Patents

Literature

1009results about How to "Solve corrosive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

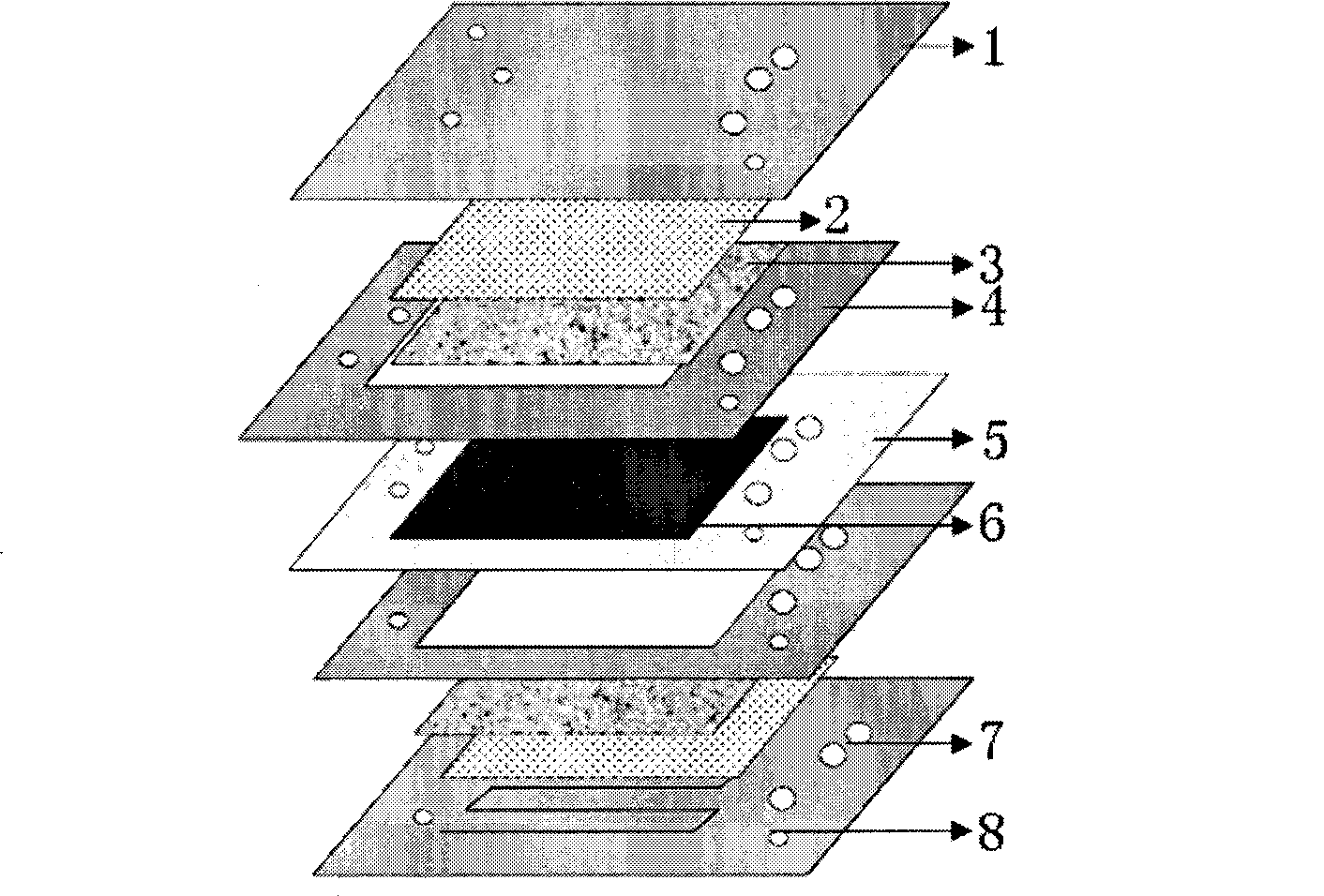

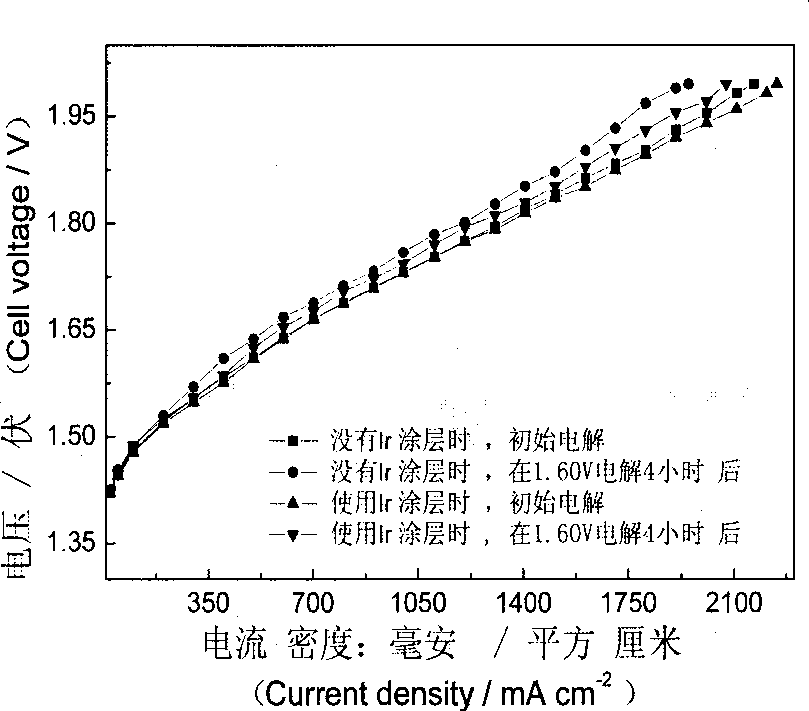

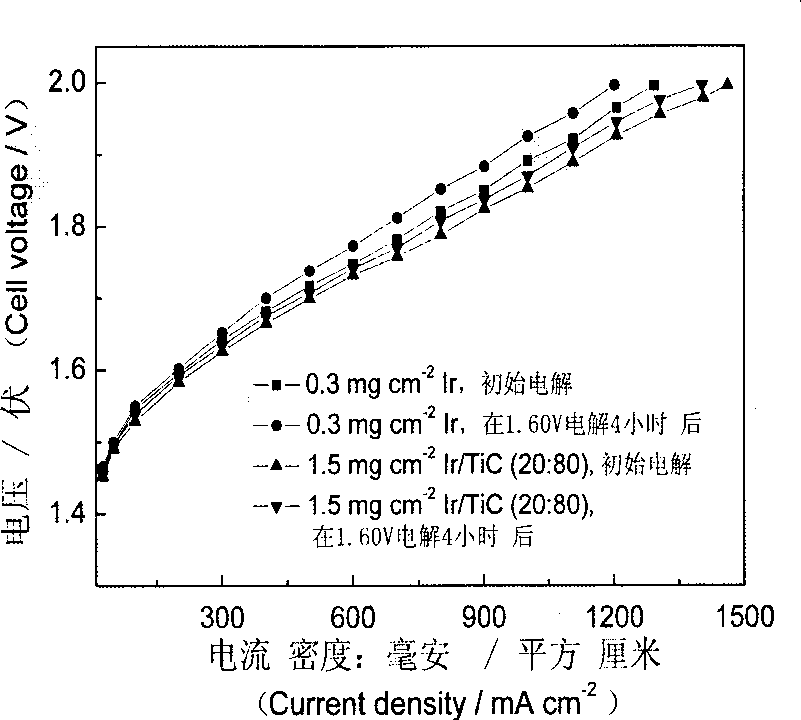

Membrane electrode for proton exchange membrane water electrolysis battery and preparation thereof

InactiveCN101388463AReduce loadReduce contact resistanceCell electrodesSolid electrolyte fuel cellsNano catalystElectrolysis

The invention discloses a proton exchange membrane water electrolyte battery membrane electrode and a process for preparation thereof, which belongs to the technical field of preparing hydrogen gas through electrolyzing water, wherein the proton exchange membrane water electrolyte battery membrane electrode comprises a polymer electrolyte membrane, an anode catalyst layer, a cathode catalyst layer, an anode diffusion layer, a cathode diffusion layer, a support layer and a flow field plate, wherein hydrophilic thin layer structures which are formed by catalyst are respectively brushed on both surfaces of the polymer electrolyte membrane. Anode catalyst is noble metal or metallic material, and the diffusion layer is carbon material or metallic material. A catalyst layer and the relative diffusion layer and the support layer are compacted in a titanium plate to prepare membrane electrode through utilizing external force under normal temperature. The invention lowers the load of catalyst, improves the operating factor of catalyst, avoids the deformation of membranes in the process of heat pressing, and is drawn supported from the catalytic and corrosion resistance property of an anti-corrosion diffusion layer with catalytic property, and the electrolytic property and the stability of a battery are improved. The invention has the advantages of simple technique, convenient operation and excellent repeatability.

Owner:SHANGHAI JIAO TONG UNIV

Fluorine-free environment-friendly type continuous casting protecting slag for the blast furnace slag containing titanium and the manufacturing process of the same

The present invention relates to steel-making crystallizer protecting dregs, and is environment protecting fluoride-free protecting dregs suitable for continuous casting of plate billet and square billet. The protecting dregs consist of sintering base material, titanium-containing blast slag, manganese ore powder, bentone, carbon black, clay shaped graphite, etc. Its production process includes the synthesis of base material and the compounding of protecting dregs. The protecting dregs may be molten in the crystallizer homogeneously to produce cast billet lubricating and heat insulating effect and has no corrosion to casting machine and no pollution to water.

Owner:CHONGQING UNIV

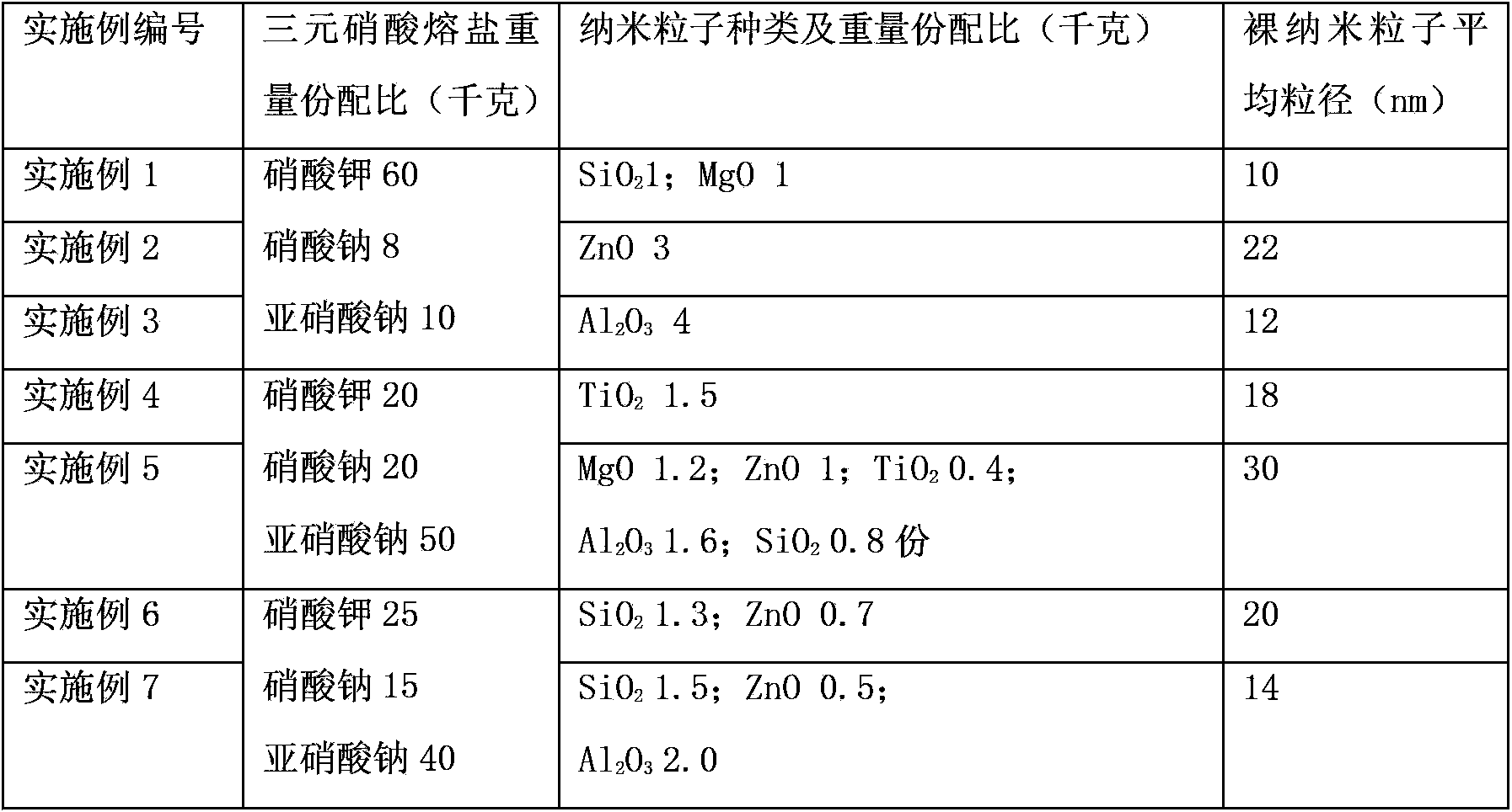

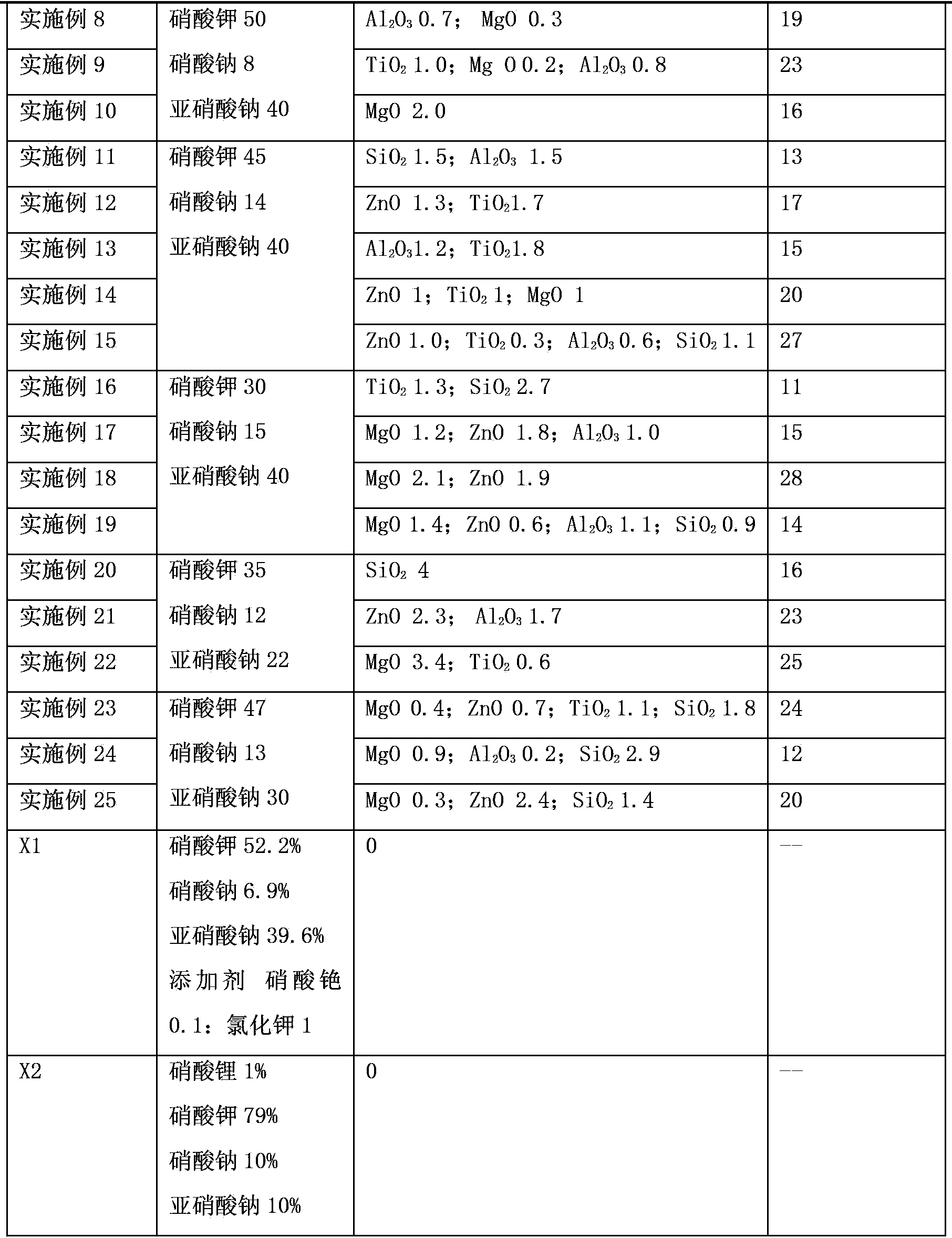

Ternary nitric acid nano-molten salt heat transfer and storage medium, preparation method and application thereof

InactiveCN103881662AOvercome solubilityOvercoming thermal conductivityHeat-exchange elementsMetal oxide nanoparticlesNanoparticles dispersion

Belonging to the technical field of heat storage and transfer, the invention provides a ternary nitric acid nano-molten salt heat transfer and storage medium, a preparation method and application thereof. The ternary nitric acid nano-molten salt heat transfer and storage medium contains a ternary nitric acid molten salt system formed by potassium nitrate, sodium nitrate and sodium nitrite. The ternary nitric acid nano-molten salt heat transfer and storage medium is characterized in that it also includes metal oxide nanoparticles and / or non-metal oxide nanoparticles. The nanoparticles are dispersed into the ternary nitric acid molten salt system to undergo compounding so as to form the ternary nitric acid nano-molten salt heat transfer and storage medium. The ternary nitric acid nano-molten salt involved in the invention has a low melting point, an upper limit use temperature up to 600DEG C, good thermal stability, and high heat conductivity, thus being very suitable for the heat storage and transfer system of industrial energy storage and solar-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

