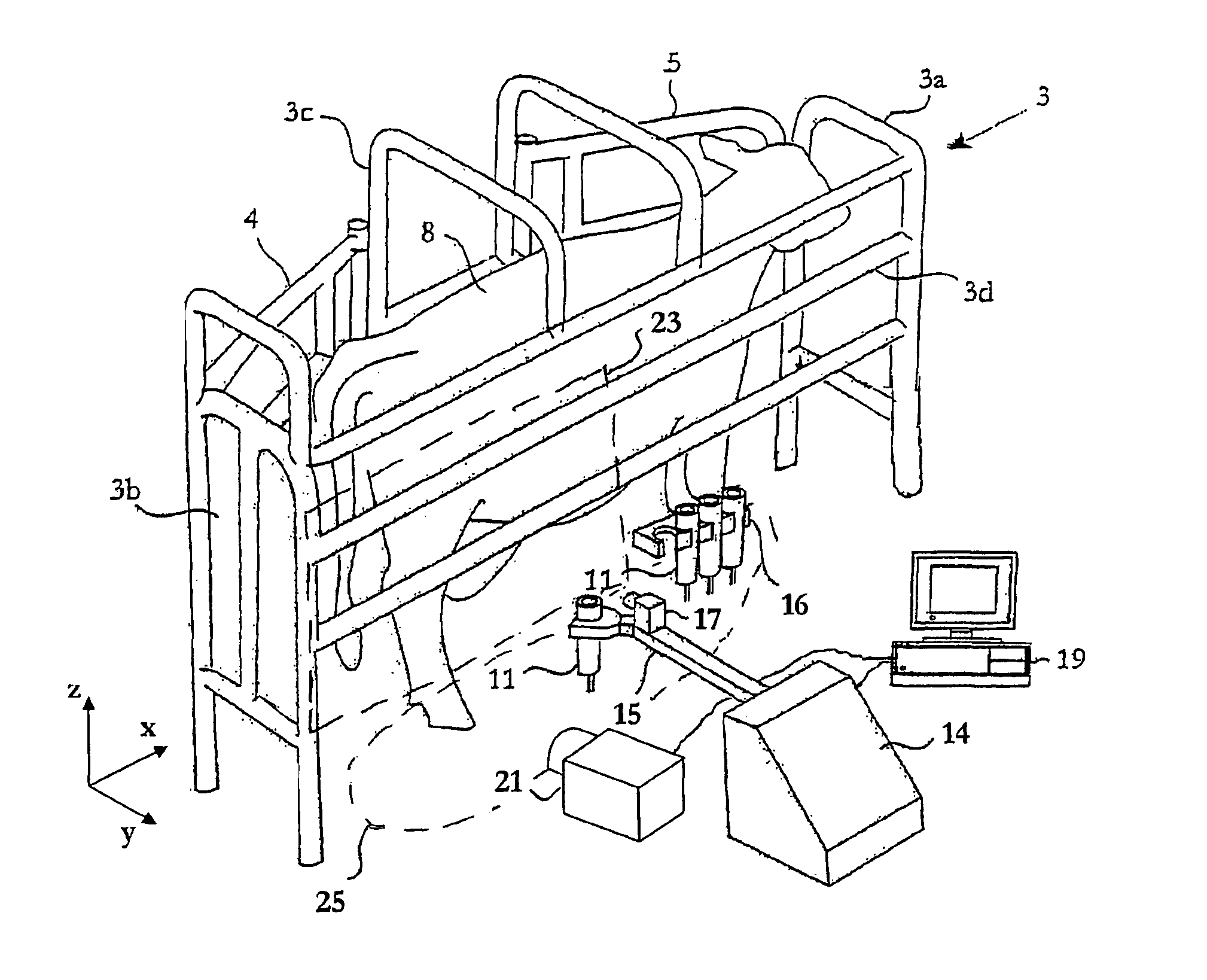

[0031]In FIG. 1 is shown a milking system or station 3 arranged for voluntary milking of freely walking animals such as cows, i.e. the cows enter the milking system 3 in order to be milked on a voluntary basis. The milking system 3 comprises a milking box having an inlet gate 4 and an outlet gate 5, which are both capable of being opened automatically. The front end of the milking box of the milking system 3 is denoted by 3a, the back end is denoted by 3b, the left side is denoted by 3c and the right side is denoted by 3d.

