Patents

Literature

313 results about "Phosphoric acid tributyl ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphoric acid tributyl ester is listed as a High Production Volume (HPV) chemical (65FR81686). Chemicals listed as HPV were produced in or imported into the U.S. in >1 million pounds in 1990 and/or 1994.

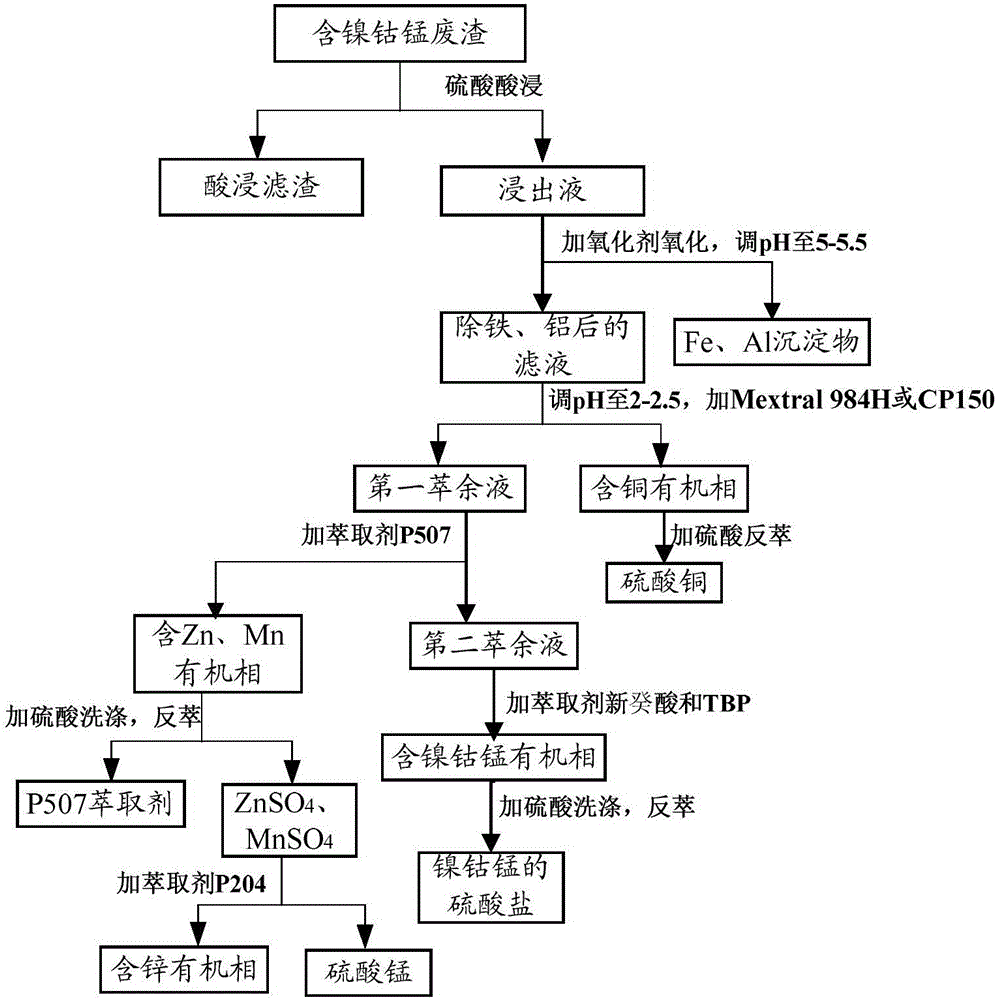

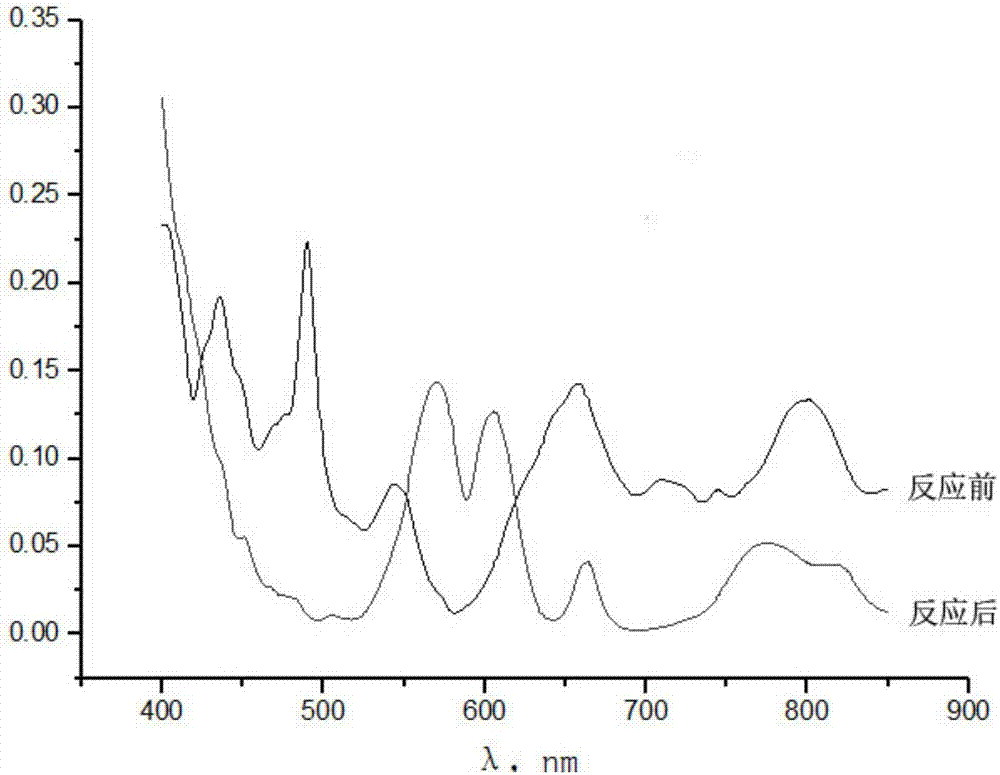

Method for recycling nickel, cobalt and manganese synchronously from waste residues containing nickel, cobalt and manganese

ActiveCN106319228AReduce separation costsSimple processProcess efficiency improvementManganeseCobalt

The invention discloses a method for recycling nickel, cobalt and manganese synchronously from a sulfuric acid leaching solution containing waste residues of nickel, cobalt and manganese. The method comprises the steps of firstly, removing iron and aluminum from the leaching solution through an oxidation and precipitation method; then, removing the element copper through extraction; then, extracting zinc; and finally, extracting nickel, cobalt and manganese synchronously with tributyl phosphate and saponified neodecanoic acid. By means of the method, nickel, cobalt and manganese in the leaching solution containing the waste residues of nickel, cobalt and manganese can be extracted and recycled synchronously; calcium and magnesium in a raw solution cannot exert an influence on the extraction process; separation cost for recycling the elements nickel, cobalt and manganese separately is lowered; and raw material cost for preparing a nickel-cobalt-manganese-salt ternary battery material is lowered.

Owner:JINGMEN GEM NEW MATERIAL

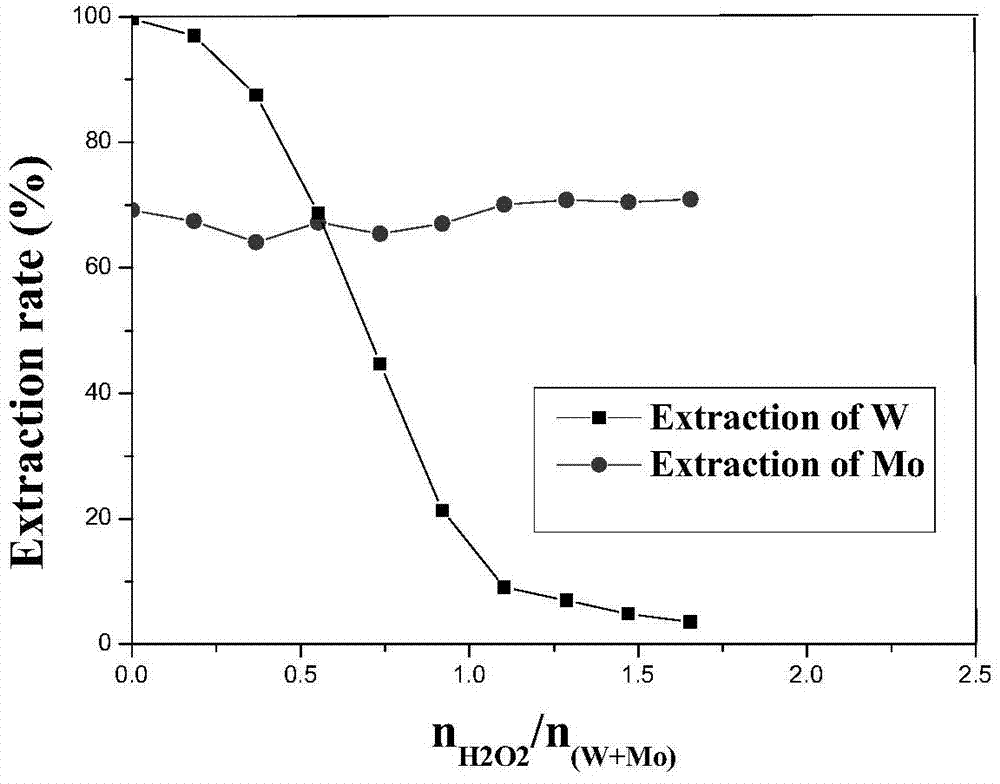

Method for extraction and separation of tungsten and molybdenum from tungsten and molybdenum mixed solution

ActiveCN102876906AOvercoming Difficult Phase Splitting ProblemsOvercoming the problem of large loss in tungsten co-extractionProcess efficiency improvementTungstateDiluent