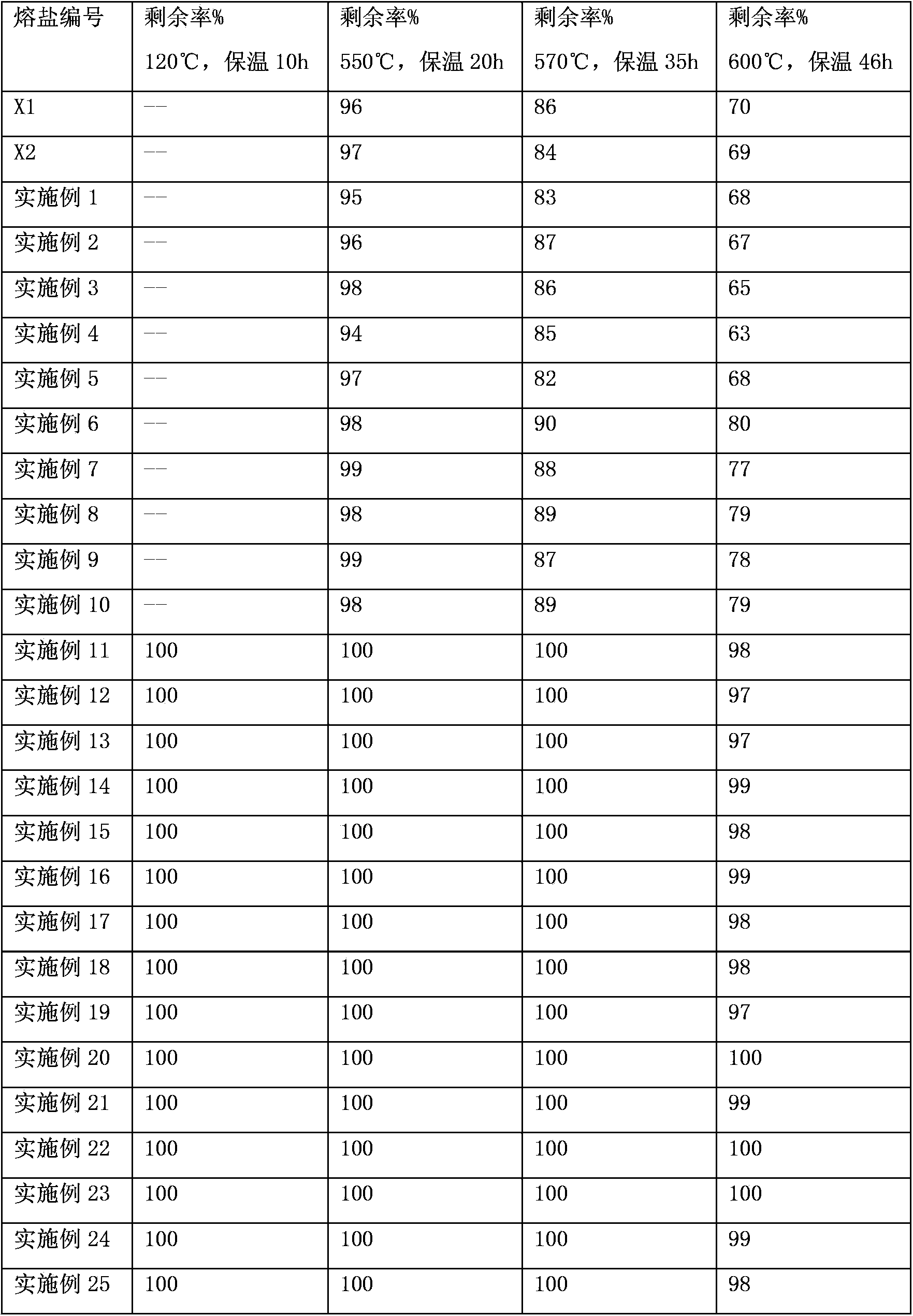

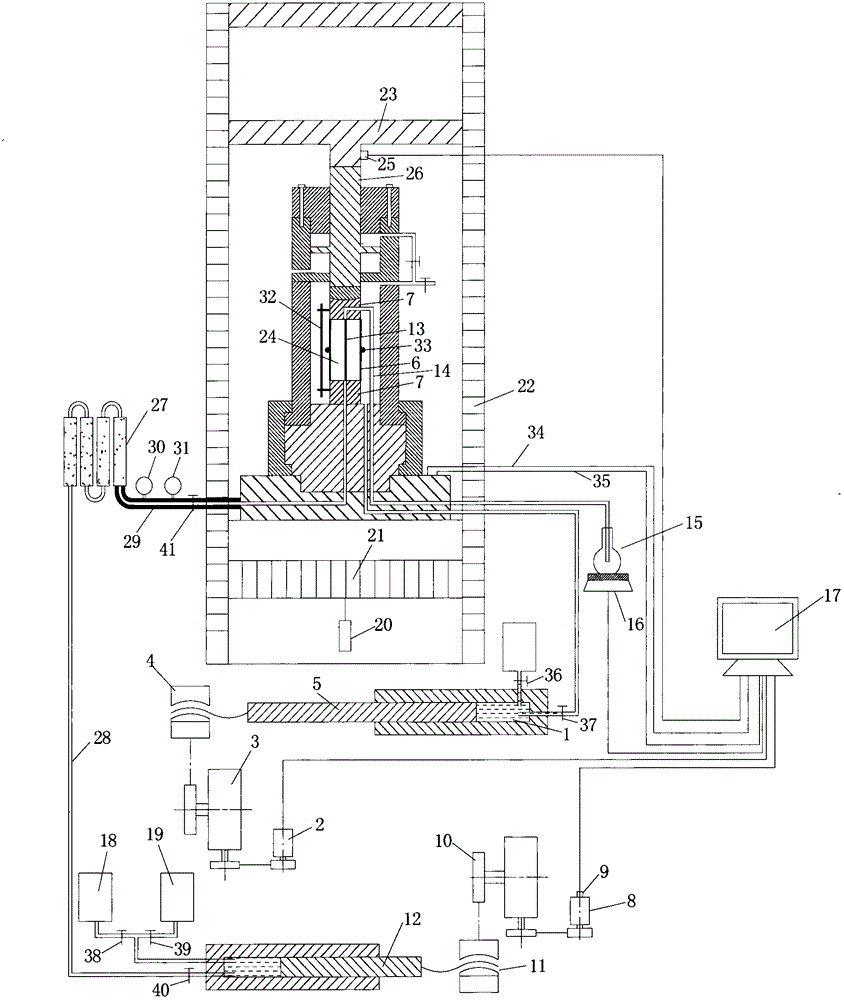

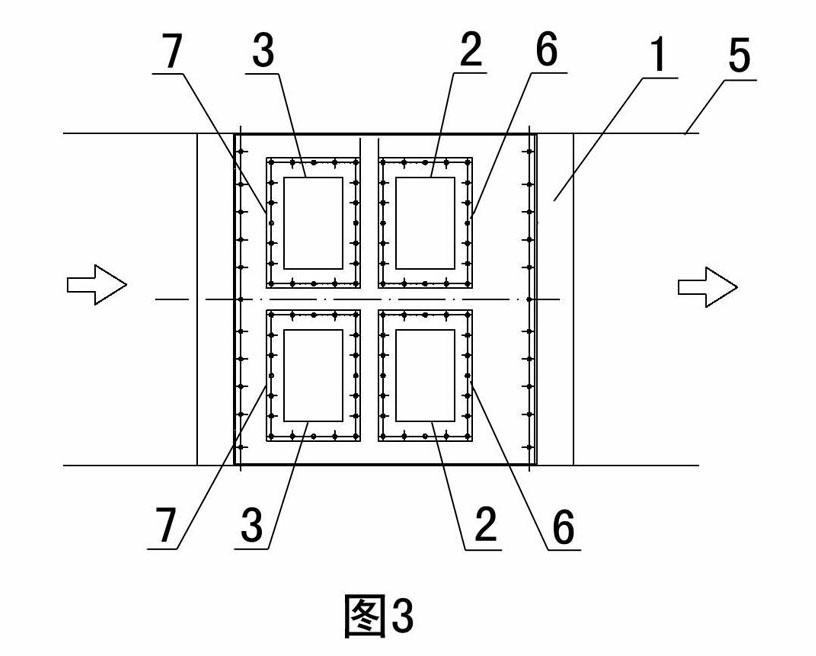

Test device for chemical solution seepage in rock single fracture at different temperatures

ActiveCN104007013ASolve corrosiveSolve the defects of crack deformation testWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesChemical solutionPressure system

The invention relates to a test device for chemical solution seepage in rock single fracture at different temperatures. The test device comprises a sample apparatus system, an axial compression system, a confining pressure system, a chemical solution pressure loading system, a servo control system and a data acquisition system. The sample apparatus system comprises a sample, a cylindrical heat-shrinkable tube and a cylindrical rigid spacer block; one end of the rigid spacer block is provided with a permeation hole, a circular permeation groove and a radial permeation groove; the chemical solution pressure loading system is provided with a heating device; the heating device comprises a heater and a temperature sensor; the heater is disposed on a solution pipe at one side of the sample apparatus system; and the solution pipe between the heater and the sample apparatus system is provided with the temperature sensor. To increase test precision, the wall of the solution pipe between the heater and the sample apparatus system is provided with a heat insulation material; and a ceramic heater is employed.

Owner:HUNAN UNIV OF SCI & TECH

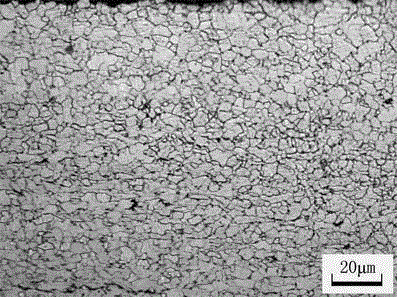

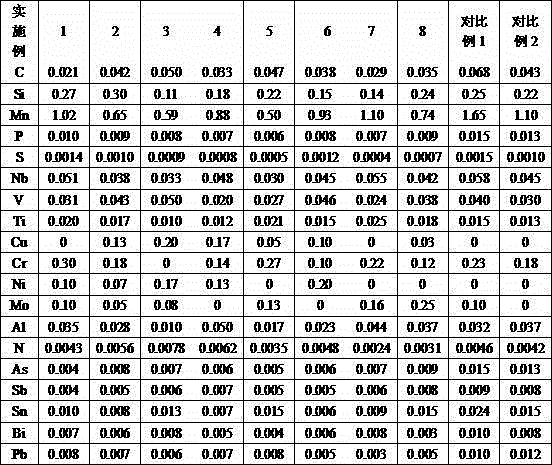

Pipeline steel excellent in acid corrosion resistance on seabed and production method

The invention discloses pipeline steel excellent in acid corrosion resistance on the seabed. The pipeline steel comprises, by weight, 0.020-0.050% of C, 0.10-0.30% of Si, 0.50-1.10% of Mn, 0.012% of P or less, 0.0015% of S or less, 0-0.20% of Cu, 0-0.30% of Cr, 0-0.20% of Ni, 0-0.25% of Mo, 0.030-0.055% of Nb, 0.020-0.050% of V, 0.010-0.025% of Ti, 0.010-0.050% of Al and 0.008% of N or less. A production method comprises the steps of heating after continuous casting and blank forming, rough rolling, precise rolling, cooling, reeling and cooling to indoor temperature. By means of the pipeline steel and the production method, an ideal complex-phase structure containing ultra-fine grain polygonal ferrite and a small number of methyl acrylate (MA) components which are distributed dispersively can be obtained, the Rt0.5 is equal to or higher than 485 MPa, the Rm is equal to or higher than 570 MPa, -20 DEG C KV2 is equal to or higher than 250 J, and -15 DEG C DWTT SA is equal to or higher than 85%. A hydrogen induced crack j (HICj) test and a sulfide stress corrosion cracking (SSCC) test indicate that no fracture or crack occurs.

Owner:武汉钢铁有限公司

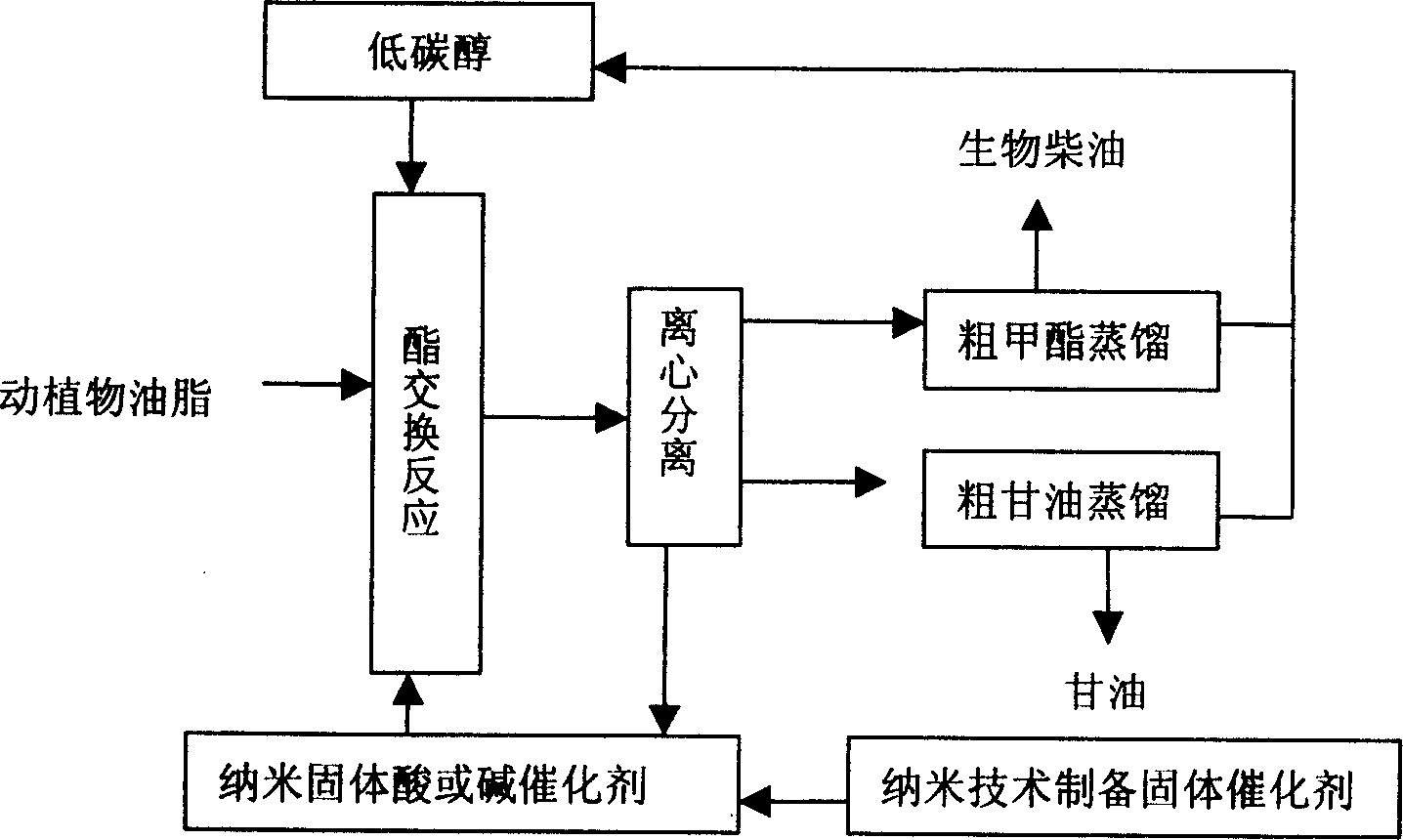

Method for preparing biological diesel oil using nano solid acid or alkali catalyst

InactiveCN1858160AEasy to useSolve corrosiveBiofuelsLiquid hydrocarbon mixture productionBiodieselVegetable oil

The present invention relates to process of preparing low carbon alkyl ester and biological diesel oil by means of nanometer solid acid or alkali catalyst. Under the action of catalyst in the amount of 1-20 wt% of animal and vegetable oil, low carbon alcohol and animal and vegetable oil in the molar ratio of 3.5-40 to 1 are reacted at the pressure from normal to 25 MPa and temperature of 40-100 deg.c to produce coarse methyl ester and glycerin, which are centrifugally separated and distilled to obtain low carbon alcohol, or neutral biological diesel oil and glycerin, separately. The present invention has biological diesel oil converting rate up to 96% and yield up to 99%, and the product meets the ASTM D 6751-02 standard. The nanometer solid acid or alkali catalyst may be used repeatedly for 3-100 times in producing biological diesel oil, and the product needs no neutralization and washing.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

