Patents

Literature

1063 results about "Pressure system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pressure system is a relative peak or lull in the sea level pressure distribution. The surface pressure at sea level varies minimally, with the lowest value measured 87 kilopascals (26 inHg) and the highest recorded 108.57 kilopascals (32.06 inHg). High- and low-pressure systems evolve due to interactions of temperature differentials in the atmosphere, temperature differences between the atmosphere and water within oceans and lakes, the influence of upper-level disturbances, as well as the amount of solar heating or radiationized cooling an area receives. Pressure systems cause weather to be experienced locally. Low-pressure systems are associated with clouds and precipitation that minimize temperature changes throughout the day, whereas high-pressure systems normally associate with dry weather and mostly clear skies with larger diurnal temperature changes due to greater radiation at night and greater sunshine during the day. Pressure systems are analyzed by those in the field of meteorology within surface weather maps.

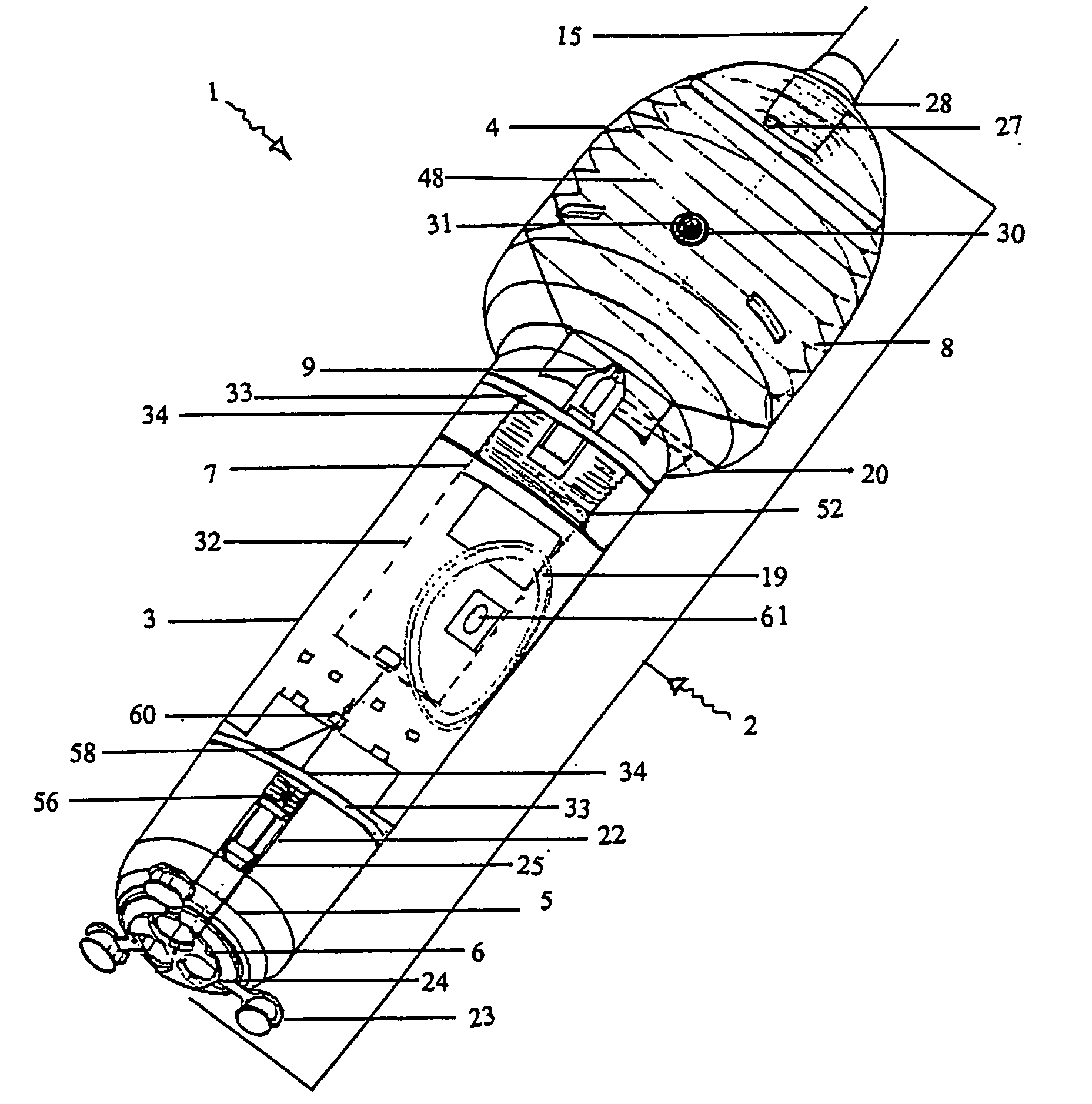

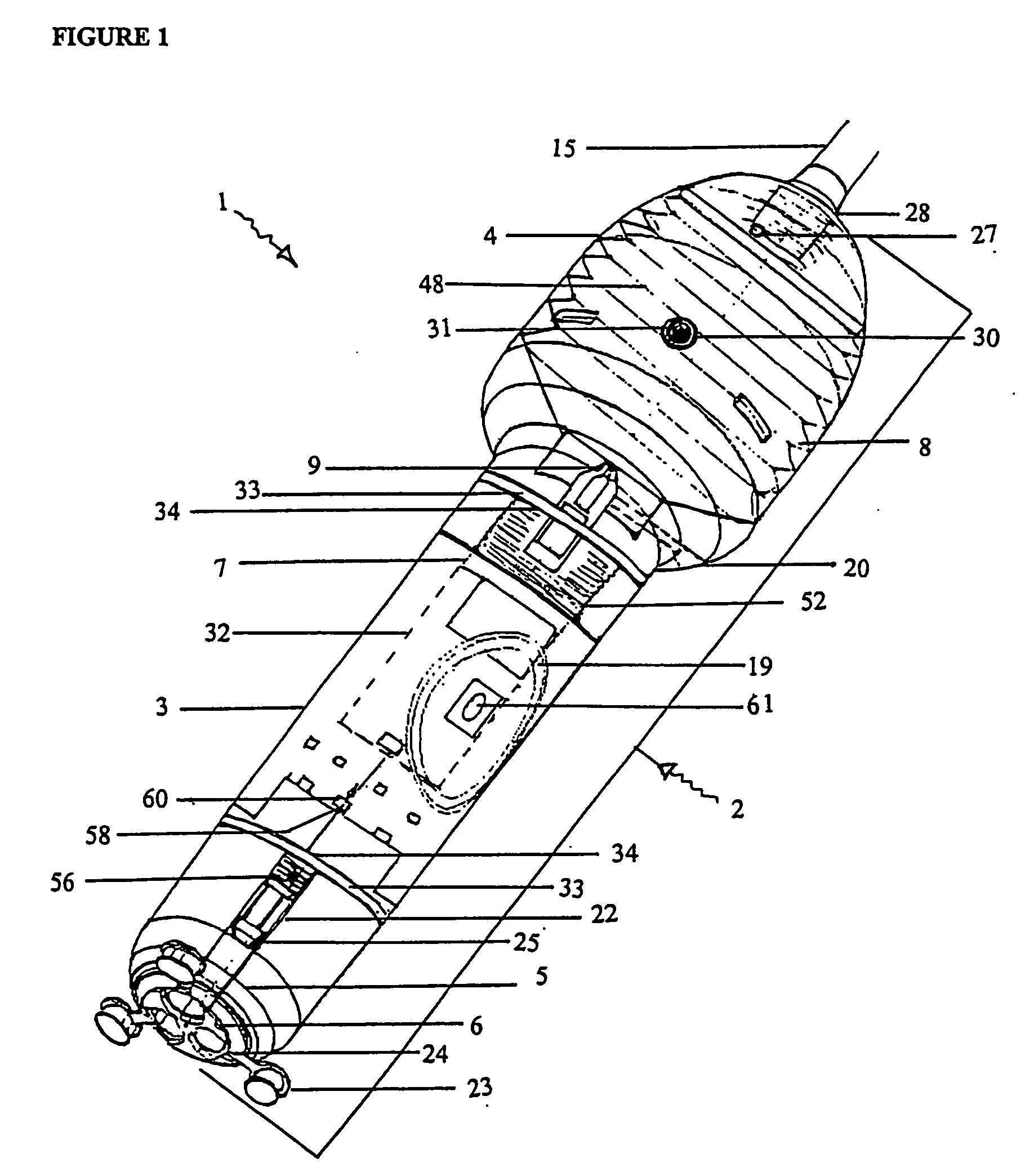

Substance delivery device

InactiveUS20050245902A1Excess rigidityPharmaceutical delivery mechanismMedical devicesPressure systemBiomedical engineering

A substance delivery device capable of insertion into a body cavity of an animal, with the delivery device including a body capable of housing a delivery apparatus capable of actively being controlled to autonomously deliver at least one substance into a body cavity of an animal, with the delivery apparatus including dedicated pressure systems to deliver the at least one substance from independent reservoirs via at least one associated outlet, with the at least one substance ranging in form from substantially fluid to substantially solid, with the device also including a programmable control device capable of initiating and regulating delivery of the at least one substance in accordance with a preferred delivery regime, and with the body further including a tail portion adapted to receive retention apparatus external to the animal and capable of effecting retention of the substance delivery device within the body cavity of an animal.

Owner:ADVANCED ANIMAL TECH

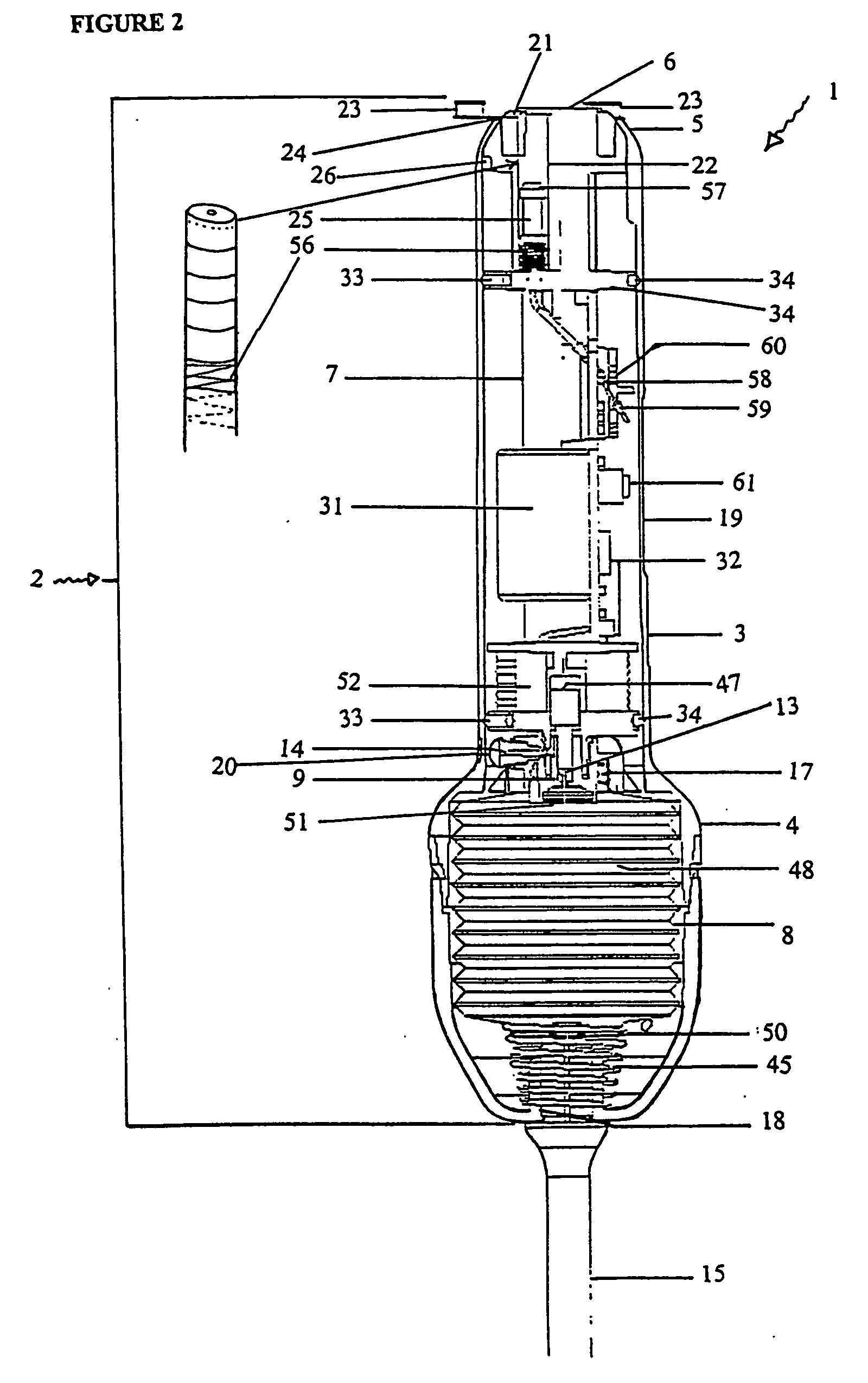

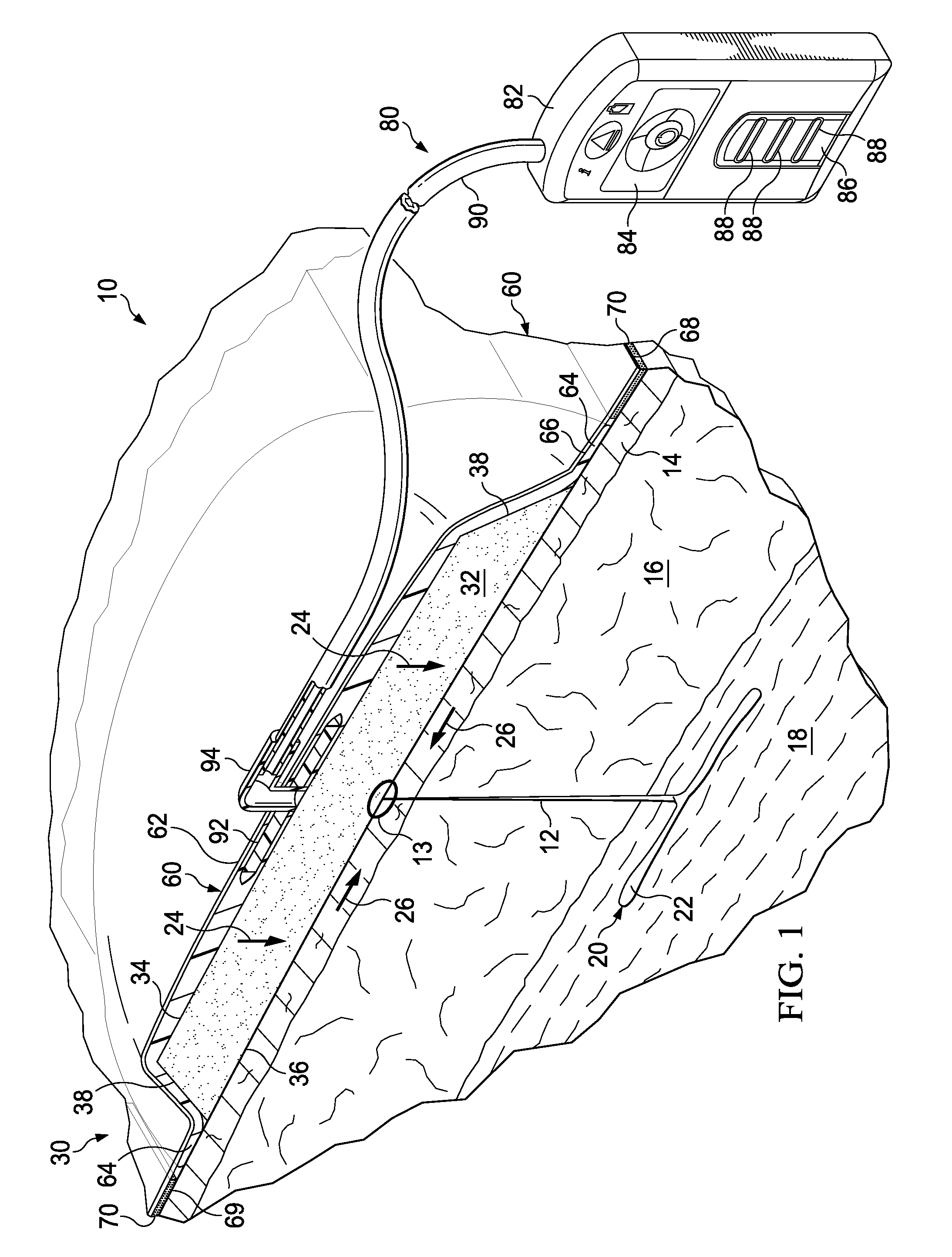

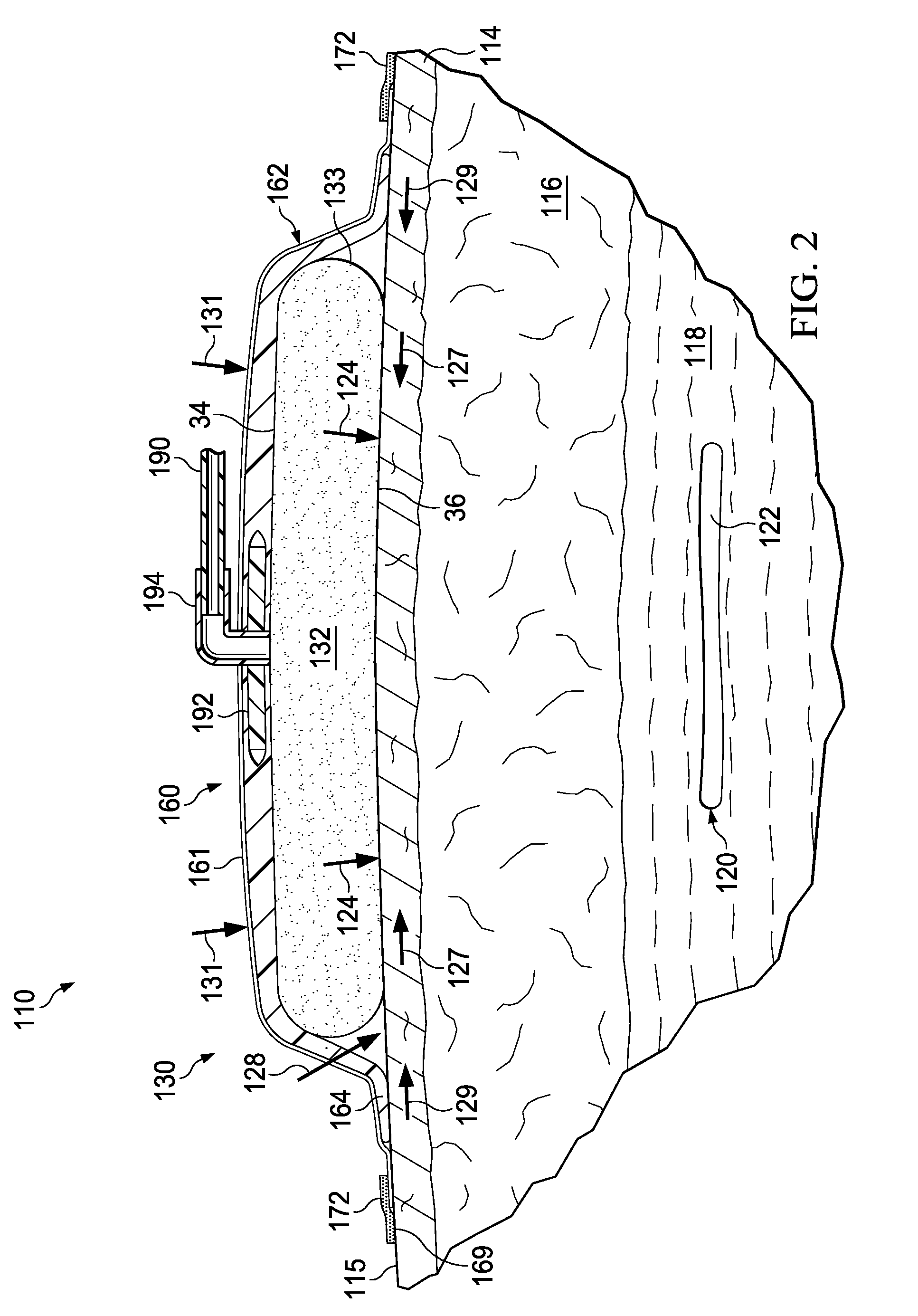

Reduced-pressure surgical wound treatment systems and methods

ActiveUS20090299257A1Reduce pressureNon-adhesive dressingsChiropractic devicesPressure systemSubcutaneous tissue

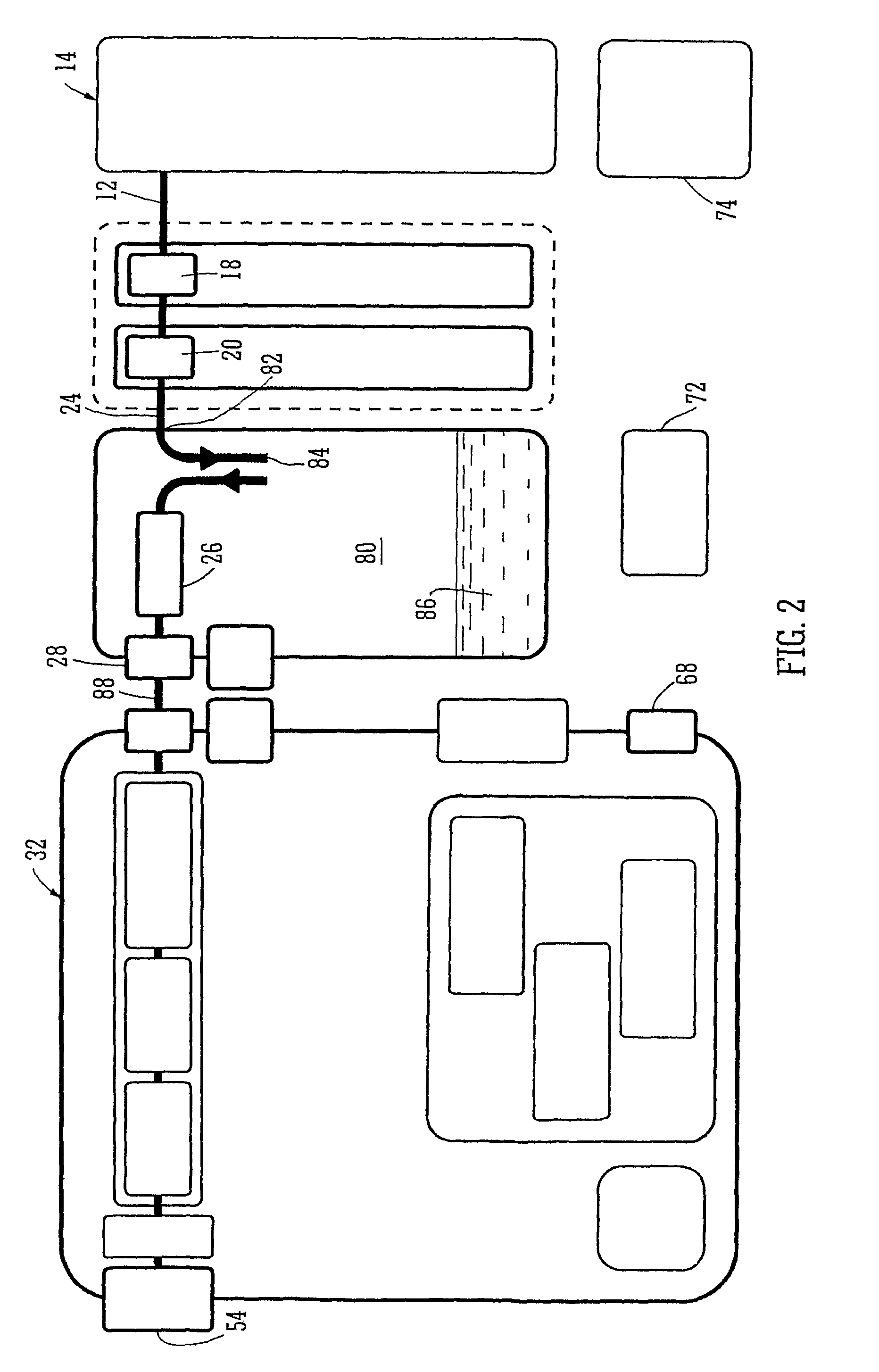

A reduced-pressure system for treating tissue, such as damaged subcutaneous tissue, includes a shaped dressing bolster for placing on the patient's epidermis and substantially sized to overlay the damaged subcutaneous tissue. The system further includes a sealing subsystem for providing a fluid seal over the shaped dressing bolster and a portion of the patient's epidermis, and a reduced-pressure subsystem for delivering a reduced pressure to the sealing subsystem. The reduced-pressure system may develop a force, which may include a vertical force that is realized at tissue site deeper than the epidermis or a closing force directed towards the incision. The shaped dressing bolster is shaped to evenly distribute the force. Other methods and systems are included.

Owner:3M INNOVATIVE PROPERTIES CO

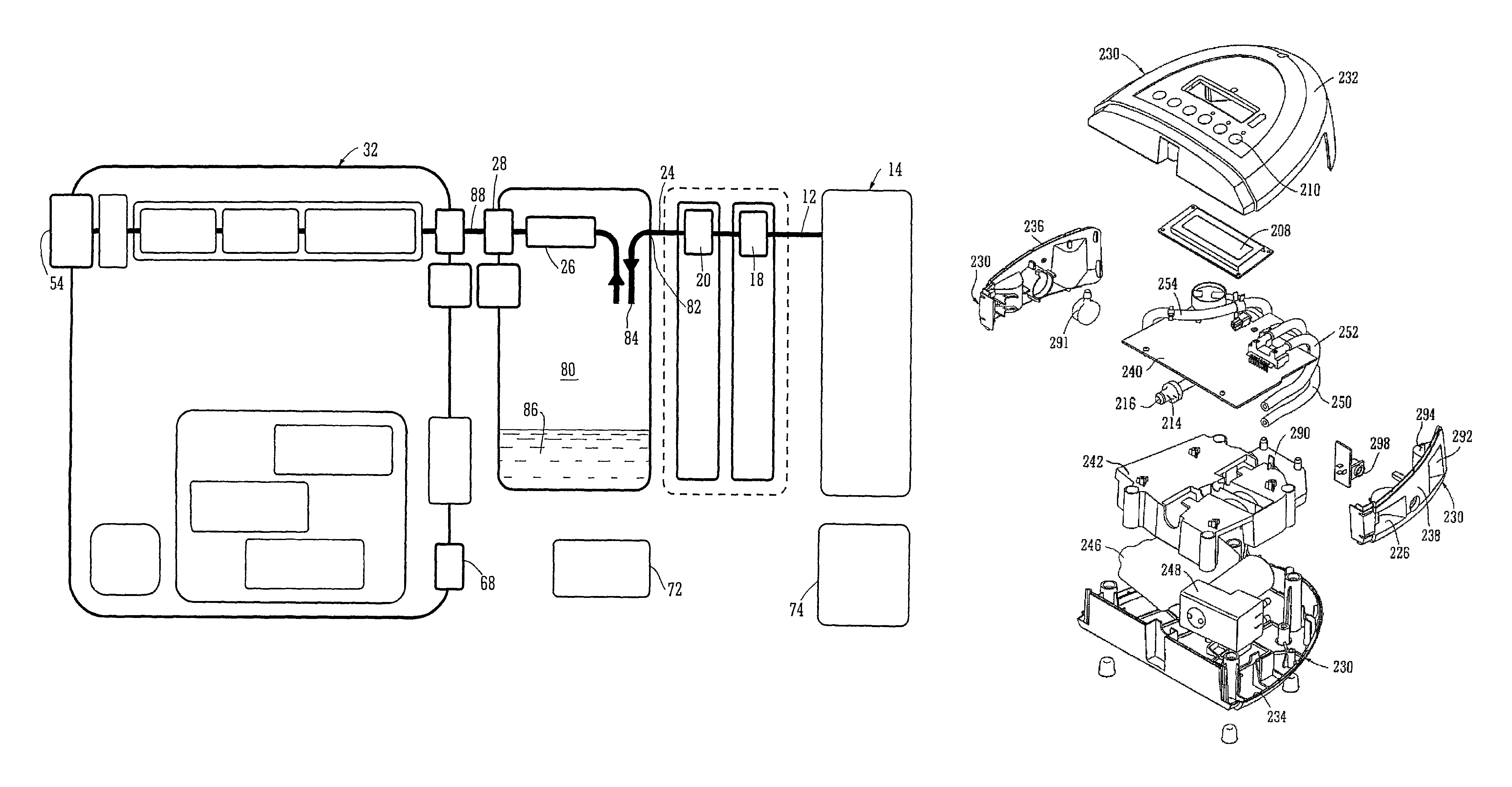

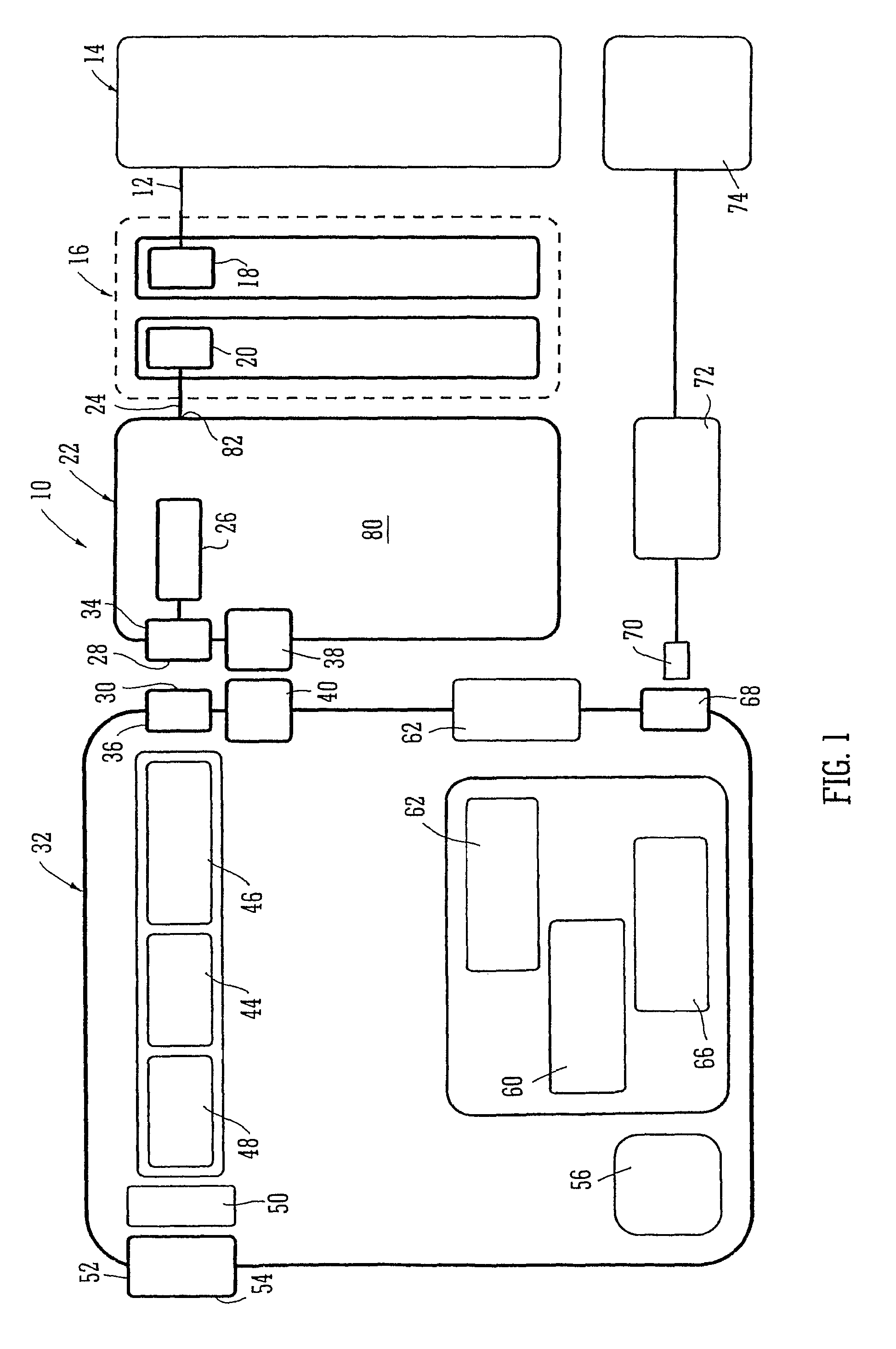

Topical negative pressure system with status indication

ActiveUS8294586B2Reduce decreaseReadily availableMedical devicesIntravenous devicesPressure systemEngineering

A method and apparatus are disclosed for indicating a status of at least one operating parameter associated with a topical negative pressure (TNP) system. The method includes the steps of generating illumination from at least one LED, the illumination having at least one characteristic corresponding to a status of at least one operating parameter associated with the TNP system and being visible to a user.