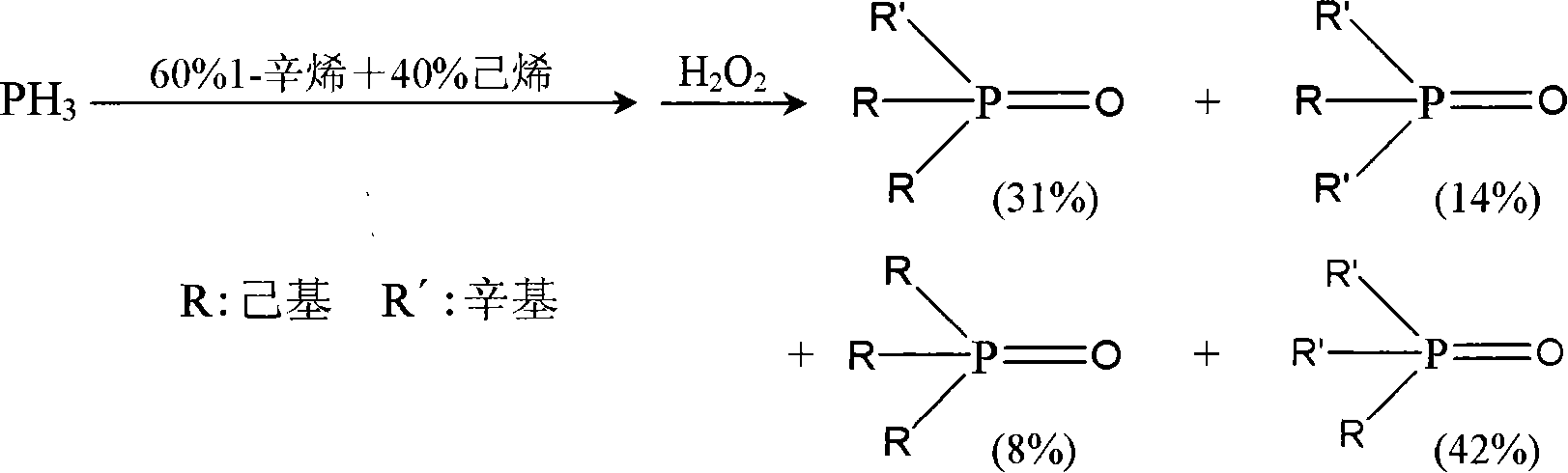

The invention provides a method for extraction and separation of tungsten and molybdenum. Hydrogen peroxide is filled in the tungsten and molybdenum mixed solution, the pH value is regulated to be acidic, and the acid tungsten mixed solution is taken as a water phase feed liquid to carry out extraction and separation with an organic phase. The organic phase comprises trialkylphosphine oxide, tributyl phosphate and a diluting agent; the organic phase conducts the multi-stage extraction with the water phase feed liquid, molybdenum is extracted into the organic phase, and tungsten is left in a raffinate, so that the separation of tungsten and molybdenum is achieved. The load-bearing organic phase adopts an alkaline back-extraction agent to carry out back-extraction to obtain a molybdenum-contained solution, and the organic phase subjected to the back-extraction returns to the extraction process. Tungsten and molybdenum are extracted and separated in the tungsten and molybdenum mixed solution containing H2O2 by adopting a novel binary mixture extracting agent, the method has the advantages that extraction and the back-extraction are high in split-phase speed, the separation effect of tungsten and molybdenum is good, the tungsten co-extraction loss is low, the loss of the organic phase as well as the environmental pollution is low, the industrialization is easy to realize, and the method is especially suitable for separating tungsten and molybdenum in the tungstate solution with high molybdenum content.

Owner:CENT SOUTH UNIV +1

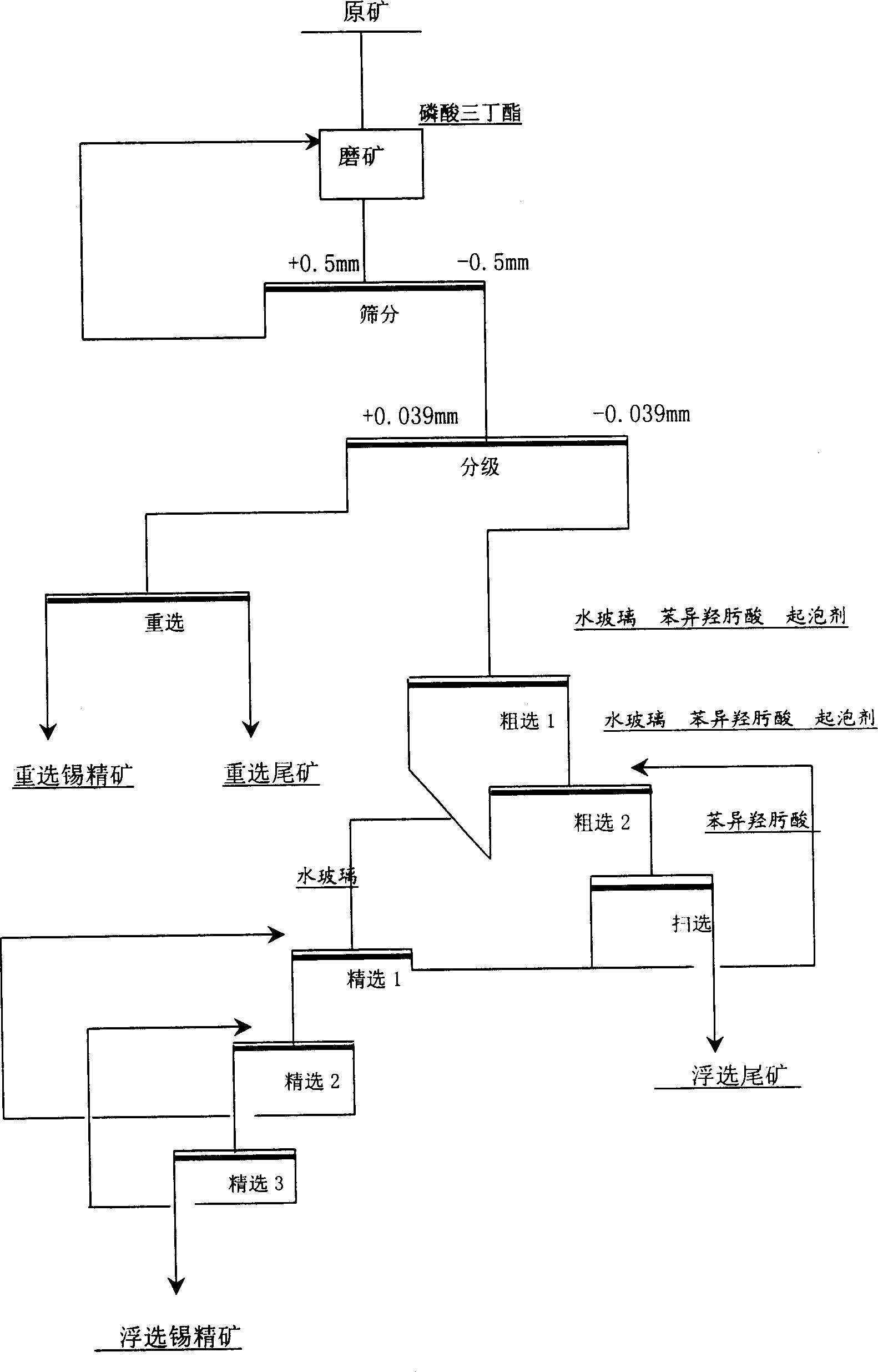

Cassiterite ore separation method

InactiveCN1721080AAvoid over crushingReduce contentFlotationCassiteritePhosphoric acid tributyl ester

Mineral separation for cassiterite ore comprises break, grinding, classification and the floatation for classified fine fraction less than 0.039mm. The floatation takes process of roughing for two times, scavenging for one time and refining for three times. It avoids over breaking, decreases fine ore greatly; as adding TBP, the ore needs not pre-desliming to recovery with floatation for the fine ore of less than 0.039mm. With this invention, for the cassiterite-quartz ore or tin placer with Sn content 0.6~2.0%, the flotation concentrate contains Sn more than 26%, the floatation recovery rate is more than 80%, and compared with traditional technique, the total recovery rate is increased more than 10%.