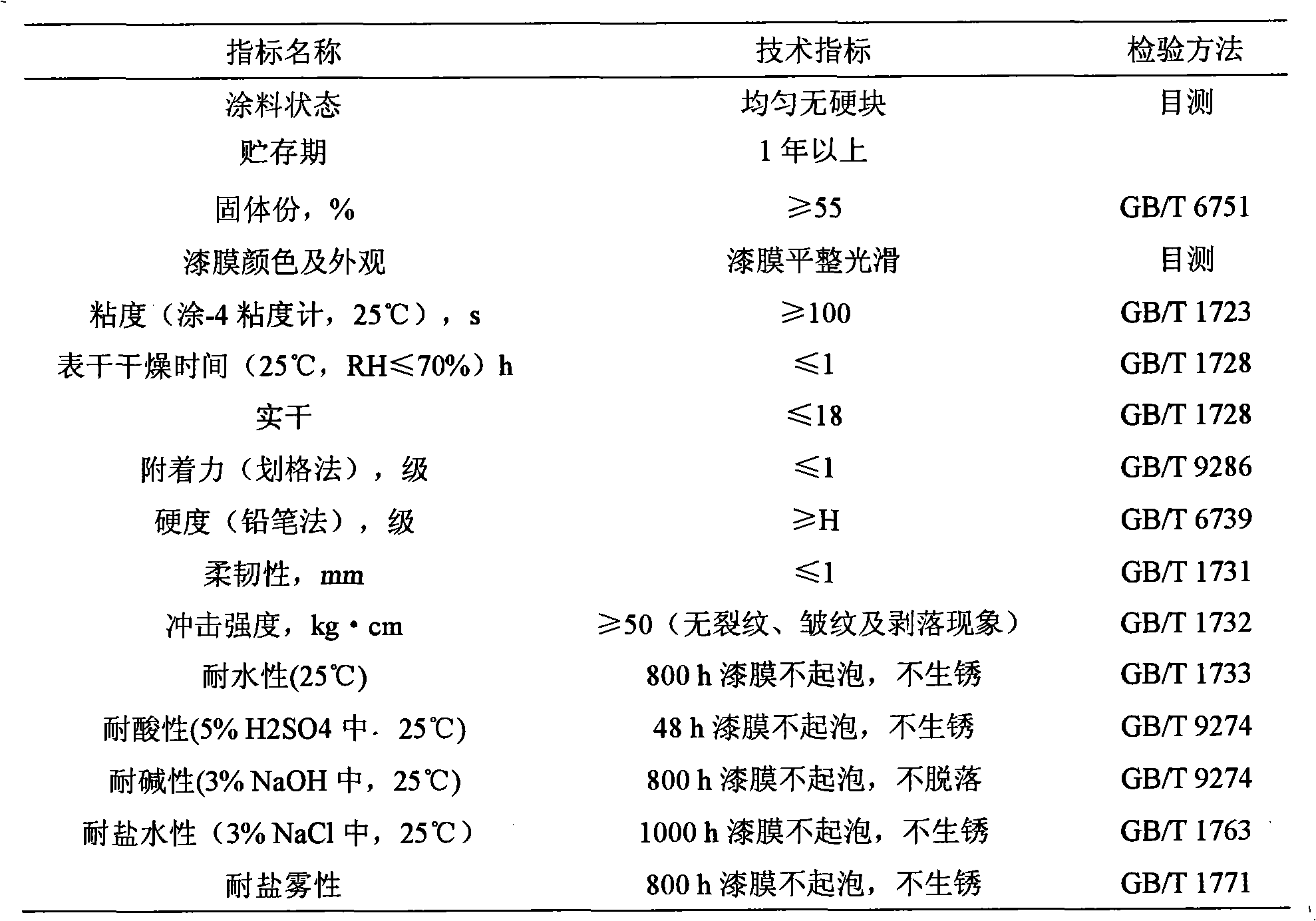

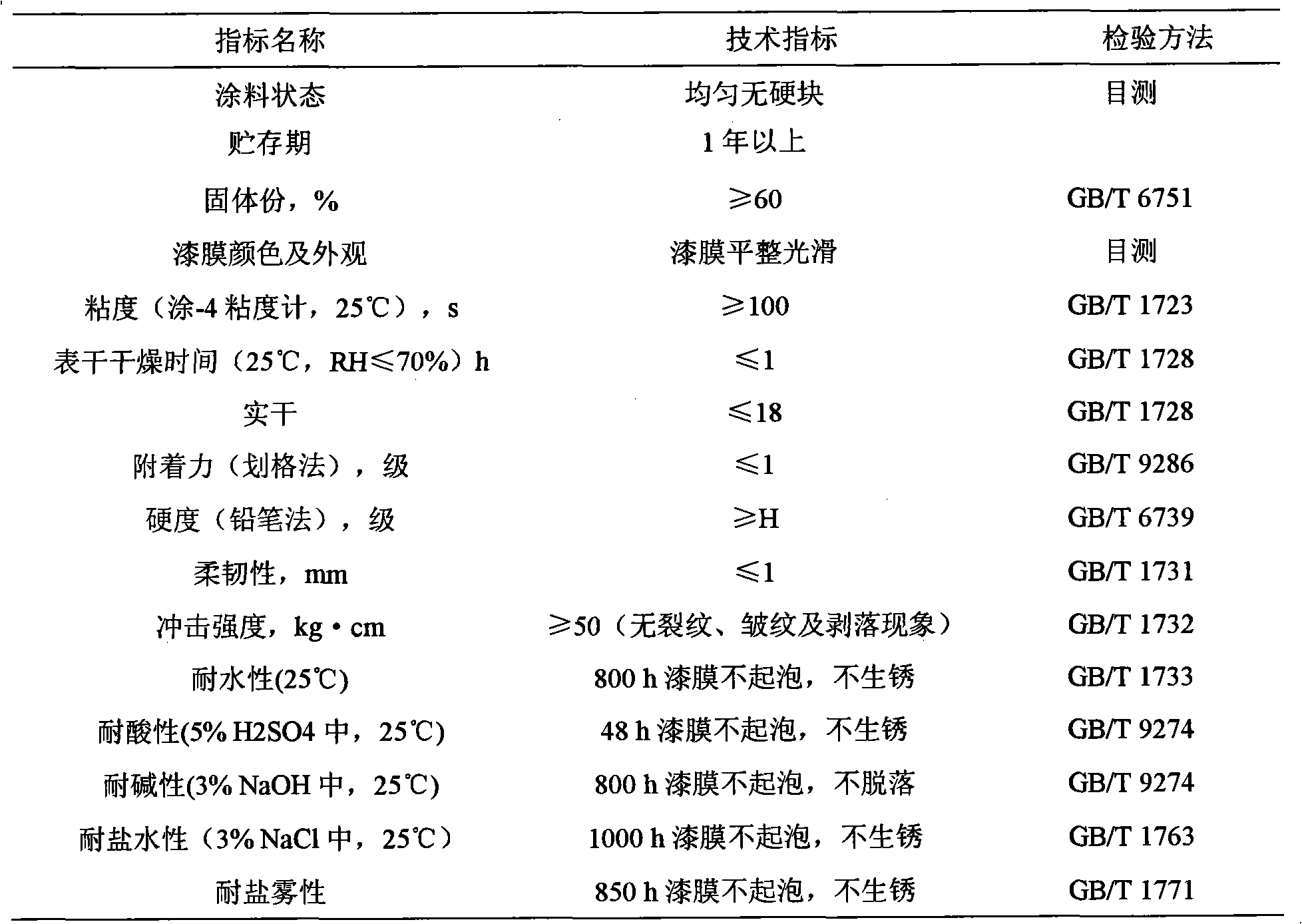

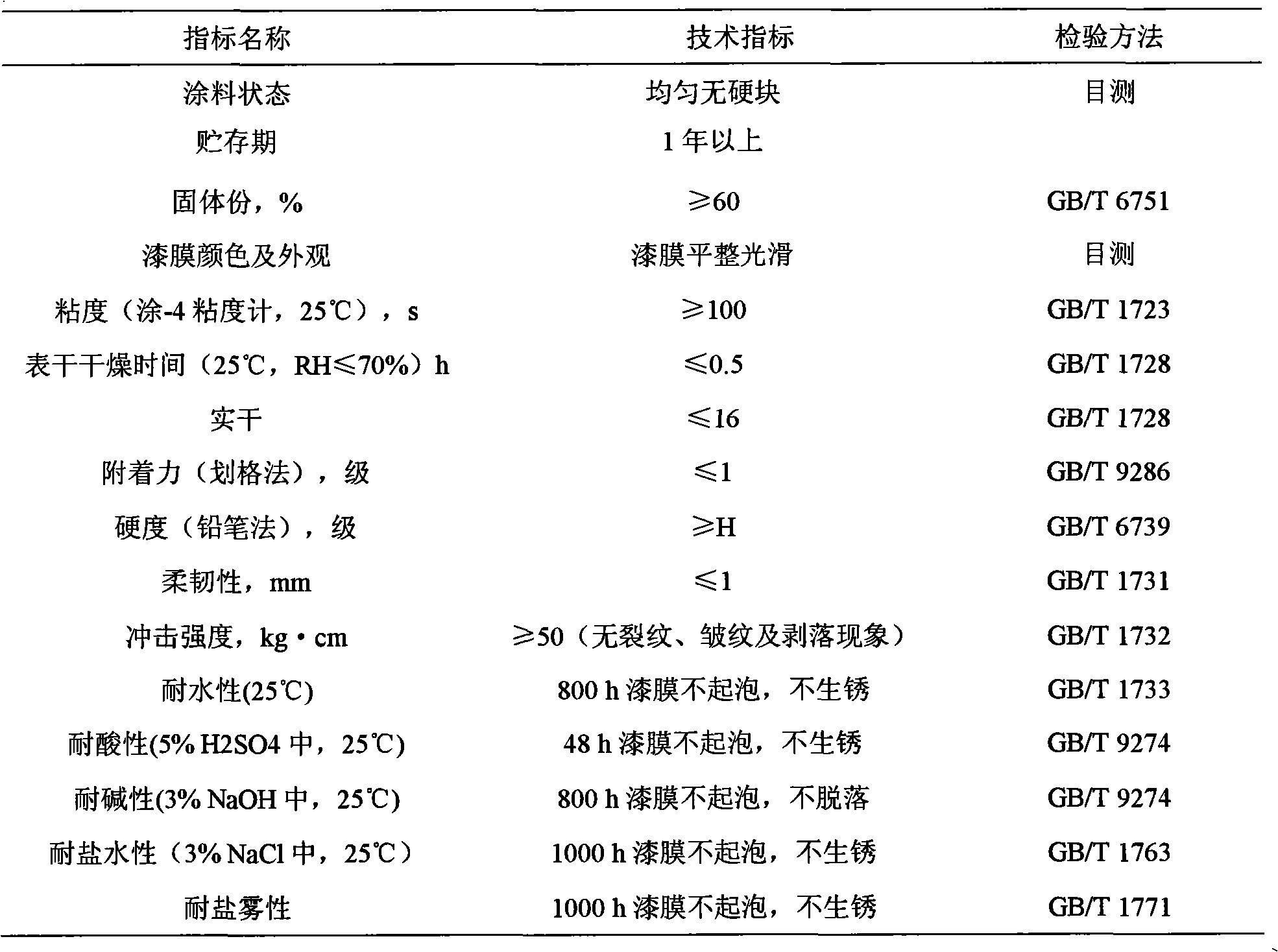

Water borne epoxy resin anticorrosive paint and preparation method thereof

InactiveCN101633814AGood value for moneyGood weather and humidity resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyHydrophilic monomer

The invention discloses a water borne epoxy resin anticorrosive paint and preparation method thereof and solves the contradiction between storage stability of water dispersion and water resistance and corrosion resistance of dispersion film in the prior art. The paint is prepared by mixing oxosilane modified water borne epoxy resin dispersion, iron oxide red, rustproofing pigment, talc powder, defoaming agent, flatting agent, flash rust proofing agent and deionized water in ratio, and the invention is characterized in that: hydrophilic monomer is introduced to epoxy resin molecular chain, so the paint has self-emulsifying characteristic; and oxosilane is applied to modifying of the water borne epoxy resin, so that the paint can be heated and self-solidified. The paint has good storage stability and good construction performance, film can be fast dried and has high rigidity after being dried, the film is bright and smooth, water proof, corrosion resistant, washing resistant, good in comprehensive performance and low in cost. The invention can meet the requirement of anticorrosive paint in the fields of storage tank, bridge and the like.

Owner:HUANGGANG NORMAL UNIV

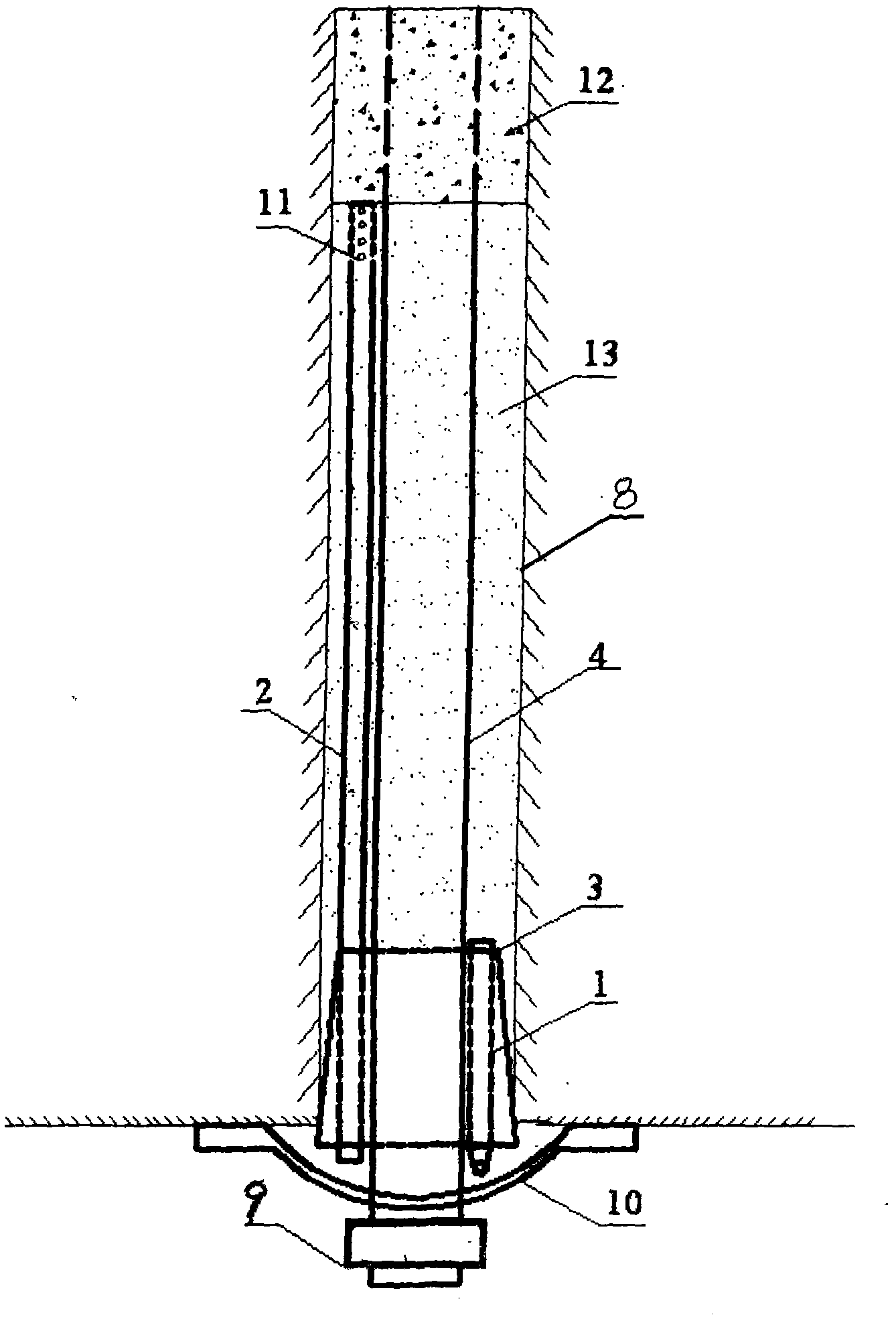

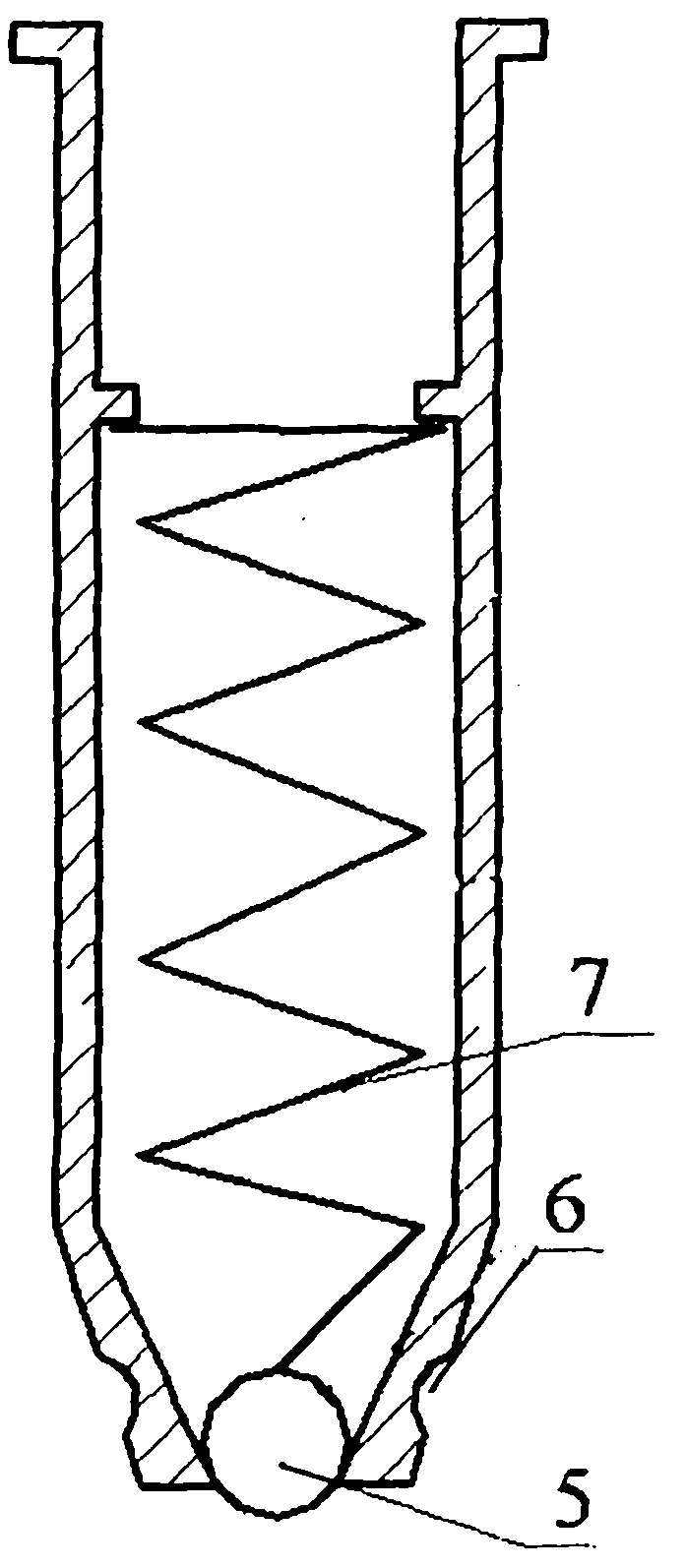

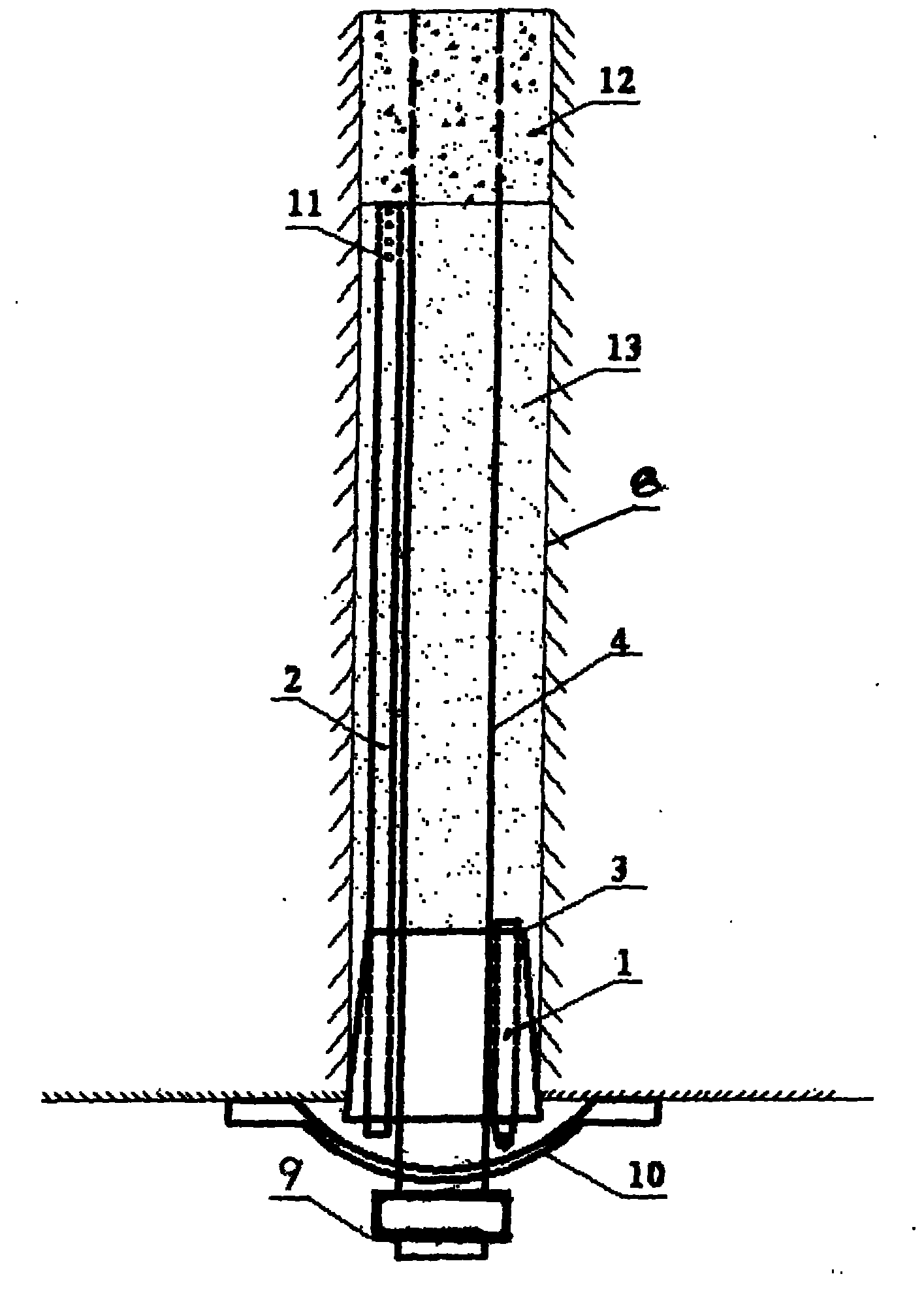

Anchoring structure for liquid-injection corrosion-resistant anchor rod or anchor cable and construction method thereof

InactiveCN102146673ASolve the sealing waterSolve corrosionAnchoring boltsBulkheads/pilesEngineeringSlurry

The invention discloses an anchoring structure for a liquid-injection corrosion-resistant anchor rod or anchor cable and a construction method thereof. The anchoring structure comprises a resin end-anchored anchor rod or anchor cable body arranged in an anchor hole, wherein a grouting-stop plug is also arranged at the opening of the anchor hole; an anchor rod head or an anchor cable head is exposed out of the anchor hole from the plug hole of the grouting-stop plug; the grouting-stop plug is also provided with two plug holes; a liquid injection nozzle is inserted into one plug hole and chemical grout is filled into the anchor hole through the liquid injection nozzle; an exhaust pipe with two open ends is inserted into the other plug hole; a check-valve ball and a return spring are arranged in the liquid injection nozzle; a locking slot connected with grouting equipment is reserved on the peripheral surface of the liquid injection nozzle; the length of the exhaust pipe is equivalent to that of the end-anchored anchor rod or anchor cable; and exhaust holes are reserved on the peripheral surface of the exhaust pipe close to the bottom of a drilled hole. The anchoring structure solves the problem of sealing water and preventing corrosion of anchor rod holes at the positions such as an arch part and the like, not only can serve as permanent support, but also can serve as temporary support.

