Method for separating magnesium and extracting lithium from salt lake brine with high magnesium-lithium ratio

A technology of salt lake brine and high magnesium-lithium ratio, applied in the direction of lithium carbonate;/acid carbonate, magnesium carbonate, magnesium hydroxide, etc., can solve the problems of the limitation of technical improvement and the lack of improvement effect, etc. Achieve the effect of solving equipment corrosion, good effect, and wide range of pH value adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

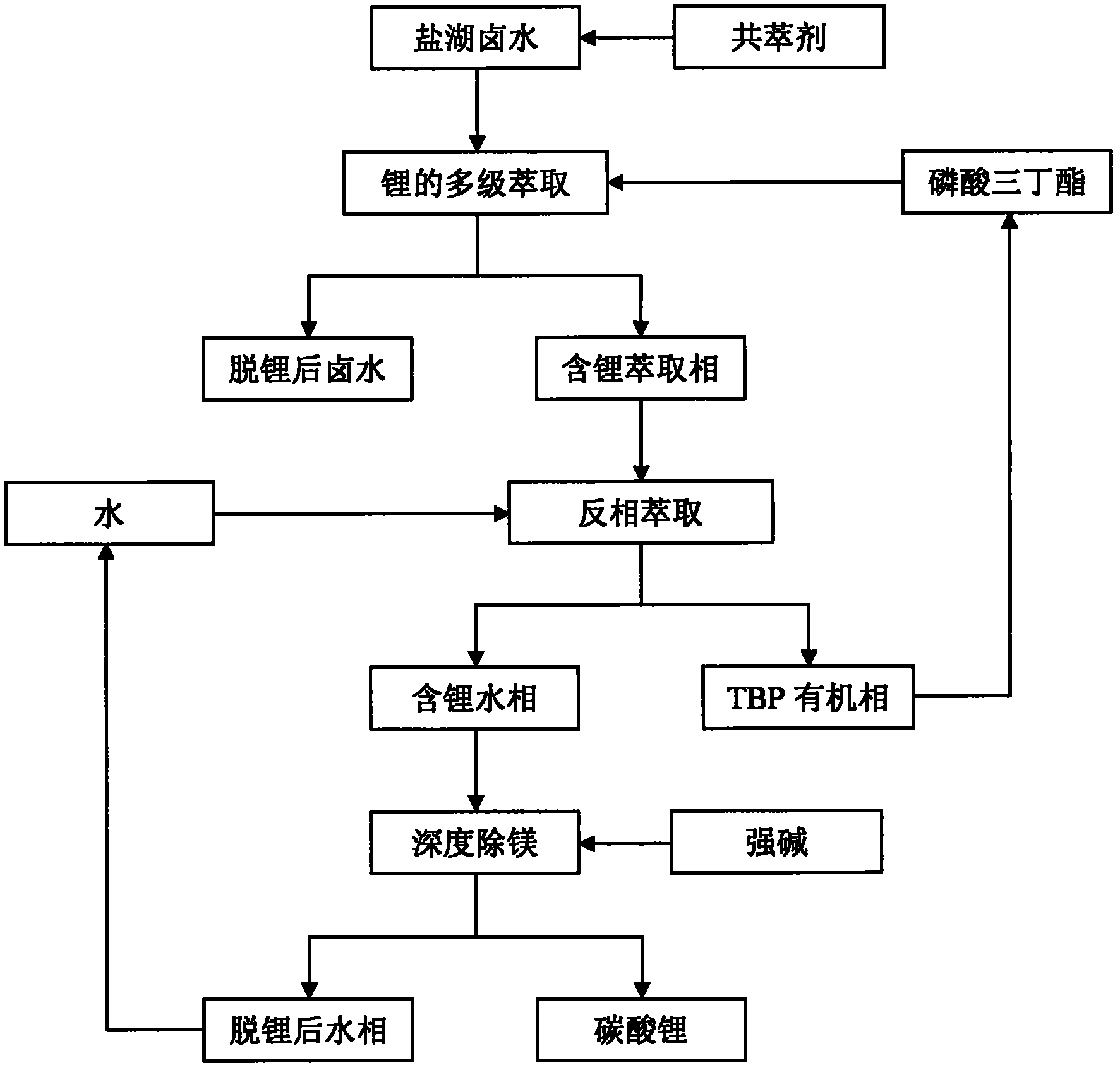

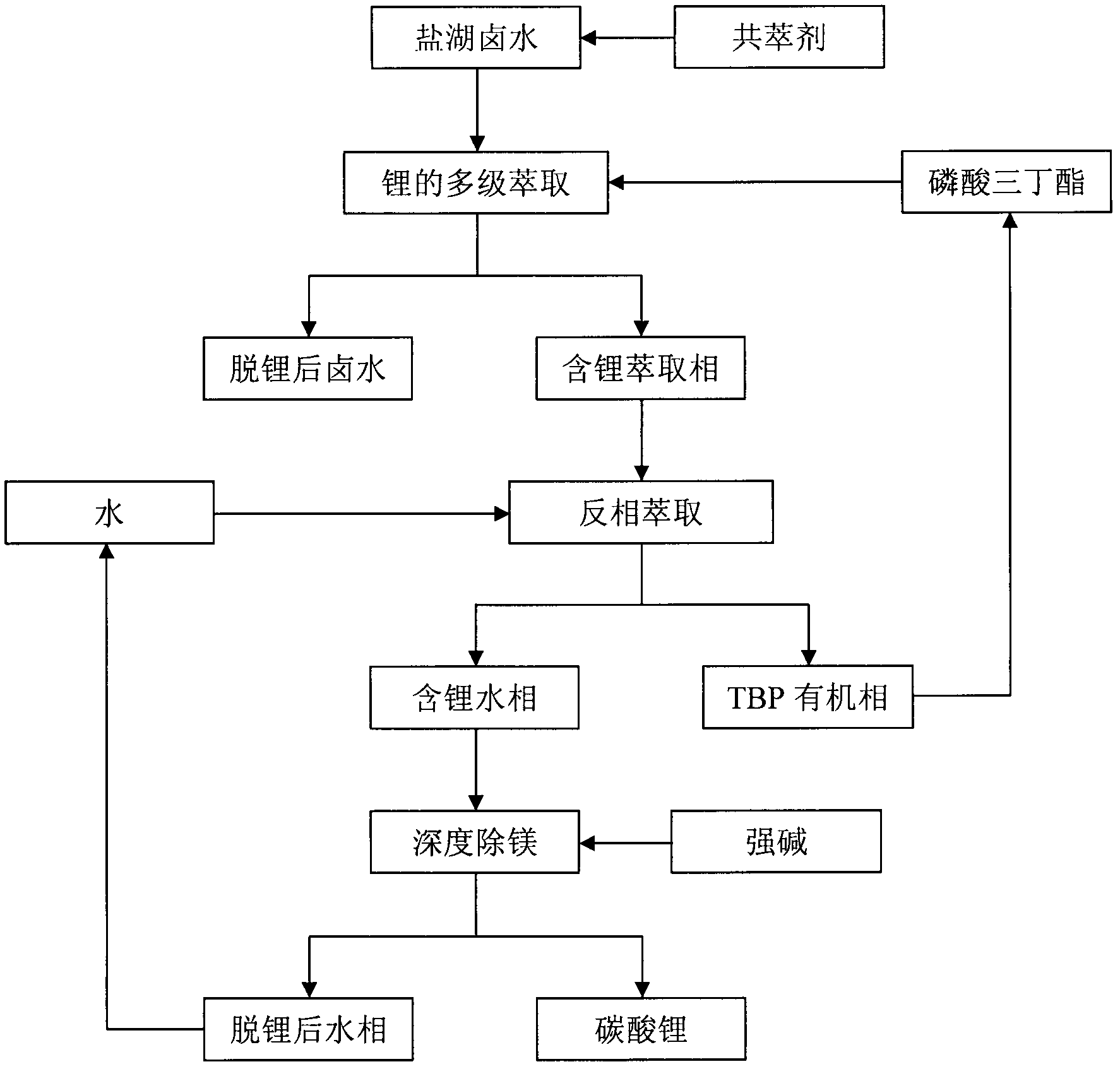

[0020] process such as figure 1 shown.

[0021] 1) Take 50mL of concentrated brine, which contains: Li + 2.21g / L, Mg 2+ 100.71g / L, Na + 3.53g / L, K + 1.85g / L, the mass ratio of magnesium to lithium is 45.6.

[0022] 2) Add the co-extraction agent sodium perchlorate in the brine, the dosage is As the standard, stir and dissolve at 25°C to obtain a pre-extraction brine solution with a pH value of 5.

[0023] 3) The organic phase TBP was added in a proportion equal to the volume of water, and a single extraction was performed at 25° C., the extraction vibration time was 10 min, and the two phases were separated.

[0024] 4) Use pure water as the stripping agent, mix the organic phase and water at a volume ratio of 1:1, carry out stripping at 25°C, strip for 10 minutes, let stand for 15 minutes, and then separate the two phases.

[0025] 5) After back-extraction, the aqueous phase is adjusted to pH ≥ 12 with caustic soda, and the magnesium is treated with Mg(OH) 2 The form...

Embodiment 2

[0028] 1) Take 50mL of concentrated brine, which consists of Li + 0.48g / L, Mg 2+ 96.21g / L, Na + 3.53g / L, K + 1.85g / L, the mass ratio of magnesium to lithium is 200.4.

