Method for recovering plutonium from radioactive spent fuel

A spent fuel and radioactive technology, applied in recycling technology, plutonium compounds, climate sustainability, etc., can solve problems such as increased Pu generation, complex solvent reuse process, and increased total radioactivity, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the effect test of organic phase DMHAN reduction Pu (IV)

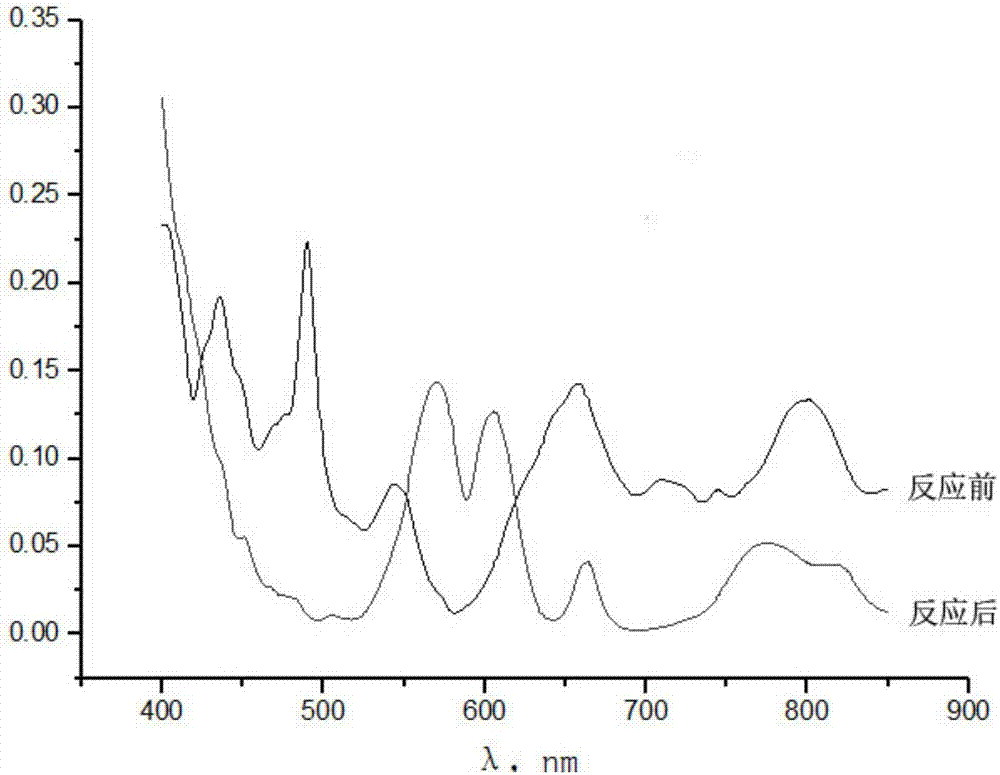

[0031] The 30% TBP / n-dodecane organic phase containing 1.02g / L Pu receives a radiation dose of 1.4Wh / L, and generates about 100mg / L of HDBP. The solution spectrum shows that Pu(IV) appears at 720nm and 740nm -Characteristic absorption peaks of HDBP complexes. Mix the above-mentioned Pu-containing organic phase with 30% TBP / n-dodecane organic phase containing 0.31mol / L DMHAN at a volume ratio of 1:1, and the brown Pu(IV) is reduced in less than 5 seconds into blue Pu(III). After 1 minute of mixing, the solution spectrogram shows that Pu(III) characteristic absorption peaks appear at 570nm and 605nm, and the Pu(IV) characteristic absorption peaks at 720nm and 740nm disappear, as figure 1 shown. From the changes in the spectra, it can be seen that even in the presence of HDBP, DMHAN in the organic phase can fully reduce Pu(IV).

[0032] For the above-mentioned TBP organic phase containing HDBP, if...

Embodiment 2

[0033] Embodiment 2: the test of supplementary stripping plutonium in the organic phase

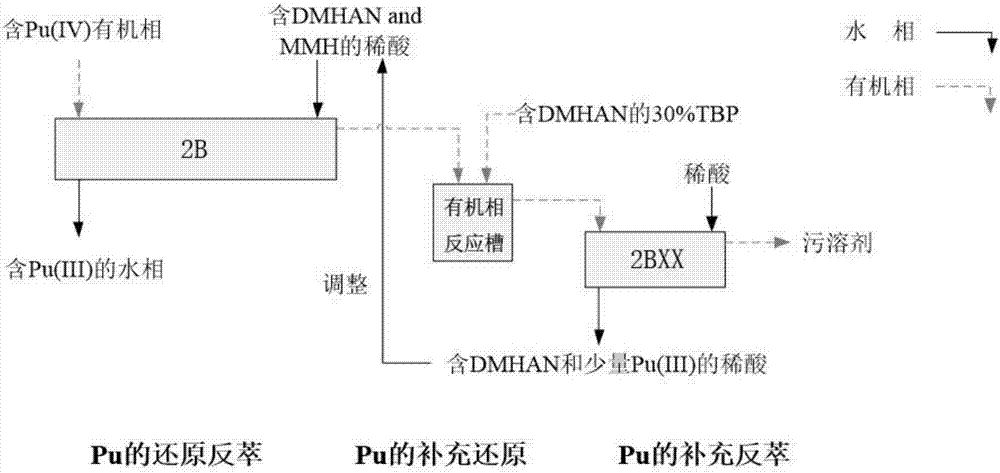

[0034] A supplementary stripping test for plutonium in the organic phase is designed, the process is as follows figure 2 Shown:

[0035] (1) Back-extract most of Pu(IV) with dilute nitric acid aqueous solution containing DMHAN and MMH in the 2B tank, and reduce the concentration of nitric acid and nitrous acid in the organic phase at the same time to avoid DMHAN and Pu(IV) in the subsequent organic phase Since the plutonium concentration in the organic phase of each sample in the 2B tank is very low, the number of plutonium stripping stages in the 2B tank can be appropriately reduced;

[0036] (2) The organic phase after the stripping of the 2B tank containing a small amount of Pu (IV) enters the organic phase reaction tank, reacts with 30% TBP containing DMHAN, and the organic phase after the reaction contains Pu (III) and DMHAN, and flows into the 2BXX tank;

[0037](3) In the 2BXX t...

Embodiment 3

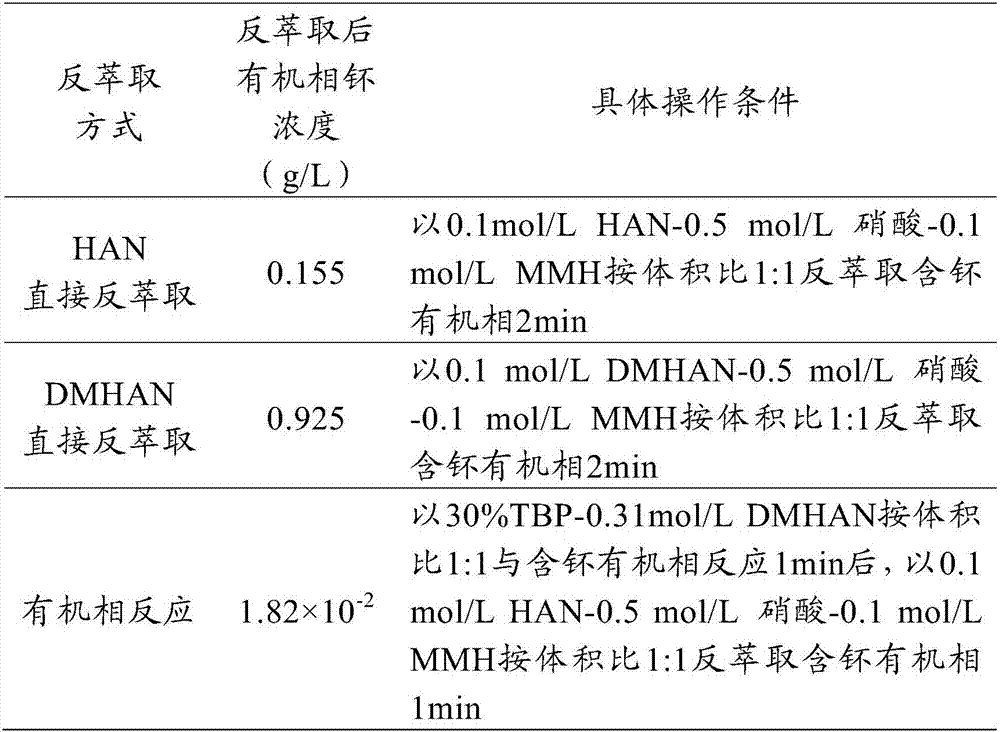

[0040] Embodiment 3: Effect comparison of different ways of recovering plutonium from the organic phase

[0041] Prepared plutonium-containing organic phase (29%TBP-1%HDBP-0.158g / LPu-0.250mol / L HNO 3 ), the plutonium was stripped in different ways, and the operating conditions and plutonium stripping effects are shown in Table 1. As can be seen from Table 1, since the amount of HDBP is much greater than the amount of plutonium, HAN is directly used to strip Pu in the organic phase (there is no organic phase reduction for Pu(IV), so Pu(IV) is reduced during direct stripping. ) is very slow) has almost no effect, and directly adopts DMHAN for plutonium stripping (the organic phase reduction of Pu(IV) is not carried out, so although the speed of reducing Pu(IV) in direct stripping is higher than that of HAN, it still cannot meet the requirements. Requirements) the effect is also very limited, the plutonium stripping method can obviously improve the stripping effect of plutonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com