Owner:SHANDONG UNIV OF SCI & TECH

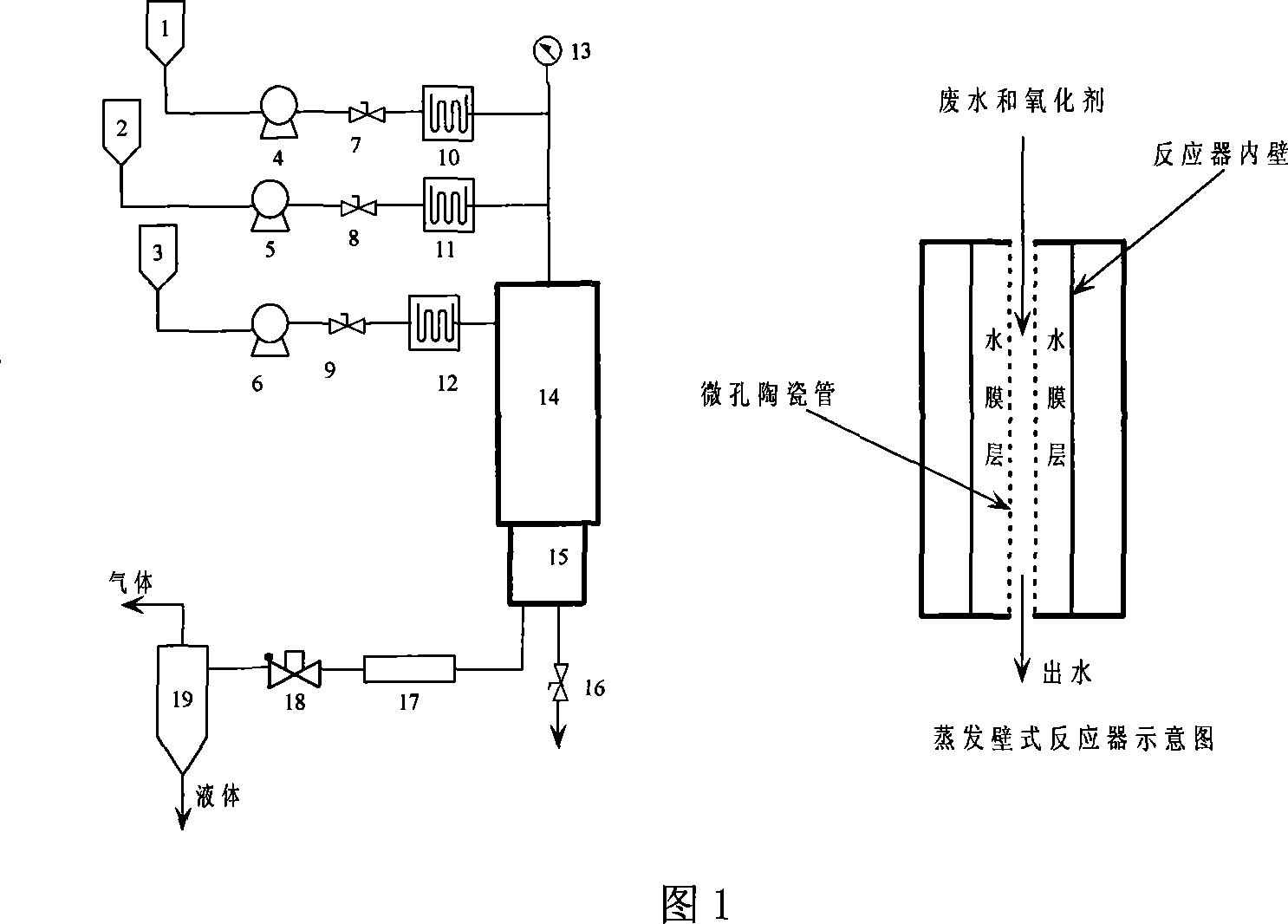

Method for treating high-concentration organic waste water in acroleic acid production

InactiveCN101182065ASolve corrosiveSolve the problem of pipeline blockageNature of treatment waterWater/sewage treatment by oxidationHigh concentrationHigh pressure

The invention relates to a high concentrated organic compound wastewater treating method in the acrylic acid production, including that firstly oxidant and deionized water are mixed for preparing oxidant solution and is put in an oxidant tank. Secondly, wastewater and clear water for the acrylic acid production are respectively arranged in a wastewater tank and a clear water tank and catalysts are added in the wastewater. Thirdly, a pre-heater is heated to be at the temperature of 300-400 degree Celsius and a reactor is heated to be at the temperature of 400-600 degree Celsius. Fourthly, a high pressure plunger pump is opened, in which a sampler is put. The wastewater and the oxidant solution enter a microporous ceramic tube of the reactor after being preheated and pressurized respectively. The supercritical water oxidation under the pressure of 22-28MPa and the temperature of 374-600 degree Celsius is implemented. The clear water infiltrates into the microporous ceramic tube through an exine of a ceramic film. Fifthly, the treated effluent is qualified to be discharged through the cooling and the gas-liquid separation. The invention solves problems of the reactor inner wall corrosion and the tube blockage of a traditional supercritical water oxidation technology. The organic removal rate reaches to 99.99 percent above. And no secondary pollution can be made. The invention is friendly to the environment.

Owner:DONGHUA UNIV

Method for preparing tungsten carbide abrasion resistant composite coating by penetration brazing method

ActiveCN101637838AHigh bonding strengthFast heat conductionSoldering apparatusWelding/soldering/cutting articlesEpoxyBond interface

The invention relates to a method for preparing tungsten carbide abrasion resistant composite coating by a penetration brazing method, belonging to the field of coating preparation in materials processing engineering. The invention comprises the following steps: (1) pasting coating metal powder cloth containing tungsten carbide-cobalt (WC-Co), nickle (Ni) and chromium (Cr) mixed powder on a metalsubstrate by using epoxy resin bonding agent; (2) preparing welding material metal powder cloth from BNi-2 brazing material and pasting the welding material metal powder cloth on the coating metal powder cloth obtained in the step (1); and (3) carrying out penetration brazing in a vacuum furnace to form a metallurgical bonded interface. The tungsten carbide abrasion resistant composite coating canbe applicable to protection of mechanical elements in the field of generating plant, petroleum, aviation, food, plastics and the like.

Owner:JIANGXI HENGDA HI TECH CO LTD

Brass surface passivation solution and passivation method

InactiveCN102002695ASolve corrosiveSolve discolorationMetallic material coating processesPolyethylene glycolPhytic acid

The invention discloses brass surface passivation solution and a passivation method. The formula in a chrome-free passivation process comprises 2.5 to 6ml / L of phytic acid, 9 to 12ml / L of hydrogen peroxide, 1 to 7g / L of boric acid, 2 to 16ml / L of polyethylene glycol-400 and 1 to 10g / L of additive. The passivation temperature is 35 to 45 DEG C; the pH value is 2 to 4; and the passivation time is 55 to 65 seconds. A brass sample is placed in the passivation solution, and then the corrosion resistance of a brass surface can be obviously improved and the corrosion resistance of the brass is a little better than that of a bichromate passivated film. The passivation method is expected to substitute the bichromate passivation technology and has a wide application prospect.

Owner:JIANGXI UNIV OF SCI & TECH

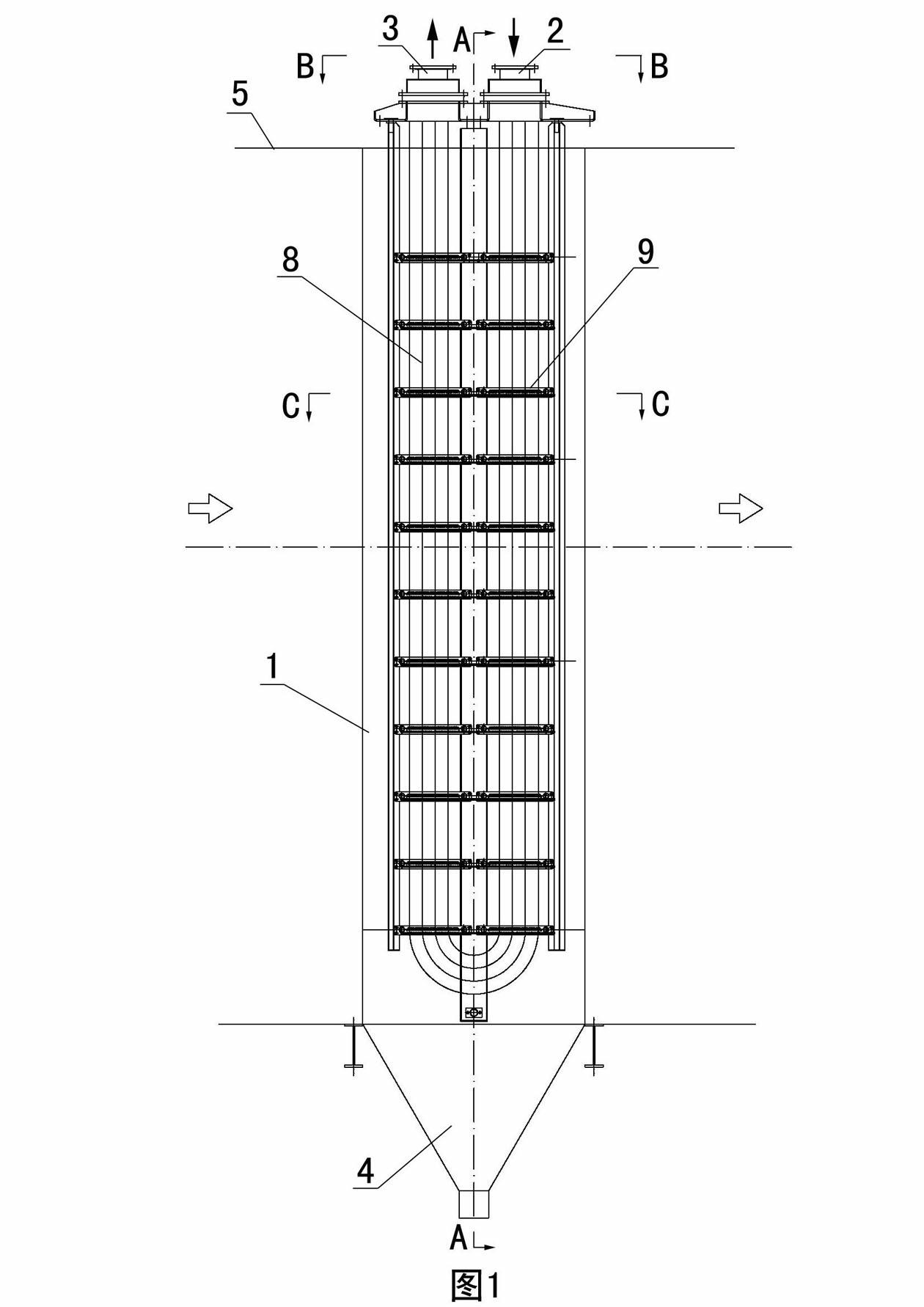

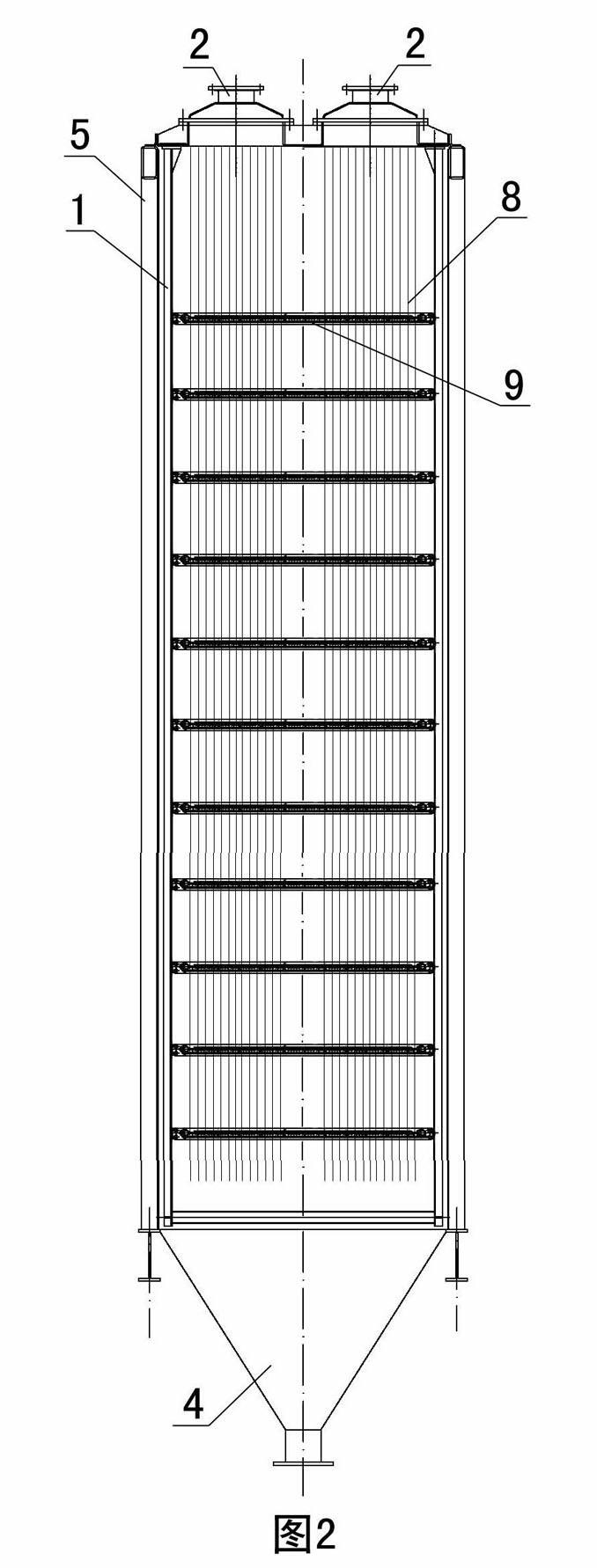

Module type flue gas heat exchanger with fluorine plastic pipes

ActiveCN102607299ALow temperature corrosion resistanceStrong antifoulingHeat exchanger casingsStationary tubular conduit assembliesFlue gasEngineering

A module type flue gas heat exchanger with fluorine plastic pipes comprises a heat exchanger casing and a heat exchange pipe, wherein the upper end of the heat exchanger casing is provided with water inlets and water outlets, and the lower end of the heat exchanger casing is provided with a drain outlet. A water inlet end plate is detachably connected to the position of the water inlets and provided with water inlet holes, and a water outlet end plate is detachably connected to the position of the water outlets and provided with water outlet holes. The heat exchange pipes are U-shaped fluorine plastic heat exchange pipe bundles, water inlet ends of the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles are communicated with the water inlet holes, water outlet ends of the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles are communicated with the water outlet holes, and positioning nets are parallelly distributed in the heat exchanger casing from top to bottom at intervals. Module type design is adopted by the flue gas heat exchanger, equipment utilizing rate of the flue gas heat exchanger is greatly improved, the positioning nets are used by the flue gas heat exchanger at a fixed interval so as to fix the fluorine plastic pipes in the fluorine plastic heat exchange pipe bundles, and shaking deformation of the flexible fluorine plastic pipes caused by flowing impact of flue gas can be avoided.

Owner:北京新世翼节能环保科技股份有限公司

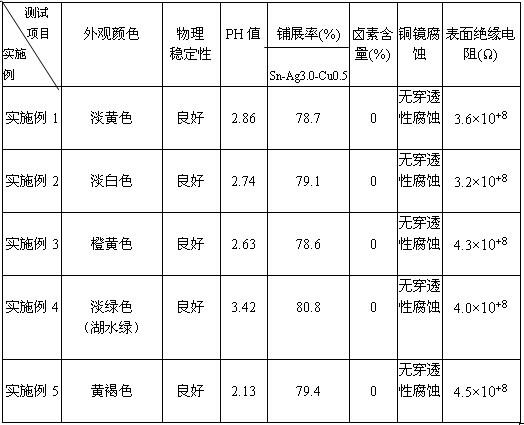

Low-content modified rosin halogen-free soldering flux for lead-free solder wires

InactiveCN102357746AAvoid cleaningNot corrosiveWelding/cutting media/materialsSoldering mediaAntioxidantElectron

The invention discloses a low-content modified rosin halogen-free soldering flux for lead-free solder wires. The low-content modified rosin halogen-free soldering flux comprises the following components in percentage by weight: 9-27% of an organic acid activator, 1-5% of a surfactant, 0.01-1% of a corrosion inhibitor, 0.1-1% of an antioxidant, 2-4% of a film-forming agent, 1-8% of modified rosin and the balance of an organic solvent. The soldering flux for the lead-free solder wires has the advantages of no halogen, good solderability, bright and full welding spots, high spreading rate, a small amount of the modified rosin, fewer post-welding residues and being free from a cleaning procedure, and the surface insulation resistance of a welded substrate is more than 1*10+8 ohms, which meets the requirements of the electronical industry standard; and meanwhile mixed alcohols with different boiling points are used as the organic solvent, which can lower the content of the VOC (volatile organic compound) so as to prevent photochemical smog and air pollutions.