[0029] 2) Add the co-extraction agent sodium perchlorate in the brine, the dosage is As the standard, stir and dissolve at 25°C to obtain a brine solution before extraction, and adjust the pH value of the solution to 7.

[0030] 3) Add the organic phase according to the volume ratio of the oil phase and the water phase as 2:1, the organic phase is composed of 80% TBP and 20% kerosene, carry out a single extraction at 25 ° C, extract vibration time for 30 min, stand still for 30 min, and then two phase separation.

[0031] 4) Use pure water as the stripping agent, mix the organic phase and water at a volume ratio of 1:1, carry out stripping at 50° C., strip for 10 minutes, let stand for 30 minutes, and then separate the two phases.

[0032] 5) After stripping, the water phase is adjusted to pH ≥ 12 with s...

Embodiment 3

[0035] 1) Take 50 mL of brine containing boron and sulfate radicals after concentration, which consists of: Li + 1.80g / L, Mg 2+ 90.51g / L, Na + 6.89g / L, K + 1.85g / L, 28.82g / L, B 2 o 3 20.89g / L, the mass ratio of magnesium to lithium is 50.3.

[0036] 2) Add the co-extraction agent sodium perchlorate in the brine, the dosage is Standard, stirred and dissolved at 25°C to obtain a pre-extraction brine solution.

[0037] 3) The organic phase TBP was added according to the volume ratio of the oil phase and the water phase at 2:1, and a single extraction was performed at 25° C., the extraction vibration time was 10 min, and the two phases were separated.

[0038] 4) Use pure water as the stripping agent, mix the organic phase and water at a volume ratio of 1:1, carry out stripping at 60° C., strip for 10 minutes, let stand for 15 minutes, and then separate the two phases.

[0039] 5) After stripping, the water phase is adjusted to pH ≥ 12 with sodium carbonate and caustic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com