Owner:黎东明

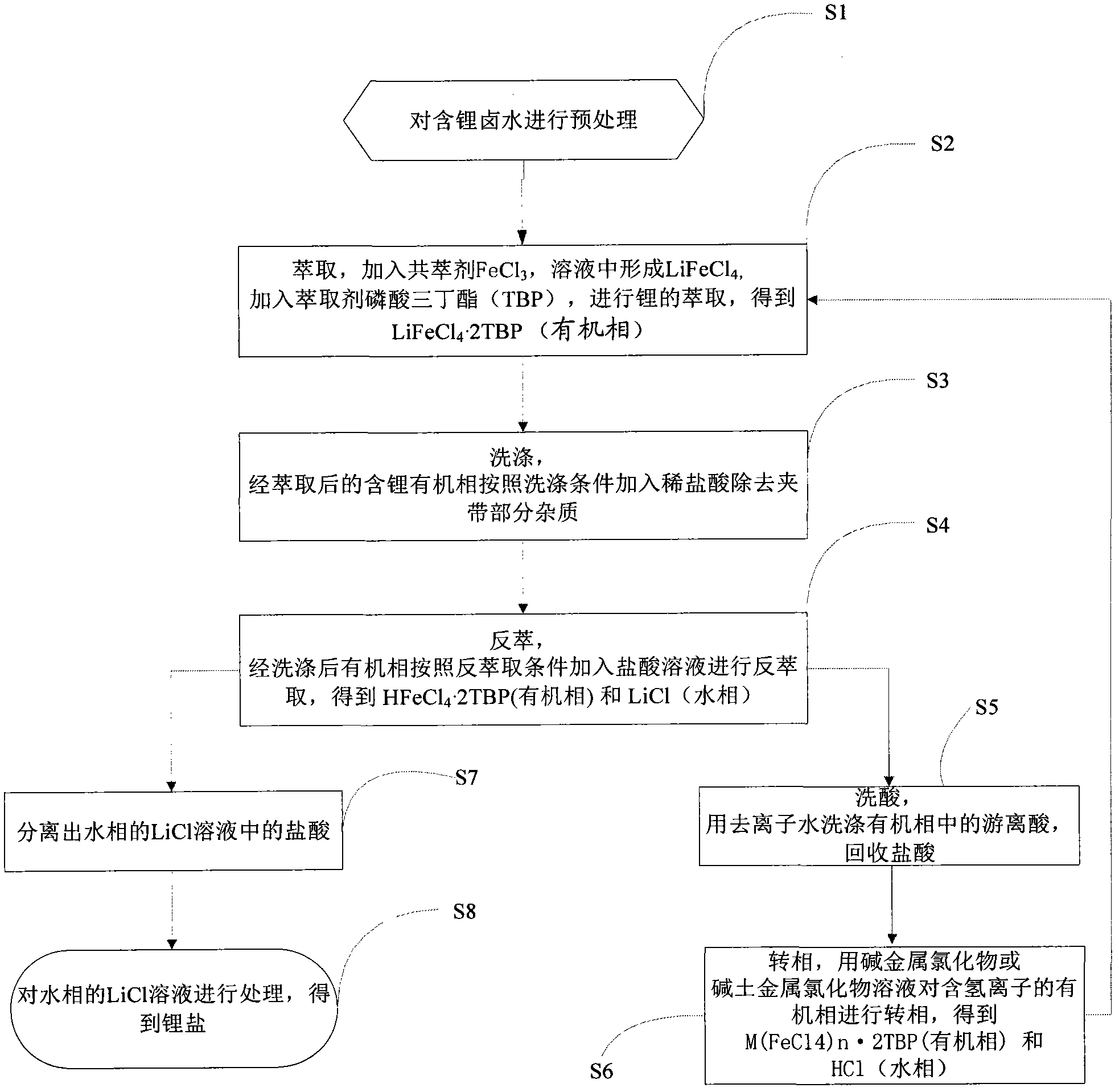

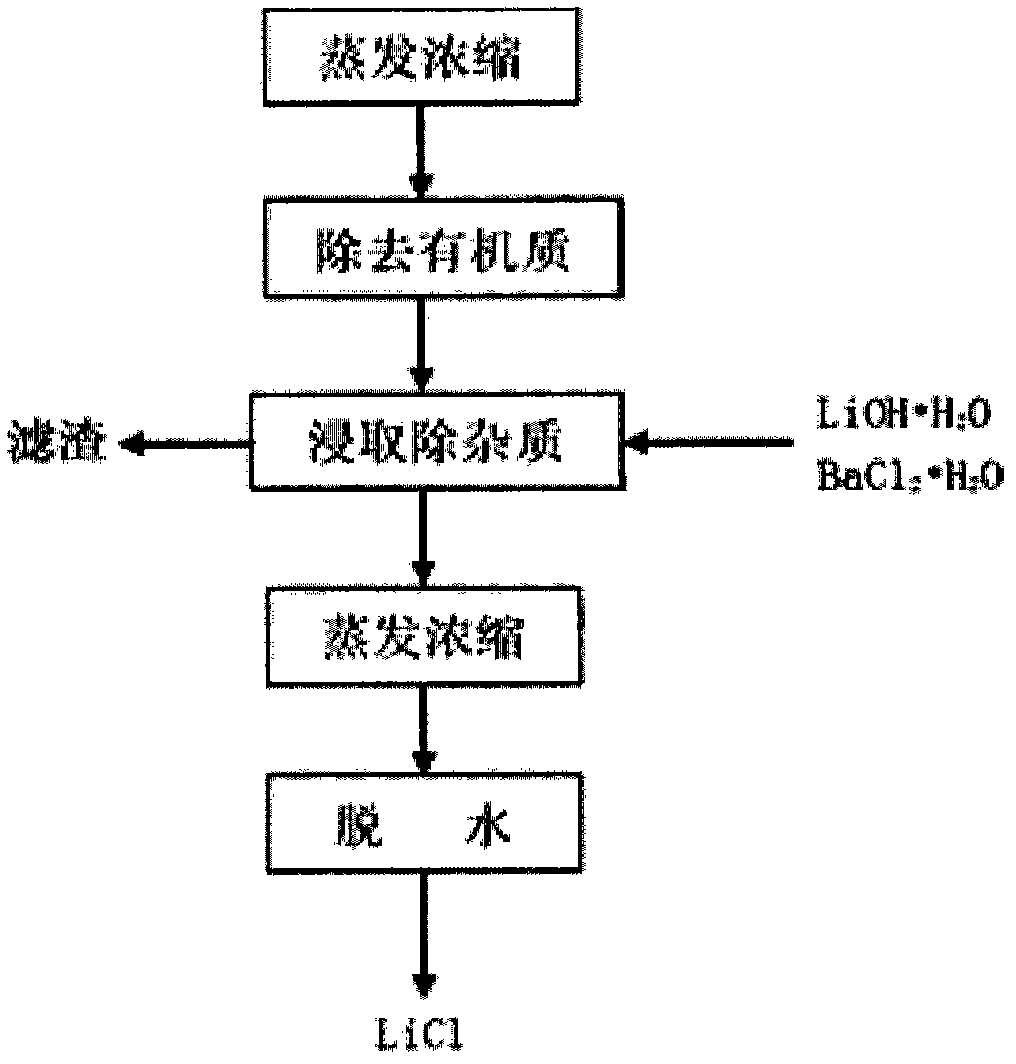

Method for extracting lithium salt from lithium brine

InactiveCN102992358AIncrease profitAvoid hydrolysisLithium halidesLithium carbonates/bicarbonatesLithiumAlkaline earth metal

The invention provides a method for extracting lithium salt from lithium brine. The method comprises the following steps: extraction step: adding a co-extracting agent FeCl3 and an extraction agent tributyl phosphate (TBP) to lithium brine to extract lithium so as to obtain an organic phase LiFeCl4.2TBP and a water phase raffinate; reverse extraction step: adding a hydrochloric acid liquor to the organic phase LiFeCl4.2TBP for reverse extraction to obtain organic phase LiFeCl4.2TBP and water phase LiCl; and phase inversion step: inversing phase for the organic phase LiFeCl4.2TBP containing hydrogen ions by a liquor of alkali chloride, alkaline earth chloride or a mixture MCln (n is greater than or equal to 1) as a phase inversion agent to obtain an organic phase M(FeCl4)n.2TBP. According to the method for extracting lithium salt from lithium brine provided by the invention, the production cost of extracting lithium salt can be lowered.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Seed coating agent for rapeseed

InactiveCN1475117AImprove economyDry weight increaseBiocideClimate change adaptationDiseasePolyvinyl alcohol

A coating agent for rape seed is prepared from assistant, chemical and water through proportionally mixing and stirring. Said assistant includes filming agent, surfactant, anti-freezing agent, penetrant, etc. Said chemical includes insecticide, bactericide, plant growth regulator, trace element, fertilizer, etc. Its advantage is high effect to prevent and eliminate diseases and pests and increaseyield.

Owner:ZHEJIANG UNIV

Method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas

InactiveCN101597073AHigh purityHigh selectivityChemical industryThiocyanic acidLiquid wasteSodium thiocyanate

The invention discloses a method for preparing sodium thiocyanate by using desulphurization waste liquid of coke oven gas, and belongs to the technical field of utilization of desulphurization waste liquid of the coke oven gas. The method comprises the following steps: using the desulphurization waste liquid of the coke oven gas as a raw material, firstly, filtering the waste liquid in vacuum, using tributyl phosphate to extract thiocyanate radicals in the waste liquid, then using sodium hydroxide solution to back-extract the extract, and finally concentrating and crystallizing the extract, and washing and drying the crystals to obtain sodium thiocyanate crystals. The method uses the desulphurization waste liquid of the coke oven gas to prepare a sodium thiocyanate product with the purity as high as 93 to 95 percent so as to change waste into valuable and makes full use of waste resources; and the method is simple, saves energy, has no three-waste discharge, is favorable for environmental protection, has low production cost and good economic benefit, and develops a new path for the utilization of the desulphurization waste liquid resources of the coke oven gas. The sodium thiocyanate product prepared by the method can be widely applied in the industries of medicaments, textile, printing and dyeing, pesticide, chemistry and the like.

Owner:CHONGQING UNIV

Recovery method of lithium in waste battery

ActiveCN102002595AGuaranteed puritySimple processProcess efficiency improvementHigh concentrationRecovery method

The invention discloses a recovery method of lithium in a waste battery. In the recovery method, with lithium-containing faffinate generated in the wet-treatment process of the waste battery as a raw material and ketone compounds, tributyl phosphate and sulphonated kerosene as extraction organic phase, the pH of value the raw material of the lithium-containing faffinate is adjusted; then the lithium-containing faffinate is subjected to multistage countercurrent extraction; lithium in the lithium-containing faffinate enters the organic phase; and the organic phase loaded with the lithium is subjected to the multistage countercurrent extraction to obtain a lithium-containing strip liquor with high purity and high concentration. The liquor can be used for subsequently preparing various high-purity lithium salts. With the technology, over 85 percent of lithium in the lithium-containing faffinate can be directly recovered for preparing the high-purity lithium salts and has remarkable recovery value.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

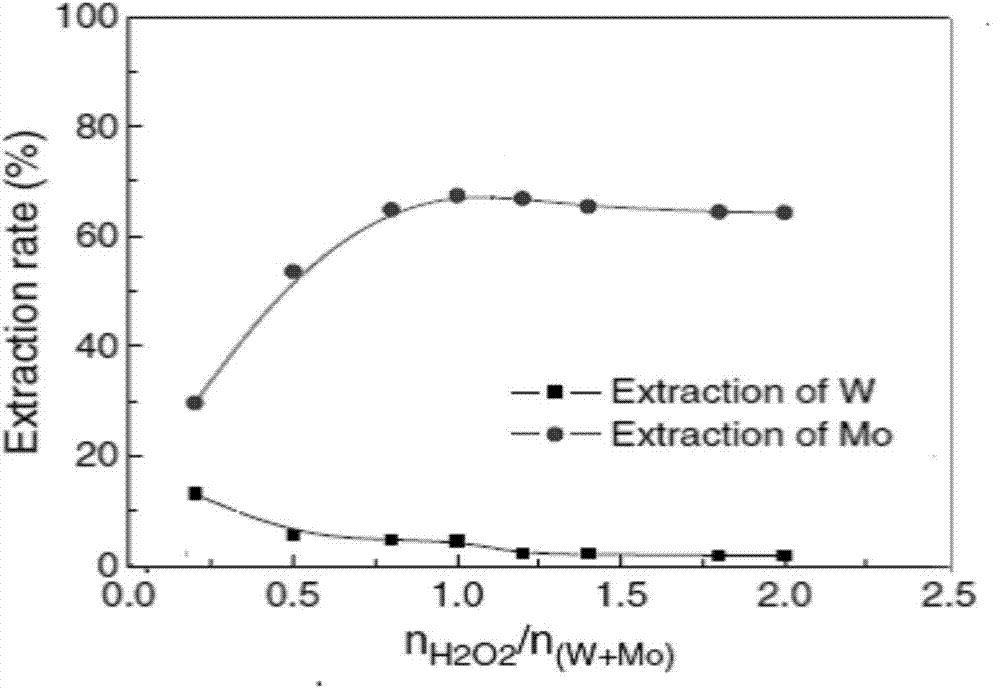

Method for extracting and separating tungsten and molybdenum in high-phosphorus mixed solution containing tungsten and molybdenum

ActiveCN104711422ARealize extraction and separationSimple methodProcess efficiency improvementPhosphomolybdic acidPhosphate

The invention relates to a method for extracting and separating tungsten and molybdenum in a high-phosphorus mixed solution containing tungsten and molybdenum. The method comprises the following steps: adding hydrogen peroxide in the high-phosphorus mixed solution containing tungsten and molybdenum for acidity adjustment and control, and converting phosphotungstic acid and phosphomolybdic acid into peroxy-phosphotungstic acid and peroxy-phosphomolybdic acid; then, taking a mixture of tributyl phosphate (TBP) and methyl phosphate dimethyl heptyl ester (P350) as an extracting agent, extracting the peroxy-phosphomolybdic acid into an organic phase, and leaving the peroxy-phosphotungstic acid in an aqueous phase; from now on, after decomposing the peroxy-phosphotungstic acid in extraction raffinate in the way of heating or ultraviolet irradiation or introduction of sulfur dioxide, extracting tungsten in the solution again with a fresh mixed extracting agent, and finally realizing extraction and separation of tungsten and molybdenum from complex material liquid. The method is small in tungsten co-extraction loss, can effectively solve the extraction and separation problem of tungsten and molybdenum in the high-phosphorus mixed solution containing tungsten and molybdenum, and is easy to realize industrialization.