Owner:SMITH & NEPHEW INC

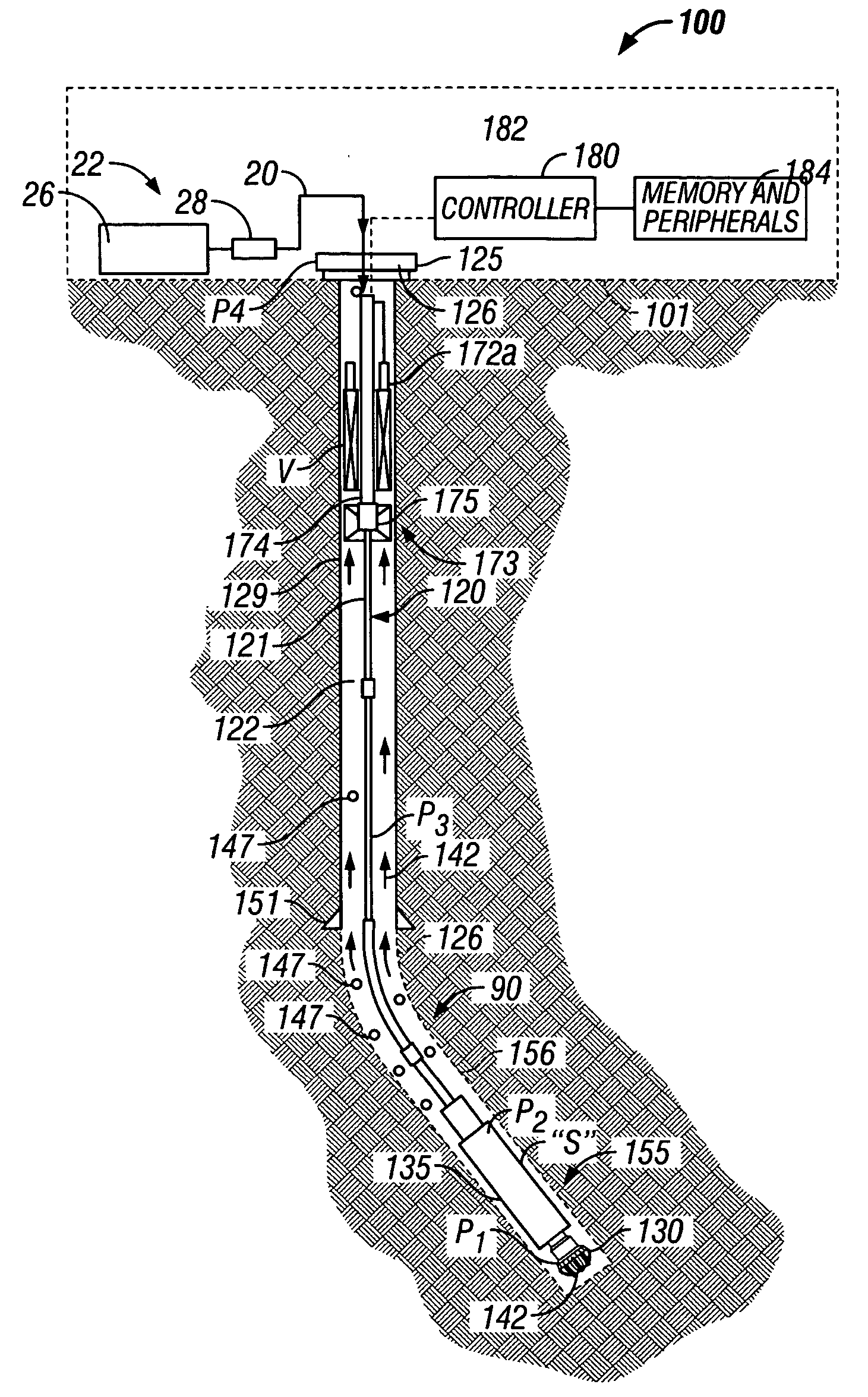

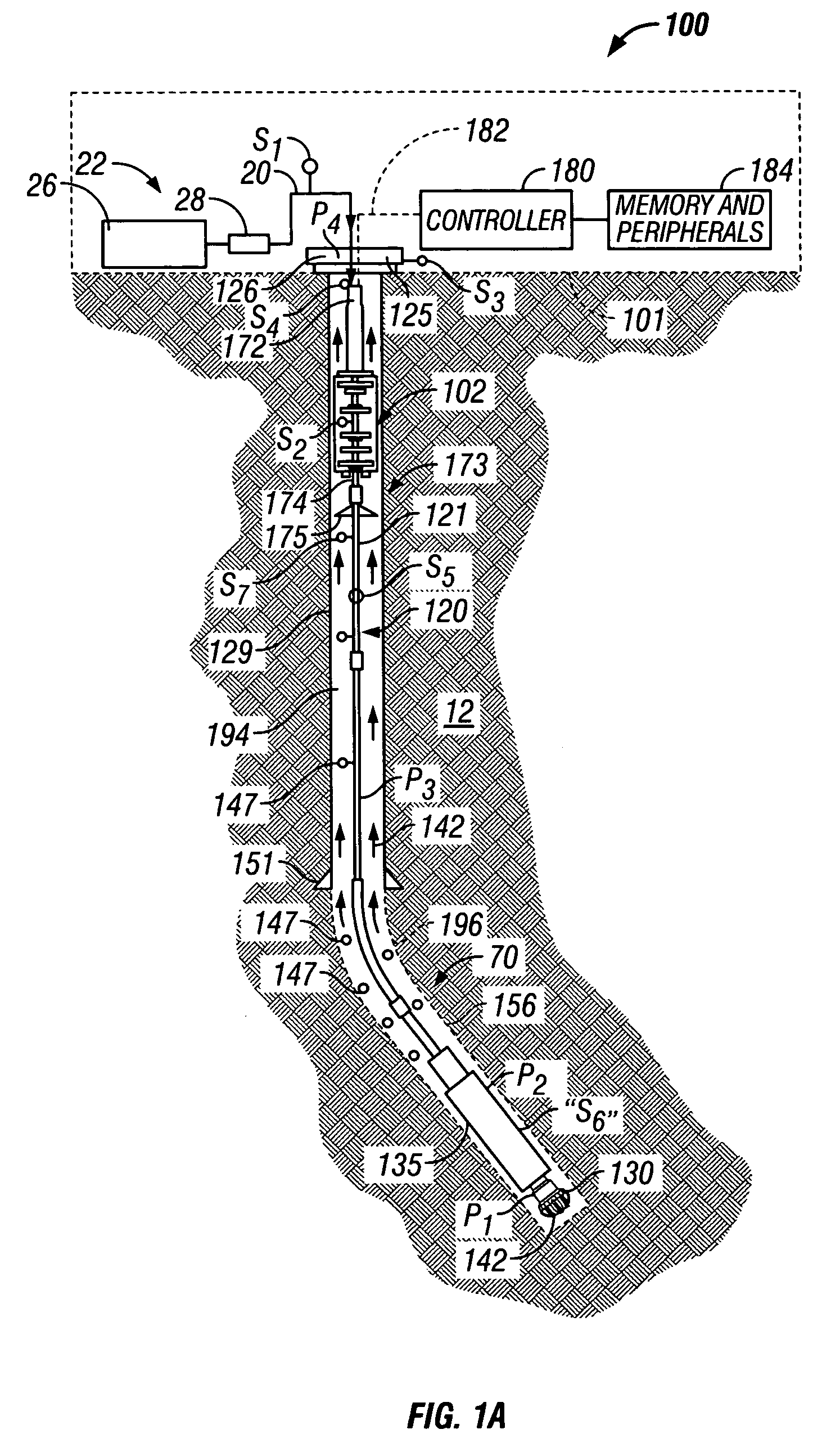

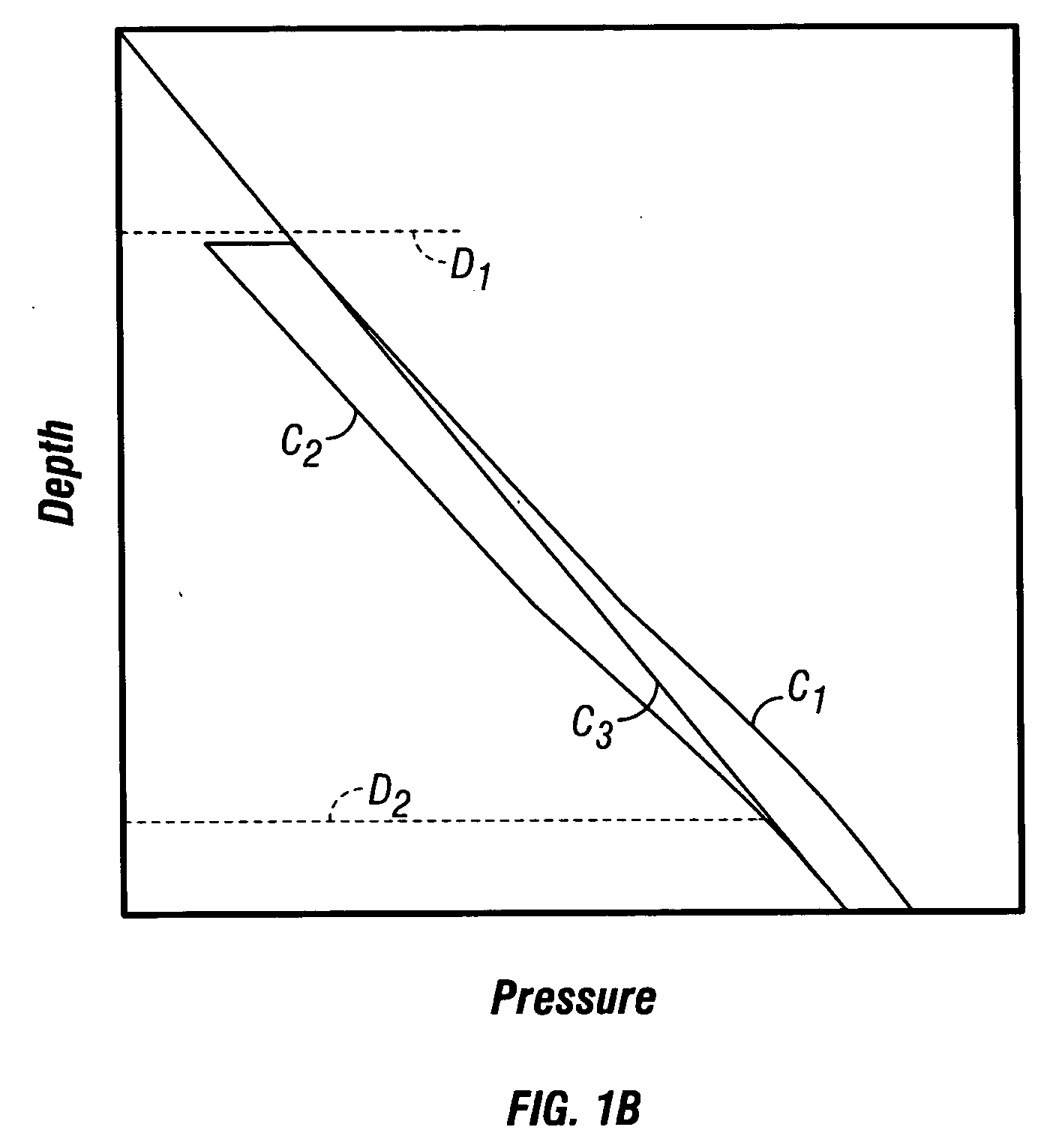

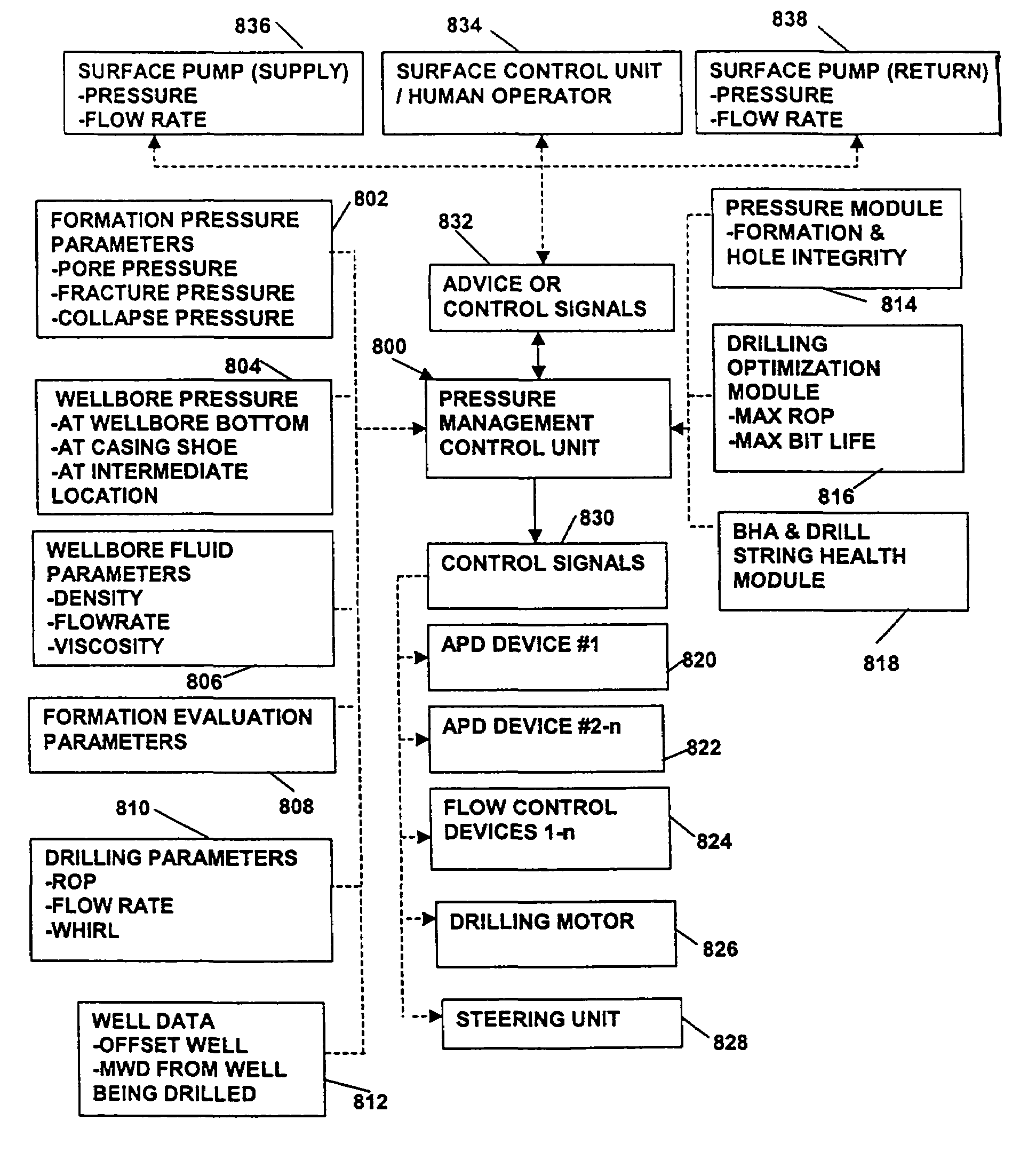

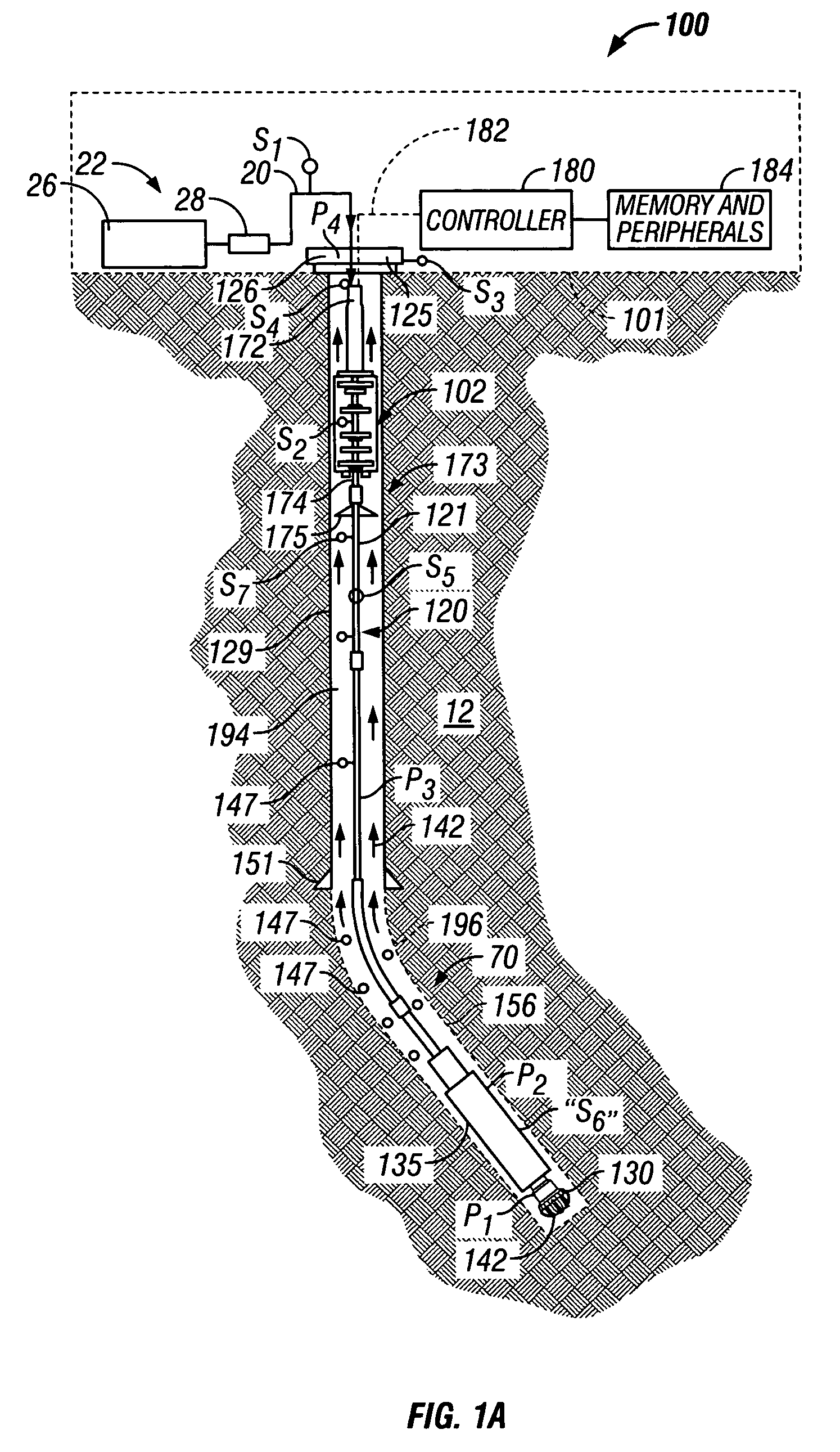

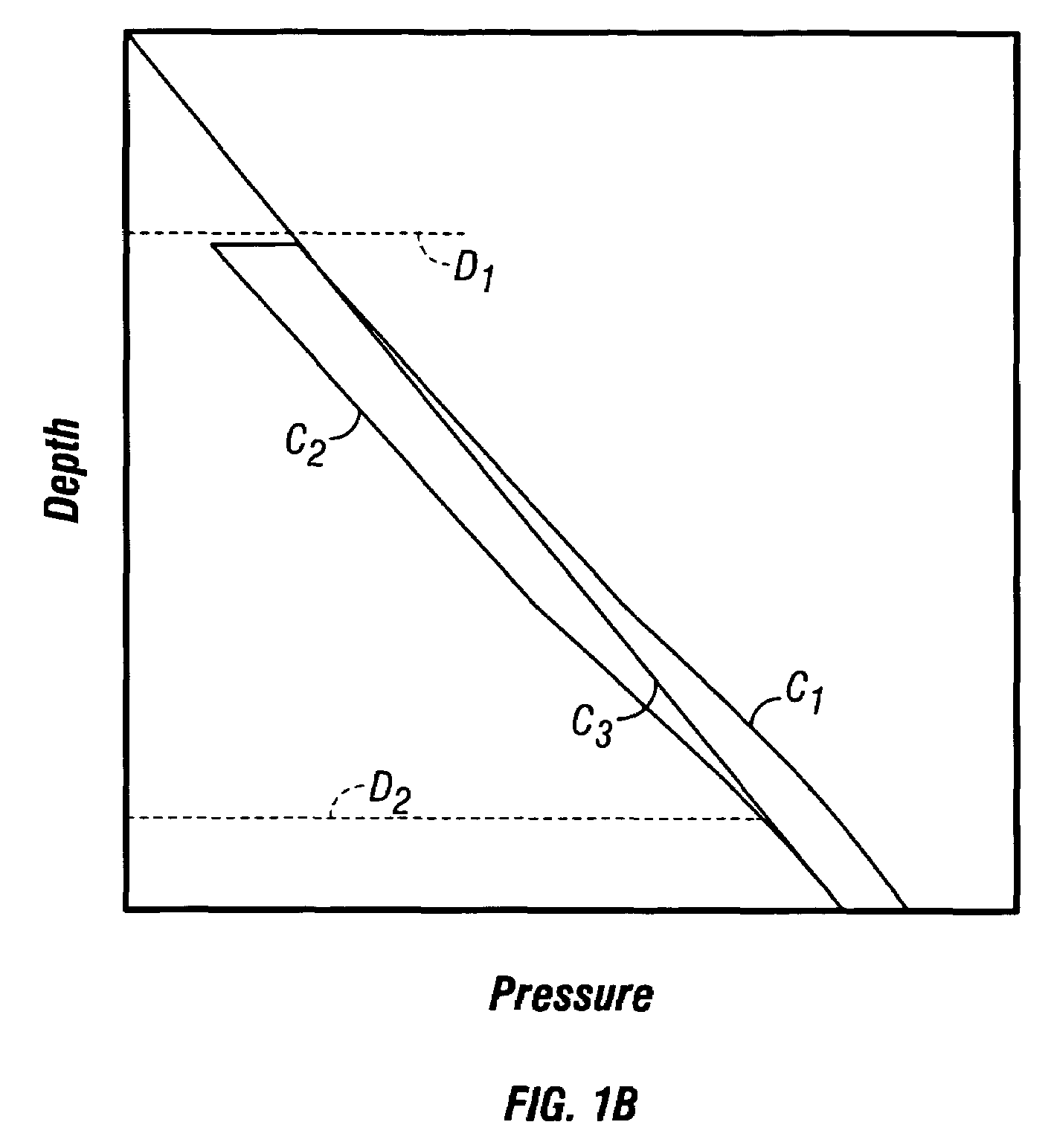

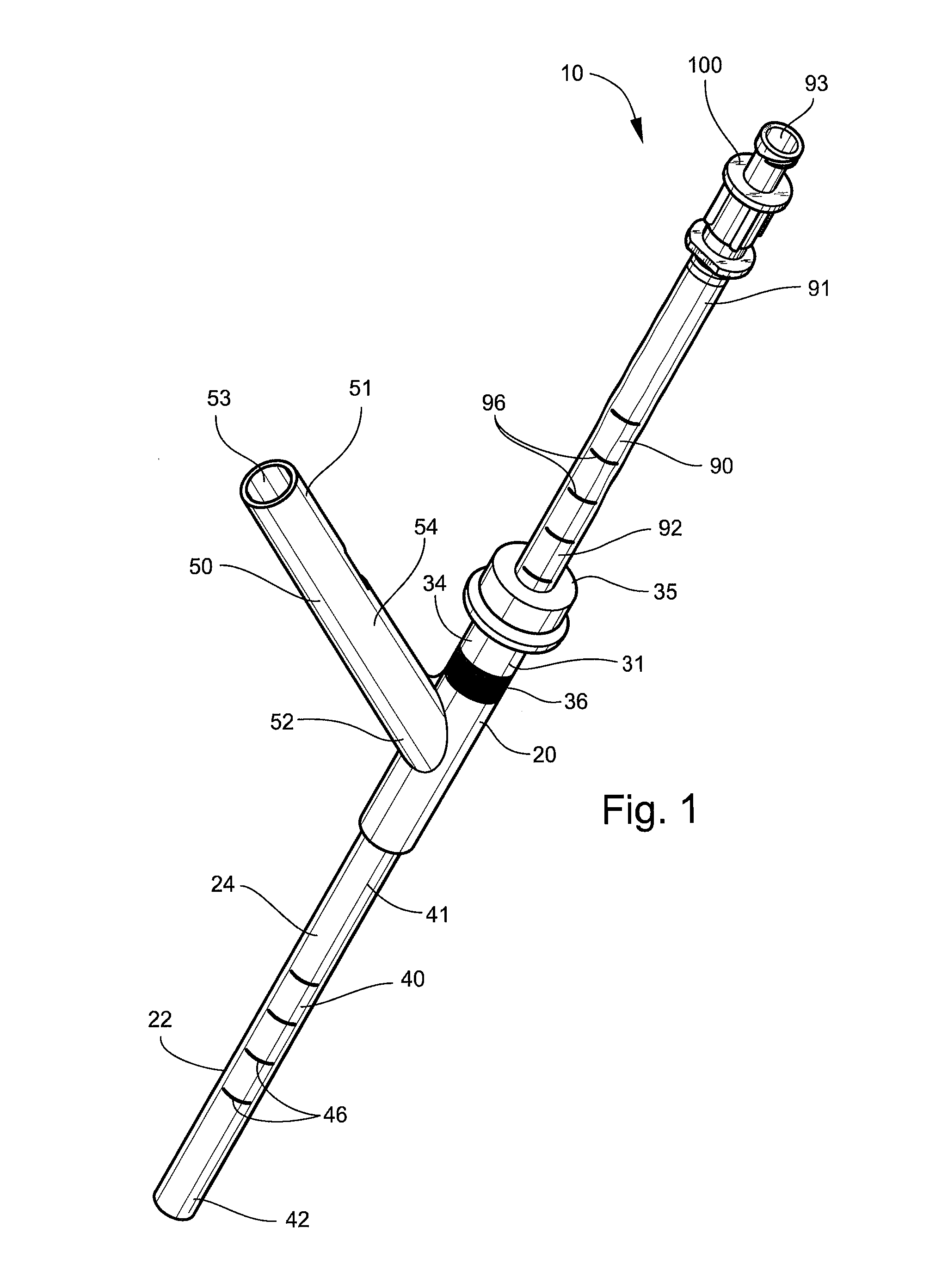

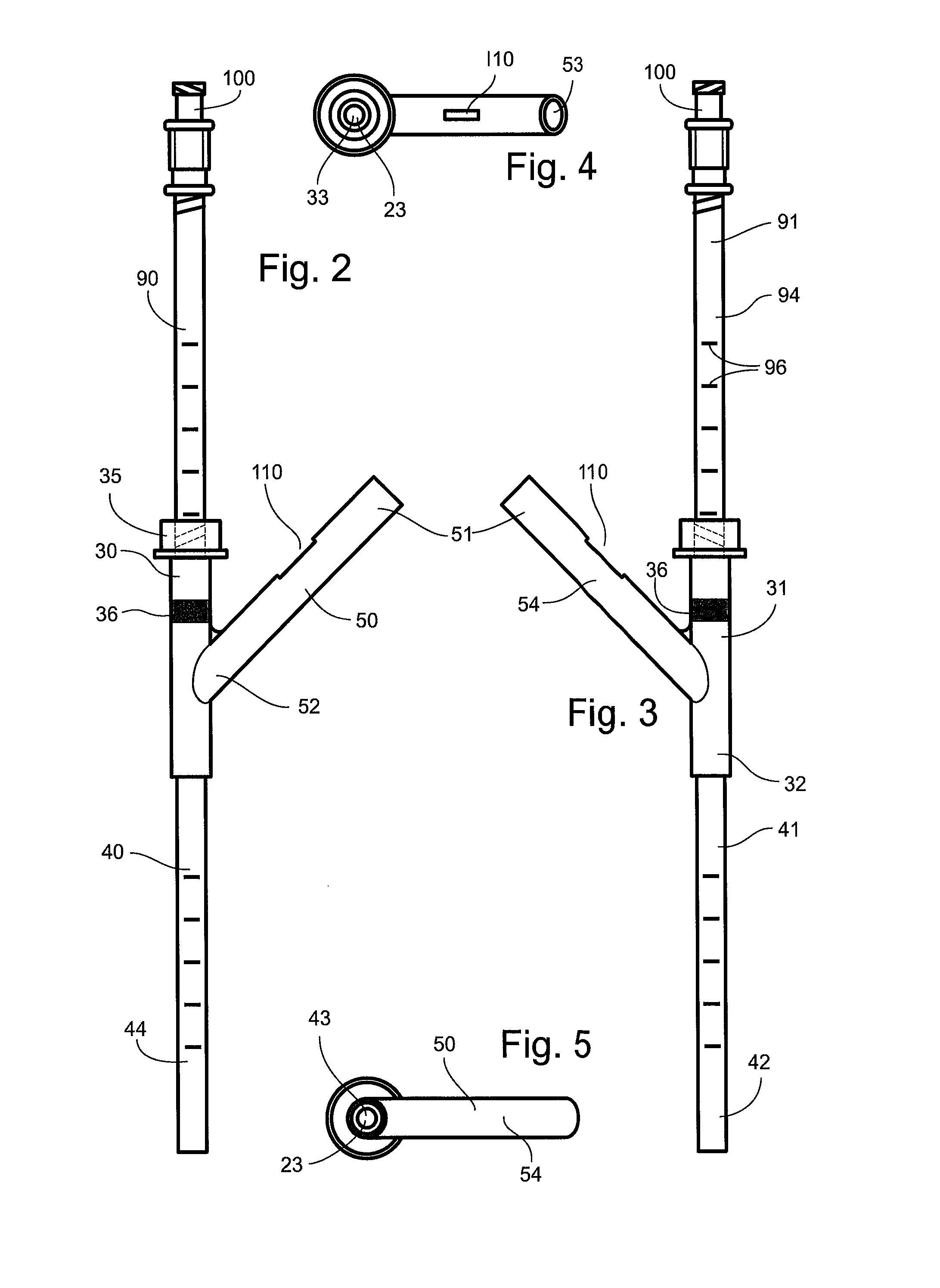

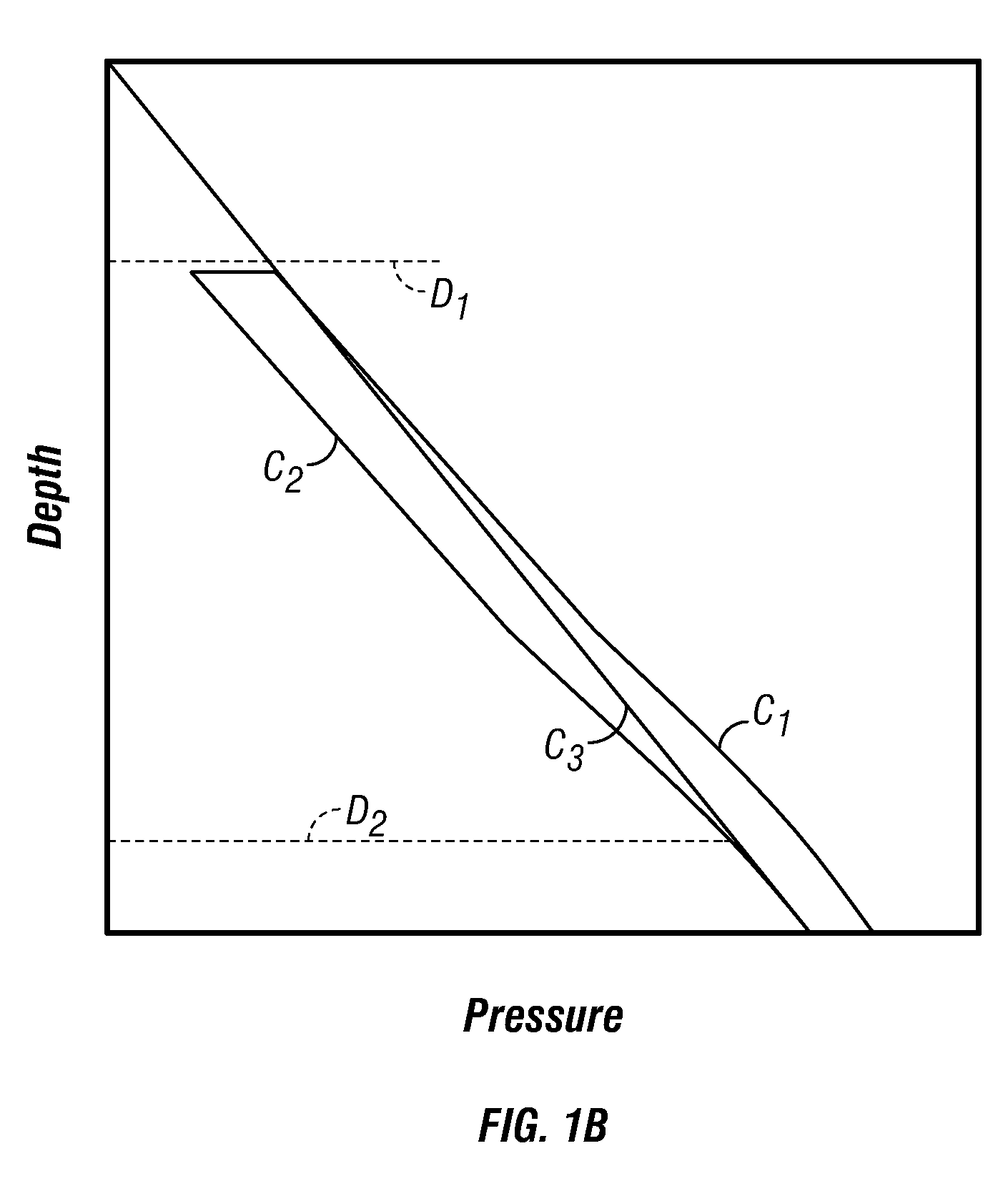

Control systems and methods for active controlled bottomhole pressure systems

InactiveUS20050098349A1Eliminate needCertain applicationDrilling rodsConstructionsPressure systemControl system

Methods and control systems are provided for a wellbore drilling system having an active differential pressure device (APD device) in fluid communication with a returning fluid. The APD Device creates a differential pressure across the device, which reduces the pressure below or downhole of the device. In embodiments, a control unit controls the APD Device to provide a selected pressure differential at a wellbore bottom, adjacent a casing shoe, in an intermediate wellbore location, or in a casing. In one arrangement, the control system is pre-set at the surface such that the APD Device provides a substantially constant pressure differential. In other arrangements, the control system measures one or more parameters (e.g., wellbore pressure, formation parameters, BHA parameters, etc.) and adjusts an operating parameter of the APD Device to provide a desired pressure differential. Devices such as an adjustable bypass can be used to control the APD Device.

Owner:BAKER HUGHES INC

Control systems and methods for active controlled bottomhole pressure systems

InactiveUS7174975B2Increase pressureEliminate needDrilling rodsConstructionsPressure systemDifferential pressure

Methods and control systems are provided for a wellbore drilling system having an active differential pressure device (APD device) in fluid communication with a returning fluid. The APD Device creates a differential pressure across the device, which reduces the pressure below or downhole of the device. In embodiments, a control unit controls the APD Device to provide a selected pressure differential at a wellbore bottom, adjacent a casing shoe, in an intermediate wellbore location, or in a casing. In one arrangement, the control system is pre-set at the surface such that the APD Device provides a substantially constant pressure differential. In other arrangements, the control system measures one or more parameters (e.g., wellbore pressure, formation parameters, BHA parameters, etc.) and adjusts an operating parameter of the APD Device to provide a desired pressure differential. Devices such as an adjustable bypass can be used to control the APD Device.