Owner:苏州之侨新材料科技有限公司

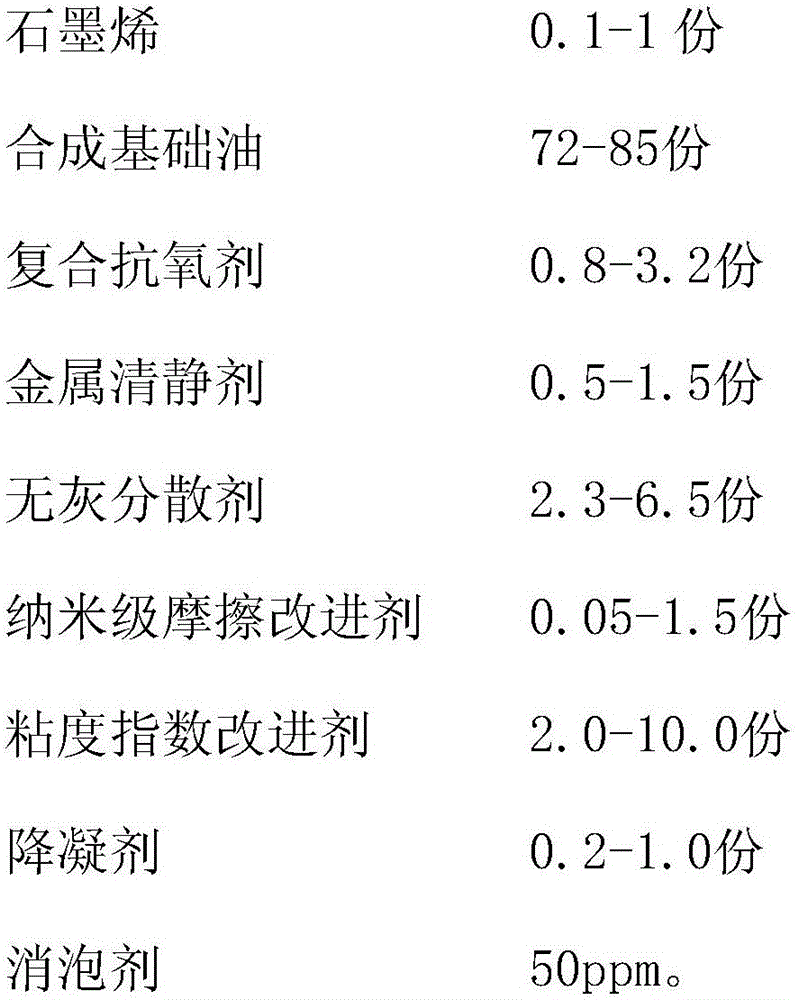

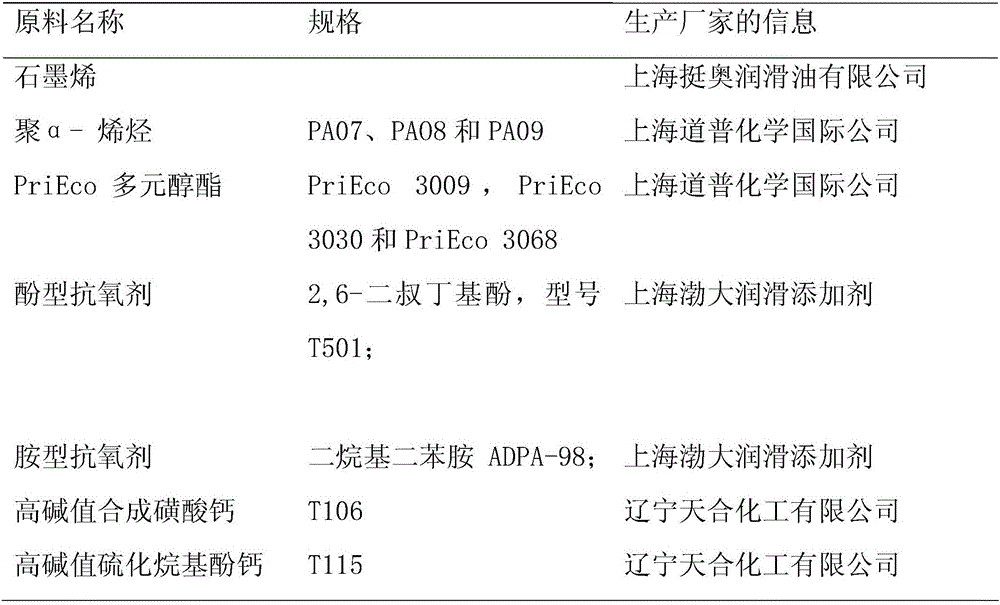

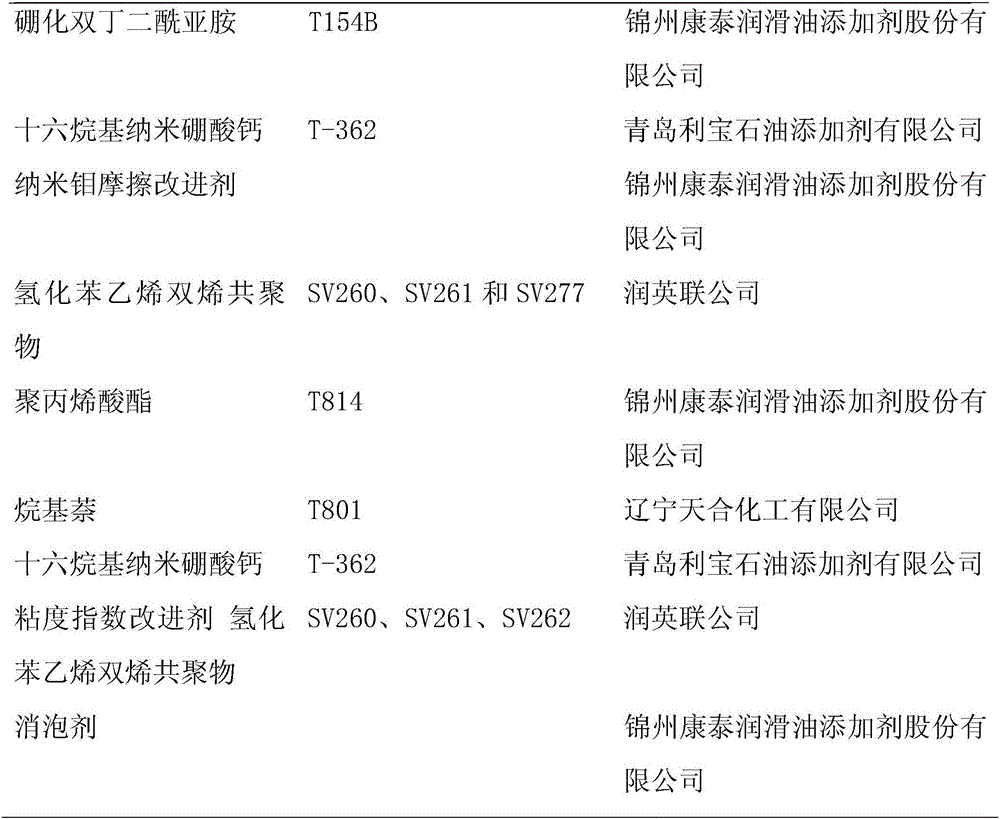

Graphene-containing lubricating oil and preparation method thereof

The invention relates to a graphene-containing lubricating oil and a preparation method thereof. The graphene-containing lubricating oil comprises the following components by weight: 0.1-1 part of graphene, 72-85 parts of synthetic base oil, 0.8-3.2 parts of a composite antioxidant, 0.5-1.5 parts of a metal detergent, 2.3-6.5 parts of an ashless dispersant, 0.05-1.5 parts of a nanoscale friction modifier, 2.0-10.0 parts of a viscosity index improver, 0.2-1.0 part of a pour point reducer, and 50ppm of a defoamer. The preparation method includes: putting the synthetic base oil into a blending kettle, performing stirring, then adding the pour point reducer, the viscosity index improver, the composite antioxidant, the metal detergent, the ashless dispersant, and the nanoscale friction modifier, stirring the substances evenly, adding graphene and the defoamer, maintaining the original temperature, stirring the materials evenly, and performing standing. The graphene-containing lubricating oil provided by the invention solves the problems of corrosion and selectivity in traditional lubricating oil additives, at the same time the process is improved, and the ultrasonic dispersion link of graphene is eliminated.

Owner:SHANGHAI INST OF TECH

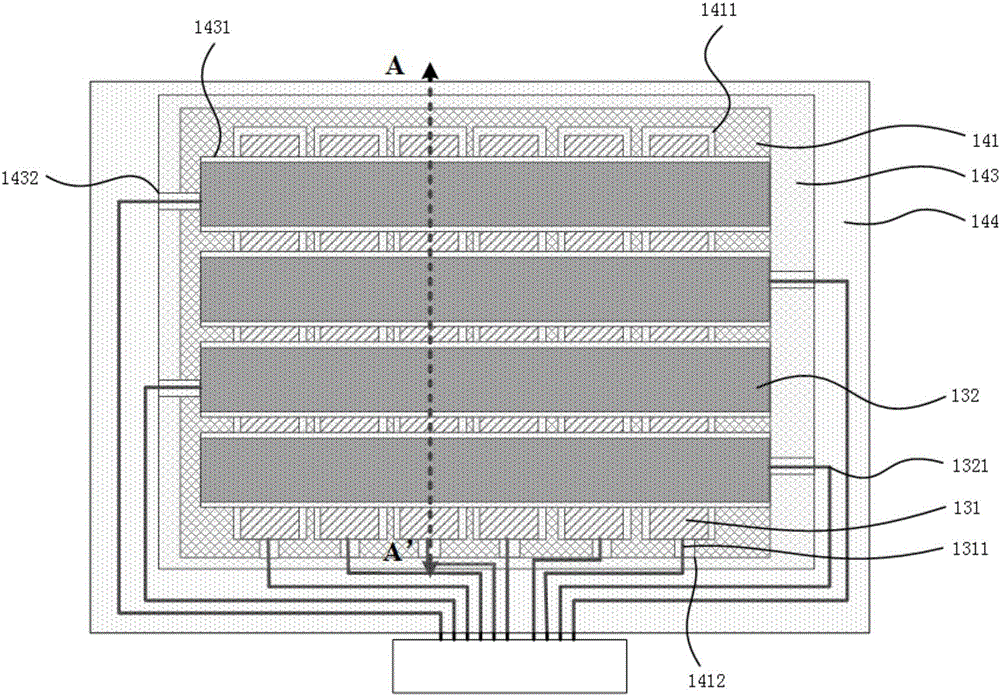

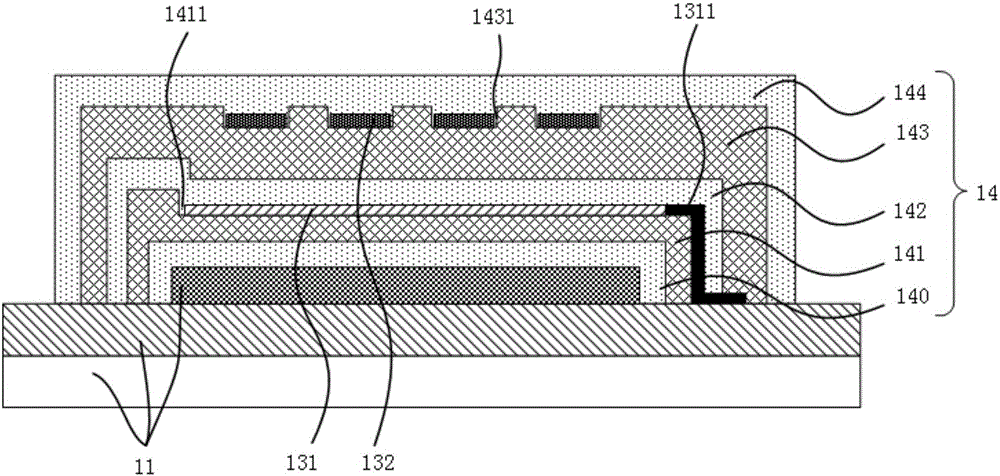

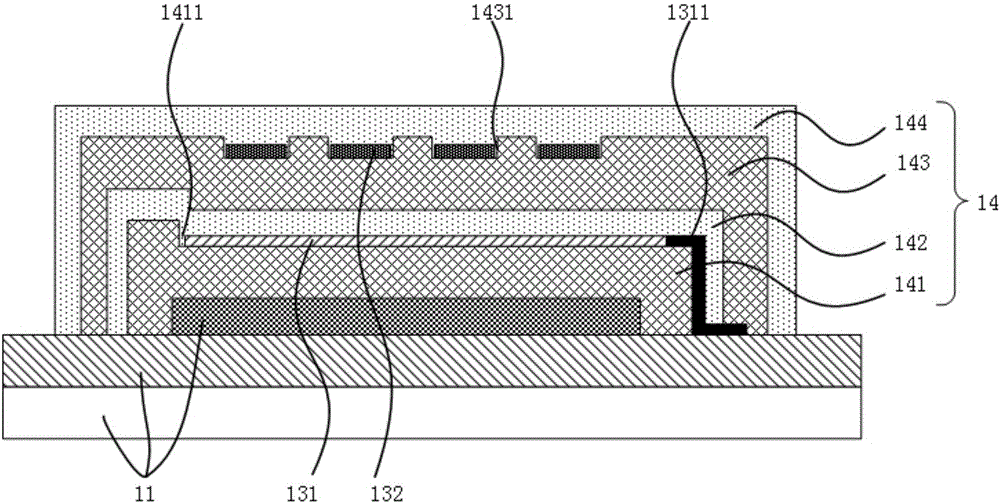

Organic light-emitting display panel

ActiveCN106293258AAvoid corrosionDoes not increase thicknessSolid-state devicesInput/output processes for data processingOrganic layerEngineering

The invention discloses an organic light-emitting display panel. The organic light-emitting display panel comprises an organic light-emitting element array substrate, a thin-film encapsulation layer covering the organic light-emitting element array substrate, a plurality of touch-control driving electrodes, a plurality of touch-control sensing electrodes, a plurality of first touch-control routing lines, and a plurality of second touch-control routing lines, wherein the first touch-control routing lines are electrically connected with the corresponding touch-control driving electrodes; the second touch-control routing lines are electrically connected with the corresponding touch-control sensing electrodes; the thin-film encapsulation layer comprises a first organic layer and a second organic layer; a plurality of first grooves and a plurality of second grooves are formed in the first organic layer, and a plurality of third grooves and a plurality of fourth grooves are formed in the second organic layer; the touch-control driving electrodes are located in the first grooves, and the first touch-control routing lines are located in the second grooves; the touch-control sensing electrodes are located in the third grooves, and the second touch-control routing lines are located in the fourth grooves; the first touch-control routing lines and the second touch-control routing lines are located in the thin-film encapsulation layer. The organic light-emitting display panel provided by the invention is used for meeting the requirement that the touch-control routing lines are not easy to corrode.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Ethanol gasoline and preparation method thereof

ActiveCN101812332ALong stable periodSolve corrosiveLiquid carbonaceous fuelsFuel additivesSwelling capacityAlcohol

The invention discloses ethanol gasoline, which is characterized by consisting of the following raw materials in part by volume: 60 to 70 parts of regular gasoline, 2 to 10 parts of absolute ethanol, 10 to 20 parts of latent solvent, 13 to 23 parts of surfactant, 10 to 15 parts of combustion improver, 3 to 10 parts of corrosion inhibitor and 7 to 15 parts of detergent dispersant. The invention also discloses a preparation method of the ethanol gasoline. The ethanol gasoline has the advantages of high storage stability, high intersolubility, no corrosion, no swelling capacity and readily available raw materials, can be used together with other alcohol automobile gasoline such as methanol gasoline and the like in any ratio, and also can be directly used with common gasoline of the same standard in any proportion; the octane level reaches or exceeds the standards of No. 93 and No.95 clear gasoline; and the overall performance of the ethanol gasoline can meet standard requirements of the No.93 clear gasoline.