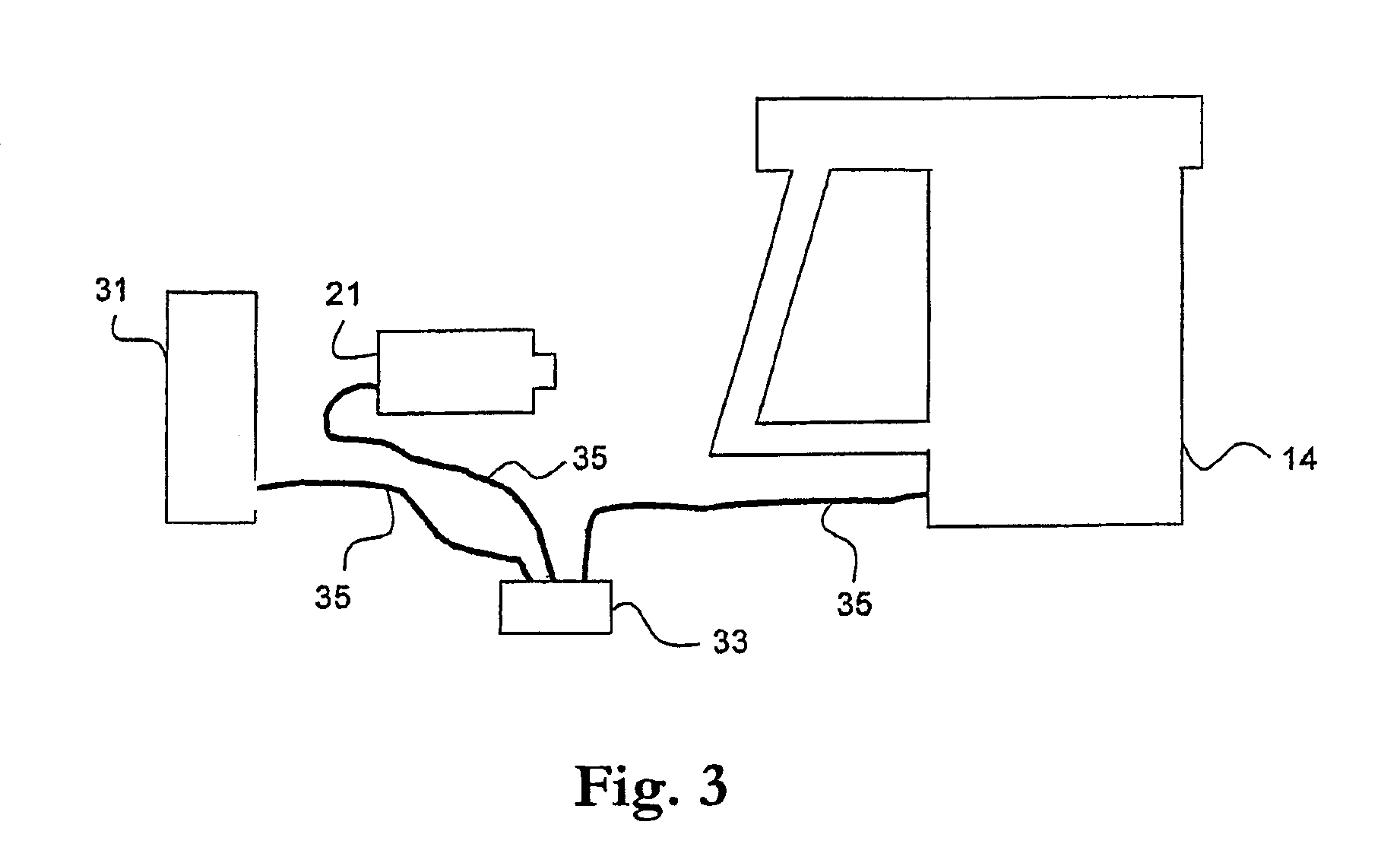

[0032]The milking system 3 comprises further an automatic milking machine (not explicitly illustrated) including teat cups 11 connected to an end unit by means of milk lines (only the portions attached to the teat cups 11 are shown in FIG. 1). The milking system further comprises a milking robot or automatic handling device 14 including a processing and control device 19 and a robot arm 15 provided with a gripper. The milking robot 14 is arranged to automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com