Owner:BAKER HUGHES HLDG LLC

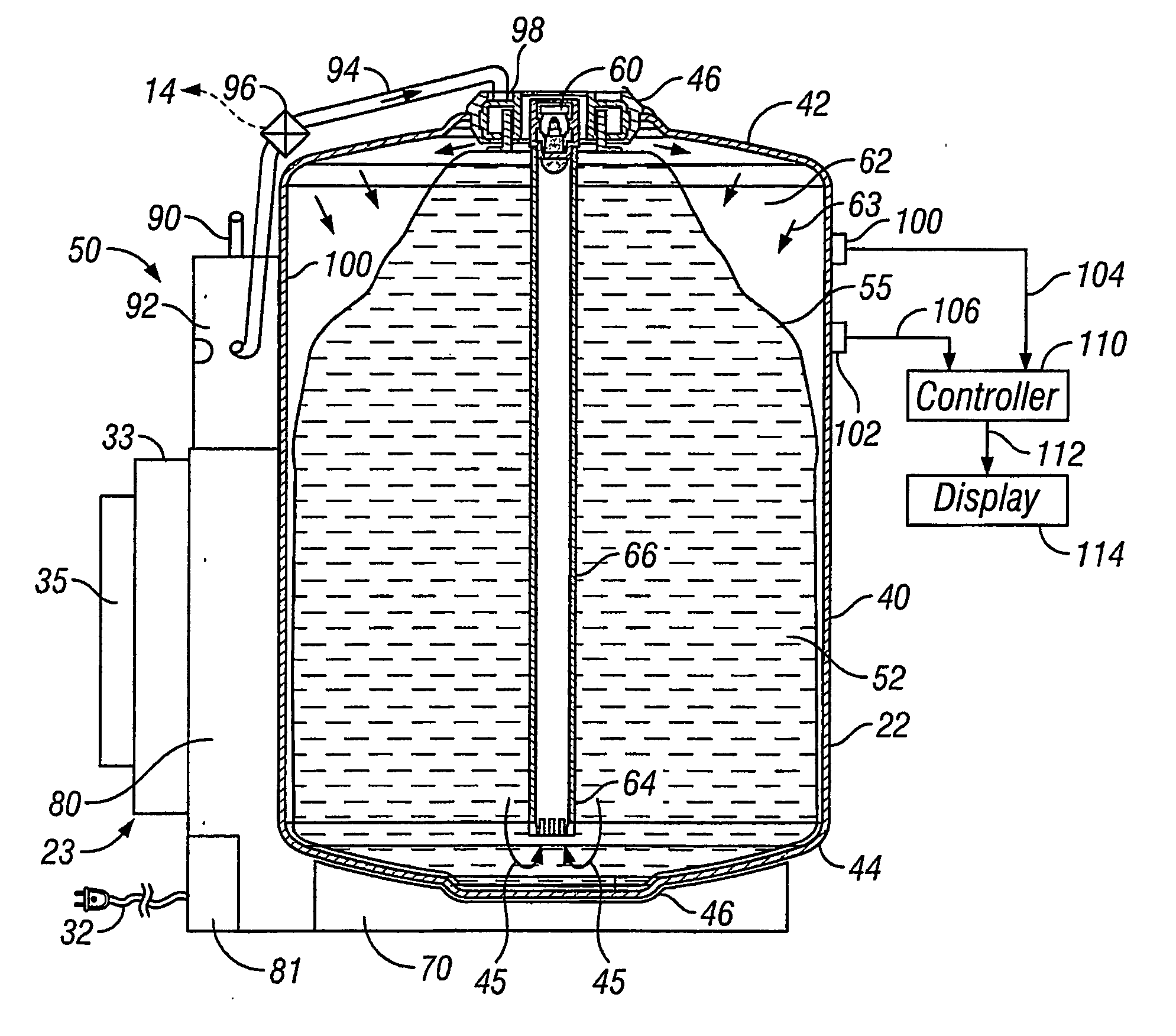

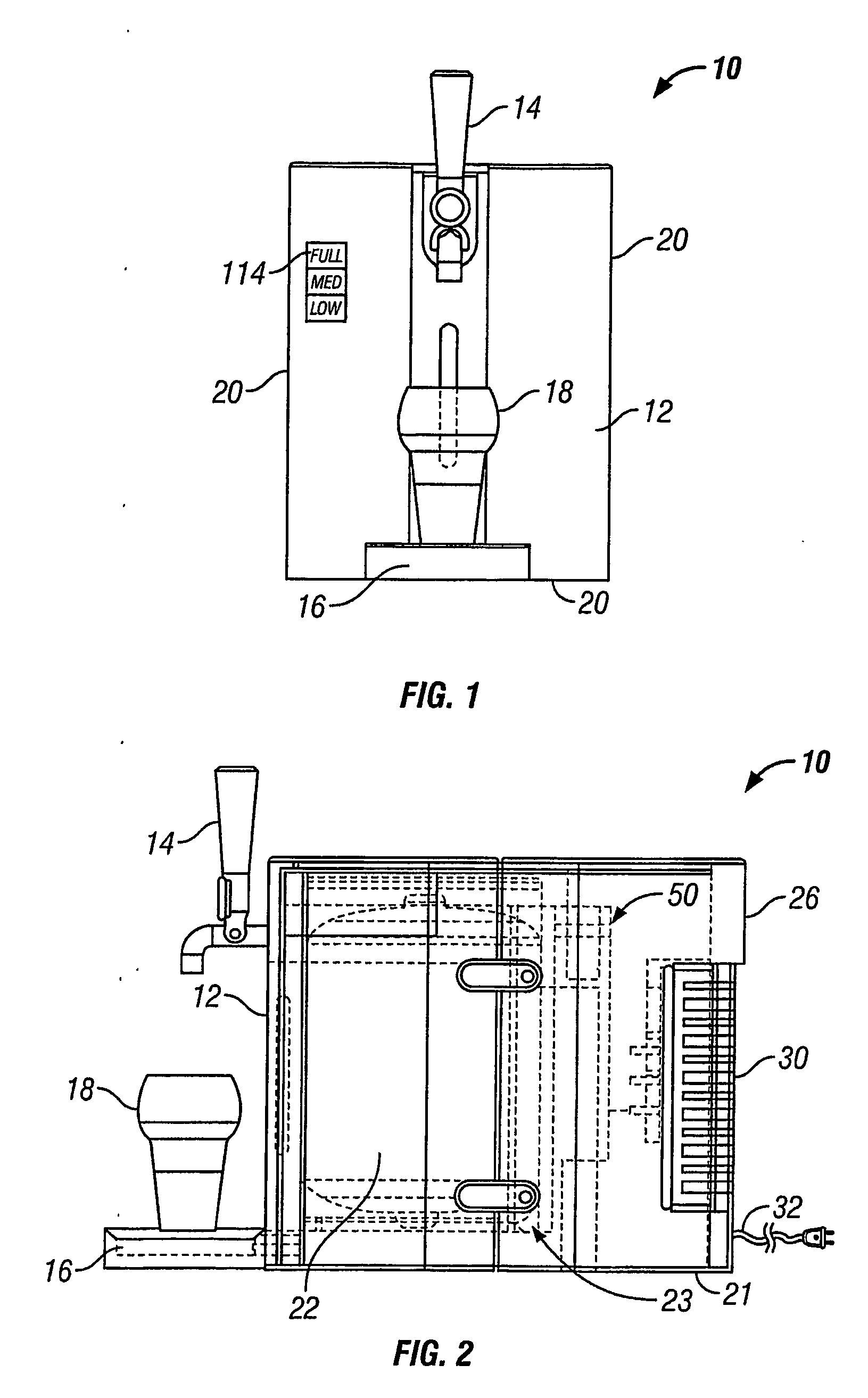

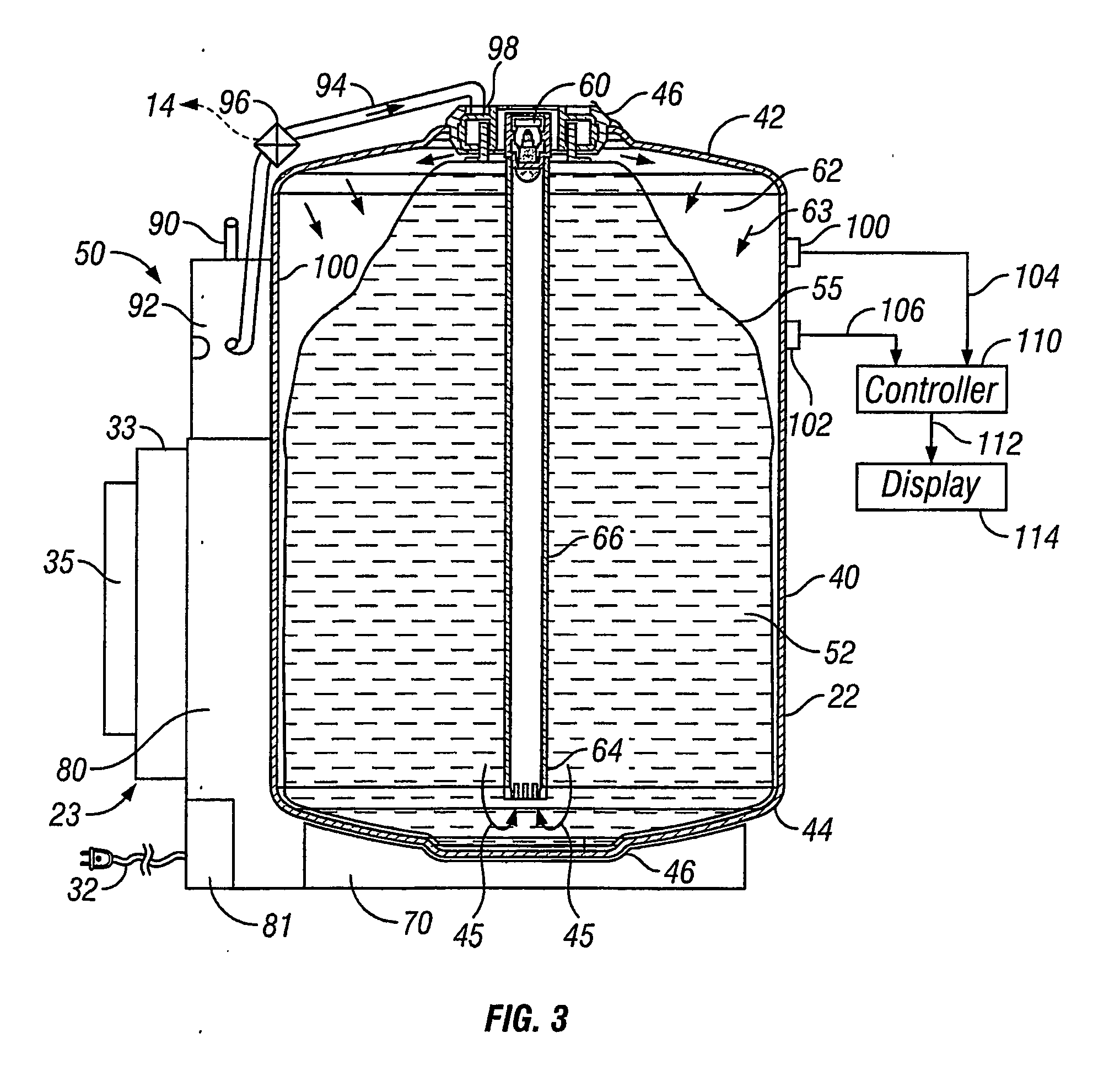

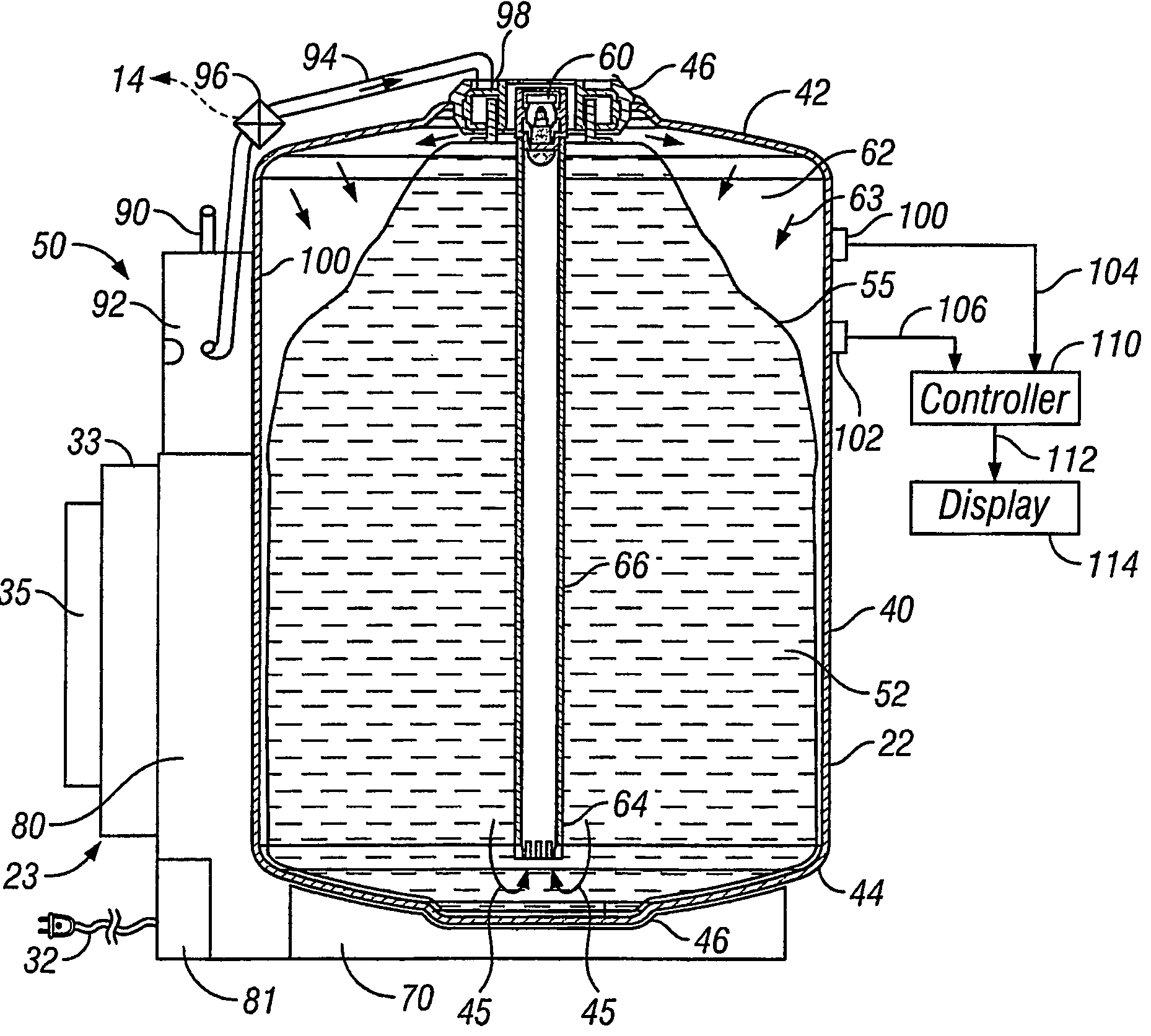

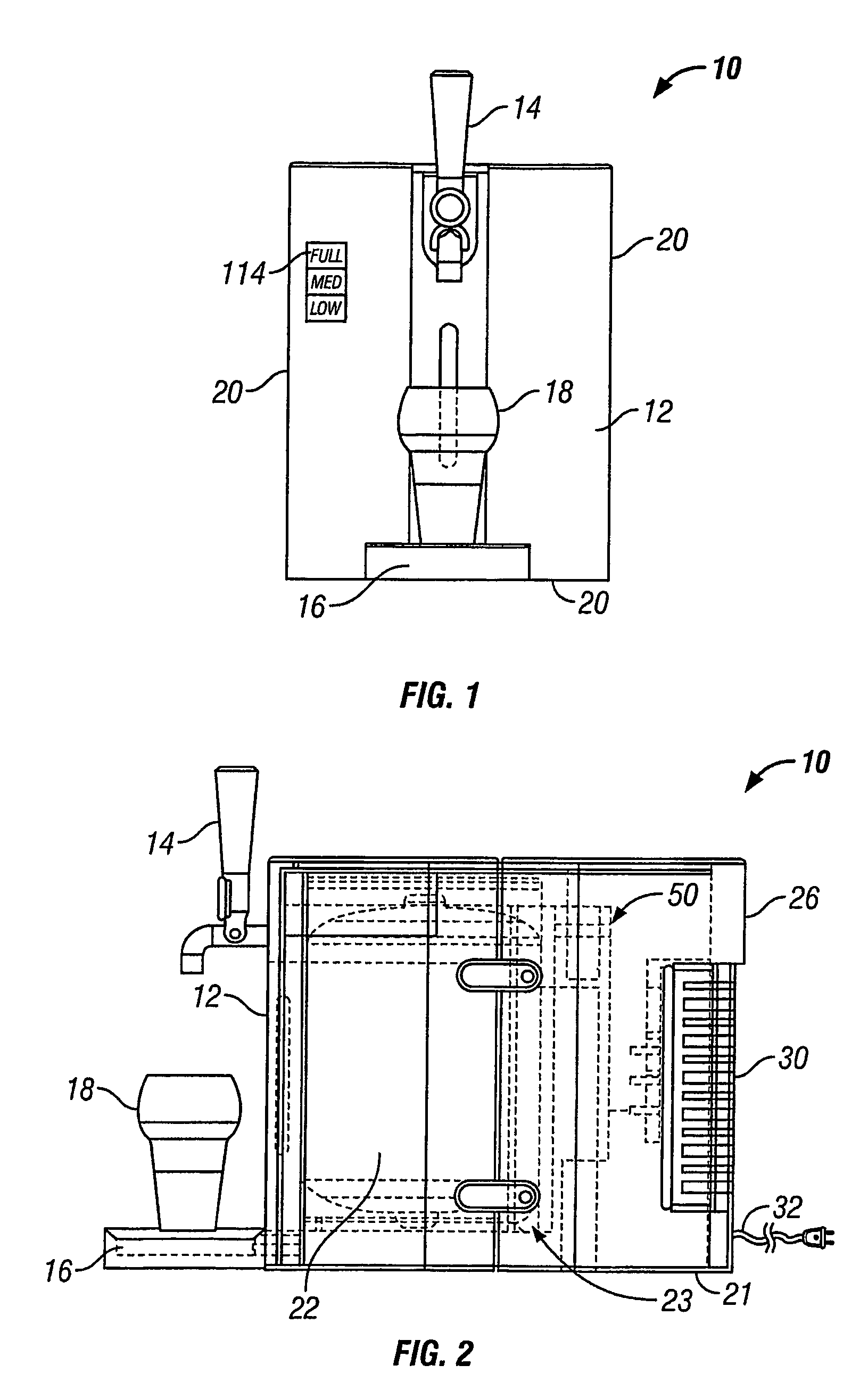

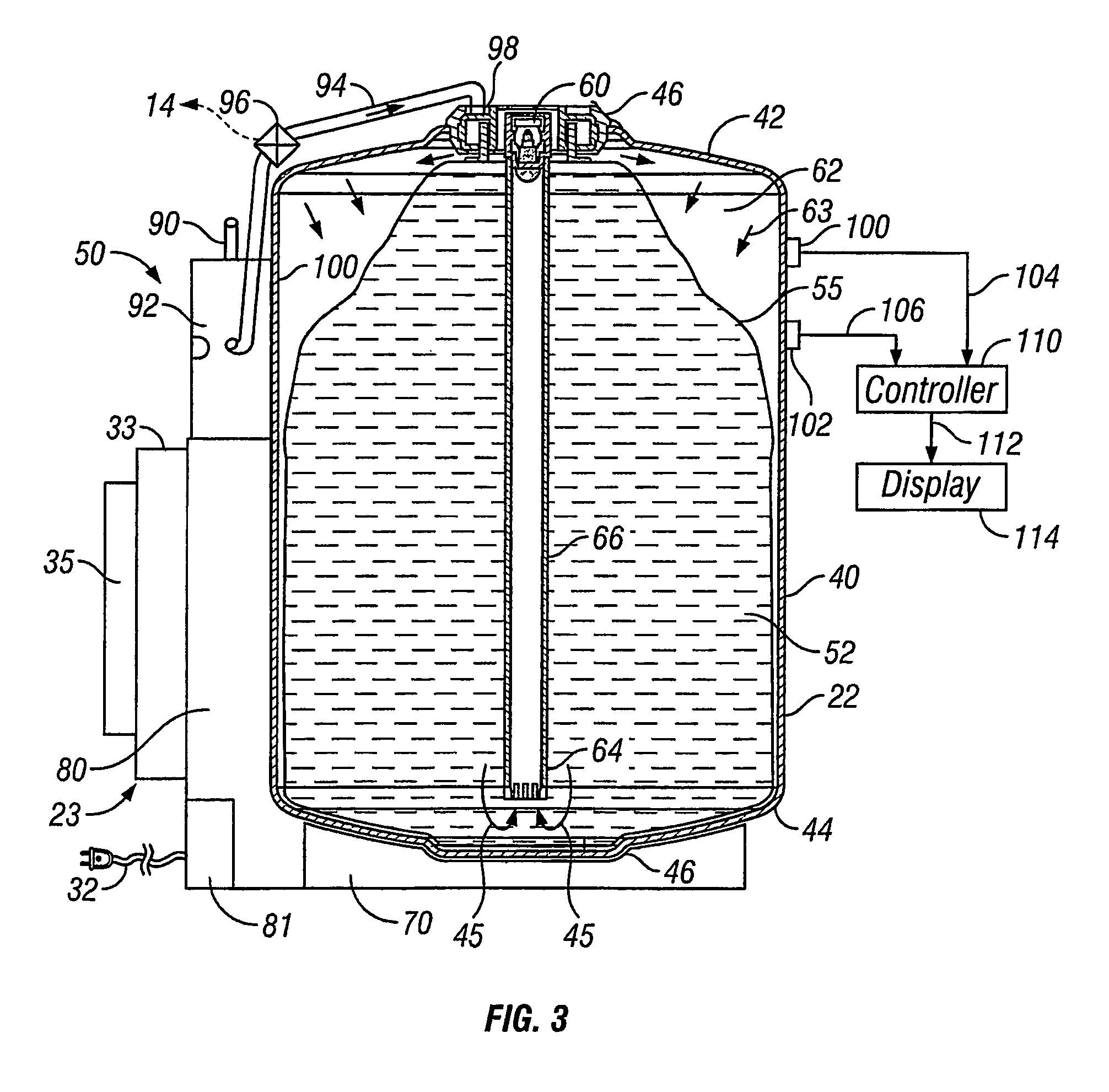

Beer dispensing system with gas pressure reservoir

ActiveUS20060138177A1Reduce dampening pressure fluctuationSufficient pressureLiquid transferring devicesVolume meteringPressure systemPressure sense

A home beer dispensing apparatus has a keg having a self-contained bag filled with a beer and a pressure system. The pressure system creates a pressurized air space between the keg inner walls and the bag to assist in the dispensing of the beer. The pressure system has a keg one-way air valve mounted to a top wall of the keg to permit entry of pressurized air into the keg. The pressure system has a pressure reservoir mounted in the dispensing apparatus outside the keg and in fluid flow communication with the keg one-way valve. The reservoir stores a charge of pressurized air and supplies at least a portion of this charge to the keg through the keg air valve when the dispensing apparatus is operated to dispense the beer. The reservoir provides a reserved charge of pressurized gas that is on hand to reduce dampening pressure fluctuations during beer dispensing which can result in beer frothing, especially during the early stages of beer dispensing when the air head space in the keg is small. Further, the apparatus may also have a pressure sensing system adapted to measure time rate of pressure change in the keg. The apparatus has a signaling device responsive to the time rate of pressure change in the keg to produce a signal related to volume of beer remaining in the bag. Preferably, the signal is displayed visually on the dispensing apparatus.

Owner:ANHEUSER BUSCH INBEV SA

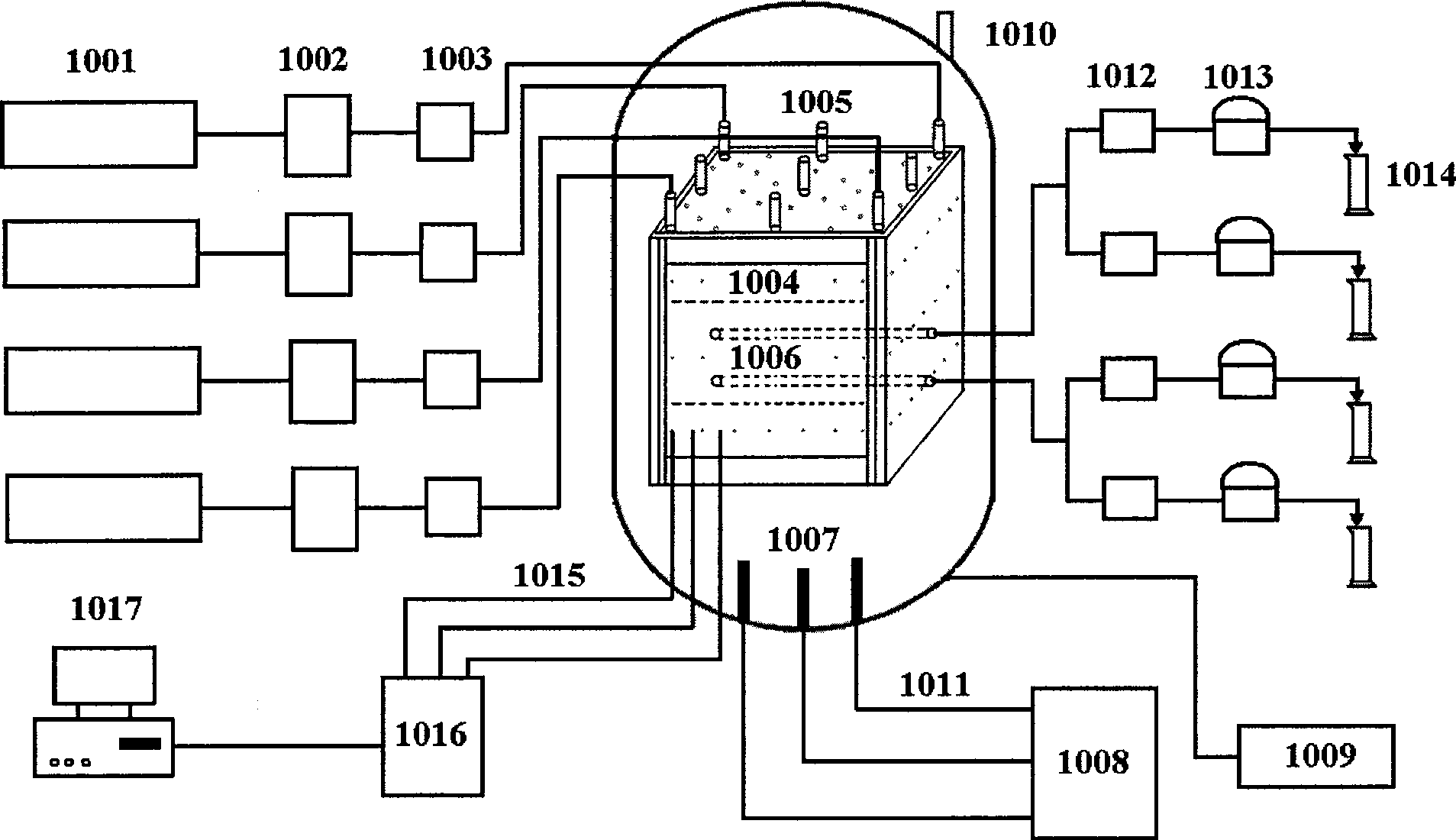

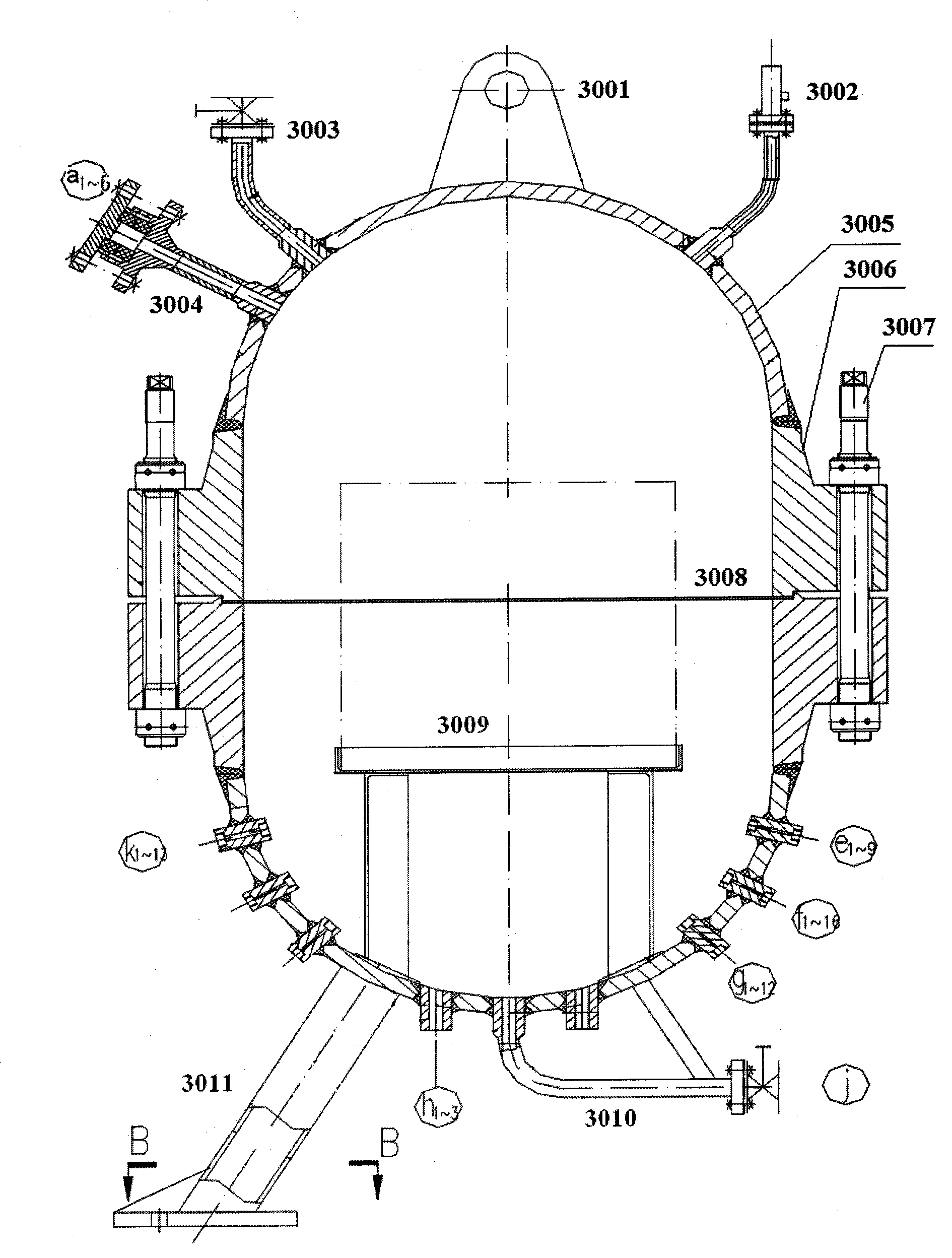

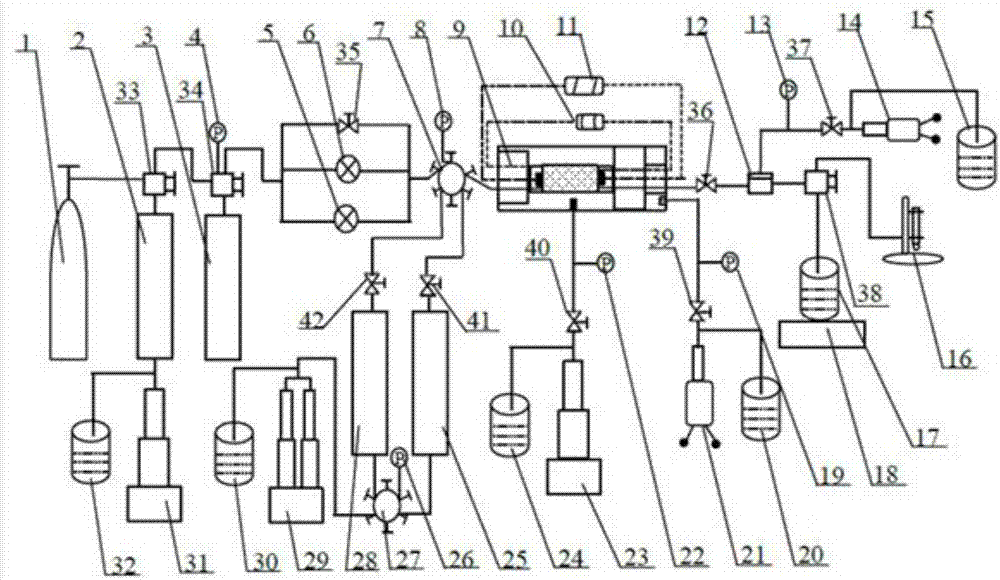

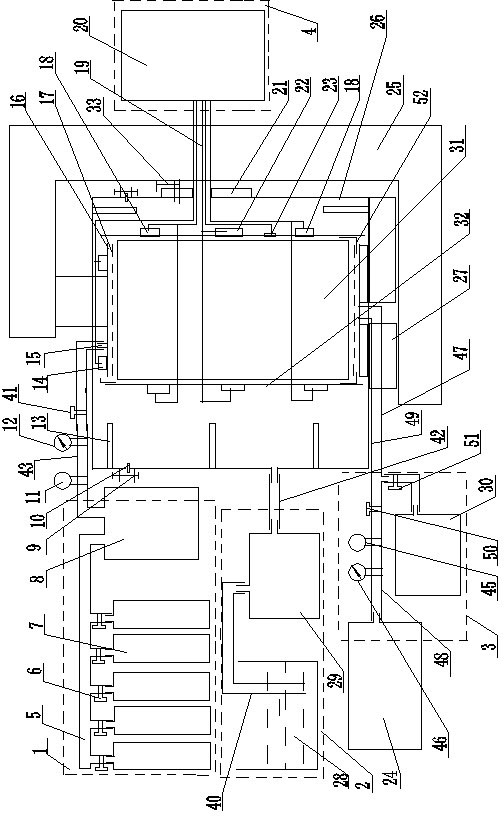

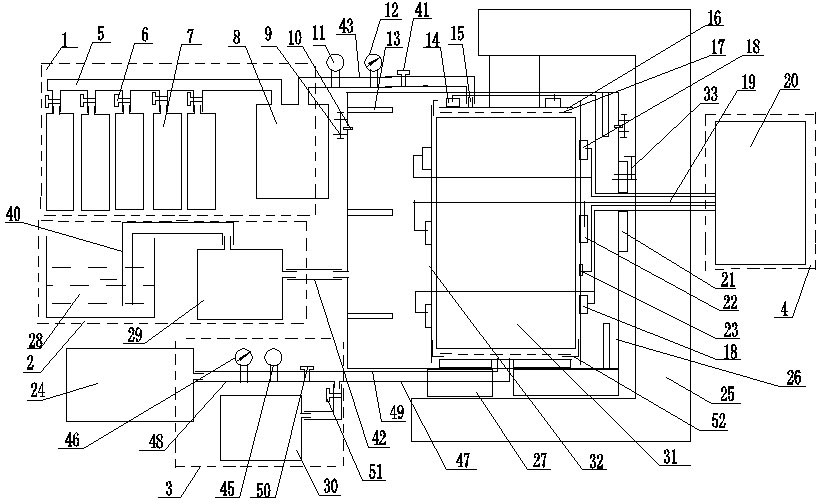

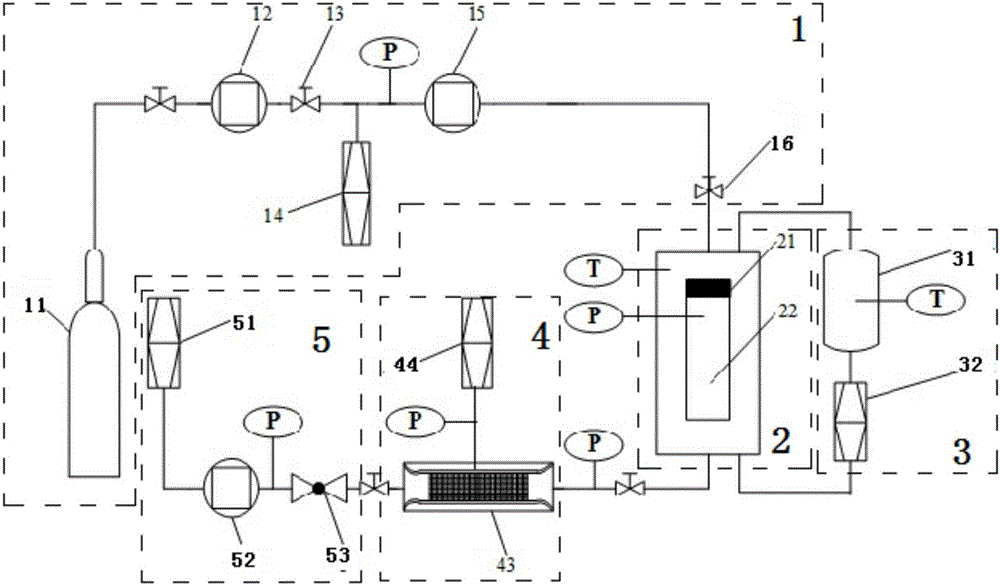

Oil pool development simulation system, oil pool model body and its data processing method

ActiveCN101476458AEasy to observeSolve the simulationSurveyFluid removalThree dimensional simulationPressure system

The invention relates to an oil deposition steam injection thermal recover multi-mode linkage three-dimensional simulation system. The system comprises a steam injecting system, an oil deposit model body, a burden pressure system, and a data acquiring and graph processing system, wherein the oil deposit model body is used for simulating an actual oil deposit; and the oil deposit model body comprises a shell of an oil deposit model, a heat insulating layer, a simulative oil deposit, a simulative straight well, a simulative horizontal well, a pressure guiding pipe, and a thermocouple and an interface of the thermocouple. The technical proposal realizes the simulation of steam thruput elastic energy, and the design of high-temperature and high-pressure oil deposit model body meets the requirements of well networks and well types for various assemblies.