Owner:CENT SOUTH UNIV

Method for extracting lithium from salt lake brine

ActiveCN104357676AEasy to operateReduce tributyl phosphate concentrationProcess efficiency improvementHigh concentrationKerosene

The invention provides a method for extracting lithium from salt lake brine. The method comprises the following steps: 1) preparing extract organic phases which comprise a composite extracting agent and a diluent, wherein the composite extracting agent is prepared by mixing tributyl phosphate with N,N-bis(2-ethylhexyl)-3-butanone acetamide according to a volume percent ratio of 50% to 50%; the diluent is sulfonated kerosene; 2) preparing an extract water phase which is an LiCl-MgCl2-H2O system; 3) adding HCl and FeCl3.6H2O to the extract water phase, wherein the ratio of amount of substances of iron and lithium is controlled to be 1.3 to 1, the acid concentration is 0.5mol / L, and the lithium concentration is 1-3g / L; 4) standing after fully mixing the extract water phase obtained in the step 3) with the extract organic phases obtained in the step 1) in a volume ratio of 1 to 2, and then separating a liquid phase. By adopting the method, the problems that the corrosivity of high-concentration tributyl phosphate towards extraction equipment is stronger and the dissolution loss of the extracting agent in water is serious in long-term operation are solved, and the lithium extraction efficiency of the prior art is achieved. The extraction method is simple and reliable to operate.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

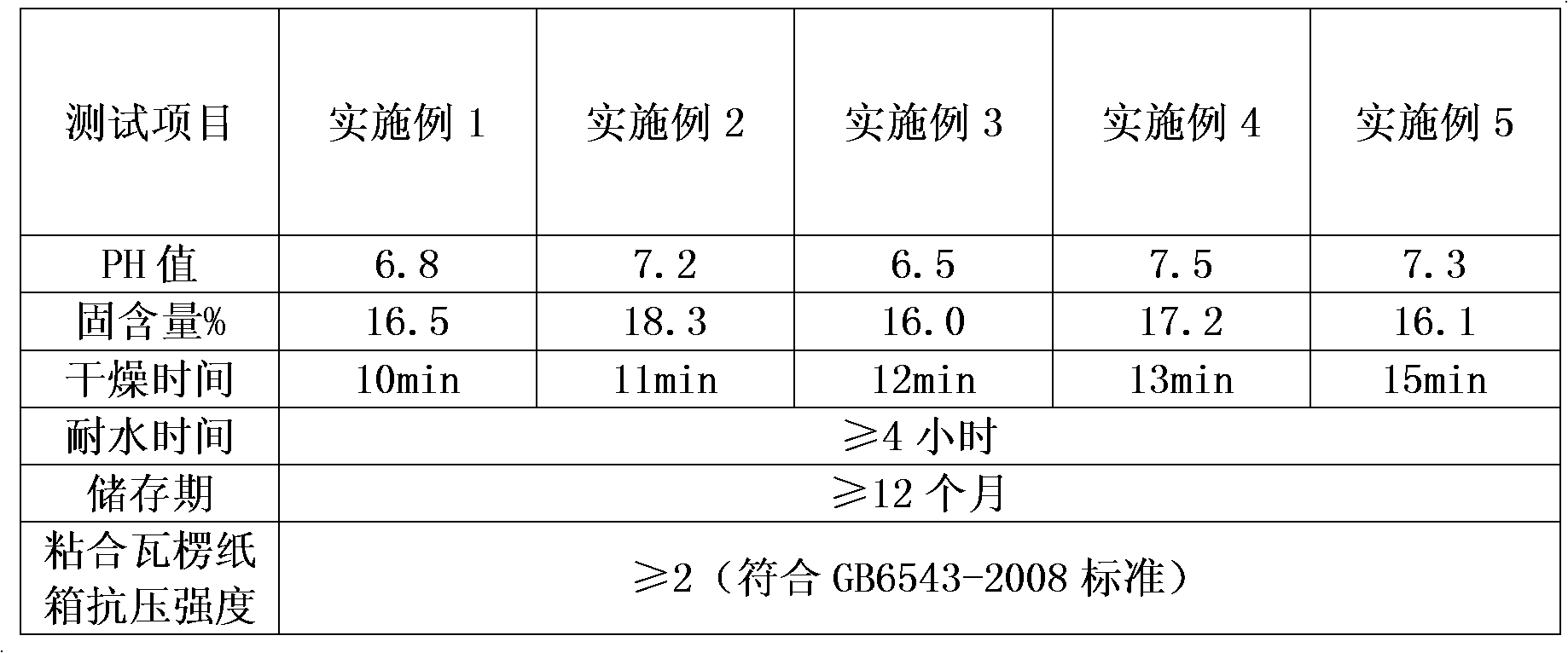

Preparation method of starch adhesive for adhering cartons

InactiveCN102433084AWill not damageStable storageNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveDrying time

The invention discloses a preparation method of a starch adhesive for adhering cartons, which belongs to the technical field of adhesive preparation, and comprises: adding 450 to 600 weight parts of water and 100 weight parts of starch into a reaction kettle; uniformly stirring, and adding 3 to 8 weight parts of hydrogen peroxide; reacting for 0.5 to 1 hour, and slowing adding 5 to 12 weight parts of aqueous solution of sodium hydroxide; stirring and reacting for 110 to 130 minutes, adding 0.2 to 0.8 weight part of crosslinking agent, 0.01 to 0.05 weight part of ferrous sulfate, 9 to 16 weight parts of water-proof agent, 10 to 20 weight parts of catalyst, 0.2 to 1.2 weight parts of tackifier, 0.05 to 0. 1 weight part of preservative, 15 to 18 weight parts of quick drying agent, and 0.5 to 1 weight part of tributyl phosphate in turn; stirring and reacting for 55 to 65 minutes; and obtaining the starch adhesive for adhering cartons. The method has the advantages that: the starch adhesive is stable in storage and is environment-friendly; the drying time is short, and the water-proof time is long; and the starch adhesive meets national standards.

Owner:CHANGSHU KAILIDA HONEYCOMB PACKING MATERIALS

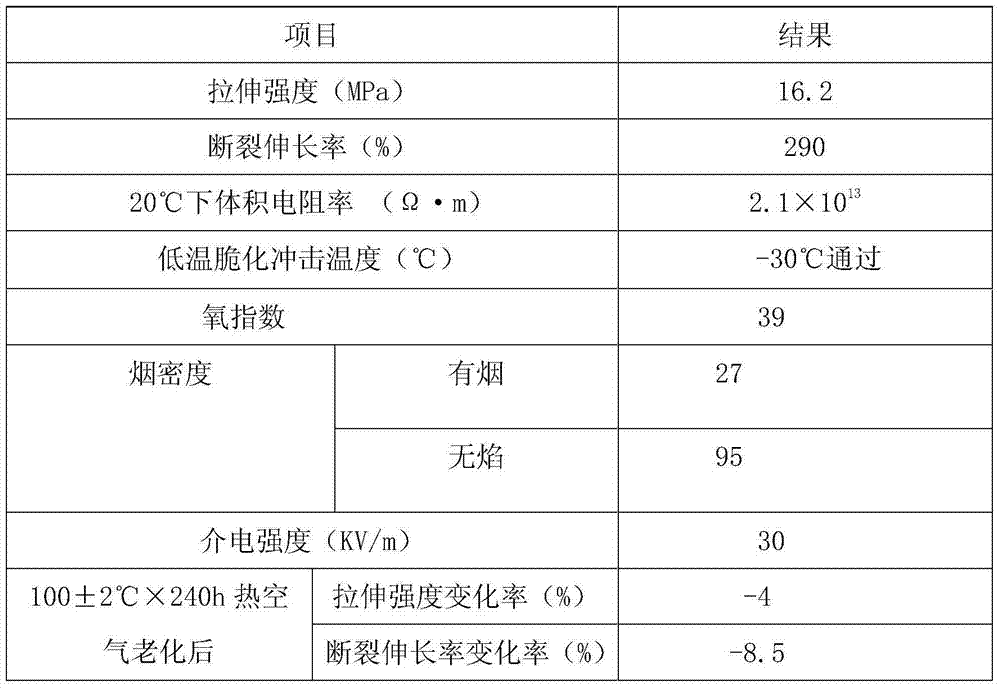

Low-smoke halogen-free flame-retardant polyolefin cable material

ActiveCN103571008AGood dispersionImprove uniformityPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneTripropylene glycol

The invention provides a low-smoke halogen-free flame-retardant polyolefin cable material which is prepared from the following raw materials in parts by weight: 30-40 parts of ethylene-vinyl acetate copolymer (EVA), 50-70 parts of high-density polyethylene (HDPE), 4-5 parts of chlorinated polyethylene, 15-20 parts of low-density polyethylene, 40-50 parts of aluminum hydroxide (Al(OH)3), 30-40 parts of magnesium hydroxide (Mg(OH)2), 5-6 parts of amino-terminated polyol ester, 2-3 parts of tributyl phosphate, 5-8 parts of epoxy soybean oil, 5-7 parts of glycerol, 1-2 parts of antioxidant 1035, 1-2 parts of barium stearate, 1-2 parts of nano silicon carbide, 1-2 parts of tripropylene glycol diacrylate, 1-2 parts of phosphate, 1.0-3.0 parts of PE (polyethylene) wax, 1-2 parts of silane coupling agent KH-550, 1-2 parts of zinc stearate and 15-18 parts of modifying filler. Due to the adoption of the technical scheme, the dispersibility of the low-smoke halogen-free flame-retardant polyolefin cable material is obviously enhanced, and the uniformity and surface smoothness of the material system are enhanced.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

