Concentrated calf fodder and use method thereof

A concentrated feed and calf technology, applied in animal feed, animal feed, applications, etc., can solve the problems of not being able to achieve perennial milking, reduce the conception rate of cows, unfavorable mechanized milking, etc., and achieve the benefit of mechanical milking and Large-scale operation, beneficial to growth and development, and the effect of increasing the speed of weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

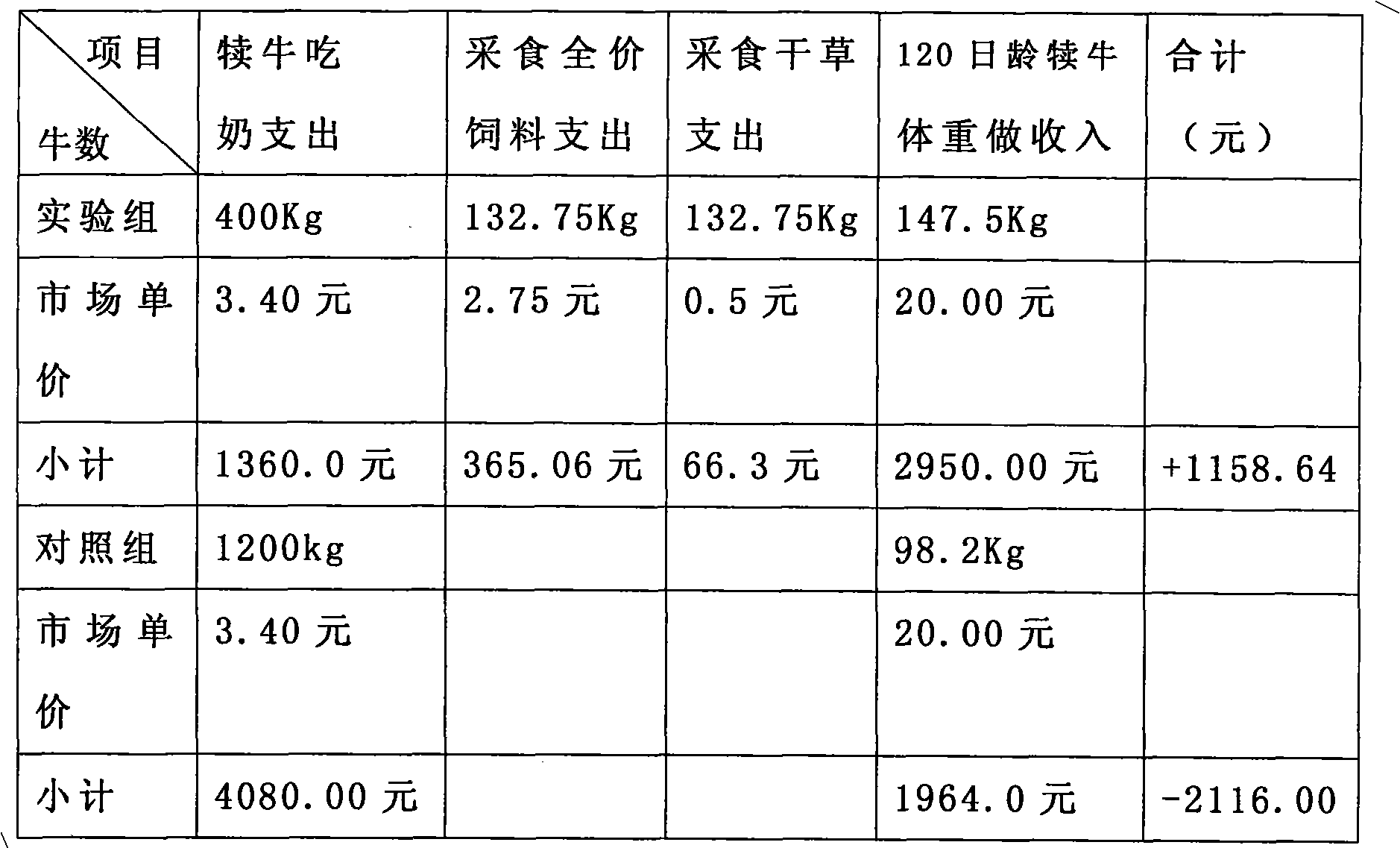

Examples

Embodiment Construction

[0014] This calf concentrated feed is composed of protein feed and compound premix, and the following is just a common preparation method.

[0015] The protein feed is composed of the following raw materials by weight: bean cake (protein ≥ 40%) 30000g, corn gluten powder 4000g, cottonseed meal 18000g, bran 7000g, DDGS (dried distiller's grains) 30000g, Sekeling 400g, yeast 400g, compound Enzyme 200g.

[0016] The composite premix is composed of the following raw materials by weight: 1000g of table salt, 2400g of fluorspar powder, 500g of magnesium sulfate, 100g of sodium diacetate, 500g of calcium hydrogen phosphate, 400g of soda, 1000g of sodium humate, 2800g of stone powder, monens Element 20g, 96% copper sulfate pentahydrate 20g, 98% ferrous sulfate heptahydrate 20g, 98% manganese sulfate monohydrate 20g, 98% zinc sulfate heptahydrate 20g, 90% cobalt chloride 15g, 95% Sodium selenite pentahydrate 10g, 98% potassium iodide 3g, 90% bacitracin zinc 5g, 92% L-lysine hydrochl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com