Owner:PETROCHINA CO LTD

Beer dispensing system with gas pressure reservoir

ActiveUS7810679B2Suppress pressure fluctuationsReduces compressor ratingLiquid transferring devicesVolume meteringPressure systemPressure sense

A home beer dispensing apparatus has a keg having a self-contained bag filled with a beer and a pressure system. The pressure system creates a pressurized air space between the keg inner walls and the bag to assist in the dispensing of the beer. The pressure system has a keg one-way air valve mounted to a top wall of the keg to permit entry of pressurized air into the keg. The pressure system has a pressure reservoir mounted in the dispensing apparatus outside the keg and in fluid flow communication with the keg one-way valve. The reservoir stores a charge of pressurized air and supplies at least a portion of this charge to the keg through the keg air valve when the dispensing apparatus is operated to dispense the beer. The reservoir provides a reserved charge of pressurized gas that is on hand to reduce dampening pressure fluctuations during beer dispensing which can result in beer frothing, especially during the early stages of beer dispensing when the air head space in the keg is small. Further, the apparatus may also have a pressure sensing system adapted to measure time rate of pressure change in the keg. The apparatus has a signaling device responsive to the time rate of pressure change in the keg to produce a signal related to volume of beer remaining in the bag. Preferably, the signal is displayed visually on the dispensing apparatus.

Owner:ANHEUSER BUSCH INBEV SA

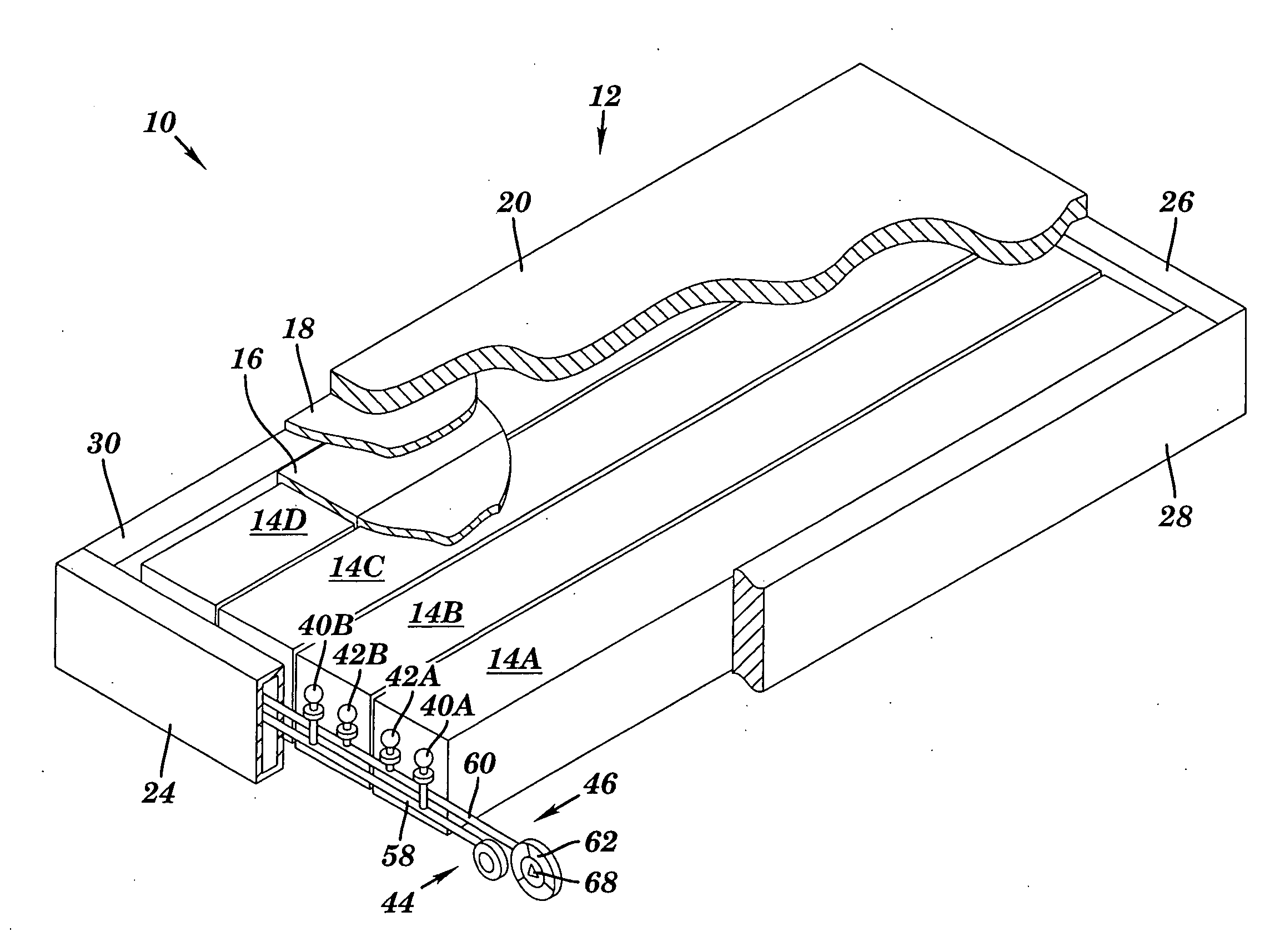

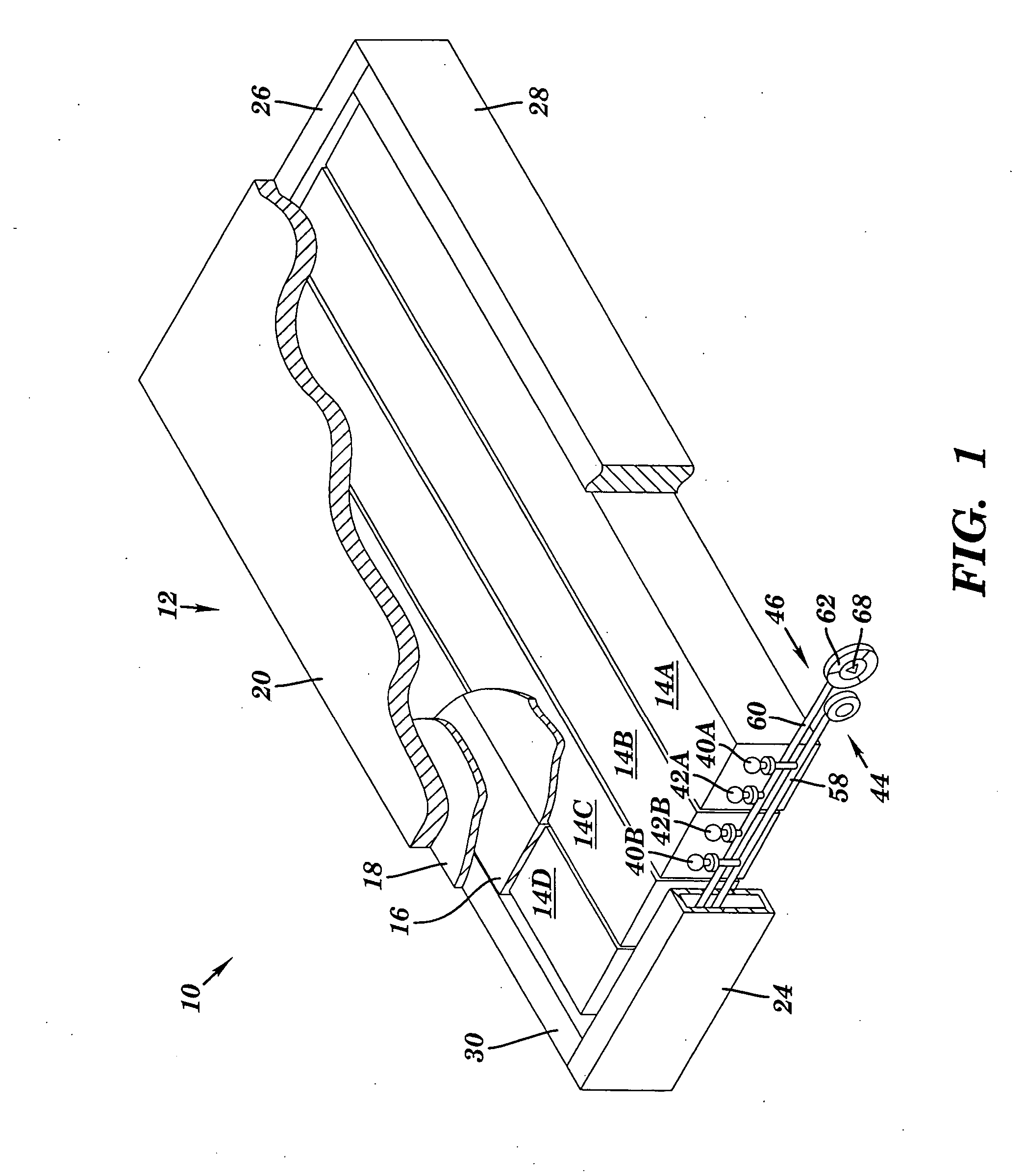

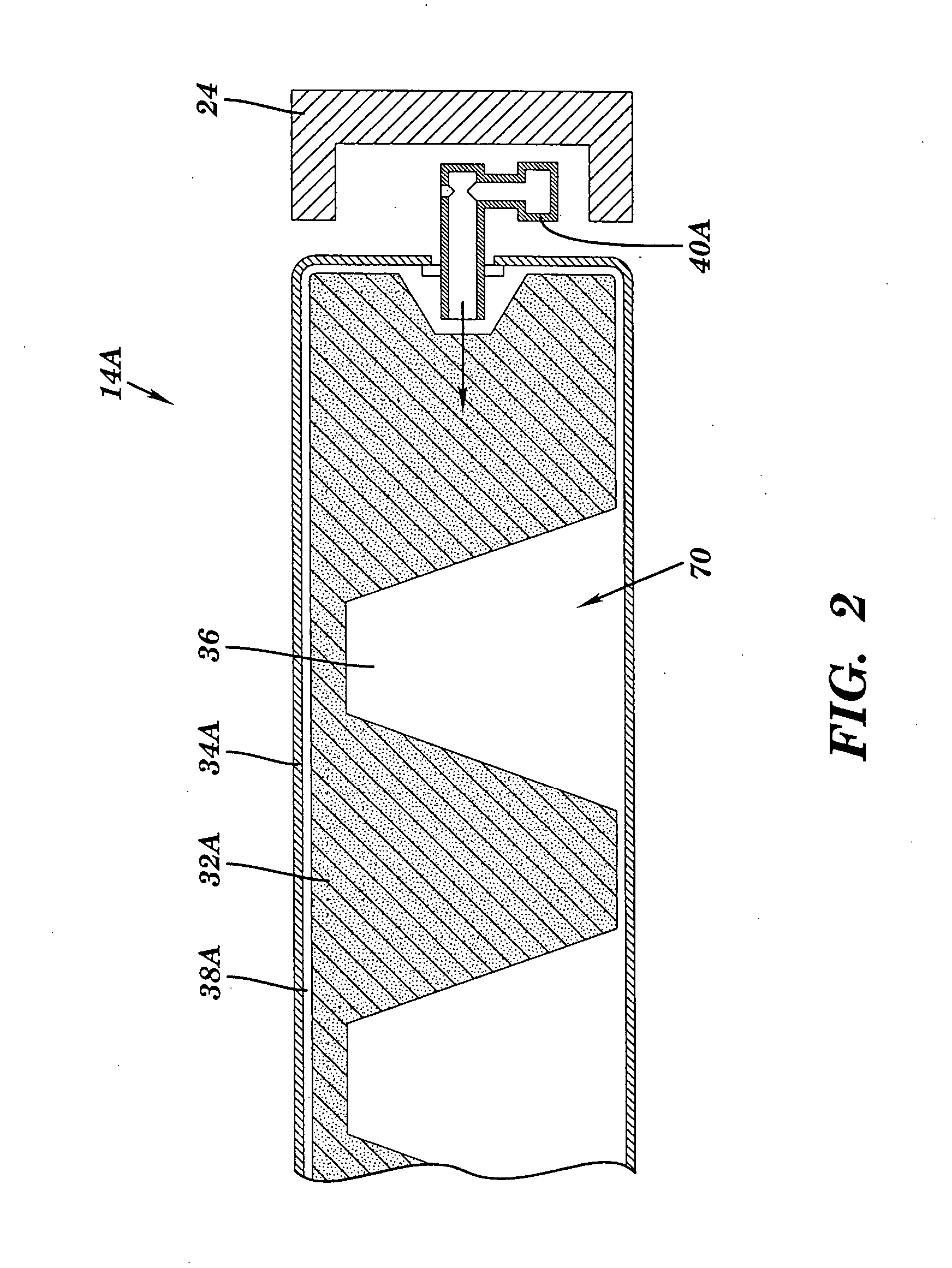

Inflatable cushioning device with manifold system

InactiveUS20050125905A1Few moving partsMinimal maintenanceStuffed mattressesSpring mattressesSupporting systemPressure system

A cushioning device for a body support such as a mattress, seat, sofa, or the like where support is obtained from a fluid in fluid cells having a spring bias. The cushioning device is self-inflating, self-adjusting, and provides a low interface pressure under the entire contact surface of a patient. Shear force scraping damage is prevented by a sleeve apparatus. A support system apparatus provides separately adjustable pressure support zones. For physical therapy, an alternating pressure system provides alternating lifting and lowering pressure zones under a patient.

Owner:WCW INC

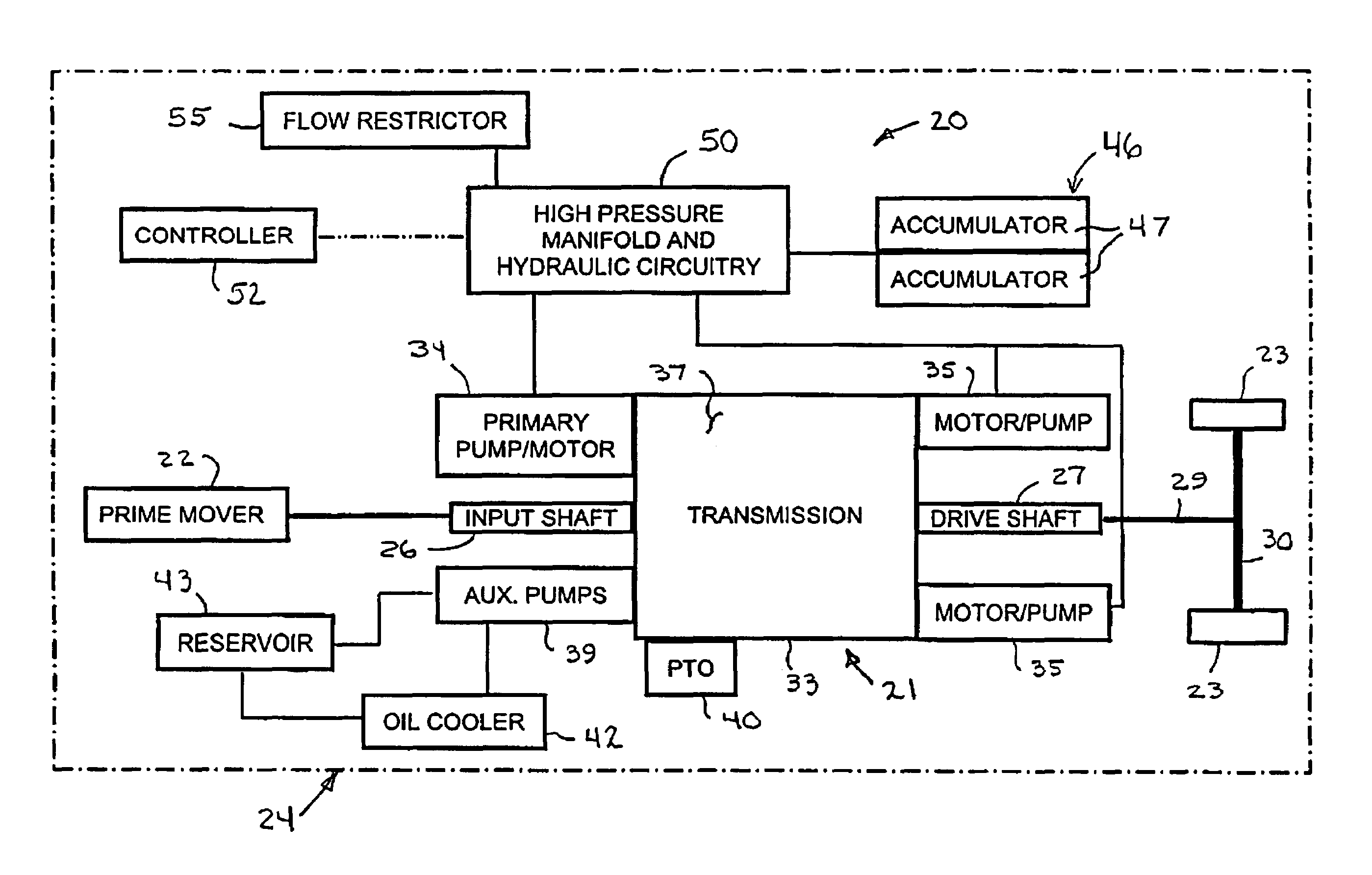

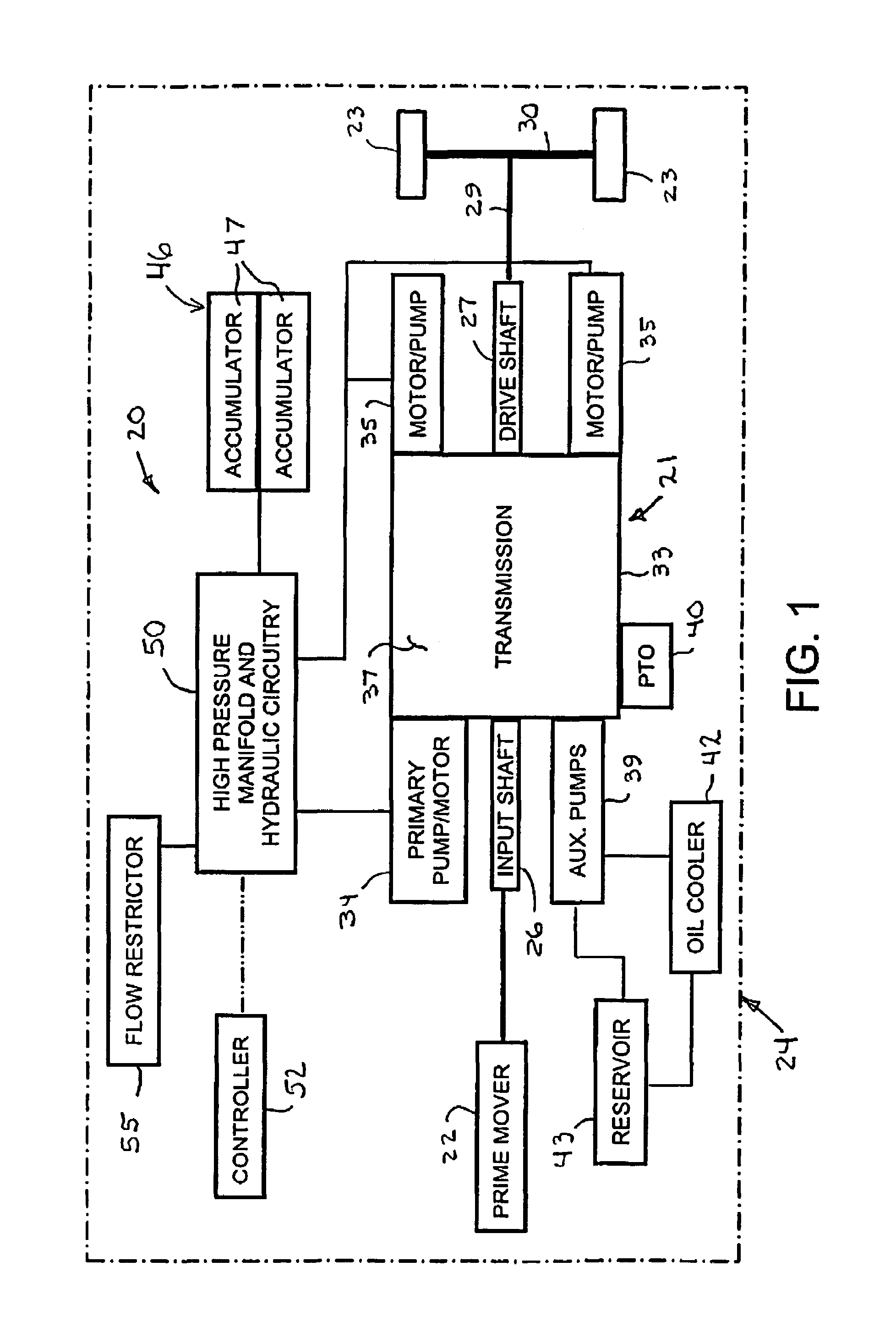

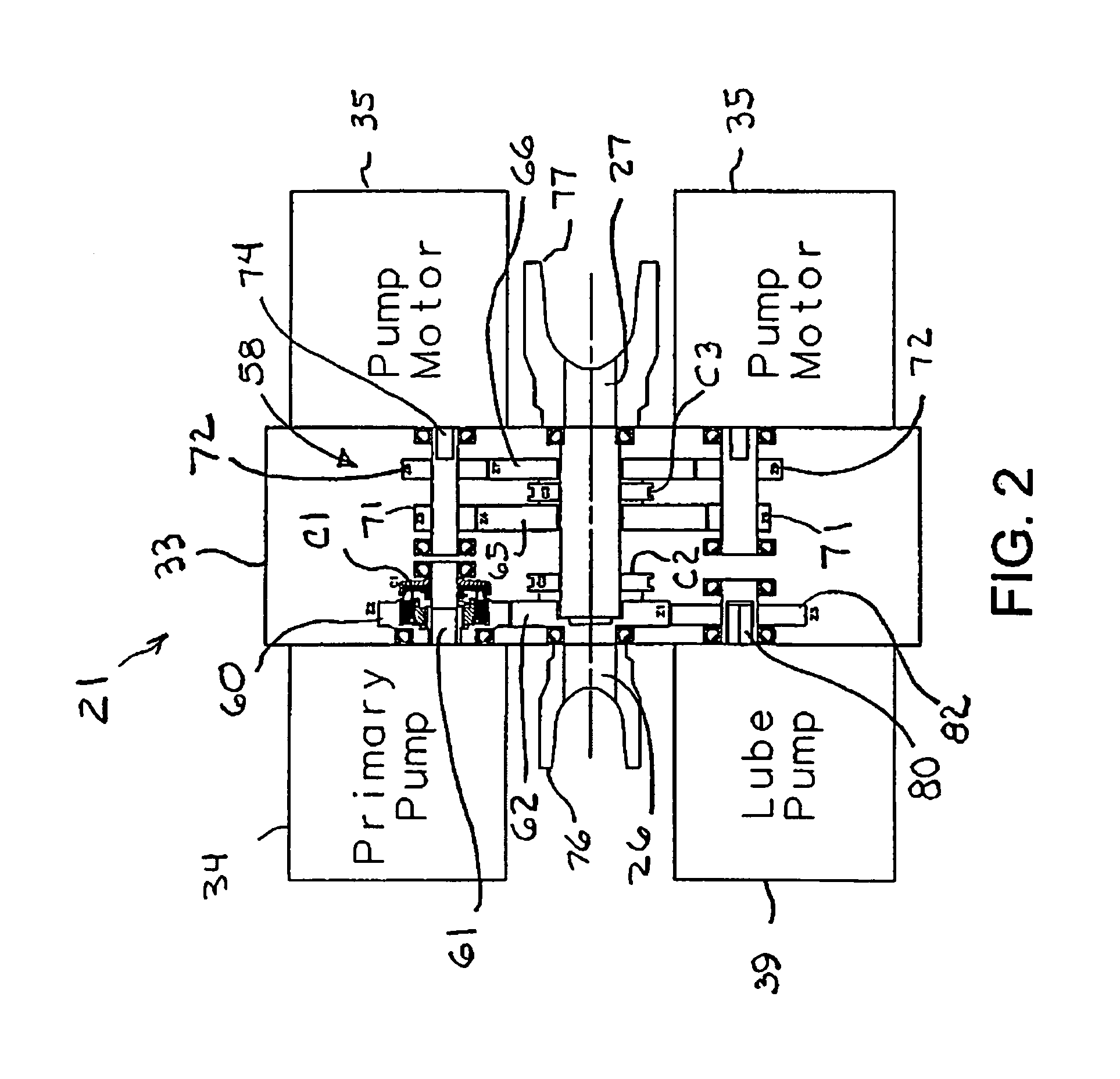

Gear box for hydraulic energy recovery

A hydraulic energy recovery and a mechanical drive system in one unit that also provides integral mounting of hydraulic pump / motors for primary drive, secondary drive, and pumps for cooling, lubrication, and low pressure systems along with a mounting position for a power take-off device.

Owner:PARKER HANNIFIN CORP

Nano-grid micro reactor and methods

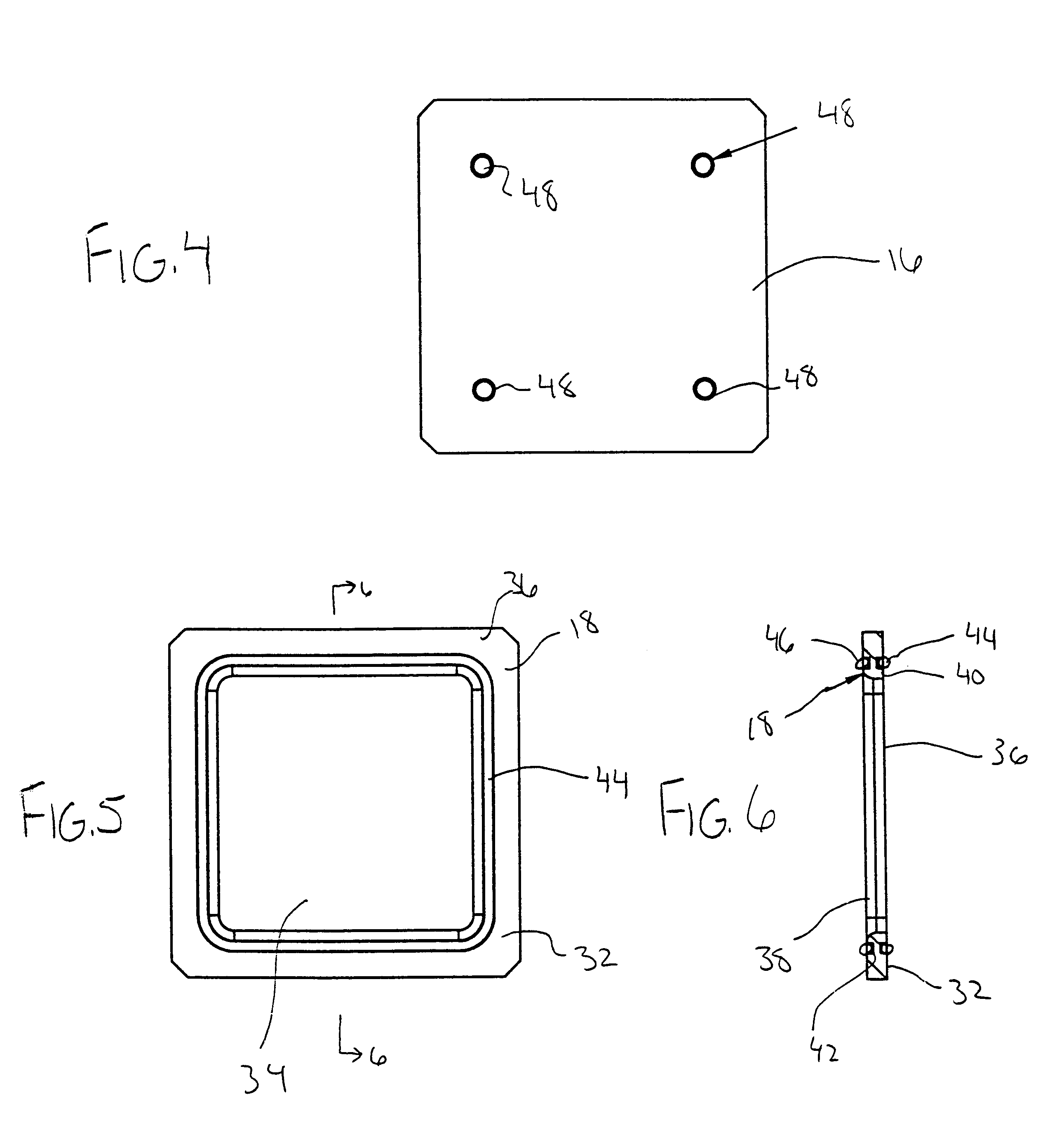

InactiveUS6309889B1Prevent and reduce chanceBioreactor/fermenter combinationsSequential/parallel process reactionsPressure systemPositive pressure

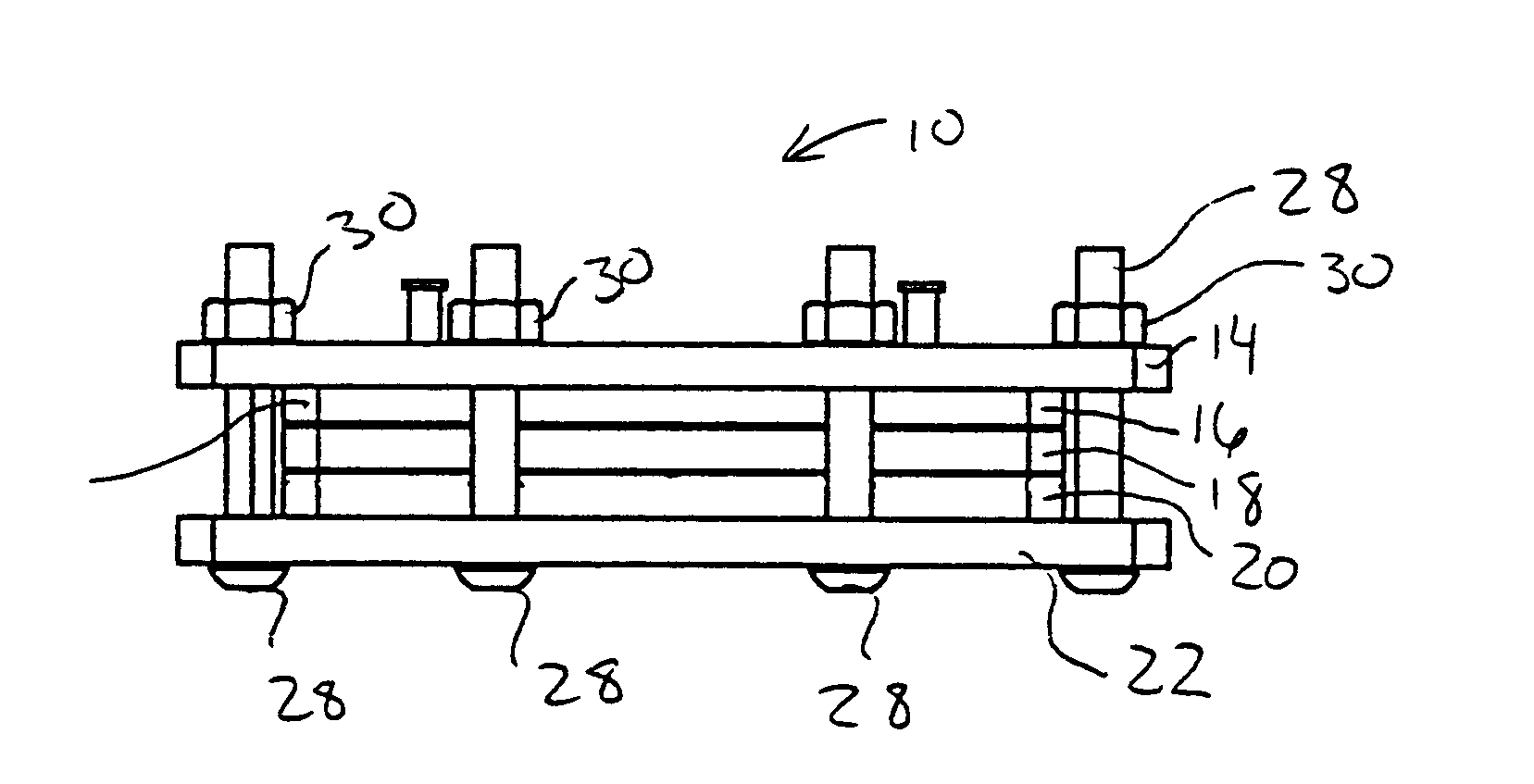

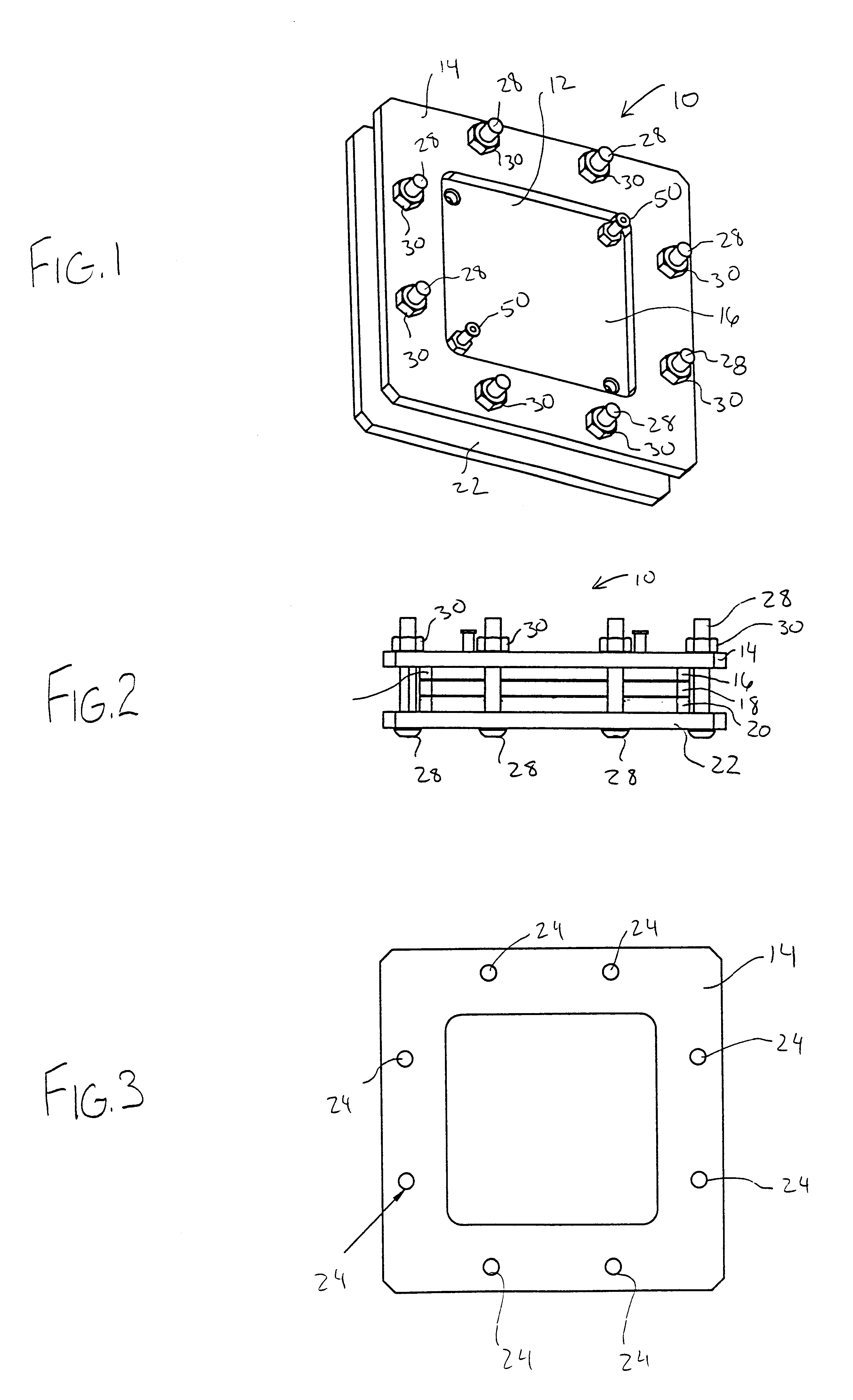

The invention provides exemplary devices and methods to facilitate the performance of assays. In one embodiment, one such device comprises a holding member having a top surface, a bottom surface, and a plurality of holding locations that are adapted to hold at least one article, such as a solid support and / or a cell. When within the holding locations, the articles are preferably disposed below the top surface. A membrane is positioned above the top surface of the holding member, and a pressure system is provided to apply positive pressure to the membrane to force the membrane against the top surface of the holding member. In this way, a seal may be provided between the holding locations.