Owner:SHANDONG TAIDE NEW ENERGY

Polymer-type water glass curing agent and application in water glass chemical grouting materials

InactiveCN101885591AResolution timeSolve the strength problemOther chemical processesBuilding constructionsSolubility(Hydroxyethyl)methacrylate

The invention relates to a polymer-type water glass curing agent with easily-controlled curing time and high toughness. The curing agent is mainly formed by polymerizing and copolymerizing double bonds-containing acids such as crylic acid, methacrylic acid and the like and double bonds-containing esters such as butyl methacrylate, vinyl acetate, hydroxy-ethyl methacrylate and the like by latex. The polymer-type water glass curing agent of the invention is a novel water-soluble water glass curing agent, which can control the curing time of the water-soluble grouting materials by controlling the content of carboxyl and ester group in a polymer. By using the curing agent, a water glass consolidating body has vey high compressive strength and toughness, synthetically overcomes the shortages of too fast curing time, high corrosiveness, low consolidating body strength and the like of an acid curing agent which is commonly used in the water glass grouting materials and the shortages of poor water solubility, slow curing time and the like of an organic ester curing agent, and can be widely applied in the field of anti-seepage stoppage engineering.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Corrosion and scale inhibitor for industrial recirculated cooling water

InactiveCN101302060AGood anti-scaling effectGood synergyScale removal and water softeningEutrophicationTricarboxylic acid

The invention provides a corrosion and scale inhibitor for industrial circulated cooling water, which is applicable to a composite for mitigating metal corrosion added into a water body with ultra-low hardness, low alkalinity and strong corrosiveness. The corrosion and scale inhibitor is characterized by comprising the following compositions in percentage by weight: 5 to 20 percent of 2-hydroxyphonoacetic acid, 5 to 25 percent of 2-phosphonobutane-1, 2, 4 - tricarboxylic acid, 10 to 40 percent of acrylic acid-2-acrylamido-2-methylpropane sulfonic acid copolymer, 1 to 8 percent of zinc chloride, 1 to 5 percent of copper corrosion inhibitor, and the balance being water. The corrosion and scale inhibitor has lower contents of inorganic phosphorus and zinc salt, can prevent scale sedimentation of medicine on one hand, and can reduce eutrophication of the water body and heavy metal pollution on the other hand, thereby facilitating the environmental protection.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD +1

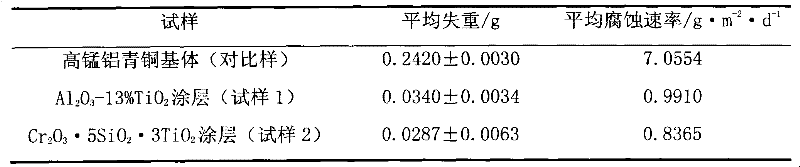

Method for preventing corrosion and marine creature fouling on ship propeller

InactiveCN102336256ASolve corrosiveSolve the defacementVessel cleaningMolten spray coatingOxide ceramicThermal spraying

The invention relates to a method for preventing corrosion and marine creature fouling on a ship propeller. Cathode protection, a ceramic insulating coating and a metallic antifouling coating are organically combined in the method. The method comprises the following steps of: removing scales on the surface of the copper alloy propeller, obtaining a uniform and rough surface, and spraying a metallic adhesive coating by adopting a thermal spraying method; preparing a metallic oxide ceramic insulating coating on the surface of the adhesive coating by adopting the thermal spraying method, wherein the ceramic insulating coating comprises single-component oxides such as Al2O3, Cr2O3 and the like and multi-component composite powder of TiO2 or SiO2 with low melting point; preparing the metallic antifouling coating on the ceramic insulating coating, wherein the metallic antifouling coating is made of pure copper or copper alloy with antifouling function; and meanwhile, performing cathode protection on the propeller. The ceramic and the metallic coating adopted in the method have higher bonding force and longer protection life, the current requirement of the ship cathode protection is reduced, the corrosion and marine creature fouling problems of the ship propeller can be simultaneously solved, and the ceramic and the metallic coating have obvious corrosion resistance and antifouling effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

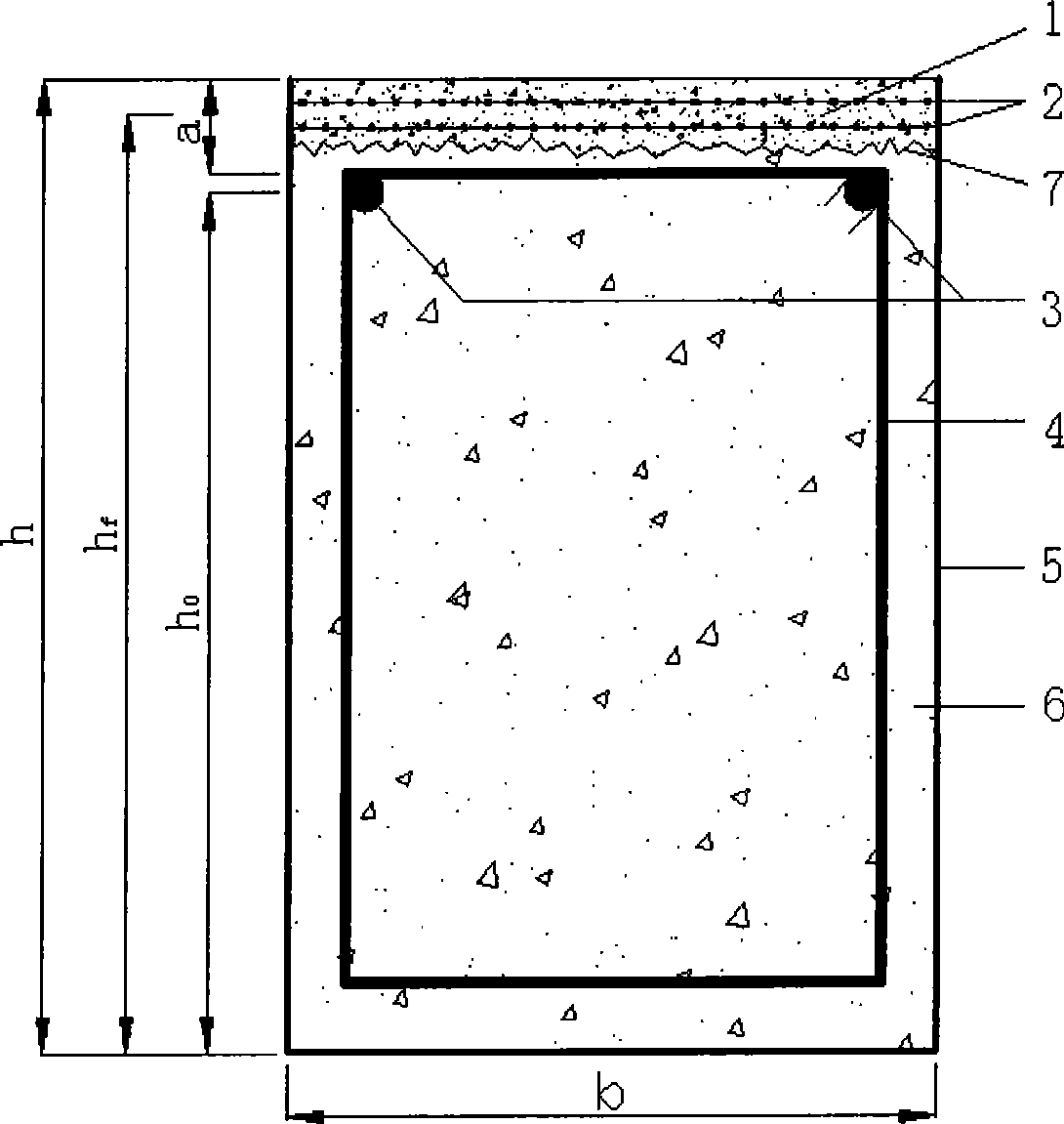

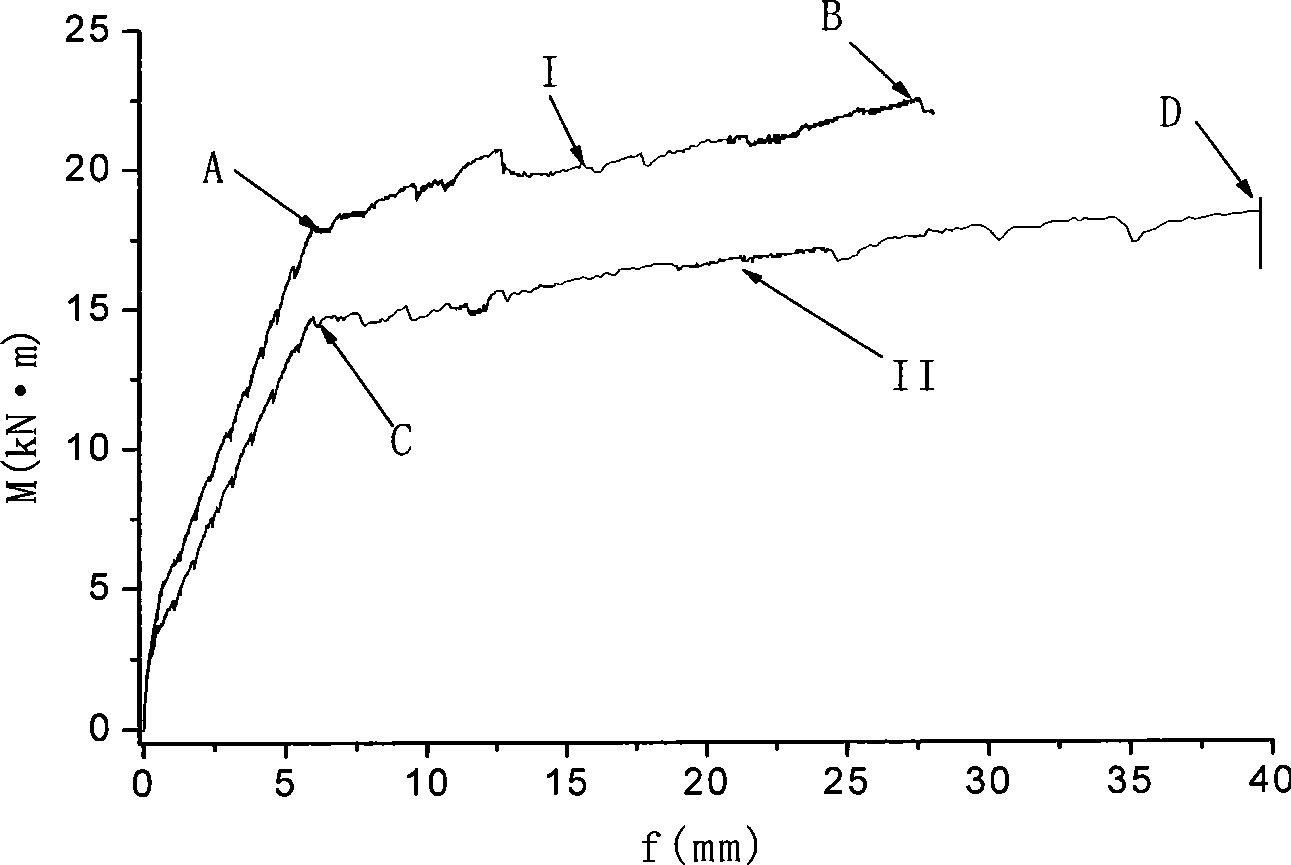

Construction structure for textile reinforced composite reinforced bar concrete and manufacturing method thereof

InactiveCN101481930AHigh strengthLimit or improve cracksSolid waste managementBuilding reinforcementsFiberRebar corrosion

The invention belongs to the technical field of concrete reinforcement, relating to utilizing fiber mesh grids to enhance the concrete strength. The arrangement of structural reinforcing steel, the thickness of concrete protective layers of main stress ribs and the grade of the concrete strength of the invention are designed according to the design criterion of a reinforced concrete structure. The invention is characterized in that before the initial setting of the concrete, fine concrete and the fiber mesh grids are cast on the outer side of the stretched and drawn area of the structure or the external surface of a large-scale integral structure, the total thickness of the fiber mesh grids and the fine concrete ranges from 10mm to 20mm, concrete with equal thickness of external surfaces are replaced, and the fiber mesh grids are evenly distributed in the fine concrete. The grid type or the plate type structure of the invention can adopt the structure of replacing partial reinforcing steel with the fiber mesh grids. The invention can effectively control cracks and solve the problems of concrete cracking and reinforcing steel corrosion, and has the advantages of firm bonding of the boundary surfaces of the fine concrete and the concrete, light self weight, low production cost, corrosion resistance, safe and durable usage, etc.

Owner:DALIAN UNIV OF TECH

Anti-sticking and wear resistant polyurea coating and its preparation method

ActiveCN102492357ASolve the adhesionSolve corrosivePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention relates to an anti-sticking and wear resistant polyurea coating and its preparation method. The coating is prepared by blending of component A and component B. Specifically, the component A is synthesized by the following raw materials by weight: 90-120 parts of isocyanate, 40-60 parts of polyether polyol and 20-30 parts of fluorocarbon diol; and the component B is prepared by the following raw materials by weight: 500-800 parts of polyether amine, 400-600 parts of organosilicon diamine, 300-400 parts of high activity polyether polyol, 400-500 parts of an amino chain extender, 80-100 parts of an amino cross-linking agent, 100-150 parts of a high boiling point diluent, 5-10 parts of a composite catalyst, 400-600 parts of composite nano-metal oxide surface active materials, 600-800 parts of a filling material, and 40-60 parts of a pigment. The invention also includes a preparation method of the anti-sticking and wear resistant polyurea coating. A coating layer obtained by spraying of the anti-sticking and wear resistant polyurea coating in the invention has strong adhesion, and has good adhesion resistance, wear resistance, corrosion resistance, as well as impact resistance. Therefore, the anti-sticking and wear resistant polyurea coating of the invention is especially suitable for spraying on the lining surface of a heavy transport dump truck.

Owner:湘江涂料科技有限公司

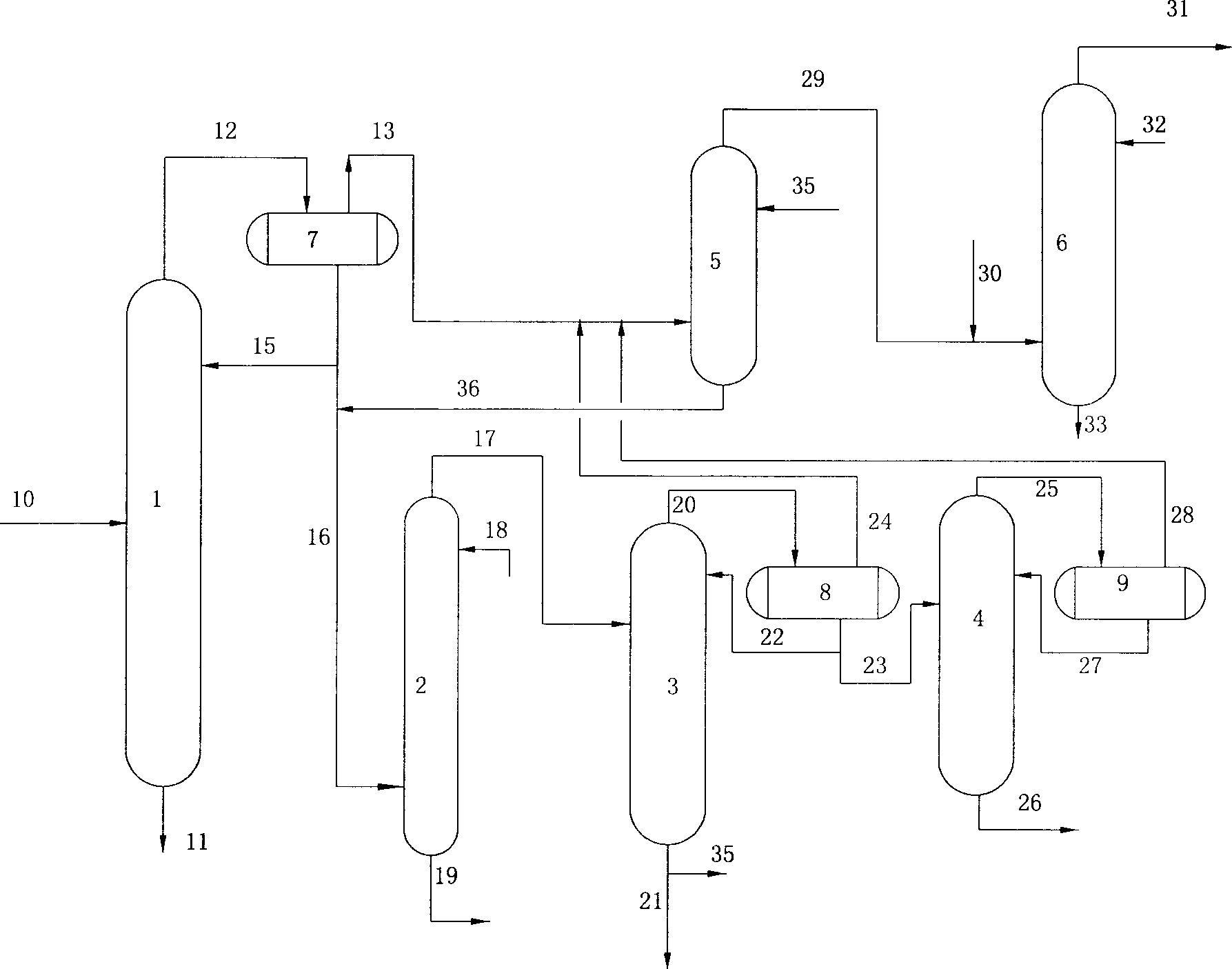

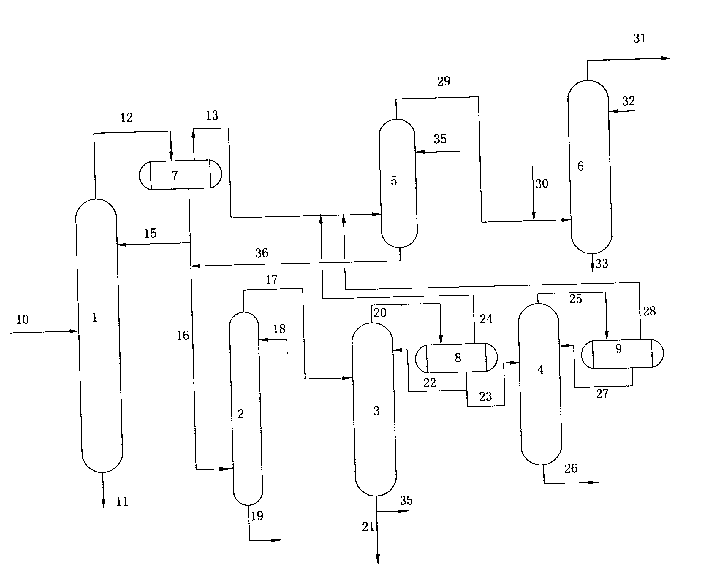

Method for separating hydrocarbon hydrocracking products

The separation method of hydrocracked product of hydrocarbons incldudes stabilization tower, hydrogen sulfide washing tower, debutanizing tower, deethanizing column and light hydrocarbon absorption tower. The stabilizatino tower is designed according to cutting portion or all C6 component, the absorption oil of light hydrocarbon absorption tower is from tower bottom product flow of debutanizing tower, the overhead gas of stabilizaltion tower, overhead gas of debutanizing tower and overhead gas of deethanizing column are mixed, and fed into light hydrocarbon absorption tower to recover light hydrocarbon, and the tower bottom rich absorption oi lof light-hydrocarbon absorption tower and hydrogen sulfide washing tower feeding material coming from stabilizatino tower and mixed, and fed into hydrogen sulfide washing tower. The C3 and C4 components can be completely recovered, and its liquified gas yield is high.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