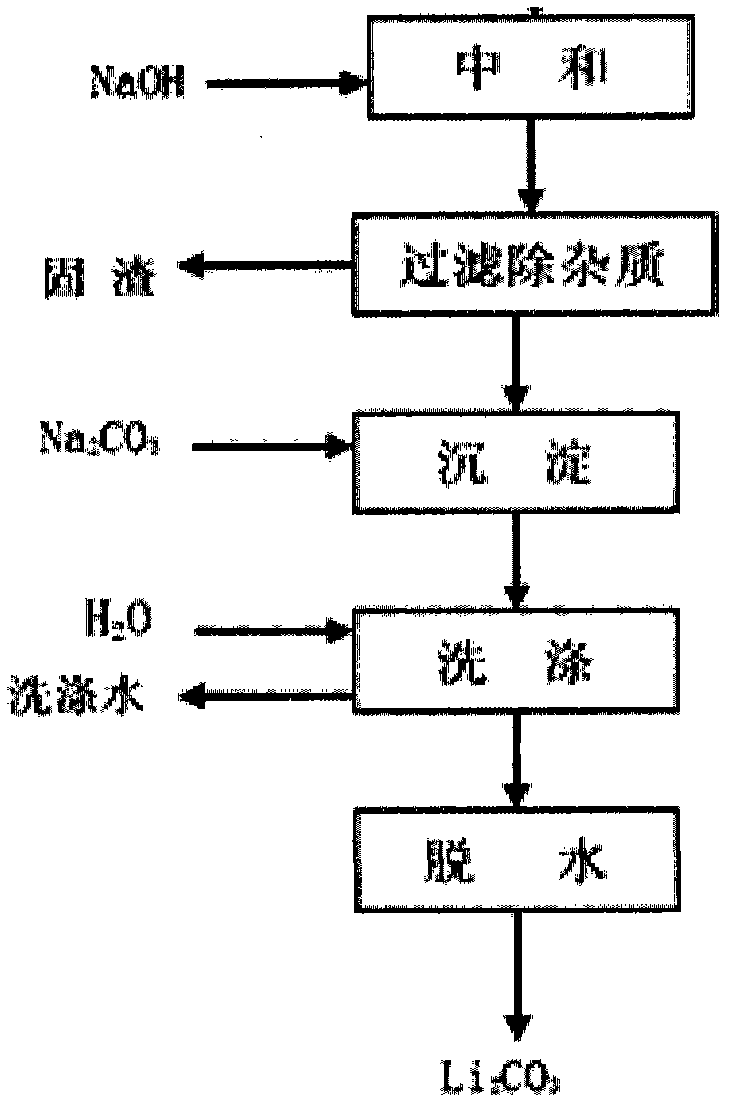

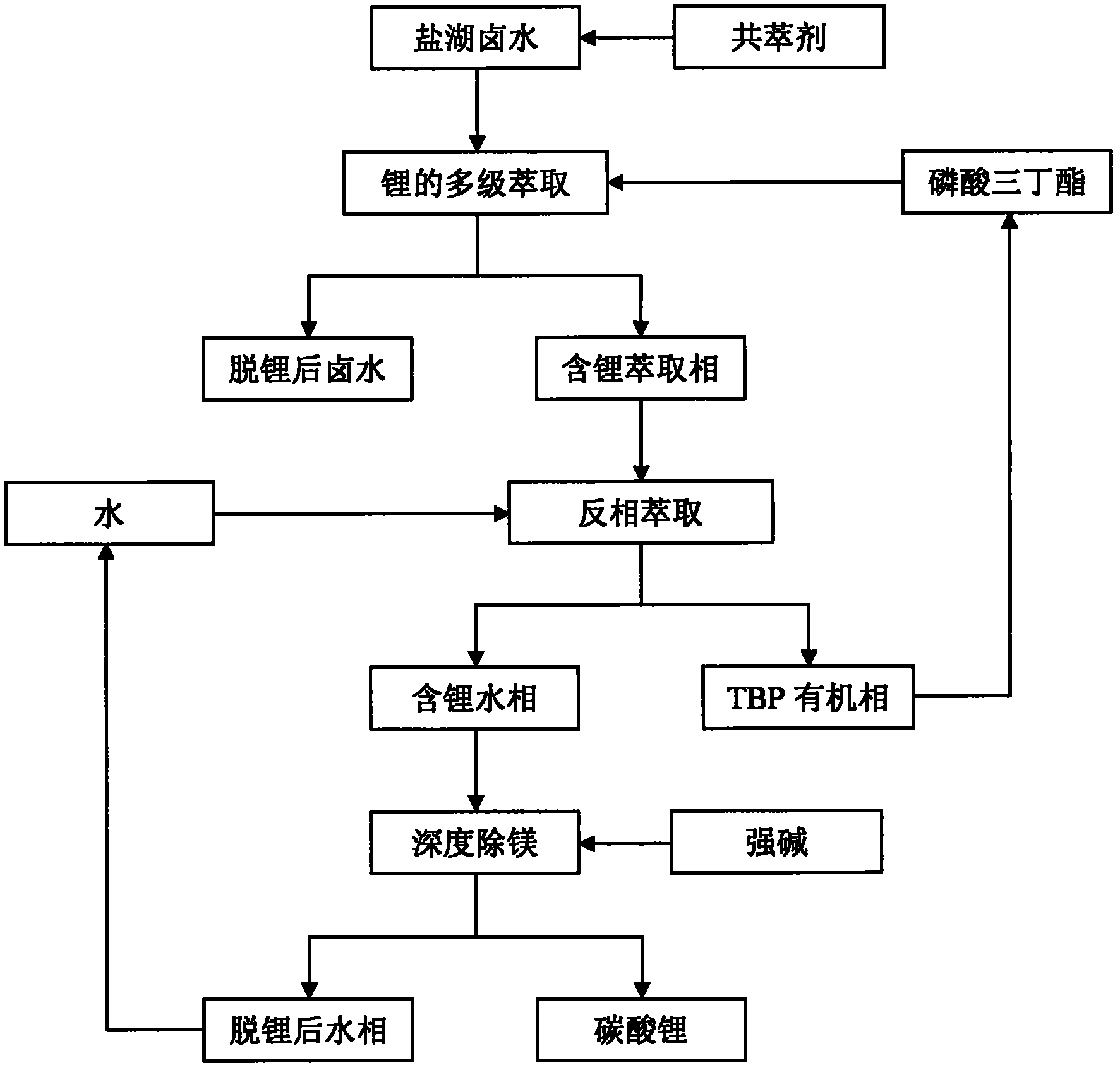

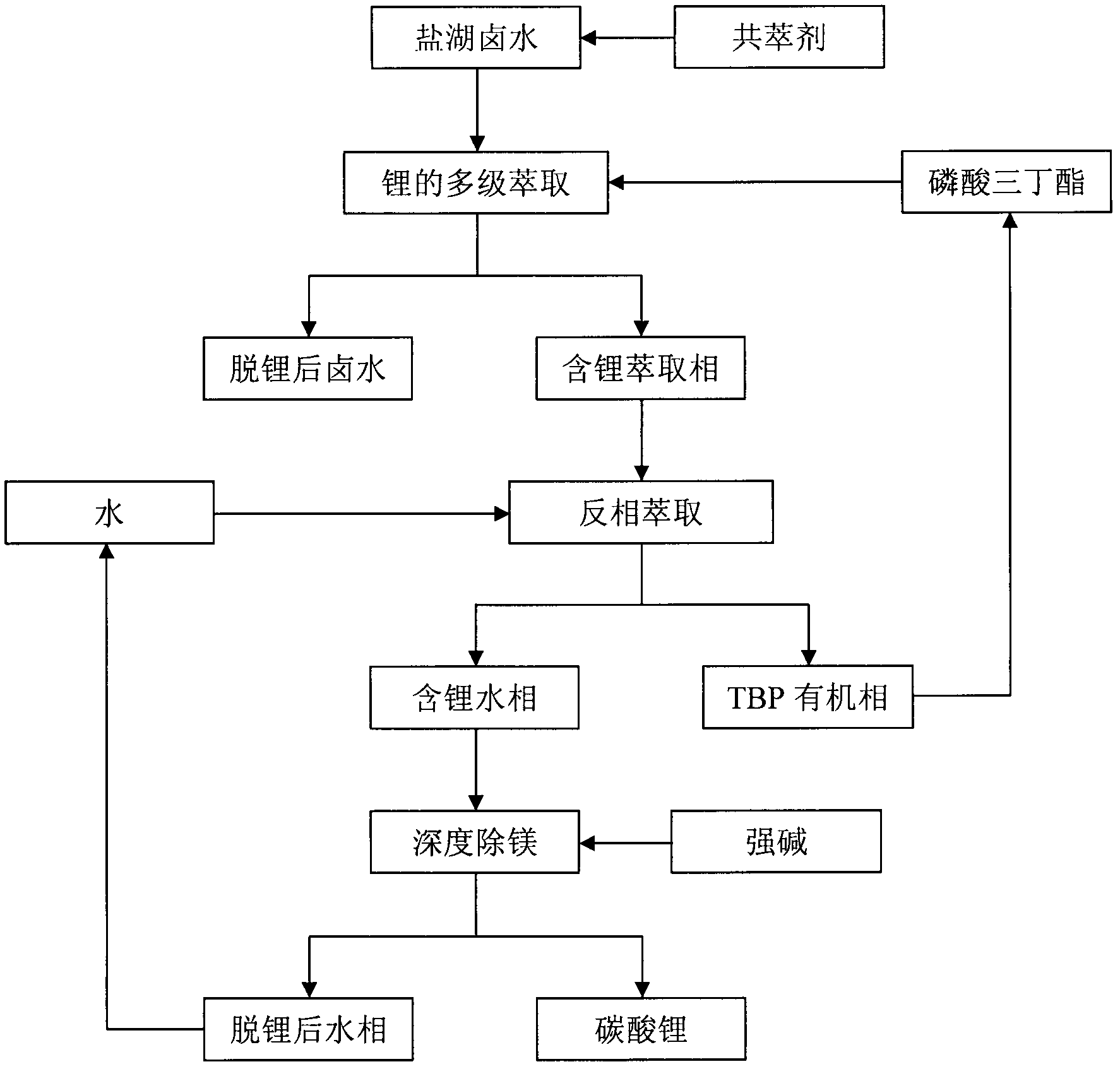

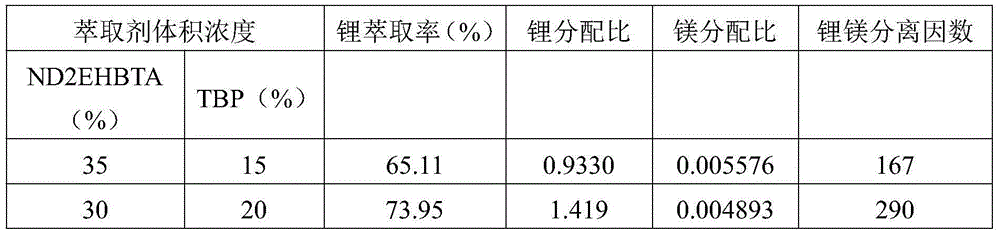

Method for separating magnesium and extracting lithium from salt lake brine with high magnesium-lithium ratio

InactiveCN102633284AStable in natureEasy to separateMagnesium carbonatesLithium carbonates/bicarbonatesHigh magnesiumKerosene

The invention discloses a method for separating magnesium and extracting lithium from salt lake brine with a high magnesium-lithium ratio. With adoption of the method, tributyl phosphate is taken as an extractant, number 200 solvent oil or kerosene is taken as a diluent, perchlorate is taken as a co-extraction agent, and water is taken as a stripping agent to form an extraction system; and lithium carbonate is prepared through extraction, reversed-phase extraction and deep magnesium removal by the salt lake brine. The method has the following beneficial effects: 1. the property of the co-extraction agent is stable, lithium magnesium separation can be carried out in neutral brine and the pH value of an aqueous phase needs not to be controlled; 2. the emulsification phenomenon doesn't exist and a third phase doesn't appear in the extraction process, two phases are easy to separate, the reversed-phase extraction is carried out by water and the device has little corrosion; and 3. the whole technique is simple in process, high in lithium extraction rate, good in separation effect and low in economic cost, is suitable for industrial production of the salt lake brine and is low in environmental damage degree because the co-extraction agent in water can be recycled.