Owner:GLAXO GROUP LTD +1

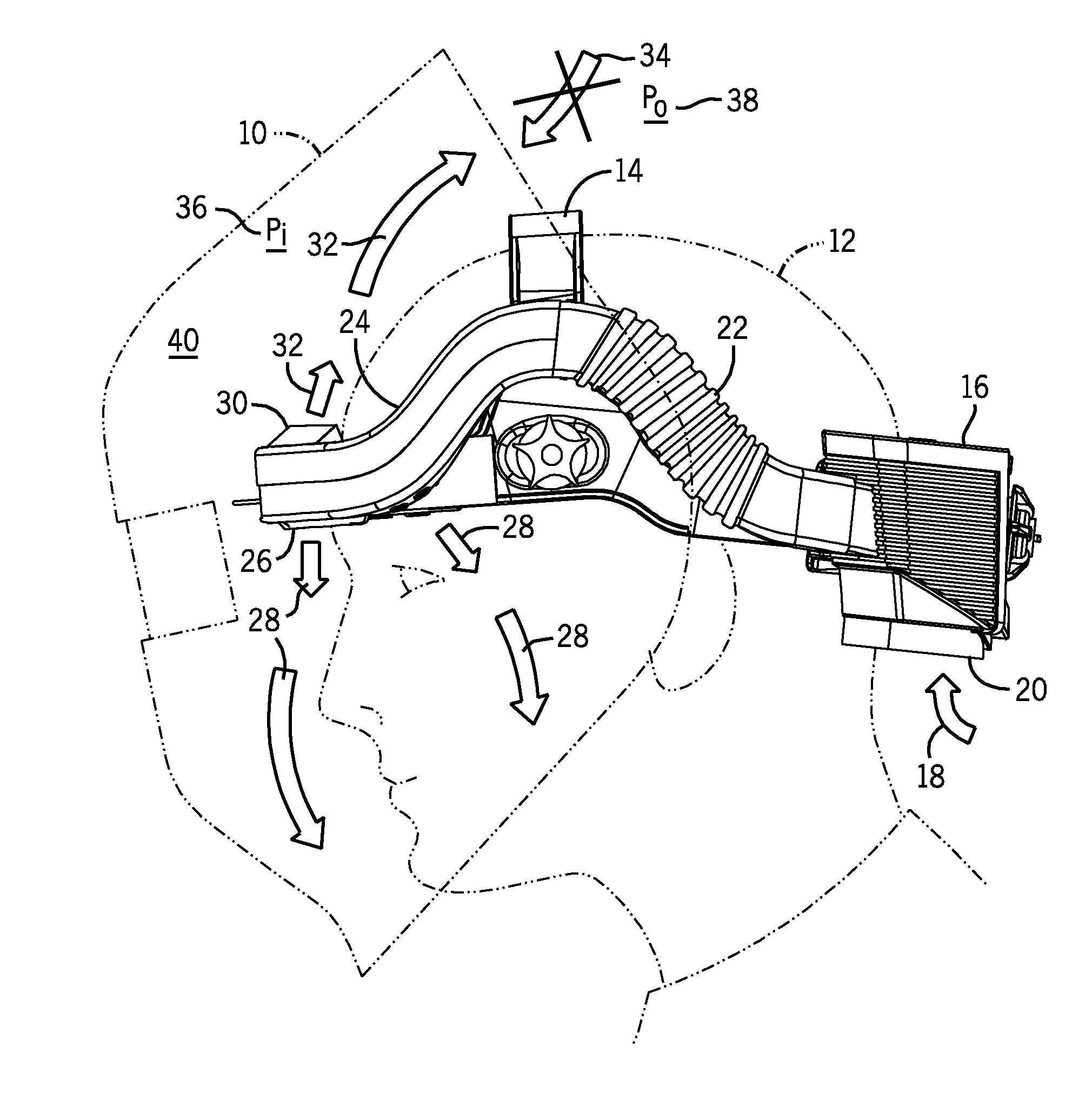

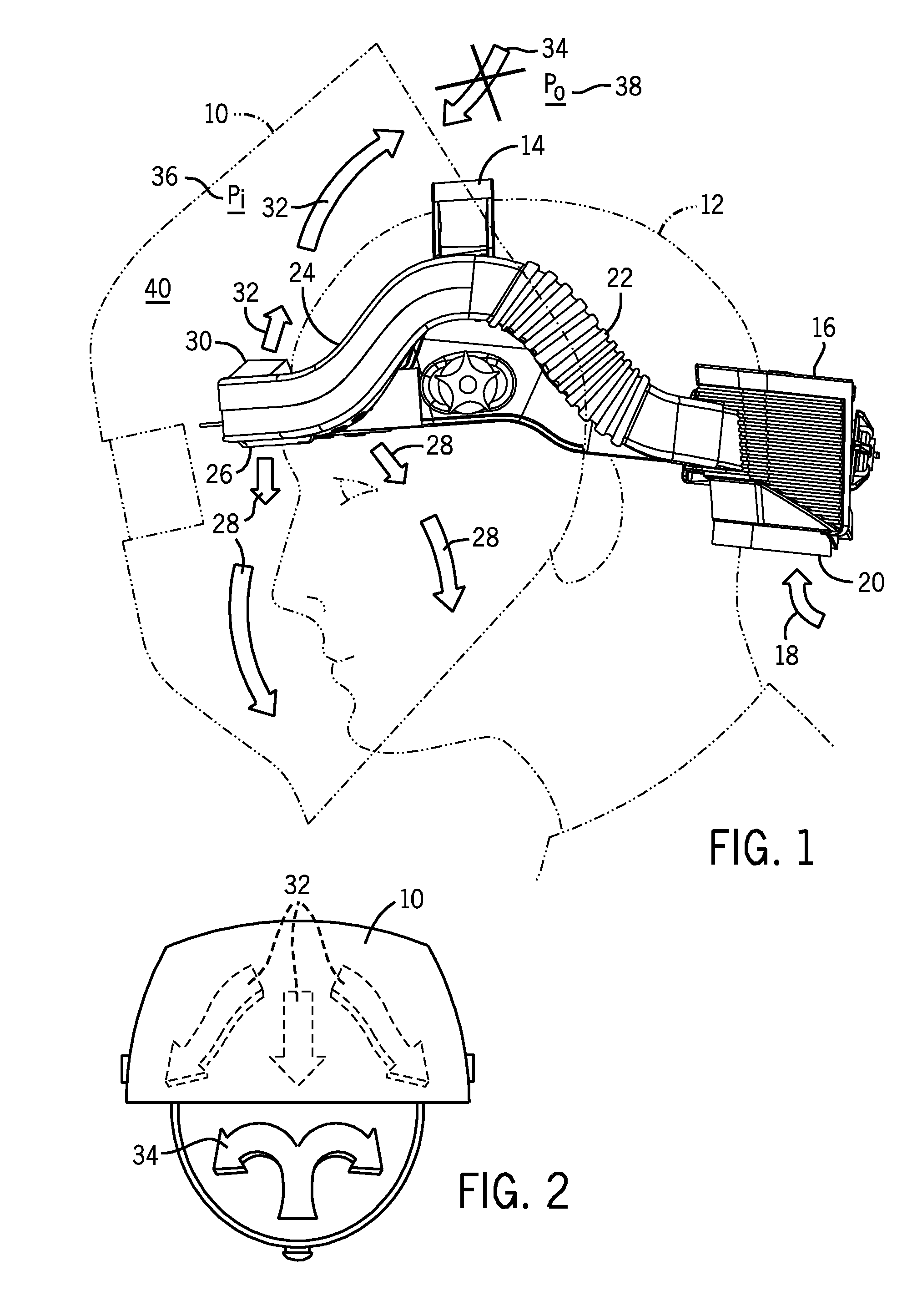

Welding helmet positive air pressuring system and method

A method and system for controlling ventilation in a welding helmet is provided. The invention may be adapted to a wide variety of system types, and may reduce or eliminate the need for a shroud or barrier around the head and neck of the welder, of the type used in PAPR systems. The airflow system includes forward and rearward air streams, directed onto the face of the welder, onto the top of the head of the welder, and toward the back of the head of the welder. The air streams help to cool the welder, provide a fresh source of air for breathing, and create a positive pressure system that reduces or excludes entrainment of contaminated external air into the forwardly directed air flow. Certain embodiments may include streams that are filtered, split or redirected via deflectors and conduits to achieve the aforementioned goals.

Owner:ILLINOIS TOOL WORKS INC

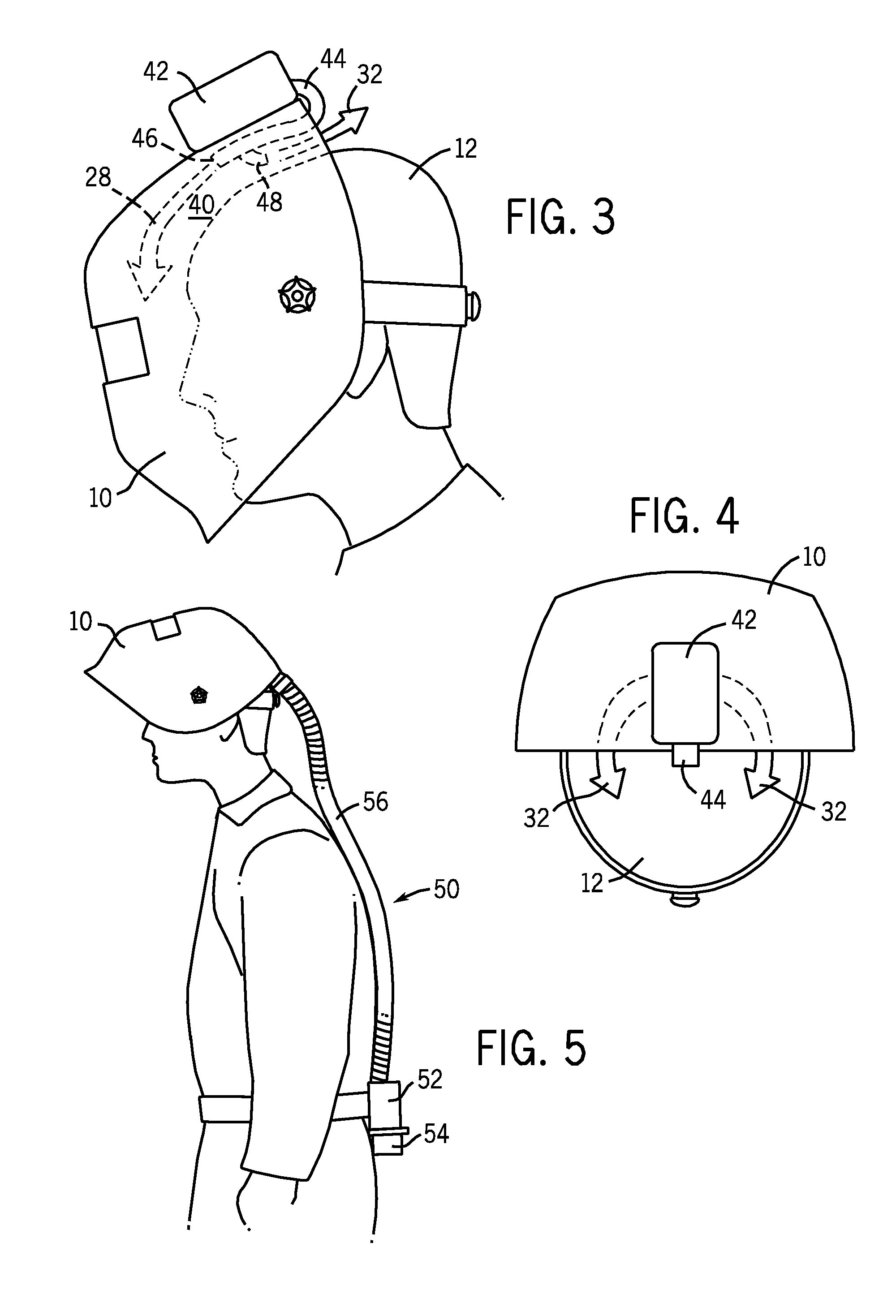

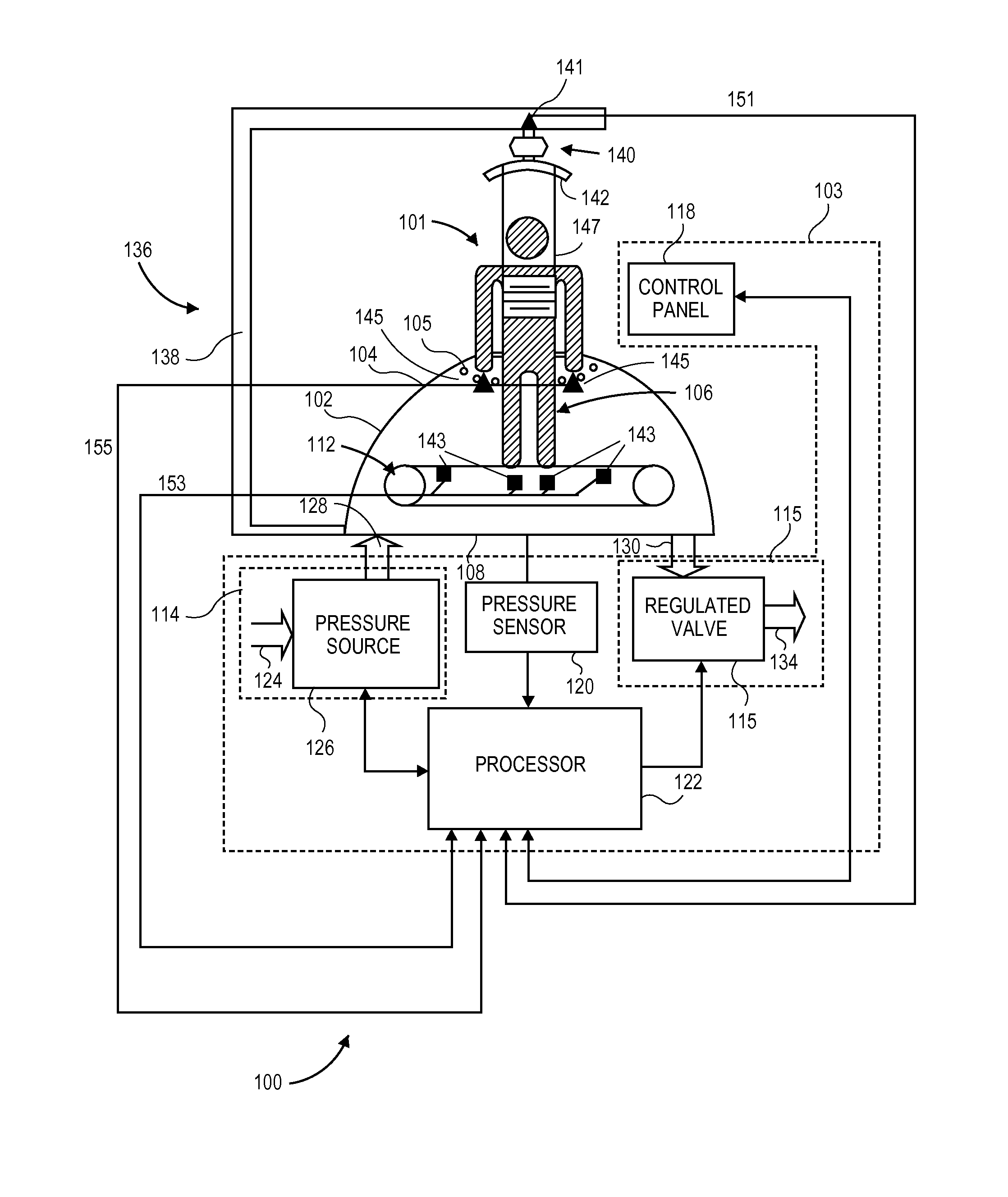

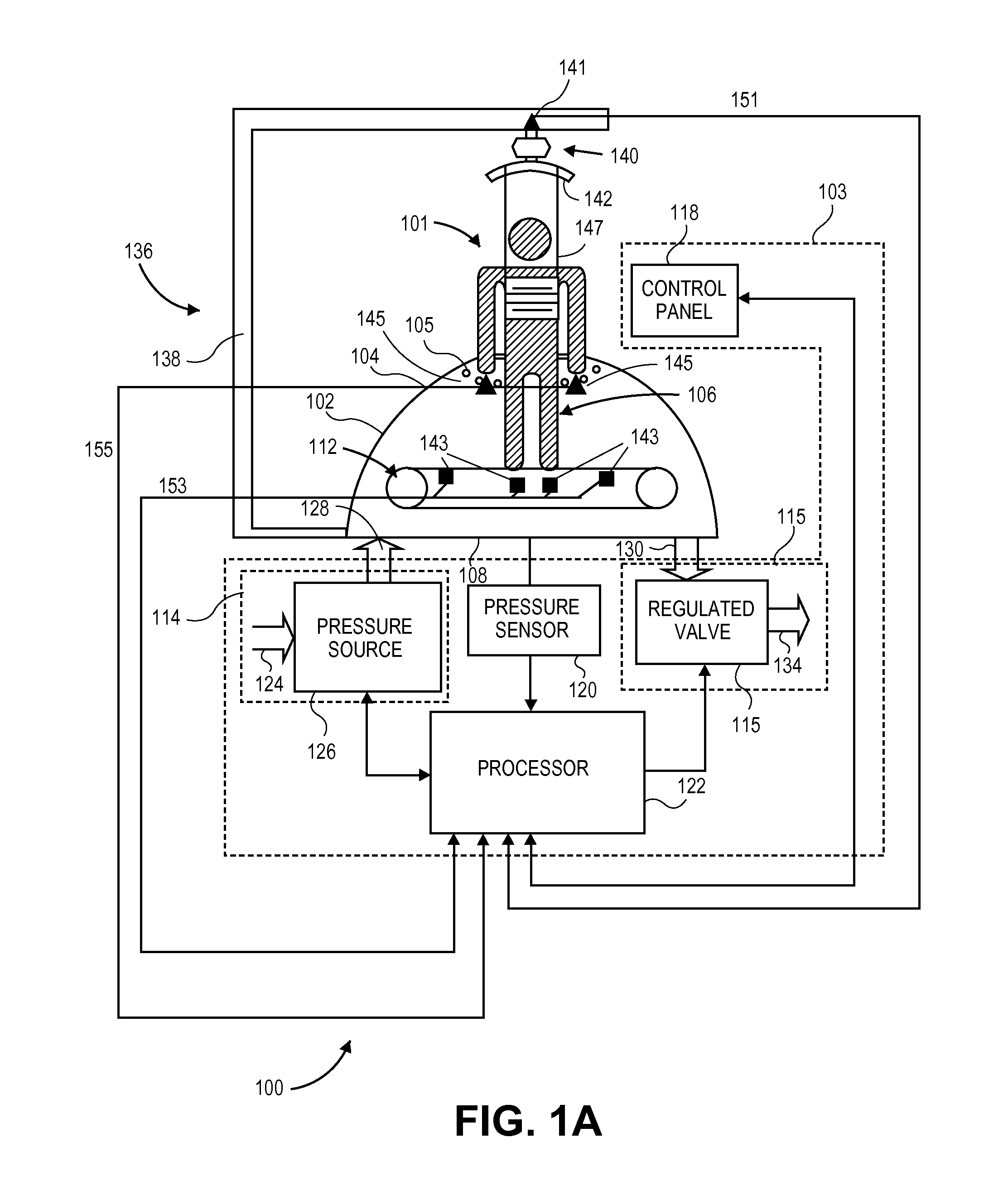

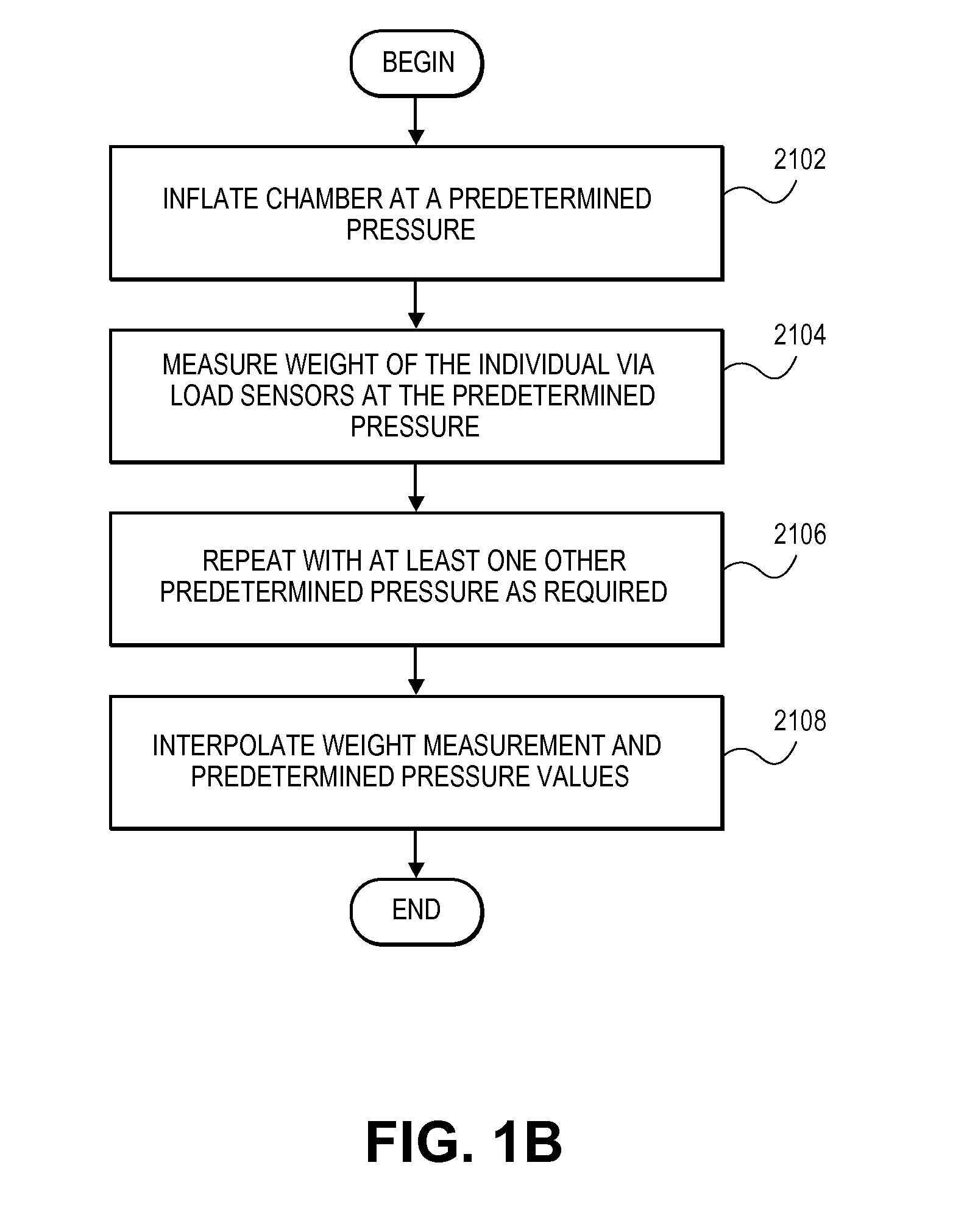

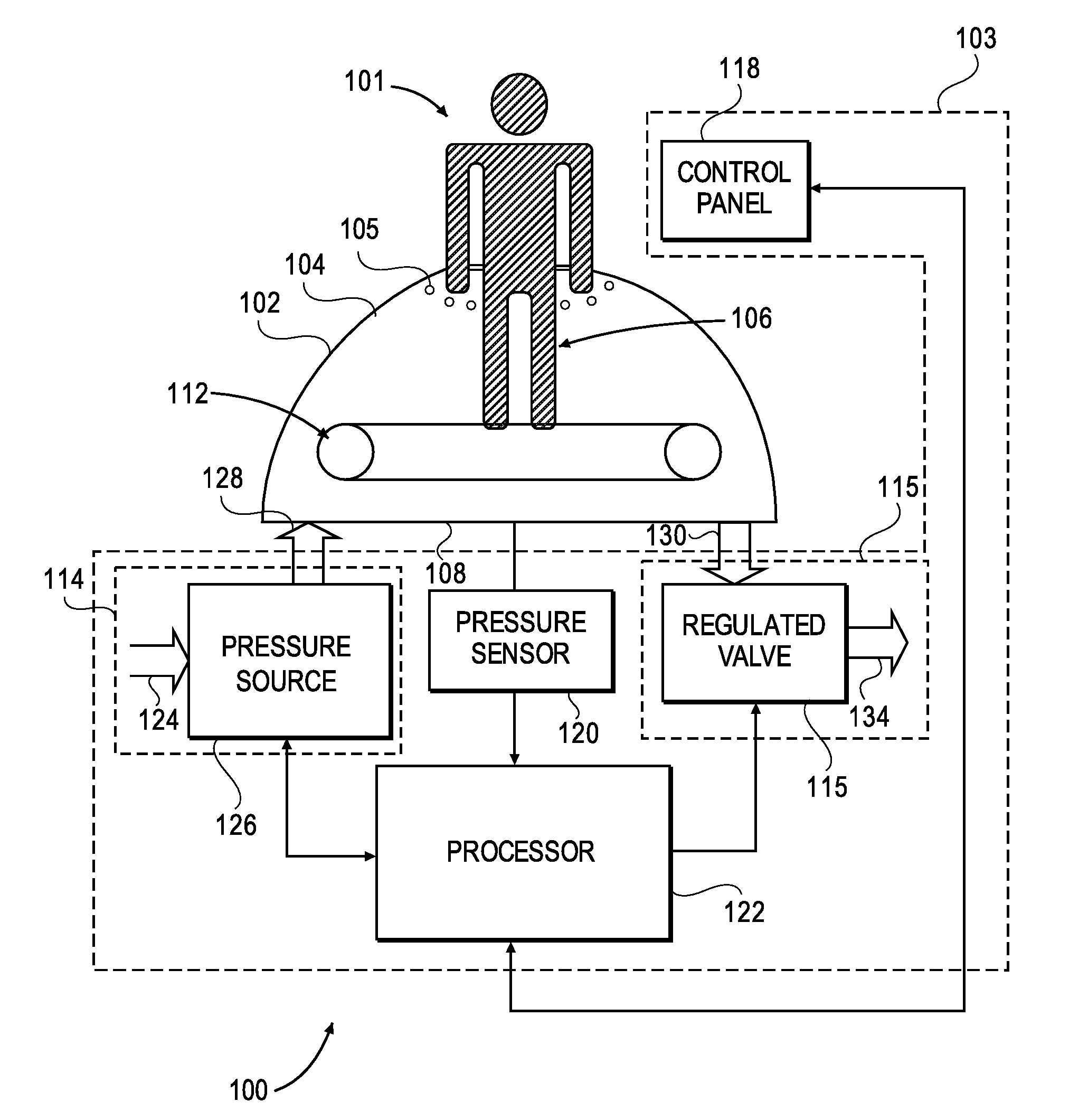

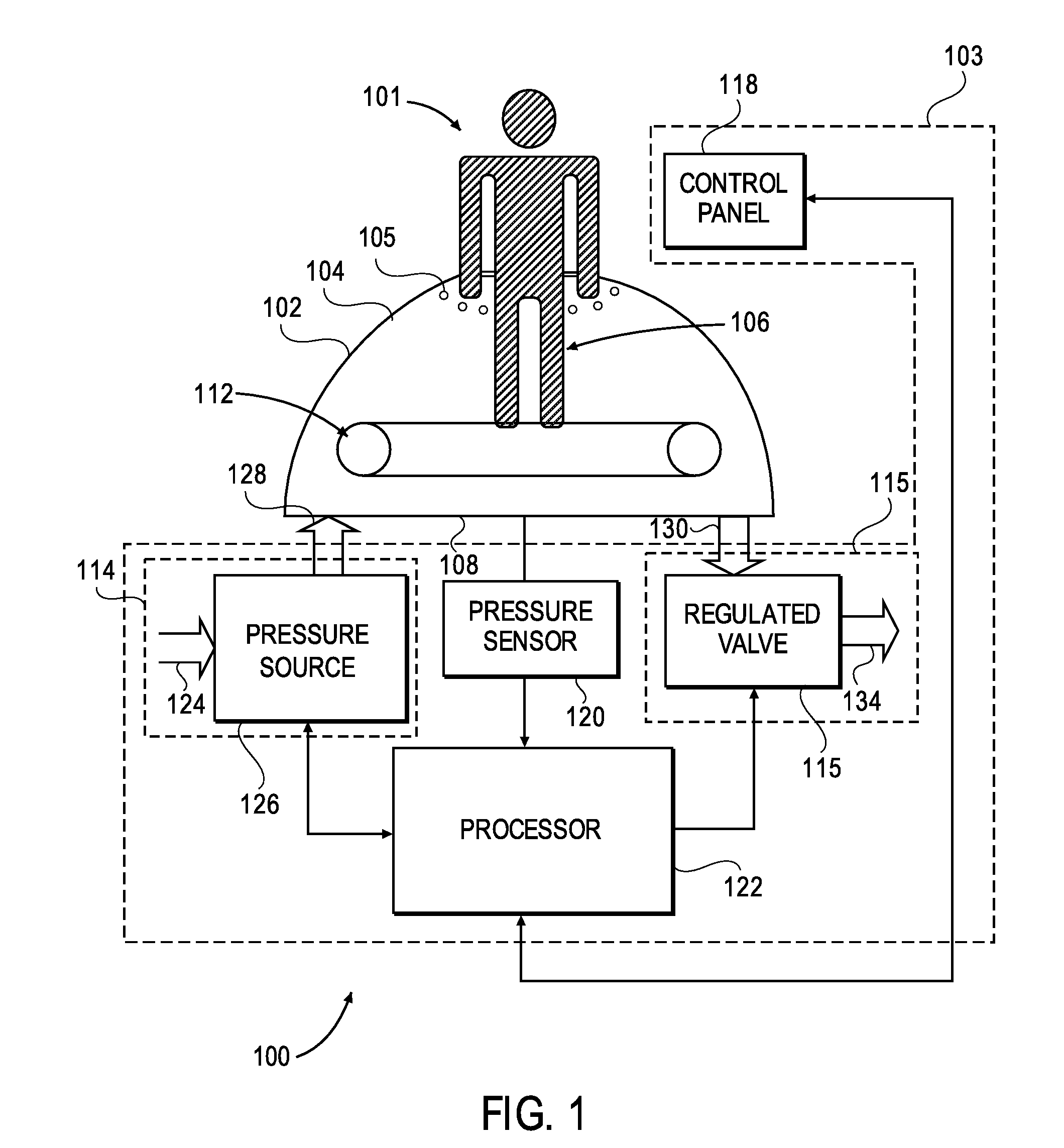

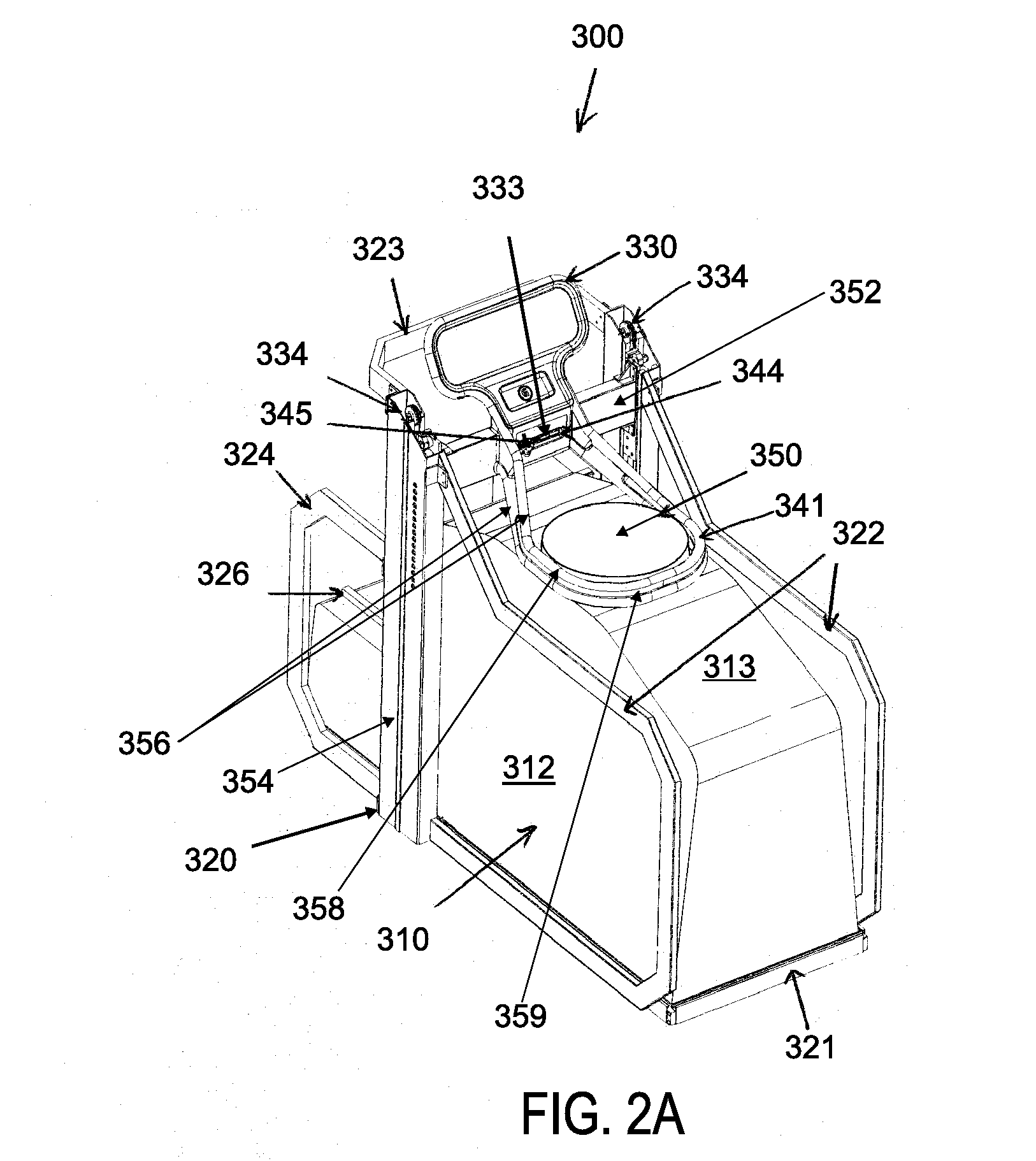

Differential air pressure systems and methods of using and calibrating such systems for mobility impaired users

InactiveUS20120238921A1Improve cardiovascular functionImprove mobilityPneumatic massageDiagnosticsPressure systemPositive pressure

Described herein are various embodiments of differential air pressure systems and methods of using and calibration such systems for individuals with impaired mobility. The differential air pressure systems may comprise an access assist device configured to help a mobility impaired user to stand in a pressure chamber configured to apply a positive pressure on a portion of the user's body in the seals pressure chamber. The system may further comprise load sensors configured to measure the user's weight exerted inside and outside the chamber. The system may be calibrated by determining a relationship between the actual weight of the user and the pressure in the chamber, where the actual weight of the user may be measured by more than one load sensor and at least one load sensor is not in the chamber.

