Preparation method and application of magnetic silicon dioxide composite microsphere

A technology of silicon dioxide and composite microspheres, applied in the field of immunochemical tests, can solve the problems of poor compression and corrosion resistance of microspheres, easy corrosion of magnetic core ferric oxide, etc. The effect of good dispersion and simple purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

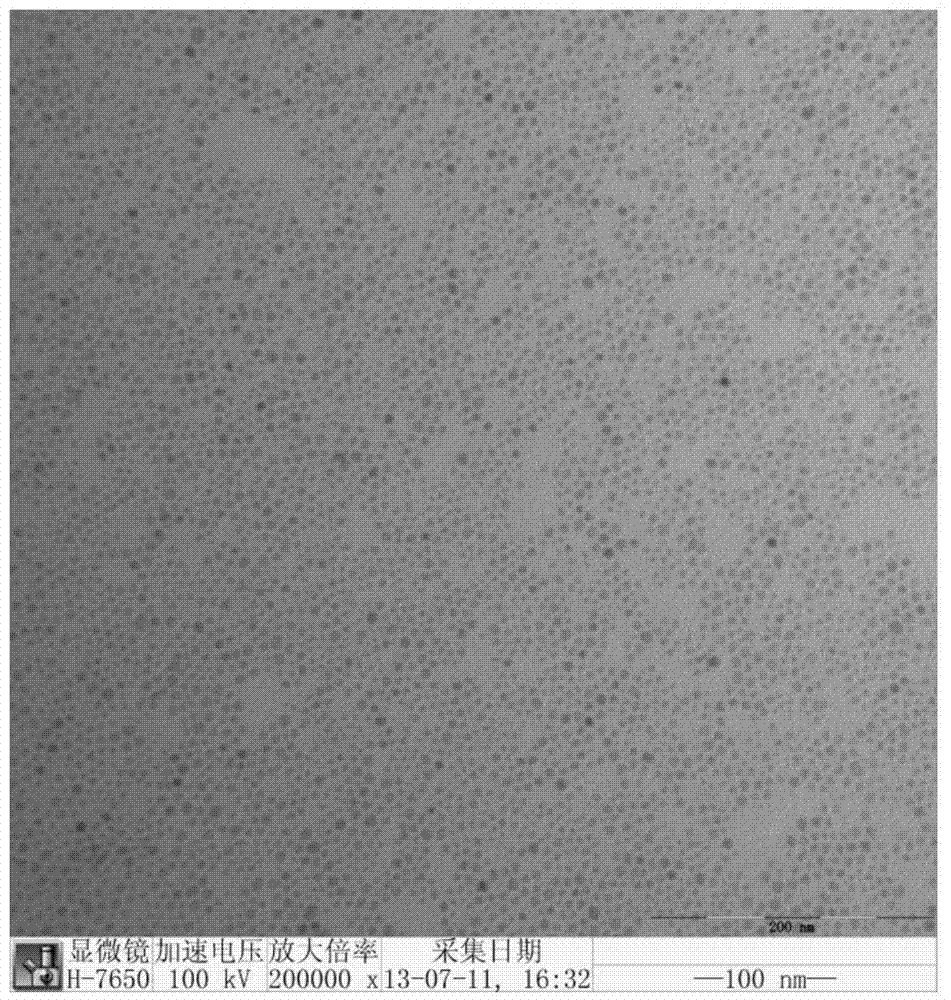

[0035] 1. Fe 3 o 4 Preparation of nanoparticles

[0036] 1. Preparation of iron oleate precursor

[0037] 2.7gFeCl 3 ·6H 2 O was dissolved in a mixed solution of water, ethanol and n-hexane with a volume of 70mL, and then 8.875g of sodium oleate was added, stirred magnetically under a nitrogen atmosphere at room temperature, heated to 70°C, condensed and refluxed for 4h. After the reaction was completed, the instrument was closed, and the solution was cooled to room temperature, separated by a separatory funnel, the upper organic phase contained a mixture of ferric oleate, the upper organic phase was washed with deionized water, dried in vacuo, and the solvent n-hexane was removed to obtain brown The brown waxy solid is the iron oleate precursor.

[0038]2. Preparation of Fe by high temperature pyrolysis of iron oleate precursor 3 o 4 Nanoparticles

[0039] Dissolve 1 g of iron oleate precursor in 5.56 mL of octadecene, add 0.16 mL of oleic acid, stir magnetically, he...