Owner:XIANGTAN UNIV

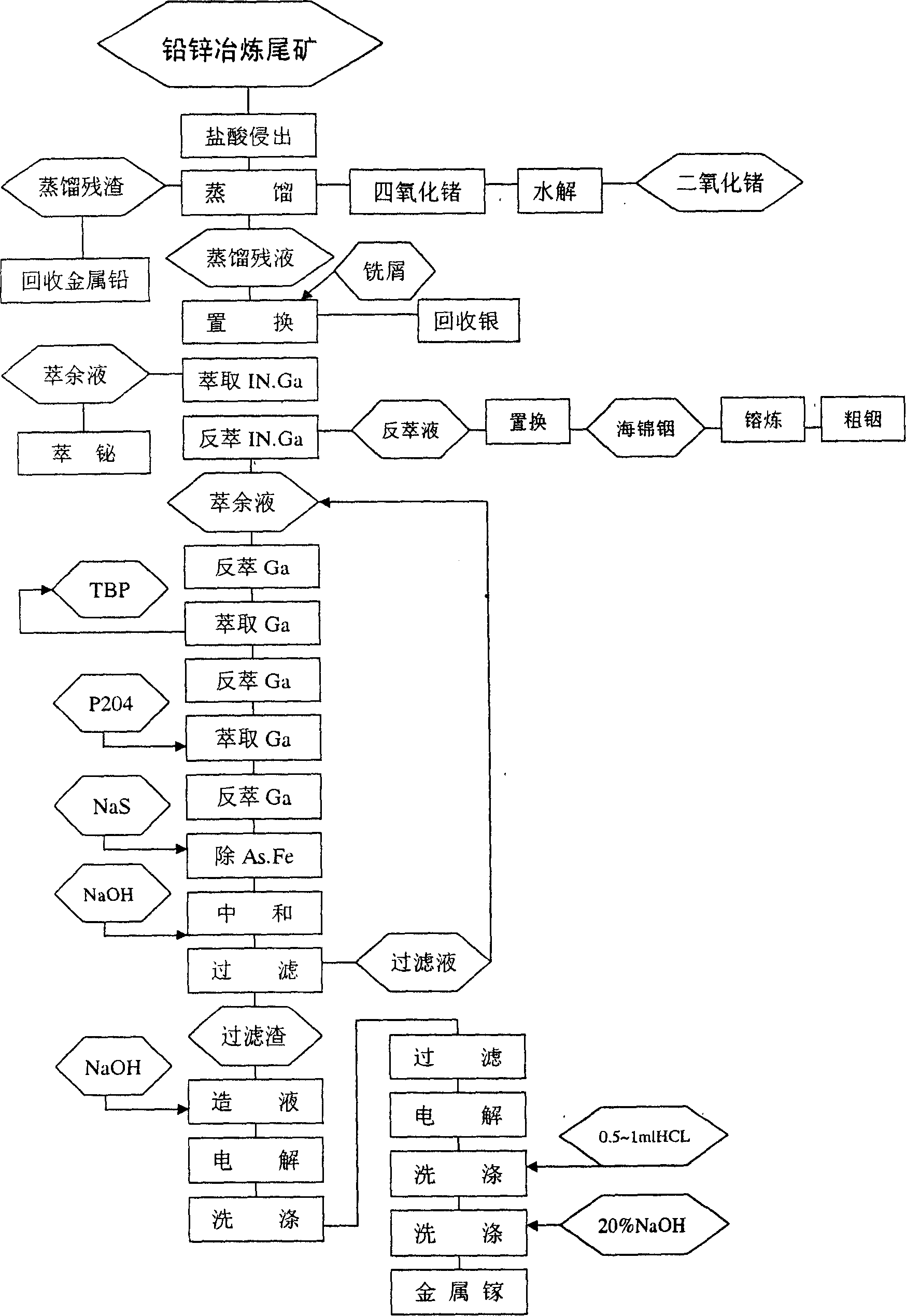

Technology for extracting Gallium metal from lead-zine tail ore slug smelting by extracting-electrolytic method

InactiveCN1775972AWide variety of sourcesLow pricePhotography auxillary processesProcess efficiency improvementOrganic solventPhosphoric acid

The invention relates to a technology to distil metal gallium by extraction- electrolyze method that adopts lead zinc smelt tailing mine containing gallium as raw material, and TBP and 2-phosphoric acid as extractant. The invention realizes the comprehensive utilization and development for resource and is benefit to environment. It is low cost, simple technology and has notable comprehensive benefits.

Owner:SHAOGUAN HUAWEI INDAL

Method for extracting lithium from salt lake brine

InactiveCN104357677AEasy to operateReduce concentrationProcess efficiency improvementHigh concentrationSalt lake

The invention provides a method for extracting lithium from salt lake brine. The method comprises the following steps: adding HCl and FeCl3.6H2O to an extract water phase (an LiCl-MgCl2-H2O system), and controlling the ratio of amount of substances of iron and lithium to be 1.3 to 1; standing after fully mixing the extract water phase with an extract organic phase in a volume ratio of 1 to 2, and separating a liquid phase. By adopting the method, the problems that the corrosivity of high-concentration tributyl phosphate towards extraction equipment is stronger and the dissolution loss of an extracting agent in water is serious in long-term operation are solved, and the lithium extraction efficiency of the prior art is achieved. The extraction method is simple and reliable to operate.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

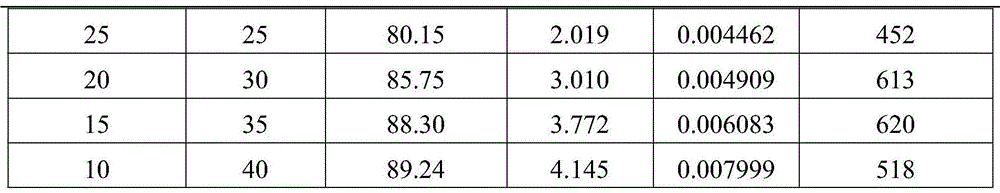

Method for recycling uranium from uranium extraction coal residue with wet method

InactiveCN101619397AHigh recovery rateLow costProcess efficiency improvementEcological environmentSilicic acid

The invention discloses a method for recycling uranium from uranium extraction coal residue with a wet method, which comprising the following steps: (1) particle size requirements: crashing the coal residue below 200 meshes; (2) oxidation and acid leaching: in a dilute sulphuric acid-hydrofluoric acid medium, using peroxide as an oxidizer to carry out reverse oxidation leaching twice; (3) desilicification and purification: using ammonia to adjust the pH value of once leaching filtering liquid of the uranium to 9.8-10.2, enabling the silicon in the solution to become silicic acid sediments, after filtering, carrying out ion exchange on the filtering liquid, desilicificating slag and stockpiling; (4) ion exchange: using a 717 type ion exchange resin to carry out exchange absorption by the filtering liquid, and then using 1 mol / L of NaCl-0.1 mol / LH2SO4 of mixed solution to elute the resin, after using tributyl phosphate to carry out extraction and back-extraction on eluent, obtaining uranium concentrates containing about 65% of the uranium. The invention successfully extracts and separates the uranium from the uranium extraction coal residue to produce the uranium concentrates, has t high recycling rate of uranium as high as 80-85% and low cost, and comprehensively utilizes the uranium extraction waste, thereby eliminating the influence of the radiation wastes on the ecological environment.

Owner:JIUJIANG BAIDUN VANADIUM TECH TRADING

Washing resistive exterior wall coating and preparation method thereof

The invention relates to an exterior wall coating which comprises the following raw materials in parts by weight: 80-90 parts of a water based acrylic emulsion, 15-20 parts of a styrene-acrylic emulsion, 30-60 parts of nano bentonite, 3-4 parts of sodium carboxymethylcellulose, 2-3 parts of butyl methacrylate, 1-2 parts of dimethyl dimercaptoacetic tin isooctylate, 0.6-1 part of phenethyl phenol polyoxyethylene ether, 0.5-1 part of glass fiber, 0.8-1 part of 1, 2-di(triethoxy silicon base) ethane, 0.1-0.2 part of tributyl phosphate, 3-5 parts of a coalescing agent and 10-20 parts of deionized water. The produced coating disclosed by the invention is less in raw material loss, less in gel generation, simple in process, hard in film, good in luster, strong in impact resistance, difficult to crack, flexible in texture, strong in decoration, high in weather resistance and washing resistance, strong in adhesive force, long in service life, and free from special smell, heavy metals such as mercury and lead, and formaldehyde volatiles, so that the coating is in accordance with technical demand of environmental-friendly coatings. The coalescing agent is added, so that the coating is very high in stability, and efficient in adhesiveness and film-forming property. The compactness of the coating film is increased, and the film-forming quality is improved, so that a film has the advantages of strong adhesive force, no holes and rifts, uniform compactness and the like.

Owner:CHUZHOU MAISITE NEW BUILDING MATERIAL

Water-based graphite core rod lubricant

The water plumbago mandril lubricant which applies to metal thermoplastic processing, especially applies to roller mandril uses plumbago powder as lubricant, uses compound resin latex as film agent, uses borax or tripoly sodium phosphate as antioxidant, hexa sodium phosphate as dispersant, natrium stearate calcium soap as stabilizing agent, phosphate butyl tri-ester as antifoam, carboxyl ethyl fibrin as thick-increasing agent, 1,2-propyl diethanol as film assistant agent, the residual is water.

Owner:JINHUA INDAL HENGYANG CITY HIGH NEW TECH AREA

Concrete mold release agent

The invention discloses a concrete mold release agent, and belongs to the field of building materials. The concrete mold releasing agent disclosed by the invention comprises the following components in part by weight: 15 to 40 parts of polyvinyl alcohol, 10 to 15 parts of epoxy resin, 15 to 25 parts of microcrystalline wax, 1 to 10 parts of nonylphenol polyoxyethylene ether, 1 to 5 parts of rosin, 1 to 2 parts of tri-butyl-phosphate, 1 to 8 parts of sodium alginate, 1 to 6 parts of an anti-rust agent, and 200 to 800 parts of water. The concrete mold release agent has a good mold release effect; the concrete is smooth after a mold is released; the service life of a steel mold can be prolonged; the concrete mold release agent has an anti-rust performance.

Owner:栾晓健

New thermochromic ink

The invention provides a new thermochromic ink comprising the following main components: 50-55 parts of a binder material, 1.5-2.5 parts of a crosslinking agent, 38-42 parts of a thermo-achromatizing reversible discoloring pigment and 5-8 parts of a defoaming agent, the binder material is a polyvinyl alcohol resin powder material, the crosslinking agent is a boric acid solution, and the defoaming agent is tributyl phosphate. The invention discloses the new thermochromic ink, the thermochromic ink is reasonable in component configuration, in line with energy saving and environmental protection requirements, simple in preparation process, and moderate in production cost, and the prepared ink is good in covering power, bright in color, good in wear resistance, high in color sensitivity, and very suitable for the fields of food security labels and thermal packaging materials and the like.

Owner:SUZHOU ZHONGYA INK

Method for producing alumina through bauxite acid process

ActiveCN101823742ARealize comprehensive utilizationEasy to handleAluminium compoundsAluminium chlorideKerosene

The invention relates to a method for producing alumina through a bauxite acid process, which comprises the following steps that: (1) alumyte with the Al-Si ratio of 1.5 to 5 or the ferric oxide content of 10 to 50 percent is selected as the raw material, crushed and put into a closed container to be leached, and hydrogen chloride gas is blown in during the leaching process; (2) TBP and sulfonated kerosene are added into leachate to be extracted, and extraction phase and the raffinate phase are obtained after extraction; (3) the aluminum chloride solution is separated from the extraction phase, and then the aluminum chloride solution is heated and decomposed, the pyrolysis temperature is 400 to 900DEG C, and the pyrolysis time is 5 to 60min, and alumina and hydrogen chloride gas are obtained. The extraction phase is back extracted to obtain ferric chloride solution and pyrolysed to obtain ferric oxide. The method for producing alumina through bauxite acid process realizes the effective treatment to low-grade and high-iron bauxite ore, has high resource utilization rate, realizes the integrated utilization of aluminum, iron, silicon and other valuable elements; and that the hydrogen chloride is added in through a continuous spraying and blowing method during the leaching process can improve the ore blending and provide the production capability.