Owner:ALTERG INC

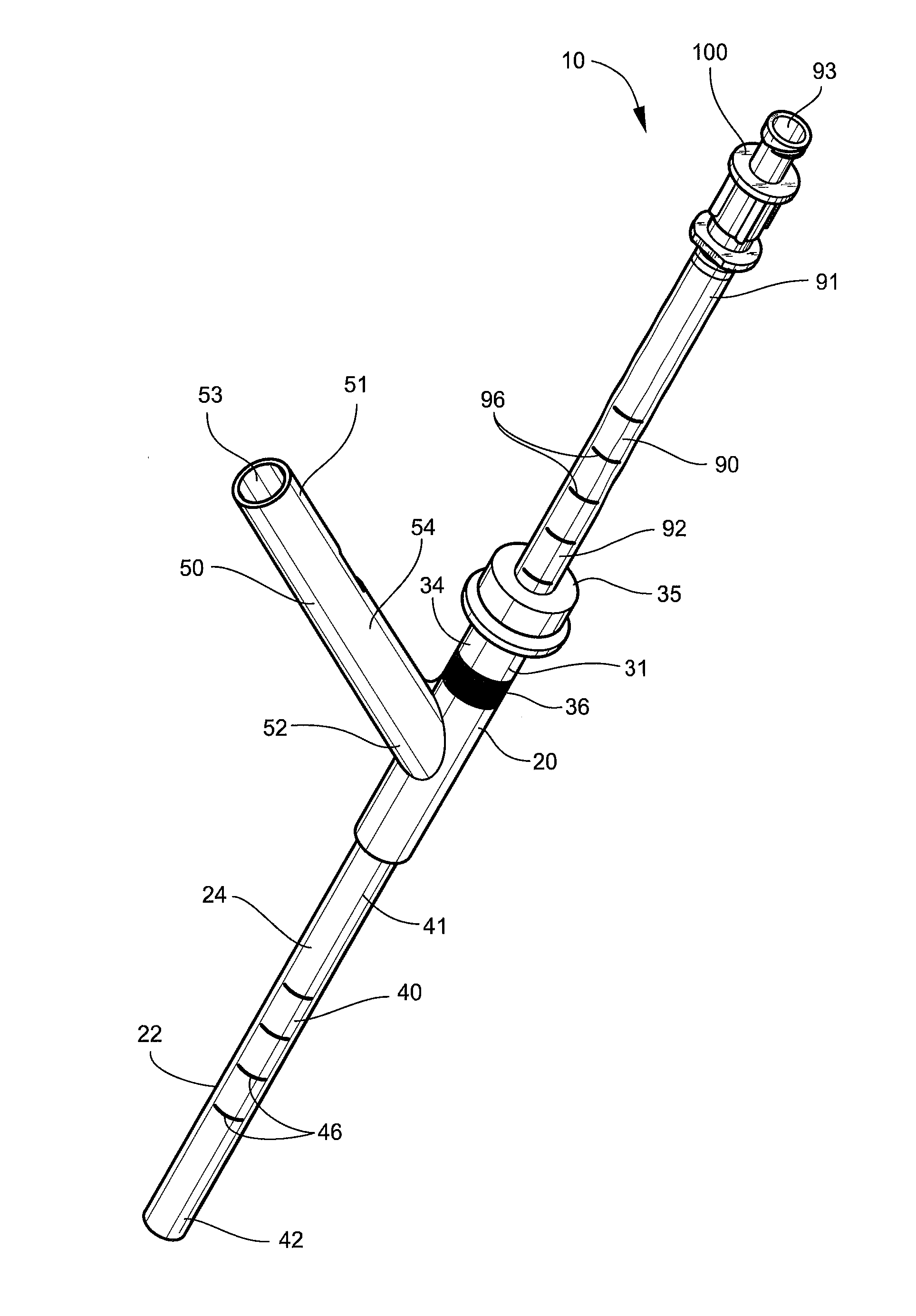

Suction evacuation device

A method for removing a stone from a patient comprising the steps of: providing a suction evacuation assembly which includes a sheath and one or more side arms; inserting and positioning a distal end of the sheath into a lumen or cavity of a patient's body containing a stones; connecting a tube to one of the side arms and to a collection bottle; connecting another tube to the collection bottle and a negative pressure system; visualizing the stone or foreign body using a scope inserted through the assembly; activating the negative pressure system in order to remove the stone from the cavity if the diameter of the stone is narrower than an inside diameter of the sheath and the side arm, or performing a lithotripsy on the stone to create fragments with a decreased diameter which allow the passage through the assembly; and collecting the stone in the collection bottle.

Owner:GUANGZHOU WELLLEAD MEDICAL EQUIP CO LTD

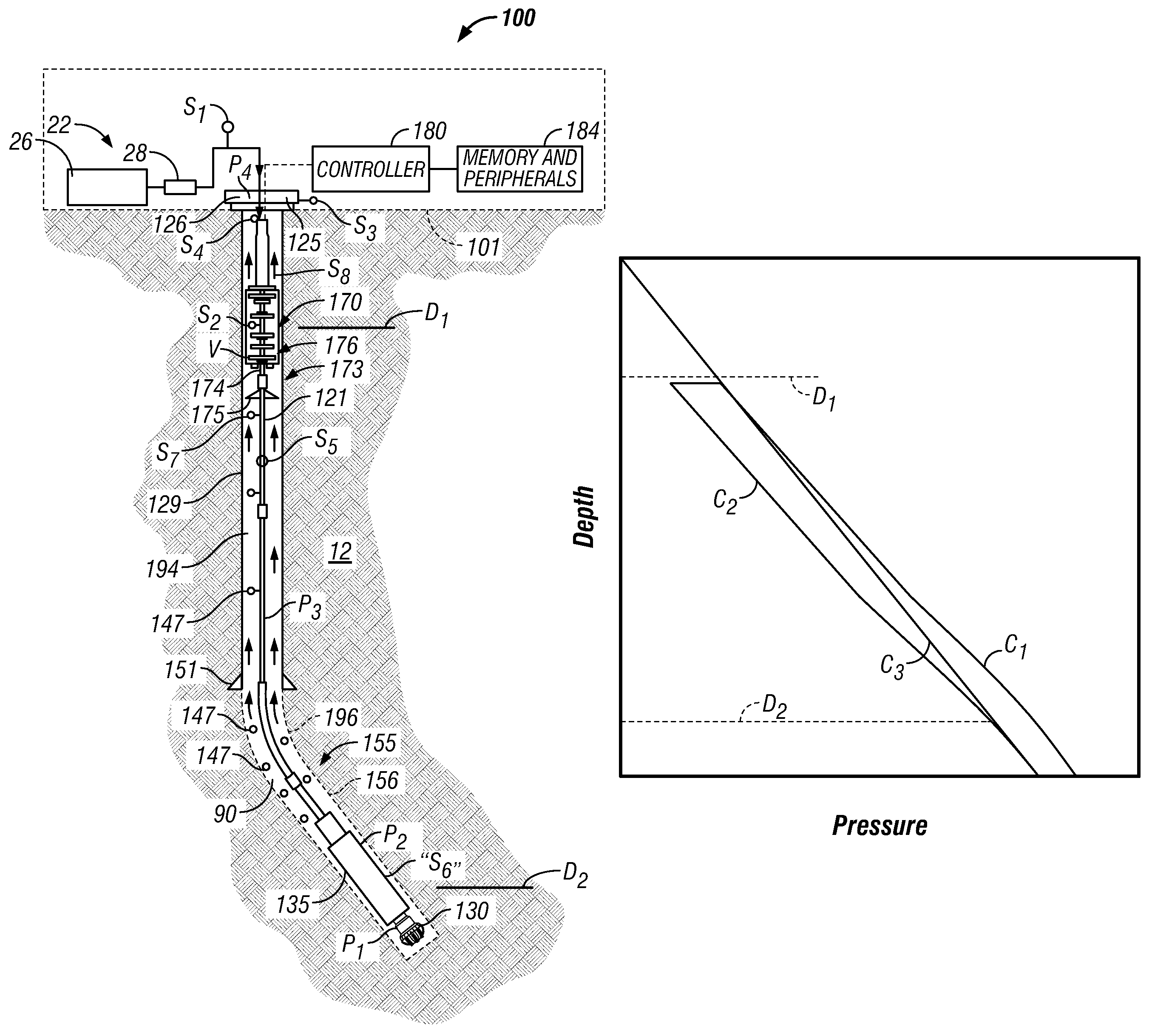

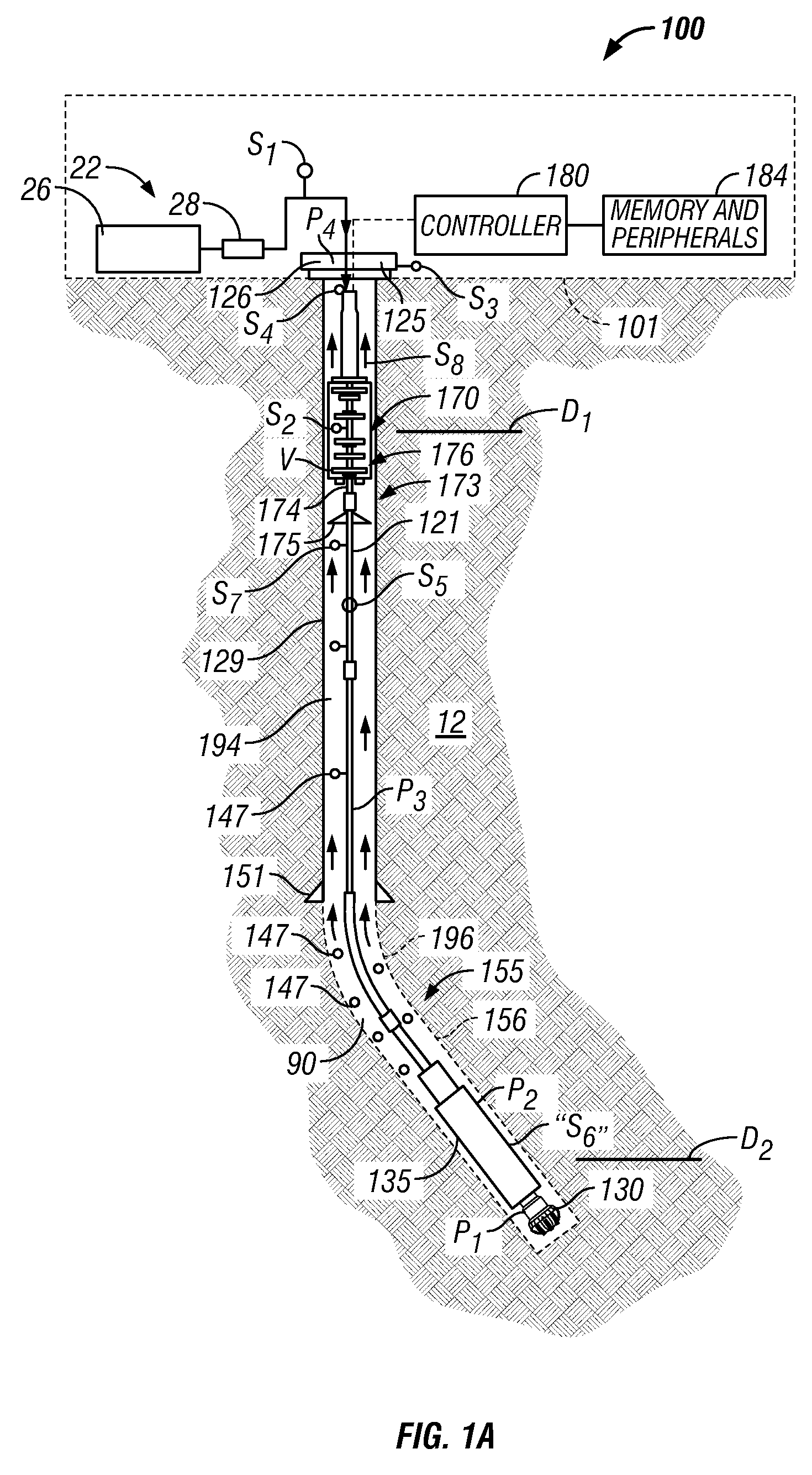

Active controlled bottomhole pressure system and method with continuous circulation system

An APD Device provides a pressure differential in a wellbore to control dynamic pressure loss while drilling fluid is continuously circulated in the wellbore. A continuous circulation system circulates fluid both during drilling of the wellbore and when the drilling is stopped. Operating the APD Device allows wellbore pressure control during continuous circulation without substantially changing density of the fluid. The APD Device can maintain wellbore pressure below the combined pressure caused by weight of the fluid and pressure losses created due to circulation of the fluid in the wellbore, maintain the wellbore at or near a balanced pressure condition, maintain the wellbore at an underbalanced condition, reduce the swab effect in the wellbore, and / or reduce the surge effect in the wellbore. A flow restriction device that creates a backpressure in the wellbore annulus provides surface control of wellbore pressure.

Owner:BAKER HUGHES HLDG LLC

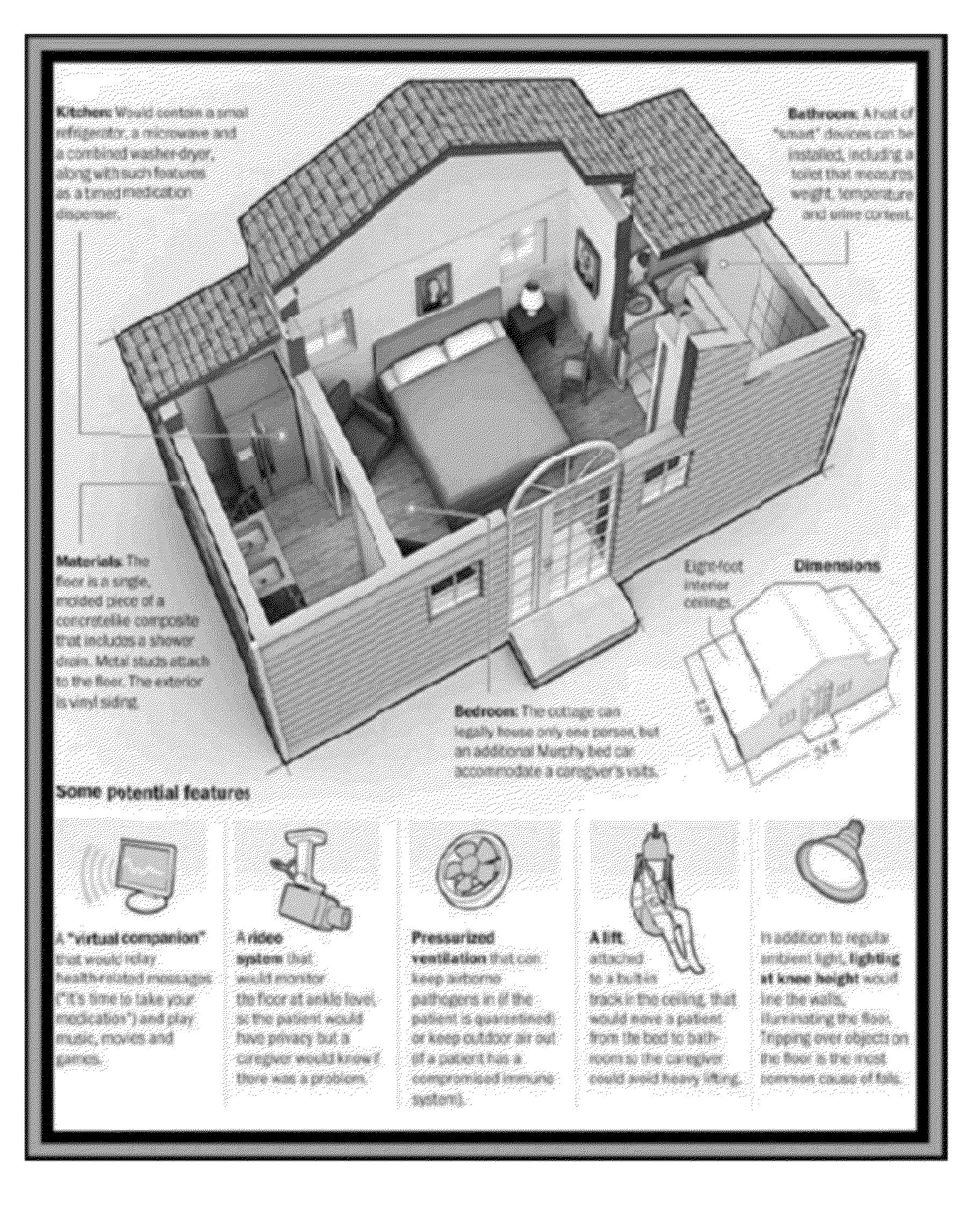

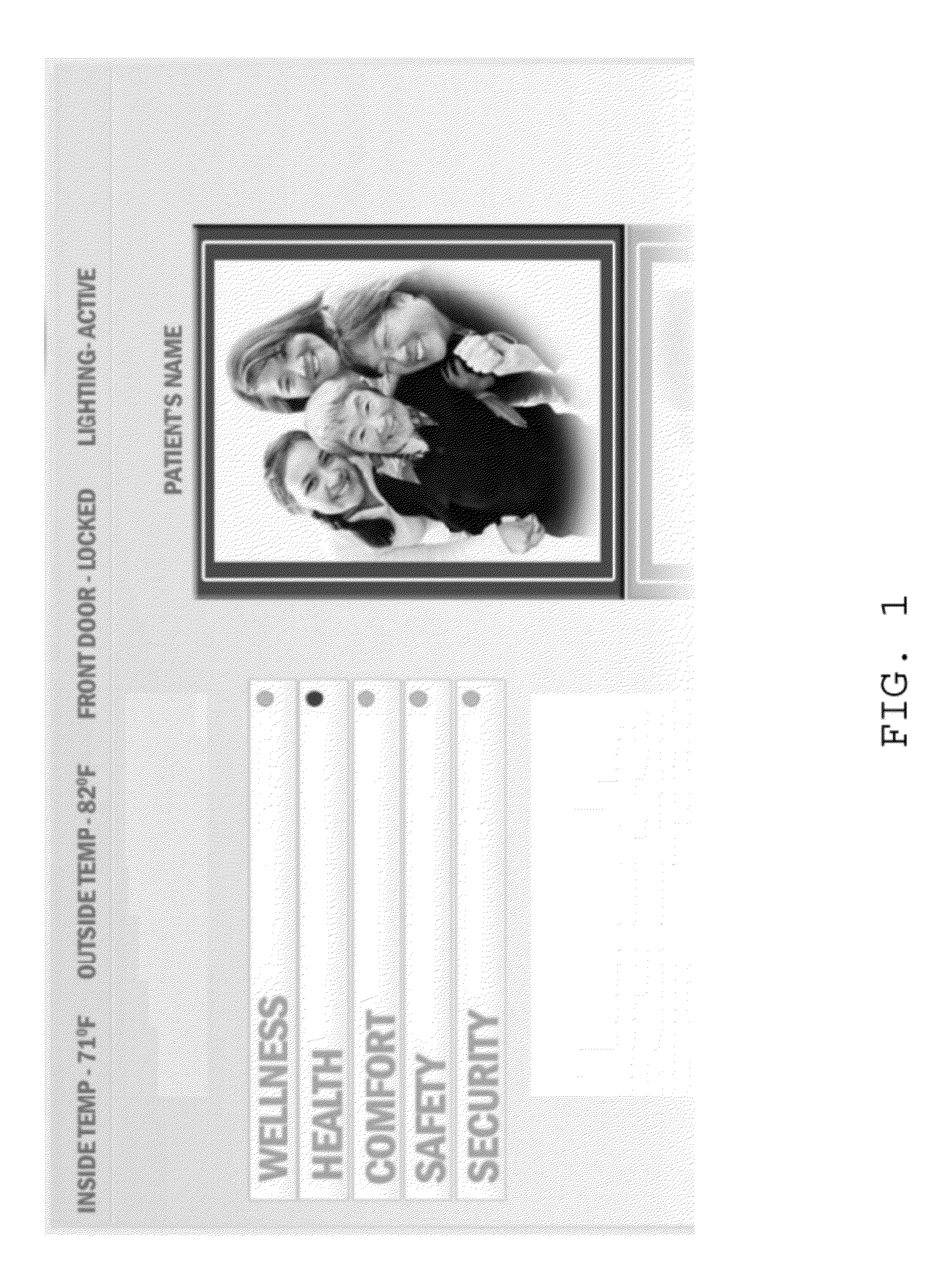

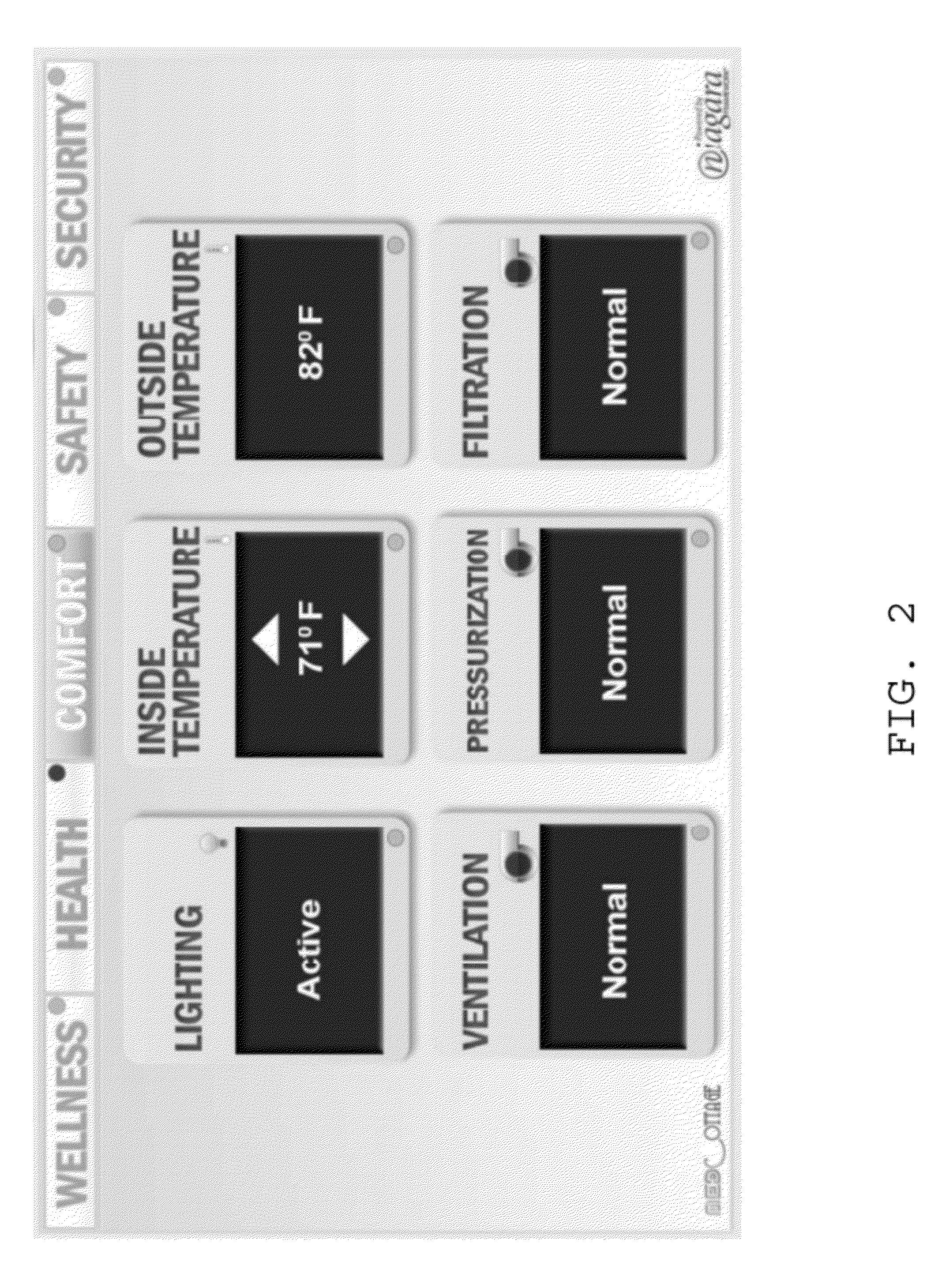

Medical Modules and Monitoring Systems

InactiveUS20120284040A1Roof covering using slabs/sheetsData processing applicationsCaregiver personPressure system

The present invention relates to portable dwellings, rooms, and patient monitoring systems for promoting an independent living or assisted living environment. More particularly, the present invention relates to strong, portable housing equipped with monitoring and air pressurization systems, which can be installed next to a caregiver's home or within a room in the caregiver's home. In preferred embodiments, provided is a portable dwelling comprising: walls and a roof in a fixed exterior configuration, wherein the walls will not fail under wind resistance of up to 200 mph; a positive or negative pressure system for keeping contaminants out of or in the interior; and a patient monitoring system comprising means for capturing an image of a patient in a room, a means for remotely transmitting the image to a caregiver and having the ability to communicate only a restricted or selective view of the image to the caregiver.