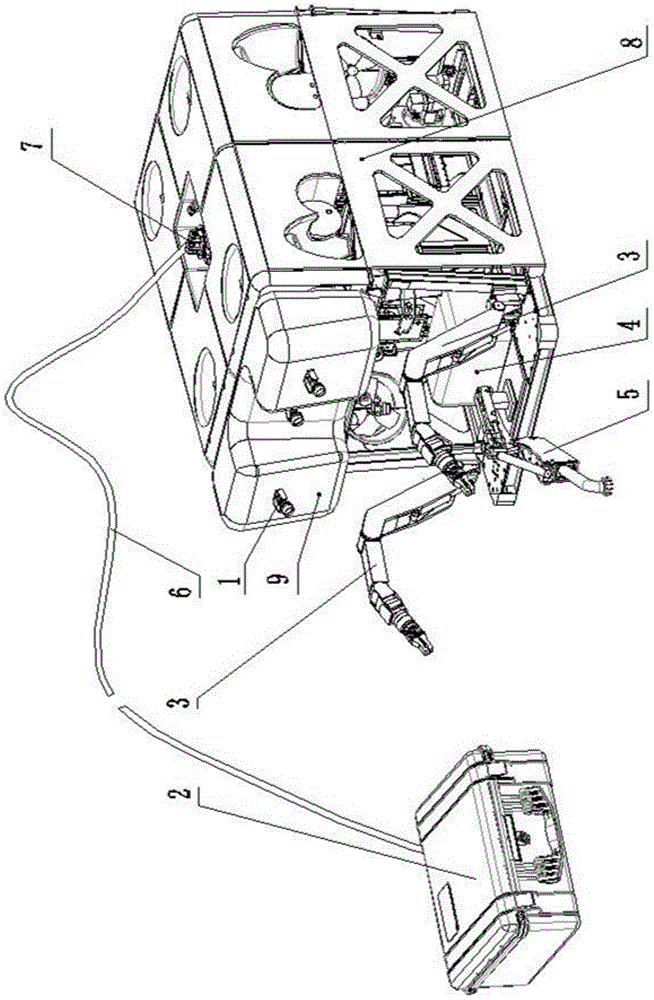

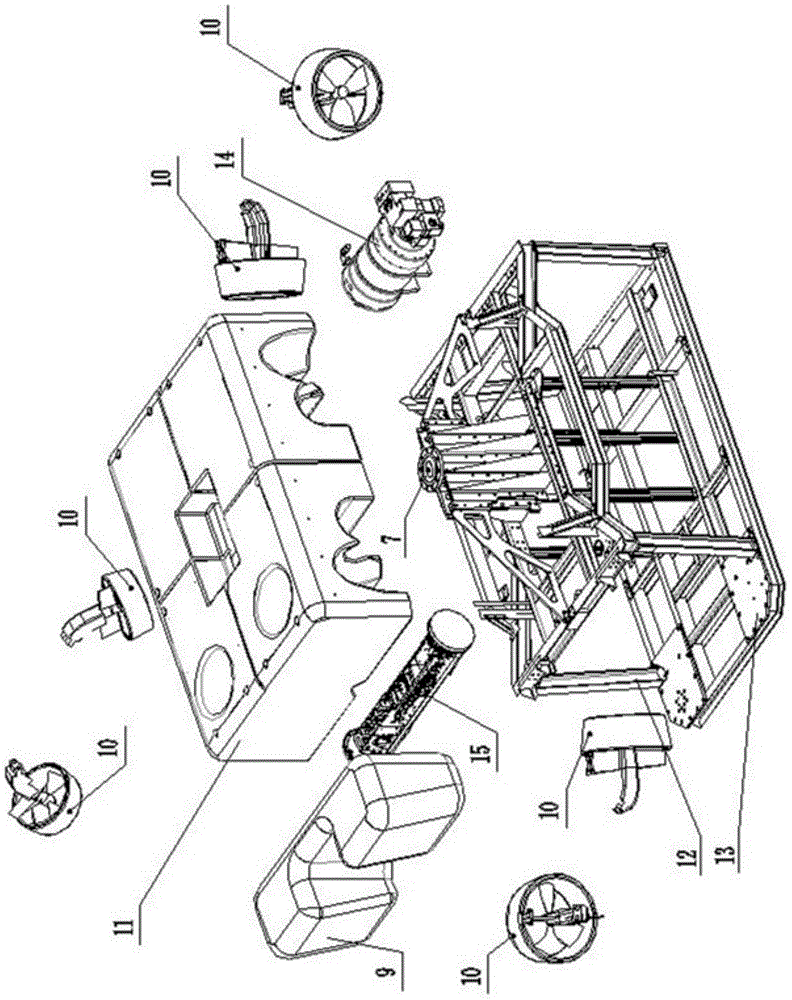

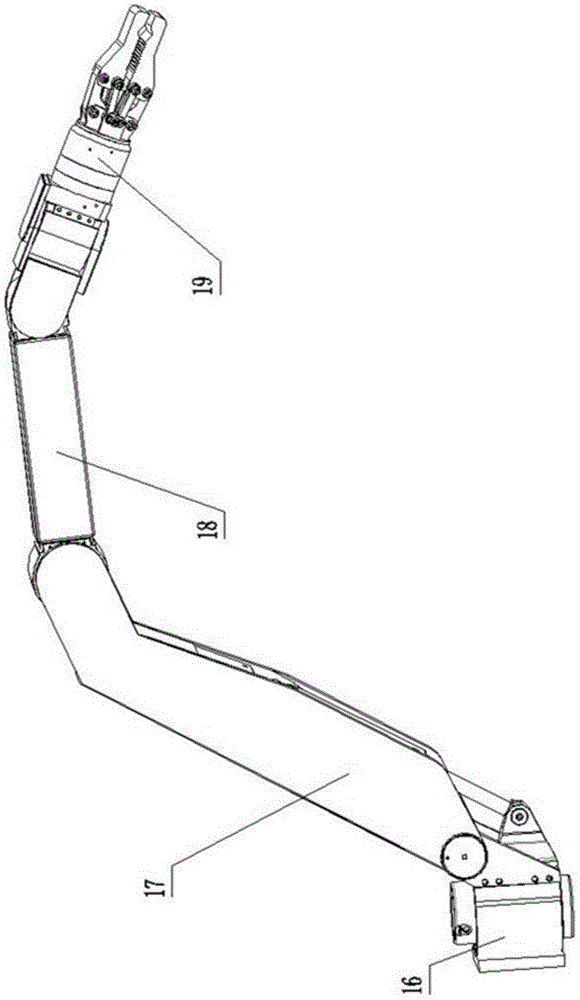

Underwater unmanned operation aquaculture robot

InactiveCN104813975AStrong ability to workAccelerated corrosionProgramme-controlled manipulatorClimate change adaptationCommunication interfaceRobotic arm

The invention discloses an underwater unmanned operation aquaculture robot. An unmanned underwater vehicle is connected with a remote control station through a communication cable; a base plate is provided with a frame and a hydraulic system; the frame is provided with a communication interface, a plurality of propellers and a control system; the communication interface is connected with the communication cable; a rear buoyancy unit is connected with the frame through a frame side plate; the rear buoyancy unit is connected with a front buoyancy unit; the front buoyancy unit is provided with a plurality of cameras; the frame is provided with two mechanical arms; the base plate is provided with a bait storage tank and a feeding and capture execution device which are connected with each other. According to the underwater unmanned operation aquaculture robot, the working capability is high, the corrosion resistance to the seawater is high, carried operation tools are more, the manipulation is simple, the object grabbing technology is accurate, the combination is rapid and convenient, the function configuration is flexible and diverse, the efficiency is high, and the cost is low.

Owner:DALIAN HEHAI TECH CO LTD

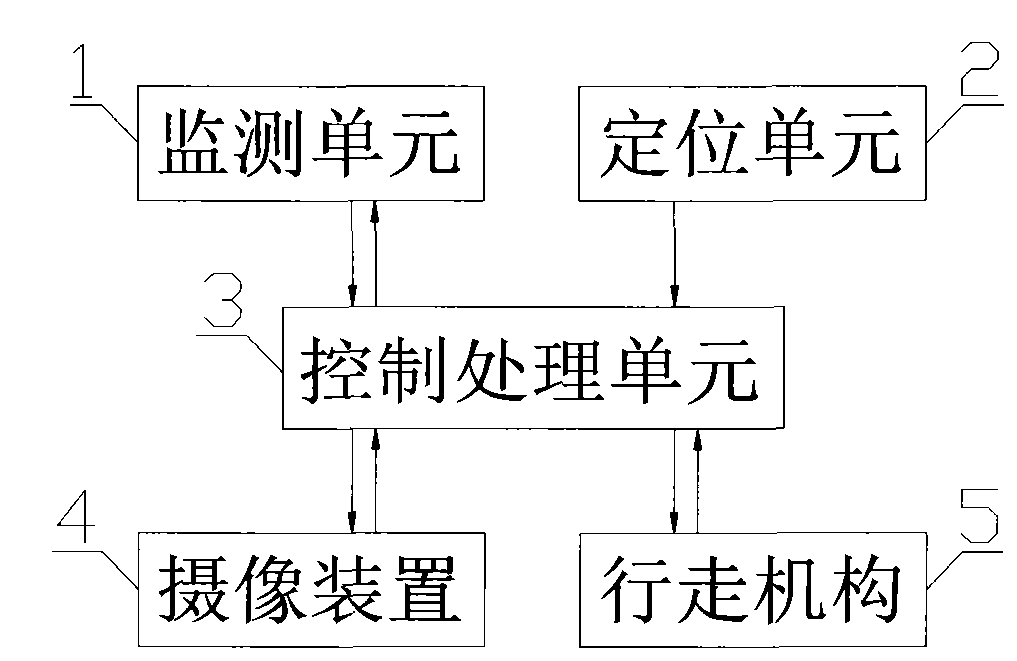

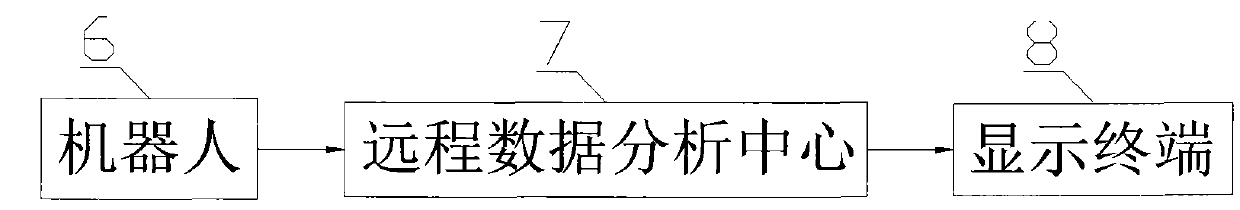

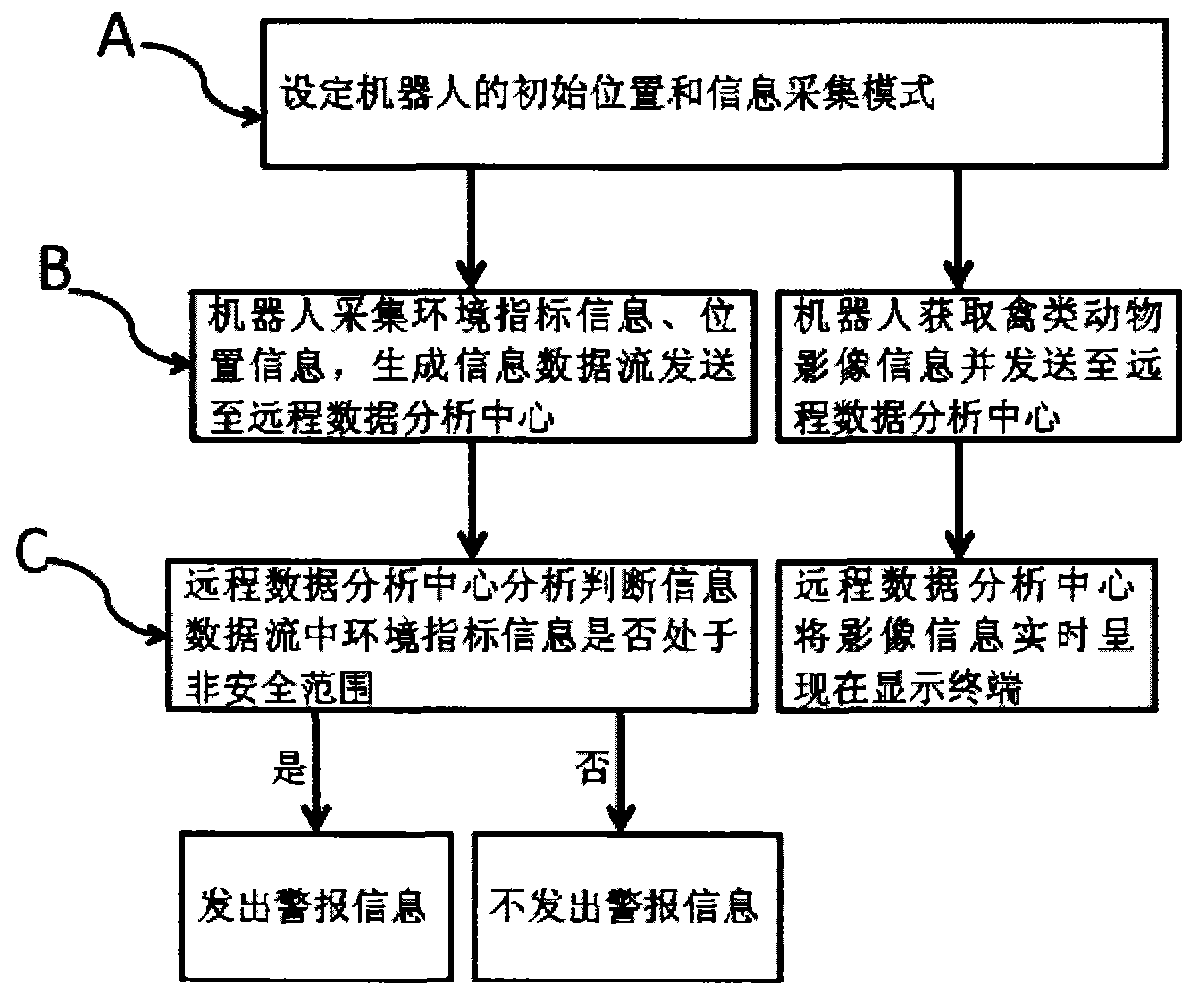

Robot for poultry house environment monitoring and monitoring method and system thereof

InactiveCN103995509AIncrease the amount of sample dataHigh precisionMeasurement devicesProgramme total factory controlMonitoring systemEngineering

The invention discloses a robot for poultry house environment monitoring and a monitoring method and system comprising the robot. The robot for poultry house environment monitoring comprises a monitoring unit, a positioning unit, a control processing unit, a photographic device and a walking mechanism. The invention further provides the poultry house environment monitoring system comprising the robot and the method for conducting monitoring with the application of the system. According to the robot, the system and the method, the number of monitoring positions inside a poultry house can be increased, so that the data size of environment monitoring samples is improved, and the problem that monitoring accuracy is poor in the prior art is solved.

Owner:BEIJING HUAKE SHUNENG TECH DEV

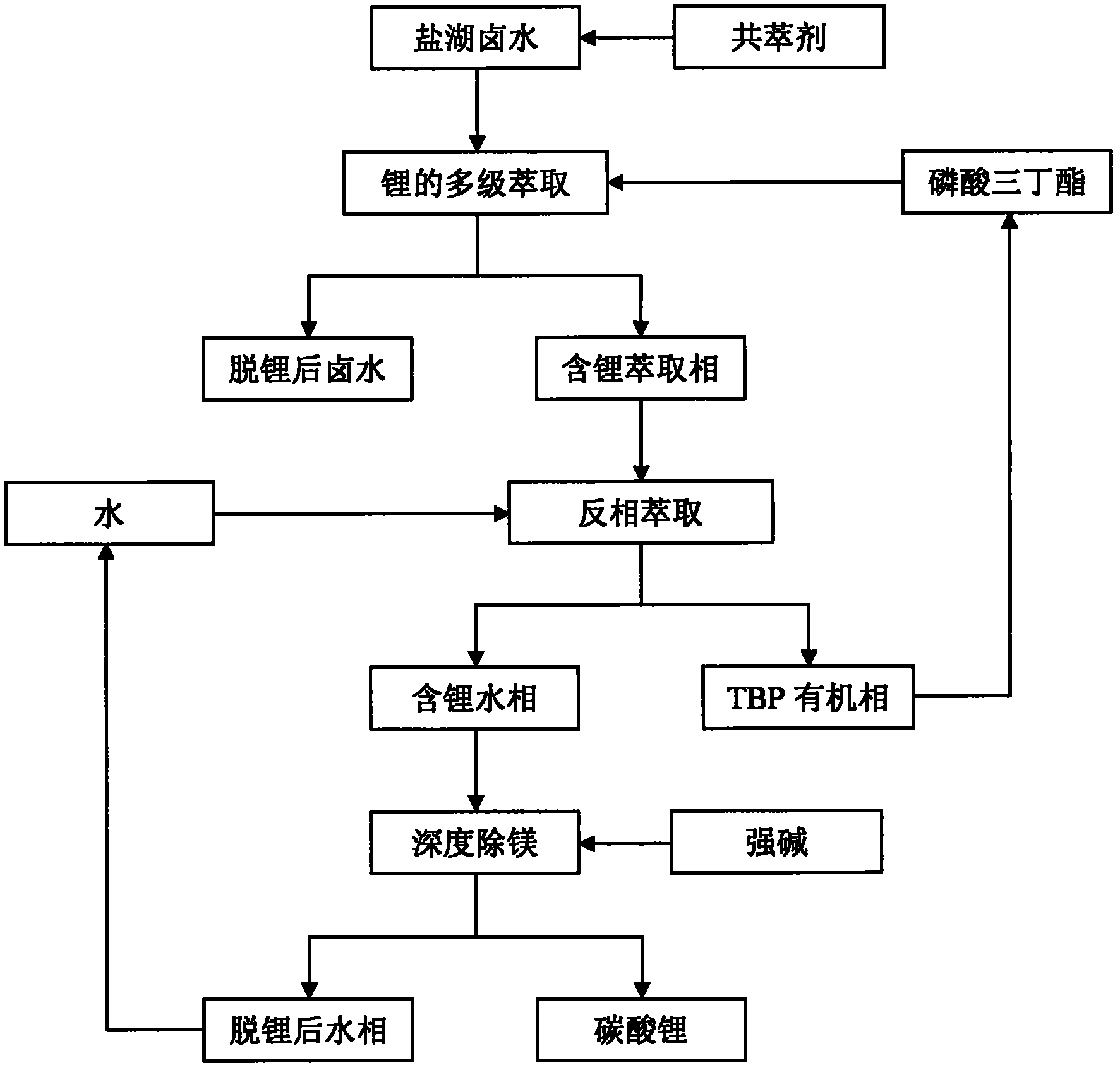

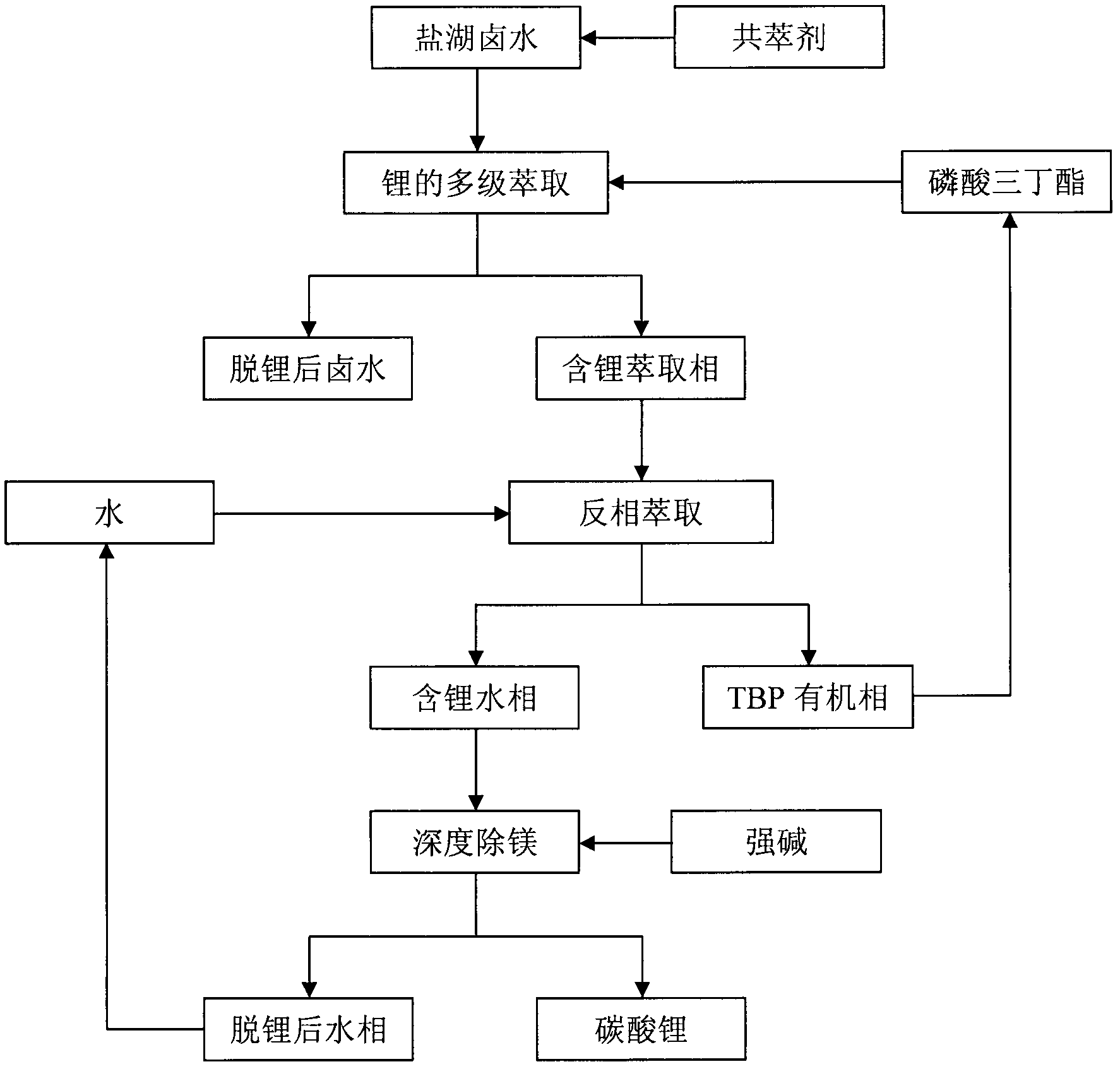

Method for separating magnesium and extracting lithium from salt lake brine with high magnesium-lithium ratio