Owner:DONGDA NONFERROUS SOLID WASTE TECH RES INST LIAOLING CO LTD

Technique for separating high purity yttrium oxide through solvent extraction

InactiveCN1563442AImprove extraction capacityLow liquid requirementProcess efficiency improvementAcetic acidPhosphoric acid

This invention relates to a technology for extracting and separating pure Y oxide applying HAB as the extractant, TBP as the additive, among which, HAB is composed of HA+HB, HA is secondary hepayl phenoxy instead of acetic acid, secondary octyl phenoxy instead of acetic acid etc. HB is a salt base phosphoric acid P204, P507, Cyanax 272, Cyanex 302.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

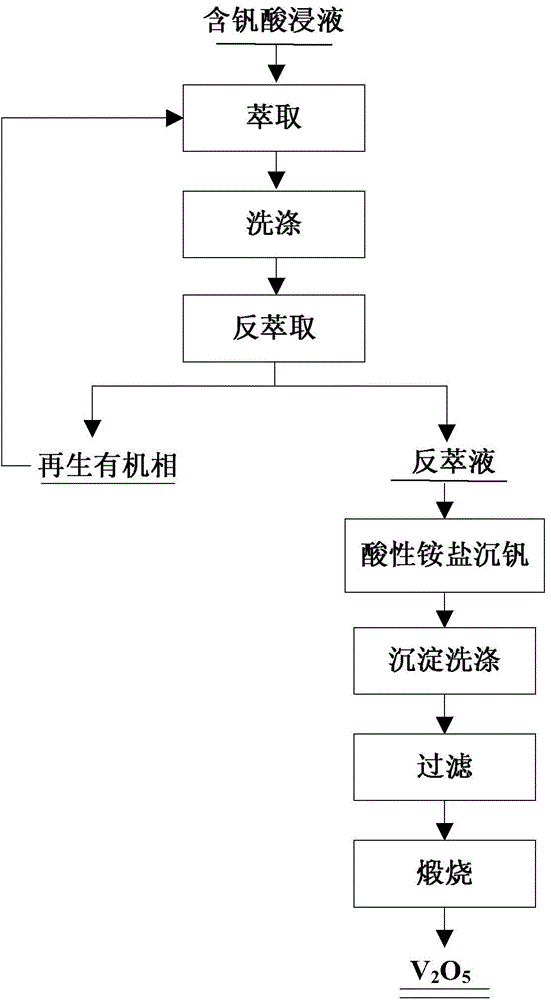

Production method of vanadic oxide

The invention relates to a production method of vanadic oxide, belonging to the field of resource recovery and solving the technical problem of providing a production method of the vanadic oxide. The production method of vanadic oxide comprises the following steps of a, extraction: extracting on immersion liquid which contains vanadic acid by taking a mixture formed from tertiary amine, sulfonated kerosene and tributyl phosphate as an extractant; b, washing: washing a loading organic phase; c, back extraction: carrying out the back extraction on the washed loading organic phase by taking a sodium carbonate solution as a back-extractant, wherein an obtained supernatant is a regenerated organic phase, and an obtained subnatant is back extraction liquid; d, acidic ammonium salt vanadium precipitation: stirring the back extraction liquid to obtain precipitates; e, washing the precipitates; calcining the washed precipitates to obtain the vanadic oxide. The product obtained through the production method is high in grade, and the purity of the final vanadic oxide achieves more than 99.99%. According to the production method, the recovery rate of an integral production process exceeds 76%.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

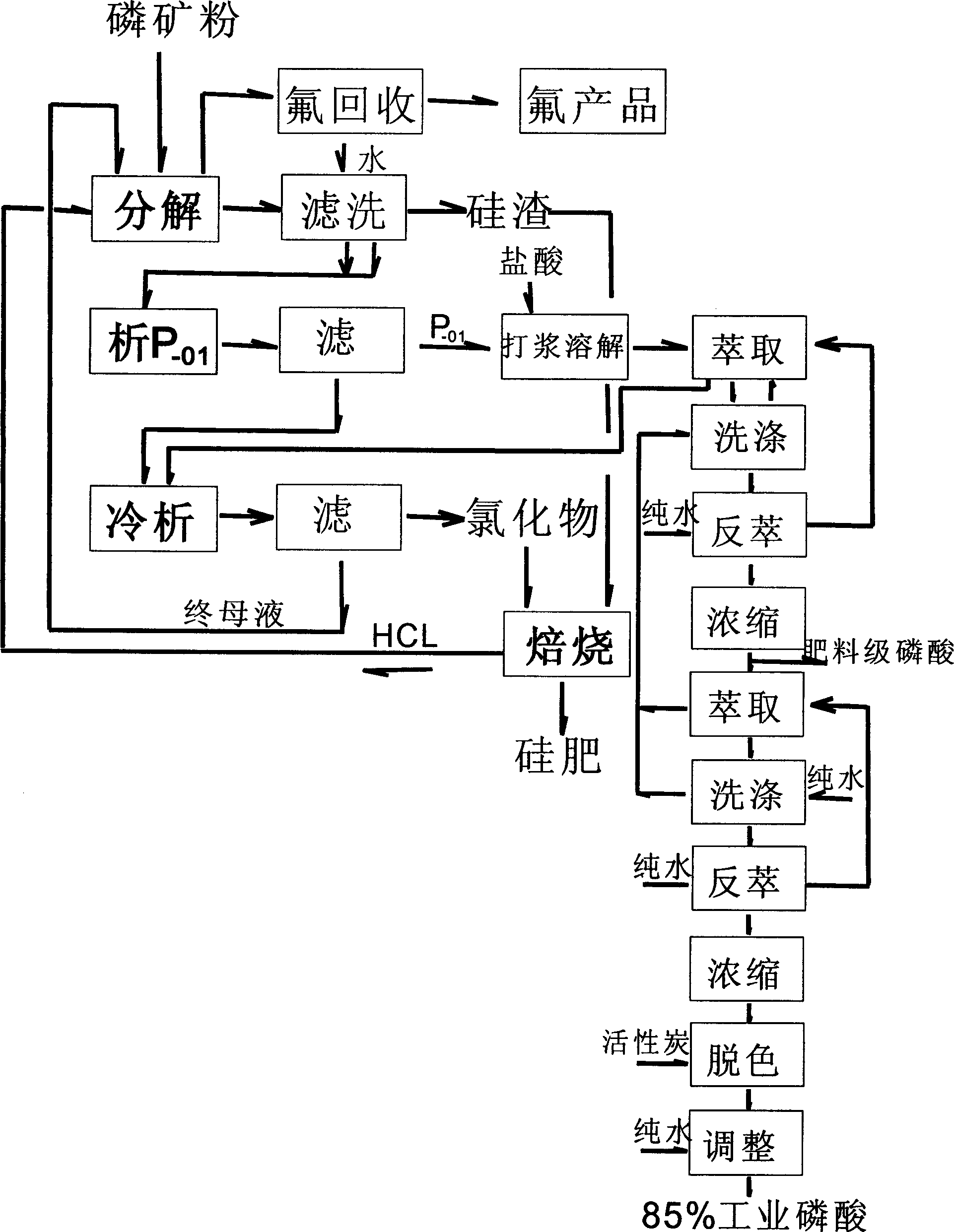

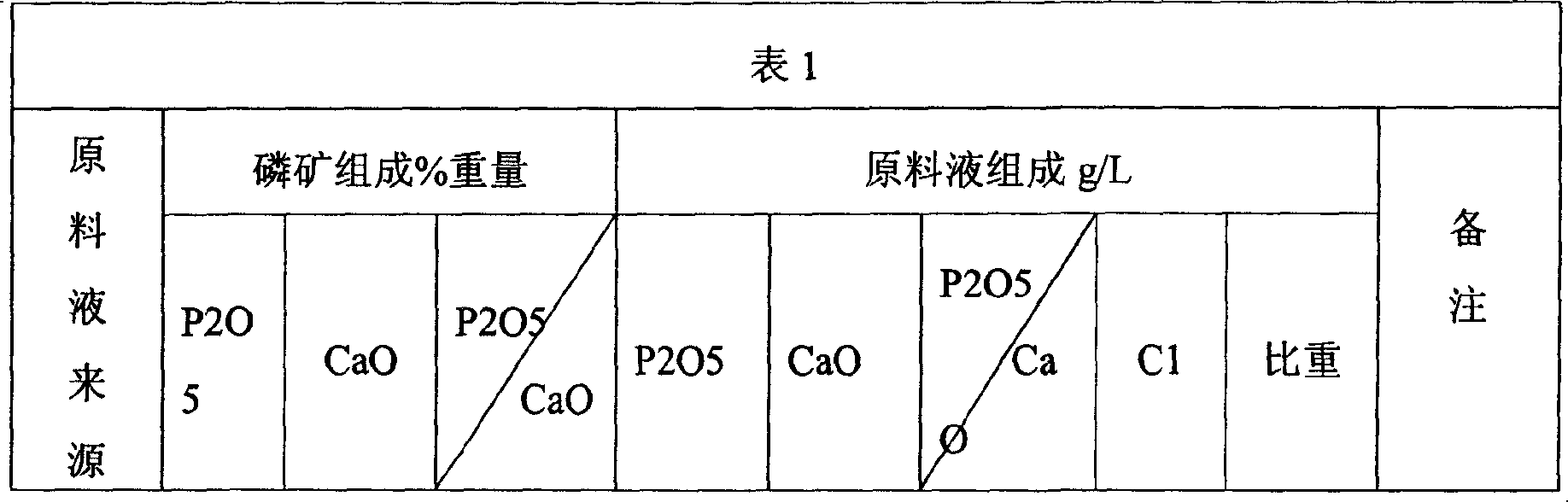

Process for mfg. industrial phosphoric acid by low-grade phosphorus deposit in hydrogen chloride decomposition

A process for preparing industrial phosphoric acid by use of hydrochloric acid to decompose the low-and medium-grade phosphorus ore includes such steps as using hydrochloric acid to decompose phosphorus ore to obtain calcium chlorophosphate, using hydrochloric acid to prepare slurry, dissolving the calcium chlorophosphate in it, extracting by tri-butyl phosphate, concentrating, extracting by tri-butyl phosphate and isopropyl ether, concentrating, and de-coloring to obtain 85% industrial phosphoric acid. Its advantage is no environmental pollution.

Owner:湖北中磷科技有限公司

Water-emulsified chloroprene rubber modified asphalt waterproof paint and preparation method thereof

InactiveCN102936439AMeet waterproof requirementsChloropene polymer coatingsBituminous coatingsPlasticizerNeoprene

The invention discloses a water-emulsified chloroprene rubber modified asphalt waterproof paint and a preparation method thereof. The formula of the water-emulsified chloroprene rubber modified asphalt waterproof paint comprises the following raw materials: 15-20 parts of petroleum asphalt, 25-35 parts of chloroprene rubber latex, 1-2 parts of resin, 1-1.5 parts of assistant, 0.5-0.8 part of regulator, 0.3-0.4 part of plasticizer, 0.01-0.02 part of vulcanizing agent, 5-10 parts of functional powder and 30-50 parts of water, wherein the assistant comprises emulsifier, stabilizer, film-forming assistant, thickener, dispersant and antisettle agent; the regulator comprises defoaming agent and 0.1-0.2 part of pH value regulator; and the defoaming agent comprises 0.2-0.6 part of organic silicon defoaming agent and 0.2 part of tributyl phosphate. The waterproof paint is prepared from chloroprene rubber latex modified emulsified asphalt and can meet the waterproofing requirement of a concrete bridge floor.