Owner:DUPIN KENNETH JOE

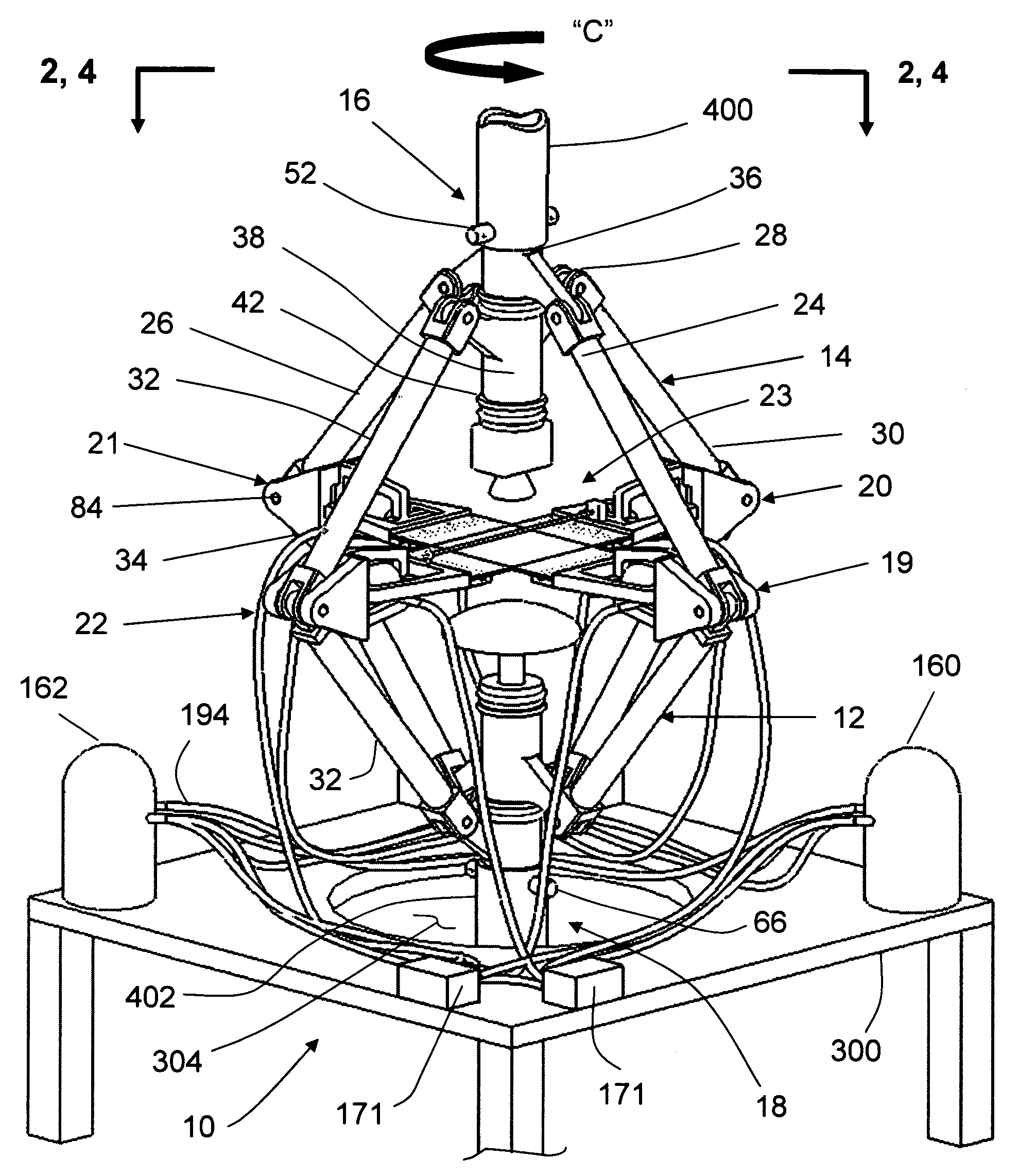

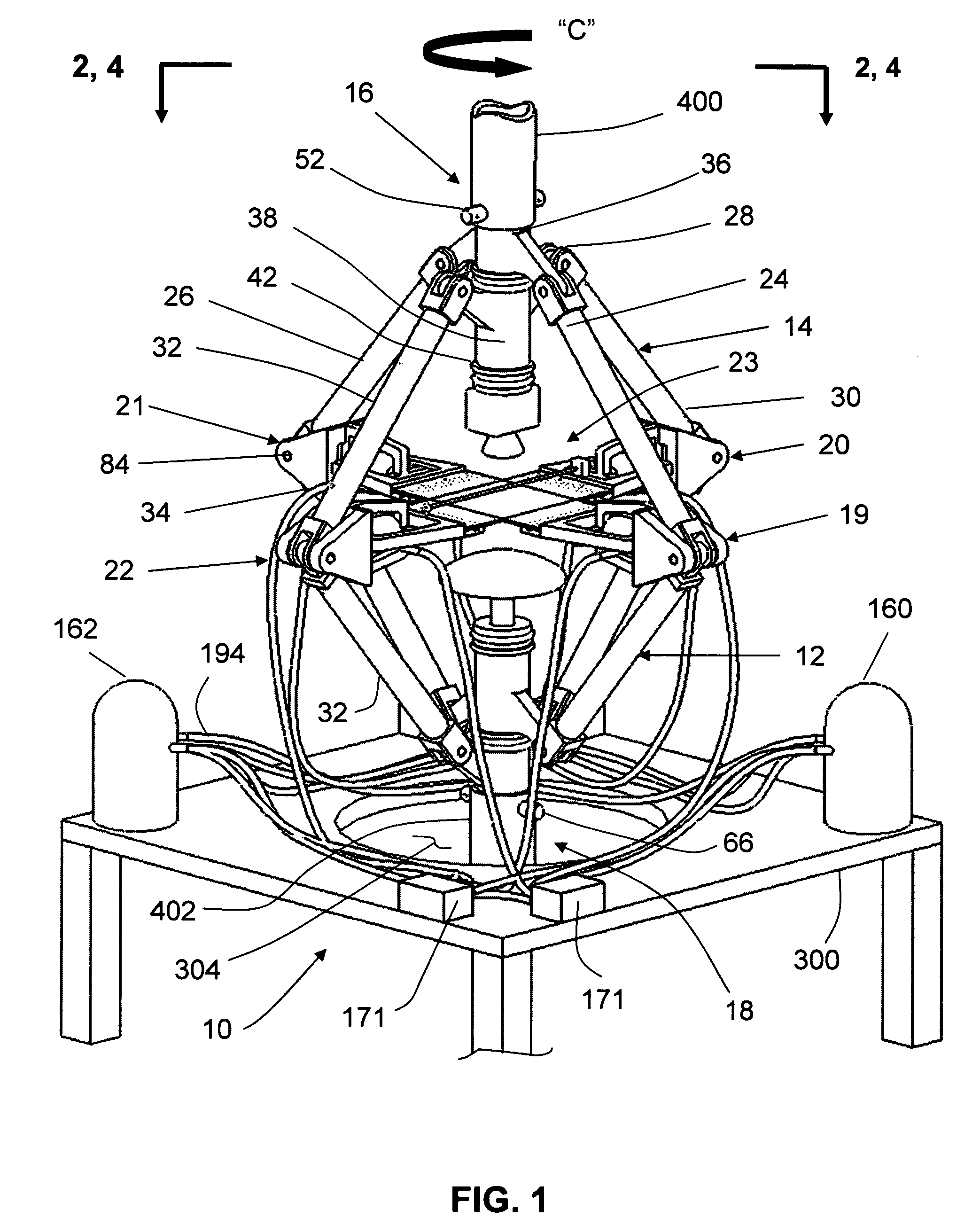

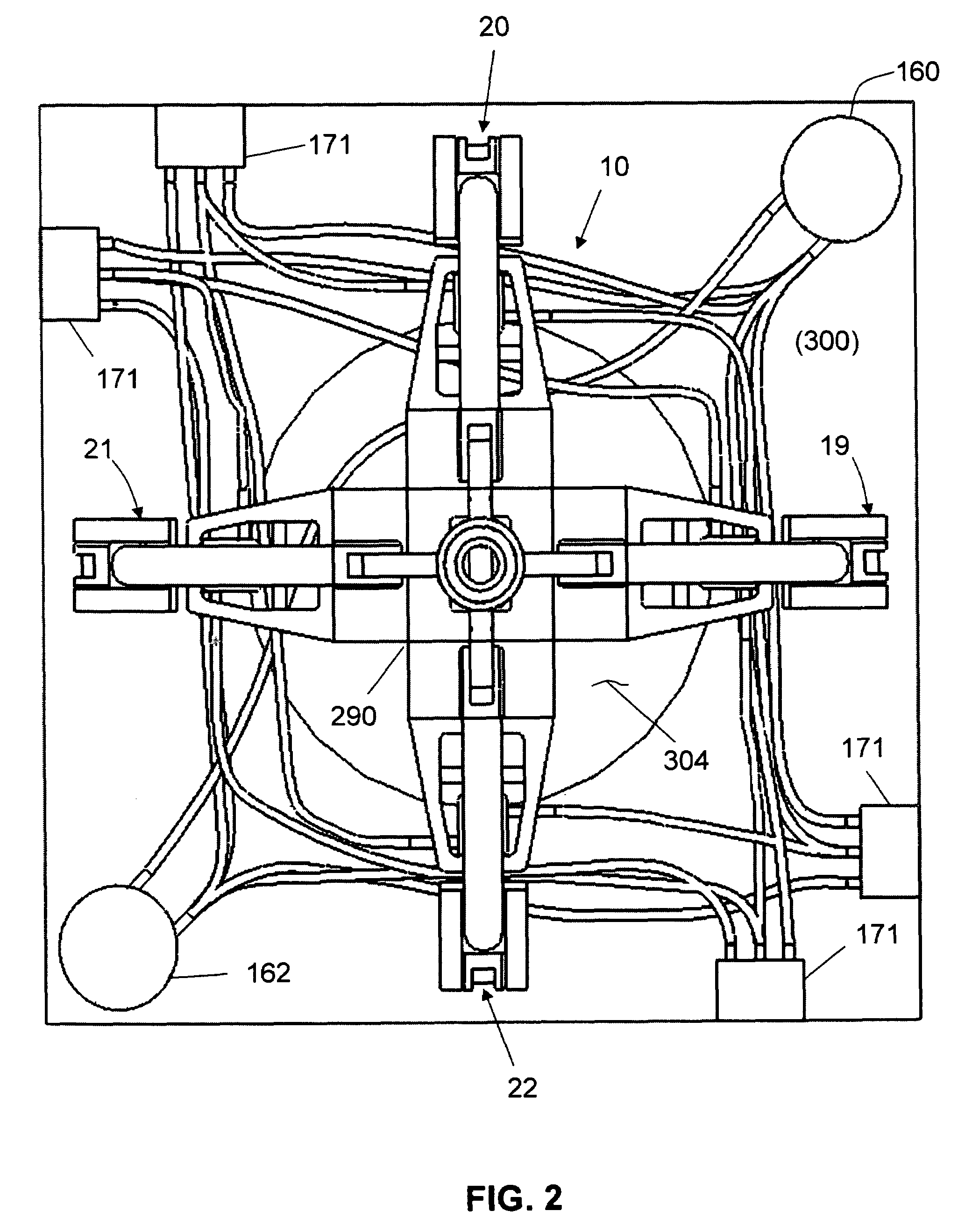

Biaxial and shear testing apparatus with force controls

InactiveUS7204160B1Apparatus is enlargedForce measurementMaterial strength using tensile/compressive forcesPressure systemEngineering

A testing apparatus having four-bar linkages pivotable to sleeves on opposite vertices with the sleeves of each vertex rotationally attached to each other. Links of each linkage are pivotally attached to loading plate assemblies securing a test specimen. During loading, the assemblies move toward or away from each other; thereby, applying compression or tension to the specimen. A pressure system fluidly impacts opposite faces of a piston of the assembly such that one of the faces is pressurized and impacts arms of the assembly for a sliding motion to move toward or away from the longitudinal axis of the apparatus thereby, applying a compression or tensile load on the specimen or augmenting the loads applied by the movement of the loading plate assemblies. The pressure system includes a controller connected to a reservoir, a pressurized source, a plurality of shutoff valves and pressure-adjustable check valves.

Owner:NAVY UNITED STATES OF AMERICA

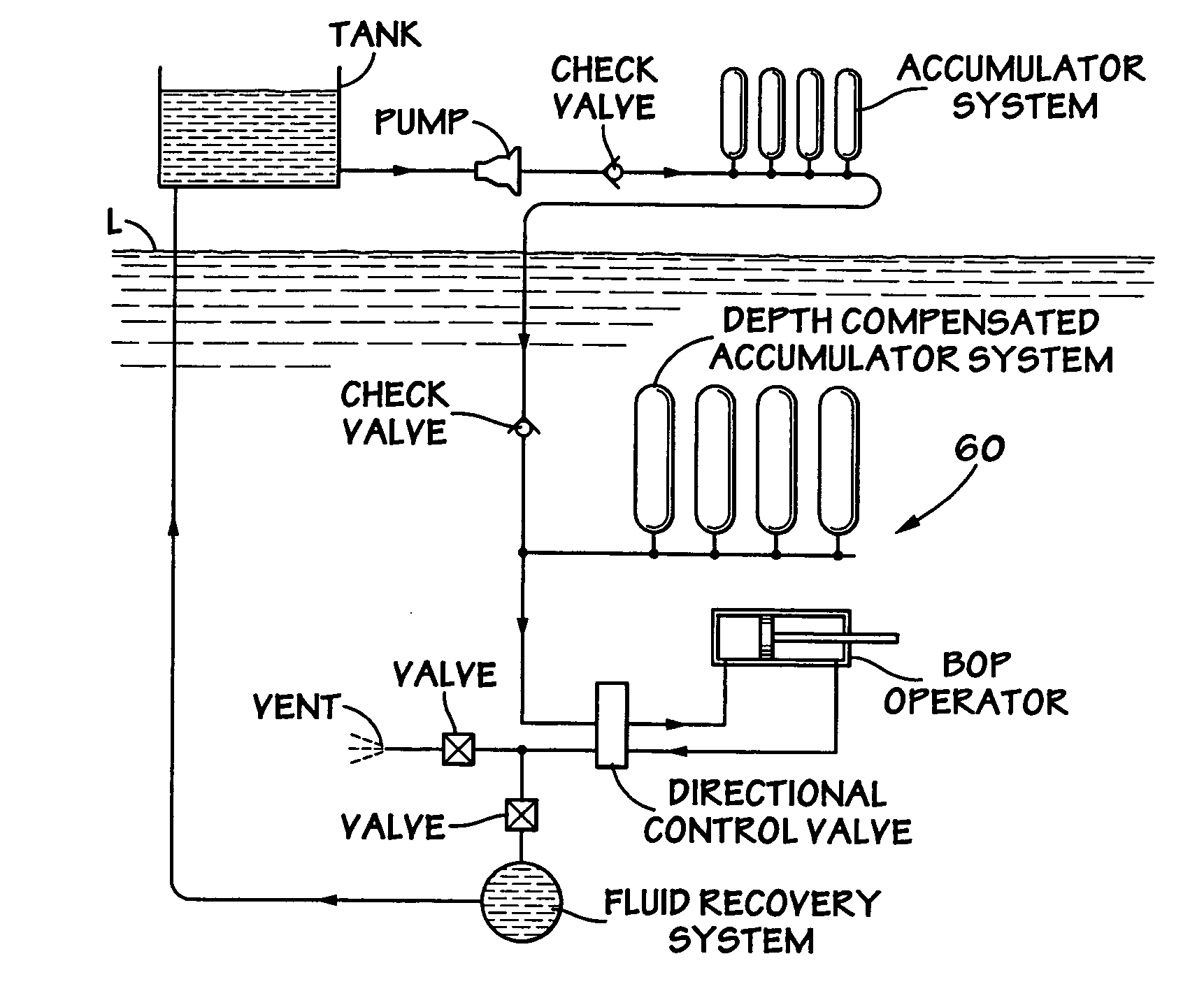

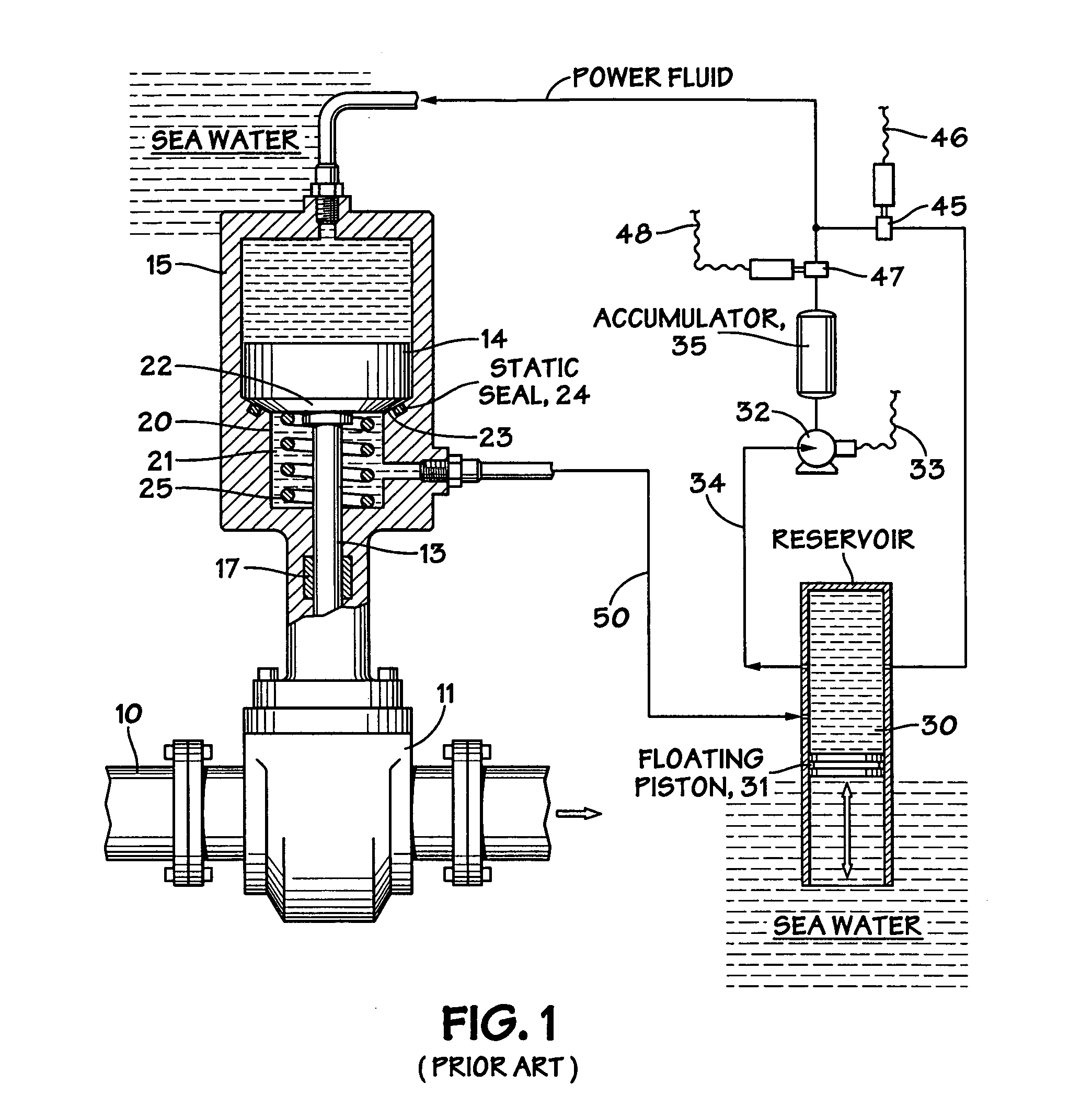

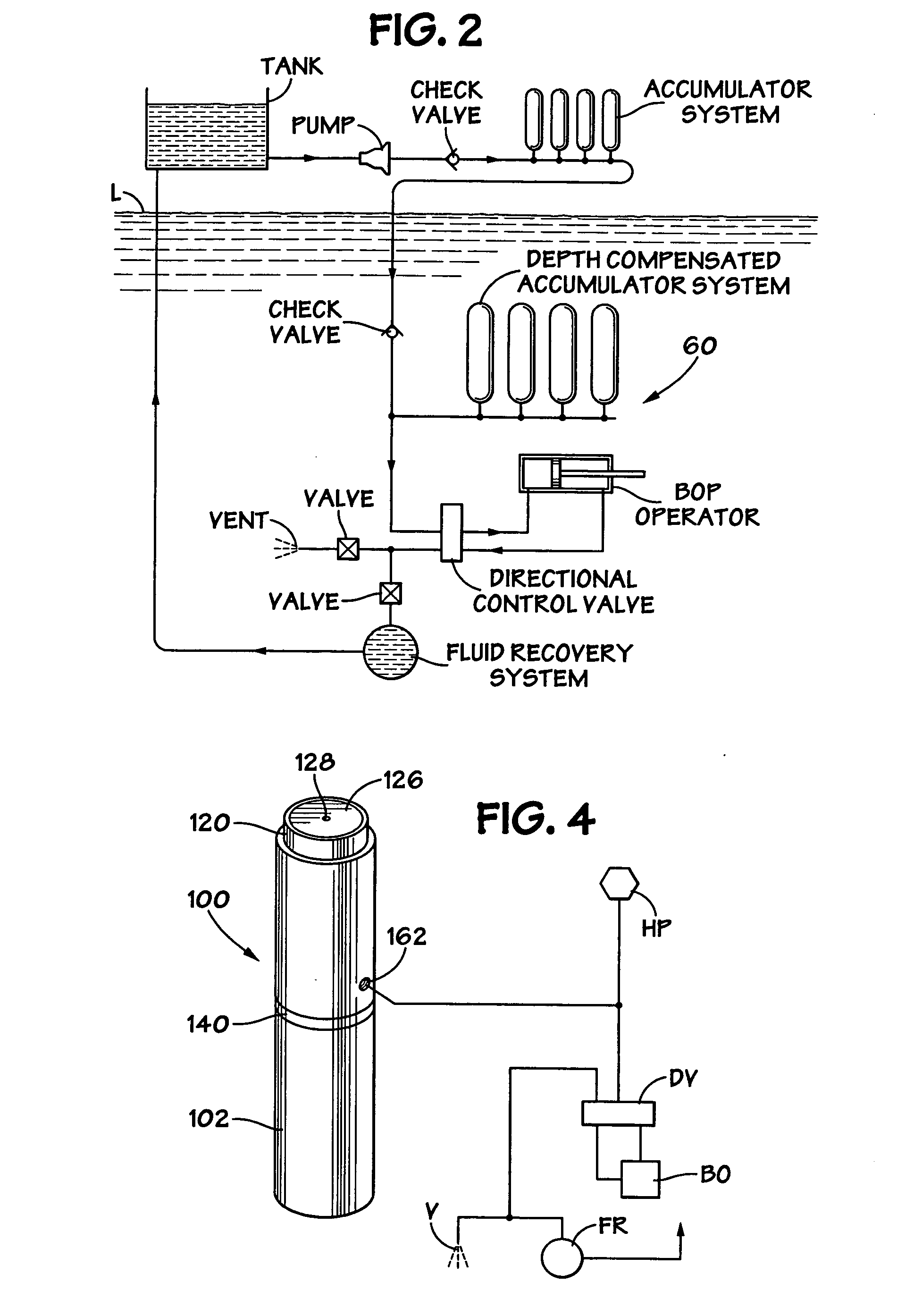

Subsea pressure systems for fluid recovery

ActiveUS20080185046A1Effective expansionReduce amountLevel controlEqualizing valvesOcean bottomPressure system

Systems and methods for recovering power fluid from a device under water and for pumping recovered power fluid to a surface of the water, the systems and methods, in certain aspects, including: flowing fluid from a subsurface apparatus to a subsurface recovery system, the fluid initially provided to the subsurface apparatus to power the subsurface apparatus; and the subsurface recovery system including pump apparatus for selectively pumping recovered fluid to a fluid container above a surface of the water. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:NAT OILWELL VARCO LP

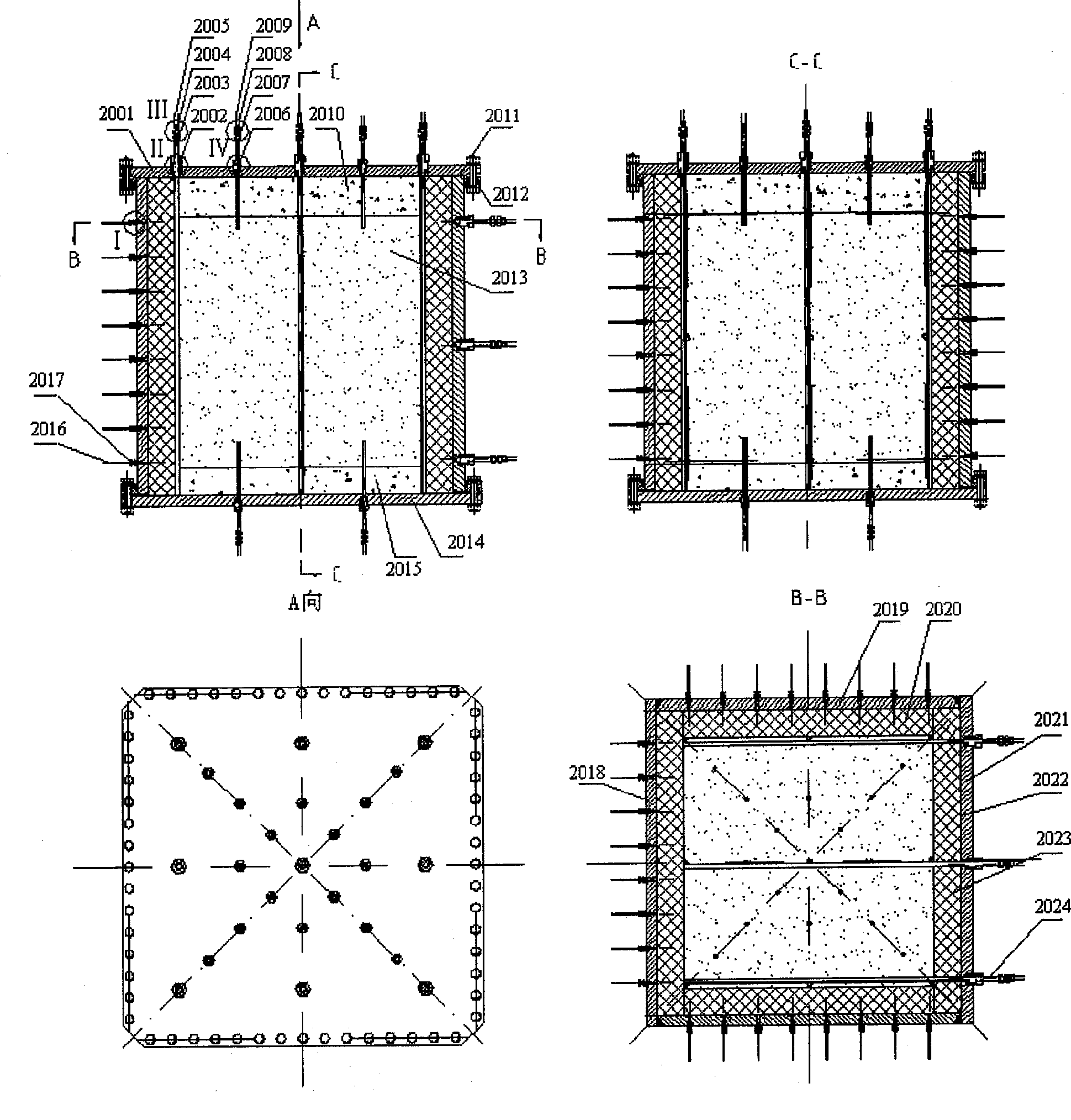

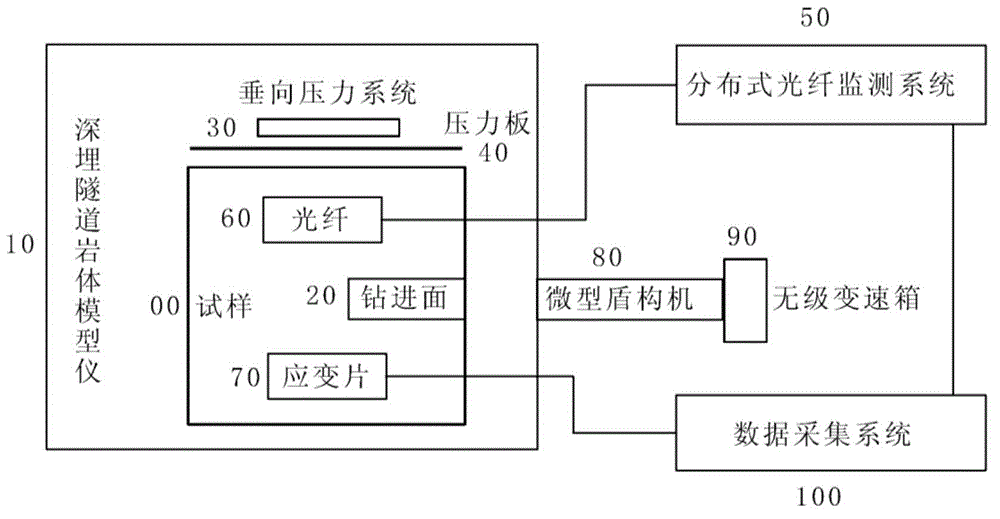

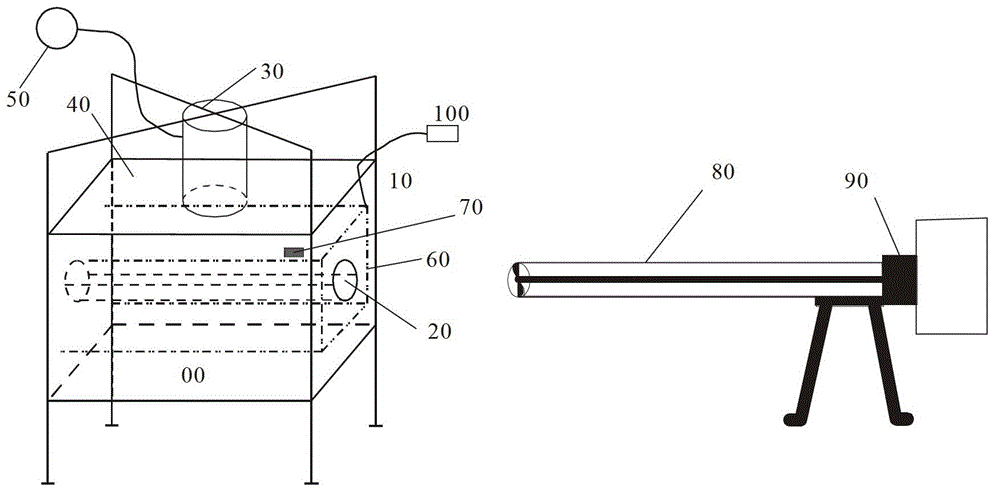

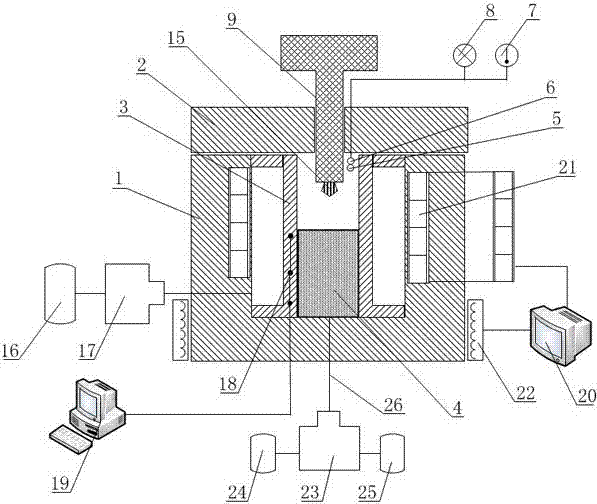

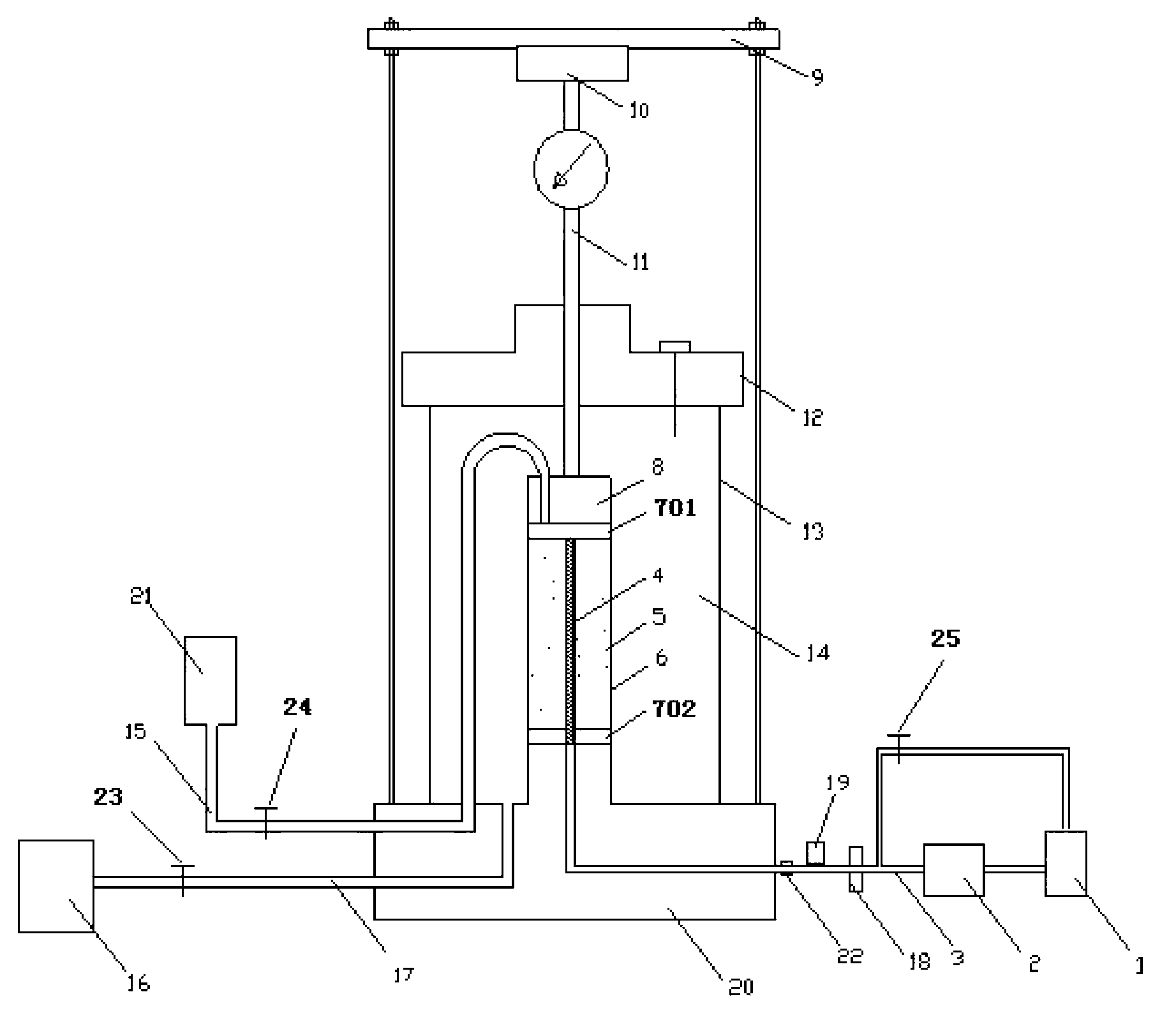

Device and method for physical simulation test of stability of deep tunnel surrounding rock

InactiveCN102721604ASafe Tunnel Construction SpeedEfficient tunnel construction speedStrength propertiesSoil mechanicsData acquisition

The invention discloses a device and a method for a physical simulation test of the stability of a deep tunnel surrounding rock and relates to a rock-soil mechanic technology. A structure of the device is that a pressure plate is covered on a sample in a deep tunnel rock body model instrument, and a vertical pressure system is arranged on the pressure plate and used for loading so as to simulate and exert gravity stress. A miniature shield machine drills into the sample from a drilling surface, and the miniature shield machine, a stepless speed changing box and a motor are sequentially connected to achieve drilling. Eight optical fibers and six strain gauges are distributed in the sample, the optical fibers are connected with a distributed optical fiber monitoring system, and the distributed optical fiber monitoring system and the strain gauges are respectively connected with a data acquiring system so as to achieve detection and recording. By means of the device and the method for the physical simulation test of the stability of the deep tunnel surrounding rock, a development and change law of stress strain when a deep tunnel rock body is excavated in tunnel construction can reappear accurately, and a novel solving path for researching the stability of the grotto surrounding rock and forming mechanism of rock burst in the tunnel construction.

Owner:INST OF GEOMECHANICS

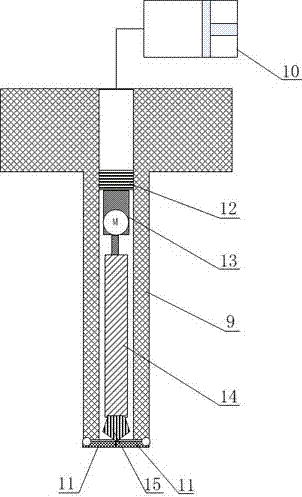

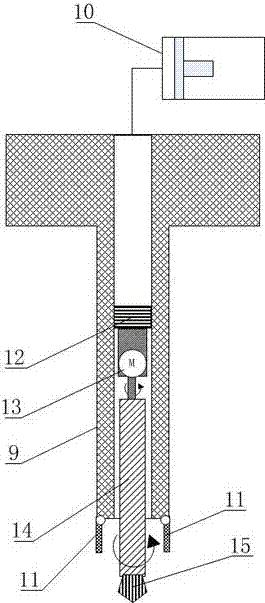

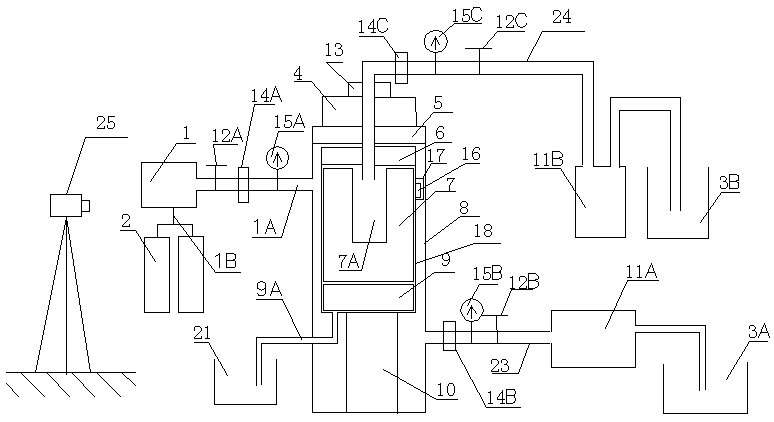

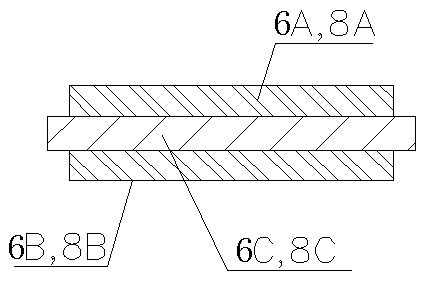

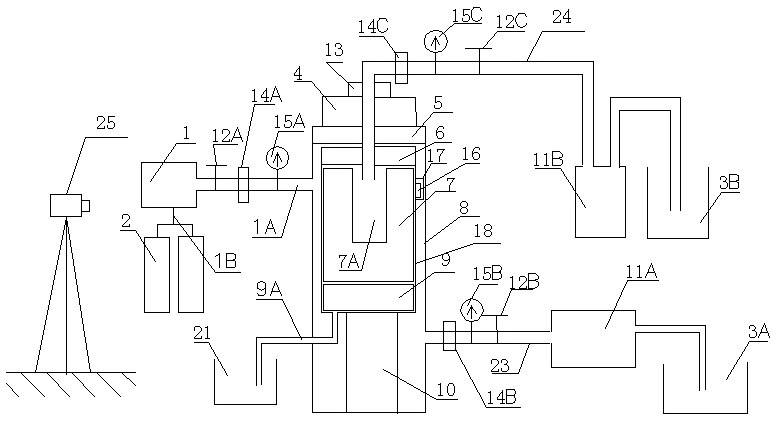

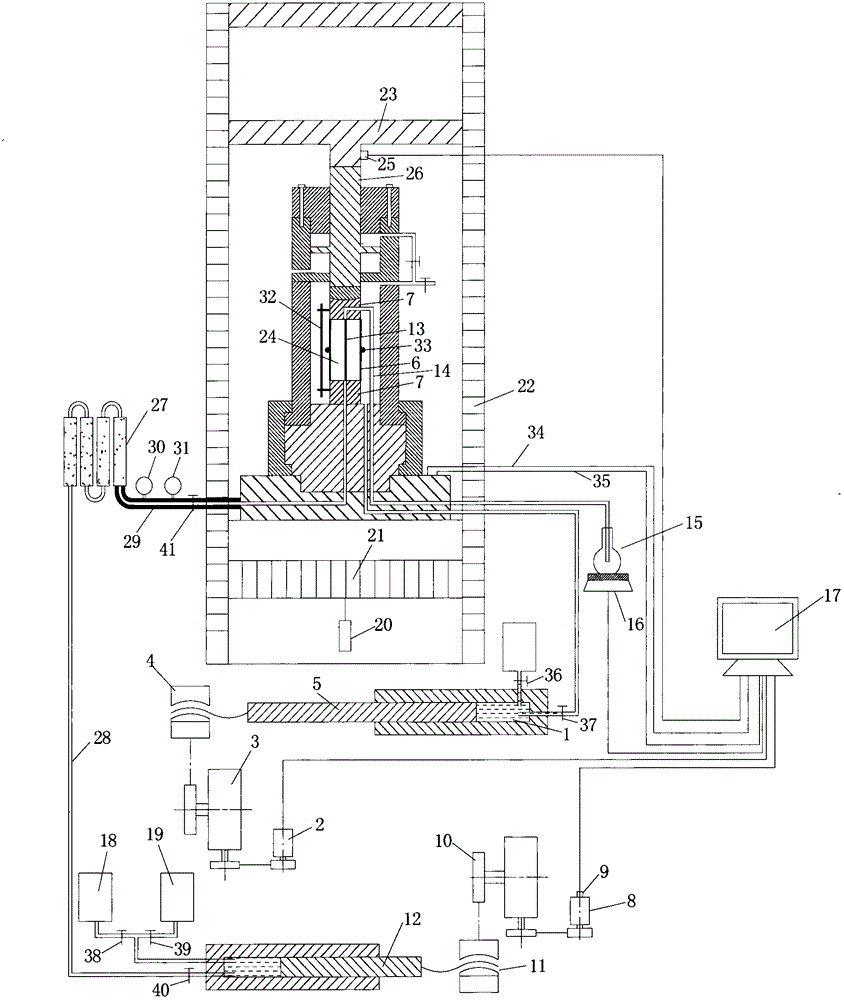

Multifunctional drill bit rock breaking experiment device and method capable of testing triaxial strength parameter of rock

ActiveCN107505207AIncrease profitShort timeMaterial strength using tensile/compressive forcesStress–strain curveRock sample

The invention discloses a multifunctional drill bit rock breaking experiment device capable of testing the triaxial strength parameter of rock. The device comprises a main body device, a pressure head structure, a confining pressure system, an acoustic emission system, a temperature control system and a pore material injection system. The device has the benefits as follows: the real temperature, crustal stress and pore pressure of a stratum can be simulated in a closed environment, a triaxial mechanical test and a drill bit rock breaking test can be completed simultaneously, a stress-strain curve of a rock sample, dynamic vibration of a drill bit and a drill column, bit pressure and influences of footage on the rock sample can be determined, an experiment basis is provided for research of mechanical properties of complex oil and gas reservoirs and drill bit rock breakage under multiple conditions, a rock breaking experiment can be conducted while conventional mechanical properties of the rock are tested, two experiments can be completed once after the designed temperature and pressure conditions are met, the total time consumption is reduced, and the utilization rate of underground rock cores can be effectively increased.