InactiveCN102633284AStable in natureEasy to separateMagnesium carbonatesLithium carbonates/bicarbonatesHigh magnesiumKerosene

The invention discloses a method for separating magnesium and extracting lithium from salt lake brine with a high magnesium-lithium ratio. With adoption of the method, tributyl phosphate is taken as an extractant, number 200 solvent oil or kerosene is taken as a diluent, perchlorate is taken as a co-extraction agent, and water is taken as a stripping agent to form an extraction system; and lithium carbonate is prepared through extraction, reversed-phase extraction and deep magnesium removal by the salt lake brine. The method has the following beneficial effects: 1. the property of the co-extraction agent is stable, lithium magnesium separation can be carried out in neutral brine and the pH value of an aqueous phase needs not to be controlled; 2. the emulsification phenomenon doesn't exist and a third phase doesn't appear in the extraction process, two phases are easy to separate, the reversed-phase extraction is carried out by water and the device has little corrosion; and 3. the whole technique is simple in process, high in lithium extraction rate, good in separation effect and low in economic cost, is suitable for industrial production of the salt lake brine and is low in environmental damage degree because the co-extraction agent in water can be recycled.

Owner:XIANGTAN UNIV

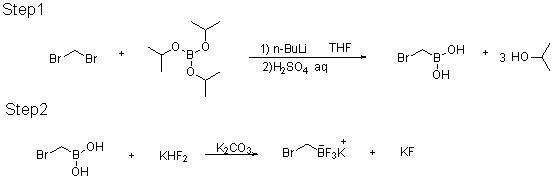

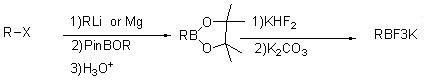

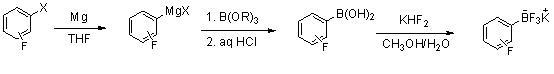

Method for preparing potassium trifluoroborate series compounds

InactiveCN102060867ASolve corrosiveAvoid affecting yieldGroup 3/13 element organic compoundsOrganic baseBoronic acid

The invention relates to synthesis of organic compounds, and provides a method for preparing potassium trifluoroborate series compounds. The method comprises the following steps of: adding organic boric acid or organic borate and solvent (THF (tetrahydrofuran), or MTBE (Methyl Tertiary Butyl Ether), or ethyl acetate, or methanol) into a reaction kettle lined with tetrafluoroethylene plastic at room temperature; adding potassium bifluoride and water at normal temperature, stirring for 1 to 12 hours, and reacting to prepare a solid-liquid mixture; adding solid potassium ion containing inorganic or organic alkali into the solid-liquid mixture after the reaction is completed, neutralizing until the pH is between 7 and 9, and continuously stirring for 1 to 5 hours; directly filtering to obtain a solid coarse product after stirring is completed; dissolving the coarse product with solvent, filtering and concentrating, adding nonpolar solvent, and pulping to obtain high-quality RBF3K series compounds. The method is easy to operate, has mild reaction conditions, and can realize scale-up production; and the product prepared by the method has high yield and excellent purity, and the cost is greatly reduced.

Owner:大连联化医药技术有限公司

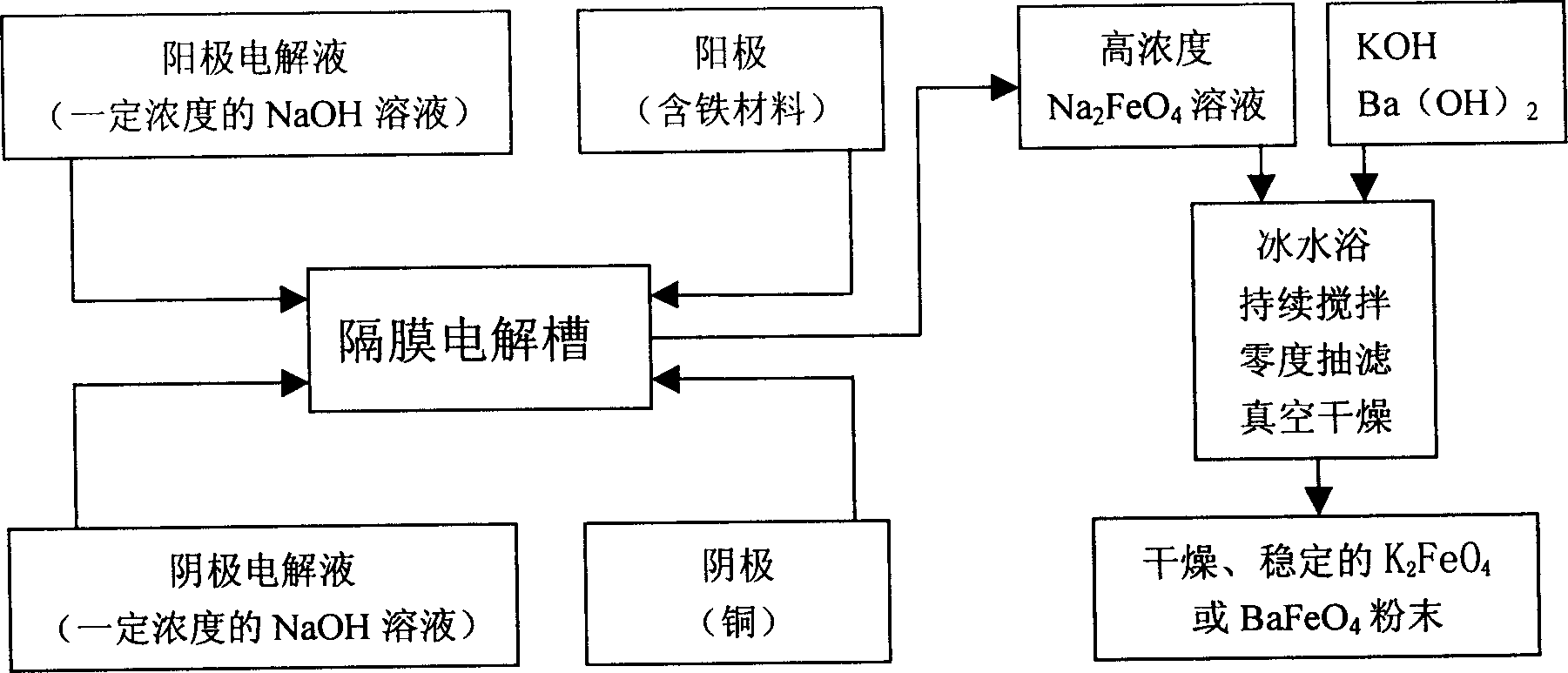

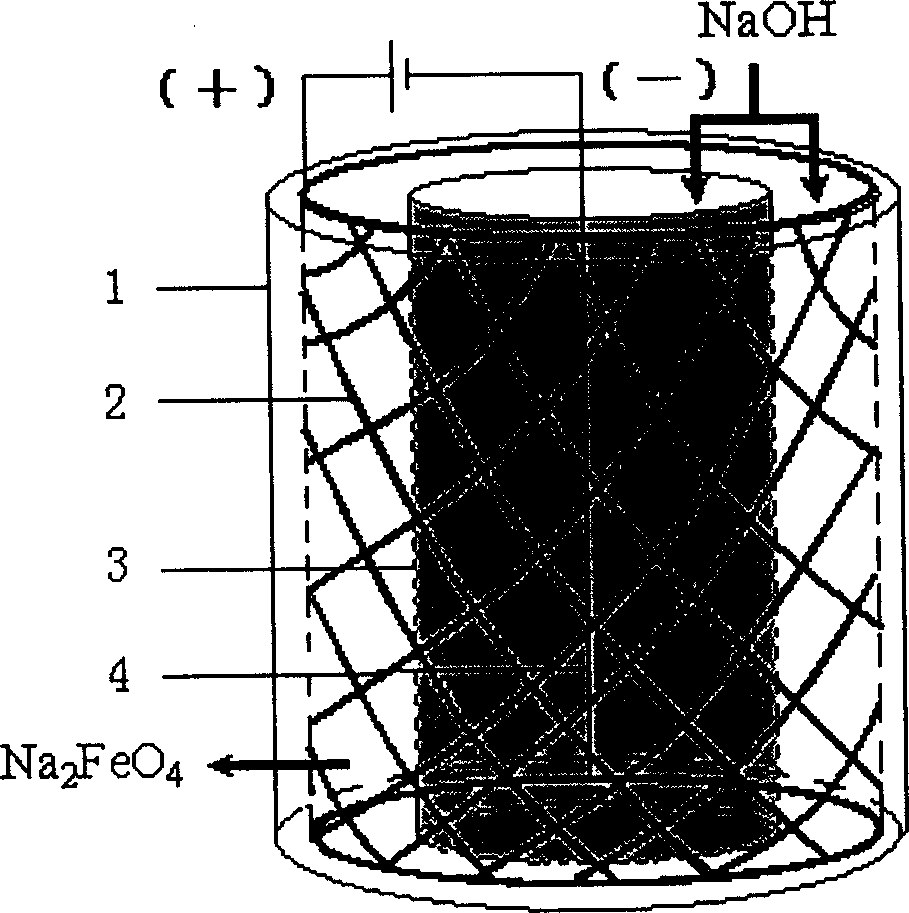

Direct electrochemical process of preparing ferrate

InactiveCN1740398AImprove electrolysis efficiencyReduce manufacturing costElectrolysis componentsHigh concentrationElectrolysis

The present invention belongs to the field of chemical preparing technology, and is especially direct electrochemical process of preparing ferrate. The preparation process prepares ferrate inside one diaphragm type cylindrical electrolytic bath with pure sodium hydroxide as electrolyte. While controlling electrolyte concentration, reaction temperature and applied voltage, high concentration sodium ferrate solution is first prepared, and potassium ferrate or barium ferrate is then prepared via adding potassium ion or barium ion. The present invention has simple technological process and low cost, and is suitable for large scale preparation of ferrate.

Owner:FUDAN UNIV

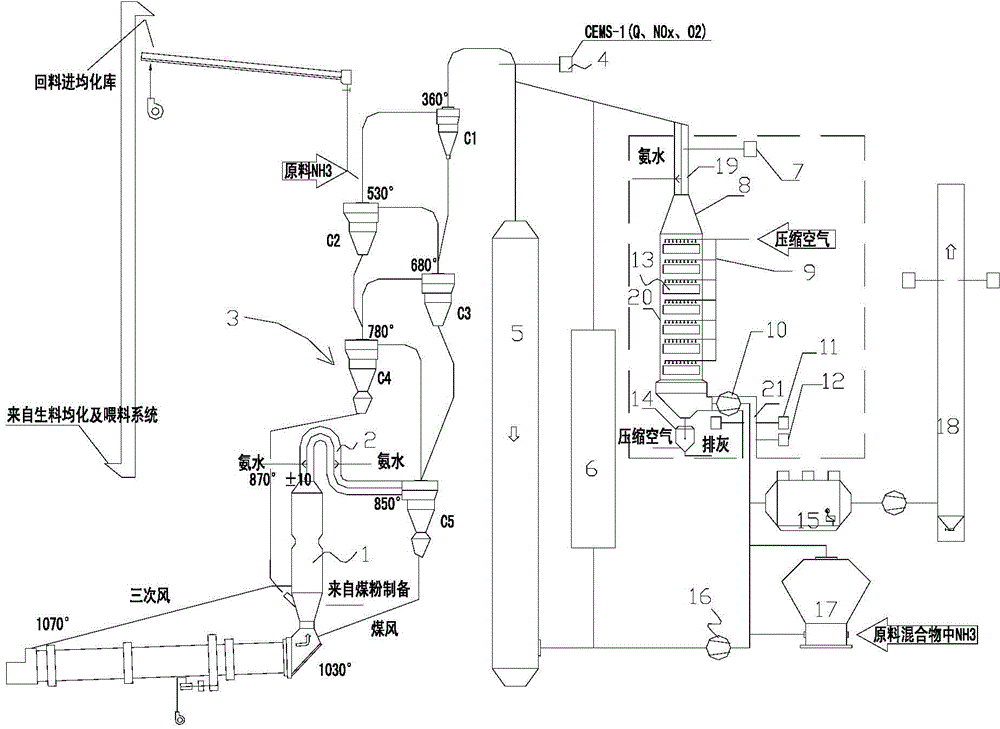

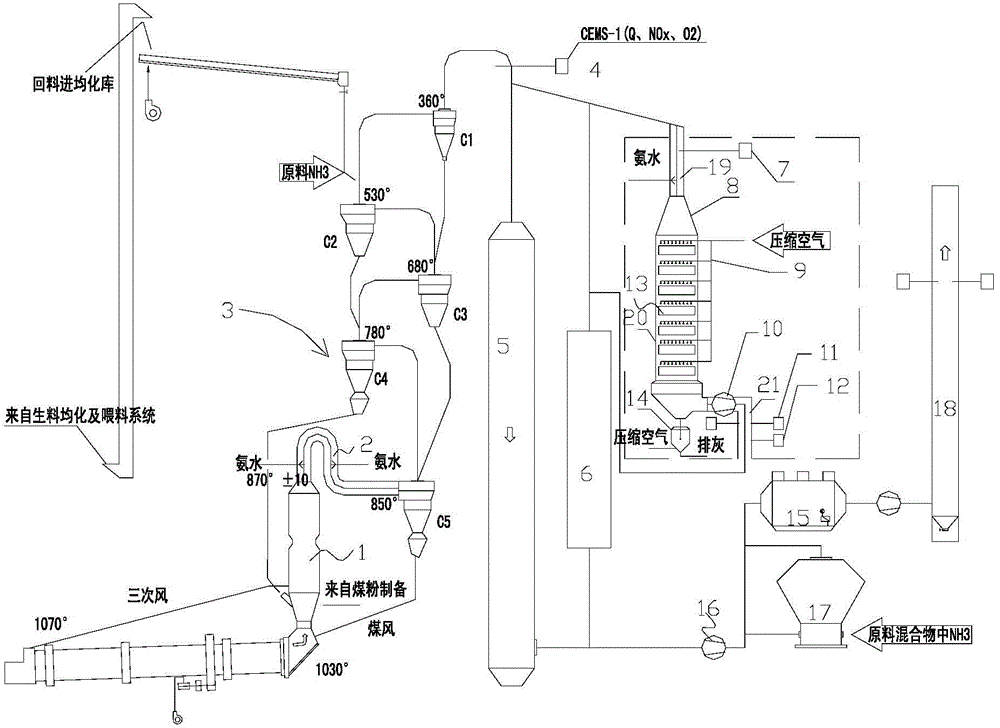

SCR denitration device and method applied to high-dust-content smoke from kiln tail of cement clinker production line

ActiveCN104645828AFlow field stabilityDoes not affect thermal efficiencyNitrous oxide captureDispersed particle separationProduction lineSprayer

The invention discloses an SCR (selective catalytic reduction) denitration device and an SCR denitration method applied to high-dust-content smoke from a kiln tail of a cement clinker production line. The device comprises a cement kiln decomposing furnace, a preheater, an afterheat boiler, a raw mill, an electric dust remover and a kiln tail chimney which are connected in sequence along the smoke direction, and further comprises an SCR reactor, wherein the SCR reactor comprises a reactor shell; an inlet divergent section is arranged at the top of the reactor shell, and an ash bucket is arranged at the bottom of the reactor shell; an inlet flue of the SCR reactor is connected with the preheater and the inlet divergent section and is provided with a reducer sprayer; a plurality of catalyst layers are arranged in the reactor shell in sequence from top to bottom; a plurality of steam ash blowers correspond to the catalyst layers one to one and are arranged above the corresponding catalyst layers; an outlet flue of the SCR reactor is connected with the bottom of the reactor shell and an upstream flue or a downstream flue of the afterheat boiler and is additionally provided with a high-temperature fan. On the basis that a high-temperature dust remover is not arranged, the SCR denitration device can handle with the smoke characteristics of high NOx load fluctuation, temperature fluctuation and high dust content.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE +1

Anticorrosive wear-resistant paint for oilfield pipelines

InactiveCN104130662AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to an anticorrosive wear-resistant paint for oilfield pipelines. The paint is characterized by comprising the following components by weight: 25-35 parts of epoxy resin, 5-15 parts of organic silicon resin, 0.5-5 parts of ceramic micropowder, 10-20 parts of nano-graphite powder, 5-15 parts of an epoxy resin curing agent, and 10-20 parts of butanone. The paint provided by the invention can provide a protective coating with high corrosion resistance, wear resistance, high adhesion and impact resistance for various steel pipelines of oilfield.

Owner:西安和泰化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com