Owner:HUBEI UNIV OF TECH +1

Antifreezing fluid for automobile engine

PendingCN103773323ARaise the ratioLow costHeat-exchange elementsAlkaline earth metalSodium phosphates

The invention discloses an antifreezing fluid for an automobile engine, relating to an antifreezing fluid for an automobile. The antifreezing fluid comprises the following components in parts by weight: 0-20 parts of propylene glycol, 0-20 parts of ethylene glycol, 0-20 parts of butanediol, 0-1 part of sodium phosphate, 0-1 part of sodium silicate, 0-30.0 parts of hydrochloride, 0-12 parts of borax, 0-18 parts of petroleum resin, 0-10 parts of glycine, 0-10 parts of 1,2-aminoazophenylene, 0-1.0 part of defoamer and 0-60 parts of water, wherein sodium phosphate, sodium silicate and borax are used as buffer agents; dimethicone or tributyl phosphate is used as the defoamer; dihydric alcohol is used as an antifreezing agent; 1,2-aminoazophenylene is used as a corrosion inhibitor; hydrochloride is one selected from alkaline metal, alkaline earth metal and third main group element hydrochlorides; glycine and petroleum resin are used as mildew preventives. The antifreezing fluid is capable of effectively preventing a circulation cooling fluid from being frozen, free of corrosion to a cooling system and incapable of freezing when used at low temperature of 40-50 DEG C below zero.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Modified corn starch adhesive and preparation method thereof

InactiveCN103333637AImprove liquidityImprove stiffnessNon-macromolecular adhesive additivesStarch adhesivesCardboardNon toxicity

The invention relates to a modified corn starch adhesive and a preparation method thereof. The modified corn starch adhesive is mainly composed of corn starch, hydrogen peroxide, sodium hydroxide, tributyl phosphate, borax, a dispersant, a drier, polyvinyl alcohol, water and the like. The modified corn starch adhesive has the characteristics of strong adhesion, good fluidity, non-toxicity, and tastelessness; and cardboards prepared through using the modified corn starch adhesive have the characteristics of good stiffness, fast drying speed and the like.

Owner:ZHANGJIAGANG LUYUAN STARCH FACTORY

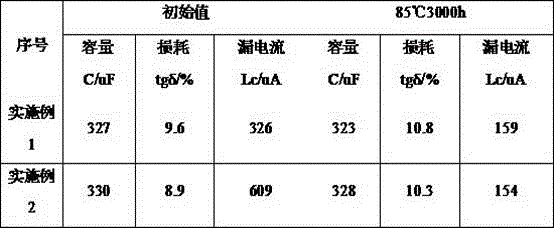

650V high-voltage aluminium electrolytic capacitor working electrolyte and preparation method thereof

InactiveCN106531443ALow viscosityLight weightLiquid electrolytic capacitorsDiethylene glycol monobutyl etherPolymer science

A 650V high-voltage aluminium electrolytic capacitor working electrolyte includes, in percentage by mass, 50% to 80% of a main solvent, 20% to 40% of auxiliary solvents, 5% to 15% of solutes, 1% to 8% of a sparking voltage enhancing agent; and the auxiliary solvents are two or more of a gamma-butyrolactone, DMF, polyethylene glycol 200, polyethylene glycol 400, a nano silica solution, glycerol, propylene carbonate, ethylene carbonate, tributyl phosphate, diethylene glycol monobutyl ether, trienthylene glycol dimethacrylate and diethylene glycol. The 650V high-voltage aluminium electrolytic capacitor working electrolyte has the advantages of low viscosity and high conductivity.

Owner:CENT SOUTH UNIV

Method for separating cerium, reclaiming fluorin and preparing cerous fluoride ultra-micro powder for mixed extraction system

This invention discloses the method for separating cerium and recovering fluorine and preparing ultramicro-powder cerium trifluoride. In this invention method, bastnasite ore or the mixture containing bastnasite ore and eremite ore is used as raw material mixed with sulfuric acid or nitric acid or the mixture containing both in optional ratio. The extractant is the mixture containing EXTR1 and EXTR2. Said EXTR1 is trialkyl phosphine oxide or dimethyl heptyl methyl-phosphonate or tritutyl phosphate; and said EXTR2 is di(2-ethylhexyl) phosphate, or mono 2-ethyl-hexyl 2-ethyl-hexyl-phosphonate, or di (2,4,4-trimethyl pentyl) phosphonate. The diluent is paraffine or sulfonated kerosene. The products of Ce3+ and cerium trifluoride are obtained after the loading organic phase is proceeded washing and back-extraction. The purity of the cerium trifluoride is 99.9-99.999%, and the grain size distribution is 40-300nm, the recovery rate of cerium is greater than 95%, and fluorine than 98%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

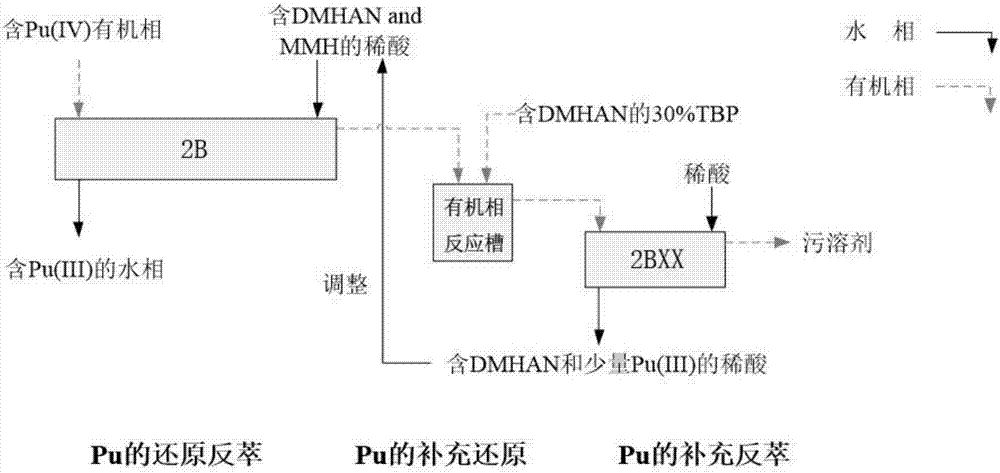

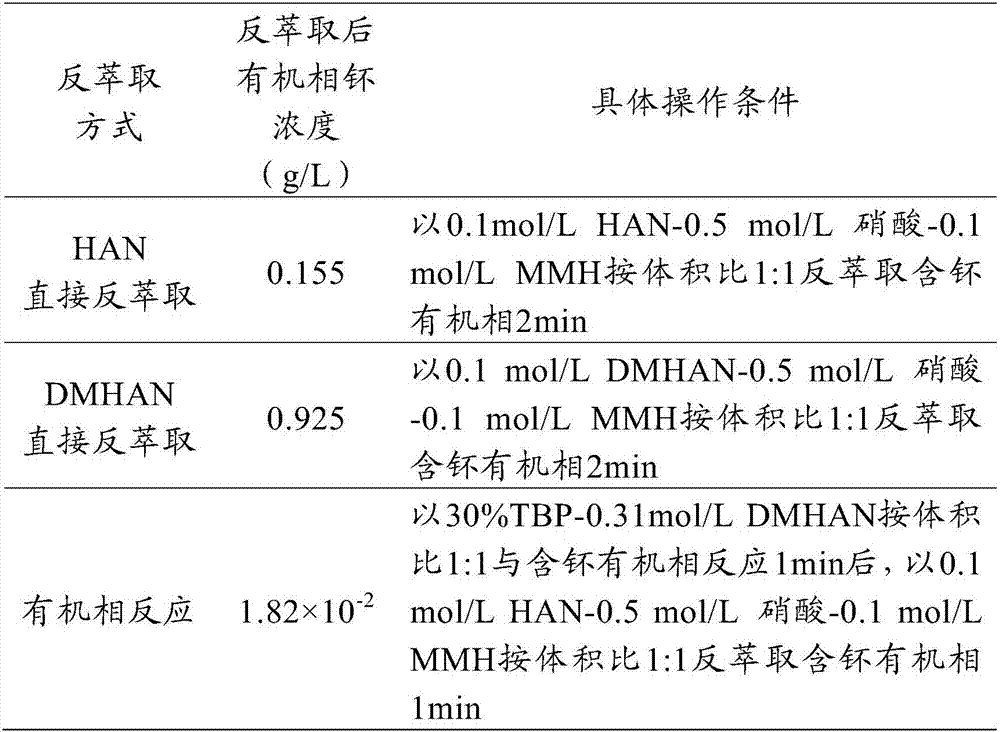

Method for recovering plutonium from radioactive spent fuel

ActiveCN106893878AAvoiding the Problems of Reductive ExtractionImproving the efficiency of recycling plutoniumPlutonium compoundsNuclear energy generationOrganic solventPhosphoric acid tributyl ester

The invention belongs to the technical field of treatment of nuclear materials and relates to a method for recovering plutonium from a radioactive spent fuel. The method sequentially comprises the following steps: performing extraction: extracting tetravalent plutonium in an aqueous solution of the radioactive spent fuel with an organic solvent containing tributyl phosphate; performing reduction on plutonium with a reducing agent: adding an organic solvent containing dimethylhydroxylamine in an organic phase to reduce the tetravalent plutonium into trivalent plutonium; and performing back extraction: adding a dilute acid aqueous solution in the organic phase to perform back extraction on the plutonium into a water phase, and performing recovering. Through adoption of the method for recovering the plutonium from the radioactive spent fuel, disclosed by the invention, the efficiency of recovering the plutonium from the radioactive spent fuel can be obviously improved compared with HAN back extraction, and the problem caused by reduction and extraction with U (IV) can be solved at the same time.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Weather-resistant anti-abrasion modified polyurethane waterborne paint

The invention discloses weather-resistant anti-abrasion modified polyurethane waterborne paint. The waterborne paint is prepared from, by weight, 80-120 parts of modified polyurethane, 10-30 parts of polyacrylate emulsion, 5-15 parts of dioctyl phthalate, 2-8 parts of tributyl phosphate, 1-5 parts of glycerin alkyd resin, 3-9 parts of 3-aminopropyltrimethoxysilane, 1-5 parts of ethylene glycol butyl ether, 2-6 parts of hydroxymethyl cellulose, 1-5 parts of titanium dioxide, 2-4 parts of talcum powder, 1-5 parts of silicon dioxide, 2-4 parts of zinc oxide, 4-6 parts of aluminium oleate, 5-9 parts of pigments, 2-5 parts of flexibilizers, 1-6 parts of defoaming agents, 3-5 parts of flatting agents, 4-8 parts of mildew preventives, 3-8 parts of dispersing agents and 15-25 parts of deionized water. The invention further discloses a method for preparing the weather-resistant anti-abrasion modified polyurethane waterborne paint. The obtained waterborne paint has good weather resistance and abrasion resistance, has excellent water resistance, heat stability and adhesion between coated objects on the basis that a raw material is good in softness, chemical resistance and environment-friendly performance, and is excellent in comprehensive performance, good in durability and wide in application prospect.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com