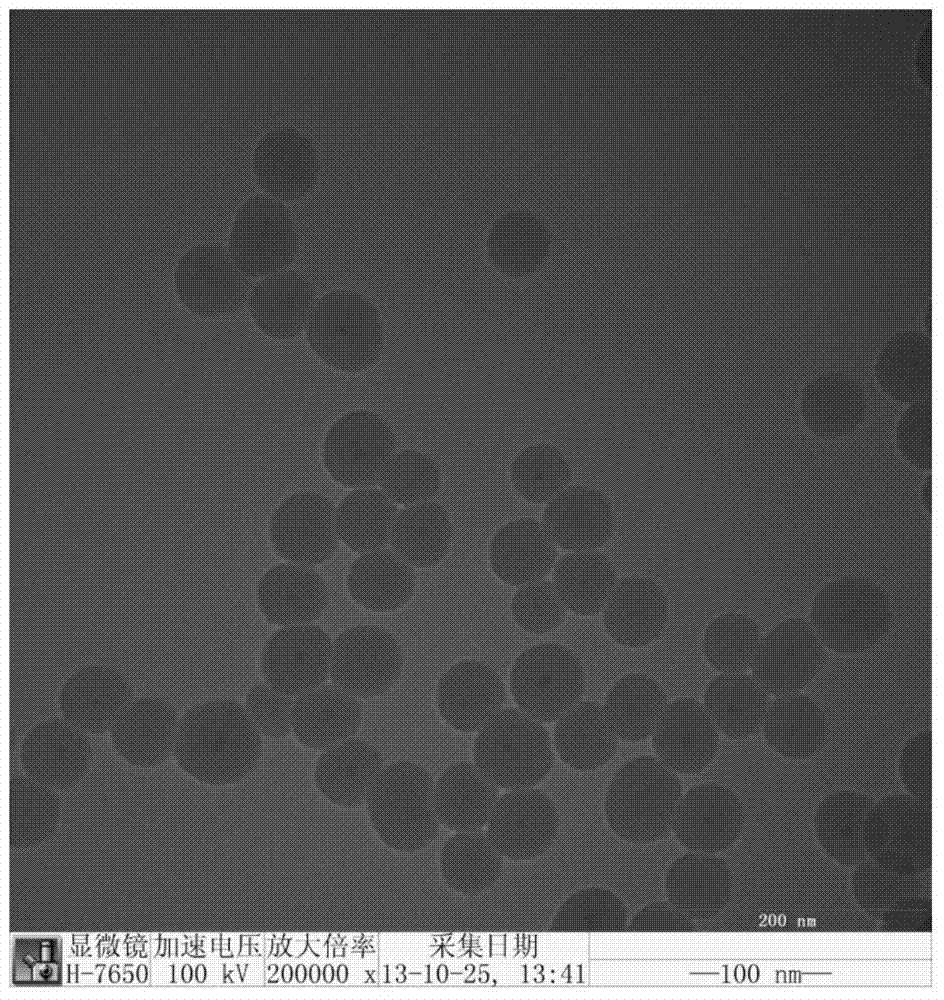

Embodiment 2

[0051] 1. Fe 3 o 4 Preparation of nanoparticles

[0052] 1. Preparation of iron oleate precursor

[0053] 2.7gFeCl 3 ·6H 2 O was dissolved in a mixed solution of water, ethanol and n-hexane, with a volume of 70 mL, and then 8.875 g of sodium oleate was added, stirred magnetically under a nitrogen atmosphere at room temperature, heated to 50 ° C, condensed and refluxed for 6 h. After the reaction was completed, the instrument was closed, and the solution was cooled to room temperature, separated by a separatory funnel, the upper organic phase contained a mixture of ferric oleate, the upper organic phase was washed with deionized water, dried in vacuo, and the solvent n-hexane was removed to obtain brown The brown waxy solid is the iron oleate precursor.

[0054] 2. Preparation of Fe by high temperature pyrolysis of iron oleate precursor 3 o 4 Nanoparticles

[0055] Dissolve 1 g of iron oleate precursor in 5 mL of octadecene, add 0.15 mL of oleic acid, stir magnetically...

Embodiment 3

[0063] 1. Fe 3 o 4 Preparation of nanoparticles

[0064] 1. Preparation of iron oleate precursor

[0065] 2.7gFeCl 3 ·6H 2 O was dissolved in a mixed solution of water, ethanol and n-hexane with a volume of 70mL, and then 8.875g of sodium oleate was added, stirred magnetically under a nitrogen atmosphere at room temperature, heated to 80°C, condensed and refluxed for 3h. After the reaction was completed, the instrument was closed, and the solution was cooled to room temperature, separated by a separatory funnel, the upper organic phase contained a mixture of ferric oleate, the upper organic phase was washed with deionized water, dried in vacuo, and the solvent n-hexane was removed to obtain brown The brown waxy solid is the iron oleate precursor.

[0066] 2. Preparation of Fe by high temperature pyrolysis of iron oleate precursor 3 o 4 Nanoparticles

[0067] Dissolve 1 g of iron oleate precursor in 6 mL of octadecene, add 0.18 mL of oleic acid, stir magnetically, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com