Owner:SOUTHWEST PETROLEUM UNIV

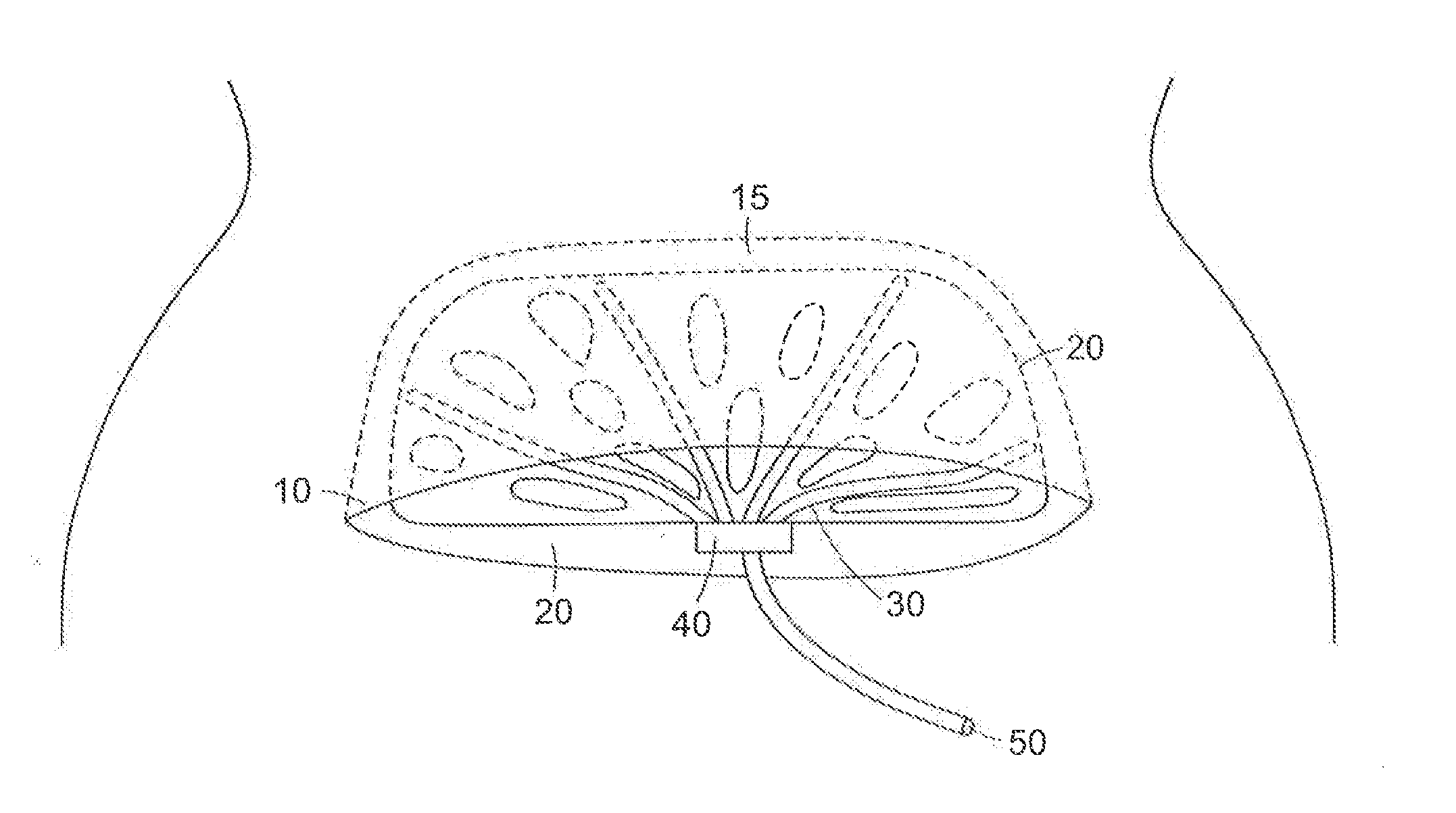

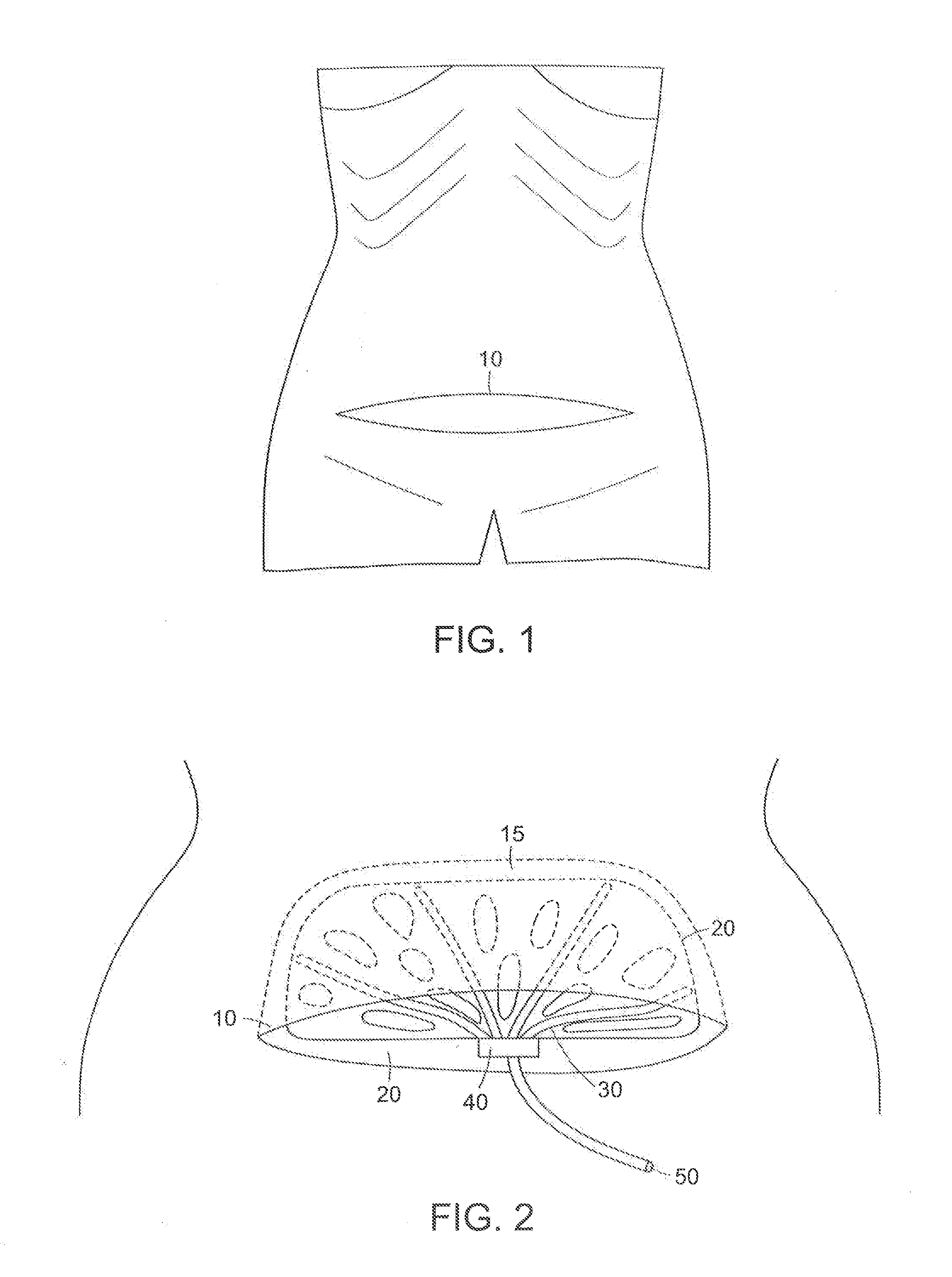

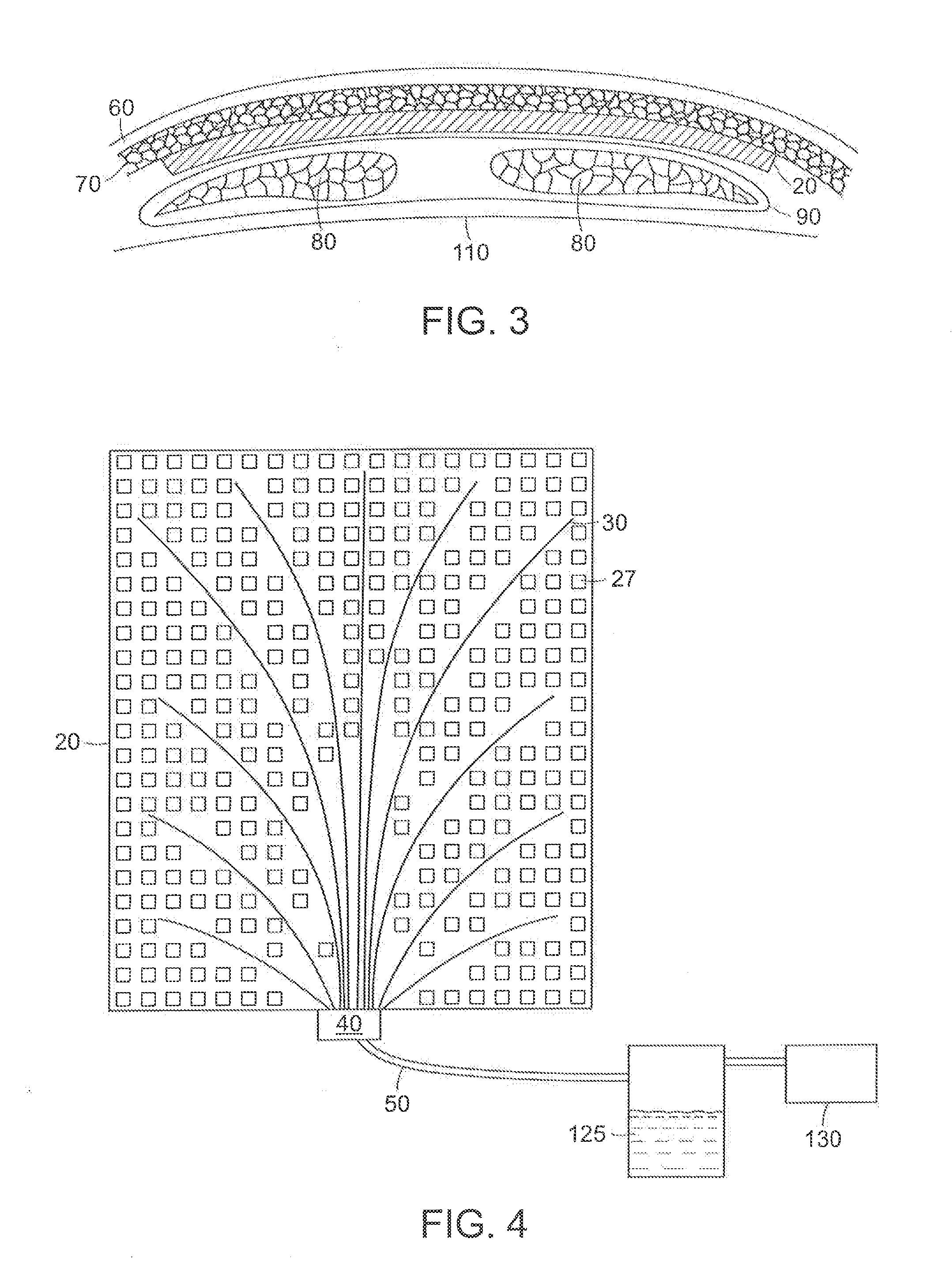

Surgical cavity drainage and closure system

ActiveUS20130274717A1Treating and preventing seromaGood drainageUltrasonic/sonic/infrasonic diagnosticsSuture equipmentsWound dressingSurgical department

A surgical drain device includes a matrix of biodegradable polymer material and a plurality of drain tubes attached to the matrix. The device is implanted within a surgical wound to treat the presence of seromas, for example, and is used to promote drainage, tissue adhesion, and wound closure. The drain tubes converge into a common collection tube that leads wound fluid outside the body under gravity feed or negative pressure applied to the collection tube. The matrix contains an array of apertures that allow tissue contact across the device. A preferred embodiment comprises a tissue anchoring system including anchor elements such as hooks or barbs. The device can be used with a negative pressure system to further improve the drainage band can also be used with a wound dressing. The device and systems containing the device are particularly useful to promote the healing of surgical wounds from abdominal surgery.

Owner:UNIV OF MASSACHUSETTS

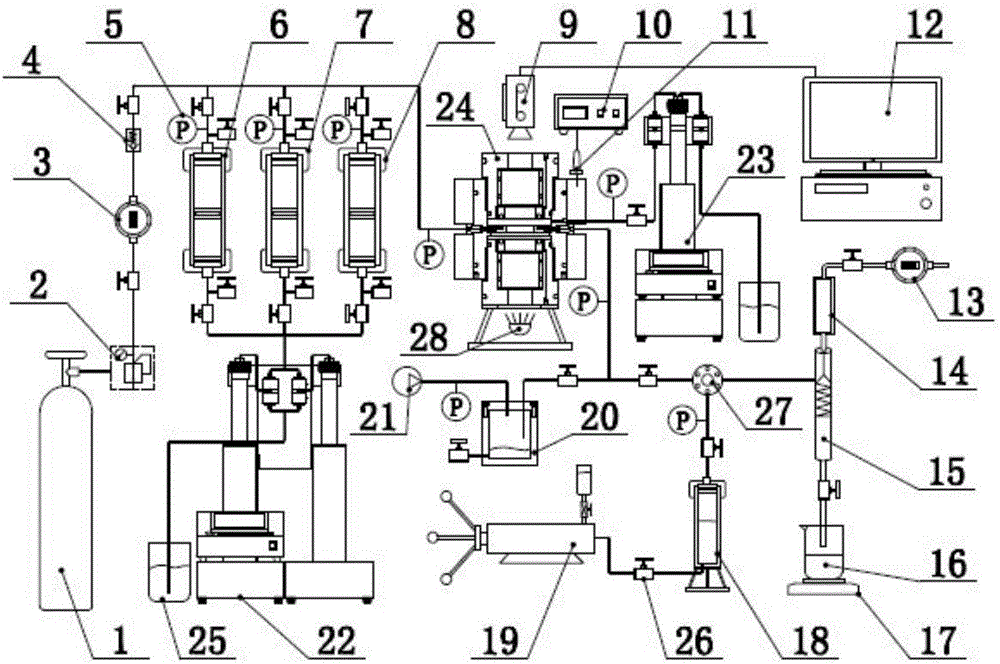

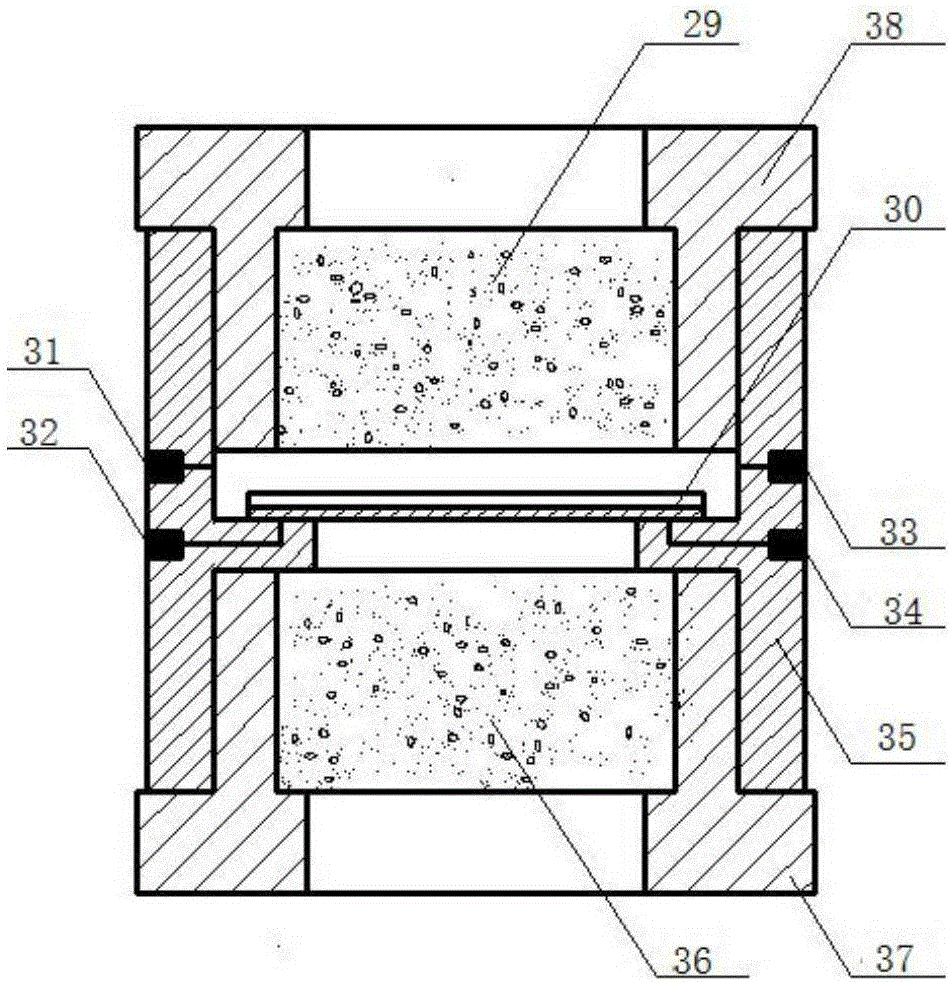

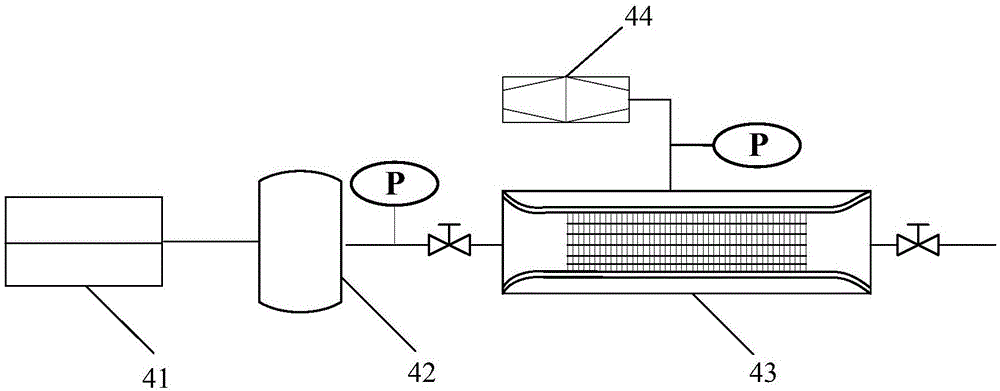

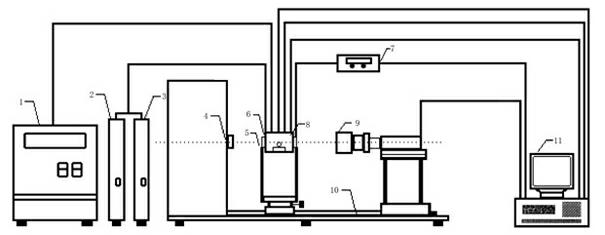

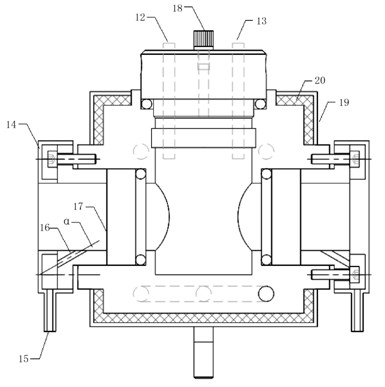

Visualization microscopic experimental device and method for displacing super heavy oil by using high-temperature high-pressure carbon dioxide

ActiveCN106437637AConvenient and effective temperatureConvenient and effective confining pressure sizeOther gas emission reduction technologiesFluid removalMicroscopic scaleHigh pressure

The invention provides a visualization microscopic experimental device and a visualization microscopic experimental method for displacing super heavy oil by using high-temperature high-pressure carbon dioxide, and belongs to the technical field of oil production. The device comprises a model clamper clamping a microscopic visual model, a replacement system, a back pressure system, a confining pressure system, a pressure monitoring system, a temperature control system and an image acquisition system. The device can control temperature and pressure simply and conveniently, has a small use space, is superior in safety performance, is simple and convenient to operate, can accurately simulate an oil reservoir actual condition, can clearly observe oil-gas action changes during carbon dioxide displacement in real time under a visual condition, and has very important significances for researching a precipitation law of asphaltene, the influence of the precipitation law on the recovery ratio, and the widespread use and promotion of a carbon dioxide displacement experiment in the petroleum industry.

Owner:UNIV OF SCI & TECH BEIJING

Device and method for testing expanding and percolation characteristics of microfractures of compact reservoir

ActiveCN107063963AAccurate measurementEasy to assemblePermeability/surface area analysisPressure systemRock core

The invention relates to a device and method for testing expanding and percolation characteristics of microfractures of a compact reservoir, belonging to the technical field of oil-gas field development. The device comprises a triaxial rock core holding device, a microfracture expanding pressure system, a microfracture detection system, a percolation displacement system and a percolation data collection system. The method comprises the following steps: (1) applying an axial pressure to a rock core in the triaxial rock core holding device so as to expand microfractures; (2) monitoring development and evolution characteristics of the microfractures of the rock core by virtue of an ultrasonic fault detector, and monitoring deformation characteristics of the rock core by virtue of a stress-strain detection instrument; and (3) testing percolation characteristics of fluid under different microfracture development conditions of the rock core by virtue of a percolation displacement device. The device and the method disclosed by the invention have the beneficial effects that a measurement result is accurate, the assembling is convenient, the operation is simple, the percolation characteristics of oil, gas and water in the microfractures of the compact reservoir can be tested, and the necessary technical support can be provided for fracture development of the compact reservoir.

Owner:ZHEJIANG OCEAN UNIV

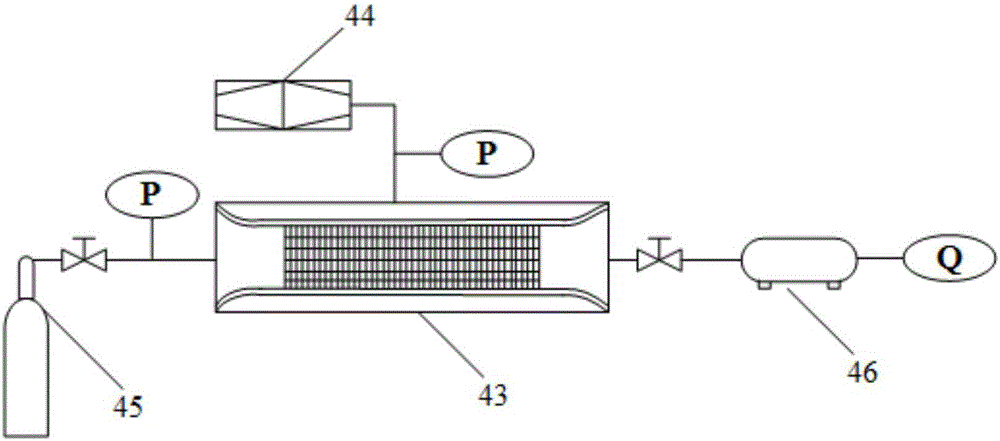

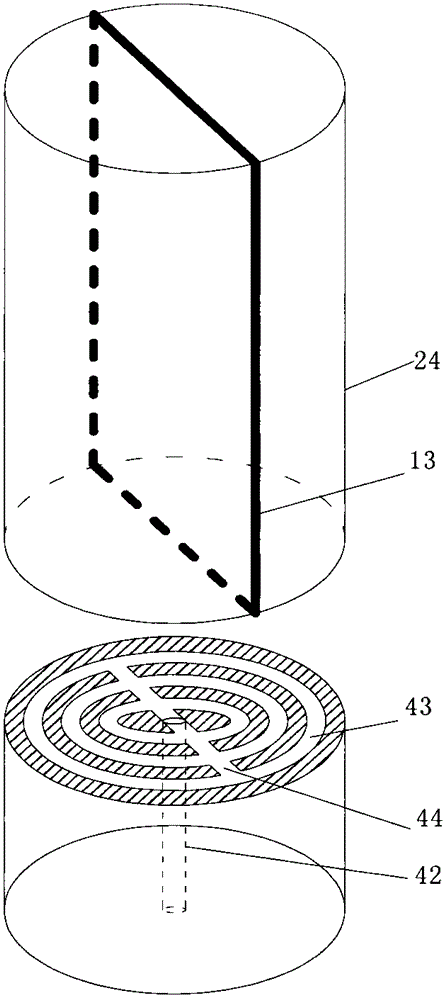

Device for Simultaneous Measurement of Gas Injection Coal Expansion and Permeability under Triaxial Stress Conditions

InactiveCN102288529ASolve the amount of deformationSolve permeabilityPermeability/surface area analysisUsing fluid meansPressure systemStress conditions

The invention discloses a device for simultaneously measuring expansion and permeability rate of gas injected into a coal rock under a tri-axial stress condition. The device comprises a gas injection system (1), a confining pressure system (2), an axial pressure loading machine (25), a permeability measuring system (3) and a data acquisition system (4), wherein the gas outlet port of the gas injection system (1) is connected with the gas inlet port of the confining pressure system (2) through a high pressure gas inlet pipe (43); the axial pressure loading machine (25) is arranged at the external part of the confining pressure system (2); the permeability measuring system (3) is connected with the gas outlet port of the confining pressure system (2) through a high pressure gas pipe; and the data acquisition system (4) is connected with the confining pressure system (2) through a data line with a sensor. According to the device provided by the invention, the problem of measuring coal-body deformations and permeability variations of different adsorption gases at different temperatures and different pressures is effectively solved; in addition, the permeability and coal-body change laws caused by a gas injection displacement in the process of developing coal bed gases are effectively simulated so that the production practice is beneficial to be further guided.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Indoor grouting testing device under simulation of complex stress effect and testing method thereof

InactiveCN103018152ASolve drainage problemsDoes not affect the drainage effectPermeability/surface area analysisRubber membranePressure system

Owner:HUNAN UNIV OF SCI & TECH

Coal and rock bore hydraulic fracture experimental apparatus

InactiveCN102031954AImprove fracturing effectEasy to take pictures and recordEarth material testingFluid removalPressure systemAcoustic emission

The invention discloses a coal and rock bore hydraulic fracture experimental apparatus, which comprises a sample device system, a confining pressure system, a fracture system, a sealing system and a monitoring system, wherein the sample device system comprises a sample cylinder, the bottom in the sample cylinder is provided with a screen drum of which the bottom is provided with a water outlet pipe, a sample is accommodated in the sample cylinder above the screen drum, and a simulated bore is formed in the sample; the confining pressure system comprises an air filling subsystem and a water filling subsystem; the fracture system comprises a fracture high-pressure water pump of which a water outlet is communicated with the simulated bore through a fracture pipeline; the sealing system comprises a sample cylinder sealing device and an experimental cylinder sealing device; and the monitoring system comprises an acoustic emission sensor arranged on an external wall of the sample cylinder. By the coal and rock bore hydraulic fracture experimental apparatus, a simulated experiment can be performed in a laboratory to investigate the change rules of crack initiation, expansion and extension in the hydraulic fracture process of a coal mine underground coal seam bore, and know a crack extending direction so as to guide field fracture; therefore, the fracture effect is greatly improved.

Owner:HENAN POLYTECHNIC UNIV

Evaluating method of oil and gas reservoir seepage by supercritical carbon dioxide fracturing fluid and method thereof

ActiveCN106644871ASimple and fast operationEasy to implementPermeability/surface area analysisTemperature controlPressure system

The invention belongs to the technical field of irregular oil gas development and production increase, and particularly relates to an evaluating method of oil and gas reservoir seepage by supercritical carbon dioxide fracturing fluid and a method thereof; a carbon dioxide pressurizing and filling system provides carbon dioxide air source and pressure, and is connected with a supercritical carbon dioxide fracturing fluid phase balance reaction system; the supercritical carbon dioxide fracturing fluid phase balance reaction system is linked with a temperature control system in parallel; a core displacement and permeability measuring system is respectively connected with the supercritical carbon dioxide fracturing fluid phase balance reaction system and a return pressure system, so that the fracturing fluid is effected on the core; the return pressure system provides necessary return pressure for experiment, so as to simulate the real formation condition. The device can adjust the experiment temperature and pressure according to different experiments, and exactly determine the damage rate of the supercritical carbon dioxide fracturing fluid core, and study influences of supercritical carbon dioxide fracturing fluid on the core damage rate under different experimental conditions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Differential air pressure systems

Described herein are various embodiments of differential air pressure systems and methods of using such systems. The differential air pressure system may comprise a chamber configured to receive a portion of a user's lower body and to create an air pressure differential upon the user's body. The differential air pressure system may further comprise a user seal that seal the pressure chamber to the user's body. The height of the user seal may be adjusted to accommodate users with various body heights.

Owner:ALTERG INC

Test device for chemical solution seepage in rock single fracture at different temperatures

ActiveCN104007013ASolve corrosiveSolve the defects of crack deformation testWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesChemical solutionPressure system

The invention relates to a test device for chemical solution seepage in rock single fracture at different temperatures. The test device comprises a sample apparatus system, an axial compression system, a confining pressure system, a chemical solution pressure loading system, a servo control system and a data acquisition system. The sample apparatus system comprises a sample, a cylindrical heat-shrinkable tube and a cylindrical rigid spacer block; one end of the rigid spacer block is provided with a permeation hole, a circular permeation groove and a radial permeation groove; the chemical solution pressure loading system is provided with a heating device; the heating device comprises a heater and a temperature sensor; the heater is disposed on a solution pipe at one side of the sample apparatus system; and the solution pipe between the heater and the sample apparatus system is provided with the temperature sensor. To increase test precision, the wall of the solution pipe between the heater and the sample apparatus system is provided with a heat insulation material; and a ceramic heater is employed.

Owner:HUNAN UNIV OF SCI & TECH

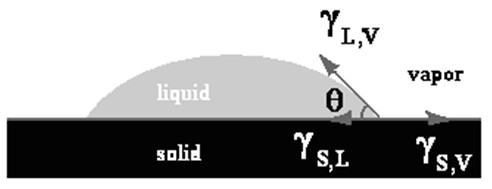

Device for measuring droplet contact angle and rolling angle under temperature control, humidity control and pressure control condition

InactiveCN102621042AHigh degree of automationImprove test accuracySurface/boundary effectSimultaneous control of multiple variablesEngineeringHigh pressure

The invention belongs to the technical field of chemical measurement and in particular relates to a device for measuring a droplet contact angle and a rolling angle under a temperature control, humidity control and pressure control condition. A temperature control system is used for accurately controlling the temperature in a specimen box within a range from -20 DEG C to +200 DEG C; a humidity control system is used for controlling the relative humidity range at 0-100%; a vacuum / pressure control system comprises a high pressure system and a vacuum system; the pressure control range is from 10-6 Pa to 8.5 MPa; an anti-fogging device is used for preventing the surface of a glass window from fogging; a high speed image pickup system is used for obtaining a testing droplet contour image; the image sampling speed can reach 1400 thousand frames per second; the highest resolution reaches 1280x800; image sampling data is transmitted to a computer system by a data wire; and the image is fitted by using software according to a Young-Laplace equation so as to the contact angle, rolling angle, advancing angle, backing angle and viscoelastic property of the droplet. The device provided by the invention has the advantages of high automatic degree, testing accuracy, good experiment result repeatability, suitability for a wide temperature range, broad humidity, high pressure and negative pressure system to measure the contact angle, rolling angle, advancing angle, backing angle and lag angle of the droplet.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com